Gas carburetion method for gear wheel in heavy-duty car

A gas carburizing, heavy-duty vehicle technology, applied in metal material coating process, coating, solid diffusion coating, etc. Obtain the structure of the infiltrated layer, the carbon concentration gradient of the infiltrated layer and the hardness gradient, etc., to achieve a good carbon concentration gradient distribution of the infiltrated layer, improve the internal quality, and have a good hardness gradient distribution.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

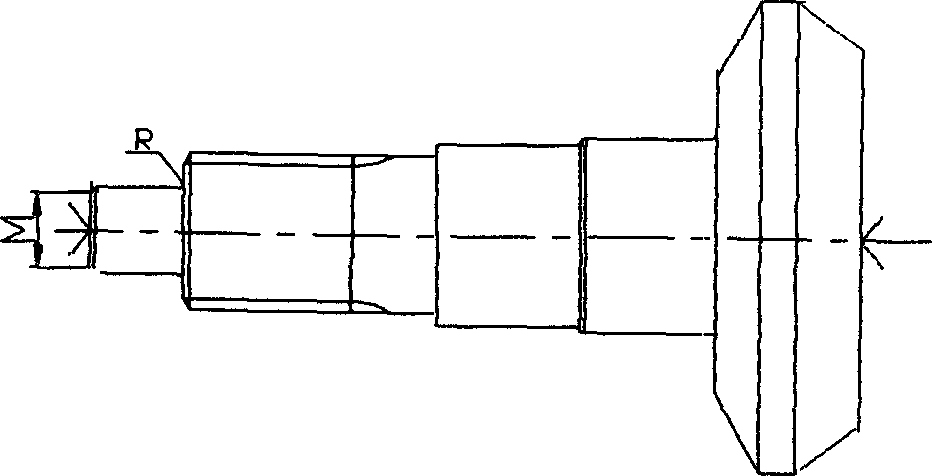

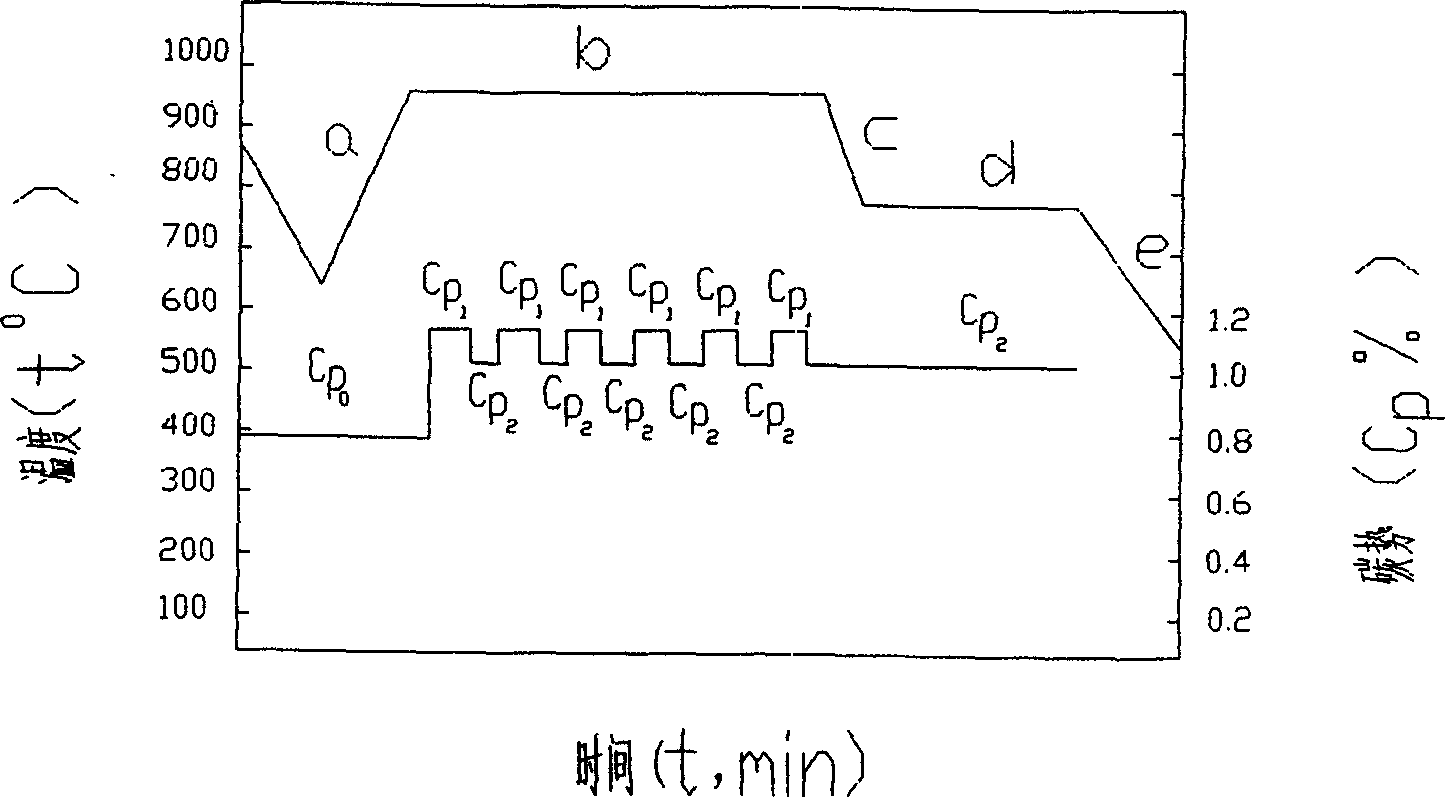

[0024] Example: figure 1 A schematic diagram of the structure of a heavy-duty vehicle gear is given. The gear is a heavy-duty automobile active bevel gear, with a single weight of 18Kg, a modulus of 10, a number of teeth of 21, and a material of 22CrMoH. The technical requirements: the effective carburizing layer depth is 1.1-1.4, and the surface hardness after quenching is HRC59-63. The hardness of the core is HRC33-48, and the metallographic structure conforms to the ZBJ04001-88 automotive gear metallographic carburizing standard. The equipment used is a controlled-atmosphere sealed box-type multi-purpose furnace with a furnace capacity of 40 pieces. Parameters such as time, carbon potential, and temperature can be set and executed in the program of the PVH system, and the process program can be displayed on the screen and has a fault self-diagnosis function. The time is controlled by the time relay; the carbon potential is controlled by the carbon controller, and the sign...

PUM

| Property | Measurement | Unit |

|---|---|---|

| modulus | aaaaa | aaaaa |

| hardness | aaaaa | aaaaa |

| hardness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com