Patents

Literature

826results about How to "Extended useful life" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

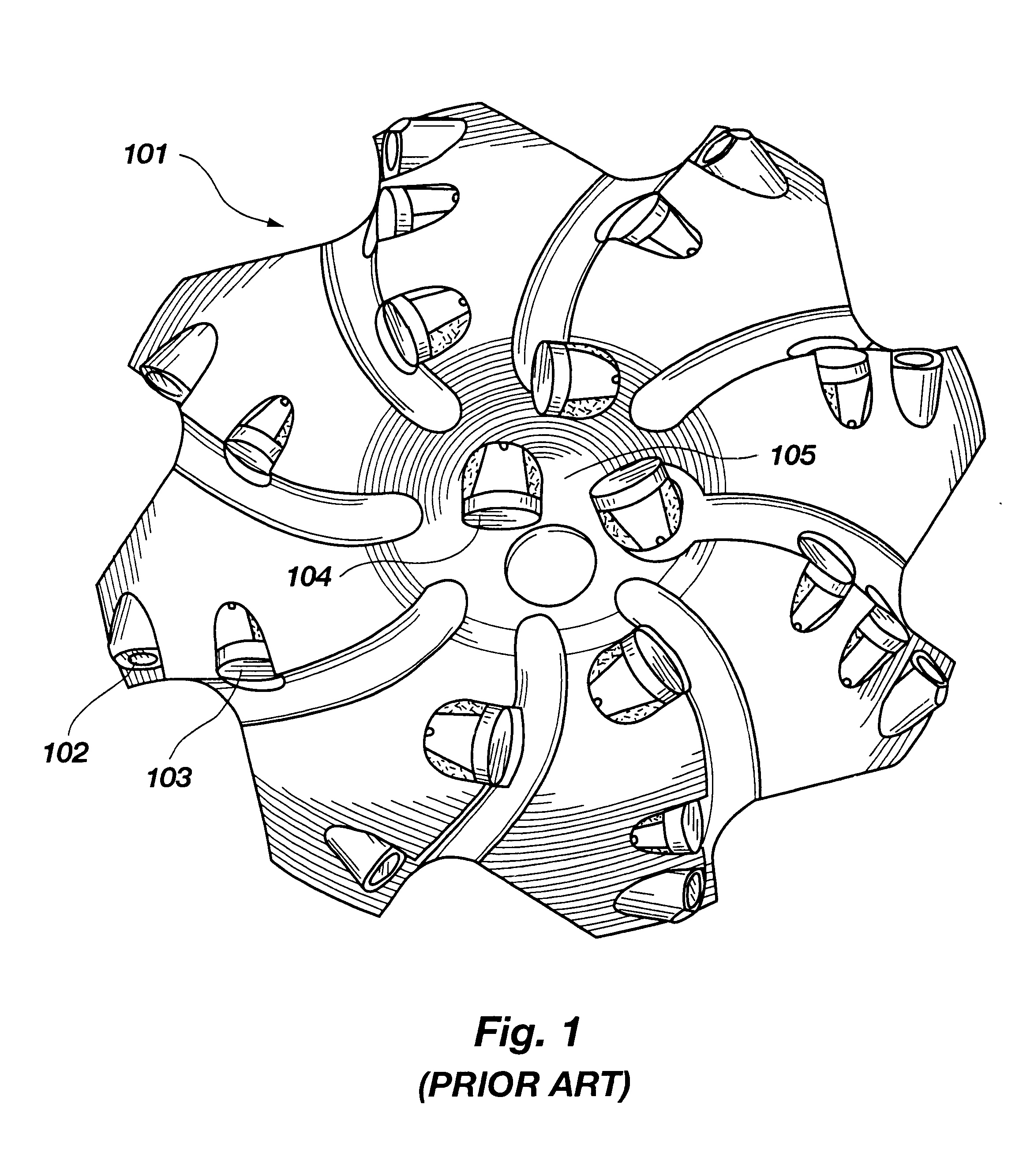

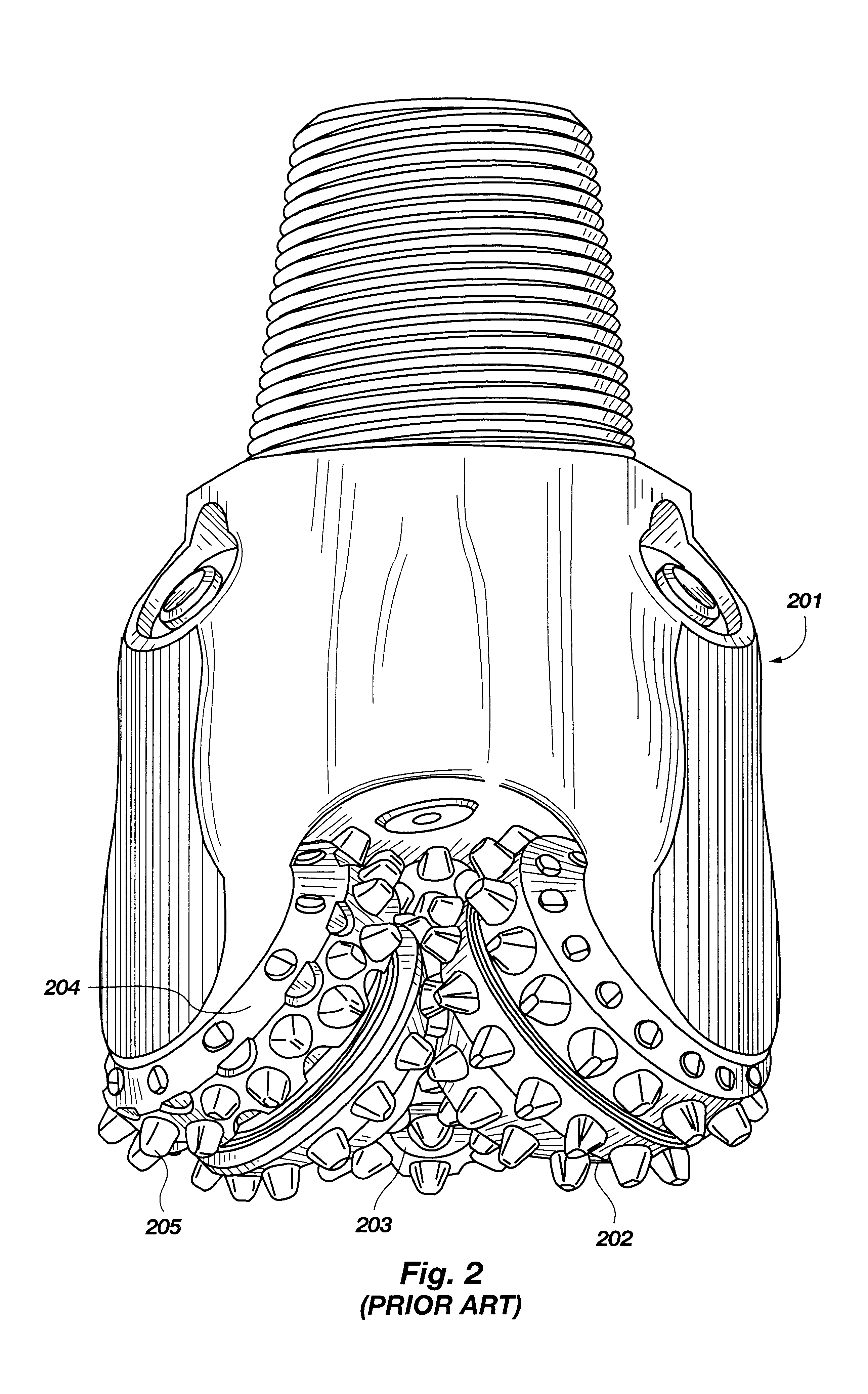

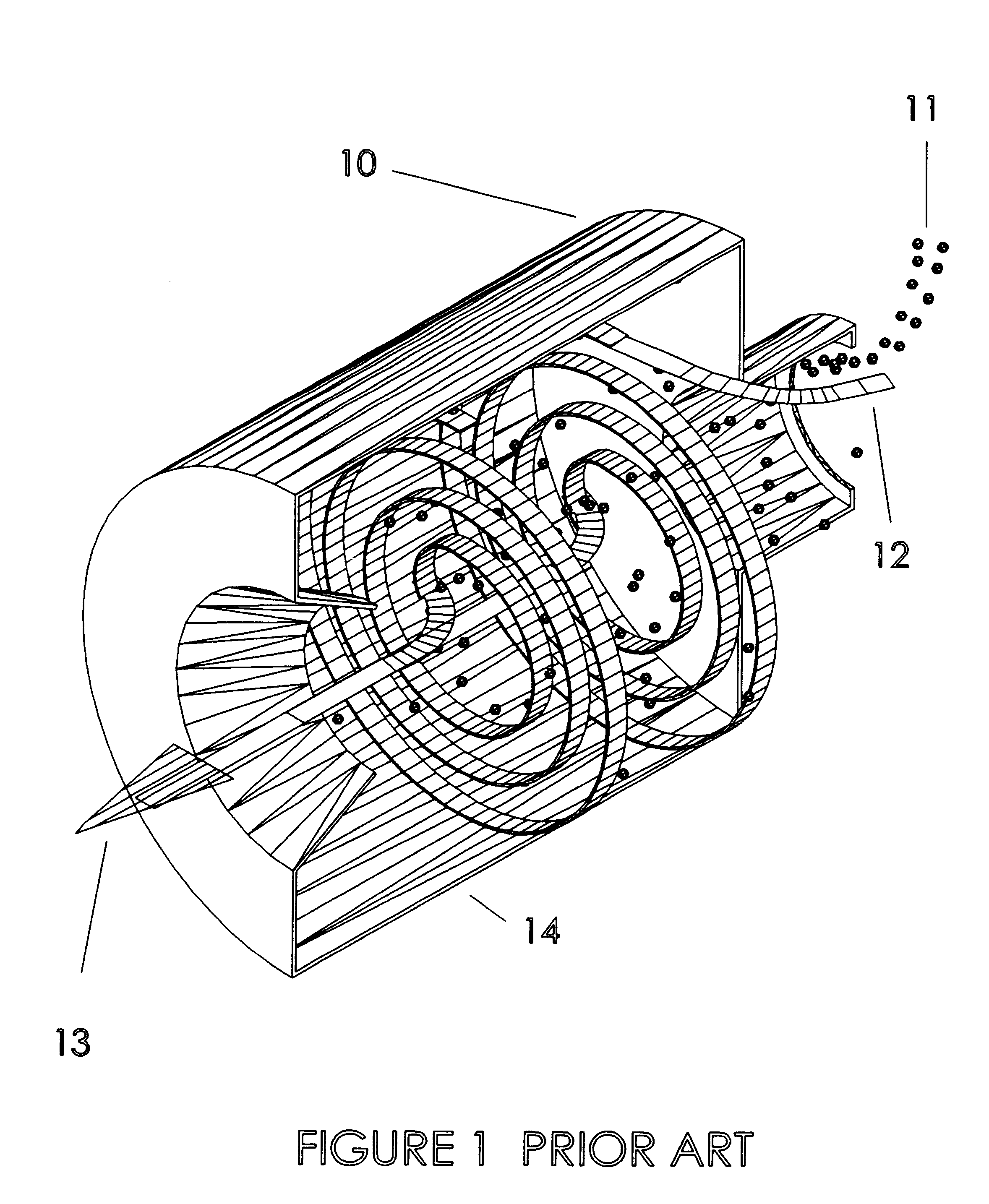

Superabrasive cutting element with enhanced durability and increased wear life and apparatus so equipped

InactiveUS6202770B1Extended service lifeReduced tendency to catastrophically spallDrill bitsConstructionsEngineeringMechanical engineering

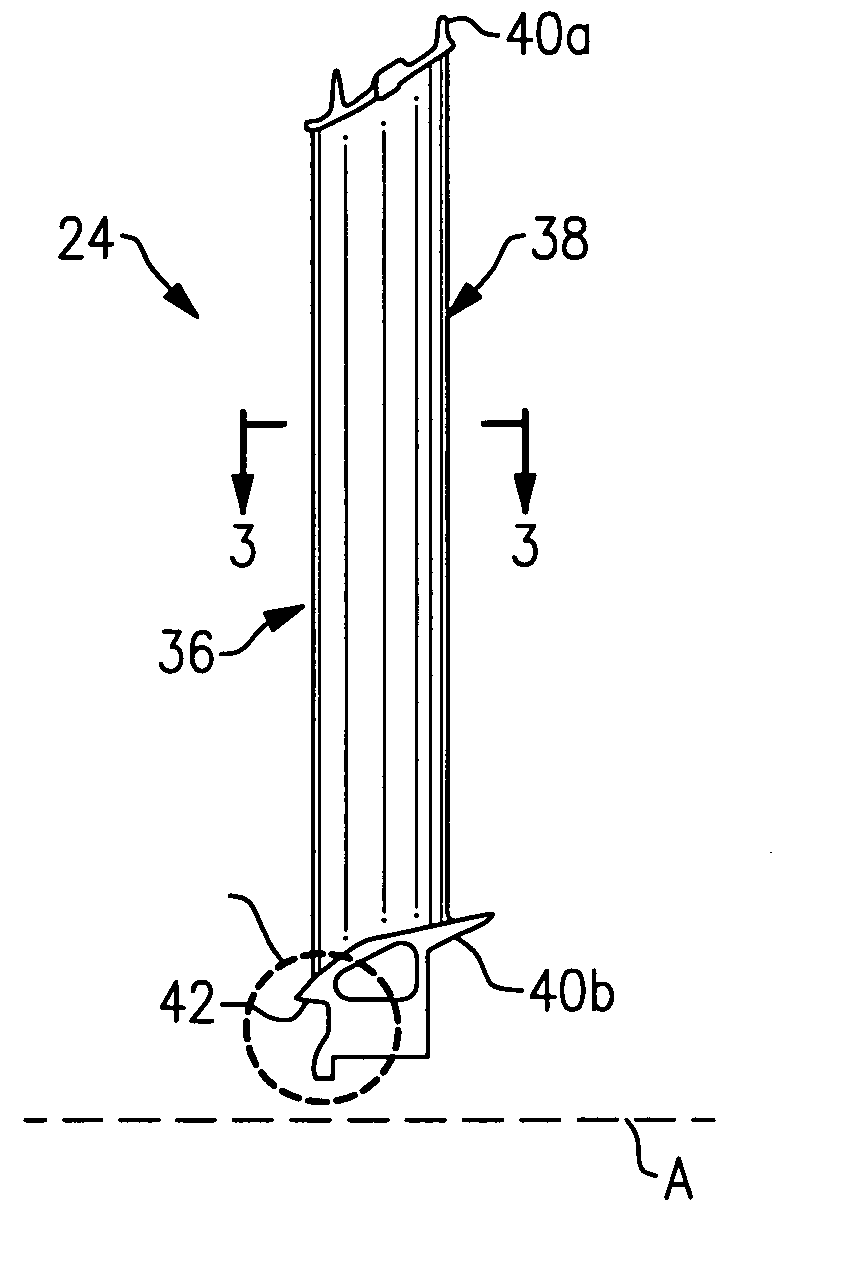

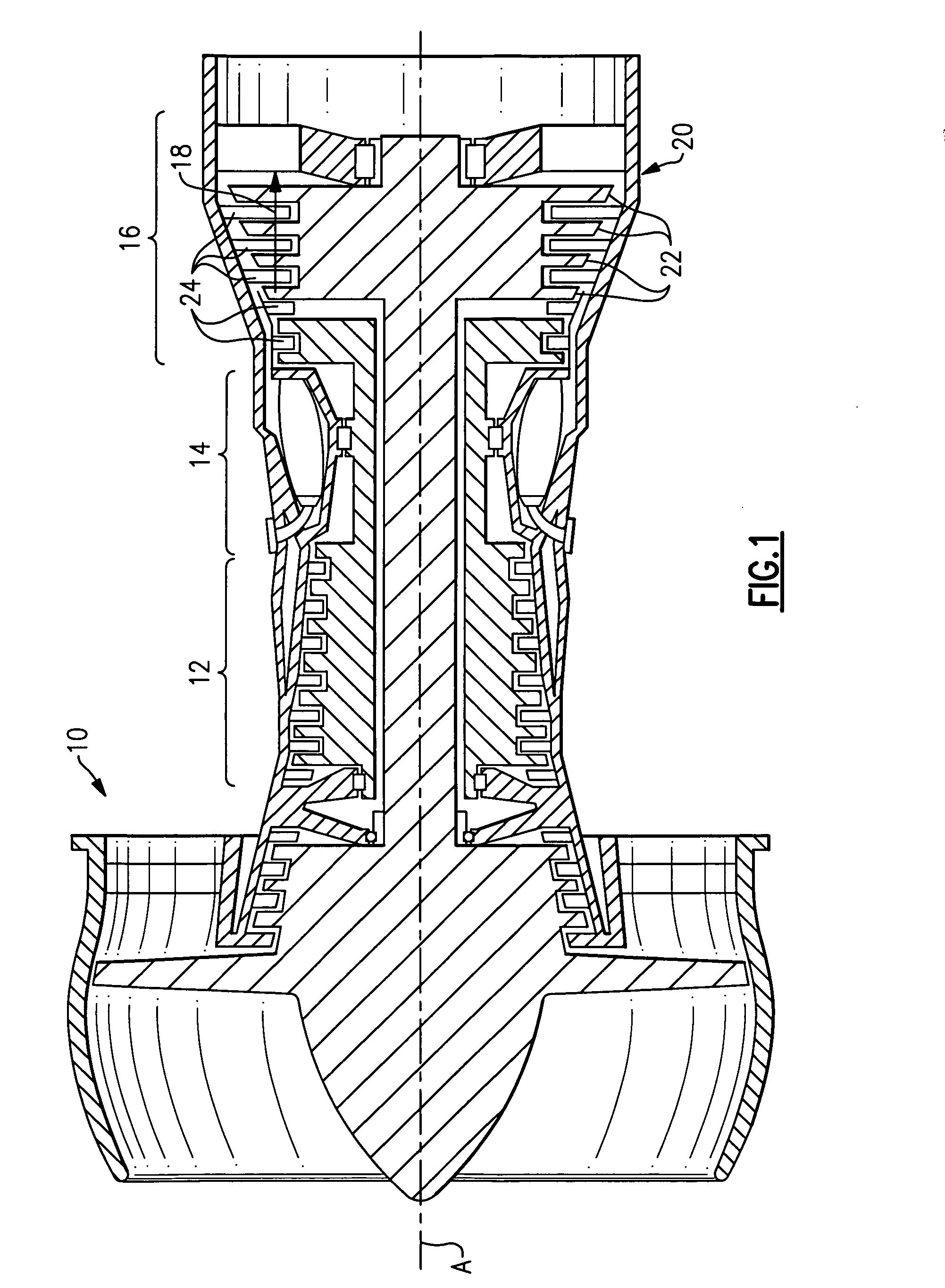

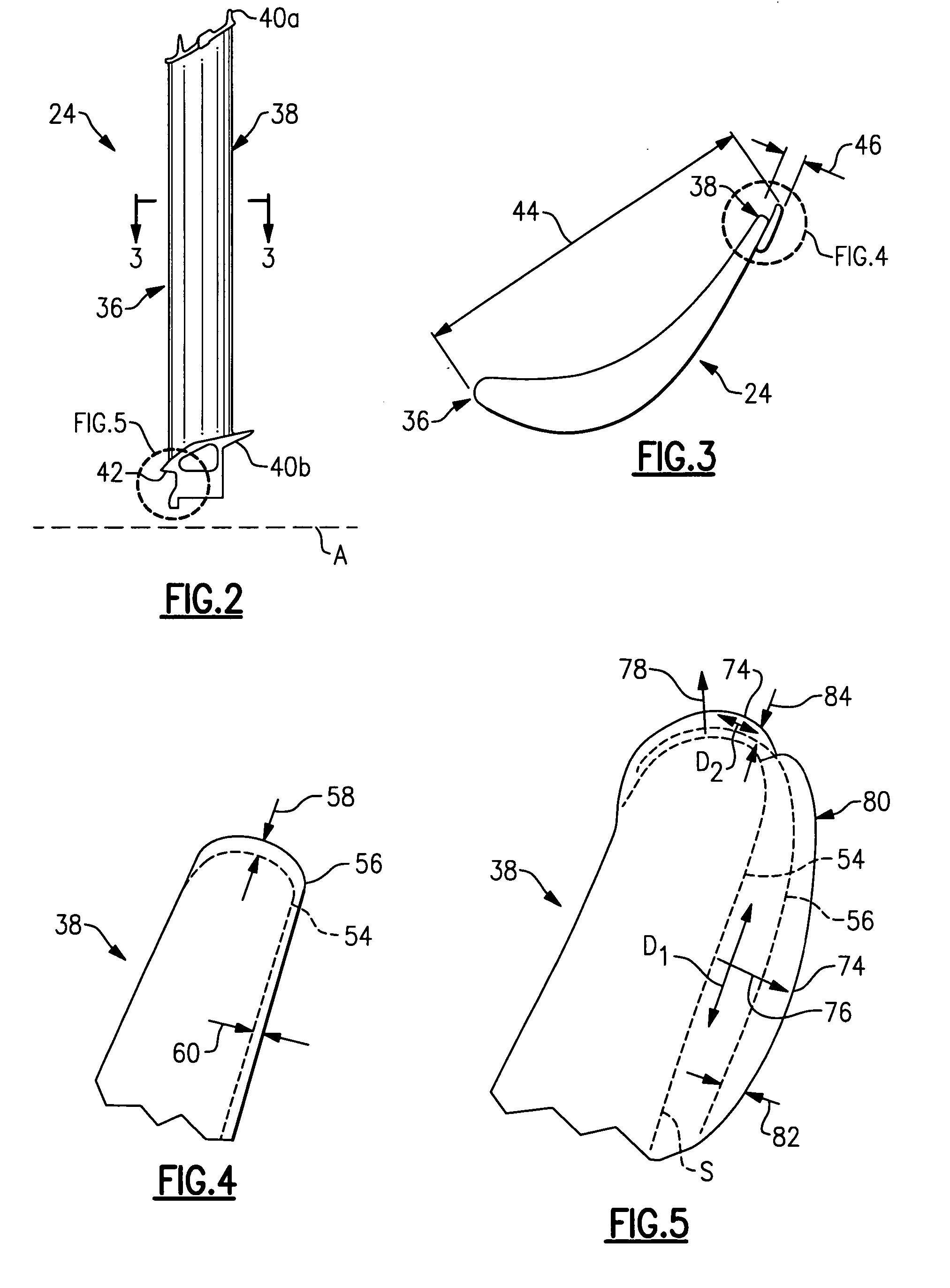

A cutting element for use in drilling subterranean formations. The cutting element includes a superabrasive table mounted to a supporting substrate. The superabrasive table includes a two-dimensional cutting face having a cutting edge along at least a portion of its periphery, and a first surface extending forwardly and inwardly from a location radially interior of the cutting edge at a first angle of orientation with respect to the longitudinal axis of the cutting element. The cutting face also includes at least a second surface located between the first surface and the cutting edge and oriented at a different, greater angle to the longitudinal axis than the angle of orientation of the first surface.

Owner:BAKER HUGHES INC

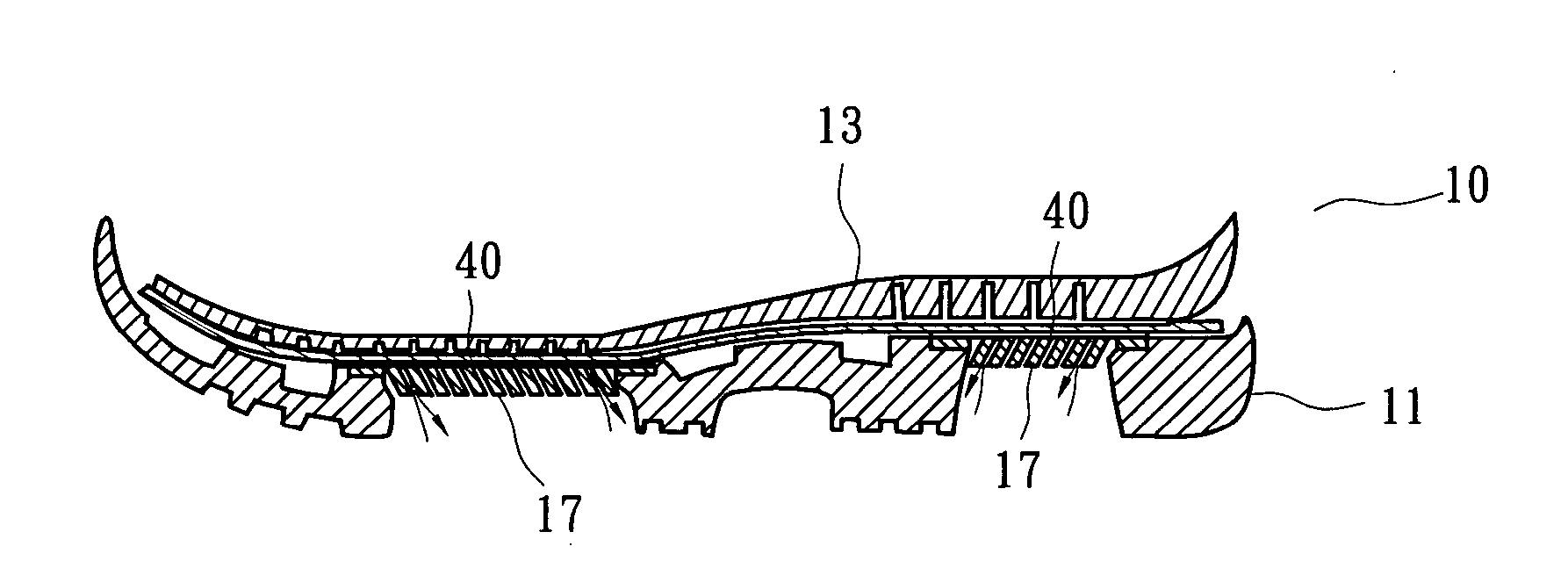

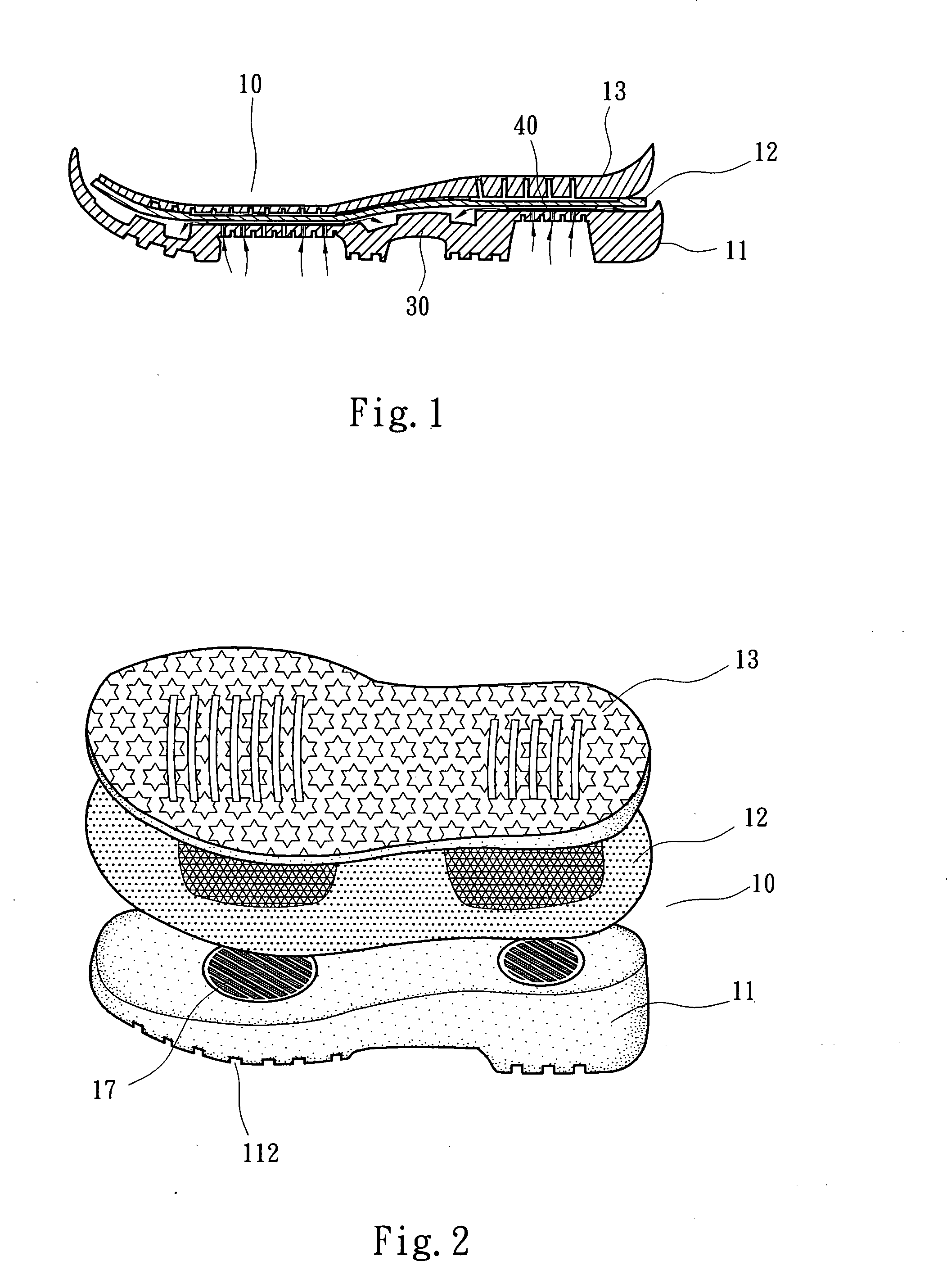

Sole structure with complex waterproof and gas-permeable material and manufacturing method thereof

InactiveUS20050126036A1Extended service lifeExtended useful lifeSolesDomestic footwearPlastic materialsMaterials science

Owner:WU HUEI LING

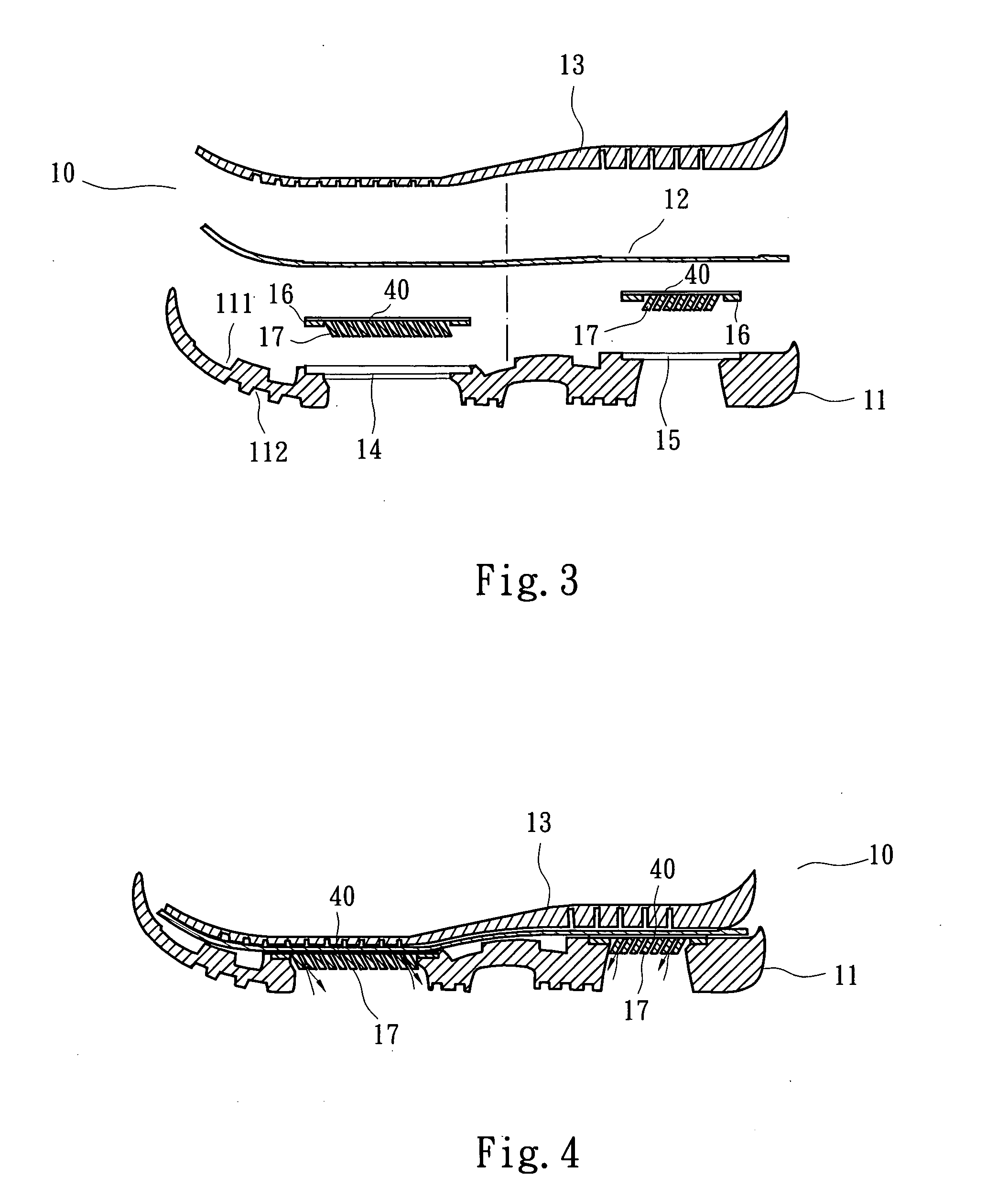

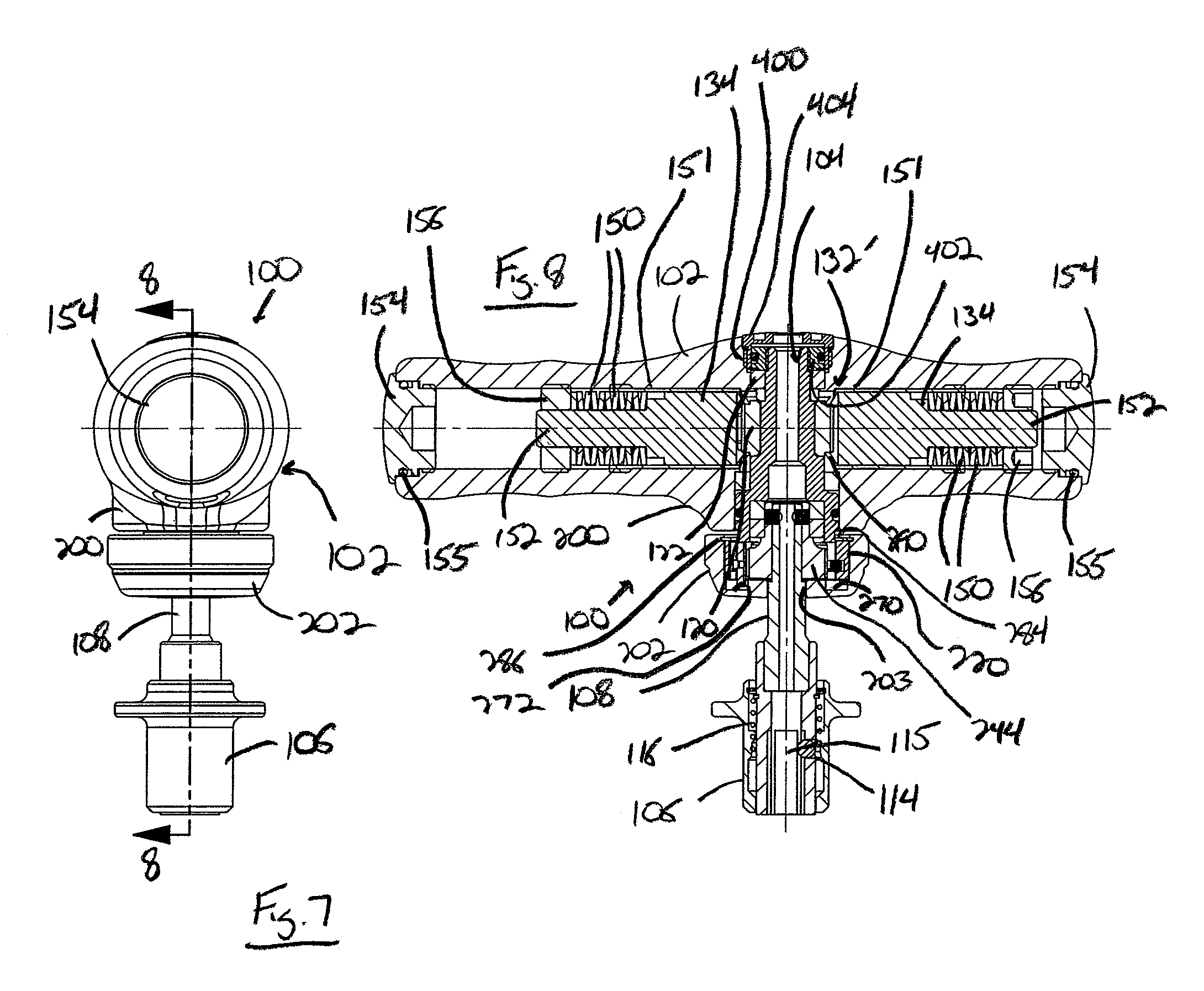

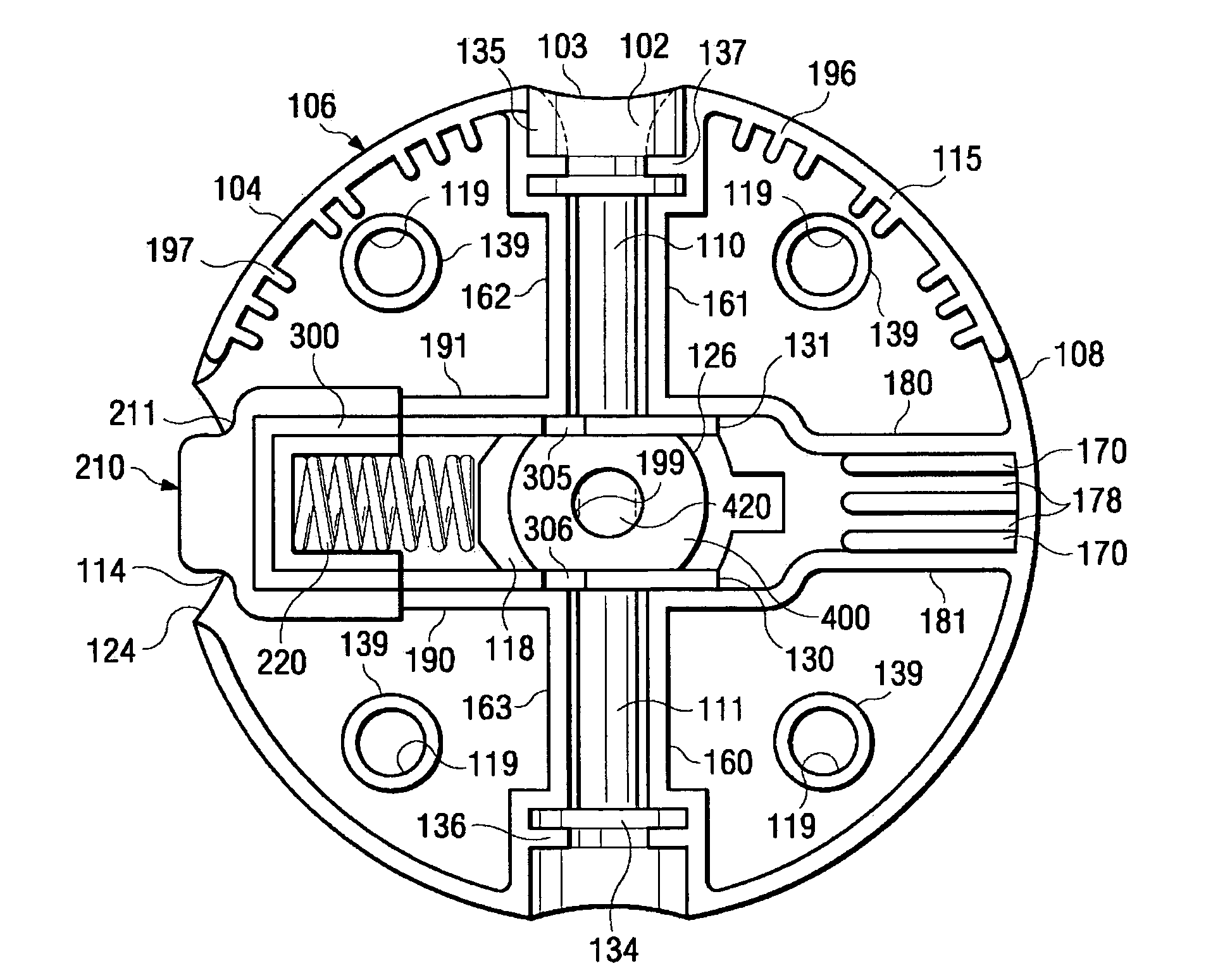

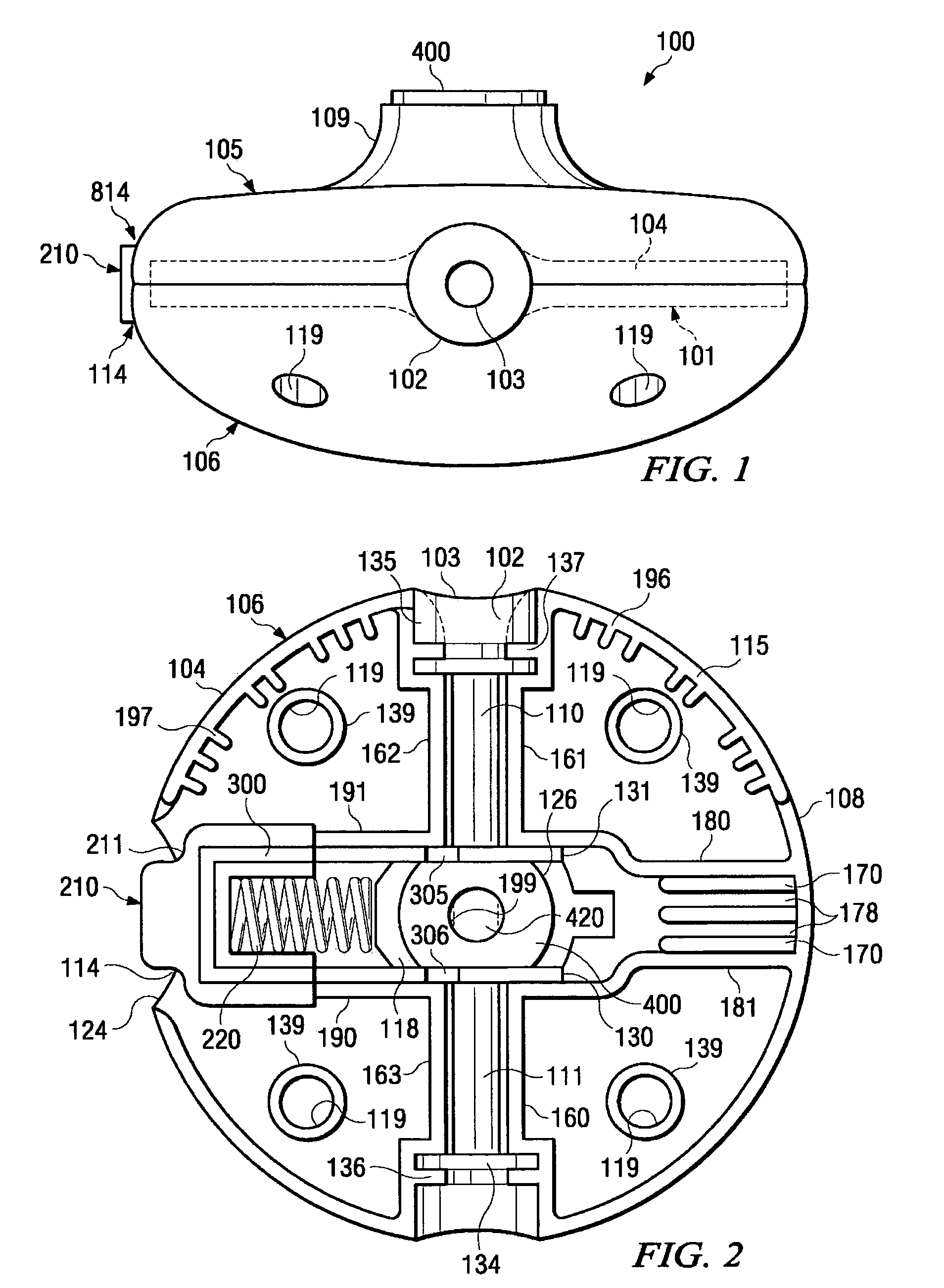

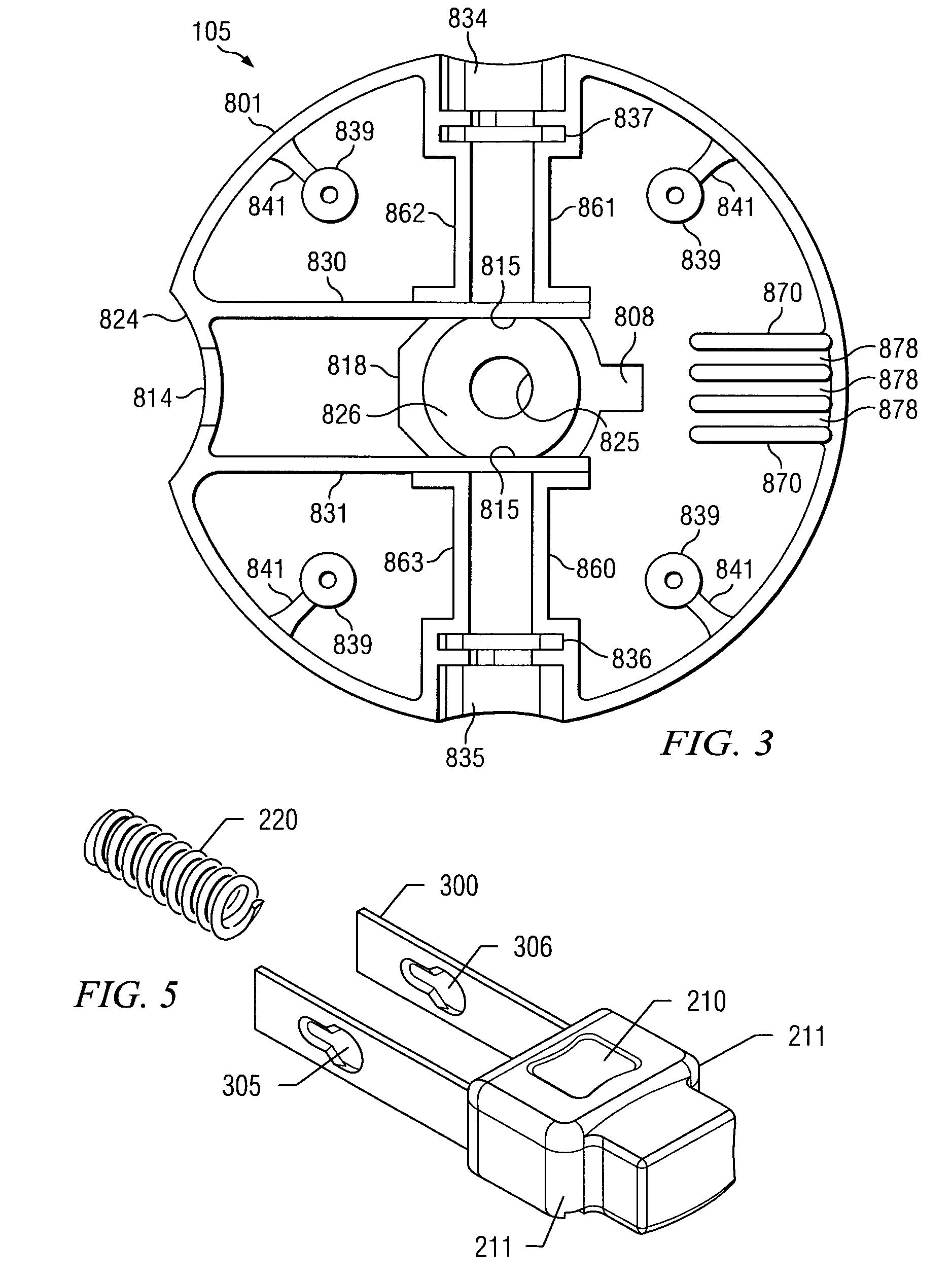

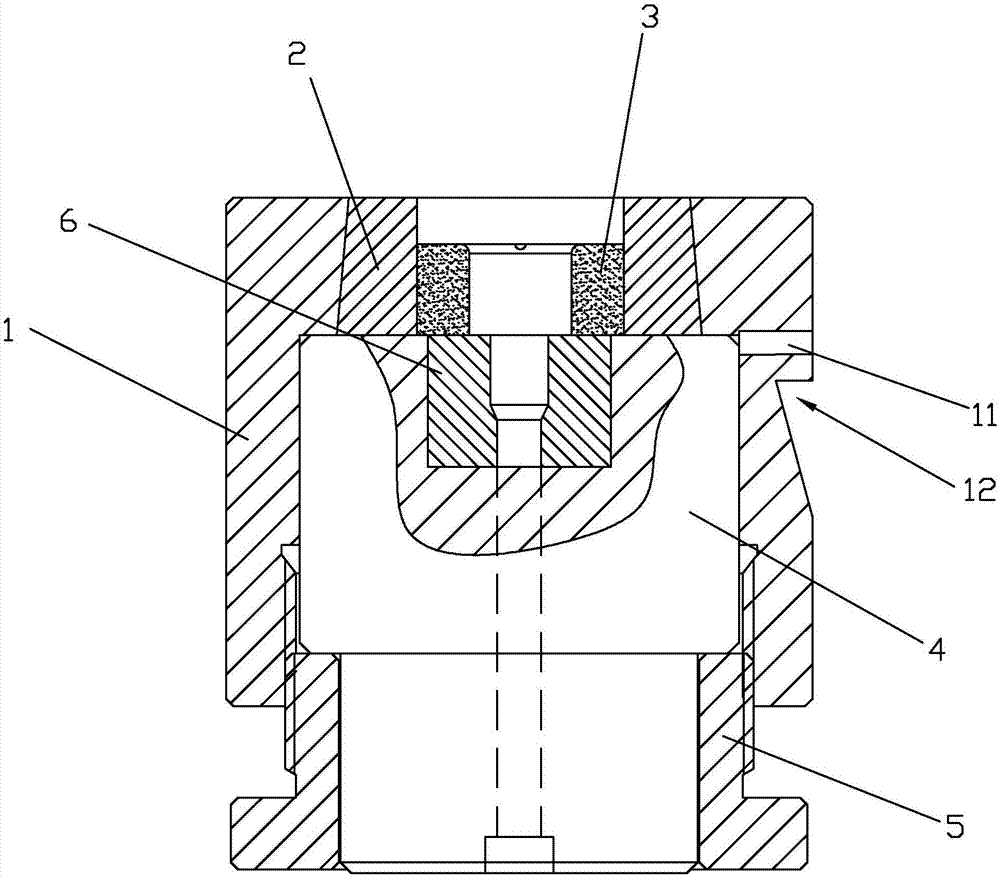

Ratcheting torque wrench

InactiveUS7430945B2Low profileReduces friction and resulting wearSpannersWrenchesDrive shaftControl theory

A tool is provided for driving fasteners that includes a torque limiting mechanism therein. The torque limiting mechanism includes a first frictional engagement member disposed on the drive shaft for the tool that is engaged by one or more second frictional engagement members disposed on one or more sides of the first frictional member. The second frictional engagement members are biased into engagement with the first member by biasing members disposed within the handle that can be adjusted in order to provide more or less of a biasing force to control the frictional engagement of the second member with the first member and thereby control the torque limiting function of the torque limiting mechanism. In addition, a drive shaft is also engaged with a ratcheting mechanism that enables the tool to drive a fastener into a suitable substrate in only a single direction.

Owner:GAUTHIER BIOMEDICAL

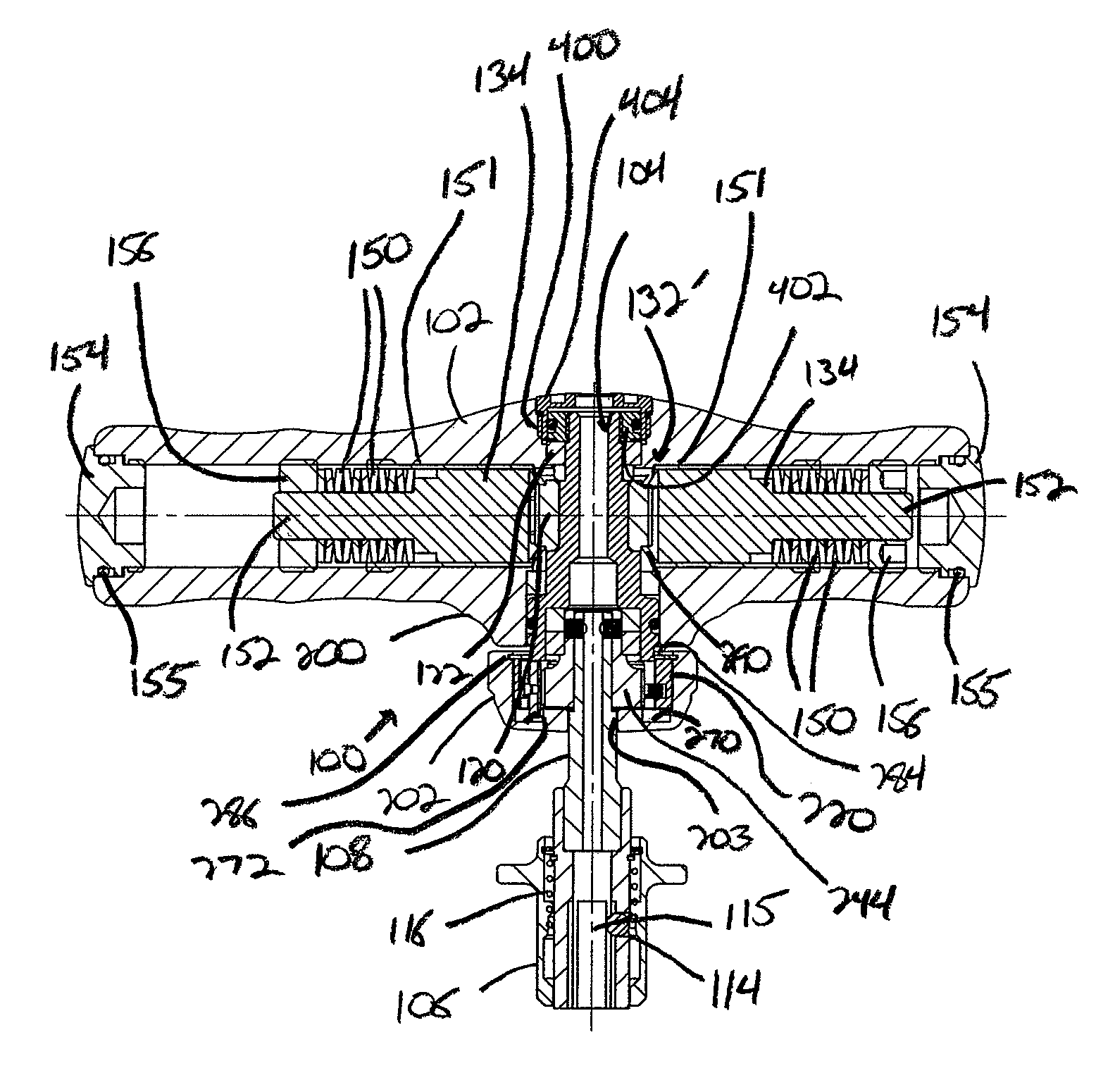

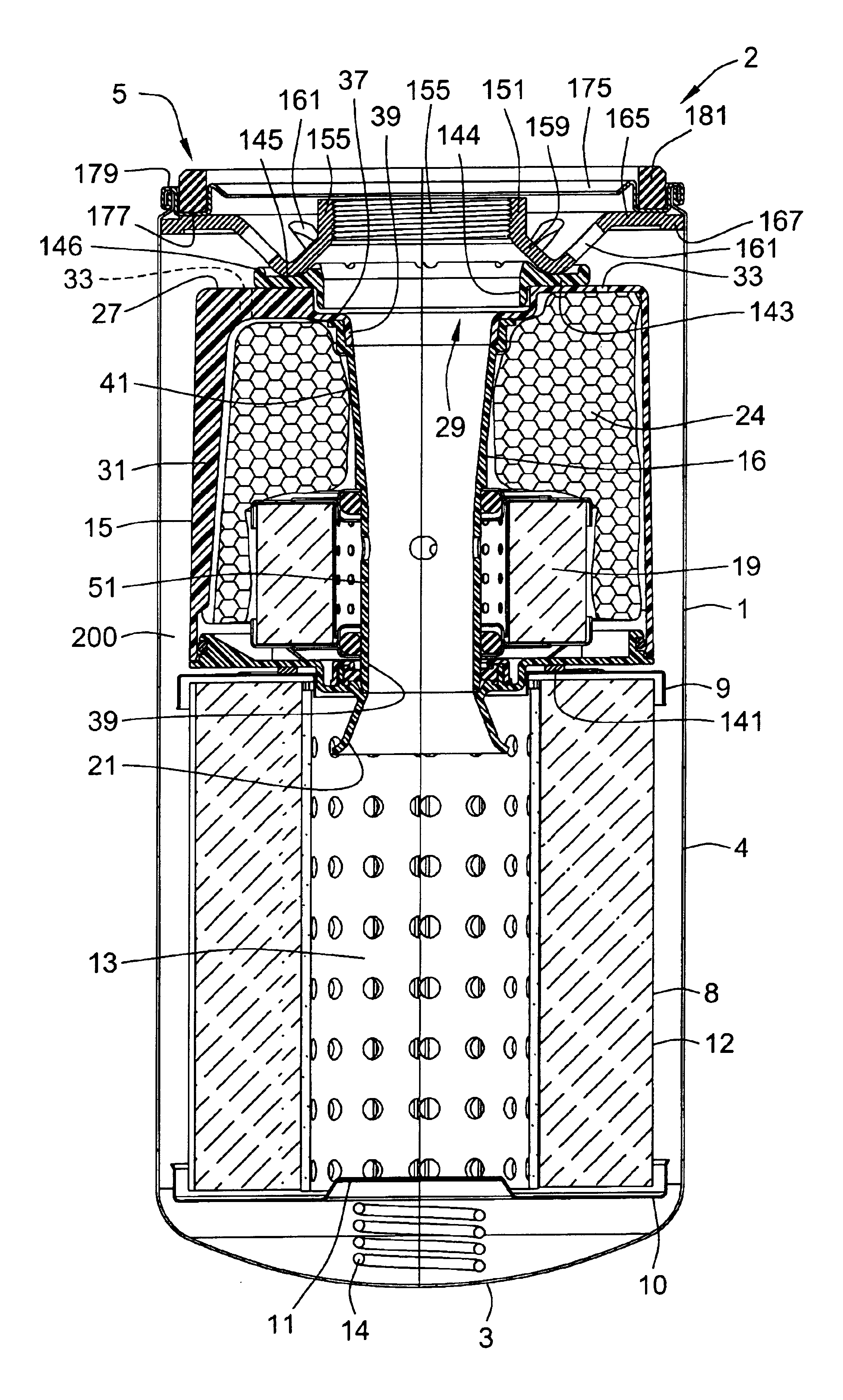

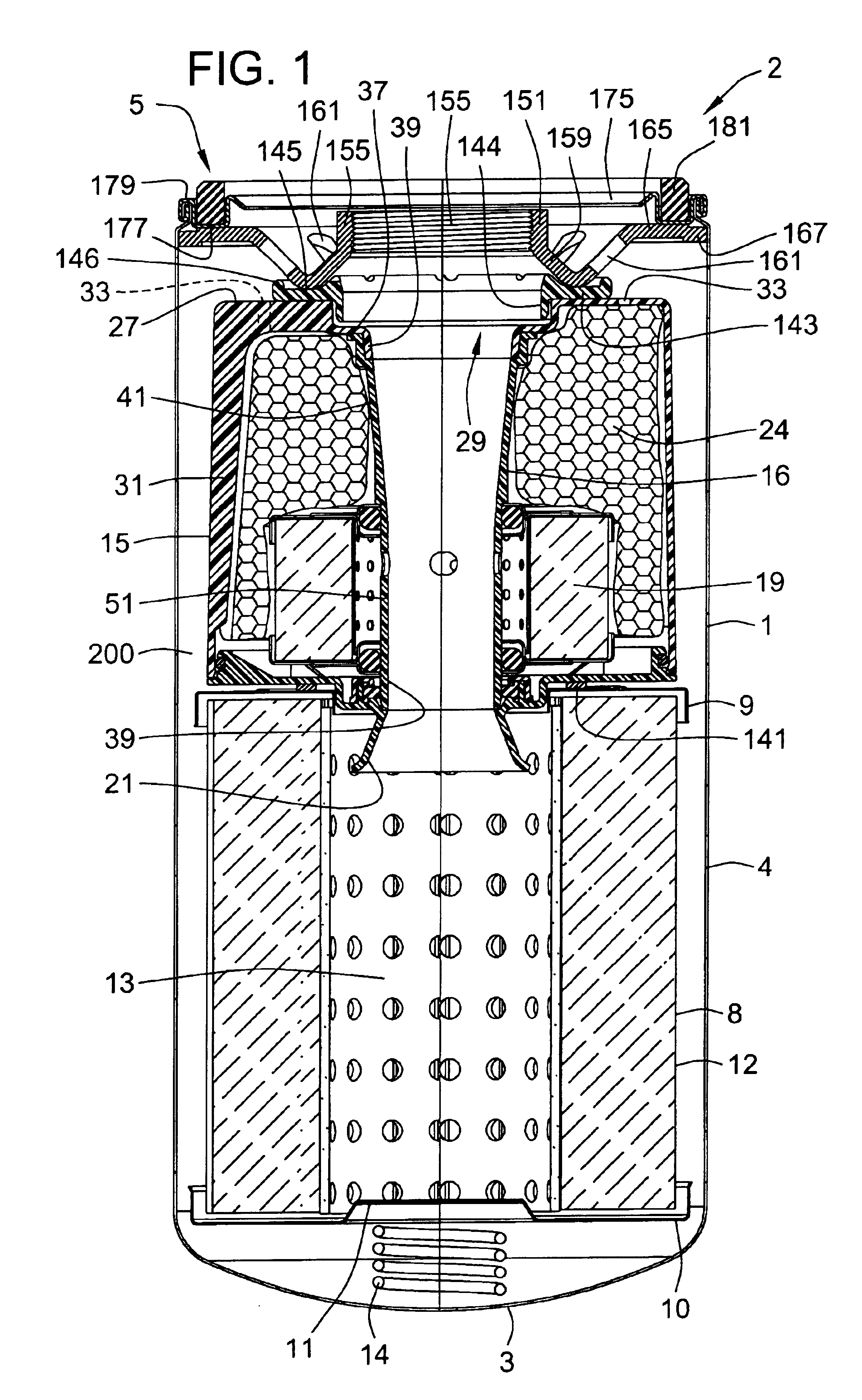

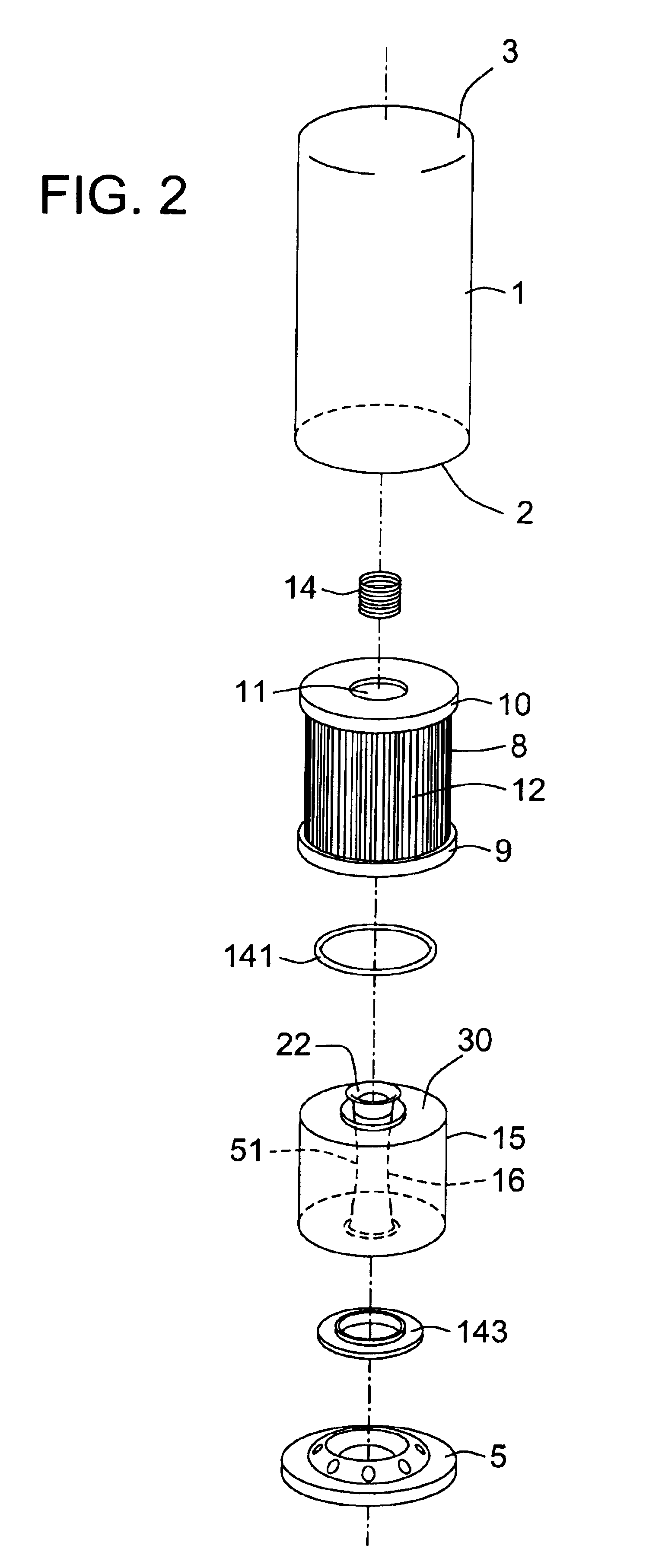

Combination particulate and acid-neutralizing filter

InactiveUS6969461B2Reduce operating costsExtended useful lifeMachines/enginesLoose filtering material filtersPressure reductionPressure difference

The present invention provides a filter apparatus for use in removing impurities and acids contained in a fluid that includes a particulate filter and an acid-neutralizing filter. Preferably, the particulate filter and the acid-neutralizing filter are positioned within a housing. A conduit having a pressure reduction section is arranged to create a pressure differential across the acid-neutralizing filter such that a portion of the fluid to be filtered by the filter apparatus passes through the acid-neutralizing filter.

Owner:BALDWIN FILTERS +1

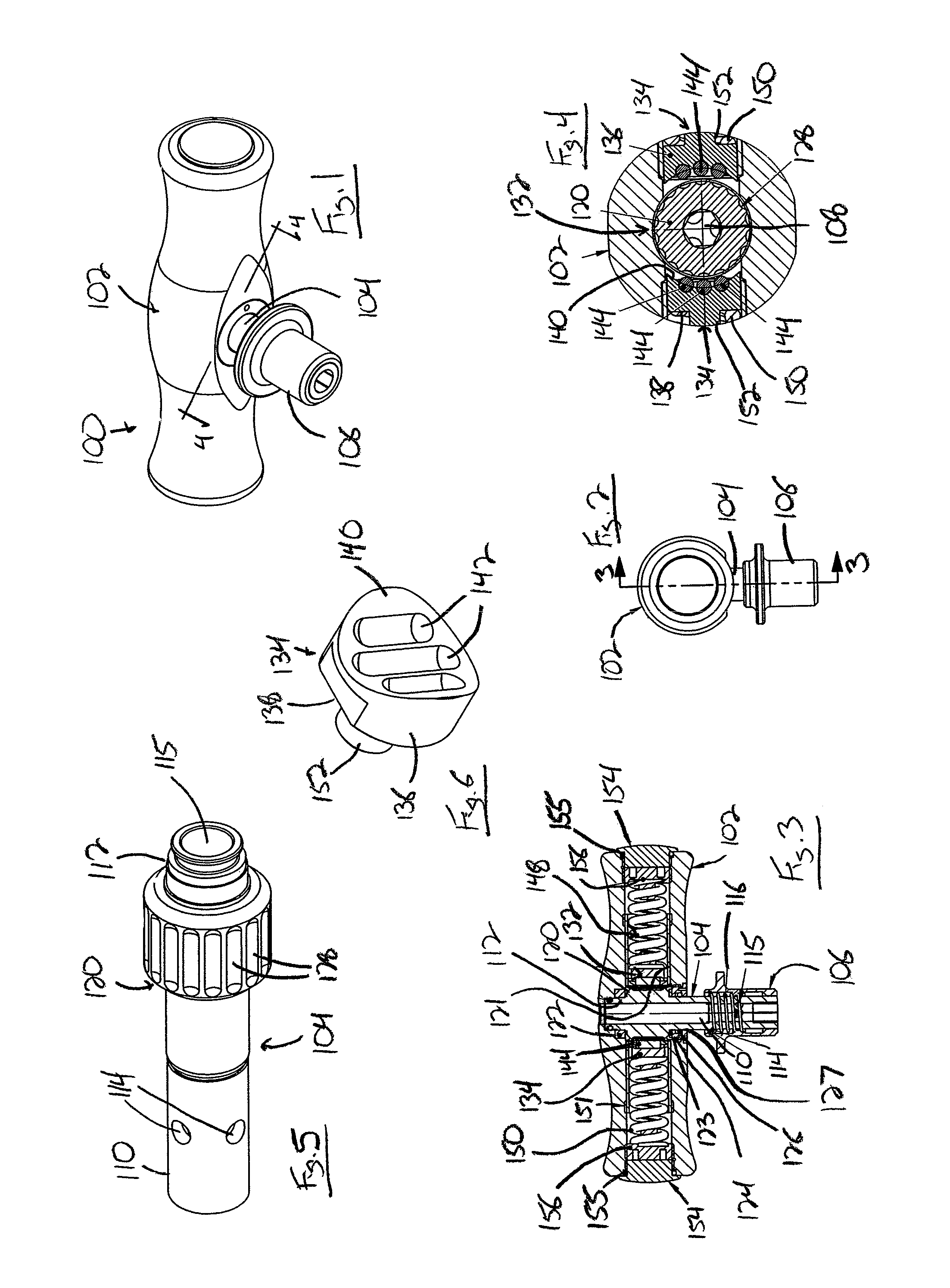

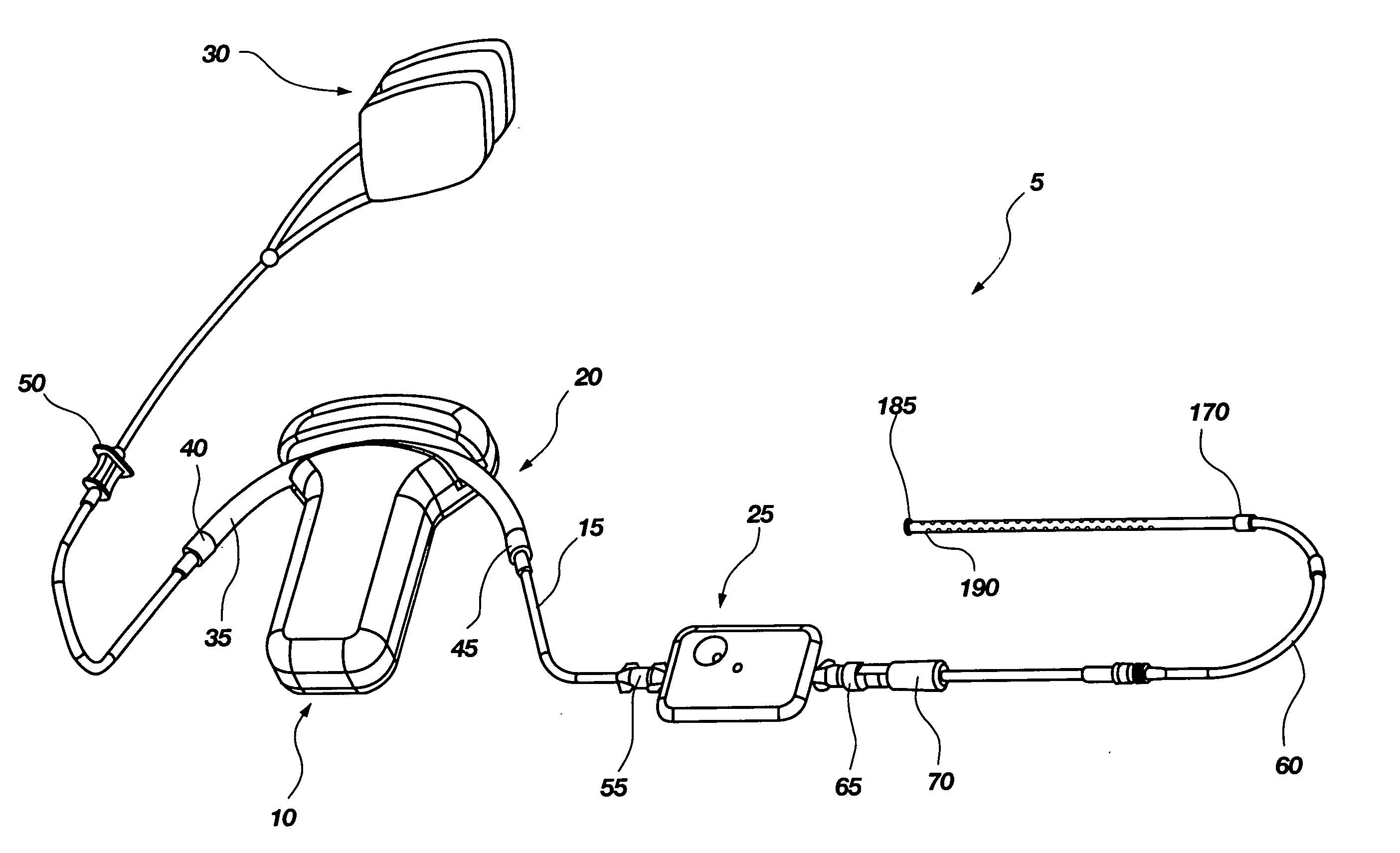

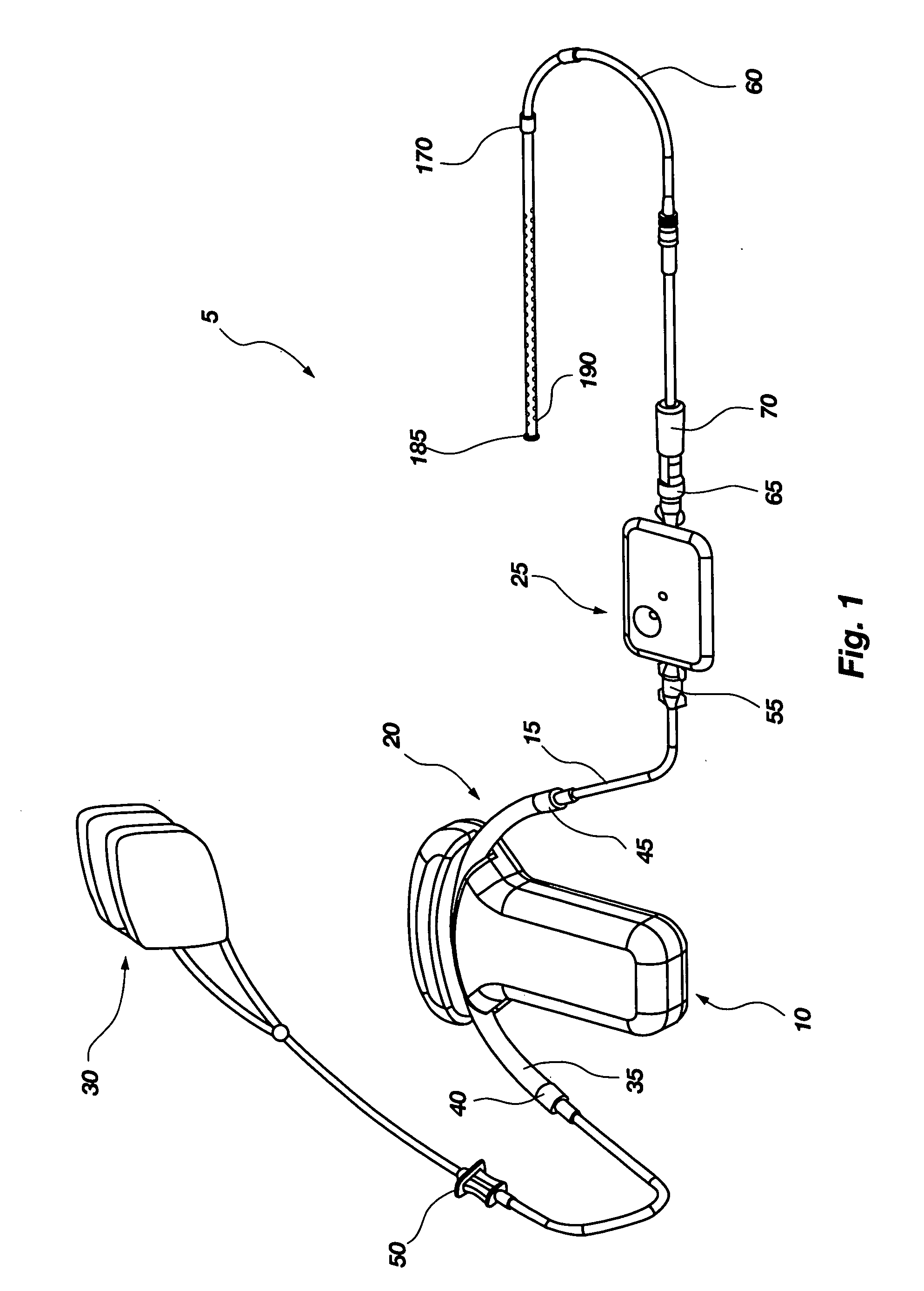

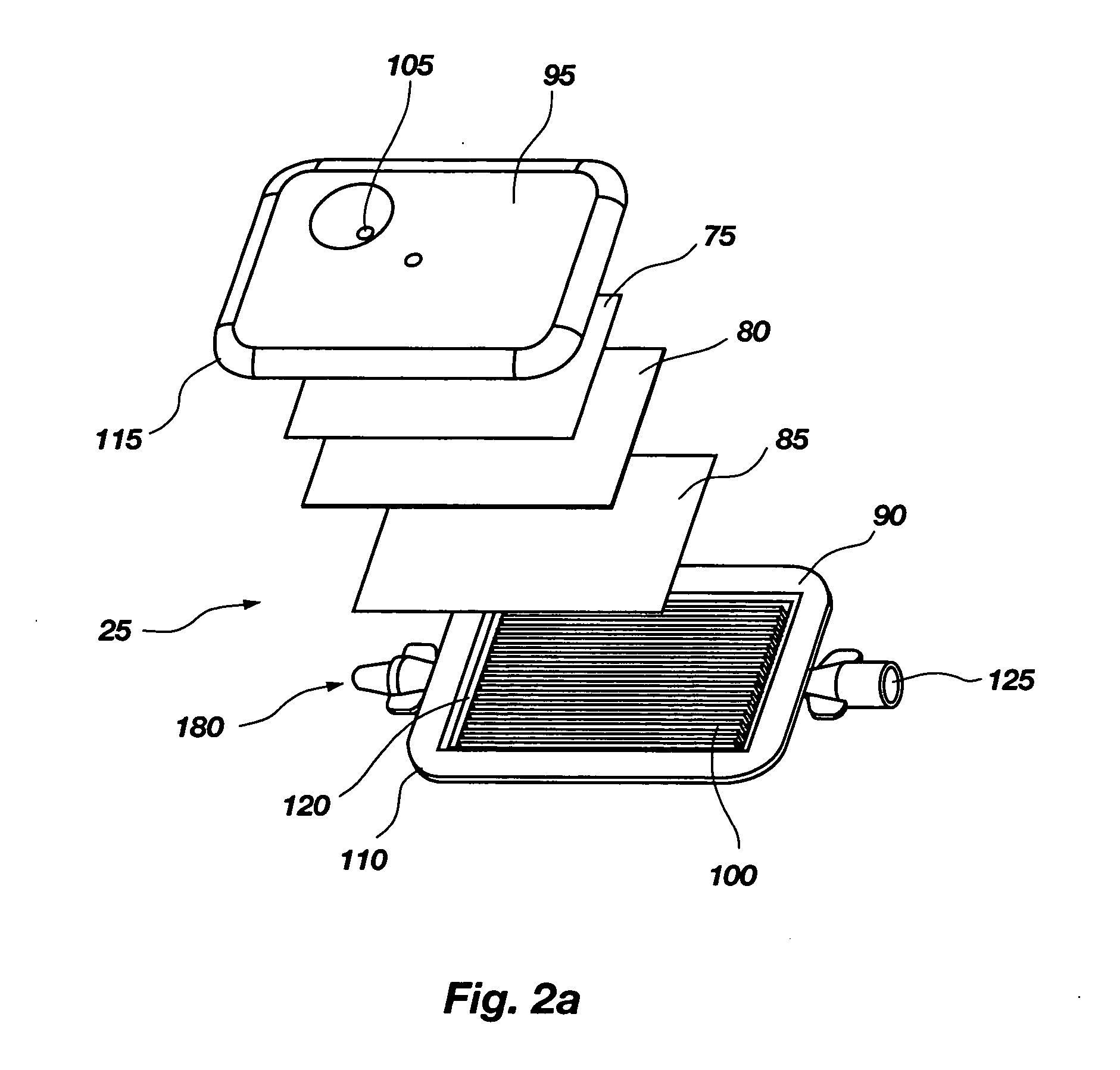

Apparatus and method for peritoneal dialysis

InactiveUS20050131340A1Extended useful lifeReduce morbidityMedical devicesCatheterRenal functionSystem pressure

An apparatus and method for treatment of end stage renal decline and failure through peritoneal dialysis enabling ambulatory transfer of dialysate to and from the peritoneum of a renal patient, this in synthesis and coordination with normal physiological rhythms of the patient. The system remains unobtrusive and less restrictive of patient ambulation and orientation. The present invention includes expendables disposability of which facilitates safe reuse of more expensive portions and is sufficiently simple for use in a home care environment. It may be designed to incorporate real-time, interactive or remote monitoring and regulation and visual or audible indication of system pressures, chemical balances and other important variables.

Owner:SORENSON DEVMENT

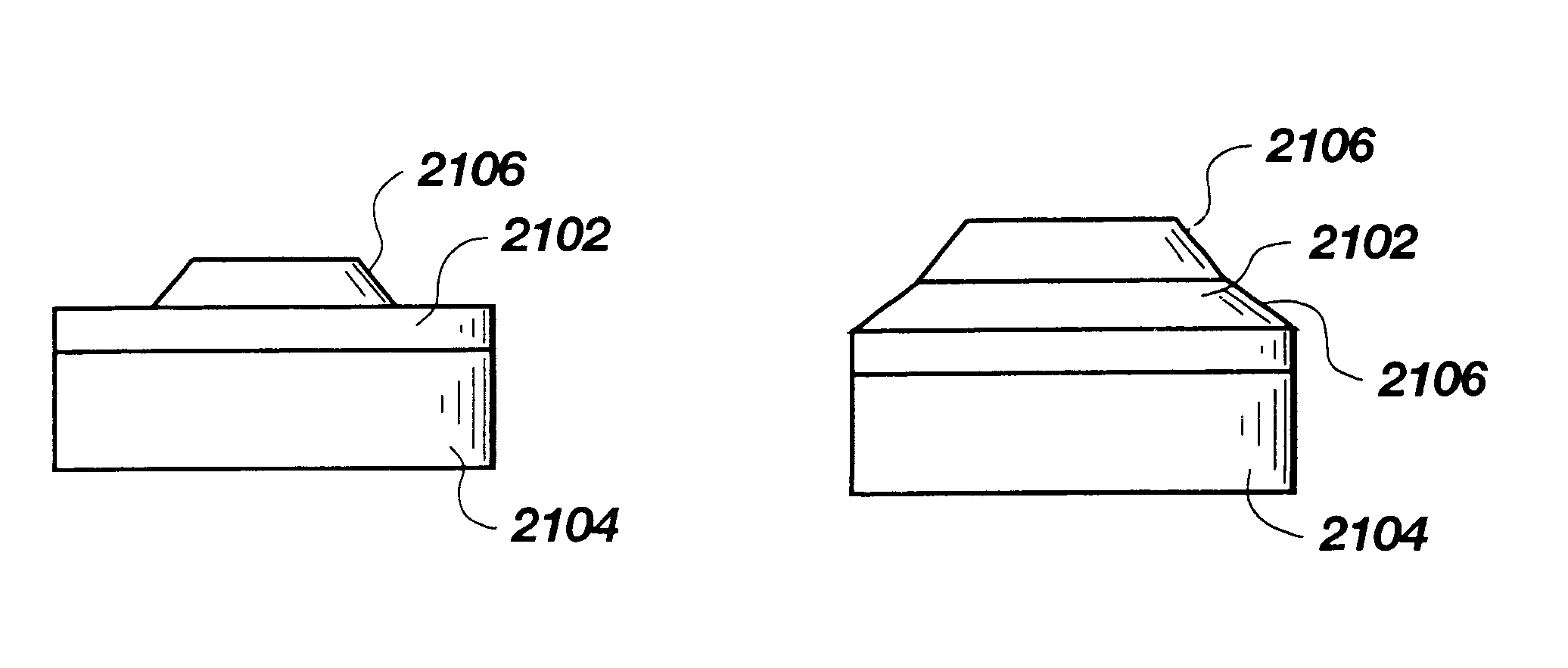

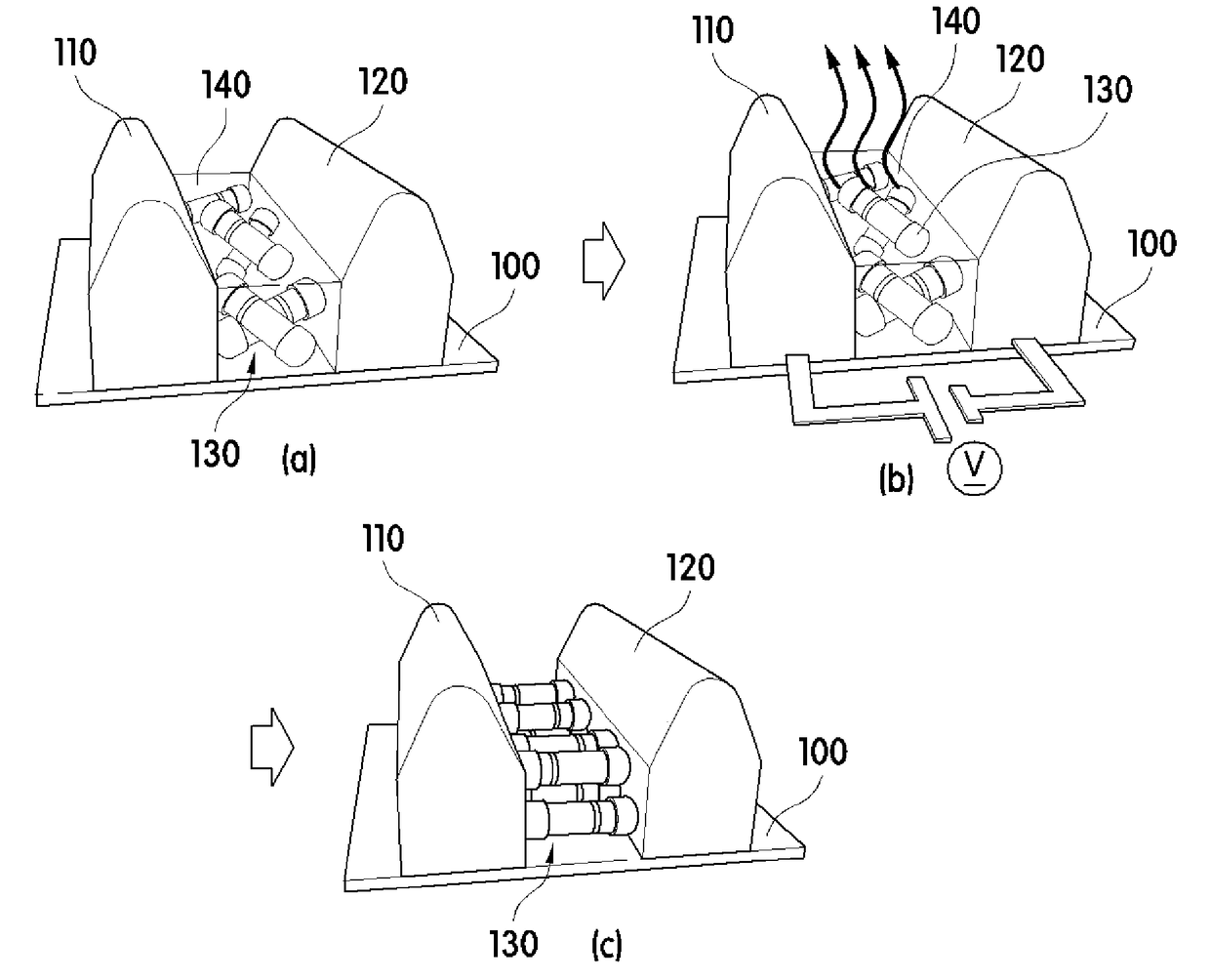

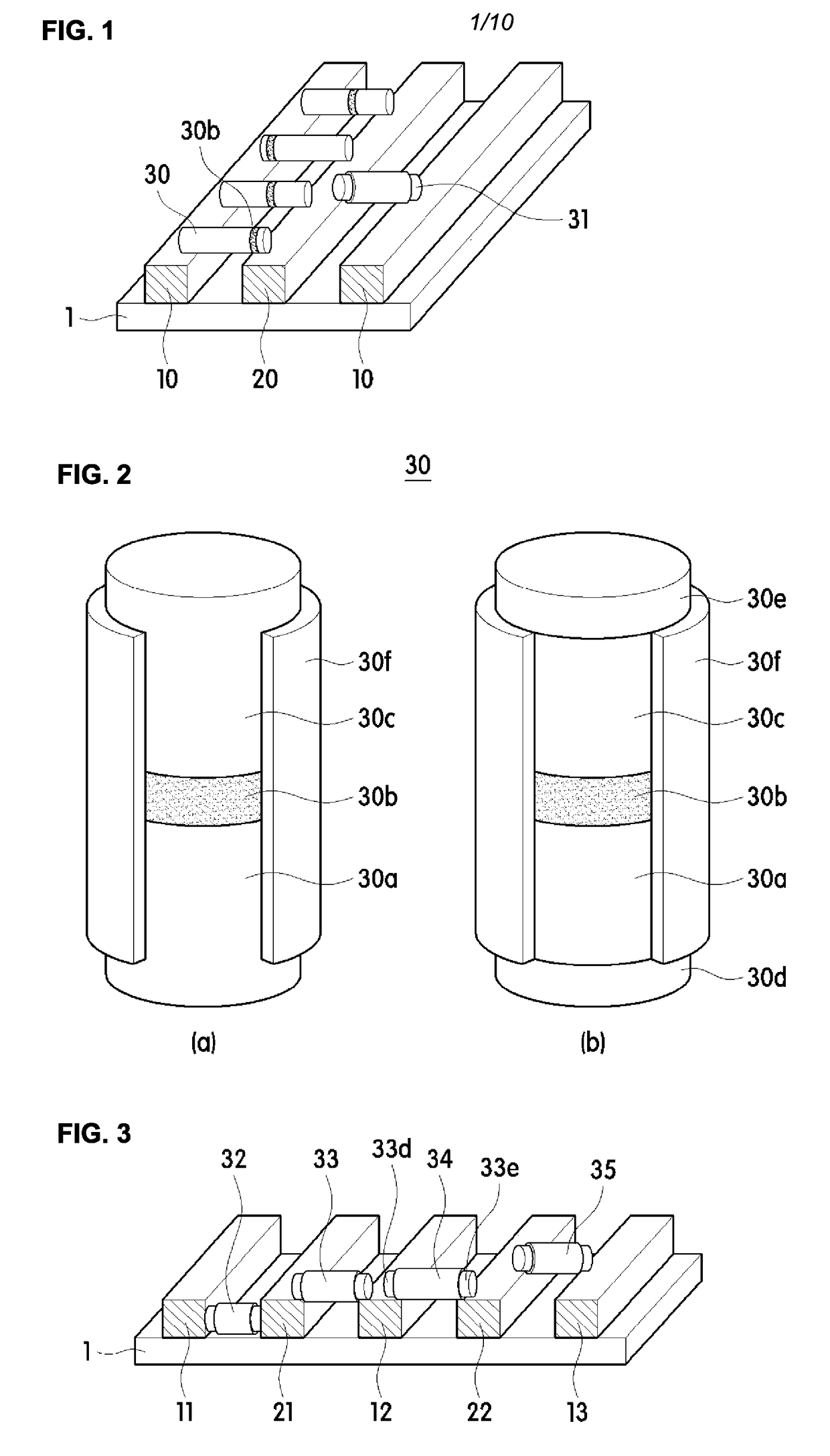

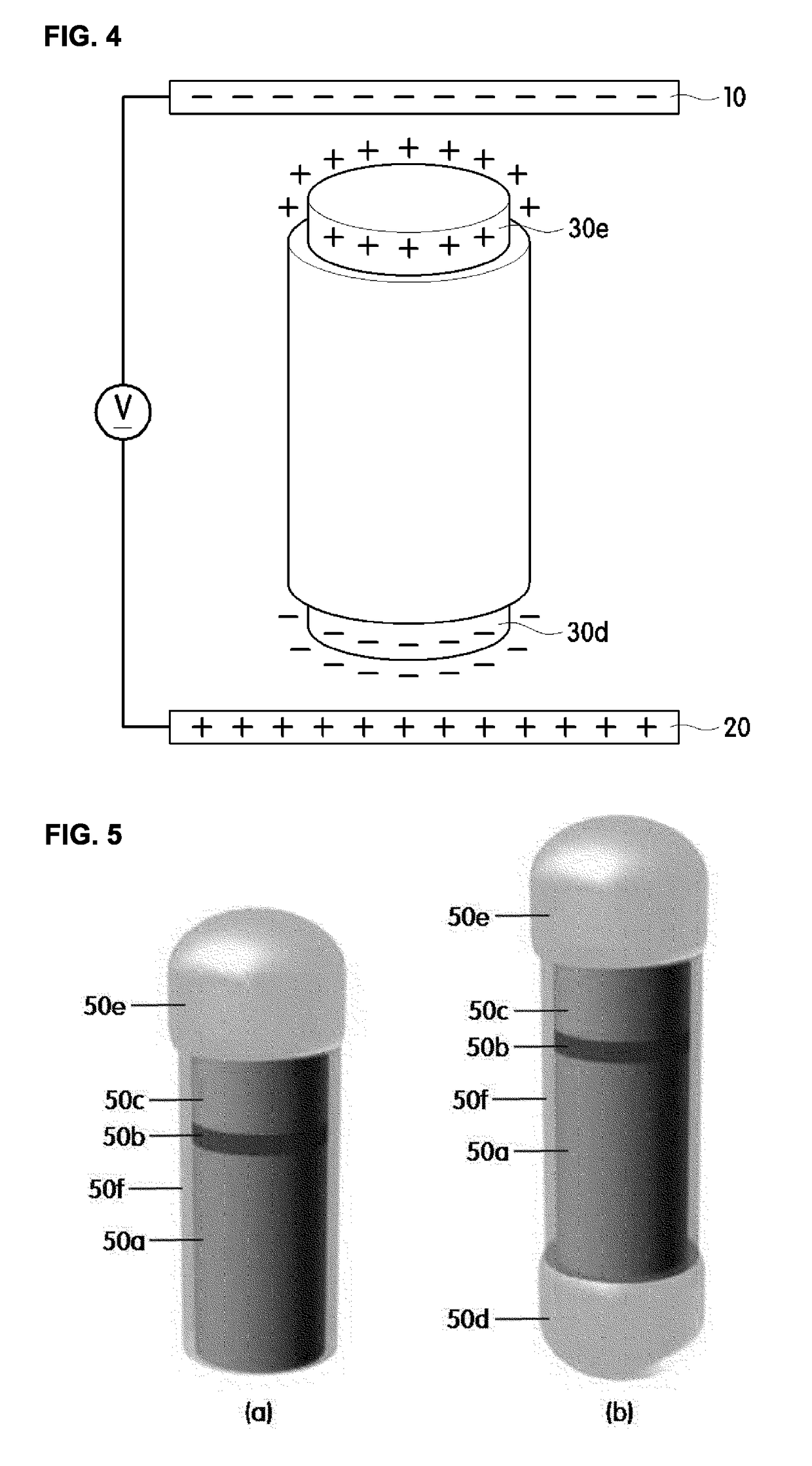

Micro-led element for horizontally-aligned assembly, method for manufacturing same, and horizontally-aligned assembly comprising same

ActiveUS20170317228A1Easy to layEasy alignmentNanostructure assemblySolid-state devicesElectricityEngineering

The present invention relates to a nano-scale light-emitting diode (LED) element for a horizontal array assembly, a manufacturing method thereof, and a horizontal array assembly including the same, and more particularly, to a nano-scale LED element for a horizontal array assembly that can significantly increase the number of nano-scale LED elements connected to an electrode line, facilitate an arrangement of the elements, and implement a horizontal array assembly having a very good electric connection between an electrode and an element and a significant high quantity of light when a horizontal array assembly having the nano-scale LED elements laid in a length direction thereof and connected to the electrode line is manufactured, a manufacturing method thereof, and a horizontal array assembly including the same.

Owner:SAMSUNG DISPLAY CO LTD

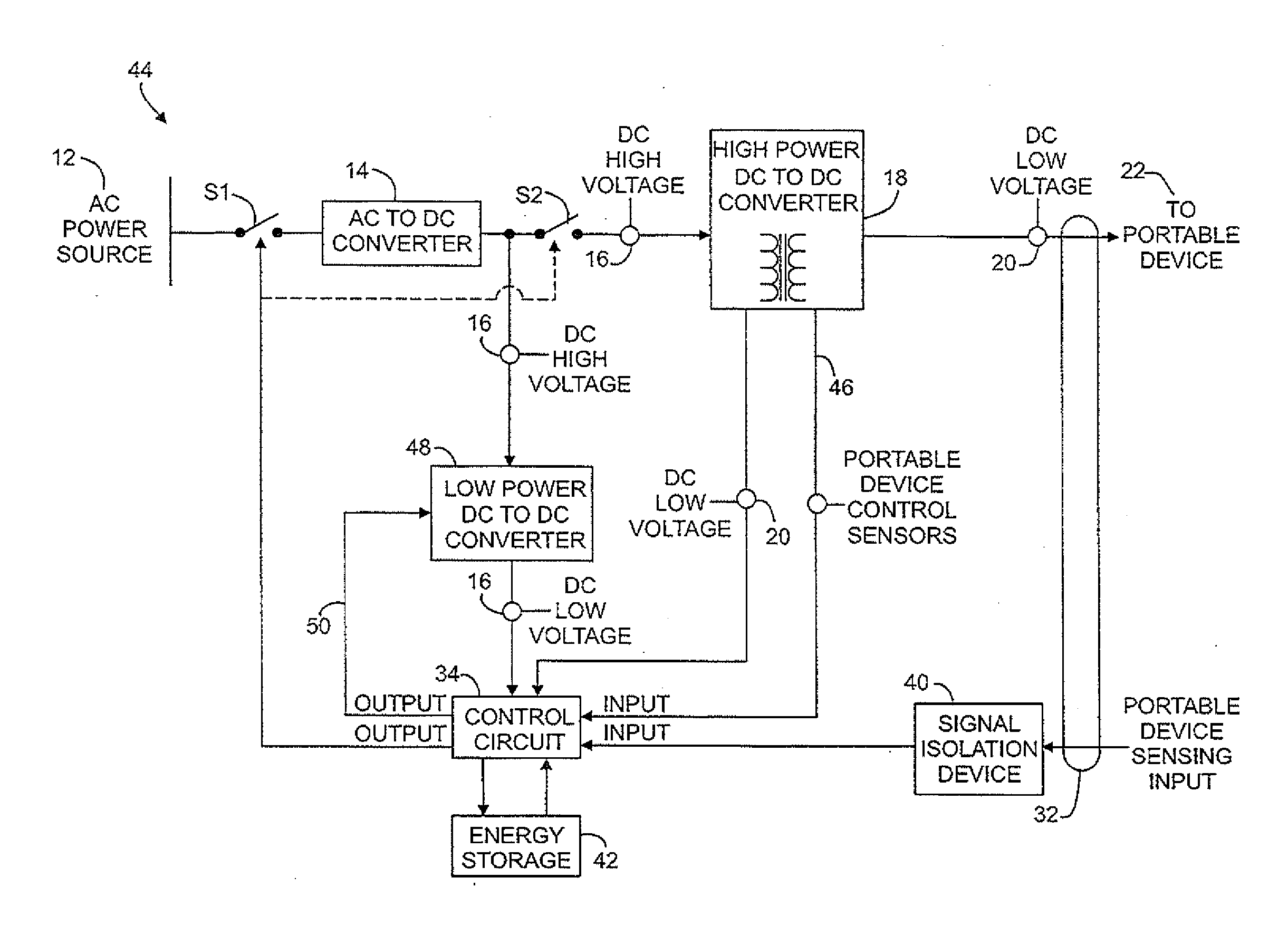

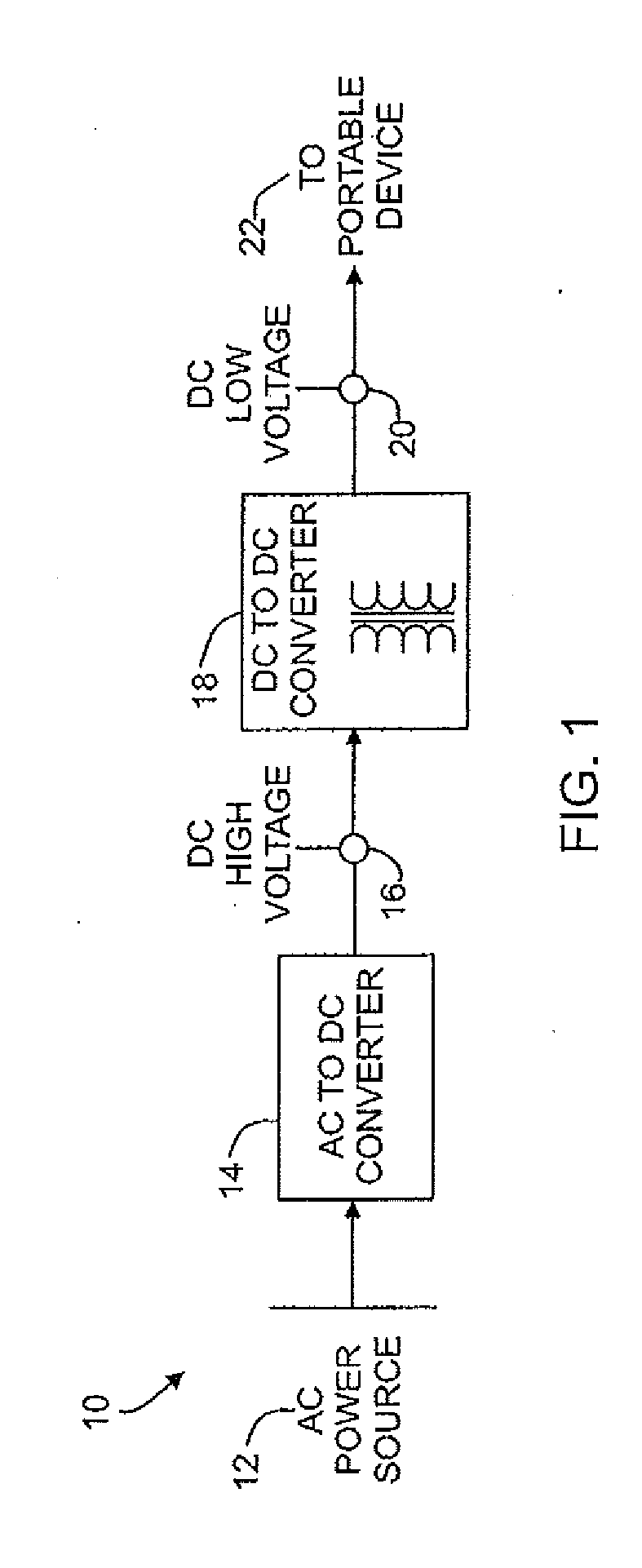

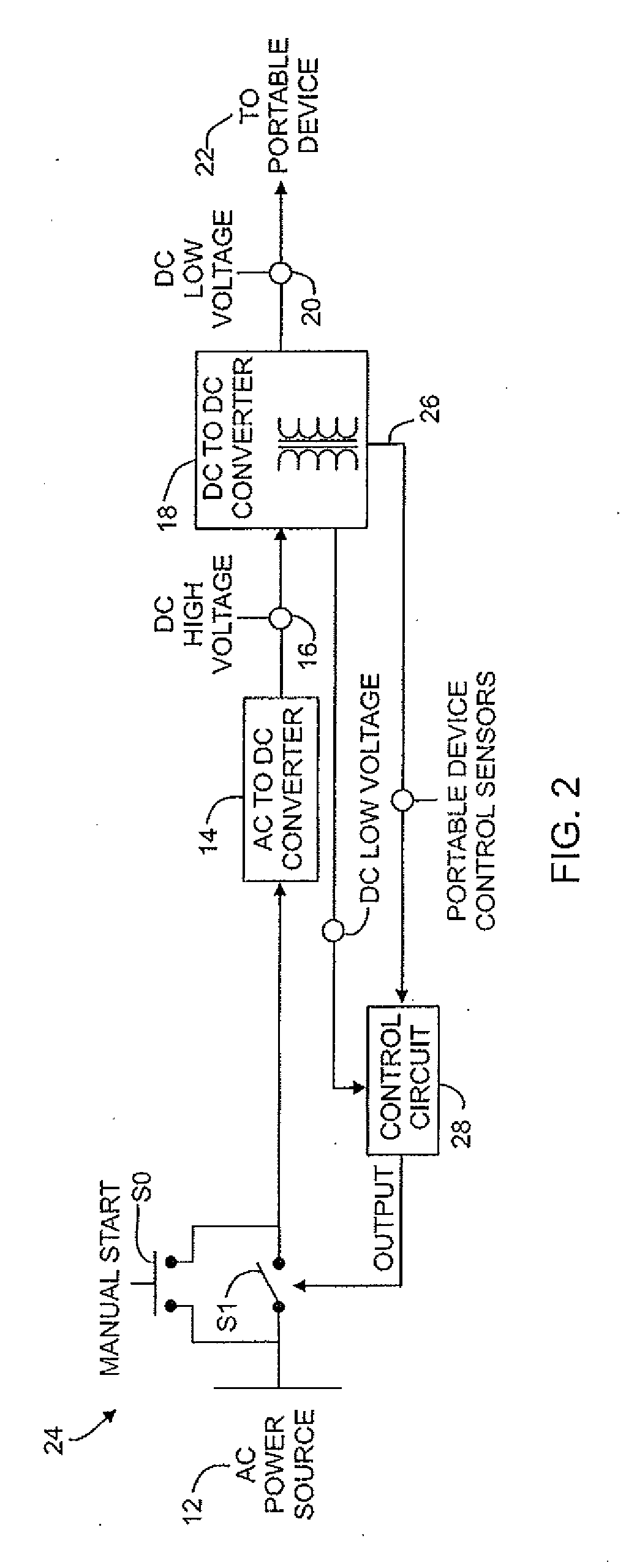

Energy saving cable assembly

InactiveUS20130093381A1Control over charging functionExtended service lifePower network operation systems integrationElectric powerElectrical conductorEngineering

A power charger circuit converts input energy to DC output energy, with the input energy flowing in a first direction such as via a cable having multiple conductors to provide the output energy, with the power charger including at least one switch having an open state and a closed state, the open state to interrupt the flow of input energy and the power charging circuit allowing for energy flow in a second direction opposite the first direction so that the switch may be moved to the closed state.

Owner:HORIZON TECHNOLOGIES

Liquid cooled shield for improved piercing performance

ActiveUS20090230097A1Extended useful lifeCut quality of plasmaPlasma welding apparatusSolid cathode detailsAirflowMolten metal

A shield for a plasma arc torch that pierces and cuts a metallic workpiece producing a splattering of molten metal directed at the torch, the shield protecting consumable components of the plasma arc torch from the splattering molten metal. The shield can include a body, a first surface of the body configured to be contact-cooled by a gas flow, a second surface of the body configured to be contact-cooled by a liquid flow, and a seal assembly configured to be secured to the body and disposed relative to the second surface configured to retain the liquid flow contact-cooling the second surface.

Owner:HYPERTHERM INC

Reversible color-changing sanitizer-indicating nonwoven wipe

ActiveUS20100247371A1Extended useful lifeReliable indicationBiocideLayered productsAmmonium compoundsComposite material

A nonwoven wipe having a reversible sanitizer indicator for multiple uses and recharges is provided. The nonwoven wipe includes a cloth-like nonwoven fabric coated with a reversible color-changing ink formulation. During use, the nonwoven wipe is impregnated with a quaternary ammonium compound-based sanitizer. When the level of free quaternary ammonium compound falls below a threshold level, the color-changing ink formulation changes from a first color to a second color, indicating the need to recharge the wipe. When the nonwoven wipe is recharged with sanitizer solution, the color-changing ink formulation changes back to the first color.

Owner:ILLINOIS TOOL WORKS INC

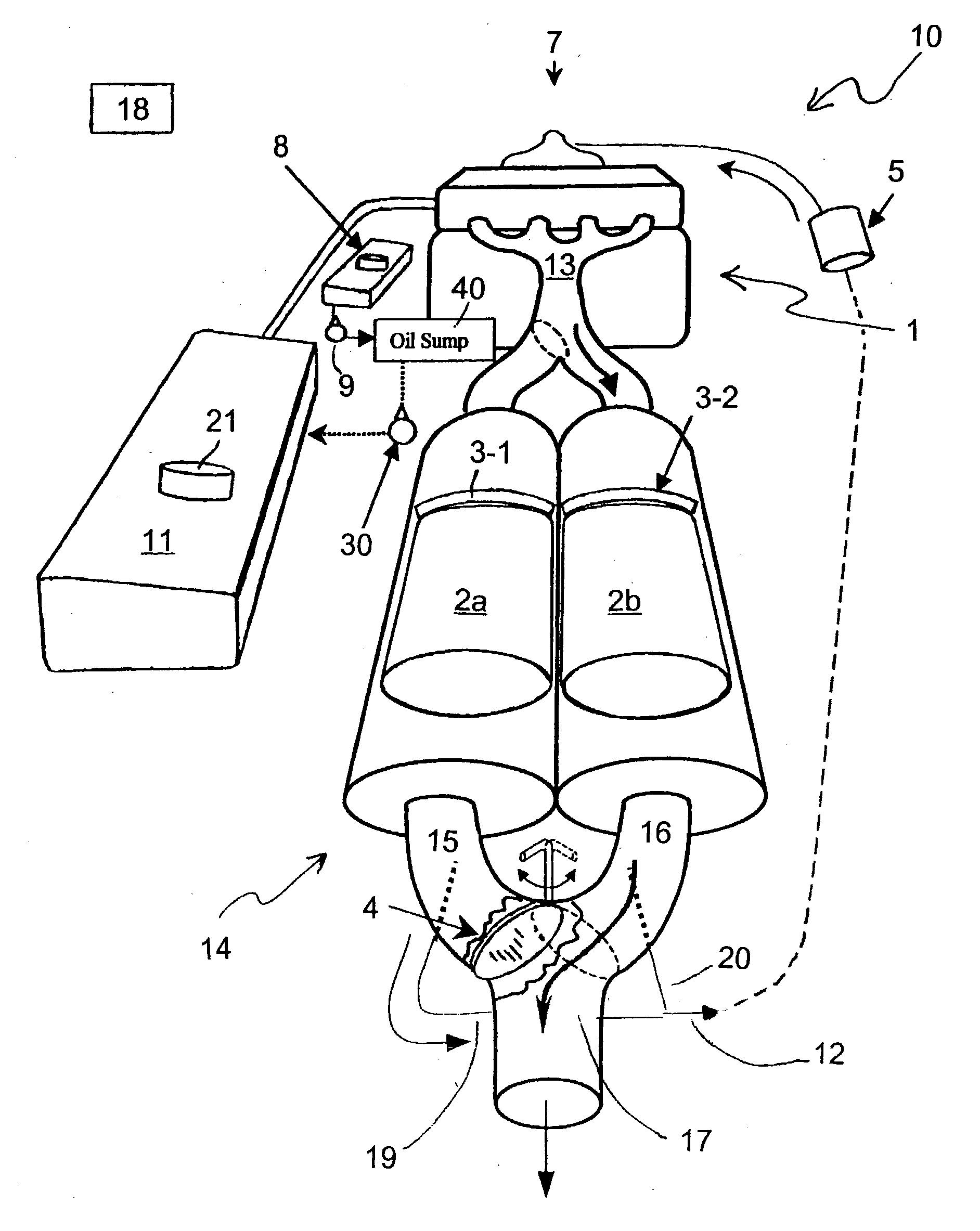

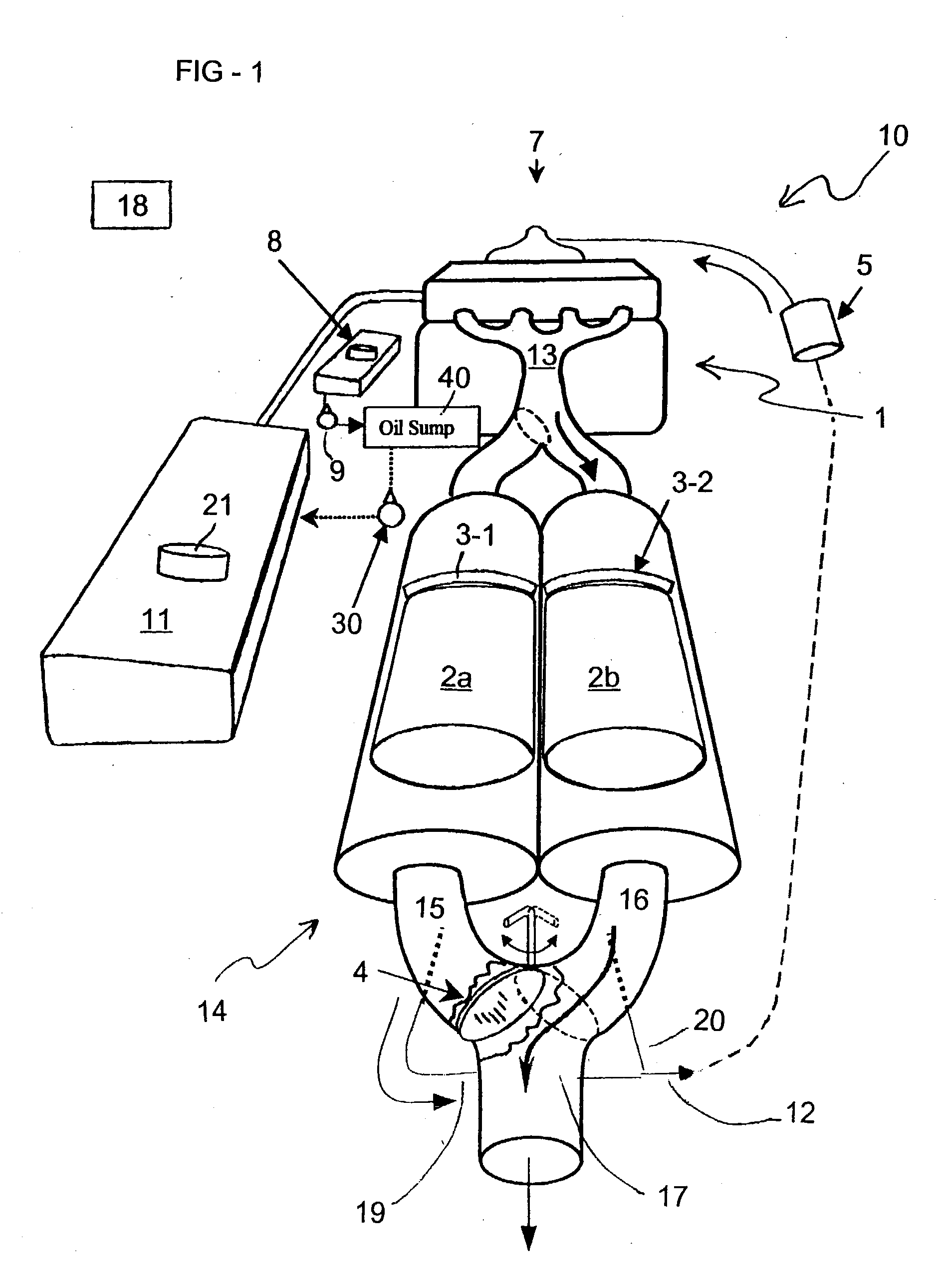

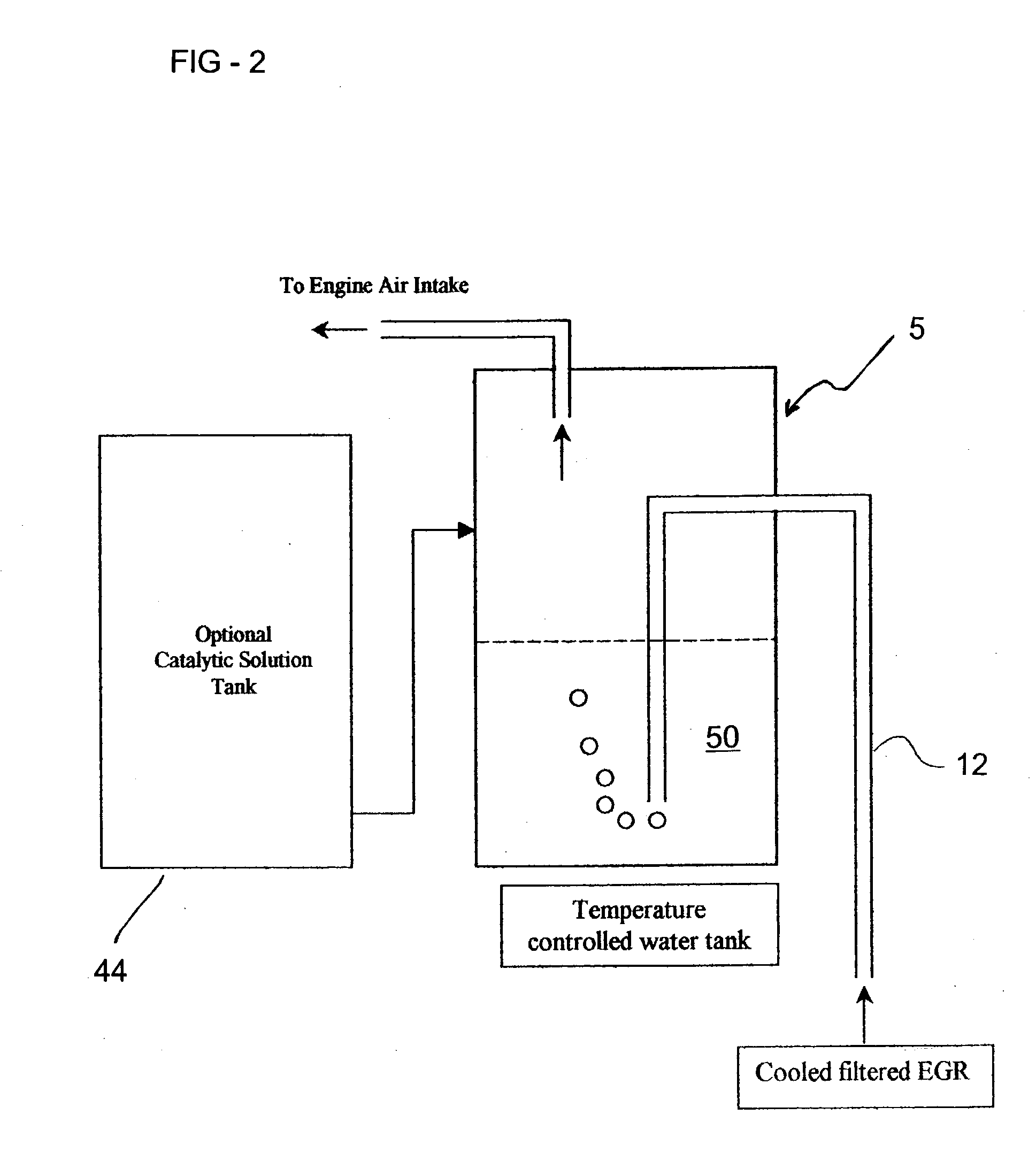

System for and methods of operating diesel engines to reduce harmful exhaust emissions and to improve engine lubrication

InactiveUS20040194454A1Facilitates DPF regenerationAnti-wear propertyInternal combustion piston enginesNon-fuel substance addition to fuelOil additiveExhaust gas emissions

A Diesel engine anti-wear lubricant oil additive composition that includes organo-metallic compounds of Cu, Ce, etc., is used to catalytically bum-off diesel particulate matter (PM) collected by diesel particulate filter (DPF). A fuel borne catalyst (FBC) of Cu,Ce,Fe etc., required for regenerating the DPF is made by blending a predetermined quantity of used engine oil, removed from the engine crankcase oil system, with fuel in the fuel tank of a diesel engine equipped with DPF and EGR systems. A method of fumigating water and catalytic compounds of Cu, Fe, Ce, etc., into the air-intake system of a diesel engine in the EGR gases from the DPF or air, to reduce both PM and NOx emissions from a diesel engine, with improved engine lubrication performance, is also disclosed.

Owner:RIM JULIUS J

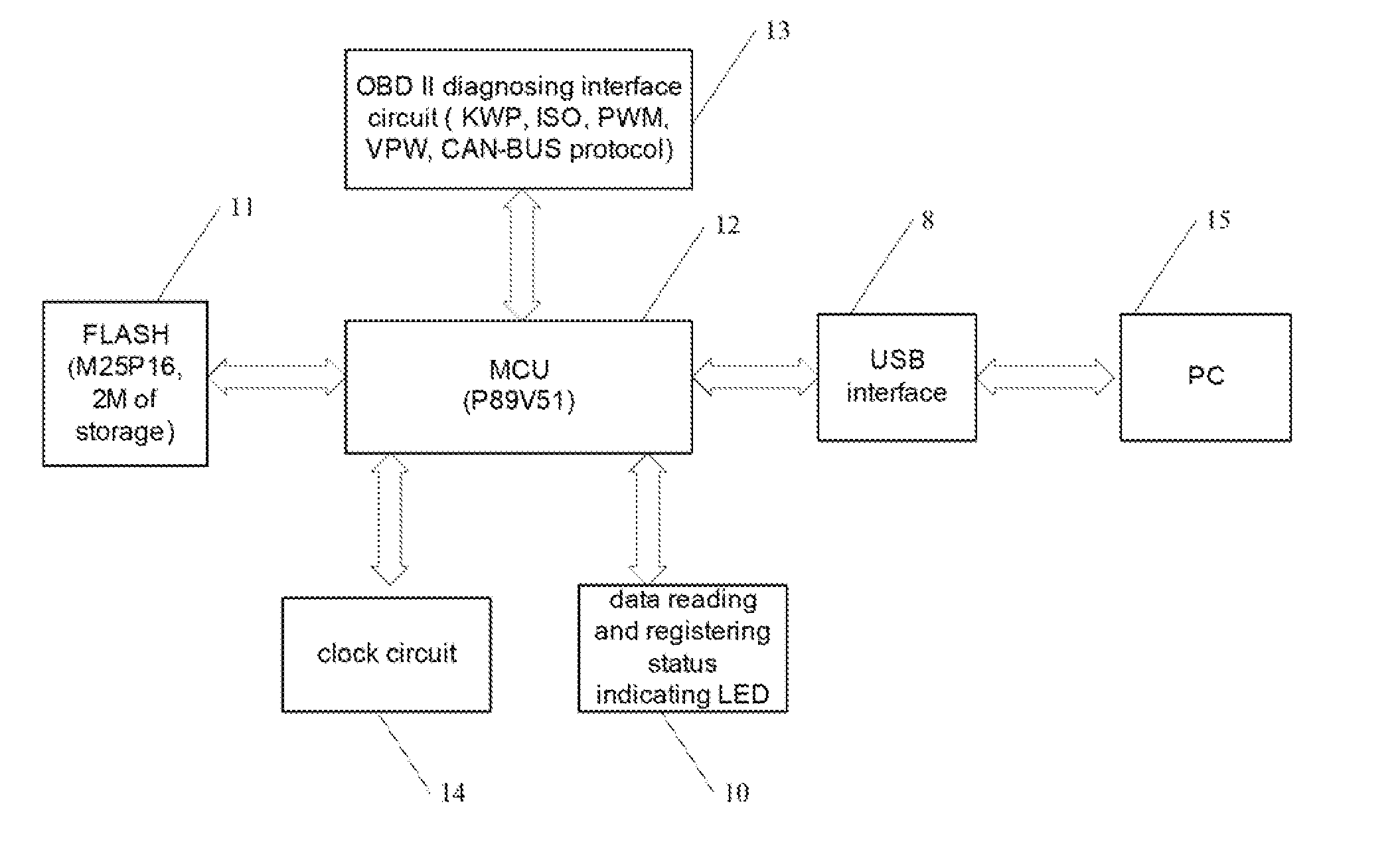

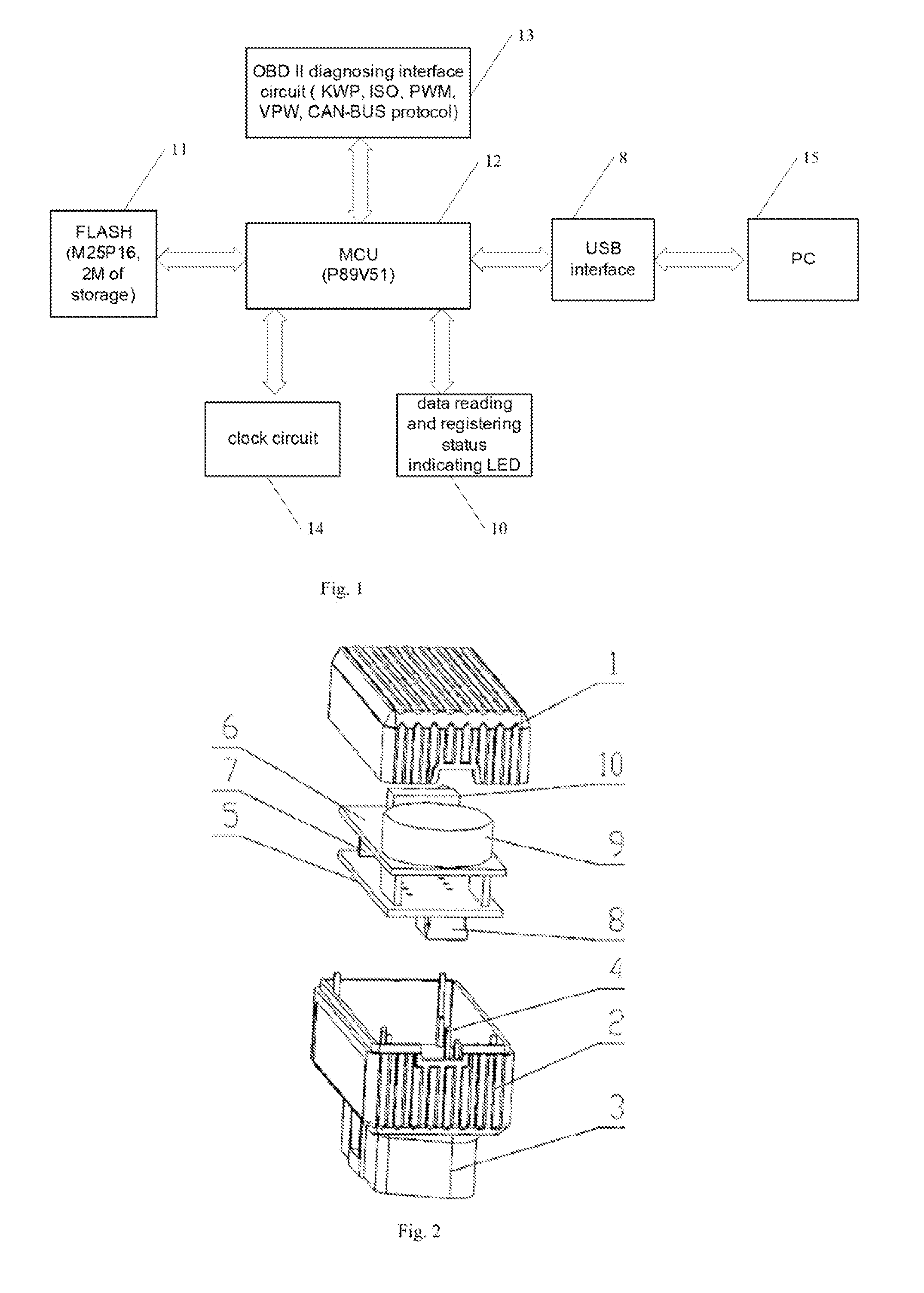

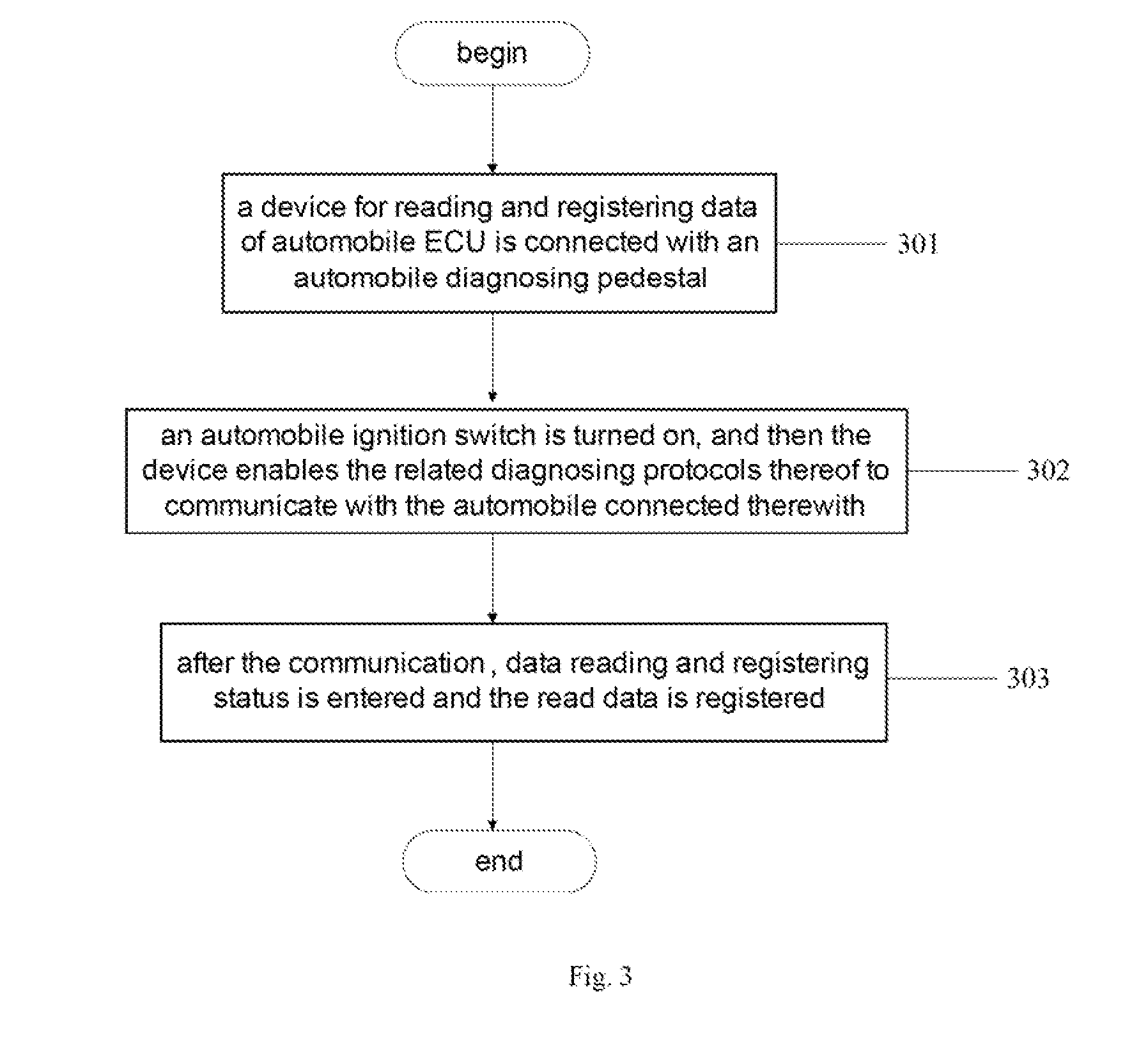

Device and method for reading, registering and analyzing data of automobile ECU

InactiveUS20100293081A1Easy to optimizeEasy maintenanceProgramme controlVehicle testingCommunication interfaceComputer science

A device for reading and registering data of automobile ECU includes: a memory (11); a data processing unit (12) connected with the memory for processing collected data; a diagnosing interface circuit (13) communicatingly connected with the data processing unit and an automobile diagnosing pedestal and specially configured in accordance with automobile ECU protocol of various series of automobiles; a data communication interface (8) for communication between the device and an associated equipment thereof; a unit (14) for marking the occurring time to the registered data; a data reading and registering status indicating unit (10). The present invention also discloses a method for real-time reading and registering data of automobile ECU, an automobile diagnosing system and a diagnosing method. (FIG. 1)

Owner:LAUNCH SOFTWARE DEV

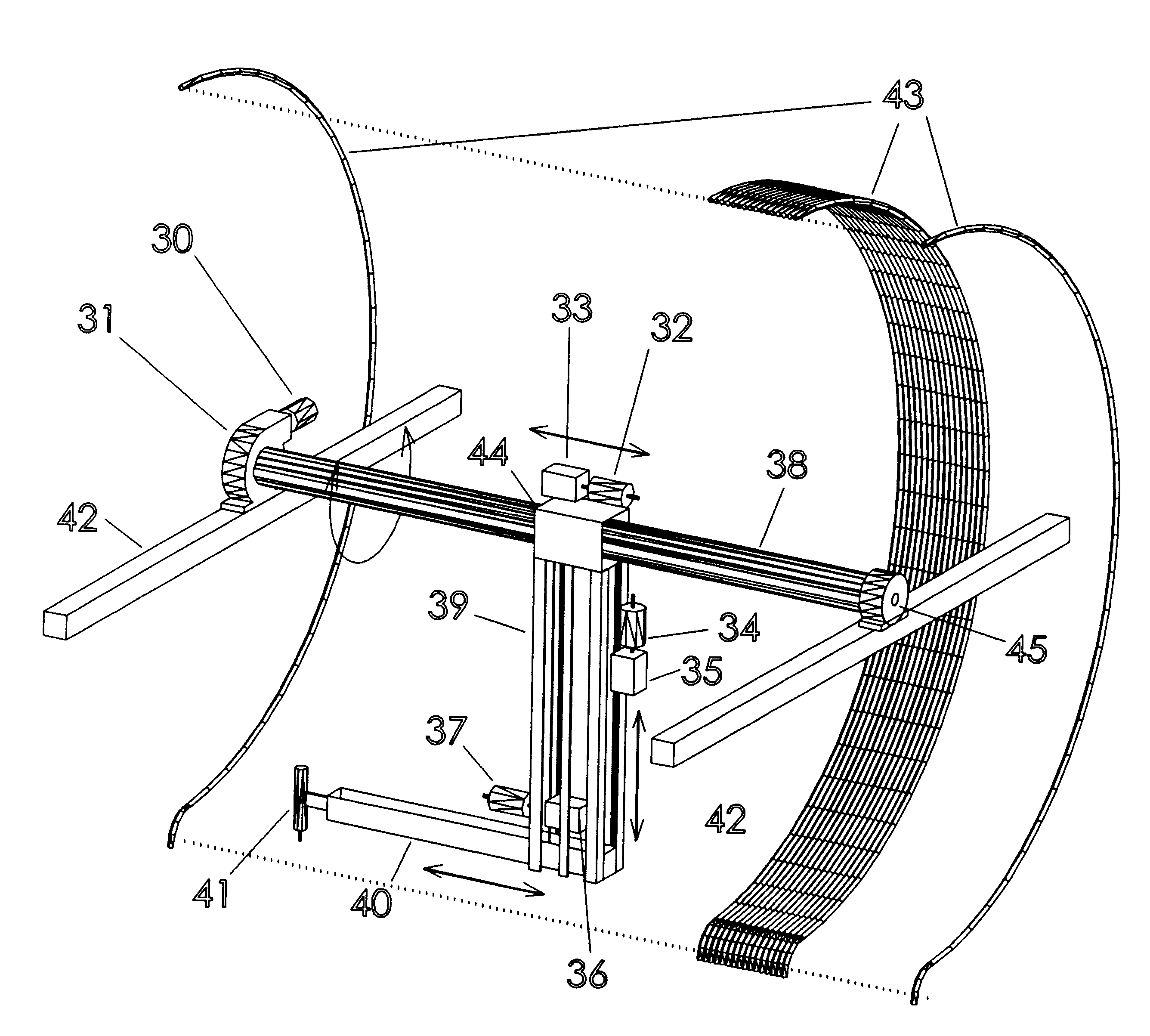

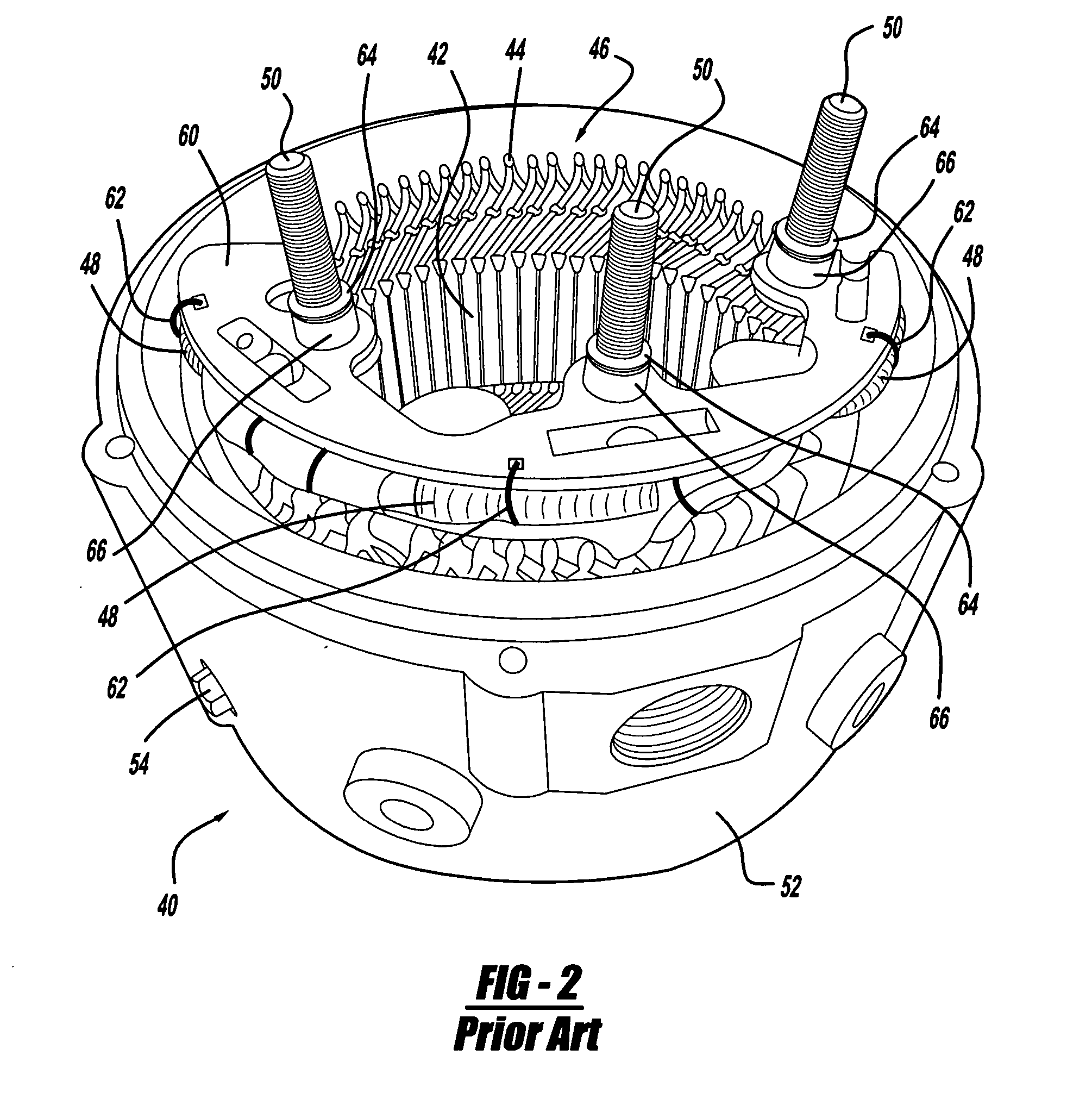

Boiler automated welding system (BAWS)

InactiveUS6230072B1Minimize boiler down timeExtended useful lifeProgramme controlArc welding apparatusDual axisLaser scanning

The Boiler Automated Welding System (BAWS) is an automatic welding system for repair of worn boiler tubes in cyclone boilers. Repair of these tubes is essential for extending the life of this component used within electrical power plants. The BAWS utilizes: 1) a multiaxis positioner which forms the required cylindrical coordinate motion system, 2) a tube tracking systems for determination of motion paths during welding, 3) a two axis gimbaled welding torch holder for orientation of the welds relative to the motion path, 4) an integrated welding system and 5) a computer controller which coordinates these devices in a logical method.The BAWS multiaxis positioner allows for orientation of the system within the cyclone boiler to take advantage of the symmetry of the tube layout (cylindrical coordinates). The positioner allows each individual tube to be scanned and a weld path determined using a laser scanning device. This information is then processed through the computer which coordinates the multiaxis positioner, welding system, and gimbaled torch holder to place a weld bead upon the scanned tube. This process is repeated systematically until the surface of one tube is covered with new weld metal. The entire sequence is then repeated on adjacent boiler tubes until the cyclone boiler unit is completed.

Owner:POWELL JOHN W +2

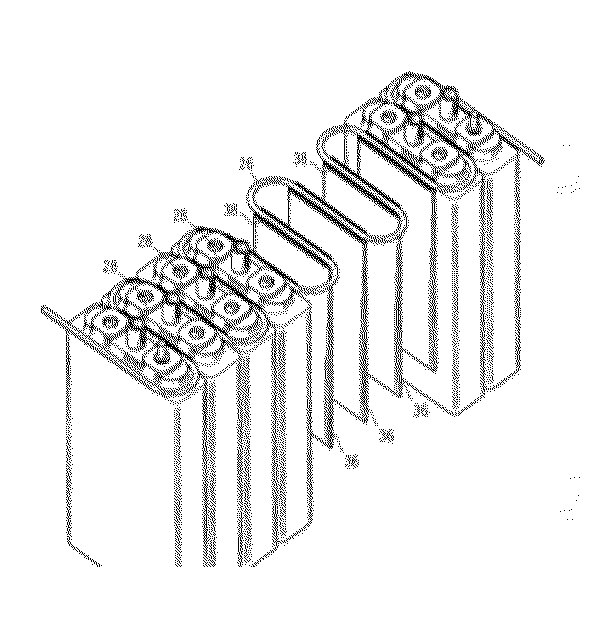

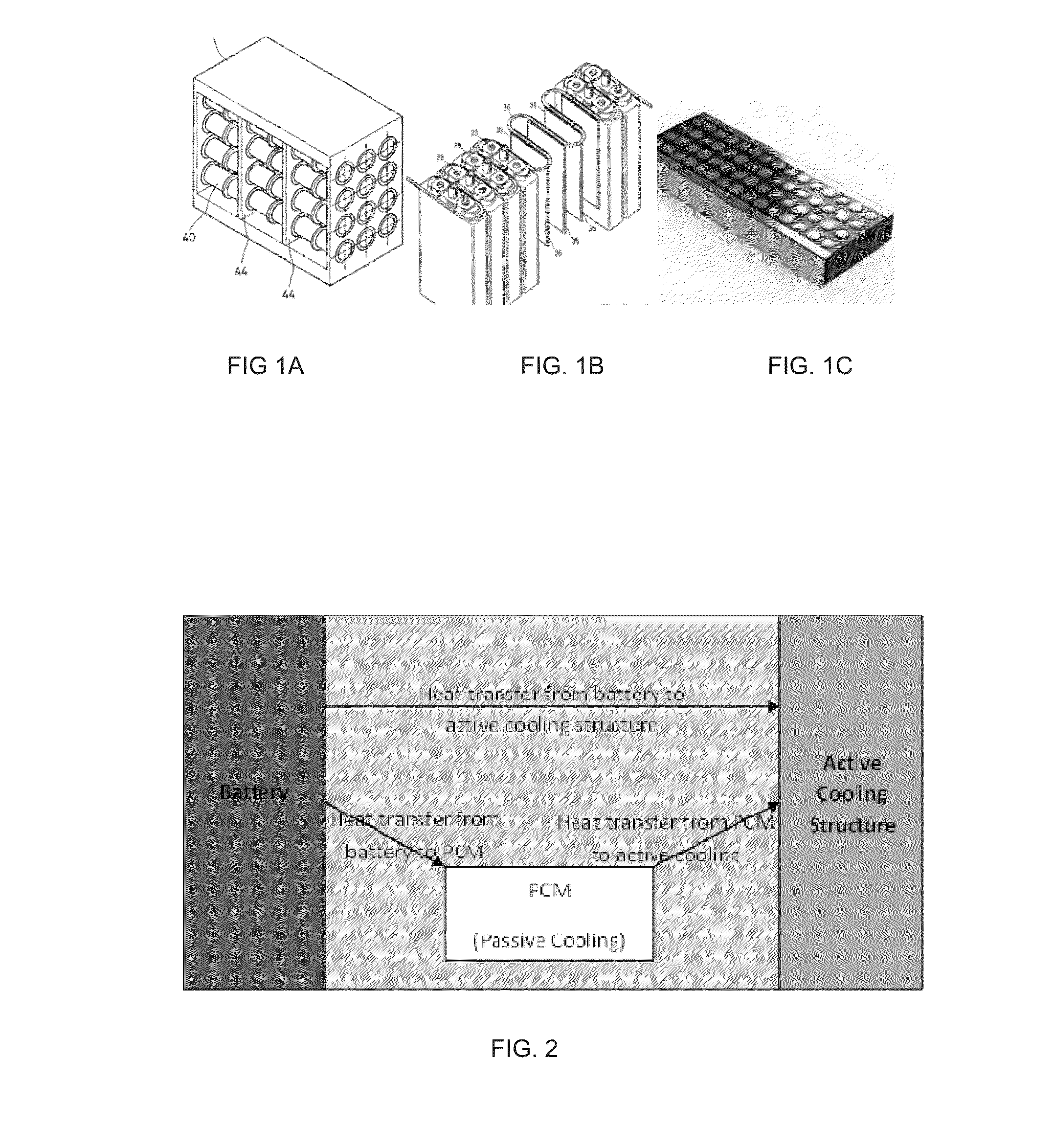

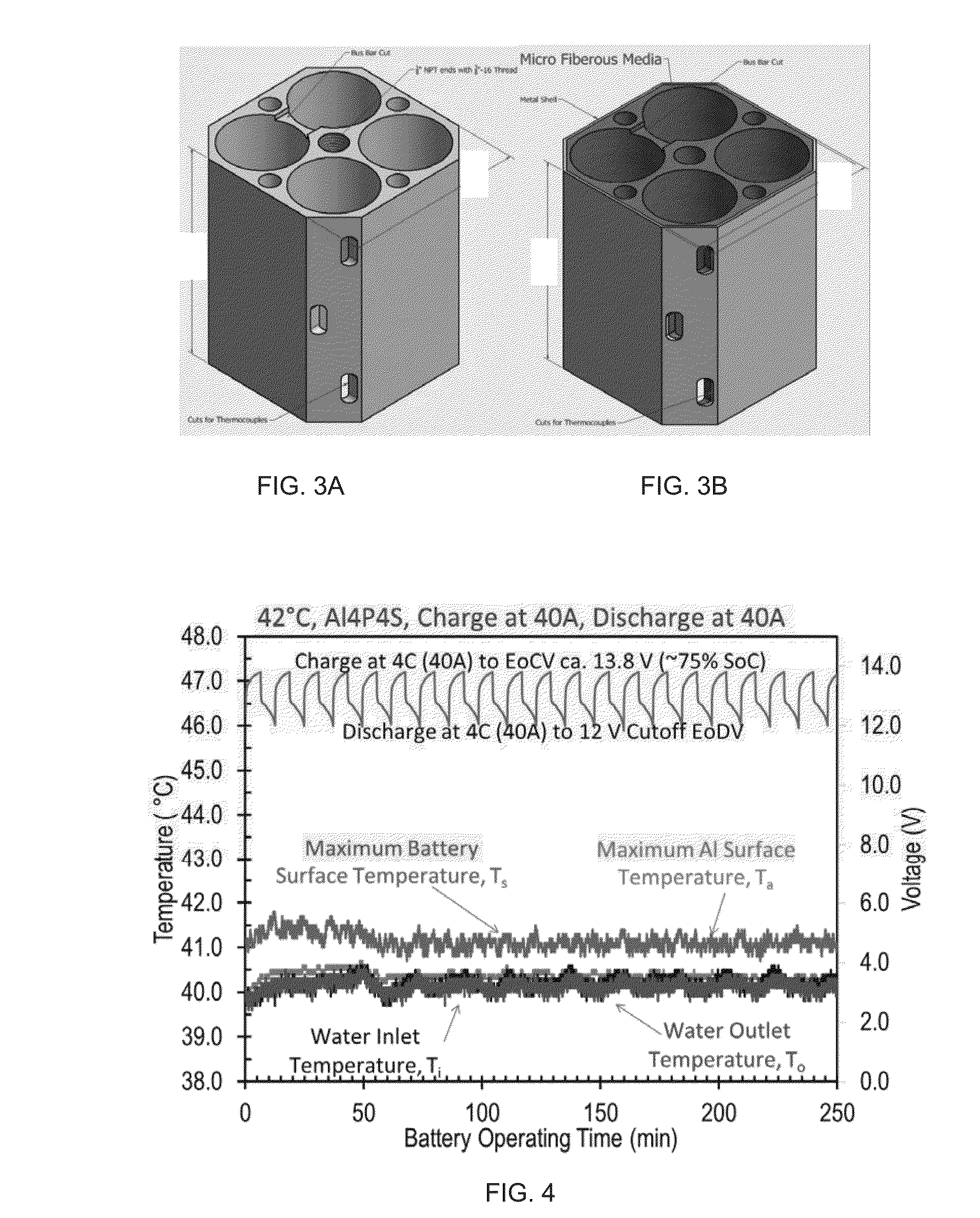

Thermal Management Systems for Energy Storage Cells Having High Charge/Discharge Currents and Methods of Making and Using Thereof

ActiveUS20150236386A1Improved interfacial heat transferFast heat transferCell temperature controlBattery isolationFiberActive cooling

Thermal management systems for high energy density batteries, particularly arrays of such batteries, and methods of making and using thereof are described herein. The system includes one or more thermal conductive microfibrous media with one or more phase change materials dispersed within the microfibrous media and one or more active cooling structures. Energy storage packs or arrays which contain a plurality of energy storage cells and the thermal management system are also described. Further described are thermal or infrared shielding blankets or barriers comprising one or more thermal conductive microfibrous media comprising one or more phase change materials dispersed within the microfibrous media.

Owner:INSTREETCARICRON

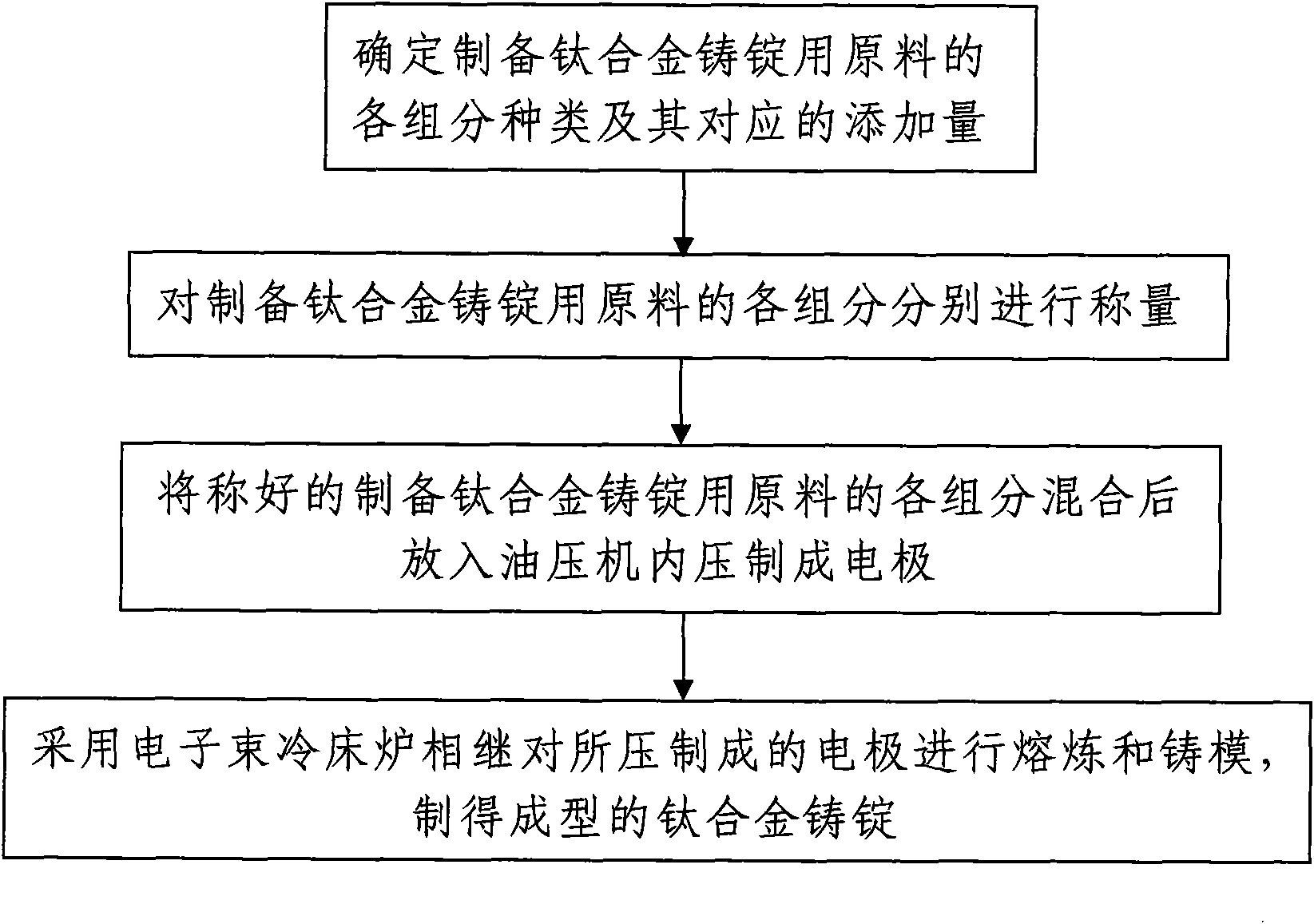

Method for preparing titanium alloy ingots through electron-beam cold bed furnaces by adopting conventional raw materials

The invention discloses a method for preparing titanium alloy ingots through electron-beam cold bed furnaces by adopting conventional raw materials. The method comprises the following steps: firstly, determining the species of every component of raw material for preparing the titanium alloy ingots, as well as corresponding addition amount thereof; secondly, weighing; thirdly, mixing the weighed components of the raw material for preparing the titanium alloy ingots, putting the mixture into an oil press and pressing the mixture to form electrodes; and fourthly, adopting an electron-beam cold bed furnace to melt and mold the pressed electrodes in succession and obtaining the molded titanium alloy ingots. The method has the advantages of simple process, convenient operation, good use effects and the capability of adopting simple-substance aluminum and master alloy of the aluminum and other conventional raw materials to successfully prepare the titanium alloy ingots. In addition, the prepared titanium alloy ingots have excellent performance and can effectively solve the defect and deficiency that the prior process for producing the titanium alloy ingots needs to use a large amount of return material.

Owner:NORTHWEST INSTITUTE FOR NON-FERROUS METAL RESEARCH

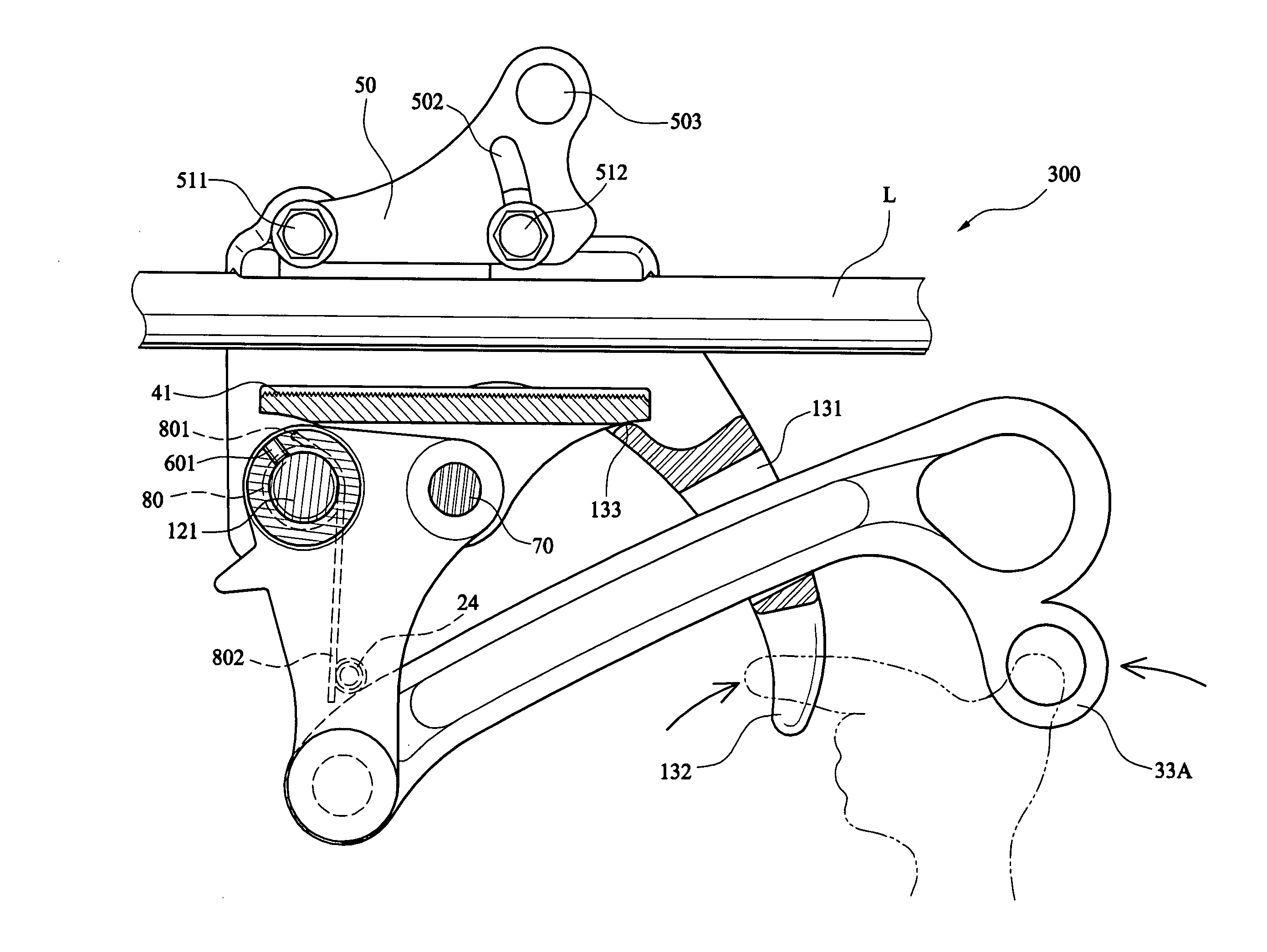

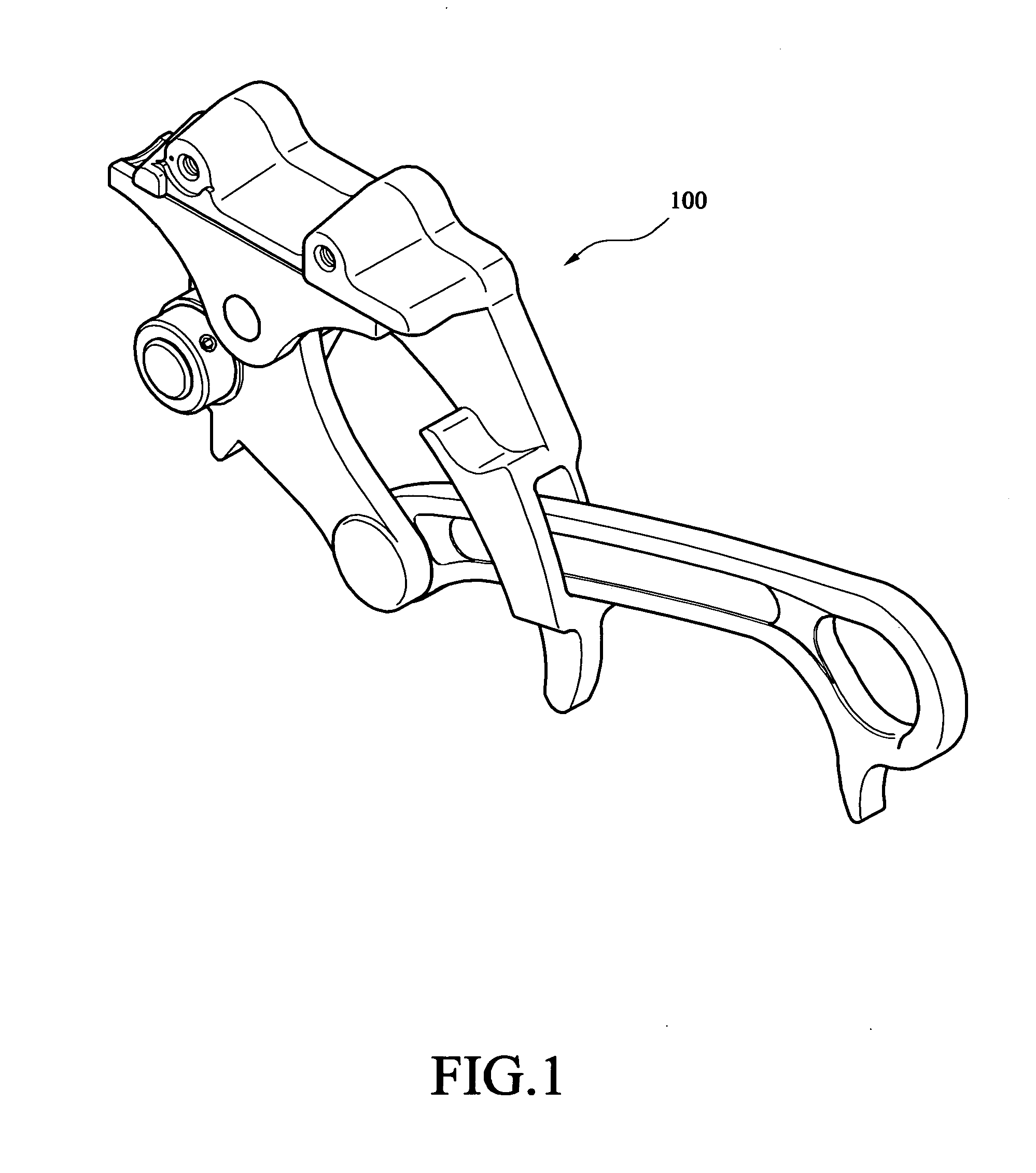

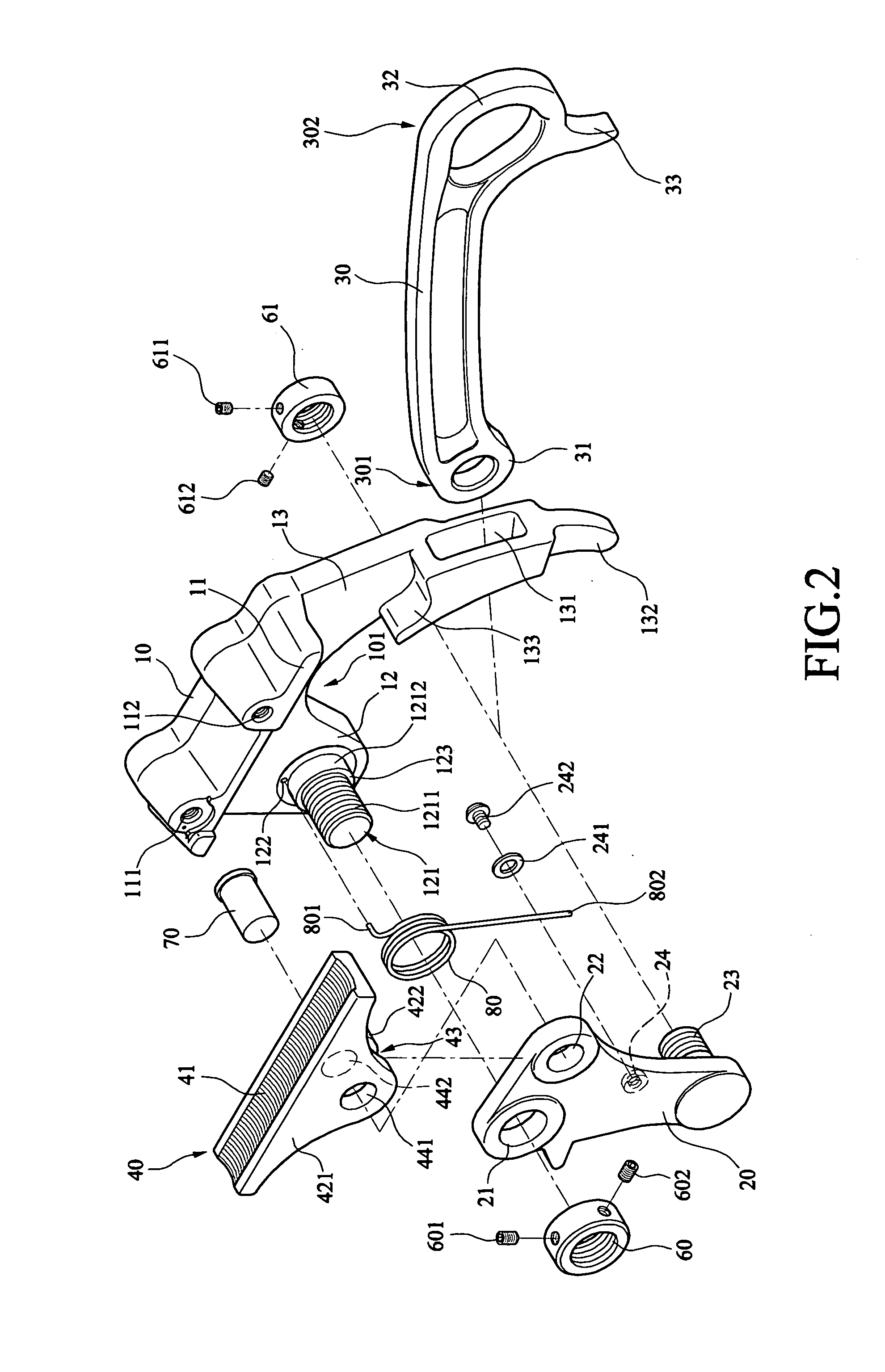

Trigger grip

ActiveUS20120005863A1Easy to operateEasy to assembleSnap fastenersRopes and cables for vehicles/pulleyEngineeringMechanical engineering

Owner:LIU JAMES KE +1

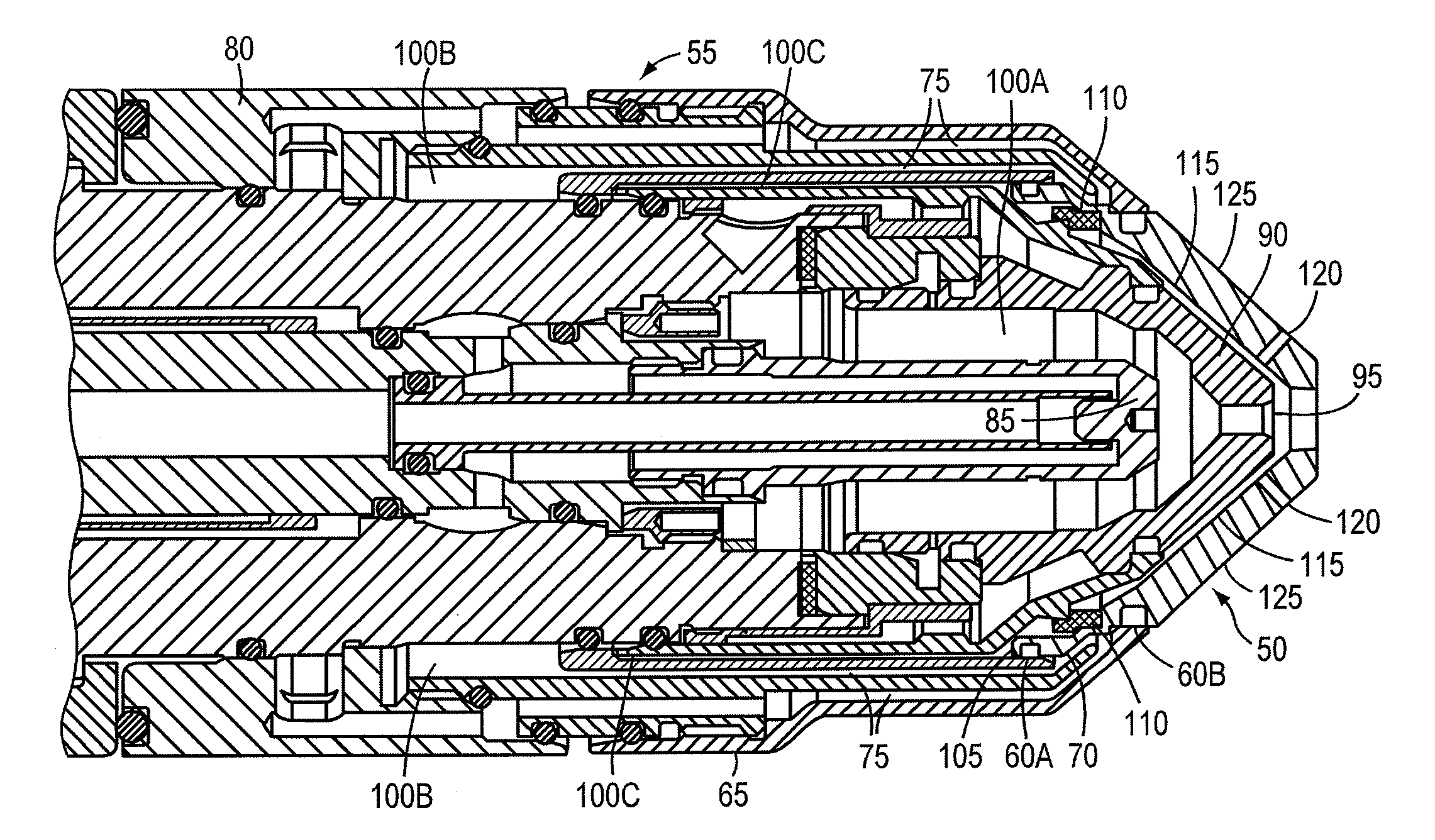

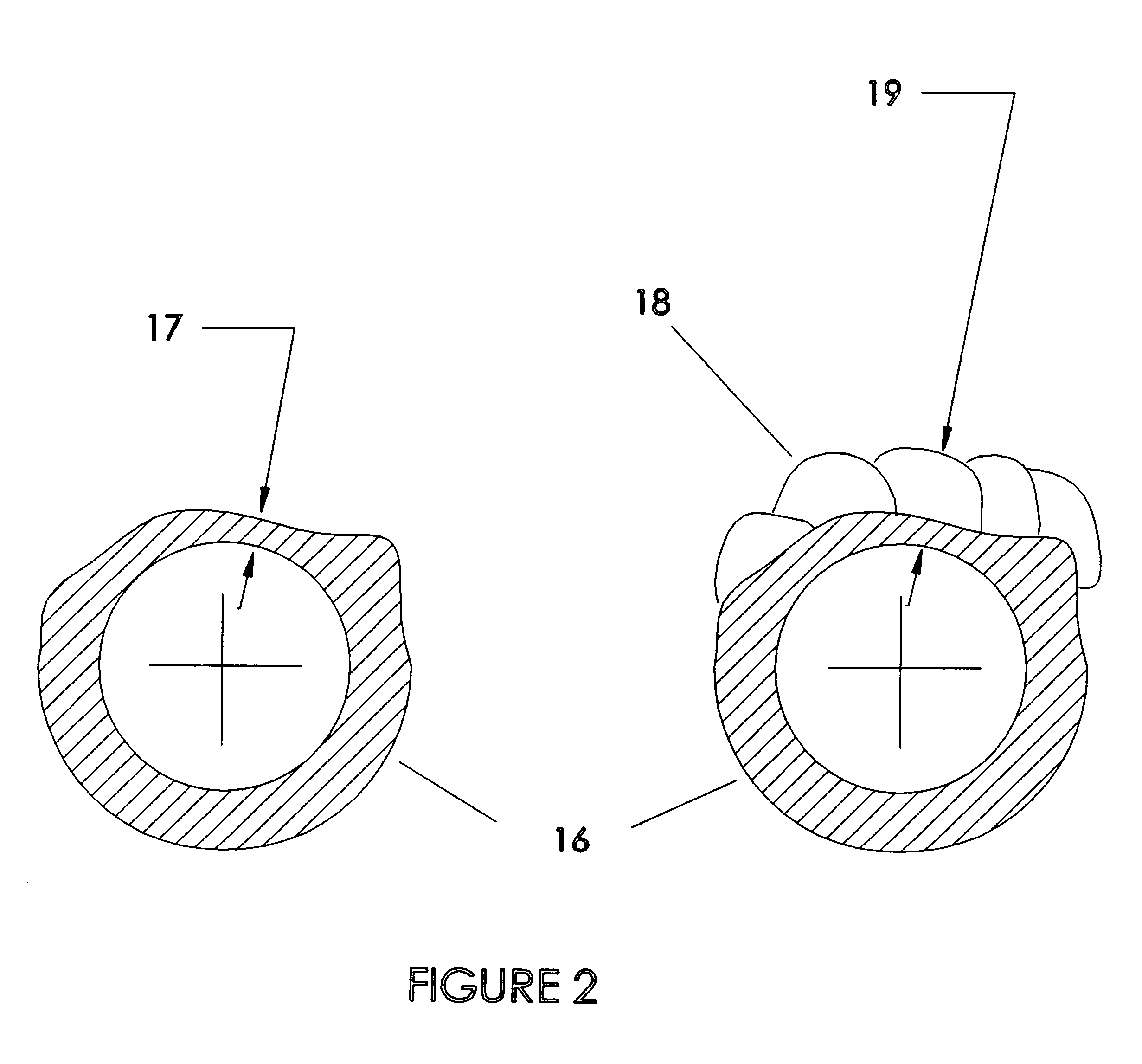

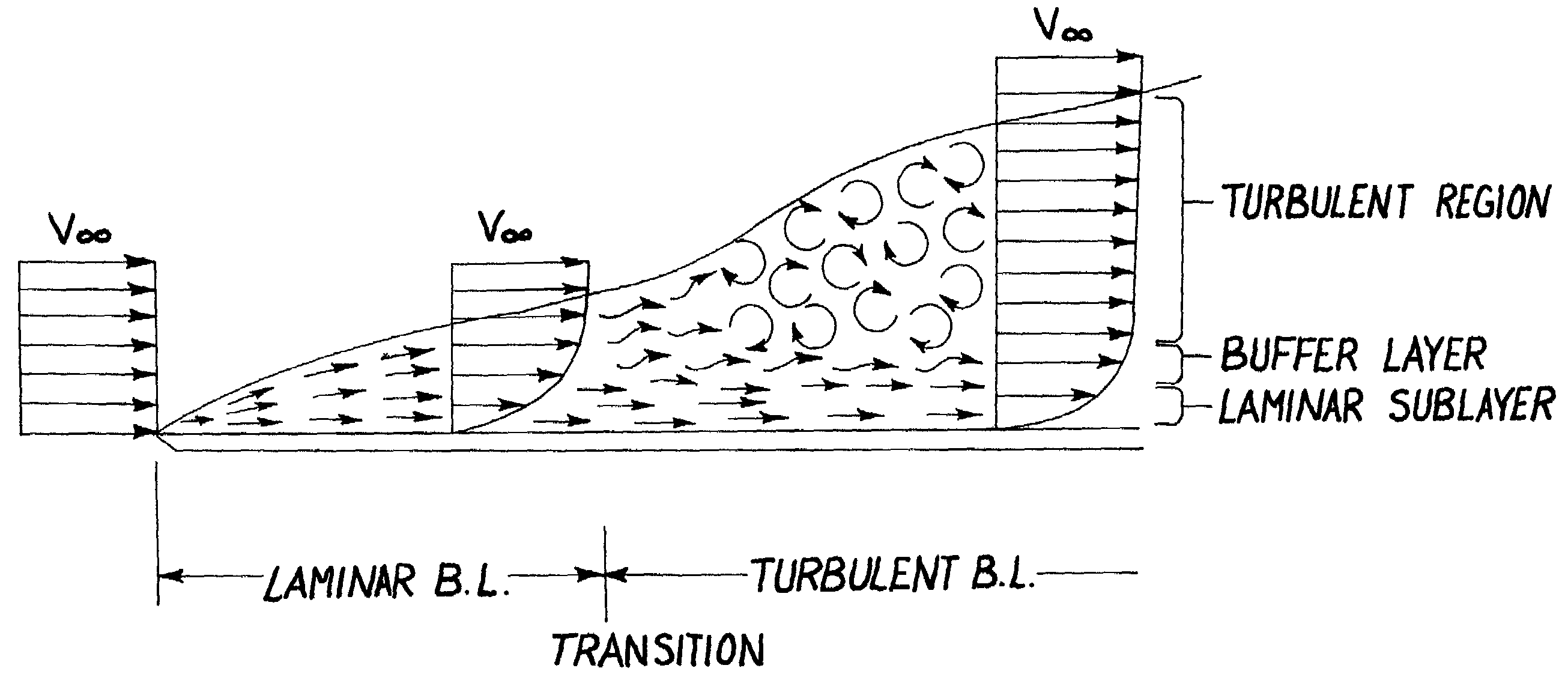

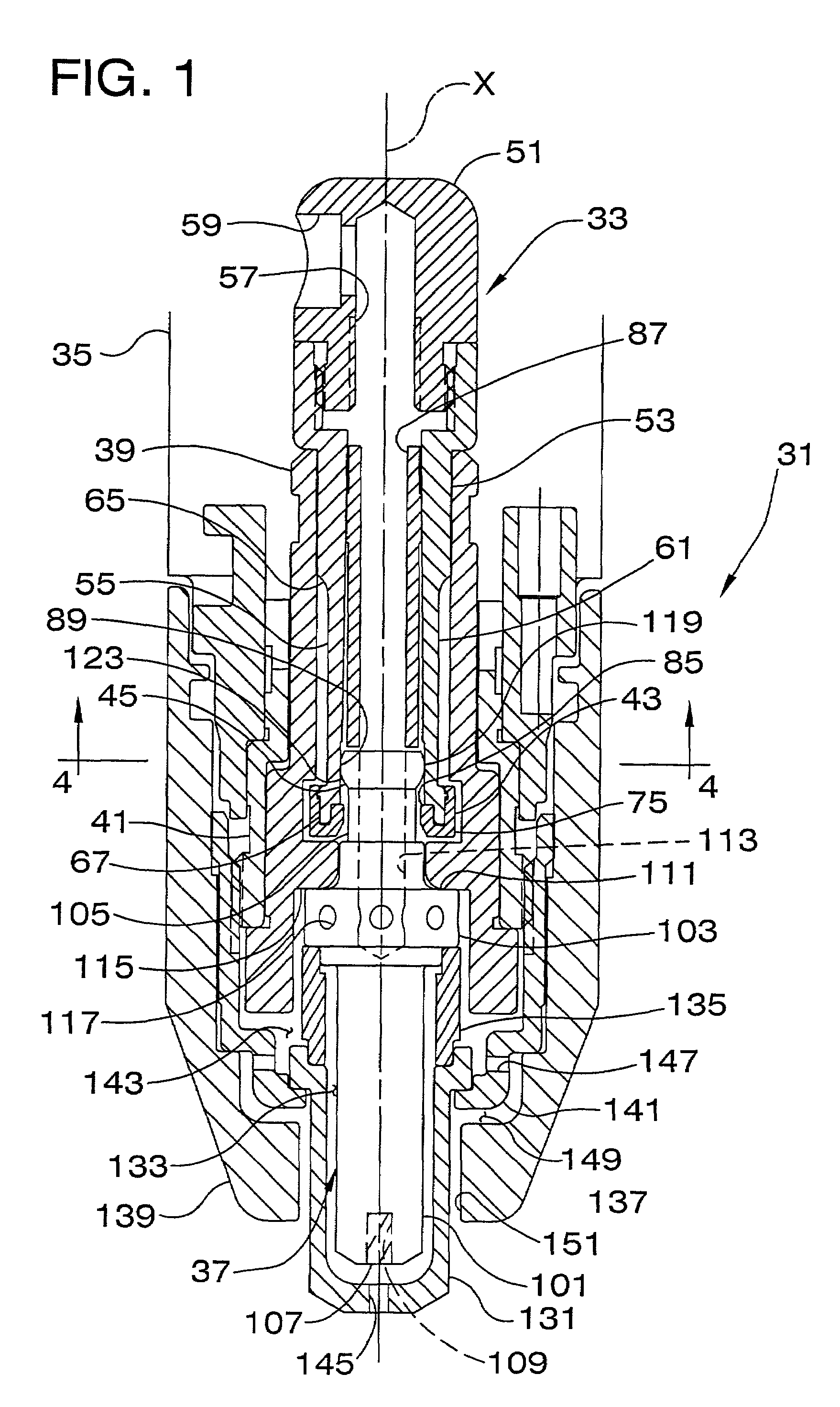

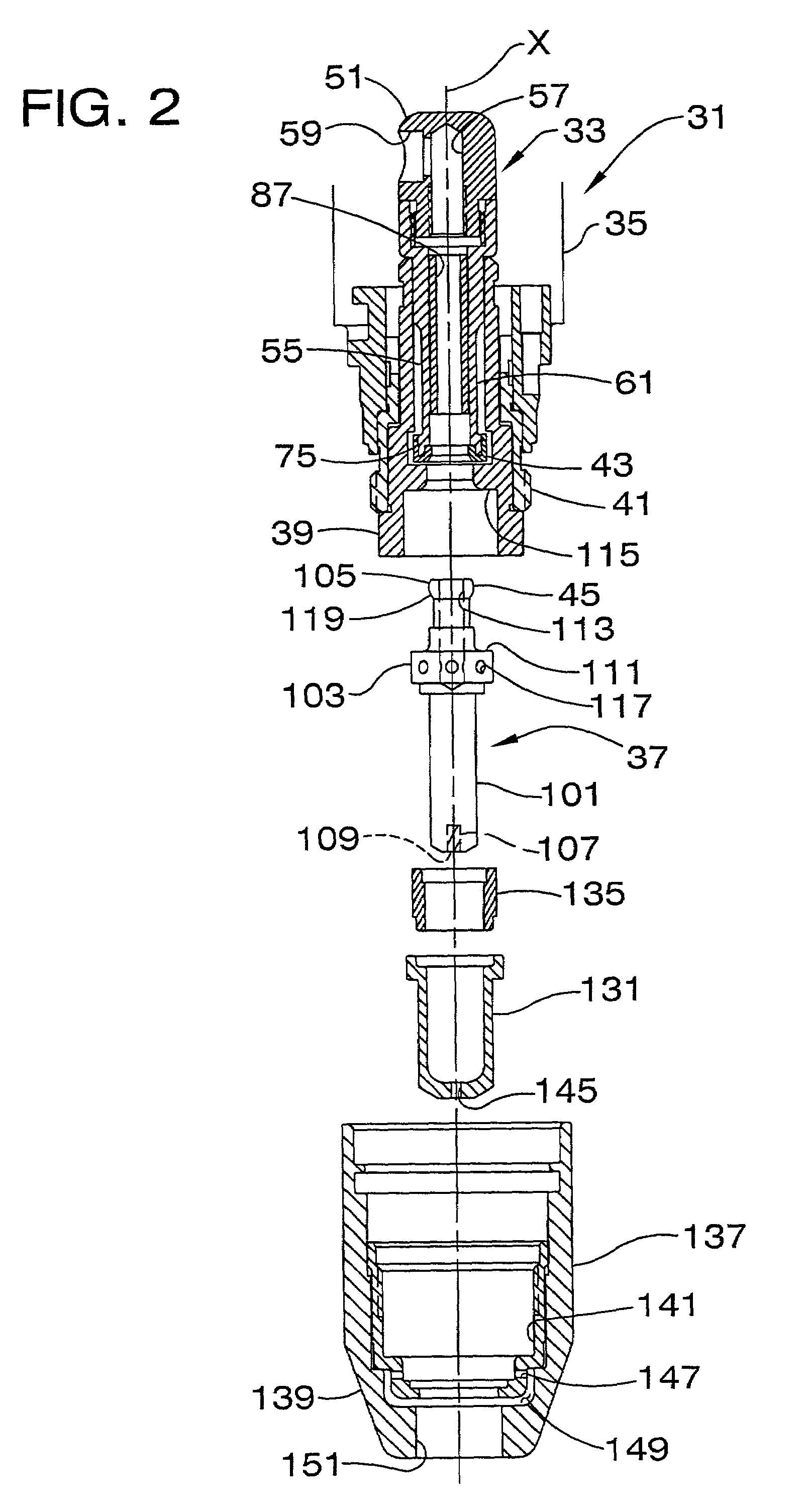

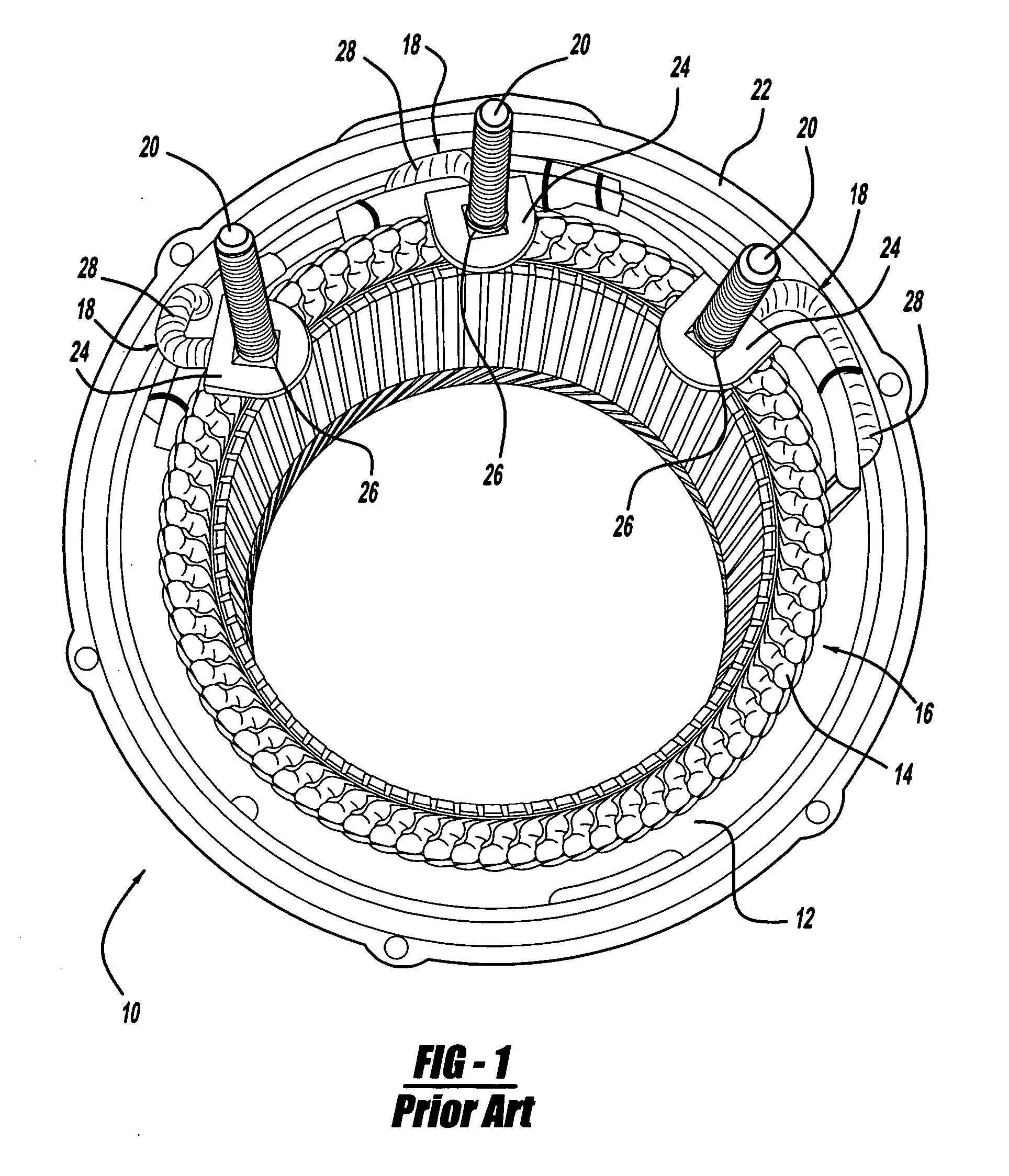

Plasma arc torch and method for improved life of plasma arc torch consumable parts

InactiveUS6987238B2Enhances convective coolingExtended service lifePlasma welding apparatusWelding/cutting media/materialsEngineeringTorch

A plasma arc torch and method for improving the life of the consumable parts of the plasma arc torch, including the electrode, the tip and the shield cap. The method includes turbulating gas as it flows over the exposed surfaces of the electrode, tip and shield cap to increase turbulence in the hydrodynamic boundary layer of the gas flow, thereby enhancing convective heat transfer. The result of enhanced cooling is improved consumable parts life. For example, to increase the turbulence of the gas flow over the outer surface of the electrode, the plasma arc torch electrode has a roughened, or textured outer surface formed with dimples, axially extending grooves or spiraling grooves formed in the outer surface of the electrode. The inner and outer surfaces of the tip and the inner surface of the shield cap are similarly textured.

Owner:VICTOR EQUIP

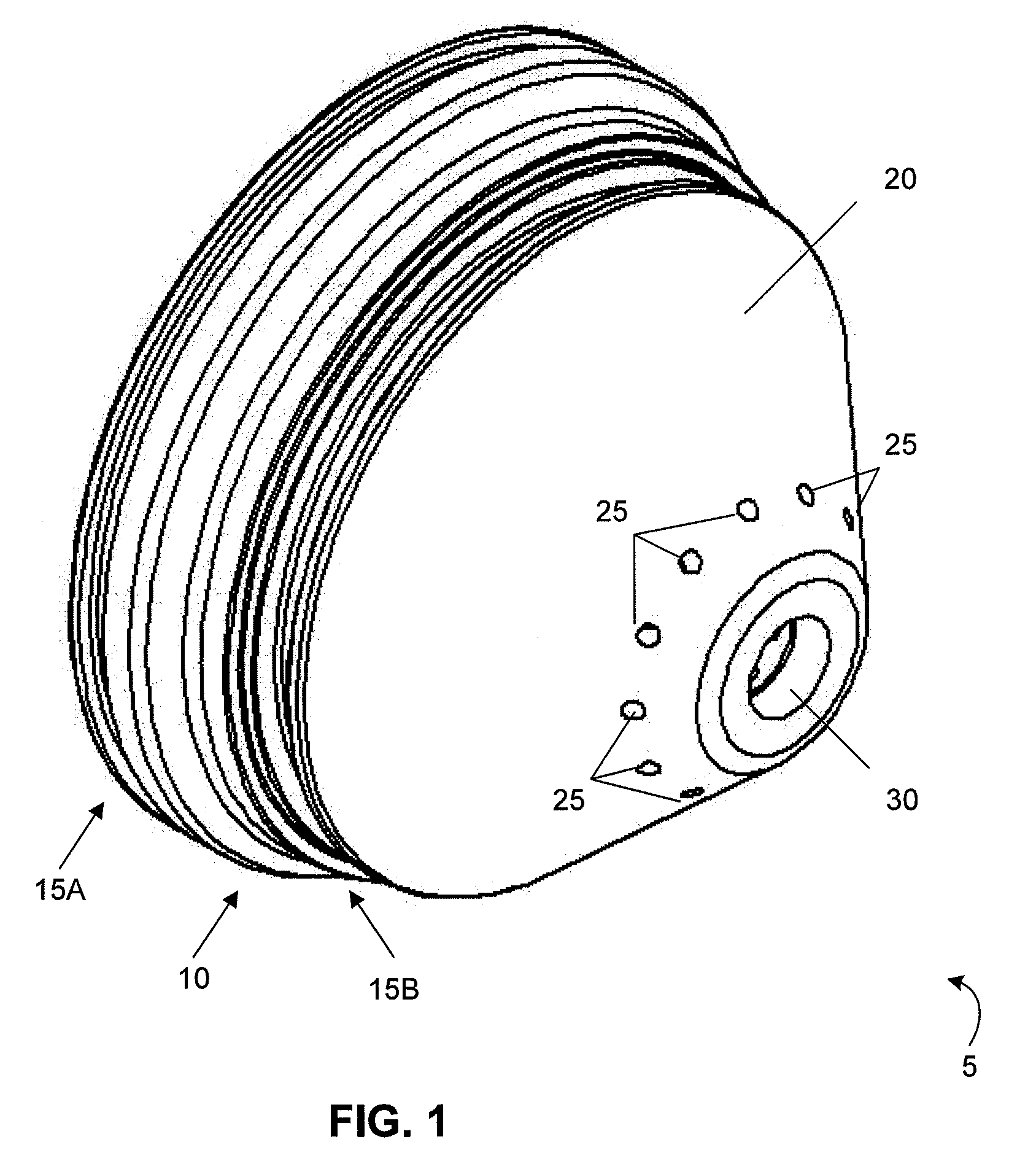

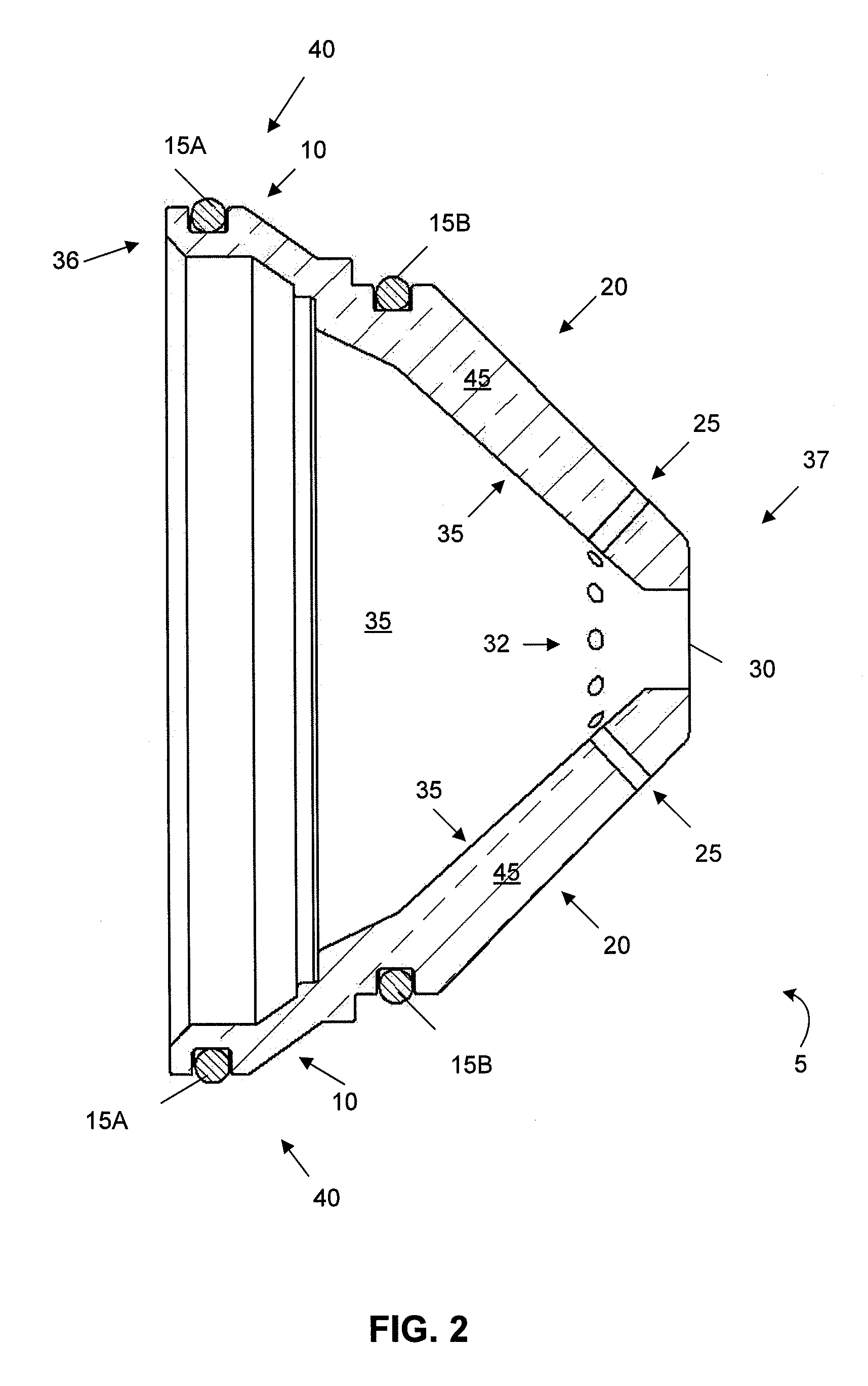

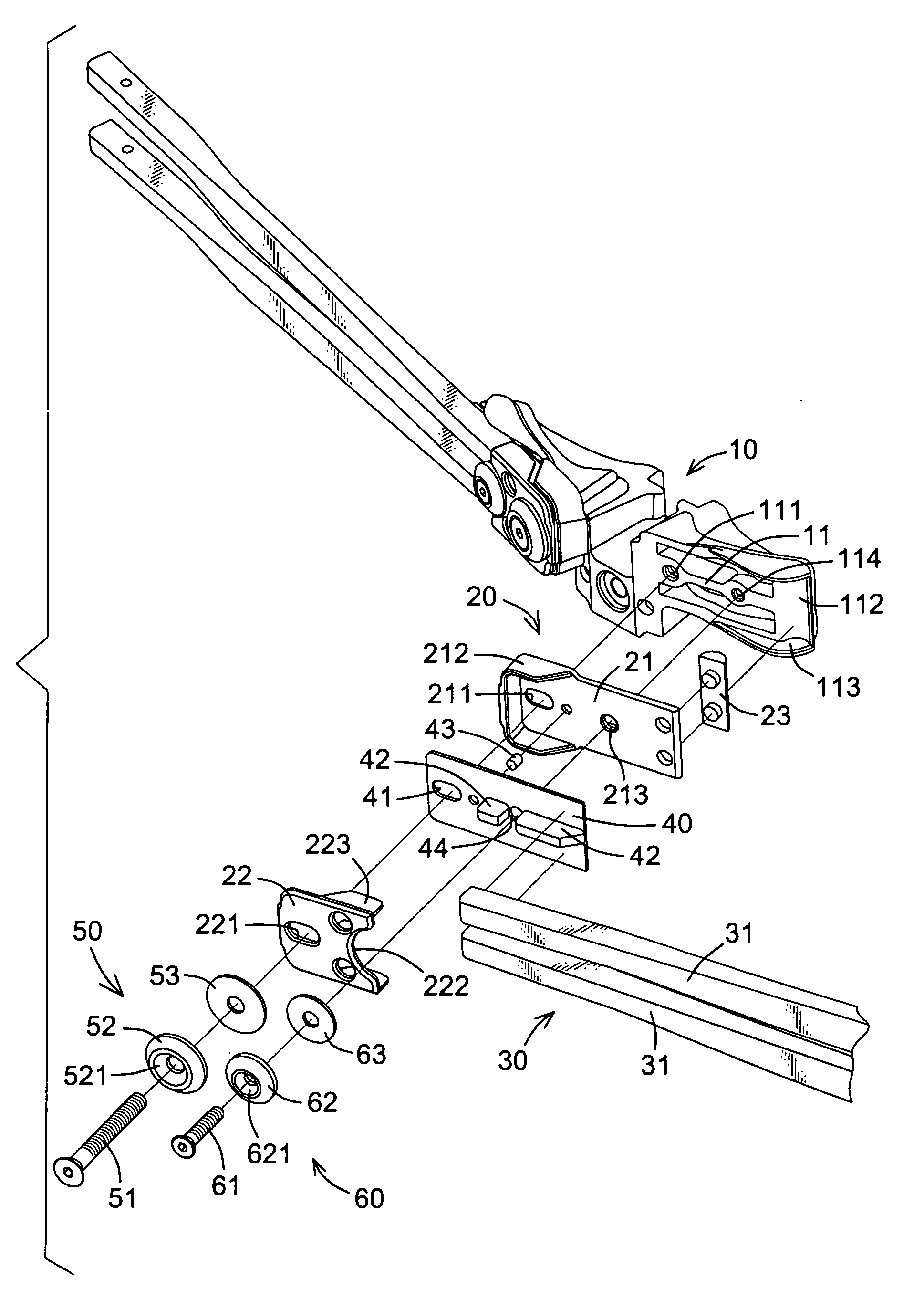

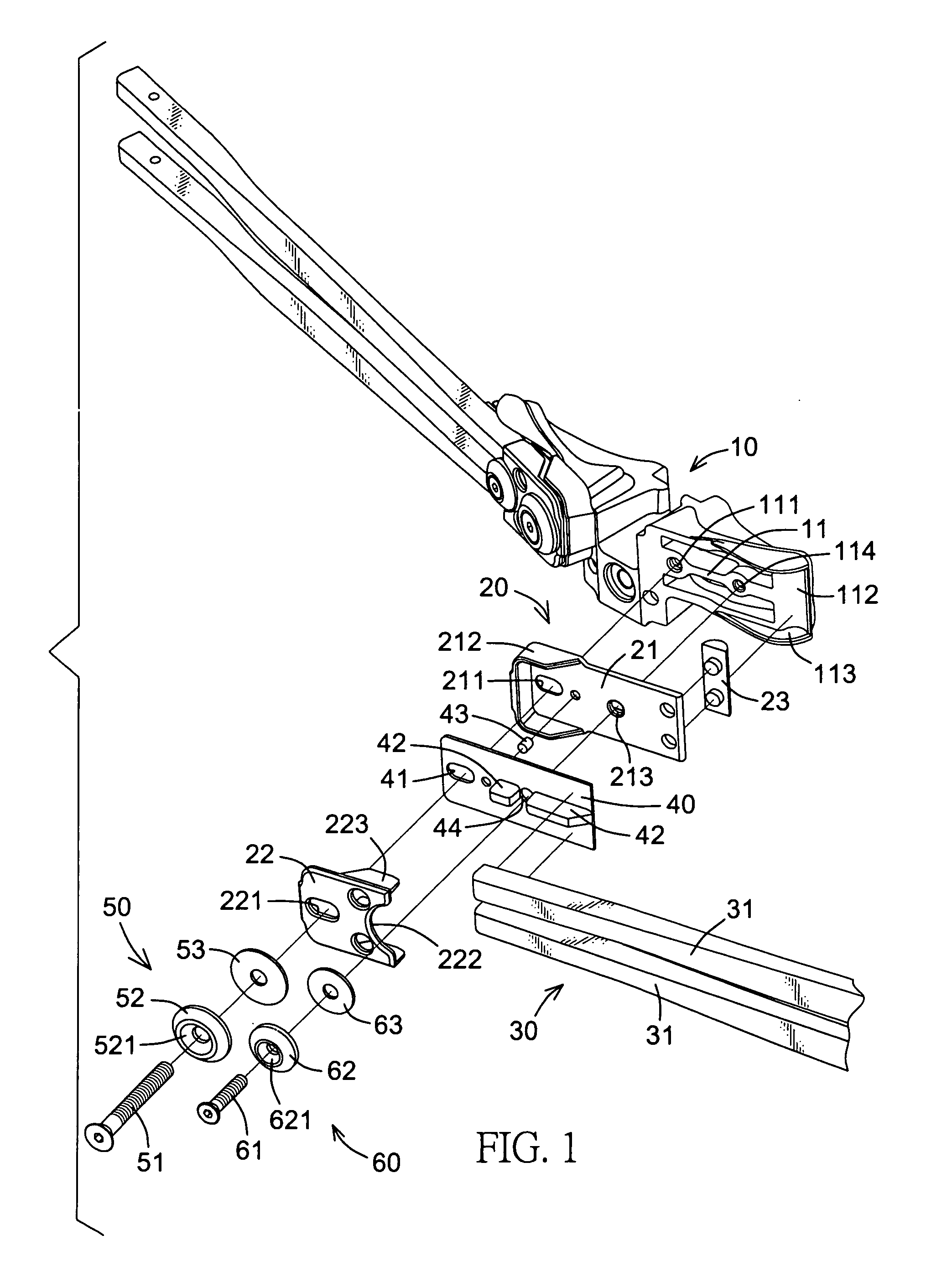

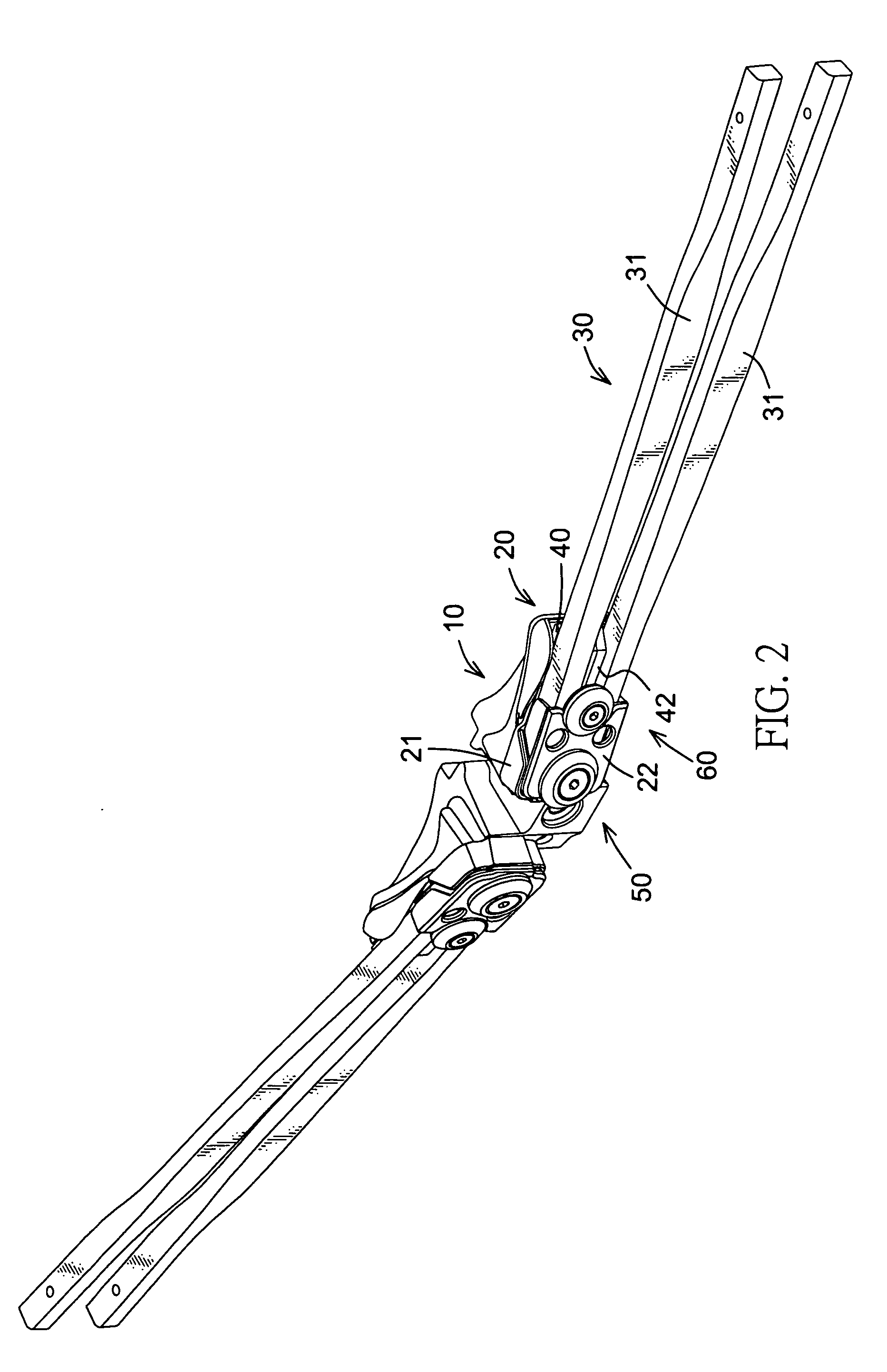

Bow for a crossbow

InactiveUS20080072888A1Extended useful lifeEasy to replaceBows/crossbowsEngineeringMechanical engineering

A bow for a crossbow includes a retainer, two holders, two limbs, two mounting members and two fastening members. The retainer has two inclined surfaces having a receiving recess. Each holder is mounted on one of the inclined surfaces and includes a base, a cover and a semicircular pivot. The semicircular pivot is mounted detachably on the outer end of the base and corresponds to and abuts with the receiving recess of the inclined surface. Each buffer is mounted between one of the limbs and the base of a corresponding holder for absorbing the force applied to the limb and reducing stress concentration to prolong the useful life of the limb.

Owner:POE LANG ENTERPRISE

Suspended inserts to provide wheel conditioning

InactiveUS20030234143A1Reduce defectsLightweight productionBraking membersFriction liningControl theoryBrake shoe

A brake shoe is used on a railway vehicle for both applying a braking force and simultaneously reconditioning a wheel tread surface of a wheel disposed on such railway vehicle during a normal braking application on such vehicle. The brake shoe comprises a backing plate having a predetermined configuration and a first friction type material formed into a brake shoe and having a predetermined shape. There is a brake surface for engaging a wheel tread having a predetermined configuration and having a predetermined surface area. A second friction type material is formed as a discrete insert, having a predetermined shape and a predetermined width, and molded into first friction type material. One surface of the discrete insert being disposed coincidently as part of the brake surface of the brake shoe. The second friction type material exhibits greater abrasive properties than does the first friction type material.

Owner:WESTINGHOUSE AIR BRAKE TECH CORP

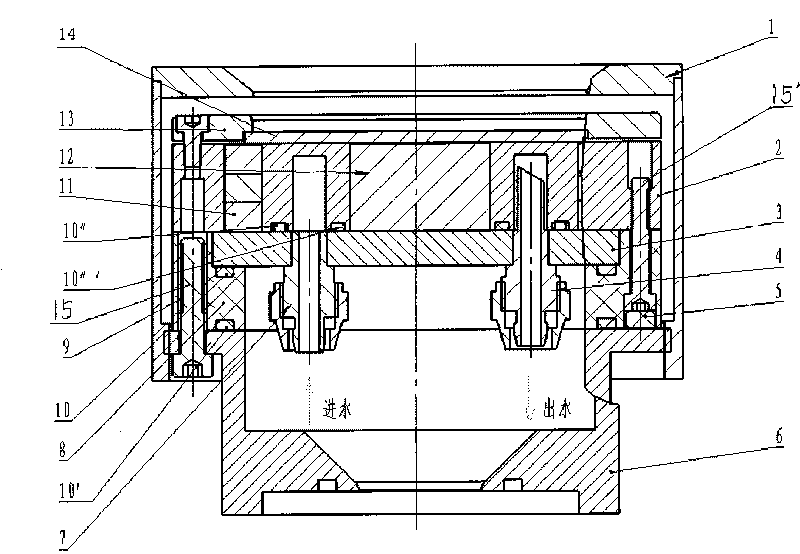

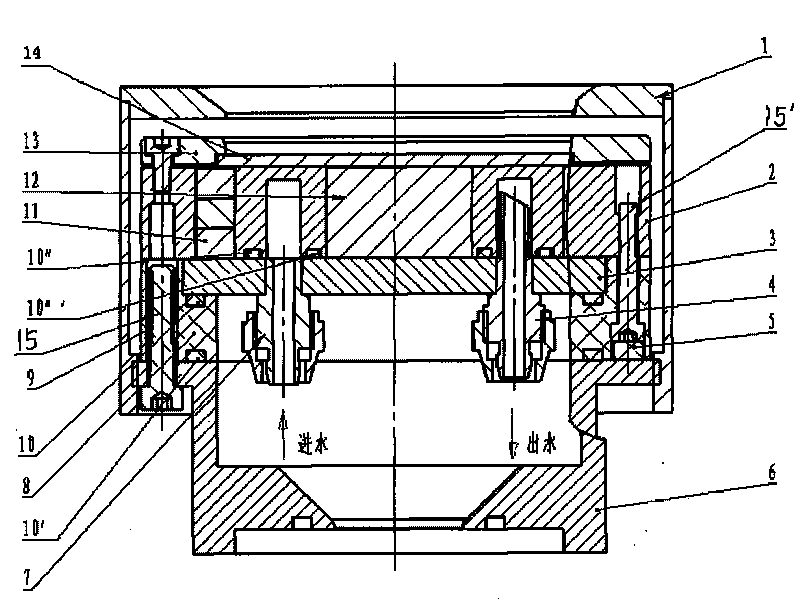

Magnetic control sputtering target

ActiveCN101736300AExtended useful lifeThe highest magnetic induction intensity is largeVacuum evaporation coatingSputtering coatingSputteringRubber ring

The invention discloses a permanent-magnet magnetic control sputtering target with a round plane, which can sputter magnetic materials and is composed of an outer shield cover, a magnetic steel seat, a pole shoe, an insulating seat, a permanent seat, a target gland bush, inner magnetic steel, outer magnetic steel, a water inlet nozzle, a water outlet nozzle, an attachment bolt, a hermetical rubber, and the like, wherein a thread manual adjustable structure is adopted between the outer shield cover and the permanent seat, the materials of the magnetic steel seat are oxygen-free copper, the inner magnetic steel is arranged at the center of the magnetic steel seat, the periphery of the magnetic steel seat is drilled to form a plurality of pinholes for installing the outer magnetic steel, and target materials are directly laid on the magnetic steel seat and fixed by the target gland bush. The pole shoe is made of permeability materials, when the magnetic control target works, a direct current or radio-frequency power supply is applied to the pole shoe, the water inlet nozzle and the water outlet nozzle are welded by argon arc welding under the pole shoe, cooling water enters from a low place and outflows from a high place, and hermetical seal is realized by the hermetical rubber ring. The materials of the insulating seat are temperature-resistant insulating materials which can be used in vacuum, and are installed between the permanent seat (anode) and the pole shoe (cathode), and an insulating cap has the insulating action between an electriferous screw (cathode) and the permanent seat (anode). The invention has simple structure and low cost.

Owner:SHENYANG SCI INSTR RES CENT CHINESE ACAD OF SCI

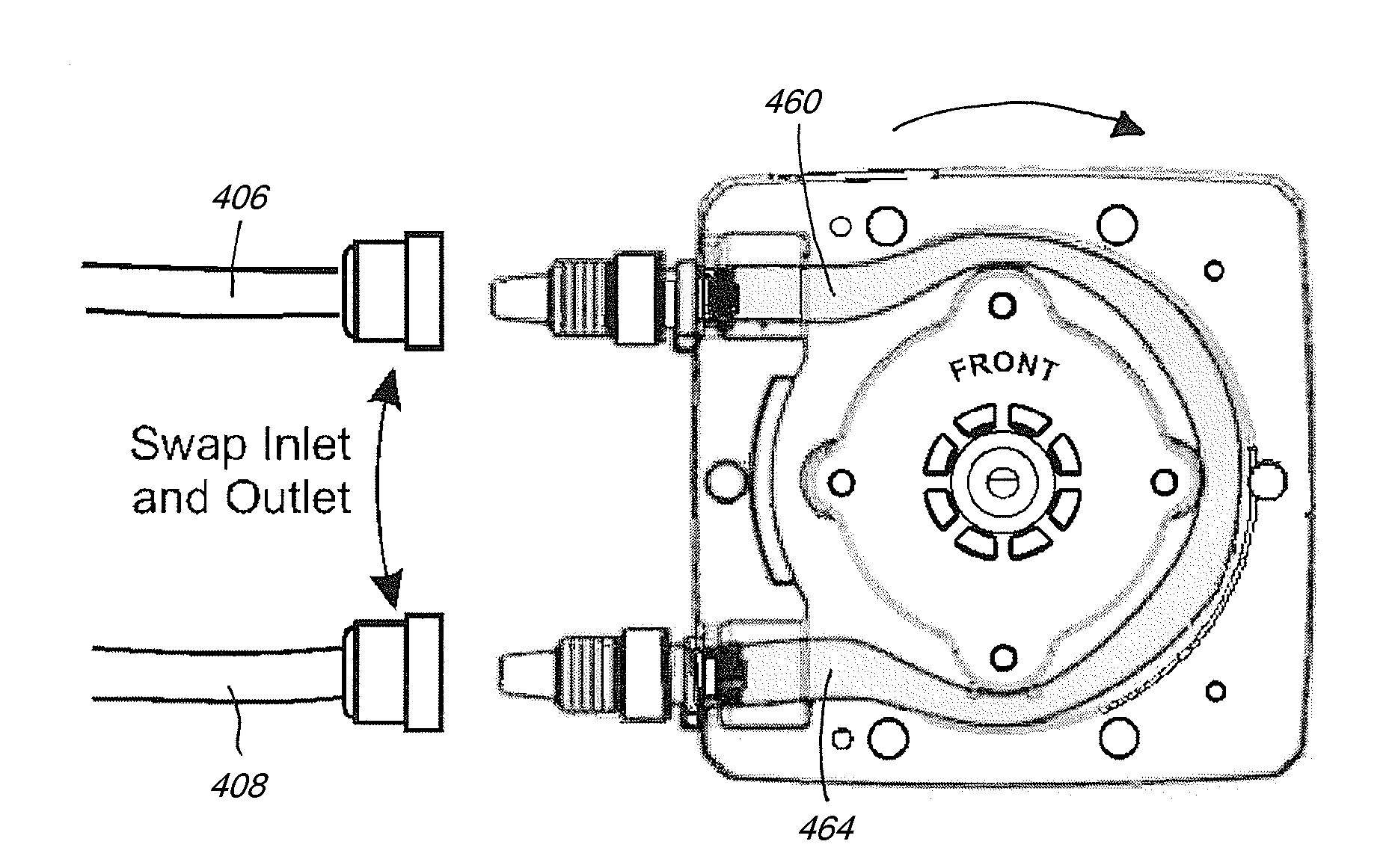

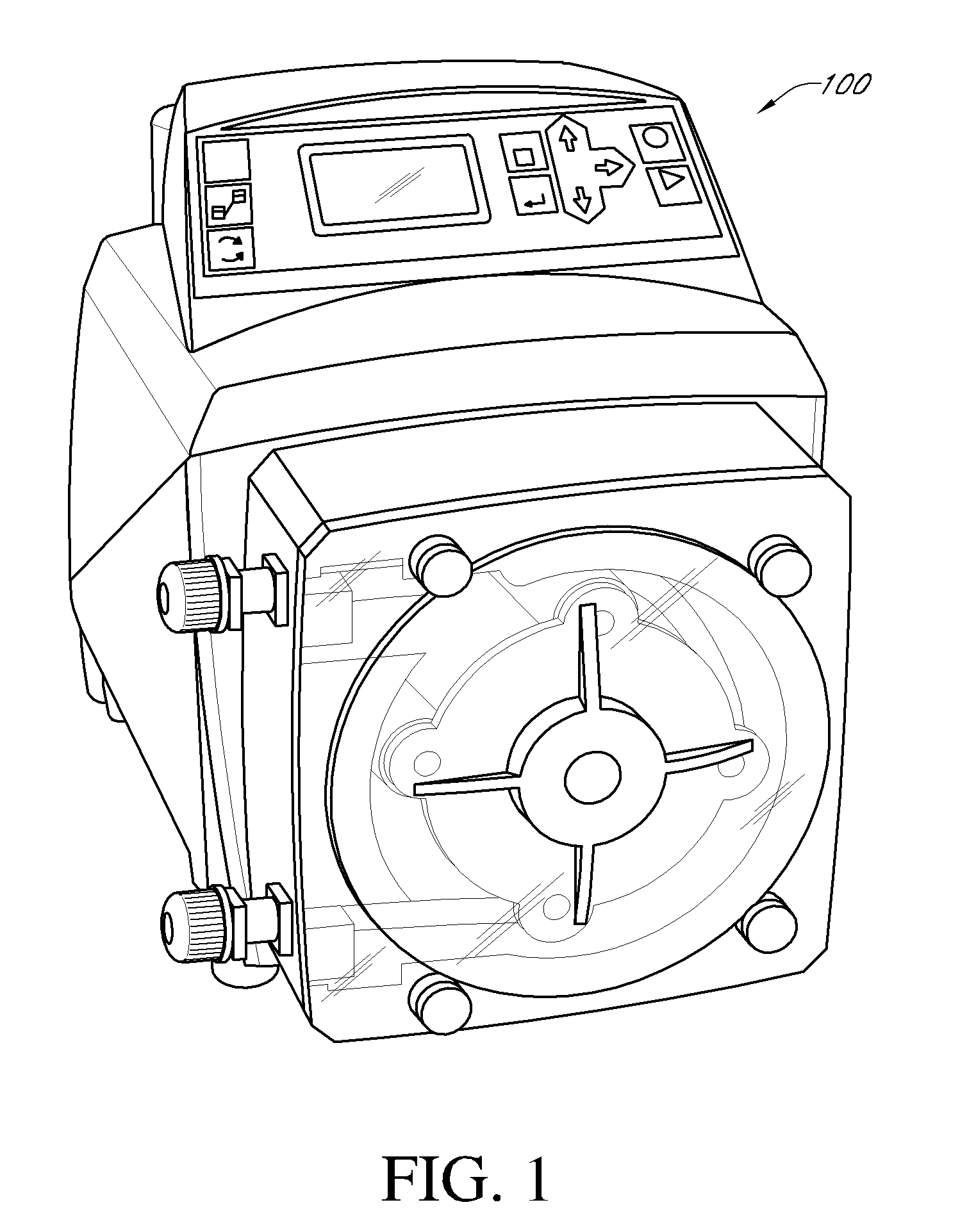

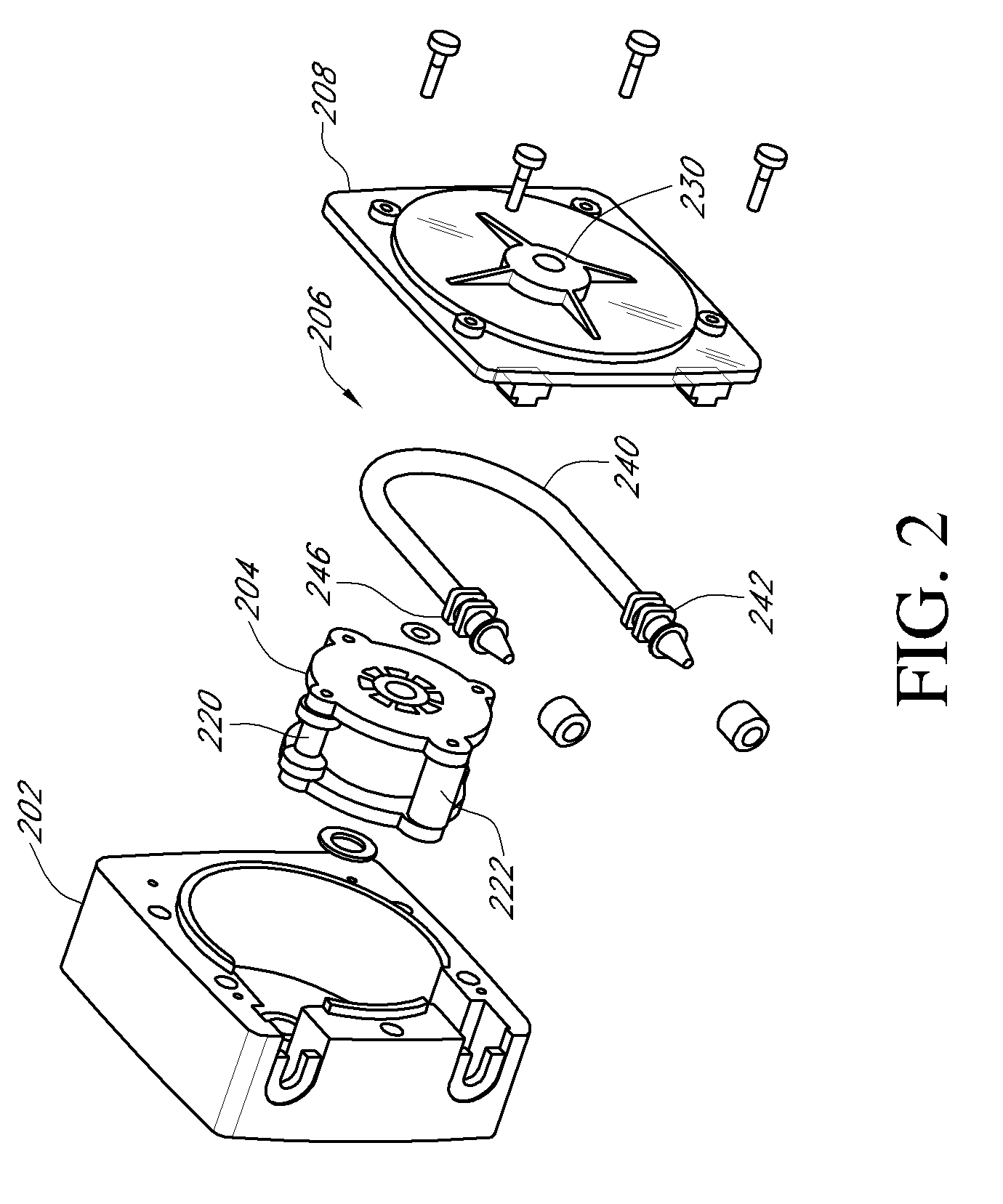

Method of extending tubing life of a peristaltic pump

A method is provided for extending useful life of tubing of a peristaltic pump. The method can comprise switching inlet and discharge hoses between respective inlet and outlet ends of the tubing of the peristaltic pump, and reversing a direction of rotation of a rotor of the peristaltic pump. In implementations of methods disclosed herein, the useful life of the tubing of a peristaltic pump can be approximately doubled.

Owner:BLUE WHITE INDS

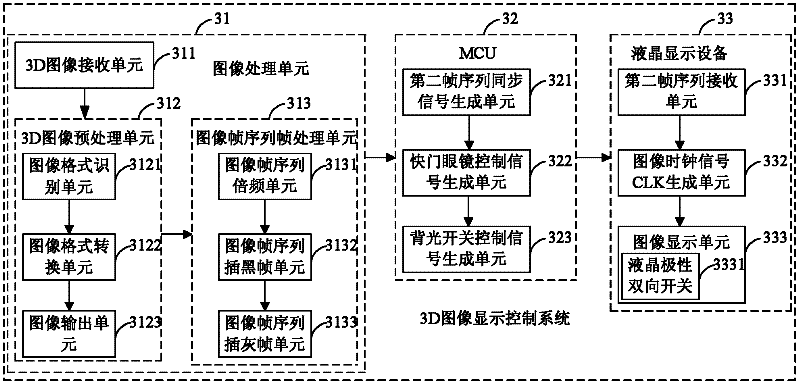

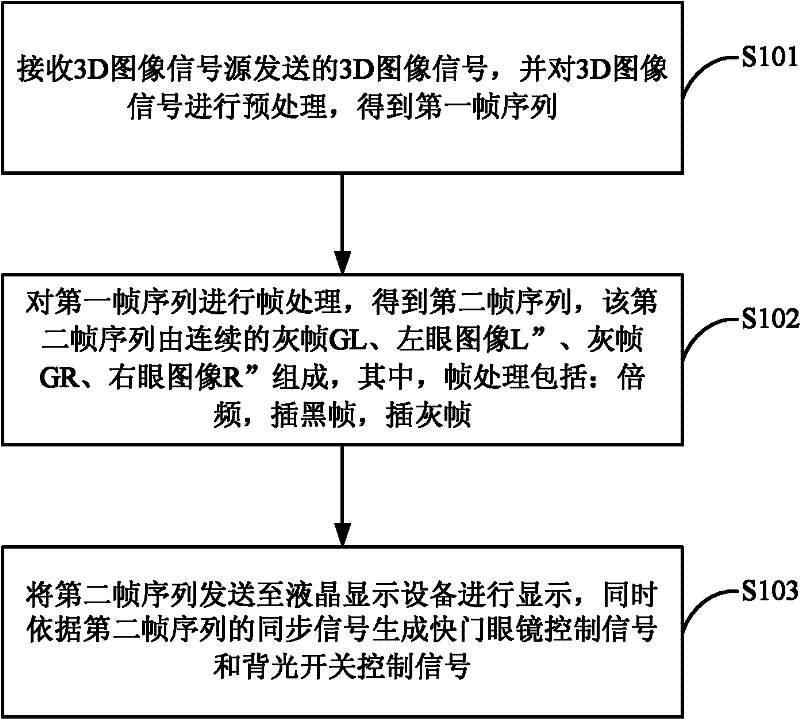

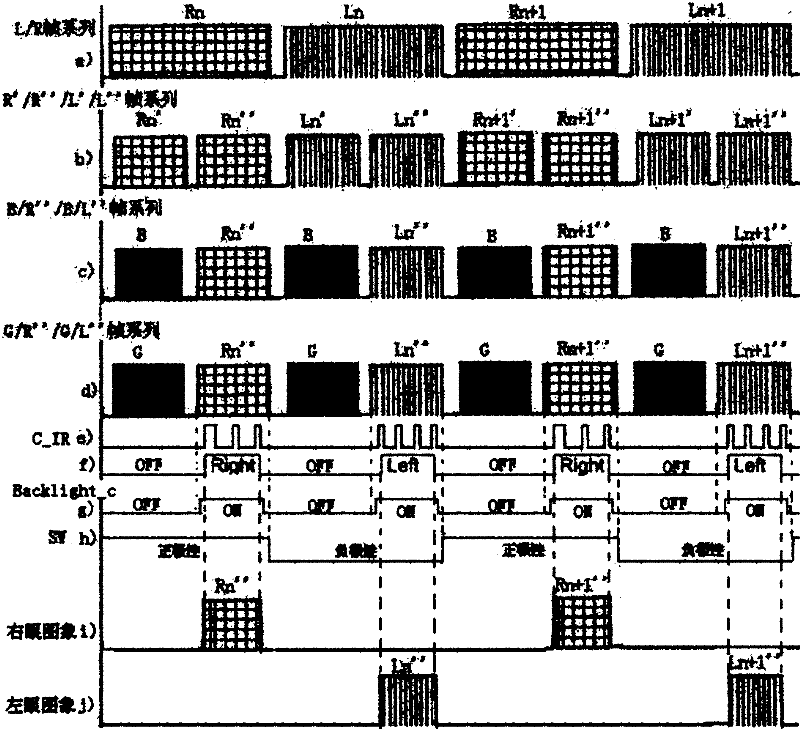

Three-dimensional (3D) image display control method and system

InactiveCN102196290ALarge deflection angleFast deflection angleStatic indicating devicesSteroscopic systemsFrame sequenceLiquid-crystal display

The invention is applied in the field of liquid crystal display, and provides a three-dimensional (3D) image display control method and a 3D image display control system. The method comprises the following steps of: receiving a 3D image signal from a 3D image signal source, and pre-processing the 3D image signal to obtain a first frame sequence; performing frame processing on the first frame sequence to obtain a second frame sequence consisting of a gray frame GL, a left-eye image L'', the gray frame GR and a right-eye image R'' which are continuous, wherein the frame processing comprises frequency multiplication, black frame interpolation and gray frame interpolation; and transmitting the second frame sequence to a liquid crystal screen for display, simultaneously generating a shutter glasses control signal and a backlight switching control signal according to a synchronizing signal of the second frame sequence, controlling the switching state of shutter glasses by using the shutter glasses control signal, and controlling the switching state of a backlight source of the liquid crystal display screen by using the backlight switching control signal. The embodiment of the invention fulfills the aim of definitely displaying a 3D image by performing the pre-processing and the frame processing on the 3D image.

Owner:SHENZHEN SKYWORTH RGB ELECTRONICS CO LTD

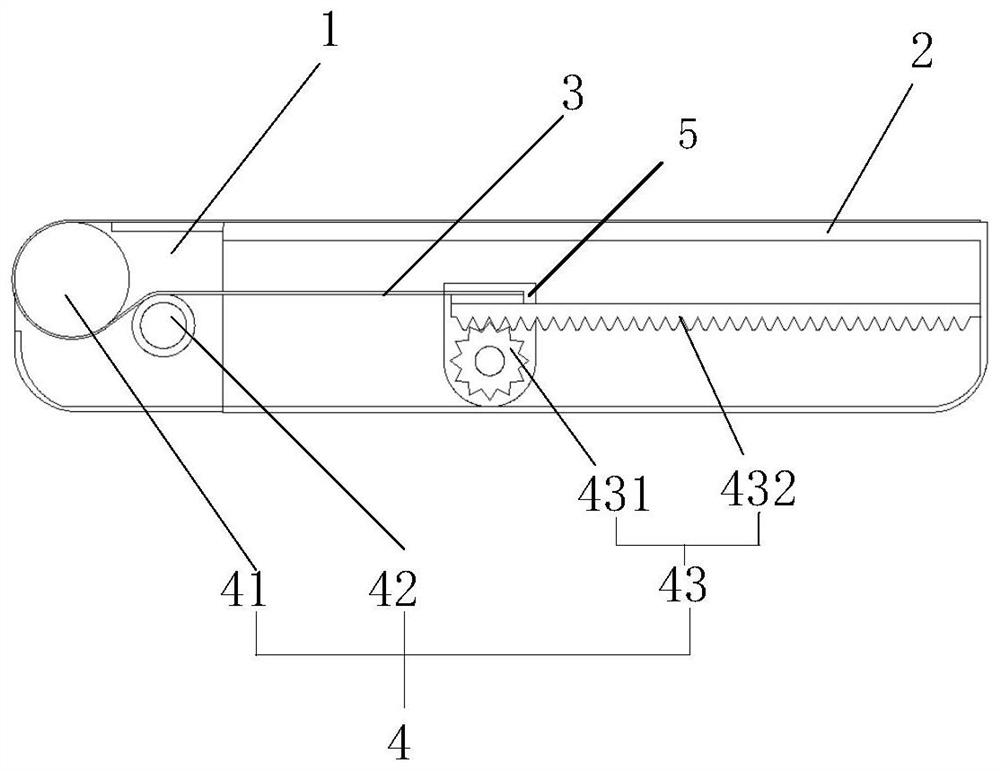

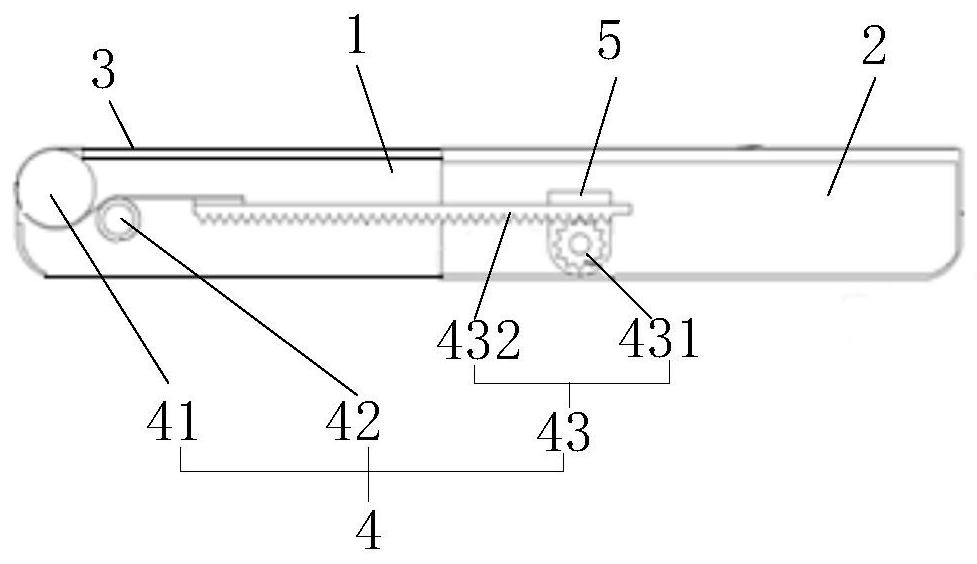

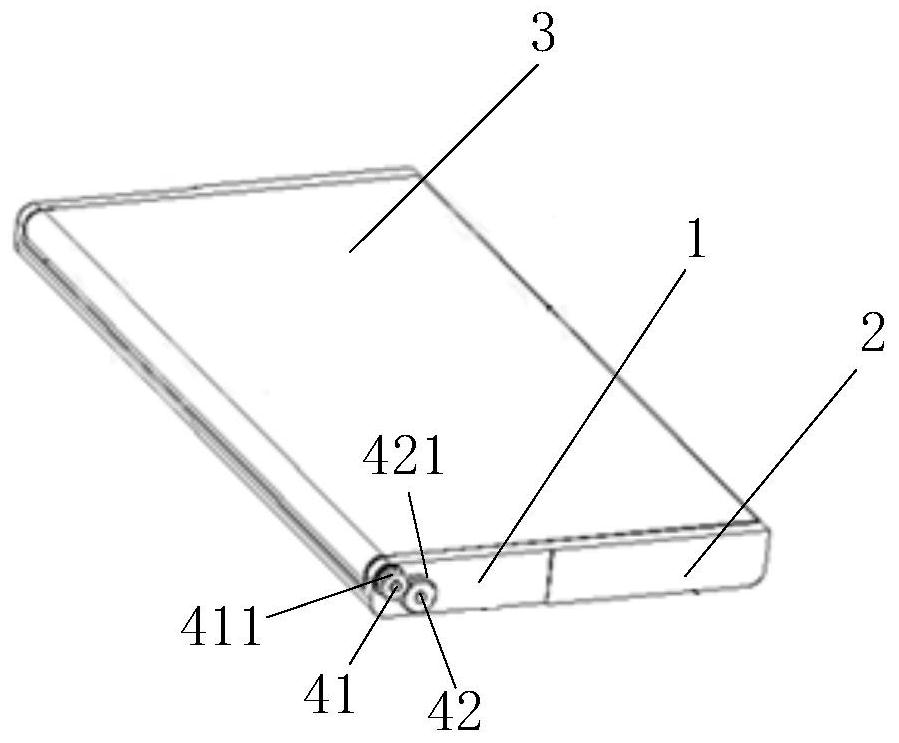

Display device and electronic equipment

PendingCN111768709AAvoid damageExtended useful lifeFriction gearingsIdentification meansDisplay deviceEngineering

The embodiment of the invention provides a display device and electronic equipment, and belongs to the technical field of display. The display device comprises a sliding machine shell, a fixed machineshell, a flexible screen and a conveying assembly. The sliding machine shell is in sliding connection with the fixed machine shell. The conveying assembly comprises a rolling shaft, a pre-tighteningshaft and a transmission part. The rolling shaft and the pre-tightening shaft are both hinged to the sliding machine shell. The transmission part is fixed in the fixed machine shell. A first end of the flexible screen is fixed to the fixed machine shell, the flexible screen covers the outer surface of the top of the fixed machine shell, and a second end of the flexible screen winds the rolling shaft and is fixed to the transmission part. The pre-tightening shaft is located between the rolling shaft and the transmission part, and the outer surface of the top of the pre-tightening shaft abuts against the flexible screen. Thus, the outer surface of the pre-tightening shaft abuts against the flexible screen all the time, the contact area between the flexible screen and the rolling shaft is increased, meanwhile, the flexible screen is always subjected to supporting force of the pre-tightening shaft, and the flexible screen can be always matched with the outer surface of the rolling shaft under the effect of the supporting force of the pre-tightening shaft.

Owner:BOE TECH GRP CO LTD

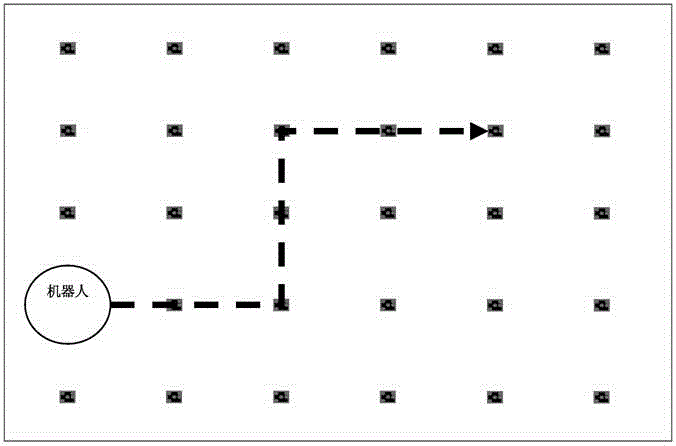

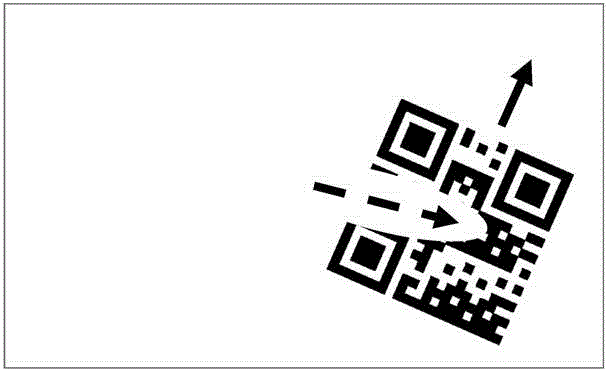

Robot global space positioning method based on graphical labels and camera

InactiveCN105783915AExtended useful lifeAvoid damageNavigational calculation instrumentsNavigation by terrestrial meansGraphicsComputer vision

The invention relates to a robot global space positioning method based on graphical labels and a camera.The method comprises the steps that the graphical labels are laid every a certain distance in the working space of a robot; a processor sets the movement path of the robot so that the robot can observe the graphical labels through the camera on the movement path; when the robot can not observe the graphical labels, the space position of the robot is calculated according to the advancing mileage of the robot; when the robot shoots the graphical labels through the camera, the angles of the robot relative to the graphical labels and the position of the robot are worked out, and the global positioning information of the robot is acquired through the space position of the graphical labels.The ground labels can be recognized through the camera, and therefore the space positions of the robot or other devices can be corrected, contact with the robot does not exist, maintaining is easy, the recognition speed is high, installation is easy, and rearrangement can be conducted many times.

Owner:ZHUINENG ROBOTICS SHANGHAI CO LTD

Turbine component trailing edge and platform restoration by laser cladding

ActiveUS20070160476A1Extended useful lifeExtended service lifeTurbinesBlade accessoriesFilling materialsTrailing edge

A method of restoring a gas turbine engine component includes depositing a filler material onto a sulphidation section of an underside of a turbine engine platform and laser consolidating the filler material to produce a restored surface on the underside. The sulphidation section includes sulphidation pit portions that are filled during the laser consolidating to produce the restored surface. An eroded trailing edge of a turbine airfoil is laser cladded to produce a restored trailing edge thickness.

Owner:RAYTHEON TECH CORP

Head for a rotary line trimmer apparatus

InactiveUS7536792B2Prevents excessively acute and sharp bendingPremature damageMowersMetal working apparatusMechanical engineeringKinetic energy

An improved head for a flexible line trimmer apparatus is provided. The improved head includes a metal tubing that extends through the head and surrounds a cutting line of selected length. The tubing is provided with a flared exit portal increasing the efficiency of the head. The contact surface eliminates the possibility of the cutting line fusing to plastic surfaces due to heating caused by friction. The head is surrounded with an interior perimeter counterweight to store kinetic energy on each end having a parabolic surface of revolution concentric with the axis of the tubing. A replaceable cartridge is provided to increase the ease of maintenance and the useful life of the head.

Owner:MOORE MARK R

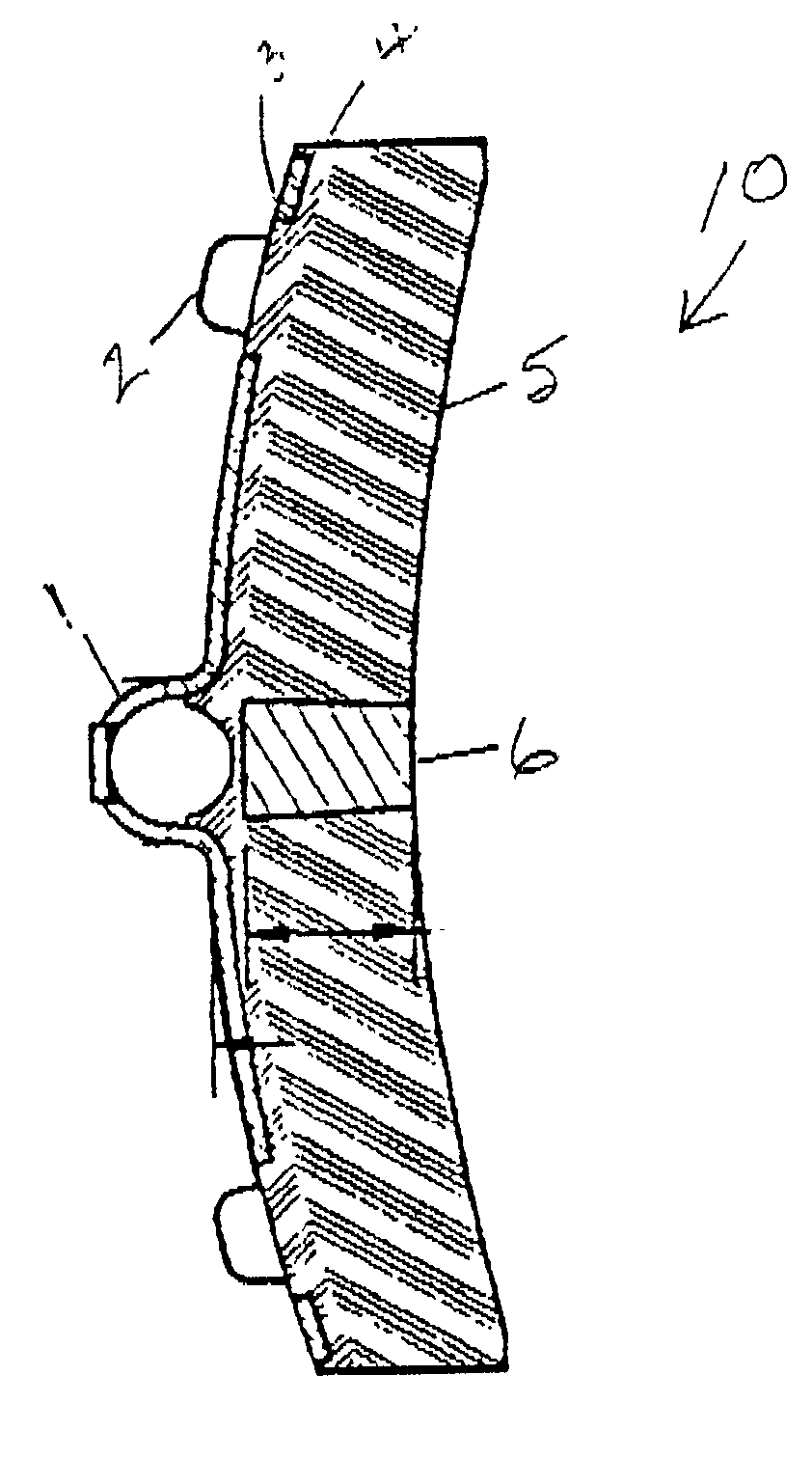

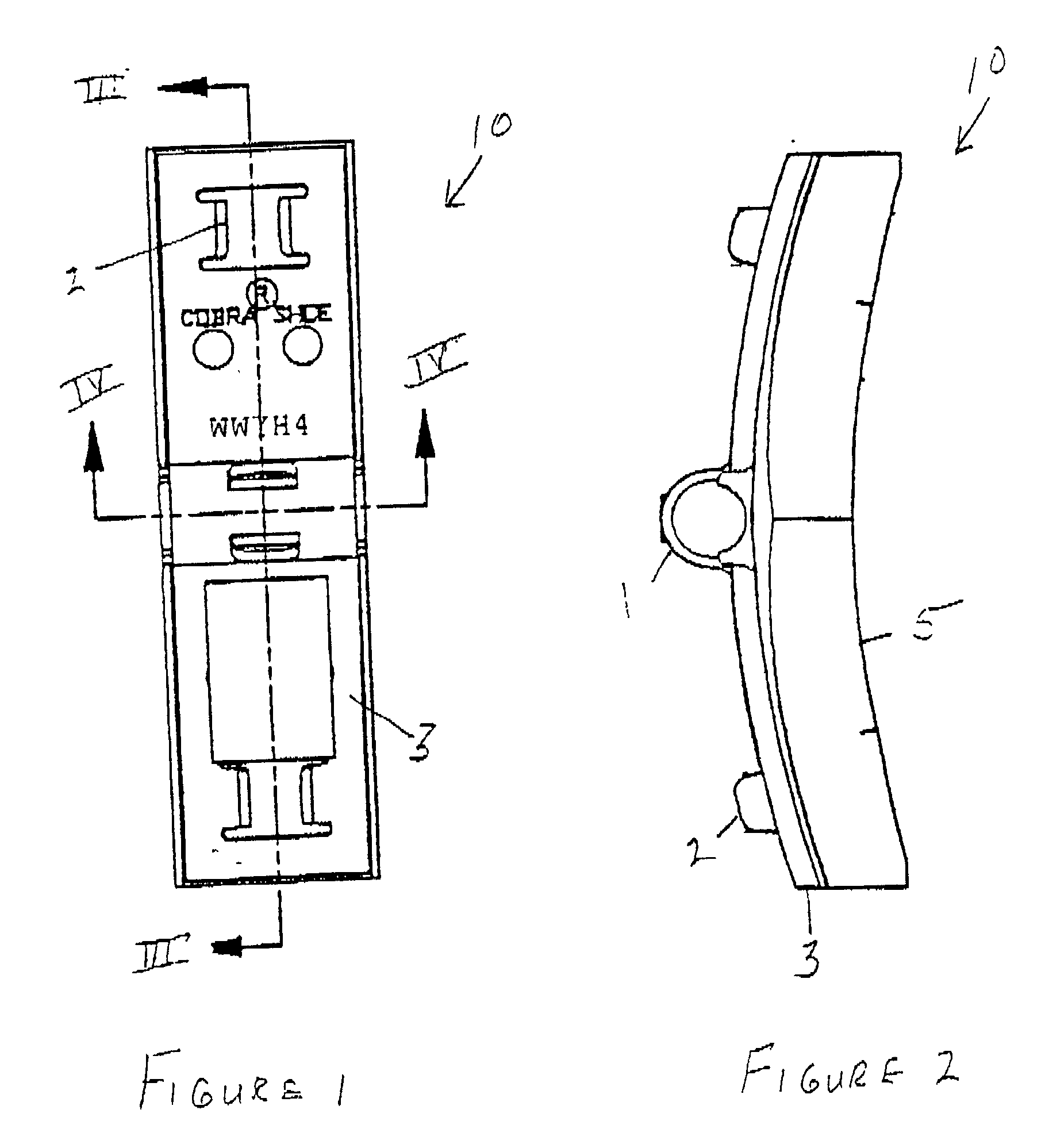

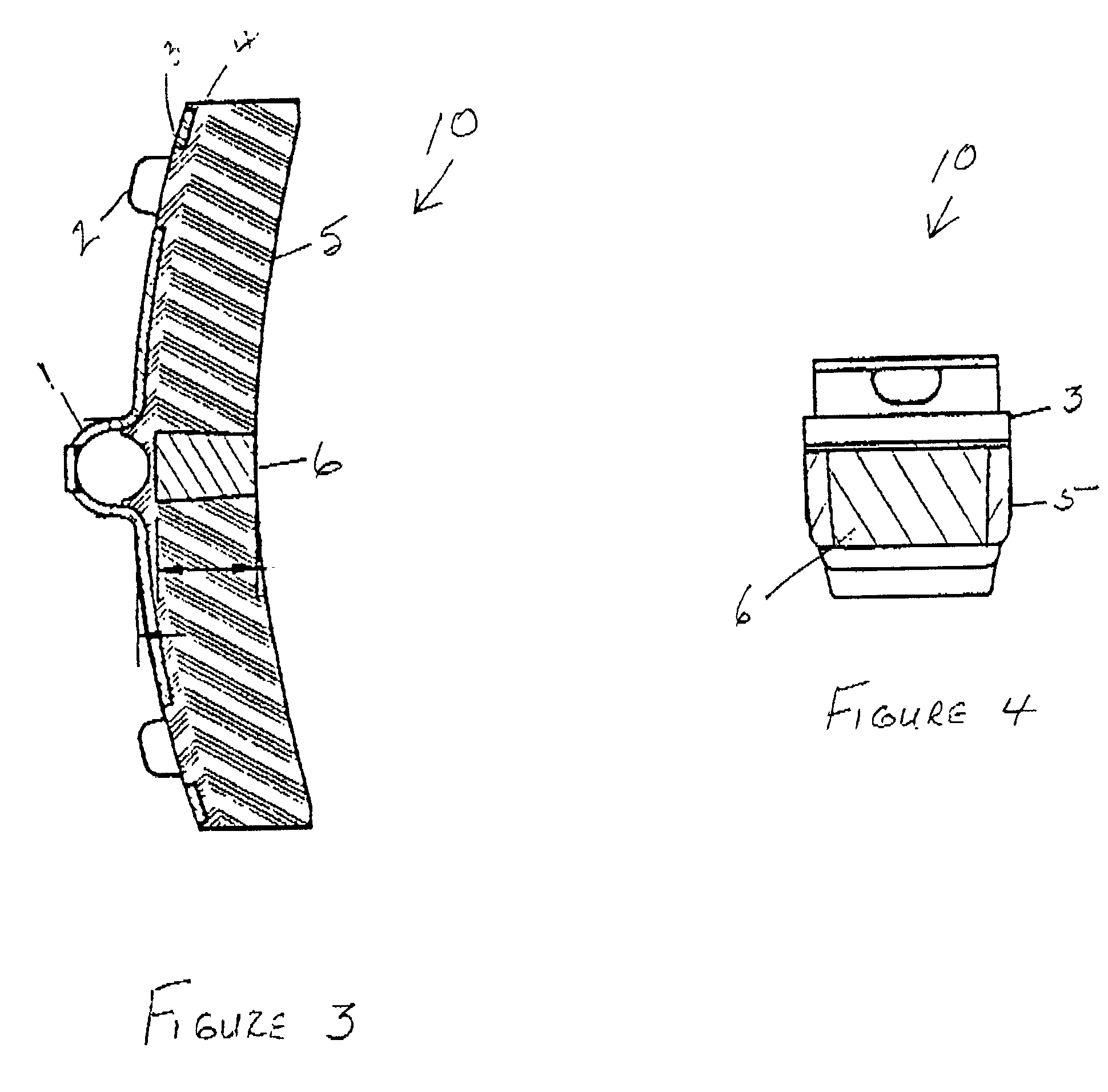

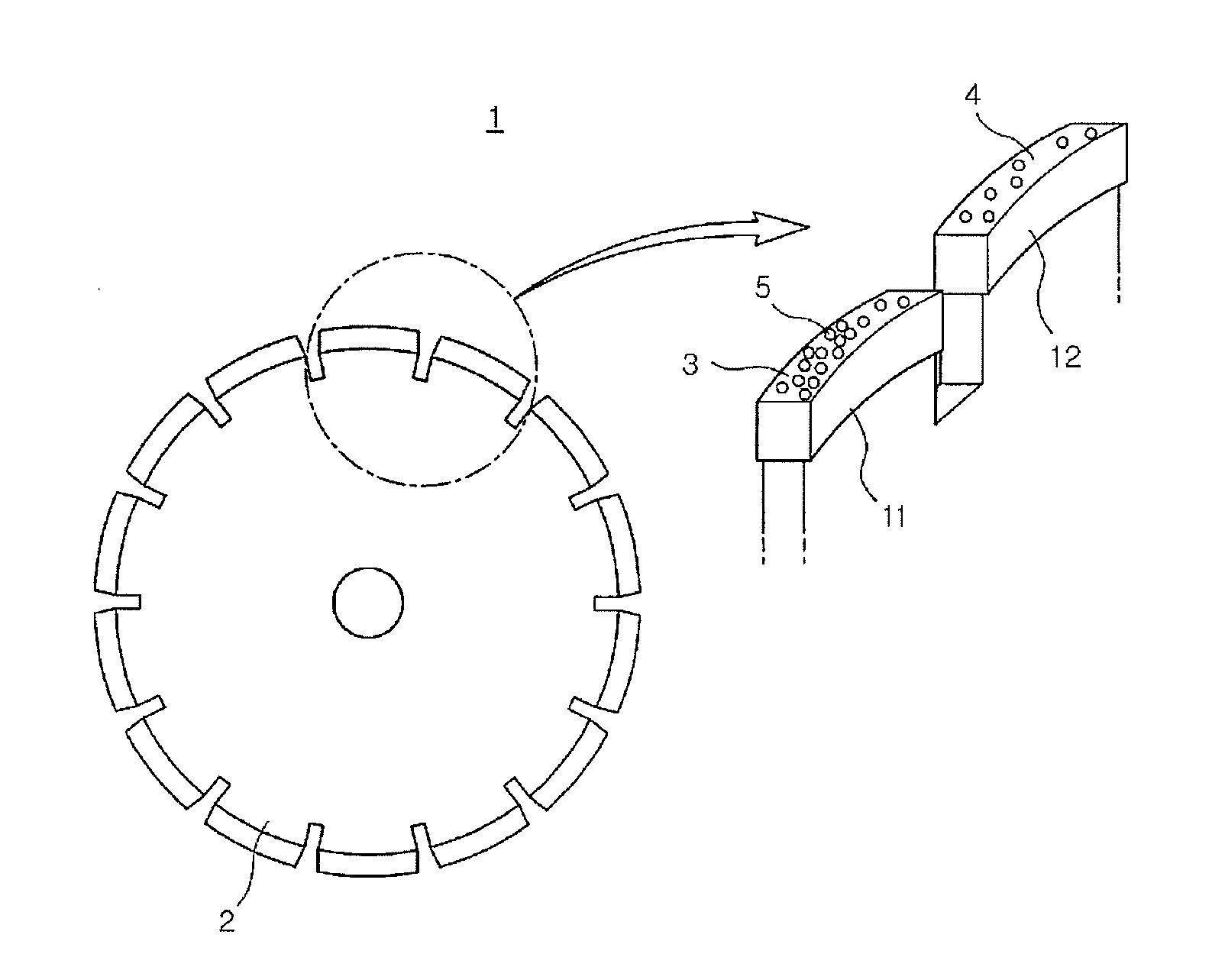

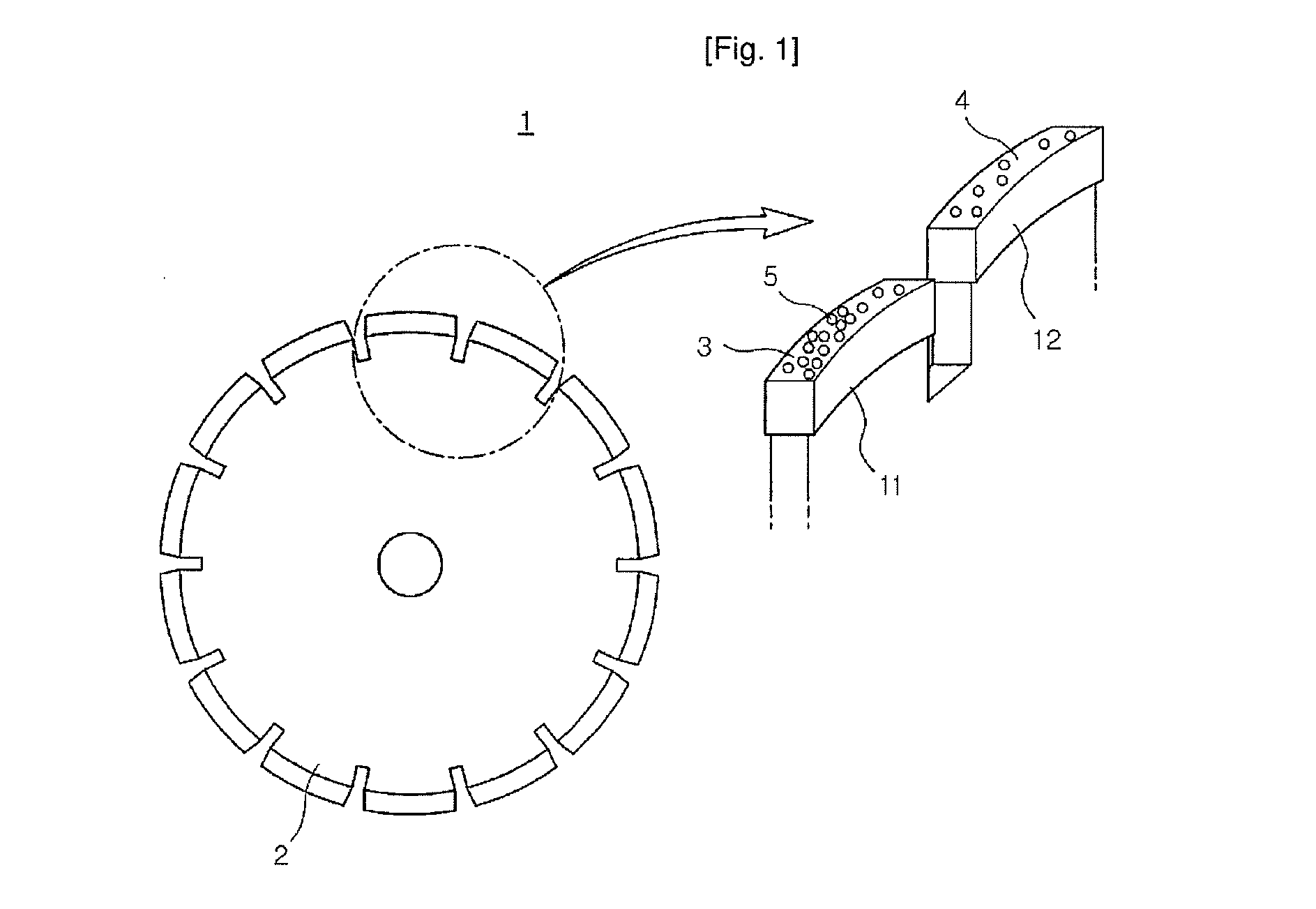

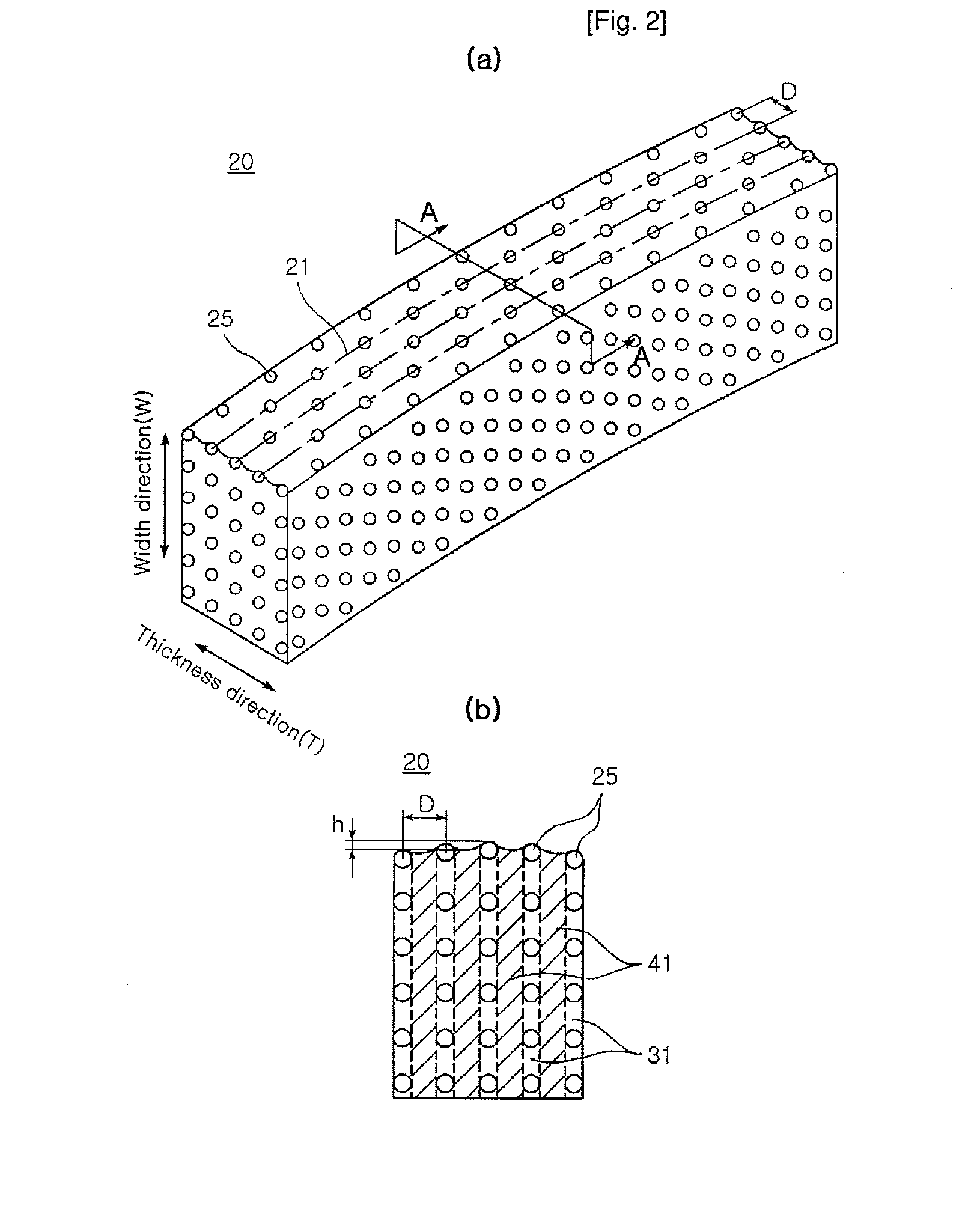

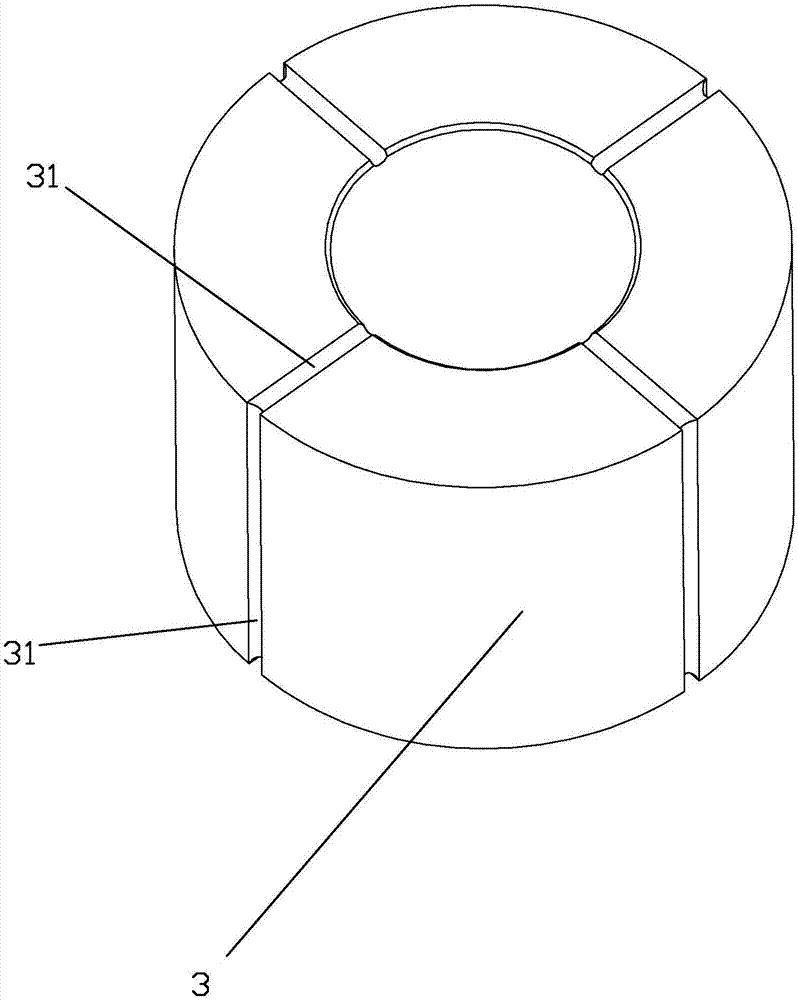

Cutting Segment for Cutting Tool and Cutting Tools

ActiveUS20080202488A1Increase cutting rateExtended useful lifeBonded abrasive wheelsSaw bladesBrickCutting oil

The invention provides a cutting segment for a cutting tool for cutting or drilling a brittle work piece such as stone, bricks, concrete and asphalt, and a cutting tool having the cutting segment. The cutting segment includes a cutting surface for cutting a work piece and a plurality of abrasive particle layers. The abrasive particle layers are disposed perpendicular to a cutting direction. Each of the abrasive layers has a plurality of abrasive particle rows in a width direction of the cutting segment. Each of the abrasive rows has a plurality of abrasive particles arranged in a line. Further, the abrasive layers have a plurality of blank sections therebetween. In the blanks sections, abrasive particles are absent or have a concentration of 70% or less with respect to those in the abrasive rows. In addition, the blank sections include relatively thick blank sections and relatively thin blank sections.

Owner:NIWA DAIYAMONDO INDS +1

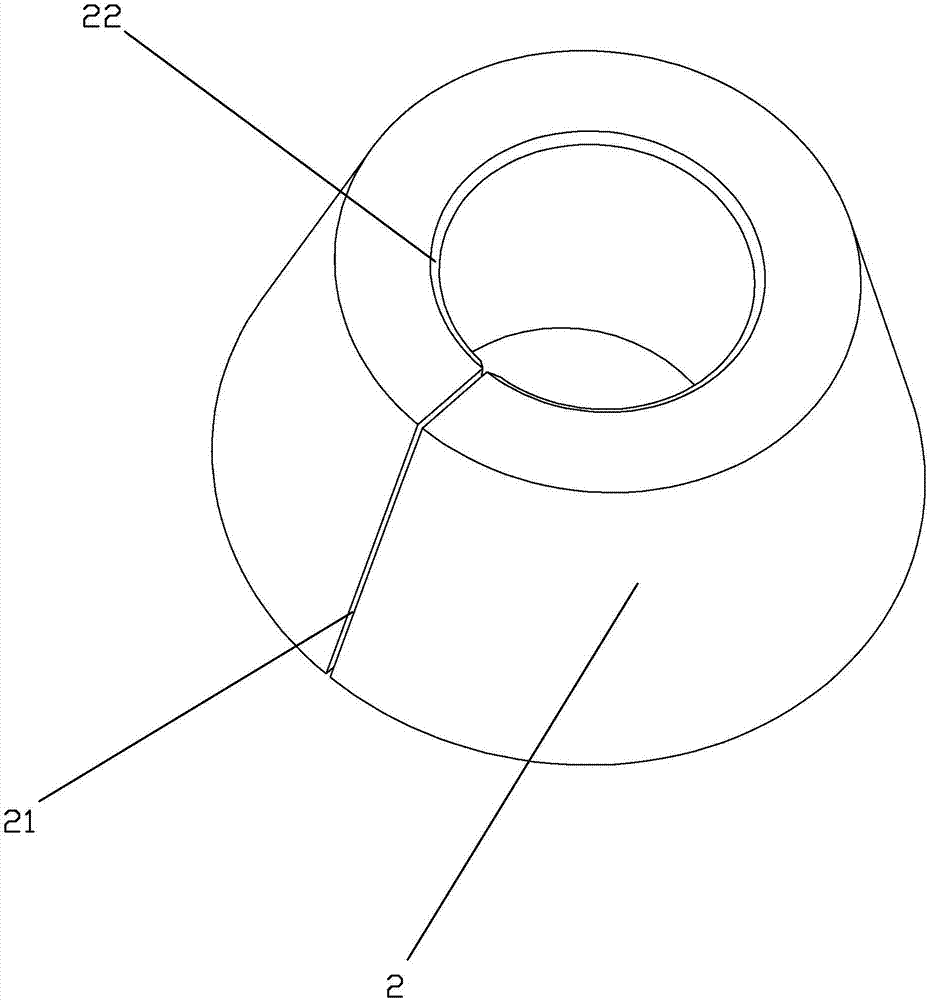

Cold upsetting die and machining technology thereof

InactiveCN106955960AExtended useful lifeGuaranteed accuracyForging/hammering/pressing machinesDying backEngineering

The invention discloses a cold upsetting die and a machining technology thereof. The cold upsetting die comprises a shell and an inner die; the shell comprises a die shell, a ladder hole penetrating the two end faces of the die shell is formed in the die shell, a conical segment is arranged at the small end of the ladder hole, the conical segment is located on the upper surface of the die shell, the large end of the ladder hole is located on the lower surface of the die shell, the inner die comprises a conical reinforcing ring matched with the inner wall of the conical segment, an inner die core is arranged in the reinforcing ring, an axial cutting opening penetrating the inner surface and the outer surface of the reinforcing ring is formed in the side face of the reinforcing ring, an inner die back pad abutting against the lower end of the inner die is arranged in the position, below the inner die, in the ladder hole, a thread part in threaded connection with the shell is arranged below the inner die back pad, and the thread part abuts against the inner die back pad so as to enable the reinforcing ring to shrink and clamp the inner die core. The cold upsetting die can conveniently achieve detaching and assembling of the die core and die shell, meanwhile, the higher precision is achieved, the machining technology of the die can conveniently machine the components of the die, and the service life of the die is longer.

Owner:SANMEN TONGSHUN RIVET

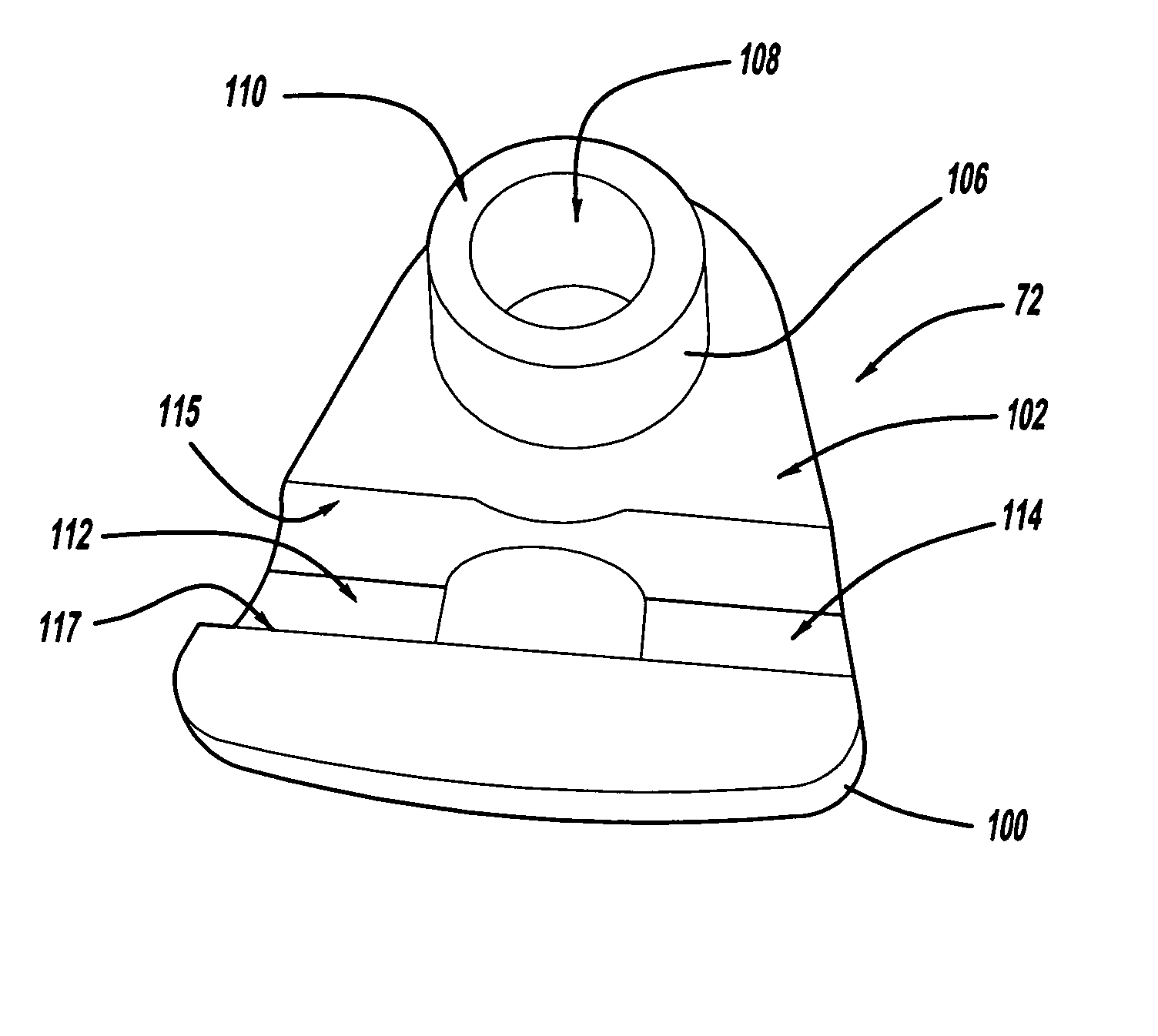

50 DN alternator stator terminal insulator apparatus

InactiveUS20060208584A1Facilitate assemblyExtended useful lifeWindingsSupports/enclosures/casingsStatorAlternator

An oil-cooled 50 DN stator terminal insulator comprising an insulating base member with an insulating bushing extending from a top surface of the base member for insulating one of multiple stator lead terminals, and associated parts kit. The insulator includes a central aperture for receiving the terminal such that the insulator and the terminal are independently movable with respect to the remaining terminals of the stator in order to facilitate assembly of the stator and a rectifier housing having a plurality of openings extending from an internal surface to an external surface. The ability of the terminal with the insulator to move independent of the remaining terminals provides the stator with resistance to vibrations.

Owner:KIRKMAN ROBERT ERNEST +1

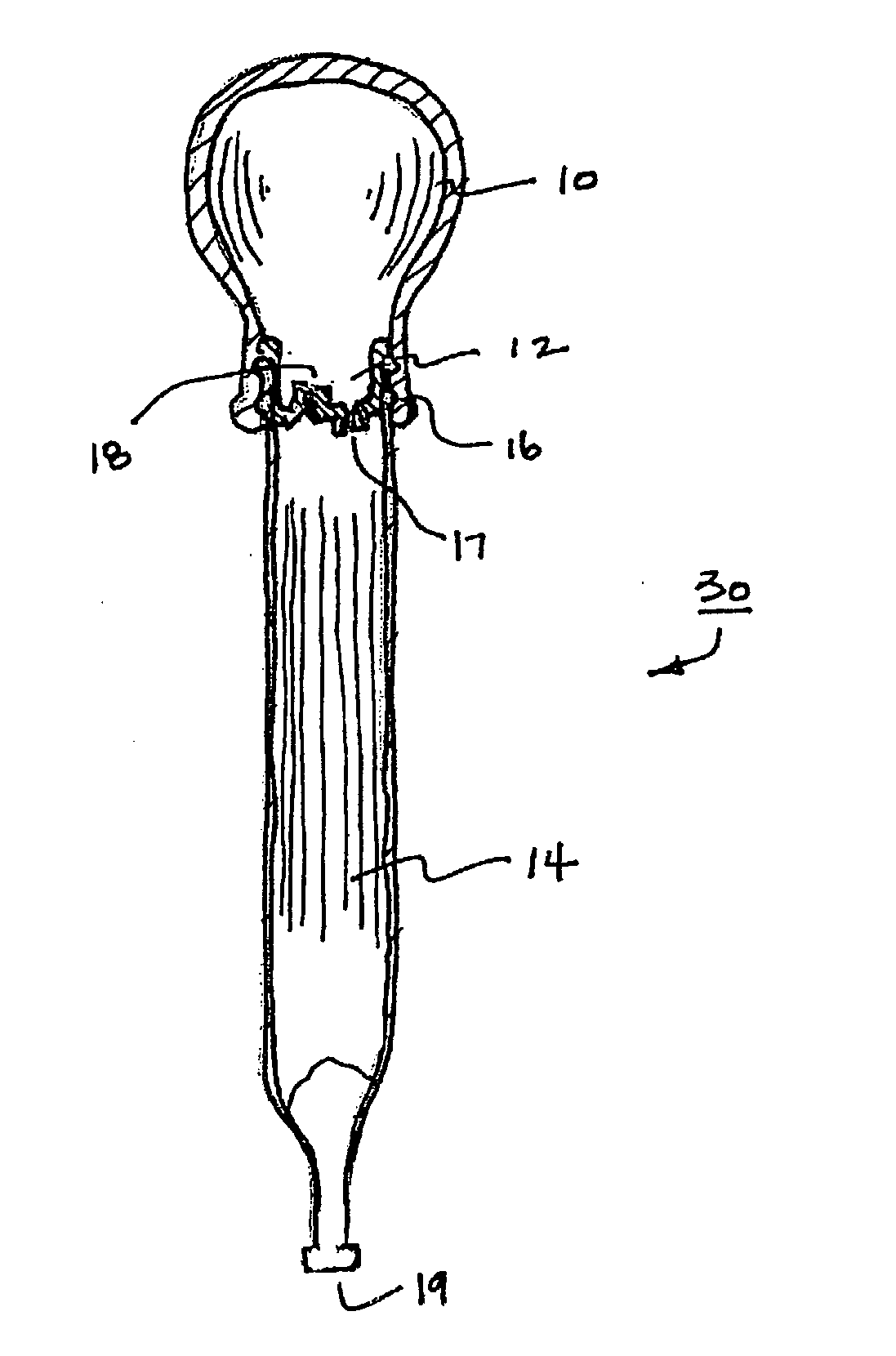

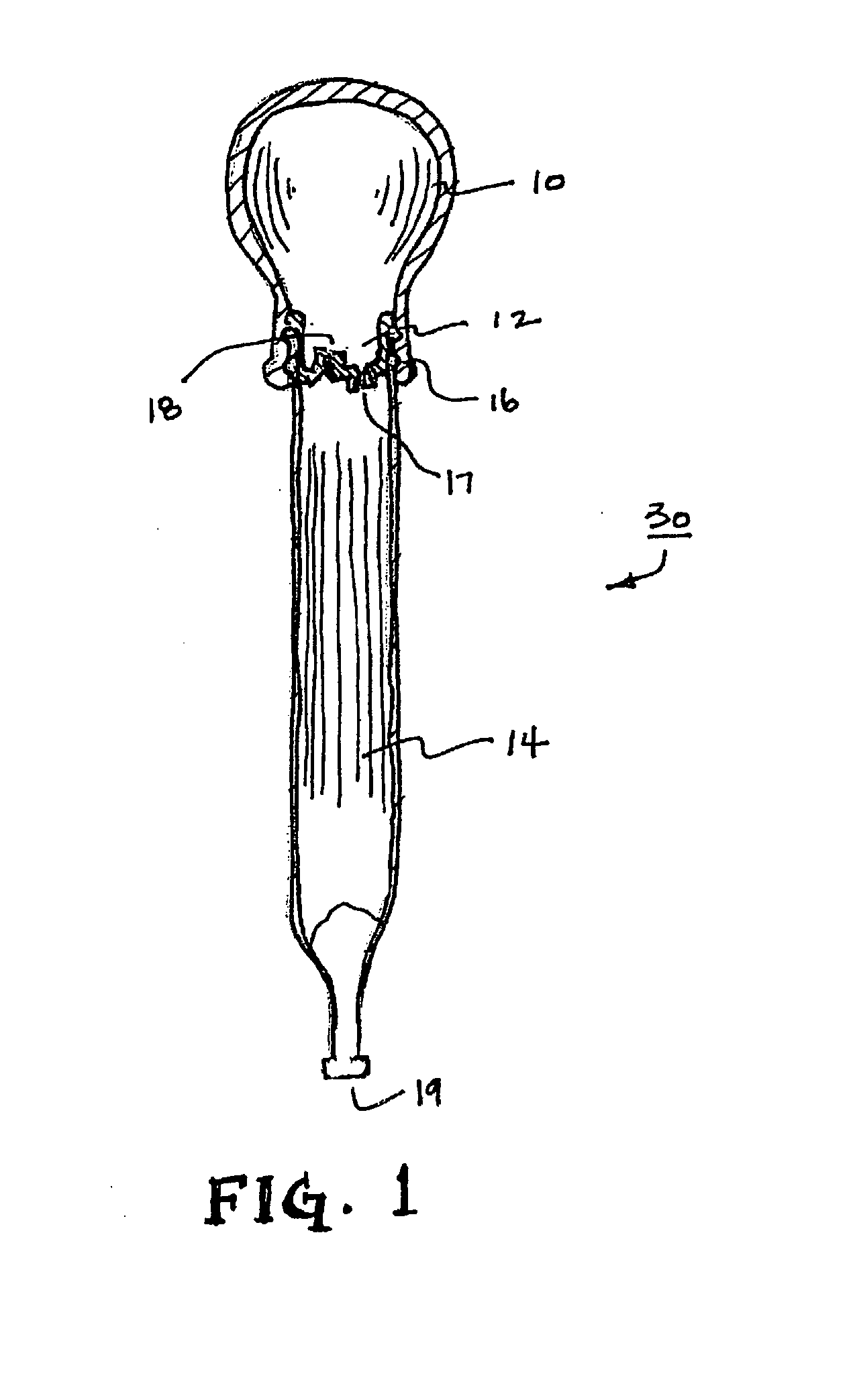

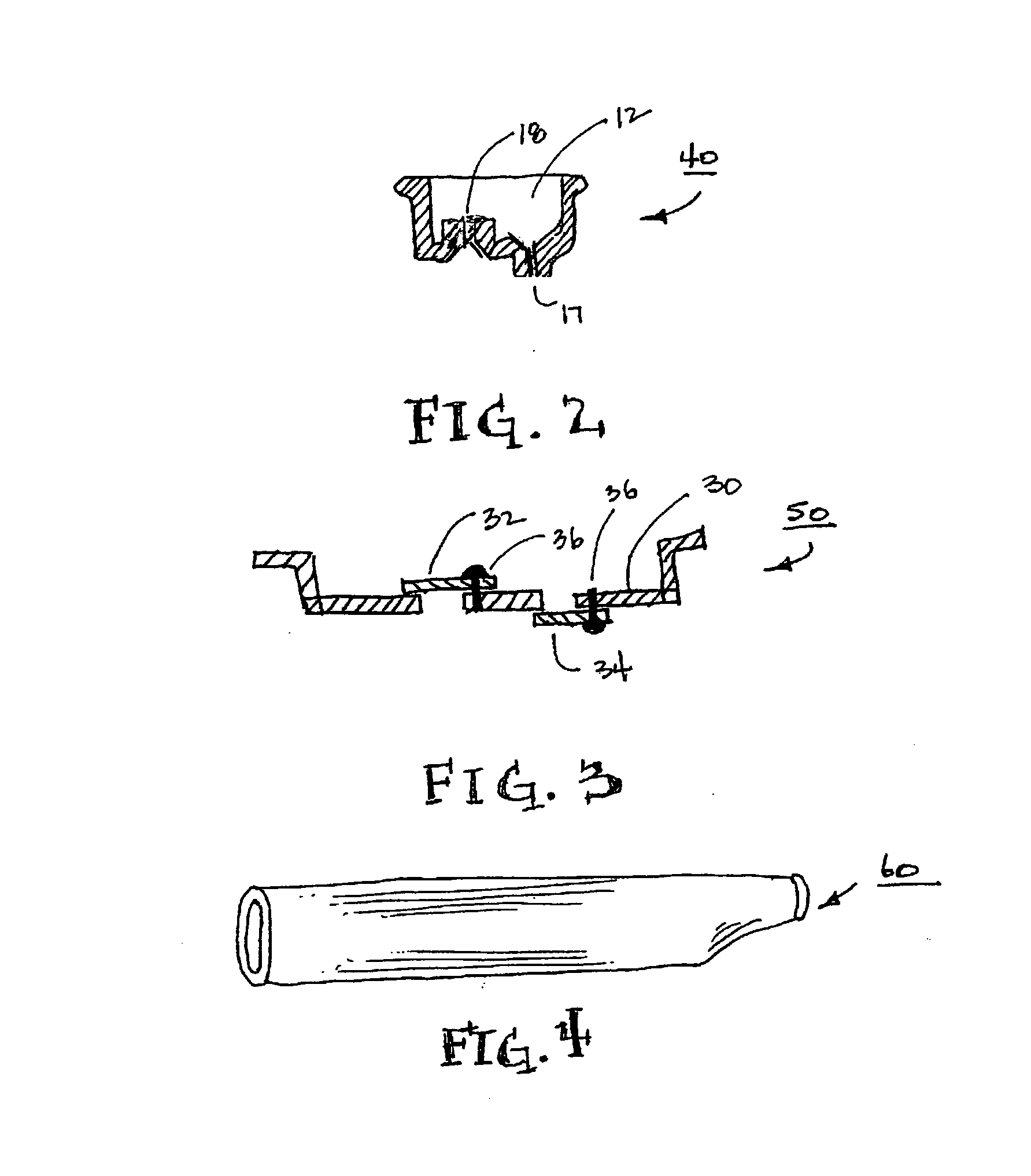

Leak Resistant Siphoning Device For Use in Fluid Transfer

InactiveUS20080202631A1Less fluid spillageImprove securityMeat/fish preservationSolid materialEngineeringPressure difference

An improved, leak resistant, siphoning device that includes an elongated hollow body member, a means for filling and emptying the hollow body member, such as an elastomeric resilient suction bulb and a valve placed between the hollow member and the filling / emptying means. The suction bulb defines a chamber therein, so that when it is squeezed and released it will create suction to direct fluid up through the first open head end into the elongated hollow body member using pressure differential. Squeezing the suction bulb can release the liquid and partial solids held within the elongated hollow body member out of the first open head end. The suction bulb also has an optional opening for venting heated air from the bulb, and a means to selectively close the opening for creating vacuum or pressure required to draw or expel liquid from the tube.

Owner:SPRIEGEL ANDREW R +1

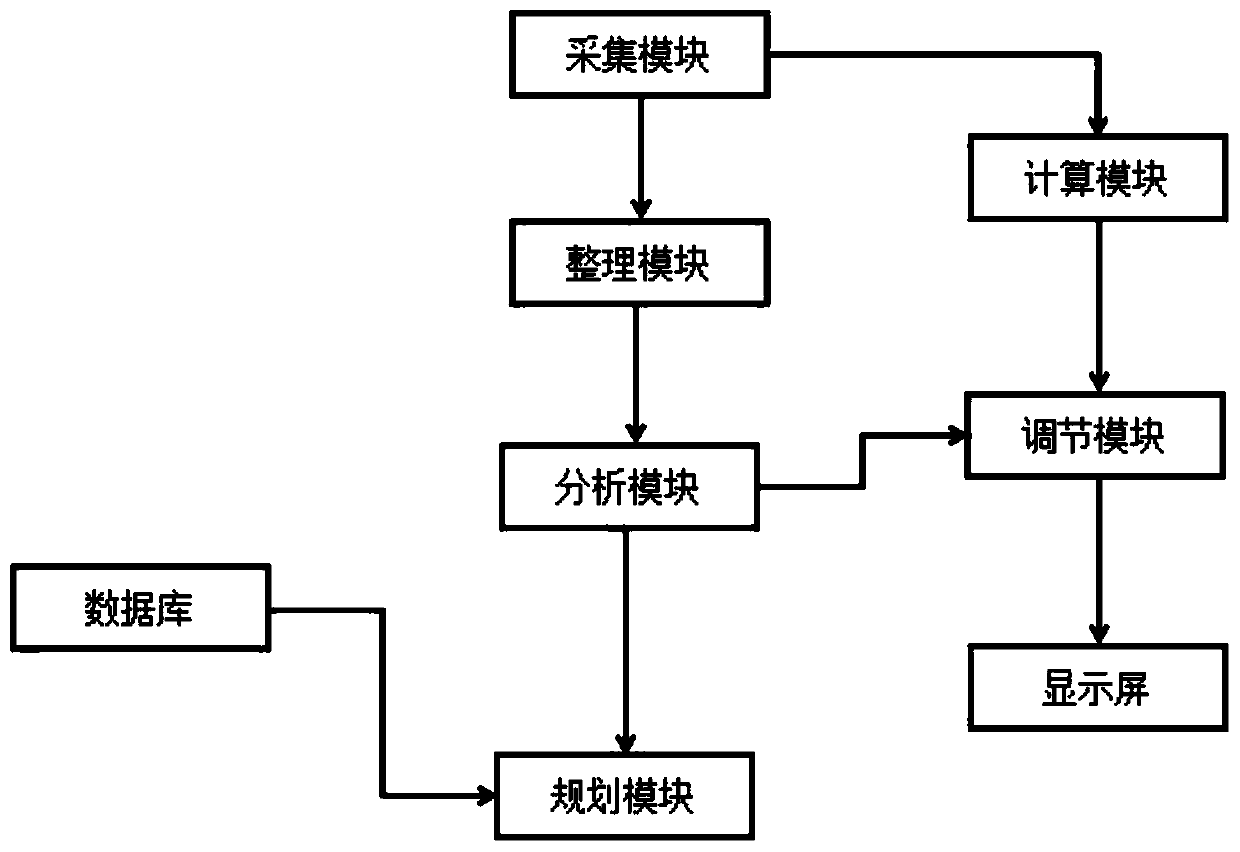

Production equipment management planning system based on big data

ActiveCN111045410ASolve the problem that the time required for part replacement cannot be clearly obtainedImprove the protective effectTotal factory controlProgramme total factory controlManagement planningAcquisition apparatus

Owner:JIESHOU XUNLIDA ELEVATOR CO LTD

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com