Patents

Literature

181 results about "Rouging" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Rouging is a form of corrosion found in stainless steel. It can be due to iron contamination of the stainless steel surface due to welding of non-stainless steel for support columns, or other temporary means, which when welded off leaves a low chromium area.

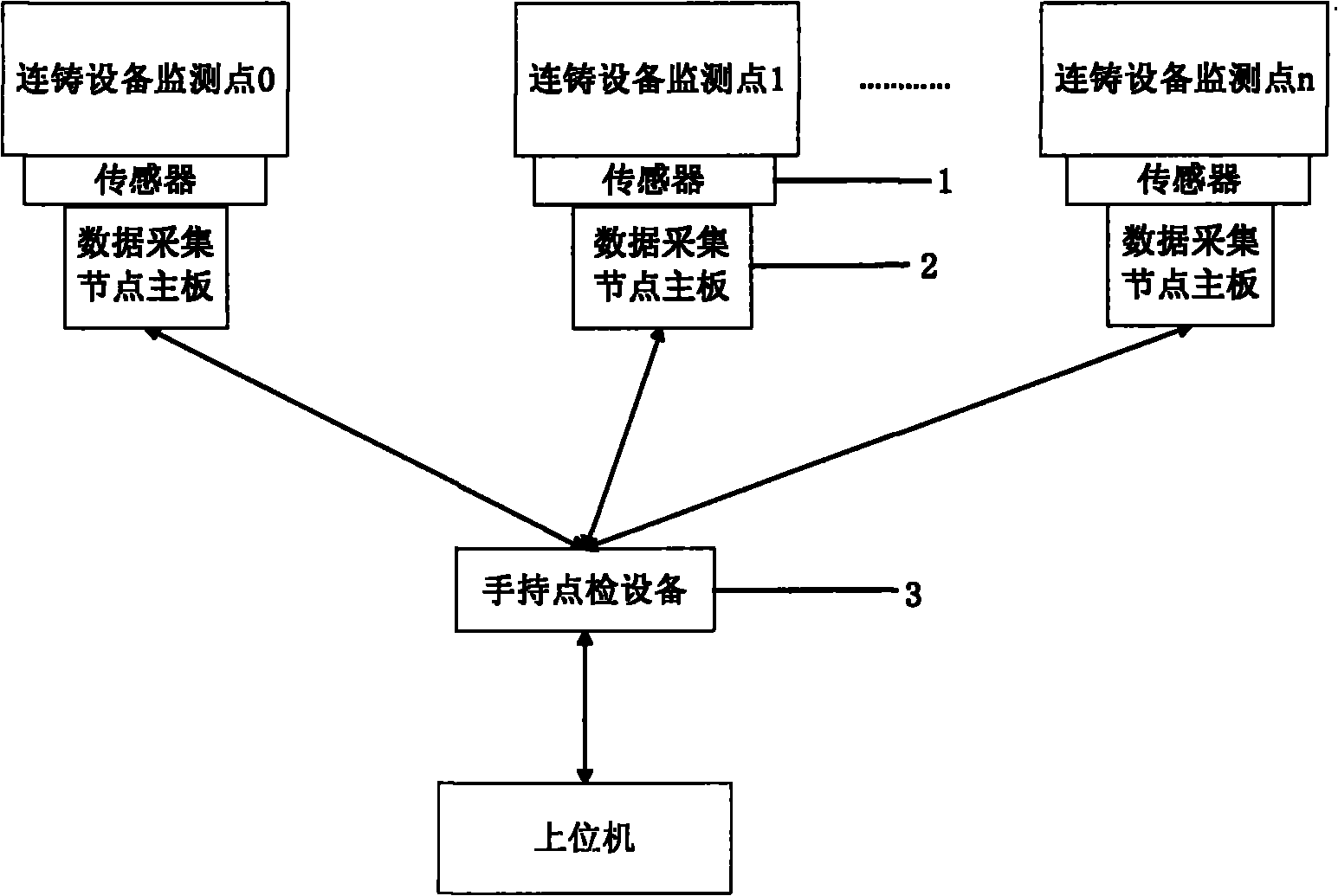

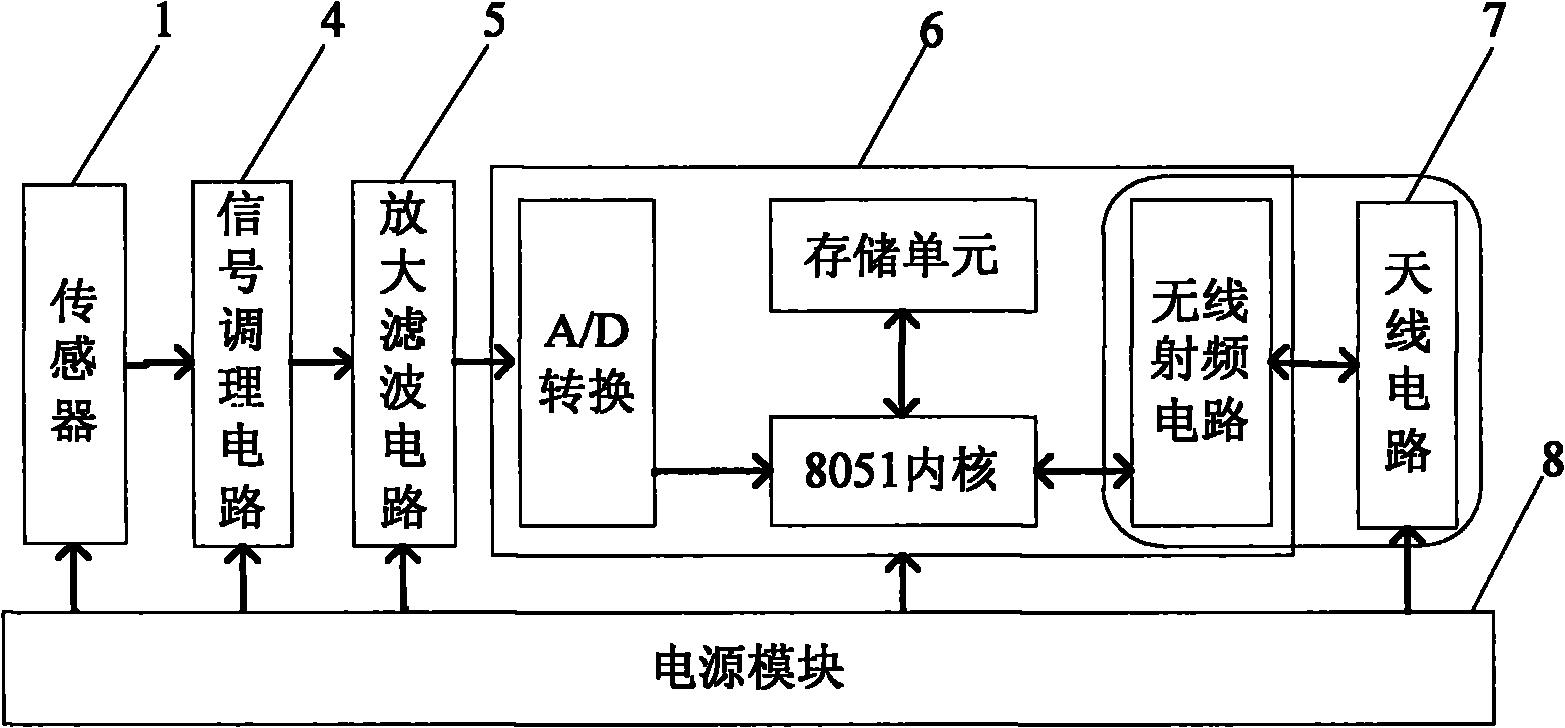

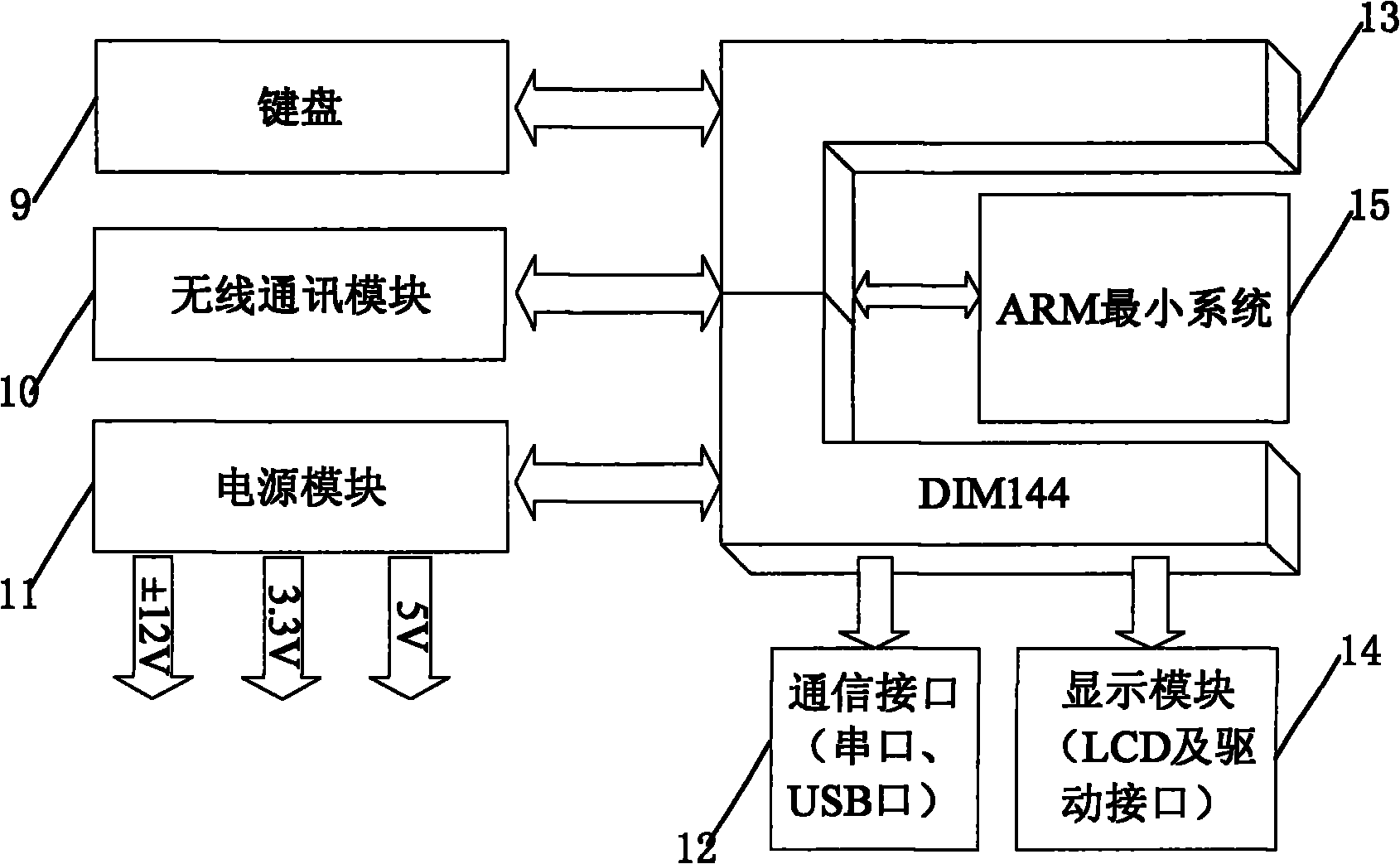

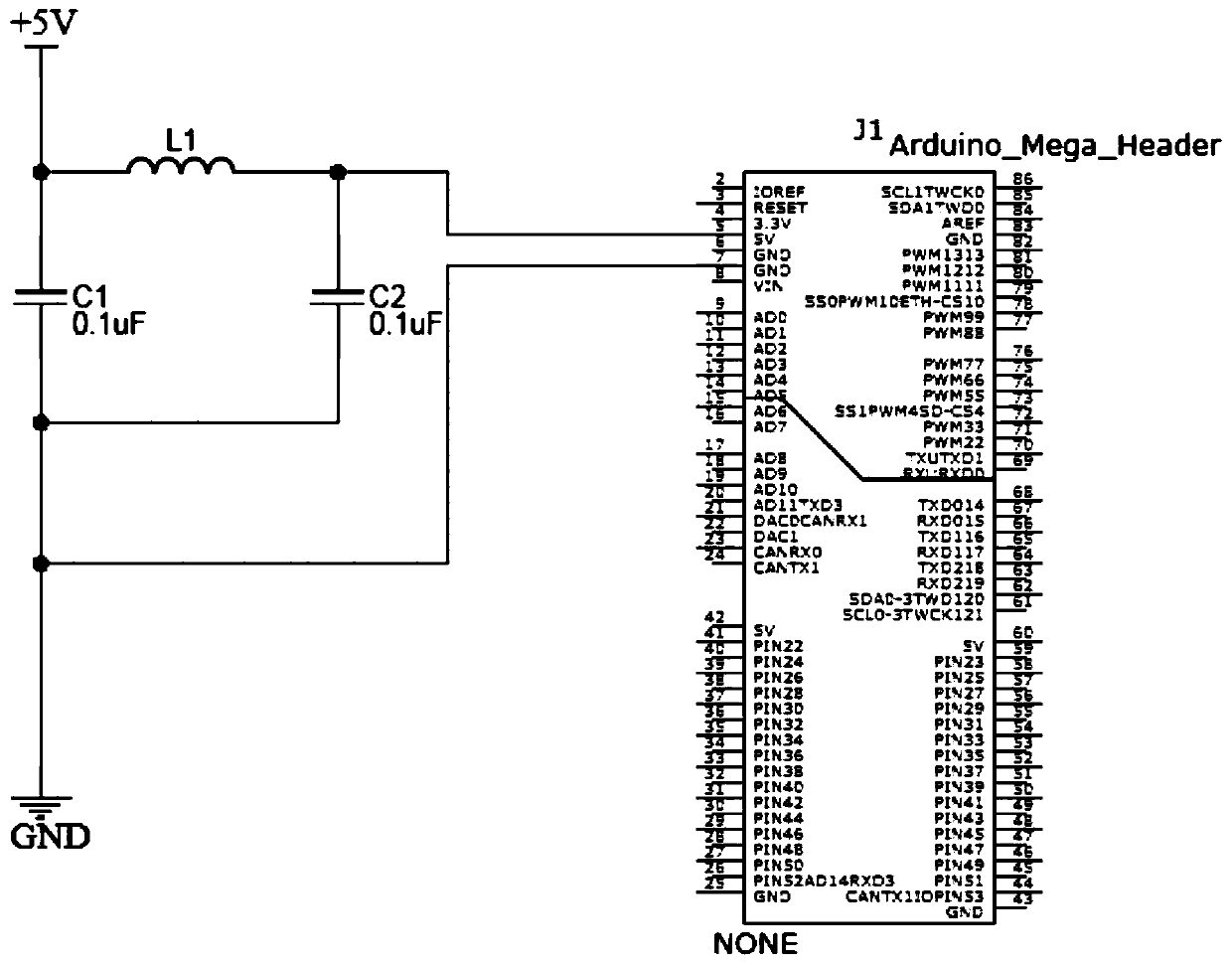

Iron and steel continuous casting equipment oriented method and device for forecasting faults

InactiveCN102072829AReduce the hassle of wiringLow application costStructural/machines measurementSpecial data processing applicationsDecompositionResidual service life

The invention relates to an iron and steel continuous casting equipment oriented method and device for forecasting faults. The device is characterized in that sensors installed on iron and steel continuous casting equipment are used for acquiring real-time status parameters of the equipment; the signals are processed by signal conditioning circuits, amplifying and filtering circuits and A / D conversion modules of data acquisition nodes and the data are sent to handheld spot inspection equipment via radio circuits supporting the Zigbee protocols; the handheld spot inspection equipment receives and analyzes the data; eigenvectors of equipment status data are constructed based on decomposition and construction carried out by wavelet packets, the eigenvectors are used as samples, support vector data description is utilized to train a single-value classifier, and the domesticated classifier is utilized to compute the health index of the equipment and describe the deterioration curve of the equipment so as to further forecast the residual service life of the equipment; the data acquisition node main boards comprise the sensors, the signal conditioning circuits, the amplifying and filtering circuits, single chips and antenna circuits; and the handheld spot inspection equipment comprises a radio communication module, an advanced RISC machines (ARM) minimum system, a keyboard and a display module. The method and the device have the beneficial effects of adopting the radio communication mode and abandoning the traditional industrial buses, being applied in the harsh production equipment such as iron and steel continuous casting lines, reducing the trouble of arranging lines and lowering the application cost.

Owner:TONGJI UNIV

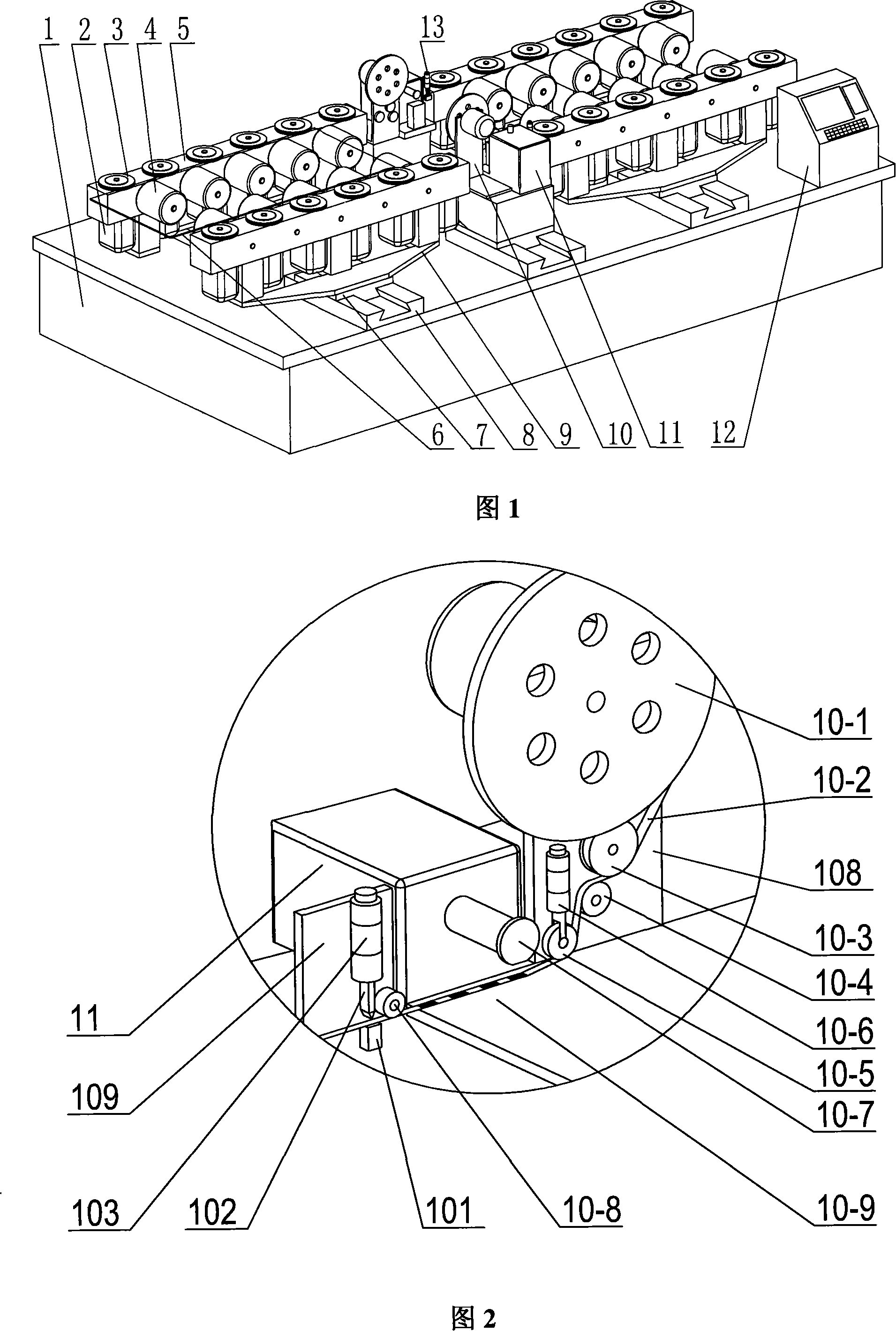

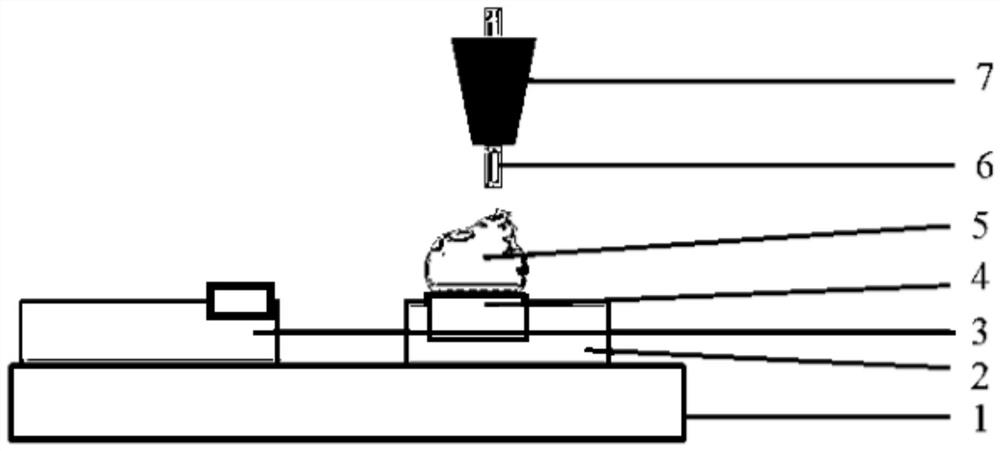

Ultrasonic soldering equipment for solar cell electrode

InactiveCN101110458ASatisfy the pressure line requirementsImprove efficiencyFinal product manufactureSemiconductor devicesElectrical batteryEngineering

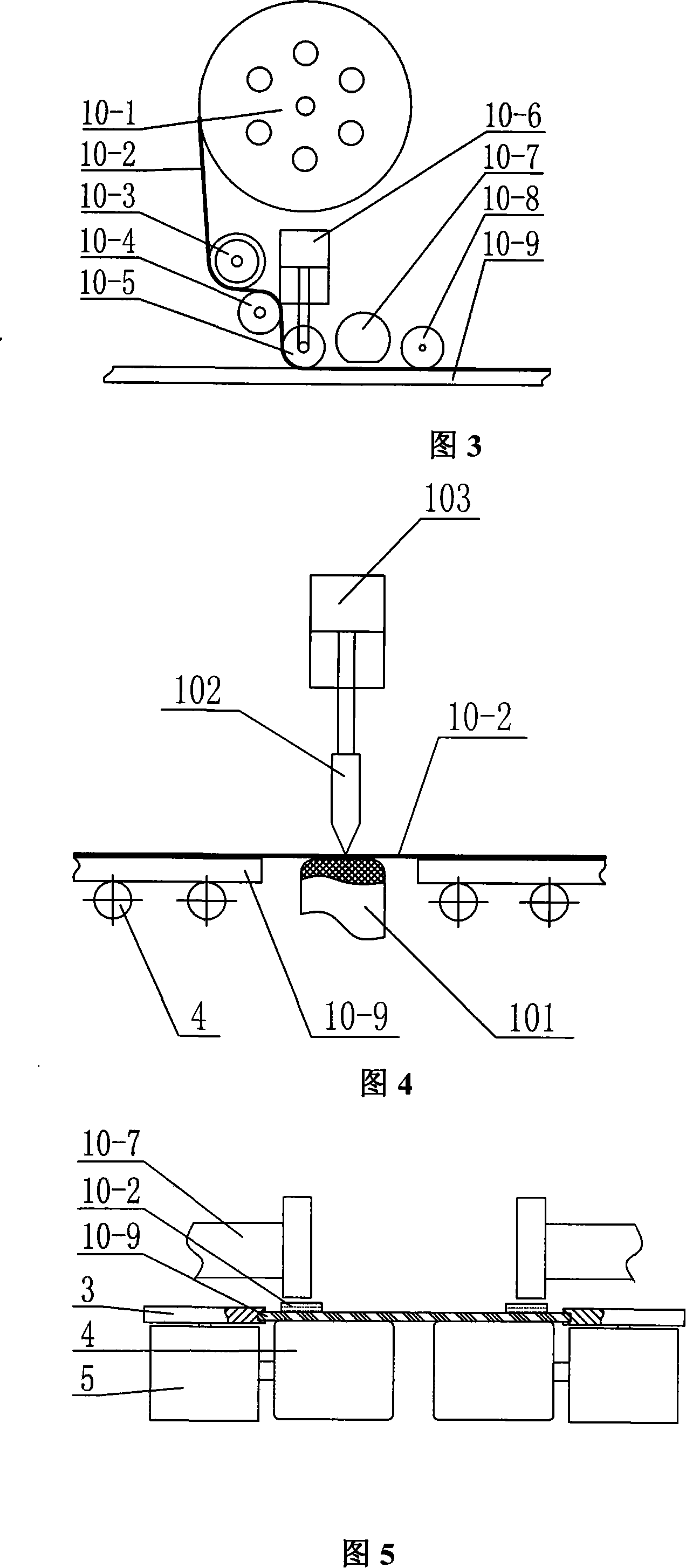

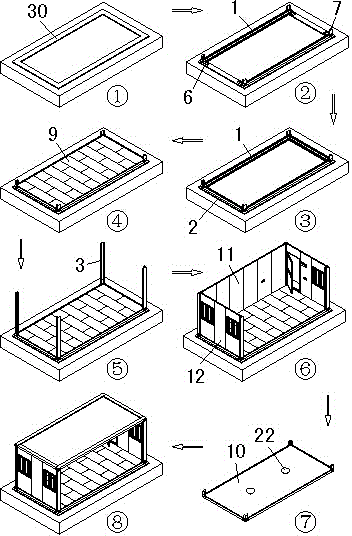

The present invention discloses an automatic ultrasonic wave welding equipment for welding amorphous silicon solar cell electrode, which aims to improve current ultrasonic wave metal spot welding machine and add a mechanical wire pressing and take-up device and method to replace manual wire pressing and laying and is technically characterized in that a working table is composed of a feeding zone, a welding zone and a discharging zone. An electrode wire 10-2 is coiled on an uncoiling wheel 10-1 of the electrode wire pressing device 10. A guide wheel 10-3 and an extension-resistant tightening pulley 10-4 are arranged on a front slab bracket 108 below the uncoiling wheel 10-1. A corresponding ultrasonic wave welding head 10-7 is mounted between a coiling wheel 10-5 and a flattening wheel 10-8. The present invention is suitable for automatic welding of thin film solar cell electrode with glass or flexible material as substrate, thus ensuring high precision, nice appearance and equal distance between welding spots, improving welding efficiency and eliminating rosin joint.

Owner:李毅

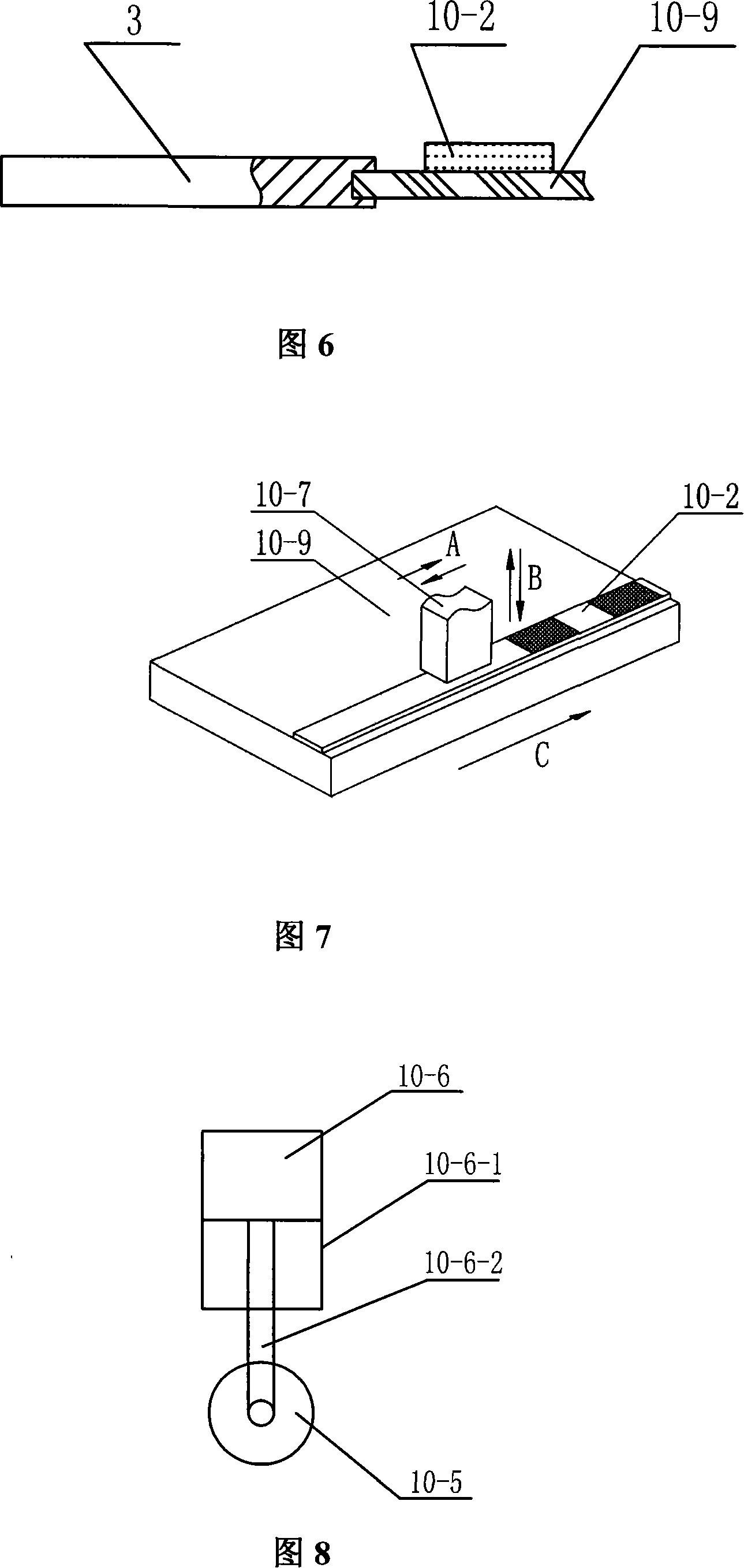

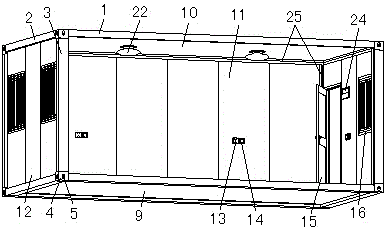

Construction method and structure of spliced type standard temporary houses

ActiveCN105649207AHigh dimensional accuracyImprove interchangeabilityClimate change adaptationBuilding material handlingBolt connectionElectric wire

The invention discloses a construction method and structure of spliced type standard temporary houses. The construction method adopts a standard manufacturing mode, in the splicing process, only a framework adopts bolts for connection, other parts are all connected in a clamping or plugging mode, and the whole splicing process does not need welding. The framework is formed by bending and forming Q235 galvanized steel plates 3 mm thick overall, is high in strength and is not prone to rusting, thereby improving the circulation rate. All components are high in size accuracy and good in interchangeability, only galvanized bolts are adopted for connection in the splicing process, assembling and disassembling are simple, convenient and rapid, and the construction period is short. Combination is flexible, and office rooms, temporary meeting rooms, dormitories, dining rooms, bathrooms, toilets, standard rooms, power distribution rooms, water pump rooms and the like with different areas and different purposes can be obtained in a freely spliced mode. All wires are pre-buried in wall boards at a time when processed in a factory and do not need to be arranged on site. The construction method and structure of the spliced type standard temporary houses further have the characteristics of firmness, durability, dampproofness, wind resistance, fireproofness, corrosion resistance, heat insulation, sound insulation and heat preservation.

Owner:CHINA CONSTR FOURTH ENG DIV

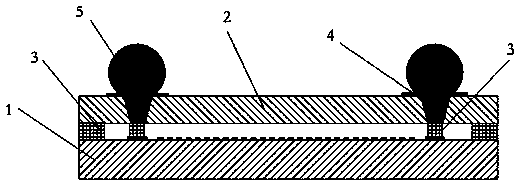

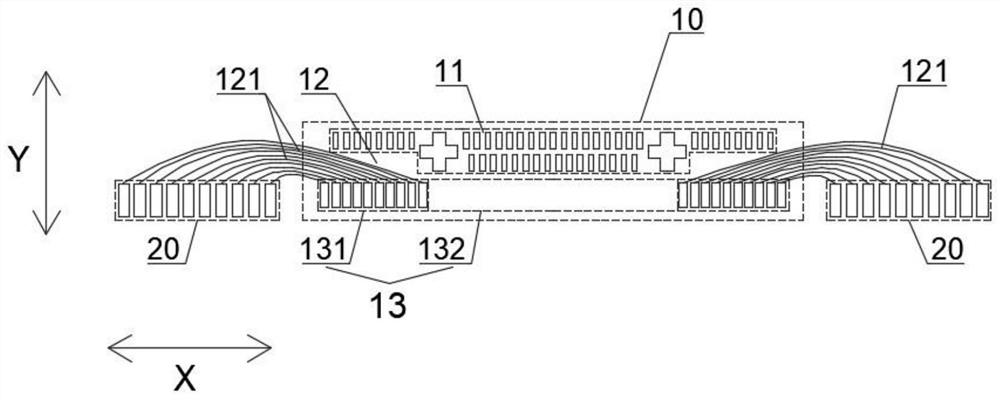

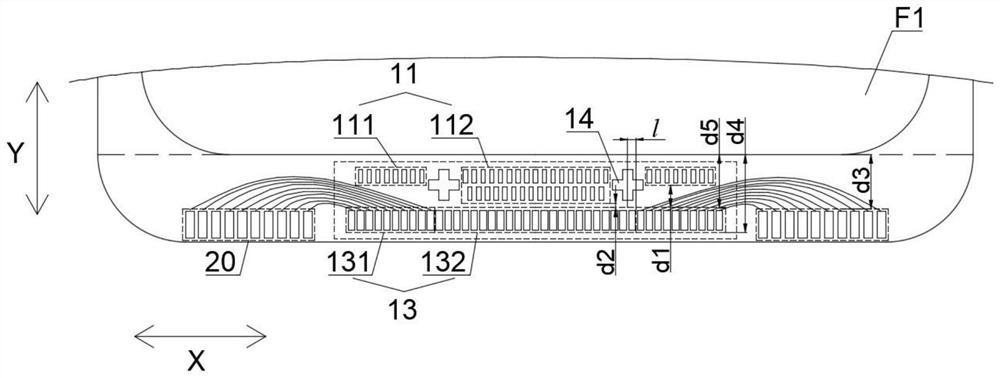

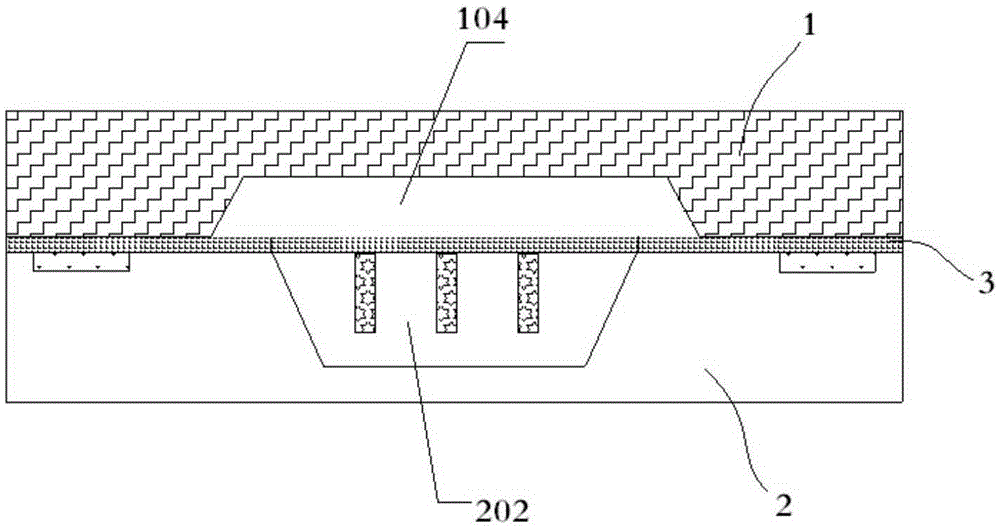

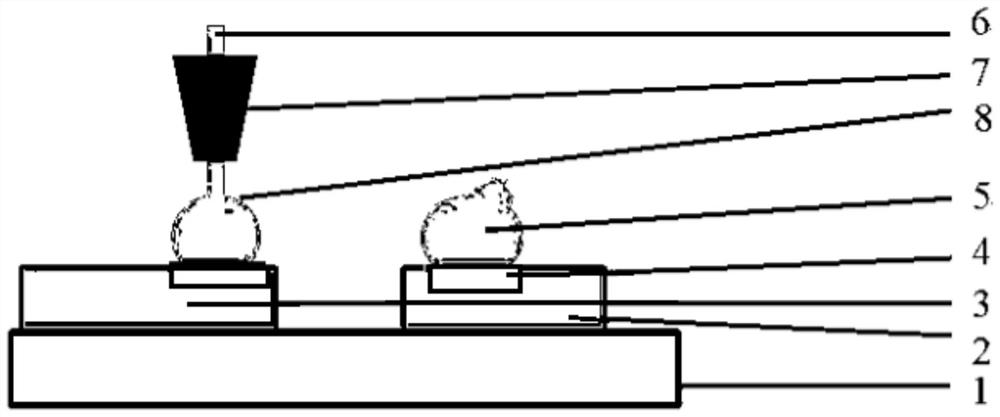

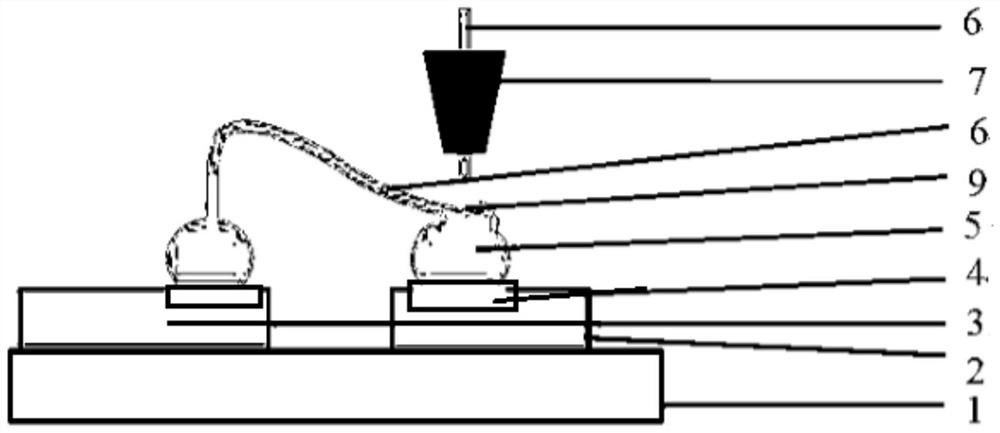

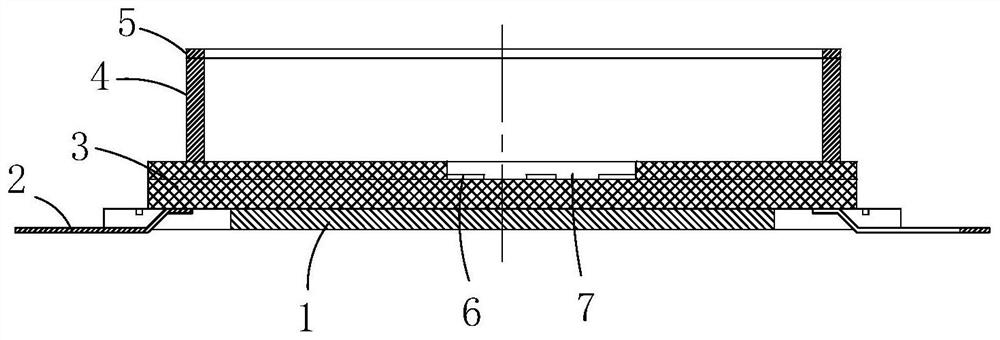

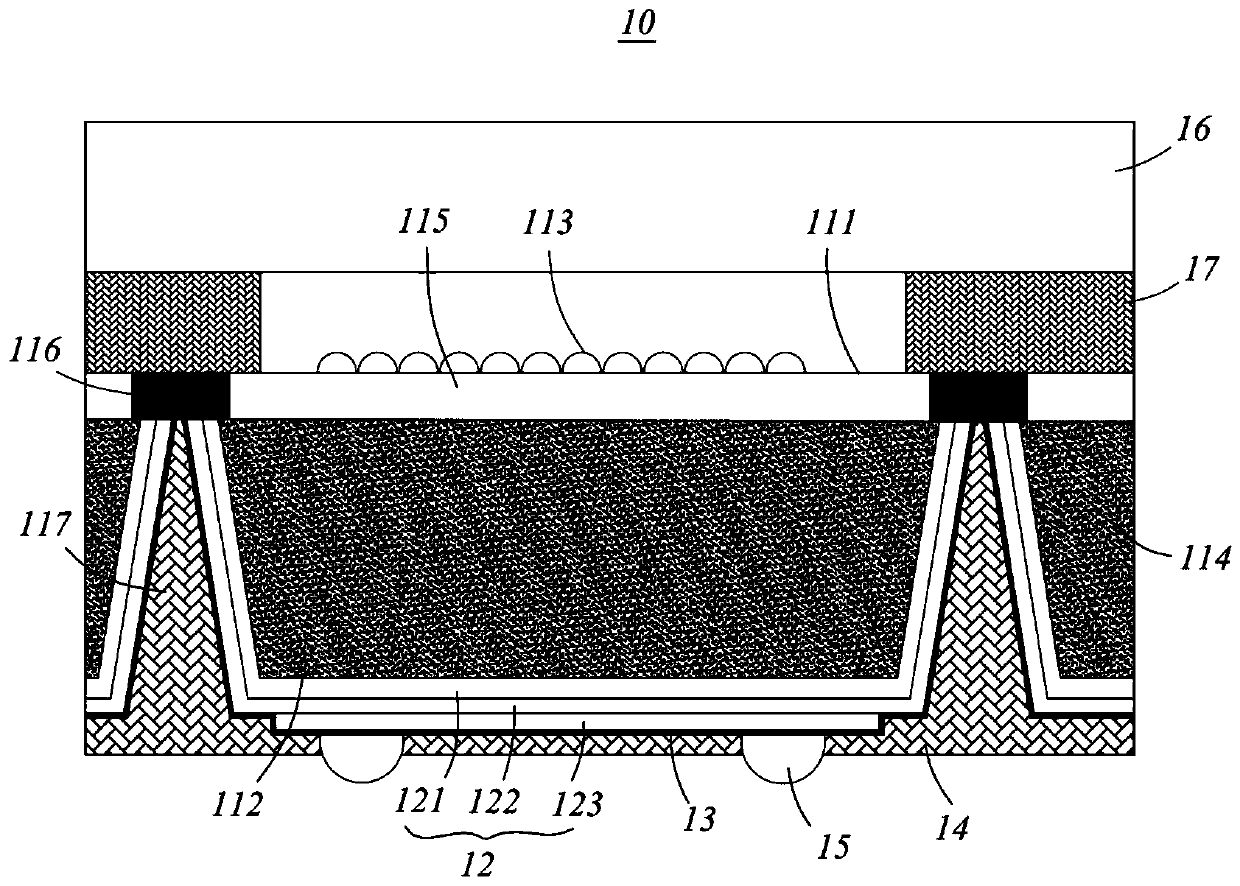

Encapsulation structure, electronic equipment and encapsulation method

ActiveCN105655310ASimple preparation processLow costSemiconductor/solid-state device detailsSolid-state devicesMiniaturizationElectrical connection

The invention discloses an encapsulation structure which comprises a substrate, a fan-out unit and a wiring layer, wherein the fan-out unit comprises a first chip and a second chip; the first chip comprises a first pin array; the second chip comprises a second pin array; the fan-out unit also comprises a third pin array; the first pin array, the second pin array and the third pin array are opposite to the substrate; the wiring layer is bridged between the first pin array and the second pin array and used for connecting the first pins in the first pin array to corresponding second pin in the second pin array; the substrate is provided with a welding pad electrically connected with the wiring layer in the substrate; the third pin array is connected with the welding pad. The invention also discloses electronic equipment and an encapsulation method. The encapsulation structure disclosed by the invention has the advantages of low difficulty in production, low cost and miniaturization.

Owner:HUAWEI TECH CO LTD

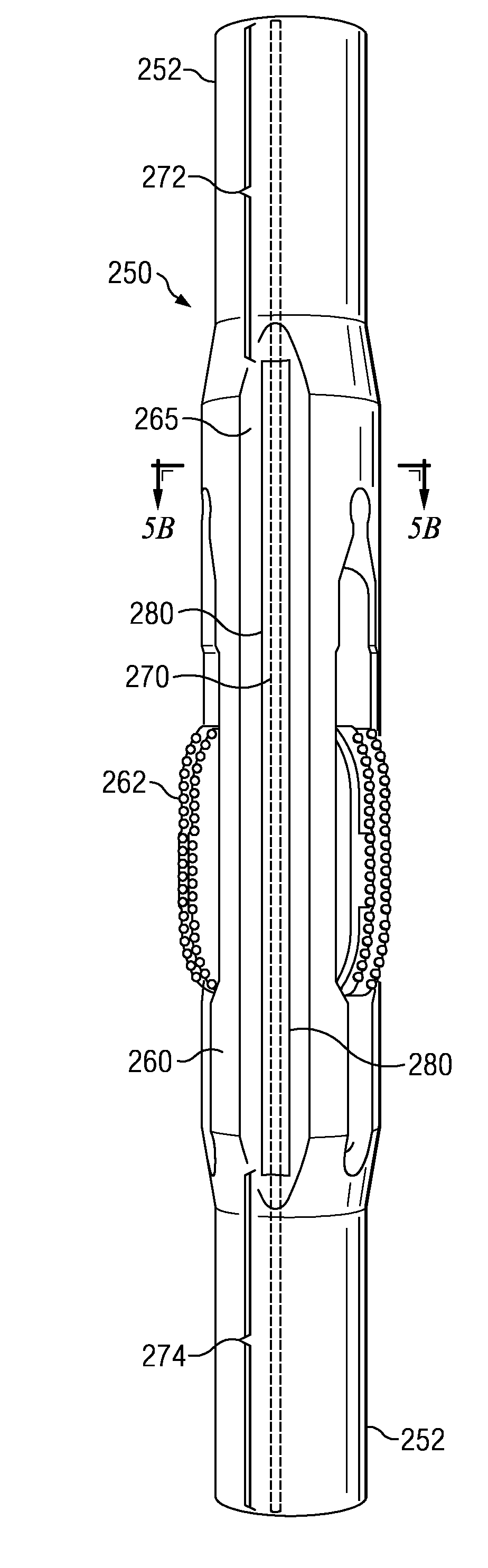

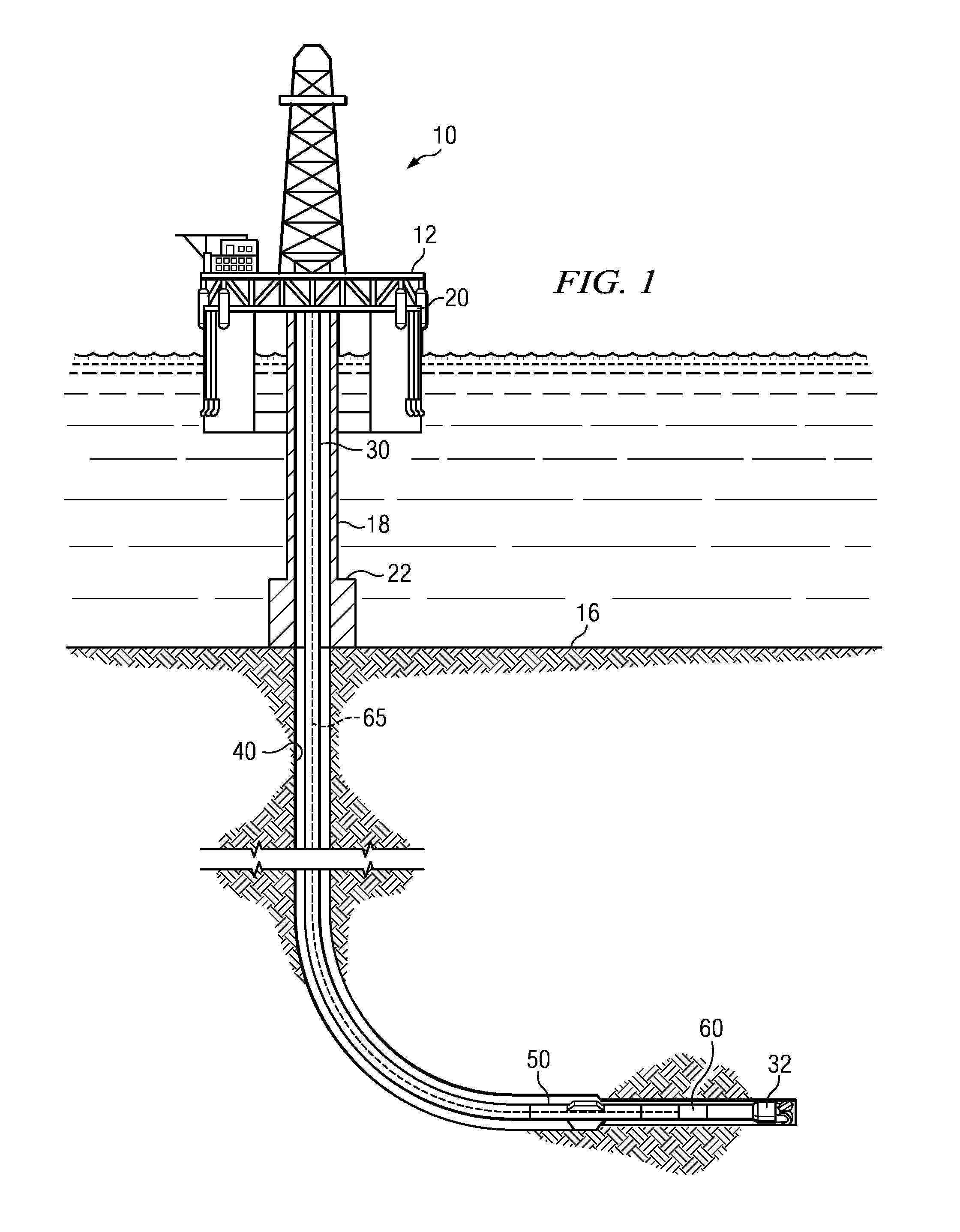

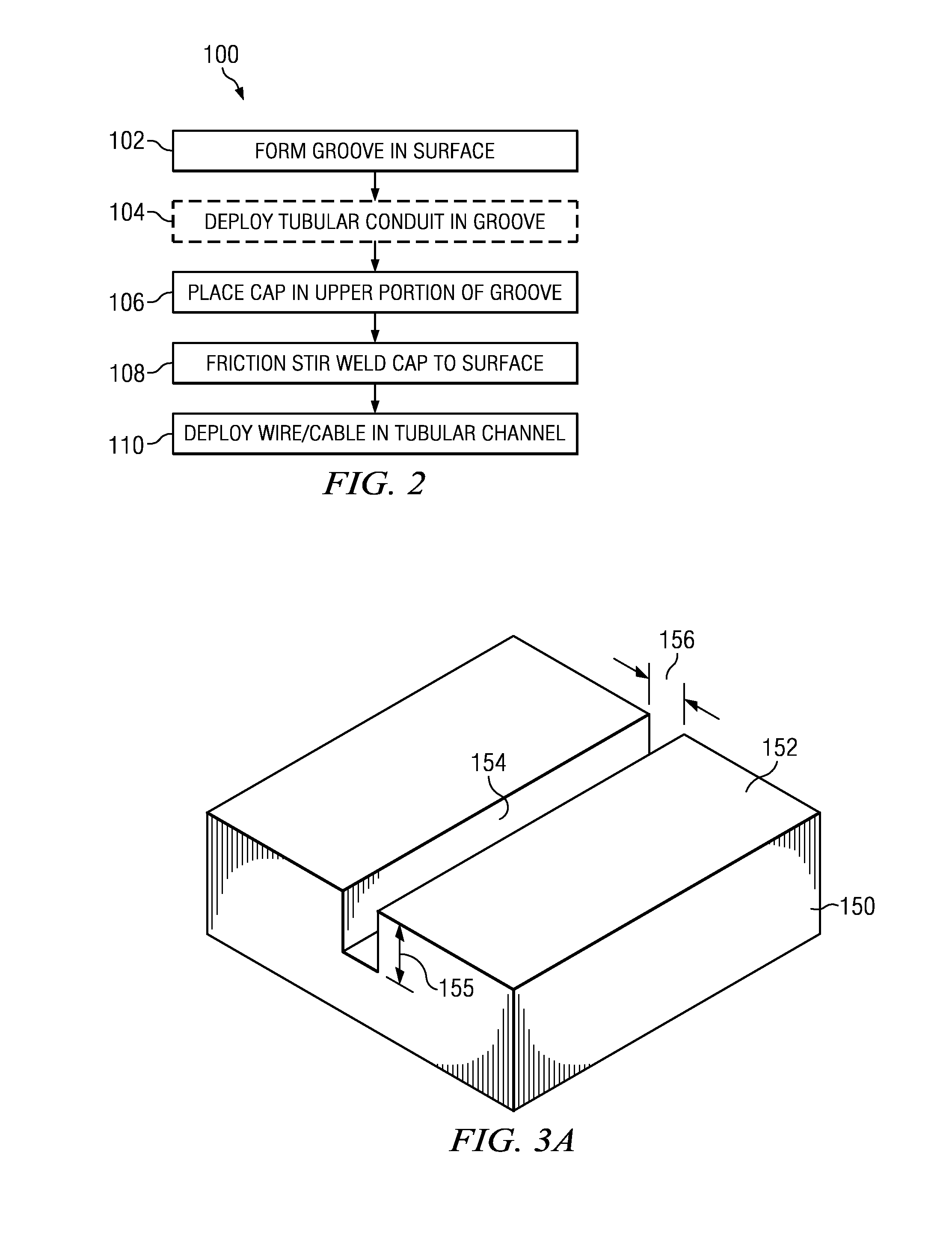

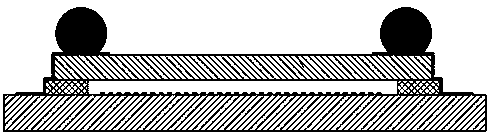

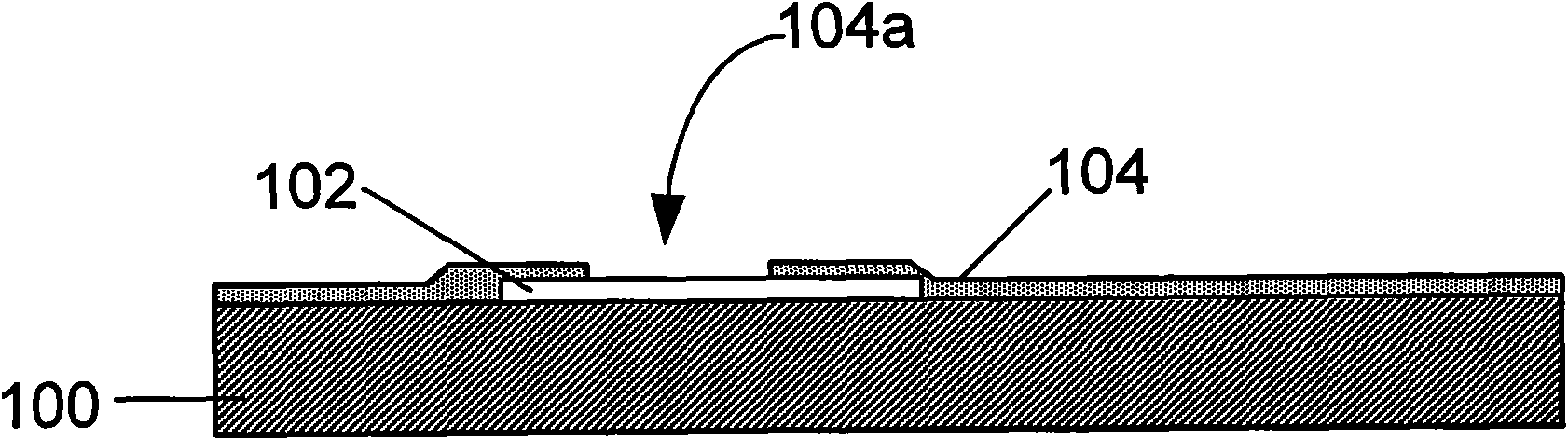

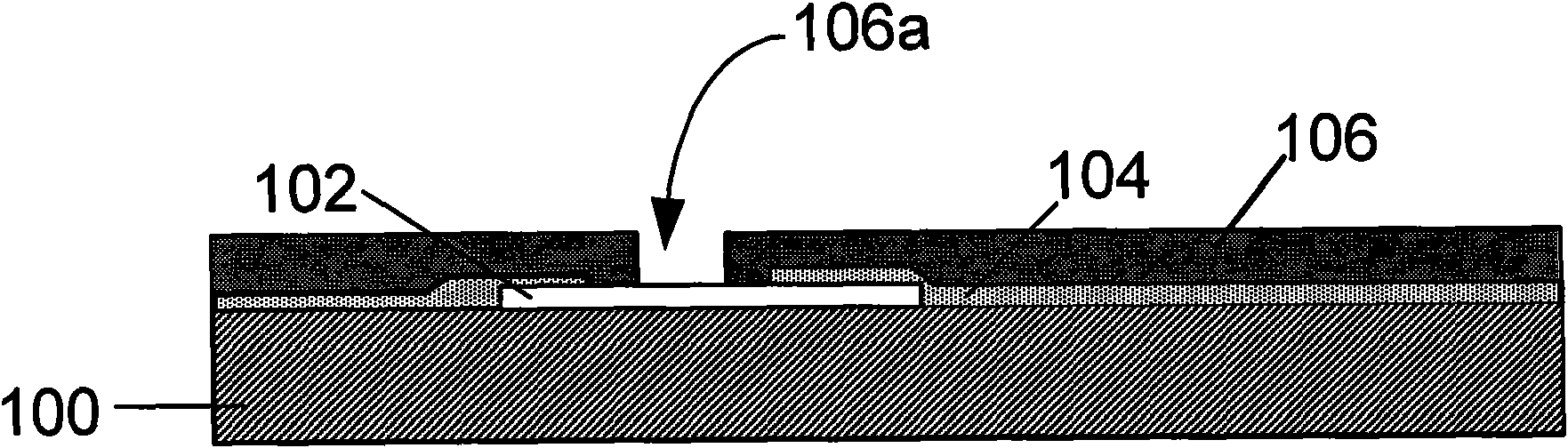

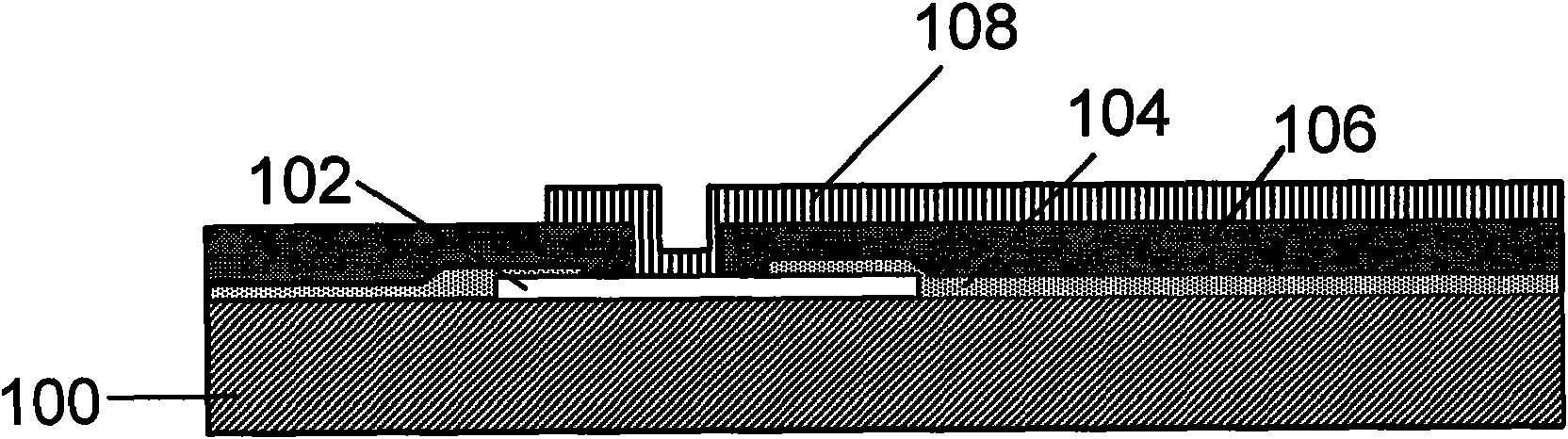

Article of manufacture having a sub-surface friction stir welded channel

InactiveUS20110240372A1Low costShorten the timeDrill bitsDrilling rodsElectrical conductorWear resistant

A method for routing an electrical conductor through a sub-surface channel in substantially any suitable metallic article of manufacture includes friction stir welding a cap in a groove formed in a surface of the article so as to form the sub-surface channel. An electrical conductor is then routed through the channel. The channel may further include a substantially tubular conduit formed therein with the electrical conductor being routed through the conduit. The friction stir weld zone formed during friction stir welding is generally harder and more wear resistant that the article body.

Owner:SMITH INT INC

Airtight wafer level packaging structure and process of surface acoustic wave device

PendingCN107919862AIncreased shear strengthImprove air tightnessImpedence networksElectrical connectionHermetic packaging

The invention discloses an airtight wafer level packaging structure and process of a surface acoustic wave device. A circle of bonding layer metal is plated on the periphery of a working surface of afunctional chip, a circle of bonding layer metal is plated on a position corresponding to each piece of chip bonding layer metal on a sealing cover wafer, and the functional chip and the sealing coverwafer are correspondingly combined together through gold-gold bonding or eutectic bonding; an external circuit wiring circuit and an external electrode are arranged on one surface of the sealing cover wafer deviating from the working surface of the functional chip; an external welding ball is made on the external electrode; and a conduction hole is formed in the sealing cover wafer to electrically connect the working surface circuit of the functional chip with the external welding ball through the conduction hole and the external electrode in sequence. By adoption of the airtight wafer levelpackaging structure and process, high chip shear strength, good heat dissipation performance, and airtight package of the wafer level (WLP) surface acoustic wave device with controllable internal atmosphere are achieved, and the reliability is high.

Owner:CETC CHIPS TECH GRP CO LTD

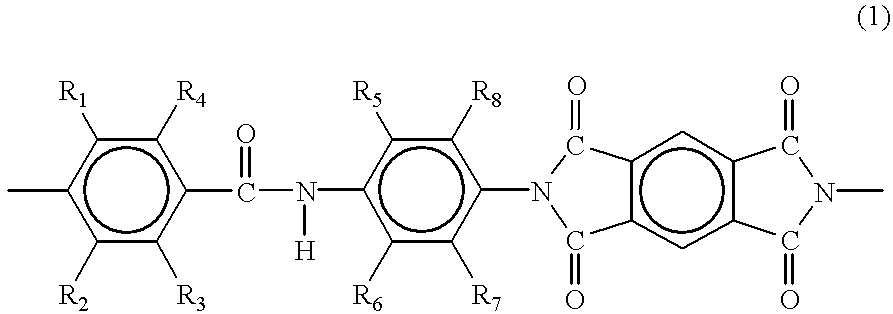

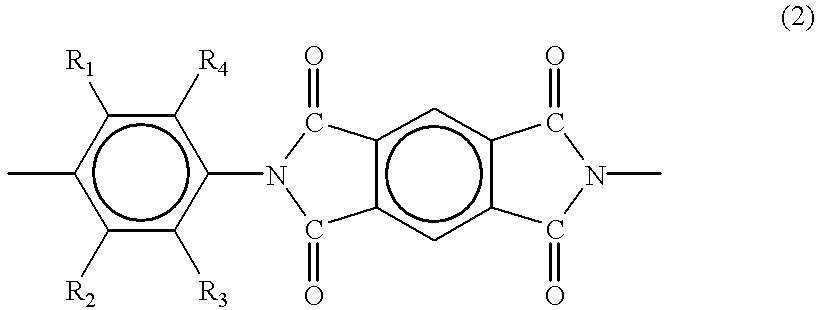

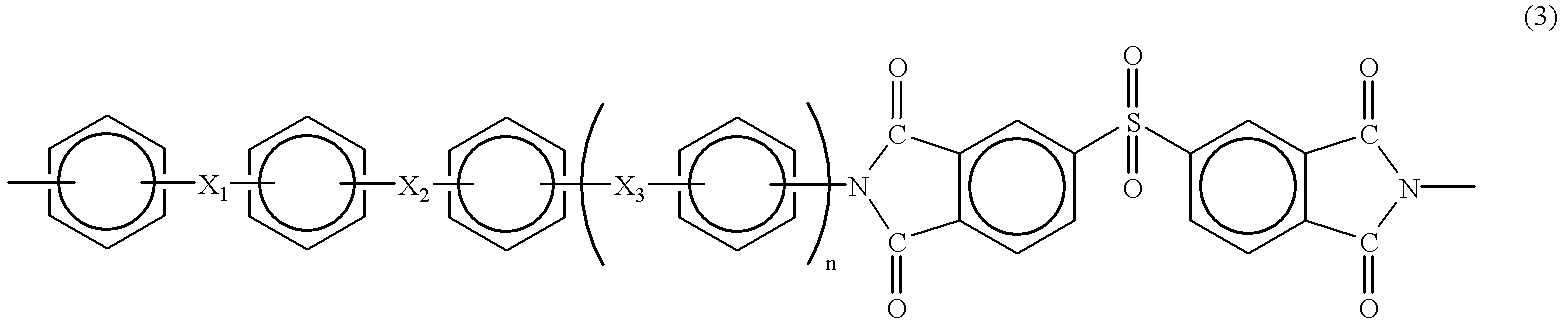

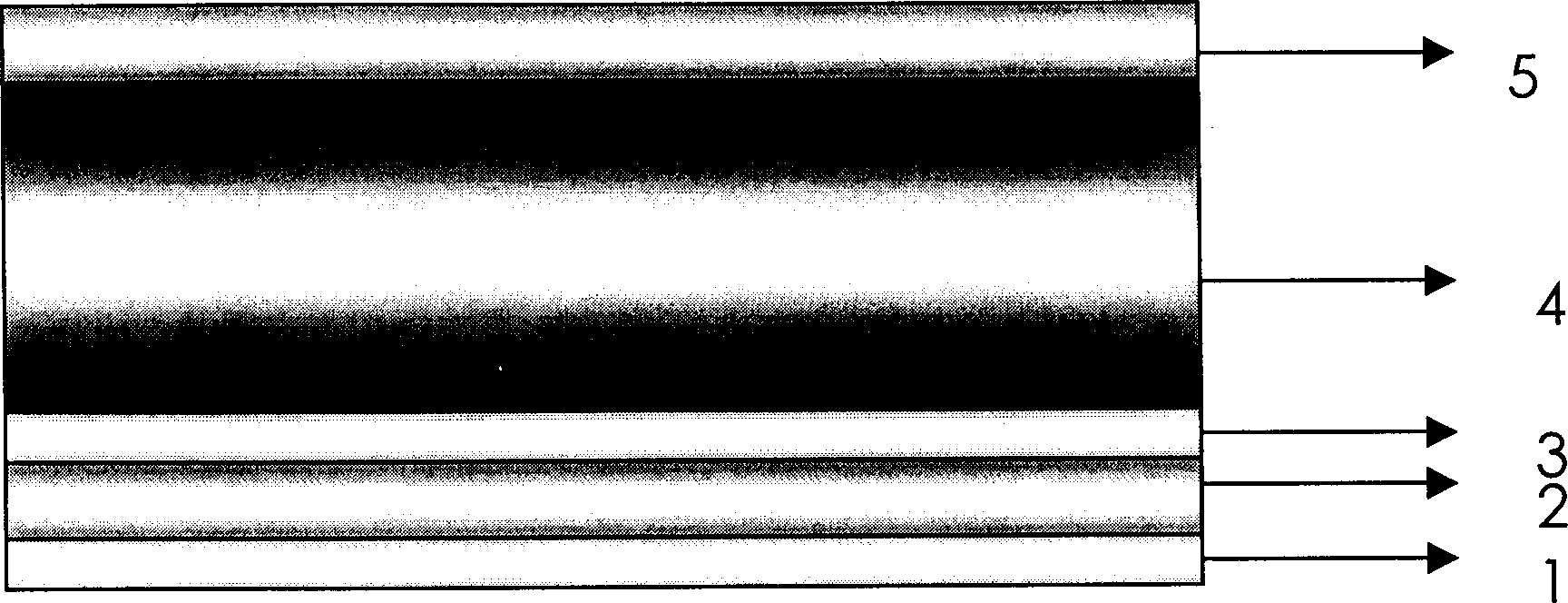

Laminate for HDD suspension and its manufacture

InactiveUS6203918B1Manual label dispensersPretreated surfacesElectrical conductorUltimate tensile strength

This invention relates to laminates for use in HDD suspensions which are composed of a stainless steel base material and successive layers formed thereon of polyimides and an electrical conductor and in which the linear expansion coefficient of the polyimide layer is controlled in the range of 1x10-5 / ° C. to 3x10-5 / ° C. and the adhesive strength between stainless steel and polyimide and that between polyimide and electrical conductor are controlled at 0.5 kg / cm or more. This invention also relates to a process for preparing laminates for use in HDD suspensions comprising applying a solution of polyimide precursors or polyimides to a stainless steel base material with a thickness of 10 to 70 mum in one layer or more, drying, performing heat treatment at 250° C. or more to form a layer of polyimides with a thickness of 3 to 20 mum and a linear expansion coefficient of 1x10-5 / ° C. to 3x10-5 / ° C. and contact-bonding said layer of polyimides under heat to a layer of electrical conductor with a thickness of 3 to 20 mum.Laminates of this invention for use in HDD suspensions are practically free of deflection during etching and are suited for integrally-wired HDD suspensions.

Owner:NIPPON STEEL CHEMICAL CO LTD

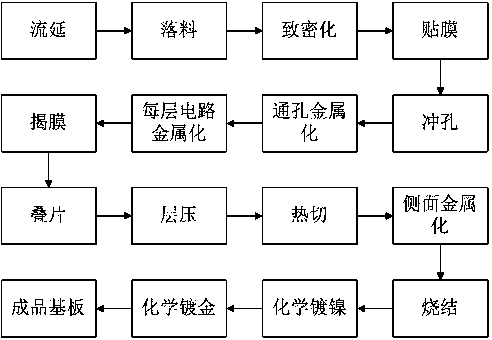

Multi-layer aluminum nitride substrate for highly integrated module level packaging, and manufacturing method thereof

InactiveCN109545771AReduce volumeSolve the heat dissipation problem of miniaturized and highly integrated module-level packagingSemiconductor/solid-state device detailsSolid-state devicesGreen tapeThermal expansion

The invention relates to a multi-layer aluminum nitride substrate for highly integrated module level packaging, and a manufacturing method thereof. The structure of the substrate comprises upper and lower surface layers, wherein the upper and lower surface layers are high-precision and high-density metalized welding pads; the side walls of the substrate are fully metalized; and the substrate is internally provided with multi-layer metalized wiring. The upper and lower surface layer metalized welding pads are welded with ball gates of a silicon-based chip; the side walls are fully metalized torealize signal shielding; the multi-layer metalized wiring inside the substrate satisfies complicated circuit signal transmission and interconnection. By utilizing a multi-layer co-firing process, aluminum nitride ceramic is selected as the ceramic base body material, tungsten is used as the metallization material, a green tape binding micro-deformation process adopted, and a tungsten metal circuit layer on the surface layer is plated by adopting chemical nickel-plating and chemical gilding processes. The multi-layer aluminum nitride substrate and the manufacturing method thereof have the advantages that the aluminium nitride substrate and the silicon-based chip are highly matched in coefficients of thermal expansion, and the reliability of ball gate welding packaging of the silicon-basedchip is realized; and the thermal conductivity of the substrate is increased to 170 W / mK, thereby being capable of meeting the high power density packaging and heat dissipation requirements of the highly integrated module.

Owner:NO 55 INST CHINA ELECTRONIC SCI & TECHNOLOGYGROUP CO LTD

Wiring technology of copper doped metal based on A1 material

InactiveCN1414623AImproved resistance to electromigrationGood hole filling abilitySemiconductor/solid-state device manufacturingCopperSilicon

A metal wring process of Cu doping based on Al material mainly uses the physical deposition method to deposit multiple layers of films with Ta, TaN, Ta, Al, TaN within the same equipment continuously, among which Al metal is added with Cu and Si atom to raise antielectromigration ability of Al metal wiring. At the bottom of Al layer, a composite blocking layer is to prevent Al and Cu from diffusing to silicon slice and media. The deposition of Al metal is in two steps of low temperature and high temperature with Al seed crystal layer deposited in low temperature having a good compactness and Al layer deposited in high temperature having a good porefilling ability and a good back-flow result. TaN layer above Al metal layer can be used as a blocking layer as well as top covering layer and antireflective layer of photoetching.

Owner:SHANGHAI INTEGRATED CIRCUIT RES & DEV CENT +1

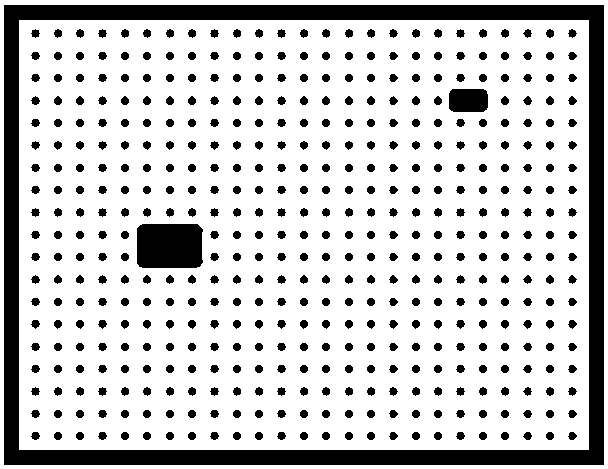

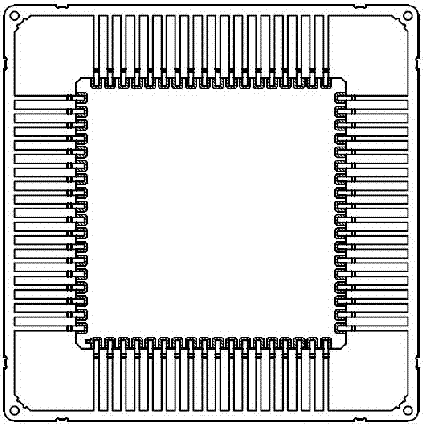

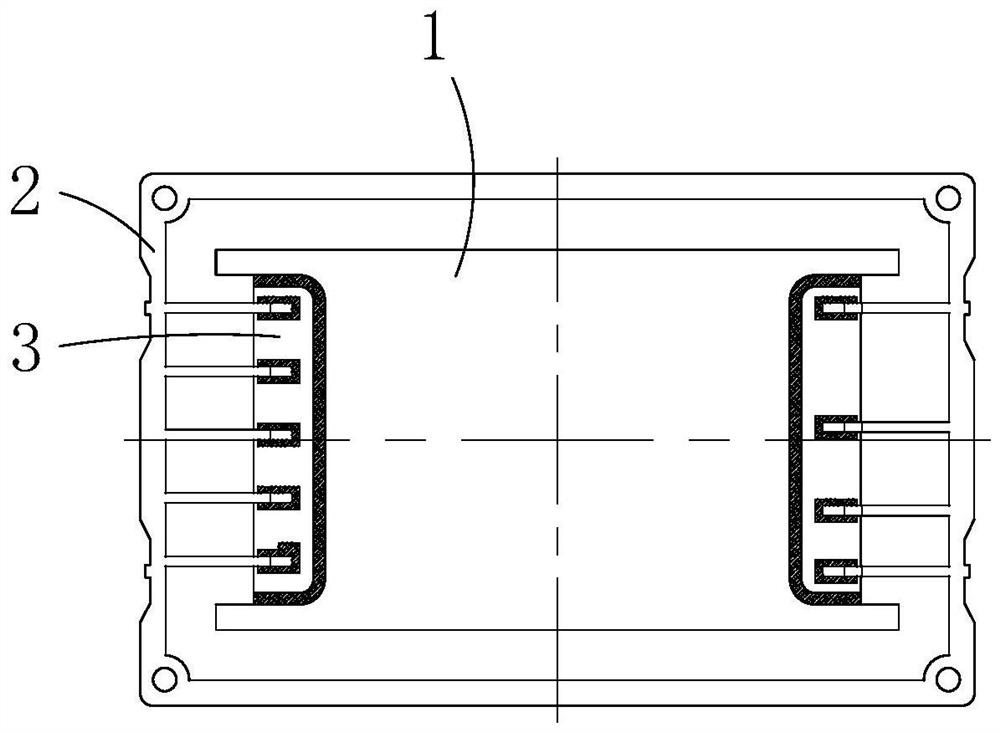

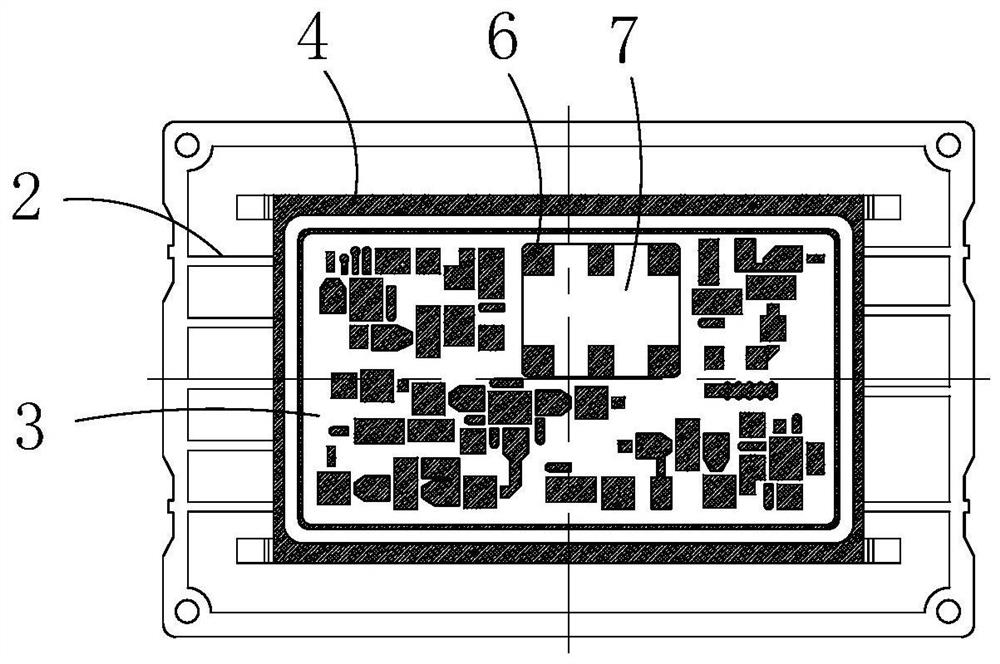

Multichip integrated CQFP ceramic housing and manufacturing method thereof

InactiveCN107204322AMeet weldingFulfil requirementsSemiconductor/solid-state device detailsSolid-state devicesCapacitancePerformance index

The present invention is a multichip integrated CQFP ceramic housing of a capacitor between high-insulation low leads and manufacturing method thereof. The outline dimension of the structure is 25.4mm*25.4mm*3.0mm, the dimension of an inner cavity is 21.8*21.8*1.25mm, the pitch of an external lead is 1.27mm, and the distance of an internal lead is 0.1mm-0.15mm. A porcelain portion comprises 8 layers of wirings. The method comprises: 1) employing high-insulation micro-crystalline ceramic as base materials; 2) performing sintering under the porcelain portion after the sintering; 3) performing chemical nickeling process of the porcelain portion after sintering; 4) welding a metal lead and a metal frame on the corresponding positions of the porcelain portion through a ceramic die; 5) performing nickel electroplating and gold electroplating of the housing which completes braze welding; and 6) realizing different gold plating thicknesses of the chip, the lead and the welding ring are of the same product through local production. The manufactured ceramic packaging housing can satisfy requirements of welding and bonding of different chips, has good air tightness and reliability, can satisfy the requirements of each item performance index of the national military standard.

Owner:NO 55 INST CHINA ELECTRONIC SCI & TECHNOLOGYGROUP CO LTD

Preparation method of wire harness

ActiveCN103647202AIncrease productivityEasy to operateLine/current collector detailsWire rodTin plating

The invention discloses a preparation method of a wire harness. The preparation method comprises the processing steps of 1, wiring, that is, carrying out wiring and positioning on a professional positioning gauge, wherein the number of wiring and positioning groups is multiple; 2, laser radiation and half-stripping, that is, calculating the radiation size and the half-stripping size of the multiple groups of wires, determining the laser radiation position, carrying out laser radiation on the multiple groups of wires in one time, and then carrying out half-stripping on the wires; 3, grounding piece welding; 4, secondary laser radiation, secondary half-stripping and tin plating, that is, carrying out secondary laser radiation on the wires, completing secondary half-stripping and plating tin; 5, connector welding; and 6, reinforcing, that is, carrying out dispensing reinforcement on a welding point after the connector welding is finished, thereby completing the preparation of the whole wire harness. Multiple wire harnesses can be welded in one time by adopting the wire harness preparation method provided by the invention, thereby improving the production efficiency of the wire harnesses greatly.

Owner:SUZHOU LUZHIYAO TECH

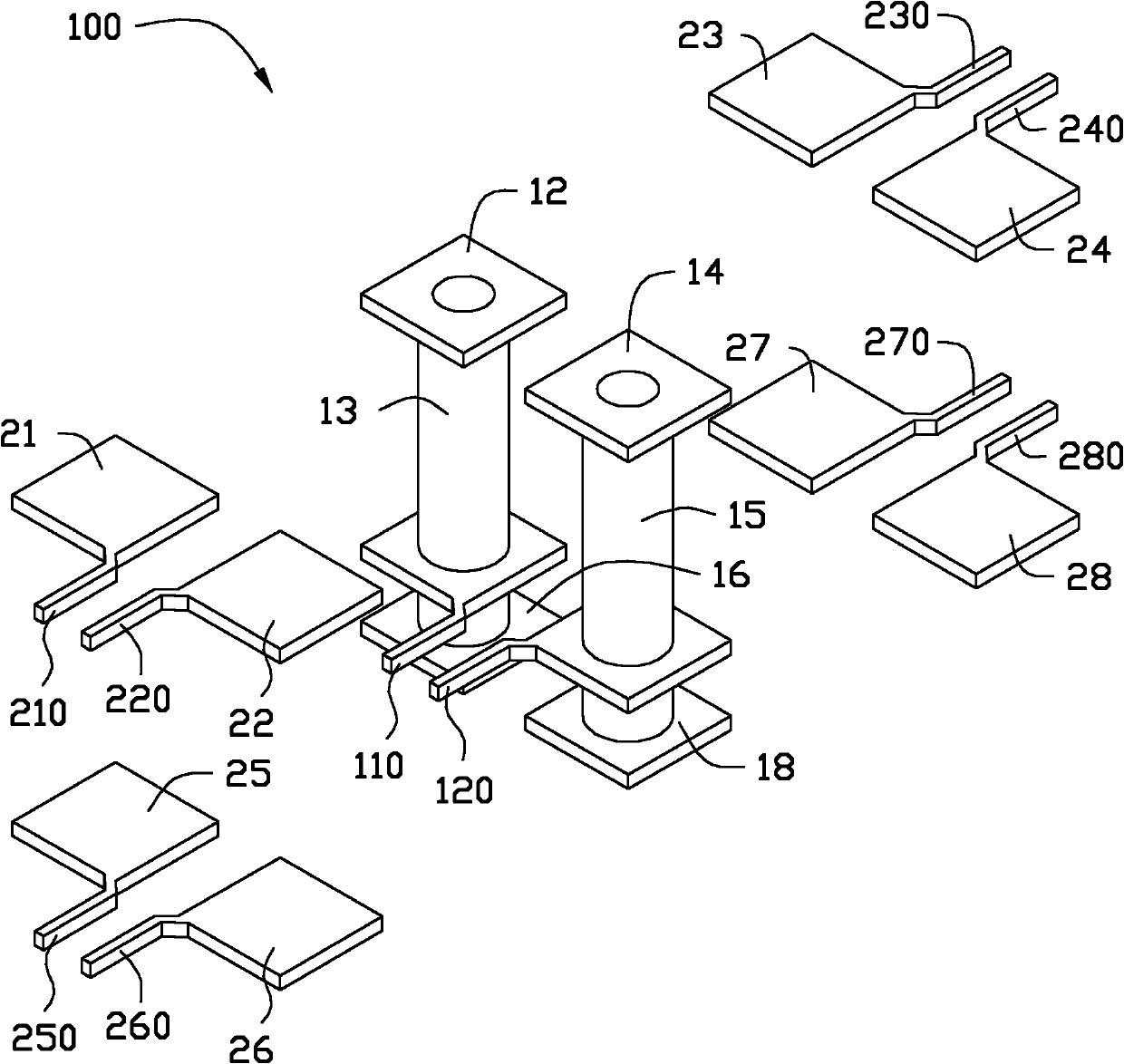

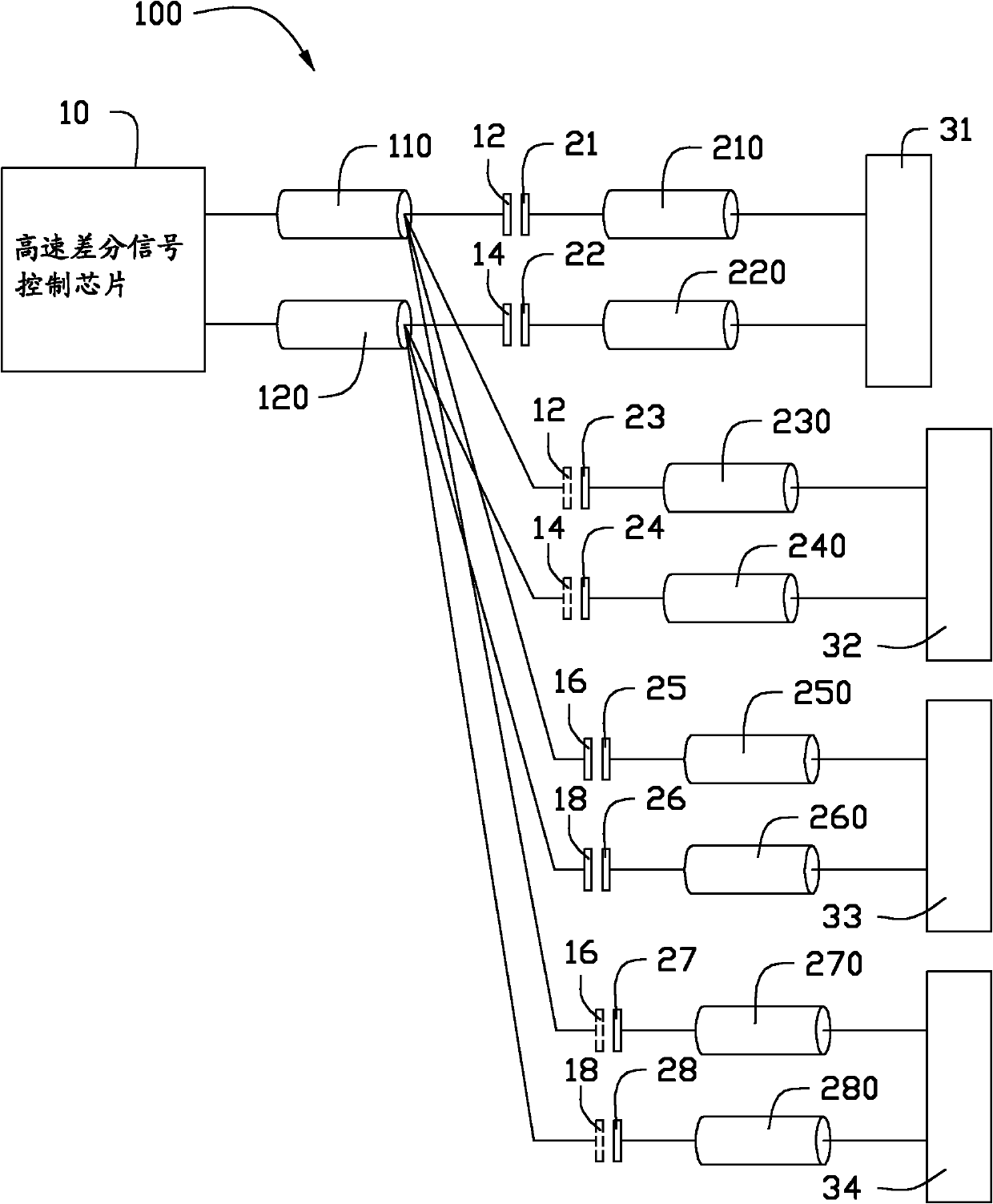

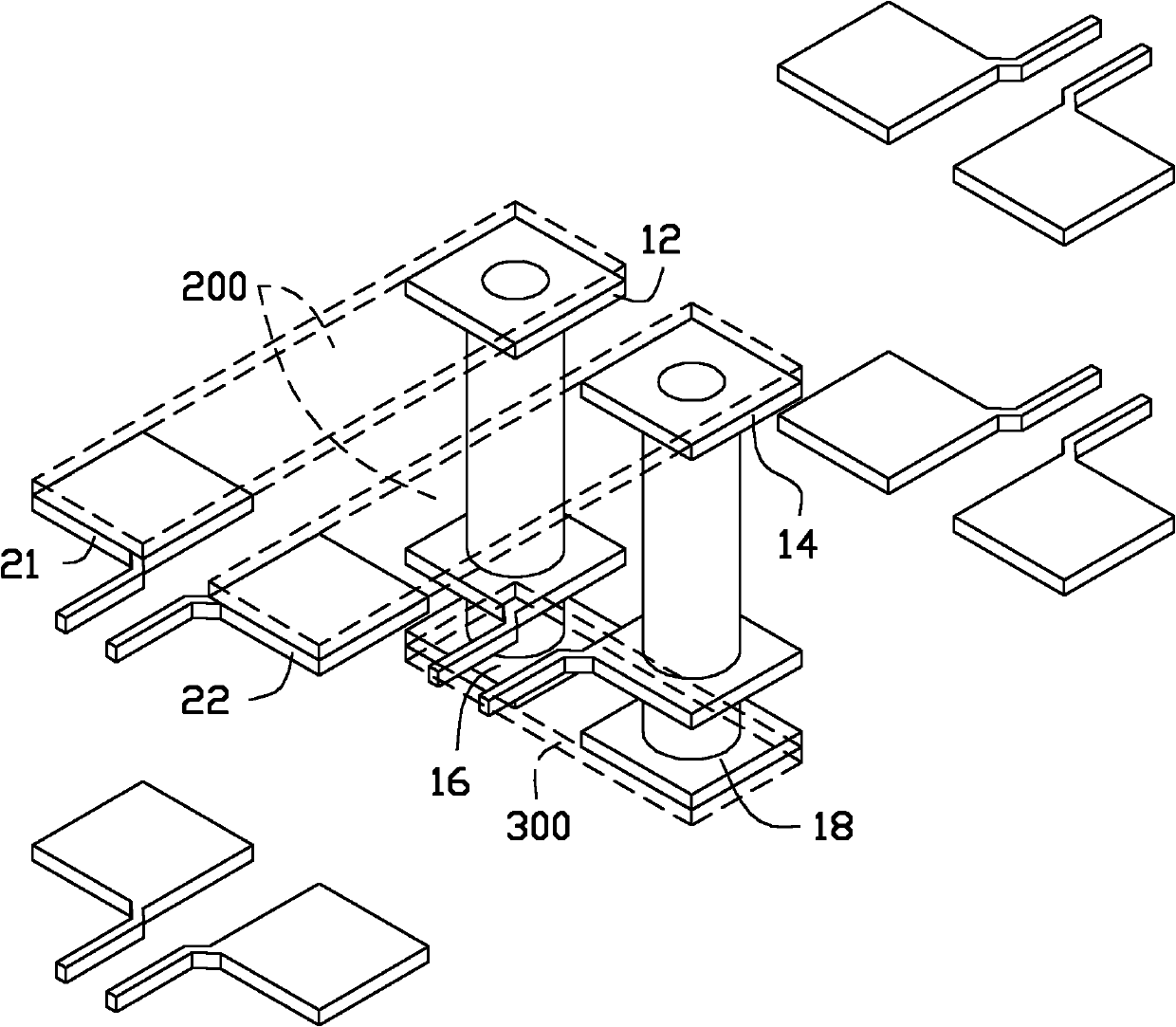

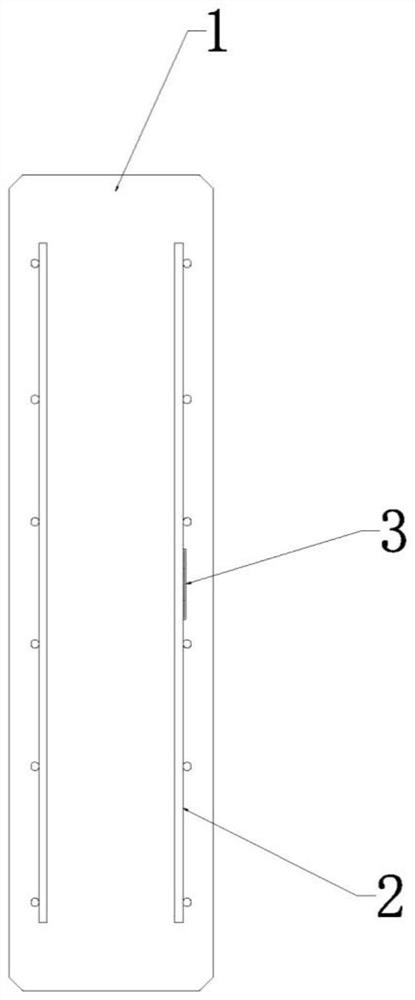

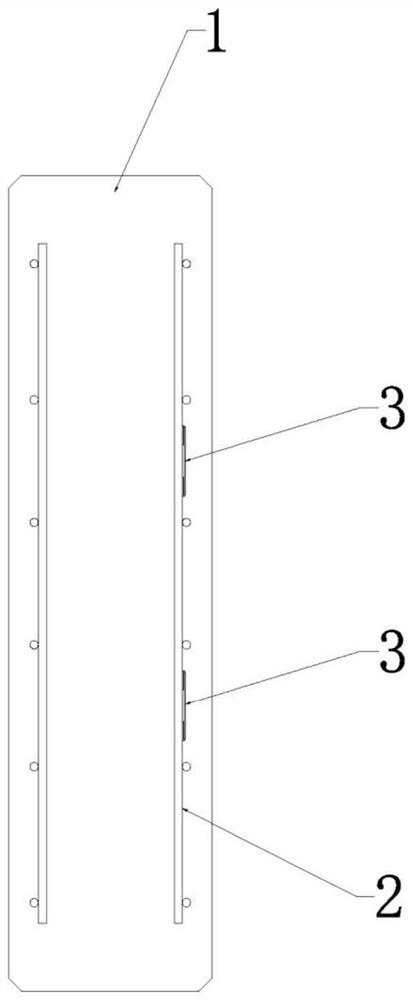

Printed circuit board with high-speed differential signal wiring structure

A printed circuit board with a high-speed differential signal wiring structure comprises a high-speed differential signal control chip, a first to eighth coupling capacitor welding pad, a first to fourth connector welding pad, a plurality of transmission lines and a first to fourth shared welding pad, wherein the high-speed differential signal control chip is selectively connected with the first to fourth connector welding pad through the first to fourth shared welding pad. The printed circuit board with the high-speed differential signal wiring structure can be selectively connected with a plurality of connectors.

Owner:YANTAI POWER SUPPLY COMPANY OF STATE GRID SHANDONG ELECTRIC POWER

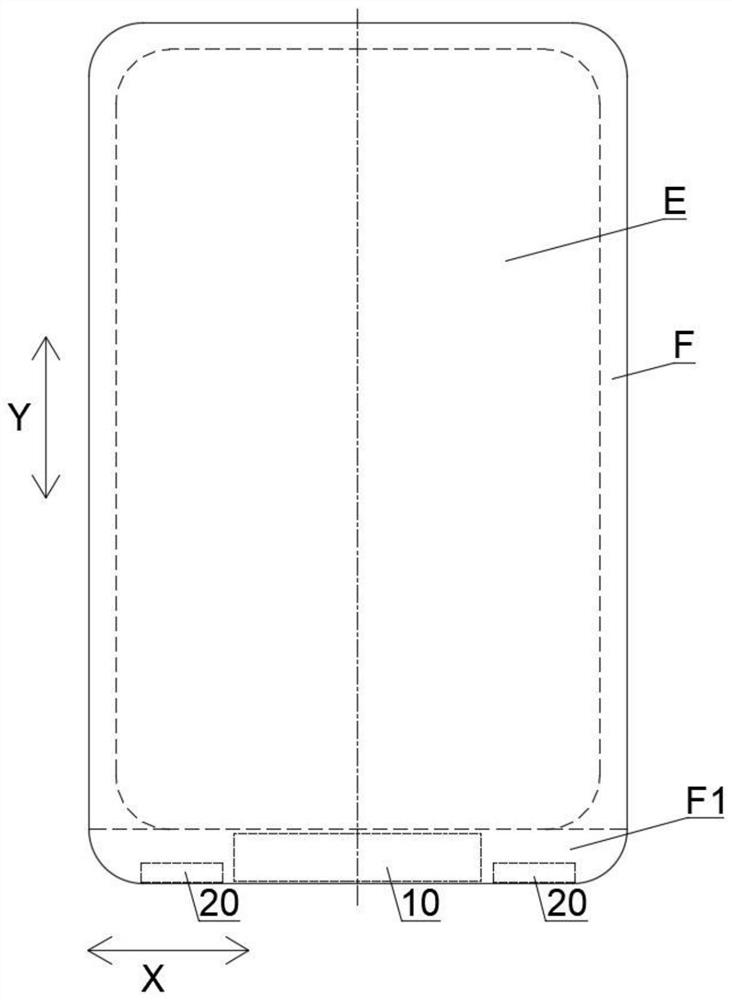

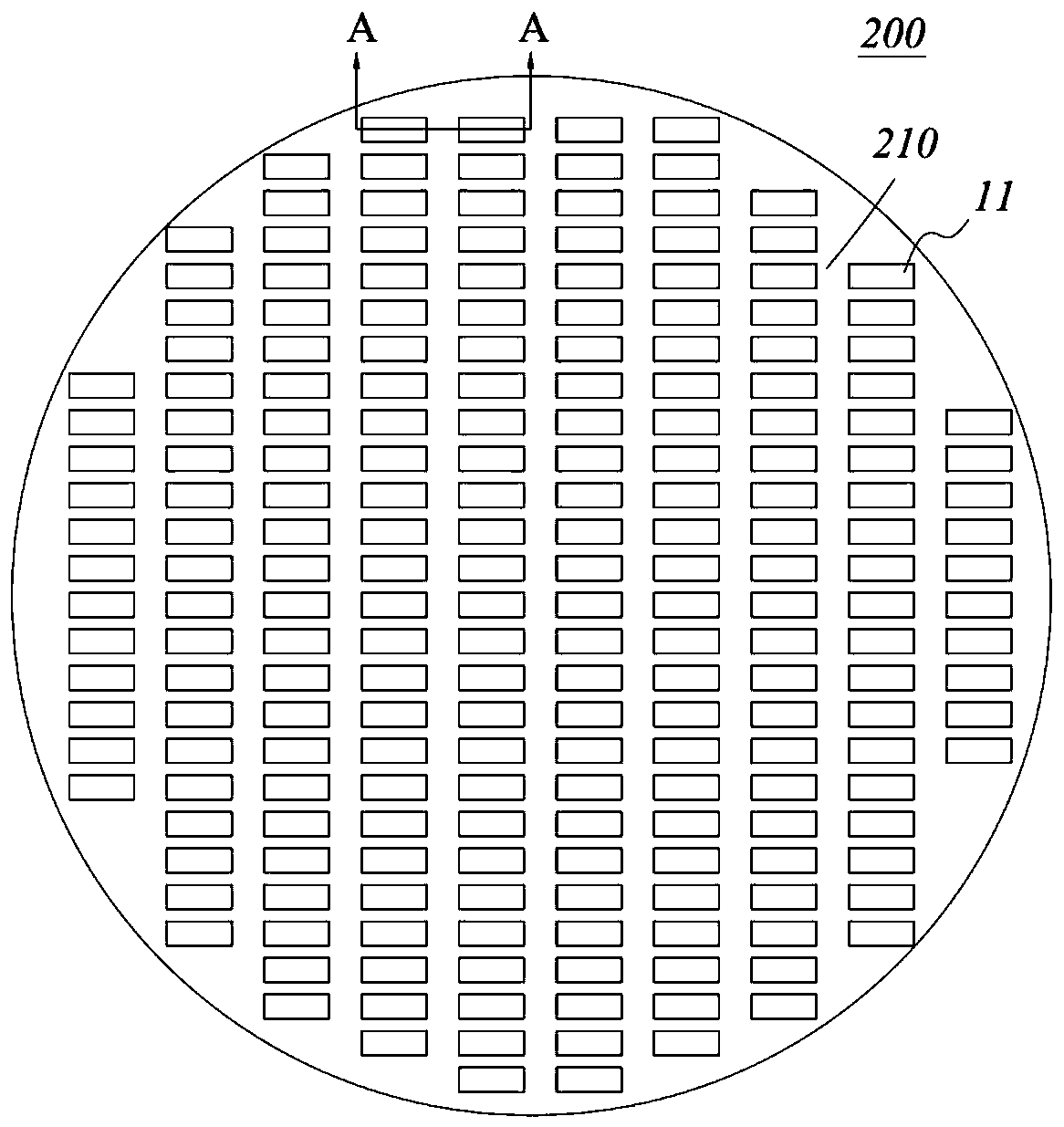

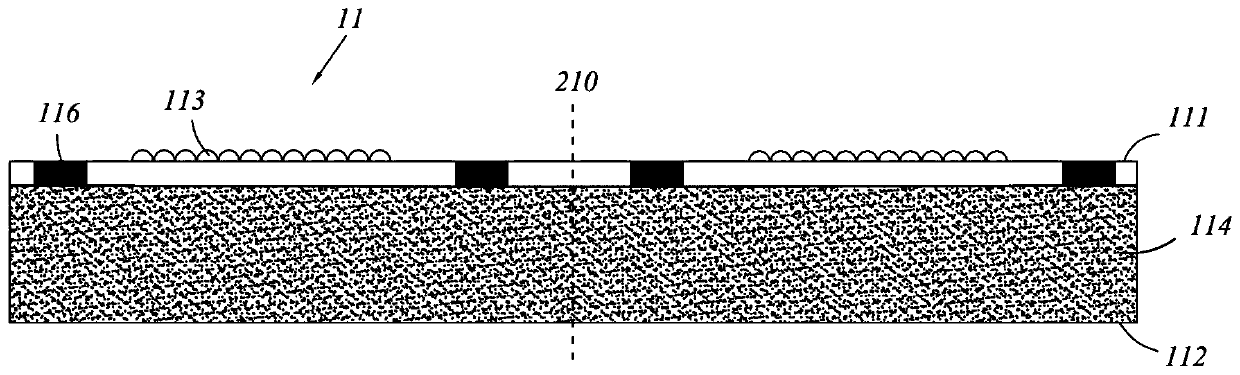

Wafer level chip size packaging structure and manufacturing method thereof

ActiveCN102013403AReduce manufacturing stepsEliminate the process steps of viasSemiconductor/solid-state device detailsSolid-state devicesChip sizeEngineering

The invention provides a manufacturing method of a wafer level chip size packaging structure, which comprises the following steps of: providing a wafer, and arranging a welding pad on the wafer; performing the photo processing of a rewiring layer on the wafer; forming and etching the rewiring layer so as to form a required pattern, wherein the rewiring layer is electrically connected with the welding pad; performing the photo processing of a second passivation layer on the wafer; etching the second passivation layer to form a through hole of the second passivation layer so as to expose the rewiring layer, curing the second passivation layer and removing scum; implanting a welded ball in the through hole of the second passivation layer, wherein the welded ball and the rewiring layer are electrically connected; and inspecting the quality of the wafer before product delivery. The invention also provides the wafer level chip size packaging structure manufactured according to the manufacturing method. The manufacturing method of the invention saves processing steps and materials and reduces the cost and the competitiveness of the product.

Owner:SEMICON MFG INT (SHANGHAI) CORP

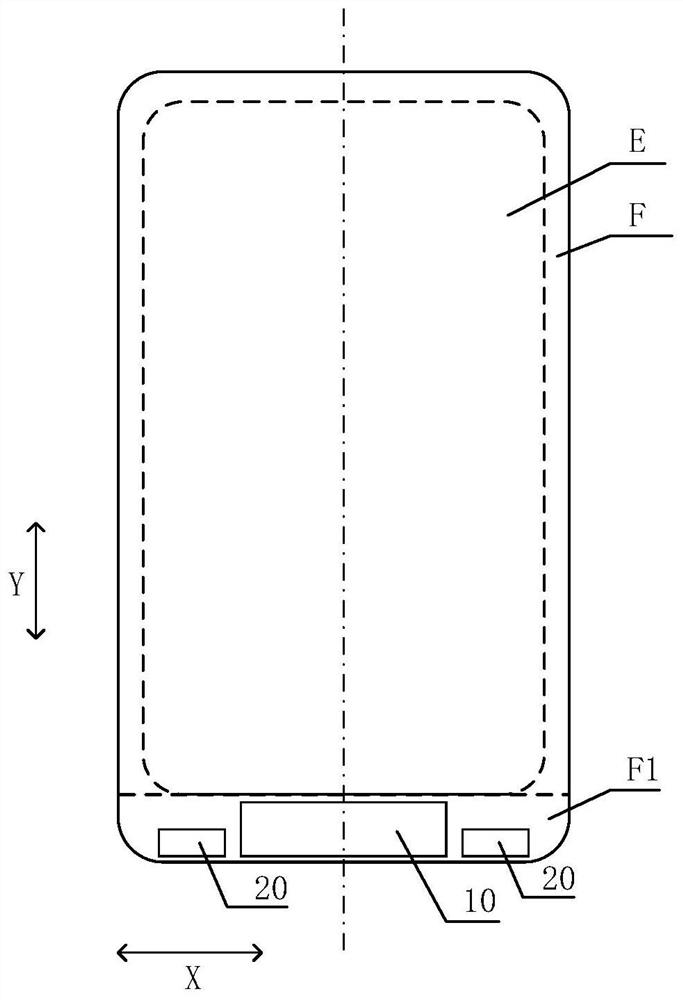

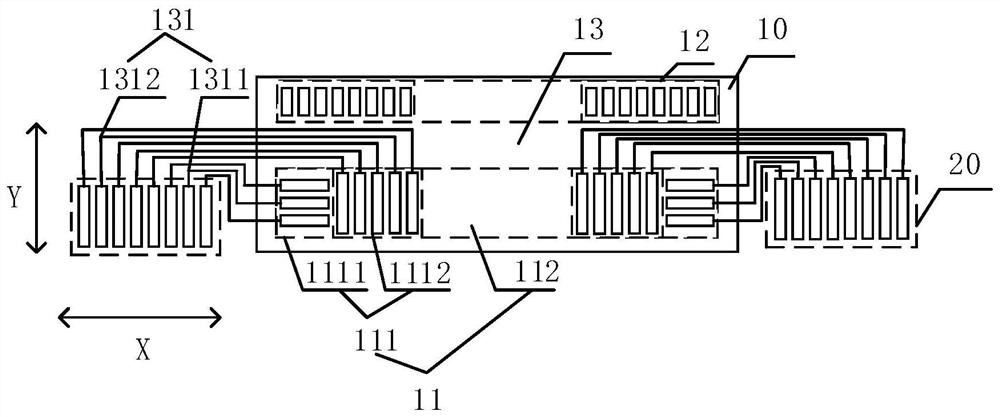

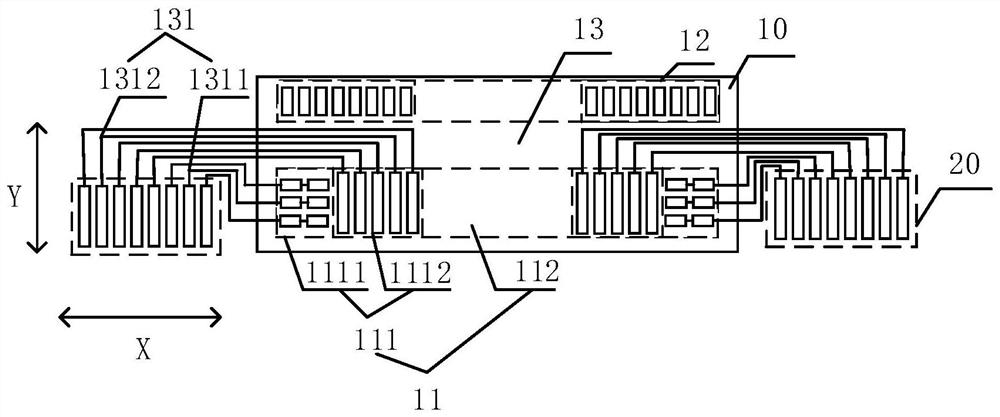

Array substrate, display panel and display device

PendingCN111933030AAchieve narrow bezel designReduce widthPrinted circuit aspectsSolid-state devicesFlexible circuitsDisplay device

The invention discloses an array substrate, a display panel and a display device. The array substrate is provided with a binding area. The binding area comprises a driving chip binding area and flexible circuit board binding areas, the driving chip binding area is distributed in the middle of the binding area, the flexible circuit board binding areas are distributed on the two sides of the drivingchip binding area in the second direction, the driving chip binding area is provided with a first bonding pad, a wiring area and a second bonding pad which are successively distributed in a first direction, the first bonding pad is arranged close to the first area, the second bonding pad comprises a second welding spot group and an isolation area, the second welding spot group is located on two sides of the isolation area in the second direction, second welding spots of the second welding spot group are connected with the flexible circuit board binding areas through wires, and the wires passthrough the wiring area. According to the invention, the layout requirement of the wire for connecting the flexible circuit board binding areas and the second welding spot group can be met, the problems of difficult wiring, easy interference between signals and the like caused by insufficient wiring space are avoided, and implementation of the narrow frame design of the display panel is facilitated.

Owner:KUNSHAN GO VISIONOX OPTO ELECTRONICS CO LTD

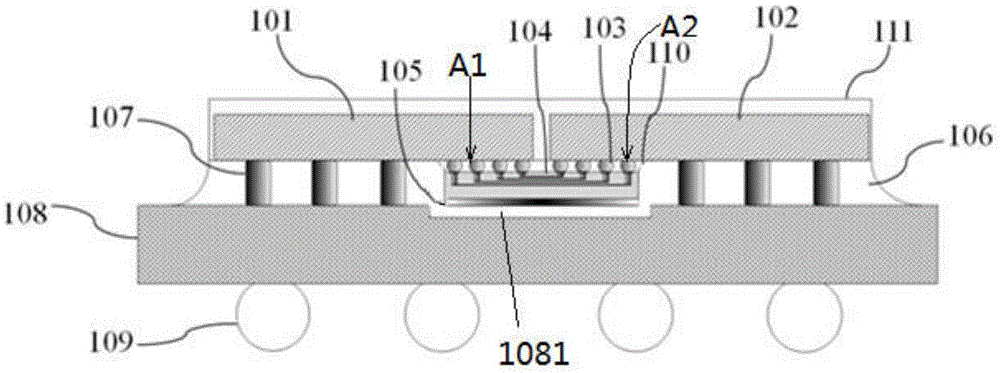

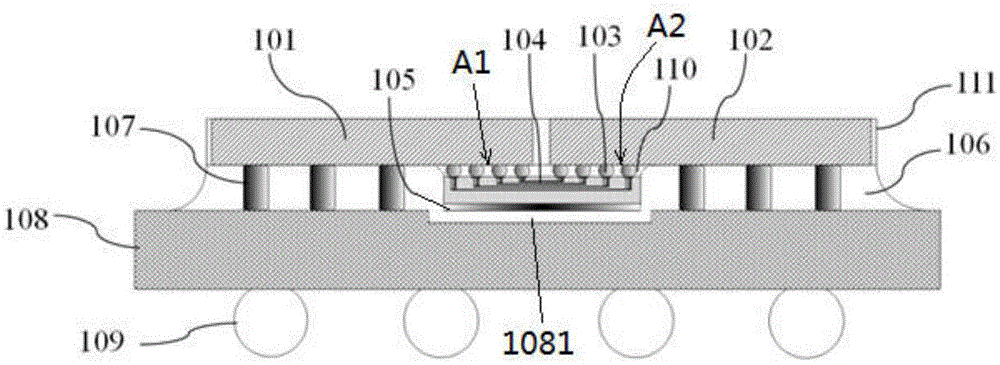

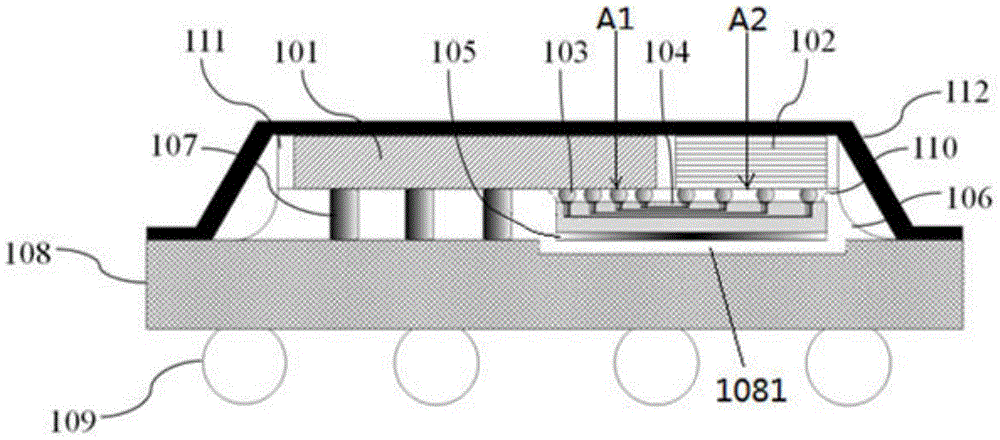

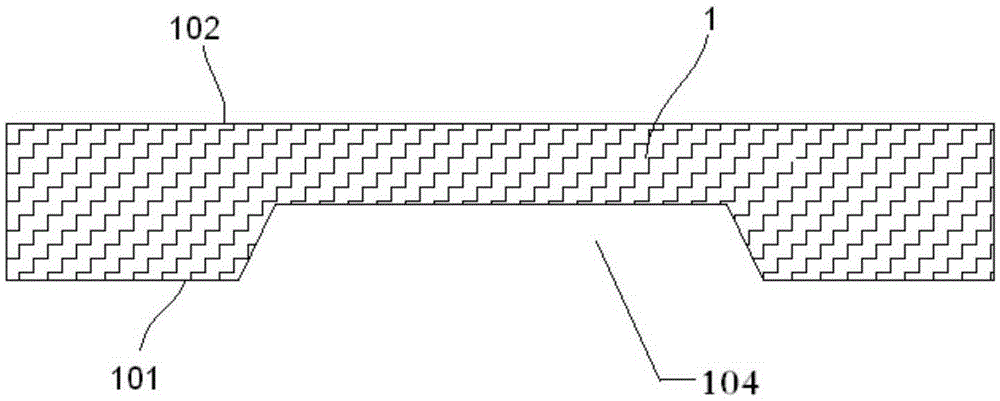

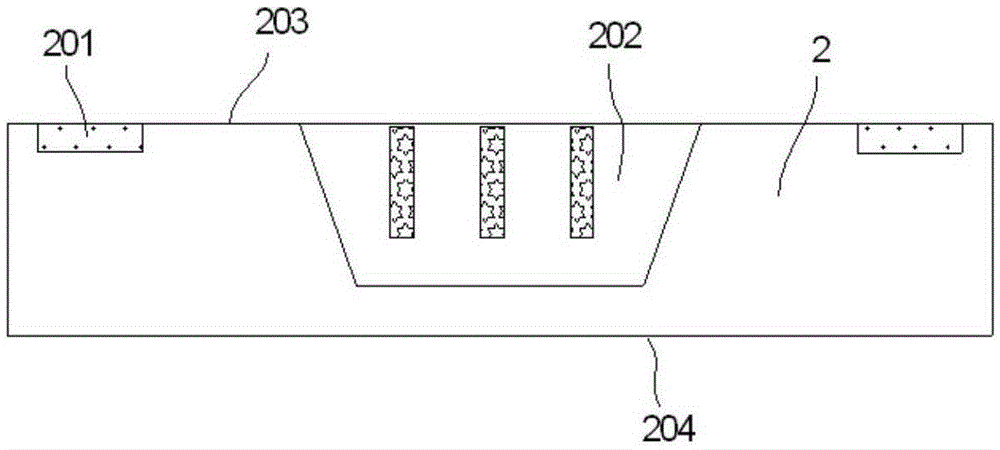

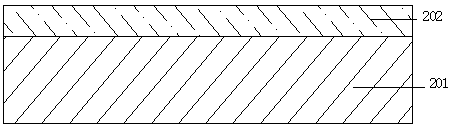

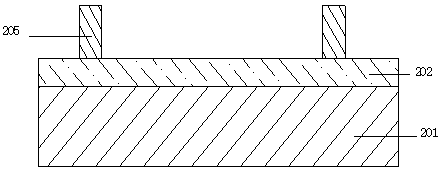

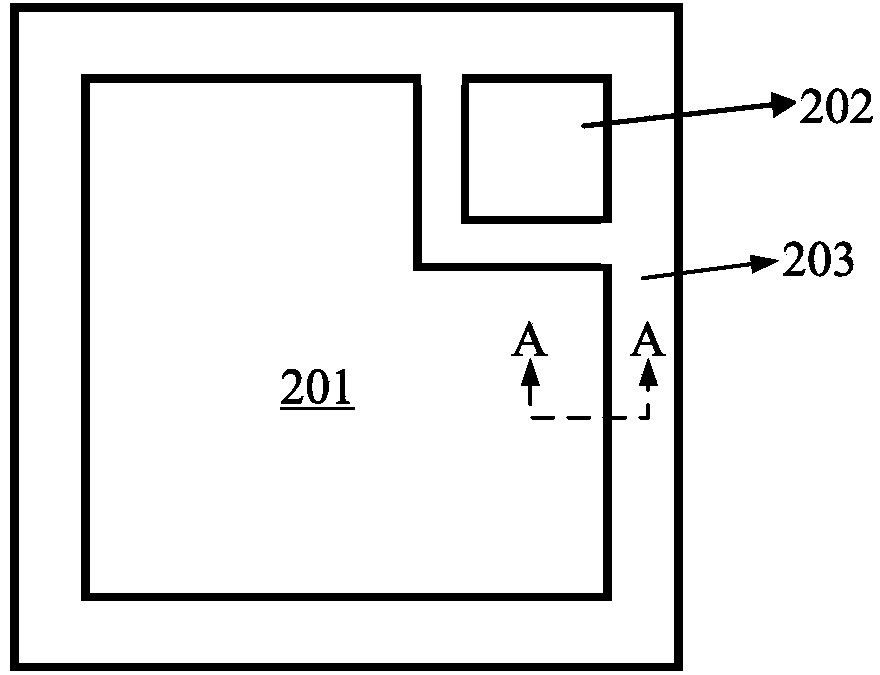

Packaging structure for transferring chip bonding stress and production method thereof

InactiveCN105347291AAffect performanceReduce performanceDecorative surface effectsSolid-state devicesThermal expansionEngineering

The invention discloses a packaging structure for transferring chip bonding stress and a production method thereof. The packaging structure comprises a functional chip and a cover board made of the same material as a substrate thereof, wherein a function surface of the functional chip is provided with a functional zone and a plurality of conductive welding pads arranged at the periphery of the functional zone; the cover board is provided with a first surface with a cavity and a second surface opposite to the first surface; the first surface of the cover board is bonded with the function surface of the functional chip; the second surface of the cover board is subjected to re-wiring to form a metal line layer which extends to the conductive welding pads; and a metal line cannot extend to a cutting path position. Through changing the previous design structure adopting chip back wiring to a design structure adopting front wiring, the influence of the stress which is generated by back operation on the chip functional zone is reduced; and furthermore, the material of which the substrate of the functional chip is made is used to make the cover board and wiring is carried out on the cover board, so that a problem of mismatching of a coefficient of thermal expansion between the cover board and the chip is avoided, and the packaging process steps are simple.

Owner:HUATIAN TECH KUNSHAN ELECTRONICS

Array substrate, display panel and display device

ActiveCN112180643AReduce widthSave spaceSolid-state devicesSemiconductor/solid-state device manufacturingFlexible circuitsDisplay device

The invention discloses an array substrate, a display panel and a display device. A binding area of the array substrate comprises a driving chip binding area and a flexible circuit board binding area,the driving chip binding area is provided with a first bonding pad, the first bonding pad comprises a welding spot set and an isolation area, the welding spot set comprises a first welding spot set and a second welding spot set, the first welding spot set comprises a plurality of first welding spots arranged side by side in the first direction, the second welding spot set comprises a plurality ofsecond welding spots arranged side by side in the second direction, the second welding spot set is located between the first welding spot set and the isolation area, and the first welding spot set and the second welding spot set are connected with the flexible circuit board binding area through wires. And only the lead connected with the second welding spot set passes through the wiring area. Thelayout requirement of the wire for connecting the binding area of the flexible circuit board and the welding spot set can be met, the problems of difficult wiring, easy interference between signals and the like caused by insufficient wiring space are avoided, and the narrow frame design of the display panel is realized.

Owner:KUNSHAN GO VISIONOX OPTO ELECTRONICS CO LTD

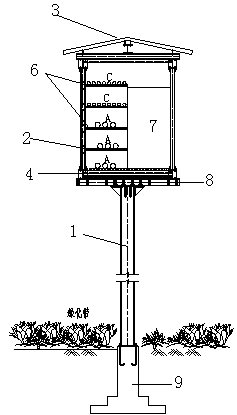

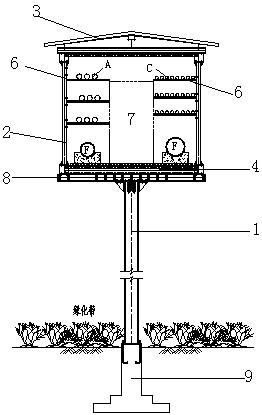

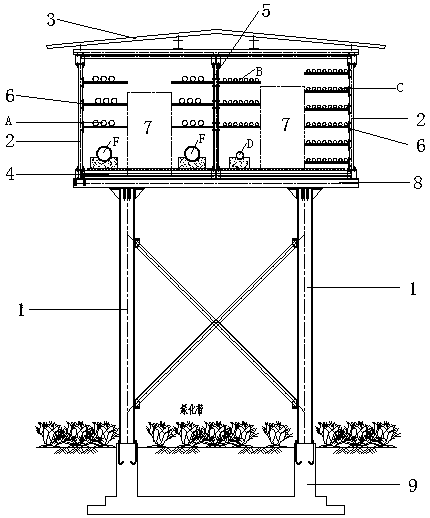

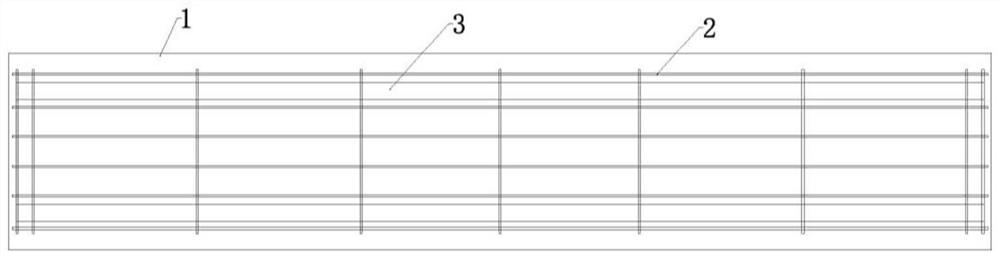

Overhead pipe gallery for comprehensive wiring

PendingCN107769141AMeet related needsMeet needsOverhead installationBridge applicationsLine tubingArchitectural engineering

The invention relates to a pipe gallery for same-trench laying of cables, in particular to an overhead pipe gallery for comprehensive wiring. The overhead pipe gallery for comprehensive wiring is structurally characterized by comprising a vertical supporting post and a comprehensive pipe gallery body, the comprehensive pipe gallery body consists of a plurality of pipe gallery segments, and every pipe gallery segment comprises left and right sidewalls, a herringbone top cover and a bottom plate, wherein the left and right sidewalls stand on two sides of the bottom plate and positioned between the top cover and the bottom plate; a plurality of cantilever supports for erecting various pipelines are mounted on the sidewalls and extend towards a cabin to suspend, one end of the vertical supporting post is mounted on a ground foundation or a supporting surface in a supported manner, and the upper end face of the other end of the vertical supporting post is connected with the bottom plate ofevery pipe gallery segment. Both the pipe gallery segments and the vertical supporting post are prefabricated steel members, the prefabricated steel members of the pipe gallery segments are mounted and spliced on site after placing of one onsite ground foundation, and opening surfaces of the front and back pipe gallery segments are connected to form the integrated comprehensive pipe gallery finally. The overhead pipe gallery for comprehensive wiring has the advantages of low cost, simplicity in operation, short construction period and convenience in construction, maintenance and overhaul.

Owner:POWERCHINA FUJIAN ELECTRIC POWER SURVEY & DESIGN INST CO LTD

Embedded keel type autoclaved aerated concrete plate as well as manufacturing method and use method thereof

PendingCN113389300ASolve the problem of insufficient hanging strengthReduce dispersion rateConstruction materialCovering/liningsMesh reinforcementRebar

The invention discloses an embedded keel type autoclaved aerated concrete plate as well as a manufacturing method and a using method thereof. The embedded keel type autoclaved aerated concrete plate comprises an autoclaved aerated concrete layer, a reinforcing mesh cage and a metal plate used for being connected with hanging pieces, the reinforcing mesh cage and the metal plate are both embedded in the autoclaved aerated concrete layer, and the metal plate is connected with the reinforcing mesh cage in a welded mode. When the embedded keel type autoclaved aerated concrete plate is used, the hanging pieces are driven into the autoclaved aerated concrete layer, and the hanging pieces penetrate through the metal plate and are anchored with the metal plate; and then an outer decoration layer is installed on the surface of the autoclaved aerated concrete layer and fixed to the hanging pieces. According to the embedded keel type autoclaved aerated concrete plate as well as the manufacturing method and the using method thereof, the gravity of the outer decoration layer is transmitted to the reinforcing mesh cage through the metal plate, the problem that the hanging strength of a traditional autoclaved aerated concrete plate is insufficient is solved, in the construction process, on-site trepanning is not needed, precision is easier to control, the discrete probability of the outer decoration layer and the autoclaved aerated concrete plate is reduced, the outer decoration layer and the embedded keel type autoclaved aerated concrete plate can be arranged at an interval, and gaps are used for wiring, pipeline arrangement and the like.

Owner:HANGZHOU ZETONG ARCHITECTURE ENERGY SAVING NEW MATERIALS CO LTD

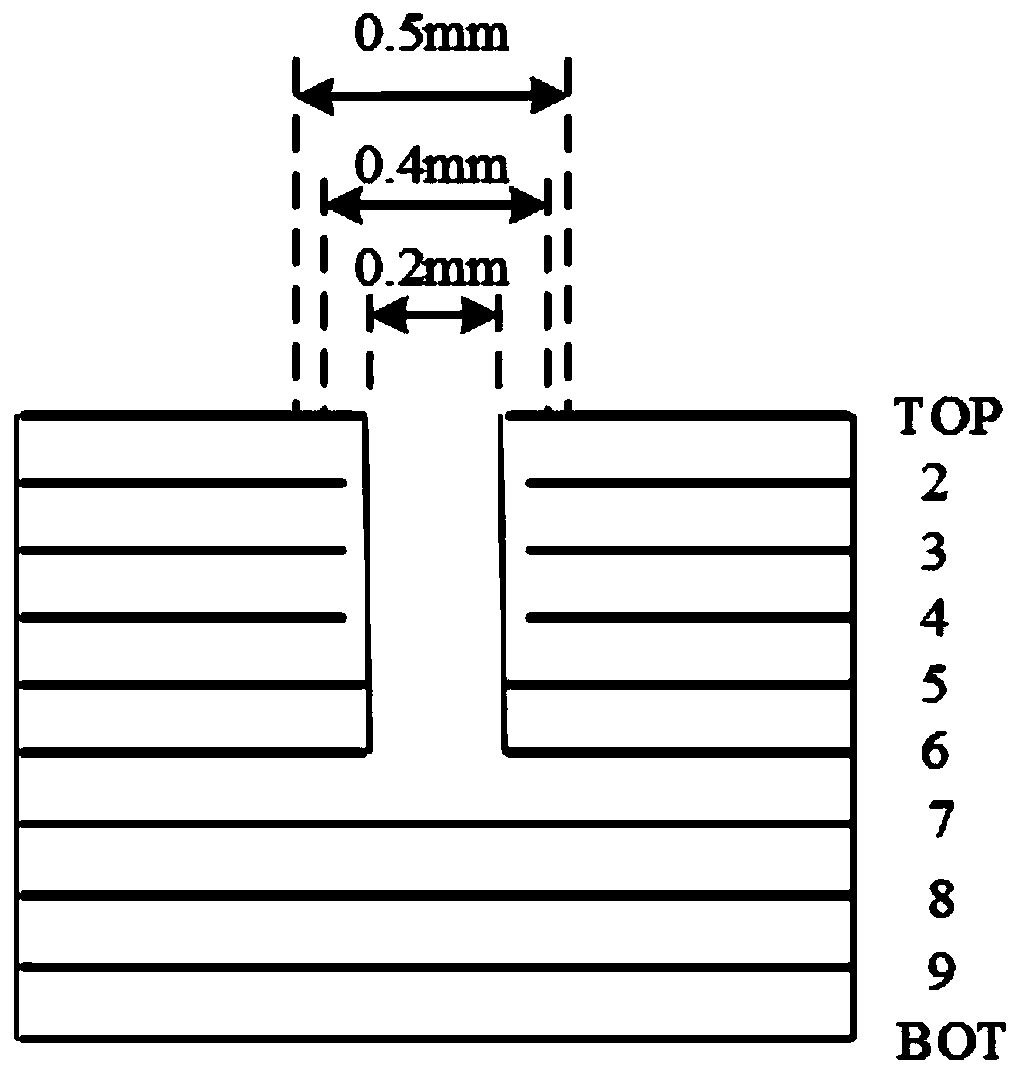

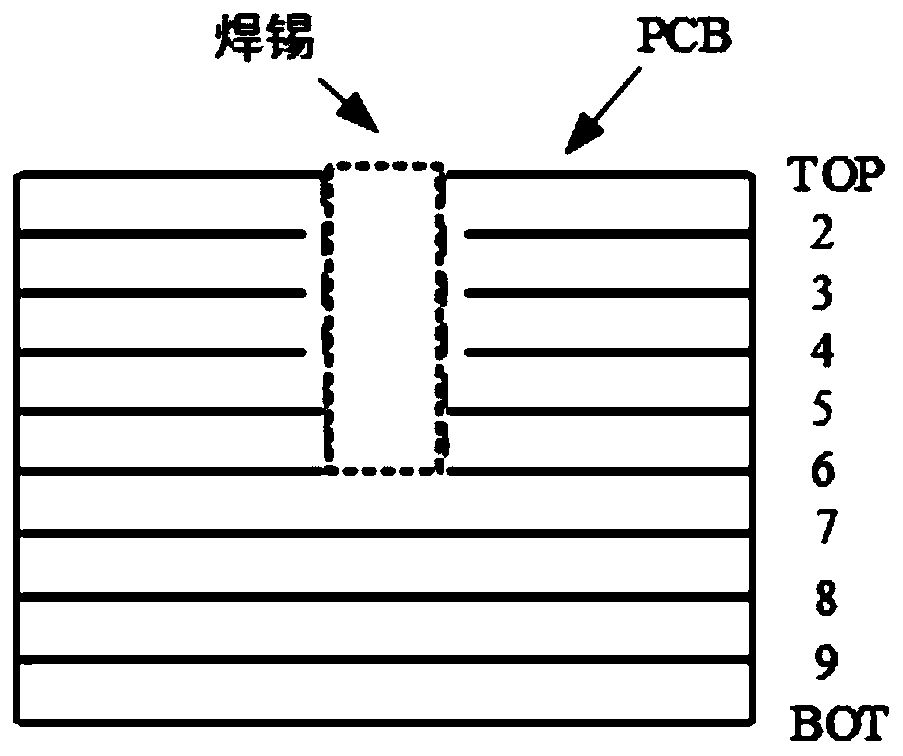

PCB, layout method and device thereof and storage medium

ActiveCN111295040ALarge carrying capacitySave trace areaHigh current circuit adaptationsTinningScreen printing

The invention relates to a PCB and a layout method and device thereof, and a storage medium. The method comprises the steps of S1 laying a copper sheet on the surface layer of the PCB in a bottleneckregion of a power transmission plane in a current transmission direction; arranging a windowing area and a steel mesh area on the surface copper sheet; arranging a silk-screen label with the surface copper sheet as the center; laying a wiring forbidding area on an adjacent layer between the secondary outer layer and the power supply layer; S2 during PCB processing, carrying out silk-screen printing on a marking area , using a milling cutter for groove milling, wherein the groove milling depth only drills through the low-voltage large-current power supply layer, and the next layer of the powersupply plane is not contacted; and S3 finally, during PCB surface mounting, carrying out local thickening treatment on the steel mesh area at the milling groove, increasing the tinning amount in the milling groove, and finally, filling the groove hole with tin.

Owner:INSPUR SUZHOU INTELLIGENT TECH CO LTD

Three-dimensional POP packaging structure and packaging method thereof

ActiveCN107919333ASolve warpingGuaranteed reliabilitySemiconductor/solid-state device detailsSolid-state devicesHigh densitySolder ball

The invention discloses a three-dimensional POP packaging structure and a packaging method thereof, which belong to the technical field of semiconductor packaging. The three-dimensional POP packagingstructure comprises at least two layers of vertically-stacked packaging bodies and a high-density flexible conversion plate carrying a rewiring metal layer, wherein the back surface of the lower packaging body is thinned to expose BGA welding balls and metal bumps to play roles of interconnection and conduction; the high-density flexible conversion plate is prepared by adopting a Liftoff process,and the needs of high-density packaging can be met. The upper packaging body and the lower packaging body are connected through packaging body III BGA support welding balls, the structure separates and independently prepares the rewiring metal layer in the traditional POP structure, and on one hand, the warping problem in the traditional process can be solved, and the high-density flexible conversion plate can meet the needs of high I / O ratio packaging.

Owner:JIANGYIN CHANGDIAN ADVANCED PACKAGING CO LTD

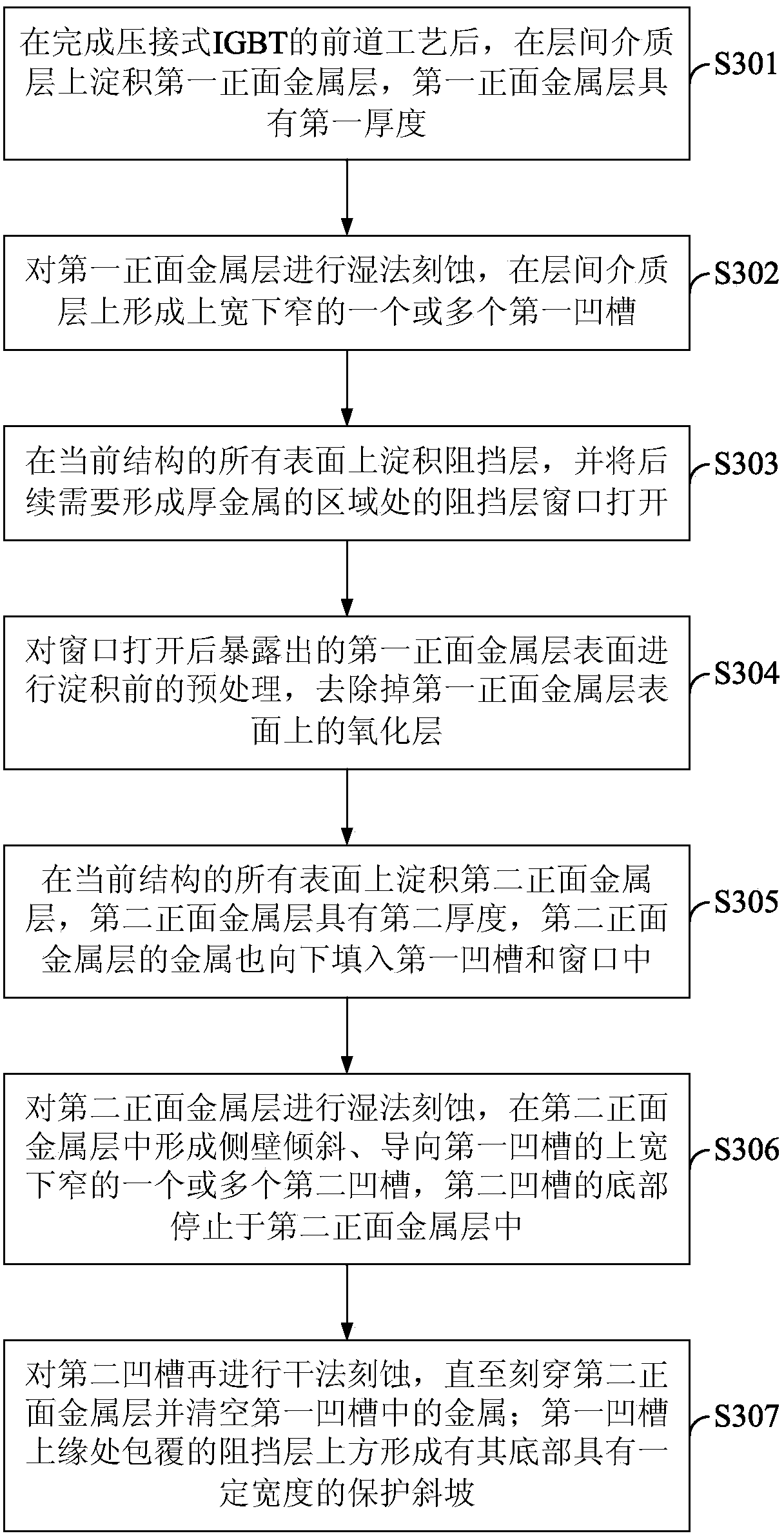

Front metal process for compression joint IGBT

ActiveCN104241125ASolid-state devicesSemiconductor/solid-state device manufacturingPre treatmentOxide

The invention provides a front metal process for a compression joint IGBT. The process comprises the steps that a first front metal layer is deposited on an interlayer dielectric layer; the first front metal layer is subjected to wet etching, so that a first groove which is wide on the upper portion and narrow on the lower portion is formed in the interlayer dielectric layer; a barrier layer is deposited on all surfaces of the current structure, and a barrier layer window in a region where thick metal needs to be formed is opened; the surface, exposed after the window is opened, of the first front metal layer is subjected to pretreatment before deposition, so that an oxide layer is removed; a second front metal layer is deposited on all the surfaces of the current structure; the second front metal layer is subjected to wet etching, so that a second groove is formed in the second front metal layer, wherein the side walls of the second groove incline, and the second groove guides the first groove and is wide on the upper portion and narrow on the lower portion; the second groove is subjected to dry etching, the second front metal layer is etched through, and metal in the first groove is cleared up; a protection slope is formed on the barrier layer wrapped at the upper edge of the first groove, wherein the bottom of the protection slope has a certain width. By means of the front metal process, thick front metal and thin front metal in different wiring regions are obtained.

Owner:上海积塔半导体有限公司

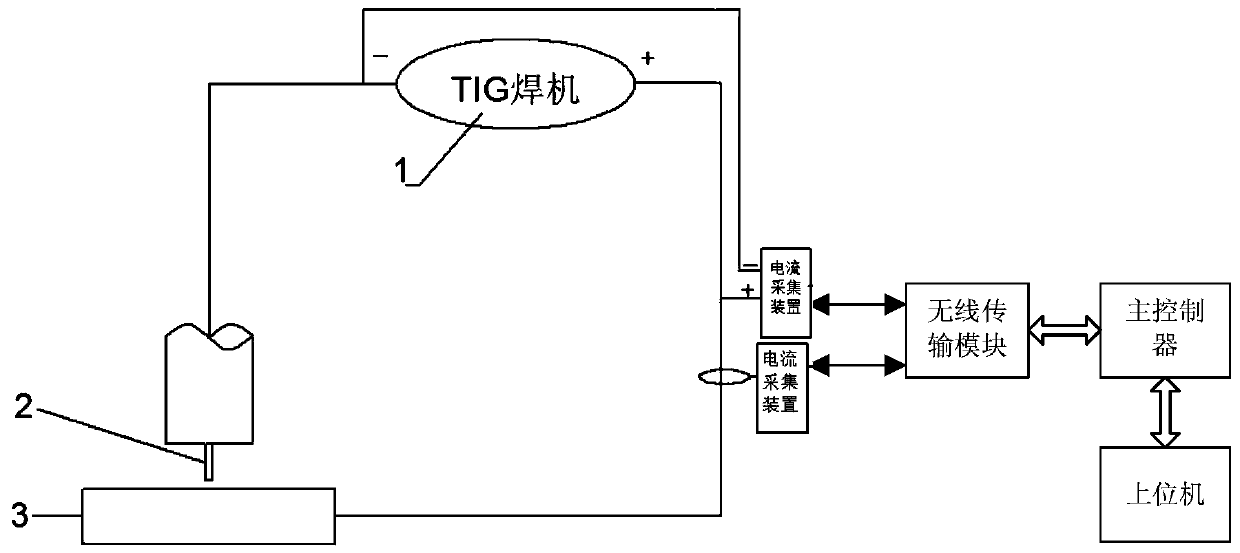

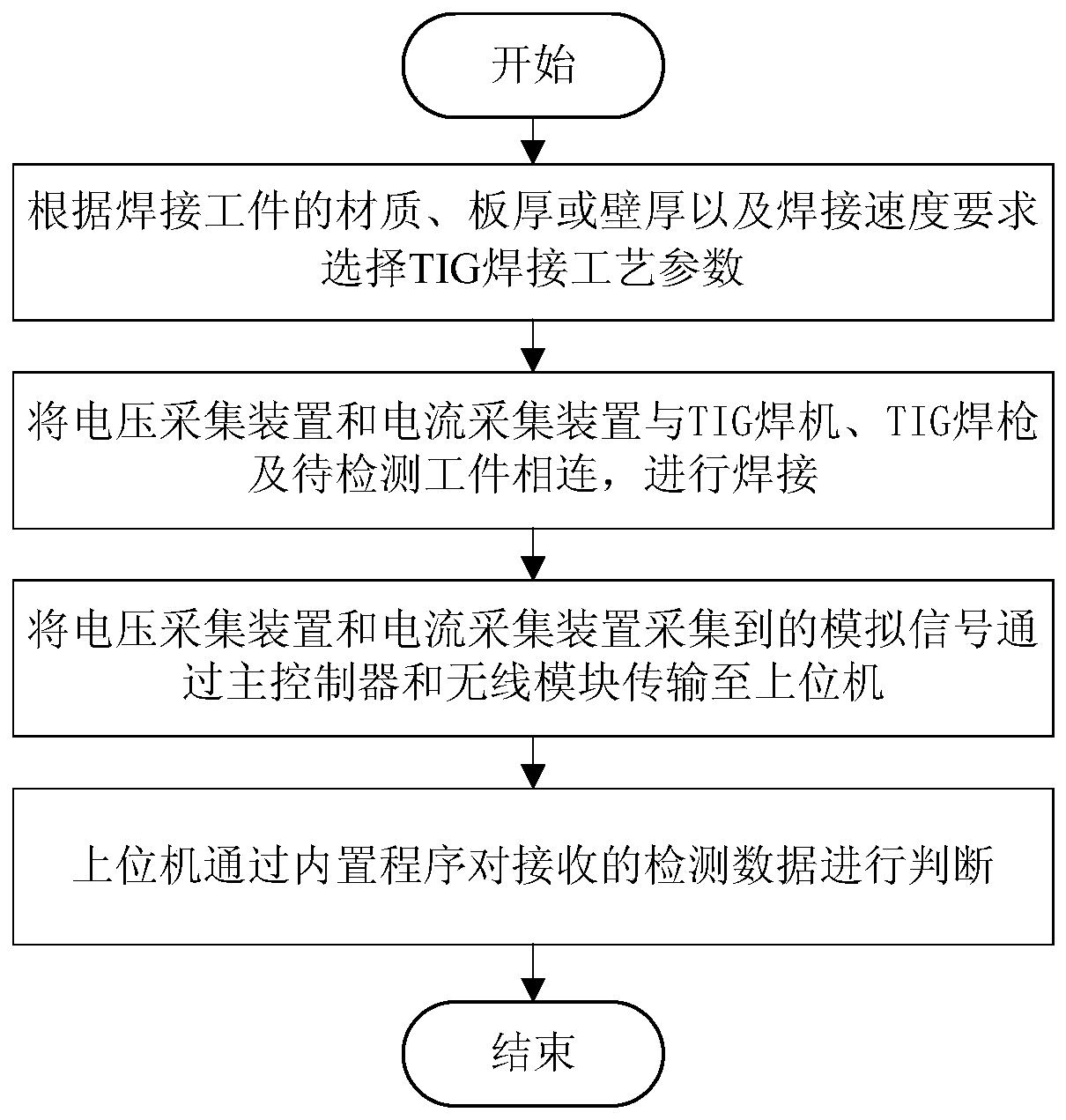

Device and method for wirelessly detecting welding parameters

PendingCN110899933ASolve wiring troubleSolve scalabilityWelding accessoriesInterference (communication)Current sensor

The invention provides a device and method for wirelessly detecting welding parameters, and relates to the technical field of welding. According to the device and the method, the method comprises thesteps of: collecting current and voltage signals during welding work through a current sensor and a voltage current; removing industrial interference waves from the collected electric signals by a signal conditioning circuit, performing A / D conversion through a single-chip microcomputer to convert analog signals into digital signals; transmitting the converted digital signals to an upper computerthrough a wireless transmission module; and storing and displaying information such as a data oscillogram and the like on the upper computer. The upper computer stores a welding parameter range, whenthe detected data is not the same as a given parameter range, the upper computer achieves feedback functions such as automatic prompting and alarm. The wireless communication technology is applied tothe welding detection process, so that the problems that the environment of a welding workshop is complex, a wired detection method is troublesome in wiring, poor in expansibility, high in cost, difficult to check line faults and the like are effectively solved, errors can be found in time conveniently, adjustment is conducted in time, and the welding quality is improved.

Owner:SHENYANG UNIV

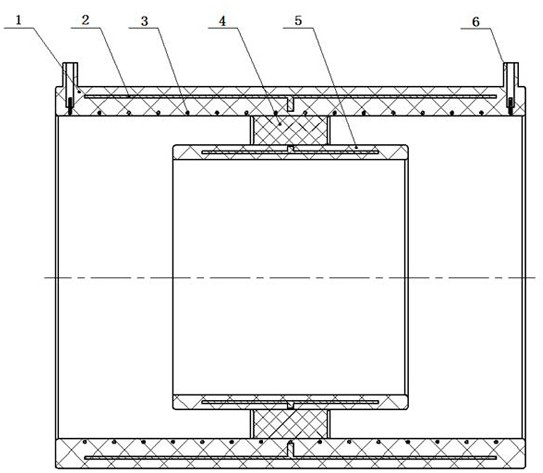

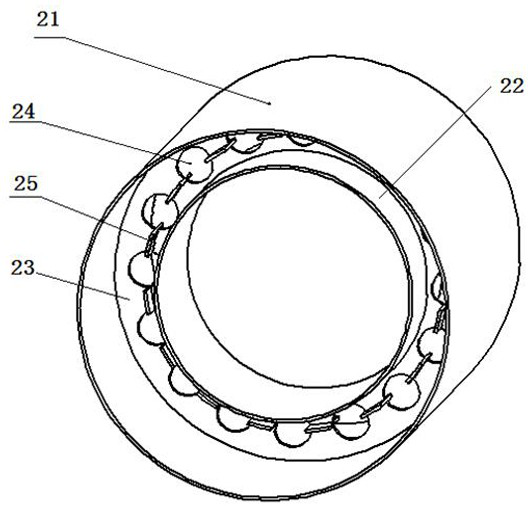

Electric melting pipe fitting with barrier function and manufacturing method thereof

ActiveCN113864559AHigh strengthImprove pressure resistanceCoatingsPipe connection arrangementsCopper wirePipe fitting

The invention discloses an electric melting pipe fitting with a barrier function. The electric melting pipe fitting comprises a pipe fitting body, a copper insert, a copper wire, an EVOH barrier layer and binding posts, the pipe fitting body comprises a plastic outer layer and a plastic inner layer, the copper insert is embedded in the pipe fitting body, the EVOH barrier layer is arranged in the middle of the pipe fitting body and between the plastic outer layer and the plastic inner layer, the copper wire is arranged on the inner surface of the plastic outer layer by adopting a front wiring process, the number of the binding posts is two, the binding posts are arranged at two ends of the outer surface of the plastic outer layer correspondingly, the copper wire serves as a resistance wire, the two ends of the copper wire are connected with the two binding posts correspondingly, the binding posts are connected with an external welding machine and are used for heating the resistance wire, and therefore the inner wall of the electric melting pipe fitting body is heated, and the electric melting pipe fitting body and two to-be-connected pipes are fused and connected. The invention further provides a preparation method of the electric melting pipe fitting. According to the technical scheme, the problems that a barrier type nonmetal composite pipe is poor in connection, and the barrier function cannot be achieved at the connecting position are solved, and the pipe fitting is convenient to connect and construct and suitable for being popularized.

Owner:LINHAI WEIXING NEW BUILDING MATERIALS CO LTD

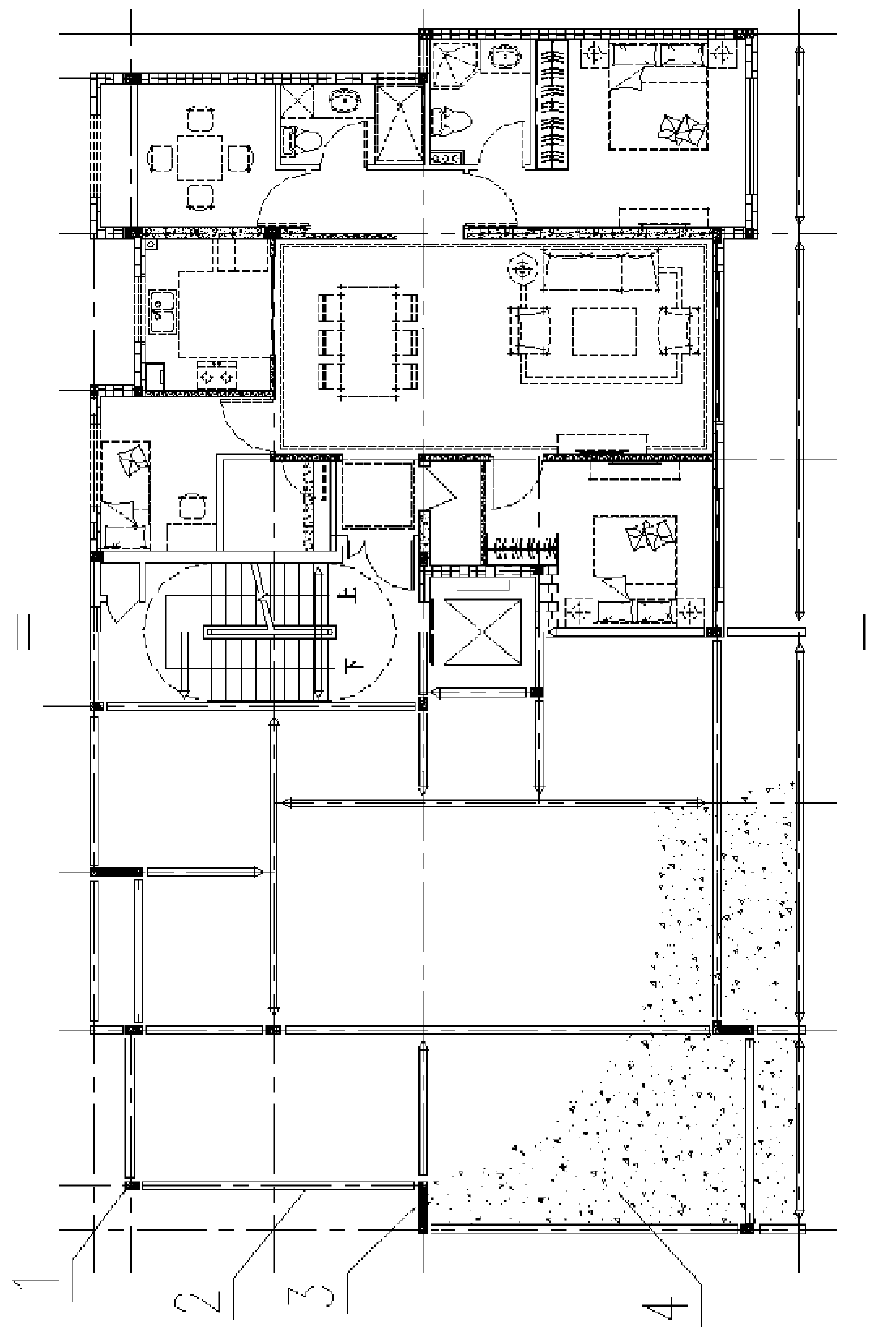

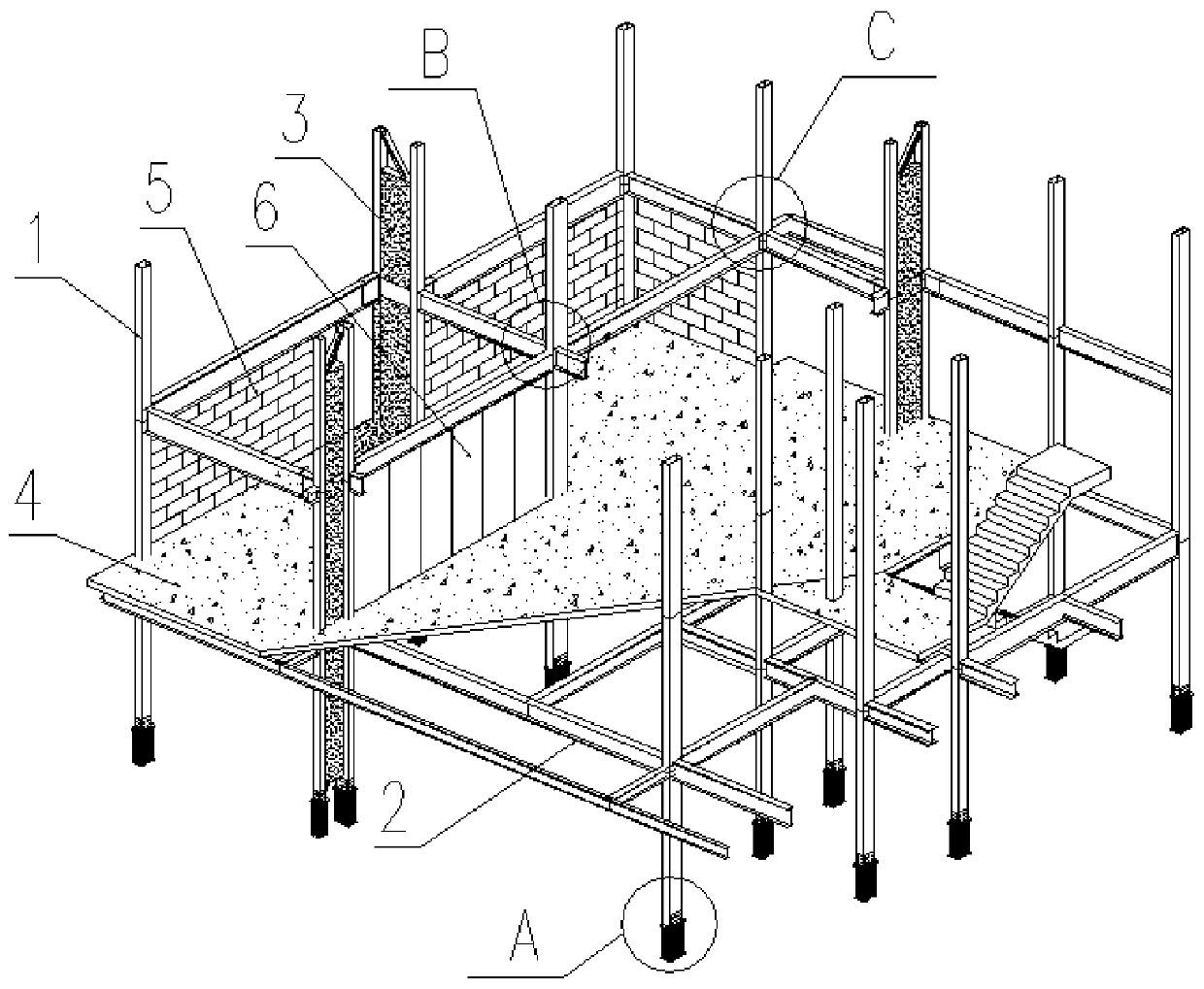

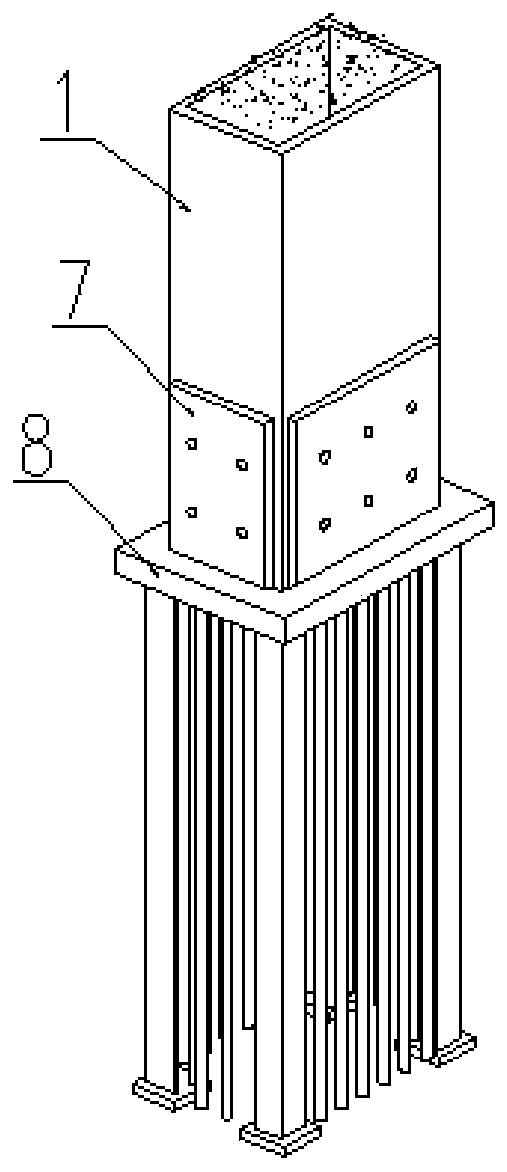

Assembled concrete filled steel tubular column steel frame-beam column wall residence system

PendingCN111255061AImprove lateral force resistanceReduce layoutWallsDwelling buildingFloor slabLine tubing

The invention relates to an assembled concrete filled steel tubular column steel frame-beam column wall residence system. The system is formed by assembling a rectangular cross-section column body, anH-shaped steel beam, a steel beam column wall, a floor slab, a base layer inner wall body and an enclosure outer wall. In order to achieve the purpose that a beam column is not exposed indoors, the column body with the narrow side width smaller than the thickness of the base layer inner wall body is adopted to be connected with the beam column, and the outer side of the long side of the column body is coated with a fireproof coating to achieve the thickness equal to the thickness of the wall body; the steel beam with the flange width smaller than the thickness of the base layer inner wall body is selected to be connected with the wall body, a steel mesh is laid on the outer side of a steel beam web to prevent cracking, a cavity between the steel mesh and the steel beam web is filled witha filler, a leveling layer is arranged along the outer side of the steel mesh to the surface of the base layer inner wall body, and the steel beam is integrally flush with the surface of the base layer inner wall body; the steel beam column wall integrates the functions of the column, the support and the enclosure wall into a whole, a larger anti-side force can be formed, and the requirements suchas equipment opening, and equipment pipe penetrating can be met; and the assembled concrete filled steel tubular column steel frame-beam column wall residence system has the advantages that the beamcolumn is not exposed indoors, the spatial layout is reasonable, pipeline arrangement of pipelines are convenient, and the like.

Owner:浙江力维数智建筑科技有限公司

Chip bonding pad ball mounting leveling and secondary welding method

PendingCN114050136AIncreased Strength ReliabilityGood lookingSemiconductor/solid-state device detailsSolid-state devicesSolder ballStructural engineering

The invention provides a chip bonding pad ball-mounting leveling and secondary welding method, and the method achieves the fishtail bonding of a lead and a flat interface at the top end of a ball-mounting during secondary welding through introducing a ball-mounting shaping process. According to the method, the welding process sequence for secondary welding of a plurality of chip bonding pads in the prior art is changed, the process sequence of centralized ball mounting, centralized sharp-cap-shaped welding ball flattening and shaping and centralized secondary welding is adopted, the consistency of ball mounting morphology is improved, and the stability of the secondary welding process is improved. Aiming at an electronic device adopting a chip bonding pad secondary welding process, the consistency in the welding process is improved, the abnormities of fishtail wire warping, wire shrinkage after fishtail bonding and the like in the welding process are reduced, and the strength reliability of chip bonding pad secondary welding is improved. The method has the advantages of high yield, high efficiency, high welding strength and the like under the conditions of multi-chip interconnection, laminated chip interconnection, reverse welding of the frame carrier and the chips under the condition of complex wiring and the like.

Owner:XIAN MICROELECTRONICS TECH INST

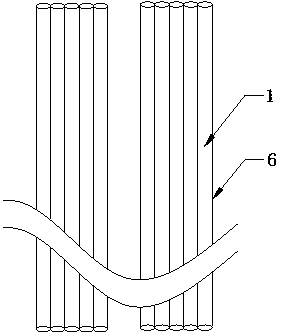

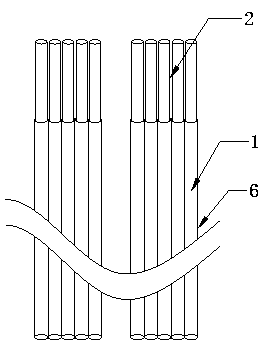

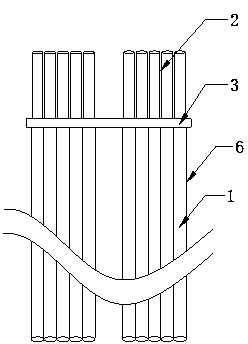

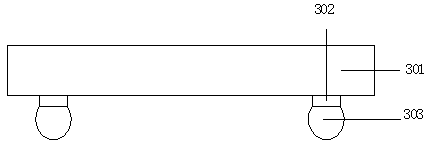

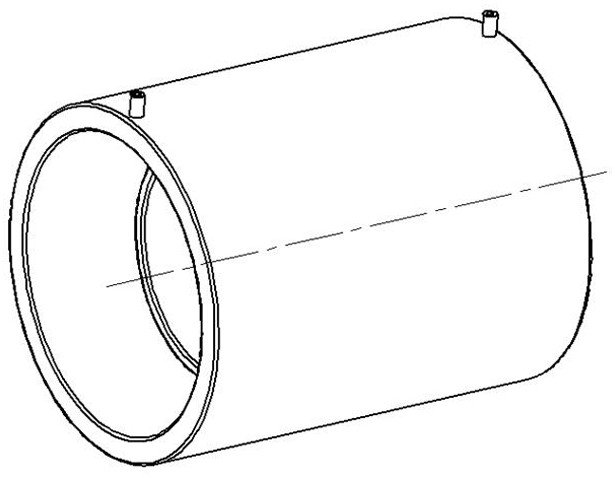

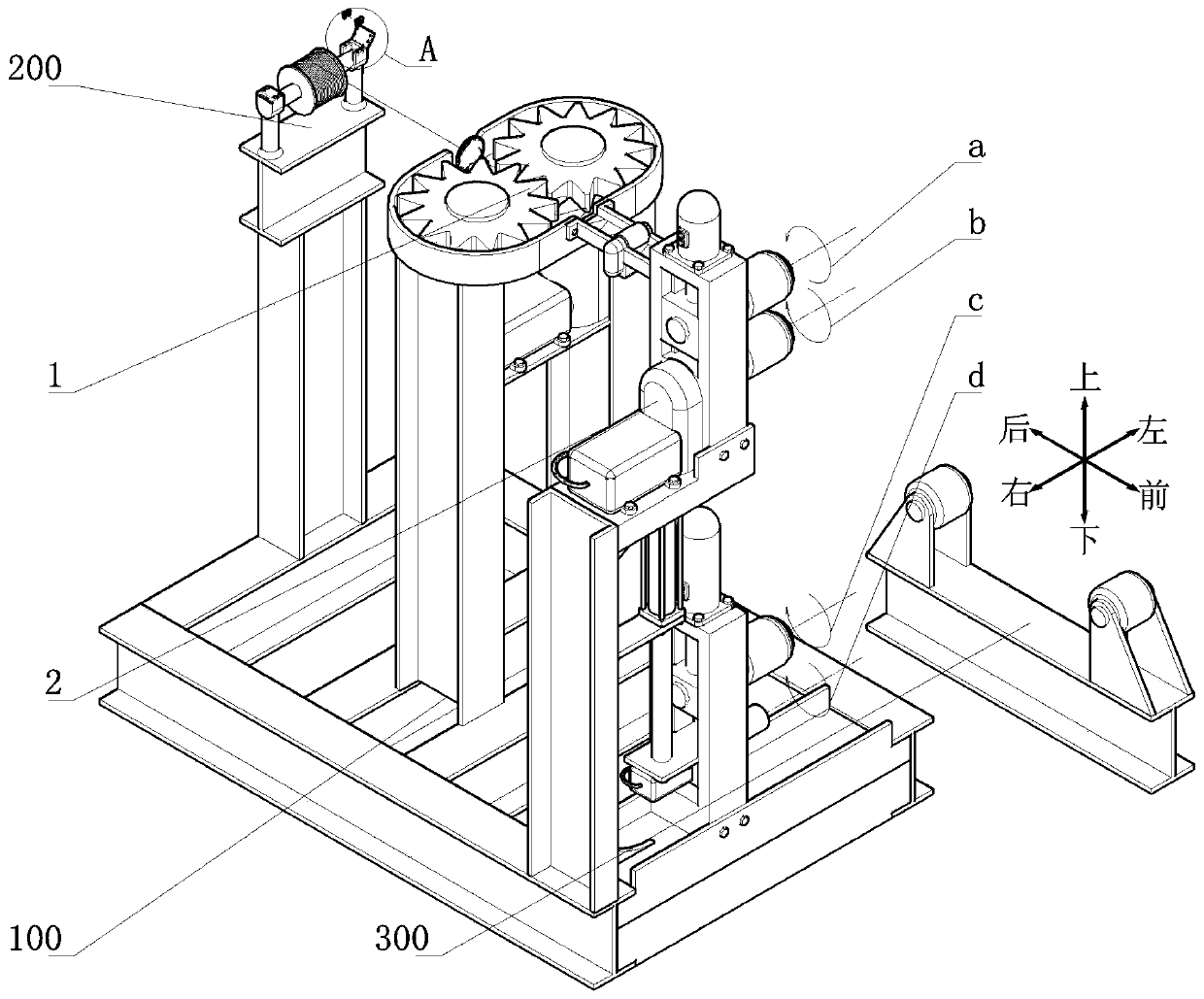

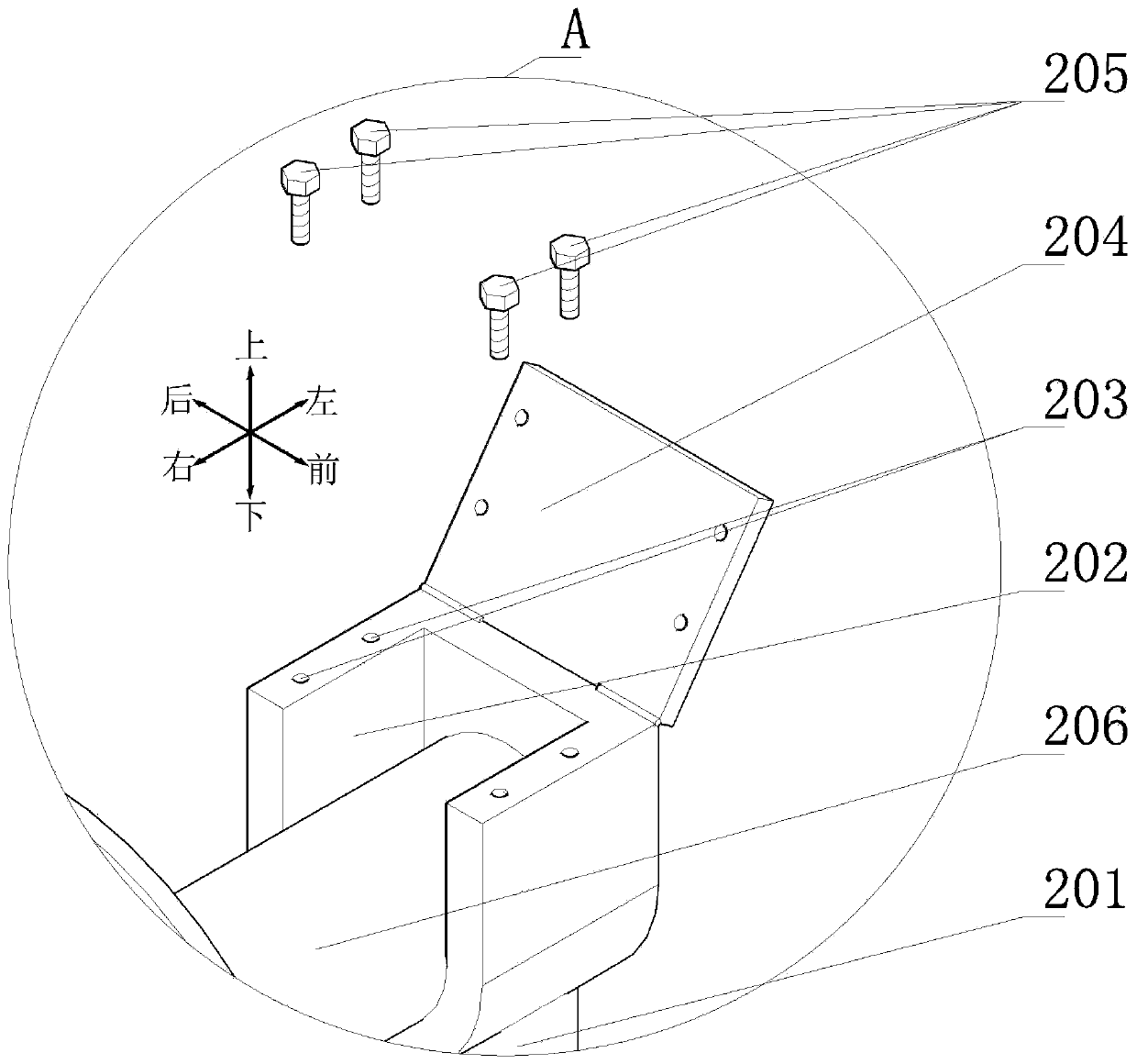

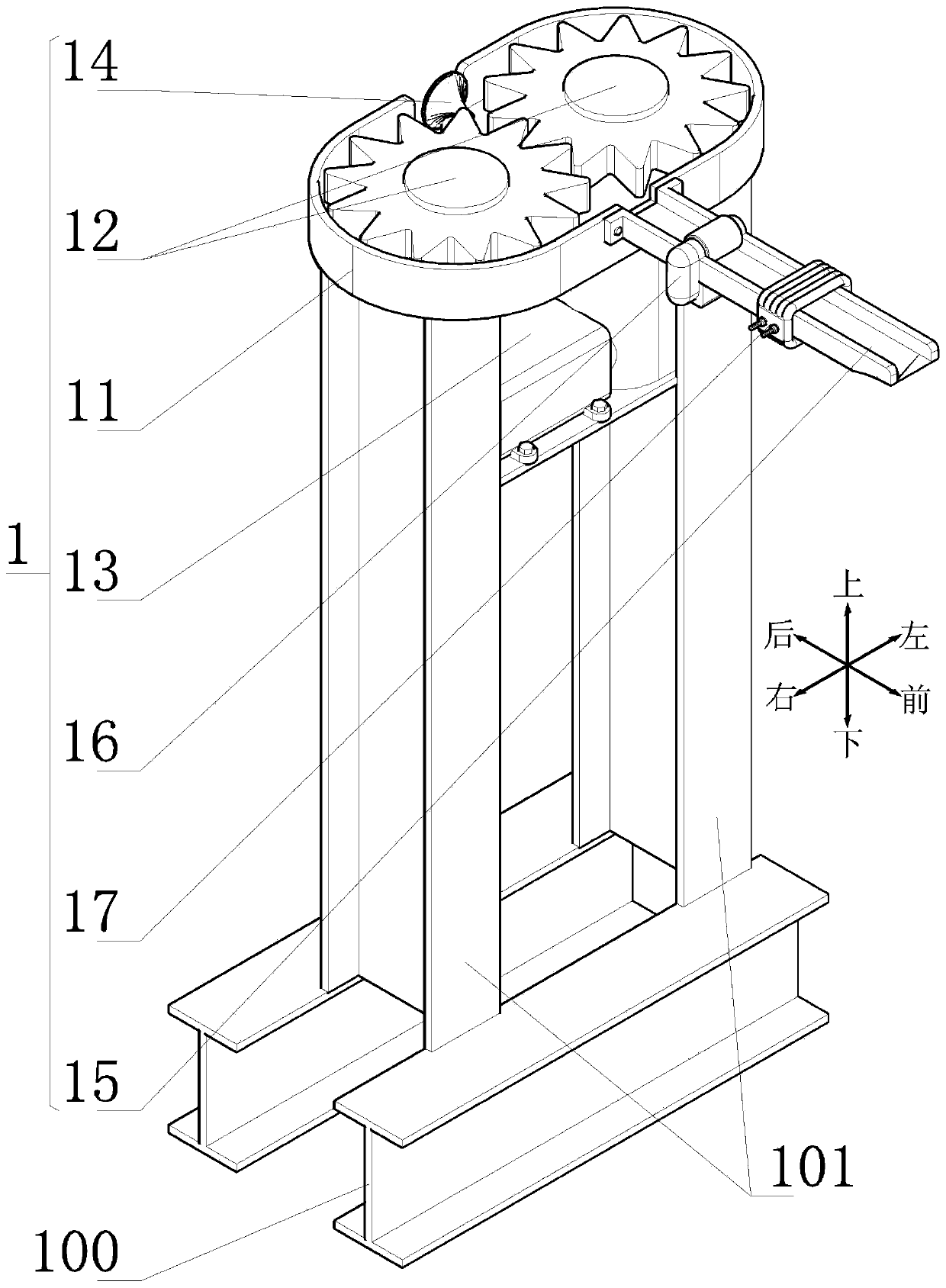

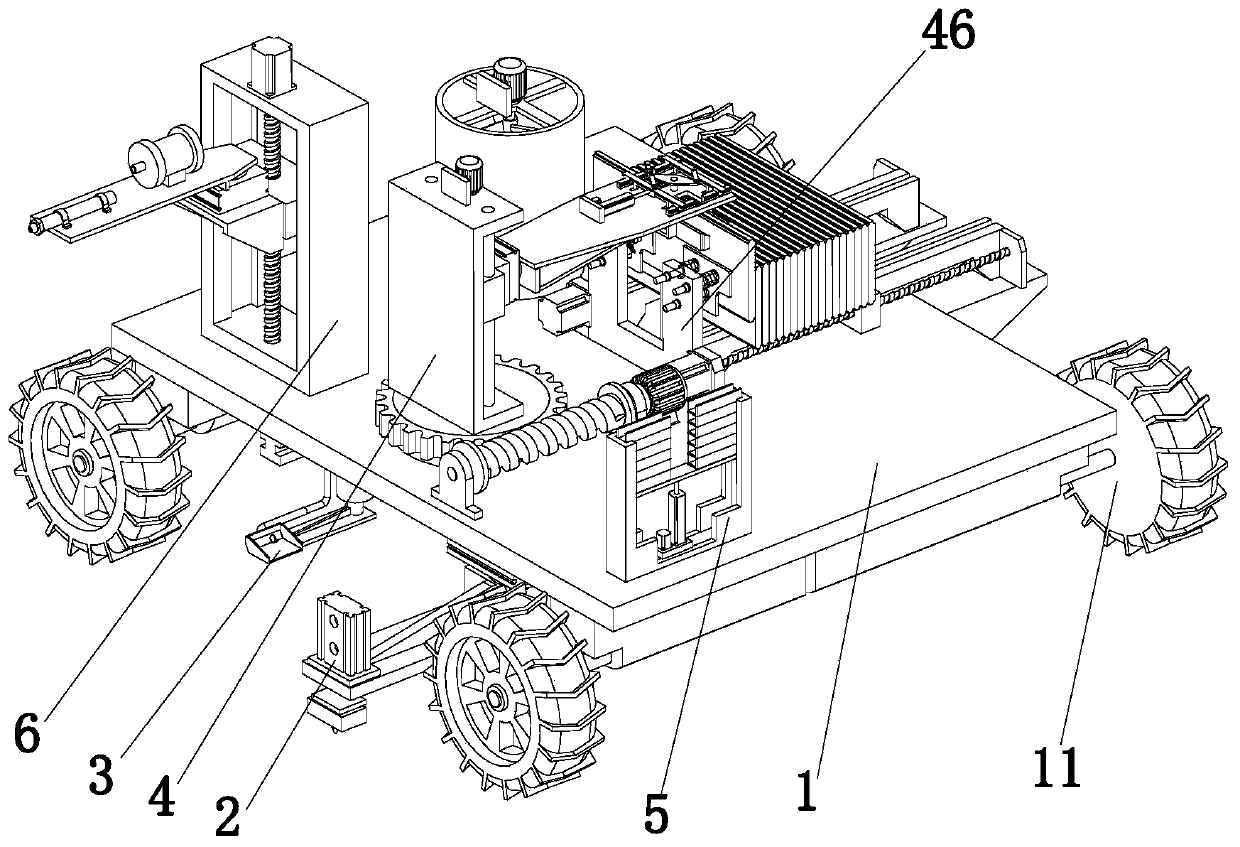

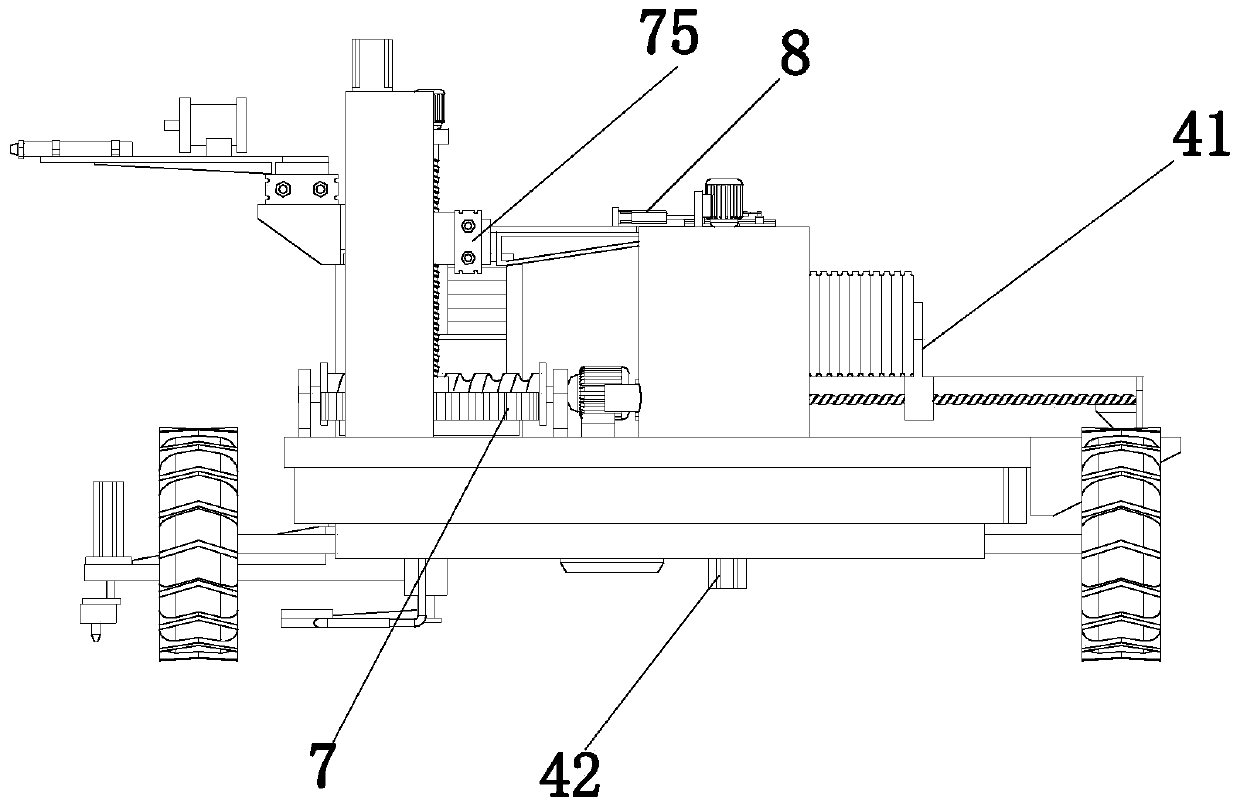

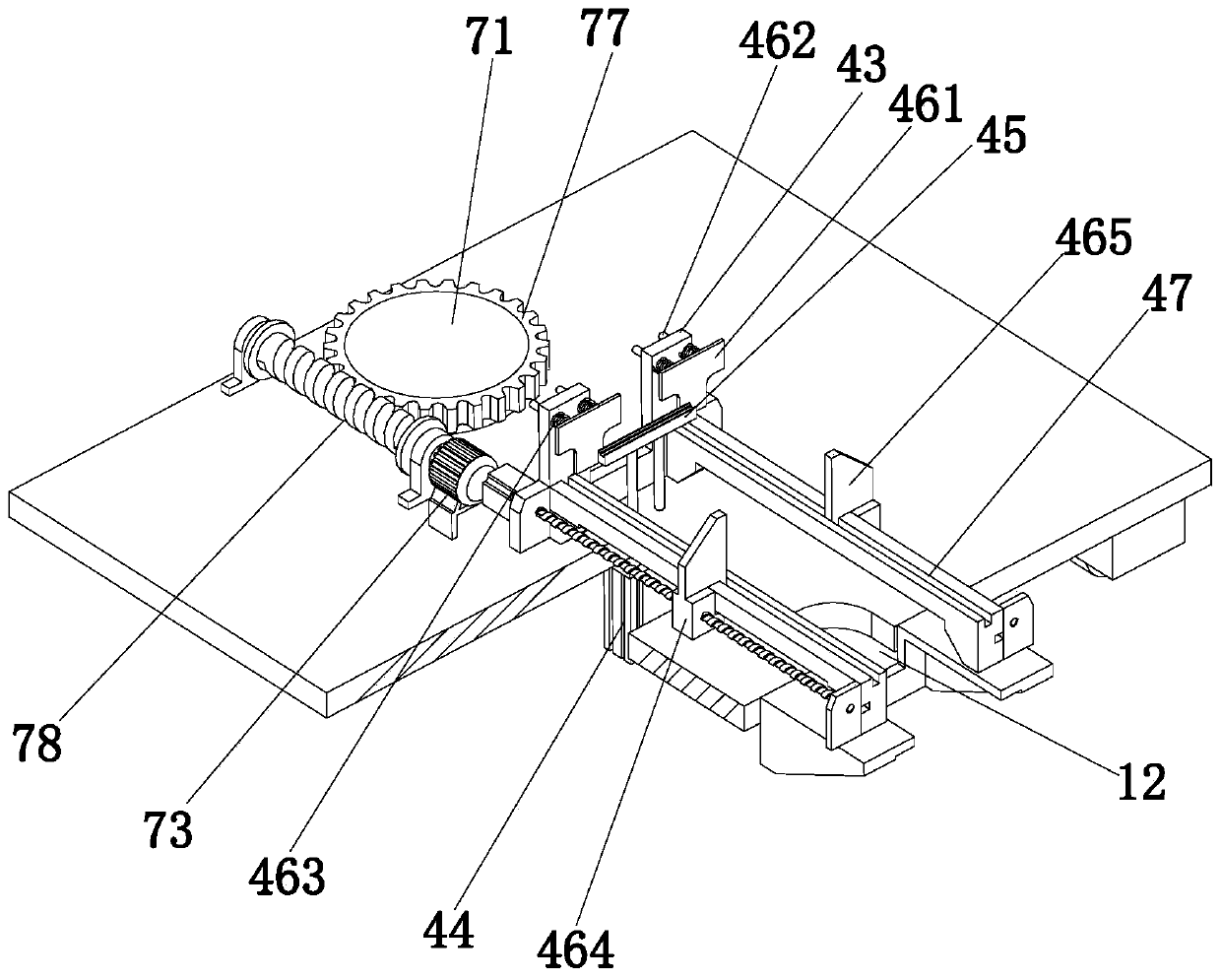

A wiring device for butt welding of ultra-high molecular weight polyethylene straight pipe and its working method

The invention relates to a wiring device for butt welding of ultra-high molecular weight polyethylene straight pipes and its working method, comprising a support base including a cross arm, a feeding device, a support roller and a control device; The second support vertical beam; the first support vertical beam is equipped with a shaping device, the shaping device includes a protective groove, a tooth surface pressing wheel, a first motor, a lead wire device, a wire feeding chute, a pressing wheel, and a heating component; the second The second support vertical beam is equipped with a cutting device including a disc pressing mechanism and a grinding mechanism. The disc pressing mechanism includes an upper slideway, a first slider, an upper pressing roller, an upper hydraulic cylinder, a second motor for the supporting roller, and a reduction box. The grinding mechanism includes a glide path, a first lower slider, a lower pressure roller, a lower hydraulic cylinder, a second lower slider, a grinding head, a third motor, and a stroke electric cylinder. The invention relates to a wiring device for butt welding of ultra-high molecular weight polyethylene straight pipes and a working method thereof, which automatically arranges regular electric heating wires to improve wiring efficiency, and the electric heating wires are reliably fixed on the outer wall of the straight pipe.

Owner:SHANDONG XIANHE POLYMER MATERIALS +1

CSOP type ceramic shell, amplification filter and manufacturing method

PendingCN114050130AImprove air tightnessImprove toleranceImpedence networksSemiconductor/solid-state device detailsLead frameCo-fired ceramic

The invention provides a CSOP type ceramic shell, an amplification filter and a manufacturing method, and belongs to the technical field of ceramic packaging, the CSOP type ceramic shell comprises a ceramic substrate, a metal wall body, a metal chassis and a lead frame; the ceramic substrate is provided with interconnection holes, and metal tungsten columns are arranged in the interconnection holes; the metal wall body is arranged on the front surface of the ceramic substrate and forms a packaging cavity with the ceramic substrate; the metal chassis is arranged on the back surface of the ceramic substrate; the lead frame is connected to the back surface of the ceramic substrate and is connected with the metal tungsten columns; the ceramic substrate is made of aluminum oxide high-temperature co-fired ceramic. According to the CSOP type ceramic shell provided by the embodiment of the invention, the high-temperature co-fired ceramic is adopted to replace low-temperature co-fired ceramic, the high-temperature co-fired ceramic substrate and the lead frame are welded together during welding, and then the ceramic substrate, the metal chassis and the metal wall body are welded together by adopting the high-temperature welding flux, so that the processing cost and the processing difficulty are reduced; and the requirements of high-density wiring, batch, miniaturization, low cost, high reliability of an assembly process and the like can be met.

Owner:THE 13TH RES INST OF CHINA ELECTRONICS TECH GRP CORP

Lightweight aggregate concrete wallboard laying equipment

InactiveCN111456458AAvoid safety hazardsReduce labor intensityBuilding material handlingArchitectural engineeringSlurry

The invention discloses lightweight aggregate concrete wallboard laying equipment, and belongs to the technical field of building equipment. The lightweight aggregate concrete wallboard laying equipment comprises a vehicle body, an automatic wiring mechanism, a slurry-setting and trowelling mechanism, a wallboard material-moving mechanism, a U-shaped steel plate card storage mechanism and a splicing seam curing mechanism, wherein the wallboard material-moving mechanism comprises a wallboard stacking assembly and a vertical laying assembly; the wallboard stacking assembly comprises a limiting material-lifting part, two first lead screw sliding tables, two material pushing plates and two heightening frames; and a first through groove is formed in the vehicle body. According to the lightweight aggregate concrete wallboard laying equipment, wallboards can be automatically and vertically laid through the wallboard material-moving mechanism and the U-shaped steel plate card storage mechanism, U-shaped steel plate cards can further be mounted on the wallboards, and curing agents can be automatically smeared in splicing seams through the splicing seam curing mechanism, so that the labor intensity of workers is reduced; and the lightweight aggregate concrete wallboard laying equipment is high in automation degree, and can greatly improve the laying efficiency of a construction team andreduce the manpower input.

Owner:卢天文

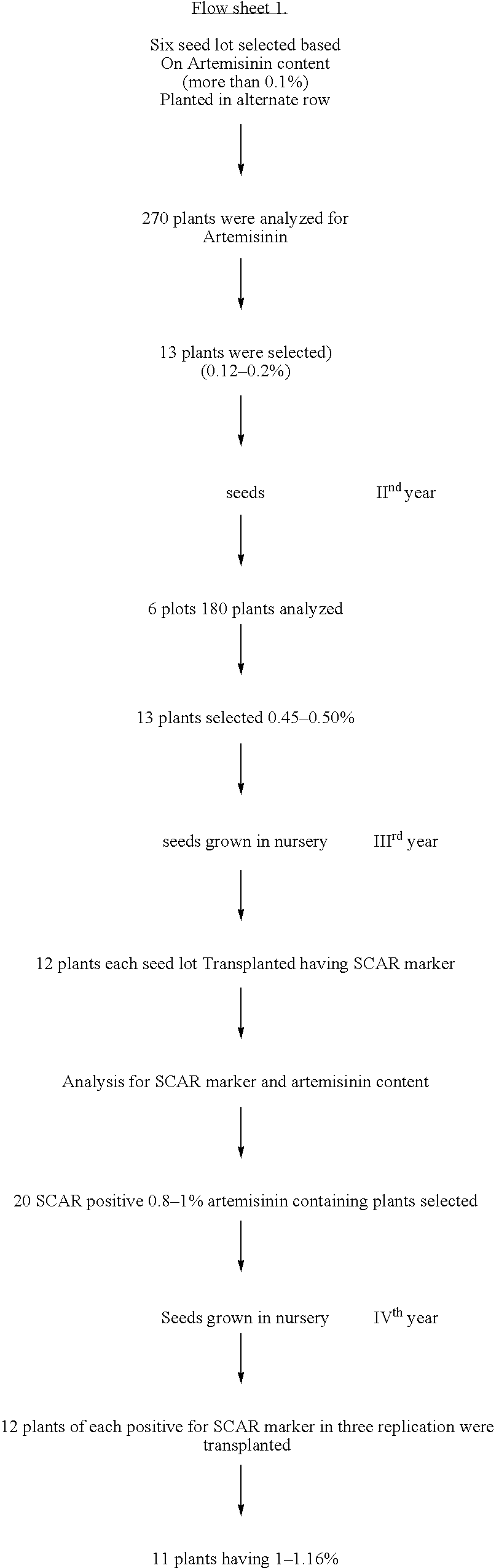

High Artemisinin yielding plant genotype 'CIM-Arogya'

ActiveUS20070089211P1Other foreign material introduction processesVector-based foreign material introductionGenotypeArtemisia annua

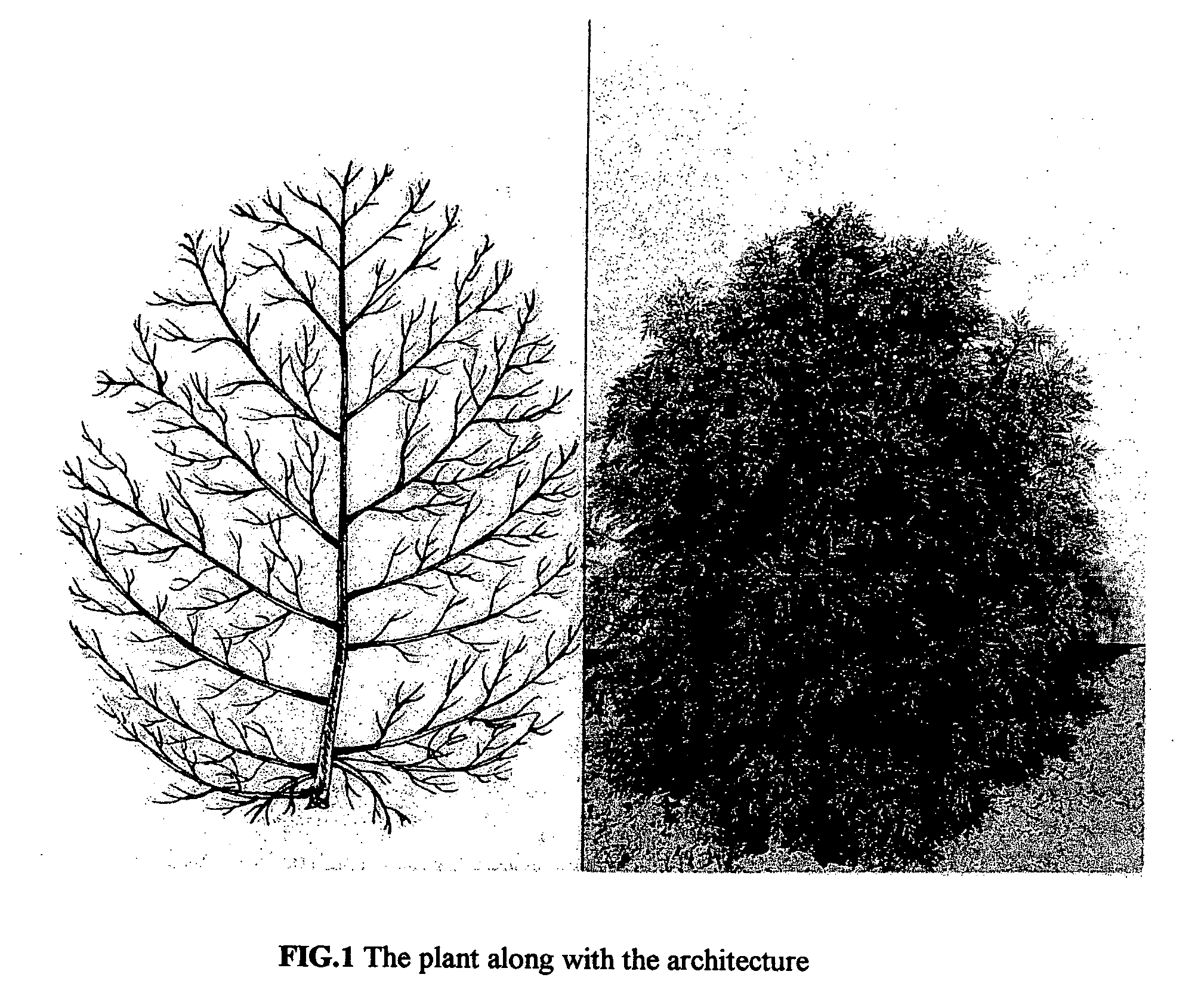

The present invention is related to the development of a novel, distinct high herb and artemisinin yielding genotype of Artemisia annua obtained through systematic marker assisted breeding followed by selection of uniform population in a methodical way wherein the genotype is distinct, uniform and stably maintainable by continuous rouging of off types in the population using DNA marker at early seedling stage from nursery itself and suitable for commercial cultivation.

Owner:COUNCIL OF SCI & IND RES

Packaging structure, semiconductor device and packaging method

PendingCN111370375AImprove the isolation effectImprove stress strengthSemiconductor/solid-state device detailsSolid-state devicesEpoxyDevice material

The invention discloses a packaging structure, a semiconductor device and a packaging method. The packaging structure comprises a chip unit which comprises a substrate and a client layer located on the surface of the substrate, wherein the surface, deviating from the substrate, of the client layer is defined as a first surface, the surface, deviating from the client layer, of the substrate is defined as a second surface, and a welding pad is formed in the client layer; welding bulges which are formed on the second surfaces of the chip units; a metal wiring layer which is electrically connectedbetween the welding pad and the welding bulges; and an insulating layer which is formed between the metal wiring layer and the chip unit, wherein the insulating layer comprises a silicon dioxide layer and a Si3N4 layer which are sequentially formed on the surface of the chip unit. The insulating layer of the packaging structure adopts a SiO2 + Si3N4 + epoxy resin three-layer structure, and through the structure, the moisture isolation effect can be greatly improved, and the stress resistance strength of the packaging structure is also greatly improved.

Owner:CHINA WAFER LEVEL CSP

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com