Assembled concrete filled steel tubular column steel frame-beam column wall residence system

A technology of steel pipe concrete columns and steel frames, which is applied to residential buildings, walls, building components, etc., can solve the problems of neglecting building functions, occupation of indoor usable area, exposed beams and columns, etc., and achieve convenience, flexibility and space Reasonable layout, improved lateral force resistance, and small indoor area occupation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0029] The following will clearly and completely describe the technical solutions in the embodiments of the present invention with reference to the drawings in the embodiments of the present invention.

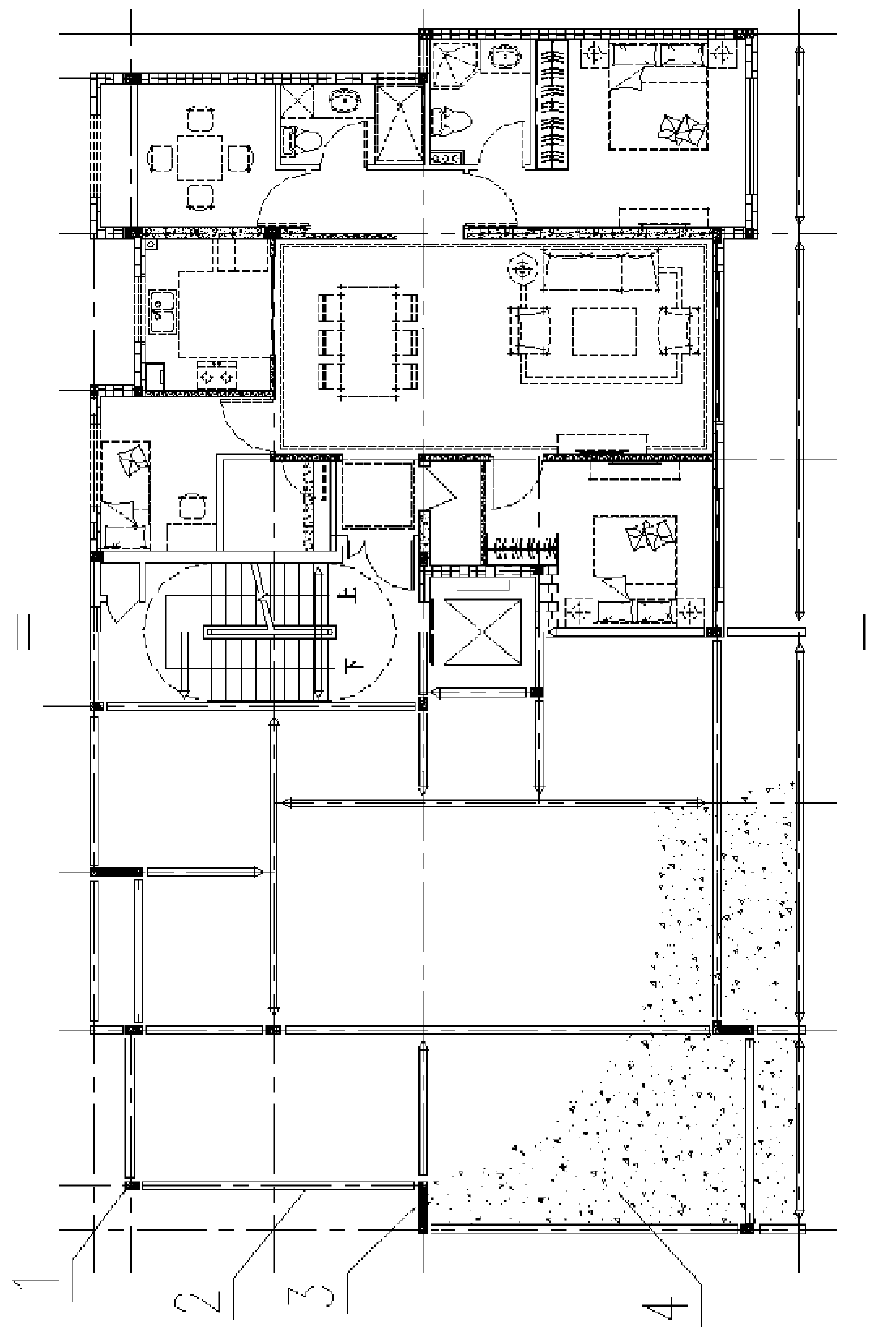

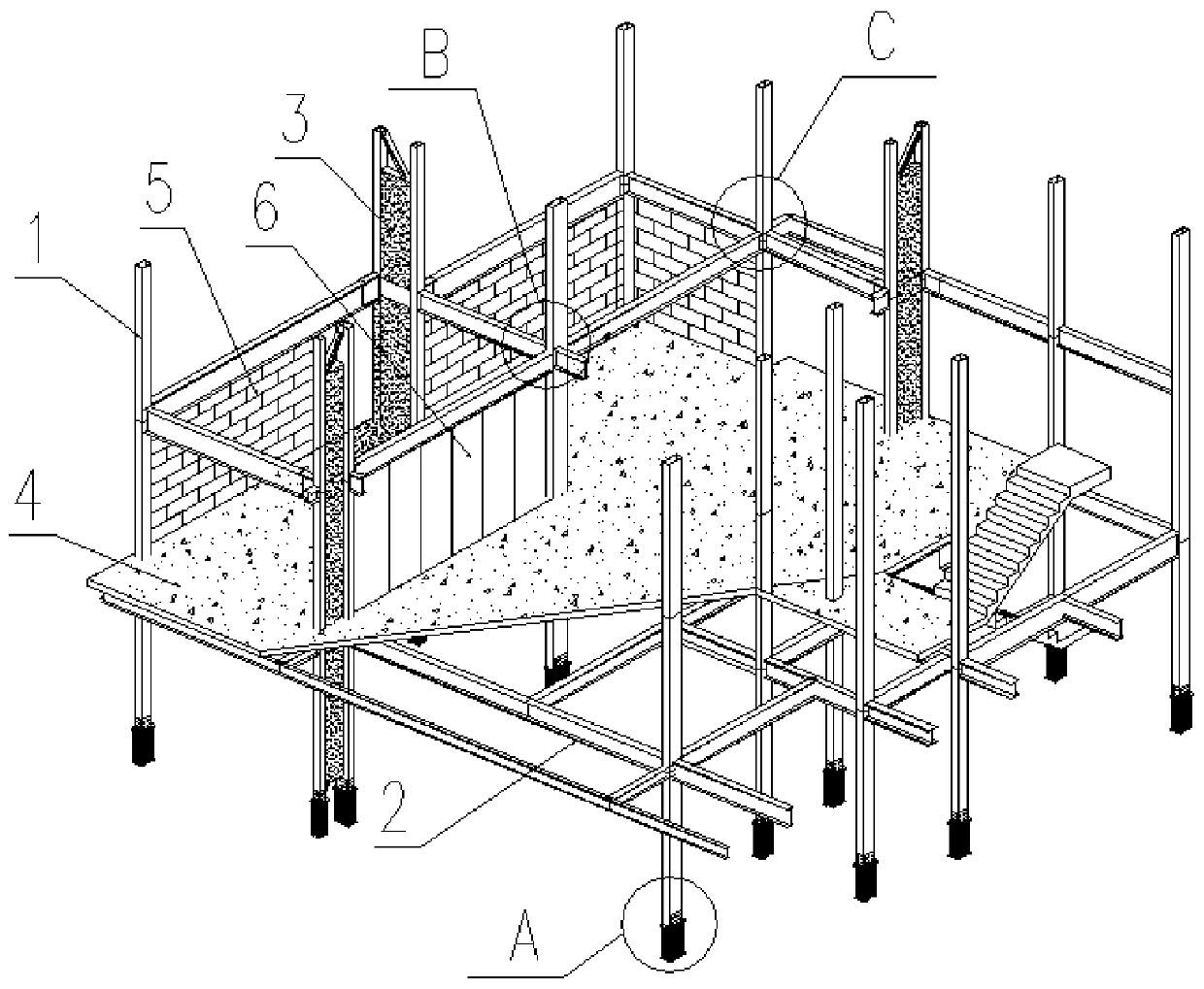

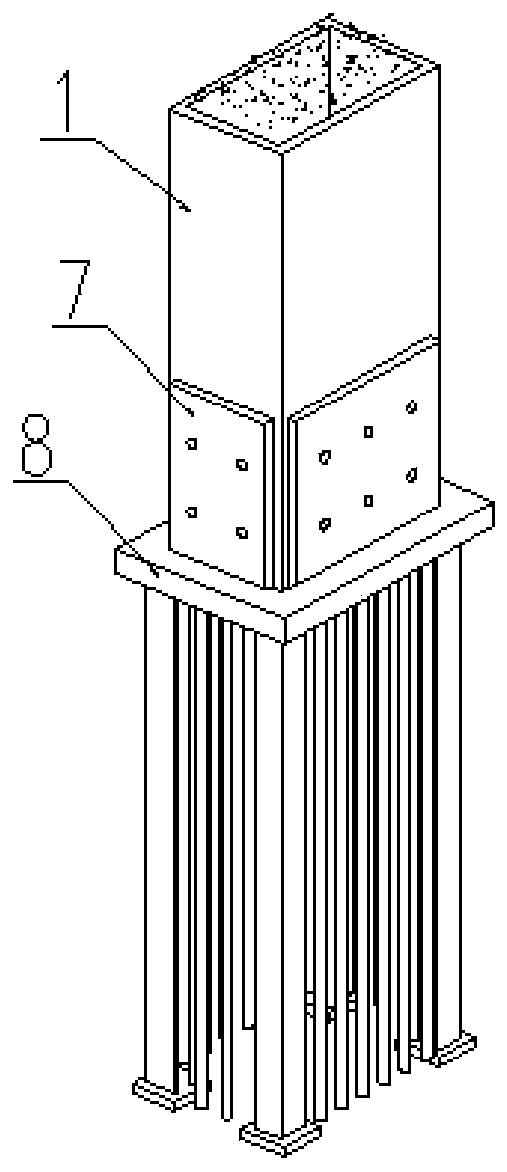

[0030] This embodiment discloses a prefabricated steel pipe concrete column steel frame-beam column wall residential system, such as figure 1 and figure 2 As shown, it is mainly composed of a column body 1 with a rectangular cross section, an H-shaped steel beam 2, a steel beam column wall 3, a floor slab 4, a base inner wall 6 and an enclosure outer wall 5. In order to reflect the construction advantages of steel structure buildings, the above-mentioned components in this embodiment are all industrial prefabricated parts, which are prefabricated and assembled in the factory in advance, and can be assembled and connected by bolts or welding on the construction site. For the floor 4, the cast-in-place concrete floor is used On-site pouring, the internal cavities and joints of...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com