Patents

Literature

736results about "Manufacturing environment conditioning" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

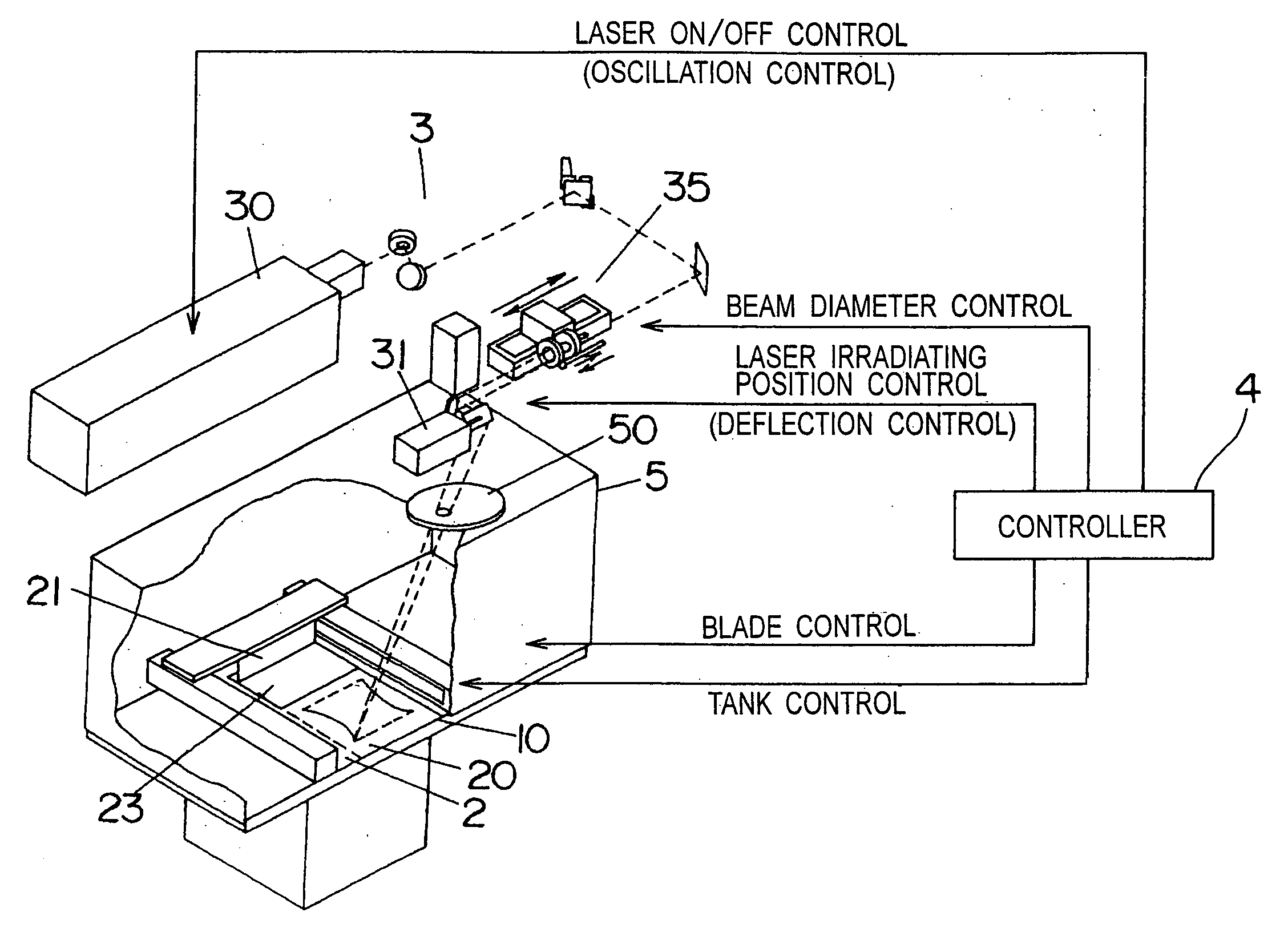

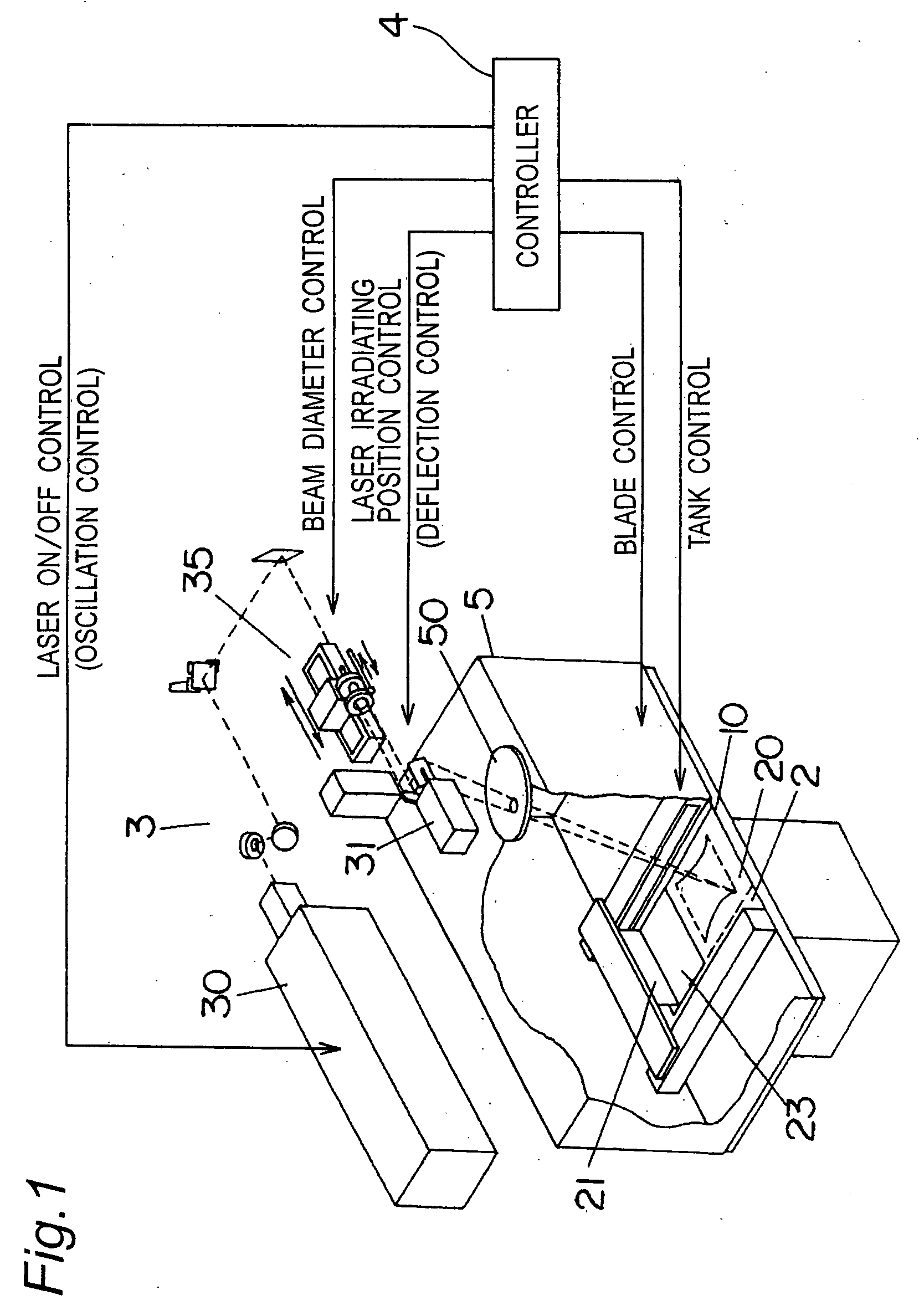

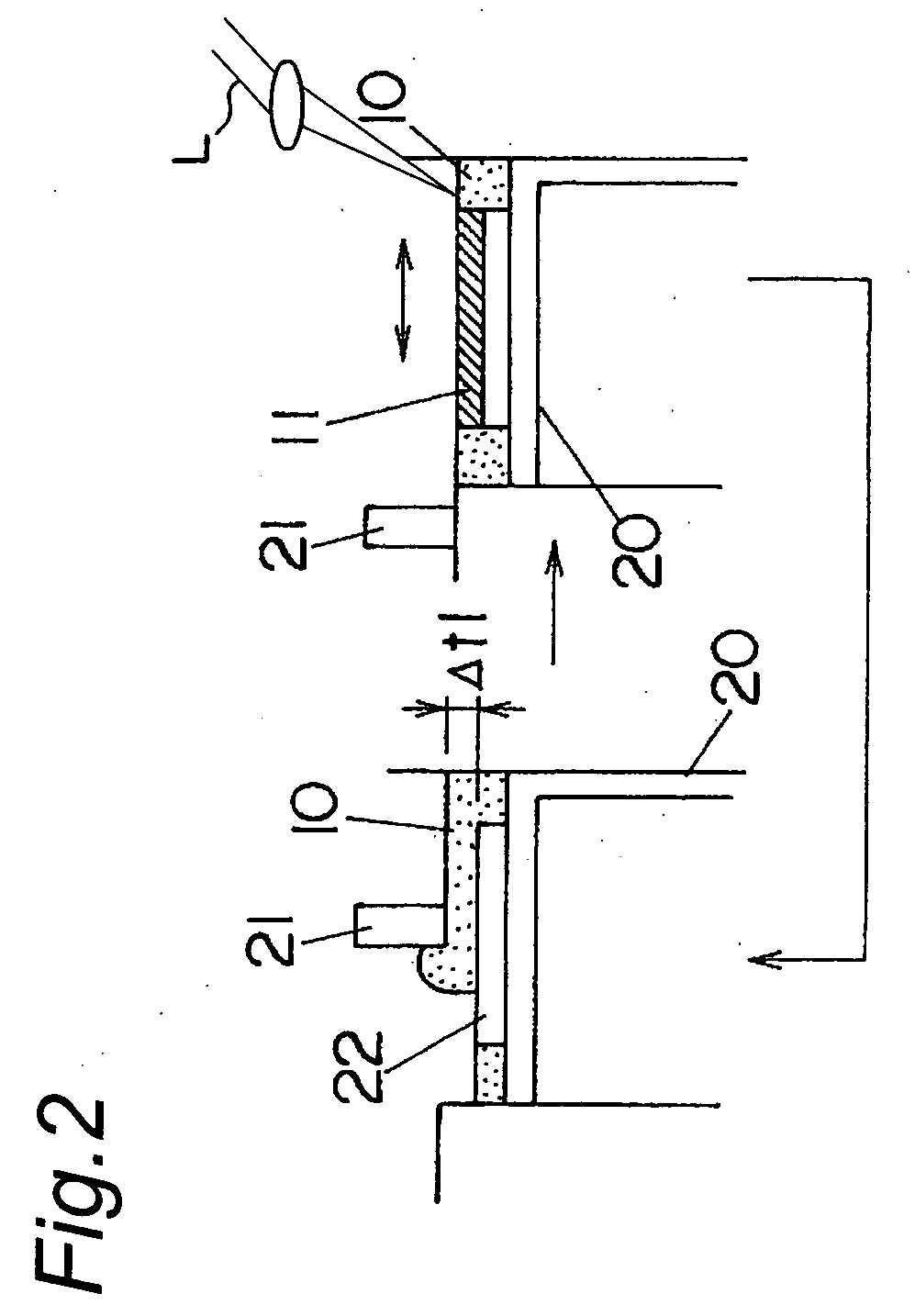

Three dimensional structure producing device and producing method

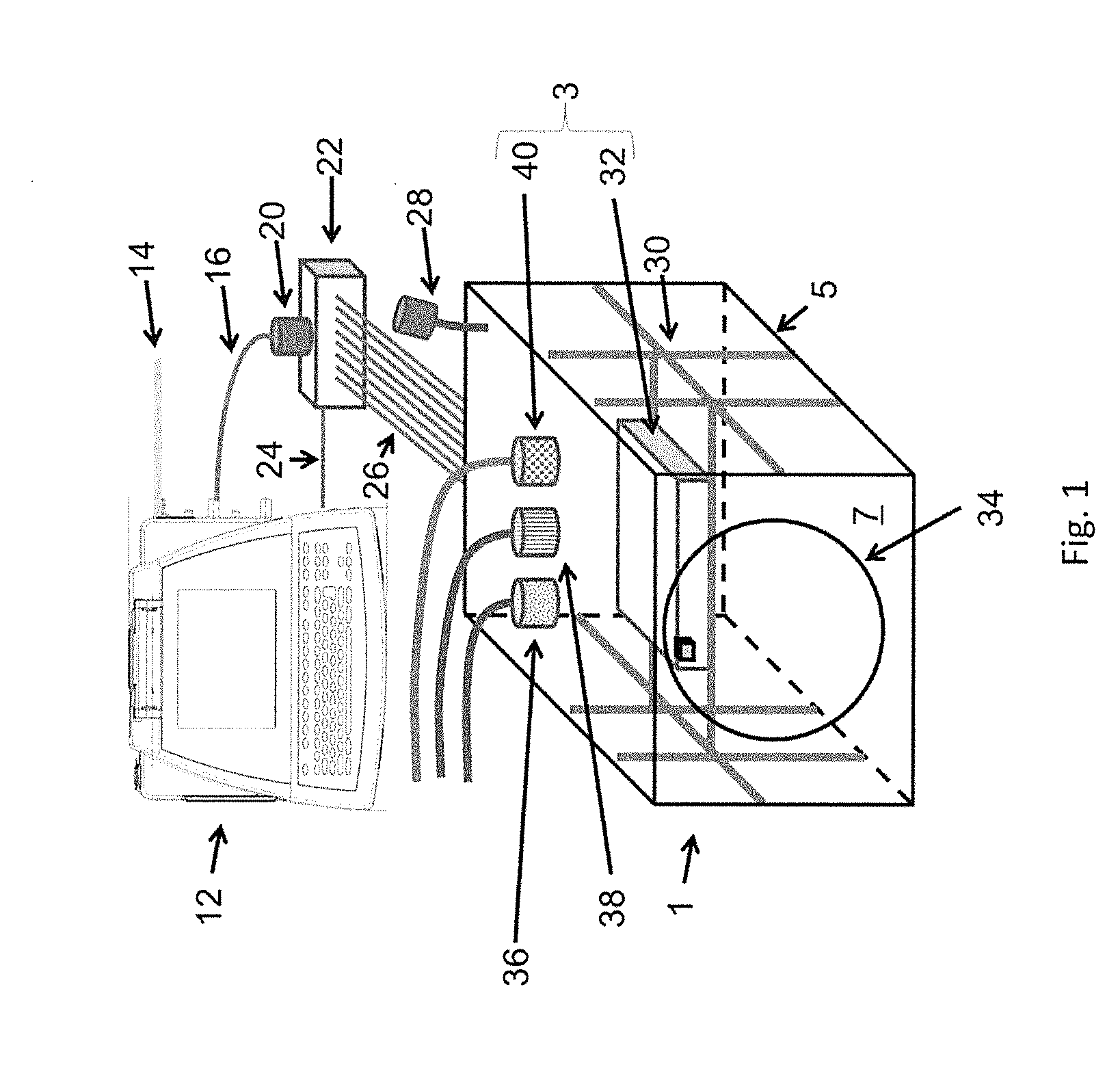

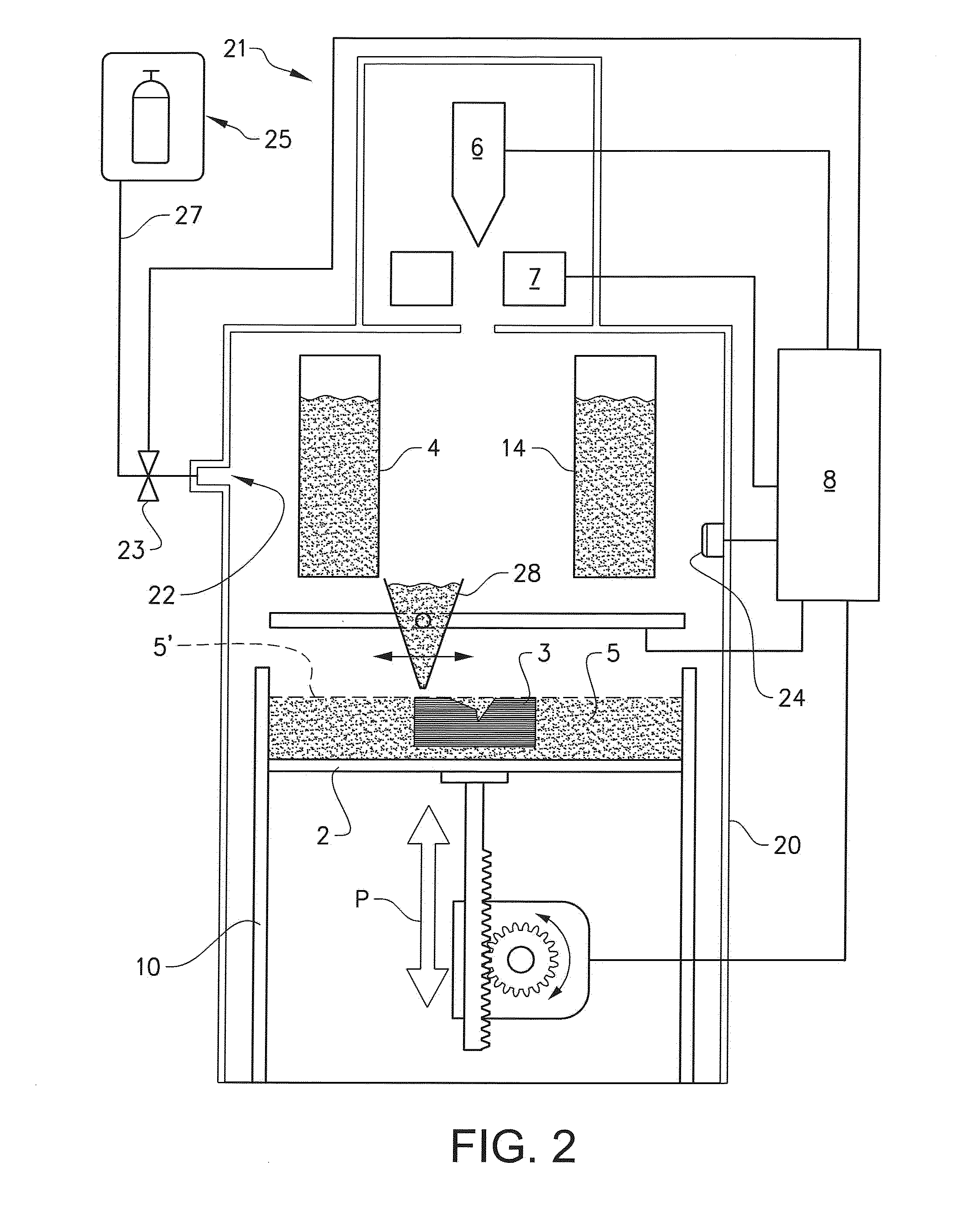

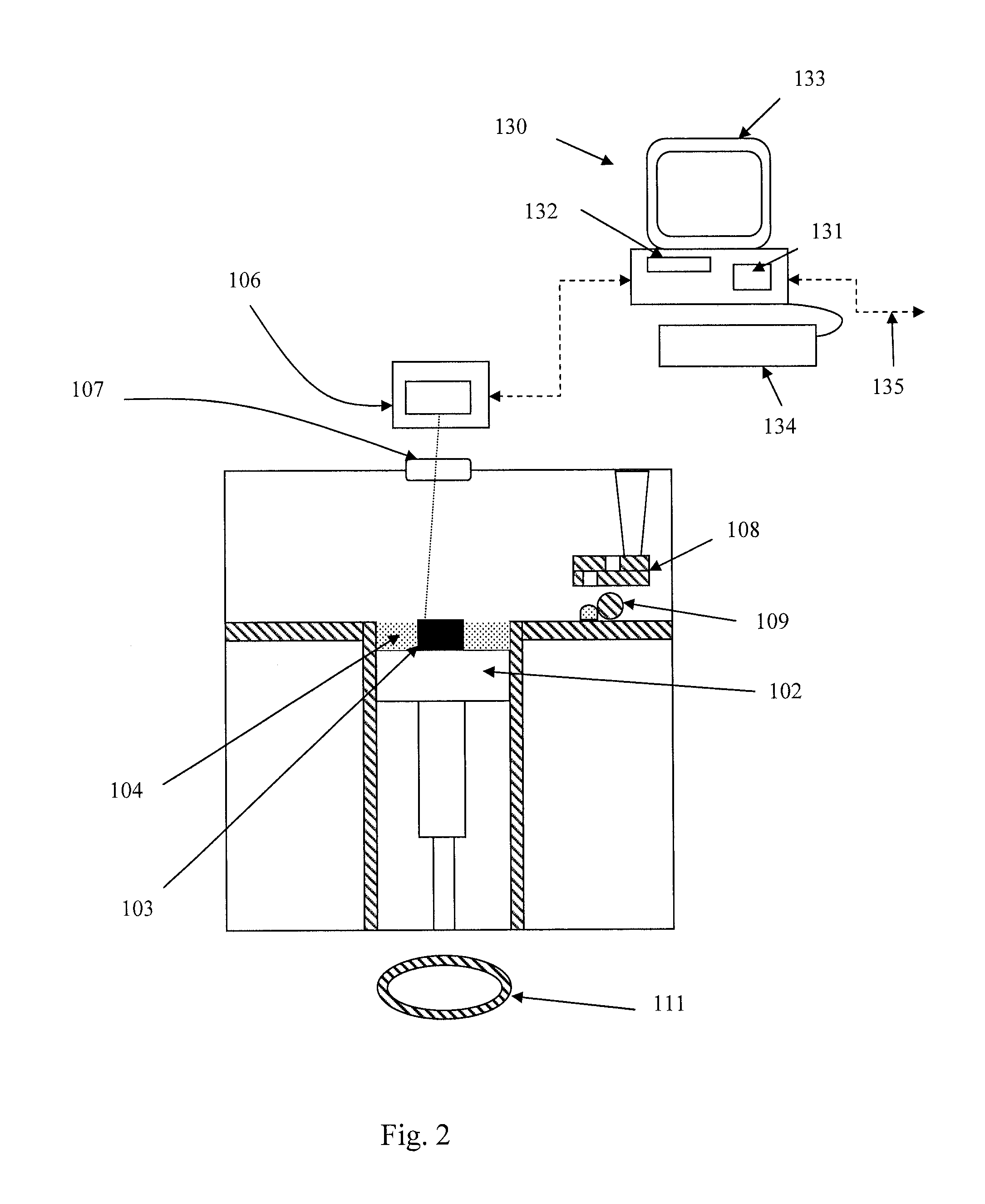

An apparatus for making a three-dimensional object includes a powdery layer-forming unit for forming a powdery layer on a table and an optical beam-irradiating unit for irradiating an optical beam on a predetermined region of the powdery layer to sinter the predetermined region. The optical beam-irradiating unit is disposed at a position spaced from immediately above an optical beam-irradiating range to obliquely irradiate the optical beam on the powdery layer. Because fumes generated by irradiating and heating the powdery layer with the optical beam rise towards a position immediately above them, the optical beam is irradiated from the position spaced from immediately above the optical beam-irradiating range, thereby reducing a cloud of the optical beam-irradiating unit that may be caused by the fumes.

Owner:MATSUSHITA ELECTRIC WORKS LTD

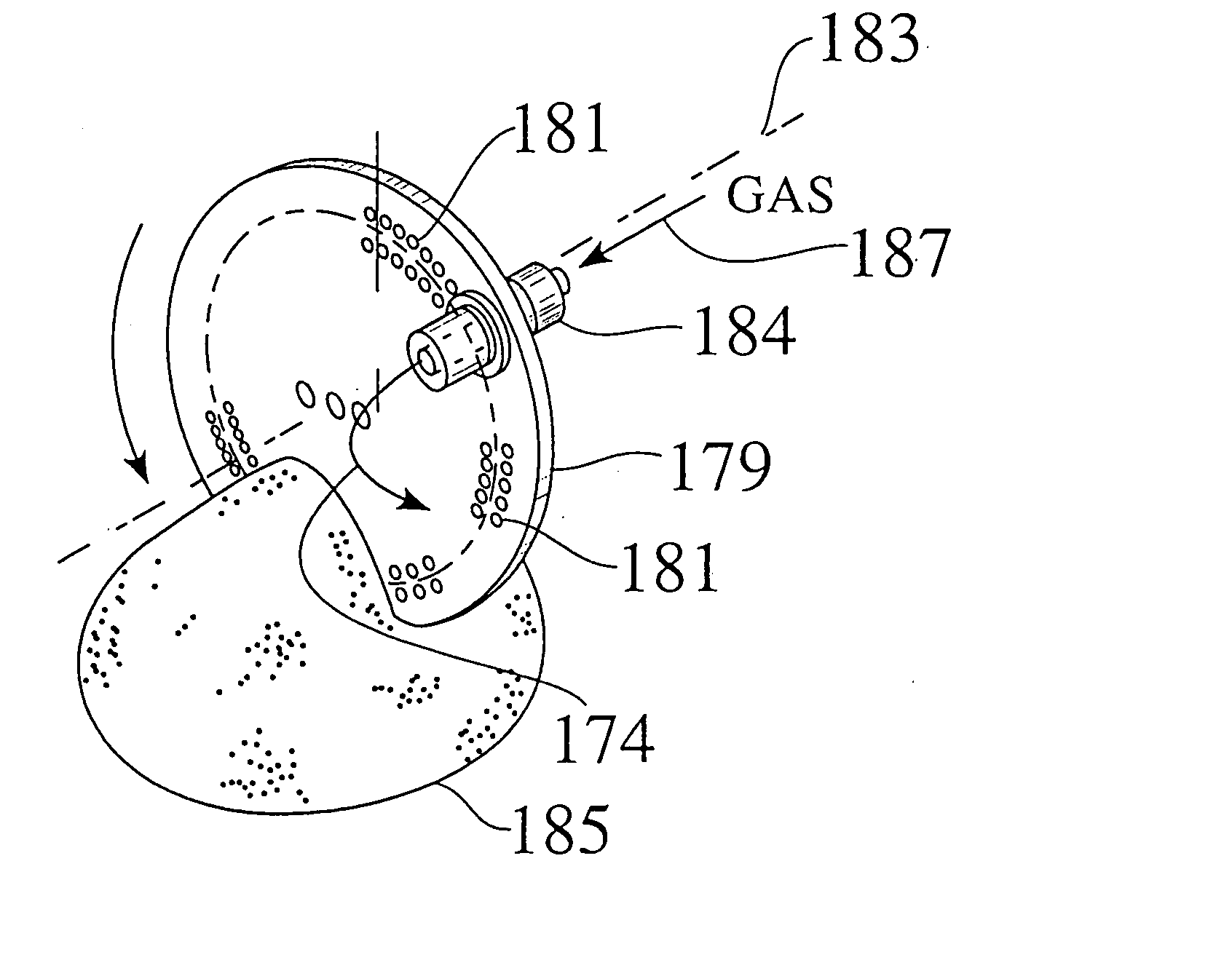

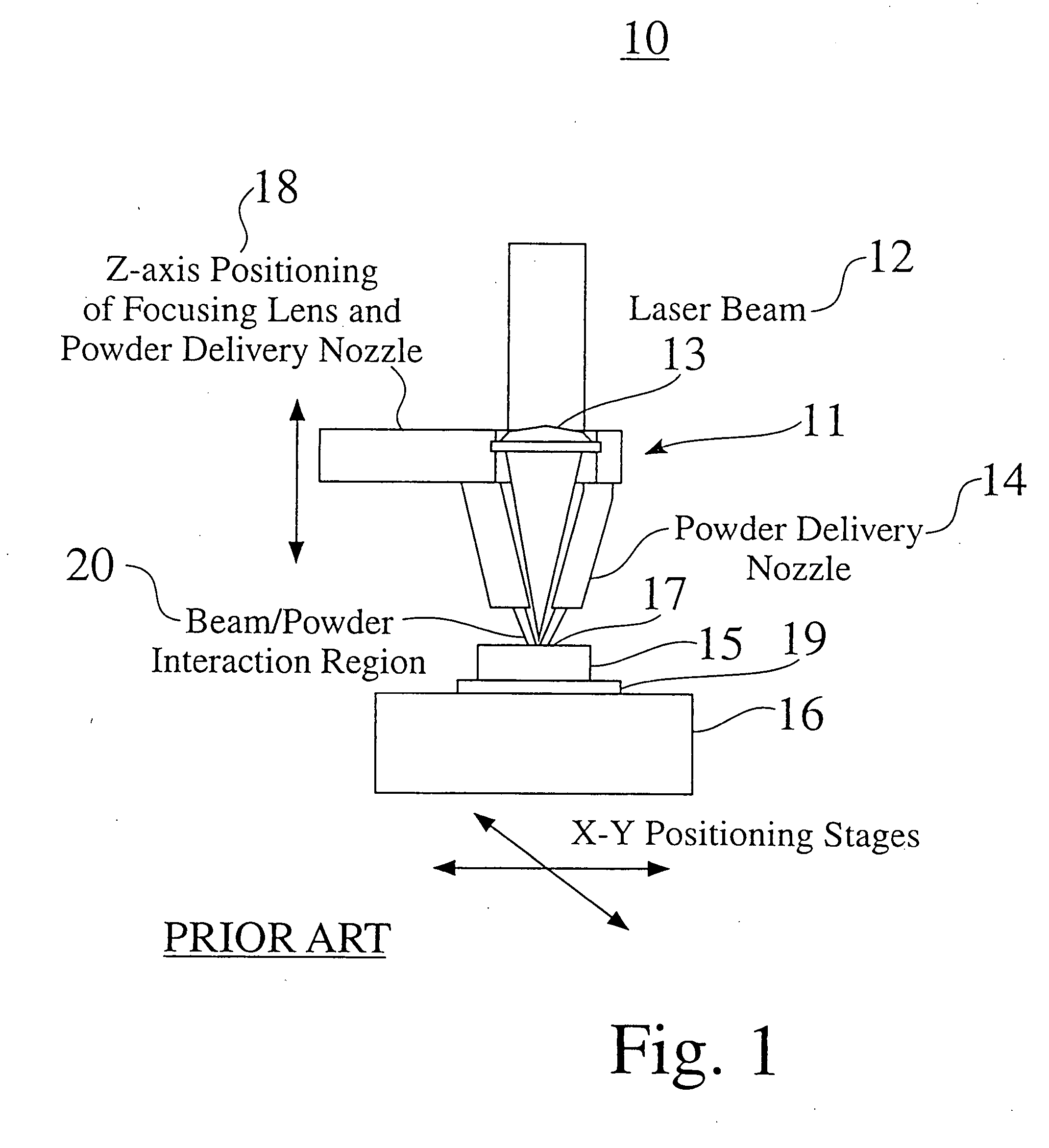

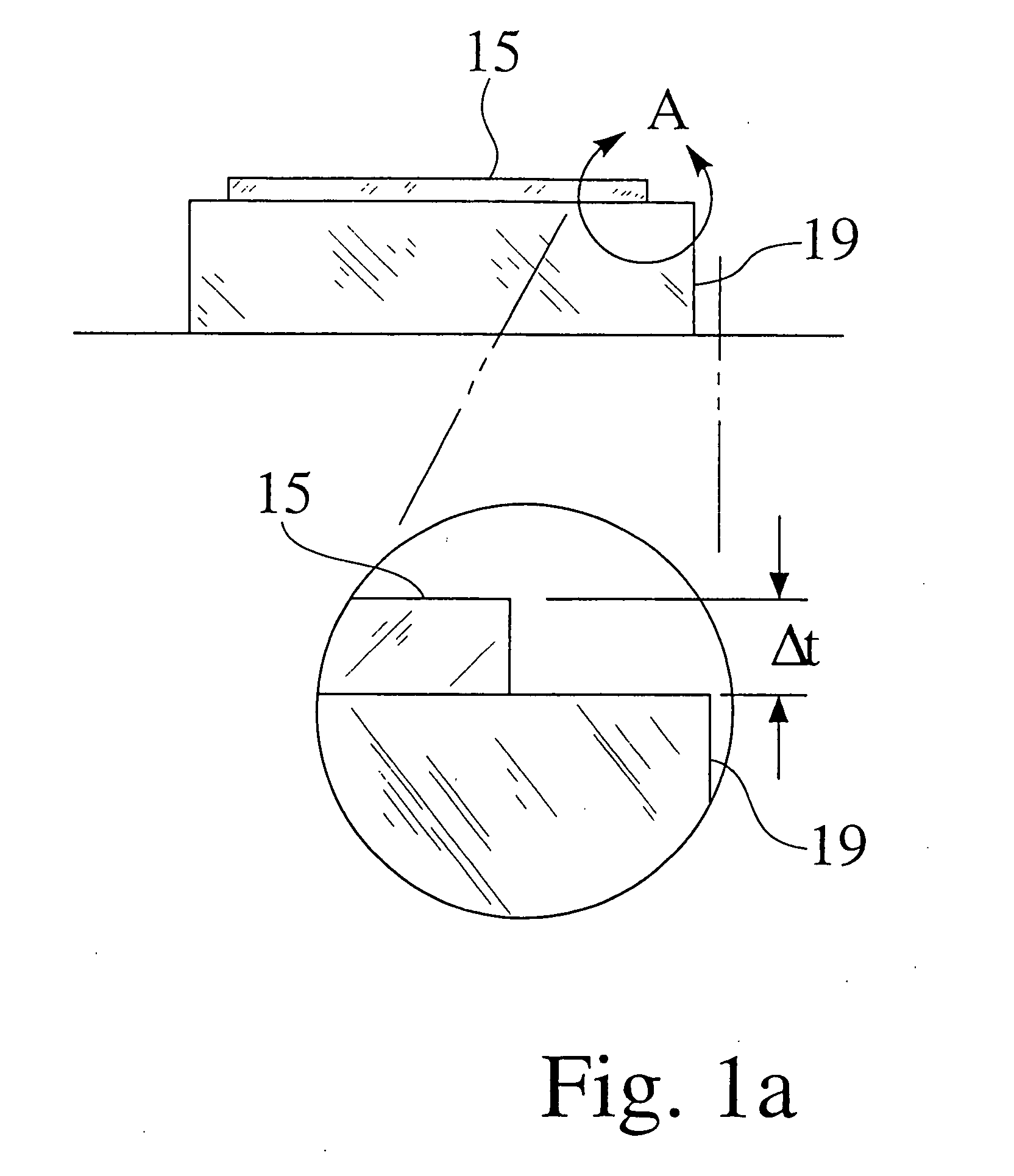

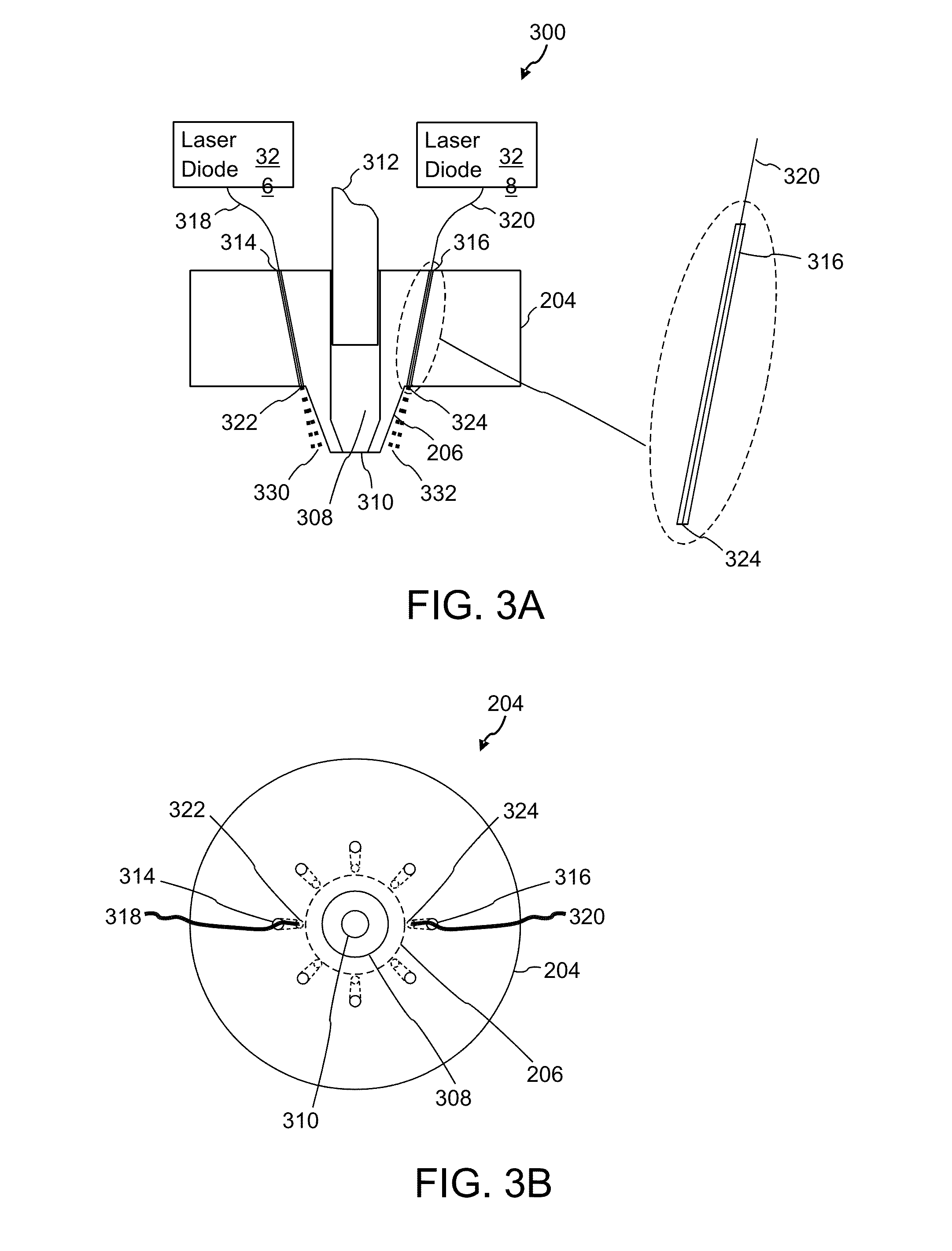

Powder feeder for material deposition systems

InactiveUS20050133527A1Small sizeEliminate warpingPower operated devices3D object support structuresSolid componentCoolant flow

A method and apparatus for embedding features and controlling material composition in a three-dimensional structure (130) is disclosed. The invention enables the control of material characteristics, within a structure (130) made from a plurality of materials, directly from computer renderings of solid models of the components. The method uses stereolithography and solid model computer file formats to control a multi-axis head (480) in a directed material deposition process (123). Material feedstock (126, 127) is deposited onto a pre-heated substrate (19). Depositions (15) in a layer-by-layer pattern, defined by solid models (141, 146), create a three-dimensional article having complex geometric details. Thermal management of finished solid articles (250-302), not available through conventional processing techniques, is enabled by embedded voids (152) and / or composite materials (126, 127), which include dissimilar metals (210, 216). Finished articles control pressure drop and produce uniform coolant flow and pressure characteristics. High-efficiency heat transfer is engineered within a solid structure by incorporating other solid materials with diverse indexes. Embedding multi-material structures (132, 134) within a normally solid component (141) produces articles with diverse mechanical properties. Laser and powder delivery systems (420, 170) are integrated in a multi-axis deposition head (480) having a focused particle beam (502) to reduce material waste.

Owner:OPTOMEC DESIGN CO

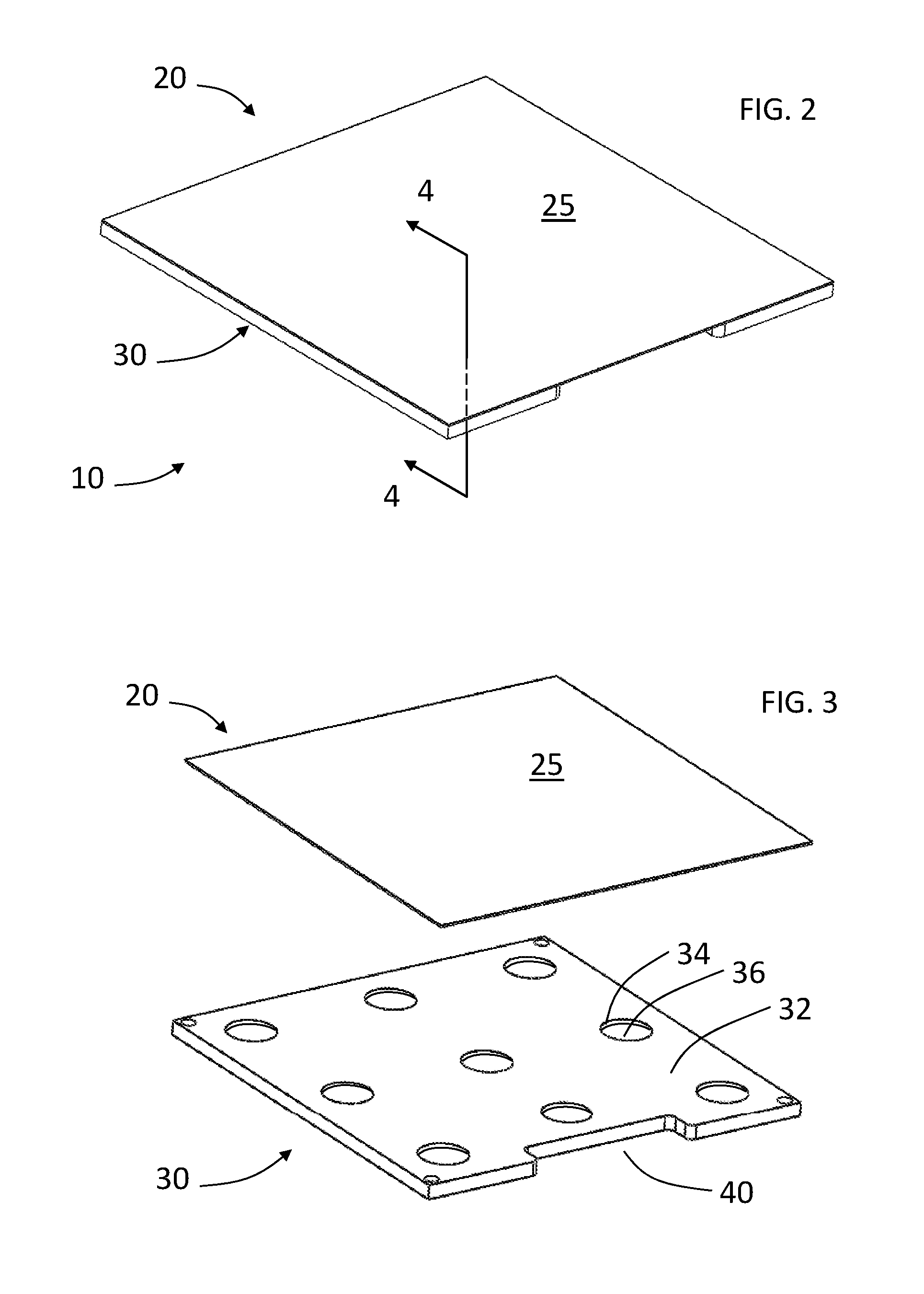

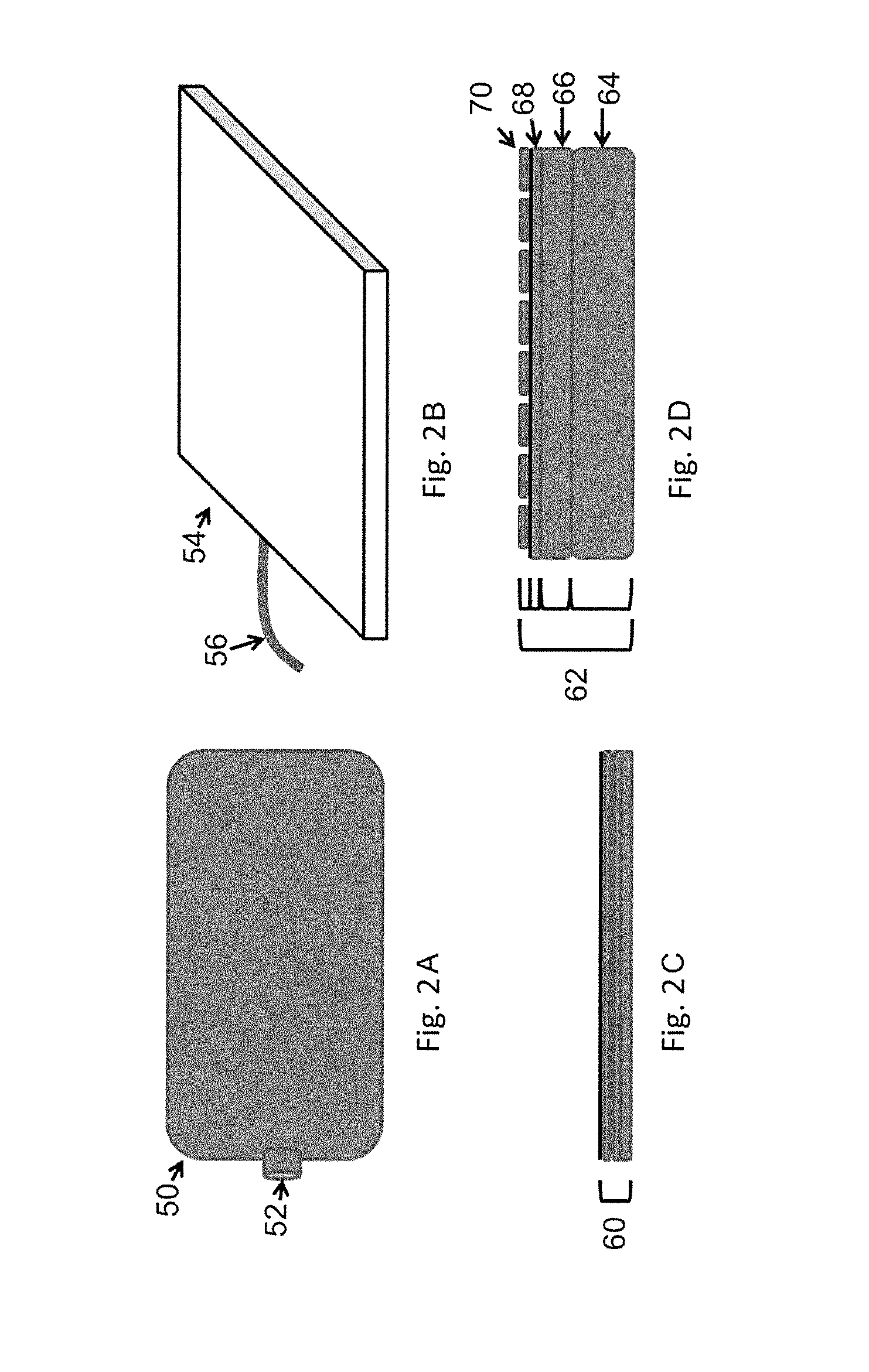

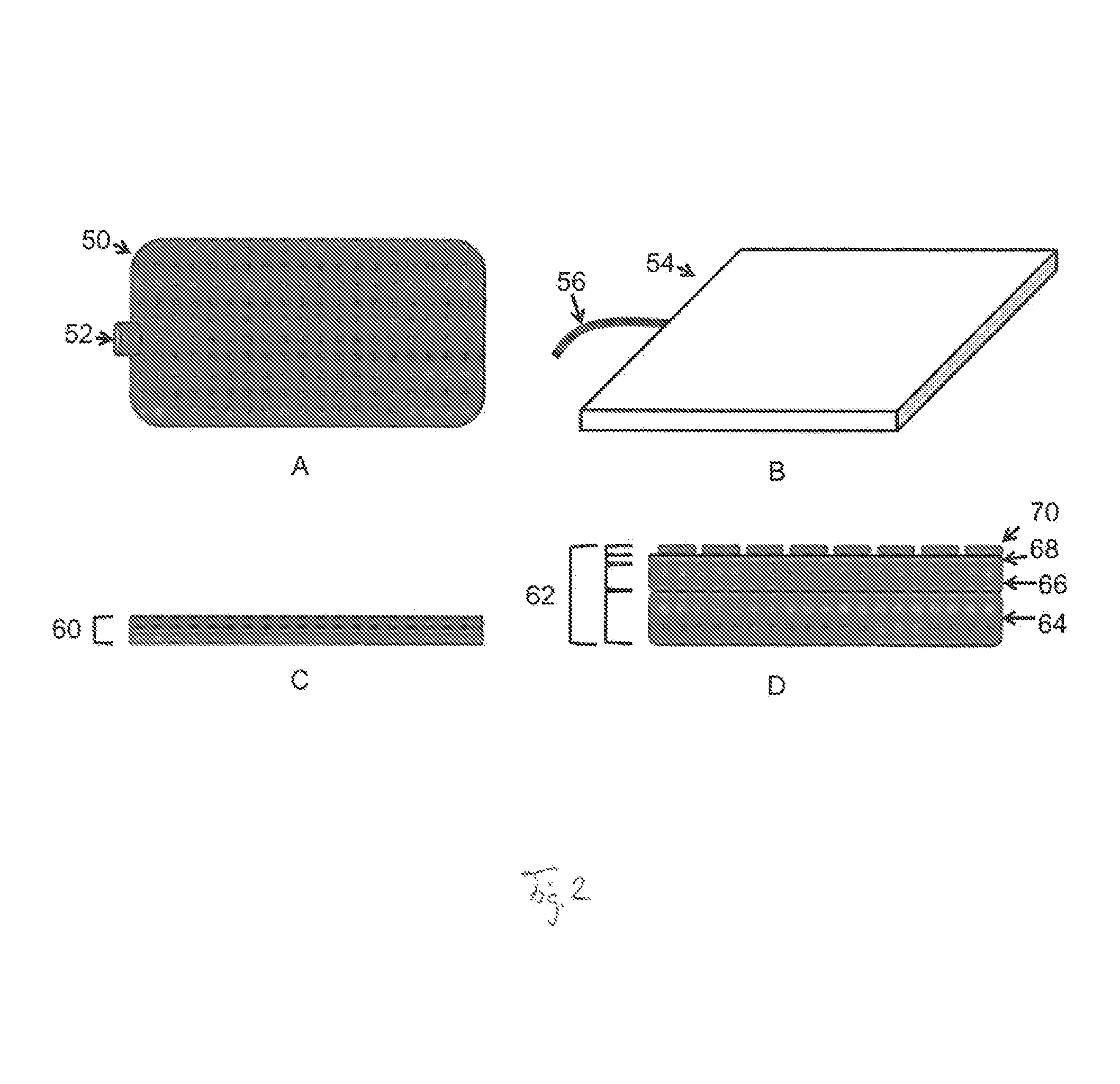

3D Print Bed Having Permanent Coating

PendingUS20170036403A1Improve adhesionSufficient level of adhesionManufacturing platforms/substratesPretreated surfacesEpoxyWater based

A coated print bed for a 3D printer having a permanent print-surface coating permanently secured to a print bed substrate plate, having a smooth, planar surface that provides an adhesive interface layer between a first layer of an applied plastic print material and the coated print bed. The coating contains a matrix-forming compound, such as a solvent- or water-based epoxy resin, an adhesive material, and optionally a filler. The user can print a series of print object directly onto the permanent print surface coating of the coated print bed, without having to refresh or refurbish the print surface, such as by applying to the print bed surface a temporary coating such as painter's tape, or a liquid adhesive.

Owner:EZ PRINT

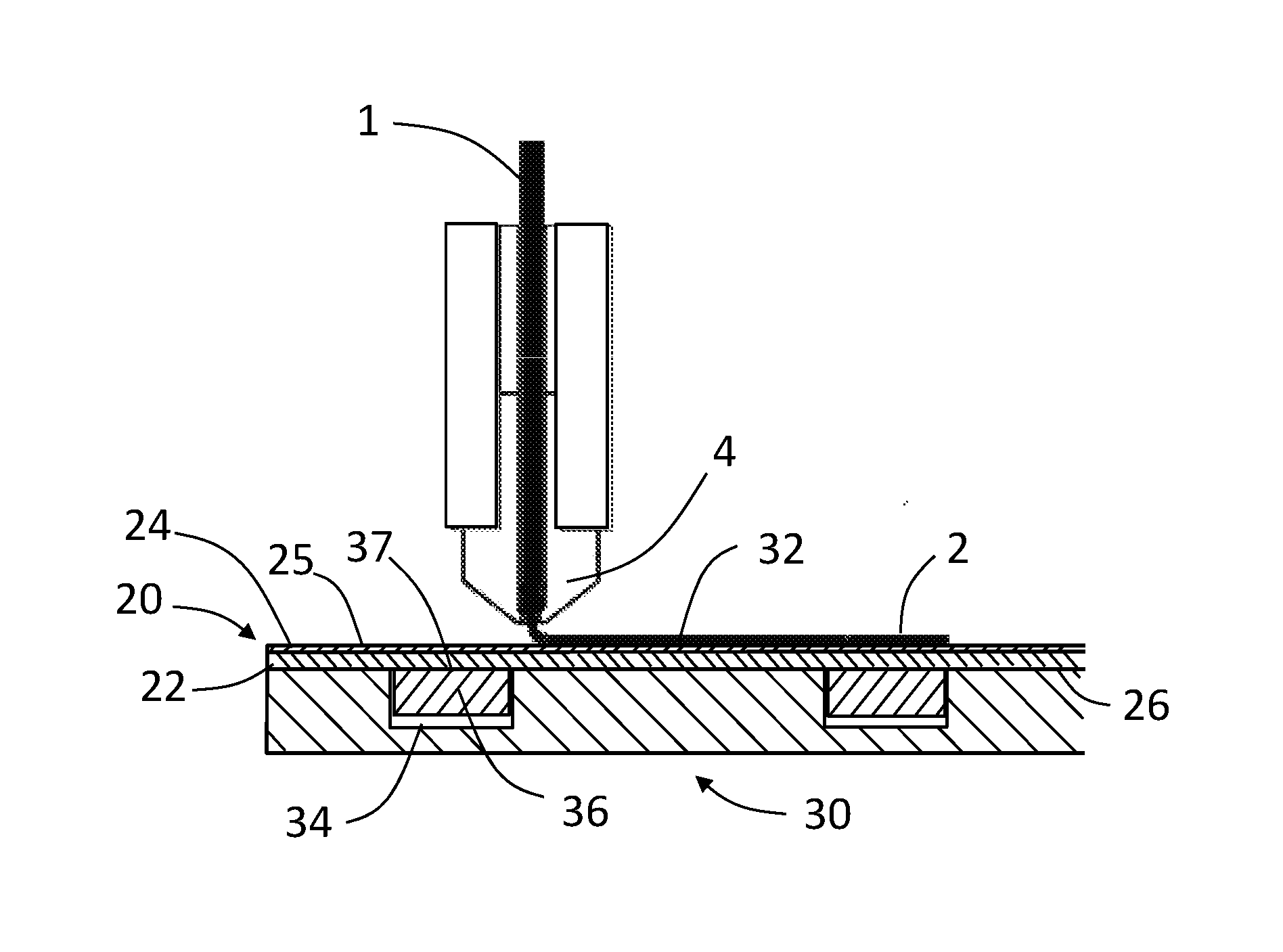

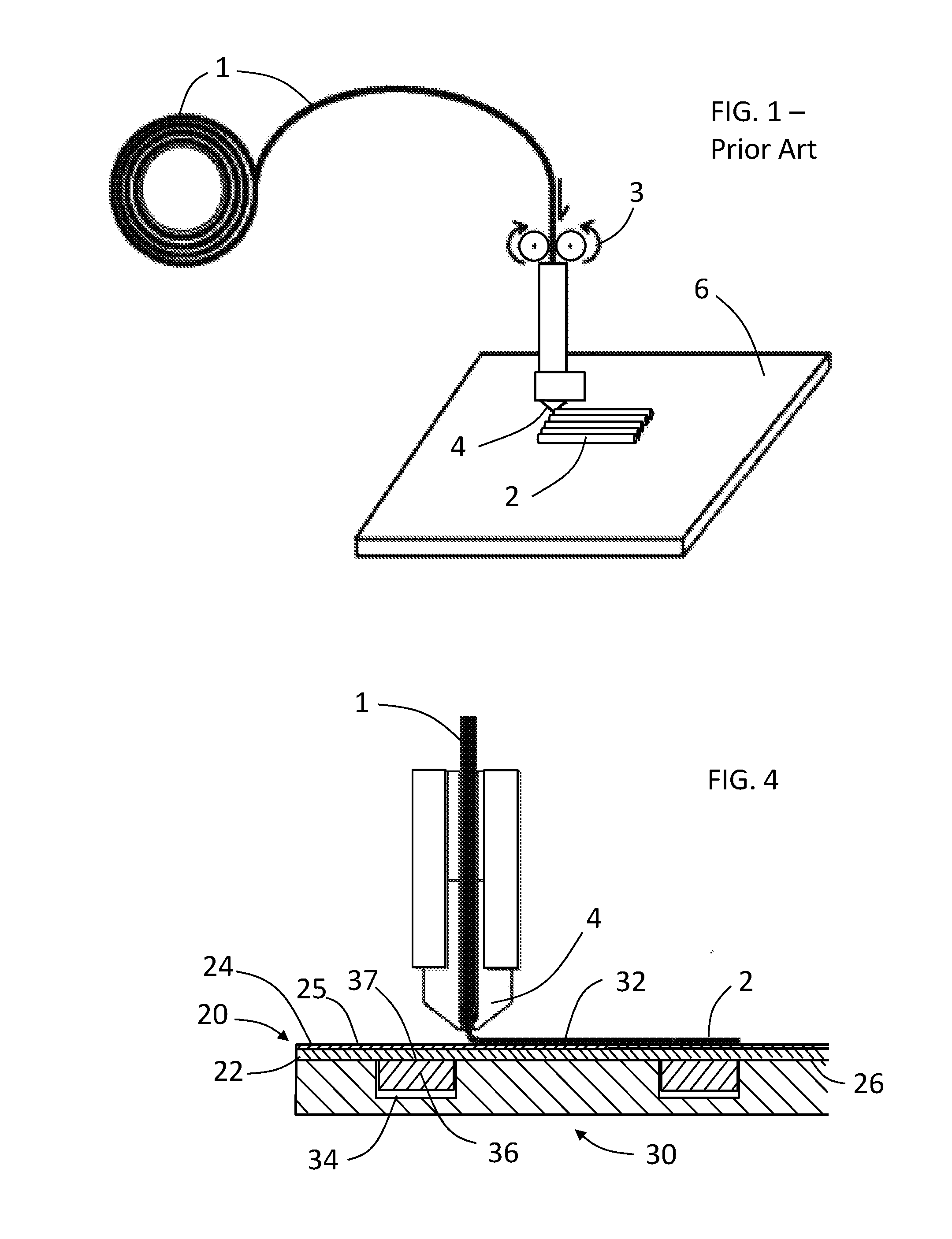

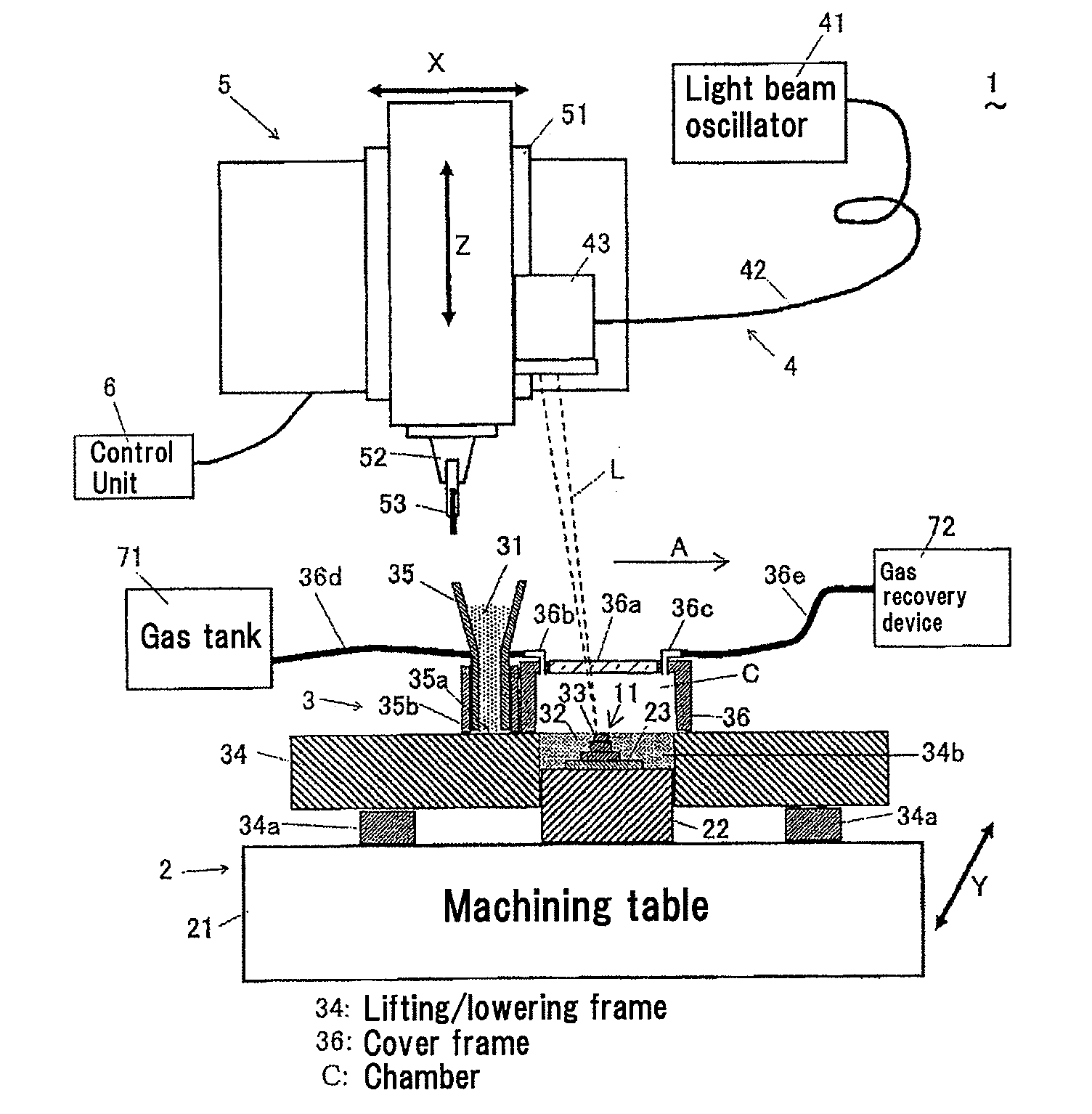

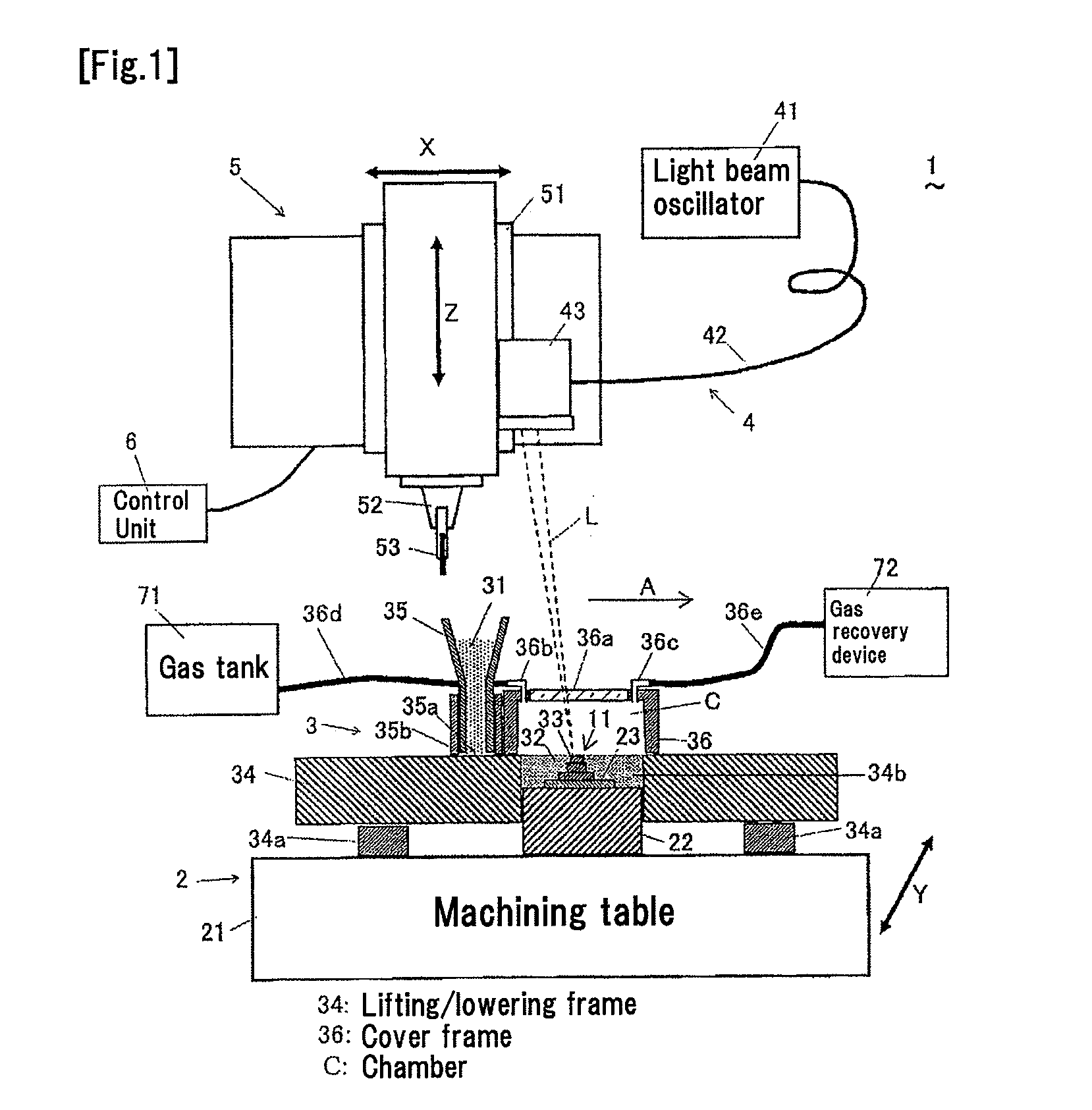

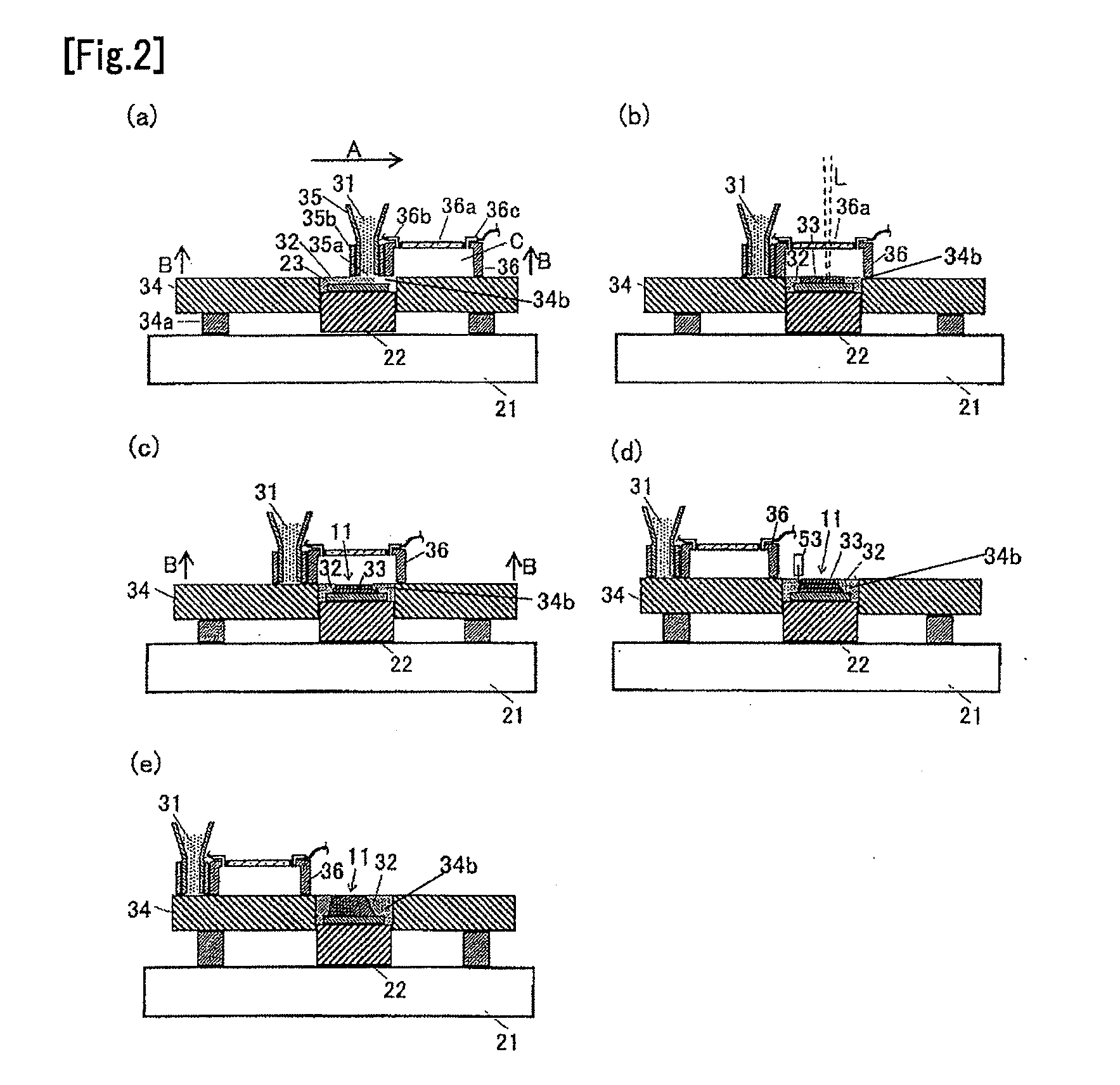

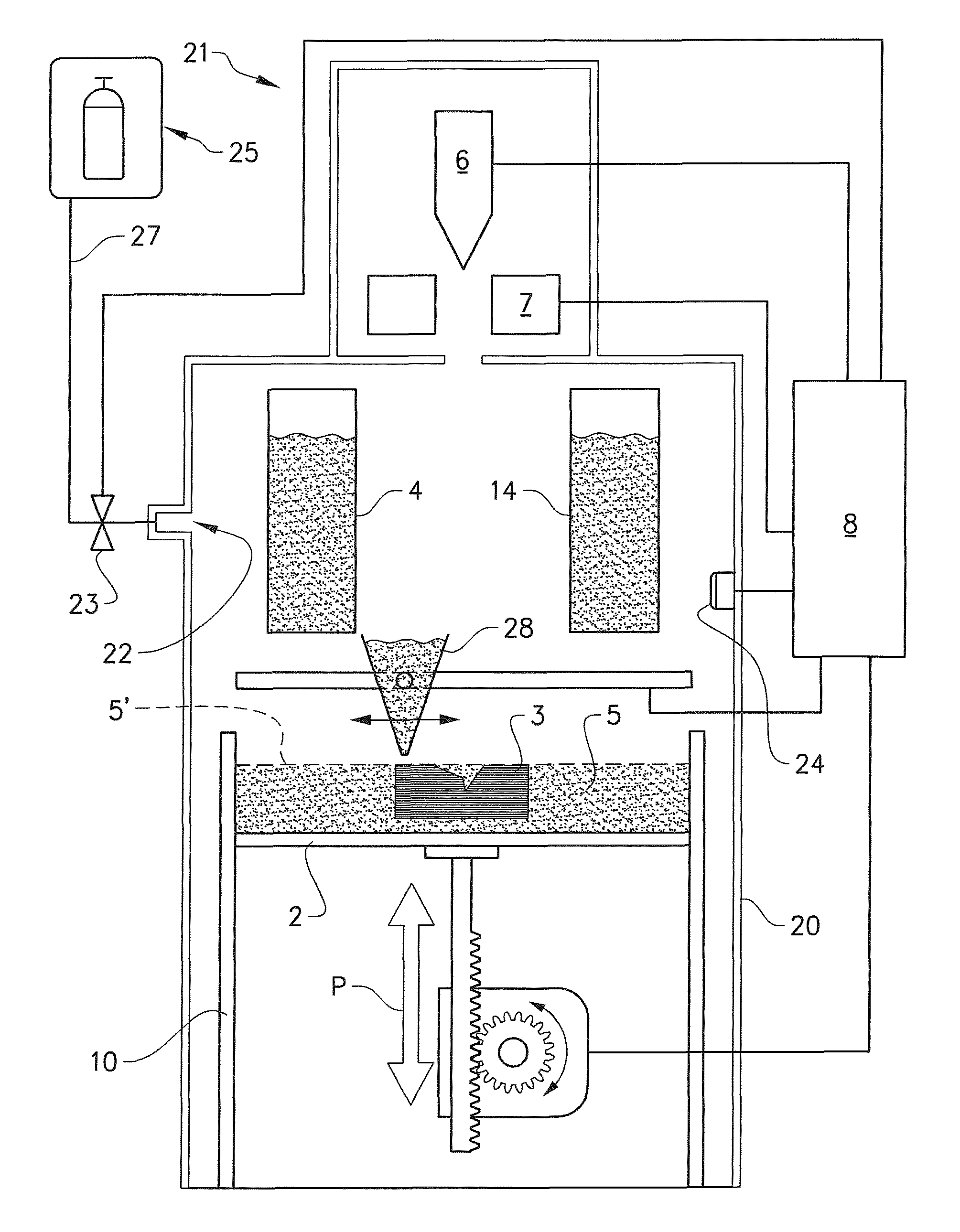

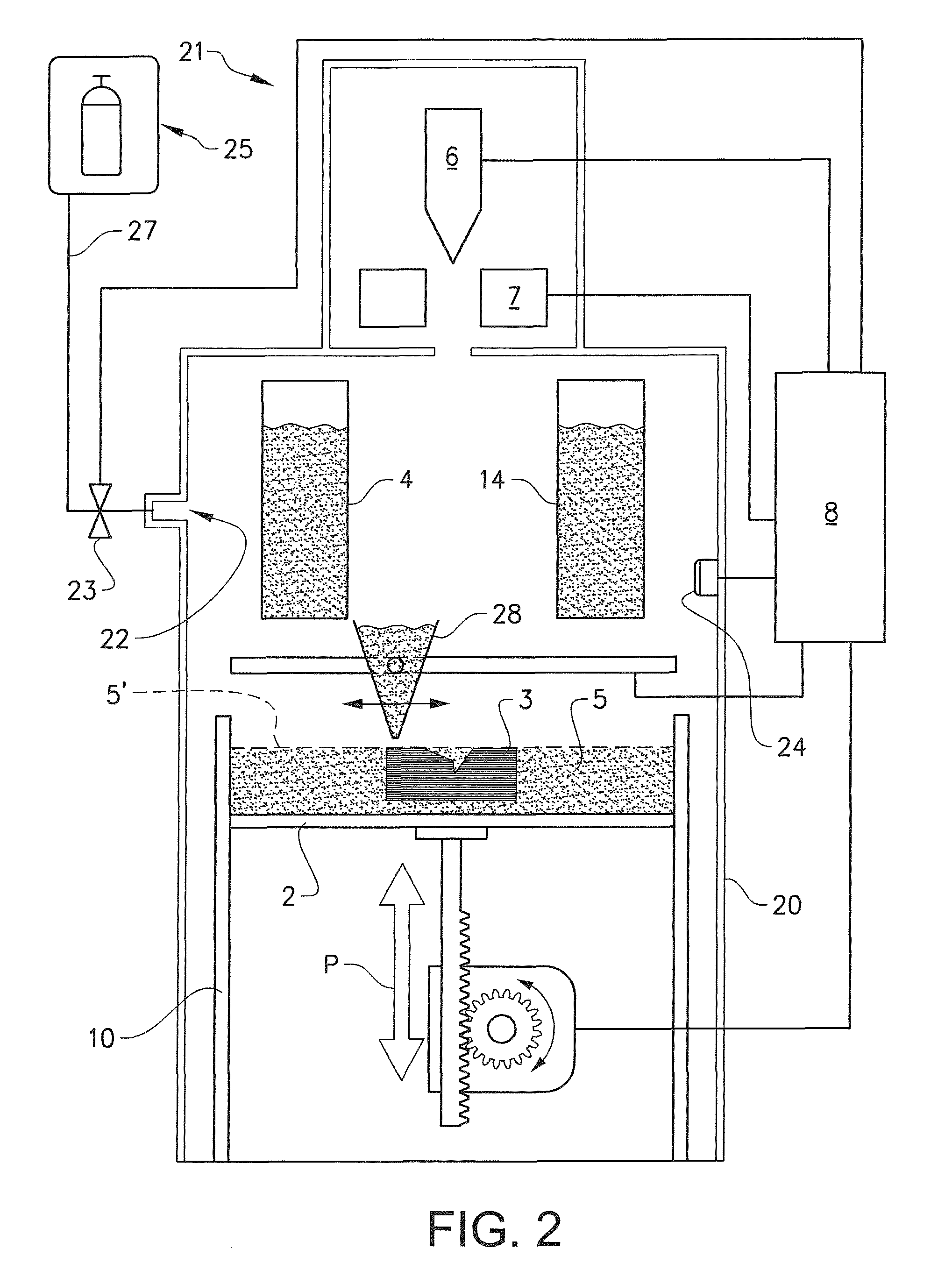

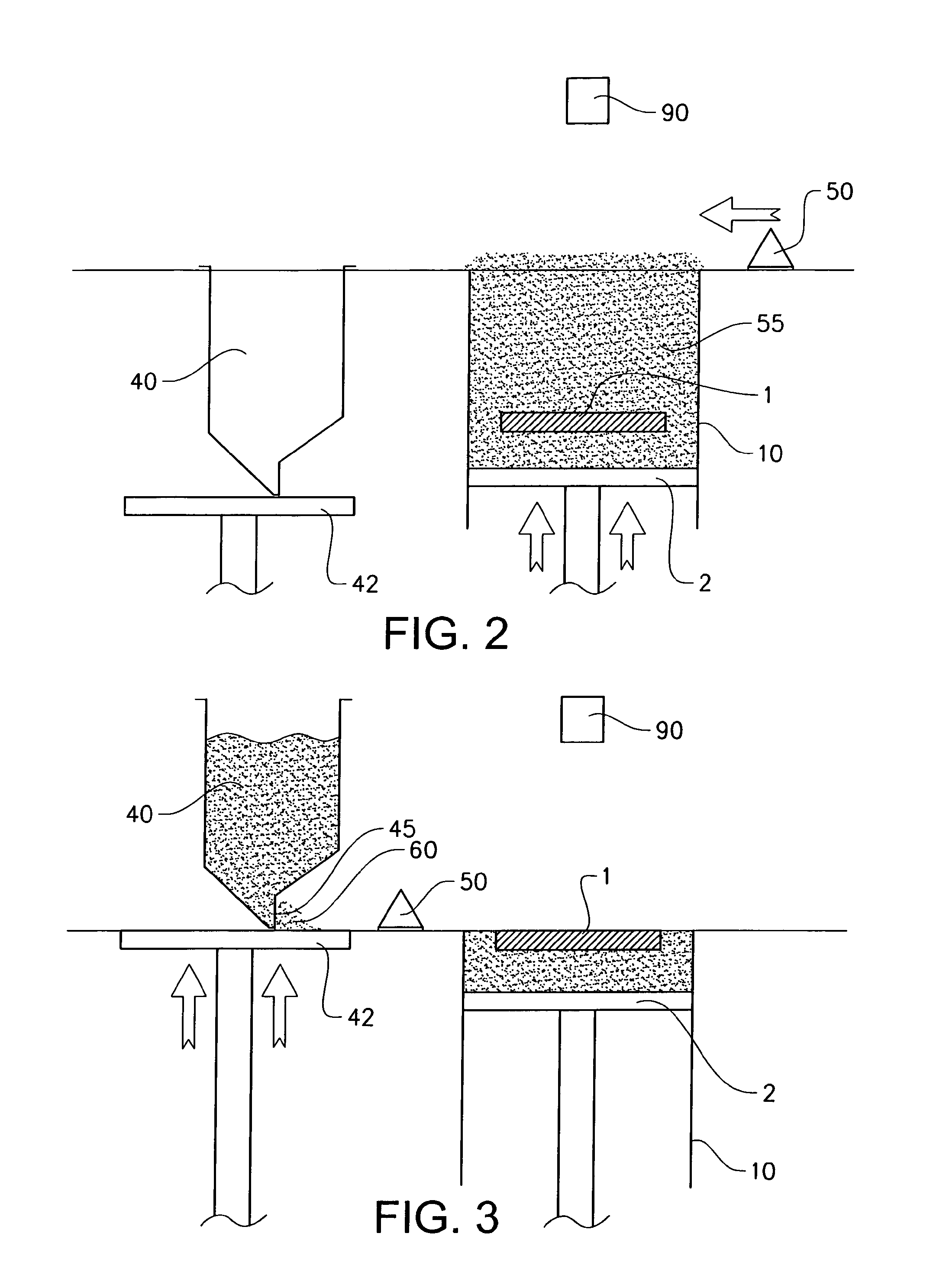

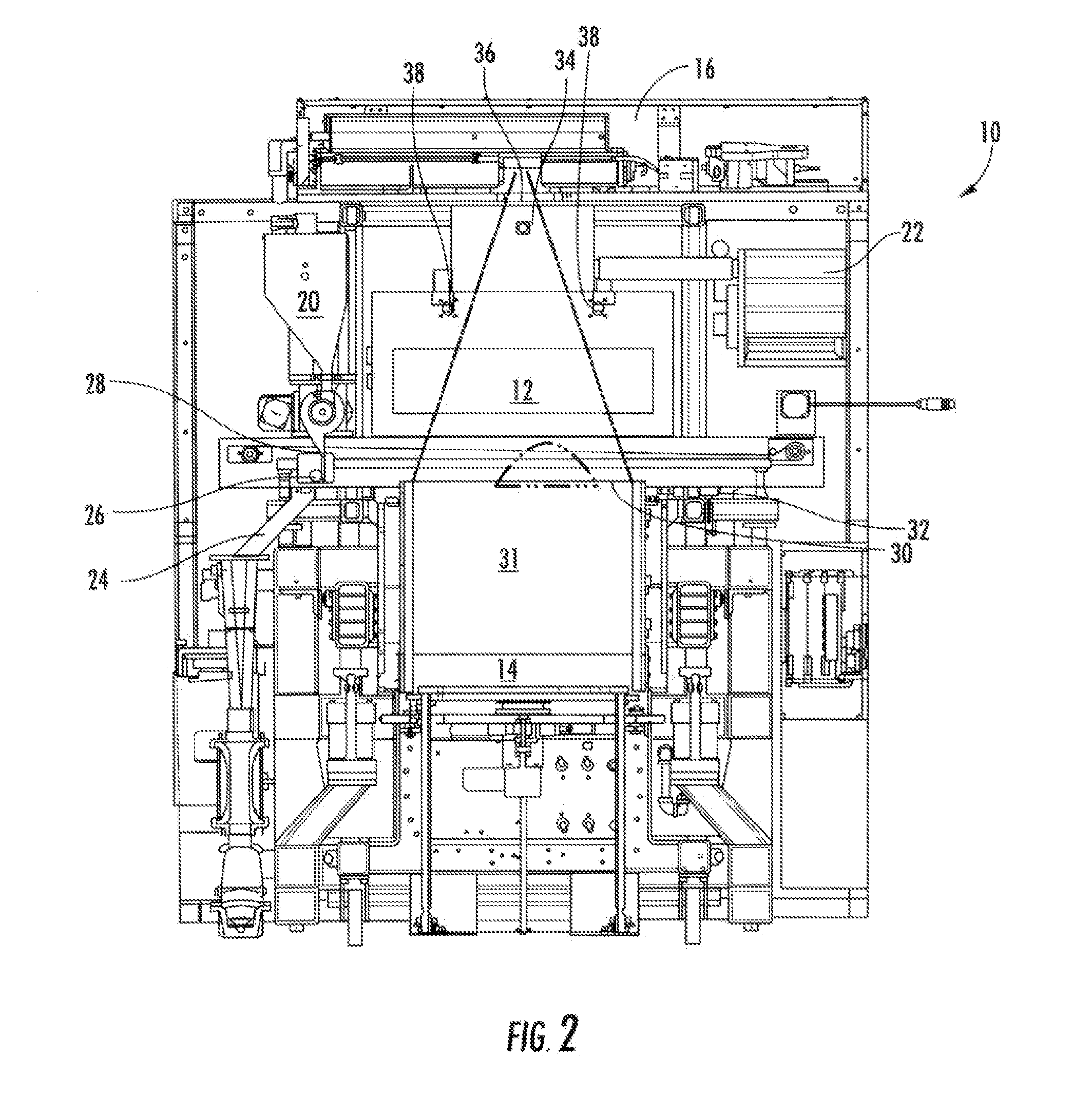

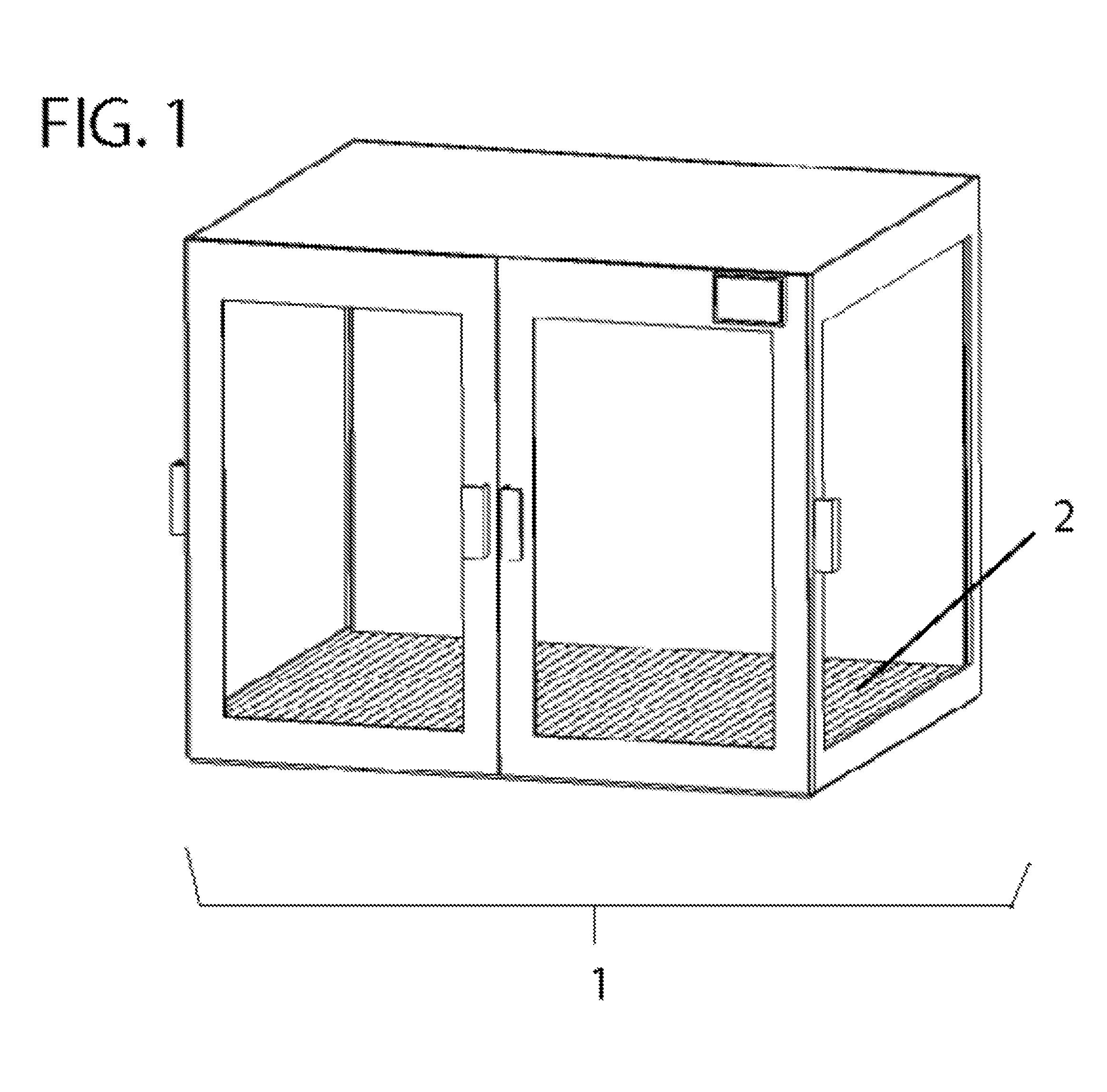

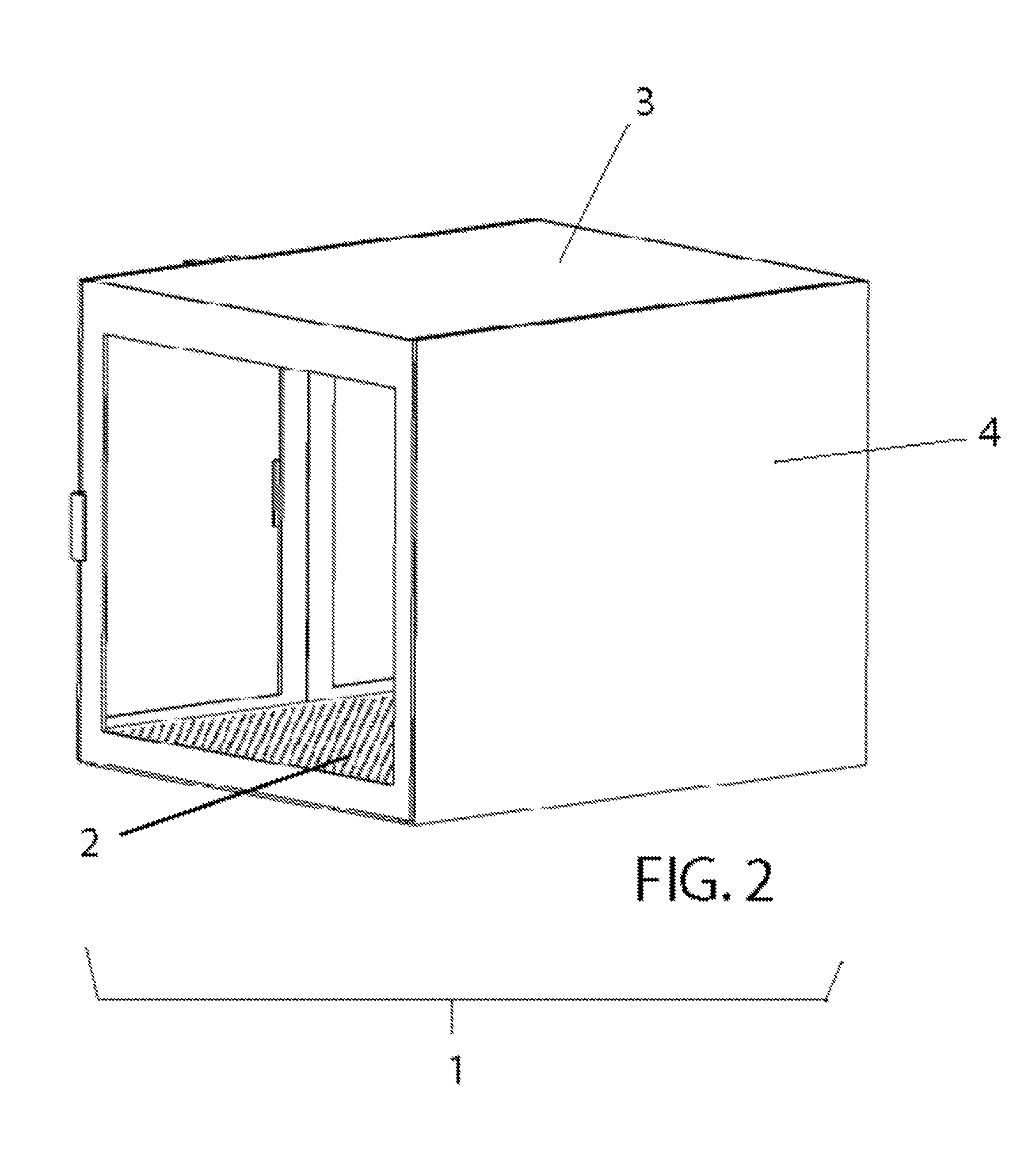

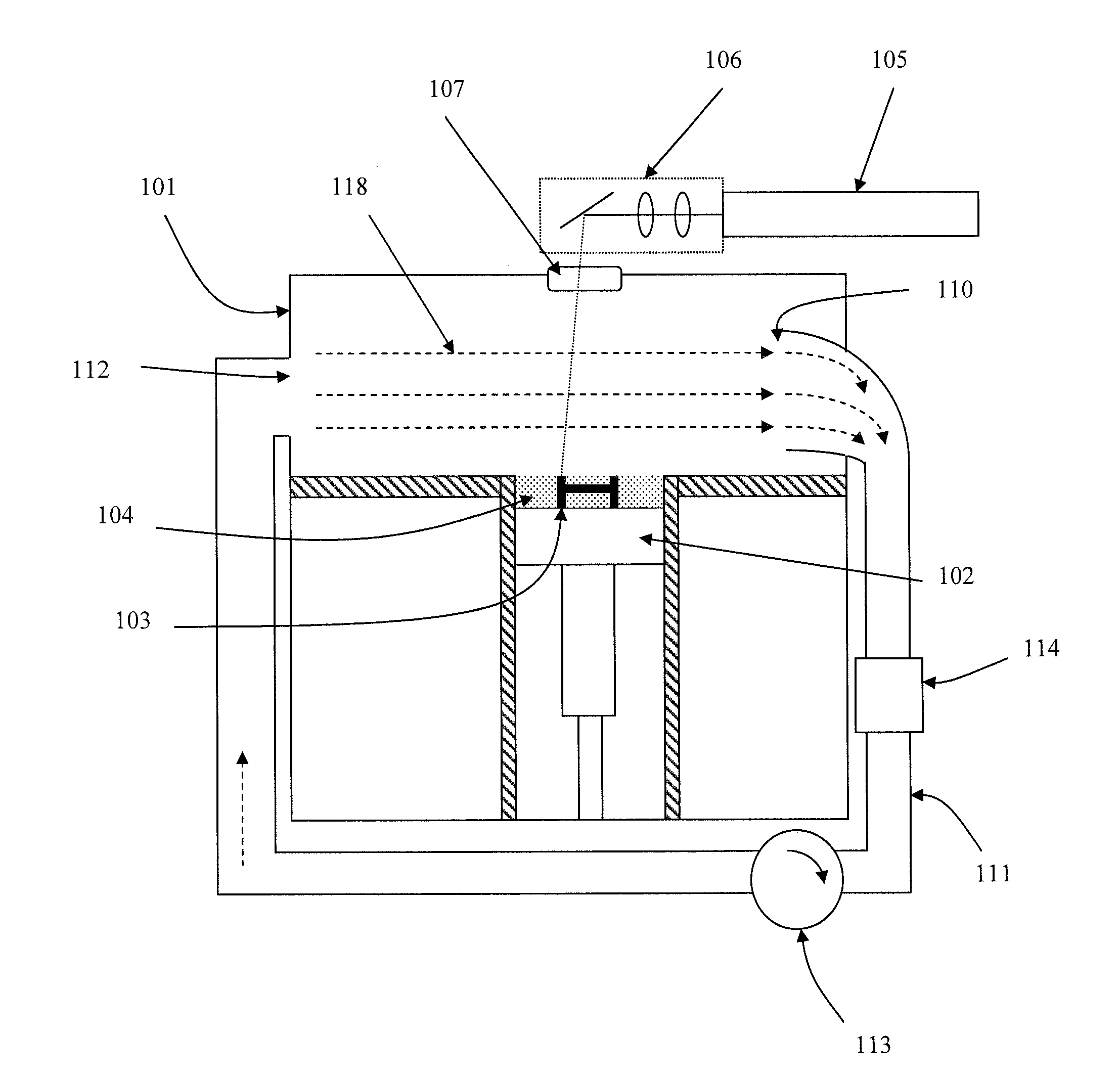

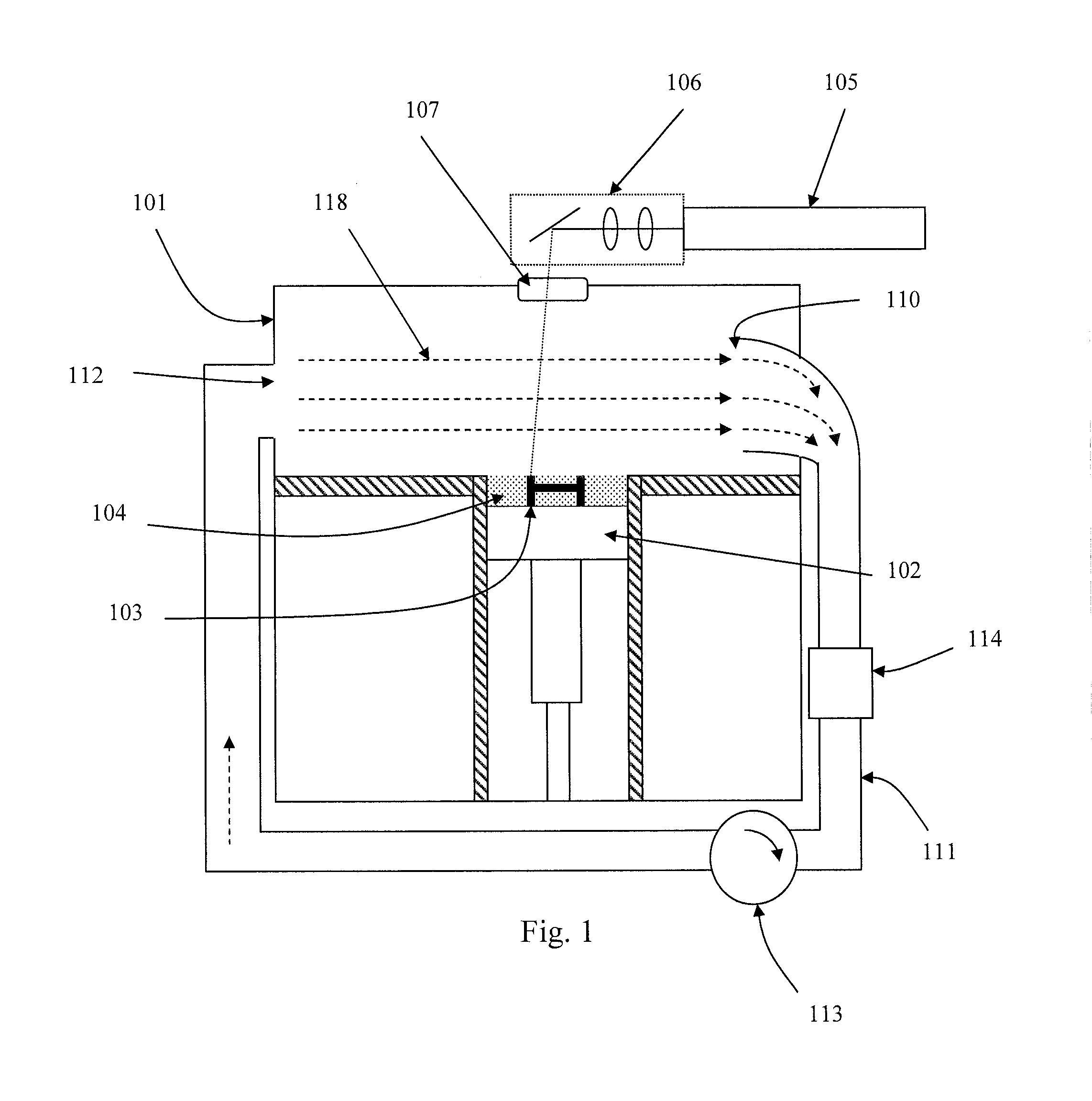

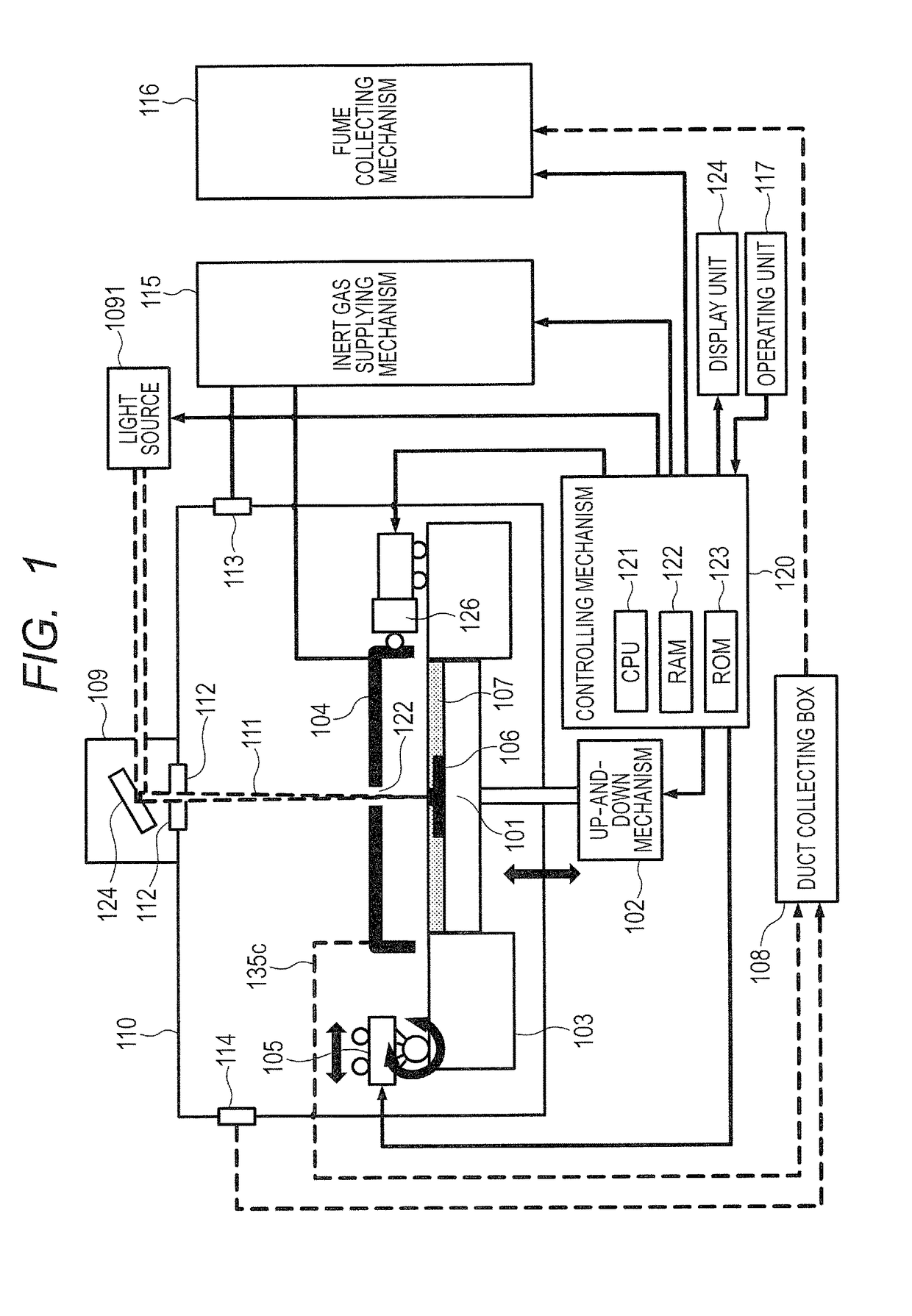

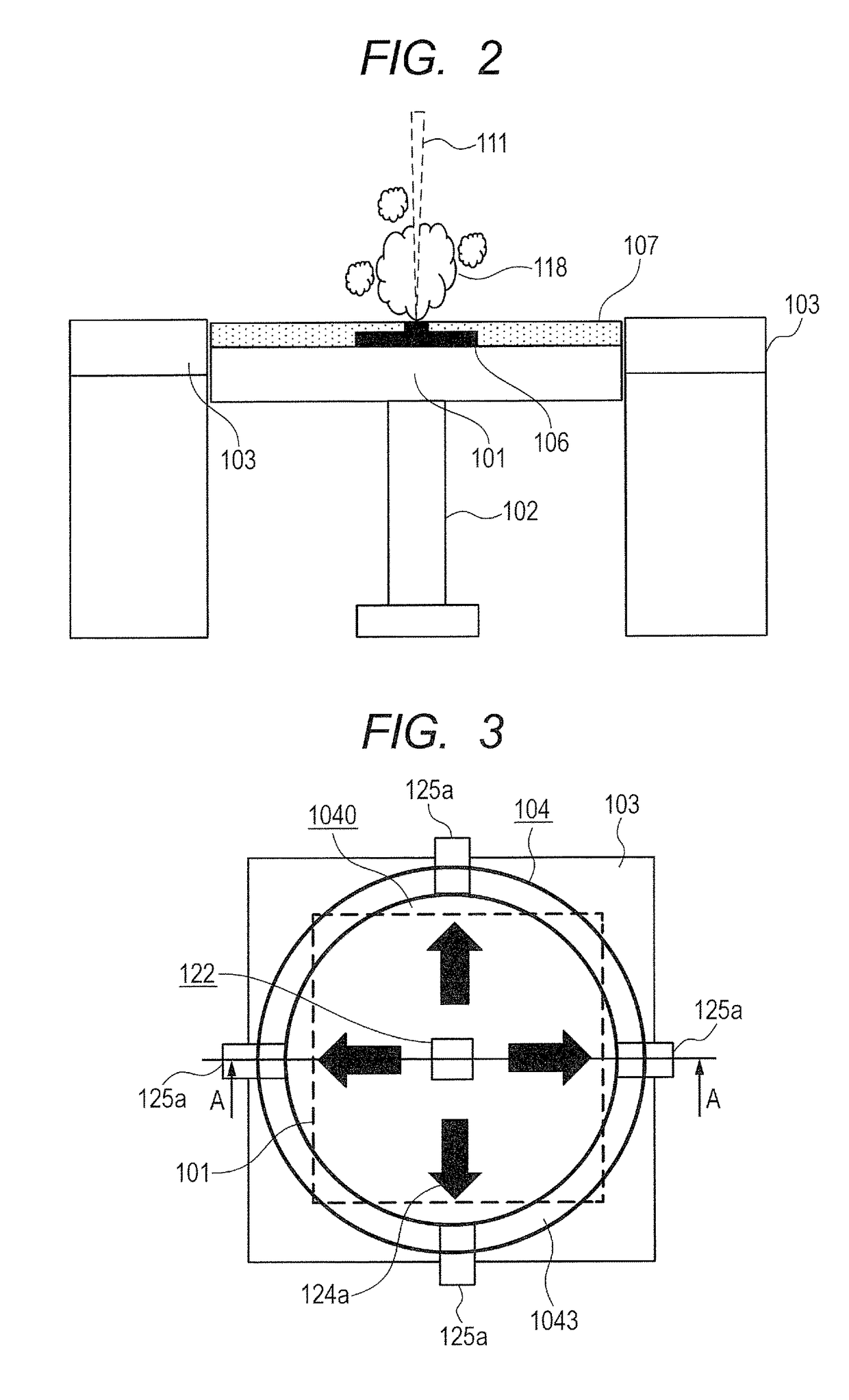

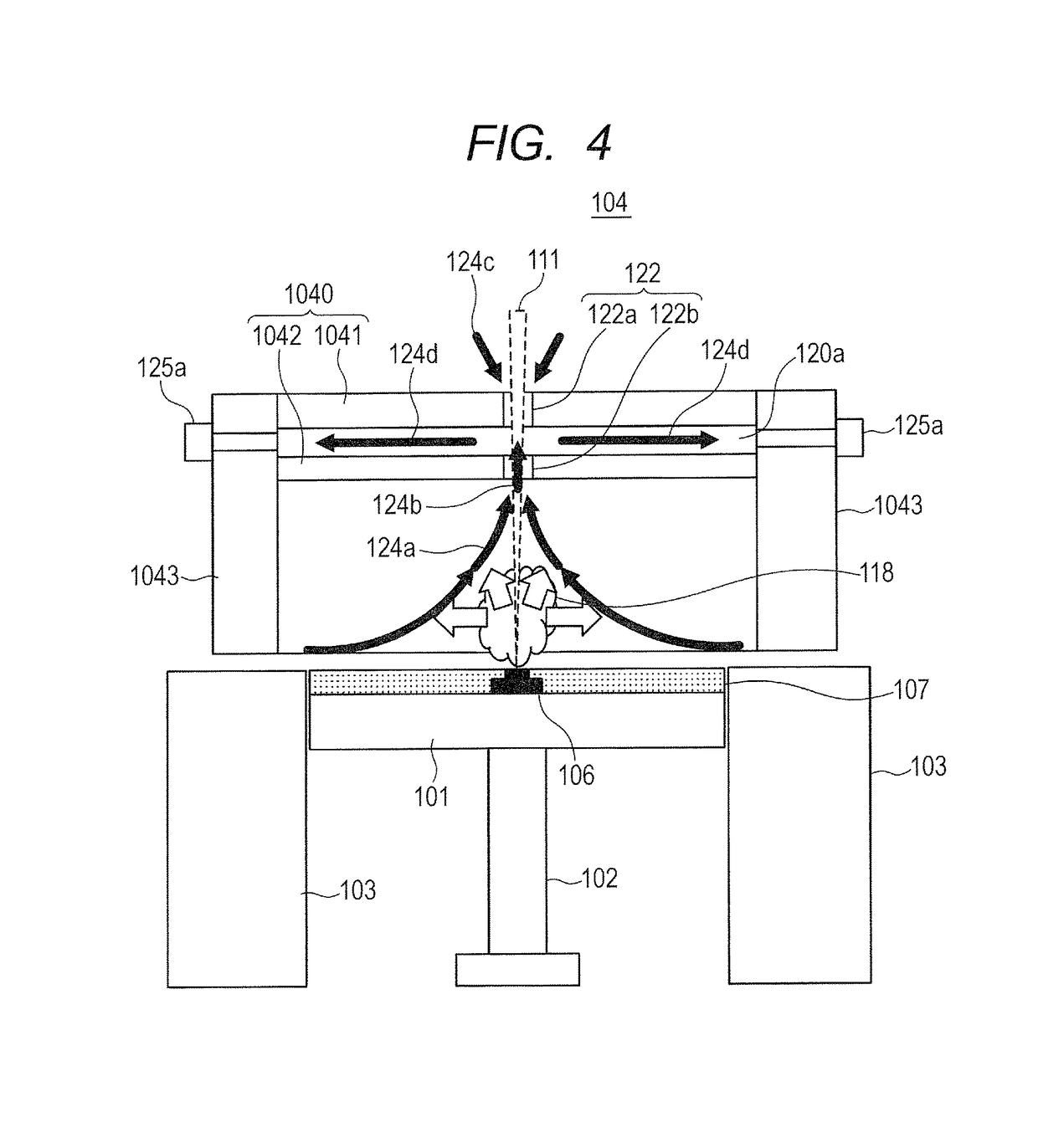

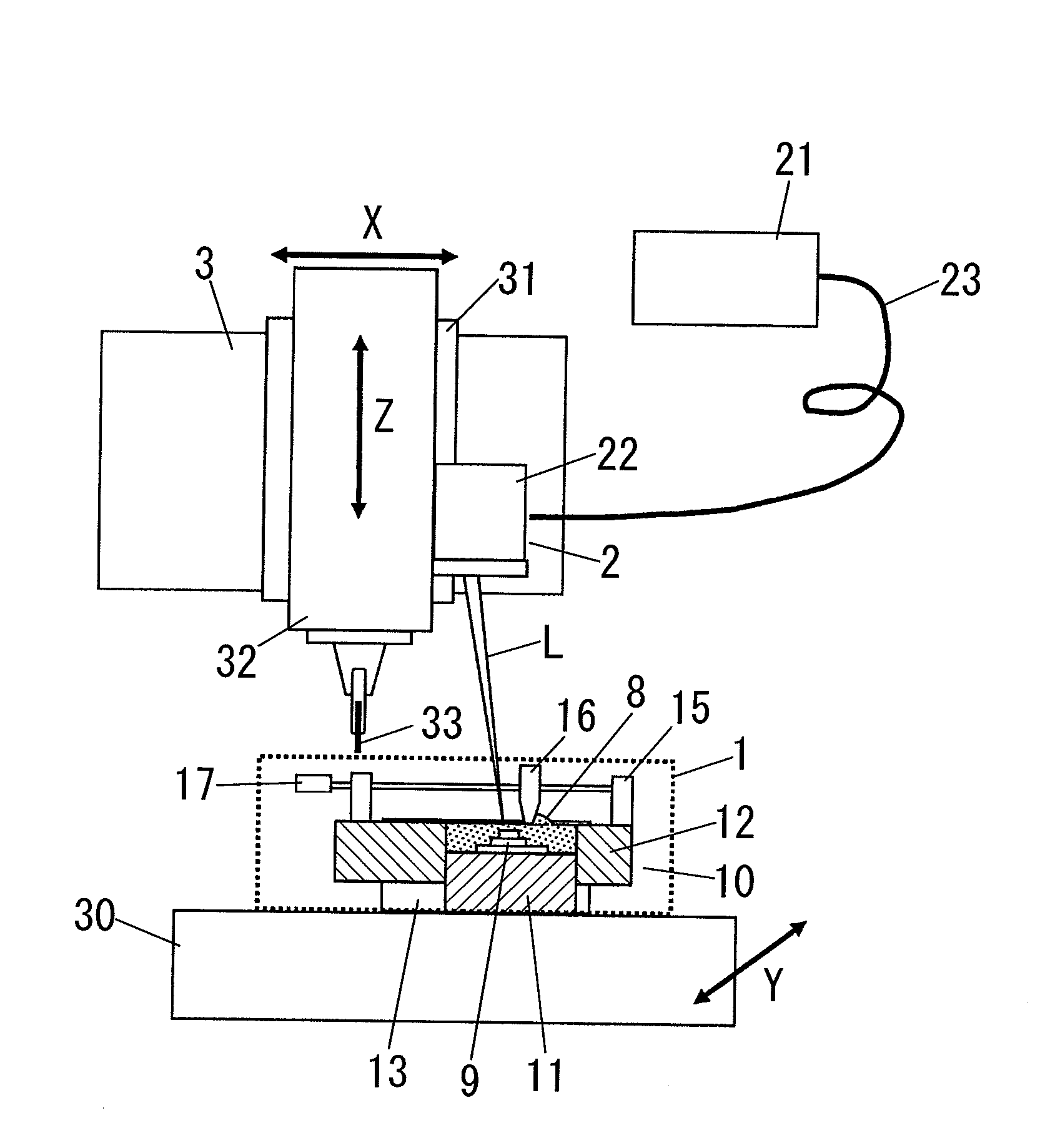

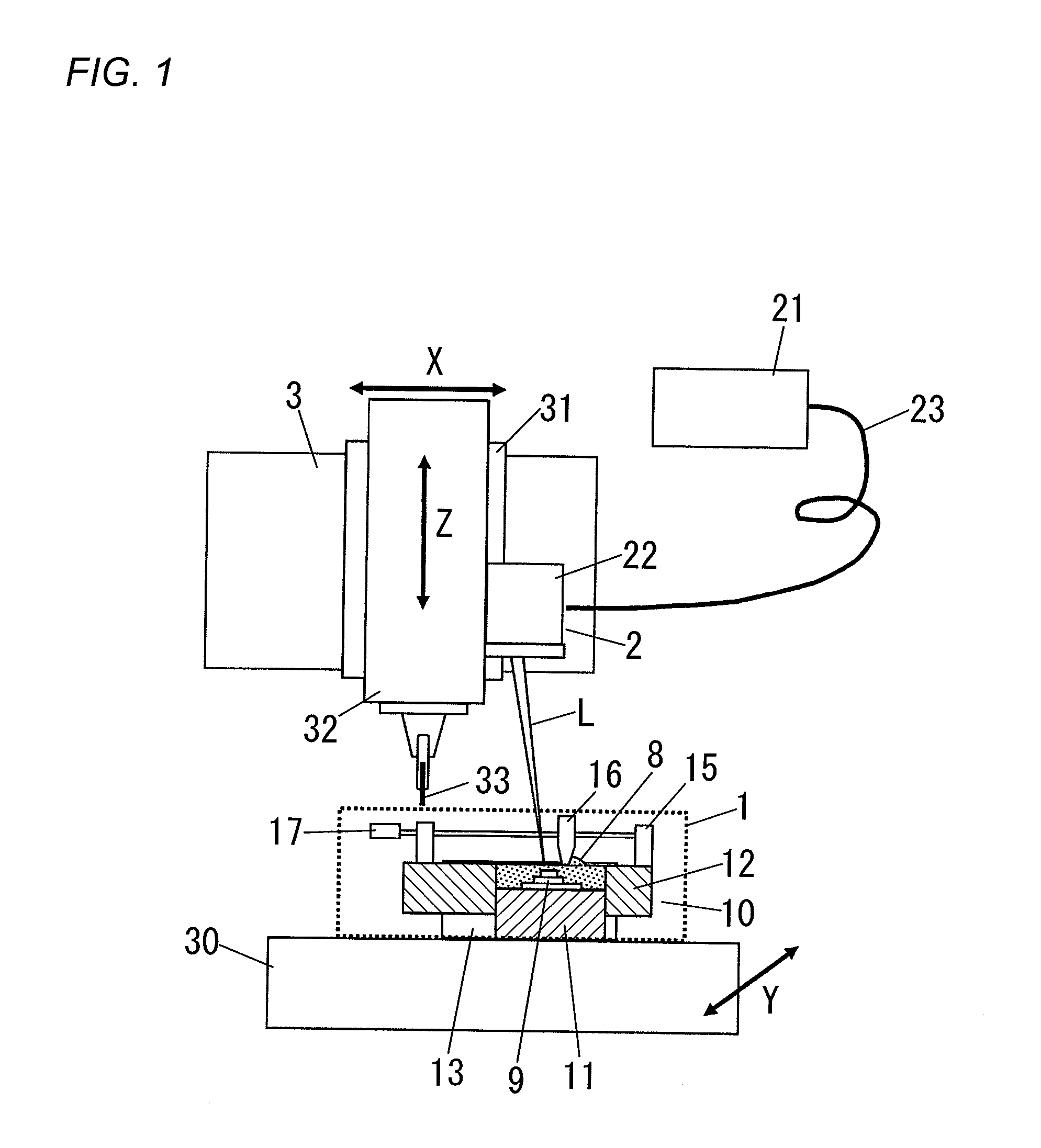

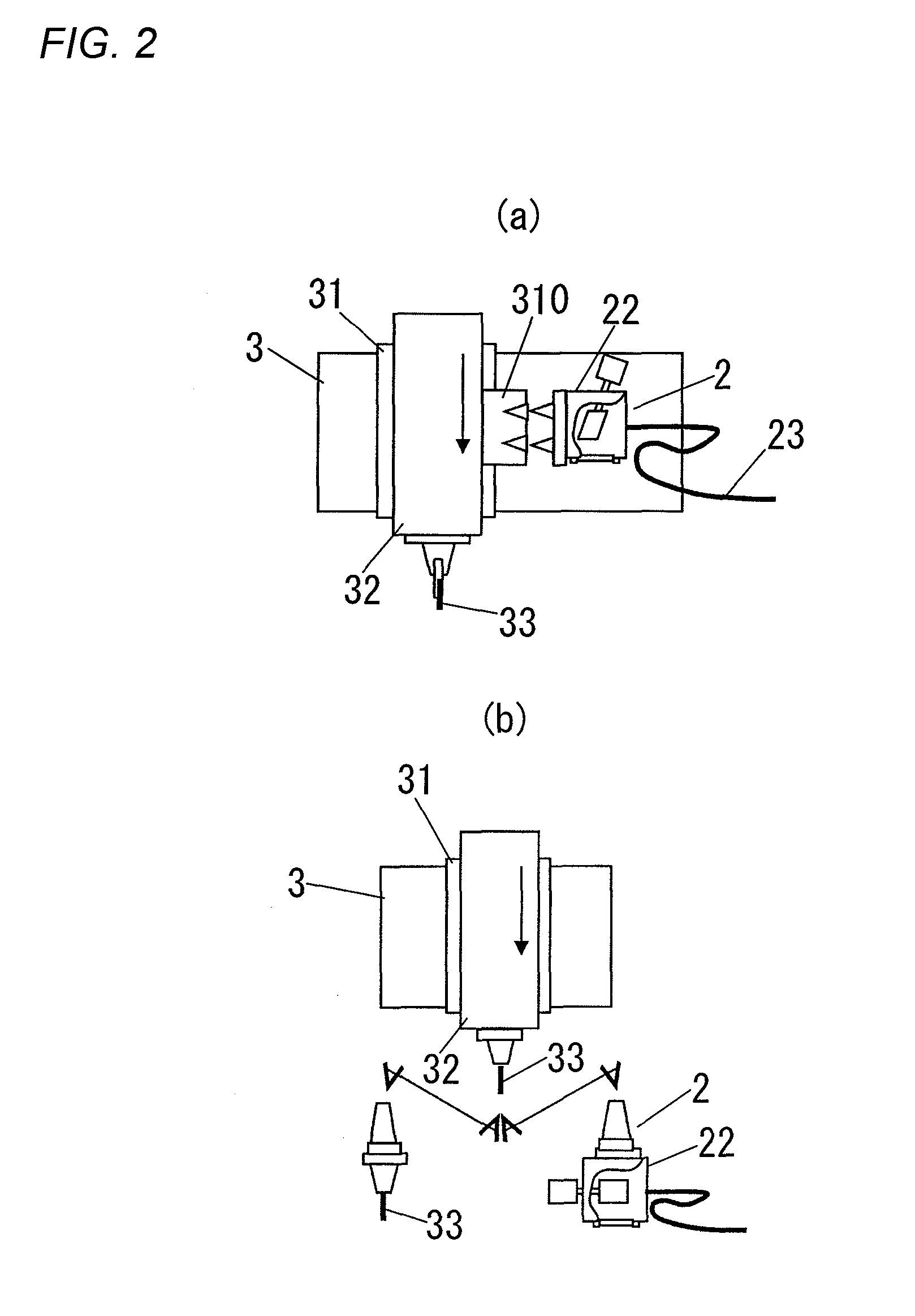

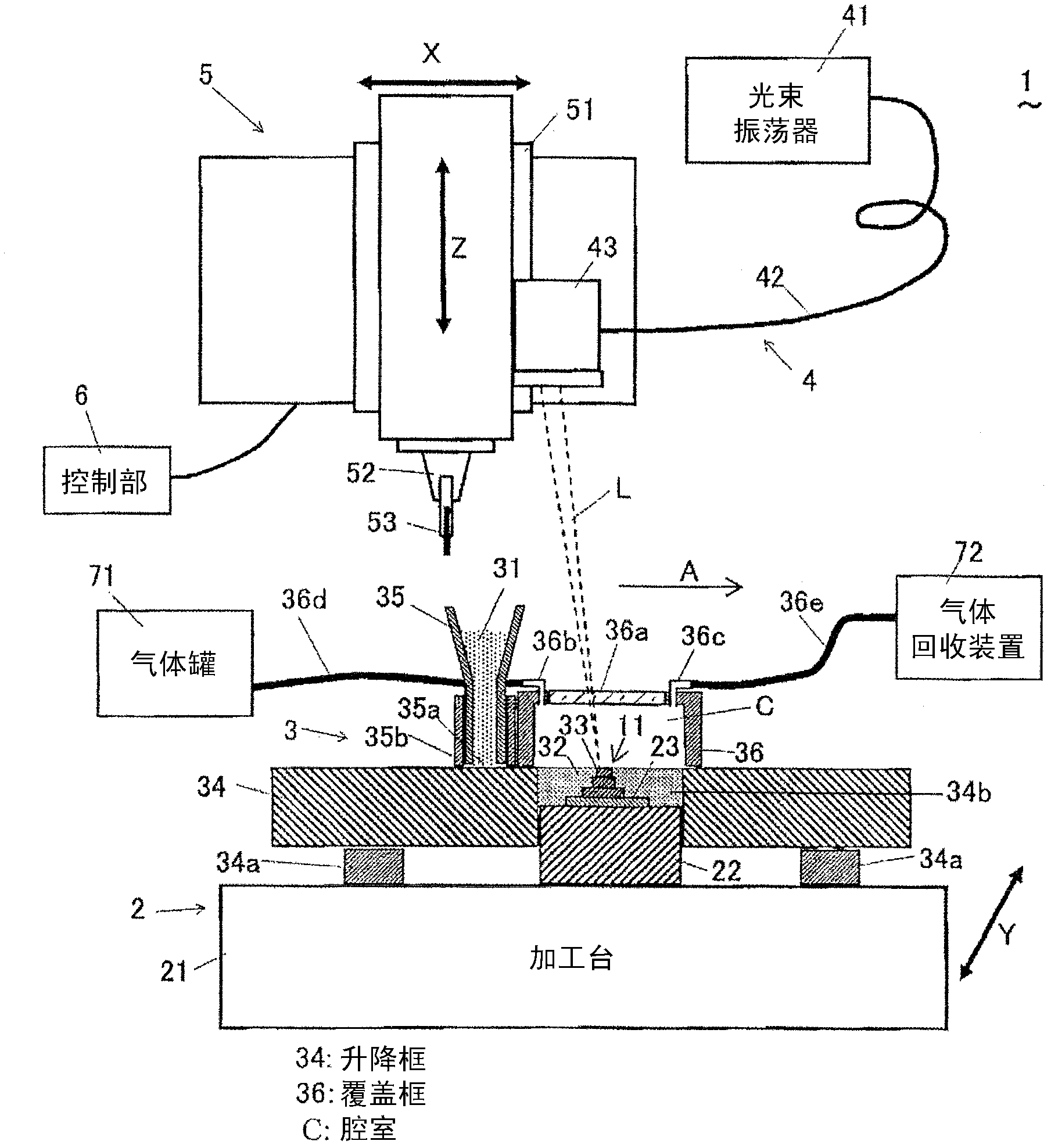

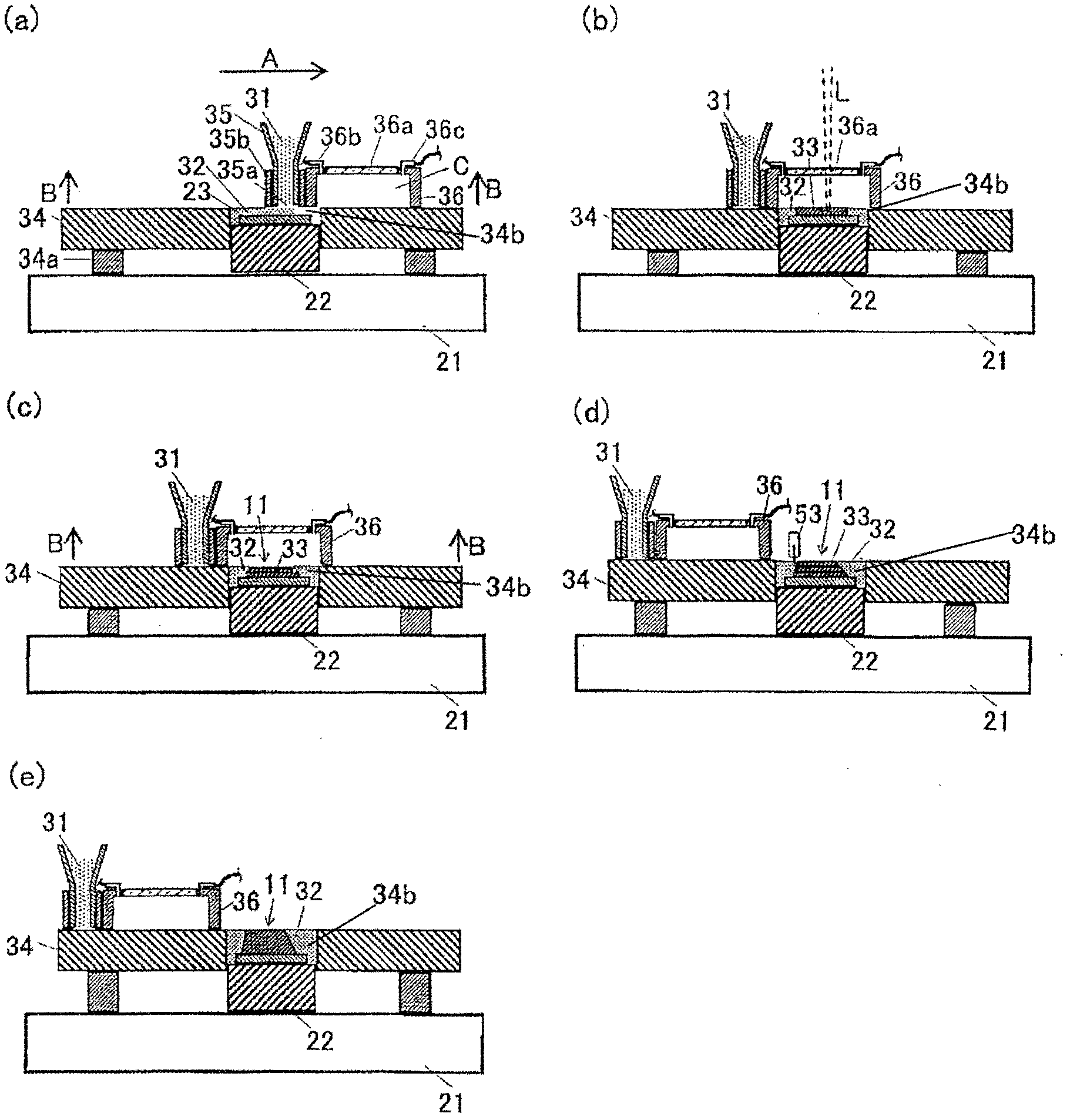

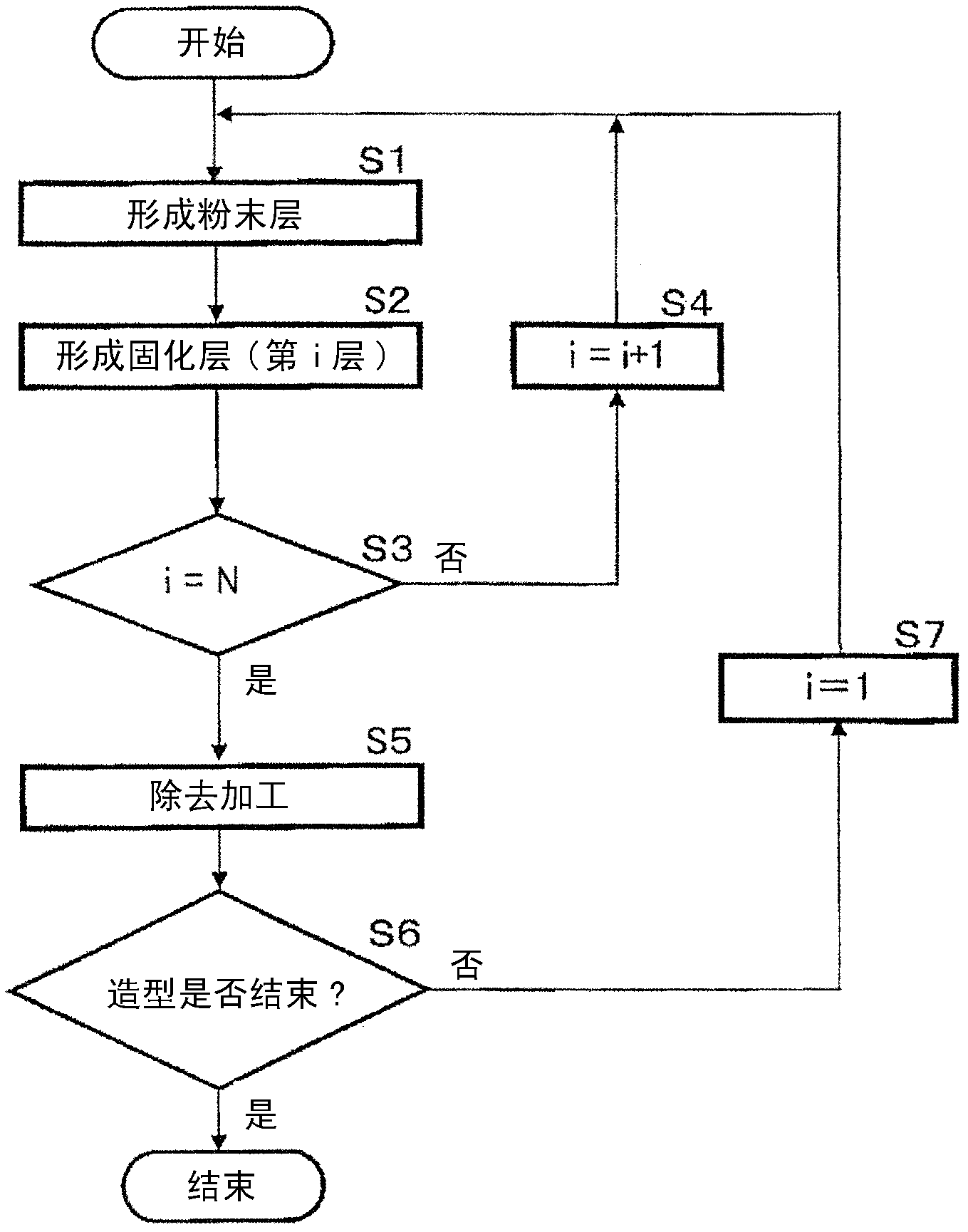

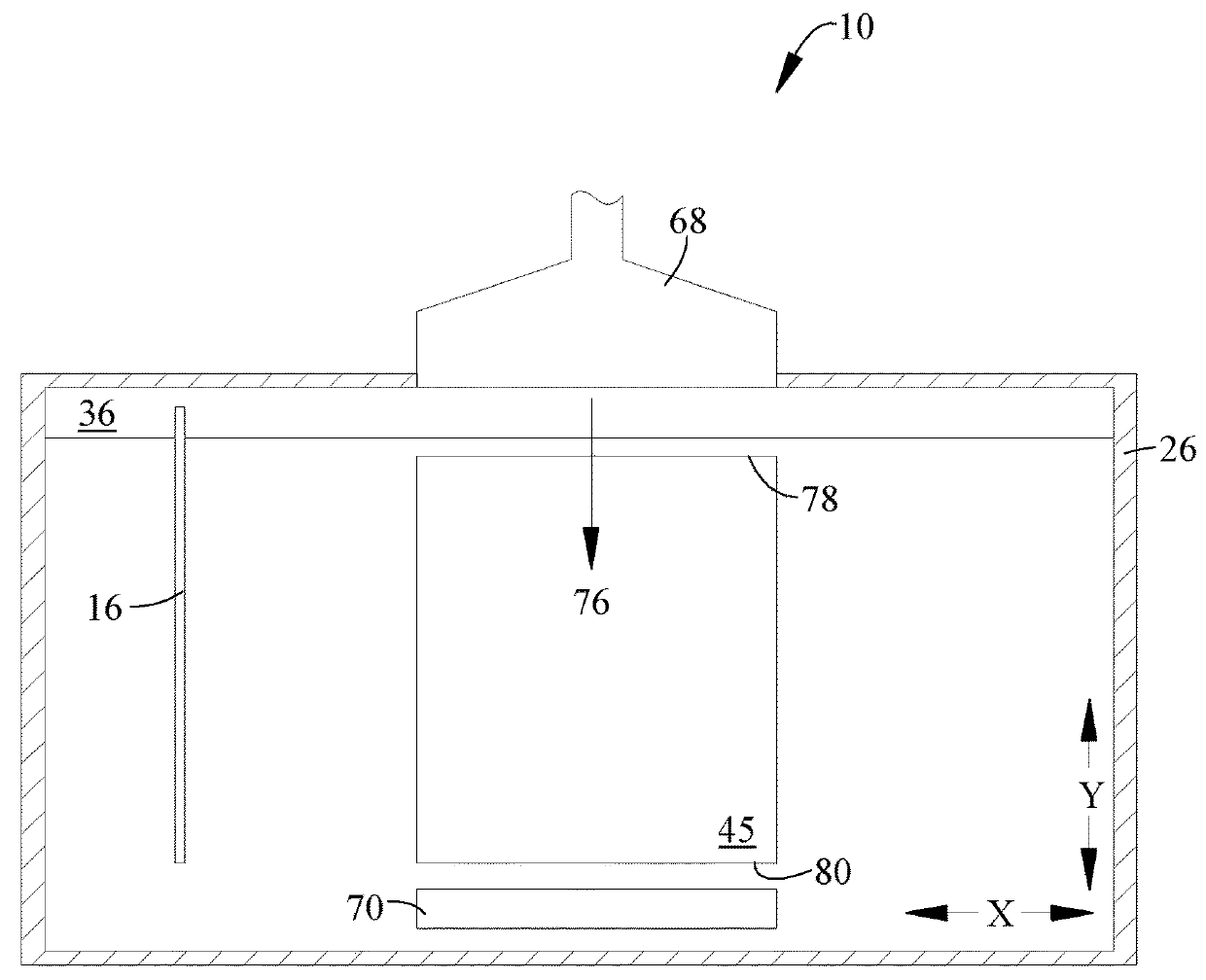

Layered-modeling device and method using said device for manufacturing three-dimensional objects

InactiveUS20120126457A1Easily eliminatingImprove machining accuracyAdditive manufacturing apparatusAuxillary shaping apparatusLayered modelLight beam

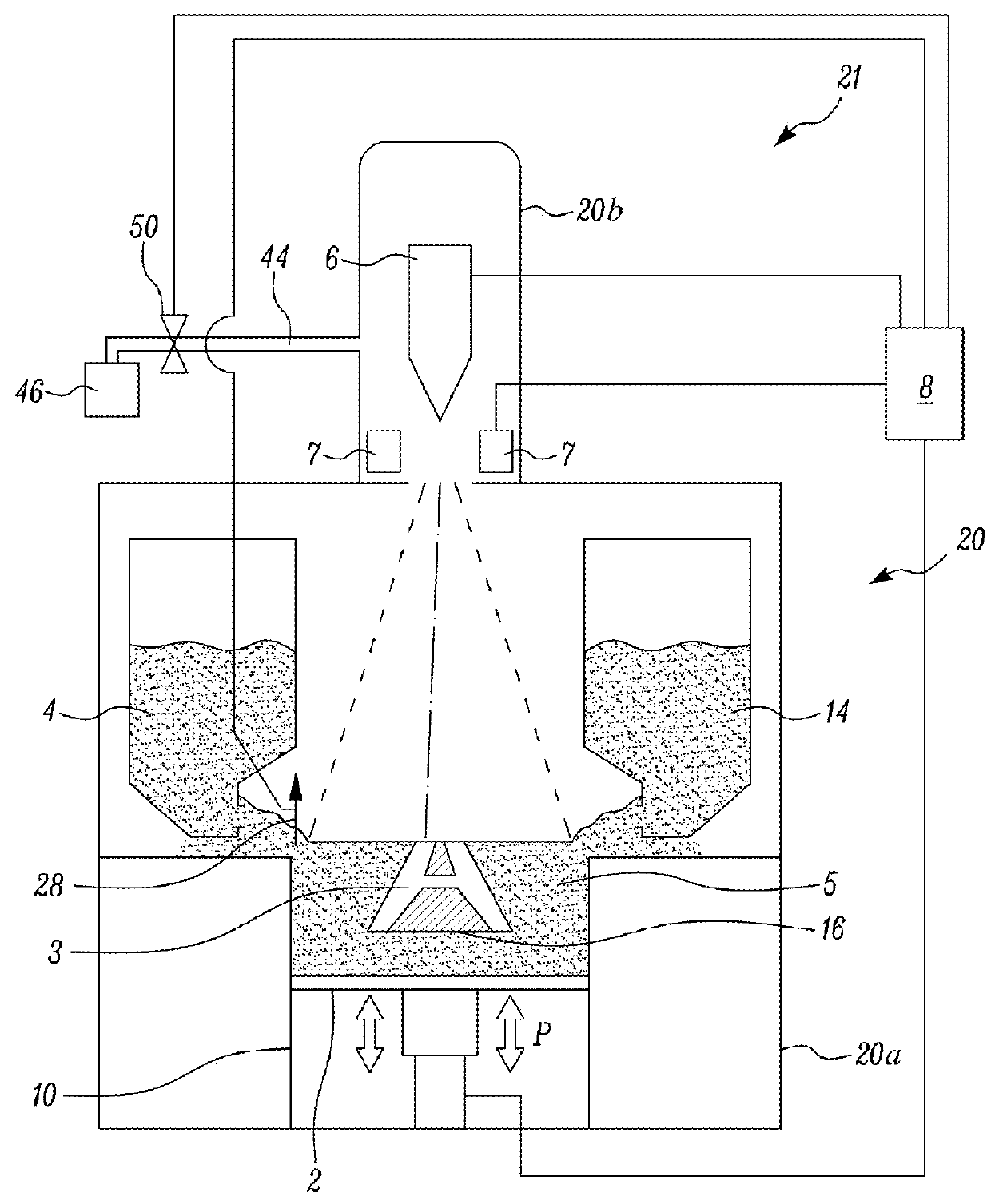

An object of the present invention is to easily eliminate fumes inside a chamber, so as to improve a positional accuracy of irradiation with a light beam and a machining accuracy in a method for manufacturing a three-dimensional shaped object. A stacked-layers forming device 1 includes a powder layer forming unit 3, a light beam irradiating unit 4, a base 22 which is fixed and on which a powder layer 32 is formed, a lifting / lowering frame 34 which surrounds the circumference of the base 22 and is freely capable of being lifted and lowered, a cover frame 36 which has a window 36a allowing transmission of light beam in its top surface, and whose bottom surface is opened, and which is disposed on the lifting / lowering frame 34 to form a chamber C, and a gas tank 71 for supplying an ambient gas. The lifting / lowering frame 34 is lowered to reduce the volume of the chamber C, so as to discharge fumes generated inside the cover frame 36, which performs replacement with the ambient gas. Since the volume of the chamber C is reduced, it is possible to easily eliminate the fumes, which makes it possible to improve the positional accuracy of irradiation with the light beam L, and the machining accuracy.

Owner:PANASONIC INTELLECTUAL PROPERTY MANAGEMENT CO LTD

Method and apparatus for increasing the resolution in additively manufactured three-dimensional articles

ActiveUS9079248B2High resolutionHigh pressure levelAdditive manufacturing apparatusIncreasing energy efficiencyPowder bedImage resolution

Owner:ARCAM AB

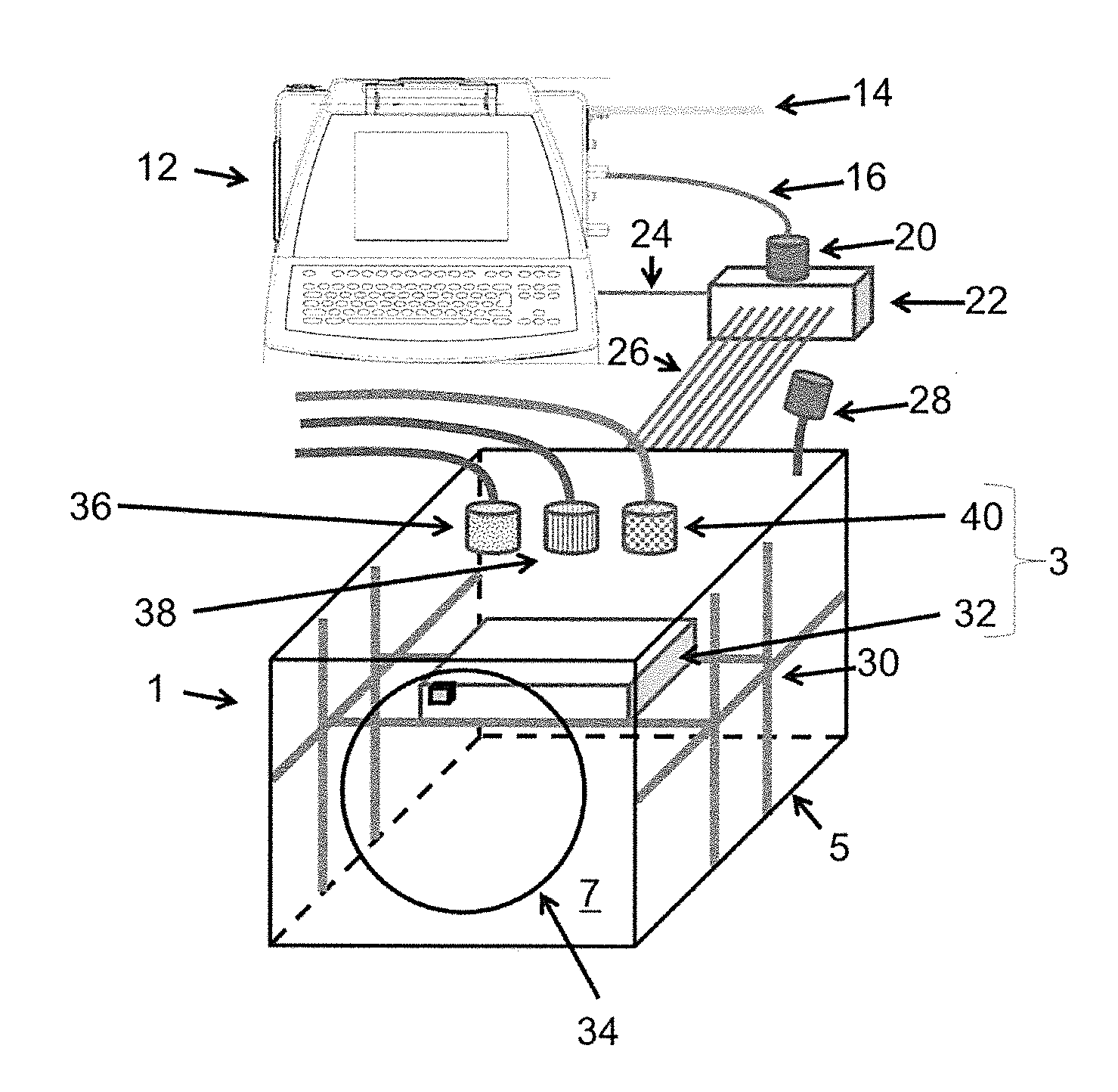

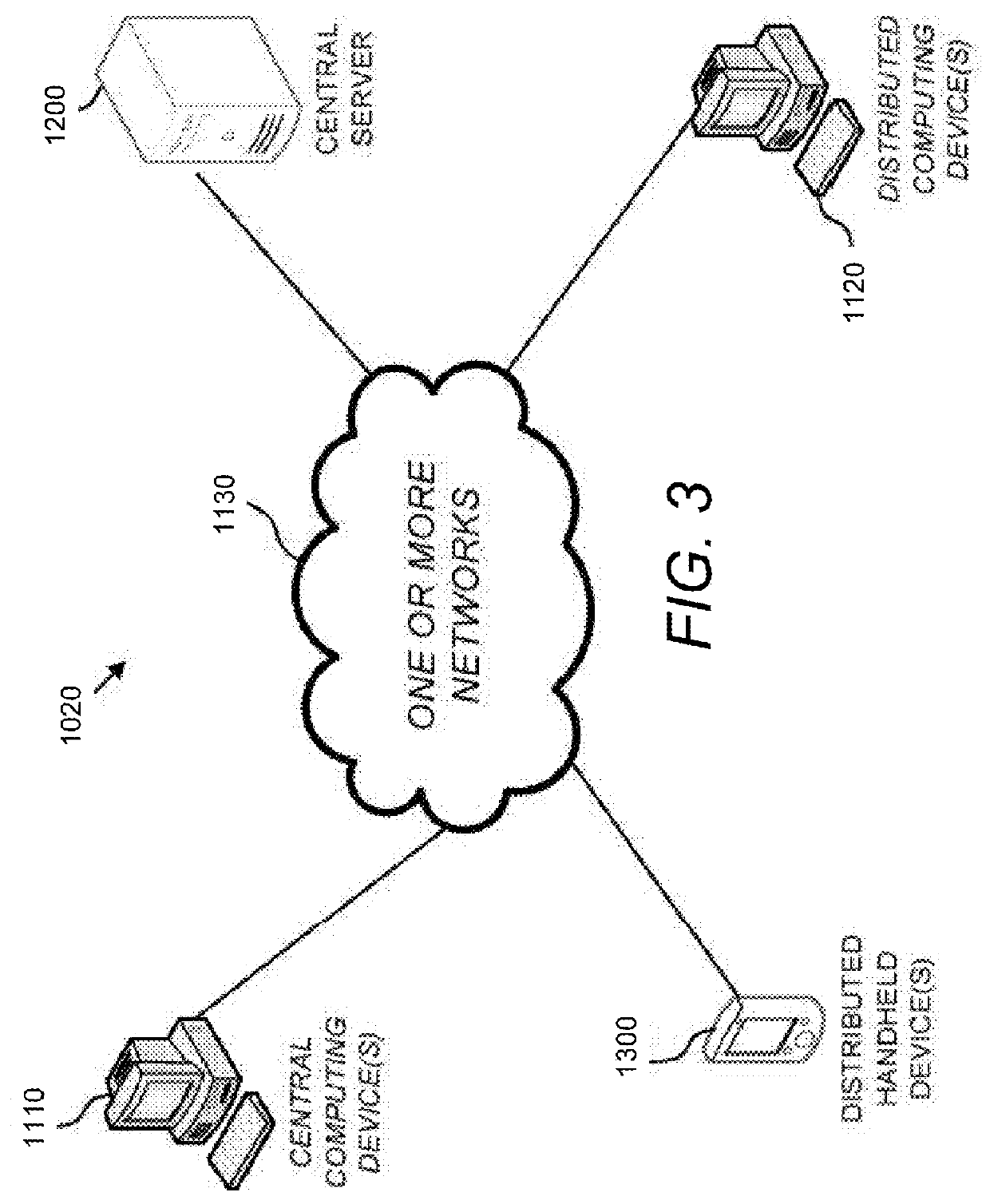

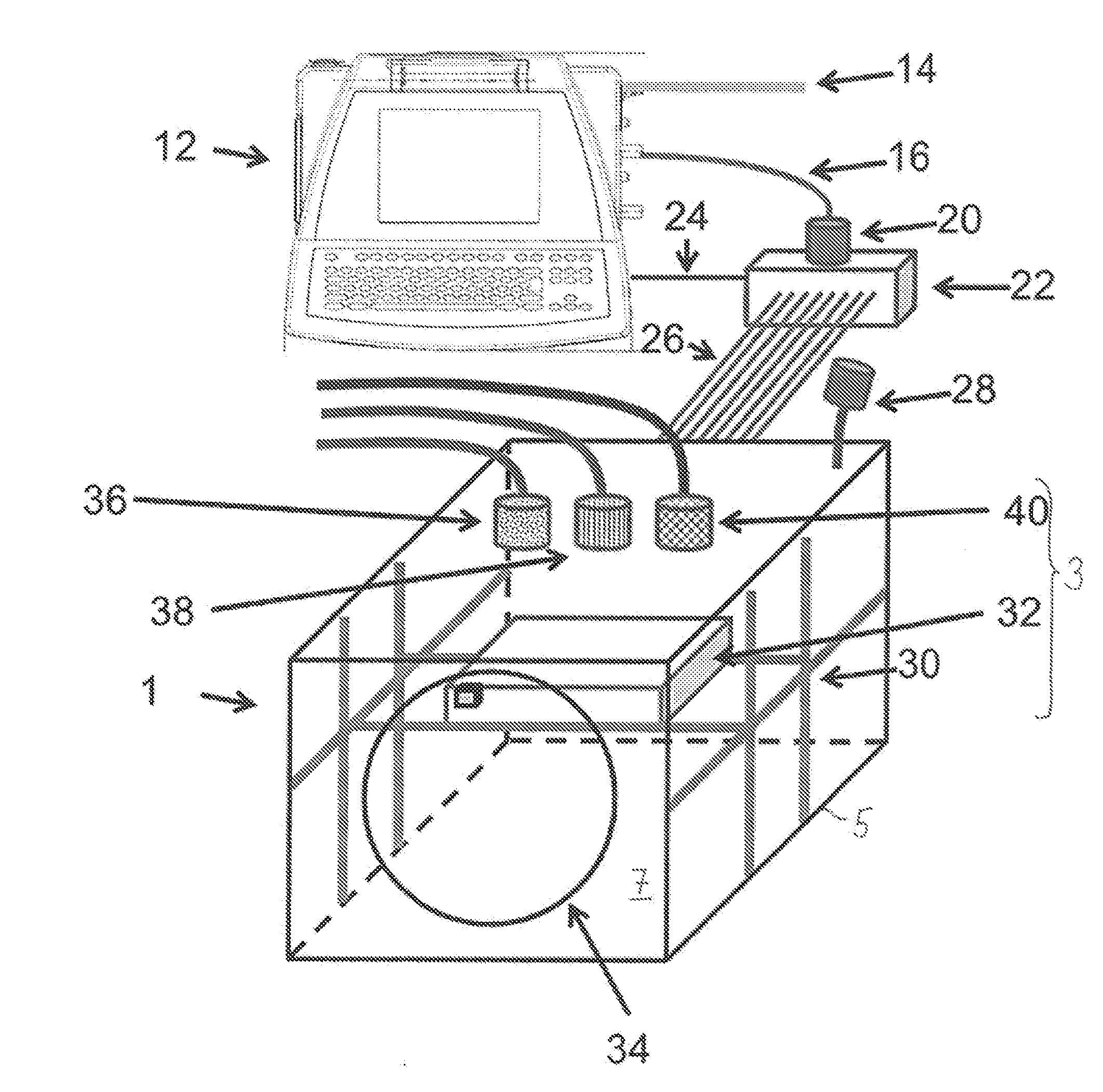

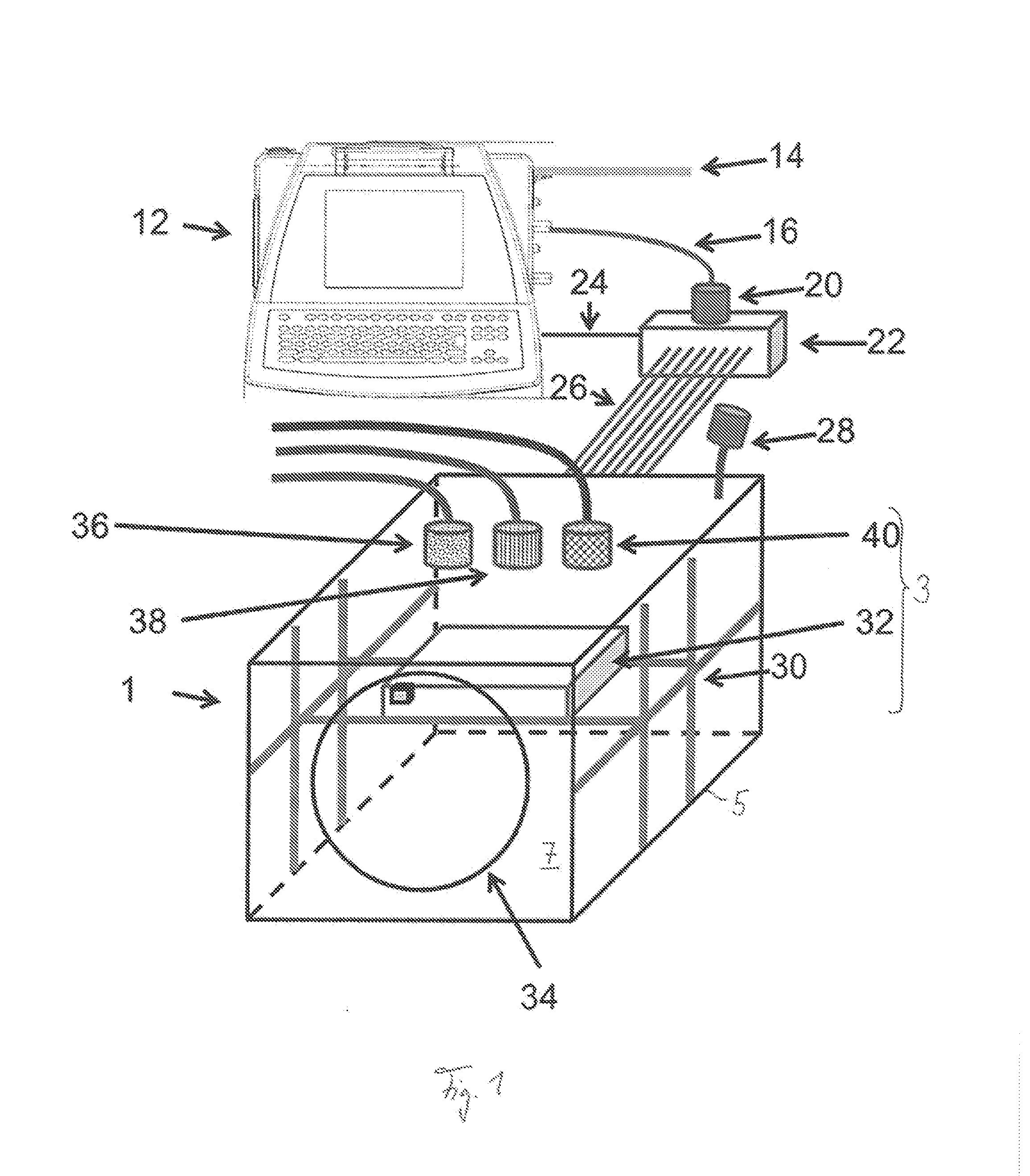

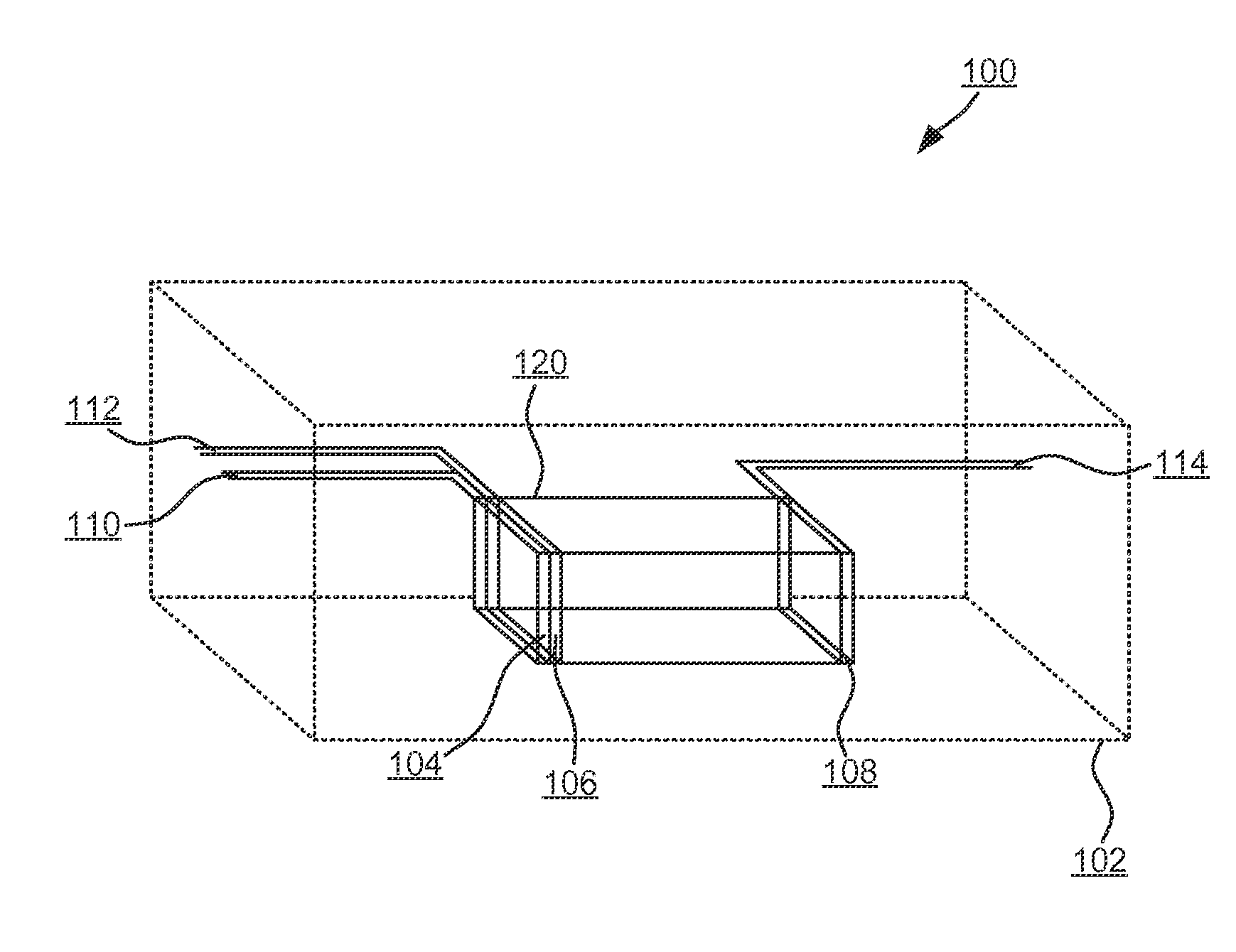

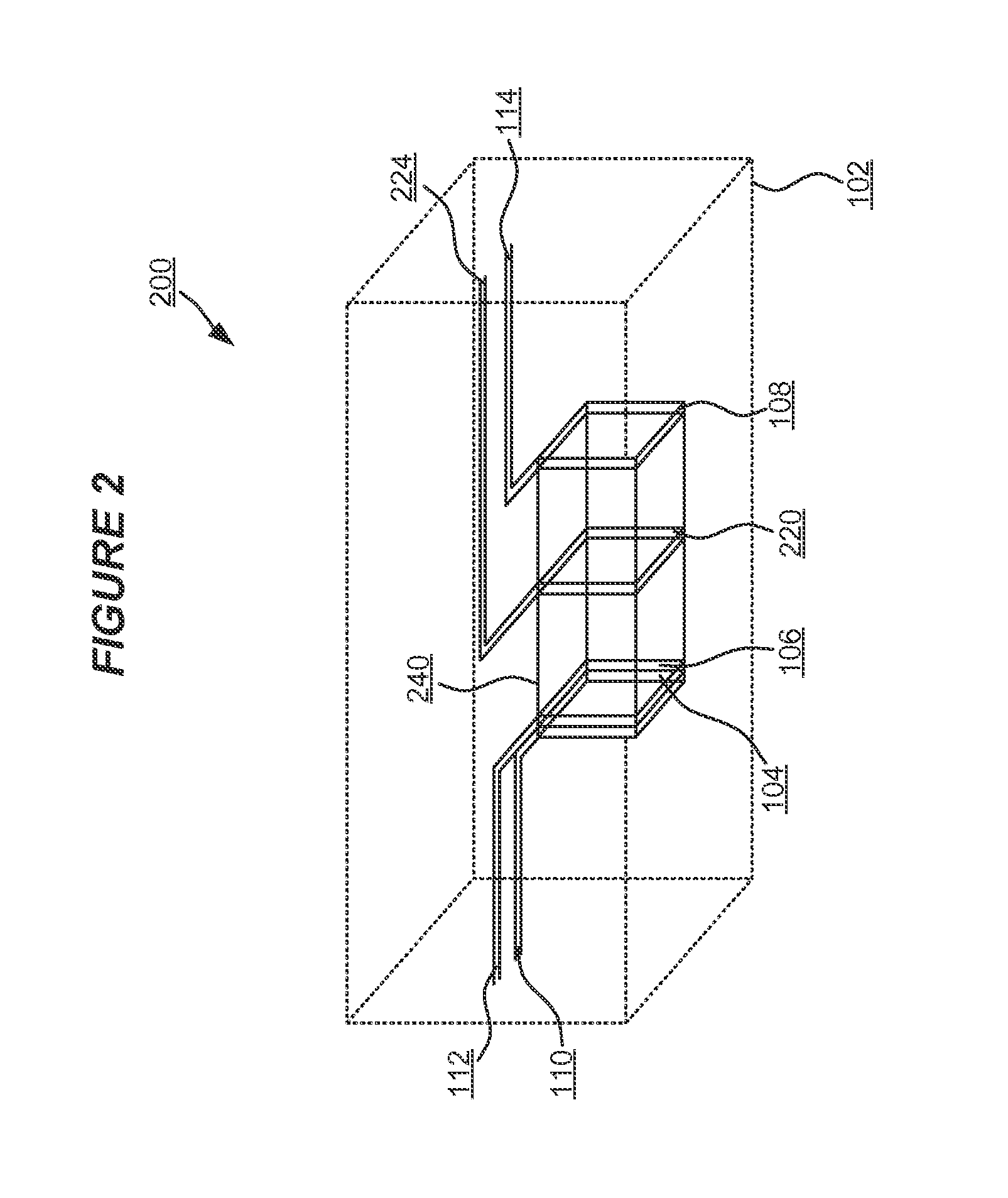

Manufacturing within a single-use container

ActiveUS20160068793A1Function increaseProgramme-controlled manipulatorBioreactor/fermenter combinationsNumerical controlThree degrees of freedom

A manufacturing assembly has at least a sterilizable chamber containing at least one of a three-dimensional printing device (additive manufacturing), a Computer Numerical Controlled (CNC) finishing head (subtractive manufacturing), a vacuum-forming unit, an injection-molding unit, a laser-cutting unit, a ultrasonic-welding unit, a robotic arman analysis device, a sampling device or a combination thereof. A plurality of individual sterilizable chambers may be aseptically connected into a network of sterilizable chambers that provides additional functionality for the manufacturing assembly. A sterilizable printer assembly may include at least one printing head, a printing platform, and a driving mechanism adapted to perform a movement of the at least one printing head relative to the printing platform along three degrees of freedom; a printer housing enclosing the printer assembly in a sterile manner, at least one aseptic connector fluidly connected to a corresponding one of the at least one printing head.

Owner:SARTORIUS STEDIM BIOTECH GMBH

Powder pre-processing for additive manufacturing

ActiveUS20150290710A1Shorten the timeRemove moistureManufacturing enclosuresTransportation and packagingMetallurgyPre treatment

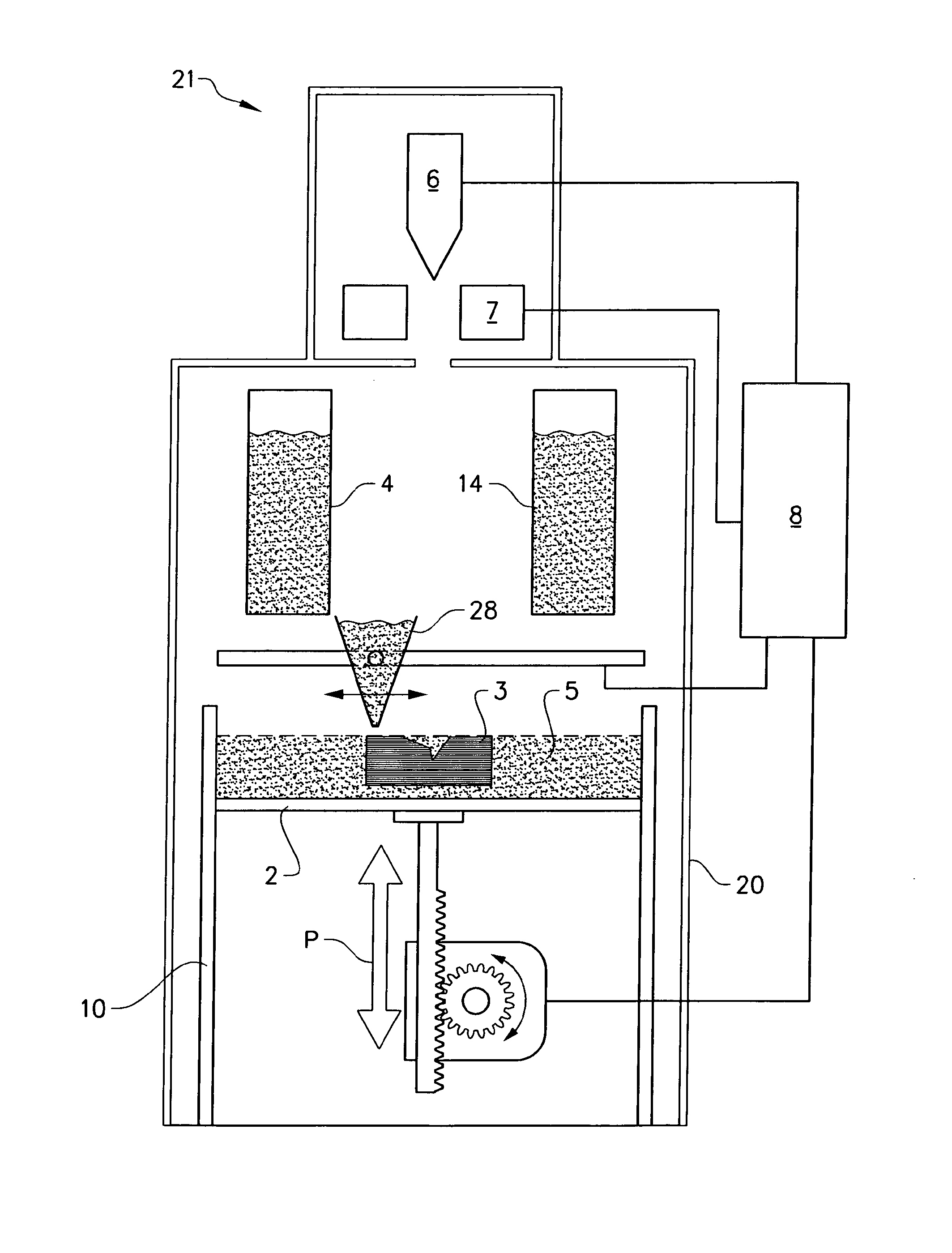

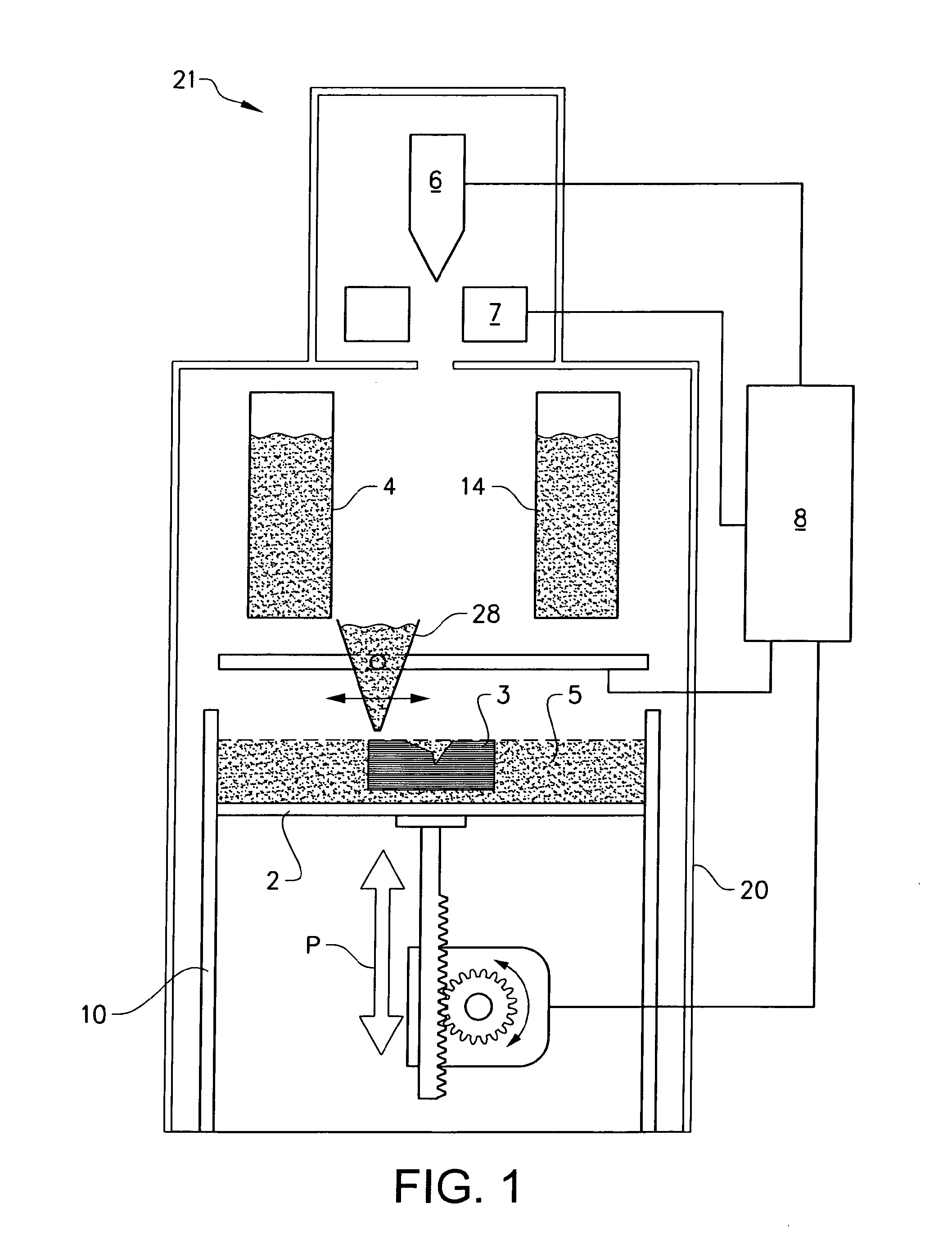

The present invention relates to a method for removing moisture from powder to be used in an additive manufacturing process for forming a three-dimensional article through successive fusion of parts of at least one layer of a powder bed provided on a work table, which parts corresponds to successive cross sections of the three-dimensional article, characterized in that said method comprising the steps of: providing at least a first powder tank and at least at least a second powder tank, providing a predetermined amount of powder on a movable table inside said first powder tank, heating the top surface of the powder in said first powder tank to a predetermined temperature interval for removing moisture from said powder, raising said movable table a predetermined distance, moving a predetermined thickness of the powder material from said first powder tank to said second powder tank.

Owner:ARCAM AB

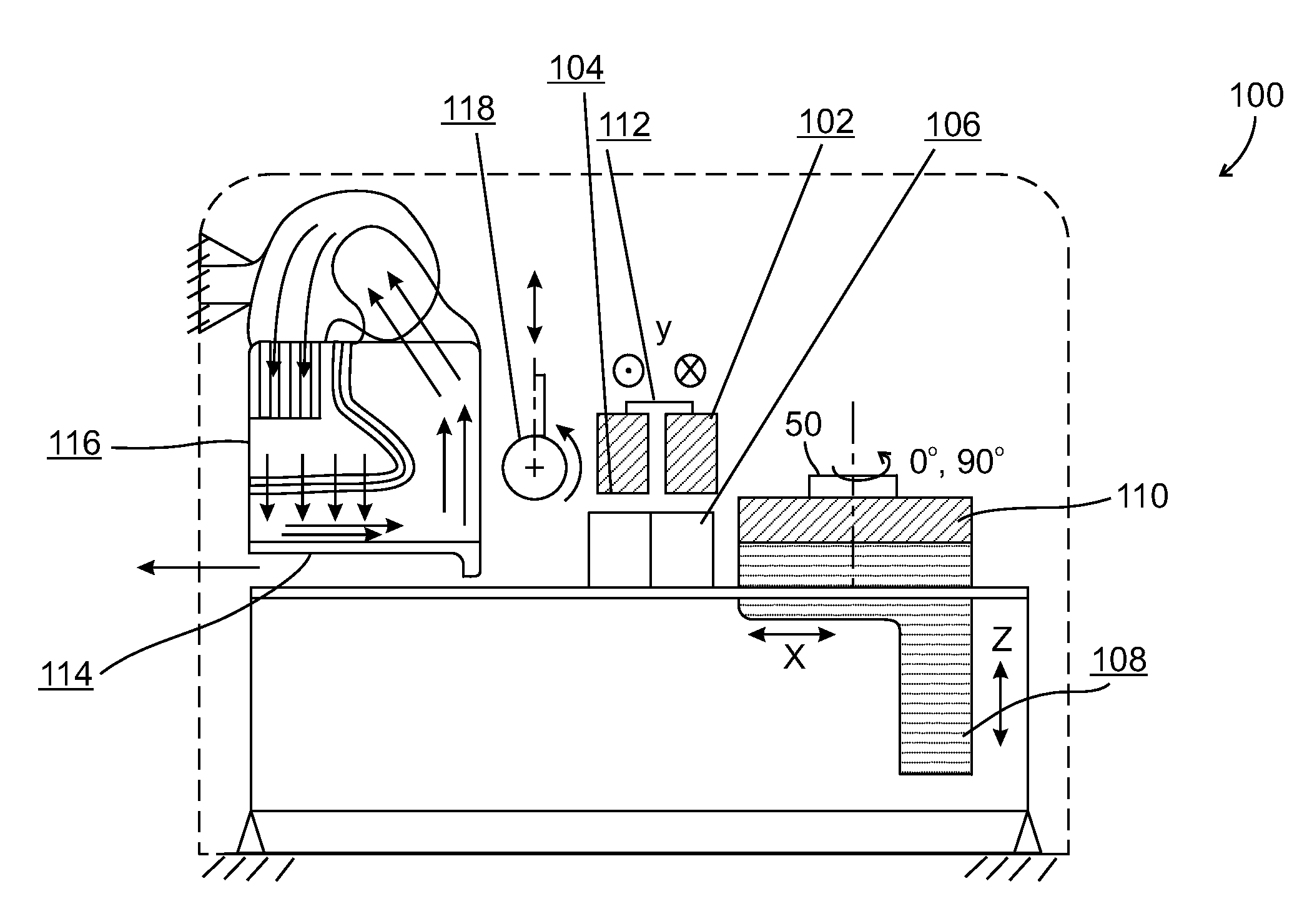

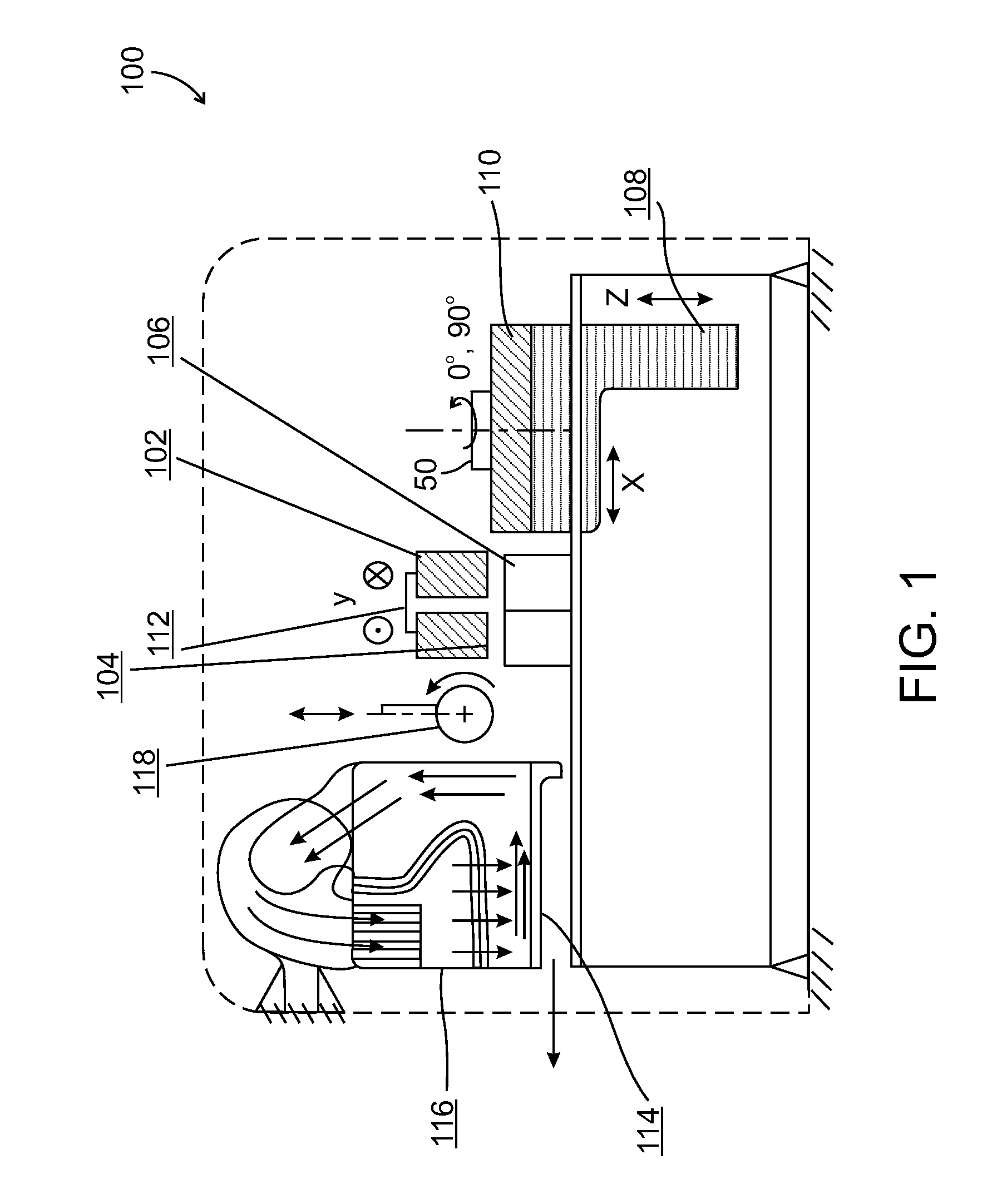

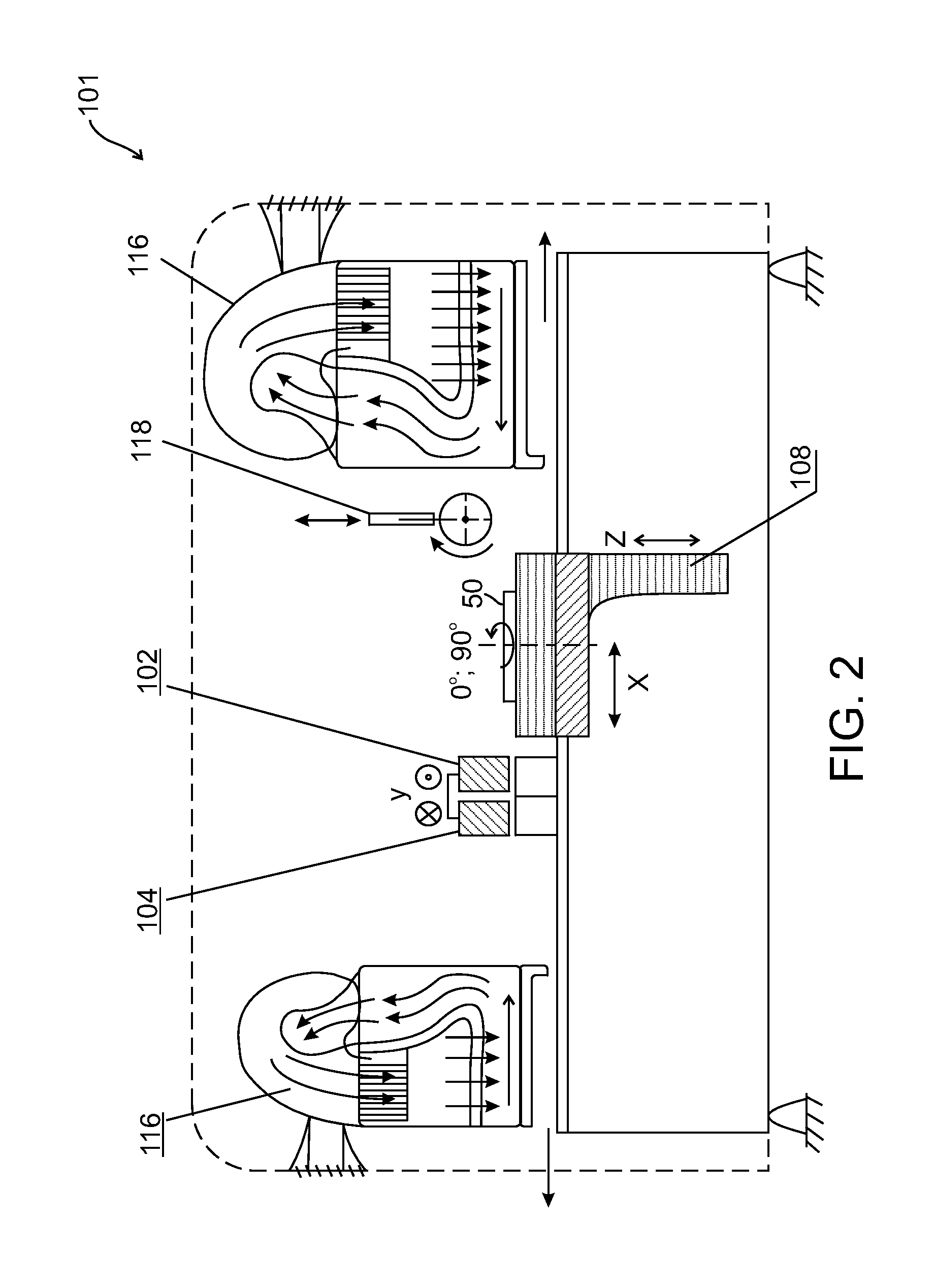

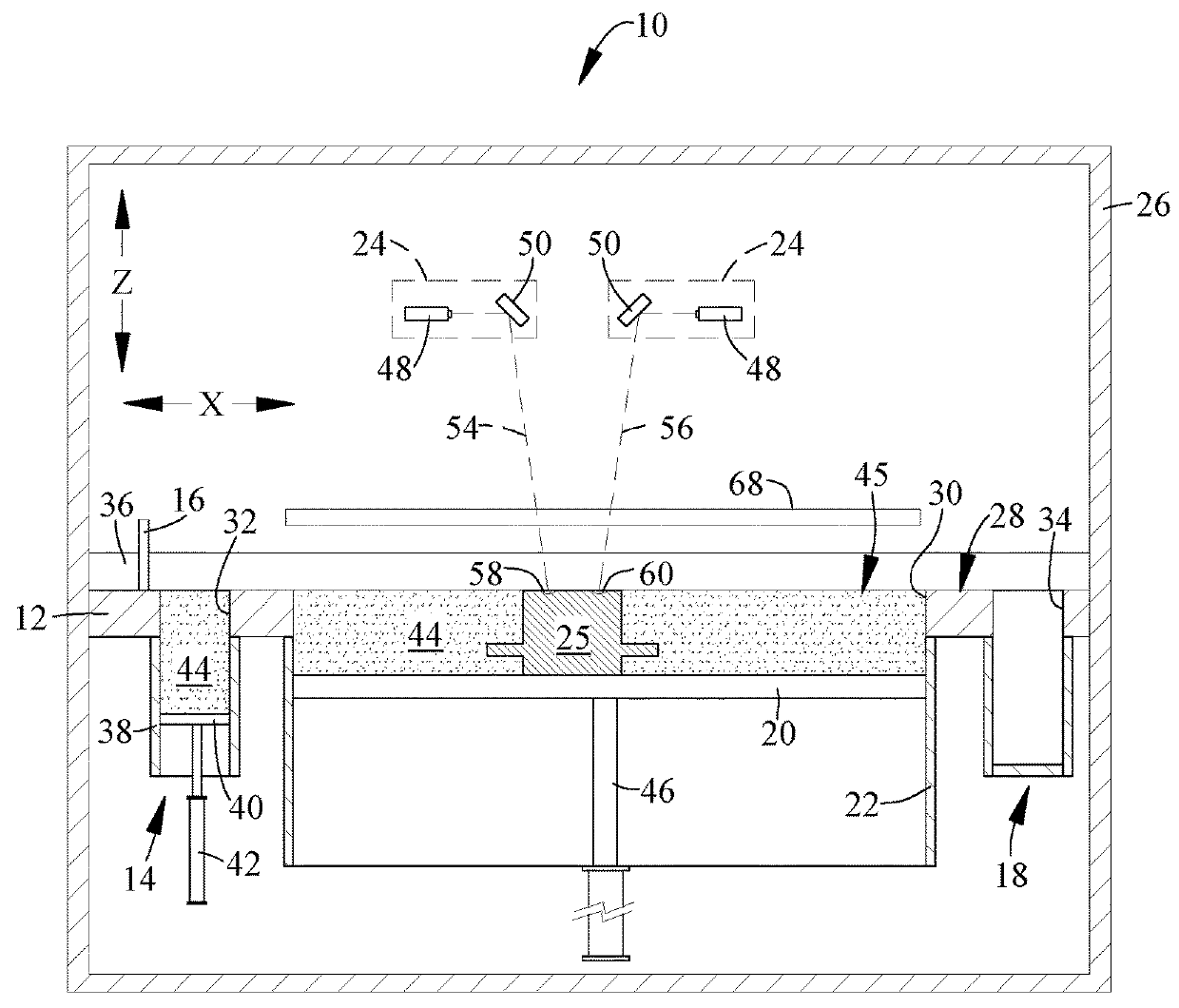

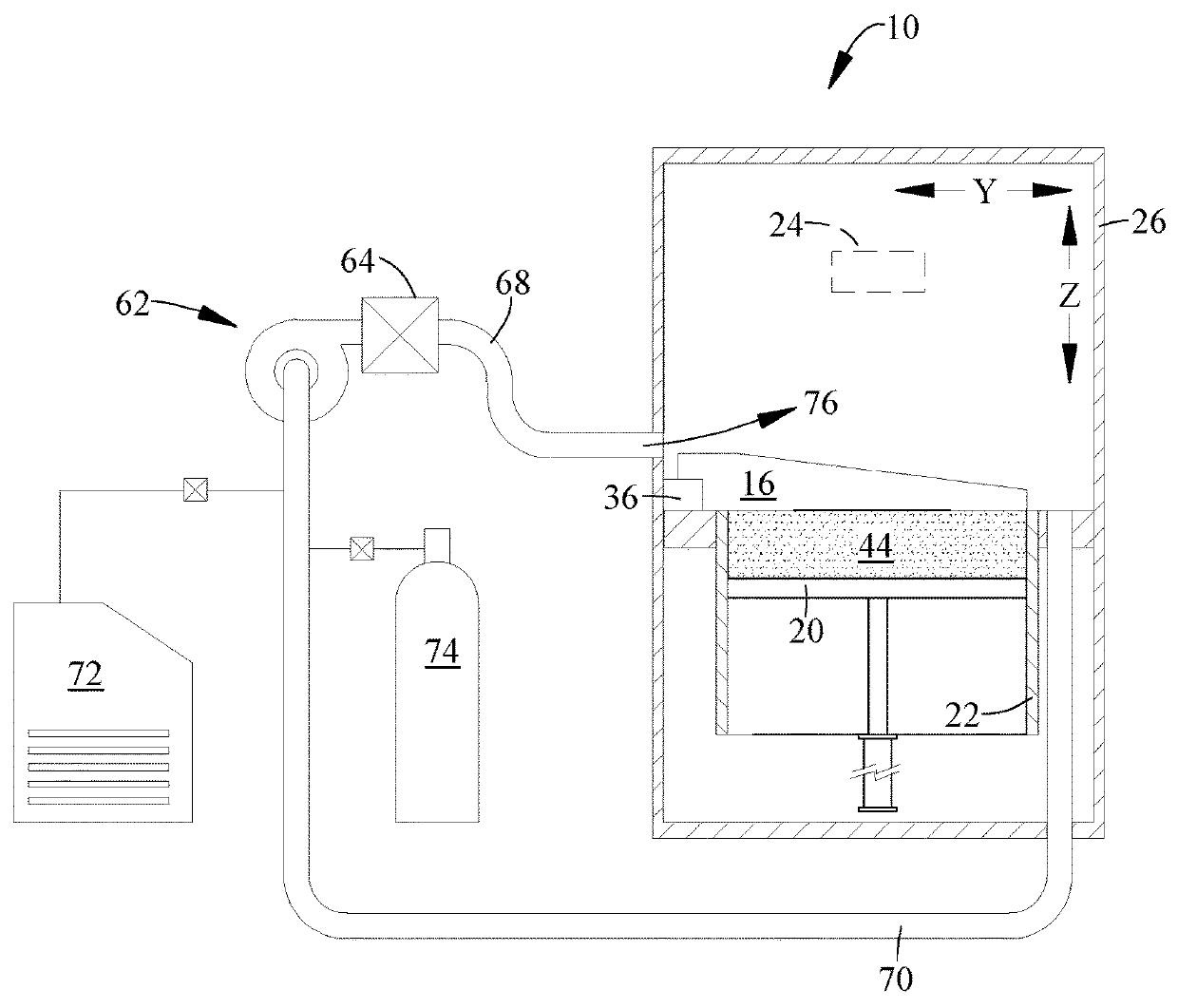

Additive manufacturing apparatus and method

ActiveUS20160136731A1Additive manufacturing apparatusDirt cleaningManufactured apparatusProcess engineering

An additive manufacturing apparatus for building objects by layerwise consolidation of material. The apparatus includes a build chamber containing a working area, a high energy beam for consolidating material deposited in the working area in layers and a flow device for generating a gas flow across at least a part of the working area from a gas inlet to a gas outlet. The gas inlet and gas outlet are arranged to be movable within the build chamber.

Owner:RENISHAW PLC

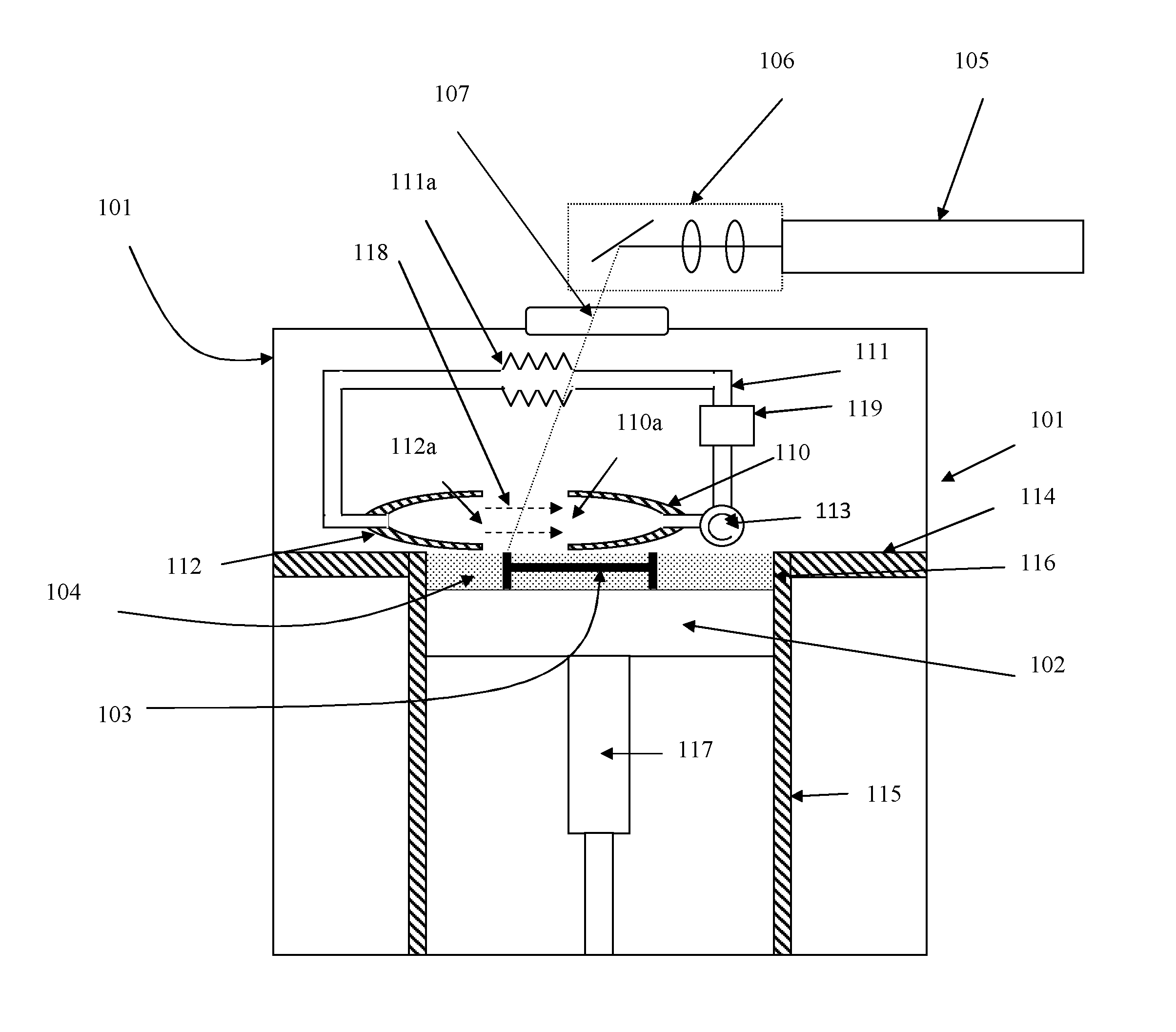

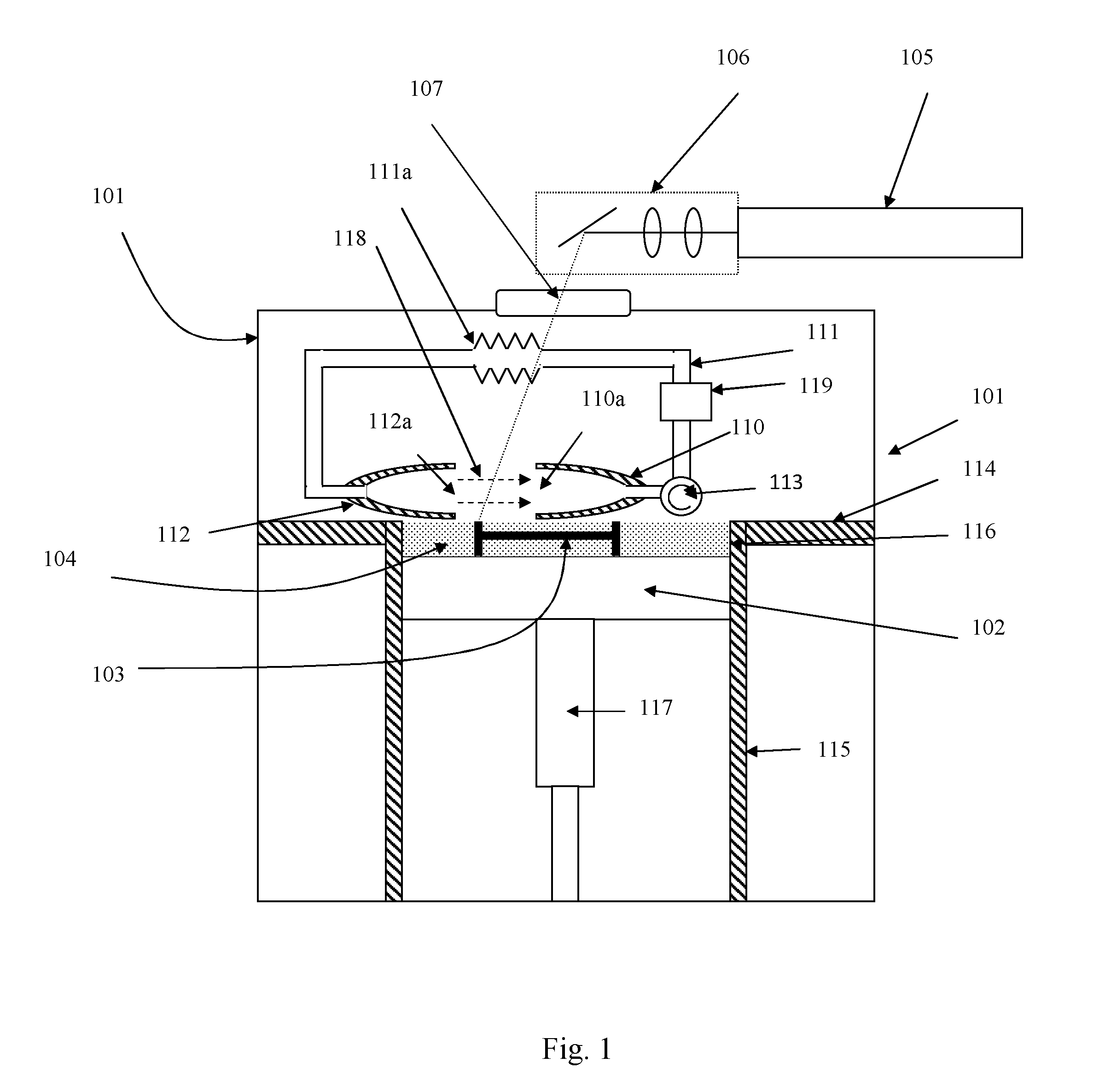

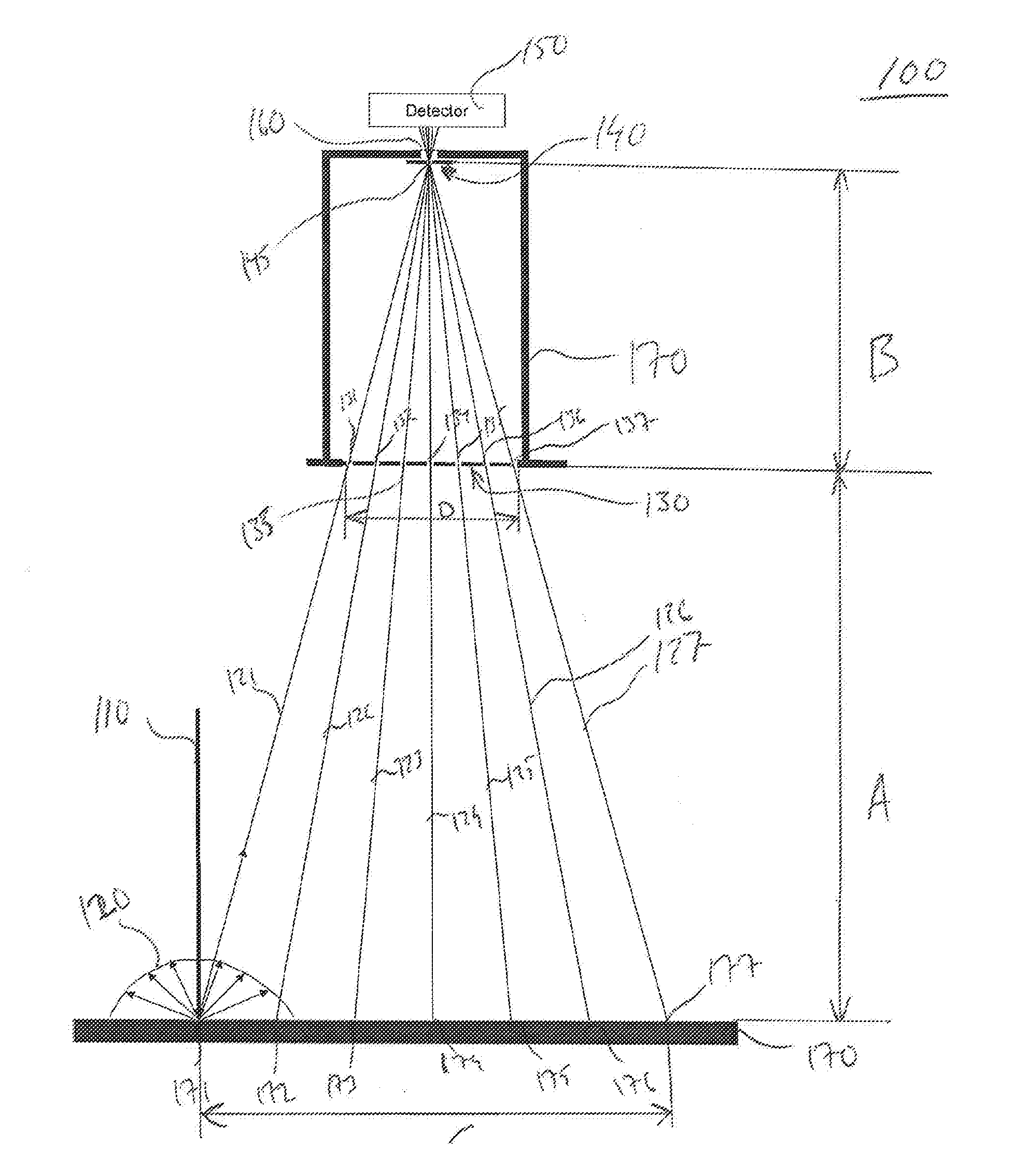

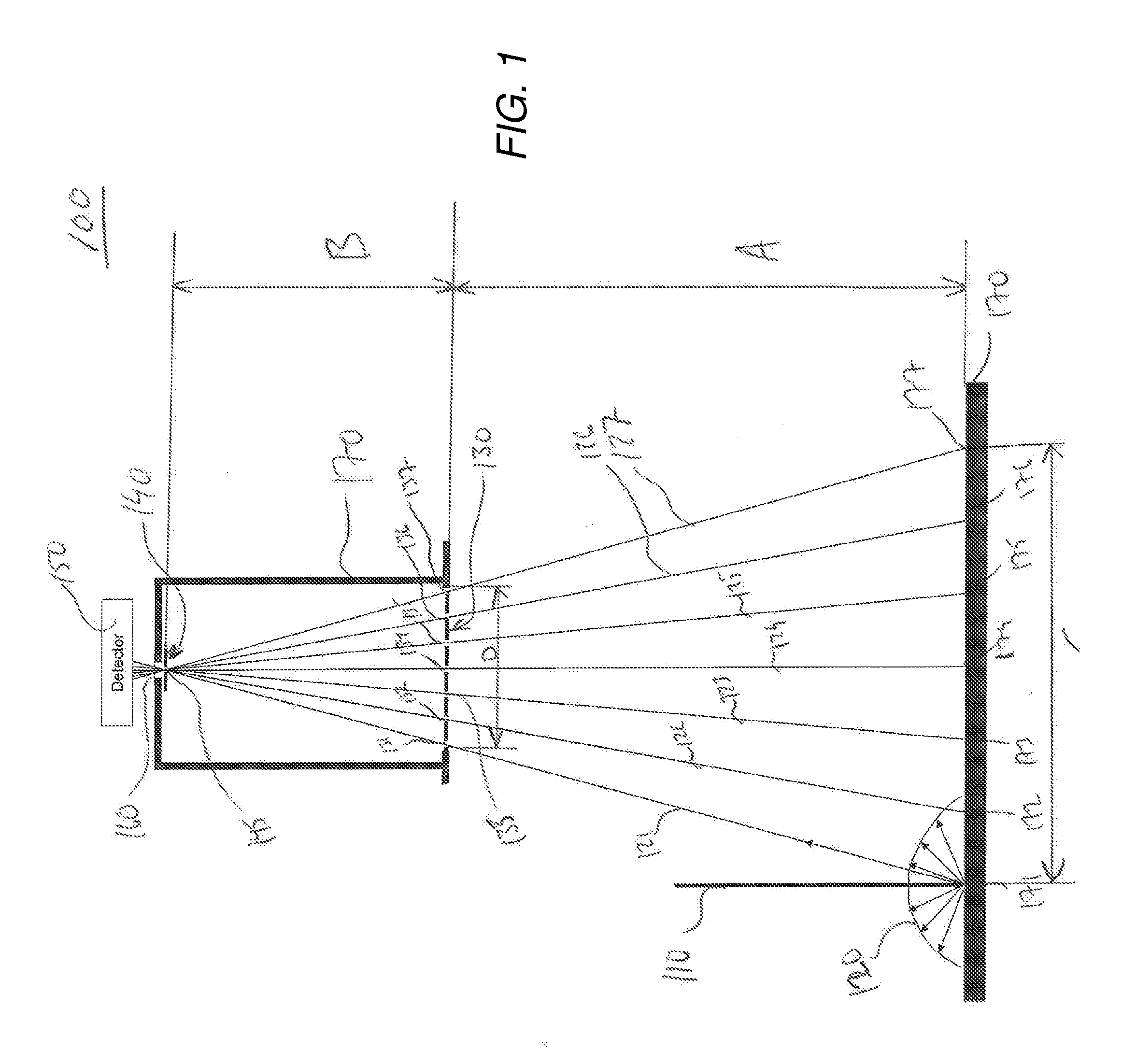

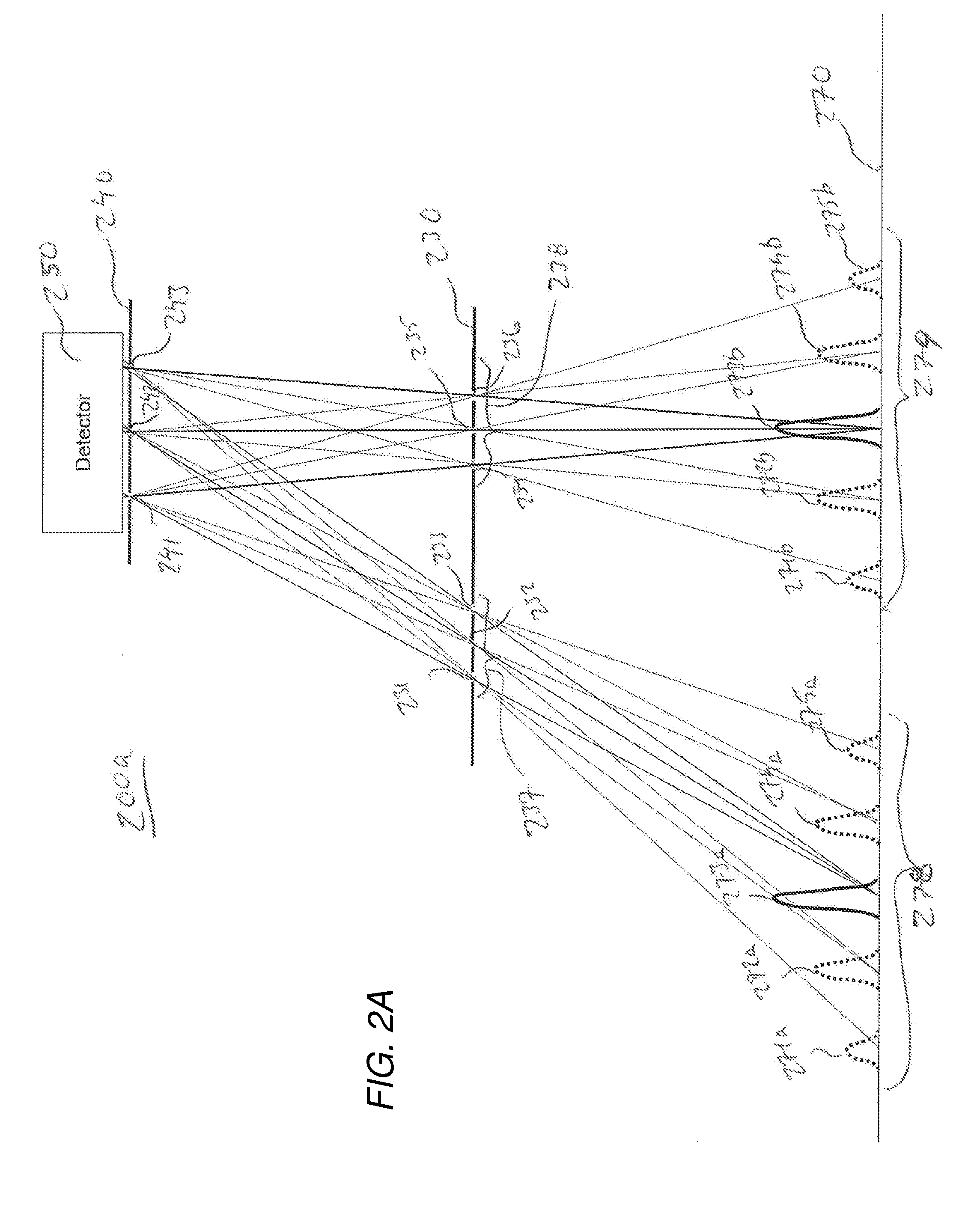

Method and device for characterizing an electron beam

ActiveUS20160211116A1Solve the lack of spaceEasy to manufactureAdditive manufacturing apparatusElectric discharge tubesGratingX-ray

A device for detecting X-rays radiated out of a substrate surface, said device comprising at least one X-ray detector, a resolver grating and a modulator grating, said resolver grating with at least one opening facing towards said X-ray detector is arranged in front of said X-ray detector. Said modulator grating is provided between said resolver grating and said substrate at a predetermined distance from said resolver grating and said substrate, where said modulator grating having a plurality of openings in at least a first direction, wherein said x-rays from said surface is spatially modulated with said modulator grating and resolver grating.

Owner:ARCAM AB

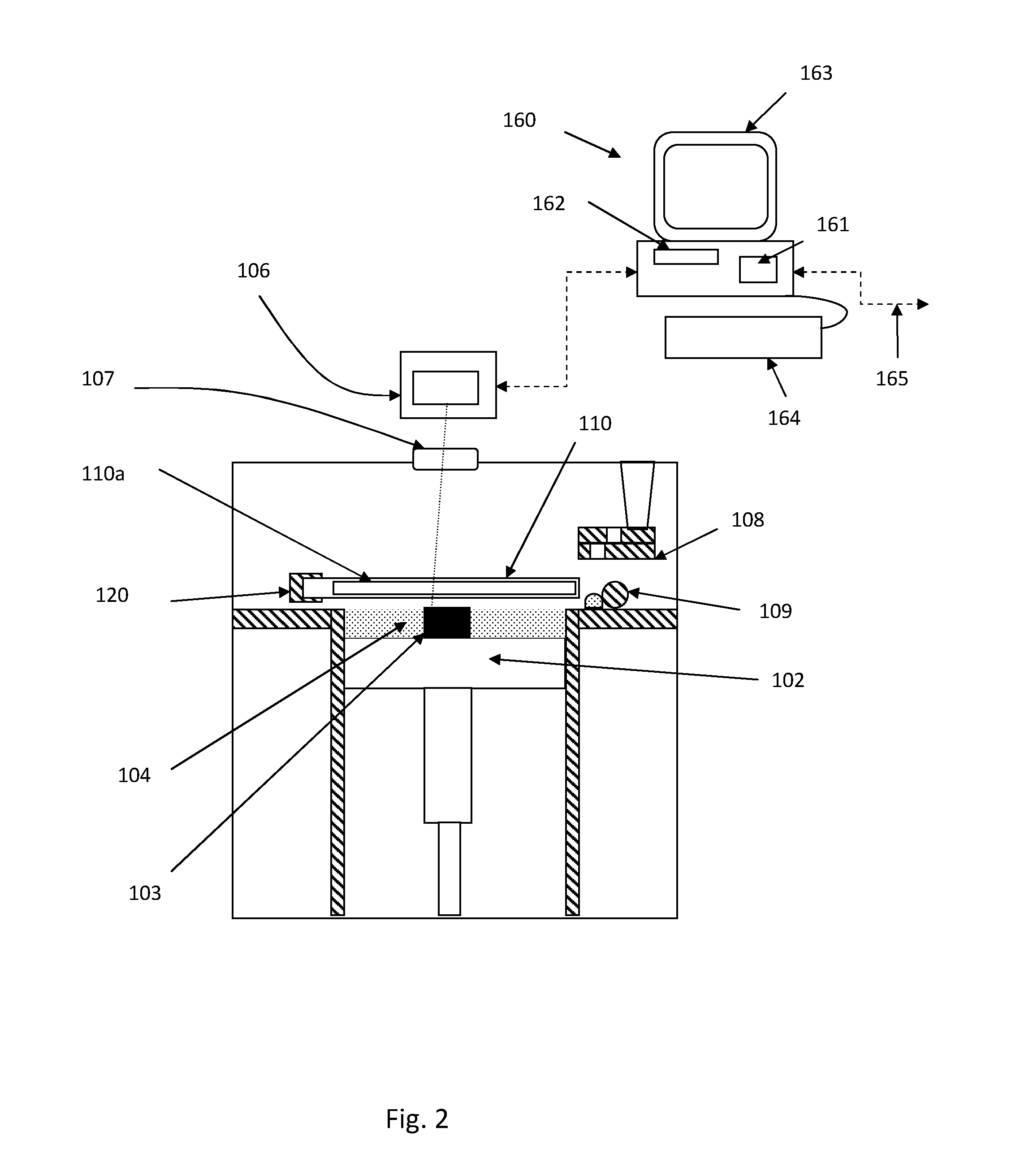

Method and apparatus for increasing the resolution in additively manufactured three-dimensional articles

ActiveUS20140370323A1High pressure levelHigh beam qualityAdditive manufacturing apparatusIncreasing energy efficiencyImage resolutionVacuum chamber

A method for increasing the resolution when forming a three-dimensional article through successive fusion of parts of a powder bed, said method comprising providing a vacuum chamber, providing an electron gun, providing a first powder layer on a work table inside said vacuum chamber, directing an electron beam from said electron gun over said work table causing the powder layer to fuse in selected locations to form a first cross section of said three-dimensional article, providing a second powder layer on said work table, directing the electron beam over said work table causing said second powder layer to fuse in selected locations to form a second cross section of said three-dimensional article, reducing the pressure in the vacuum chamber from a first pressure level to a second pressure level between the providing of said first powder layer and said second powder layer.

Owner:ARCAM AB

Enhanced additive manufacturing

InactiveUS20160052079A1Shorten the timeSmall volumeAdditive manufacturing apparatusElectric discharge tubesBeam sourceVacuum level

Various embodiments of the present invention relate to a method for operating an additive manufacturing apparatus in which a three-dimensional article is formed. Said method comprising the steps of: providing a vacuum chamber having at least a first and a second section, wherein said first and second sections are openly connected to each other, providing a predetermined vacuum level inside said vacuum chamber, providing a layer of powder material on a work table in said first section of said vacuum chamber, directing an electron beam from said at least one electron beam source provided in said second section over said work table to fuse in first selected locations according to said model to form a first cross section of said three-dimensional article, purging said second section with a dry gas when said vacuum chamber is open for prohibiting ambient air into said second section.

Owner:ARCAM AB

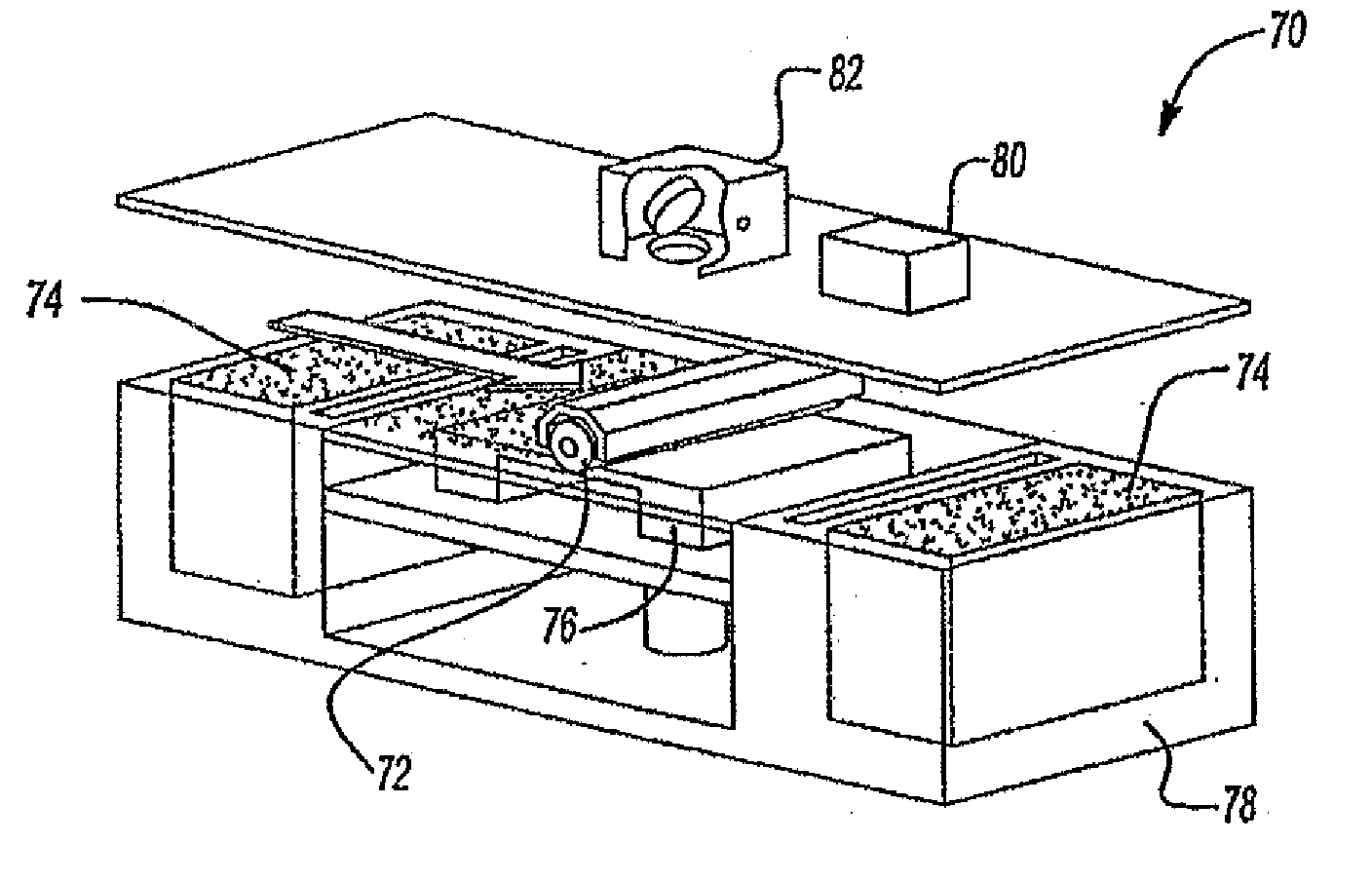

Chute for Laser Sintering Systems

ActiveUS20140265045A1Reduce the possibilityHigh densityManufacturing heating elementsAuxillary shaping apparatusRadiant heaterUltimate tensile strength

There is provided improved laser sintering systems that increase the powder density and reduce anomalies of the powder layers that are sintered, that measure the laser power within the build chamber for automatic calibration during a build process, that deposit powder into the build chamber through a chute to minimize dusting, and that scrubs the air and cools the radiant heaters with recirculated scrubbed air. The improvements enable the laser sintering systems to make parts that are of higher and more consistent quality, precision, and strength, while enabling the user of the laser sintering systems to reuse greater proportions of previously used but unsintered powder.

Owner:3D SYST INC

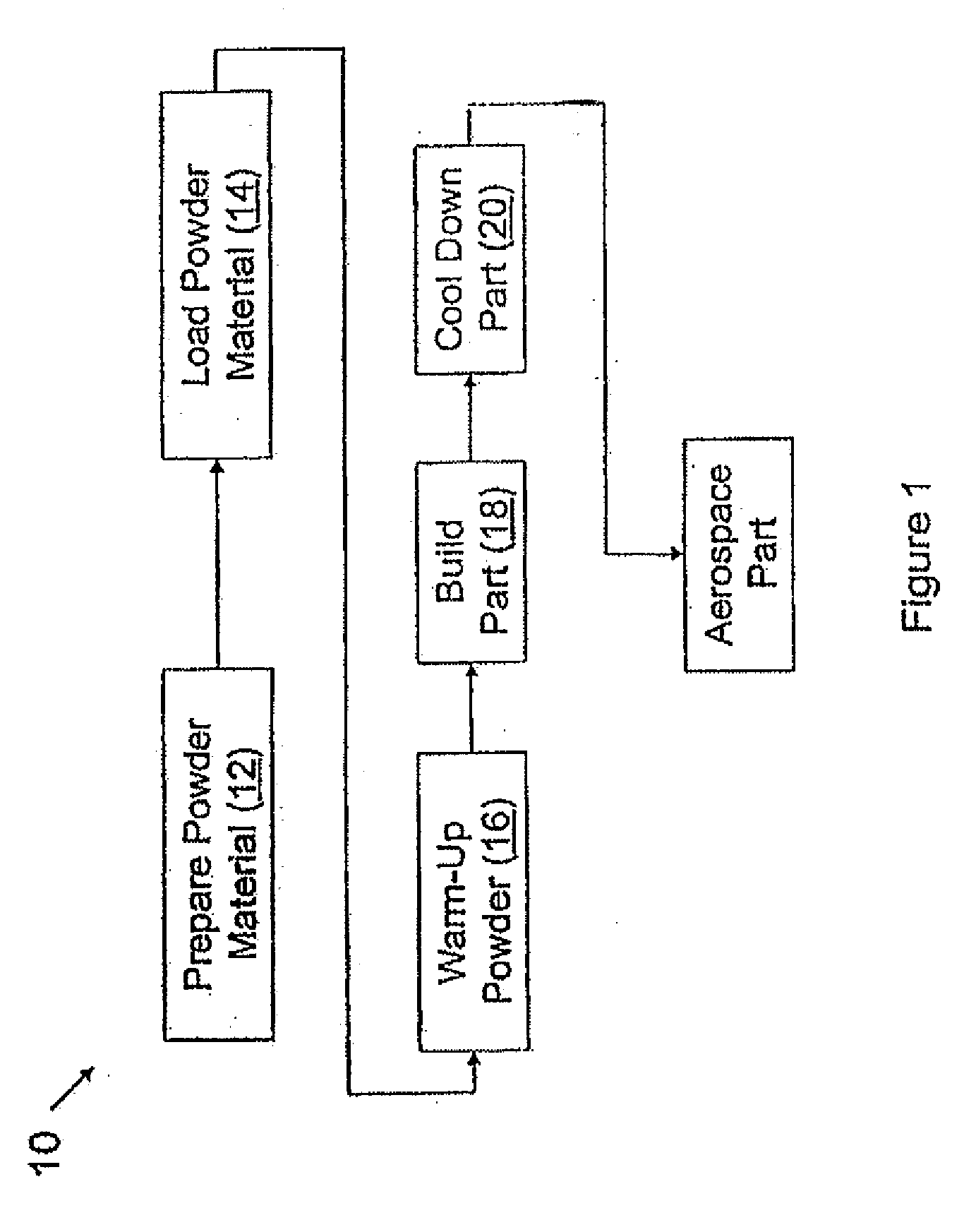

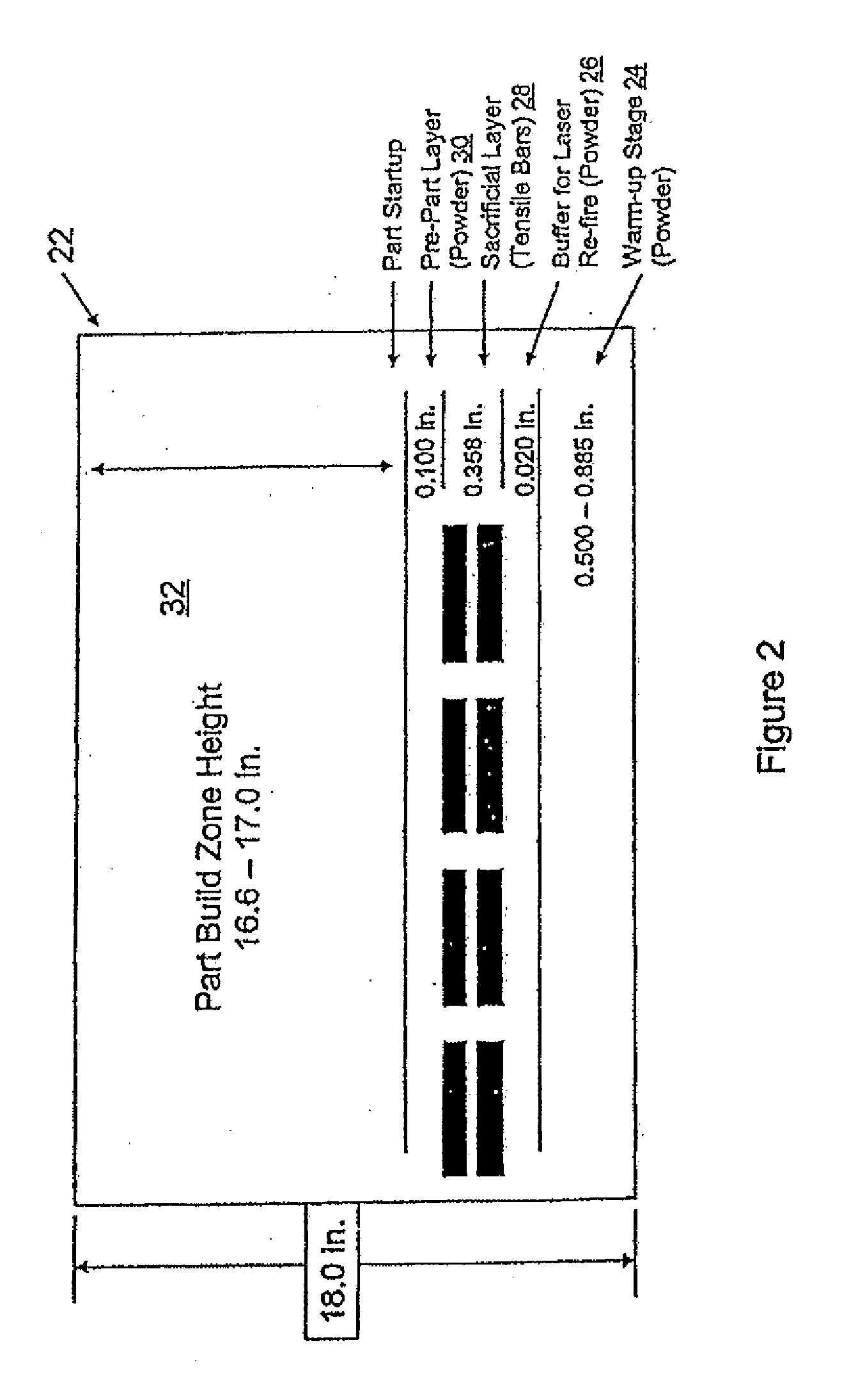

Optimal dimensional and mechanical properties of laser sintered hardware by thermal analysis and parameter optimization

InactiveUS20100174392A1Additive manufacturing apparatusAnalogue computers for control systemsEngineeringMechanical property

A process for establishing manufacturing parameters includes computer simulating a manufacture of a laser-sintered part based on a set of manufacturing parameters, calculating a set of physical properties of the simulated manufacture, and modifying the set of manufacturing parameters based on the calculated set in order to obtain a desired set of physical properties.

Owner:ROCKETDYNE

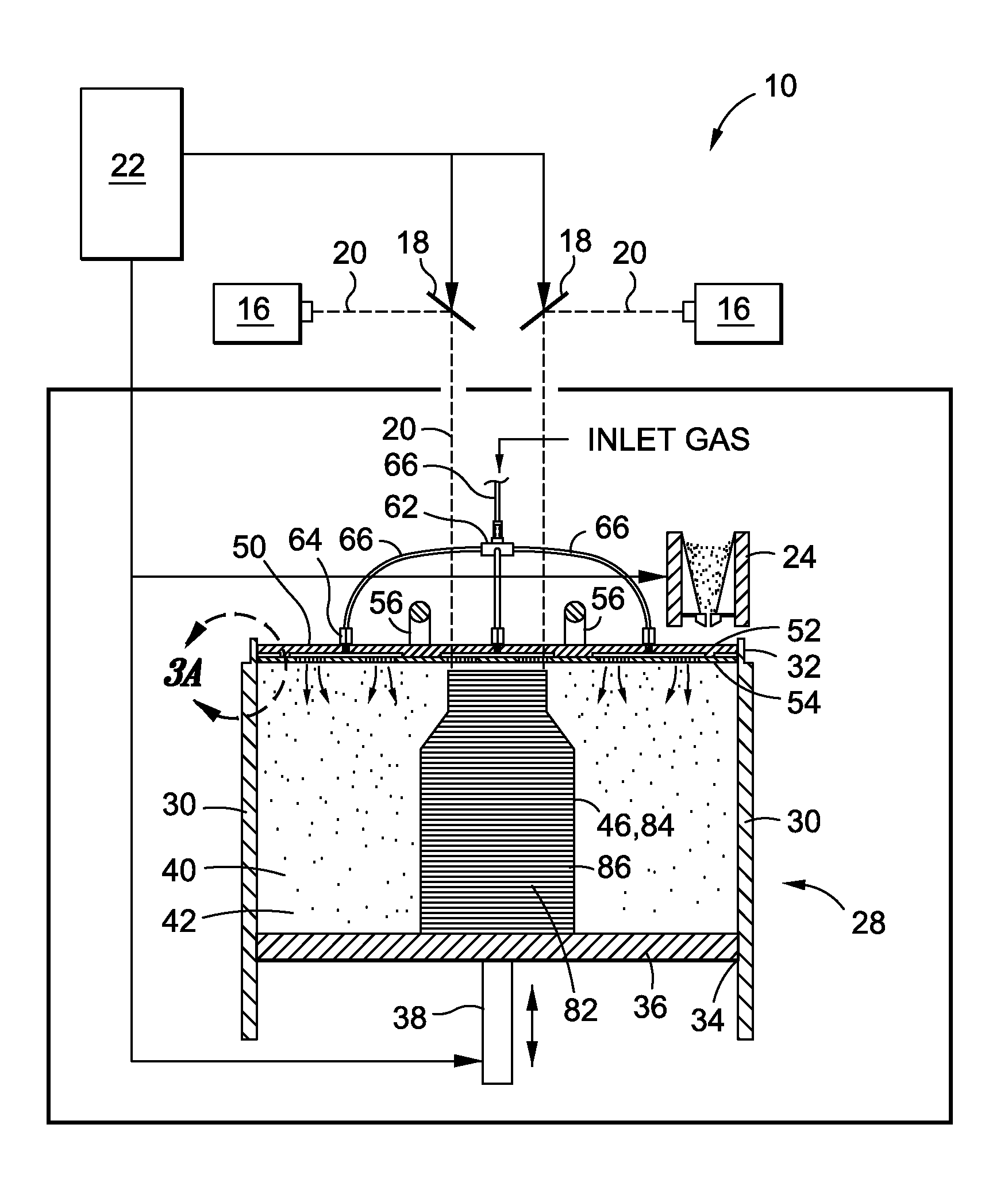

Recirculating gas system for a manufacturing device.

InactiveUS20160214175A1Additive manufacturing apparatusIncreasing energy efficiencyProcess engineeringActuator

Owner:NORDSTROM JAMES

Selective laser solidification apparatus and method

ActiveUS20140271965A1Uniform heightAdditive manufacturing apparatusAuxillary shaping apparatusLaser scanningLaser beams

A selective laser solidification apparatus including: a powder bed onto which a powder layer can be deposited, a gas flow unit for passing a flow of gas over the powder bed along a gas flow direction, a laser scanning unit for scanning a laser beam over the powder layer to selectively solidify at least part of the powder layer to form at least one object and a processing unit for selecting a scanning sequence of the laser beam based on the gas flow direction.

Owner:RENISHAW PLC

System and method for direct inkjet printing of 3D objects

InactiveUS20150298394A1Quality improvementHigh volume percentageManufacturing platforms/substratesLiquid surface applicatorsEngineeringDelivery system

A direct inkjet printing system for fabricating a part by an additive manufacturing process includes an ink delivery system operative to circulate the ink, a printhead associated with the ink delivery system, the printhead operative to dispense ink from the ink delivery system through a plurality of nozzles and based on a defined pattern, a building table for receiving the dispensed ink one layer at a time based on the defined pattern, wherein the part is formed from a plurality of layers of the ink dispensed from the printhead and a drying station operative to perform a drying process on layers of the ink dispensed from the printhead on a per layer basis.

Owner:STRATASYS LTD

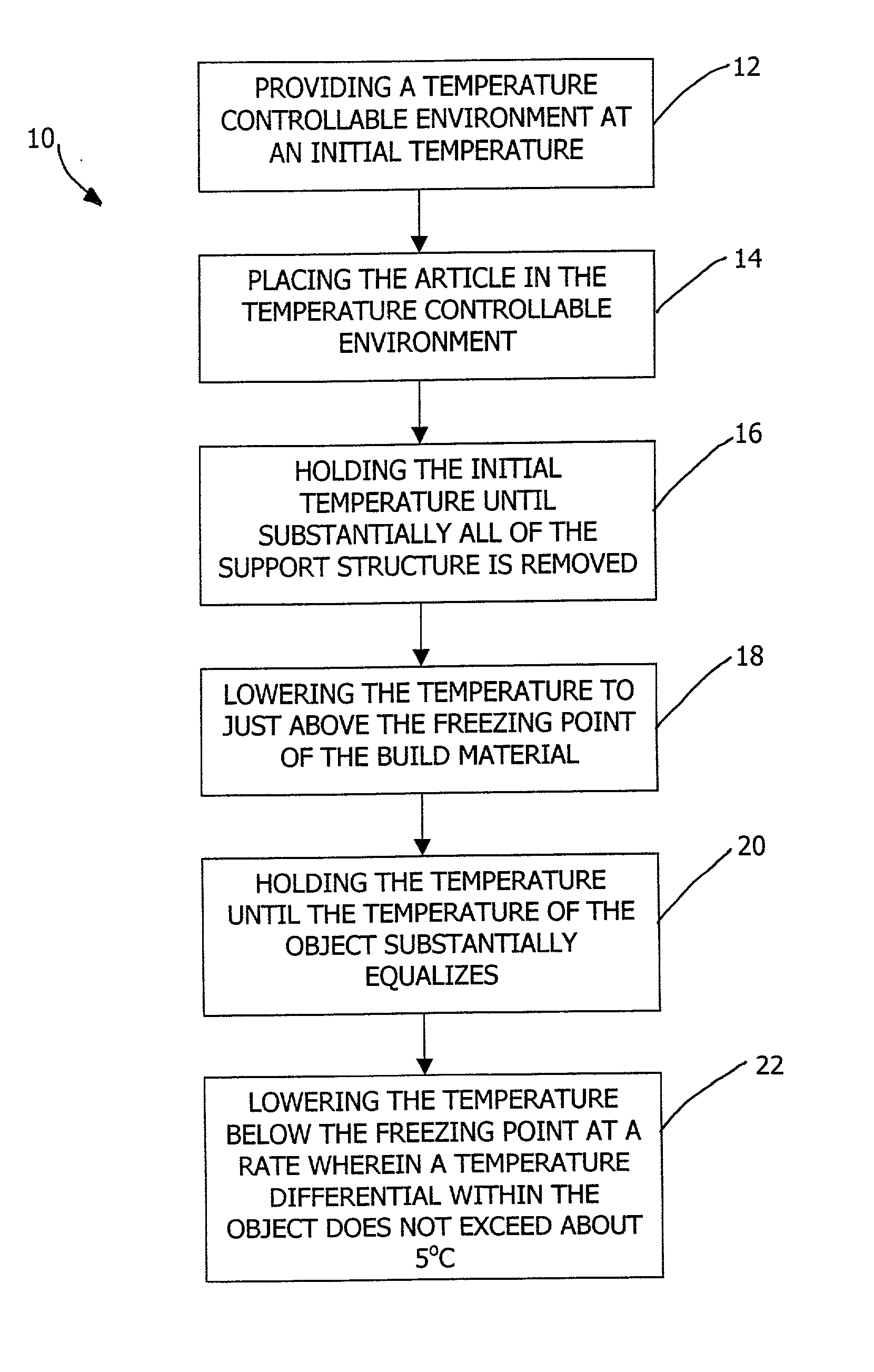

Targeted cooling in a 3D printing system

InactiveUS20160207263A1Additive manufacturing apparatusTemperature control using digital meansActive coolingEngineering

Support structure bonding in objects manufactured by 3D printing techniques is improved by one or more targeted active cooling sources that reduce the bond strength between 3D model layers and any support structures they are in contact with. A controller may use current print layer information, current print direction or other print information to activate cooling to reduce bond strength between one or more layers. This targeted cooling enables easier removal of support structure material from a finished 3d object.

Owner:GORDON MARK CHRISTOPHER

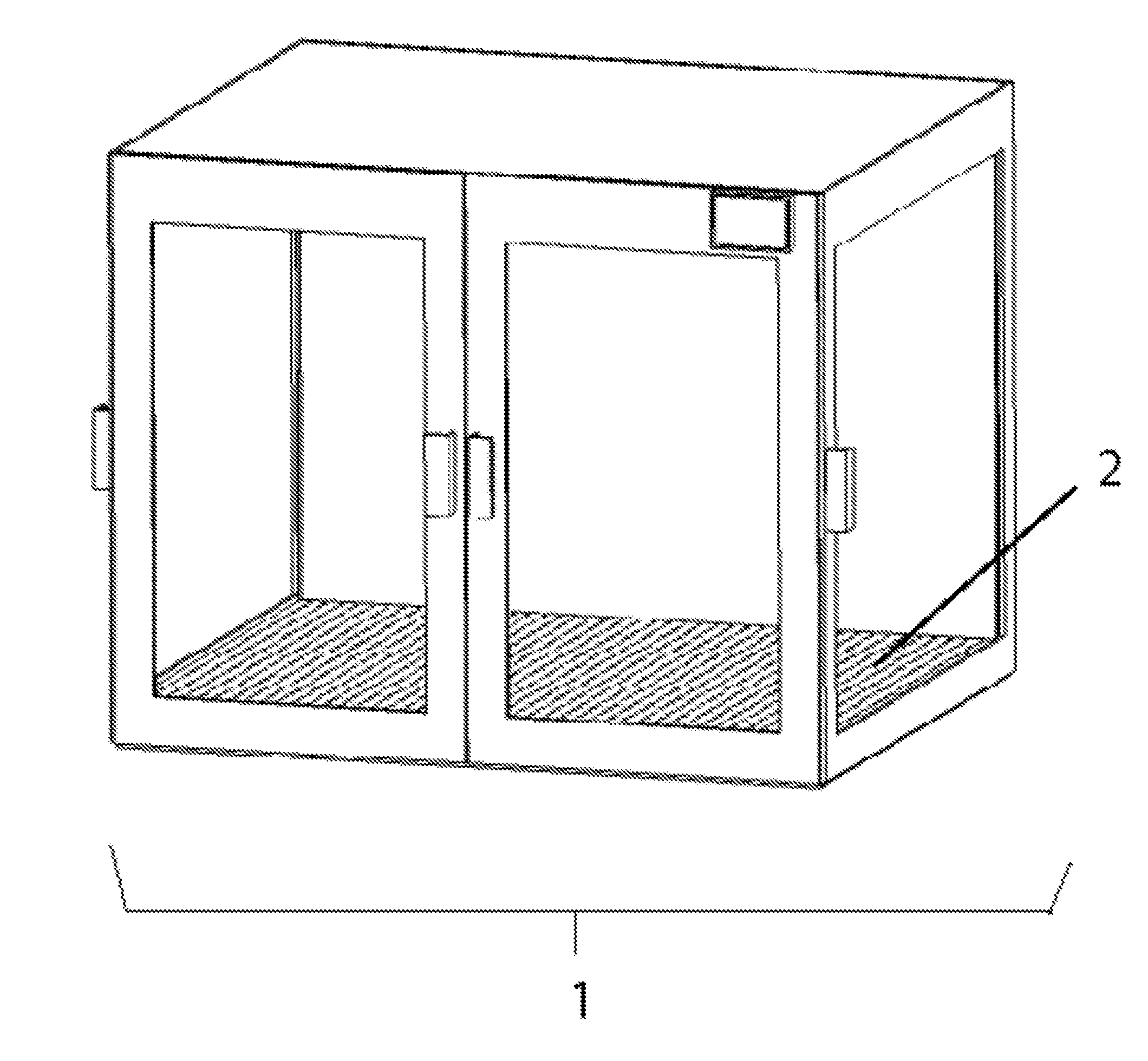

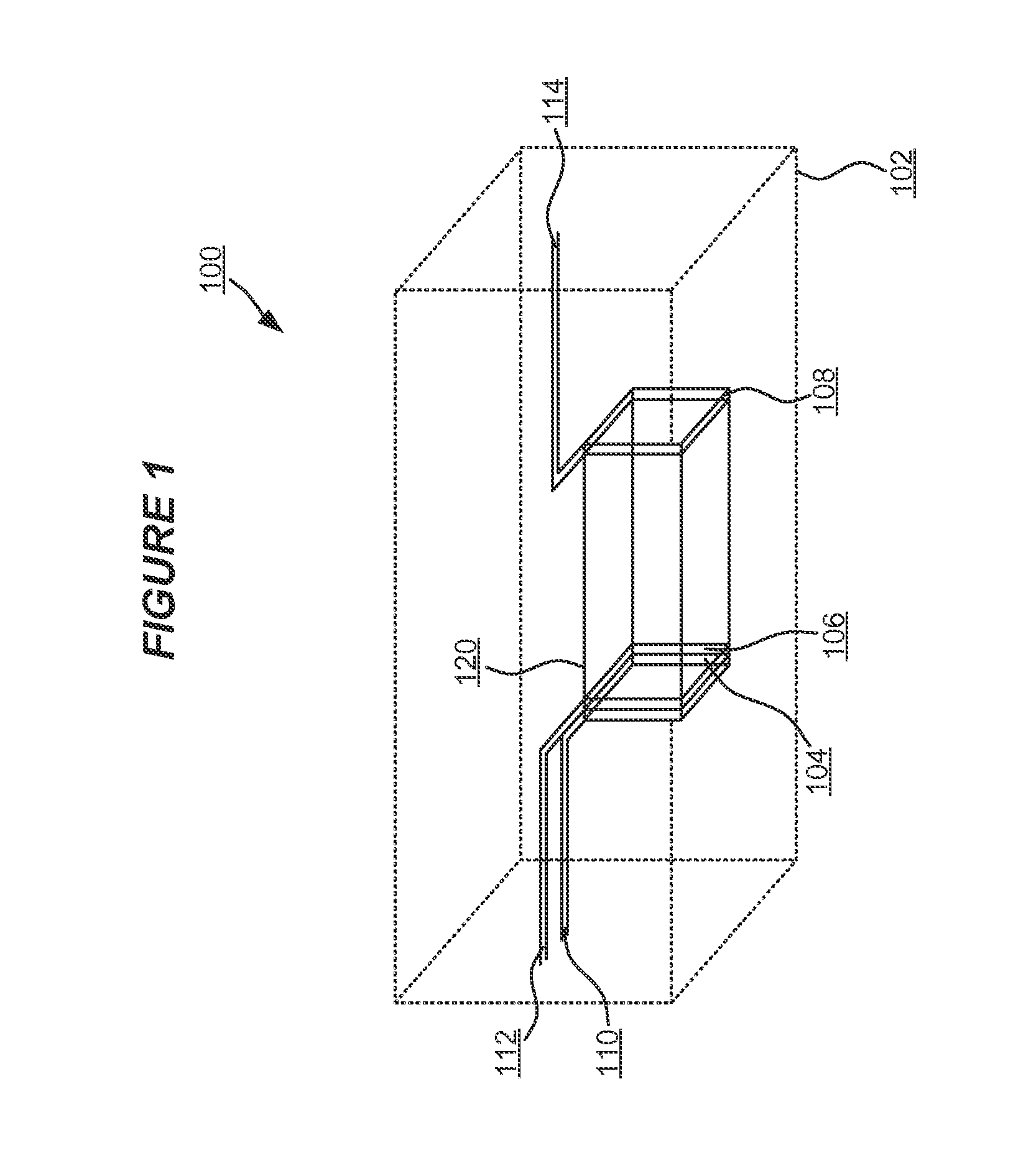

Single-use biological 3 dimensional printer

ActiveUS20150035206A1Inhibit transferKeep sterileConfectionerySweetmeatsThree degrees of freedomSingle use

A three dimensional printing device has a sterilizable printer assembly including at least one printing head, a printing platform, and a driving mechanism adapted to perform a movement of the at least one printing head relative to the printing platform along three degrees of freedom; a printer housing enclosing the printer assembly in a sterile manner, at least one aseptic connector fluidly connected to a corresponding one of the at least one printing head.

Owner:SARTORIUS STEDIM BIOTECH GMBH

Apparatus for avoiding deposits on optical components in the laser sintering process

ActiveUS20130101803A1Avoid condensationAvoid depositionManufacturing platforms/substratesLayered productsLaserSintering

The present invention provides a process and an apparatus for the layer-by-layer production of three-dimensional objects, wherein material vapours formed during processing in the construction chamber are prevented from deposition on apparatus components by exposing the gases to deposition surfaces where the materials condense and deposit.

Owner:EVONIK OPERATIONS GMBH

Three-dimensional modeling apparatus, three-dimensional model body manufacturing method, and three-dimensional modeling data

ActiveUS20170282245A1Efficiently preventing diffusionSuppress DiffuseAdditive manufacturing apparatusIncreasing energy efficiencyDimensional modelingLaser light

In a three-dimensional modeling apparatus, diffusion of fumes generated around the modeling stage accompanying irradiation with an energy beam can be efficiently prevented. Three-dimensional modeling is performed by repeating scanning a modeling material arranged on a modeling stage with laser light to form a solidified layer. A cover is provided that locally surrounds an irradiation portion on the modeling material arranged on the modeling stage irradiated with the laser light, and suppresses diffusion of the fumes caused by irradiation with the laser light. In the cover, a stream of gas containing the fumes is regulated so as to cause the fumes to flow toward an upward portion inside the cover apart from the irradiated portion irradiated with the laser light.

Owner:CANON KK

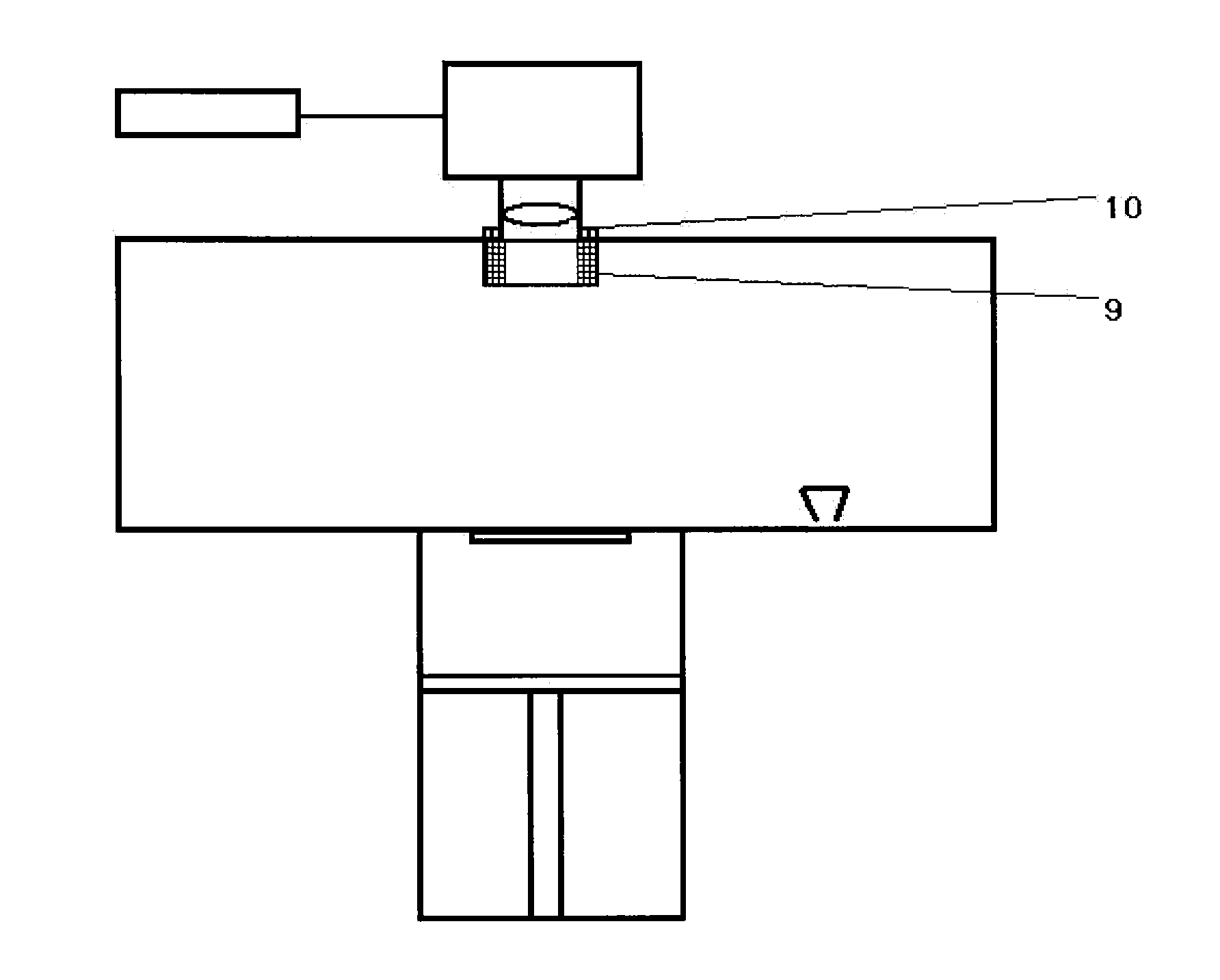

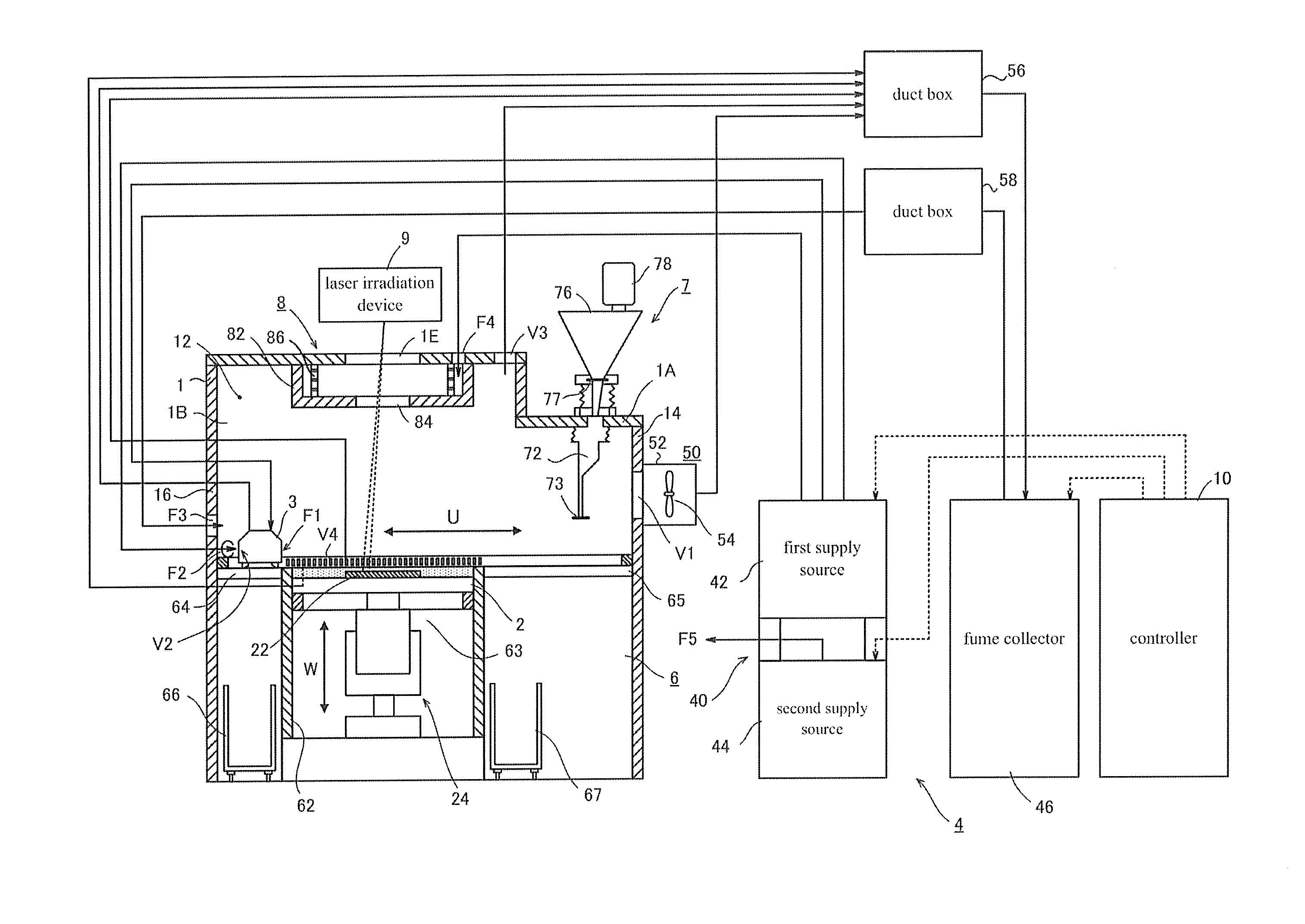

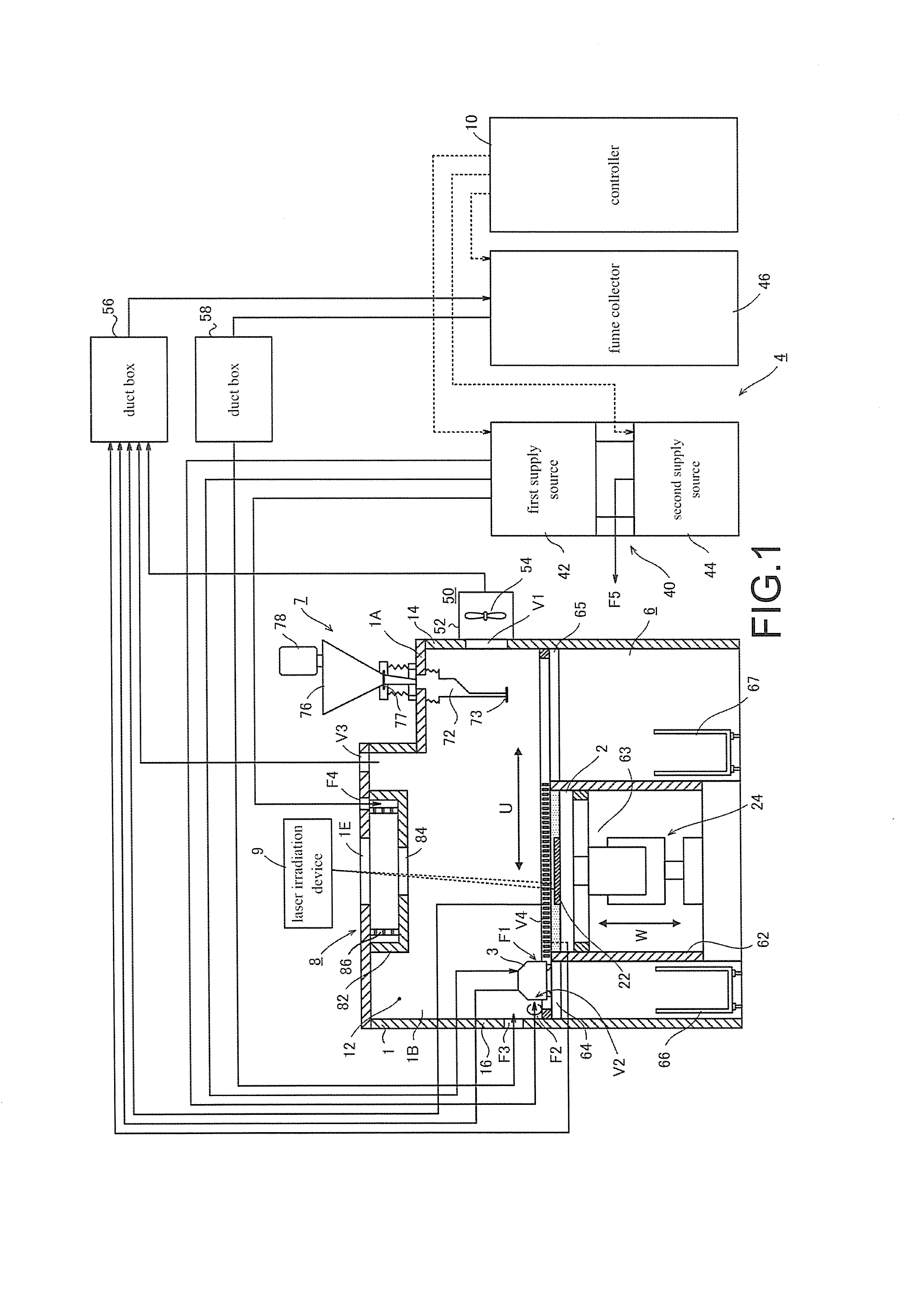

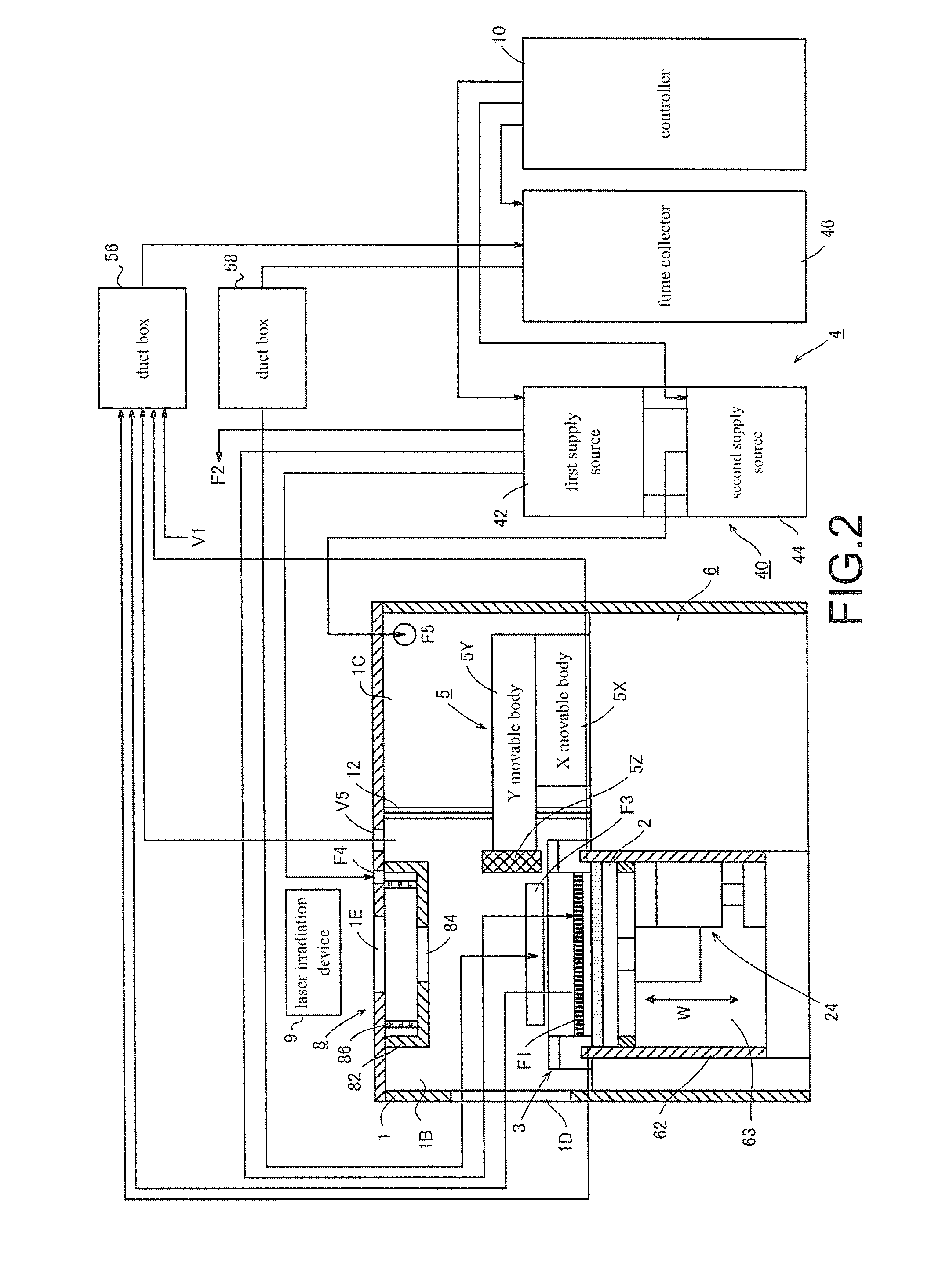

Metal 3D printer

ActiveUS20170014905A1Improve efficiencyVentilation capability is enhancedAdditive manufacturing apparatusIncreasing energy efficiency3d printerIrradiation

A metal 3D printer includes: a housing (1) forming a molding chamber (1B); a recoater head (3) reciprocating in the direction of a horizontal U axis in the molding chamber to form a powder layer of a metal; a laser irradiation device (9) irradiating an irradiation region in the powder layer with a laser beam to form a sintered layer; and an inert gas supply device (4). The inert gas supply device includes: a first suction port (V1) disposed on one (14) of the side walls facing each other in the direction of the U axis, which is far away from the irradiation region; a first blowout port (F1) disposed on a side of the recoater head to face the first suction port; and a second blowout port (F2) disposed to face the first suction port across the irradiation region.

Owner:SODICK CO LTD

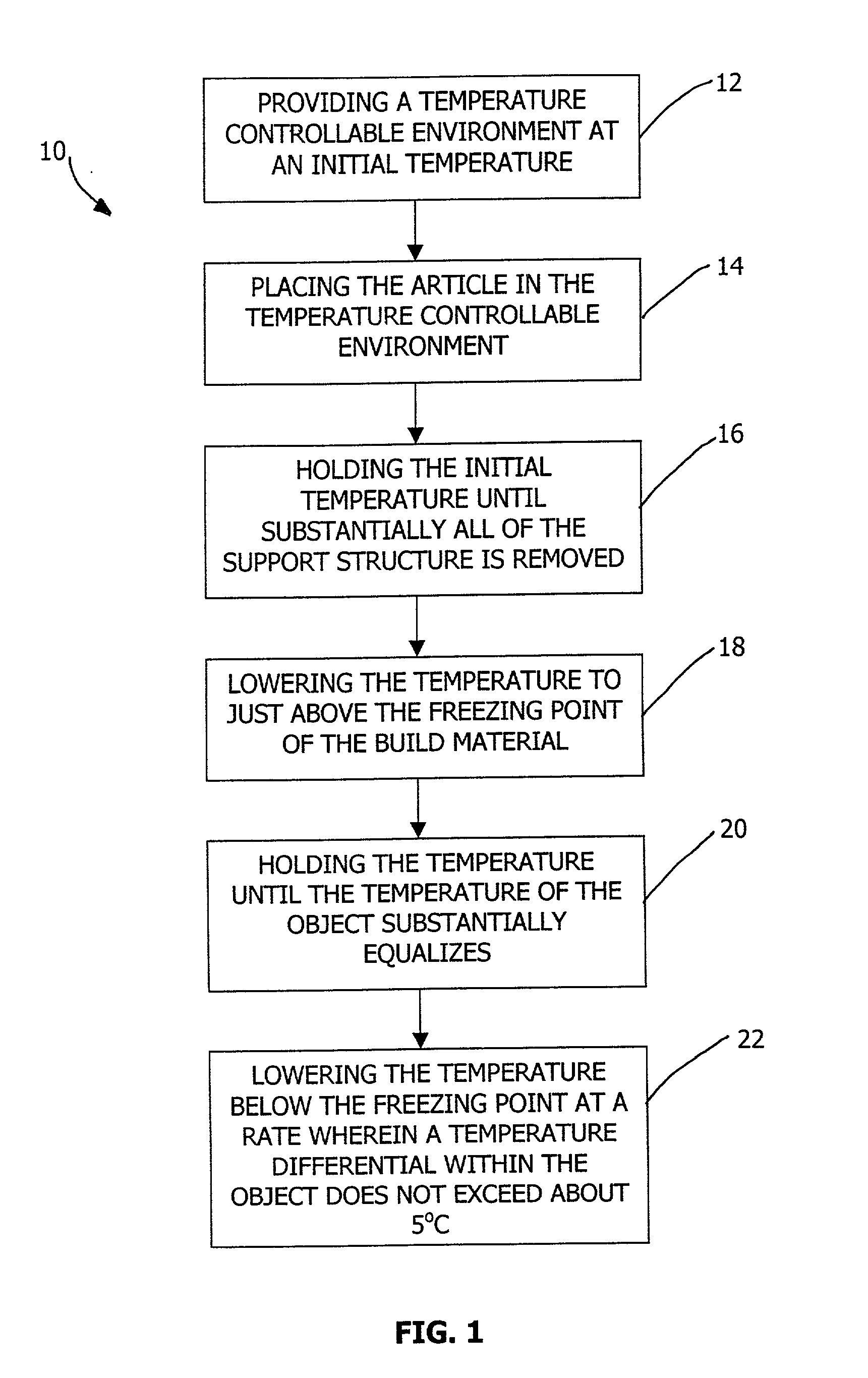

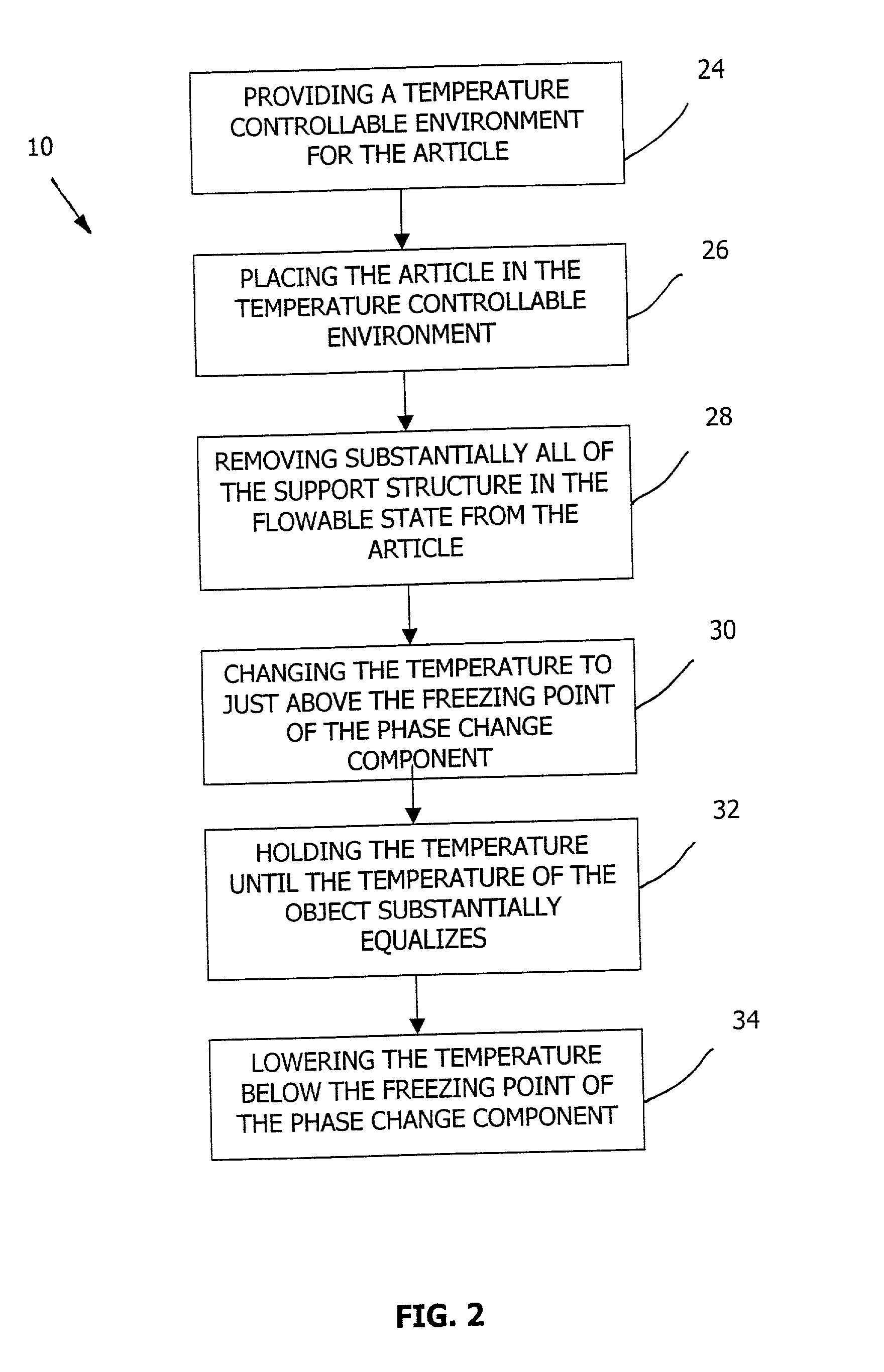

Post processing three-dimensional objects formed by solid freeform fabrication

InactiveUS20030067098A1Manufacturing heating elementsWood working apparatusEngineeringPhase-change material

A method for removing supports from a three-dimensional object formed by solid freeform fabrication. The three-dimensional object and support structure both contain a phase change component in order to achieve the desired phase change characteristics needed for dispensing the material. The method prevents the phase change material within the three-dimensional object from migrating within the object during post processing to remove the support structure.

Owner:3D SYST INC

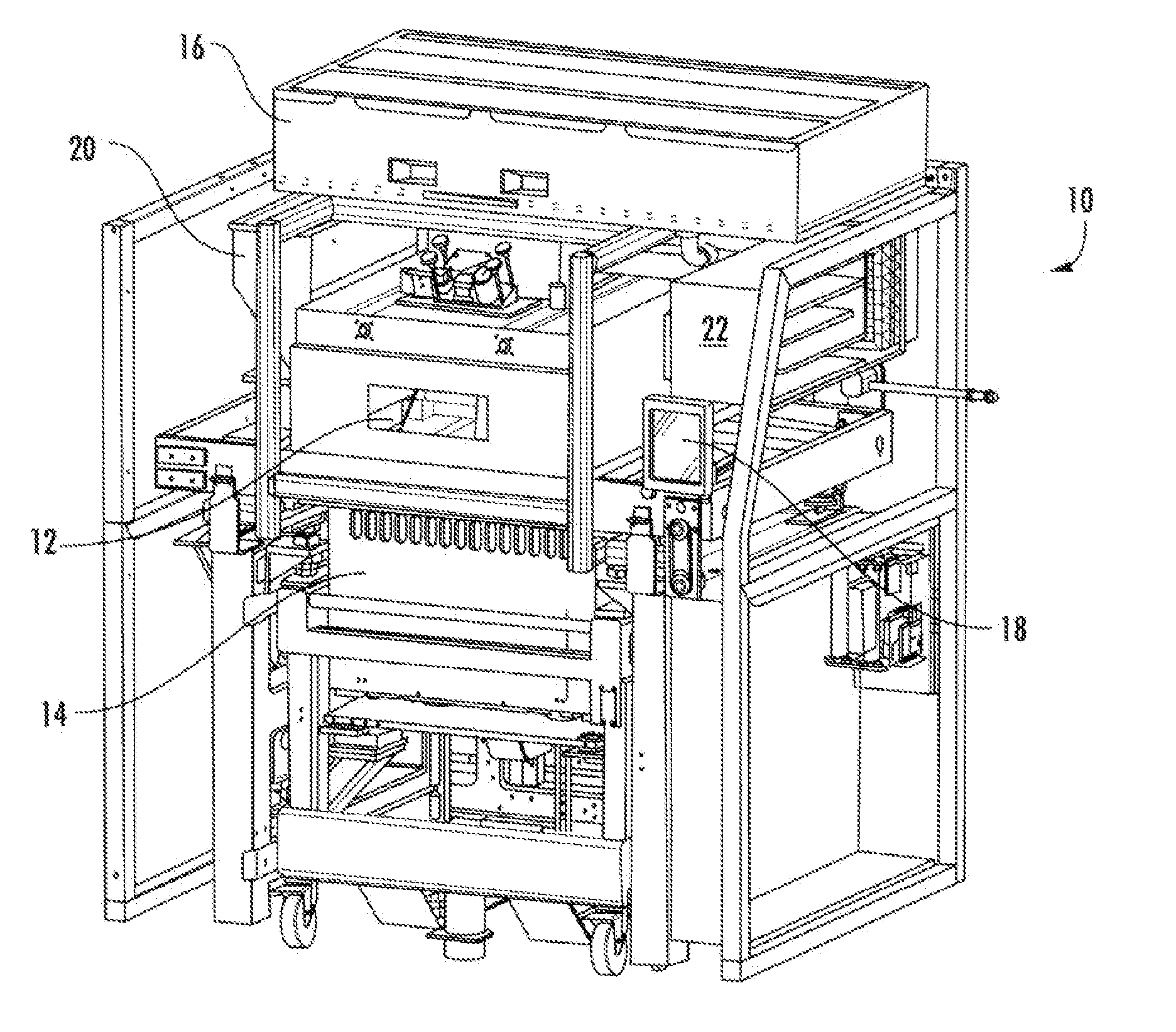

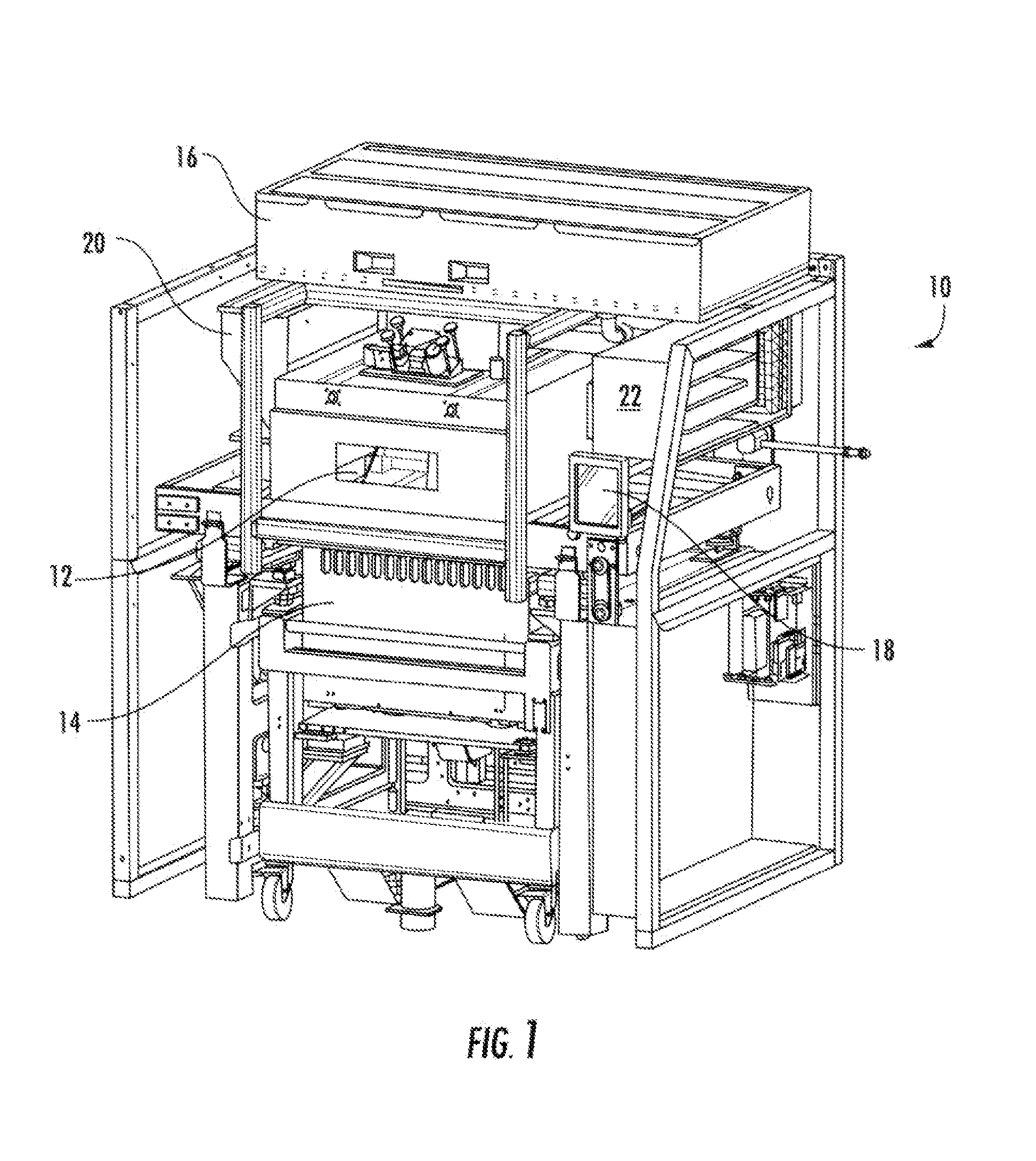

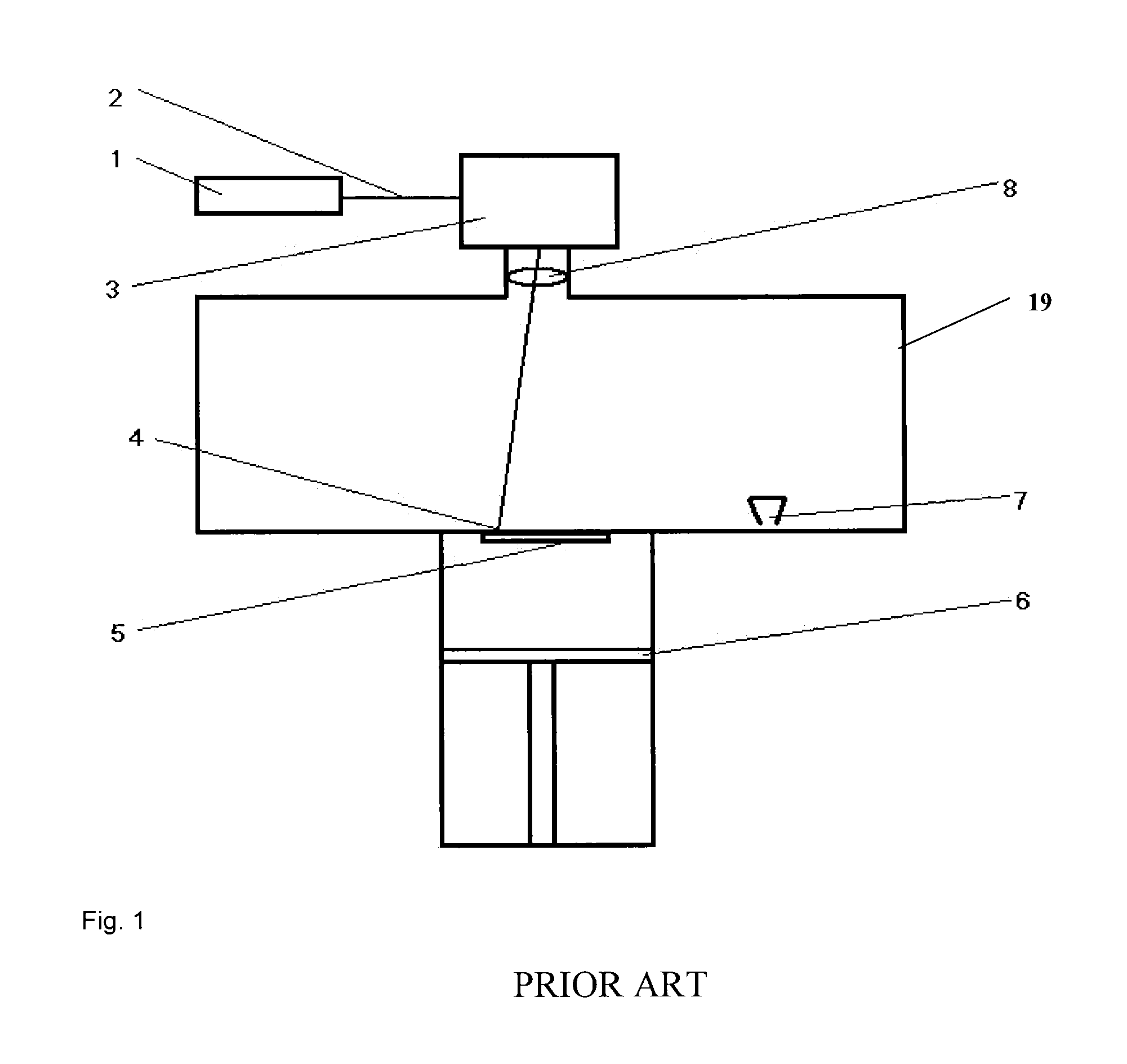

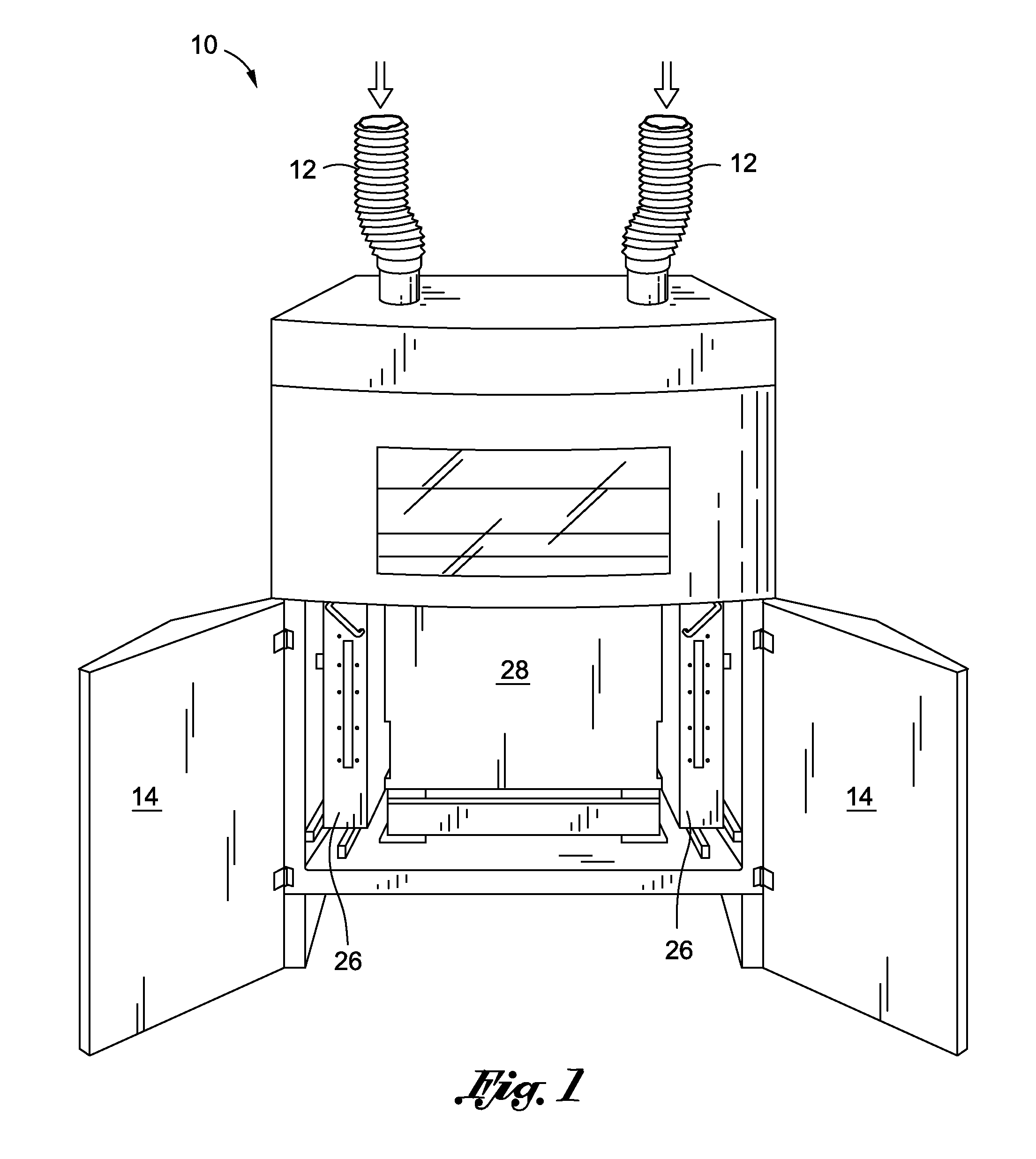

Lamination shaping apparatus

ActiveUS8070474B2Easy to makeAvoid volatilityLiquid surface applicatorsMechanical working/deformationLight beamEngineering

A lamination shaping apparatus has a powder layer preparing means and an optical unit which irradiates a light beam to an intended portion of a powder layer so as to sinter or melt for solidifying the portion into a cured layer. Preparation of the powder layer and curing of the cured layer are repeated to fabricate a three-dimensional object in which a plurality of the cured layers are laminated and integrated. The apparatus includes a fixed base carrying thereon the powder layer and the cured layer, an elevator frame surrounding a periphery of the fixed base, and driving means for driving the elevator frame to move vertically. The powder layer is formed within a space above the base and surrounded by an interior surface of the elevator fame such that the powder layer (cured layer) can be stacked on the base with the base being kept at a fixed position, thereby facilitating to fabricate a precisely shaped object.

Owner:MATSUSHITA ELECTRIC WORKS LTD

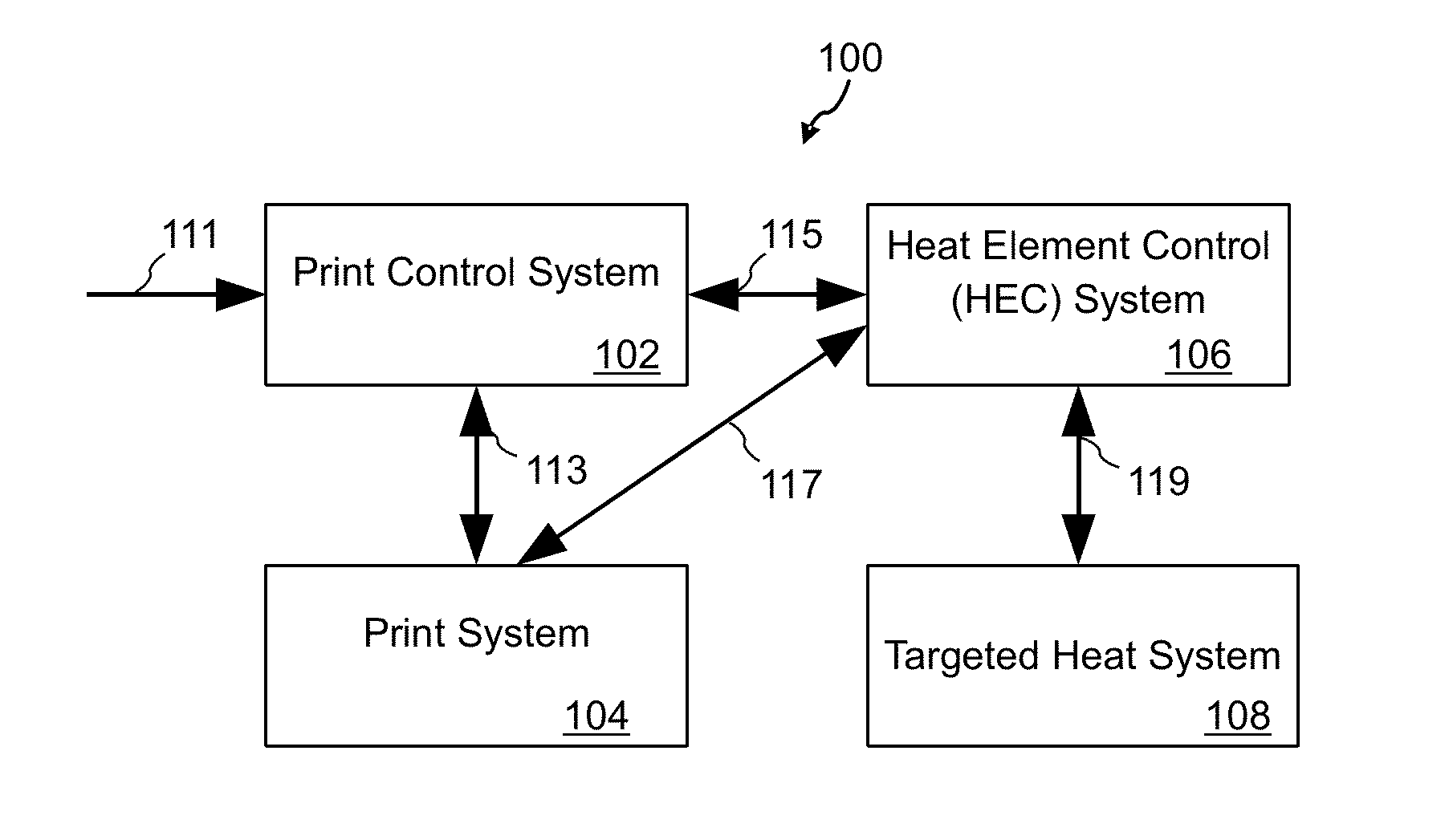

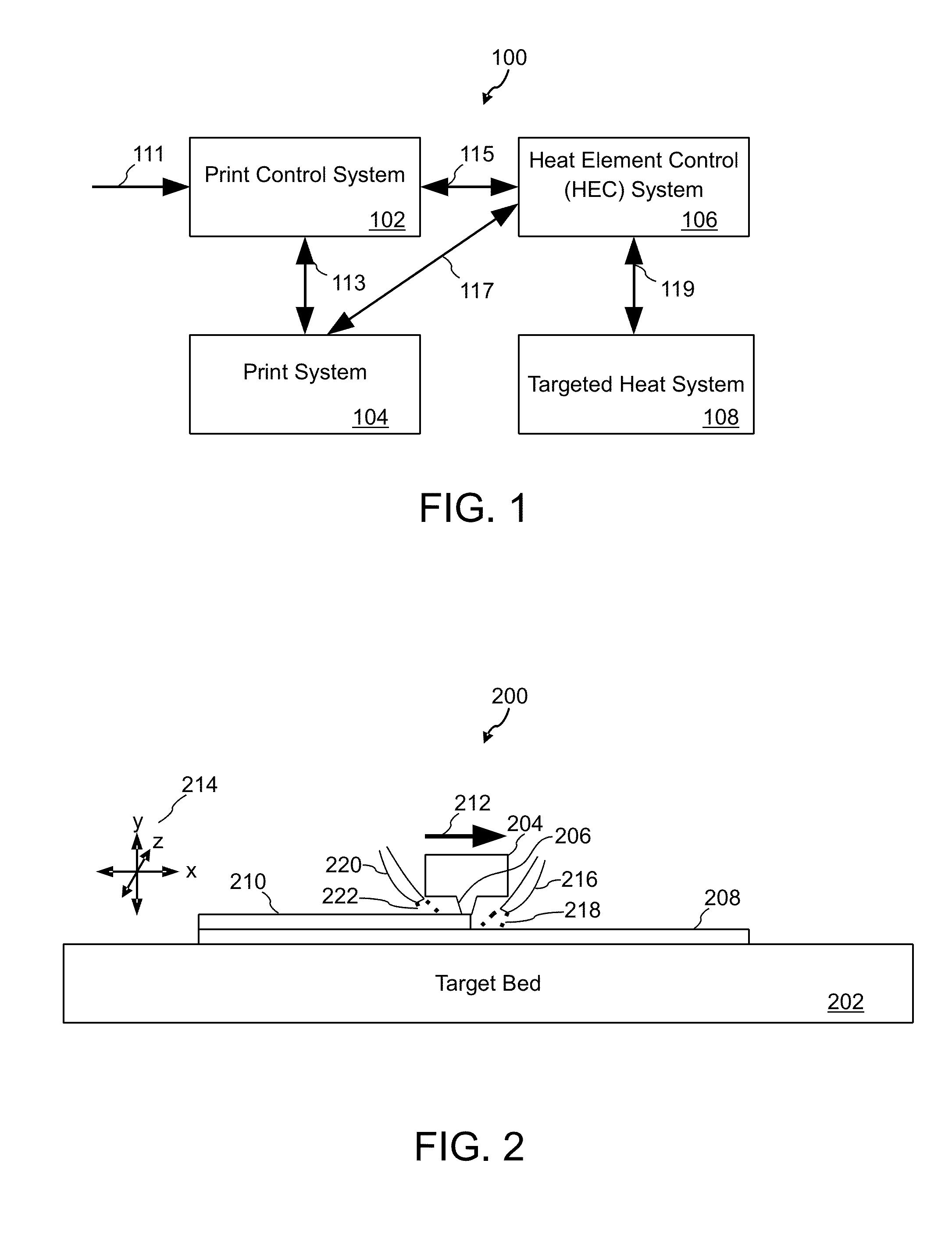

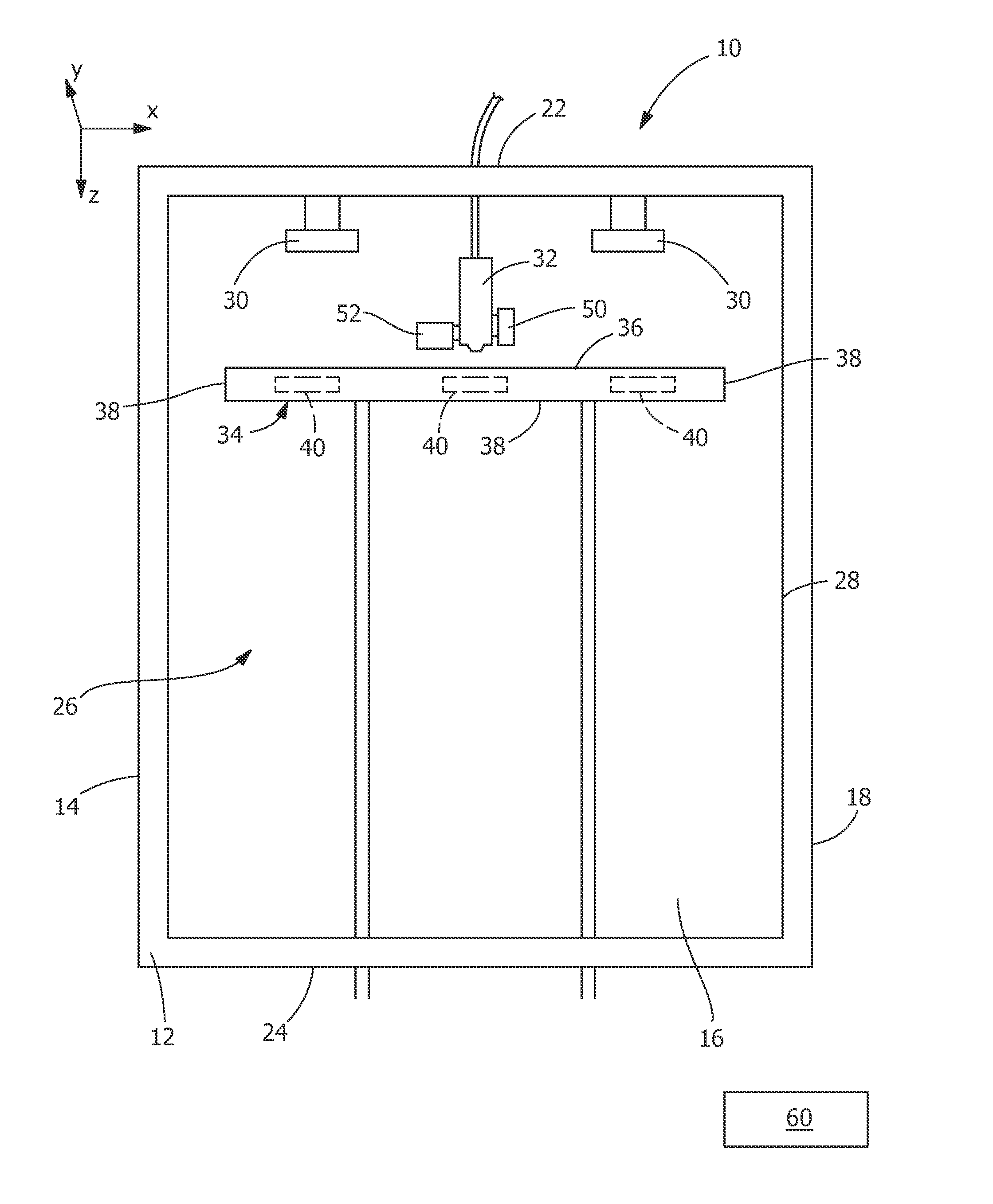

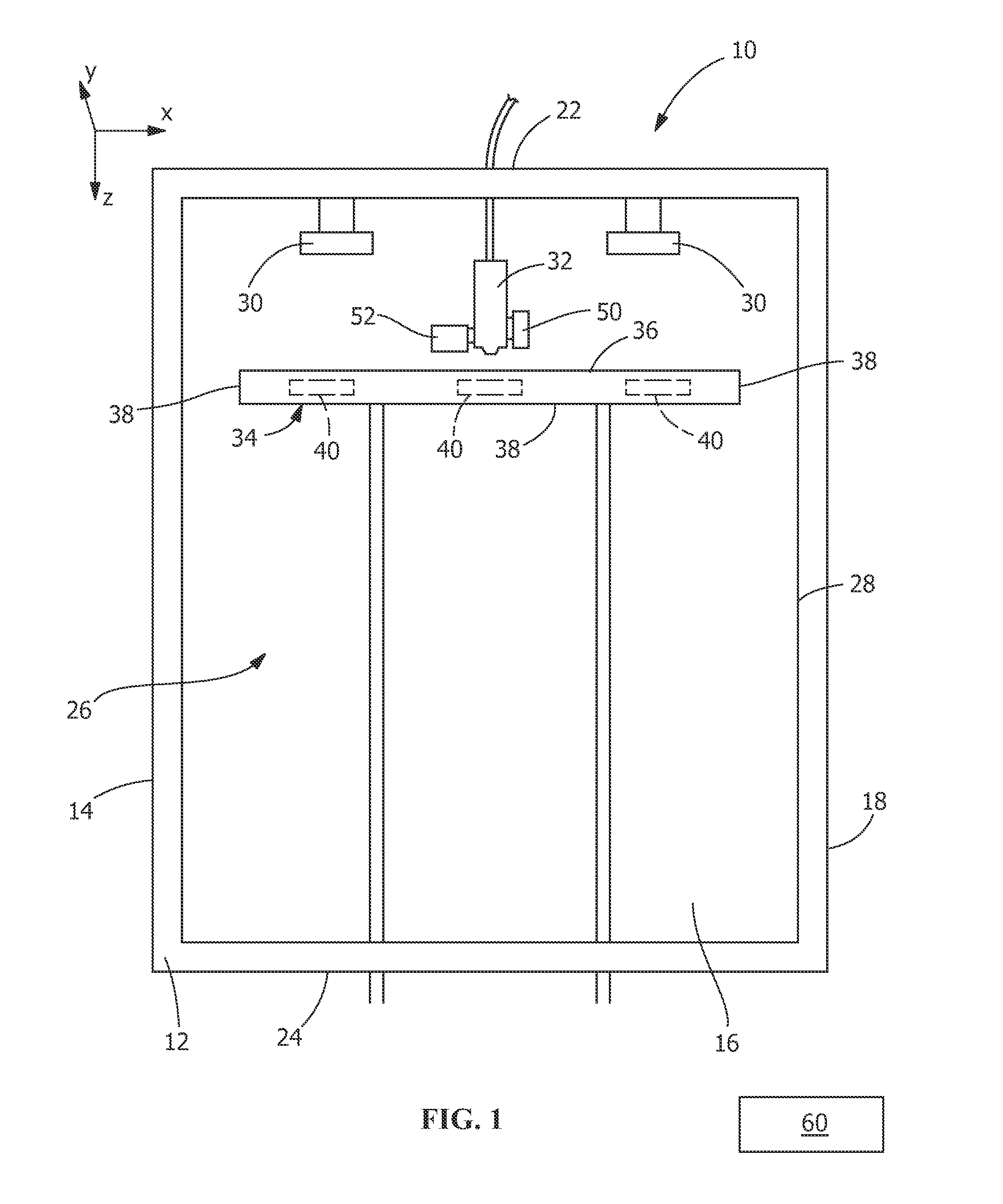

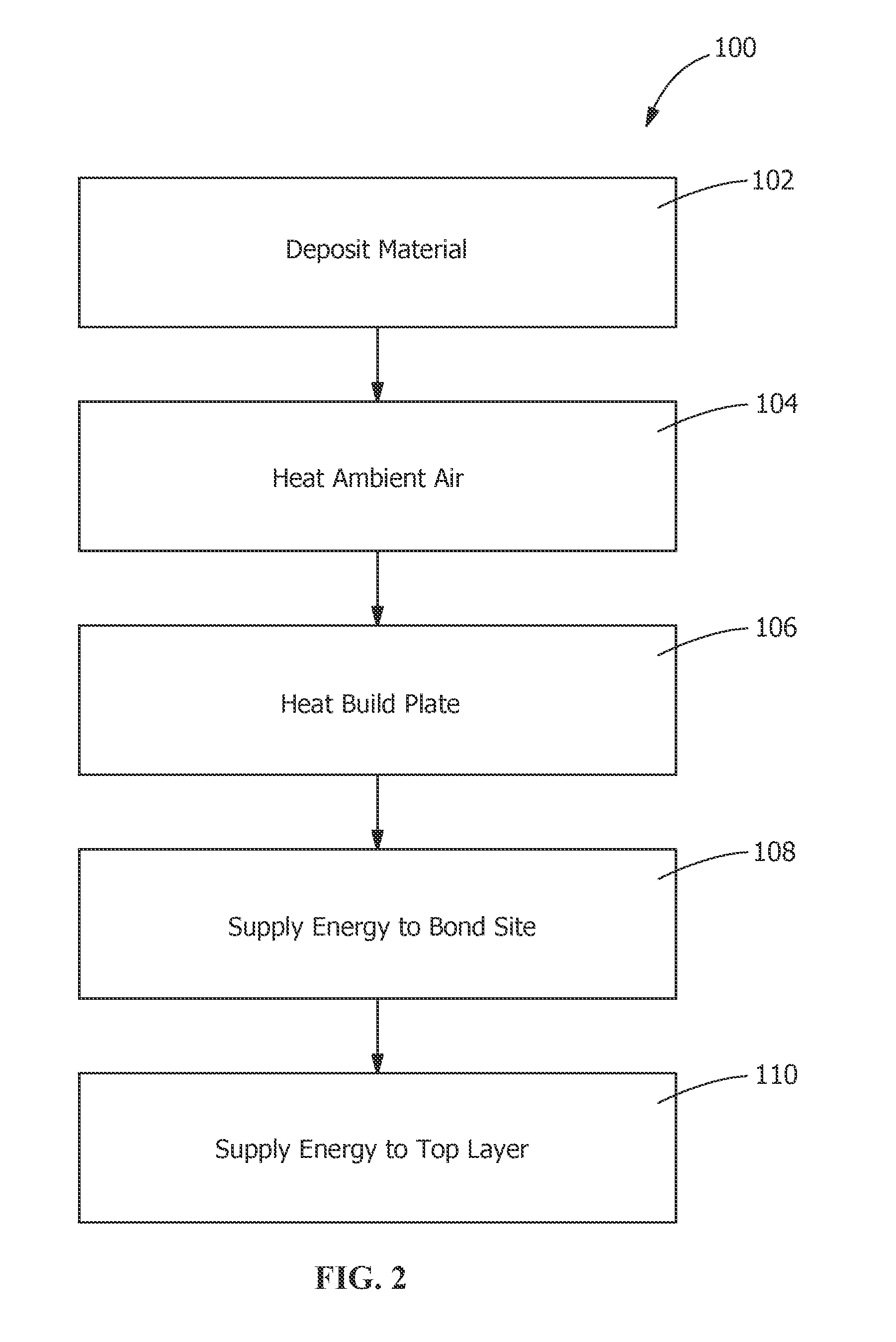

Apparatus and method for producing objects utilizing three-dimensional printing

InactiveUS20160096327A1Minimize warping and thermal stressImprove bindingDielectric heatingConfectioneryEngineering3 dimensional printing

A method and apparatus for the fabrication of an article made using a three-dimensional printing process. The invention includes depositing material from a print head onto a build plate located in a build chamber to form an article, heating ambient air in the build chamber to a first temperature which acts as a proper sink temperature for cooling of the article, and heating the build plate to a second temperature which is higher than the first temperature. The first and second temperatures are controlled to minimize warping and thermal stress of the article.

Owner:TE CONNECTIVITY CORP

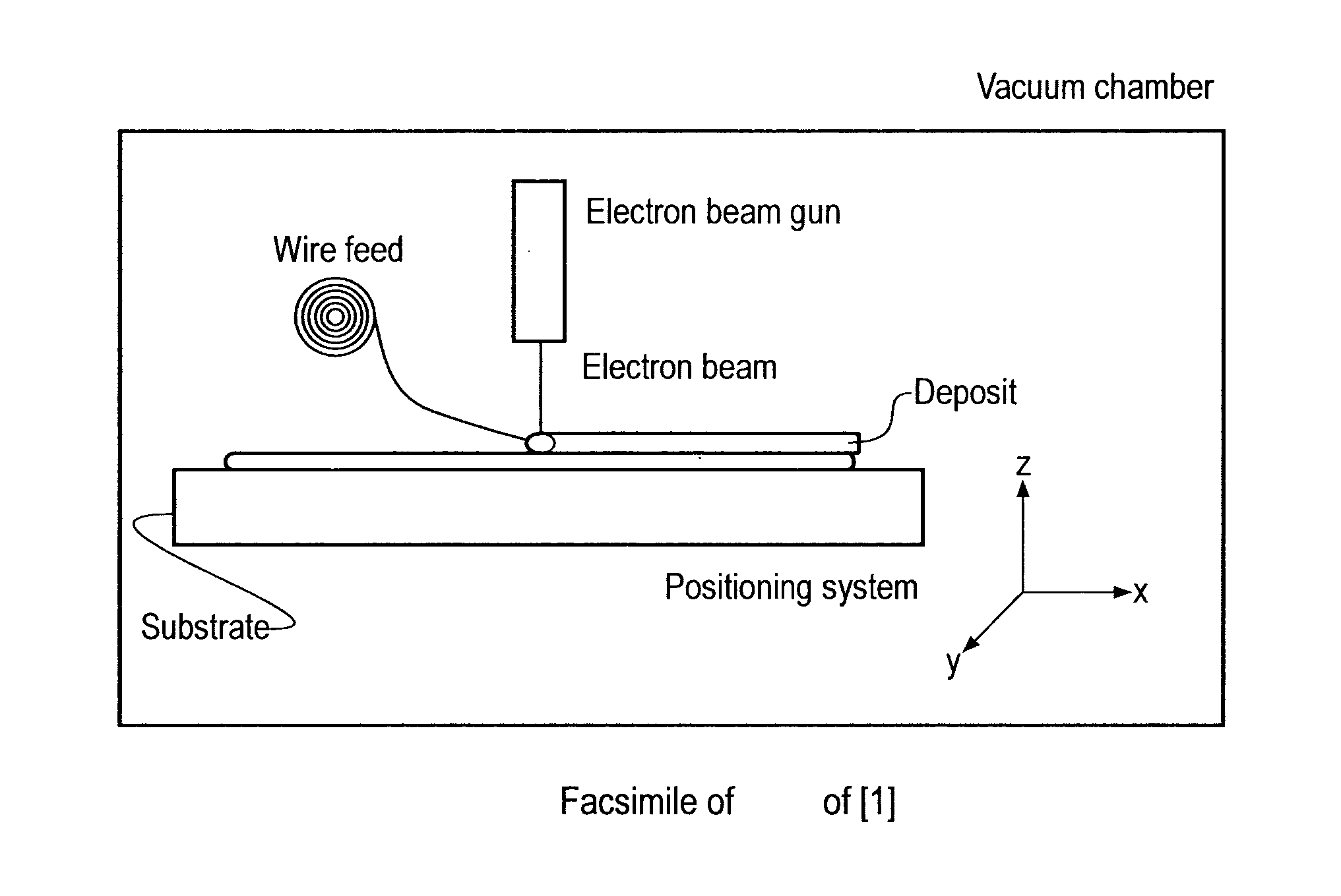

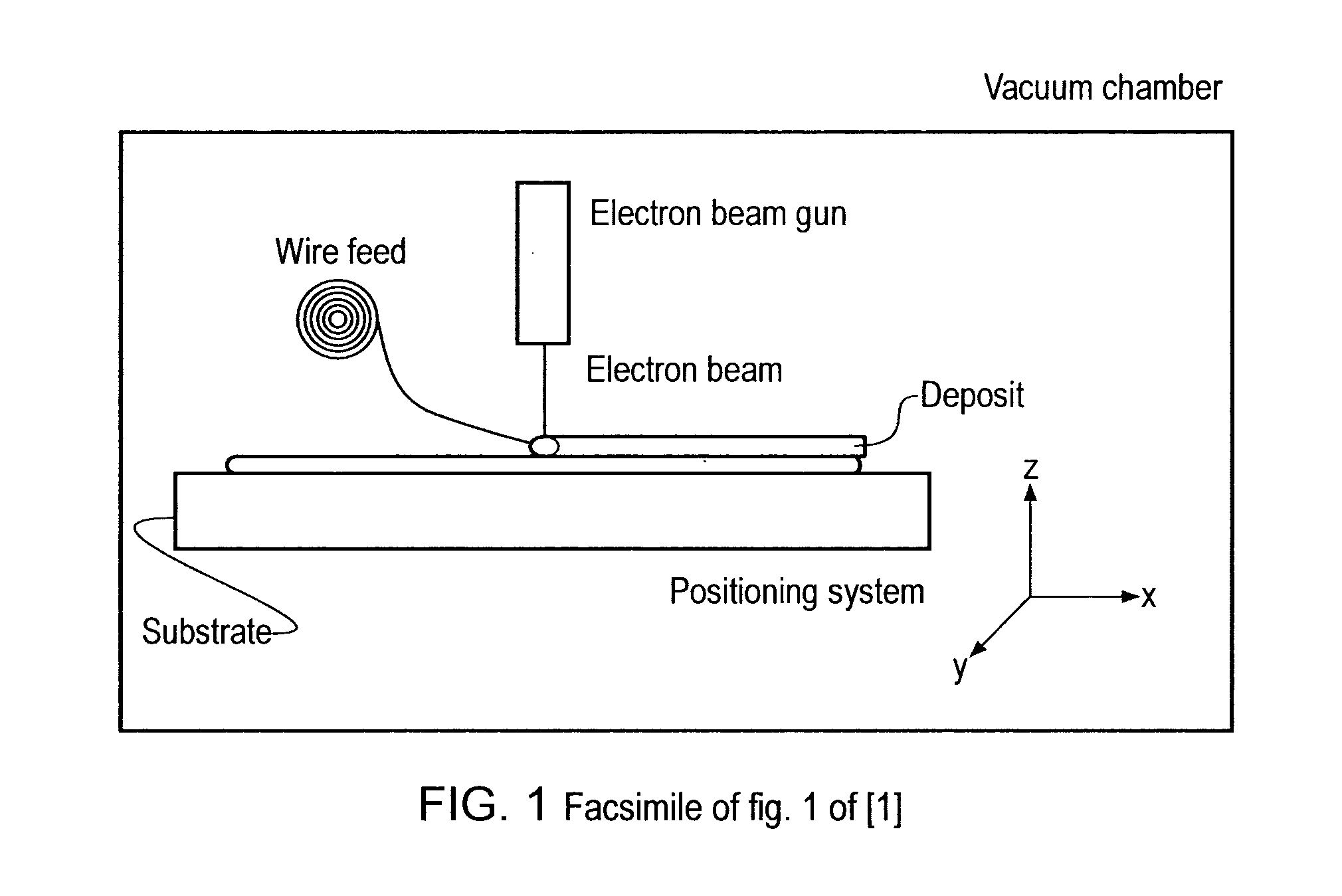

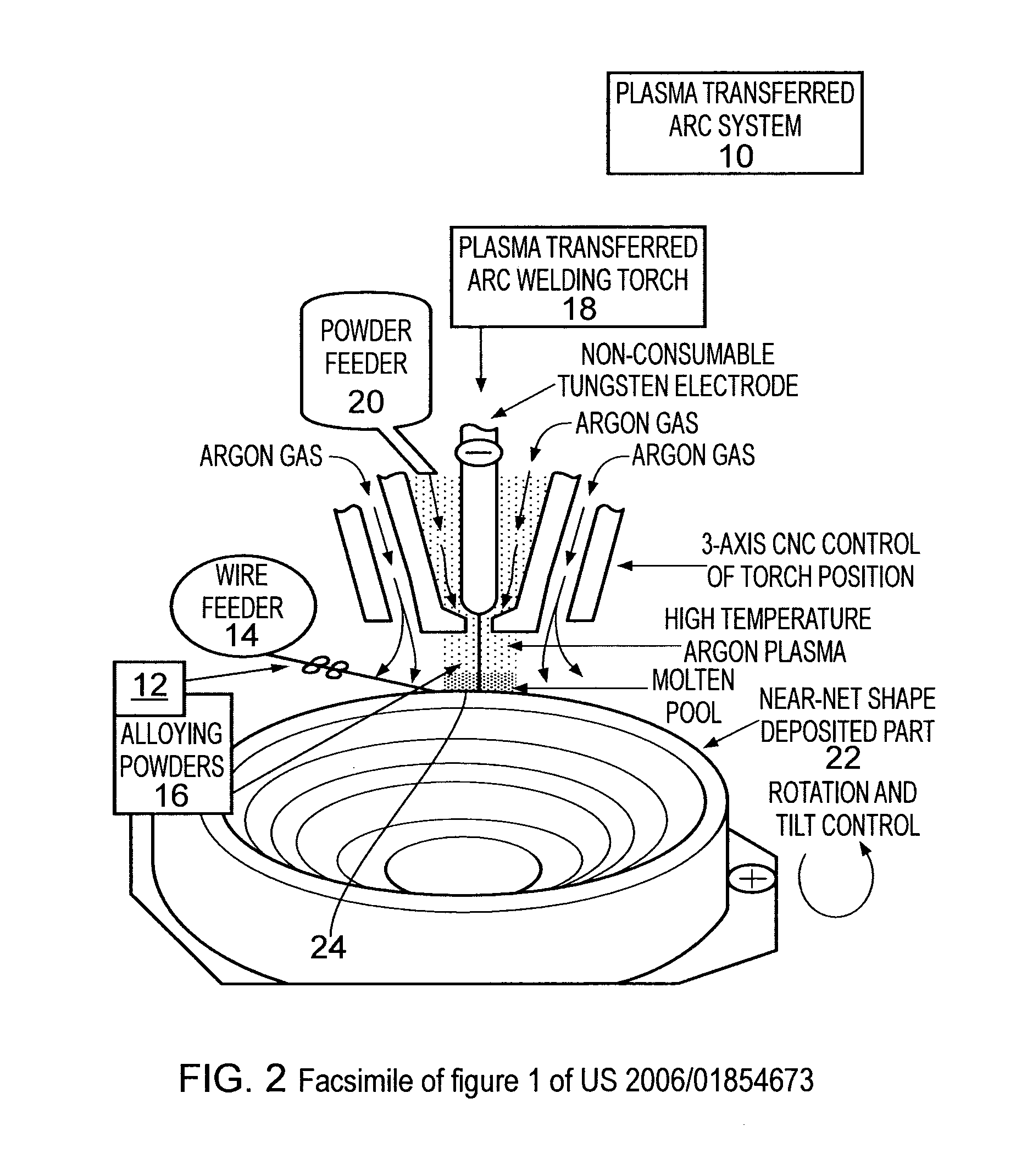

Method and device for manufacturing titanium objects

ActiveUS20120193335A1Rapid layered manufactureManufacturing driving meansWelding/cutting auxillary devicesHigh energyNuclear engineering

This invention relates to a method and reactor of manufacturing an object by solid freeform fabrication, especially an object made of titanium or titanium alloys. The reactor of production of an object of a weldable material by solid freeform fabrication comprises a reactor chamber which is closed to the ambient atmosphere, wherein the reactor is given a design such that all adjacent wall elements forming the reactor chamber are joined with an obtuse angle (larger than 90°), the actuator located below the reactor chamber is given a design such that the actuator protrudes into the reactor chamber through an opening at the bottom of the reactor chamber holding the support substrate inside the reactor chamber, the opening is sealed by at least one elastic gas impermeable membrane which is gas tight attached to the reactor wall at the opening and to the actuator, the actuator located outside the reactor chamber is given a design such that the actuator protrudes into the reactor chamber through an opening at the side of the reactor chamber holding the high energy plasma transferred arc welding torch with wire feeder of the weldable material inside the reactor chamber, the opening is sealed by the at least one elastic gas impermeable membrane which is gas tight attached to the reactor wall at the opening and to the actuator, and the reactor is equipped with at least one closable gas inlet located at the lowest level of the reactor chamber and at least one closable gas outlet located at the highest level of the reactor chamber.

Owner:NORSK TITANIUM

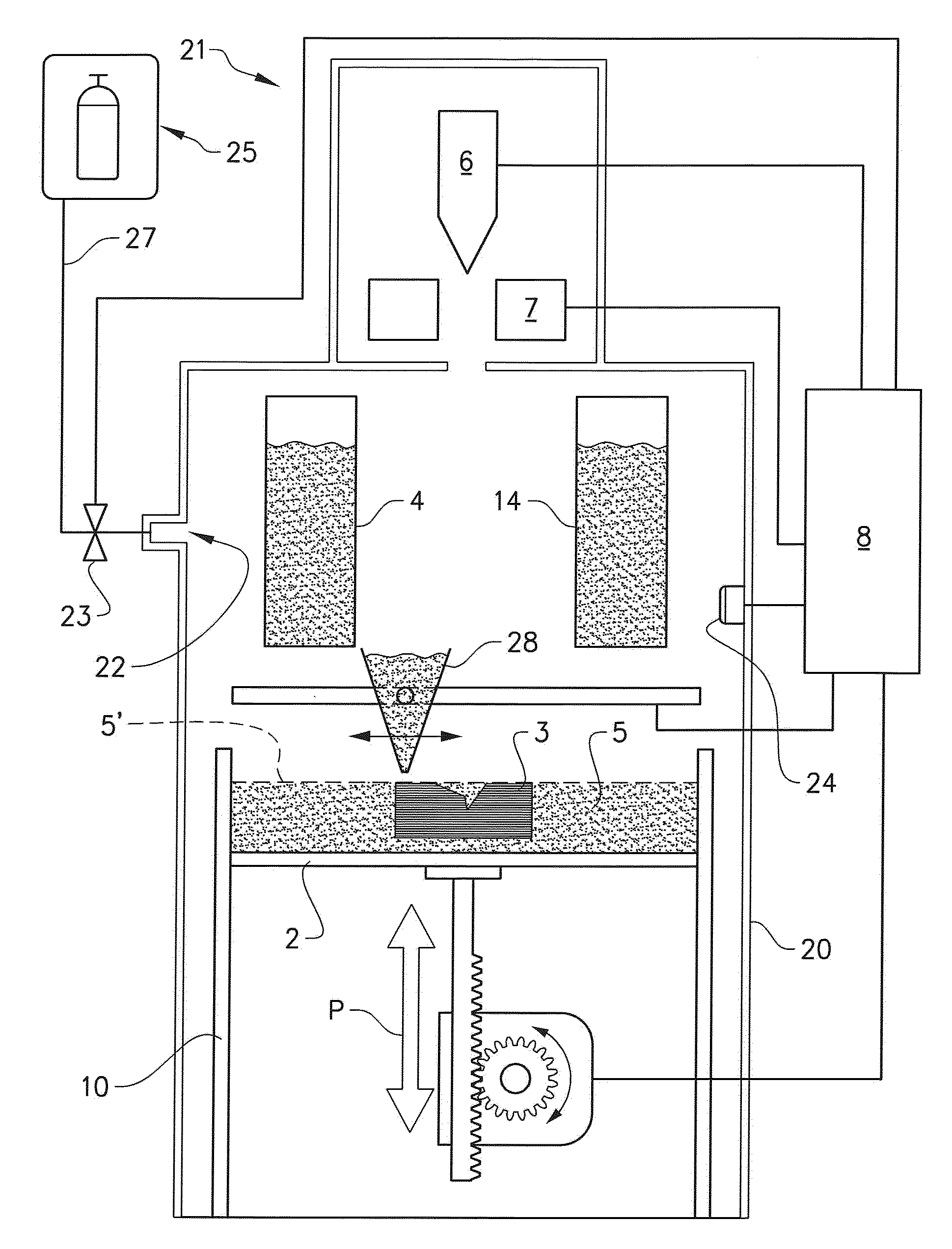

Layered-modeling device and method using said device for manufacturing three-dimensional objects

InactiveCN102438779AEasy to removeGood precisionAdditive manufacturing apparatusIncreasing energy efficiencyLayered modelShielding gas

Provided is a method for manufacturing three-dimensional objects. Said method can easily remove fumes from a chamber and improves the fabrication precision and the irradiation-positioning precision of a light beam. A layered-modeling device (1) is provided with: a powder-layer formation unit (3); a light-beam irradiation unit (4); a fixed base (22) on which a powder layer (32) is formed; a raising / lowering frame (34) which surrounds the base (22) and can move freely up and down; a covering frame (36) which is disposed above the raising / lowering frame (34), thereby forming a chamber (C); and a gas tank (71) which supplies an atmosphere gas. The top surface of the covering frame has a window (36a) through which the light beam passes, and the bottom surface of the covering frame is open. By lowering the raising / lowering frame (34), the volume of the chamber (C) is decreased, and fumes which were generated inside the covering frame (36) are exhausted and replaced with the atmosphere gas. The decrease in the volume of the chamber (C) allows the fumes to be removed easily, and improves the fabrication precision and irradiation-positioning precision of the light beam (L).

Owner:PANASONIC CORP

Method for emissions plume monitoring in additive manufacturing

ActiveUS20180178286A1Additive manufacturing apparatusIncreasing energy efficiencyEngineeringMonitoring methods

A method of monitoring an additive manufacturing process in which one or more energy beams are used to selectively fuse a powder to form a workpiece, in the presence of one or more plumes generated by interaction of the one or more energy beams with the powder. The method includes using at least one sensor to generate at least one signal representative of a trajectory of one or more of the plumes.

Owner:GENERAL ELECTRIC CO

Printed active device

ActiveUS20150270089A1Reduce manufacturing costLow costAdditive manufacturing apparatusControl electrodesElement spaceElectrical connection

Owner:BRITISH TELECOMM PLC

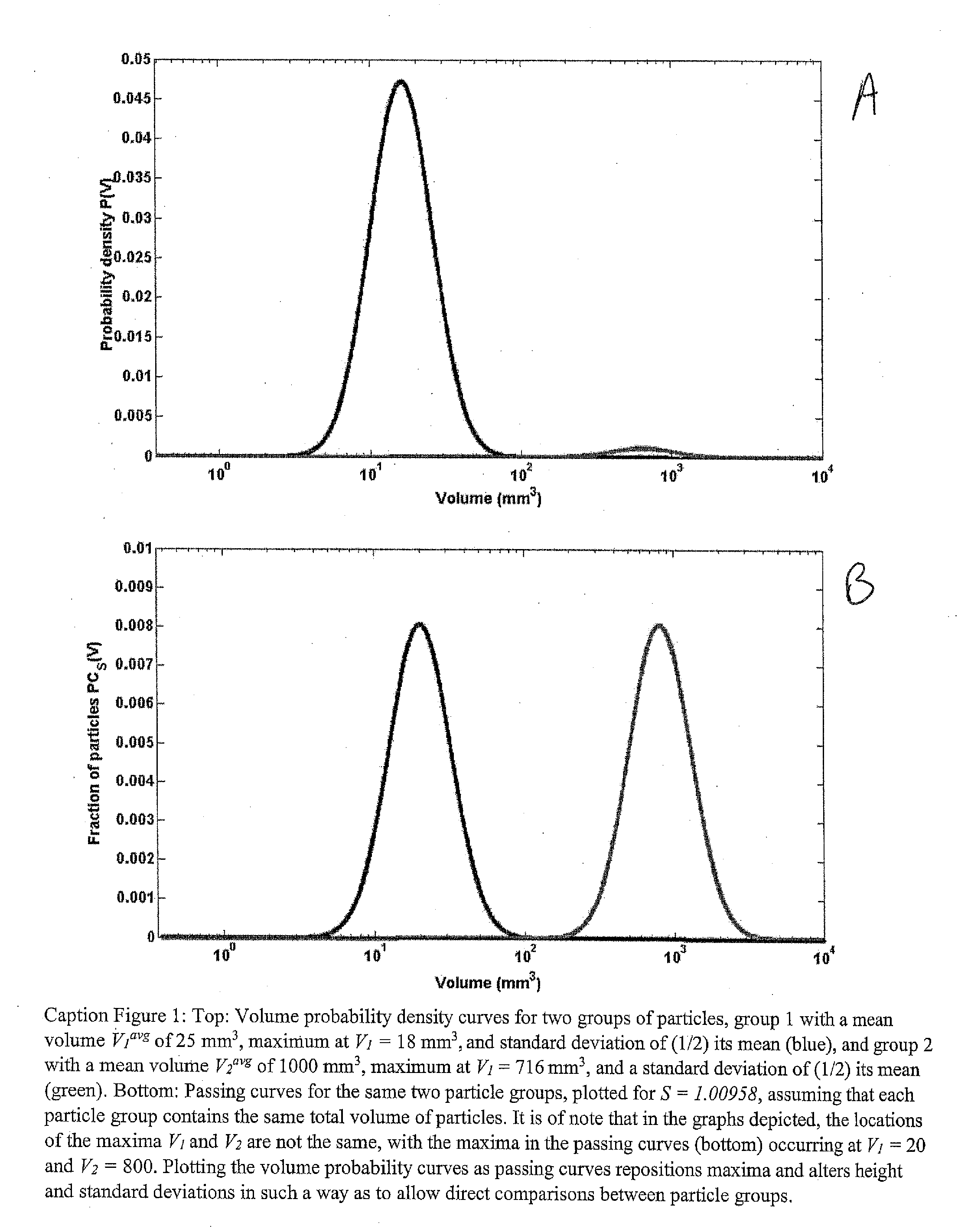

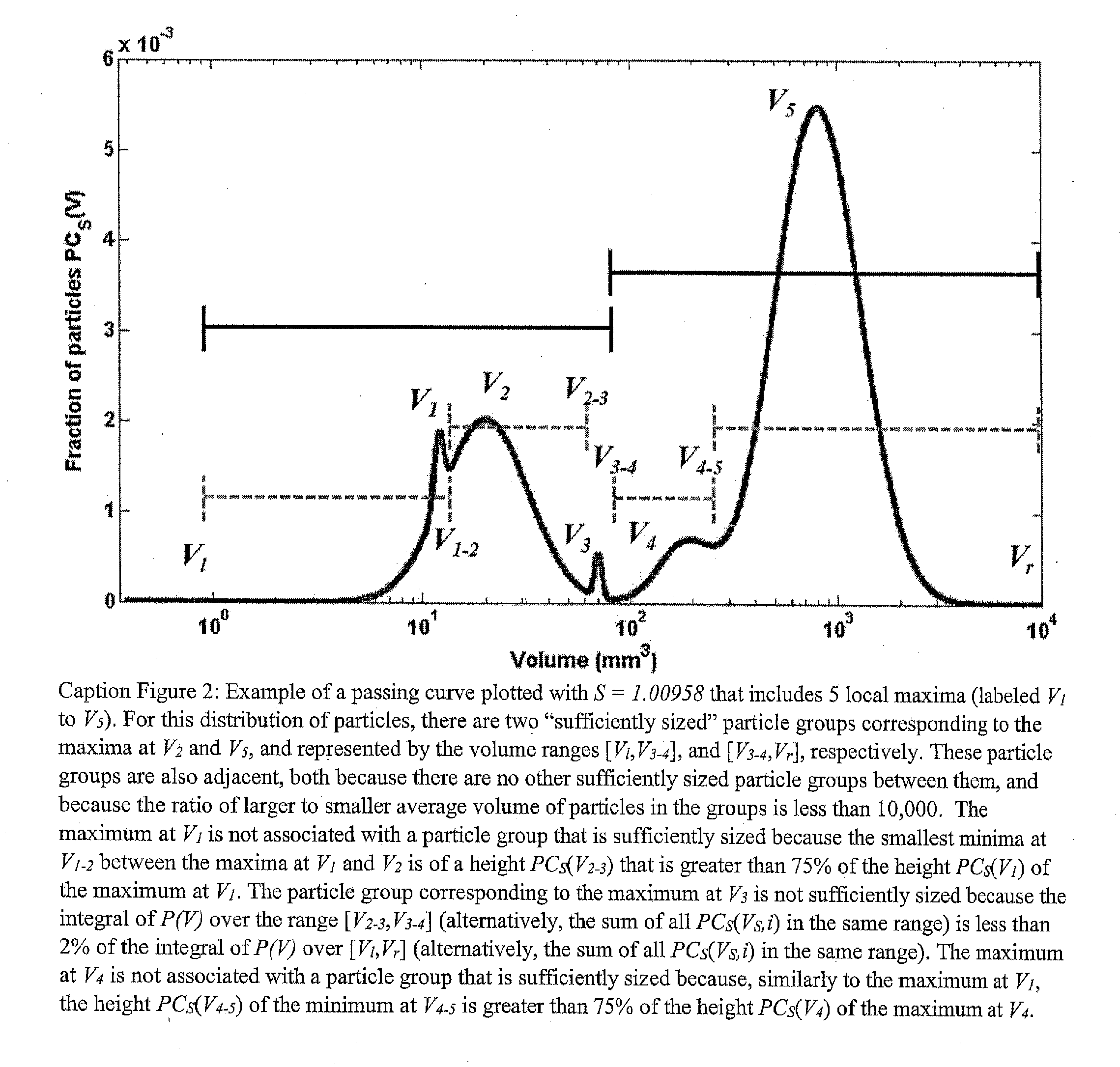

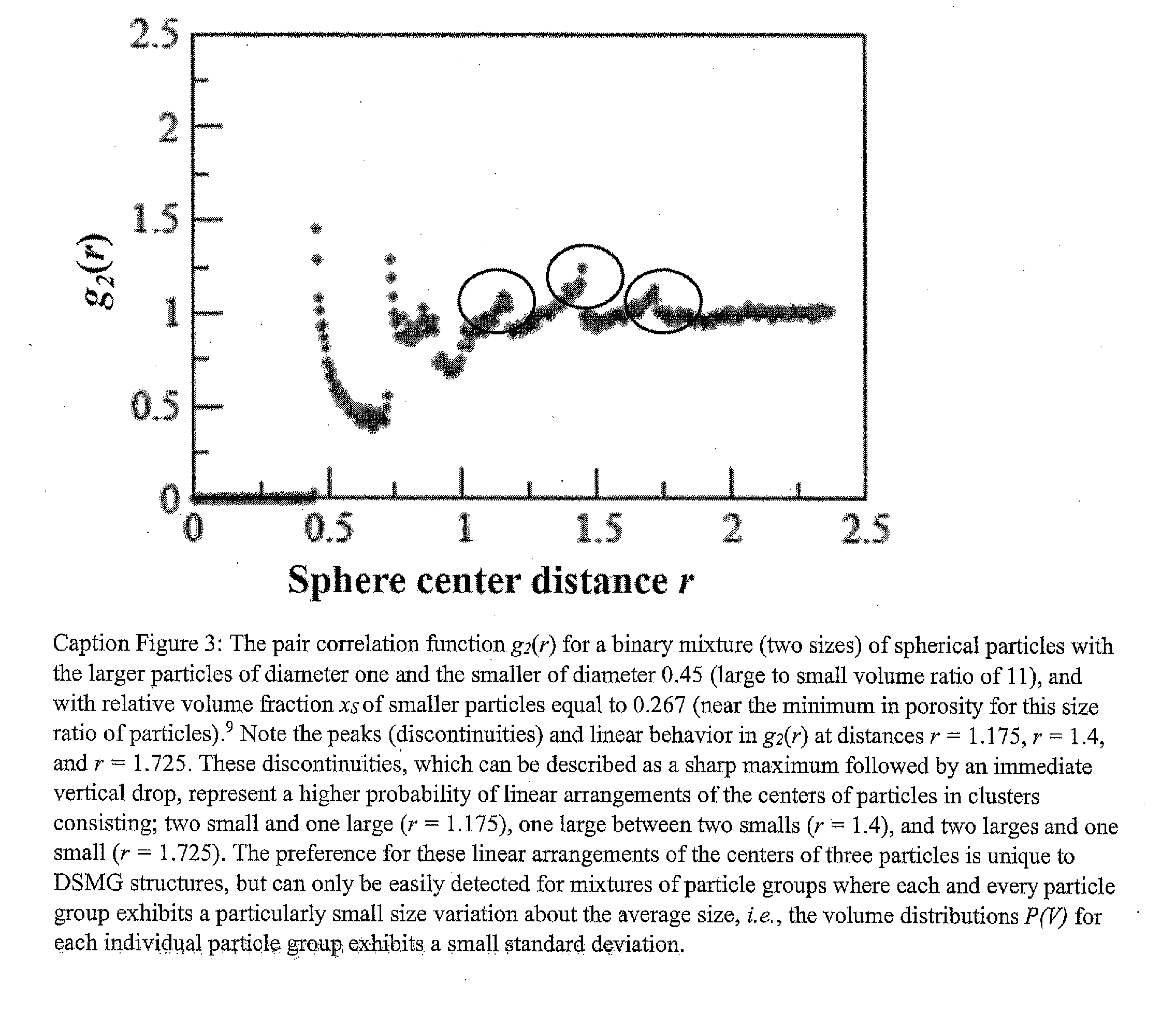

Density enhancement methods and compositions

ActiveUS20160200045A1Reduce porosityMore manufactureAdditive manufacturing apparatusLayered productsVolumetric Mass DensitySolvent

The present invention relates to granular composite density enhancement, and related methods and compositions. The applications where these properties are valuable include but are not limited to: 1) additive manufacturing (“3D printing”) involving metallic, ceramic, cermet, polymer, plastic, or other dry or solvent-suspended powders or gels, 2) concrete materials, 3) solid propellant materials, 4) cermet materials, 5) granular armors, 6) glass-metal and glass-plastic mixtures, and 7) ceramics comprising (or manufactured using) granular composites.

Owner:THE TRUSTEES FOR PRINCETON UNIV +1

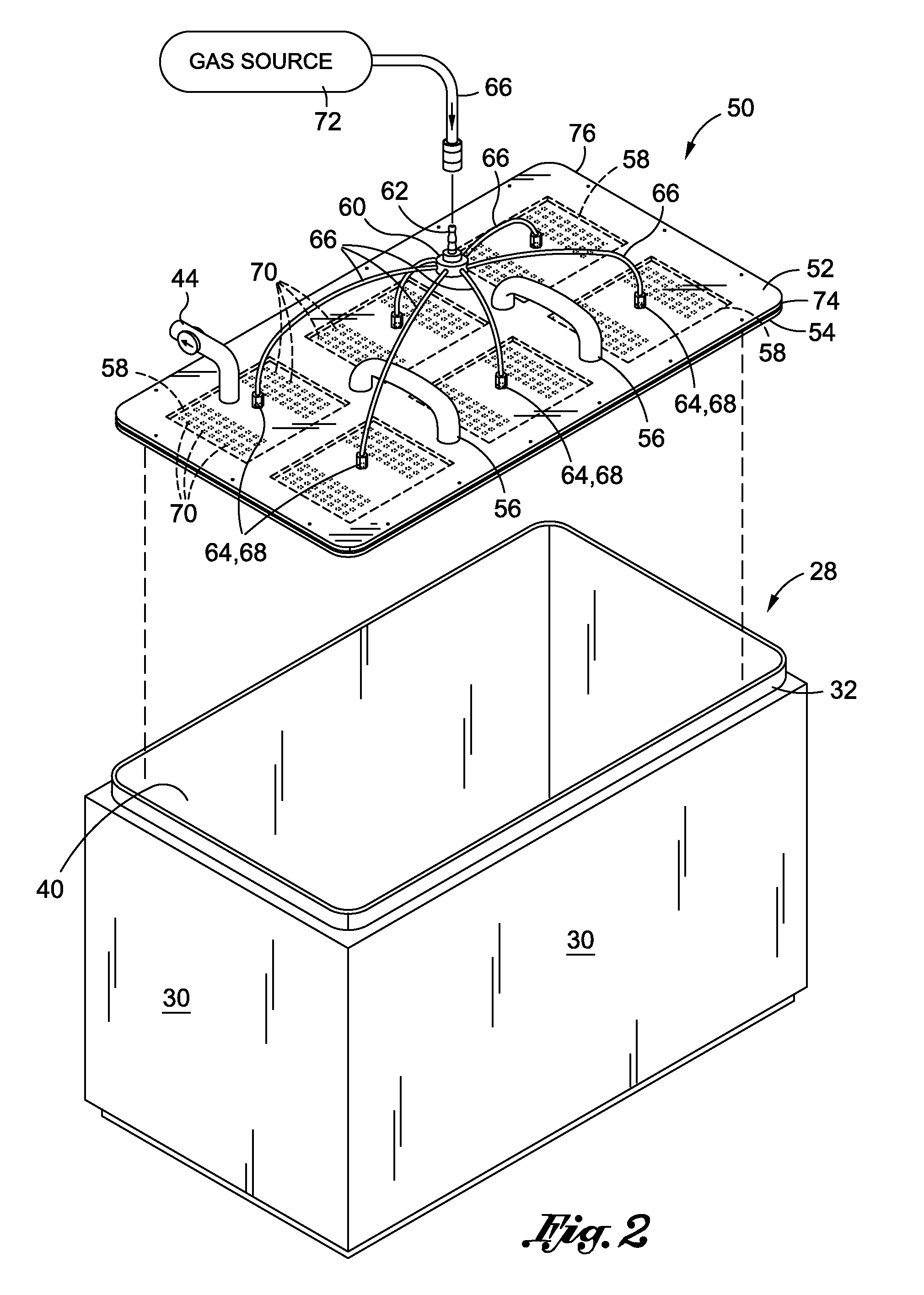

Purge and sealant cap for selective laser sintering build frame

ActiveUS20090255912A1Minimizing and preventing infusionPromotes even distributionAdditive manufacturing apparatusAuxillary shaping apparatusSelective laser sinteringEngineering

A selective laser sintering apparatus is adapted contain or receive a build frame and comprises a cap assembly which includes a removable plate assembly having at least one gas inlet formed therein. The removable plate assembly sealingly covers the build frame. The cap assembly further comprises at least one gas line fluidly connectable to the gas inlet via a gas port to deliver inert gas to the interior of the build frame. The plate assembly comprises upper and lower plates defining a spacing therebetween. A seal extends around a periphery of the upper and lower plates and is sandwiched therebetween to enclose the spacing. The lower plate has a plurality of gas inlets formed therein which are in fluid communication with the spacing such that inert gas may be delivered to the build volume while the cap assembly is installed thereupon.

Owner:THE BOEING CO

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com