Airtight wafer level packaging structure and process of surface acoustic wave device

A surface acoustic wave device and wafer-level packaging technology, which is applied to electrical components, impedance networks, etc., can solve the problems of increasing size, achieve the effects of improved air tightness, high shear strength, and improved processing efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0031] The present invention will be described in detail below in conjunction with the accompanying drawings and specific embodiments.

[0032] The packaging technology is applied in the technical field of packaging of high-reliability surface acoustic wave devices. Specifically, the functional chip of the surface acoustic wave device and the capping wafer are bonded together by wafer packaging technology to form an airtight seal.

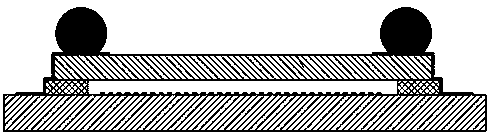

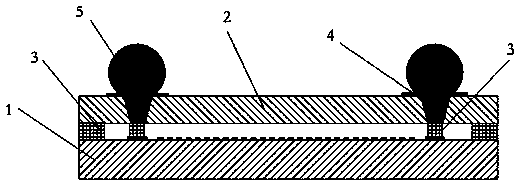

[0033] The structure of the surface acoustic wave device targeted by this packaging process is as follows: figure 2 As shown, it can be seen from the figure that the surface acoustic wave device includes a functional chip 1 and a capping wafer 2, a circle of bonding layer metal 3 is plated on the periphery of the working surface of the functional chip 1, and the capping wafer 2 A circle of bonding layer metal 3 is also plated on the corresponding position of each chip bonding layer metal, and the functional chip 1 and the capping wafer 2 are bonde...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com