Patents

Literature

790results about How to "Improve the first Coulombic efficiency" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Hard carbon cathode material for lithium ion power and energy storage battery and preparation method of hard carbon cathode material

ActiveCN103094528ALow costImprove cycle performanceCell electrodesCarbon preparation/purificationElectrical batteryEnergy storage

The invention relates to a preparation method of a hard carbon cathode material. The preparation method comprises the step of preparing the hard carbon cathode material by using thermosetting resin or pyrolysis products of a mixture of thermosetting resin and thermoplastic resin as a hard carbon matrix and adopting a carbon material as a coating. In the preparation process of the hard carbon cathode material, a curing agent and a doping matter can be added. The hard carbon cathode material prepared by adopting the preparation method has the characteristics of high capacity, high first-time coulombic efficiency, excellent rate performance, low cost and the like, and is suitable for industrialized production.

Owner:JIXI BTR GRAPHITE IND PARK CO LTD +2

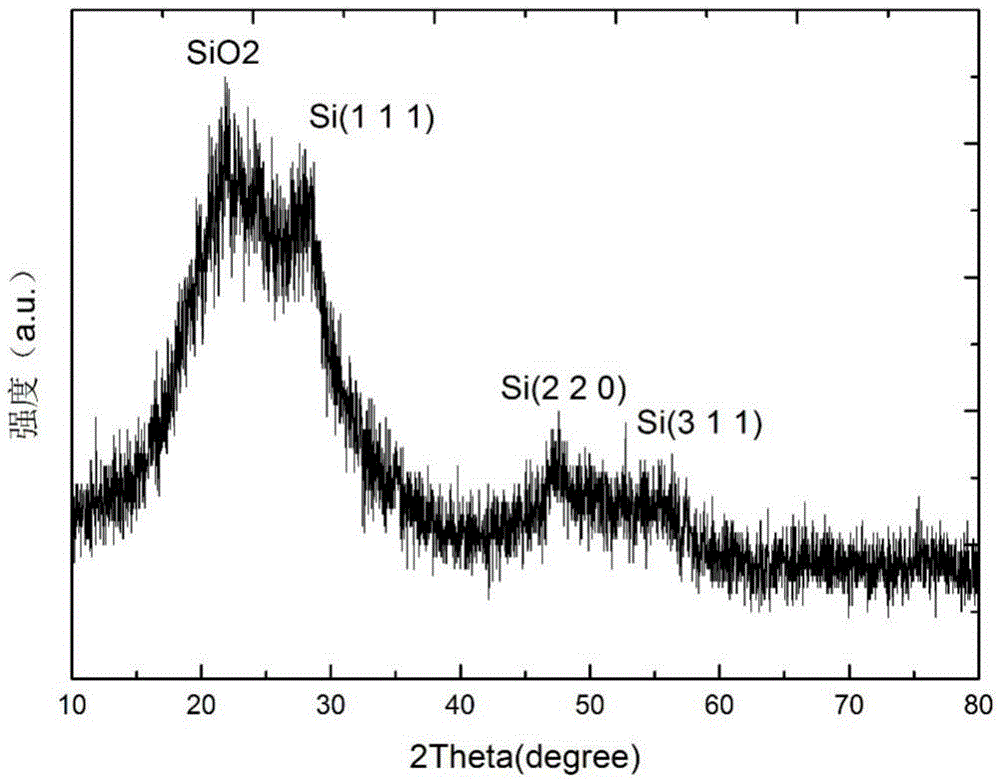

Silicon-based composite material and preparation method and applications thereof

ActiveCN103400971AGuaranteed lattice structureKeep aliveCell electrodesHigh temperature storageAlcohol

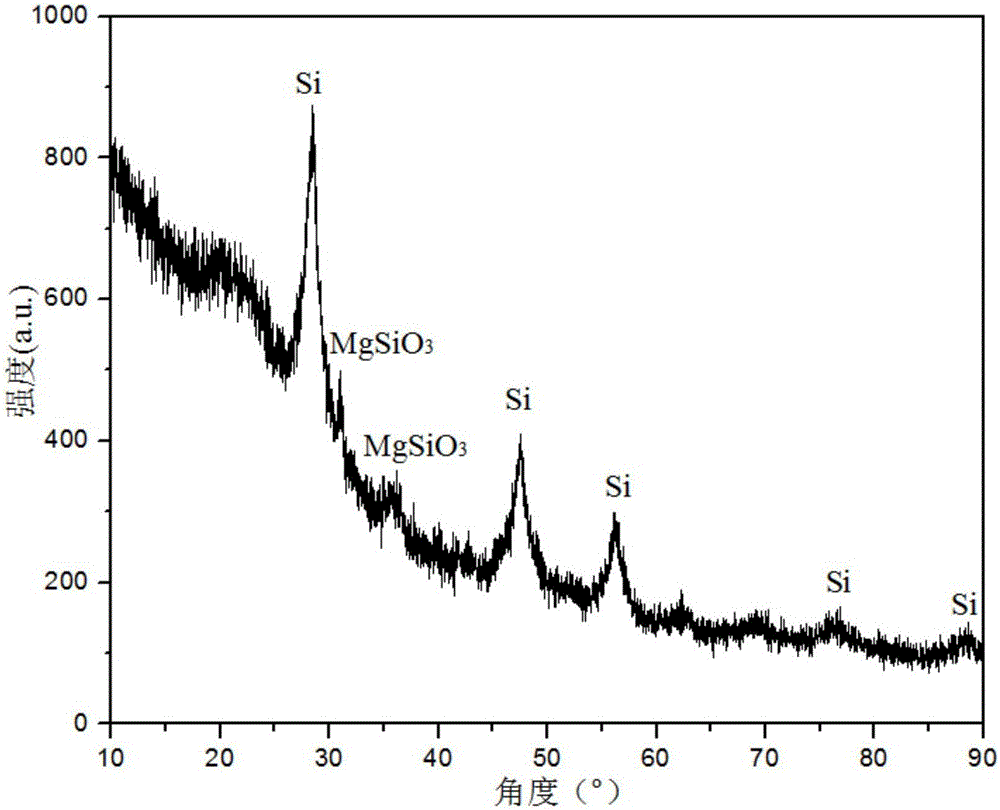

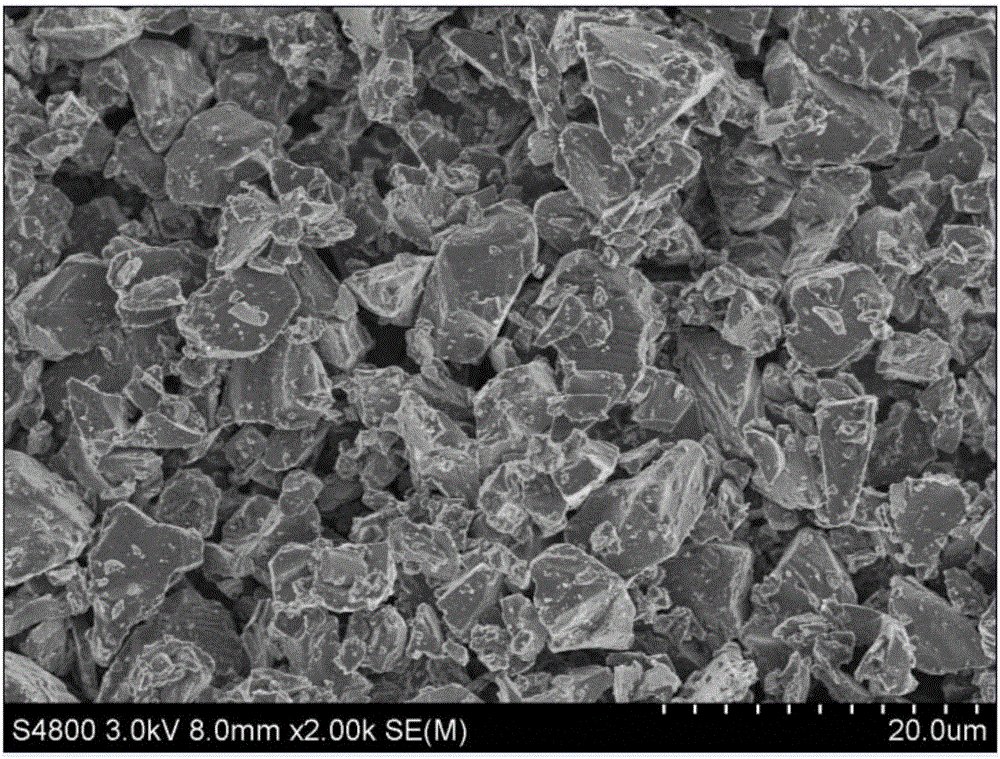

The invention provides a silicon-based composite material, which is prepared from silicon particles, silicate and optional carbon, wherein the mixture of the silicate and the optional carbon forms a massive body, and the silicon particles are dispersed in the massive body. A preparation method comprises the following steps of: dispersing the silicon particles into absolute ethyl alcohol and / or deionized water to form suspension liquid; dispersing the silicate and the optional carbon into the absolute ethyl alcohol and / or the deionized water to form suspension liquid; ultrasonically oscillating the two kinds of suspension liquid respectively, and then stirring; dropwise adding the suspension liquid of the silicon particles into the suspension liquid of the silicate and the optional carbon to form mixed liquid, heating and stirring the mixed liquid until evaporating the mixed liquid into paste; then, putting the paste in an oven to be dried to obtain masses, and grinding and sieving to obtain undersize particles; and conducting heat treatment in an inert atmosphere, and grinding and sieving to obtain the silicon-based composite material. According to the silicon-based composite material, a lattice structure of the silicon particles can be ensured, therefore the activity of the silicon particles is ensured, and the energy density, the first-time coulomb efficiency and the high-temperature storage performance of lithium ion batteries are increased.

Owner:NINGDE AMPEREX TECH

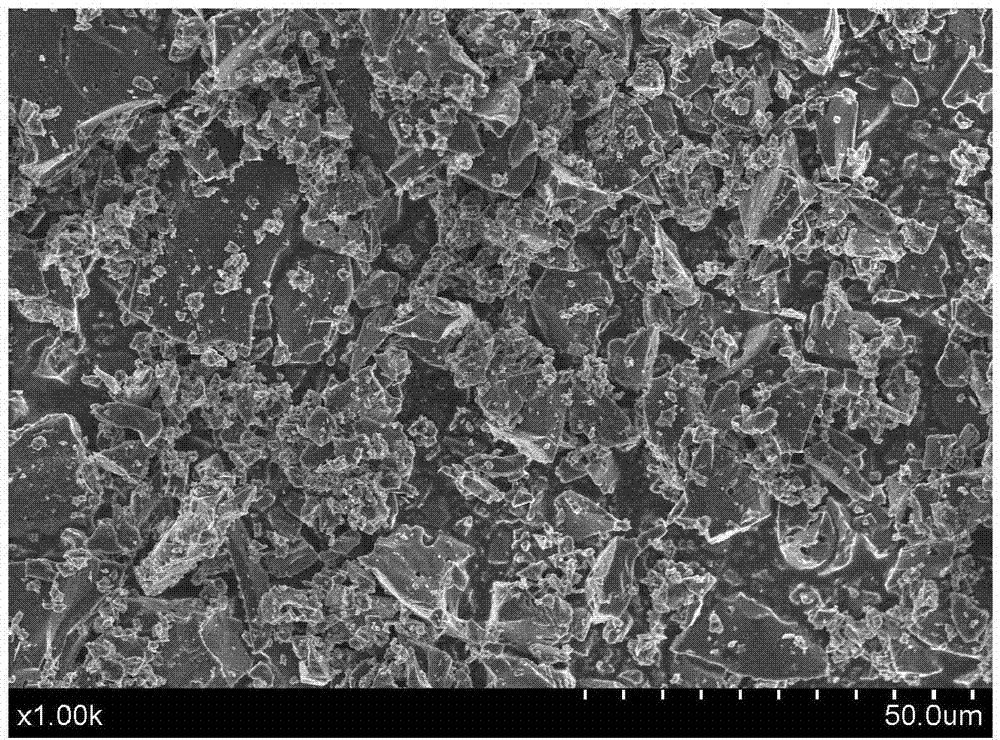

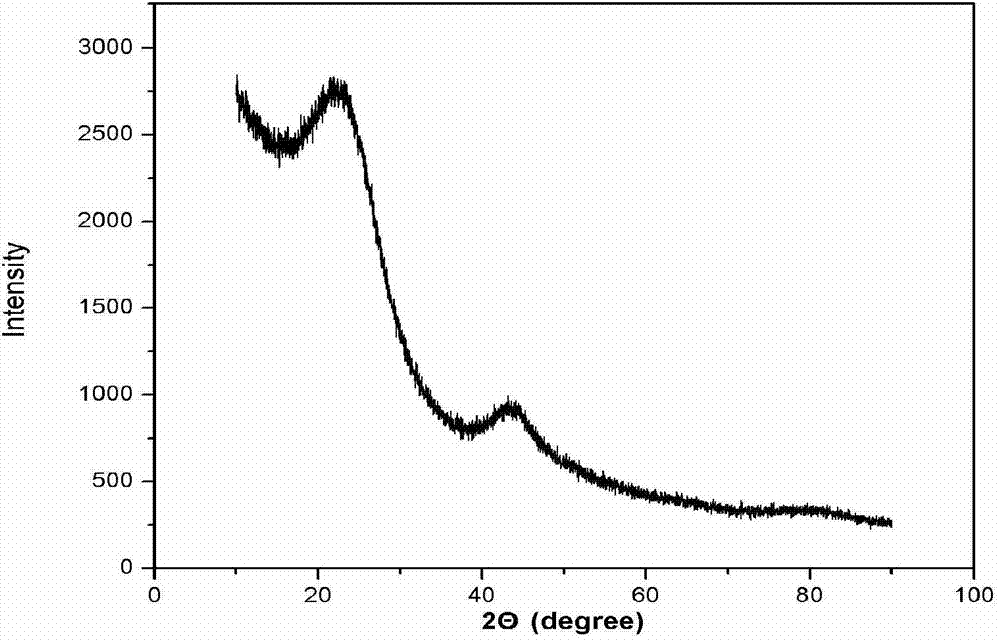

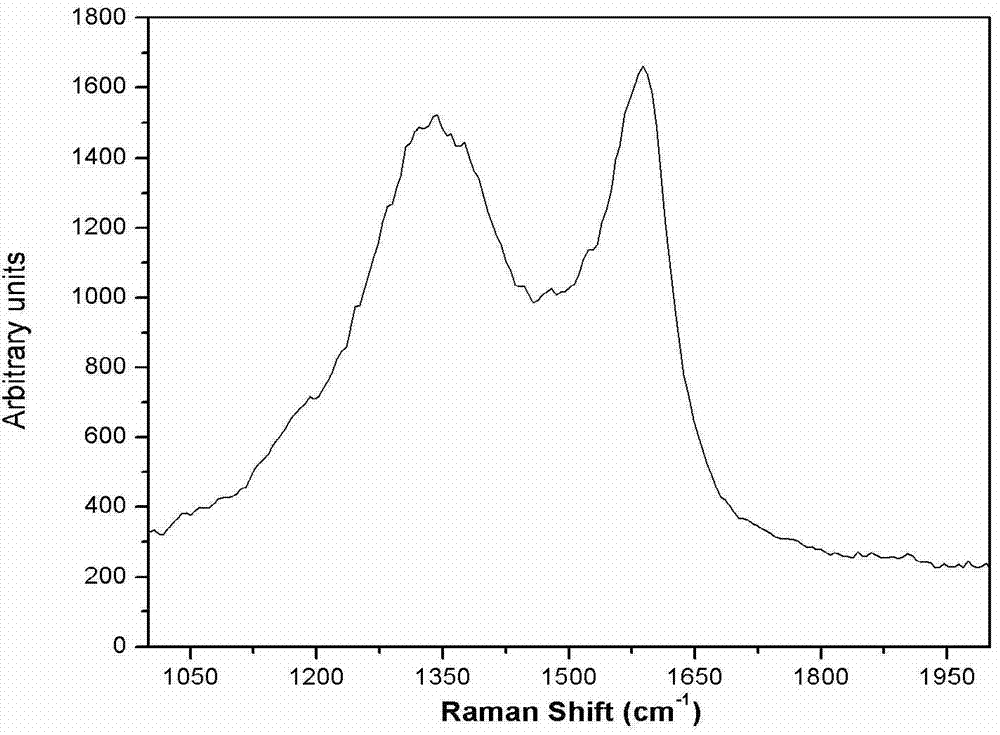

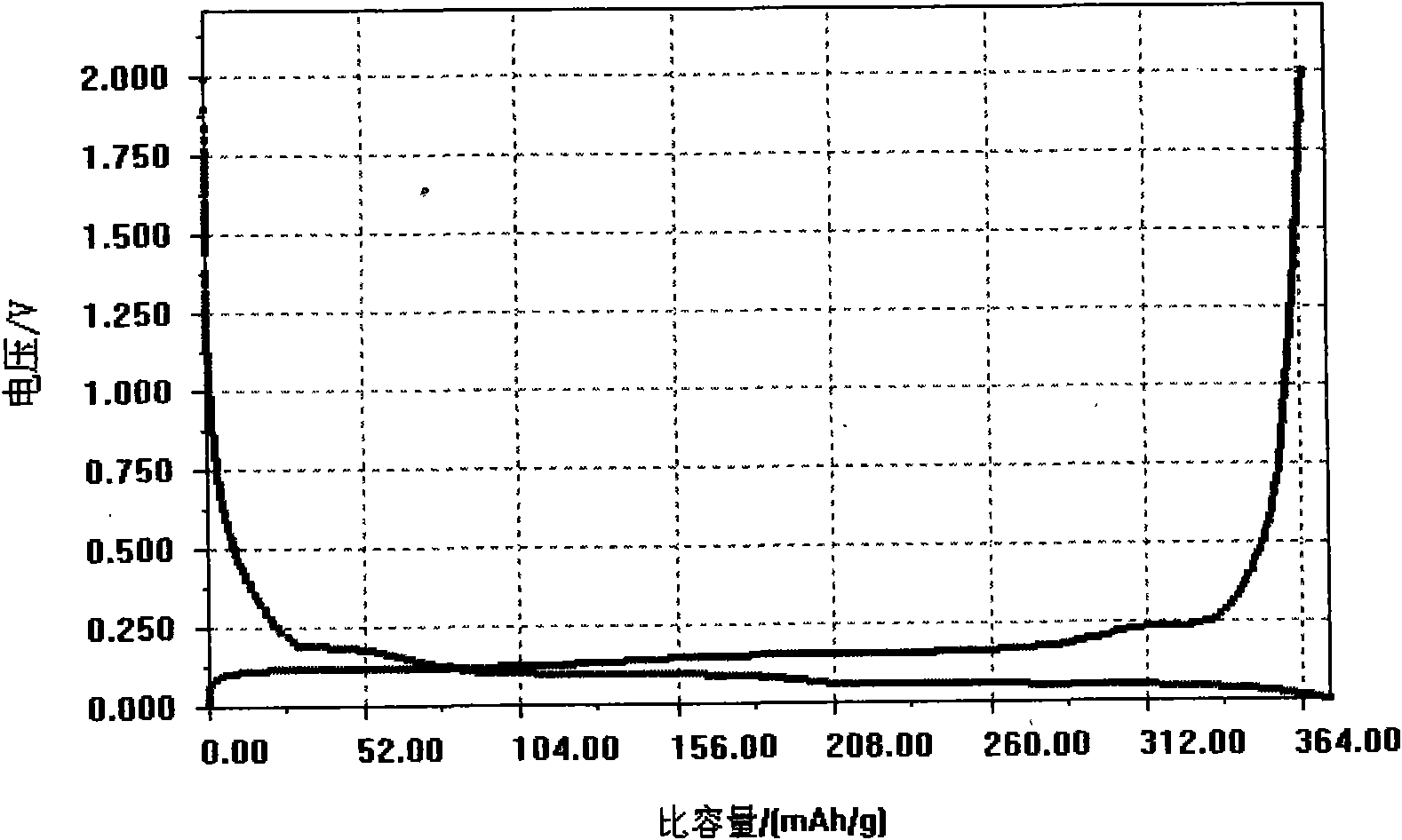

Composite hard carbon cathode material of lithium ion battery and preparation method thereof

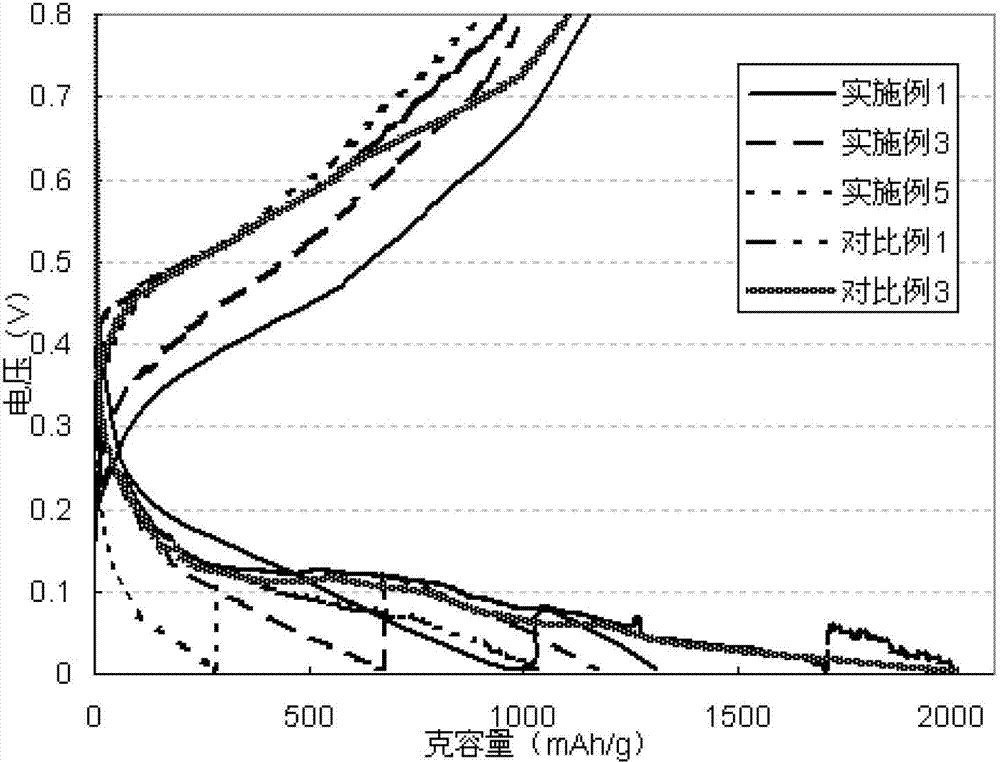

ActiveCN101887966AIncrease capacityImprove the first Coulombic efficiencyCell electrodesSodium-ion batteryCharge discharge

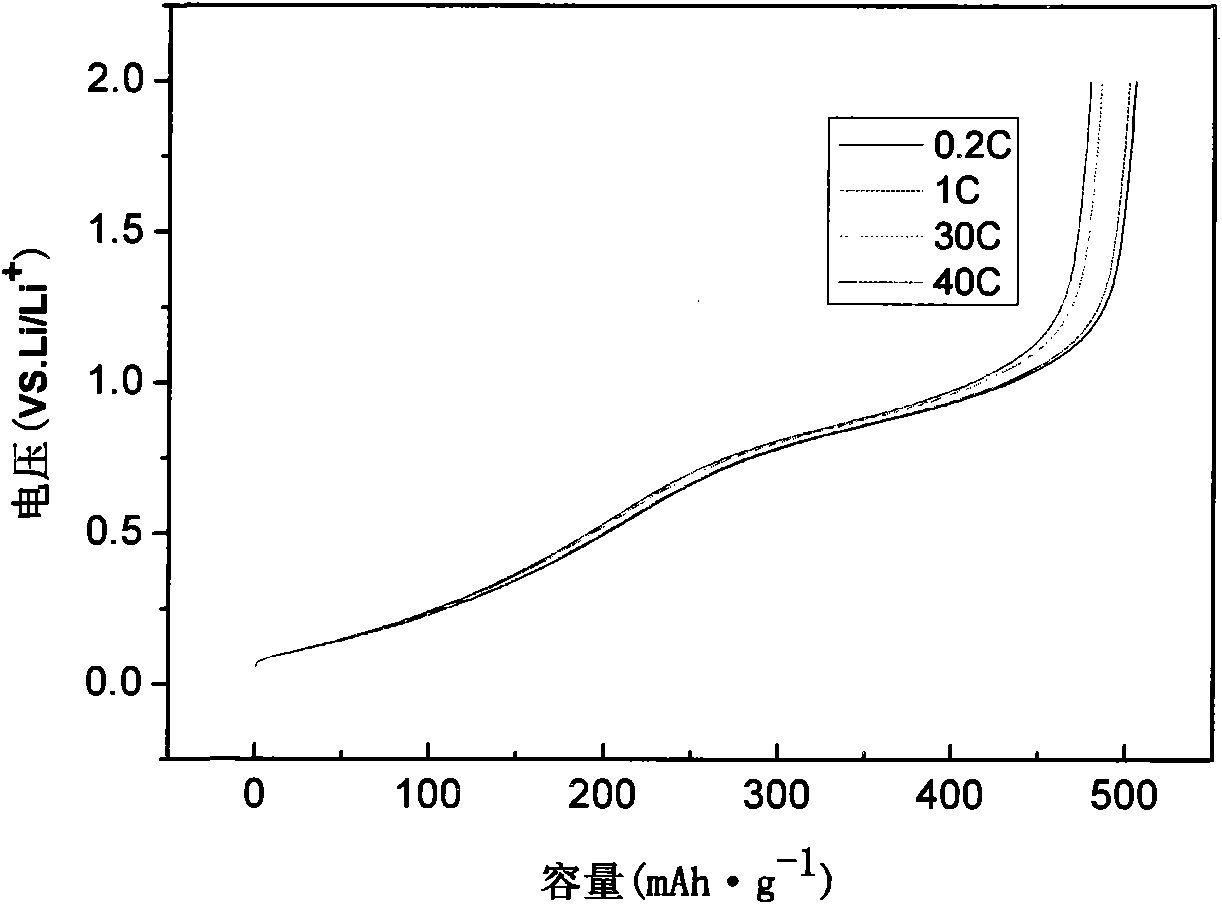

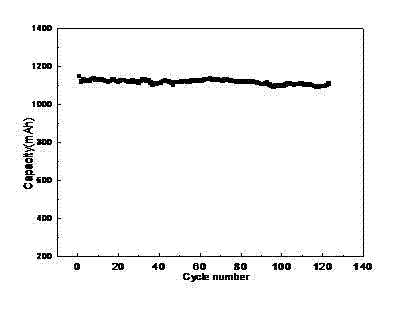

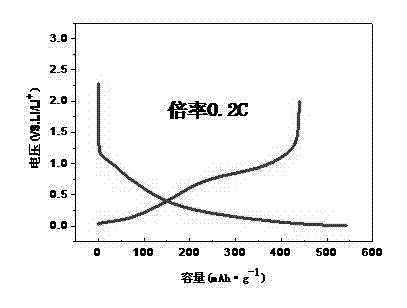

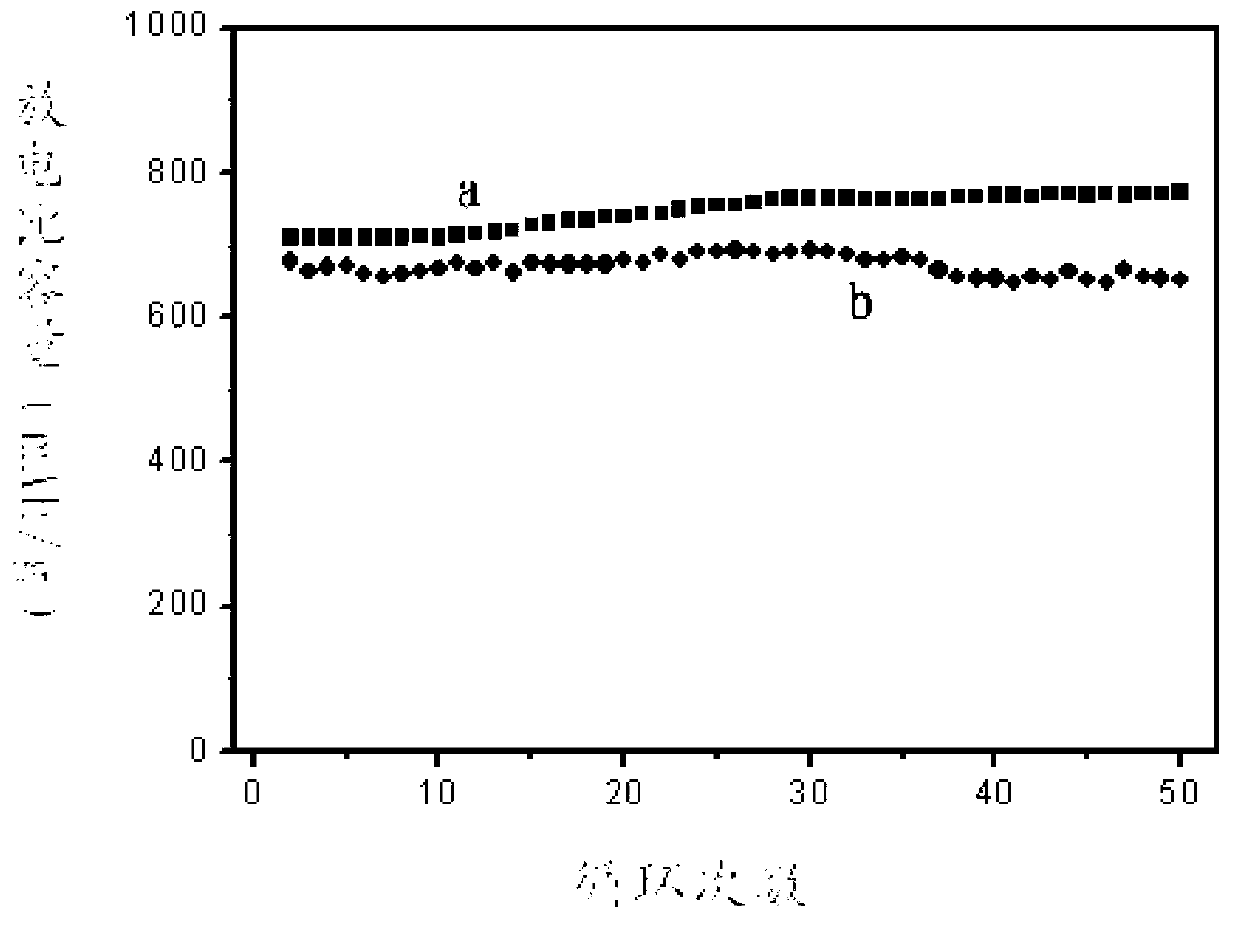

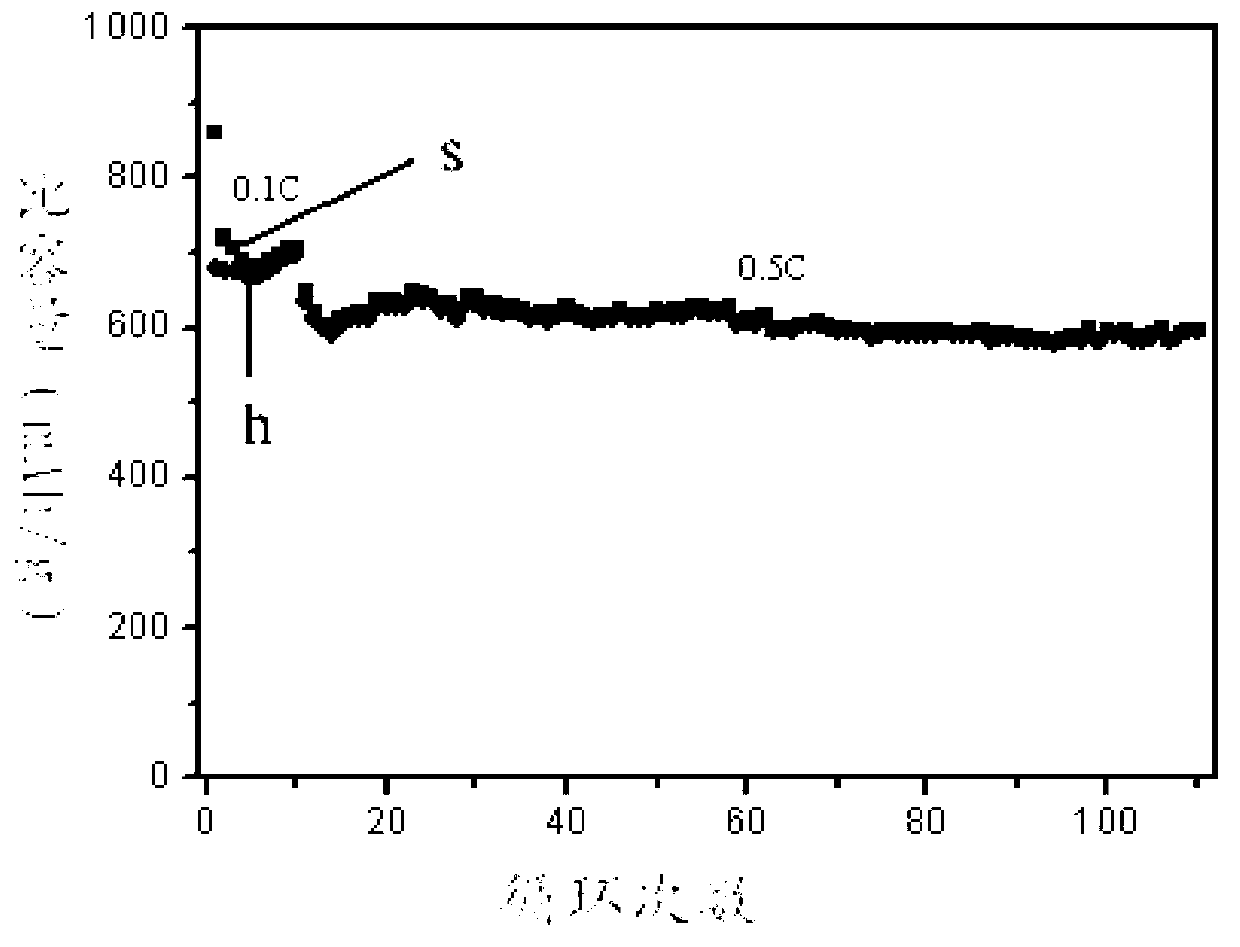

The invention discloses a composite hard carbon cathode material of a lithium ion battery and a preparation method thereof, aiming at improving the first coulombic efficiency. In the composite hard carbon cathode material, a coating object is coated outside a hard carbon matrix, a precursor of the hard carbon matrix comprises a thermoplastic resin which forms the hard carbon matrix by pyrolysis, and a precursor of the coating object is an organic matter. The preparation method comprises the steps of curing, pyrolyzing, pulverizing and coating. Compared with the prior art, a curing agent and adopant are added to the resin for curing, the cured mixture is taken as a carbon source, and then the carbon source is pyrolyzed and coated to finally obtain the composite hard carbon cathode material; and the first reversible capacity of the obtained composite hard carbon cathode material is more than 455.2mAh / g and the first coulombic efficiency thereof is more than 79.4% in the case of 0.2C, thus the obtained composite hard carbon cathode material has high capacity and high first coulombic efficiency, meets the requirement of the lithium ion battery with high capacity, high multiplying power and excellent high and low temperature cycle performance on the charge-discharge performances of the cathode material, has low production cost and is suitable for industrial production.

Owner:JIXI BTR GRAPHITE IND PARK CO LTD +2

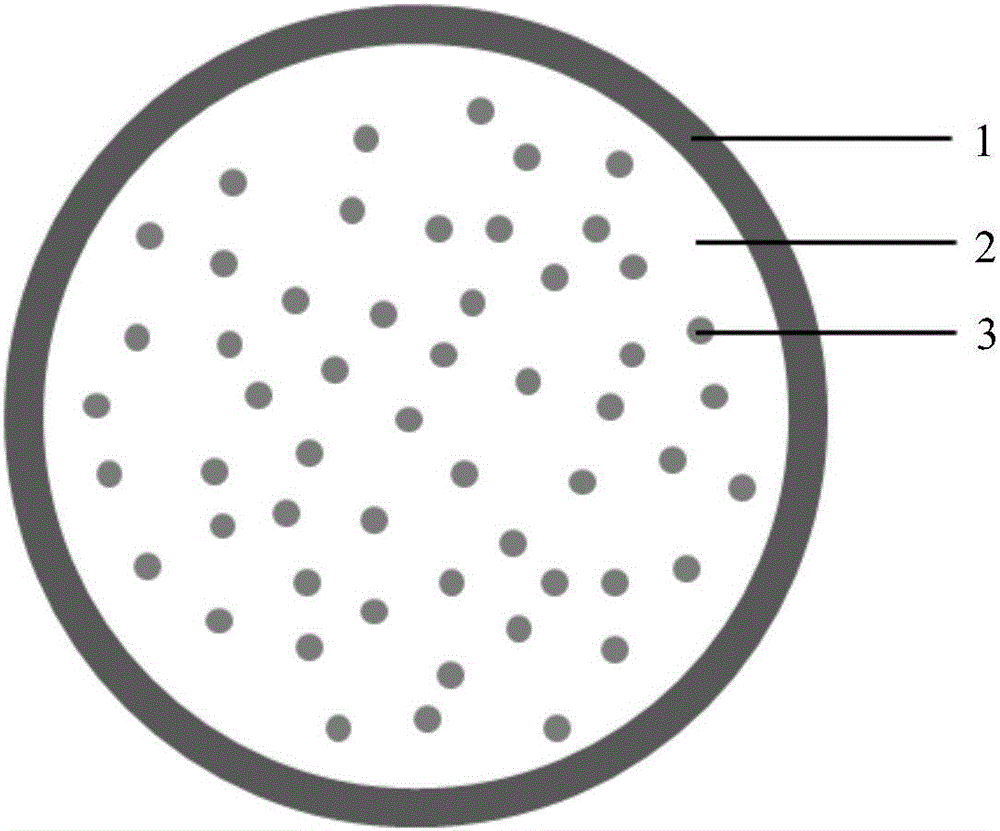

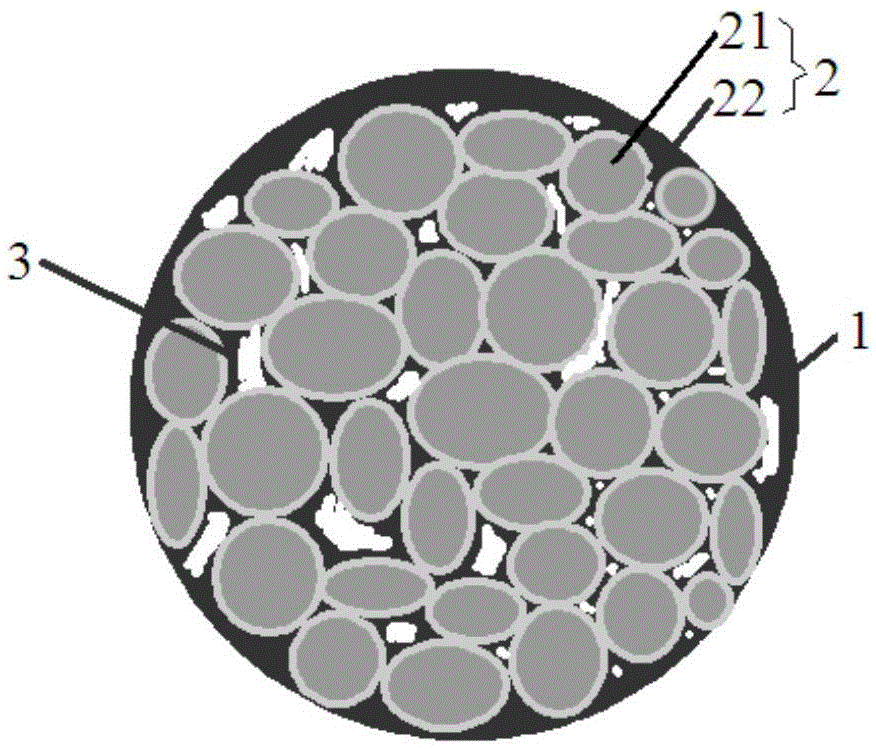

Doped multi-layer core-shell silicon-based composite material for lithium ion battery and preparation method thereof

ActiveCN109599551AInhibits and buffers swellingPrevent partial failureMaterial nanotechnologySecondary cellsCarbon filmComposite film

The present invention relates to a doped multi-layer core-shell silicon-based composite material for a lithium ion battery, and a preparation method thereof. Other than being doped with a necessary lithium element, the material is also doped with at least a non-metallic element and a metal element; the material has a structure in which a silicon oxide particle doped with elements is taken as a core, and a multilayer composite film which is tightly coated on the surface of the core particle is taken as a shell; the core particle contains uniformly dispersed monoplasmatic silicon nanoparticles,the content of doping elements gradually decreases from the outside to the inside without a clear interface, and a dense lithium silicate compound is formed on the surface of the core particle by embedding and doping the lithium element; and the multilayer composite film is a carbon film layer and a doped composite film layer composed of the carbon film layer and other elemental components. The doped multi-layer core-shell silicon-based composite material provided by the present invention has a high capacity, good rate performance, high coulombic efficiency, good cycle performance, a low expansion rate, and other electrochemical characteristics when the material is used for the negative electrode of lithium ion battery.

Owner:BERZELIUS (NANJING) CO LTD +1

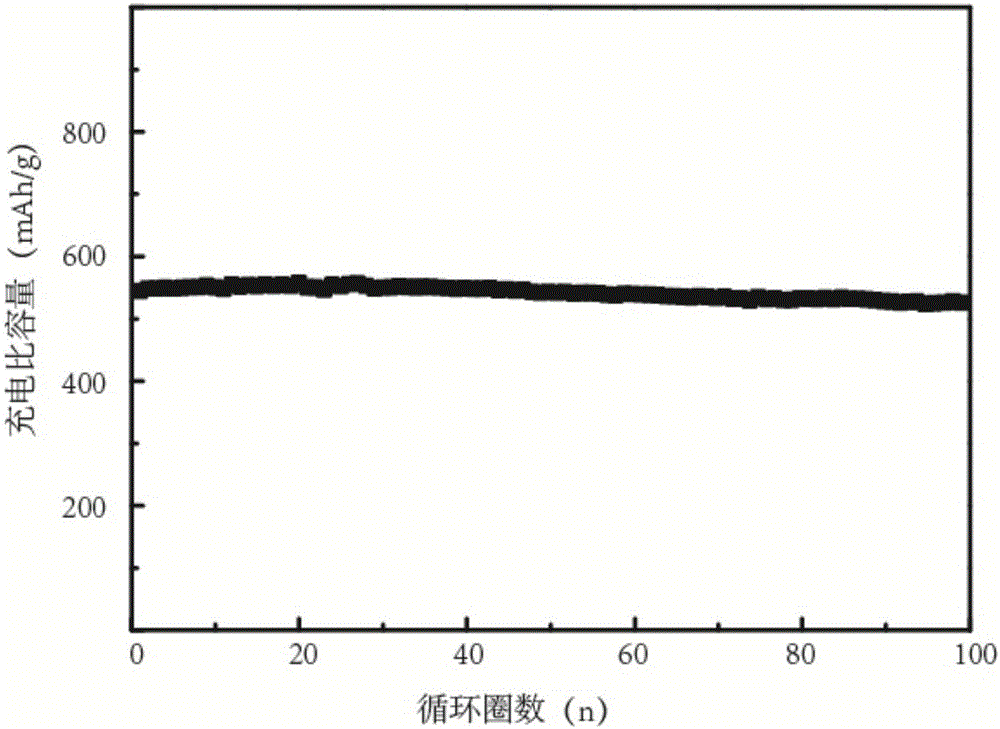

Hard carbon negative electrode material of lithium ion battery, preparation method and application of hard carbon negative electrode material

InactiveCN102820455AIncrease capacityImprove the first Coulombic efficiencyCell electrodesDischarge efficiencyPhysical chemistry

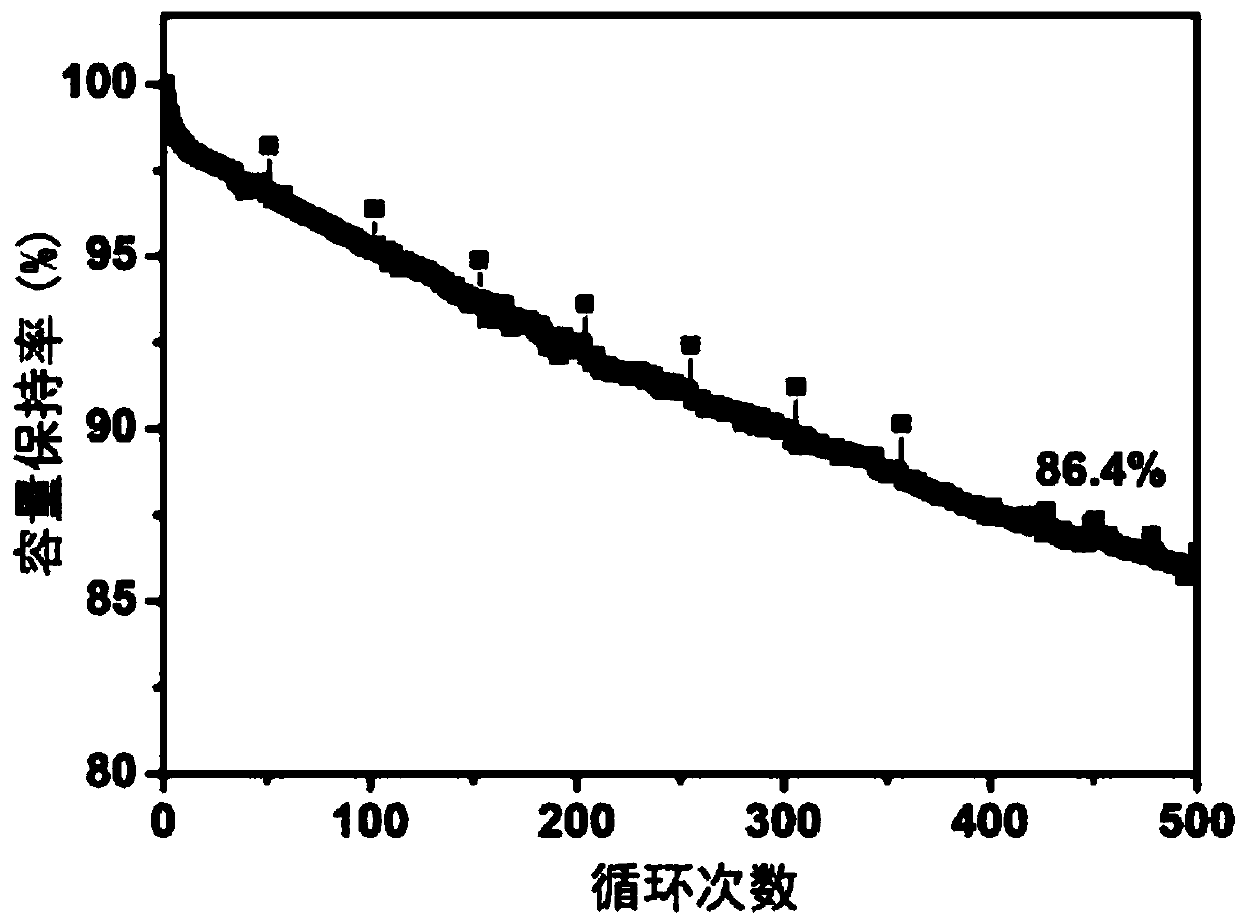

The invention relates to a hard carbon negative electrode material of a lithium ion battery, and a preparation method and application of the hard carbon negative electrode material. The hard carbon negative electrode material is doped with silicon and phosphorus, wherein the mass ratio of silicon precursor, phosphorus precursor and hard carbon precursor is 1:(0.1 to 5):(5 to 30). Due to the addition of silicon / phosphorus, the hard carbon negative electrode material provided by the invention is remarkably improved in the first discharge capacity (up to 550.8mAh / g), the first charge / discharge efficiency (up to 80.9%) and the first coulombic efficiency by doping, is remarkably reduced in the irreversible capacity, and has the advantages of excellent cycle performance and rate capability, good PC (poly carbonate) consistency and high PC resistance, wherein the capacity retention ratio is above 95% after discharge cycle for 100 weeks at a high discharge rate of 10C.

Owner:天津市贝特瑞新能源科技有限公司

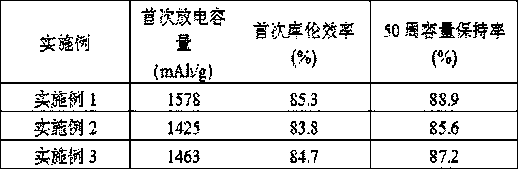

Compound and preparation method thereof as well as negative electrode prepared by adopting compound and lithium ion battery

ActiveCN106356508AImprove consistencyImprove dispersion uniformityCell electrodesSecondary cellsElectrical batterySilicon oxygen

The invention relates to a compound and a preparation method thereof as well as a negative electrode prepared by adopting the compound and a lithium ion battery. The compound comprises silicon, silicon oxide SiOx (x is greater than 0 and is less than or equal to 2) and silicate, wherein positive ion elements of the silicate are reductant elements, and Si, O and the reductant elements in the compound are uniformly distributed. Reductants used in the compound are heated and insulated in the environment of negative pressure, so that SiO steam reacts with reductant steam in the form of a gas phase so as to condense to obtain the compound, and then the compound is further used as a raw material so as to prepare a modified silica negative electrode material. The negative electrode material is suitable for the lithium ion battery, the prepared lithium ion battery has high charge and discharge specific capacity and excellent first coulombic efficiency, the charge capacity is 1447 mAh / g or above, the discharge capacity is 1213 mAh / g or above, and the first coulombic efficiency is 83.8% or above.

Owner:BTR NEW MATERIAL GRP CO LTD

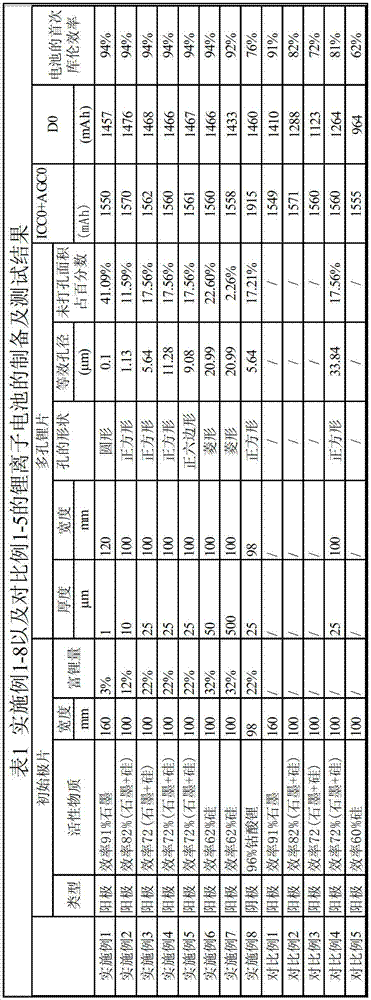

High-capacity metal lithium powder composite cathode and preparation method thereof, and multi-layer composite electrode

InactiveCN102201565AHigher quality than capacityQuality improvementNon-aqueous electrolyte accumulator electrodesAdhesiveTin

The invention discloses a high-capacity metal lithium powder composite cathode and a preparation method thereof and a multi-layer composite electrode. The high-capacity metal lithium powder composite cathode comprises the following components in part by weight: 1 to 80 parts of metal lithium powder, 10 to 90 parts of cathode powder, 1 to 10 parts of conductive agent, 1 to 4.5 parts of adhesive and 0 to 0.5 part of surfactant. By compounding the metal lithium powder with materials such as graphite, soft carbon, hard carbon, tin and oxides thereof, silicon and oxides thereof and the like, mass ratio capacity and volume ratio capacity of a cathode material are improved, using amount of active substances is reduced, and the battery specific capacity is improved; the specific capacity of the cathode can be adjusted by adjusting the rate of metal lithium to the graphite; short circuit in a battery caused by piercing of a diaphragm through metal dendritic crystal growth can be effectively prevented through the separation of an insulating protective layer, so that the safety performance of the battery is improved; and the metal lithium powder is counteracted with irreversible capacity loss of the cathode, and primary Kulun efficiencies of the graphite, the hard carbon, the soft carbon, the tin, the silicon and other cathode materials are improved.

Owner:EC POWER LLC

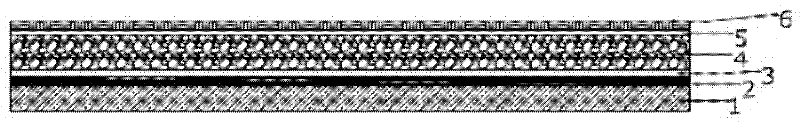

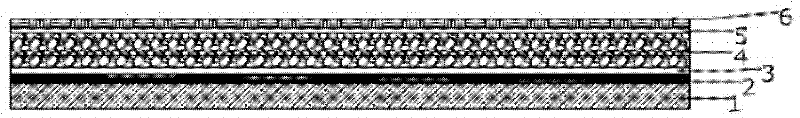

Lithium-rich pole piece of lithium ion battery and preparation method thereof

ActiveCN103199217AImprove the first Coulombic efficiencyIncrease energy densityElectrode manufacturing processesSecondary cellsAdhesivePole piece

The invention provides a lithium-rich pole piece of a lithium ion battery and a preparation method thereof. The lithium-rich pole piece comprises a current collector, a diaphragm and a porous lithium piece, wherein the diaphragm contains an active material and is formed on the current collector; the diaphragm and the current collector form an initial pole piece; and the porous lithium piece covers the diaphragm, and the capacity of the porous lithium piece is matched with the capacity of lithium added to the anode. The preparation method comprises the following steps of: preparing a slurry from the active material, a conductive agent, an adhesive and a solvent, and then applying the slurry on the current collector and drying to obtain the initial pole piece, so that the slurry applied on the current collector becomes the diaphragm after being dried; punching a metal lithium piece to obtain the porous lithium piece, so that the capacity of the porous lithium piece is matched with the capacity of lithium added to the anode; and covering the diaphragm surface of the initial pole piece with the porous lithium piece, to obtain the lithium-rich pole piece of the lithium ion battery. According to the invention, the lithium amount added to the anode can be precisely controlled, the lithium adding uniformity is increased, the first coulombic efficiency, the energy density and the electrochemical properties of the battery are increased, battery deformation is alleviated, the process is simple, and the cost is low.

Owner:DONGGUAN AMPEREX TECH

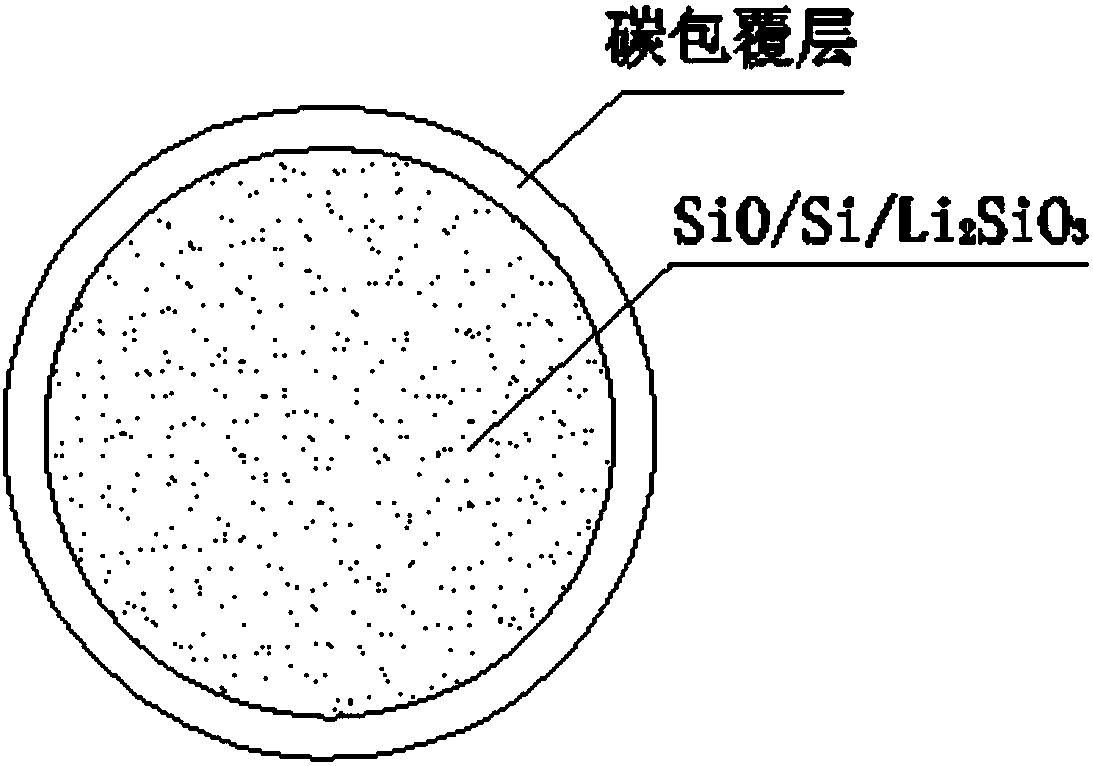

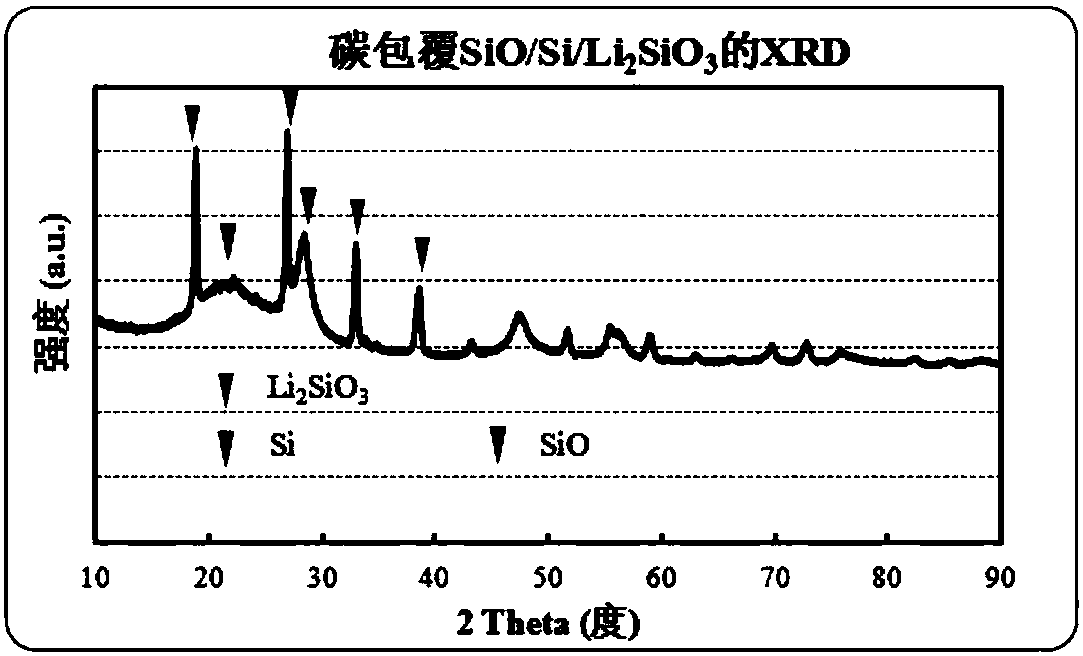

Silicon monoxide/silicon/lithium metasilicate composite negative electrode material and preparation method thereof

InactiveCN108269979AIncrease capacityImprove the first Coulombic efficiencyCell electrodesSilicon monoxideShielding gas

The invention discloses a silicon monoxide / silicon / lithium metasilicate composite negative electrode material. The silicon monoxide / silicon / lithium metasilicate composite negative electrode material comprises a silicon monoxide / silicon / lithium metasilicate composite material and an inorganic matter coating layer. The invention also provides a preparation method of the silicon monoxide / silicon / lithium metasilicate composite negative electrode material. The preparation method comprises the following steps: taking silicon monoxide and an inorganic compound of lithium element, mixing and ball-milling the silicon monoxide and the inorganic compound of the lithium element, sintering the obtained mixture in a protection gas environment, and naturally cooling the sintered mixture to obtain the silicon monoxide / silicon / lithium metasilicate composite material; and mixing and ball-milling the silicon monoxide / silicon / lithium metasilicate composite material and sintering the obtained mixture undera protection gas condition. The preparation method of the silicon monoxide / silicon / lithium metasilicate composite negative electrode material has the advantages of simplicity, safety, low cost, and easiness in operation and industrial production, and the obtained composite negative electrode material has the advantages of high reversible capacity, excellent cycle performances and high initial Coulomb efficiency.

Owner:HEFEI GUOXUAN HIGH TECH POWER ENERGY

Composite, preparation method and application thereof in lithium ion secondary battery

ActiveCN106816594AImprove performanceRaw materials are easy to getMaterial nanotechnologySilicaCarbon coatingSilicon oxide

The invention discloses a composite. The composite comprises nanometer silicon, a lithium-containing compound and a carbon coating, or comprises nanometer silicon, a silicon oxide, a lithium-containing compound and a carbon coating. The method comprises the following steps: (1) mixing a carbon-coated silicon oxide and a lithium-source solid phase; and (2) thermally processing a prefabricated lithium precursor obtained in step (1) in a vacuum or non-oxidative atmosphere to obtain the composite. The method is simple, small in requirement on equipment, and low in cost; the obtained composite is stable in structure; the structure and property cannot be degraded after long-term storage; a battery prepared from a negative electrode material containing the composite is high in lithium taking-off capacity, high in first coulomb efficiency, and high in circulating performance; the charging capacity is equal to or above 1920mAh / g; the discharging capacity is equal to or above 1768mAh / g; and the first effect is equal to or more than 90.2%.

Owner:BTR NEW MATERIAL GRP CO LTD

Torispherical cathode material for lithium ion battery and preparation method thereof

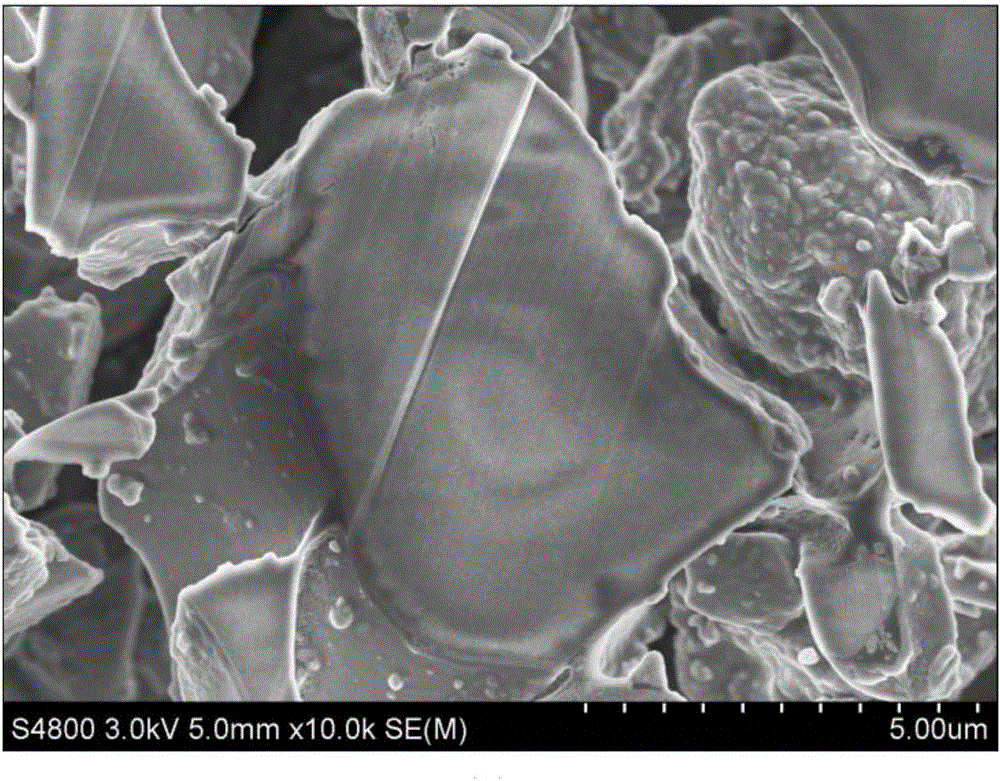

ActiveCN101916844AImprove the first Coulombic efficiencyLong cycle lifeCell electrodesCapacitanceMicrostructure

The invention discloses a torispherical cathode material for a lithium ion battery, which has a 'shell-core' graphite composite microstructure, wherein an inner core may be spherical natural graphite, spherical artificial graphite, a mesocarbon microbead or a mixture of the three; a shell is a graphitized product of asphalt; an interlayer distance between the inner core and the shell ranges from 0.3360 to 0.3390nm; and the torispherical cathode material has a mesoporous structure with an aperture of 10 to 50nm, and the ratio of granular length to granular width of the graphite composite ranges from 1.0 to 2.0. The torispherical cathode material for the lithium ion battery has the advantages that: 1, the high-rate performance of the electrode material is improved; and the discharge capacitance of the electrode material still reaches 320 to 340mAh / g after 300 times of circulation at a 5C rate; 2, preparation cost is low and atmosphere pollution is avoided; and 3, the shape of the graphite raw material used by the invention is torispherical and favorable for the cladding uniformity of the asphalt and can better strengthen the structural stability of the composite.

Owner:JIANGXI ZHENGTUO NEW ENERGY TECH CO LTD

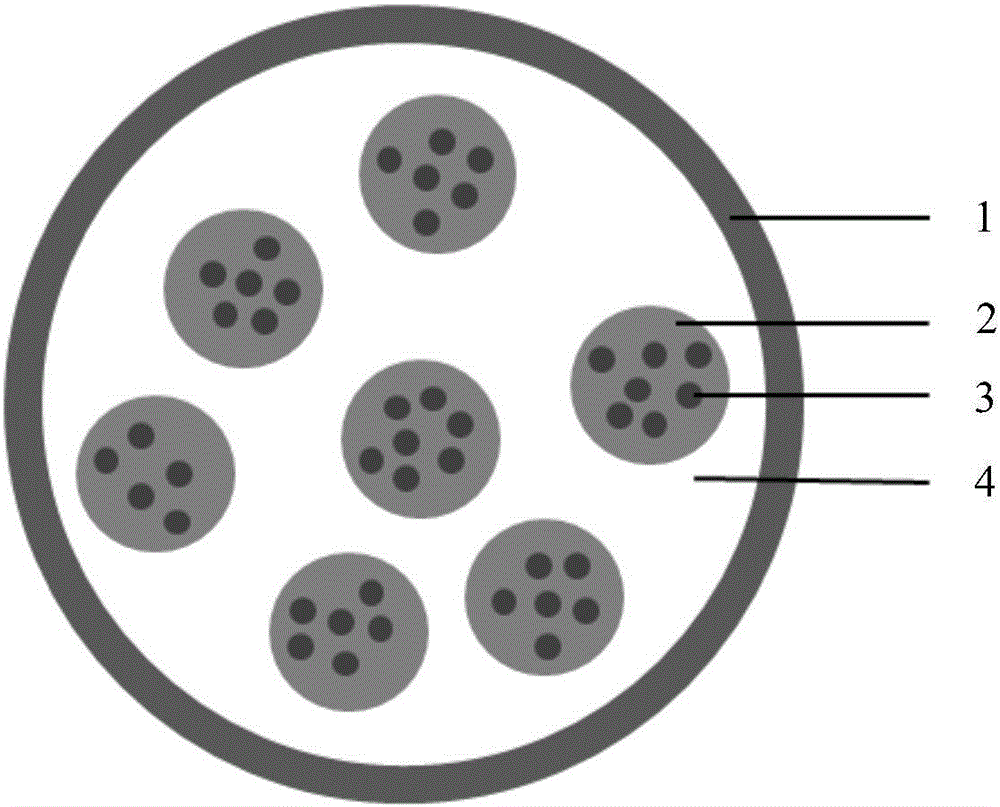

Lithium ion battery cathode material and preparation method thereof as well as lithium ion battery

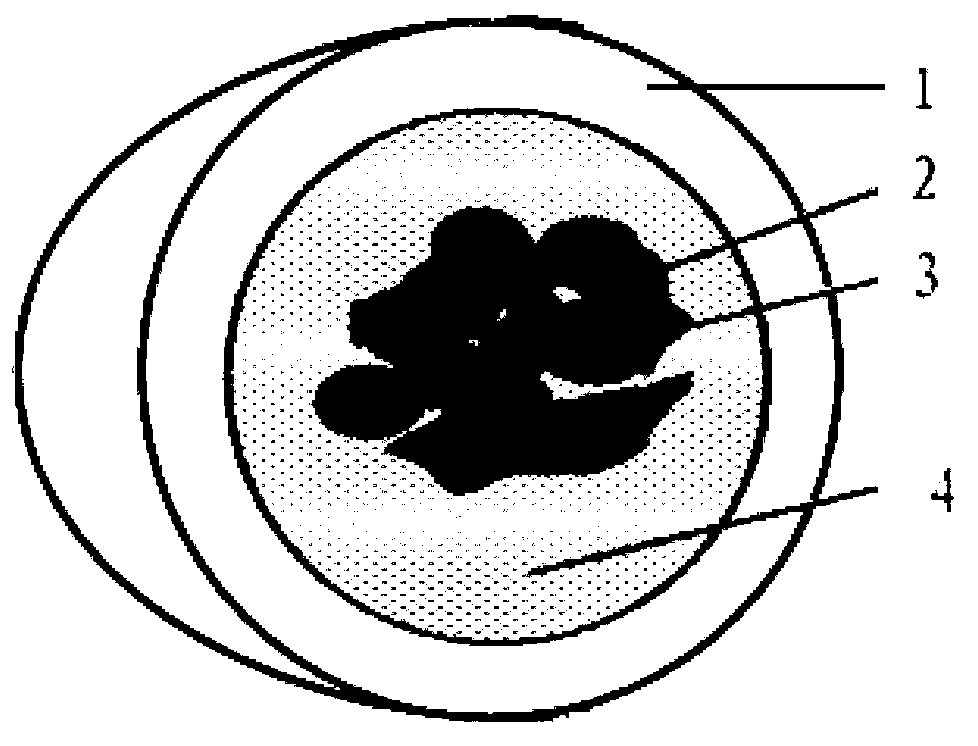

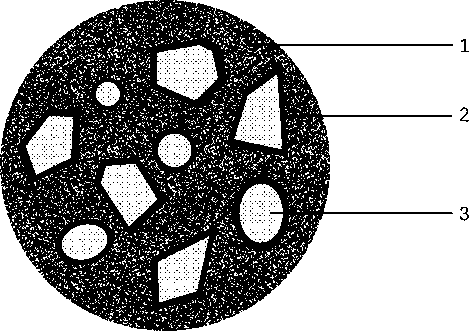

ActiveCN103346293AImprove conductivityBuffers large volume changesCell electrodesSecondary cellsNanoparticleNetwork structure

The invention provides a lithium ion battery cathode material and a preparation method of the lithium ion battery cathode material as well as a lithium ion battery. The lithium ion battery cathode material comprises an inner core, a middle layer outside the inner core and an outer shell wrapping the middle layer, the inner core is Si-C particles, the middle layer is a foam layer, the outer shell is an amorphous carbon layer and the Si-C particles are formed by Si particles and C materials. Compared with the prior art, a middle carbon foam layer existing between the Si-C particle inner core and the amorphous carbon outer shell can form an conductive network structure, thus improving conductivity of a material and buffering enormous volume change of Si particles in the charge-discharge processes; and the amorphous carbon outer shell layer can maintain the core-shell structure of the cathode material, and the cladding layer of the core-shell structure can buffer the volume change, improve cycling stability of electrodes, reduce contact between active substances and an electrolyte, improve first coulombic efficiency of an electrode, prevent nanoparticle aggregation and enhance electrode conductivity.

Owner:宁波富理电池材料科技有限公司

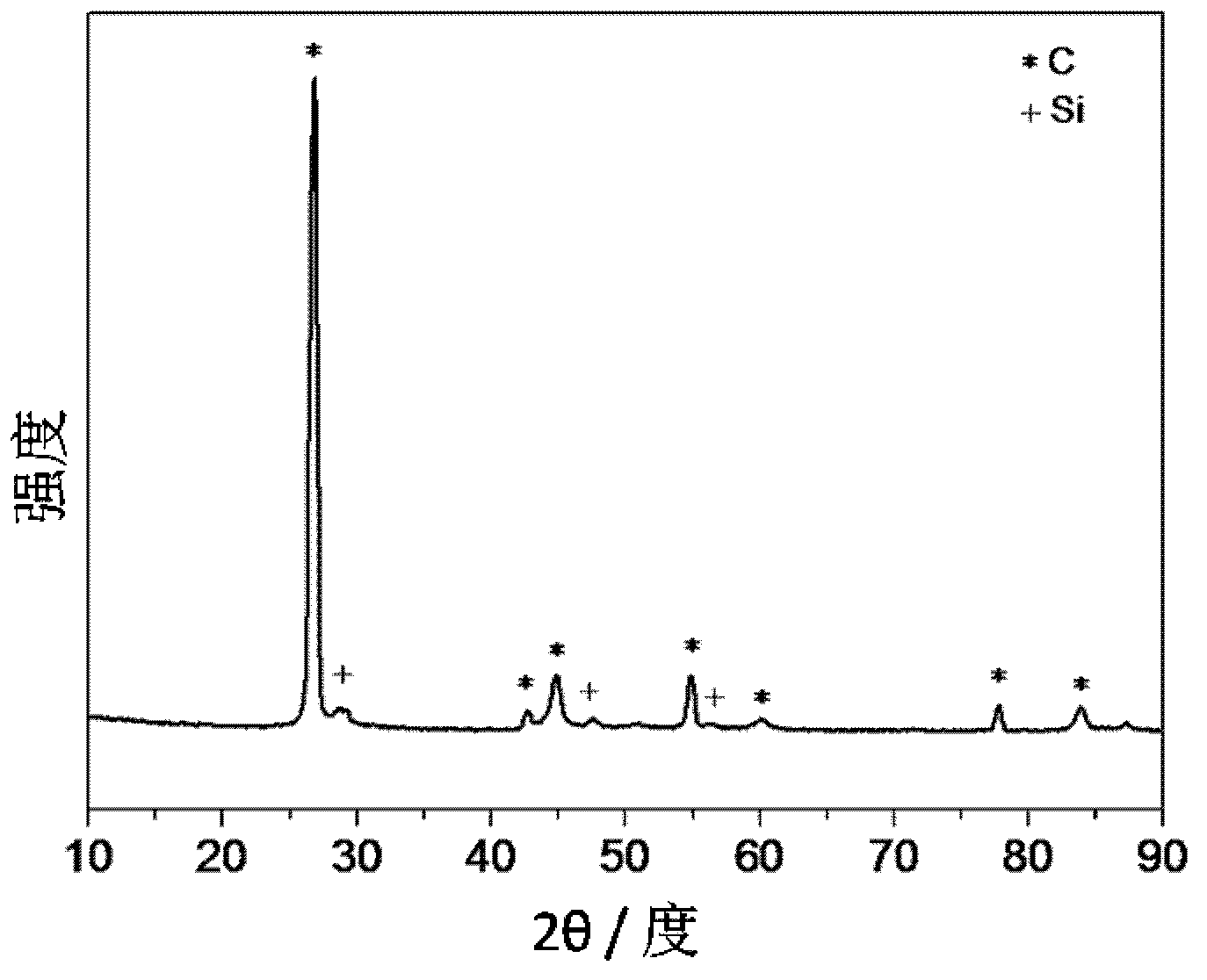

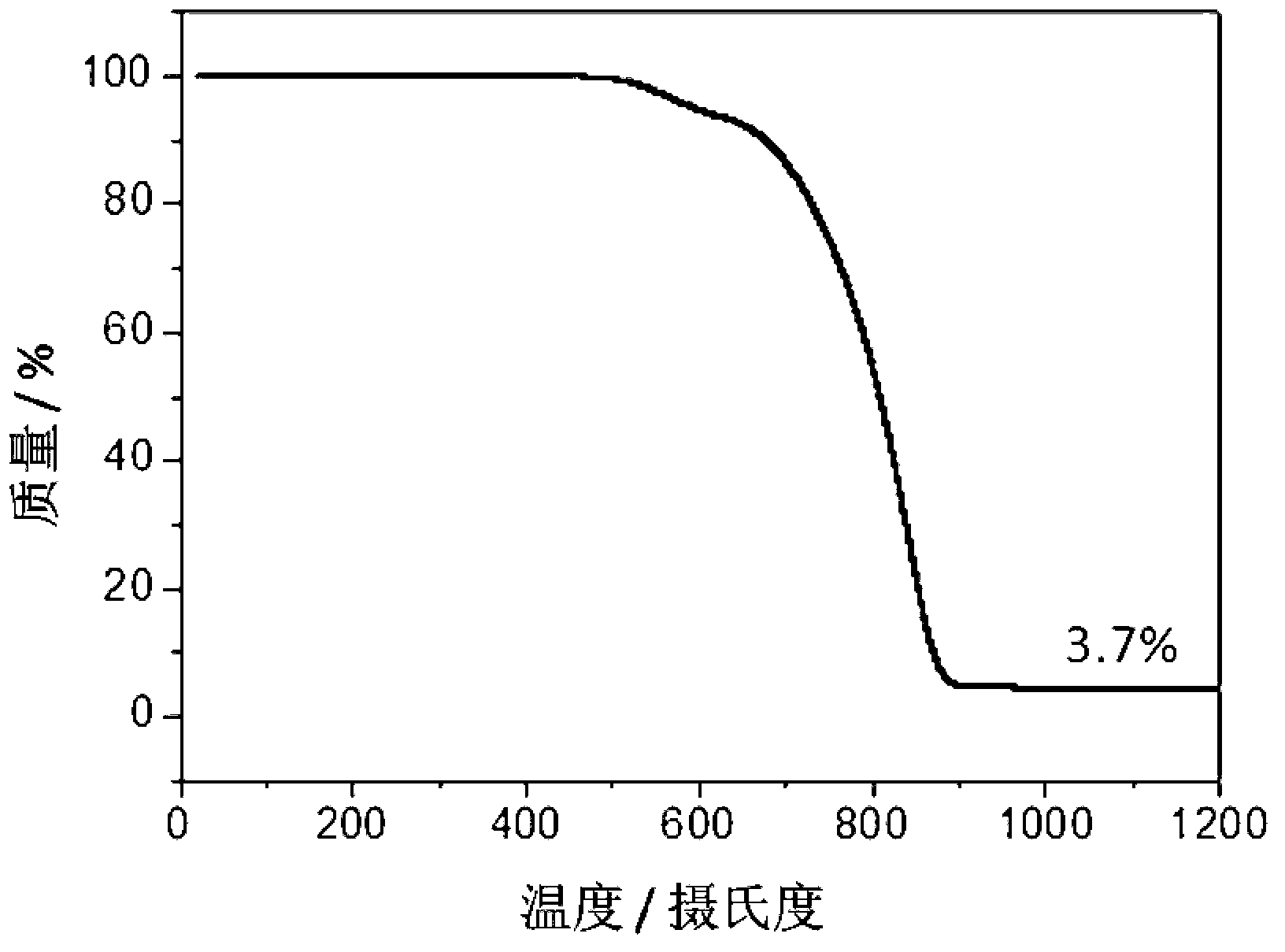

SiO<x>/C composite cathode material, method for preparing same and application of SiO<x>/C composite cathode material

ActiveCN105655564AImprove conductivityIncrease capacityCell electrodesSecondary cellsCarbon compositesCarbon layer

The invention provides an SiO<x> / C composite cathode material, a method for preparing the same and application of the SiO<x> / C composite cathode material. The SiO<x> / C composite cathode material is of a core-shell structure. A shell layer of the SiO<x> / C composite cathode material is a carbon layer, a core of the SiO<x> / C composite cathode material comprises a plurality of silicon carbon composite material particles, the silicon carbon composite material particles include SiO<x> particles and amorphous conductive carbon layers, the amorphous conductive carbon layers cover the surfaces of the SiO<x> particles, and free spaces are reserved between the silicon carbon composite material particles. The SiO<x> / C composite cathode material, the method and the application have the advantages that the SiO<x> / C composite cathode material is excellent in conductivity, firm in structure and stable in capacity, the coulomb efficiency and the cycle performance can be greatly improved, technological conditions for the method are controllable, the SiO<x> / C composite cathode material prepared by the aid of the method is stable in performance and high in production efficiency, and the production cost can be reduced.

Owner:王凤鸣

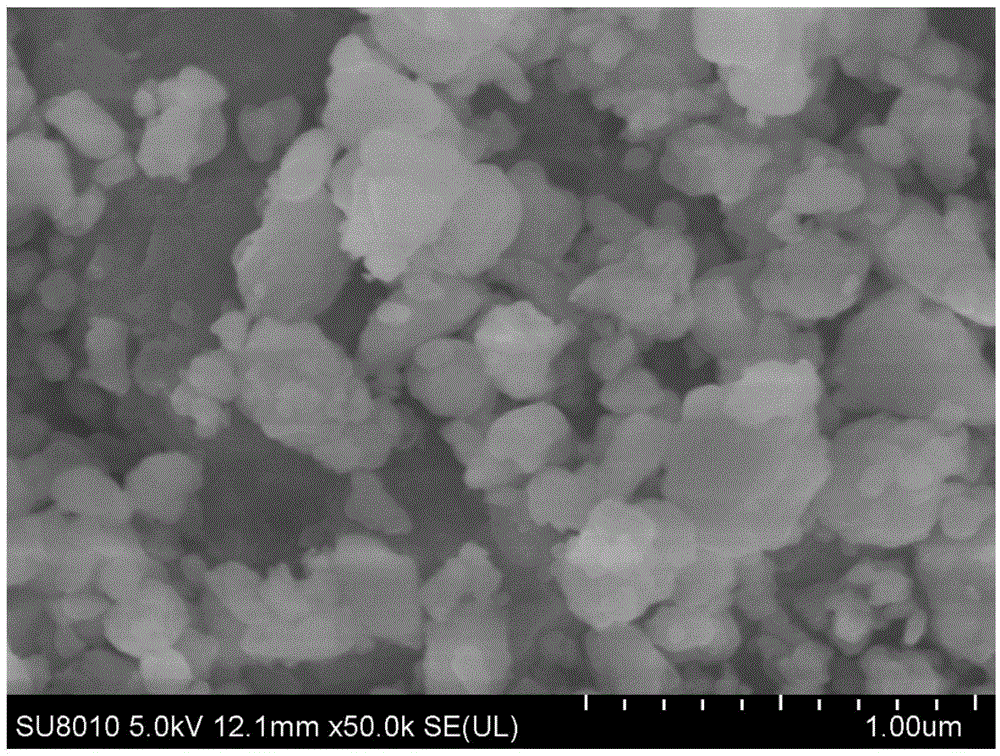

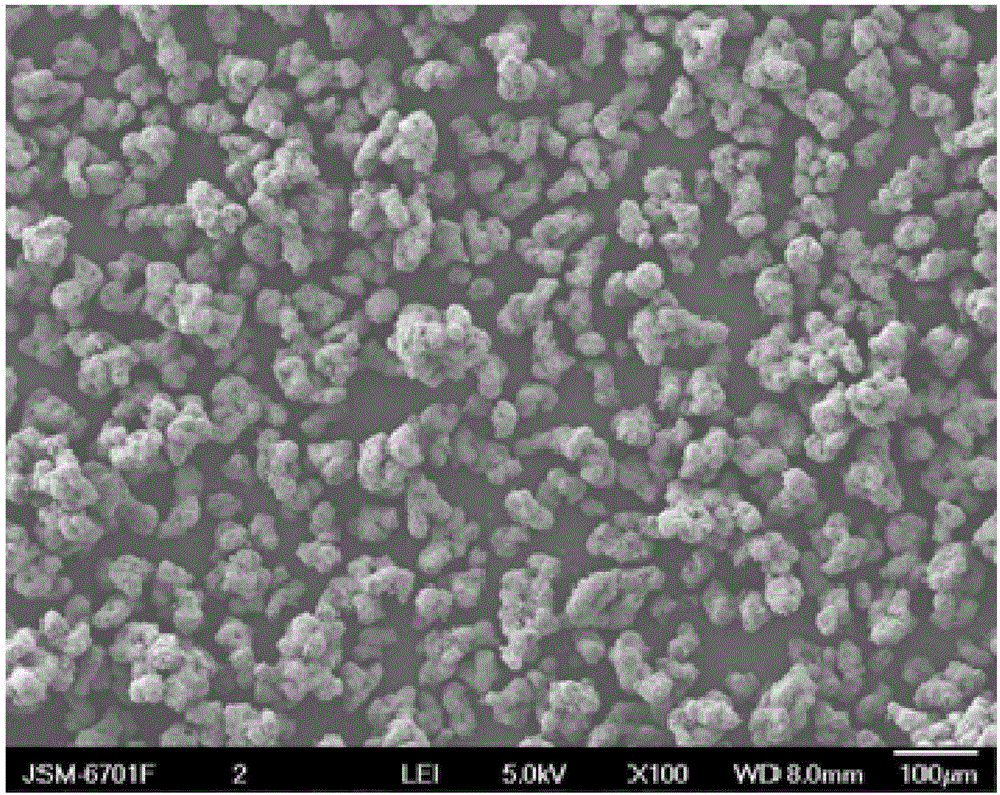

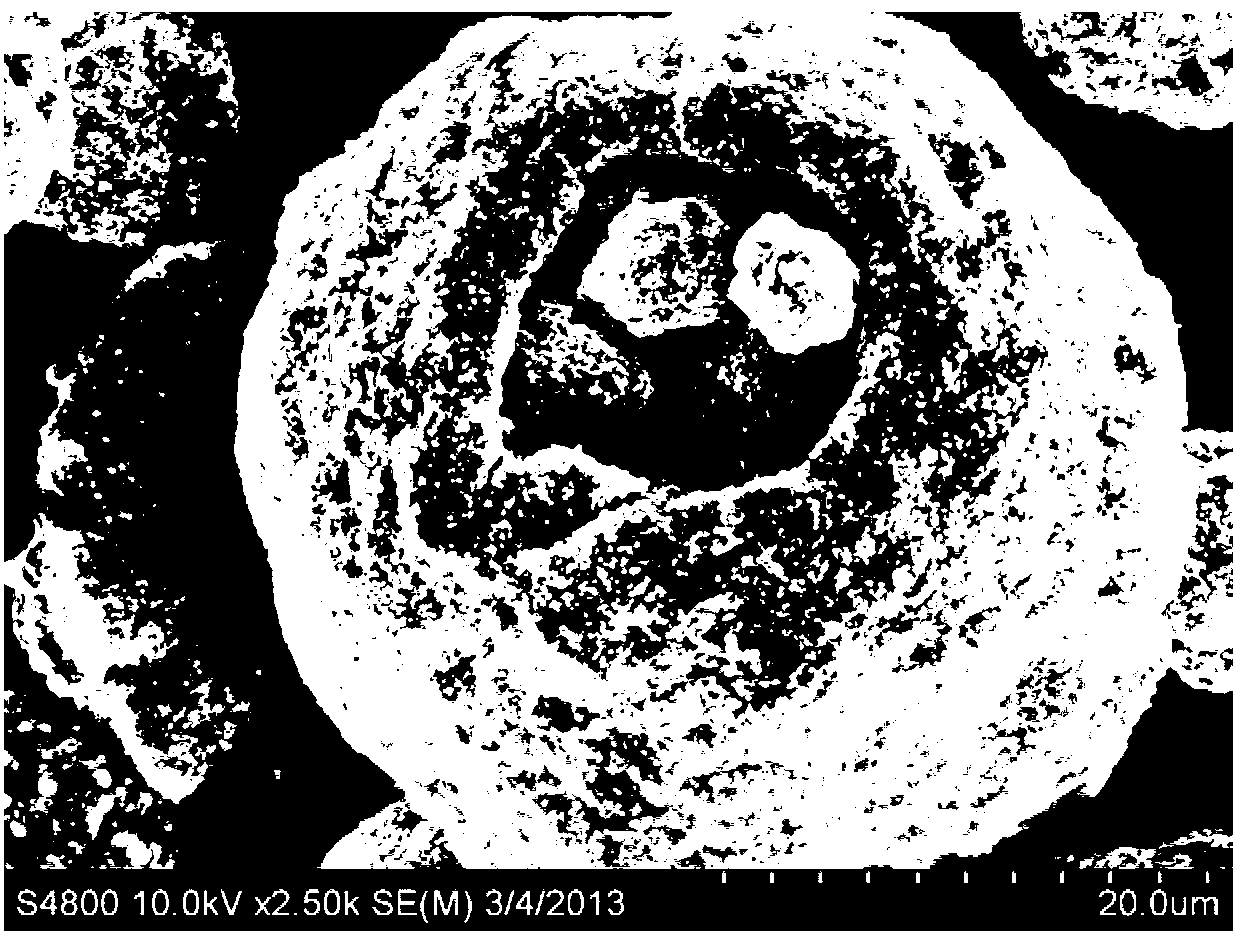

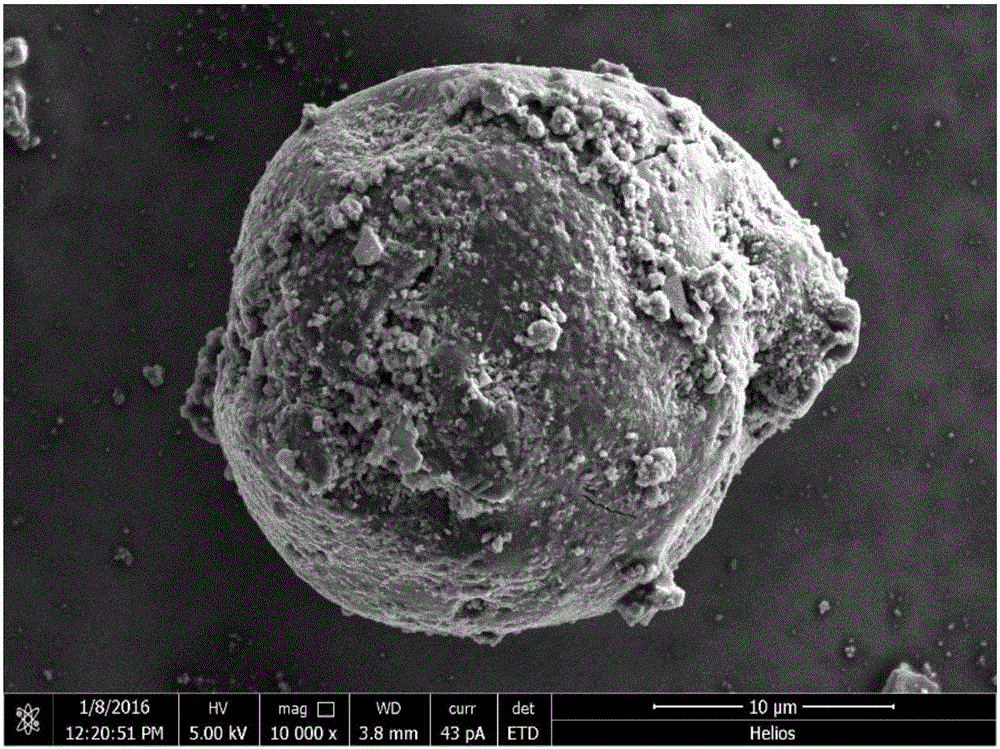

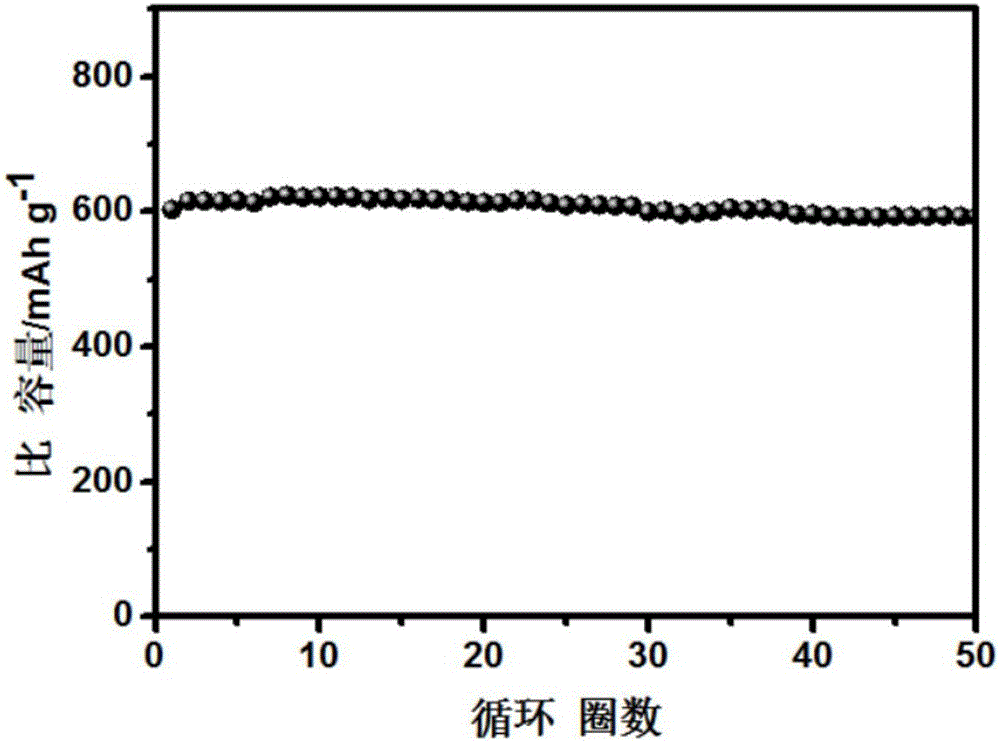

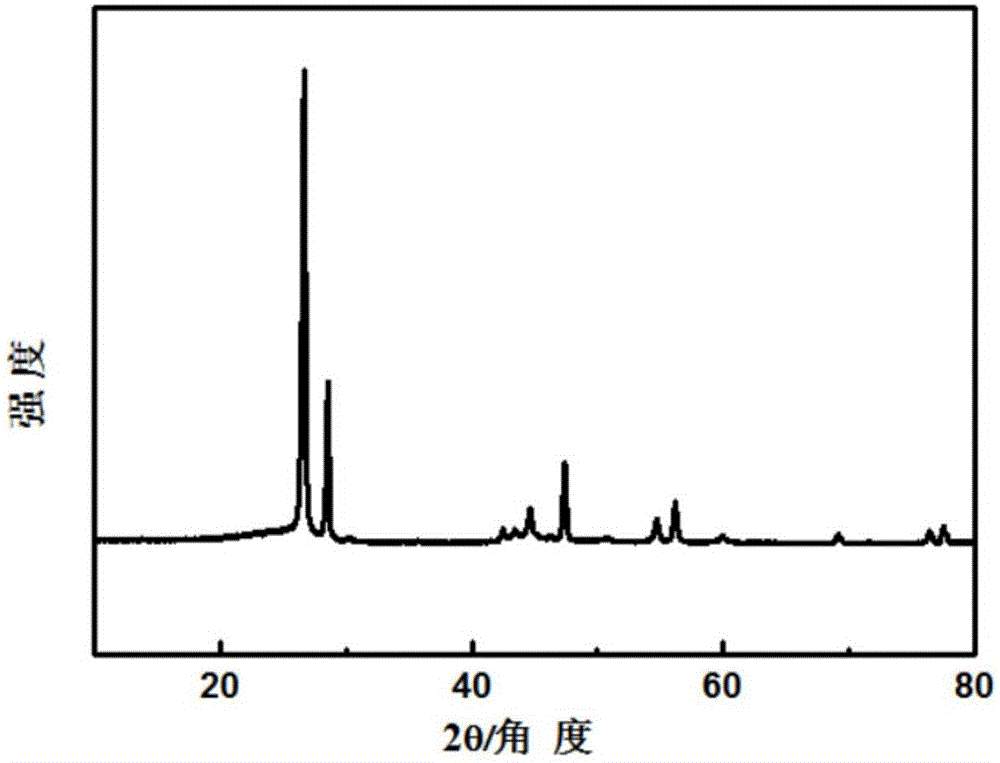

Silicon/carbon composite microsphere negative electrode material as well as preparation method and application for same

ActiveCN103311522AStable structureImprove charge and discharge cycle lifeCell electrodesSolventCarbon black

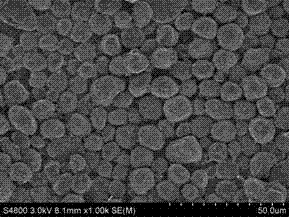

The invention relates to a silicon / carbon composite microsphere negative electrode material as well as a preparation method and an application for the same. The silicon / carbon composite microsphere negative electrode material is silicon / carbon composite microspheres internally provided with pore structures; and each microsphere comprises a matrix material of hard carbon, and an active material of silicon powder. The preparation method for the silicon / carbon composite microsphere negative electrode material comprises the following steps of: uniformly mixing silicon powder, soft carbon, carbon black, a soluble carbon-containing organic adhesive and a solvent with formula amounts to obtain a slurry; and performing spray-drying and carbonization on the slurry to obtain the silicon / carbon composite microsphere negative electrode material. The silicon / carbon composite microsphere negative electrode material provided by the invention has the advantages of being high in tap density, high in reversible capacity, good in cyclicity, good in rate capability, safe and reliable, and high in first-week coulombic efficiency; the preparation method provided by the invention is simple in process, environment-friendly, low in energy consumption and cost, and easy to realize large-scale production.

Owner:INST OF PROCESS ENG CHINESE ACAD OF SCI

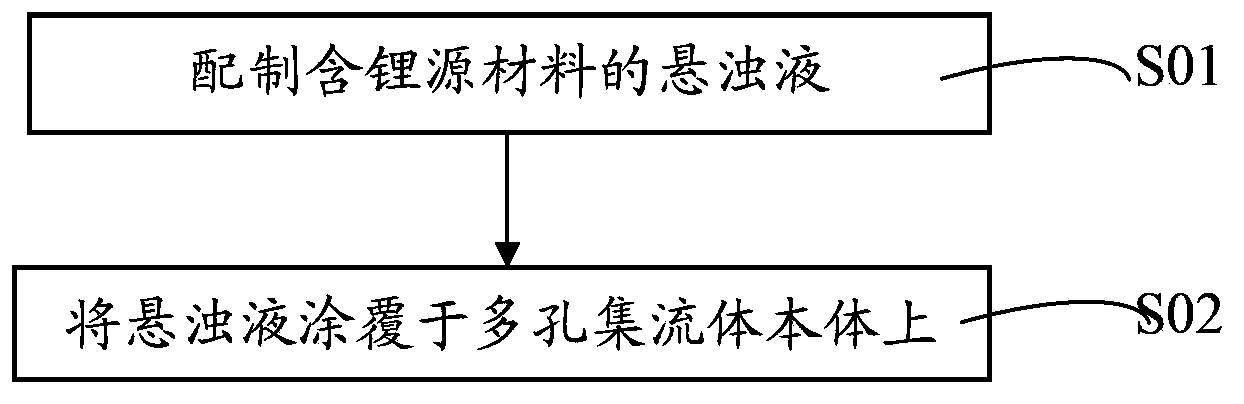

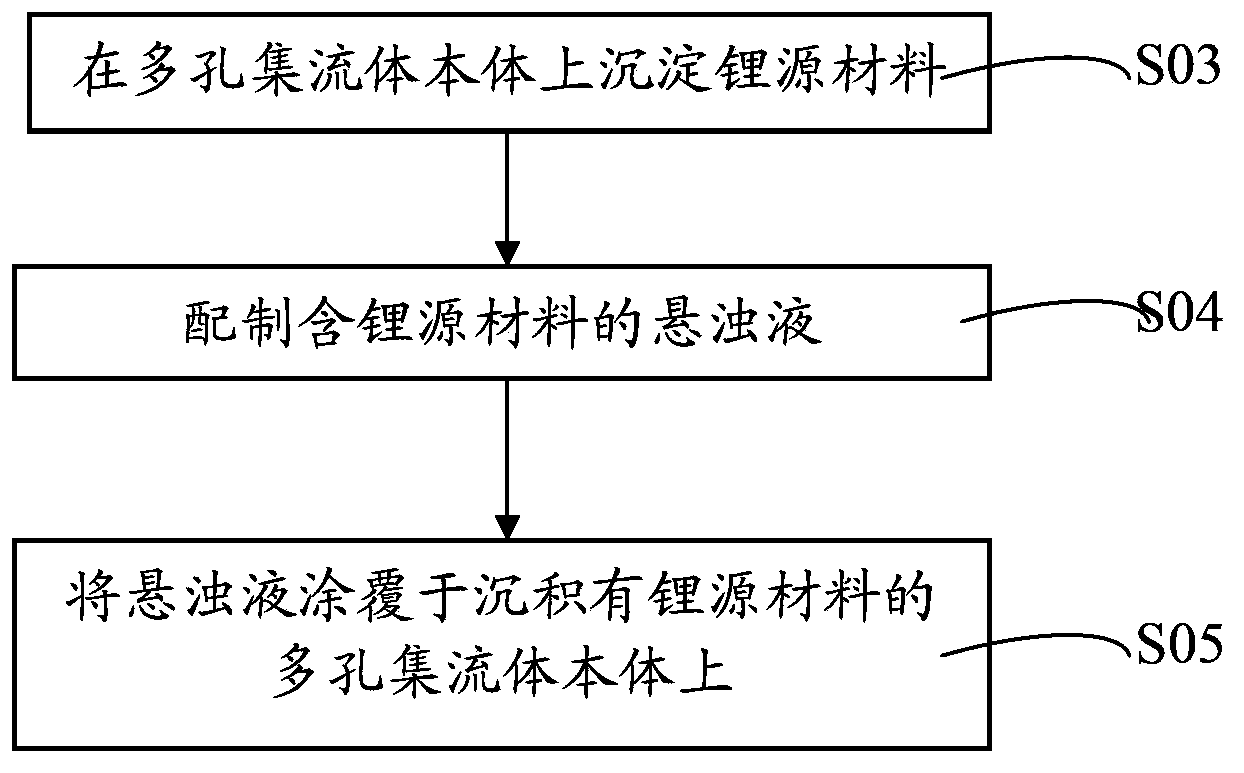

Lithium battery current collector, pole piece, lithium battery, preparation method thereof and application of lithium battery

ActiveCN103794800AEffectively fixedImprove securityFinal product manufactureElectrode carriers/collectorsLithium metalSource material

The invention discloses a lithium battery current collector and a preparation method thereof, a lithium battery pole piece and a preparation method thereof, a lithium battery and a preparation method and application thereof. The lithium battery current collector includes a porous current collector body, which is filled or / and deposited with a lithium source material. The lithium source material is a lithium metal or / and lithium-rich material. The lithium battery pole piece and the lithium battery both contain the lithium battery current collector. The lithium battery current collector provided by the invention enables the lithium source material to be effectively fixed in the current collector body. The lithium battery pole piece containing the lithium battery current collector can make the lithium in the lithium source material ionize during electrochemical activation and completely absorbed by a positive active material in an anode layer or a negative active material in a cathode layer so as to compensate the lithium ion lost in an initial charge / discharge process, thereby reducing the irreversible capacity. Therefore, the lithium battery has high initial coulombic efficiency and capacity as well as safety performance.

Owner:HUAWEI TECH CO LTD

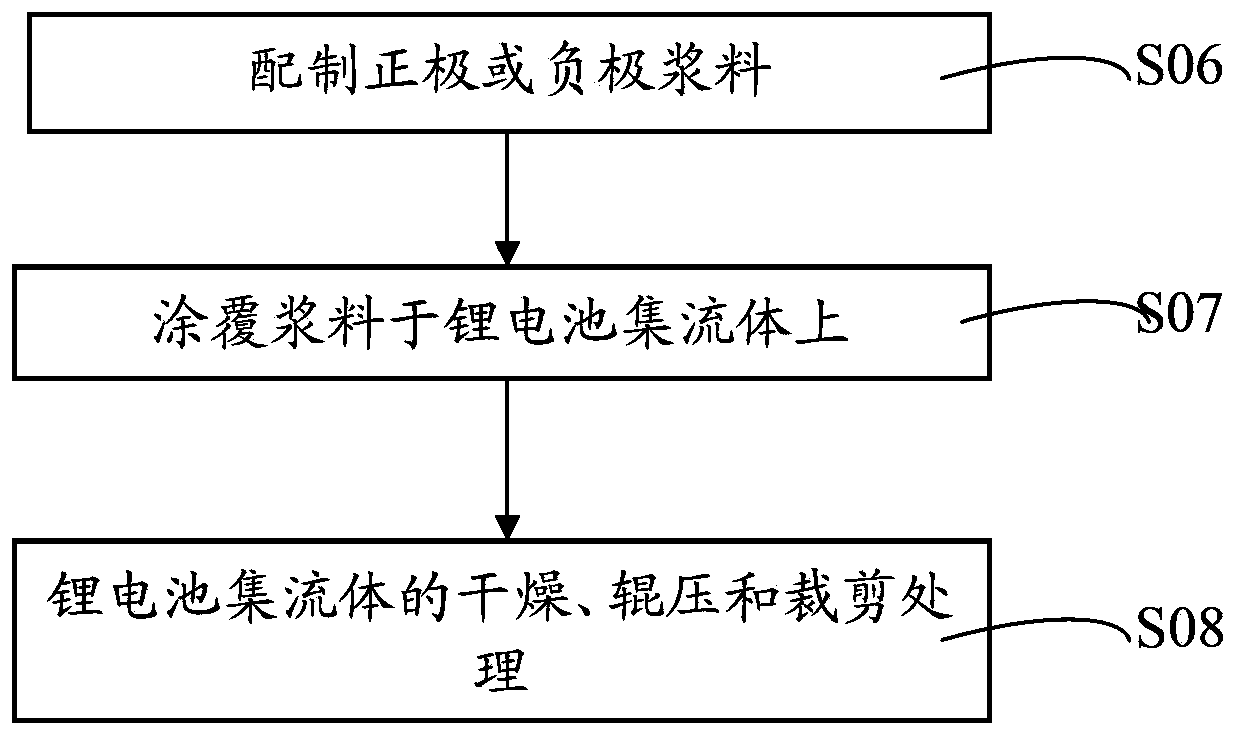

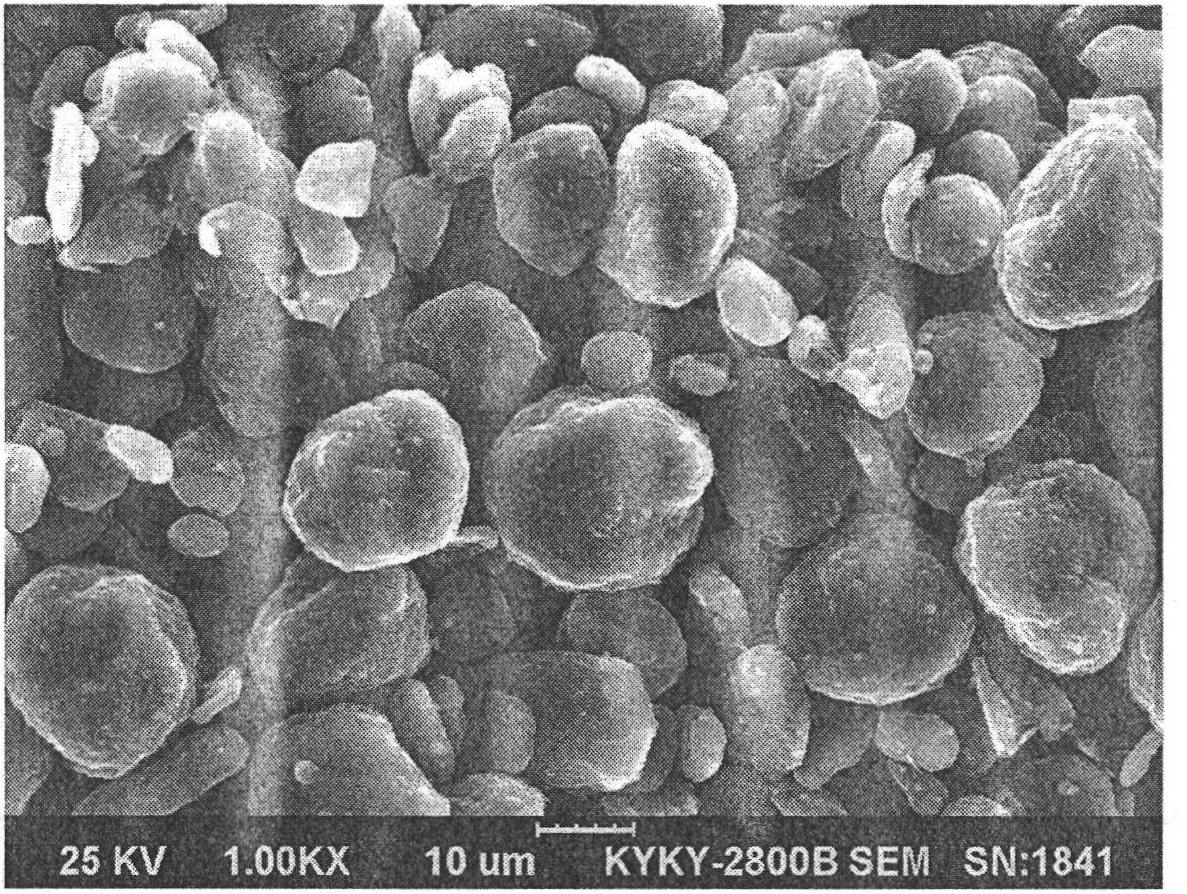

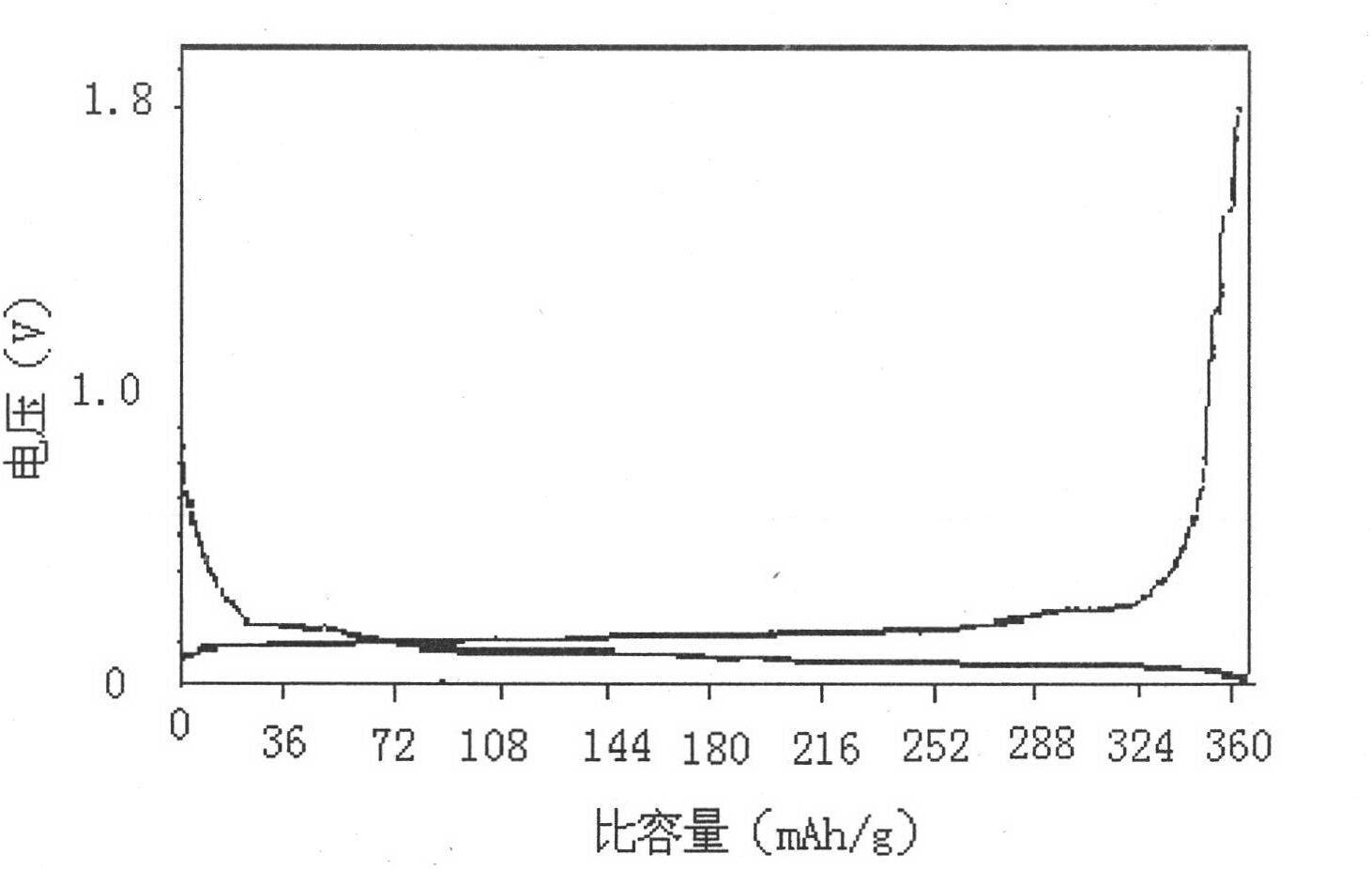

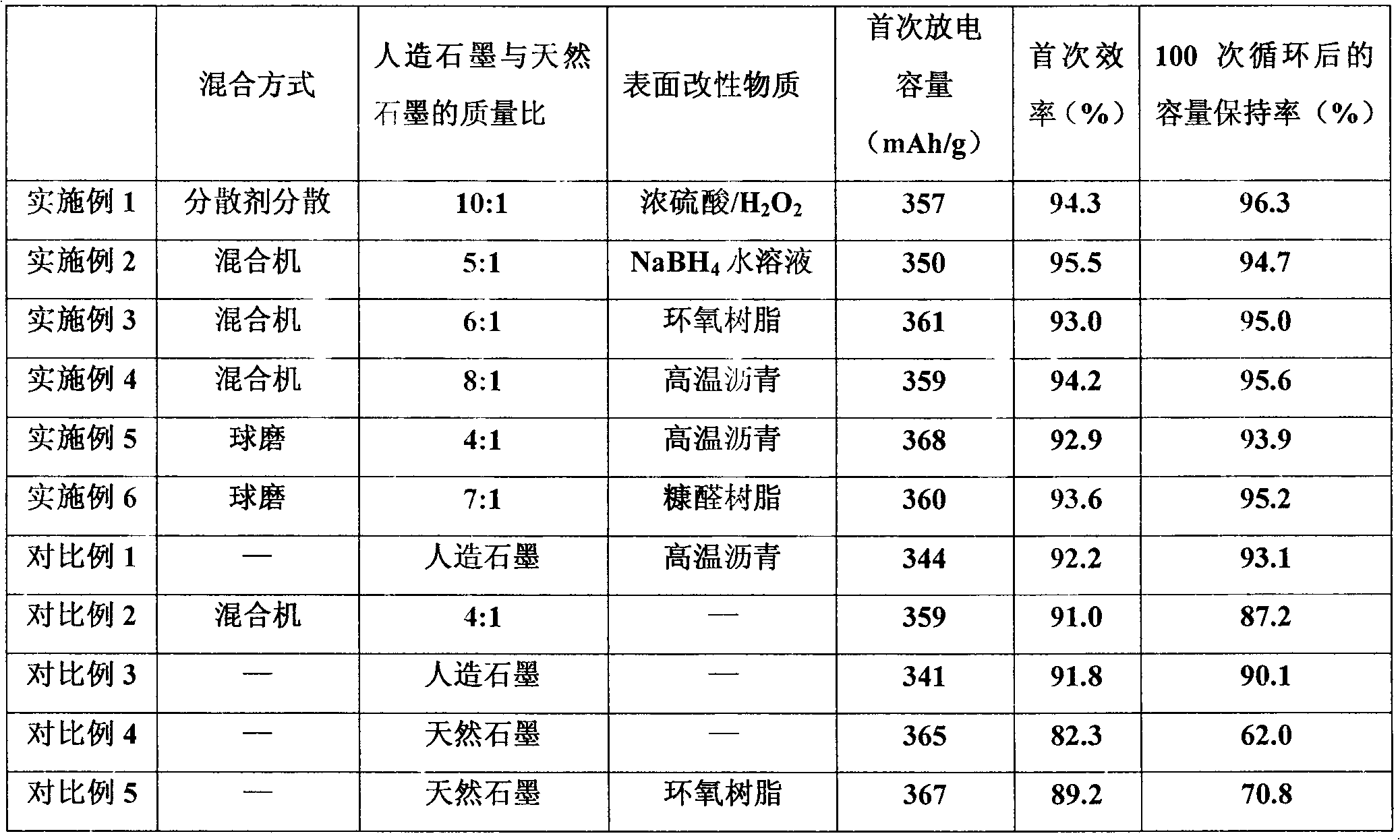

High-capacity graphite material and preparation method as well as application thereof

InactiveCN102659091AImprove discharge capacityImprove first-time efficiencyGraphiteCell electrodesMass ratioMetallurgy

The invention relates to a high-capacity graphite material and a preparation method as well as application thereof. The high-capacity graphite material comprises artificial graphite and natural graphite, wherein the mass ratio of artificial graphite to natural graphite is 20:1 to 1:1. According to the preparation method, the artificial graphite and the natural graphite are uniformly mixed according to a certain mass ratio, and then surface modification is carried out on the mixture. The prepared graphite material has the advantages of high discharge capacity, high first efficiency, long cycle life, low cost and the like; the discharge capacity of the high-capacity graphite material can reach up to more than 350mAh / g (even reach up to more than 368mAh / g); a half-cell of the high-capacity graphite material charges and discharges at the 1C multiple power; after the high-capacity graphite material cycles for 100 times, the capacity retention ratio of the high-capacity graphite material is still more than 90% (even reaches up to more than 96.3%); the first efficiency reaches up to more than 95.5%; and the manufacturing cost is reduced by about 1-10%. The high-capacity graphite material provided by the invention not only can meet the requirement of a lithium ion power battery for the high multiplying power charge-discharge of the material, but also reduces the manufacturing cost of the cathode material of the lithium ion battery.

Owner:天津市贝特瑞新能源科技有限公司

Pre-lithiation method of lithium ion battery negative electrode material

ActiveCN104538591AImprove the first Coulombic efficiencyIncrease capacityElectrode carriers/collectorsElectrolyte accumulators manufactureElectrical conductorReaction speed

The invention discloses a pre-lithiation method of a lithium ion battery negative electrode material. The method is characterized in that by adopting a method of coating or covering the surface of metal lithium with a lithium ion barrier layer and / or controlling a resistance value of a connection conductor, the pre-lithiated current magnitude is limited, and the reaction speed of a primary battery between metal lithium and negative electrode materials is regulated so as to regulate the lithium-intercalation speed of the negative electrode material and formation speed of surface SEI films, and the circulation performance of the negative electrode material is improved based on the improvement on coulombic efficiency for the first time of the negative electrode material; moreover, the method is simple in process and easy to operate, and suitable for pre-lithiation of the commercial lithium ion battery negative electrode material; lithium consumed by irreversible reaction is supplemented, so that the coulombic efficiency for the first time and the capacity of the battery are increased, and the circulation performance of the battery is improved.

Owner:TIANJIN B&M SCI & TECH

Core-shell structured carbon for cathode material of lithium ion battery and preparation method thereof

InactiveCN101969122AImprove energy density and power densityGood coulombic efficiencyCell electrodesSecondary cellsLithium electrodeLarge capacity

The invention relates to the technical field of lithium ion batteries, in particular to core-shell structured carbon for a cathode material of a lithium ion battery and a preparation method thereof, and the lithium ion battery taking the core-shell structured carbon as the cathode material and a preparation method thereof. The core-shell structured carbon comprises a hard carbon material serving as a 'core' and soft carbon 'shell' which is coated on the surface of the 'core'. On the one hand, the hard carbon material serving as the 'core' provides a large number of spaces for storing lithium and channels for lithium ions to move, and the energy density and power density of the material are improved, and on the other hand, the soft carbon 'shell' with a graphite structure ensures that the material has high coulombic efficiency and cycle performance, so that the lithium ion battery made of the core-shell structured carbon serving as the cathode material has high capacity, high power characteristic, high cycle performance and high first charge and discharge coulombic efficiency, the preparation method is simple, and the cost is low.

Owner:DONGGUAN MCNAIR NEW POWER

Modified high nickel ternary positive electrode material and its preparation method and lithium ion battery

InactiveCN108206277AImprove the first discharge capacityImprove the first Coulombic efficiencyCell electrodesSecondary cellsAluminium-ion batteryElectrical conductor

The invention discloses a modified high nickel ternary positive electrode material. The surface of a high nickel ternary positive electrode material is coated with a coating layer containing a fast ion conductor. The fast ion conductor has the chemical general formula of Li3x1La2 / 3-x1Ma1TiNz1O3, Li2+2x2Zn1-x2GeO4 or LiM'2(PO4)3, wherein M represents Ba<2+> and / or Sr<2+>, N represents Al<3+> and / orZr<4+>, x1 is greater than or equal to 0.04 and less than or equal to 0.167, a1 is greater than or equal to 0 and less than or equal to 1, z1 is greater than or equal to 0 and less than or equal to 1, x2 is greater than -0.3 and less than 0.8, and M' represents one or more of Zr, Ti, Ge and Hf. Compared with the existing positive electrode material, the modified high nickel ternary positive electrode material is provided with the coating layer containing the fast ion conductor and the coating layer can react with residual lithium on the surface of the material to reduce residual lithium on the surface of the material and inhibit side reactions of the residual lithium and the electrolyte so that material surface stability and cycle performances are improved. The modified high nickel ternary positive electrode material has good lithium ion deintercalation ability, improves the first discharge capacity of the material and first coulombic efficiency and has a good application prospect. The invention also discloses a preparation method of the modified high nickel ternary positive electrode material and a lithium ion battery.

Owner:CONTEMPORARY AMPEREX TECH CO

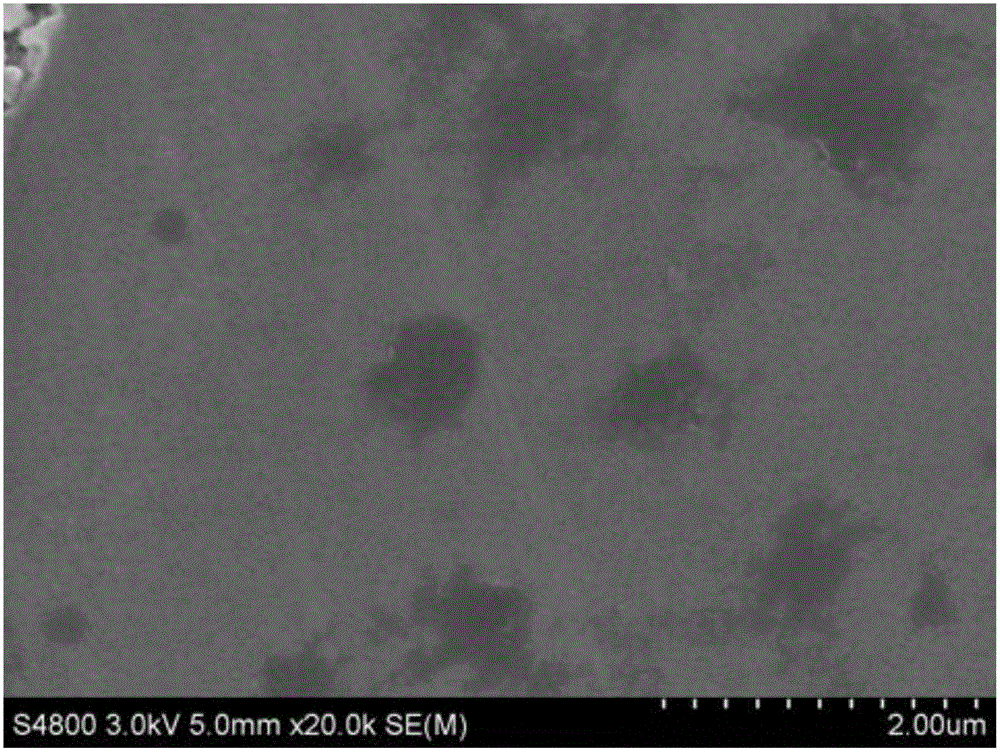

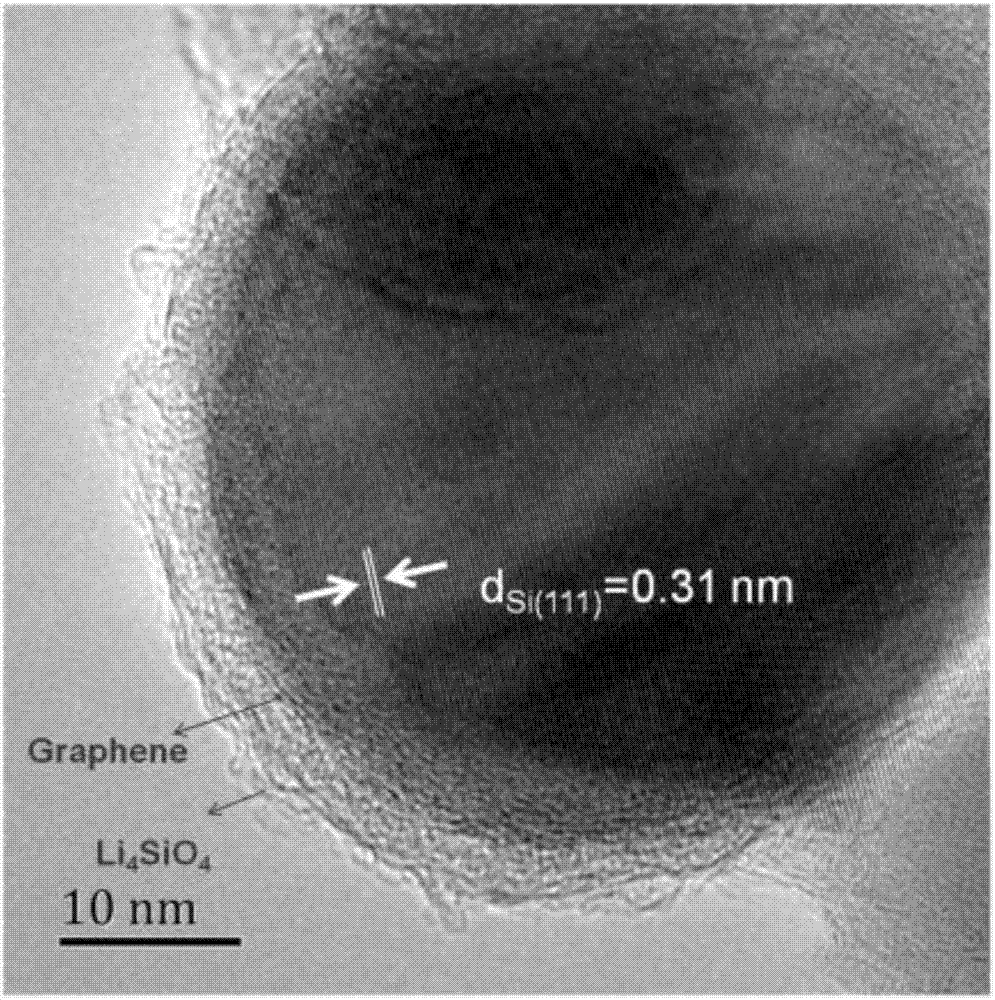

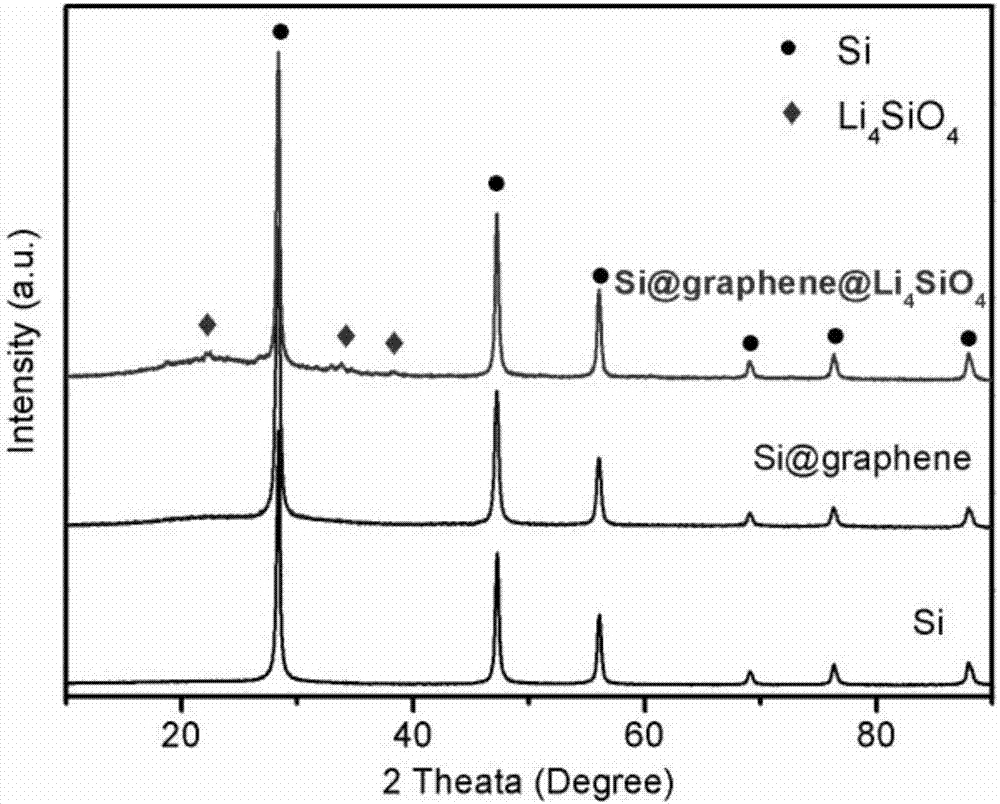

Graphene modified silicon monoxide and carbon composite microsphere, and preparation method and application thereof

ActiveCN106410158AAlleviate volume expansionActive connectionCell electrodesBatteriesCarbon compositesSilicon monoxide

The invention provides a graphene modified silicon monoxide and carbon composite microsphere prepared from graphene, asphalt and silicon monoxide, and a preparation method and an application thereof. Asphalt and silicon monoxide bulk are adopted as raw materials, so the cost is low; a high temperature and high pressure reaction is adopted to obtain a silicon monoxide and carbon composite material in a liquid phase, so the technology is simple; and a dispersant can be recycled, so no waste liquid is generated, and no toxic substances are discharged. The above obtained material has a small specific surface area, and is in favor of forming a stable SEI film; a graphene two-dimensional material has an obvious modification effect, effectively connects active substances, and alleviates volume expansion of an electrode, and good dispersion and reasonable cavity of silicon monoxide make the material have excellent cycle performances.

Owner:BEIJING IAMETAL NEW ENERGY TECH CO LTD

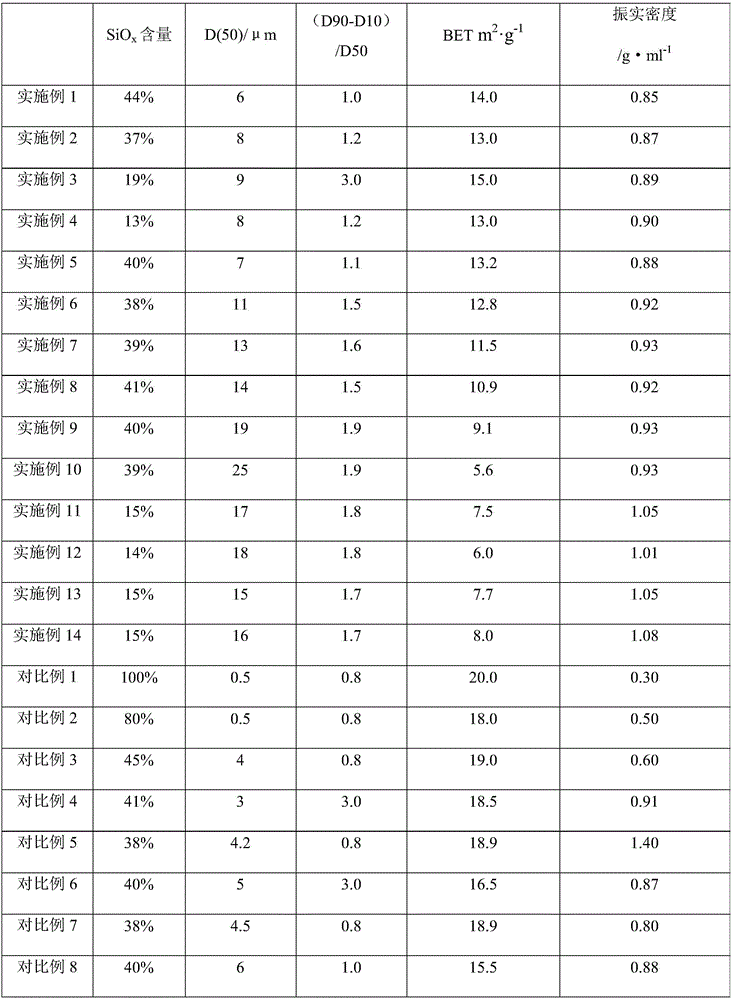

Lithium ion battery SiO composite material as well as preparation method and application thereof

ActiveCN104638237AImprove the first Coulombic efficiencyImprove capacity playCell electrodesSecondary cellsCarbon coatingHigh rate

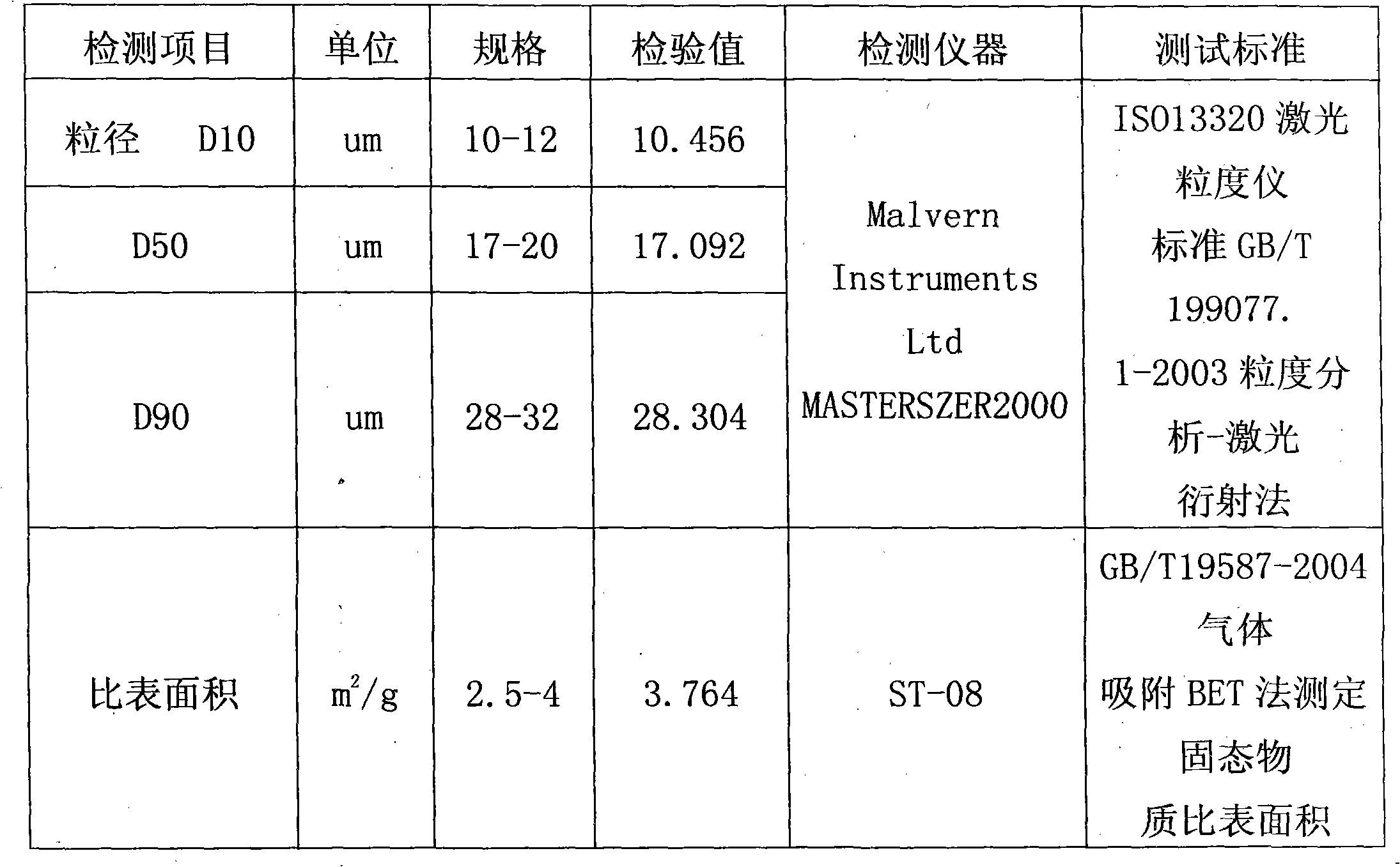

The invention relates to a lithium ion battery SiO composite material which comprises powder and a conductive carbon coating layer, wherein the chemical formula of the powder is SiOx; x is greater than 0.9 and less than 1.1; the volume of powder with particle diameters below 1.0mu m accounts for less than 15.0% of that of all the SiOx powder; D90 / D10 is greater than 3.0 and less than 15.0; D90 is less than 25.0mu m; Dmax is less than 50.0mu m; and the median particle diameterD50 of the SiOx changes within 0.5-2.0mu m before and after carbon coating. When the composite material charges and discharges at 0-1.5V as a lithium ion battery cathode material, the reversible specific capacity is high (over 1,650mAh / g), the initial coulomb efficiency is up to a theoretical value (over 79.0%), and meanwhile the composite material has excellent cycle performance, excellent conductive performance and low volume expansion, is suitable for high-rate charge and discharge, and can be applied to the power market.

Owner:BTR NEW MATERIAL GRP CO LTD

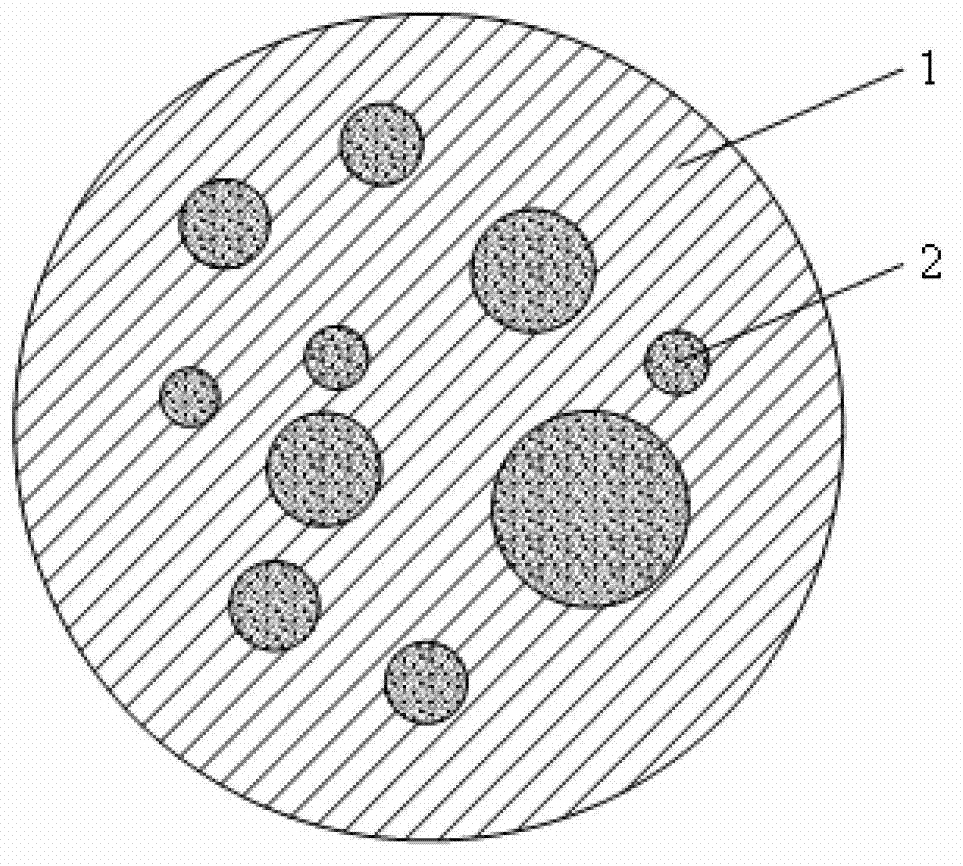

Method for supplementing lithium to lithium ion battery pole piece

InactiveCN106410120AImprove the first Coulombic efficiencyImprove cycle performanceSecondary cellsElectrode collector coatingElectrical batterySlurry

The invention belongs to the technical field of lithium ion batteries and particularly relates to a method for supplementing lithium to a lithium ion battery pole piece. The method includes the following steps that 1, lithium colloidal particles of core-shell structures are prepared, shell layers are made of rubber and / or resin, core layers are made of metal lithium, and metal lithium is coated with the shell layer materials to form the lithium colloidal particles; 2, the lithium colloidal particles obtained in the step 1 and an electrode active material are mixed to prepared into electrode active slurry, then the surface of a current collector is evenly coated with the mixed electrode active slurry, and drying is carried out. The lithium colloidal particles of the core-shell structures are used for the battery pole piece to prepare a lithium-rich battery pole piece. The method for supplementing lithium to the lithium ion battery pole piece is easy to operate, safe and efficient, the risk that metal lithium is oxidized is avoided, the requirements for the environment and equipment are low, the production cost can be reduced, meanwhile, the first-time coulombic efficiency and cycle performance of a lithium ion battery adopting the battery pole piece are both obviously improved, and battery capacity losses caused by irreversible cycle are greatly reduced.

Owner:DONGGUAN TAFEL NEW ENERGY TECH CO LTD +1

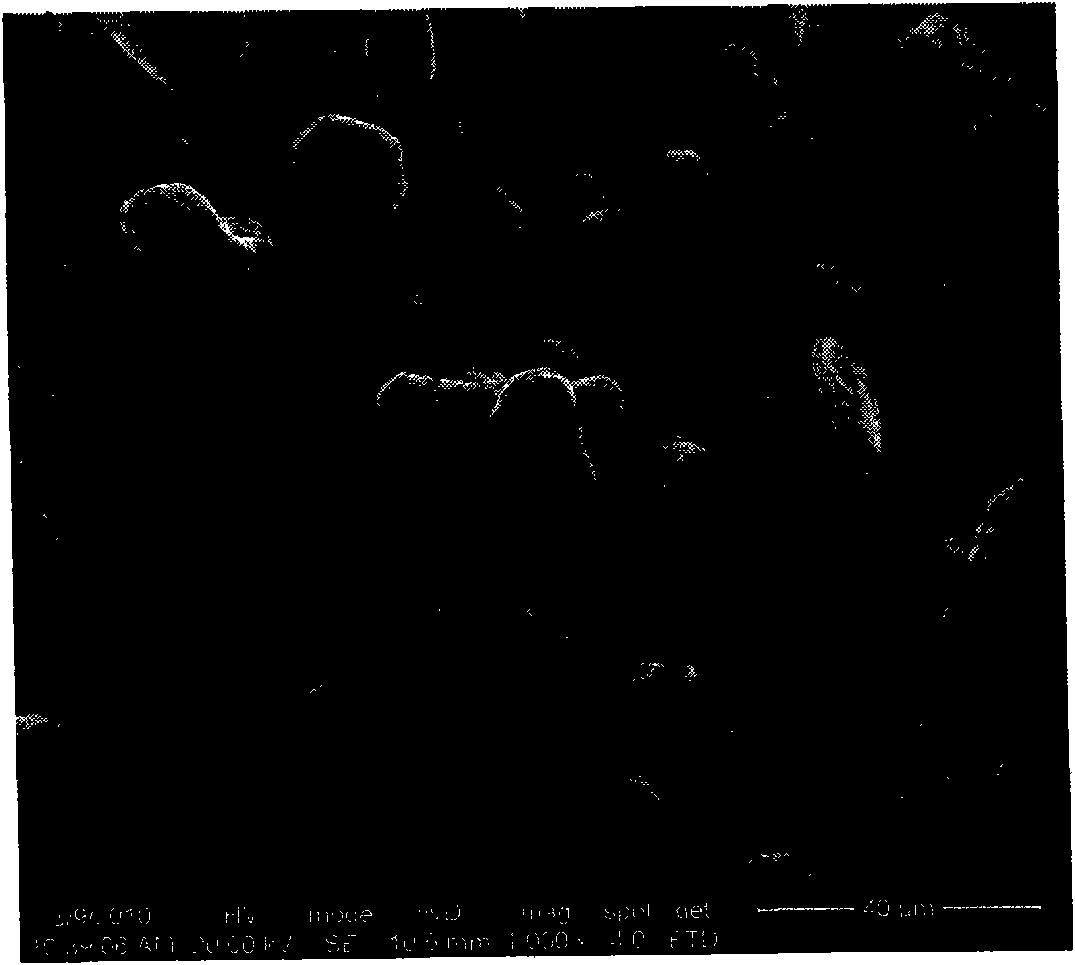

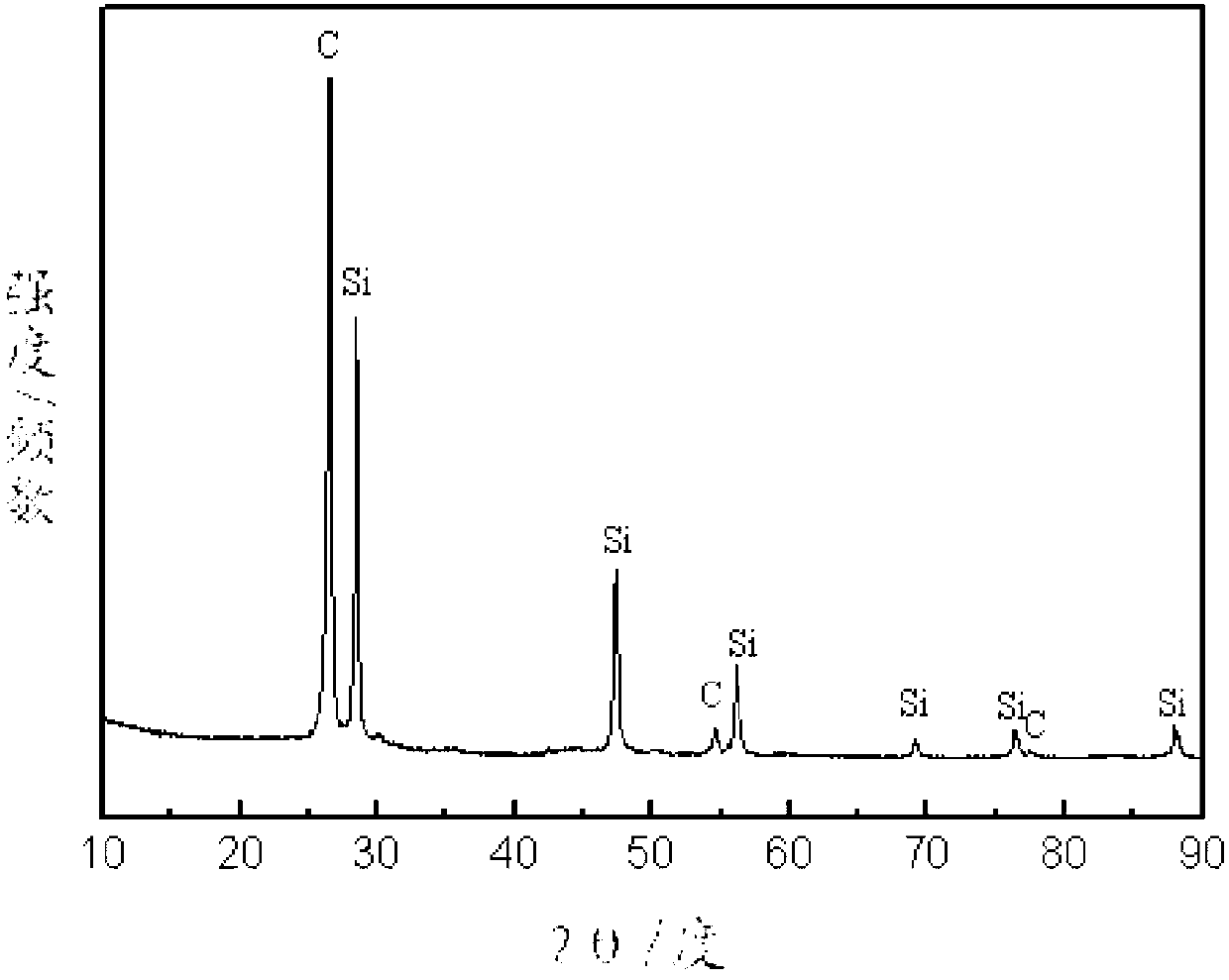

Pre-lithiated and graphene-coated mesoporous SiO negative electrode material and preparation method thereof

The invention discloses a pre-lithiated and graphene-coated mesoporous SiO negative electrode material and a preparation method thereof. The method comprises the following steps: firstly, adding metal lithium to a non-aqueous solvent to form a lithium solution; secondly, adding graphene oxide to a dispersing solvent and carrying out ultrasonic treatment to obtain 0.5-60g / L of graphene oxide dispersion; adding nano mesoporous SiO microspheres with the specific surface area of 500-700m<2> / g to the dispersion, and carrying out ultrasonic treatment; adding the lithium solution under a stirring condition; adding a lithium complexing agent, stirring, filtering and washing to obtain a precursor; and finally drying the precursor in vacuum, grinding evenly, packing into a corundum boat, sintering in an inert atmosphere furnace, and cooling along with the furnace, so as to obtain the pre-lithiated and graphene-coated mesoporous SiO negative electrode material. The composite material is prelithiated in the process of preparing the graphene-coated mesoporous SiO negative electrode material; and the initial Coulomb efficiency, the cycle performance and the charge and discharge specific capacity of a silicon oxide negative electrode material are improved.

Owner:李震祺 +1

Lithium ion battery and lithium-rich anode sheet

ActiveCN103490041AImprove the first Coulombic efficiencyIncrease energy densityElectrode carriers/collectorsSecondary cellsPhysicsCurrent collector

The invention provides a lithium ion battery and a lithium-rich anode sheet. The lithium-rich anode sheet comprises: a current collector; and a diaphragm, which contains an active substance and is formed on the current collector, wherein the diaphragm and the current collector form an initial anode sheet. The current collector in the initial anode sheet is a porous current collector. The initial anode sheet is rich in lithium on one side, and the lithium rich amount matches the lithium supplement capacity needed by the initial anode sheet. The lithium ion battery includes: a cathode sheet; an anode sheet; an isolation membrane disposed between the cathode sheet and the anode sheet; and an electrolyte solution. The anode sheet is a lithium-rich anode sheet. The lithium-rich anode sheet of the lithium ion battery provided by the invention not only overcomes the excess lithium supplement problem in traditional lithium-rich anode sheets, and also can effectively control the lithium supplement amount of the anode so as to realize uniform lithium supplement and enhance the first coulombic efficiency of the lithium ion battery adopting the lithium-rich anode sheet. Thus, the energy density of the lithium ion battery is greatly improved, and the lithium ion battery can be ensured with better electrochemical properties.

Owner:DONGGUAN AMPEREX TECH

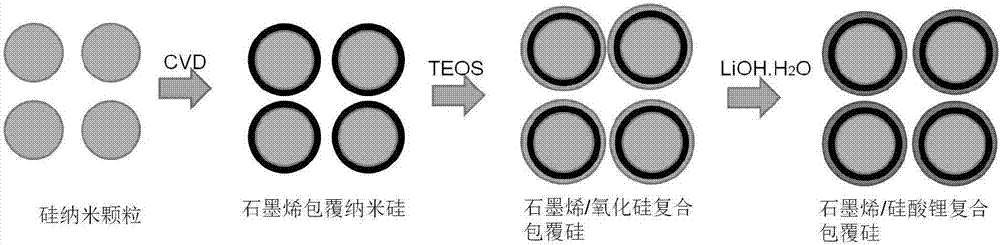

Graphene/solid-state electrolyte composite coated silicon composite negative electrode and preparation method thereof

ActiveCN107579239ASimple processCoated evenlyCell electrodesSecondary cellsElectrochemical responseSolid state electrolyte

The invention discloses a graphene / solid-state electrolyte coated silicon composite material and a preparation method thereof. The preparation method comprises the following steps: coating a silicon-based material with a layer of graphene through a chemical vapor deposition method, and accumulating concentrated ammonia water into an oxide through a precursor ester of an oxide for coating to obtainan oxide and graphene co-coated silicon negative electrode material; performing lithiation on the composite material with lithium hydroxide monohydrate to finally obtain the graphene / solid-state electrolyte coated silicon composite material. In the composite material, graphene directly grows on the surfaces of silicon particles, and the surface of graphene is coated with solid-state electrolyte,thereby forming double-layer coating. The graphene inside can increase the electronic conductivity of the silicon-based material, and relieve volume expansion of silicon. The coating solid-state electrolyte outside can improve the Coulomb efficiency and the magnification performance of the silicon-based negative electrode material, reduce the electrochemical reaction between the negative electrodematerial and electrolyte, increase the Coulomb efficiency of the silicon-based negative electrode and improve the high current charging and discharging performance of the material.

Owner:深圳索理德新材料科技有限公司

Lithium ion battery cathode material and preparation method thereof

ActiveCN103346324APromote circulationBuffers large volume changesCell electrodesCarbon compositesNanoparticle

The invention provides a lithium ion battery cathode material and a preparation method of the lithium ion battery cathode material. The lithium ion battery cathode material comprises an inner core and an outer shell wrapping the inner core, a hollow layer exists between the outer shell and the inner core, the inner core is made of a Si-C composite material, the outer shell is made of a C composite material, and the C composite material is formed by a C material and a first amorphous carbon precursor. Compared with the existing Si-C composite material, the hollow layer between the inner core Si-C composite material and the outer shell C composite material can buffer enormous volume change of Si particles in the discharge process, thus endowing the cathode material with good cycle performance; and at the same time, the outer shell can be buffer volume change, reduce stress, improve cycling stability of electrodes, reduce contact between active substances and an electrolyte, improve first coulombic efficiency of an electrode, prevent nanoparticle aggregation and enhance electrode conductivity.

Owner:NINGBO INST OF MATERIALS TECH & ENG CHINESE ACADEMY OF SCI

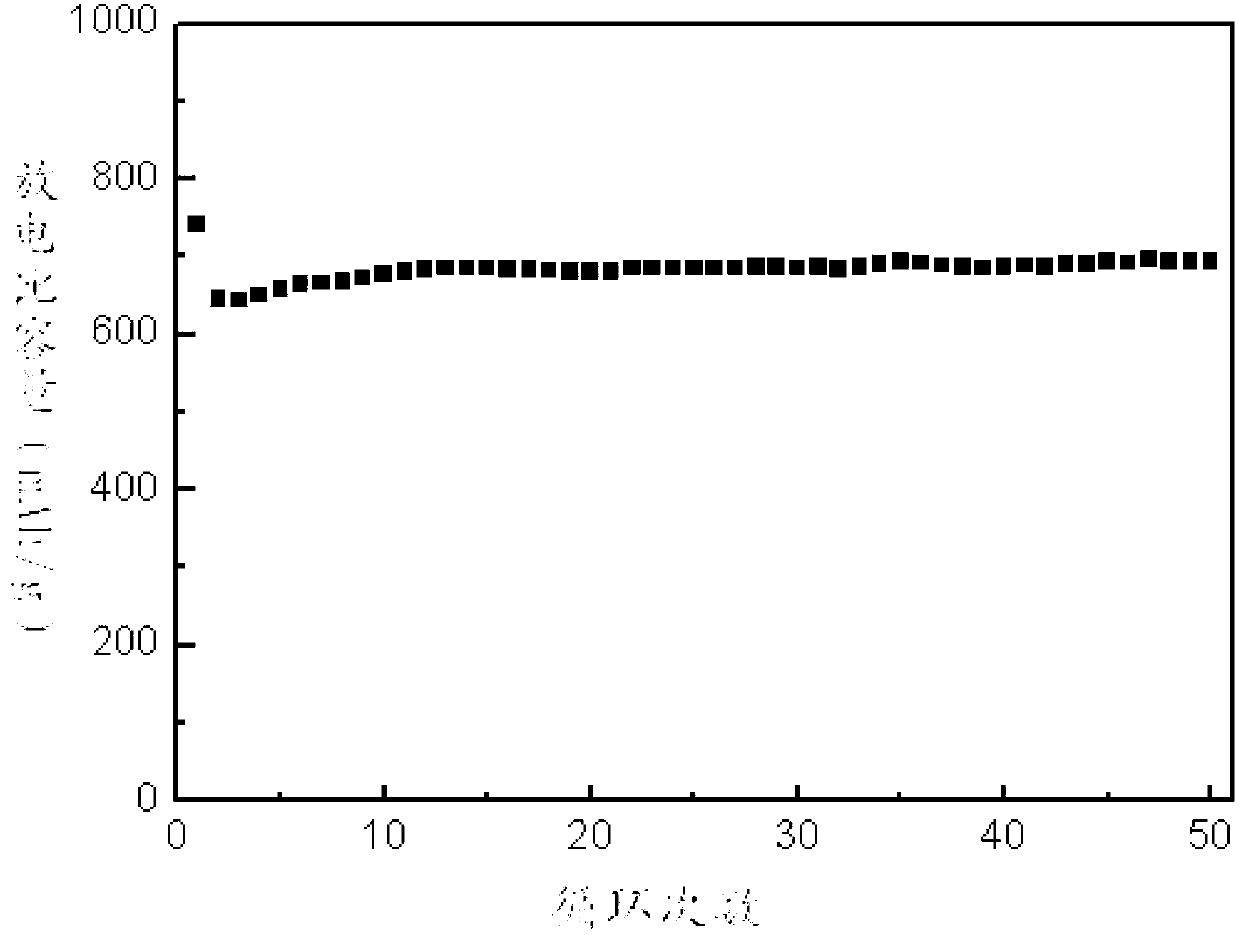

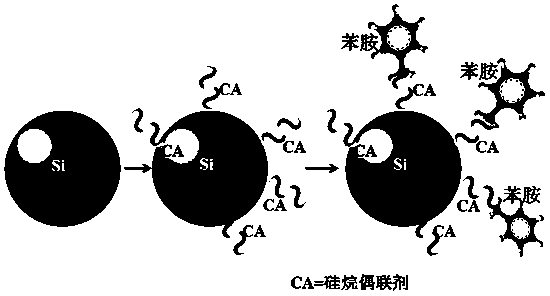

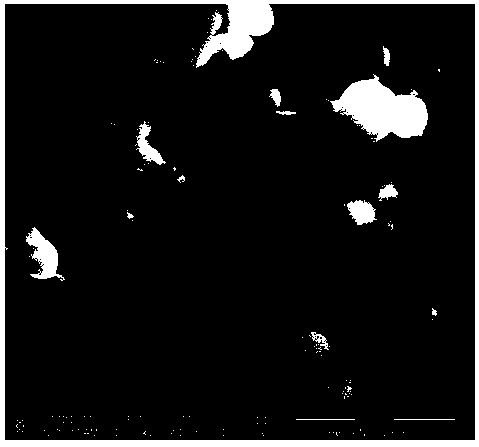

Silicon-base negative material with silane coupling agent and conductive polymer two-layer cladding structure as well as preparation method and application of material

ActiveCN103996834AImprove the first Coulombic efficiencyImprove cycle stabilityCell electrodesSecondary cellsConductive polymerIn situ polymerization

The invention discloses a silicon-base negative material with a silane coupling agent and conductive polymer two-layer cladding structure as well as a preparation method and application of the material. The silicon-base negative material is characterized in that monomer silicon is adopted as a substrate, the substrate is coated with a silane coupling agent decorative layer, and the silane coupling agent decorative layer is coated with protonic acid doping-state conductive polyaniline. The preparation method comprises the following steps: (1) ultrasonically blending a silane coupling agent and silicon powder, and refluxing the mixture of the silane coupling agent and the silicon powder at a given temperature so as to decorate the silicon powder; (2) ultrasonically blending aniline monomer and decorated silicon powder in an acid solution system, and performing in-situ polymerizing on the aniline monomer and the decorated silicon powder to obtain a silicon-base composite material which is coated with the conductive polymer; (3) washing, suction-filtering and vacuum-drying the mixed solution to obtain the silicon-base negative material with the silane coupling agent and conductive polymer two-layer cladding structure. When being doped in graphite, the silicon-base negative material can be used for preparing a negative material of a lithium ion battery. The preparation method is simple and easy, low in manufacturing cost, good in repeatability and convenient for industrialized mass production.

Owner:HARBIN INST OF TECH

Modified lithium manganese oxide electrode material for lithium ion secondary battery and synthesizing method thereof

InactiveCN102208640AImprove featuresImprove crystallization propertiesCell electrodesAluminium-ion batterySodium-ion battery

The invention provides a modified lithium manganese oxide electrode material for a lithium ion secondary battery, which is characterized in that the general formula is Li(4-x)A(x+y)Mn(5-y)O12.epsilonBOz. The synthesizing method comprises the following steps: weighing and mixing raw materials evenly in accordance with the stoichiometric ratio in the general formula and then adding the mixture of the raw materials to a container; adding an oxidizing solution, evening mixing and reacting for over 10 minutes, and then taking the materials out, washing and drying; and then carrying out high-temperature calcination and reaction for 1-30 hours at a temperature of 400-1200 DEG C under an oxygen-contained atmosphere, and cooling to obtain the modified lithium manganese oxide electrode material. Compared with an existing electrode material and a synthesizing technology, the modified lithium manganese oxide electrode material produced in the production process can improve the crystalline characteristic and the purity of products as well as the specific capacity, the initial coulomb efficiency, the cyclical stability and other characteristics in electrochemical property; and the modified lithium manganese oxide electrode material improves performances of the lithium ion battery, promotes the wider applications of the lithium ion battery and has significant economic meanings and practical value.

Owner:王明月

Lithium ion battery pre-lithiated silicon-carbon multilayer composite negative electrode material and preparation method thereof

ActiveCN110620223AIsolated electrolyteGood mechanical propertiesCell electrodesSecondary cellsCvd grapheneLithium electrode

The invention discloses a lithium ion battery pre-lithiated silicon-carbon multilayer composite negative electrode material and a preparation method thereof. The composite negative electrode materialcomprises an amorphous carbon matrix, pre-lithiated silicon monoxide particles and a graphene material, wherein the graphene material is uniformly coated on an outer surface of the pre-lithiated silicon monoxide to form composite particles, and the composite particles are uniformly dispersed in the amorphous carbon matrix. After the silicon monoxide is pre-lithiated, the first effect of the silicon-based negative electrode material is greatly improved, the graphene material is light in weight, high in strength and excellent in conductivity, so mechanical property and conductivity of the composite material are greatly improved, the amorphous carbon matrix plays a role in isolating electrolyte and preventing silicon from being in contact with the electrolyte to generate a large number of unstable SEI films, and experiments show that the composite negative electrode material prepared has characteristics of good mechanical property, high conductivity, high initial coulombic efficiency andstable cycle performance.

Owner:SHENZHEN XIANGFENGHUA TECH CO LTD +1

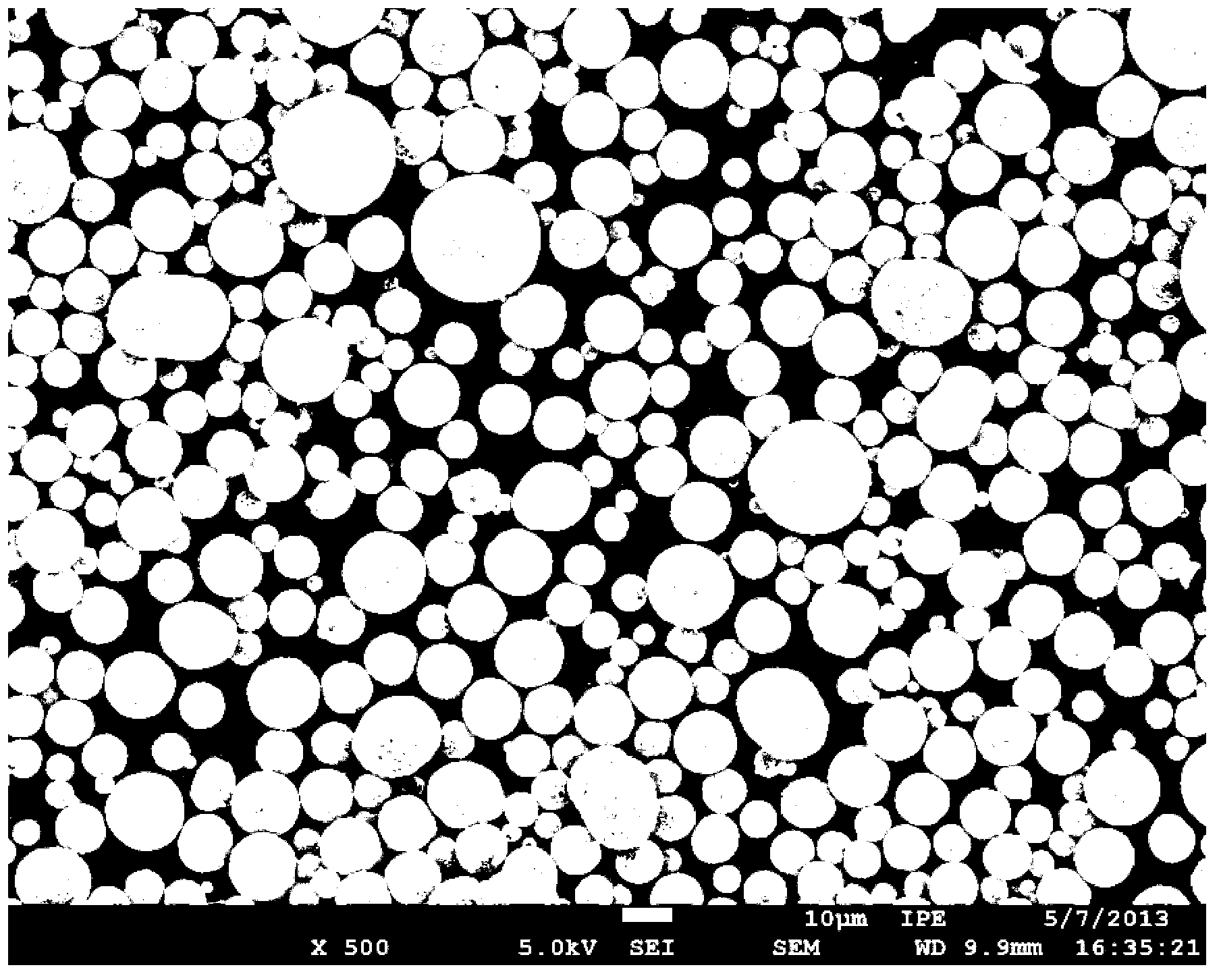

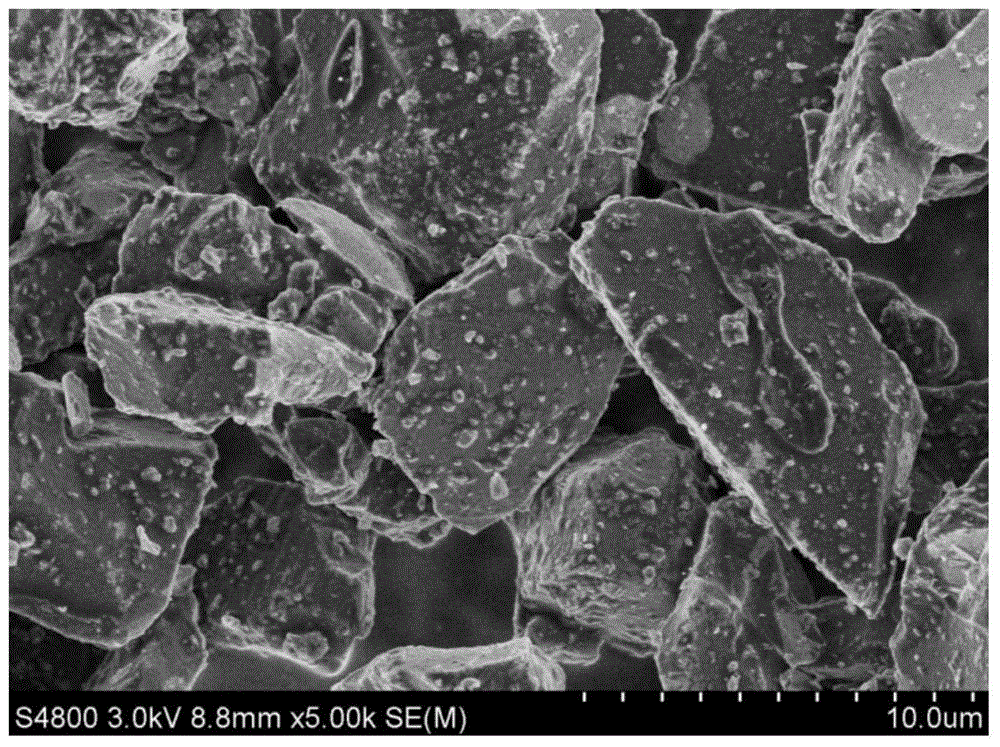

Silicon carbon composite microsphere, and preparation method and application thereof

ActiveCN106384825ASmall specific surface areaImprove cycle stabilityCell electrodesSecondary cellsCarbon compositesMicrosphere

The invention provides a silicon carbon composite microsphere, and a preparation method and application thereof. The method comprises the following steps that (1) silicon dispersion liquid is prepared: 30 to 95 percent of asphalt and 5 to 70 percent of silicon are used as raw materials, and are dispersed in an organic solvent; ball milling is performed; (2) other carbon sources are added into grinding liquid; the ball milling is further performed; (3) the dispersion liquid obtained through the ball milling is added into a high-temperature high-pressure reactor; high-temperature high-pressure reaction is performed under the inert gas protection; (4) products obtained in the third step are subjected to suction filtration to obtain solid particles; (5) the solid particles obtained in the fourth step are subjected to high-temperature carbonizing treatment in inertia non-oxidizing atmosphere to obtain the silicon carbon composite microsphere. The method has the advantages that the asphalt and the micron silicon are used as raw materials; the raw materials are cheap and are easy to obtain; a dispersing agent is nontoxic and can be recovered; the process is simple; the sphericity degree of the obtained material is good; the tap density is high; the specific surface is small; a stable SEI membrane is favorably formed; the circulation stability is excellent.

Owner:BEIJING IAMETAL NEW ENERGY TECH CO LTD

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com