Patents

Literature

53results about How to "Poor dispersion" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

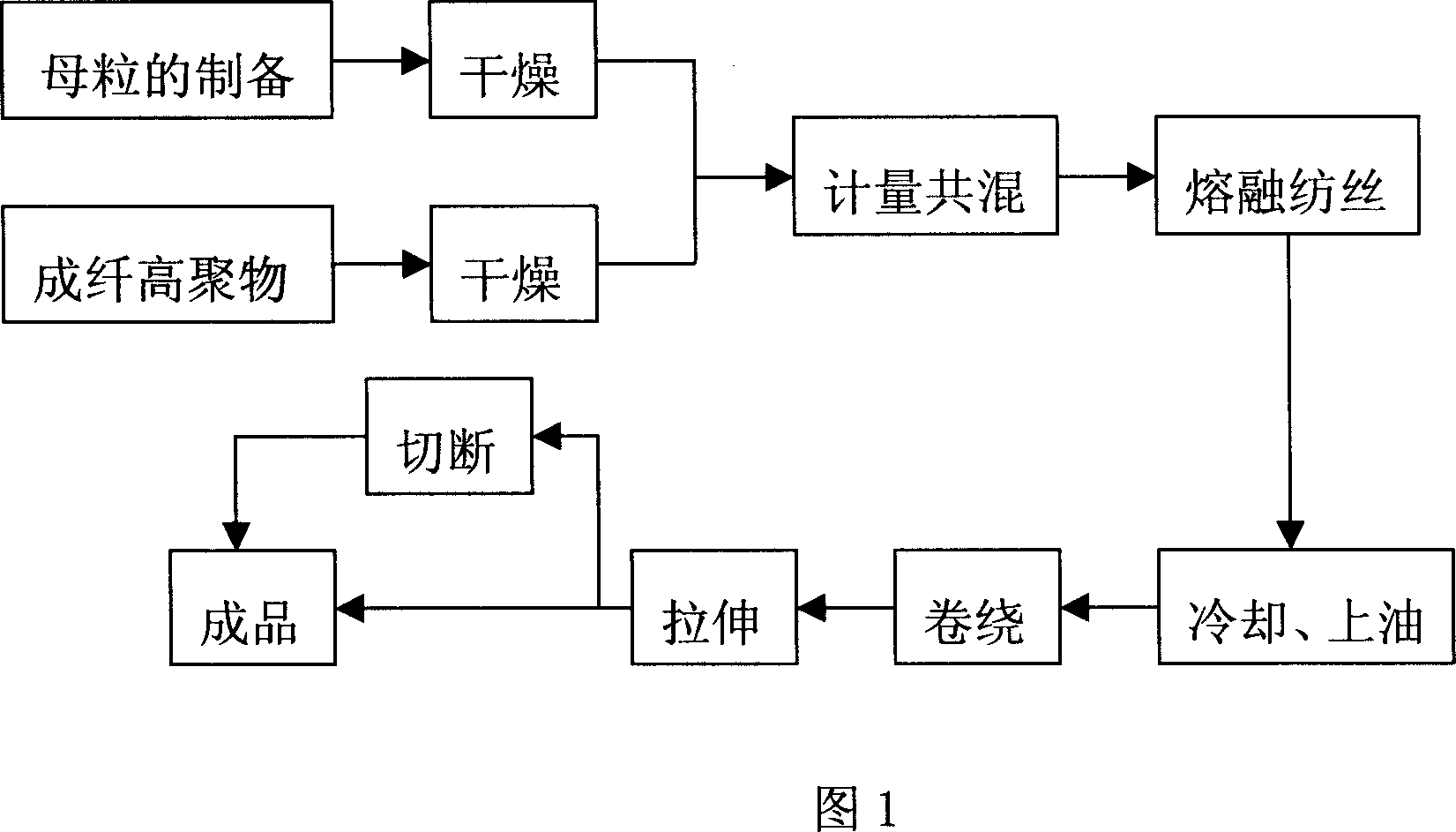

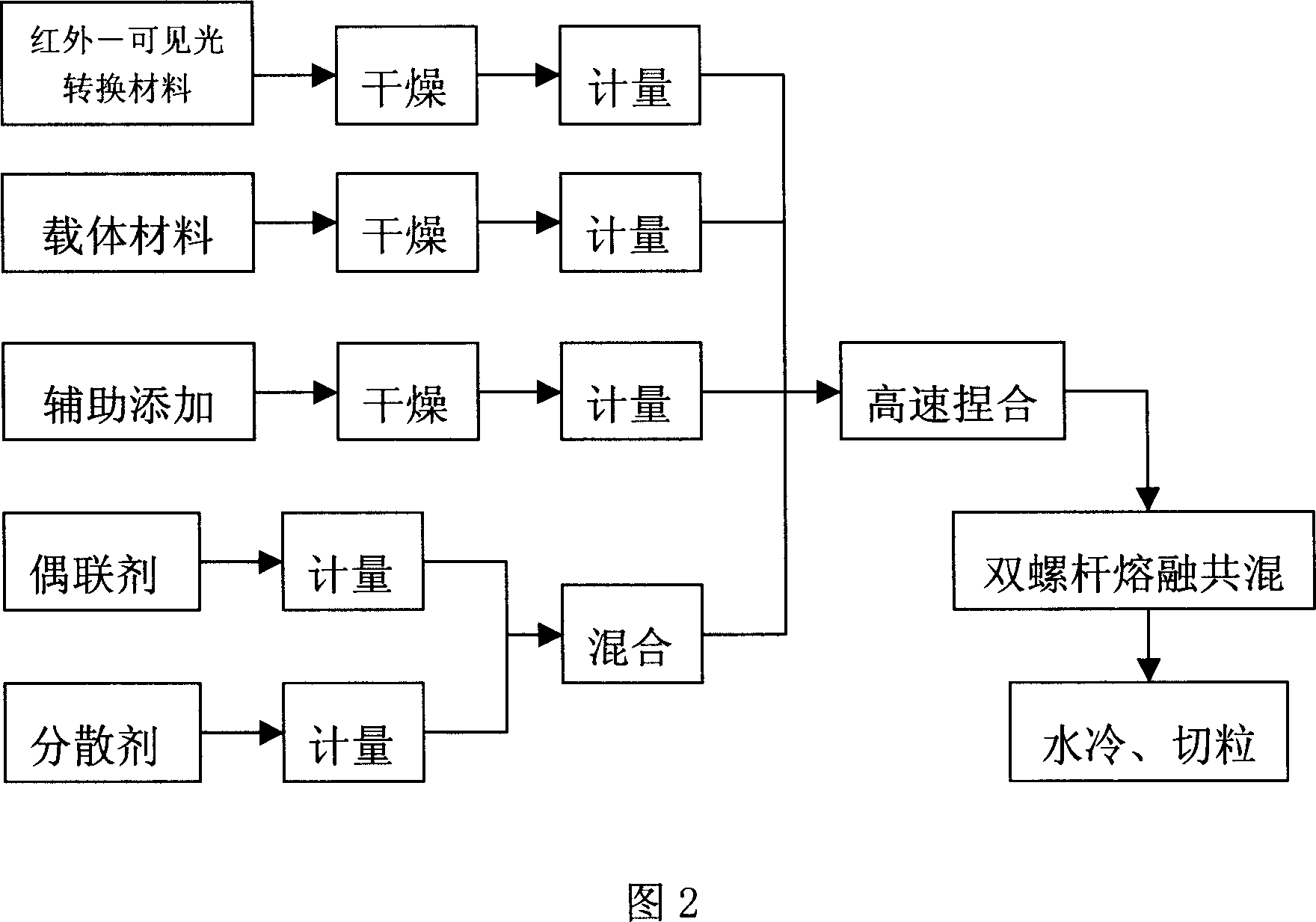

Infrared anti-false fiber and its production method and use

InactiveCN1966785AHigh processing technology requirementsImprove concealmentLight effect designsMonocomponent polypropylene artificial filamentFiberOptoelectronics

The infrared camouflage fiber is composed of infrared and visible light fertile material 1-15%, fiber-forming high polymer 64-98%, coupling agent 0.1-3%, disperser 0.1-3%, and auxiliary additive 1-4%. It includes the following manufacturing procedures: 1) the preparation of infrared camouflage base, 2) preparation of spinning material. 3) Spinning and extension. It can be applied to trade marks, packing of name brands, certificates, bills, banking cards, stamps or invoices. It has good false proof and concealing effect, and long endurance.

Owner:DONGHUA UNIV

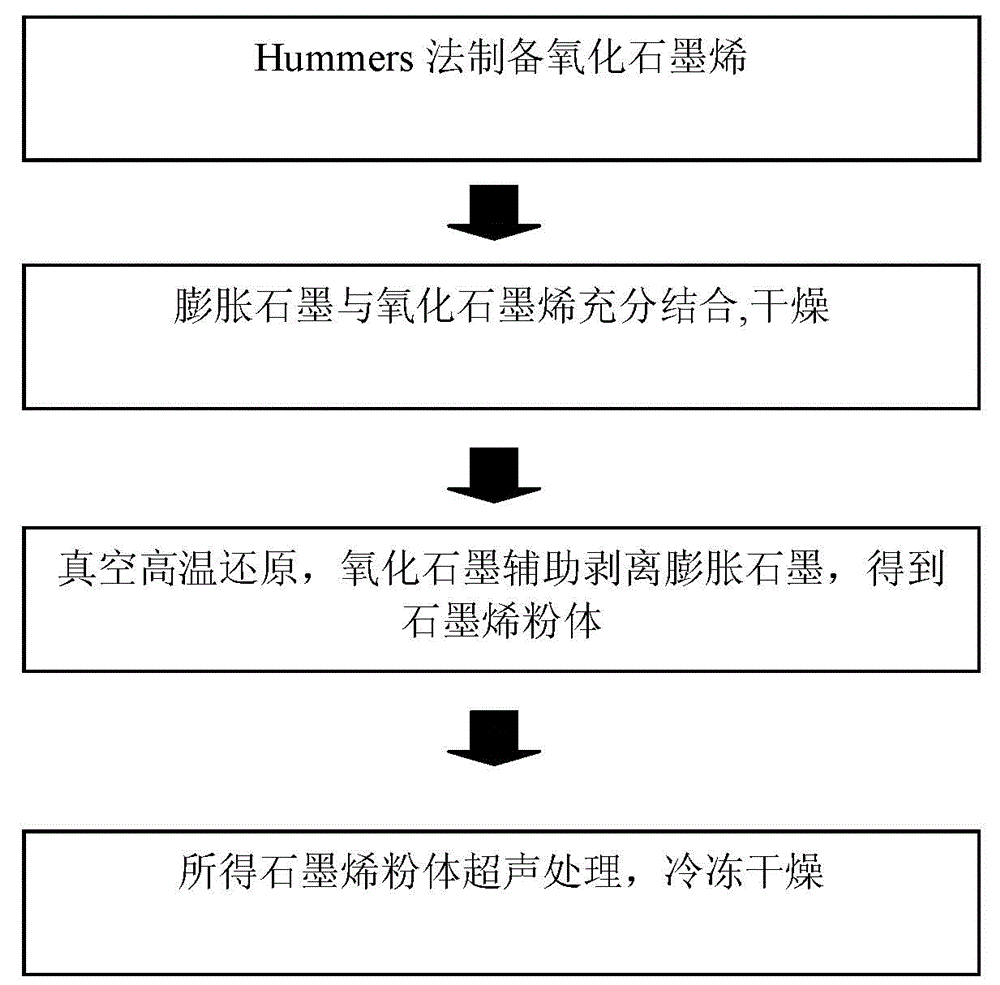

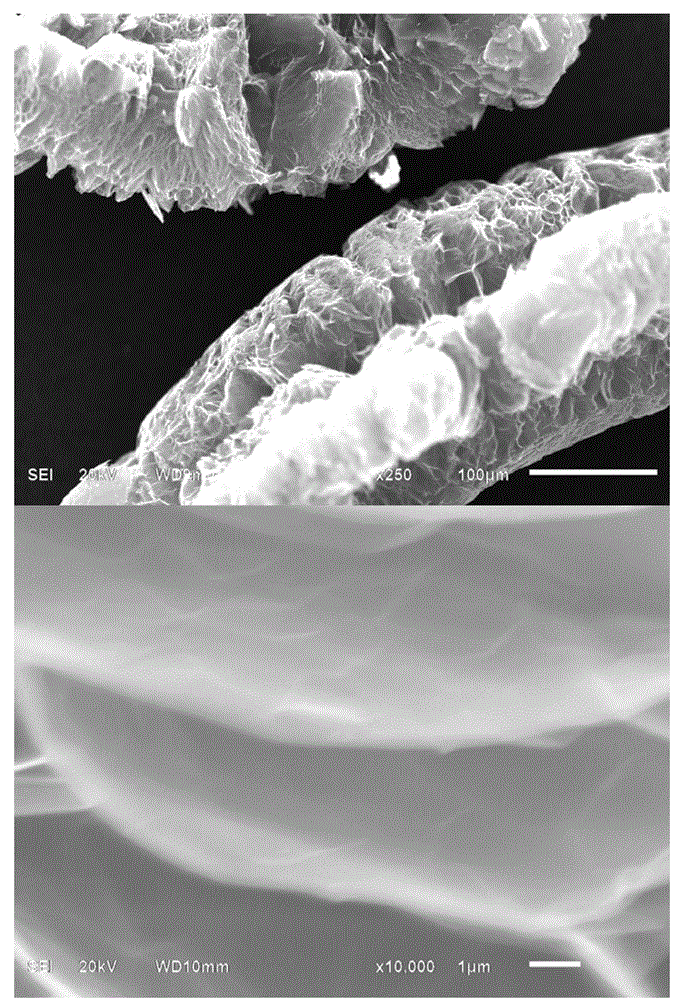

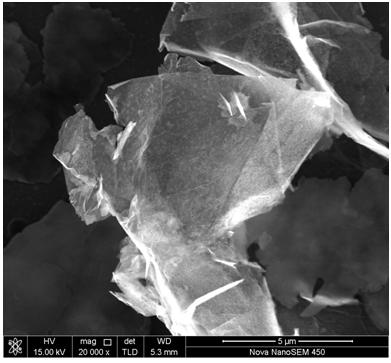

High-quality graphene and preparation method thereof

The invention relates to high-quality graphene and a preparation method thereof. The preparation method includes the steps of (1) wrap-embedding graphene oxide into the lamellas in expanded graphite to obtain a graphene oxide / expanded graphite mixture; and (2) performing thermal-treatment to the graphene oxide / expanded graphite mixture so that the expanded graphite can be stripped with assistance of a reaction force from high-temperature expansion reduction of the graphene oxide, thereby preparing the graphene powder. In the invention, the graphene oxide is wrap-embedded into the lamellas in the expanded graphite, and the expanded graphite is stripped-away with the impact force of a violent reaction in the high-temperature expansion reduction of the graphene oxide, thereby obtaining loosen graphene powder. The expanded graphene is controllable in the number of layers, is free of defect, is less in impurities and is high in purity.

Owner:SHANGHAI INST OF CERAMIC CHEM & TECH CHINESE ACAD OF SCI

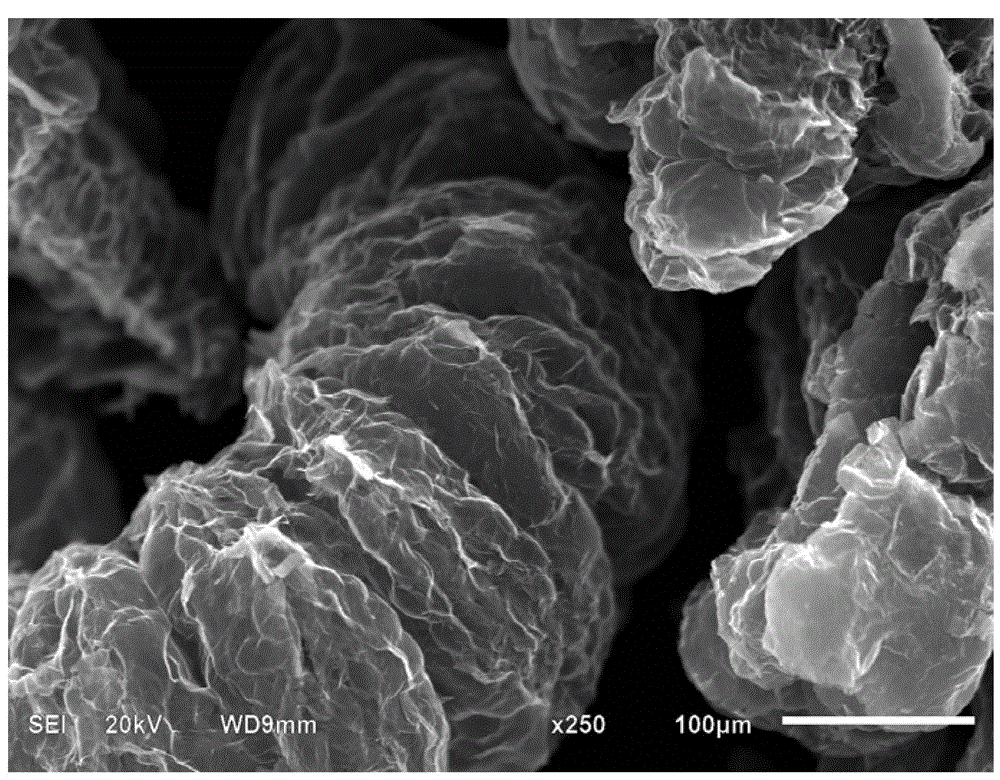

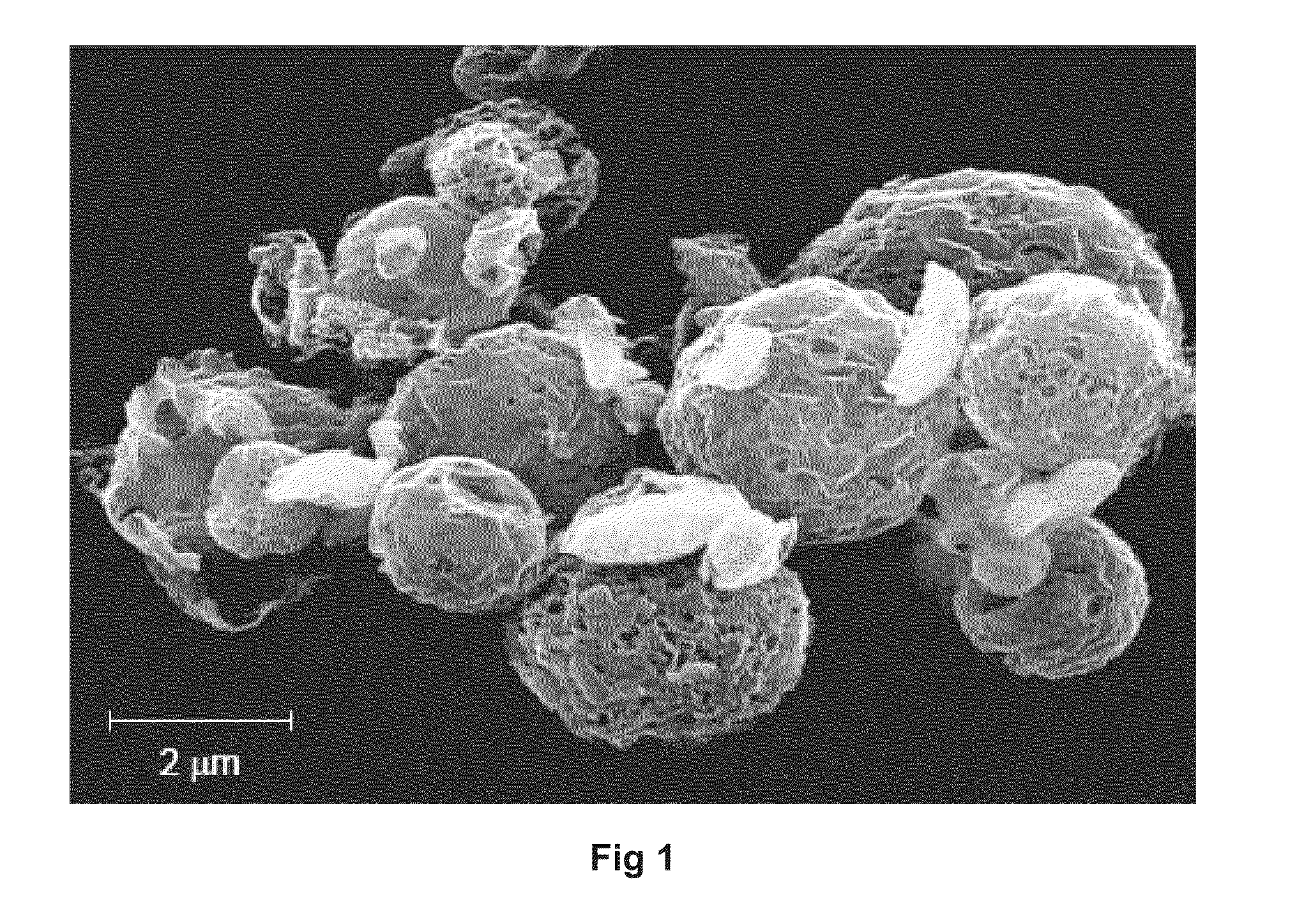

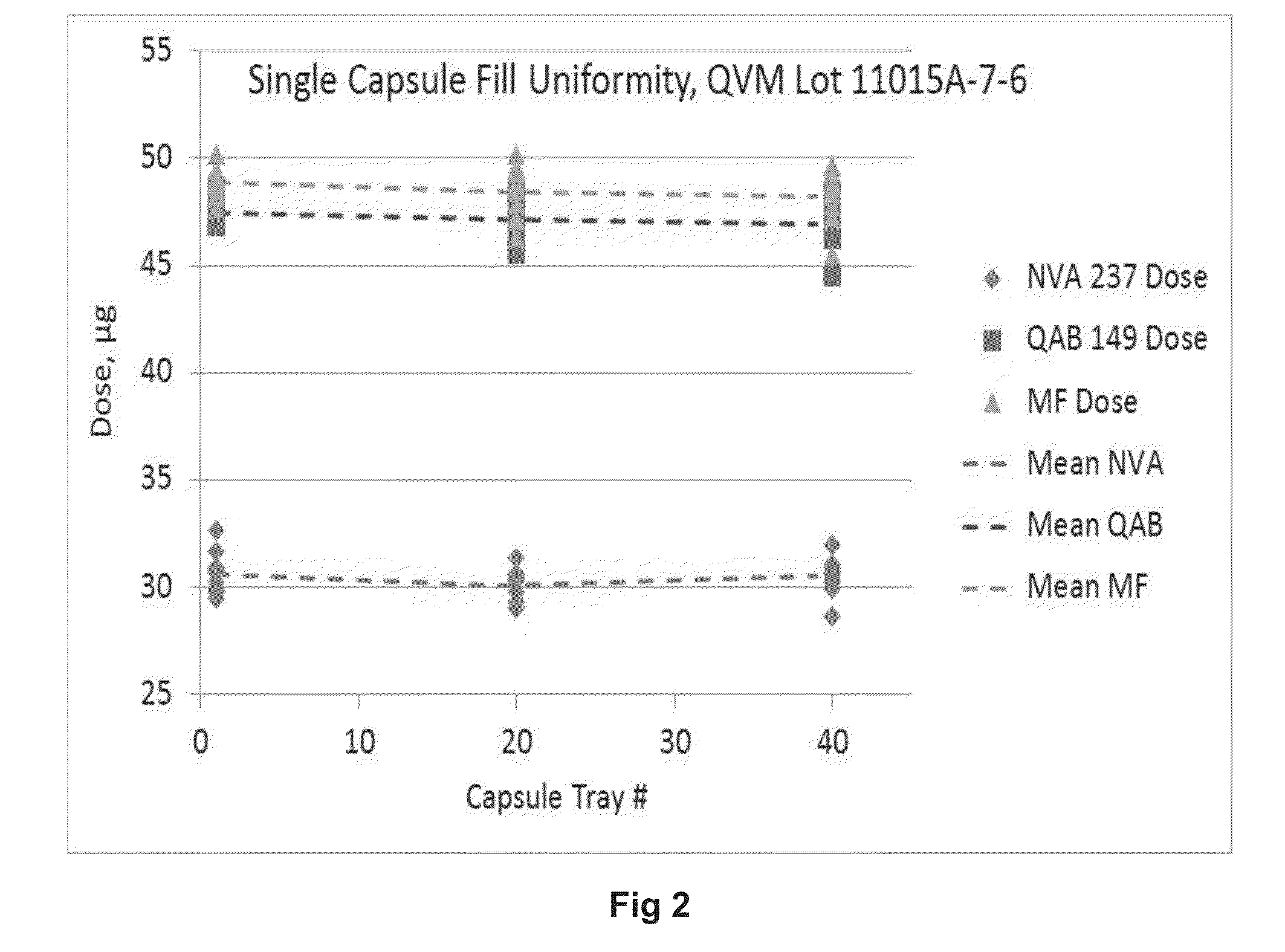

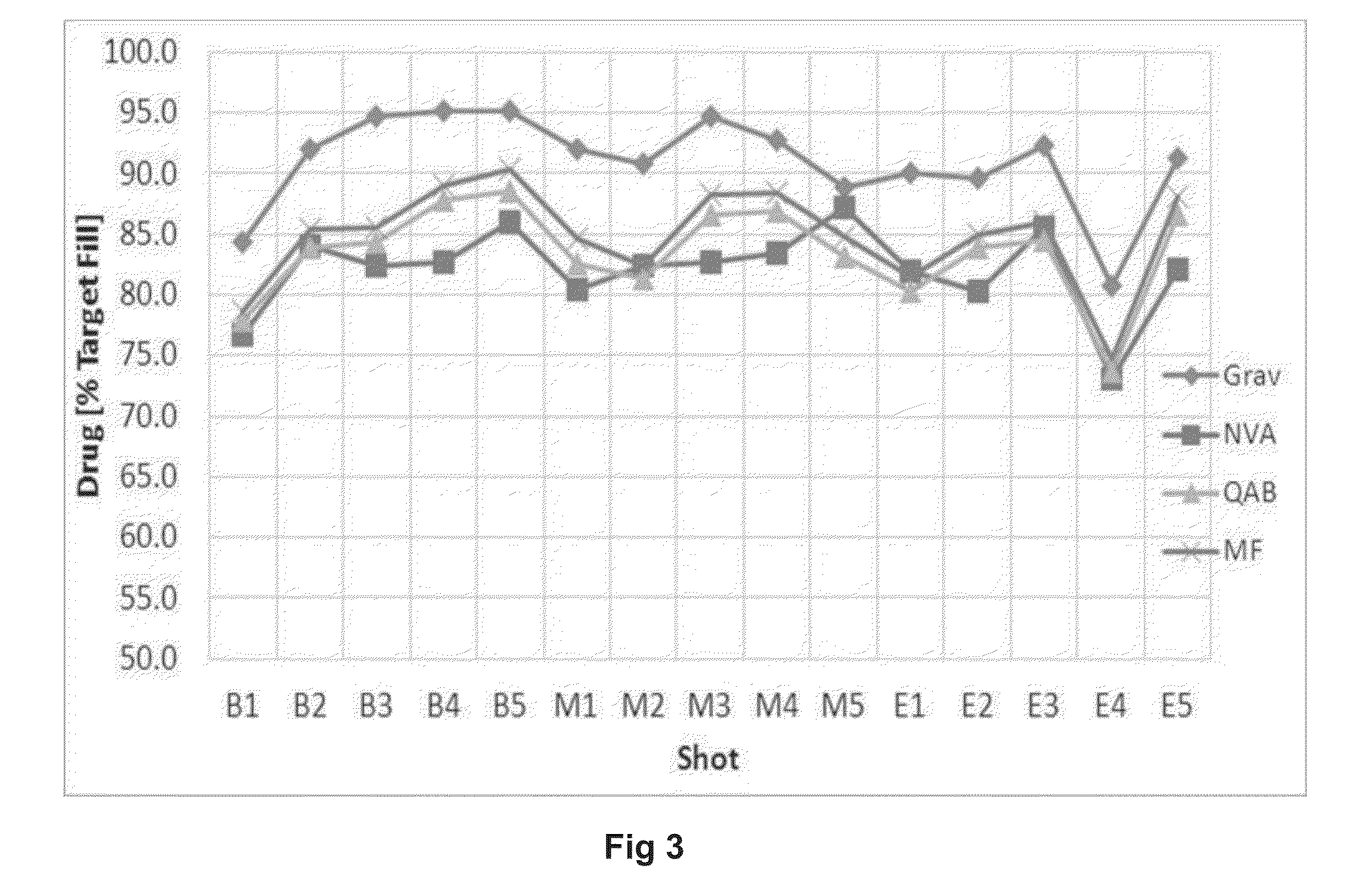

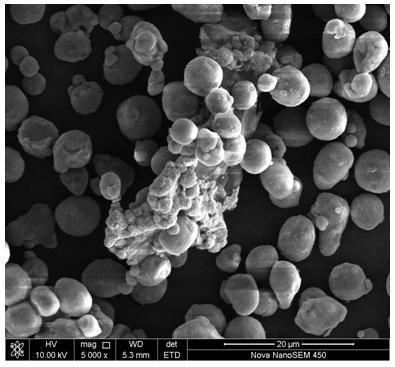

Respirable agglomerates of porous carrier particles and micronized drug

Embodiments of the present invention provide a dry powder composition comprising porous carrier particles associated with one, two, three or more micronized drugs or APIs wherein an ordered mixture between the micronized drug or drugs and the carrier particle results, such that the micronized drug or drugs adhere strongly to the carrier particles forming a stable ordered mixture of respirable agglomerates. Embodiments of the present invention further comprise a spray-drying process to create the respirable agglomerates. Embodiments of the present invention further relate to the use of the dry powder formulation comprising respirable agglomerates for the treatment of a patient having a disease or condition which is treatable thereby.

Owner:NOVARTIS AG

Method for prepn. of separated protein specially used for dairy products

InactiveCN1513342AImprove solubilityWell mixedProtein composition from vegetable seedsMilk productsSpray drying

A process for preparing the separating protein dedicated for milk products includes low-temp deoiling of soybean slices, primary extracting, separating protein liquid from dregs, secondary extracting, separating protein liquid from dregs, degassing, depositing in acid, separating the primary milk curd from whey, water washing, separating the secondary milk curd from whey, enzymolyzing, ageing, sterilizing, spray drying, and coating phosphatide.

Owner:哈高科大豆食品有限责任公司

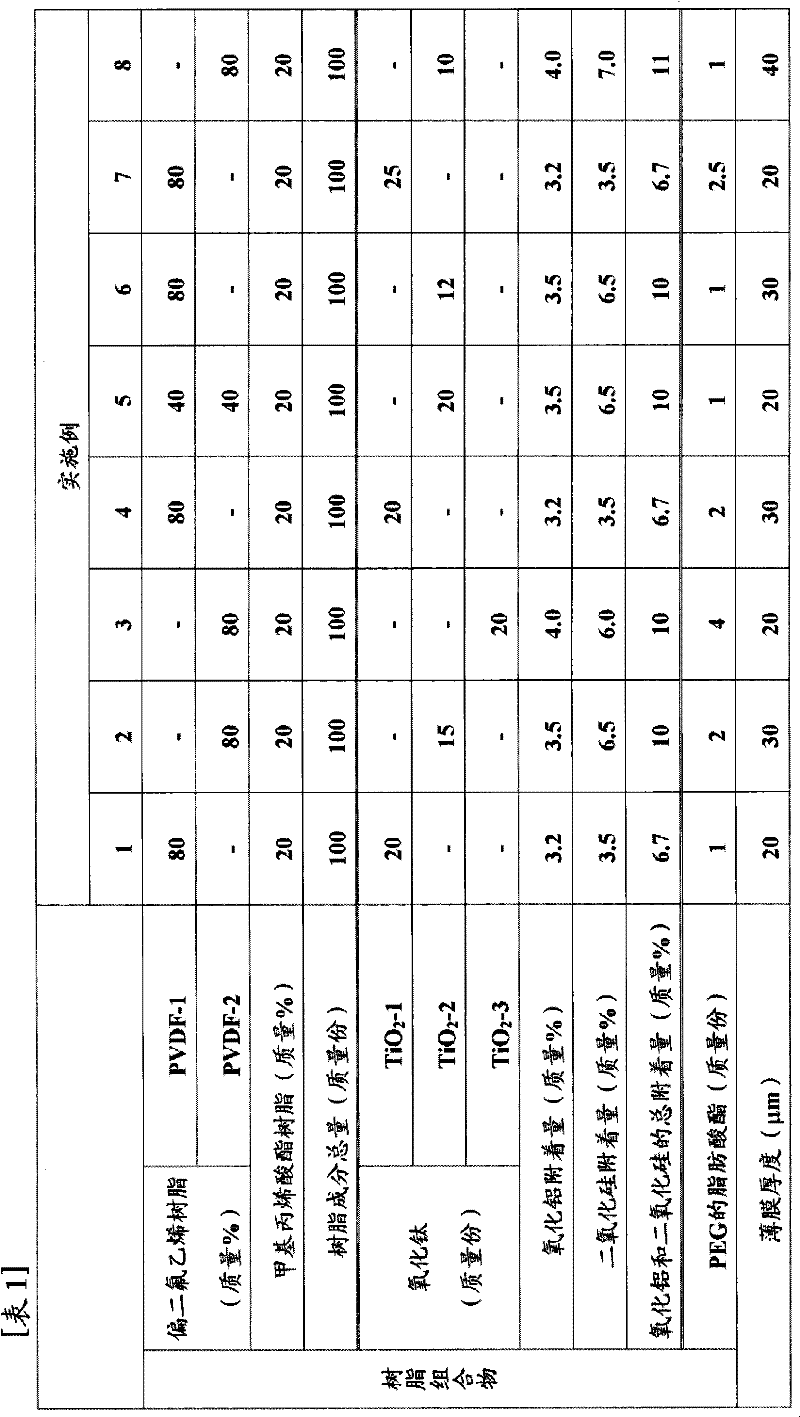

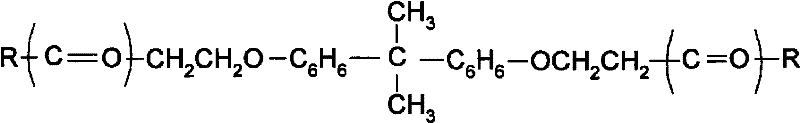

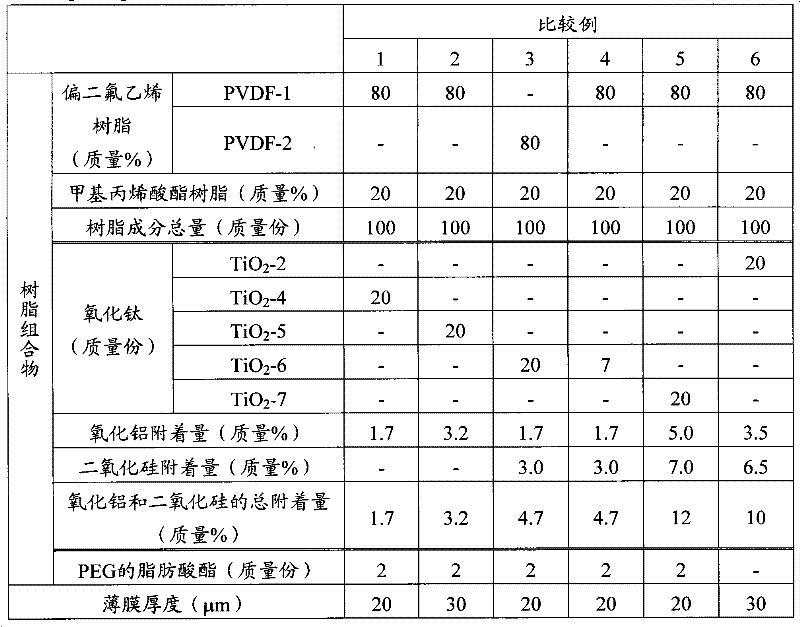

Vinylidene fluoride-based resin film

ActiveCN102317371APoor dispersionGood adhesionAgricultural articlesSynthetic resin layered productsMethacrylatePolyethylene glycol

Disclosed is a vinylidene fluoride-based resin film which is highly adhesive to a substrate material, achieves good dispersibility even in the case of containing a pigment in a large amount and is highly heat-stable in molding. Specifically disclosed is a vinylidene fluoride-based resin film which is produced by adding, to resin components comprising a vinylidene fluoride resin and a methacrylate resin, titanium oxide being surface-treated with alumina and silica and a fatty acid ester of polyethylene glycol and / or a derivative of the same, each in a definite amount. Specifically disclosed is another vinylidene fluoride-based resin film comprising at least a top face layer and a back face layer each having the aforesaid composition, wherein the composition ratio of the vinylidene fluoride resin to the methacrylate resin in the top face layer is controlled in the range of 70:30 to 95:5 in terms of mass ratio, and the composition ratio of the vinylidene fluoride resin to the methacrylate resin in the back face layer is controlled in the range of 5:95 to 45:55 in terms of mass ratio. In either case, the total amount of alumina and silica attached to titanium oxide is controlled in the range of 5 to 11% by mass based on the total mass of titanium oxide.

Owner:DENKA CO LTD

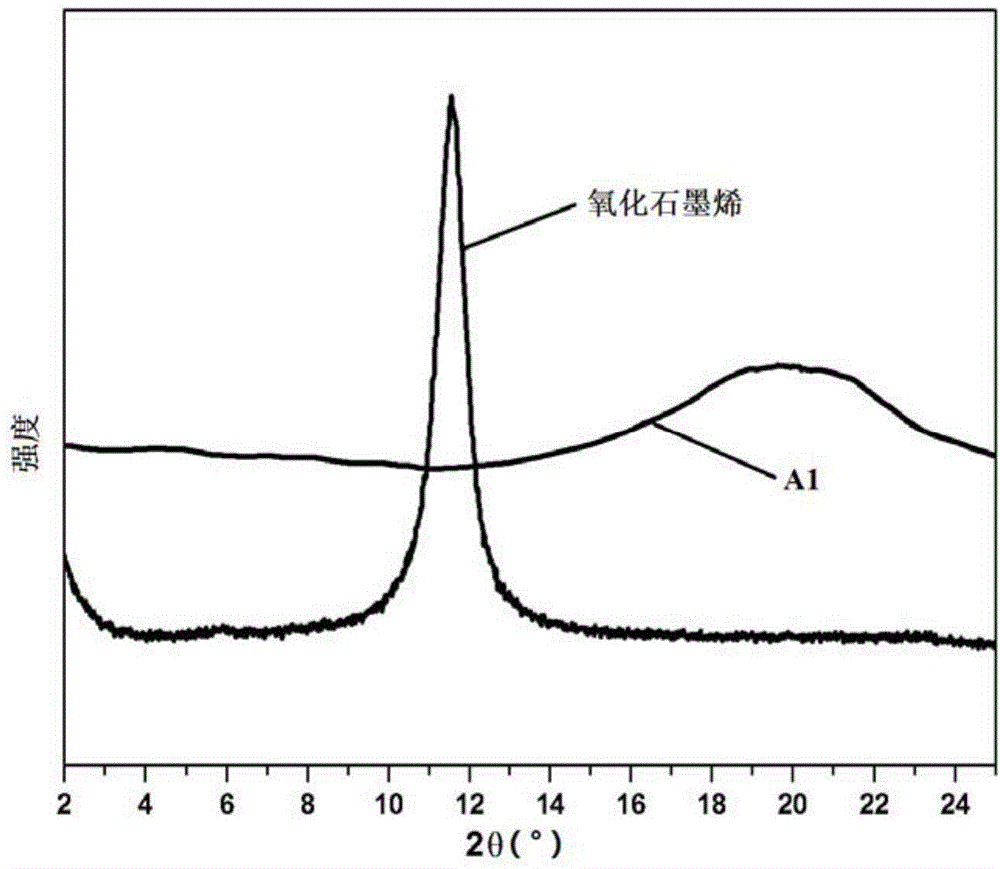

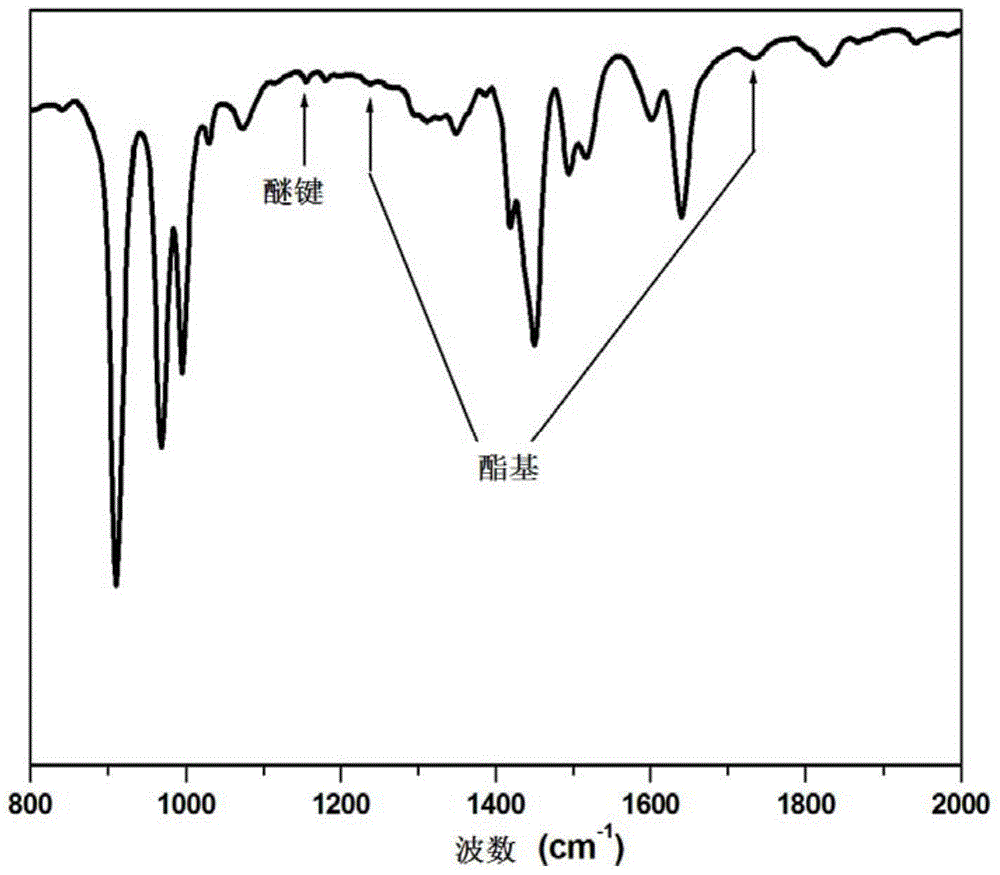

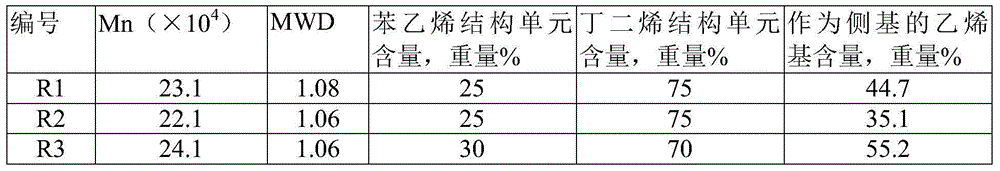

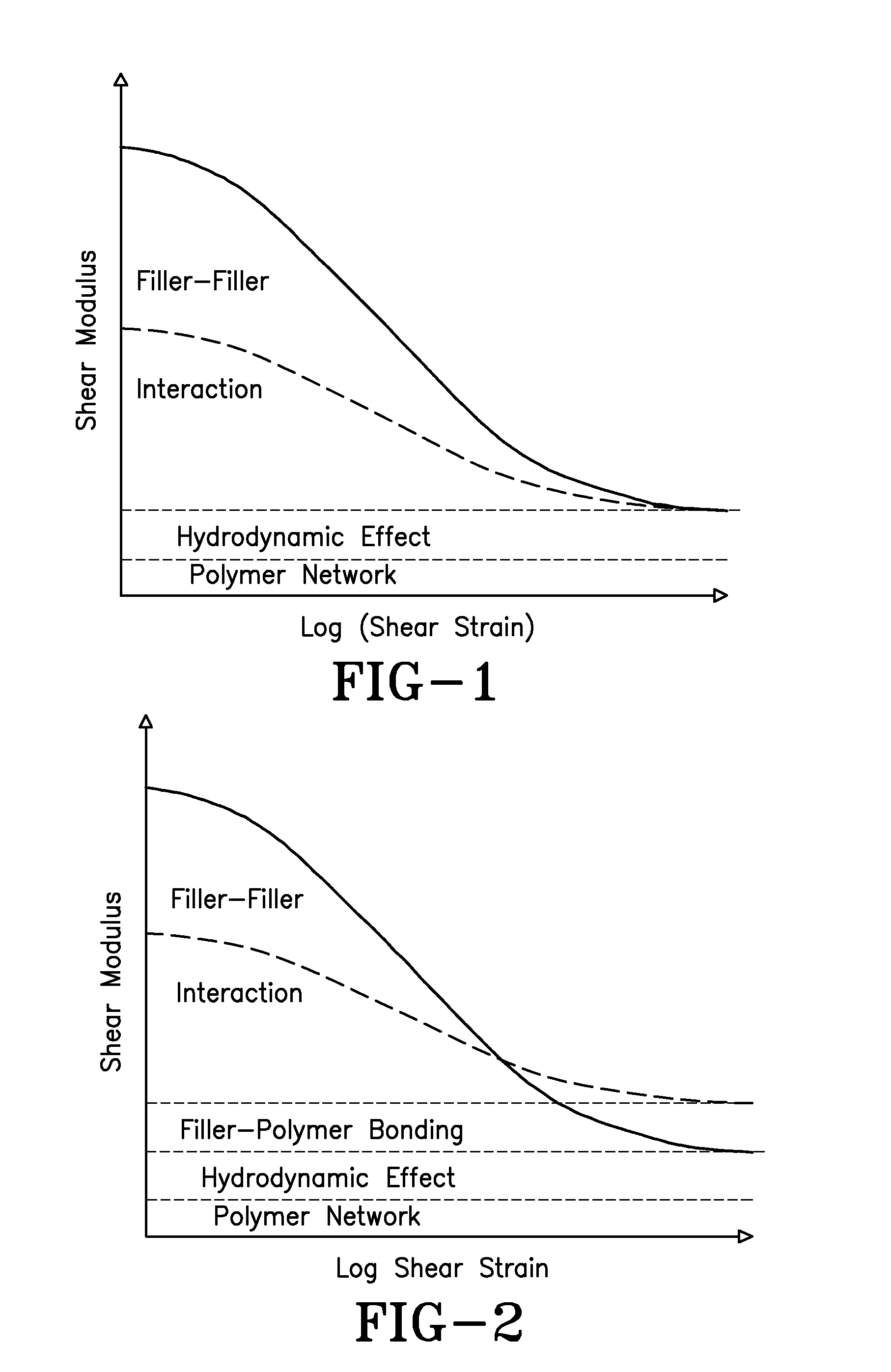

Graphene oxide-epoxidized styrene butadiene rubber compound, preparation method thereof and vulcanized rubber

The invention discloses a graphene oxide-epoxidized styrene butadiene rubber compound, a preparation method thereof and vulcanized rubber. The compound comprises graphene oxide and epoxidized styrene butadiene rubber, wherein graphene oxide accounts for 0.1-15 parts by weight in 100 parts by weight of epoxidized styrene butadiene rubber; when 2<theta> in an XRD (x ray diffraction) spectrum of the compound ranges from 2 degrees to 12 degrees, a diffraction peak of graphene oxide does not appear; a characteristic peak of ester appears near 1,750 cm <-1> and 1,240 cm <-1> in an infrared spectrum of the compound; and a characteristic peak of ether linkage appears near 1,150 cm <-1> in the infrared spectrum of the compound. In the compound, graphene oxide and epoxidized styrene butadiene rubber form chemical bond combination, so that the tensile break strength can be higher, and further obtained vulcanized rubber has better mechanical property.

Owner:CHINA PETROLEUM & CHEM CORP +1

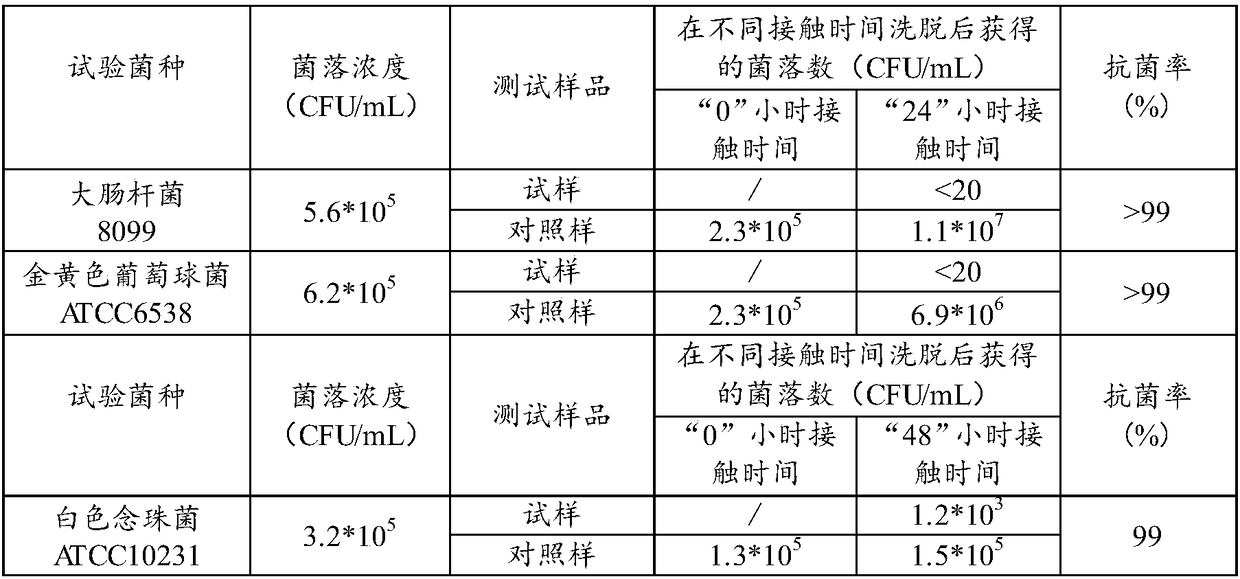

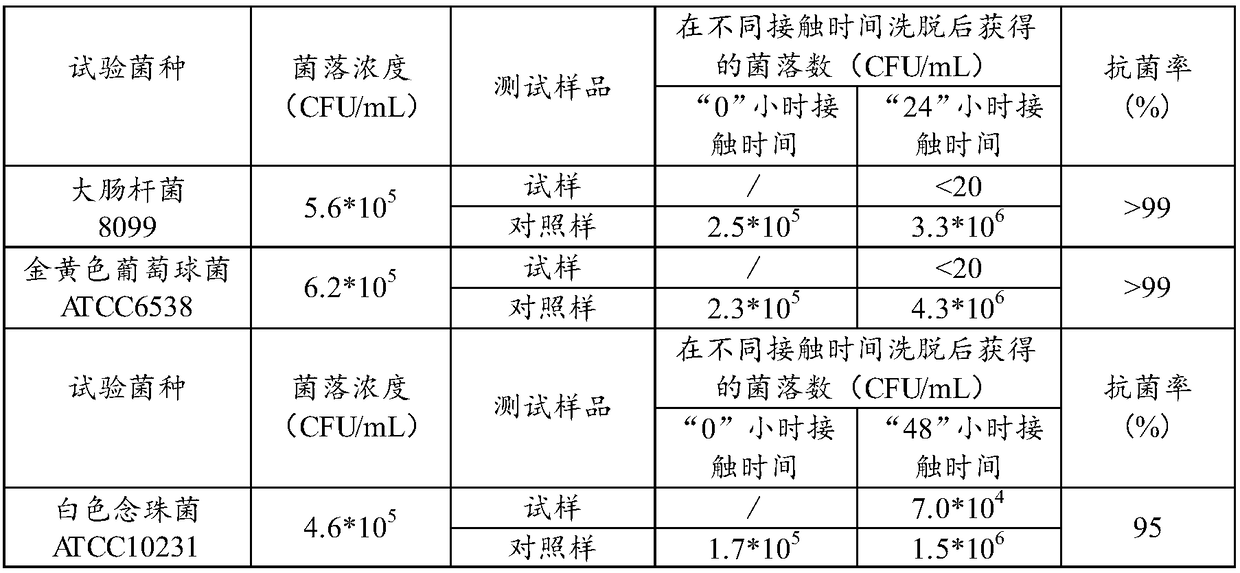

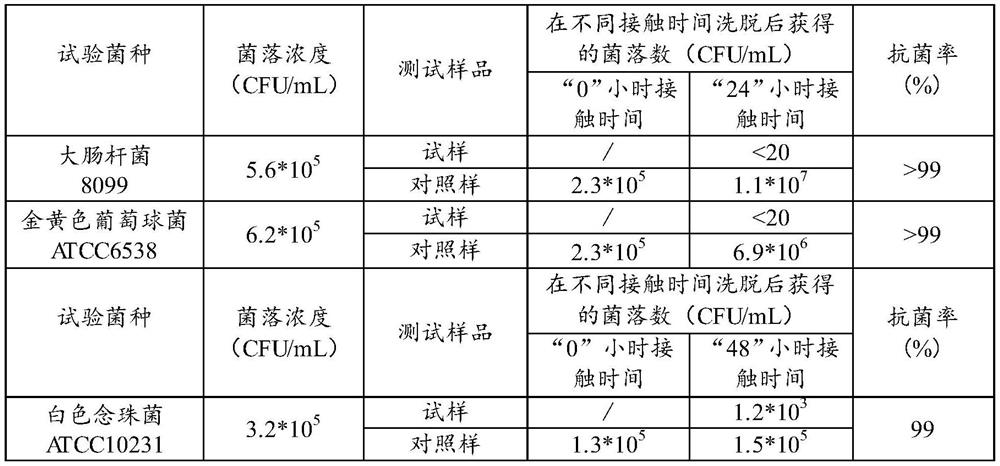

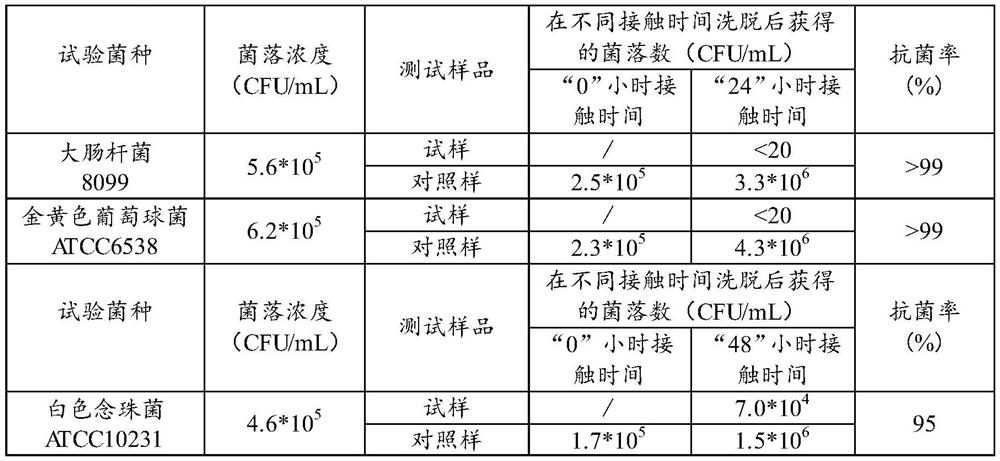

Preparation method of nano-silver antibacterial agent, nano-silver antibacterial agent, antibacterial plastics and preparation method of antibacterial plastics

The invention discloses a preparation method of a nano-silver antibacterial agent, the nano-silver antibacterial agent, antibacterial plastics and a preparation method of the antibacterial plastics. The preparation method of the nano-silver antibacterial agent comprises the following steps: adopting a liquid-phase chemical reduction method, wherein the liquid phase is a hydroxyl-containing water-free organic solvent, and a protective agent and a penetrating agent can serve as reactive reduction agents; reducing Ag<+> into nano Ag particles at a certain temperature, and finally forming a stablesolution of a silver-containing complex with the protective agent, the penetrating agent and the solvent under a certain conditions, thereby obtaining the stable, colorless, transparent and water-free nano-silver antibacterial solution. The nano-silver antibacterial agent prepared by the method achieves an excellent antibacterial effect when applied to the antibacterial plastics.

Owner:宝鸡霍夫纳米复合材料研究院有限公司

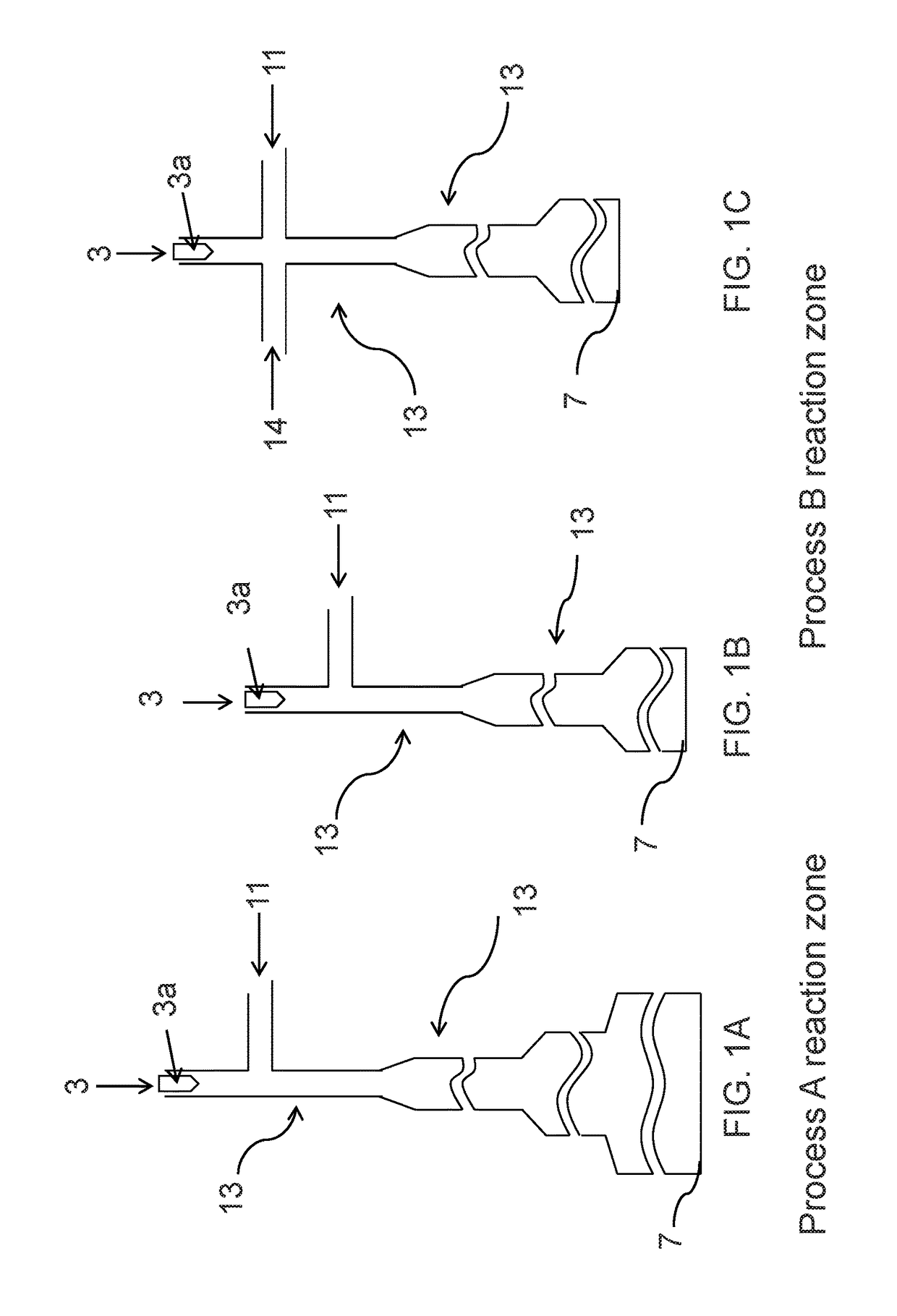

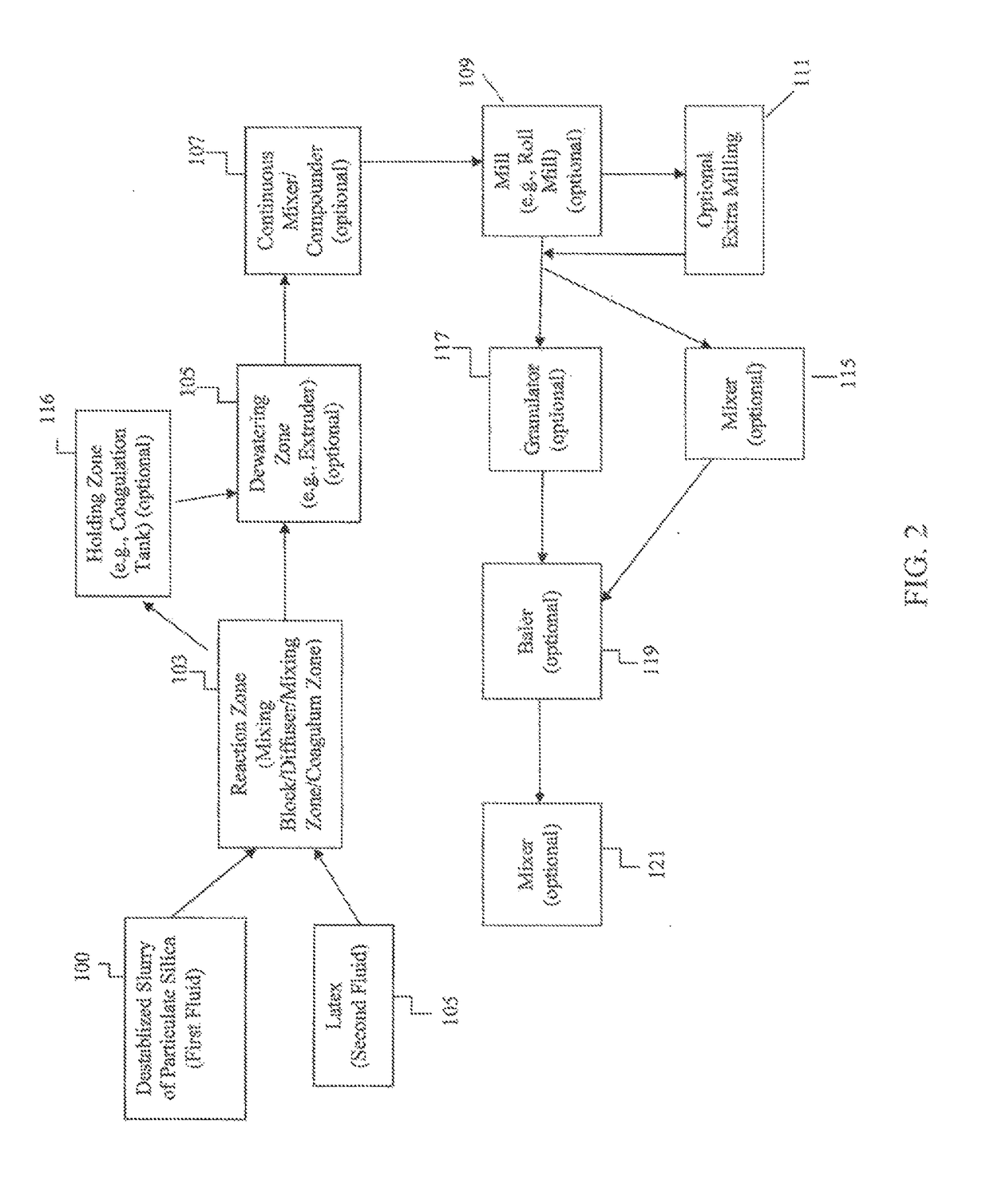

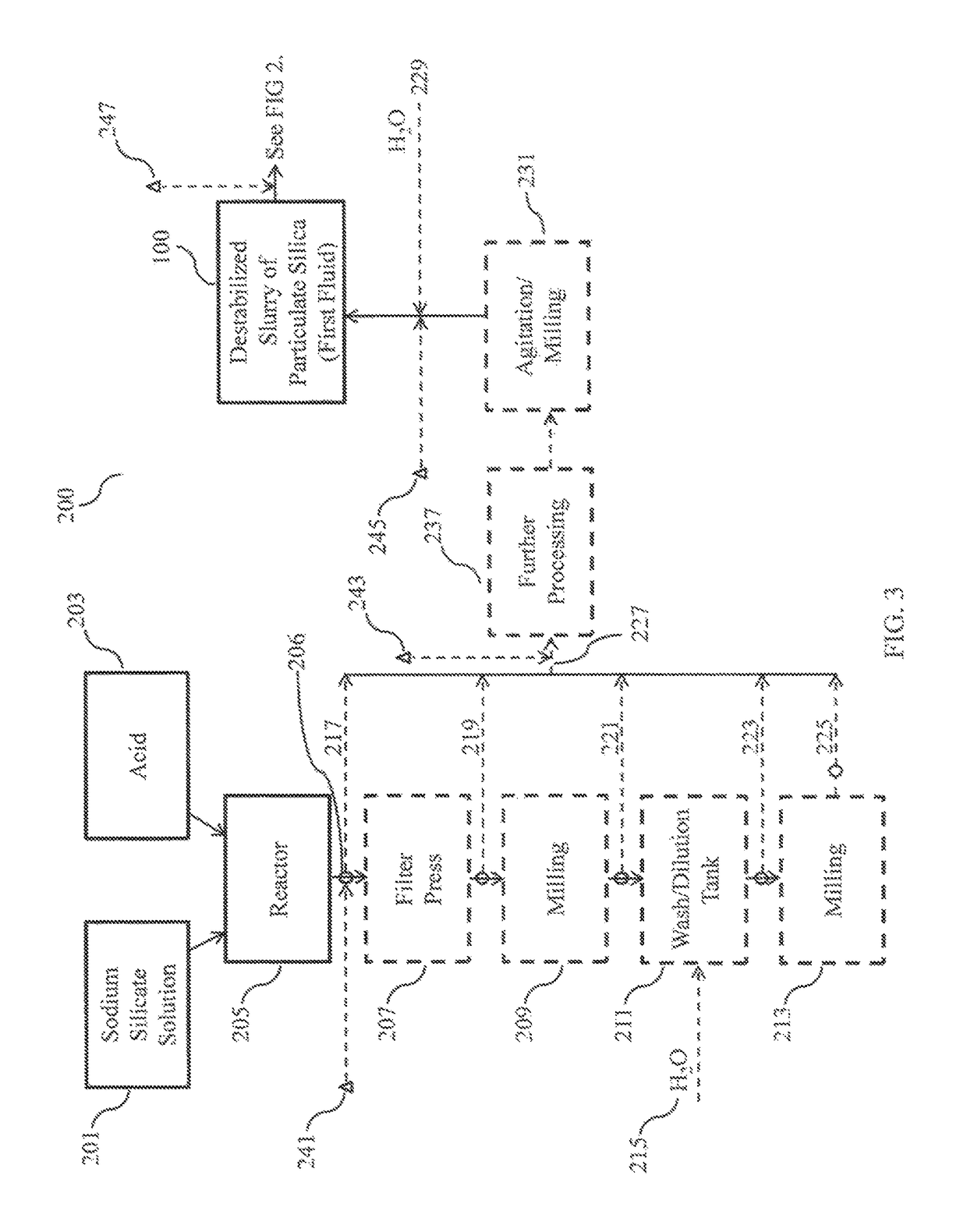

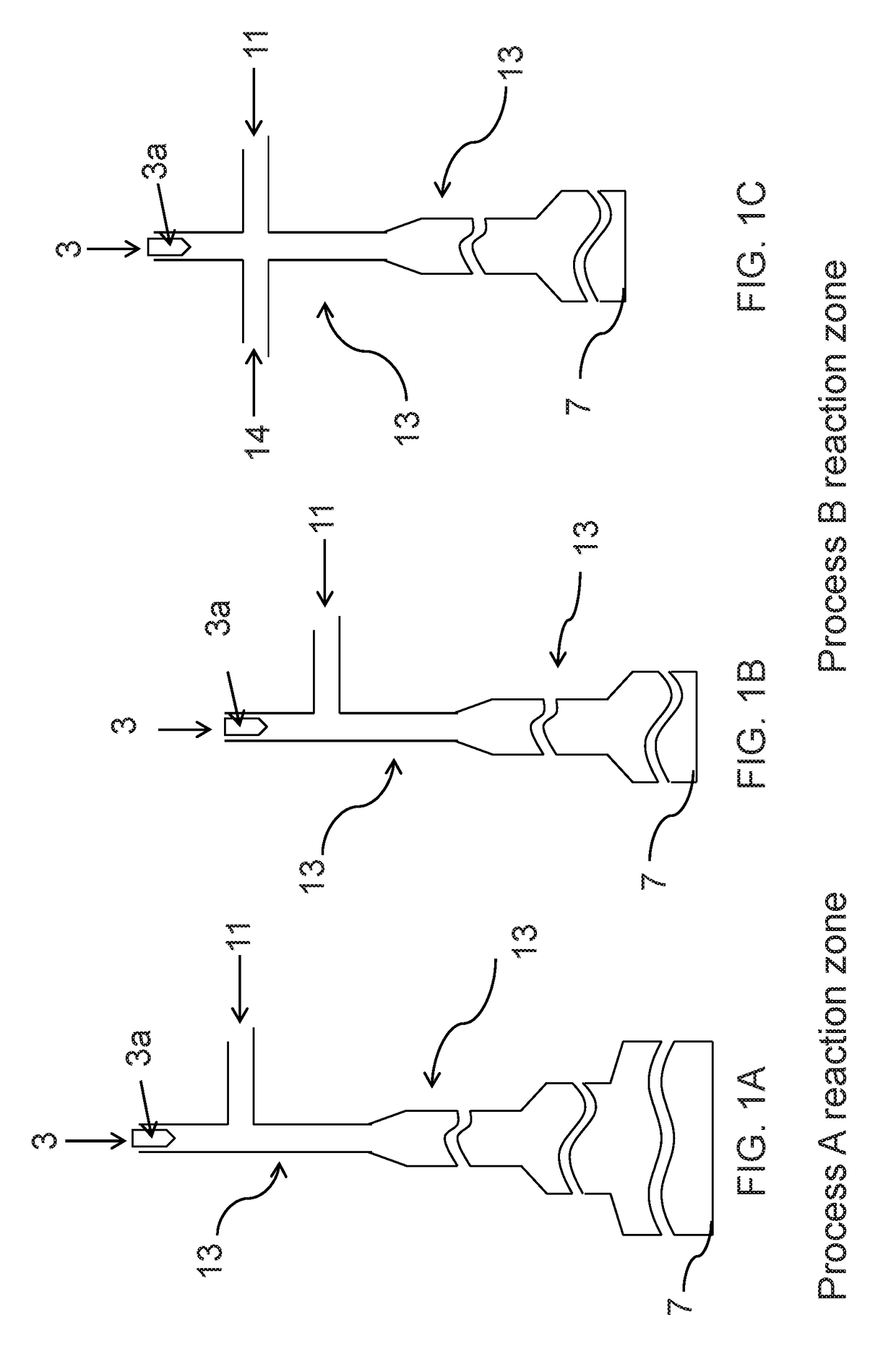

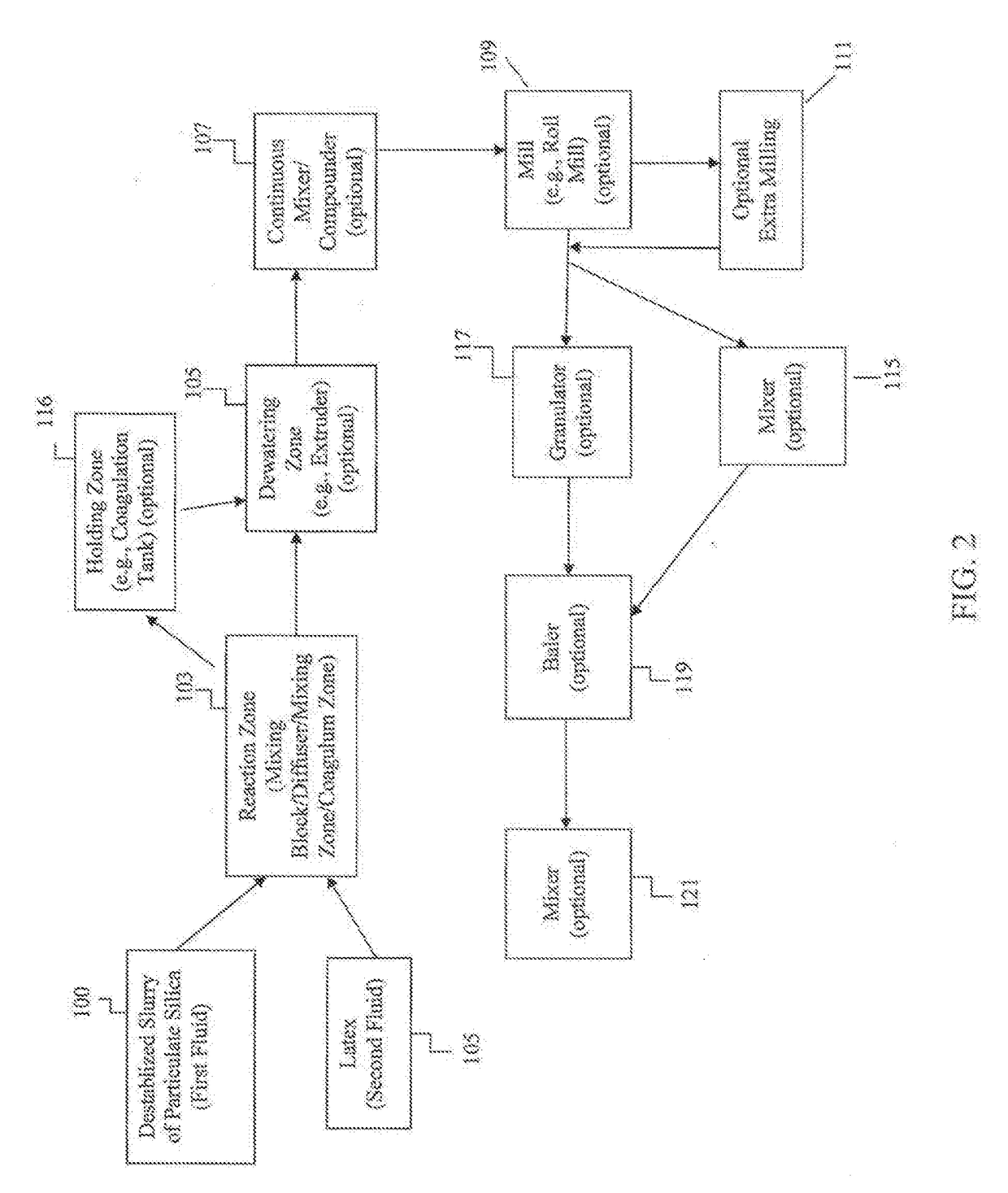

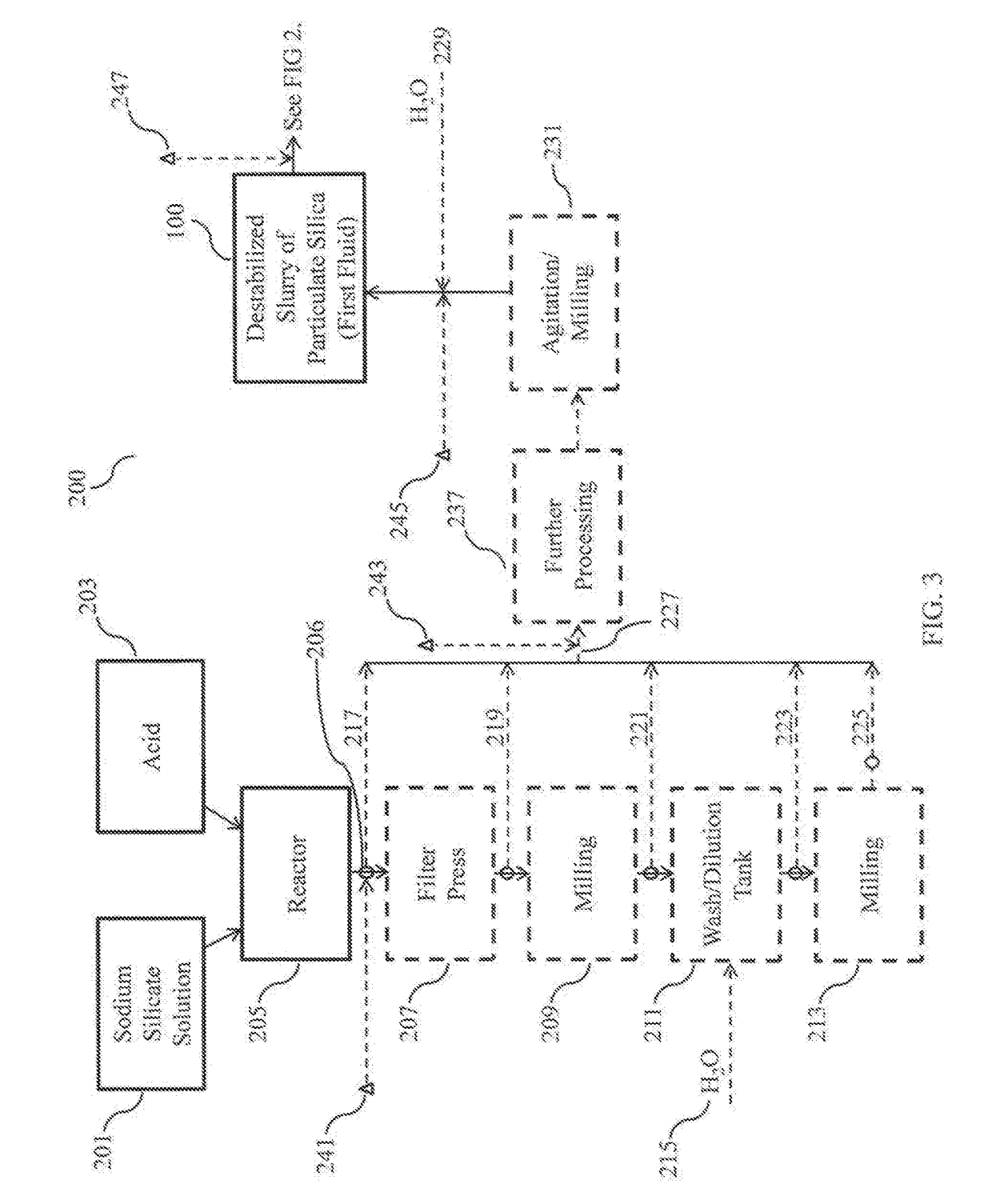

Methods of making an elastomer composite reinforced with silica and products containing same

Methods to make a silica elastomer composite with a destabilized dispersion of a never-dried, or as-produced, precipitated silica are described, along with silica elastomer composites made from the methods. The advantages achieved with the methods are further described.

Owner:CABOT CORP

High-strength wear-resistant natural rubber composite material and preparation method thereof

PendingCN112321909AImproves tensile strength and abrasion resistanceReduce tanglingSilicon nitrideMicrocrystalline cellulose

The invention discloses a high-strength wear-resistant natural rubber composite material and a preparation method thereof. The rubber material is prepared from the following raw materials: natural rubber, epoxidized natural rubber, modified silicon nitride, microcrystalline white mica powder, modified halloysite nanotubes, nano microcrystalline cellulose, calcium sulfate whiskers, lignocellulose staple fibers, aramid staple fibers, zinc borate, neodymium stearate, an accelerant and sulfur. The natural rubber and epoxidized natural rubber are used as main materials, lignocellulose staple fibersand aramid staple fibers are added into a system at the same time, are uniformly dispersed in the system, have good adhesiveness with the system, and are matched with modified silicon nitride, microcrystalline white mica powder, modified halloysite nanotubes, calcium sulfate whiskers and nano microcrystalline cellulose, a significant role in enhancing wear resistance is realized, and the tensilestrength, tearing strength and wear resistance of the composite material are remarkably improved while the vulcanization characteristic of the rubber compound is maintained.

Owner:侯光宇

Carbon white in use for synthetic rubber, and preparation method

InactiveCN1916059AGood dispersionPoor dispersionSilicon oxidesSynthetic rubberDispersion coefficient

This invention discloses a white carbon black for synthesizing rubber. The white carbon black comprises more than 90 wt. % SiO2, and has a specific surface area of 150-380 m2 / g. When the white carbon black is used as tire rubber or silicon rubber additive, the weight ratio of the white carbon black to ruuber is (20-85): 100, while the dispersion coefficient of the white carbon black in rubber is up to 95-100%. This invention also discloses a technique for producing the white carbon black. The technique comprises dissolving, synthesizing, filtering and spraying to directly produce the white carbon black, and can lower the cost.

Owner:周玉芳 +1

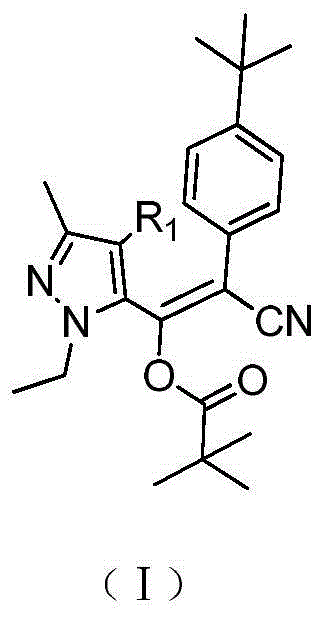

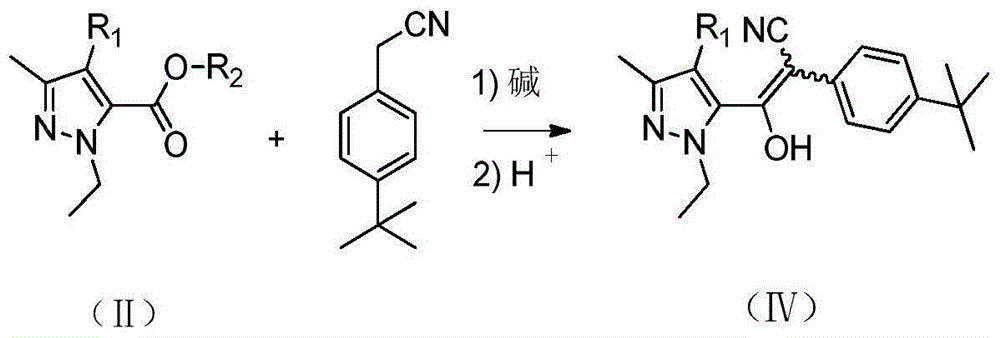

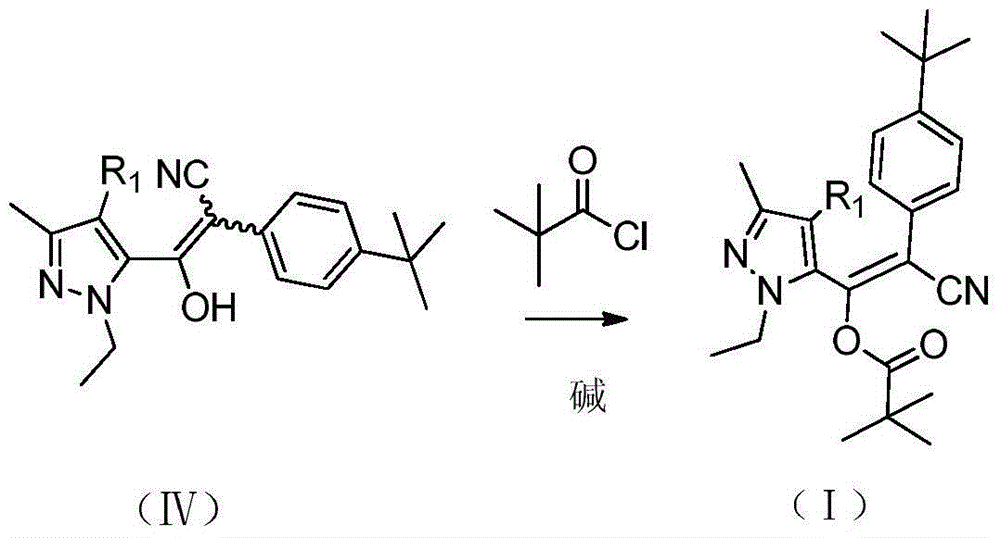

Preparation method of pyrazolyl acrylonitrile compound

The invention belongs to the field of organic synthesis, and concretely relates to a preparation method of a pyrazolyl acrylonitrile compound. A pyrazole carboxylic ester compound and p-tert-butylphenylacetonitrile are shown in a general formula (II), in the existence of an organic solvent and alkali, a reaction is carried out at 60-160 DEG C, 2-(4-(tert-butyl)phenyl)-1-(1-ethyl-3-methyl-1hydrogen-5-pyrazolyl)-2-cyan vinyl alcohol sodium salt or kali salt is obtained as shown in a general formula (III), a reaction is directly carried out between the obtained compound (III) and pivaloyl chloride at 60-160 DEG C, and the pyrazolyl acrylonitrile compound as shown in a general formula (I) is obtained. The method has the advantages of high yield of the target compound, low 'three wastes (waste gas, waste water and industrial residue)' discharge, and simple operation; and the method is suitable for large scale industrial production.

Owner:SHENYANG SINOCHEM AGROCHEMICALS R&D CO LTD

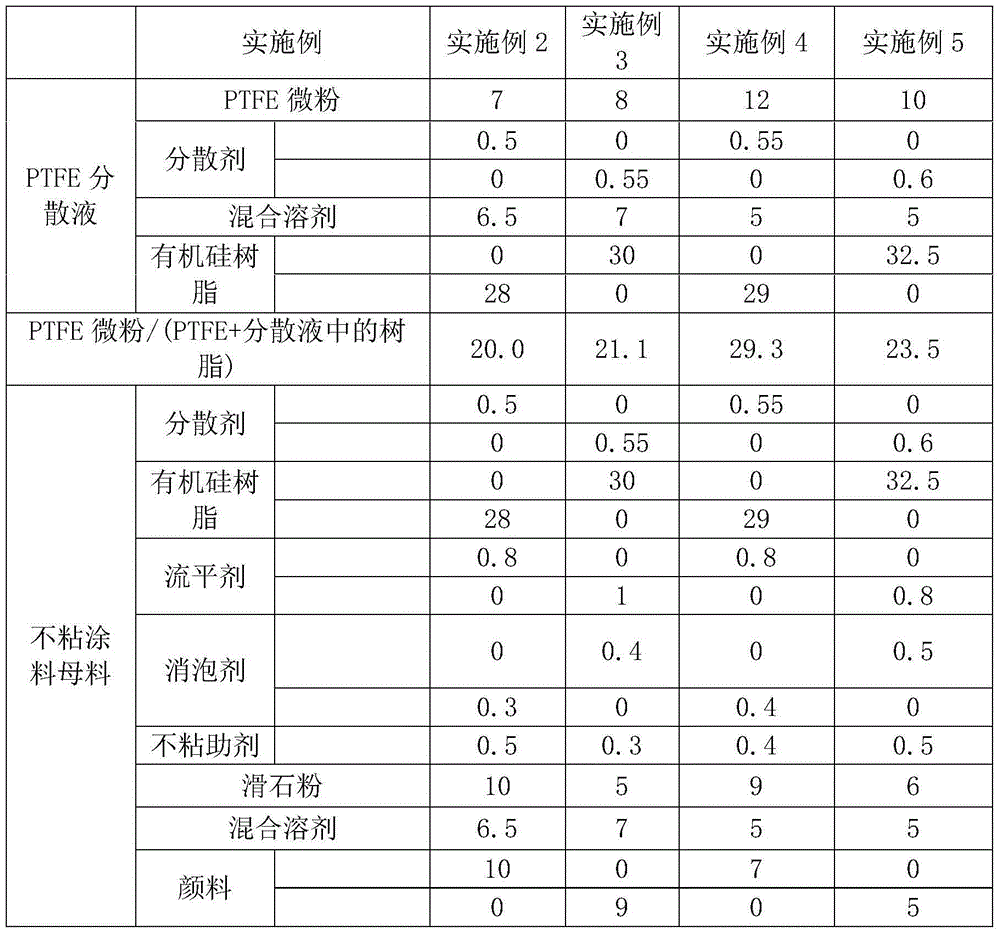

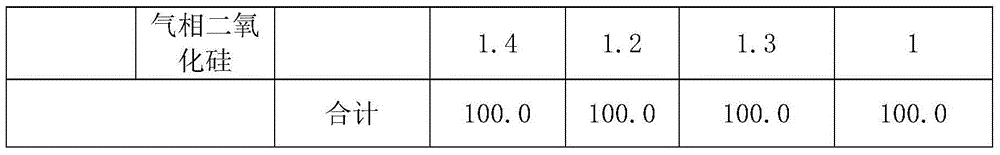

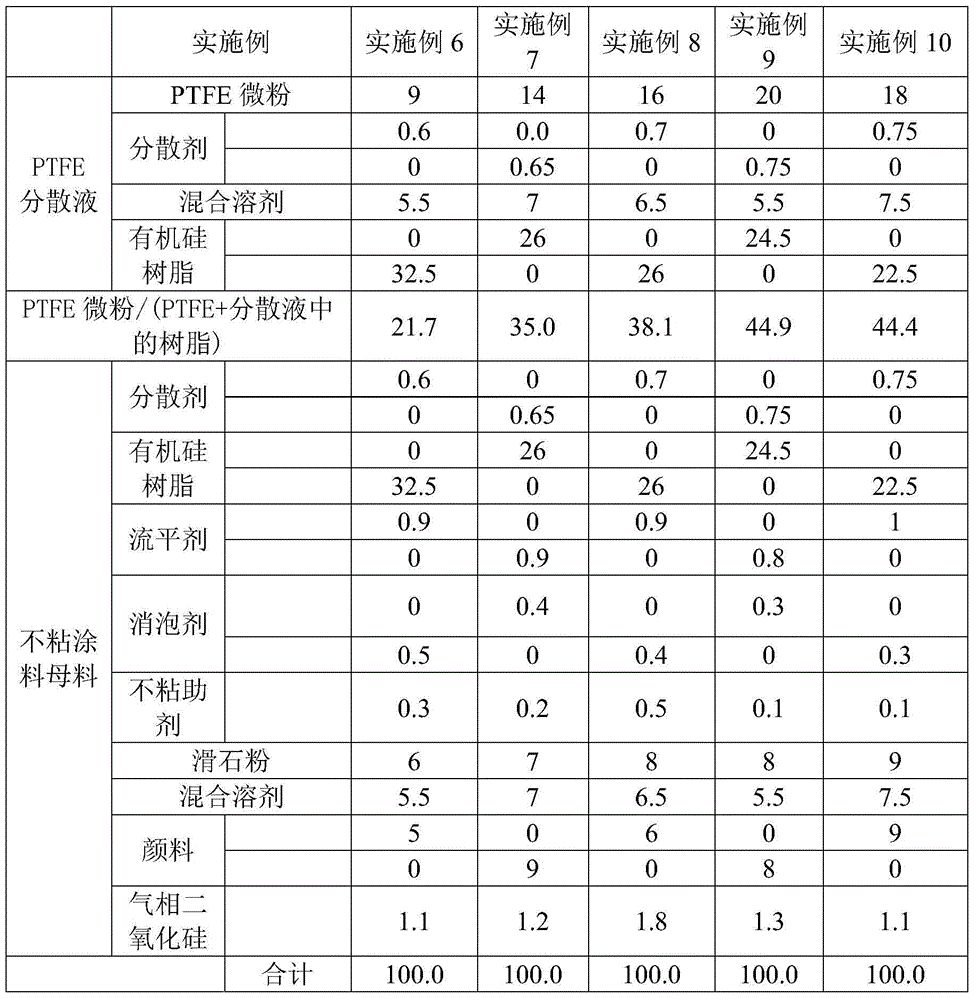

Dispersing method of PTFE superfine powder and application of dispersion liquid thereof in non-stick coating

The invention discloses a dispersing method of PTFE superfine powder and application of the dispersion liquid thereof in non-stick coating. The dispersing method of PTFE superfine powder comprises the following steps: (1) sequentially adding PTFE superfine powder, a dispersing agent, a solvent and resin into a clean solvent; and (2) stirring for dispersion with a propeller to obtain the dispersion liquid of the PTFE superfine powder, wherein the stirring speed is 200-300rmp, the dispersing time is 1-4h, and the dispersing temperature is lower than 30 DEG C. The invention also introduces application of the dispersion liquid and non-stick coating. The dispersing method of the PTFE superfine powder is simple in technology and convenient to operate and does not need additional equipment; and by adopting the method disclosed by the invention, the PTFE superfine powder and resin have perfect wetting dispersity and disperse system stability, second aggregation of the stored PTFE superfine powder is avoided, and the problem of dispersion of the PTFE superfine powder added into the coating as an additive is solved.

Owner:科创(衢州)化工技术开发有限公司

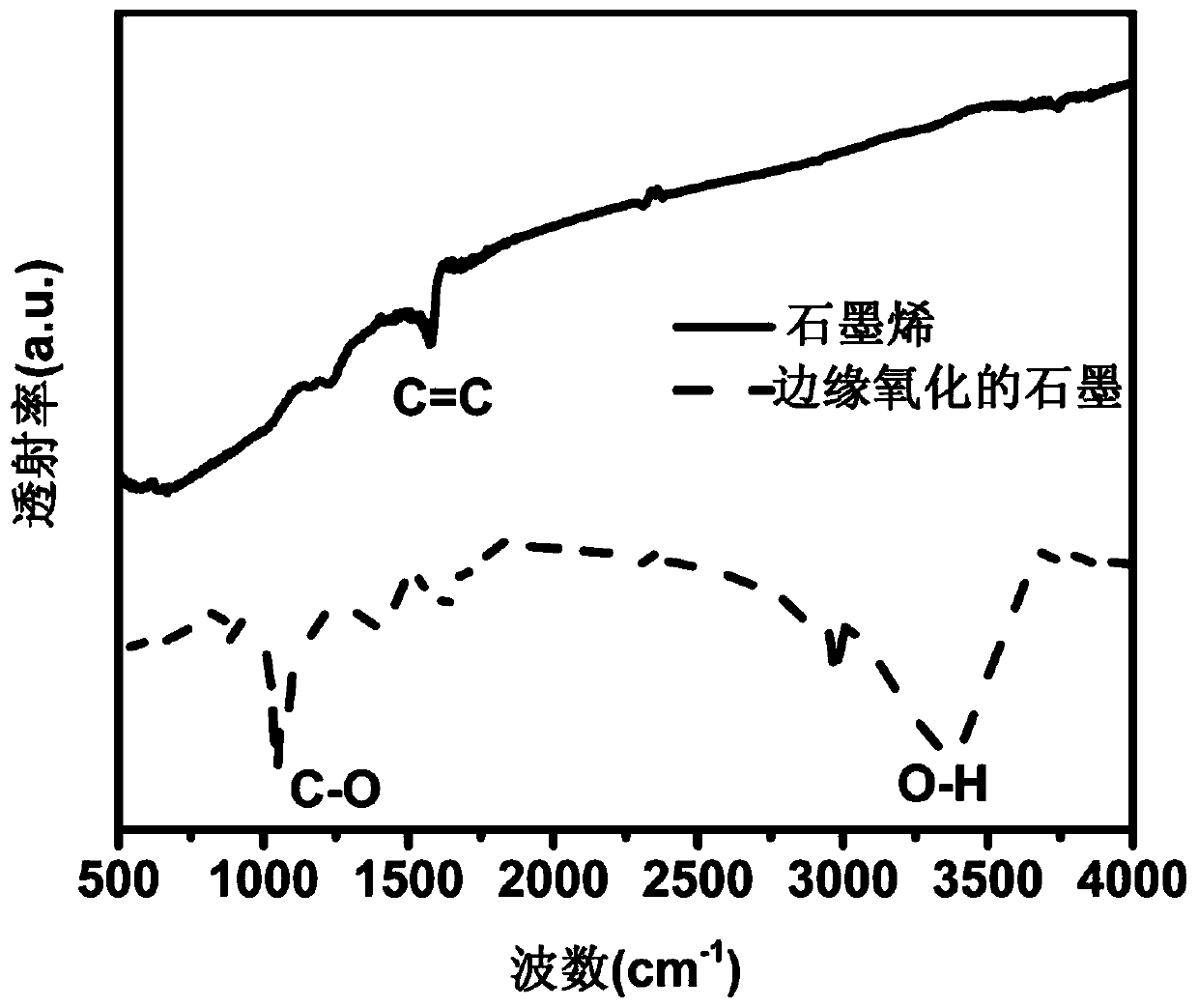

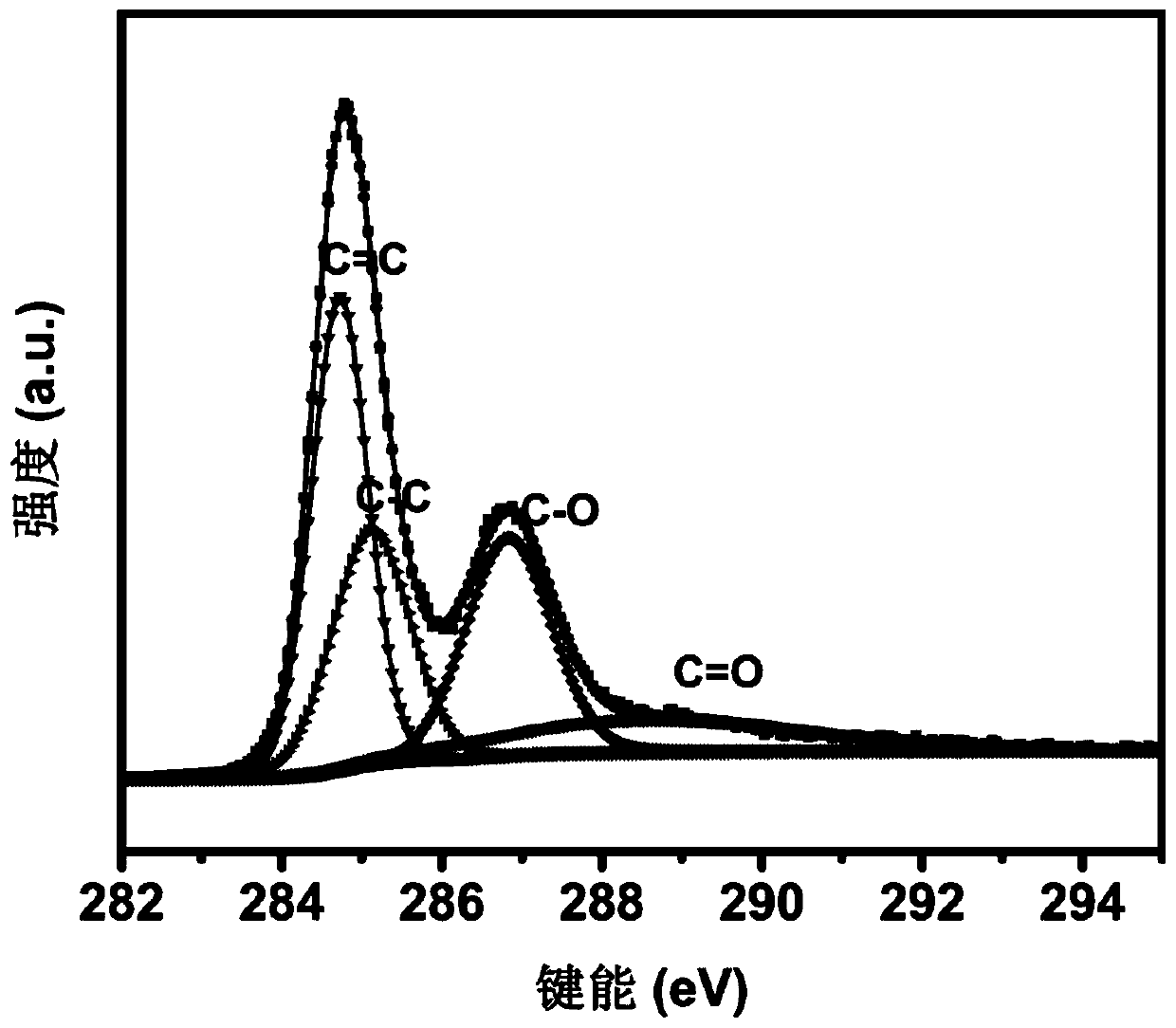

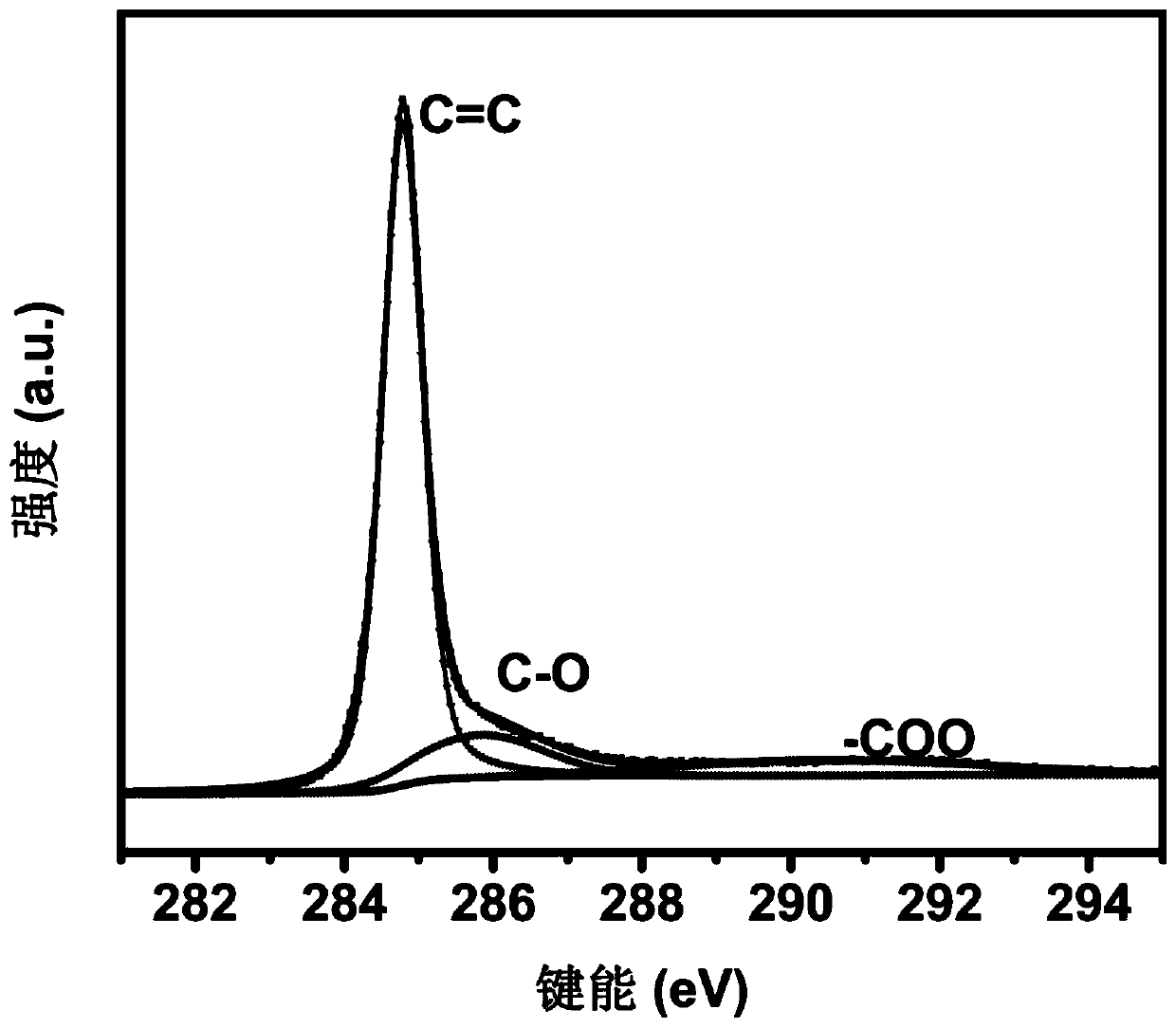

Preparation method of graphene material and application of graphene material in preparation of lithium ion battery

InactiveCN111039282AReduce pollutionShort preparation timeCell electrodesGraphenePhysical chemistryLithium-ion battery

The invention provides a preparation method of a graphene material and the application of the graphene material in preparation of a lithium ion battery. According to the preparation method, simple, convenient and easy-to-obtain graphite powder is used as a raw material, and the graphite powder is oxidized by adopting a plasma oxidation-chemical oxidation combined technology to prepare a graphene oxide precursor; then graphene oxide is prepared from the graphene oxide precursor through a plasma oxidation technology; and finally, the graphene material is prepared by adopting a plasma reduction technology. Compared with a single chemical oxidation process, the preparation method disclosed by the invention has the advantages that consumed time is shorter, large-scale production can be realized, functional groups can be added for modification in the preparation process, no explosion risk exists in the preparation process, and environmental pollution is very small; the edge of the prepared graphene is oxidized to generate carbonyl groups, hydroxyl groups and other hydrophilic groups, so the solubility of the graphene in an aqueous solution is increased; compared with the original graphite oxide material, the prepared graphene material has the advantages that interlayer spacing is obviously increased, and stripping effect is obvious; and when the graphene material is used for preparing a lithium ion battery negative electrode material, the specific capacity of the lithium ion battery negative electrode material in actual use is close to a theoretical value during initial chargingand discharging.

Owner:HEFEI INSTITUTES OF PHYSICAL SCIENCE - CHINESE ACAD OF SCI +1

Method for making a dispersion

InactiveUS20100116172A1Poor dispersionIncrease volumeMaterial nanotechnologyBuilding insulationsNanoparticleMicroparticle

The present disclosure relates a method of making a dispersion. Microparticles, nanoparticles and an asphalt component are mixed to form a dispersion. A sufficient amount of nanoparticles provides for an increase in material throughput relative to a comparable dispersion that is free of nanoparticles.

Owner:3M INNOVATIVE PROPERTIES CO

Alumina-based adsorbent containing sodium and doped with an alkali element for capturing acidic molecules

ActiveUS20170225144A1Improve performanceLarge capacityGas treatmentOther chemical processesSorbentMetal

The present invention relates to an adsorbent comprising an alumina support and at least one alkali element, said adsorbent being obtained by introducing at least one alkali element, identical to or different from sodium, onto an alumina support the sodium content of which, expressed as Na2O equivalent, before the introduction of the alkali element or elements, is comprised between 1000 and 5000 ppm by weight with respect to the total weight of the support. The invention also relates to processes for the preparation of said adsorbent and use thereof in a process for the elimination of acidic molecules such as COS and / or CO2.

Owner:INST FR DU PETROLE

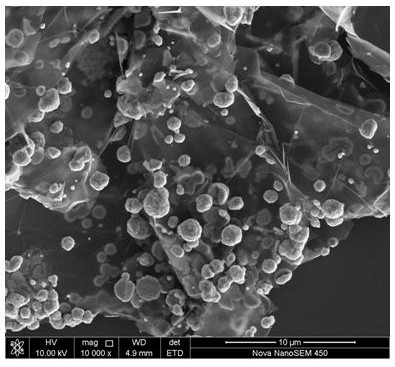

Copper-plated graphene aluminum-based composite material and preparation method thereof

ActiveCN112281012APoor dispersionEasy reunionLiquid/solution decomposition chemical coatingAluminium powderAluminium matrix

The invention provides a copper-plated graphene aluminum-based composite material and a preparation method thereof. The method comprises the following steps that S1, solution-method copper plating treatment is conducted on the surface of graphene powder, and copper-plated graphene powder is prepared; S2, the copper-plated graphene powder prepared in the step S1 and aluminum powder are mixed through an electrostatic self-assembly method, and copper-plated graphene and aluminum composite powder is prepared; and S3, the copper-plated graphene and aluminum composite powder prepared in the step S2is sintered by adopting a spark plasma sintering process to prepare the copper-plated graphene aluminum-based composite material. According to the copper-plated graphene aluminum-based composite material and the preparation method thereof, the copper-plated graphene is used as a reinforcing body, and copper particles can be uniformly coated on the surface of graphene, so that the graphene is uniformly dispersed in an aluminum matrix, the interface bonding of the graphene and the aluminum matrix is improved, and the hardness and the wear resistance of the composite material are improved.

Owner:NANCHANG HANGKONG UNIVERSITY

Environmentally-friendly paste discharge agent for textile printing and preparation method thereof

ActiveUS20140148518A1Improve grinding efficiencyGood dispersibilityOther chemical processesTransportation and packagingTextile printerChemical reaction

The invention discloses an environmentally-friendly pasty discharge agent for textile printing and a method for preparing the environmentally-friendly pasty discharge agent. The environmentally-friendly pasty discharge agent for textile printing is formed by the following raw materials according to part by weight: decamethylcyclopentasiloxane: 30-60 parts; thiourea dioxide: 40-70 parts; surfactant: 1-3 parts; and glycerol: 3-6 parts. Decamethylcyclopentasiloxane is put into a ball mill, a surfactant is added into the ball mill to make the decamethylcyclopentasiloxane dispersed or dissolved uniformly and then stirred uniformly, and then thiourea dioxide is added into the ball mill and ground together for 1-3 hours. In the invention, the special liquid compound decamethylcyclopentasiloxane does not chemically react with the thiourea dioxide; in addition, it isolates the thiourea dioxide from outside water and air, thus increasing the stability of the thiourea dioxide. The discharge effect is excellent, the defects of low dissolvability, poor dispersion uniformity in the discharge paste, poor net permeability and insufficient discharge effect of the common thiourea dioxide as the discharge agent are overcome, and there is no influence on the touch of the discharged and printed textiles.

Owner:ZHEJIANG SCI-TECH UNIV

Method for making organic light emitting diode

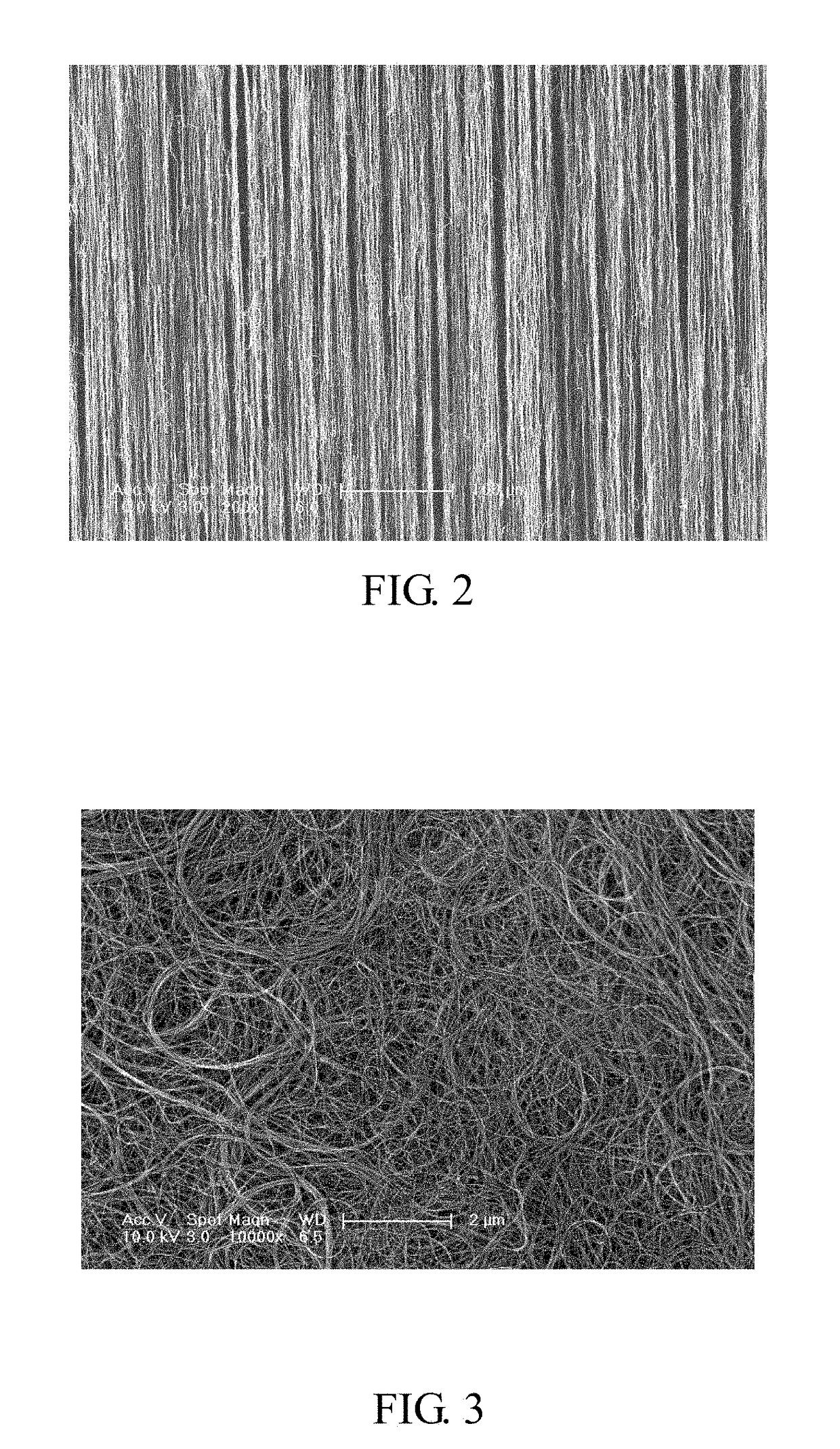

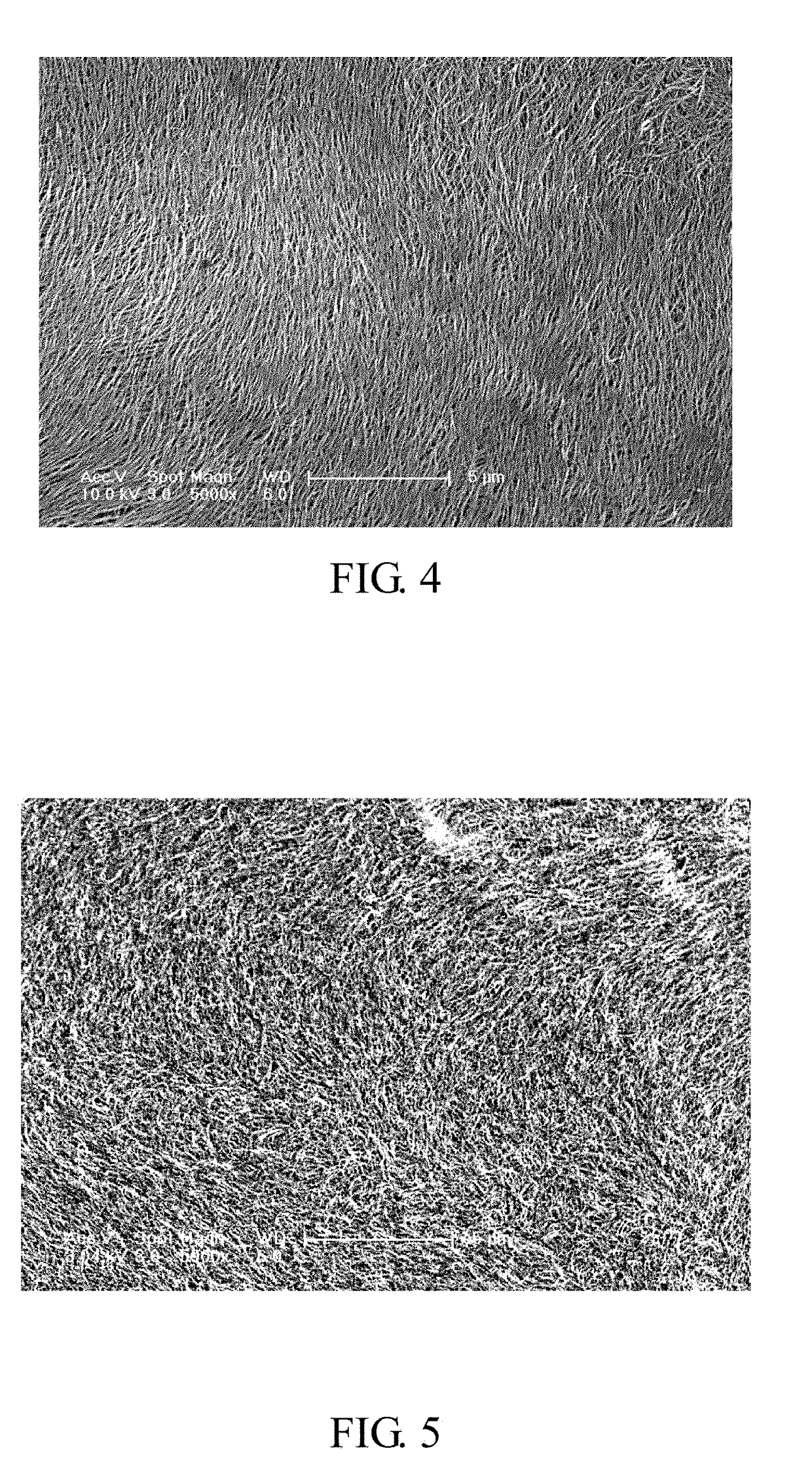

ActiveUS20190067622A1Poor dispersionHigh viscositySolid-state devicesSemiconductor/solid-state device manufacturingCarbon nanotubeHole transport layer

A method for making an organic light emitting diode includes providing a preform structure including an anode electrode, a hole transport layer, and an organic light emitting layer stacked on each other in that order. A carbon nanotube composite structure including a polymer and a plurality of first carbon nanotubes dispersed in the polymer is also provided. The plurality of first carbon nanotubes is substantially parallel to each other, and a part of surface of the plurality of first carbon nanotubes is exposed from the polymer. The preform structure, the carbon nanotube composite structure and a cathode electrode are stacked on each other in that order.

Owner:TSINGHUA UNIV +1

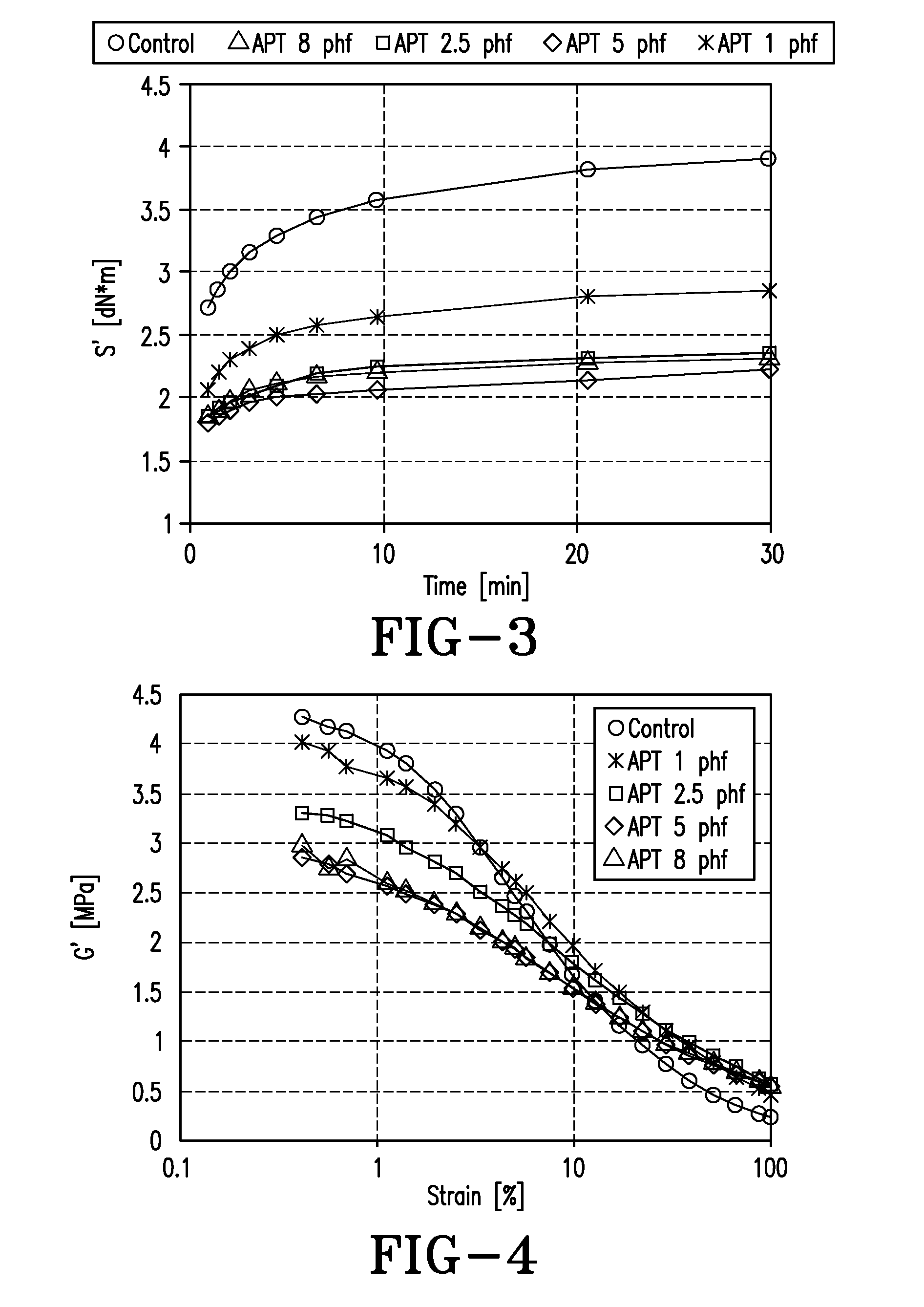

Preparation and use of functionalized elastomers in rubber compositions containing silica filler and tire components thereof

InactiveUS9133281B2Increase stiffnessPoor dispersionSpecial tyresPost polymerizationPrecipitated silica

This invention relates to preparation and use of in situ functionalized elastomers in a rubber composition, namely post polymerization functionalization of elastomers, in rubber compositions containing precipitated silica filler reinforcement and tires having components thereof.

Owner:THE GOODYEAR TIRE & RUBBER CO

Method for producing metal powder-containing composition

InactiveCN103747897AInhibition of poor dispersionExcellent stability over timeMaterial nanotechnologySpark gap detailsMetal alkoxideSalt water

The purpose of the present invention is to provide a method for producing a metal powder-containing composition that has excellent re-dispersibility and excellent long-term stability by solving the problems of solidification of the composition and sedimentation of the metal powder, said problems being caused by poor dispersion due to the fact that the metal powder is coated with a metal oxide in the composition that contains the metal powder. A method for producing a metal powder-containing composition of the present invention is a method for producing a metal powder-containing composition that contains a metal powder and a binder component. This method for producing a metal powder-containing composition comprises: a step wherein a metal oxide is produced by hydrolyzing a metal alkoxide and a metal powder is coated with the metal oxide; and a step wherein the metal powder coated in the above-mentioned step is heated to 70 DEG C or higher in an organic solvent.

Owner:SHOWA DENKO KK

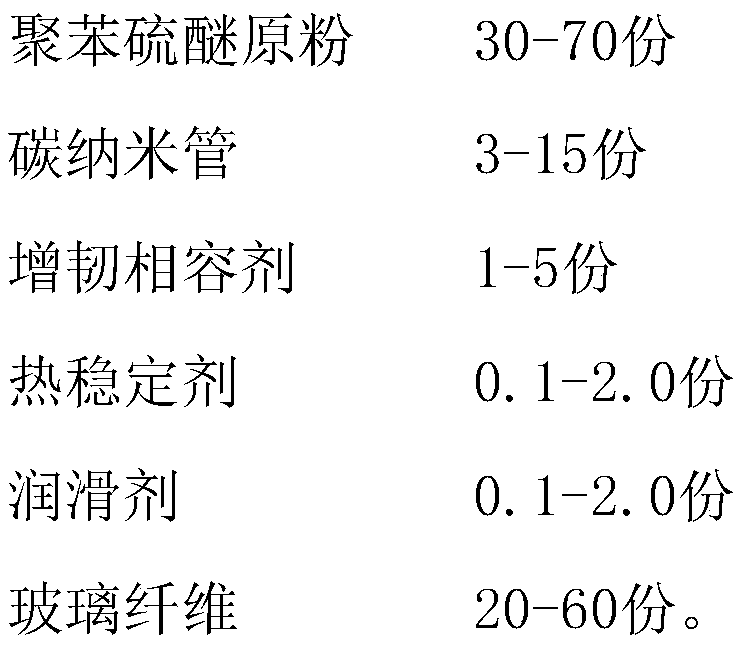

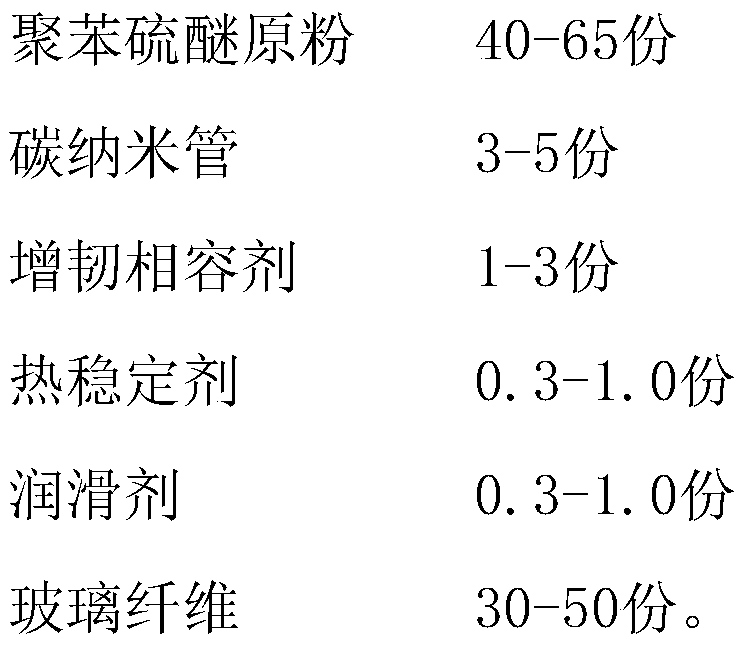

Glass fiber reinforced PPS-CNT (polyphenylene sulfide-carbon nano tube) conductive composite and preparation method thereof

The invention relates to the technical field of high polymer materials, in particular to a glass fiber reinforced PPS-CNT (polyphenylene sulfide-carbon nano tube) conductive composite and a preparation method thereof. The PPS-CNT conductive composite is prepared from raw materials in parts by weight as follows: 30-70 parts of PPS raw powder, 3-15 parts of CNTs, 1-5 parts of a toughening compatibilizer, 0.1-0.2 parts of a heat stabilizer, 0.1-2.0 parts of a lubricant and 20-60 parts of glass fibers. The glass fiber reinforced PPS-CNT conductive composite with high cost performance and high performance is provided in order to solve the problems that an existing graphite conductive PPS material does not have sufficient mechanical property and is high in addition amount and difficult to process and a carbon fiber conductive PPS material is high in adding proportion, poor in dispersion and high in cost.

Owner:深圳市高科塑化有限公司

Method for preparing corrosion-resistant encapsulating material for lithium battery

InactiveCN108822448AImprove corrosion resistanceImprove anti-corrosion performanceMagnetic stirrerFluorocarbon

The invention discloses a method for preparing a corrosion-resistant encapsulating material for a lithium battery. The method comprises the following steps: (1) preparing an activated fluorocarbon resin prepolymer: adding ethanol into a magnetic stirrer, then, adding fluorocarbon resin, starting up the magnetic stirrer, carrying out stirring for 15 to 25 minutes at a stirring temperature of 85 DEGC to 95 DEG C at a stirring revolution rate of 115r / min to 125r / min, then, adding graphene oxide and a nonionic surfactant, and continuing to carry out stirring for 25 to 35 minutes. According to themethod for preparing the corrosion-resistant encapsulating material for the lithium battery, disclosed by the invention, the operation is simple, and the corrosion resistance of the encapsulating material can be obviously improved.

Owner:合肥仁德电子科技有限公司

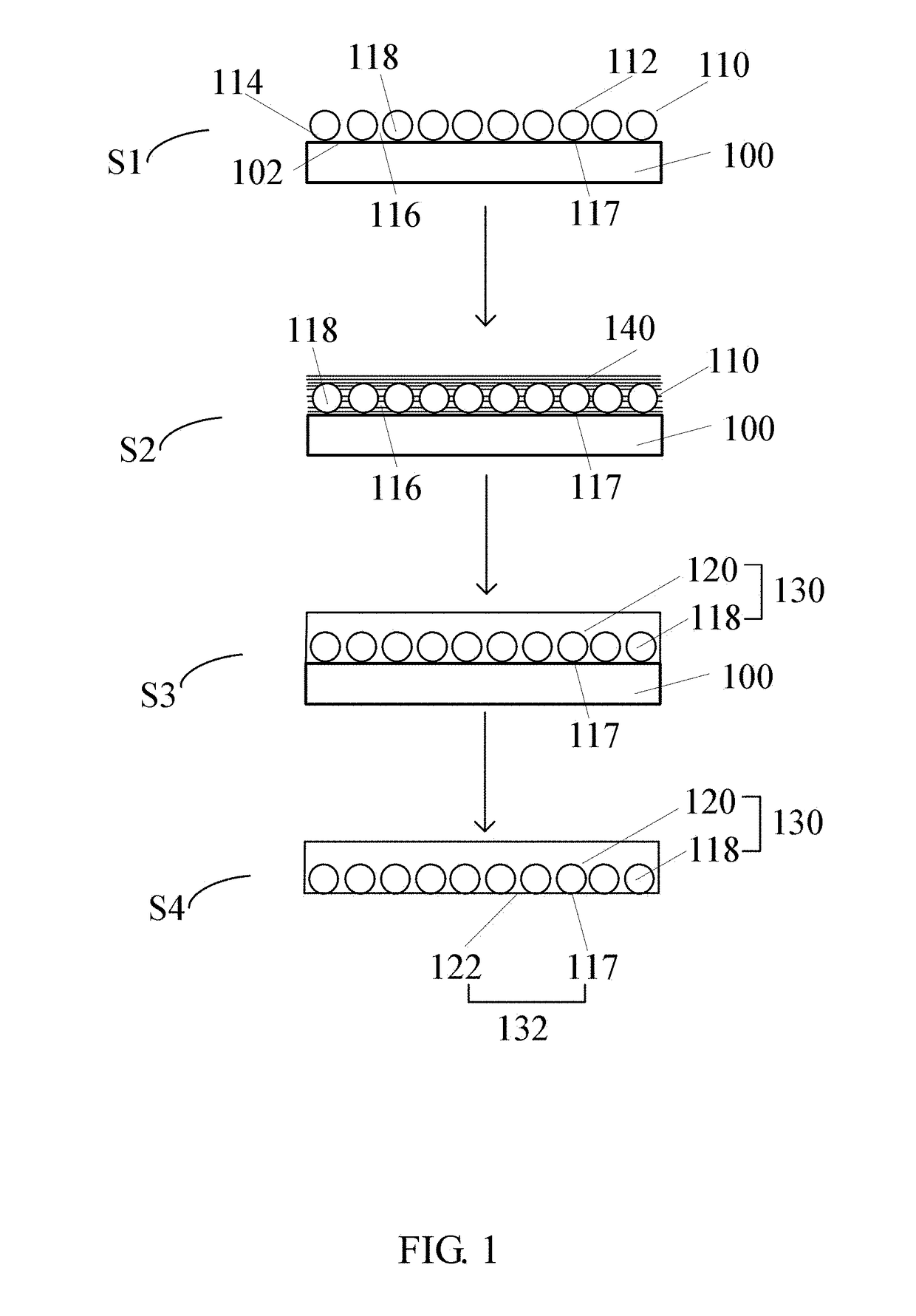

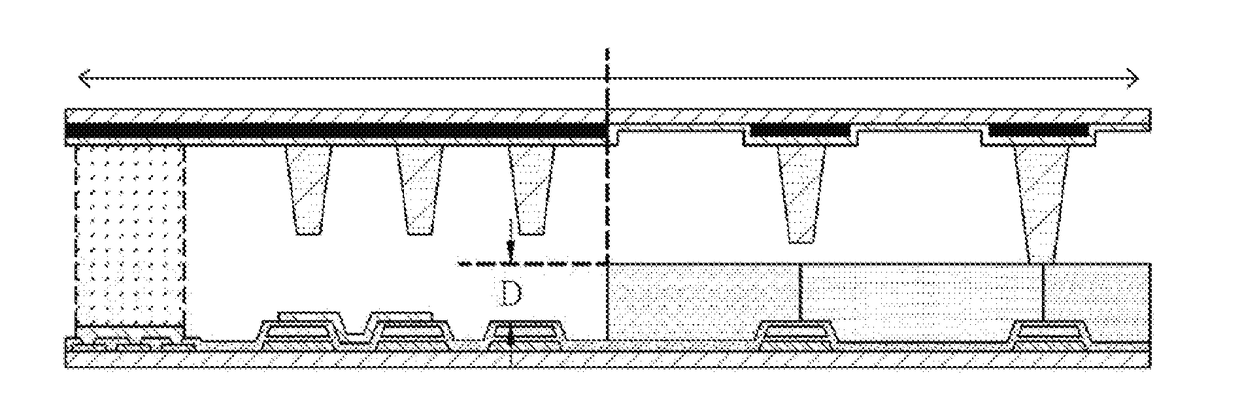

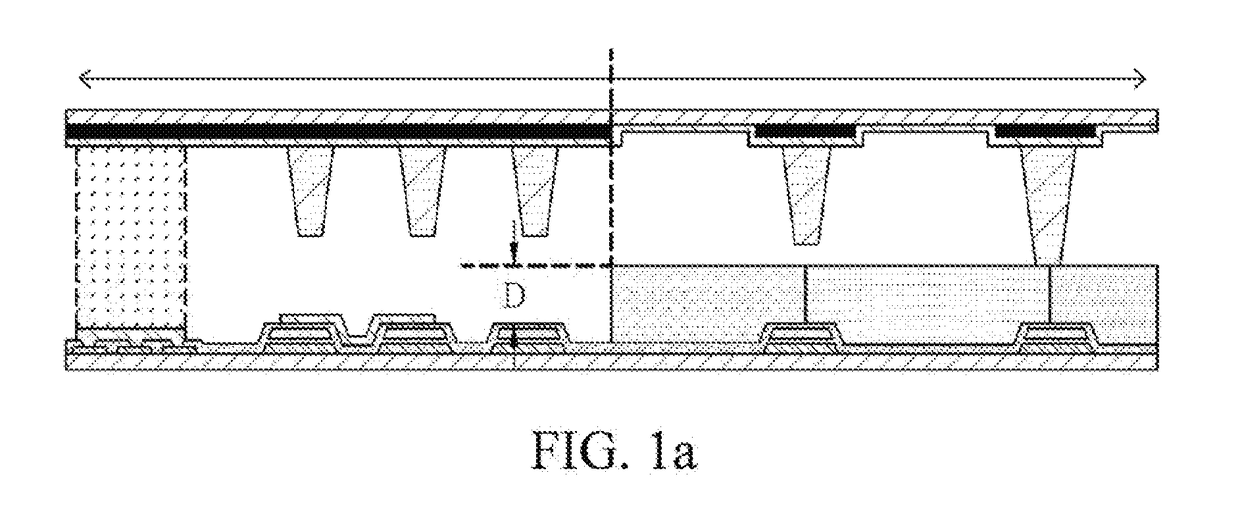

Method for manufacturing liquid crystal display panel

This application relates to a method for manufacturing a liquid crystal display panel, including: providing a first substrate; providing a second substrate including a display region and a bezel region, where the bezel region is located on an edge of the second substrate and surrounds the display region; forming a color filter layer on the display region of the second substrate, where the color filter layer has a first thickness; forming a flat layer on the bezel region of the second substrate, where the flat layer surrounds the color filter layer, the flat layer has a second thickness, and the second thickness is the same as the first thickness, so that the flat layer is flush with the color filter layer, and the flat layer is connected to the color filter layer to form a same plane.

Owner:HKC CORP LTD +1

Rubber composition for tire tread and pneumatic tire using the same

ActiveUS8242199B2Improve wear resistancePoor dispersionPigmenting treatmentAlkali metal halidesCombustionReaction temperature

Owner:BRIDGESTONE CORP

Preparation method of nano silver antibacterial agent, nano silver antibacterial agent, antibacterial plastic and preparation method of antibacterial plastic

The invention discloses a preparation method of a nano-silver antibacterial agent, the nano-silver antibacterial agent, antibacterial plastics and a preparation method of the antibacterial plastics. The preparation method of the nano-silver antibacterial agent comprises the following steps: adopting a liquid-phase chemical reduction method, wherein the liquid phase is a hydroxyl-containing water-free organic solvent, and a protective agent and a penetrating agent can serve as reactive reduction agents; reducing Ag<+> into nano Ag particles at a certain temperature, and finally forming a stablesolution of a silver-containing complex with the protective agent, the penetrating agent and the solvent under a certain conditions, thereby obtaining the stable, colorless, transparent and water-free nano-silver antibacterial solution. The nano-silver antibacterial agent prepared by the method achieves an excellent antibacterial effect when applied to the antibacterial plastics.

Owner:宝鸡霍夫纳米复合材料研究院有限公司

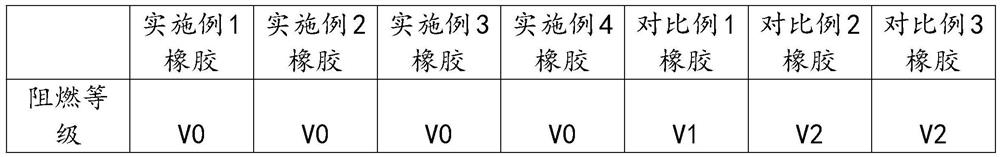

Modified phosphorus-nitrogen type flame retardant and preparation method thereof

InactiveCN112080038APoor dispersionGood dispersionGroup 5/15 element organic compoundsPentaerythritolAqueous sodium hydroxide

The invention provides a modified phosphorus-nitrogen type flame retardant and a preparation method thereof. The preparation method comprises the following steps: adding pentaerythritol into a three-neck flask, putting the flask into an ice-water bath, stirring for 30 minutes at the rotating speed of 100 to 120 r / min, dropwise adding phosphorus oxychloride while stirring, controlling the dropwiseadding time to be 15 minutes, absorbing tail gas by using a sodium hydroxide aqueous solution with the mass fraction of 20% in the dropwise adding process, after dropwise adding is finished, stirringfor 30 minutes at a constant speed, then heating to 60 to 70 DEG C, and stirring for 2 hours at a constant speed at the temperature. In the step S3, melamine and cyanuric acid are mixed and subjectedto hydrogen bond compounding, then a mixed solution A prepared from a second product is added, and the second product is added, so that the formation of a melamine cyanurate large-plane network structure can be interfered and inhibited, the particle size is refined. and the prepared modified phosphorus-nitrogen type flame retardant has good dispersity.

Owner:中著(杭州)知识产权运营有限公司

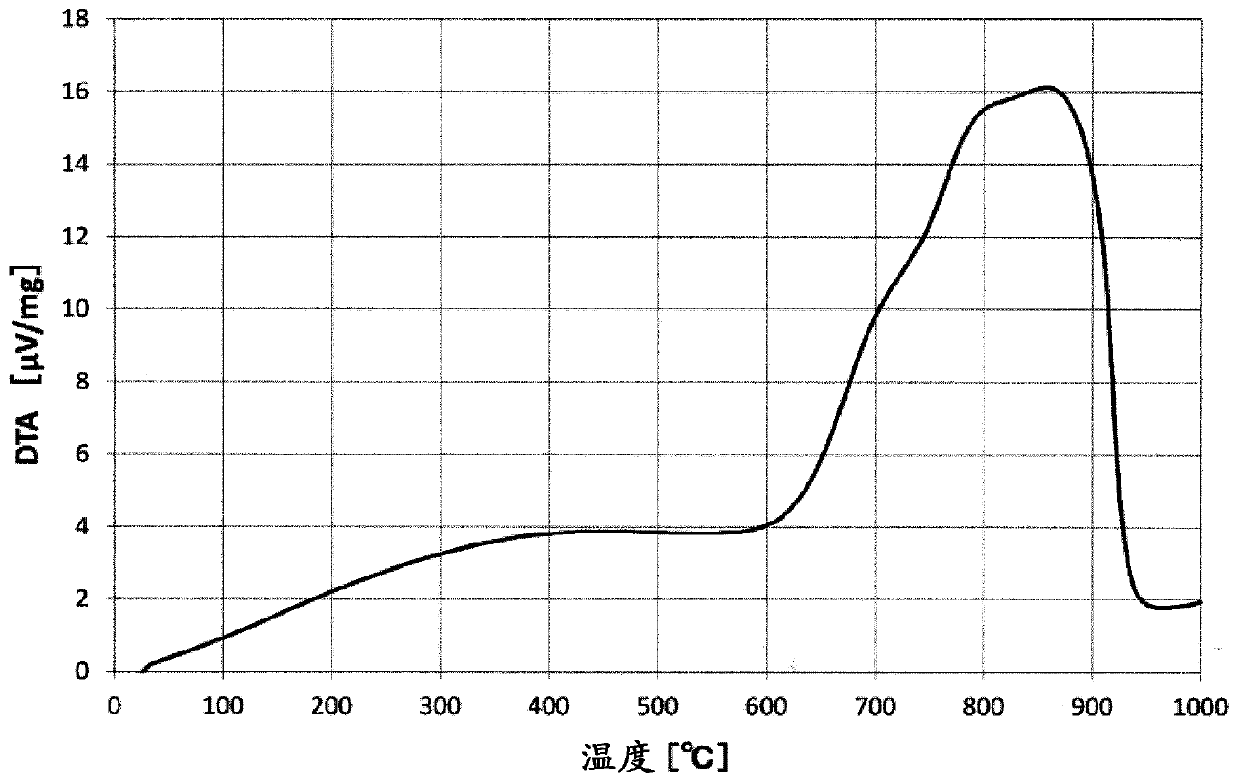

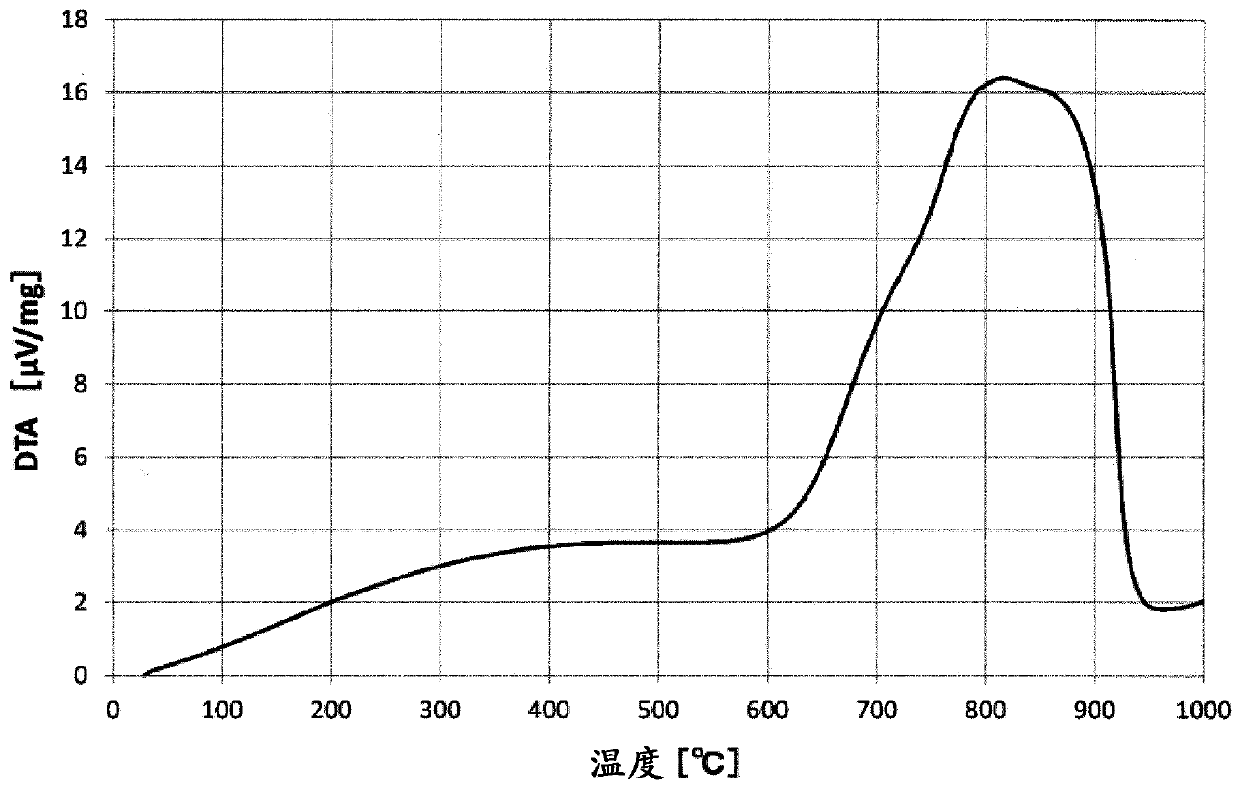

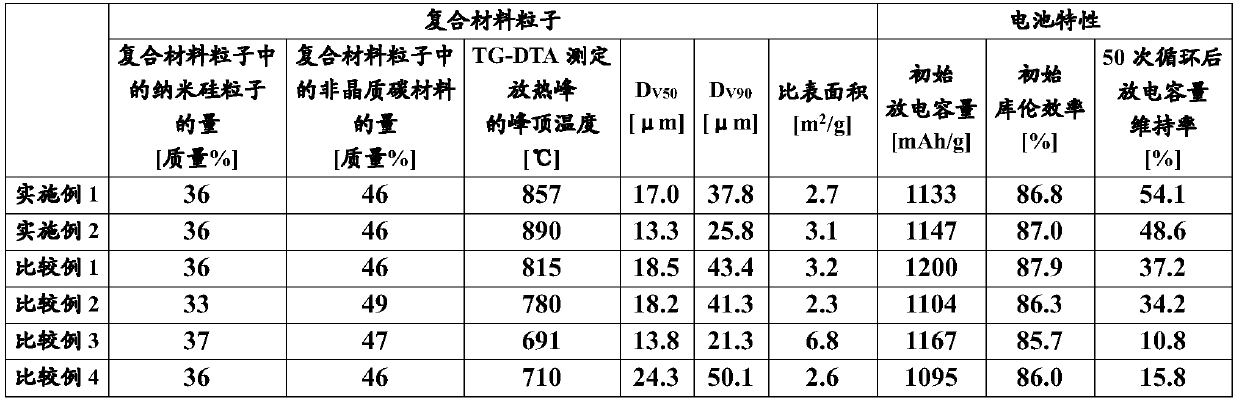

Negative electrode material for lithium ion secondary cell, method for producing same, paste for negative electrode, negative electrode sheet, and lithium ion secondary cell

ActiveCN111418097AImprove featuresImprove initial discharge capacitySiliconGraphiteNano siliconElectrical battery

The present invention pertains to a negative electrode material for a lithium ion secondary cell, the negative electrode material comprising composite material particles that contain nano-silicon particles in which the 50% particle diameter (Dn50) in the number-based cumulative grain size distribution of primary particles is 5-100 nm, graphite particles, and an amorphous carbon material. The composite material particles are such that the nano-silicon particle content is 30-60% by mass (inclusive) and the amorphous carbon material content is 30-60% by mass (inclusive), the 90% particle diameter(DV90) in the volume-based cumulative grain size distribution of the composite material particles is 10.0-40.0 um, the BET specific surface area is 1.0-5.0 m2 / g, and the peak temperature of the exothermic peak in DTA measurement of the composite material particles is 830-950 deg C. According to the present invention, it is possible to provide: a negative electrode material having a high initial discharge capacity of 1000 mAh / g or greater, the negative electrode material being capable of reaching a high initial coulomb efficiency and high cycle characteristics; and a lithium ion secondary cellin which said negative electrode material is used.

Owner:UMICORE AG & CO KG

High-toughness and aging-resistant ABS material

The invention discloses a high-toughness and aging-resistant ABS material, which comprises the following raw materials by weight: 100 parts of ABS resin, 0.5-5.0 parts of alkylated graphene oxide or alkylated reduced graphene oxide and 1.0-10.0 parts of a nano cellulose / attapulgite composite material. Compared with the prior art, according to the invention, graphene oxide is alkylated by tetraoctyl ammonium bromide and 1-iodododecane, so that the dispersity of graphene oxide in a polypropylene material can be remarkably improved, and the toughness of the ABS material is remarkably optimized; moreover, the nano cellulose / attapulgite composite material is also added, so that the toughness and aging resistance of the ABS material can be further improved.

Owner:叶丹平

Methods of making an elastomer composite reinforced with silica and products containing same

Methods to make a silica elastomer composite with a destabilized dispersion of a never-dried, or as-produced, precipitated silica are described, along with silica elastomer composites made from the methods. The advantages achieved with the methods are further described.

Owner:CABOT CORP

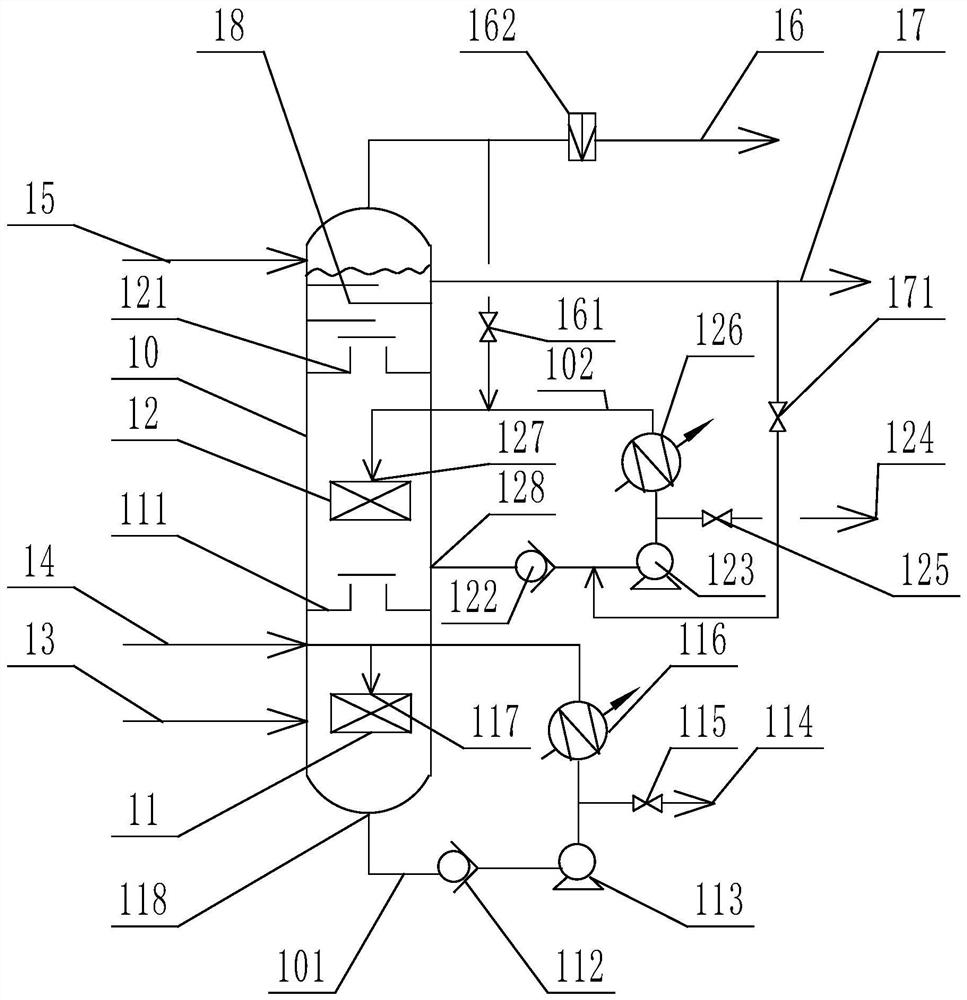

Device and method for polycondensation of polyol by using cyclic compound

PendingCN114471403AImprove efficiencyImprove product molecular weight distributionProcess control/regulationChemical/physical/physico-chemical microreactorsCyclic compoundMaterials science

Owner:NANJING YANCHANG REACTION TECH RES INST CO LTD

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com