Patents

Literature

379results about "Saw blades" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

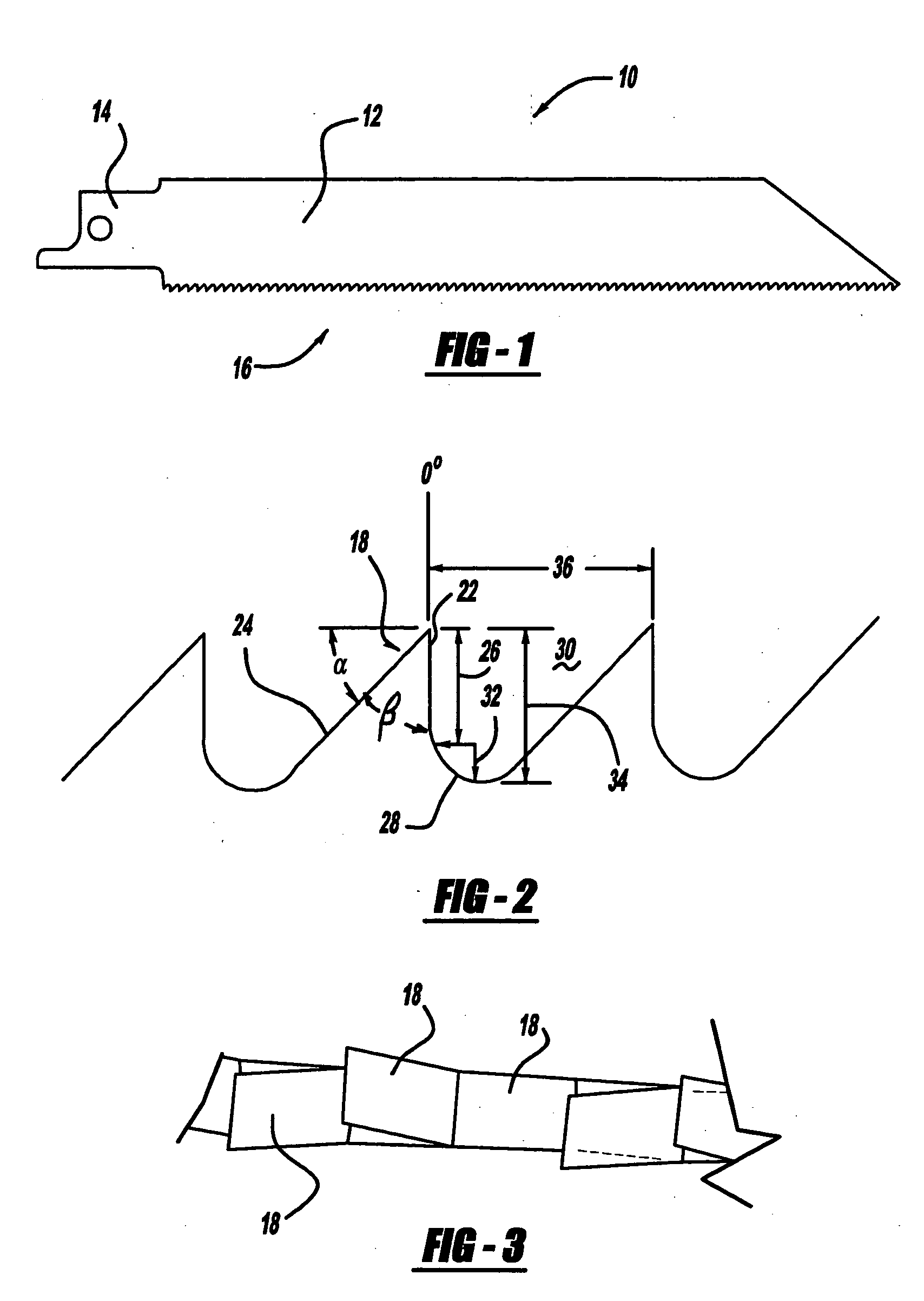

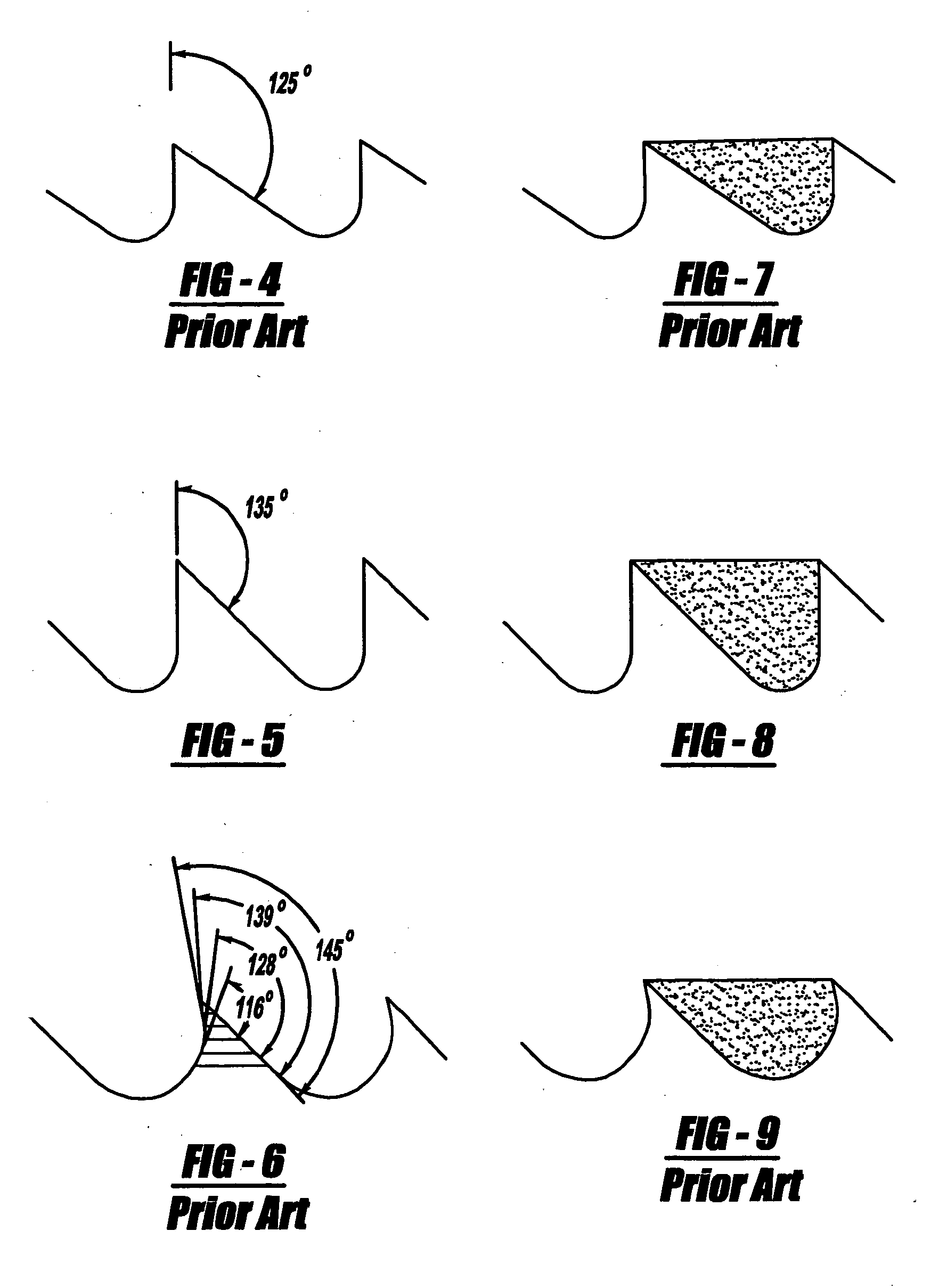

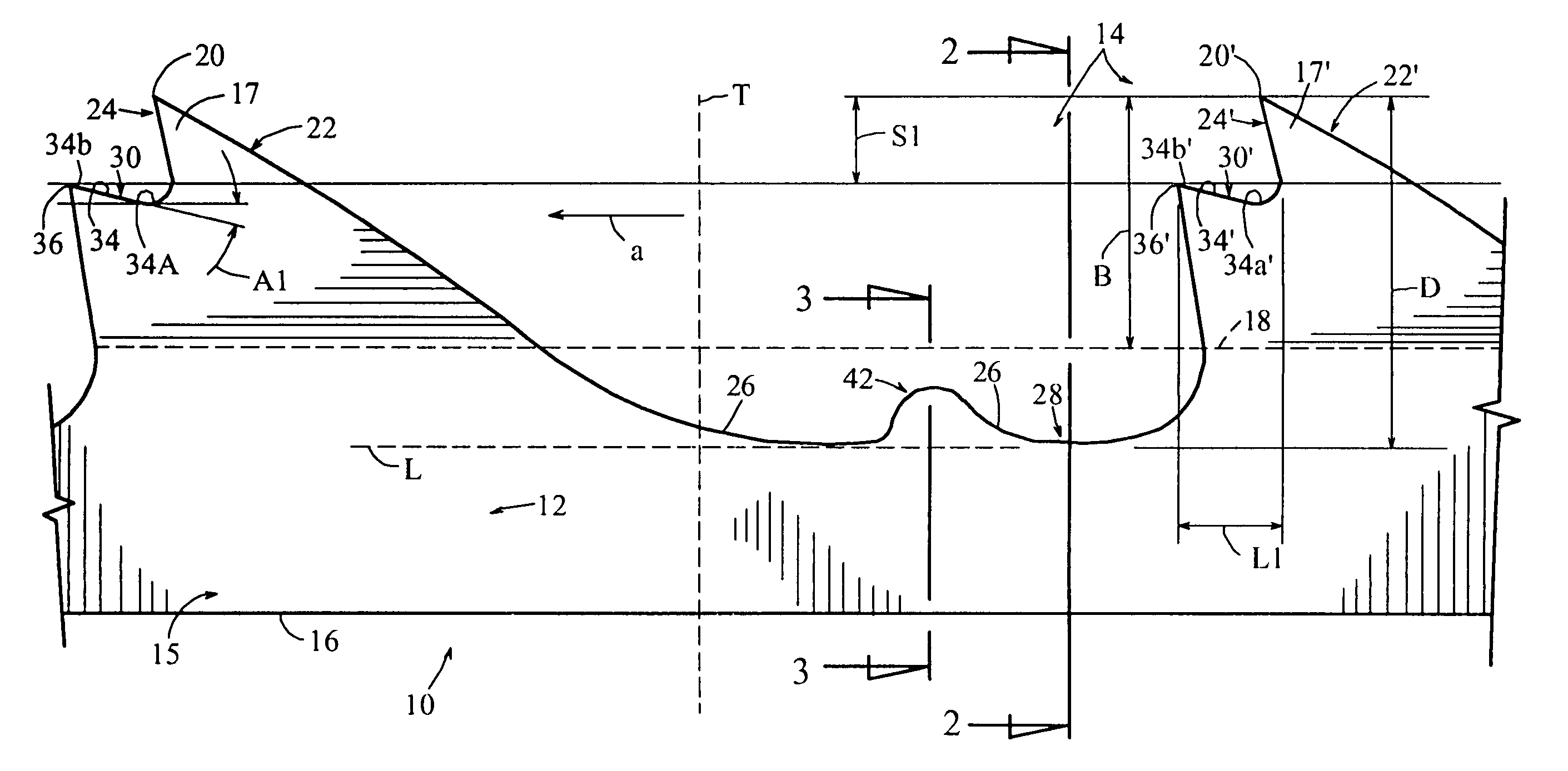

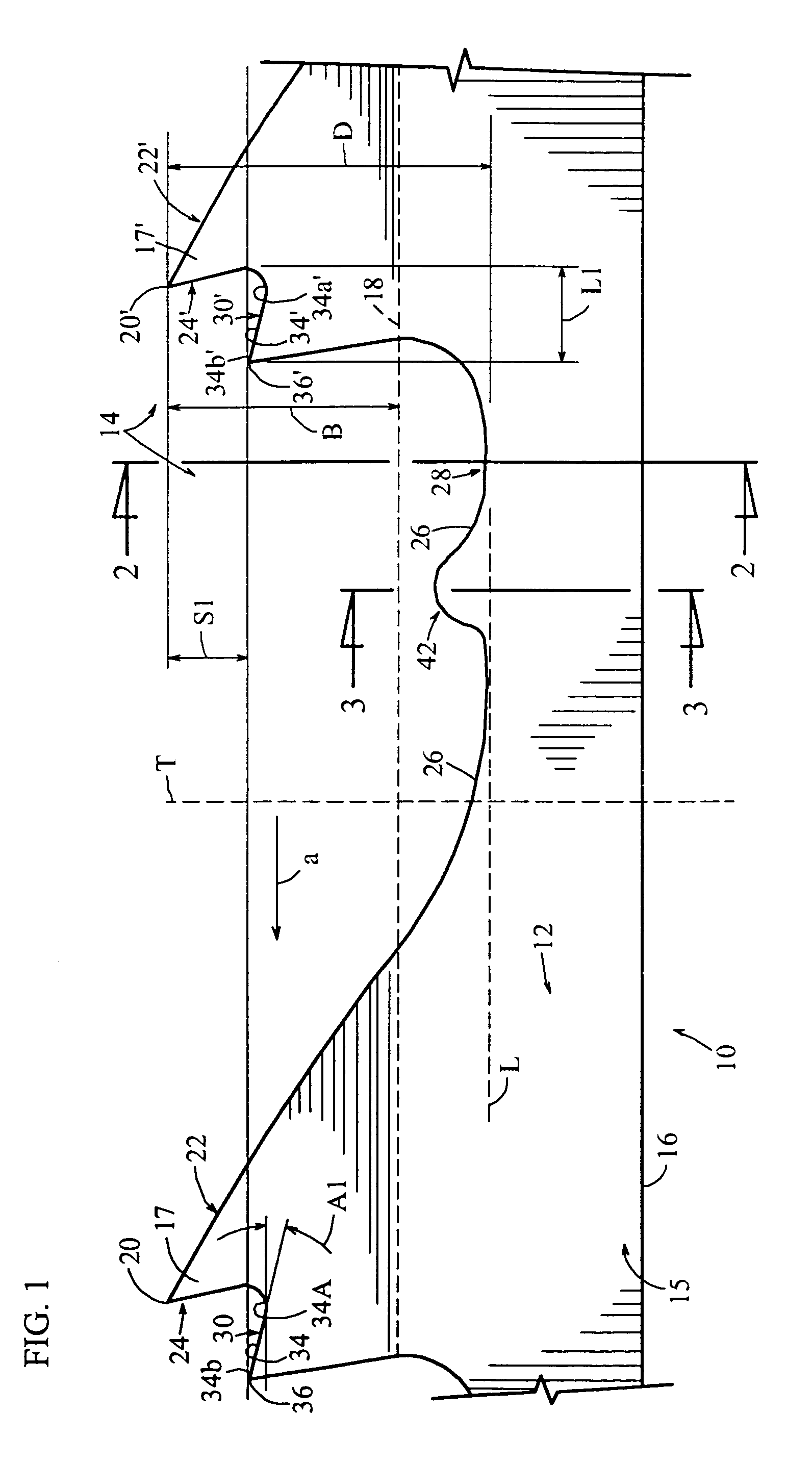

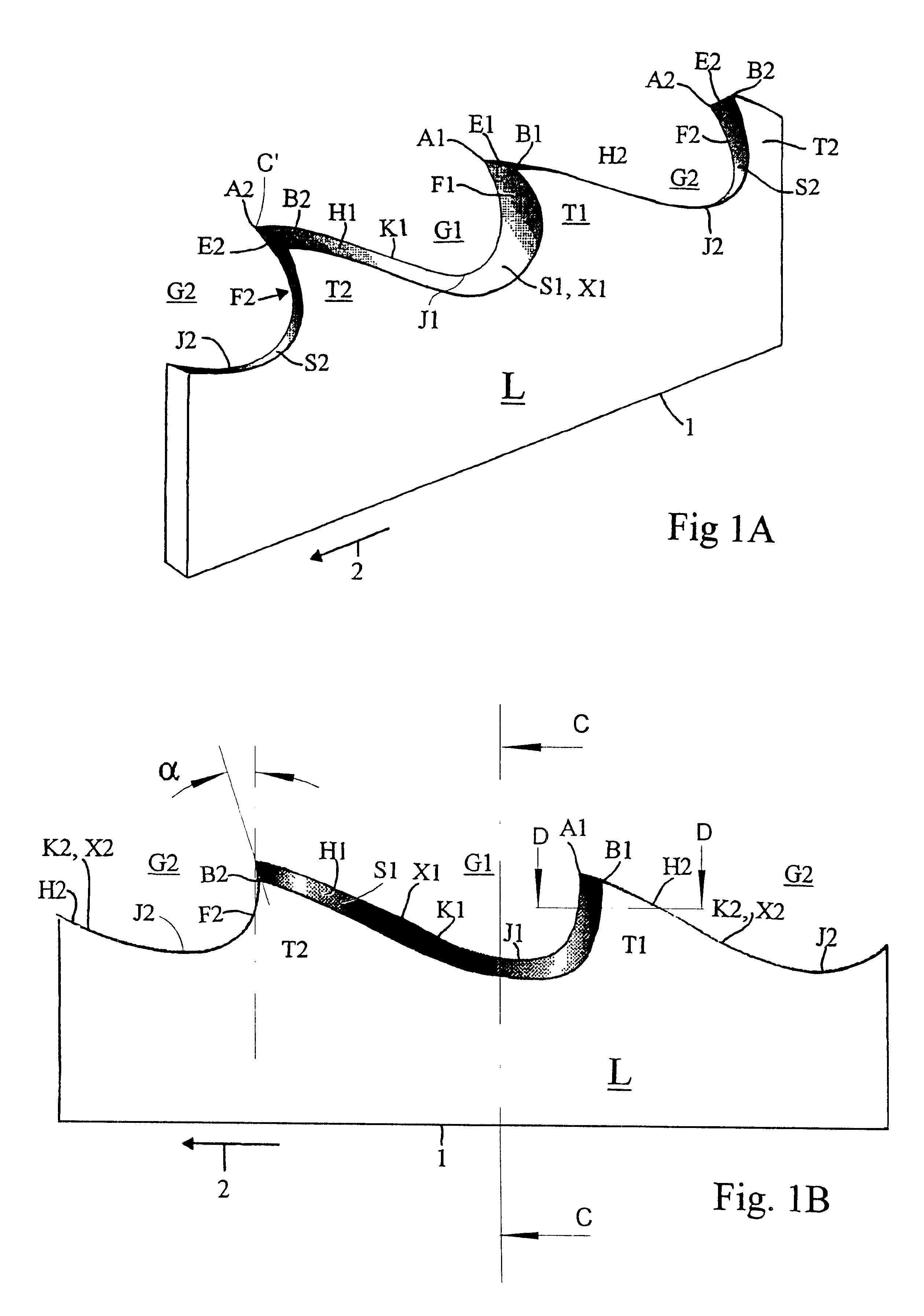

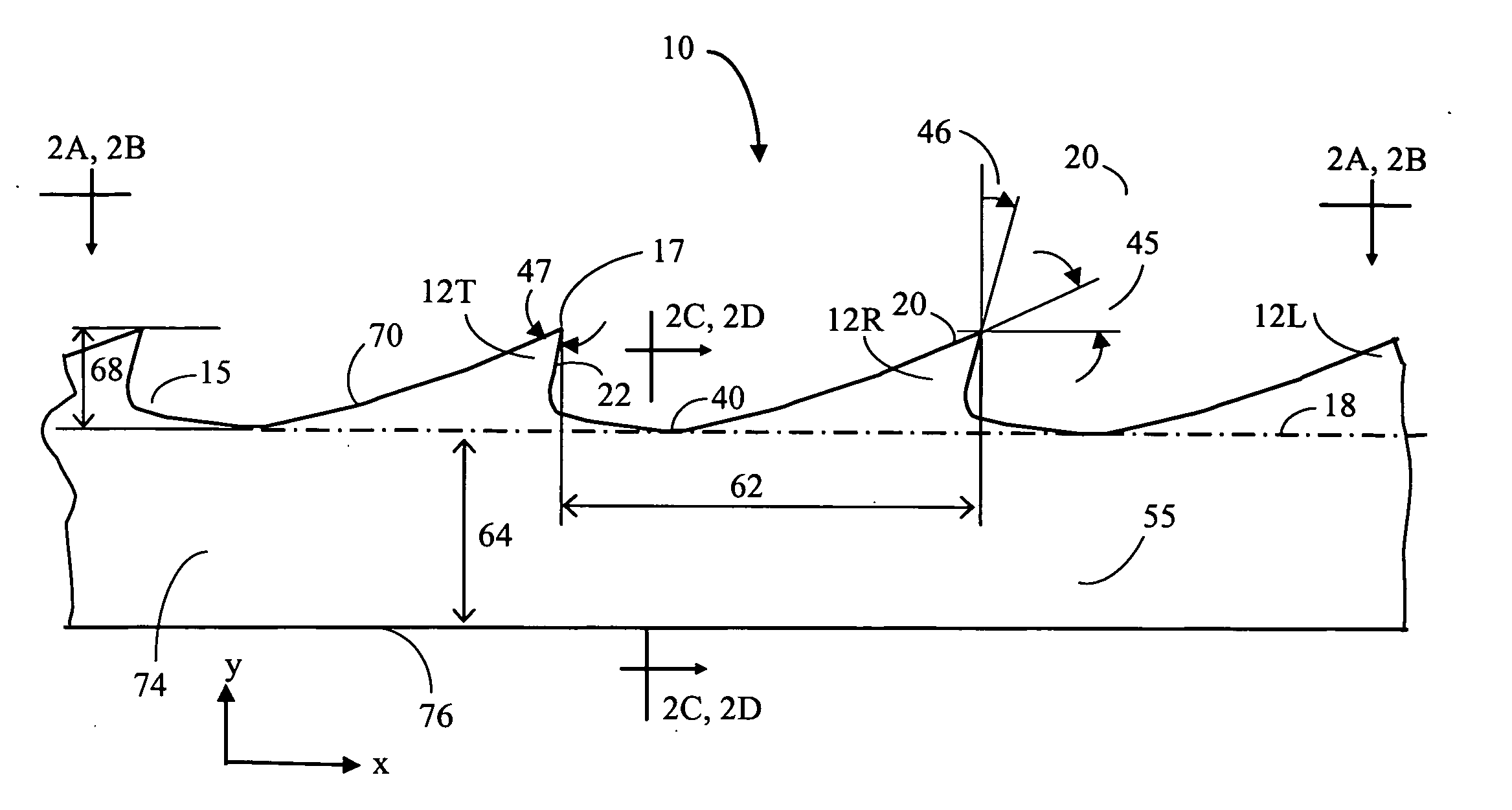

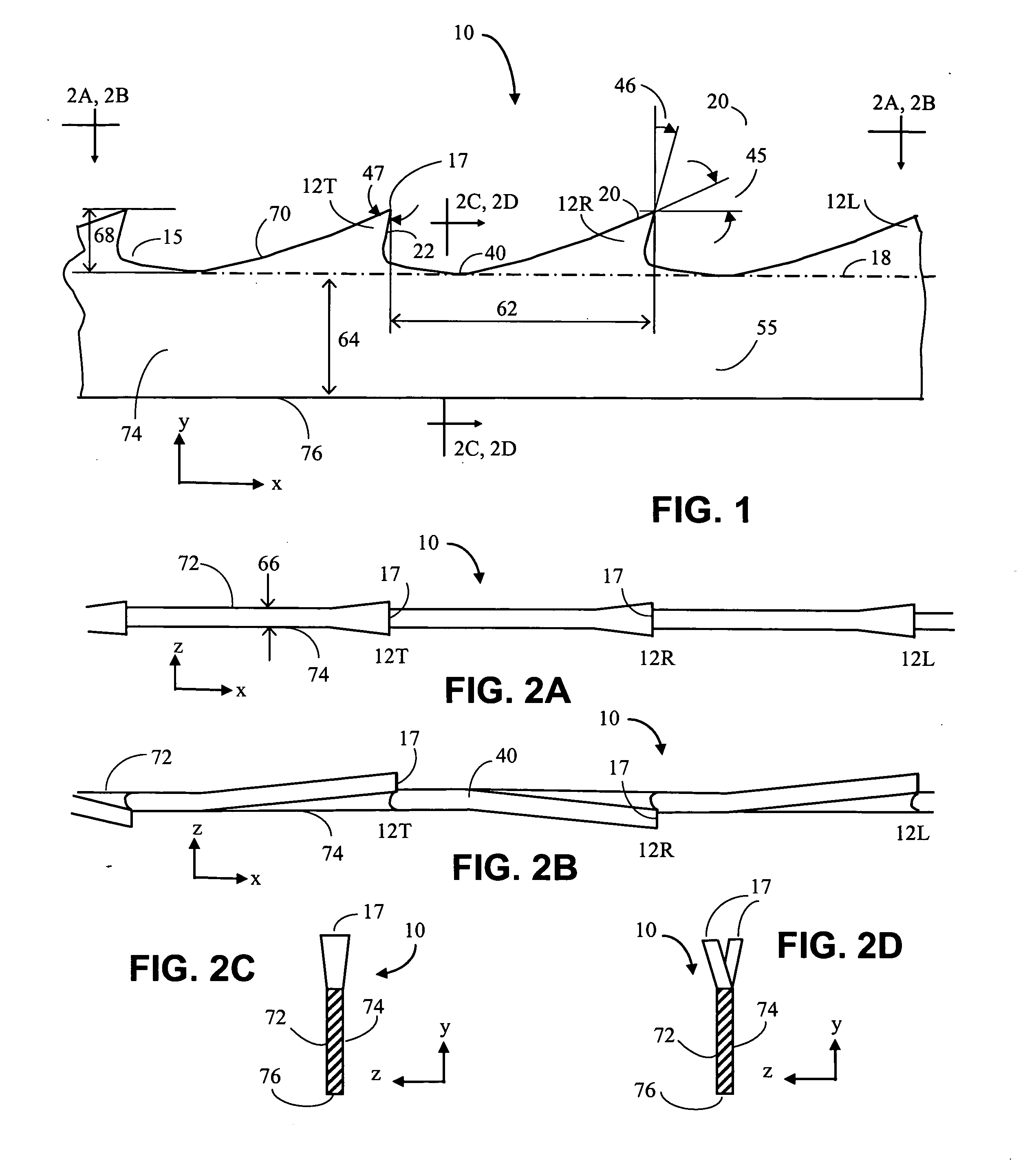

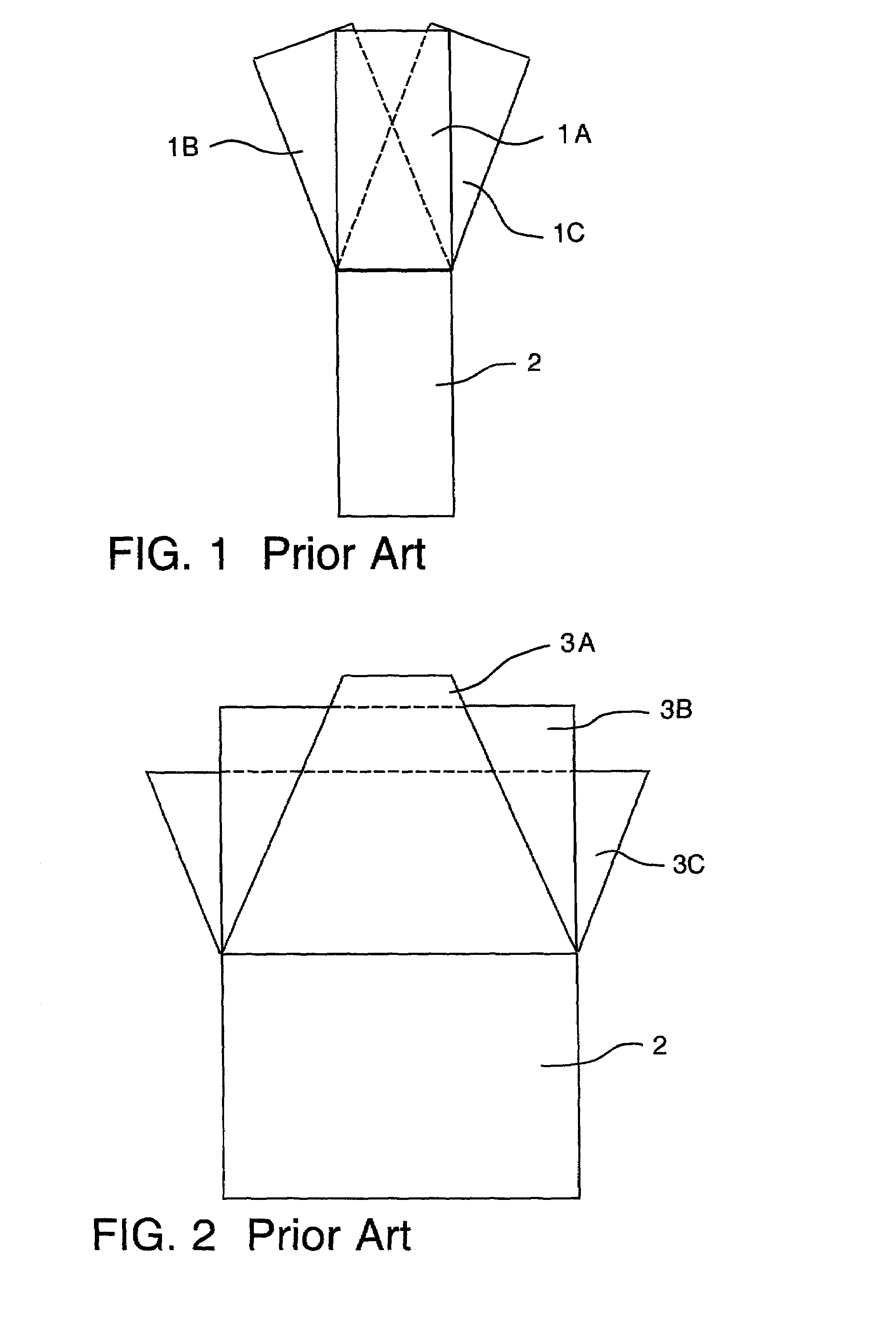

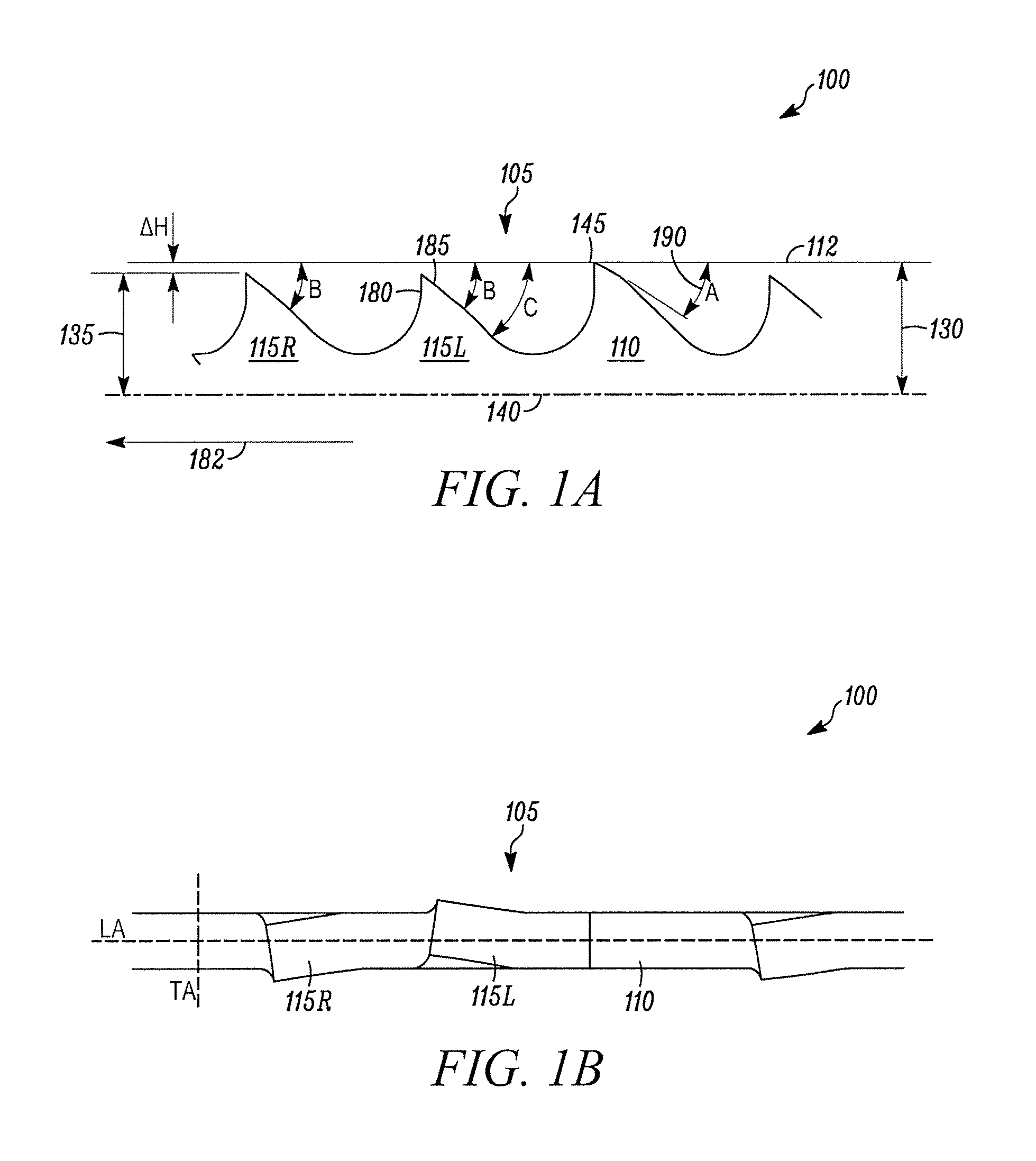

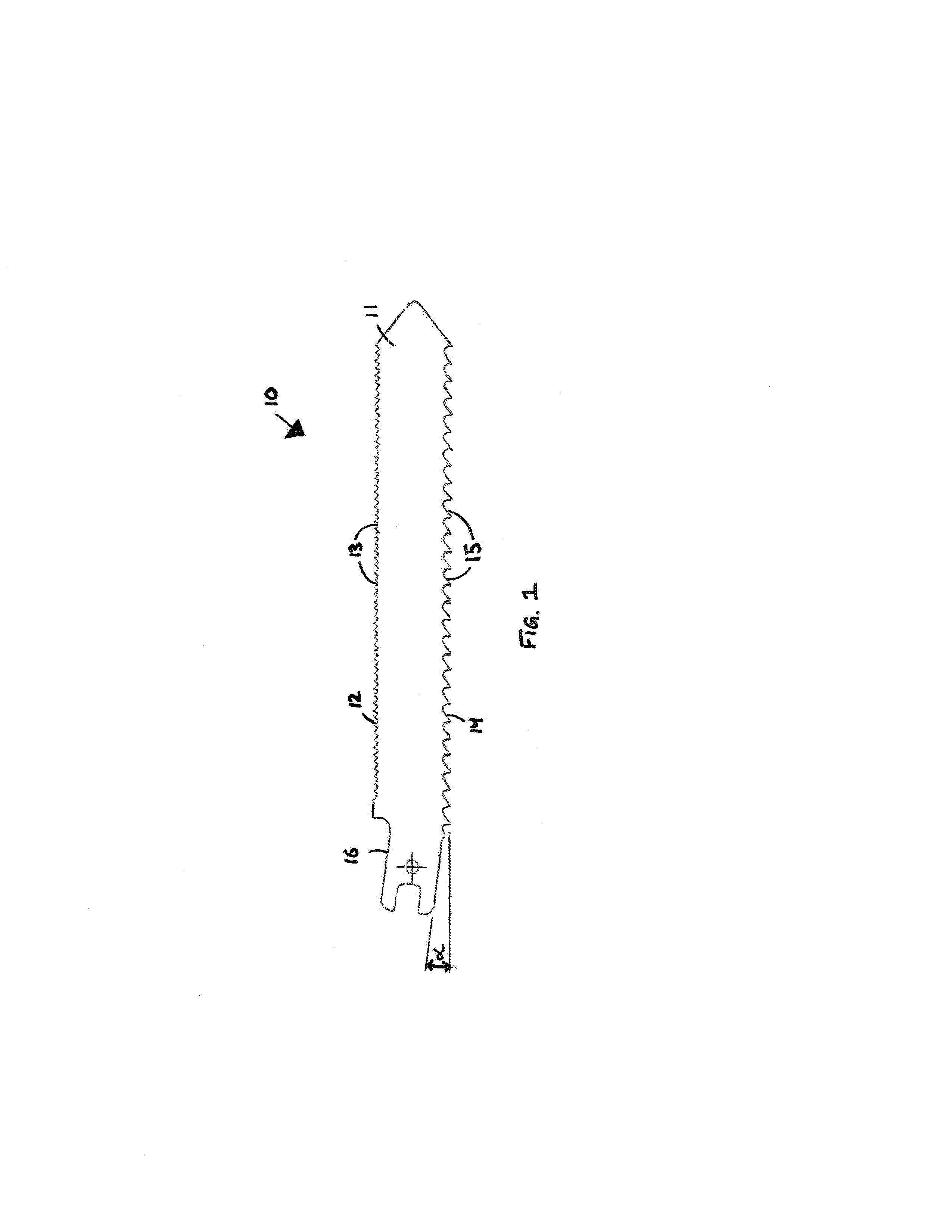

Tooth form design for reciprocating saw blade

A reciprocating saw has a tooth form that decreases the cutting time of the saw blade and extends the life of the saw blade. The tooth height is longer than conventional metal cutting reciprocating saws. Also, the tooth form has a larger gullet. The tooth rake angle remains substantially constant during the life of the saw blade.

Owner:BLACK & DECKER INC

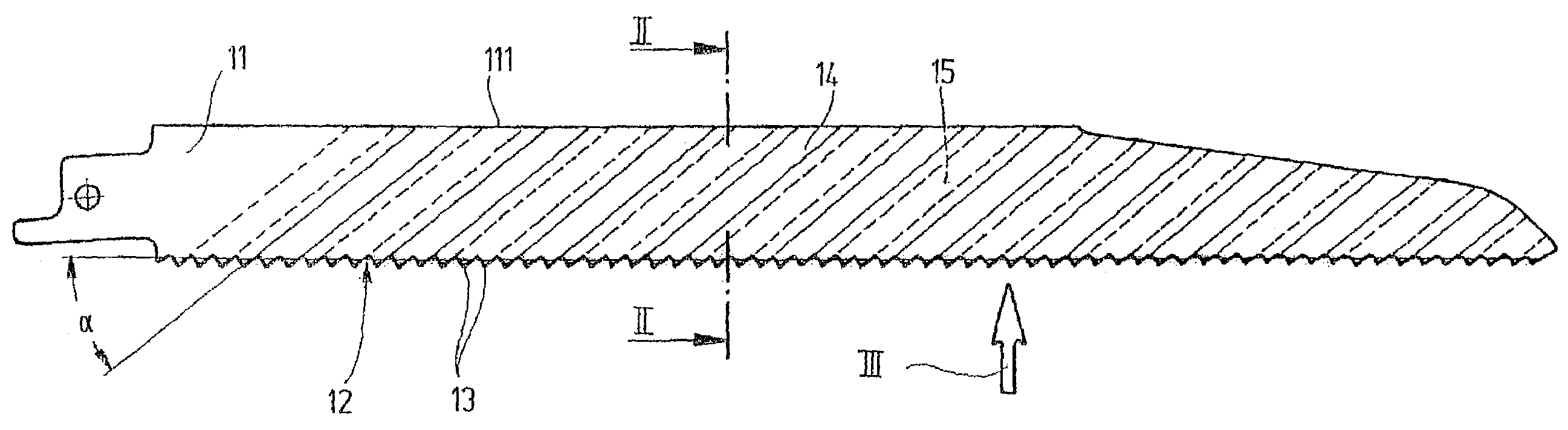

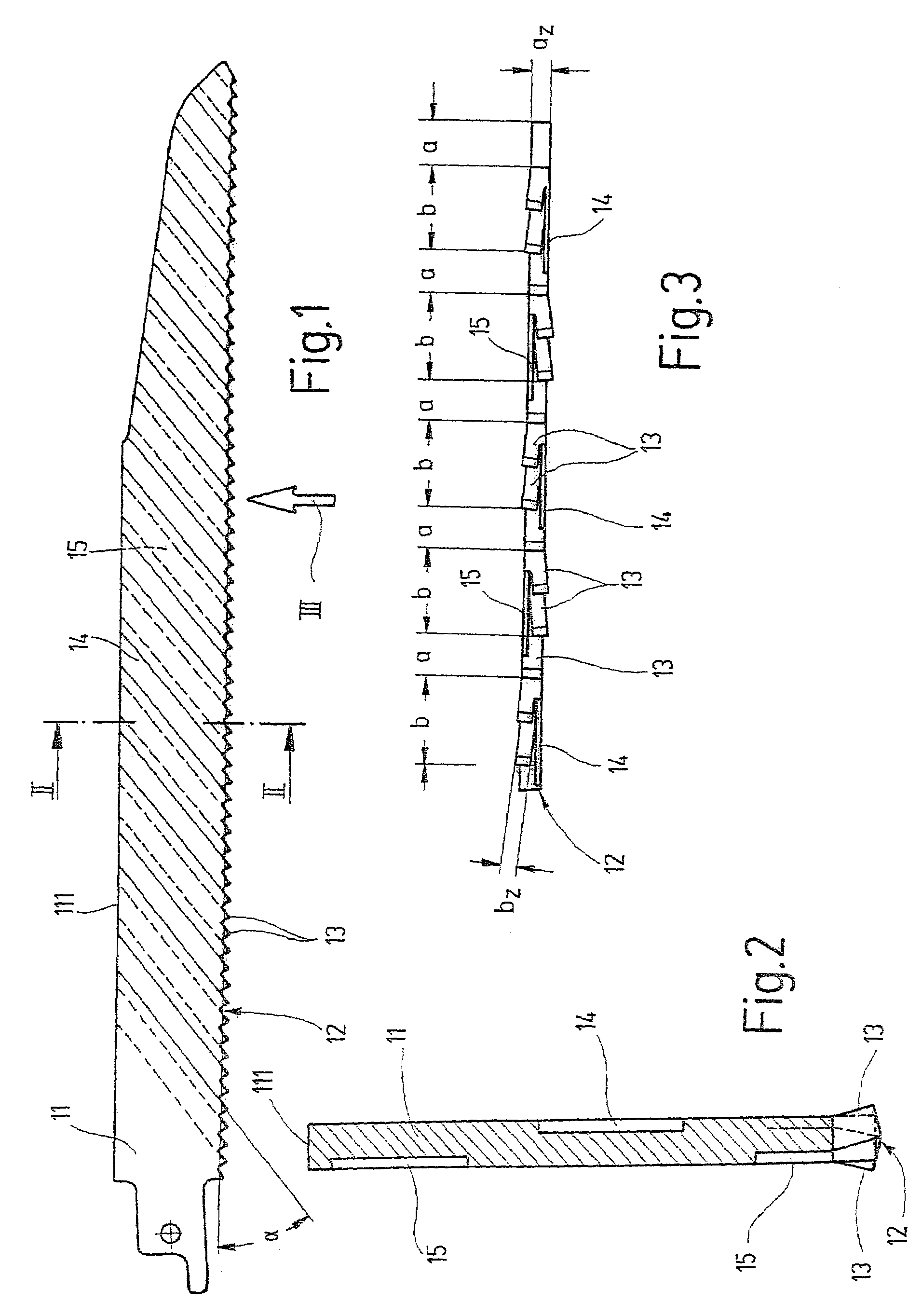

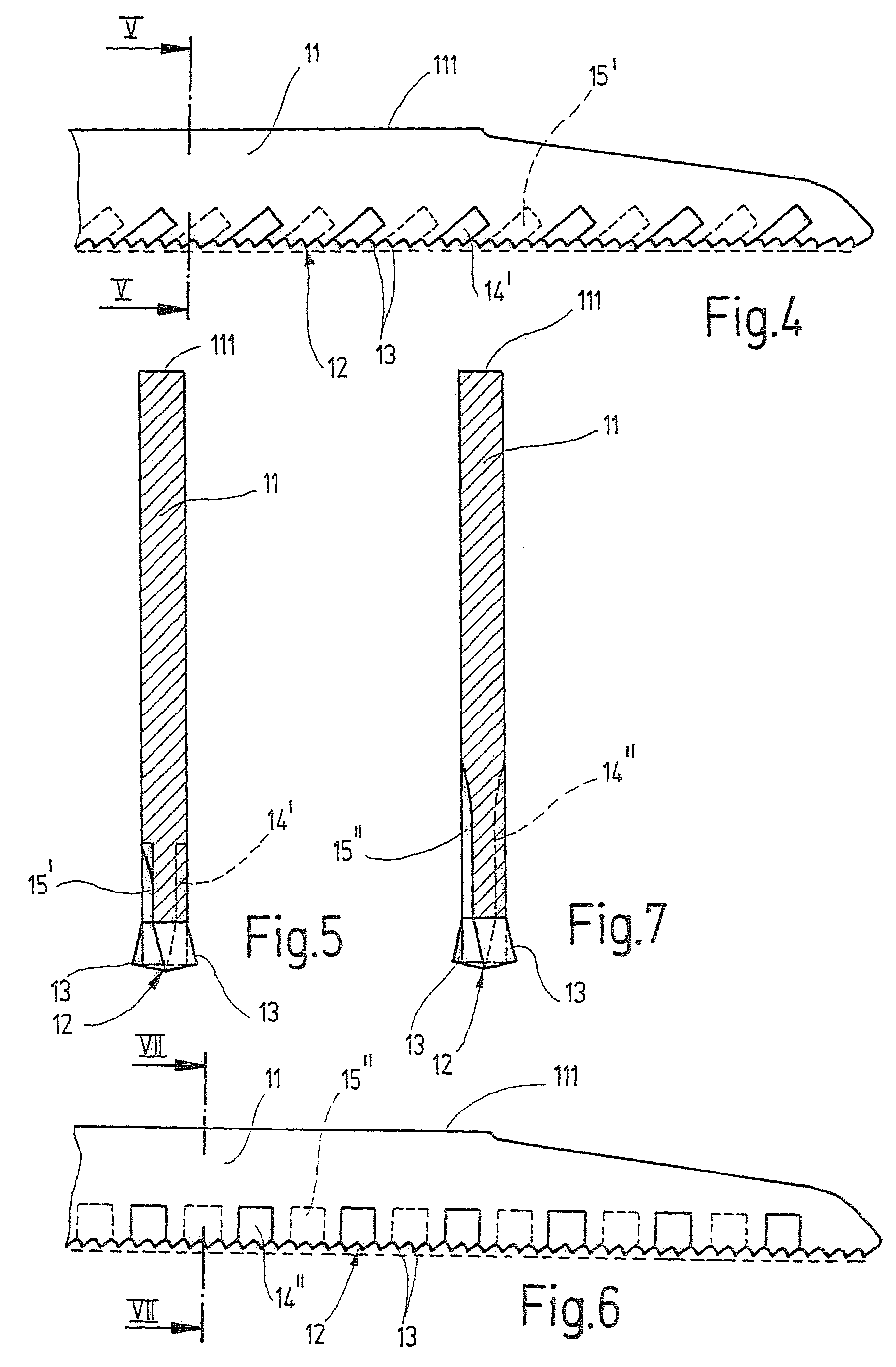

Saw blade for hand-held tools

InactiveUS7127979B2Prolong lifeIncrease forceMetal sawing devicesMetal sawing tool makingHand heldEngineering

Owner:ROBERT BOSCH GMBH

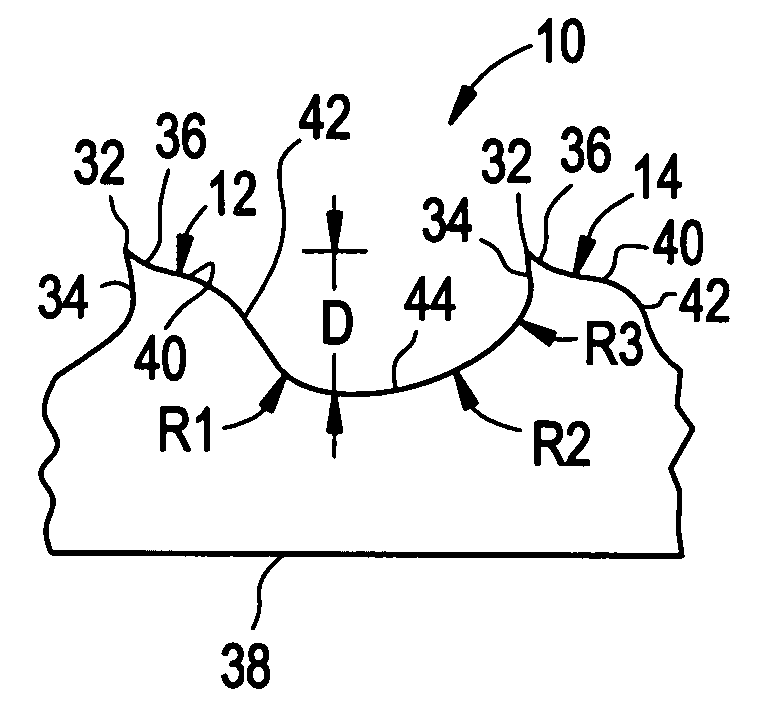

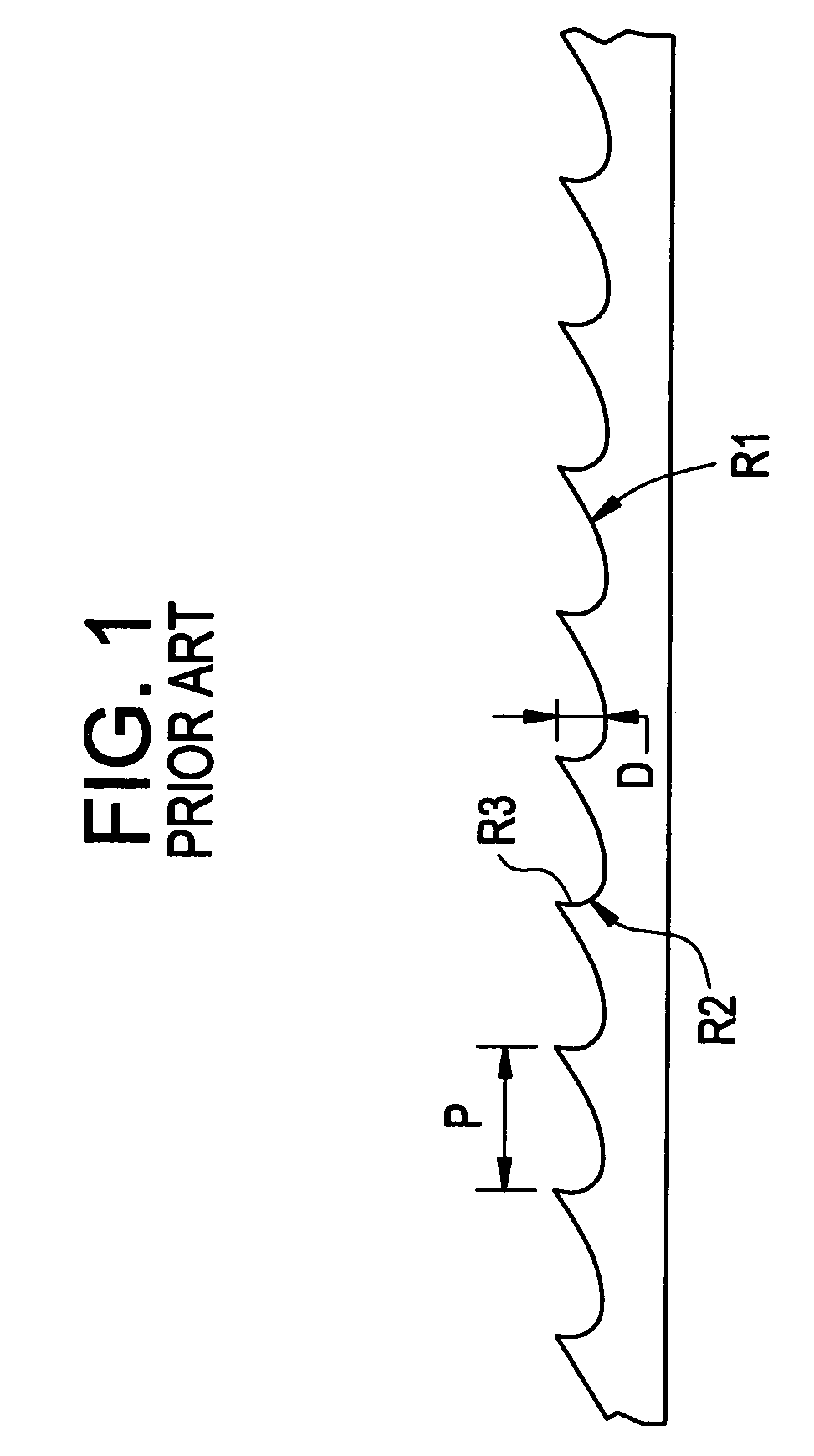

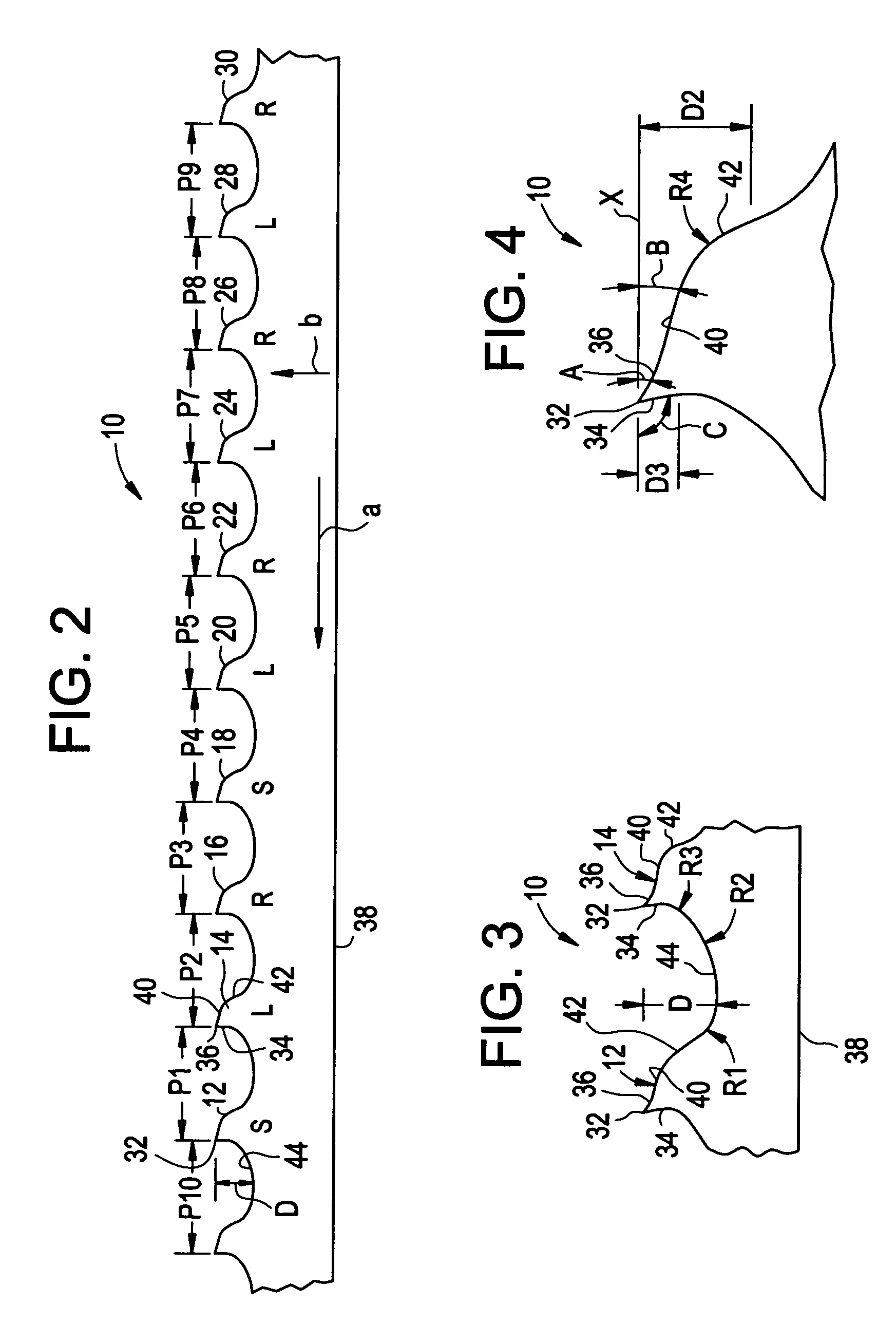

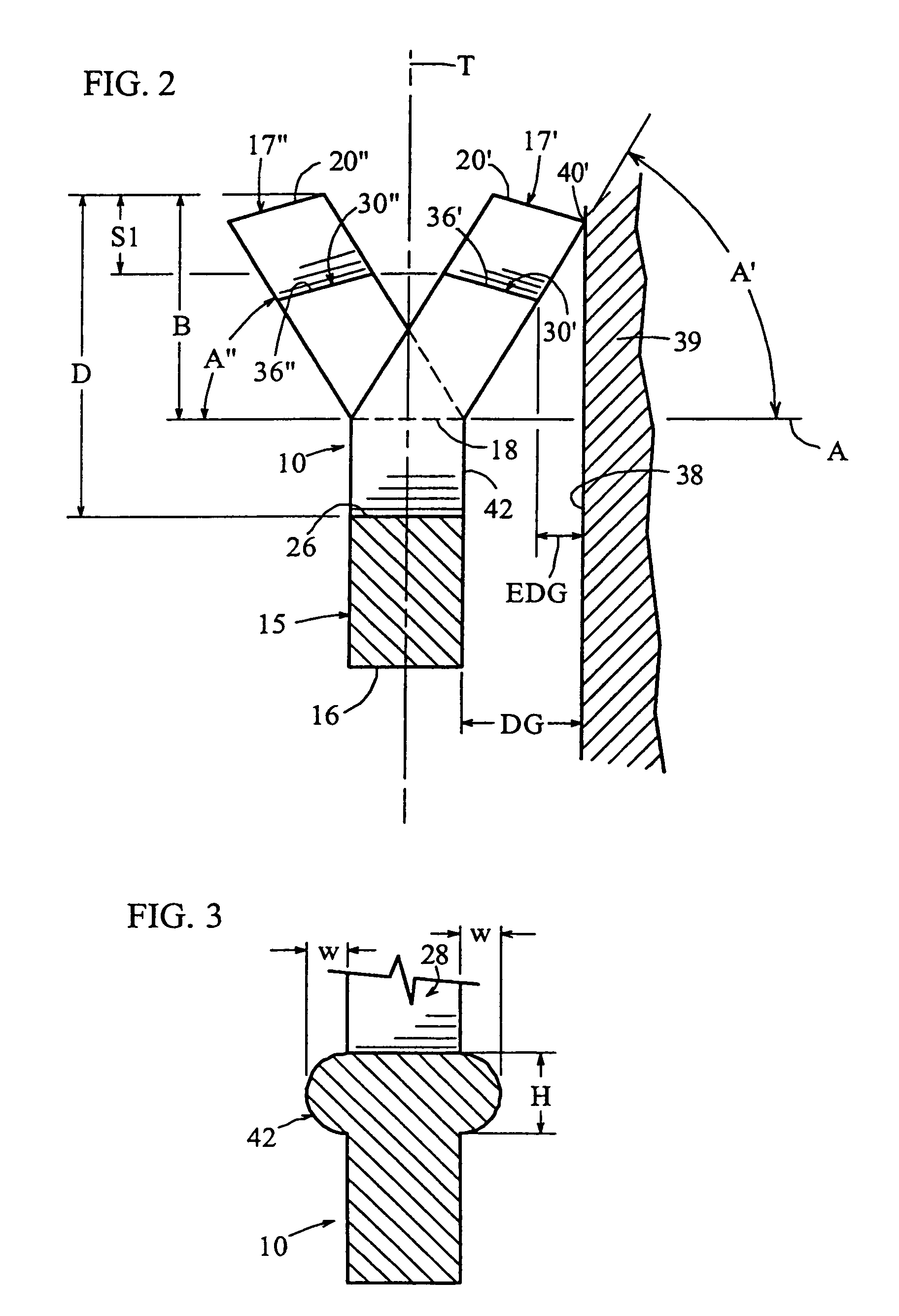

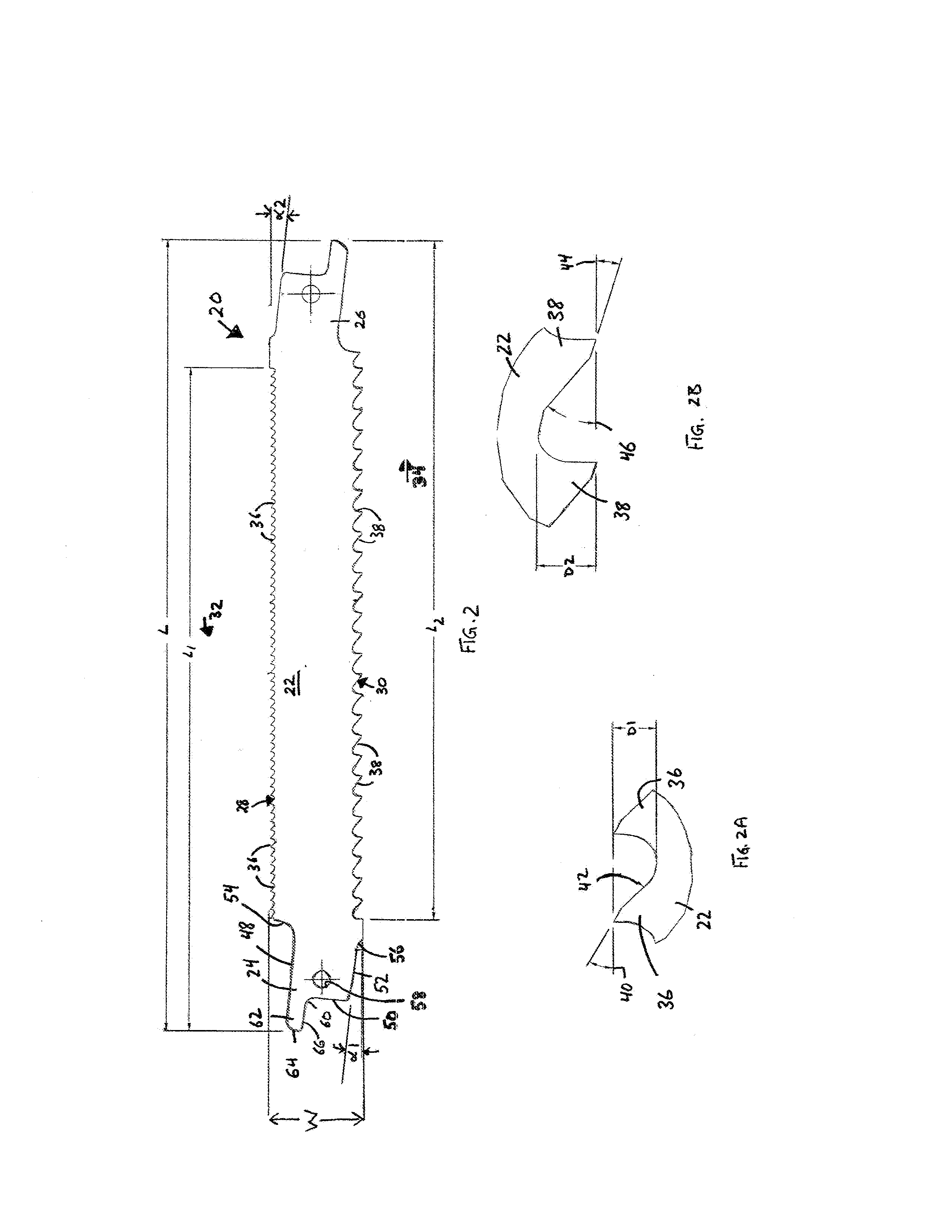

Saw blade having increased tooth stiffness and resistance to fatigue failure

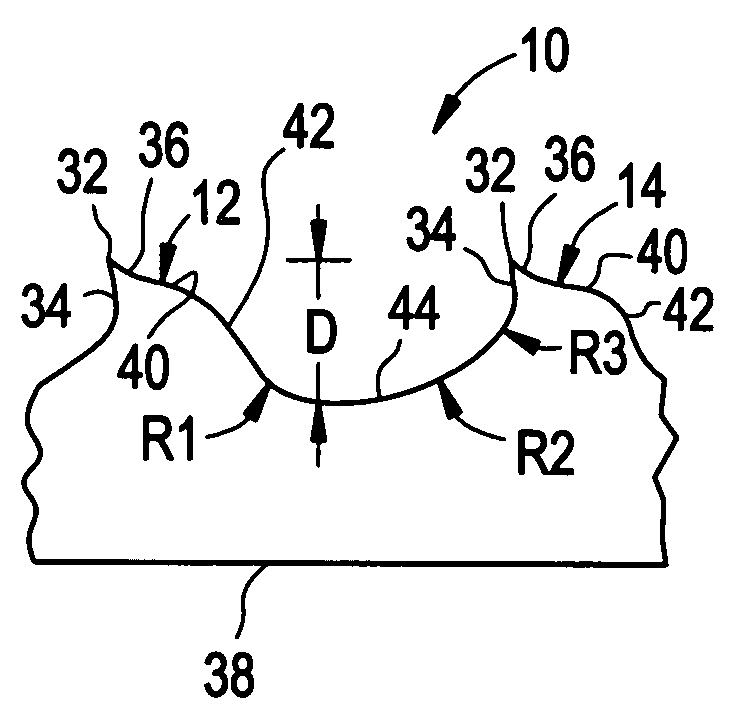

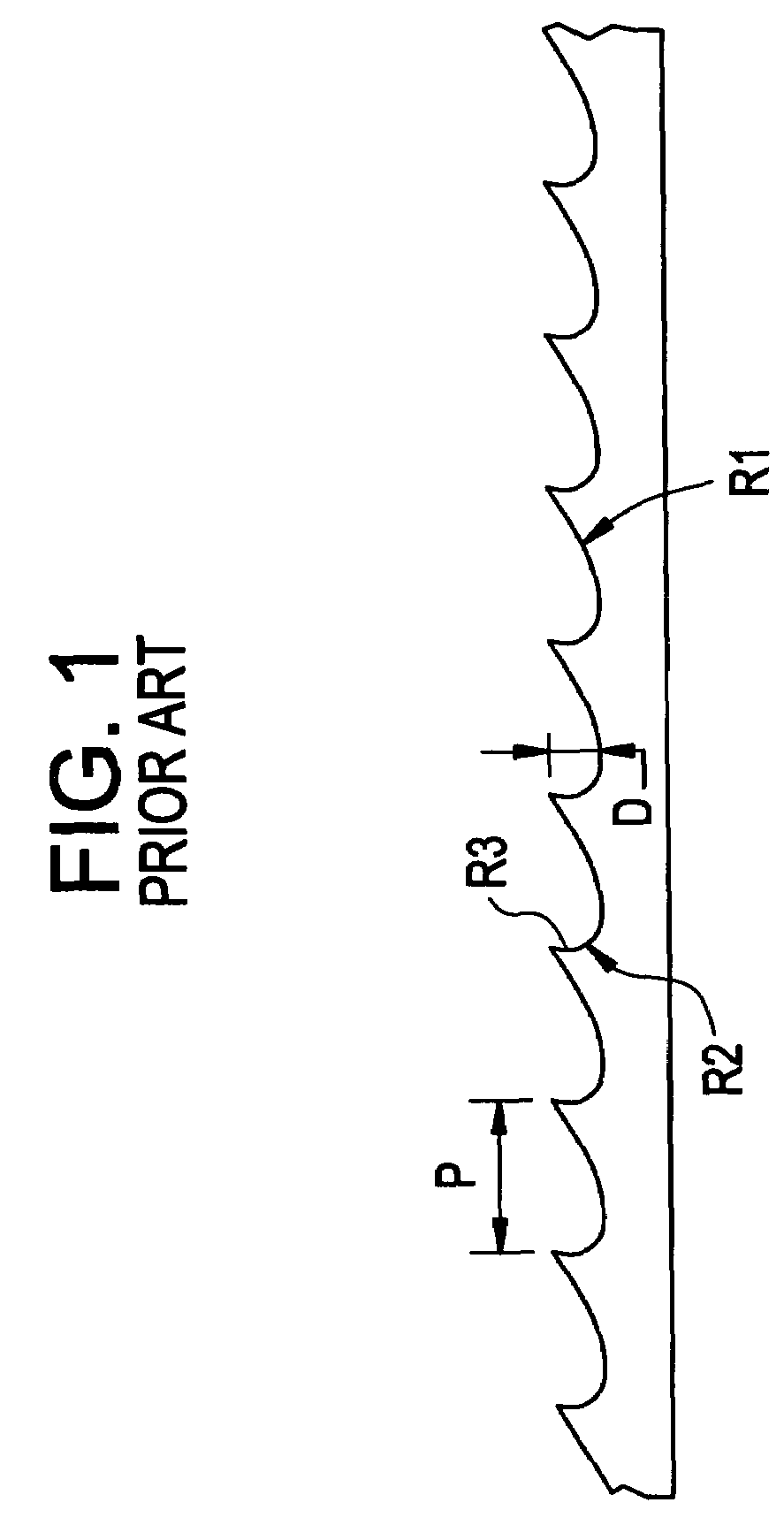

InactiveUS20060065098A1Increase Section WidthPrevent set collapseMetal sawing devicesMetal sawing toolsEngineeringWood cutting

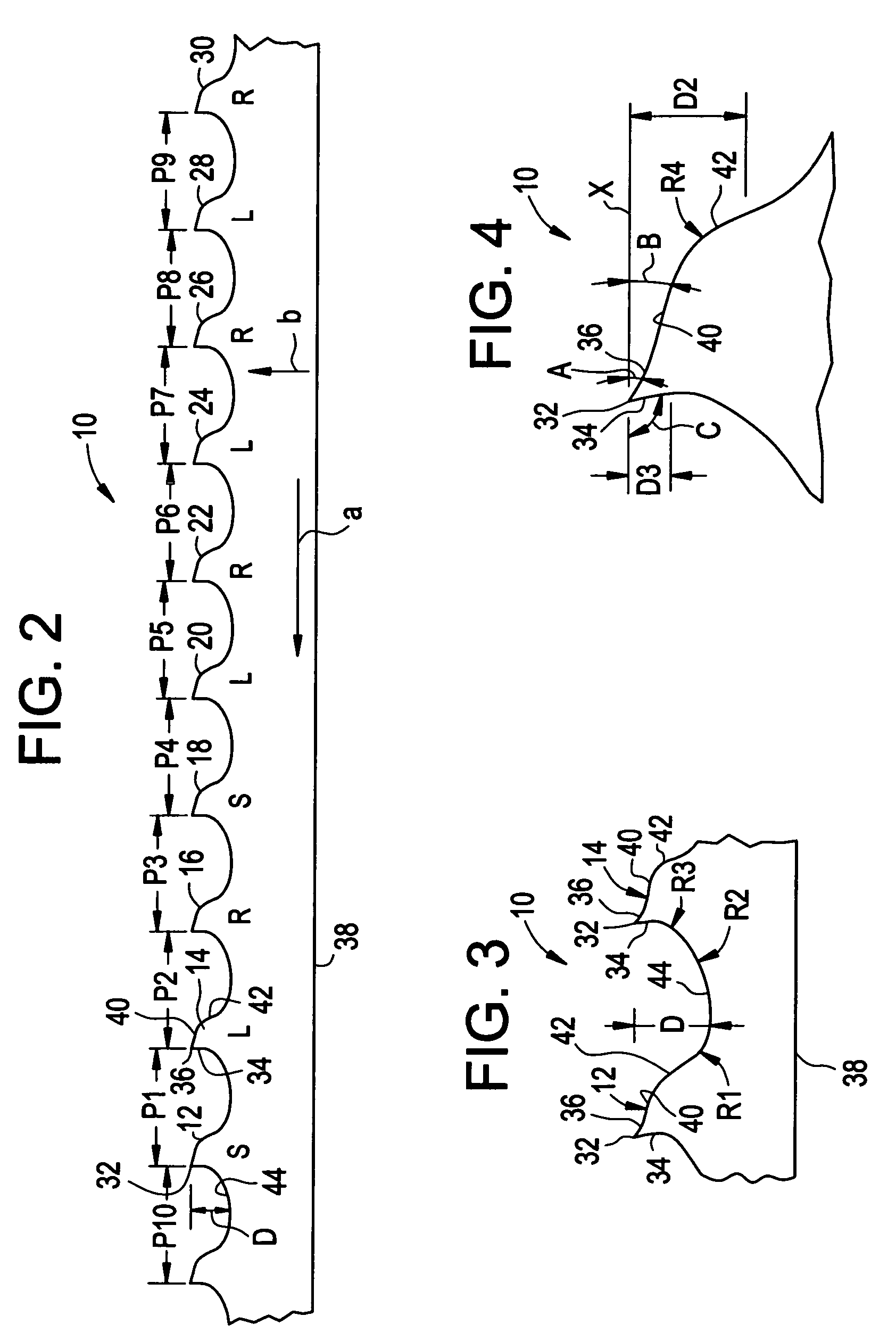

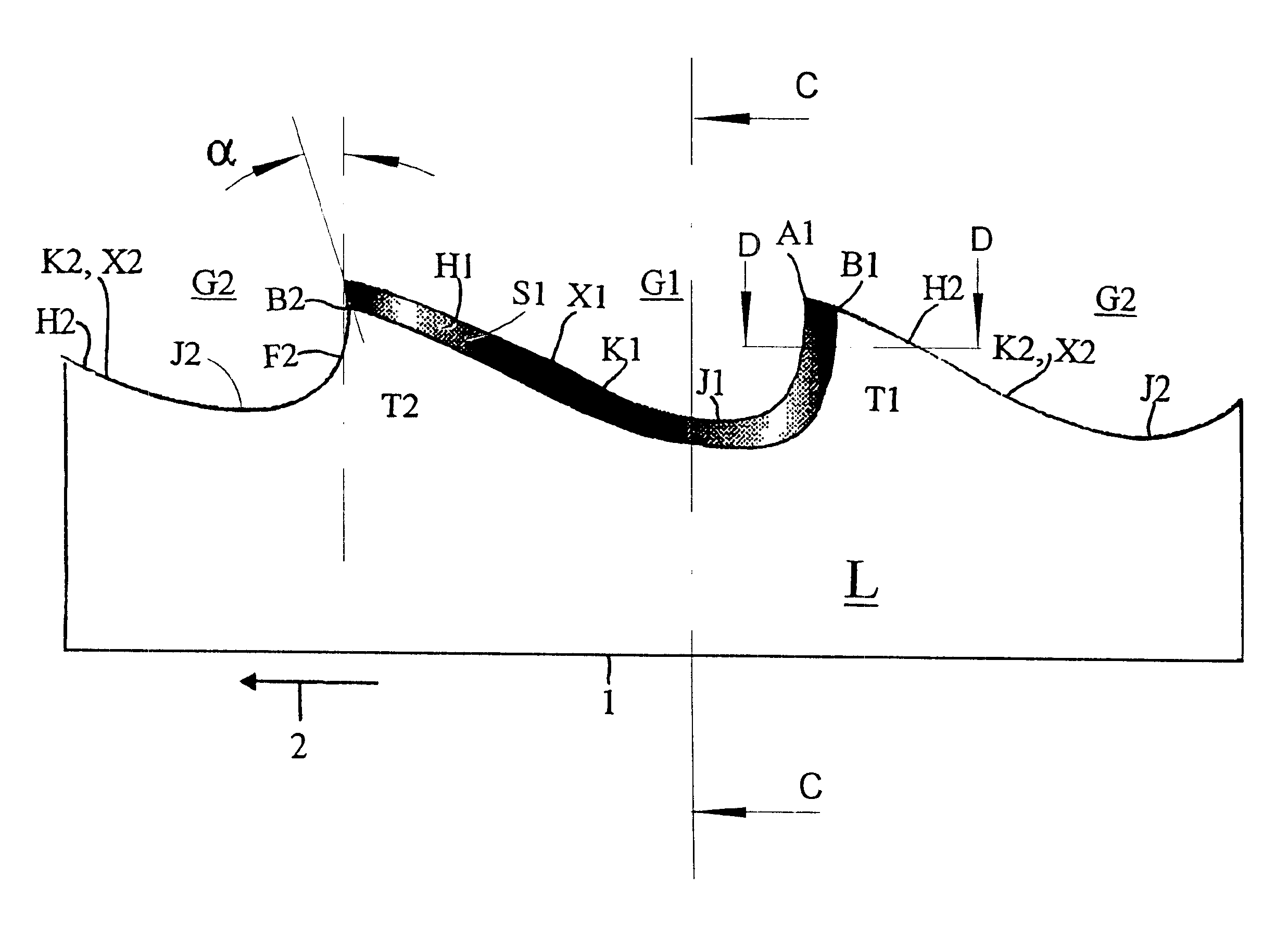

A wood-cutting band saw blade includes a cutting edge defined by a plurality of teeth spaced relative to each other, wherein each tooth includes a tip; a rake face formed on one side of the tip; a primary clearance surface formed on an opposite side of the tip relative to the rake face; a secondary clearance surface formed on an opposite side of the primary clearance surface relative to the tip; a tertiary clearance surface formed on an opposite side of the secondary clearance surface relative to the primary clearance surface; and a gullet located on an opposite side of the rake face relative to the tip and defining a depth (D) between a base surface of the gullet and the tip. Each tooth further defines a first gullet radius (R1) located between the gullet and tertiary clearance surface; a second gullet radius (R2) extending between a base surface of the gullet and the rake face; and a pitch (P) between the respective tooth and a preceding tooth in a cutting direction of the saw blade. In each tooth, R2>D>R1, D / P is within the range of about 25% to about 35% and R2 / R1≧about 1.4. R1 defines a minimum radius (Rmin) at a base of the gullet and Rmin / D>about 20%.

Owner:IRWIN IND TOOL CO

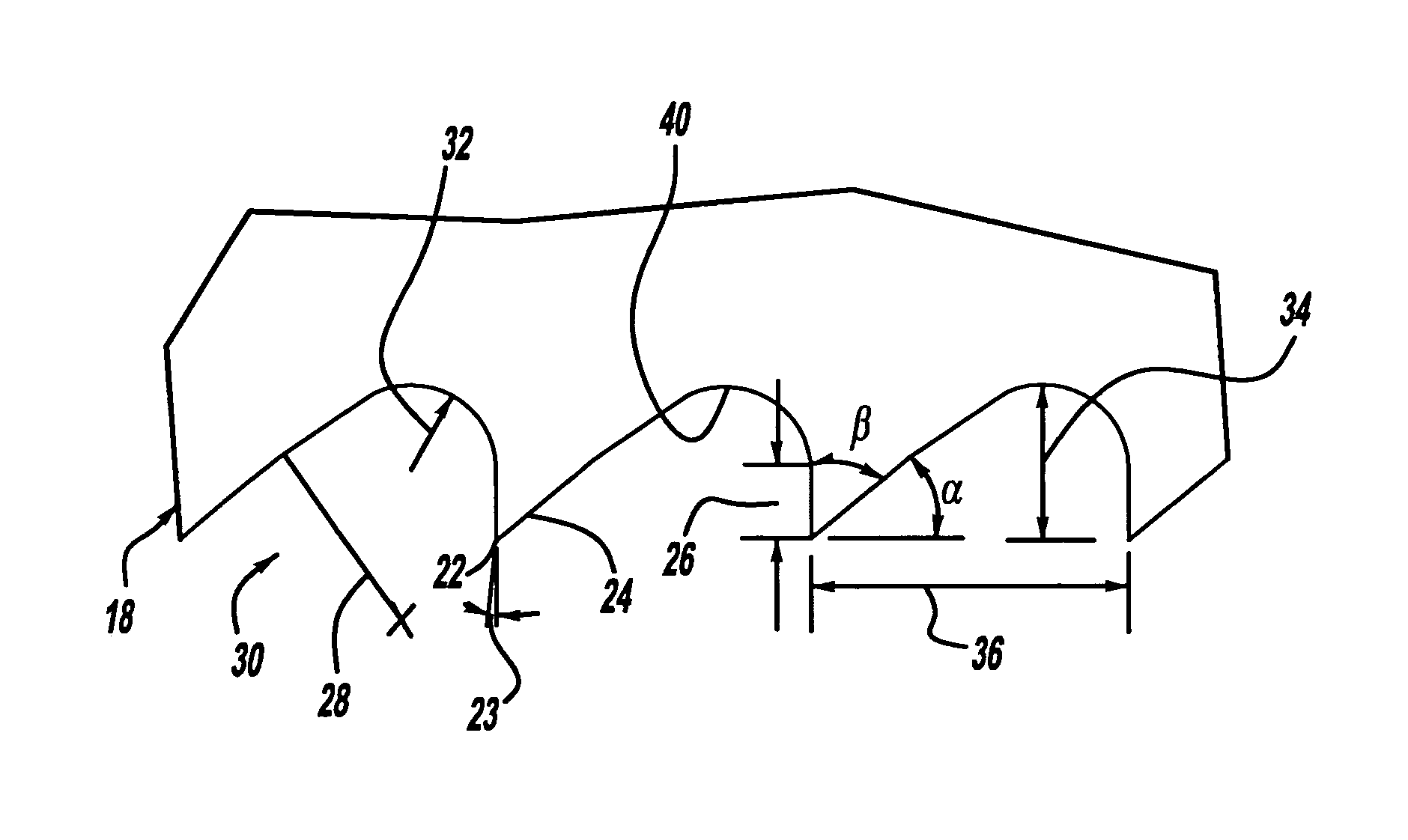

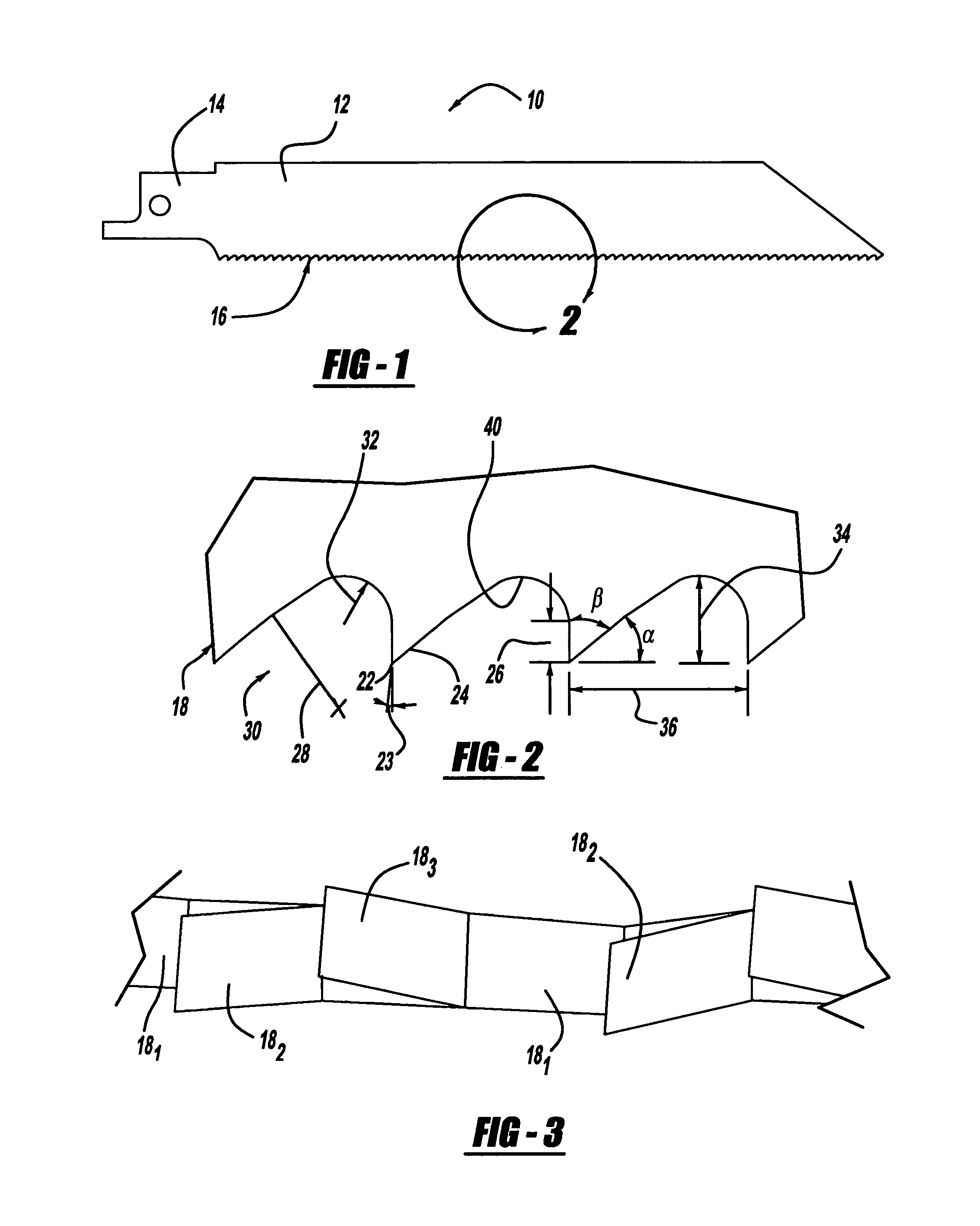

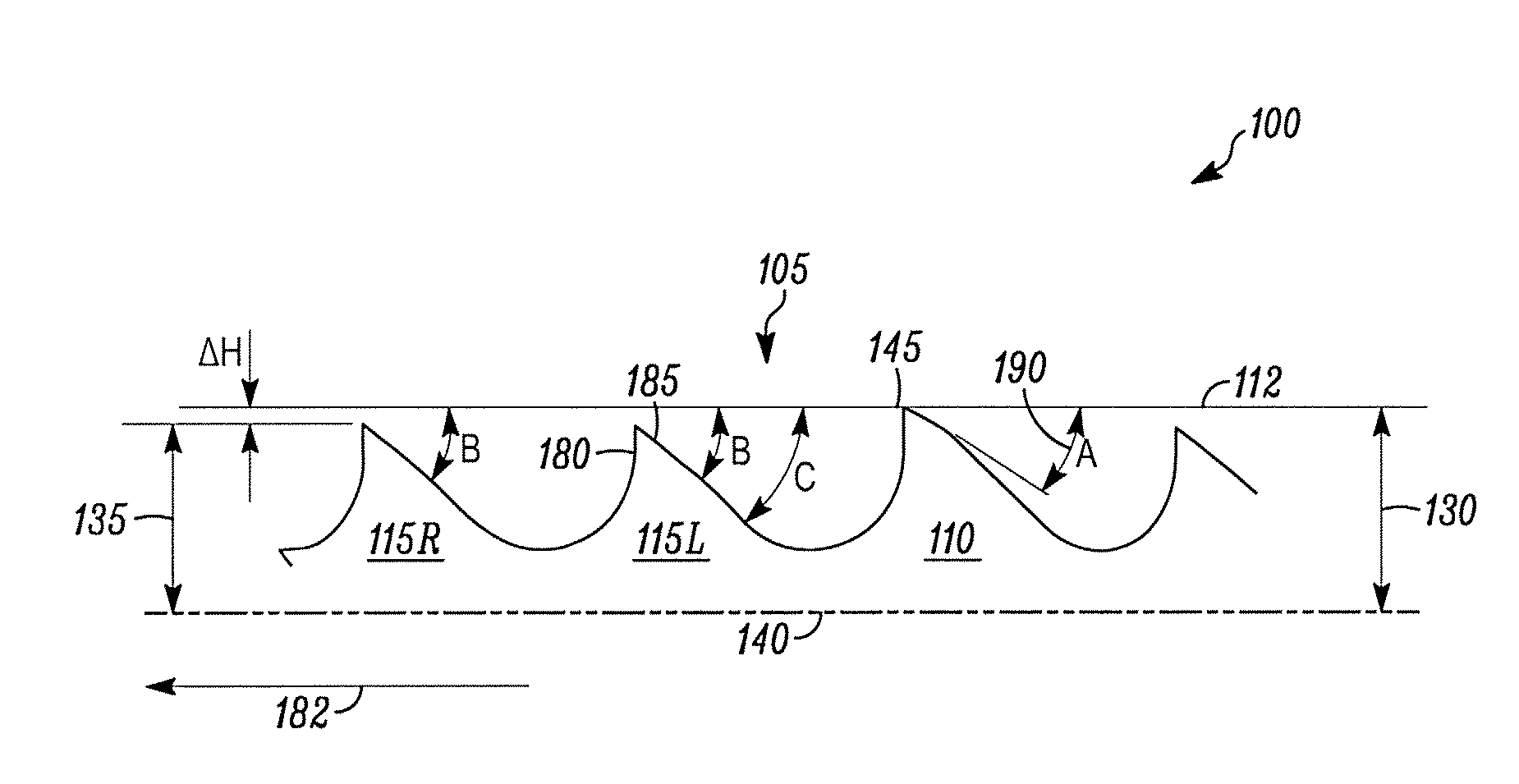

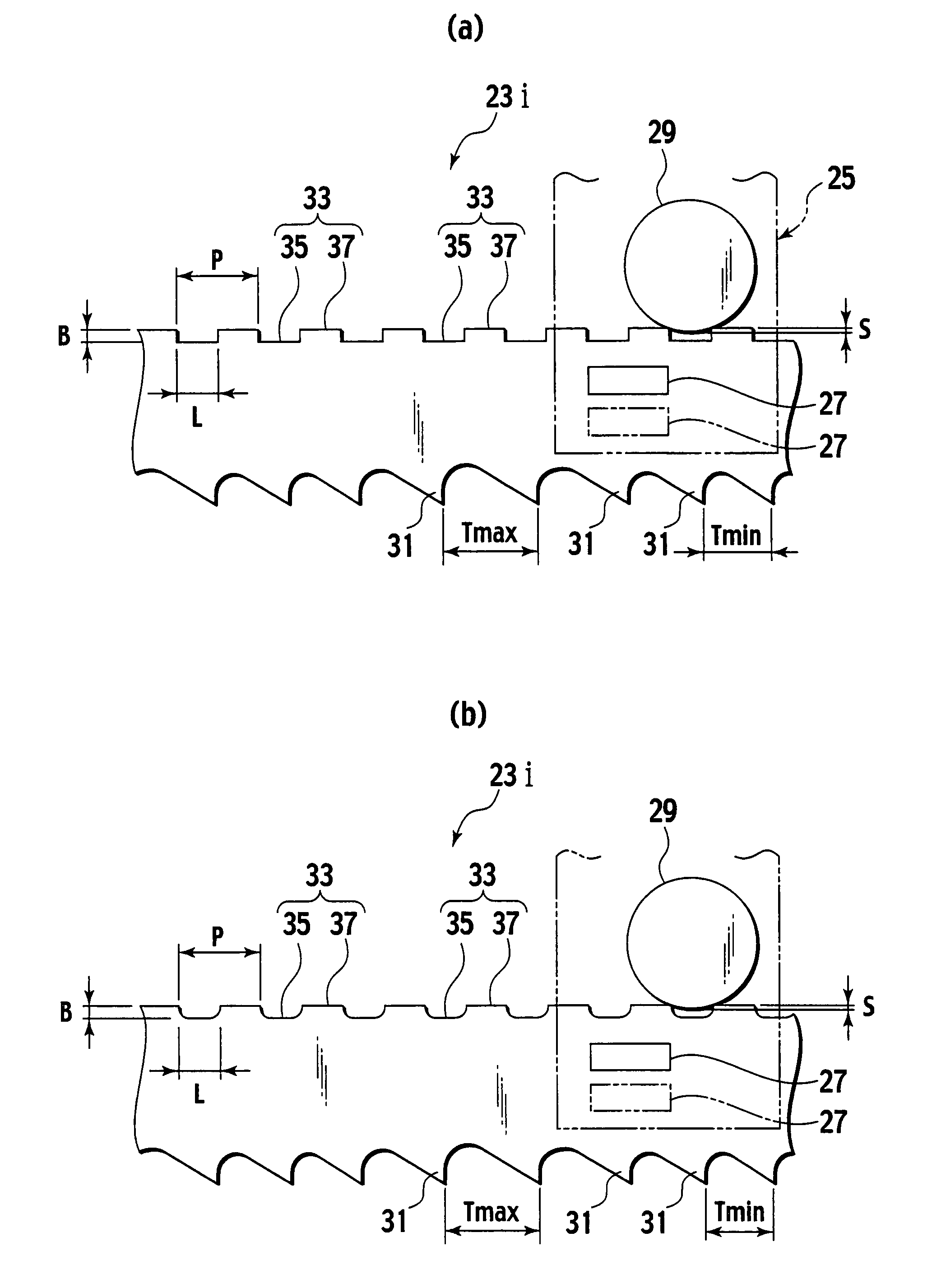

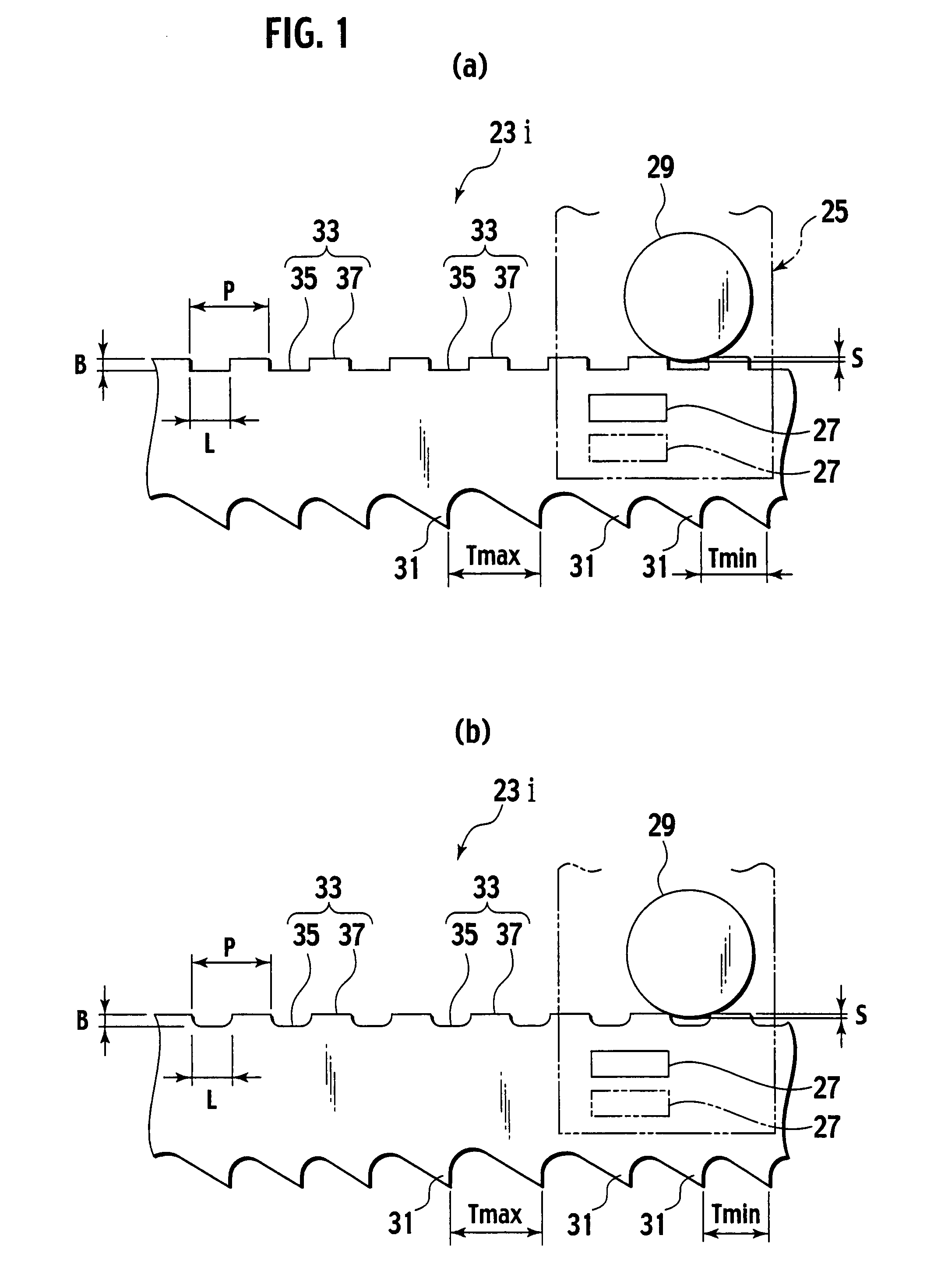

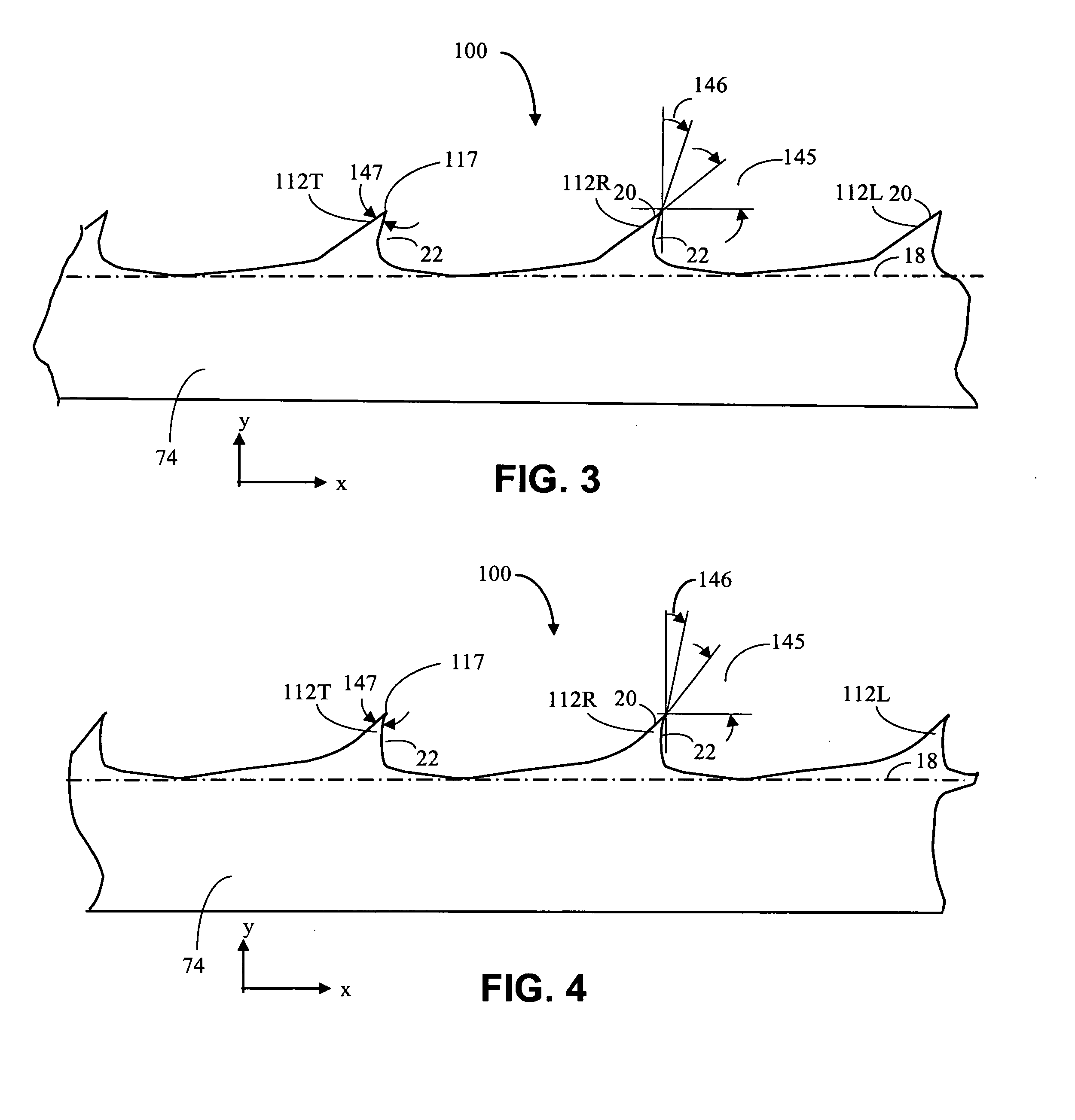

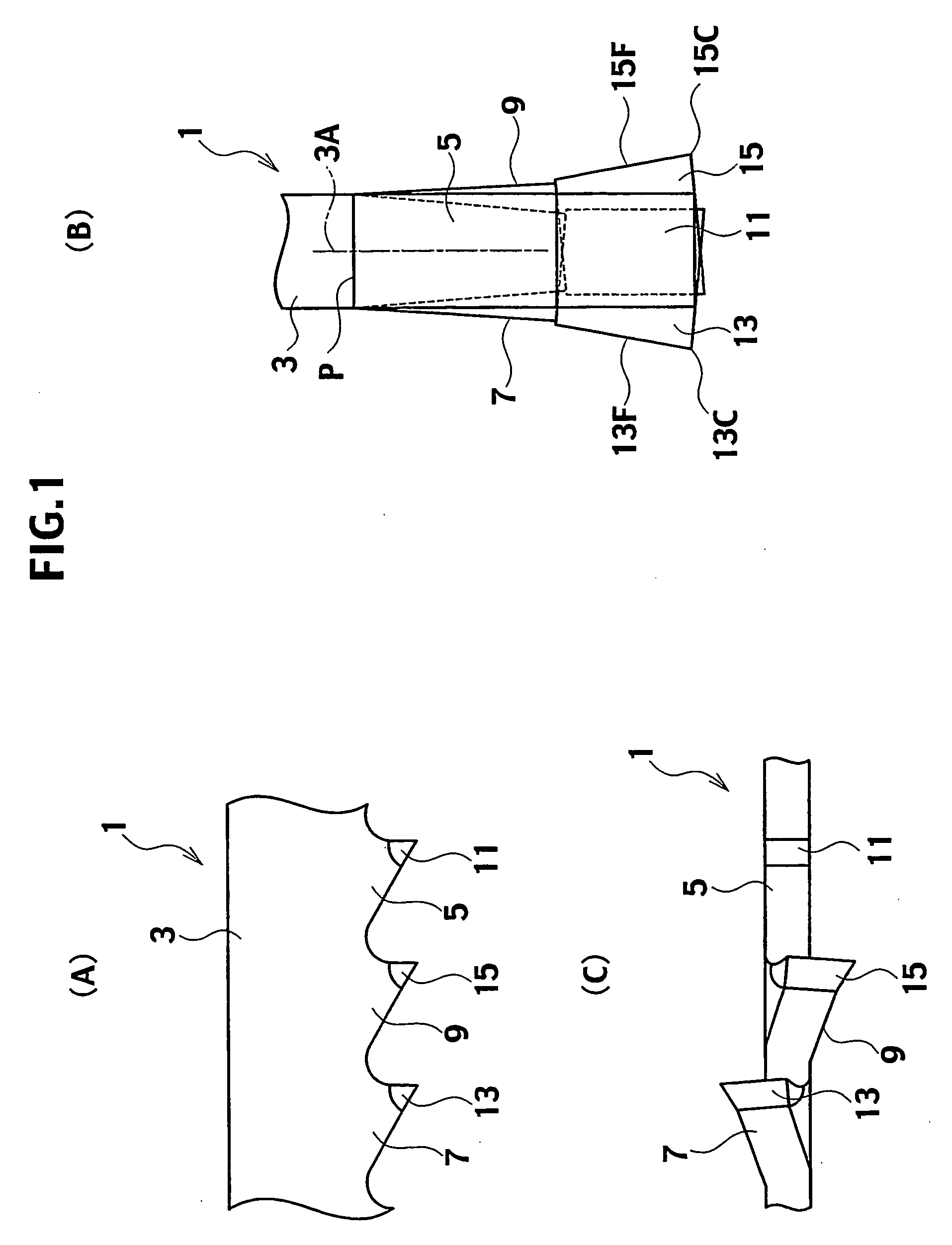

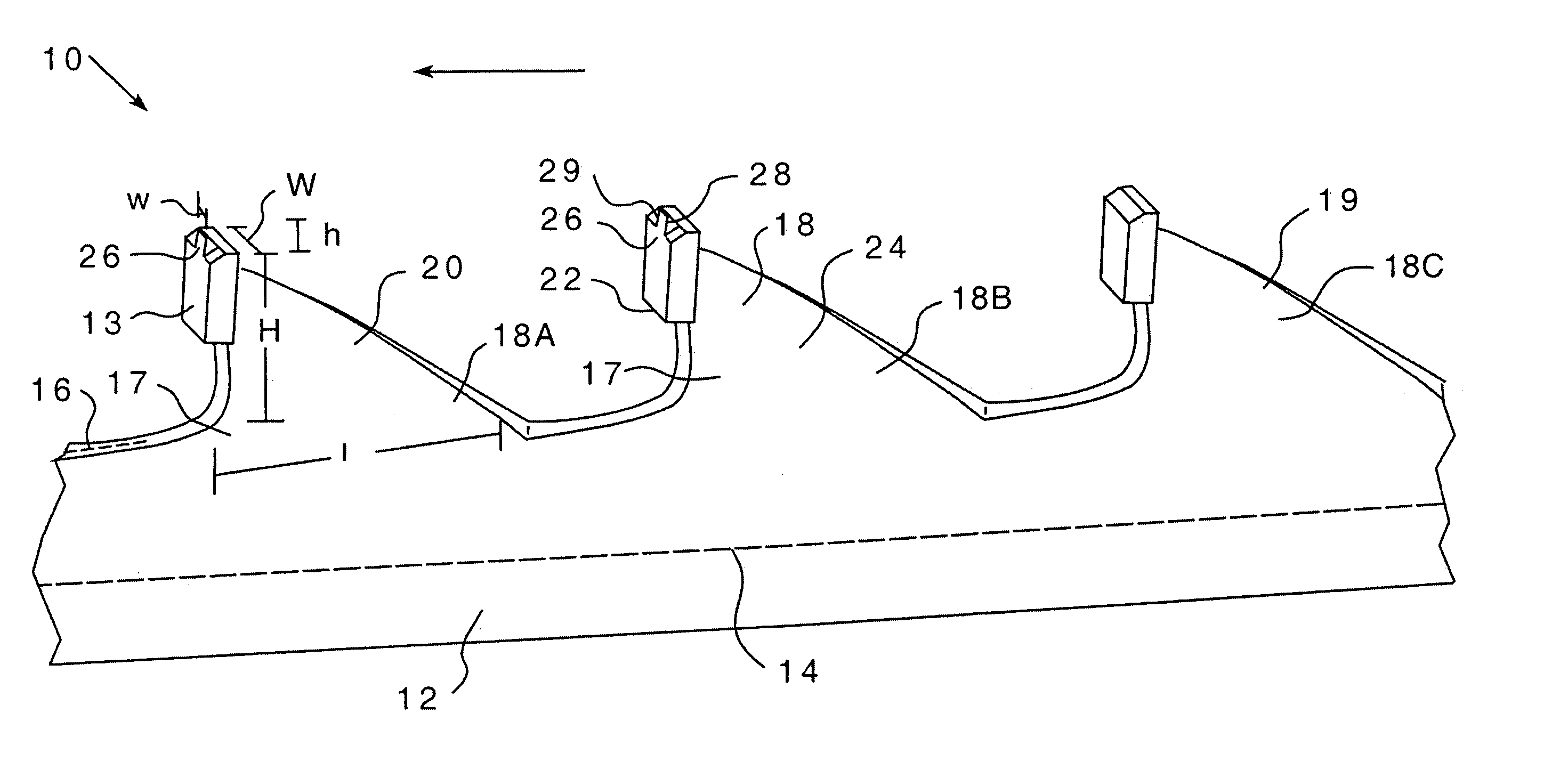

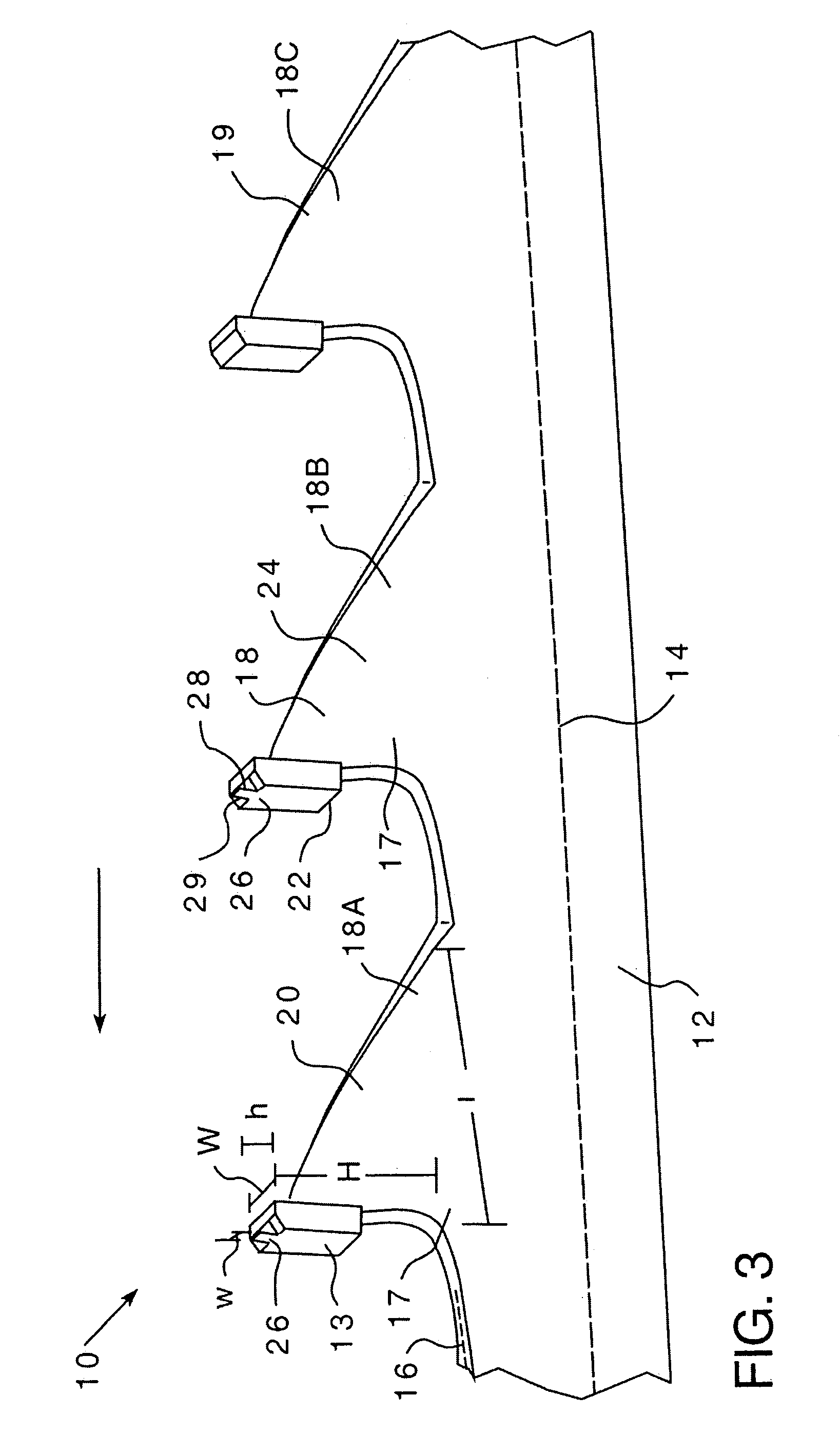

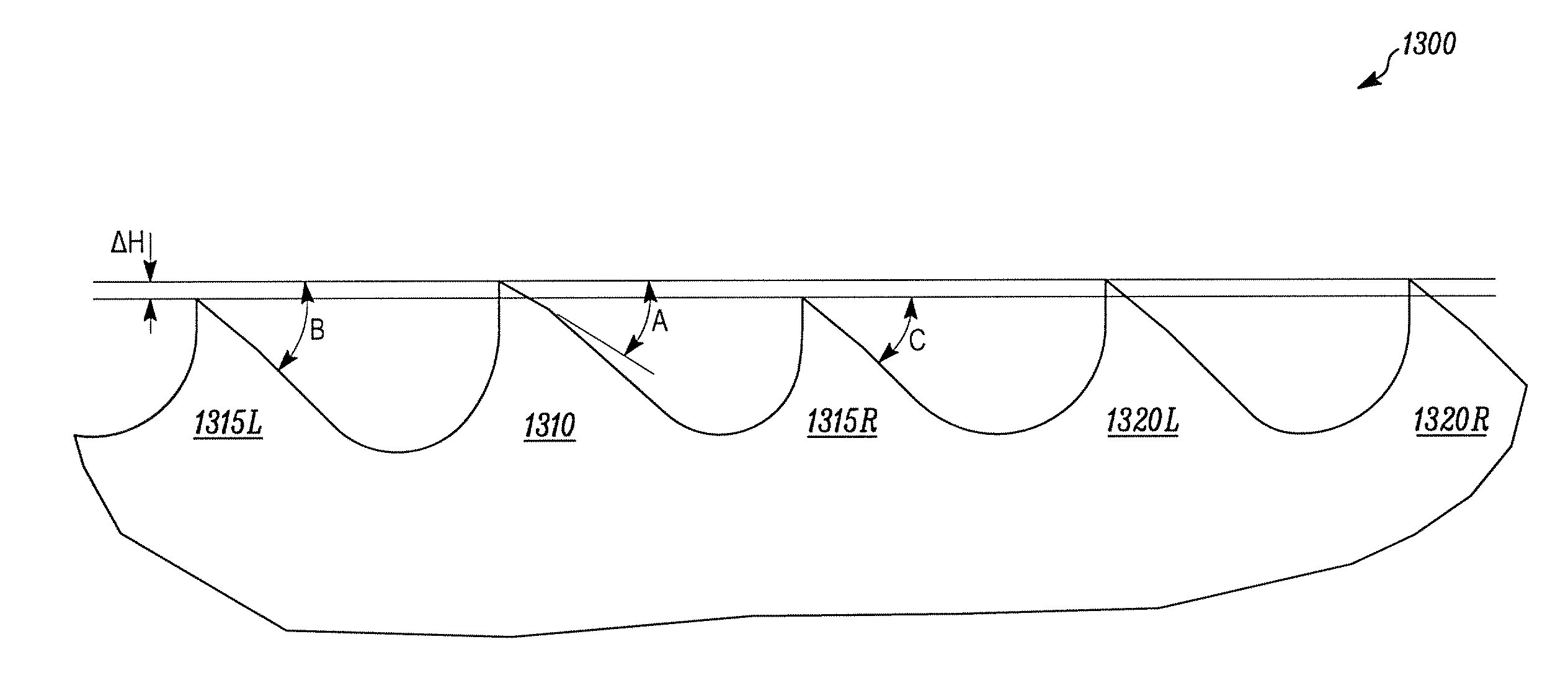

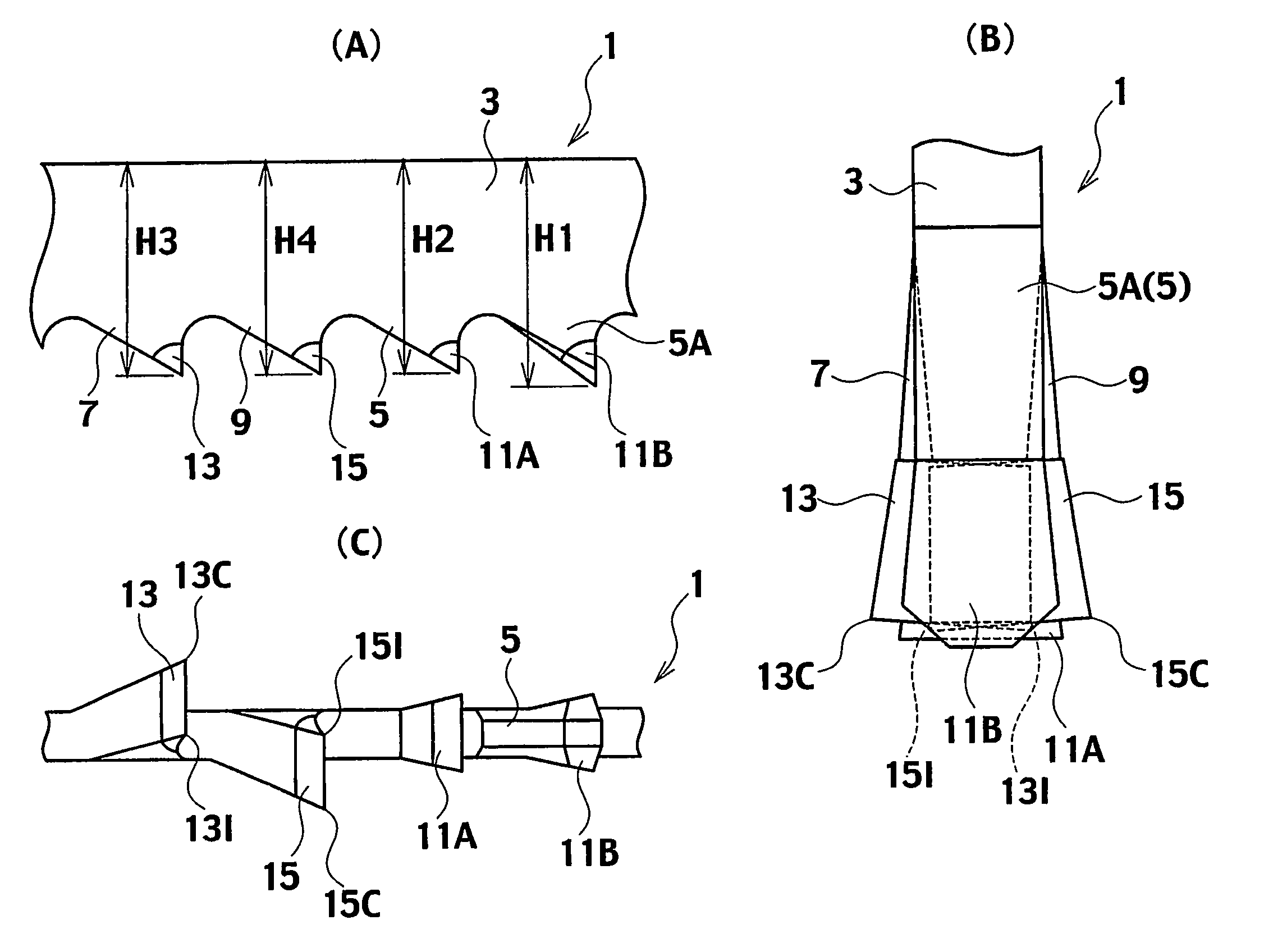

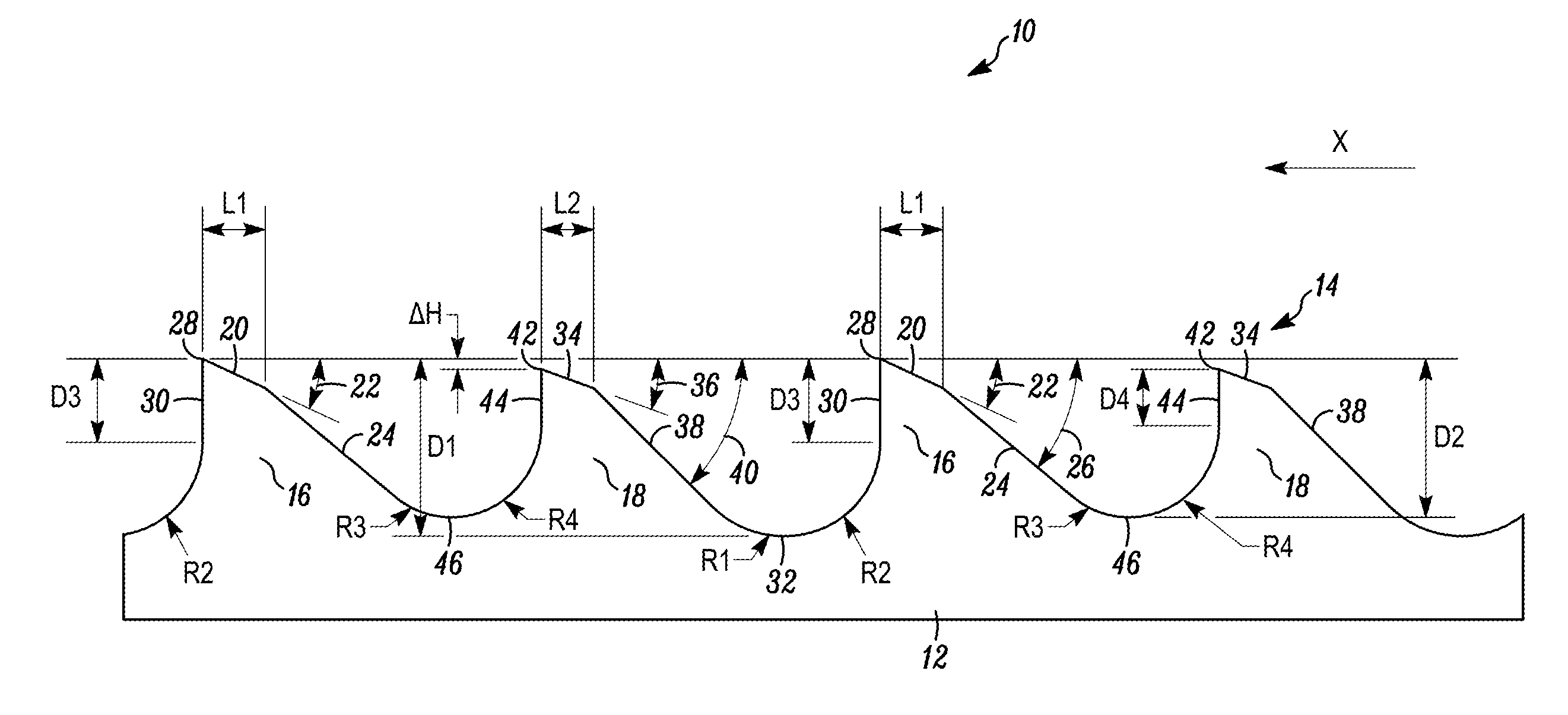

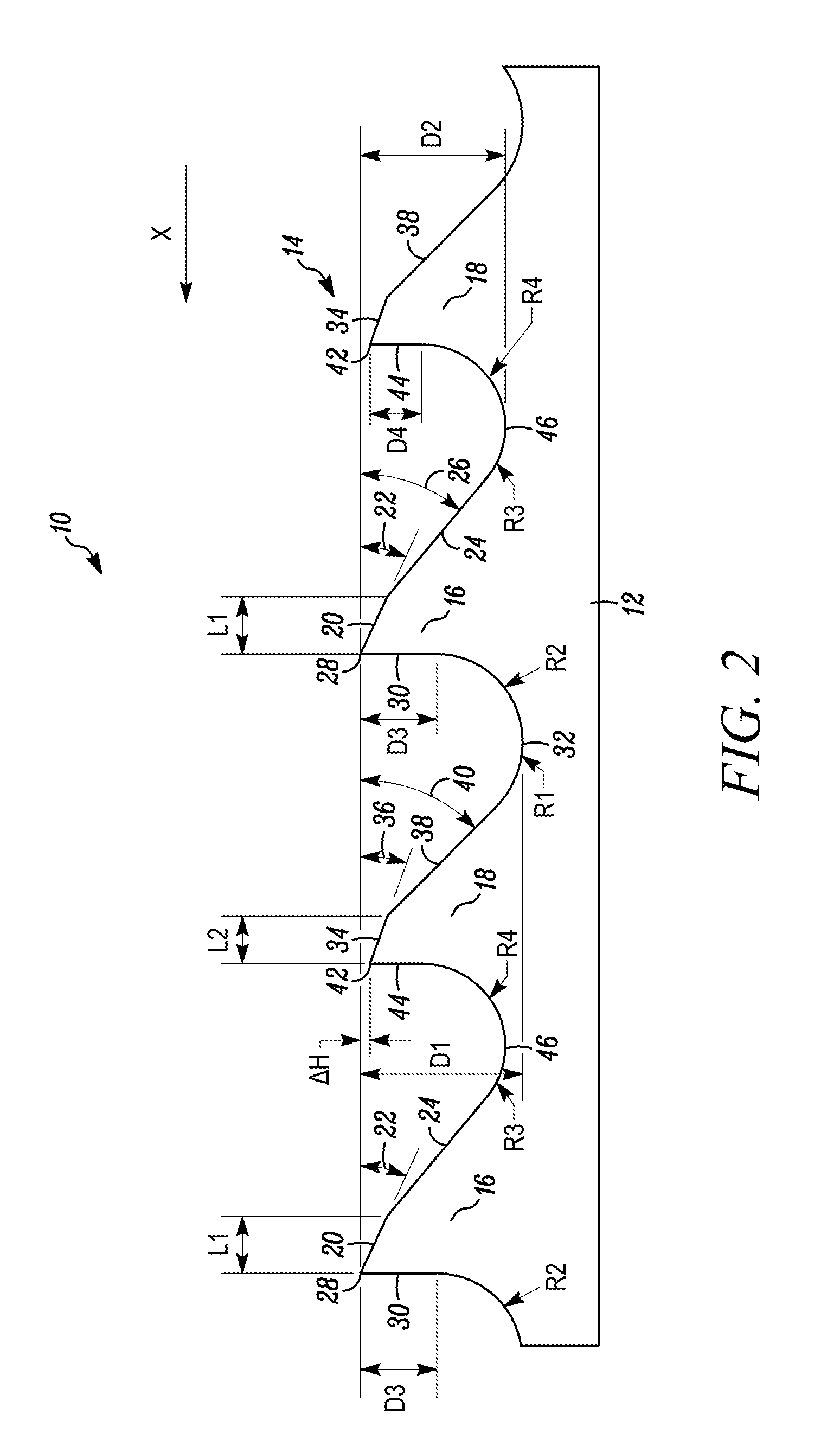

Reciprocating Saw Blade Having Variable-Height Teeth and Related Method

ActiveUS20080307936A1Improve performanceIncrease cutting forceMetal sawing devicesMetal sawing toolsPortable powerEngineering

A reciprocating saw blade, for use in a portable power reciprocating saw including a chuck for releasably engaging the saw blade, includes a tang having an elongated axis and being engageable with the chuck for attaching the saw blade to the reciprocating saw. The saw further includes a blade portion having a cutting edge that defines a plurality of cutting teeth. The cutting teeth define a repeating pattern of successive groups of teeth. Each group of teeth is less than about a half inch in length, and includes a plurality of laterally offset teeth, at least one relatively high first tooth and at least one relatively low second tooth. Prior to tooth set, the at least one relatively high first tooth is at least about 0.002 inch higher than the at least one relatively low second tooth.

Owner:BLACK & DECKER INC

Tooth form design for reciprocating saw blade

A reciprocating saw has a tooth form that decreases the cutting time of the saw blade and extends the life of the saw blade. The tooth height is longer than conventional metal cutting reciprocating saws. Also, the tooth form has a larger gullet. The tooth rake angle remains substantially constant during the life of the saw blade.

Owner:BLACK & DECKER INC

Saw blade having increased tooth stiffness and resistance to fatigue failure

InactiveUS7174823B2Increase Section WidthIncrease stiffnessMetal sawing devicesMetal sawing toolsEngineering

A band saw blade comprising a plurality of teeth, wherein each tooth comprises a tip; a rake face formed on one side of the tip; a primary clearance surface formed on an opposite side of the tip relative to the rake face; a secondary clearance surface formed on an opposite side of the primary clearance surface relative to the tip; and a gullet located on an opposite side of the rake face relative to the tip and defining a depth (D) between a base surface of the gullet and the tip. Each tooth further defines a first gullet radius (R1) located between the gullet and the secondary clearance surface; a second gullet radius (R2) extending between a base surface of the gullet and the rake face; and a pitch (P) between the respective tooth and a preceding tooth. In each tooth, R2>D>RQ, and D / P is between about 25% and 35%.

Owner:IRWIN IND TOOL CO

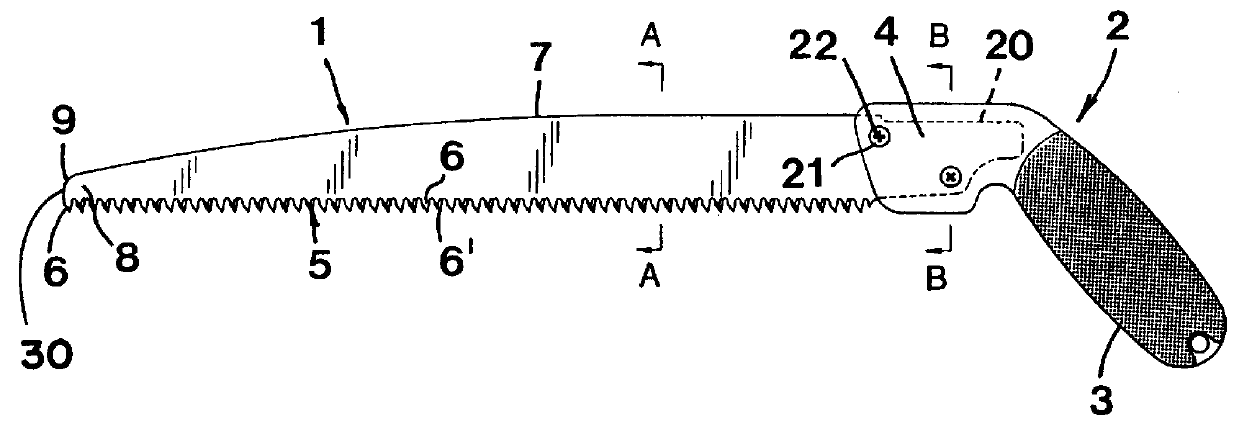

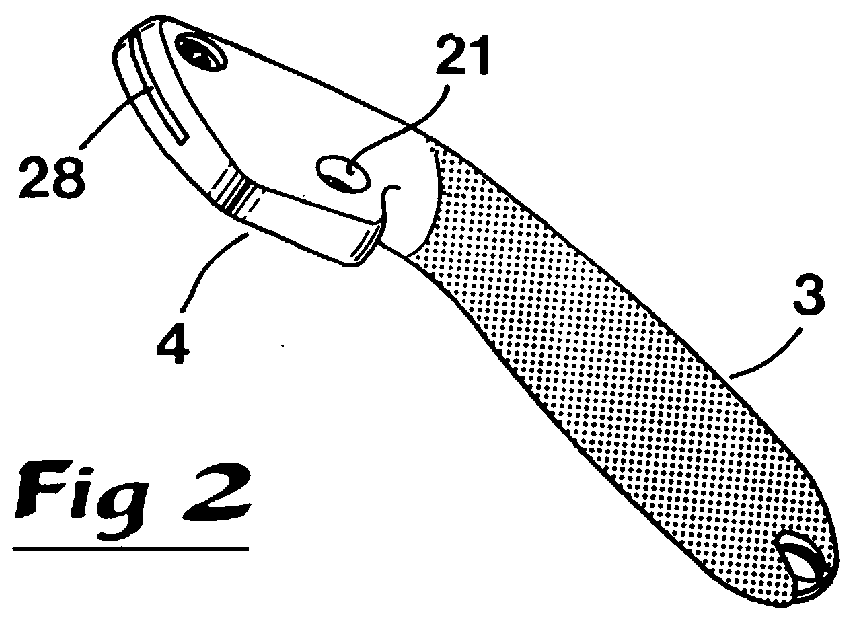

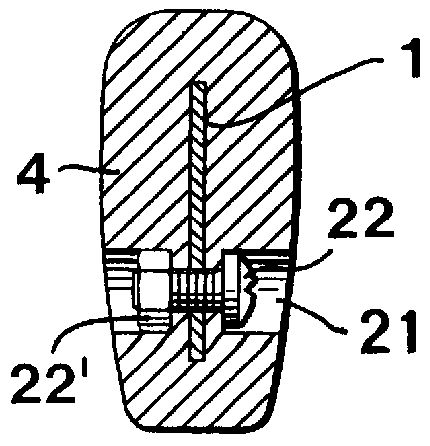

Pruning saw

A pruning saw includes an elongated sawblade which has a line of cutting teeth. Opposite sides of the blade extending between the line of teeth and the back edge are concave. A thinnest waist between the concave sides is located closer to the line of teeth than to the back where the blade has its maximum height. A front edge of the blade forms a rounded corner where it intersects the back edge.

Owner:SANDVIK AB

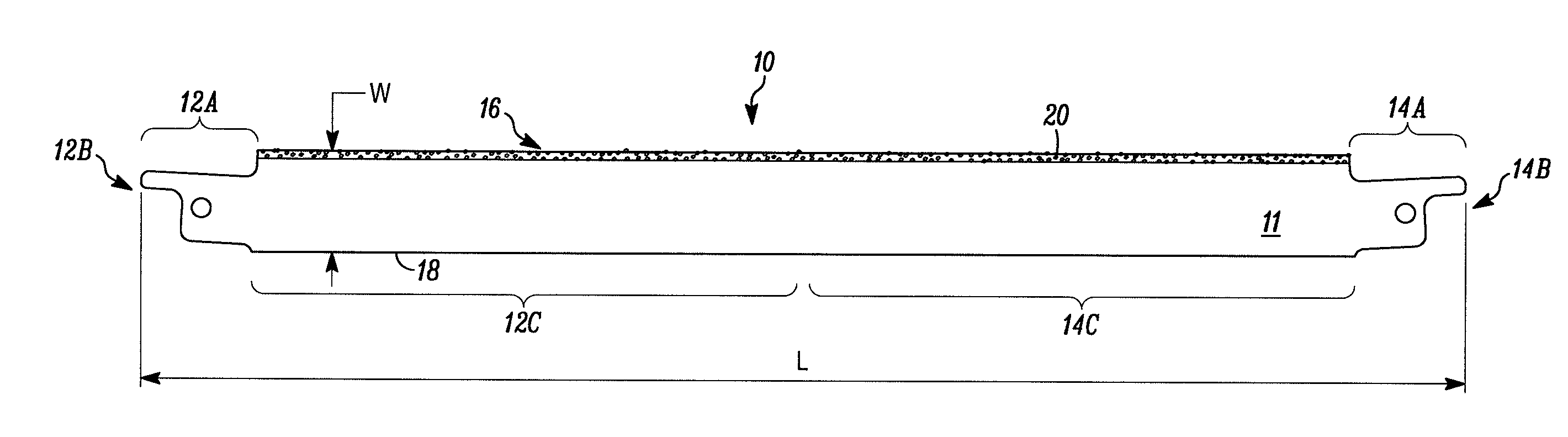

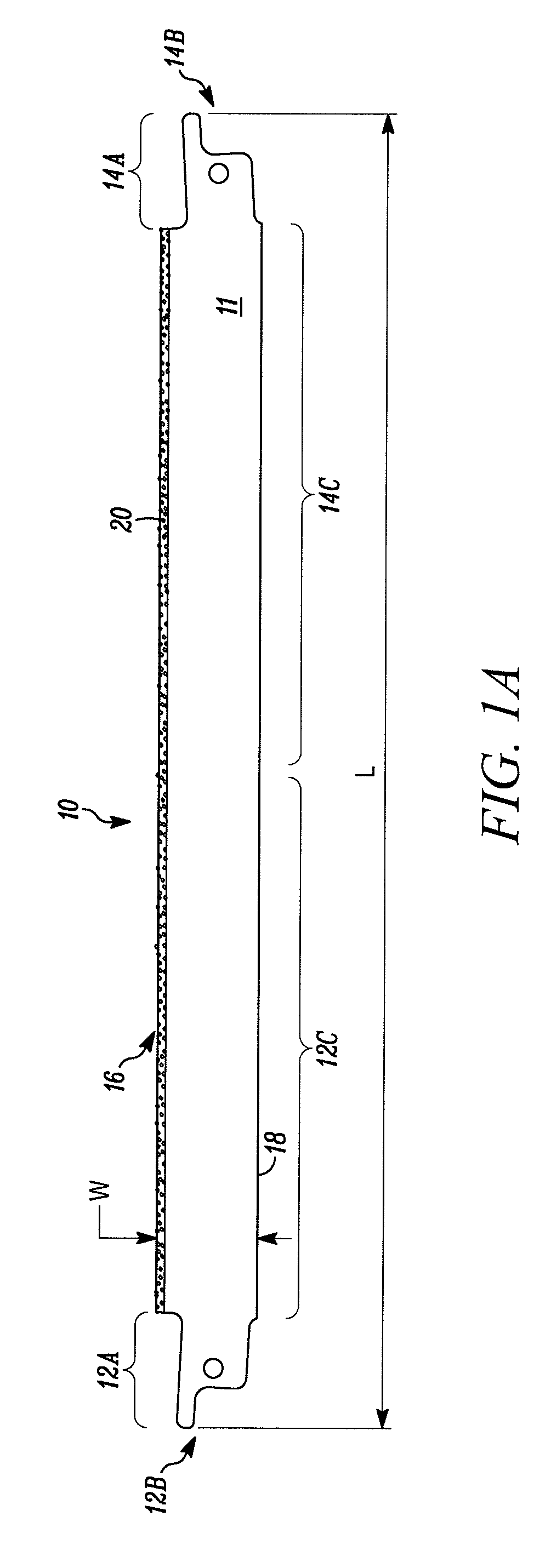

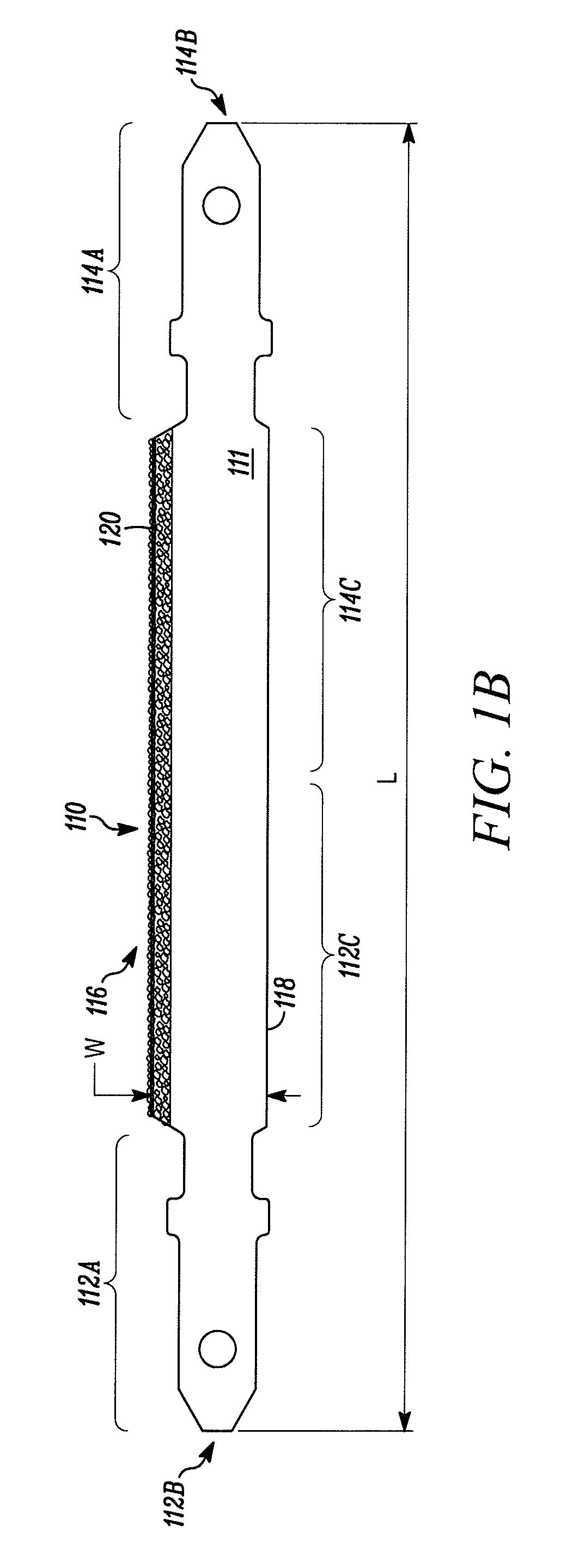

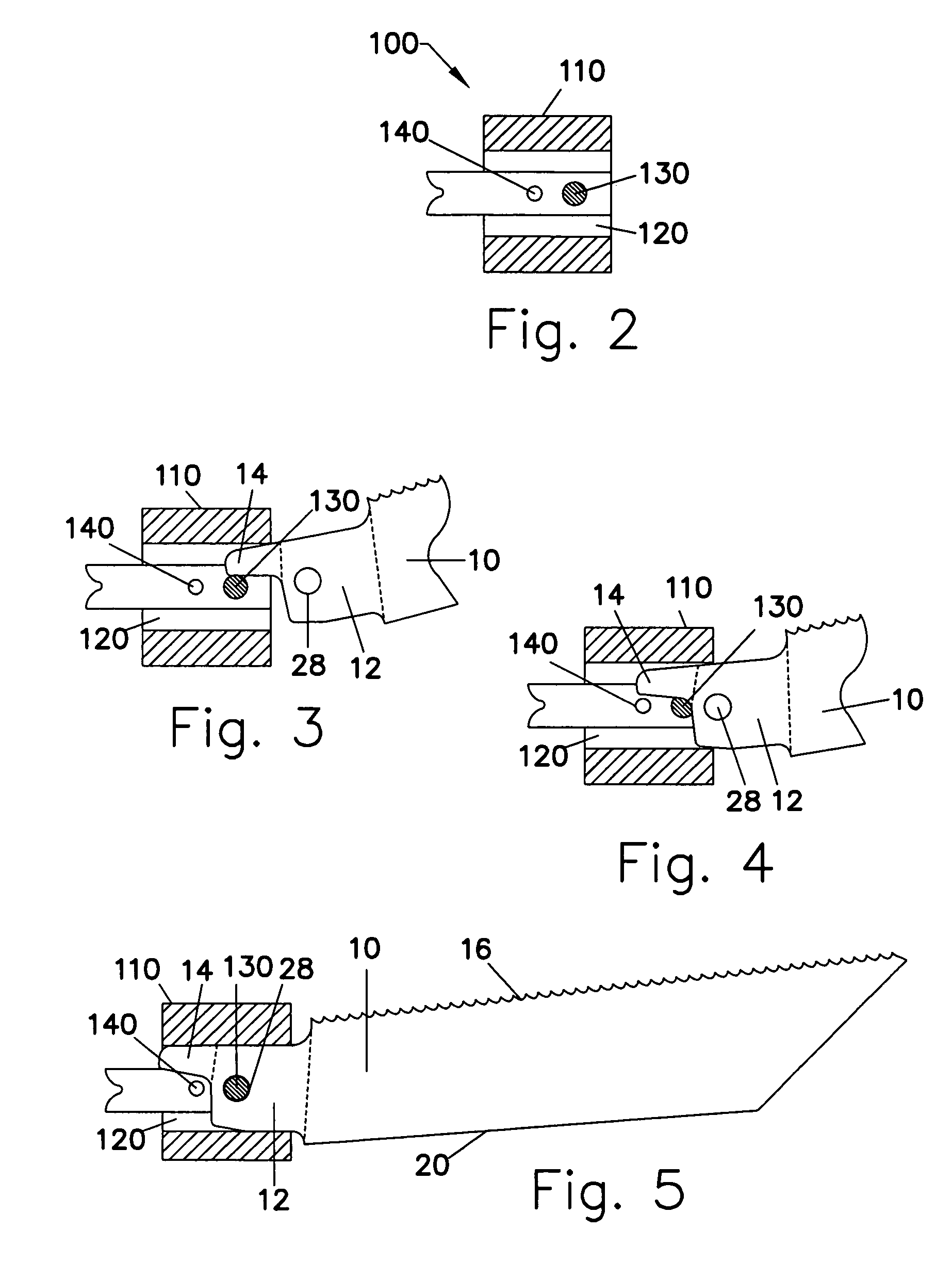

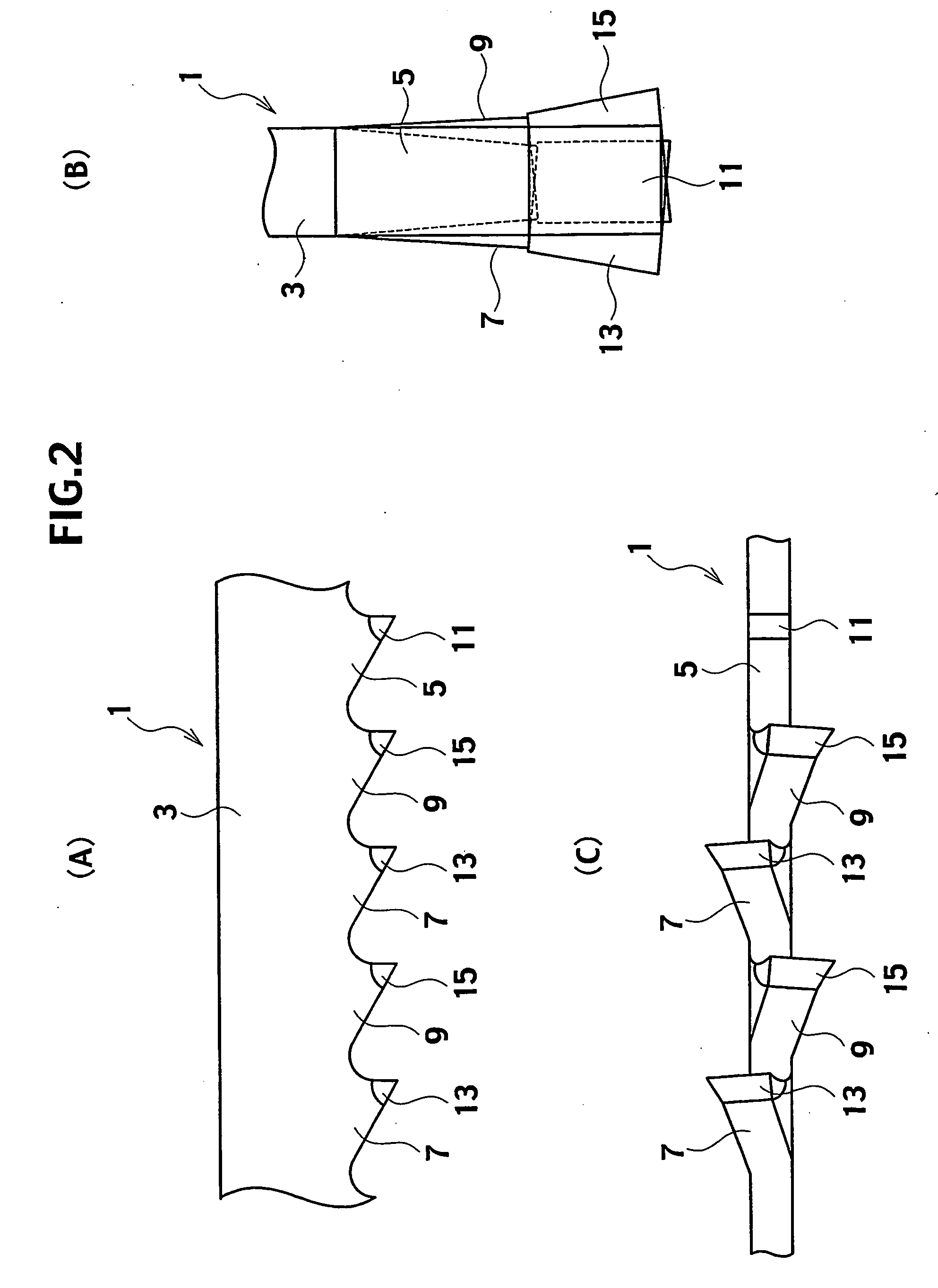

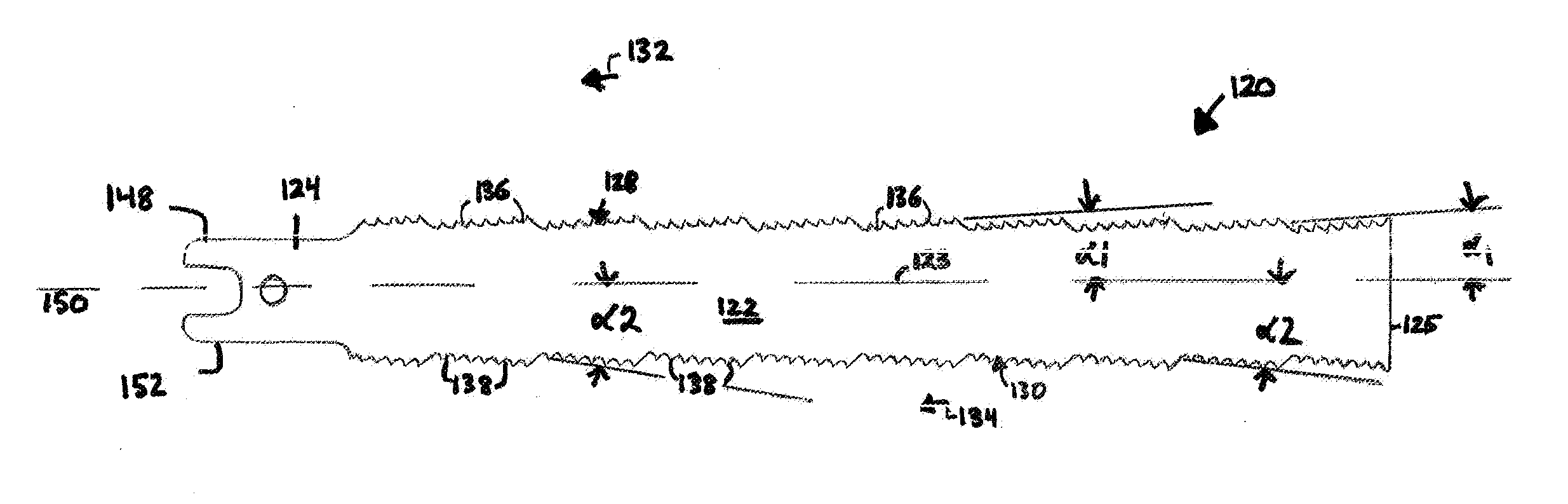

Reciprocating Saw Blade With Tangs On Each End And Related Method

ActiveUS20100218389A1Improve wear lifeReadily apparentMetal sawing devicesMetal sawing toolsReciprocating motionEngineering

A reciprocating saw blade has a first end with a first tang and a second end with a second tang. The first and second tangs are alternatively engageable with the chuck of a reciprocating saw. The reciprocating saw blade defines a substantially uniform cutting edge extending from approximately the first end to approximately the second end of the blade. The first tang is engageable with the chuck of the reciprocating saw for fixedly securing the first end of the blade to the reciprocating saw and forming with the second tang the free end of the saw blade. Alternatively, the second tang is engageable with the chuck of the reciprocating saw for fixedly securing the second end of the blade to the reciprocating saw and forming with the first tang the free end of the reciprocating saw blade drivable in a reciprocating motion by the reciprocating saw.

Owner:BLACK & DECKER INC

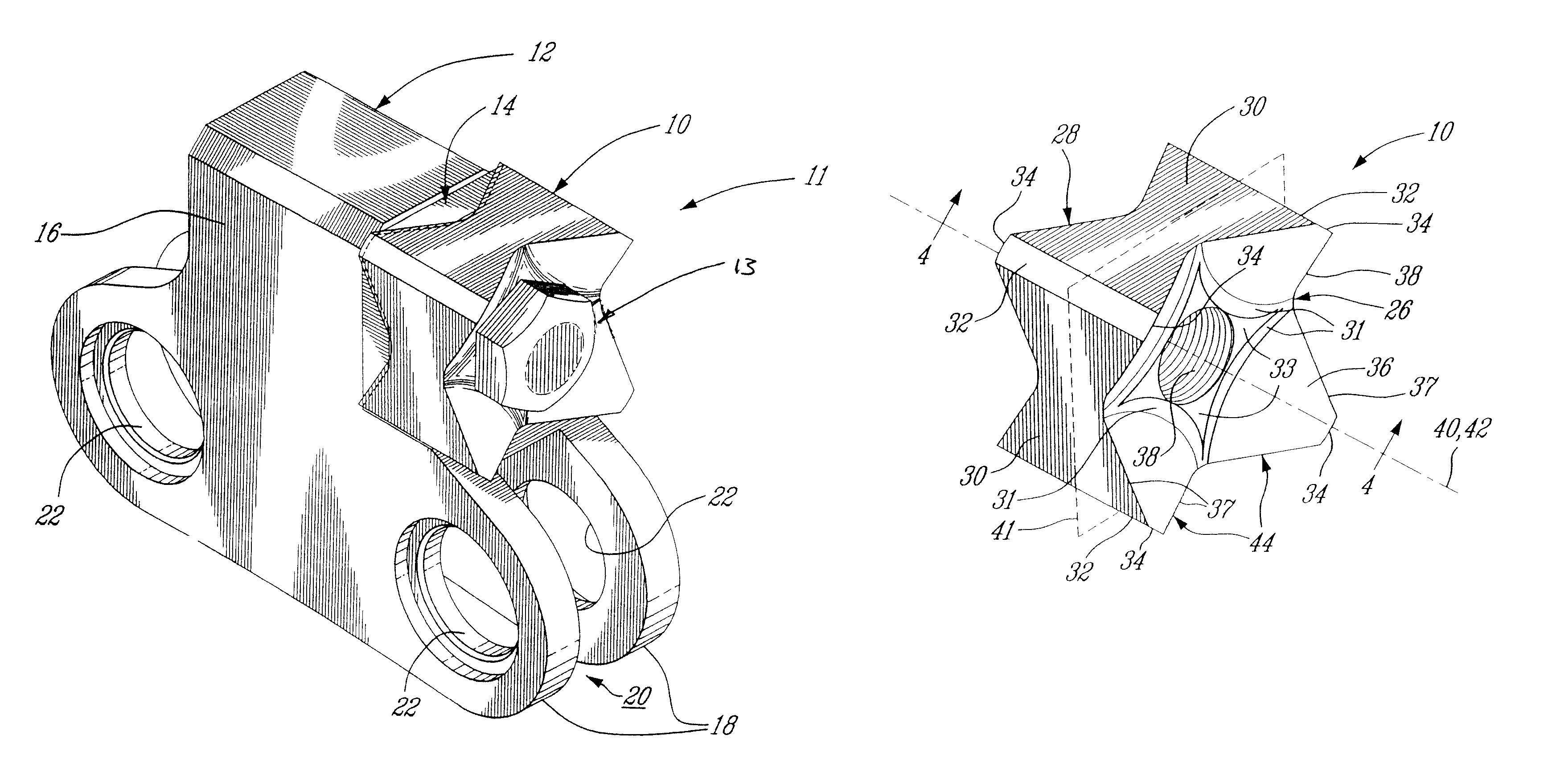

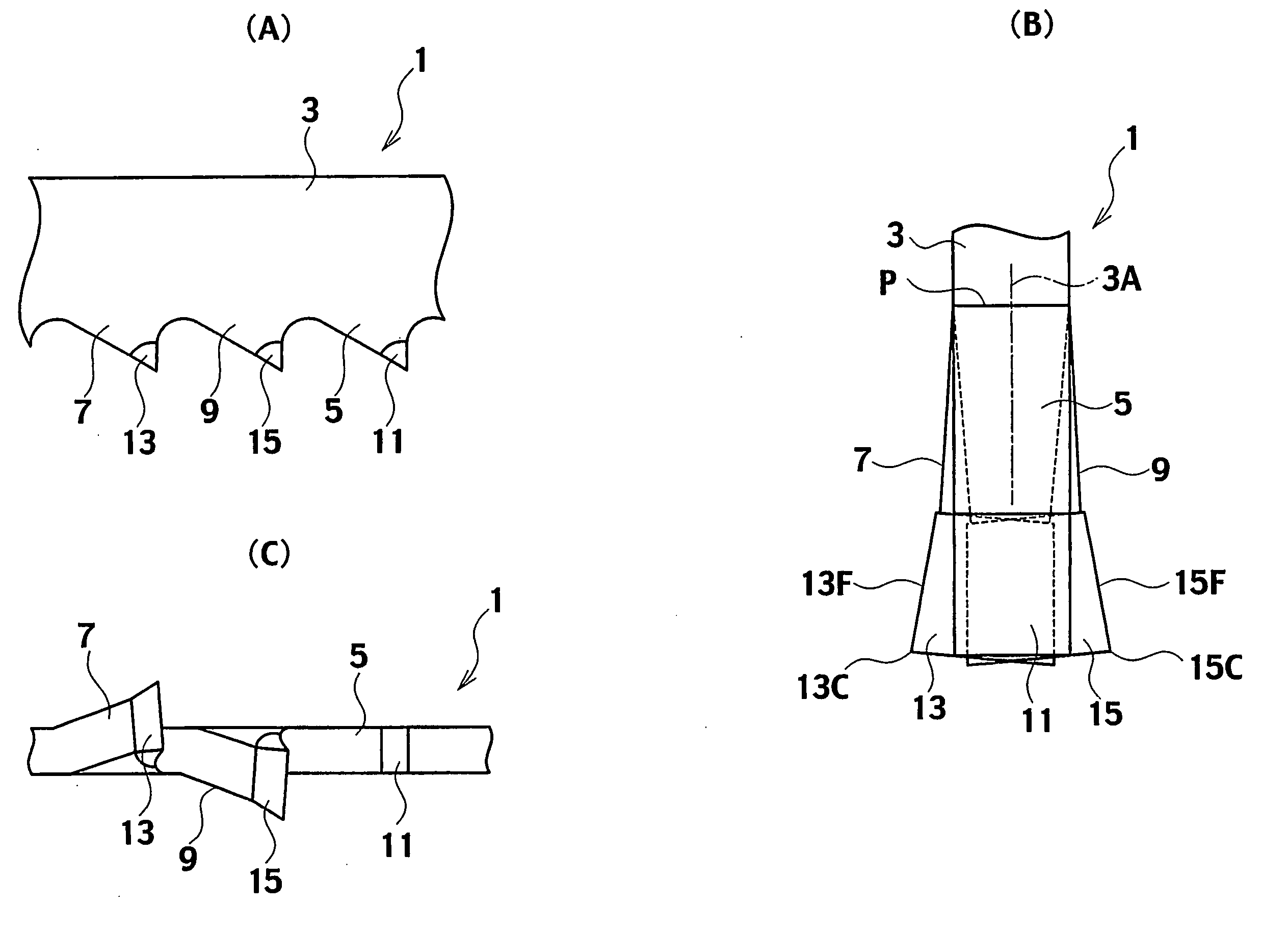

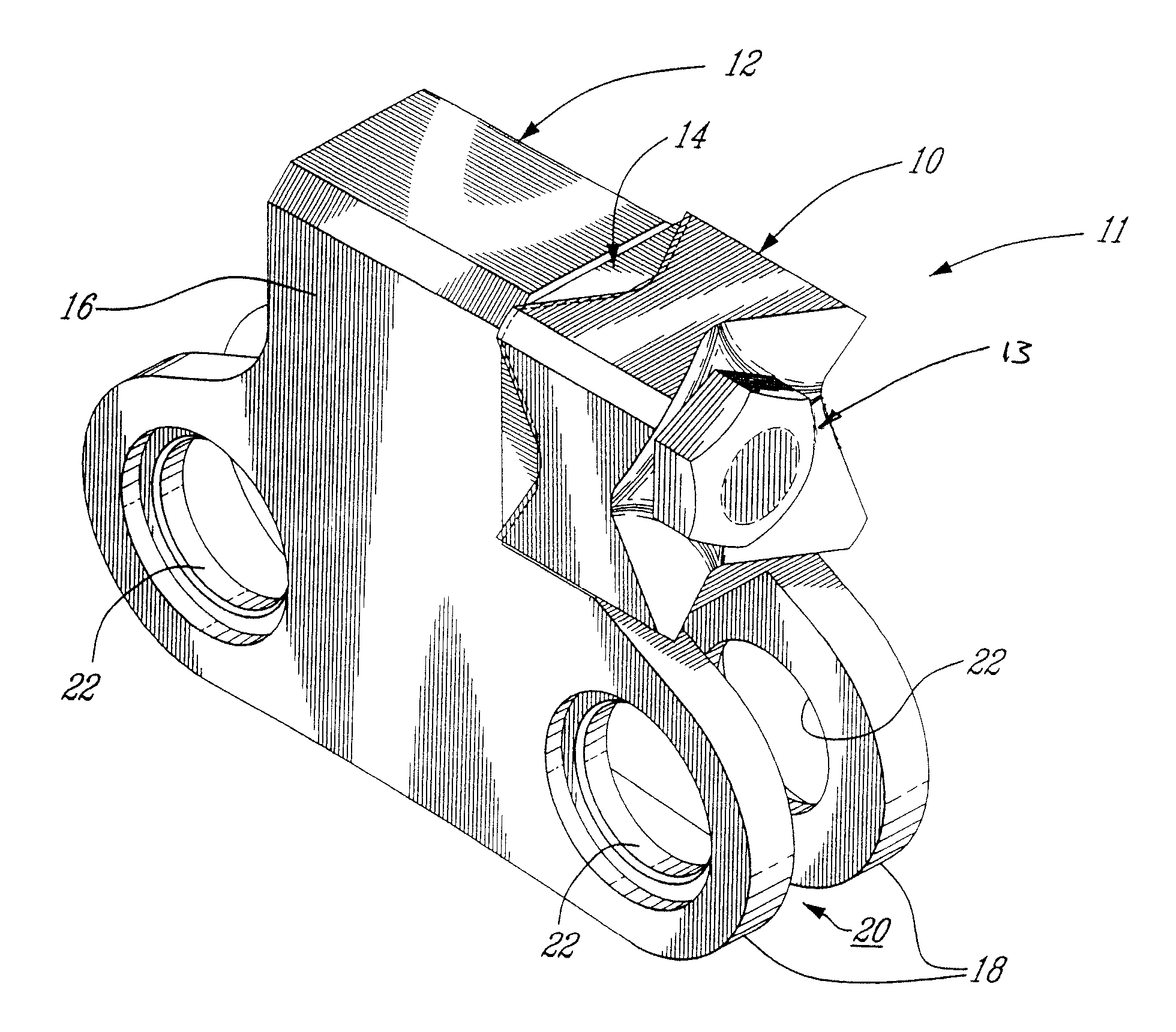

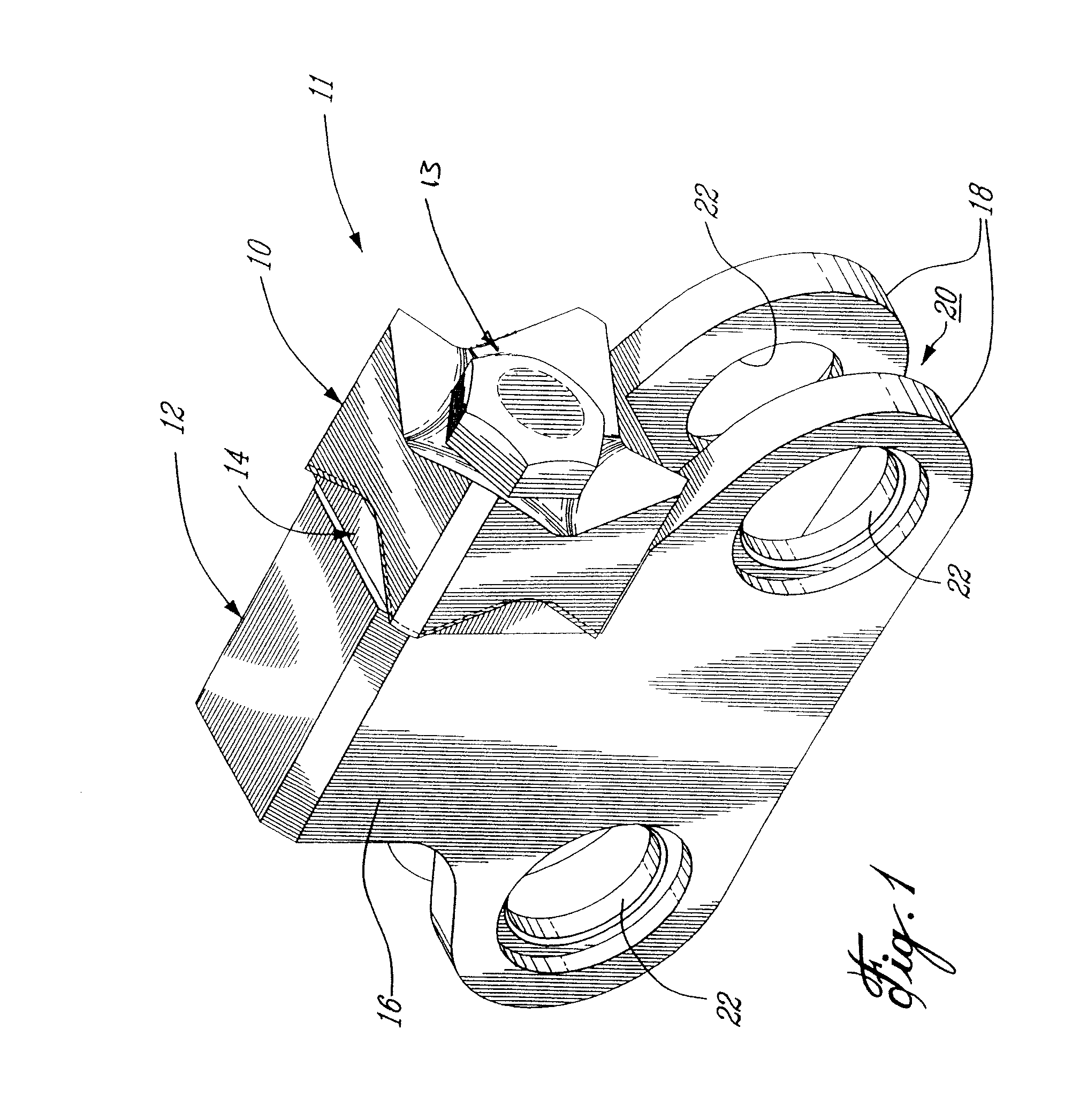

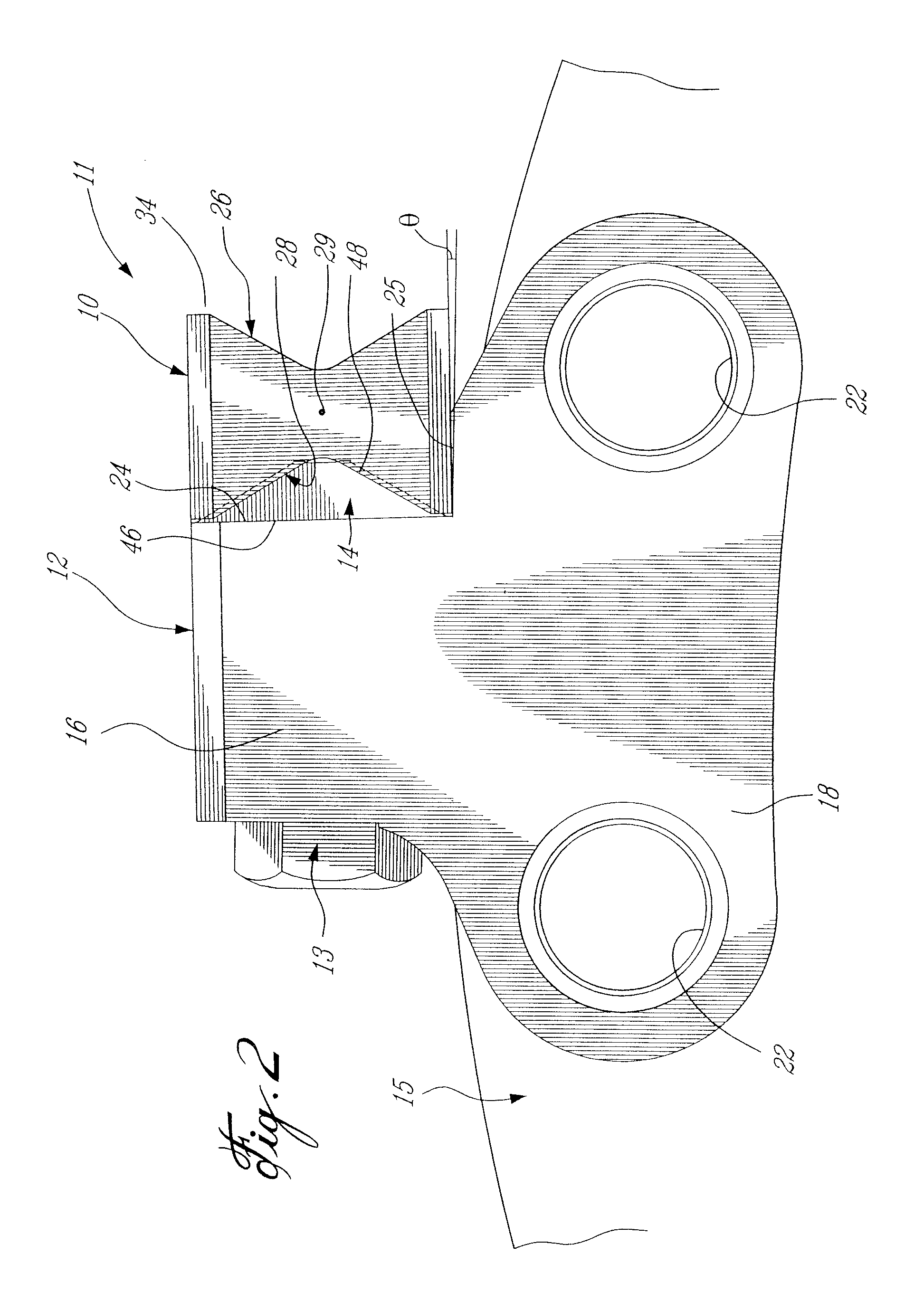

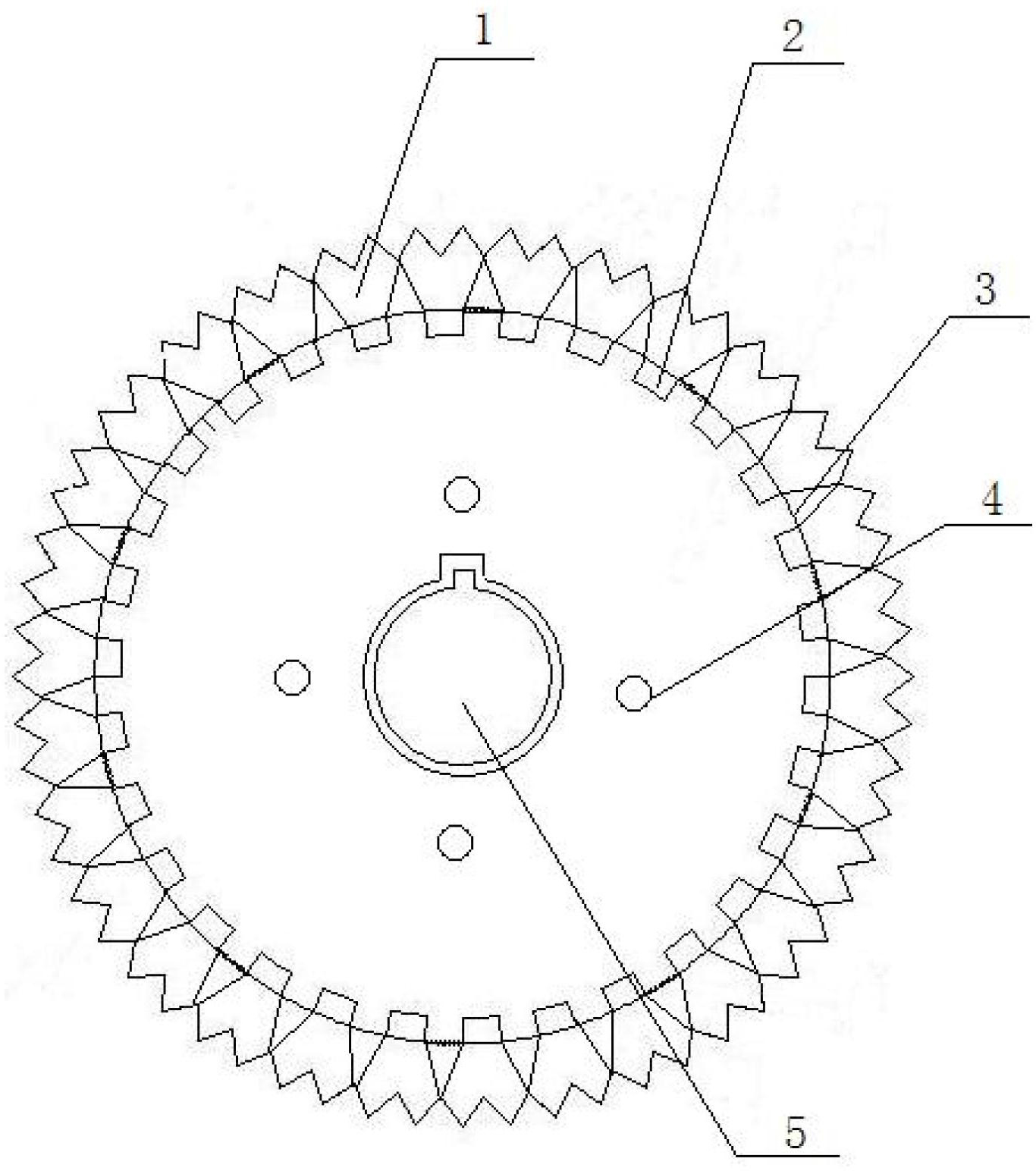

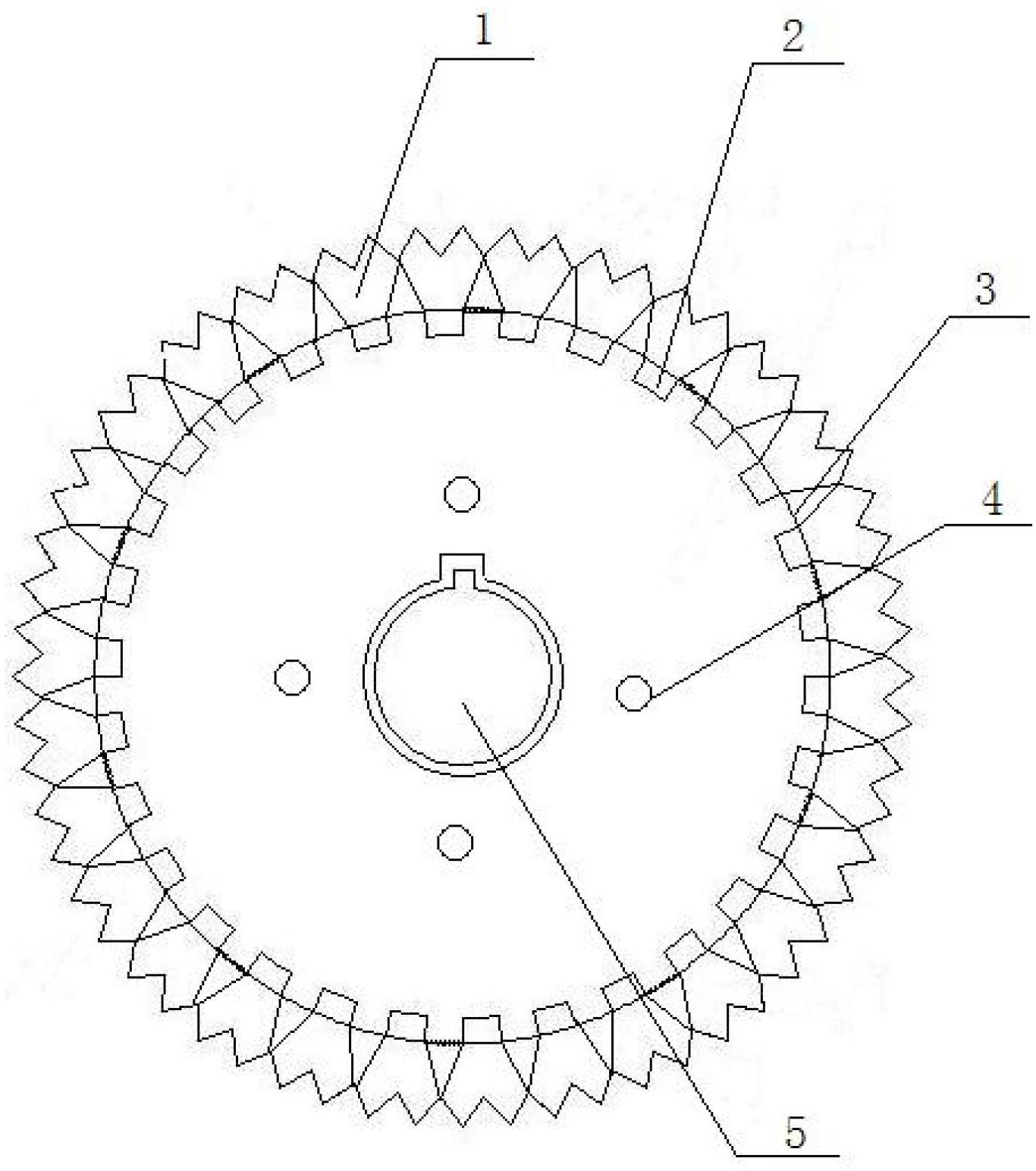

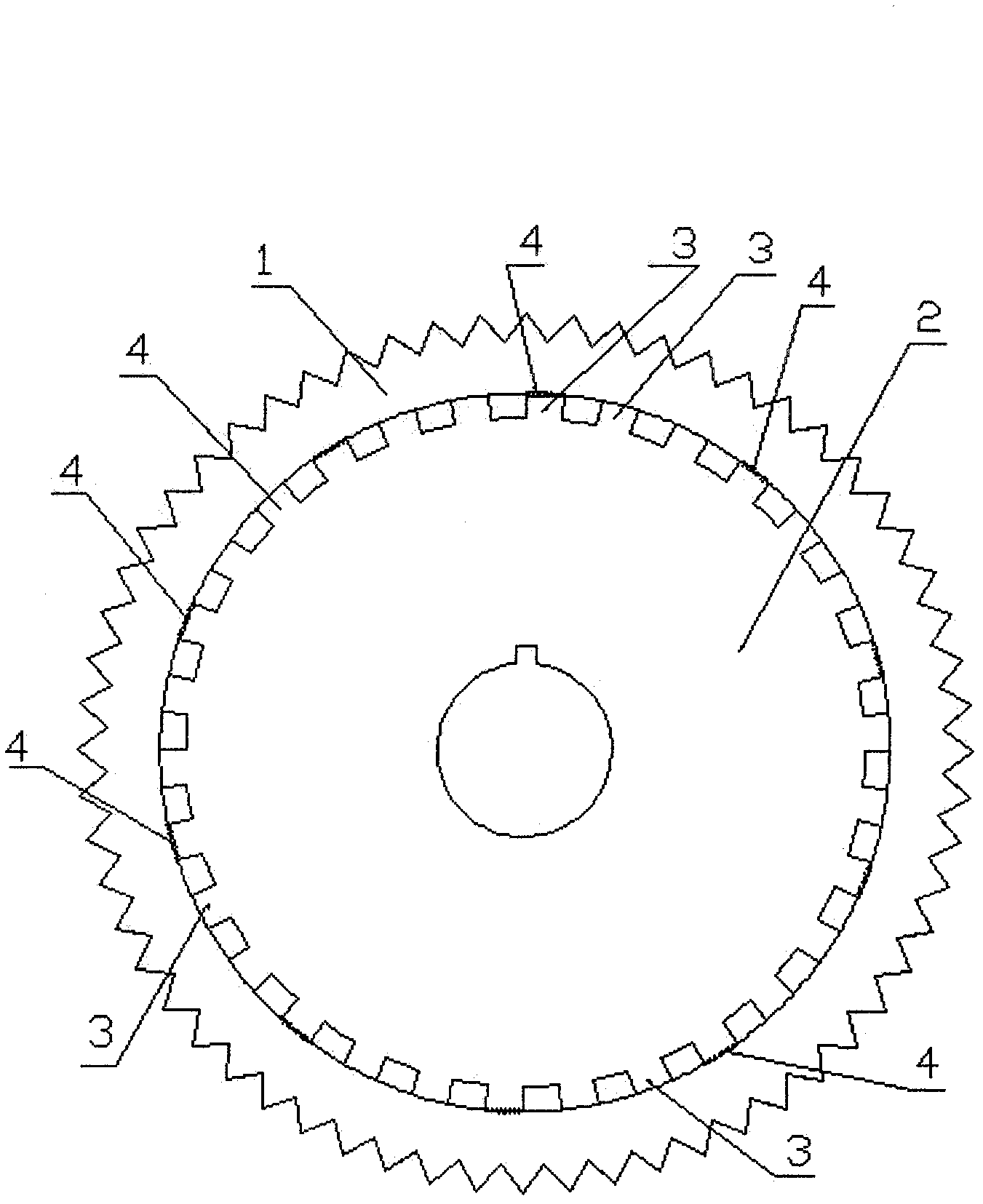

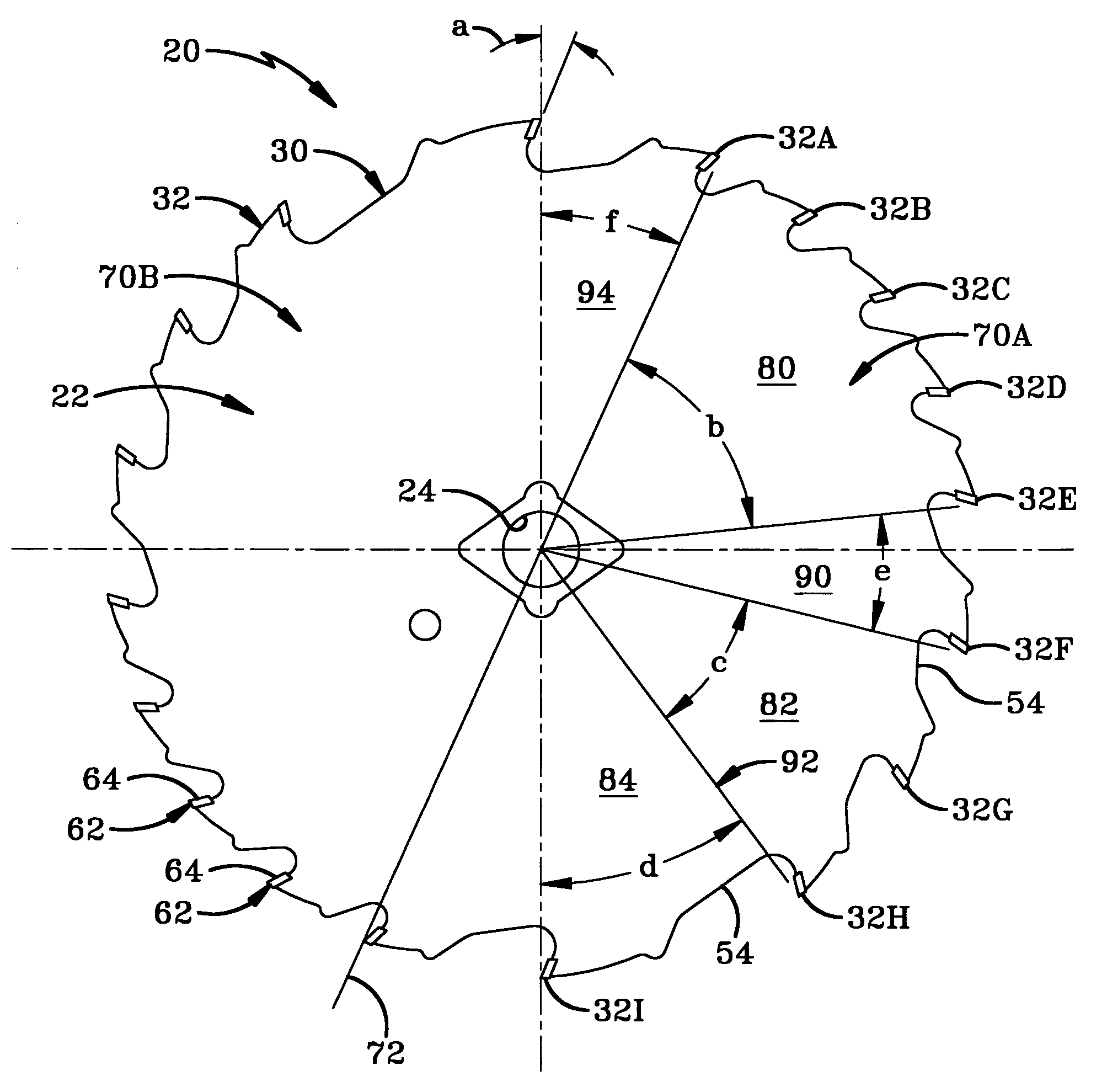

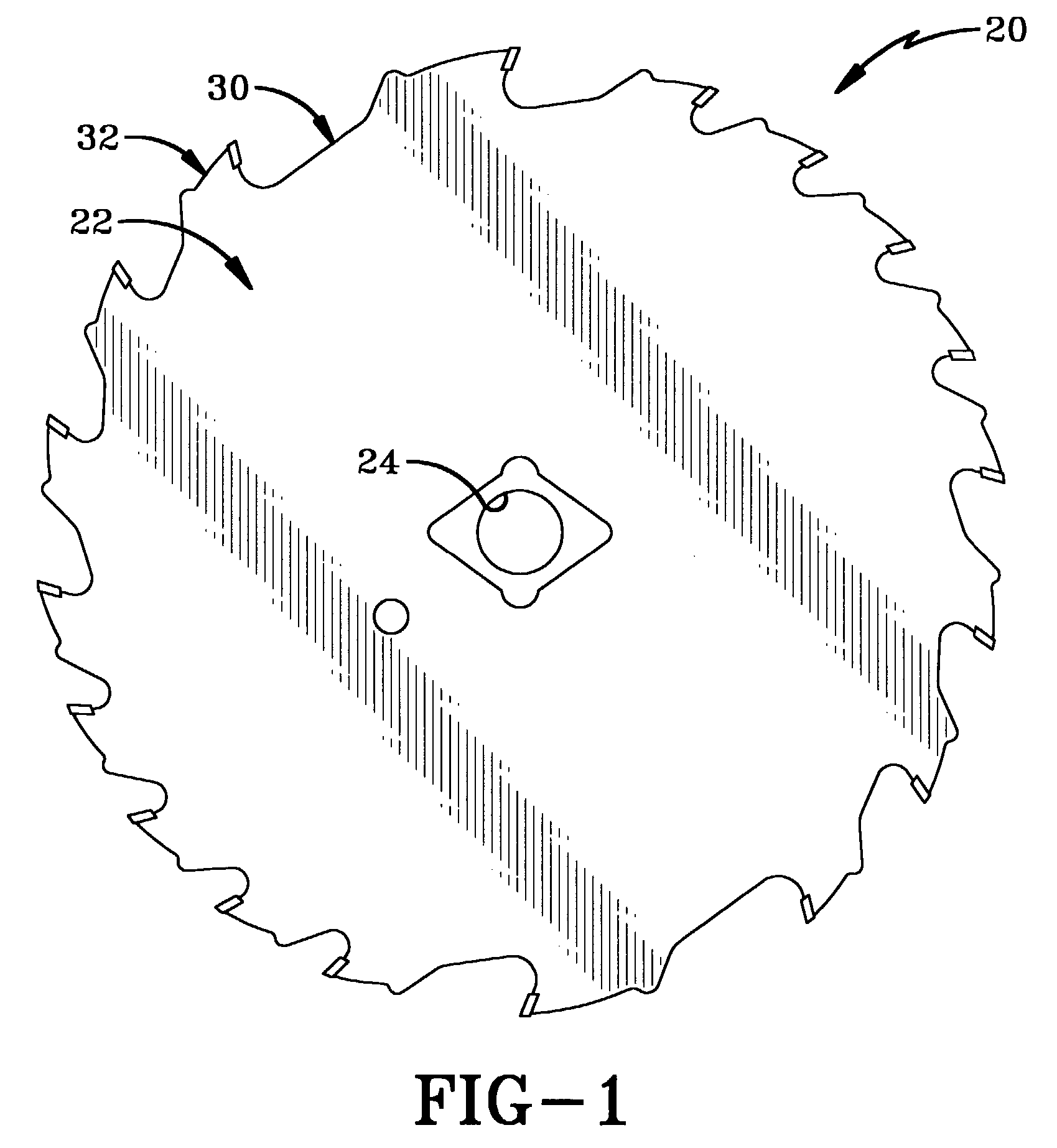

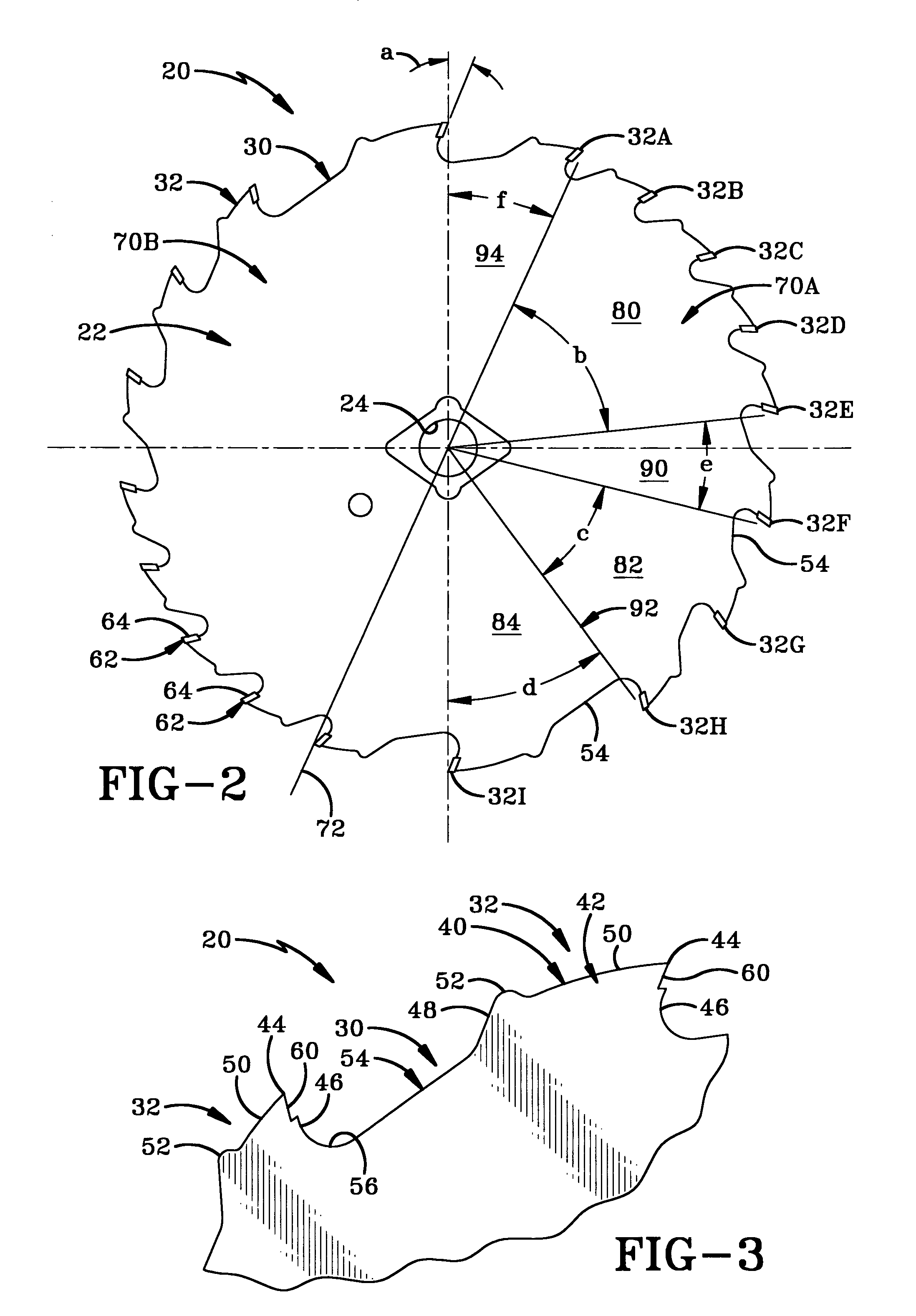

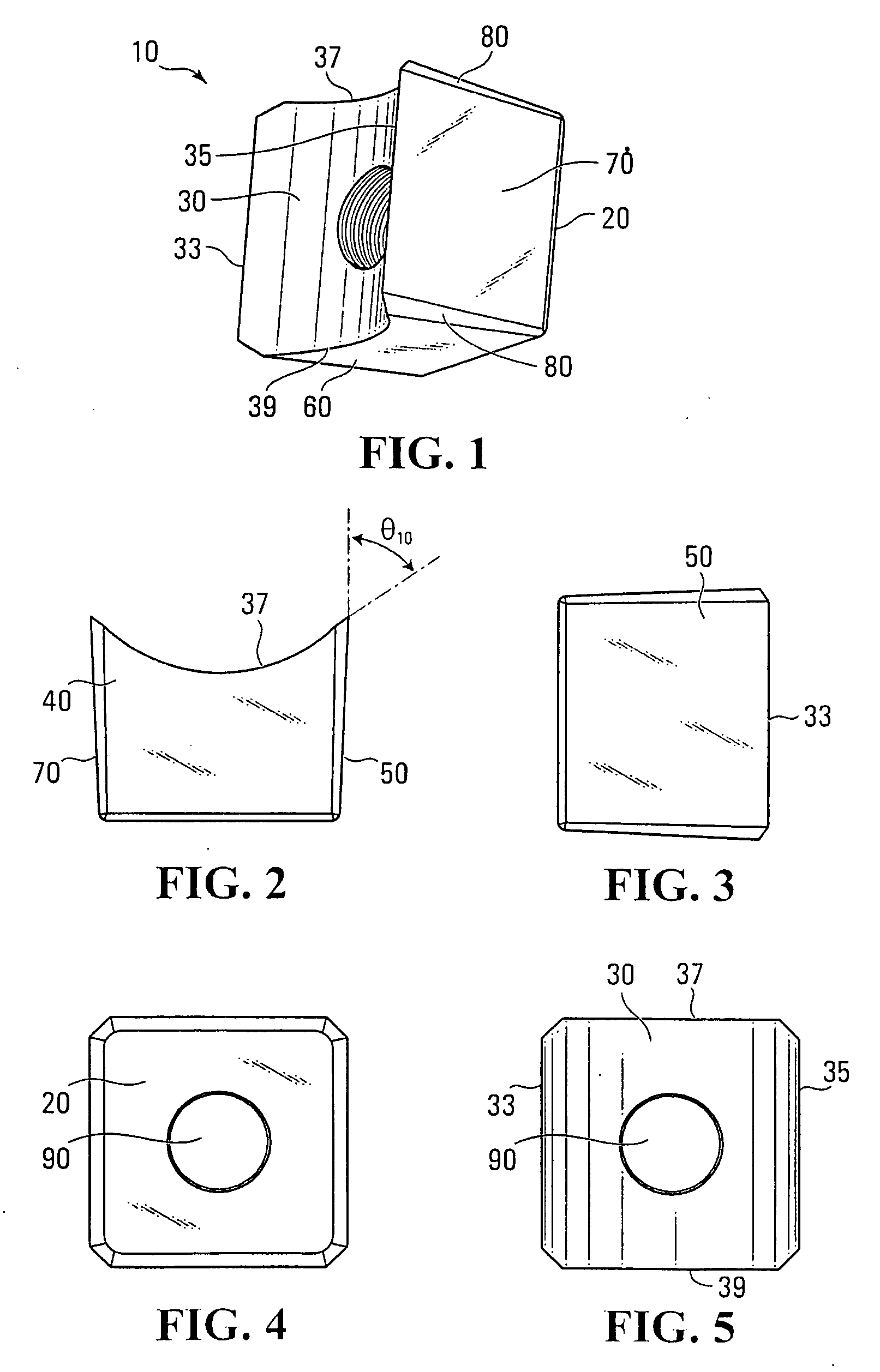

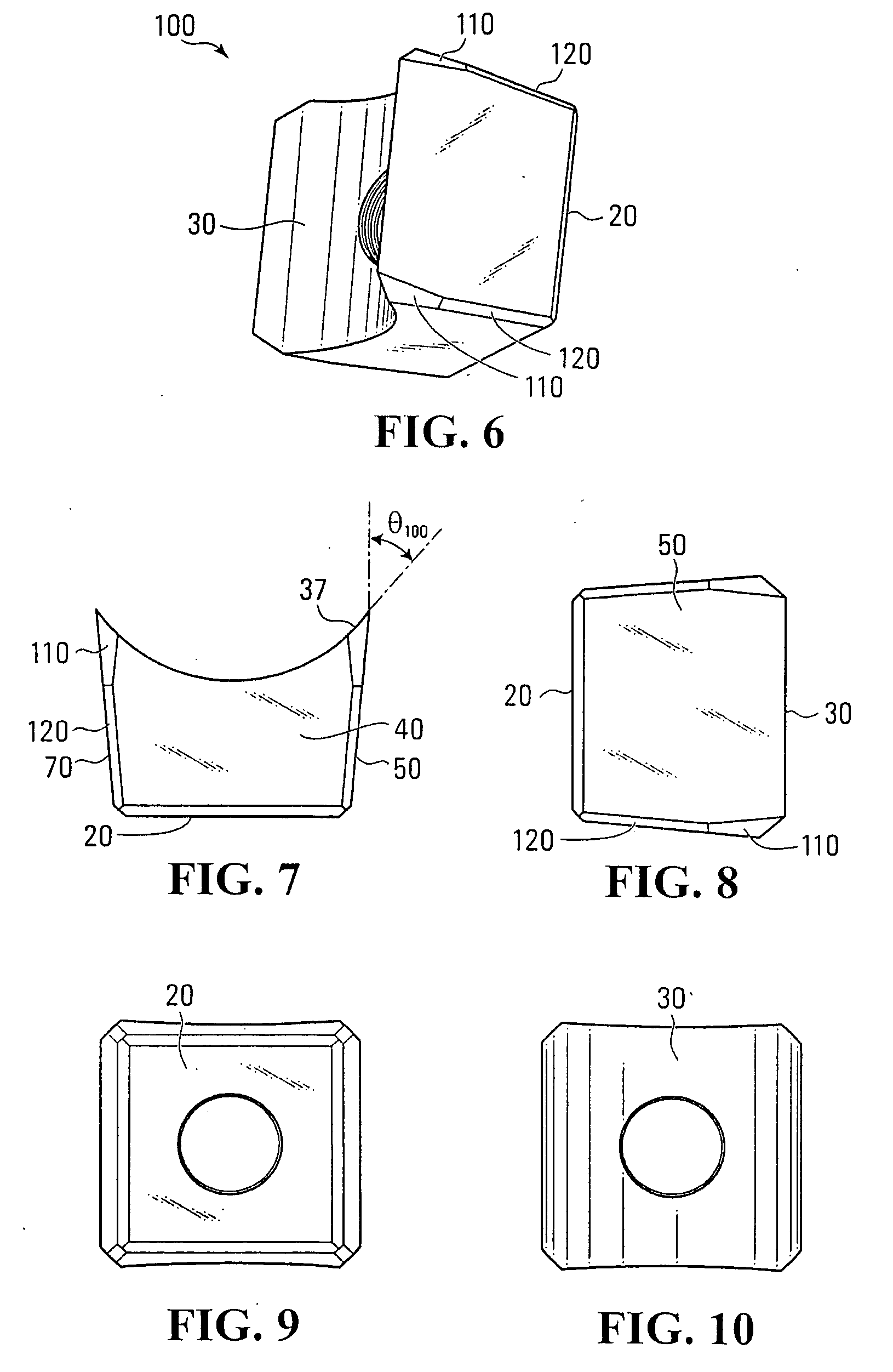

Reversible saw tooth

A replaceable saw tooth for a rotary cutting machine. The saw tooth comprises more than two cutting edges on each of two opposed faces thereof. More specifically, the saw tooth may comprise a body having two cutting faces disposed opposite each other and spaced apart by at least four side faces which are each parallel to an opposite one of the side faces. The side faces are parallel to a central axis extending between the two cutting faces. Four cutting edges are defined between the side faces and each of the two cutting faces.

Owner:QUADCO

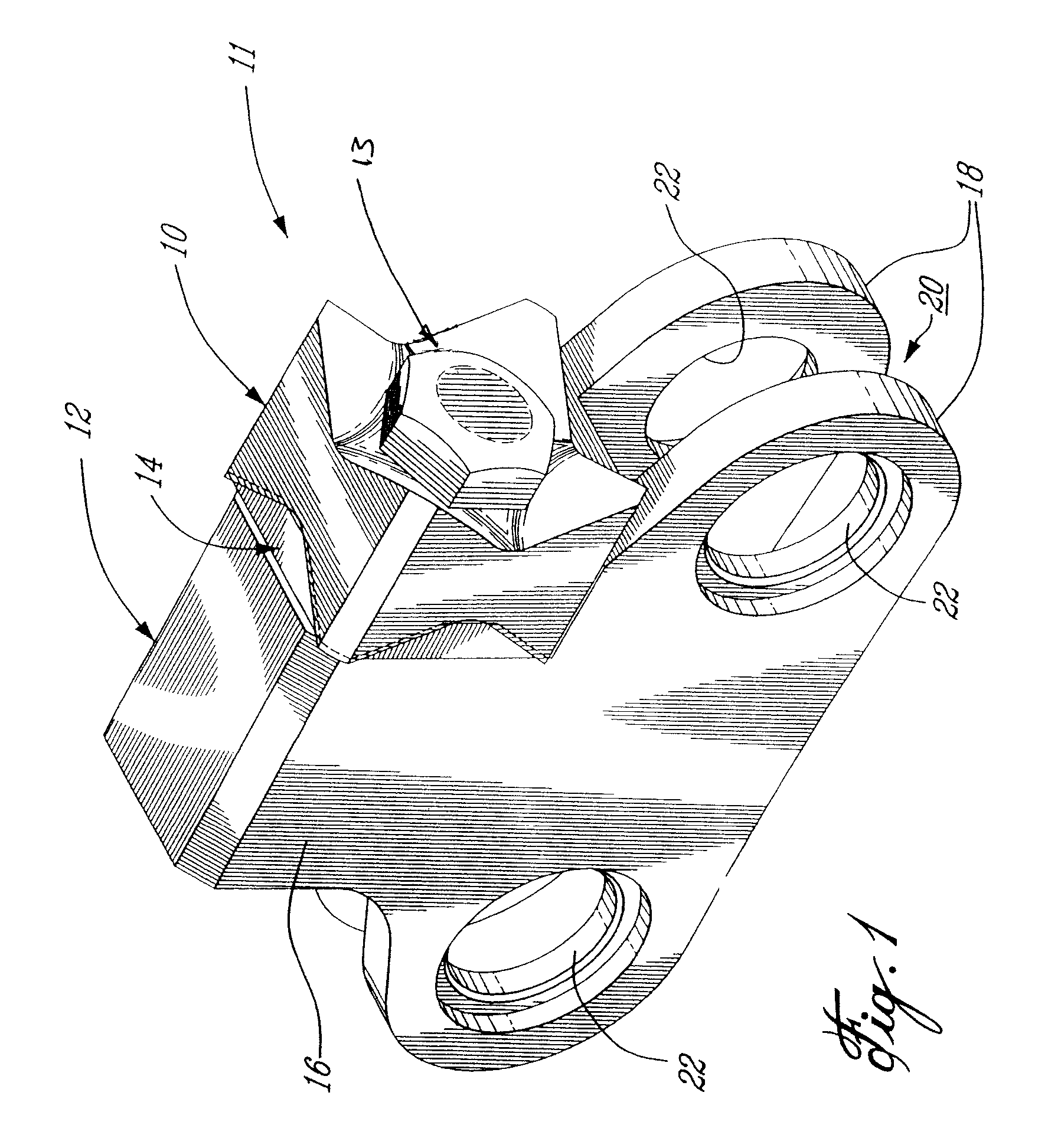

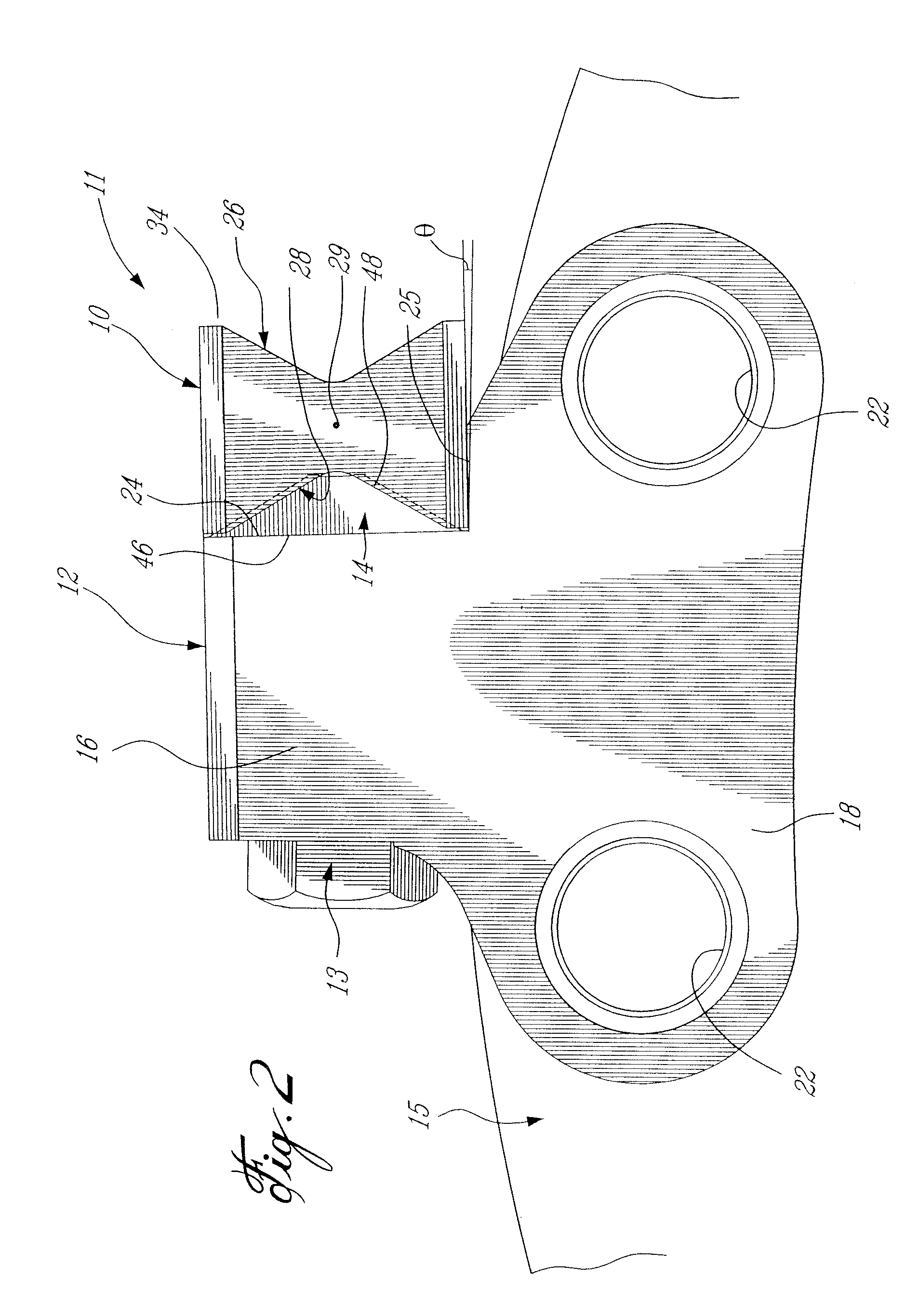

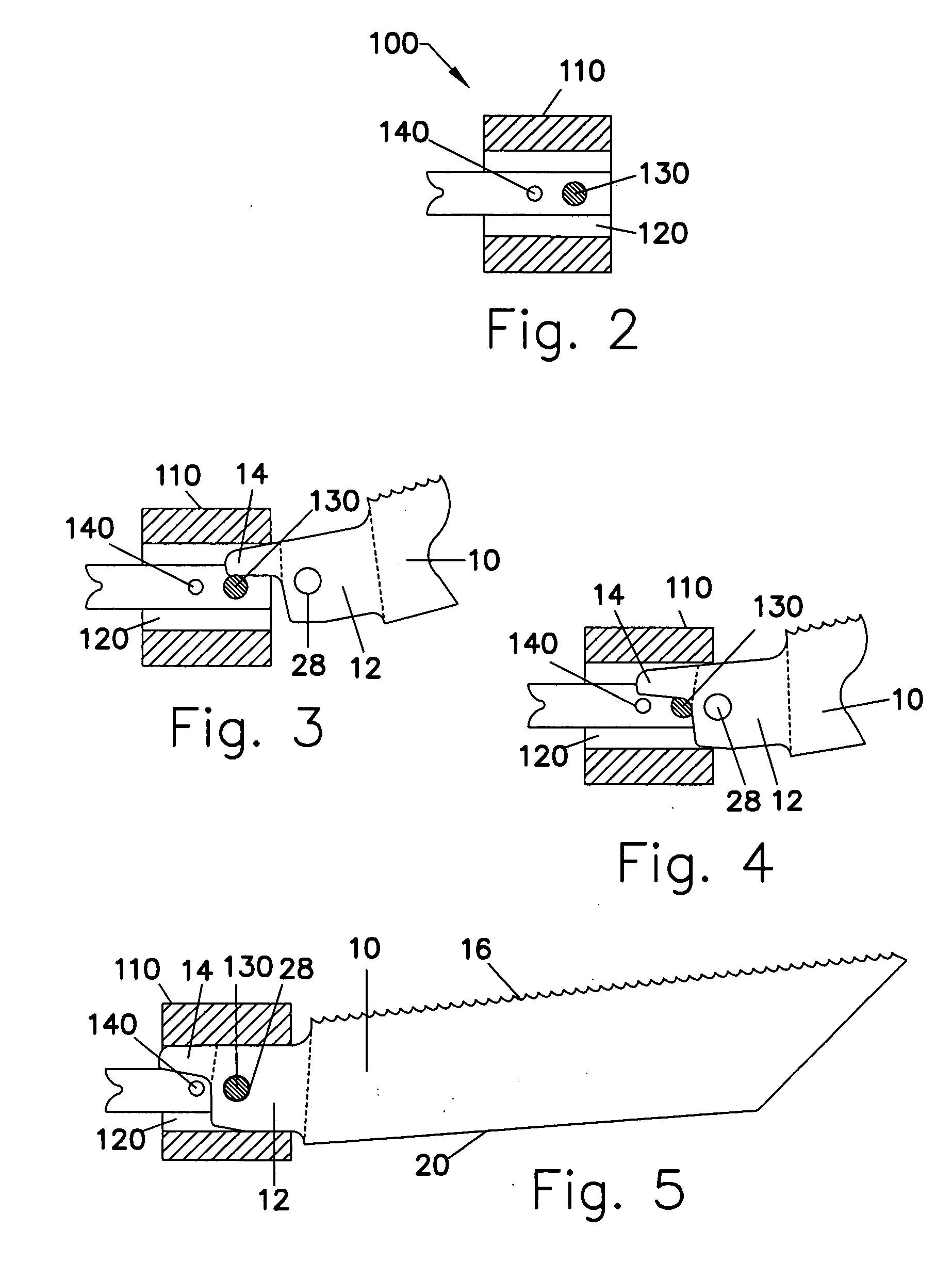

Reciprocating saw blade with tapered tang stem

InactiveUS7600458B2Facilitates effective and efficient engagementIncrease resistanceMetal sawing devicesMetal sawing toolsEngineeringCutting force

Owner:BLACK & DECKER INC

Wood cutting band saw blade

InactiveUS8113100B1Minimizing dust collectionReadily apparentMetal sawing devicesMetal sawing toolsWood cuttingEngineering

A wood cutting band saw blade includes a cutting edge and a back edge, wherein the cutting edge is defined by a plurality of teeth spaced relative to each other. The plurality of teeth include a plurality of set teeth each having a tip, each defining a bend plane, and each including a shelf located at least partially between the tip and the bend plane for reducing saw dust passing to the kerf and accumulating on the band saw blade. Each of the set teeth may define a relief surface and a cutting surface where the relief surface extends from one side of the tip in a direction opposite that of the movement of the band saw blade and the cutting surface extends from another side of the tip. The shelf includes a shelf surface extending from the cutting surface and may terminate in a shelf tip.

Owner:BLACK & DECKER INC

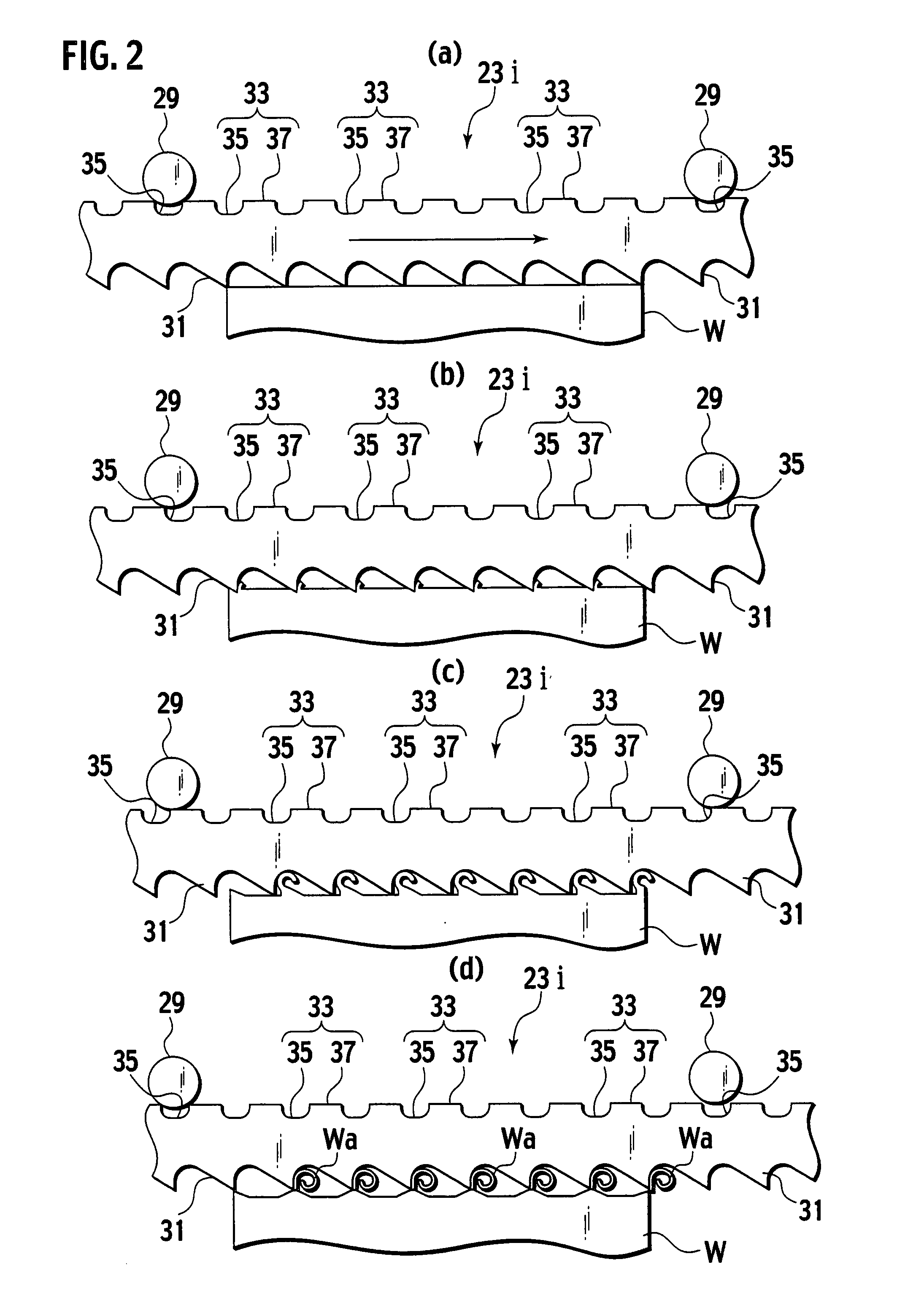

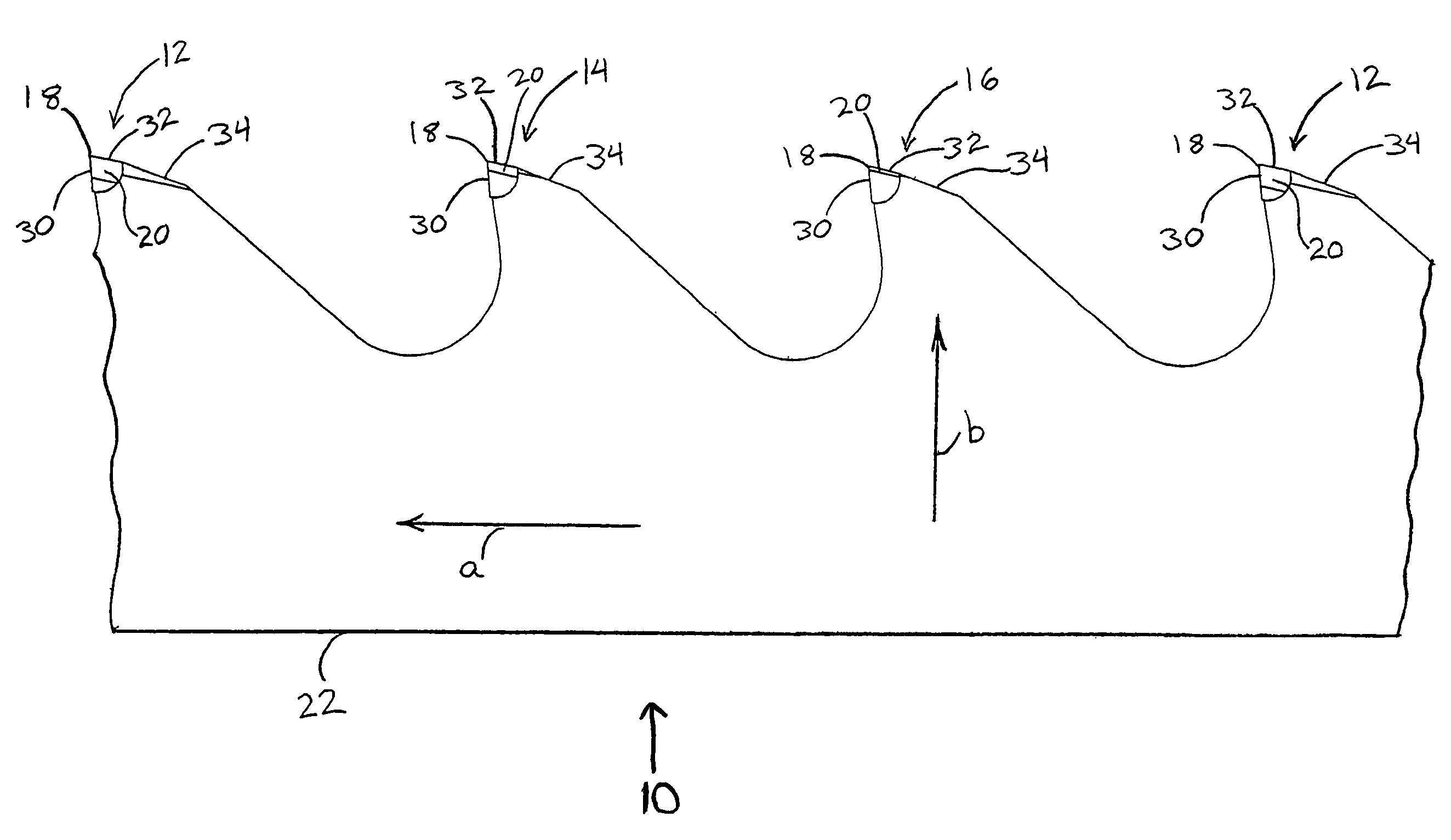

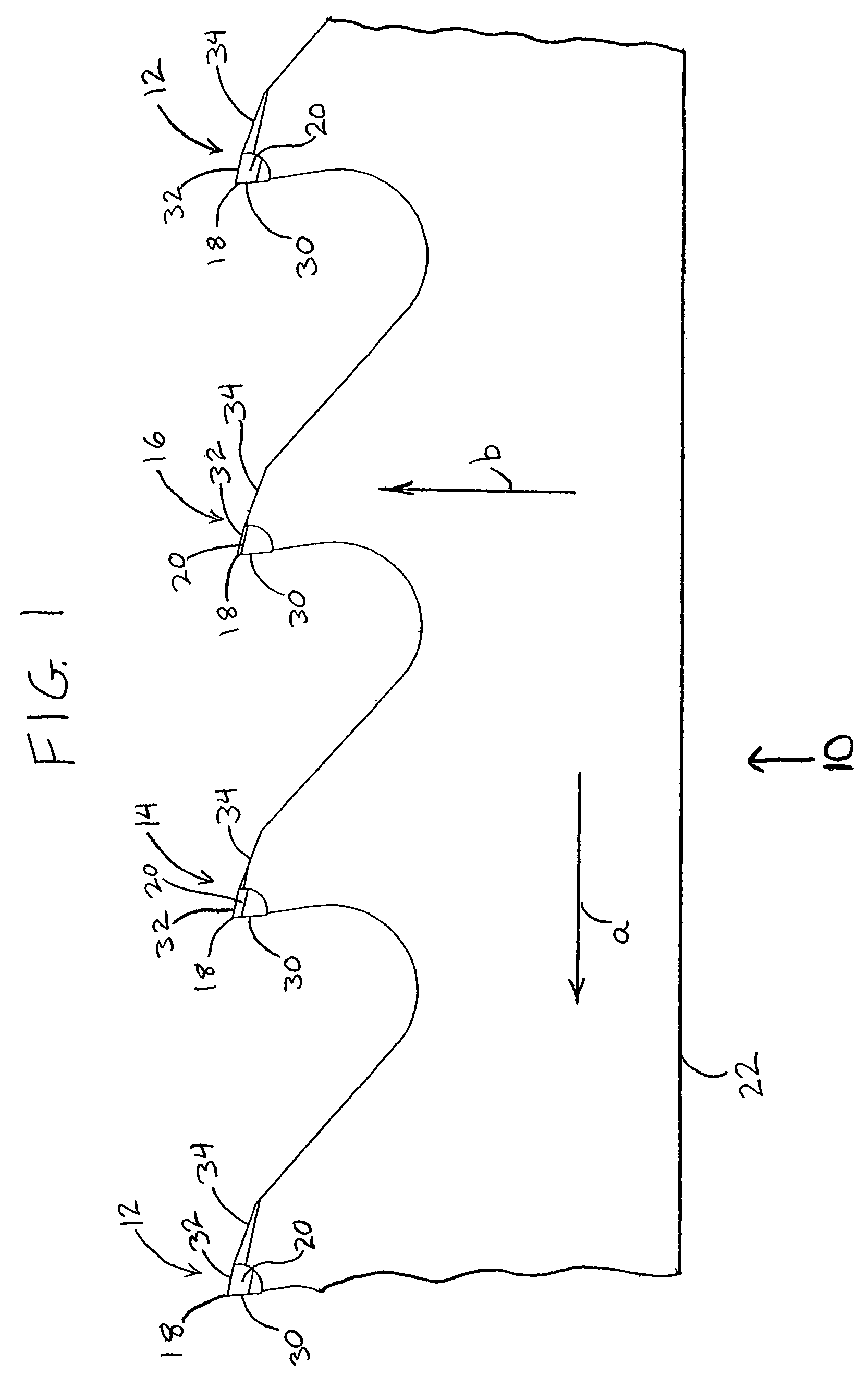

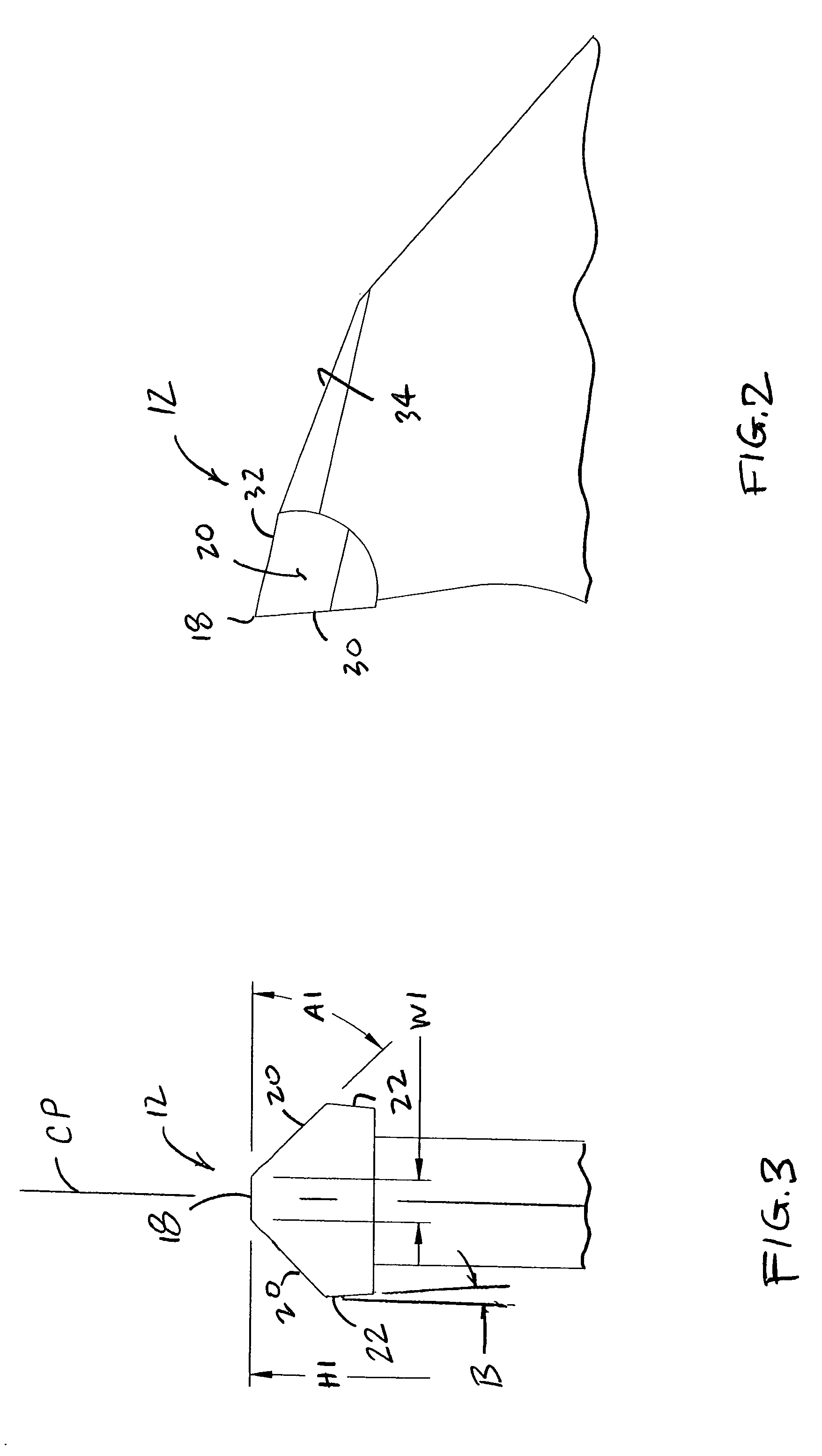

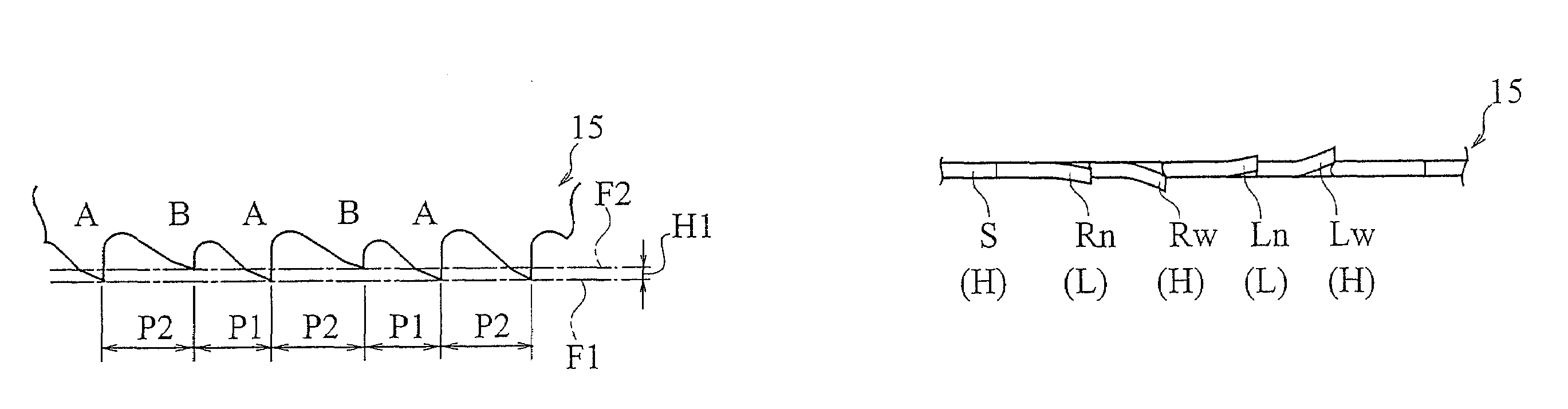

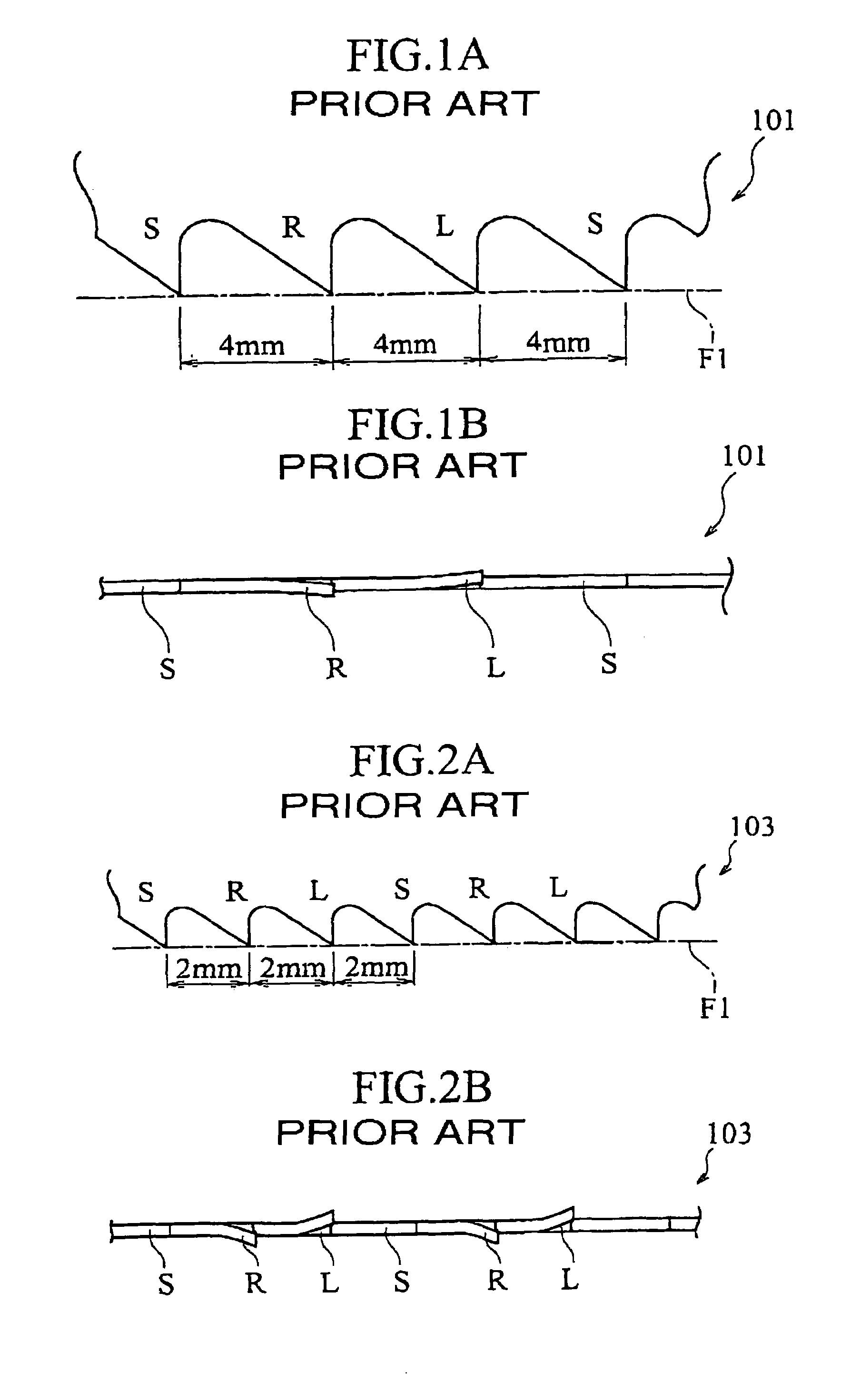

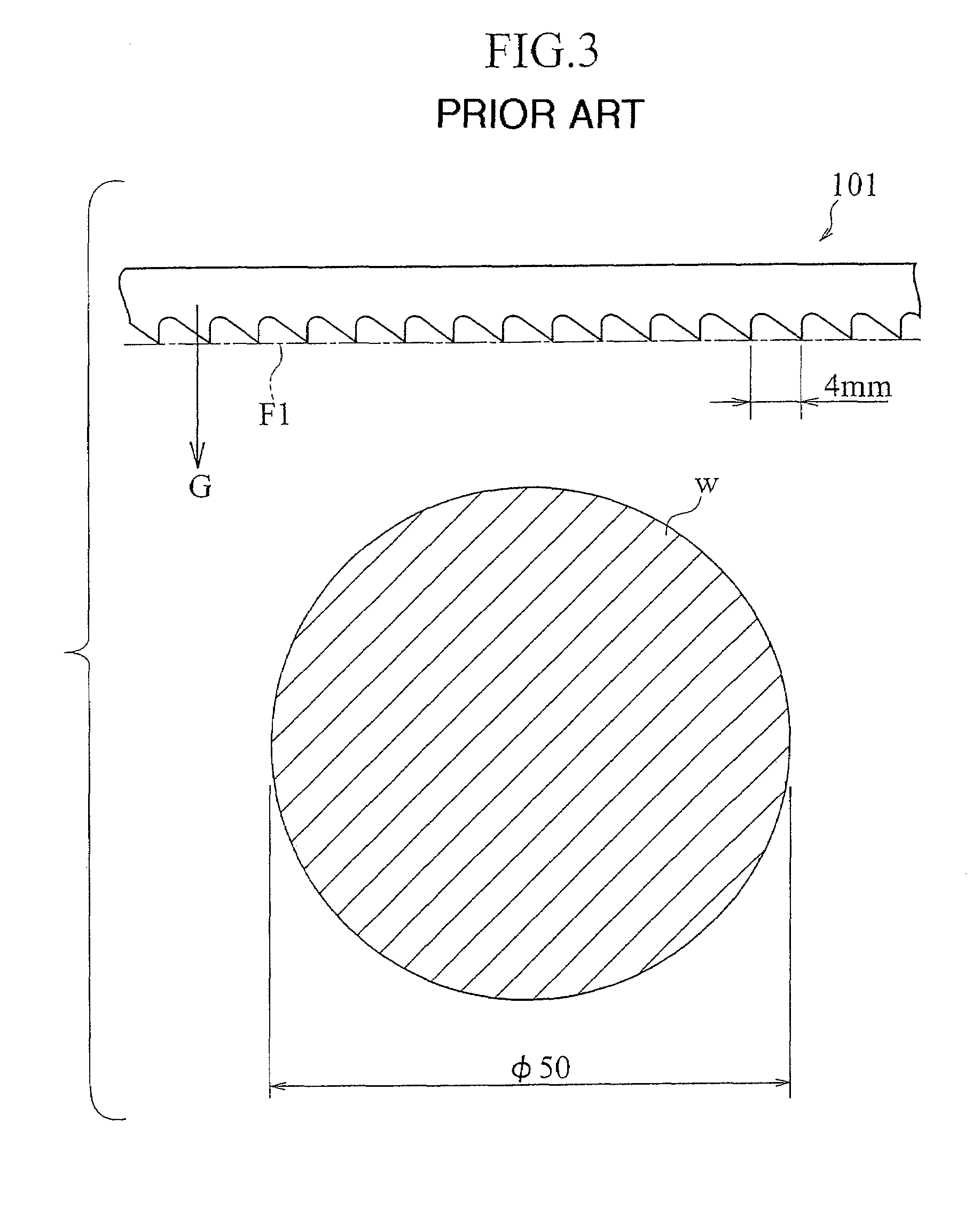

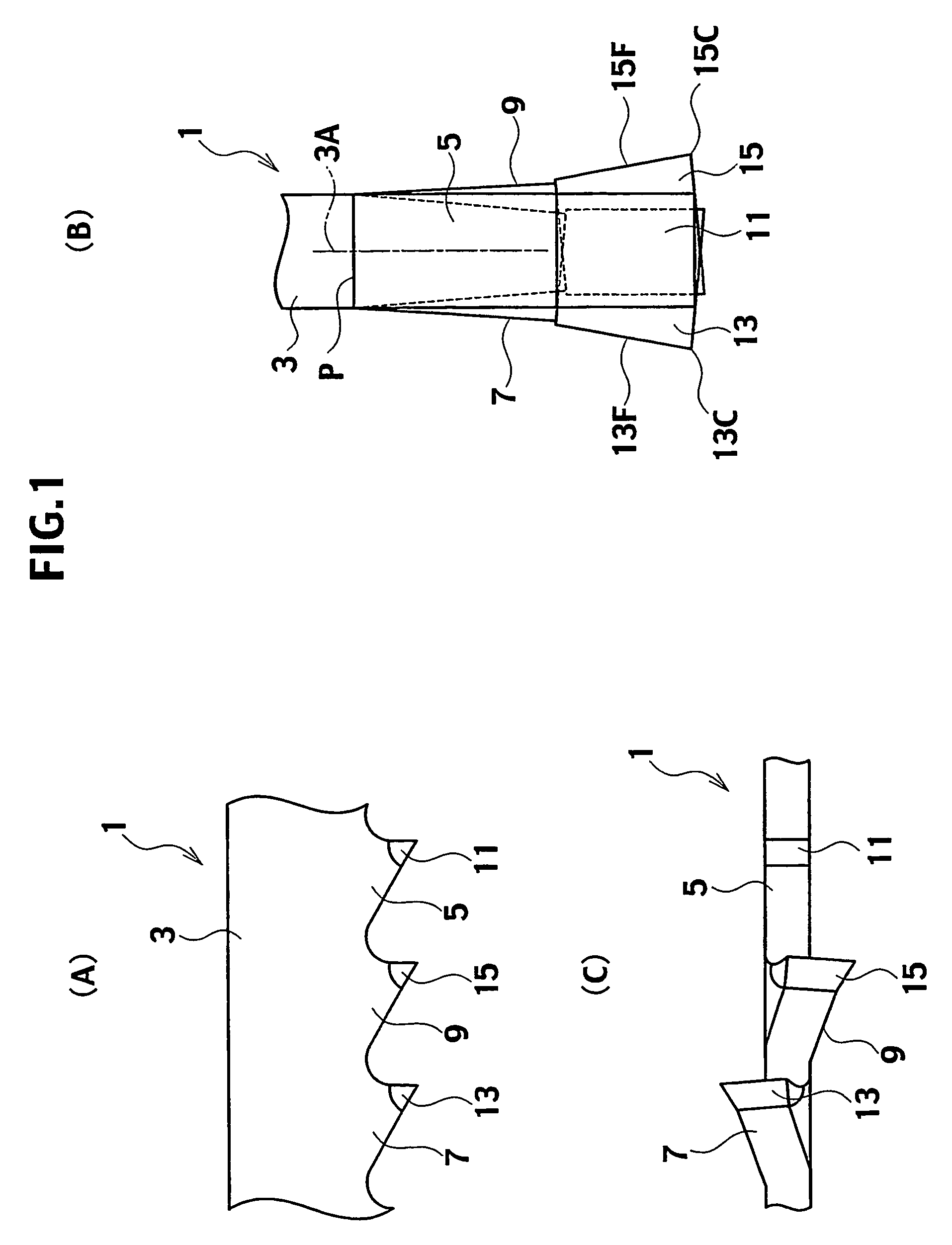

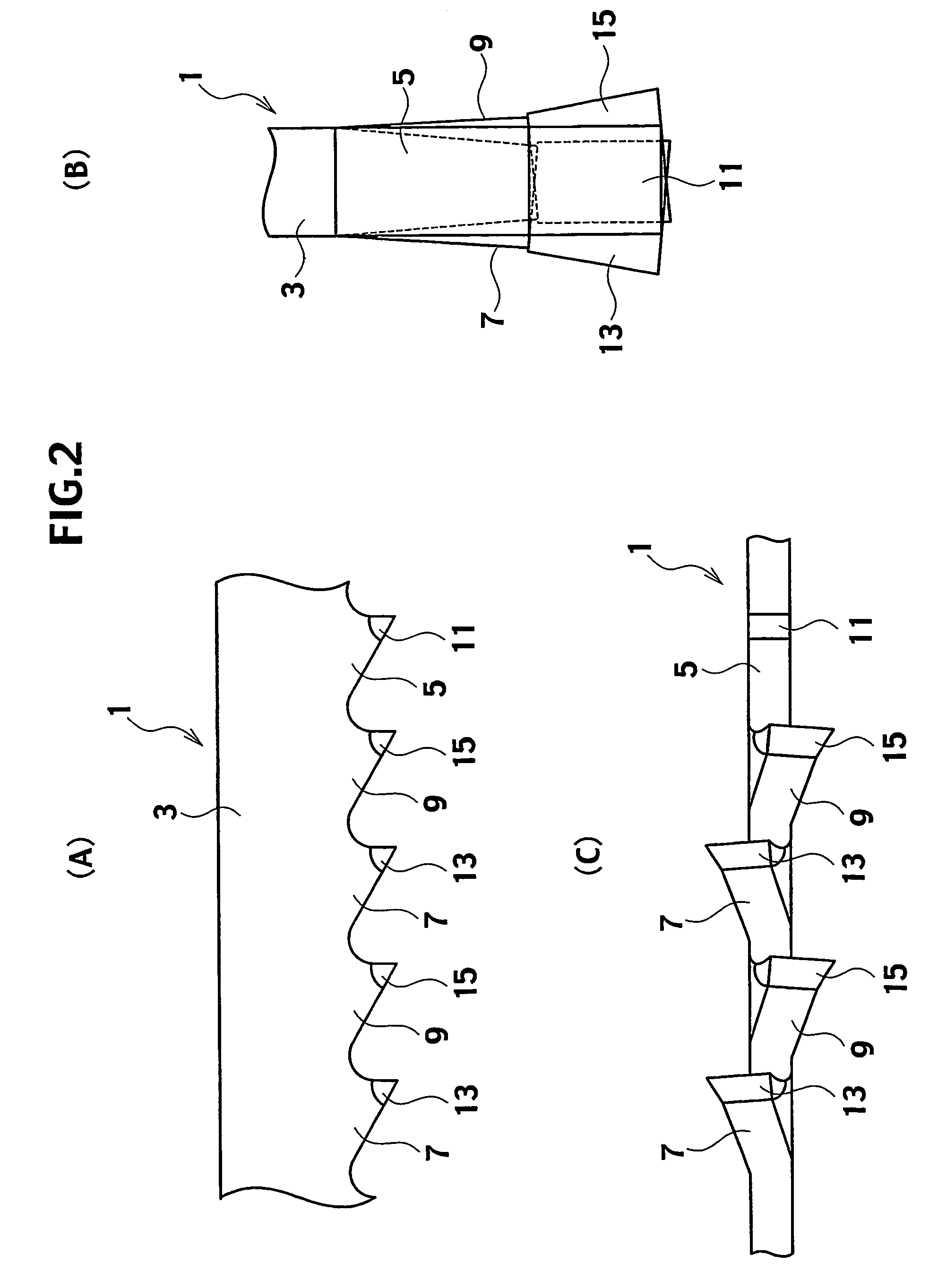

Band Saw Blade and Cutting Method

ActiveUS20080121079A1Reduce cut lengthReduce resistanceMetal sawing devicesMetal sawing toolsEngineering

Concave / convex portions are consecutively formed on a back of a band saw blade. The concave / convex portions include concave portions engageable with and disengageable from a backup guide of a band saw guide unit, and convex portions adjacent to the concave portions. A length of each of the concave / convex portions is configured to be equal to or smaller than four times a maximum pitch of a tooth top of each tooth.

Owner:AMADA CO LTD

Band saw blade

Owner:HAKANSSON WILLIAM +1

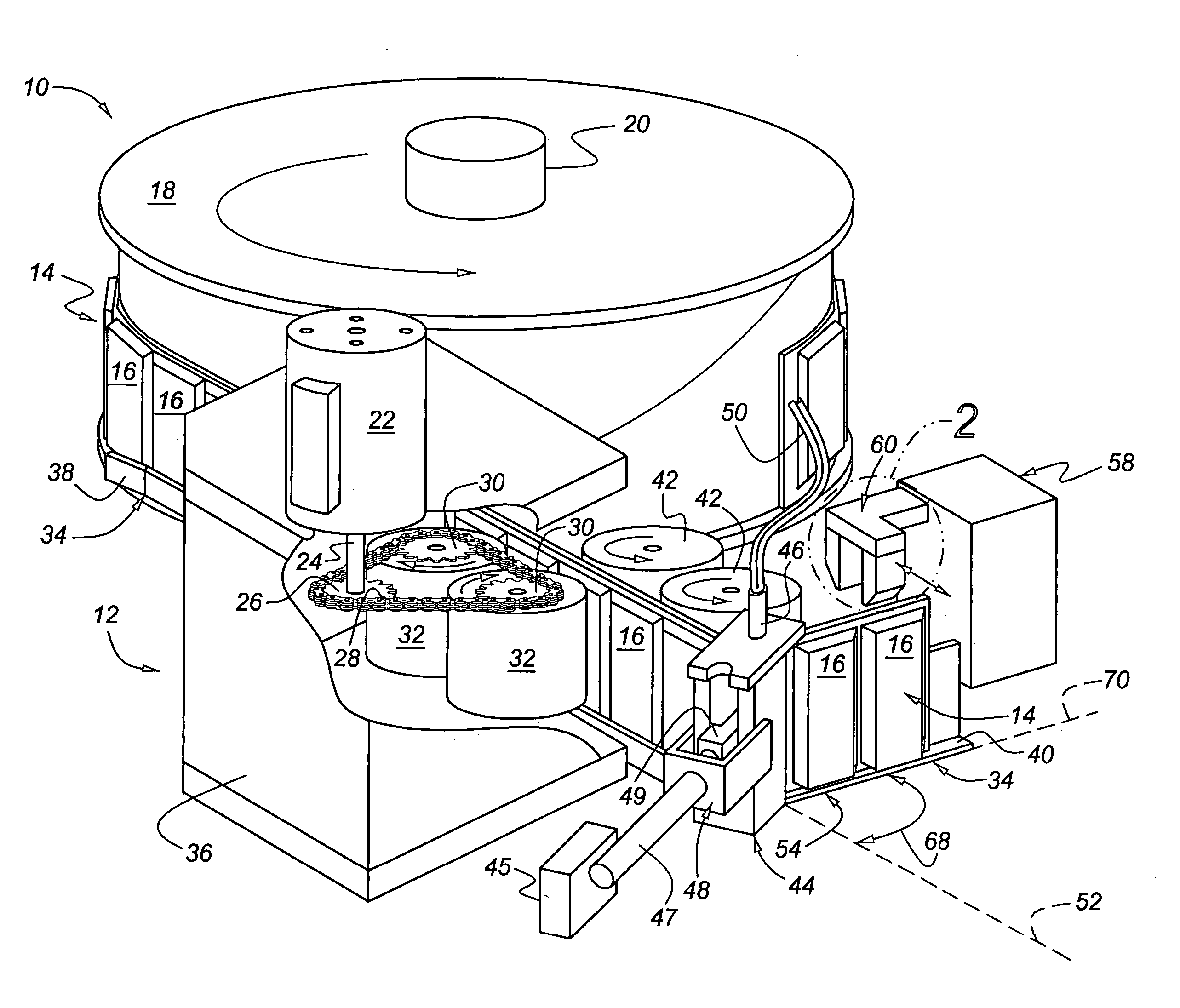

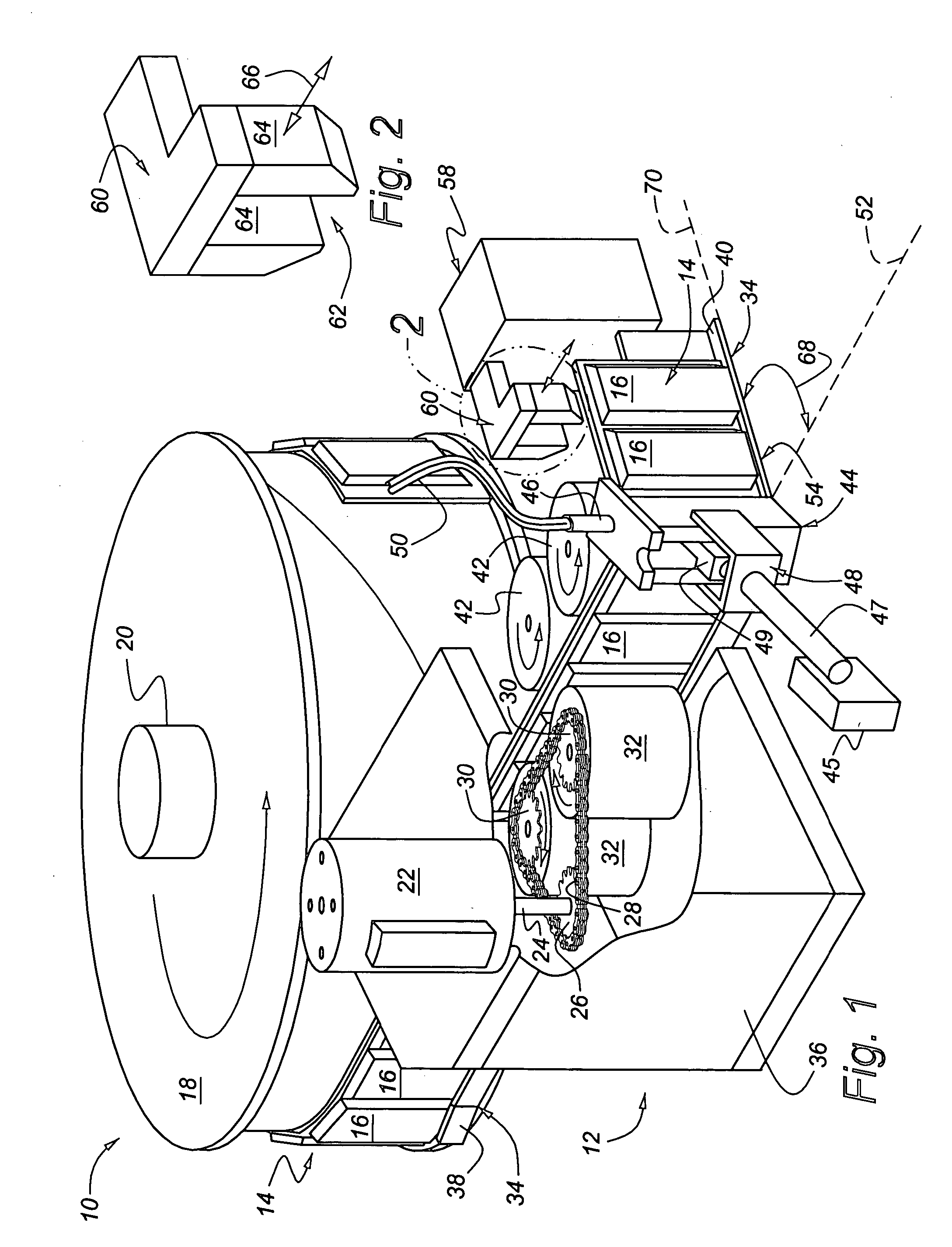

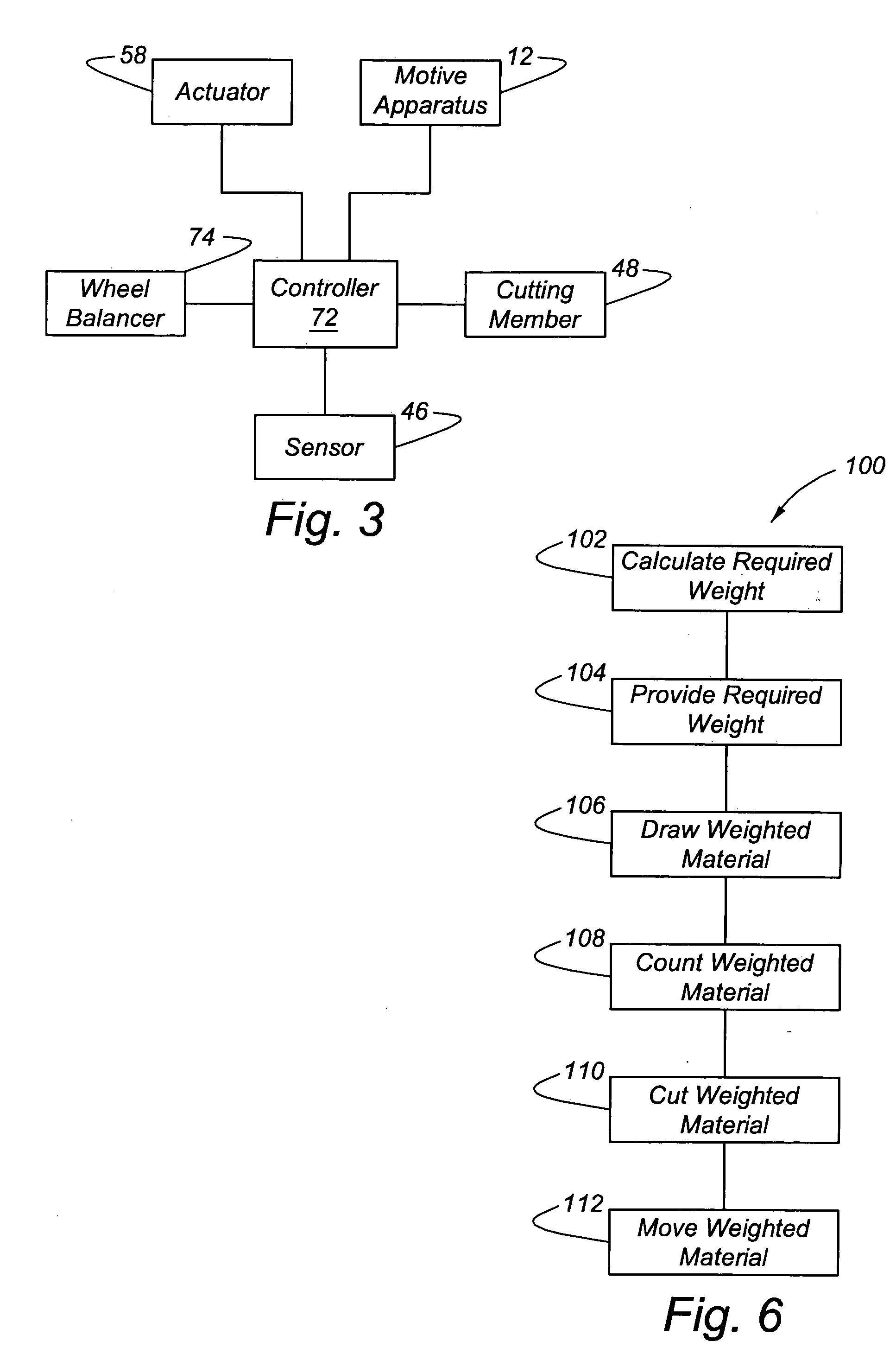

Adhesive wheel weight dispensing apparatus

InactiveUS20060016309A1Reduce potential errorReduce container spaceStatic/dynamic balance measurementGang saw millsEngineeringMechanical engineering

An apparatus for dispensing a predetermined amount of adhesive weighted tape includes a controller adapted to receive a request for a desired amount of adhesive weighted tape and an elongated track member adapted to receive a supply of the adhesive weighted tape. A sensor is mounted adjacent a second end of the track member. The sensor in communication with the controller is operable to transmit a signal to the controller corresponding to a measured amount of weighted tape passing thereby. A motive apparatus in communication with the controller is adapted to move the weighted tape from a first end to the second end of the track member in response to the signal from the sensor. A cutting member disposed adjacent the second end of the track member is in communication with the controller and is adapted to cut the weighted tape in response to the signal from the sensor.

Owner:GM GLOBAL TECH OPERATIONS LLC

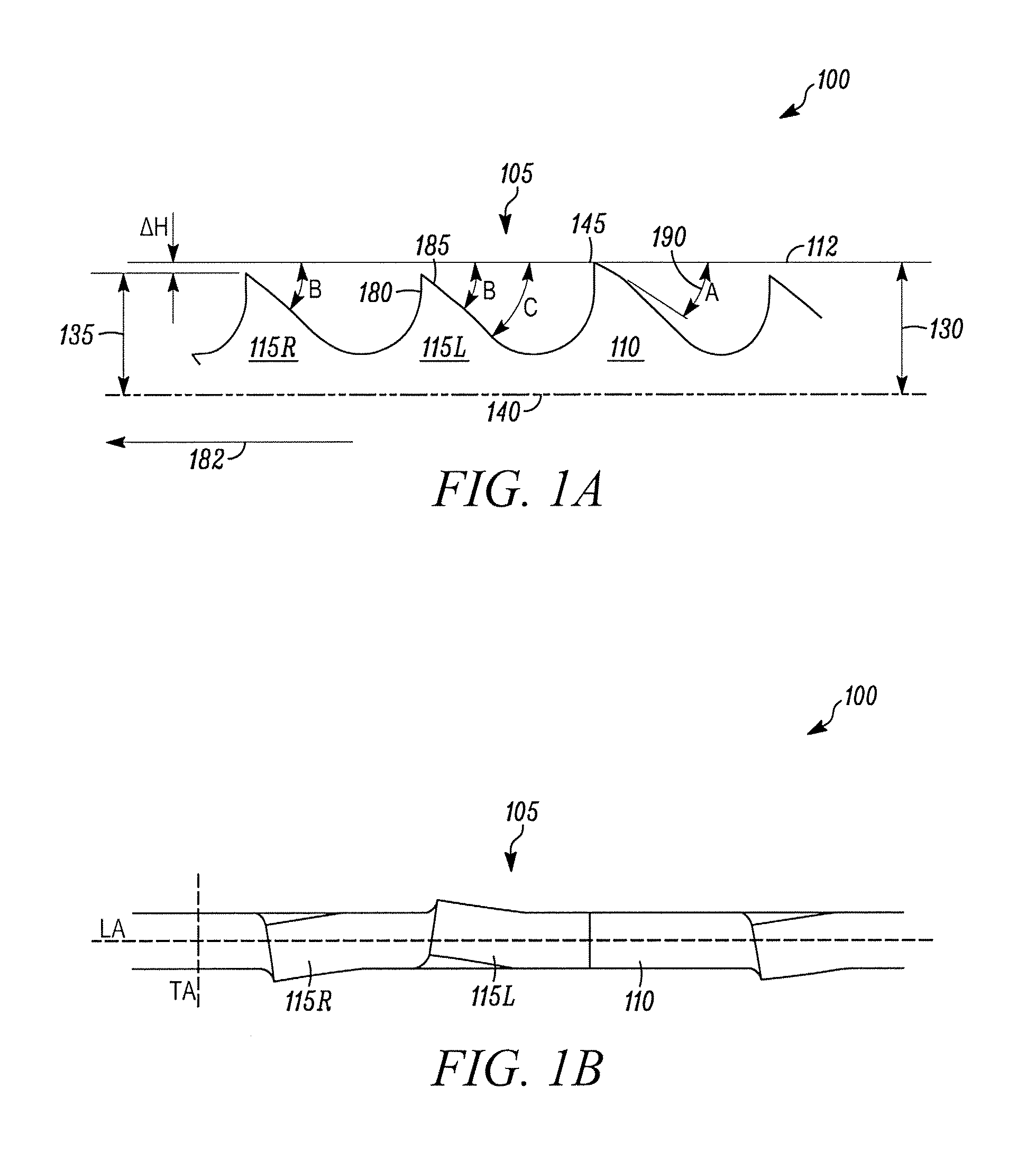

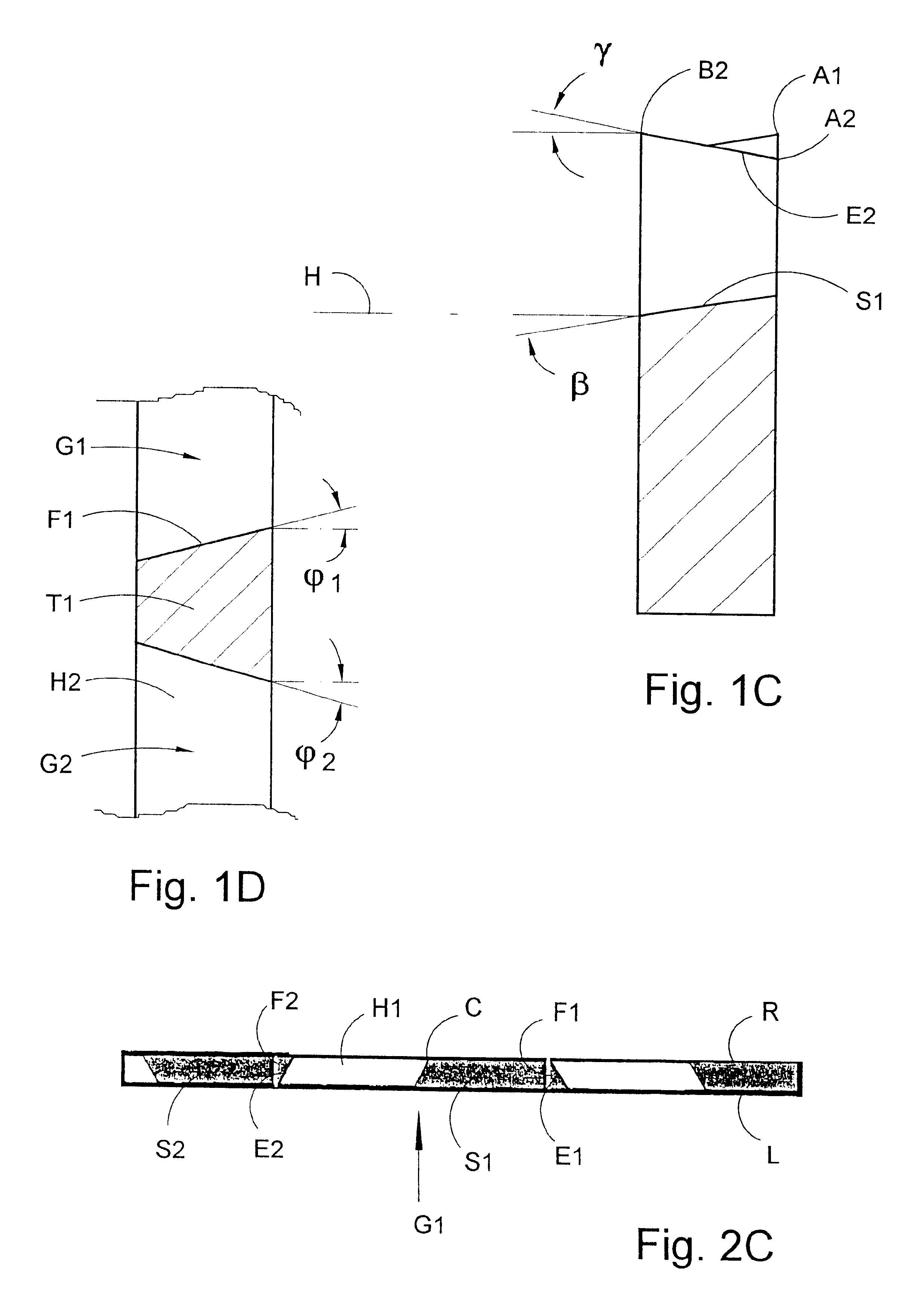

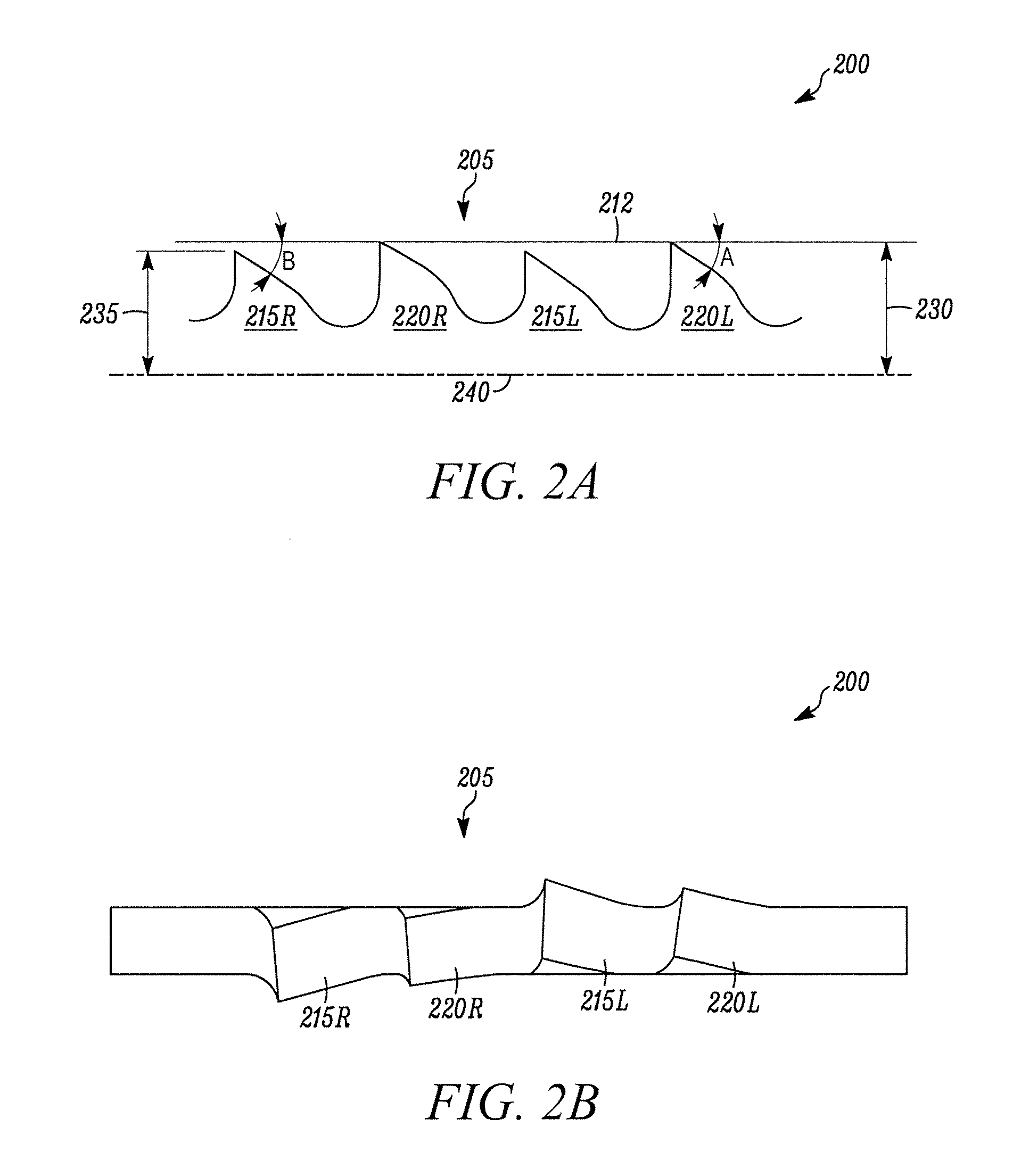

Multi-chip facet cutting saw blade and related method

ActiveUS7131365B2Improved blade life and straightness of cutHigh rateMetal sawing devicesMetal sawing toolsAcute angleKnife blades

A metal cutting band saw blade has a plurality of cutting teeth defining a cutting direction, and a repeating tooth pattern of between 3 and 7 teeth. Each tooth defines a laterally-extending upper surface having a width and a height with respect to the back edge of the blade, and side surfaces extending laterally and downwardly on opposite sides of the upper surface relative to each other at acute angles relative to the upper surface. The teeth located rearwardly of the first tooth with respect to the cutting direction of the saw blade define progressively lower heights and progressively smaller acute angles of the side surfaces, and the widths of the upper surfaces of these teeth are greater than the width of the upper surface of the respective first tooth.

Owner:BLACK & DECKER INC

Band saw blade

InactiveUS20070199416A1Improve efficiencyImprove performanceMetal sawing toolsSaw bladesEngineeringKnife blades

Owner:COOKS SAW MFG

Saw blade

A saw blade includes left and right set teeth which are set in a lateral direction, as viewed in a cutting direction of cutting teeth. The left and right set teeth include dovetail shaped set teeth, each having a tooth tip formed into a dovetail shape gradually enlarged in the lateral direction, respectively; and a straight tooth, which is not set. The straight tooth includes a dovetail shaped straight tooth having a tooth tip formed into a dovetail shape gradually enlarged in the lateral direction. In the straight tooth, inclinations are formed on both of left and right ends at the tooth tip, which is formed into the dovetail shape gradually enlarged in the lateral direction.

Owner:AMADA CO LTD

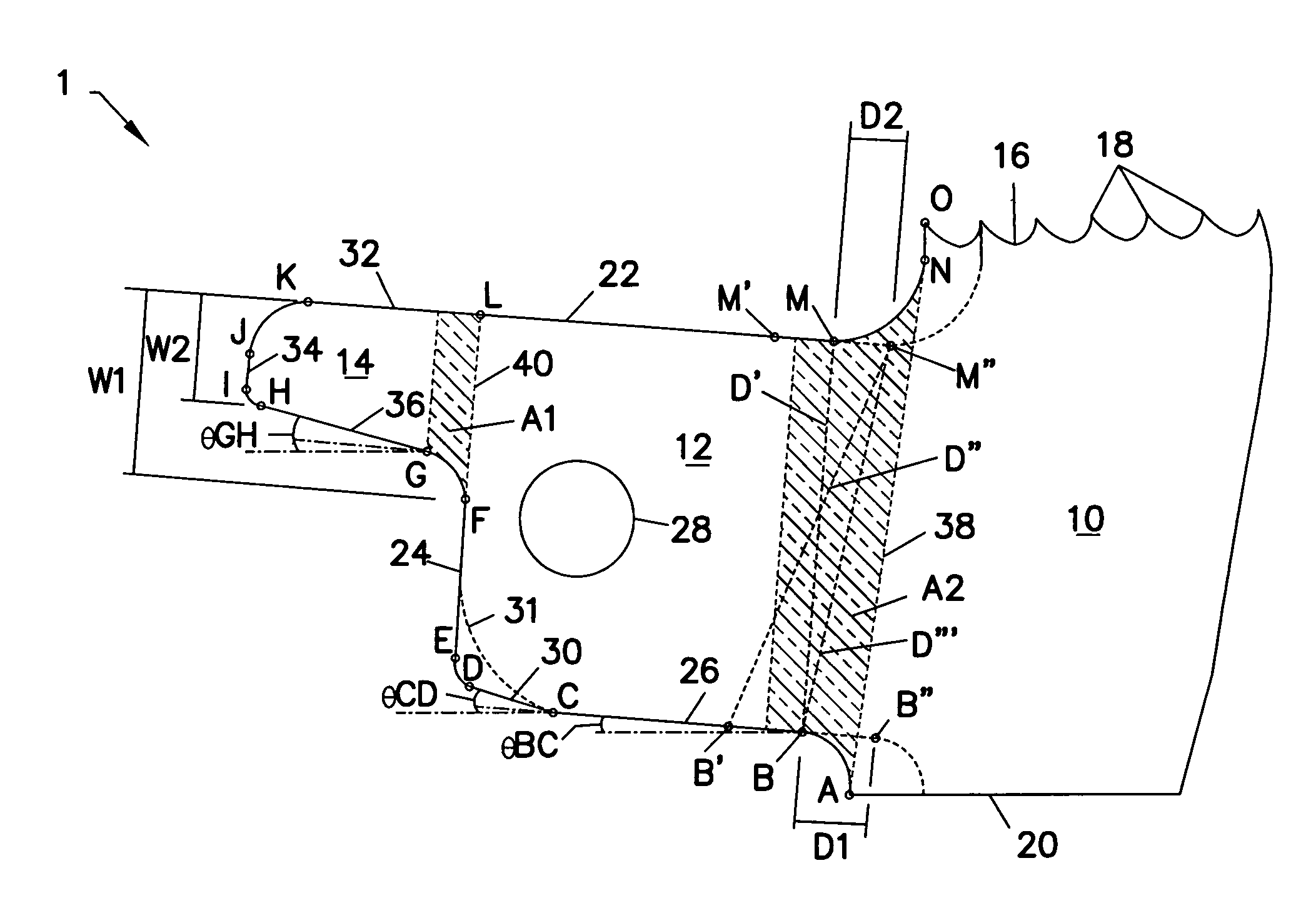

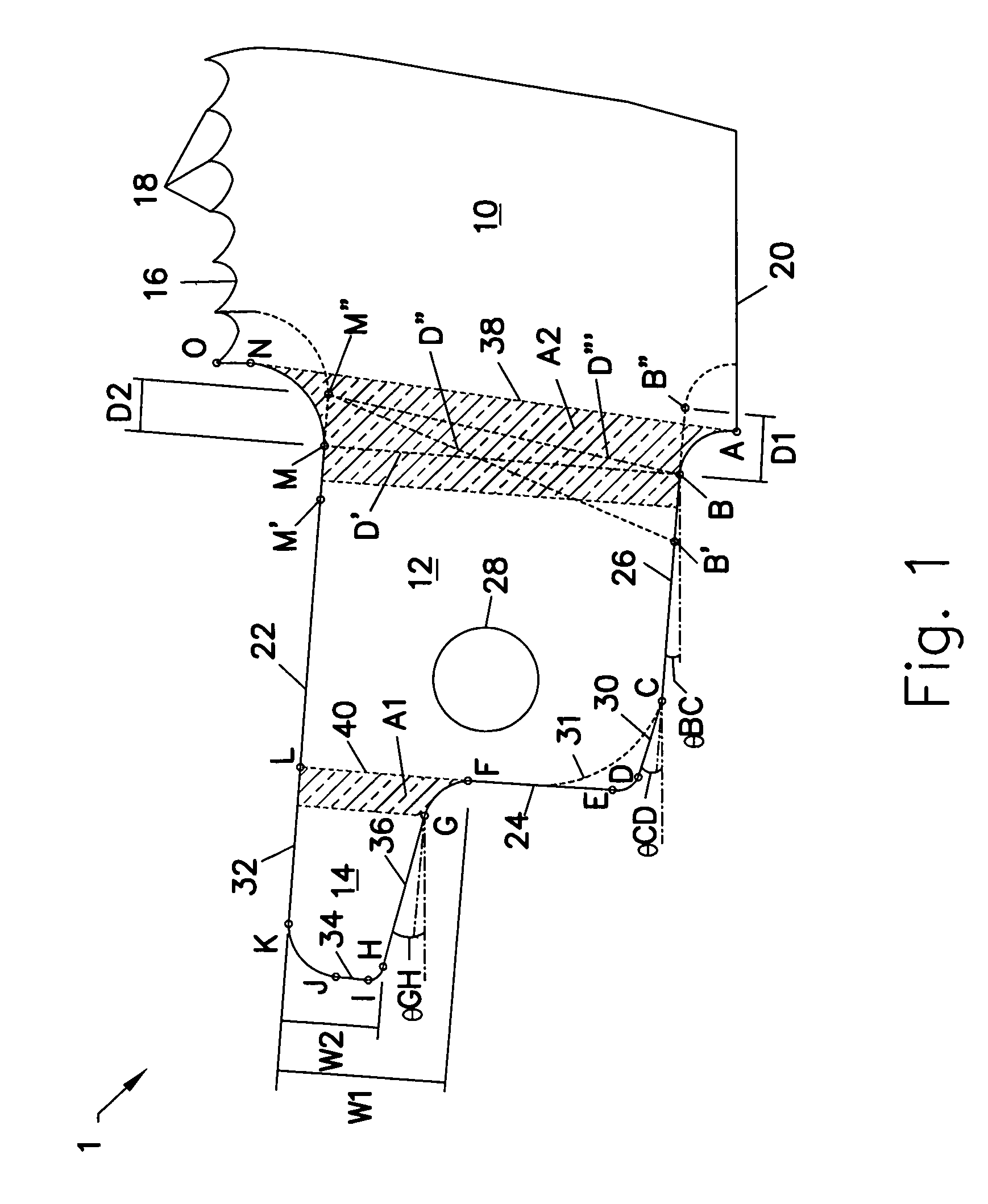

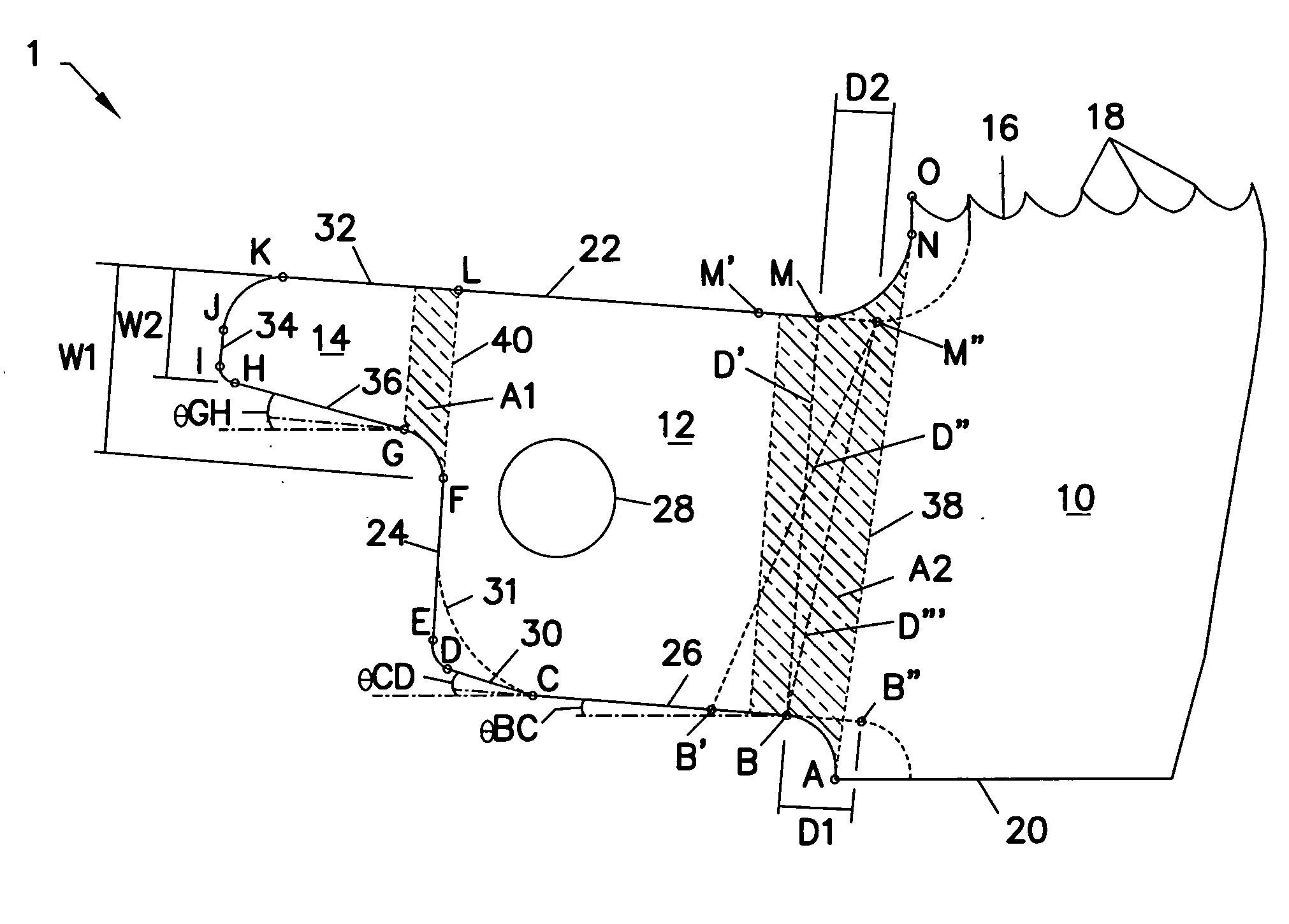

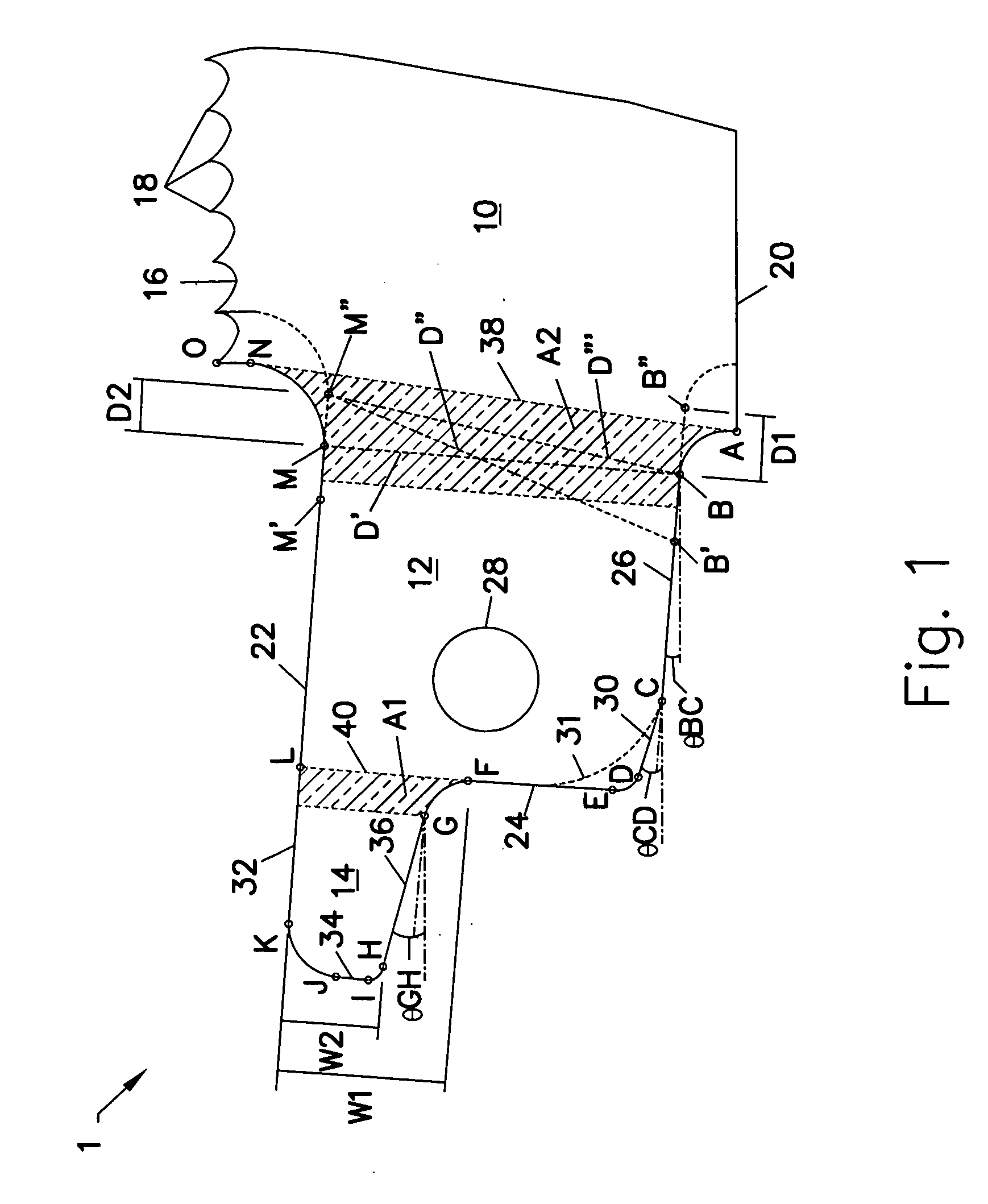

Reciprocating saw blade with tapered tang stem

InactiveUS20050235799A1Facilitates effectiveFacilitates efficient engagementMetal sawing devicesMetal sawing toolsCutting forceMechanical engineering

There is provided a reciprocating saw blade having a tapered tang stem. The tang has a tang portion with at least three outer edges and a stem portion with at least three outer edges. The profiles of the tang portion and particularly the stem portion are such that they facilitate the effective and efficient engagement of the saw blade with any of numerous different keyed or keyless chucks of reciprocating saws. The tang / stem profile also advantageously provides for increased strength for resisting failure and / or fatigue stemming from a cutting force applied to the saw blade during use.

Owner:BLACK & DECKER INC

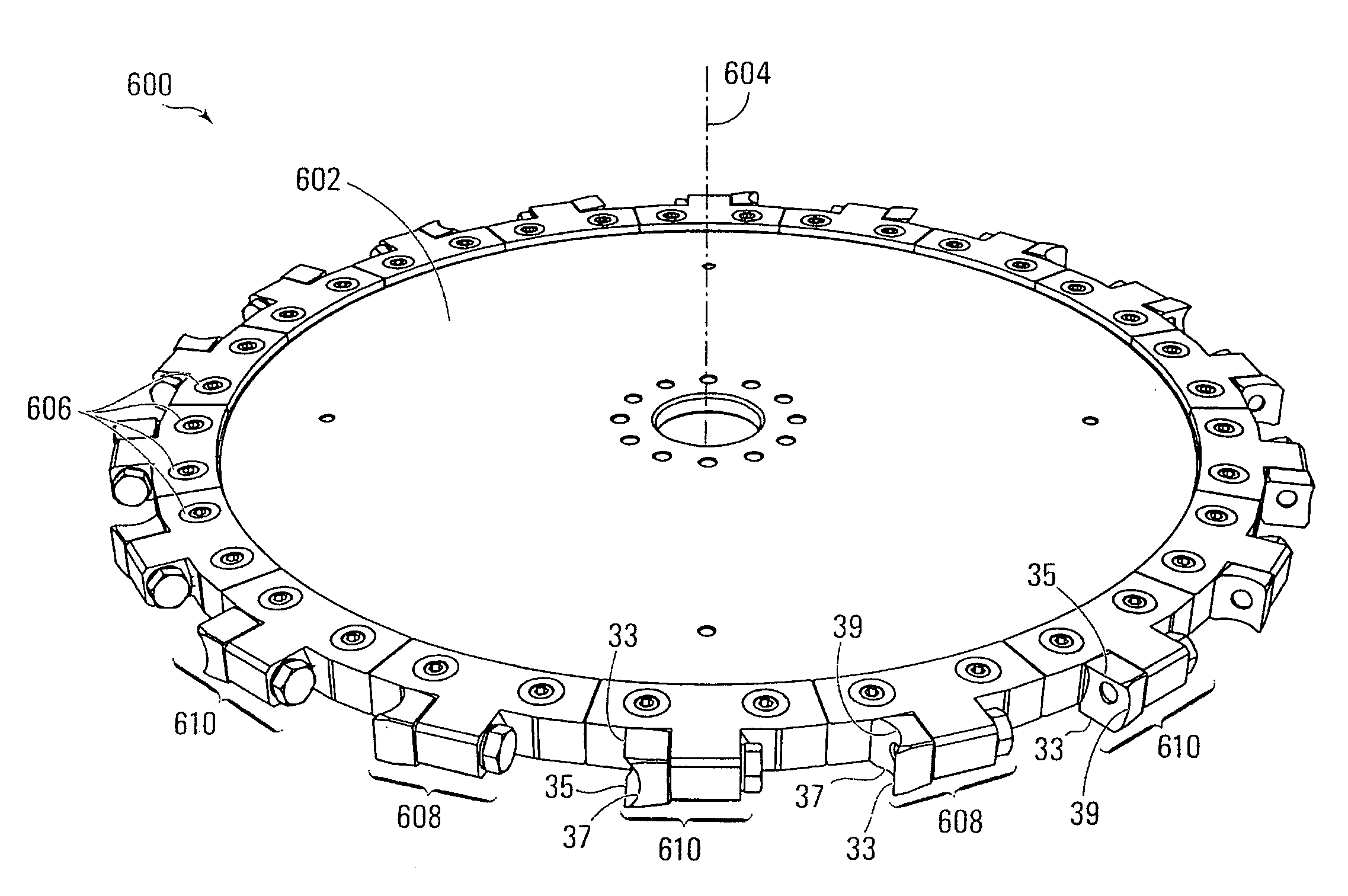

Rotary cutting machine with replaceable cutting teeth

A rotary cutting machine comprises a circular rotating element having a transverse axis of rotation and which is mounted to the rotary cutting machine for rotation about the axis of rotation. A plurality of cutting teeth are mounted to the circular rotating element at spaced apart locations about its circumferential periphery. The cutting teeth are reversible and removably fastened to the circular rotating element. Each cutting tooth includes opposed first and second cutting faces spaced apart by lateral surfaces extending therebetween. The first and second cutting faces define at least four of the cutting edges thereon, such that the cutting teeth are selectively mountable on the circular rotating element in any one of at least eight different positions, each of the positions providing a different one of the cutting edges in the operable cutting position.

Owner:QUADCO

Bandsaw blade with cutting extensions

A saw blade that includes a bandsaw body and a plurality of unset teeth having a generally uniform height. The teeth are disposed on the bandsaw body. At least some of the teeth have a cutting extension that extends above the uniform height of the teeth.

Owner:GENENCOR INT INC

Novel disk saw blade

InactiveCN102658568AOvercoming easy scrappingOvercoming the serious flaw of wasteMetal sawing toolsCircular sawsEngineering

The invention relates to a novel disk saw blade. The disk saw blade is provided with a round sawtooth-fixing disk, which is provided with oblate fixing pin holes; the top of the edge of the outer circle of the sawtooth-fixing disk is connected with a connecting plate, and lotus-shaped sawteeth are connected with the top of the connecting plate, and are fixed on the top of the connecting plate by interlayer fixing pins.

Owner:张庆德

Reciprocating saw blade having variable-height teeth and related method

ActiveUS8210081B2Increase loadHigh teethMetal sawing devicesMetal sawing toolsPortable powerEngineering

A reciprocating saw blade, for use in a portable power reciprocating saw including a chuck for releasably engaging the saw blade, includes a tang having an elongated axis and being engageable with the chuck for attaching the saw blade to the reciprocating saw. The saw further includes a blade portion having a cutting edge that defines a plurality of cutting teeth. The cutting teeth define a repeating pattern of successive groups of teeth. Each group of teeth is less than about a half inch in length, and includes a plurality of laterally offset teeth, at least one relatively high first tooth and at least one relatively low second tooth. Prior to tooth set, the at least one relatively high first tooth is at least about 0.002 inch higher than the at least one relatively low second tooth.

Owner:BLACK & DECKER INC

Structure of disc saw sheet

The invention provides a structure of a disc saw sheet. Sawteeth are made on the outer circle of a ring, the installation parties are of a round structure, tooth-shaped connection bridges are arranged on the outer circle of the installation part, a sawtooth part is arranged on the installation part, the connection bridges and the sawtooth part are welded together through welding spots. In the structure, if the sawtooth part is damaged to be declared as useless, the connection bridge is cut off only, a new sawtooth part and the original installation part are welded again through other connection bridges on the other connection bridges which are not welded, and normal work can be conducted. Therefore, the structure can overcome the defects that an existing disc saw sheet is easy to scrap and waste.

Owner:刘惠如

Double-Sided Reciprocating Saw Blade and Related Method

InactiveUS20130174701A1Improve performanceEasy to useMetal sawing devicesMetal sawing toolsEngineeringMechanical engineering

A reciprocating saw blade has a blade body defining first end and second ends. A first cutting edge is located on one side of the blade body, and a second cutting edge is located on an opposite side of the blade body thereof. A first tang is located at one end of the blade body and defines a first acute cutting angle of the first cutting edge. A second tang may be located at another end of the blade body and defines a second acute cutting angle of the second cutting edge. The first and second tangs are alternately and releasably engageable by the chuck of the reciprocating saw. At least one cutting edge may be defined by a plurality of groups of cutting elements. Each group of cutting elements is oriented at a respective acute cutting angle relative to a tang edge that defines an effective cutting angle for that group of cutting elements.

Owner:BLACK & DECKER INC

Saw blade

Owner:AMADA CO LTD

Variable tooth saw blade

An apparatus for cutting materials and more specifically an improved saw blade includes a plurality of variable teeth thereon. The variable tooth saw blade cuts faster and smoother while reducing harmonic vibrations. Specifically, the teeth on the saw blade are grouped into sections with differing circumferential widths and differing spacing between the sections.

Owner:BLACK & DECKER INC

Saw blade

A saw blade includes left and right set teeth which are set in a lateral direction, as viewed in a cuffing direction of cutting teeth. The left and right set teeth include dovetail shaped set teeth, each having a tooth tip formed into a dovetail shape gradually enlarged in the lateral direction, respectively; and a straight tooth, which is not set. The straight tooth includes a dovetail shaped straight tooth having a tooth tip formed into a dovetail shape gradually enlarged in the lateral direction. In the straight tooth, inclinations are formed on both of left and right ends at the tooth tip, which is formed into the dovetail shape gradually enlarged in the lateral direction.

Owner:AMADA CO LTD

Saw blade tooth form for abusive cutting applications

ActiveUS20120000338A1Resists wearImprove wear lifeMetal sawing devicesTransportation and packagingEngineeringKnife blades

A recip saw blade has a blade body and a cutting edge extending along the blade body and defined by a repeating pattern of two consecutive teeth suitable for abusive cutting applications. The blade defines a relatively coarse tooth pitch. The two consecutive teeth, which may be bi-metal, include a high tooth and a relatively low tooth in comparison to the high tooth. Each high tooth and low tooth include a primary clearance surface defining a relatively shallow primary clearance angle that is about 28° or less, and a secondary clearance surface defining a relatively steep secondary clearance angle in comparison to the primary clearance angle. The primary clearance angle of the high tooth is steeper than the primary clearance angle of the low tooth, such as between about 23° and 28°, and the secondary clearance angle of the high tooth is shallower than the secondary clearance angle of the low tooth.

Owner:BLACK & DECKER INC

Tooth for a circular saw or mower drum

A tooth for a circular saw or a mower drum that can be used to cut standing trees or brush and undergrowth. The tooth has four cutting edges arranged in a first pair of opposed cutting edges that are generally straight and a second pair of opposed cutting edges that are generally concave. The tooth is mounted in a holder in a first or second cutting position that orients a cutting edge of the first or second pair to physically contact and effect a cutting method to a cuttable material. In a first cutting method, a generally straight cutting edge contacts the material, resulting in a slicing action. In a second cutting method, a generally concave cutting edge contacts the material, resulting in a gouging action. Teeth in the circular saw or brush mower alternate between first and second cutting positions, allowing both cutting methods to be applied to cuttable material.

Owner:QUADCO

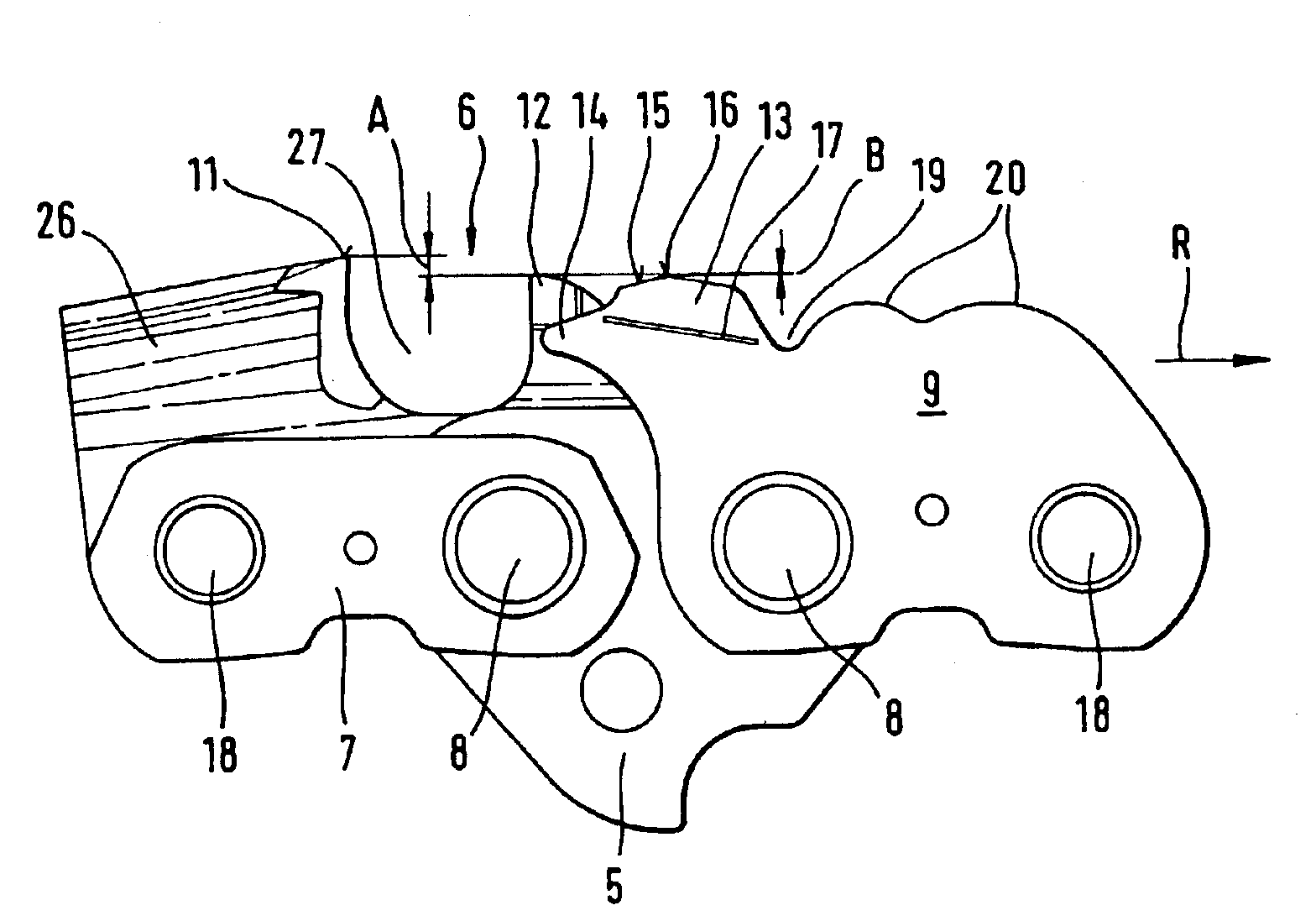

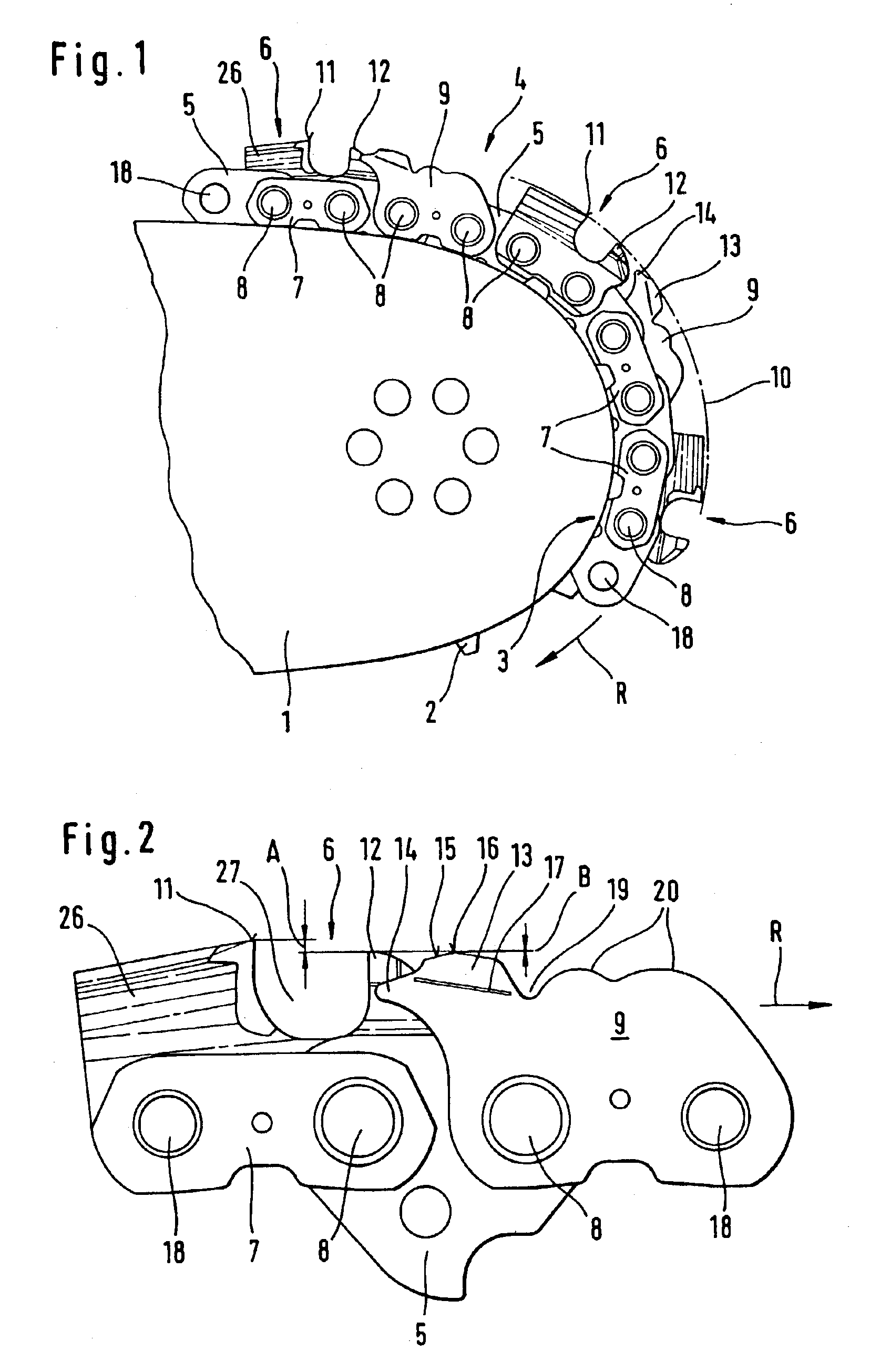

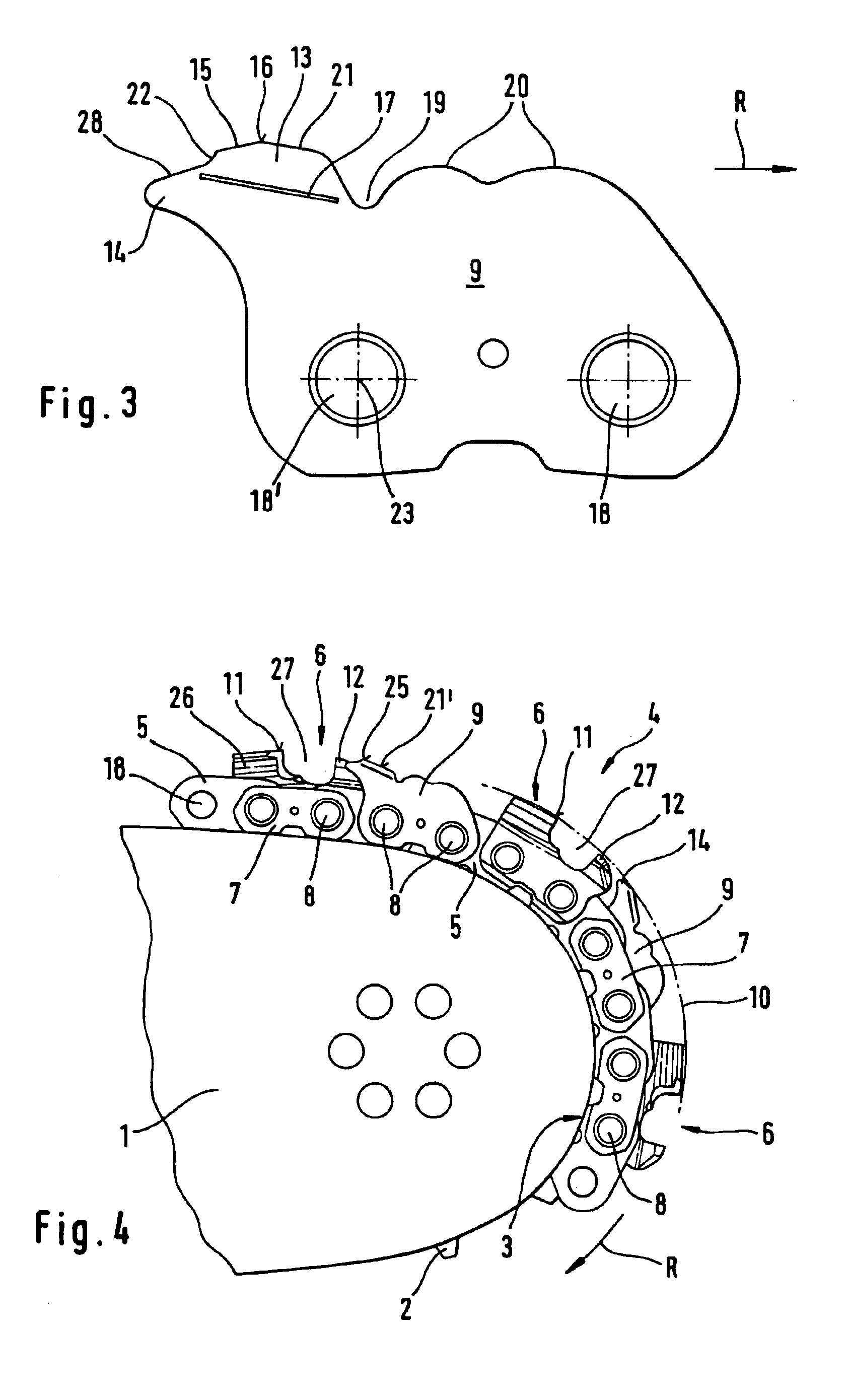

Saw chain

InactiveUS6871573B2Improve cutting performanceImprove cutting effectSaw bladesMetal working apparatusEngineeringChain saw

A saw chain for a power chain saw is provided and comprises drive links and side links that connect them, whereby alternatingly disposed on one and the other longitudinal side of drive links, in place of a side link, are a cutter link and a leading safety link. The cutter link has a cutter tooth and a leading depth limiter, whereby the safety link is provided with a projecting nose for support against the base of a cut. The nose extends in the direction toward the depth limiter. The safety link is provided with a side portion disposed in front of the nose. The side portion has an elevated contact surface, which, when the saw chain is curved in the reversing region, is disposed on the path of a top cutting edge of the cutter tooth, and when the saw chain is extended reaches at least nearly to the height of the depth limiter.

Owner:ANDREAS STIHL AG & CO KG

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com