Selective metal electro-deposition device and application thereof

A metal electrodeposition and electrodeposition technology, which is applied in the field of selective ultrasonic-assisted spraying metal electrodeposition devices, can solve the problems of little improvement in material surface quality and performance, low automation of processed parts, and difficult control of processing quality. Improvement of appearance quality and internal structure, improvement of coating quality, and high hardness effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

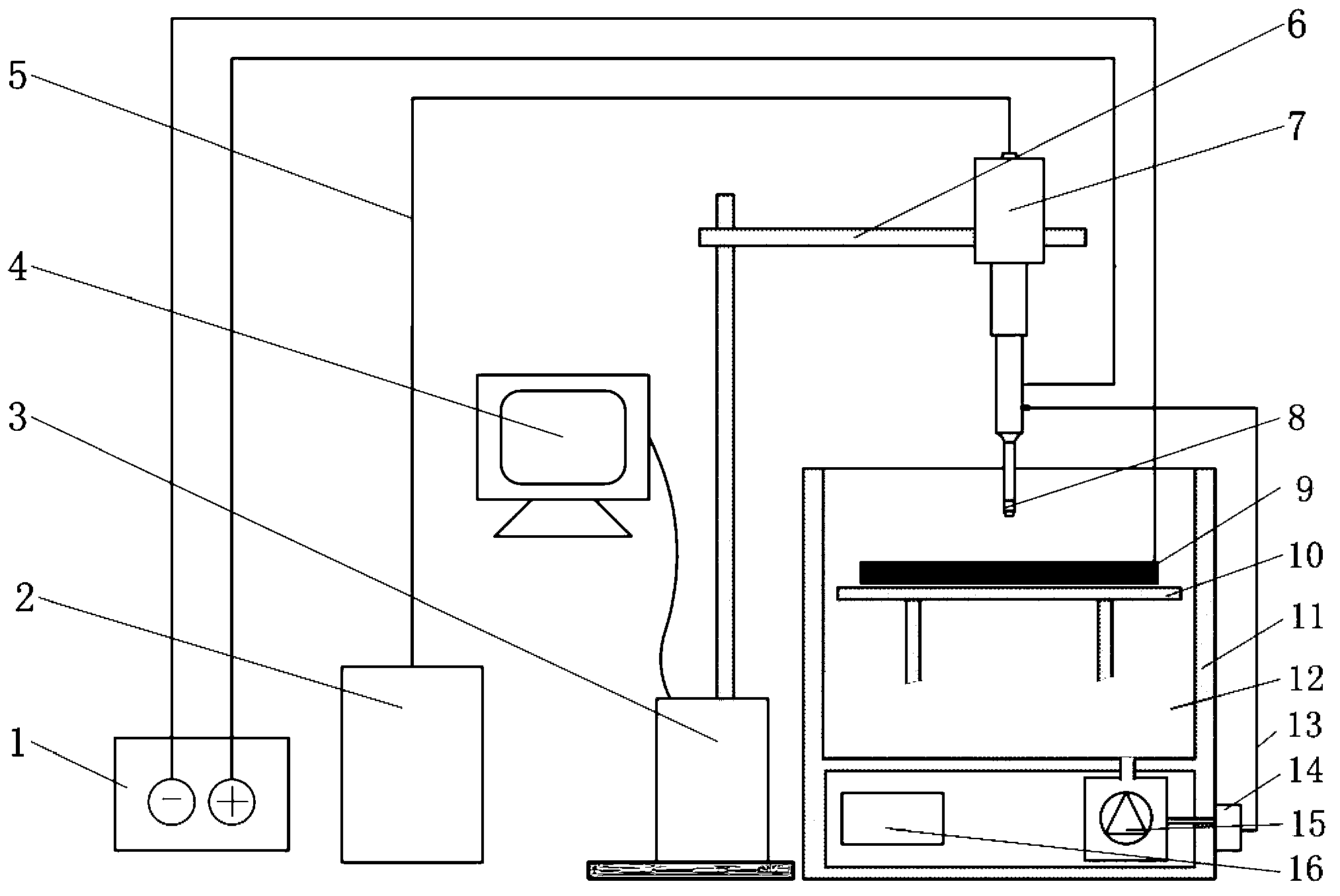

[0016] In an embodiment of the metal electrodeposition method provided by the present invention, during the metal electrodeposition process, the plated parts are placed horizontally on the support plate in the liquid storage tank, and then the positive electrode of the power supply and the anode (ultrasonic assisted spraying device) Connection, the negative pole is connected to the cathode (plated piece), during the electrodeposition process, an electric field is formed in the electrolyte by the anode and the cathode, ultrasonic waves are applied to the electrolyte, and the electrolyte is sprayed onto the surface of the plated piece through the electrolyte spraying device; at the same time , The temperature of the electrolyte is kept stable through the temperature control device, the moving speed and line of the nozzle are set in the computer of the three-coordinate numerical control platform, and the flow control valve adjusts the flow of the electrolyte. In the process of cat...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com