Negative electrode material for lithium ion secondary cell, method for producing same, paste for negative electrode, negative electrode sheet, and lithium ion secondary cell

A secondary battery and negative electrode material technology, applied in the field of negative electrode materials, can solve the problem of low cycle characteristics of lithium-ion secondary batteries and achieve the effect of improving battery characteristics

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

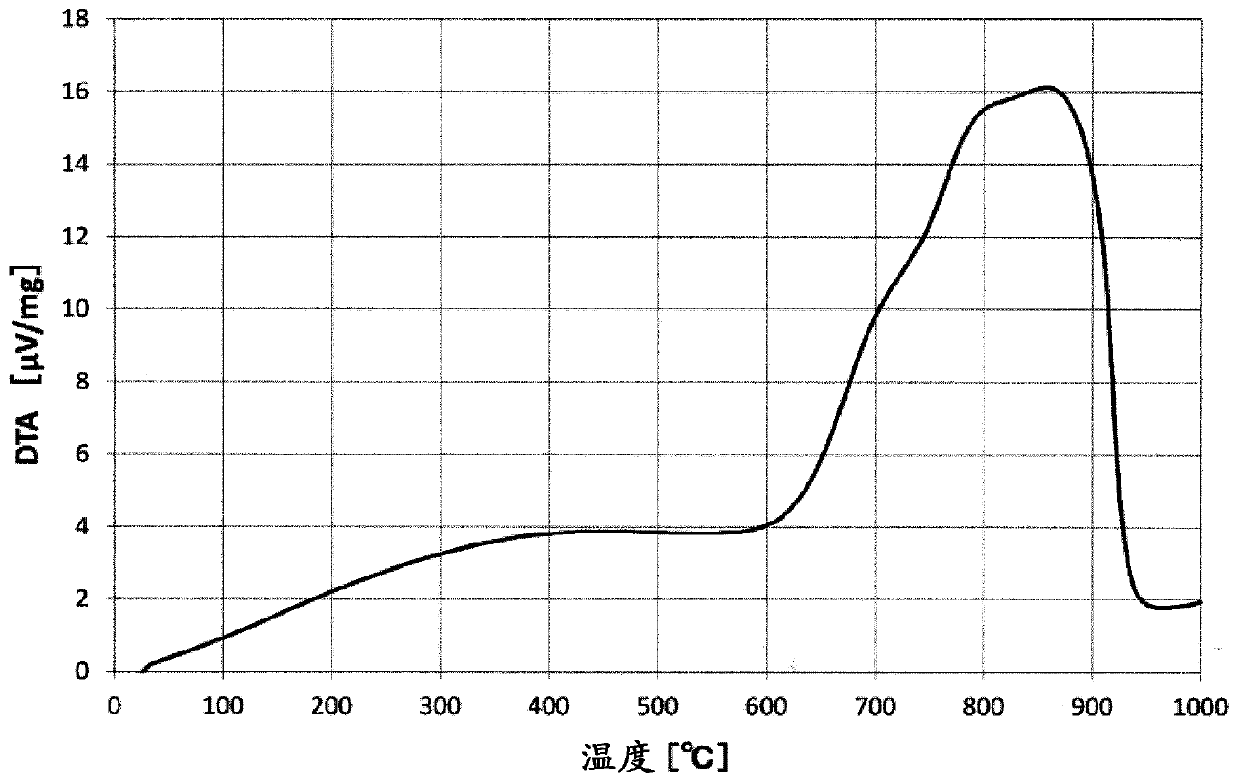

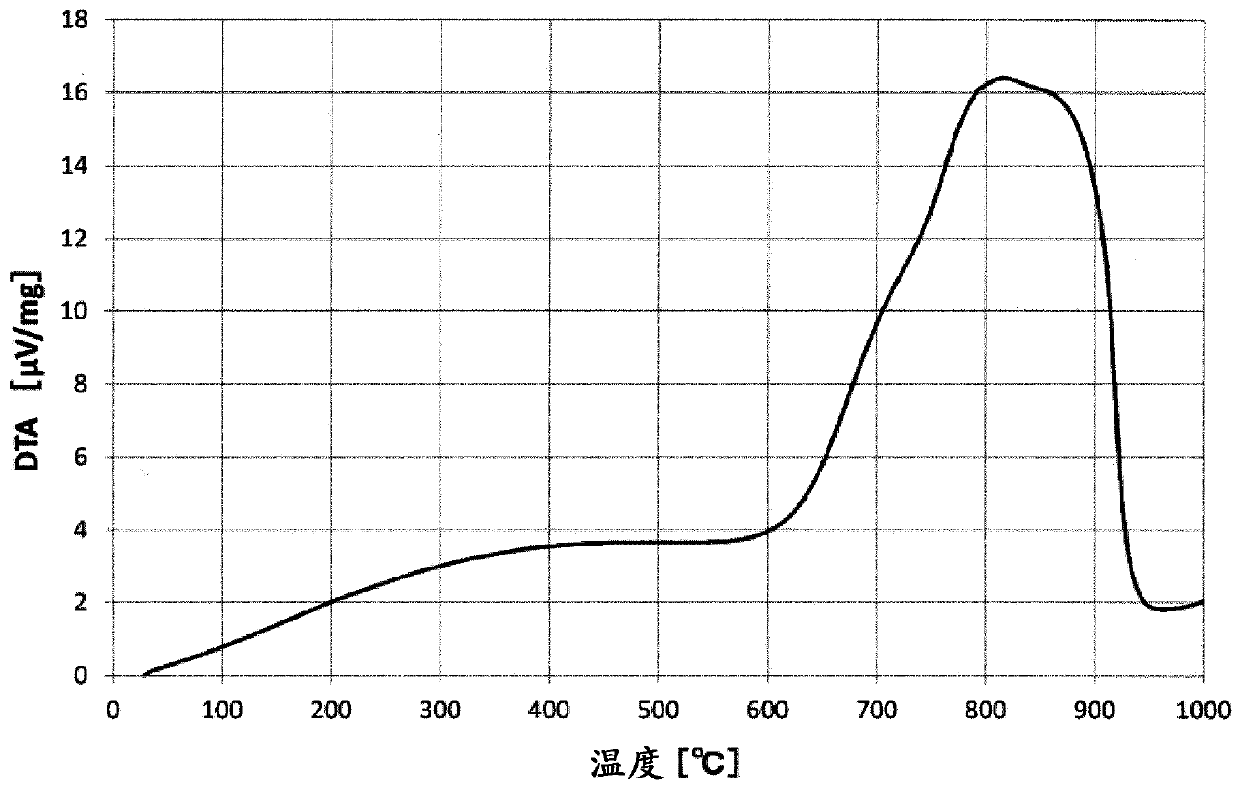

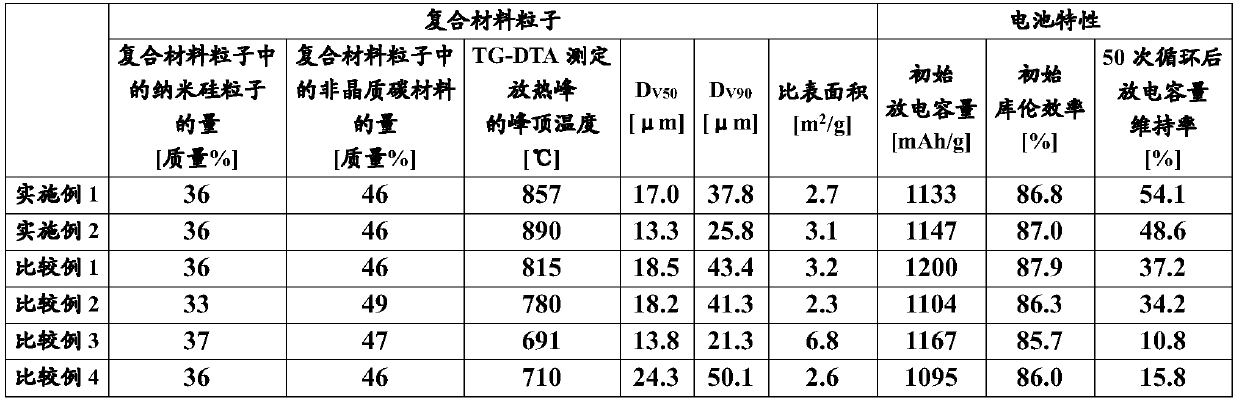

Examples

Embodiment 1

[0134] 4.4 kg of nano-silicon-containing particles 1 and 3.8 kg of graphite particles were weighed, charged into Cyclomix CLX-50 (manufactured by Hosokawa Micron Co., Ltd.), and mixed at a peripheral speed of 24 m / sec for 10 minutes.

[0135] The mixed powder was filled in a bowl made of alumina, and the temperature was raised to 1050° C. at 150° C. / hour under nitrogen gas flow, maintained for 1 hour, and then cooled to room temperature at 150° C. / hour. The heat-treated product was recovered from an alumina bowl, and then pulverized with a Bantam mill (manufactured by Hosokawa Micron Co., Ltd., mesh 0.5 mm) to obtain a composite material A.

[0136] Next, 2.4 kg of composite material A and 5.0 kg of nano-silicon-containing particles 1 were weighed, put into Cyclomix CLX-50 (manufactured by Hosokawa Micron Co., Ltd.), and mixed for 10 minutes at a peripheral speed of 24 m / s to form Mix powder.

[0137] The mixed powder was put into a bowl made of alumina, and the temperature w...

Embodiment 2

[0140] Weigh 22.2g of particles containing nano-silicon 1 and 19.0g of graphite particles, drop into a rotary cutting mill, flow nitrogen, keep an inert atmosphere and mix at 25000rpm (peripheral speed 150m / s) under high-speed stirring for 1 minute.

[0141] The mixed powder was filled in a bowl made of alumina, and the temperature was raised to 1050° C. at 150° C. / hour under nitrogen flow, kept for 1 hour, and then cooled to room temperature at 150° C. / hour. The heat-treated product was recovered from an alumina bowl, and then pulverized with a Bantam mill (manufactured by Hosokawa Micron Co., Ltd., mesh 0.5 mm) to obtain a composite material B.

[0142] Next, weigh 11.9g of composite material B and 25.0g of nano-silicon-containing particles 1, drop into a rotary cutting mill, flow nitrogen, maintain an inert atmosphere and stir and mix at a high speed of 25000rpm (peripheral speed 150m / sec).

[0143] The mixed powder was filled in a bowl made of alumina, and the temperature ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| specific surface area | aaaaa | aaaaa |

| specific surface area | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com