A clamping device for range hood oil cup

A clamping device and fume-absorbing technology, applied in applications, household appliances, household components, etc., can solve the problems of low plate fixing accuracy, high labor intensity, poor fixing effect, etc., to achieve precise forming, easy maintenance, The effect of reducing the burden

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment approach 1

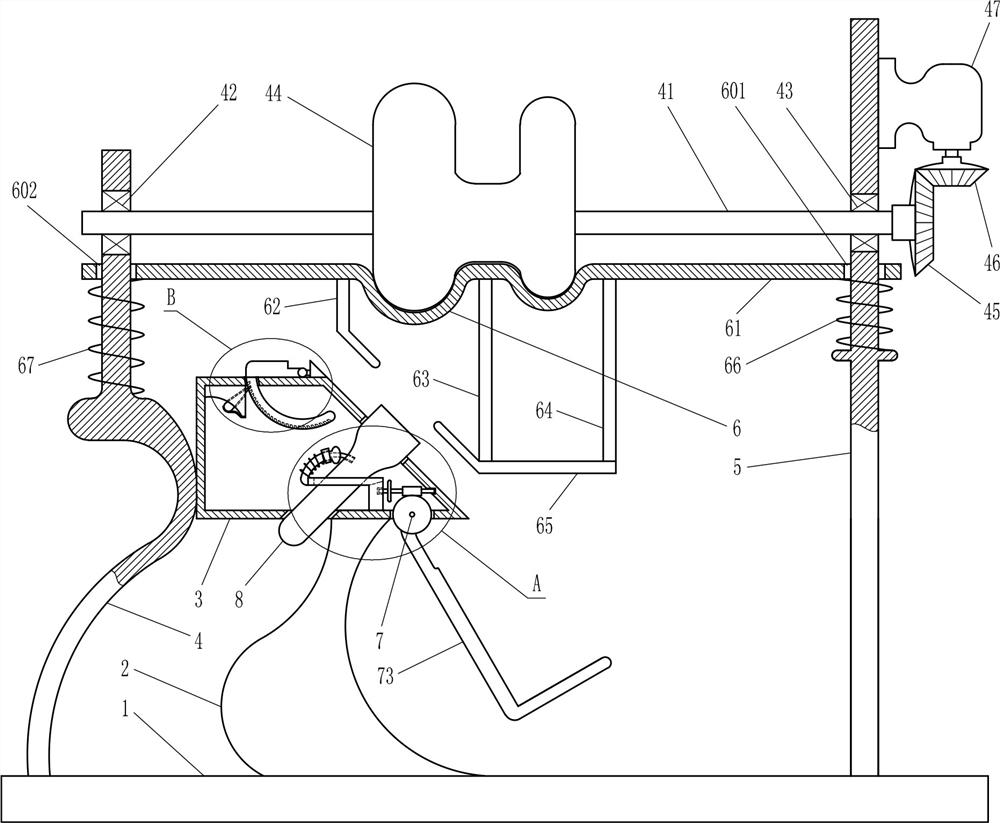

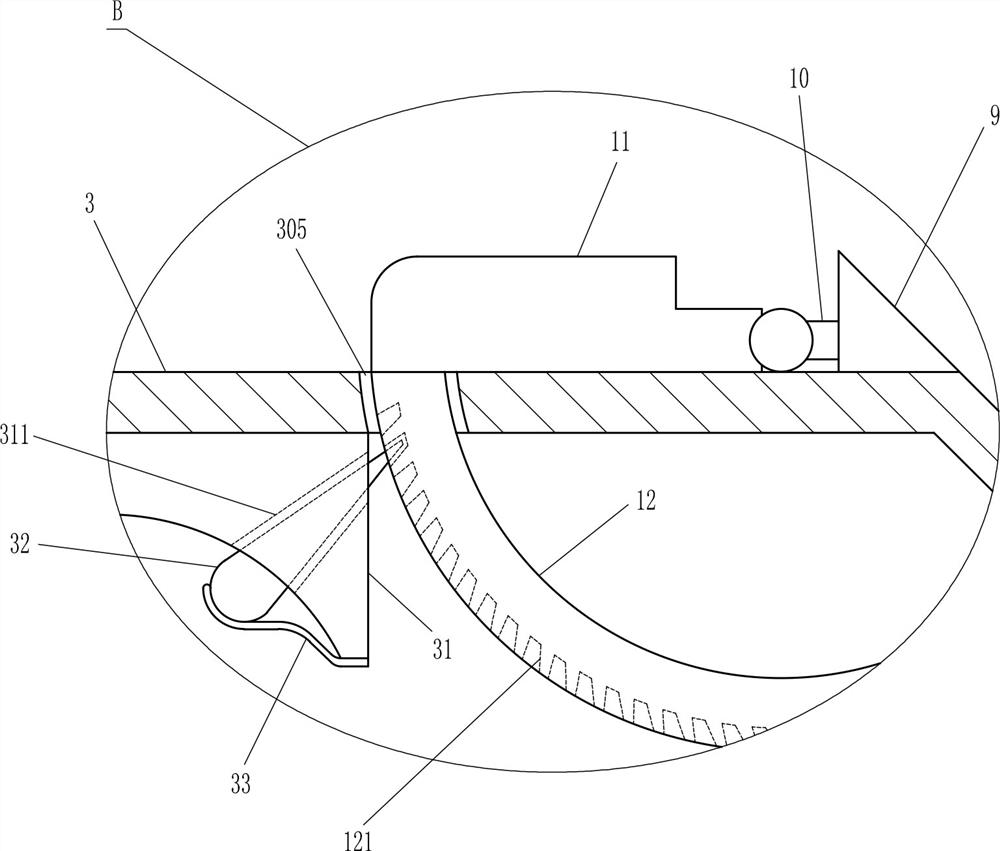

[0019] Please see Figure 1-3, the application is a clamping device for range hood oil cup, including a base 1, a large bracket 2, a wedge-shaped frame 3, a left bracket 4, a right bracket 5, a pressing device 6, a bending device 7, a large The positioning column 8, the triangular block 9, the hinge block 10, the swing plate 11 and the arc guide plate 12, the bottom end of the large bracket 2 is connected with the upper surface of the base 1 by welding, and the outer bottom surface of the wedge frame 3 is connected by welding The way is connected with the top of the large bracket 2, the right slope of the wedge frame 3 has a large round hole 301 inclined, the inner right slope of the wedge frame 3 has a horizontal first blind hole 302, the first blind hole 302 Be arranged below the large round hole 301, the bottom surface of the wedge frame 3 is vertically provided with a movable groove 303, the movable groove 303 is arranged on the right side of the top of the large bracket 2...

Embodiment approach 2

[0022] Please see Figure 1-3 , on the basis of Embodiment 1, the pressing device 6 includes a large lifting plate 61, a large pressing plate 62, a first connecting plate 63, a second connecting plate 64, a long pressing plate 65, a first spring 66 and a second spring 67, the large lifting plate 61 is arranged on the top of the triangular block 9, the hinged block 10 and the swing plate 11, the right end of the large lifting plate 61 has a first lifting hole 601, and the top of the right bracket 5 is located in the first lifting hole 601. The left end of lifting plate 61 has second lifting hole 602, and the top of left support 4 is positioned at second lifting hole 602, and the upper end of big pressing plate 62, the upper end of first connecting plate 63 and the upper end of second connecting plate 64 are all connected with The bottom surface of the big lifting plate 61 is connected by welding, the big pressing plate 62, the first connecting plate 63 and the second connecting...

Embodiment approach 3

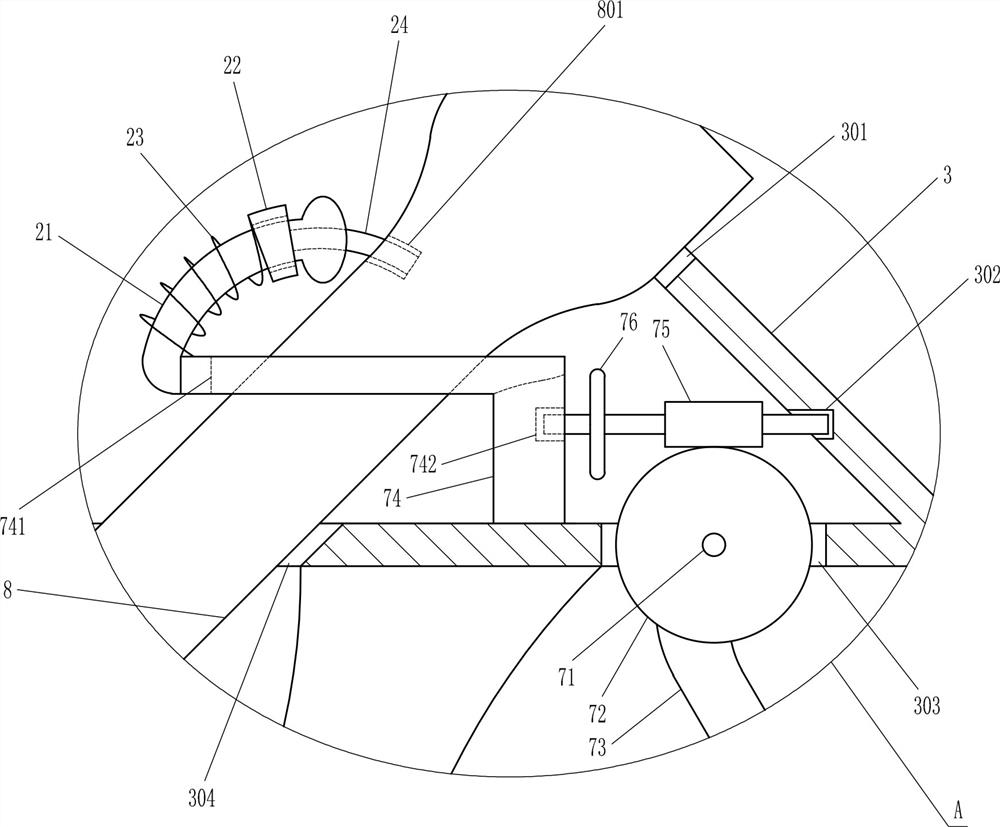

[0025] Please see Figure 1-3 , on the basis of Embodiment 1 and Embodiment 2, the bending device 7 includes a rotating shaft 71, a worm wheel 72, an L-shaped pressing plate 73, an L-shaped fixing plate 74, a worm screw 75 and a rotating disk 76, and the rotating shaft 71 is located at In the movable groove 303, the front end and the rear end of the rotating shaft 71 are connected to the wedge frame 3 by welding, the center position of the worm wheel 72 is rotatably sleeved on the rotating shaft 71, and the left upper end of the L-shaped extrusion plate 73 is connected to the worm wheel. The lower side of 72 is connected by welding, the lower right end of the L-shaped fixed plate 74 is connected with the inner bottom surface of the wedge frame 3 by welding, and the lower right end of the L-shaped fixed plate 74 is arranged between the movable groove 303 and the inclined hole 304 Between, the upper left part of the L-shaped fixed plate 74 has a lift groove 741, the large positi...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com