High-speed steel strengthened and hardened through combination of Laves phase and mu phase and preparation method of high-speed steel

A high-speed steel and preparation process technology, which is applied in the field of high-speed steel and its preparation through Laves phase and μ phase composite strong hardening, can solve the problems of low hardness and wear resistance, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

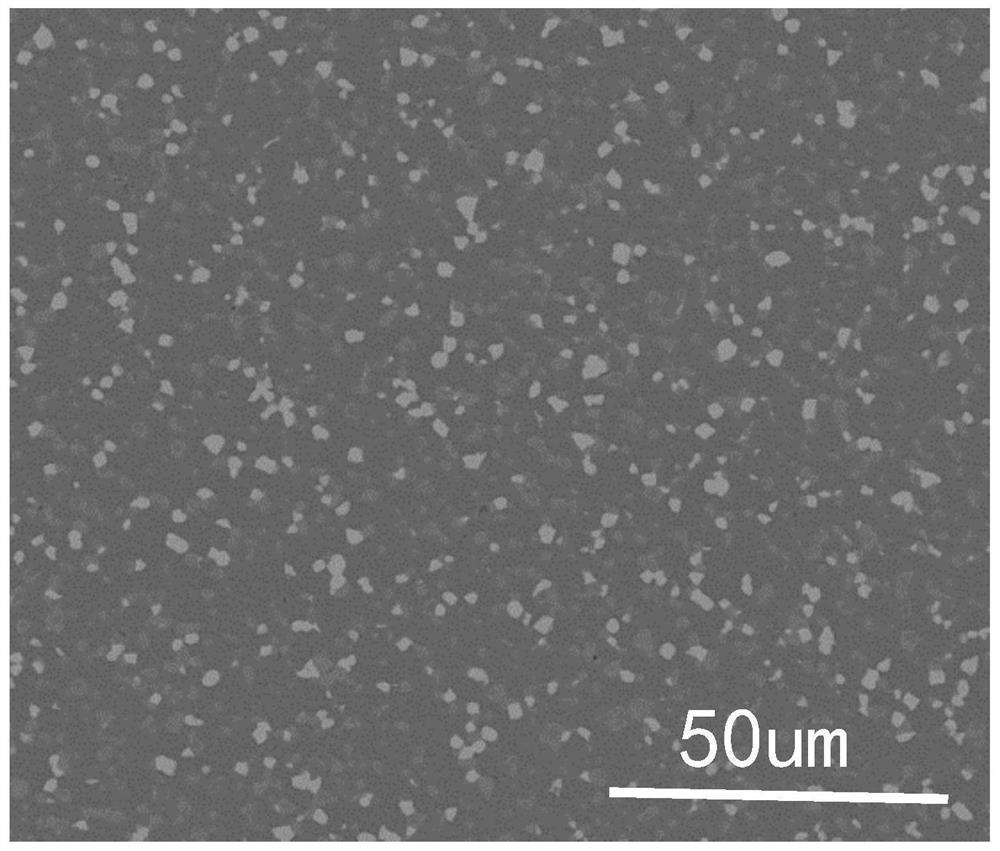

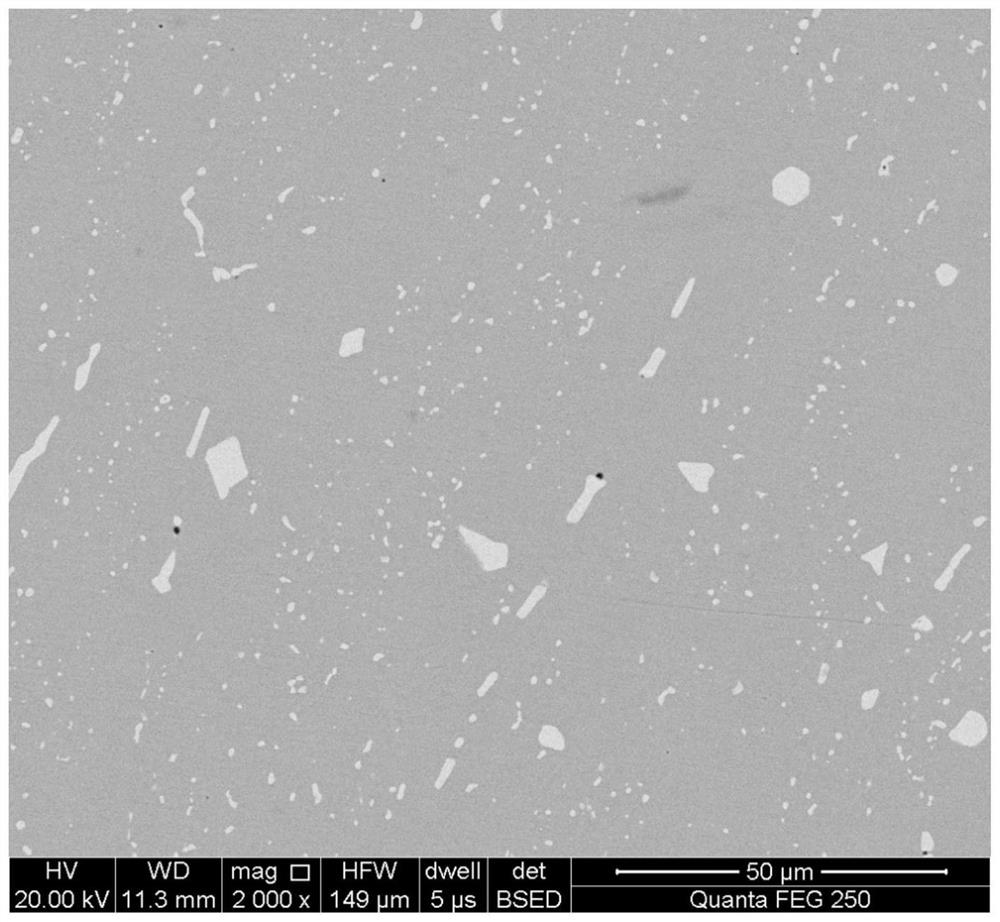

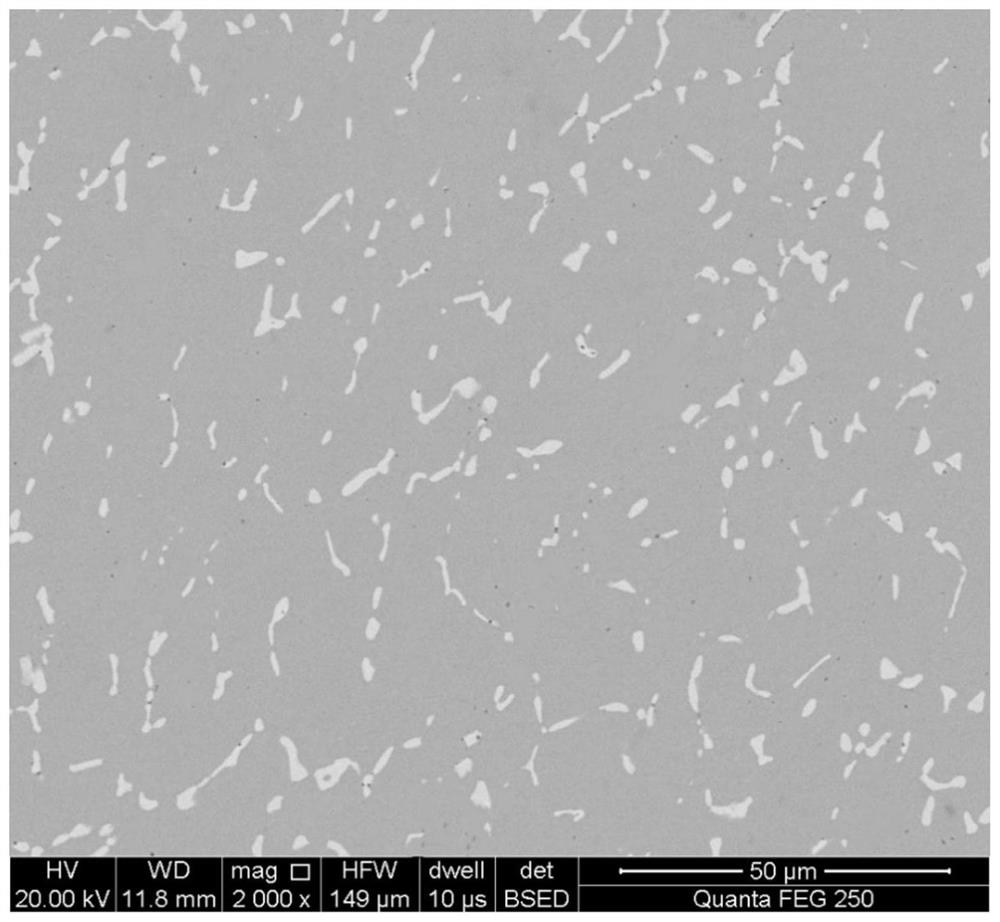

Image

Examples

Embodiment 1

[0044] The raw materials are prepared according to the design formula, and the mass percentages are: Fe: 50%, Co: 20%, Mo: 15%, W: 8%, Nb: 3%, Ti: 3%. Put the raw material powder, 0.5wt% carbon black, and 3wt% paraffin wax as a forming agent into a roller ball mill in a nitrogen atmosphere for wet ball milling. The ball milling medium is alcohol, the ball-to-material ratio is 6:1, and the ball milling time is 48 hours. The ball-milled mixed raw material is dried and granulated by wiping and sieving, and is subjected to two-way molding with a pressing pressure of 200 MPa to obtain a cold compact. The obtained compact is sintered in a vacuum sintering furnace with a maximum sintering temperature of 1380° C., and a sintered compact is obtained after cooling. The sintered compact was subjected to solution treatment in a salt bath and cooled by oil cooling. The solution temperature was 1270°C and the solution time was 12 minutes. The solid solution material hardness is HRC42.7. T...

Embodiment 2

[0046] The raw materials are prepared according to the design formula, and the mass percentages are: Fe: 56%, Co: 20%, Mo: 13%, W: 5%, Nb: 4%, Ti: 2%. Put the raw material powder, 0.5wt% carbon black, and 3wt% paraffin wax as a forming agent into a roller ball mill in a nitrogen atmosphere for wet ball milling. The ball milling medium is alcohol, the ball-to-material ratio is 6:1, and the ball milling time is 50h. The ball-milled mixed raw materials were dried and granulated by wiping and sieving, and passed through two-way molding with a pressing pressure of 180 MPa to obtain a cold compact. The obtained compact is sintered in a vacuum sintering furnace with a maximum sintering temperature of 1340° C., and the sintered compact is obtained after cooling. The sintered billet was solid solution treated in a salt bath and cooled by oil cooling. The solid solution temperature was 1260°C, the solid solution time was 15 minutes, and the solid solution material hardness was HRC42.3. ...

Embodiment 3

[0048] The raw materials are prepared according to the design formula, and the mass percentages are: Fe: 56%, Co: 18%, Mo: 12%, W: 4%, Nb: 2%, Ti: 2%. Put the raw material powder, 0.6wt% carbon black, and 4wt% paraffin wax as a forming agent into a roller ball mill in a nitrogen atmosphere for wet ball milling. The ball milling medium is alcohol, the ball-to-material ratio is 5:1, and the ball milling time is 50h. The ball-milled mixed raw materials were dried and granulated by wiping and sieving, and passed through two-way molding with a pressing pressure of 180 MPa to obtain a cold compact. The obtained compact is sintered in a vacuum sintering furnace with a maximum sintering temperature of 1330° C., and the sintered compact is obtained after cooling. The sintered compact was subjected to solution treatment in a salt bath and cooled by oil cooling. The solution temperature was 1260°C and the solution time was 15 minutes. The solid solution material hardness is HRC42.2. Th...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

| flexural strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com