Sole structure with complex waterproof and gas-permeable material and manufacturing method thereof

a technology of waterproof and gas-permeable materials and manufacturing methods, which is applied in the field of water-proof and gas-permeable sole structures, can solve the problems of difficult to combine materials with each other with glue, make users uncomfortable, and cause bending force and impact on the sol

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

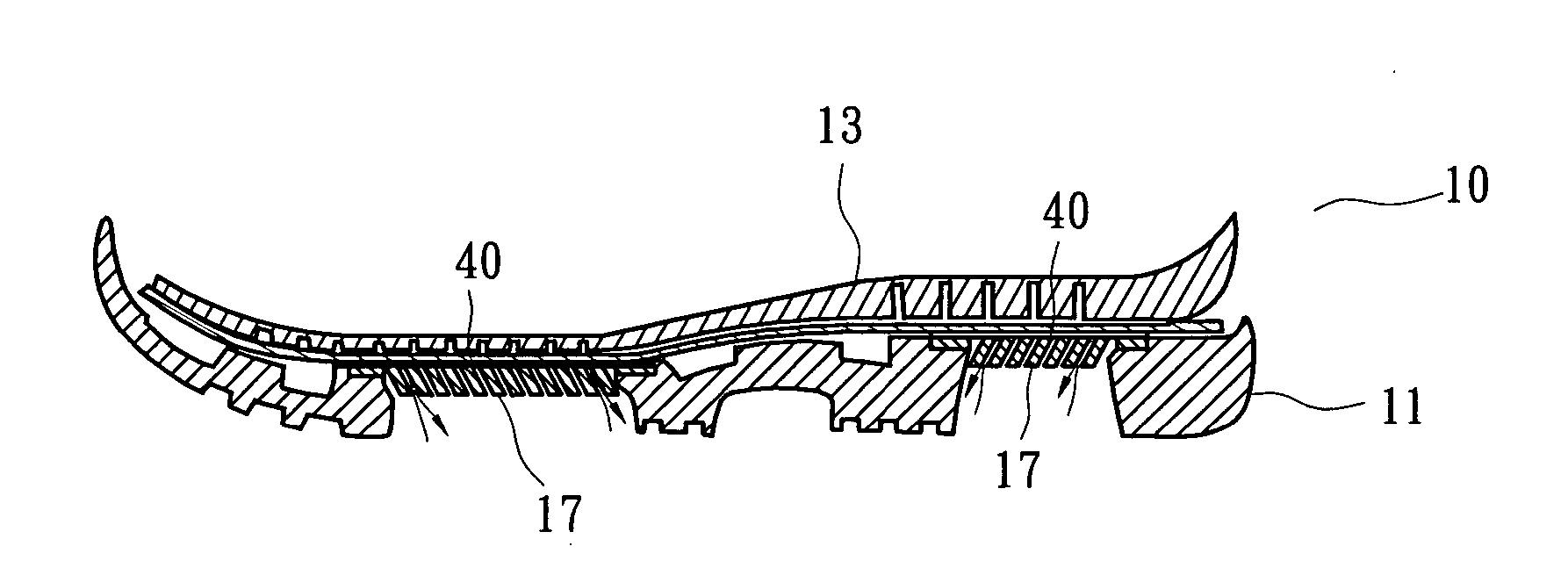

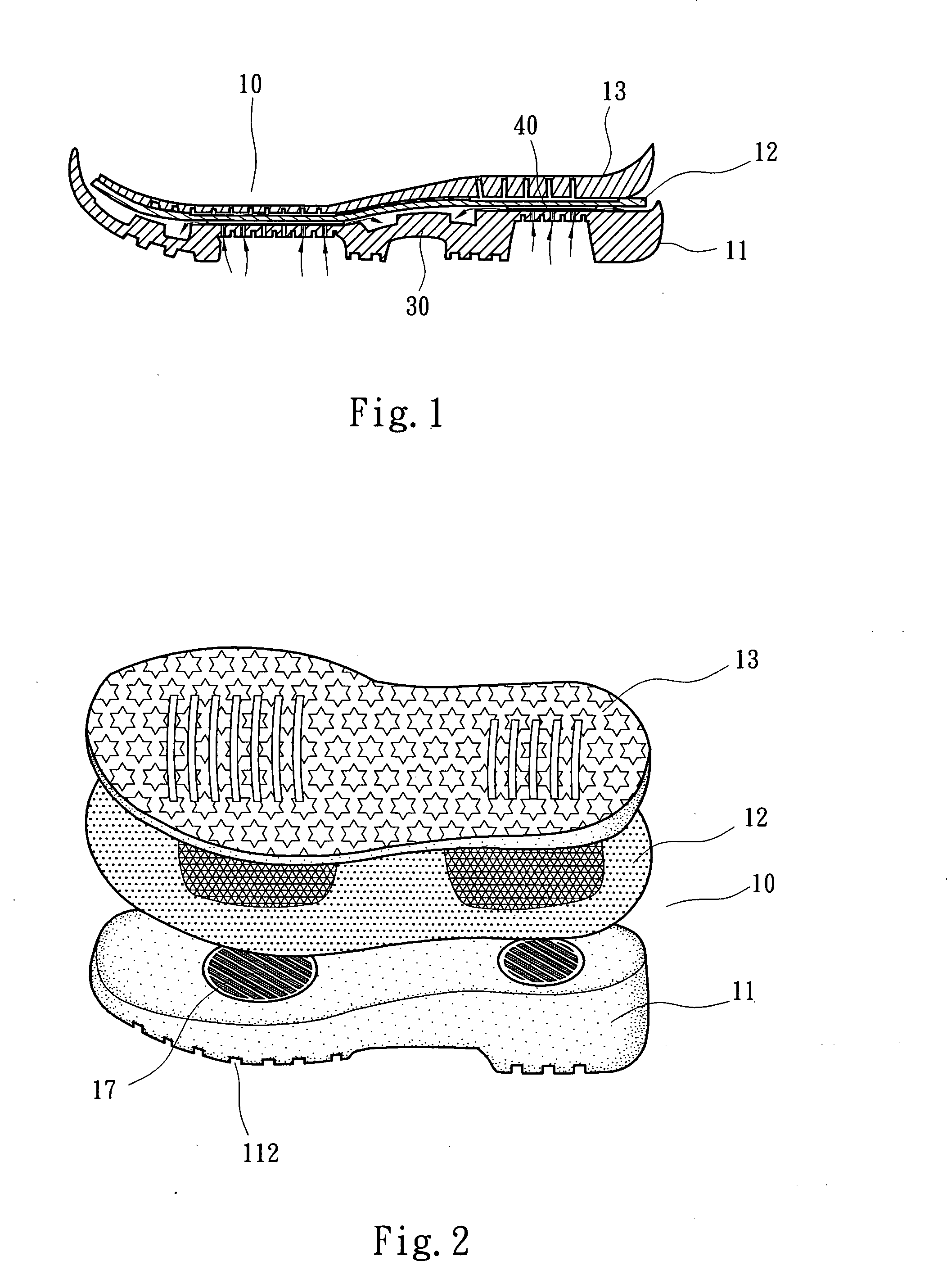

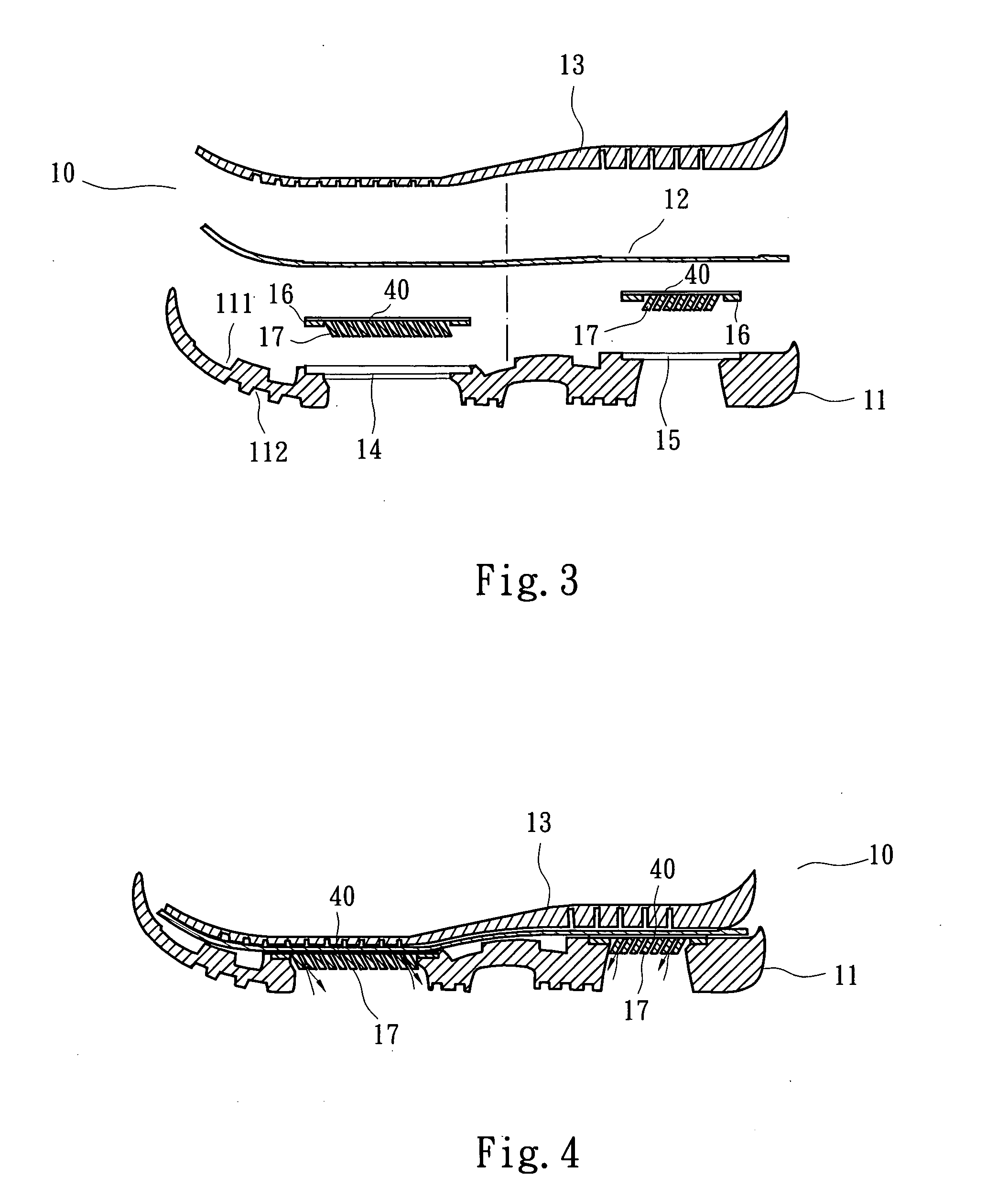

[0024] Please refer to FIGS. 2 and 3. The sole structure 10 with complex waterproof and gas-permeable material of the present invention includes a large substrate 11. The large substrate 11 can be selectively made of any of TPR, PVC, TPU and the likes. A middle substrate 12 and / or an insole 13 are overlaid on the large substrate 11. A predetermined section of inner face of the large substrate 11 is formed with through holes 14, 15 which can have any geometric profile. The through holes 14, 15 are arranged on front half, rear half or other section of the large substrate 11.

[0025] A plane blank 16 combined with waterproof and gas-permeable film 40 is laid on the inner face 111 of the large substrate 11 to correspondingly cover the through holes 14, 15. The plane blank 16 is made of a material identical to or compatible with the material of the waterproof and gas-permeable film 40. The plane blank 16 is formed with an array-type through hole 17 corresponding to the through hole 14 or ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com