Self-resetting steel frame eccentric supporting system with large headroom

An eccentric support, self-reset technology, applied in building components, building types, earthquake-proof and other directions, can solve the problems of frame system self-reset, door openings, etc., achieve good seismic performance and reset ability, improve lateral force resistance performance, welding seam Effects with more controllable precision and quality

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

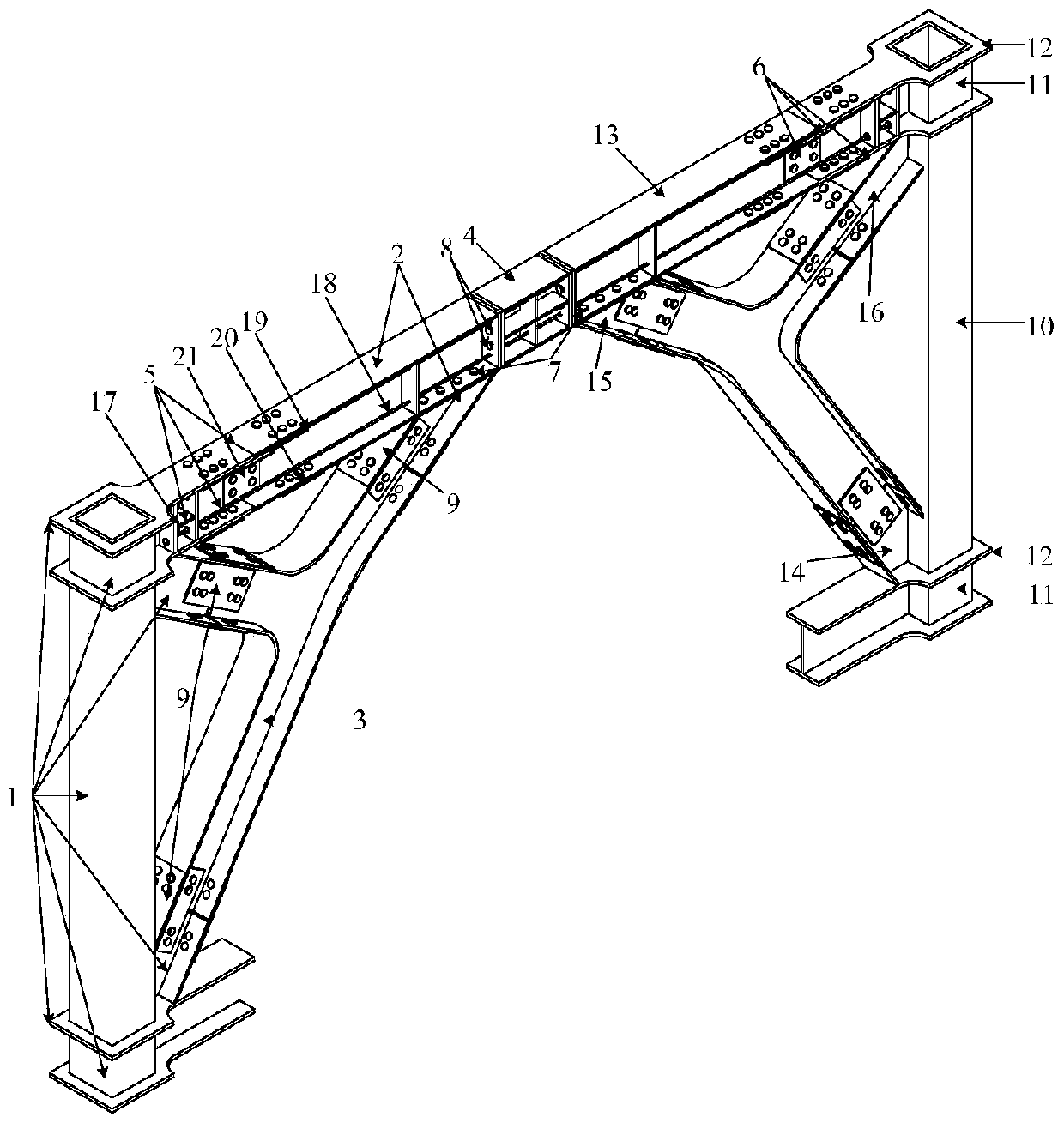

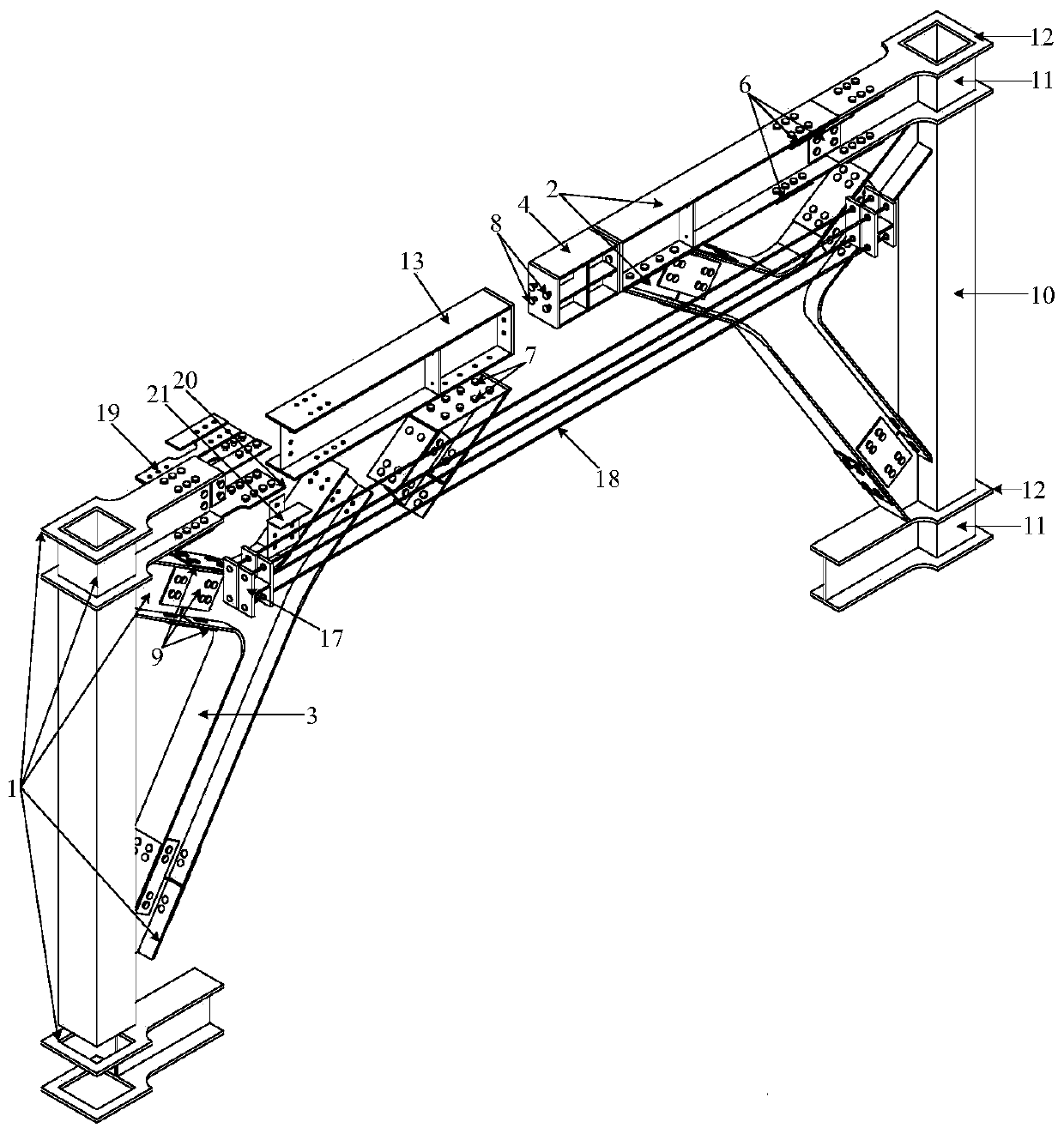

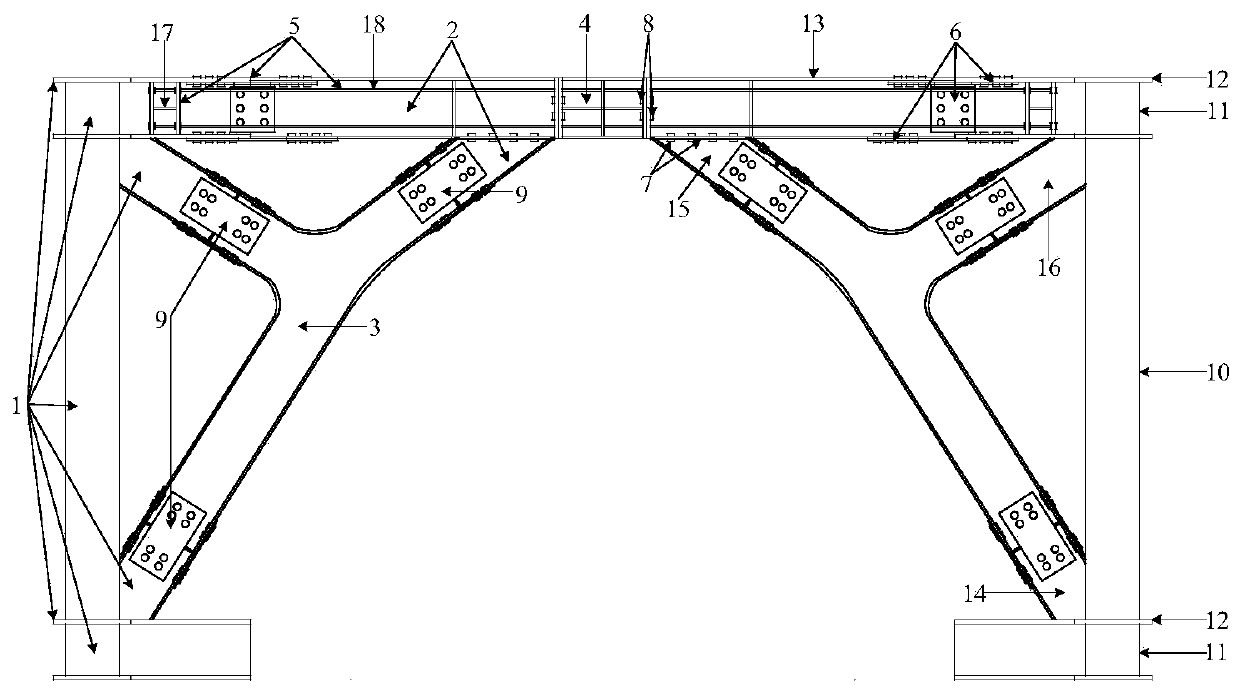

[0018] The following describes the implementation of this patent in detail with reference to the drawings.

[0019] Such as Figure 1~3 As shown, a self-resetting steel frame eccentric support system with large clearance includes the following components.

[0020] 1——Welded combined special-shaped column;

[0021] 2——I-beam section with diagonal support rod;

[0022] 3——Y-shaped diagonal brace;

[0023] 4——Energy-consuming beam section;

[0024] 5——Combined self-reset device;

[0025] 6——Beam-column node connection device;

[0026] 7——The first connecting device;

[0027] 8——The second connecting device;

[0028] 9——The third connecting device;

[0029] 10——The upper steel pipe column;

[0030] 11——Chinese square steel pipe column;

[0031] 12——Cantilever beam section;

[0032] 13——I-beam section;

[0033] 14——The first inclined support rod;

[0034] 15——The second inclined support rod;

[0035] 16——The third inclined support rod;

[0036] 17-tooling;

[0037] 18-cable;

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com