Tungsten copper alloy with low tungsten content and preparation method of tungsten copper alloy

A technology of tungsten copper alloy and tungsten content, which is applied in the field of alloys to achieve the effect of uniform structure and high density

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

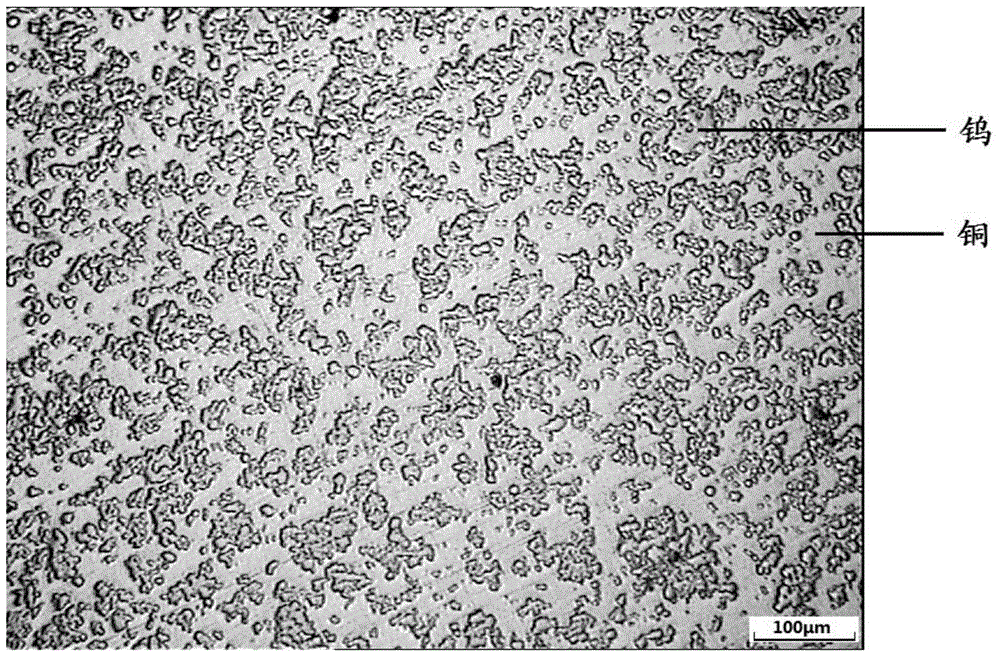

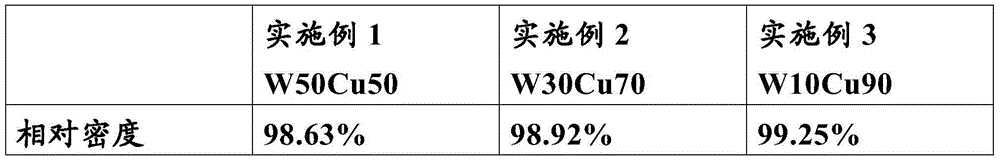

Embodiment 1

[0051] Embodiment 1: the preparation of the tungsten-copper alloy (W50Cu50) that tungsten content is 50wt%, copper content is 50wt%

[0052] The preparation method comprises the following steps:

[0053] (1) get purity ≥ 99.95%, the average Fischer particle size is 5 micron tungsten powder, get purity ≥ 99.95%, the average particle size is the electrolytic copper powder of -300 purpose;

[0054] (2) Carry out powder pretreatment to the tungsten powder with airflow crushing and grading equipment (equipment model MQW10), to break up the agglomeration of the tungsten powder;

[0055] (3) Mix the dispersed tungsten powder and electrolytic copper powder obtained in step (2) uniformly in a powder mixer to obtain a mixed powder;

[0056] (4) Cold isostatic pressing of the mixed powder obtained in step (3), with an isostatic pressure of 300 MPa, to obtain a green compact with a thickness of 20 mm;

[0057] (5) pre-sintering the green compact obtained in step (4) in a hydrogen-throug...

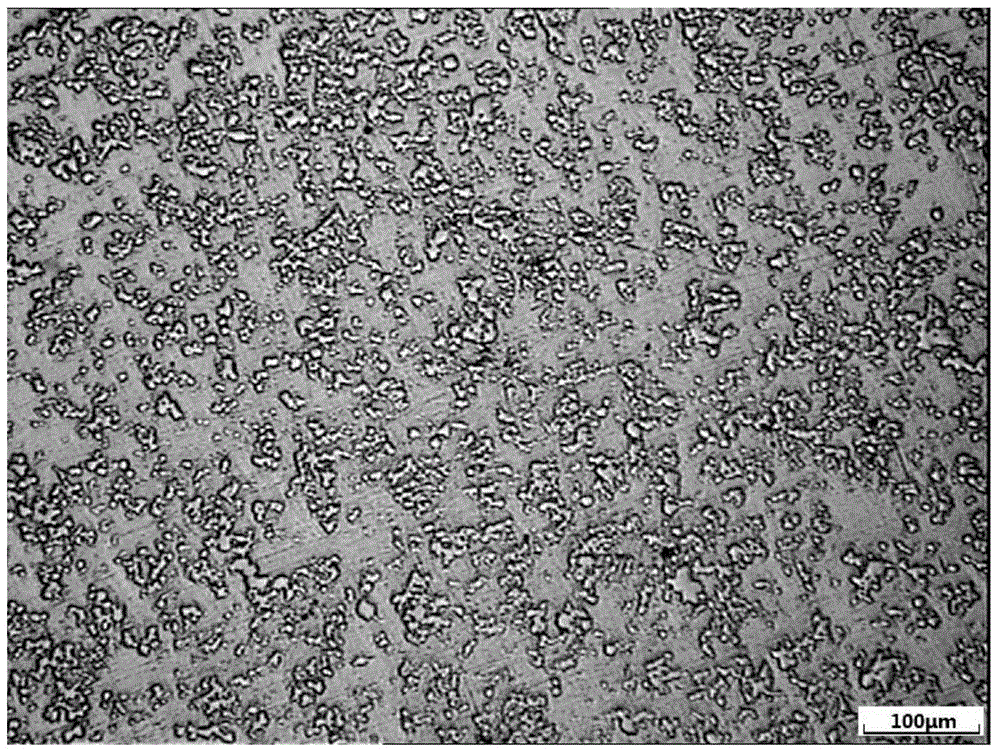

Embodiment 2

[0066] Embodiment 2: the preparation of the tungsten copper alloy (W30Cu70) that tungsten content is 30wt%, copper content is 70wt%

[0067] The preparation method comprises the following steps:

[0068] (1) get purity ≥ 99.95%, the average Fischer particle size is 8 micron tungsten powder, get purity ≥ 99.95%, the average particle size is the electrolytic copper powder of -300 purpose;

[0069] (2) Carry out powder pretreatment to the tungsten powder with airflow crushing and grading equipment (equipment model MQW10), to break up the agglomeration of the tungsten powder;

[0070] (3) Mix the dispersed tungsten powder and electrolytic copper powder obtained in step (2) uniformly in a powder mixer to obtain a mixed powder;

[0071] (4) Cold isostatic pressing of the mixed powder obtained in step (3), with an isostatic pressure of 200 MPa, to obtain a green compact with a thickness of 20 mm;

[0072] (5) pre-sintering the compact obtained in step (4) in a hydrogen-passing resi...

Embodiment 3

[0080] Embodiment 3: the preparation of the tungsten copper alloy (W10Cu90) that tungsten content is 10wt%, copper content is 90wt%

[0081] The preparation method comprises the following steps:

[0082] (1) get purity ≥ 99.95%, the average Fischer particle size is 3 micron tungsten powder, get purity ≥ 99.95%, the average particle size is the electrolytic copper powder of -300 purpose;

[0083] (2) Carry out powder pretreatment to the tungsten powder with airflow crushing and grading equipment (equipment model MQW10), to break up the agglomeration of the tungsten powder;

[0084] (3) Mix the dispersed tungsten powder and electrolytic copper powder obtained in step (2) uniformly in a powder mixer to obtain a mixed powder;

[0085] (4) Cold isostatic pressing of the mixed powder obtained in step (3), the isostatic pressing pressure is 100MPa, to obtain a green compact, and the thickness of the green compact is 20mm;

[0086] (5) pre-sintering the compact obtained in step (4) ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com