Printed circuit board with high-speed differential signal wiring structure

A printed circuit board, high-speed differential technology, applied in the direction of printed circuit components, electrical connection printed components, etc., can solve the problems of inability to share, increase the cost of the motherboard, and achieve the effect of saving costs

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

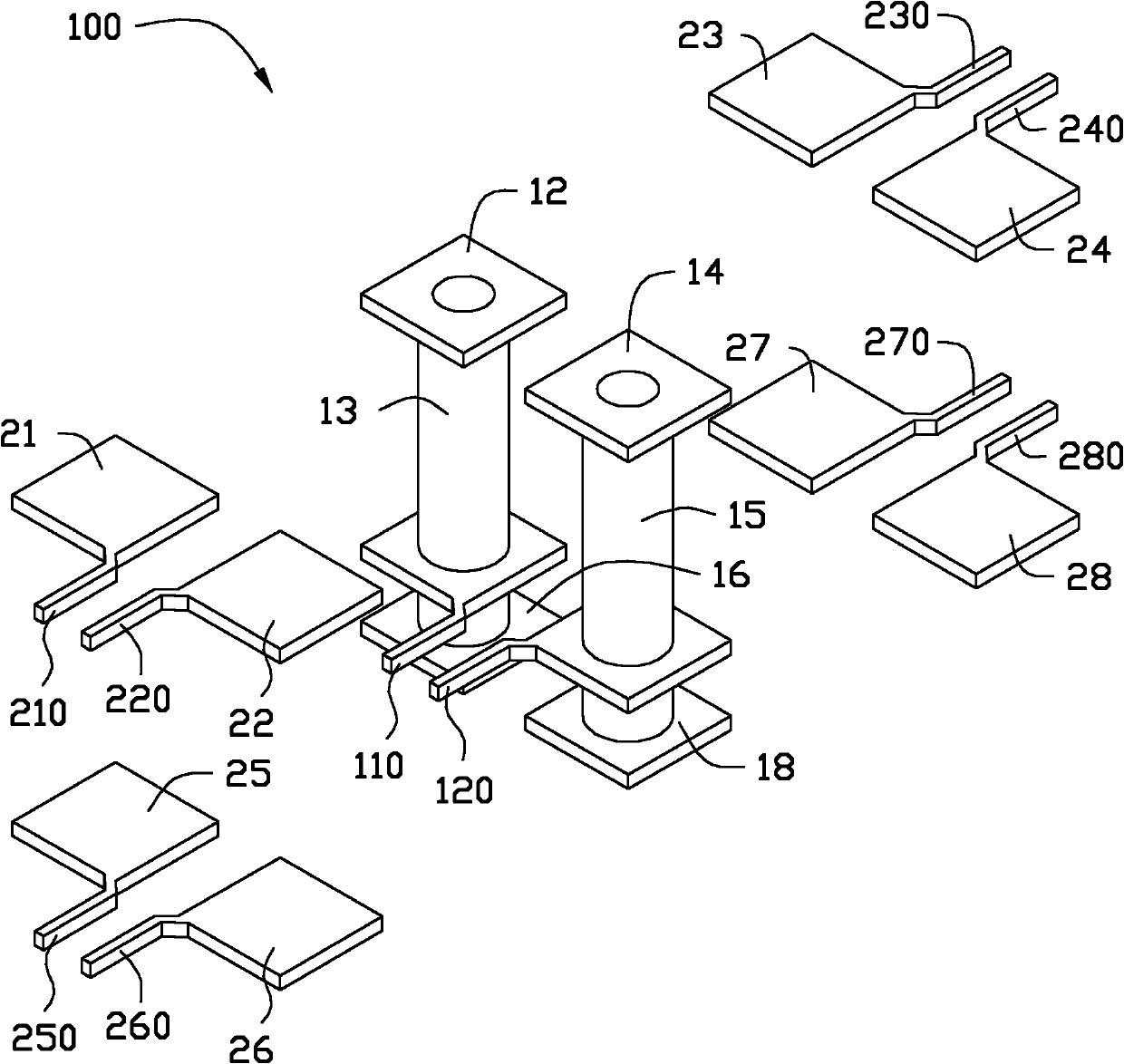

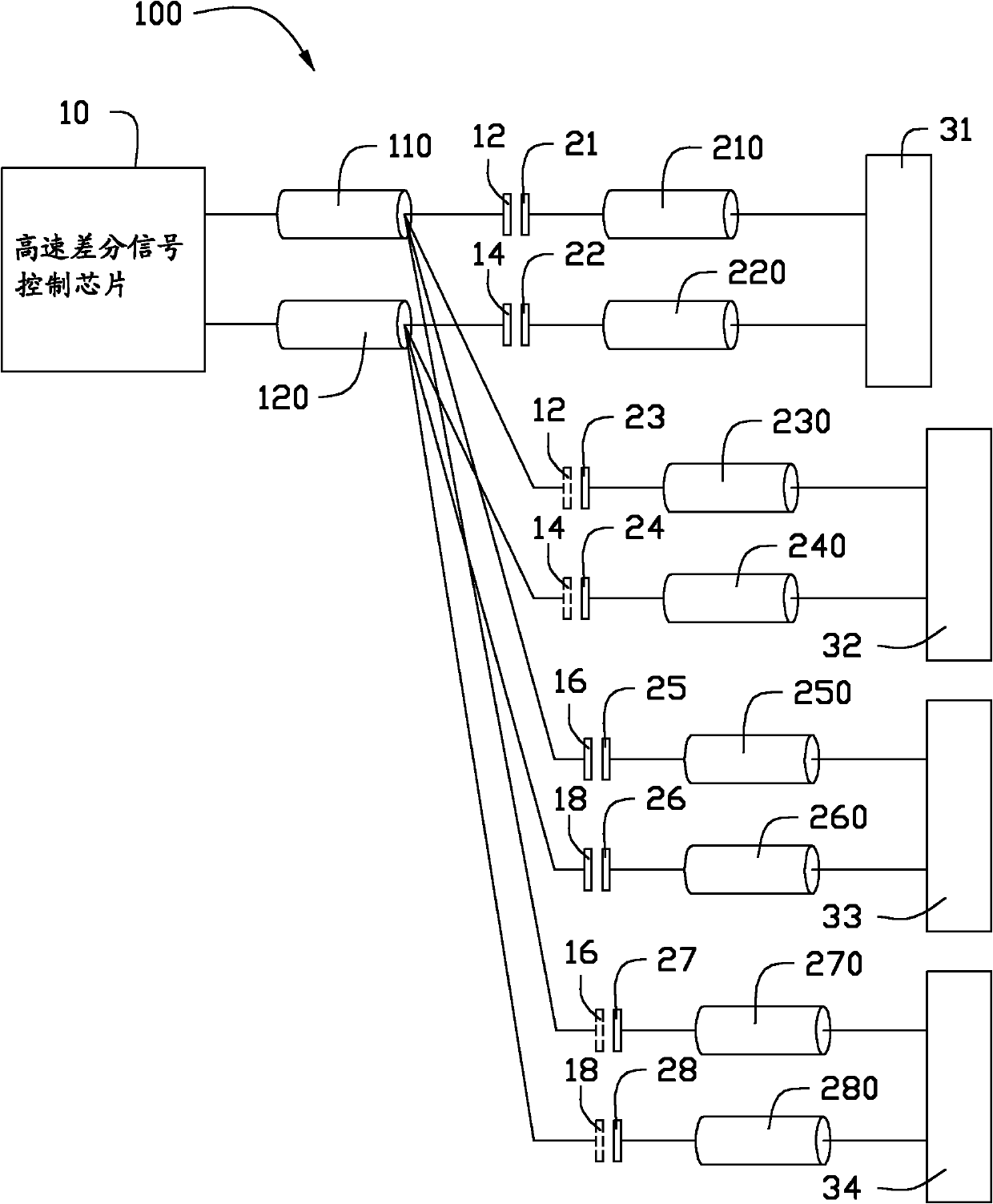

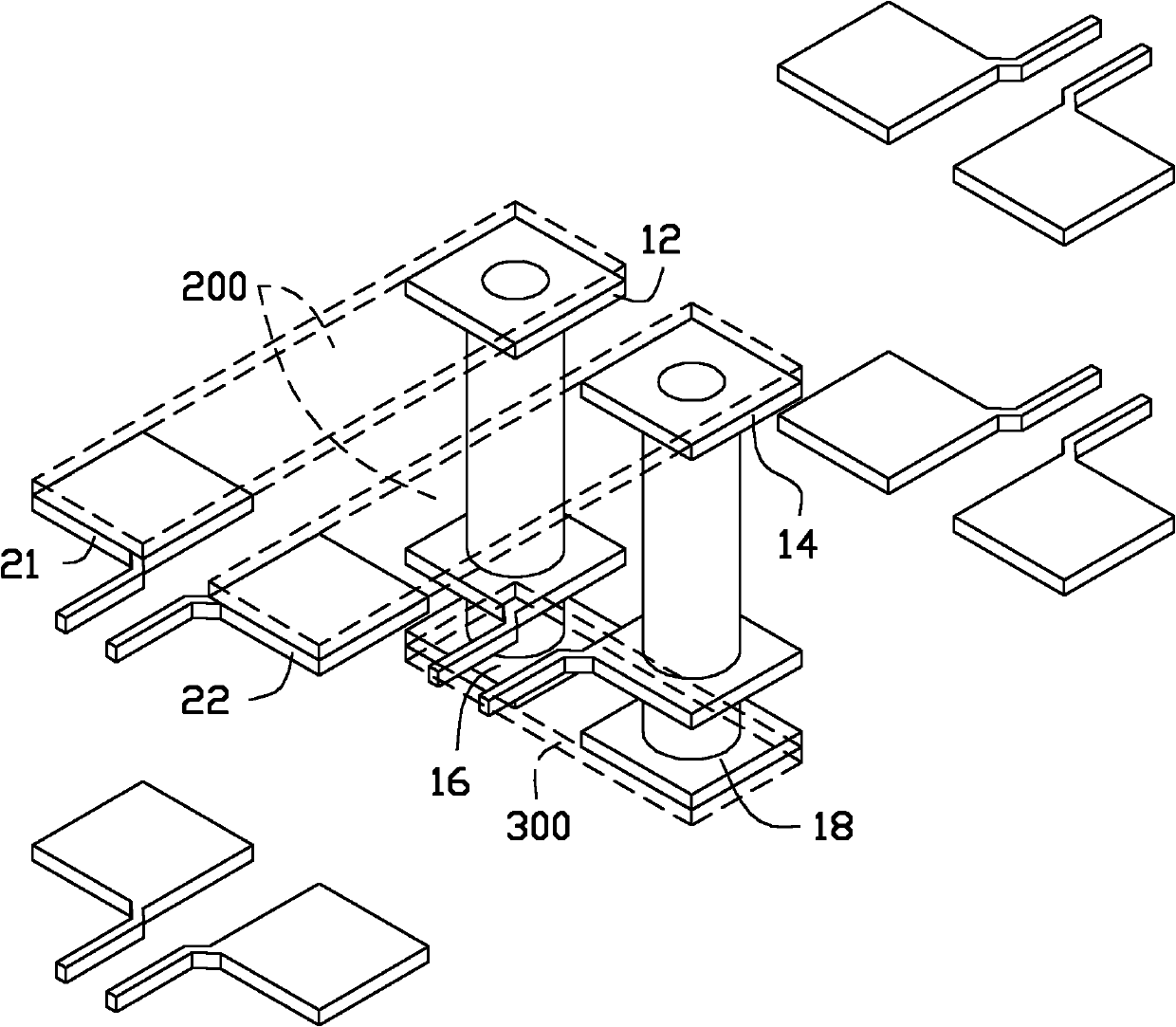

[0025] Please also refer to figure 1 and figure 2 A preferred embodiment of the printed circuit board 100 with a high-speed differential signal wiring structure of the present invention includes a high-speed differential signal control chip 10, first to eighth coupling capacitor pads 21-28, first to fourth connector pads 31-34, transmission lines 110, 120, 210, 220, 230, 240, 250, 260, 270, and 280, first to fourth shared pads 12, 14, 16, and 18. Wherein, the first and second connector pads 31 and 32, the transmission lines 210, 220, 230 and 240, the first to fourth coupling capacitor pads 21-24, the first and second shared pads 12, 14 are all arranged on the upper layer of the printed circuit board, the third and fourth connector pads 33 and 34, the transmission lines 250, 260, 270 and 280, the fifth to eighth coupling capacitor pads 25-28, the first The third and fourth shared pads 16, 18 are all arranged on the lower layer of the printed circuit board, and the transmissi...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com