Preparation method and application in luminescent element thereof of CuInS2-ZnS/ZnSe/ZnS semiconductor quantum dots with core-shell structure

A cuins2-zns, core-shell structure technology, applied in the direction of semiconductor devices, luminescent materials, chemical instruments and methods, etc., can solve the problems that cannot meet the needs of diodes, and achieve the effect of low cost, high yield, and saturated colors

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

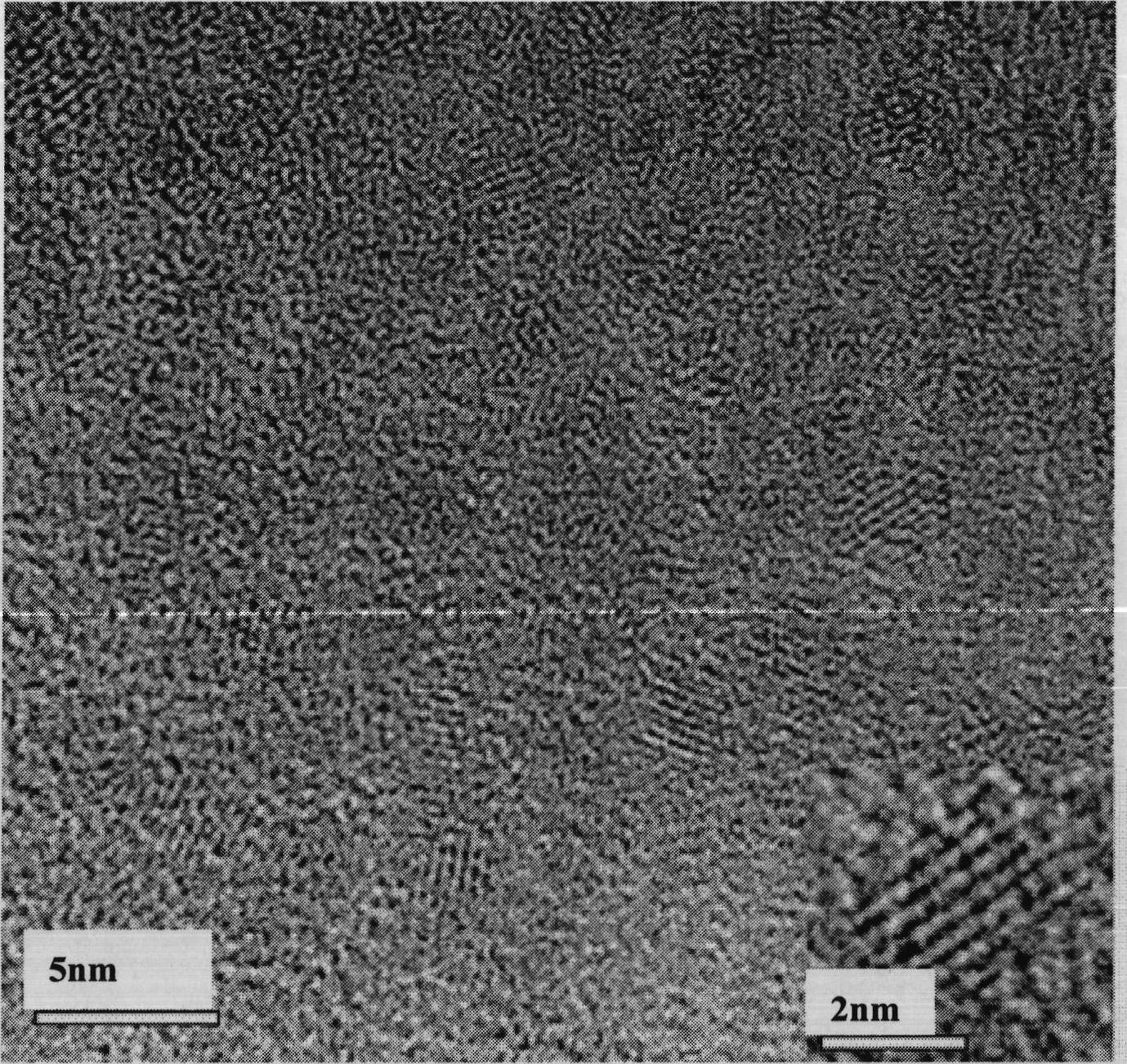

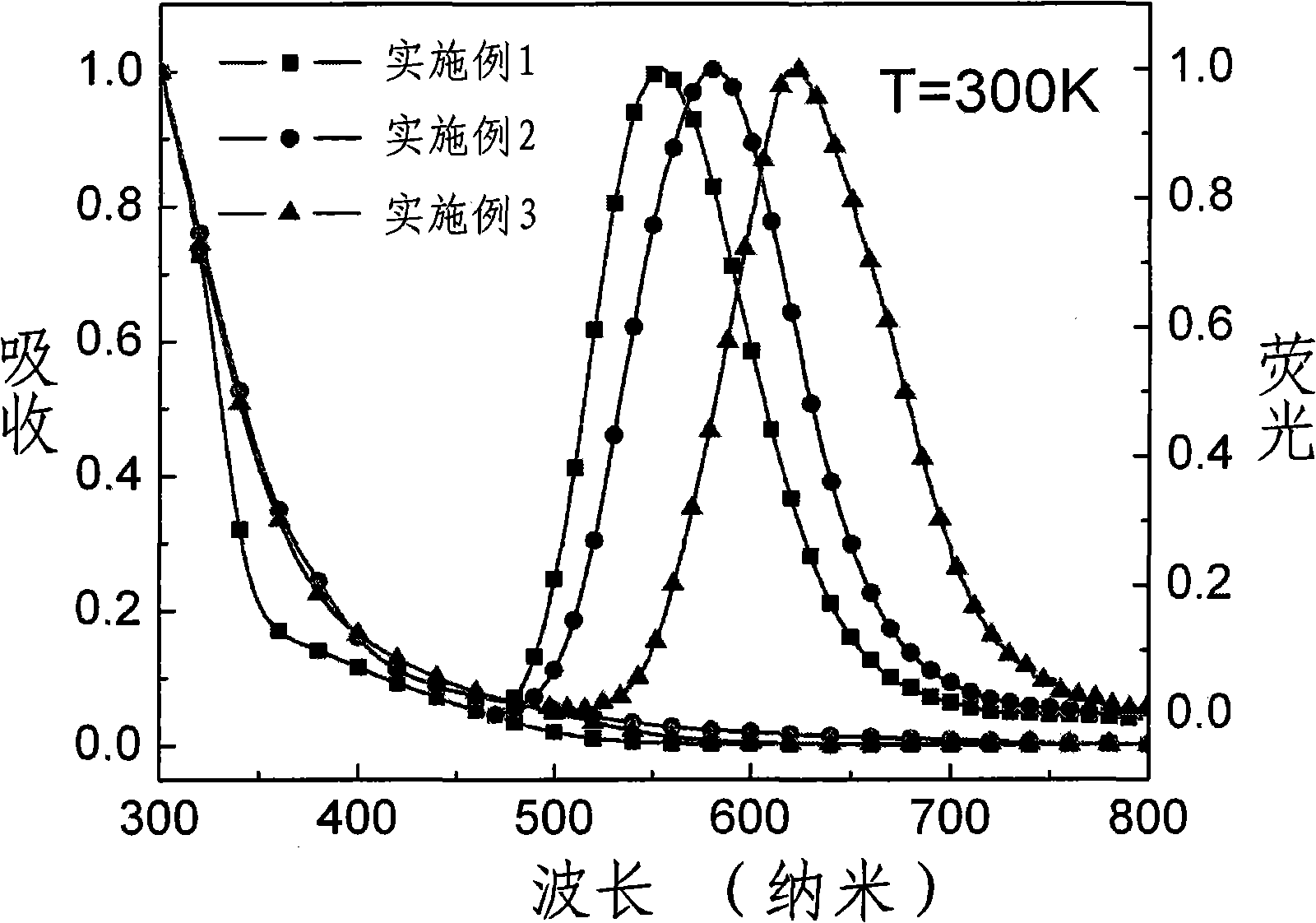

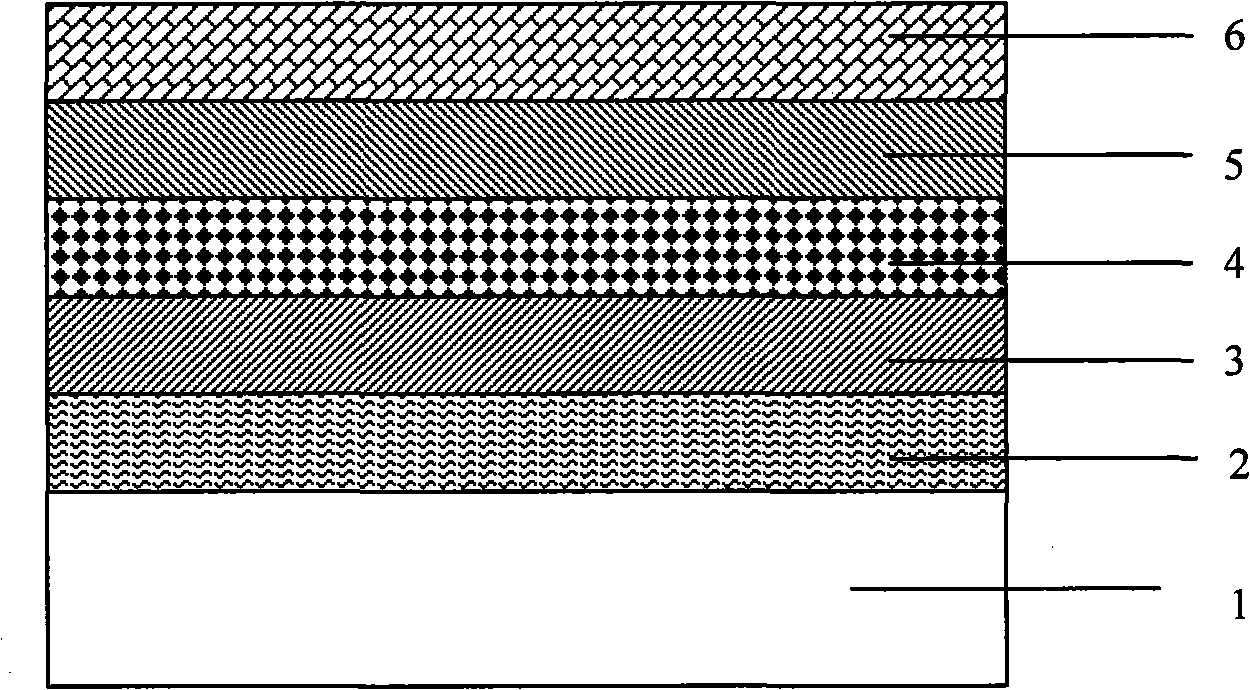

Embodiment 1

[0036] Put 2mL of the above original solution into a 10mL three-neck flask, and then pass through N 2 Remove the air in the three-necked flask, and immerse the three-necked flask in an oil bath preheated to 250°C, react for 60s, and DECZn decomposes into ZnS. The excess sulfur reacts further with copper ions and indium ions to obtain a ZCIS alloy colloidal solution. The whole solution is clear red or brown. Dissolve ZnO in a mixed solution of oleic acid and octadecene, and dissolve selenium powder in tributylphosphine. These two solutions were added to the ZCIS colloidal solution to react to obtain CuInS 2 -ZnS / ZnSe single-layer shell quantum dot colloidal solution, and then add DECZn solution to the solution to react to obtain CuInS 2-Colloidal solution of core-shell structure quantum dots of ZnS / ZnSe / ZnS double shell. Remove the oil bath heating device, add n-dodecanethiol to the colloidal solution of the core-shell structure quantum dots of the above-mentioned double sh...

Embodiment 2

[0038] Put 2mL of the above original solution into a 10mL three-neck flask, and then pass through N 2 Remove the air in the three-necked flask, and immerse the three-necked flask in an oil bath preheated to 200°C, react for 100s, and DECZn decomposes into ZnS. The excess sulfur reacts further with copper ions and indium ions to obtain a ZCIS alloy colloidal solution. The whole solution is clear red or brown. Dissolve ZnO in a mixed solution of oleic acid and octadecene, and dissolve selenium powder in tributylphosphine. These two solutions were added to the ZCIS colloidal solution to react to obtain CuInS 2 -ZnS / ZnSe single-layer shell quantum dot colloidal solution, and then add DECZn solution to the solution to react to obtain CuInS 2 -Colloidal solution of core-shell structure quantum dots of ZnS / ZnSe / ZnS double shell. Remove the oil bath heating device, add n-dodecanethiol to the colloidal solution of the core-shell structure quantum dots of the above-mentioned double ...

Embodiment 3

[0040] Put 2mL of the above original solution into a 10mL three-neck flask, and then pass through N 2 Remove the air in the three-necked flask, and immerse the three-necked flask in an oil bath preheated to 160°C to react for 200s, DECZn decomposes into ZnS. The excess sulfur reacts further with copper ions and indium ions to obtain a ZCIS alloy colloidal solution. The whole solution is clear red or brown. Dissolve ZnO in a mixed solution of oleic acid and octadecene, and dissolve selenium powder in tributylphosphine. These two solutions were added to the ZCIS colloidal solution to react to obtain CuInS 2 -ZnS / ZnSe single-layer shell quantum dot colloidal solution, and then add DECZn solution to the solution to react to obtain CuInS 2 -Colloidal solution of core-shell structure quantum dots of ZnS / ZnSe / ZnS double shell. Remove the oil bath heating device, add n-dodecanethiol to the colloidal solution of the core-shell structure quantum dots of the above-mentioned double sh...

PUM

| Property | Measurement | Unit |

|---|---|---|

| luminance | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

| emission peak | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com