Patents

Literature

196results about How to "Avoid carbon deposits" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Catalyst for preparing arene from synthesis gas through one-step conversion and preparation method of catalyst

ActiveCN106215972AImprove catalytic performanceHigh selectivityHydrocarbon from carbon oxidesMolecular sieve catalystsRare-earth elementMolecular sieve

The invention relates to catalysts, in particular to a catalyst for preparing arene from synthesis gas through one-step conversion and a preparation method of the catalyst. The catalyst is prepared from, by mass, 30%-70% of zirconium-containing perovskite, 30%-60% of multistage porous zeolite molecular sieve and 0.1%-10% of oxide additive. The preparation method comprises the steps that 1, a salt compound of at least one of IA, IIA, VB, VIB, VIIB, IIB and IVA family elements and rare earth elements is weighed according to the components of the catalyst and added into water or alcohol to be prepared into a solution A; the multistage porous zeolite molecular sieve is weighed and added into the solution A, suction filtration, washing and filter cake drying are carried out to obtain solid powder, then the solid power and the zirconium-containing perovskite are mixed, ground and calcined, hydrogen or mixed gas of hydrogen and inert gases is introduced, heating is carried out for reduction, the reduced solid sample is tablet molded, and the catalyst is prepared.

Owner:XIAMEN UNIV

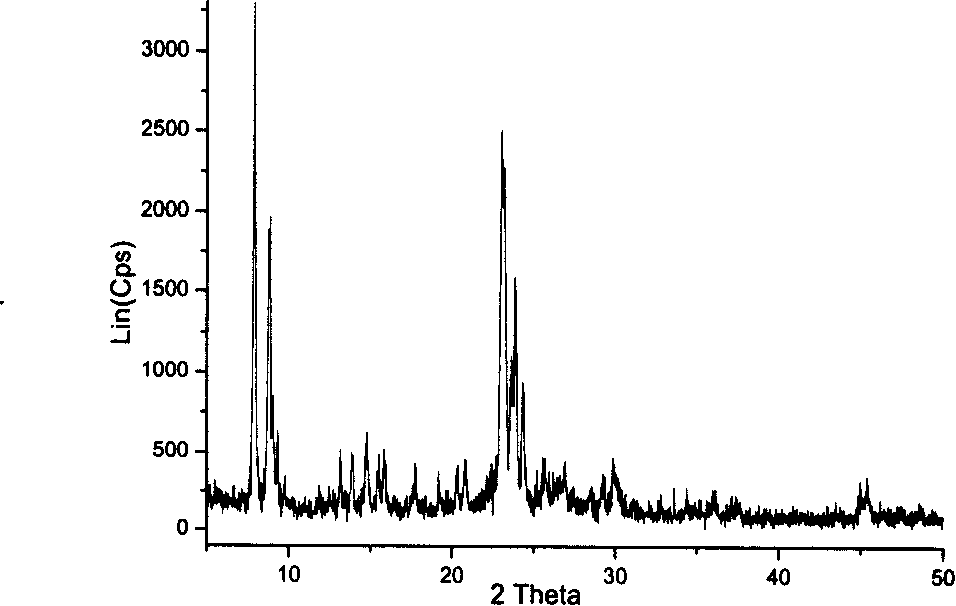

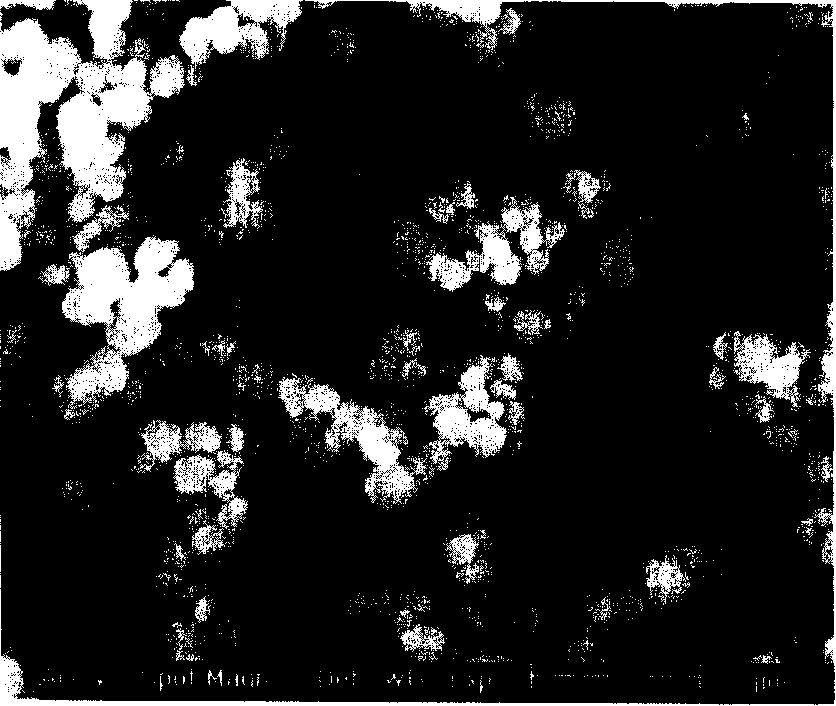

Method for preparing fine grain ZSM-5/mordenite composite molecular sieve

ActiveCN101190418ALarge specific surface areaSmall specific surface areaMolecular sieve catalystsBulk chemical productionNaphthaMordenite

The invention relates to the preparation method of a small crystal ZSM-5 / mordenite composite molecular sieve, mainly solving the problems in the existing preparation process of ZSM-5 / mordenite composite molecular sieve of bigger crystal of the composite molecular sieve, low catalytic activity and fast activity loss in the reaction in which ethene and propylene are prepared by the catalyzing and cracking of naphtha. The invention well resolves the problems by adopting the technical proposal that the ZSM-5 with decent silica alumina ratio and the crystal seed of mordenite is added in the synthetic process of the molecular sieve and the PH value of the molecular sieve raw material solution system is adjusted to 9-14 in the preparation process. The ZSM-5 / mordenite composite molecular sieve prepared by the method can be applied in the industrial production, in which ethene and propylene are prepared by the catalyzing and cracking of naphtha.

Owner:CHINA PETROLEUM & CHEM CORP +1

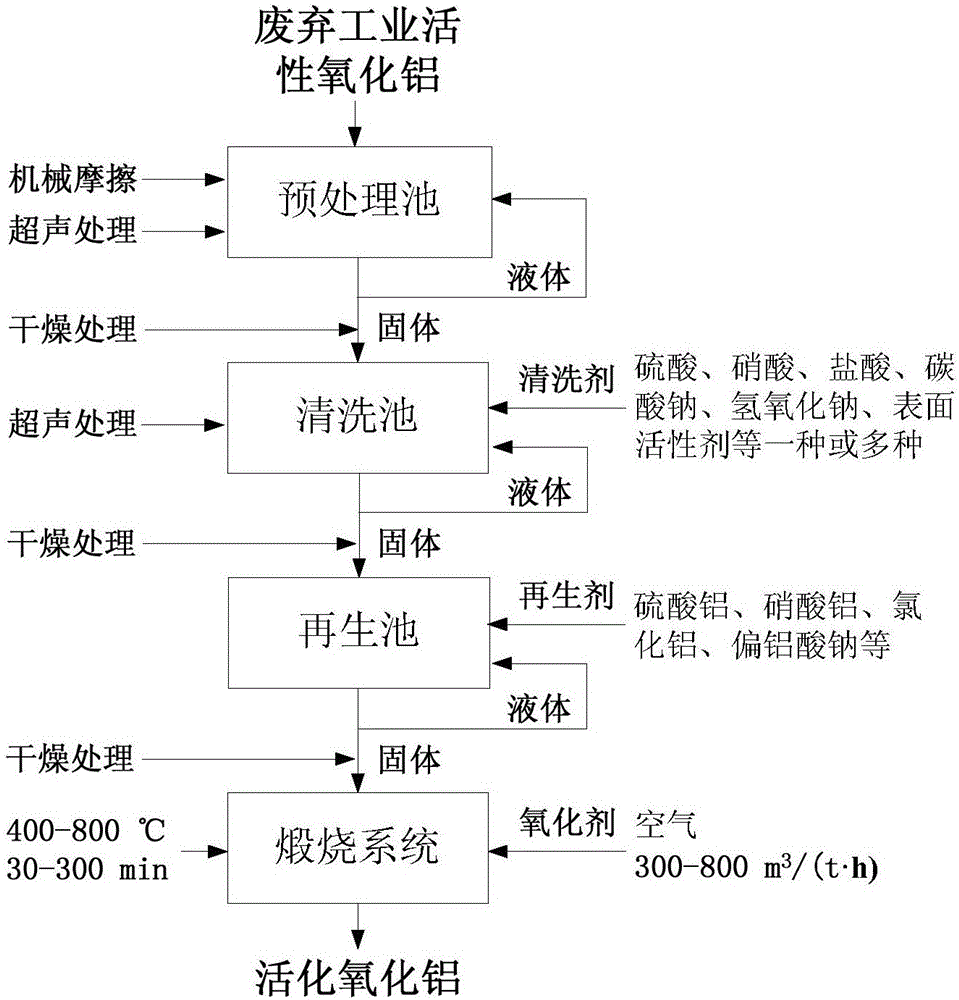

Method for activating and regenerating waste industrial activated aluminum oxide

ActiveCN106629796AHigh pore volumeRealize resource utilizationOther chemical processesAluminates/aluminium-oxide/aluminium-hydroxide purificationAir atmosphereActivated Aluminum Oxide

The invention discloses a method for activating and regenerating waste industrial activated aluminum oxide. The method comprises pretreatment, cleaning liquid impregnation treatment and regeneration treatment; adopted cleaning liquid is selected from at least one of acid liquor and alkali liquor and surfactant solution; the regeneration treatment comprises regenerated liquid impregnation and calcination treatment, and adopted regenerated liquid is selected from aluminum-contained solution; the calcination treatment is performed under air atmosphere, and air inlet amount is 300 to 800 m<3> / (h.t). According to the method for activating and regenerating the waste industrial activated aluminum oxide provided by the invention, an original pore structure channel is dredged through a physical and chemical method, and a new pore structure is regenerated on the basis of the existing pore structure to obtain activated aluminum oxide with high specific surface area and high pore volume.

Owner:杭州贝采催化剂有限公司 +1

Mesoporous carbon-supported composite metal oxide catalyst and preparation method thereof

InactiveCN102485331AIncrease surface areaLarge apertureHydrocarbonsMetal/metal-oxides/metal-hydroxide catalystsMesoporous carbonCarbon deposition

The invention discloses a mesoporous carbon-supported composite metal oxide catalyst and a preparation method thereof. Compared with the prior art, the mesoporous carbon-supported composite metal oxide catalyst has a high specific surface area and a large aperture size, is conducive to rapid diffusion of reactants and products in an aperture channel, avoids deep oxidation, coking and carbon deposition, and has good catalyst activity and a long catalyst life.

Owner:CHINA PETROLEUM & CHEM CORP +1

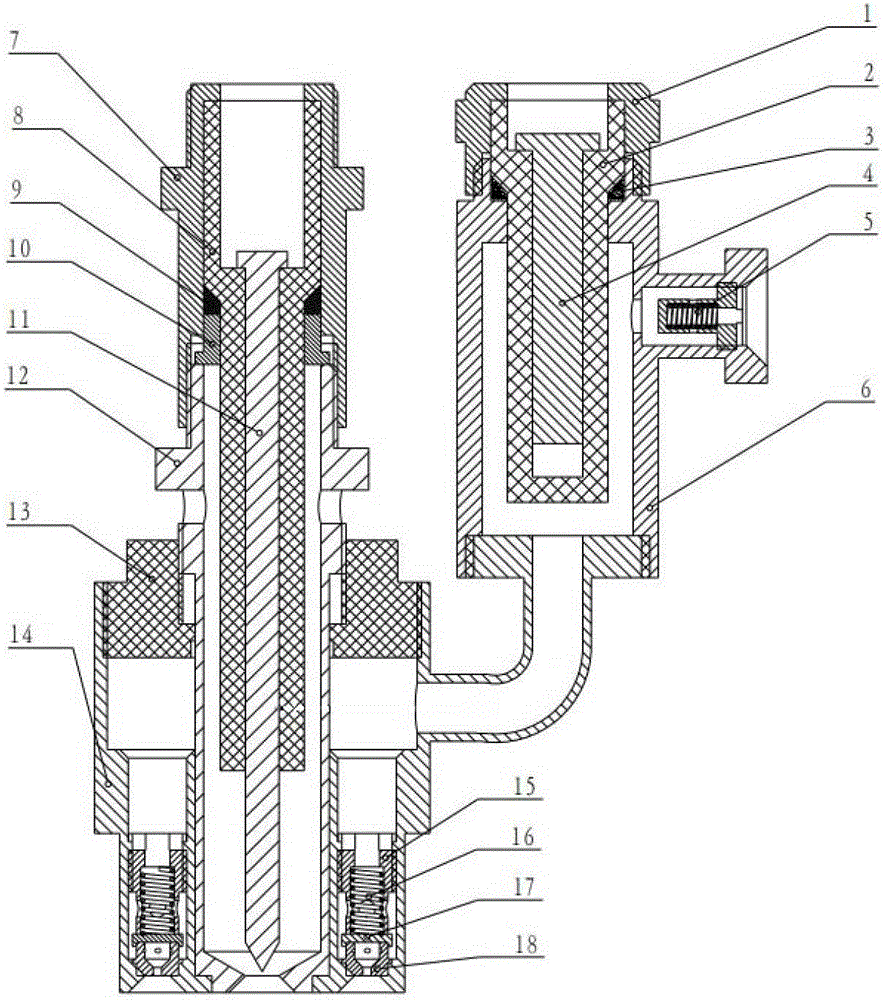

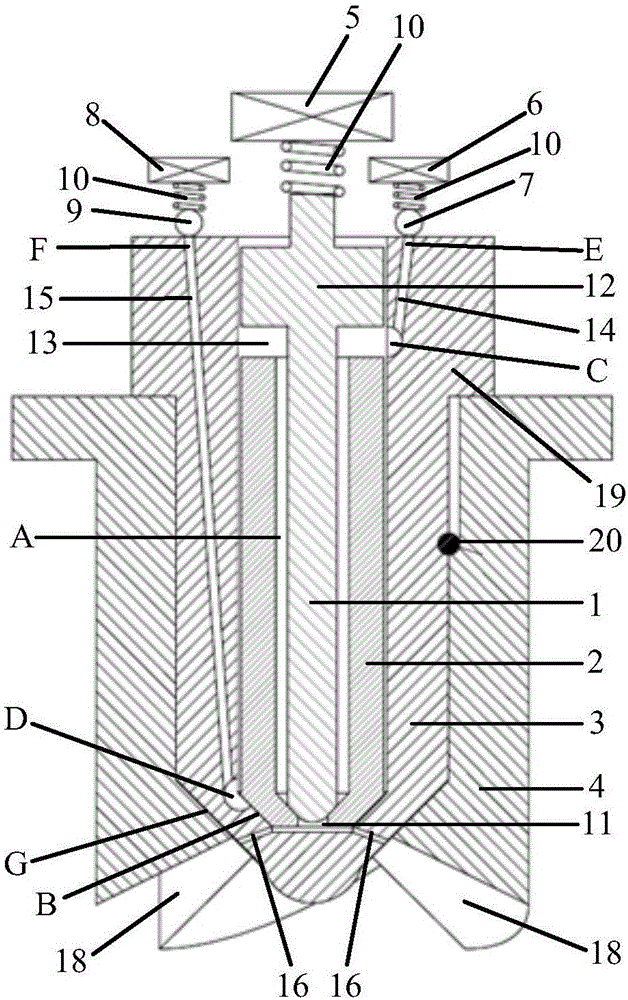

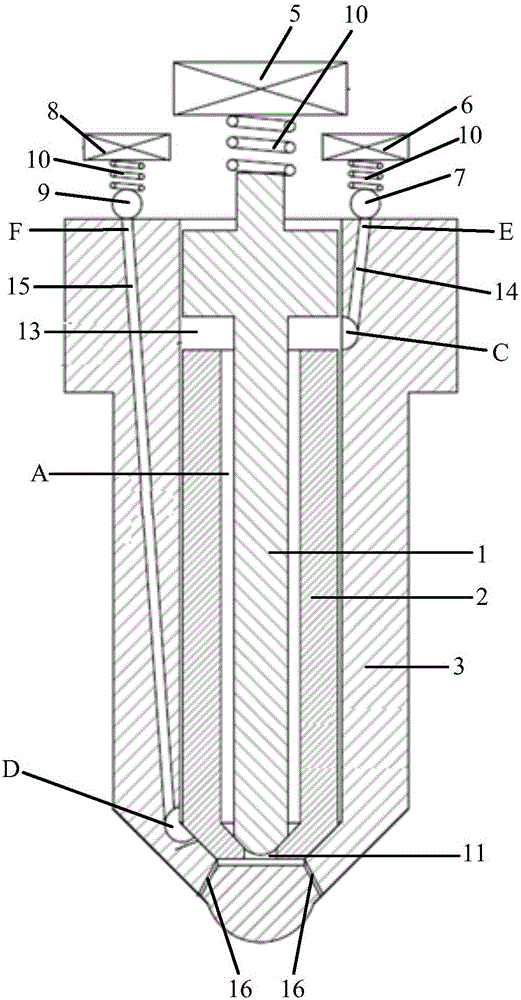

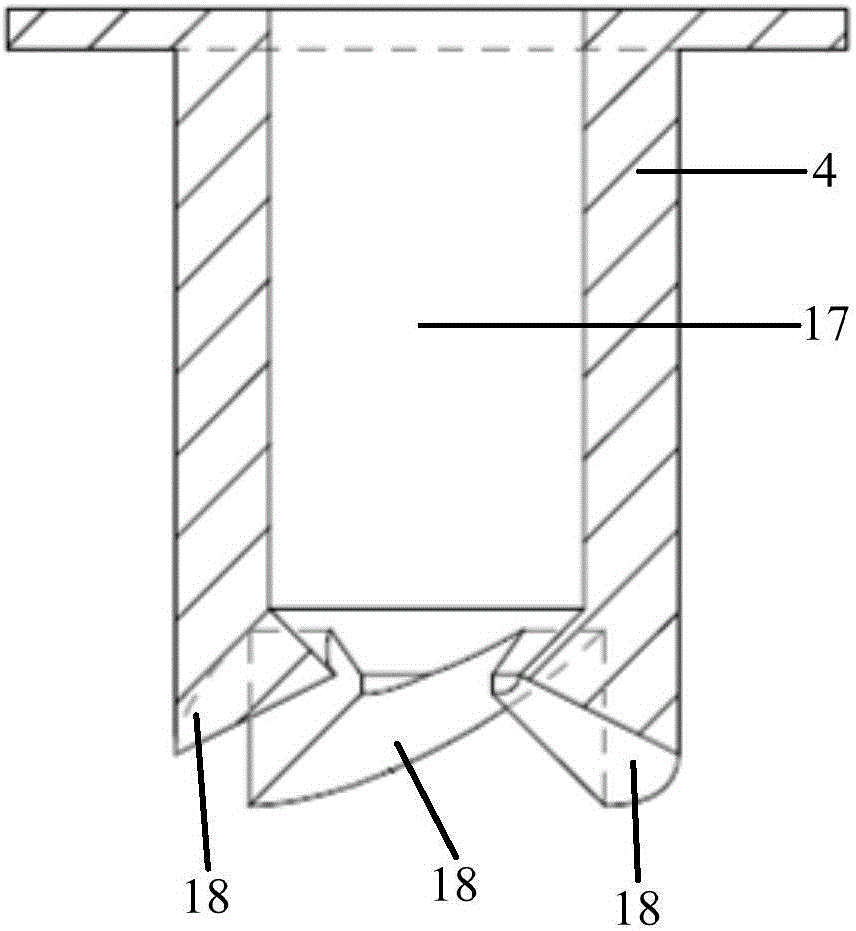

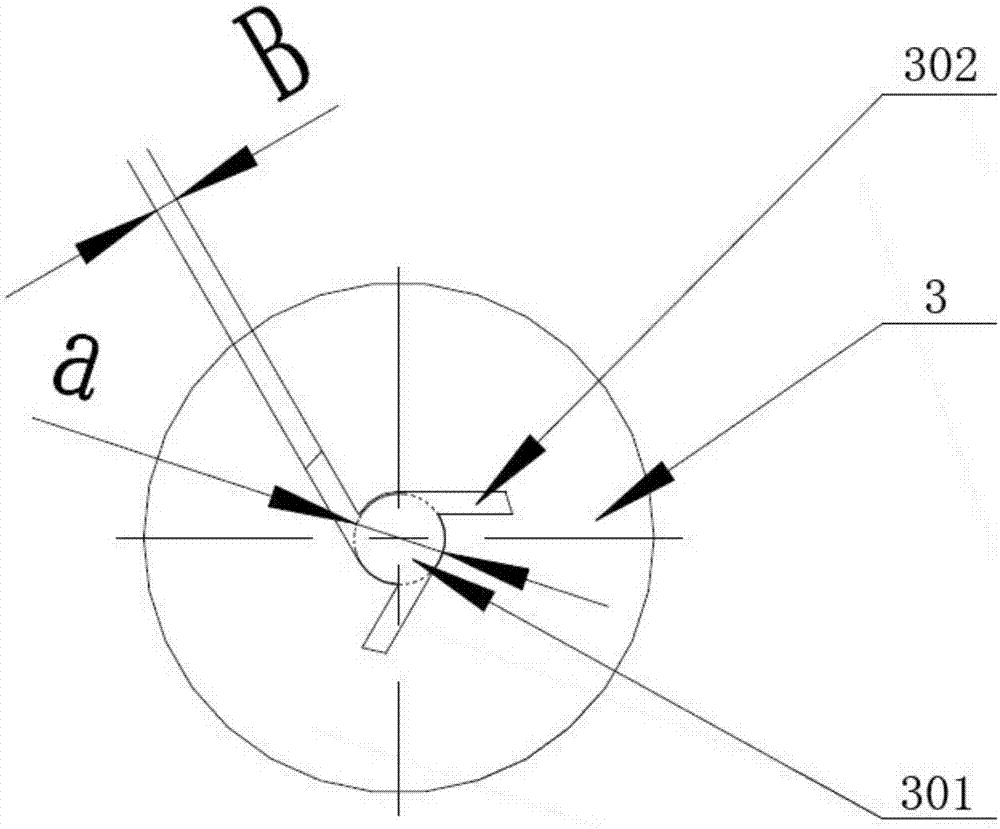

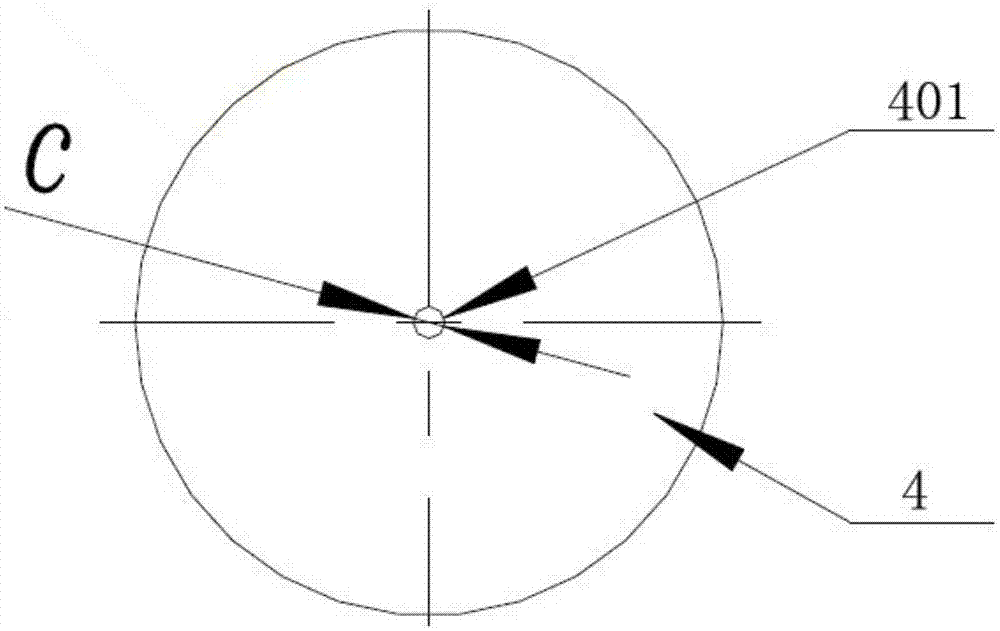

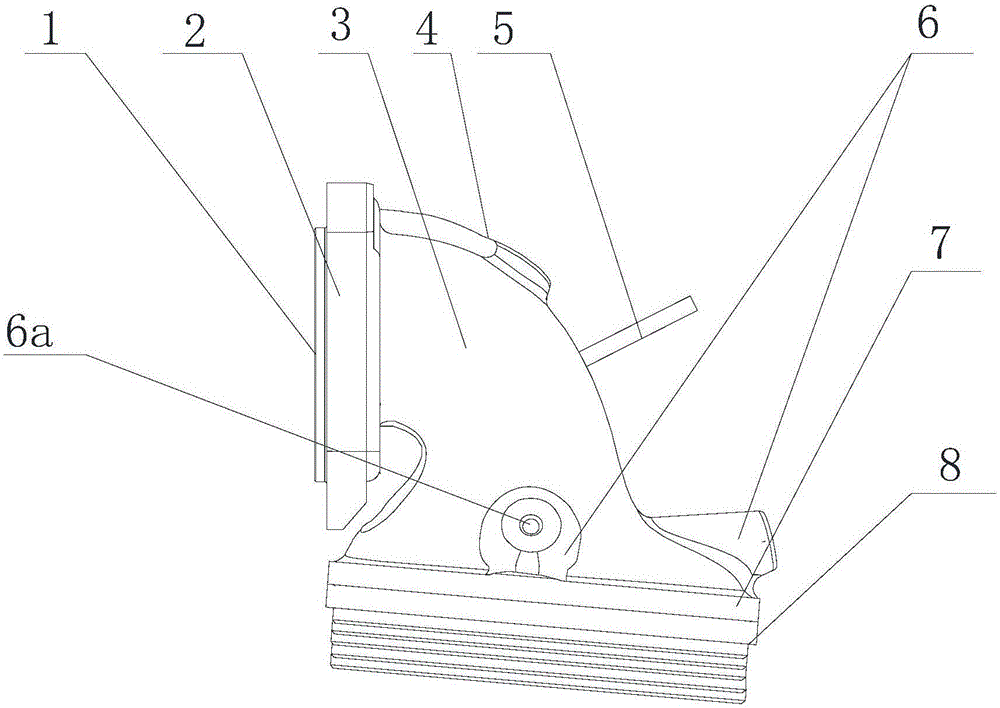

Plasma catalysis ignition integrated nozzle

InactiveCN102980209AGood drop spectrumLower activation energyContinuous combustion chamberPlasma jetCombustion chamber

The invention provides a plasma catalysis ignition integrated nozzle which is a plasma assisted atomization and plasma ignition integrated nozzle formed by a low-temperature plasma discharge assembly, a fuel pressure atomization nozzle assembly and a high-energy plasma ignition assembly. A barrier medium uniformly discharges to ensure that a liquid fuel partially pyrolyzes to generate a large quantity of gas activated components, so that a gas-liquid coexisting plasma microcell is formed, fuel activation energy and ignition energy are reduced, physical conditions of gas assisted atomization are formed, and atomization effect is improved. A plasma ignitor is arranged on the middle of a multi-point nozzle and is positioned in a combustion chamber low-pressure region, plasma and fuel atomized particles are well mixed to generate a chemical reaction, and a stable high-temperature ignition core is easily formed. Ignition is directly carried out by adopting a plasma jet, and because the plasma jet has special discharge characteristics and larger discharge energy and is highly concentrated in energy, the ignition reliability and the ignition concentration limit of a gas turbine are greatly improved. The plasma catalysis ignition integrated nozzle can be applied to a combustion chamber of the gas turbine.

Owner:三亚哈尔滨工程大学南海创新发展基地

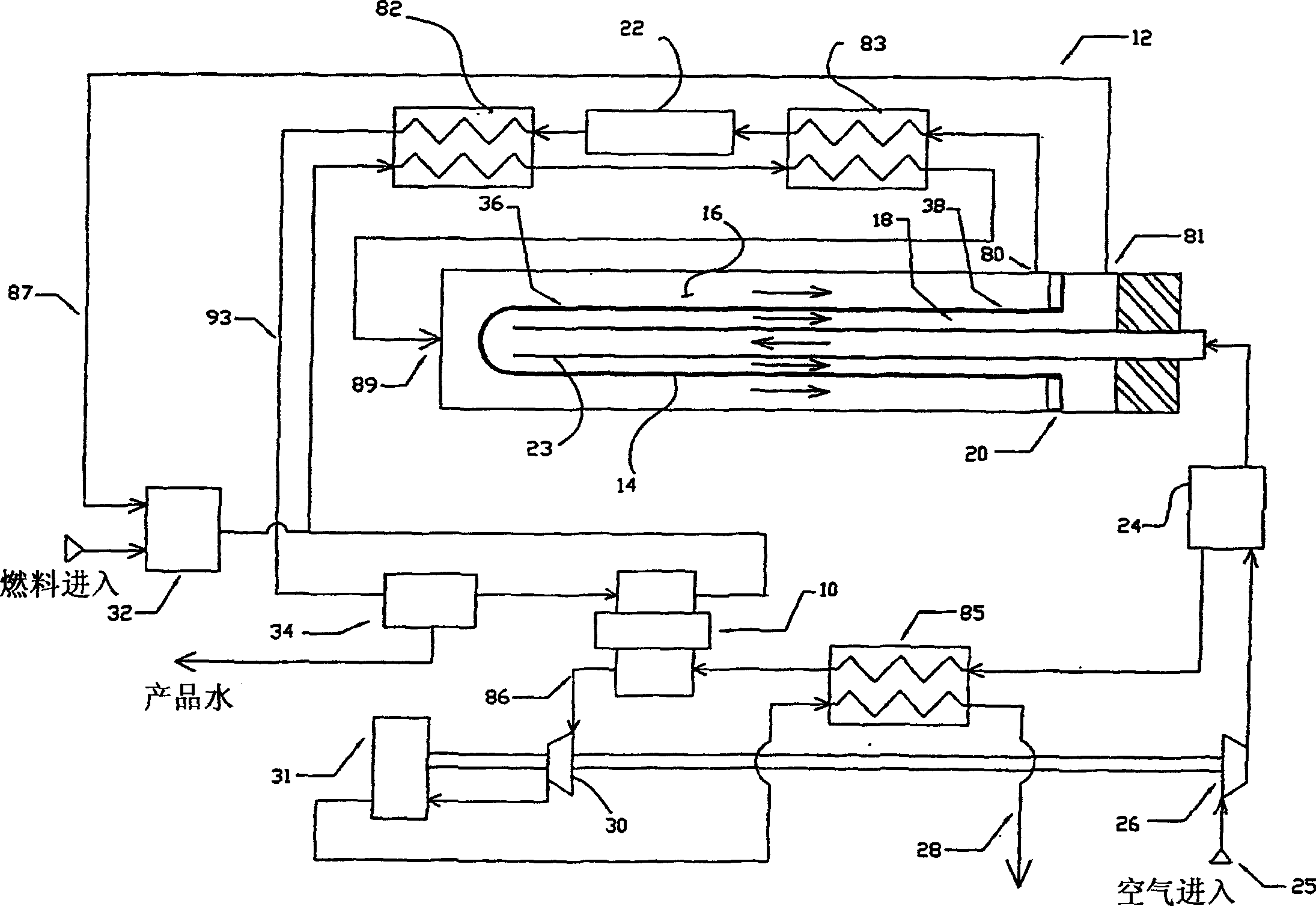

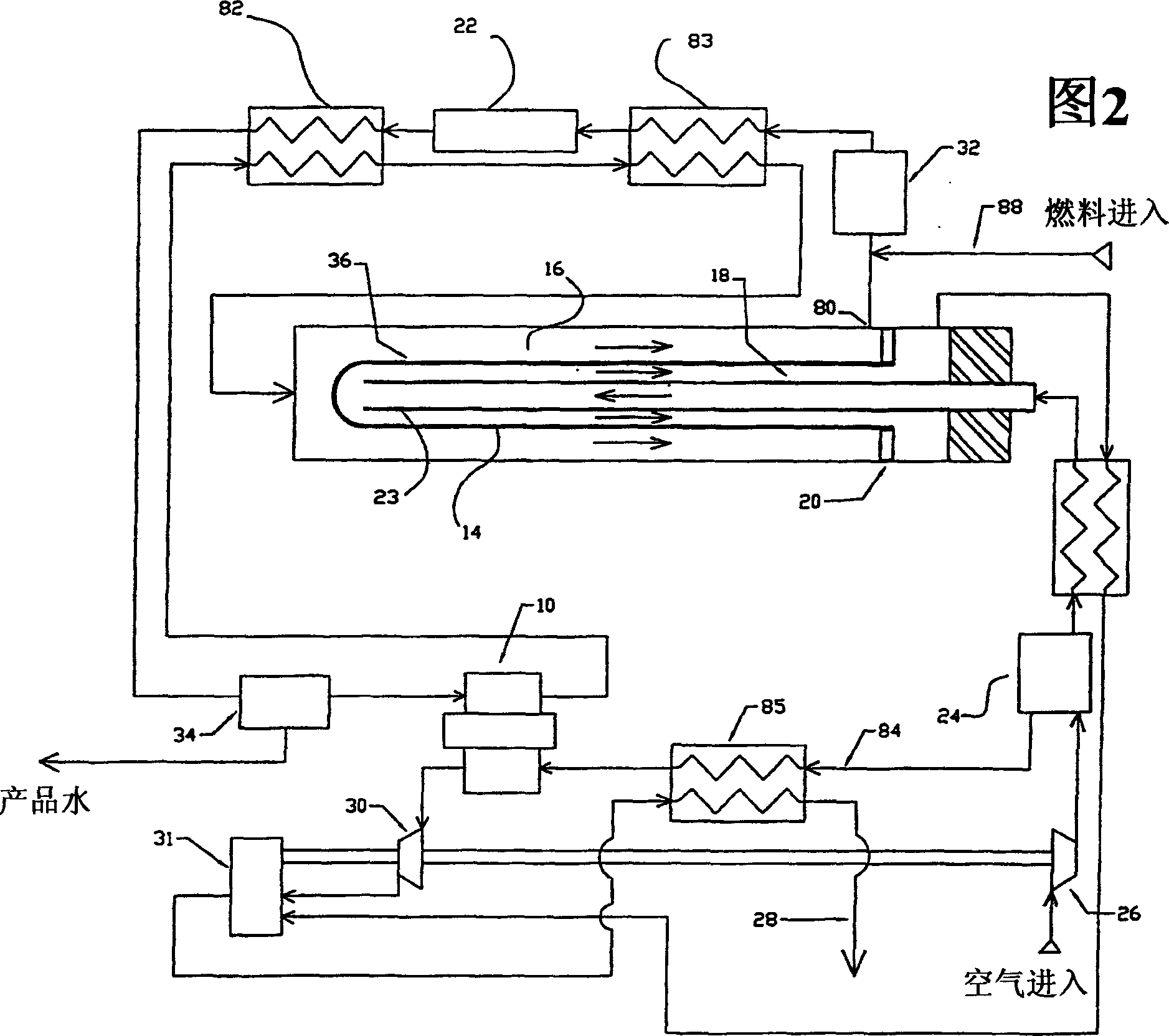

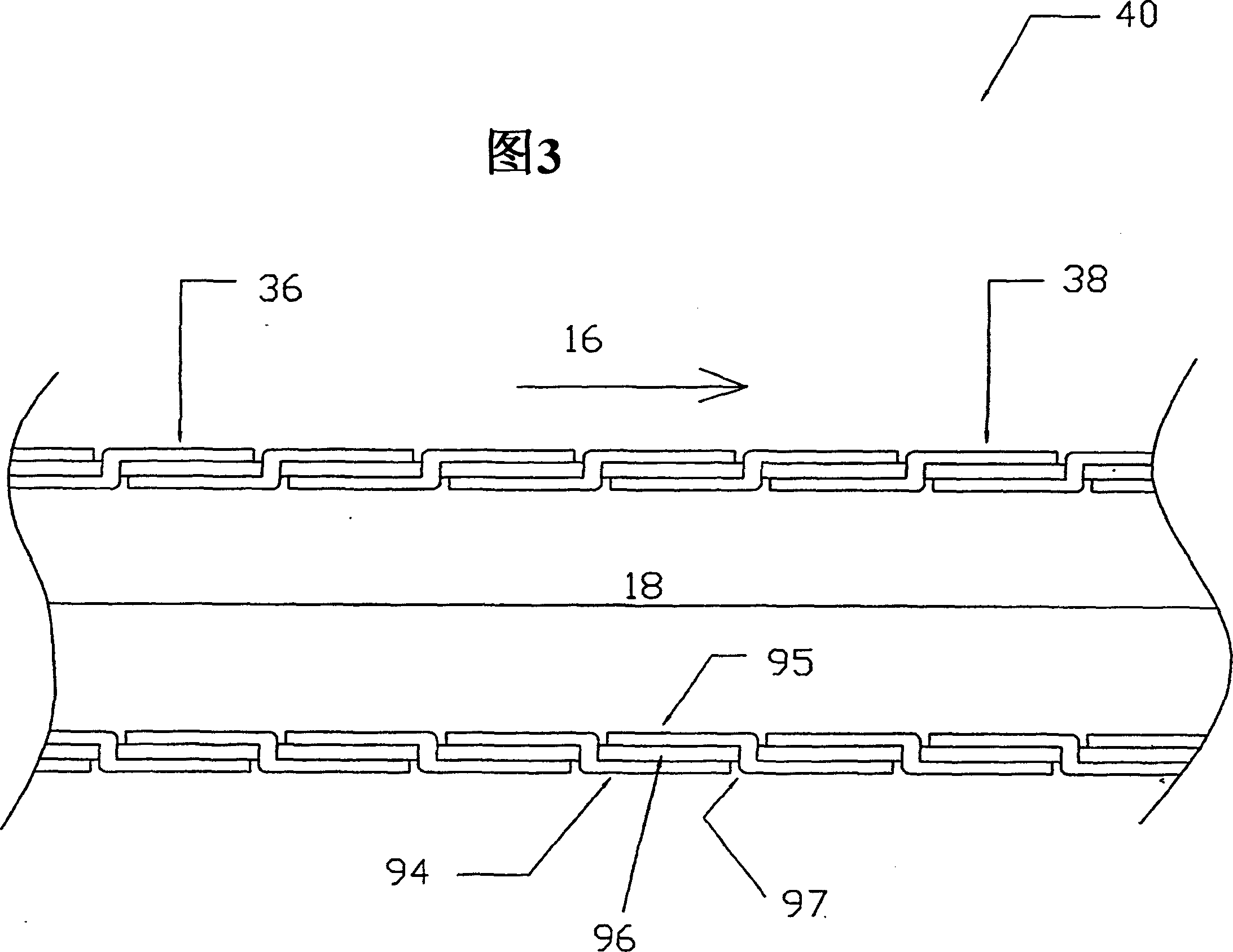

Solid oxide fuel cell systems

Enhanced high temperature fuel cell systems, such as solid oxide fuel cell systems and molten carbonate fuel cell systems are disclosed. Embodiments of the disclosure include solid oxide and molten carbonate fuel cell systems incorporating gas separation apparati facilitating the recycle of hydrogen fuel from fuel cell anode exhaust for supply to the fuel cell anode inlet. Further embodiments of the disclosure include solid oxide and molten carbonate fuel cell systems incorporating inventive combinations of anode materials conducive to combination with enriched hydrogen fuel. Other embodiments of the disclosure include gas separation apparatus for providing enriched oxygen feed to the cathode inlet of solid oxide and molten carbonate fuel cells.

Owner:QUSIR TECH

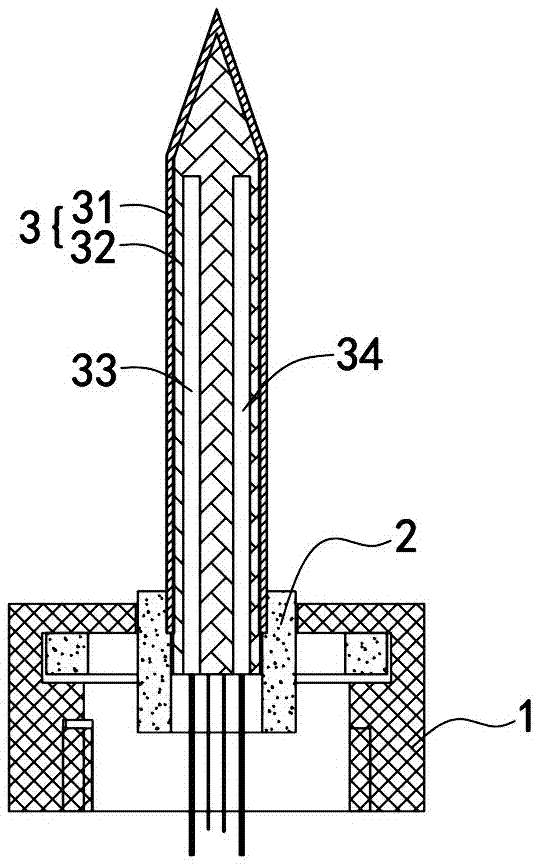

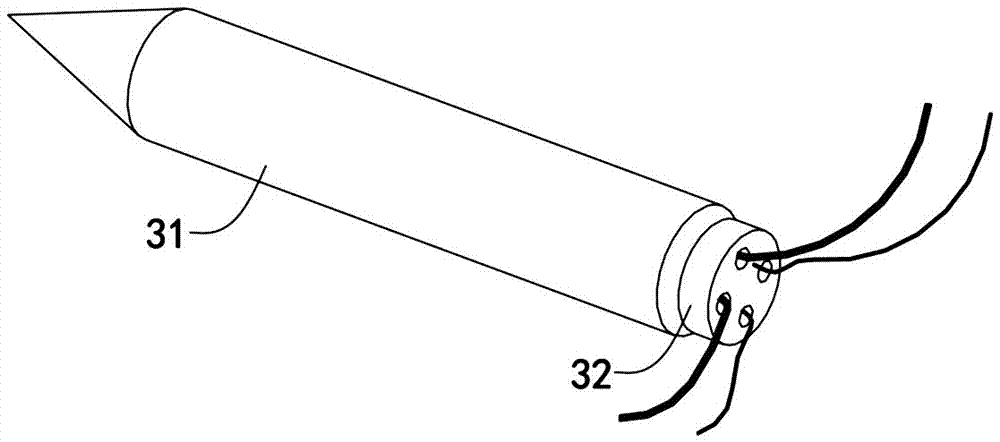

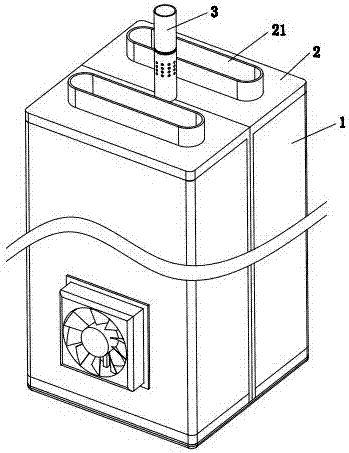

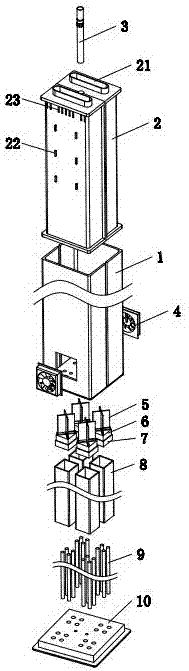

Circumferential heating type baking needle used for electronic cigarette and electronic cigarette

InactiveCN107252139AEvenly bakedQuick installationHeater elementsTobacco devicesEngineeringElectronic cigarette

The invention discloses a circumferential heating type baking needle used for an electronic cigarette and the electronic cigarette. The circumferential heating type baking needle used for the electronic cigarette comprises a baking needle head internally provided with an heating element, the exterior of the baking needle head is plated with a non-stick coating, the non-stick coating is a teflon non-stick coating or a teflon non-stick nano coating, a fixed support and a ceramic base are arranged on the baking needle head, the ceramic base is fixed in the fixed support, and the braking needle head is fixedly inserted into the ceramic base; the circumferential heating type baking needle used for the electronic cigarette is arranged in the electronic cigarette. The circumferential heating type baking needle used for the electronic cigarette and the electronic cigarette have the advantages that baking heating is uniform, installation is easy and rapid, the cigarette flavor is more mellow, tar and nicotine in the cigarette are reduced, health and hygiene are achieved, carbon deposition does not exit in use, and energy conservation and environmental protection are achieved.

Owner:SHENZHEN BUDDY TECH DEV CO LTD

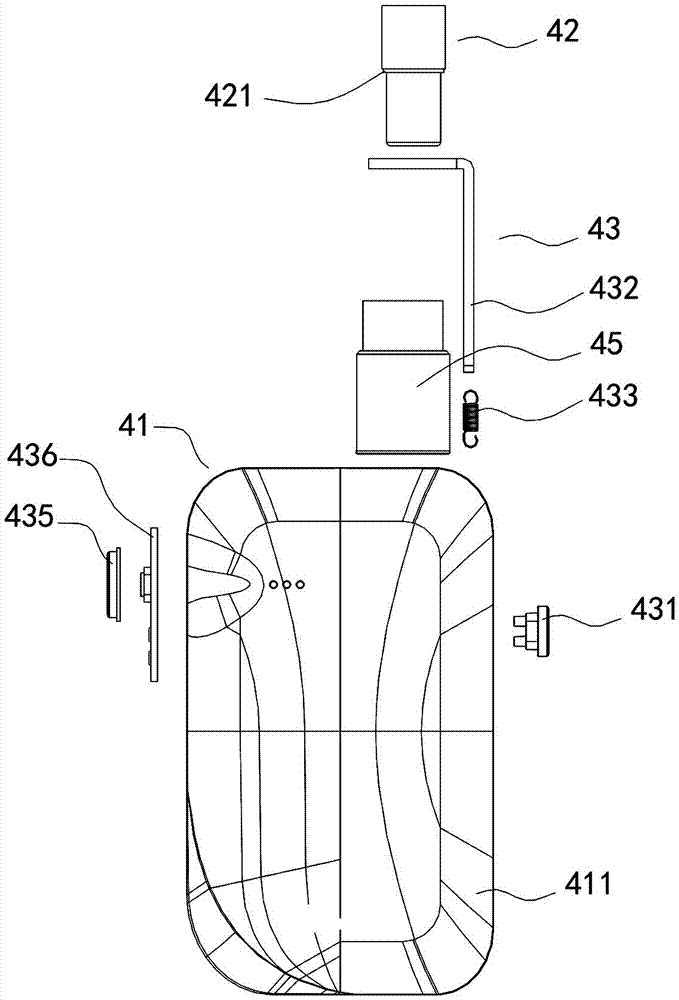

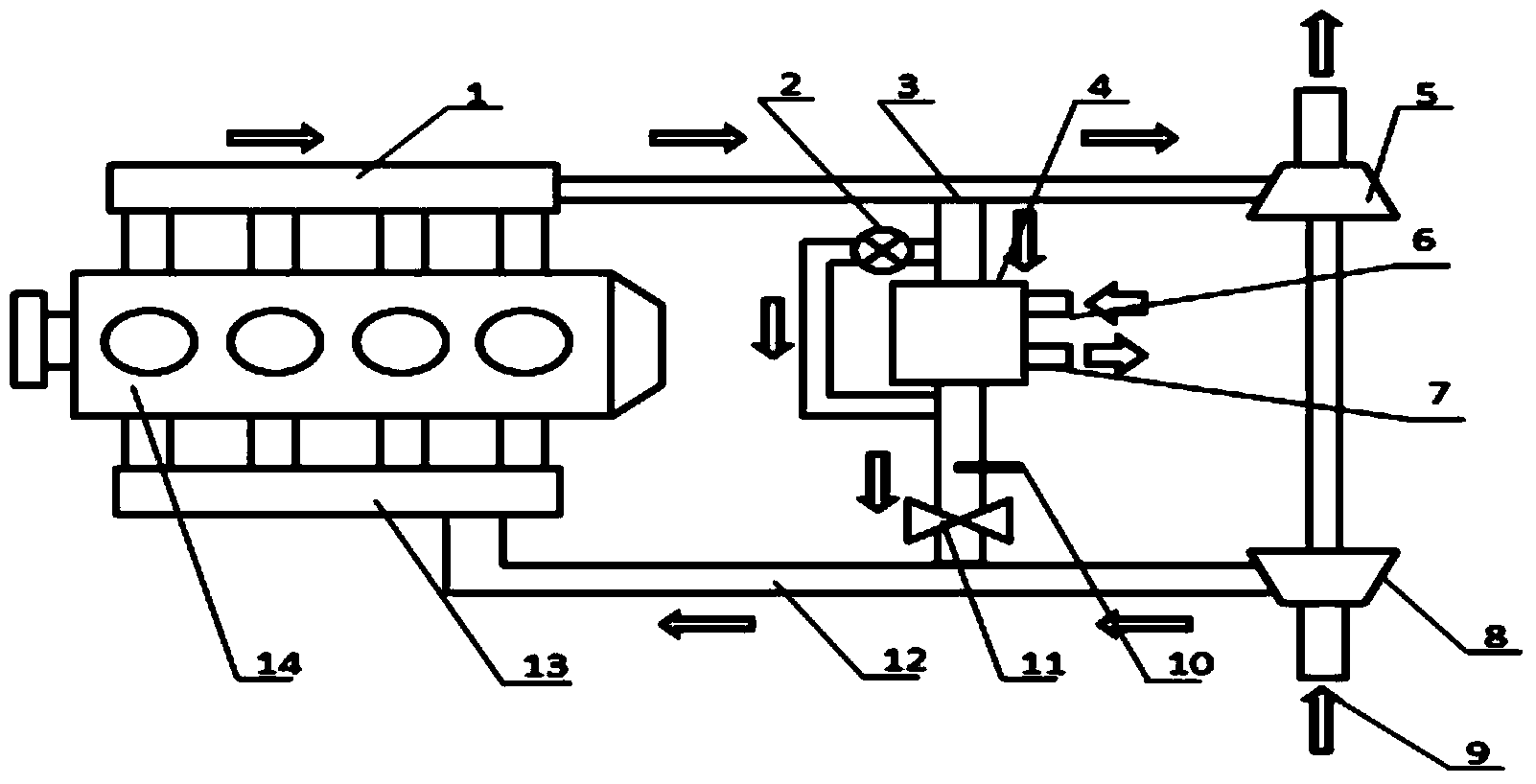

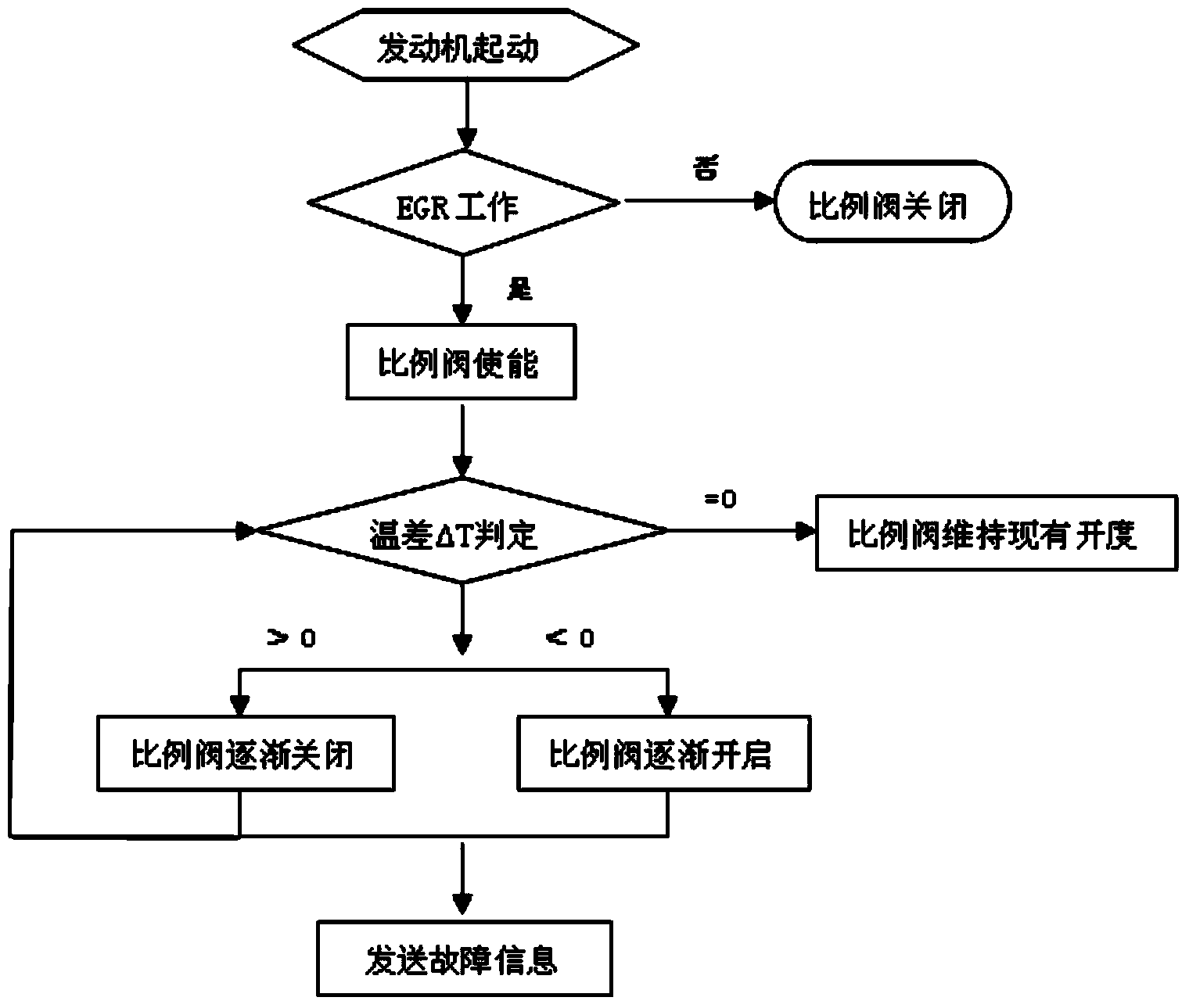

Engine EGR (Exhaust Gas Recirculation) system

InactiveCN103485937ASimple structureAvoid carbon depositsInternal combustion piston enginesNon-fuel substance addition to fuelExhaust fumesExhaust gas recirculation

The invention discloses an engine EGR (Exhaust Gas Recirculation) system, comprising an EGR cooler, an EGR valve, a by-pass line and a temperature sensor, wherein the EGR valve is communicated with the gas outlet end of the EGR cooler; the by-pass line is connected with the EGR cooler in parallel; an exhaust gas flow control proportional valve which is connected with an ECU (Engine Control Unit) in a controlling way is mounted at the inlet of the by-pass line; the temperature sensor is arranged between the outlet of the by-pass line and the EGR valve and is taken as an input end used for collecting the valve inlet exhaust gas temperature of the EGR valve by the ECU. The engine EGR system is simple in structure; the by-pass line which is connected with the EGR cooler in parallel and is provided with the proportional valve is adopted; the temperature of the valve inlet exhaust gas entering the EGR valve is adjusted by adjusting the opening proportion of the proportional valve; the EGR valve inlet exhaust gas temperature is controllable under all operating working conditions of an engine; the EGR system is free of carbon deposition and gum deposit; therefore the temperature of the mixed gas entering an engine cylinder can be well controlled; the optimal states of engine performance and discharge are realized; the cooling efficiency of the EGR cooler is monitored in real time, so that the reliability of a product is ensured.

Owner:GUANGXI YUCHAI MASCH CO LTD

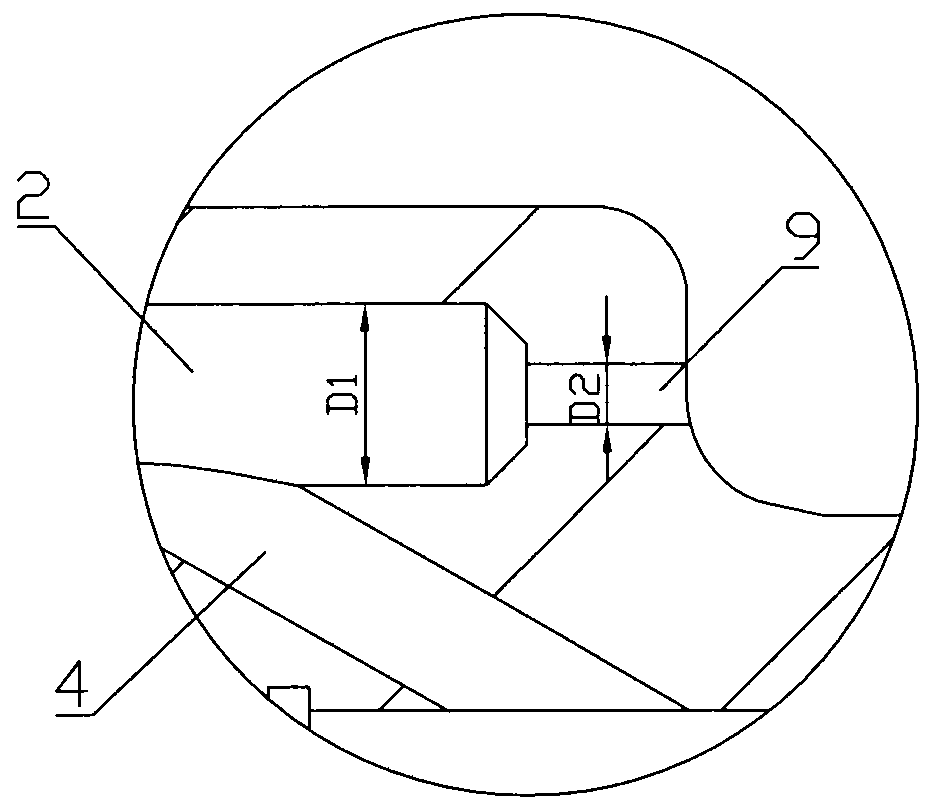

Close-range collision type double-fuel engine nozzle component

InactiveCN106837639AEmission reductionImprove atomization effectMachines/enginesSpecial fuel injection apparatusClose rangeNeedle valve

The invention relates to a close-range collision type double-fuel engine nozzle component and belongs to the technical field of engine nozzles. The close-range collision type double-fuel engine nozzle component comprises a needle valve, a sleeve valve, a nozzle body, a collision sleeve, a needle valve electromagnet, a first fuel channel electromagnet, a first ball valve, a second fuel channel electromagnet, a second ball valve and a spring, wherein the needle valve is located in the sleeve valve, and the sleeve valve is provided with a fuel outlet; the nozzle body is provided with a first mounting groove, a first fuel channel and a second fuel channel, the conical face of the first mounting groove is in tight contact with the conical face on the outer surface of the sleeve valve, the first ball valve is arranged at the inlet of the first fuel channel, and the second ball valve is arranged at the inlet of the second fuel channel; the nozzle body is provided with a conical face, the conical face of the nozzle body is provided with a spray hole, and the spray hole is communicated with the first mounting groove; the collision sleeve is provided with a second mounting groove, the nozzle body is mounted in the second mounting groove, and the collision sleeve is provided with a collision platform. The close-range collision type double-fuel engine nozzle component can improve a collision spray effect, avoid the generation of a wall-face oil film and accumulated carbon, and lower soot discharge quantity.

Owner:SHENYANG AEROSPACE UNIVERSITY

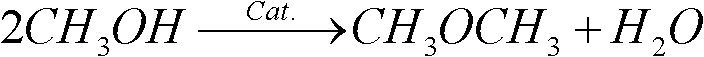

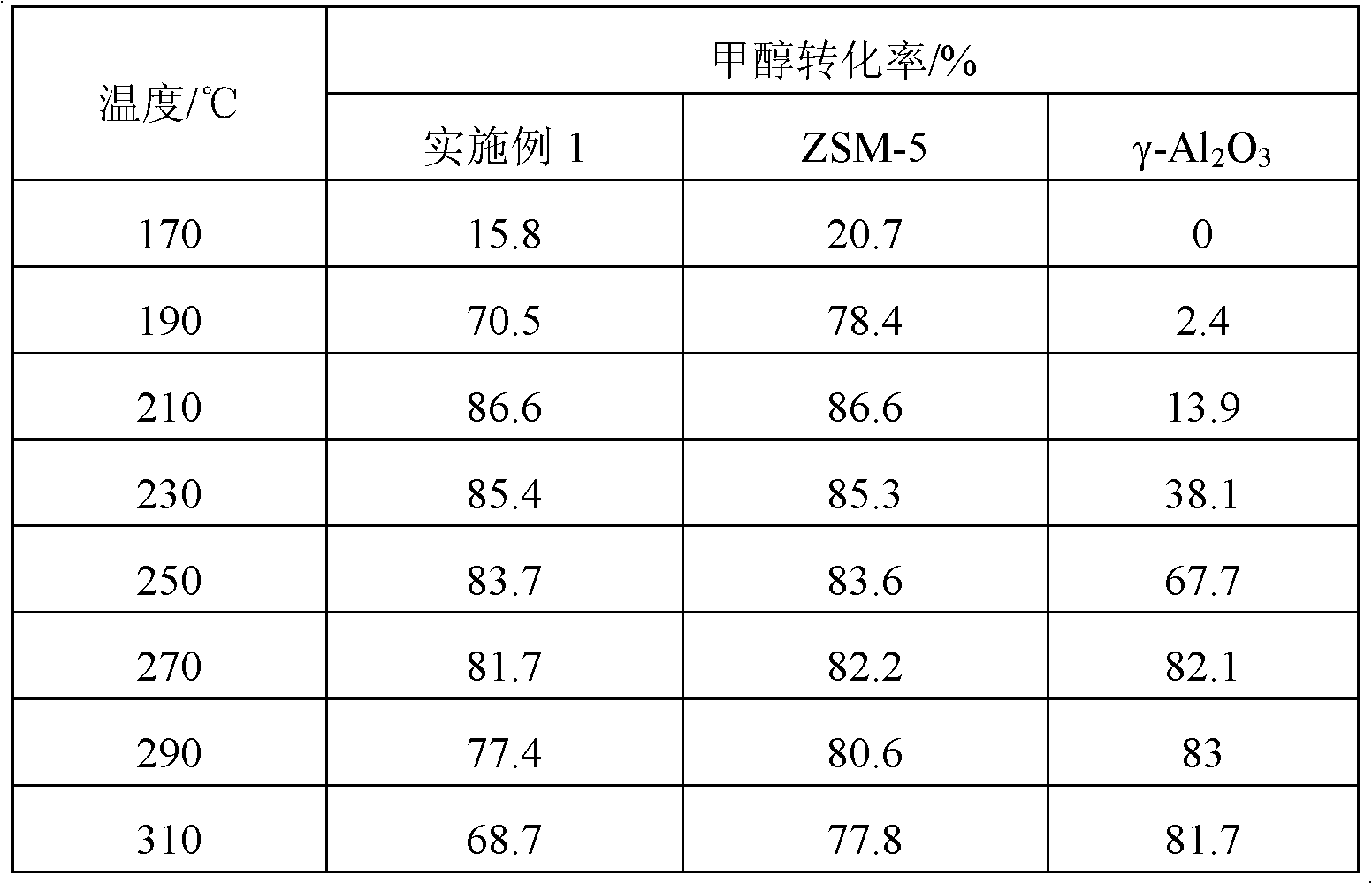

Catalyst for preparing dimethyl ether by methanol and preparation method thereof

InactiveCN102671690AReduced activityImprove stabilityFerrierite aluminosilicate zeoliteMolecular sieve catalystsMolecular sieveSurface layer

The invention discloses a preparation method of a catalyst for preparing dimethyl ether by methanol. The method comprises the following steps: firstly, dissolving a template agent in strong alkaline solution, and adding microporous molecular sieves to be dipped so as to obtain mixed liquor, secondly, performing primary crystallization and cooling on the mixed liquor, adjusting the pH of the mixed liquor to be 6 to 11, performing secondary crystallization on the mixed liquor, and then filtering, washing and drying the mixed liquor so as to obtain dried solid powder, and thirdly, performing ammonium ion exchange, washing and drying on the solid powder in ammonium salt solution, and calcining to remove the template agent and NH3 so as to obtain the catalyst. The catalyst for preparing dimethyl ether by methanol disclosed by the invention is based on cellular material, adopts strong base to dissolve material to partly destroy microcellular structures, then performs hydrothermal reconstruction in the condition that quaternary ammonium salt template agent exists, so as to form mesoporous structure and obtain the hierarchical pore structure catalyst containing millipore and mesopore. According to the catalyst, the microcellular structures are kept, the activity decline of the catalyst is prevented, hollow structures are formed, products can be separated from the surface layer of the catalyst conveniently, and carbon distribution is prevented. According to the preparation method, the stability, the activity and the selectivity of the catalyst are improved.

Owner:HENAN UNIV OF SCI & TECH

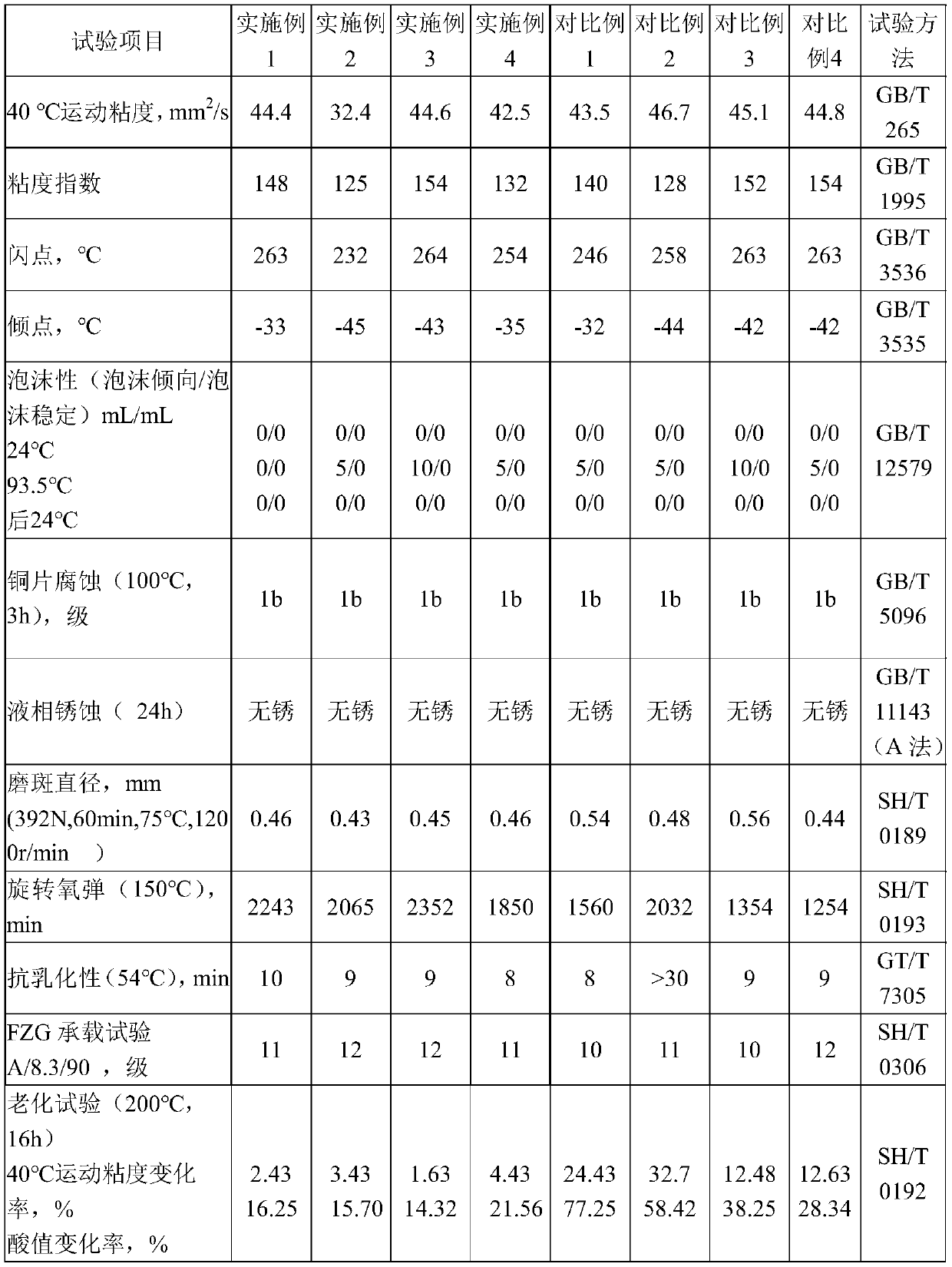

Long-life air compressor oil composition

InactiveCN111234906AInhibition of viscosity growthGood extreme pressure and anti-wear propertiesLubricant compositionProcess engineeringBase oil

The invention discloses a long-life air compressor oil composition. The long-life air compressor oil composition comprises the following components in percentage by weight: 0.6-1.5% of an ashless composite additive, 0.3%-1.0% of an antioxidant, 0.1%-0.5% of an extreme pressure anti-wear agent, and 0.002% to 0.005% of an anti-foaming agent, with the balance being base oil, wherein the base oil comprises a mixture of III-type hydrogenated base oil and alkyl naphthalene base oil or polyether base oil. The air compressor oil provided by the invention has excellent high-temperature detergency and oxidation resistance, and can effectively avoid the generation of oil sludge and carbon deposit; excellent wear resistance and hydrolytic stability are achieved, and excellent wear resistance protection is provided for the air compressor; the excellent heat conduction efficiency can help to reduce the temperature and oil temperature of the compressor; and the oil change period is long and can reach6000 hours or above. In addition, compared with known long-life air compressor oil, the air compressor oil has the advantages of being low in cost, simple in preparation method, easy to popularize and apply on a large scale and the like.

Owner:LONGPAN LUBRICATION NEW MATERIAL TIANJIN CO LTD +1

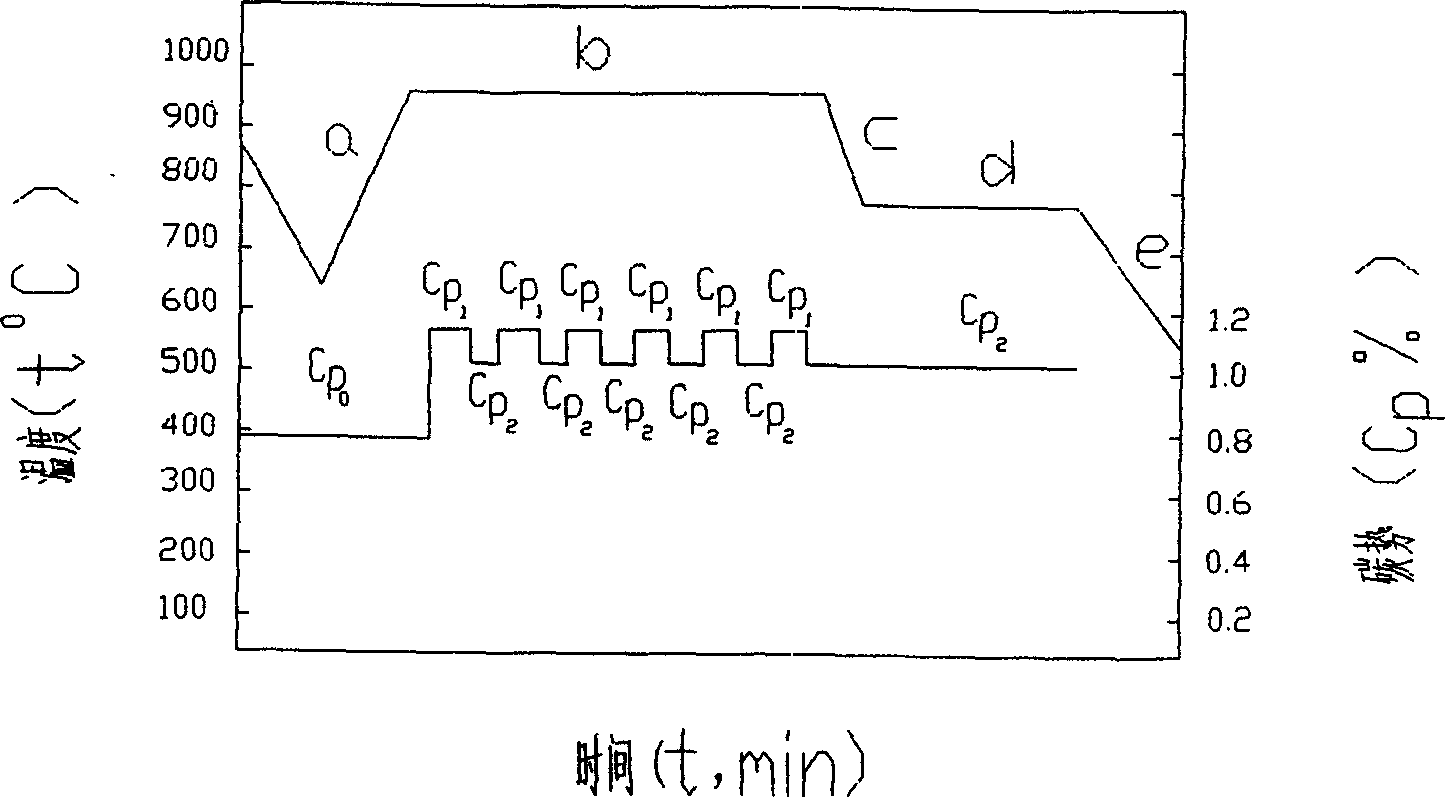

Gas carburetion method for gear wheel in heavy-duty car

InactiveCN1600892AAvoid carbon depositsAvoid formingSolid state diffusion coatingCarbon potentialGear wheel

This invention relates to gas carburizing the toothed-wheel of heavy duty automobile. It is characterized that this invention utilizes carbon-potential pulsation type gas carburizing, so it overcomes the prior art short comings that carbonization is proceeded under high carbon-potential and diffusion is finished under low carbon-potential. After quenching, the working-pieces have excellent carburized layer concentration gradient distribution, hardness gradient distribution and carburized layer histogram. This inventive method makes parts thus carburized have long service life under complex condition, after the parts are carburized and have gentle hardness gradient.

Owner:CHINA NATIONAL HEAVY DUTY TRUCK GROUP

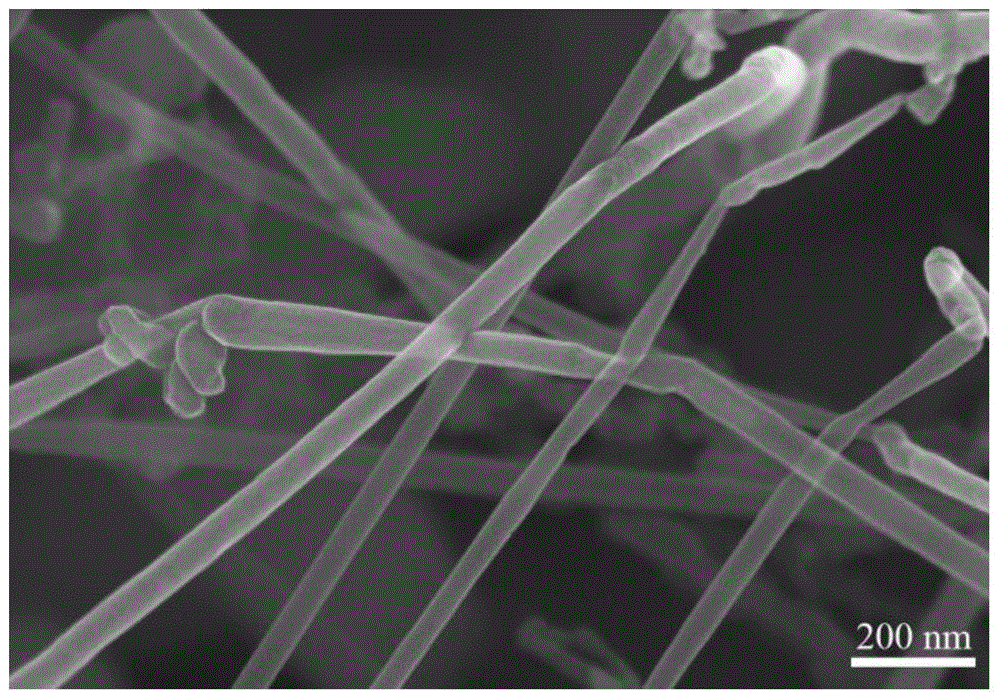

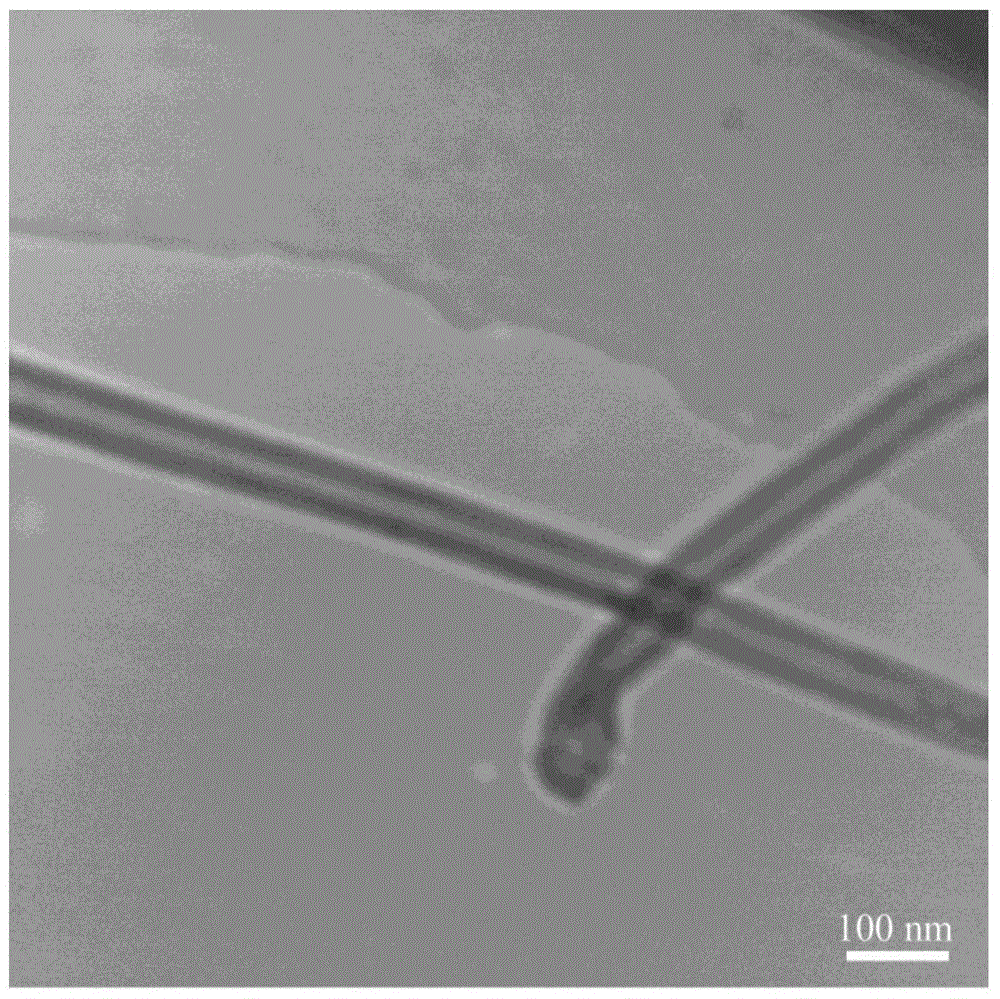

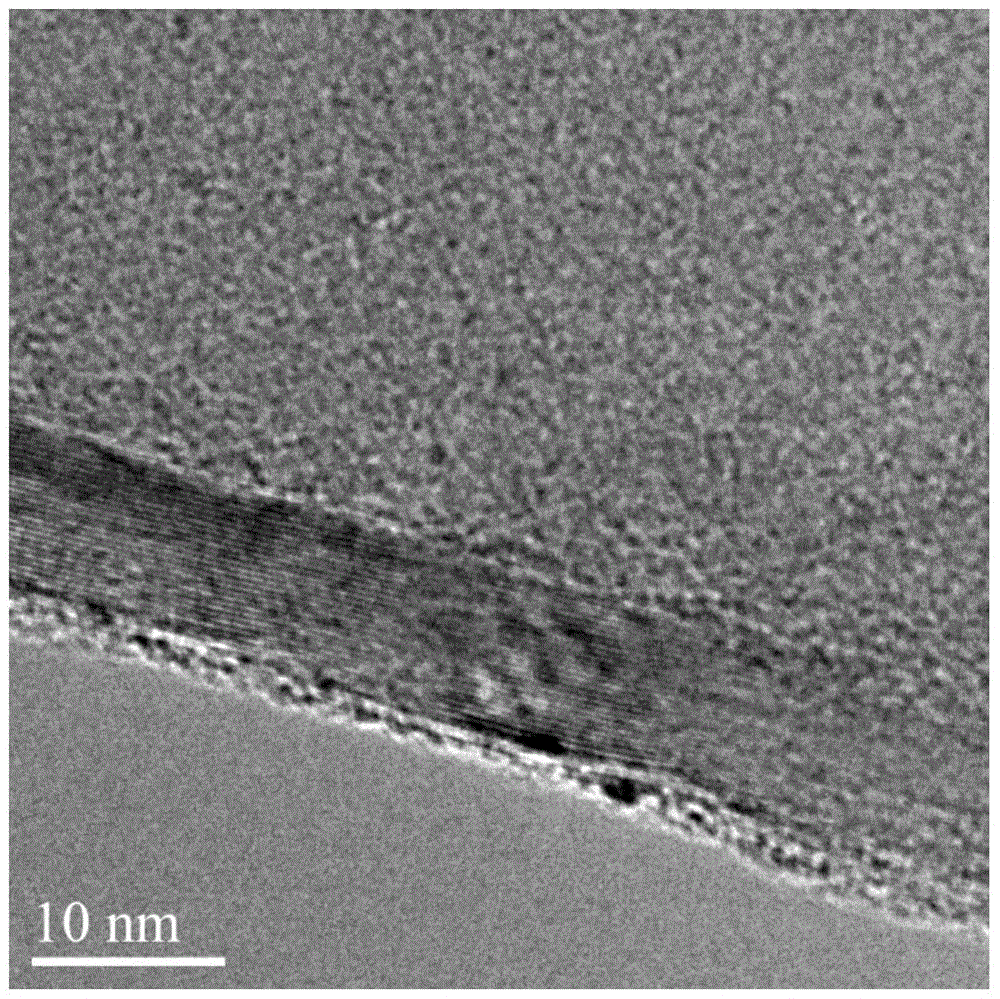

Method and device for preparing carbon nano tube by taking high-sulfur heavy oil as carbon source

ActiveCN105776172AEasy reunionAvoid inactivationMaterial nanotechnologyMetal/metal-oxides/metal-hydroxide catalystsCarbon nanotubeFuel oil

The invention provides a method and device for preparing a carbon nano tube by taking high-sulfur heavy oil as a raw material, and belongs to the technical field of petrochemical industry and carbon materials.The invention provides a method for preparing the carbon nano tube by taking the heavy oil of which the mass fraction of sulfur ranges from 2.11% to 4.9% as a carbon source and taking a 304 stainless steel substrate of which the surface is loaded with nickel and magnesium oxide as a catalyst through a chemical vapor deposition method, and provides the device needed in preparing the carbon nano tube by taking the high-sulfur heavy oil as the carbon source simultaneously.The method and device for preparing the carbon nano tube by taking the high-sulfur heavy oil as the carbon source have the advantages that the prepared catalyst is suitable for directly preparing the carbon nano tube by taking the high-sulfur heavy oil as the raw material, the diameter of the prepared carbon nano tube ranges from 30 nm to 90 nm, the tube cavity is large, the tube wall is smooth, and the purity and the degree of graphitization are high; the method has the advantages that the raw materials are low in price and rich in source, the problem that high sulfur content in the carbon source makes the catalyst inactivated is solved, and a new way is provided for high value added utilization of the heavy oil.

Owner:BEIJING UNIV OF CHEM TECH

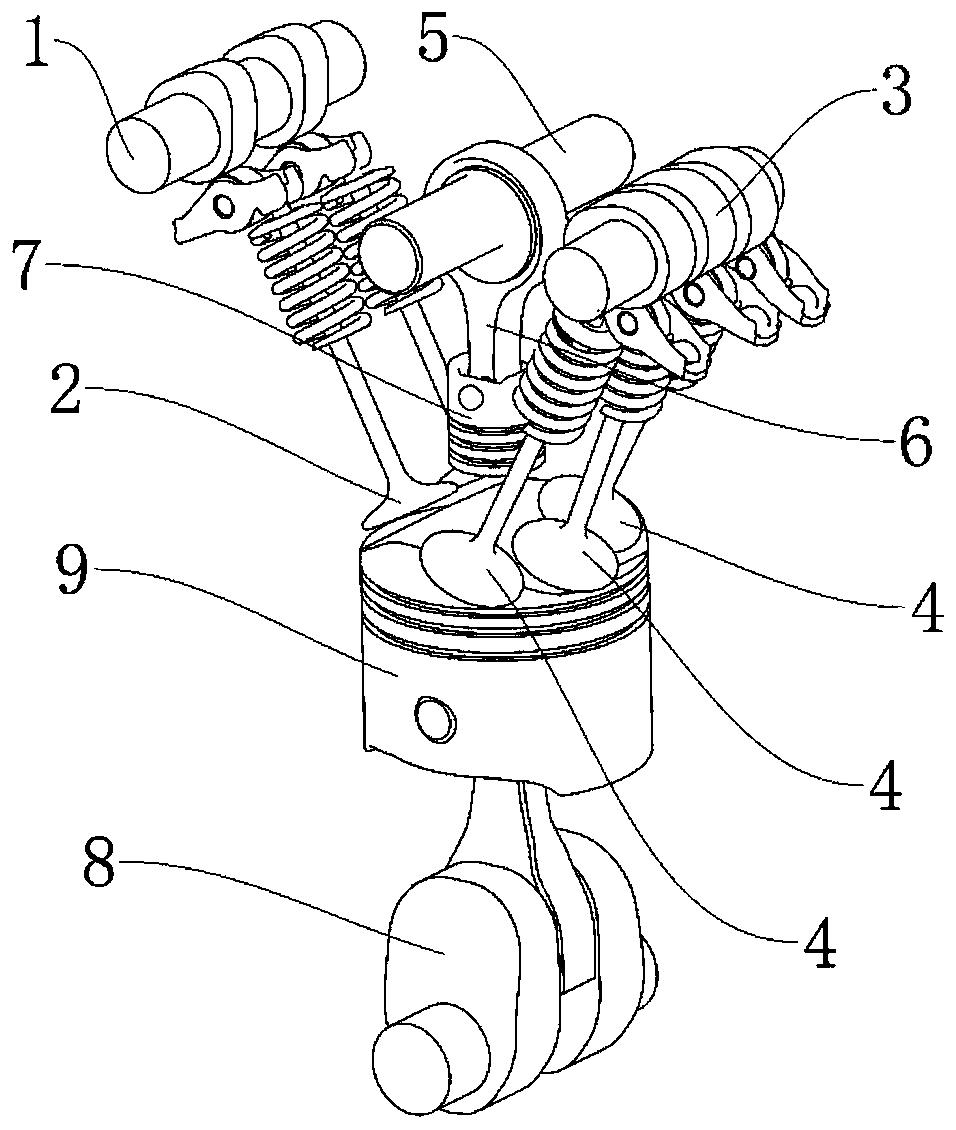

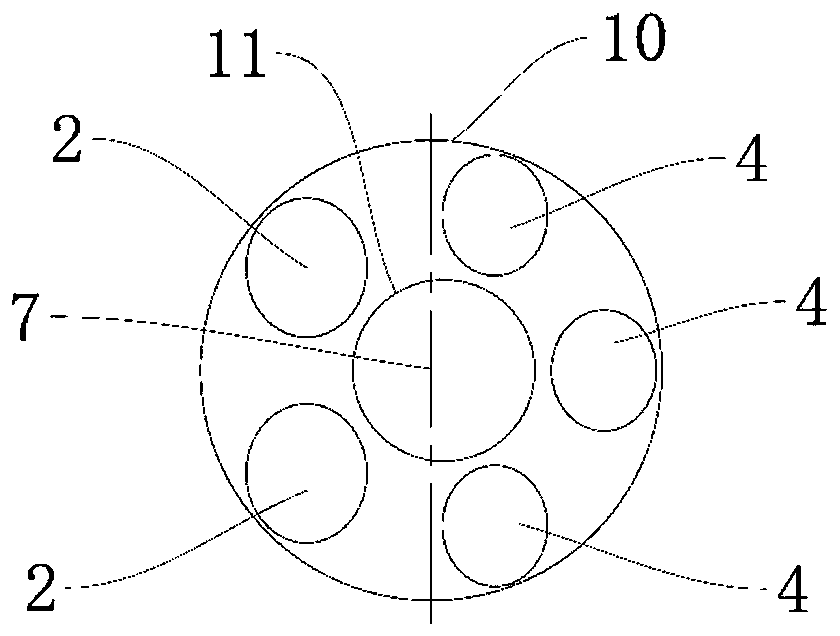

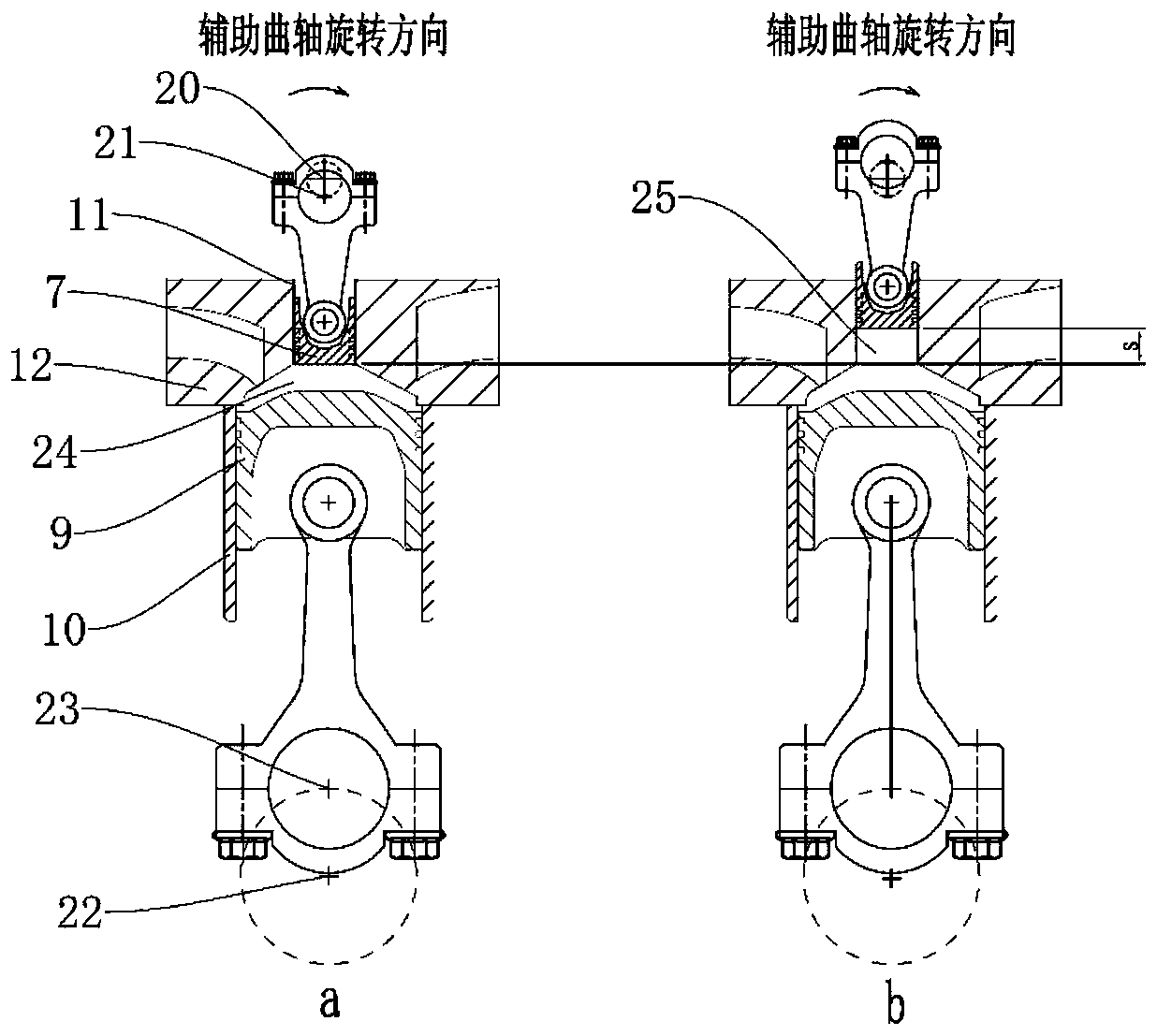

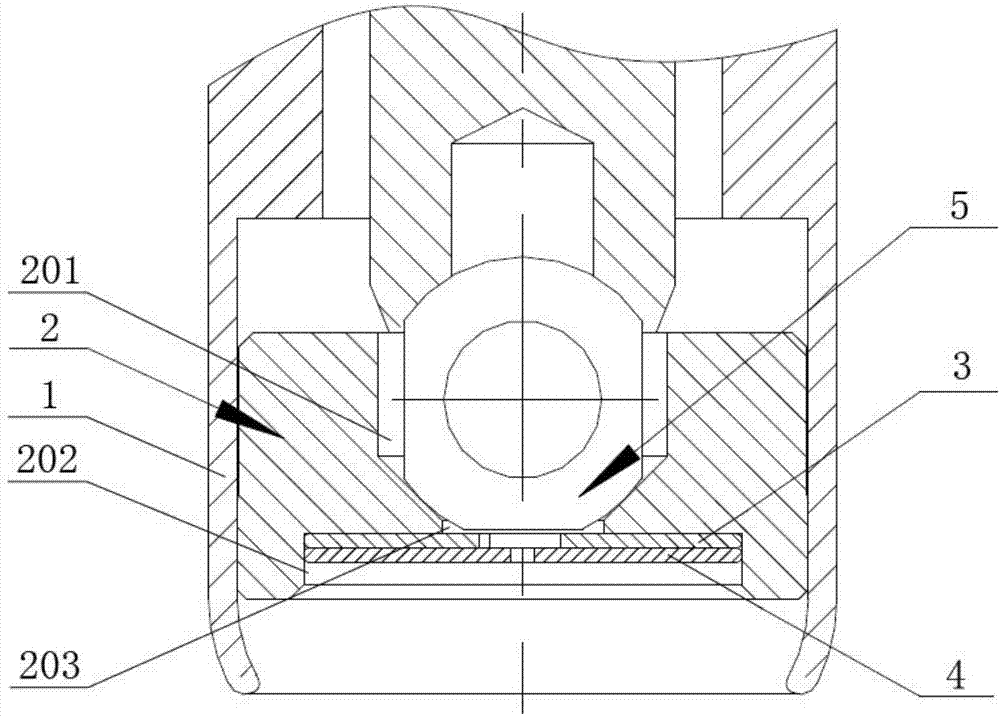

Variable-compression-ratio internal combustion engine

InactiveCN109854370AImprove cooling effectEffective lubricationEngine controllersMachines/enginesExternal combustion engineElectric machinery

The invention provides a variable-compression-ratio internal combustion engine which changes the compression ratio of the internal combustion engine by changing the volume of a combustion chamber. Thevariable-compression-ratio internal combustion engine comprises a gas feeding door, a gas exhausting door, an assisting piston, an assistant connecting rod, an assistant cylinder, an assistant crankshaft, an assistant crankshaft running and adjusting mechanism and other parts of the internal combustion engine, wherein the assistant crankshaft running and adjusting mechanism comprises a control motor, a chain wheel, an inner gear ring, an eccentric bearing, a planetary wheel and an assistant crankshaft gear; a crankshaft and the assistant crankshaft of the internal combustion engine rotates atspeed ratio of 2: 1 or 1: 1. When the assistant crankshaft running and adjusting mechanism does not adjust, the compression ratio of the internal combustion engine is unchanged. When a piston expandsand act, the assistant piston expands and acts, so that the internal combustion is capable of changing the expansion ratio.

Owner:HUNAN DAZE POWER TECH CO LTD

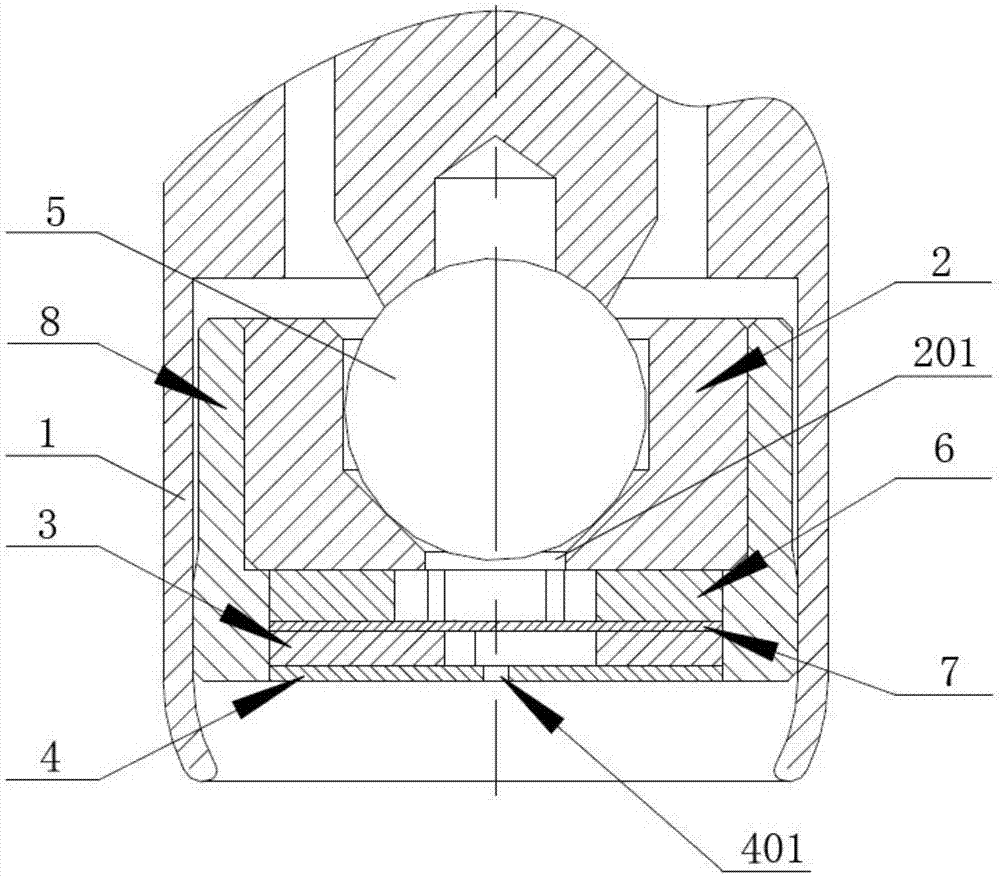

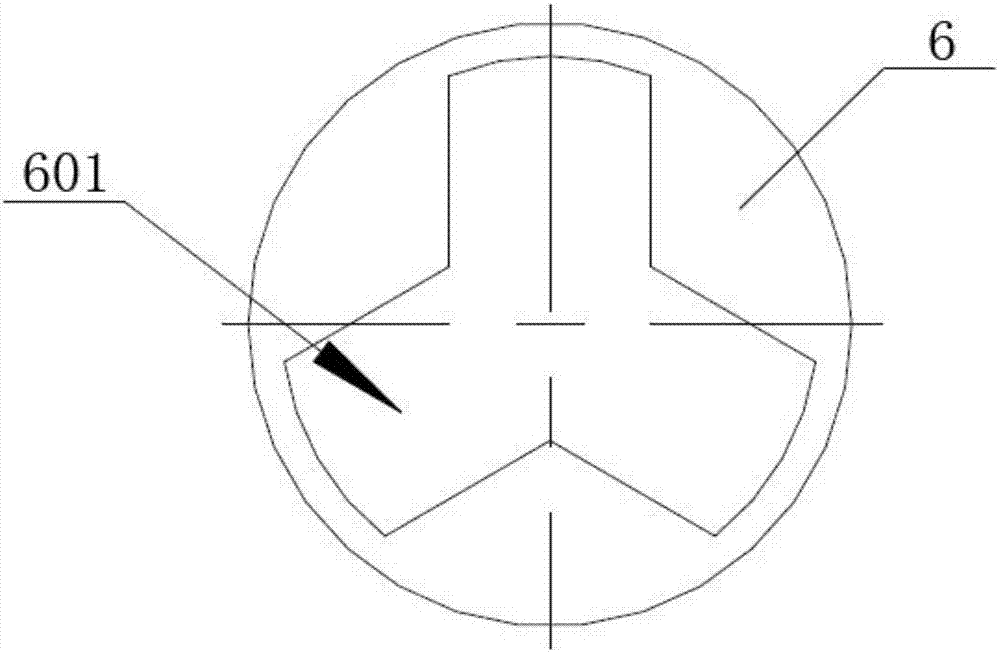

Single-hole atomizing oil sprayer and swirl atomizing structure thereof

ActiveCN107956619AThorough atomizationFine granularityFuel injection apparatusMachines/enginesCombustionSprayer

The invention discloses a swirl atomizing structure of a single-hole atomizing oil sprayer and further discloses the single-hole atomizing oil sprayer. The swirl atomizing structure comprises a pipe body, a valve seat, a swirl piece and a metering piece, a first mounting groove is formed in the top end of the valve seat, a second mounting groove is formed in the bottom end of the valve seat, and the first mounting groove and the second mounting groove communicate with each other through a valve hole. The swirl piece is tightly attached to the bottom face of the second mounting groove, and themetering piece is tightly attached to the bottom face of the swirl piece. A swirl hole is formed in the swirl piece, and a metering hole is formed in the metering piece. A plurality of swirl grooves are formed in the swirl piece. After a fluid passes through the valve hole, under the effect of the swirl grooves, a fluid beam is impacted to form a turbulent flow or a swirl flow distributed in the swirl groove direction, then when the fluid passes through the metering hole, the atomizing effect is obviously improved, the fluid is more thoroughly atomized, the particle size of atomized particlesis more fine, the fuel oil atomizing effect is improved, mixing and sufficient combustion of fuel oil and air are facilitated, carbon is prevented from being accumulated in a cylinder, and the vehicleemission cleanness is improved. The single-hole atomizing oil sprayer has the beneficial effects.

Owner:GUANGXI CARTIER TECH CO LTD

Full-mold casting paint and preparation method thereof

InactiveCN107052231AImprove high temperature resistanceImprove conductivityFoundry mouldsFoundry coresFiberSurface-active agents

The invention discloses full-mold casting paint, and belongs to the technical field of casting paint. The full-mold casting paint comprises, by weight, 15-17 parts of crystalline flake graphite, 10-15 parts of cyanite powder, 20-24 parts of spodumene powder, 8-10 parts of ceramic fibers, 6-9 parts of zirconium silicate powder, 14-15 parts of aluminum powder, 4-7 parts of forsterite powder, 0.5-0.8 part of iron oxide powder, 17-20 parts of phenolic resin, 1-2 parts of methyl alcohol, 0.01-0.05 part of a surface active agent, 4-6 parts of a defoaming agent, 1-2 parts of an anticorrosive agent, 0.5-1 part of a carbon adsorbing agent, and 24-26 parts of water. The invention further discloses a preparation method of the full-mold casting paint. The full-mold casting paint is environmentally friendly, resistant to corrosion, excellent in high-temperature resistance and fire resistance and high in mechanical strength.

Owner:安徽华飞机械铸锻有限公司

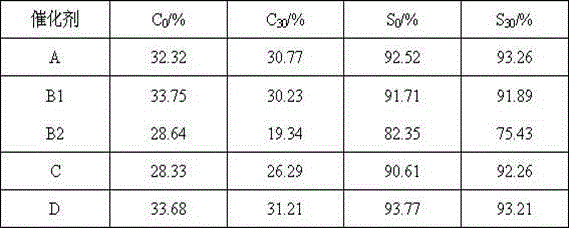

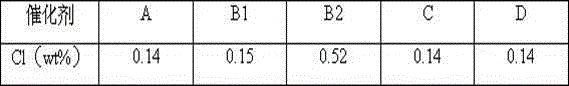

Preparation method for dehydrogenation catalyst

ActiveCN104549245AEvenly dispersedAvoid crackingMetal/metal-oxides/metal-hydroxide catalystsPotassium nitrateDehydrogenation

The invention discloses a preparation method for a dehydrogenation catalyst. The preparation method comprises the following steps: (1) uniformly mixing chloroplatinic acid, potassium nitrate and water to obtain impregnation liquid; (2) impregnating an inorganic oxide carrier in the impregnation liquid obtained in the step (1) to obtain an impregnated carrier; (3) performing programmed heating and drying on the impregnated carrier in the step (2), roasting, washing, and performing drying and dewatering to obtain the dehydrogenation catalyst. According to the method, the hydrothermal dechlorination process does not need to be carried out, so that the preparation method for the catalyst is simplified, the aggregation growth of Pt particles is avoided, the energy consumption is reduced, and the production cost is reduced.

Owner:CHINA PETROLEUM & CHEM CORP +1

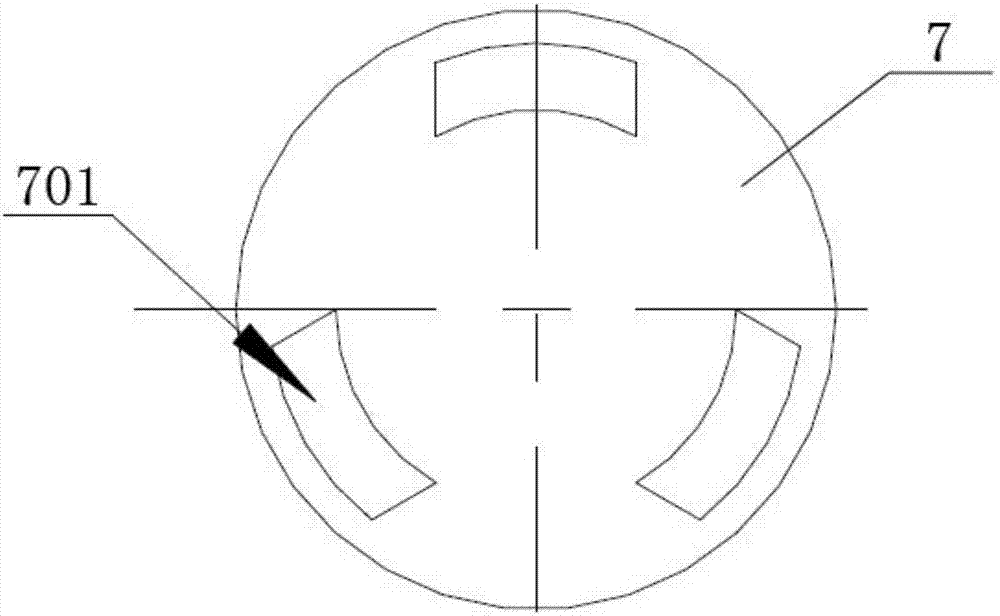

Single-hole atomization oil sprayer and front atomization structure thereof

ActiveCN107989731AThorough atomizationFine granularityFuel injection apparatusMachines/enginesCycloneCombustion

The invention discloses a front atomization structure of a single-hole atomization oil sprayer. The front atomization structure of the single-hole atomization oil sprayer comprises a pipe body, a mounting sleeve, a valve base, a flow separation piece, a flow passing piece, a cyclone piece and a metering piece. A flow separation groove is formed in the flow separation piece for dividing a fluid beam into multiple parts. A flow passing hole is formed in the flow passing piece for further performing the flow separation limiting on the divided fluid. The cyclone piece is provided with a cyclone hole and a cyclone groove; after the divided fluid passes through the cyclone groove, the bottom of the cyclone groove is shielded by the metering piece to generate acute impact and to form turbulent flows; and the turbulent flows are gathered in the cyclone hole. When the fluid beam forming the turbulent flows passes through a metering hole after passing through the cyclone hole, the atomization effect is obviously improved, the liquid atomization is more thorough, the particle size of atomization particles is finer, and the fuel atomization effect is improved; and when the structure is appliedto an engine cylinder, mixing with air and full combustion are facilitated, accumulation of carbons in the cylinder is prevented, and the vehicle discharge cleanness is improved. The invention further discloses the single-hole atomization oil sprayer; and the beneficial effects are as above.

Owner:GUANGXI CARTIER TECH CO LTD

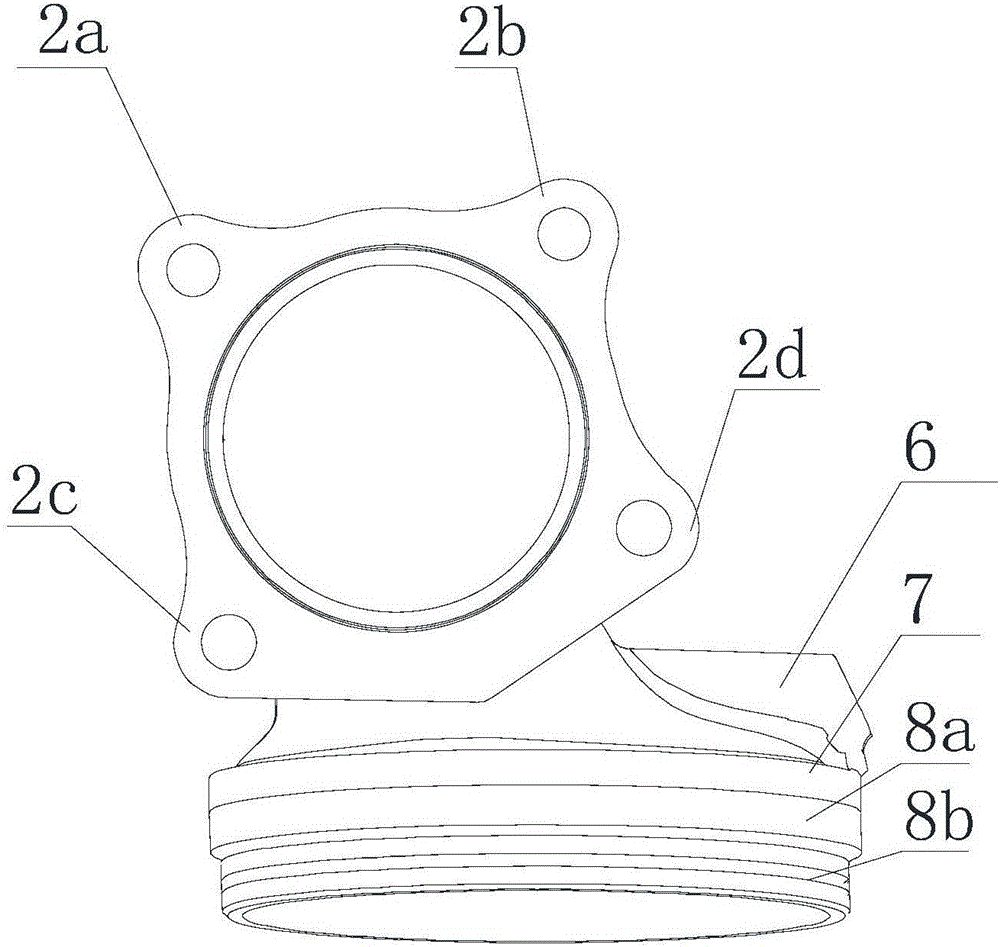

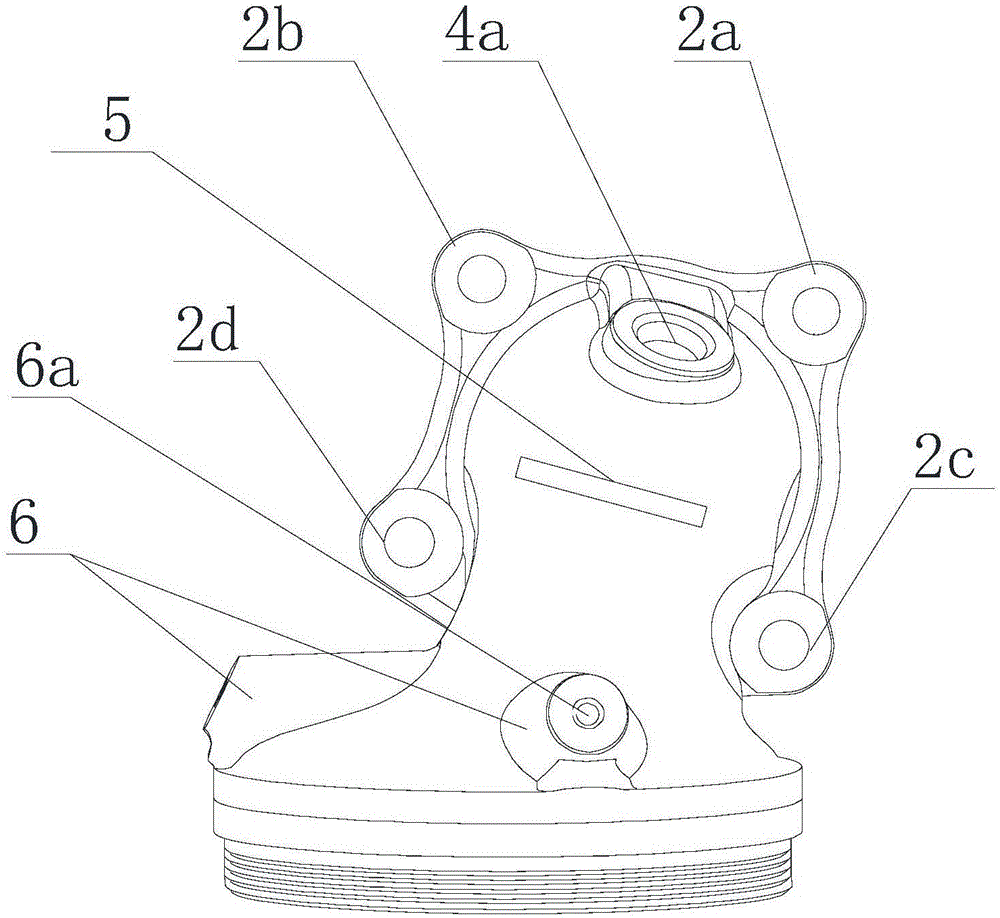

Exhaust emission connector of automobile engine and production technology thereof

InactiveCN106762071APrevent cracks etc.Improve cooling effectExhaust apparatusFoundry mouldsCorona dischargeEngineering

The invention relates to an exhaust emission connector of an automobile engine. The exhaust emission connector of the automobile engine comprises an elbow and a carbon removing and sound absorbing device, wherein the elbow is provided with a gas inlet and a gas outlet, at least one cooling fin is arranged on the outer wall of the elbow, the carbon removing and sound absorbing device communicates with the gas outlet, and a sealing washer is arranged between the carbon removing and sound absorbing device and the gas outlet; the carbon removing and sound absorbing device comprises a carbon removing and sound absorbing part and a threaded connection part, and the threaded connection part is arranged far away from the gas outlet; and the inner wall of the carbon removing and sound absorbing part is covered with a sound absorbing layer, the surface of the sound absorbing layer is covered with a heat-resisting layer, and a carbon removing box and a corona discharger are arranged on the inner wall of the carbon removing and sound absorbing device. According to the exhaust emission connector of the automobile engine, because the carbon removing box and the corona discharger are arranged on the inner wall of the carbon removing and sound absorbing device, static electricity in gas is effectively removed through the corona discharger, the carbon removing effect is improved, carbon deposition in the connector is effectively prevented, the quality of the connector is improved, and the service life of the connector is prolonged.

Owner:江苏多为机械工业有限公司

Fuel cell

ActiveCN106887617AReasonable heat exchangeImprove thermal efficiencyFuel cell heat exchangeSolid electrolyte fuel cellsCold airElectricity

The invention relates to a fuel cell which is characterized by comprising a thermal-insulation inner shell, an outer shell, pile cavity covers, ceramic tube sets, a fan, a combustion nozzle and waste gas filtering structures; the thermal-insulation inner shell is covered by the outer shell, the outer shell and the thermal-insulation inner shell are in clearance fit to form a cold air flow channel, the pile cavity covers are arranged in the thermal-insulation inner shell and in clearance fit with the thermal-insulation inner shell, every two adjacent pile cavity covers are in clearance fit to form a hot air flow channel, venting holes are formed in the thermal-insulation inner shell, each ceramic tube set is arranged in the corresponding pile cavity cover, the fan is arranged on the outer shell, the combustion nozzle is arranged on the thermal-insulation inner shell, a flame outlet of the combustion nozzle is arranged in the hot air channel, a gas inlet of the combustion nozzle is communicated with external fuel gas, and each waste gas filtering structure is arranged at a gas outlet of the corresponding ceramic tube set and is arranged at the upper portion of the pile cavity cover. The fuel cell has the advantages that the fuel cell is all prepared from solid materials, thermal efficiency of the fuel cell is high, the insides of pile covers are separated from a heating chamber, carbon deposition in the pile covers is effectively avoided, the structure is compact and ordered, and varieties of gas is prevented from being mixed in a cross mode.

Owner:FOSHAN SUOFUKE HYDROGEN ENERGY CO LTD

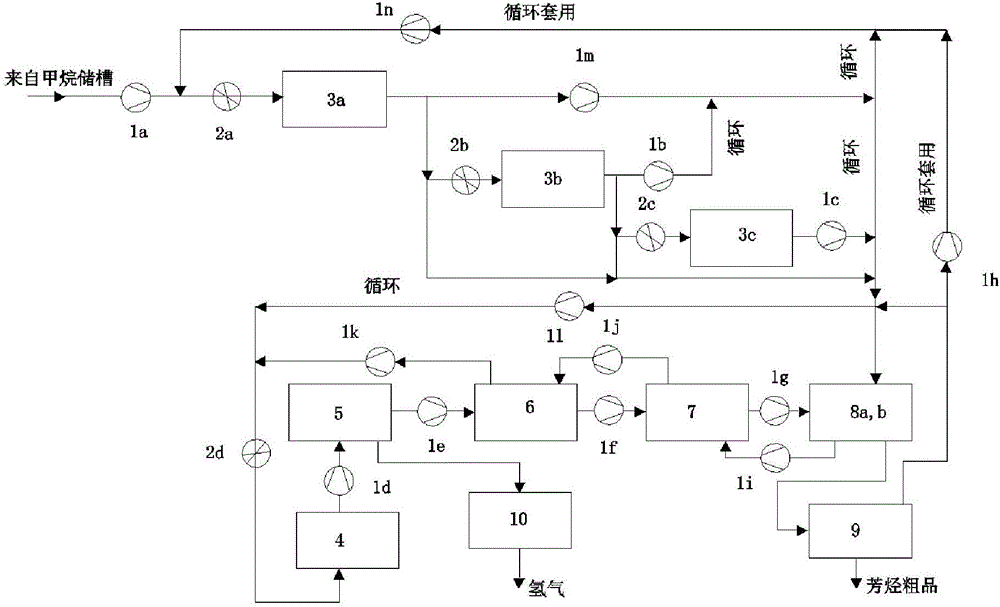

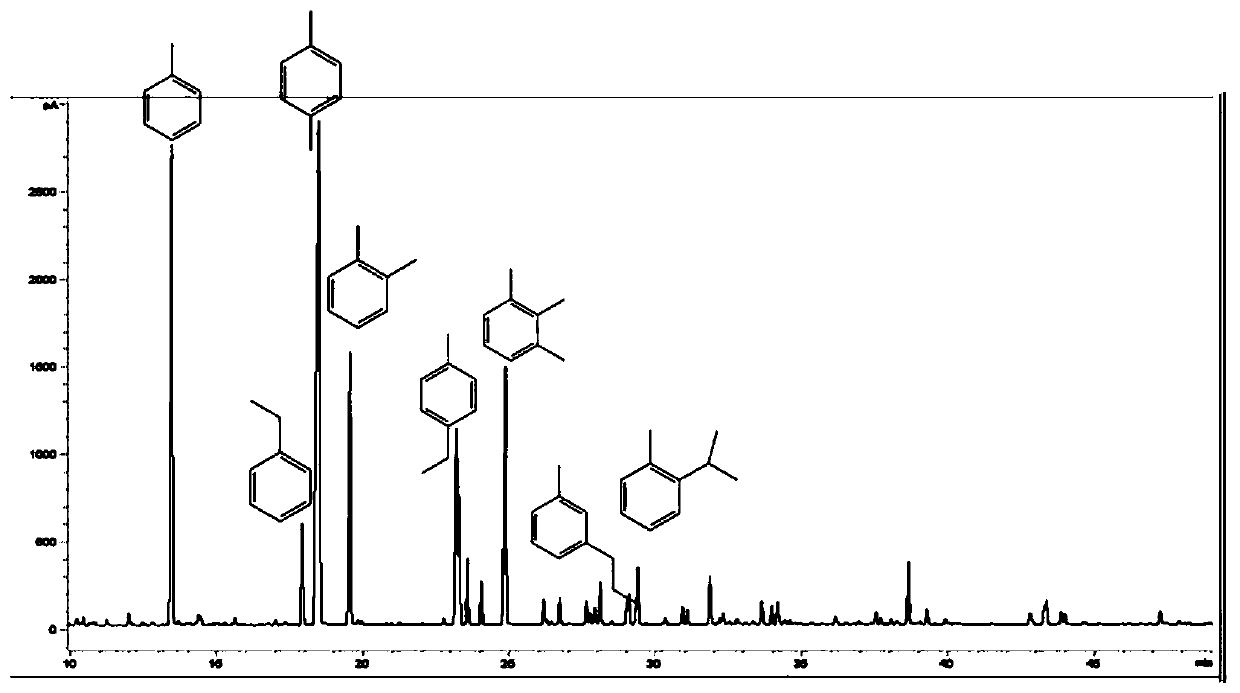

Method for preparing aromatic hydrocarbons by methane-plasma-activated oxygen-free aromatization

ActiveCN105669343ALow conversion temperatureLow costMolecular sieve catalystChemical industryAlkaneMethanoplasmatales

The invention relates to a method for preparing aromatic hydrocarbons by methane-plasma-activated oxygen-free aromatization. The method comprises a multistage-series plasma activation reactor, an aromatization reactor, a palladium hydrogen permeation membrane separator, a condensation cooler, a heat recovery device and a gas-liquid separator. Unconverted methane in the reaction system is recycled; hydrogen permeated by the palladium hydrogen permeation membrane separator is recovered through a hydrogen vacuum pump; the unpermeated ethane, acetylene, propane, butane and aromatic hydrocarbons pass through the condenser and gas-liquid separator to recover the liquid aromatic hydrocarbons; and uncondensed ethane, acetylene, propane, butane and methane are merged and return to the reaction system. The method can recover the coproduct hydrogen; the plasma is adopted to activate and induce the reaction, thereby enhancing the methane conversion rate and promoting the generation of small-molecular paraffin hydrocarbons in the reaction system; and the paraffin hydrocarbons can be recycled as a methane reaction aid and a free radical chain initiator, thereby greatly enhancing the methane aromatization selectivity and yield, reducing the carbon deposit and lowering the production cost of aromatic hydrocarbons.

Owner:ANHUI UNIV OF SCI & TECH

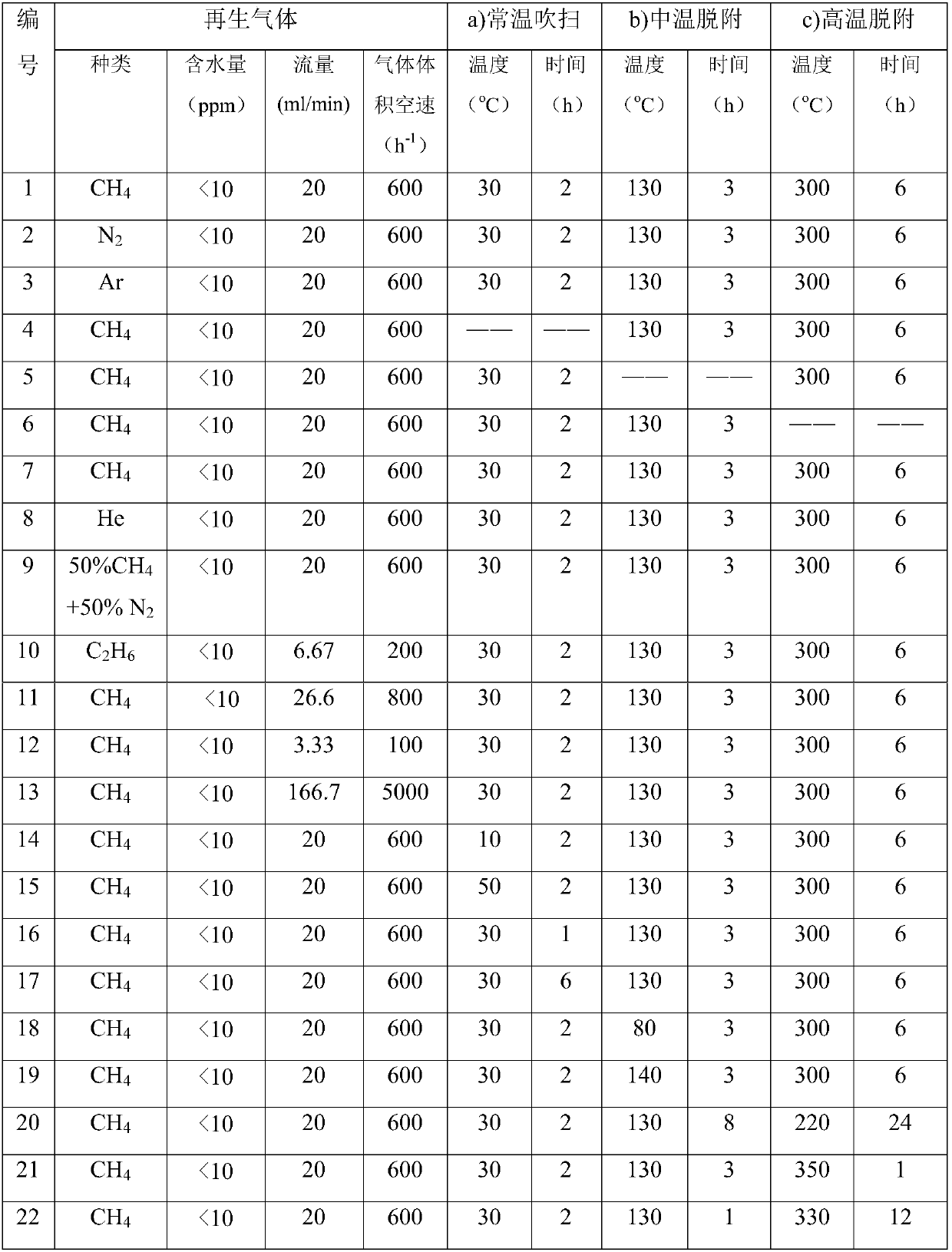

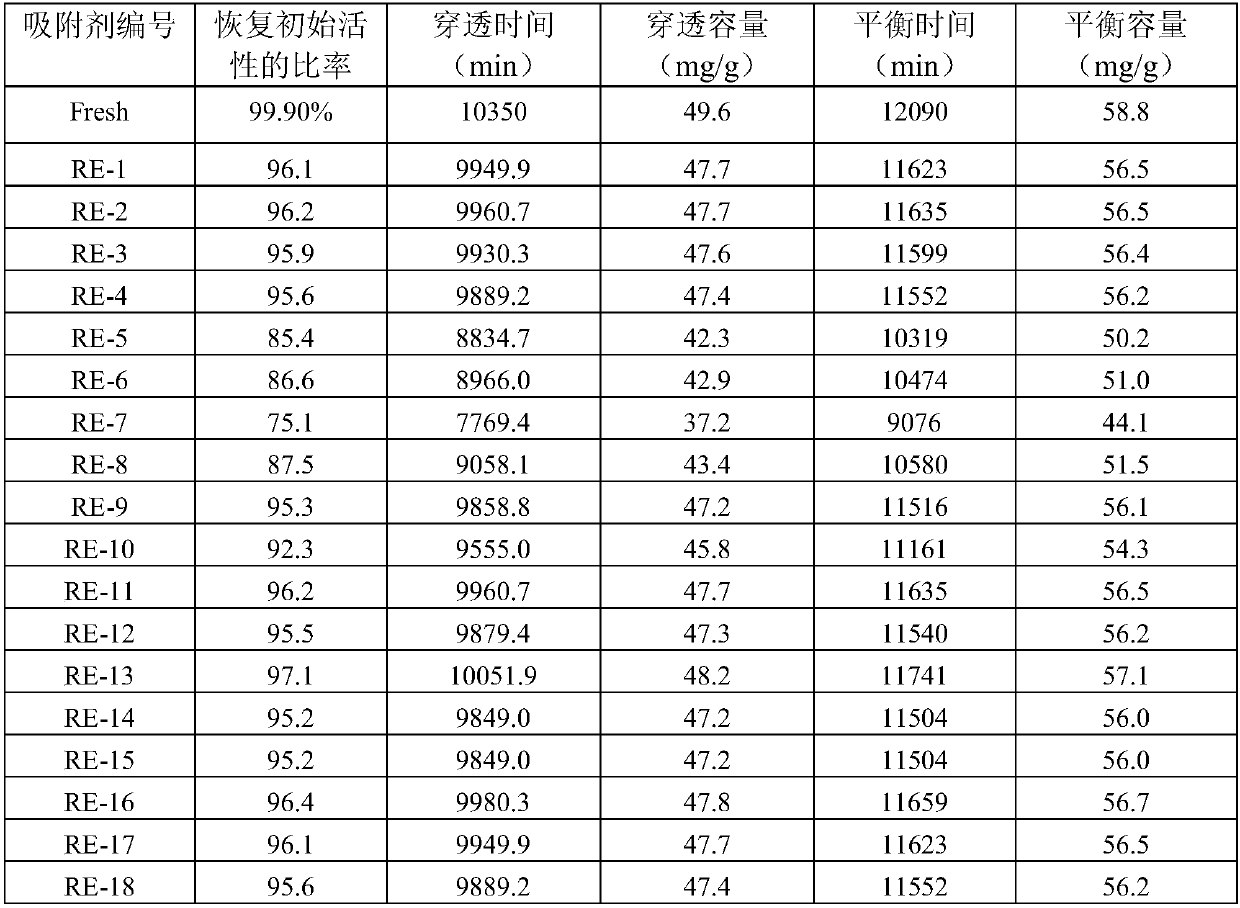

Regeneration method for removing oxygen compound containing adsorbent in low-carbon olefins

ActiveCN107774239AEasy to operateAvoid cokingCombustible gas purificationHydrocarbon oils refiningOxygen compoundDry gas

The invention relates to a regeneration method for removing an oxygen compound containing adsorbent in low-carbon olefins, and mainly solves the problems that the operation is complicated; the regeneration efficiency is low; the adsorbent can be easily coked and generate carbon deposition, so that the adsorption performance of the adsorbent is reduced or even inactivated, and the like. The regeneration method has the technical scheme that stepped programmed temperature rising is performed at lower pressure and a temperature higher than the adsorption temperature; the adsorbent requiring regeneration contacts positive or reverse flowing high-temperature drying gas with heat. The problems are well solved; the regeneration method can be used for removing the oxygen compound containing adsorbent in industrial low-carbon olefins.

Owner:CHINA PETROLEUM & CHEM CORP +1

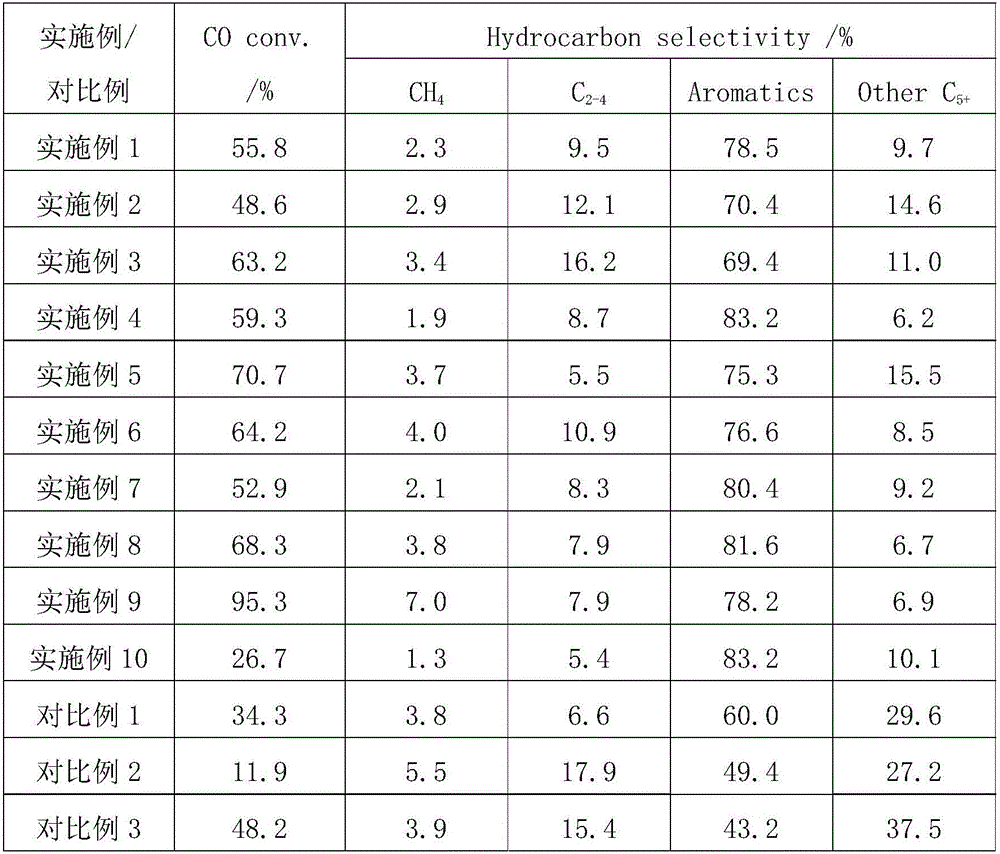

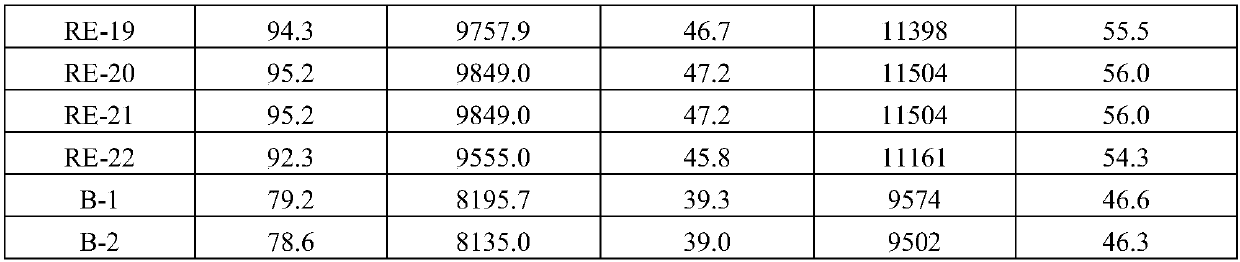

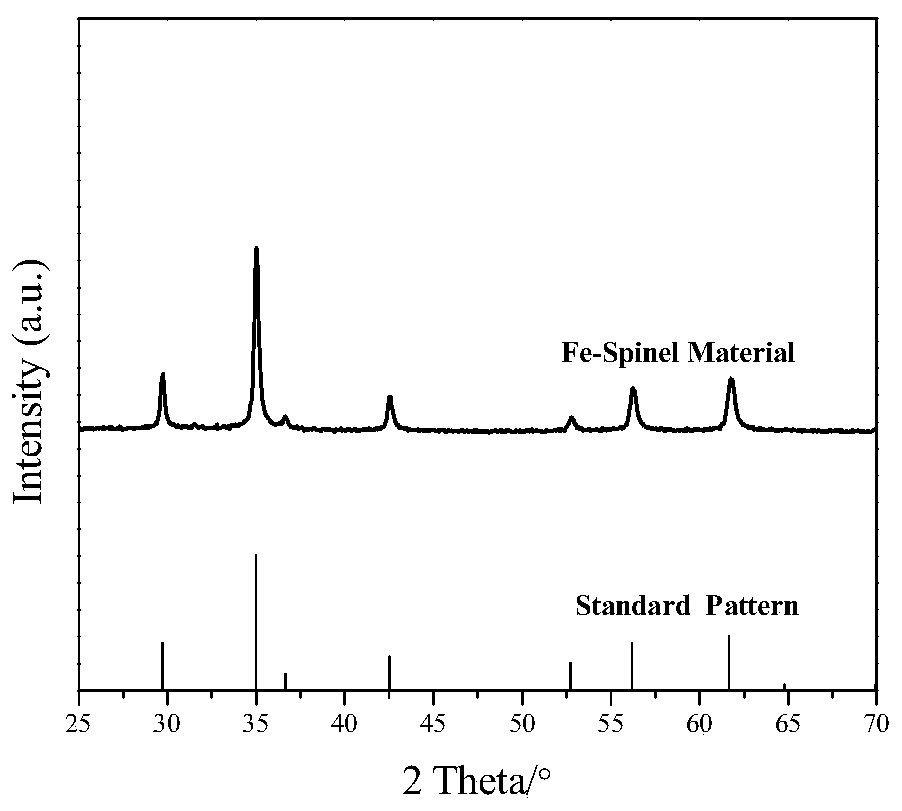

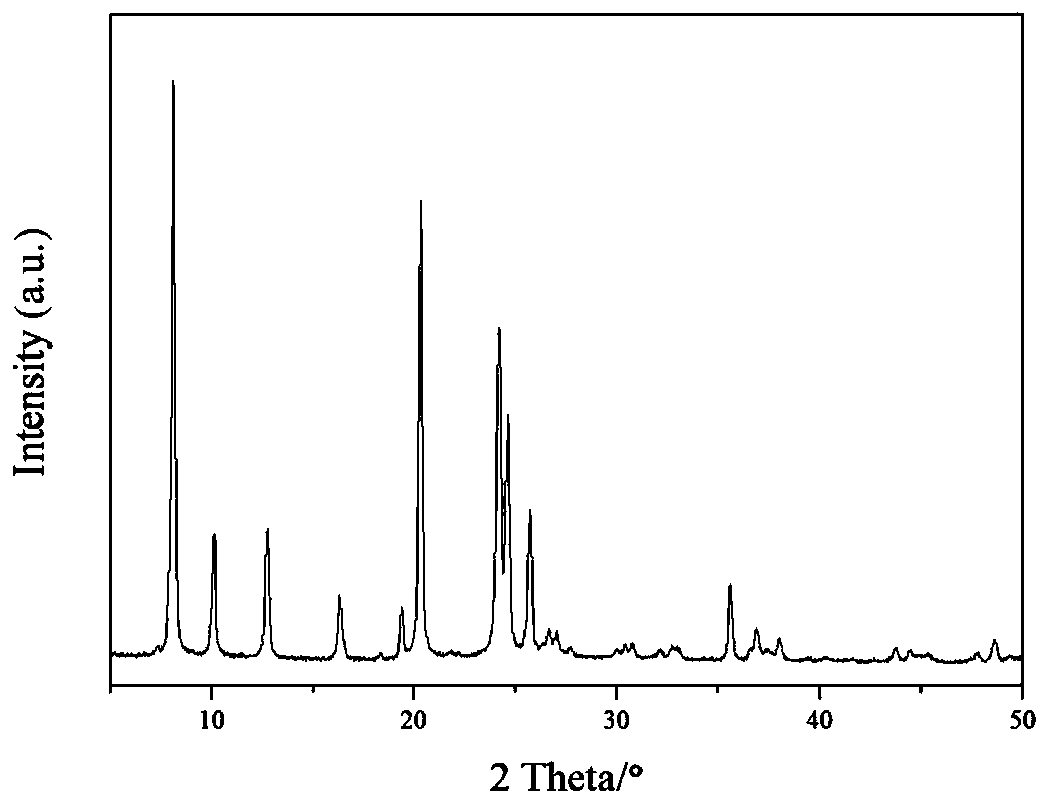

Fe-based catalyst, preparation method thereof and application thereof for preparing aromatic hydrocarbons through one-step method by synthesis gas

InactiveCN110368984AHigh selectivityLow selectivityMolecular sieve catalystsLiquid hydrocarbon mixture productionStructural stabilityFe based

The invention discloses an Fe-based catalyst for preparing aromatic hydrocarbons through a one-step method by synthesis gas and a preparation method of the Fe-based catalyst. The Fe-based catalyst isprepared from a Fe-based spinel material, molecular sieve zeolite and a metal oxide auxiliary agent, wherein the content of the Fe-based spinel material is 9.95%-79.95%, the zeolite molecular sieve is20%-90%, and the oxide auxiliary agent is 0.05-20%. The Fe-based catalyst couples preparation of olefin by the synthesis gas with aromatization reaction of the olefin, and because the spinel materialhas high structural stability and Fe dispersibility in catalytic reaction and high reactivity, light aromatics selectivity and stability are maintained during the 1000h synthesis gas catalytic conversion process, the technical problems of low aromatics selectivity, poor catalyst stability and high content of polycyclic aromatic hydrocarbons in the process preparing the aromatic hydrocarbon from the synthesis gas are solved; and the catalyst synthesis cost is low, the operation is simple, and the Fe-based catalyst and the preparation method are suitable for large-scale industrial production ofthe aromatic hydrocarbons from the synthetic gas.

Owner:SYNFUELS CHINA TECH CO LTD

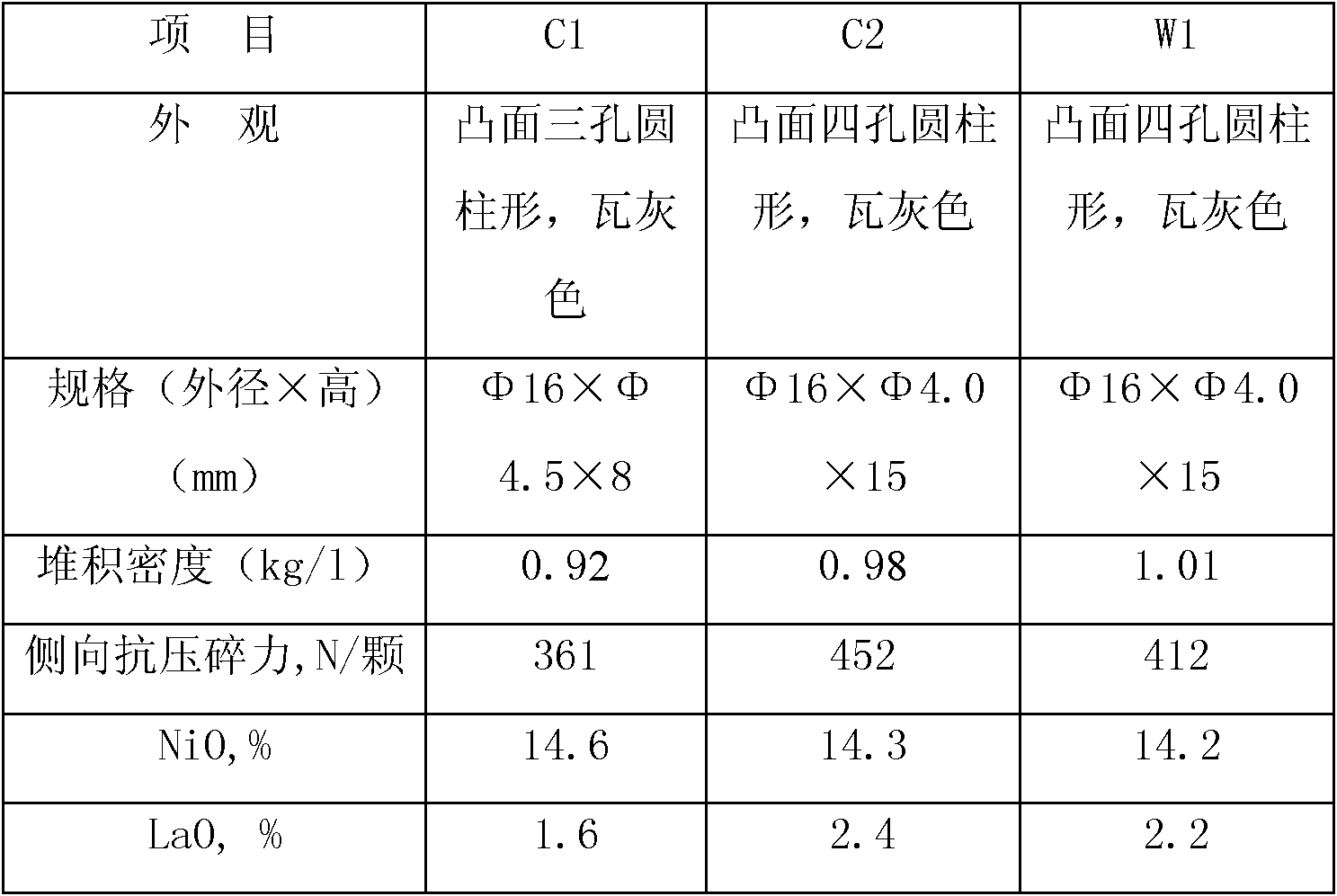

Preparation method for catalyst for hydrogen production by hydrocarbon reforming

ActiveCN102836721AHigh activityImprove anti-coking performanceHydrogenMetal/metal-oxides/metal-hydroxide catalystsSteam reformingRoom temperature

The invention relates to a preparation method for a catalyst for hydrogen production by hydrocarbon reforming. The method is characterized by comprising the following steps of: adding La(NP3)2 into deionized water to prepare a solution; placing an alumina-based carrier into the impregnating solution obtained above for isopyknic impregnation; drying after the impregnation; roasting the catalyst obtained above for 2-6 hours, and cooling to room temperature; preparing a Ni(NO3)2 solution by using Ni(NO3)2, deionized water and a surfactant; placing the catalyst prepared above into the Ni(NO3)2 solution for isopyknic impregnation; drying the sample obtained above, and then roasting; placing the sample obtained above into the Ni(NO3)2 solution again for another isopyknic impregnation the, and then drying and roasting again to obtain a product. The prepared catalyst for hydrogen production by hydrocarbon reforming has stabilized high activity; and when using hydrocarbon gas containing a large amount of C2-C4 hydrocarbons as a raw material, catalytic cracking and steam reforming of the C2-C4 hydrocarbons can be realized quickly by the prepared catalyst, preventing the C2-C4 hydrocarbons from moving down to a high temperature bed for carbon deposition.

Owner:SHANDONG GONGQUAN CHEM

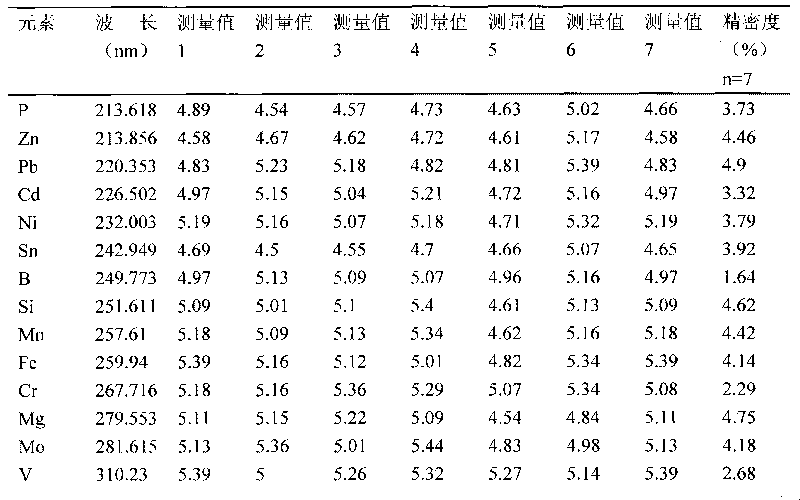

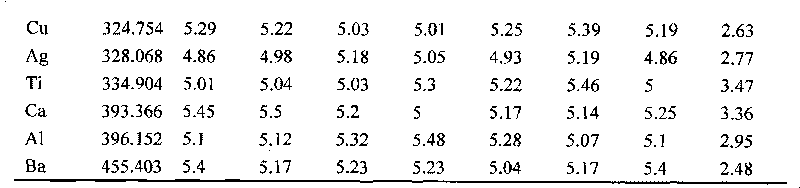

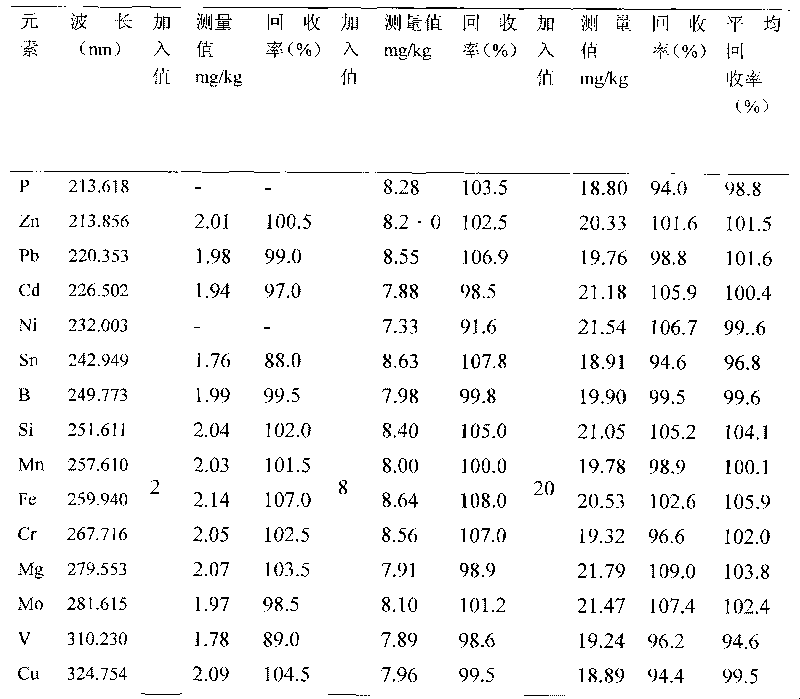

Method for detecting content of elements in oil with inductively coupled plasma (ICP) spectrometer

InactiveCN101726482AReduce formationInhibitionAnalysis by thermal excitationInductively coupled plasmaQuartz

The invention discloses a method for detecting the content of elements in oil with an inductively coupled plasma (ICP) spectrometer. The ICP spectrometer comprises a torque tube, and the torque tube is formed by three layers of concentric quartz tubes. Cooling gas is guided into the quartz tube of the outer layer, oxygen is guided into the quartz tube of the middle layer and gasoloid of the oil which is diluted by organic solution is injected into the quartz tube of the outer layer. The method for detecting the content of elements in oil with the ICP spectrometer makes up the deficiency of the prior art.

Owner:JIANGSU SKYRAY INSTR

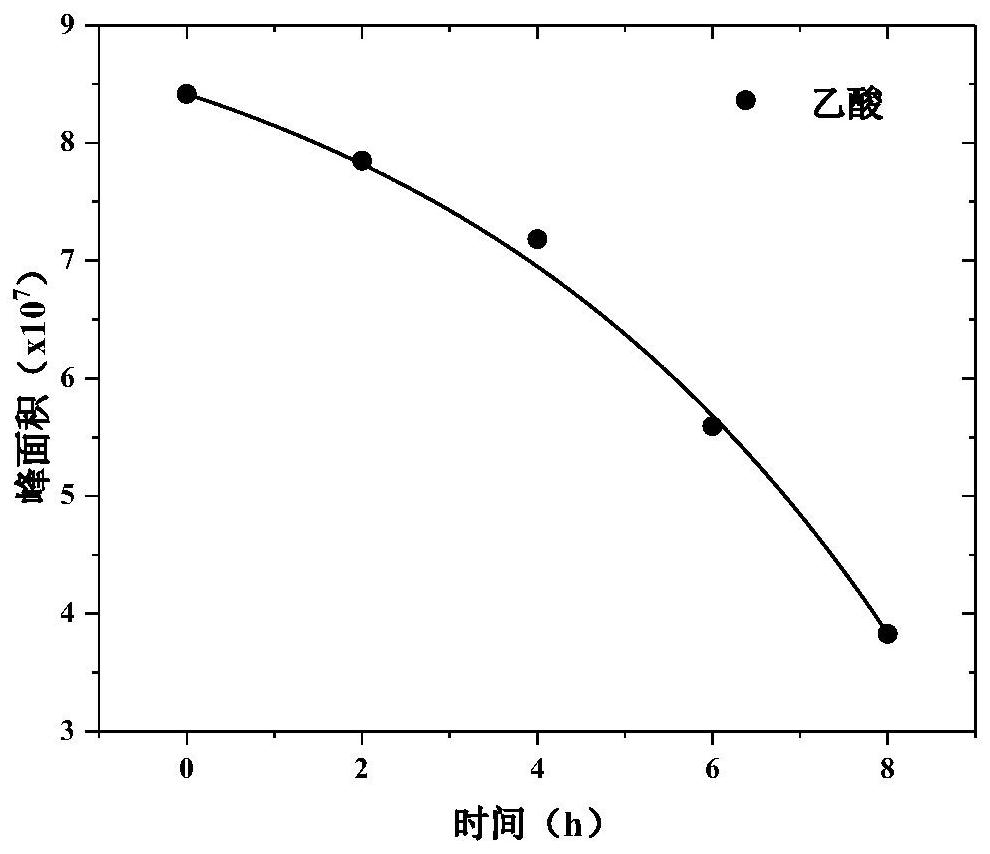

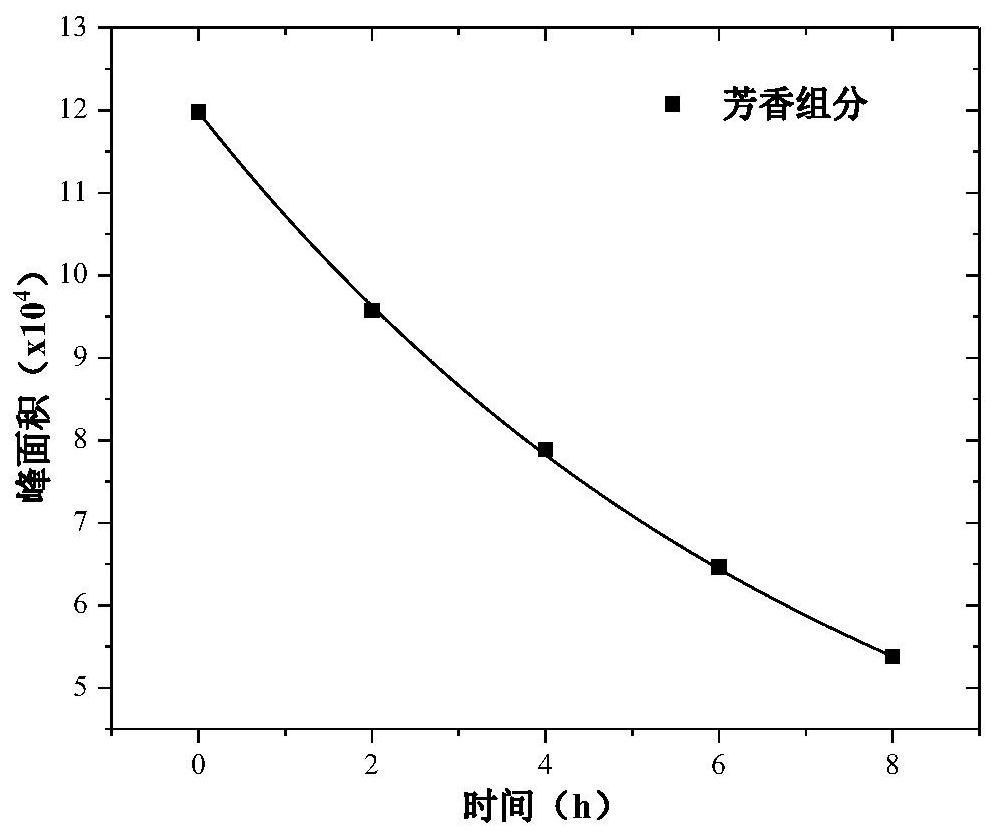

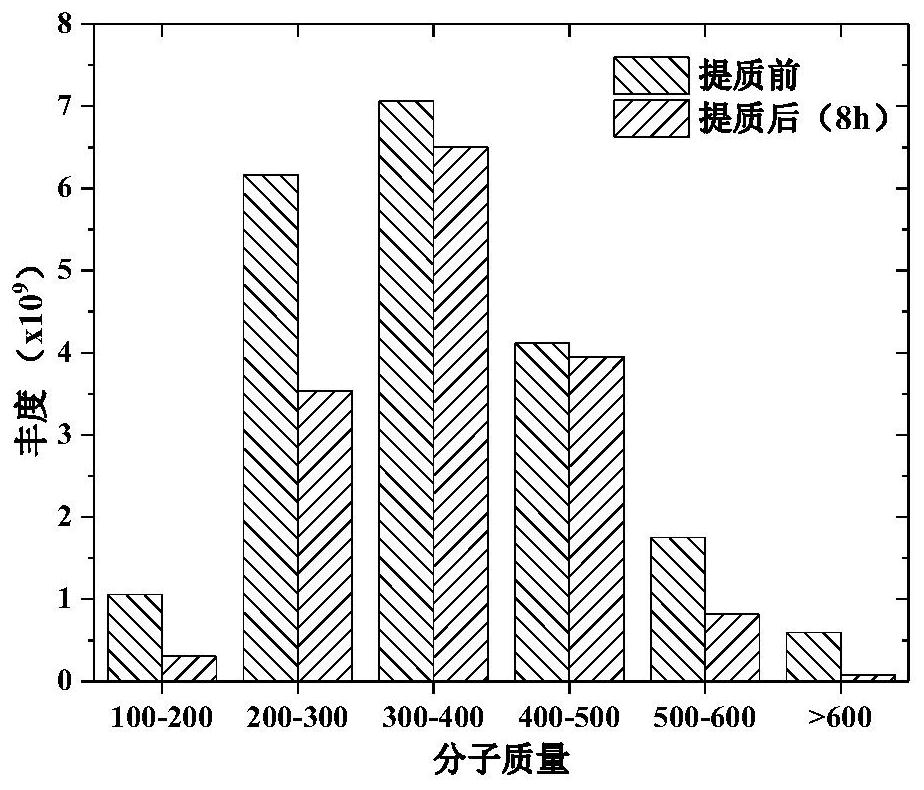

Electrochemical upgrading method for bio-oil

ActiveCN111909736AKeep carbonaceous componentsSimple processLiquid carbonaceous fuelsSupporting electrolyteElectrochemical response

The invention belongs to the field of biomass energy utilization, and discloses a bio-oil electrochemical upgrading method which comprises the following steps: (a) mixing bio-oil, an organic solvent and a supporting electrolyte to obtain a catholyte; (b) preparing an acid solution as an anolyte; (c) constructing an electrochemical reactor by adopting the catholyte and the anolyte and separating the catholyte from the anolyte through one or two ion exchange membranes, thus forming a current loop; and (d) introducing a protective gas into one side of the catholyte, and introducing current through the working electrode and the anode electrode to carry out electrochemical reaction, thereby realizing the electrochemical upgrading of the bio-oil. Compared with the prior art, the problem that carbon deposition is easily formed when the bio-oil is upgraded by a thermochemical method can be effectively solved, the bio-oil is subjected to electrochemical upgrading under mild conditions, and thecontent of bio-oleic acid, the content of aromatic components and the content of heavy components can be reduced by upgrading, so that the bio-oil is suitable for transportation and storage; and meanwhile, carbon deposition is avoided in the upgrading process.

Owner:HUAZHONG UNIV OF SCI & TECH

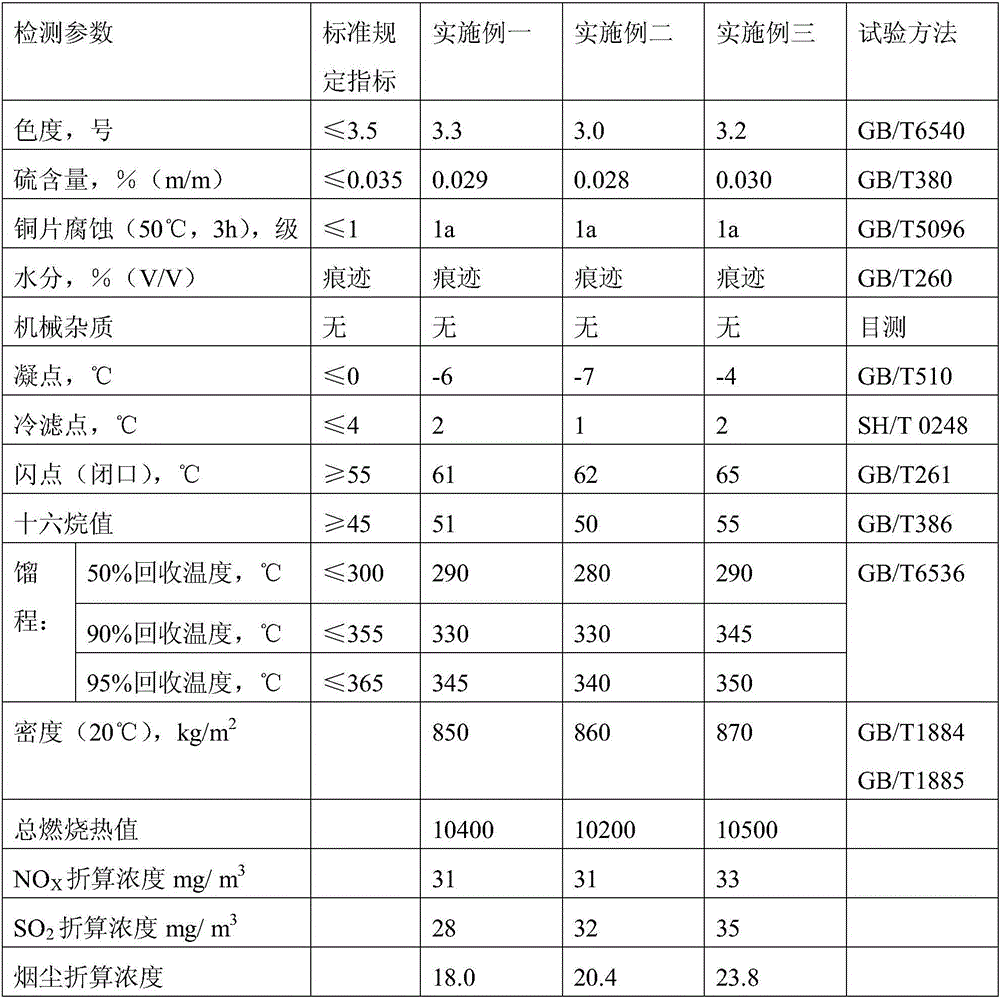

Composite fuel oil and preparation method thereof

InactiveCN105713682AHigh calorific valueImprove performanceLiquid carbonaceous fuelsOil and greaseMicrobial oil

The invention discloses composite fuel oil and a preparation method thereof. The composite fuel oil comprises components in parts by mass as follows: 5-15 parts of heavy oil, 10-40 parts of coal oil, 10-20 parts of coking light oil, 20-40 parts of vegetable oil, 5-10 parts of microbial oil, 3-6 parts of vegetable oleic acid or ethanolamine, 10-25 parts of methanol, 10-40 parts of distilled oil and 1-5 parts of additives, wherein the distilled oil is obtained from waste oil and / or diesel oil and / or illegal cooking oil through distillation, and the additives comprise a combustion improver, a dispersing agent and an anticorrosive agent. The composite fuel oil has the advantages of high heat value, stable performance and clean emission, is not prone to volatilization and is free of toxicity, smoke and odor, the requirement for ignition temperature in a use process can be met sufficiently, waste oil can be treated reasonably, and existing energy is saved.

Owner:NANJING LISHENG RECYCLE CO LTD

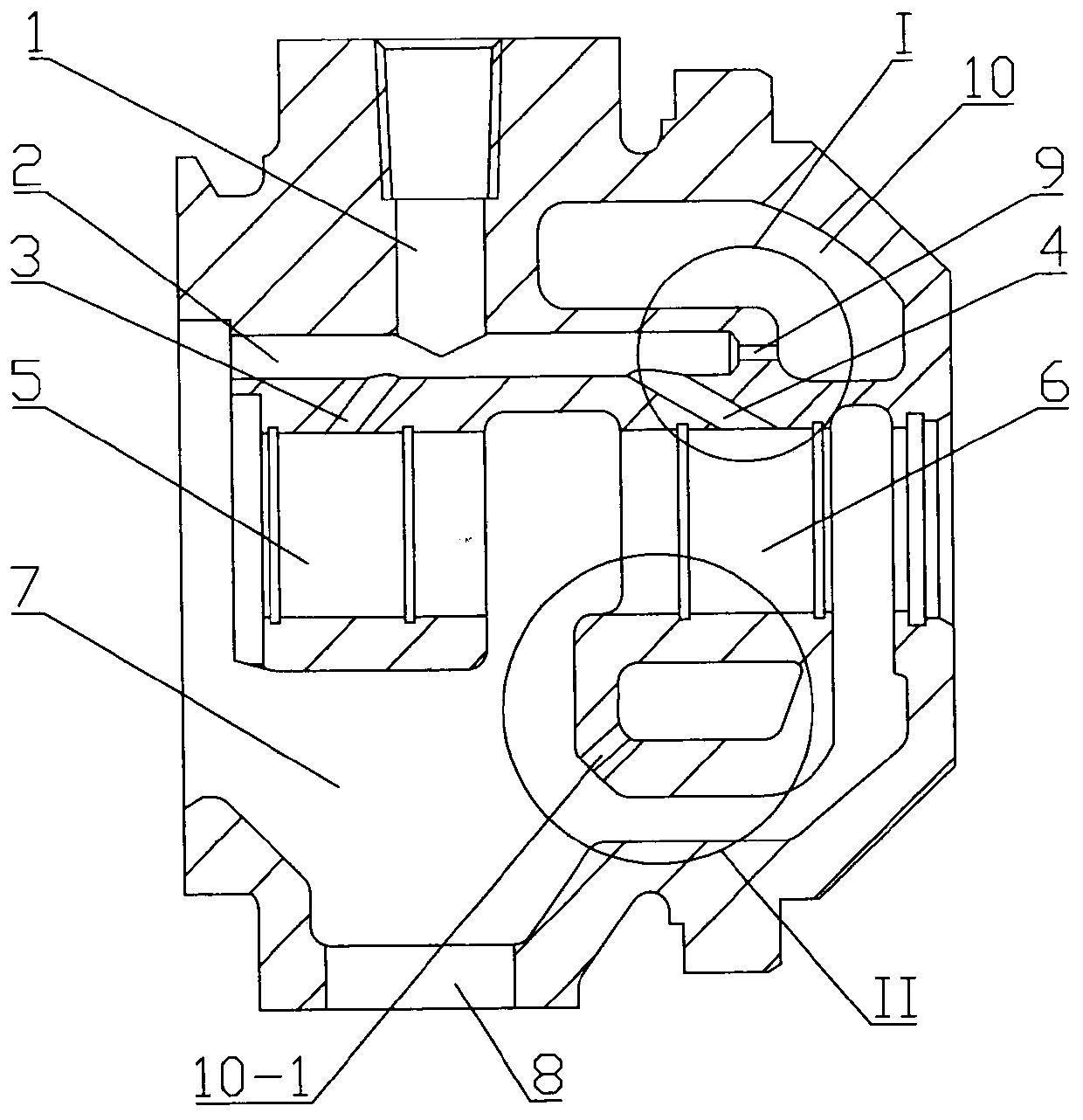

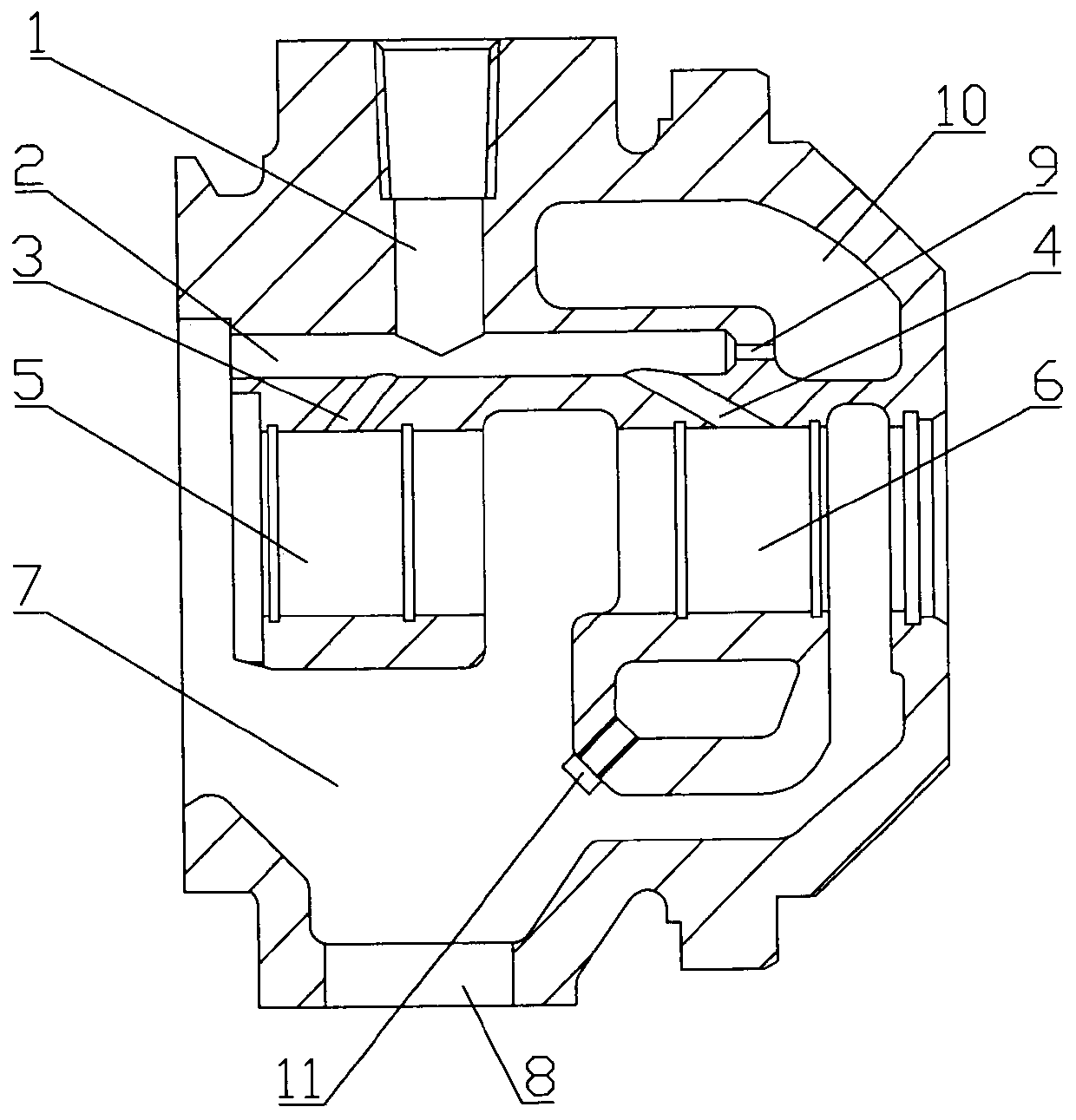

Turbocharger bearing body assembly

PendingCN107869364AReduce the temperatureGuaranteed operating conditionsMachines/enginesEngine componentsTurbochargerOil cooling

The invention relates to a turbocharger bearing body assembly. A bearing body is provided with an oil inlet hole, a main oil guide hole, an air-pressure-end oil guide inclined hole, a turbine-end oilguide inclined hole, an air-pressure-end floating bearing hole, a turbine-end floating bearing hole, a main oil chamber and an oil outlet hole. An independent cooling oil cavity is arranged at the turbine end of the bearing body, and penetrates through the upper and lower structures of the turbine end of the bearing body. An oil injection hole is arranged at the turbine end of the main oil guide hole, and communicates with the independent cooling oil cavity. A lubricating oil pressure relief hole is arranged at the bottom, near the oil outlet hole, of the independent cooling oil cavity, and communicates with the main oil chamber to facilitate the timely discharge of lubricating oil in the cooling oil cavity to the main oil chamber.

Owner:HUNAN TYEN MACHINERY

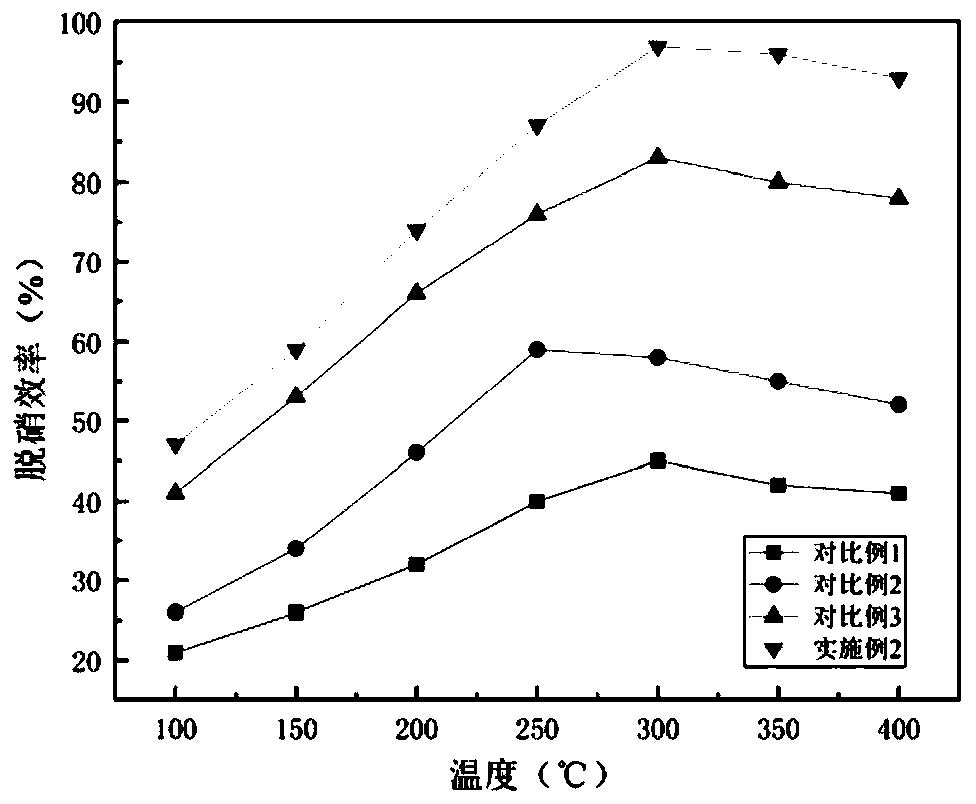

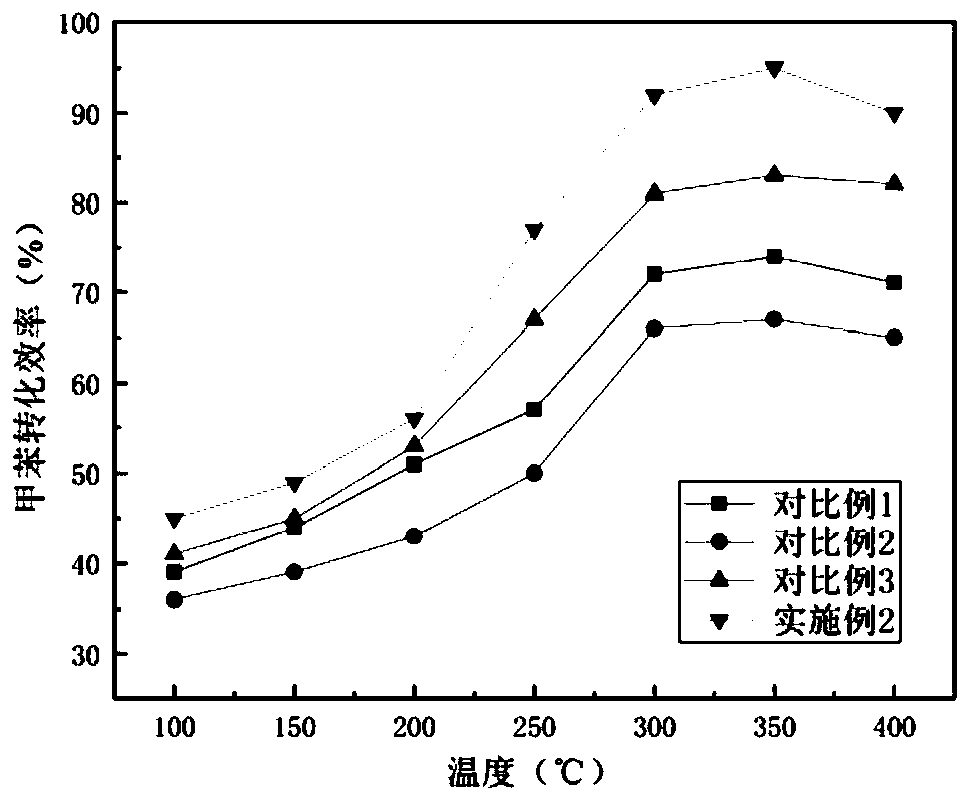

Core-shell structure catalyst for efficient and synergistic removal of NOx and toluene and preparation method thereof

InactiveCN110586177AHigh activityLow ignition temperatureGas treatmentMolecular sieve catalystsMolecular sieveActive component

The invention discloses a core-shell structure catalyst for efficient and synergistic removal of NOx and toluene and a preparation method thereof. The catalyst comprises the following components by mass percentage: 0.5%-4% of Cu, 20-30% of CeO2 and the balance carrier Beta molecular sieve. The preparation method includes: taking Cu / Beta as the core, coating the Cu / Beta core layer with CeO2, and conducting drying and calcining to obtain the Cu / Beta@CeO2 core-shell catalyst. According to the invention, Cu / Beta with strong toluene adsorption and desorption capabilities is adopted as the core, andat the same time Cu can reduce the ignition temperature of the catalyst; and secondly, the strong oxygen storage capacity of the CeO2 shell can prevent carbon deposit on the catalyst surface, thus protecting the active components of the core layer and forming a special interfacial effect with the core layer, and further improving the catalytic activity of the catalyst for toluene at low temperature.

Owner:XIANGTAN UNIV

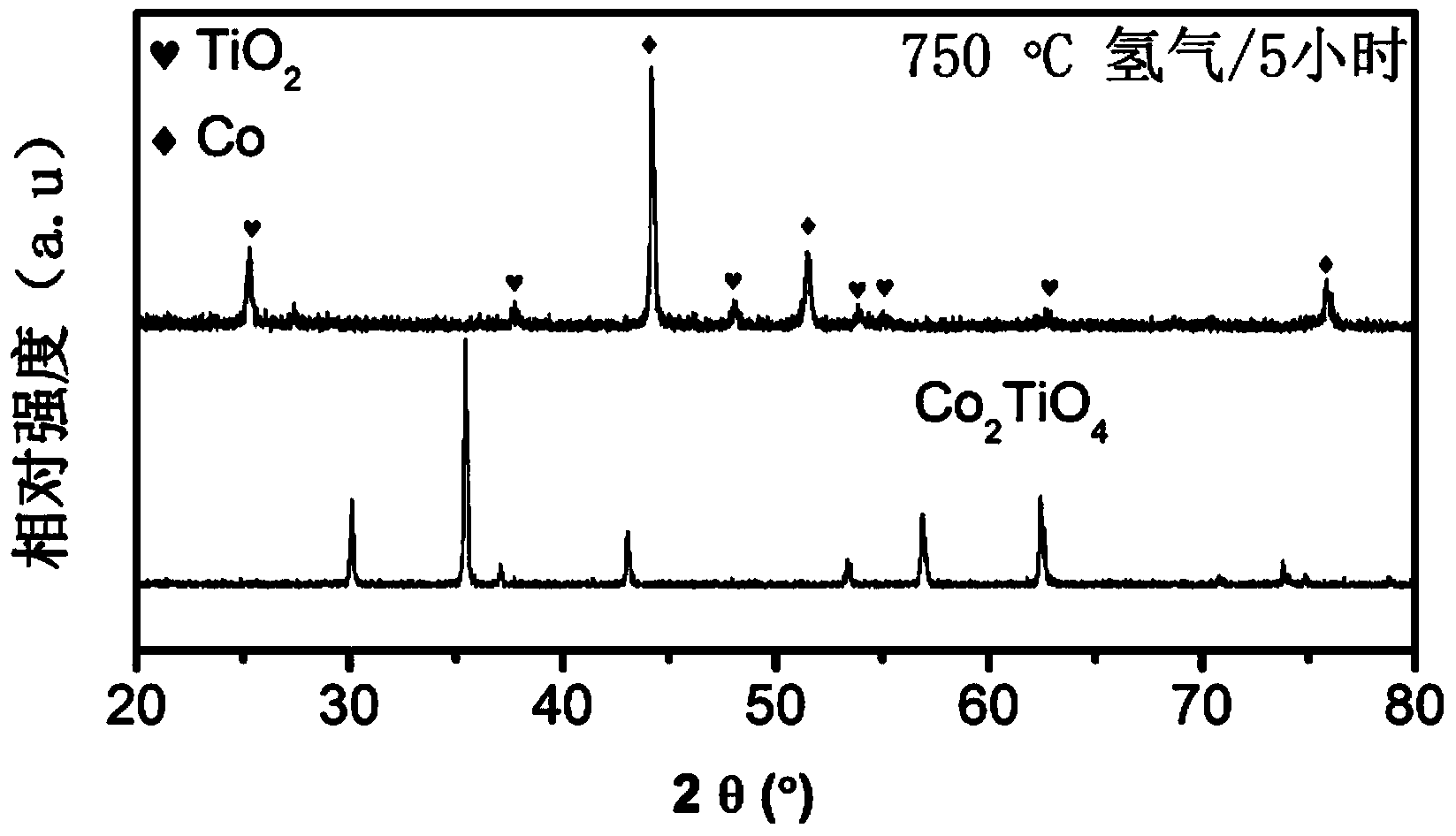

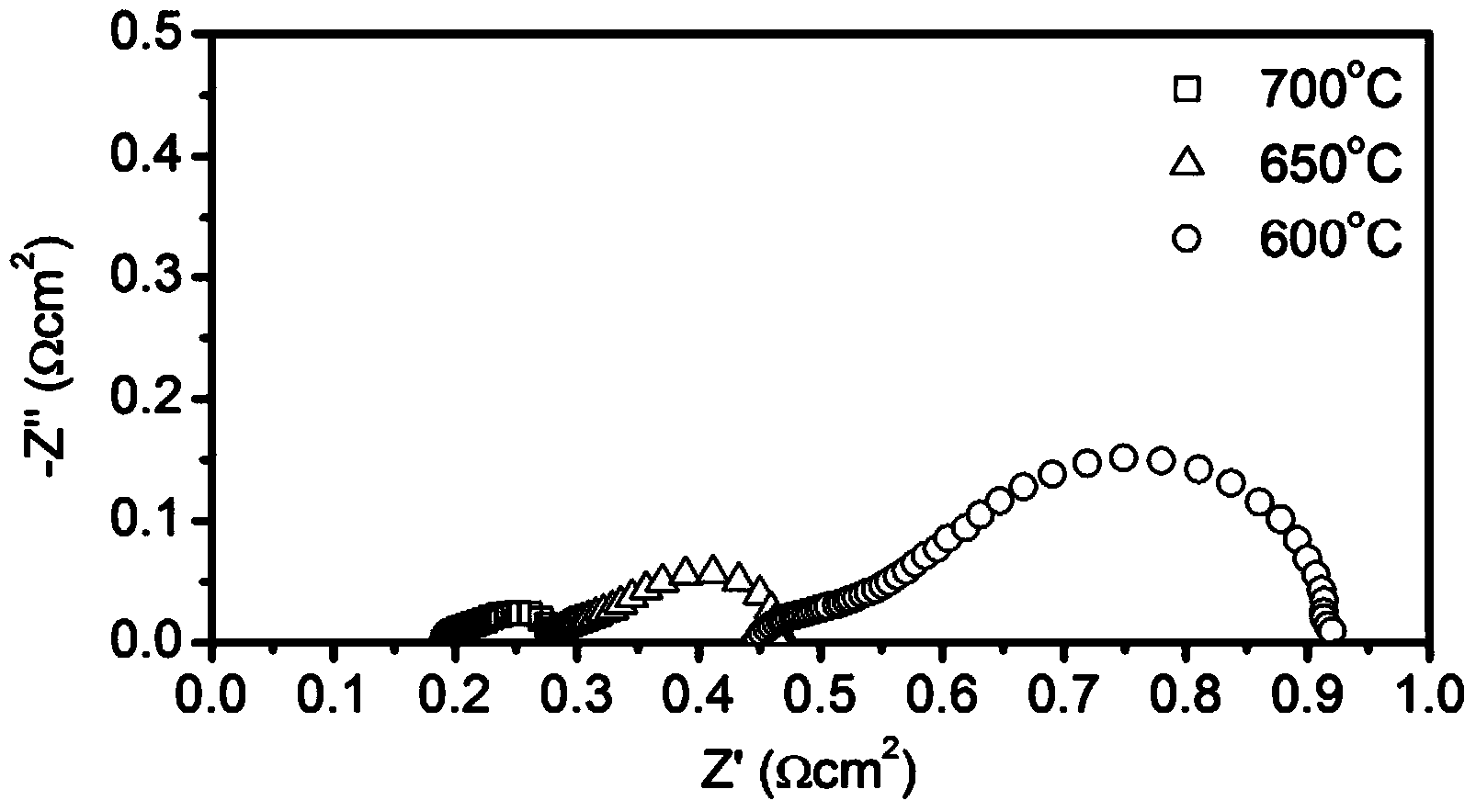

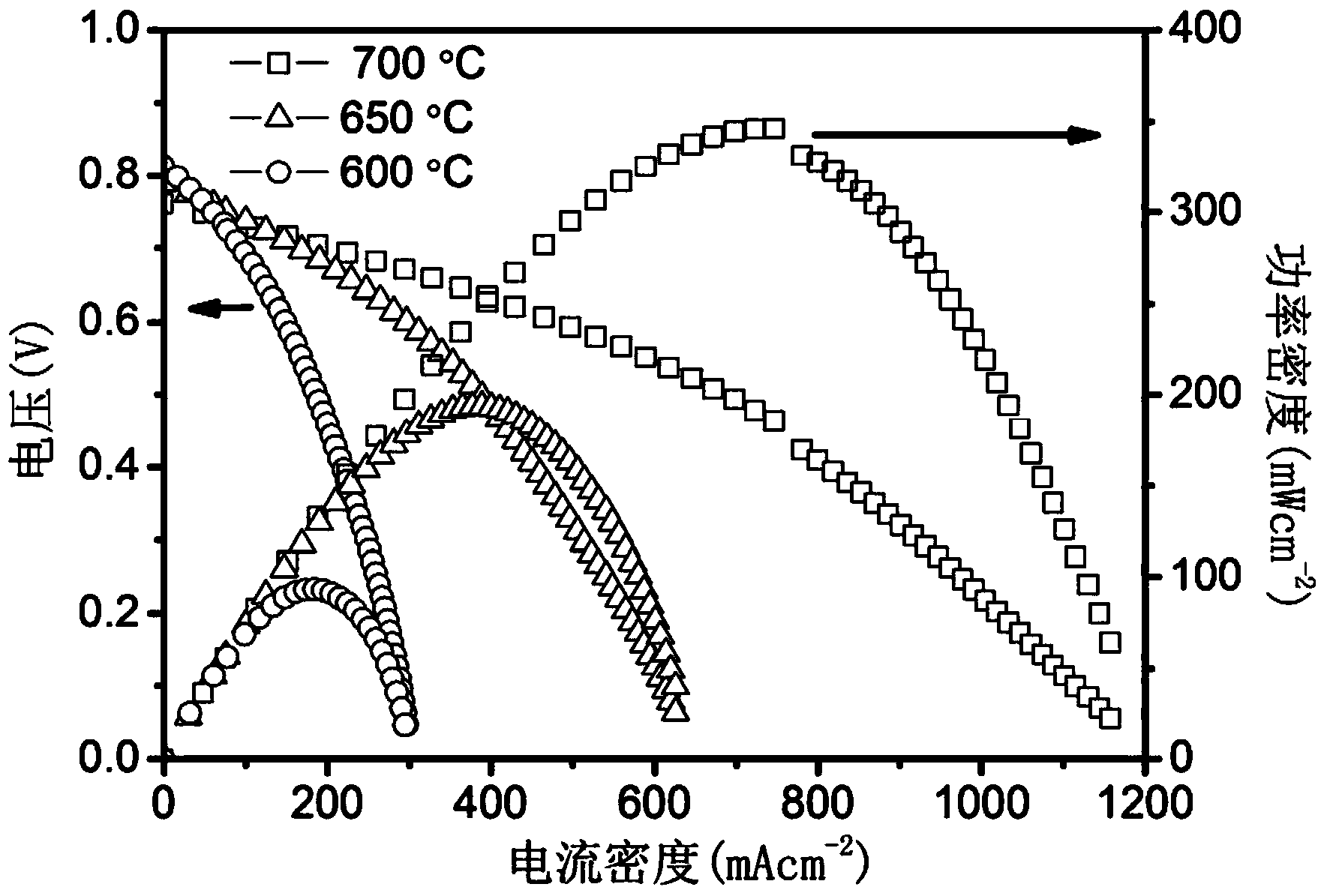

High-catalytic-activity anti-carbon-deposition anode material and preparation method thereof

The invention relates to a novel high-catalytic-activity anode material of a solid oxide fuel cell (SOFC) and a preparation method of the anode material. The anode material is characterized in that the chemical formula is Co2TiO4, and the anode material can be decomposed to be a Co phase and a TiO2 phase which have specific microstructures, wherein the Co phase is used for providing an electronic transmission channel and supplying catalytic activity to the splitting decomposition and oxidation reactions of a hydrocarbon fuel; the TiO2 phase can be used for avoiding the formation of carbon deposition, simultaneously providing an ion transmission channel and increasing the oxidation rate of fuel gas. The invention simultaneously provides a preparation method of a novel anti-carbon-deposition anode material. The anode material has the advantages of high electrical conductivity, high catalytic activity to the hydrocarbon fuel, carbon deposition resistance, simple preparation process, environmental friendliness and the like.

Owner:UNIV OF SCI & TECH OF CHINA

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com