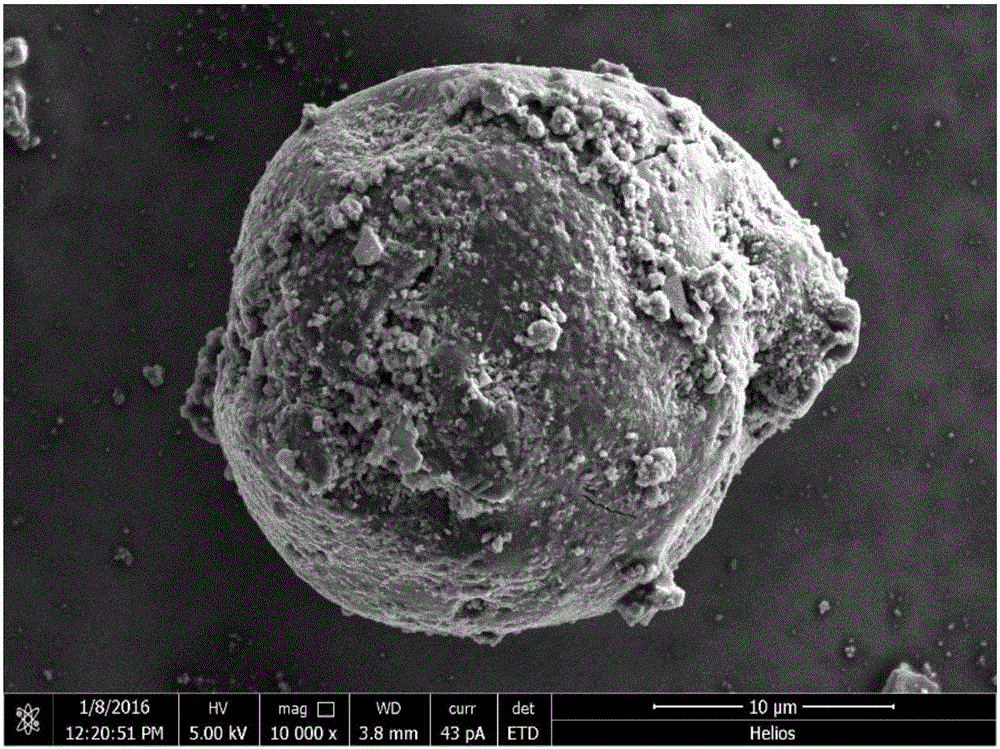

Silicon carbon composite microsphere, and preparation method and application thereof

A silicon-carbon composite and microsphere technology, applied in electrical components, electrochemical generators, battery electrodes, etc., can solve the problems of high cost, complex preparation process, low tap density, etc., and achieve high tap density and simple process. , good spherical effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

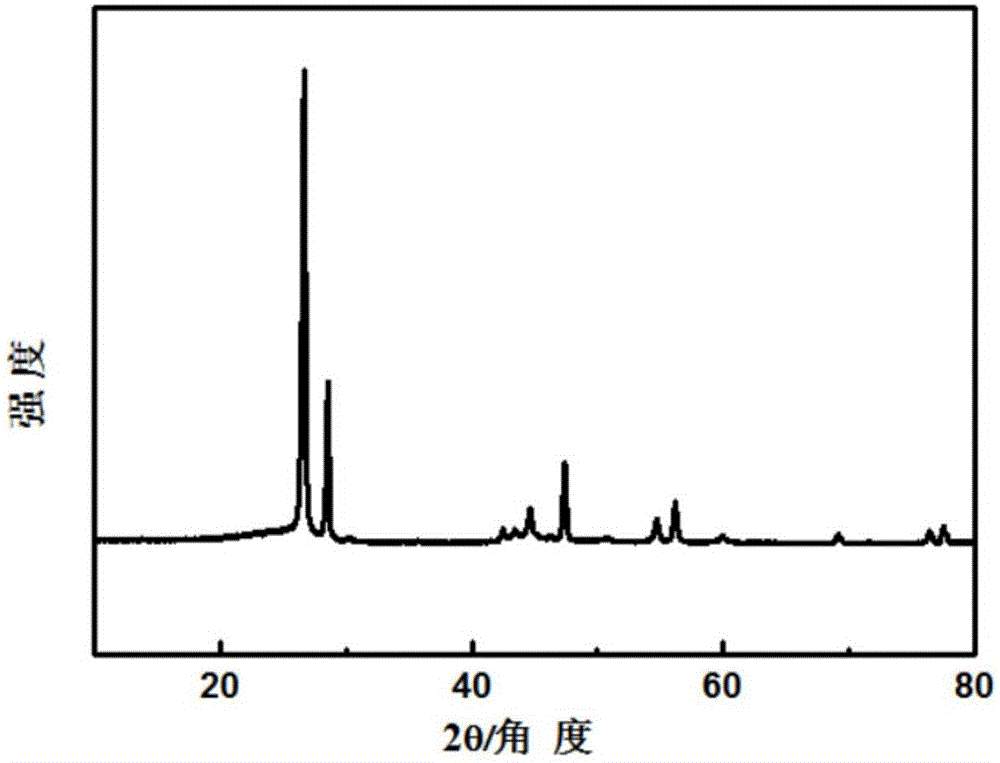

Embodiment 1

[0037] Step 1) Preparation of silicon dispersion: Disperse medium-temperature asphalt and silicon powder in polydimethylsiloxane with a mass ratio of 1:1 as the raw material, organic solvent: raw material ratio of 10:1, ball mill slurry viscosity of 500 -1000Pa·s. Use a ball mill for ball milling. The ball milling is carried out under an inert protective nitrogen atmosphere. During the ball milling, zirconia balls are added. The size of the zirconia balls is 0.1mm. The mass ratio of zirconia balls to pitch and silicon is X=10, and X is the mass of zirconia balls. / (asphalt+silicon) quality, 800rpm ball mill for 2 hours;

[0038] Step 2) Add 5 μm graphite flakes to the dispersion, the amount of graphite flakes added is 20% of the mass of raw material medium-temperature pitch and silicon powder, and further ball milling, adding zirconia balls during ball milling, the size of the zirconia balls is 0.3mm, and the size of the zirconia balls is 0.3mm. The mass ratio of balls to pi...

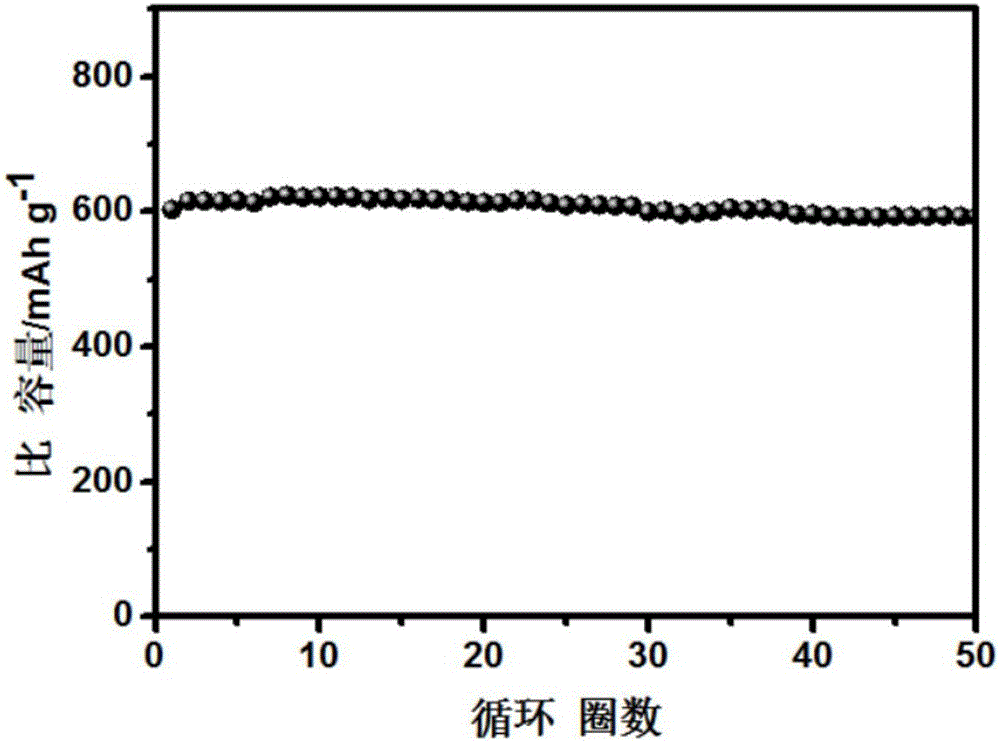

Embodiment 2

[0049] It differs from Example 1 only in that the mass ratio of medium-temperature pitch to silicon powder in step 1) is 2:1, and the carbonization temperature in step 5) is 900°C. .

[0050] The characterization of the silicon-carbon composite material is the same as in Example 1.

[0051] The positive electrode, negative electrode, electrolyte and battery assembly of the battery are the same as in Example 1. The composition of the obtained silicon carbon electrode material and the test results of the battery are listed in Table 1 and Table 2.

Embodiment 3

[0053] It differs from Example 1 only in that the mass ratio of medium-temperature pitch to silicon powder in step 1) is 3:1, and the carbonization temperature in step 5) is 800°C.

[0054] The characterization of the silicon-carbon composite material is the same as in Example 1.

[0055] The positive electrode, negative electrode, electrolyte and battery assembly of the battery are the same as in Example 1. The composition of the obtained silicon carbon electrode material and the test results of the battery are listed in Table 1 and Table 2.

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size | aaaaa | aaaaa |

| specific surface area | aaaaa | aaaaa |

| softening point | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com