Composite fuel oil and preparation method thereof

A technology of fuel oil and heavy oil, which is applied in the direction of fuel, liquid carbon-containing fuel, and petroleum industry. It can solve the problems of inconvenient storage, transportation and use, large exhaust gas emissions, and environmental pollution, so as to reduce daily maintenance and speed up combustion. , the effect of high calorific value

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

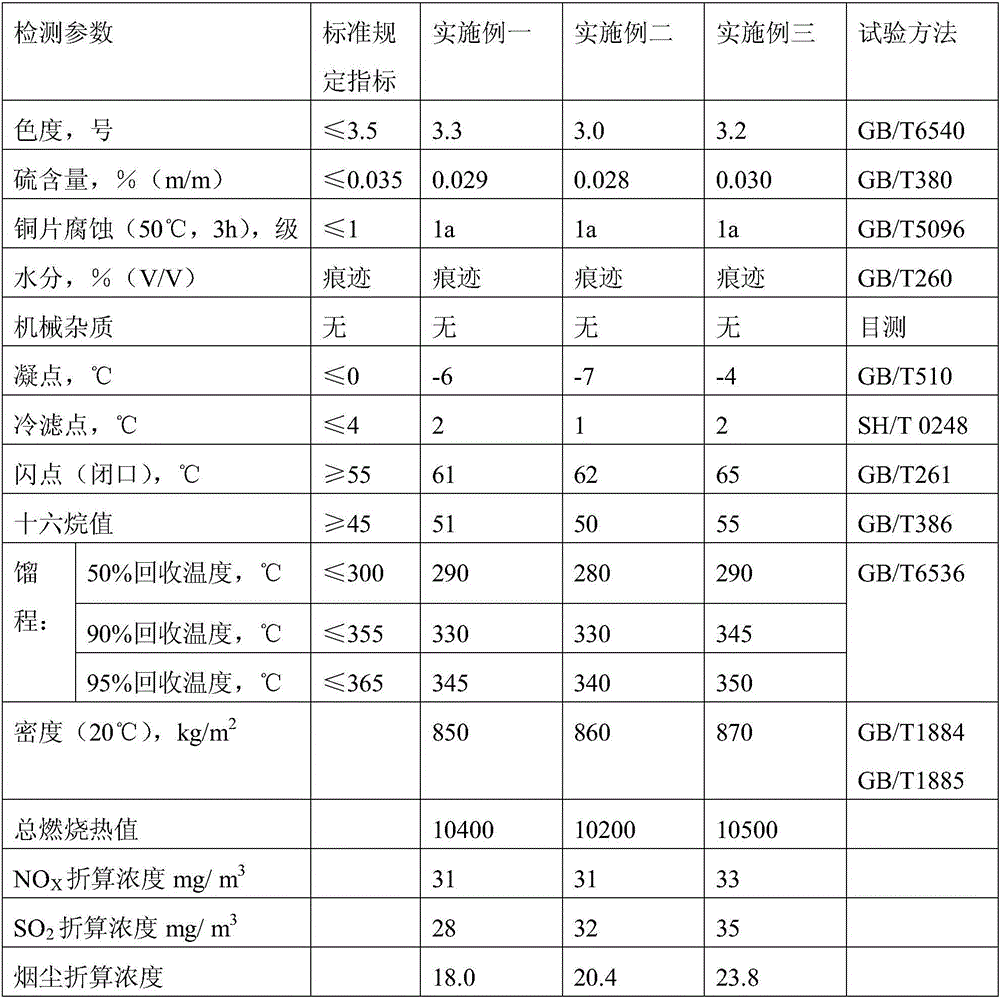

Examples

Embodiment 1

[0026] A kind of composite fuel oil, the component that it contains and the mass parts of each component are as follows:

[0027] Heavy oil: 5 parts;

[0028] Coal oil: 10 parts;

[0029] Coking light oil: 10 parts;

[0030] Vegetable oil: 20 parts;

[0031] Microbial oil: 5 parts;

[0032] Vegetable oleic acid or ethanolamine: 3 parts;

[0033] Methanol: 10 parts;

[0034] Distilled oil: 10 parts; among them, distilled oil is obtained by distillation of waste engine oil and / or diesel oil and / or gutter oil;

[0035] Additives: 1 part; the additives include a combustion enhancer, a dispersant and an anti-corrosion agent.

[0036] The vegetable oil can be waste palm oil.

[0037] The weight ratio of the combustion aid, dispersant and corrosion inhibitor is 1:1:1.

[0038] The additive also contains a coking retarder and / or a smoke suppressant.

[0039] The steps of the preparation method of this composite fuel oil are as follows:

[0040] (1) Add a diluent capable of a...

Embodiment 2

[0046] A kind of composite fuel oil, the component that it contains and the mass parts of each component are as follows:

[0047] Heavy oil: 15 parts;

[0048] Coal oil: 40 parts;

[0049] Coking light oil: 20 parts;

[0050] Vegetable oil: 40 parts;

[0051] Microbial oil: 10 parts;

[0052] Vegetable oleic acid or ethanolamine: 6 parts;

[0053] Methanol: 25 parts;

[0054] Distilled oil: 40 parts; among them, distilled oil is obtained by distillation of waste engine oil and / or diesel oil and / or waste oil;

[0055] Additives: 1 to 5 parts; the additives include a combustion enhancer, a dispersant and an anticorrosion agent.

[0056] Described vegetable oil is waste palm oil.

[0057] The weight ratio of the combustion aid, dispersant and corrosion inhibitor is (1-2):1:1.

[0058] The additive also contains a coking retarder and / or a smoke suppressant.

[0059] The steps of the preparation method of this composite fuel oil are as follows:

[0060] (1) Add a diluent ...

Embodiment 3

[0066] A kind of composite fuel oil, the component that it contains and the mass parts of each component are as follows:

[0067] Heavy oil: 10 parts;

[0068] Coal oil: 25 parts;

[0069] Coking light oil: 15 parts;

[0070] Vegetable oil: 30 parts;

[0071] Microbial oil: 8 parts;

[0072] Vegetable oleic acid or ethanolamine: 4 parts;

[0073] Methanol: 18 parts;

[0074] Distilled oil: 25 parts; among them, distilled oil is obtained by distillation of waste engine oil and / or diesel oil and / or gutter oil;

[0075] Additives: 3 parts; the additives include a combustion enhancer, a dispersant and an anticorrosion agent.

[0076] Described vegetable oil is waste palm oil.

[0077] The weight ratio of the combustion aid, dispersant and corrosion inhibitor is 1:1:1.

[0078]The present invention also provides a kind of preparation method of composite fuel oil, the steps of this method are as follows:

[0079] (1) Add a diluent capable of adjusting the thickness of the h...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com