FeCrAl/Ta alloy coating and preparation method thereof

A kind of alloy coating and coating technology, which is applied in the direction of metal material coating process, coating, vacuum evaporation plating, etc., can solve the problems of coating peeling, substrate deformation, deterioration of substrate mechanical properties and film-base interface bonding, etc. Achieve the effect of dense and uniform structure and improve service performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0033] A preparation method of FeCrAl / Ta alloy coating, comprising the following steps:

[0034] Step 1: Grind and polish the alloy base to remove the oxide layer on its surface.

[0035] The polishing and grinding method is as follows: the zirconium alloy substrate is ground by the "cross" grinding method, and the 600, 1000, 1500, and 2000-grit sandpapers are sequentially ground, and then polished on a polishing machine, and the remaining surfaces are sequentially ground with 600, 1000, and 1500-grit sandpaper. , grind off the surface oxide layer until the surface has no scratches.

[0036] The alloy matrix is a zirconium alloy, a steel matrix or a titanium alloy.

[0037] Step 2: Perform ultrasonic cleaning on the ground and polished alloy substrate in Step 1.

[0038] Specifically, take a single-side polished alloy substrate, ultrasonically clean it in acetone and ethanol for 10 minutes in turn, and then dry it to ensure that the surface of the substrate is clean and fr...

Embodiment 1

[0048] Step 1: Sandpaper and polish the zirconium alloy substrate.

[0049] Step 2: The single-sided polished zirconium alloy substrate was ultrasonically cleaned in acetone and ethanol for 10 minutes, and dried with a hair dryer.

[0050] Step 3: Fix the zirconium alloy base on the base plate, and then automatically accompany it into the vacuum coating chamber. The vacuum degree of the background should be lower than 4.0×10 before deposition. -4 Pa, and etching for 5min, the etching power is 200W.

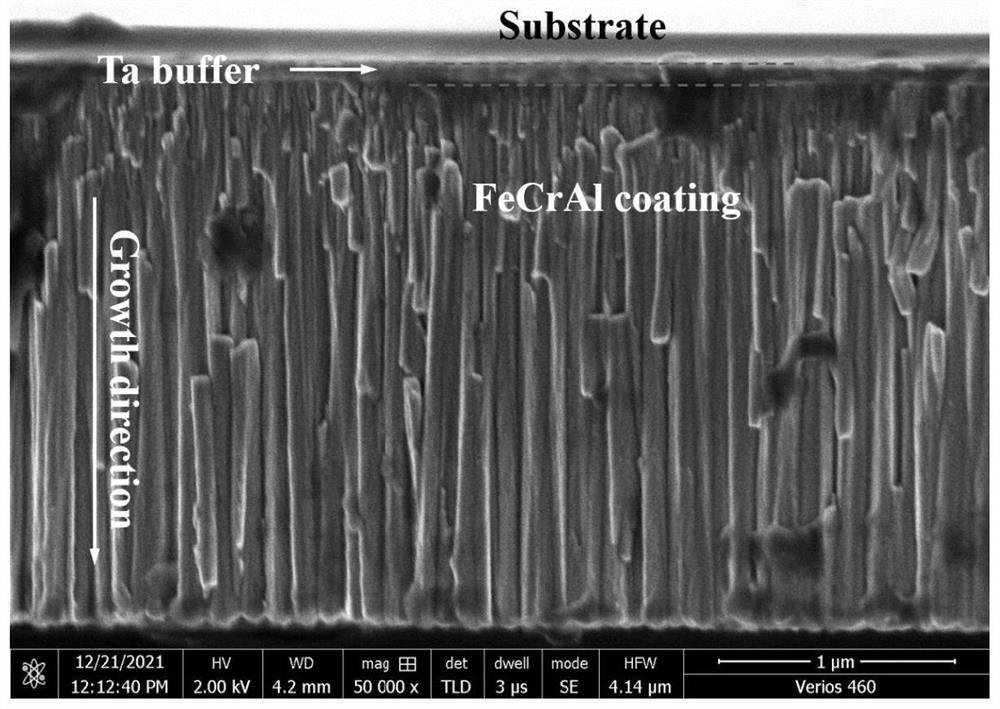

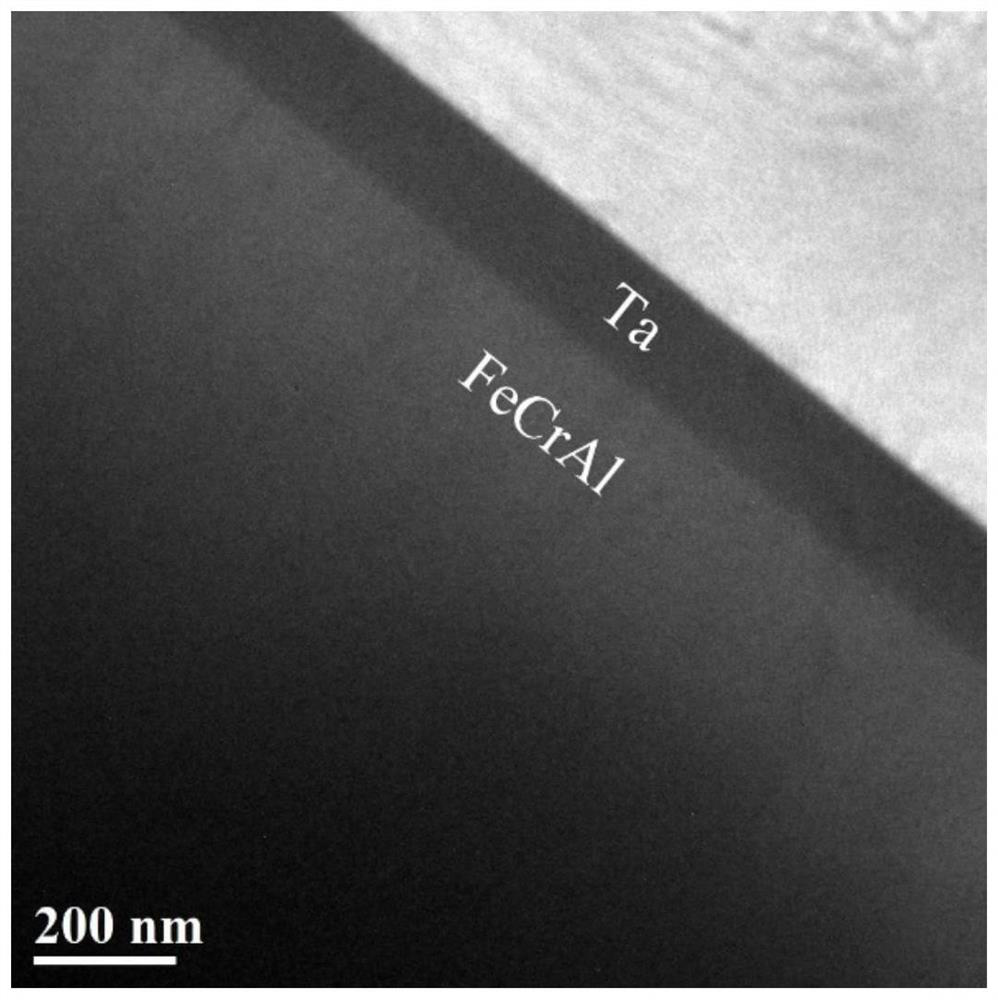

[0051] Step 4: A Ta transition layer and a FeCrAl layer are sequentially sputtered on the zirconium alloy base by the method of magnetron sputtering, and after successively sputtering and deposited to a preset thickness, the FeCrAl / Ta alloy coating is obtained by cooling to room temperature.

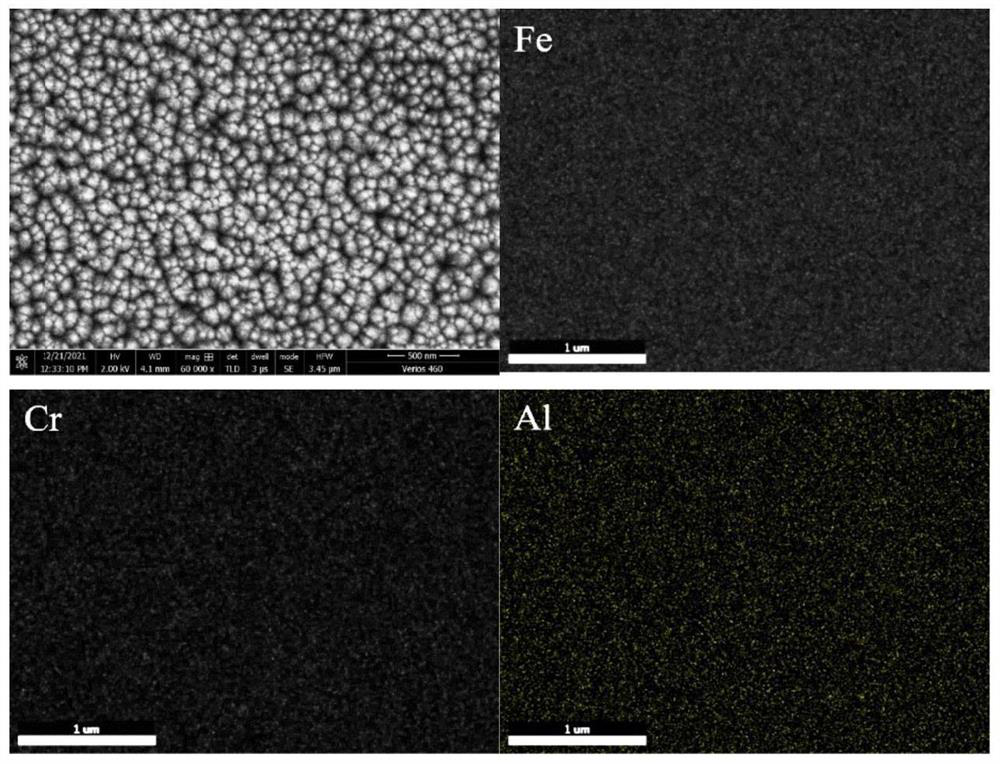

[0052] Among them, the purity of FeCrAl alloy target is 99.9wt.%, the atomic percentage of Fe:Cr:Al is 79:10:11at.%, the sputtering is performed with a DC power supply power of 200W, the pu...

Embodiment 2

[0056] Step 1: Sand and polish the steel substrate.

[0057] Step 2: The single-sided polished steel substrate was ultrasonically cleaned in acetone and ethanol for 10 minutes, and dried with a hair dryer.

[0058] Step 3: Fix the steel substrate on the base plate, and then automatically accompany it into the vacuum coating chamber. The vacuum degree of the background should be lower than 4.0×10 before deposition. -4 Pa, and etching for 5min, the etching power is 200W.

[0059] Step 4: A Ta transition layer and a FeCrAl layer are sequentially sputtered and deposited on the steel substrate by the method of magnetron sputtering, and after being sequentially sputtered and deposited to a preset thickness, the FeCrAl / Ta alloy coating is obtained by cooling to room temperature.

[0060] Among them, the purity of FeCrAl alloy target is 99.9wt.%, the atomic percentage of Fe:Cr:Al is 74:15:11at.%, the sputtering is performed with a DC power supply power of 200W, the purity of the Ta t...

PUM

| Property | Measurement | Unit |

|---|---|---|

| size | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com