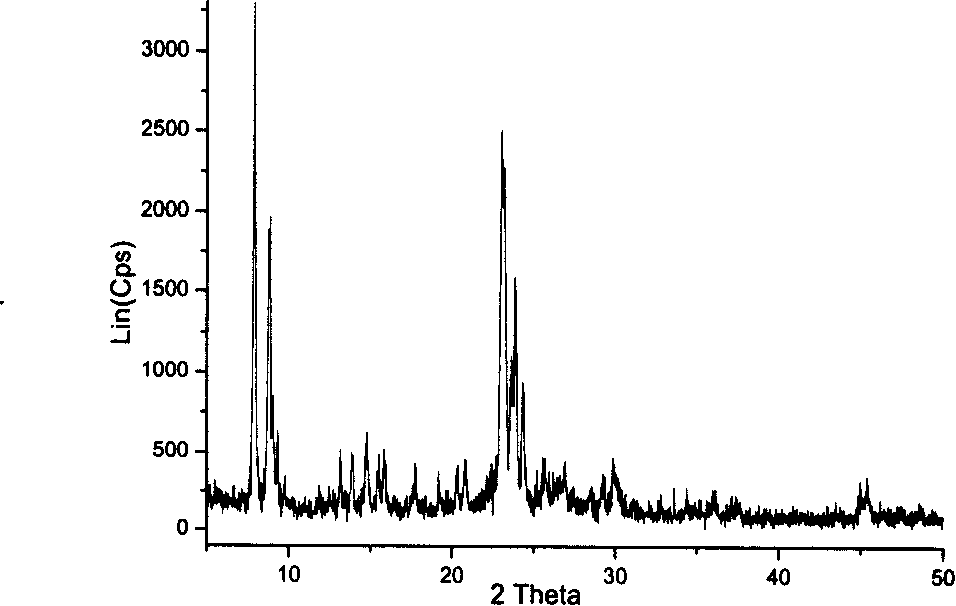

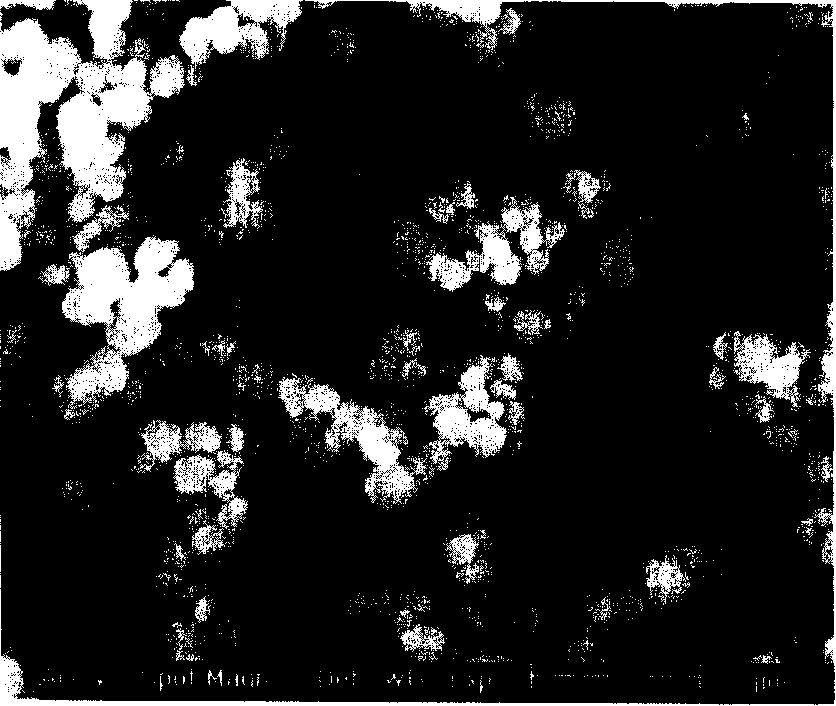

Method for preparing fine grain ZSM-5/mordenite composite molecular sieve

A technology of composite molecular sieve and mordenite, which is applied in molecular sieve catalysts, chemical instruments and methods, hydrocarbon cracking and hydrocarbon production, etc., can solve the problems of low yield of ethylene propylene, large molecular sieve crystals, easy coking, etc., and achieves good catalytic performance, Large specific surface area, the effect of preventing carbon deposition

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0019] Get 1137 grams of sodium metasilicate and dissolve in 1800 grams of deionized water. In addition, 89 grams of aluminum sulfate was dissolved in 350 grams of deionized water, and added into the sodium silicate solution under stirring. After the solution was mixed evenly, 100 g of ethylenediamine was added under stirring. After stirring evenly, the pH value was adjusted to 10.5 with 30% sulfuric acid solution, and then the stirring was continued until uniform. Conventional hydrothermal crystallization was carried out at 160° C. for 15 hours. After washing, the product was dried at 130°C for 4 hours, and then roasted at 550°C for 3 hours to obtain the required seed crystal of the present invention, denoted as M1, and the proportion of the precursor containing ZSM-5 molecular sieve in the seed crystal was about 95%.

Embodiment 2

[0021] According to the method and content provided in Example 2, the sodium metaaluminate addition is changed to 133.4 grams to obtain the required seed crystal of the present invention, which is denoted as M2, and contains the precursor of ZSM-5 molecular sieve in the seed crystal in weight percentage The body ratio is about 85%.

Embodiment 3

[0023] Dissolve 540 g of silica sol in 3000 g of deionized water and add 240 ml of 3 mol / L sodium hydroxide solution until uniform. Then 28.8 g of sodium metaaluminate was added into 1800 ml of deionized water to dissolve, then added to the aforementioned solution and stirred until uniform. Then, 96 grams of n-butylamine and 22 grams of seed crystal M1 were added under stirring. Raw material composition ratio is: SiO 2 : 0.049Al 2 o 3 : 0.1Na 2 O: 0.36M: 82H 2 O: 0.1M1, adjust the pH value of the solution to 11.5 with dilute sulfuric acid. The composite molecular sieve synthesis system was continuously stirred evenly and then conventional hydrothermal synthesis was carried out at 160° C. for 30 hours. The product was filtered and washed, dried at 130°C for 3 hours and then calcined at 550°C for 5 hours. The product was taken out and exchanged for ammonium at 90° C. for 2 hours in 1000 ml of 10% by weight ammonium nitrate solution. The product was filtered, washed, drie...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com