Patents

Literature

2793results about How to "Reasonable setting" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

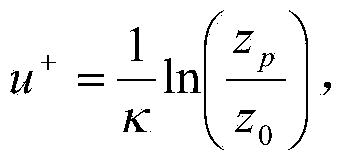

Wind resource computation method

InactiveCN104331621AAdapt to flowImprove efficiencySpecial data processing applicationsElectricityPeaking power plant

The invention provides a wind resource computation method, which comprises the following steps of analyzing original wind measurement data, and establishing a model required by CFD (computational fluid dynamics) computation on the basis of a full-height atmosphere boundary; computing wind speed and turbulent flow distribution under each wind direction condition by virtue of a CFD resolver; computing a wind resource distribution condition according to the wind speed and turbulent flow distribution under each wind direction condition, wind measurement mast coordinates, machine position coordinates, fan power data and wind condition data, and determining a position where a wind turbine generator is suitable to be mounted in a wind power plant. The method can also be used for analyzing wind resources of the wind power plant where the wind turbine generator is arranged.

Owner:CHINA DATANG CORP RENEWABLE POWER

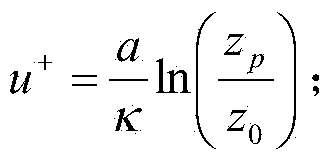

Method for optimally setting expressway traffic safety facilities

InactiveCN101818470AMaximize safetyOptimize applicable conditionsClimate change adaptationTraffic signalsRoad surfaceTransport engineering

The invention discloses a method for optimally setting expressway traffic safety facilities, which comprises the following steps of: determining key sections of the optimally-set expressway traffic safety facilities; optimally setting the safety facilities of sharp bend, inflection and continuous curve road sections; optimally setting the safety facilities of a bridge head combined with a sharp curve section; optimally setting the safety facilities of a long and steep longitudinal slope section; optimally setting an emergency lane; optimally setting the safety facilities of a long straight line section; optimally setting the safety facilities of a poor sight distance section; optimally setting the safety facilities of roads and bridges, and roads and tunnels transition sections; and optimally setting the safety facilities of a vertical crossing section. In the method, requirements of a driver on safety, quickness, high efficiency and comfortableness are fully met according to the influence of road conditions such as a plane and vertical section line, a pavement structure, roadbed and side slopes, bridges and tunnels, an overhead crossing project of the expressway on driving safety.

Owner:CHANGAN UNIV

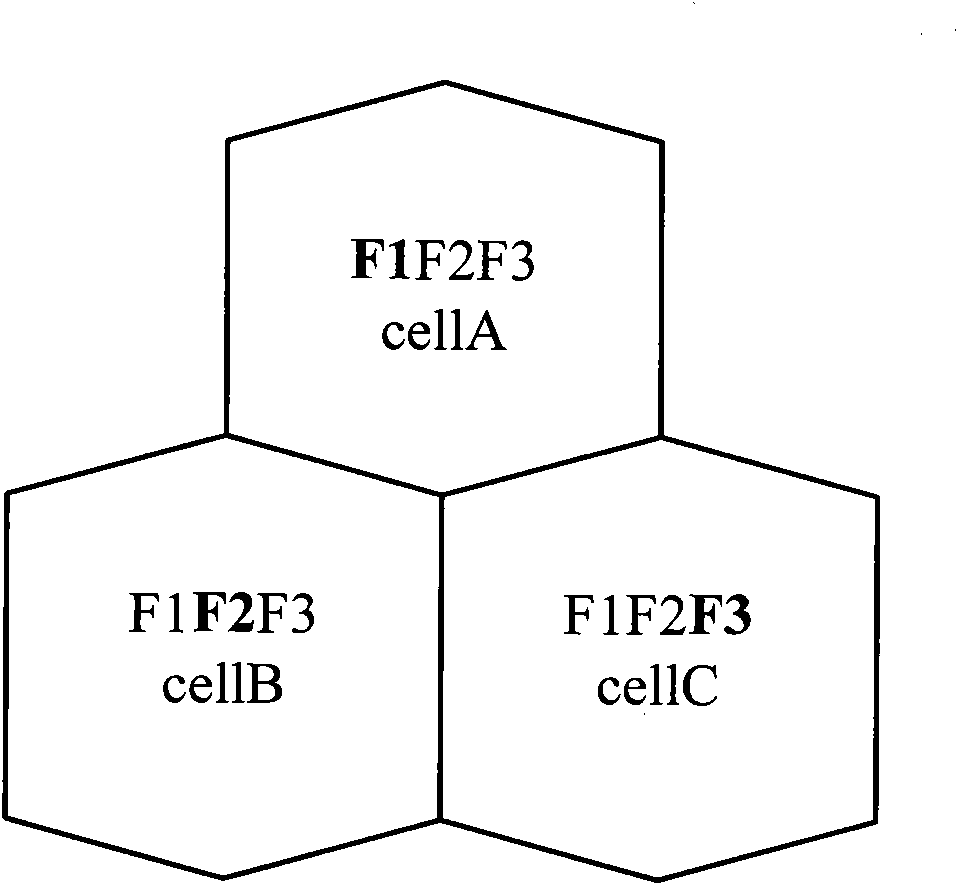

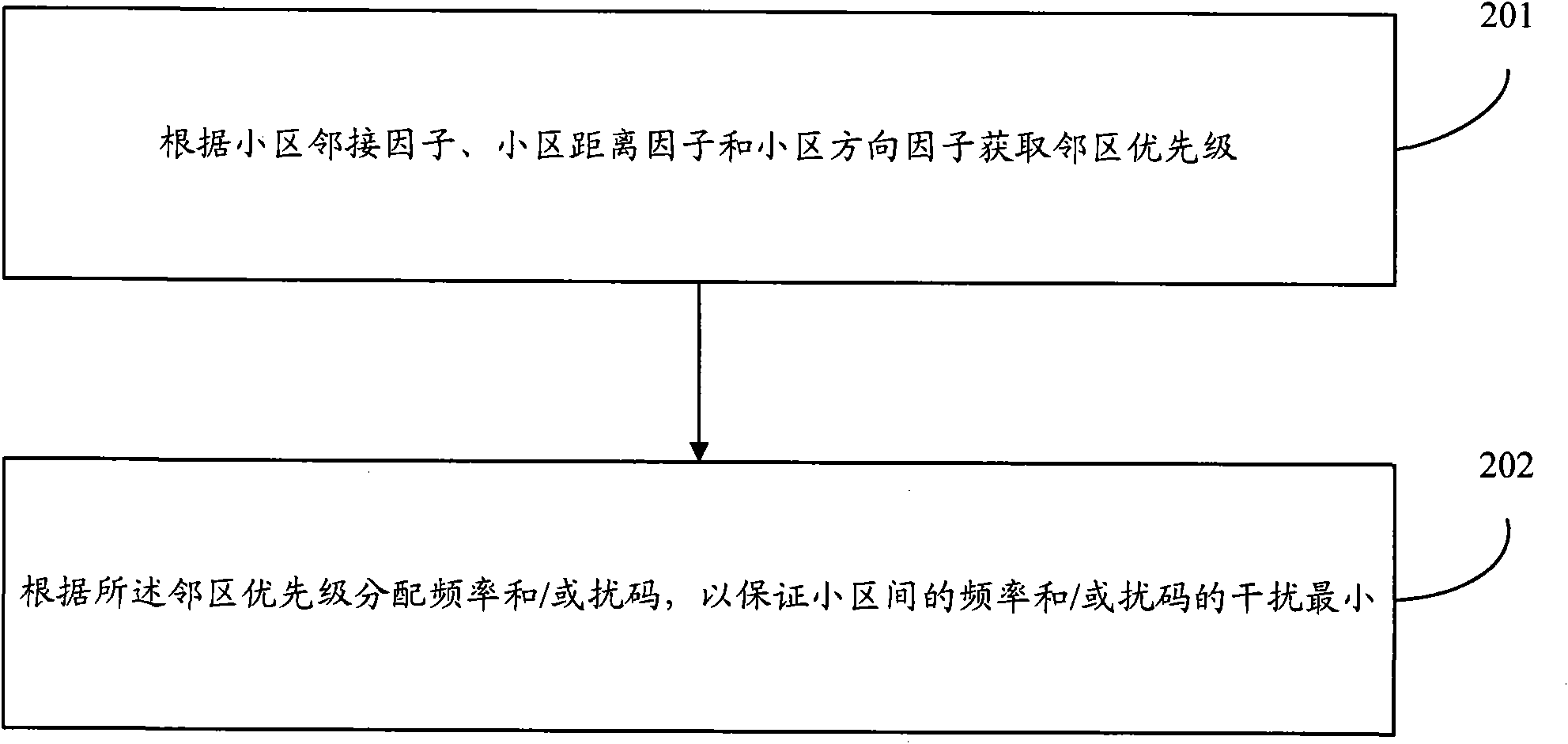

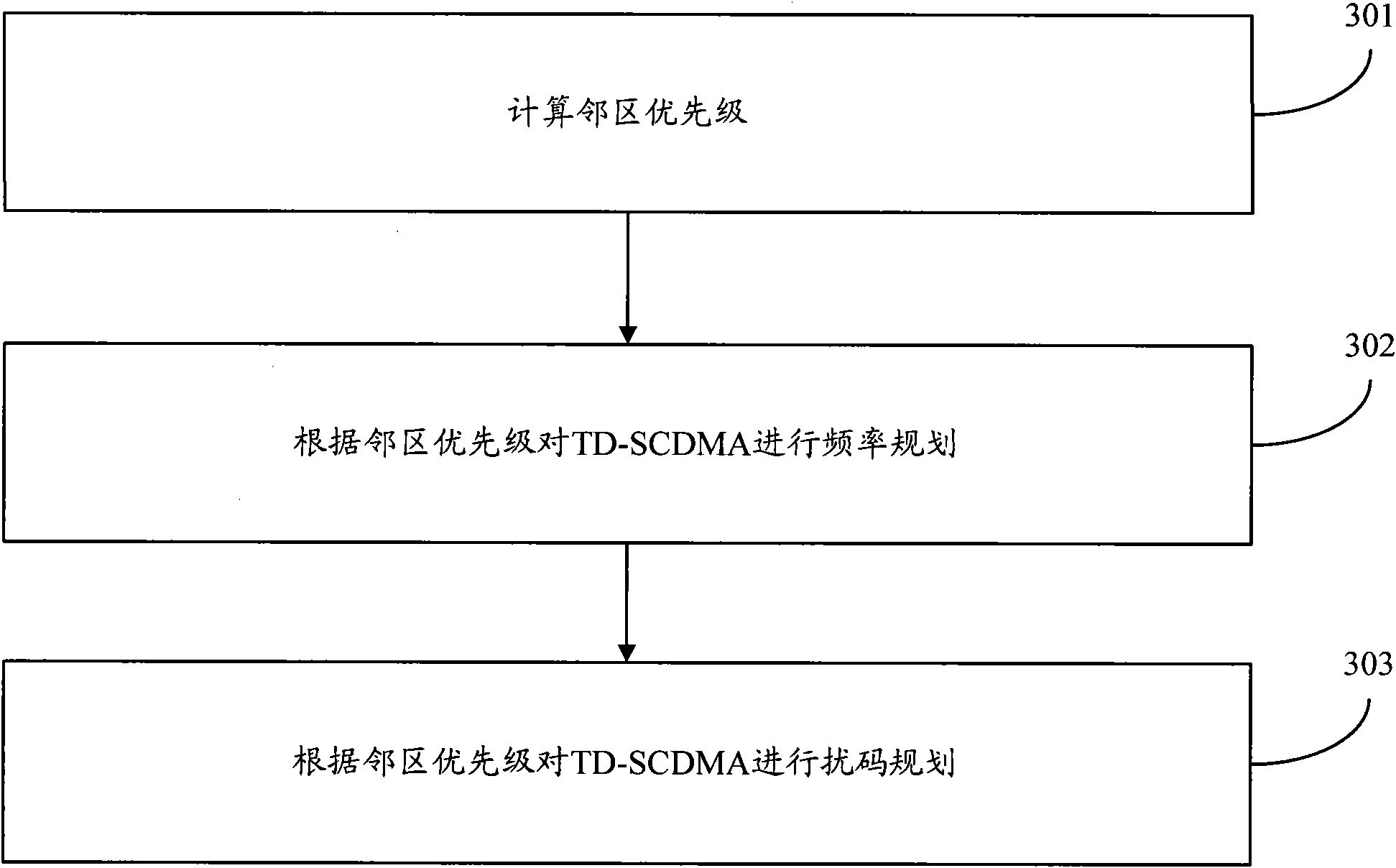

Frequency planning and scrambling code planning method and device based on adjacent zone priority level

ActiveCN102083075AMaximize utilizationImprove perceived qualityNetwork planningFactor baseResource utilization

The embodiment of the invention discloses a TD (time division) frequency planning and scrambling code planning method based on an adjacent zone priority level, comprising: an adjacent cell priority level is generated through a zone adjacent factor, a zone factor and a zone direction factor based on the base station zone attribute according to the system technical scheme; and a TD main carrier frequency is distributed according to the generated adjacent zone priority level to ensure the minimality of the frequency interferences among zones; and then, a system assigns base scrambling code blocks and scrambling codes according to the adjacent zone priority level and the frequency so as to ensure the average minimization of the mutual interference of the frequency scrambling code among zones. According to the embodiment of the invention, the calculation method of the adjacent zone priority level is more reasonable, and the setting and switching process of the adjacent zone relationship is more reasonable. Furthermore, co-frequency encounter phenomena among the adjacent zones are avoided by adopting the scheme, so that the mutual correlation of the scrambling codes among the adjacent zones is minimal, and the maximal frequency resource and scrambling code resource utilization and the minimum frequency and scrambling code interferences among zones are ensured. And the network performance indexes such as call completing rate are improved, and the client perception quality is greatly improved.

Owner:CHINA MOBILE GROUP JIANGSU

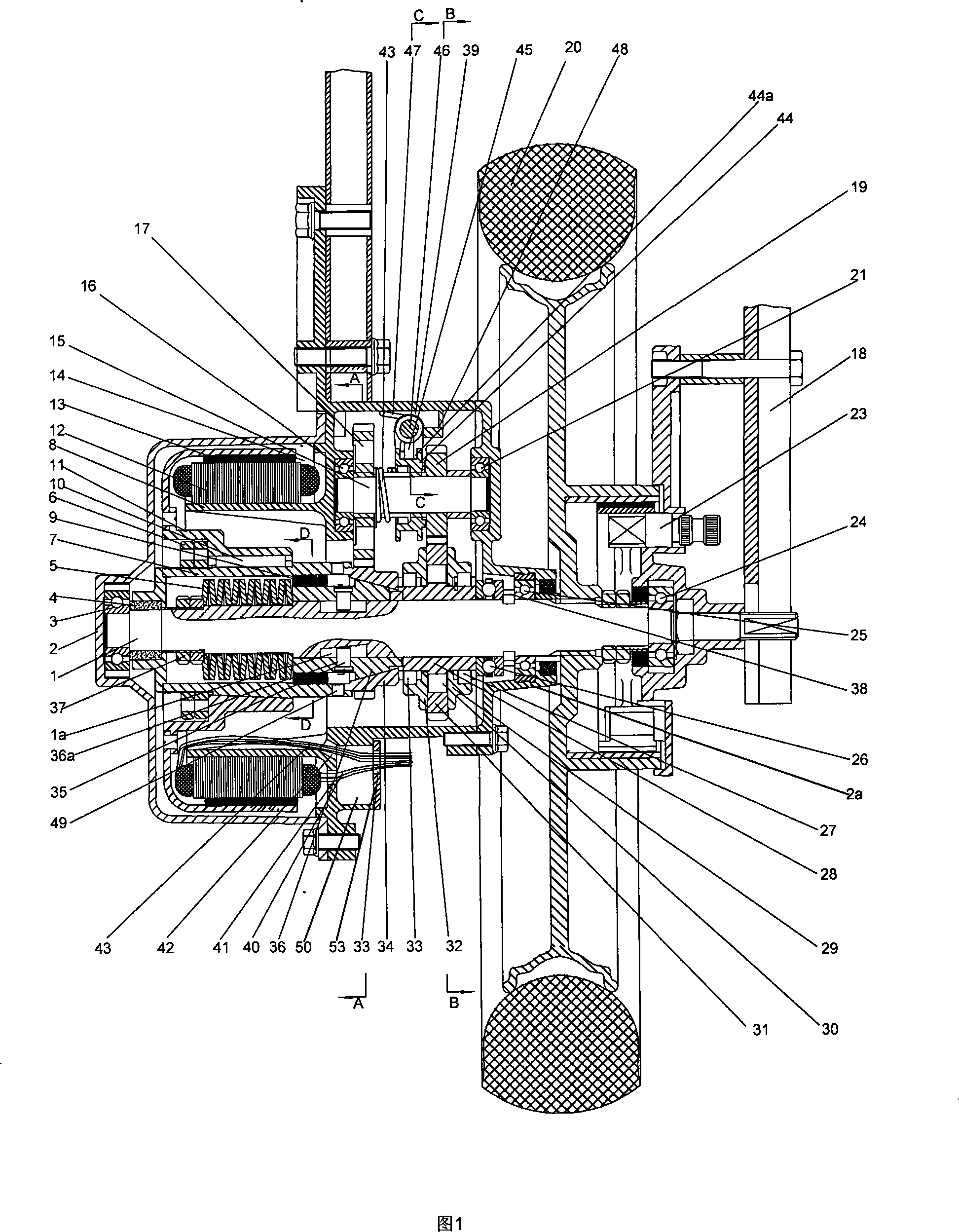

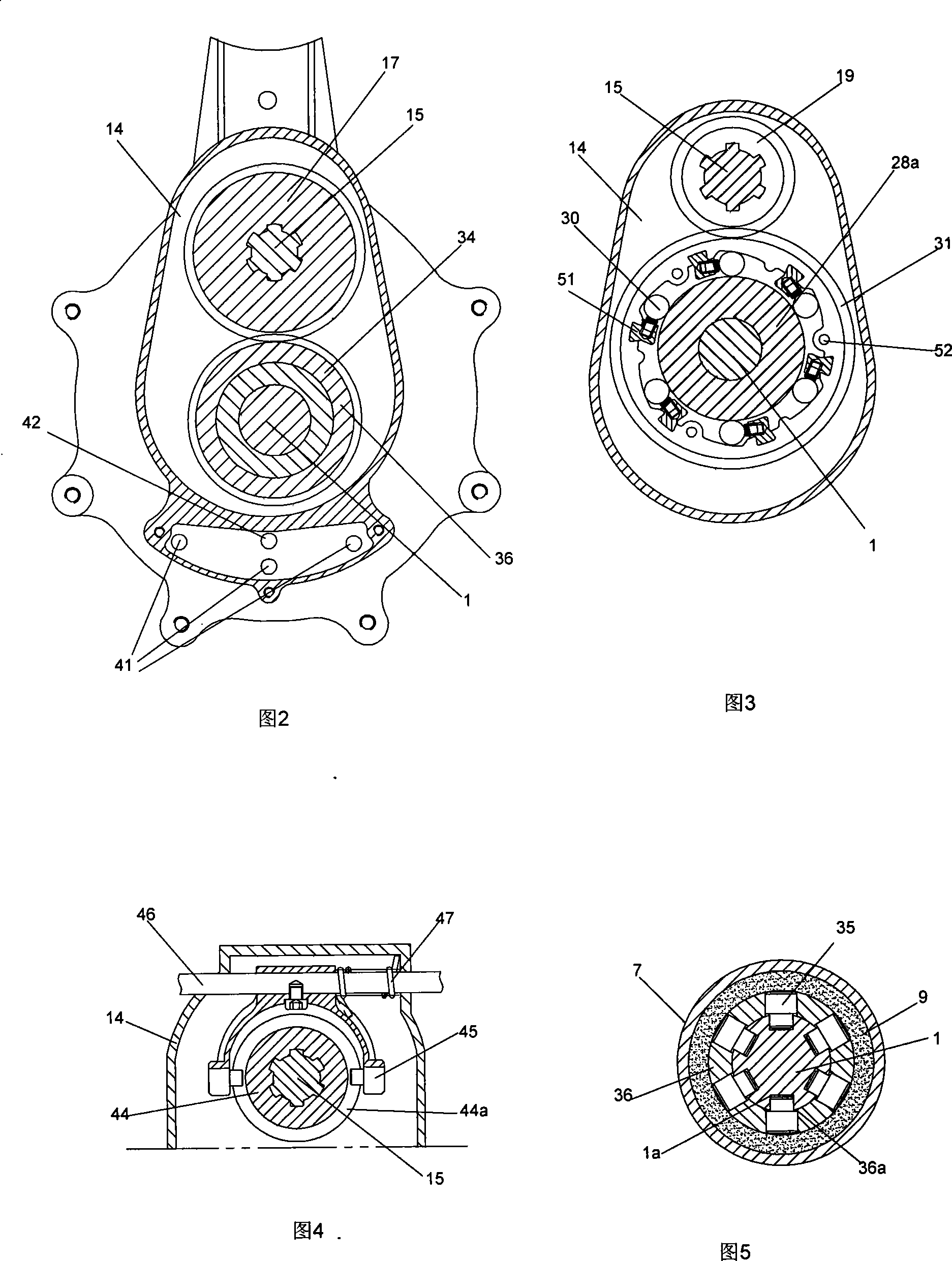

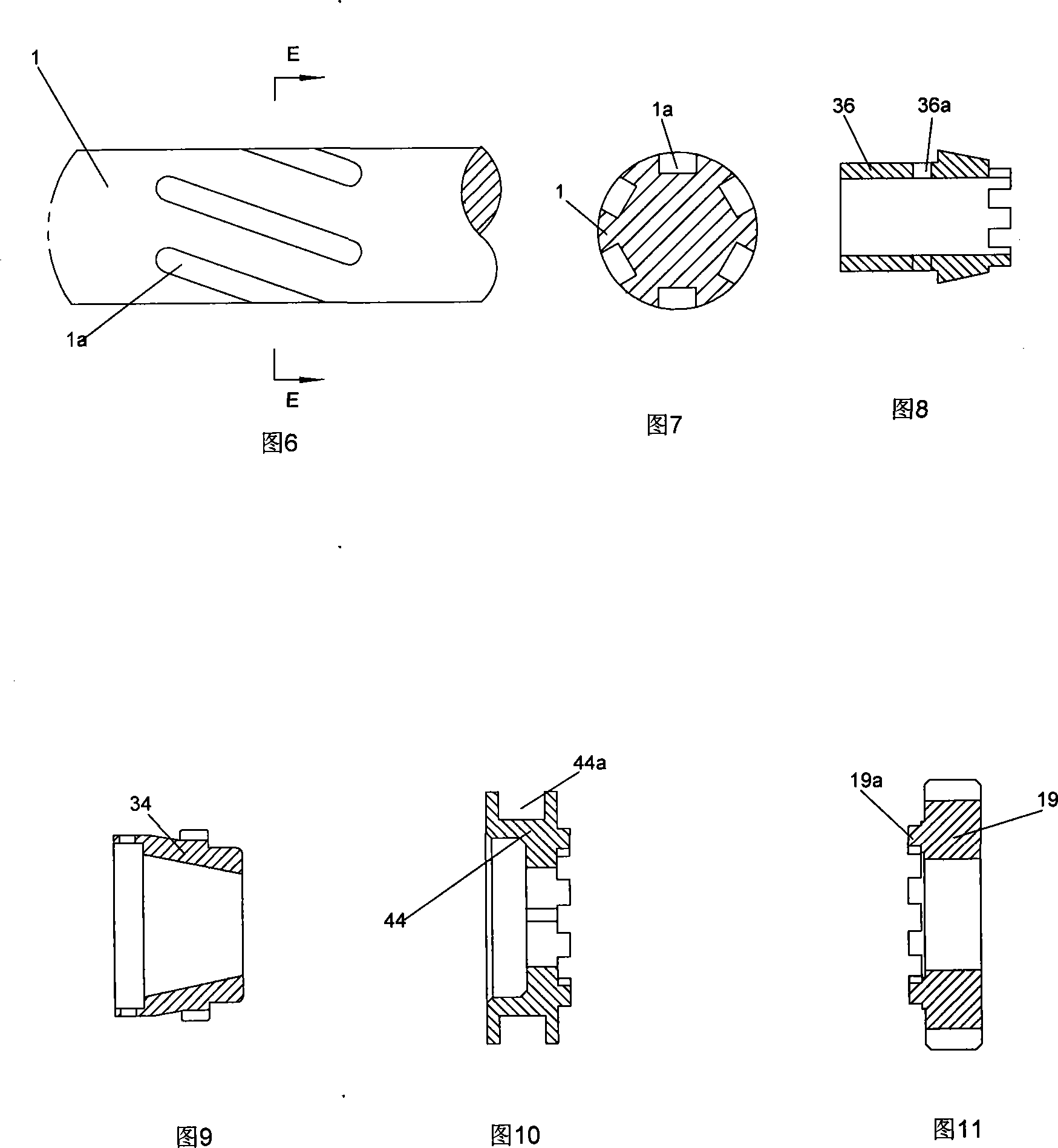

Automatic speed changing electric driven hub

InactiveCN101244747AReduce volumeIncrease in sizeWheel based transmissionMechanical energy handlingDrive shaftElectric machine

The invention discloses an automatic speed-change electrical wheel hub, comprising a left wheel hub frame, a right wheel hub frame, a housing, a motor, a transmission shaft, a wheel, a brake device arranged on the transmission shaft, and a self-adaptive two-speed automatic speed-change assembly driven by the motor rotor via a transmission device. The transmission device is arranged in the intracavity of the motor stator. The automatic speed-change electrical wheel hub has the advantages that the motor transmission device is arranged reasonably, the consumption of the manufacture materials of the housing is lowered, the whole wheel hub has a compact size and a light weight, the manufacturing cost is reduced, and the invention can enable the output power of the motor and the driving status of vehicles to always be in an optimum matching status to achieve the balancing control of the driving moment of the vehicles and the synthesized driving resistance; the speed change can be operated automatically along with the change of the driving resistance by the self adaptive without cutting off the driving force, so that the invention is beneficial to the energy-efficiency of the vehicles and the mechanical power equipment, and can satisfy the usage under the conditions of mountain areas, hills and heavy loads; and the transmission of the invention has a light weight and a compact structure.

Owner:SOUTHWEST UNIVERSITY

Educational toy suite

InactiveCN105194884AEasy to installEasy to disassembleDollsElectrical appliancesTablet computerEngineering

The invention relates to the technical field of computer vision recognition processing and provides an educational toy suite. The educational toy suite comprises a support, a helmet detector and a base plate, the support is installed on the base plate, and the helmet detector is installed on the support; a first groove is formed in the upper portion of the base plate; the bottom of the support is provided with a protrusion, the protrusion is installed in the first groove, a second groove and a third groove are formed in the top of the support, and the second groove is used for storing a tablet computer; the helmet detector is installed in the third groove. By means of the educational toy suite, the image acquisition scope of a camera of the tablet computer is expanded, the visual angle is enlarged, great interactivity is achieved, game experience is more vivid, the educational toy suite is helpful for alleviating asthenopia, harm to eyes is lowered, operational ability of children is improved, the children are promoted to make progress continuously, intelligence is developed, enjoyment is improved, the educational toy suite is more convenient to carry, move, install and detach, the cost is saved, and maintenance is facilitated.

Owner:SHANGHAI PUTAO TECH CO LTD

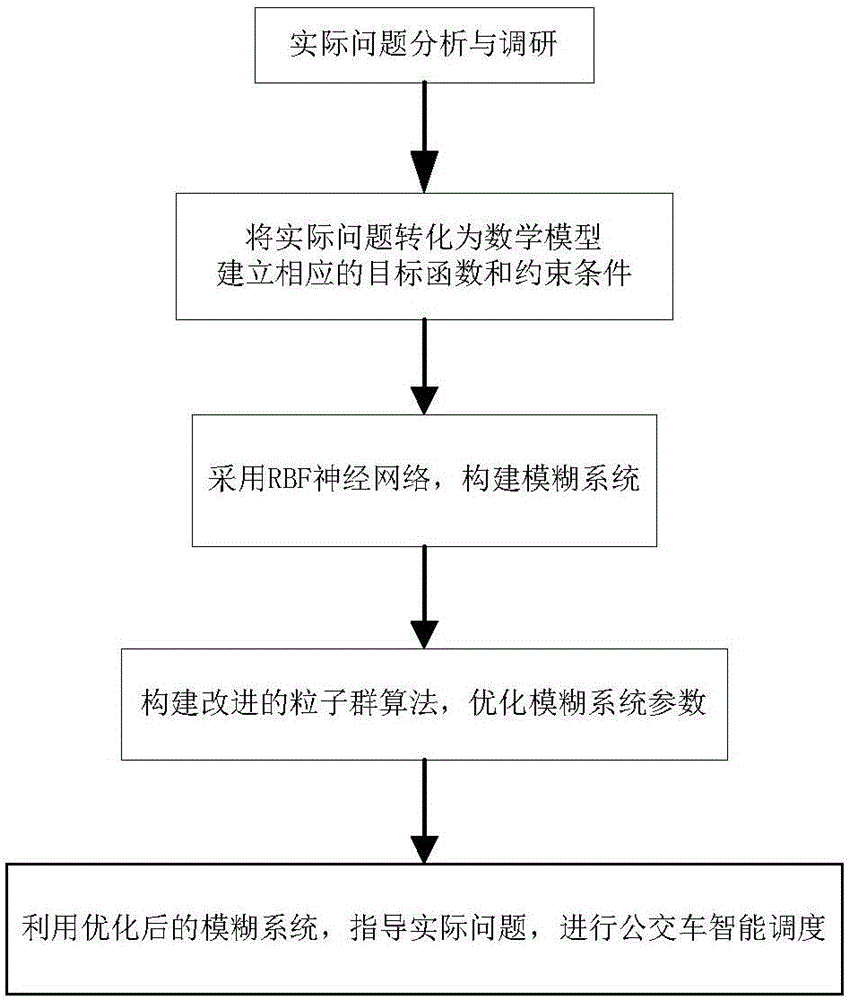

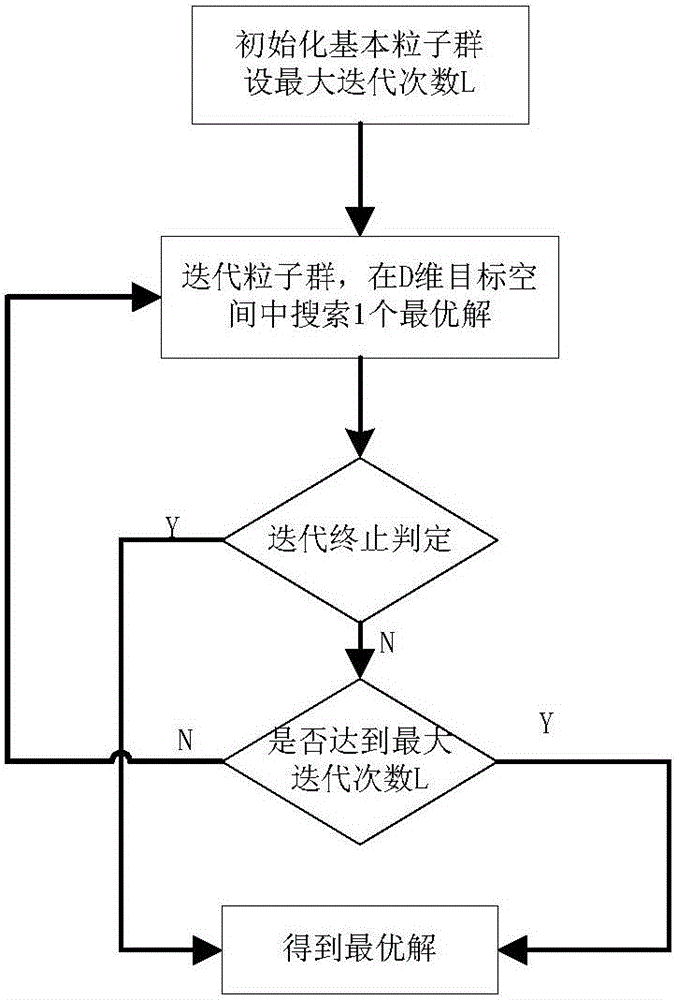

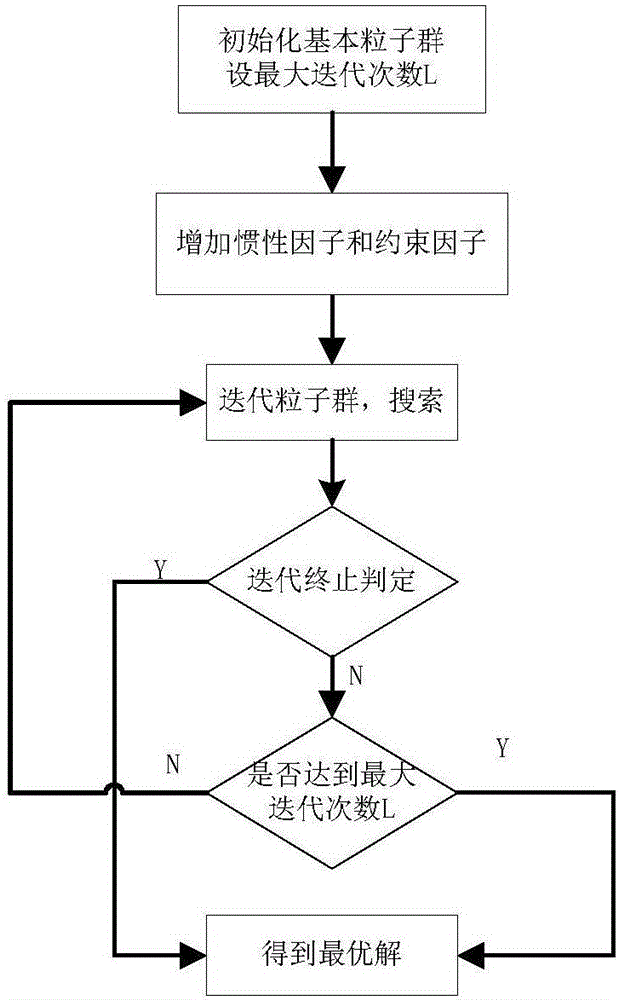

Improved fuzzy neural network bus intelligent scheduling method based on chaos theory

InactiveCN106295886ARealize intelligent schedulingEasy to fall into local optimal solutionForecastingNeural learning methodsChaos theoryAlgorithm

The invention discloses an improved fuzzy neural network bus intelligent scheduling method based on a chaos theory, and belongs to the field of intelligent transportation. According to the improved particle swarm bus intelligent scheduling method based on the chaos theory, advantages and complementarity of various algorithms are fully utilized, a series of improvement measures are also introduced, such as conjugate gradient optimization, and inertia factor and constraint factor of the particle swarm algorithm etc., the mechanism and the search performance are researched from the theoretical and practical perspectives, problems of poor global search capability and premature convergence of the conventional optimization algorithm are fundamentally solved, the diversity of population can be obviously increased, the global search capability is obviously improved, the problem of fuzzy information can be effectively dealt with, the convergence speed is fast, and a new high-efficiency method is provided for bus intelligent scheduling.

Owner:梁广俊

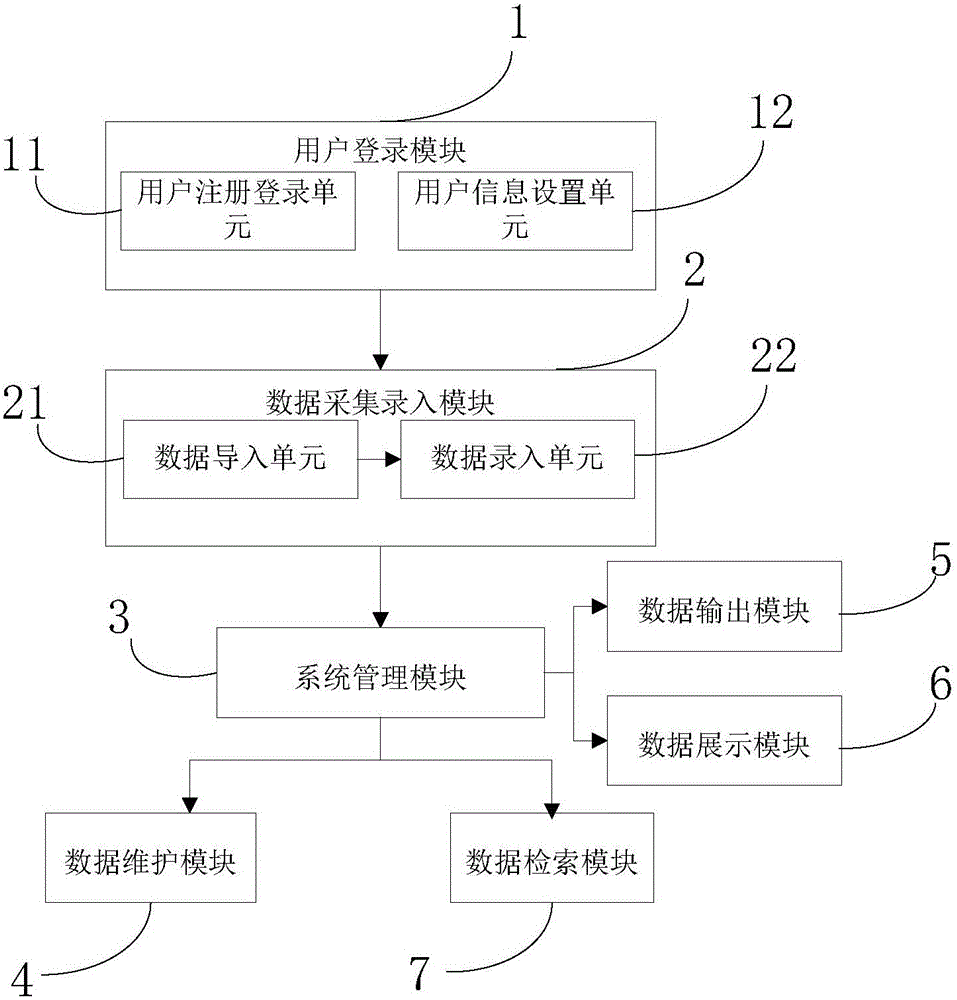

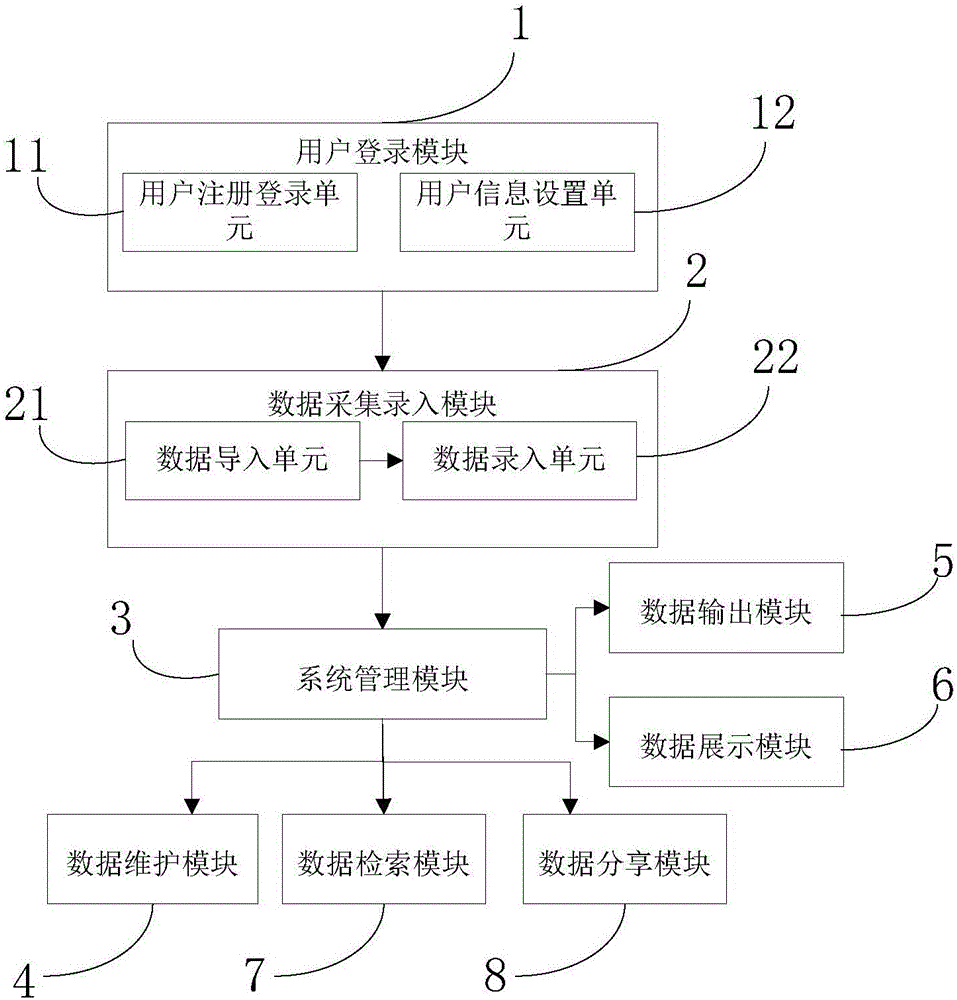

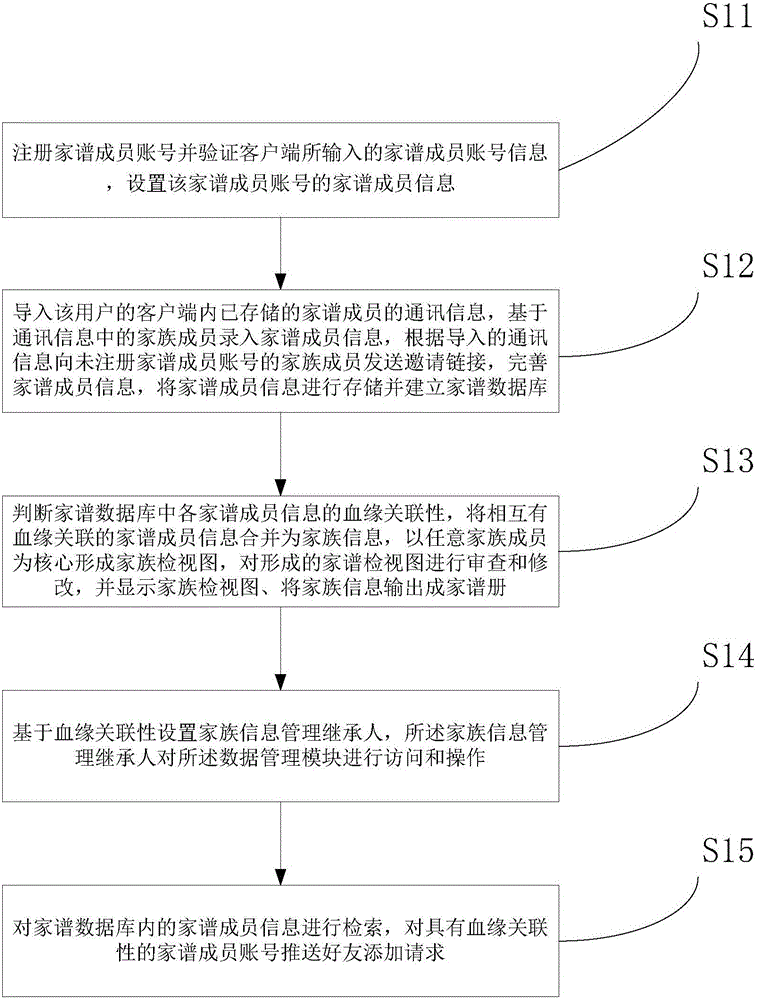

Family tree management system and method

InactiveCN106204291AReasonable settingVisual inspectionData processing applicationsData displaySystems management

The invention relates to the technical field of data management, in particular to a family tree management system and method. The family tree management system comprises a user login module, a data collecting and entering module, a system management module, a data maintenance module, a data output module, a data display module and a data retrieval module. The family tree management method comprises a corresponding method carried out on the basis of the family tree management system. By use of the family tree management system and method provided by the invention, a personal network log is integrated into a family tree system to form a rich family culture inheriting system, family member information input by a user is converted into a viewing graph so as to display the family member information in the hierarchical way of the viewing graph so as to more visually check. Compared with the prior art, the family tree management system disclosed by the invention is comprehensive in information recording and simultaneously comprises the information of each paternal line member of the family and the information of each maternal line member of the family so as to meet a requirement on truly and comprehensively recoding the family member information under a current big data environment.

Owner:宋晓亮

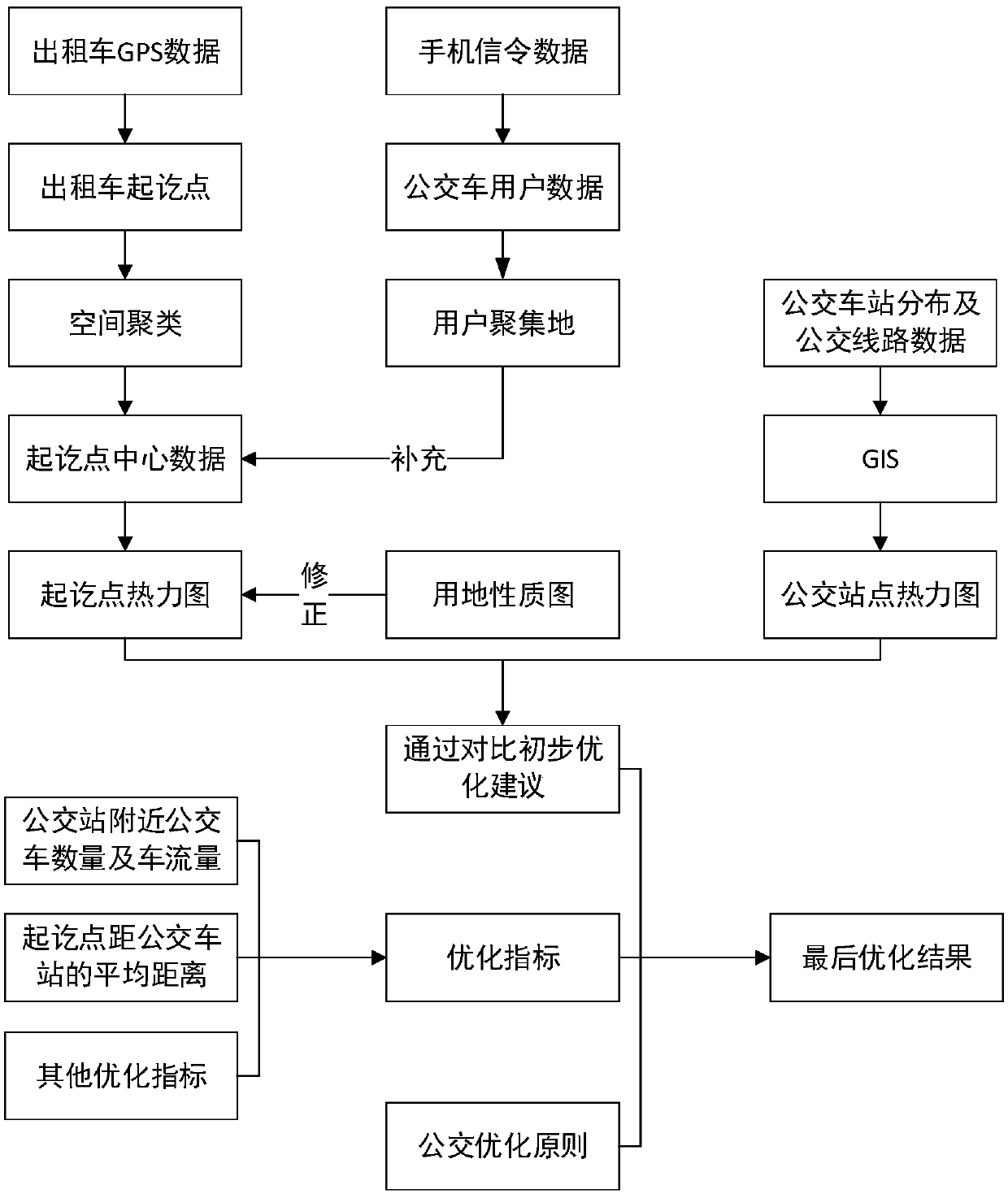

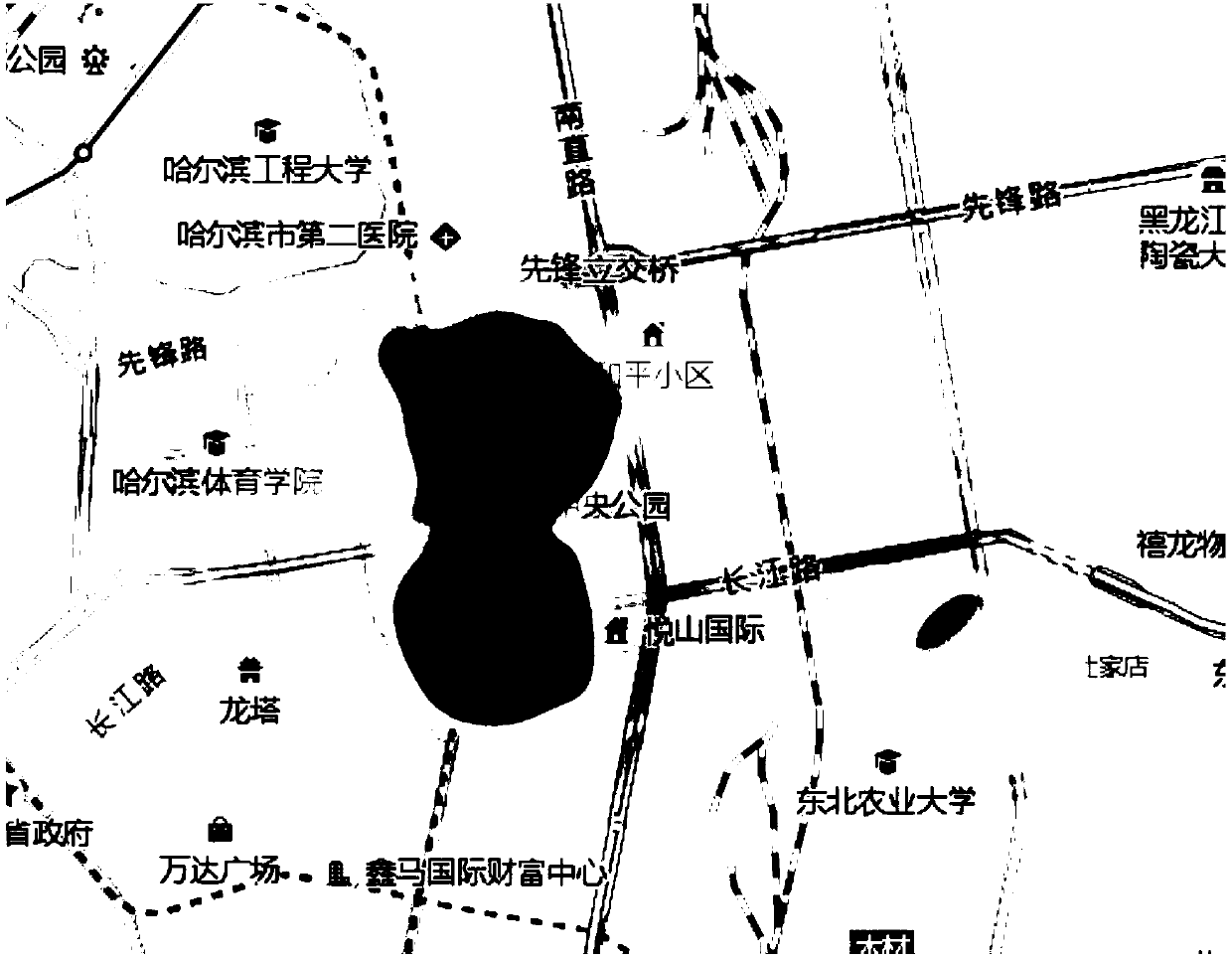

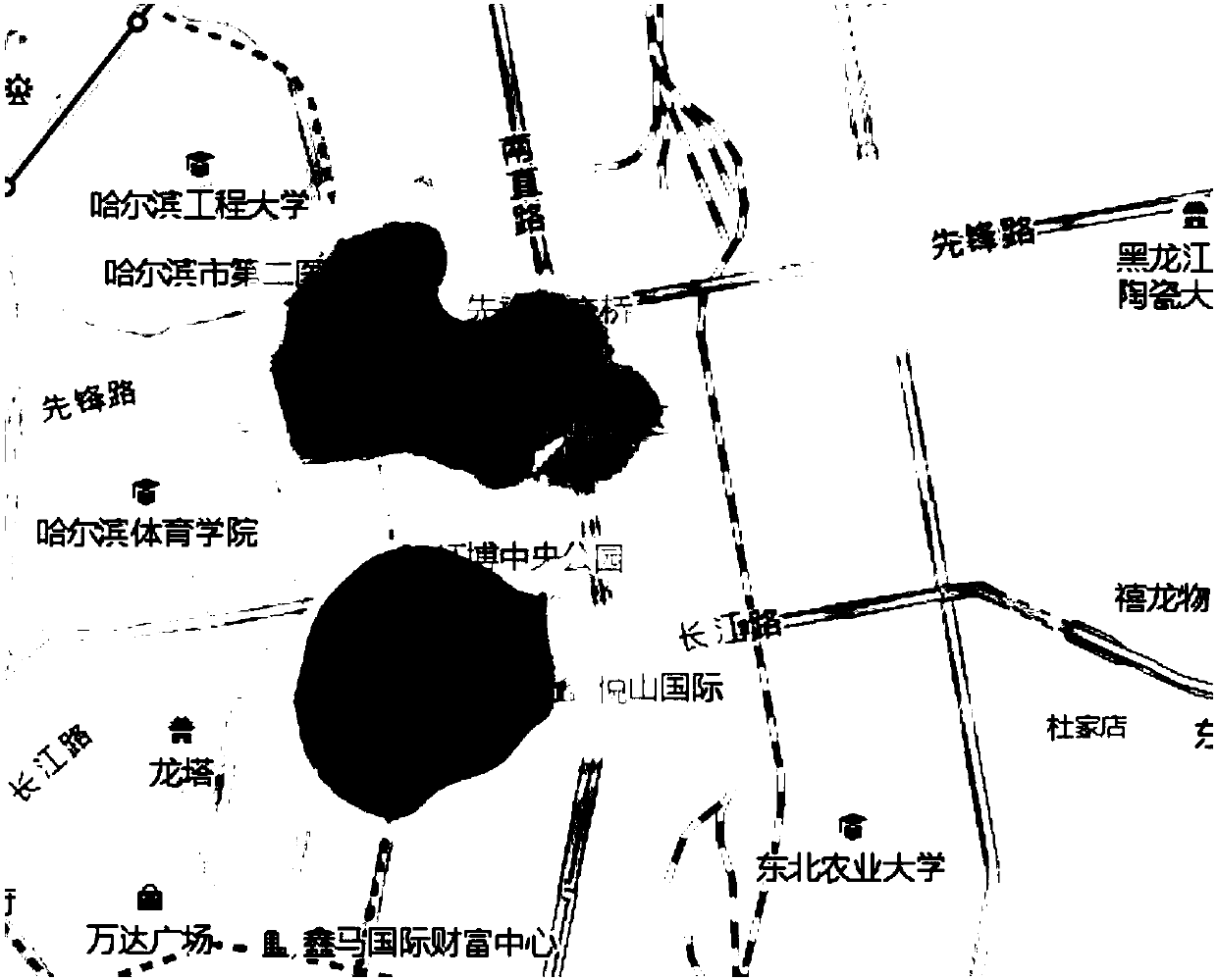

Bus line optimizing method based on taxi GPS data and mobile phone signaling data

ActiveCN108564226AImprove operational efficiencyAvoid unreasonable settingsForecastingCharacter and pattern recognitionTraffic capacityTransportation planning

The invention relates to a bus line optimizing method based on taxi GPS data and mobile phone signaling data, and aims to solve the problem of low operation efficiency of a bus line because the existing bus line is unreasonable in setting, cannot meet needs very well and does not conform to the actual situation. The bus line optimizing method comprises the following specific processes: 1, acquiring the taxi GPS data, acquiring the mobile phone signaling data, acquiring a land use map and acquiring bus stop data; 2, processing the data acquired in the step 1; 3, calculating bus line optimizingindexes according to the step 2; 31, calculating the distances from an origin point and a destination point to the nearest bus stop; 32, determining the number of bus lines included in the bus stop and the traffic flow; 33, calculating the average running speed of a road vehicle; 4, setting optimizing measures according to the optimizing indexes. The bus line optimizing method is applied to the field of public transportation planning.

Owner:HARBIN INST OF TECH

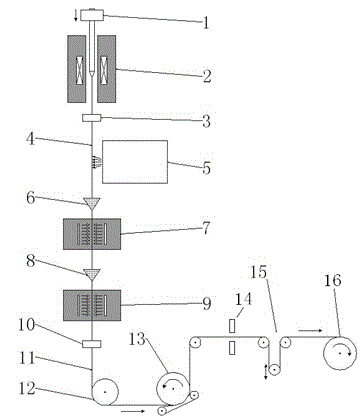

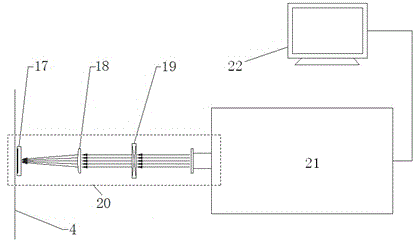

On-line optical fiber grating preparing system

ActiveCN104635295AReasonable settingImprove production efficiencyCladded optical fibrePhotomechanical apparatusSpectral formManufacturing efficiency

The invention relates to an on-line optical fiber grating preparing system, which comprises a wire drawing tower and a grating inscribing device, wherein the wire drawing tower comprises a wire drawing furnace and a prefabricated bar clamping feeding device arranged above the wire drawing furnace, a naked optical fiber diameter gauge is arranged under a furnace opening of the wire drawing furnace, the grating inscribing device is arranged under the naked optical fiber diameter gauge, an optical fiber coating curing device is arranged under the grating inscribing device along the vertical downward direction of the naked optical fiber, and a wire drawing take-up mechanism is arranged under the optical fiber coating curing device. The on-line optical fiber grating preparing system is characterized in that the grating inscribing device comprises a phase mask plate and a 193nm excimer laser, wherein the phase mask plate is arranged in a way of being next to the center of the naked optical fiber, the output end of the 193nm excimer laser is alternately provided with a diaphragm and a lens, the 193nm excimer laser outputs single-pulse laser beams, and the single-pulse laser beams are illuminated onto the phase mask plate through diaphragm shaping and lens focusing. The on-line optical fiber grating preparing system has the advantages that the arrangement is reasonable, the performance is stable, the manufacturing efficiency is high, in addition, the precision of the manufactured grating is high, the grating spectral form is good, and the consistency is high.

Owner:武汉烽理光电技术有限公司

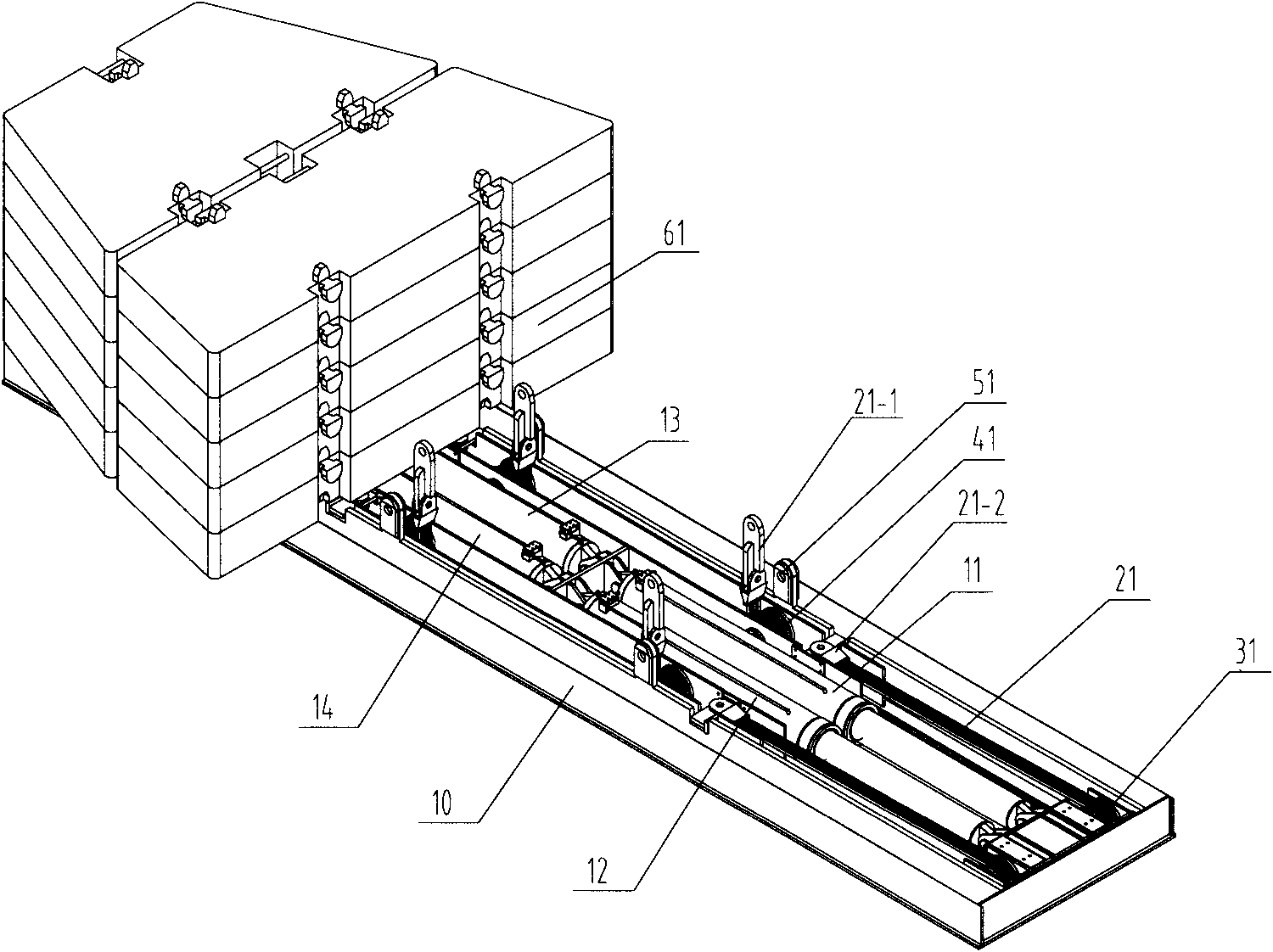

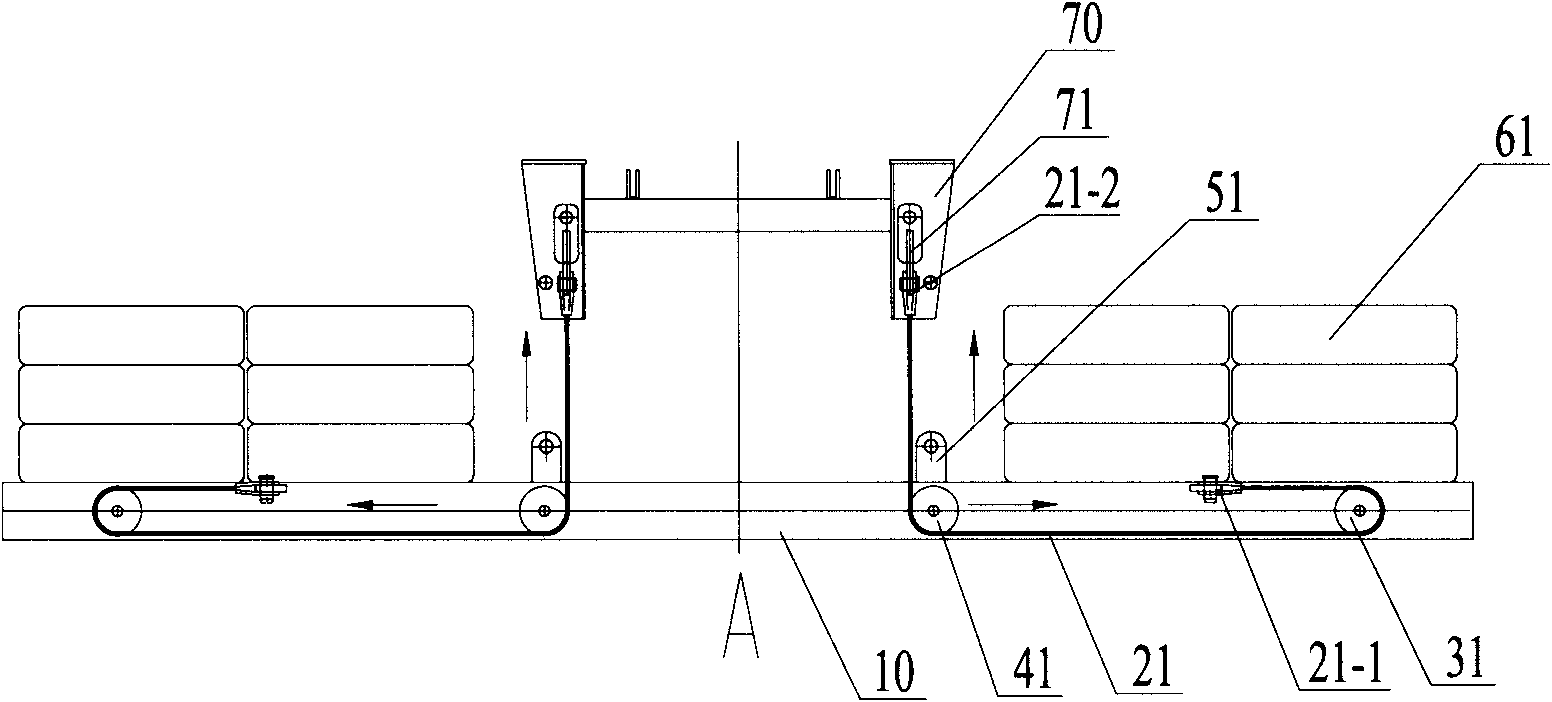

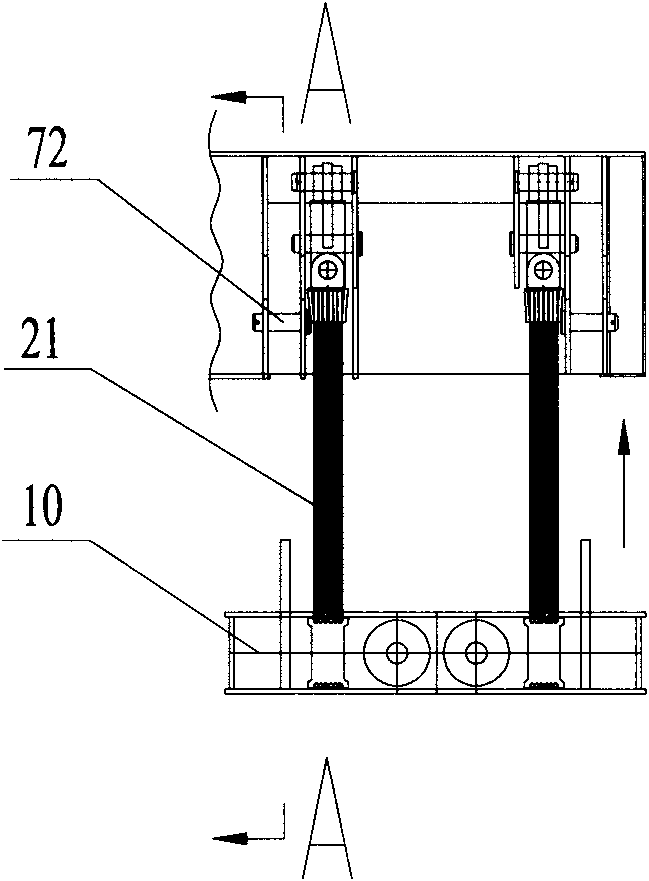

Balancing weight handling device and movable crane

The invention relates to the technical field of cranes and discloses a balancing weight handling device comprising an independently arranged tray, wherein, the upper end surfaces of two ends of the tray are used for placing a balancing weight, two ends of the tray are both provided with a cavity, at least one telescopic oil cylinder is arranged in the cavity, the fixed end of the telescopic oil cylinder is fixed with the tray, and the telescopic end of the telescopic oil cylinder is used for connecting with a tray hoisting mechanism used for hoisting the tray. The balancing weight handling device with the structure is not limited by frame plane space and rotatable table height of the movable crane, does not increase the integral size of the movable crane and ensures that the integral sizeof the movable crane does not exceed path driving standard and the structure of the integral machine is more compact; the telescopic oil cylinder can also perform the function of the balancing weight,so that the stress of the rotary table is more reasonable. The invention also provides a movable crane.

Owner:SANY AUTOMOBILE MFG CO LTD

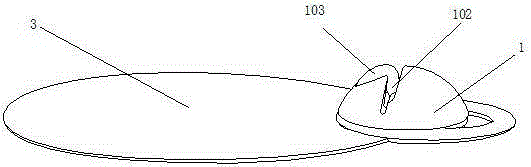

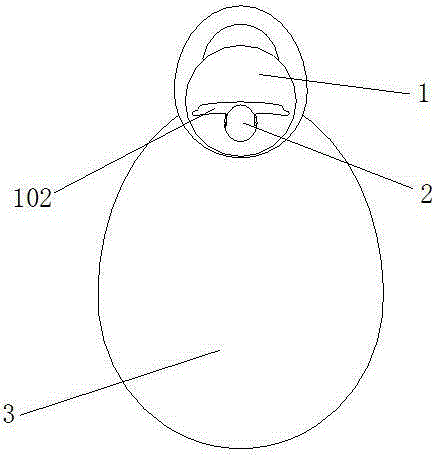

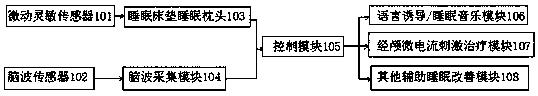

Sleep monitoring feedback and sleep auto-enhancement device

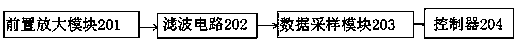

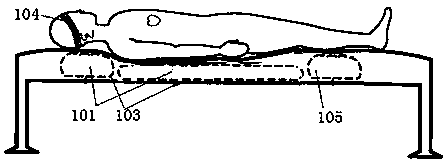

InactiveCN108078565ASimple structureReasonable settingElectrotherapyDiagnostic recording/measuringPolysomnogramMedicine

The invention provides a sleep monitoring feedback and sleep auto-enhancement device and relates to the technical field of sleep monitoring equipment. The sleep monitoring feedback and sleep auto-enhancement device comprises a micromotion sensitivity sensor, a brain wave sensor, a sleep mattress sleep pillow, a brain wave acquisition module, a control module, a language induction / sleep music module and a transcranial microcurrent stimulation treatment module. The micromotion sensitivity sensor is arranged in the sleep mattress sleep pillow and is connected to the control module. The brain wave sensor is connected to the brain wave acquisition module which is connected to the control module, and the control module is connected to the language induction / sleep music module and the transcranial microcurrent stimulation treatment module respectively. The device can be used for sleep monitoring on napping after lunch, multiple sleep latency test, and night split-sleep respiration monitoring, thereby making up for the deficiency that a traditional polysomnogram requires all-night monitoring; the device can be used not only in psychology industry but also in other different industries.

Owner:SHANGHAI HUICHENG MEDICAL SCI & EDUCATION INSTR

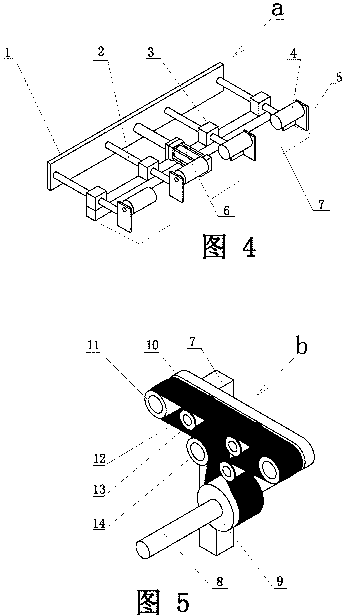

Automatic paper lamination stacking machine

The invention discloses an automatic paper lamination stacking machine which comprises a rack, wherein a paper lifting plate and a paper conveying belt are arranged in the rack; the paper conveying belt is arranged in front of the paper lifting plate; the upper plane of the paper conveying belt is lower than the upper end surface of the paper lifting plate; a paper support plate is arranged in front of the paper conveying belt; a movable paper pushing arm is arranged at the corresponding position of the paper support plate; a counting sensor is arranged in the rack at the end of the paper support plate close to the paper conveying belt and electrically connected with a control device of the machine; a lifting device is arranged on the rack and is in transmission connection with a turnover frame; a paper holding arm and a paper blocking arm are arranged on the turnover frame; a paper moving plate capable of sliding along the horizontal direction and a movable stacking paper support plate capable of going up and down in the vertical direction are mounted on the rack; the paper moving plate is located at the top of the lifting device; the movable stacking paper support plate is arranged in front of the paper moving plate; a stacking transition platform is arranged between the movable stacking paper support plate and the lifting device; a paper aligning plate is also arranged on the rack; and the paper aligning plate is located above the movable stacking paper support plate. The automatic paper lamination stacking machine disclosed by the invention has the advantages of high production efficiency and good stacking quality.

Owner:YANCHENG HONGJING MACHINERY SCI & TECH CO LTD

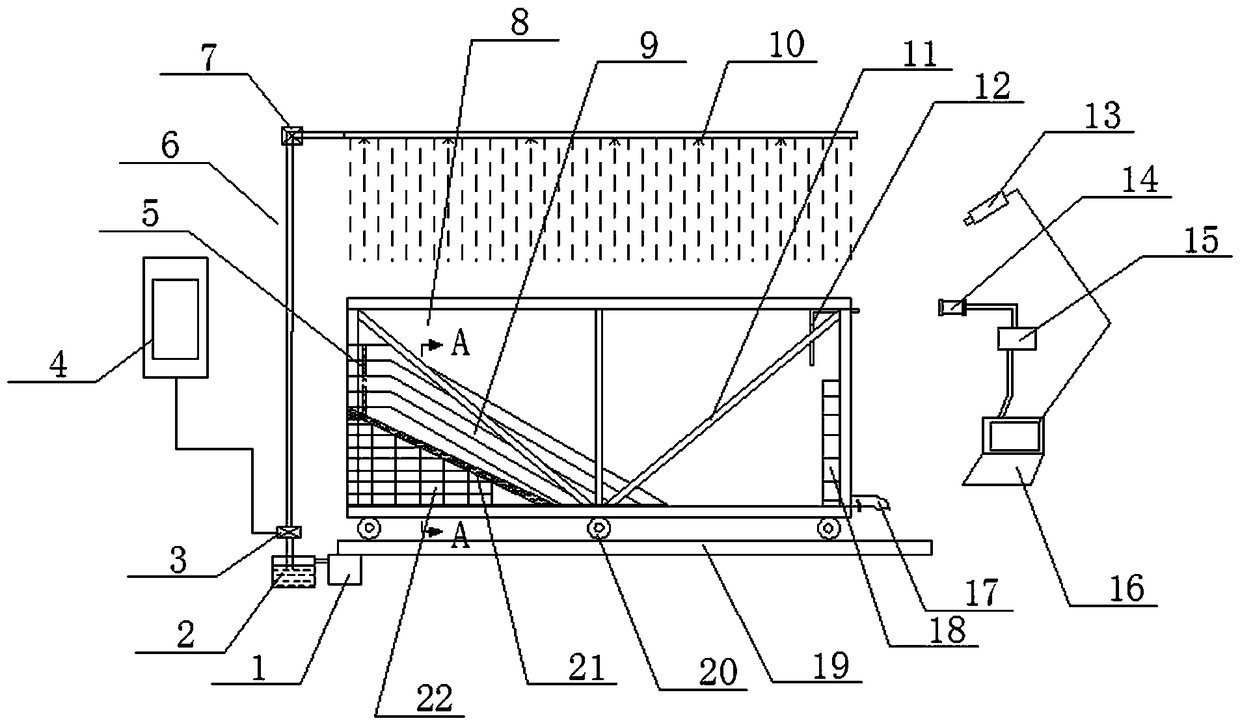

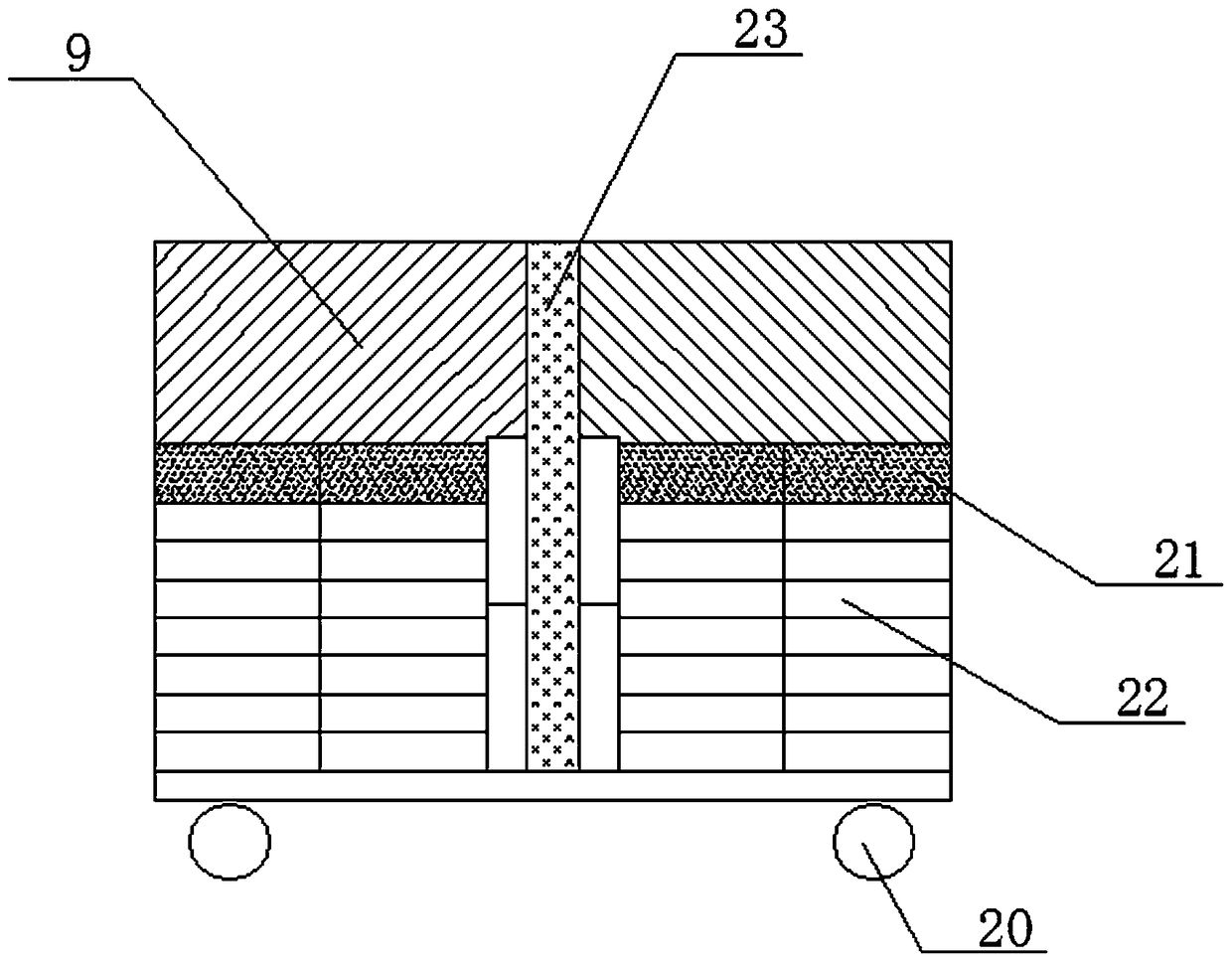

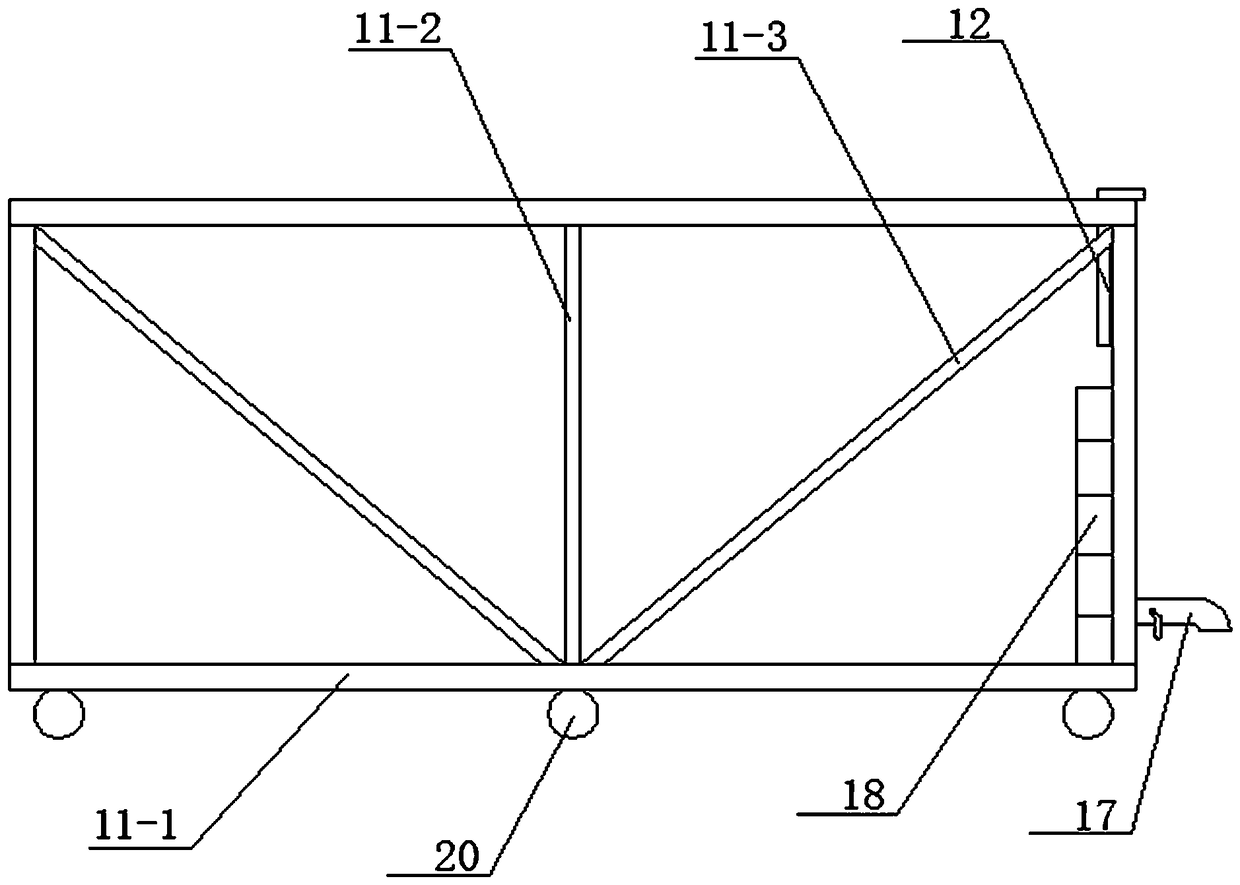

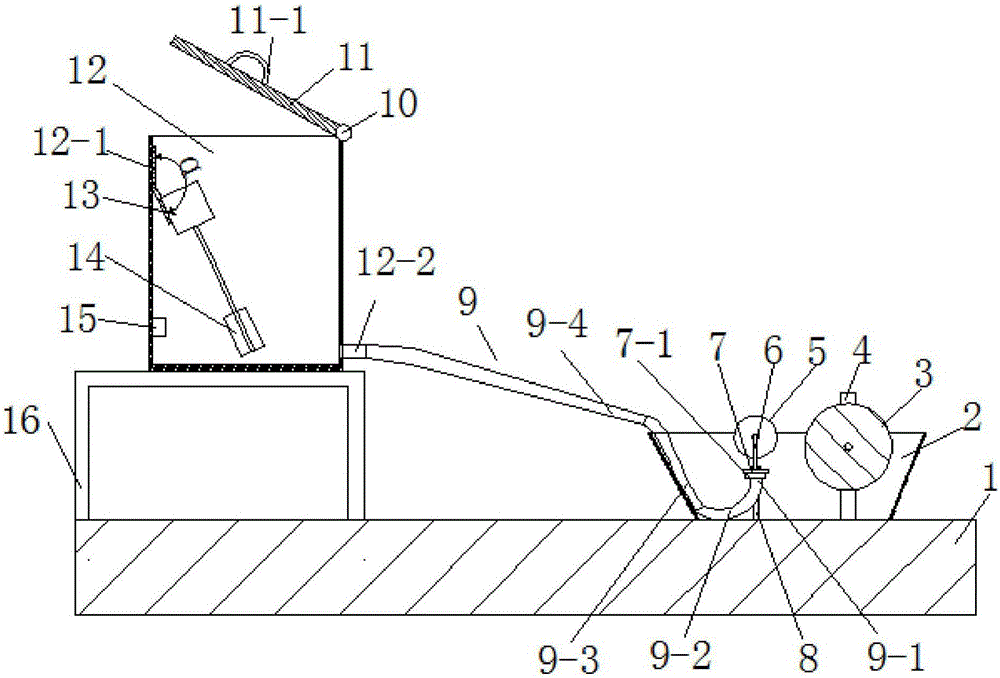

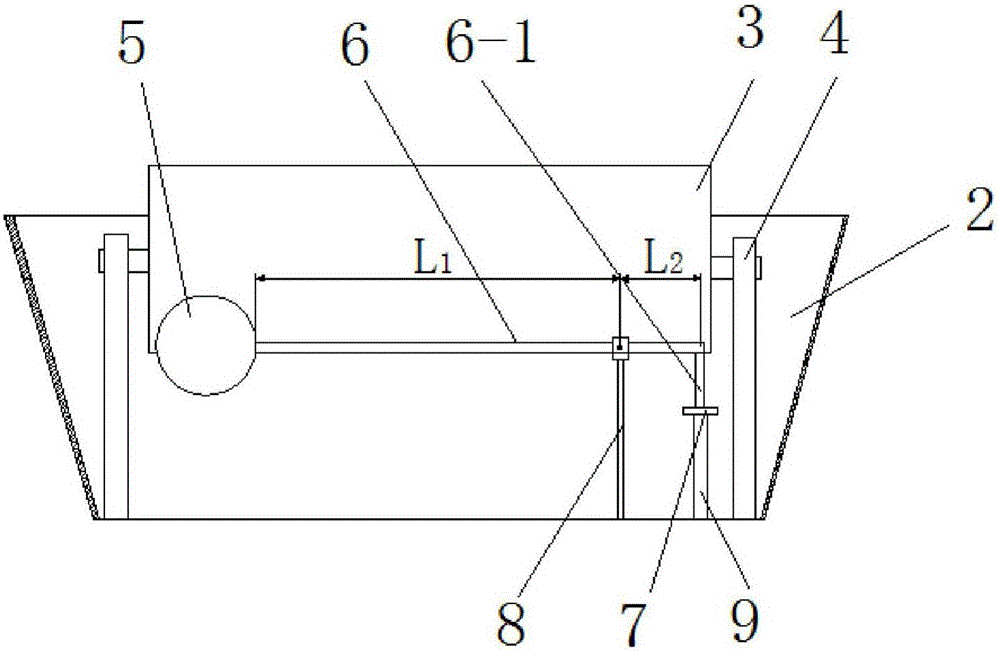

Physical simulation test device for landslides under rainfall and reservoir water level coupling effects

PendingCN109283320AReal-time monitoring of physical parametersSimple structureEarth material testingNumerical controlWater filter

The invention discloses a physical simulation test device for landslides under rainfall and reservoir water level coupling effects. The physical simulation test device comprises an artificial rainfallsimulation unit, a model box unit and a monitoring unit; the rainfall unit is provided with a high-power water pump, a water storage well, a console, a desilting basin, a water returning tank and a numerical control water dividing valve; the periphery and the bottom of the model box unit are sealed, water control valves are arranged at the front end of the model box unit, heavy casters with brakes are arranged at the bottom of the model box unit, and a sliding bed is arranged in a box; a sliding belt is arranged on the sliding bed, a sliding body is arranged on the sliding belt, a water filter pipe is arranged at the rear edge of the sliding body, sensors are arranged on the sliding body and the sliding belt, and the front edge of the box is provided with liquid level meter, water inlet pipes and the water control valves; and the monitoring unit comprises a camera, a physical quantity sensor and a data acquisition and processing system. The physical simulation test device is used forsimulating deformation failure model tests of the landslides under multiple working conditions, the physical quantity parameters of different parts of the landslides can be monitored in real time, andthe landslides under the coupling effects of multi-parameters such as the rainfall and reservoir water level can be experimented and researched.

Owner:NANCHANG INST OF TECH

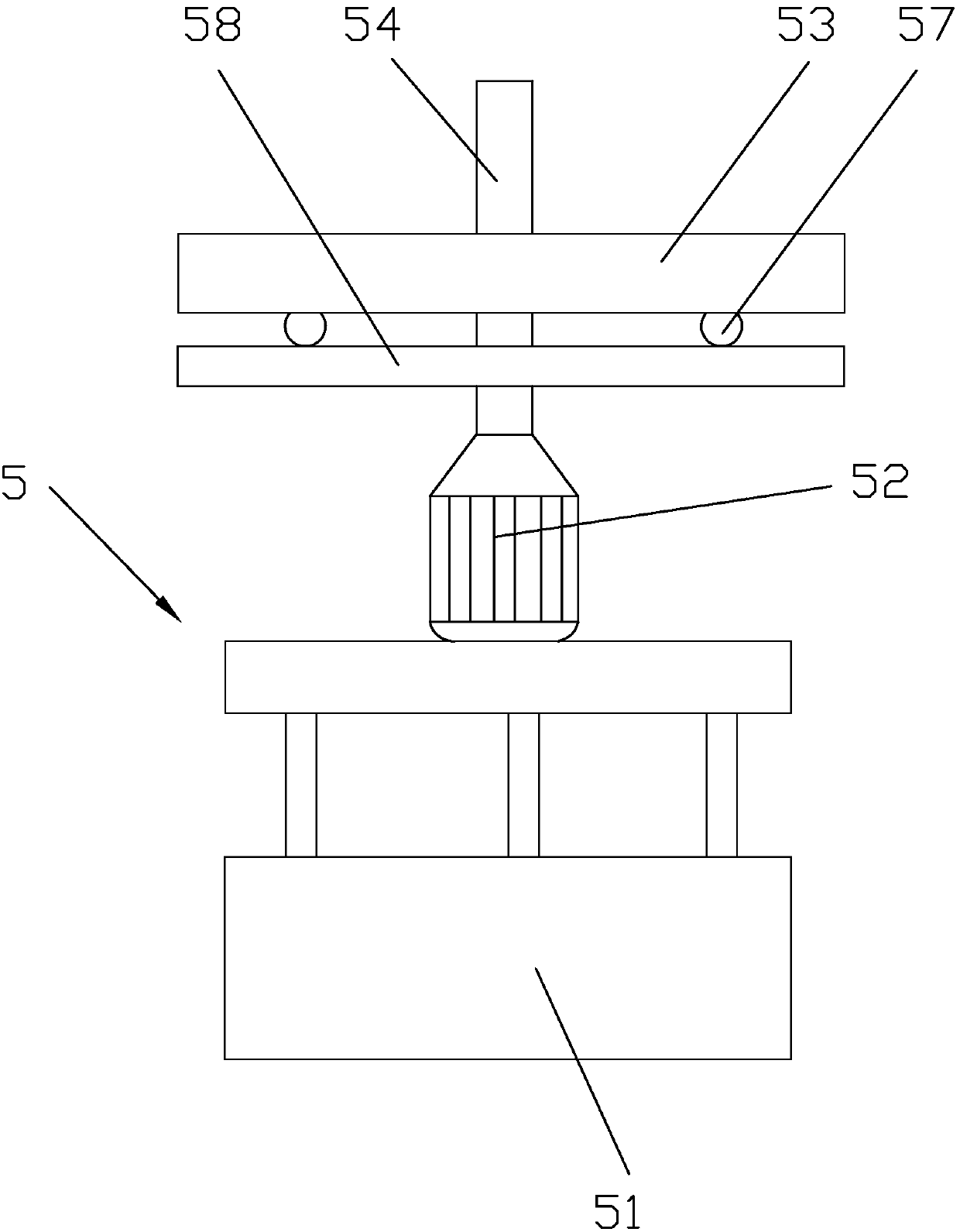

Balanced lifting device

The invention relates to the technical field of lifters, in particular to a balanced lifting device. The balanced lifting device comprises a support and a fixed shaft fixed to the support, a driving mechanism is arranged on the upper portion of the fixed shaft, a wire wheel component is arranged on the lower portion of the fixed shaft, a clutch mechanism is arranged between the driving mechanism and the wire wheel component, the wire wheel component comprises a plurality of rope stranding discs, and an overload separation mechanism is arranged between the rope stranding discs and the clutch mechanism. The balanced lifting device is distinct in functions of all the components, reasonable in arrangement and simple and easy to mount, dismount and maintain, and ascending, descending and stopping of balanced up-and-down movement of multiple controlled hung objects or points can be realized effectively; besides, the relative level condition of the objects and points can be adjusted automatically; the lifting device is widely applicable to objects such as lifting mosquito nets, lifting drying racks, ultrahigh and ultra-wide lifting curtain rails, performance activity settings and ultra-wide banner hanging rods and the like needing ascending and descending.

Owner:山东佰盛能源科技有限公司

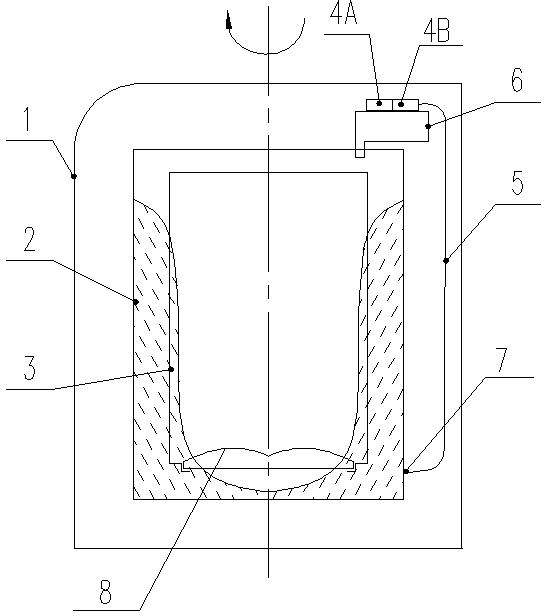

Sterilizing, disinfecting and mildew-proof barrel-cleaning washing machine and barrel-cleaning control method thereof

InactiveCN102628205AAvoid depositionEnsure normal dischargeOther washing machinesControl devices for washing apparatusImpellerInlet valve

The invention discloses a sterilizing, disinfecting and mildew-proof barrel-cleaning washing machine which comprises a shell, wherein an external water-storing barrel and an internal washing barrel are arranged in the shell; a water inlet box, a draining valve, a clutch, a program controller and a power supply part are arranged in the shell; a water inlet valve is arranged on the water inlet box; an ozone generating device is mounted on the water inlet box; an air outlet end of the ozone generating device is communicated with the bottom of a side wall of the external barrel through an ozone pipeline; the ozone generating device is connected with the program controller and the power supply part; and the draining valve and the clutch are respectively arranged and are respectively controlled by the program controller. The invention also discloses a barrel-cleaning control method of the washing machine. The sterilizing, disinfecting and mildew-proof barrel-cleaning washing machine is simple in structure and convenient in use; the internal barrel, the external barrel, the space between the internal and external barrels and the space under an impeller are cleaned and are sterilized and disinfected by using ozone; when water is discharged, the impeller is started to rotate positively and negatively by the washing machine so as to prevent line scraps and dirt in water from depositing at the bottom of the external barrel and internal barrel and on the impeller; the discharging of the line scraps and dirt is ensured; and the barrel-cleaning function is achieved.

Owner:HENAN XINFEI ELECTRICAL EQUIP

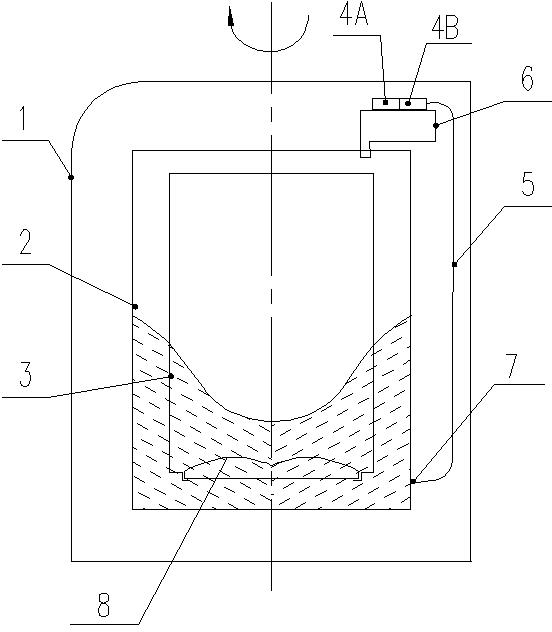

Photovoltaic solar energy, wind power and rainwater generating integrated generating set

InactiveCN105443318AIncrease profitEffective continuous lightingFinal product manufacturePV power plantsImpellerPhotovoltaic solar energy

The invention relates to the technical field of solar photovoltaic generating, in particular to a photovoltaic solar energy, wind power and rainwater generating integrated generating set. The integrated generating set comprises a bottom plate body, a wind energy collecting module, a rainwater energy collecting module and a solar energy collecting module. The wind energy collecting module comprises a bearing block and fan blades. The bearing block is connected with a rotating shaft through a bearing, and one end of the rotating shaft is fixedly connected with the fan blades. The rainwater energy collecting module comprises a hopper and an impeller, the impeller is fixedly arranged on a shaft body of the rotating shaft, and the hopper is fixedly arranged on the top of a lamp supporting pole through a hopper support. A photovoltaic solar panel is fixedly arranged on the inner surface of the hopper. The rotating shaft and the photovoltaic solar panel are connected with the generating set. By means of the integrated generating set, generating is carried out through the solar energy, the wind power and the rainwater, effective continuous lighting of a streetlamp is guaranteed, the conventional energy source is saved, and pollution is reduced. The integrated generating set has the advantages of being simple in structure, reasonable in arrangement, low in manufacturing cost and the like.

Owner:苏州华安普电力科技股份有限公司

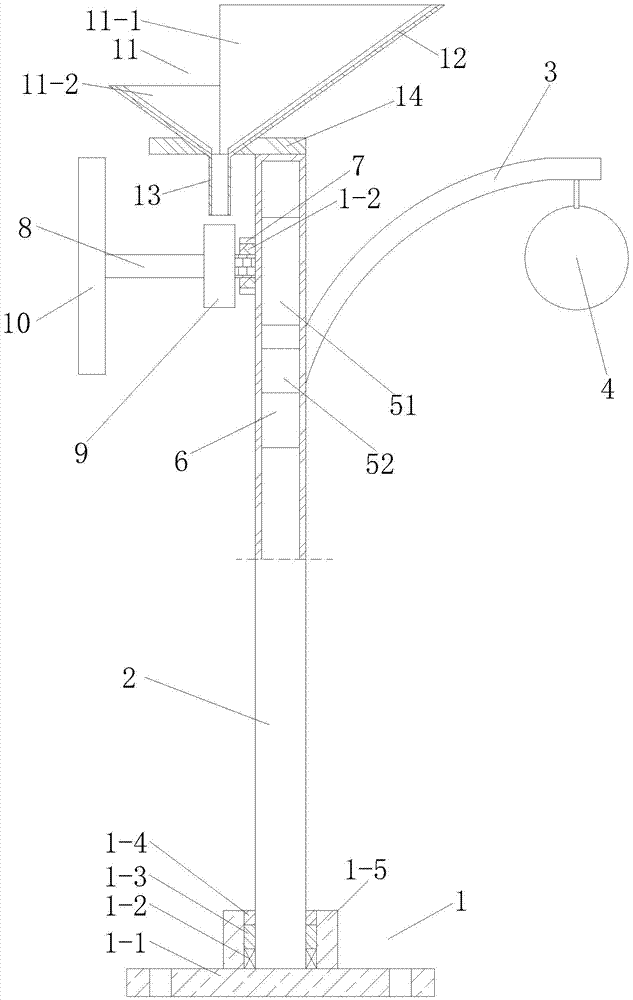

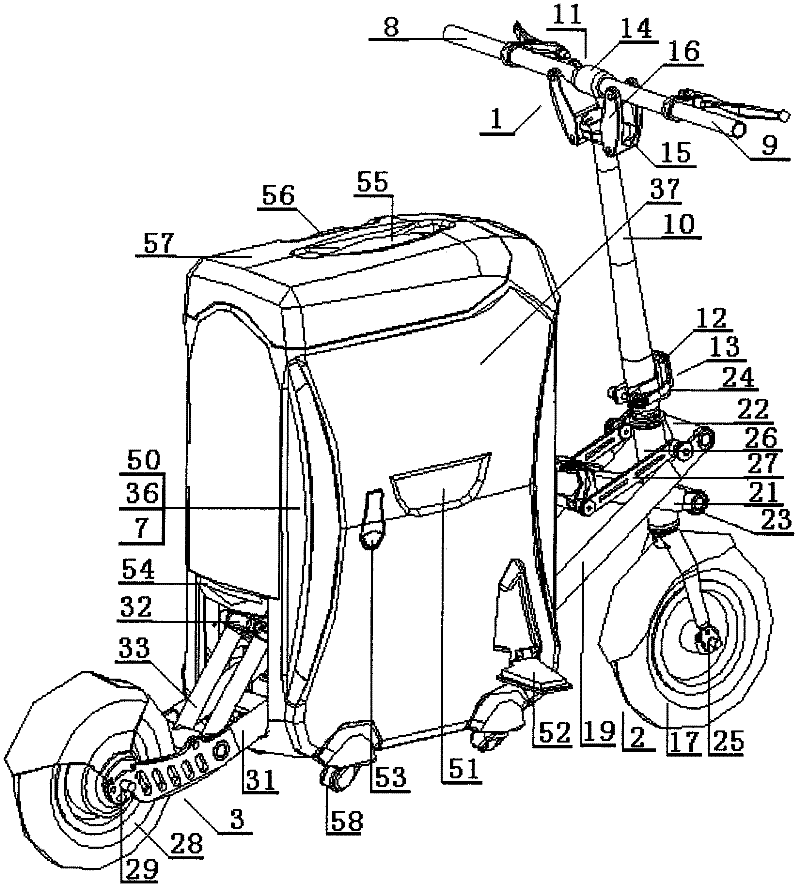

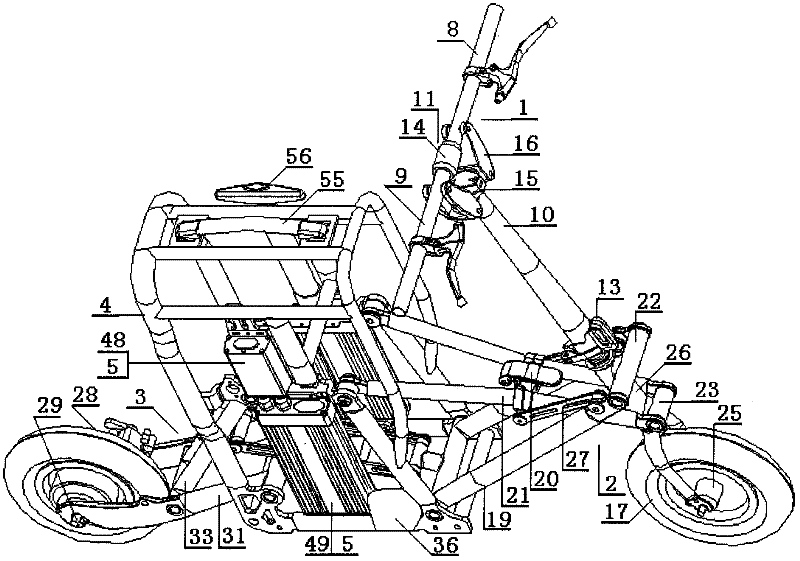

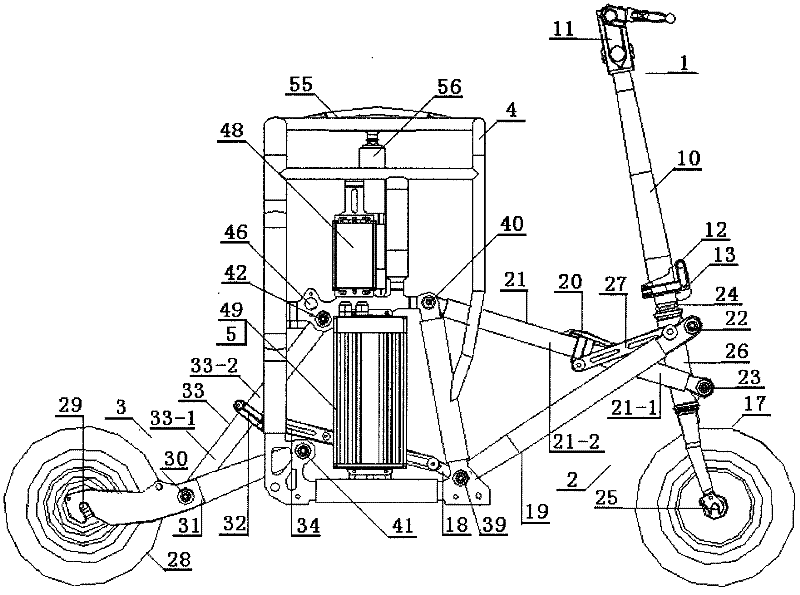

Box type folding electric bicycle

The invention relates to a box-type foldable electric bicycle, which consists of a handlebar assembly, a front wheel assembly, a rear wheel assembly, a frame assembly, a power drive mechanism, a seat assembling and a conventional traffic indicating lamp assembly, wherein a handlebar folder, a straight pipe folder and a front fork folder are arranged on the handlebar assembly; a rear fork folder is arranged on the rear wheel assembly, the frame assembly comprises a frame, a frame inner liner, a frame outer cover and a folding and locking mechanism; and the conventional traffic indicating lamp assembly comprises a headlamp, steering lamps and a brake lamp. When the box-type foldable electric bicycle is in a folded state, a left handlebar and a right handlebar are folded obliquely and lean against a straight handlebar pipe; the straight handlebar pipe is obliquely folded towards a front fork, is limited by the folding and locking mechanism together with the front wheel assembly and the rear wheel assembly which are folded and pull each other, and is collected in the cavity of the frame inner liner; and the external side of the frame is covered by the frame outer cover. The assembliesare reasonably foldable. Since the front wheel assembly and the rear wheel assembly are crosswise arranged in the folded state, the box-type foldable electric bicycle has the characteristics of scientific structure, reasonable layout, convenience and rapidness in folding and unfolding, regular shape, attractive appearance, smooth surface, small volume, convenience in storage, carrying and use andvery high practicability.

Owner:方剑治

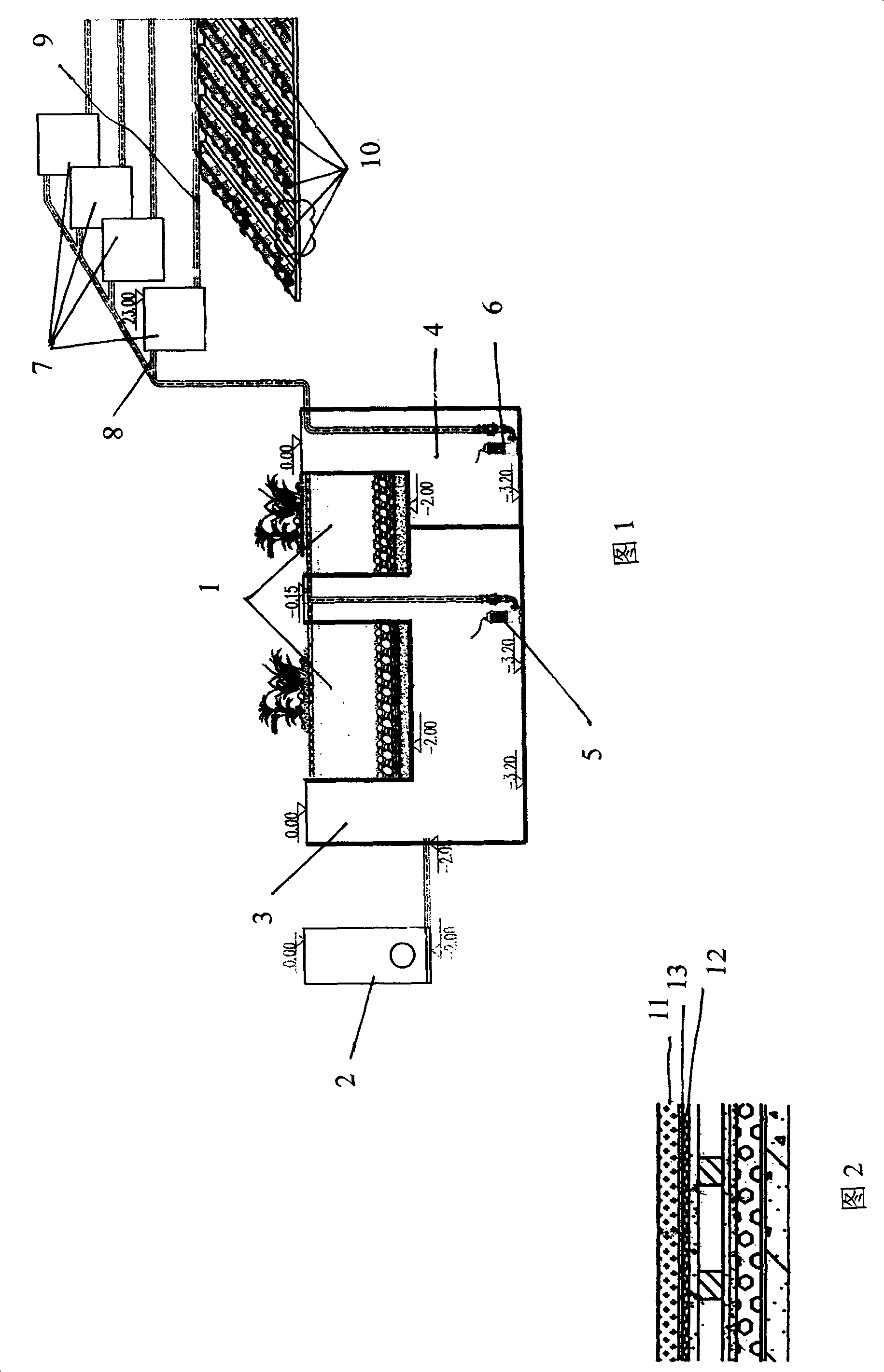

A system for collecting and processing residence zone sanitary sewage and stormwater for roofs planting

InactiveCN101161053ATake advantage ofMeet the needs of filtration processingClimate change adaptationWatering devicesConstructed wetlandThermal insulation

The invention relates a collection and treatment system of domestic sewage and rainwater in residential community, which is used for roof plantation. The invention includes construceted wetland, underground sewage and rainwater collection and treatment structure, roof irrigation device and planting soil layer. The pinciple of the underground sewage and rainwater collection and treatment structure seperated into reservoir, wetland clear water tank and sewage well, is: firsti, the sewage after treatment flows through pipes into the reservoir which has a pump arranged on its base; second, the sewage is lifted by the pump to constructed wetland which filters the sewage; then, the filtered sewaged flows into wetland clear water tank which also has a pump arranged on its base and has pips connected with the roof. Theroof irrigation device includes a plurality of roof clear water boxes arranged on the roof, outlet pipes, and drip irrigation pipes. The planting soil layer is layed averagely on the roof in a manner that a soil layer with a soil layer depth of 10cm and a soil bulk density of 120kg / m2, is layed on a geotextile layer layed on a water storage board which is layed on a thermal insulation board.

Owner:邱学武

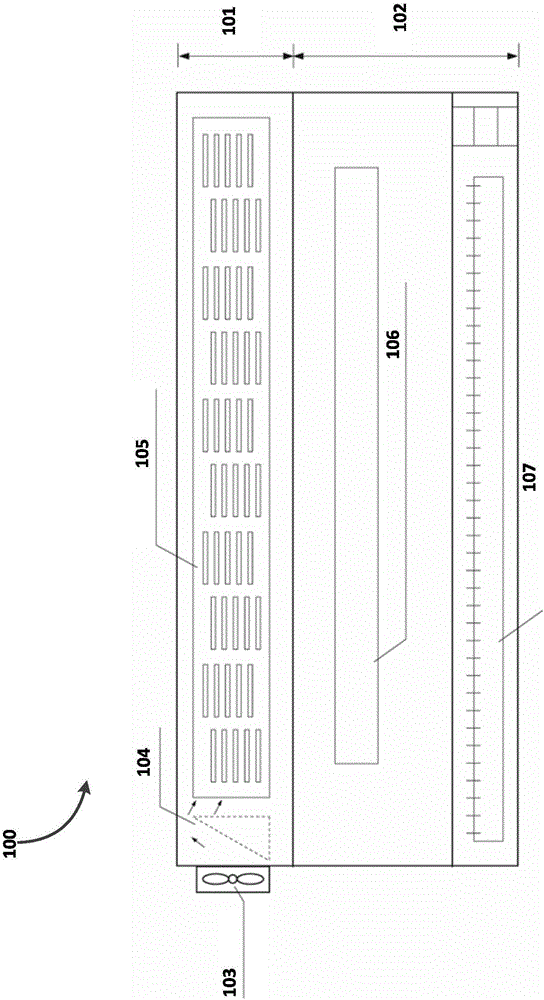

Compact fresh air exhaust purification air conditioner all-in-one machine

ActiveCN106765650AEasy dischargeVersatileLighting and heating apparatusSpace heating and ventilation detailsAir conditioningWaste management

The invention relates to a compact fresh air exhaust purification air conditioner all-in-one machine. The machine comprises a fresh air exhaust port, a fresh air-exhaust fan configured to lead in fresh air during forwards rotating and exhaust air to be exhausted from the all-in-one machine during reversely rotating, a guide plate for leading the fresh air to a filter device, a main air return inlet for leading in returned air from indoors, a filter module for purifying and filtering the returned air leaded from the main air return inlet and the fresh air guided by the guide plate, a secondary air return inlet arranged behind the filter module in a circulating air flowing direction and used for leading in the returned air from indoors, a circulating air fan for leading circulating air and leading in the returned air from the secondary air return inlet, a cooling device communicated with an air conditioner outdoor unit for cooling the circulating air and the returned air, and a circulating air outlet for outputting the circulating air. The all-in-one machine can realize fresh air, exhaust, purification and air conditioning functions, saves the space, reduces the noise, and saves electric energy.

Owner:深圳新科特智慧医疗科技有限公司

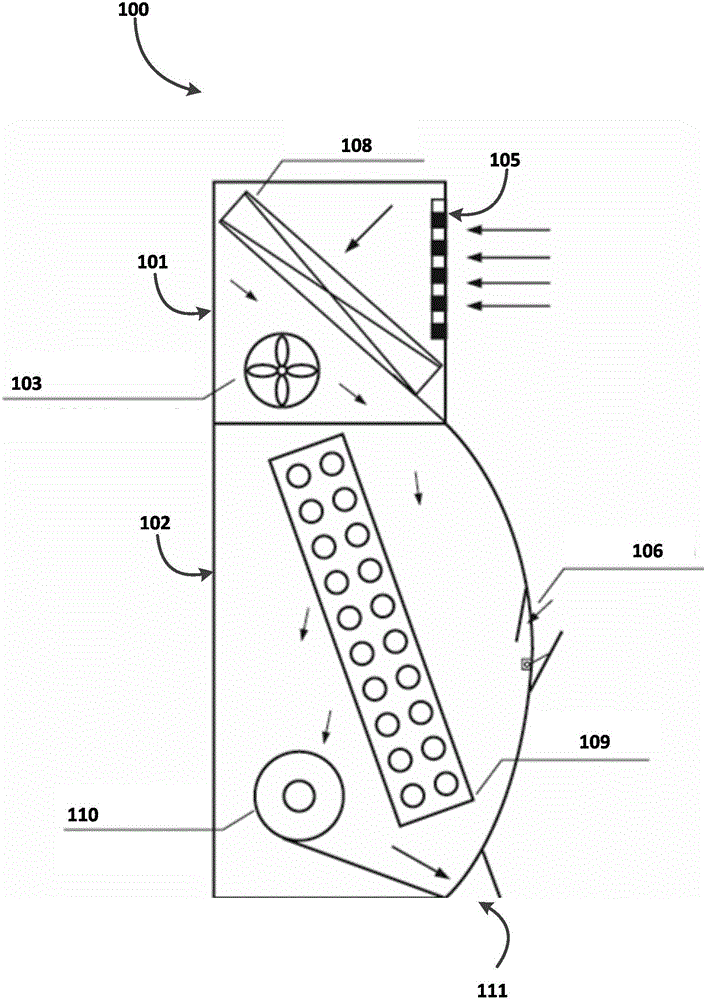

Aeration type sewage treatment device and method

InactiveCN106698823AStrong storageAvoid cloggingTreatment using aerobic processesSpecific water treatment objectivesHazardous substanceSewage

The invention mainly discloses an aeration type sewage treatment device and method. The technical scheme is as follows: the device comprises a primary sedimentation tank, a biodegradation tank and a disinfection tank, wherein a filtering device is arranged in the primary sedimentation tank and comprises a filtering plate and a collection box; the biodegradation tank comprises a facultative tank, an aerobic tank and a clarifying tank in mutual connection; a biological packing frame is arranged in the facultative tank; an aeration device is arranged in the aerobic tank and comprises a lifting cylinder, a spiral aerator and a rotating disk; the spiral aerator is mounted on the upper side of the lifting cylinder; a rotating shaft of the spiral aerator penetrates the rotating disk; and aerobic microbial packing is arranged on the rotating disk. Particle impurities of sewage are removed by the primary sedimentation tank, and then the sewage enters the biodegradation tank for reacting and finally is subjected to disinfection treatment. In the invention, through multi-stage treatment of the sewage, harmful substances in the sewage are separated and degraded better, the blocking phenomenon does not happen frequently, the treatment efficiency is high while the effect is good, and the treated sewage reaches the national discharge standard.

Owner:ZHEJIANG BUSINESS TECH INST

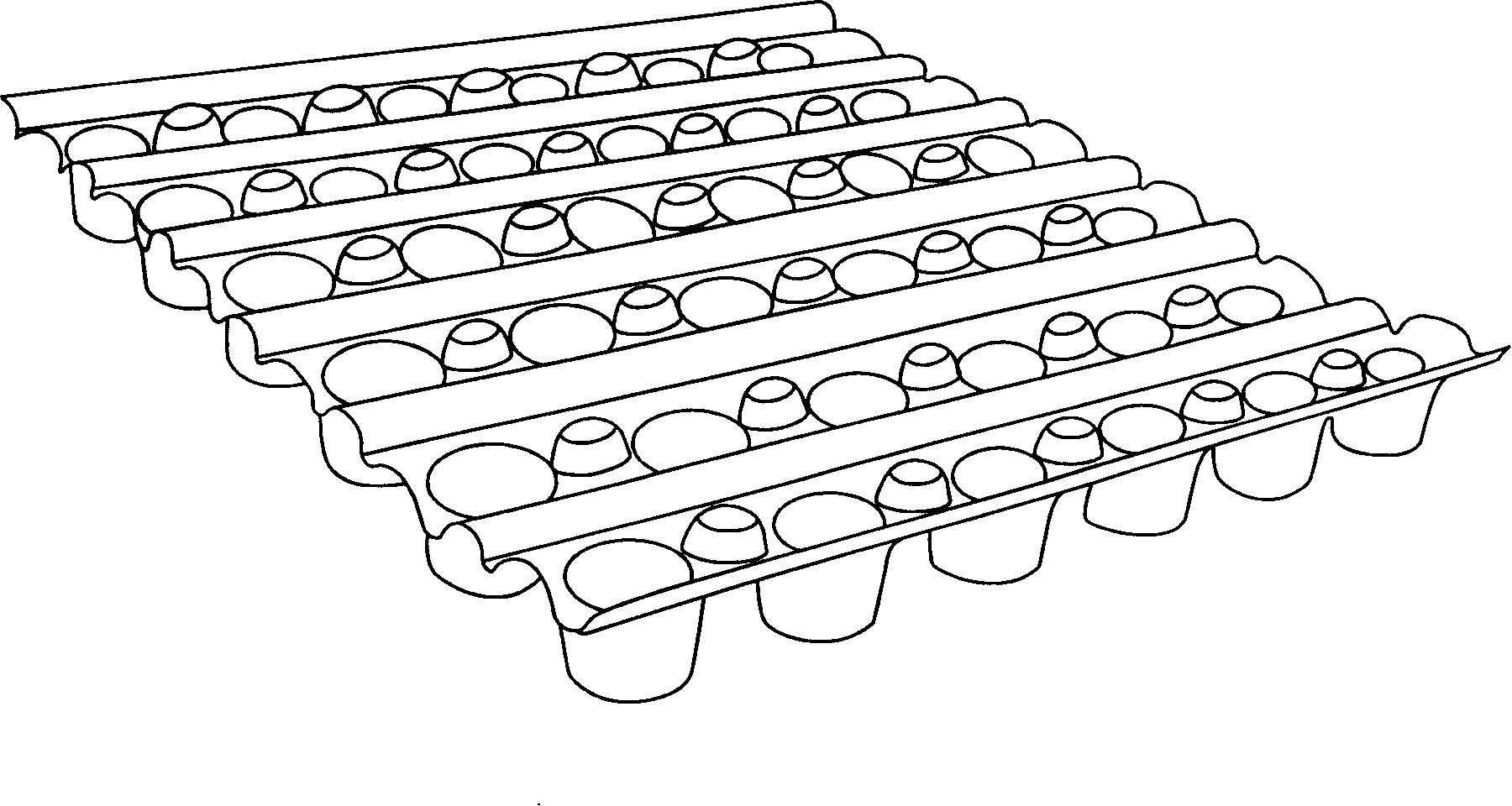

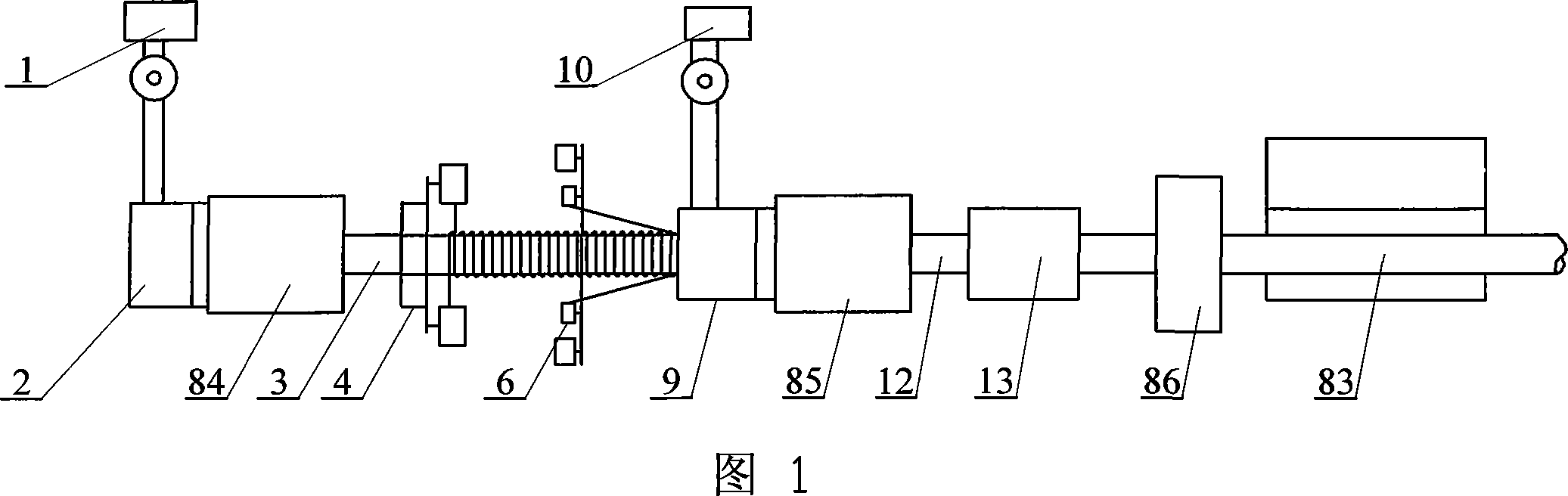

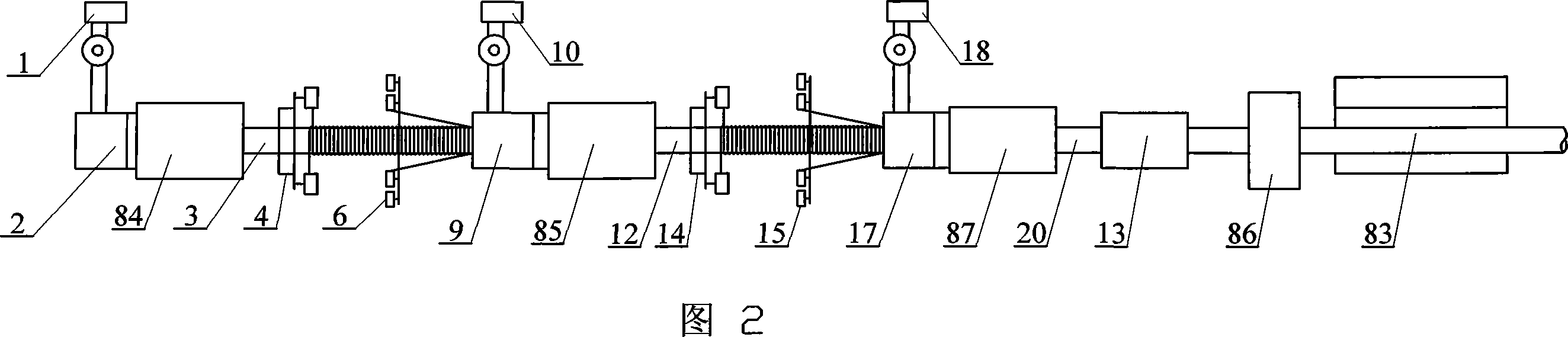

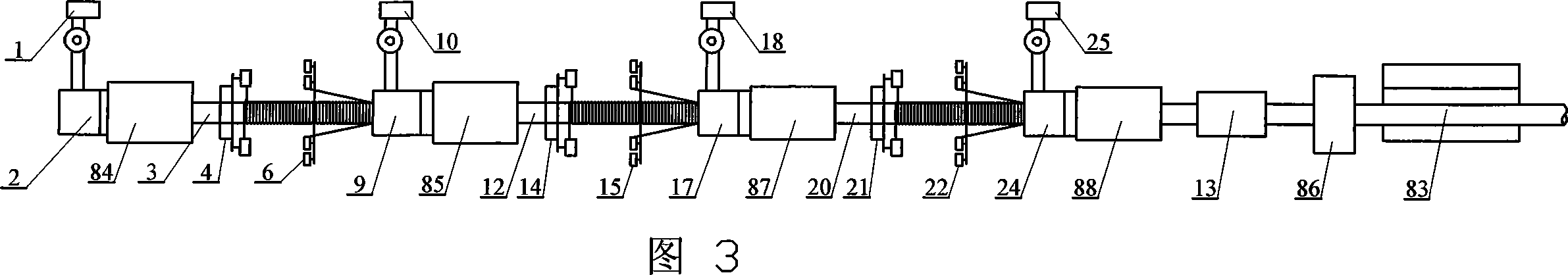

Method for producing steel mesh reinforced plastic composite pipes and its self-contained equipment

InactiveCN101077613AFast shapingEasy to shapeTubular articlesPlastic forming machineProcess configuration

The present invention is process and apparatus for producing steel net reinforced plastic composite pipe as one kind of steel structure reinforced plastic composite pipe. The process includes: extruding hot molten plastic into the inner plastic forming machine and cooling to obtain the inner plastic pipe blank layer, winding steel wire and arranging longitudinal wire onto the inner plastic pipe blank layer to form steel net, setting inside the first plastic pipe forming machine and extruding hot molten plastic into the first plastic pipe forming machine to form the composite plastic blank comprising one inner plastic pipe blank layer, one steel net layer and one outer plastic coating layer, and cutting to obtain the steel net reinforced plastic composite pipe. The equipment includes also one cooling water tank.

Owner:李富春

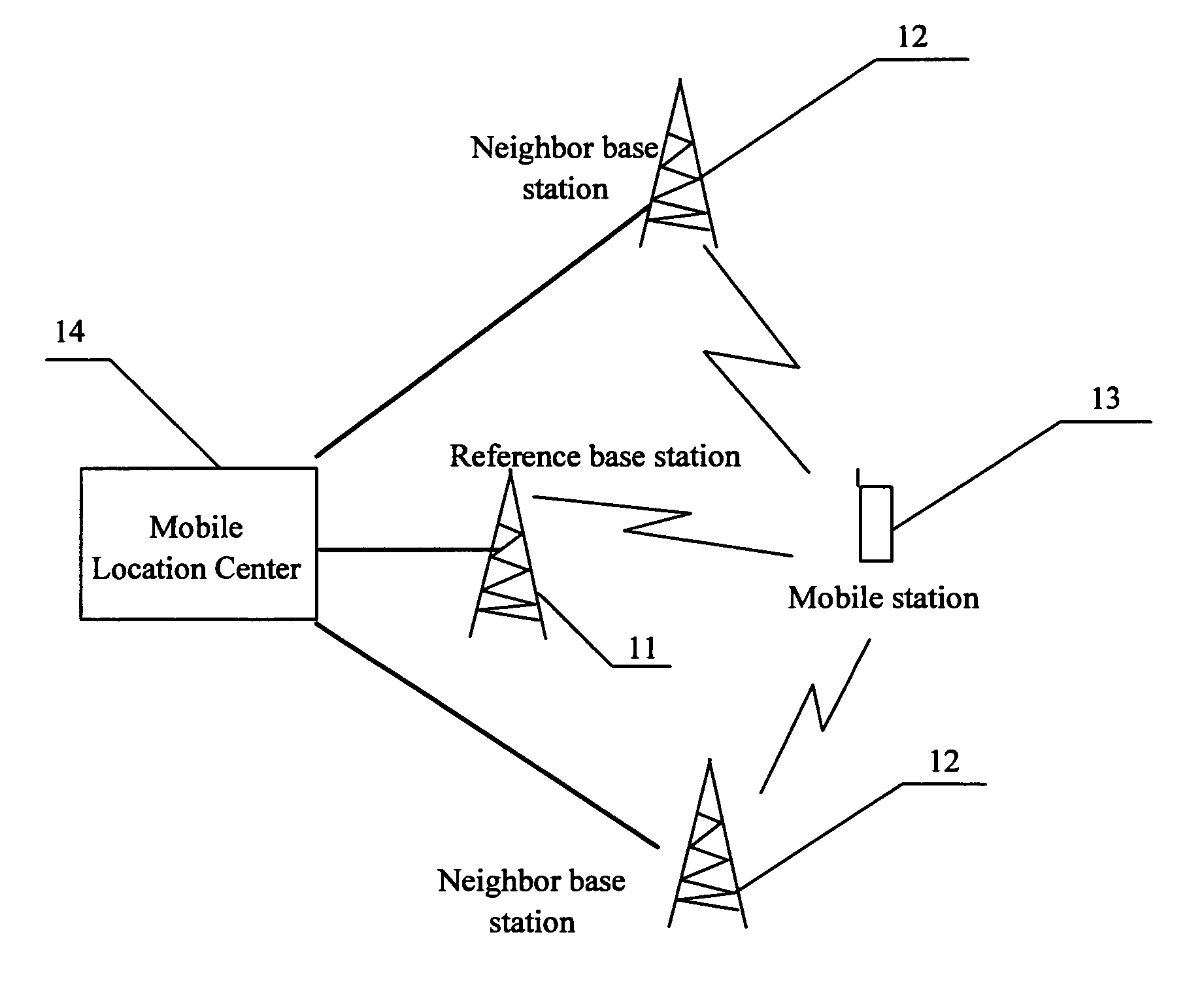

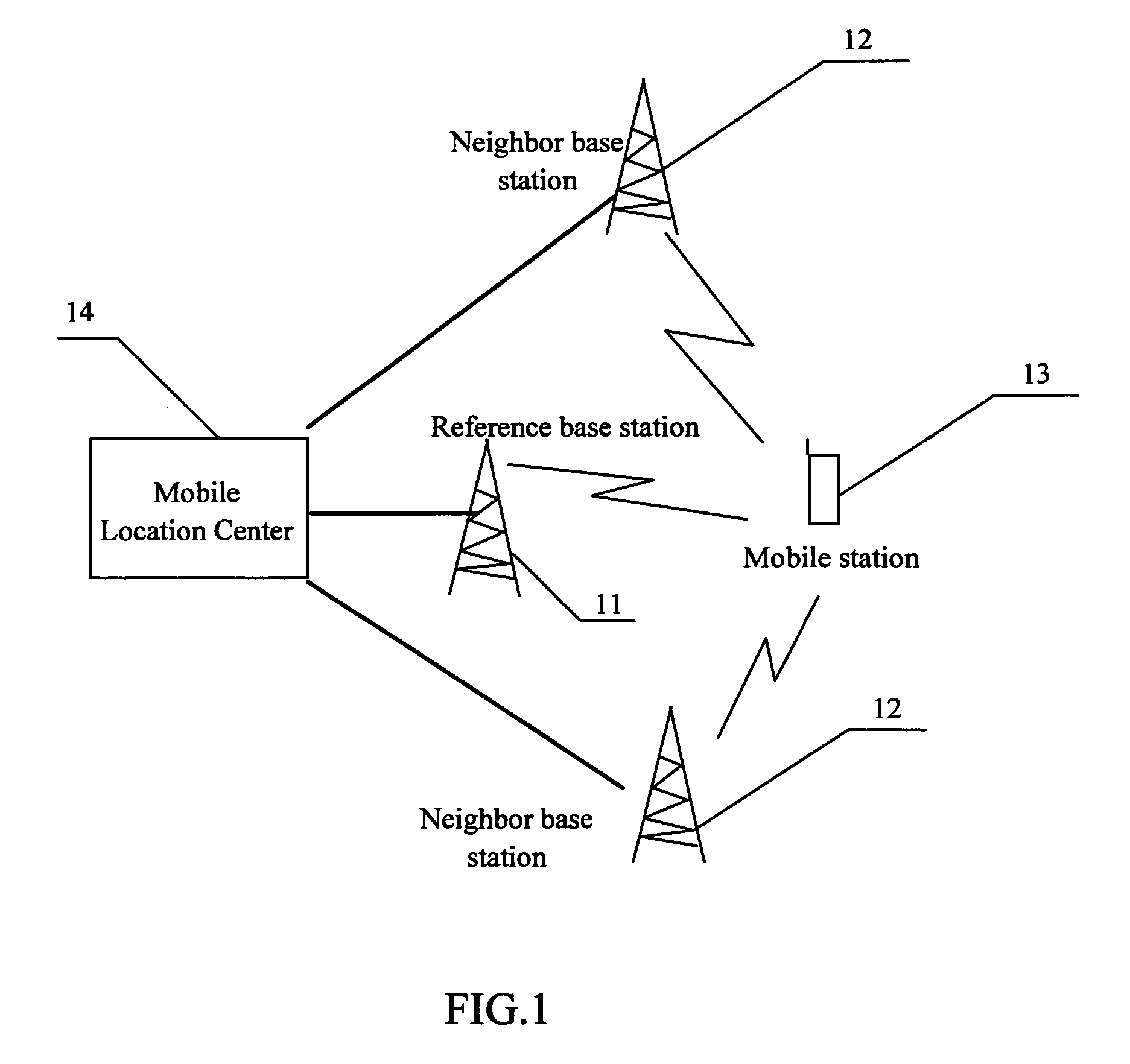

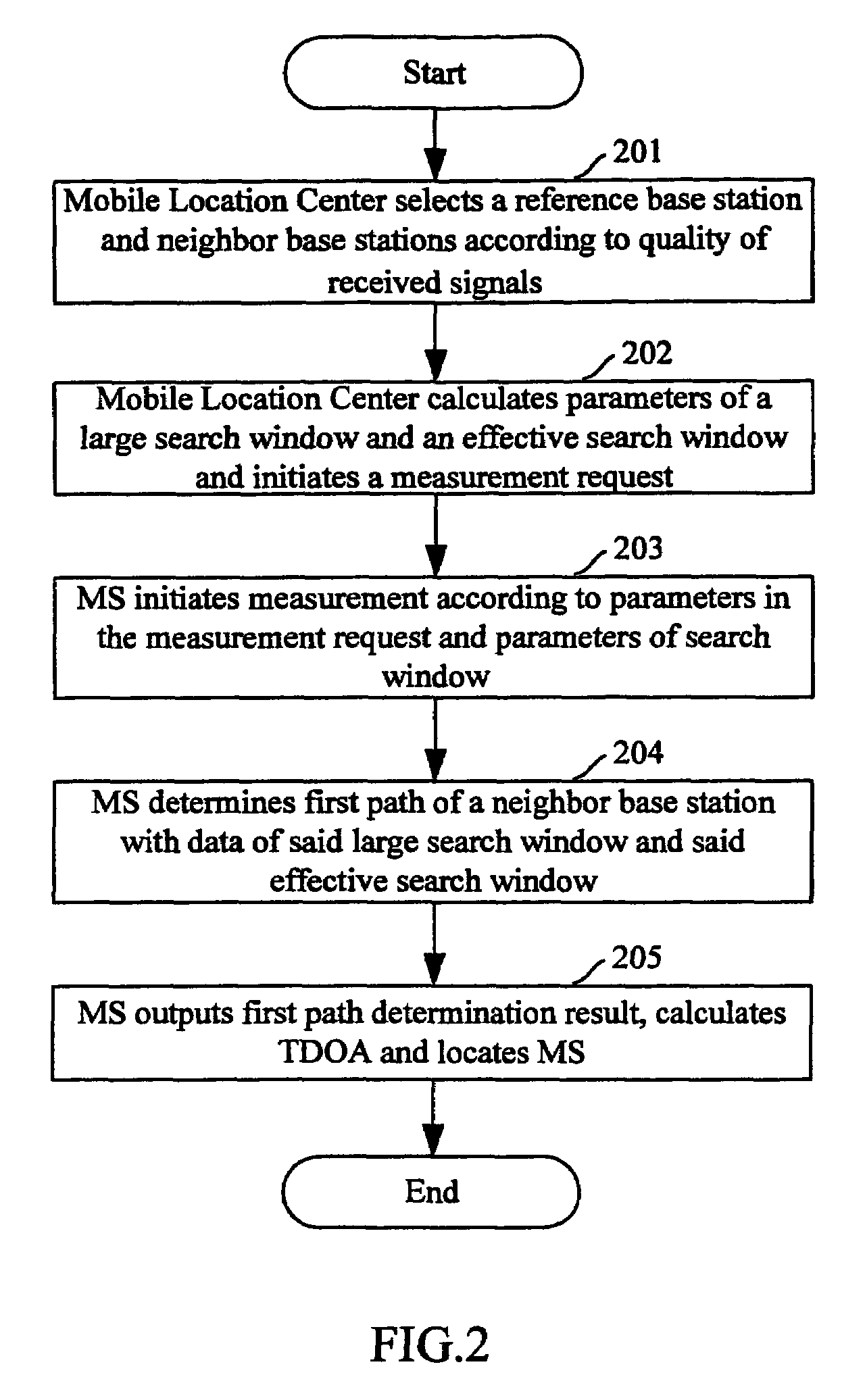

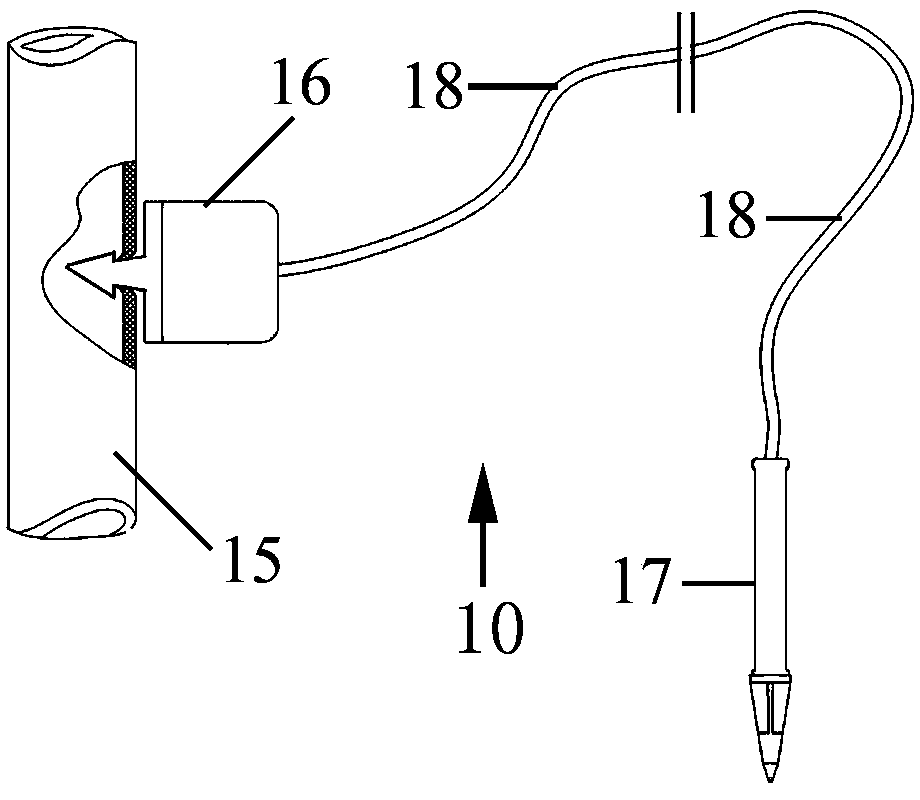

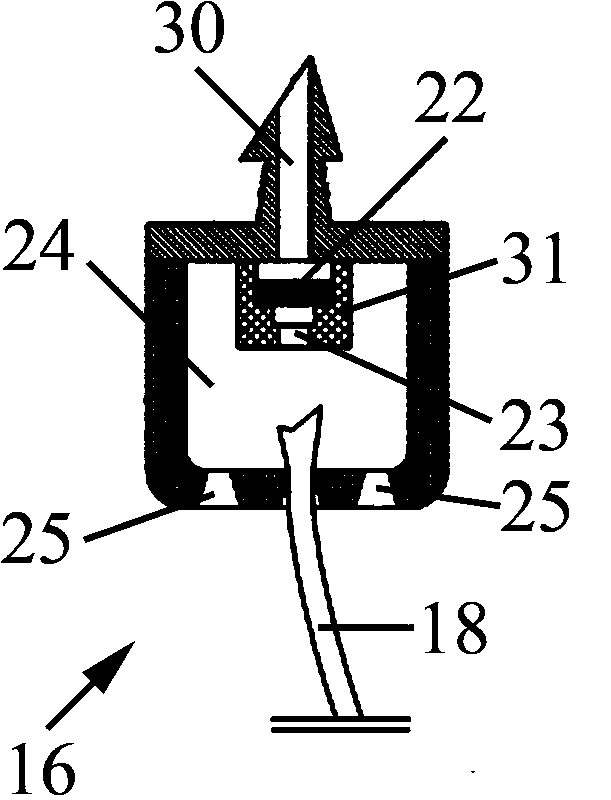

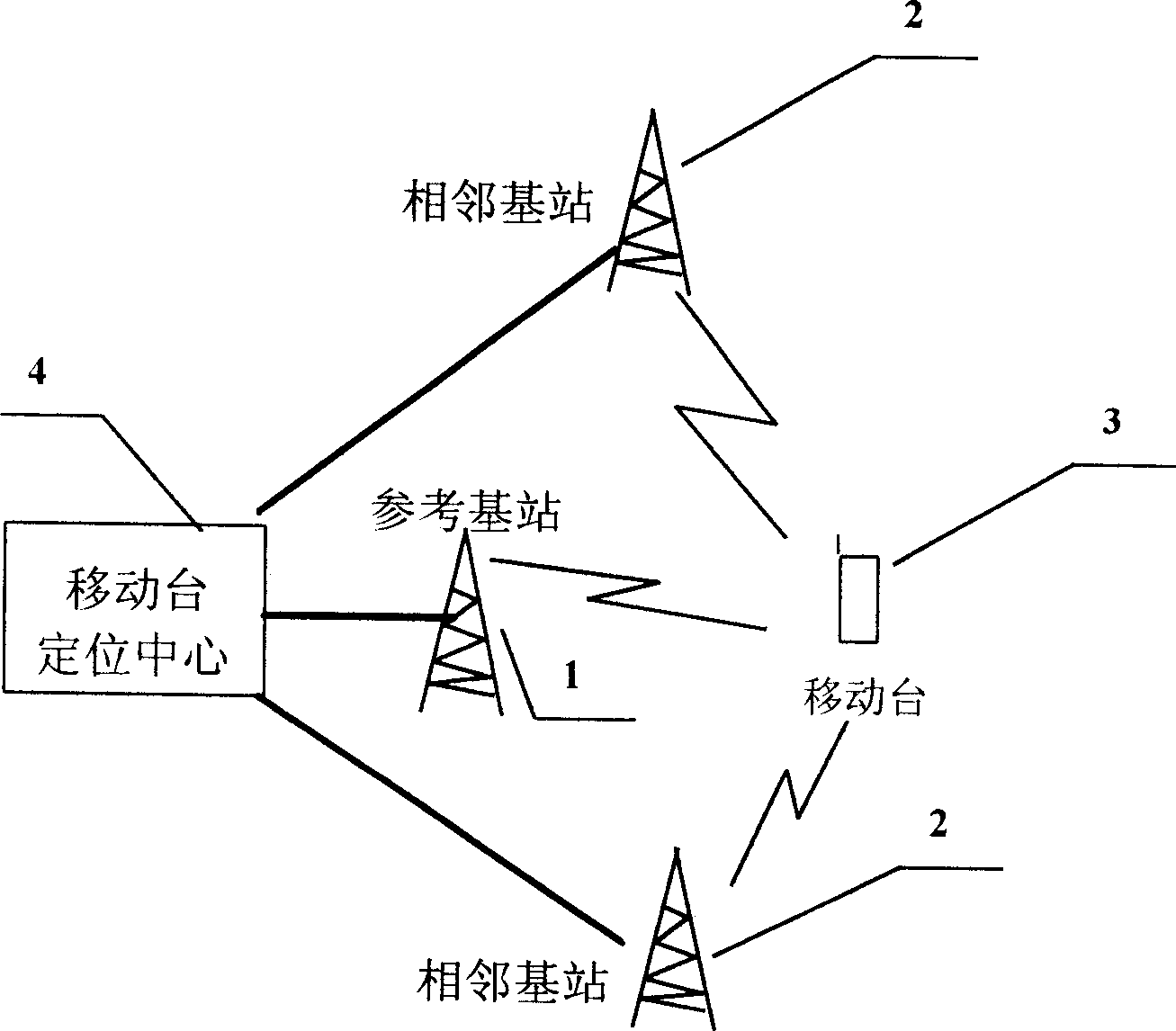

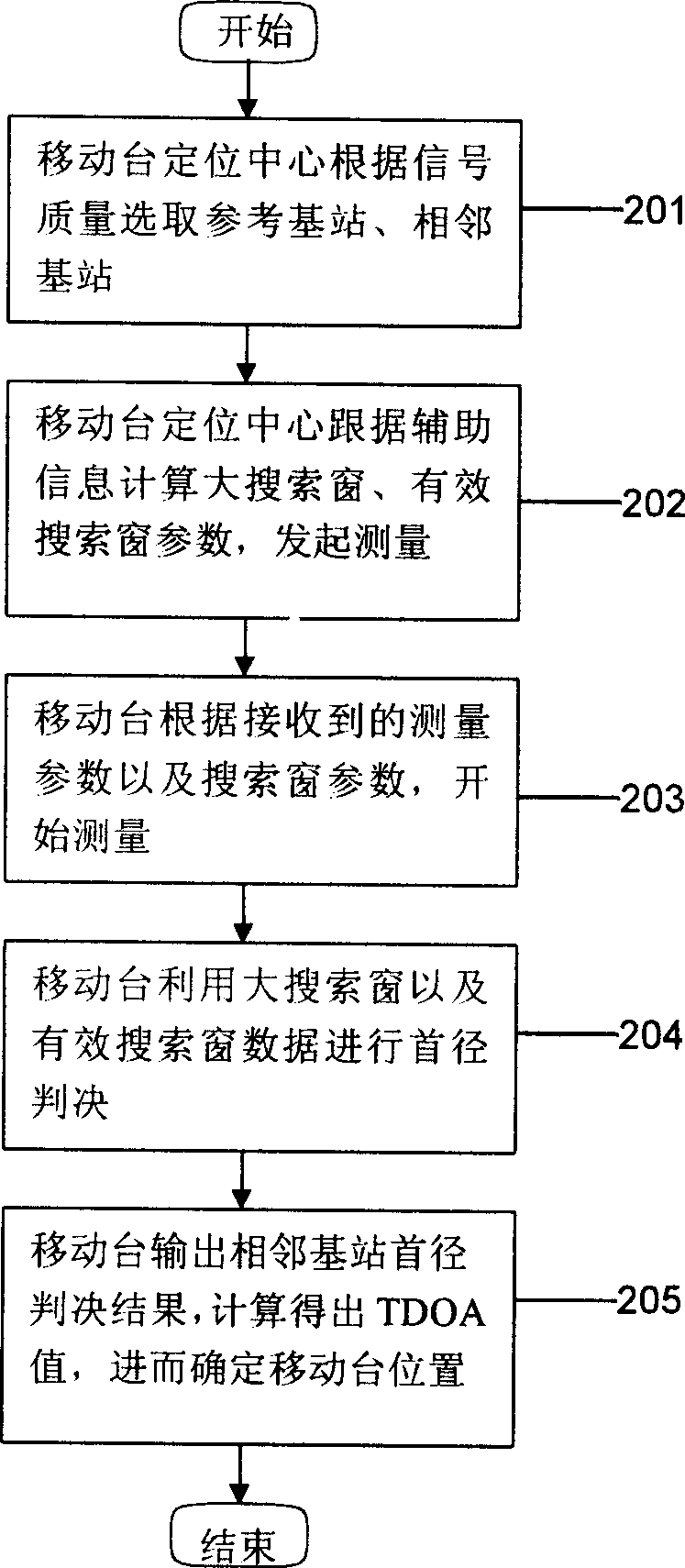

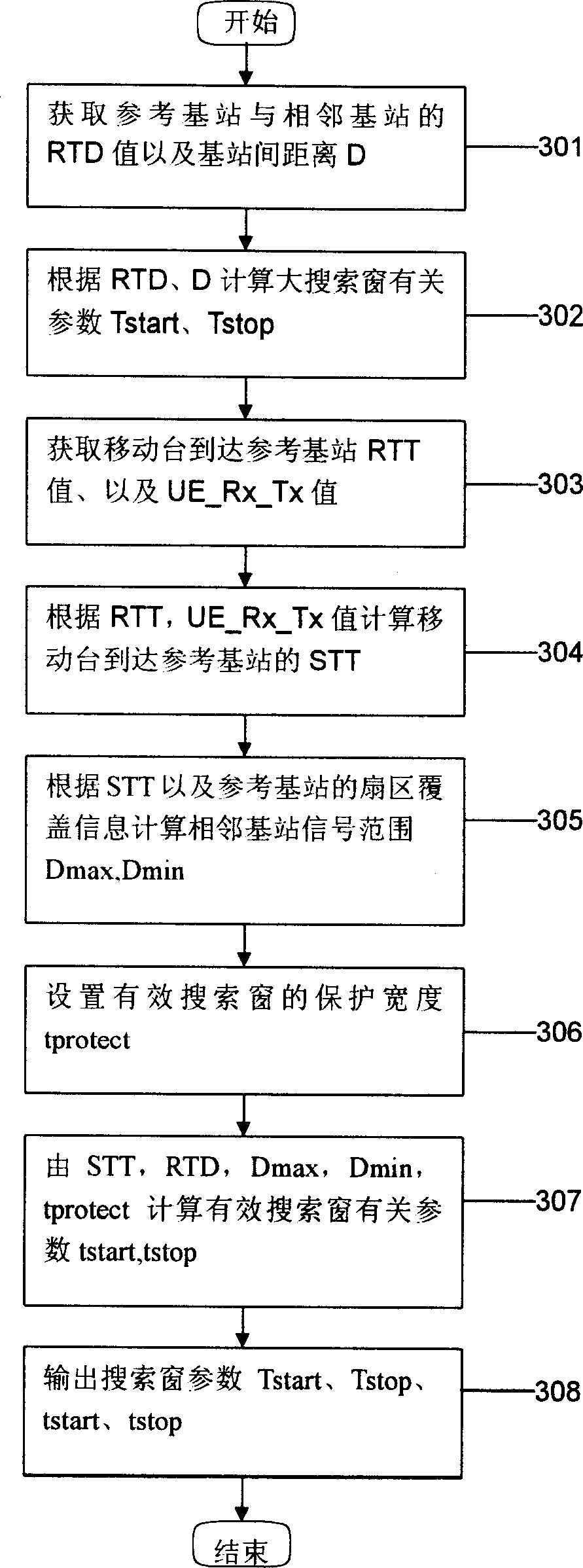

Method of locating and measuring a mobile station

InactiveUS7065369B2High measurement accuracyHigh positioning accuracyError preventionFrequency-division multiplex detailsMobile stationWireless positioning

The invention discloses a method of locating and measuring a mobile station, which relates with the radio locating technique in mobile communication field. Comparing with the conventional radio locating technique, the method improves the first path determination method of a neighbor base station downlink signal as follows: with geometrical relationship such as the distance between a MS to the reference base station and the distance between a neighbor base station to the reference base station, an effective range of the downlink signal first path of the neighbor base station can be calculated; the effective range is an effective search window that is shorter than the original large search window, and the first path determination of the neighbor base station downlink signal is made within the effective search window. The invention raises the first path determination accuracy of a neighbor base station downlink signal, so the mobile station locating accuracy is raised too.

Owner:HUAWEI TECH CO LTD

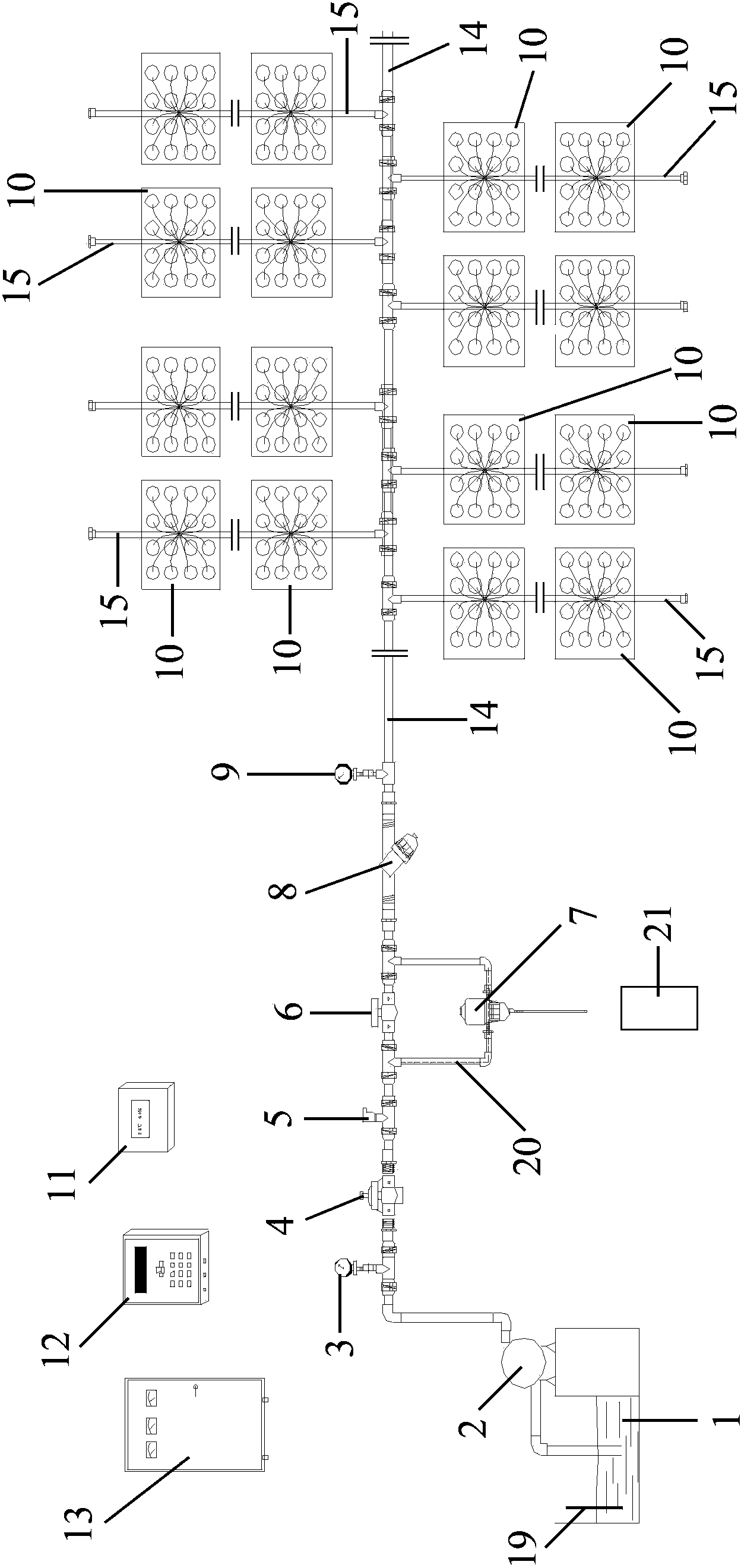

Dripping arrow irrigation automatic control system, manufacturing method of dripping arrow irrigation automatic control system and dripping arrow irrigation method

ActiveCN104380902APromote growthIncrease productionPressurised distribution of liquid fertiliserDirect liquid fertiliser deliveryExhaust valveAutomatic control

The invention relates to a dripping arrow irrigation automatic control system, a manufacturing method of the dripping arrow irrigation automatic control system and a dripping arrow irrigation method. The dripping arrow irrigation automatic control system consists of a reservoir, a water pump, a water level sensor, a conveying main pipeline, a fertilization pipeline, a conveying branch pipeline, a temperature sensor, a main controller, a start controller, a water taking pressure gauge, an electromagnetic valve, a suction and exhaust valve, a fertilization control valve, a filter and a water conveying pressure gauge; the reservoir is arranged at the initial end of the conveying main pipeline; the water level sensor is arranged in the reservoir; the water level sensor is connected with the main controller; the water pump is arranged on the reservoir and is used for drawing a water source in the reservoir; the water taking pressure gauge, the electromagnetic valve, the suction and exhaust valve, the fertilization control valve, the filter and the water conveying pressure gauge are sequentially arranged on the initial section of the conveying main pipeline; the fertilization control valve is mounted on the initial section of the conveying main pipeline; a fertilizer is uniformly conveyed into the conveying main pipeline by the fertilization conveying pipeline. The dripping arrow irrigation automatic control system is scientifically designed, has a reasonable structure and uniform flow, is reasonable in system arrangement, is stable in pressure in the pipelines, has wide applicability and has a wide application range; a dripping arrow takes effects of a water dropper and an insertion arrow, has a small size and high intensity, has powerful use functionality and is convenient to mount and use.

Owner:TIANJIN WATER RESOURCES RES INST

Localization measurement method of mobile station

InactiveCN1434305AImprove the accuracy of head path judgmentReasonable settingPosition fixationRadio transmission for post communicationMobile stationWireless positioning

The invention provides a position measurement method of mobile station. It advances the judging method of the head diameter of the down signal, uses the geometrical relations such as the distance between the mobile station and the referenced base station and the between the adjacent base station and the referenced one to calculate out the effective range of the head diameter of the down signal ofthe adjacent station, according to the parameter of the effective range, and fractionizes out the effective searching window in which thus it makes the judgement of the head diameter.

Owner:HUAWEI TECH CO LTD

Floating ball automatic ink adding device

InactiveCN105799324AInk level stabilitySolution to short lifePrinting press partsPrinting inkEngineering

Owner:TAICANG XINHE PRINTING & PACKAGING

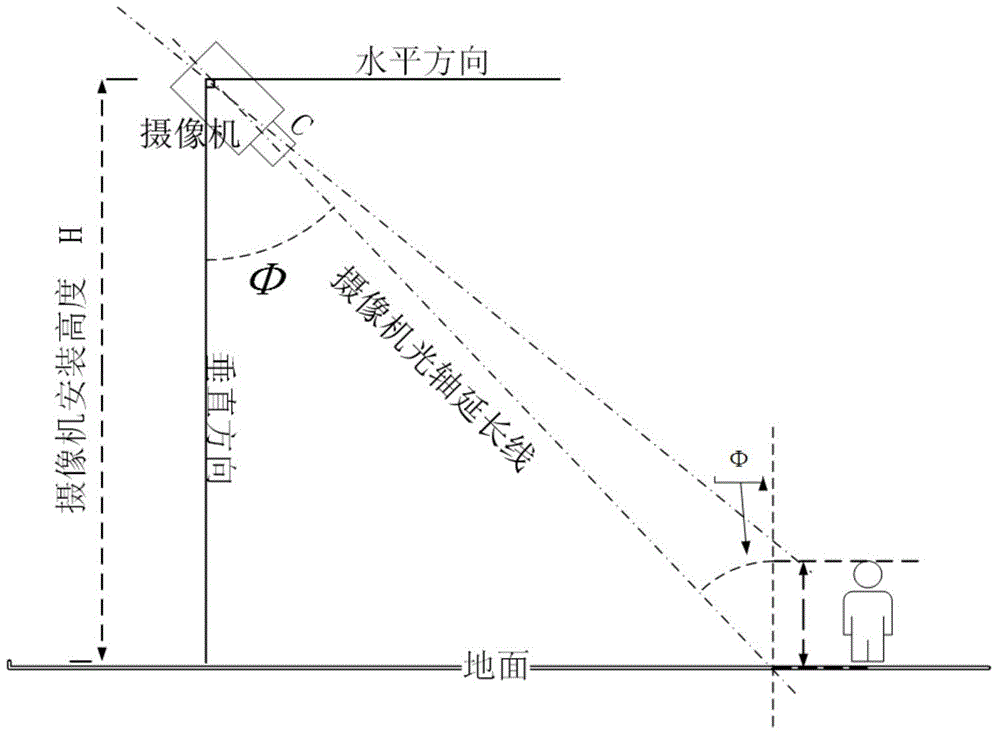

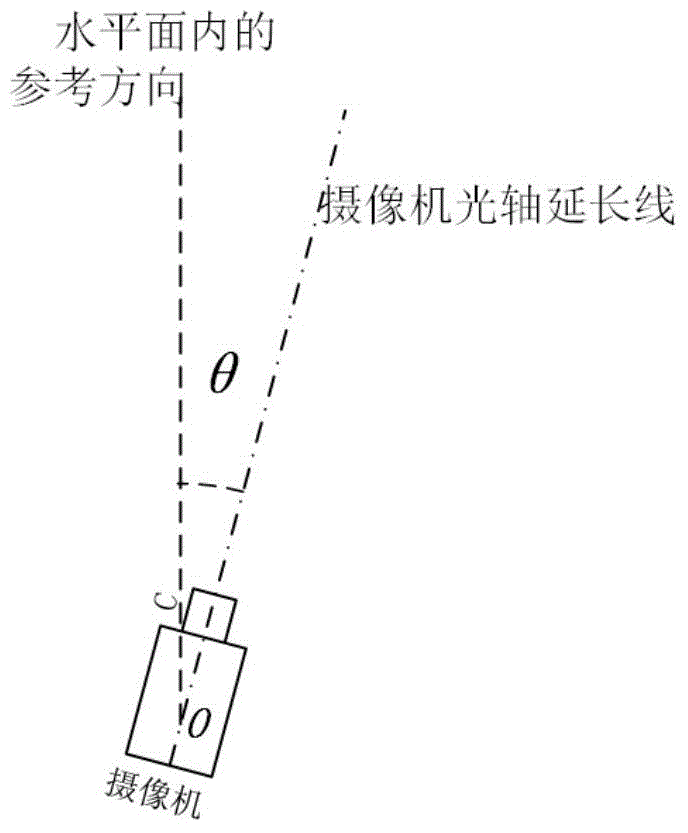

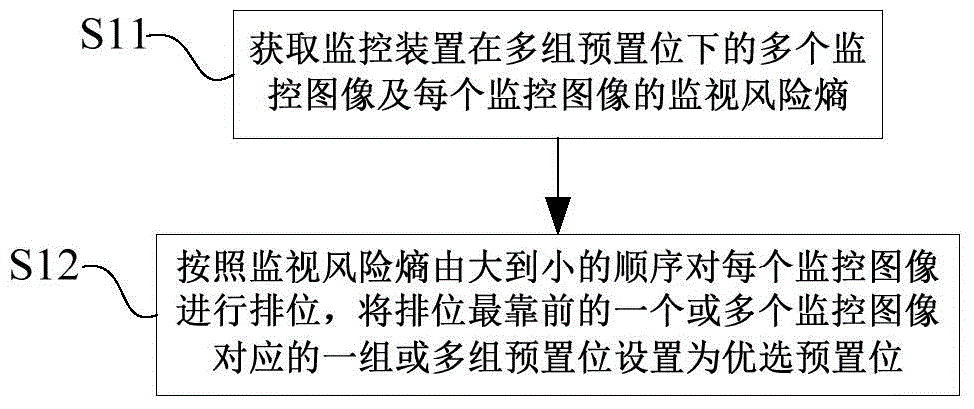

Monitoring device preset position setting method, monitoring device preset position switching method, and corresponding systems

ActiveCN106303403AImprove monitoring effectReasonable settingImage analysisClosed circuit television systemsReal-time computingIndustrial engineering

The invention provides a monitoring device preset position setting method, a monitoring device preset position switching method, and corresponding systems. According to the monitoring device preset position setting method and the monitoring device preset position setting system, first, multiple monitoring images of a monitoring device under multiple groups of preset positions and the monitoring risk entropy of each monitoring image are acquired, and then, the monitoring images are sorted according to the monitoring risk entropy from big to small, and one or more groups of preset positions corresponding to the first one or more monitoring images are set as optimal preset positions. According to the monitoring device preset position setting method and the monitoring device preset position setting system, each monitoring image is analyzed automatically and the monitoring risk entropy thereof is acquired, and the preset position corresponding to the monitoring image with the maximum monitoring risk entropy is selected as an optimal preset position of the monitoring device. Thus, a best monitoring effect is ensured, setting is reasonable, and the defect that preset position setting is unreasonable due to inexperienced operators in the prior art is overcome.

Owner:CHINESE PEOPLE'S PUBLIC SECURITY UNIVERSITY

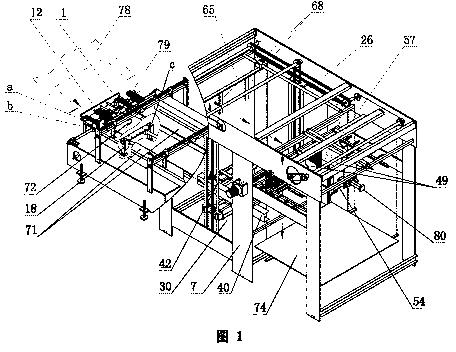

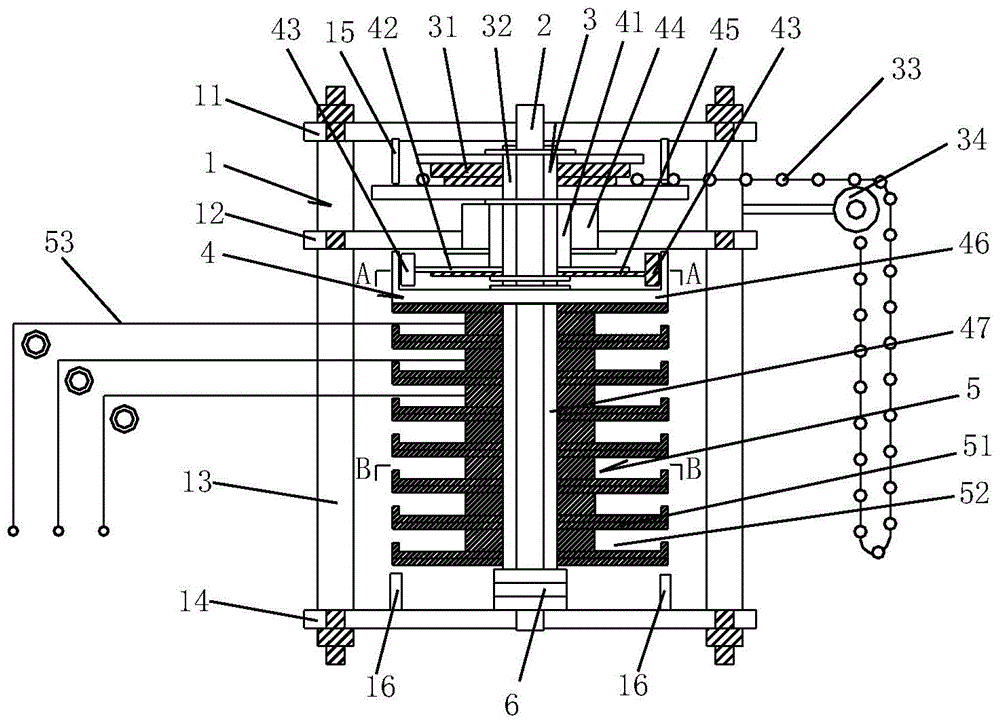

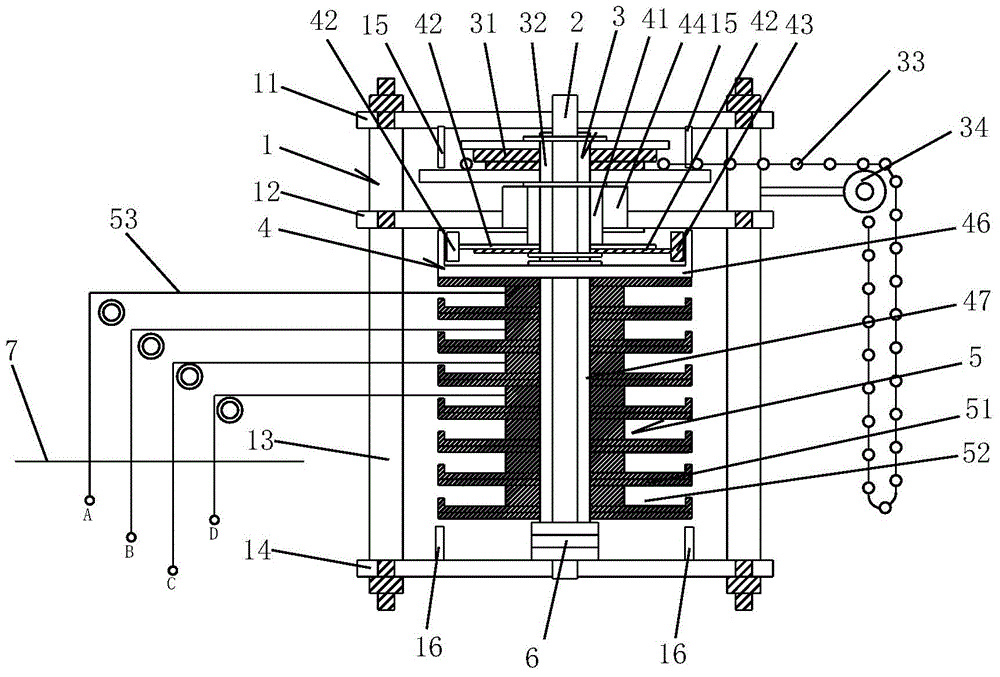

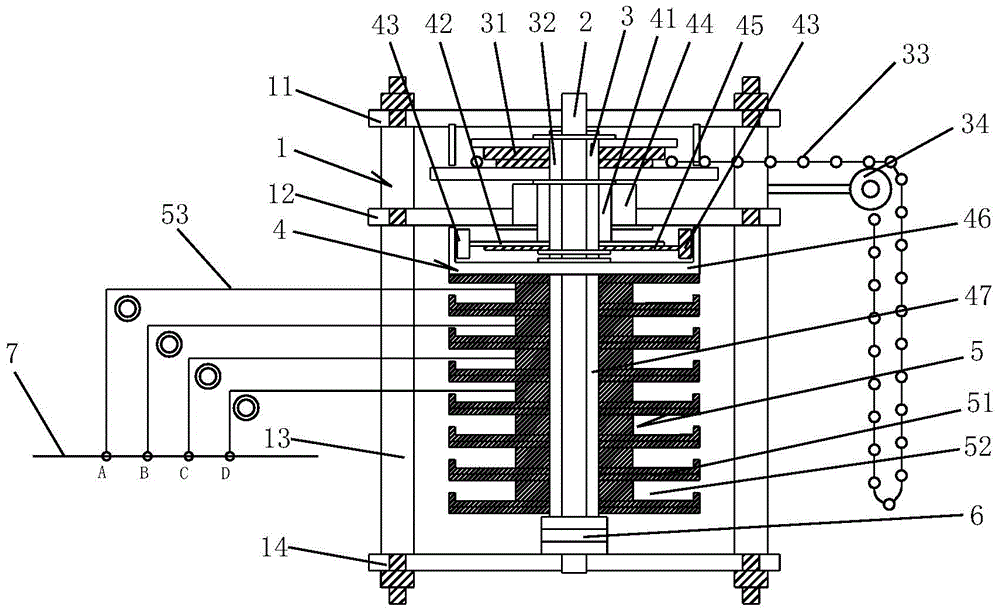

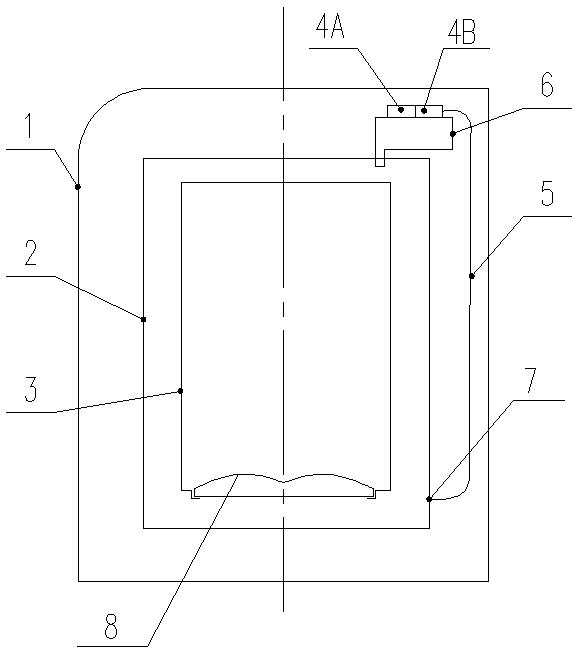

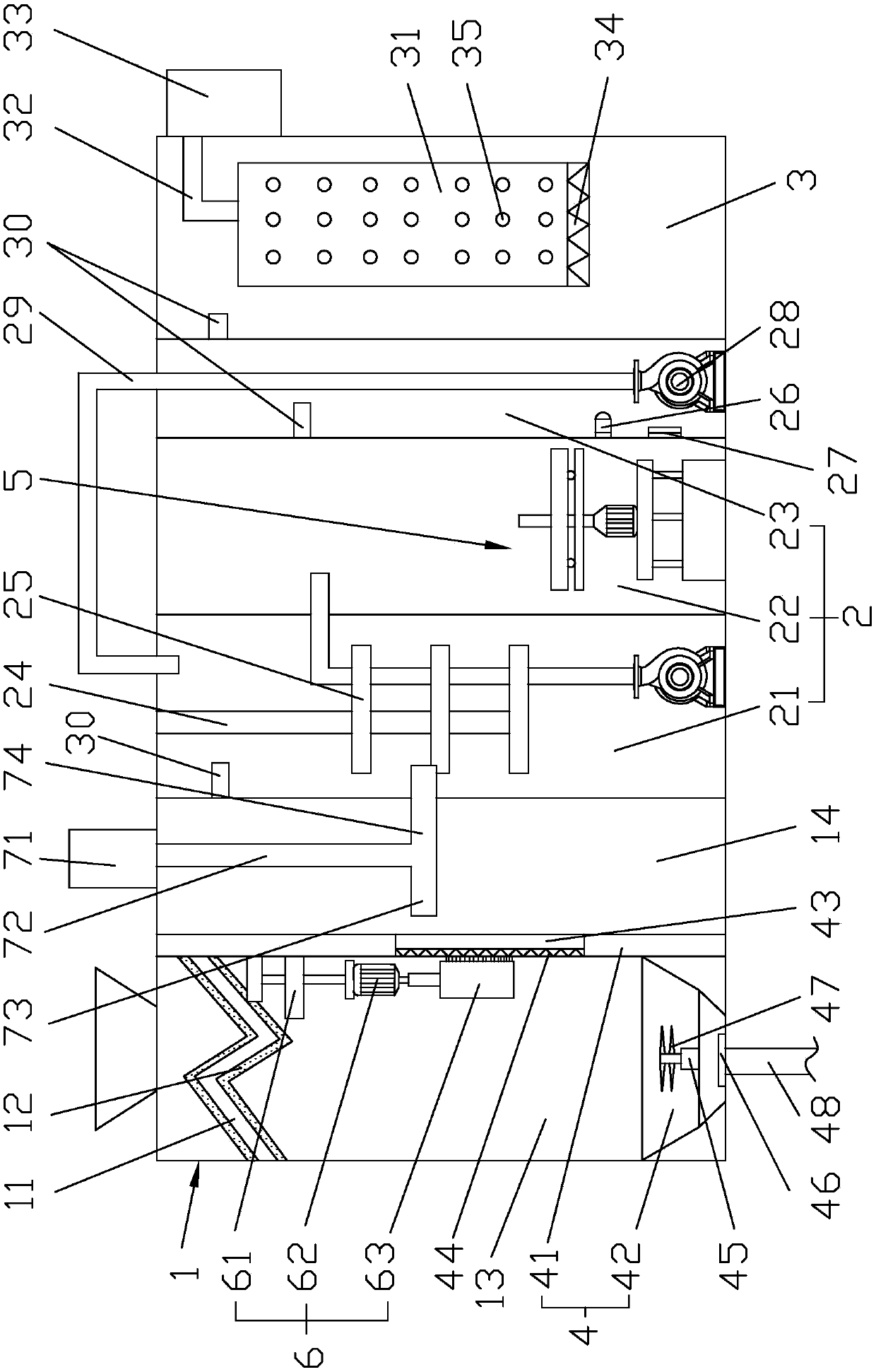

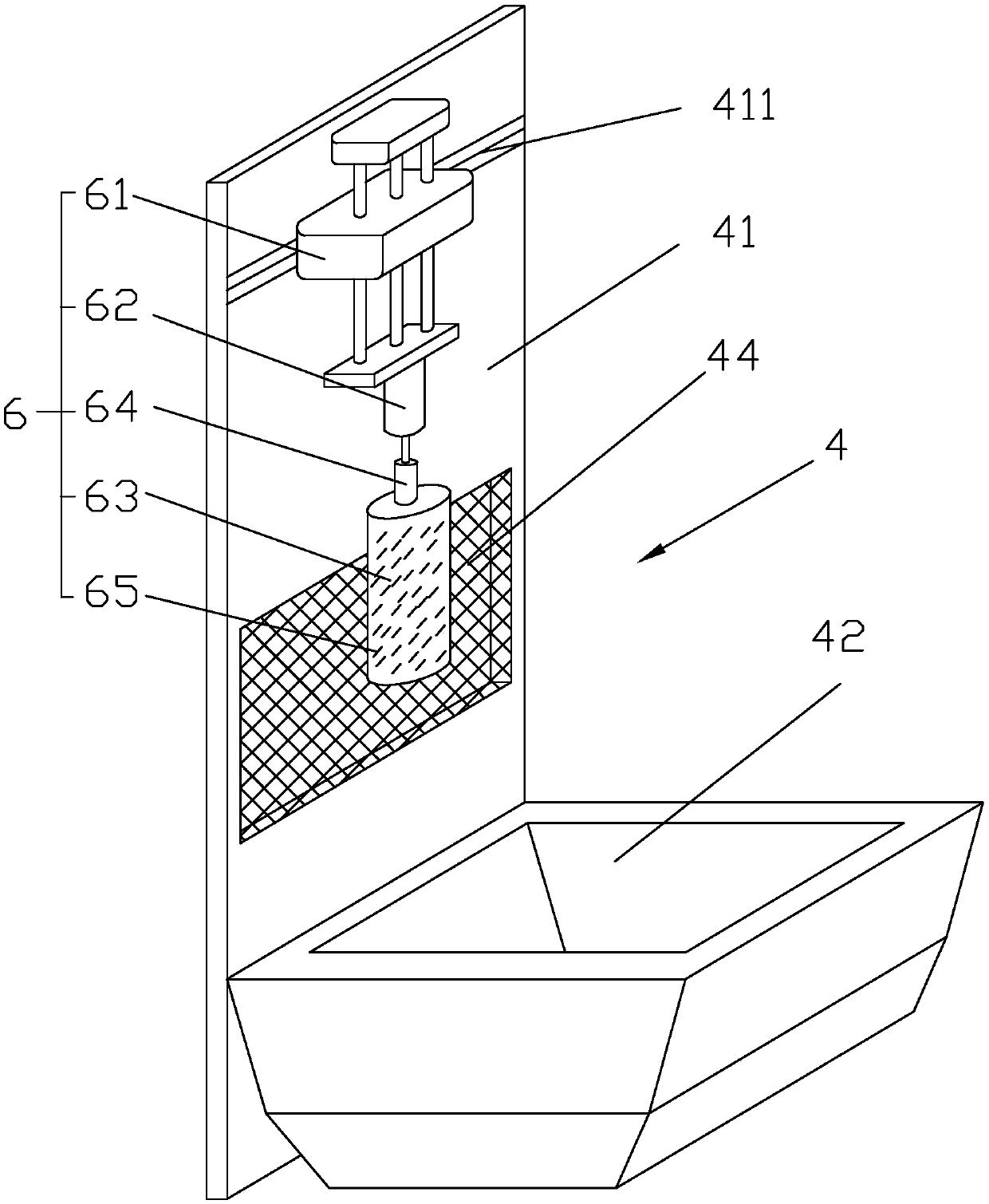

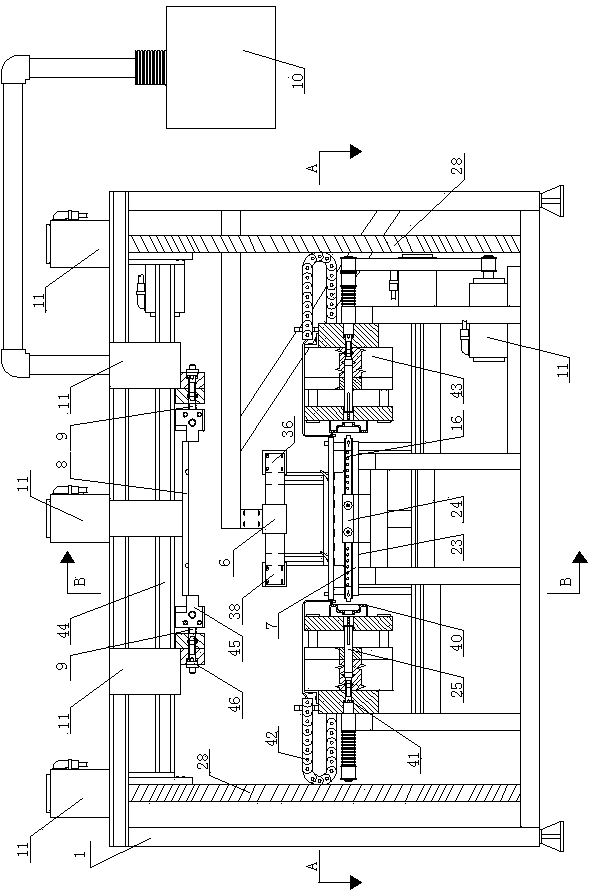

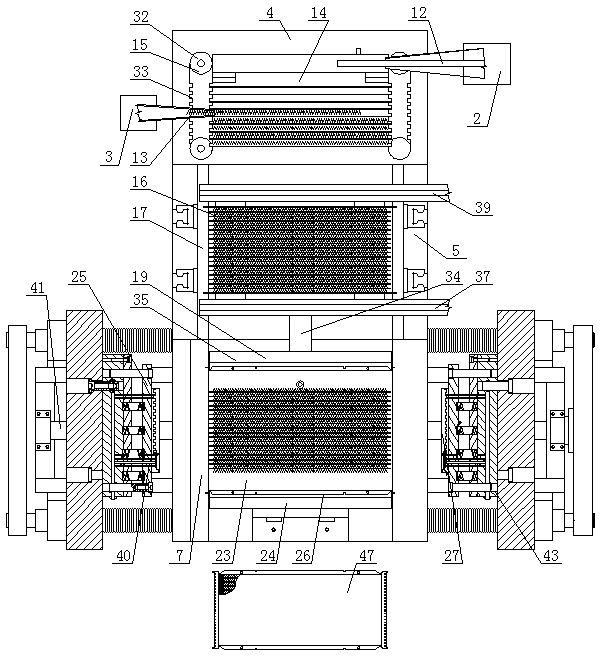

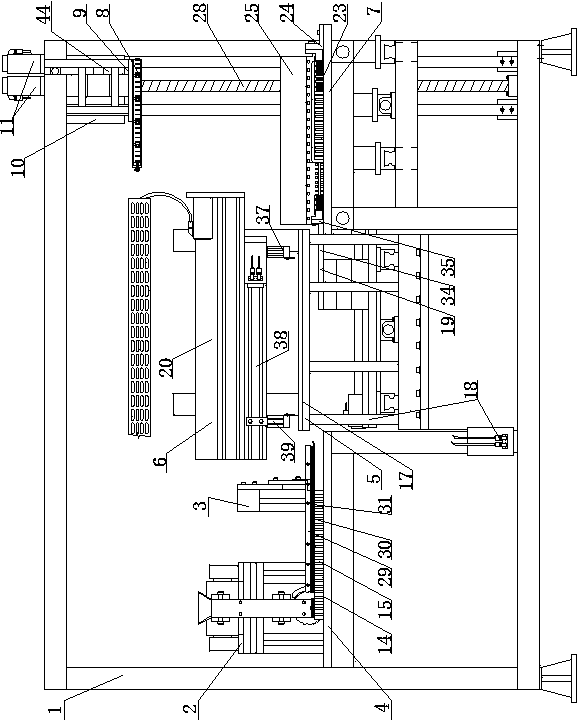

Numerical control assembly device for automobile radiator core production line

ActiveCN104259858ASave human effortImprove work efficiencyAssembly machinesNumerical controlProduction line

The invention discloses a numerical control assembly device for an automobile radiator core production line, belongs to a core assembly device, and aims to solve the problems of low efficiency and low precision existing in the prior art. According to the adopted technical scheme, the device comprises a rack, a radiating tube conveying device, a radiating belt turning and conveying device, a radiating tube and radiating belt automatic arrangement table, a core lifting conveying table, a front and rear manipulator assembly automatic operation mechanism, a radiator core assembly table, a core pressing device, a belt tidying device, a controller and a servo motor, wherein the radiating tube conveying device, the radiating belt turning and conveying device, the radiating tube and radiating belt automatic arrangement table, the core lifting conveying table, the front and rear manipulator assembly automatic operation mechanism, the radiator core assembly table, the core pressing device, the belt tidying device, the controller and the servo motor are arranged on the rack; the radiating tube and radiating belt automatic arrangement table, the core lifting conveying table and the radiator core assembly table are arranged on the rack from back to front in sequence; the radiating tube conveying device and the radiating belt turning and conveying device are positioned on the left and right sides of the radiating tube and radiating belt automatic arrangement table respectively; the front and rear manipulator assembly automatic operation mechanism is arranged above the core lifting conveying table; the core pressing device and the belt tidying device are positioned above the radiator core assembly table; the controller is adopted for control.

Owner:山东厚丰汽车散热器有限公司

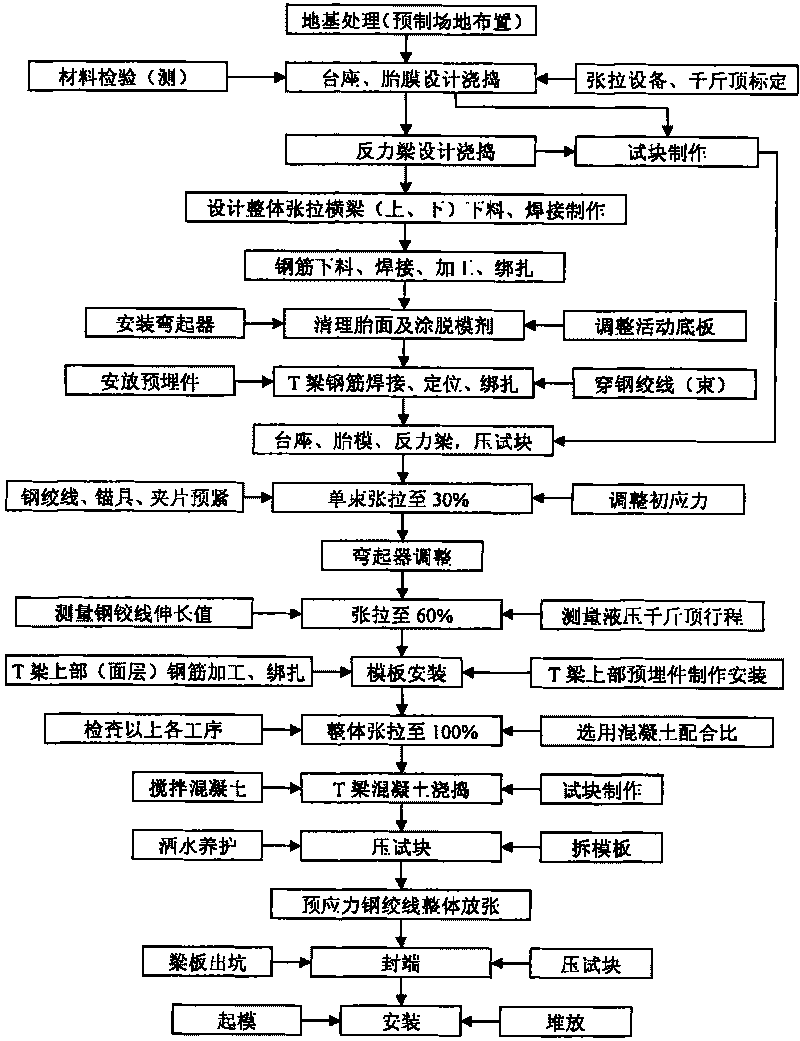

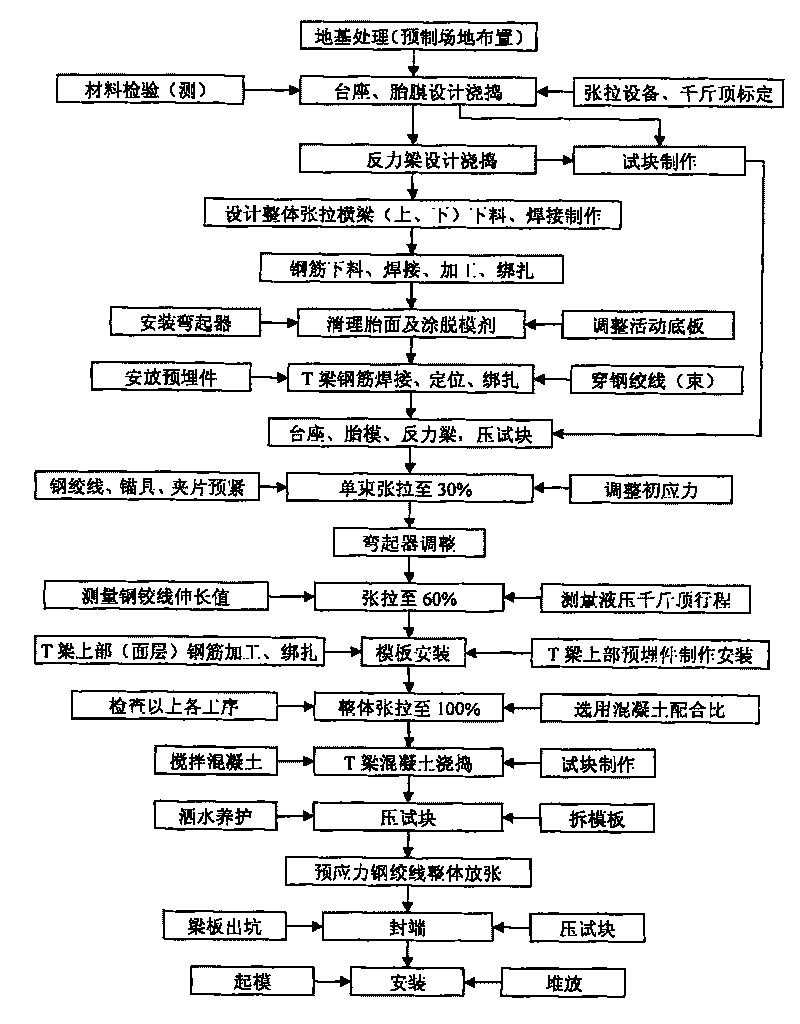

Pretensioning method construction technology of 50m broken line reinforced concrete T-shaped beam

ActiveCN101748681AImprove stabilityGood self-anchoring bonding effectBridge erection/assemblyBridge materialsShaped beamPolygonal line

The invention discloses a pretensioning method construction technology of 50m broken line reinforced concrete T-shaped beams, belonging to the technical field of bridge building constructions. The construction technology comprises the following steps of: foundation treatment; the design and fabrication of footstalls; the design and fabrication of reaction beams; the design and fabrication of tension beams; the design and fabrication of uplift piles; the fabrication and pre-embedment of a bent-up device; the design and fabrication of stranded steel wire tension connectors; the processing and colligation of reinforcing steel bars; the blanking and strand pricking of stranded steel wires; the tensioning of pre-stressed tendons; the fabrication and installation of templates; the pouring and maintenance of concrete; the relaxation of the pre-stressed tendons; and the pit-out and installation of T-shaped beams. The invention can solve various difficult problems in the prestress tensioning construction of high-span broken line reinforced concrete T-shaped beams and fills the gap of the technology of China, and the whole construction technology process and relevant control parameters has scientific and reasonable configuration, can meet the requirements of design and construction on quality, safety and the like, and have high operational instruction property. The invention can be widely applied to the stranded steel wire tensioning construction in structures similar to the high-span broken line pretensioning method T-shaped beams, the box girder and the like in engineering of large-scale buildings, bridges, wharfs and the like.

Owner:浙江省建投交通基础建设集团有限公司

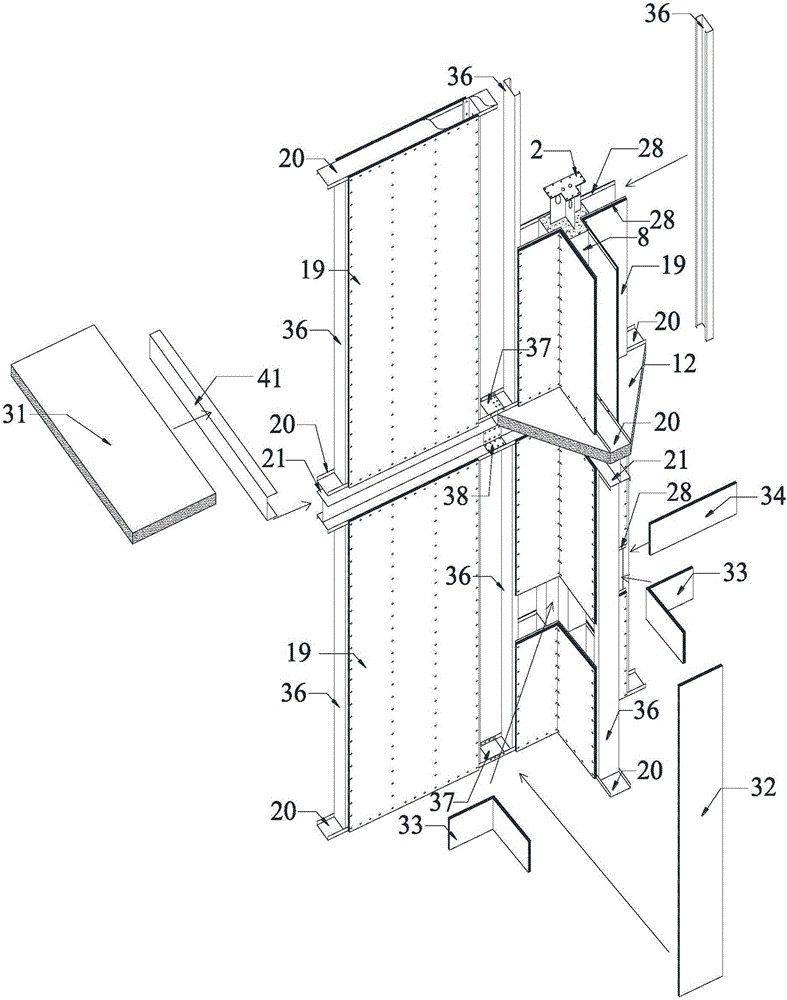

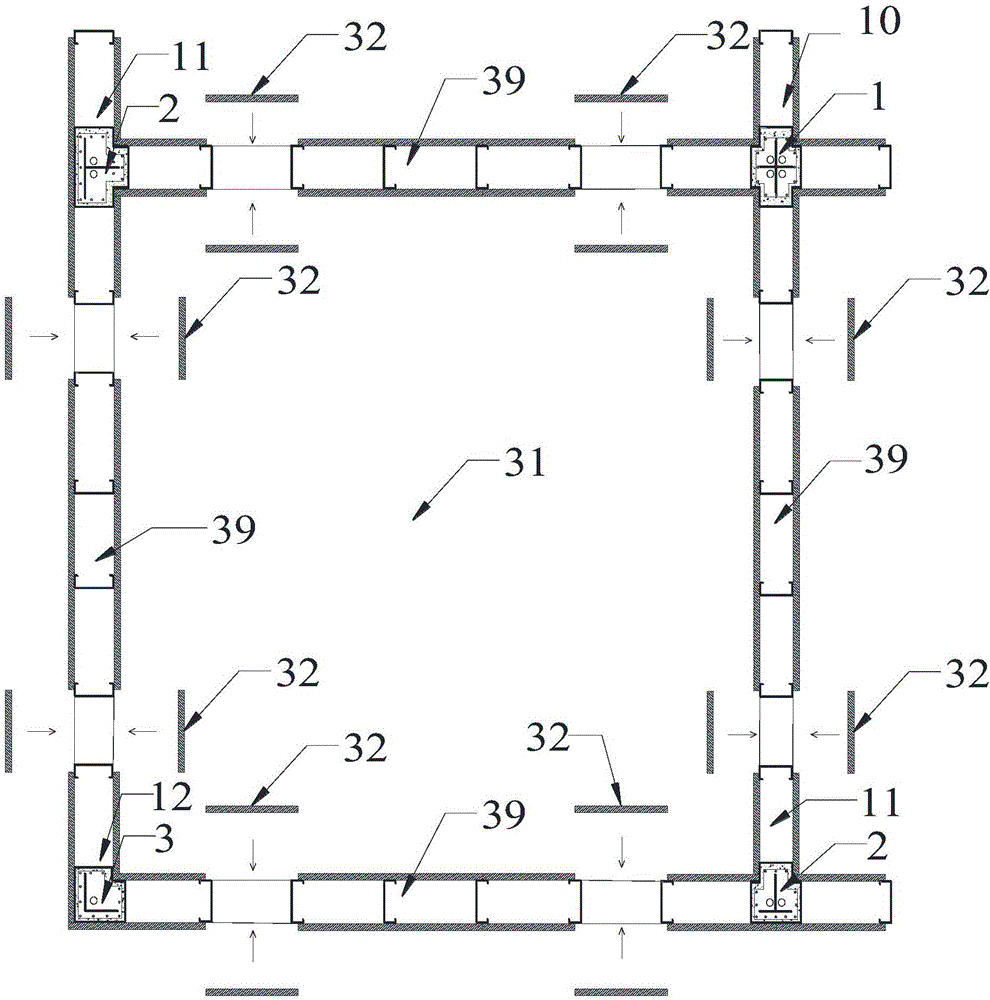

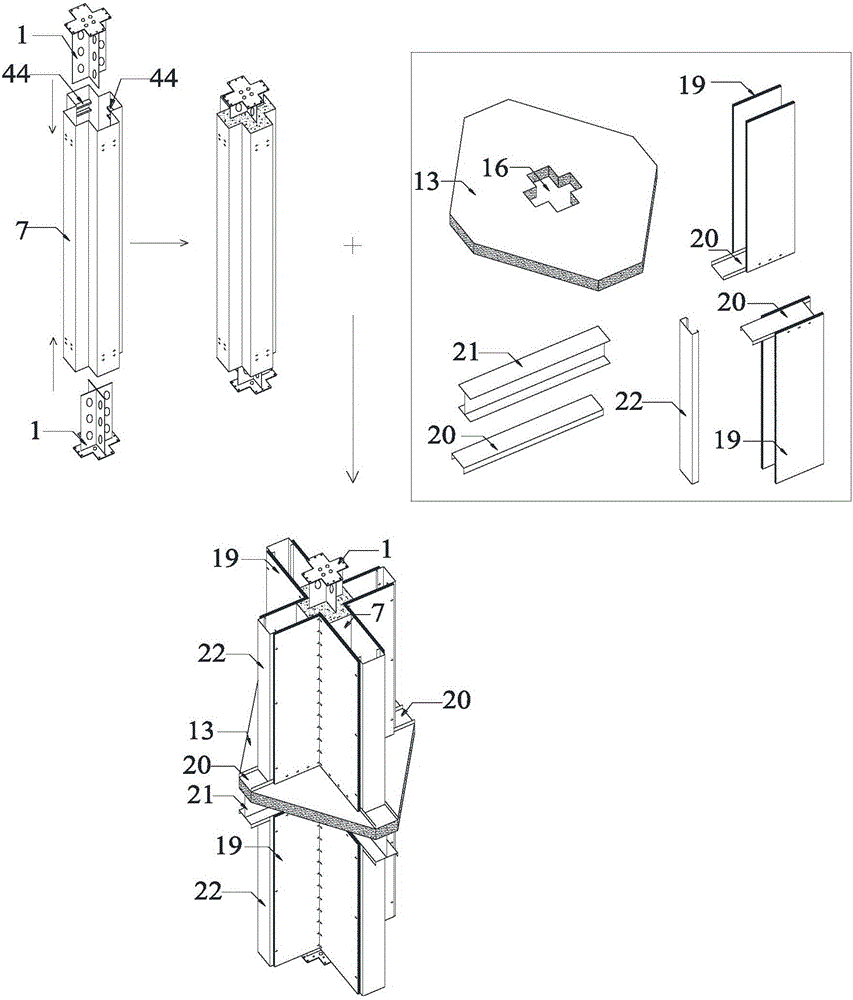

Multilayer cold-formed steel integrally prefabricated house and splicing method thereof

ActiveCN105696817AReduce on-site construction workloadHigh degree of industrializationBuilding material handlingDwelling buildingFloor slabEngineering

Owner:SOUTHEAST UNIV

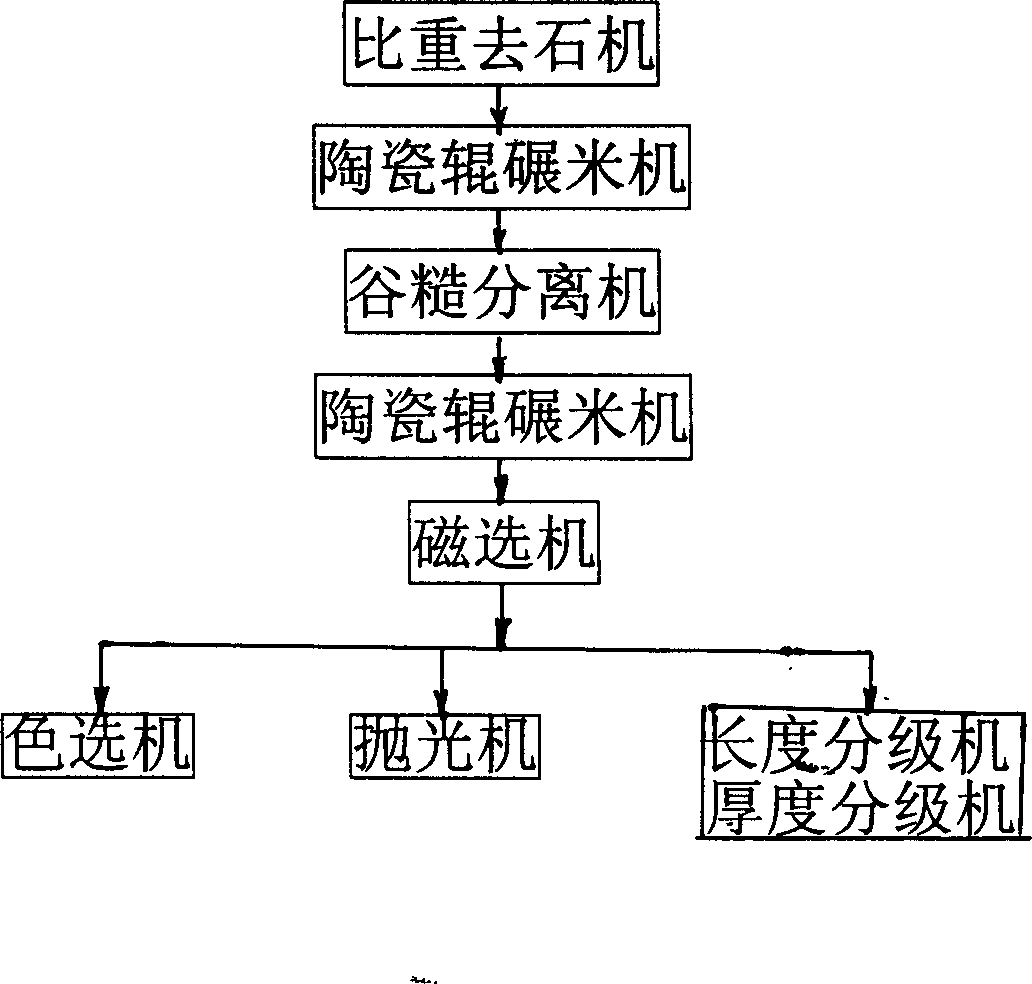

Rice fine-processing production line

InactiveCN1806922AReasonable settingIncrease roughnessGrain huskingCombination devicesProduction lineBroken rice

The invention relates the rice fine finishing production line. The production line comprises specific density stone removing machine, ceramic abrasive roll rice polishing machine, grain separating machine, magnetic cobber, buffing machine, length classifier, thickness classifier, compressed air station and dust-collecting equipment. The finishing work comprises primary rouging, separating grain, fine rolling, second rouging and final treatment. The reasonable production line improves the rate of husked rice, reduces the broken rice and the waste of grain and increases the grain availability ratio.

Owner:刘益民

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com