Patents

Literature

67results about How to "Reduced shrinkage deformation" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

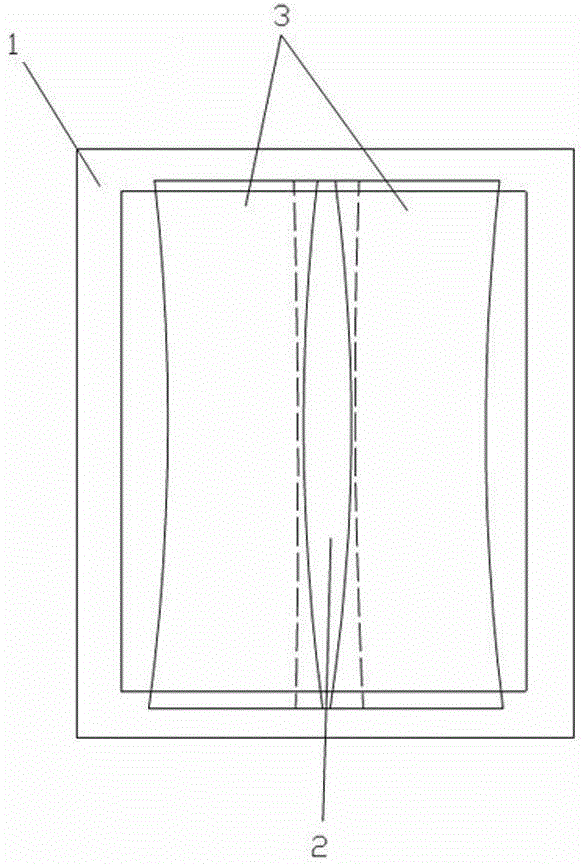

Manufacturing method of masks

ActiveCN104611669ASmall shrinkage deformationReduce shrinkage problemsVacuum evaporation coatingSputtering coatingPhysicsEngineering

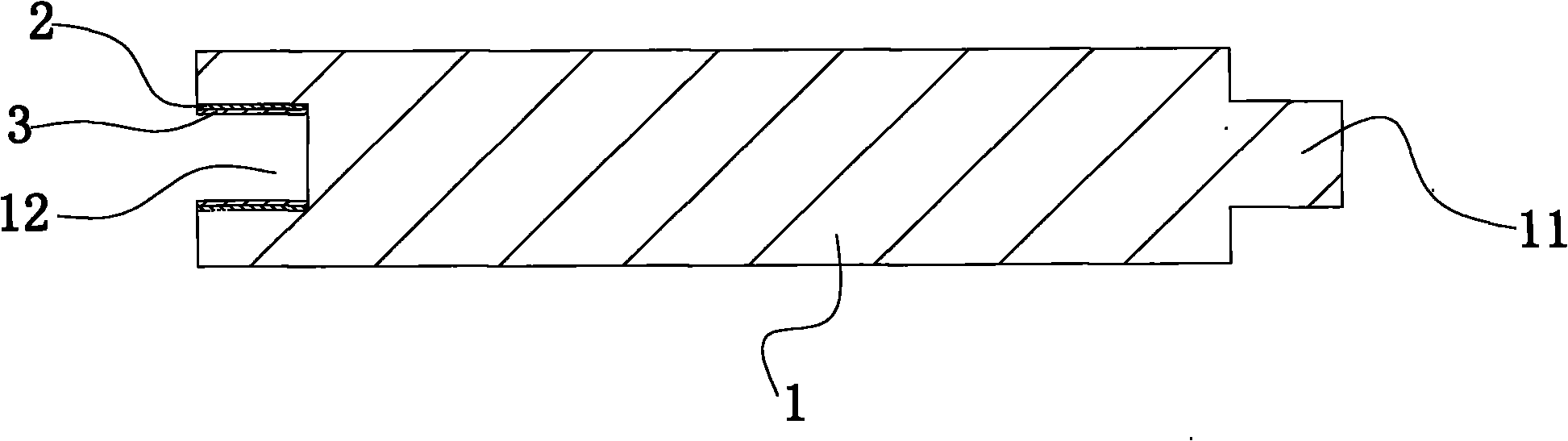

The invention discloses a manufacturing method of masks. The manufacturing method comprises the following steps: (1) measuring an environment temperature T1; (2) tensioning the two ends of a shielding mask, and fixing the shielding mask on a mask frame and calculating the deformation of the shielding mask; (3) fixing masks in the left region and the right region of the mask frame, respectively, wherein the edges of the masks are as long as the overlapping part of the shielding mask; calculating the deformation of the masks; (4) putting the mask frame on which the shielding mask and the masks are fixed into a heating room and heating to a temperature T2 for thermal expansion; (5) welding and fixing the overlapping regions of the masks and the shielding masks in an environment at the temperature T2; and (6) taking out the mask frame from the heating room and cooling to the temperature T1. By the manufacturing method dislcosed by the invention, the shrinking deformation problem due to tension can be effectively reduced and the quality of the mask is improved, and the method is capable of meeting the requirements of manufacturing the masks of high PPI display screen products.

Owner:TRULY HUIZHOU SMART DISPLAY

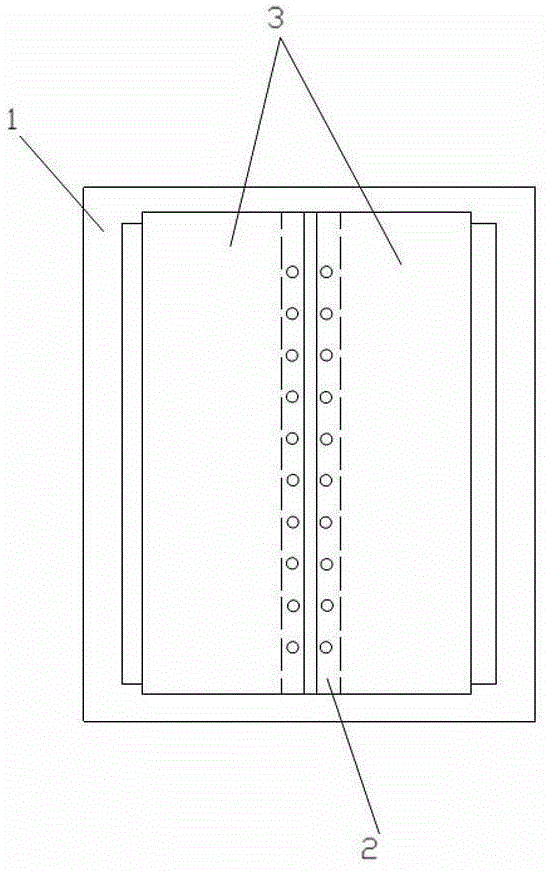

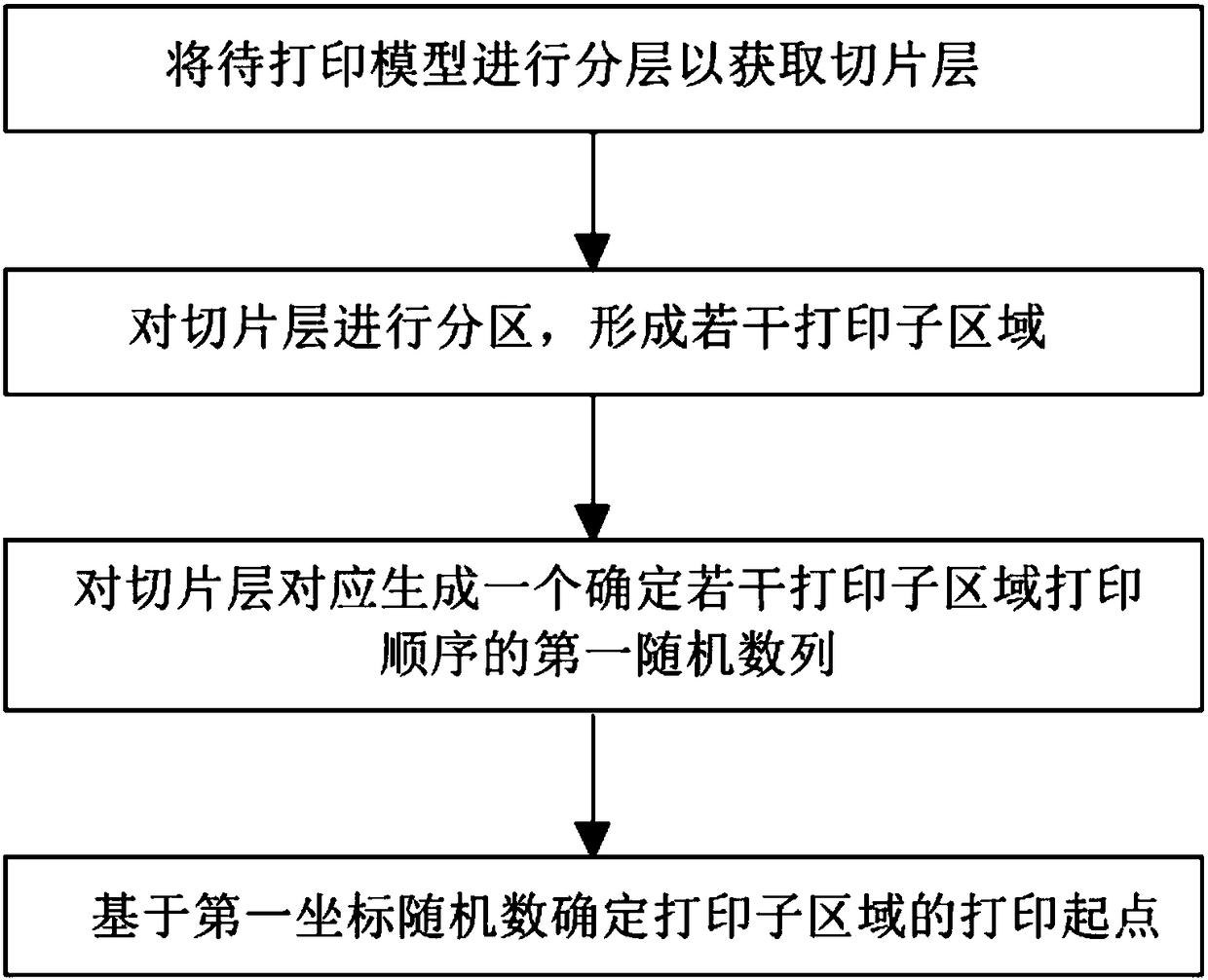

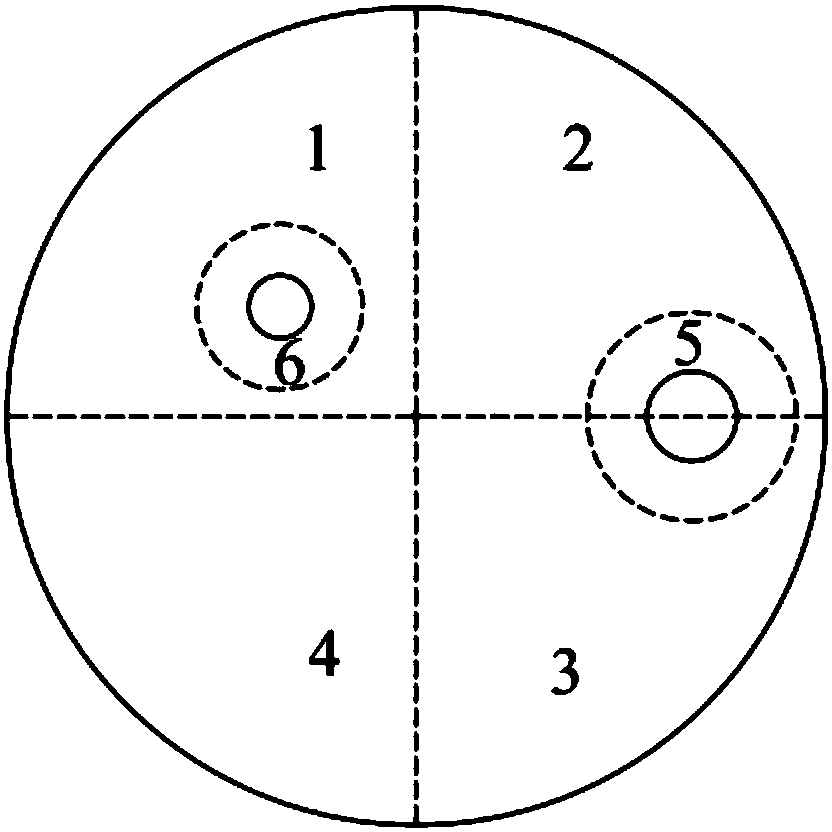

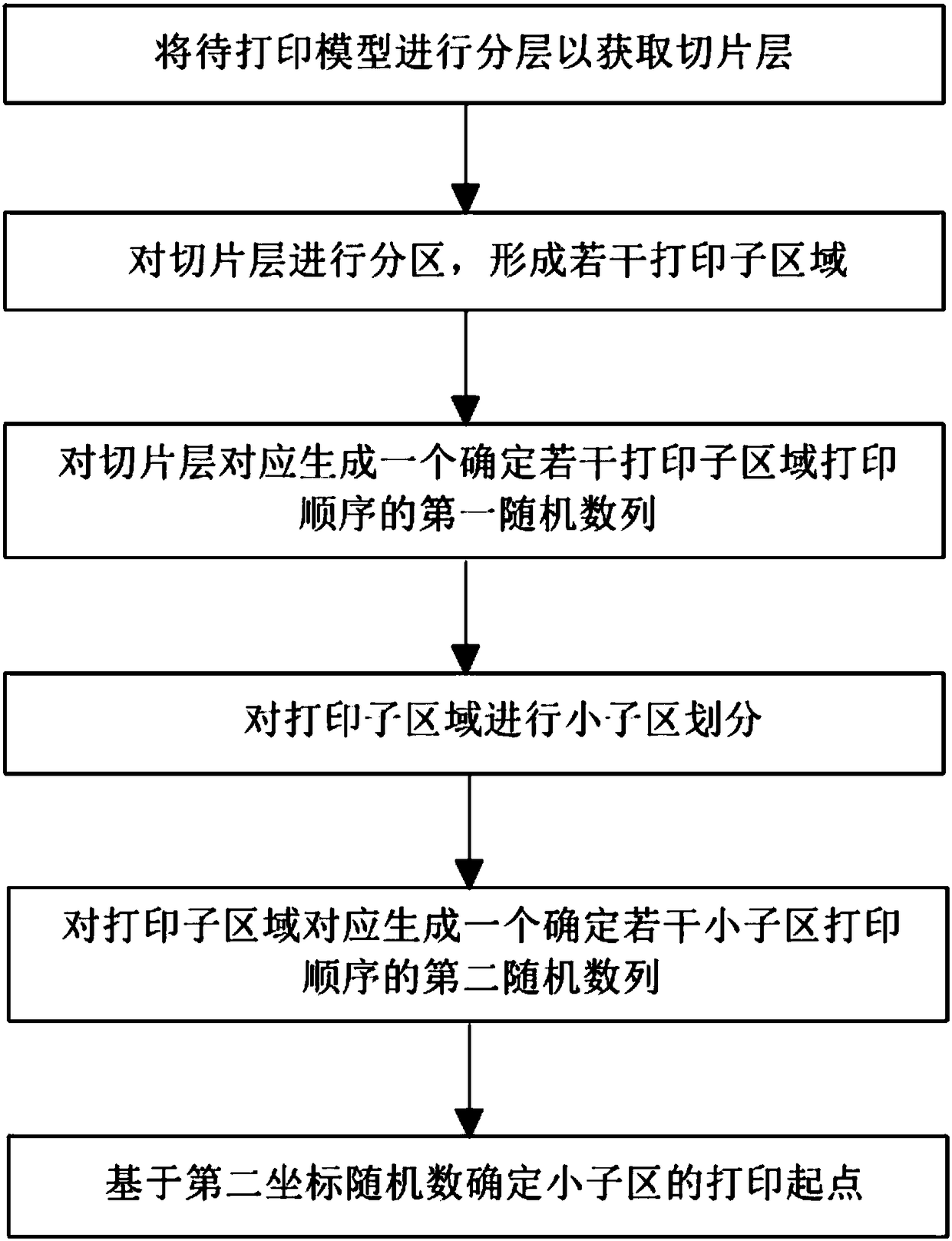

Printing path generation method of metal additive manufacturing

ActiveCN108326301AWith randomnessReduced shrinkage deformationAdditive manufacturing apparatusIncreasing energy efficiencyThermal deformationPath generation

The invention belongs to the technical field of 3D printing and particularly discloses a printing path generation method of metal additive manufacturing. The printing path generation method comprisesthe following steps that a model to be printed is layered so that section layers can be obtained; the section layers are partitioned, and a plurality of printing sub-regions are formed; a first randomnumber sequence determining the printing sequence of the multiple printing sub-regions is correspondingly generated for each section layer; and for the section layer, the printing sub-regions are sequentially printed according to the corresponding first random number sequence. According to the printing path generation method of the metal additive manufacturing, by means of the random distributionthought, the residual stress can be effectively reduced, the thermal deformation is reduced, and the surface quality and the size precision of parts are improved.

Owner:SHENZHEN YIDONG AVIATION TECH CO LTD

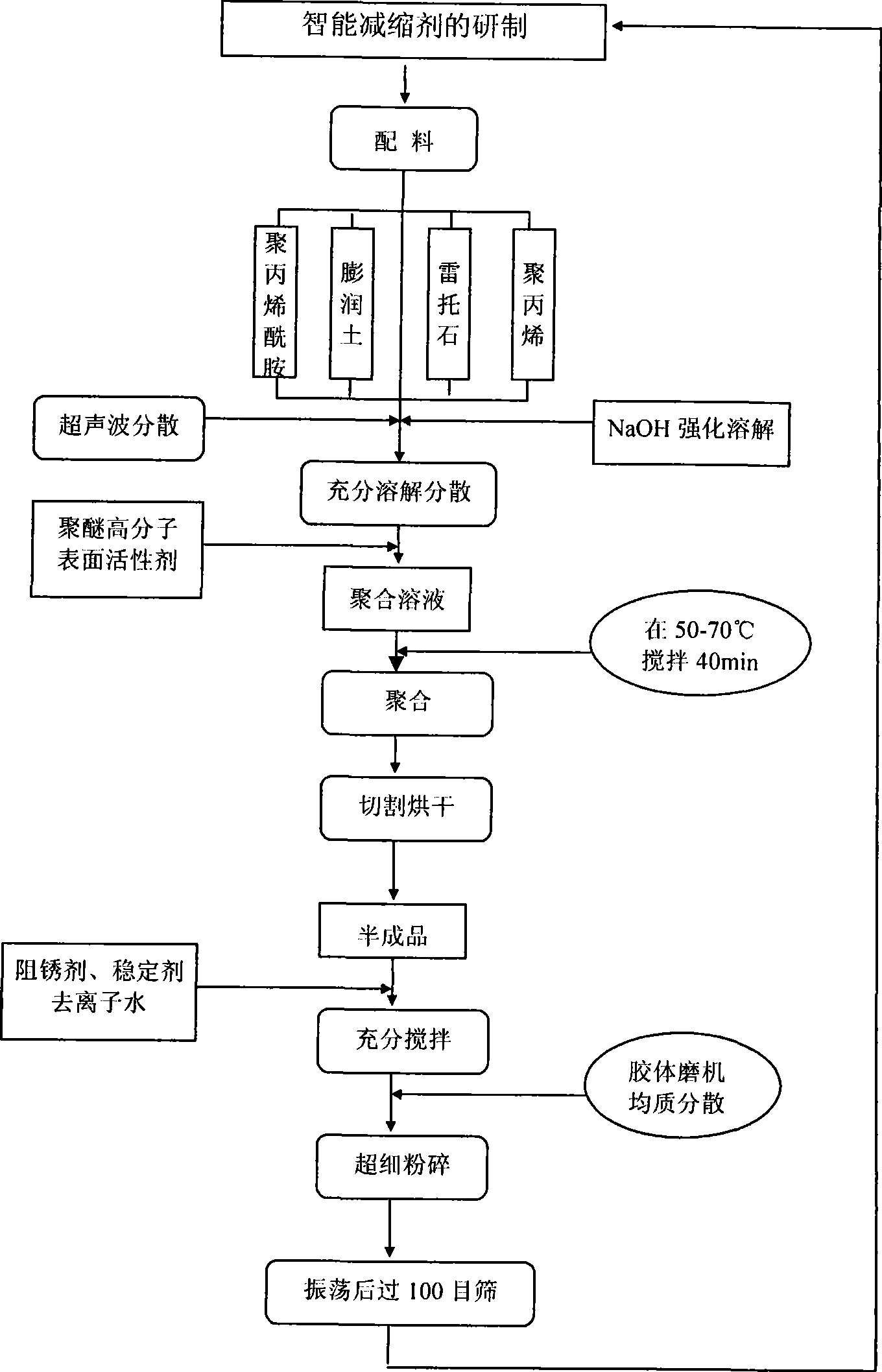

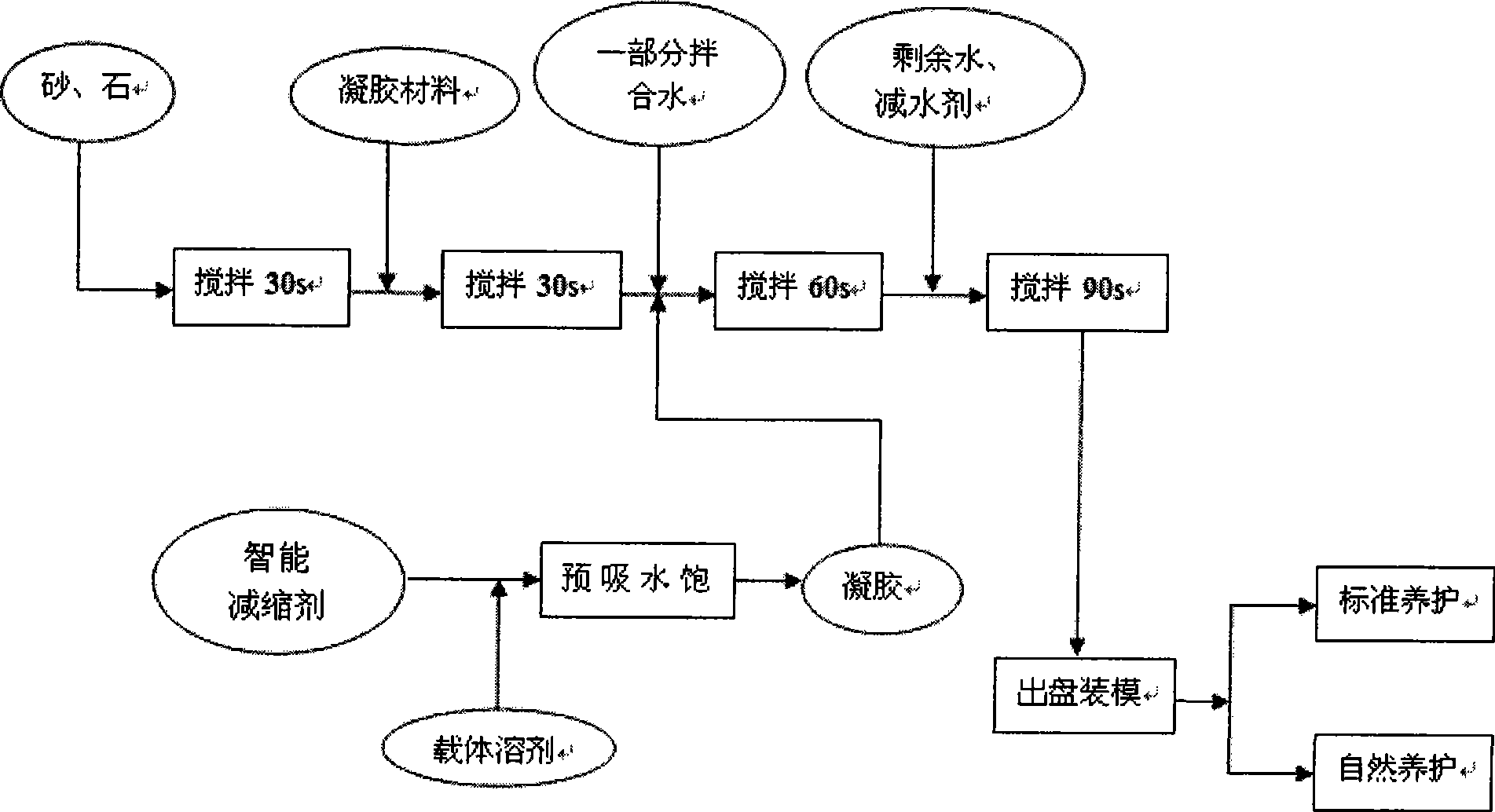

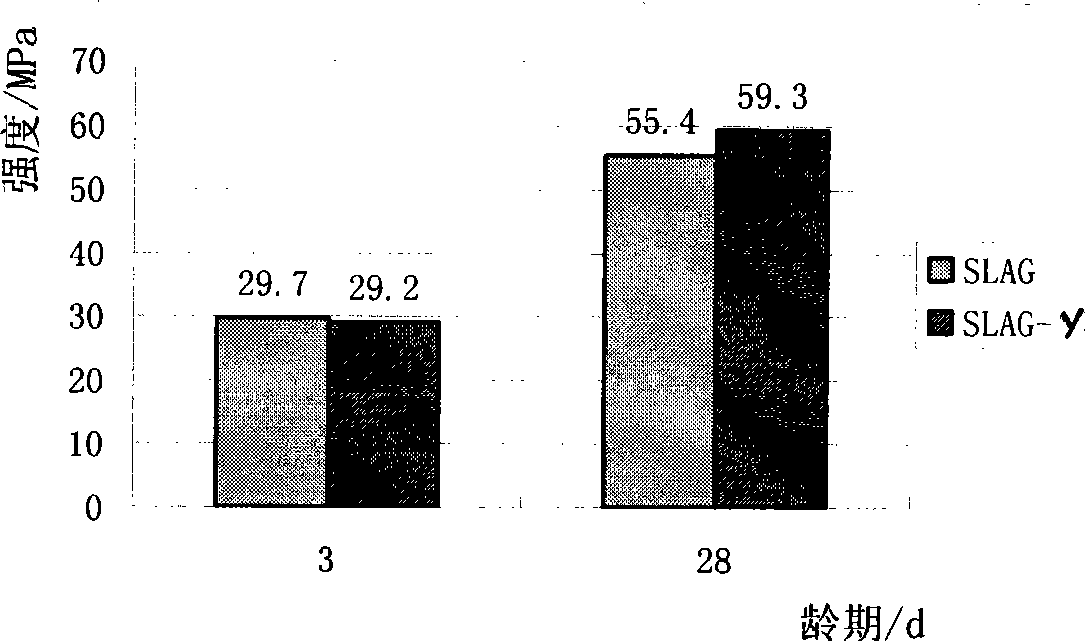

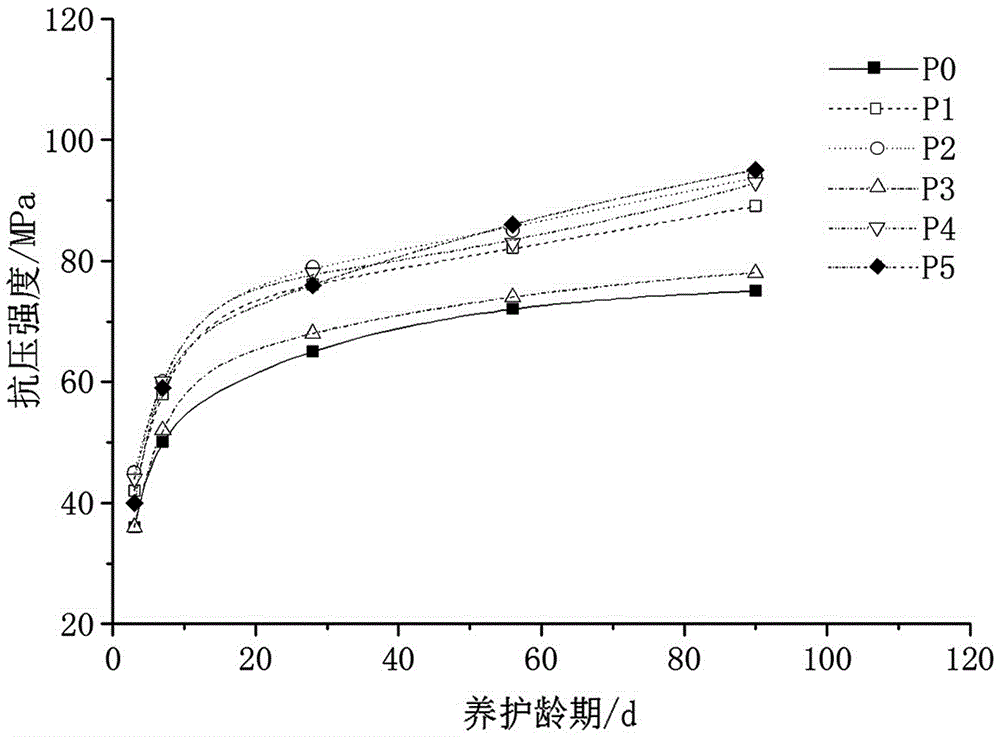

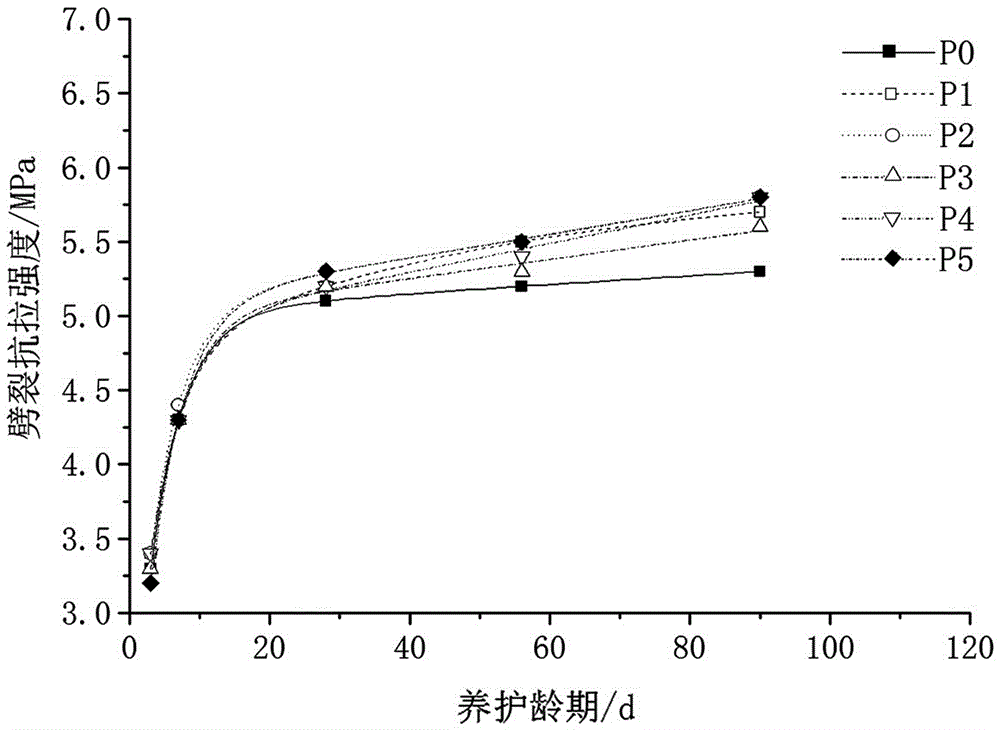

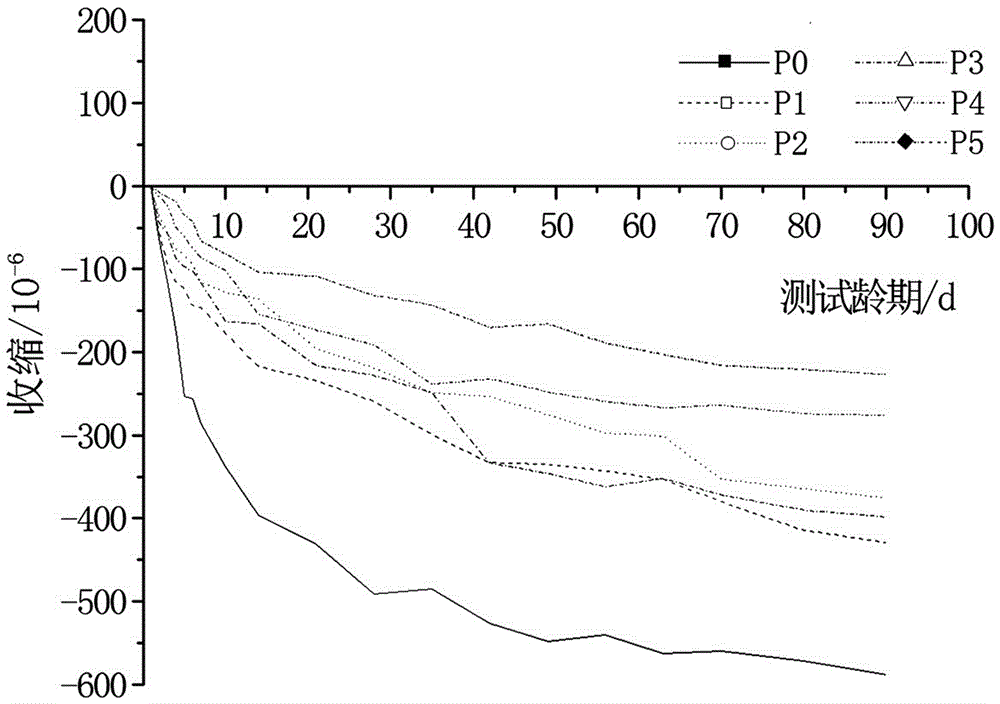

Intelligent shrinkage reducing agent for concrete, preparation method and application thereof

InactiveCN101367633ASolve the problem of drying shrinkageControl autogenous shrinkageUltimate tensile strengthNew materials

The invention relates to a material which is developed with an aim at the facts that the prior concrete has the characteristics of low water binder ratio and great amount of external addition of minerals, the water contained in the prior concrete hardly satisfies the requirement on the full hydration of gel materials and the effect of external water supply for maintenance is not satisfactory. The aim of the invention is to provide an intelligent shrinkage reducing agent preparation process for concrete; as the concrete shrinkage reducing agent, the material can intelligently provide humidity in the concrete, and the addition of the material accounts for 0.03 to 0.05 wt percent with respect to the gel material in the concrete. The test result shows that the intelligent shrinkage reducing agent can keep the water in the concrete in a certain degree; the addition of the intelligent shrinkage reducing agent with an appropriate amount can remarkably reduce the shrinkage and deformation of the concrete so as to achieve the aim of improving the durability of the concrete.

Owner:NANJING BAOYAN AUTOMATION

Polypropylene wire material for 3D printing and preparation method thereof

ActiveCN108641197ANo significant change in melting pointWon't breakAdditive manufacturing apparatusWire rodPolymer science

The invention discloses a polypropylene wire material for 3D printing and a preparation method thereof. The polypropylene wire material is composed of co-polypropylene, low-melting-point homo-polypropylene, inorganic filler, thermoplastic elastomers, a plasticizer and a stabilizer. The polypropylene wire material is low in material crystallinity degree, shrinkage distortion and warping, has good 3D printing effects and printing accuracy, and can reduce cost to a large extent. The preparation method for the polypropylene wire material for 3D printing is simple in technology and lower in production equipment requirement, can achieve large-scale production and popularization, and has a wide market prospect.

Owner:WANHUA CHEM GRP CO LTD

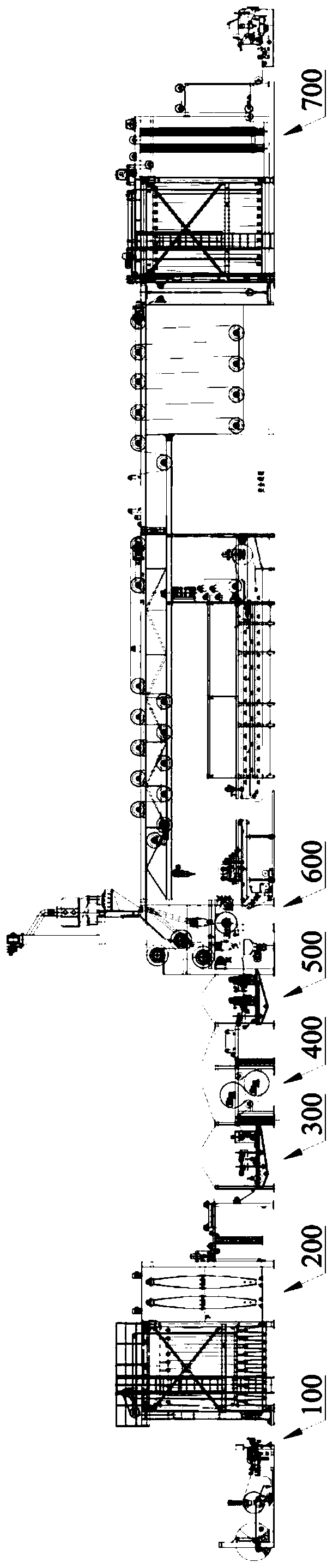

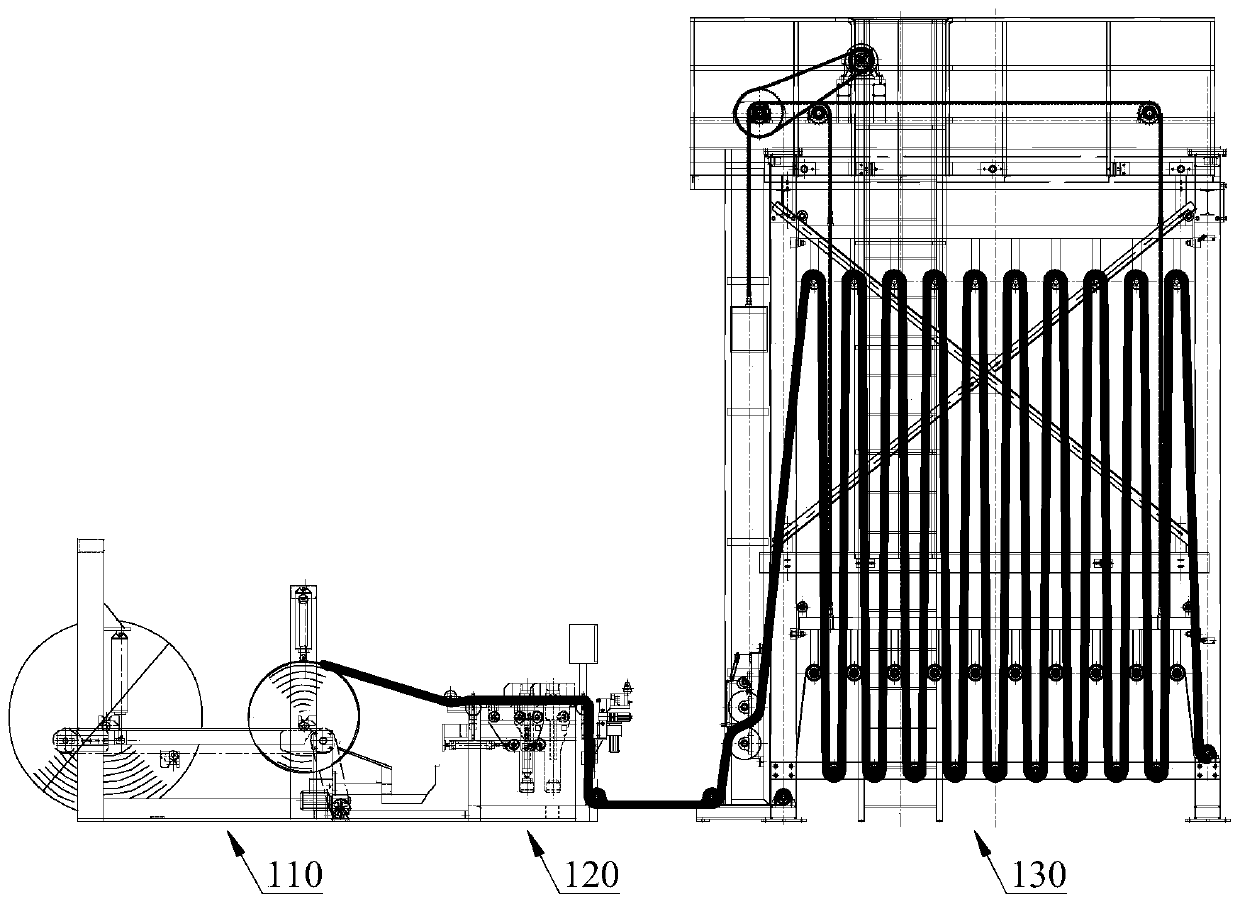

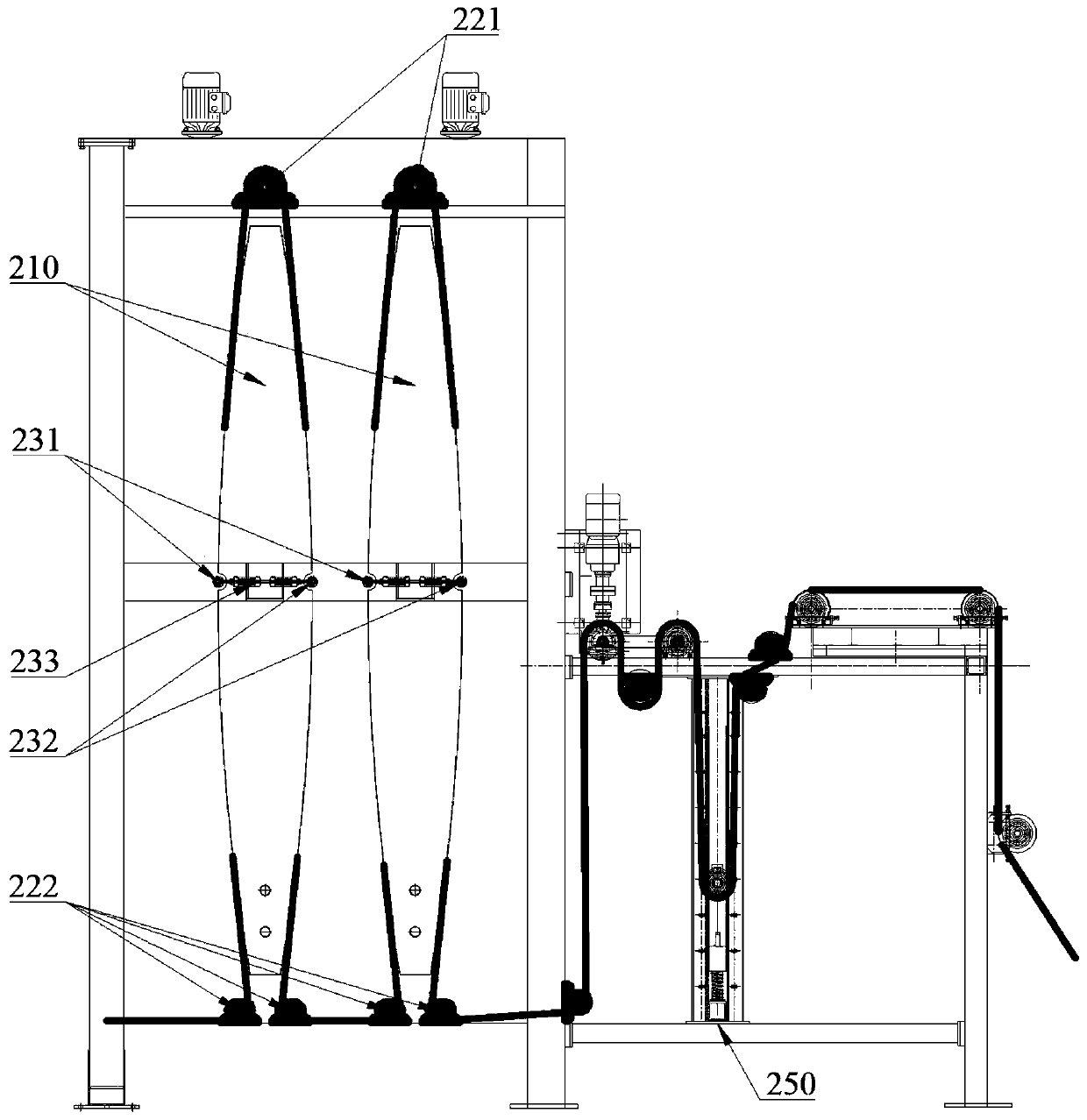

Asphalt waterproof roll production line

PendingCN111169138APrevent pulling each otherReduce the likelihood of stretchingLiquid surface applicatorsLaminationBituminous waterproofingCoating system

The invention relates to the technical field of asphalt waterproof roll production equipment and discloses an asphalt waterproof roll production line. The asphalt waterproof roll production line at least comprises a padding drying system, an asphalt pre-soaking system, a system for drying after pre-soaking, an asphalt coating system, a film covering and / or sanding system and a roll winding systemwhich are arranged in sequence, wherein each system is provided with an independent driving mechanism for traction of a padding / roll. In each system, the independent driving mechanism is used for pulling the padding / roll to pass through the system, so the padding / roll is effectively prevented from being pulled by different systems, and therefore, the possibility that the padding / roll is stretchedis reduced, and a shrinkage deformation amount is effectively reduced; and the independent driving mechanism applied to each system can ensure the advancing speed of the padding / roll in each system, so the synchronization rate of each system in the production line is improved.

Owner:KESHUN WATERPROOF TECH CO LTD

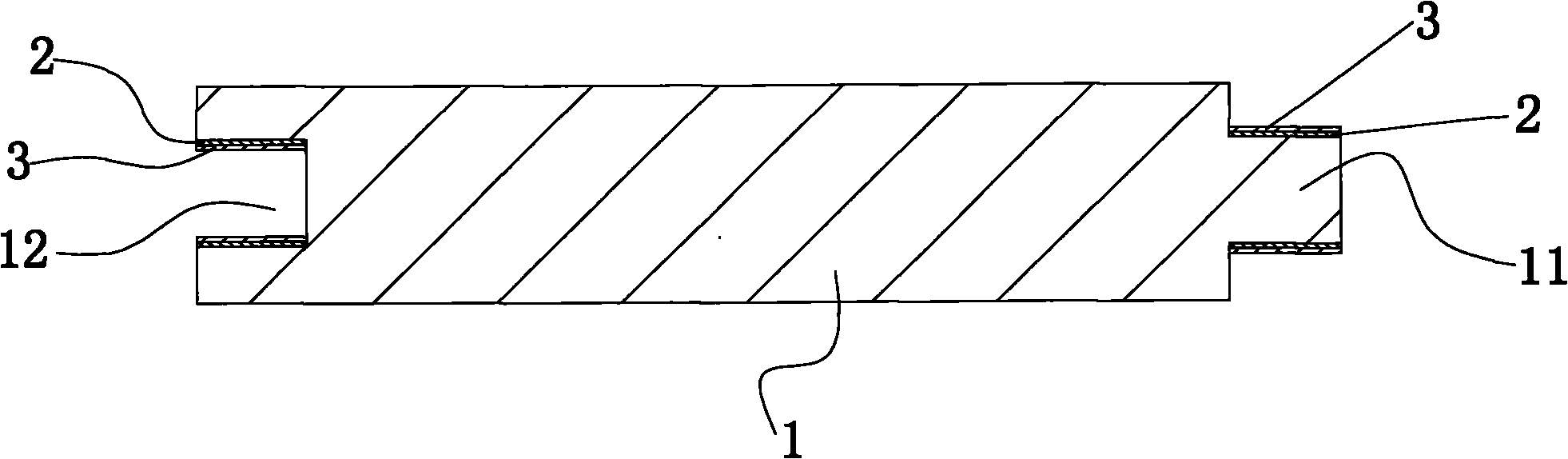

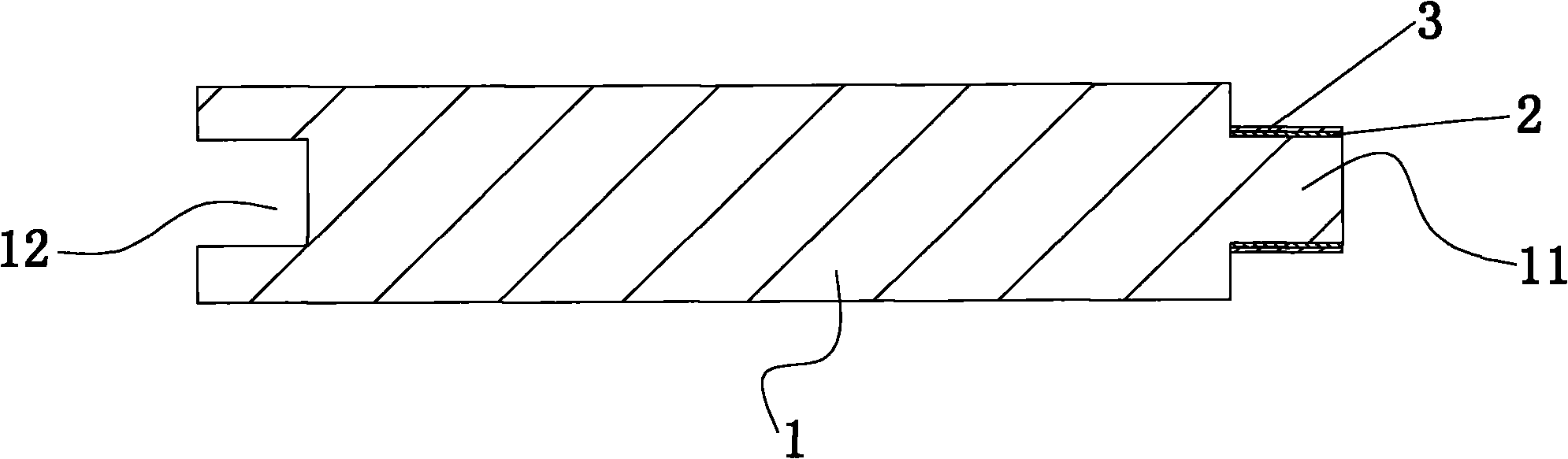

Glued groove-and-tongue floor

InactiveCN102080438AImproving the gluing installation processStable splicingFlooringEngineeringTongue and groove

The invention discloses a glued groove-and-tongue floor, which comprises a floor body, wherein the floor body is provided with a joint tongue and a joint groove. The glued groove-and-tongue floor is characterized in that: a pressure sensitive glue layer is coated on the joint tongue and / or the joint groove. The glued groove-and-tongue floor has the advantages that: 1, the pressure sensitive glue layer is pre-coated on the joint tongue and / or the joint groove, namely the tongued and grooved positions, of the floor so as to greatly improve a floor gluing mounting process and the mounting efficiency, save time, avoid the surface of the floor being polluted and achieve higher environmental friendliness; 2, adjacent floor blocks can be separated without any damage after being glued and spliced by pressure sensitive glue, so the floor is convenient to disassemble and rearrange after faults are produced in arrangement and pavement, and the after-service cost of the product is reduced; and 3, the adhesive power of the pressure sensitive glue can greatly strengthen an interlocking force between tongues and grooves of the floors and make securer and more stable the splicing of the floor, thereby greatly reducing the problem of contraction joint deformation of the paved floor as well as noises caused by friction between the tongues and grooves of the floors and greatly improving the mounting quality of the floor.

Owner:GUANGDONG YINGRAN WOOD IND

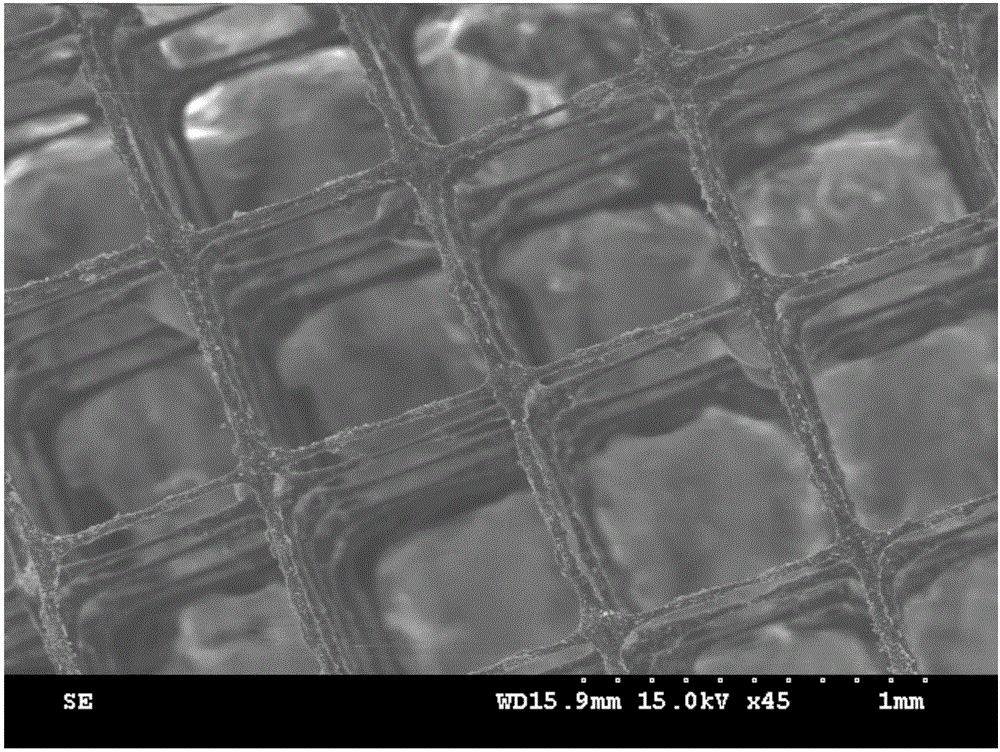

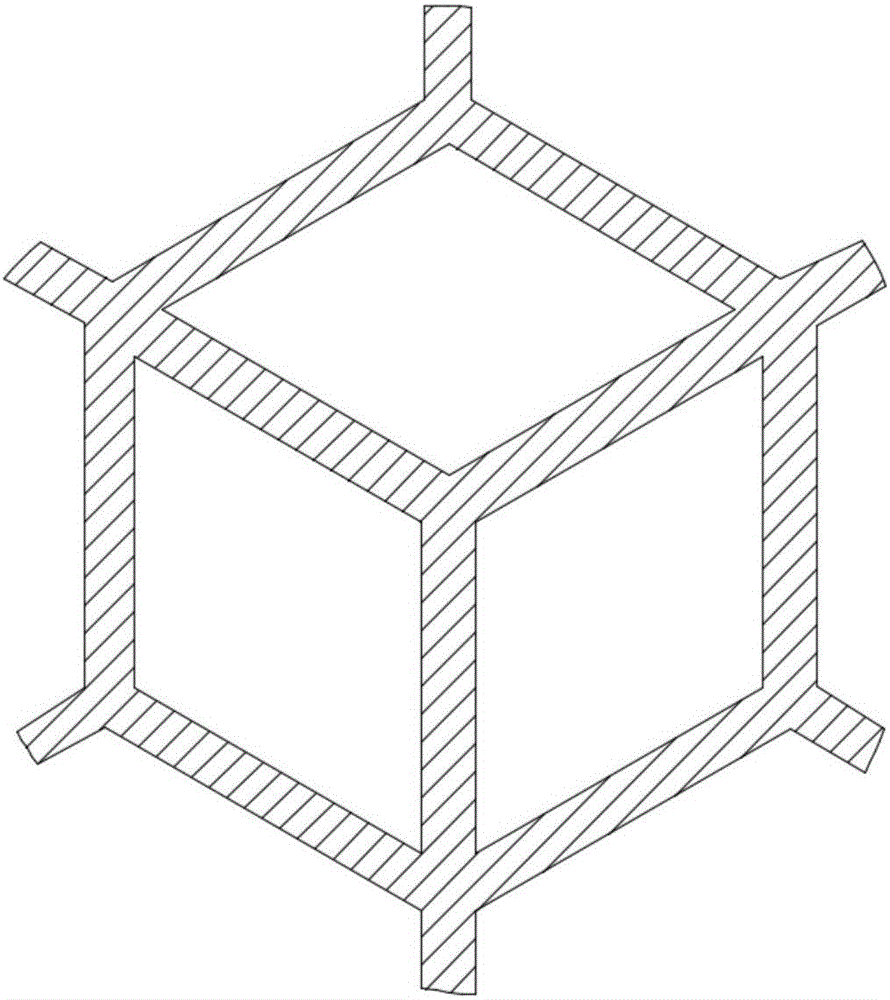

Personalizedly customized reticular porous carbon and preparation method thereof

ActiveCN106542516AReduce distortionReduced shrinkage deformationCarbon preparation/purificationPorosityPolymer

The invention discloses personalizedly customized reticular porous carbon and a preparation method thereof. The reticular porous carbon has a precise personalizedly customized shape and internal micro pores. The porosity of the reticular porous carbon is 70%-99.5%, the diameter of inscribed circles of all faces of micro polyhedrons forming the reticular porous carbon is 0.2-3 mm, and the diameter of inscribed circles of cross sections of polyhedron connecting rods is 0.02-1.5 mm. The preparation method comprises the following steps: designing a shape contour and an internal pore structure of a porous digital model; preparing a reticular porous carbon precursor by using a material-increasing preparation method; filling the interior of the porous carbon precursor with a burying sintering material; placing the porous carbon precursor filled with the burying sintering material in a 500-1000 DEG C vacuum or a protecting atmosphere, and carrying out pyrolysis; and finally, removing the burying sintering material, then carrying out 1100-3000 DEG C graphitization treatment to obtain the graphitized reticular porous carbon. The method overcomes the defects of distortion and shrinkage deformation of a porous polymer in a pyrolysis process, and makes up for the shortcomings that a traditional reticular porous carbon preparation method difficultly realizes precise control of a macroscopic shape and a micro pore structure.

Owner:XI AN JIAOTONG UNIV

Shell preparation method for investment casting

ActiveCN108746496AEffective identification of stress concentration locationsEffectively identify the easy-to-deform position of the investment patternFoundry mouldsFoundry coresInvestment castingMold filling

The invention relates to a shell preparation method for investment casting. The shell preparation method comprises the steps of stiffener determining, reinforced investment pattern module preparation,shell preparation, stiffener removal, investment pattern removal and shell roasting. According to a casting piece structure, the investment pattern stress situation and mold filling solidification process computer simulation, the position of a stiffener is determined, and the investment pattern and the shell are prevented from deformation advantageously and are supported. By removing the stiffener, a hole channel and a demolding opening are formed in the investment pattern, the shell can be separated from the investment pattern without being turned over, and the surface quality of an inner cavity of the shell is improved.

Owner:BAIMTEC MATERIAL CO LTD

Folding mechanism, folding screen and mobile terminal

ActiveCN111536143AEasy to foldReduce stretchPivotal connectionsTelephone set constructionsStructural engineeringMechanical engineering

Owner:GUANGDONG OPPO MOBILE TELECOMM CORP LTD

Preparation technology of two-component resin adhesive with water resistance and wear resistance

ActiveCN105441013AImprove liquidityReduced shrinkage deformationNon-macromolecular adhesive additivesEpoxy resin adhesivesHigh pressureWear resistance

The invention discloses a preparation technology of a two-component resin adhesive with water resistance and wear resistance. The preparation technology comprises following steps: preparing a component A adhesive; preparing a component B adhesive; mixing the component A adhesive and the component B adhesive, and homogenizing a mixture by a high pressure homogenizer at the pressure of 19-22 MPa to prepare the two-component resin adhesive. The preparation technology has the advantages as follows: the production and construction environments are improved, and product curing time is optimized; the technical procedure is simple, the operation is convenient, the construction efficiency and the construction quality are guaranteed, and the prepared adhesive has both wear resistance and water resistance.

Owner:平顶山鑫晟新材料有限公司

Super-absorbent-resin-type self-maintenance material for concrete and preparation method

ActiveCN105646767AExcellent self-maintenance performance indexSelf-Care Performance GuaranteeCross-linkSelf maintenance

Disclosed are a super-absorbent-resin-type self-maintenance material for concrete and a preparation method of the self-maintenance material. The method comprises: introducing a super-absorbent-resin-type functional component material for water maintenance into concrete, wherein the material includes deionized water, disodium ethylene diamine tetraacetate, triethanolamine, interpenetrating polymer networks, acrylic acid and a derivative thereof, acrylamide and a derivative thereof, a reducing agent, a cross-linking agent, and an initiator, and carrying out a constant-temperature polymerization reaction, standing, shearing, drying, and pulverizing to prepare the self-maintenance material. Disodium ethylene diamine tetraacetate, triethanolamine, and interpenetrating polymer networks which can highly absorb an alkaline ionic solution are introduced, so that the problem that a conventional super absorbent resin is poor in absorption of a cement hydrated solution is overcome. (Un-neutralized) acrylic acid and the derivative thereof are adopted, and the preparation method and device are simplified. The self-maintenance material has an absorption rate ratio of water to a concrete mixture centrifugate being 0.5-1.2, and a particle size of 0.1-50.0 mum. The risk that a self-maintenance material is liable to cause poor workability and lost mechanical properties of concrete is lowered.

Owner:RES INST OF HIGHWAY MINIST OF TRANSPORT +2

Modified repair mortar

The invention discloses modified repair mortar. The modified repair mortar is prepared by mixing sulphoaluminate cement, ordinary silicate cement, quartz sand, a complex early strength agent, a water-retaining agent, anti-crack fibers, a water reducing agent and water. According to the modified repair mortar, a sulphoaluminate cement and ordinary silicate cement mixed cementing material is adopted, the optimal mix and match proportion is selected, the early strength of the mortar is high, the setting time is proper, and construction is convenient. In addition, the complex early strength agent, the water-retaining agent, the water reducing agent and the like are added, and therefore better strength of the mortar in early stage and later stage is effectively guaranteed. The anti-crack fibers are added in the components, shrinkage deformation of the mortar is greatly reduced, when the mortar is under stress, the anti-crack fibers play an active prevention role in generation and development of cracks, the shrinkage deformation is obviously reduced, and cracks generated in the repair mortar setting and hardening processes and under stress are reduced.

Owner:张耀忠

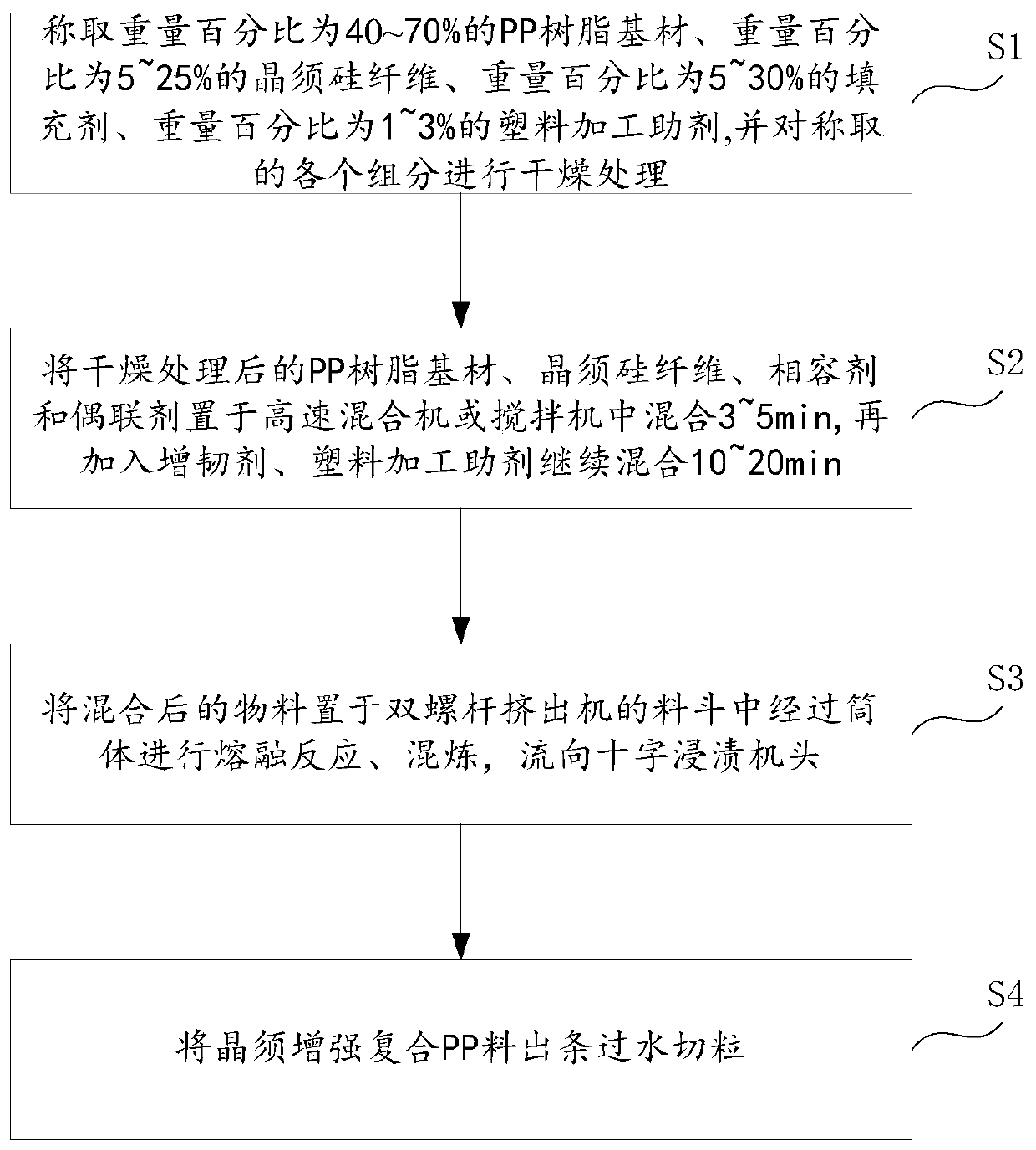

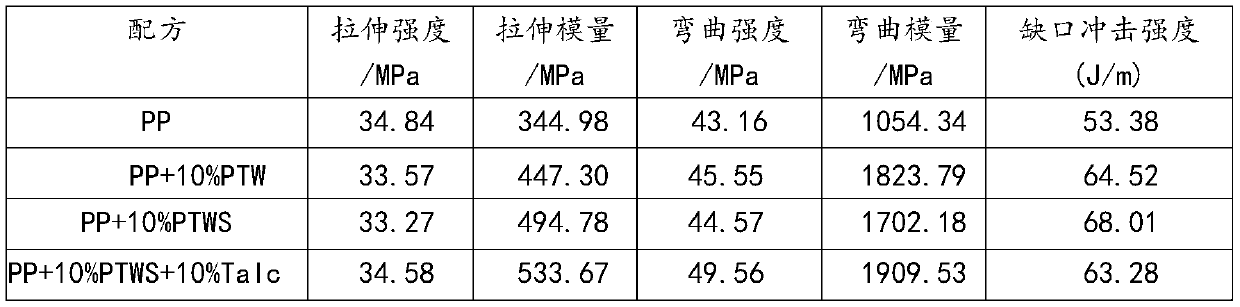

Whisker reinforced composite PP material, preparation method thereof and plastic pipeline

The invention discloses a whisker reinforced composite PP material, a preparation method thereof and a plastic pipeline. The whisker reinforced composite PP material is prepared from the following components in percentage by weight: 40 to 70 percent of PP resin base material, 5 to 25 percent of whisker silicon fiber, 5 to 30 percent of filler and 1 to 3 percent of plastic processing aid. Accordingto the whisker reinforced composite PP material, the preparation method thereof and the plastic pipeline, the strength, the chemical stability, the dispersity, the high temperature resistance and theinsulativity of the composite material can be improved, and the ignition loss and the oil absorption rate are reduced. By adopting the whisker reinforced modified material, glass fiber exposure can be eliminated, the appearance of the plastic pipeline can be improved, the flatness of the inner wall can be improved, the friction coefficient can be reduced, the thermal deformation temperature can be increased, the flame retardancy can be improved, the shrinkage deformation rate can be reduced, warping can be overcome, the processability can be improved, the product rigidity can be improved, thematerial specific gravity can be reduced, and the production cost can be reduced.

Owner:顾顺昌

Wall body material with mould inhibiting function and preparation method thereof

The invention discloses a wall body material with a mould inhibiting function and a preparation method thereof and relates to the technical field of wall body materials. The wall body material is prepared from the following raw materials in parts by weight: 35 to 45 parts of ceramic micropowder, 25 to 30 parts of expanded perlite, 15 to 20 parts of mould inhibitor, 15 to 20 parts of polymer emulsion, 10 to 15 parts of natural mildew preventive, 10 to 15 parts of acidized carbon fiber, 3 to 4 parts of EDTA disodium salt and 35 to 45 parts of silica sol. The wall body material disclosed by the invention has the advantages of simple use method, good mechanical property and good mould inhibiting effect.

Owner:HEFEI WANZHIJING DOORS & WINDOWS CO LTD

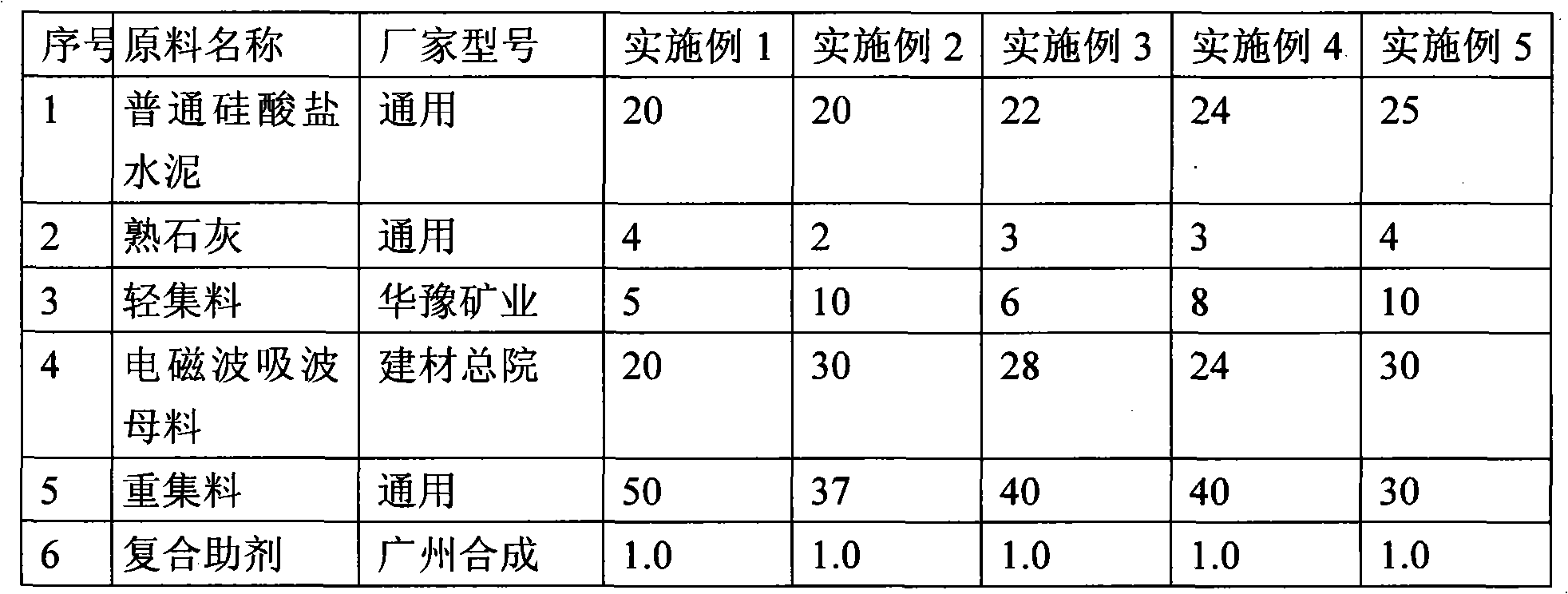

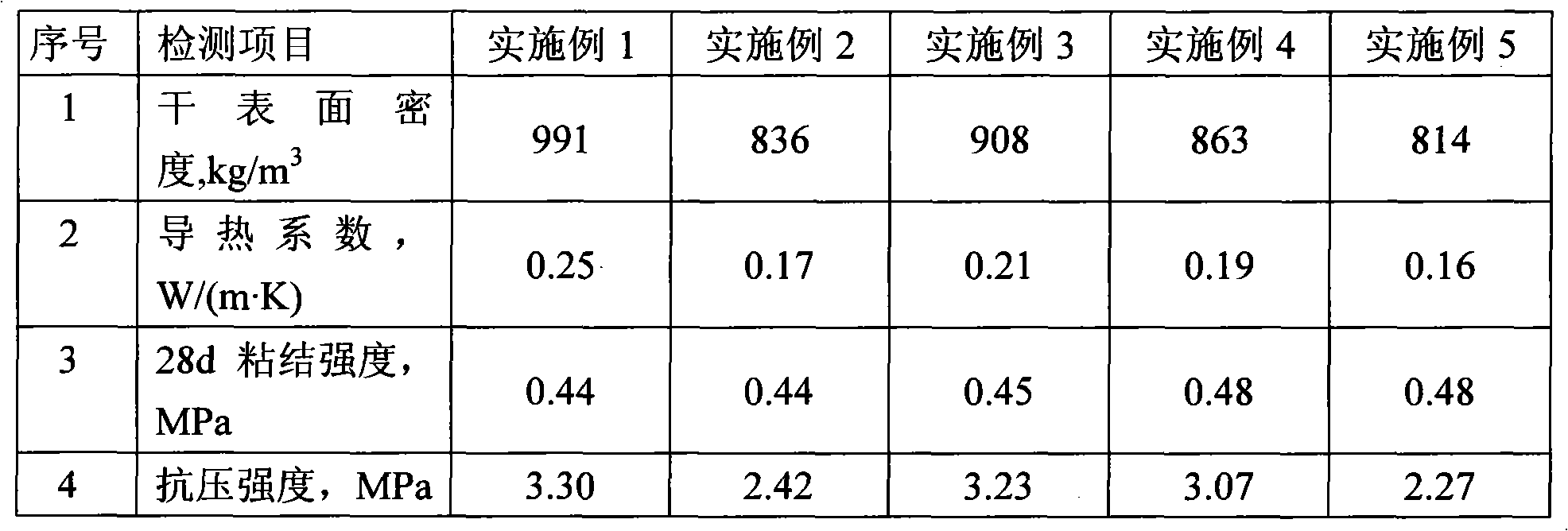

Lightweight plastering mortar and construction method thereof

The invention discloses lightweight plastering mortar, which is characterized in that the mortar is formed by mixing the following components in part by weight: 20 to 25 parts of common silicate cement, 2 to 4 parts of slaked lime, 5 to 10 parts of light aggregate, 20 to 30 parts of electromagnetic wave absorption master batch, 30 to 50 parts of heavy aggregate and 1.0 part of composite auxiliaryagent, wherein the light aggregate is an inorganic vitrified hollow micropore material with fineness of less than 100 meshes, and the heavy aggregate is common river sand. The construction method comprises the following steps of: diluting the lightweight plastering mortar by adding water in an amount which is 30 to 50 percent of the weight of the mortar, mechanically or manually stirring the mortar till the mortar is mixed uniformly, and mechanically coating the mortar or manually constructing the mortar when the mortar reaches the viscosity suitable for mechanical coating or manual construction. The lightweight plastering mortar with function of shielding and absorbing electromagnetic wave can shield and absorb the outdoor electromagnetic wave, absorb the indoor electromagnetic wave and reduce the diffuse reflection of the indoor electromagnetic wave, is light and energy-saving, reduces the consumption of unit area material and has low unit area manufacturing cost; and when used for a lightweight wall, the lightweight plastering mortar can prevent hollowing, cracking and dropping, is favorable for mechanized construction, and has simple process.

Owner:SHENZHEN GRANDLAND DECORATION GROUP

Flame retardance heat aging resistant PVC (polyvinyl chloride) foaming trough plate

InactiveCN109517291AGood oil resistanceImprove heat aging resistancePolyvinyl chlorideChlorinated paraffins

The invention discloses a flame retardance heat aging resistant PVC (polyvinyl chloride) foaming trough plate. The flame retardance heat aging resistant PVC foaming trough plate comprises the following raw materials in parts by weight: 60-70 parts of polyvinyl chloride, 10-28 parts of nitrile rubber, 5-13 parts of chlorinated polyethylene rubber, 4-9 parts of a thermoplastic polyurethane elastomer, 5-11 parts of polyamic acid, 2-8 parts of alpha-zirconium phosphate, 5-8 parts of attapulgite, 2-7 parts of muscovite, 3-9 parts of bamboo powder, 8-17 parts of composite foaming agent, 4-11 parts of flame retardant, 0.3-1 part of an aluminum-titanium composite coupling agent, 0.3-1.2 parts of dicumyl peroxide, 0.2-1.3 parts of sulfur, 1.7 parts of an accelerant, 15-30 parts of dioctyl phthalate, 2-9 parts of chlorinated paraffin, 1-3 parts of phenyl phosphorus dichloride, 3-5 parts of resorcinol, and 2-3 parts of a composite heat stabilizer. The flame retardance heat aging resistant PVC foaming trough plate provided by the invention has good heat aging resistance, excellent flame retardance and long service life.

Owner:安徽优丽普科技有限公司

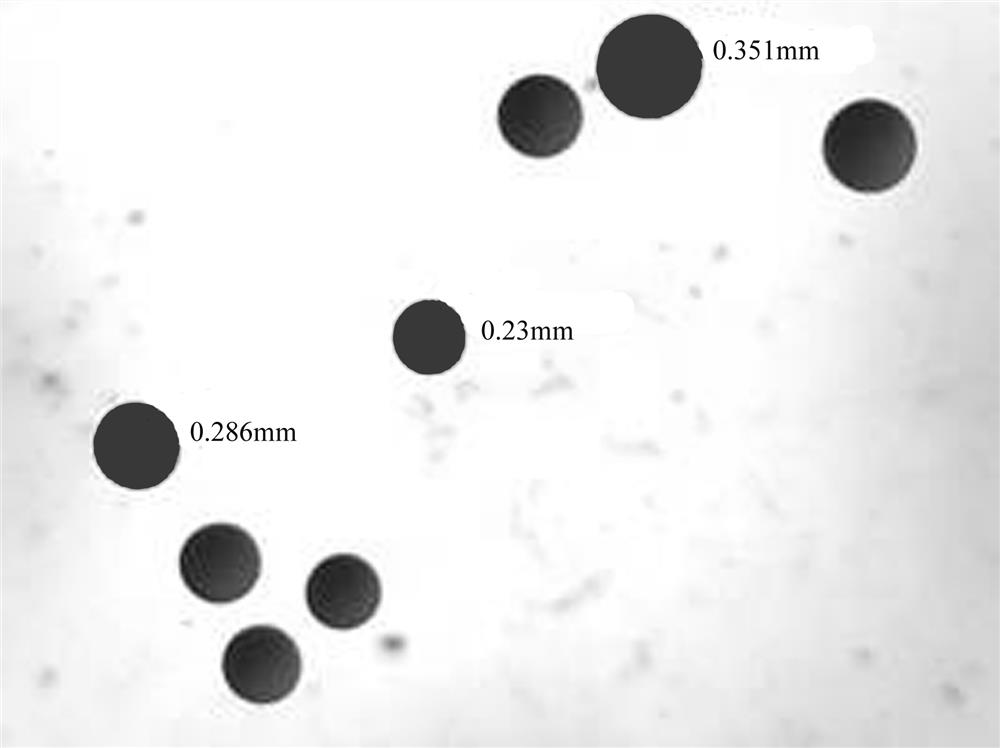

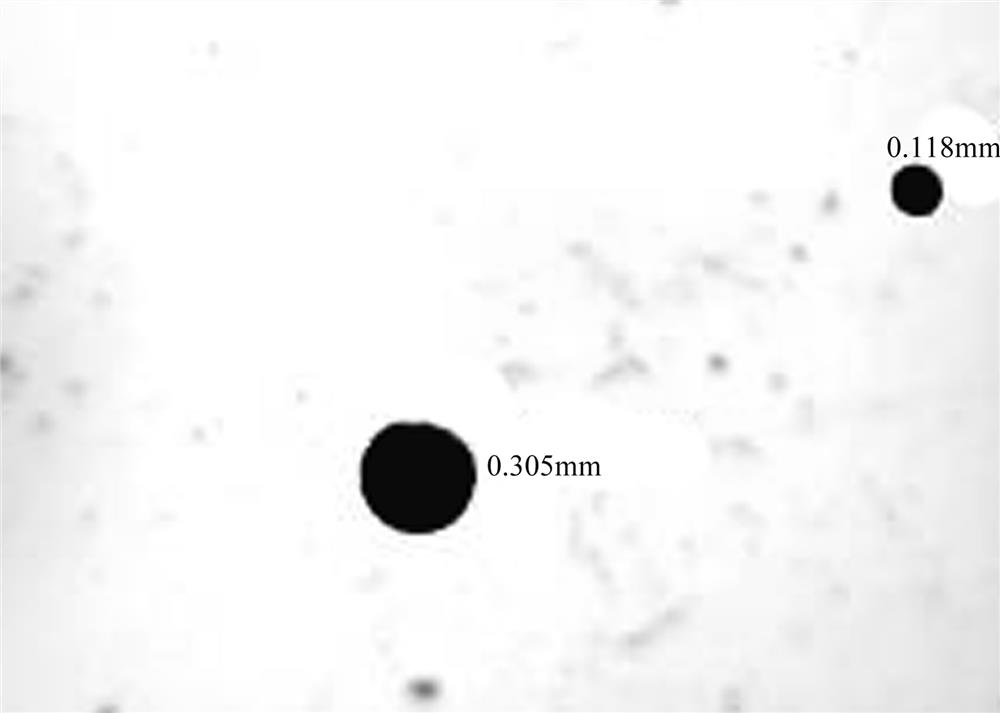

Method for preparing ceramic microspheres by adopting direct titration molding technology

PendingCN112939611AHigh shapeUniform internal structureGranulation by liquid drop formationCeramic shaping apparatusMicrosphereFirming agent

The invention discloses a method for preparing ceramic microspheres by adopting a direct titration molding technology. The method mainly comprises the following steps: weighing ceramic powder and a water solvent, carrying out ball milling on the ceramic powder and the water solvent to obtain ceramic slurry with a solid content of 75-85%, adding a curing agent into the ceramic slurry, and conducting uniform mixing, wherein forming of the ceramic slurry is carried out on dispensing machine system equipment; preparing a super-hydrophobic film on the surface of an inclined-plane track, controlling the ceramic slurry injected by a titration needle cylinder to form liquid drops with sizes of 0.1-1.5 mm, allowing the liquid drops to drop to the top end of the inclined-plane track, and enabling the liquid drops to freely roll to the bottom end from the top end of the inclined-plane track so as to complete curing to form a ball blank; and drying the ball blank for 5-10 hours at a temperature of 100-120 DEG C, conducting degreasing for 10-20 hours at a temperature of 550-600 DEG C, performing sintering at a temperature of 1400-1550 DEG C, and keeping the ball blank at the temperature for 2-5 hours to obtain the ceramic microspheres. The prepared ceramic microspheres are high in sphericity degree and uniform in internal structure, and have the advantages of being low in process cost, few in procedure, high in efficiency, easy to achieve automatic control and the like.

Owner:725TH RES INST OF CHINA SHIPBUILDING INDAL CORP

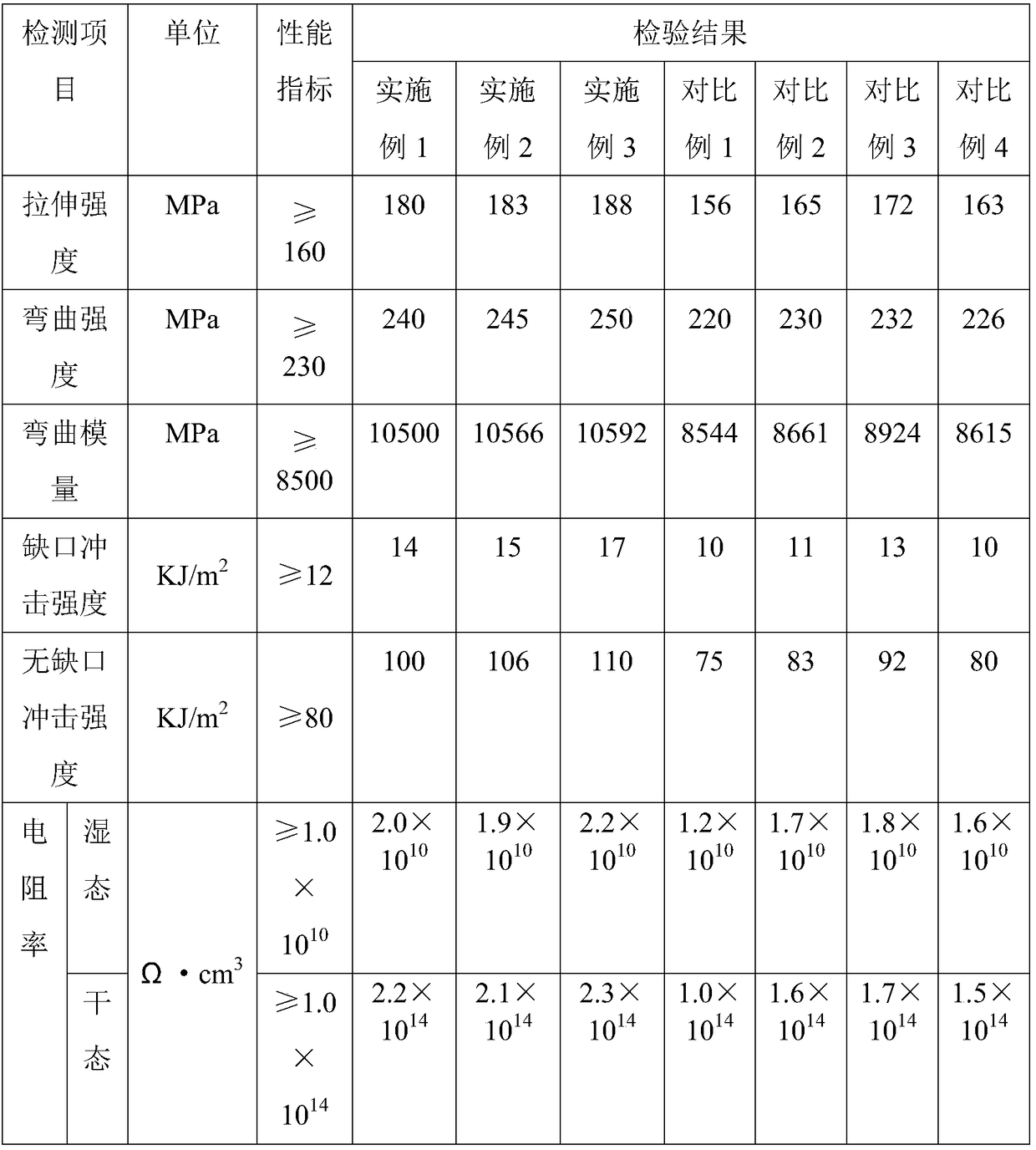

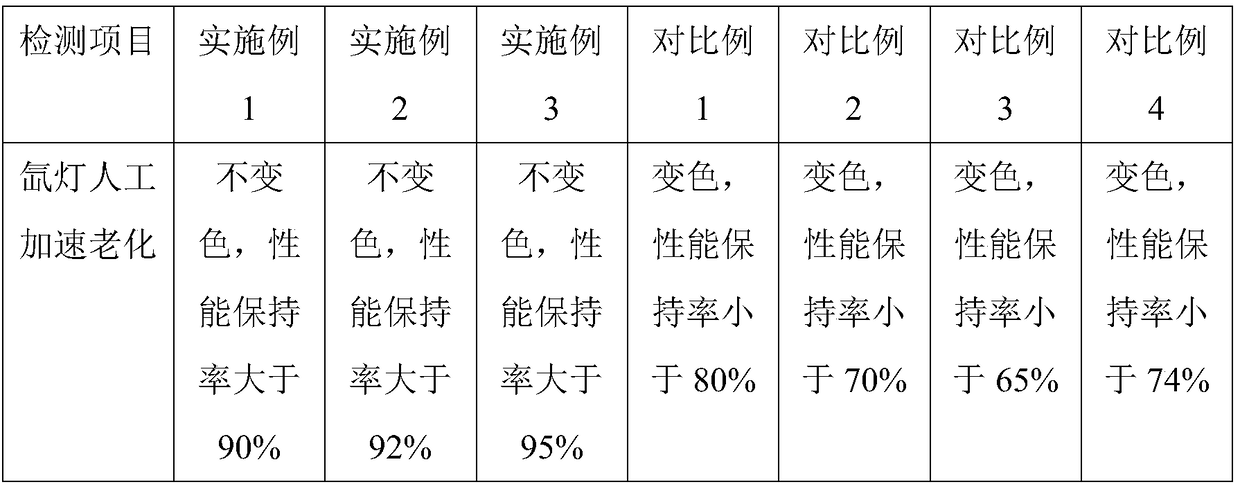

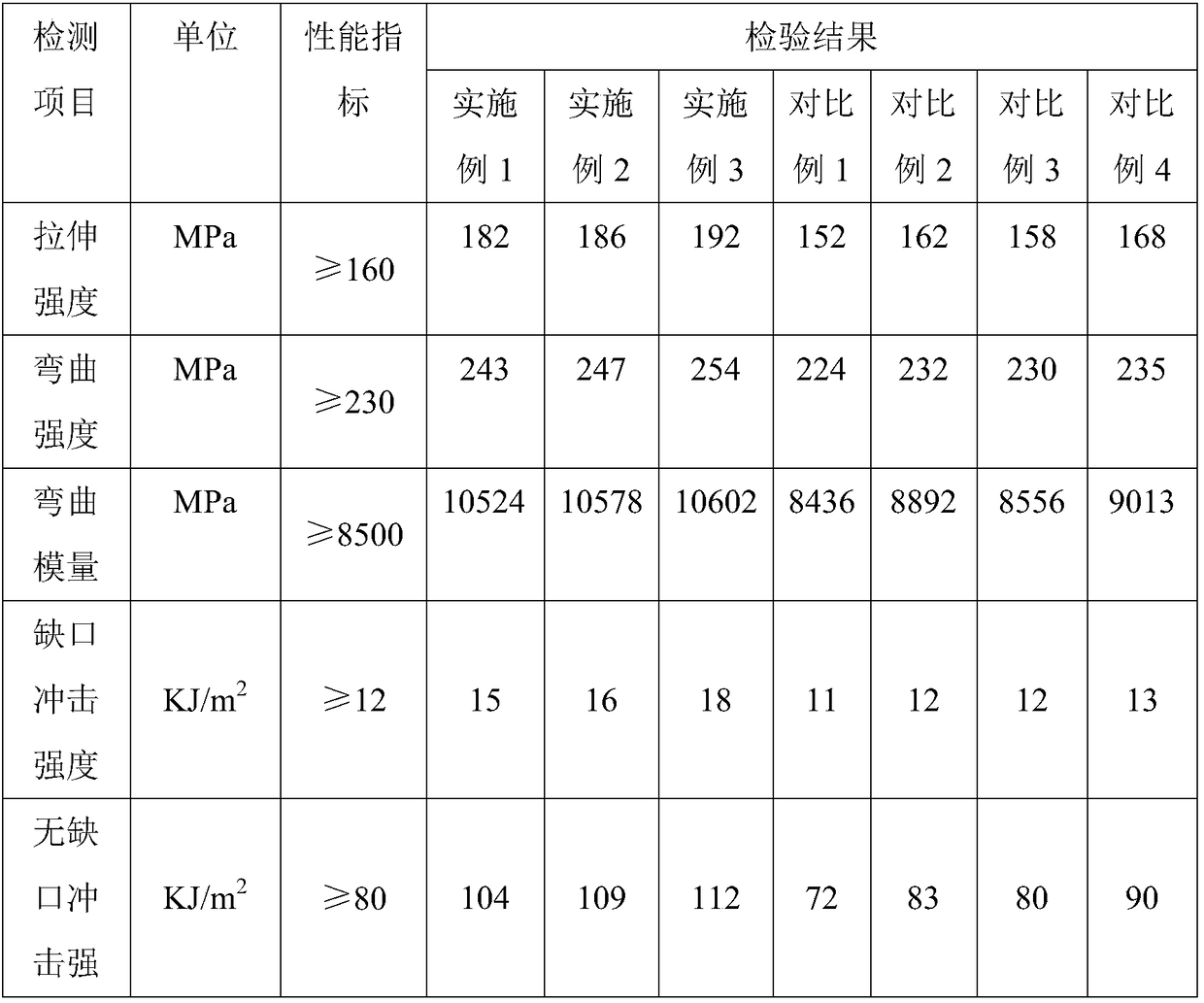

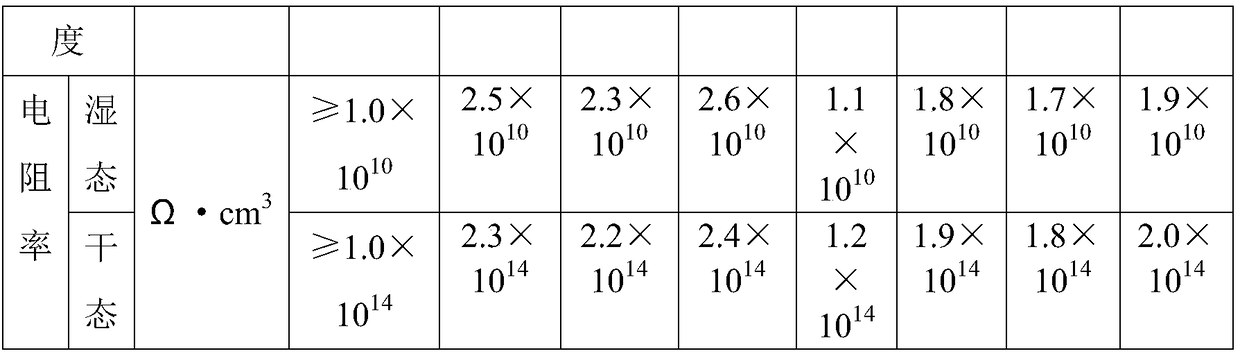

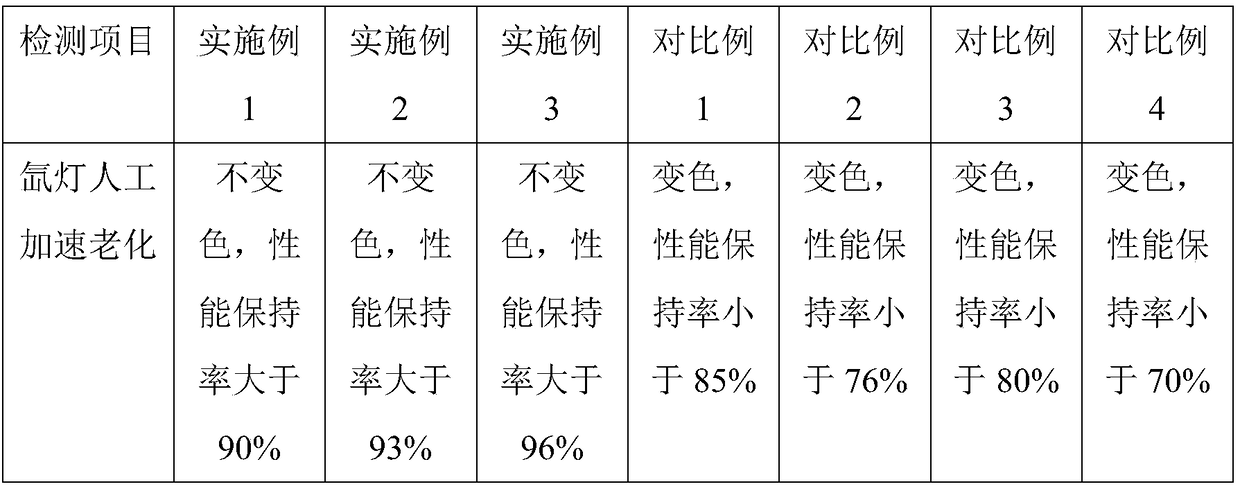

Weatherproof glass fiber reinforced PA66 high-speed rail sleeve material and preparation method thereof

The invention belongs to the technical field of polymer materials, and particularly relates to a weatherproof glass fiber reinforced PA66 high-speed rail sleeve material and a preparation method thereof. The material comprises, by weight, the following components: 44.0-58.3% of PA66 resin, 5.0-10.0% of PA6T resin, 0.3-0.5% of antioxidant 1000, 0.3-0.5% of antioxidant 1098, 0.3-0.5% of lubricant, 5.0-10.0% of inorganic filler, 0.5-1% of toughening agent and 0.3-0.5% of weatherproof agent, 30-33% of glass fiber. The material has the advantages of low cost, high strength, strong toughness, fatigue resistance, stable size, good aging resistance, good weatherproof performance and the like, and can meet the high standard requirement of a high-speed rail sleeve.

Owner:GUANGDONG SHUNDE SHUNYAN NEW MATERIALS

Stainless steel seamless oil pipe for automobile

The invention discloses a stainless steel seamless oil pipe for an automobile. A manufacturing method of the stainless steel seamless oil pipe for the automobile comprises the steps that PVC resin with the polymerization degree being about 2500 is selected, buna-N rubber is used as modified resin, a tricarboxymethyl propane triacrylate (TMPA) monomer is used as a cross-linking agent, an electronicbeam is adopted for carrying out irradiation modification on mixed rubber of the PVC resin and the buna-N rubber, and the outer surfaces of the two ends of a straight pipe are coated with the mixed rubber. The inner wall smoothness and inner structure of the steel pipe for the automobile are uniform, the internal smoothness problem is solved through the principle that the outer diameter is matched with the wall thickness, capillary cracks of the inner wall brought by original blank materials of the steel pipe are eliminated, steel pipe internal structure uniformity is achieved, the fine grainstructure is obtained, the outer surface of the straight pipe is evenly coated with the mixed rubber of the PVC resin and the NBR, the oil resistance of the TP304 stainless steel seamless steel pipeis improved, the shrinkage deformation rate is small, and long-term use is facilitated.

Owner:上海新行不锈钢管有限公司

Anti-cracking surface-grinded brick and preparation method thereof

InactiveCN107879724AReduce the probability of crackingImprove dry crack resistanceCeramic materials productionClaywaresBrickPolymer science

The invention discloses an anti-cracking surface-grinded brick and a preparation method thereof. The anti-cracking surface-grinded brick has a raw material formula which comprises the following raw materials in percentages by weight: 20% to 40% of plastic pug, 20% to 30% of full-body brick clinker particles with a particle size of 10 to 15 meshes, 10% to 15% of vitrified brick clinker particles with a particle size of 20 to 30 meshes, 20% to 35% of a feldspar solvent and 1% to 3% of an anti-cracking agent, wherein the anti-cracking agent has a formula composed of the following components in percentages by weight: 20% to 40% of a pure acrylic emulsion, 5% to 20% of alkyl ethenone modified cellulose, 1% to 5% of phosphate, 1% to 5% of polyvinyl alcohol, 10% to 15% of bentonite, 2% to 5% of apolyacrylic emulsion and 15% to 35% of water. According to the invention, on the premise of no damage to green-brick strength and sintering strength, the shrinkage deformability of a green brick is effectively reduced; the usage amount of the plastic pug is greatly reduced in the process of extrusion molding; the usage amount of large waste ceramic particles can be greatly improved; the strengthof the green brick is improved; a drying shrinkage rate and a sintering shrinkage rate are low; plasticity is strong; and drying cracks and sintering cracks are avoided from generation.

Owner:FOSHAN HENGTAI HONGSHI CERAMIC CO LTD

Wear-resistant scratch-resistant antibacterial BOPET film and preparation method thereof

InactiveCN111907165AGood wear resistance and scratch resistanceImprove scratch resistanceSynthetic resin layered productsFlat articlesPtru catalystBoPET

The invention discloses a wear-resistant scratch-resistant antibacterial BOPET film. The film is composed of a surface layer A, a core layer B and a bottom layer C. A thickness ratio of the surface layer A to the core layer B to the bottom layer C is (2-5): (20-40): (2-5); the surface layer A and the bottom layer C are located on the two sides of the core layer B; the surface layer A is an antibacterial layer; the core layer B is a filling layer; and the bottom layer C is wear-resistant scratch-resistant layer; The surface layer A comprises the following raw materials: PET slices, a compositeantibacterial agent, a catalyst and a stabilizer. The core layer B is a PCTG copolyester slices. The bottom layer C comprises the following raw materials: PET slices, a toughening agent, a KH550 silane coupling agent, a functional additive, a catalyst and a stabilizer. The invention also discloses a preparation method of the wear-resistant scratch-resistant antibacterial BOPET film. The BOPET filmprepared by the invention has the advantages of wear resistance, scratch resistance, lasting antibacterial property; and the method is simple in production process, wide in raw material sources and low in production cost.

Owner:李法雷

A kind of polypropylene wire rod and preparation method thereof for 3D printing

ActiveCN108641197BNo significant change in melting pointWon't breakAdditive manufacturing apparatusElastomerPolymer science

The invention discloses a polypropylene wire material for 3D printing and a preparation method thereof. The polypropylene wire material is composed of co-polypropylene, low-melting-point homo-polypropylene, inorganic filler, thermoplastic elastomers, a plasticizer and a stabilizer. The polypropylene wire material is low in material crystallinity degree, shrinkage distortion and warping, has good 3D printing effects and printing accuracy, and can reduce cost to a large extent. The preparation method for the polypropylene wire material for 3D printing is simple in technology and lower in production equipment requirement, can achieve large-scale production and popularization, and has a wide market prospect.

Owner:WANHUA CHEM GRP CO LTD

Method for directly titrating and forming ceramic microspheres through gel casting of track

A method for directly titrating and forming ceramic microspheres through gel casting of a track comprises the following steps: firstly, processing a track disc with a plurality of semicircular tracks, pasting a heating belt on the surface of one side, opposite to the semicircular tracks, of the track disc, spraying hydrophobic coating on the surfaces of the semicircular tracks, and drying the hydrophobic coating through the heating belt; then preparing ceramic slurry; and finally, carrying out titration forming, obliquely placing the track disc, enabling an included angle of 10-15 degrees to be formed between the track disc and the horizontal direction, enabling the semicircular tracks to face upwards, placing the titration disc at the top end of the track disc, enabling a plurality of titration needle cylinders of the titration disc to be respectively aligned with the top ends of the semicircular tracks, and then heating the track disc at 120-150 DEG C by using the heating belt, and then injecting the ceramic slurry into the titration disc, so that ceramic slurry liquid drops roll downwards on the semicircular track and are heated and cured into ceramic microsphere blanks. The preparation method has the advantages of low process cost, few procedures and easiness in realization of automatic production, and the prepared ceramic microspheres are high in sphericity and uniform in internal structure.

Owner:725TH RES INST OF CHINA SHIPBUILDING INDAL CORP

Novel preparation method of epoxy tooling board

The invention relates to a novel preparation method of an epoxy tooling board. The novel preparation method comprises the following steps in sequence: feeding each material of a component A into a stirrer based on the fixed ratio; stirring and mixing for 40 to 80 minutes; feeding each material of a component B into the stirrer based on the fixed ratio; stirring and mixing for 40 to 80 minutes; respectively conveying the uniformly-mixed components A and B into a vacuum gapped tank through an automatic metering device based on the ratio of A to B of (4:1) to (1:1); stirring for 40 to 80 minutes; conveying the qualified materials of the uniformly-mixed components A and B into a vacuum tank by the automatic metering device; filling under the vacuum condition; curing the filled material for 1.5 to 3 hours at normal temperature; and curing at high temperature of 90 to 100 DEG C, thus obtaining the epoxy tooling board. The novel preparation method of the epoxy tooling board is high in automatic control degree, low in labor cost, high in production efficiency, stable in quality, low in density, high in strength and low in deformation rate.

Owner:江苏恒隆通新材料科技有限公司

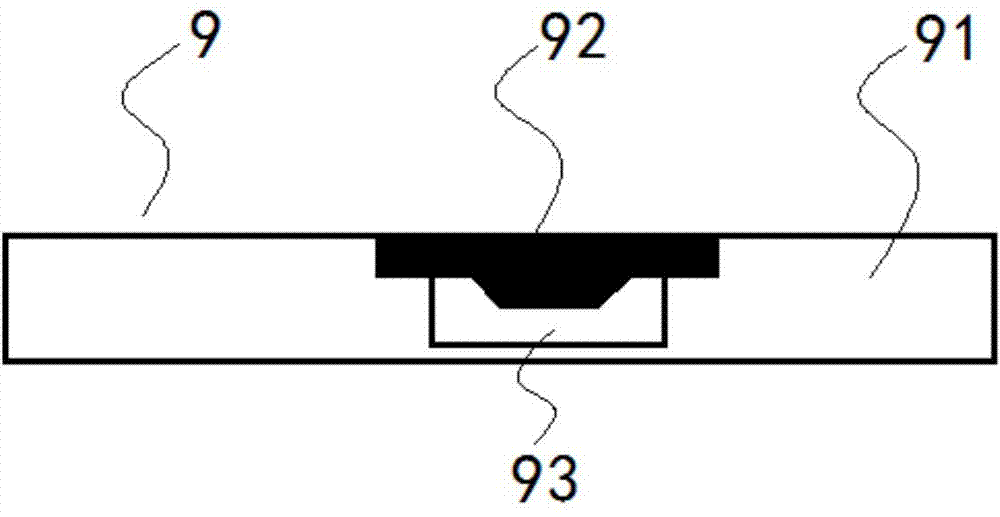

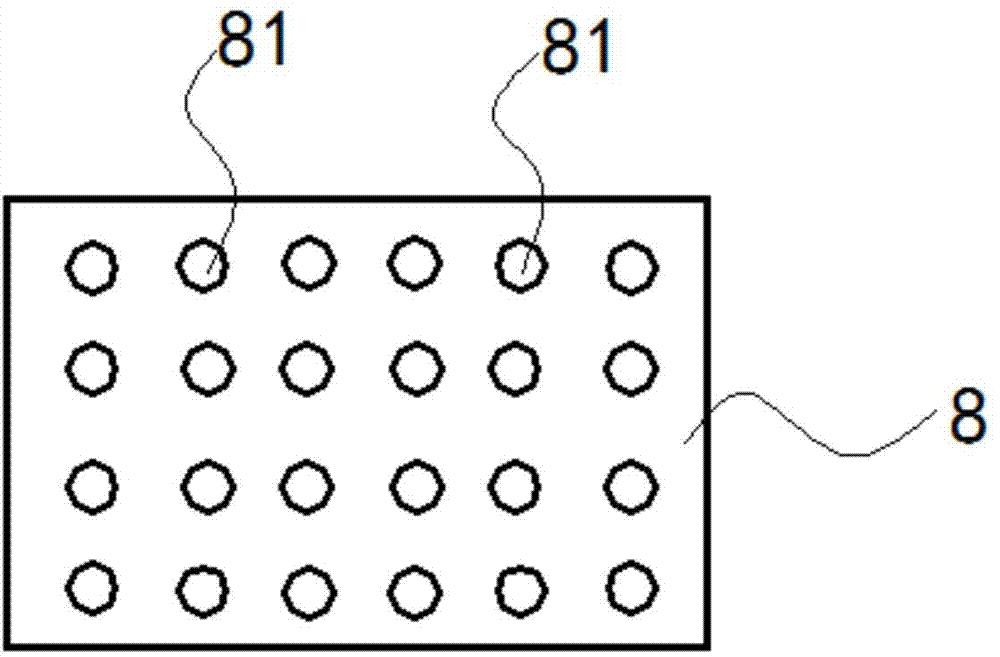

IC card packaging device and method

ActiveCN104733358AKeep it flatImprove aestheticsSemiconductor/solid-state device manufacturingEngineeringHot pressing

The invention discloses an IC card packaging device and method. The IC card packaging device comprises a packaging platform, hot pressing devices, cold pressing devices, negative pressure devices, a transmission device and power devices, wherein the hot pressing devices and the cold pressing devices are sequentially arranged in the IC card transmission direction, the hot pressing devices comprise hot pressing heads, and the hot pressing heads are internally provided with heating devices; the cold pressing devices comprise cold pressing heads, the packaging platform is provided with card grooves adapted to the size of an IC card, the bottom surface of each card groove is provided with adsorption holes, and the negative pressure devices are communicated with the adsorption holes. When the cold pressing heads conduct cold pressing on the IC cards in the card grooves, plastic card bases in the card grooves are absorbed by the adsorption holes through negative pressure, so that the lower surfaces of the plastic card bases in a softening state become regular and flat, and then the beautiful degree of the card surfaces is greatly improved.

Owner:HONGBO CO LTD

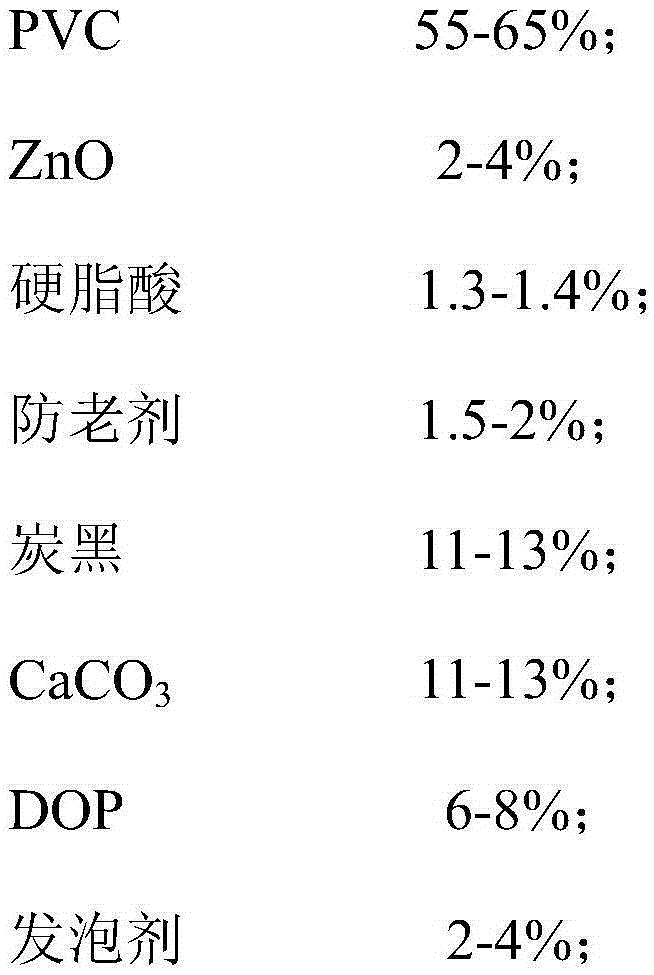

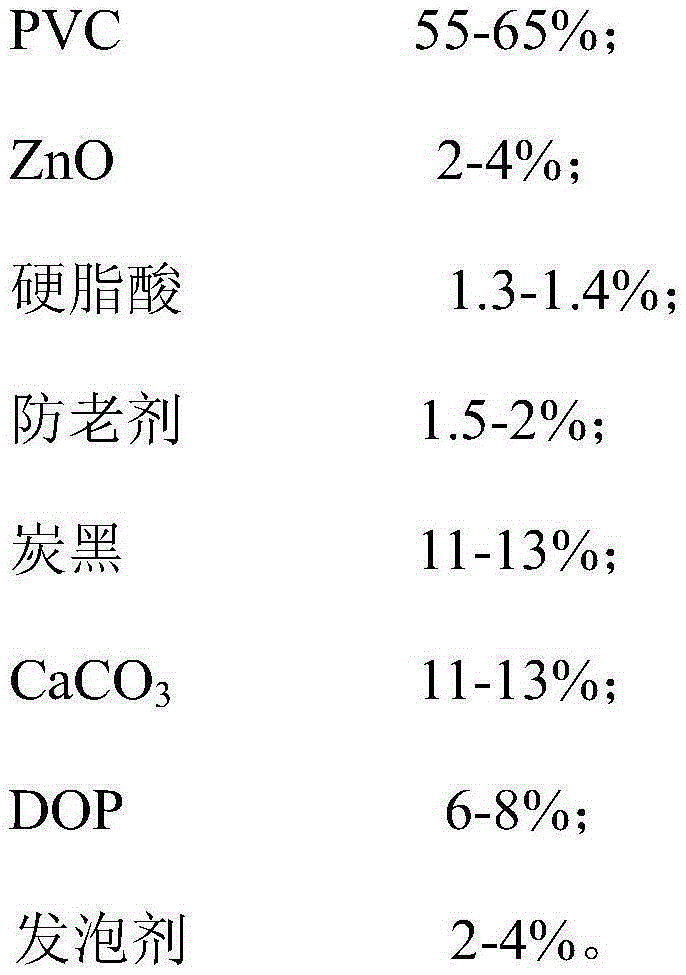

A kind of pvc sole foam material

The invention discloses a PVC sole foaming material, which comprises the following components, by weight: 55-65% of PVC, 2-4% of ZnO, 1.3-1.4% of HSt, 1.5-2% of an anti-aging agent, 11-13% of carbon black, 11-13% of CaCO3, 6-8% of DOP, and 2-4% of a foaming agent. The prepared PVC sole foaming material has characteristics of good elasticity, low density, flexibility, and low shrinkage deformation rate.

Owner:山东源邦新材料股份有限公司

Weatherproof glass fiber reinforced PA66 common railway track gauge block material and preparation method thereof

Belonging to the technical field of macromolecular materials, the invention in particular relates to a weatherproof glass fiber reinforced PA66 common railway track gauge block material and a preparation method thereof. The weatherproof glass fiber reinforced PA66 common railway track gauge block material provided by the invention includes the following components by weight percentage: 39.0-52.8%of PA66 resin, 5.0-10.0% of PA6T resin, 0.6-1.0% of an antioxidant, 0.3-0.5% of a lubricant, 5.0-10.0% of inorganic filler, 1.0-2.0% of a toughening agent, 0.3-0.5% of a weathering agent, and 35-37% of glass fiber. The weatherproof glass fiber reinforced PA66 common railway track gauge block material provided by the invention has the characteristics of low cost and excellent comprehensive performance, and meets the high standard requirements of track gauge blocks. The weatherproof glass fiber reinforced PA66 common railway track gauge block material provided by the invention has low water absorption, good water resistance and excellent dimensional stability, and improves the product lifetime.

Owner:GUANGDONG SHUNDE SHUNYAN NEW MATERIALS

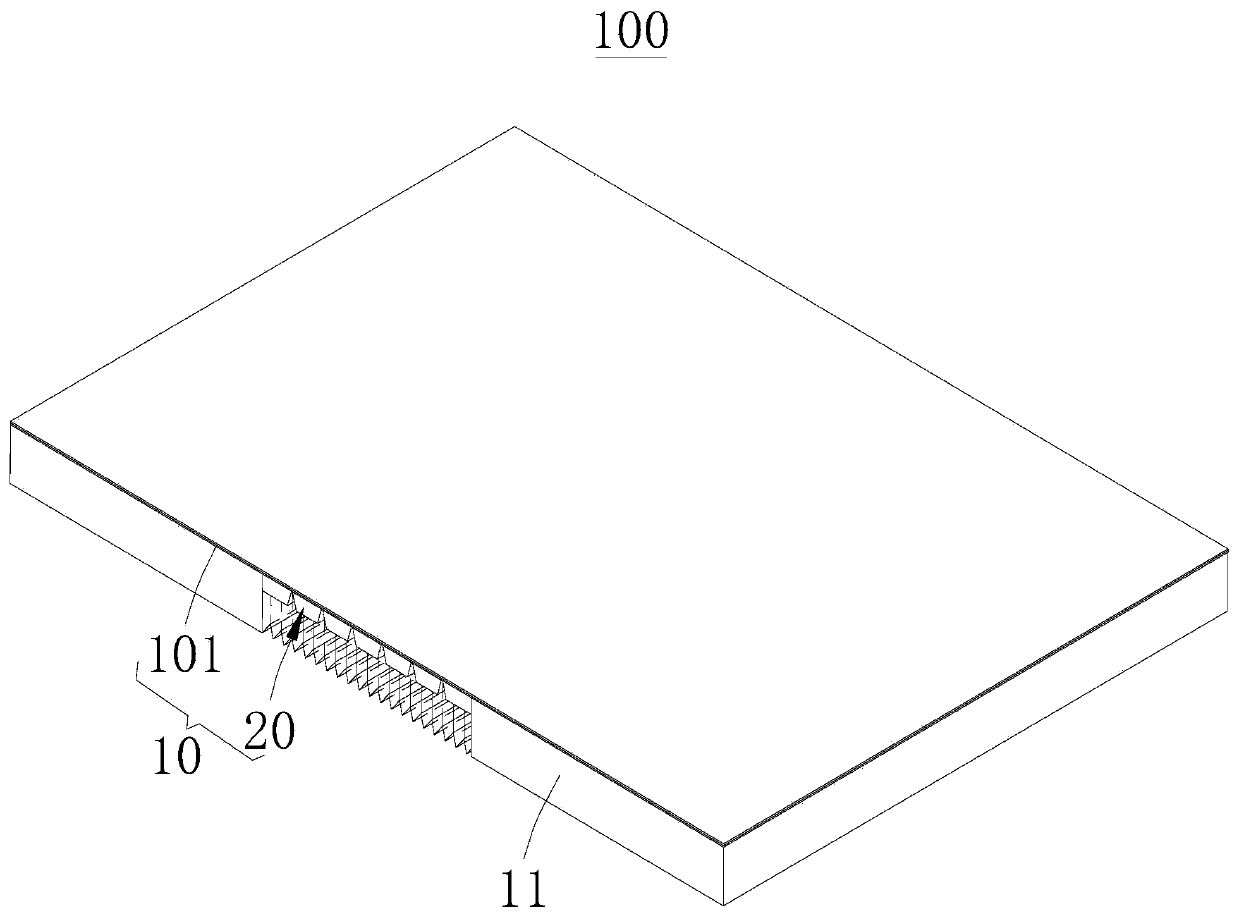

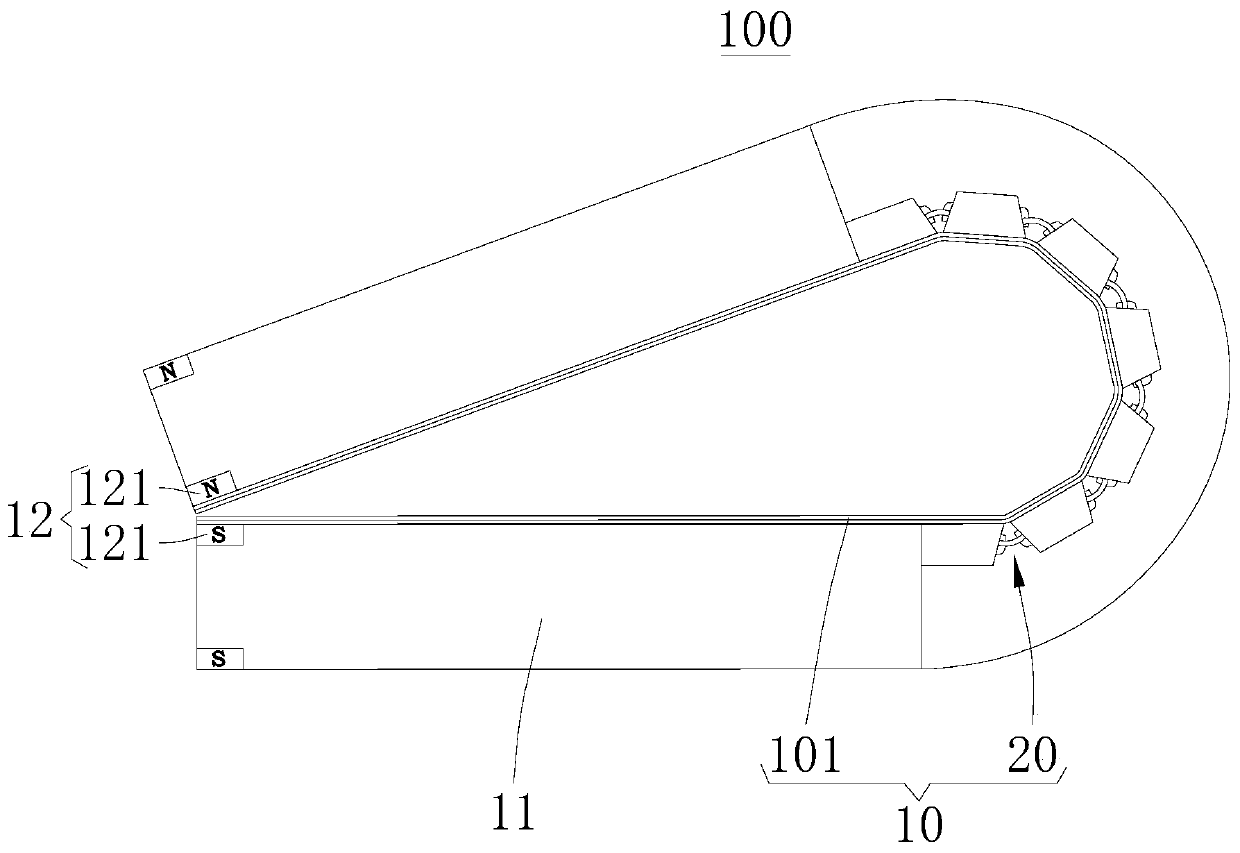

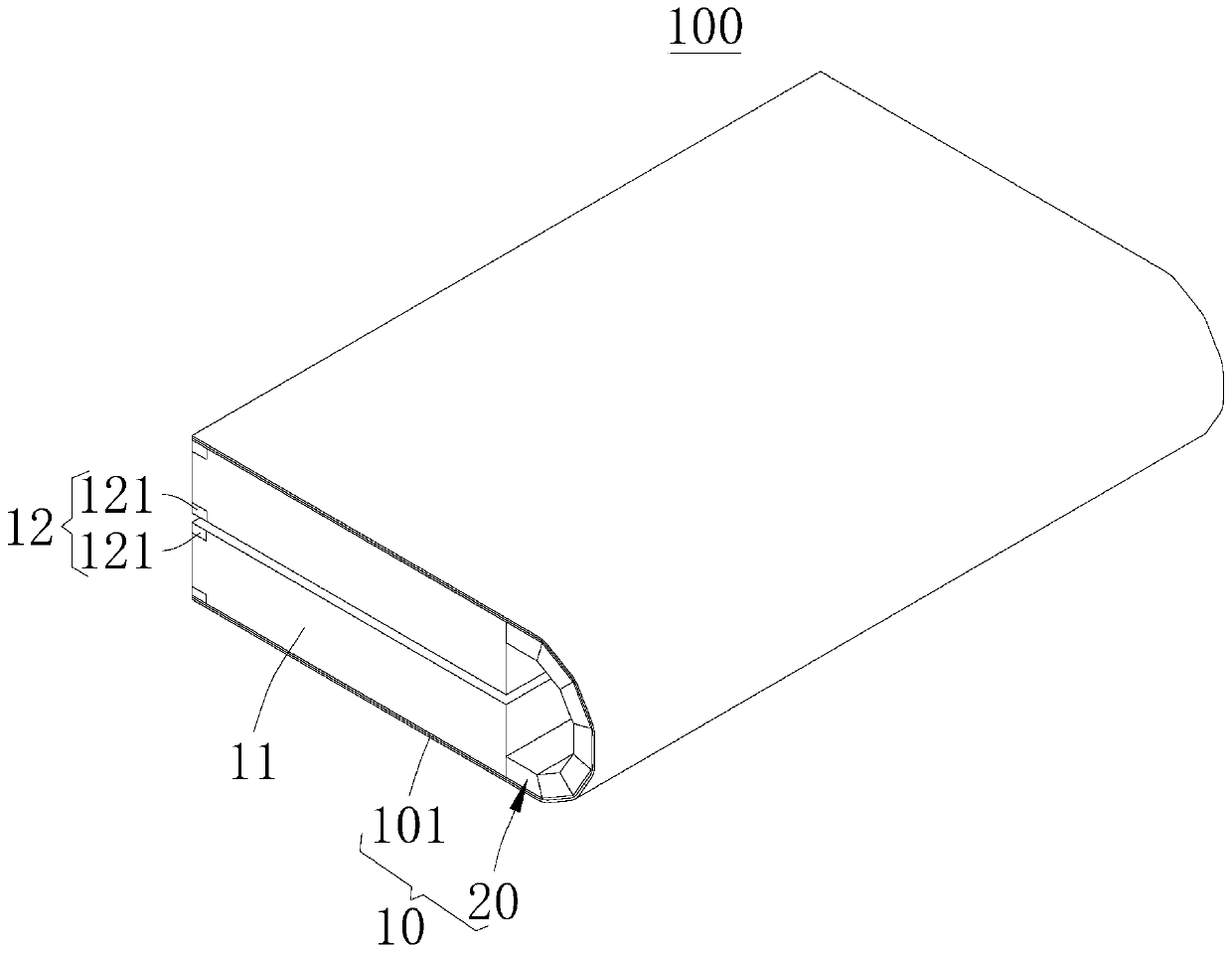

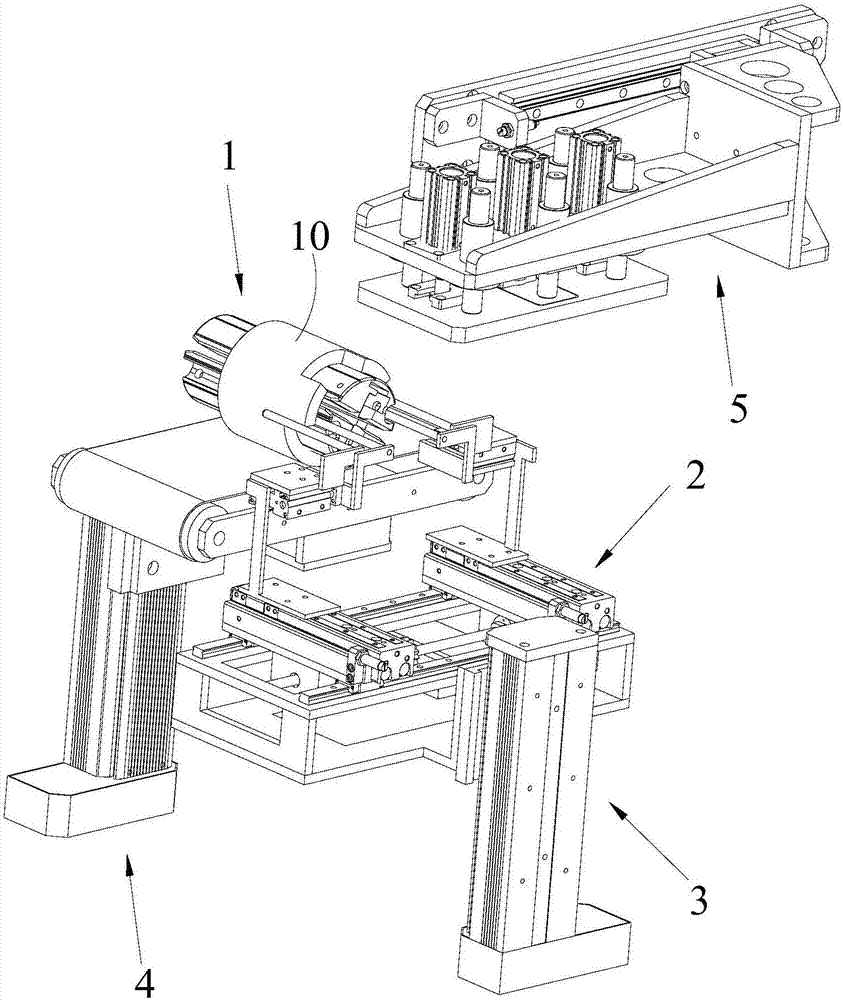

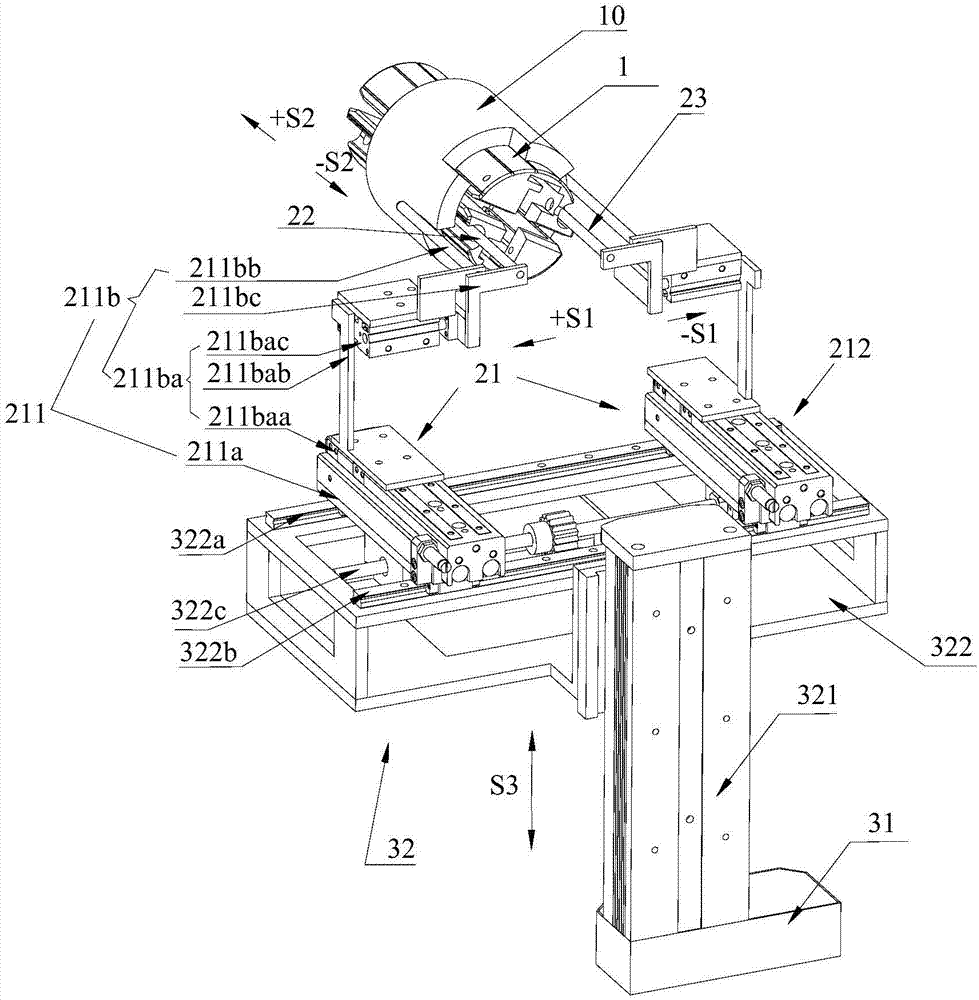

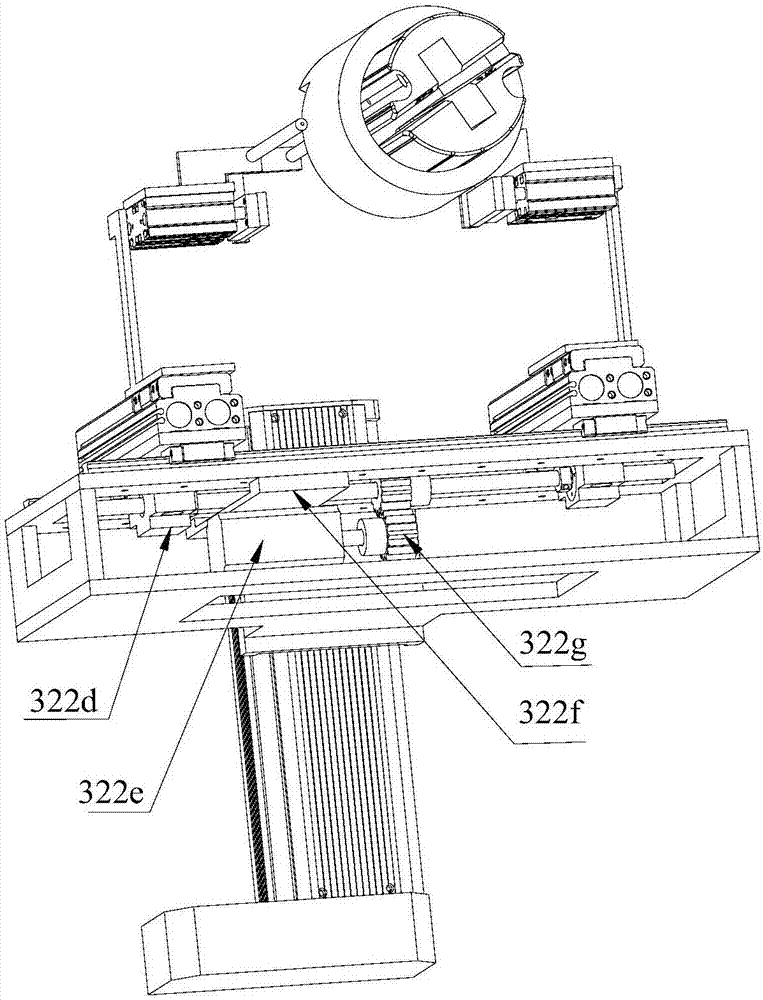

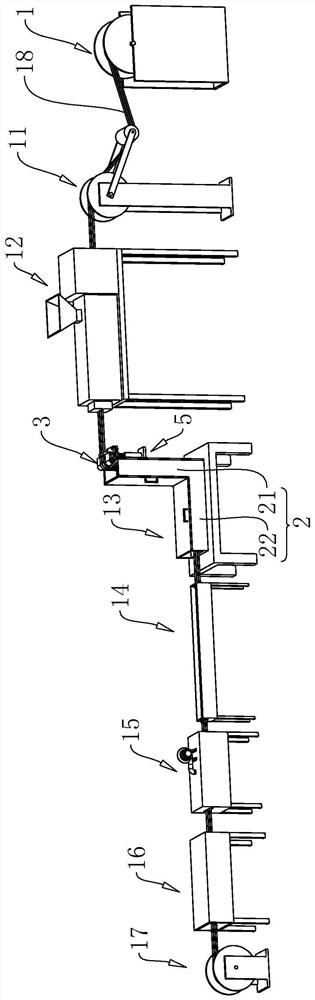

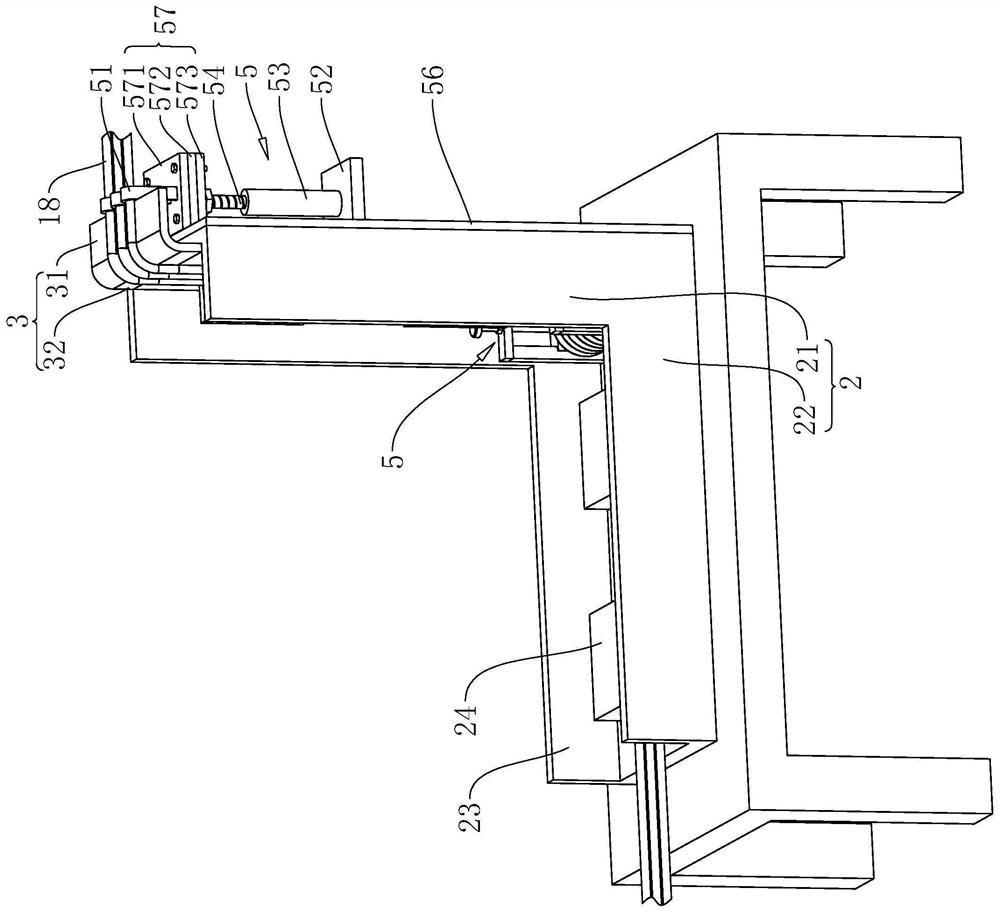

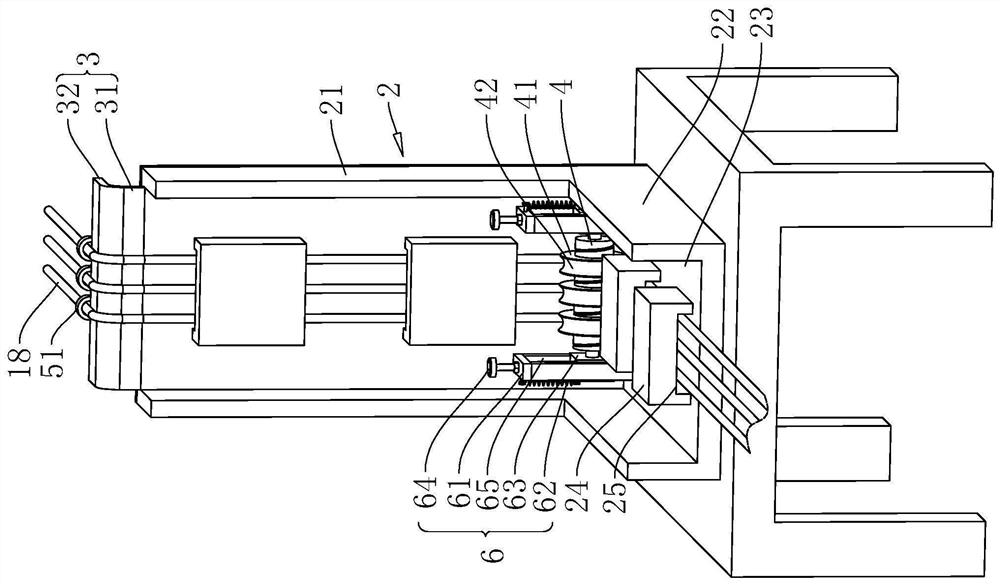

Rolled product processing apparatus

ActiveCN106960975AImprove processing qualityReduced shrinkage deformationAssembling battery machinesFinal product manufactureEngineeringProduct processing

The invention relates to a rolled product processing apparatus. The processing apparatus comprises a roll needle and a shaping mechanism, wherein the shaping mechanism comprises a movable part, a first acting part and a second acting part, wherein the movable part is connected with at least one of the first acting part and the second acting part; the movable part has an effect of enabling the first acting part and the second acting part to generate a stretching stroke to be far from each other relatively; accommodating grooves used for accommodating the first acting part and the second acting part respectively are formed in the outer surface of the roll needle; in the stretching stroke, the first acting part and the second acting part can apply acting forces of opposite directions to the rolled product so as to stretch the rolled product; and at the starting end of the stretching stroke, the first acting part and the second acting part are both positioned in the corresponding accommodating grooves. By virtue of the scheme, shrinkage deformation amount of the rolled product to a hollow part of the rolled product is reduced, so that the processing quality of the rolled product, such as a wound cell, can be improved consequently.

Owner:CONTEMPORARY AMPEREX TECH CO

Production method of UV stereoscopic lens transfer paper

ActiveCN114369969ANo pollutionReduce pollutionNon-fibrous pulp additionSpecial paperPhysical chemistrySolid content

The invention relates to a production method of UV stereoscopic lens transfer paper, which comprises paper and a PET base film with a corona layer on the surface, the corona layer is coated with a water-based release layer, the water-based release layer is coated with a UV transfer nano adhesive layer, and the production method comprises the following steps: water-based release coating coating, UV transfer nano adhesive layer coating, UV transfer nano adhesive layer coating, UV transfer nano adhesive layer coating, UV transfer nano adhesive layer coating, UV transfer nano adhesive layer coating, UV transfer nano adhesive layer coating, UV transfer nano adhesive layer coating, UV transfer nano adhesive layer coating, UV transfer nano adhesive layer coating, UV transfer nano adhesive layer coating and UV transfer nano adhesive layer coating. The three-dimensional lens has the advantages that the UV transfer nano adhesive layer is a 100% solid content coating, so that a deep-line lens effect can be perfectly copied under the condition of cold pressing, the 3D stereoscopic impression is strong, the layering sense is strong, a better visual effect and an outstanding anti-counterfeiting effect are achieved, and the anti-counterfeiting effect is good. Due to the fact that the UV transfer nanometer glue layer is coated with the aluminum plating layer, the overall thickness is increased through the UV transfer nanometer glue layer, the effect of the three-dimensional lens can be greatly improved, a good anti-fake effect can be achieved, and the product is higher in end.

Owner:ZHEJIANG YAXIN PACKAGE MATERIAL

Low-shrinkage shaping high-coaxiality cable cladding production line

PendingCN112757600AReduced shrinkage deformationImprove coaxialityDomestic articlesCoatingsPhysicsEngineering

The invention relates to a low-shrinkage shaping high-coaxiality cable cladding production line, and relates to the technical field of cable production. The production line comprises a feeding device, an extrusion molding device, a cooling device, a drying device, a driving device and a receiving device which are arranged in sequence, wherein a pre-shaping device is arranged between the extrusion molding device and the cooling device, the pre-shaping device comprises an L-shaped heating support, a guide plate and a redirecting shaft, the L-shaped heating support comprises a vertical section and a horizontal section which are connected, the vertical section is located below a discharging end of the extrusion molding device, and the horizontal section is located at a feeding end of the cooling device; one end of the guide plate is mounted on the inner side of the vertical section, and the other end of the guide plate extends towards the discharge end of the extrusion molding device; and the redirecting shaft is mounted on the L-shaped heating support and located at the right angle of the L-shaped heating support, and a gap is formed between the peripheral wall of the redirecting shaft and the L-shaped heating support. The production line has the advantages that uniform cladding of a cladding material in the circumferential direction of a cable is facilitated, and the shrinkage deformation is small, so that the coaxiality of the cable and a sheath is improved.

Owner:常州永波电子有限公司

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com