Patents

Literature

1006 results about "Chain saw" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

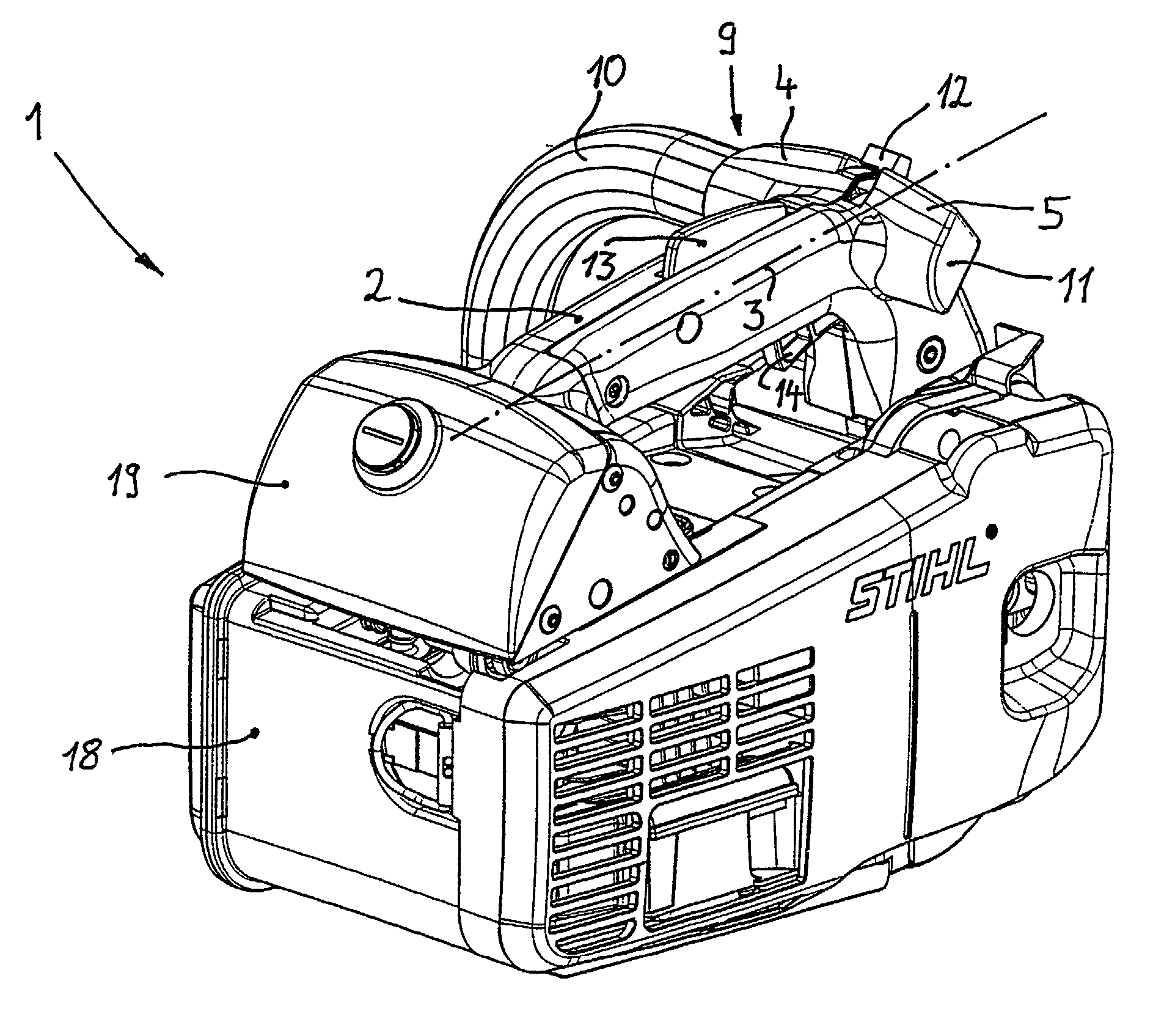

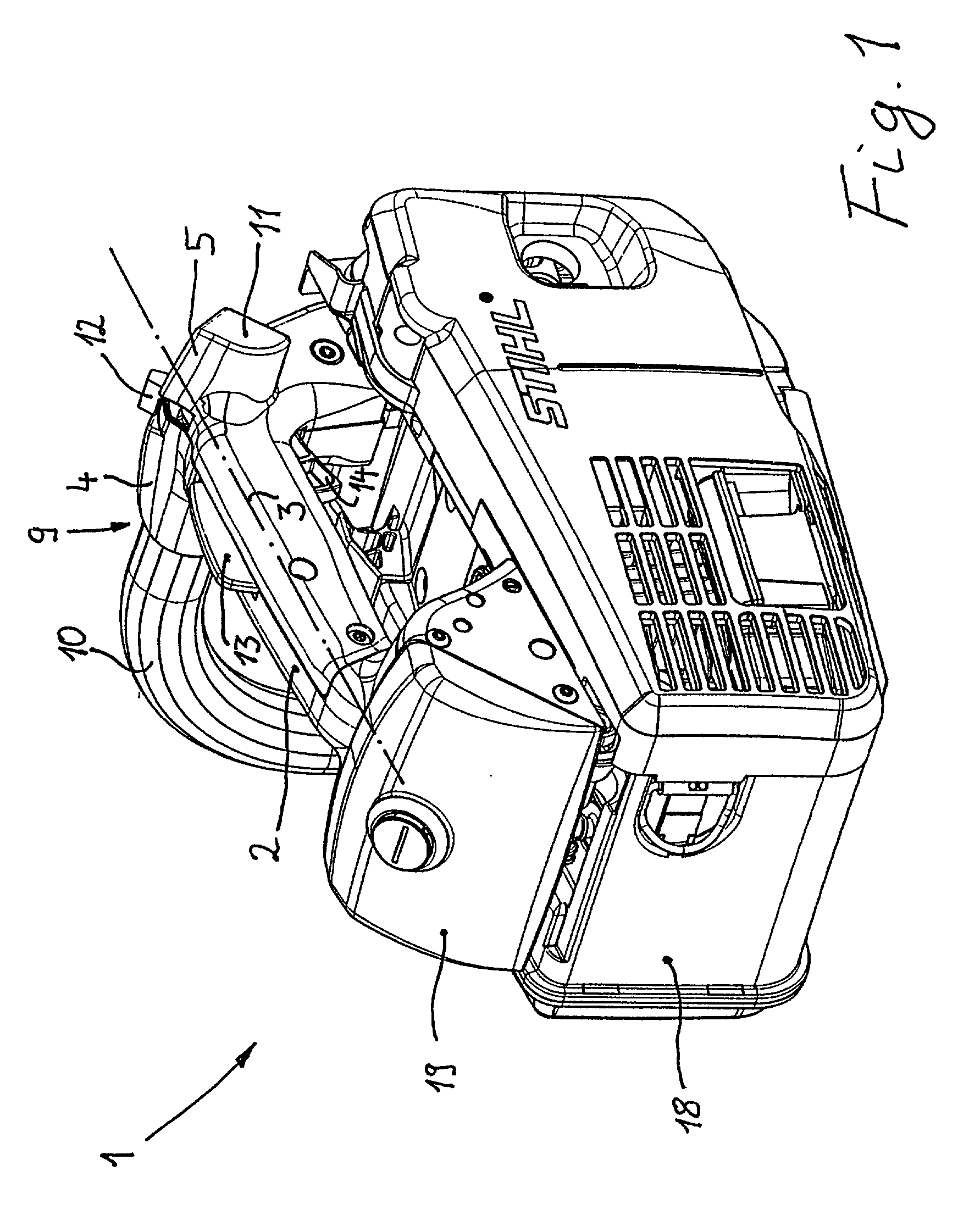

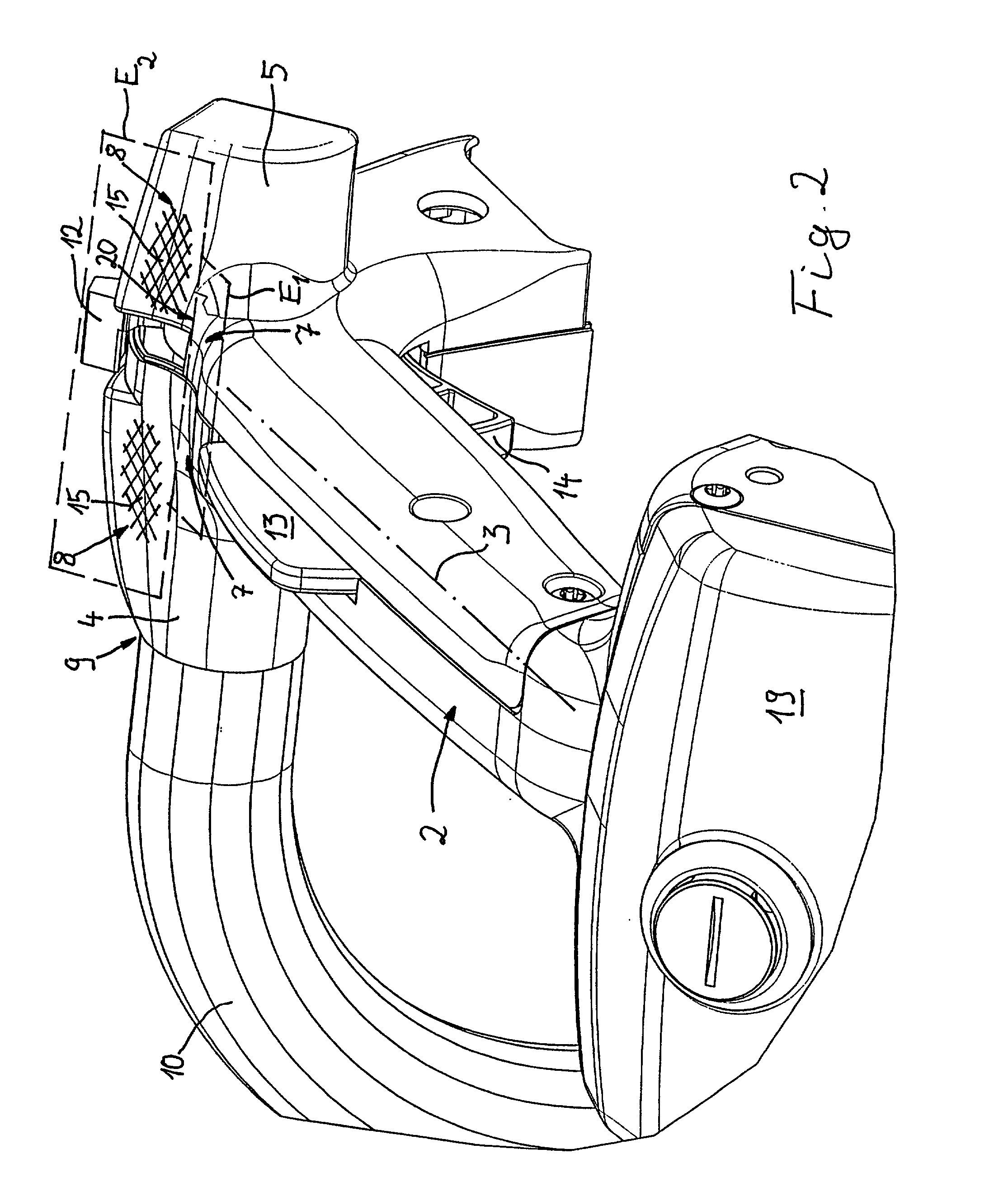

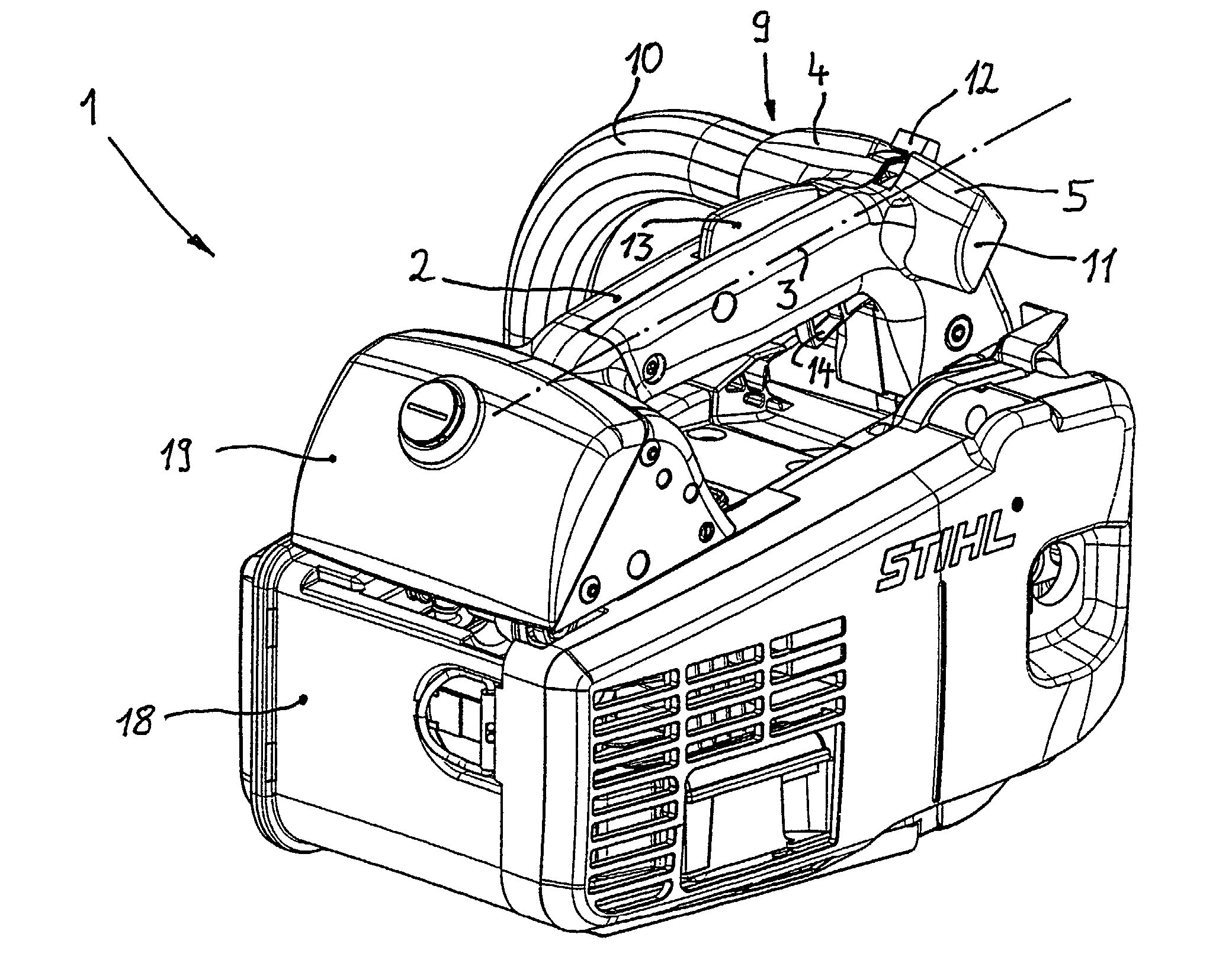

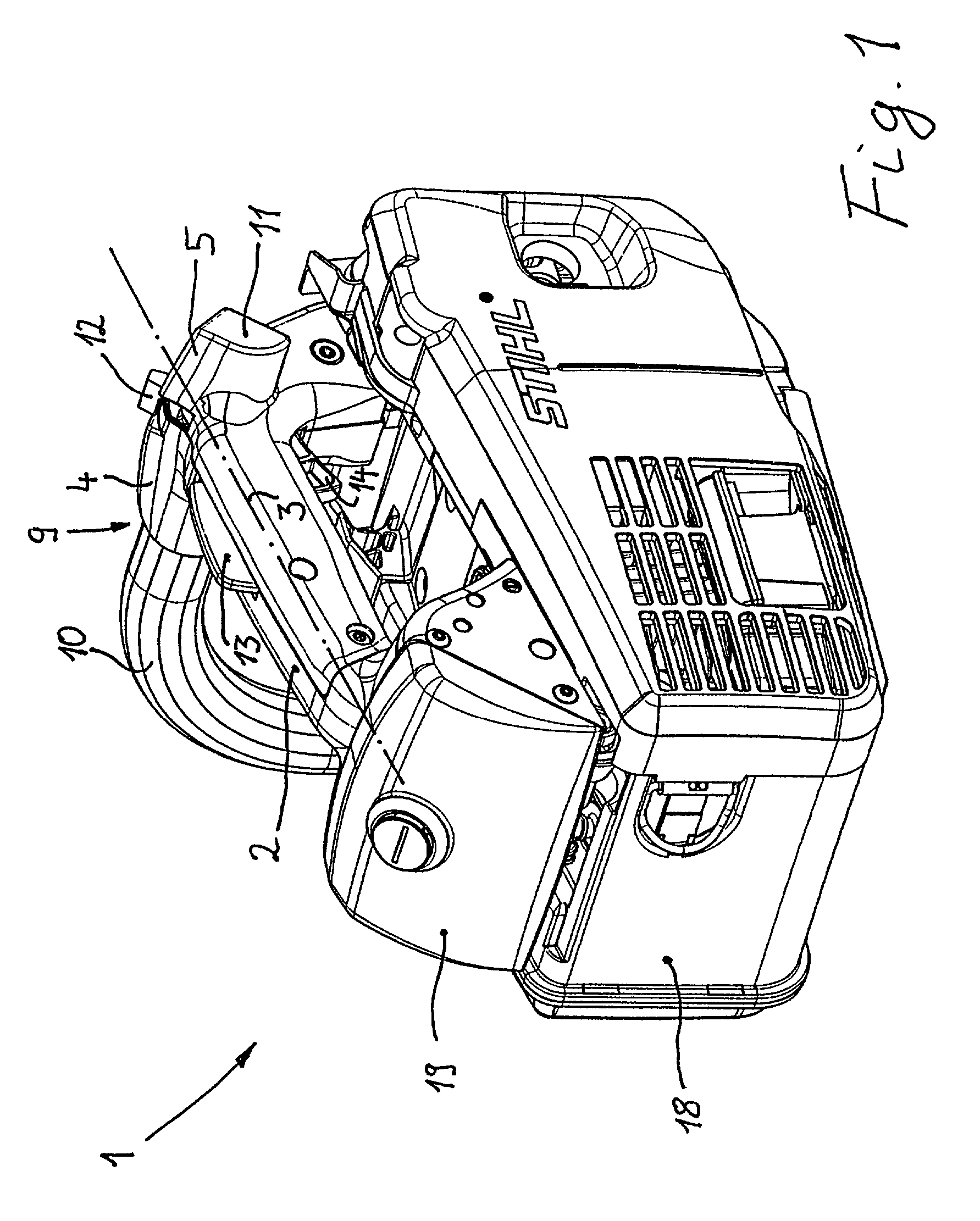

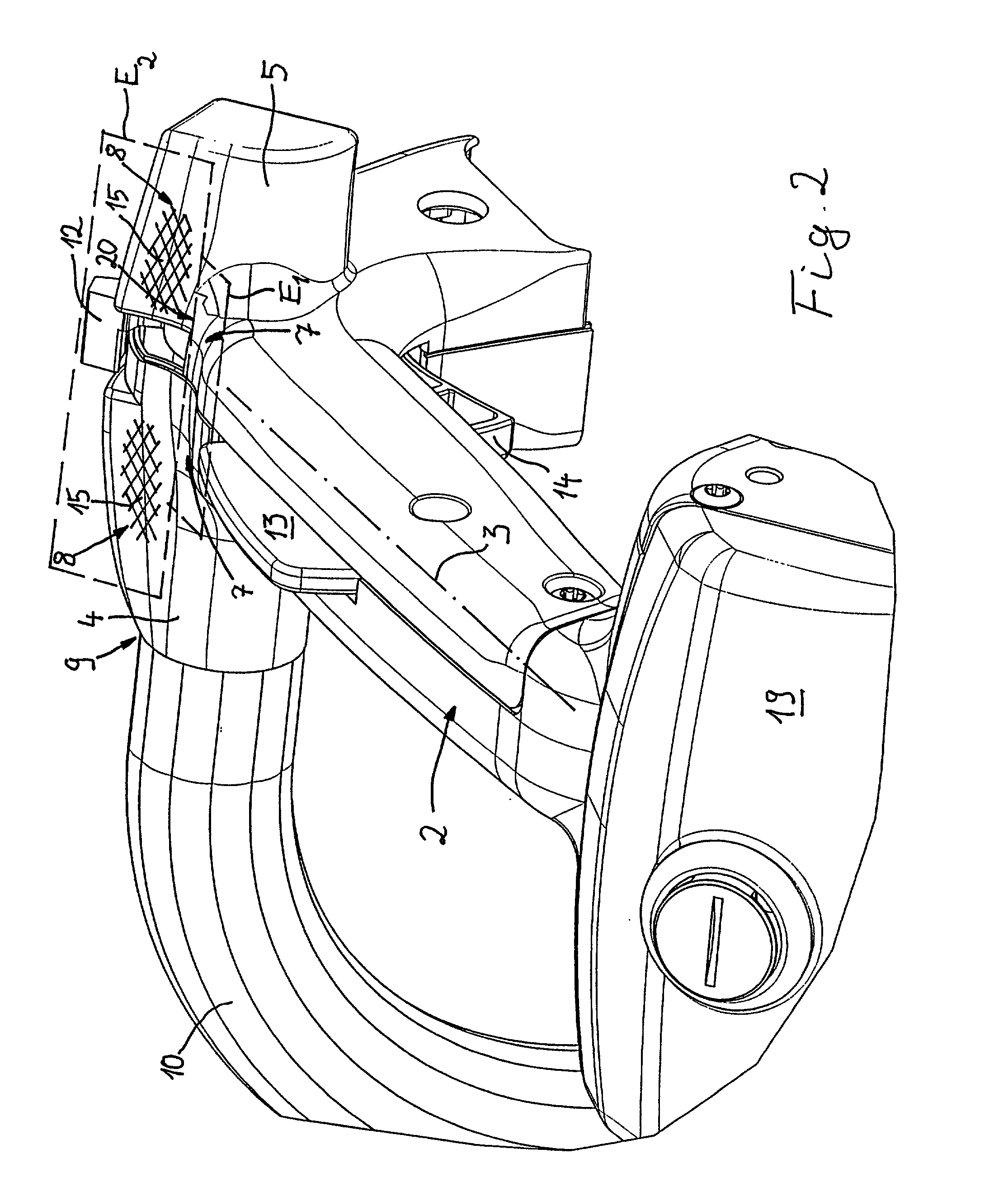

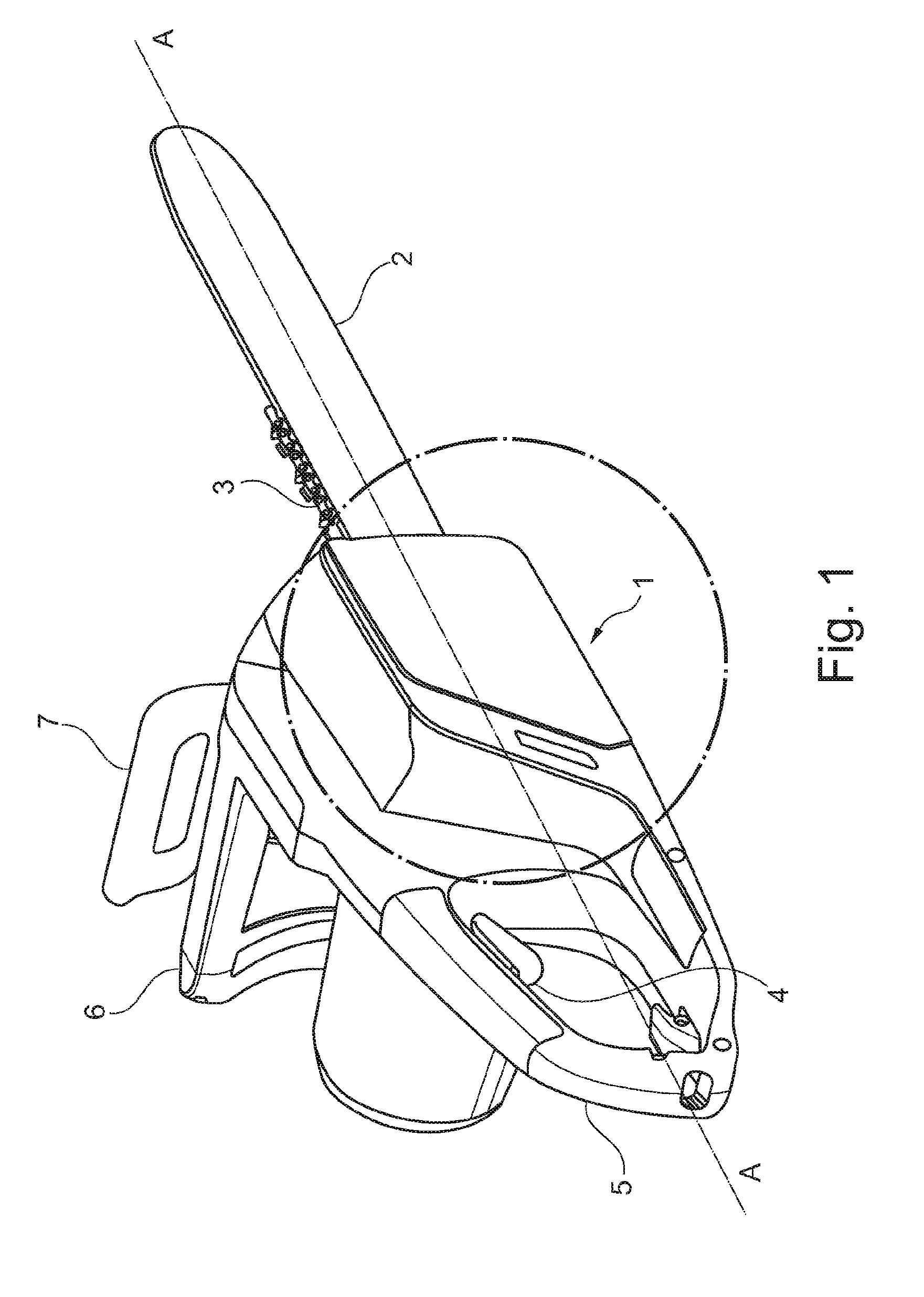

Portable handheld work apparatus having thumb supports

InactiveUS20020129502A1Prevent slippingGreat hand forceMetal sawing devicesChain sawsHand heldChain saw

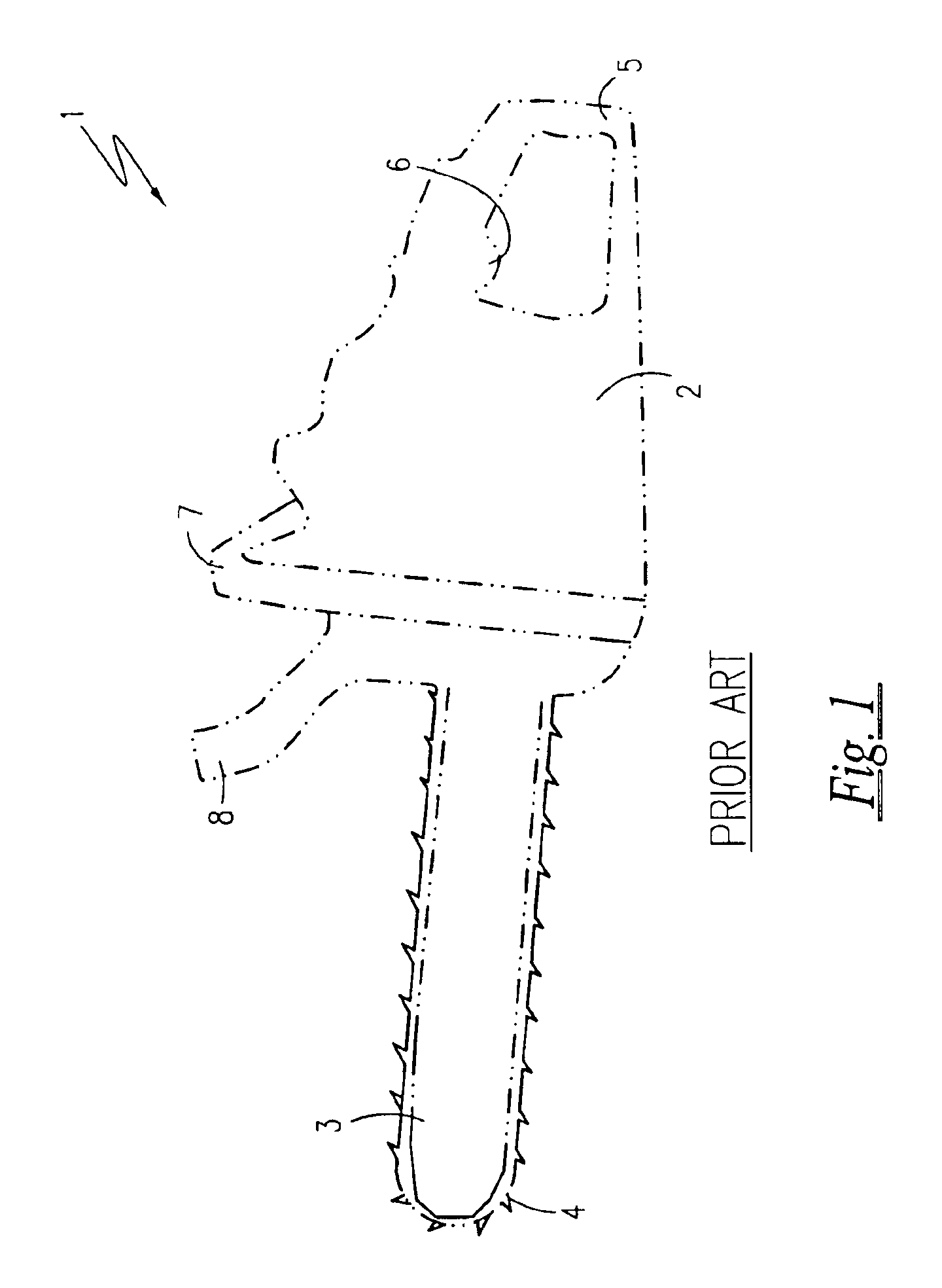

The invention relates to a portable handheld work apparatus including a chain saw, a vacuum / blower apparatus or the like. The work apparatus has a handle (2) for carrying and guiding the work apparatus (1). Thumb supports (4, 5) are provided on both sides with respect to the longitudinal axis (3) of the handle (2).

Owner:ANDREAS STIHL AG & CO KG

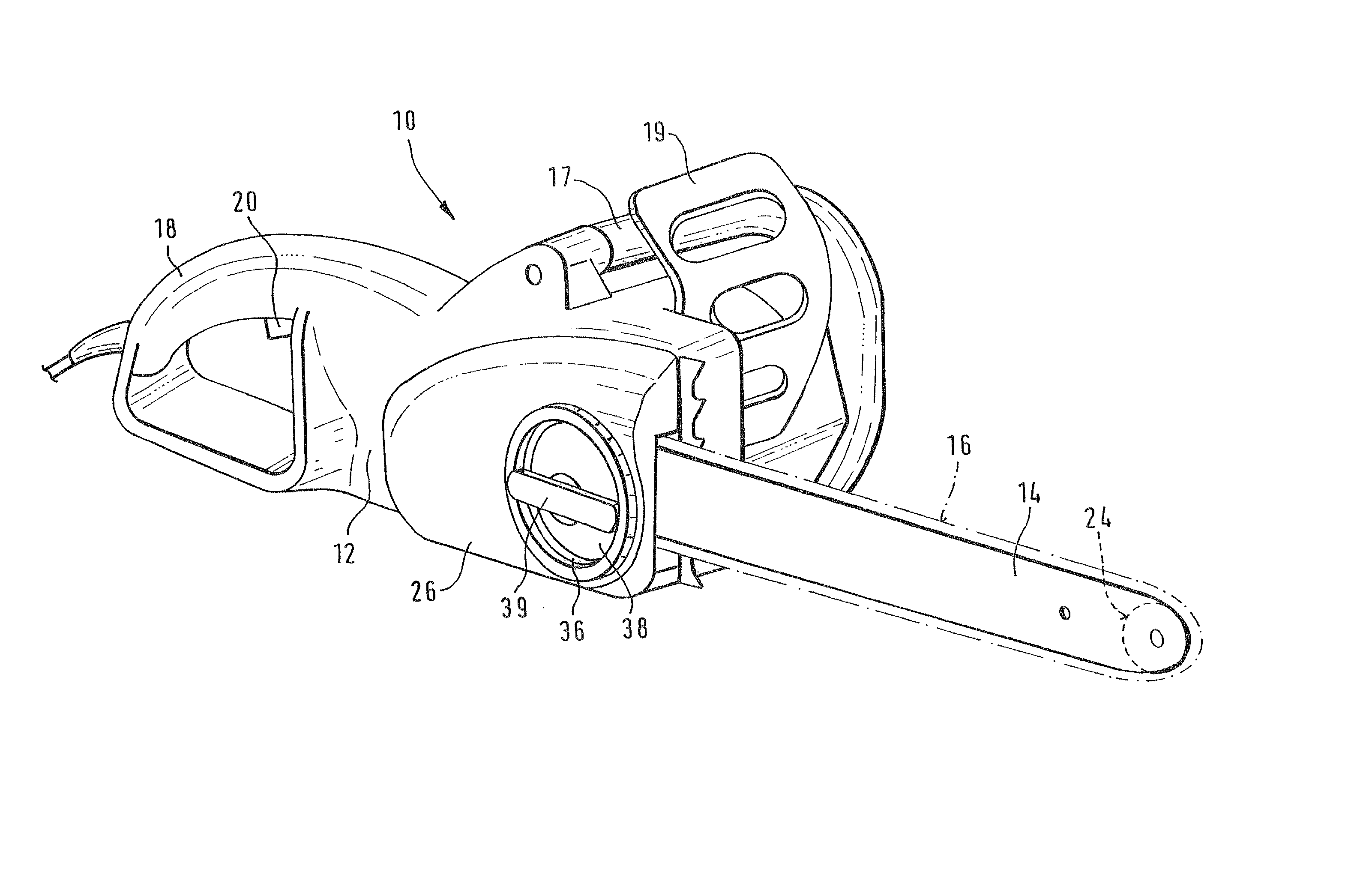

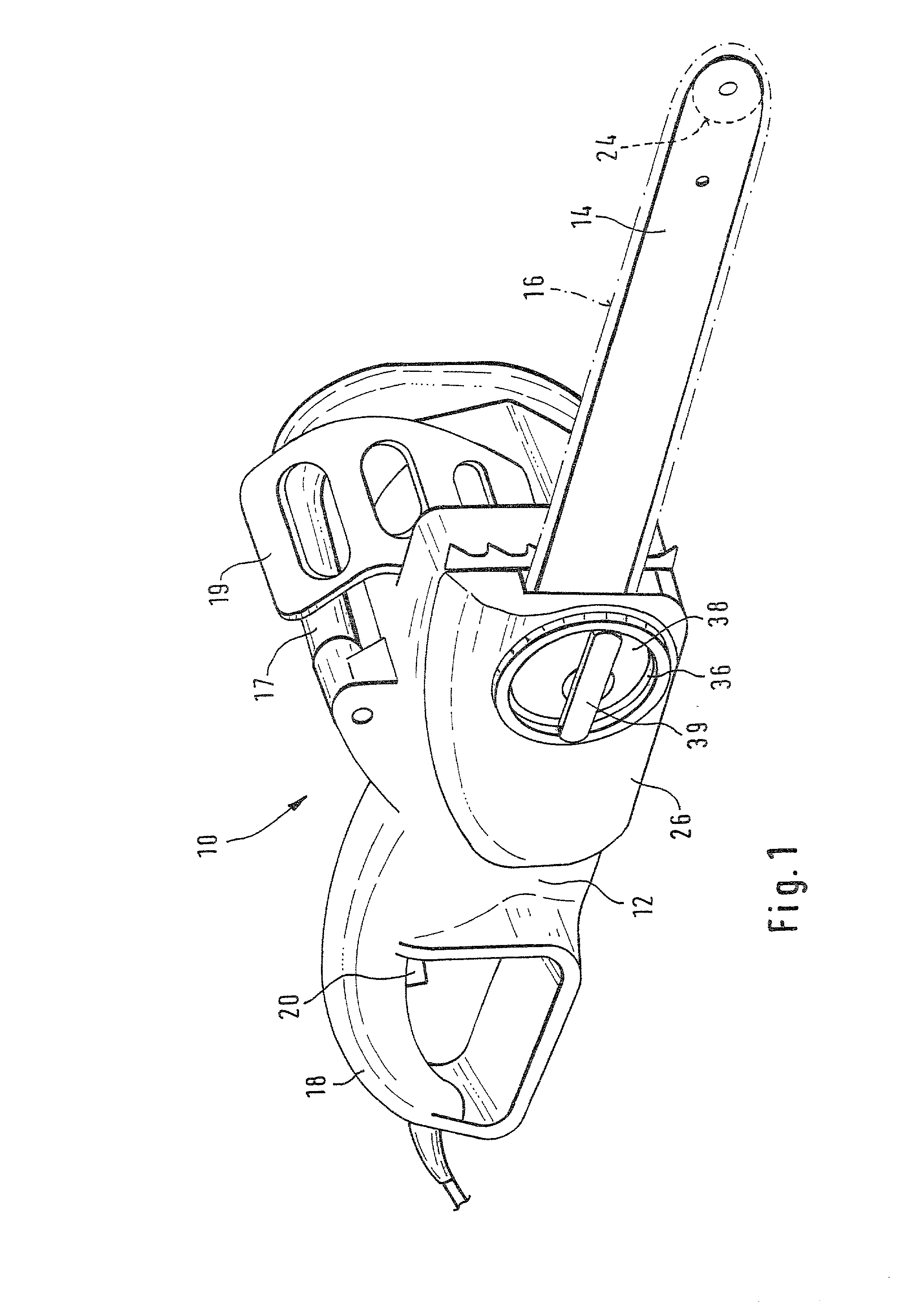

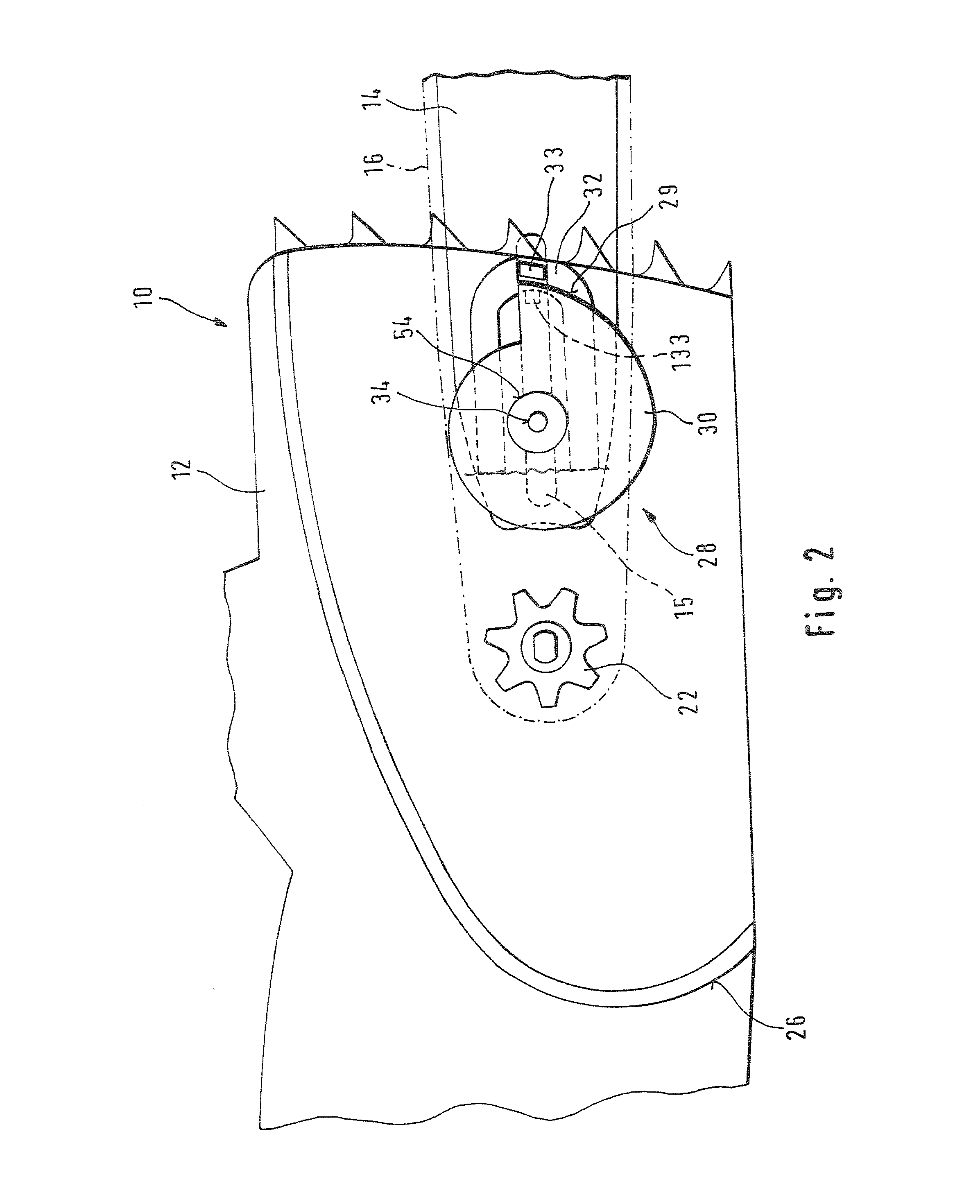

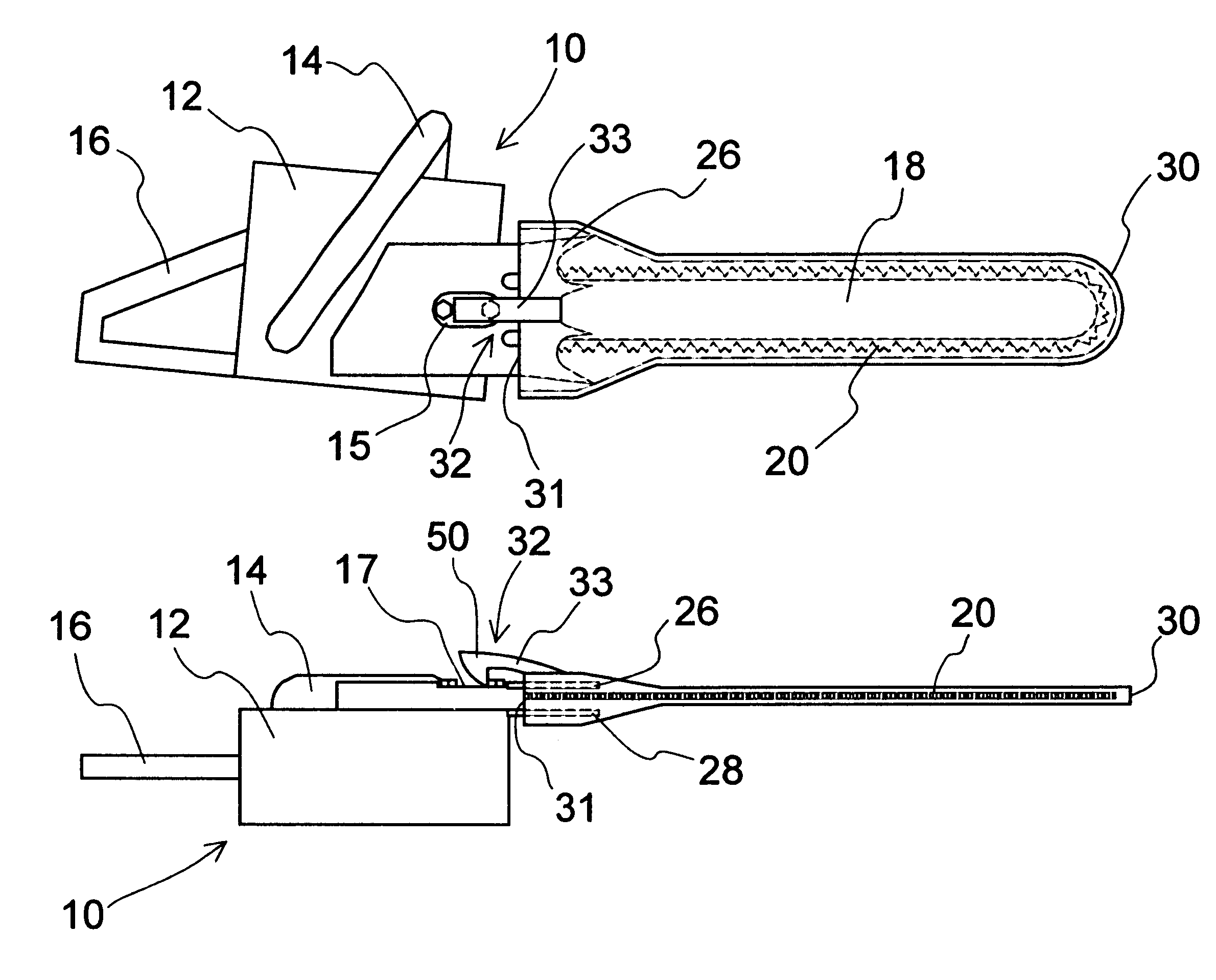

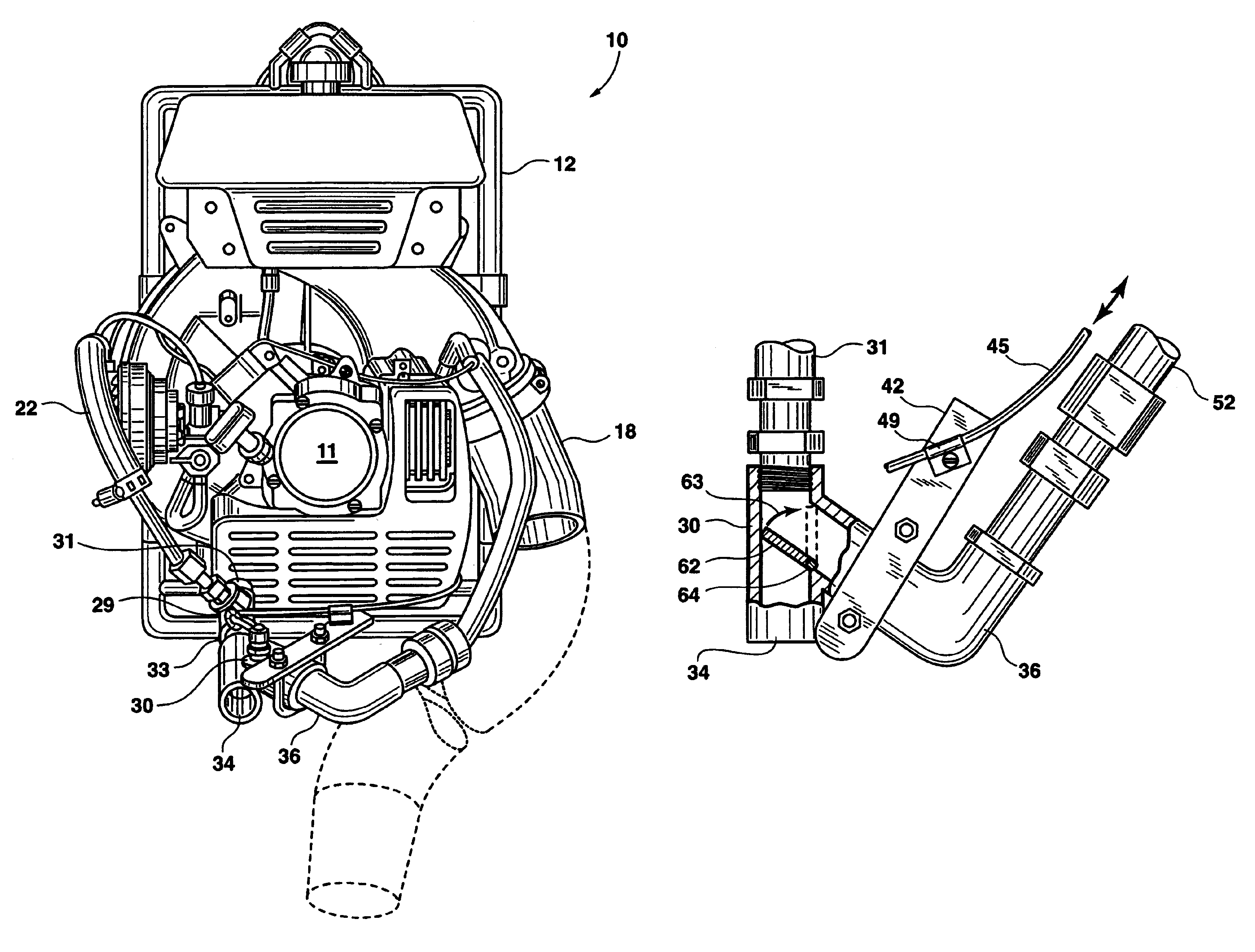

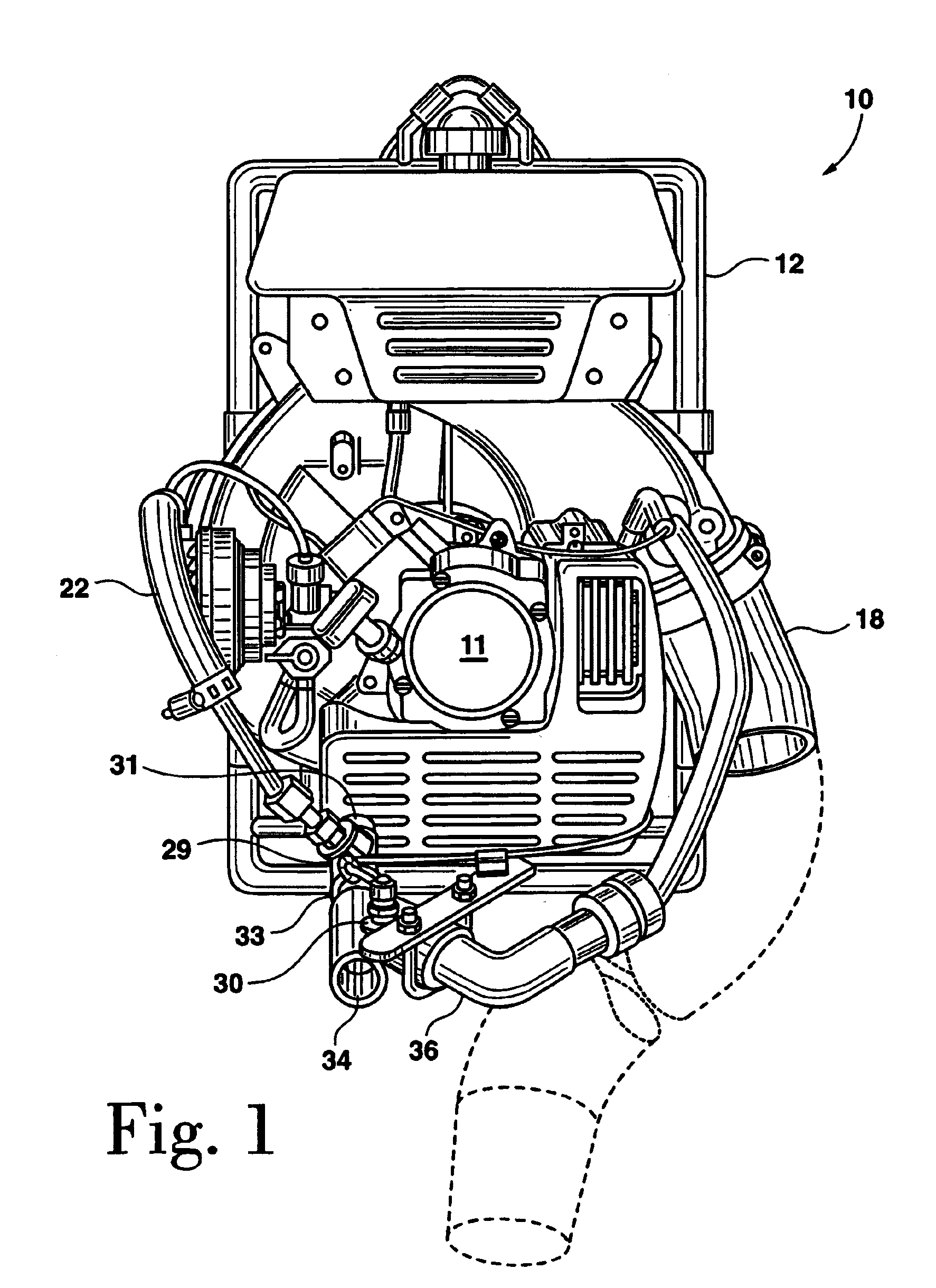

Chain saw

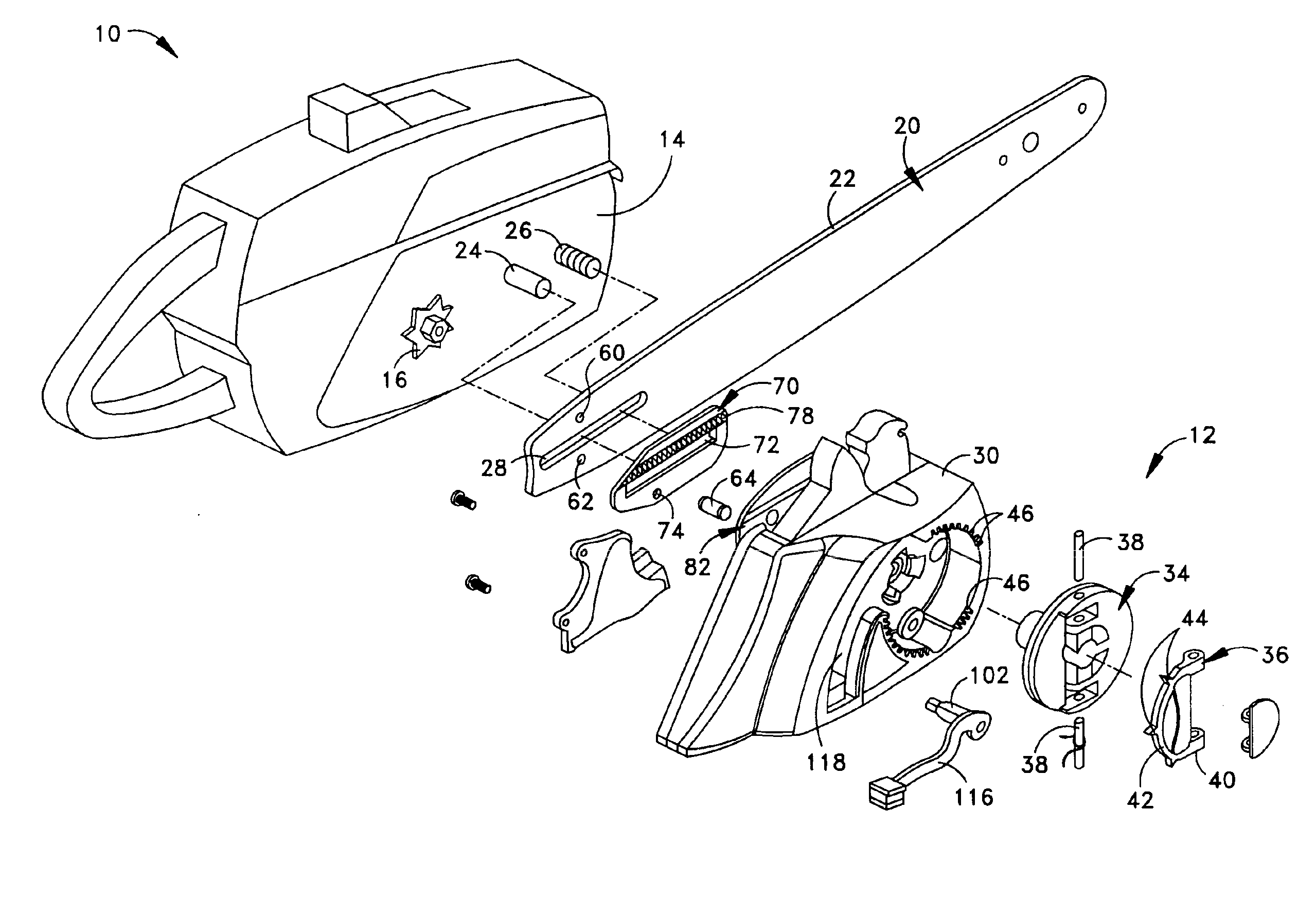

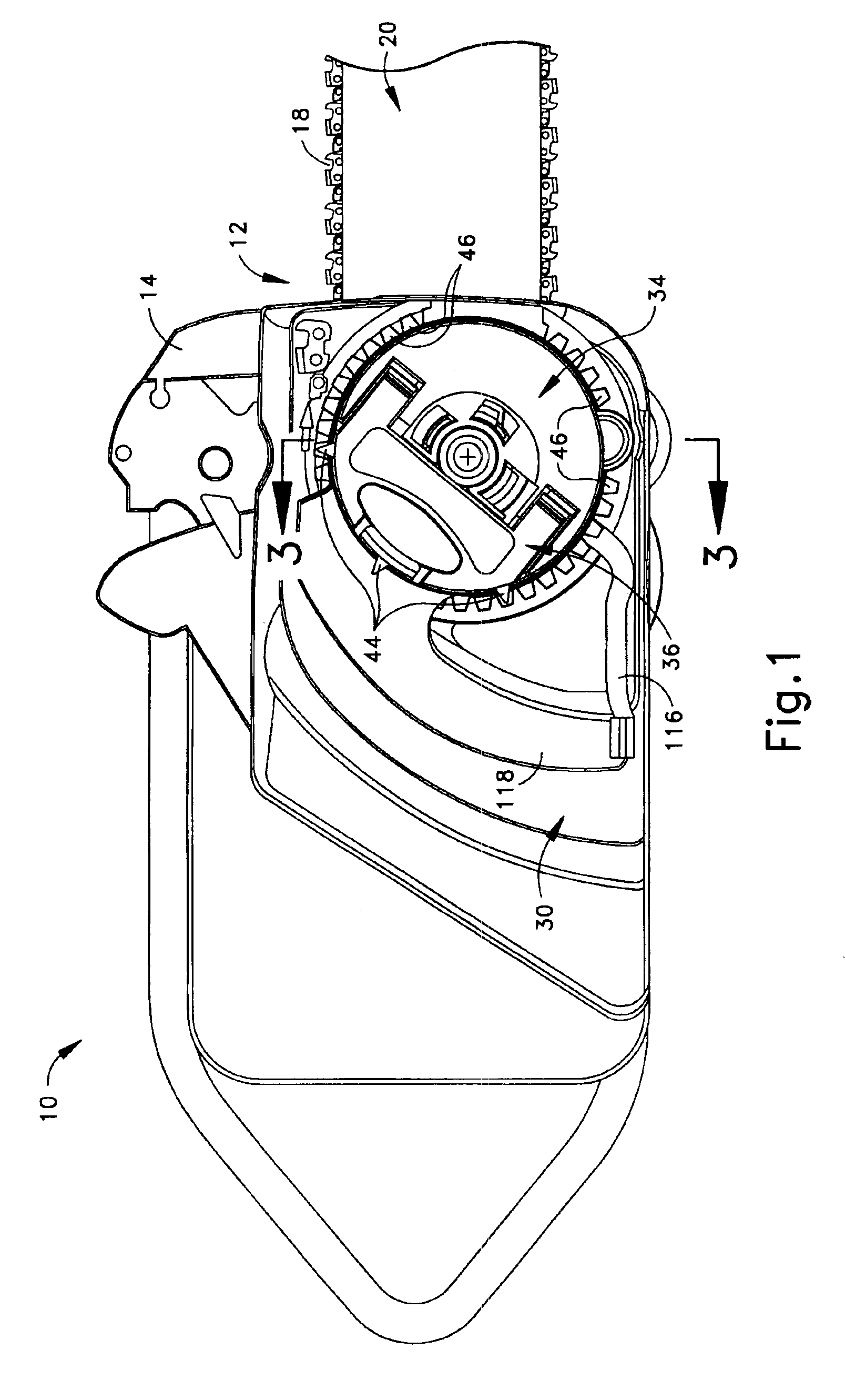

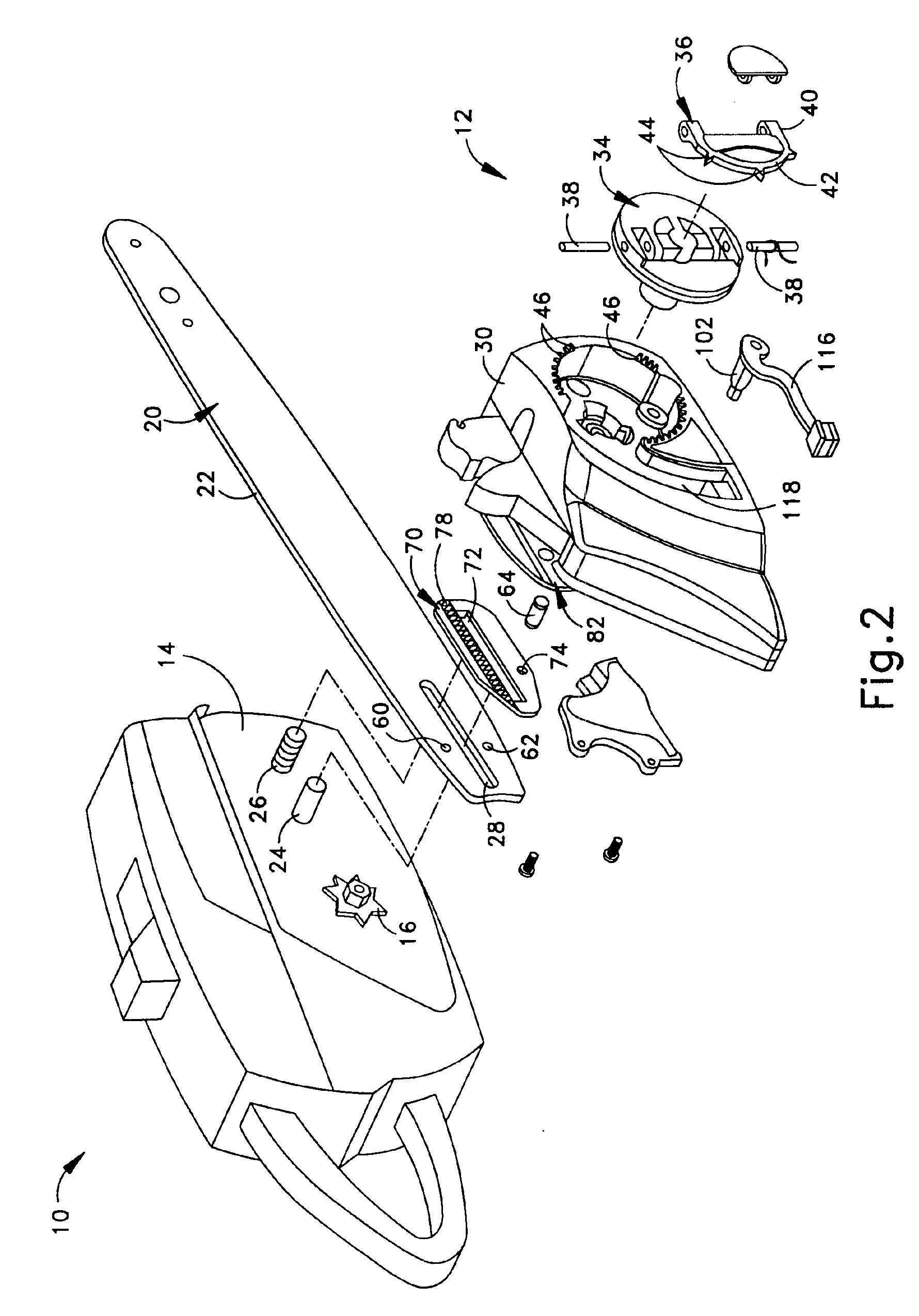

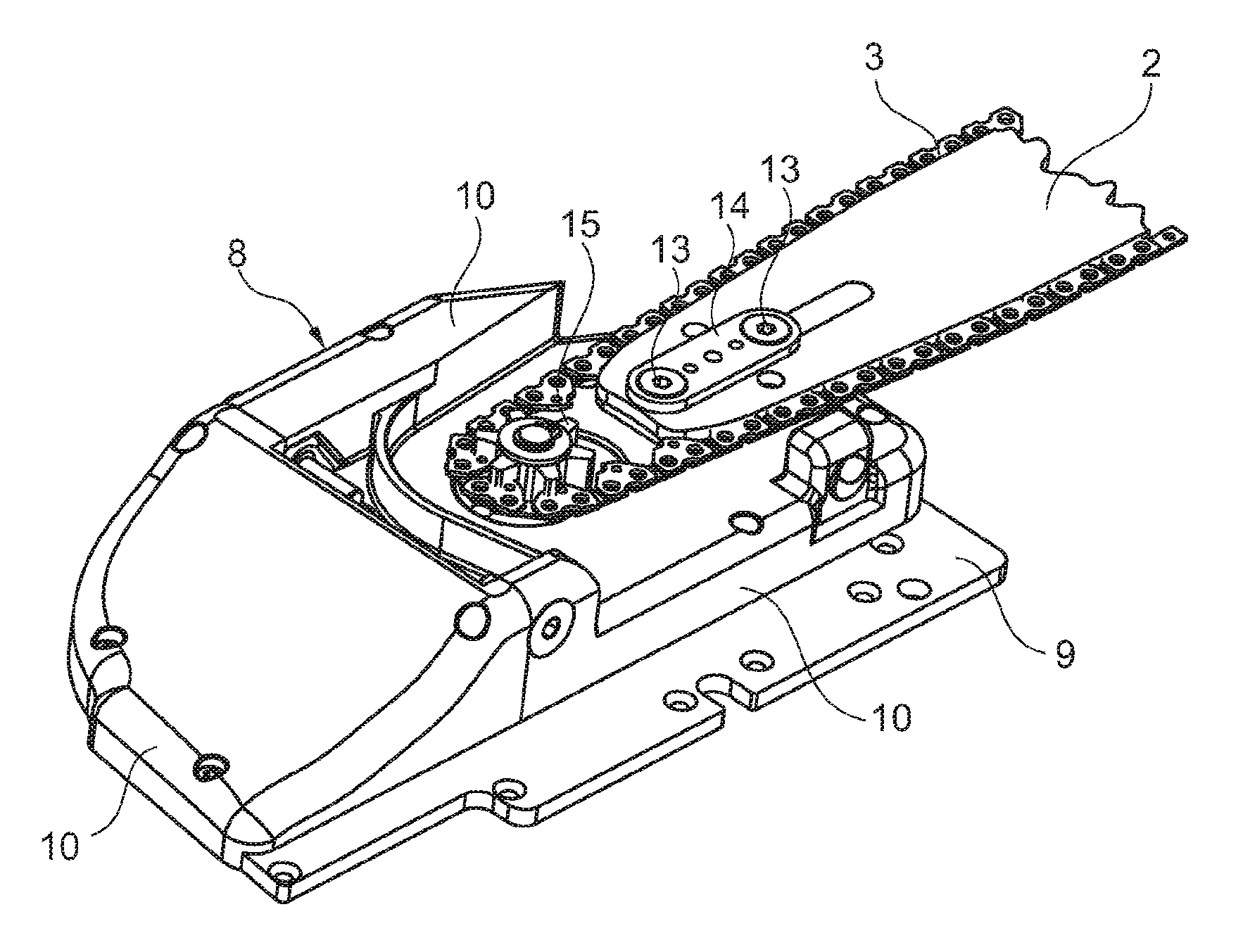

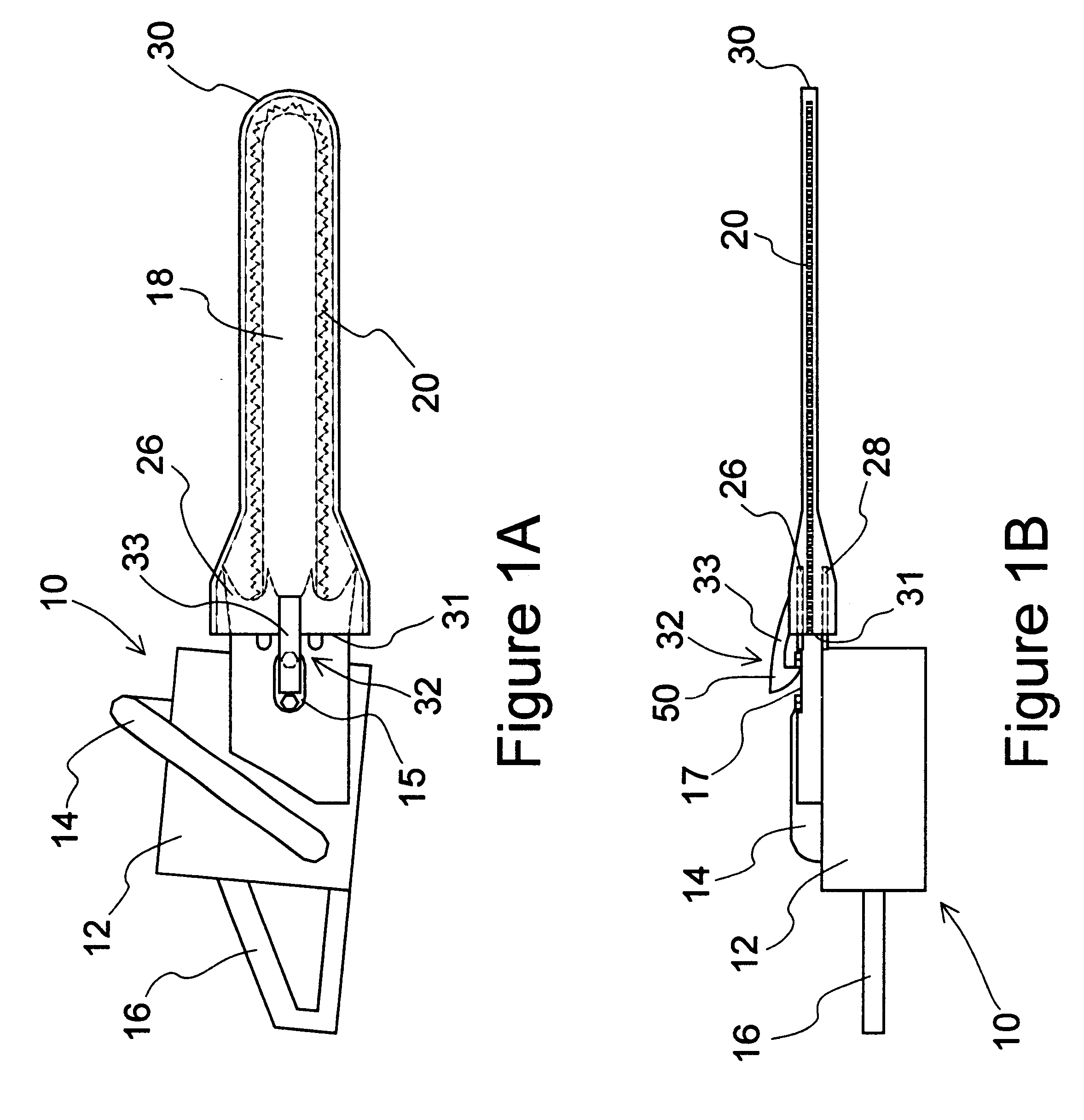

InactiveUS20020124421A1Reduce tensionStable positionMetal sawing devicesMetal sawing accessoriesSprocketEngineering

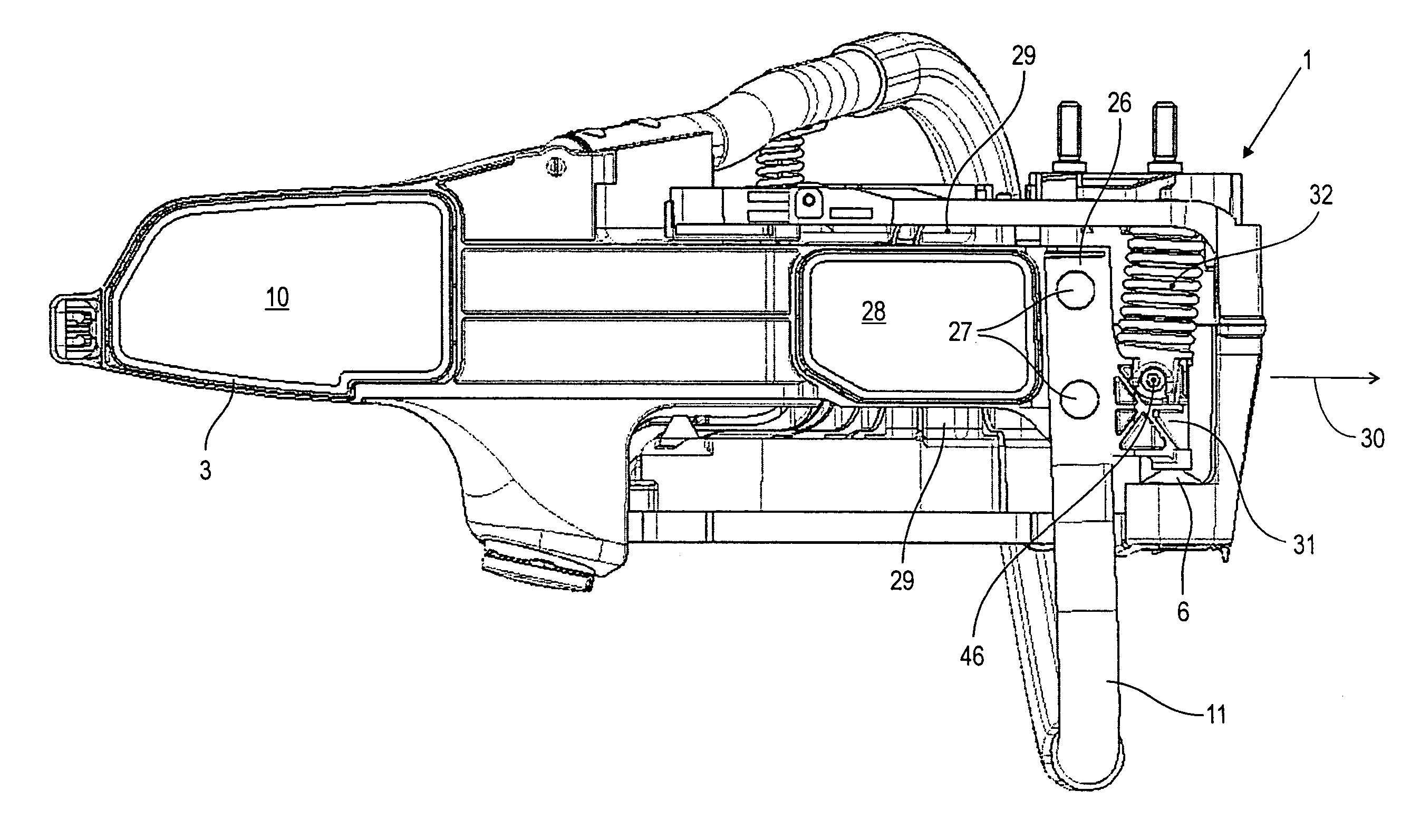

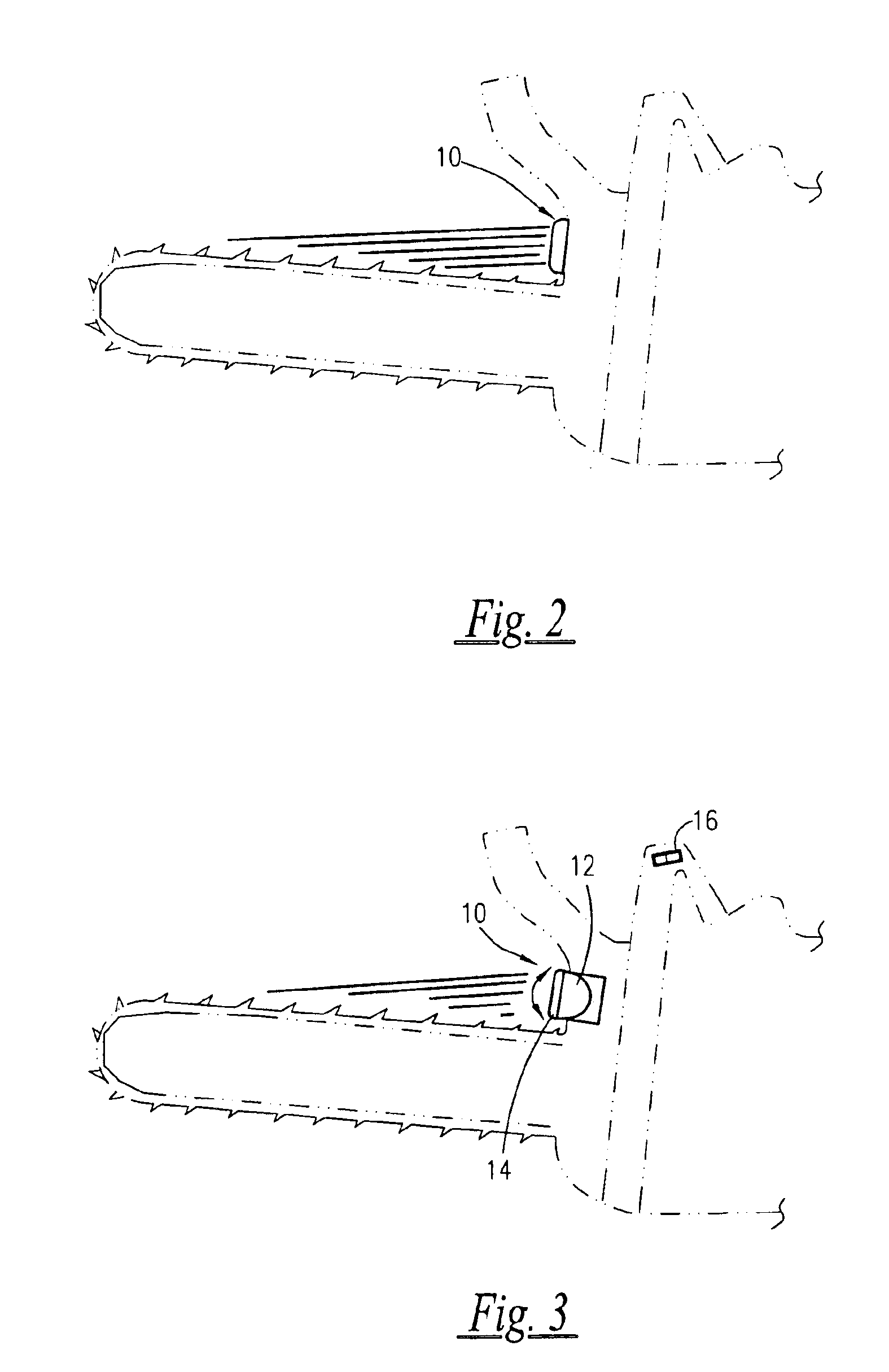

The chain tension of a motorized chainsaw (10) with a housing (12), a sprocket (22) mounted thereon, and a blade (14) that is aligned with this sprocket, which blade protrudes beyond the housing (12) and guides a saw chain (16) engaged with the sprocket (22) in a revolving manner, where the blade (14) is mounted such that it can be adjusted by means of longitudinal displacement in relation to the housing (12) and / or the sprocket (22) by means of a chain tensioning device (28) and where the chain tensioning device (28) has a stop (32) that can be fixed to the blade (14) and a cam (30) that can be rotated by means of a rotational member (36, 38) can be adjusted in a more comfortable and reliable fashion by virtue of the fact that the cam (30) can be locked in a form-fitting and rotationally secure manner in relation to the housing (12) by way of the rotational member (36, 38).

Owner:ROBERT BOSCH GMBH

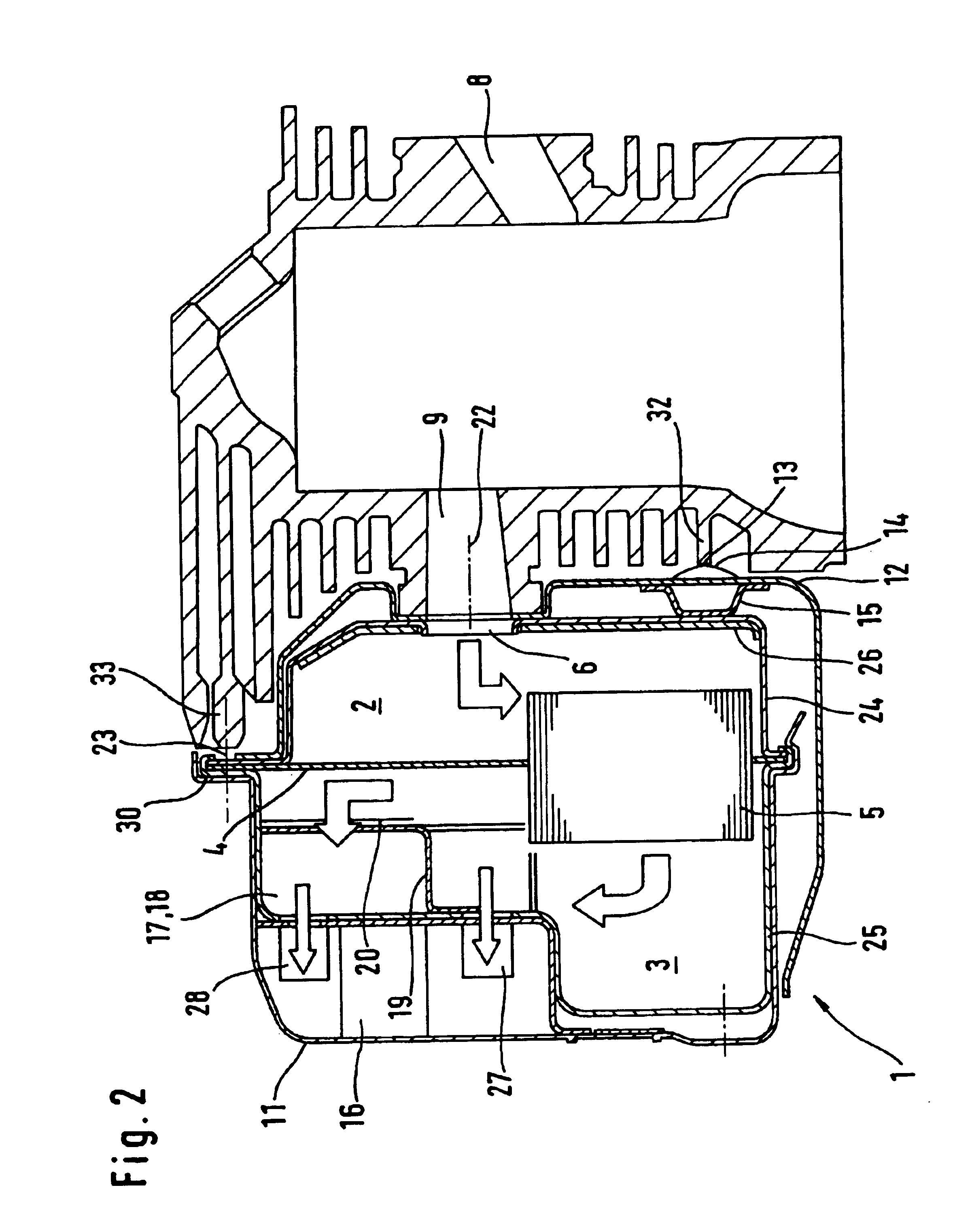

Muffler with catalytic converter

PCT No. PCT / SE96 / 00805 Sec. 371 Date Dec. 19, 1997 Sec. 102(e) Date Dec. 19, 1997 PCT Filed Jun. 19, 1996 PCT Pub. No. WO97 / 01023 PCT Pub. Date Jan. 9, 1997Muffler with catalytic converter (1) essentially arranged in direct connection with a combustion engine's exhaust port and especially intended for portable working tools such as chain saws. At least one partition (2) is embodied in the muffler, or instance in the form of a baffle (3), and the partition (2) comprises one or several apertures (9, 10), through which the exhaust flow passes in order to flow from one side of the partition to the other side, and the partition is at least partly coated with a catalyzing layer.

Owner:ELEXTROLUX +1

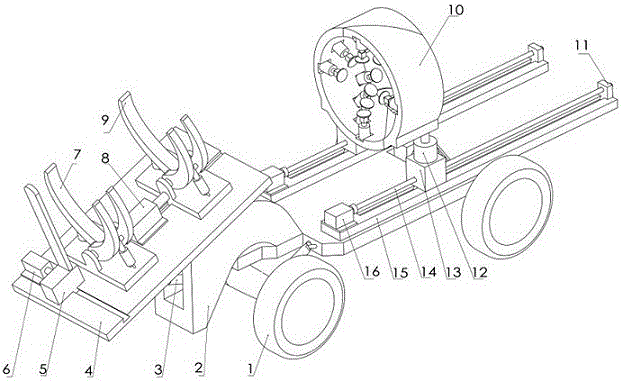

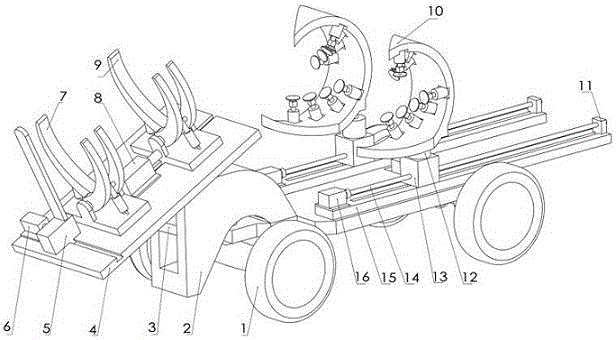

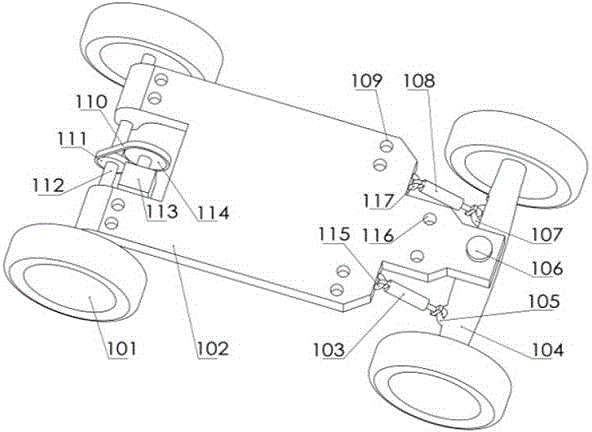

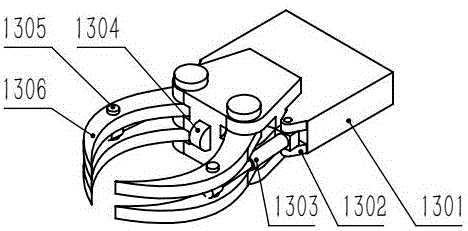

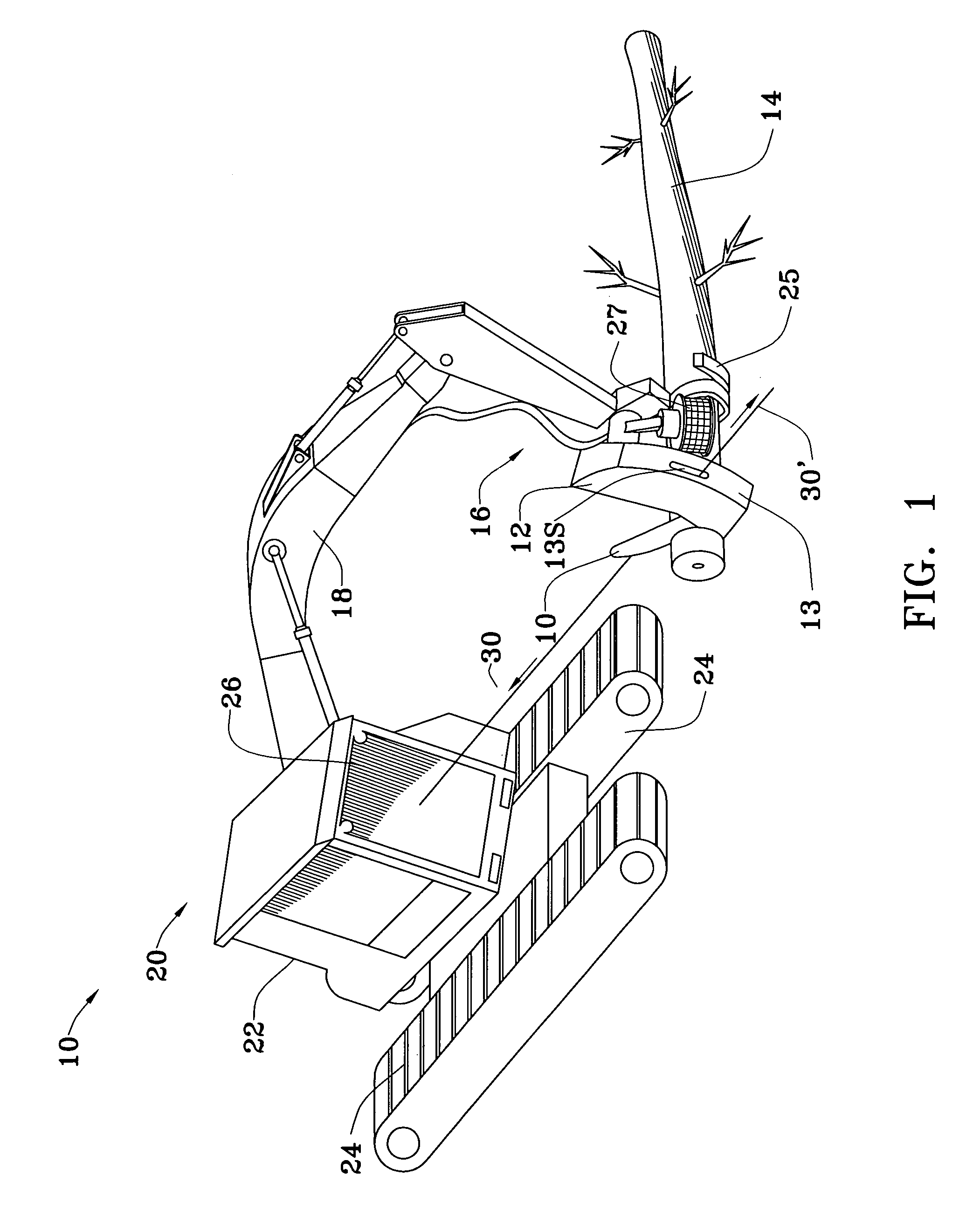

Automatic lumbering and pruning robot

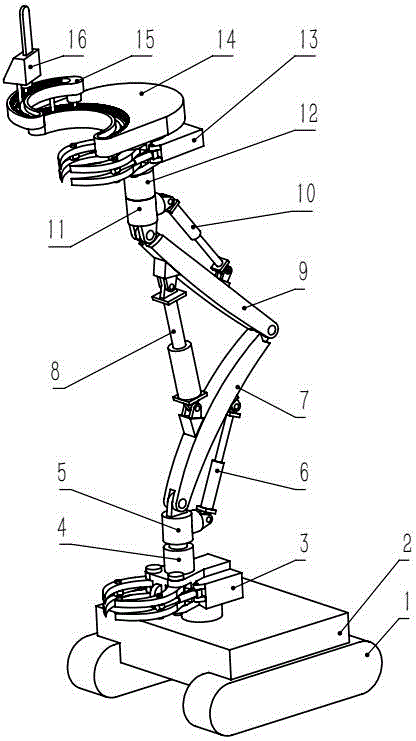

InactiveCN106416930AReduce labor intensityEnsure safetyForestryHydraulic cylinderUltimate tensile strength

The invention discloses an automatic lumbering and pruning robot, comprising a traveling device, a supporting arm, a first hydraulic cylinder, a supporting plate, a chain saw, a first electric cylinder, a first pair of tongs, a second electric cylinder, a second pair of tongs, a pruning device, two lead screw supports, two first stepper motors, two sliding supports, two lead screws, two track boards and two second stepper motors. The automatic lumbering and pruning robot can achieve automatic operation of lumbering, pruning and fixed-scale cutting, thus improving the work efficiency greatly, reducing the labor intensity of workers, and guaranteeing the safety of the workers to the greatest extent.

Owner:徐洪恩

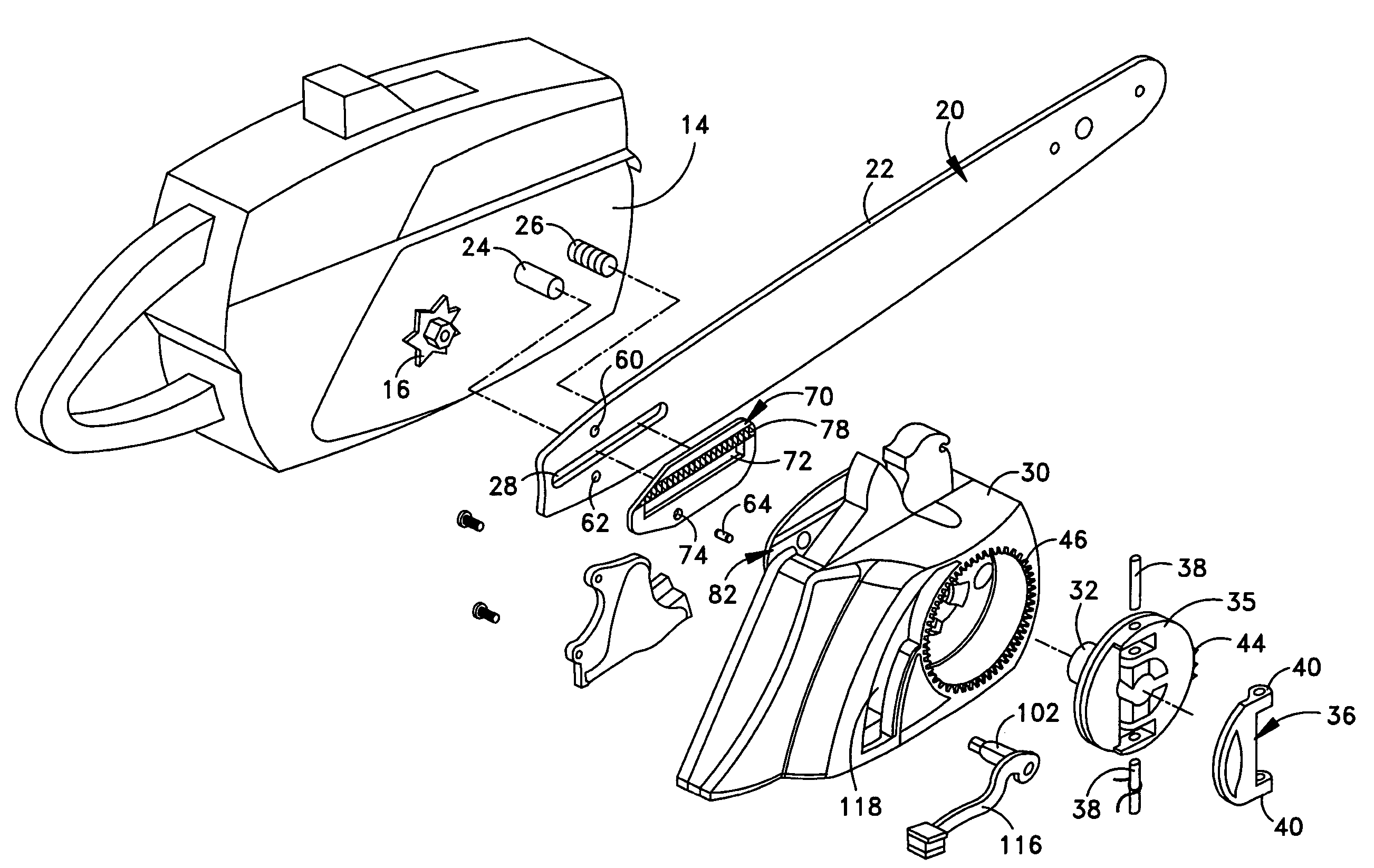

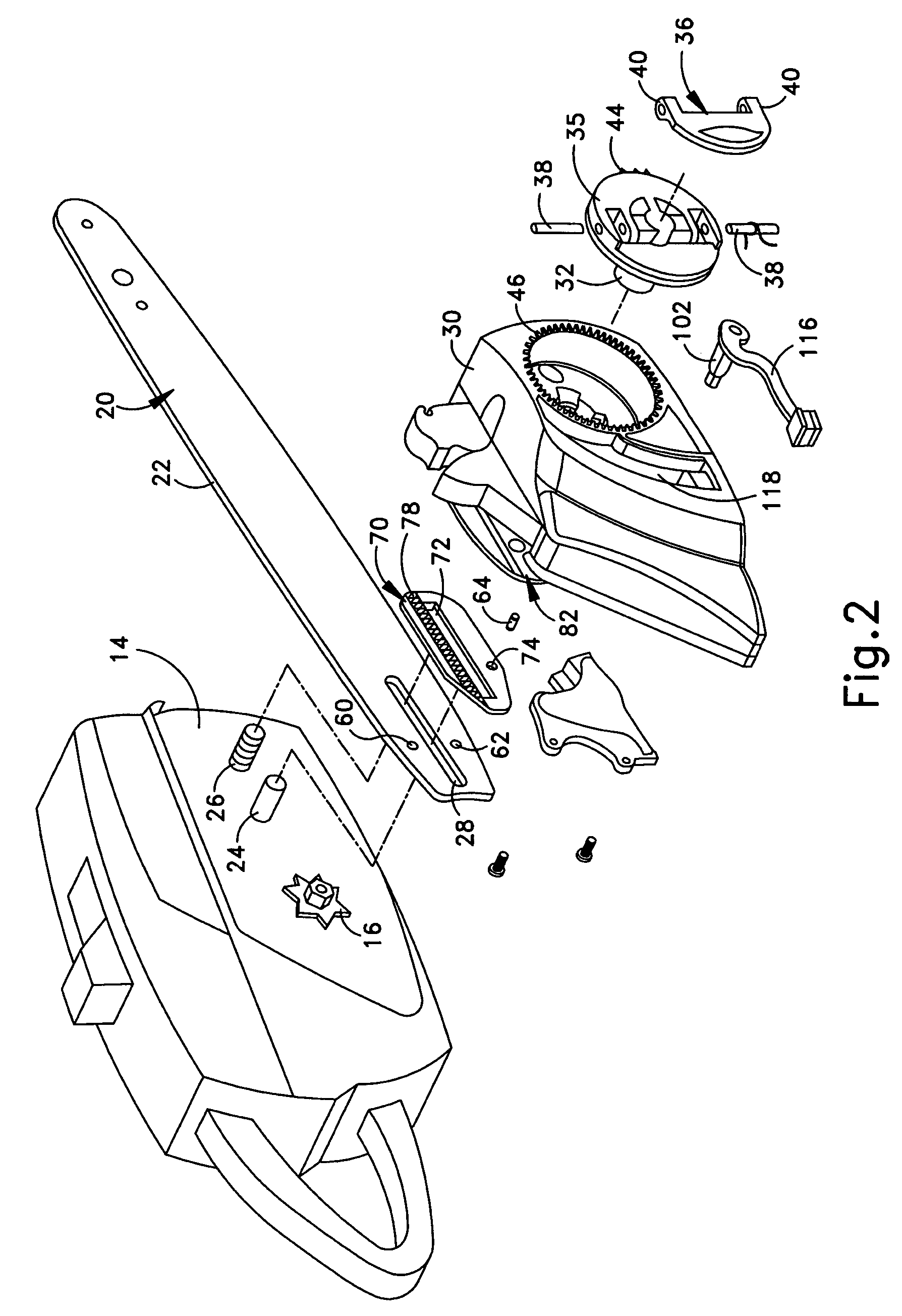

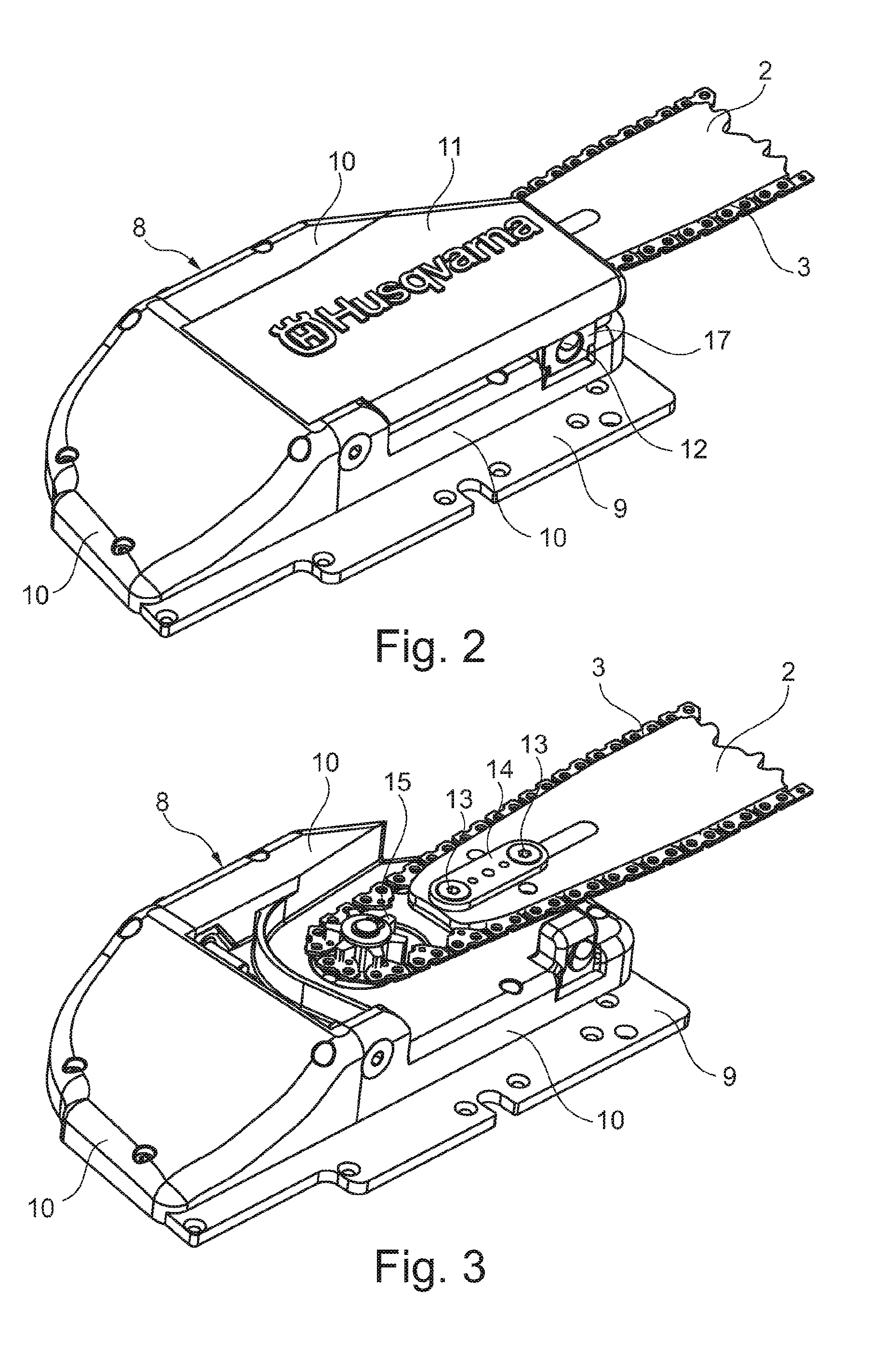

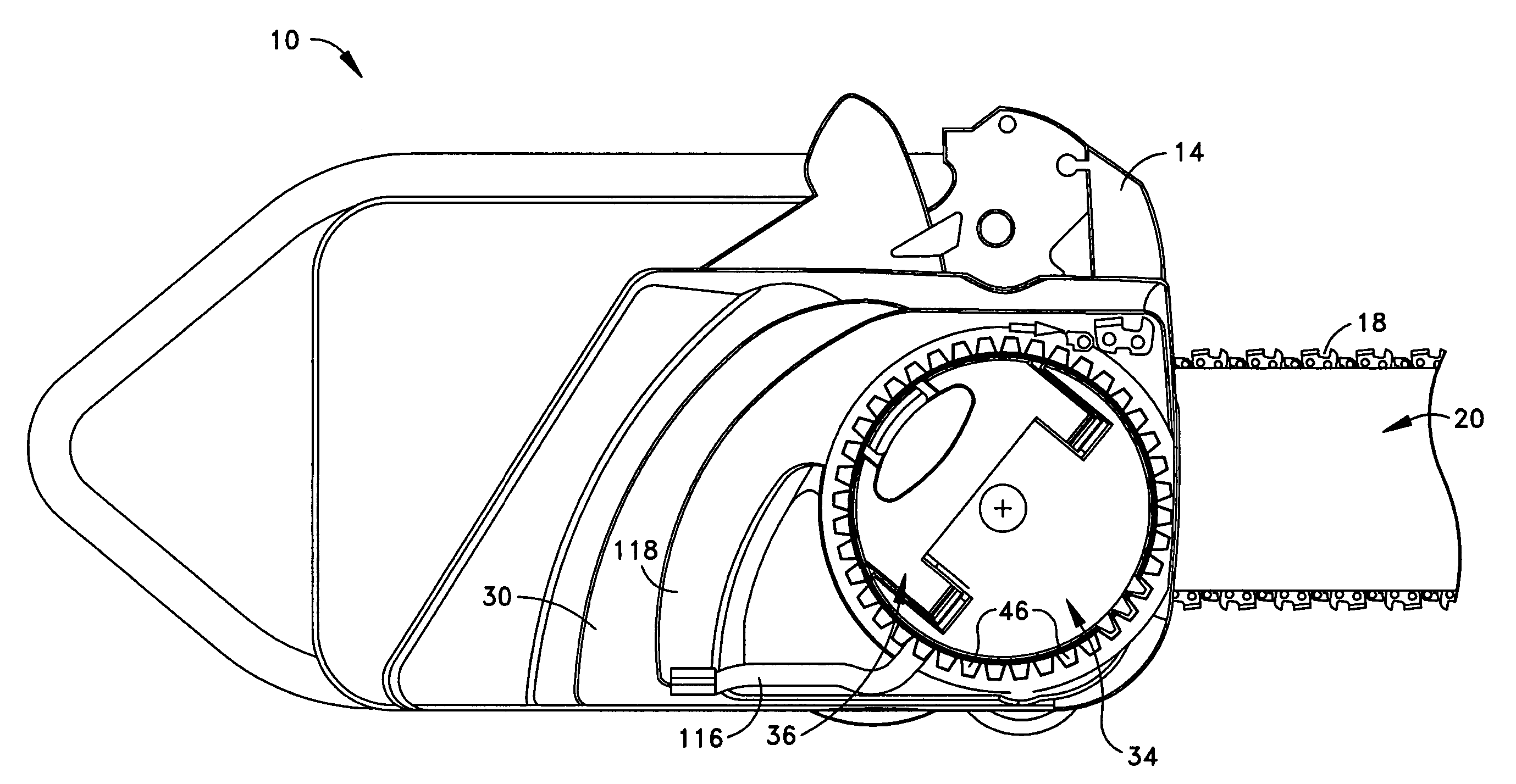

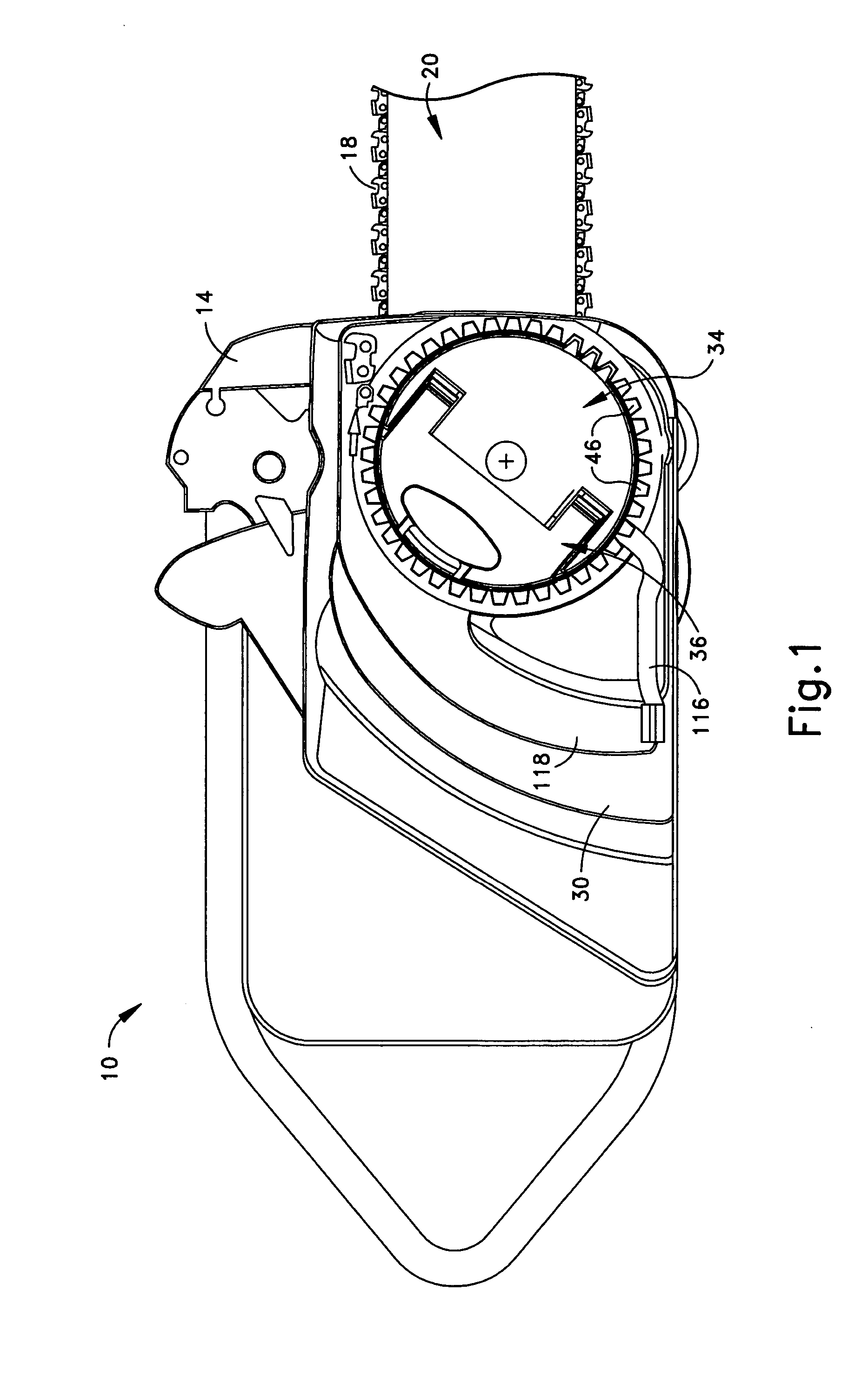

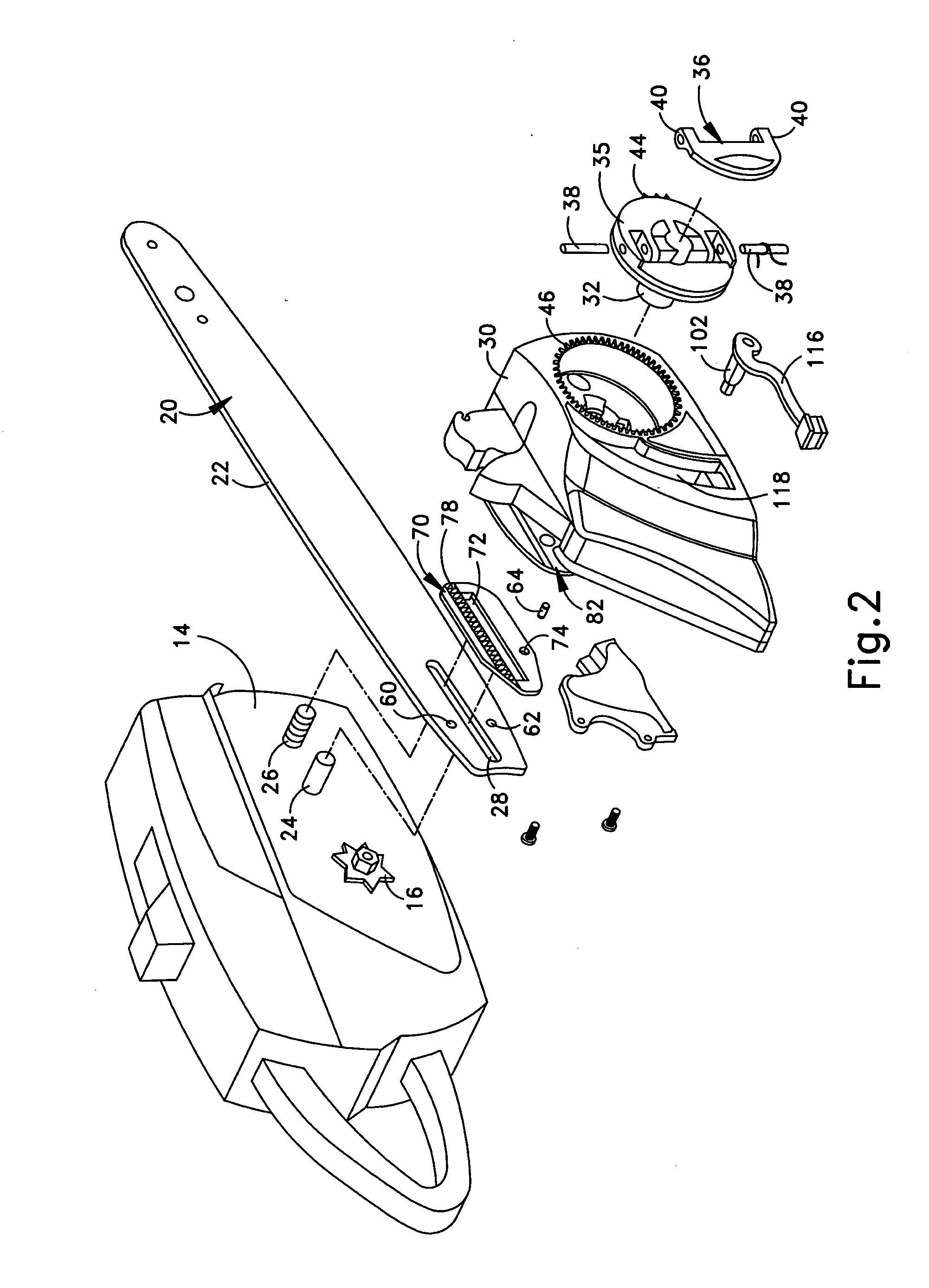

Chain saw adjuster mechanism with locking teeth

InactiveUS6877233B1Improved ease of movementTightening torqueMetal sawing devicesMetal sawing accessoriesEngineeringChain saw

A tensioning mechanism for adjusting tension of a cutting chain in a chain saw. A rotatable knob operates with an engine chassis, clutch cover, and guide bar, whereby the knob may be rotated between a tightened position and loosened position, by which the guide bar is loosened and may be adjusted. The knob is provided with a knob handle, pivotally connected to the knob and pivotable between locked and unlocked positions. When the knob handle is in the locked position, at least one, but not all, of a plurality of handle engagement points engage with corresponding fixed engagement points that are fixed relative to the clutch cover. When the knob handle is in the unlocked position, the handle engagement points are disengaged from the fixed engagement points. Further, the engagement points are visible when the knob handle is in both locked and unlocked positions.

Owner:HUSQVARNA OUTDOOR PROD INC

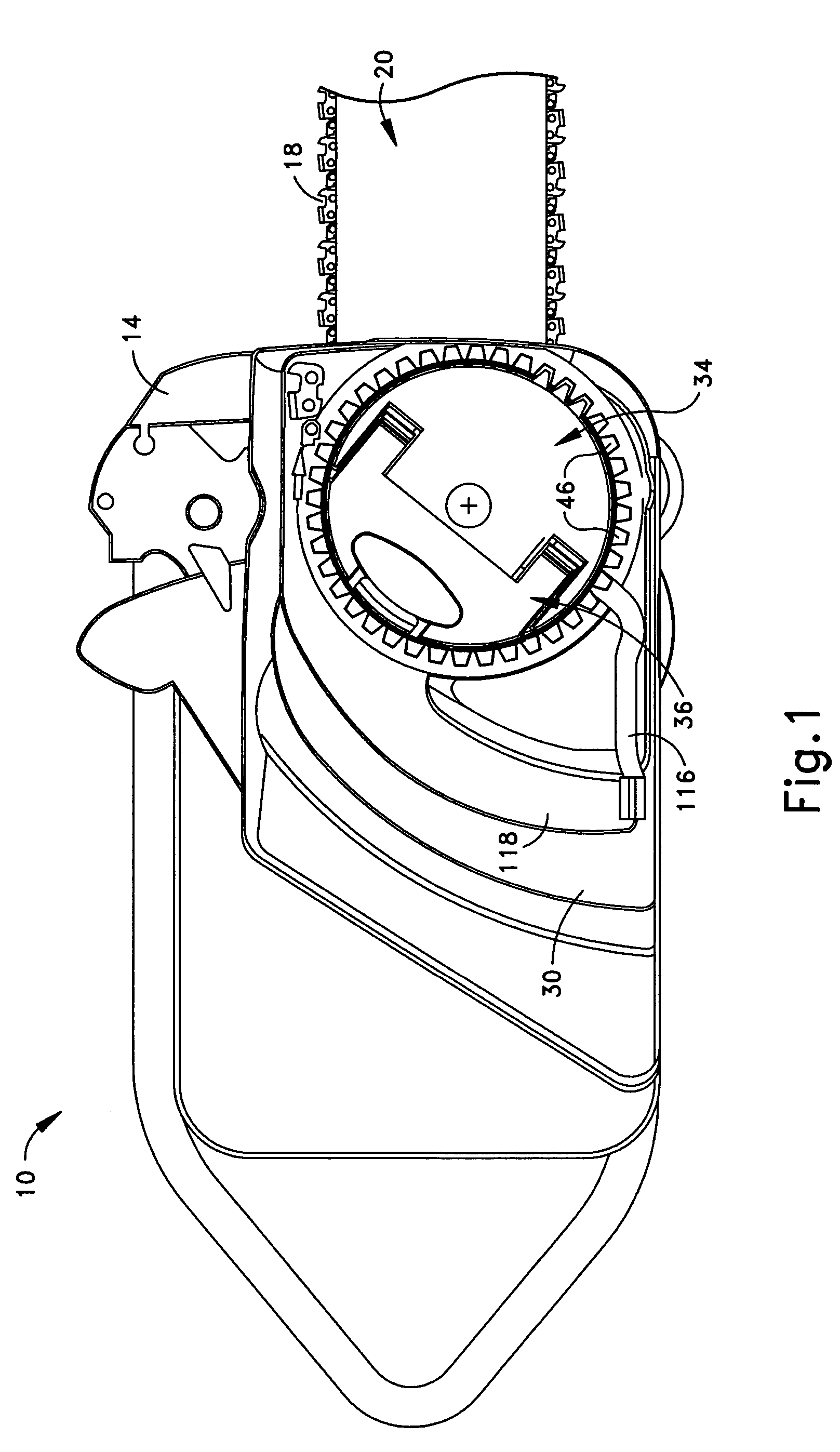

Bar knob with cam-operated locking mechanism

InactiveUS7434502B2Positive securing of the knobMetal sawing devicesMetal sawing accessoriesLocking mechanismEngineering

A chain saw includes a retaining assembly for a tensioning arrangement for adjusting the tension of the cutting chain in the chain saw. The retaining assembly includes a rotatable knob for operation with the chain saw's engine chassis, clutch cover, and guide bar and is rotatable about an axis of rotation between a tightening position for holding the guide bar in place and a loosening position enabling the guide bar to be repositioned whereby the tension in the cutting chain is adjusted. A locking mechanism is provided for locking and unlocking the knob. When the locking mechanism is in a locking position, moveable engagement points of the locking mechanism extended beyond the confines of the knob and engage fixed engagement points. When the locking mechanism is in the unlocking position, the moveable engagement points, having moved inwardly of the confines of the knob, are disengaged from the fixed engagement points.

Owner:HUSQVARNA OUTDOOR PROD INC

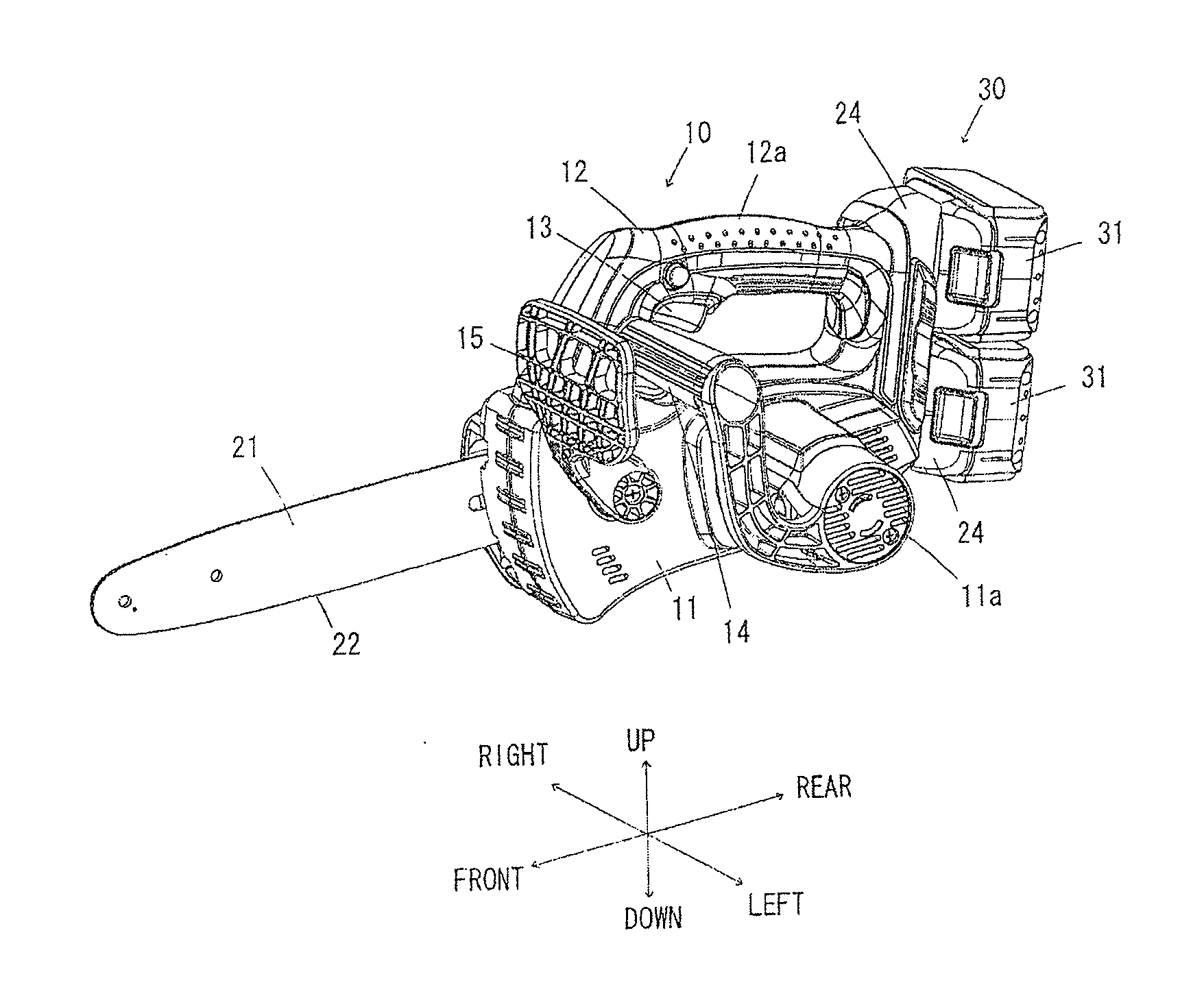

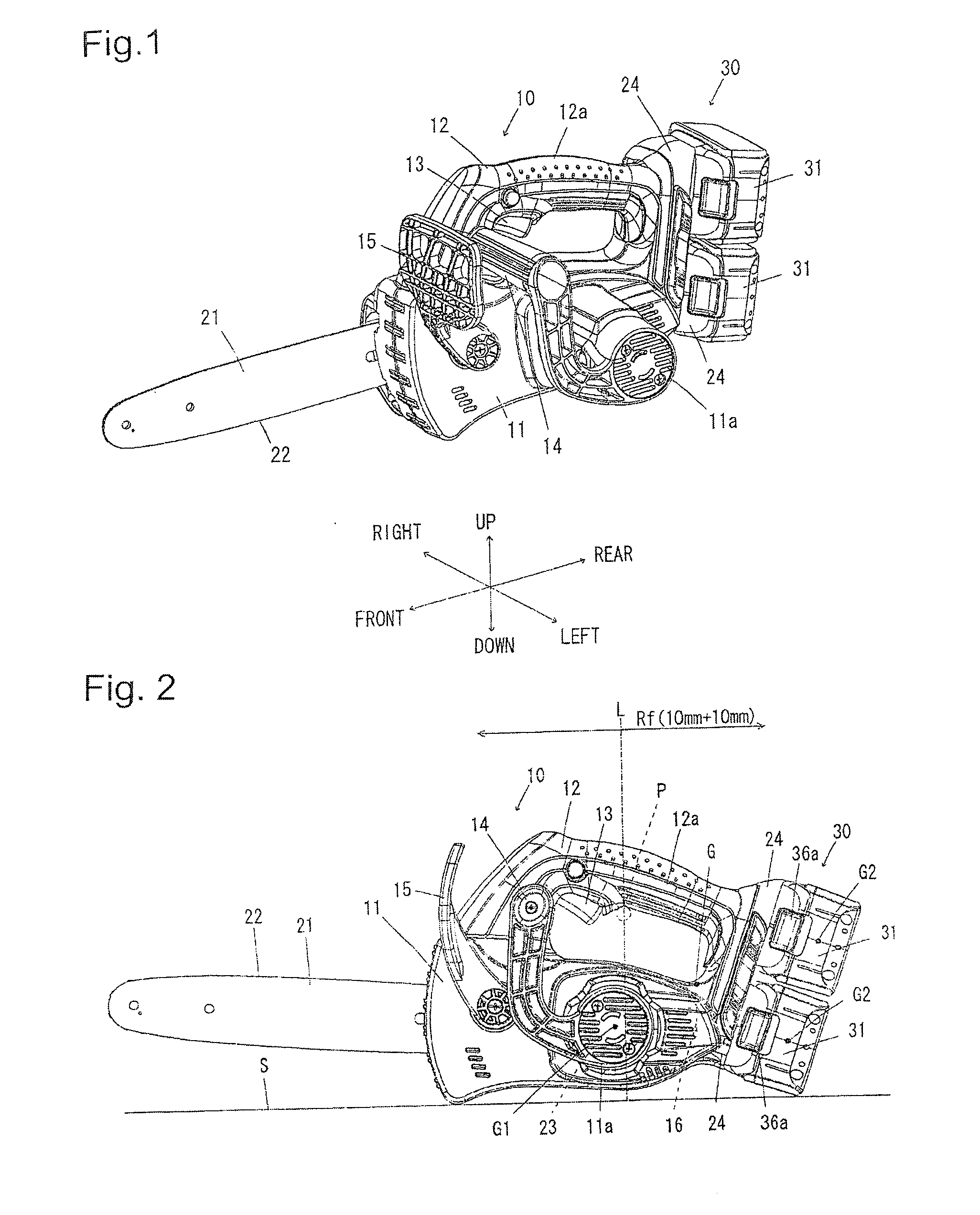

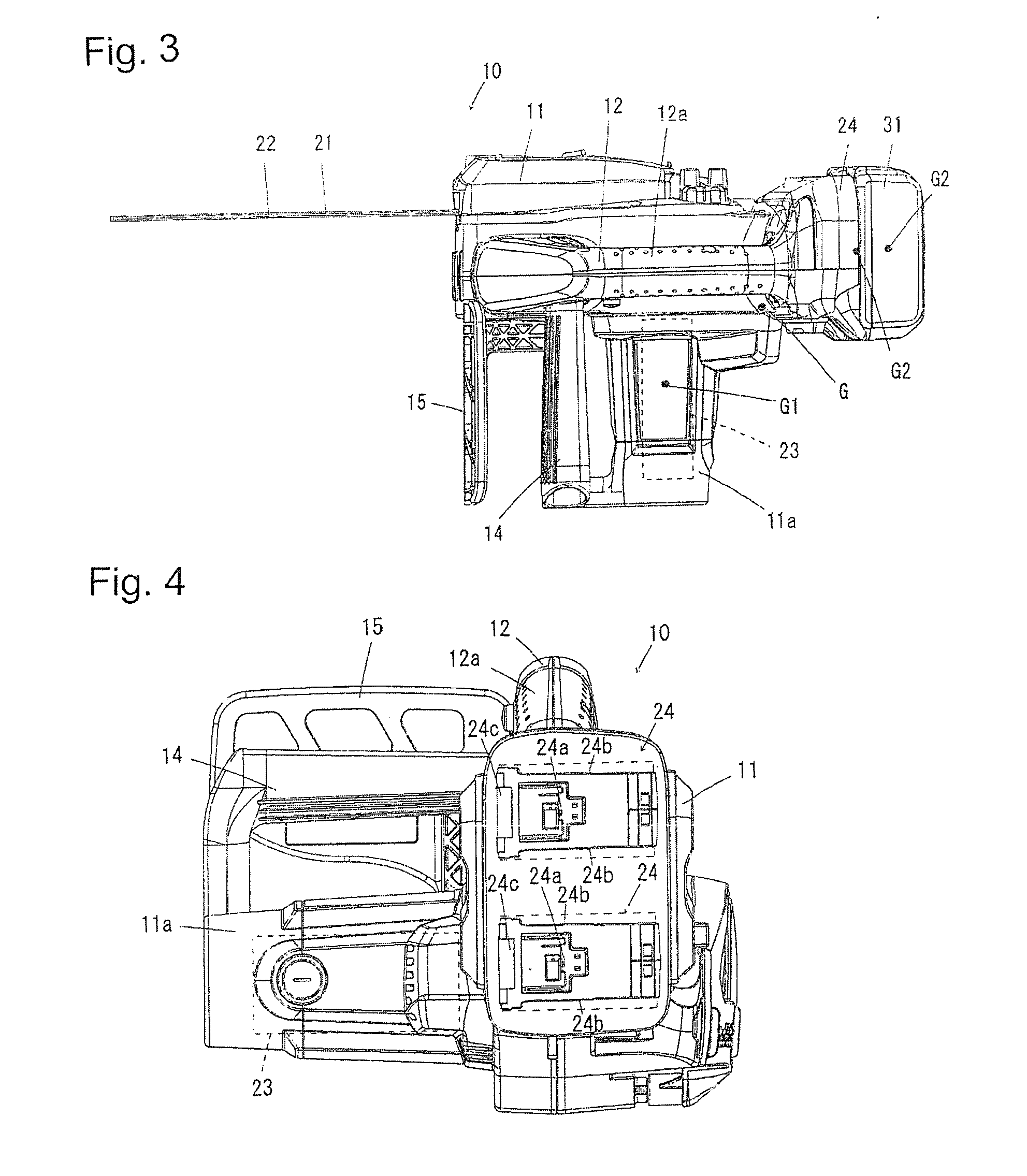

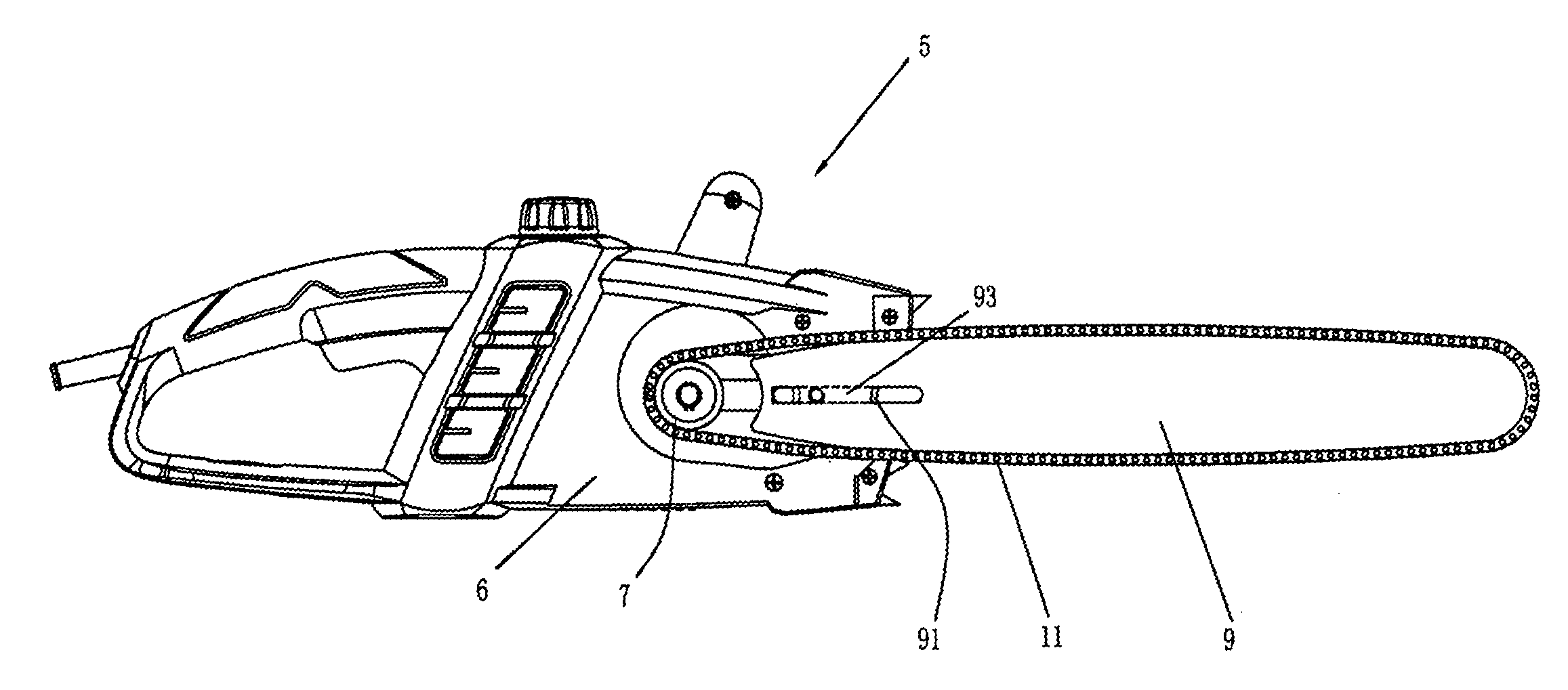

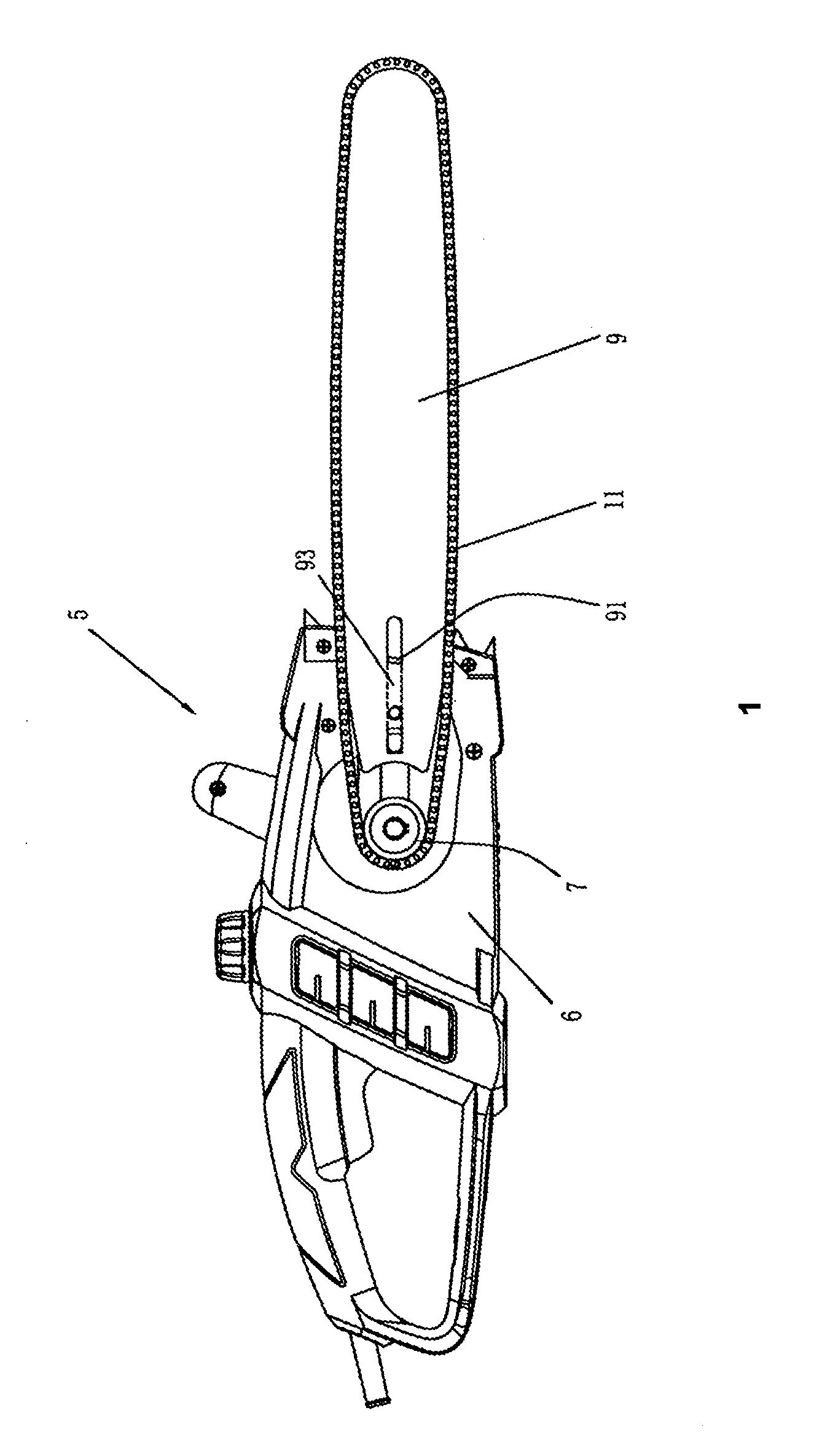

Chainsaw

ActiveUS20150375416A1Easy to operateEasy to removeMetal sawing devicesMetal sawing accessoriesRechargeable cellEngineering

A chainsaw includes a body housing, an elongated guide bar projecting forward from the body housing, a saw-chain mounted on the periphery of the guide bar for rotation, an electric motor mounted within the body housing for rotating, and a top handle provided on an upper portion of the body housing above the guide bar and extending in a fore-and-aft direction. A plurality of rechargeable battery packs is mounted on the body housing as a source of power supply for the electric motor. The battery packs are mounted to the body housing in such a manner that a center of gravity of the chainsaw observed from the back side is positioned in a two times extent of lateral width of a gripe portion of the top handle at both sides of a vertical centerline of the gripe portion.

Owner:MAKITA CORP

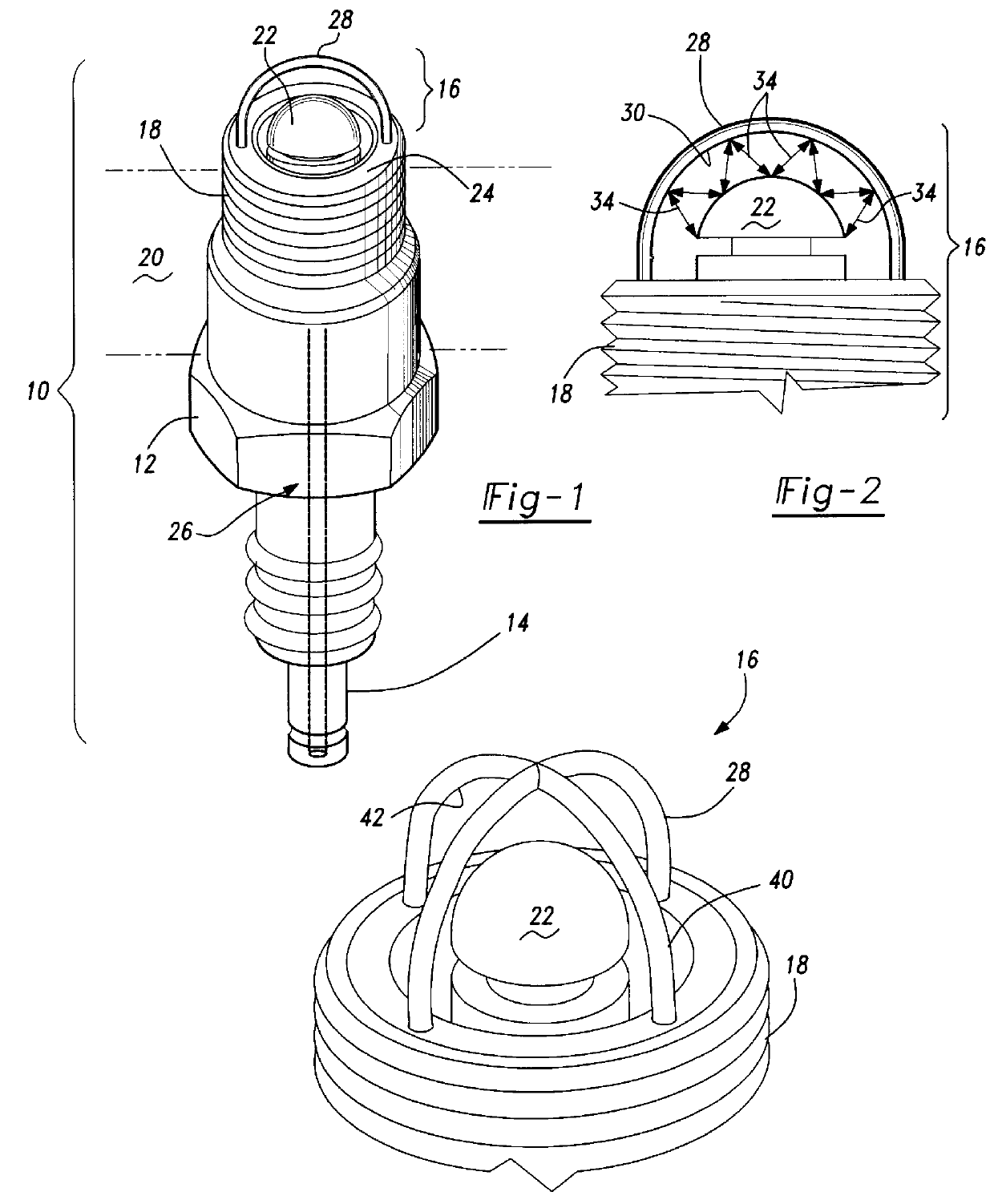

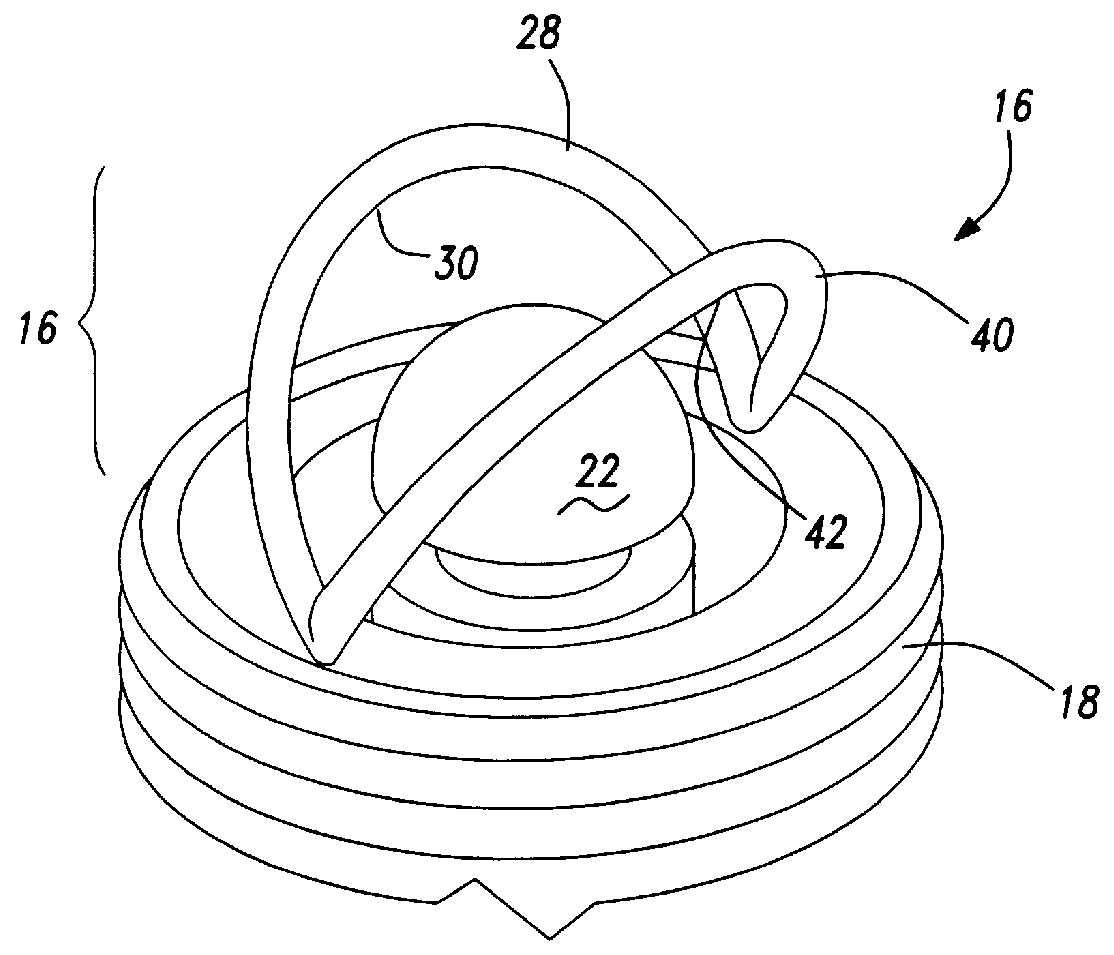

Spark plug

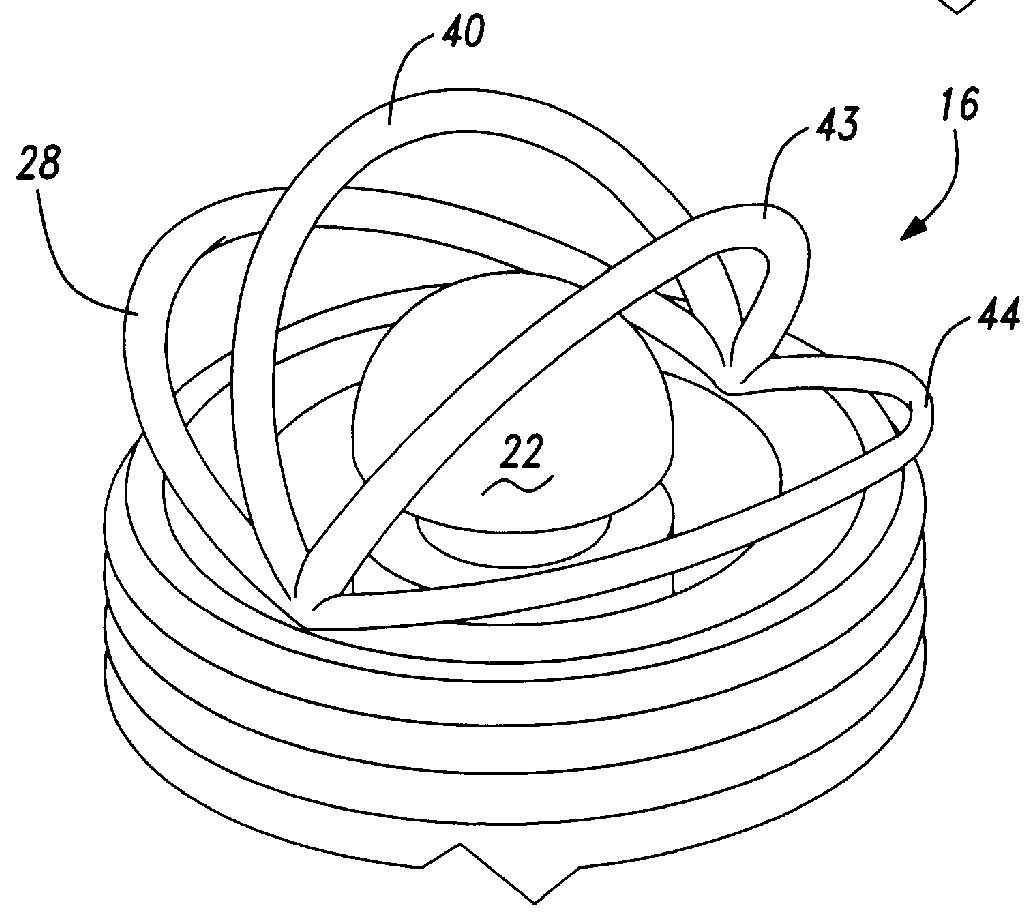

A very unique universal bi-directional firing spark plug for any spark ignited internal combustion engine, whether racing, industrial, truck, aeronautical, automotive, recreational or residential (for trimmers, edgers, brush cutters, leaf blowers, leaf vacuums, chain saws, augers, tillers, lawnmowers, riding mowers, tractors, generators, etc.). This spark plug eliminates misfire and improves gas mileage, peaks engine performance, horsepower, and increases the RPM range, while utilizing and enhancing current ignition systems. In addition, this spark plug serves as a low emission device that reduces the effects of global warming, acid rain, and smog via greatly reduced emissions through vastly improved fuel combustion within all internal combustion engines by operating at a 24:1 air-to-fuel ratio. This unique spark plug is comprised of an elongated or non-elongated body with an electrical connector at one end. An absolute aerodynamic semispherical dome or sphere electrode is secured to the other end of the body. At least one absolute aerodynamic semicircular electrode is also secured to the body adjacent to the dome or sphere electrode such that the semicircular electrode has its inner surface equidistantly spaced from the dome or sphere electrode's surface. The electrodes can be fabricated from various metals, alloys, and / or precious metals and can also be coated with various metals, alloys, and / or precious metals. Alternate embodiments of the invention include two, three or four or more semicircular electrodes, all of which have a surface equidistantly spaced from the aerodynamic semispherical dome or sphere electrode along its complete arc length.

Owner:CG PEGASUS HANGER

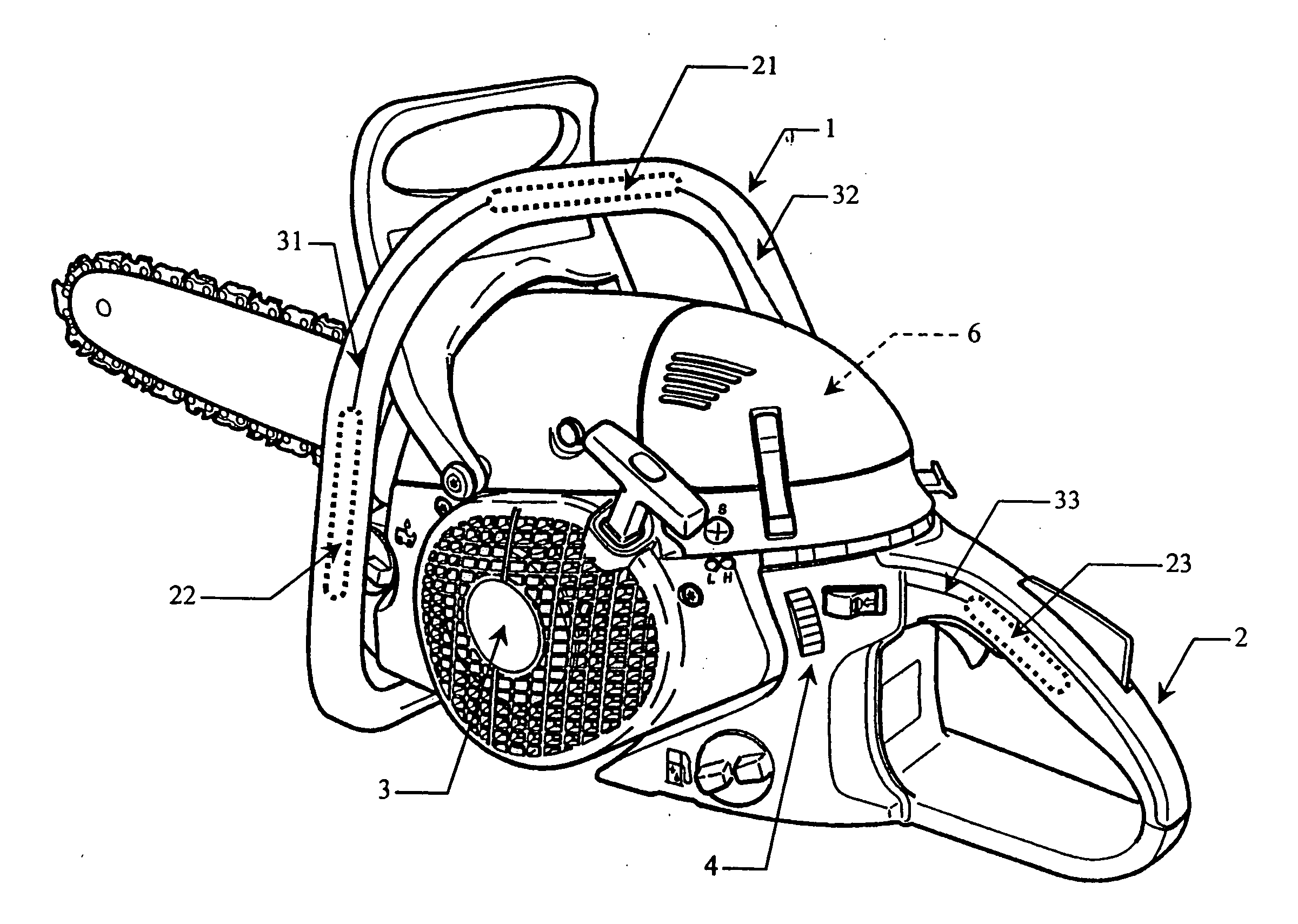

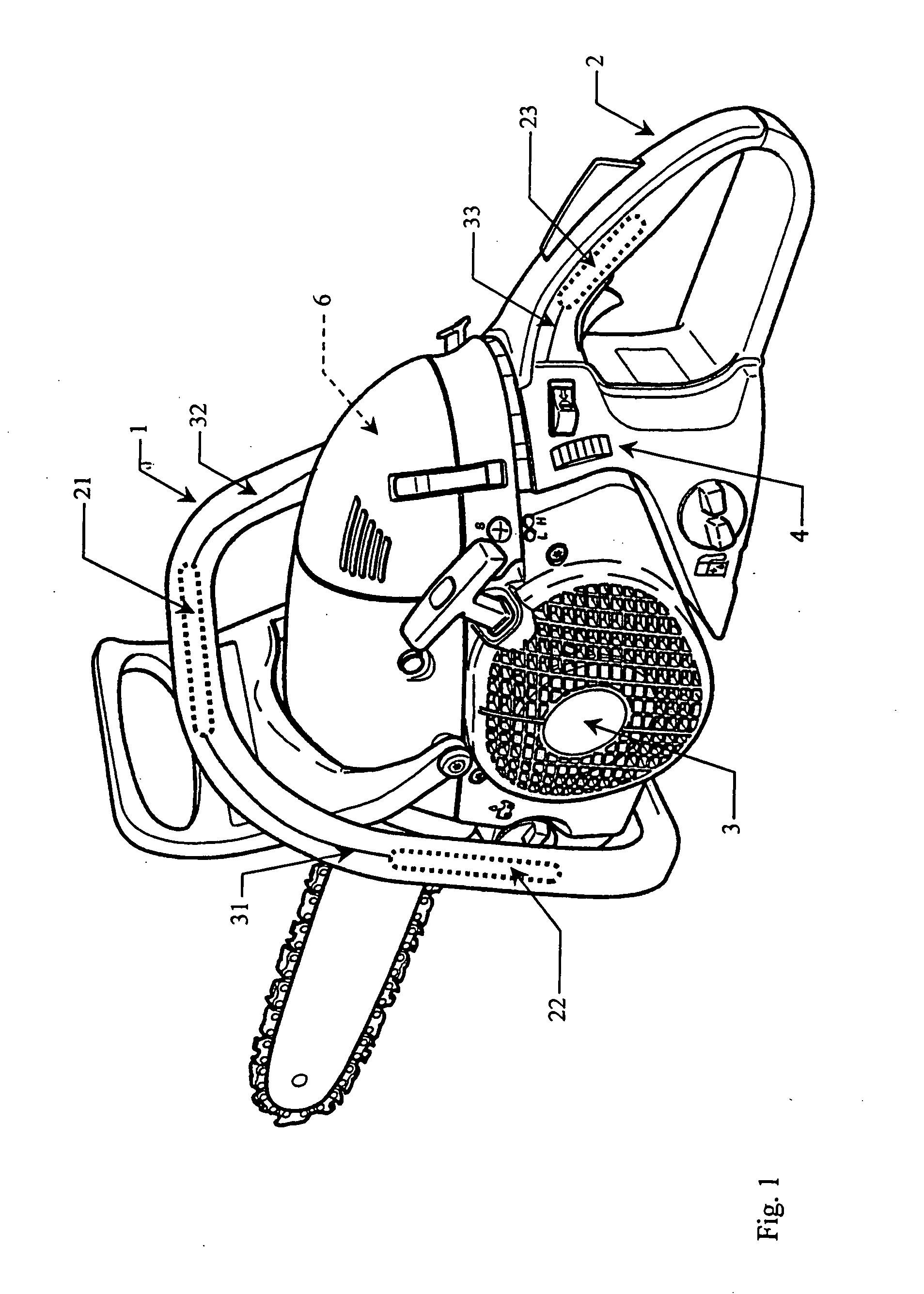

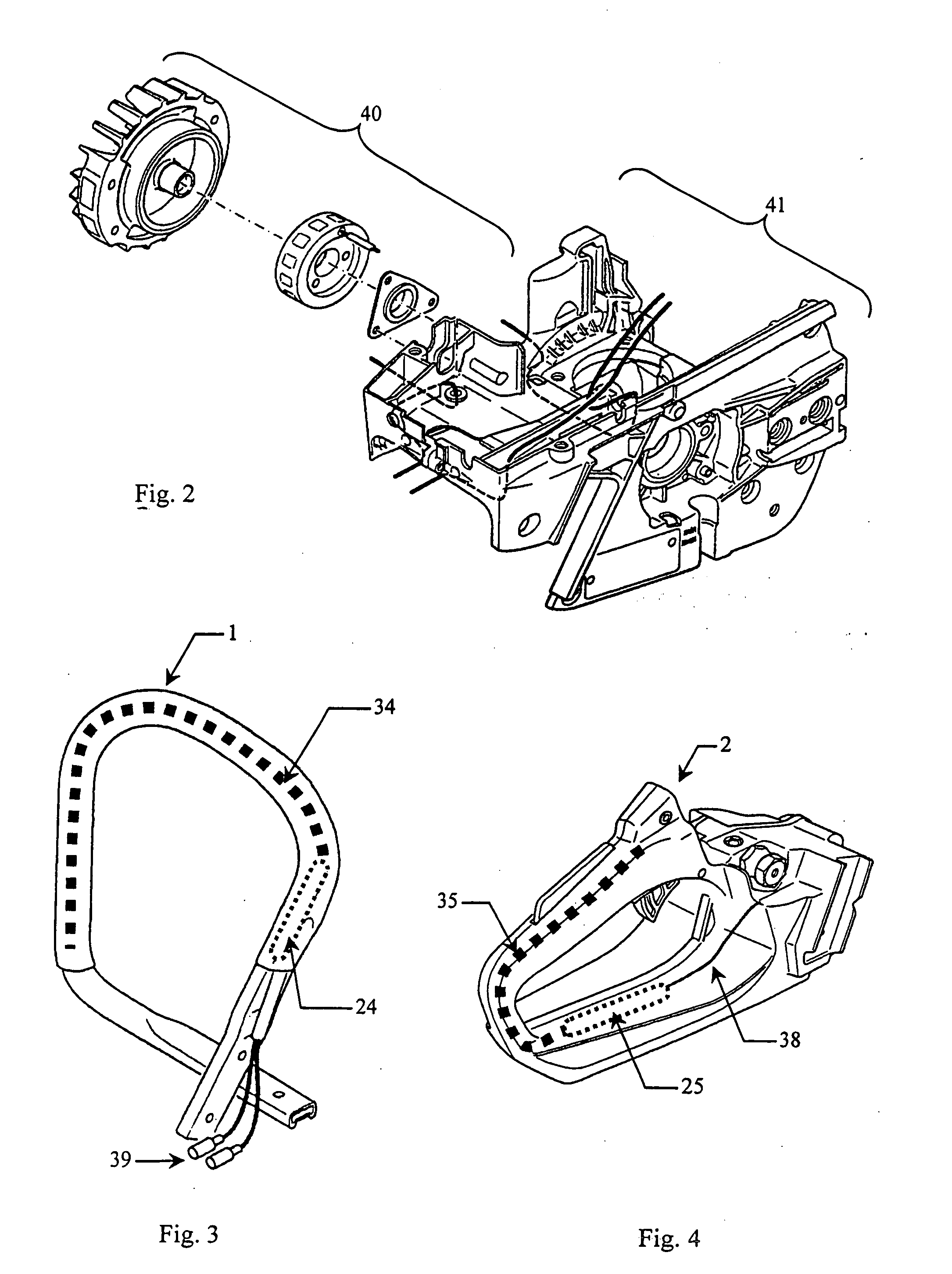

Antivibration device

InactiveUS6994068B2Level of tension is lowEfficient constructionMetal sawing devicesAir coolingMotor driveInternal combustion engine

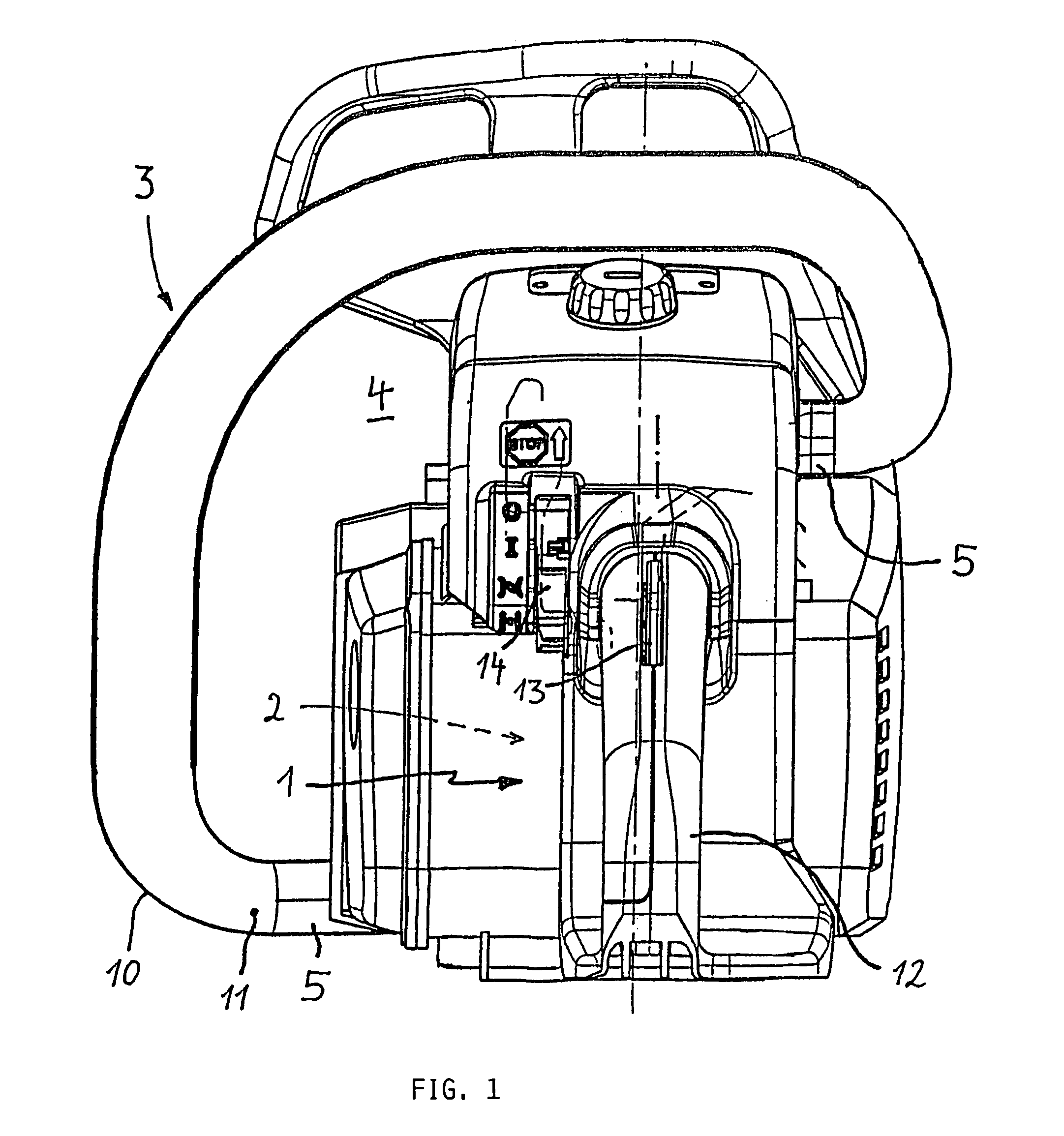

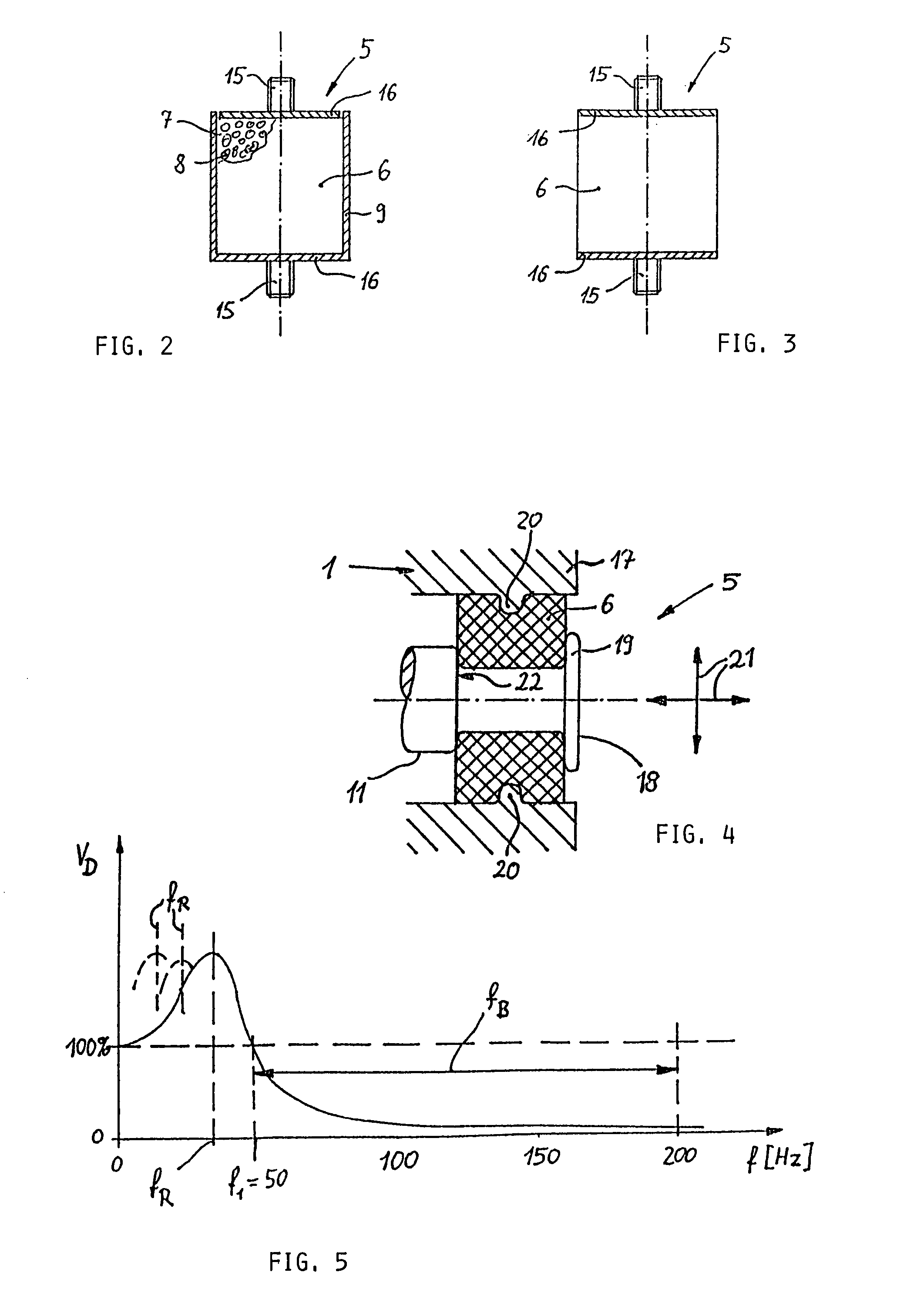

An antivibration device is mounted between a motor unit (1) having an internal combustion engine (2) and a vibration-insulated unit (3) of a portable handheld work apparatus (4) such as a motor-driven chain saw, cutoff machine, suction / blower apparatus or the like. The antivibration device (5) includes a vibration damper (6) made of foamed elastic material (7).

Owner:ANDREAS STIHL AG & CO KG

Portable handheld work apparatus having thumb supports

InactiveUS7168132B2Quality improvementIncreased complexityTravelling carriersWing handlesHand heldEngineering

Owner:ANDREAS STIHL AG & CO KG

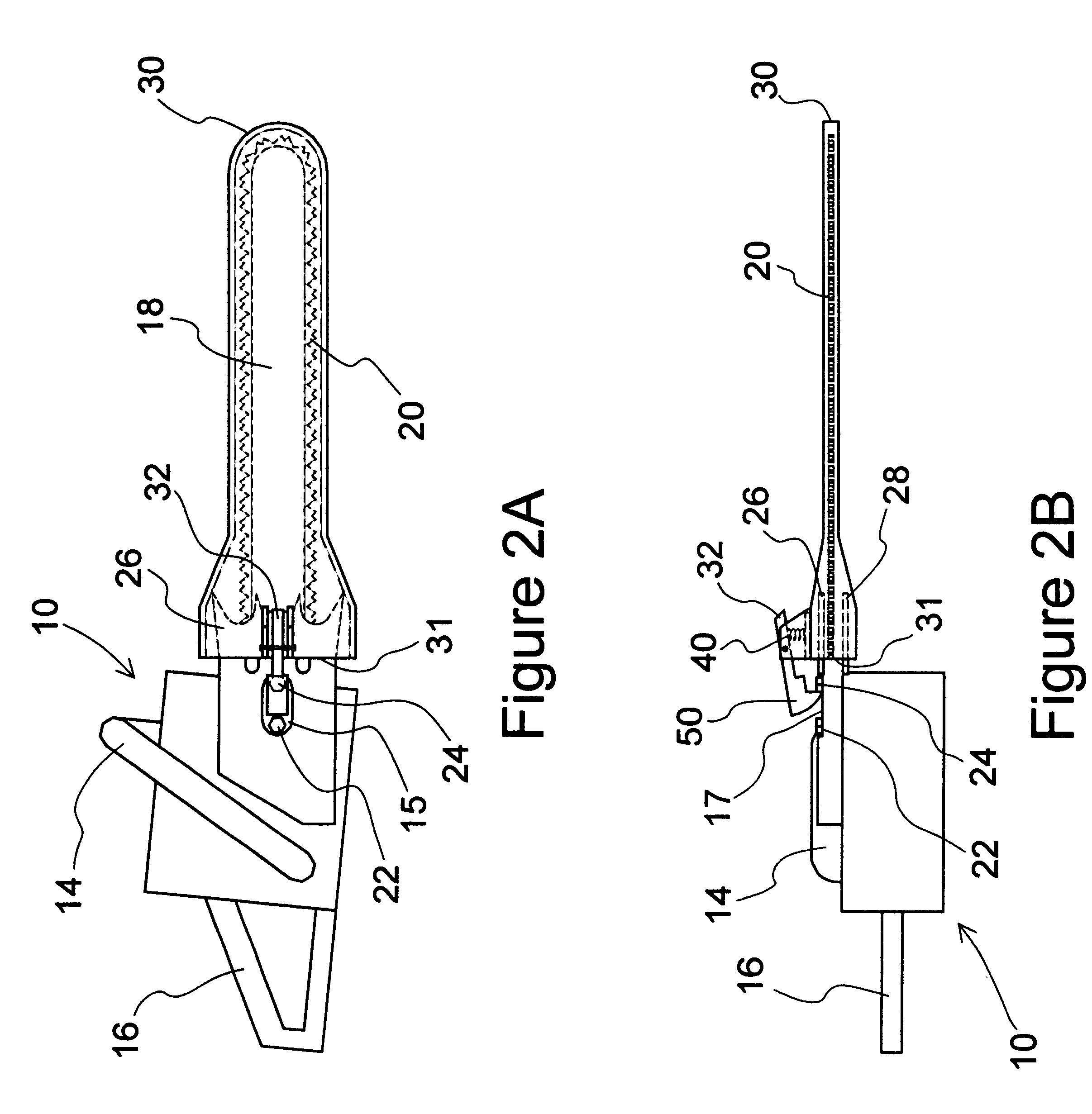

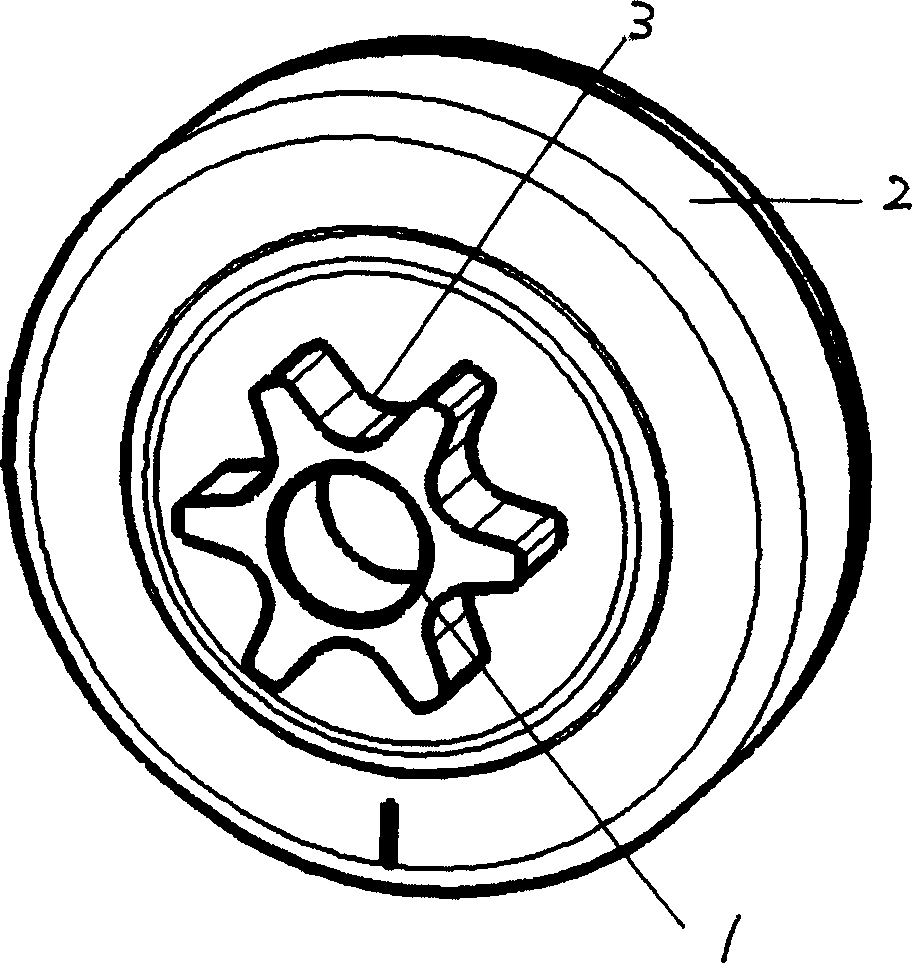

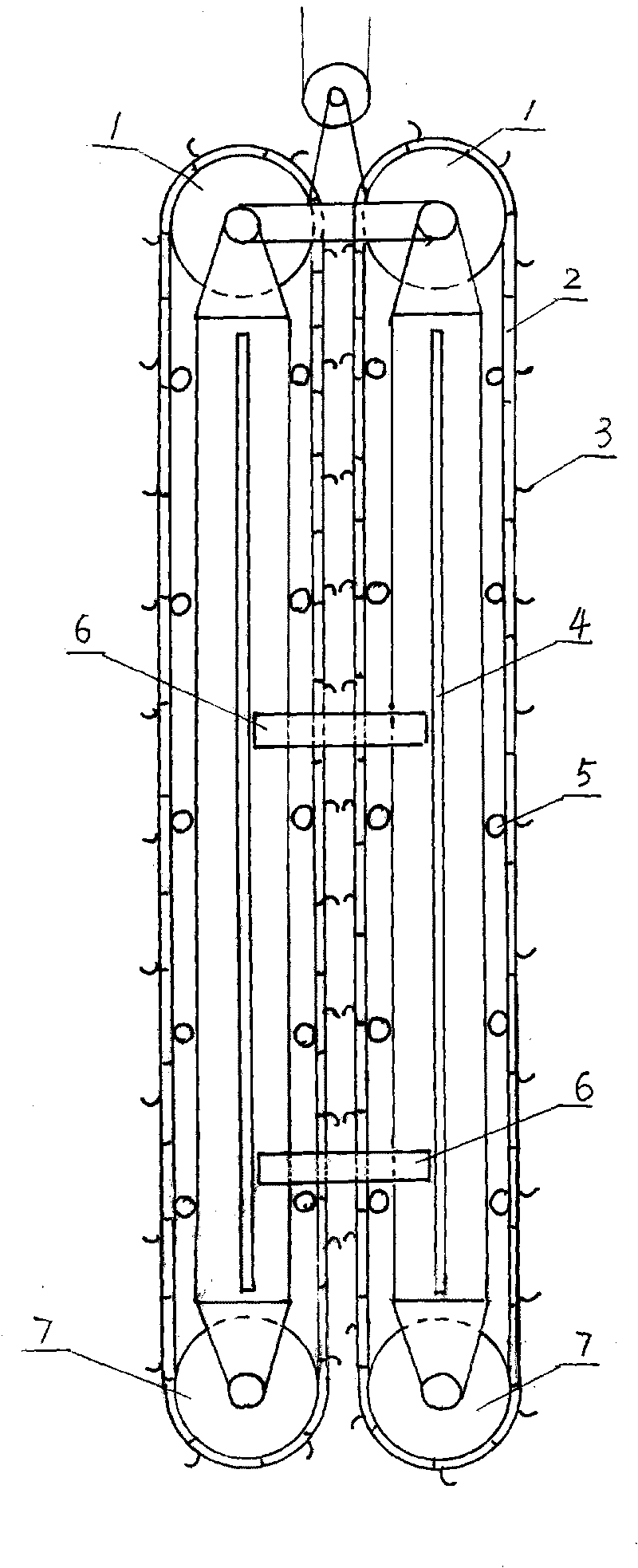

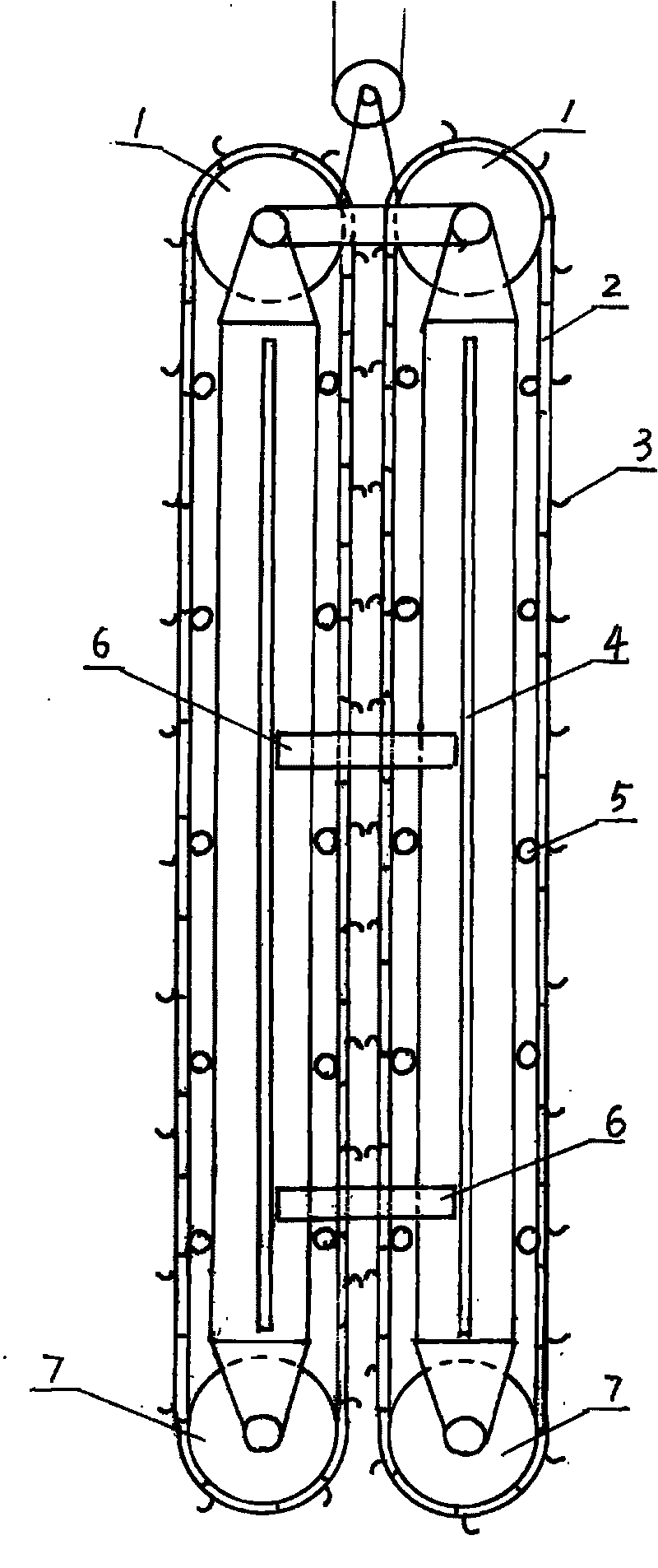

Quick-action chain tensioning device for a chainsaw, and such mechanism and method

InactiveUS20140106915A1Easy to disassembleFacilitate attachment/detachmentGearingChain sawsRatchetGear drive

To facilitate the demounting of a chain (3) from a chainsaw, the saw has a lever arm preferably in the form of hinged cover (11) arranged to displace the sprocket (15) towards the guide bar (2) the other upon opening of the cover (11). Upon closing the cover (11), the sprocket (15) is displaced in the opposite direction to pre-tension the chain (3). The sprocket (15, 115) may be driven over a gear transmission (27, 127), which when the chain (3, 103) is running at ordinary cutting speed uses resulting forces to automatically tension the chain (3, 103) by displacing the sprocket (15, 115) away from the guide bar (2, 102). A ratchet mechanism (34) may be provided to maintain the chain tension upon reduction of the chain speed by preventing the sprocket (15) from moving toward the guide bar (2).Alternatively, a mechanism for automatically tensioning the chain (3, 238) of a chainsaw includes a driving inner sprocket (76, 201), and an outer ring member (77, 204) surrounding the inner sprocket (76, 201). A spring (64, 87, 228) may be provided for assisting the ratchet mechanism or as a substitute therefore.

Owner:HUSQVARNA AB

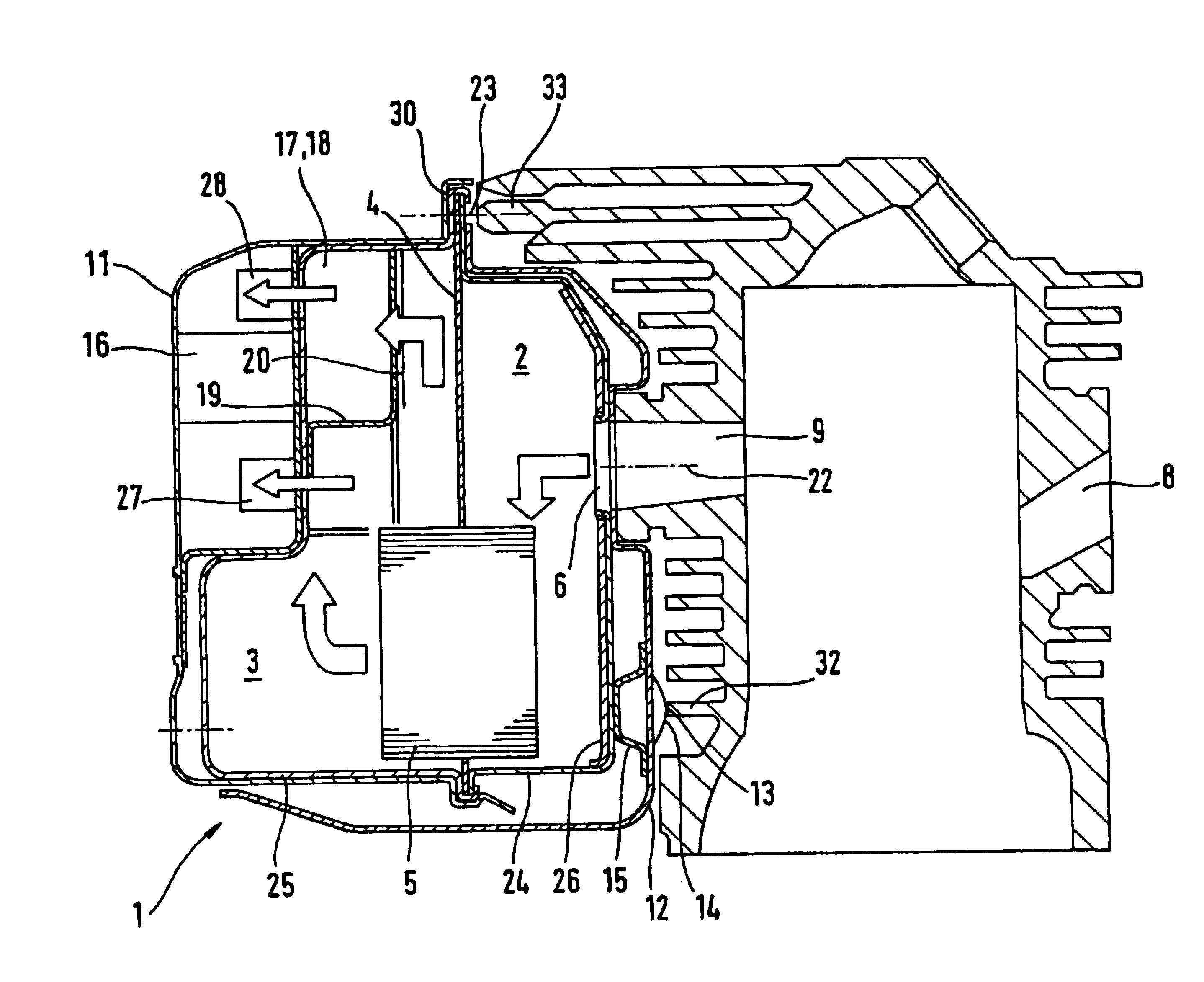

Muffler assembly

ActiveUS6955043B2Smooth connectionClosely connectedExhaust apparatusSilencing apparatusInterior spaceHand held

A muffler assembly for an internal combustion engine of a portable handheld work apparatus such as a motor-driven chain saw, cutoff machine or the like includes an exhaust-gas muffler (1) which has a muffler housing (10). The muffler housing (10) is formed essentially from two half shells (24, 25) connected substantially fluid-tight to each other. The interior space of the muffler housing (10) includes at least two chambers (2, 3) which are partitioned from each other by a partition wall (4). A catalytic converter (5) is mounted in the partition wall (4). In the interior space of the muffler housing (10), an exhaust-gas inlet (6) opens which is connected to an exhaust-gas stub (9) of the cylinder (8) of the engine. The exhaust-gas muffler has an exhaust-gas outlet (7) which conducts exhaust gas from the interior space. The exhaust-gas muffler (1) is connected with threaded fasteners at at least three attachment points (22, 23) to the cylinder (8) in order to obtain a good fixation of the exhaust-gas muffler on the cylinder (8) of the engine. At least two attachment points (22) are arranged in the region of the exhaust-gas stub (9).

Owner:ANDREAS STIHL AG & CO KG

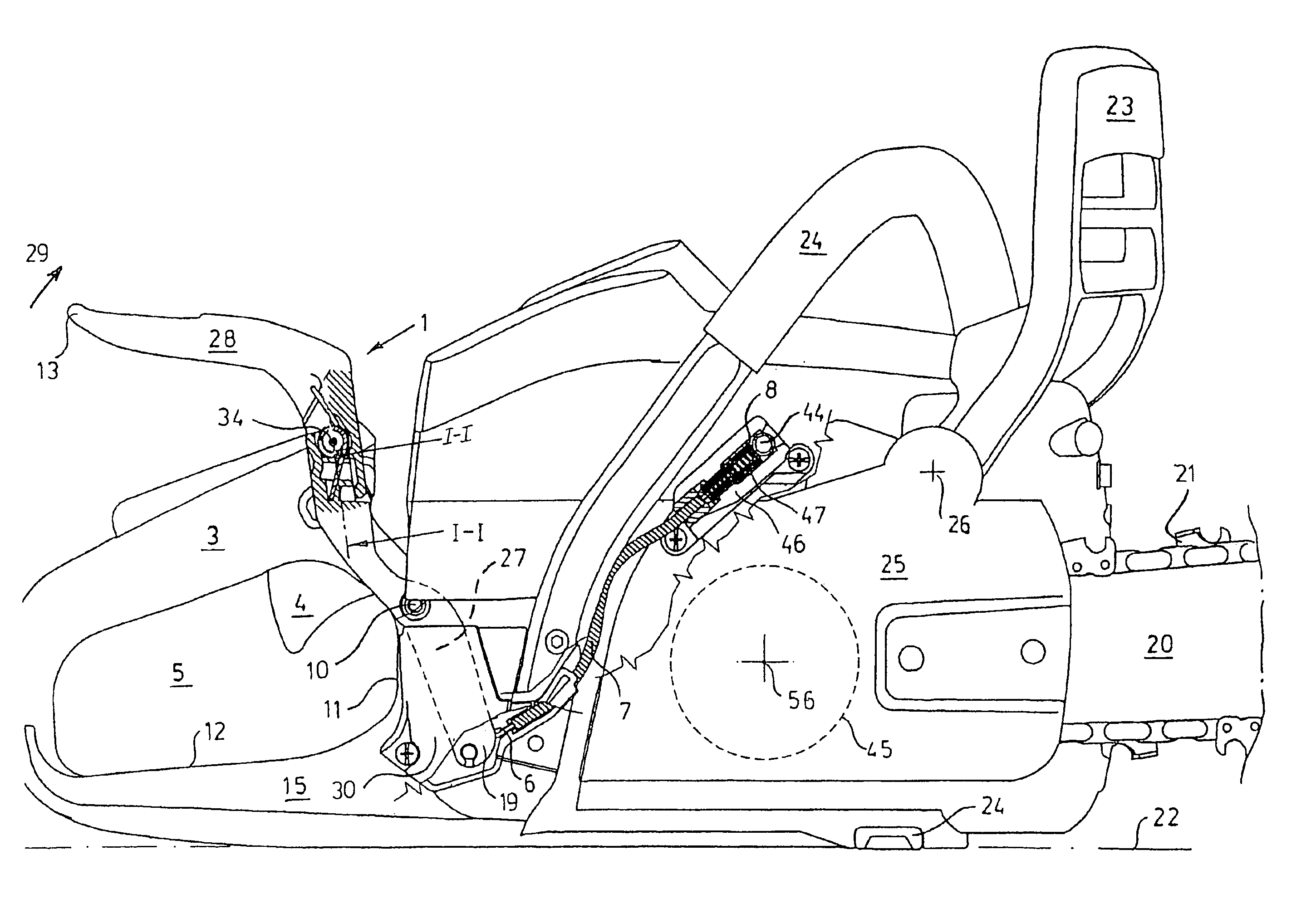

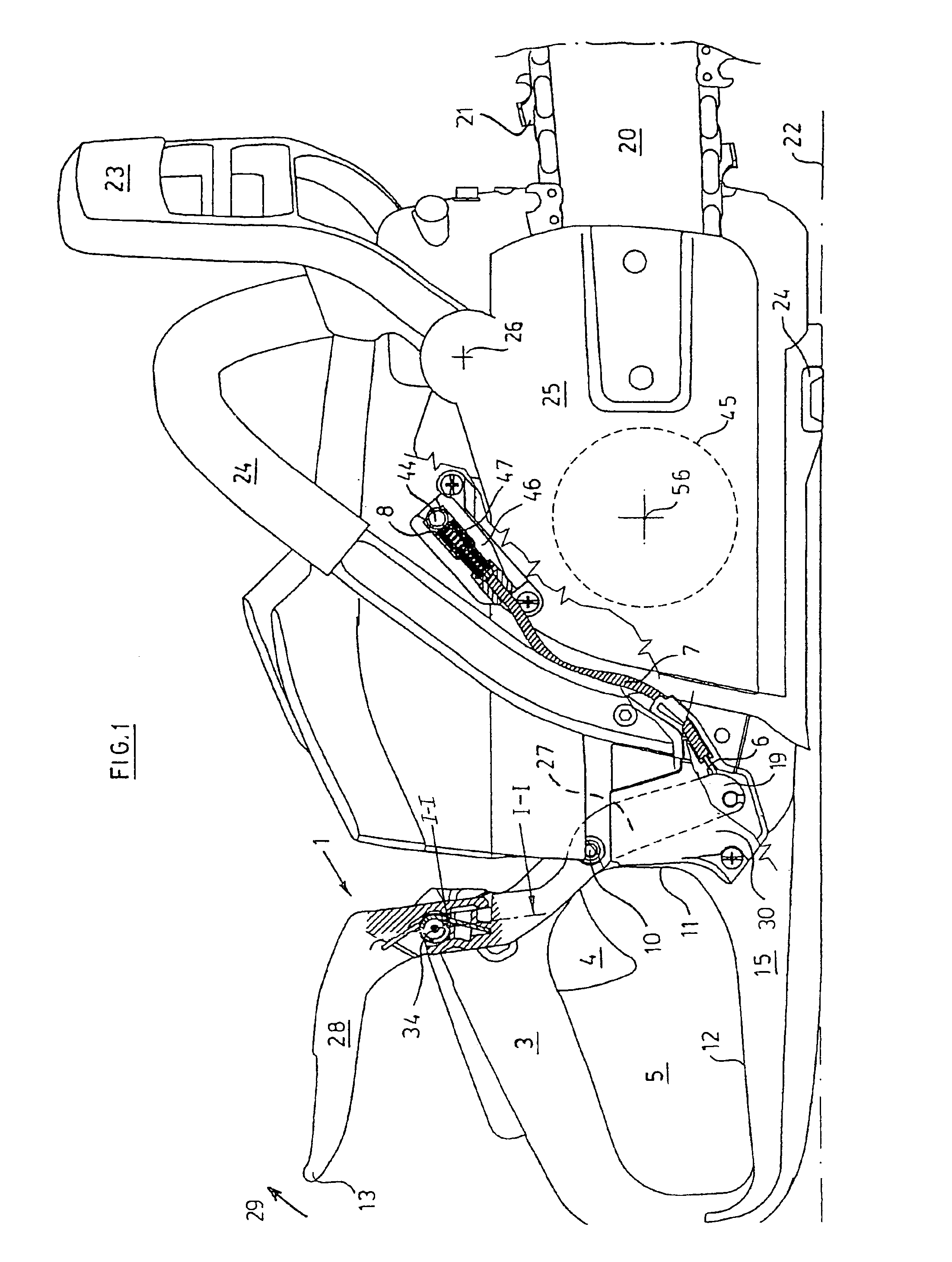

Trigger device for chain brake

InactiveUS6842987B1Favorable geometry of motionShorter and straighter drawingMetal sawing devicesMetal sawing accessoriesThrottle controlHand held

A brake triggering device with a pivotably mounted trigger arm (1) located in connection to a handheld working tool's, mainly a chain saw's (2), rear handle (3), with a throttle control (4) and a handle opening (5) located below the handle (3), so that the trigger arm (1), when the saw changes inclination in relation to the operator's forearm, e.g. at the event of kickback or fall, is actuated by the operator's hand or arm, whereby the trigger arm (1) via a transfer mechanism actuates a brake (9) so that this stops the movement of the saw chain. The pivot (10) of the trigger arm is located in connection to a front (11) or a bottom (12) side of the handle opening (5).

Owner:HUSQVARNA AB

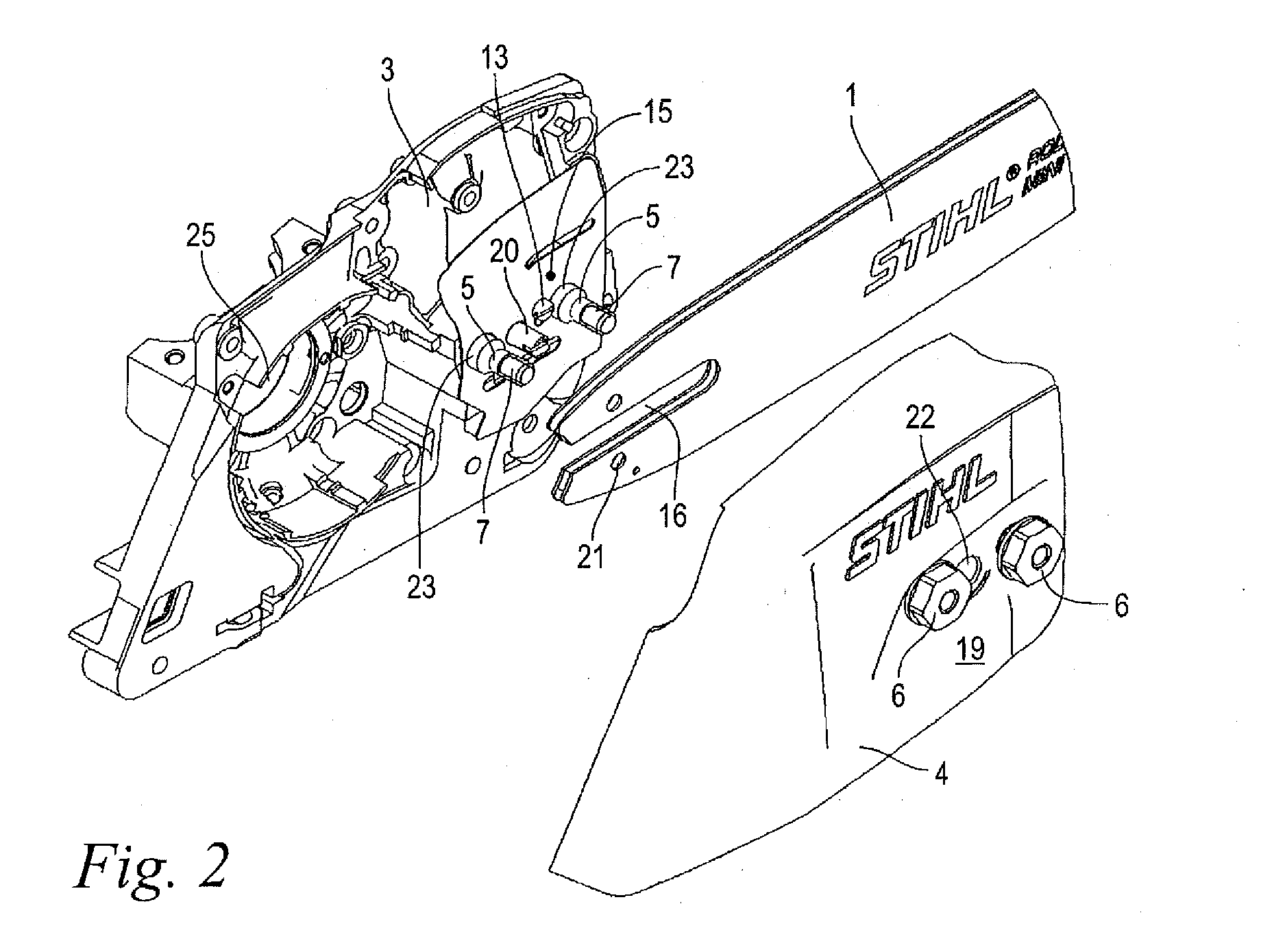

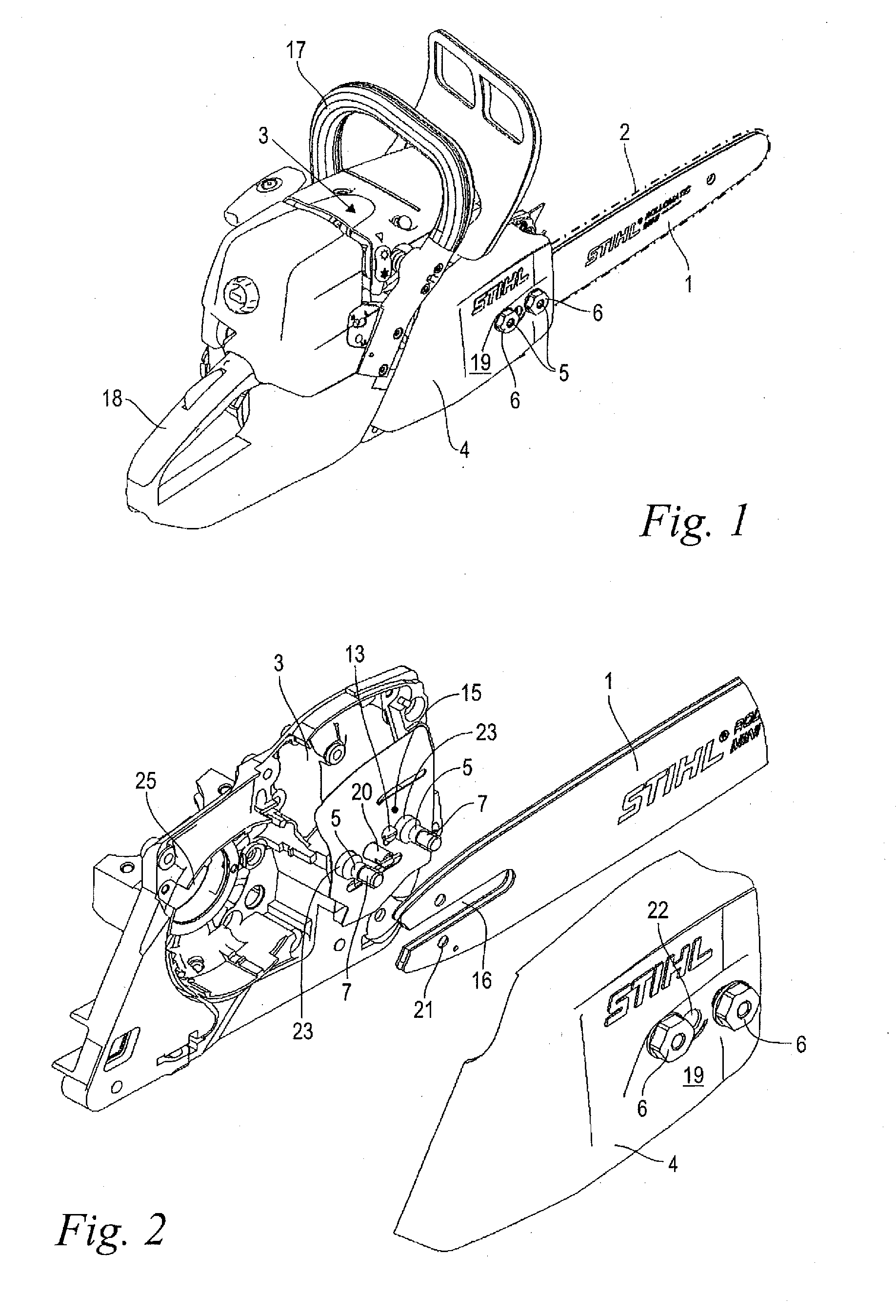

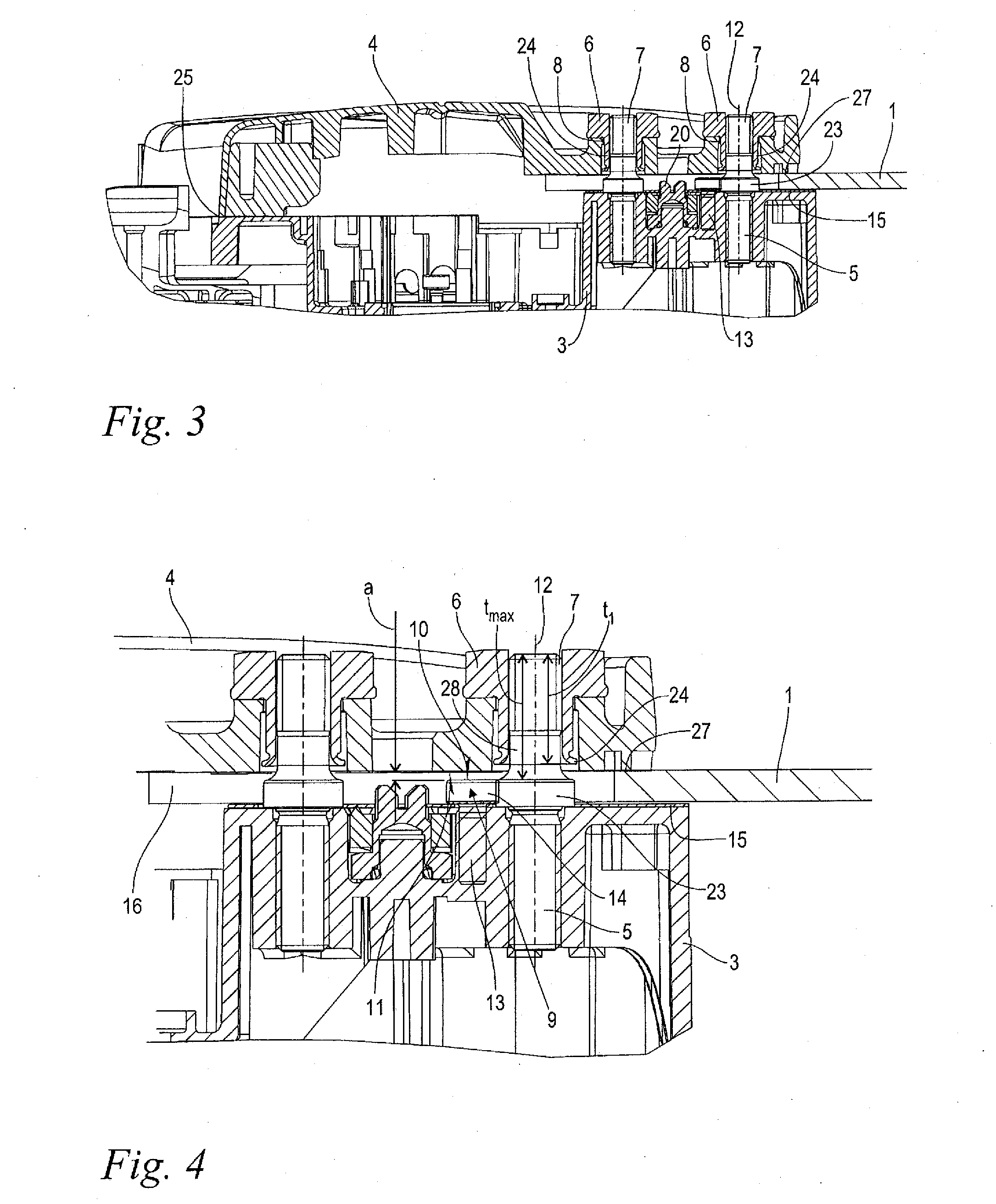

Chain Saw

ActiveUS20110232110A1Effective structureReduce componentsMetal sawing devicesMetal sawing accessoriesSprocketEngineering

A chain saw includes a guide bar (1) for a saw chain, a housing (3), a sprocket wheel cover (4), and at least one stud (5) fixed on the housing (3) for threadably fastening the sprocket wheel cover (4) and the guide bar (1). The free thread end (7) of the stud (5) has a maximum usable screw-in depth (tmax) for a nut (6) to be screwed thereon. A stop (9) for the sprocket wheel cover (4) having a stop surface (10) as well as a support surface (11) for contact engaging the stop surface (10) are provided. In the mounted state of the guide bar (1), a distance (a) remains between the stop surface (10) and the support surface (11). The support surface (11) contact engages the stop surface (10) of the stop (9) when the guide bar (1) is removed and the nut (6) is tightened and the nut (6) is screwed onto the studs (5) with a stop screw-in depth. The stop (9) is configured in such a manner that the maximum usable screw-in depth (tmax) is greater than the stop screw-in depth.

Owner:ANDREAS STIHL AG & CO KG

Chainsaw bar guard

InactiveUS6389700B2Improve protectionIncrease deflectionMetal sawing devicesMetal sawing accessoriesInterior spaceEngineering

An easily engageable and releasable chainsaw bar guard for protecting an individual carrying a chainsaw and for preventing damage to the cutter chain and saw dogs of a chainsaw. The bar guard comprises an elongated stiff hollow sleeve whose interior space is just slightly larger than the bar and chain to be protected. The sleeve has an opening at the proximal end for sliding the sleeve onto the guide bar, and is closed at the other end to protect the end of the bar and cutter chain. A snap-clip mechanism is fixed to the sleeve for releasably latching the proximal end of the guard to the chainsaw. The snap-clip mechanism biases a retaining claw into contact with the chainsaw bar between the nuts on the saw bar attachment / adjustment bolts. The sleeve and the snap-clip mechanism can be selectively configured to accommodate chainsaw bars of different shapes and dimensions and the spacing of whose guide bar adjustment nuts varies. The guard may optionally be provided with clips, pockets or containers for storing chainsaw tools.

Owner:PAQUIN JOSEPH GERALD RONALD

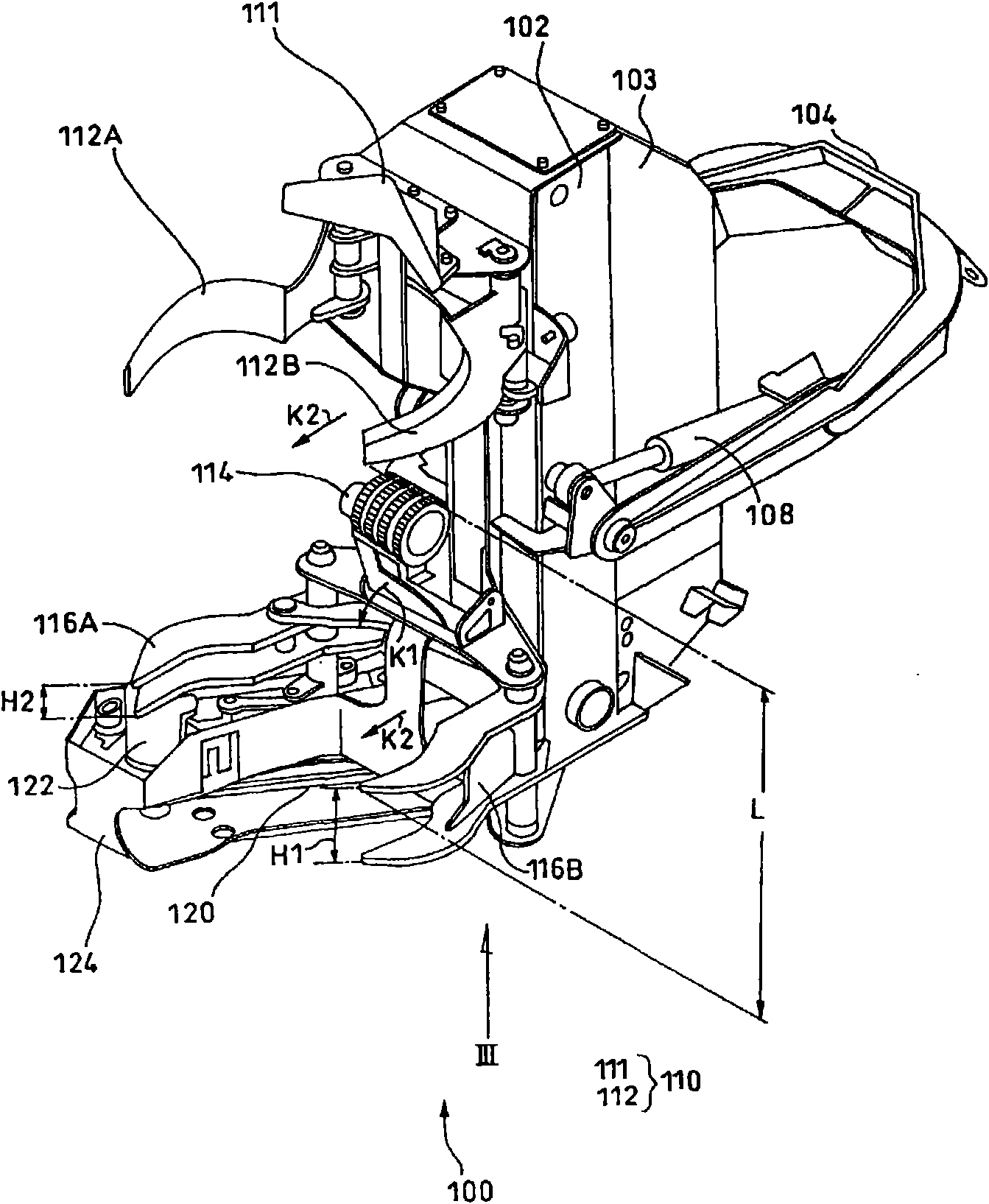

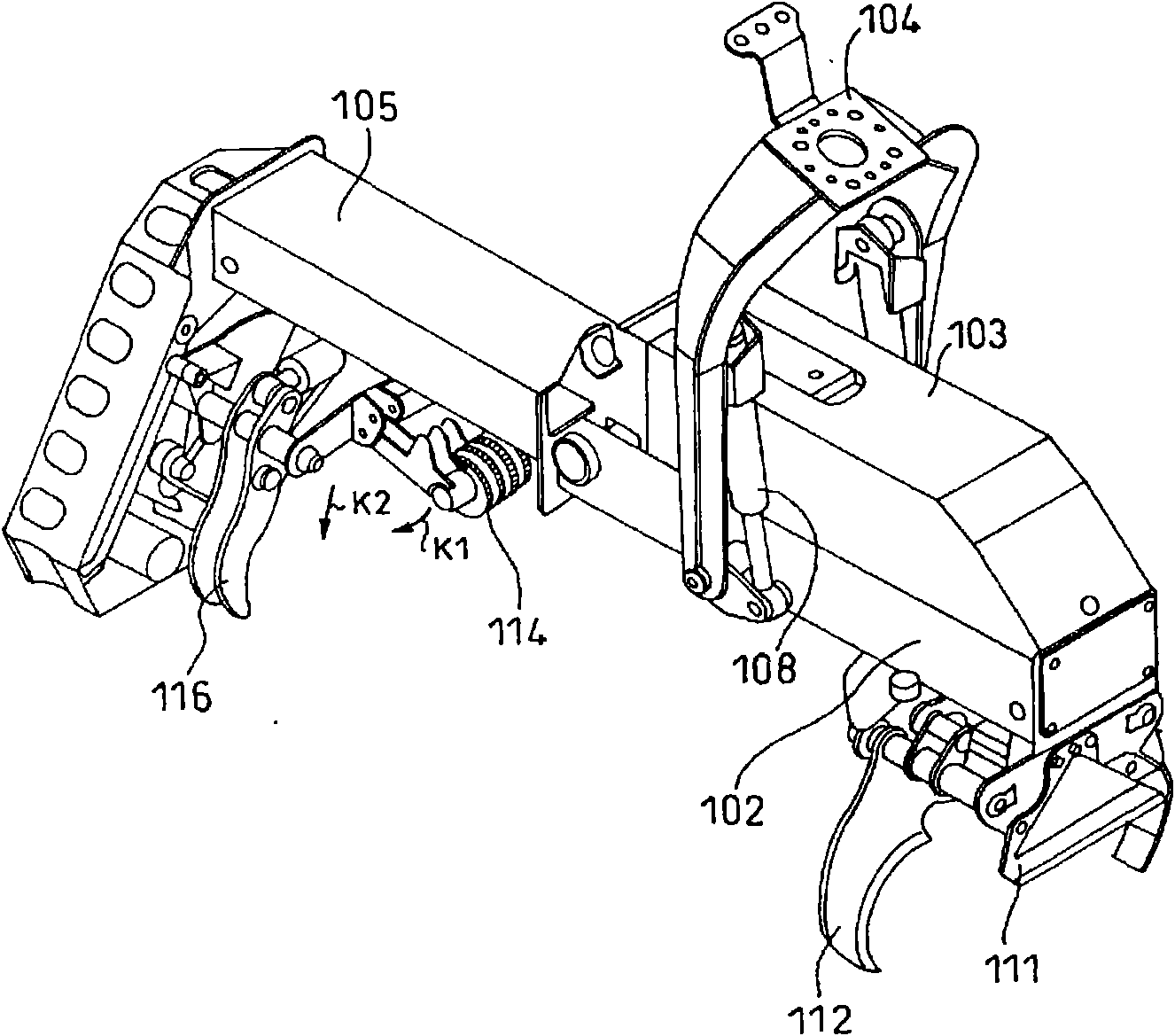

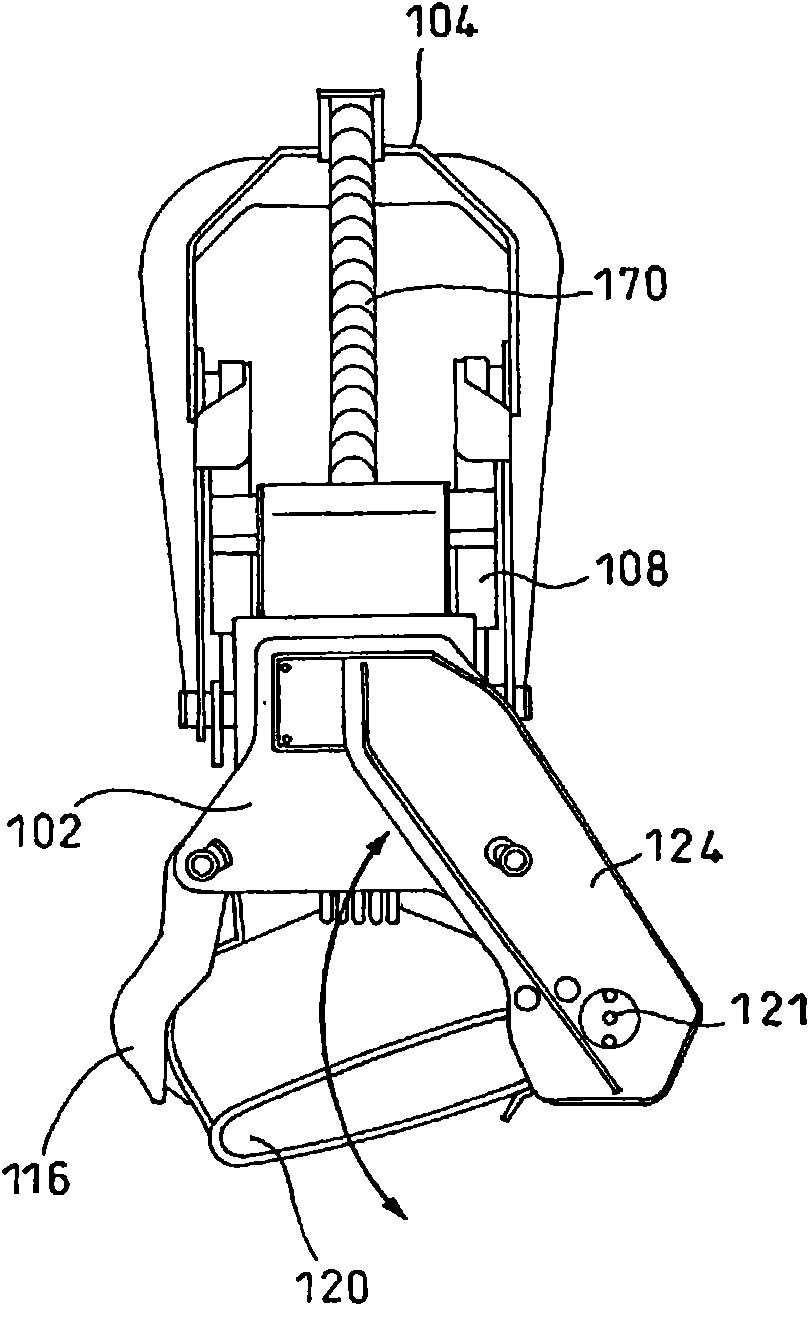

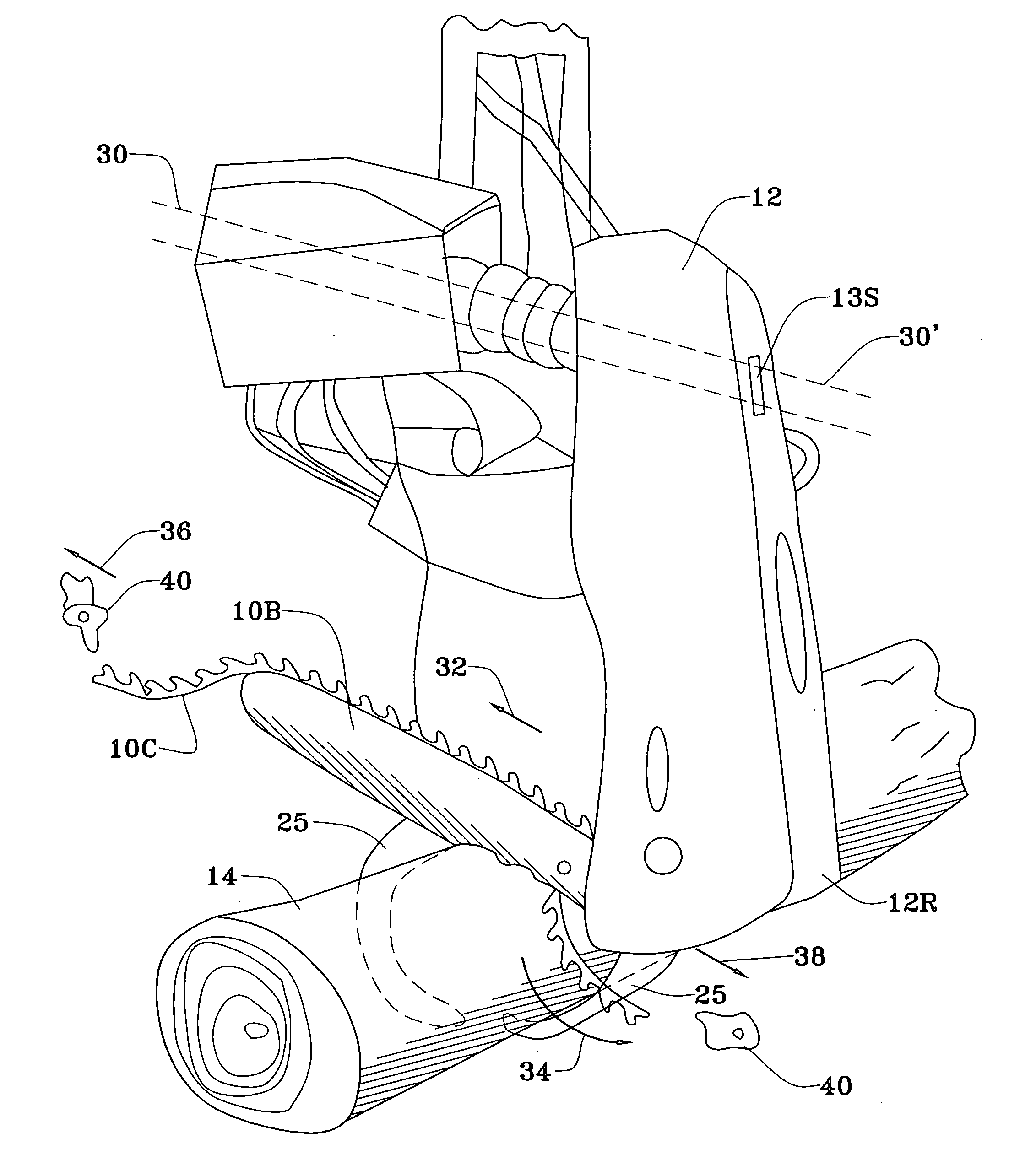

Harvester machine for wood and felling/wood making method

A harvester apparatus (100) equipped in a work vehicle and capable of at least cutting down, pruning, and cross-cutting wood, the harvester apparatus being configured to include a gripping claw (116) that can hold the wood by opening and closing in the thickness direction of the wood, a chain saw (120) capable of cutting the wood held with the gripping claw (116), a pruner (110) for pruning the wood arranged at a different position in the lengthwise direction of the gripped wood relative to the gripping claw (116), a slide frame (105) that can change the lengthwise distance between the pruner (110) and the gripping claw (116), and a sensor (130) for detecting the slide amount of the slide frame (105).

Owner:SUMITOMO CONSTRUCTION MACHINERY

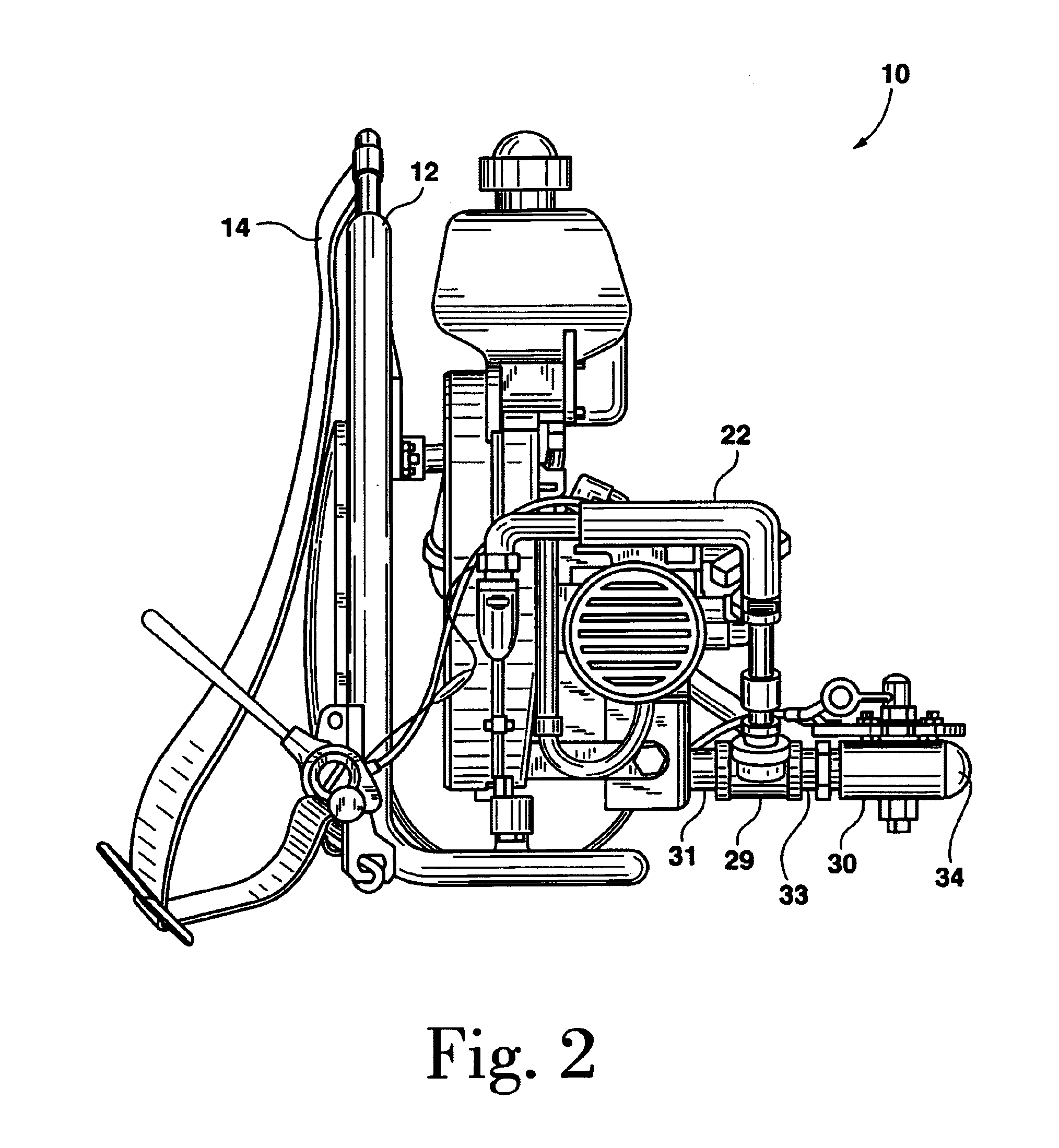

Air blower for extinguishing fires and method for extinguishing fires

The invention employs a blower of the type used by commercial landscapers. The device has an engine mounted on a frame. Shoulder straps attached to the frame allow the user to wear the device on his back leaving the hands of the operator free to operate other tools such as a chain saw or perform other tasks. Also, wearing the device on the back makes it easier to transport the device over long distances to the source of the fire or backfire to be started.The device's blower generates a stream of air at high speeds. This stream of air can be used to feed a fire when the air is directed at a fire. When used to extinguish a fire, air from the blower is tapped from a point 180 degrees removed from the blower output and mixed with exhaust from the engine. This mixture is diverted through a Y-shaped valve into the airstream coming out of the blower. When the device is used to start backfires a fire is started. The airstream, without the mixture of air and engine exhaust can be used to both encourage the propagation of the fire and direct the fire towards the main wild fire. The ability to quickly spread the backfire in the proper direction is imperative because a sudden change in wind direction or other weather conditions could cause the backfire to become as big a problem as the original fire.

Owner:EBNER EDWIN D

Saw chain

InactiveUS6871573B2Improve cutting performanceImprove cutting effectSaw bladesMetal working apparatusEngineeringChain saw

A saw chain for a power chain saw is provided and comprises drive links and side links that connect them, whereby alternatingly disposed on one and the other longitudinal side of drive links, in place of a side link, are a cutter link and a leading safety link. The cutter link has a cutter tooth and a leading depth limiter, whereby the safety link is provided with a projecting nose for support against the base of a cut. The nose extends in the direction toward the depth limiter. The safety link is provided with a side portion disposed in front of the nose. The side portion has an elevated contact surface, which, when the saw chain is curved in the reversing region, is disposed on the path of a top cutting edge of the cutter tooth, and when the saw chain is extended reaches at least nearly to the height of the depth limiter.

Owner:ANDREAS STIHL AG & CO KG

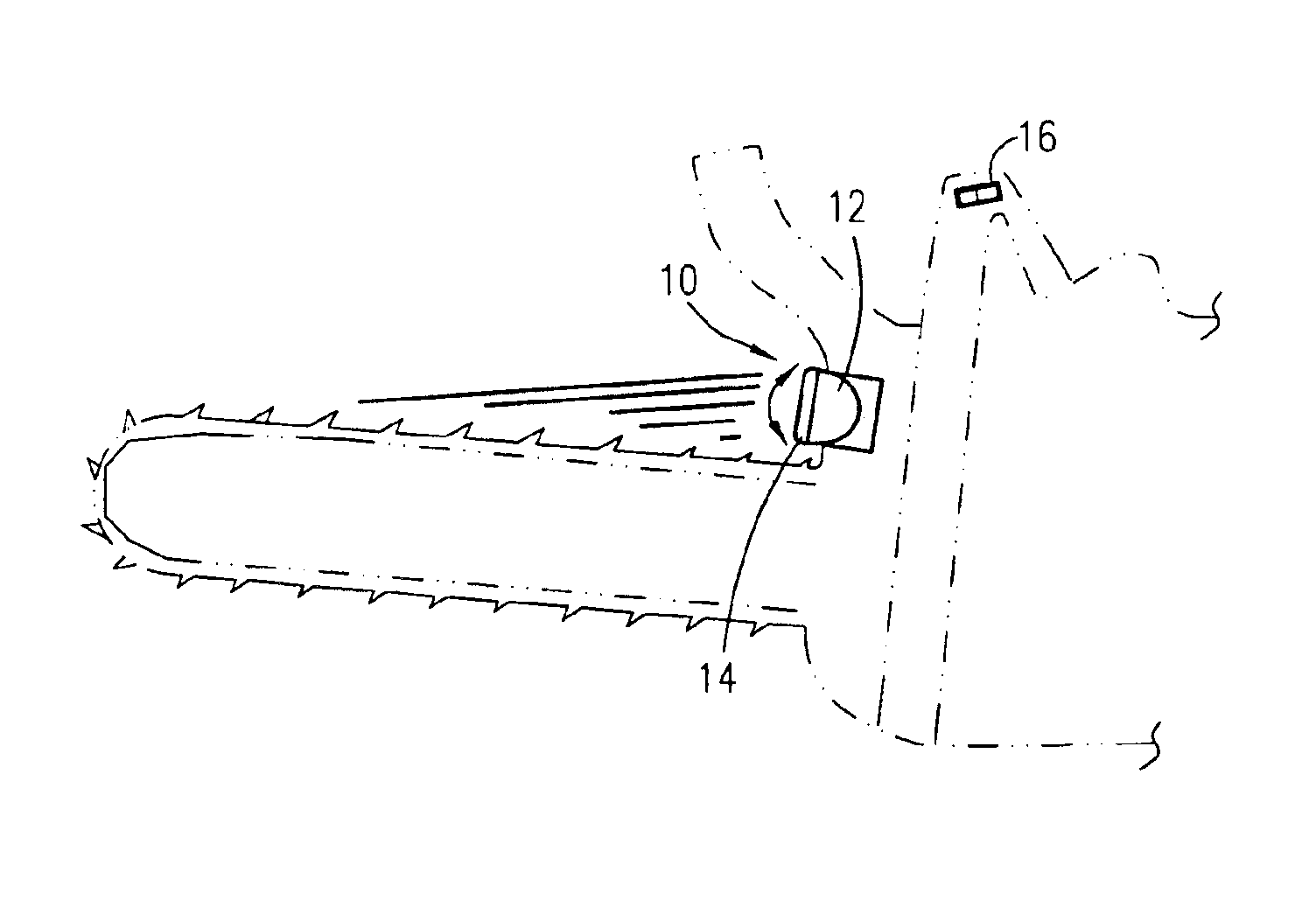

Illumination means for a chainsaw

InactiveUS6939022B2Improve the safety of useMetal sawing accessoriesLighting support devicesLight beamEngineering

An illumination means for a chainsaw is a light source generated for providing a focused beam at the bar and chain of a chainsaw. Illumination means is positioned at the front of the housing of a chainsaw. Illumination means may be integrally incorporated therein or placed onto the exterior of the housing, and may also include a pivotal shell for adjusting the projection of the light beam. Illumination means is operatively and electrically coupled to a switch that actuates generation of light.

Owner:BROOKS TIMOTHY REED

Intelligent tree climbing and pruning robot

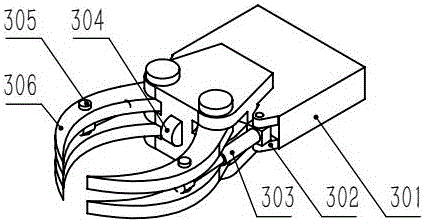

ActiveCN106428279ASafe and efficient pruning workReduce labor intensityGripping headsVehiclesHydraulic cylinderAgricultural engineering

The invention discloses an intelligent tree climbing and pruning robot, which comprises two crawler wheels, a vehicle body, a lower fixing claw, a first stepping motor, a lower bracket, a first hydraulic cylinder, a lower crank, a second hydraulic cylinder, an upper crank, a third hydraulic cylinder, an upper bracket, a second stepping motor, an upper fixing claw, a top tray, a rotating ring and a chain saw assembly. The intelligent tree climbing and pruning robot is characterized in that the two crawler wheels are mounted on the two sides of the vehicle body respectively; the lower fixing claw is fixedly mounted on the vehicle body; and the first stepping motor is fixedly mounted on the lower fixing claw. The intelligent tree climbing and pruning robot is compact in structure, small in size, high in automation degree, suitable for operation in regions with small space, such as urban roads, residential areas and the like, can prune trees safely and efficiently, and greatly reduces the labor intensity of workers.

Owner:绿艺建设集团有限公司

Manufacturing process of chain wheel for chain saw

InactiveCN1974115AIncrease productivityArbitrary designSoldering apparatusFurnace typesVolumetric Mass DensityNitrogen gas

The manufacture process of chain wheel for chain saw includes the following steps: powder metallurgy process to produce gear blank with sorted materials; precise forging through soaking graphite milk or coating graphite or setting in nitrogen protection, fast induction heating to 815-950 deg.c for less than 20 sec, fast forging in closed mold and demolding to reach gear density greater than 7.7 g / cu cm; assembling the gear to hub; and brazing and hardening in the protection of nitrogen with small amount of hydrogen inside a brazing furnace with fast cooling gas system for gas quenching to harden through phase change to reach hardness over HRC58. The manufacture process is simple, and has high production efficiency, low cost and high product precision and quality.

Owner:宓建英

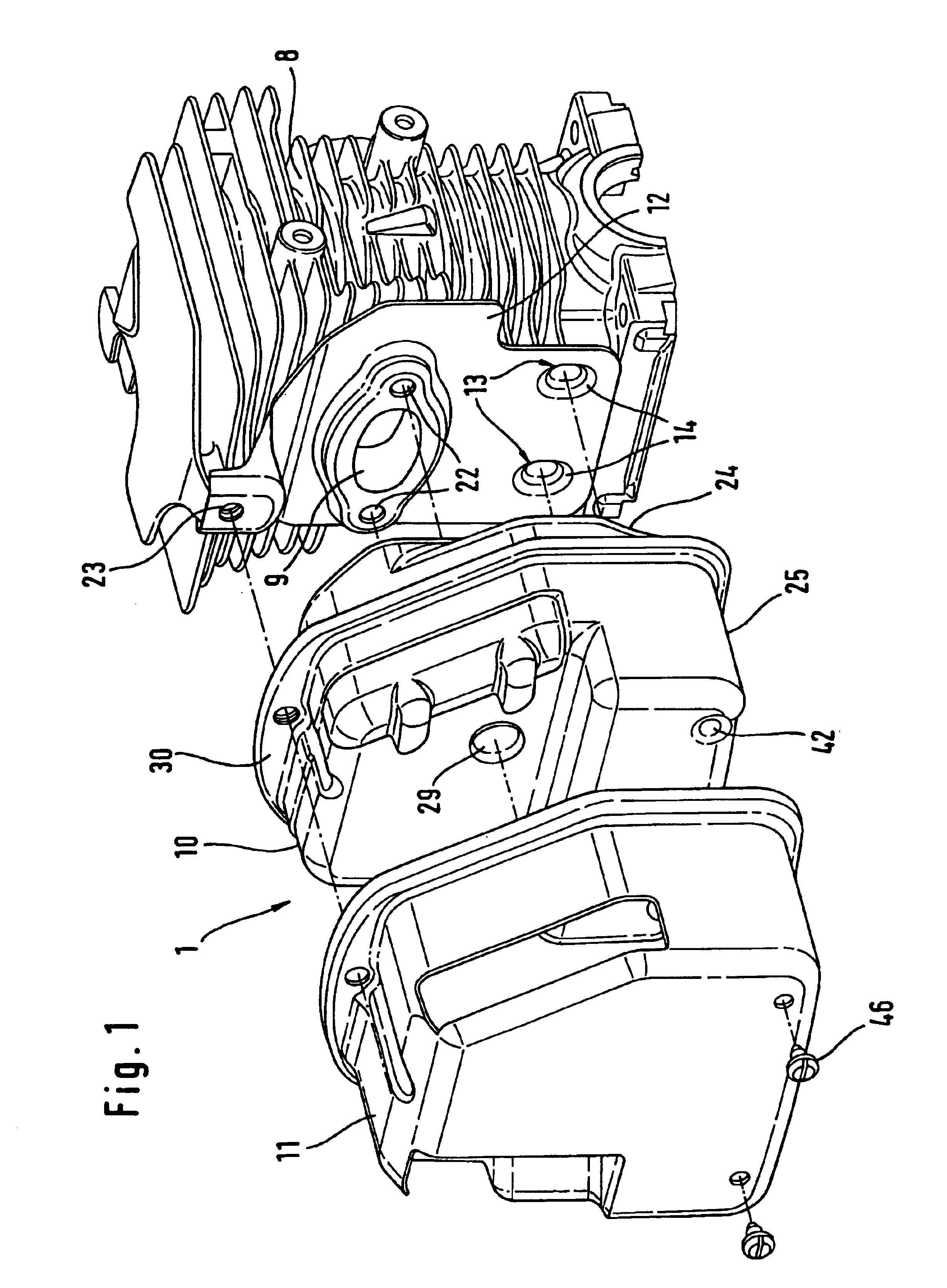

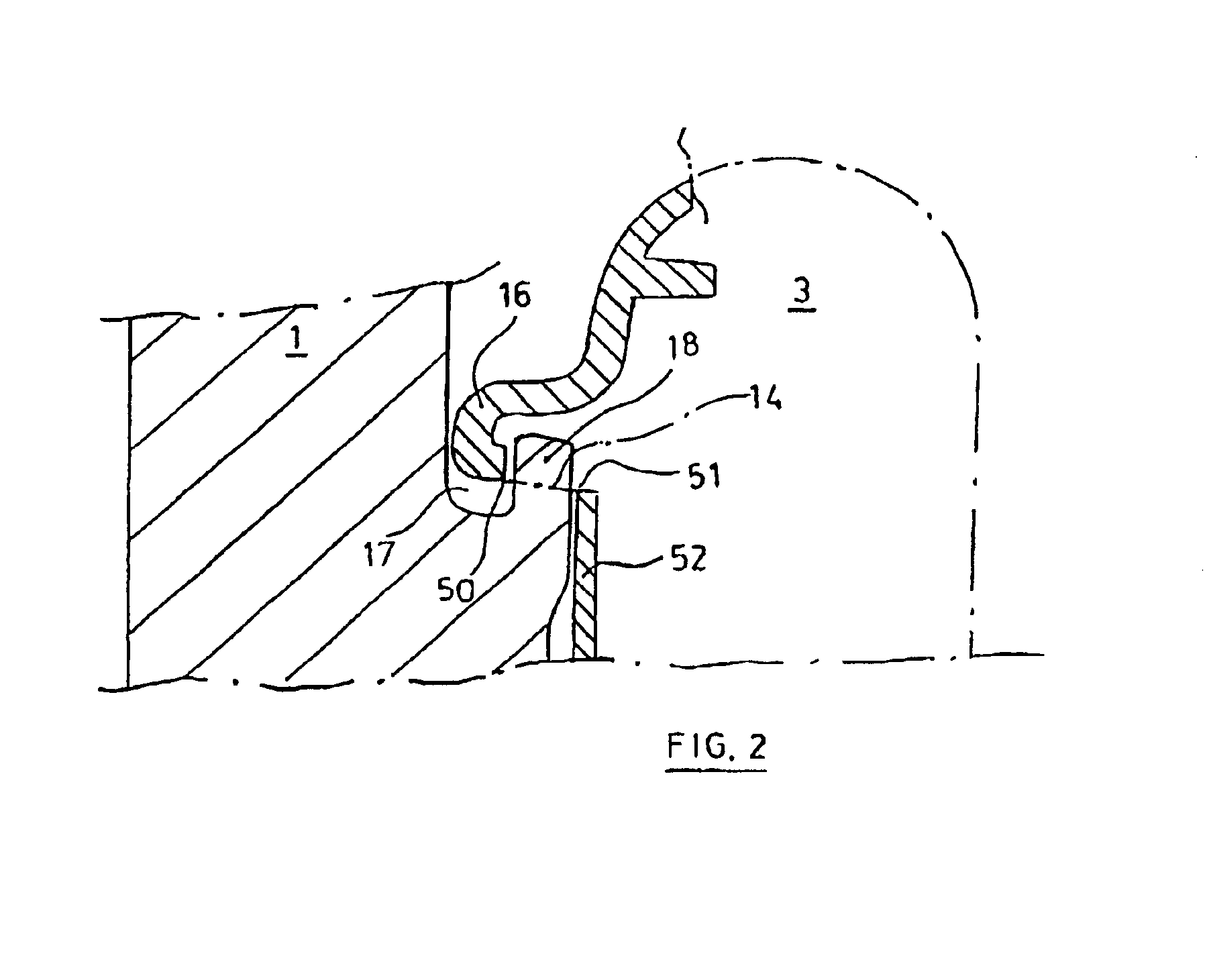

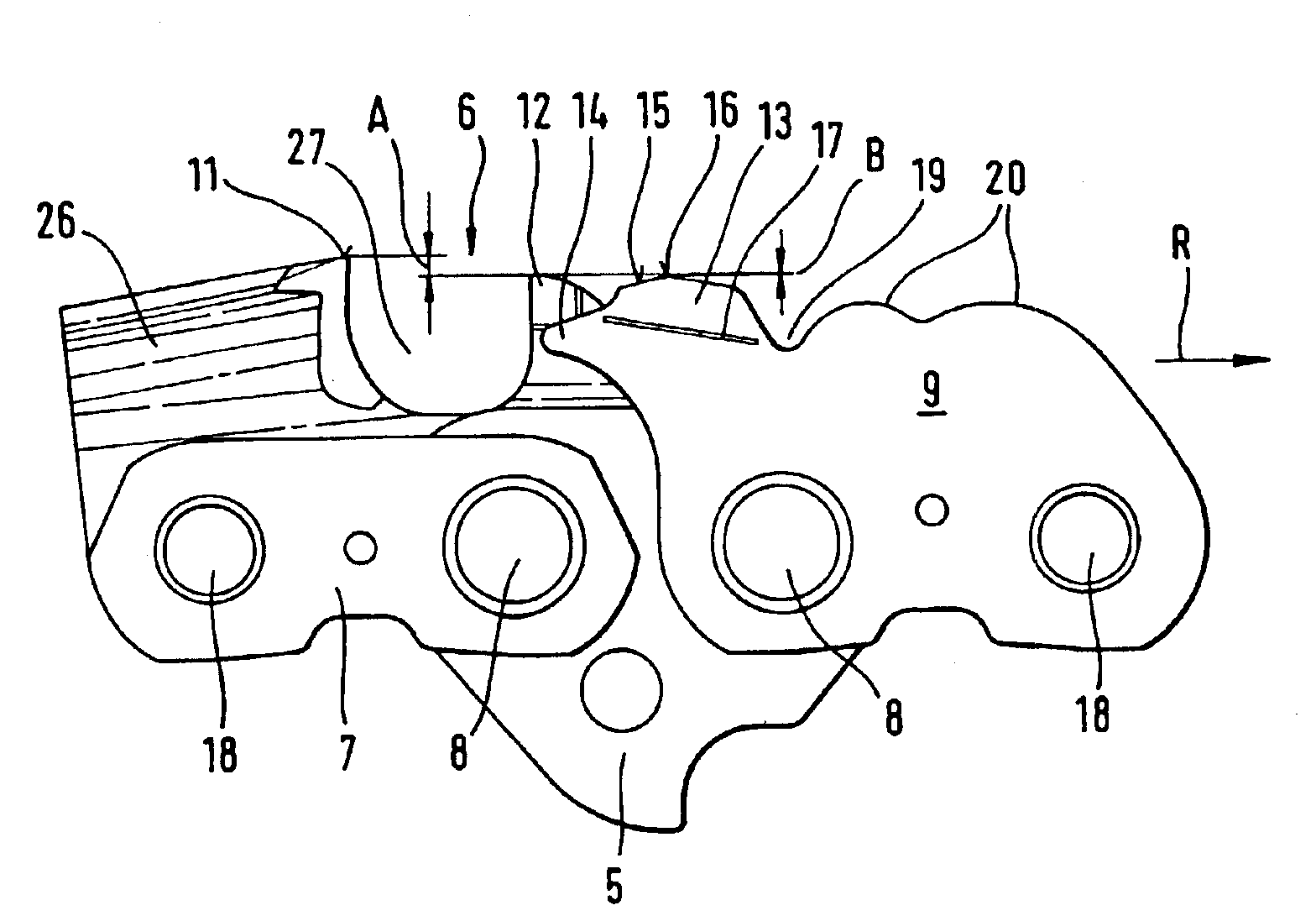

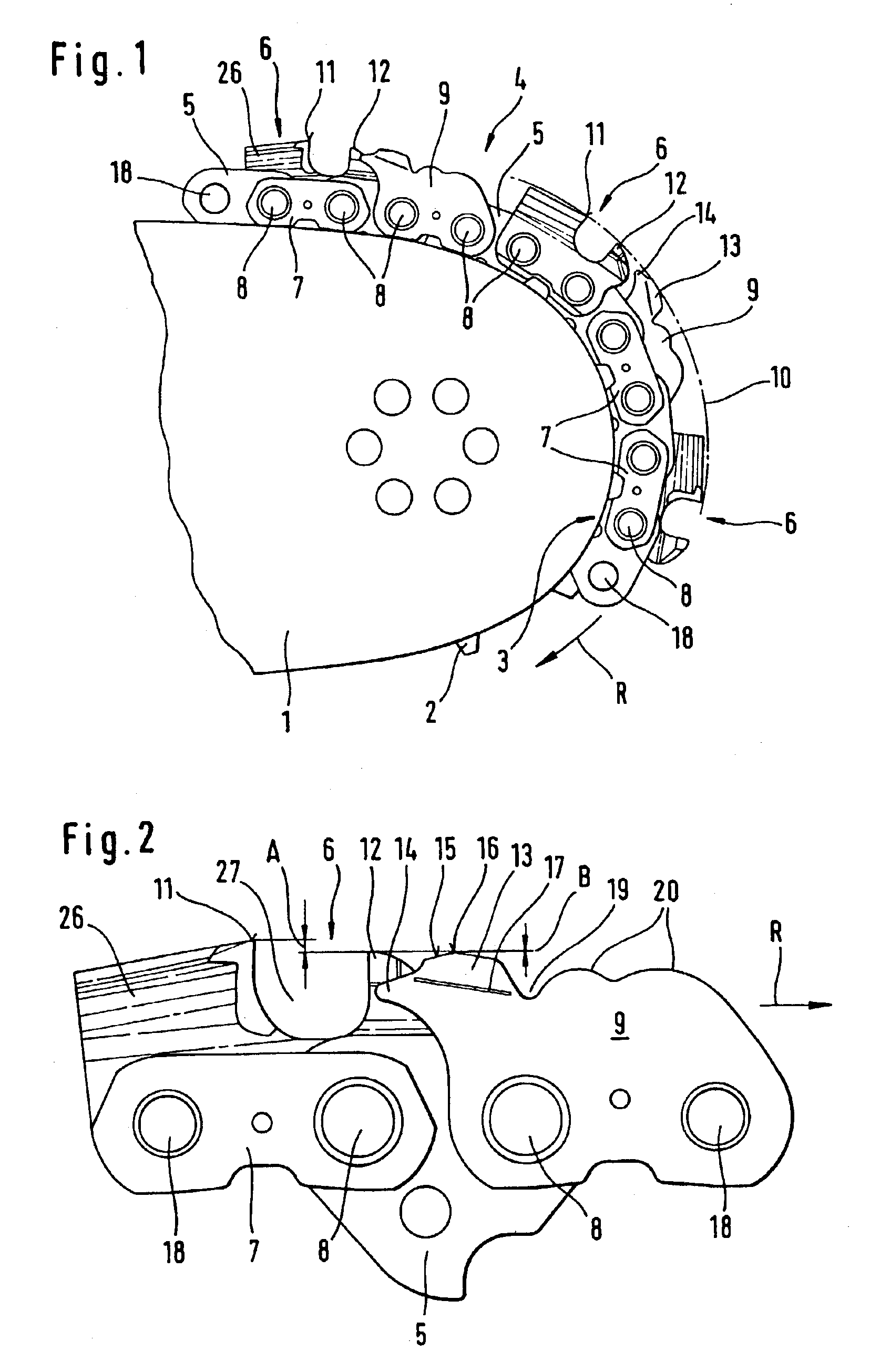

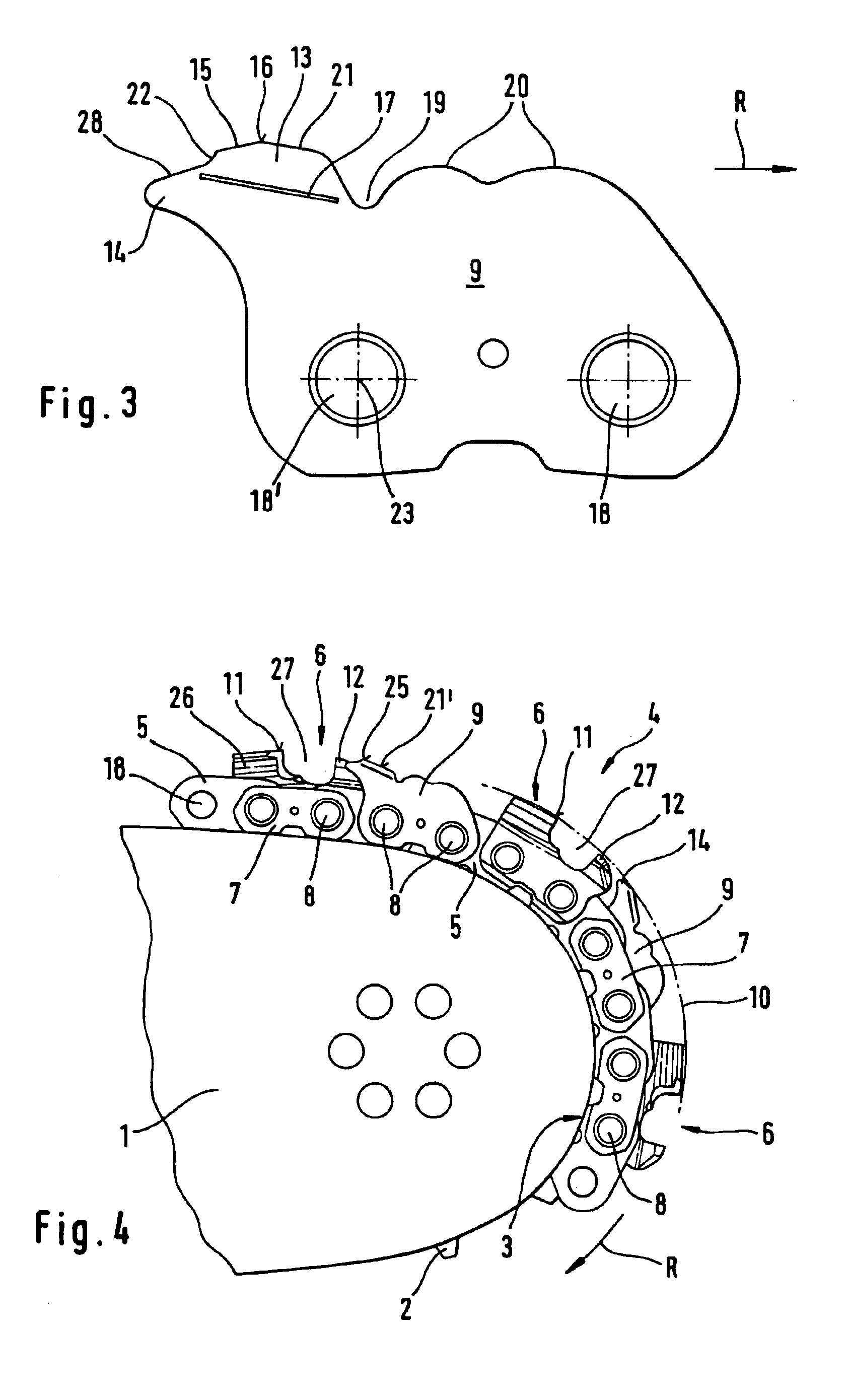

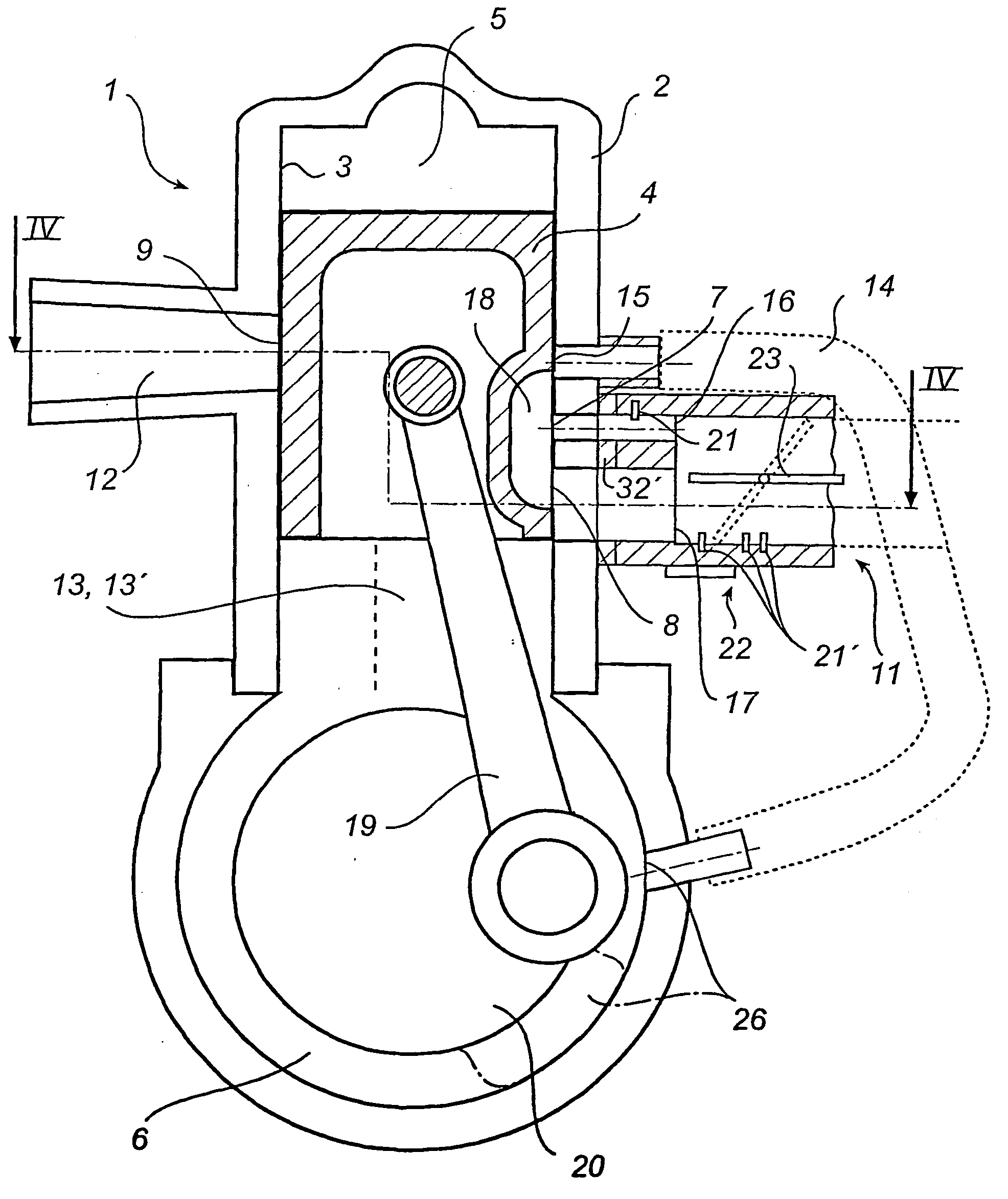

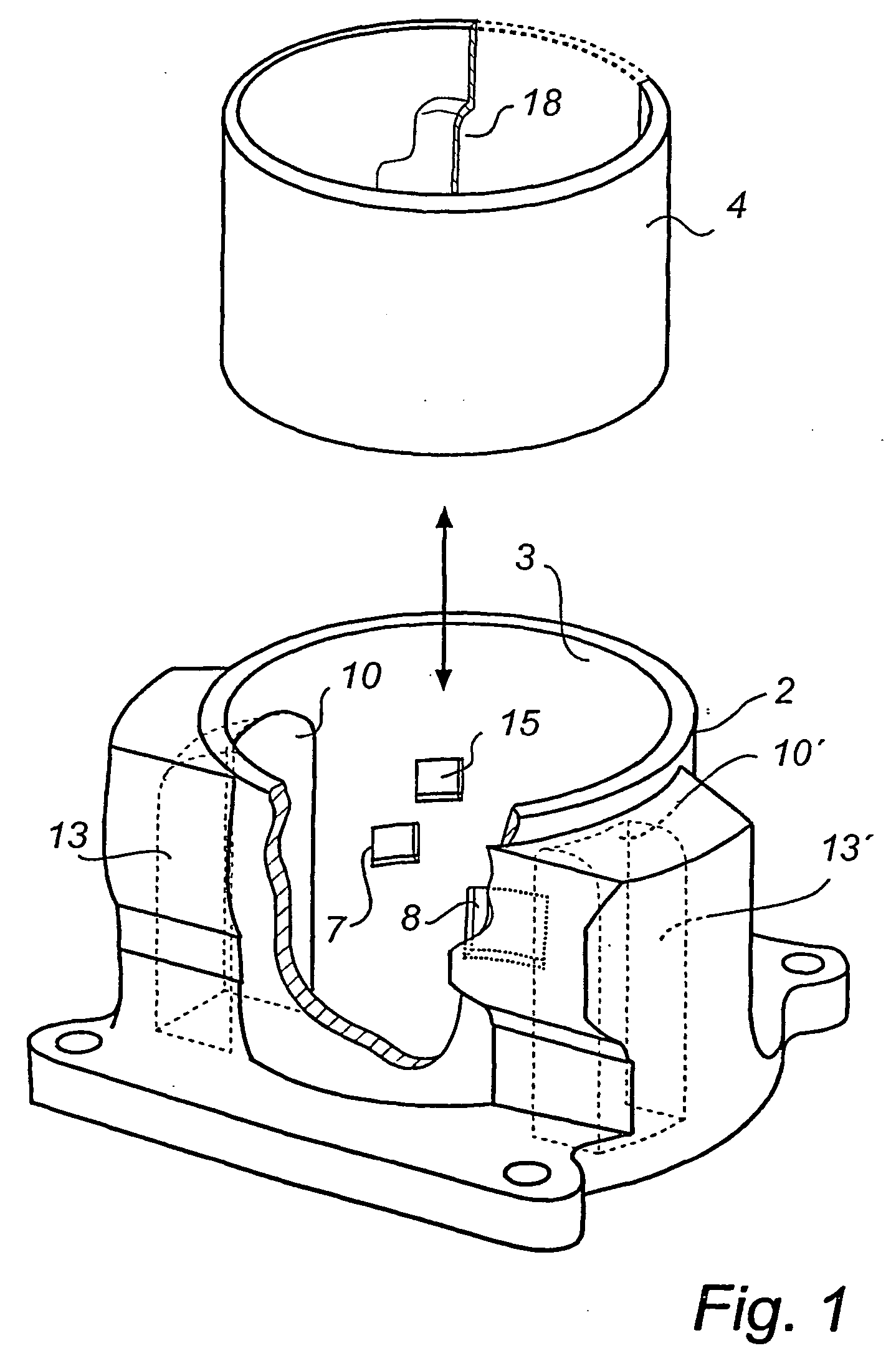

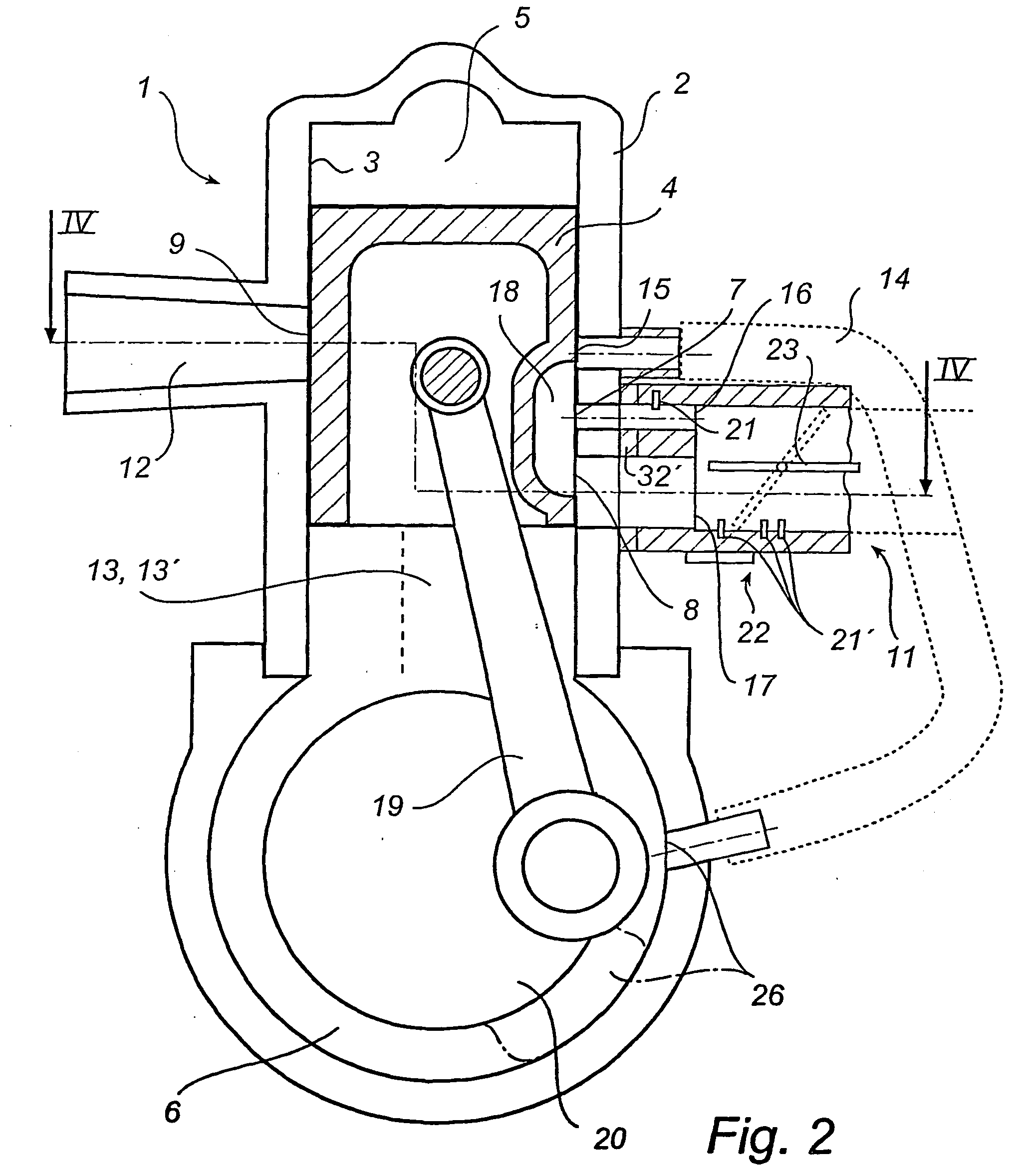

Crankcase scavenged internal combustion engine

InactiveUS20040168656A1Eliminate needCombustion-air/fuel-air treatmentCombustion enginesCombustion chamberReciprocating motion

A crankcase scavenged internal combustion engine (1) of two-stroke type, primarily intended for a handheld working tool, such as a chain saw, with a cylinder (2) and piston (4) reciprocating along the cylinder wall (3), which piston separates a combustion chamber (5) above it and a crankcase volume (6) below it, and in the cylinder wall (3) there are ports (7, 8, 9, 10, 10') arranged for inlet (11), exhaust outlet (12) and for a number of scavenging durct (13, 13'), whereby at least one auxiliary duct (14) is arranged with an auxiliary port (15) in the cylinder wall, which auxiliary port (15) is opened and closed by the piston, and whereby the inlet is divided into: a fuel inlet (16) leading to a fuel port (7) and an air inlet (17) leading to an air port (8), and these ports are opened and closed by the piston (4), which also comprises a transfer space (18), which mouth edges are limited by the piston periphery, and which, in at least one piston position, creates a connection between the fuel port (7) and the auxiliary duct's port (15), so that fuel can be supplied to the auxiliary durct (14) via the auxiliary port (15), and then, after the port (15) later on has been opened by the piston, can flow into the combustion chamber.

Owner:HUSQVARNA AB

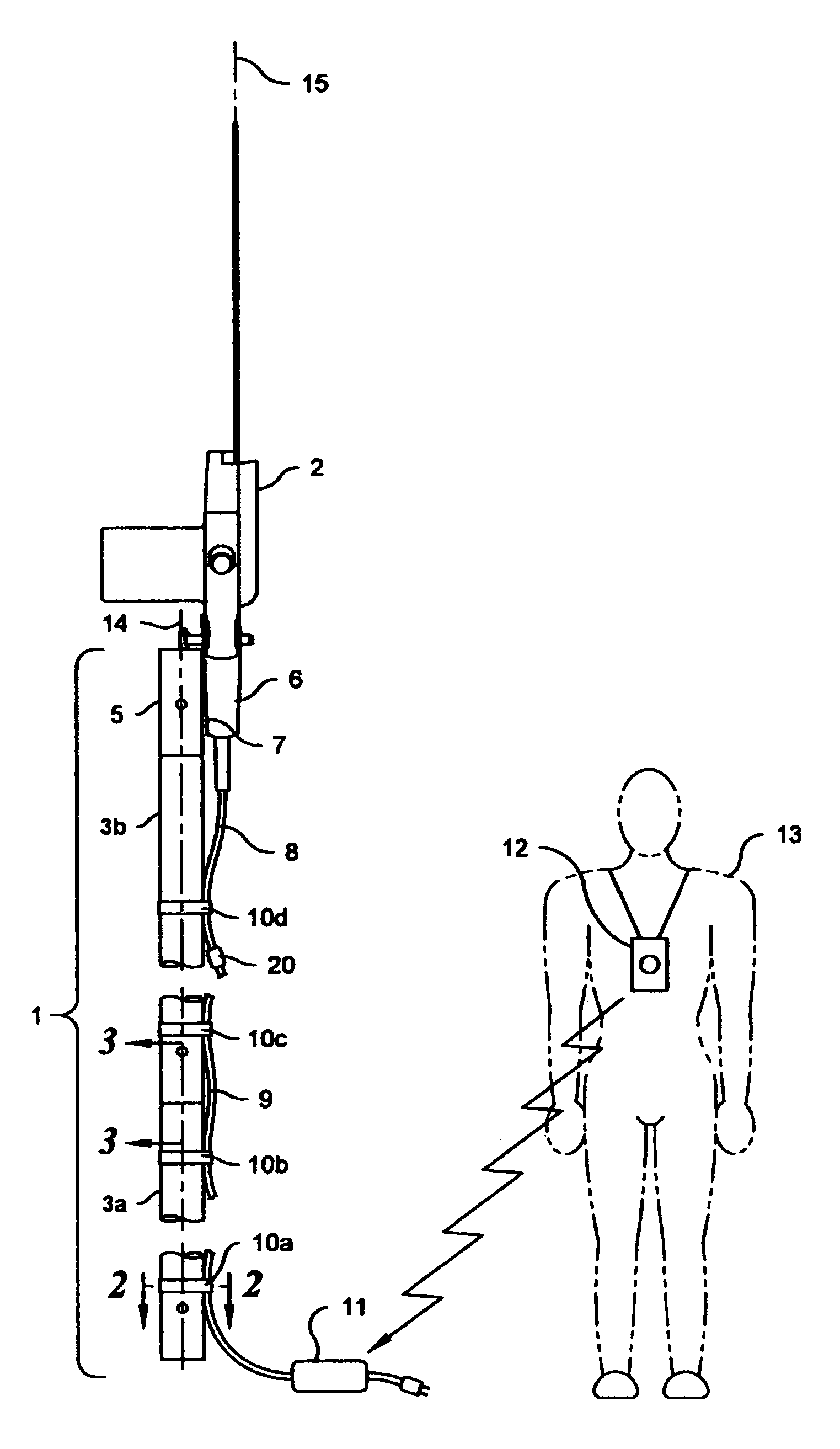

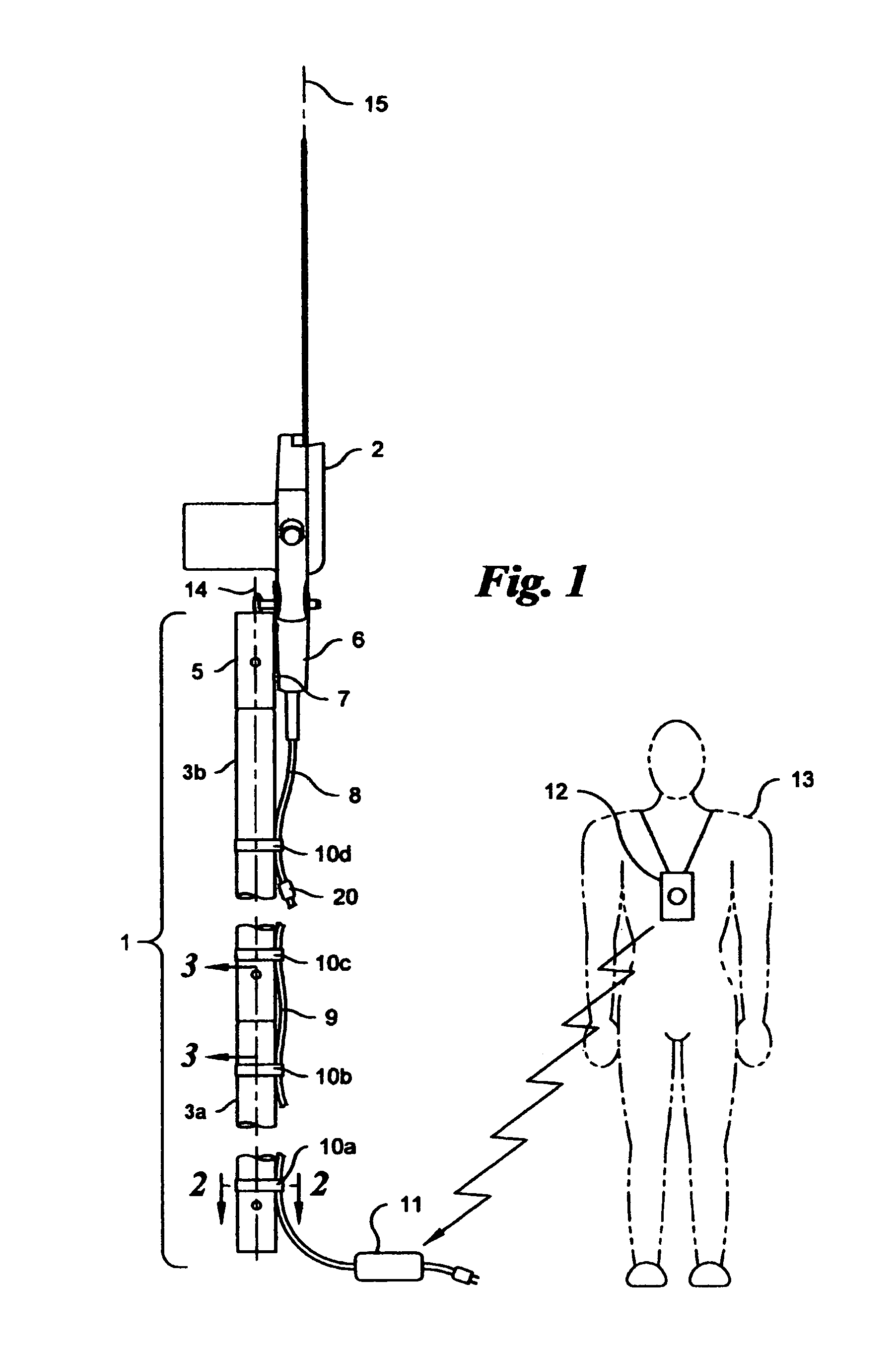

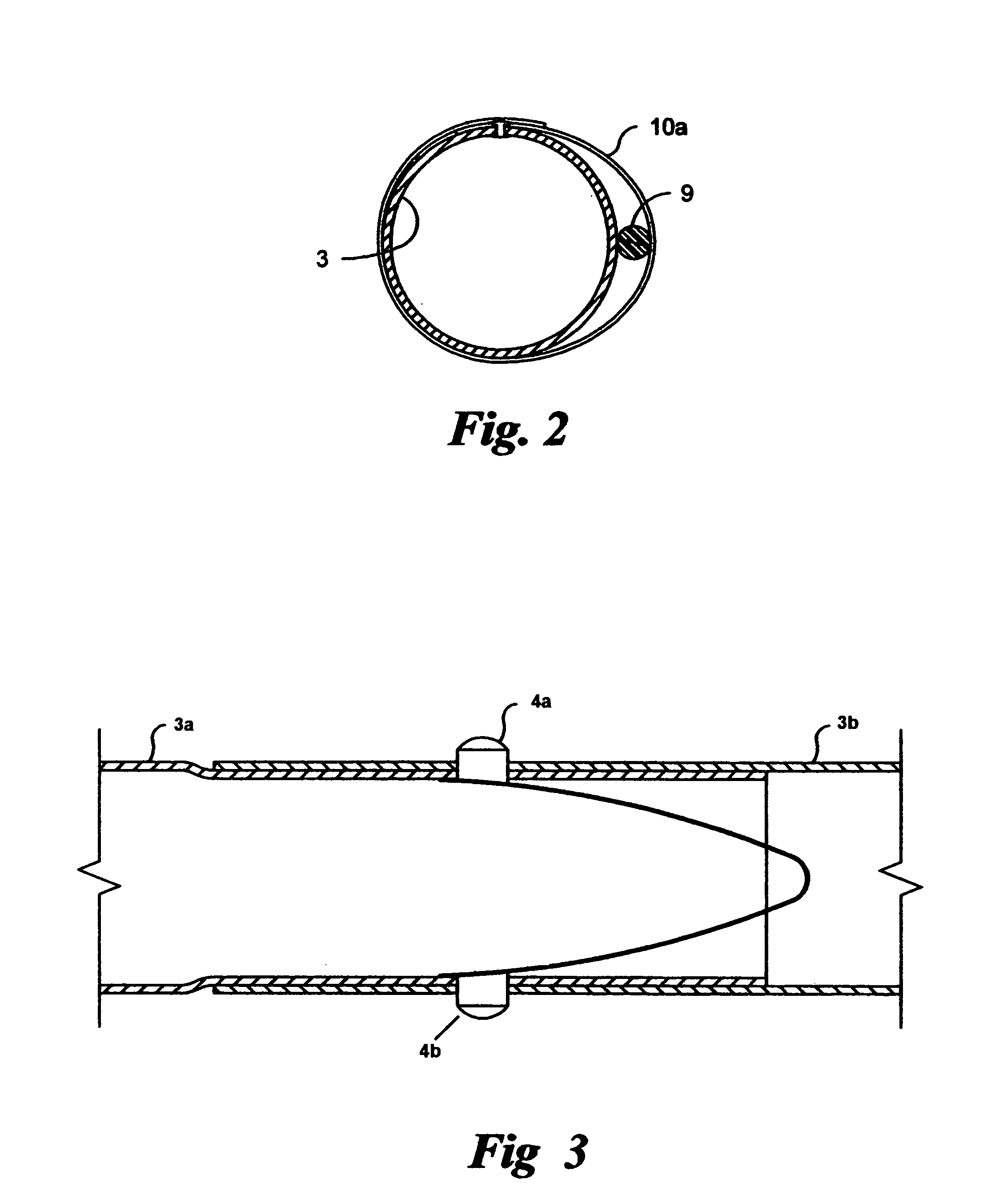

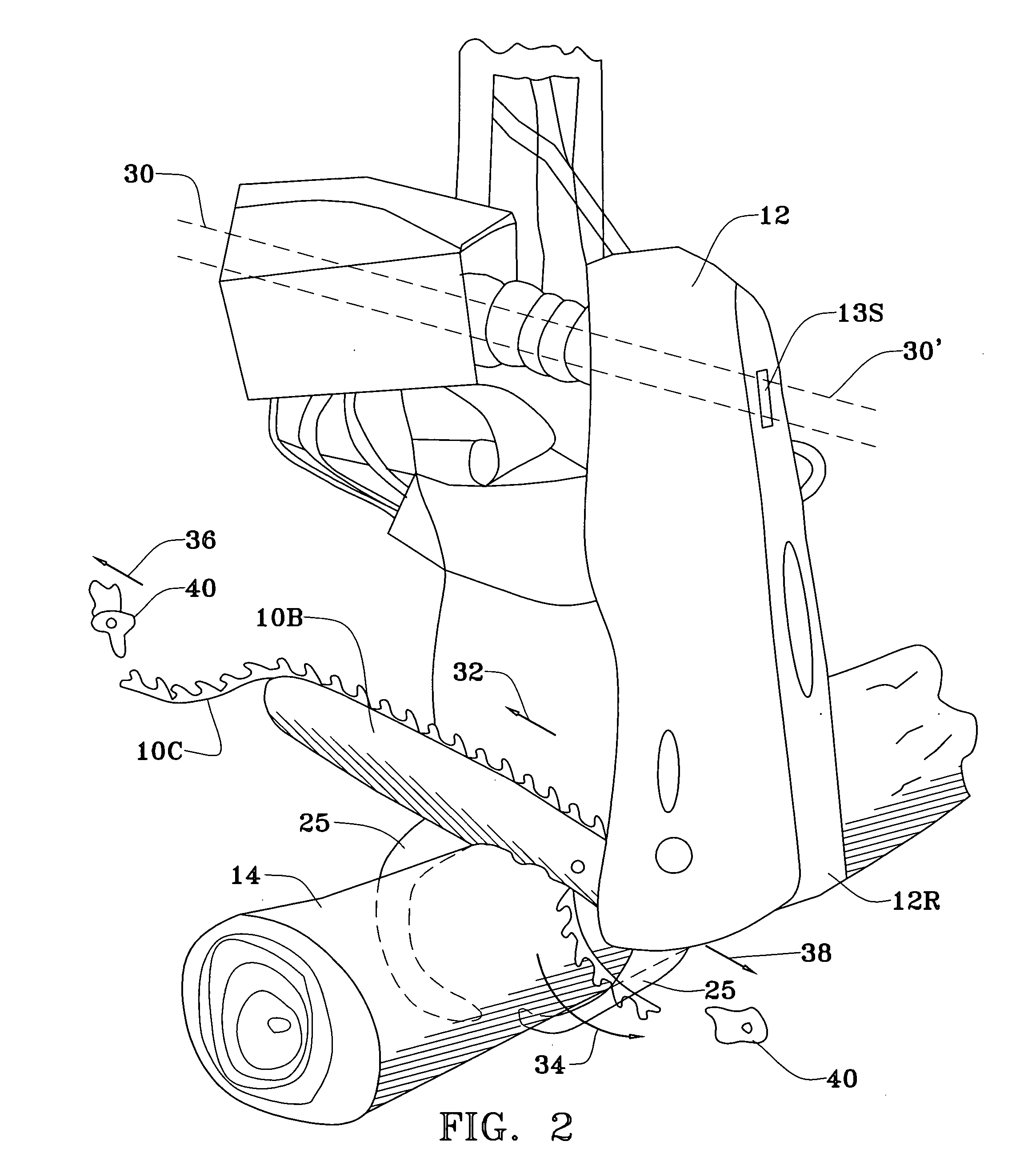

Extended reach tree maintenance apparatus

ActiveUS6904687B1Accurate attachmentVibration minimizationMetal sawing devicesCuttersElectricityAngular orientation

The present invention is an extended reach tree maintenance apparatus. The invention is comprised of a lightweight electric chain saw, at least two hollow and stackable extensions poles, a bracket, several fasteners, and a wireless ON / OFF switch. The bracket is attached to a handgrip at one end of the lightweight chain saw and has a coupler fixed along its length that facilitates its secured yet removable attachment with one extension pole. At least three fasteners pass through the bracket and contact the chain saw securing the bracket to the chain saw. One fastener depresses the trigger switch of the chain saw in the ON position. The wireless receiver switch is electrically connected to the chain saw and remotely operable via a wireless transmitter. In other embodiments, the invention further comprises a switch electrically connected between the chain saw and the wireless ON / OFF switch and fastened to an extension pole. The switch communicates electrical power to the chain saw when extension poles are within a defined angular range of operation and interrupts power when angular orientation is otherwise.

Owner:HILL SR DONALD C

Non-blasting construction method of hard-rock tunnel in city

InactiveCN105952460AImprove construction progressReduce excavation costsTunnelsRock tunnelEngineering

The invention discloses a non-blasting construction method of a hard-rock tunnel in a city. The method comprises following steps: step 1, cutting an outer shell grove along the tunnel excavation contour in a horizontal direction with a chain saw cutter in order to form a continuously-enclosed free face; step 2, utilizing the chain saw cutter to inwardly cut the cutting groove in a horizontal direction according to the set trajectory on the tunnel face and dividing the tunnel face into multiple small blocks; step 3, utilizing a crush head to crush and remove fragmented rocks on the tunnel face. The method of utilizing the chain saw cutter and the crushing head is taken for mechanically excavation. Therefore, construction speed is quickened and input in tunneling cost and equipment is reduced. In the complex situation in the city, the construction method is applied to the hard-rock tunnel so that safety, reliably and efficiency are obtained; no influence is caused to the ambient environment and residents living in the ground; easy control of overbreak of the tunnel around is obtained; and the construction method is convenient and easy to promote.

Owner:CRRC CONSTR ENG CO LTD

Chain saw hazard warning light

ActiveUS20120188089A1Sufficient protectionLine/current collector detailsEngineering safety devicesAcute angleLight beam

A chain saw hazard warning light and method for using same. A pair of oppositely-directed light sources emit light beams throughout a chain shot hazard warning zone through rectilinear, slotted openings at opposite ends of a housing. The light beams turn on, if and only if, the cutting chain is rotating about the chain guide bar; alternatively, initiation of rotation of the cutting chain is delayed to permit the light beams to turn on some time prior thereto. The zone is defined by first and second pairs of planes that diverge in opposite directions from the chain guide bar, said planes being disposed at equal, acute angles (most preferably 15°) to, and on opposite sides of, a plane that includes the chain guide bar.

Owner:THOMSEN KENNETH J

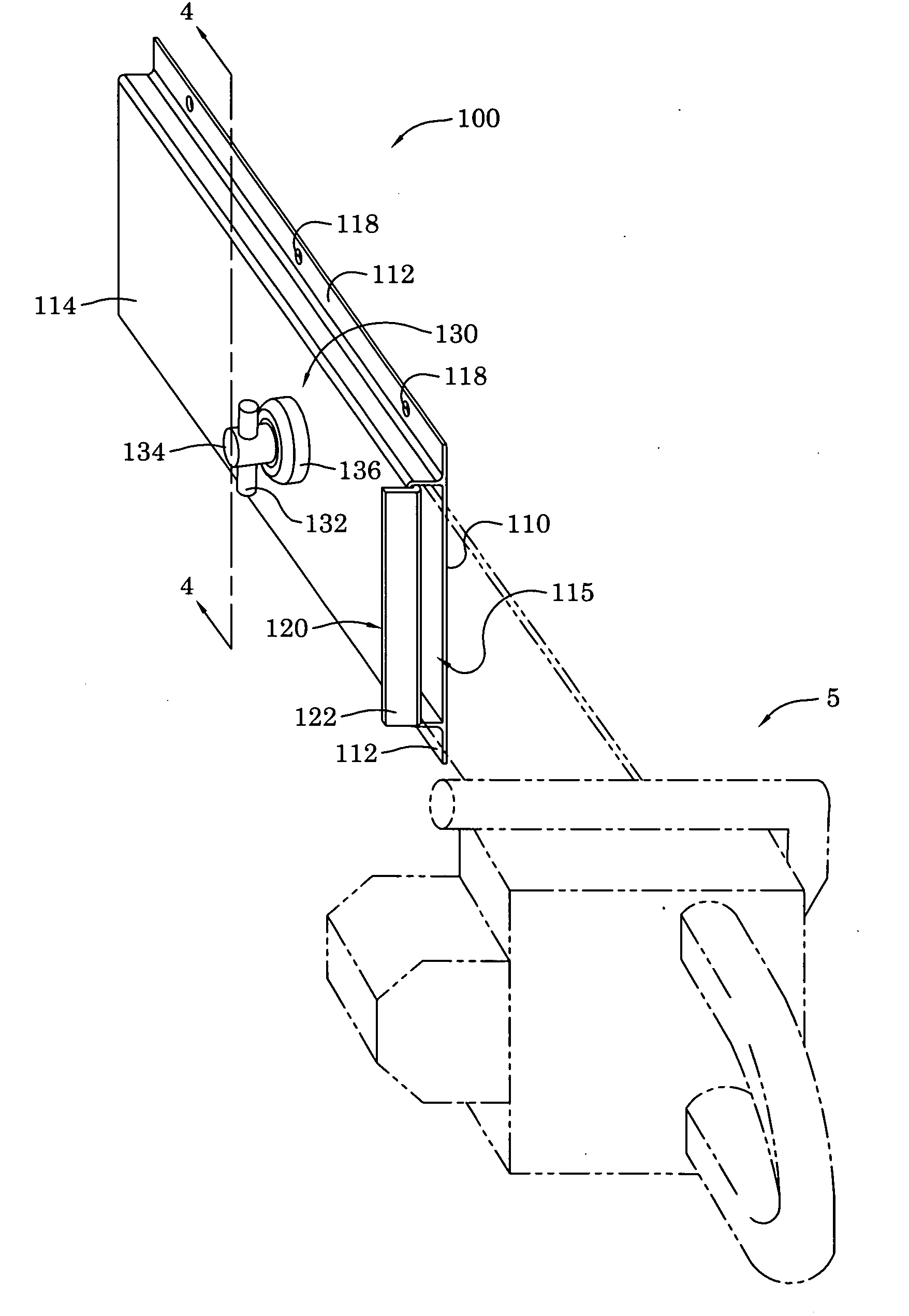

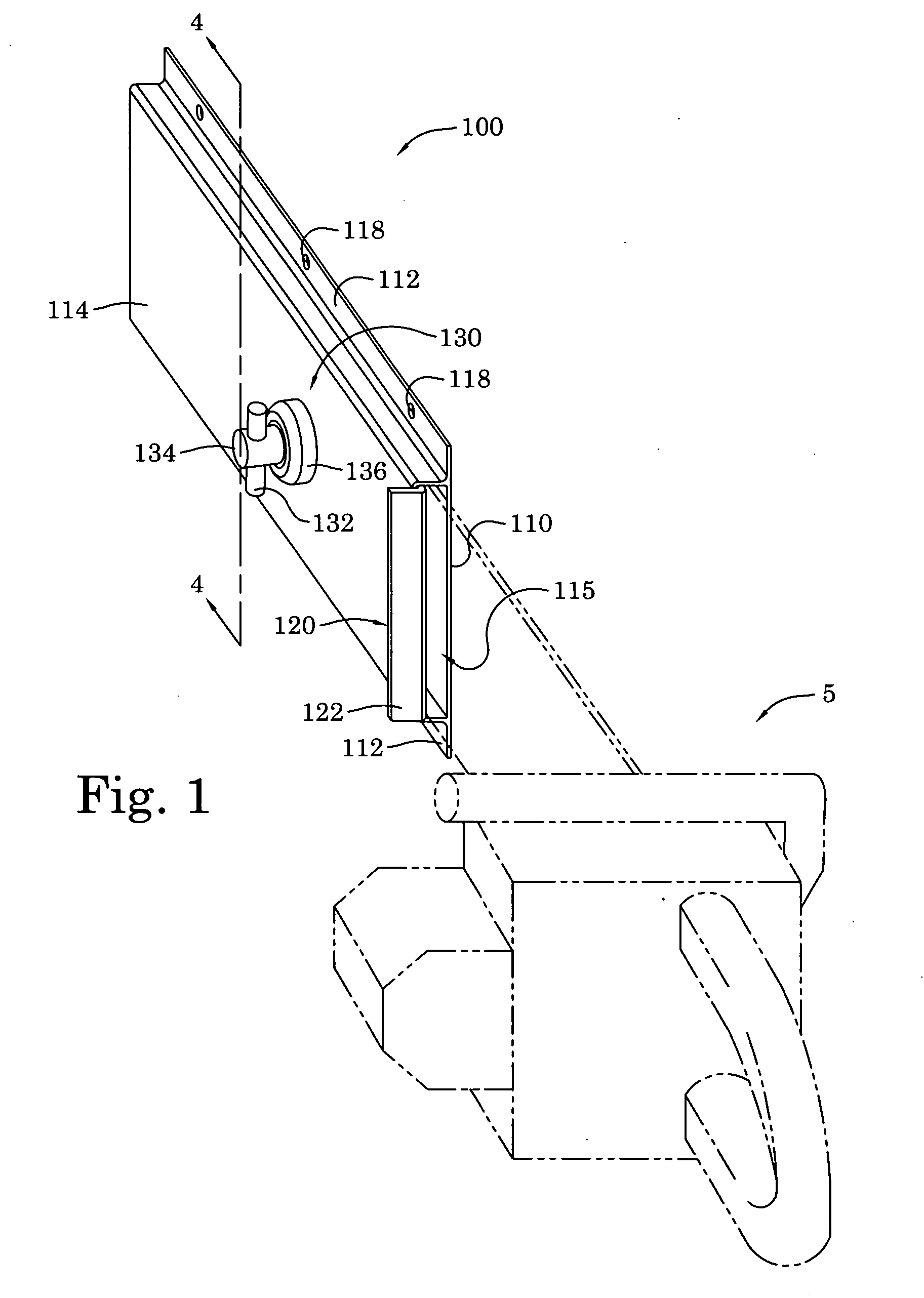

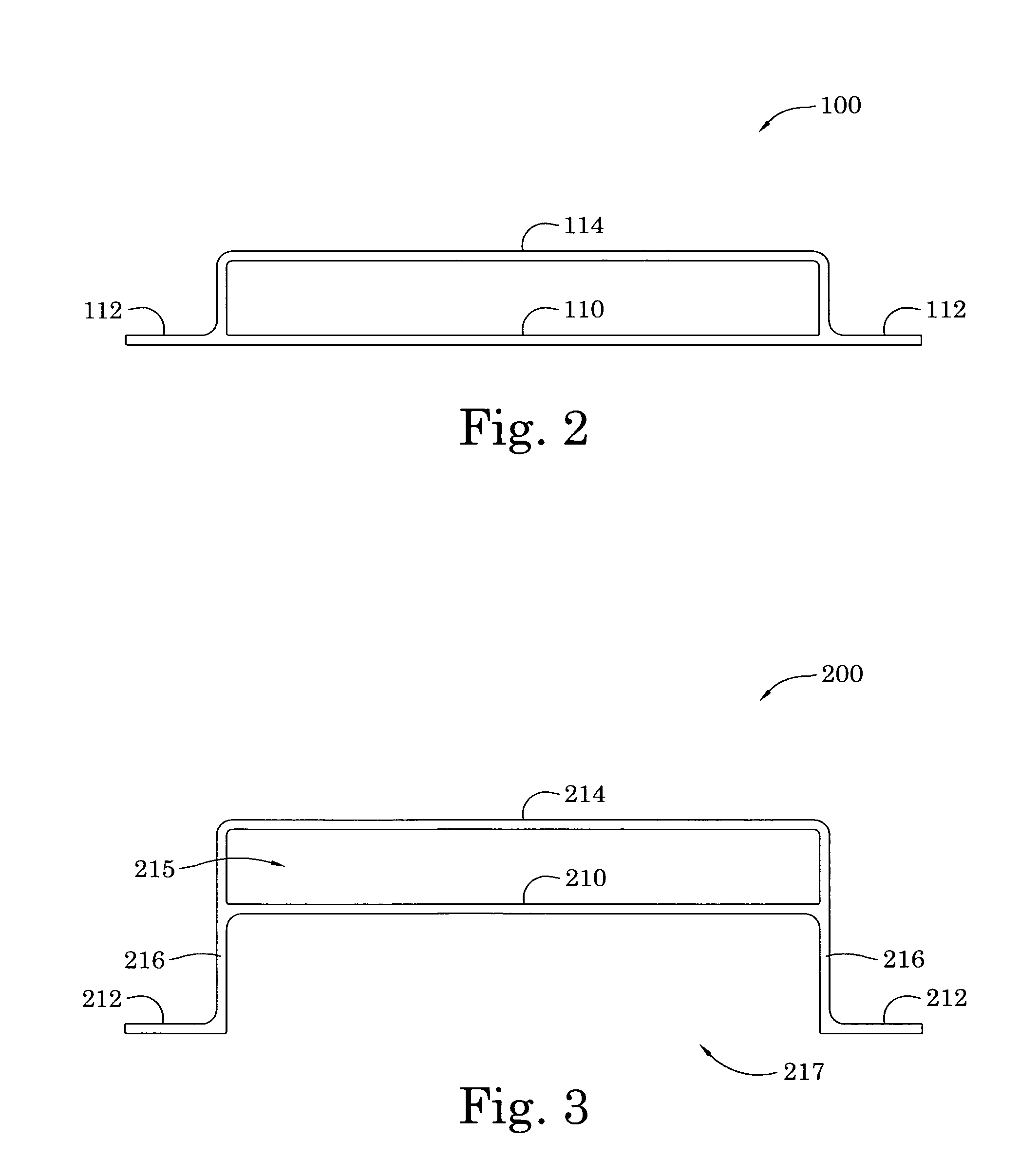

Bar knob with cam-operated locking mechanism

InactiveUS20060016081A1Positive securing of the knobMetal sawing devicesMetal sawing accessoriesLocking mechanismEngineering

A retaining assembly is provided for a tensioning arrangement for adjusting the tension of the cutting chain in the chain saw. The retaining assembly includes a rotatable knob that operates in conjunction with the chain saw's engine chassis, clutch cover, and guide bar and is rotatable about an axis of rotation between a tightening position for holding the guide bar in place and a loosening position enabling the guide bar to be repositioned whereby the tension in the cutting chain is adjusted. A locking mechanism is provided for locking and unlocking the knob for rotational movement. When the locking mechanism is in a locking position, moveable engagement points of the locking mechanism extended beyond the confines of the knob and engage fixed engagement points. When the locking mechanism is in the unlocking position, the moveable engagement points, having moved inwardly of the confines of the knob, are disengaged from the fixed engagement points.

Owner:HUSQVARNA OUTDOOR PROD INC

Hand-guidable tool with handle heating based on microwaves

The invention entails an actuatable tool, such as a chain saw, with at least one handle for manually manipulating the tool by one hand of a user. The tool includes at least one device in at least one area of the at least one handle. The device is suitable and adapted for radiating energy in the form of electromagnetic radiation in the microwave range so that a warming of the user's hand can be brought about.

Owner:DOLMAR

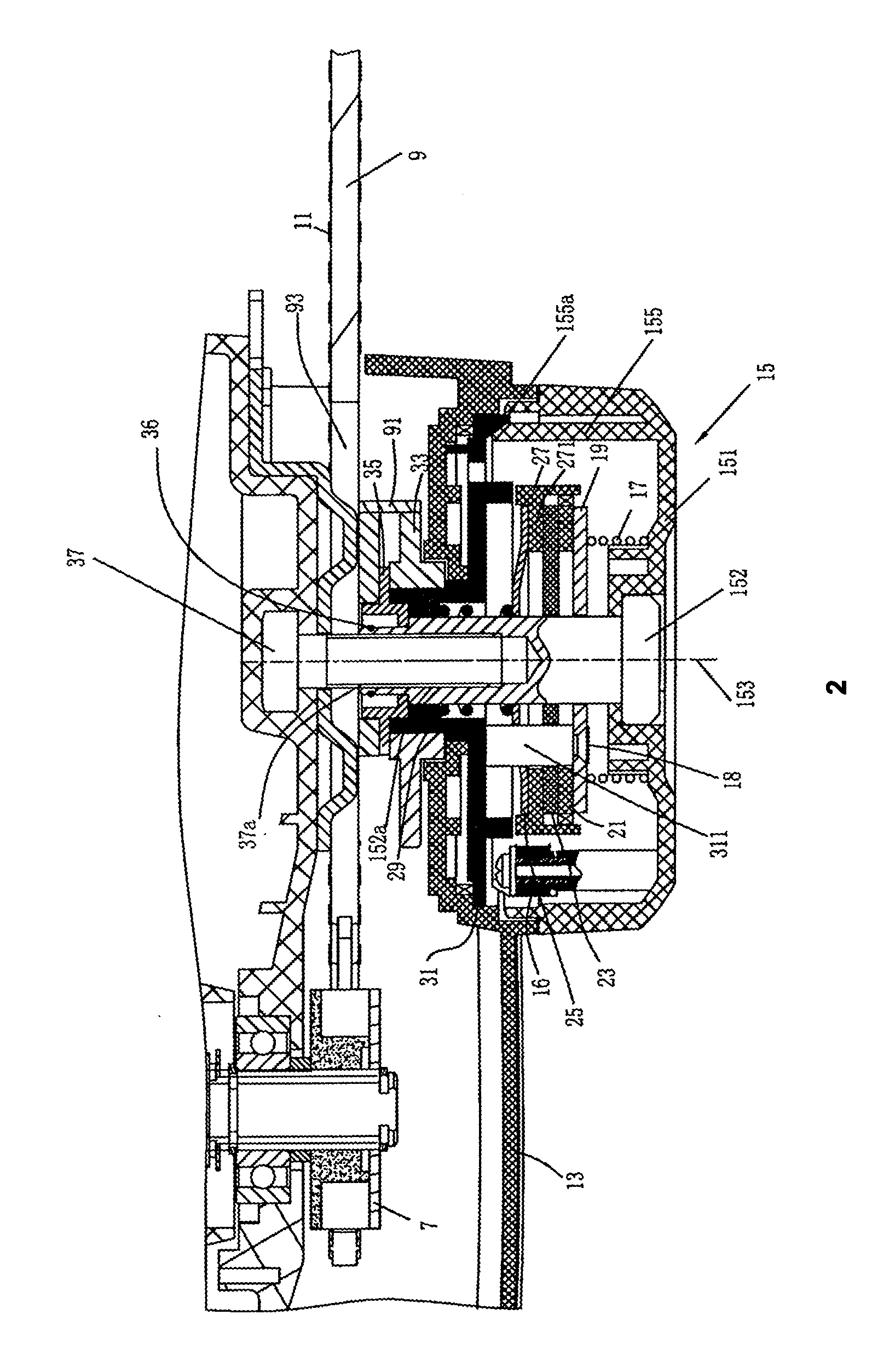

Chain saw

ActiveUS20110308096A1Stable, anti-abrasivePreventing the saw chain from loosing and jumping offMetal sawing devicesMetal sawing accessoriesSprocketEngineering

A chain saw includes a housing, a sprocket wheel which is provided in the housing for driving a saw chain, and a chain guide for guiding the movement of the saw chain. The chain guide extends out longitudinally from the housing and is movable longitudinally relative to the housing. The chain saw includes a chain tensioning device. The chain tensioning device comprises a driven member arranged on the chain guide and a driving member which drives the driven member to move the chain guide longitudinally and a rotating device rotating the driving member. A stepless clutch device is arranged between the rotating device and the driving member. The chain tensioning device presses the chain guide while it tensioning the saw chain. Thus it prevents effectively the chain guide from loosing after the saw chain is tensioned. The operation of the chain tensioning device is labour-saving. The chain tensioning device has a stable structure and it is hard to be worn.

Owner:POSITEC POWER TOOLS (SUZHOU) CO LTD

Double-chain saw slotting machine

The invention relates to a double-chain saw slotting machine, which comprises a connecting plate 6, two hydraulic motors 1, chains 2, an unearthing digging cutter 3, four tracks 4 and a limit wheel 5. The connecting plate is used for connecting two chain saws; each hydraulic motor serving as power drives each chain 2 respectively; the chain is provided with the unearthing digging cuter 3; every two tracks are positioned on both sides of each chain raw respectively and used for guiding the slotting machine; and the limit wheel 5 limits deviation of the chains. The double-chain saw slotting machine is a special tool for building diaphragm walls.

Owner:NANTONG JINHONG STEEL STRUCTURE PROJECT

Chainsaw holding apparatus

A chainsaw holder adapted for receiving a chainsaw bar and chain within an interior compartment of a mounting piece. A pressure piece fits at least partly within the interior compartment and is forced by an operator against the chainsaw bar to capture it within the compartment. The operator is adjustable to release the chainsaw bar. The operator may be a screw operator which bears upon the pressure plate. The pressure plate may have an end flange for keeping it positioned within the interior compartment. The mounting piece preferably has flanges which allow fasteners to extend therethrough and secure the apparatus to the side wall of a supporting structure such as the wall of a pickup bed.

Owner:ALCOBRA METALS

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com