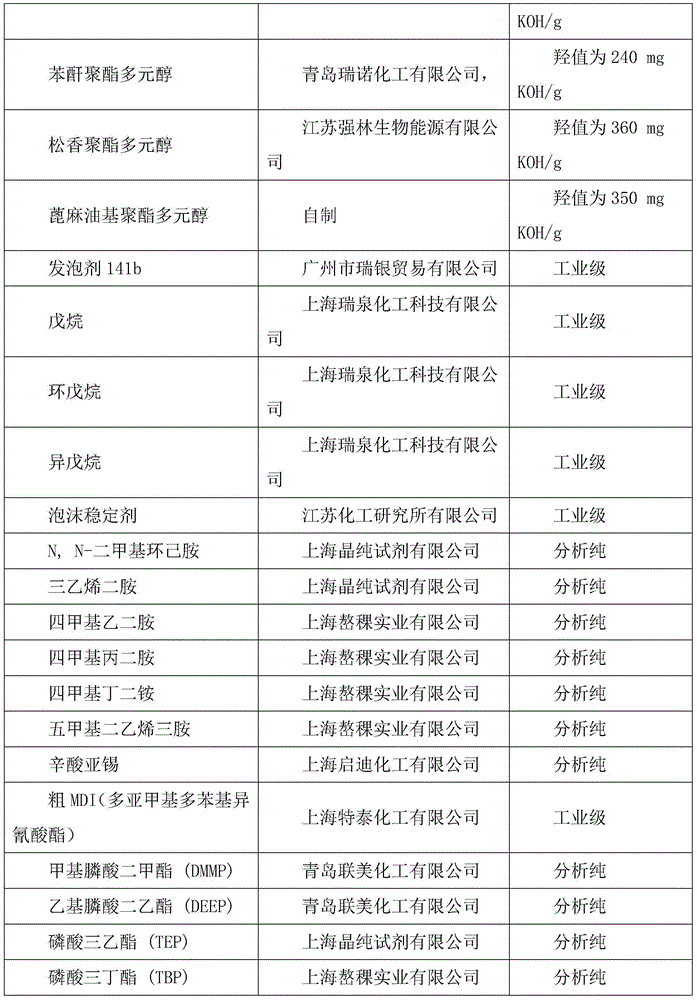

Patents

Literature

1415 results about "Graphite particle" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Process for producing nano-scaled graphene plates

InactiveUS20050271574A1Faster and cost-effective processHighly cost-effectiveMaterial nanotechnologyGraphiteGrapheneGraphite particle

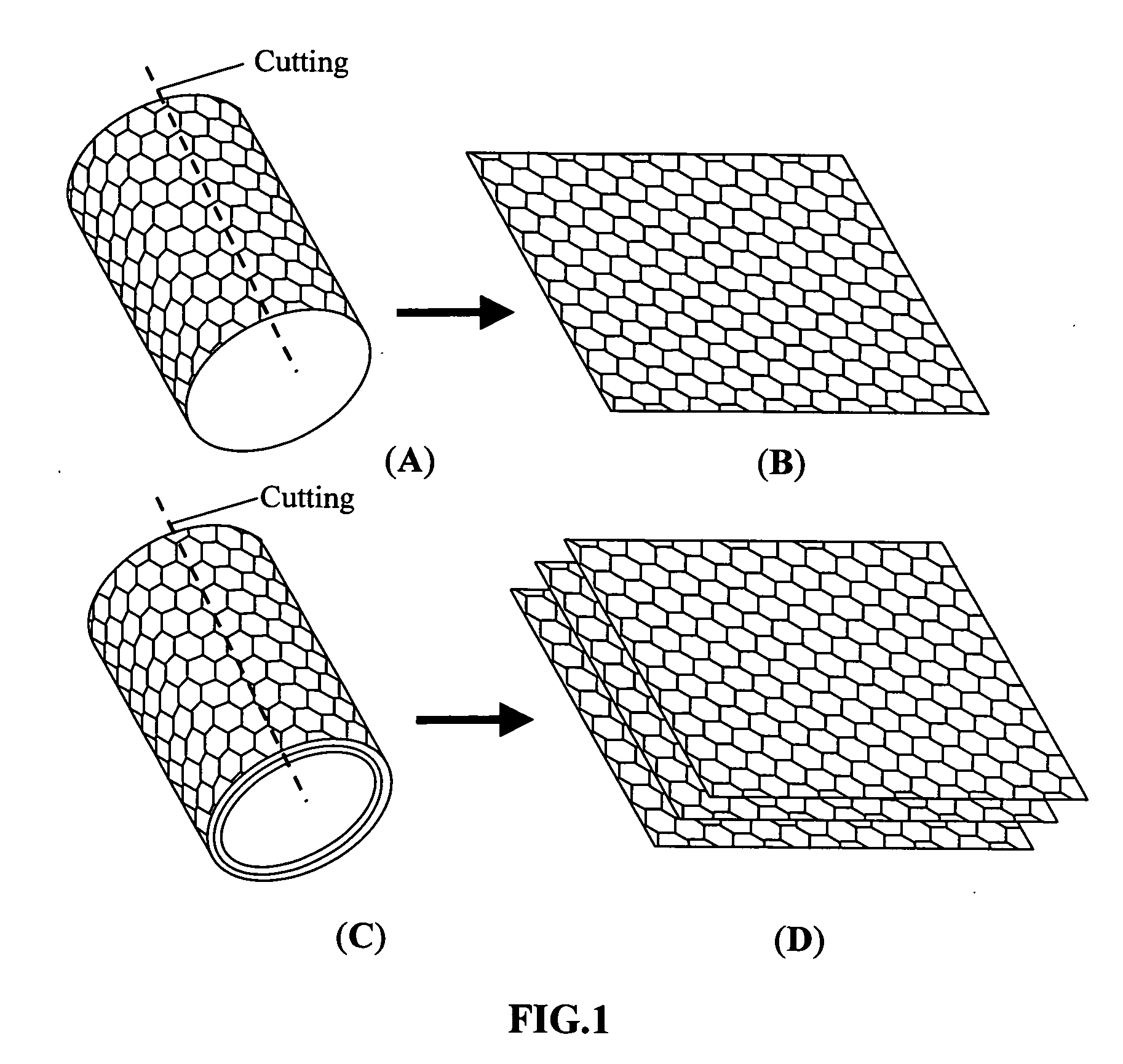

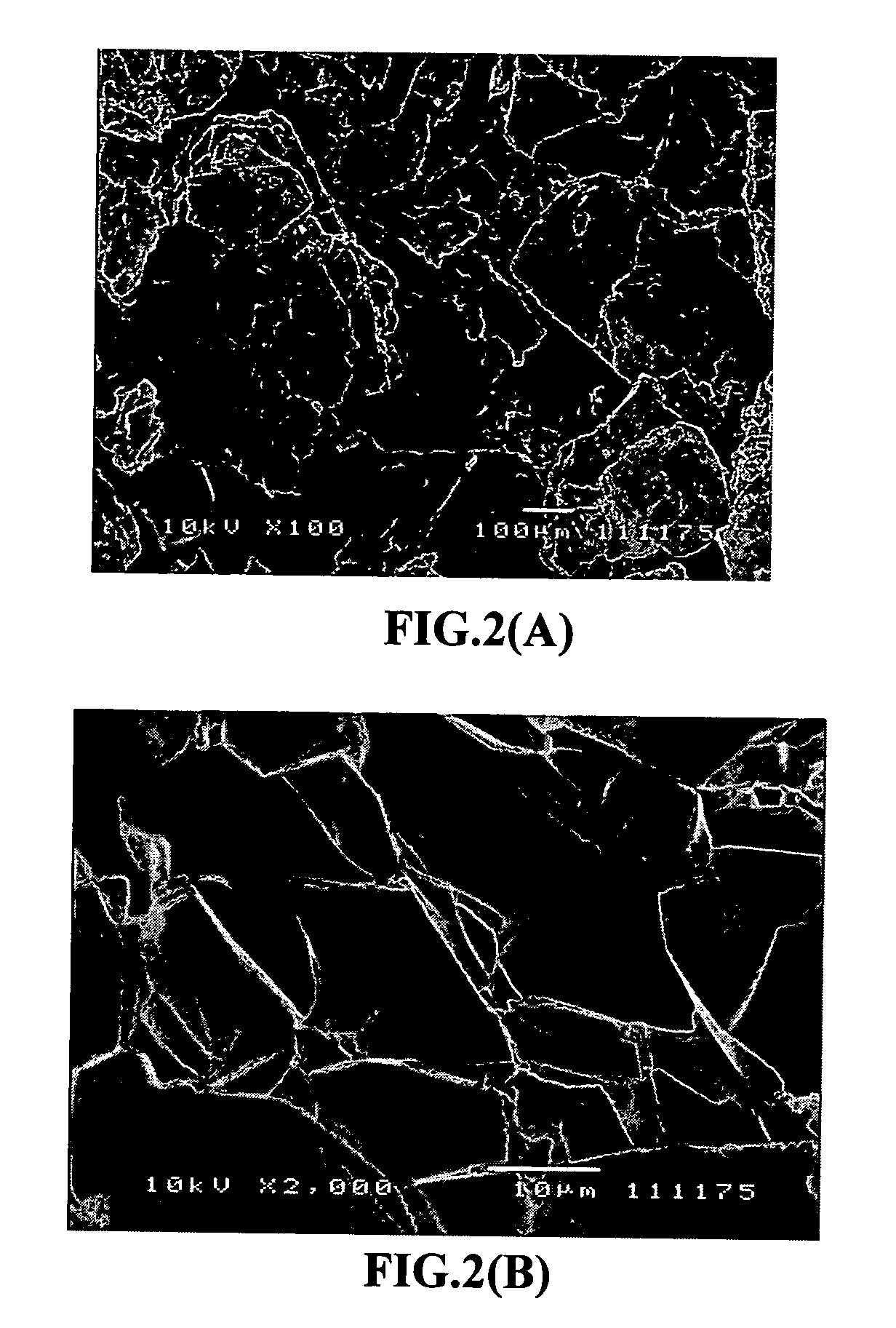

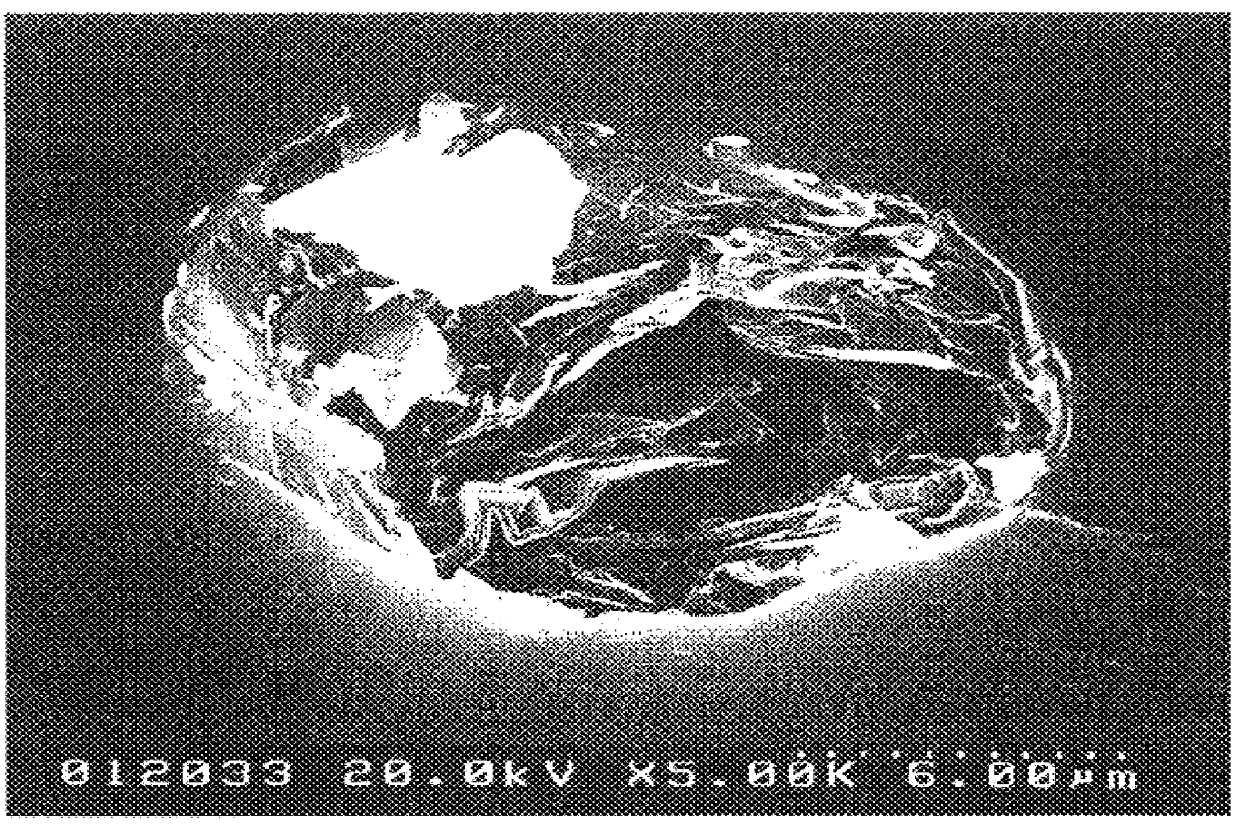

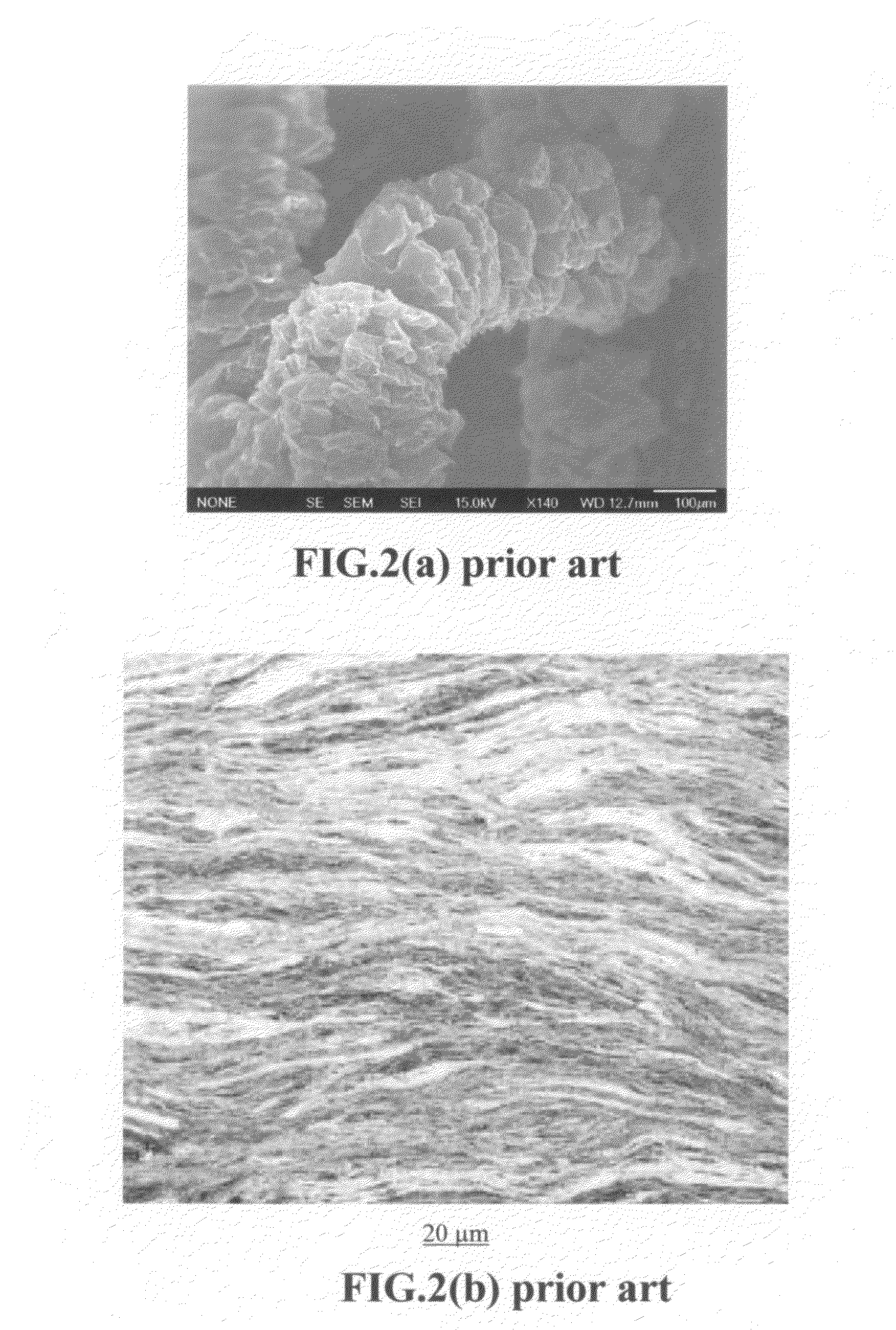

A process for producing nano-scaled graphene plates with each plate comprising a sheet of graphite plane or multiple sheets of graphite plane with the graphite plane comprising a two-dimensional hexagonal structure of carbon atoms. The process includes the primary steps of: (a) providing a powder of fine graphite particles comprising graphite crystallites with each crystallite comprising one sheet or normally a multiplicity of sheets of graphite plane bonded together; (b) exfoliating the graphite crystallites to form exfoliated graphite particles, which are characterized by having at least two graphite planes being either partially or fully separated from each other; and (c) subjecting the exfoliated graphite particles to a mechanical attrition treatment to further reduce at least one dimension of the particles to a nanometer scale, <100 nm, for producing the nano-scaled graphene plates.

Owner:GLOBAL GRAPHENE GRP INC

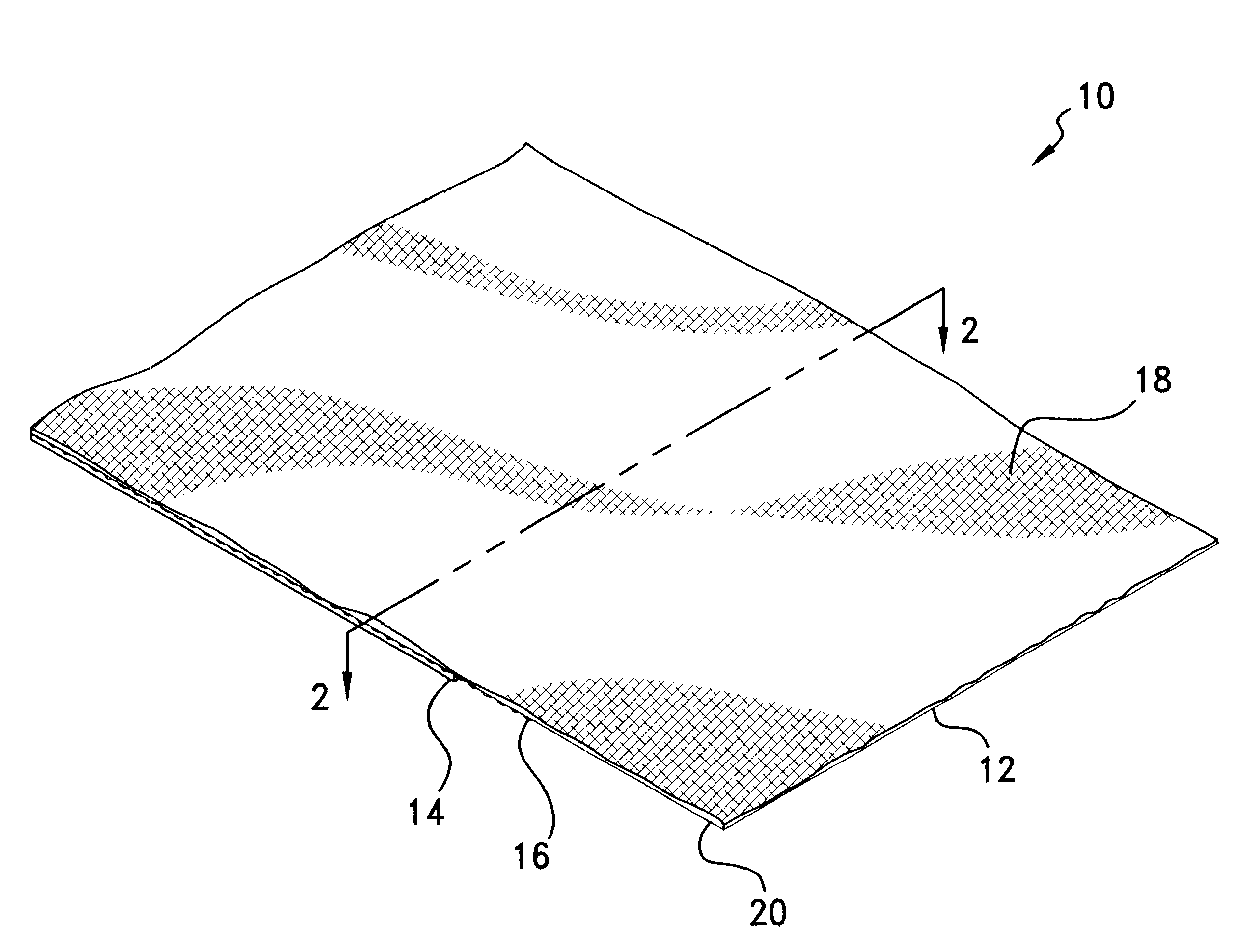

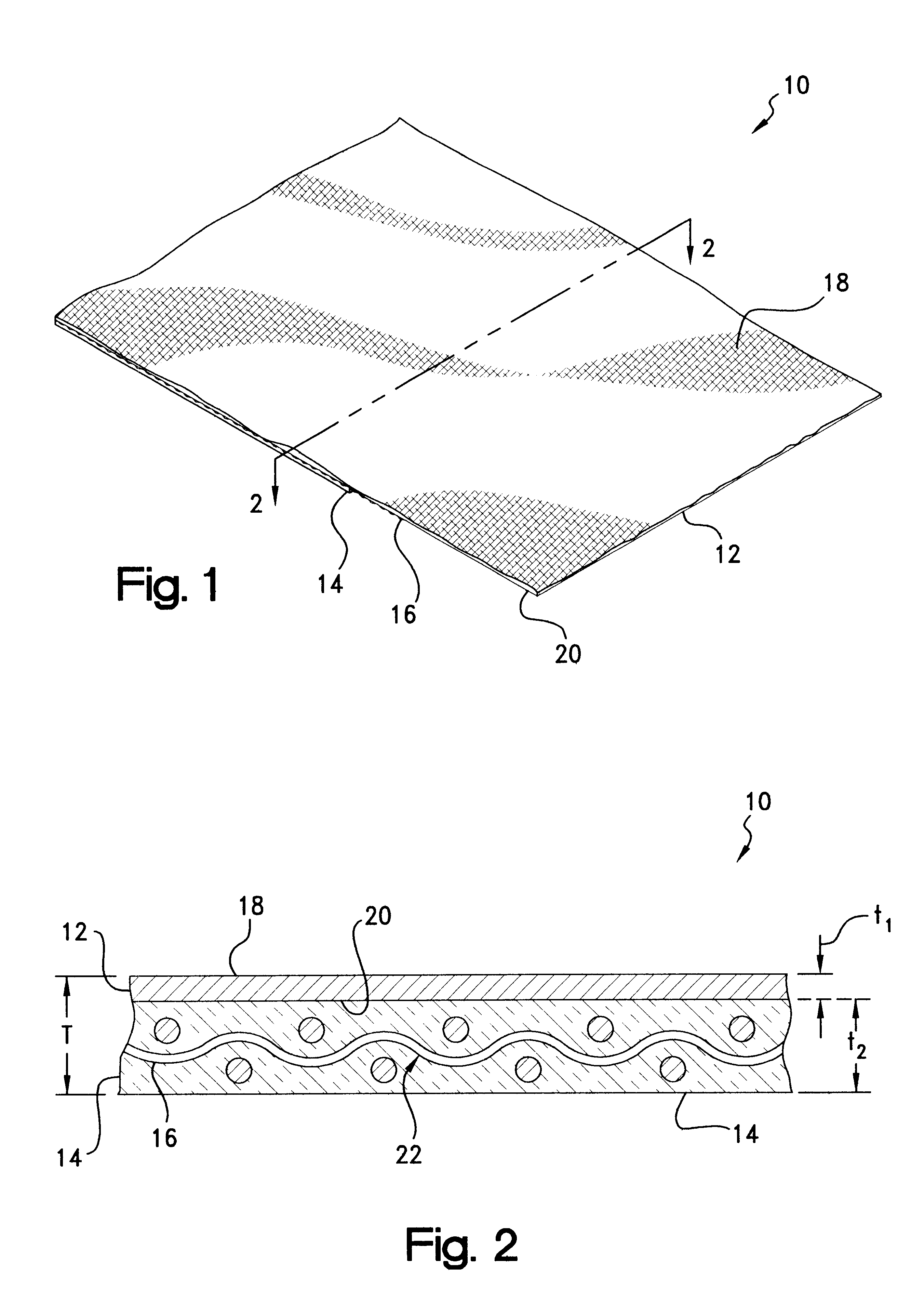

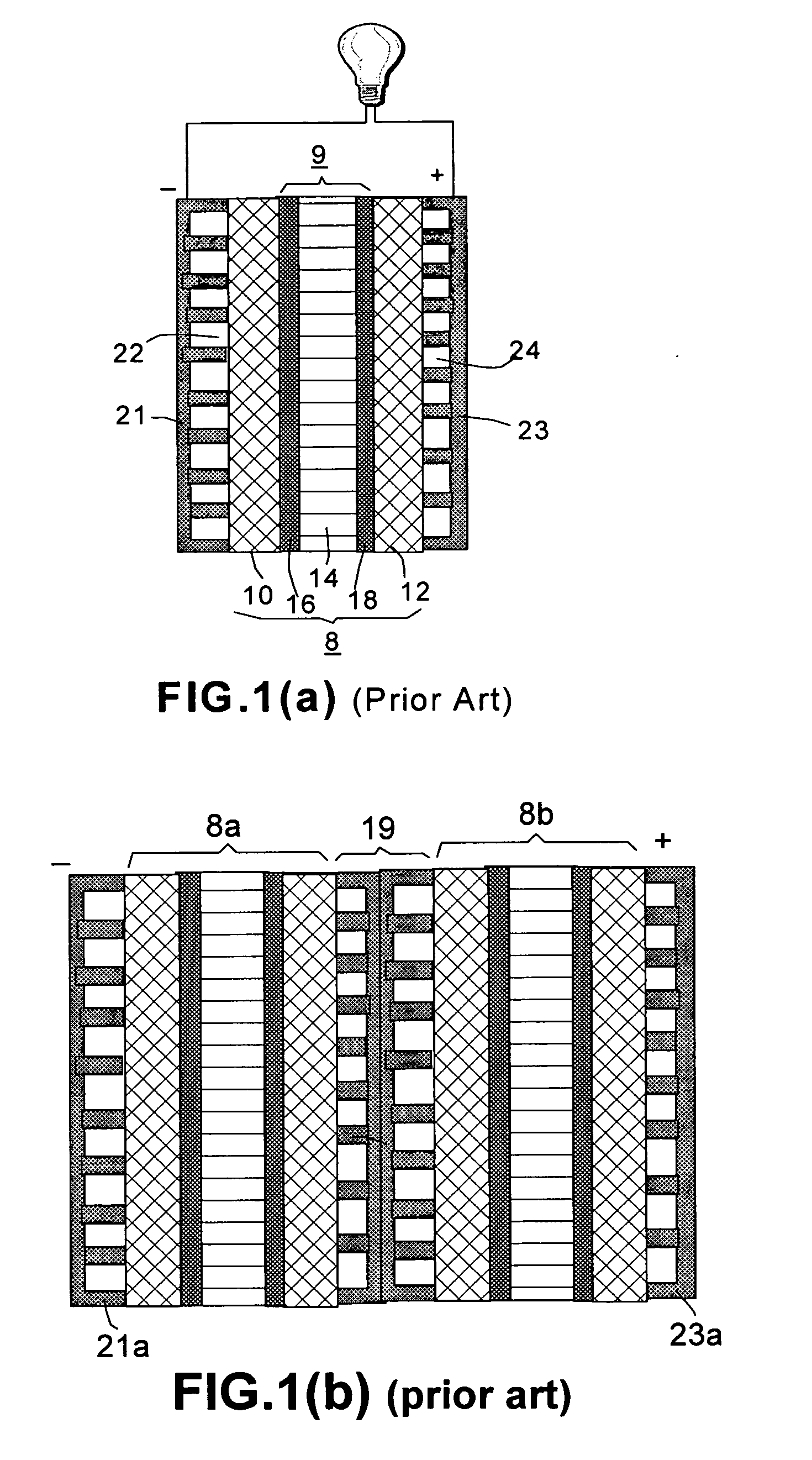

Intumescent, flame retardant pressure sensitive adhesive composition for EMI shielding applications

InactiveUS6410137B1Readily apparentGood physical propertiesScreening gaskets/sealsSynthetic resin layered productsDecabromodiphenyl etherPolybrominated Biphenyls

A flame retardant, intumescent pressure sensitive adhesive (PSA) composition for EMI shielding gaskets, tapes, wraps, and the like. The composition is formulated as an admixture of: (a) a PSA component; (b) a halogenated first flame retardant component; (c) a metal-based second flame retardant component; and (d) a filler component of expandable, intercalated graphite particles. In a representative embodiment the PSA component (a) is acrylic-based, the halogenated first flame retardant component (b) is a polybrominated diphenyl compound such as decabromodiphenyl oxide or decabromodiphenyl ether, the metal oxide-based second flame retardant component (c) is antimony oxide, antimony trioxide, or antimony pentoxide, and the filler component (d) is graphite flake.

Owner:PARKER INTANGIBLES LLC

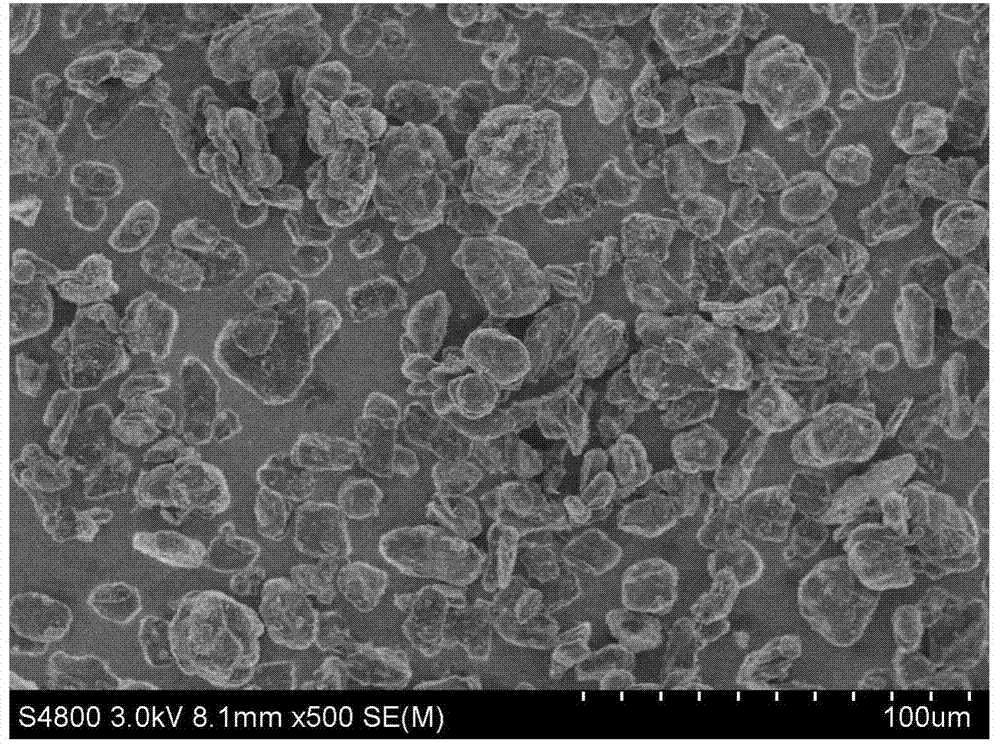

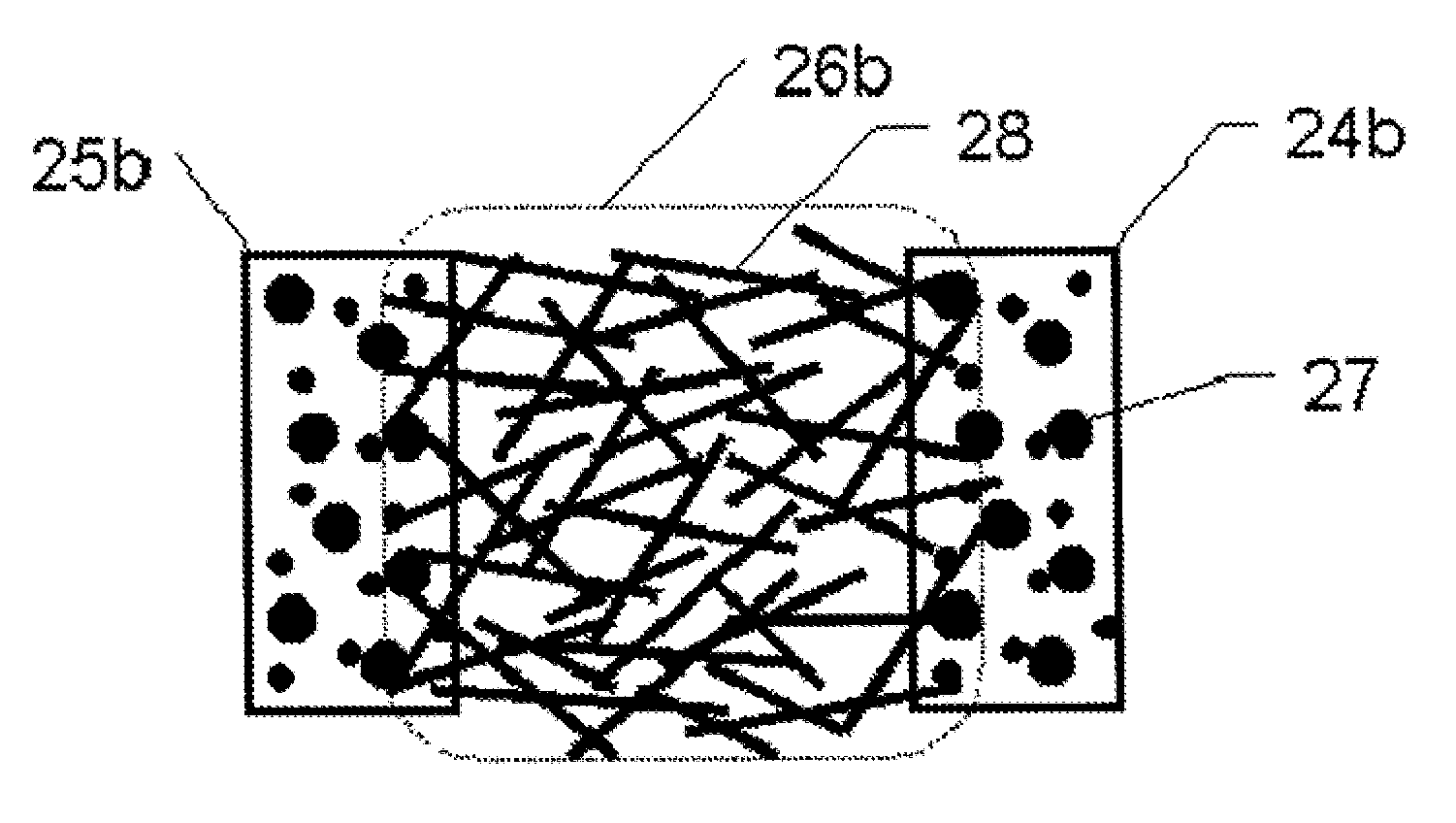

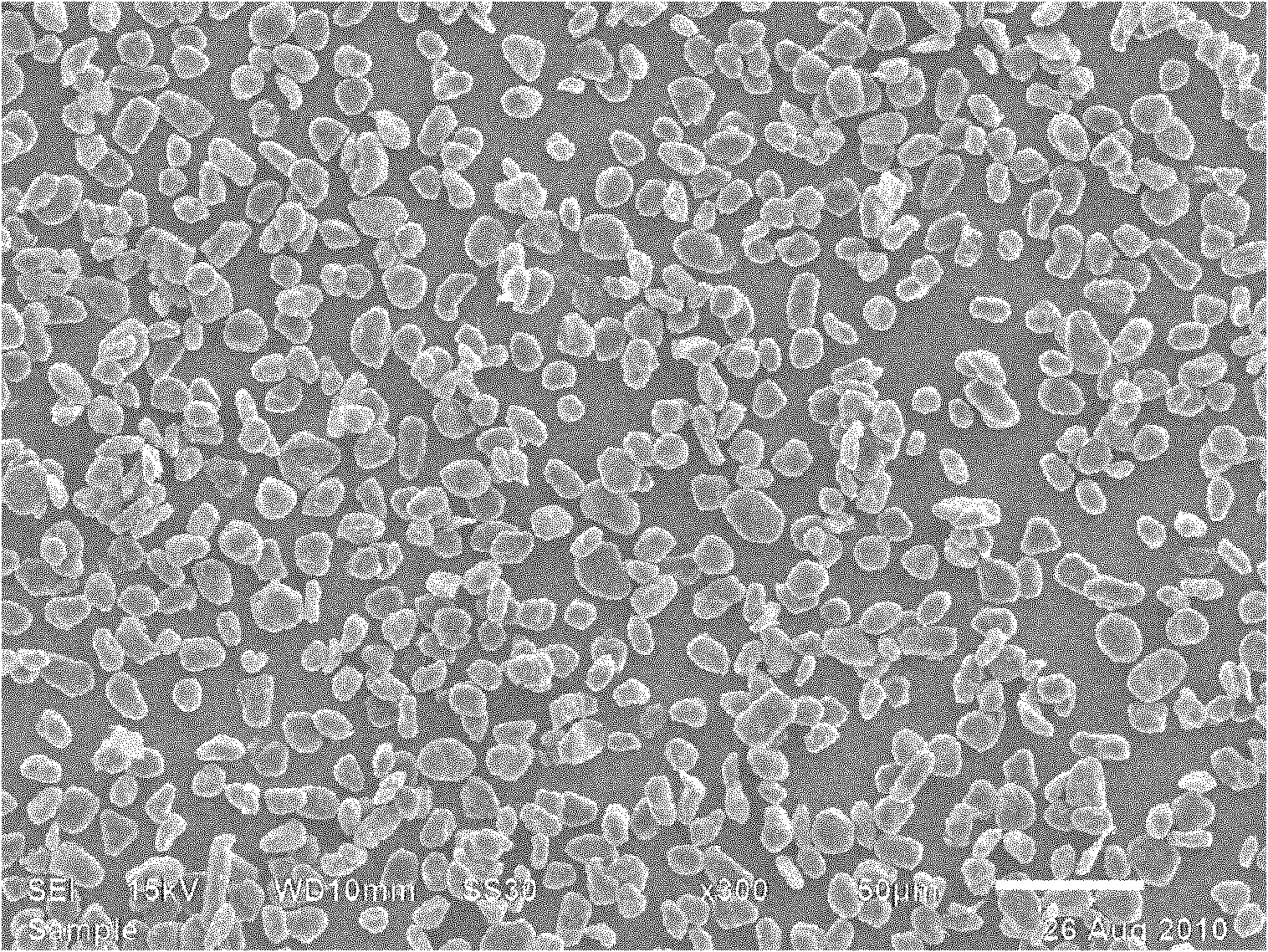

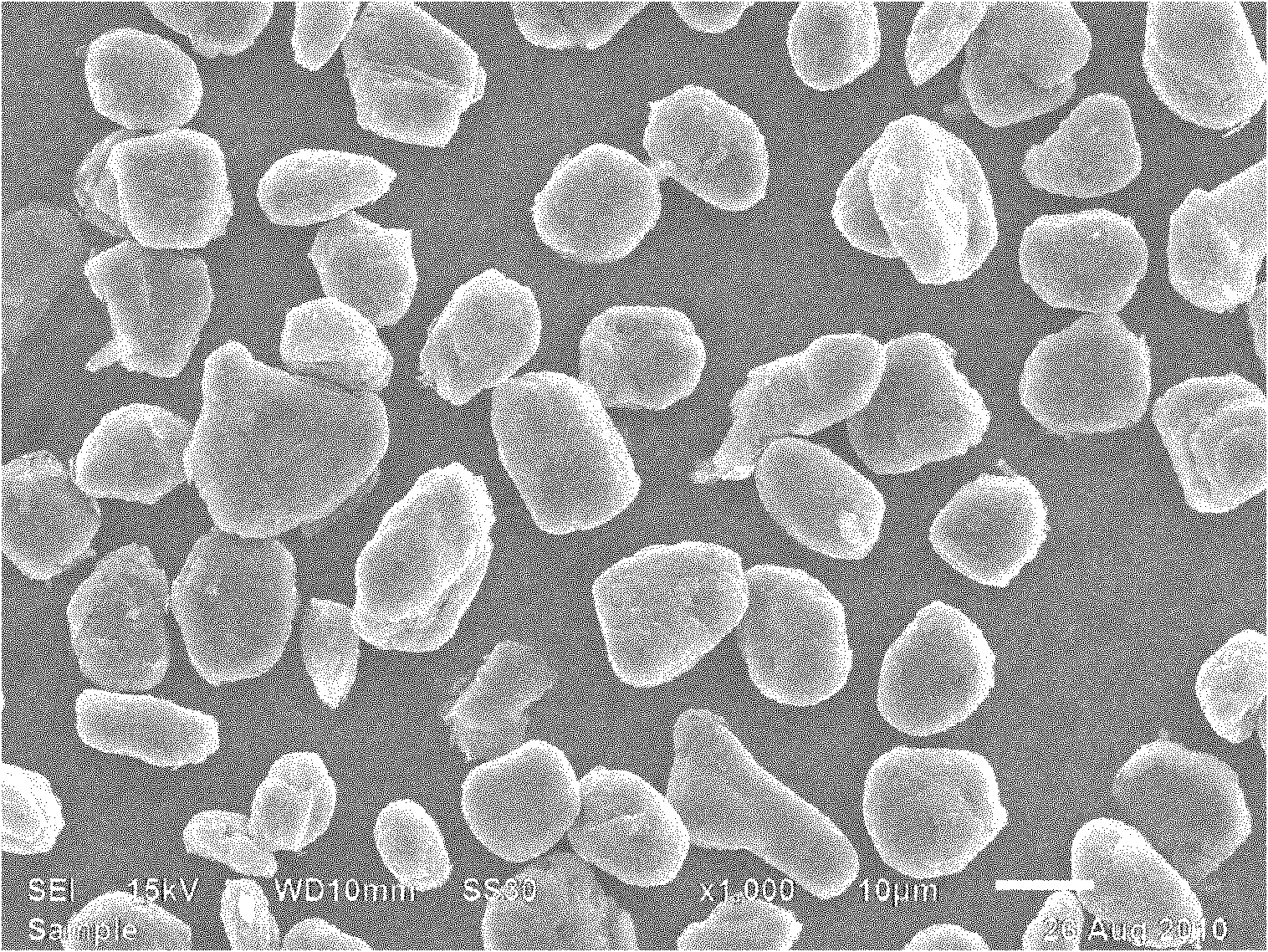

Silicon-carbon composite negative electrode material for lithium ion battery and preparation method thereof

ActiveCN103474667AImprove cycle performanceHigh charge and discharge capacityMaterial nanotechnologyCell electrodesCarbon compositesCarbon layer

The invention relates to a silicon-carbon composite negative electrode material and a preparation method thereof. The silicon-carbon composite negative electrode material successively comprises nano silicon / graphite particles, a first carbon coating layer and an organic cracking carbon layer from inside to outside. The nano silicon / graphite particles are globular or globular-like composite particles formed by employing graphite as an inner core of a volume expansion buffer substrate and coating a nano silicon particle layer; the first carbon coating layer comprises carbon nanotubes and / or amorphous carbon, the carbon nanotubes and / or amorphous carbon are interspersed in a gap network formed by gaps of the nano silicon particles and / or are coated outside the nano silicon particle layer, so that the nano silicon is tightly wrapped between the carbon nanotubes and / or between the carbon nanotubes and the graphite substrate, and besides, the material ion conductivity is effectively enhanced; the organic cracking carbon layer is an outermost coating layer of the silicon-carbon composite negative electrode material. The silicon-carbon composite negative electrode material has excellent cycle performance, excellent multiplying power charging and discharging performance and lower volume expansion effect.

Owner:BTR NEW MATERIAL GRP CO LTD

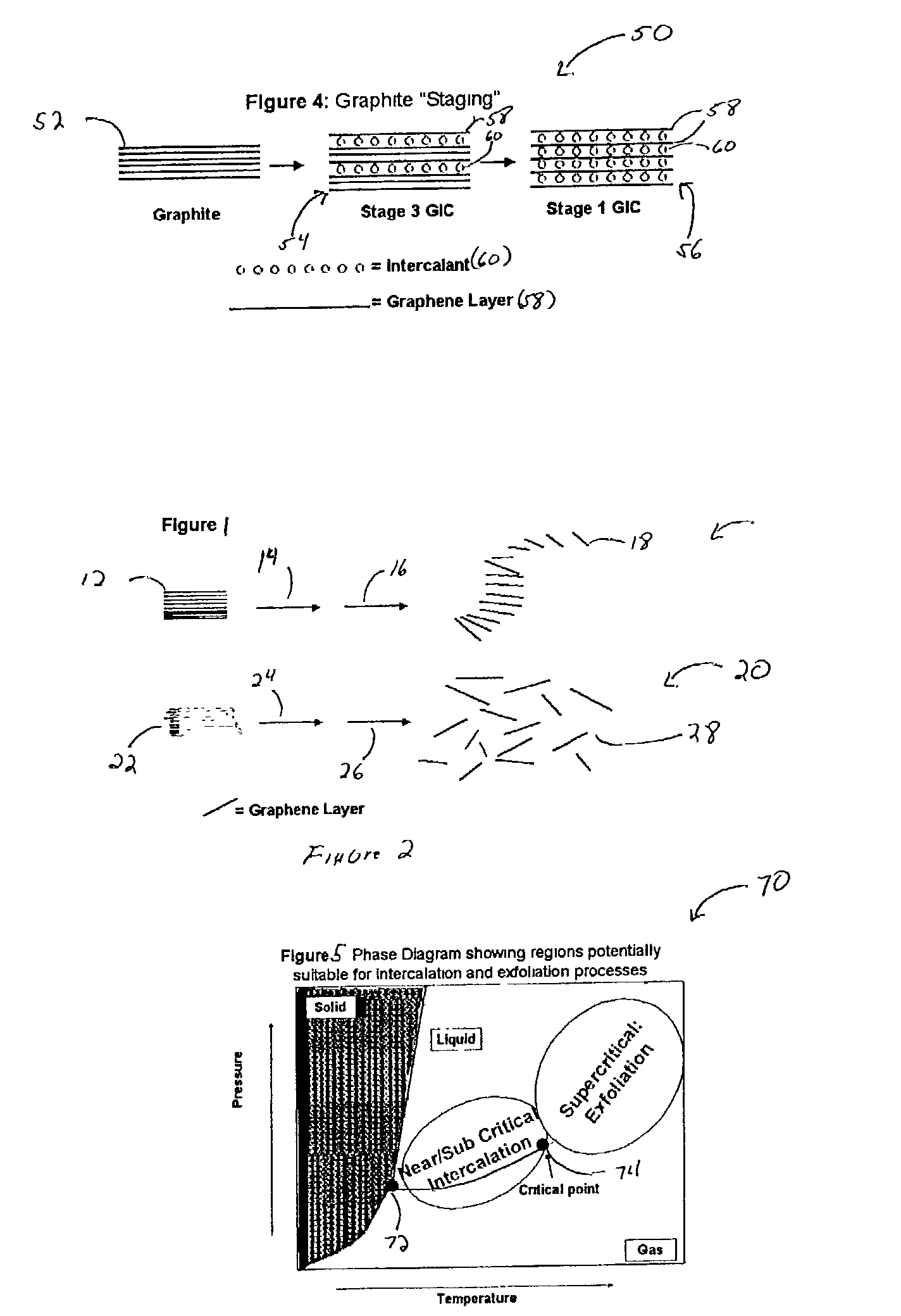

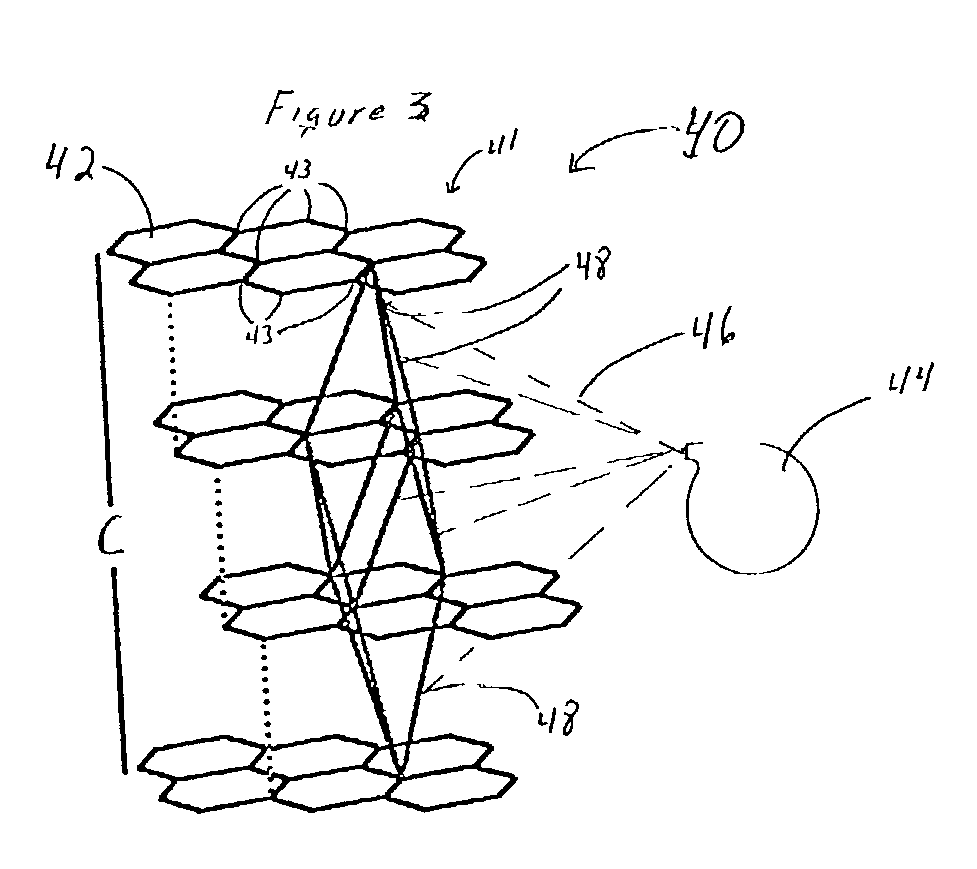

Graphite intercalation and exfoliation process

InactiveUS7105108B2Improve volume expansionReduce needMaterial nanotechnologyGraphiteConductive polymerGraphite particle

The invention relates to expanded graphite and methods of making the graphite and products that can be made from the graphite made from the inventive process. The invention includes the step of introducing a fluid into at least one of a plurality of interstices of graphite flake, wherein the fluid comprises at least one of a sub-critical point fluid, a near critical point fluid, or a supercritical fluid. The graphite flake is also intercalated with an intercalant and optionally an oxidizing agent. The invention may further include novel techniques of exfoliating the graphite. The invention may be practiced to make nano-sized graphite particles and also graphite composites. Preferred composites which may be made in accordance with the invention include conductive polymeric composites (thermally or electrically), paint composites, battery composites, capacitor composites, and pollution abatement catalyst support composites.

Owner:GRAFTECH INT HLDG INC

Lithium ion battery silicon-based composite anode material, preparation method thereof and battery

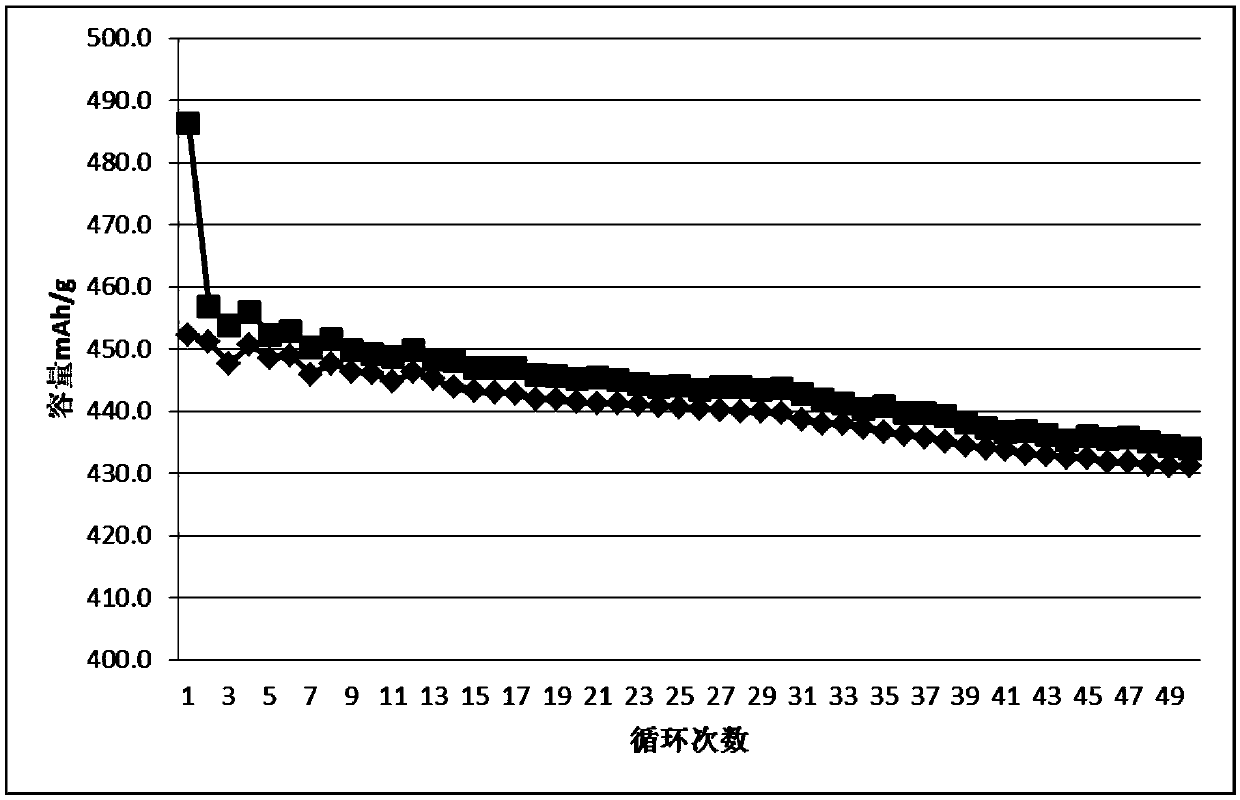

ActiveCN103682287AGood dispersionInhibit swellingCell electrodesSecondary cellsCarbon coatingRetention ratio

The invention relates to a lithium ion battery silicon-based composite anode material, a preparation method of the lithium ion battery silicon-based composite anode material, and a battery. The lithium ion battery silicon-based composite anode material adopts an embedded composite core-shell structure, a core has a structure formed by embedding nano silicon particles into a gap of an inner layer of hollowed graphite, and a shell is made from a non-graphite carbon material. According to the silicon-based composite anode material, mechanical grinding, mechanical fusing, isotropic compression processing and carbon coating technologies are combined, so that the nano silicon particles can be successfully embedded into the inner layer of the graphite and the surfaces of graphite particles are uniformly coated; the high-performance silicon-based composite anode material is obtained and is excellent in cycle performance (the 300-times cycle capacity retention ratio is more than 90%) and high in first efficiency (more than 90%); in addition, the silicon-based composite anode material is high in specific energy and compaction density, and can meet the requirements of a high-power density lithium ion battery; the preparation process is simple, the raw material cost is low, and the environment is protected.

Owner:BTR NEW MATERIAL GRP CO LTD

Negative active material for rechargeable lithium battery and method of preparing same

InactiveUS20020009646A1Increase energy densityImprove cycle lifeElectrode manufacturing processesNon-aqueous electrolyte accumulatorsCarbon filmGraphite particle

Owner:SAMSUNG SDI CO LTD

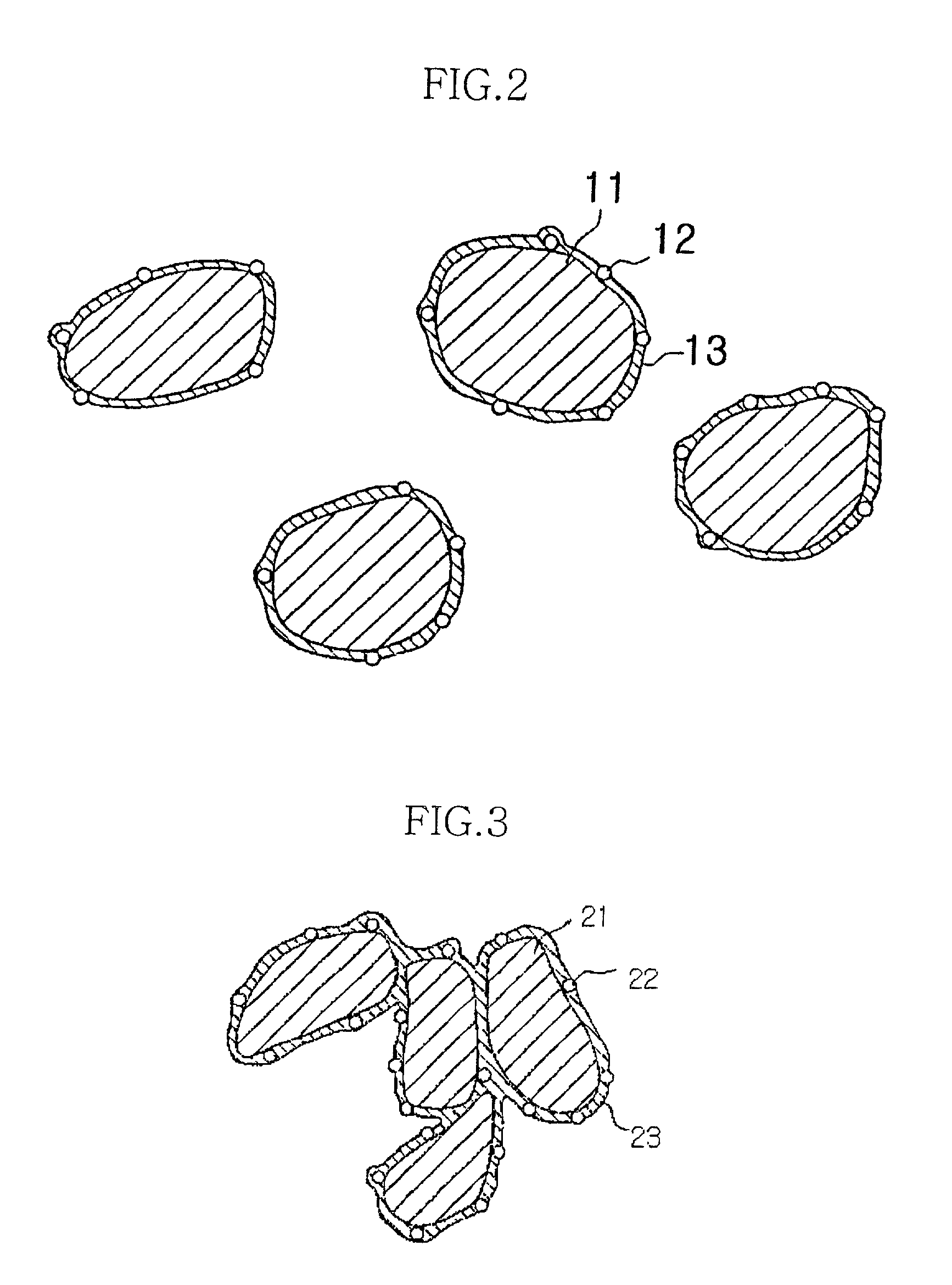

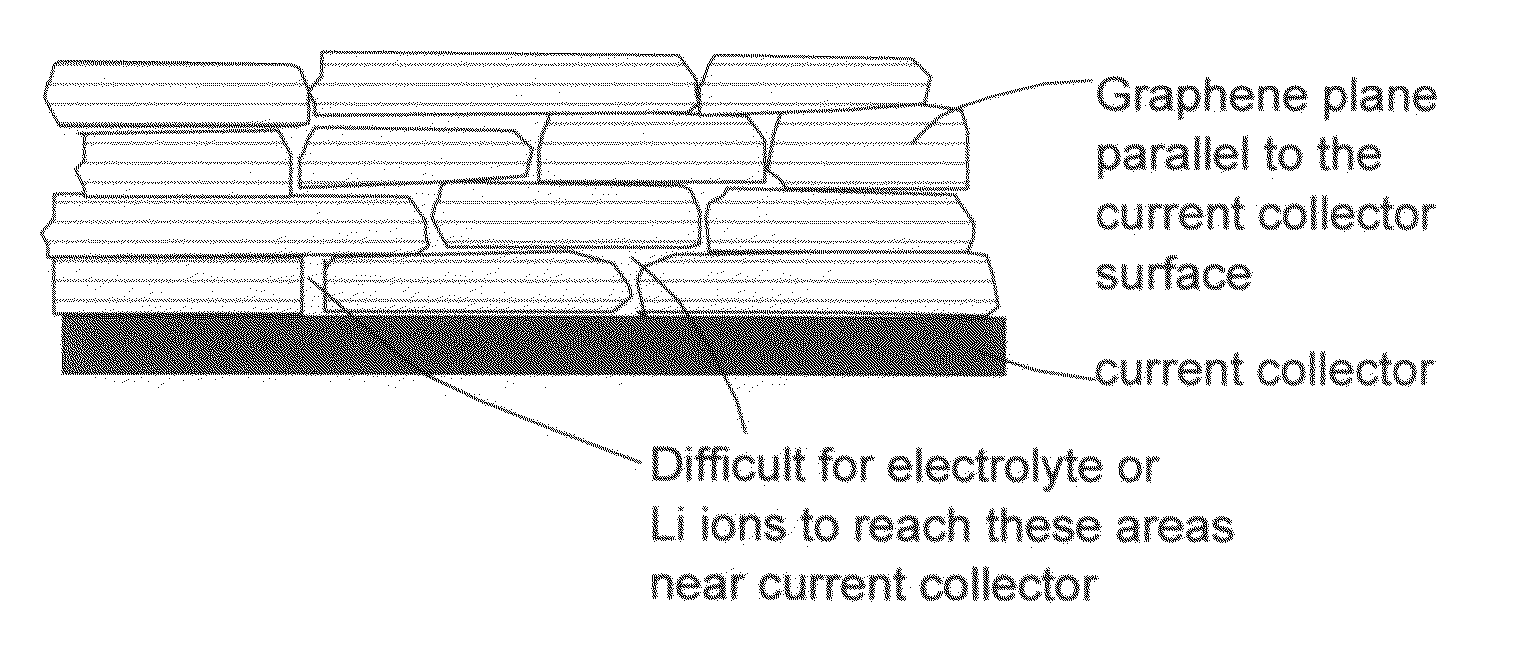

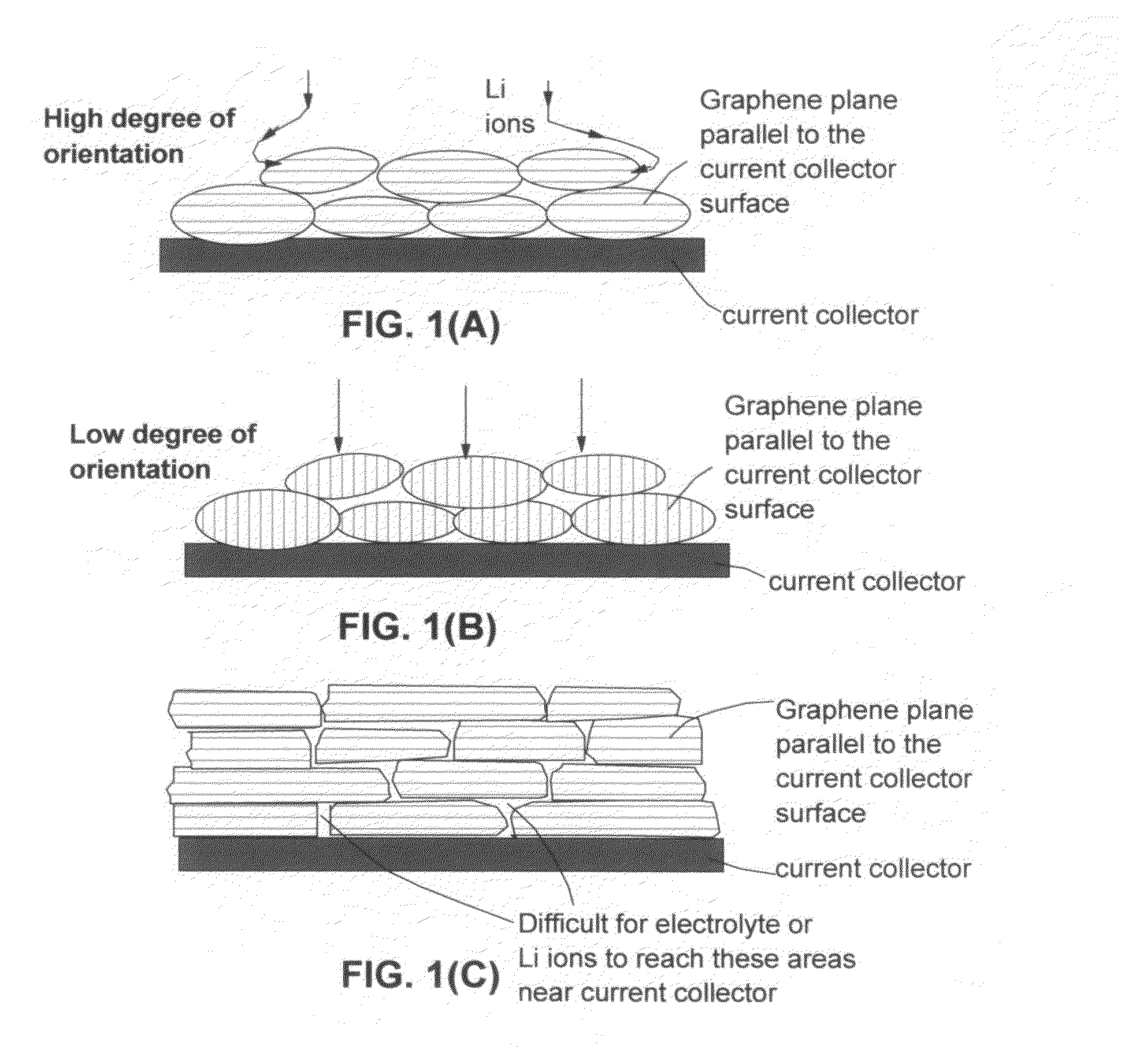

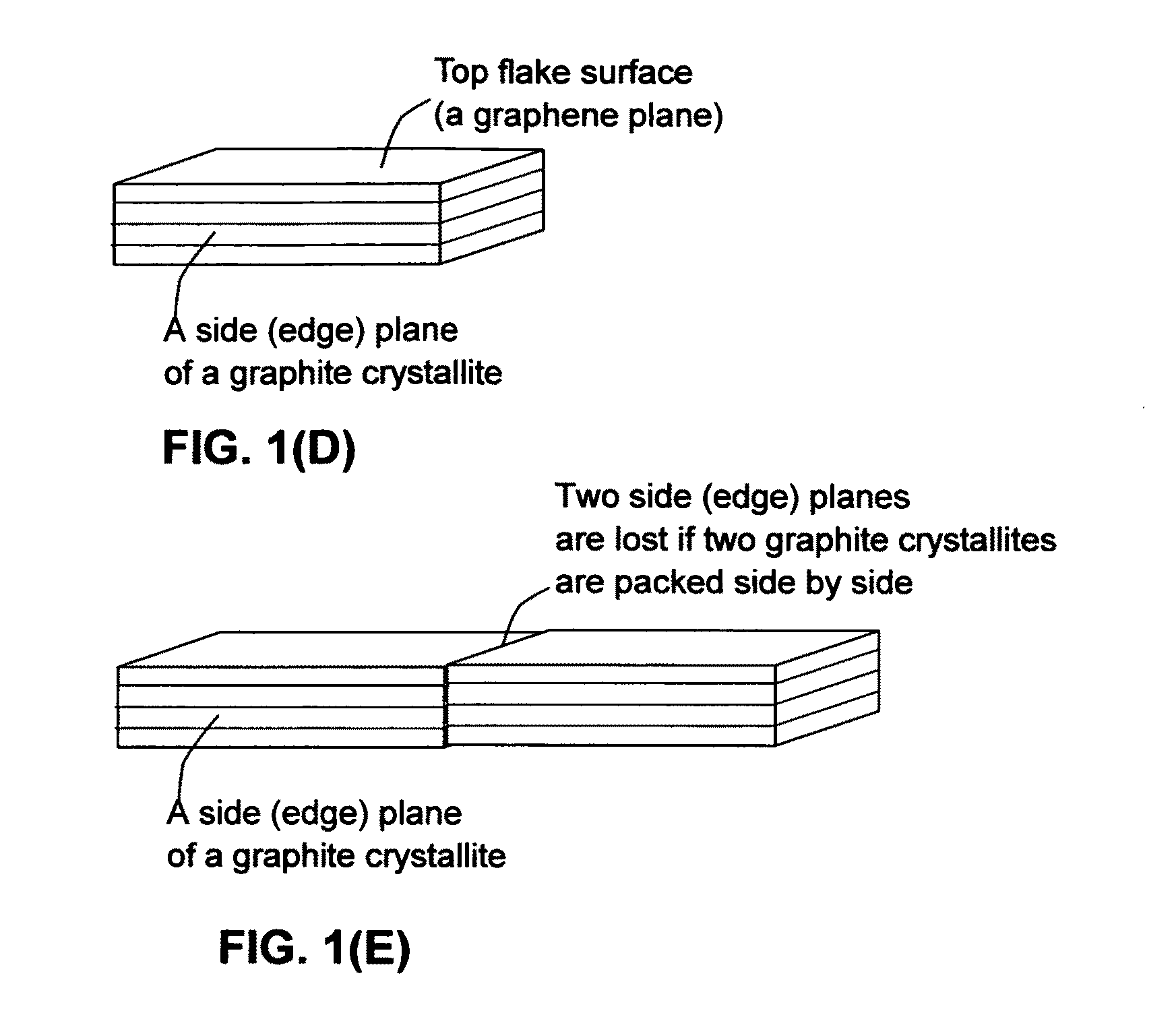

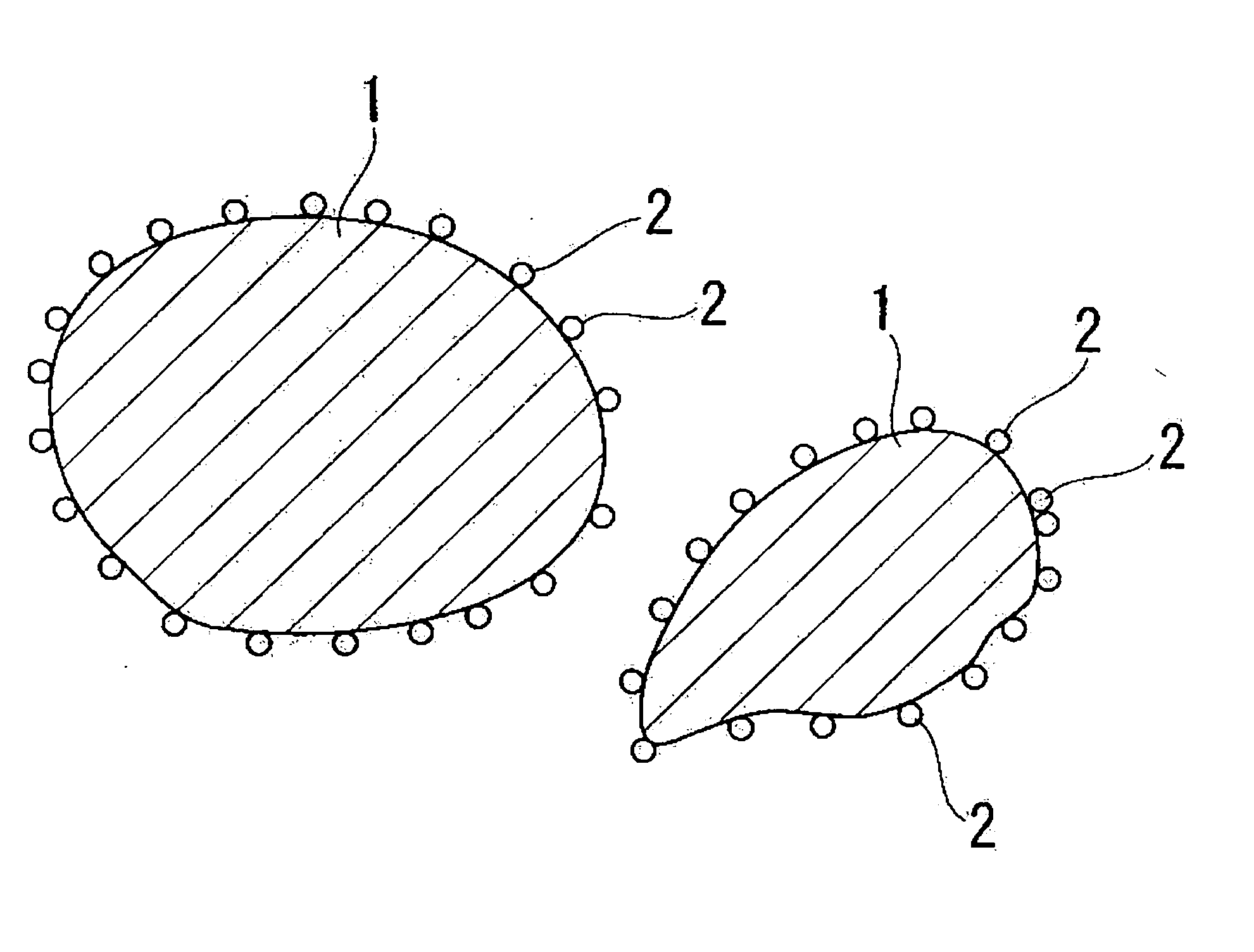

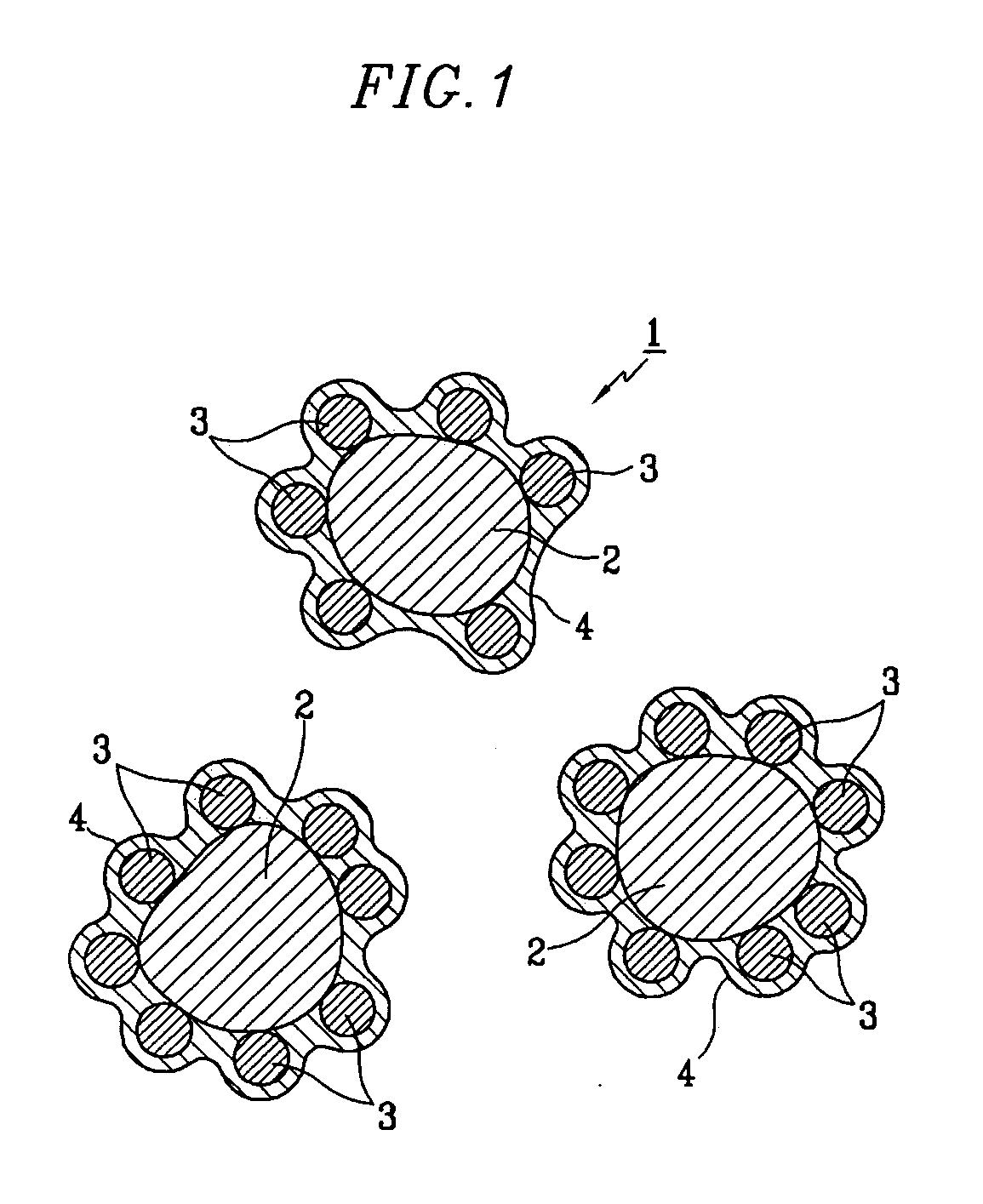

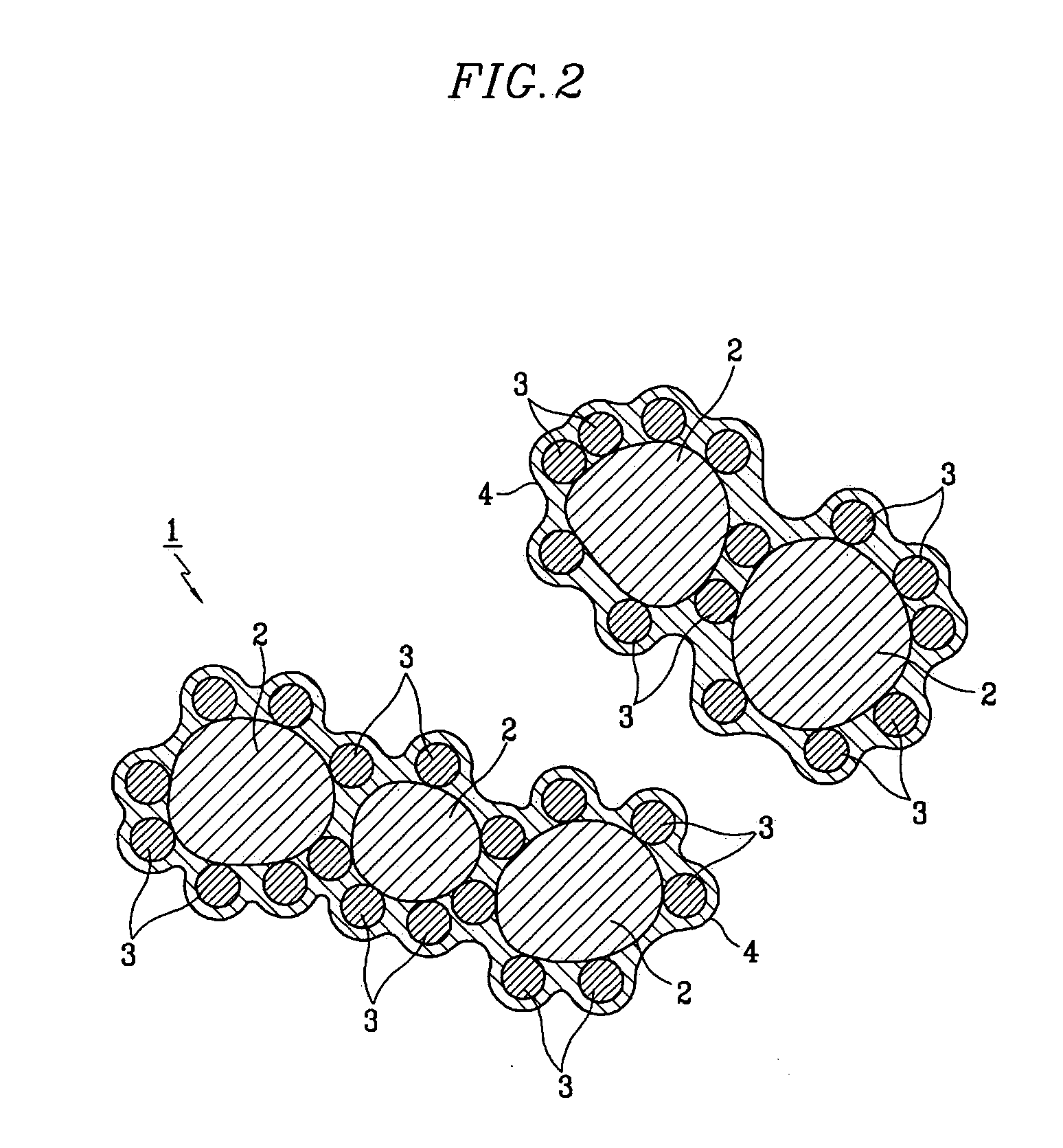

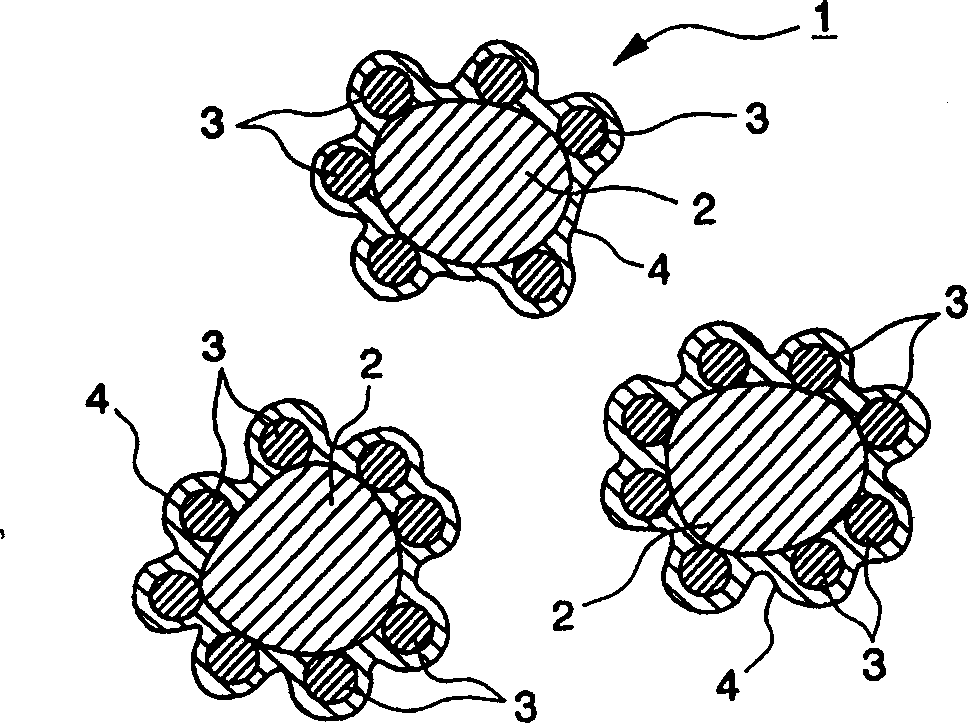

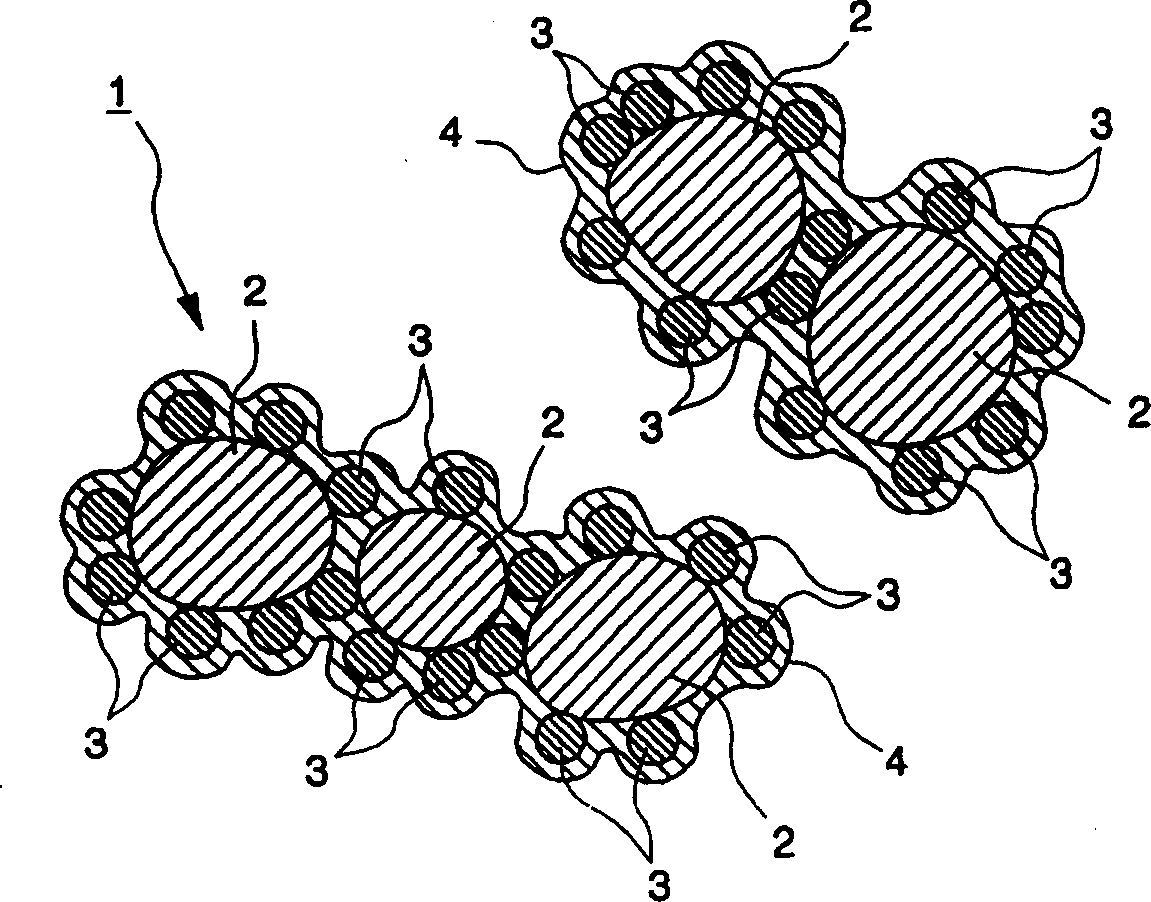

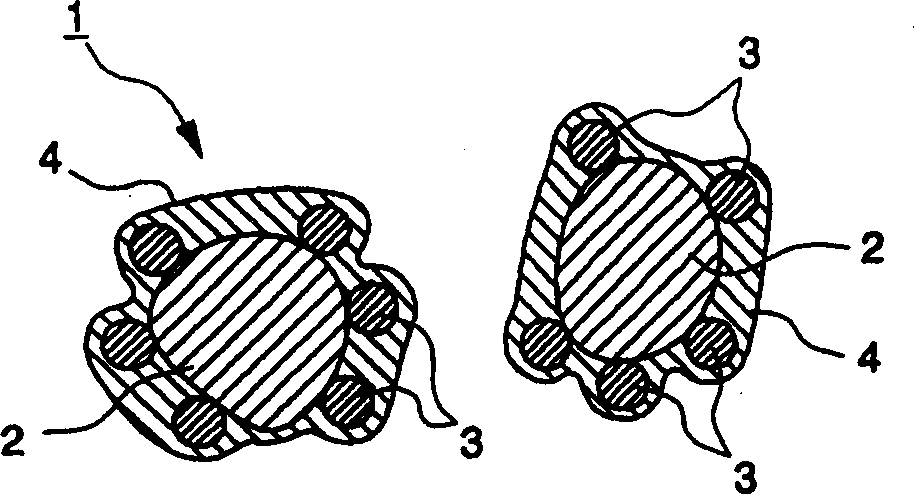

Graphite or carbon particulates for the lithium ion battery anode

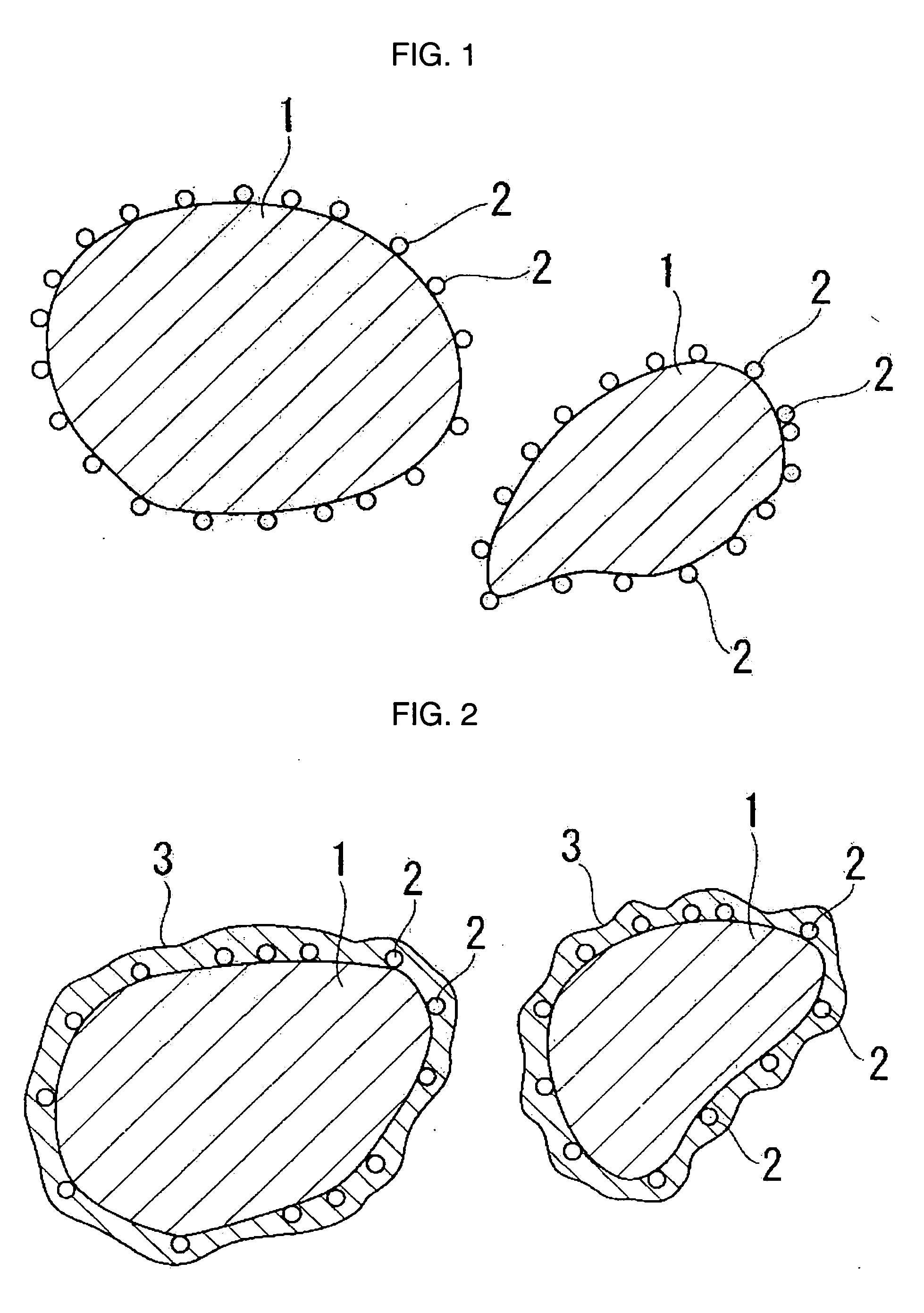

This invention provides a graphite or graphite-carbon particulate for use as a lithium secondary battery anode material having a high-rate capability. The particulate is formed of a core carbon or graphite particle and a plurality of satellite carbon or graphite particles that are each separately bonded to the core particle wherein the core particle is spherical in shape, slightly elongate in shape with a major axis-to-minor axis ratio less than 2, or fibril in shape, and wherein the satellite particles are disc-, platelet-, or flake-like particles each containing a graphite crystallite with a crystallographic c-axis dimension Lc and a lateral dimension. Preferably, Lc is less than 100 nm and the flake / platelet lateral dimension is less than 1 μm. The core particle may be selected from natural graphite, artificial graphite, spherical graphite, graphitic coke, meso-carbon micro-bead, soft carbon, hard carbon, graphitic fibril, carbon nano-fiber, carbon fiber, or graphite fiber. Preferably, the flat-shaped particles are randomly oriented with respect to one another.

Owner:GLOBAL GRAPHENE GRP INC

Electrical Appliance

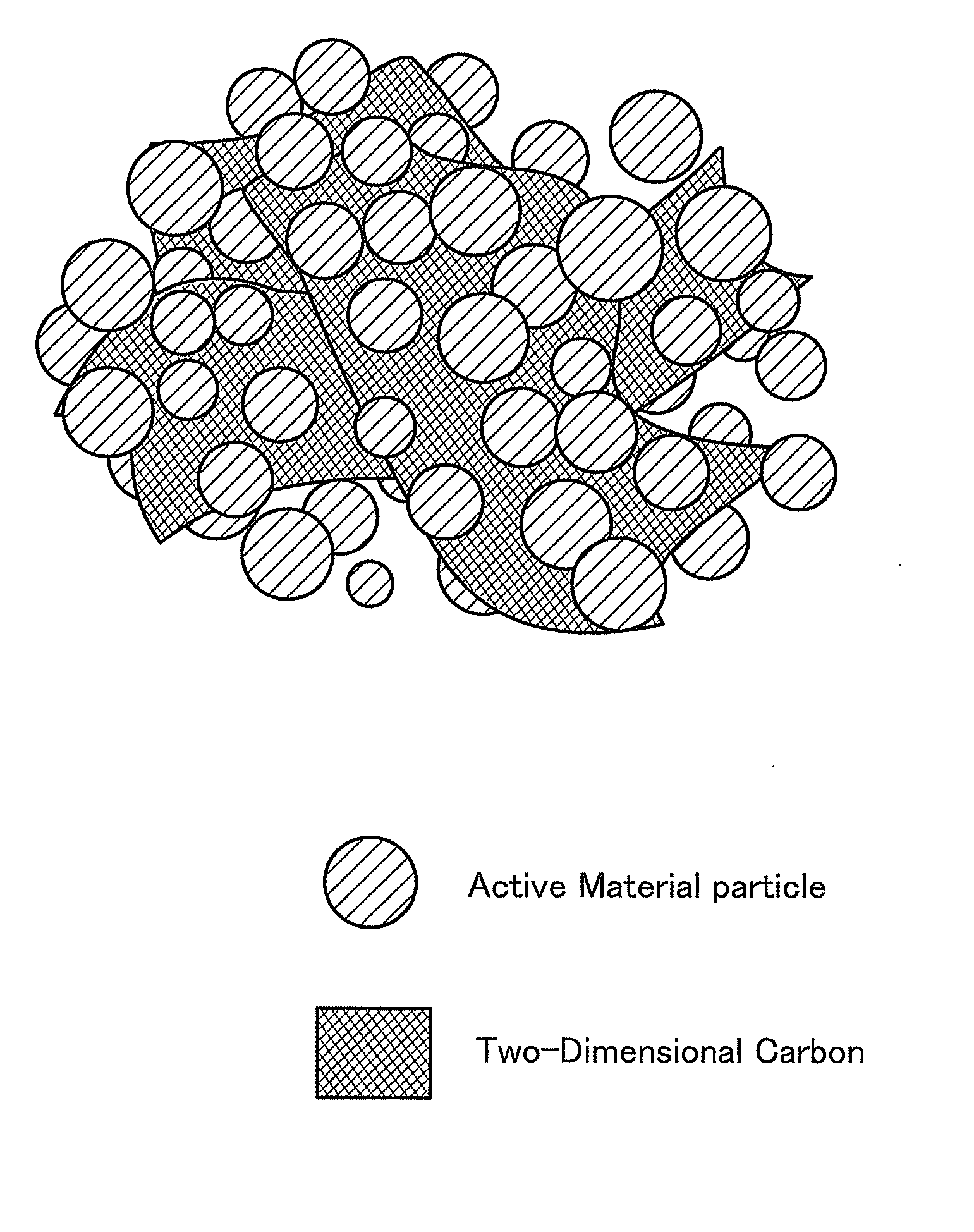

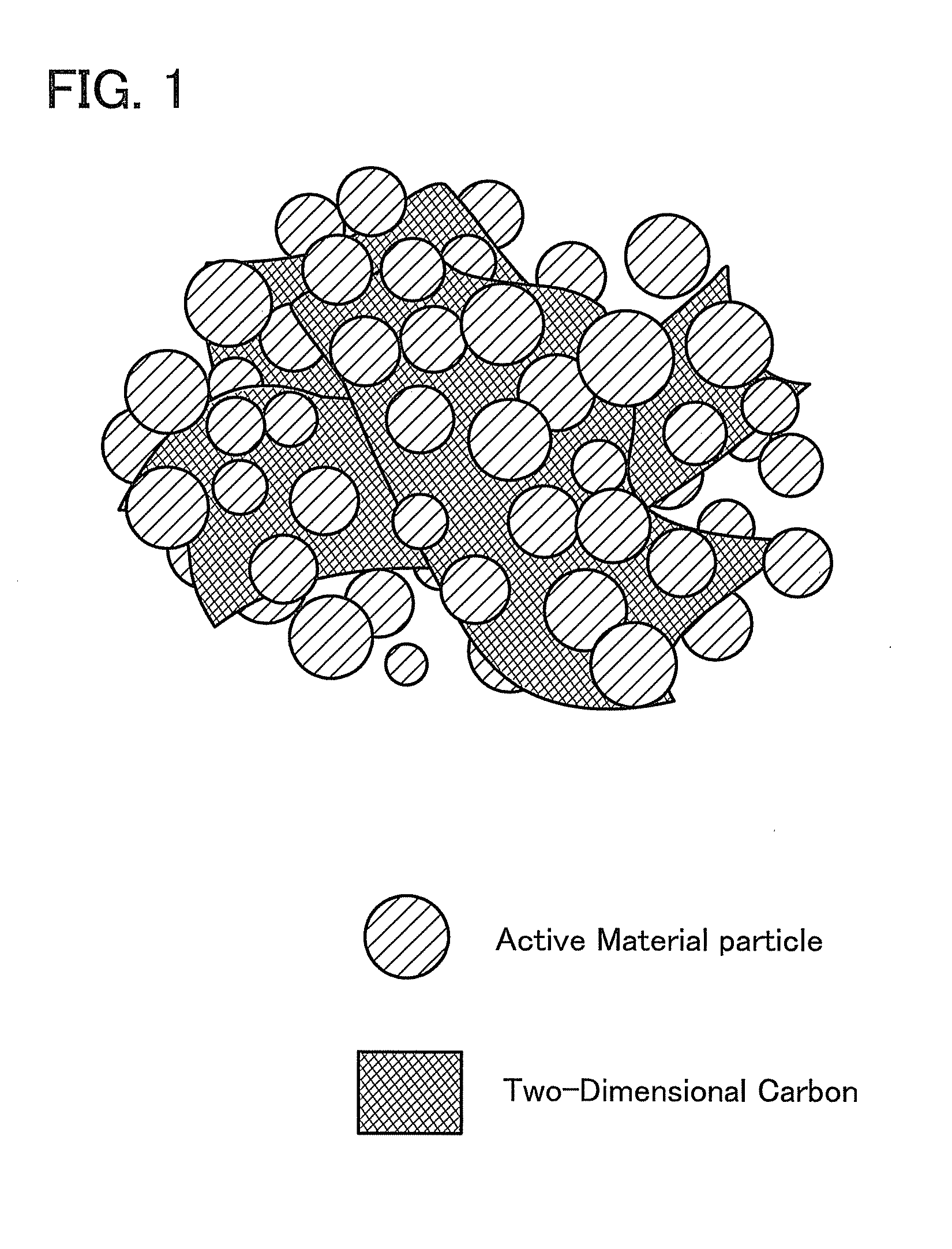

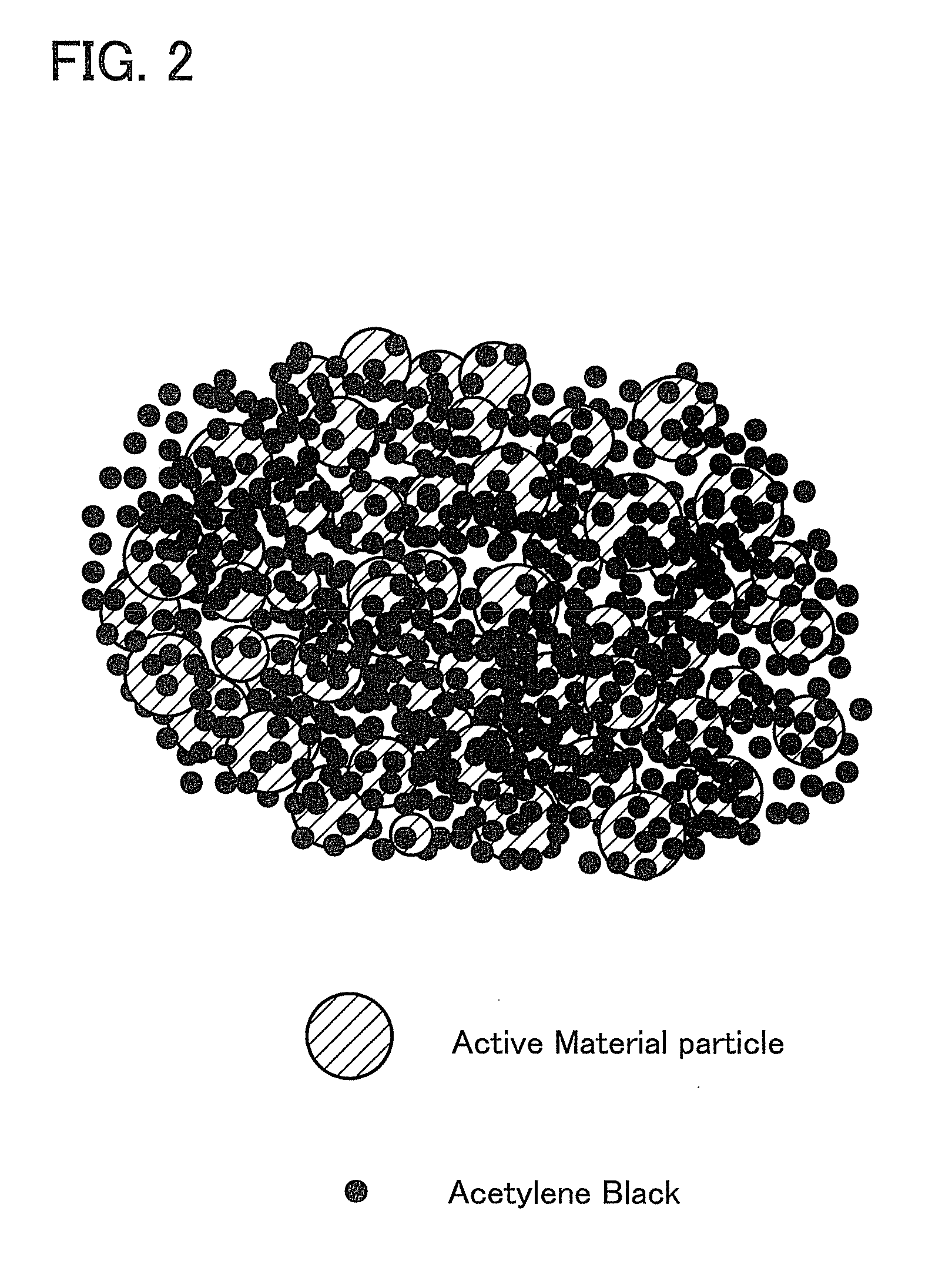

InactiveUS20120045692A1Improve conductivityLower the volumeActive material electrodesNon-aqueous electrolyte accumulator electrodesFiberCarbon fibers

An object is to increase the conductivity of an electrode including active material particles and the like, which is used for a battery. Two-dimensional carbon including 1 to 10 graphenes is used as a conduction auxiliary agent, instead of a conventionally used conduction auxiliary agent extending only one-dimensionally at most, such as graphite particles, acetylene black, or carbon fibers. A conduction auxiliary agent extending two-dimensionally has higher probability of being in contact with active material particles or other conduction auxiliary agents, so that the conductivity can be improved.

Owner:SEMICON ENERGY LAB CO LTD

Negative active material for rechargeable lithium battery, method of preparing same and rechargeable lithium battery using same

InactiveUS20050074672A1Excellent cycle characteristicsAvoid excessive changesNegative electrodesNon-aqueous electrolyte accumulator electrodesLithiumEvaporation

Disclosed is a negative active material for a rechargeable lithium battery including a composite of a graphite particle and at least one supermicroparticle, wherein the supermicroparticle has a diameter in the range of 1 nm to 100 nm, is produced using an evaporation method under a gas atmosphere, and includes elements alloyable with lithium.

Owner:SAMSUNG SDI CO LTD

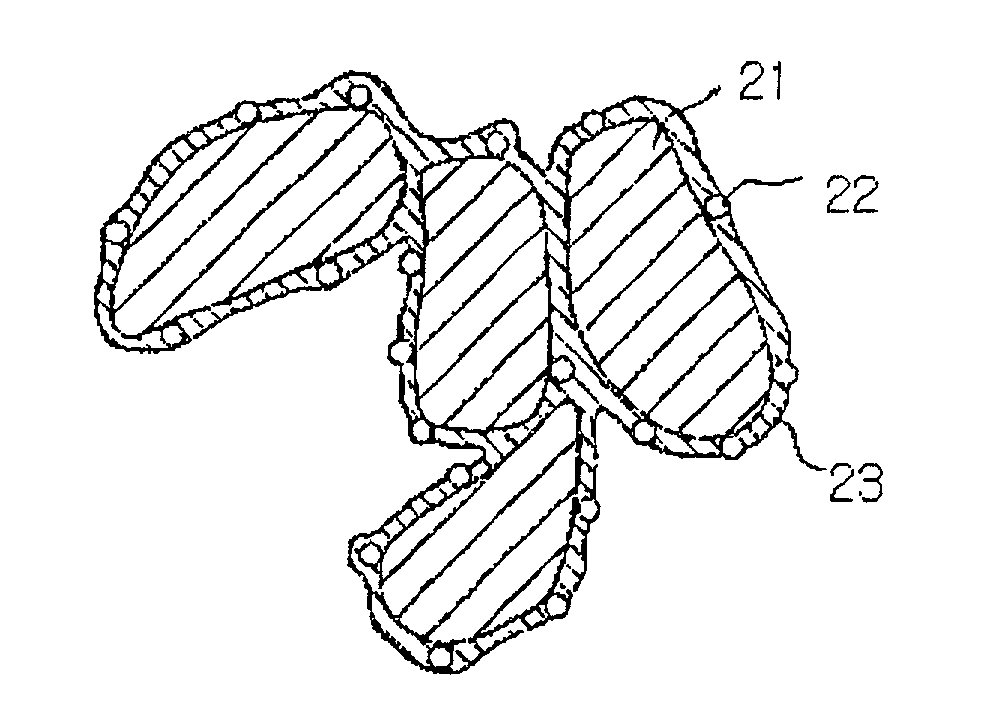

Negative active material for lithium secondary battery, method for preparing the same, negative electrode comprising the same, and lithium secondary battery comprising same

ActiveUS20100273058A1Effective supervisionImprove responseFinal product manufactureSecondary cellsCarbon compositesGraphite particle

The present invention relates to a negative active material for a rechargeable lithium battery, a method of manufacturing the negative active material, and a rechargeable lithium battery including the negative active material. The negative active material includes a sphere-shaped first graphite particle that a first particle precursor, a flake-shaped graphite piece, is linked to each other; and at least one second particle dispersed between the flake-shaped graphite pieces inside the sphere-shaped first graphite particle and selected from the group consisting of at least one element particle selected from the group consisting of Si, Sn, Al, Ge, Pb, and combinations thereof; at least one element compound particle selected from the group consisting of Si, Sn, Al, Ge, Pb, and combinations thereof; a composite particle including at least one element selected from the group consisting of Si, Sn, Al, Ge, Pb, and combinations thereof; a carbon composite particle including at least one element selected from the group consisting of Si, Sn, Al, Ge, Pb, and combinations thereof; and a combination particle thereof.

Owner:SAMSUNG ELECTRONICS CO LTD

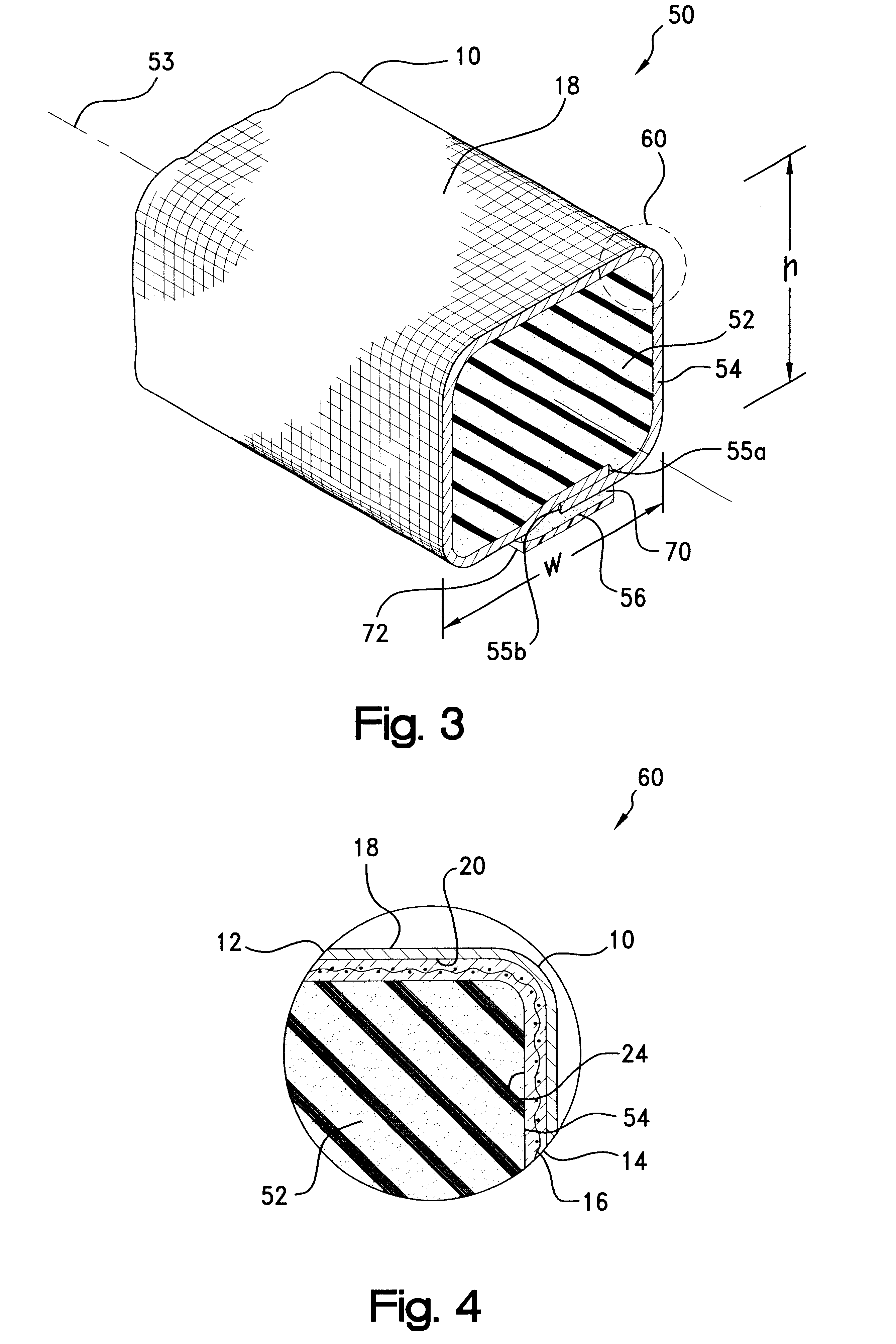

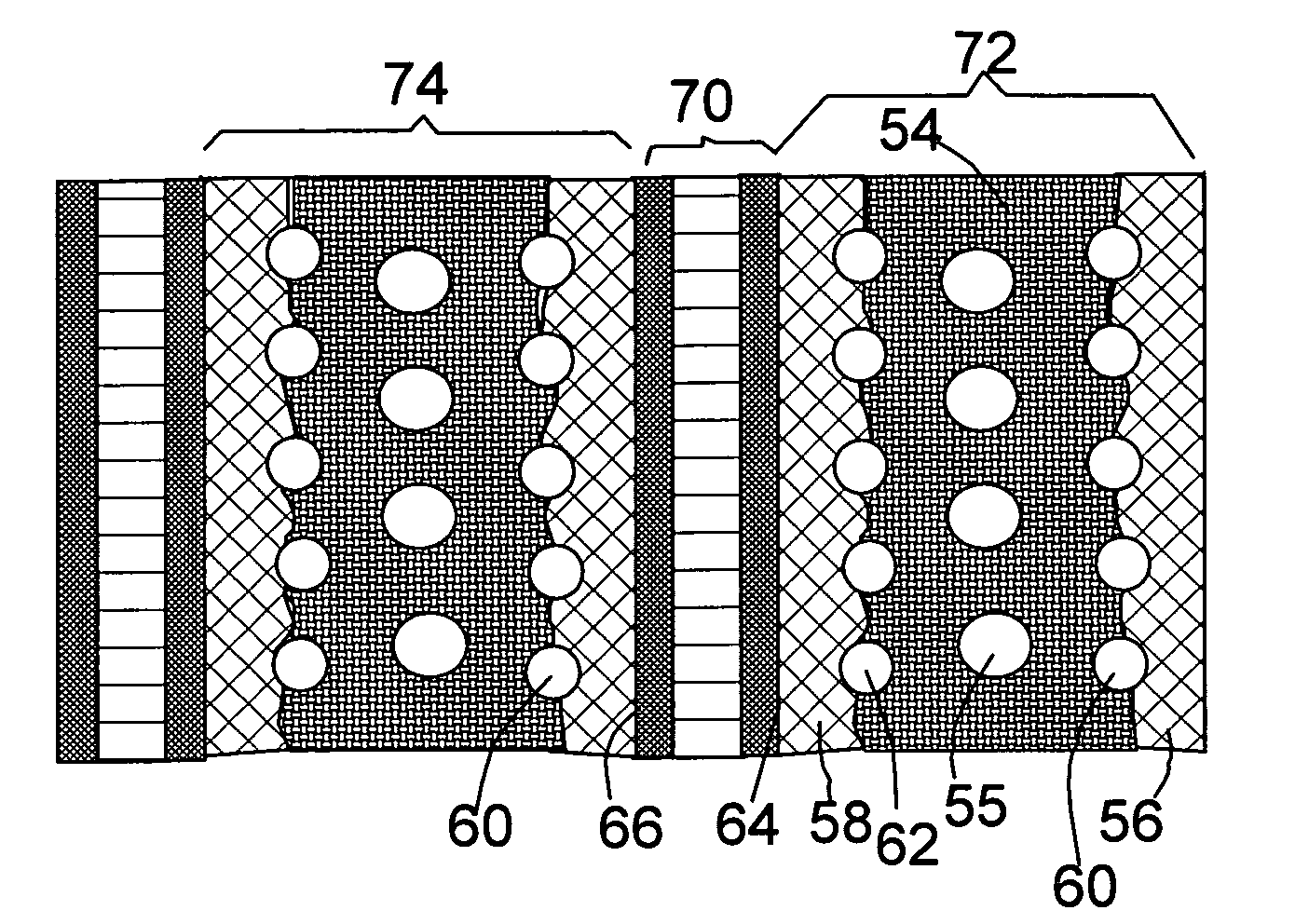

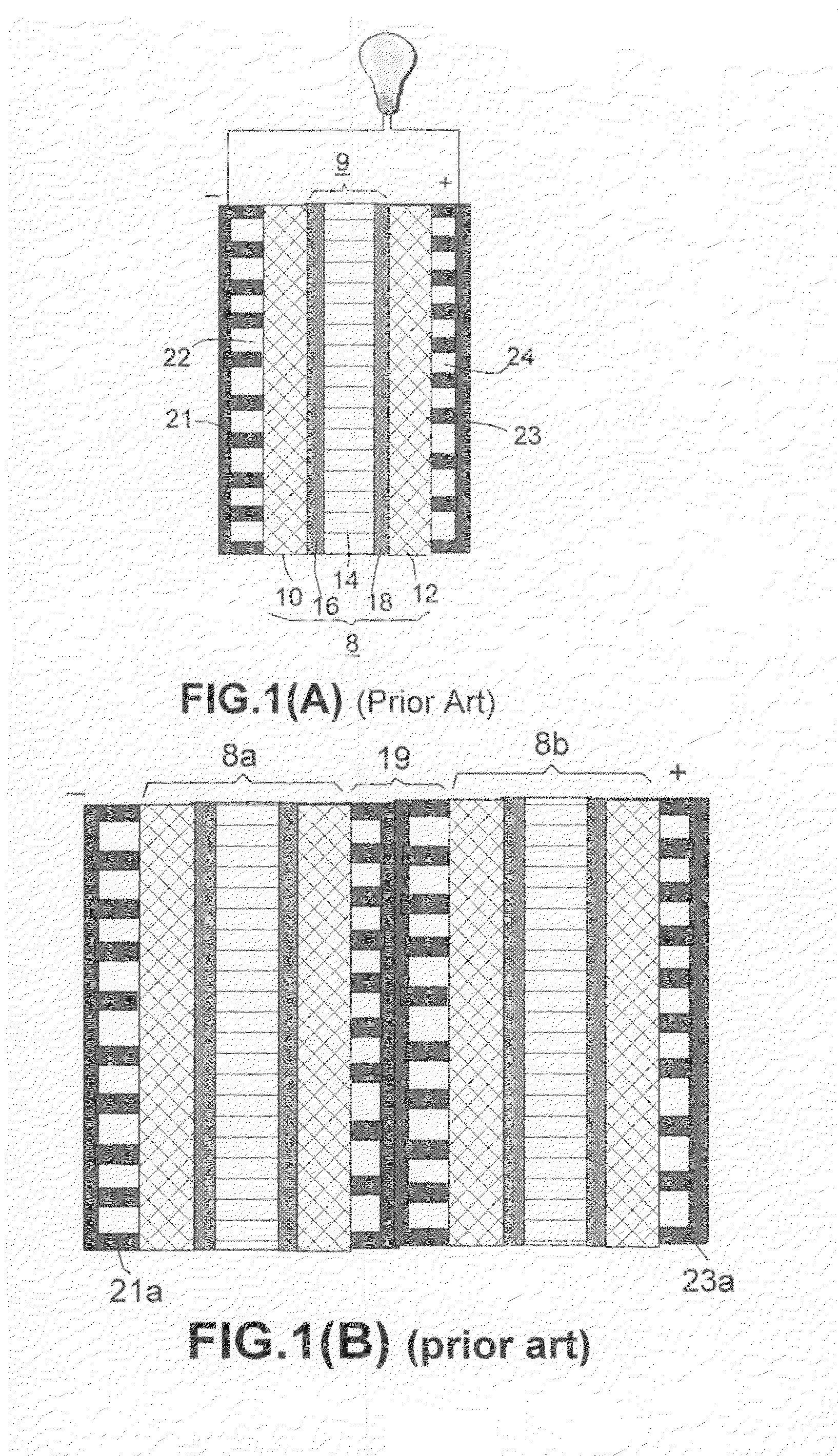

Carbon cladded composite flow field plate, bipolar plate and fuel cell

The present invention provides a carbon-cladded composite composition for use as a fuel cell flow field plate or bipolar plate. In one preferred embodiment, the composition comprises a core composite layer sandwiched between two clad layers, wherein (a) the clad layer comprises a conductive carbon or graphite material (e.g., carbon nano-tubes, nano-scaled graphene plates, graphitic nano-fibers, and fine graphite particles); (b) the core composite layer comprises a matrix resin and a conductive filler present in a sufficient quantity to render the composite layer electrically conductive with an electrical conductivity no less than 1 S / cm (preferably no less than 100 S / cm); and (c) the composition has a planar outer surface on each clad side having formed therein a fluid flow channel.

Owner:EVERPOWER SHENG TIE (XIAMEN) GRAPHENE TECH CO LTD +1

Nonaqueous electrolyte solution and nonaqueous electrolyte battery using same

ActiveUS20160013517A1Improve balanceLess battery expansionNegative electrodesLi-accumulatorsDifluorophosphateMetal particle

The object of the present invention is to provide a nonaqueous electrolyte secondary battery which has excellent balance of general performance with respect to performance including durability, capacity, resistance, and output characteristics. Provided is a nonaqueous electrolyte battery comprising a positive electrode and a negative electrode each being capable of occluding and releasing metal ions, and a nonaqueous electrolyte solution, wherein the nonaqueous electrolyte solution contains an electrolyte, a nonaqueous solvent, and at least one compound selected from the group consisting of a compound having a fluorosulfonyl structure (—SO2F), a difluorophosphate, and an isocyanate compound, and wherein the negative electrode has a negative electrode active material containing metal particles capable of alloying with Li and graphite particles.

Owner:MU IONIC SOLUTIONS CORP +1

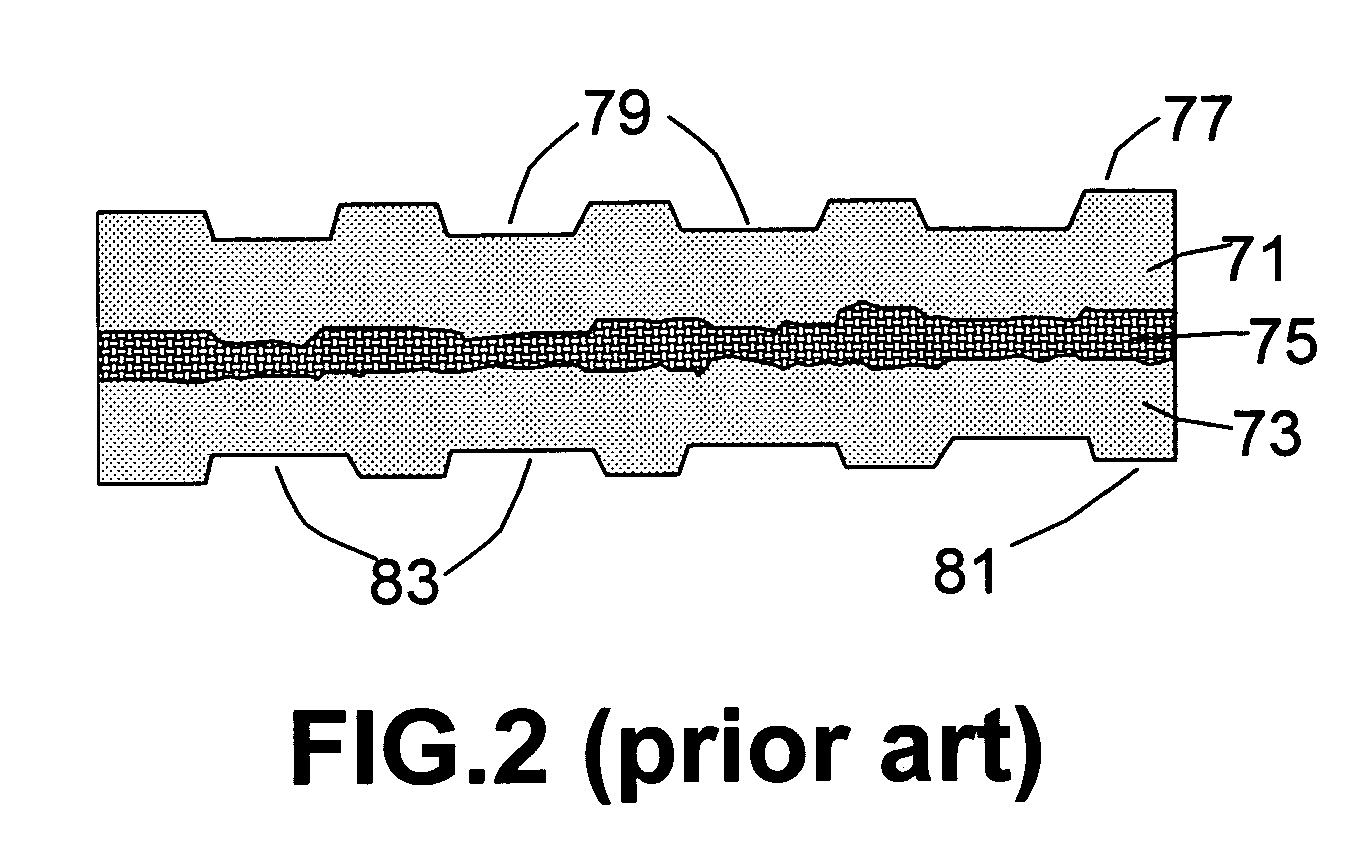

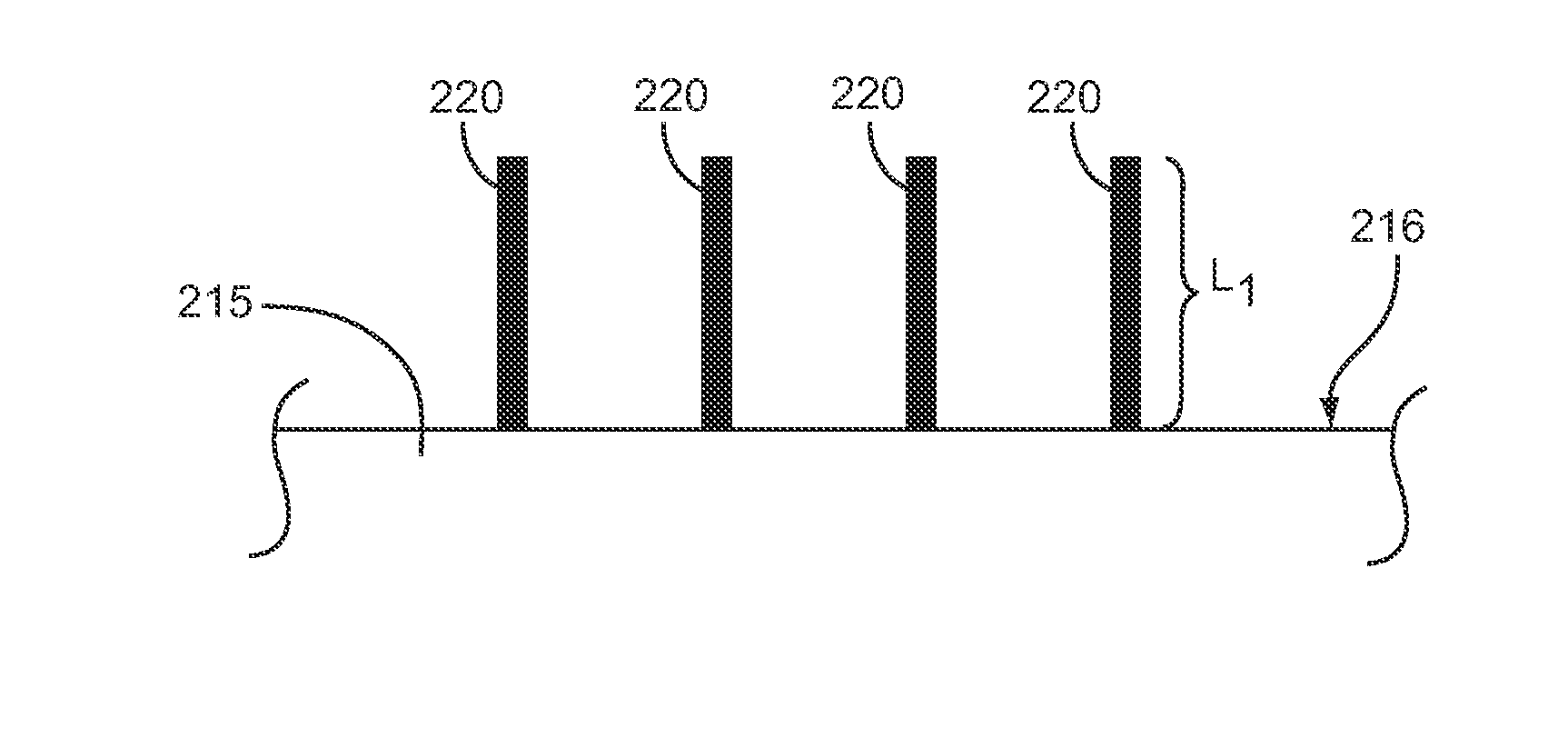

Method of producing exfoliated graphite composite compositions for fuel cell flow field plates

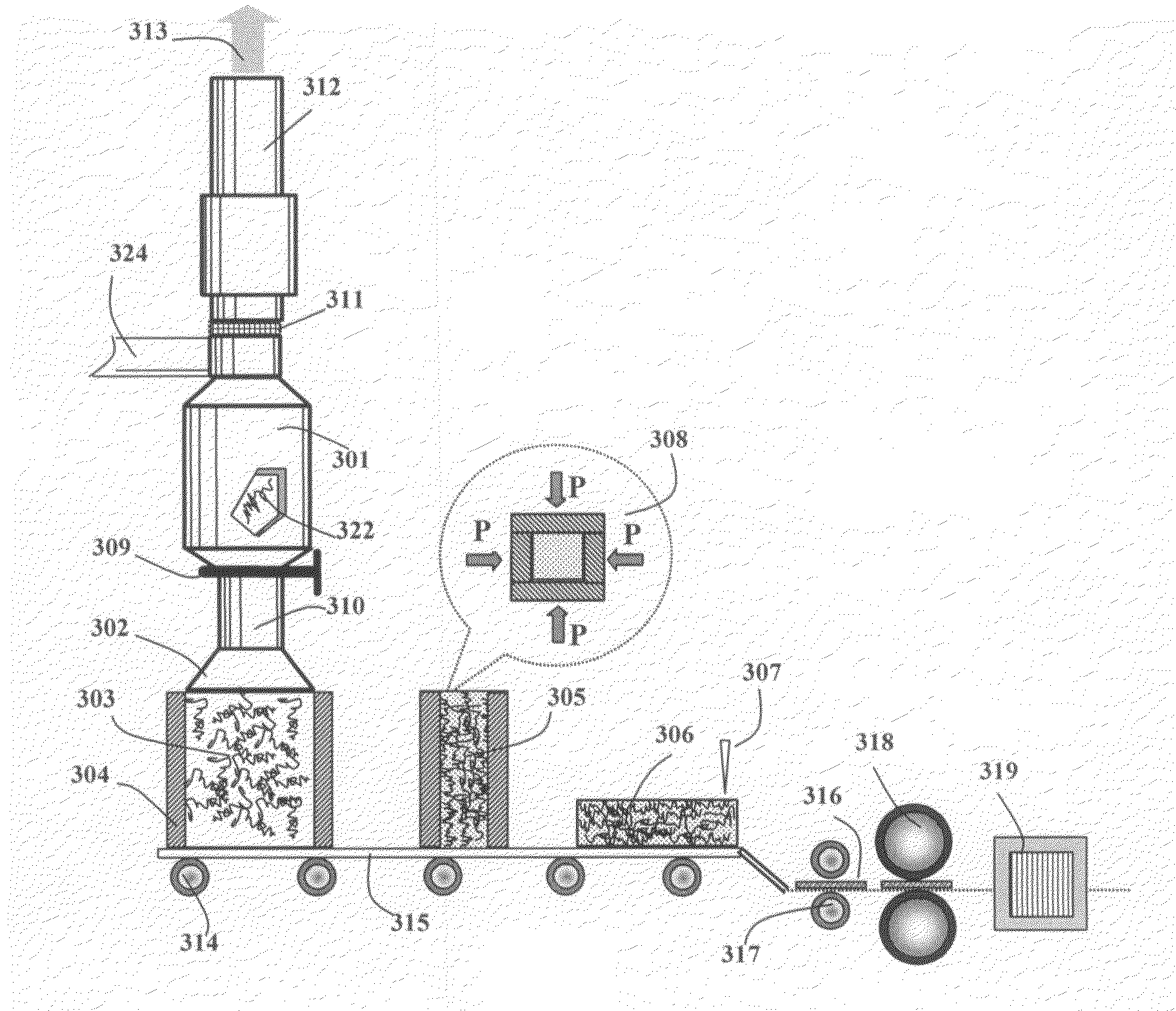

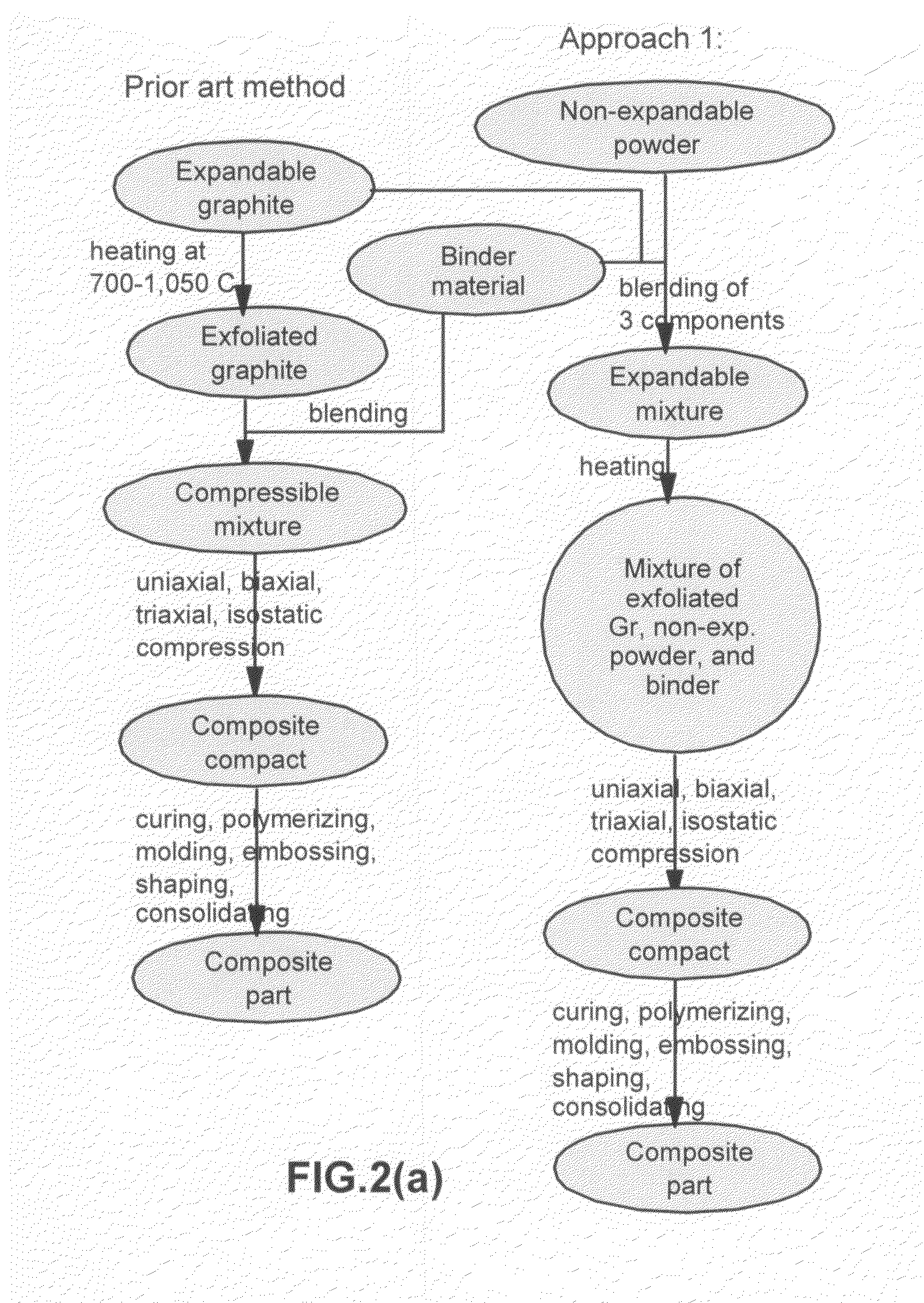

ActiveUS20080279710A1Improve adhesionEliminate or reduce this further anisotropyTransportation and packagingMetal-working apparatusFuel cellsPowder mixture

A method of producing an electrically conductive composite composition, which is particularly useful for fuel cell bipolar plate applications. The method comprises: (a) providing a supply of expandable graphite powder; (b) providing a supply of a non-expandable powder component comprising a binder or matrix material; (c) blending the expandable graphite with the non-expandable powder component to form a powder mixture wherein the non-expandable powder component is in the amount of between 3% and 60% by weight based on the total weight of the powder mixture; (d) exposing the powder mixture to a temperature sufficient for exfoliating the expandable graphite to obtain a compressible mixture comprising expanded graphite worms and the non-expandable component; (e) compressing the compressible mixture at a pressure within the range of from about 5 psi to about 50,000 psi in predetermined directions into predetermined forms of cohered graphite composite compact; and (f) treating the so-formed cohered graphite composite to activate the binder or matrix material thereby promoting adhesion within the compact to produce the desired composite composition. Preferably, the non-expandable powder component further comprises an isotropy-promoting agent such as non-expandable graphite particles. Further preferably, step (e) comprises compressing the mixture in at least two directions. The method leads to composite plates with exceptionally high thickness-direction electrical conductivity.

Owner:NANOTEK INSTR GRP LLC

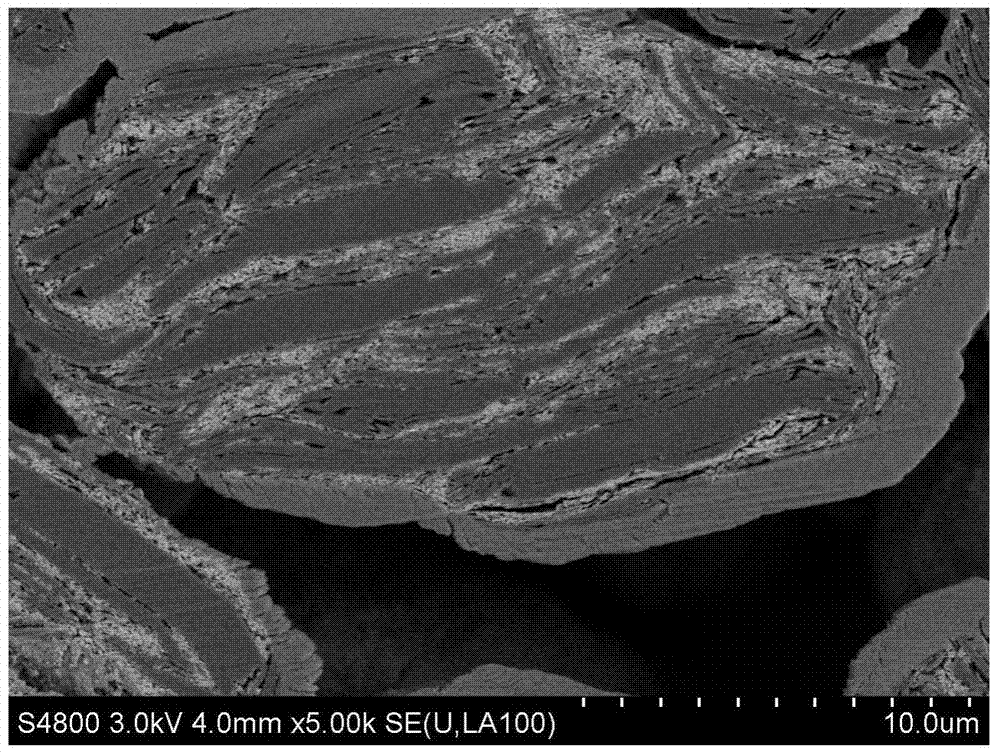

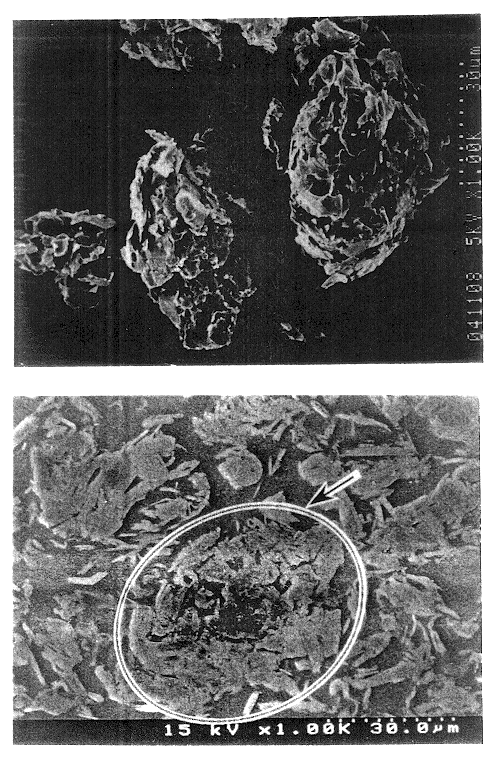

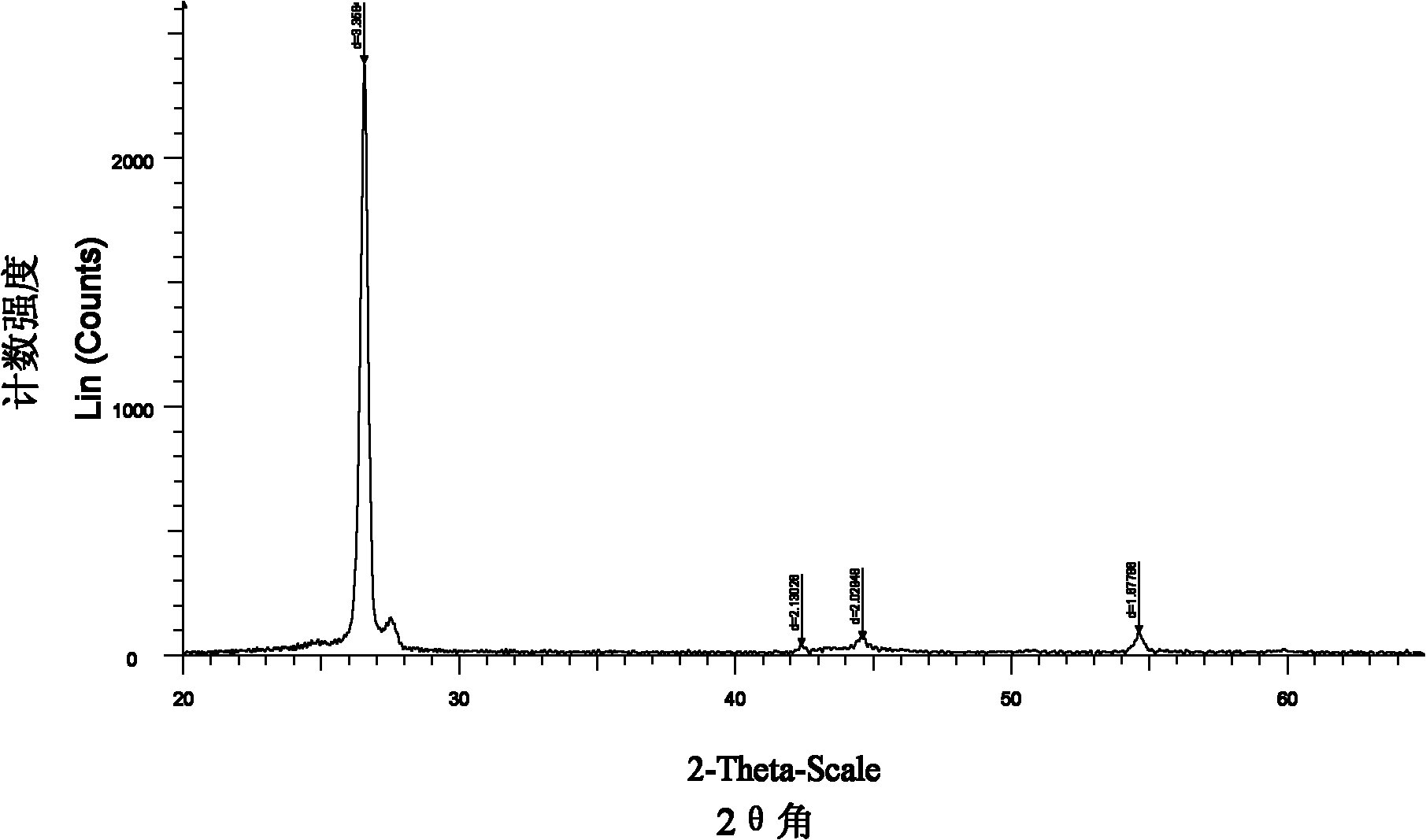

Modified graphite particles derived from scaly natural ones, production thereof and secondary battery

InactiveUS6139990APigmenting treatmentNon-aqueous electrolyte accumulatorsMicroscopic observationX-ray

Owner:MITSUBISHI CHEM CORP

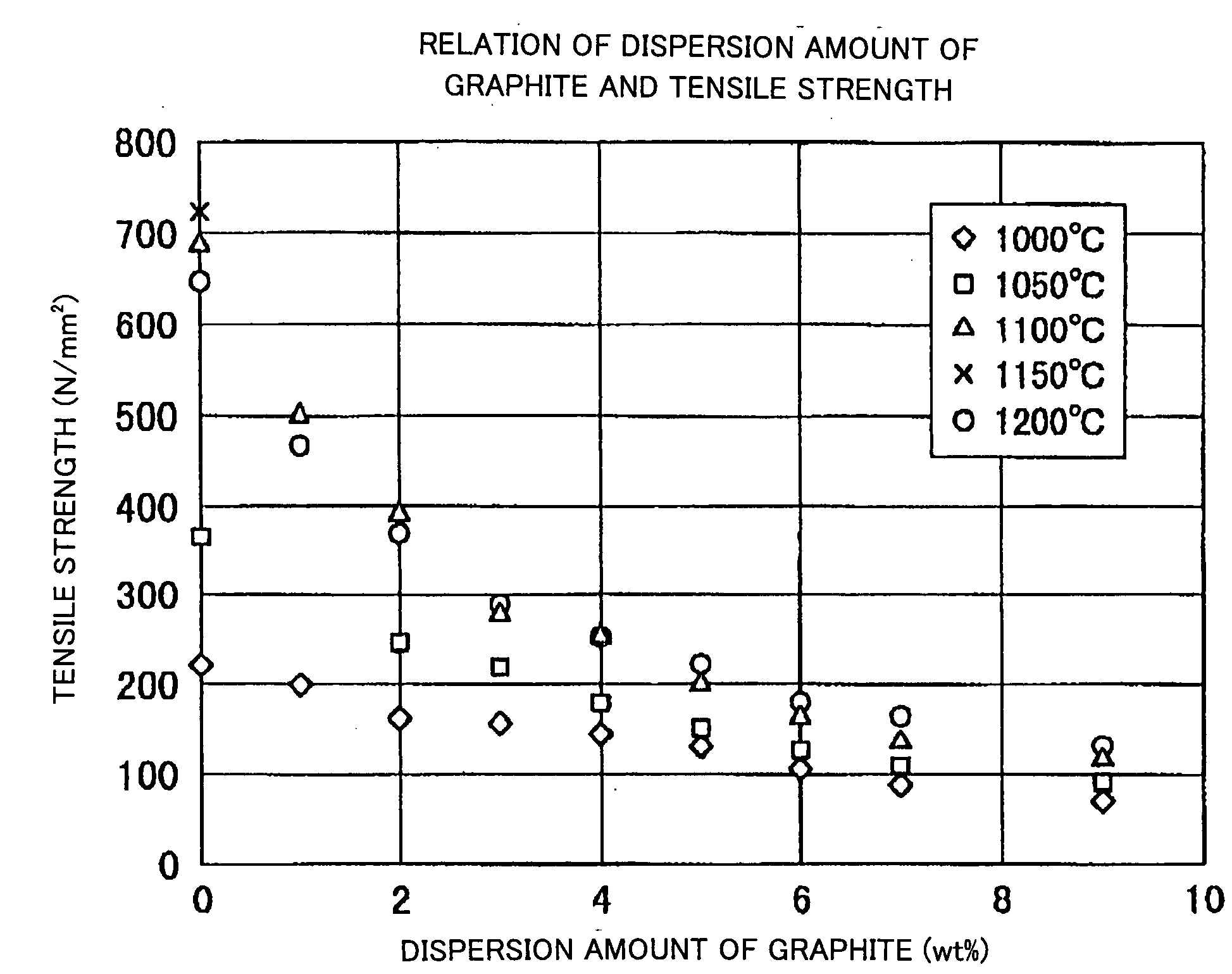

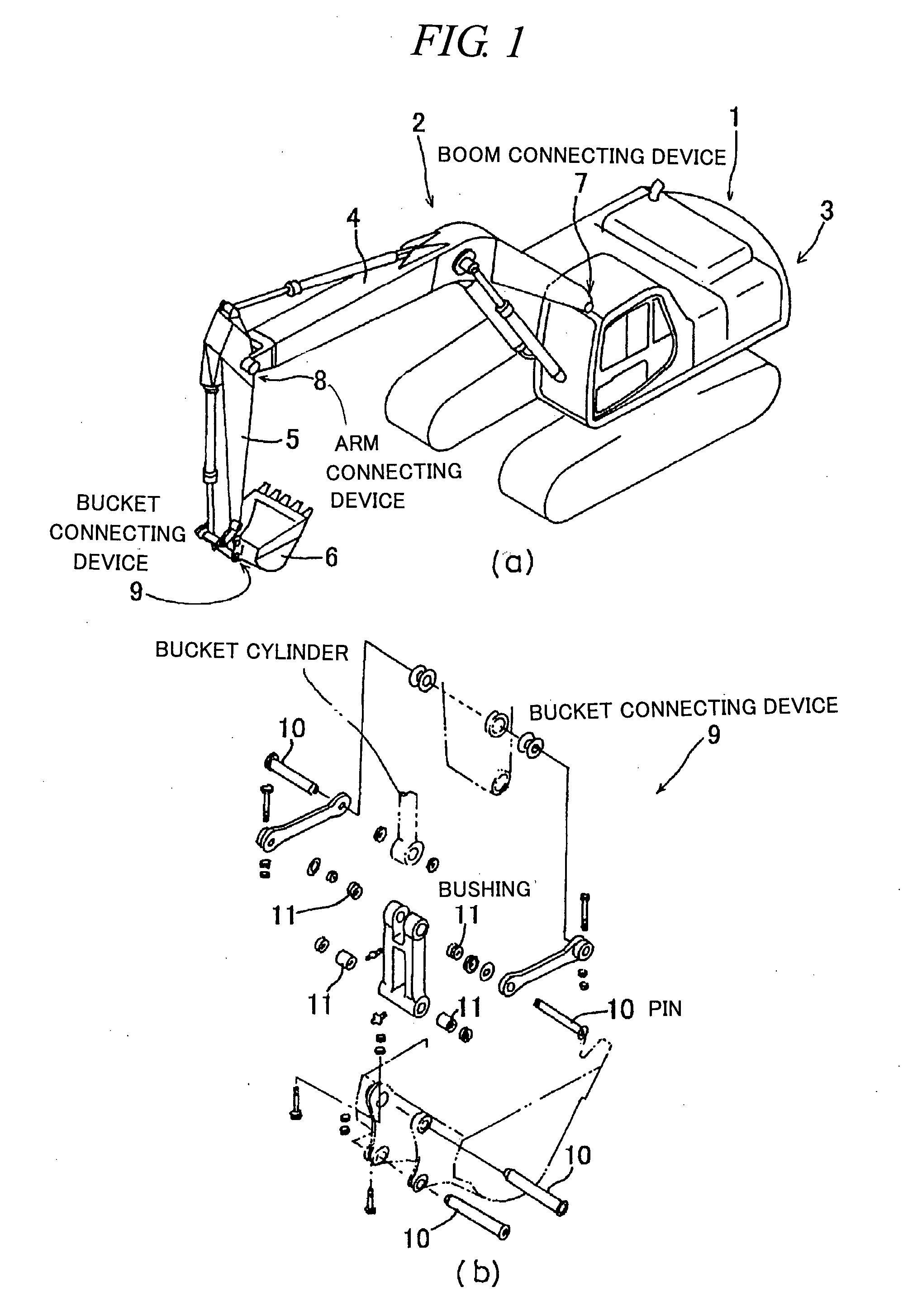

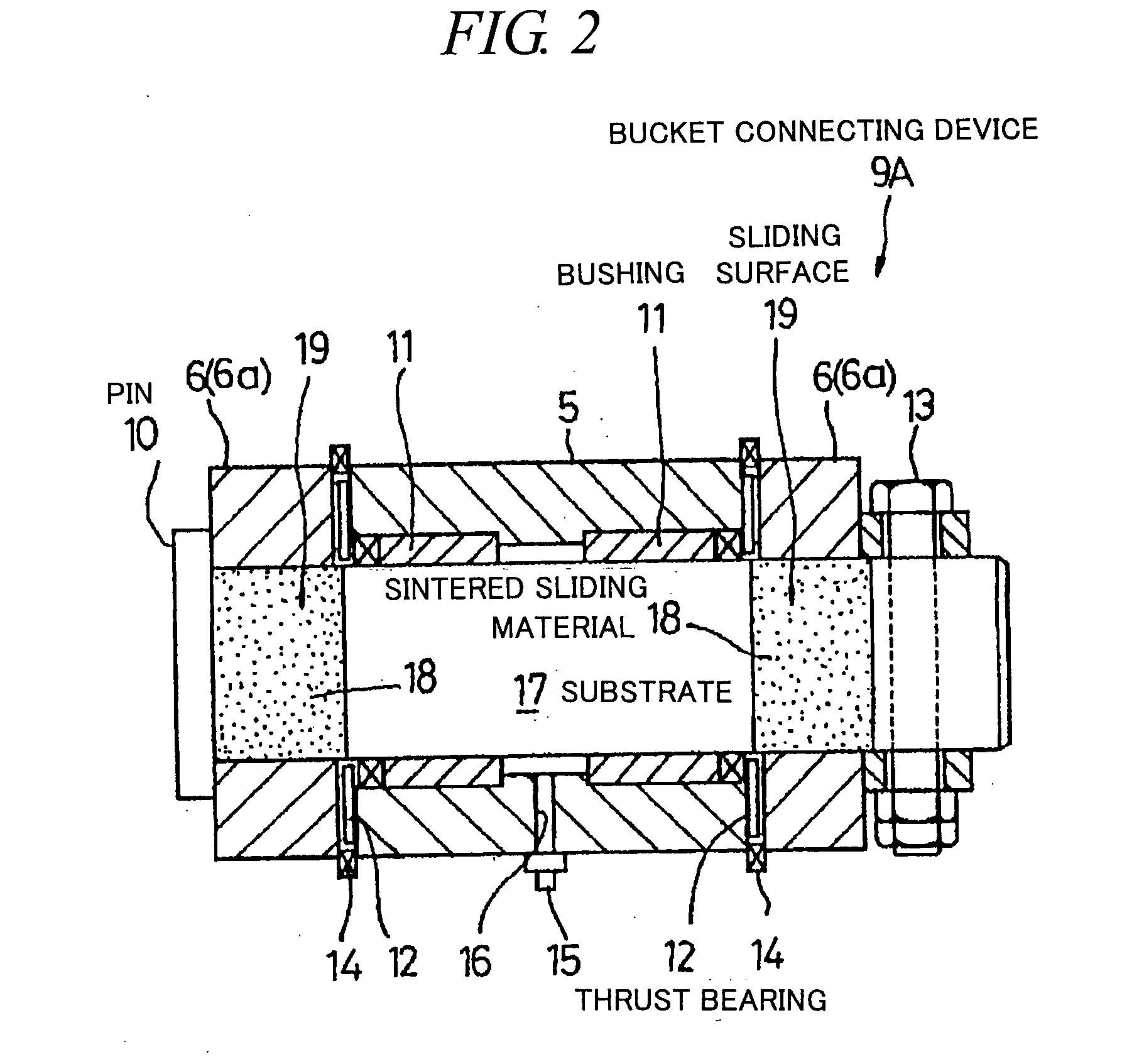

Sintered Material, Ferrous Sintered Sliding Material, Producing Method of the Same, Sliding Member, Producing Method of the Same and Coupling Device

InactiveUS20080146467A1Excellent abrasion resistanceReduce necessityBearing componentsPowder mixtureGraphite particle

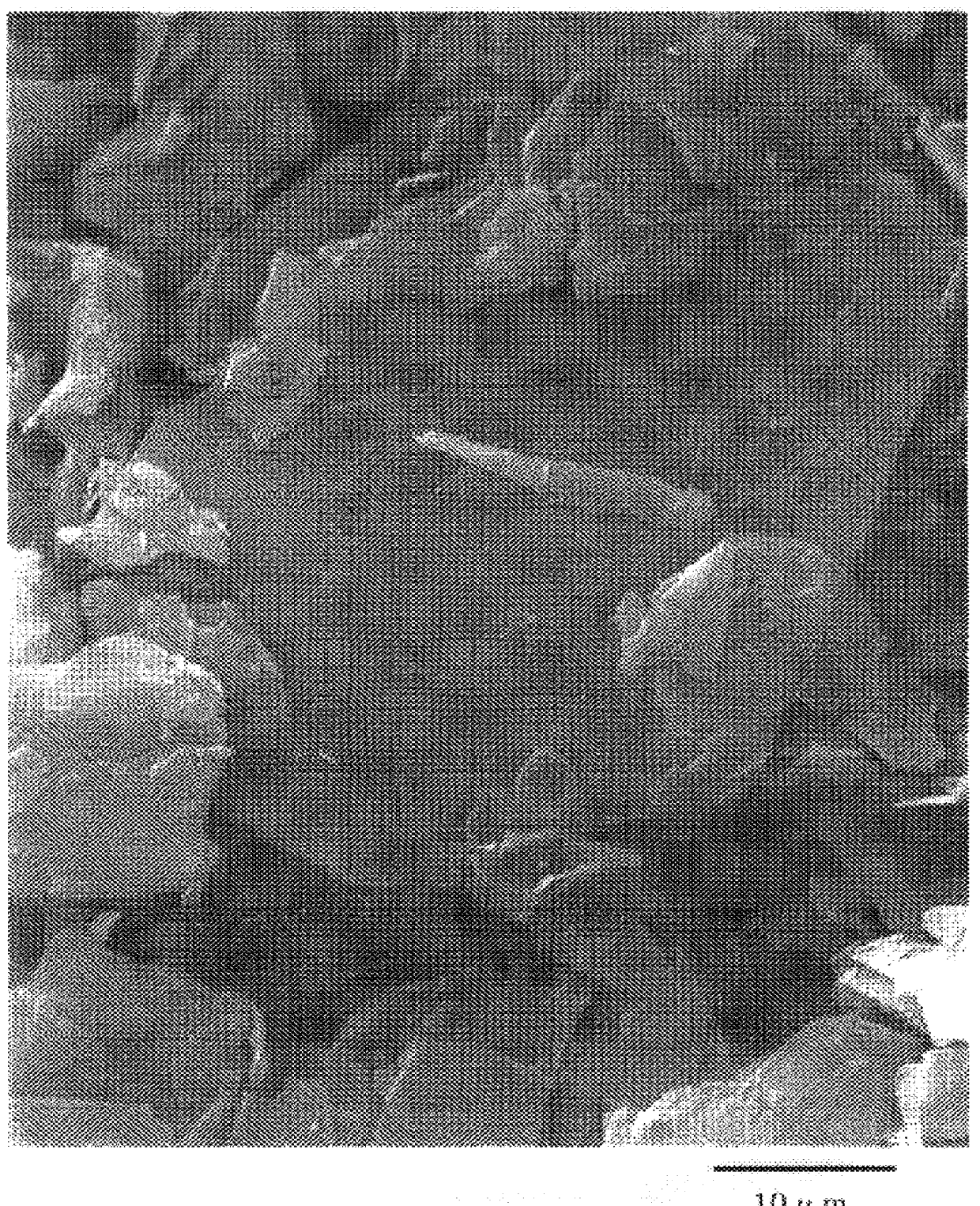

The iron-based sintered sliding material comprises: a sintered structure which contains 10-50 wt. % copper and 1-15 wt. % carbon and has been formed by sintering a powder mixture obtained by mixing at least one of an Fe—Cu alloy powder containing copper in an amount which is the solid solubility or larger and is 5-50 wt. %, excluding 50 wt. %, and an Fe—Cu—C alloy powder containing copper in an amount which is the solid solubility or larger and is 5-50 wt. %, excluding 50 wt. %, and containing carbon in an amount of 0-5 wt. %, excluding 0 wt. %, with a graphite powder and at least one of a copper powder and a copper alloy powder; and graphite particles dispersed in the sintered sliding material in an amount of 1-14 wt. % or 3-50 vol. %.

Owner:KOMATSU LTD

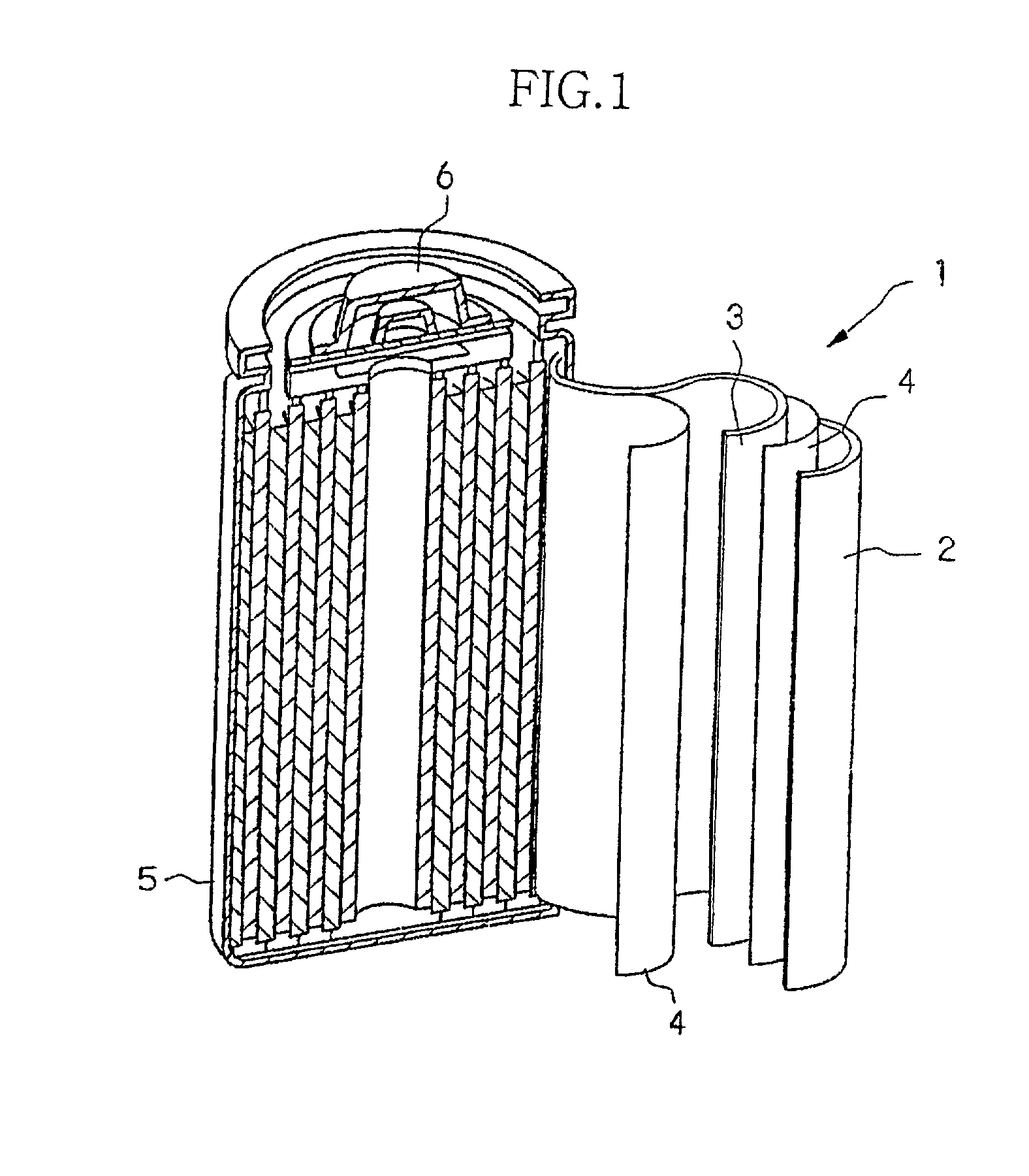

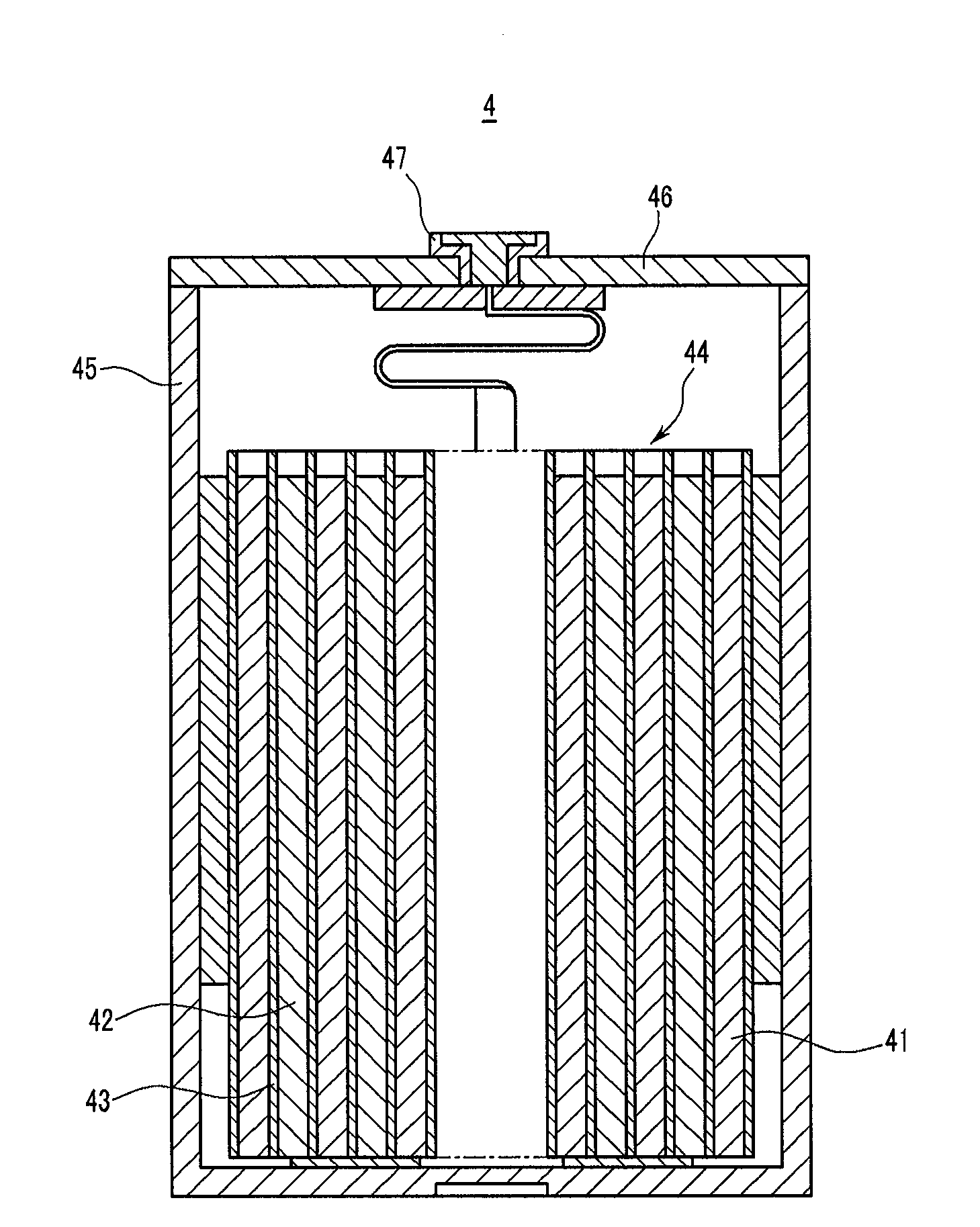

Lithium secondary cell

The present invention provides a lithium rechargeable battery including a negative electrode comprising a copper core material, to which is fixed an active material made by mixing artificial graphite particles A obtained by kneading and granulating a base material of pulverized bulk mesophase pitch with pitch in a softened state and / or thermosetting resin, carbonizing the resulting granules at 700 to 1,500 DEG C. and graphitizing the carbonized granules at 2,500 to 3,000 DEG C. with spherical graphite particles B having a high mean circularity, with a view to inhibiting the deterioration in battery capacity through the repeated charge / discharge cycles, which occurs remarkably in a high energy density lithium rechargeable battery, and providing excellent discharge characteristic and safety.

Owner:PANASONIC CORP

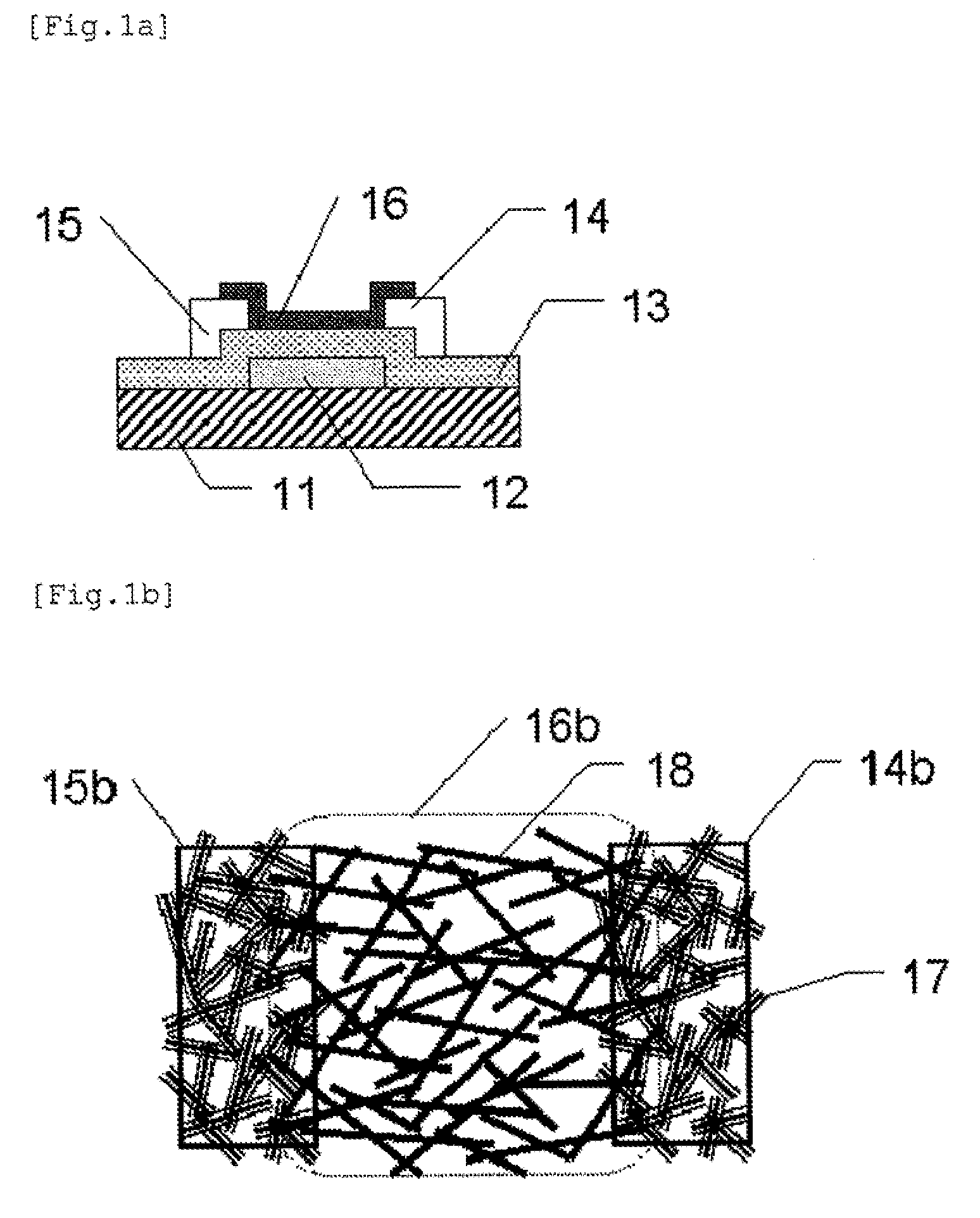

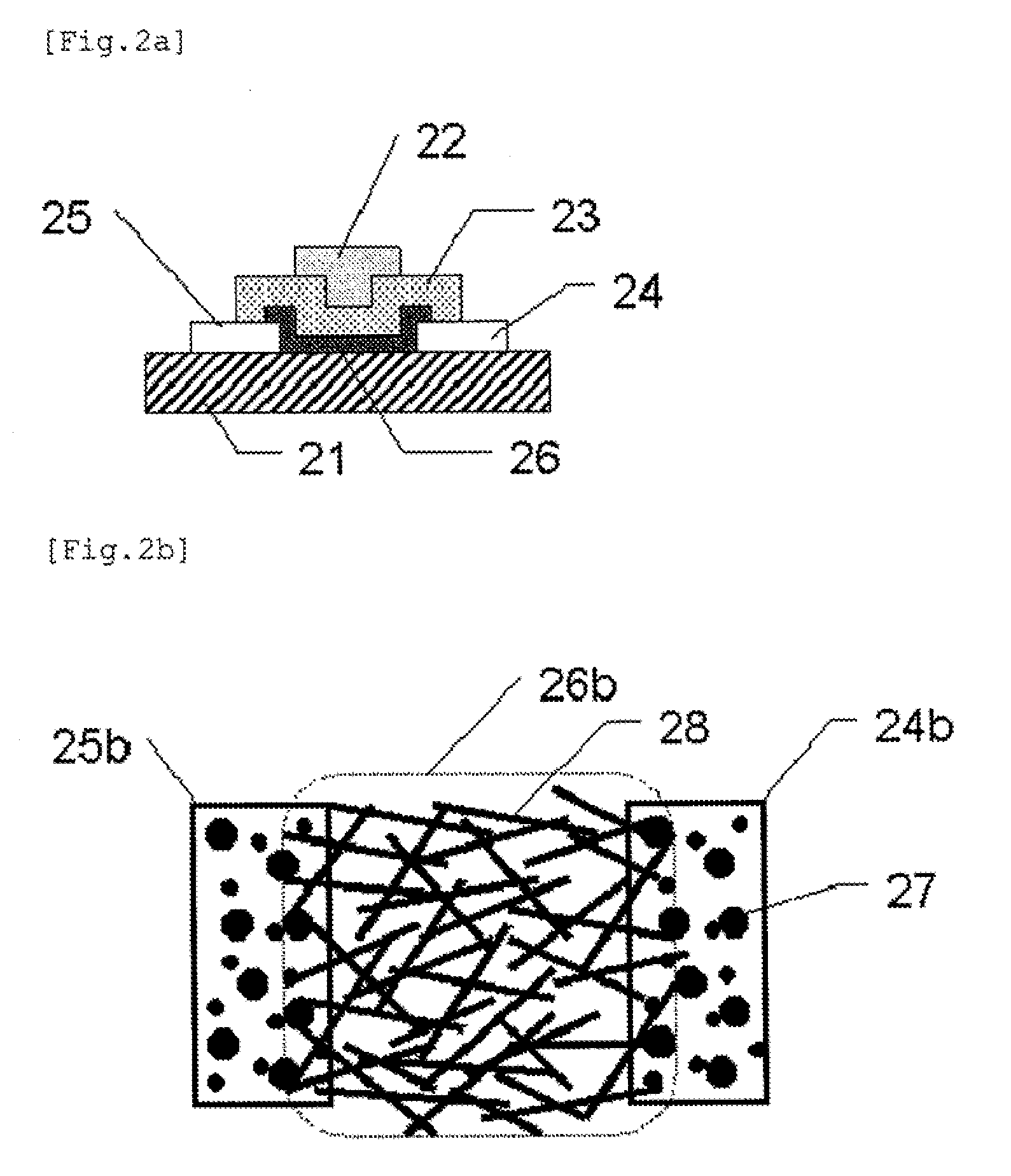

Semiconductor element

ActiveUS20100252802A1NanoinformaticsSolid-state devicesElectrical resistance and conductanceCarbon nanotube

This invention provides a semiconductor element which uses a plurality of carbon nanotubes as a current path, can reduce contact resistance of its electrode contact part, and has excellent electrical characteristics. This semiconductor element is characterized in that the semiconductor element includes a current path (16) comprised of a plurality of carbon nanotubes (18) and not less than two electrodes (14, 15) connected with the current path, wherein at least one or more of the electrodes is made of a mixture of a metal and a carbon material (17) having SP2 hybridized orbital, such as a multi-walled carbon nanotube, a glassy carbon, and graphite particles.

Owner:NEC CORP

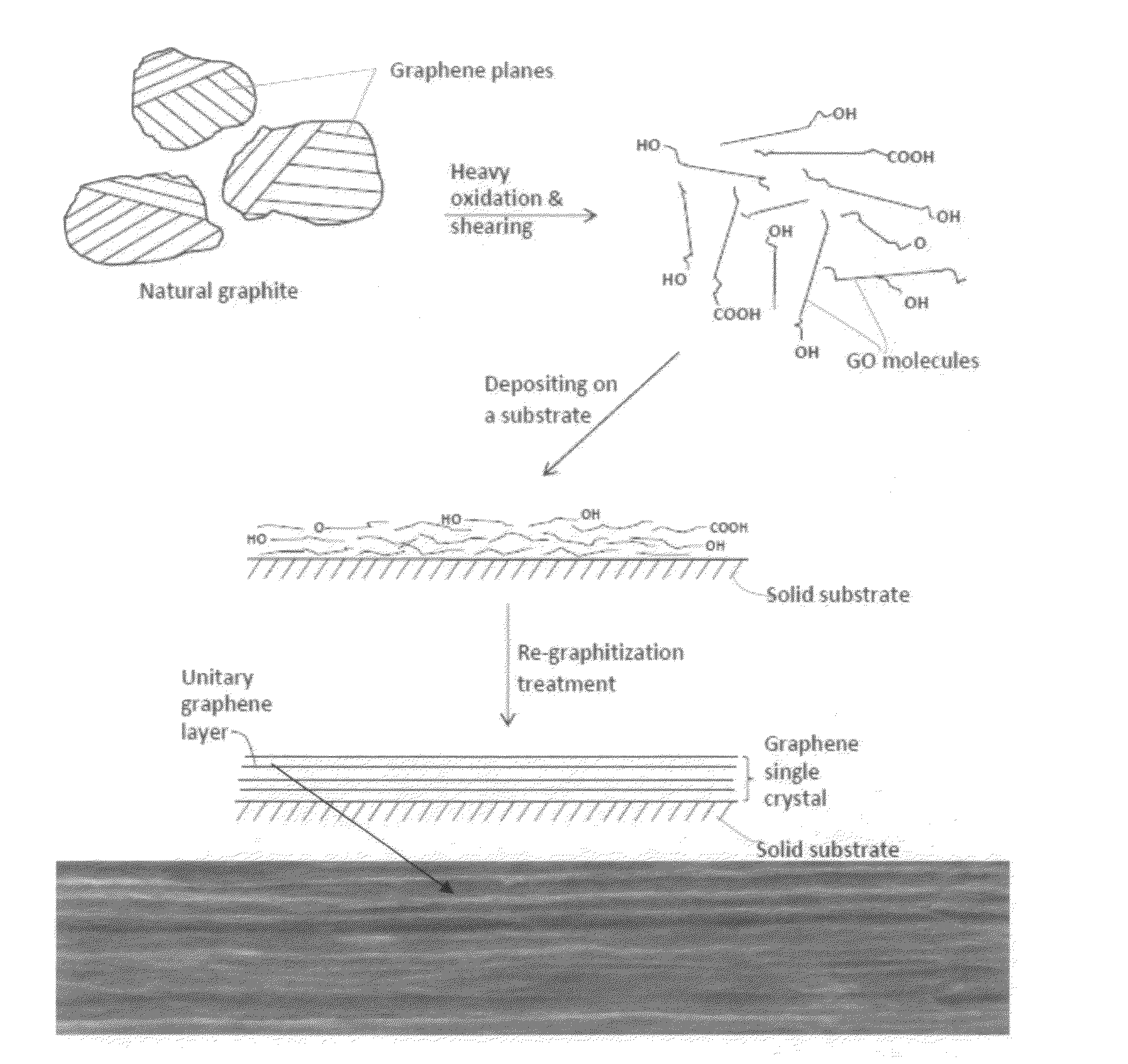

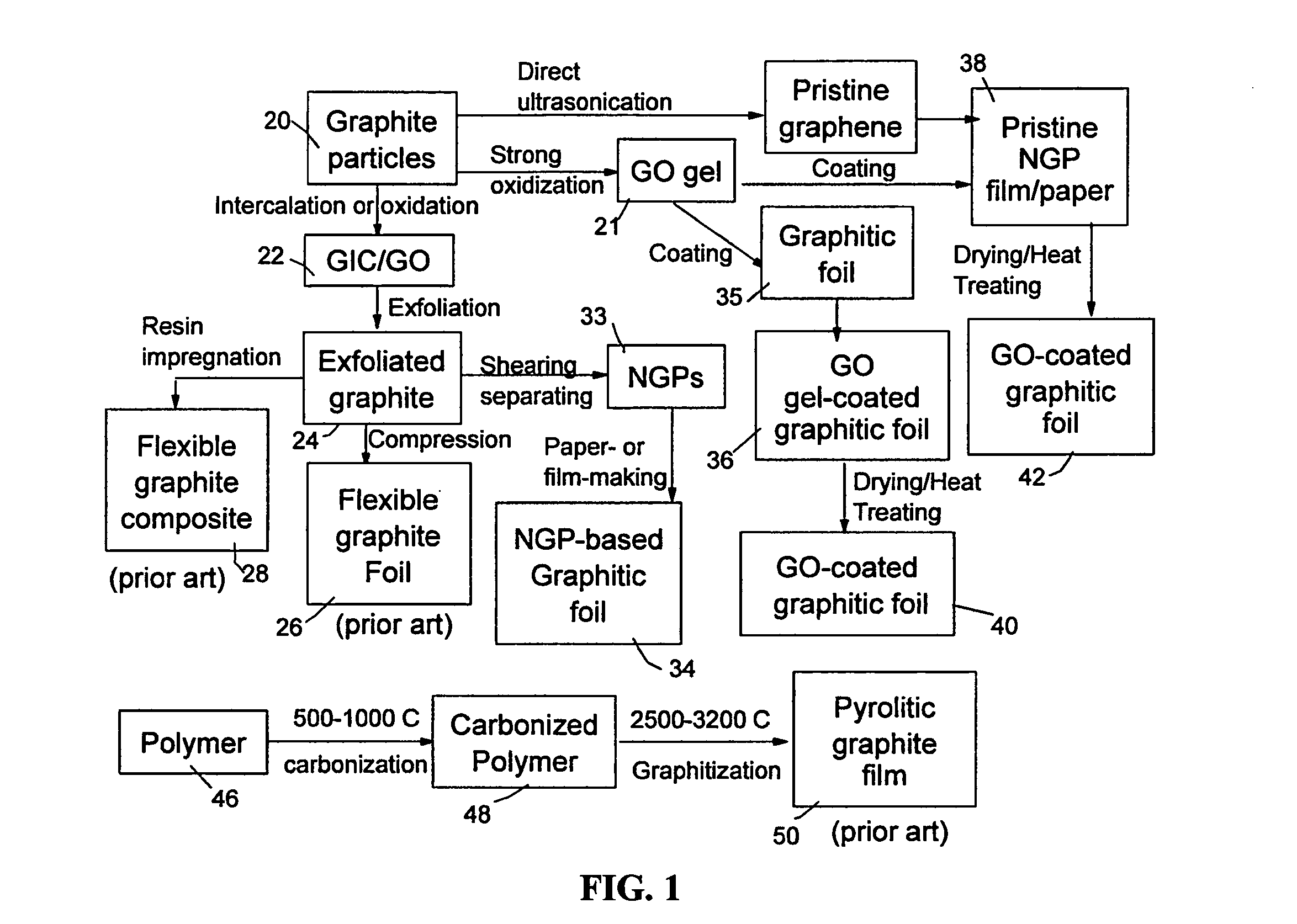

Graphene oxide-coated graphitic foil and processes for producing same

ActiveUS20140127488A1Reduce eliminateImprove surface smoothnessMaterial nanotechnologyGraphiteCarbon compositesFiber

A graphene oxide-coated graphitic foil, composed of a graphitic substrate or core layer having two opposed primary surfaces and at least a graphene oxide coating layer deposited on at least one of the two primary surfaces, wherein the graphitic substrate layer has a thickness preferably from 0.34 nm to 1 mm, and the graphene oxide coating layer has a thickness preferably from 0.5 nm to 1 mm and an oxygen content of 0.01%-40% by weight based on the total graphene oxide weight. The graphitic substrate layer may be preferably selected from flexible graphite foil, graphene film, graphene paper, graphite particle paper, carbon-carbon composite film, carbon nano-fiber paper, or carbon nano-tube paper. This graphene oxide-coated laminate exhibits a combination of exceptional thermal conductivity, electrical conductivity, mechanical strength, surface smoothness, surface hardness, and scratch resistance unmatched by any thin-film material of comparable thickness range.

Owner:GLOBAL GRAPHENE GRP INC

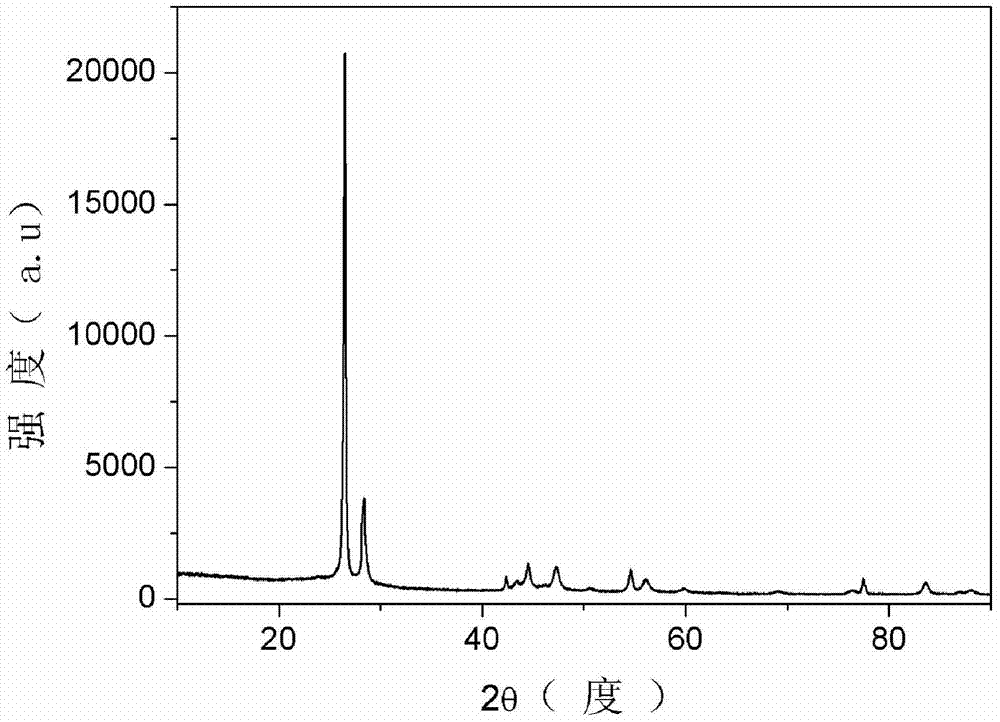

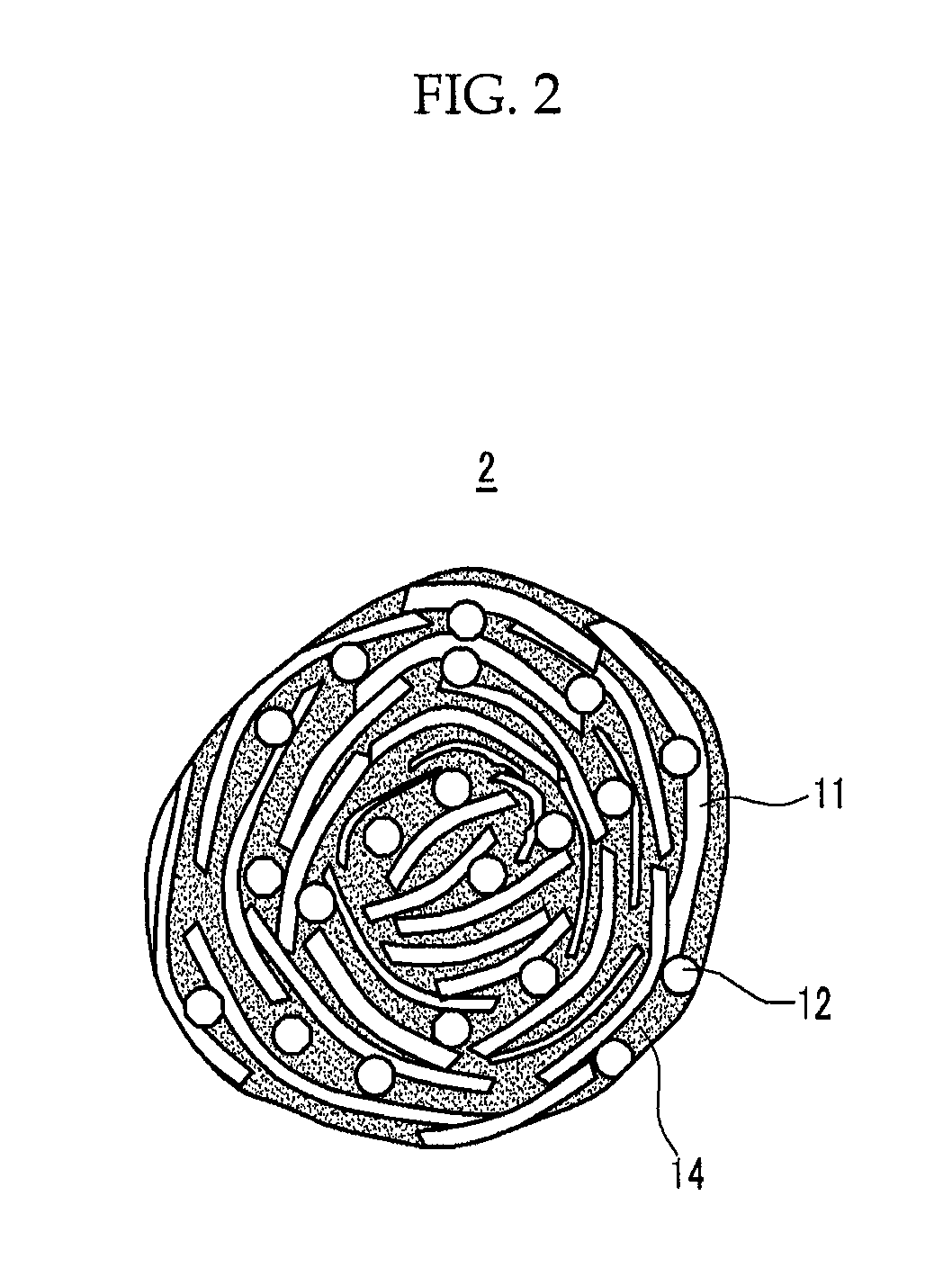

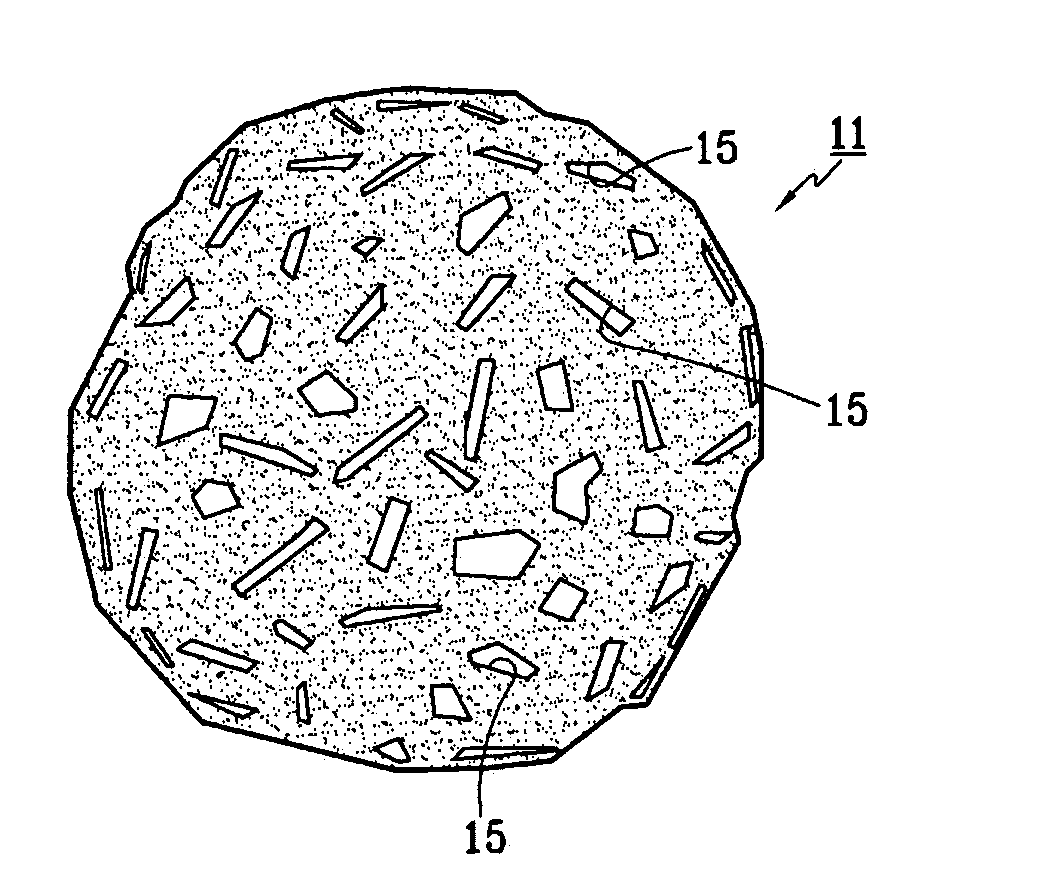

Graphite particles and lithium secondary battery using the same as negative electrode

InactiveUS6344296B1Improve featuresSolve large capacityGraphiteFinal product manufactureX-rayCharge discharge

A graphite particle obtained by assembling or binding together a plurality of flat-shaped particles so that the planes of orientation are not parallel to one another, or a graphite particle in which aspect ratio is 5 or less or specific surface area is 8 m2 / g or less or the size of crystallite in the direction of c-axis of the crystal is 500 Å or more and the size of crystallite in the direction of plane is 1,000 Å or less as measured by X ray broad angle diffraction, or a graphite particle in which pore volume of the pores having a size falling in a range of 102 to 106 Å is 0.4 to 2.0 cc / g per weight of graphite particle or pore volume of the pores having a size falling in a range of 1x102 to 2x104 Å is 0.08 to 0.4 cc / g per weight of graphite particle is suitable for production of negative electrode of lithium secondary battery, and a lithium secondary battery obtained therefrom is excellent in rapid charge-discharge characteristics, cycle characteristics, etc.

Owner:RESONAC CORPORATION

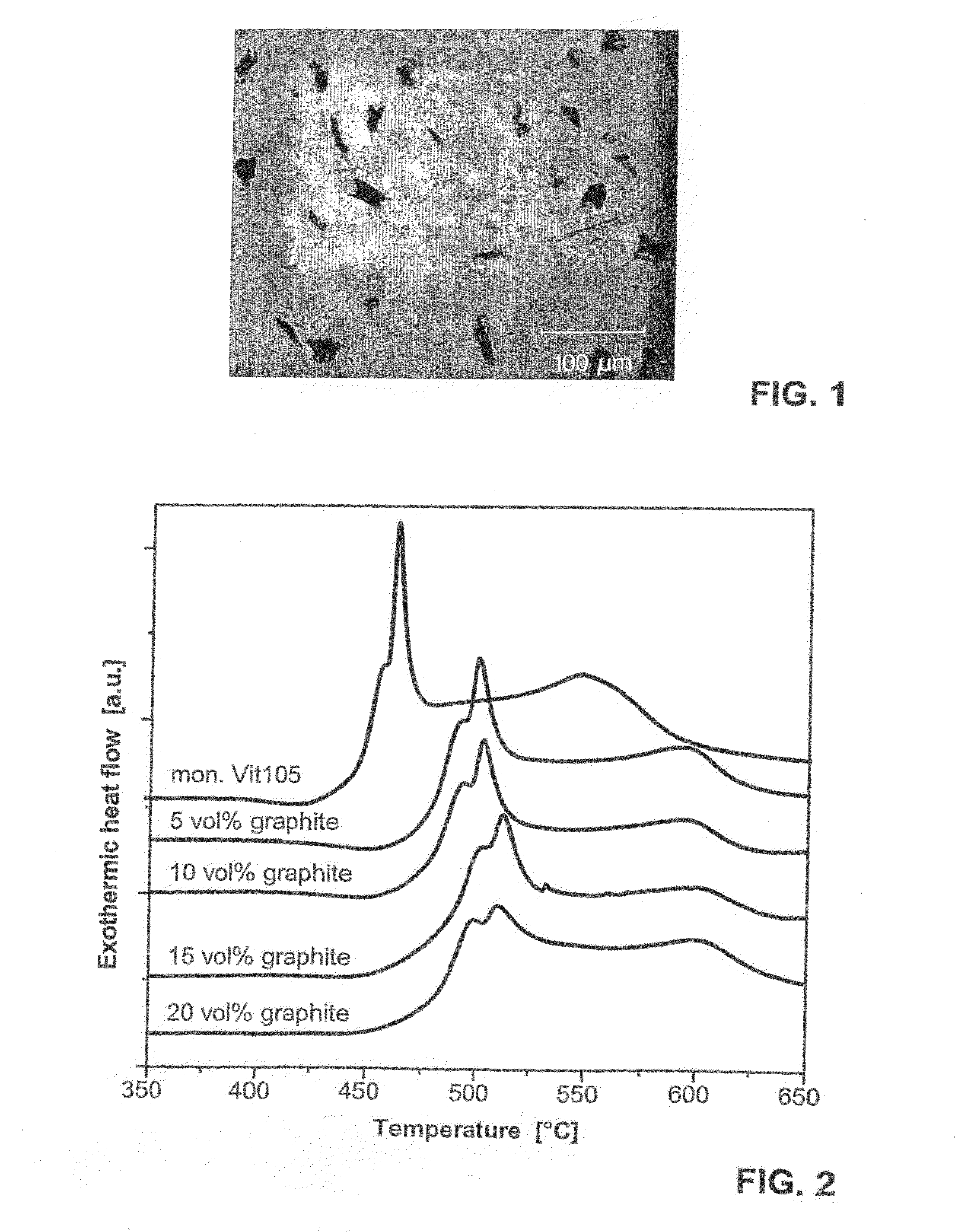

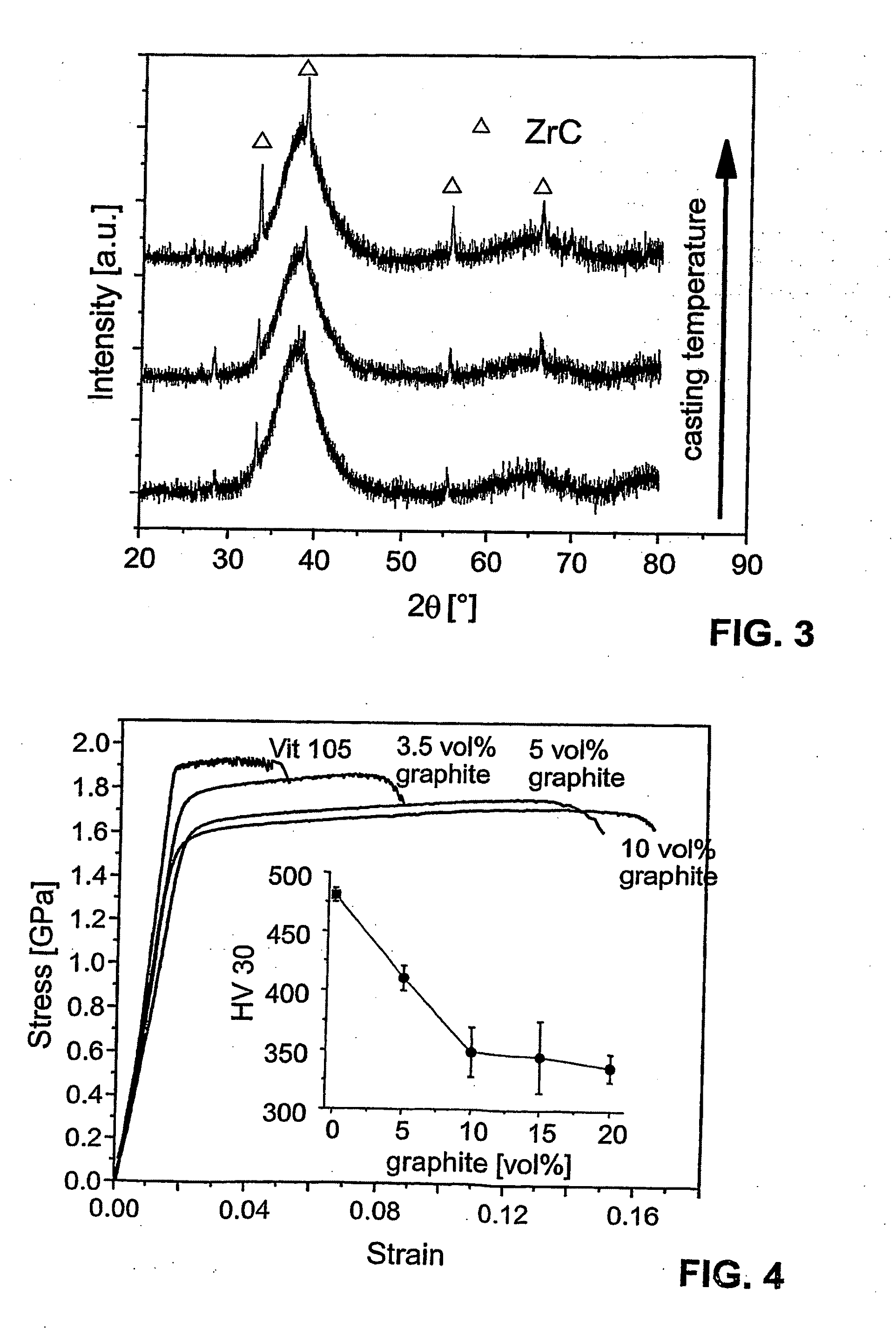

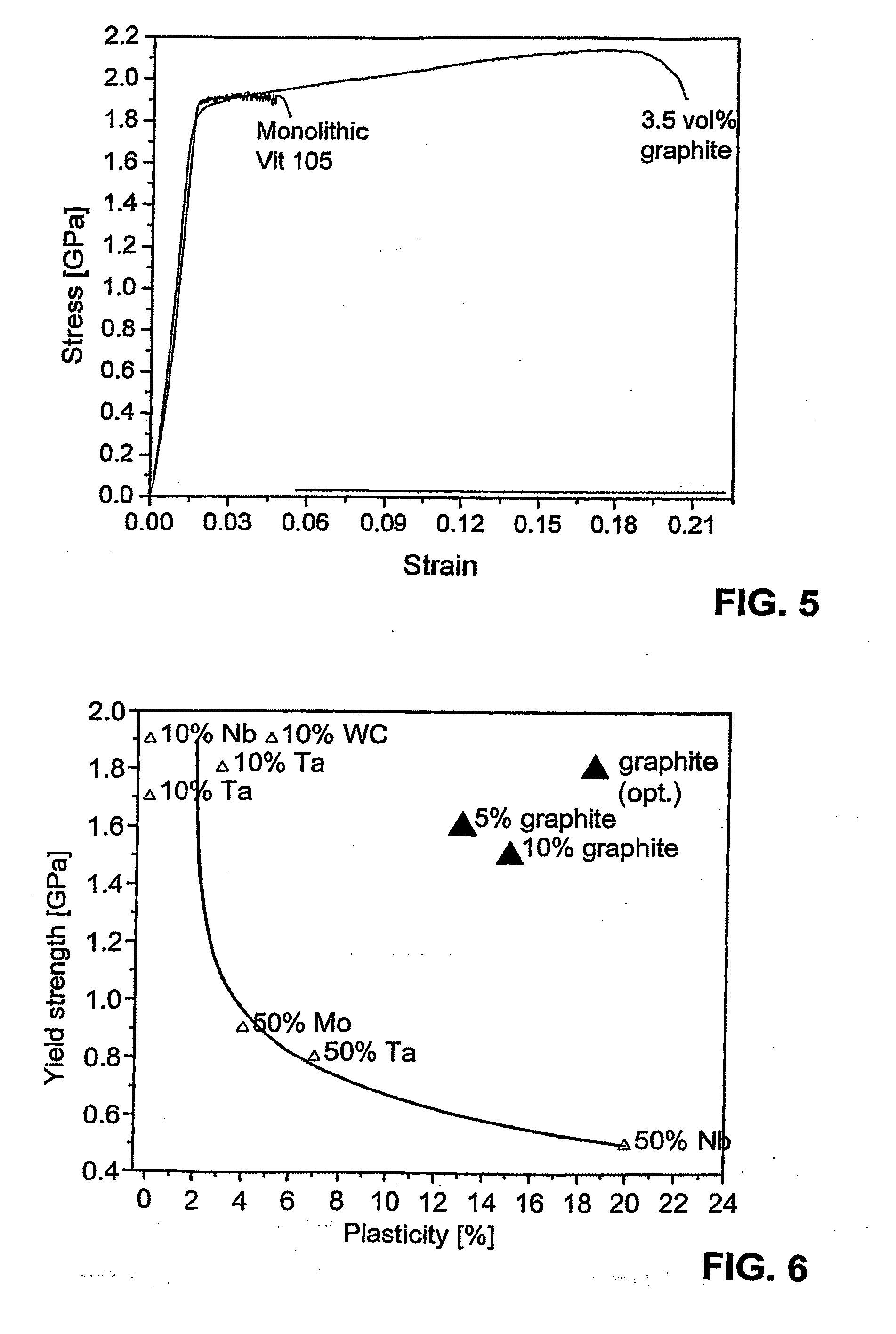

Bulk Metallic Glass/Graphite Composites

A composite material based on a bulk metallic glass is disclosed. In an amorphous alloy phase forming a substantially continuous matrix, a second phase comprising graphite particles is embedded. The alloy is preferably zirconium based. The particles may have a carbide surface layer, which may be formed phase comprising carbide particles may also be present. The composite material has high plasticity, high yield strength, good elasticity and low coefficient of friction, which renders it a good candidate for applications like joints, frictional bearings or Springs.

Owner:ETH ZZURICH

Hard carbon coated lithium ion battery anode material and preparation method thereof

InactiveCN102082272AImprove the first Coulombic efficiencyImprove cycle performanceCell electrodesHeteroatomGraphite particle

The invention discloses a hard carbon coated lithium ion battery anode material and a preparation method thereof. The anode material is characterized in that the coating material is formed by a heteroatom modifier, a hard carbon precursor material and a soft carbon precursor material, wherein the weight ratio of the heteroatom modifier to the hard carbon precursor to the soft carbon precursor is 1:(2-3.3):(3-9). The preparation method is mainly characterized by comprising the following steps: fully mixing graphite and the coating material, and then carrying out heat treatment on the mixture under the protection of inert atmosphere; preserving the temperature for 0.5-6 hours, and then cooling; and carrying out secondary high-temperature graphitization treatment under the protection of inert atmosphere. The heteroatom modifier can change the structure of the hard carbon in the coating material, and the hard carbon precursor has the characteristics of dissolvability and condensation polymerization with the soft carbon precursor asphalt, thus improving the uniformity and operability of the coated graphite particles; and the ratio of the heteroatom modifier to the hard carbon precursor to the soft carbon precursor has an important effect on the performance of the three. By optimizing the ratio of the heteroatom to the hard carbon precursor to the soft carbon precursor in the coated graphite material, the aims of increasing the capacity of the anode material and improving the cycle performance of the anode material are achieved.

Owner:湖南摩根海容新材料有限责任公司

Rechargeable lithium battery

InactiveUS20060008706A1Excellent cycle characteristicsReduce generationSolid electrolyte cellsLi-accumulatorsParticulatesSolvent

The present invention provides a lithium secondary battery having high-capacity as well as good cycle characteristics. The lithium secondary battery includes a positive electrode comprising a positive active material, a negative electrode comprising a negative active material and an electrolyte. The negative active material includes graphite particles combined to Si particulate. The electrolyte includes a solvent, a polyether modified silicone oil where a linear polyether chain is linked to a polysiloxane chain, and a solute comprising a lithium salt.

Owner:SAMSUNG SDI CO LTD

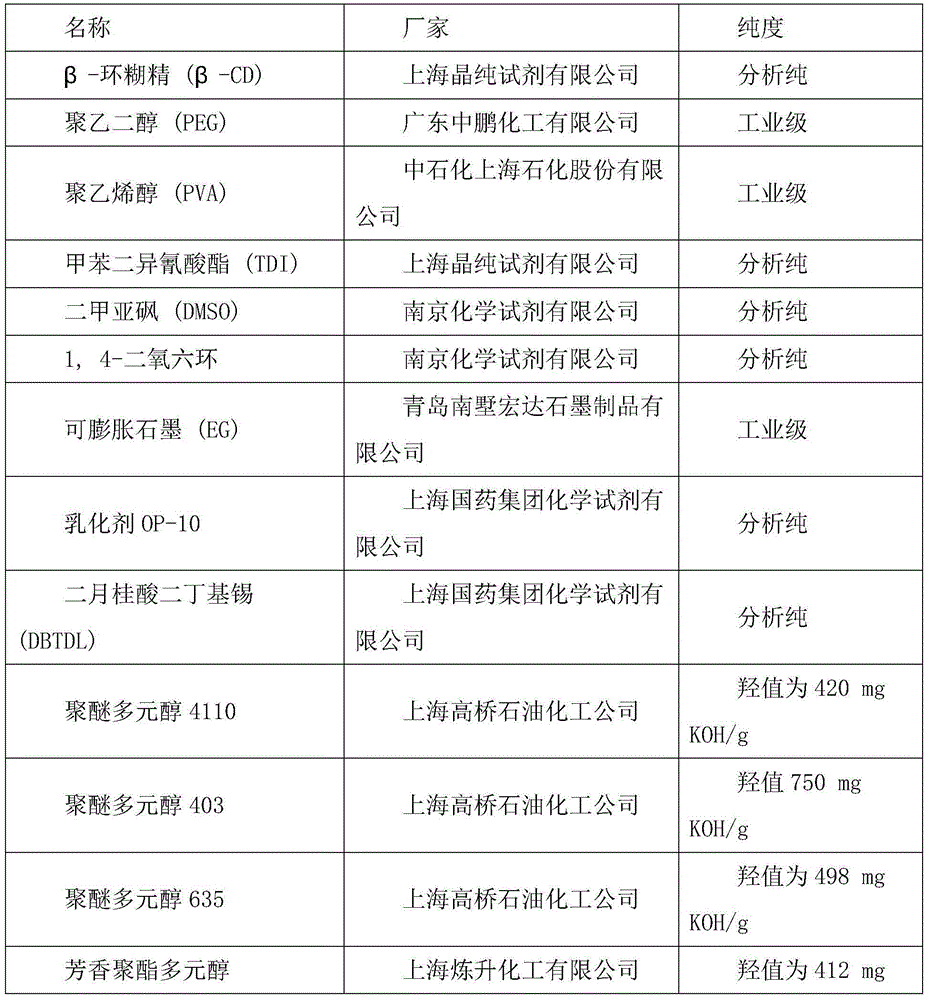

Core-shell synergistic flame retardant polyurethane microencapsulation expandable graphite and application thereof in rigid polyurethane foaming plastic

InactiveCN103554428AImprove flame retardant performanceReduce smoke productionMicroballoon preparationMicrocapsule preparationPolyesterDecomposition

The invention discloses a core-shell synergistic flame retardant polyurethane microencapsulation expandable graphite and the application of the expandable graphite in rigid polyurethane foaming plastic. The core-shell synergistic flame retardant polyurethane microencapsulation expandable graphite comprises polyether and / or polyester polyol, a foaming agent, a foam stabilizer, a catalyst, an organic phosphorus-based flame retardant, a halogen-free intumescent flame retardant, an organic modified nano inorganic filler, core-shell synergistic flame retardant polyurethane microencapsulation expandable graphite, polyisocyanate compound and isocyanate index, wherein the polyisocyanate compound has two or more isocyanate groups; the core-shell synergistic flame retardant polyurethane microencapsulation expandable graphite takes expandable graphite particles as a capsule core and takes cyclodextrin or polyurethane as a capsule shell, wherein the cyclodextrin or polyurethane is formed by crosslinking cyclodextrin / modified resin and toluene diisocynate. The expandable graphite microcapsule can effectively improve the initial decomposition temperature, the heat stability and the flame retardant effect of a material and remarkably reduces the heat release rate and the total heat release quality during combustion.

Owner:INST OF CHEM IND OF FOREST PROD CHINESE ACAD OF FORESTRY

Nonaqueous type secondary battery

InactiveUS6040092AOrganic electrolyte cellsActive material electrodesPropylene carbonateGraphite particle

A nonaqueous secondary battery includes a working electrode containing graphite particles coated with less crystallized carbon and a nonaqueous electrolyte, which contains at least ethylene carbonate and propylene carbonate.

Owner:LG CHEM LTD

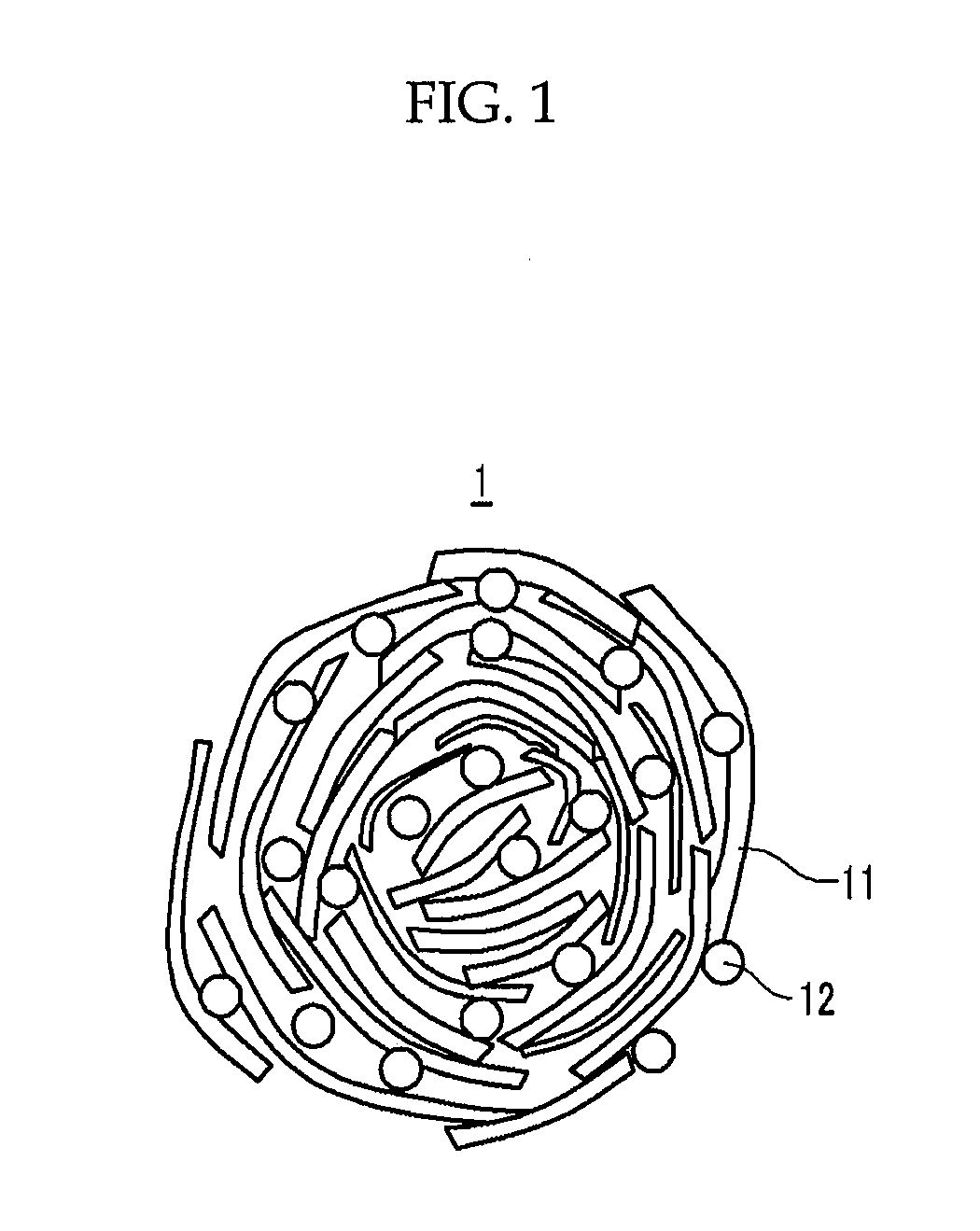

Carbon-containing material and lithium secondary cell containg the same material

InactiveCN1374712AImprove apparent conductivityImprove charge-discharge capacityActive material electrodesThin material handlingLithiumX-ray

The invention discloses a carbon-containing material, comprising: graphite particles, which have a 002 plane interval d002 of less than 0.337 nm measured by X-ray wide-angle diffraction method; composite particles, which are arranged and distributed near the surface of the graphite particles, and the composite particles contain Si and C, the particle size of which is smaller than the particle size of graphite; and an amorphous carbon layer, whose in-plane spacing d002 is greater than 0.37 nm, the amorphous carbon layer is a polymer layer and is coated on the graphite particles and composite particles, wherein the said The composite particles include: Si particles, conductive carbon materials arranged and distributed near the surface of the Si particles, and a hard carbon material layer coated on the Si particles and the conductive carbon materials, and the Si particles are composed of crystalline Si phases. Carbonaceous materials have high charge-discharge capacity and improved cycle life characteristics.

Owner:SAMSUNG SDI CO LTD

Silicon-containing composite material and its preparation method and application

ActiveCN101210112ASimple processReduce energy consumptionCell electrodesPigment treatment with macromolecular organic compoundsLithiumConductive polymer

The invention provides a siliceous composite material, comprising silicon particles, graphite particles and conducting polymer, wherein, the conducting polymer is wrapped on the surface of the graphite particles; at least part of the silicon particles is adhered to the surface of the conducting polymer. The siliceous composite material provided by the invention takes the conducting polymer as a clad material; the polymer does not need to be transformed further into 'hard carbon' and the siliceous composite material is guaranteed to have excellent conductivity; meanwhile, the aggregation between silicon particles can be avoided. When the composite material is taken as negative active material of a lithium iron battery, the lithium iron battery is guaranteed to have high reversible capacity and good cycle performance. Therefore, the invention can be used as the negative active material of the lithium iron battery. As the polymer does not need to be transformed further into the 'hard carbon' and the siliceous composite material has good conductivity in the preparation of the siliceous composite material provided by the invention, the manufacturing technique is simplified and the problem of huge energy consumption caused by the high temperature carbonization process in the prior art is solved.

Owner:BYD CO LTD

Silicon and carbon negative electrode material for lithium ion battery and preparation method thereof

InactiveCN109671942AStable structureConductivity dropMaterial nanotechnologyCell electrodesCarbon compositesSlurry

The invention discloses a silicon and carbon composite negative electrode material for a lithium ion battery. The material is a three-dimensional composite material of a core-shell structure, and sequentially comprises nanometer silicon / graphite, a conductive network layer and an organic cracking carbon layer from inside to outside, wherein the nanometer silicon / graphite uses the graphite as aninner core volume expansion buffer base body; the nanometer silicon particles are embedded in graphite particle gaps or are attached onto the surface of the graphite particles; the conductive networklayer is formed by nanometer conductive agents which penetrate and insert into silicon particle gaps, silicon particle and graphite particle gaps and graphite particle gaps and / or coat the surface ofthe nanometer silicon particles; the organic cracking carbon layer uniformly coat the surface of the silicon nanometer silicon / graphite. The invention also discloses a preparation method of the silicon and carbon negative electrode material. The dispersing agents are used for directly compounding the nanometer silicon slurry, the nanometer conducting agents and organic carbon source; the production process is simple; the operation is easy; the method is suitable for mass production. The material has excellent first time efficiency, circulation performance, rate capability and relatively low volume expansion effects.

Owner:CHENGDU GUIBAO SCI & TECH

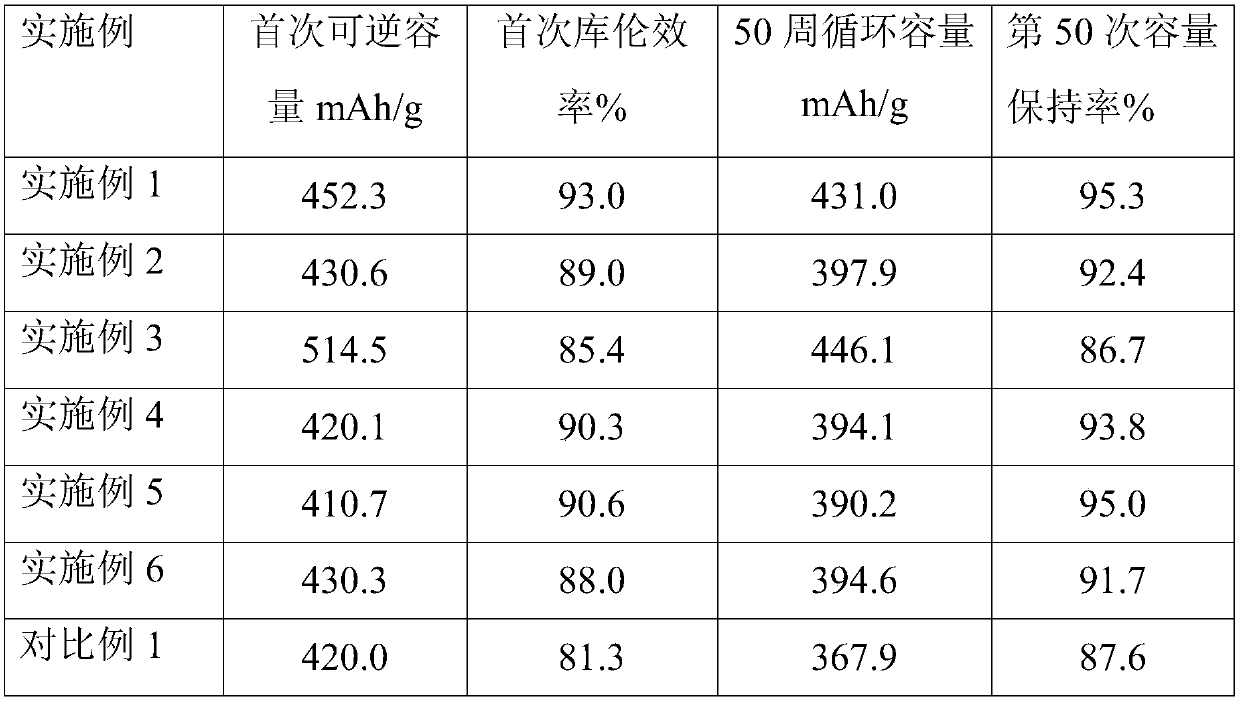

Silicon Nanostructure Active Materials for Lithium Ion Batteries and Processes, Compositions, Components and Devices Related Thereto

ActiveUS20140248543A1Highly controllableAvoid irreversibleElectrochemical processing of electrodesElectrode carriers/collectorsCopper electrodeGraphite particle

The present invention relates to nanostructured materials for use in rechargeable energy storage devices such as lithium batteries, particularly rechargeable secondary lithium batteries, or lithium-ion batteries (LIBs). The present invention includes materials, components, and devices, including nanostructured materials for use as battery active materials, and lithium ion battery (LIB) electrodes comprising such nanostructured materials, as well as manufacturing methods related thereto. Exemplary nanostructured materials include silicon-based nanostructures such as silicon nanowires and coated silicon nanowires, nanostructures disposed on substrates comprising active materials or current collectors such as silicon nanowires disposed on graphite particles or copper electrode plates, and LIB anode composites comprising high-capacity active material nanostructures formed on a porous copper and / or graphite powder substrate.

Owner:ONED MATERIAL INC

Fire retardant composition

The present invention is directed to a fire retardant composition, comprising: a primer solution; expandable graphite particles; triethyl phosphate; and aluminum trihydrate, wherein the triethyl phosphate comprises from about 1 wt. % to about 15 wt. % based on the weight of the composition.

Owner:BUILDING MATERIALS INVESTMENT

Thick film conductor composition for use in biosensors

InactiveUS6599408B1Improve electrocatalytic activityStrong electrical signalImmobilised enzymesBioreactor/fermenter combinationsElectrical conductorCombined use

The invention is directed to polymer thick film conductor compositions comprising conductive metal particles selected from the group consisting of finely divided powders of platinum group metals and mixtures thereof or metallized graphite particles; in combination with a thermoplastic polymer and optionally, graphite conductive filler.

Owner:DUPONT ELECTRONICS INC

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com