System and method for direct inkjet printing of 3D objects

a technology of direct inkjet printing and 3d objects, applied in additive manufacturing processes, additive manufacturing with liquids, manufacturing tools, etc., can solve the problems of ink retention in the print head, inability to operate, sedimentation of solid particles, etc., to achieve high volume percentage, high viscosity, and high quality

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

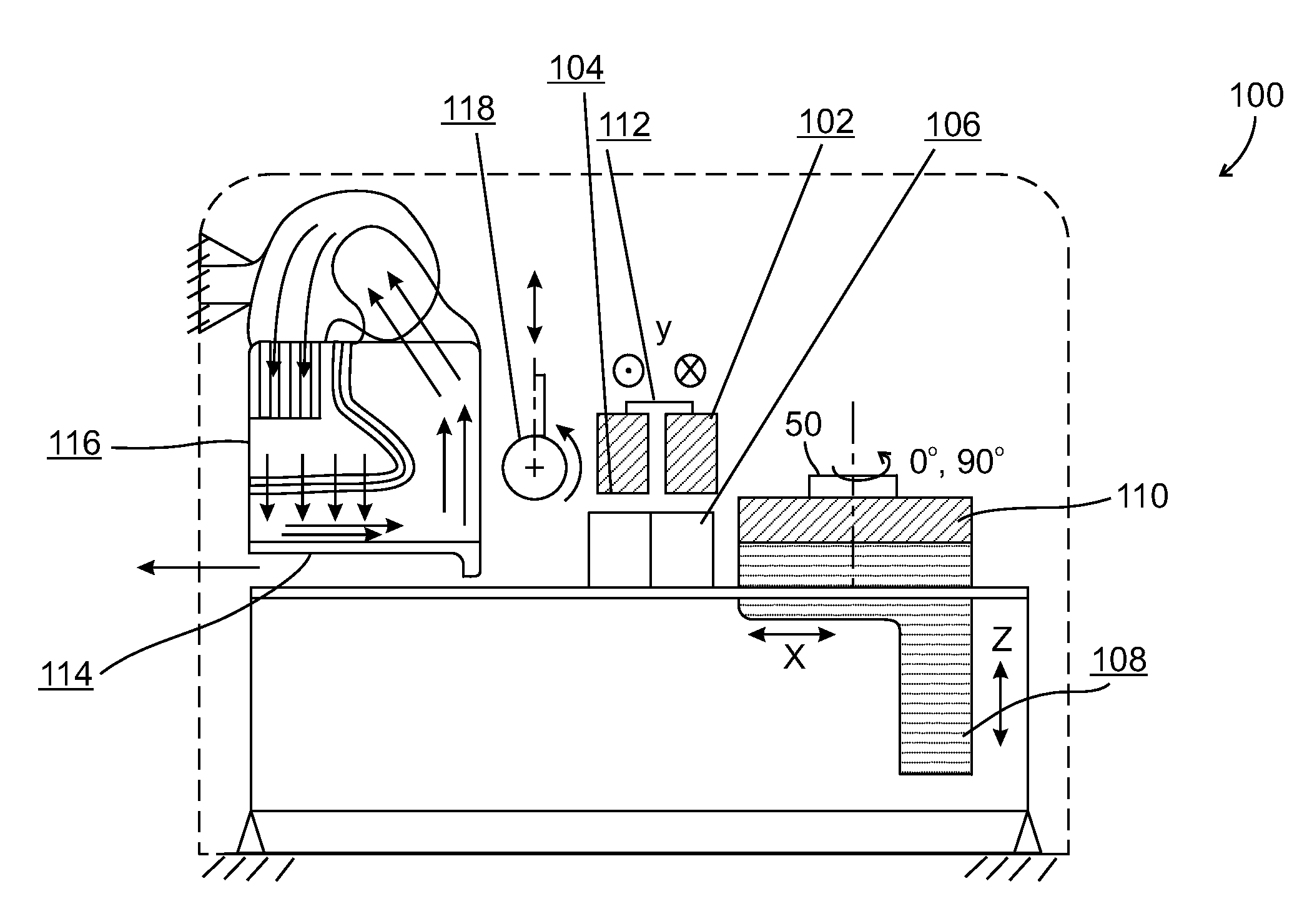

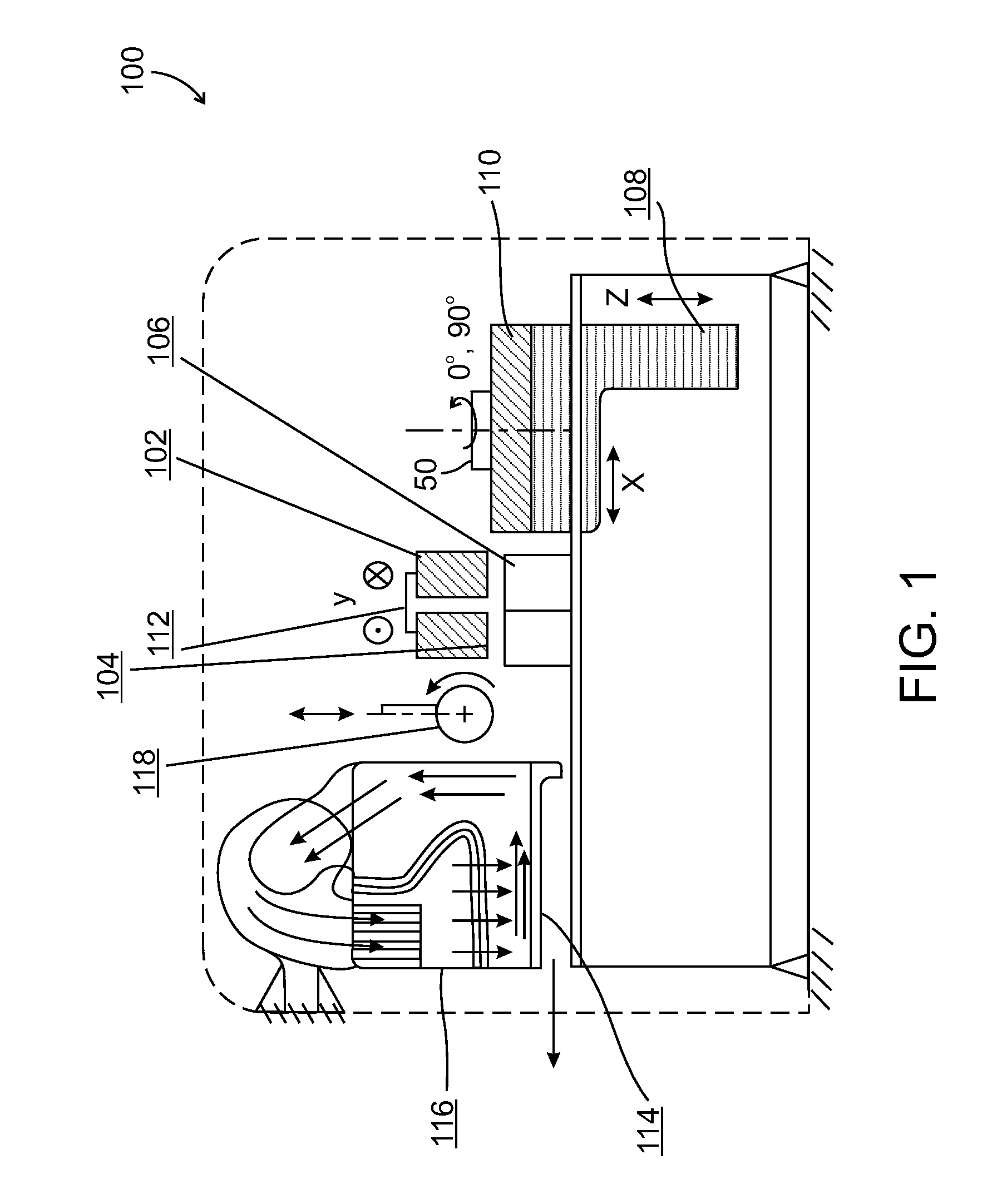

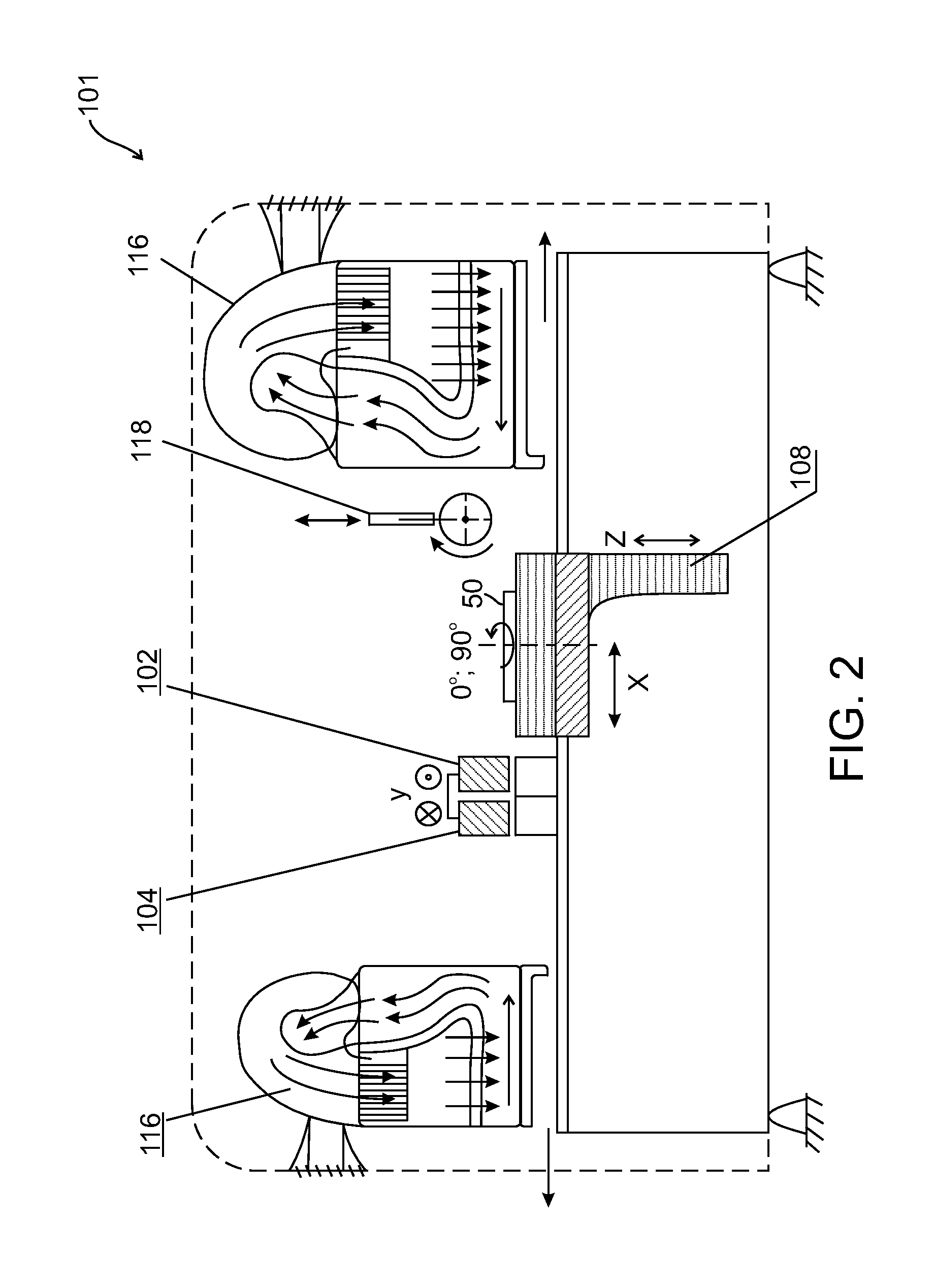

[0060]The present invention, in some embodiments thereof, relates to additive manufacturing and / or 3D printing and, more particularly, but not exclusively, to 3D printing for rapid manufacturing.

[0061]According to some exemplary embodiments there is provided a system and method using a direct inkjet printing process for fabricating 3D objects. As used herein, a direct inkjet printing process for fabricating 3D objects refers to a process for fabricating a 3D object by selectively dispensing droplets of ink as the construction and / or building material, one layer at a time based on a computed model of the 3D object. According to some embodiments of the present invention, the ink has high viscous properties, e.g. 10-20 cps due to its high volume percentage of ceramic powder, and / or encapsulated metal micro-particles. Alternatively, the construction material is a viscous ink that includes a soluble polymer. Optionally, support material for supporting a geometrical structure of the part ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Angle | aaaaa | aaaaa |

| Time | aaaaa | aaaaa |

| Viscosity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com