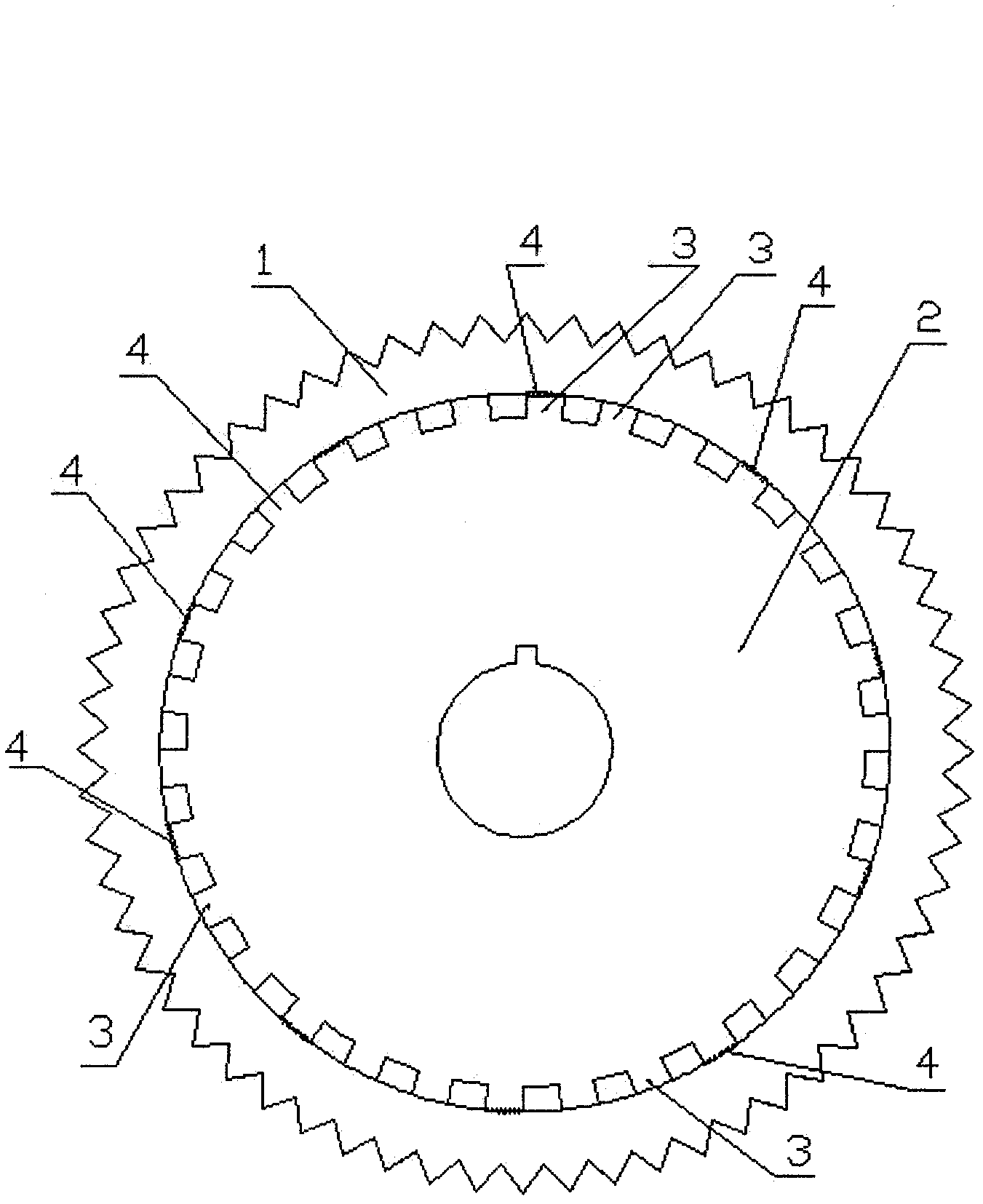

Structure of disc saw sheet

A circular saw blade and sawtooth technology, applied in the field of tools, can solve the problems of easy scrapping and easy waste, and achieve the effect of overcoming easy scrapping and easy waste.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0008] The sawtooth part (1) is a ring structure made of tool steel material, and the sawtooth is made on the outer circle of the ring; the installation part (2) is a circular structure, made of ordinary steel, on the outer circle of the installation part (2) A toothed connecting bridge (3) is made, the sawtooth part (1) is installed on the installation part (2), and the welding point (4) welds and fixes the connecting bridge (3) and the sawtooth part (1). If the sawtooth part is damaged and discarded, you only need to cut off the connecting bridge, and on other connecting bridges that have not been welded, a new sawtooth part and the original installation part are re-welded through the connecting bridge, which can work normally.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com