Harvester machine for wood and felling/wood making method

A processing method and wood technology, applied in the application, forestry, agriculture and other directions, can solve problems such as reduced operation efficiency, reduced wood value, and wood damage.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

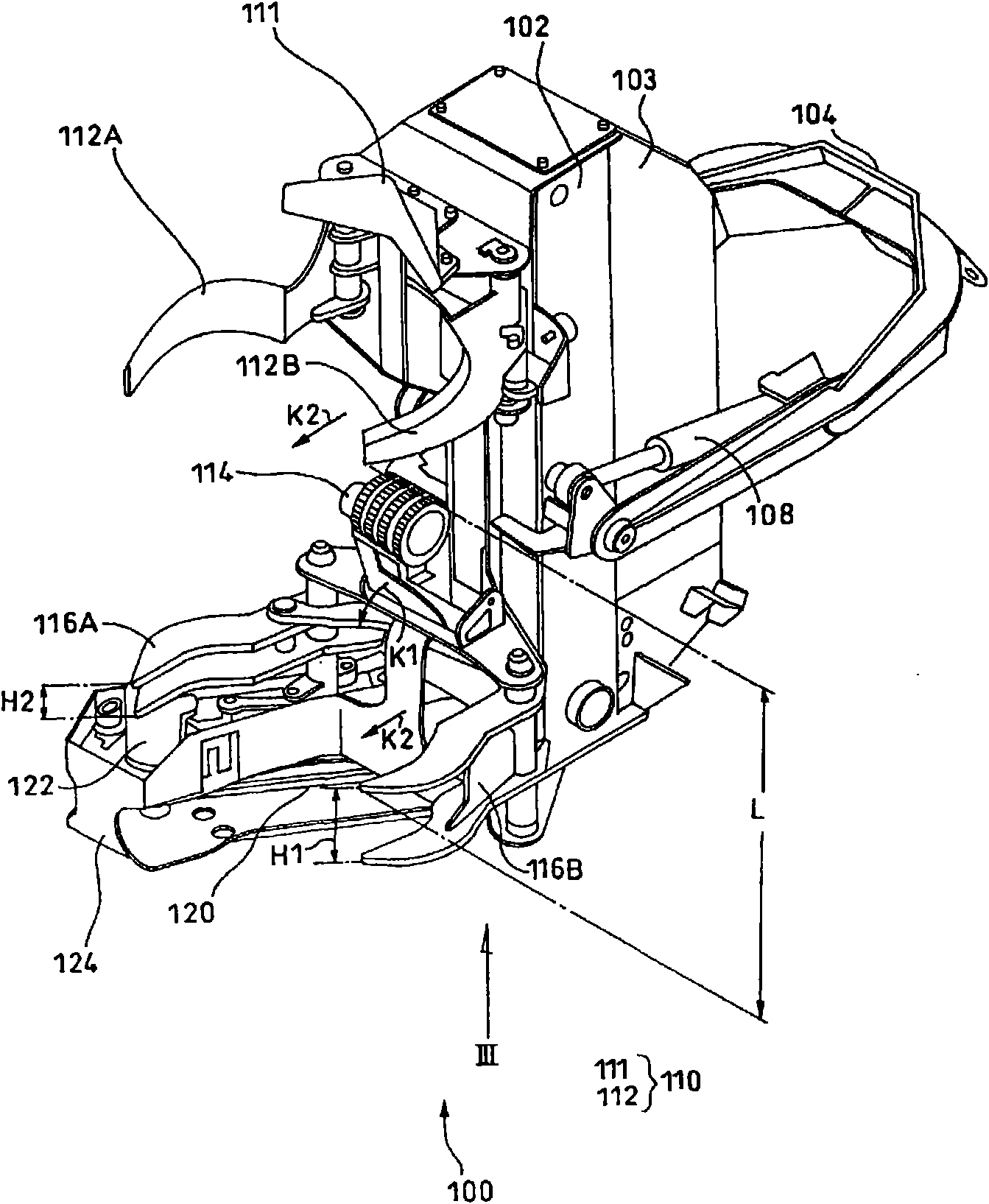

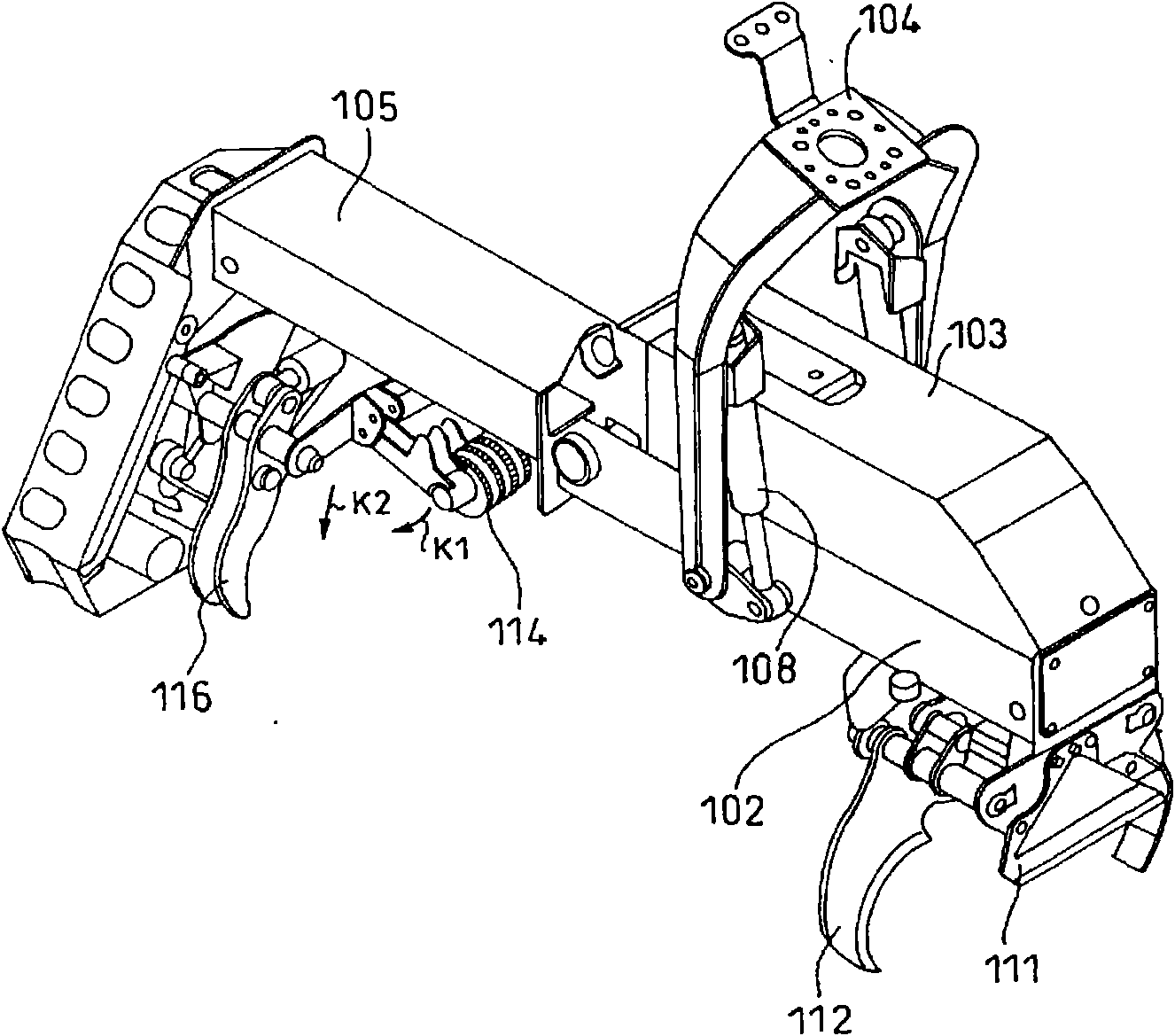

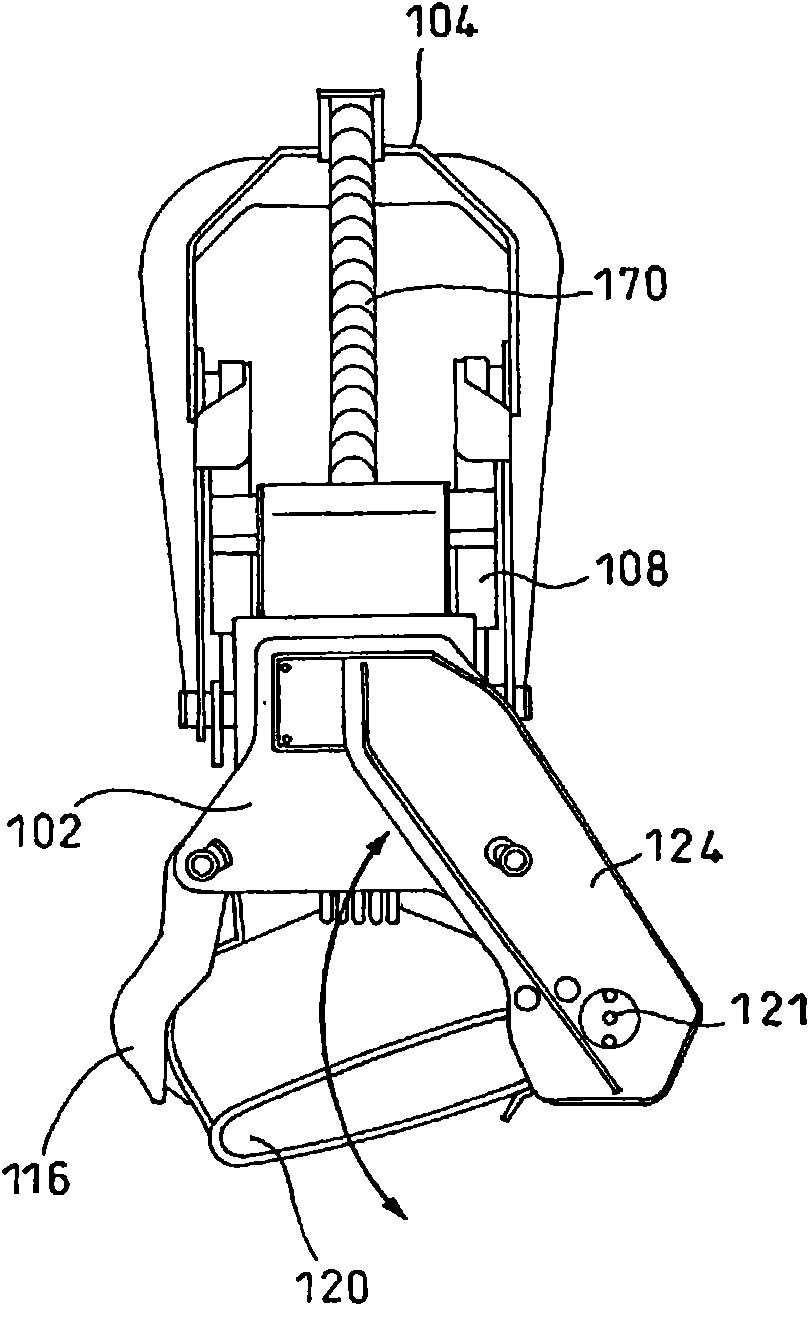

[0026] Hereinafter, an example of embodiment of the present invention will be described in detail with reference to the drawings.

[0027] figure 1 It is a perspective view of the harvesting apparatus 100 which is an example of embodiment of this invention. figure 2 It is a perspective view of the harvesting device 100 viewed from other angles. image 3 is the bottom view of the harvesting device 100 ( figure 1 Arrow III in the diagram). Figure 4 is a side view of the harvesting device 100 . In addition, in Figure 1 to Figure 4 In , the wood itself is not shown for convenience of description. For example, in figure 1 In the felling device 100 shown, it is possible to grasp such that the longitudinal direction of the wood is the vertical direction of the drawing.

[0028] This felling device 100 is used by being equipped with a working vehicle such as a forklift, as in the conventional example. Of course, the work vehicle is not limited to a forklift, and can be w...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com