Production transmission line for upper shell and lower shell of special-shaped pipe

A special-shaped pipe and transfer line technology, applied in the direction of forming tools, feeding devices, positioning devices, etc., can solve the problems of difficult one-time forming, low efficiency, irregular shape, etc., and achieve precise forming, exquisite workmanship, and setting reasonable effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0032] The present invention will be further described below in conjunction with the accompanying drawings.

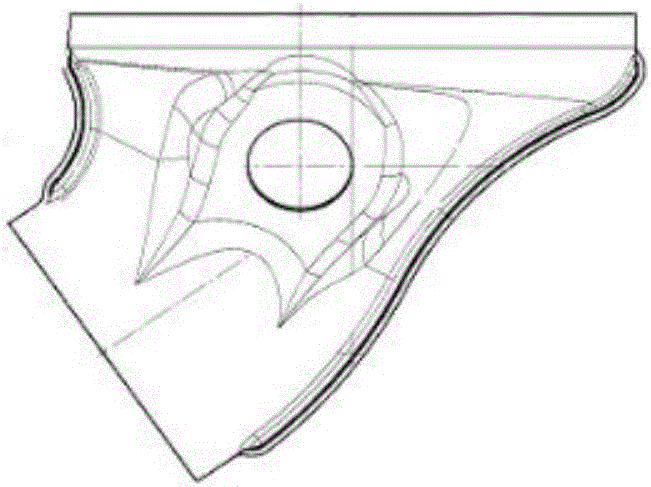

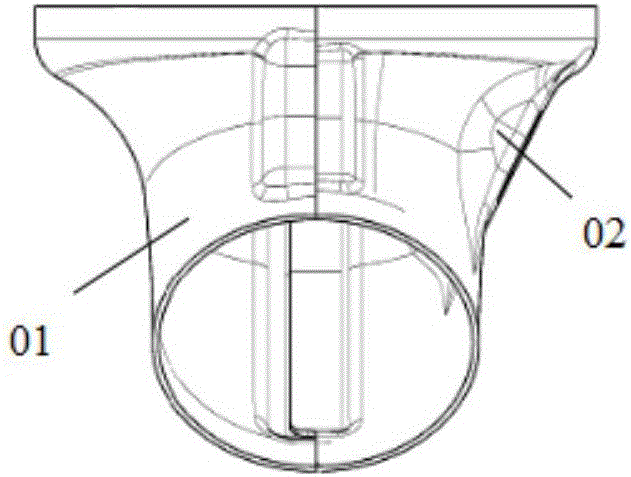

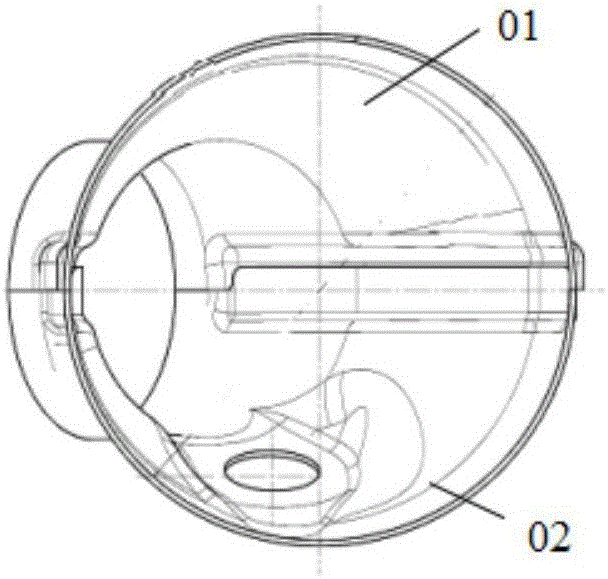

[0033] For attached Figure 1-3 The special-shaped tube shown requires 6 sets of molds to form the finished product, which are as follows from front to back:

[0034] (1) Press out the U-shaped bulge in the middle part of the blank sheet to form the profile of the upper half shell and the lower half shell, and the forming die 22 that connects the big ends of the upper half shell and the lower half shell together. After forming, the workpiece is as attached Figure 4 shown;

[0035] (2) The shaping die 23 for further shaping the workpiece drawn by the forming die 22, after shaping, the workpiece is as attached Figure 5 shown;

[0036] (3) Cut out the small mouth ends of the upper half-shell and the lower half-shell, and cut out the contour line of the middle part of the outer bending edge of the upper half-shell and the middle part of the outer bending edge of the lo...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com