Patents

Literature

237results about How to "Small shrinkage deformation" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Composite natural polymer gel material

ActiveCN105837861ALarge specific surface areaImprove mechanical propertiesAerogel preparationColloidal chemistry detailsNon solventWater based

The invention discloses a composite natural polymer gel material with a cross-linking agent. The material comprises hydrogel, organogel, aerogel and bioplastics and mainly overcomes the problem of low mechanical strength of conventional natural polymer gel materials. According to the invention, a certain amount of the cross-linking agent is added into a natural polymer water-based solution or dispersion liquid, then stirring is carried out, the obtained mixture is placed in a non-solvent for physical cross-linking, and then washing is carried out so as to obtain composite natural polymer hydrogel; water in the composite natural polymer hydrogel is replaced with an organic solution so as to prepare composite natural polymer organogel; the composite natural polymer hydrogel or organogel is dried so as to prepare composite natural polymer aerogel; the composite natural polymer aerogel is subjected to hydrophobic treatment so as to obtain hydrophobic aerogel; the composite natural polymer aerogel is subjected to heat treatment so as to obtain carbon aerogel; and one or more selected from the above-mentioned gel materials are subjected to high-temperature pressing so as to prepare composite natural polymer bioplastics. The composite natural polymer gel material prepared in the invention has the advantages of excellent mechanical properties, a high specific surface area, high elongation at break, etc., and can be easily processed into molded products of a plurality of forms.

Owner:浙江绍兴万德福生物技术有限公司 +1

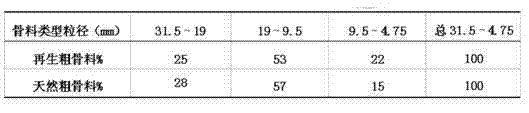

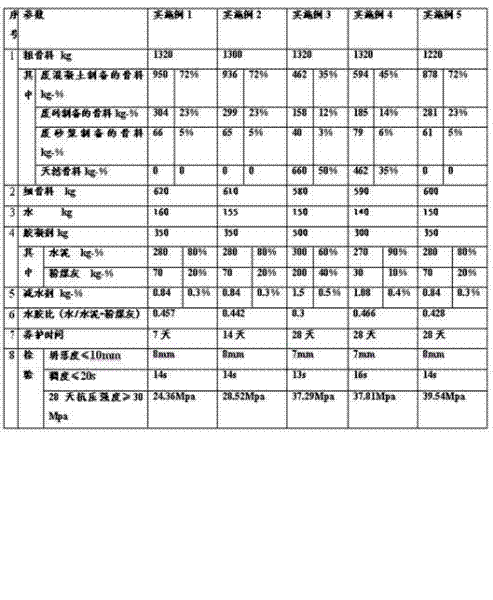

Recycled aggregate medium-dry hard concrete prepared by using building waste and preparation method of recycled aggregate medium-dry hard concrete

The invention discloses a recycled aggregate medium-dry hard concrete prepared by using building waste, which comprises the following raw materials of coarse aggregate, fine aggregate, a gelatinizing agent, a water reducing agent and water, wherein the gelatinizing agent comprises cement and coal ash, and the coarse aggregate comprises 50-100 percent of recycled coarse aggregate prepared from thebuilding waste. A preparation method of the recycled aggregate medium-dry hard concrete comprises the following steps of: pretreating the building waste, removing impurities, remaining waste concrete, waste bricks and the like; crushing and screening to prepare the recycled coarse aggregate; mixing the recycled coarse aggregate, natural sand, cement and water according to the proportion, adding the coal ash and the water reducing agent, stirring uniformly to obtain a mixture; and squeezing and forming the mixture, curing for 2 days to obtain the recycled aggregate medium-dry hard concrete. The invention solves the problems of worsening ecological environment and the like caused by difficulty in treating the building waste; and the building wastes are used for manufacturing the recycled aggregate for replacing natural aggregate, the increasingly deficient natural aggregate and damage degree to the ecological environment are reduced, and the living environment of human beings is protected. The recycled aggregate medium-dry hard concrete prepared by using the method has high strength and high abrasive resistance, and can be used for building base installations such as city roads, housing constructions and the like.

Owner:云南华威废弃物资源化有限公司

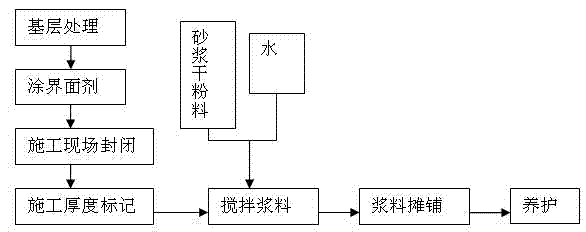

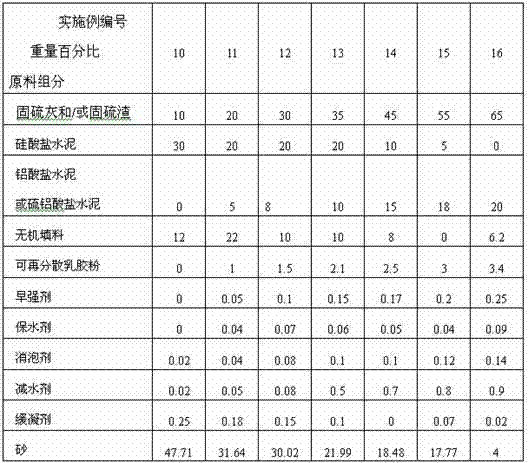

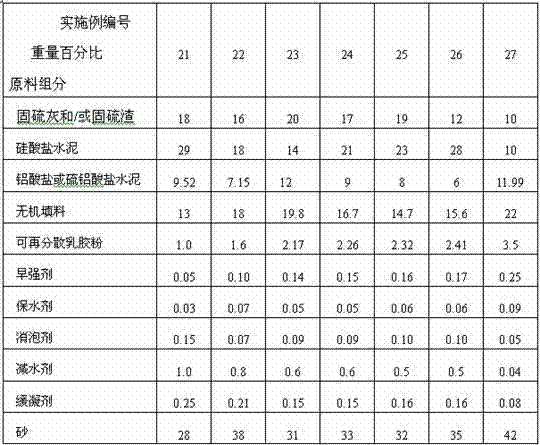

Circulating fluidized bed boiler ash cement-based self-leveling material

The invention discloses a circulating fluidized bed boiler ash cement-based self-leveling material, which is characterized by comprising the following components in percentage by weight: 10-70 percent of circulating fluidized bed boiler ash or / and cycled fluidized bed ash, 0-30 percent of silicate cement, 0-20 percent of aluminate cement or sulphoaluminate cement, 0-22 percent of inorganic filler, 0-3.5 percent of redispersible emulsion powder, 0-0.25 percent of early strength agent, 0-0.09 percent of water retention agent, 0-0.15 percent of defoaming agent, 0-1.0 percent of water reducing agent, 0-0.25 percent of inhibiting agent and 0-50 percent of sand. The cement-based self-leveling material is prepared by taking circulating fluidized bed boiler ash or / and cycled fluidized bed ash and the like as raw materials, so that circulating fluidized bed boiler ash or residues discharged by a circulating fluidized bed can be fully utilized, the waste of land resources and the pollution to the natural environment caused by open-air piling of fluidized bed boiler ash or residues are reduced, and the cost of the self-leveling material is reduced; and the prepared cement-based self-leveling material has the characteristics of high strength, high flowability, low contraction distortion and the like.

Owner:SOUTHWEAT UNIV OF SCI & TECH

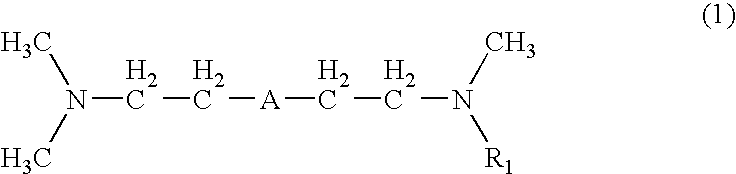

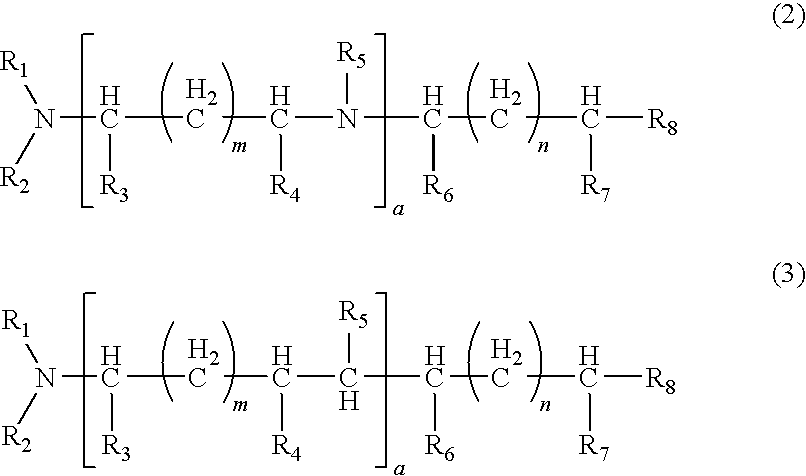

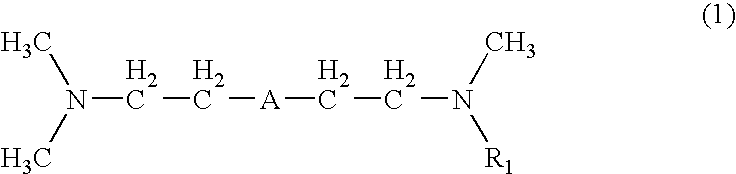

Catalyst composition for production of flexible polyurethane foam

InactiveUS20100113634A1Small shrinkageSmall overall deformationOrganic-compounds/hydrides/coordination-complexes catalystsHydrogenUnsaturated hydrocarbon

Owner:TOSOH CORP

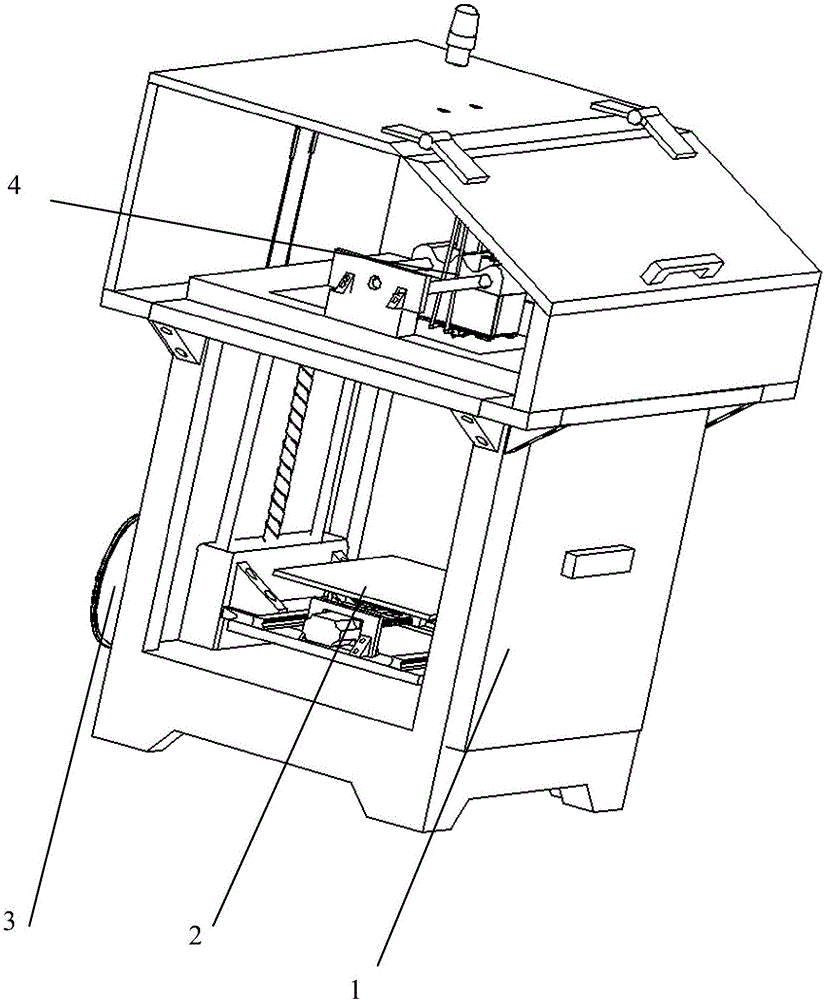

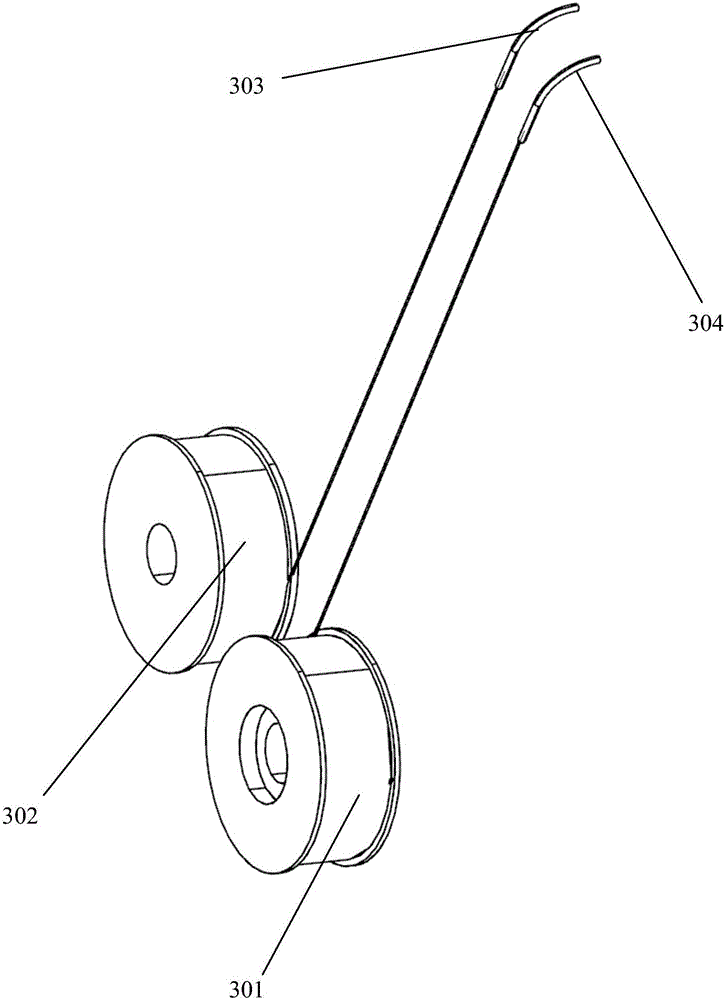

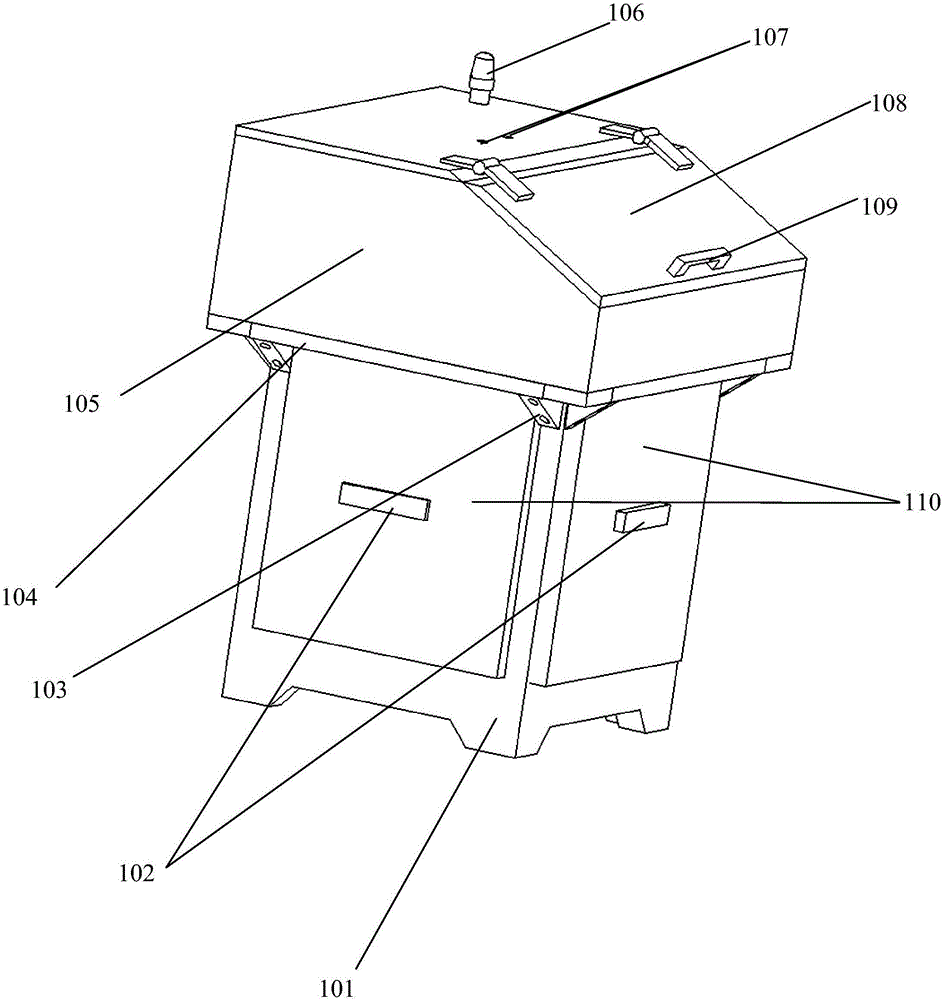

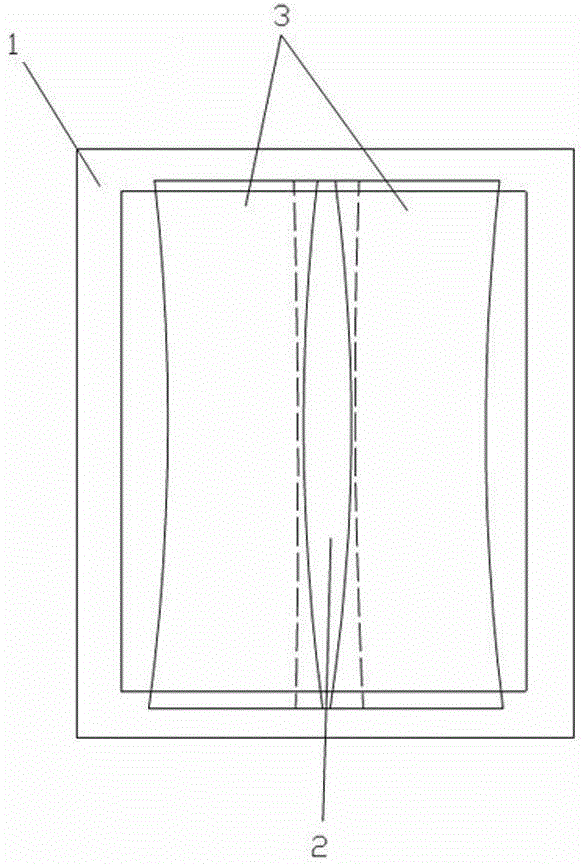

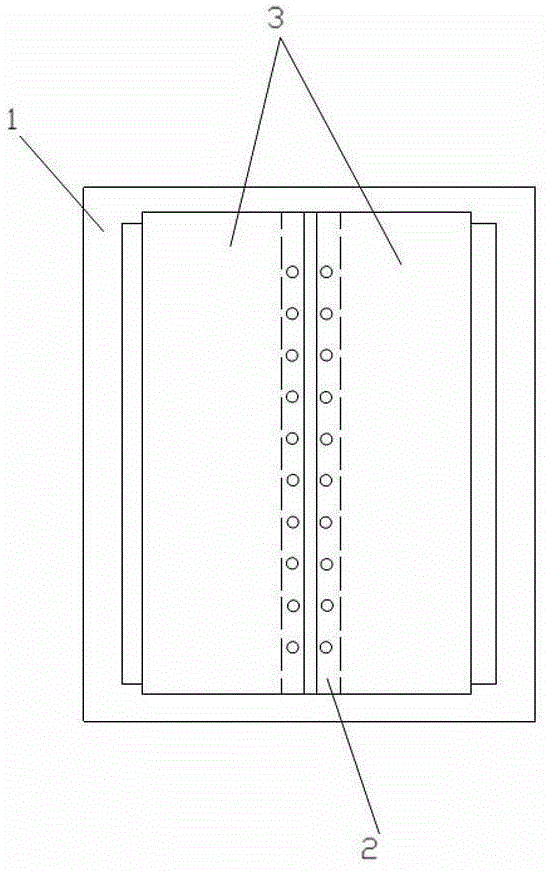

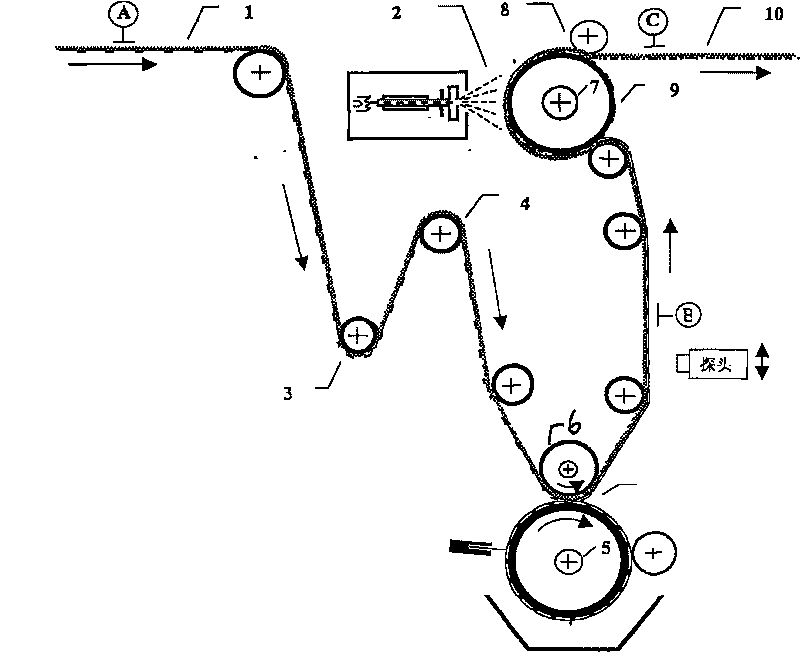

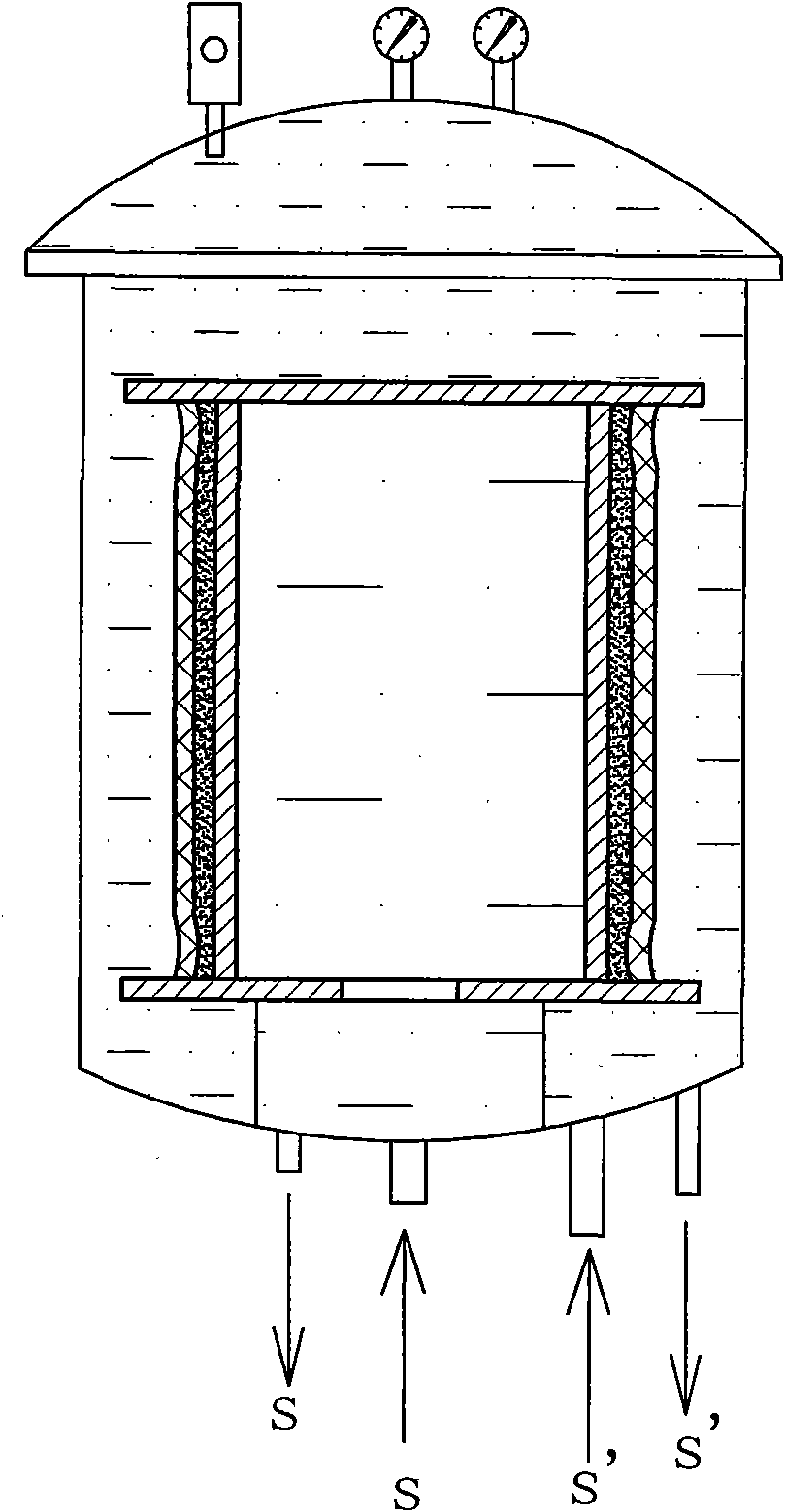

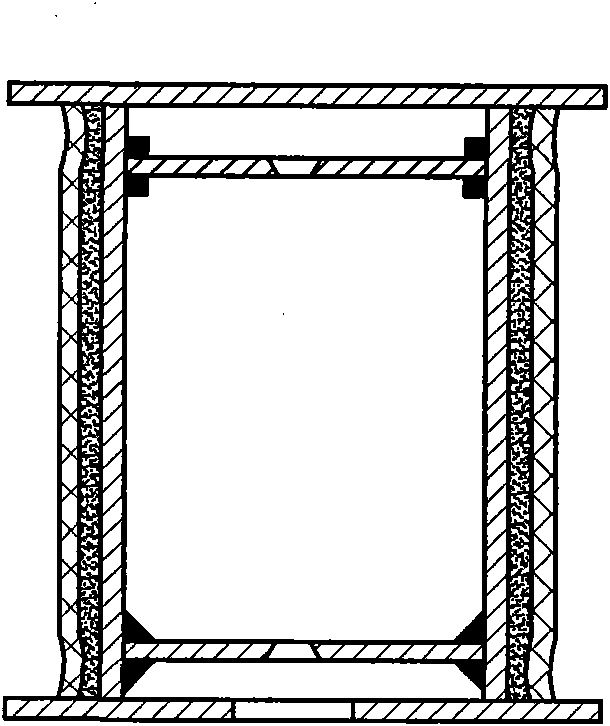

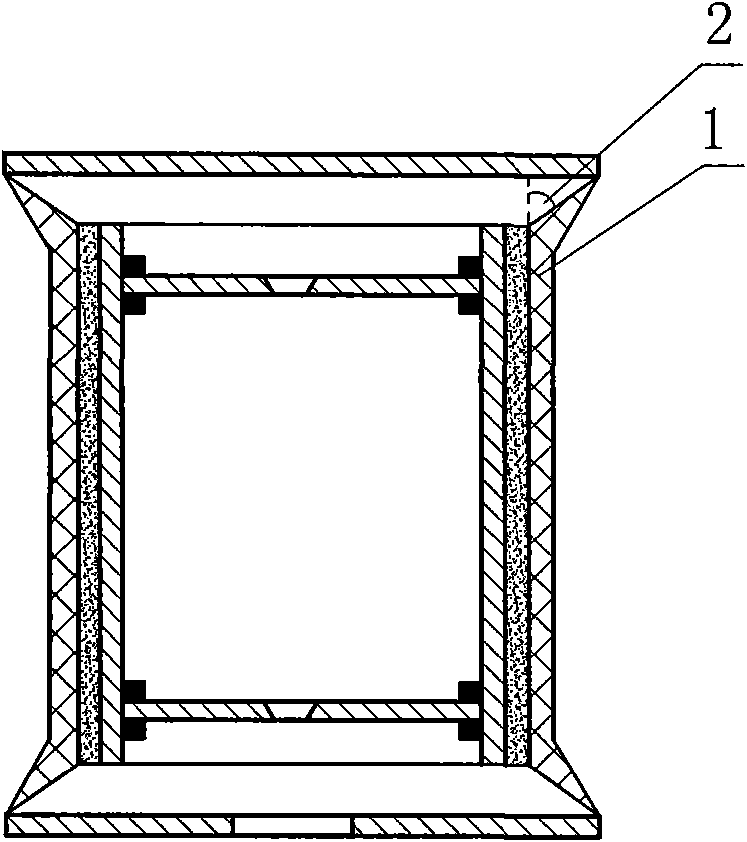

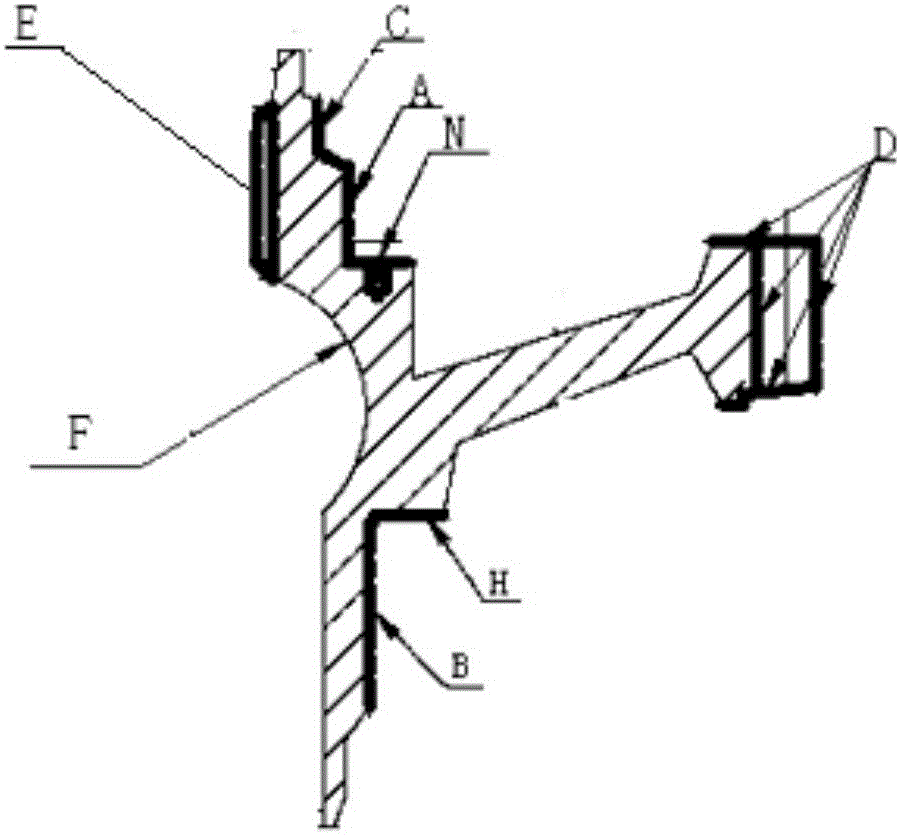

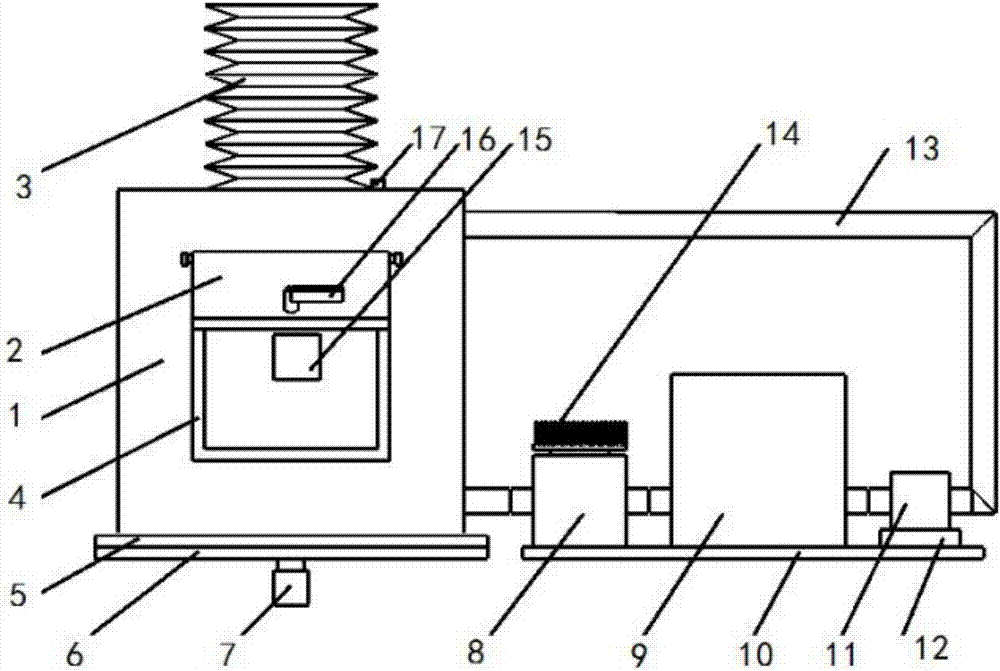

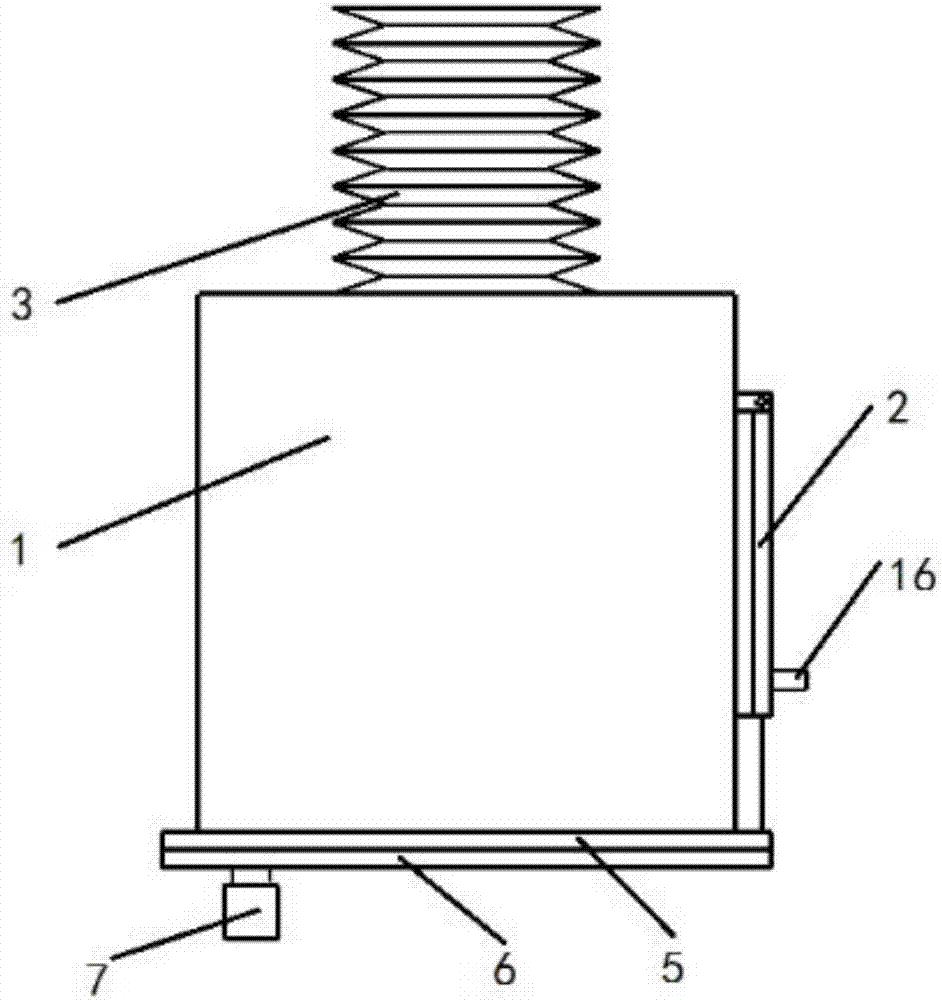

Sealed multi-material special engineering plastic additive manufacturing method and apparatus

ActiveCN106553337AImprove support strengthIncreased resistance to deformationManufacturing heating elementsManufacturing material handlingSelective laser sinteringManufacturing technology

The invention relates to sealed multi-material special engineering plastic additive manufacturing method and apparatus and belongs to the technical field of additive manufacturing of special engineering plastic. A three-axis movement platform assembly is installed inside a thermal insulation chamber assembly. A special engineering plastic filament delivery roll assembly is installed in a back surface plate of the thermal insulation chamber assembly. A spray nozzle assembly is disposed on the top of interior of the thermal insulation chamber assembly. The method and the apparatus achieve low temperature difference and low deformation in 3D printing of special engineering plastic, so that parts in complex structures, which have high crystalline degree, high mechanical strength and low surface roughness, can be formed from a high-melt-point special engineering plastic. Defects of large deformation, poor mechanical strength of a moulded part, and low size precision in a conventional high-temperature special engineering material printing process are overcome, and a defect of warping deformation during a powder moulding process in a selective laser sintering 3D printing technology is avoid. The method and the apparatus solve the problems such as high surface roughness in artificial bone 3D printing in the medical field, and have excellent medical and industrial application prospect.

Owner:JILIN UNIV

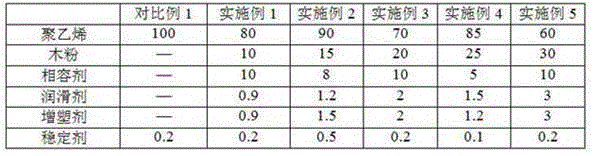

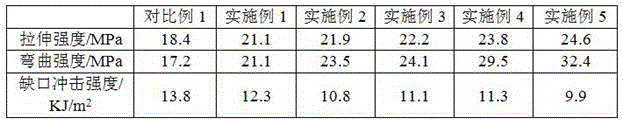

Polyethylene/wood powder composite wire for fused deposition modeling, and preparation method thereof

InactiveCN105295175APrevent crystallizationSmall shrinkage deformationAdditive manufacturing apparatusPlasticizerProcess conditions

The invention discloses a polyethylene / wood powder composite wire for fused deposition modeling, and a preparation method thereof. Raw materials and assistants used by the polyethylene / wood powder composite wire for fused deposition modeling comprise 70-90 parts of polyethylene, 10-30 parts of wood powder, 5-10 parts of a compatilizer, 0.9-3 parts of a lubricant, 0.9-3 parts of a plasticizer and 0.1-0.5 parts of a stabilizer. Addition of the wood powder to the polyethylene / wood powder composite wire inhibits crystallization of polyethylene, reduces shrinkage deformation of a fused deposition modeled product, and improves the modeling precision of the product. The fused deposition modeled product has the advantages of good toughness, improved mechanical performances and strong practicality. The invention also provides the making method of the polyethylene / wood powder composite wire. The method has the advantages of easy operation, low technological conditions and production device requirements, realization of large-scale popularization and production, wide market prospect and extremely good market benefits.

Owner:HENAN INST OF ENG

Wear-resistant and thermally stable alumina coating carrier

InactiveCN102189001AImprove wear resistanceSmall shrinkage deformationCatalyst carriersCatalyst activation/preparationNiobiumStabilizing Agents

The invention relates to a wear-resistant and thermally stable alumina coating carrier, which mainly solves the technical problem that an alumina coating is severely worn and even cracked and stripped under the action of a high temperature and water-vapor-containing air flow for a long time in the prior art. The alumina coating of the wear-resistant and thermally stable alumina coating carrier comprises at least one of gamma-Al2O3, delta-Al2O3 and theta-Al2O3 serving as a main body, at least one of samarium, thulium, yttrium, niobium, thorium, lanthanum, cerium and the like serving as a stabilizer, and at least one of calcium silicate, magnesium aluminate, zirconium aluminate, wollastonite, diopside, perlite and clay serving as an auxiliary agent, and a kernel is at least one carrier of alumina, silica, cordierite, spinel, sillimanite, andalusite and kyanite. Through the technical scheme, the problem is well solved, and the invention can be used for the industrial production of preparing the wear-resistant and thermally stable alumina coating carrier.

Owner:CHINA PETROLEUM & CHEM CORP +1

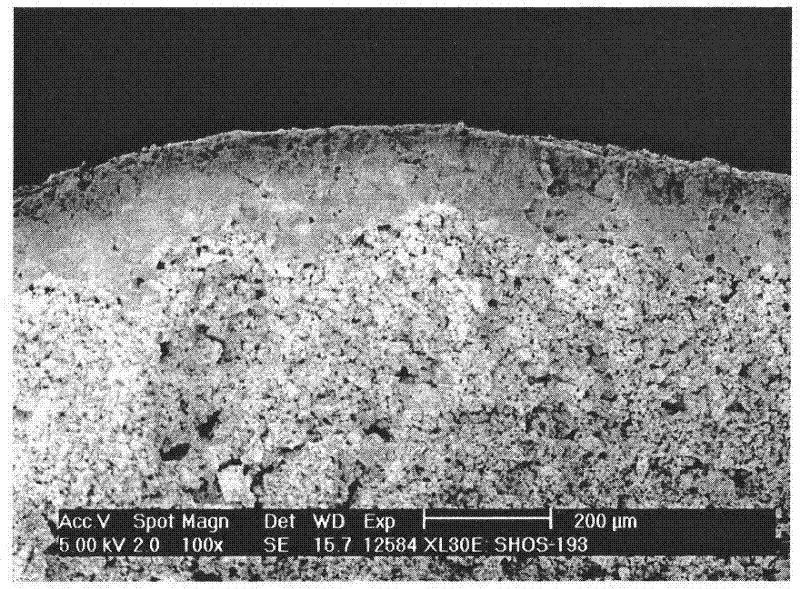

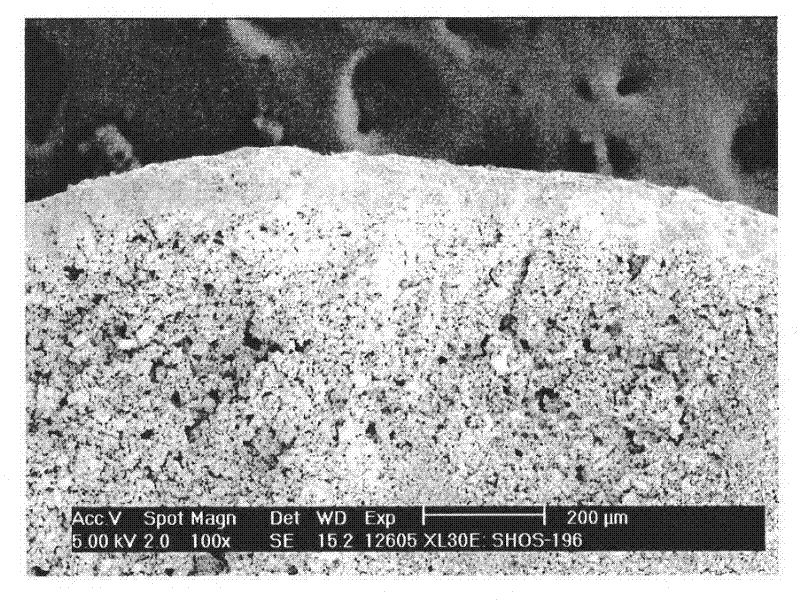

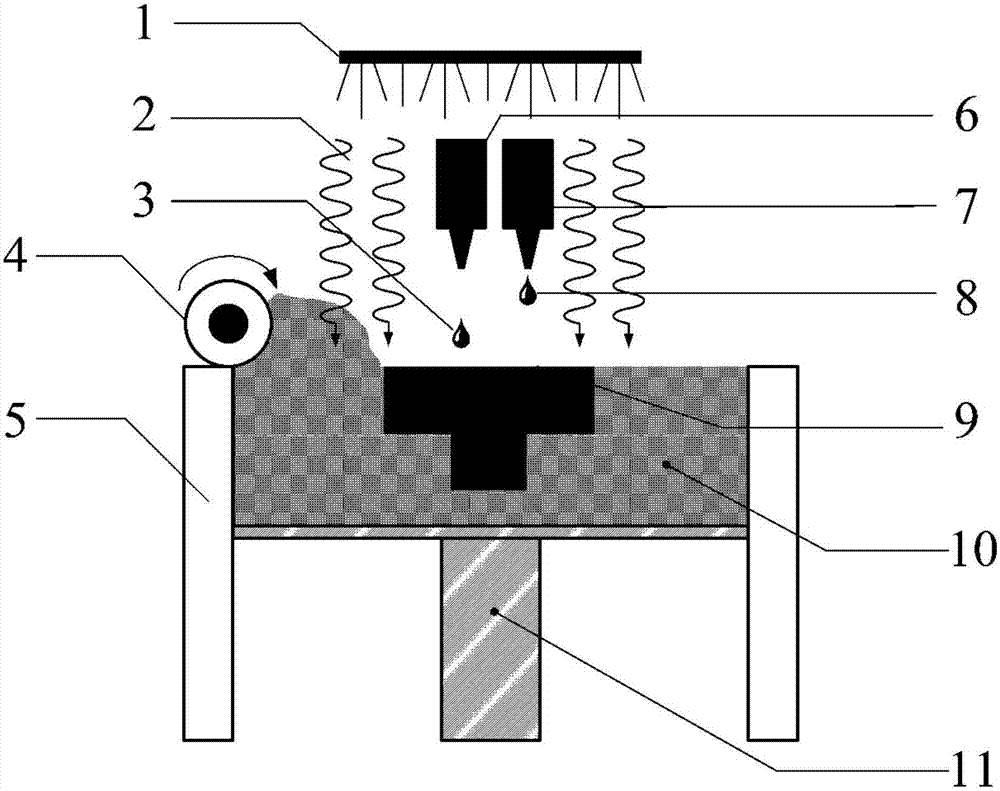

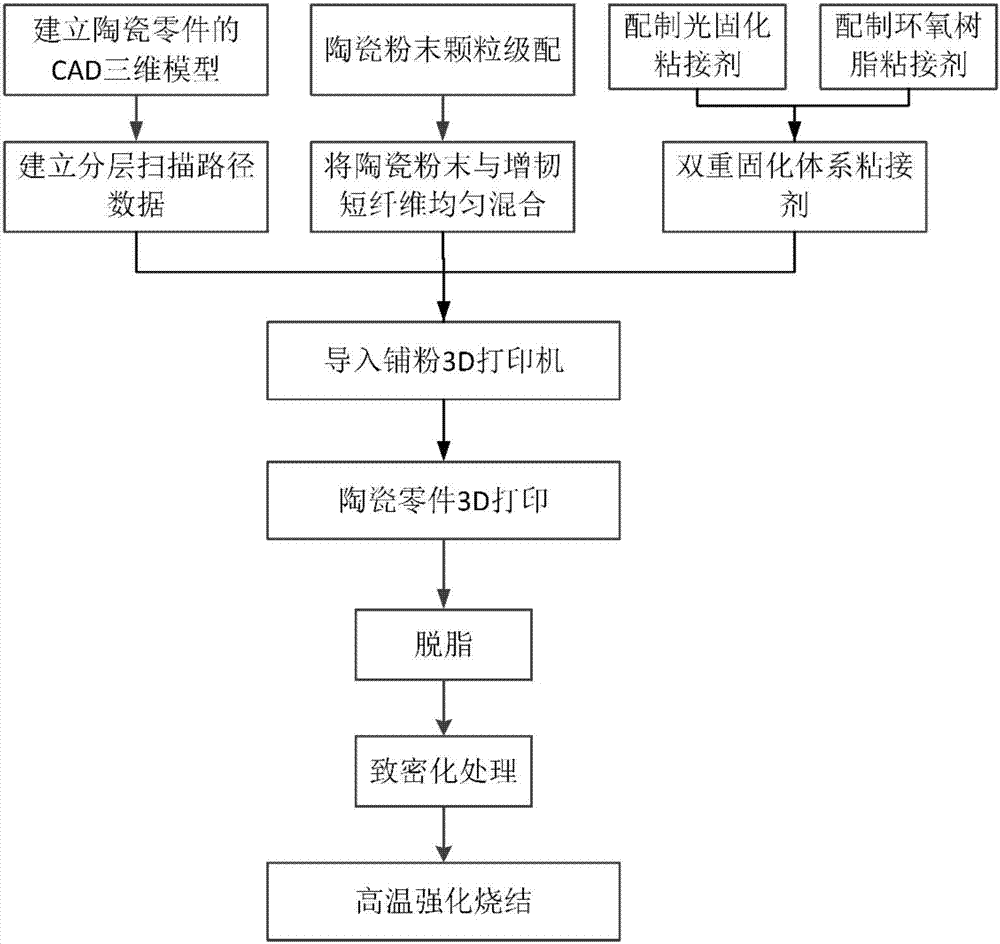

Ceramic part 3D (three dimensional) printing method based on adhesives of dual curing systems

InactiveCN107098715AWon't clogImprove curing efficiencyAdditive manufacturing apparatusSolubilityDual cure

The invention discloses a ceramic part 3D (three dimensional) printing method based on a photocuring adhesive. In a first curing system, a photosensitive resin-based adhesive solidifies quickly under the irradiation of ultraviolet light, bonds powder so as to take shape and has high curing efficiency; only when the photosensitive resin-based adhesive encounters the ultraviolet light, the photosensitive resin-based adhesive solidifies; and as the photosensitive resin-based adhesive is not likely to encounter the ultraviolet light in a spray nozzle, the photosensitive resin-based adhesive is not likely to solidify and block the printing spray nozzle. In a second curing system, an epoxy resin-based adhesive can also solidify quickly by adding polymercaptan serving as a solidification triggering agent; and as the epoxy resin and the polymercaptan triggering agent are in different spray nozzles and do not contact with each other, the epoxy resin-based adhesive is not likely to solidify and block the spray nozzle. As the adhesives of the dual curing systems are resin-based adhesives and no water is added all the time in the preparation process, the adhesives of the dual curing systems can be used for bonding water-solubility ceramic powder; and the green bodies of ceramic parts formed by the dual curing systems have very high strength and forming accuracy.

Owner:XI AN JIAOTONG UNIV

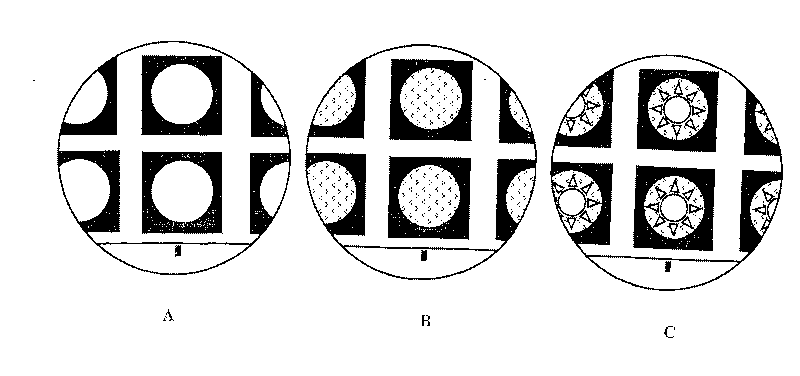

Manufacturing method of masks

ActiveCN104611669ASmall shrinkage deformationReduce shrinkage problemsVacuum evaporation coatingSputtering coatingPhysicsEngineering

The invention discloses a manufacturing method of masks. The manufacturing method comprises the following steps: (1) measuring an environment temperature T1; (2) tensioning the two ends of a shielding mask, and fixing the shielding mask on a mask frame and calculating the deformation of the shielding mask; (3) fixing masks in the left region and the right region of the mask frame, respectively, wherein the edges of the masks are as long as the overlapping part of the shielding mask; calculating the deformation of the masks; (4) putting the mask frame on which the shielding mask and the masks are fixed into a heating room and heating to a temperature T2 for thermal expansion; (5) welding and fixing the overlapping regions of the masks and the shielding masks in an environment at the temperature T2; and (6) taking out the mask frame from the heating room and cooling to the temperature T1. By the manufacturing method dislcosed by the invention, the shrinking deformation problem due to tension can be effectively reduced and the quality of the mask is improved, and the method is capable of meeting the requirements of manufacturing the masks of high PPI display screen products.

Owner:TRULY HUIZHOU SMART DISPLAY

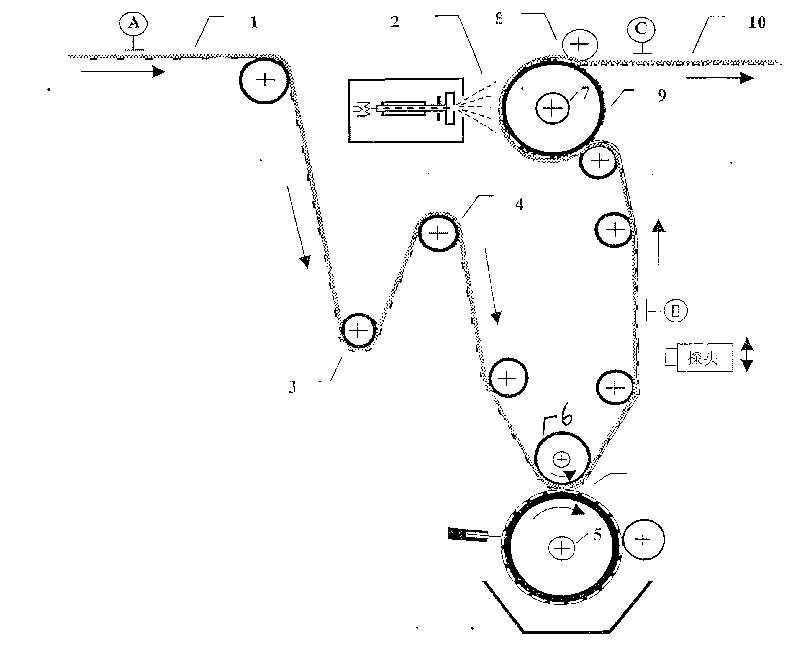

Method for printing embossment microstructure with positioned color register

ActiveCN101691091AOverprint accuracy can be controlledSmall shrinkage deformationPattern printingPlate printingDie castingEngineering

The invention relates to a method for printing an embossment microstructure with a positioned color register, in particular to a method for the integrated online printing of an embossment type optical microstructure layer which is positioned and nested with an ink color. The method comprises the following steps: taking a microstructure area as a special color for printing; printing a molding ink at a specified position; in the state that the ink area is not completely dried and solidified, attaching and die-casting the ink area in a positioning mode by an embossment microstructure mother set roller on a next printing plate roller so that the ink is embedded in an embossment microstructure groove on a mother set; and solidifying and molding a hinge for drying the ink in a coating area of a printing material and a microstructure image, wherein the embossment shaped microstructure on the mother set roller is completely copied to the ink surface of a printing stock in a mirror image mode, and a copying molding area serves as a color register printed at the specified position and can be connected with front and back printing colors to form a + / -0.15 millimeter printing registration accuracy. The method can achieve the positioned color register with a common printing and the accurate positioning of pattern and ink printing on the mother set.

Owner:上海冠众光学科技有限公司

Crosslinked polypropylene viscoelastic composite coating and preparation method thereof

InactiveCN103642356ASmall shrinkage deformationExcellent Rigidity and HardnessAnti-corrosive paintsCross-linked polyethylenePolypropylene

The invention relates to a crosslinked polypropylene viscoelastic composite coating and a preparation method thereof. The coating is prepared from components A and B by mixing, and the weight ratio of the component A to the component B is 9:1; the component A comprises the following ingredients in parts by mass: 100 parts of polypropylene, 0.05-0.2 part of an initiator, 10-20 parts of a graft, 3-5 parts of silane, 3-8 parts of an elastomer, and 0.1-0.5 part of a grafting aid; the component B comprises the following ingredients in parts by mass: 100 parts of polypropylene, 2-10 parts of a heat conducting agent, 0.1-1 part of a dispersing lubricant, 0.3-0.5 part of a surface treatment agent, 0.4-1 part of a catalyst, 1-3 parts of a dehydrating agent, and 0.1-0.4 part of an antioxidant. A base resin of the composite coating is crosslinking polypropylene which both ensures the sufficient crosslinking efficiency and reduces the crystallinity and shrinkage distortion arising from the reduction of the crystallinity in comparison with currently used crosslinking polyethylene, and a crosslinked material has excellent rigidity and hardness and also has excellent toughness and creep resistance.

Owner:天津市华鑫达投资有限公司

Polypropylene wire material for 3D printing and preparation method thereof

ActiveCN108641197ANo significant change in melting pointWon't breakAdditive manufacturing apparatusWire rodPolymer science

The invention discloses a polypropylene wire material for 3D printing and a preparation method thereof. The polypropylene wire material is composed of co-polypropylene, low-melting-point homo-polypropylene, inorganic filler, thermoplastic elastomers, a plasticizer and a stabilizer. The polypropylene wire material is low in material crystallinity degree, shrinkage distortion and warping, has good 3D printing effects and printing accuracy, and can reduce cost to a large extent. The preparation method for the polypropylene wire material for 3D printing is simple in technology and lower in production equipment requirement, can achieve large-scale production and popularization, and has a wide market prospect.

Owner:WANHUA CHEM GRP CO LTD

High-performance potassium magnesium phosphate cement mortar and preparation method thereof

InactiveCN105174901AAdjustable clotting timeSolve the condensation fastMagnesium phosphateMagnesium orthophosphate

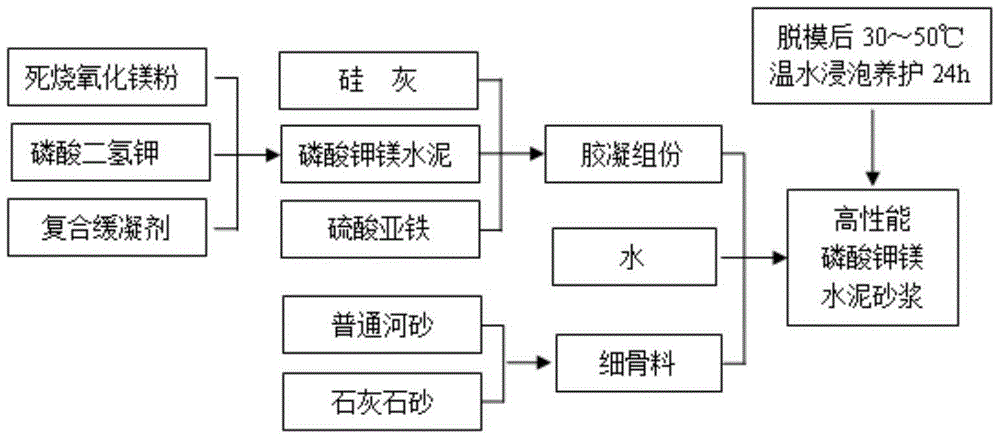

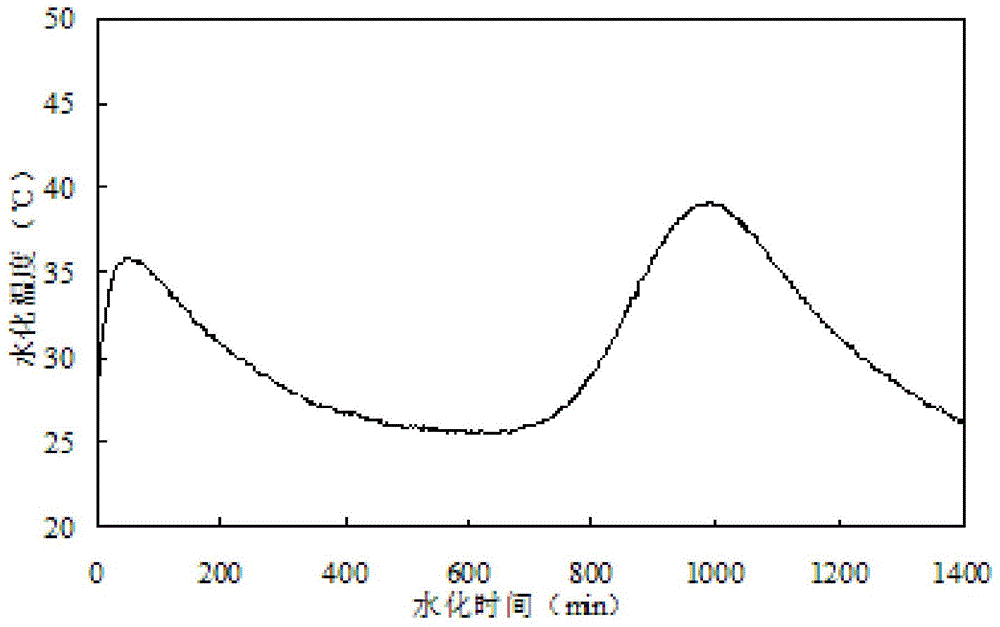

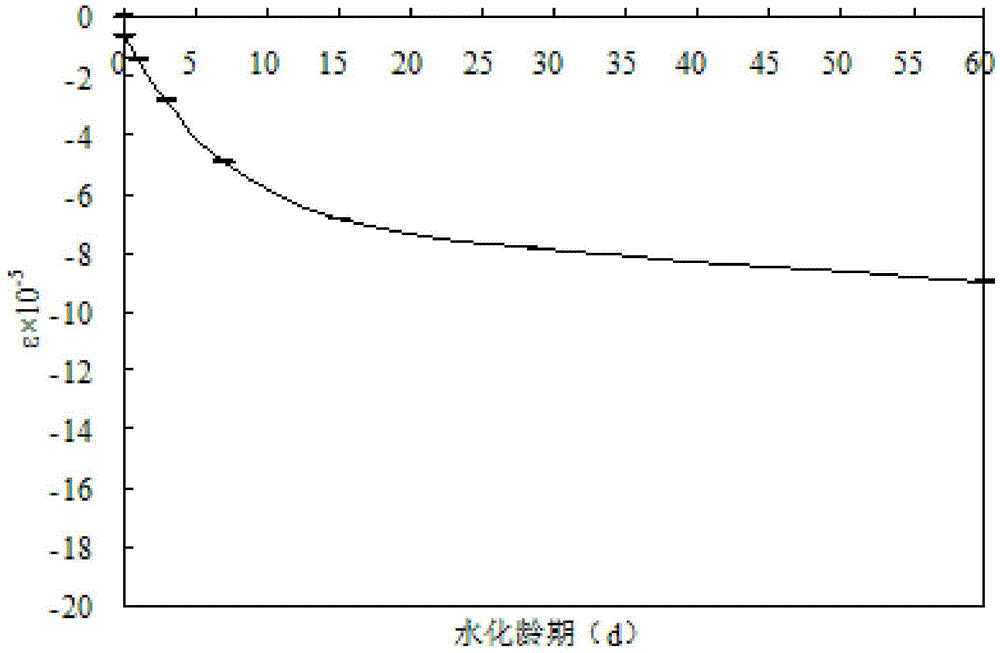

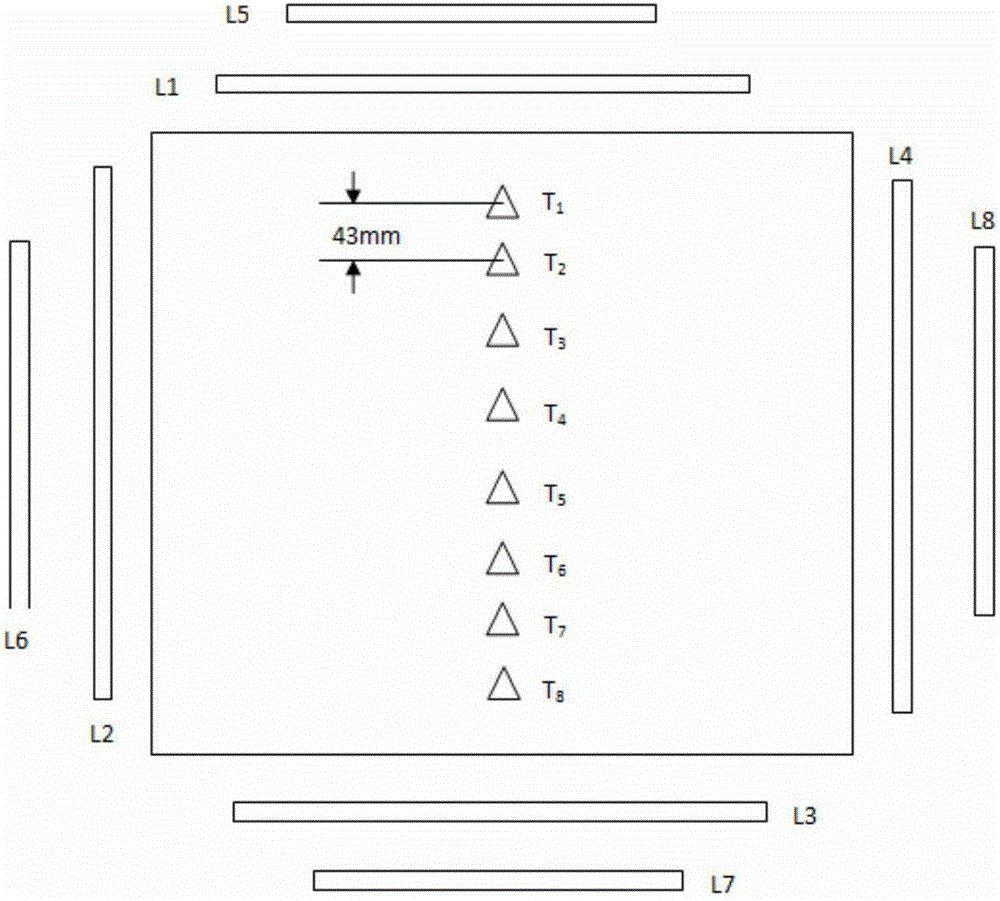

The invention discloses a preparation method of high-performance potassium magnesium phosphate cement mortar. The preparation method comprises the following steps: 1, taking dead burned magnesium oxide powder as an alkaline component and potassium dihydrogen phosphate as an acidic component, and doping a compound retarder to prepare potassium magnesium phosphate cement; 2, preparing a gelling component of the potassium magnesium phosphate cement mortar from the potassium magnesium phosphate cement, silica fume and ferrous sulfate; 3, mixing common river sand with limestone sand to prepare a fine aggregate of the potassium magnesium phosphate cement mortar; and 4, mixing the gelling component prepared in the step 2 and the fine aggregate prepared in the step 3 with water to prepare the potassium magnesium phosphate cement mortar. For the potassium magnesium phosphate cement mortar prepared by the method disclosed by the invention, the coagulation time is controllable, the hydration heat is released stage by stage, the high early strength and later strength are increased continuously, the water stability is high, the volume shrinkage is small, the aggregate cement ratio is high, the aggregate resource is rich, the price is low, and the bonding strength with an ordinary silicate concrete component is high. The high-performance potassium magnesium phosphate cement mortar disclosed by the invention is simple in preparation process, convenient to use, energy-saving, environment-friendly and relatively low in cost.

Owner:YANCHENG INST OF TECH

Selected region laser sintering and molding method of ultrahigh molecular weight polyethylene

ActiveCN105172154AImprove mechanical propertiesHigh dimensional accuracyAdditive manufacturing apparatusCeramic shaping apparatusSelective laser sinteringLaser scanning

The invention discloses a selected region laser sintering and molding method of ultrahigh molecular weight polyethylene. The selected region laser sintering and molding method comprises the following steps: (1) heating ultrahigh molecular weight polyethylene powder in selected region laser sintering and molding equipment to a pre-heated temperature; (2) molding the ultrahigh molecular weight polyethylene powder in the selected region laser sintering and molding equipment by adopting pre-set laser scanning speed and output power to obtain a molded piece; and (3) taking out the molded piece and keeping the heat at a temprature of 110-130 DEG C for 8-12 hours, and then cooling to obtain a molded part of the ultrahigh molecular weight polyethylene. The molded part of the ultrahigh molecular weight polyethylene, molded by the method disclosed by the invention, has relatively high mechanical property and size precision, has small transformation shrinkage and is particularly suitable for manufacturing medical auxiliary tools.

Owner:安徽隆源成型科技有限公司

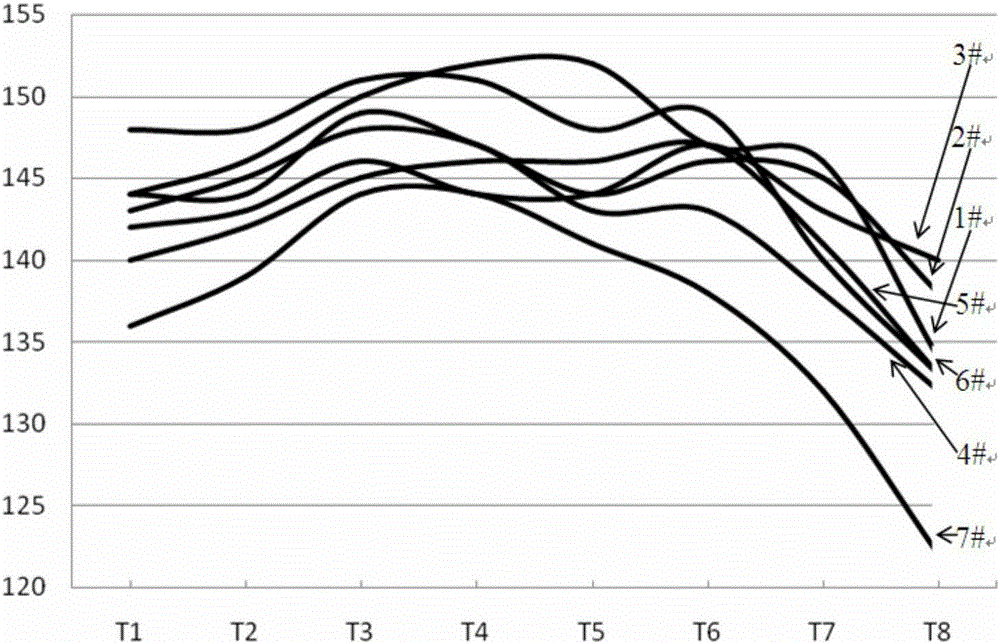

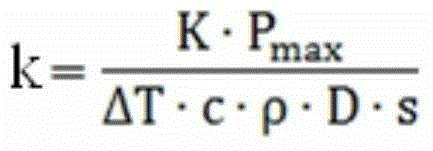

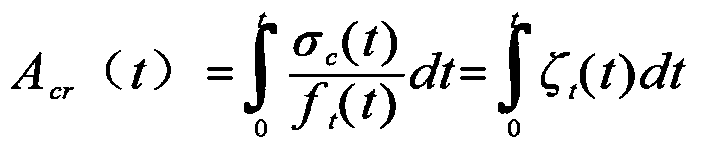

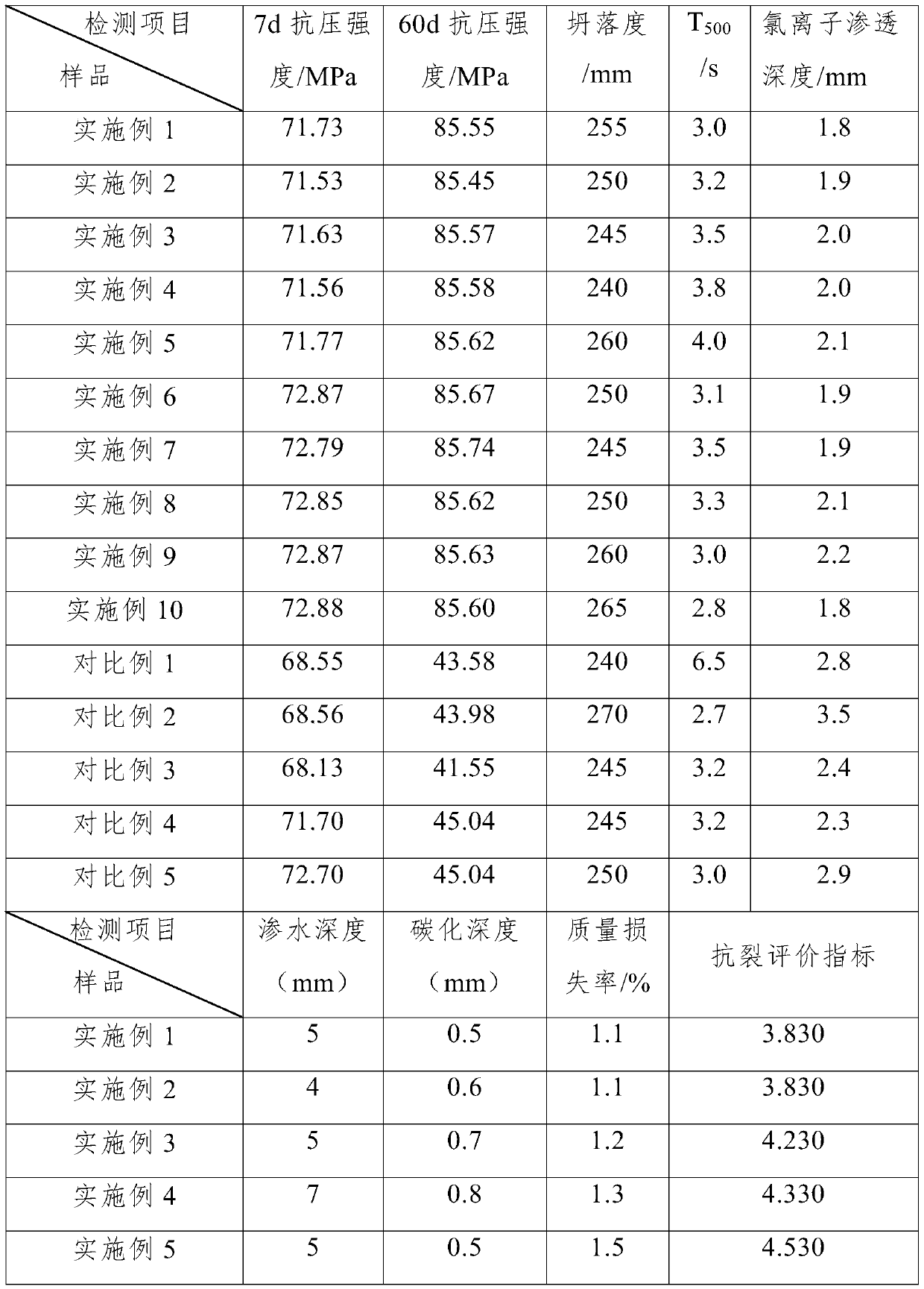

C70 mass concrete and preparation process thereof

The invention discloses C70 mass concrete. The C70 mass concrete is prepared from the following components by mass: 140 to 170 parts of water, 400 to 450 parts of cement, 1,000 to 1,200 parts of crushed stone, 550 to 650 parts of gravel, 70 to 110 parts of coal ash, 60 to 90 parts of mineral powder, 30 to 70 parts of silica fume, 8 to 10 parts of a pumping agent, 35 to 45 parts of an anti-crackingagent, and 0.3 to 0.4 part of an internal curing agent. The invention also discloses a preparation method for the C70 mass concrete. The method comprises a first step of uniformly mixing sand, graveland water and a second step of adding other components and carrying out uniform mixing under stirring. According to the composition of the mass concrete in the invention, mineral powder, silica fumeand fly ash are used as mineral admixtures and can delay the release rate of cement hydration heat and reduce the shrinkage and deformation of the concrete, and the mineral admixtures acts synergistically with the other components to inhibit the generation of cracks at the same time; and the preparation method of the invention is simple in process and easy to implement.

Owner:陕西秦汉恒盛新型建材科技股份有限公司

Interior wall plastering mortar and construction method thereof

InactiveCN101712545AHigh tensile strengthReduce stretchCovering/liningsSolid waste managementRiver sandFineness

The invention provides interior wall plastering mortar, which is prepared by mixing the following components in part by weight: 30 to 35 parts of ordinary Portland cement, 4 to 5 parts of hydrated lime, 5 to 10 parts of light aggregate, 50 to 60 parts of heavy aggregate, and 1.0 part of C-type composite auxiliary, wherein the light aggregate is an inorganic vitrified hollow cellular material of which the fineness is lower than 100 meshes; the heavy aggregate is ordinary river sand; and the C-type composite auxiliary is sold by Guangzhou Hecheng Trading Company. The construction method for the interior wall plastering mortar comprises the following steps: diluting the light energy-saving interior wall plastering mortar with water accounting for 30 to 50 percent of the weight of the mortar; and mechanically or manually stirring the diluted mortar until the mortar is mixed uniformly to achieve the viscosity suitable for mechanical spraying or manual construction. Therefore, the mortar can be sprayed mechanically or constructed manually. The interior wall plastering mortar has light weight and energy conservation, can prevent hollowness, cracking and falling off by being matched with a light wall body, can effectively reduce cracking of the mortar, ensures the quality of construction work, has the advantages of heat insulation and noise reduction, low cost of unit area, good grain composition, good peaceability, mechanical construction contribution and simple process.

Owner:SHENZHEN GRANDLAND DECORATION GROUP

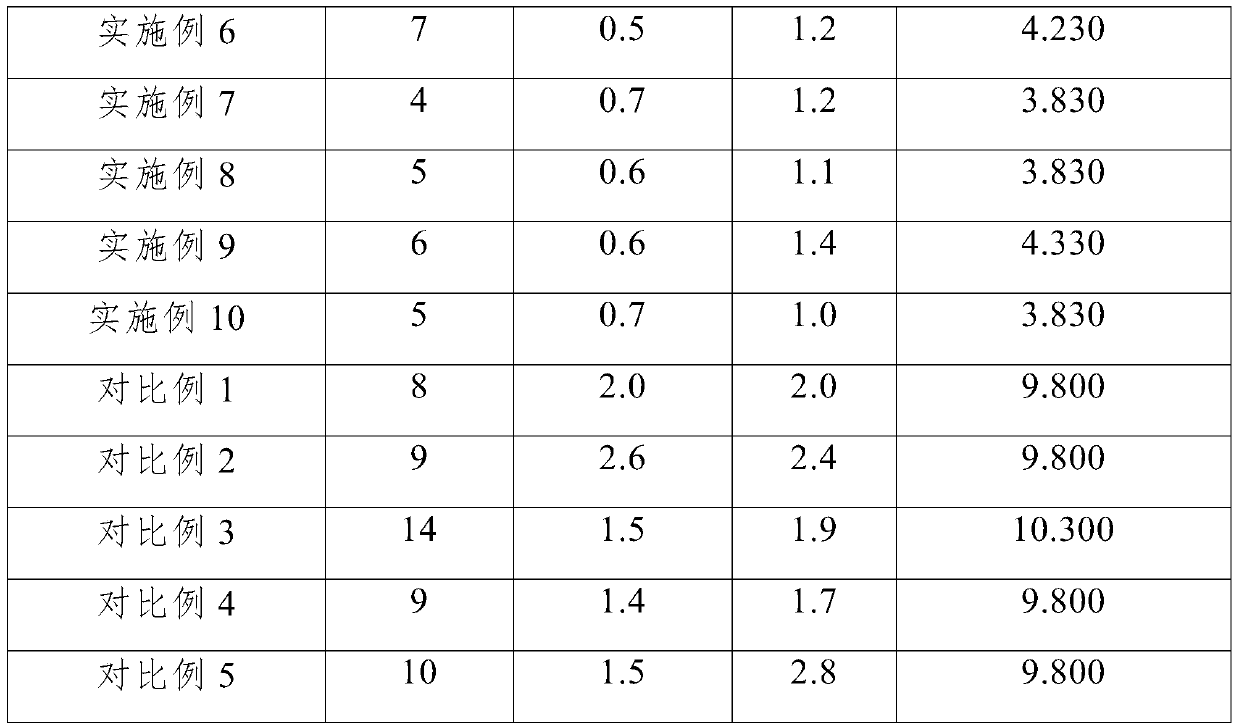

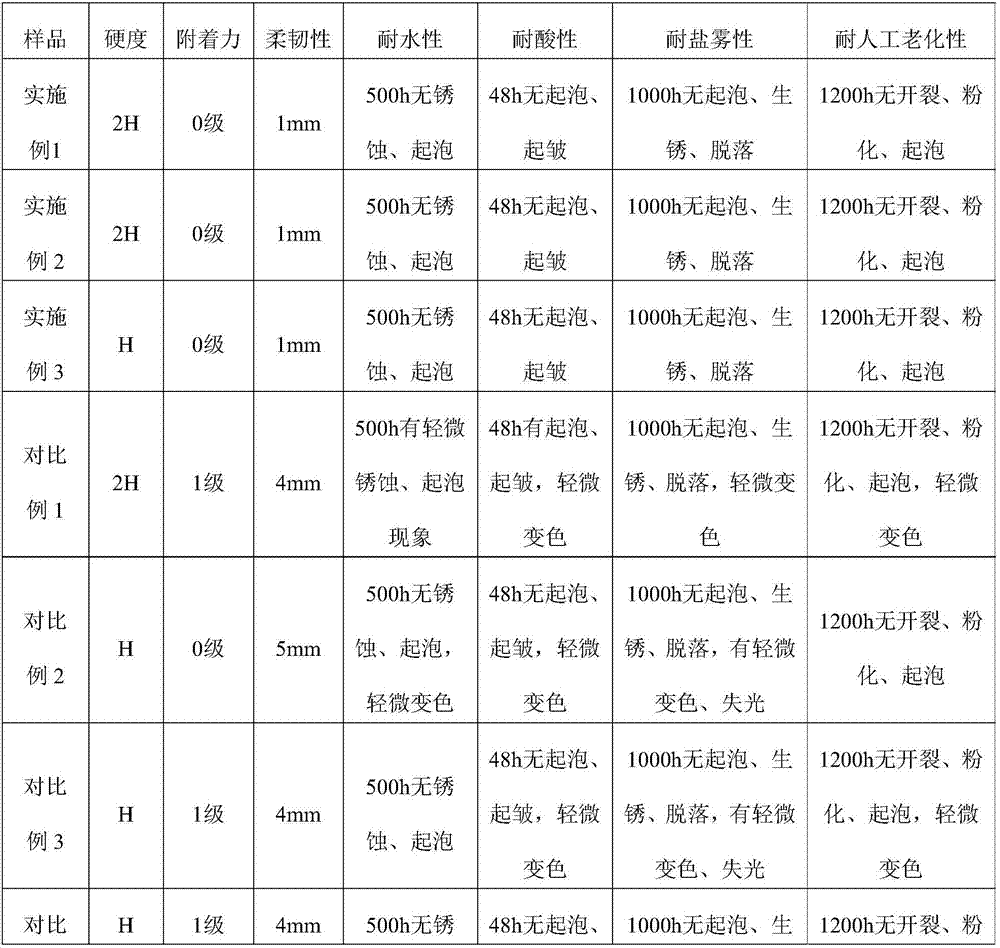

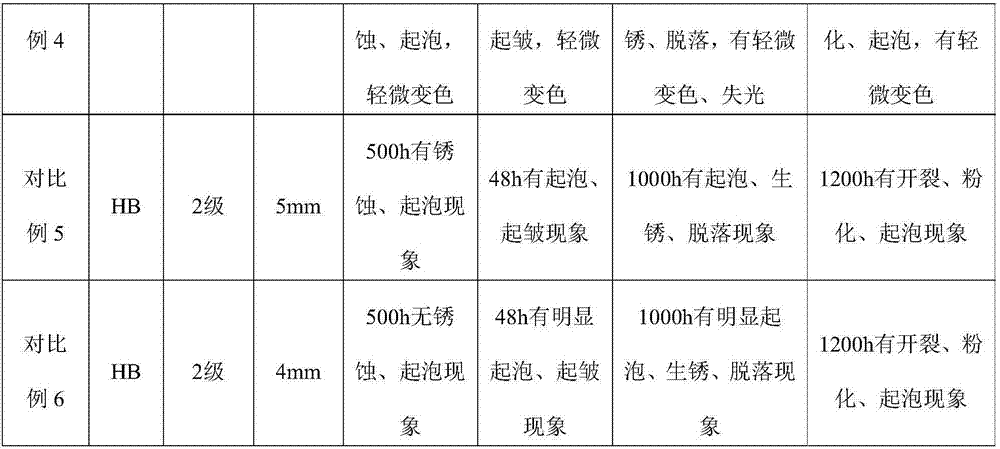

Coating method for water-based paint for engineering machines

PendingCN107234047AMeet painting requirementsImprove physicsPretreated surfacesAnti-corrosive paintsEpoxyWater based

The invention provides a coating method for water-based paint for engineering machines. The method comprises the following steps that a base material is pretreated; primer is sprayed, and baking is conducted after leveling; and finishing coat is sprayed, and baking is conducted after leveling, wherein the primer is water-based epoxy corrosion resisting primer, and the finishing coat is water-based crylic acid polyurethane finishing coat. By adoption of the coating method and in cooperation with the specific water-based paint for coating of the engineering machine base material, the defect of a paint film can be effectively avoided, and the flexibility, corrosion resistance and durability of the paint film are greatly improved.

Owner:HEBEI CHENYANG INDAL & TRADE GROUP CO LTD

Composite wax powder forming material for laser sintering and preparation method thereof

A composite wax powder forming material for laser sintering is formed by mixing bi-component wax powder materials, gaseous-phase silica, organic bentonite, diphenyl ketone light absorber and nonionic antistatic agents, wherein the bi-component wax powder materials are prepared by mixing medium-molecular-weight polyethylene wax with the ring-and-ball softening point of 80-100 DEG C and low-molecular-weight polyethylene wax with the ring-and-ball softening point of 60-80 DEG C, drying in a vacuum manner, preshrinking and quenching by liquid nitrogen. Shrinkage and buckling deformation and the like of the composite wax powder forming material during laser sintering are improved, size accuracy of sintered parts is improved, linear shrinkage of produced wax powder forming parts is 0.3-0.6%, size is stable, and high-accuracy and large-size wax patterns and wax molds can be manufactured.

Owner:ZHONGBEI UNIV

Precision titanium part manufacturing method

The invention provides a precision titanium part manufacturing method. The method includes the following steps that titanium powder with the average particle size being 46.82 micrometers, titanium powder with the average particle size being 34.48 micrometers, and titanium powder with the average particle size being 24.36 micrometers are evenly mixed; the titanium powder is added to binder particles to be mixed for 1 hour at the temperature of 175 DEG C to 180 DEG C, and feed is obtained after the mixture is cooled; the feed is injected into forming titanium part green bodies under the conditions that the injection temperature ranges from 175 DEG C to 180 DEG C, the injection pressure ranges from 70 MPa to 80 MPa, the dwell pressure ranges from 80 MPa to 85 MPa, the injection speed ranges from 60 mm / S to 65 mm / S and the cooling time is 10 S; the titanium part green bodies are degreased under the conditions that the temperature ranges from 110 DEG C to 130 DEG C, the nitric acid flow rate is 1.5 ml / min, and the nitrogen flow rate is 120 ml / min; and the degreased titanium part green bodies are sintered to form titanium parts under the conditions that the temperature rising speed is 4 DEG C / min, the temperature ranges from 1200 DEG C to 1280 DEG C, the time is 90 min and the vacuum degree is 1*10<-3> Pa. By means of the precision titanium part manufacturing method, the titanium parts in the final shape with high size precision can be manufactured directly with the low production cost.

Owner:GUANGDONG INST OF NEW MATERIALS

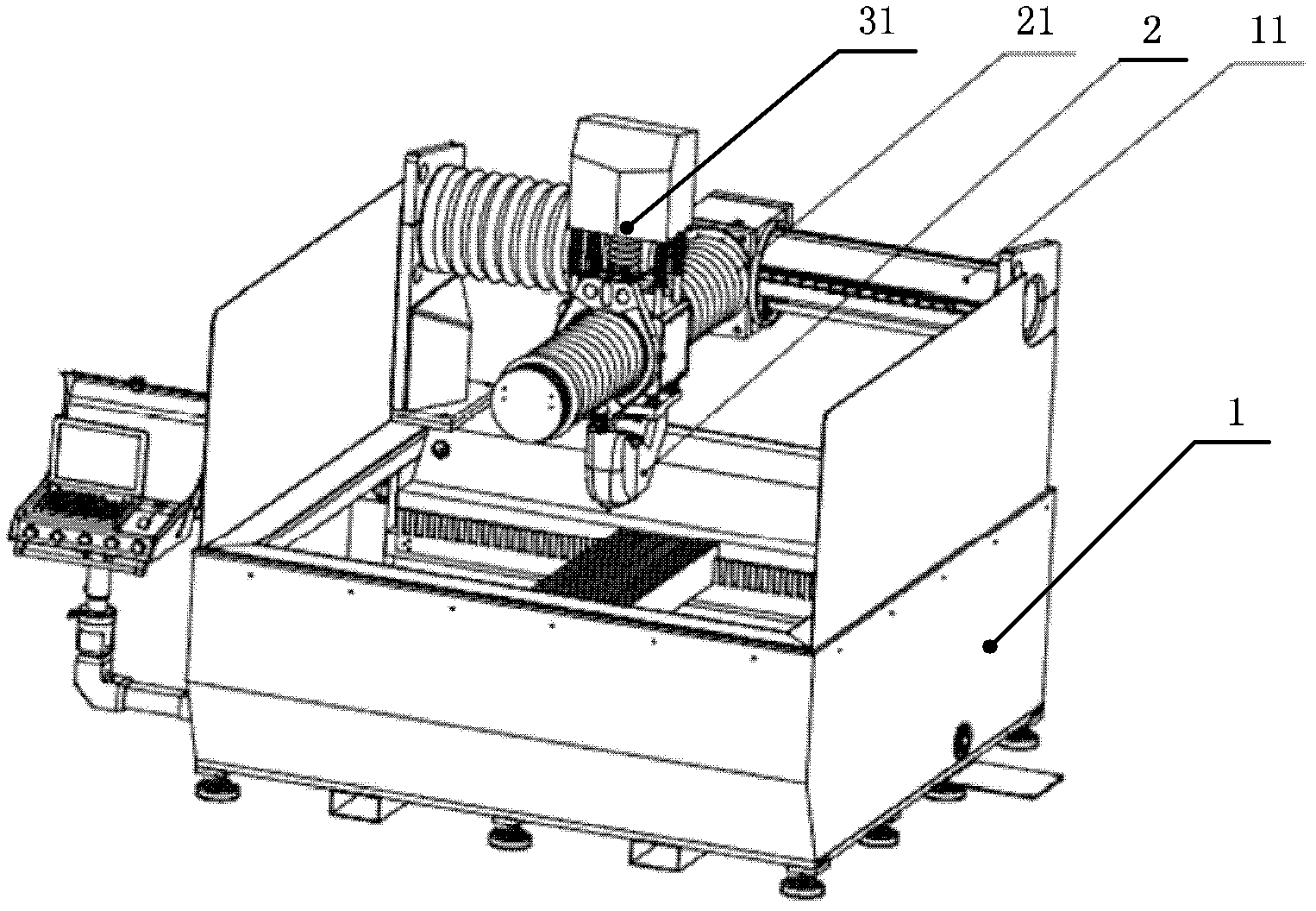

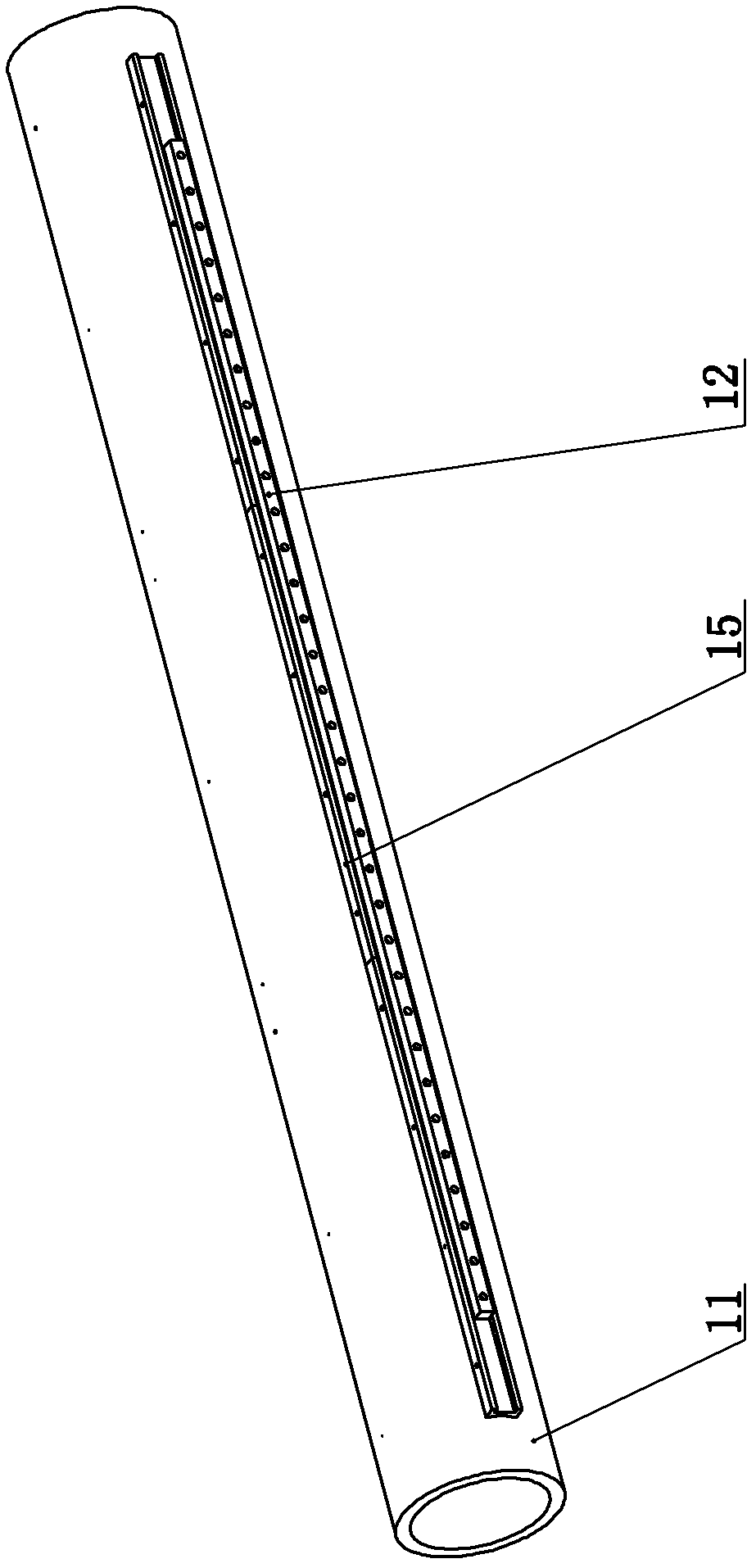

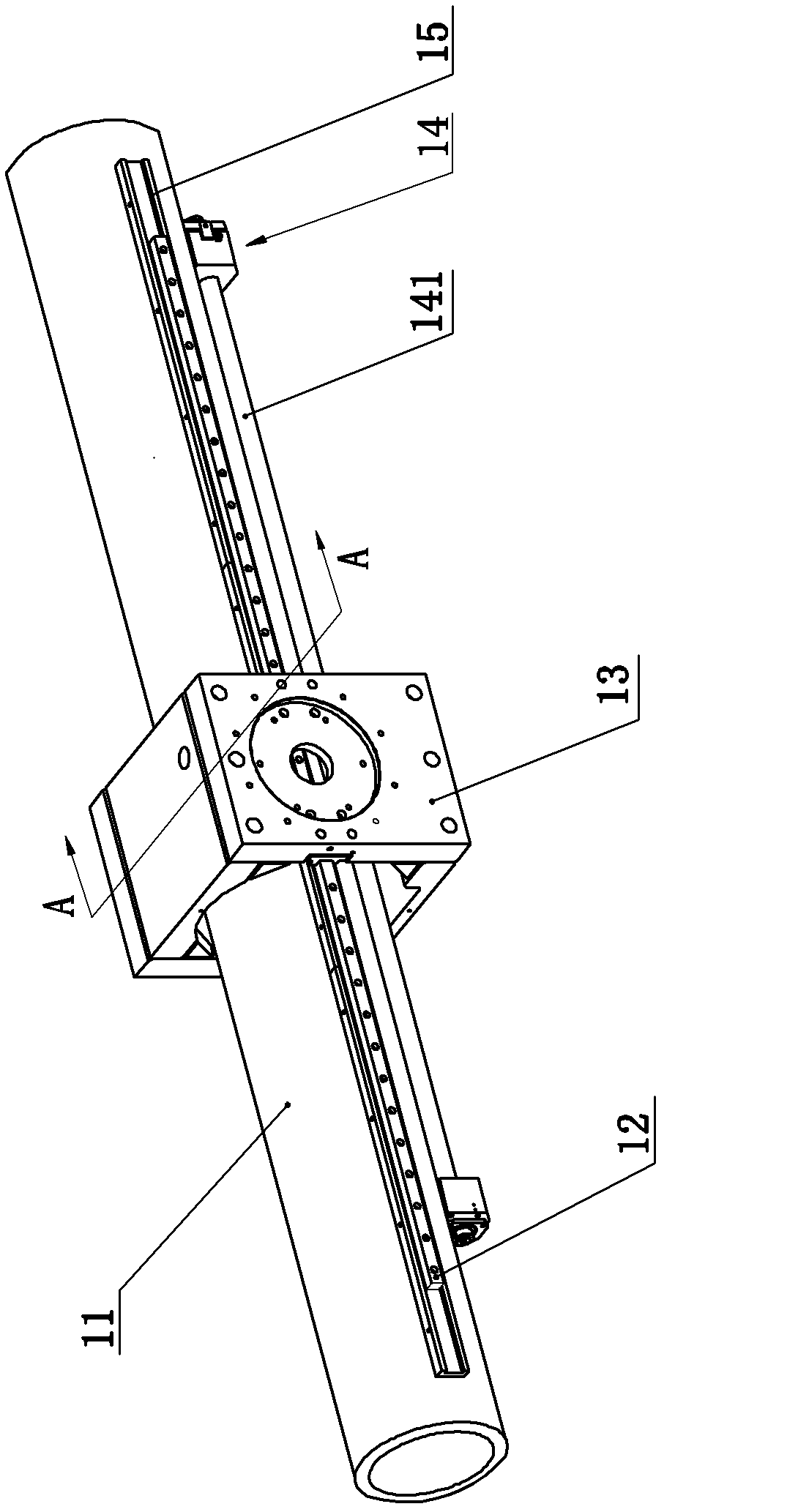

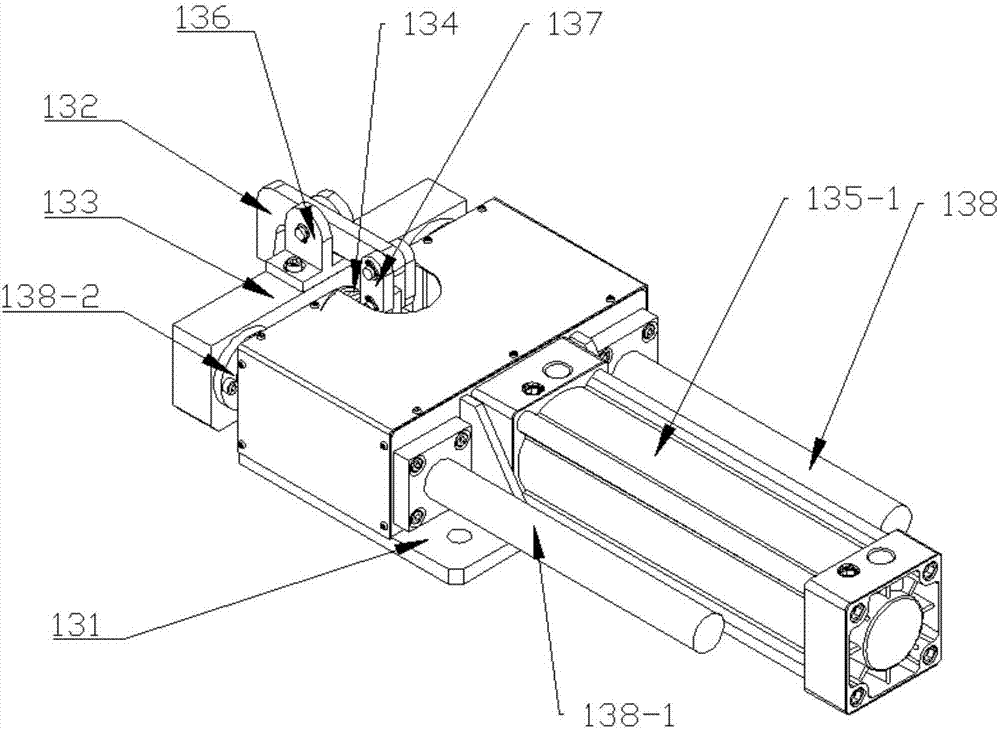

Orthogonal three-axis machine tool

ActiveCN102398224AGuaranteed machining accuracyReduce manufacturing costAbrasive machine appurtenancesAbrasive blasting machinesEngineeringCantilever

The invention provides an orthogonal three-axis machine tool. The machine tool comprises a machine tool body, an XYZ three-axis motion component and a machining head component, wherein the XYZ three-axis motion component comprises orthogonal X-axis beam, Y-axis cantilever and Z-axis sliding frame; the X-axis frame is provided with a first groove, an X-direction guide rail, a first horizontal sliding seat and a first transmission device; the Y-axis cantilever is provided with a second groove, a Y-direction guide rail, a second horizontal sliding seat and a second transmission device; and molded plastic metal is filled in at least one of gaps of joints of the first groove and the X-direction guide rail, the second groove and the Y-direction guide rail, the first horizontal sliding seat and the first transmission device, the second horizontal sliding seat and the second transmission device, the Y-axis cantilever and the first horizontal sliding seat or the Z-axis sliding frame and the second horizontal sliding seat. The parallelism, straightness and verticality of the X-direction guide rail and the Y-direction guide rail, and the verticality of the Y-direction guide rail and a Z-direction guide rail can be accurately ensured, the machining accuracy of the machine tool is ensured, and the manufacturing cost of the machine tool is greatly reduced.

Owner:柔锋机械科技(江苏)有限公司

A method of preparing a reactive-sintered silicon carbide ceramic product

A method of preparing a reactive-sintered silicon carbide ceramic product is disclosed. The method includes (1) a step of preparing slurry, namely a step of adding slurry materials into a material mixing slurry preparing device, and fully stirring the slurry materials to prepare grouting slurry; (2) a step of injecting the slurry to a porous resin mold, and molding to obtain a green body; (3) a step of putting the green body into a drying oven to obtain a dried green body; and (4) a step of subjecting the dried green body to siliconizing reactive sintering in a high-temperature vacuum sintering furnace, performing siliconizing under vacuum conditions with the highest temperature being 1350-1750 DEG C, maintaining the temperature for 0.5-5 h, and cooling a product to obtain a finished product. According to the method, the occupied space of devices in the method is low, the production efficiency is high, automatic production can be achieved, the molded product has advantages of high density, good uniformity, and the like, raw materials are nontoxic, the drying efficiency is high, the production cycle is short, a cost is greatly reduced, product uniformity is better, produced products are more diversified, and the method can achieve production of large-size special-shape complex products.

Owner:NINGBO VULCAN TECH CO LTD

Photosensitive resin for laser 3D printing and preparation method thereof

ActiveCN107698718AHigh temperature resistantSmall shrinkage deformationAdditive manufacturing apparatusEpoxyTemperature resistance

The invention discloses a photosensitive resin for laser 3D printing and a preparation method thereof. The photosensitive resin comprises the following raw materials in parts by weight: 10-40 parts ofacrylic ester with high TG value, 10-65 parts of an epoxy resin, 5-30 parts of a trimethylene oxide compound, 1-10 parts of a cationic photopolymerization initiator, 1-10 parts of a free radical typephotopolymerization initiator and 1-5 parts of a silane coupling agent. The preparation method comprises the following steps: mixing the raw materials according to the weight part ratio, and then heating and stirring at 20-80 DEG C for 30-150 minutes to enable the raw materials to become faint yellow transparent liquid. The photosensitive resin overcomes the defects of a traditional laser 3D printing medium, and has the characteristics of high temperature resistance and small shrinkage deformation, the forming effect of the print parts is guaranteed, and the quality of the print parts is effectively improved; the method is simple to operate and the photosensitive resin is convenient to prepare.

Owner:惠展电子材料(上海)有限公司

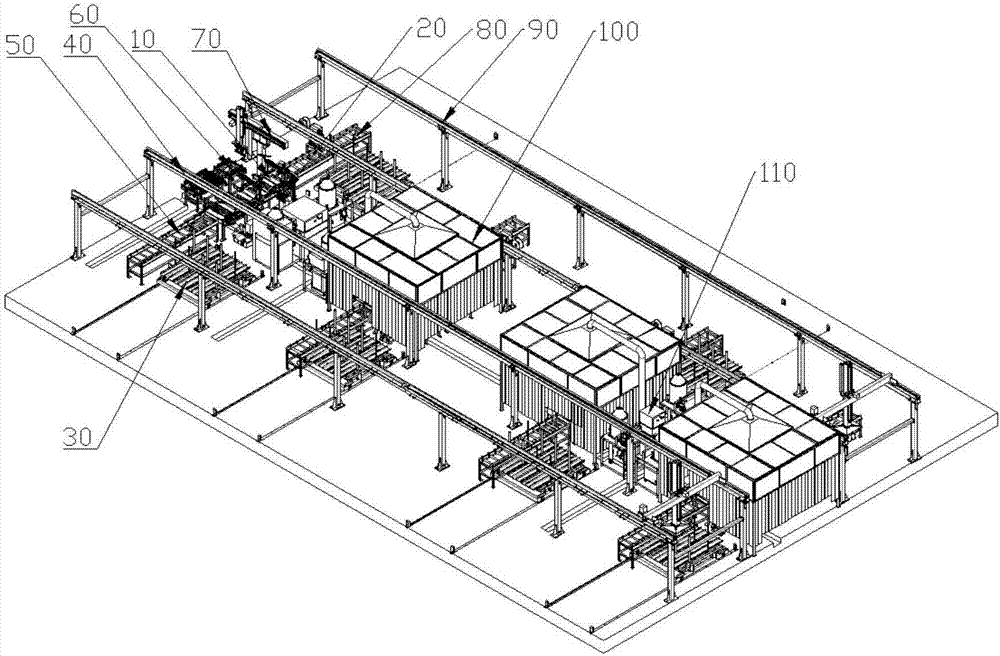

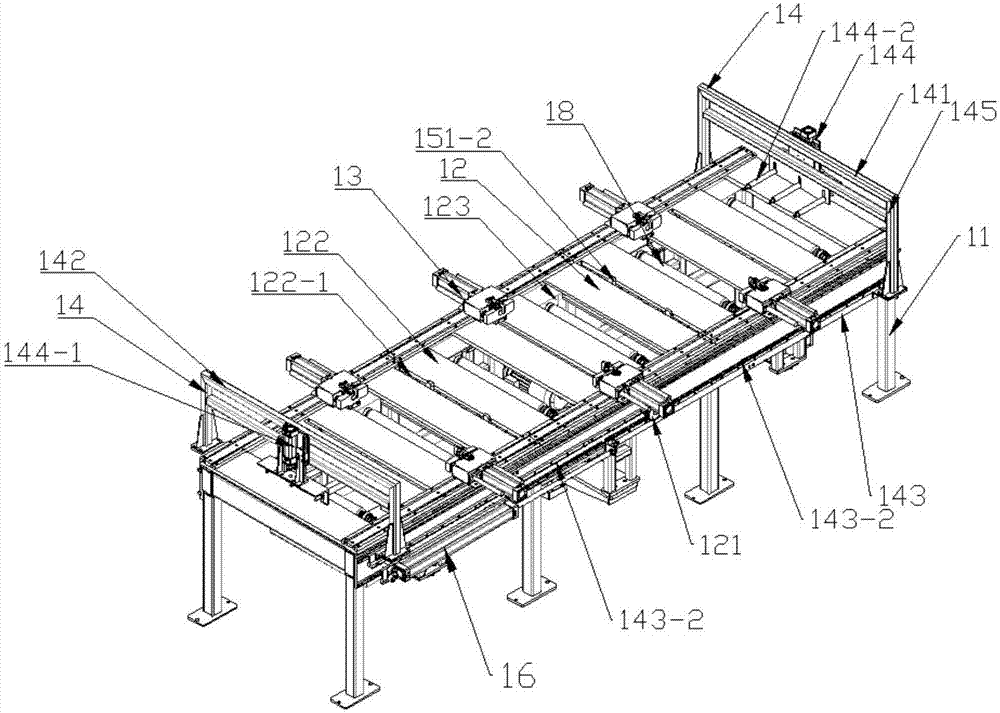

Aluminum template welding production line

InactiveCN107414328ACompact structureRealize informatizationWelding/cutting auxillary devicesAuxillary welding devicesProduction lineEngineering

The invention provides an aluminum template welding production line and relates to the technical field of welding. The aluminum template welding production line comprises a loading system, a welding system and an unloading system, wherein the loading system comprises a storage frame, a loading gantry, a loading roller frame, a small piece frame and a special small piece loading machine; the welding system comprises a welding tooling platform and a welding robot; the unloading system comprises an unloading roller frame and a finished product stacking gantry; the welding system is located in a metal plate welding room; the metal plate welding room is connected with a smoke dust purification system. The aluminum template welding production line can solve the problems that the degree of automation is low, the production efficiency is low, manual operations need to be frequently used, the welding gas causes harm to the health of body, the welded parts of the existing aluminum templates have deformation because of the action of thermal stress during welding, and the quality of the finally-welded aluminum templates is non-uniform because the welded positions of the aluminum templates are inaccurate during welding after putting the aluminum templates on the welding tooling platform through manual manners or mechanical manners in the existing aluminum template welding production line.

Owner:CHENGDU VANOV INTELLIGENT SYST EQUIP

Gum cover for vulcanizing driving belt

The invention relates to a gum cover for vulcanizing a driving belt. The gum cover is a barrel shape and the upper end and the lower end thereof are open. The gum cover is characterized in that two end surfaces are provided with a ring of sealing lips respectively. The sealing lips at two ends of the barrel-shaped gum cover and a gum cover wall form an angle. The length of the sealing lips at two ends of the gum cover is longer than the thickness of the gum cover. The profile of the sealing lips at two ends of the barrel-shaped gum cover gradually changes from thick to thin. The profile of the sealing lips is a triangle. The gum cover has the advantages of reducing the shrinking deformation due to pressurized height of the gum cover when in use and increasing the effective cutting width of a gum layer. The profile of the sealing lip gradually changes from thick to thin so that the sealing speed to the upper cover plate and lower cover plate of a die during the vulcanization process of the gum cover is quickened, and the sealing performance is improved, the abandoned belt cylinder due to whole or local leakage caused by poor sealing of the gum cover is reduced and the use time of the gum cover can be improved by more than 2 times.

Owner:唐全胜

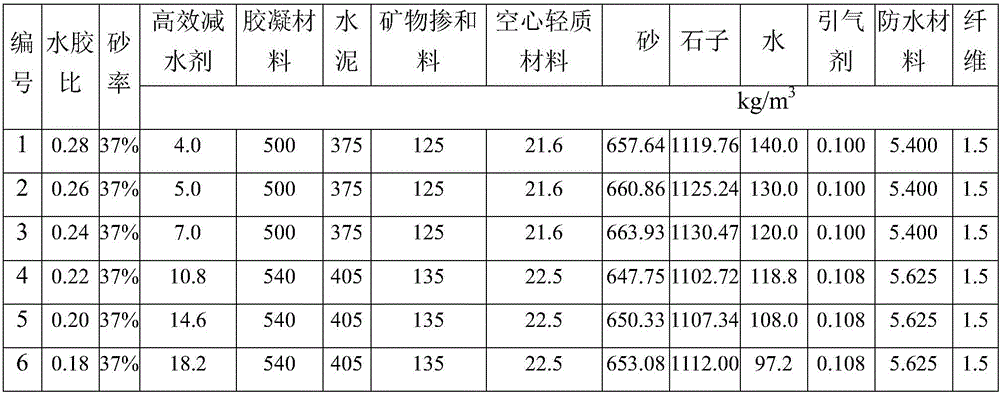

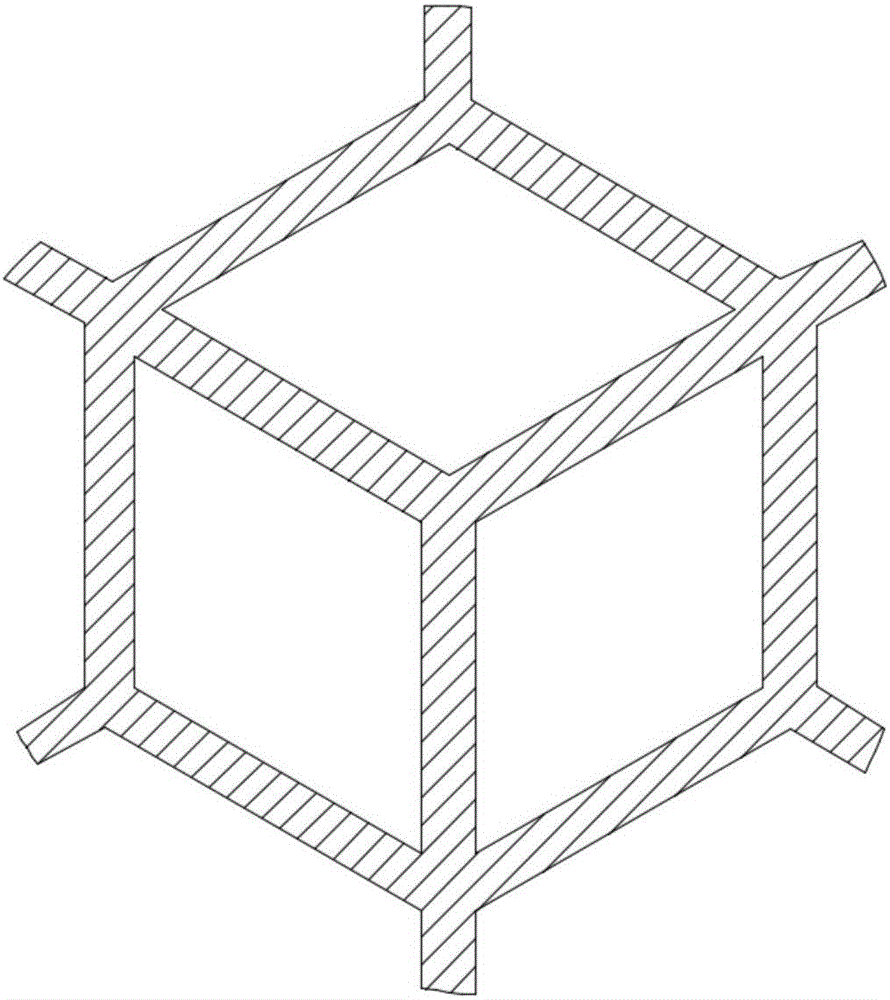

High-strength concrete adapting to humid environment and preparation method

InactiveCN106477989AImprove work performanceImprove mechanical propertiesCeramicwareHigh strength concretePorosity

The invention provides high-strength concrete adapting to the humid environment and a preparation method. Cement is taken as a cementing material, gravel is taken as aggregate, the impermeability of the concrete is improved by doping a mineral additive inside or coating the surface of concrete with a waterproof material, the concrete porosity is improved by doping a hollow lightweight material, a high-quality air entraining agent and fibers, the proportion of unhydrated cement particles in early-stage concrete is reduced by doping superwater absorbent resin so as to prevent further cement hydration caused by water absorption in the later period of the high-strength concrete in the humid environment and reduce swelling stress produced by hydration products, and high durability of the high-strength concrete structure in the humid environment is realized by doping a superplasticizer. The high-strength concrete adopts a simple construction process. The high-strength concrete is mainly applied to civil engineering in the humid environment, such as high-rise building structures, large-span bridge structures, certain special structures and other concrete engineering and is particularly applicable to certain regions with potential earthquake damage.

Owner:HARBIN ENG UNIV

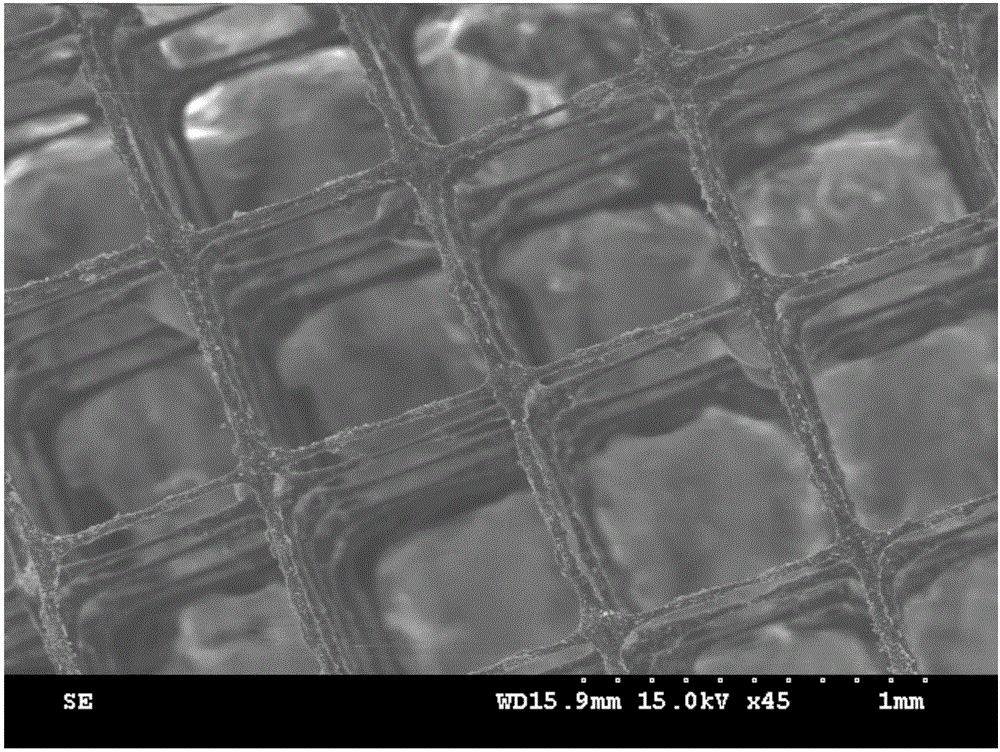

Personalizedly customized reticular porous carbon and preparation method thereof

ActiveCN106542516AReduce distortionReduced shrinkage deformationCarbon preparation/purificationPorosityPolymer

The invention discloses personalizedly customized reticular porous carbon and a preparation method thereof. The reticular porous carbon has a precise personalizedly customized shape and internal micro pores. The porosity of the reticular porous carbon is 70%-99.5%, the diameter of inscribed circles of all faces of micro polyhedrons forming the reticular porous carbon is 0.2-3 mm, and the diameter of inscribed circles of cross sections of polyhedron connecting rods is 0.02-1.5 mm. The preparation method comprises the following steps: designing a shape contour and an internal pore structure of a porous digital model; preparing a reticular porous carbon precursor by using a material-increasing preparation method; filling the interior of the porous carbon precursor with a burying sintering material; placing the porous carbon precursor filled with the burying sintering material in a 500-1000 DEG C vacuum or a protecting atmosphere, and carrying out pyrolysis; and finally, removing the burying sintering material, then carrying out 1100-3000 DEG C graphitization treatment to obtain the graphitized reticular porous carbon. The method overcomes the defects of distortion and shrinkage deformation of a porous polymer in a pyrolysis process, and makes up for the shortcomings that a traditional reticular porous carbon preparation method difficultly realizes precise control of a macroscopic shape and a micro pore structure.

Owner:XI AN JIAOTONG UNIV

Driven gear heat treatment method

ActiveCN106555154ALow costControl carburizing qualitySolid state diffusion coatingFurnace typesCopper platingOil cooling

The invention relates to a driven gear heat treatment method. According to the scheme of the driven gear heat treatment method, a copper plating layer on the surface of the area where carburization is needed is removed through machining after copper plating treatment is carried out on the whole surface of a driven gear workpiece, then, carburization treatment is carried out, and the purpose that carburization is carried out only in the local area can be achieved; before quenching treatment is carried out, the cavity area, likely to be damaged, of the copper plating layer is coated with an anti-carburization coating, dual-layer protection is carried out on the cavity area, coal oil is added during quenching for atmosphere protection, decarburization on a carburization face can be effectively prevented, carburization can be effectively avoided due to the protection of the anti-carburization coating on the cavity area, and follow-up machining is convenient; and a pressure quenching machine tool is used for oil cooling after quenching, and shrinkage distortion is effectively reduced. By means of the method, the technical effects that carburization is carried out on the designated area of the driven gear, a carburization layer is free of decarburization after carburization is completed and carburization is avoided for the cavity area can be effectively achieved, volume production is easy, and the cost is low.

Owner:CHINA HANGFA CHANGZHOU LANXIANG MACHINERY CO LTD

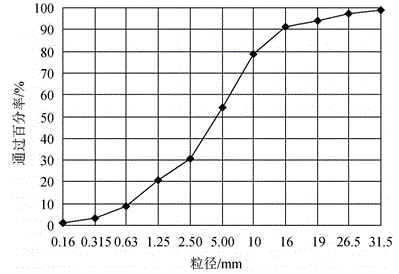

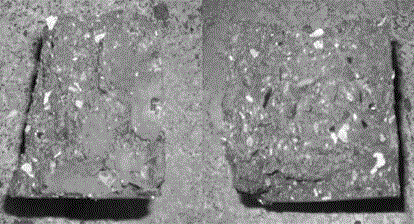

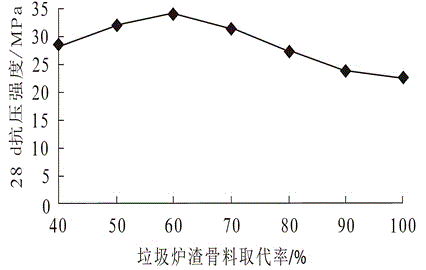

Preparation method of garbage incineration power generation furnace slag concrete

The invention discloses a preparation method of garbage incineration power generation furnace slag concrete. According to the method, during a concrete preparation process, acrylic resin is added in two batches, magnetized water is added in three batches, and stirring is carried out four times. A construction material is prepared with garbage furnace slag, such that a resource is effectively recovered and utilized. The method is simple; preparation efficiency is high; and the production process is environment friendly. Through adjusting the ratio, concrete products with different strength grades can be obtained. The finally obtained concrete has the advantages of sufficient and fine mixing, good compressive strength, good water resistance, high stability, and good comprehensive performance.

Owner:山东环兴再生资源科技有限公司

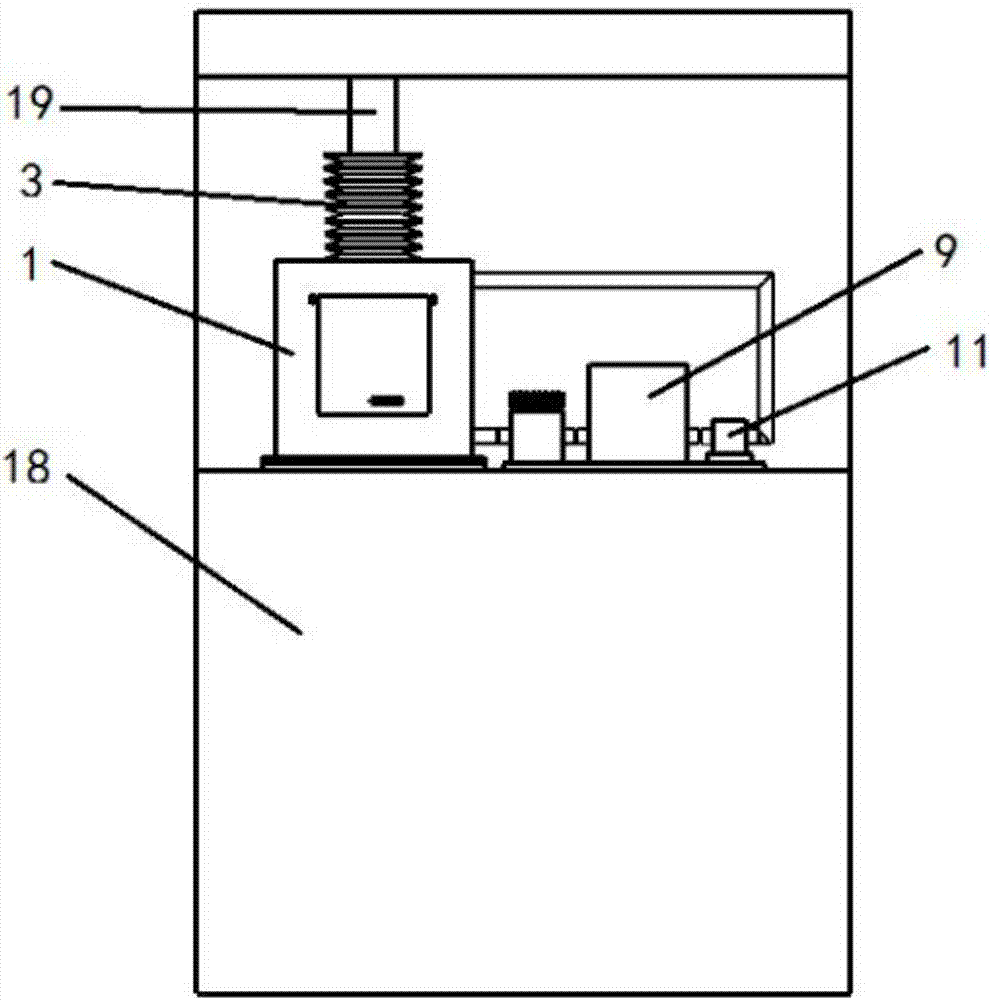

Hydrogel 3D printing internal environment control device and method

InactiveCN106945286ASimple structureReduce dehydrationAdditive manufacturing apparatusManufacturing environment conditioningThermal insulationEngineering

The invention discloses a hydrogel 3D printing internal environment control device and method. The device comprises a thermal insulation glass shell which is bonded to a connecting base plate at the bottom of the thermal insulation glass shell, then the connecting base plate is mounted by being matched with a liquid trough base plate of a printer, the top of the thermal insulation glass shell is connected to a lifting system cantilever guide rod of the hydrogel 3D printer in a sealing and sleeving mode through a seal rubber cover, and a temperature and humidity sensor is mounted on the rear wall of the inside of the thermal insulation glass shell; an upper ventilation hole and a lower ventilation hole are formed in the right side wall of the thermal insulation glass shell; the upper ventilation hole is sequentially connected with an air sucking pump, an ultrasonic wave humidification generator and a thermoelectric semiconductor square copper tube through a copper tube wrapped with thermal insulation cotton and then is connected with the lower ventilation hole of the thermal insulation glass shell, and an enclosed circulation system is formed. According to the control device, simple mounting parts for being connected with the lifting system cantilever guide rod of the printer and the printing liquid trough base plate are designed, the control device is easily applied to hydrogel 3D printing equipment, the control device is simple in whole structure, small in occupied space, easy to perform control and also easy to realize and popularize, and stable and efficient control over the internal environment is achieved.

Owner:SOUTH CHINA UNIV OF TECH

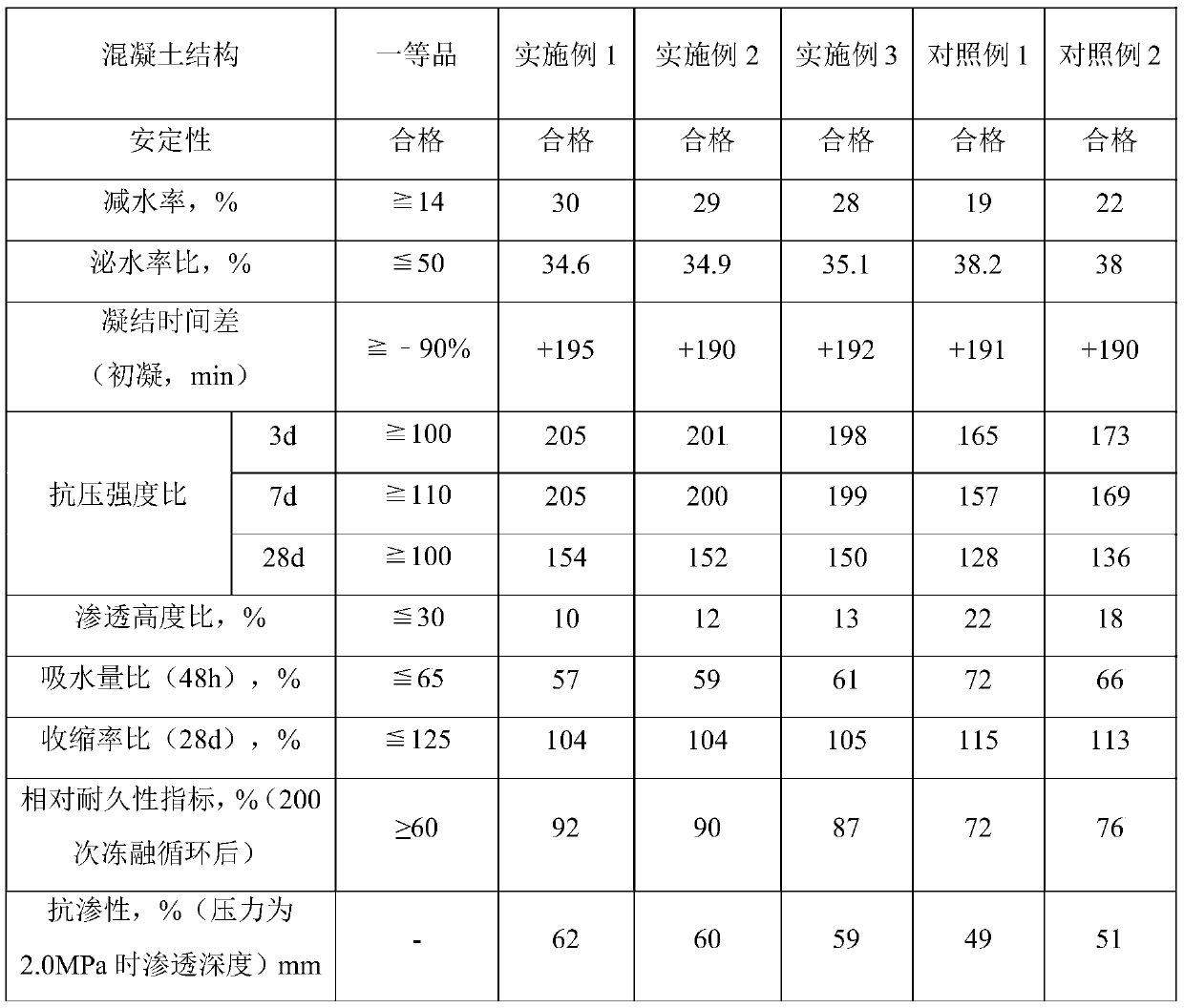

Concrete structure self-compacting waterproofing agent and preparation method and application thereof

ActiveCN111233370AReduce crackingEasy to pourSolid waste managementCrack resistanceFluosilicate salt

The invention provides a concrete structure self-compacting waterproofing agent and a preparation method and application thereof. The concrete structure self-compacting waterproofing agent comprises the following components in parts by mass: 16-19 parts of alkyl silicate, 15-18 parts of fluosilicate, 3-7 parts of a dispersing agent, 2-4 parts of molten aluminum, 4-7 parts of a water reducing agentand 2-5 parts of a slump retaining agent. The concrete structure self-compacting waterproofing agent has the functions of crack resistance, water reduction, water retention, delayed coagulation, porosity, microcrack self-healing and the like, can further improve the comprehensive properties of the concrete structure, such as strength, impermeability, durability and the like, and is beneficial toprolonging the service life of the concrete structure.

Owner:广西大胡子防水科技有限公司 +1

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com