Manufacturing method of masks

A manufacturing method and mask technology, applied in ion implantation plating, metal material coating process, coating and other directions, can solve problems such as uneven deformation of the mask, reduce shrinkage deformation problems, reduce shrinkage deformation , the effect of improving quality

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

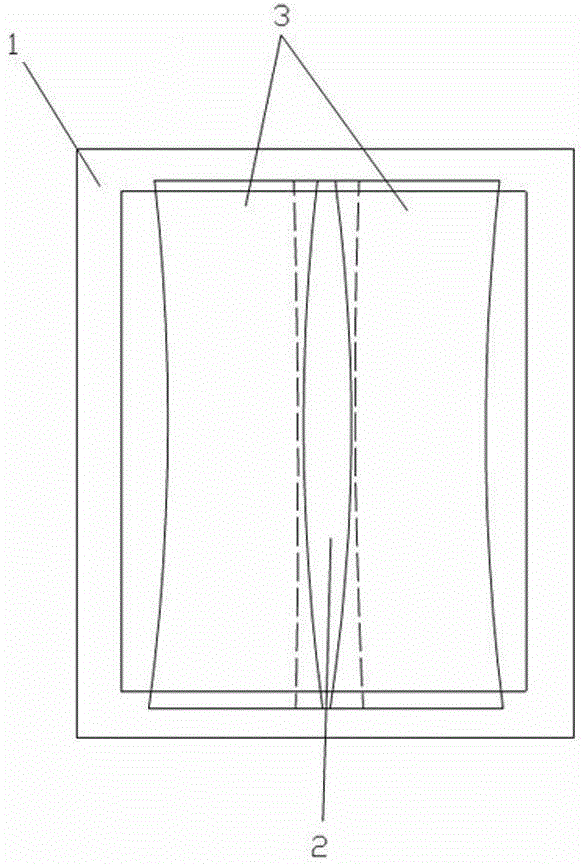

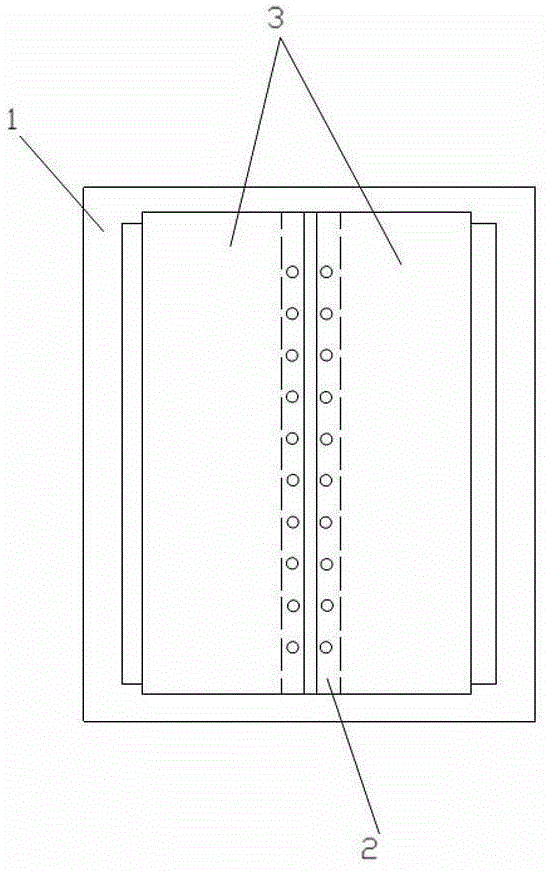

Image

Examples

Embodiment 1

[0028] The special low-expansion iron-nickel alloy Invar36 material with ultra-low expansion coefficient is used to make the shielding mask and the mask. The sizes of the shielding mask and the mask are: the thickness is 30um, the width is 60mm, and the length is 1000mm . In an environment with a workshop temperature of 25°C, the shielding mask and the mask are respectively tensioned and fixed on the mask frame with a tension of 20N, and the elastic modulus of the iron-nickel alloy Invar36 is E=1.48×10 11 N / ㎡, the coefficient of thermal expansion is ξ= 1.2×10 -6 m / ℃, then the length deformation of the shielding mask and the mask △L= F×L / (E×A)=20N×1m / (1.48×10 11 N / ㎡×6×10 -2 m×3×10 -5 m)=0.75×10 -4 m=75um; △B=△L×U1 / U2=△L×P=0.75×10 -4 m×0.3=22.5×10 -6 m =22.5um; At this time, the temperature of the workshop should be controlled as: T2=△L / (L×ξ)+T1=0.75×10 -4m / (1m×1.2×10 -6 m / °C)+25°C=62.5°C+25°C=87.5°C, if the mask frame with the block mask and the mask plate fixed is pl...

Embodiment 2

[0030] The special low-expansion iron-nickel alloy Invar36 material with ultra-low expansion coefficient is used to make the shielding mask and the mask. The sizes of the shielding mask and the mask are: the thickness is 30um, the width is 60mm, and the length is 1000mm . In an environment with a workshop temperature of 25°C, the shielding mask and the mask are respectively tensioned and fixed on the mask frame with a tension of 50N, and the elastic modulus of the iron-nickel alloy Invar36 is E=1.48×10 11 N / ㎡, thermal expansion absorption is ξ= 1.2×10 -6 m / °C, then the length deformation of the shielding mask and the mask △L= F×L / (E×A)=50N×1m / (1.48×10 11 N / ㎡×6×10 -2 m×3×10 -5 m)=1.877×10 -4 m=187.7um; △B=△L×U1 / U2=△L×P=1.877×10 -4 m×0.3=56.31×10 -6 m =56.31um; At this time, the temperature of the workshop should be controlled as: T2=△L / (L×ξ)+T1=1.877×10 -4 m / (1m×1.2×10 -6 m / °C)+25°C=156.4°C+25°C=181.4°C, if the mask frame with the block mask and mask plate fixed is pl...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Elastic modulus | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com