Patents

Literature

215results about How to "Uniform and dense tissue" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Forming device and method of aluminum-based silicon carbide particle reinforced composite material and member thereof

ActiveCN103695681ASimple molding processDense and uniform internal tissueCarbide siliconControl system

The invention provides a forming device and method of an aluminum-based silicon carbide particle reinforced composite material and a member thereof. The forming device comprises a laser system, a powder spreading system, an inert atmosphere system and a control system. By using the forming device, quick formation of the aluminum-based silicon carbide particle reinforced composite material and the member thereof can be realized. The forming method provided by the invention is simple, and adopts digitized manufacturing. The formed product is compact and uniform in texture, and any complicated members can be directly manufactured without being secondarily processed.

Owner:CHANGSHA ADVANCED MATERIALS IND RES INST CO LTD

Electroslag remelting method for difficult-processing high alloy stainless steel and electroslag remelting slag system adopting electroslag remelting method

InactiveCN102925712AImprove or increase thermoplasticityHigh yieldIncreasing energy efficiencySlagAlloy

The invention relates to an electroslag remelting method for difficult-processing high alloy stainless steel and an electroslag remelting slag system adopting the electroslag remelting method. The slag system comprises the components in parts by weight: 46-72 parts of CaF2, 15-28 parts of CaO, 24-10 parts of Al2O3 and 8-2 parts of MgO, wherein the content of impurities is less than 1.0%. The electroslag remelting slag system and the electroslag remelting method reduce the contents of harmful elements in steel, improve the purity, optimize the organization, particularly and remarkably improve the processing performance of the difficult-processing high alloy stainless steel and greatly improve the material yield.

Owner:CHONGQING MATERIALS RES INST

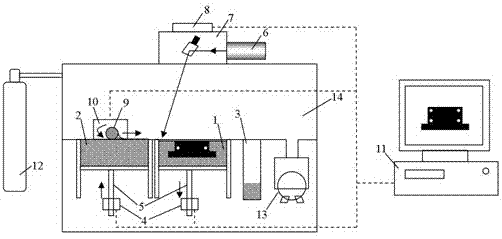

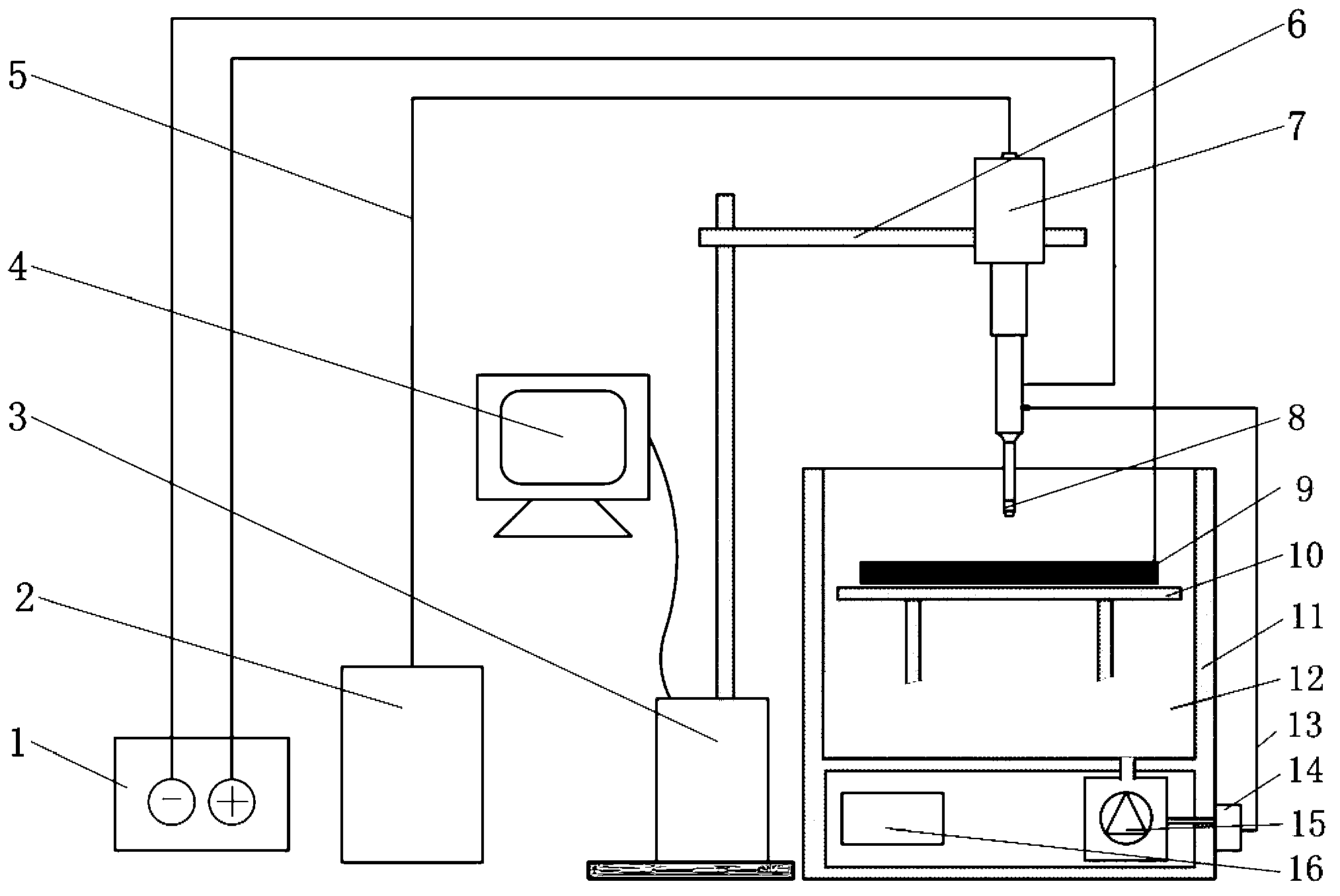

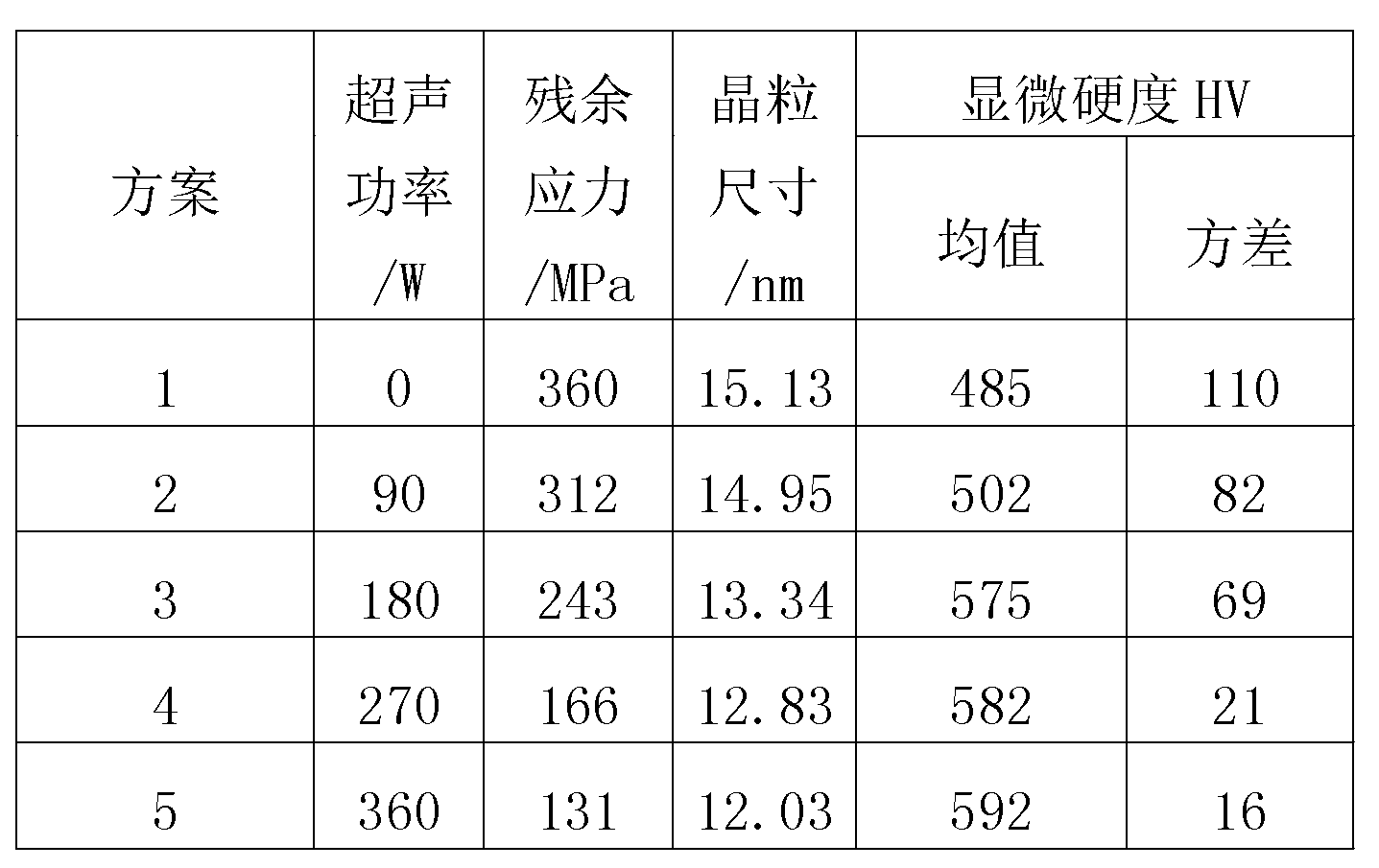

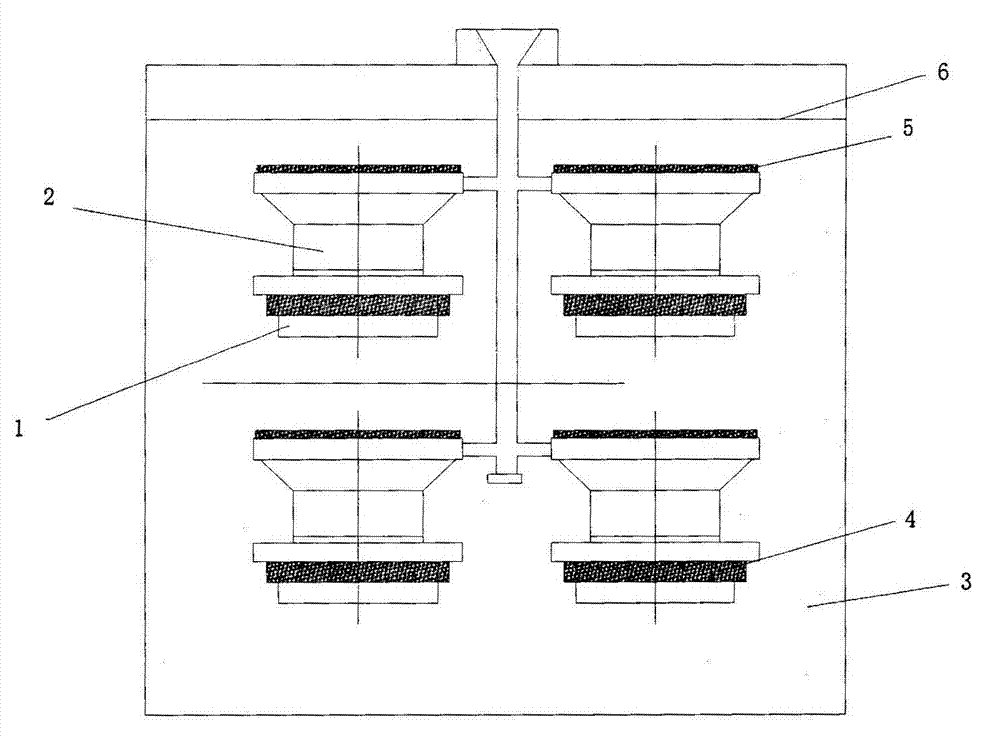

Selective metal electro-deposition device and application thereof

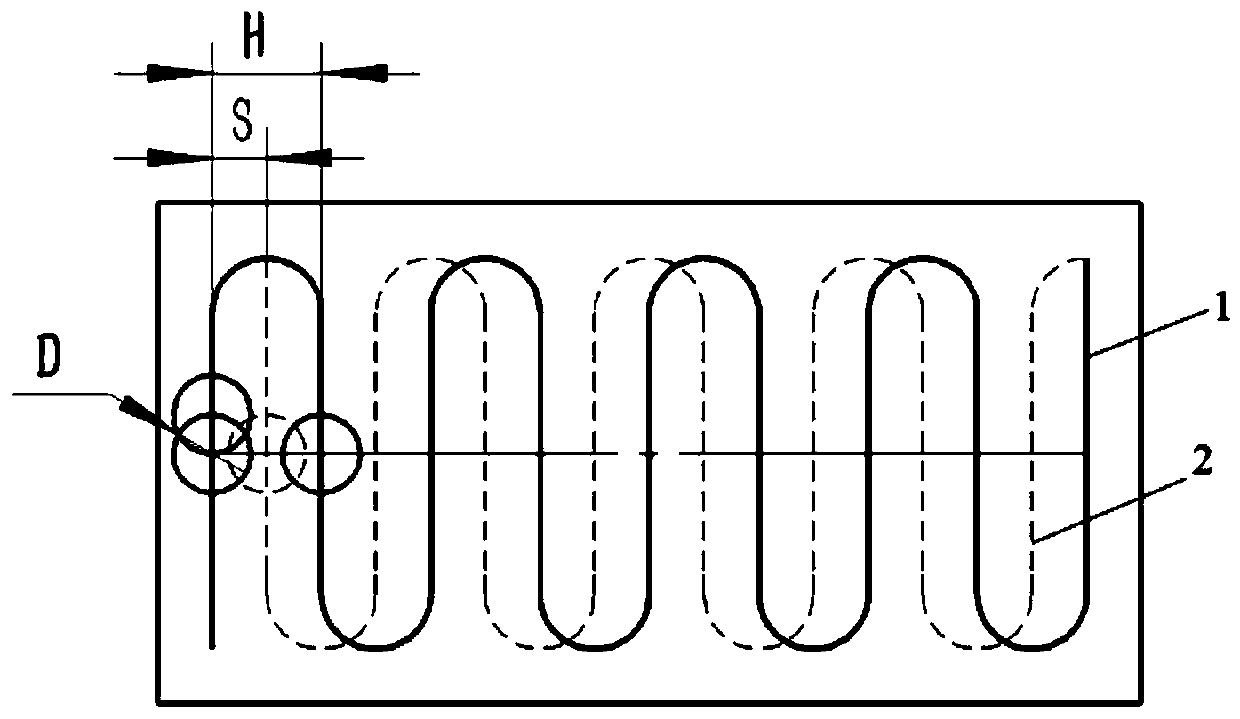

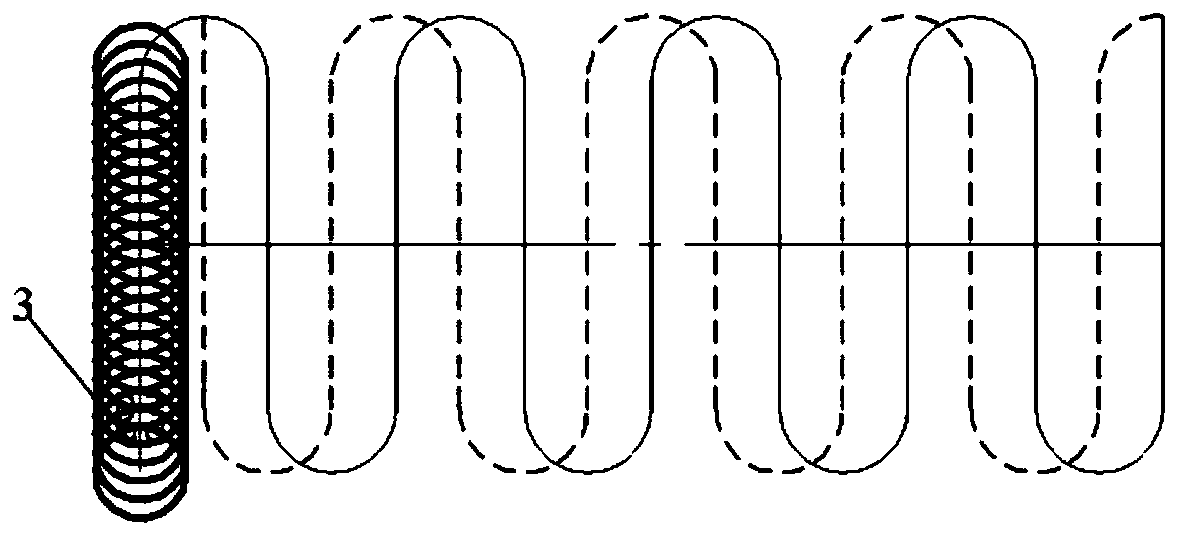

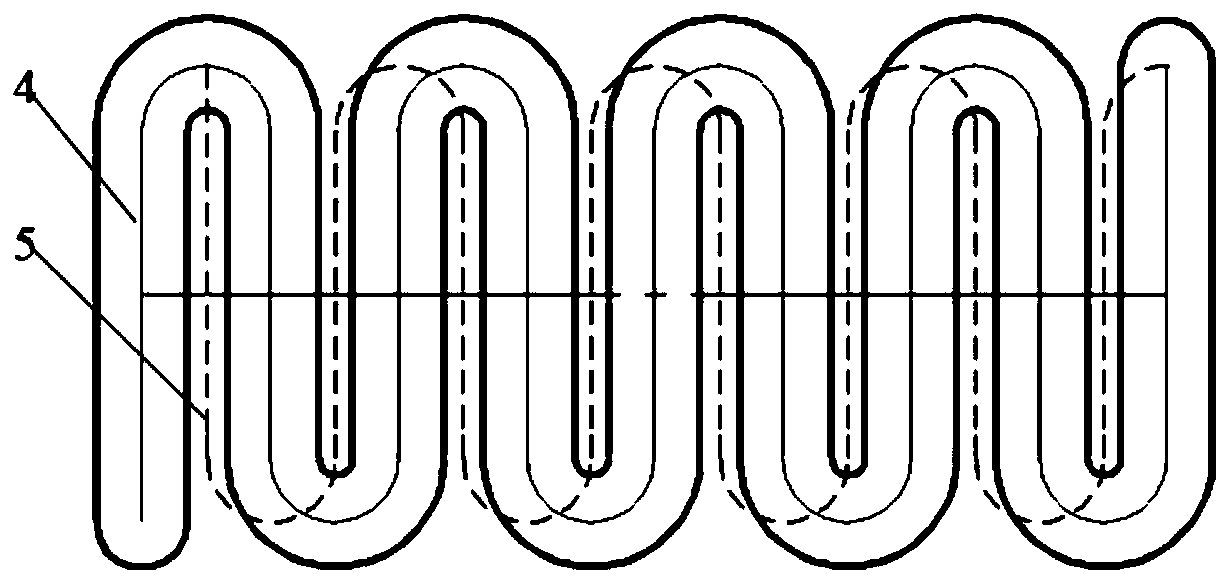

ActiveCN103255452AConducive to precise formingPromote precipitationPeristaltic pumpNumerical control

The invention belongs to the field of electrochemical process technology and relates to a selective metal electro-deposition device and application thereof. The metal electro-deposition device is characterized by comprising a liquid storage tank for containing electrolyte, a power supply namely an ultrasonic power supply electrically connected with a cathode and an anode correspondingly in electro-deposition process, an ultrasonic assistant jet apparatus supported by a rack and a three-dimensional numerical control platform which comprises a motion actuator, the rack and a computer, wherein the liquid storage tank is also externally provided with a peristaltic pump for supplying jet pressure for the electrolyte and a control valve for controlling the flow of the electrolyte, the liquid storage tank is internally provided with a temperature controller for keeping the temperature of the electrolyte, and an electrolyte nozzle is arranged at the bottom of the ultrasonic assistant jet apparatus. The selective metal electro-deposition device can improve the hardness, compactness and electro-deposition speed of a settled layer in the existing electro-deposition technology, lower the residual stress of a clad layer, and realize the selectivity of an electro-deposition area and the electro-deposition forming of parts of simple shape.

Owner:ACADEMY OF ARMORED FORCES ENG PLA

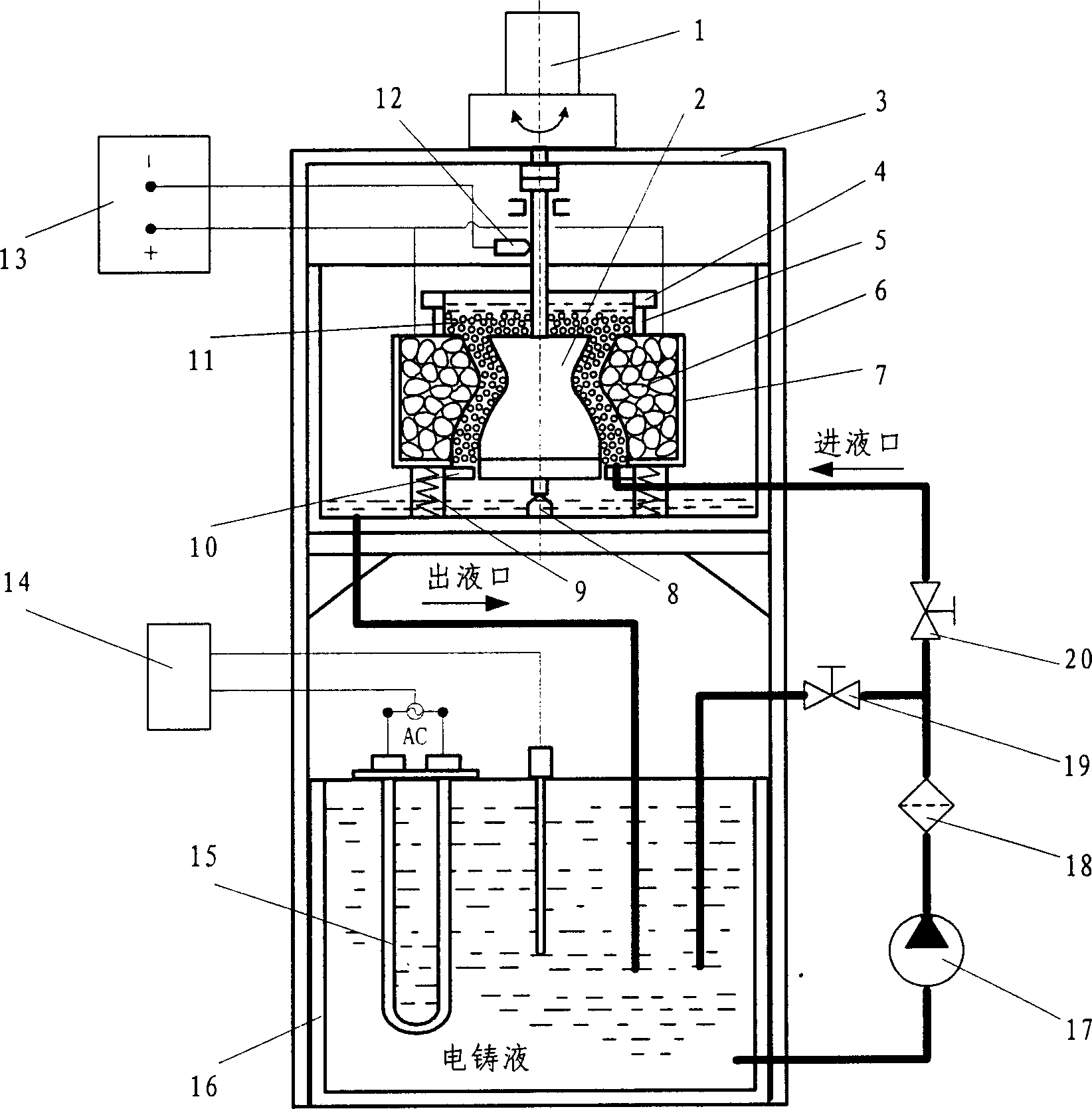

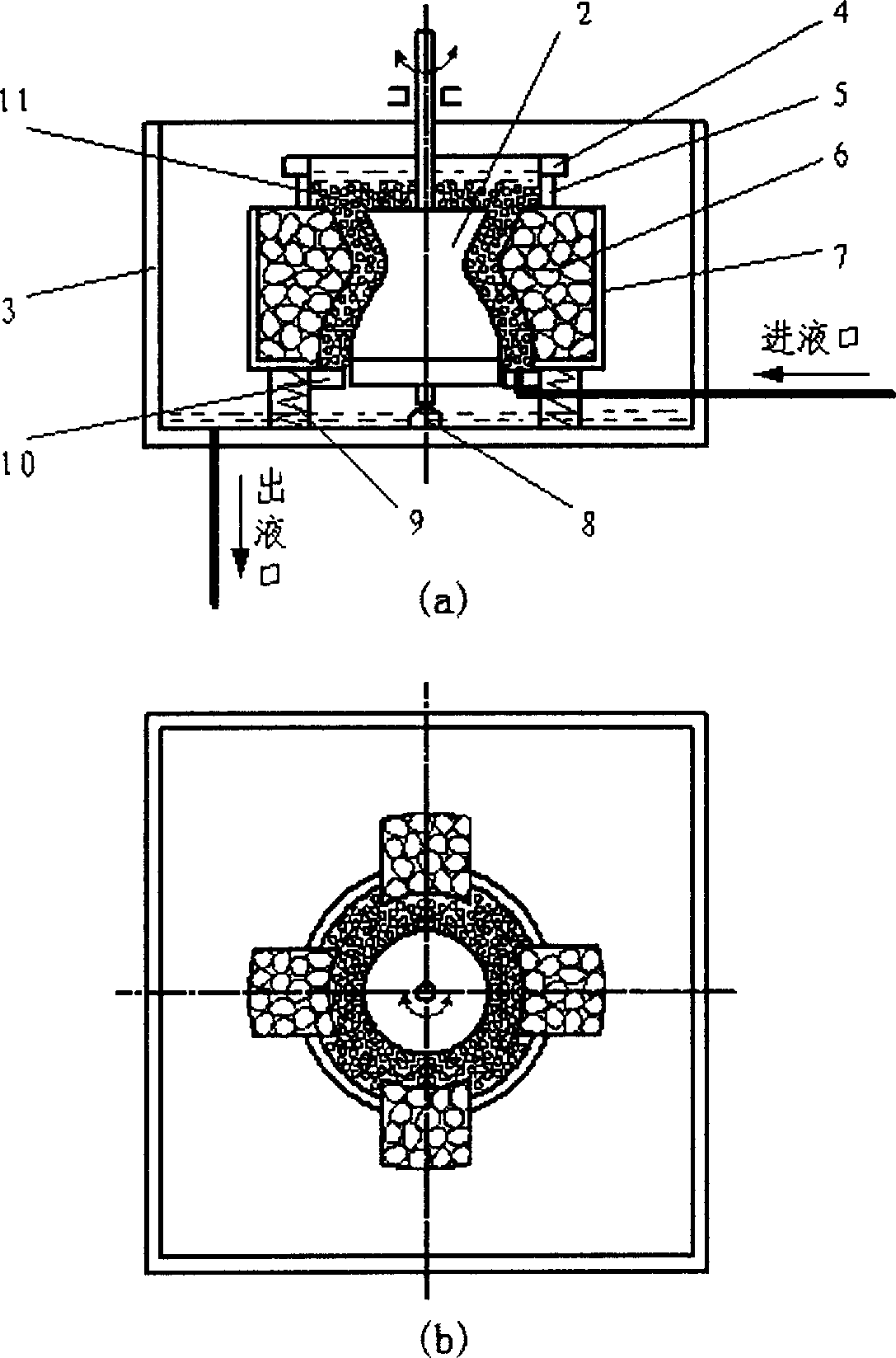

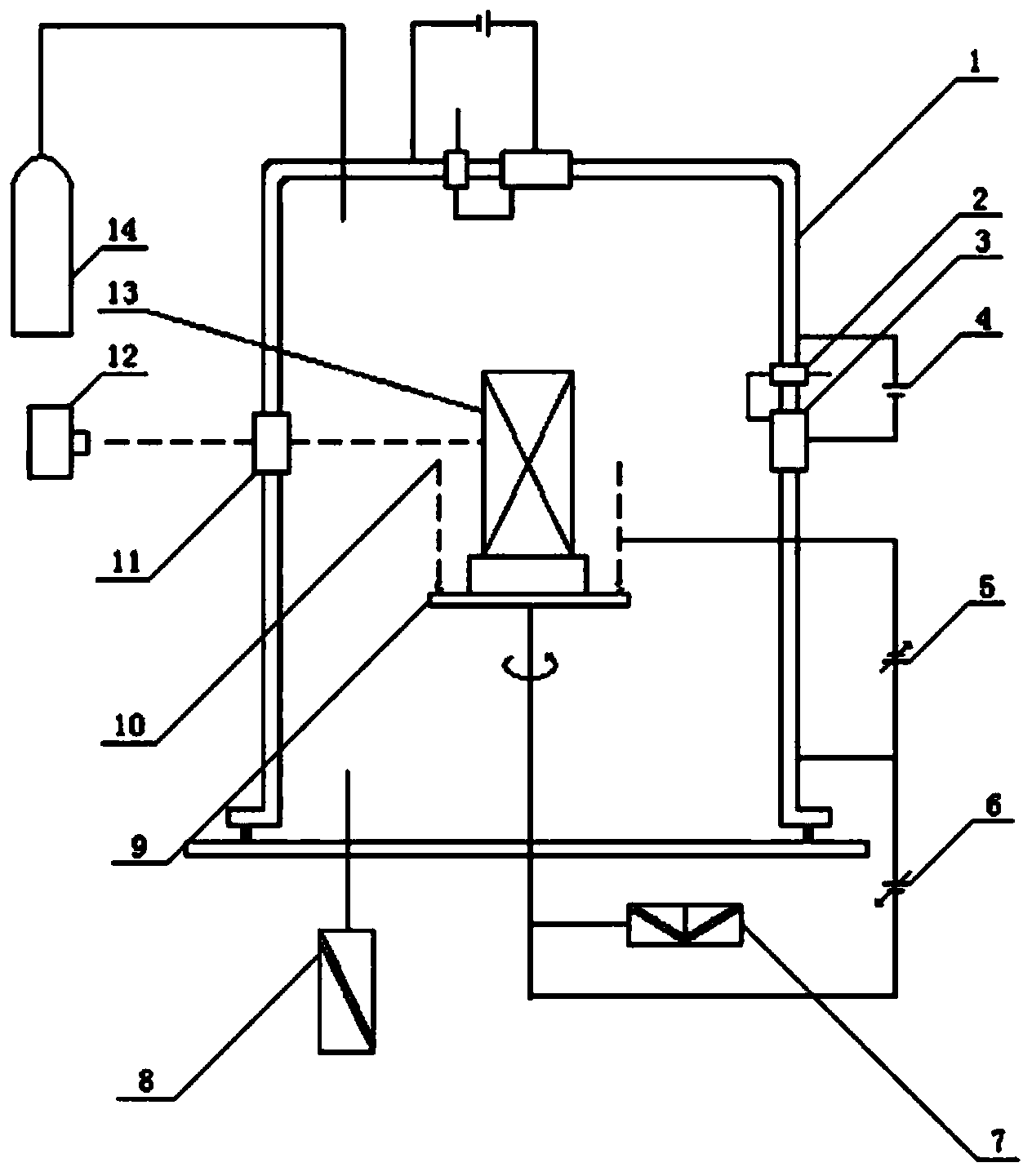

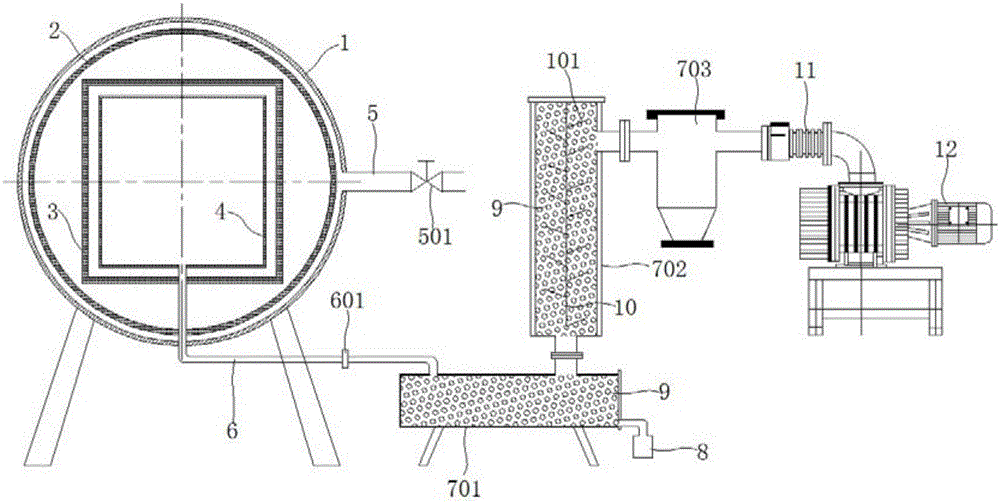

Revolving parts electroforming process and device

InactiveCN1844475AUniform and dense depositionUniform and dense tissueElectroforming processesTemperature controlBody of revolution

This invention relates to a body of revolution accessory electroforming processing method and device, which belongs to electroforming processing field. The character of this method as follows: in the electroforming liquid, adding hard particles; during the electroforming, making the hard particles do compound movement continuously to remove the attaching bubble and nubble of the deposition surface effectively by the friction, wherein the friction is to the electroforming surface form the hard particles; and the compound movement of the hard particles comes from two parts: one is the rotating movement of the cathode, the other is the vibrating of the cathode basket. The device of this invention is mainly includes: cathode rotating driving device, cathode basket vibrating driving device, temperature controlling device, electroforming liquid filtering cycle fluid supply system. This electroforming material produced by this invention has high quality.

Owner:NANJING UNIV OF AERONAUTICS & ASTRONAUTICS

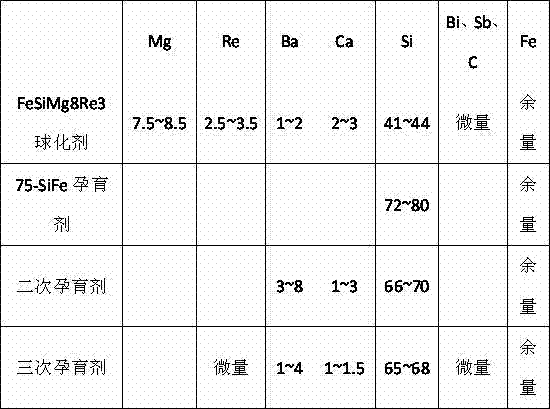

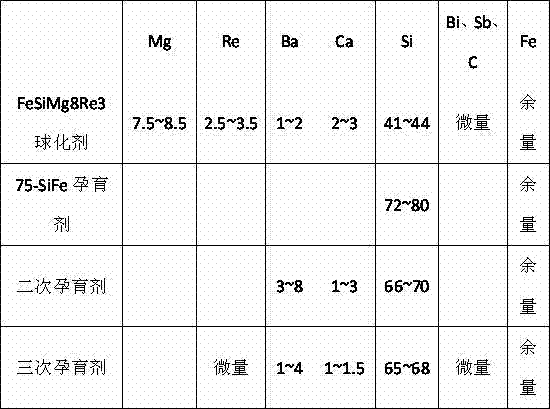

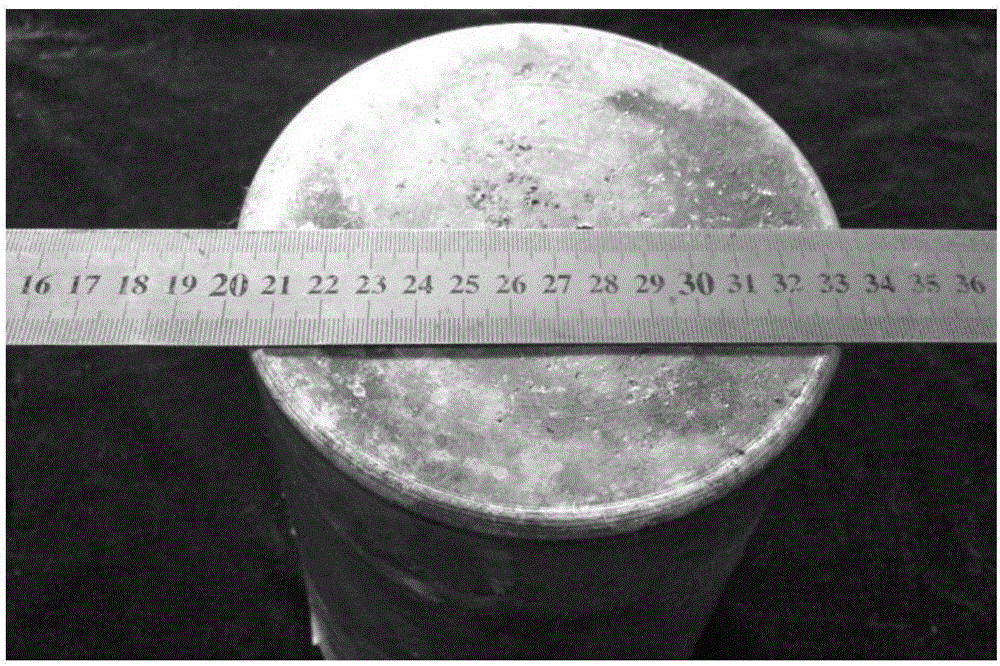

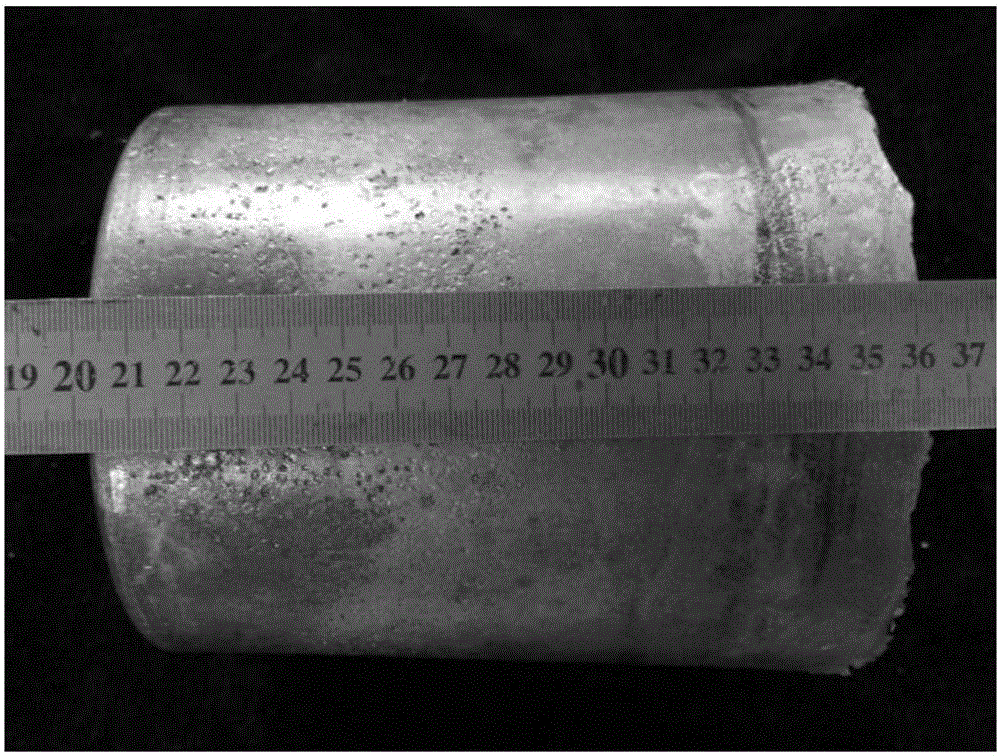

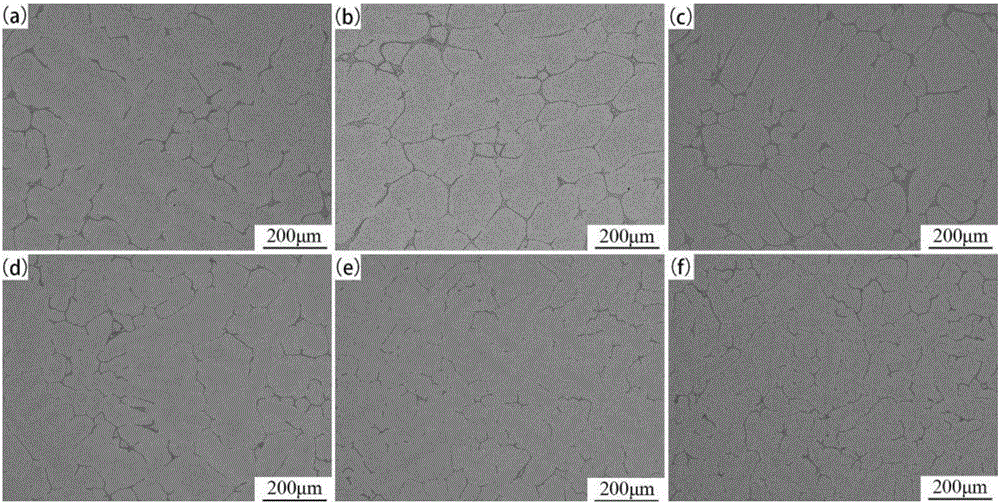

Manufacturing method of spheroidal graphite cast iron casting of wind power yaw variable-pitch device

The invention discloses a manufacturing process of a spheroidal graphite cast iron casting of a wind power yaw variable-pitch device. The process comprises the following processes of mould making, foaming and moulding, paint brushing, boxing and shaping, electric furnace smelting, tundish-covering nodulizing treatment, vacuum-assist pouring and three-time inoculation treatment, wherein the boxing and shaping process is a layered assembling process, so that the production efficiency can be improved and the process yield can be increased; cold iron is vibrated and reasonably arranged, so that the compactness of tissues in the casting can be improved and the defect of shrinkage porosity can be avoided; by virtue of the processes of electric furnace smelting and tundish-covering nodulizing treatment, the nodulizing rate of the casting can be stabilized and increased and the mechanical properties of the casting can meet the technical quality requirements of wind power castings; the spheroidal graphite cast iron casting manufactured by the process is compact and uniform in tissue, hardly has defects, has good surface quality and high size precision; the casting forming of multiple layers of castings can be realized; and the production efficiency and the process product yield are improved.

Owner:CHTC HEAVY IND

Method for preparing Al0.5CoCrFeNi high-entropy alloy

ActiveCN106756412AReduce volatilityGuaranteed compositional uniformityHigh entropy alloysSmelting process

The invention discloses a method for preparing an Al0.5CoCrFeNi high-entropy alloy. An intermediate alloy serves as a raw material, and volatilization of a low-melting-point element Al in the smelting process is greatly reduced. Meanwhile, a vacuum induction heating device is adopted, the electromagnetic stirring effect of the induction heating device is utilized, and therefore the component uniformity of a cast ingot is guaranteed. According to the method, the melting point difference between the lowest-melting-point metal Al and the highest-melting-point metal Cr is indirectly reduced, the problem of excessive volatilization of the low-melting-point Al simple substance in the smelting process is solved, and the component uniformity of the multi-element high-entropy alloy is guaranteed through the electromagnetic stirring effect existing in induction heating. Through reasonable designing of the atmosphere, the air pressure, the die preheating temperature, the smelting temperature, the heat preservation time, the casting speed and other parameters in the smelting process, a large Al0.5CoCrFeNi high-entropy alloy cast ingot is successfully prepared.

Owner:NORTHWESTERN POLYTECHNICAL UNIV

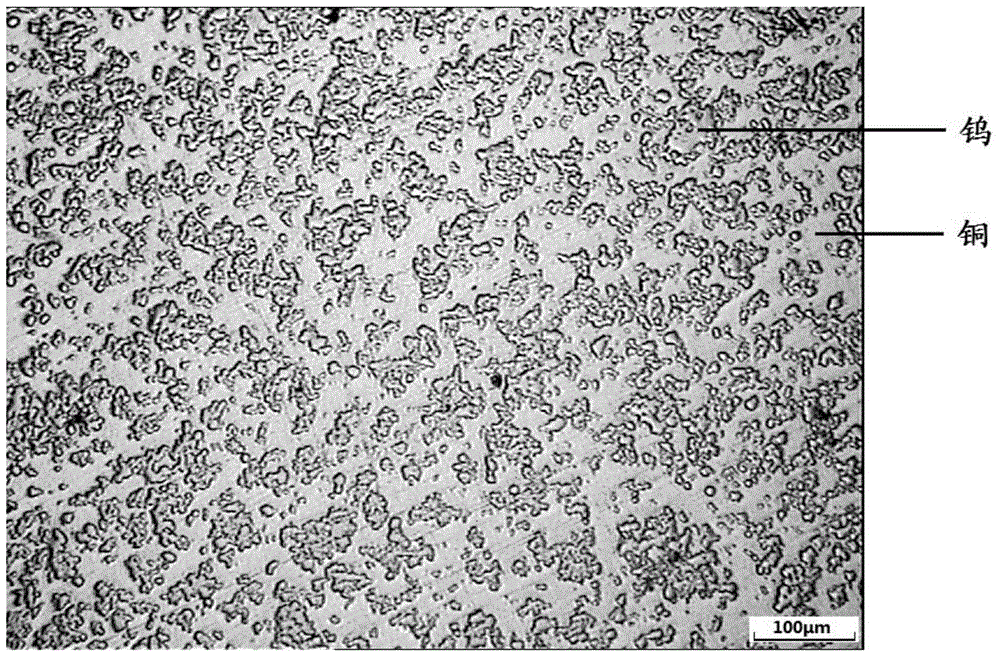

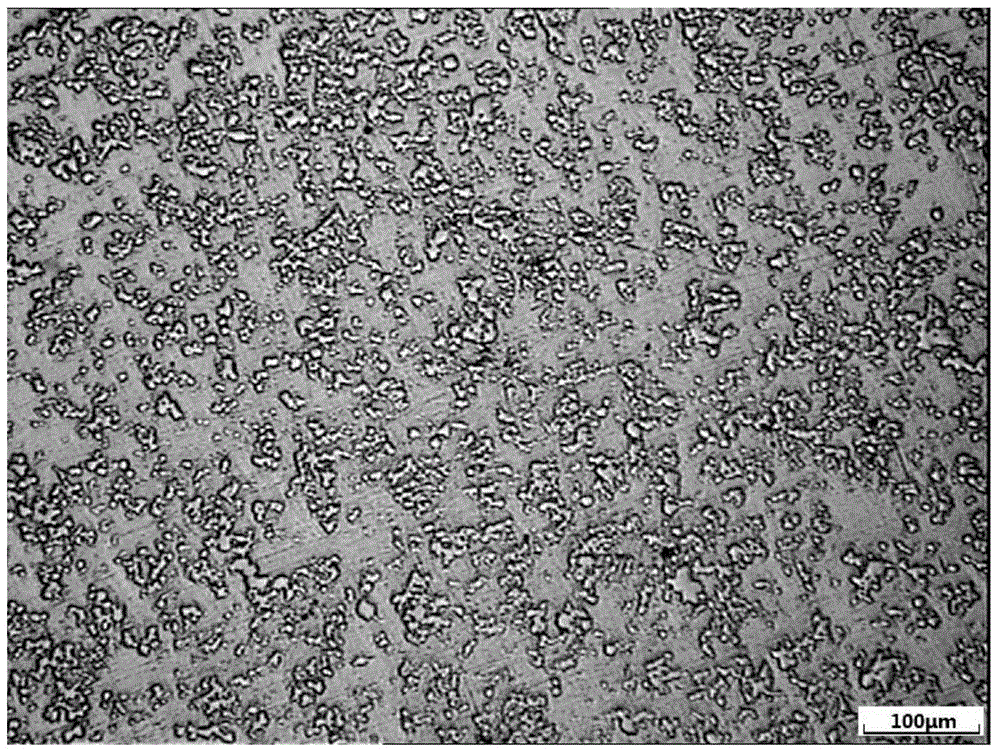

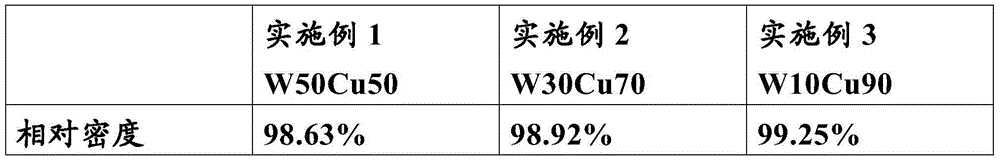

Tungsten copper alloy with low tungsten content and preparation method of tungsten copper alloy

The invention provides a method for preparing a tungsten copper alloy. The preparation method comprises the steps of preparing tungsten and copper mixed powder into a briquet for presintering, and hot-pressing the briquet at a temperature lower than a melting point of copper. The tungsten copper alloy prepared by the preparation method is uniform in texture, high in density, excellent in performance and high in rate of finished products.

Owner:BAOJI JING LONG TUNGSTEN & MOLYBDENUM CO LTD +1

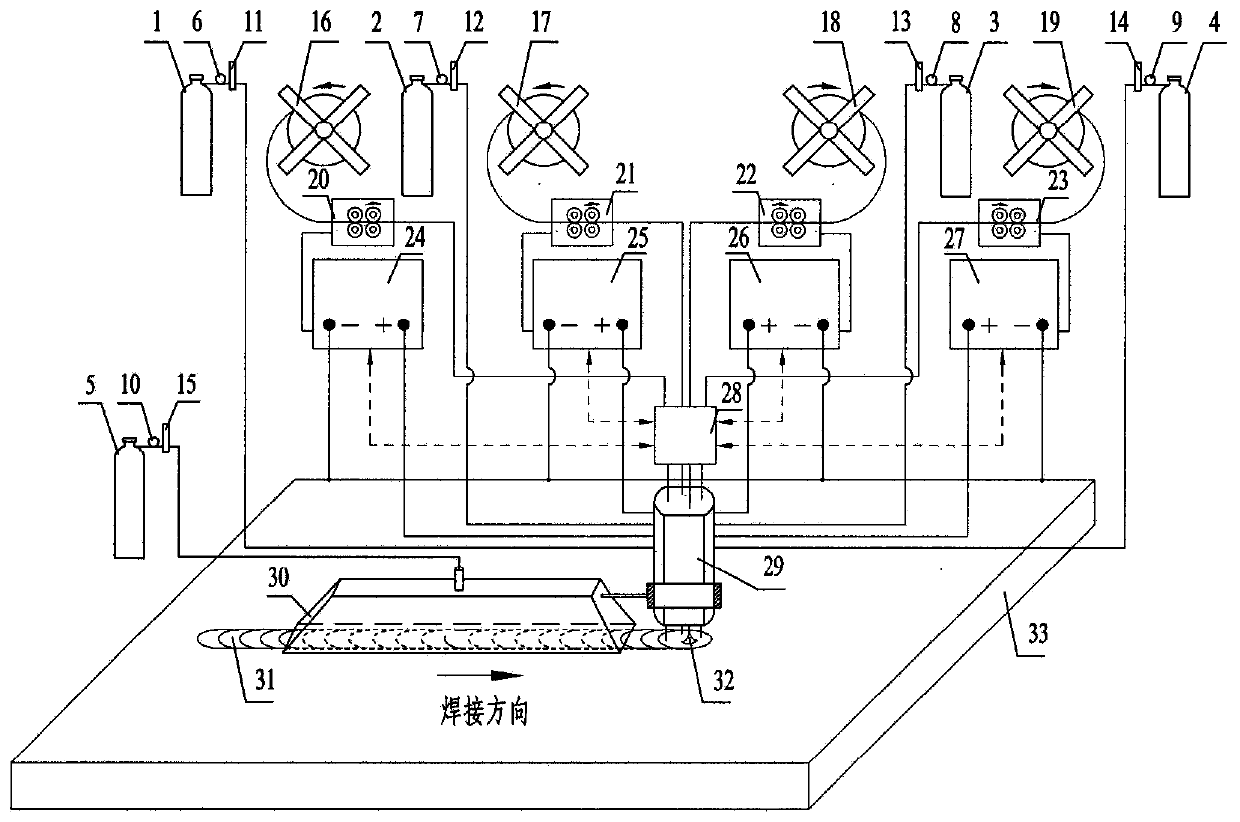

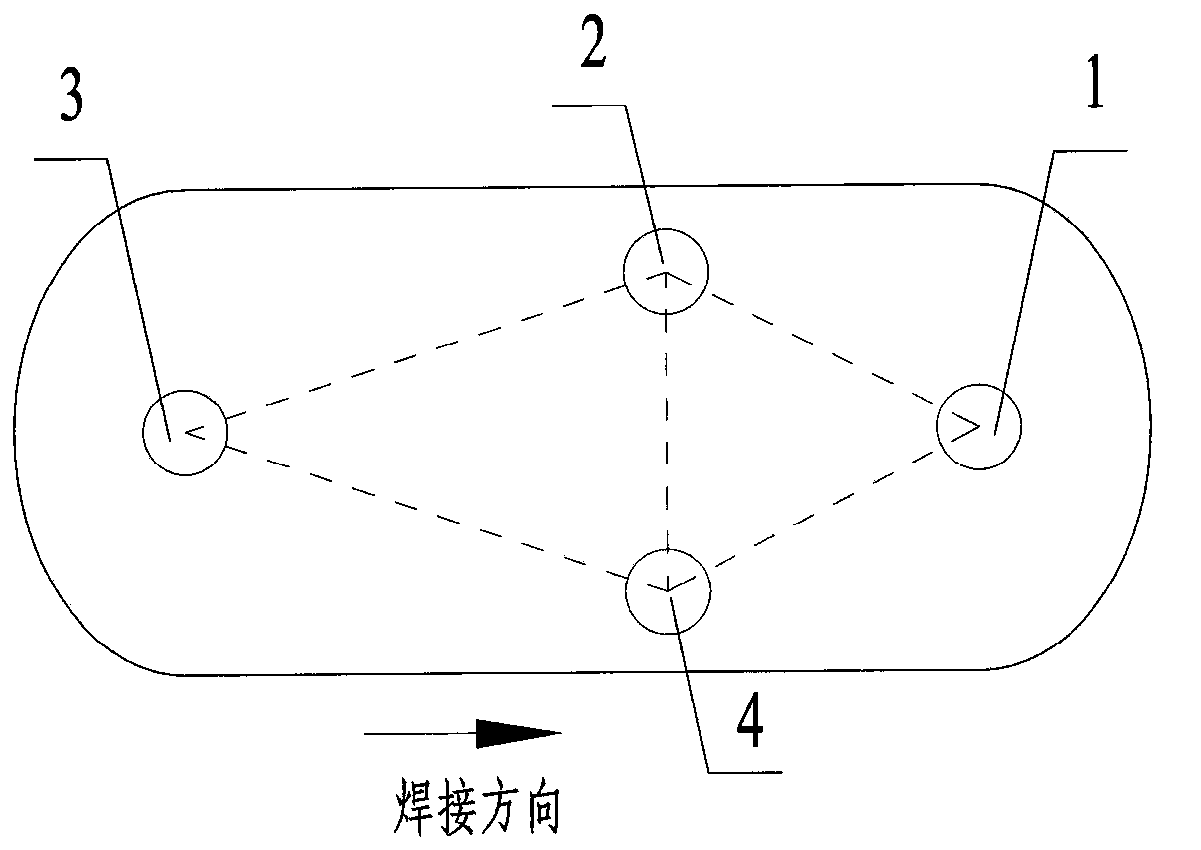

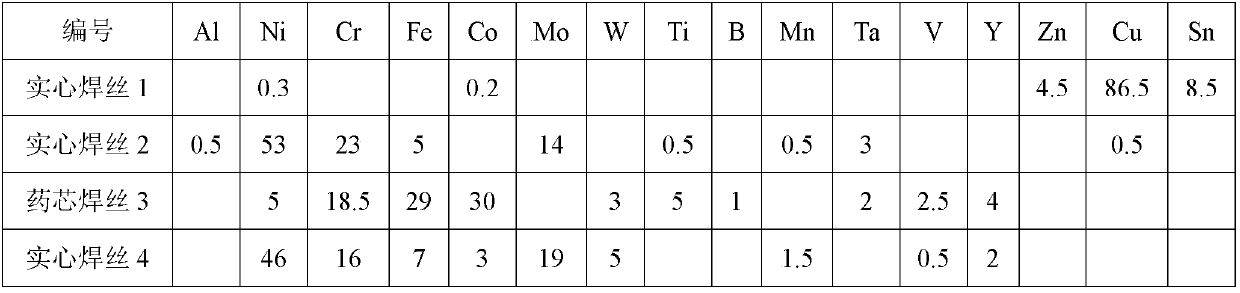

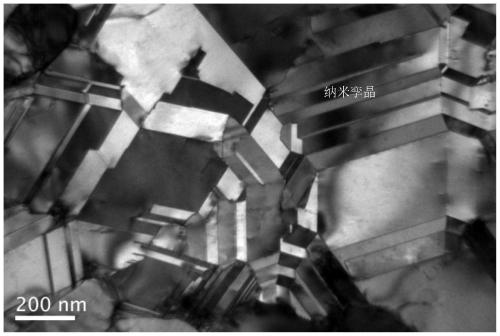

High-entropy alloy double technology preparation method

The invention relates to the technical field of high-entropy alloy, in particular to a high-entropy alloy double technology preparation method. The high-entropy alloy double technology preparation method comprises the steps that firstly, types of four welding wires and components, contents, existence forms and existence positions of welding wire elements are decomposed and designed according to the element components, contents and physico-chemical properties of high-entropy alloy needing to be prepared, and the welding wires are prepared; secondly, an integrated four-wire pulse gas shielded welding technology is adopted to cooperate with additional materials to manufacture the high-entropy alloy; and finally, a vacuum self-consumption remelting technology is adopted to refine the high-entropy alloy. According to the high-entropy alloy double technology preparation method provided by the invention, the technology is stable, the preparation efficiency is high, the cost is low, the heat input adjusting range is wide, the optional alloy element range is wide, the quantity of types of prepared high-entropy alloy is large, alloy component adjusting is convenient and accurately controllable, chemical components are uniform, the structure is compact and uniform, the degree of purity is high, and the inner quality is good.

Owner:SHIJIAZHUANG TIEDAO UNIV

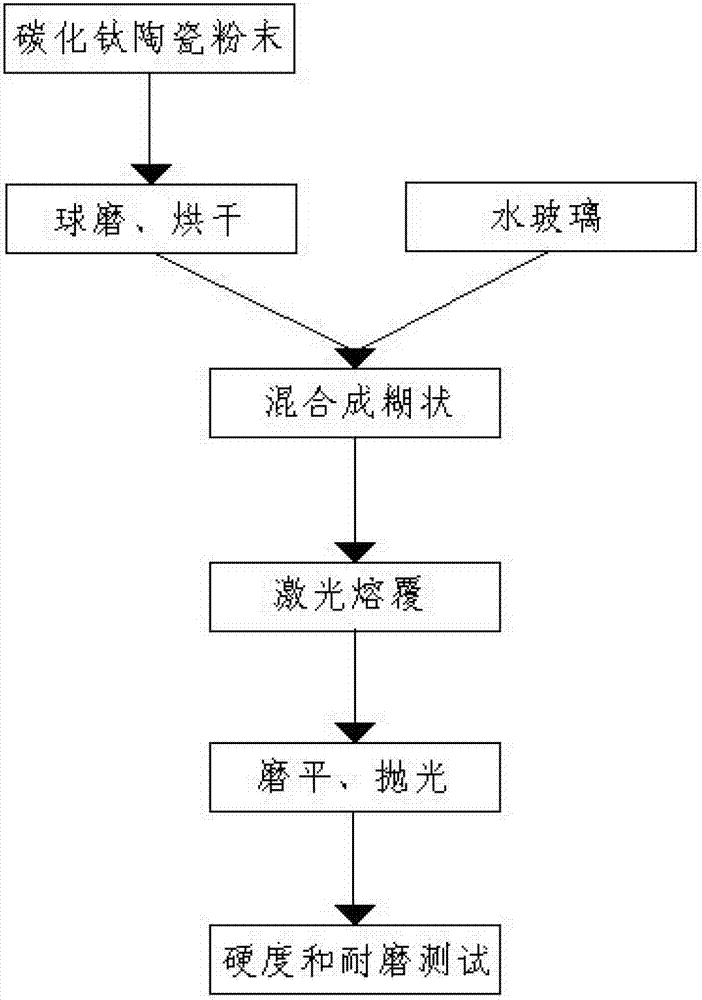

Titanium carbide metal ceramic powder and method for laser cladding of powder

InactiveCN102962447AImprove wear resistanceHigh hardnessMetallic material coating processesHardnessTitanium carbide

The invention relates to the technical field of metal surface treatment, and specifically discloses a titanium carbide metal ceramic powder and a method for laser cladding of the powder. The titanium carbide metal ceramic powder consists of titanium carbide, lanthanum oxide and nickel 60. The method comprises the following steps of: putting the titanium carbide ceramic powder in a ball mill to be ball-milled for 15 hours to 20 hours, and drying the ball-milled powder; mixing the dried powder and water glass into a paste powder; coating the paste powder onto the surface of a test block to be clad to be flatly pressed, and drying naturally; cladding the dried paste powder on the test block by using a pulsed laser machine; flatly grinding the clad test block, carrying out the polishing treatment of the clad surface, and then cleaning with anhydrous ethanol; and carrying out the hardness test and the wear test of the test block. The cladding layer obtained from the invention has the advantages of strong high temperature resistance, strong wear resistance, high hardness, compact and uniform structure, uniform thickness, grain refinement, few pores and cracks, good surface quality and the like.

Owner:SHANTOU UNIV

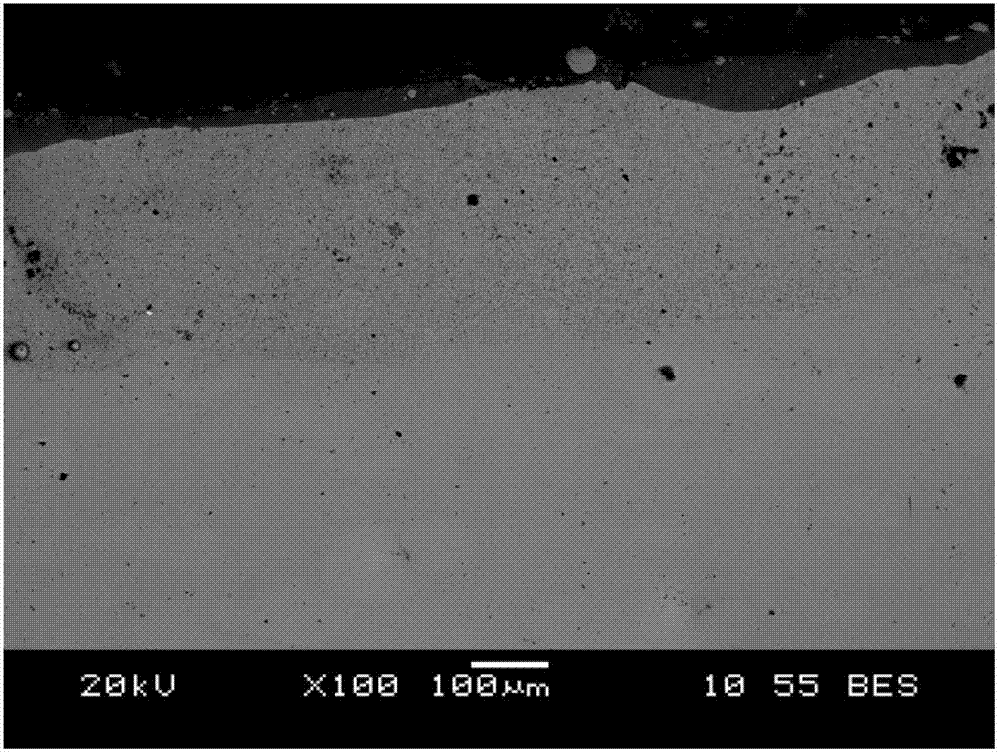

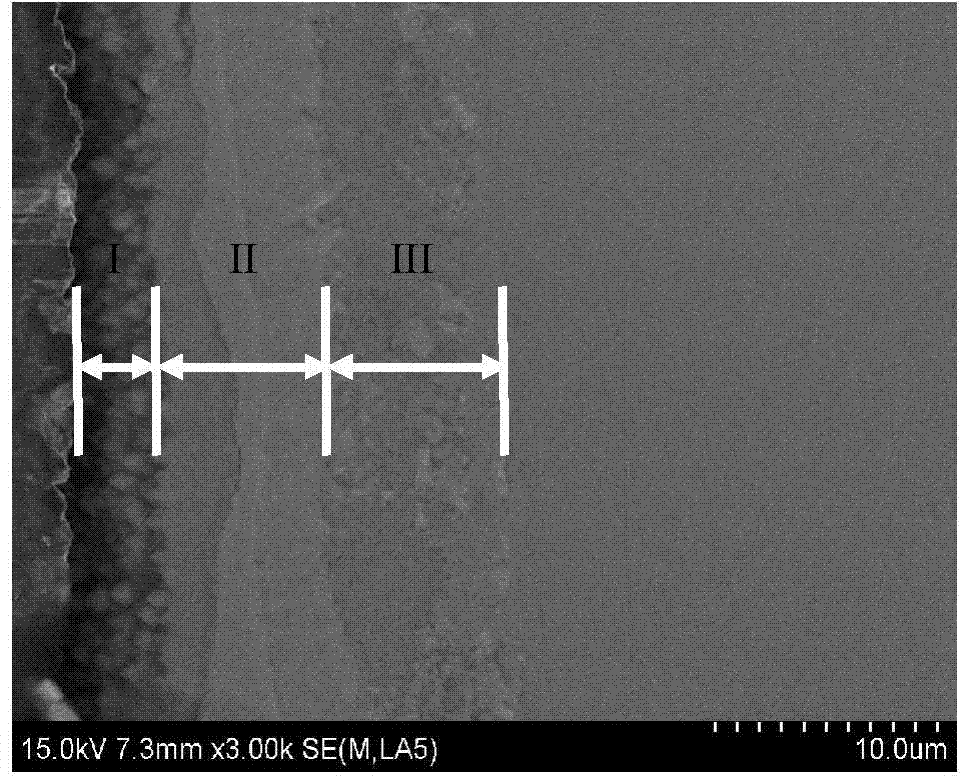

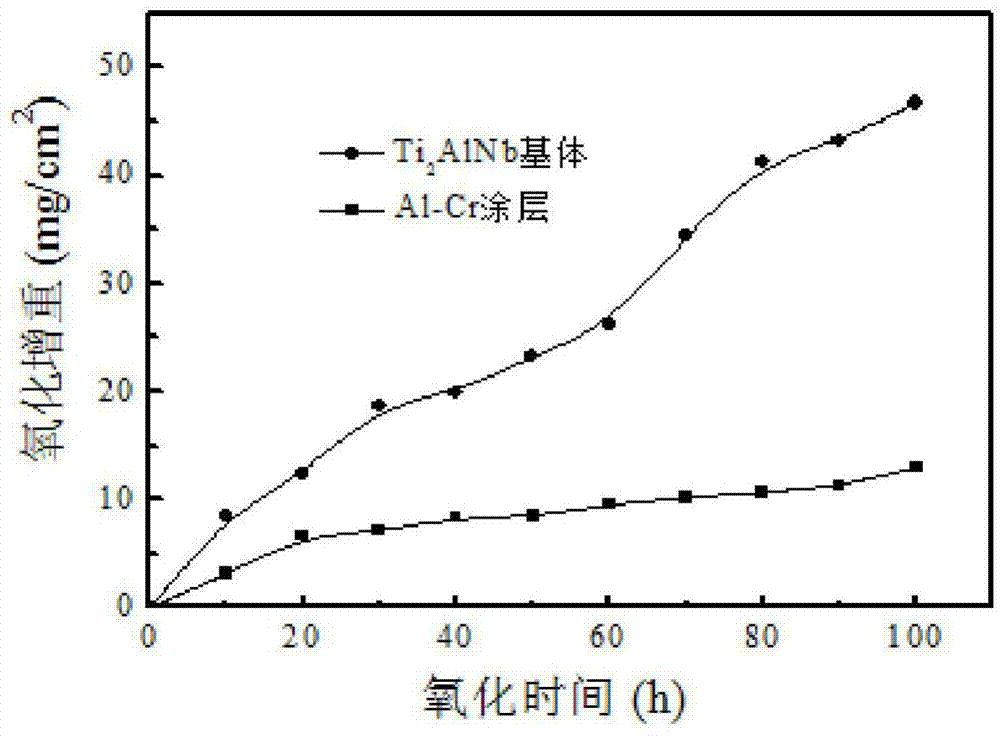

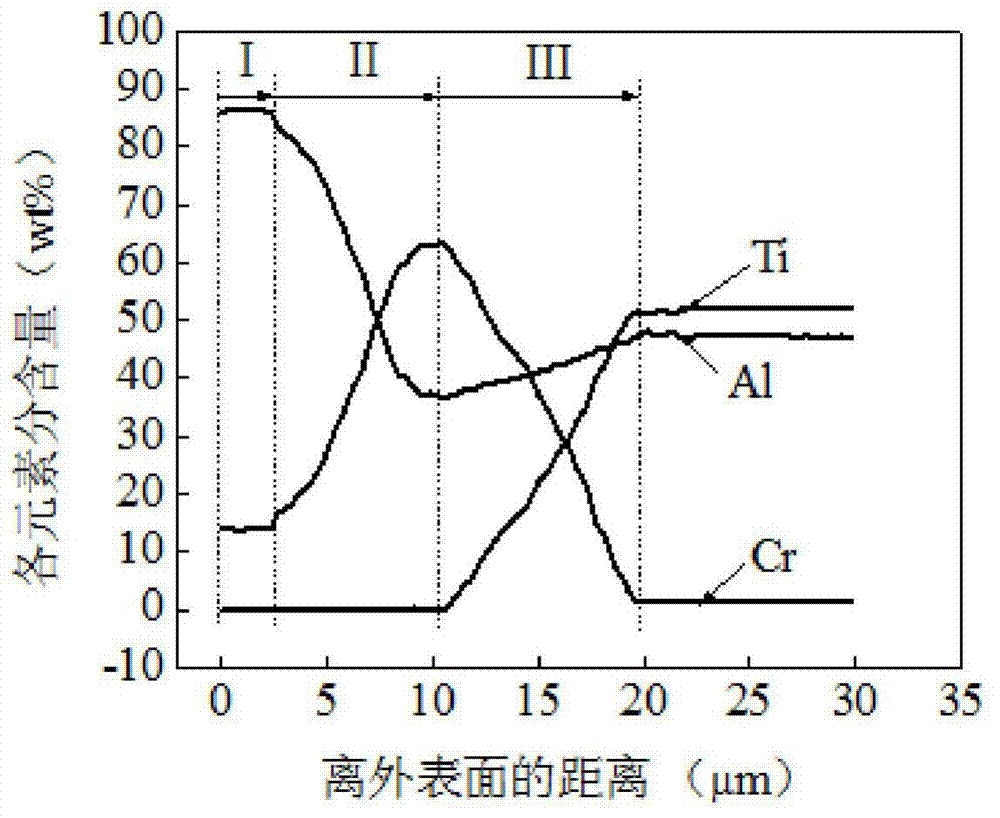

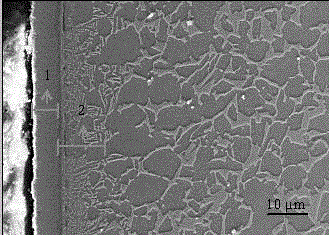

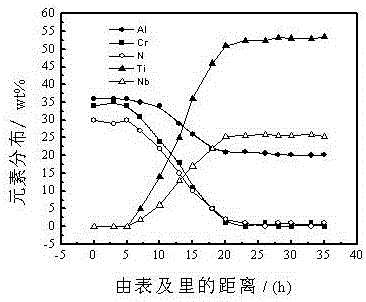

Titanium aluminum alloy surface high temperature oxidation and hot corrosion resistant Al-Cr coating and preparation method thereof

InactiveCN104760349AImprove high temperature oxidation resistanceAccelerated corrosionVacuum evaporation coatingSputtering coatingOxidation resistantThermal shock

The present invention discloses a titanium aluminum alloy surface high temperature oxidation and hot corrosion resistant Al-Cr coating; an Al-rich deposition layer, an Al-Cr alloy layer and a Cr diffusion layer are successively arranged from surface to a titanium aluminum alloy substrate. The content of Al in the Al-rich deposition layer remains the same. The content of Al in the Al-Cr alloy layer gradually reduces outside-to-inside to 70%-100% of the content of Al in the titanium aluminum alloy substrate, and the rest in the Al-Cr alloy layer is Cr. The contents of Cr and Al in the Cr diffusion layer respectively gradually reduces outside-to-inside to same as the contents of Cr and Al in the titanium aluminum alloy substrate, and the rest in the Cr diffusion layer is other elements in the titanium aluminum alloy substrate, and the contents of other elements in the Cr diffusion layer respectively gradually rise to same as the contents of the other elements in the titanium aluminum alloy substrate from zero. The invention also discloses a preparation method of the titanium aluminum alloy surface high temperature oxidation and hot corrosion resistant Al-Cr coating; the titanium aluminum alloy surface high temperature oxidation and hot corrosion resistant Al-Cr coating can give titanium aluminum alloy excellent oxidation resistance and heat resistance corrosion performance under high temperature and long term service conditions, and due to the presence of the diffusion layer of the gradient components, the reliable binding strength and excellent thermal shock resistance can be realized.

Owner:NANJING UNIV OF AERONAUTICS & ASTRONAUTICS

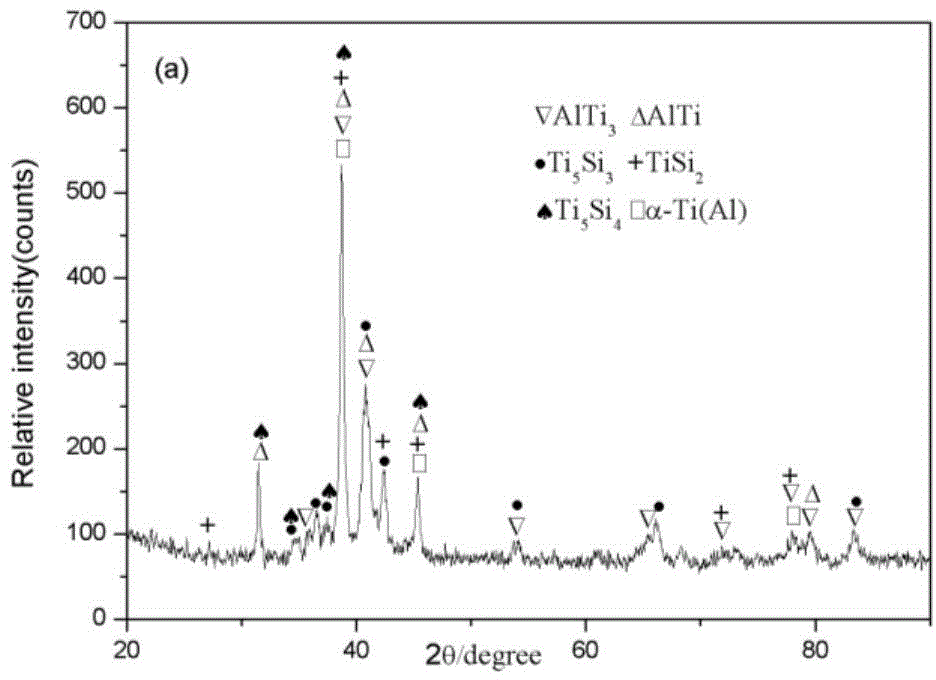

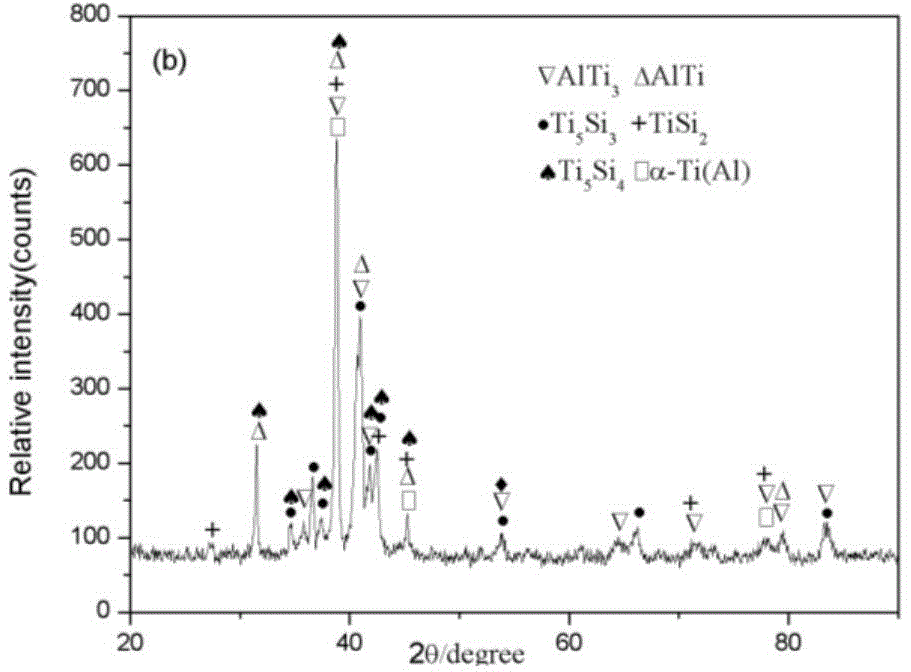

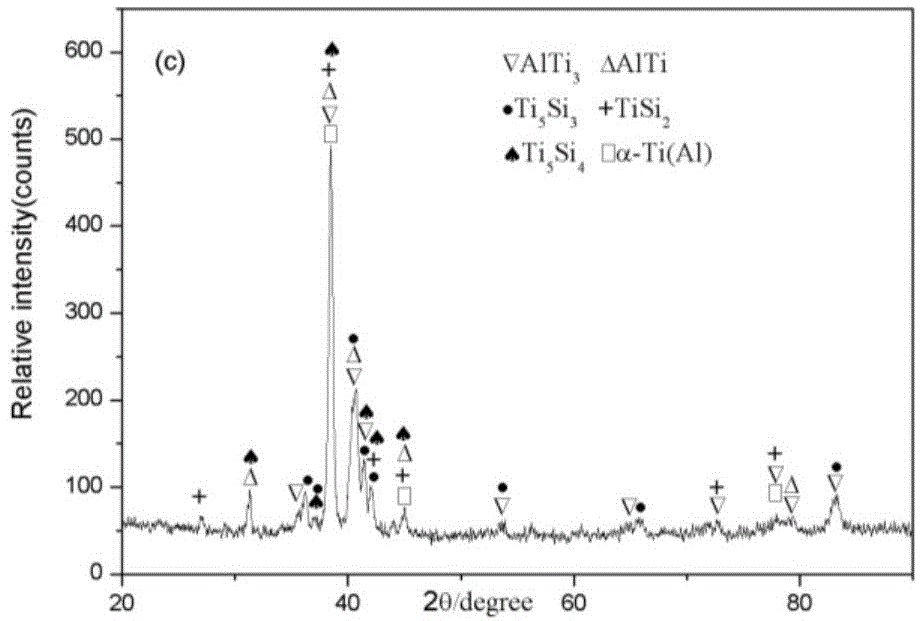

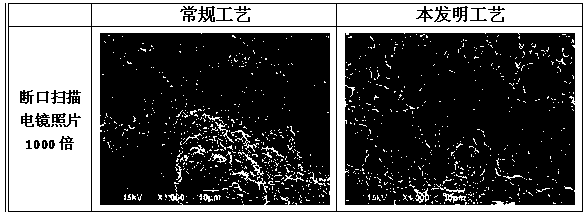

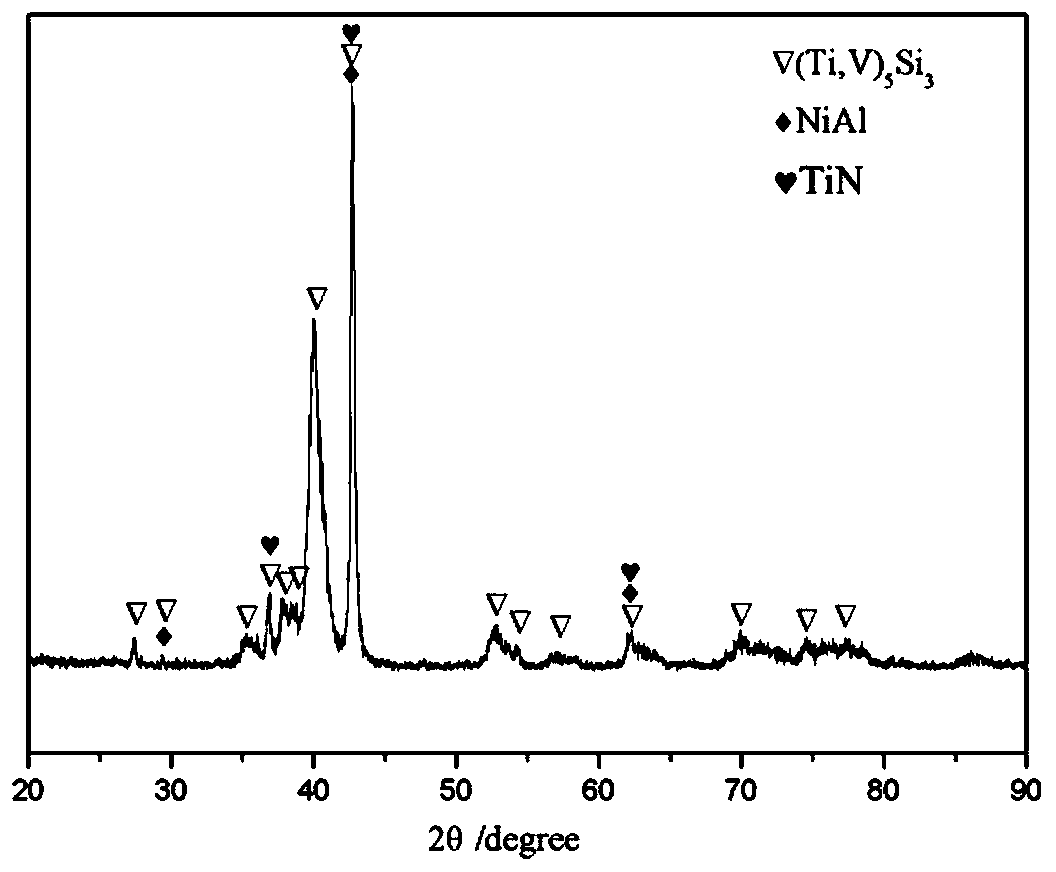

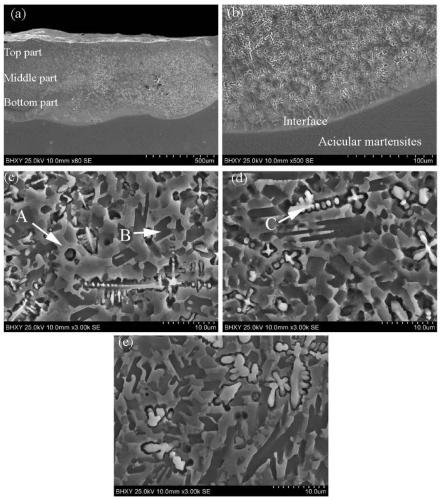

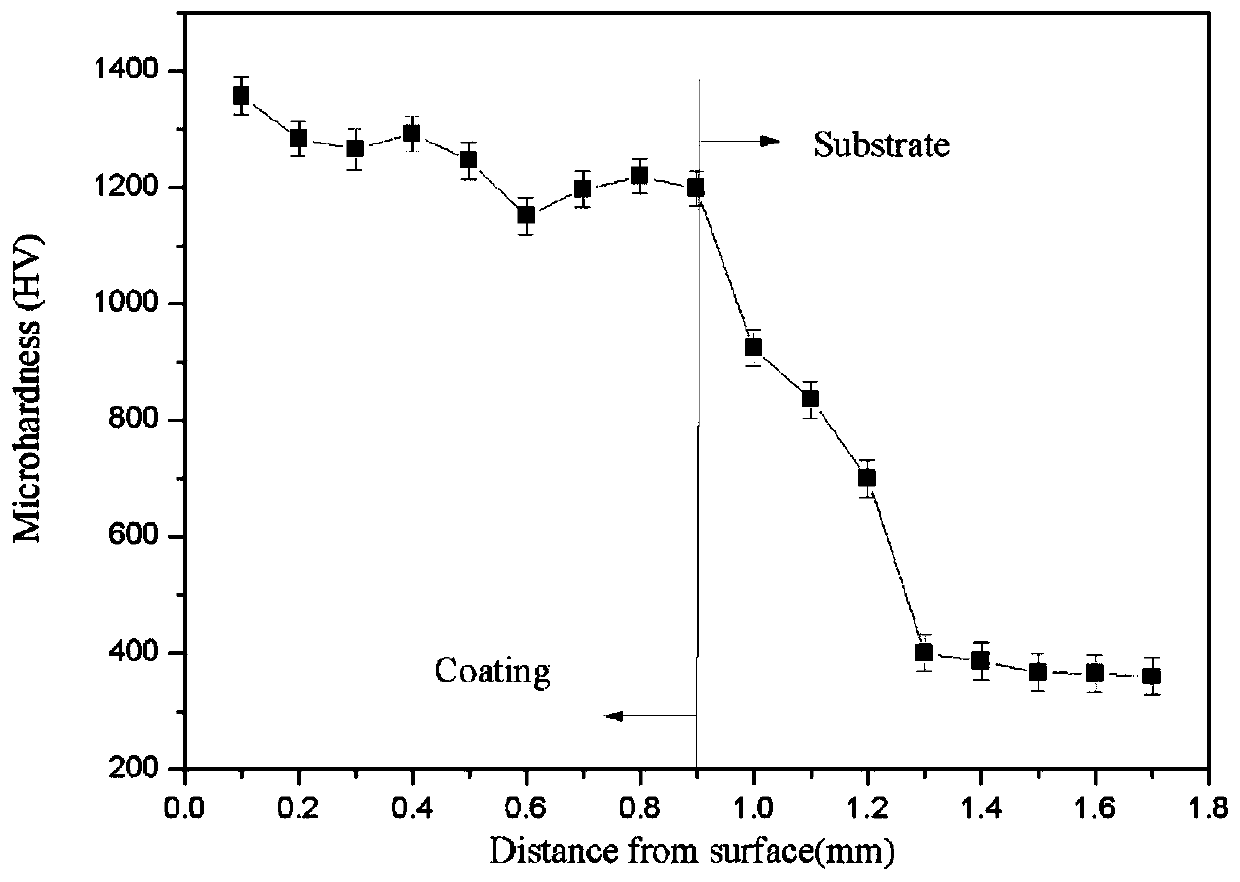

Preparation technology of intermetallic compound based ceramic composite coating on surface of titanium alloy

ActiveCN104152895AHigh hardnessGood metallurgical bondMetallic material coating processesCeramic compositeShielding gas

The invention discloses a preparation technology of an intermetallic compound based ceramic composite coating on the surface of a titanium alloy. The preparation technology comprises the following steps of: (1) uniformly mixing cladding material powder, preparing mixed powder into paste with a water glass solution, uniformly coating the surface of the titanium alloy with the paste with the coating thickness of 0.5-1.0mm, carrying out airing, and (2) carrying out laser cladding on the coating on the surface of the titanium alloy with the laser power of 800-1200W and the laser scanning speed of 2.5-7.5mm / s, and blowing argon for shielding with the shielding gas pressure of 0.2-0.4MPa, wherein a laser spot diameter is fixed at 4mm.The mixed cladding material powder comprises the following ingredients by mass percentage: 25-65% of Ti, 20-60% of Al, 5-30% of Si and 0-3% of Y2O3, or 25-65% of Ti, 20-60% of Al, 5-30% of Si, 2-40% of B4C and 0-3% of Y2O3, or 25-65% of Ti, 20-60% of Al, 5-30% of Si, 5-40% of TiC, and 0-3% of Y2O3. The composite coating prepared by the technology can significantly increase microhardness of the titanium alloy, improve wear resistance of titanium alloy components, and extend an application scope of titanium alloy spare parts.

Owner:SHANDONG UNIV

Material for aluminumbronze surface laser cladding and laser cladding method

InactiveCN101255522AImprove performanceImprove mechanical propertiesMetallic material coating processesSquare MillimeterAlloy

The invention relates to a material for laser cladding of an albronze surface and a laser cladding method. The material is composed of 25% to 35% by weight of Cu, 11.5% to 14.5% by weight of Cr, 2.0% to 3.0% by weight of Zr, 2.5% to 3.5% by weight of B, 2.5% to 3.0% by weight of Si, 5.5% to 6.5% by weight of Fe, and the balance Ni, the above materials are 100 to 300 mesh powder; the method comprises the following steps: preparing the materials in the above proportions, uniformly mixing the prepared materials, weighting the alloy powder in 0.02g to 0.08g per square millimeter according to the area of the laser cladding, presetting the alloy powder on the albronze surface by acrylics, compacting after vacuum drying (40 DEG C to 70 DEG C), scanning the preset layer by gradually reducing laser power with a speed of 6 to 8 millimeters per second and a spot diameter of 4 millimeters.

Owner:LANZHOU UNIVERSITY OF TECHNOLOGY

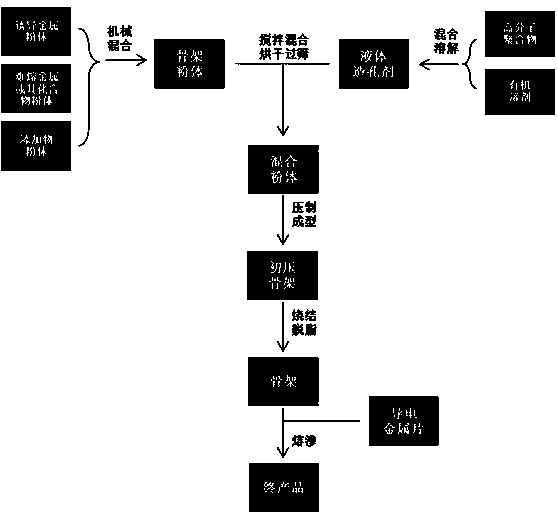

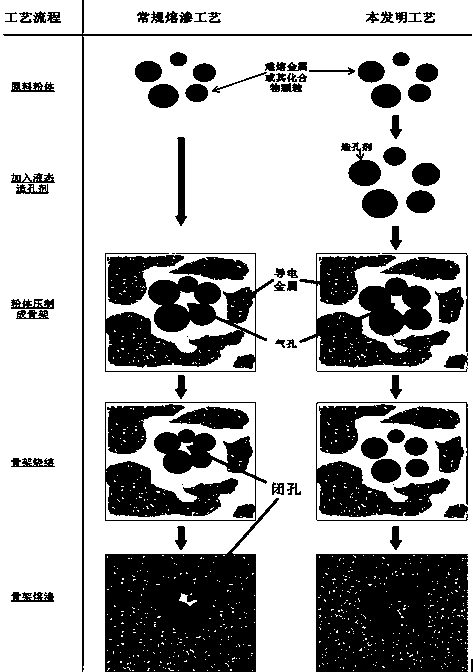

Manufacturing method of electrical contact

ActiveCN104209520AImprove infiltration effectFull penetrationElectric switchesOrganic solventPolymer

The invention relates to a manufacturing method of an electrical contact. A liquid material prepared by dissolving high-molecular polymer in an organic solvent is used as a pore-forming agent; blind holes are eliminated by the pore-forming agent; by eliminating the blind holes and simultaneously leading in a uniform and communicated pore network, infiltration performance of a skeleton is promoted; a smoother passage is created for flowing of conductive metal liquid, so that the conductive metal liquid more sufficiently permeates the skeleton to obtain an infiltration electrical contact product of which the tissues are more uniform and compact and are more firmly combined. The steps of eliminating the blind holes in the skeleton and forming the uniform and communicated pore network are implemented in a mode of leading in the liquid pore-forming agent in the powder manufacturing process and removing the liquid pore-forming agent after the skeleton is formed. By regulating the addition and the adding mode of the pore-forming agent, the form of the pores in the skeleton can be regulated so as to adapt to the requirements of different infiltration systems. The pore-forming agent used by the manufacturing method is the liquid material and can be completely gasified and removed at a specific temperature and liquid or solid residues cannot be formed in the skeleton, so that the skeleton is guaranteed to have excellent infiltration.

Owner:ZHEJIANG FUDA ALLOY MATERIALS TECH CO LTD

Preparation method of oblique oil cylinder body

The invention discloses a preparation method of an oblique oil cylinder body. The method comprises the following step of: a, preparing a metal solution which comprises the following chemical composition in percentage by weight: 0.18-0.27% of C, 1.1-2.0% of Mn, 0.6-1.25 of Si, 0.08-0.15% of V, 0.11-0.2% of Ti, 0.8-2.0% of Cr, 0.5-1.5% of Ni, trace amount-0.40% of Mo, 0.1-0.8% of WO, 0.05-0.07% of Nb, trace amount-0.23% of Al, trace amount-0.50% of Cu, no more than 0.030% of P, no more than 0.030% of S, and the balance of aluminum and inevitable foreign matters. Aiming at the defects of higher cost and low material utilization ratio, the invention provides preparation method of an aluminum alloy oil cylinder body cover which is simple in forming process, low in manufacturing cost, high in material utilization ratio, high in product strength and light in weight.

Owner:ANHUI ZHENYE MACHINERY

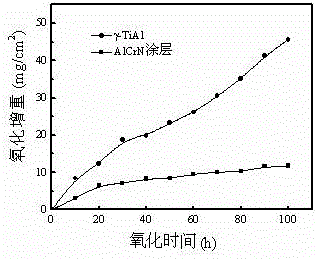

High-temperature-oxidation-resistant and abrasion-resistant AlCrN coating on surface of titanium-aluminum alloy and preparation method thereof

InactiveCN105839049AImprove wear resistanceThe surface of the coating is smooth and denseVacuum evaporation coatingSputtering coatingOxidation resistantGlow plasma

The invention discloses a high-temperature-oxidation-resistant and abrasion-resistant AlCrN coating on the surface of a titanium-aluminum alloy and a preparation method thereof. The coating is deposited on the surface of a titanium-aluminum alloy workpiece through the double glow plasma surface technology, an AlCrN deposited layer is located on the surface of the coating and is 5-10 micrometers thick, and a compact oxidized layer rich in Al2O3 and Cr oxide is formed by the AlCrN deposited layer at a high temperature; an AlCrN diffused layer is arranged in the coating and is 12-15 micrometers thick; the hardness of the obtained coating is 30-37 GPa, the room temperature friction coefficient of the coating is 0.3-0.33, and the high-temperature friction coefficient of the coating is 0.47-0.49. The preparation method includes the steps of charging, vacuumizing, workpiece surface activation, plasma permeation of the AlCrN coating, cooling and discharging. The obtained AlCrN coating solves the problem that the titanium-aluminum alloy is poor in high-temperature-oxidation resistance; meanwhile, the gradient structure of the diffused layer achieves metallurgical bonding of the coating and a substrate, and good high-temperature-oxidation resistance and good abrasion resistance are achieved.

Owner:NANJING UNIV OF AERONAUTICS & ASTRONAUTICS

High-entropy alloy coating resistant to high-temperature abrasion and preparation process and application thereof

ActiveCN109763125AHigh hardnessImprove wear resistanceMetallic material coating processesHigh entropy alloysRare earth

The invention relates to a high-entropy alloy coating resistant to high-temperature abrasion and a preparation process and application thereof. The preparation process comprises the following steps: (1) the surface of a titanium alloy sample is polished and washed; (2) metal powder, a ceramic hard phase and rare earth oxide are evenly mixed, and cladding material powder is formed to be flatly laidon the washed surface of a titanium alloy; and (3) the titanium alloy coating is prepared through laser cladding, wherein the metal powder includes Ti, Ni, Al, Si and V, a ceramic phase material is B4C or TiC or TiN, and the rare earth oxide is Y2O3. According to the high-entropy alloy coating, the hardness of a titanium alloy part can be remarkably improved, abrasion resistance of the titanium alloy part is improved, and the using range of the titanium alloy part is enlarged.

Owner:QINGDAO BINHAI UNIV

Preparation method of copper based graphene composite with high heat conductivity

ActiveCN110408969AReasonable ratioImprove wettabilityElectrolytic coatingsCurrent conducting devicesElectricityHigh intensity

The invention belongs to the field of heat conduction materials, and specifically discloses a preparation method of a copper based graphene composite with high heat conductivity. According to the preparation method, a novel sediment composition is used for direct-current electrodeposition, a certain quantity of additives are added to sediments, and the reasonable electrodeposition frequency is selected to prepare the novel copper based graphene composite with high strength and high heat conductivity. According to the copper based graphene composite prepared by using an electrodeposition preparation technique, the heat conductivity can reach 390 to 1112 W / m.k, the tensile strength reaches 300 to 450 MPa, and the application to the field of heat conduction can be met.

Owner:CHANGZHOU UNIV

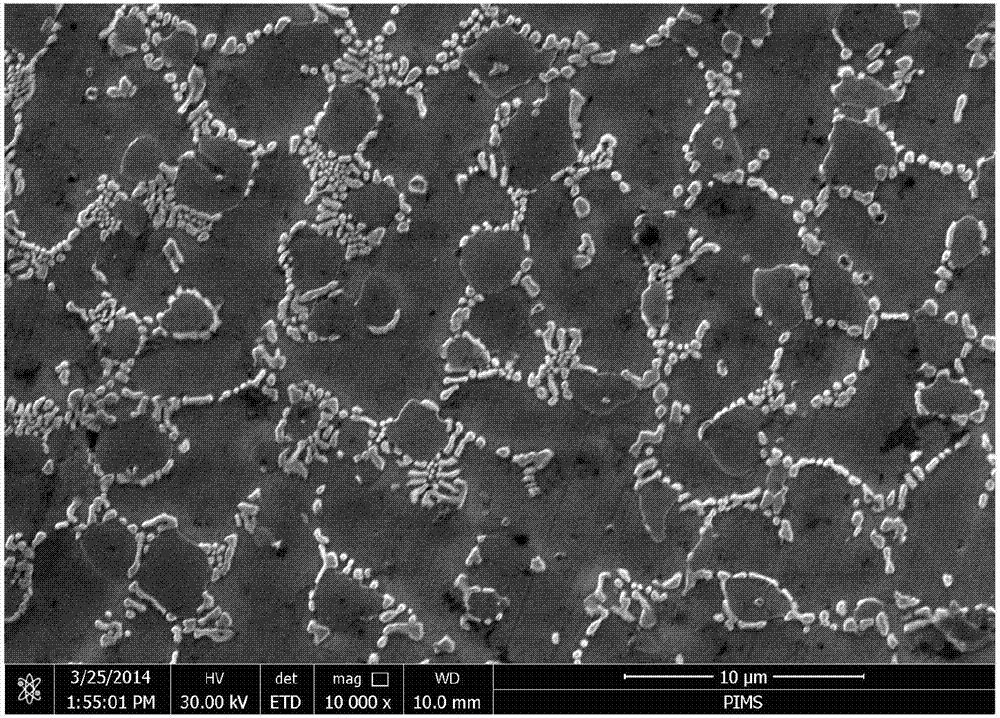

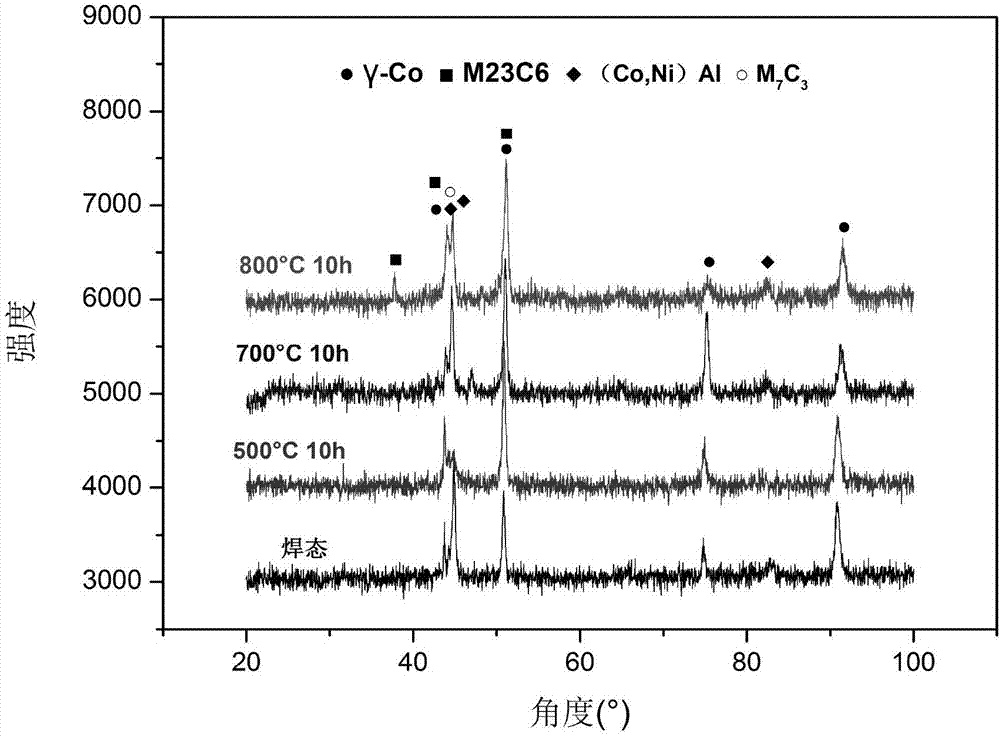

Cobalt-based alloy and cladding layer prepared from cobalt-based alloy

ActiveCN107326221AImproves abrasive wear resistanceBlock the path to rapid expansionMolten spray coatingChemical compositionMetallic materials

Provided are a cobalt-based alloy and a cladding layer prepared from the cobalt-based alloy. The cobalt-based alloy comprises Co, Ni, Cr, Fe, Si, W, C and Al. The cobalt-based alloy is specifically prepared from, by weight, 19-22.5% of Ni, 18-19.5% of Cr, 7.5-10.5% of Al, 0.8-1.1% of Fe, 0.7-1.0% of Si, 3.0-4.4% of W, 0.6-0.9% of C, and the balance Co and smaller than 0.1% of inevitable impurities, and the mass percent of Ni and Co is greater than 0.4 but smaller than 0.56, and the mass percent of Ni and Al is greater than 2 but smaller than 2.7. The cobalt-based alloy can be used for preparing the cladding layer with high abrasion resistance performance and heat fatigue resistance performance, and the cladding layer not only can be used for repairing and enhancing a friction layer of a brake disc, but also can be used as the friction layer of the brake disc and a protection layer on the surface of other metal materials needing to bear repeated heat impact and having friction abrasion in the environments like mold cavity linings, engine pistons and inner cylinders, petroleum pipeline valve inner walls.

Owner:SOUTHWEST JIAOTONG UNIV

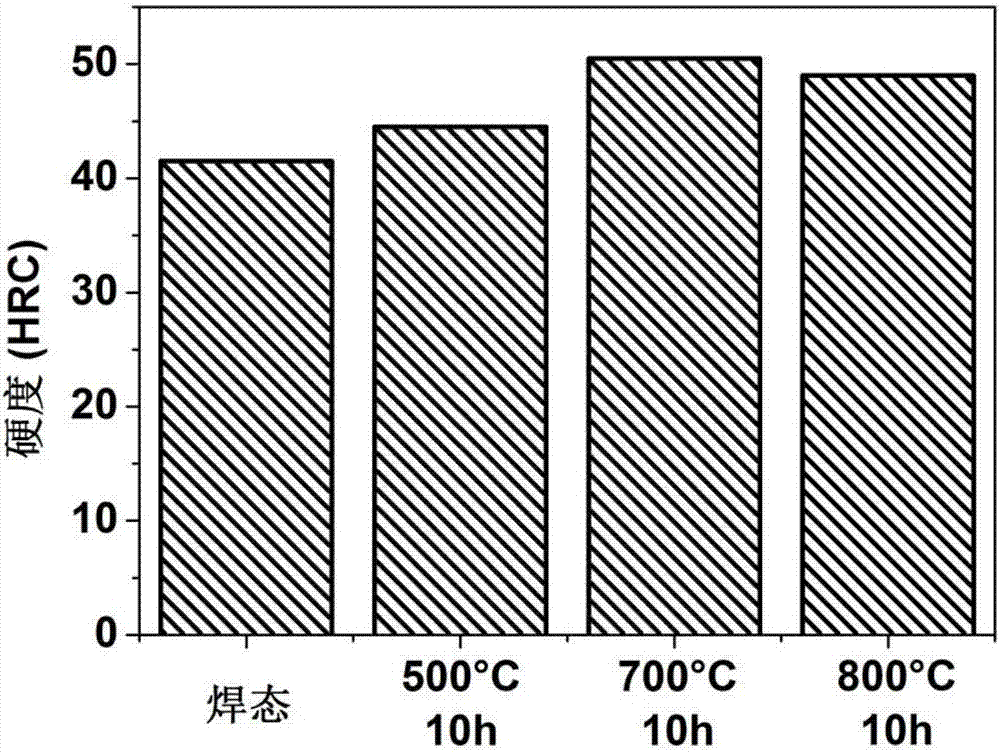

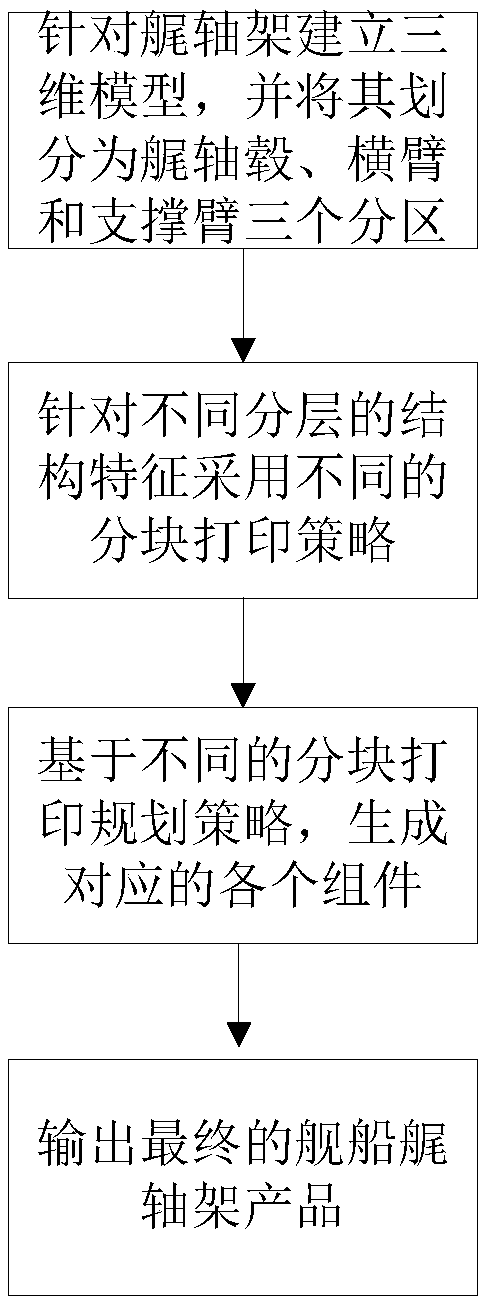

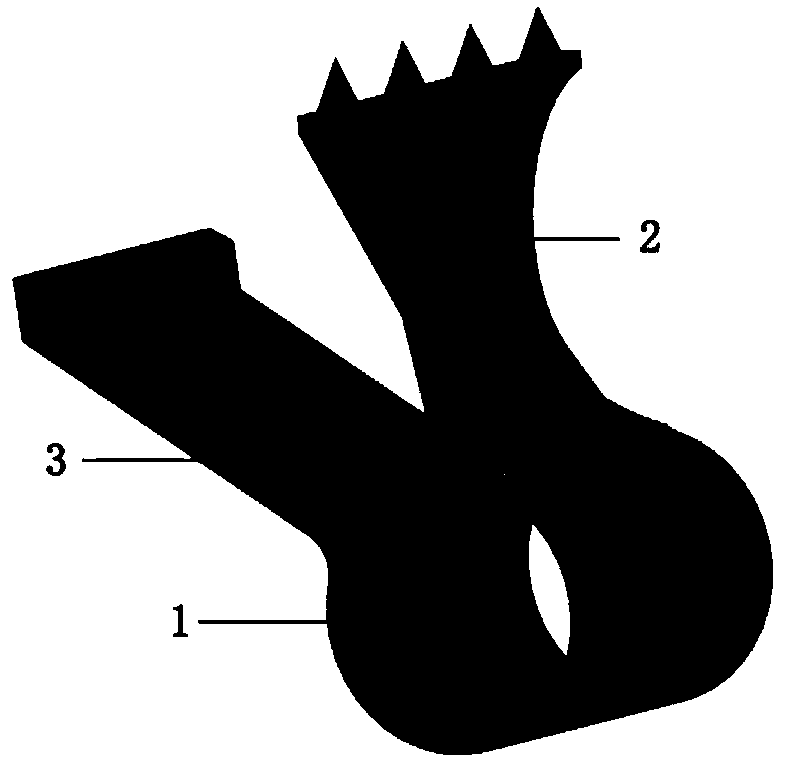

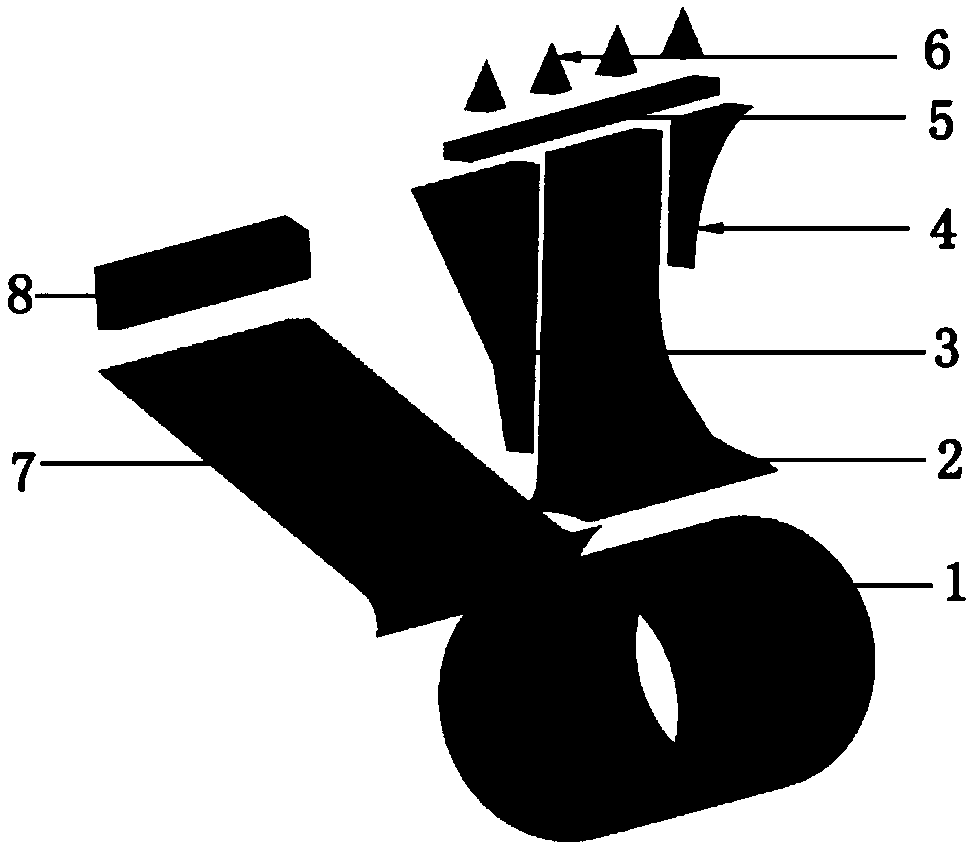

Ship tail shaft bracket electric arc wire fusing 3D printing manufacturing method and product thereof

ActiveCN108971699AUniform and dense tissueLow costArc welding apparatusManufacturing technologyMachining

The invention belongs to the technical field of ship tail shaft bracket manufacturing technologies, and discloses a ship tail shaft bracket electric arc wire fusing 3D printing manufacturing method. The method comprises the steps that (1) a corresponding three-dimensional model is built for a tail shaft bracket and is divided into three partitions corresponding to a tail shaft hub, a transverse arm and a supporting arm; (2) according to the different partitions, printing paths are planned and designed based on different principles, and a tail shaft hub printing path with all layers in ring shapes, a transverse arm printing path with all layers in rectangle shapes and a supporting arm printing path with all layers in rectangle shapes are obtained; and (3) according to the obtained differentmanufacturing paths, the electric arc wire fusing 3D printing manufacturing technology is adopted for conducting corresponding molding machining. The invention further discloses a corresponding shiptail shaft bracket product. By means of the method and the product, the problems that in the traditional ship tail shaft bracket manufacturing process, a die model is difficult, and the molding pieceperformance is poor are solved, and a new method and thinking are provided for manufacturing the tail shaft bracket.

Owner:HUAZHONG UNIV OF SCI & TECH

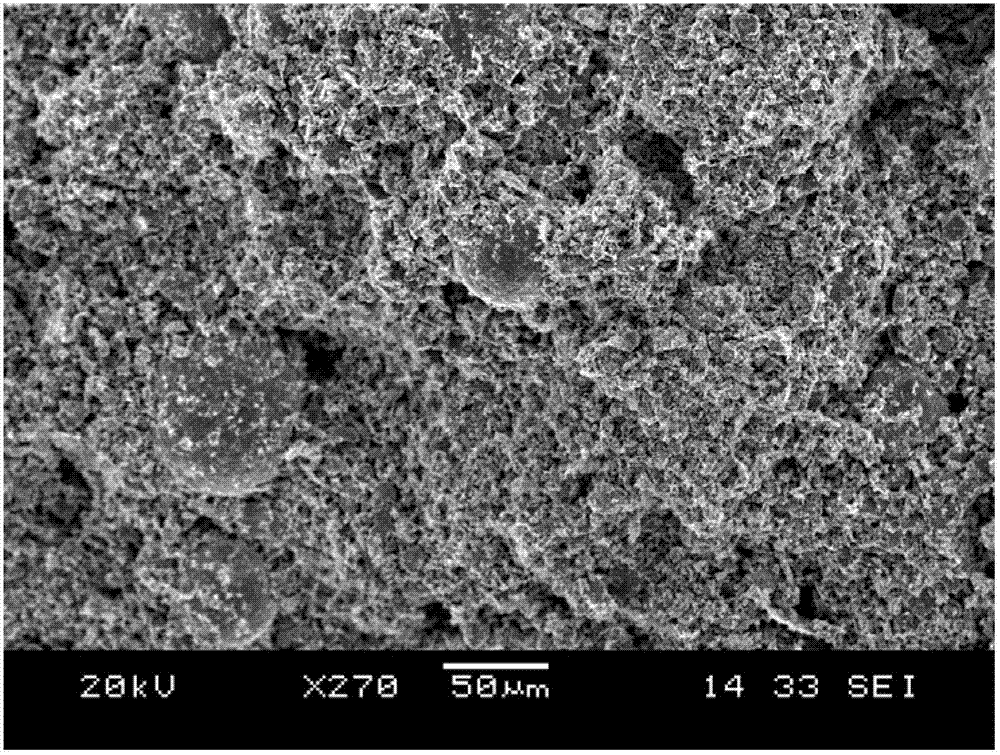

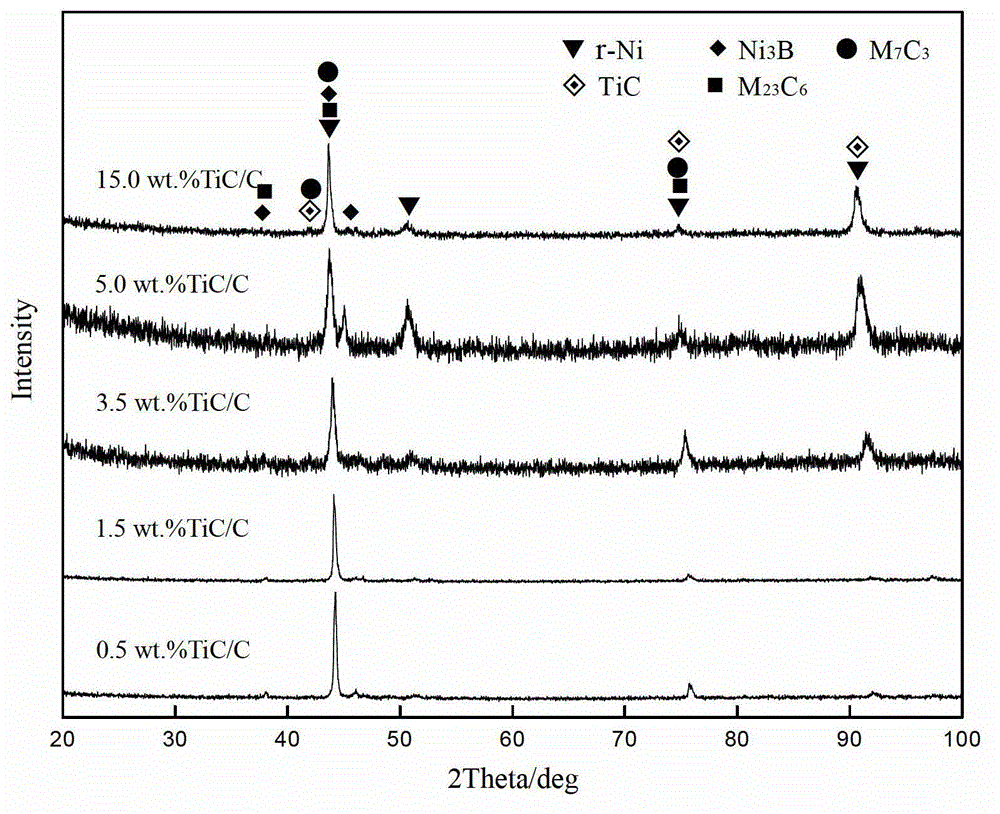

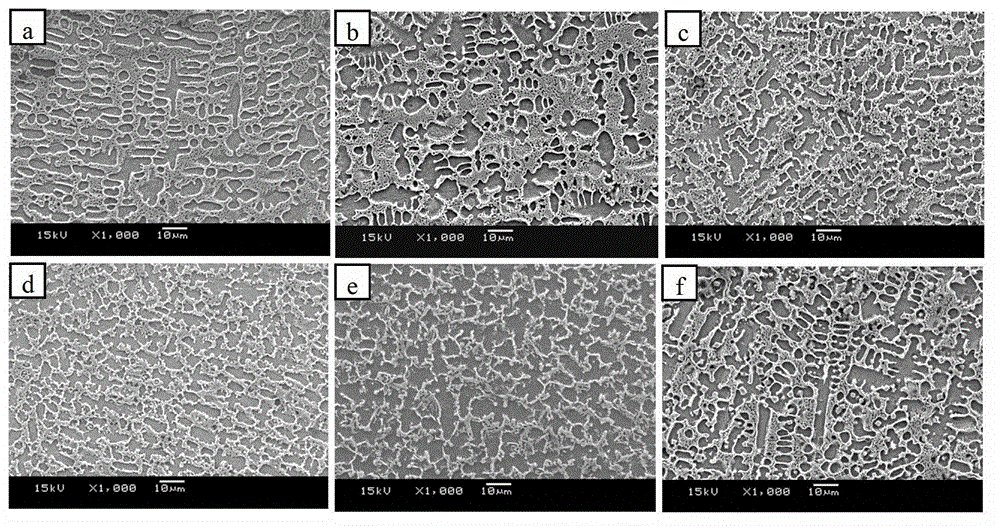

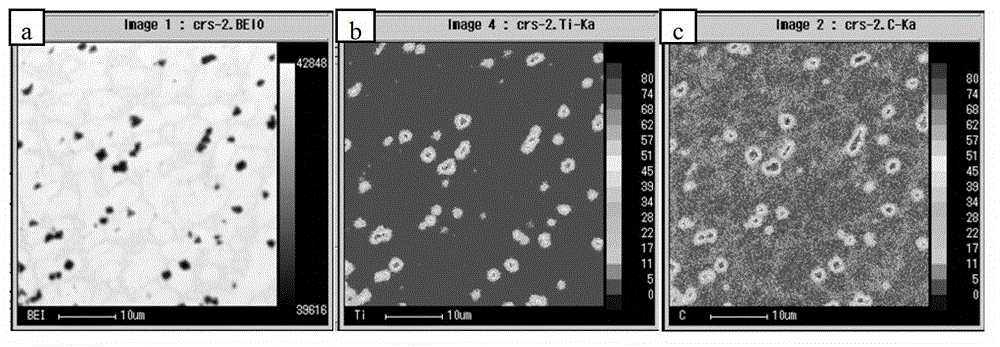

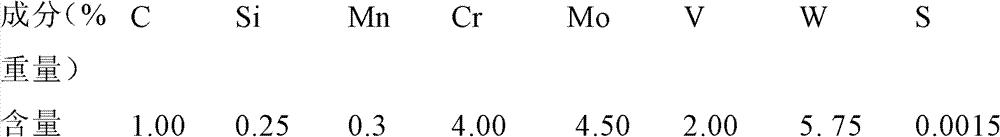

Nanocarbon clad titanium carbide enhanced nickel-based composite coating material and laser cladding process thereof

InactiveCN102978444AUniform and dense tissueImprove corrosion resistanceMetallic material coating processesProcess scaleTitanium carbide

The invention discloses a nanocarbon clad titanium carbide enhanced nickel-based composite coating material and a laser cladding process thereof, belonging to the technical field of material surface modification. The nanocarbon clad titanium carbide enhanced nickel-based composite coating material is prepared from Ni65.83 Cr15B3.0Si3.5C0.7Fe12 nickel-based self-fluxing alloy powder as a matrix material and nanocarbon clad titanium carbide of 0.5-20vol.% as a wild phase on a steel and alloy matrix by using a laser cladding technology. The nanocarbon clad titanium carbide enhanced nickel-based composite coating material has the advantages of uniform and compact coating structure, good flexibility and excellent corrosion resistance and wear resistance, has better metallurgical bonding with the matrix, can meet the requirements of carbon steel and alloy steel members for friction wear resistance under different working conditions, is large in scale and high in automation degree in a coating preparation process, and can be widely applied to fields such as aerospace, machinery, automobiles, war industry and the like.

Owner:DALIAN UNIV OF TECH

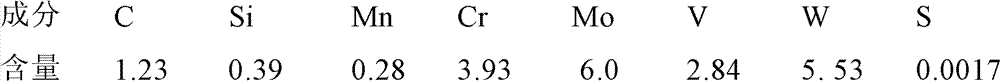

Refining method of high-speed tool steel

InactiveCN102952921AImprove cleanlinessImprove performanceProcess efficiency improvementInduction furnaceHigh-speed steel

The invention relates to a refining method of high-speed tool steel. The method comprises the steps that: a raw material is smelted in an induction furnace, and LF furnace ingot refining is carried out; and the refined molten steel is cast into an ingot. According to the invention, the adopted raw material comprises a metal material composed of high-speed tool steel scraps and low-carbon carbon steel scraps. According to total weight percentages, the metal material contains no lower than 70% of the high-speed tool steel scraps. With LF furnace refining, molten steel cleanness is substantially improved, such that a guarantee is provided for improving steel quality. With LF furnace refining, molten steel total oxygen content is lower than 20ppm; molten steel sulfur content is lower than 0.002%; and impurities larger than 10 micrometers are almost completely rejected. The high-speed steel recycled material refining method provided by the invention has the advantages of low production cost and high product cleanness.

Owner:大连永宝新材料科技有限公司

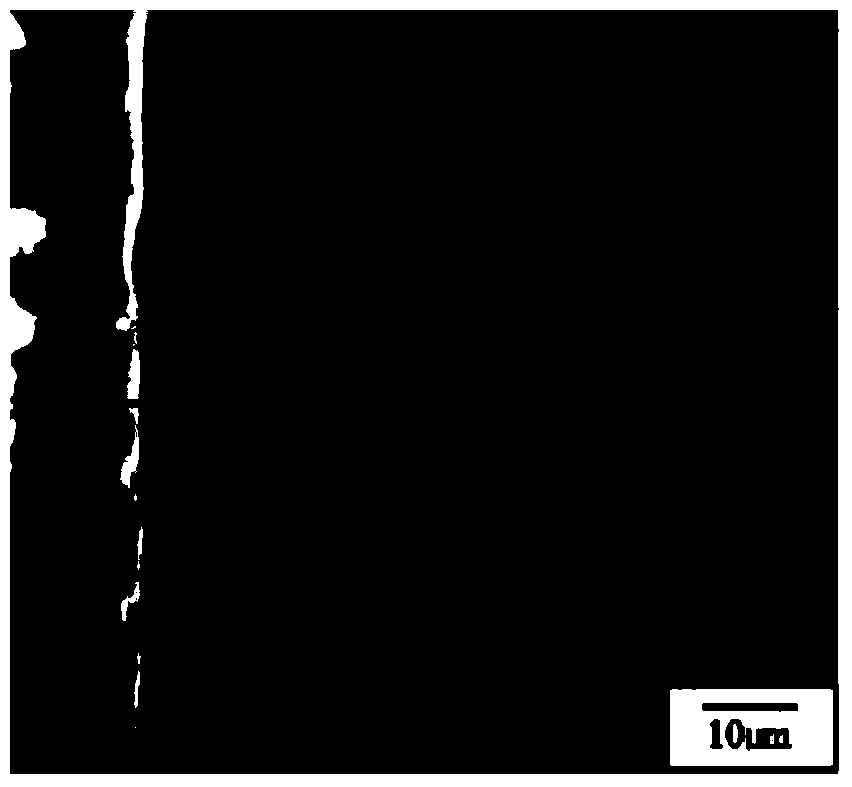

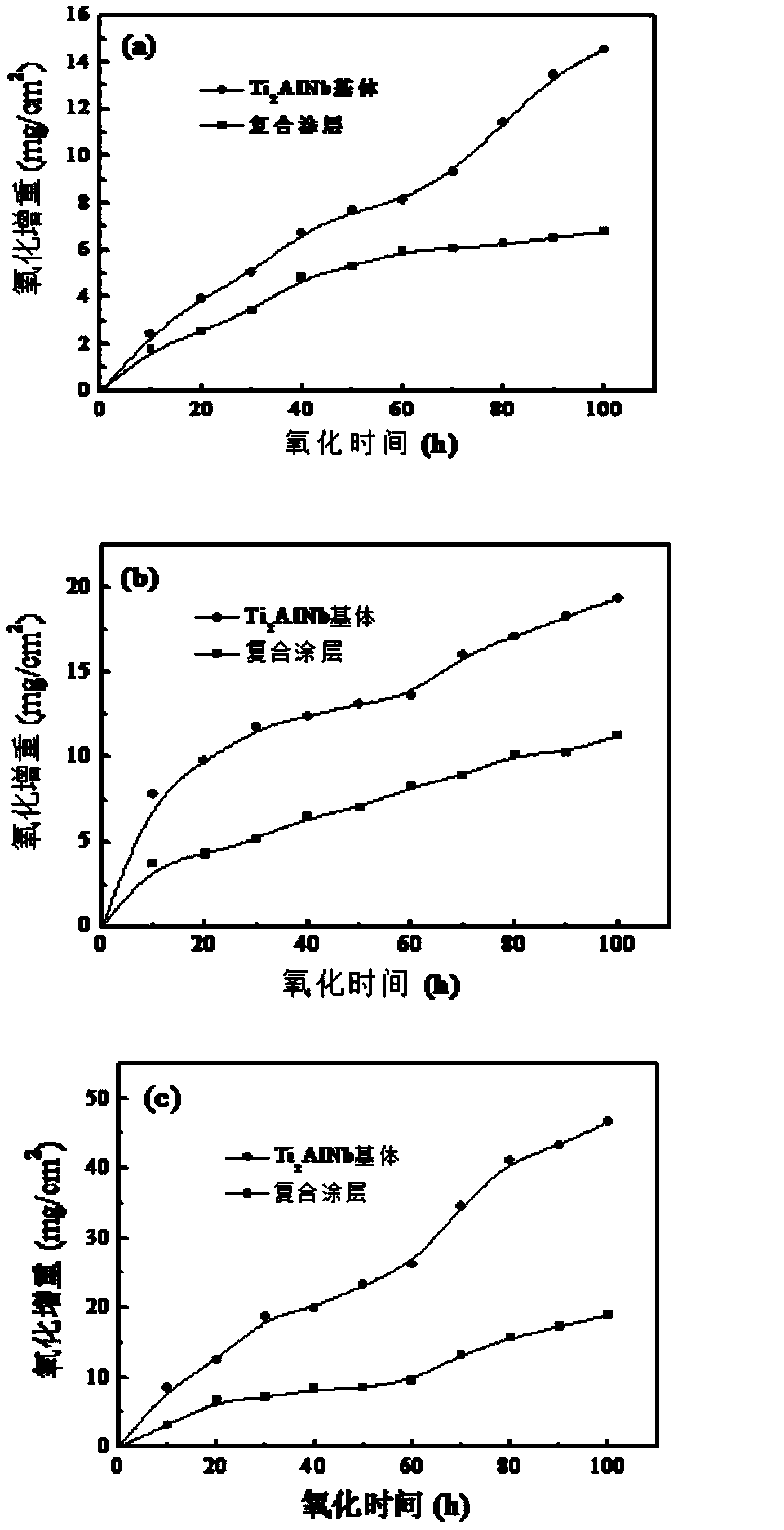

High temperature oxidation resistant composite gradient coating on Ti2AlNb alloy surface and preparation method thereof

ActiveCN104357804AImprove high temperature oxidation resistanceNo crackVacuum evaporation coatingSputtering coatingOxidation resistantGlow plasma

The invention relates to a high temperature oxidation resistant composite gradient coating on a Ti2AlNb alloy surface and a preparation method thereof. The composite gradient coating sequentially comprises a pure Al layer, an Al-Ti alloy layer and an Al-Ti-Nb mutual diffusion layer from the surface to a substrate; the Al content of the Al-Ti alloy layer is decreased in a slow gradient manner from the surface of an Al-Ti seeping layer from outside to inside, the Ti content is slowly increased, and component mutation is avoided; and Al content of the Al-Ti-Nb mutual diffusion layer is decreased in a gradient manner from the surface of a diffusion layer from outside to inside, and the Ti content and the Nb content are increased from outside to inside in a gradient manner from the surface of the diffusion layer. The preparation method comprises the steps as follows: Ti2AlNb base alloy is taken as a workpiece electrode, an Al-Ti alloy target material is taken as a source electrode, the Al-Ti alloy layer is prepared by adopting an arc-glow plasma surface metallurgy technology, and then a pure Al target material is taken as the source electrode to prepare the pure Al layer on the Al-Ti alloy layer. The technology efficiency is high, the preparation technology is simple, and the obtained coating has high oxidation resistance.

Owner:NANJING UNIV OF AERONAUTICS & ASTRONAUTICS

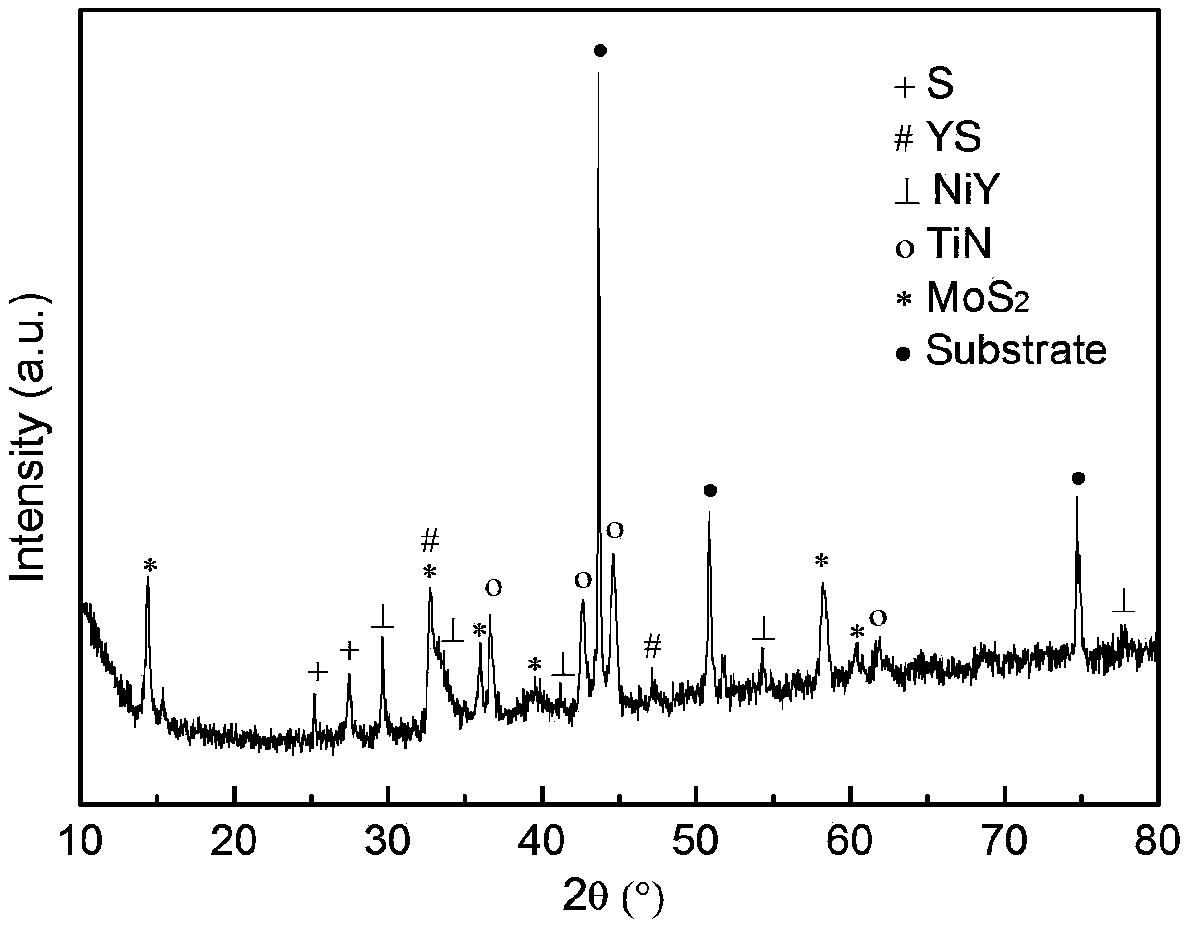

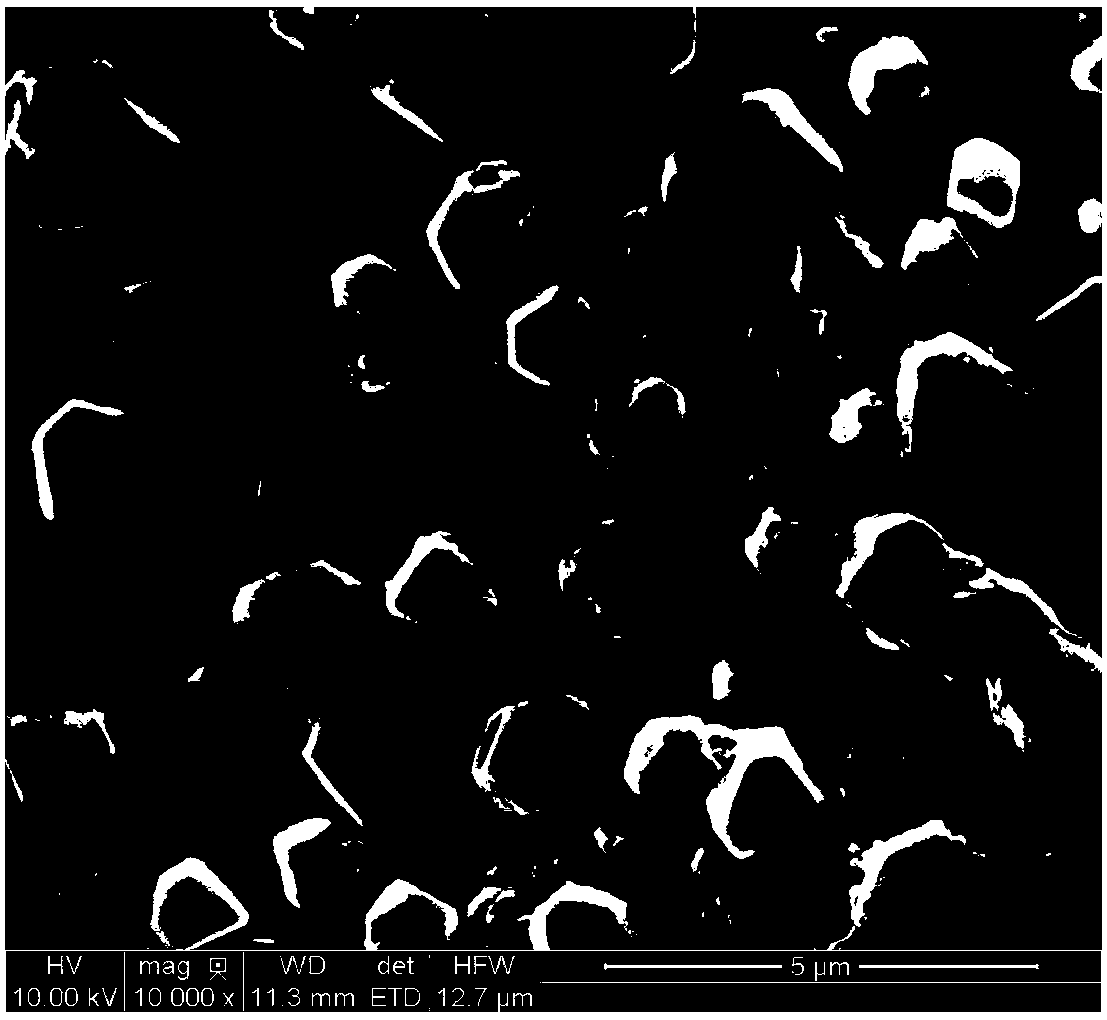

Rare earth yttrium doped molybdenum disulfide self-lubricating composite coating and preparation method thereof

ActiveCN108149220AHigh purityLow content of impurity elementsChemical vapor deposition coatingCalcium Chloride HexahydrateGas phase

The invention provides a rare earth yttrium doped molybdenum disulfide self-lubricating composite coating and a preparation method thereof. Specifically, the molybdenum disulfide self-lubricating composite coating is doped with rare earth yttrium, wherein the molar content of yttrium in the composite coating is 0.1%-5% according to the total molar content of the composite coating. According to themolybdenum disulfide self-lubricating composite coating, sublimed sulfur, yttrium chloride hexahydrate and molybdenum trioxide are adopted as raw materials, and the rare earth yttrium doped molybdenum disulfide self-lubricating composite coating is prepared through the chemical vapor deposition method. The molybdenum disulfide self-lubricating composite coating has good wear resistance and self-lubrication and excellent winding plating property. Coating deposition can be conducted on large-size complex workpieces of a complex shape.

Owner:NINGBO INST OF MATERIALS TECH & ENG CHINESE ACADEMY OF SCI

Squeeze casting preparation method for magnalium automobile engine support

The invention relates to a squeeze casting preparation method for a magnalium automobile engine support. Magnalium comprises the following raw material components by weight percent: 3.5-5.5% of Si, 1-2.5% of Fe, 0.5-2% of Ti, 0.15-0.25% of Cu, 0.01-0.05% of Mn, 10.2-15.5% of Mg, less than 0.1% of Zn, less than 0.05% of Ni, less than 0.05% of Pb, less than 0.05% of Sn and the balance of Al, wherein Fe / Ti is more than 1 and less than 2. The squeeze casting preparation method comprises the following steps: preheating the raw material components at 320-345 DEG C, and then, adding into a heated crucible melting furnace; and continually heating to 500-600 DEG C, then pumping in argon, after that, heating to 760-780 DEG C, transferring into a crane ladle, performing heat preservation, refining, casting, and then conducting solution and aging strengthening to obtain the automobile engine support with superior mechanical property. The prepared automobile engine support has the tensile strength of 320 MPa or above and the yield strength of 100-110 MPa.

Owner:过冬

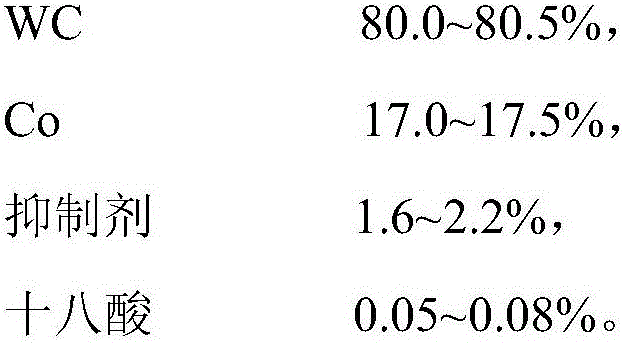

High-performance stripping and slitting knife adopting new hard alloy material and manufacturing method of stripping and slitting knife

ActiveCN105950938AHigh hardnessImprove wear resistanceTurbinesOther manufacturing equipments/toolsWear resistantAlloy

The invention discloses a high-performance stripping and slitting knife adopting a new hard alloy material and a manufacturing method of the stripping and slitting knife and belongs to the technical field of hard alloy cutters. The high-performance stripping and slitting knife adopting the new hard alloy material is manufactured with a powder metallurgy technology, and raw materials comprise components in percentage by mass as follows: 0.40%-0.50% of CT, 80.0%-80.5% of WC, 17.0%-17.5% of Co, 1.6%-2.2% of an inhibitor and 0.05%-0.08% of stearic acid. The manufacturing method of the stripping and slitting knife comprises steps as follows: blending; wet grinding; pressing; sintering; machining. On the basis that higher hardness and higher wear resistant property of a blade are guaranteed, the stripping and slitting knife can still keep excellent impact toughness and breakage resistance and can meet the slitting requirement of various metal sheets on the stripping and slitting knife, and the service life of the blade is remarkably prolonged.

Owner:MAANSHAN HENGLIDA MACHINE BLADE

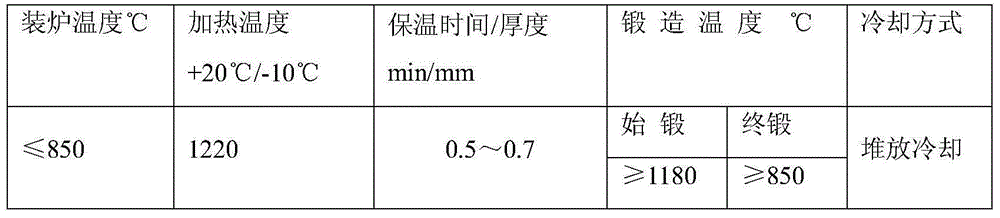

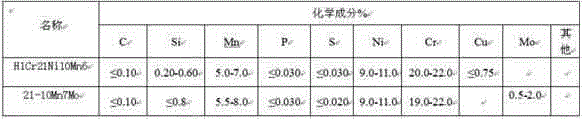

Forging method for producing 21-10Mn7Mo welding wire and blank forged by same

InactiveCN105728614AHigh purityUniform chemical compositionMetal rolling arrangementsElectric arc furnaceIngot

A forging method for producing a 21-10Mn7Mo welding wire and a blank forged by the method belong to the technical field of welding, relate to the production of a solid welding wire used for gas-shielded arc welding, a forging method, a component forged by the method and a hot-rolling technology and further relate to a steel ingot and the smelting thereof. The forged blank comprises the following chemical components in a percent by mass: smaller than or equal to 0.10 of C, smaller than or equal to 0.8 of Si, 5.5-8.0 of Mn, smaller than or equal to 0.030 of P, smaller than or equal to 0.020 of S, 9.0-11.0 of Ni, 19.0-22.0 of Cr and 0.5-2.0 of Mo, wherein the ratio of Mn to Mo is controlled between 7 and 7.5. The forging step adopted for producing the forged blank comprises the step of heating a blank, and forging temperature is controlled in a way that initial forging temperature is higher than or equal to 1180 DEG C and final forging temperature is higher than or equal to 850 DEG C. The smelting step of a forged steel ingot comprises the technical step of using an electric-arc furnace return oxygen blowing process to smelt an electroslag re-melted electrode.

Owner:天津冶金集团天材科技发展有限公司

Laser deposition additional material manufacturing method

ActiveCN110496966AEliminate hole defectsImprove performanceAdditive manufacturing apparatusIncreasing energy efficiencyManufacturing technologyLap joint

The invention relates to the technical field of additional material manufacturing and discloses a laser deposition additional material manufacturing method. The scanning manner of carrying out negative lap joint, carrying out S-shaped scanning and then carrying out reverse S-shaped scanning is adopted, and the lap joint rate is controlled within 30%-40%. Metal powder used for manufacturing a laserdeposition additional material contains active powder, defects of holes, cracks and the like in the titanium alloy laser deposition process can be eliminated, and a manufactured titanium alloy component is uniform and compact in internal texture and smooth in appearance.

Owner:TSC LASER TECH DEV BEIJING CO LTD

Electroslag remelting slag system of super duplex stainless steel

The invention relates to an electroslag remelting slag system of super duplex stainless steel. The electroslag remelting slag system comprises the following ingredients by weight percentage: 55-74% ofCaF2, 5-20% of CaO, 5-20% of Al2O3, 5-15% of MgO and 1-15% of SiO2. According to the electroslag remelting slag system, optimal slag alkalinity is achieved by adjusting contents of basic oxides, namely CaO and MgO, and acidic oxides, namely SiO2 and Al2O3; and the electroslag remelting slag system is particularly applicable to electroslag remelting of the super duplex stainless steel, improves purity of the super duplex stainless steel, reduces a content of harmful impurity elements, optimizes an ingot structure, greatly improves processability of the stainless steel increases a hot processing yield and contributes to achieving excellent mechanical properties and corrosion resistance.

Owner:CHONGQING MATERIALS RES INST

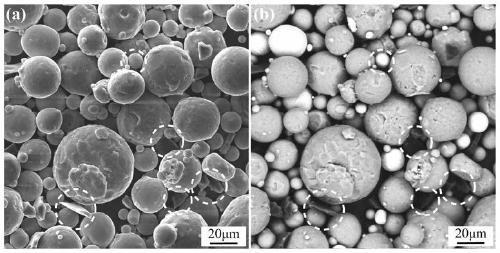

Preparation method used for laser 3D printing metal ceramic composite powder

ActiveCN111118323AImprove chemical reaction rateAdequate responseAdditive manufacturing apparatusTransportation and packagingSelective laser meltingCeramic composite

The invention discloses a preparation method used for laser 3D printing metal ceramic composite powder, and belongs to the field of preparation of powder materials for laser 3D printing. Through the physical method, pure Ti powder and pure B4C powder particles are coated (or bonded) according to the mass ratio of 2.6:1, drying and ball grinding crushing treatment are carried out in sequence, and aTi / B4C composite powder material is prepared; and then the powder material and AlSi1-Mg powder are added into a ball grinder to be subjected to vacuum ball grinding, and finally the evenly-mixed powder for the laser 3D printing metal ceramic composite is prepared. By means of the preparation method, the technical problem that in the 3D printing process of an existing metal ceramic composite, dualwild phases cannot be synthesized is solved, the reaction rate of Ti and B4C particles in the laser 3D printing process is increased, and the content of a ceramic wild phase in the dual-phase composite is increased; and the prepared composite powder can be used for laser near-net forming or selective laser melting and other high-energy beam 3D printing processes.

Owner:KUNMING UNIV OF SCI & TECH

Corrosion-resistant rare earth bearing steel and preparation method thereof

InactiveCN111254359AImprove internal qualityImprove corrosion resistanceProcess efficiency improvementElectric furnaceCorrosionTa element

The invention relates to corrosion-resistant rare earth bearing steel and a preparation method of the corrosion-resistant rare earth bearing steel. The corrosion-resistant rare earth bearing steel comprises the following components of, by weight percentage, 0.90-1.10wt% of C, 0.20-0.40wt% of Si, 0.20-0.50wt% of Mn, 1.35-1.70wt% of Cr, 0.12-0.26wt% of Cu, 0.015-0.035wt% of Alt, P<=0.020wt%, S<=0.010wt%, 0.003-0.005wt% of a rare earth alloy, and the balance of Fe and inevitable impurities. By adding trace rare earth, the sizes of inclusions are refined, the number of the inclusions is reduced, and the fatigue life of the bearing steel is remarkably prolonged; and meanwhile by adding the element Cu, the corrosion resistance of the bearing steel is improved, and the surface quality of thebearing steel is remarkably improved.

Owner:SHANDONG IRON & STEEL CO LTD

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com