Patents

Literature

34results about How to "Shorten prepumping time" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

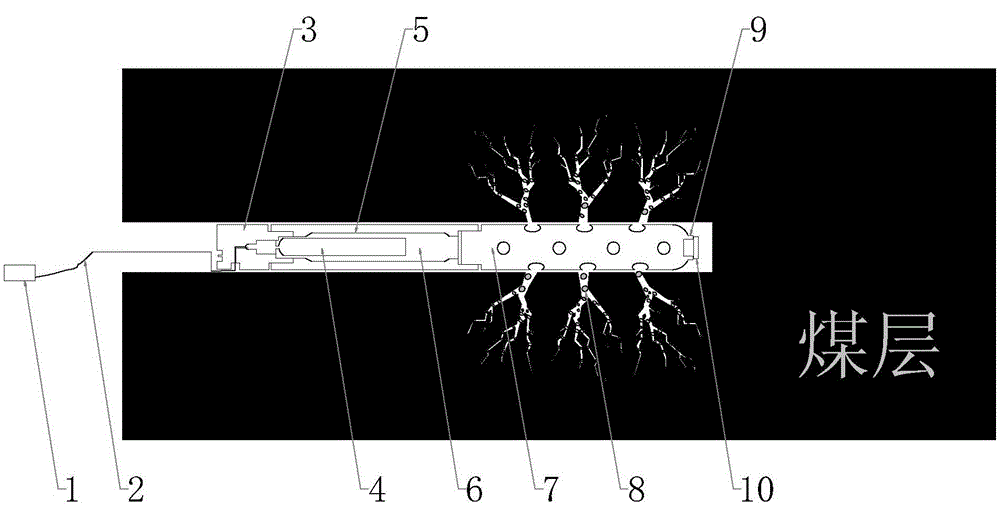

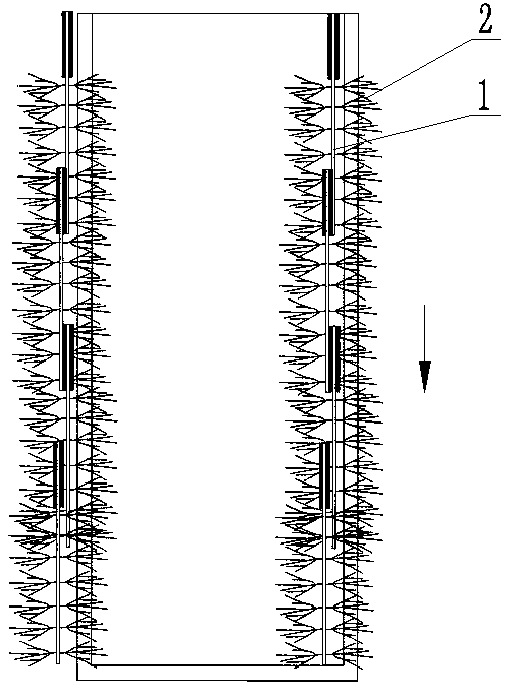

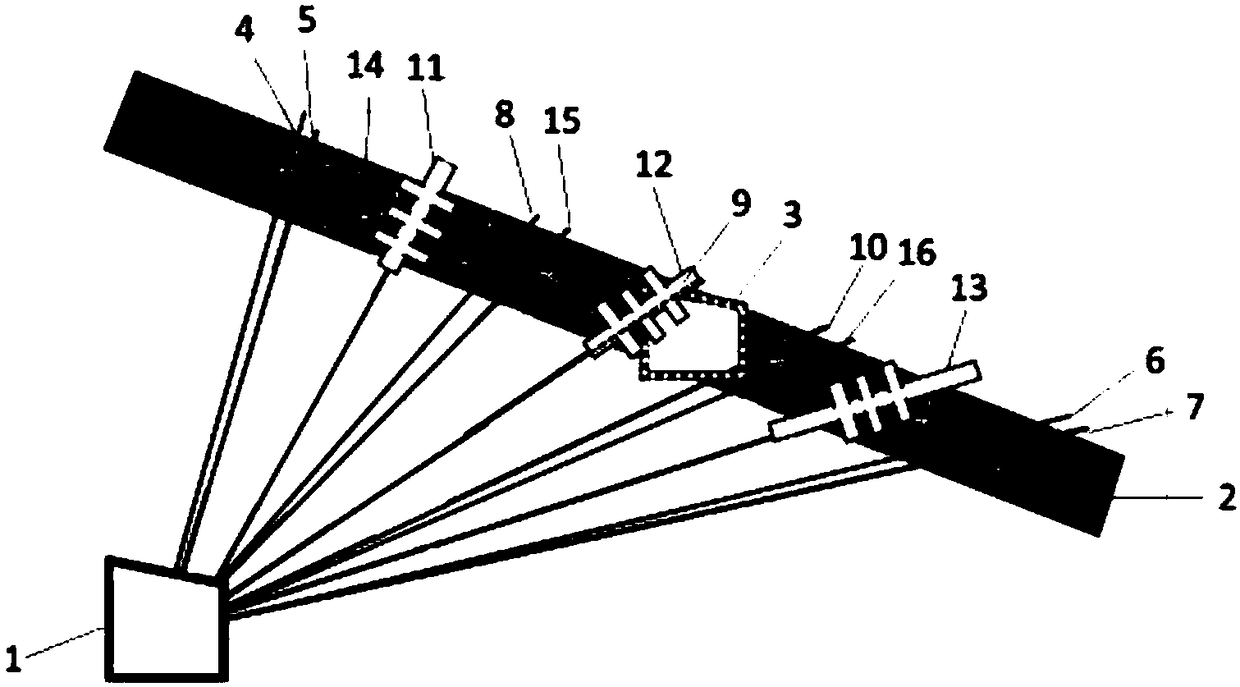

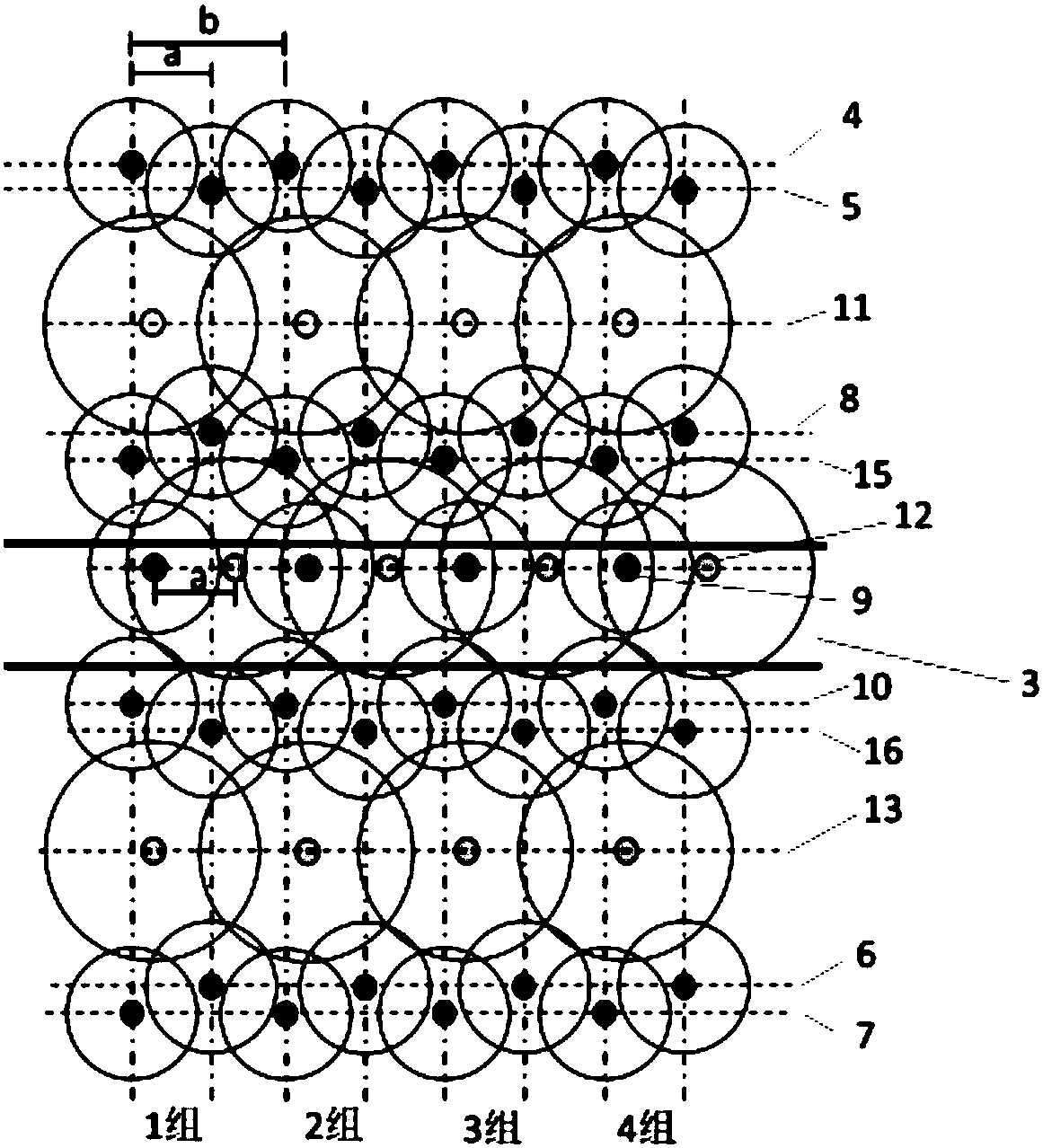

Coal seam reaming system using three-dimensional (3D) swirling water jet and reaming and fracturing method for permeability enhancement

InactiveCN102213077AEasy to crackLarge range of pressure reliefDrill bitsConstructionsHydraulic pumpHigh pressure water

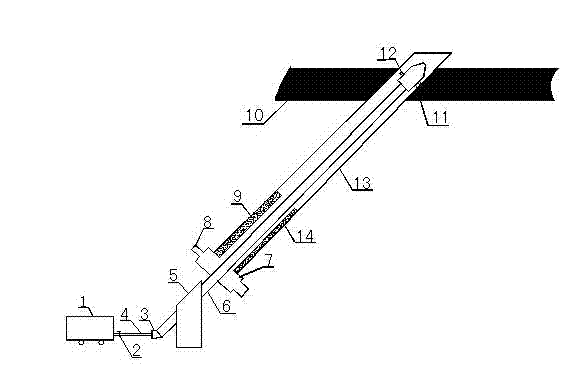

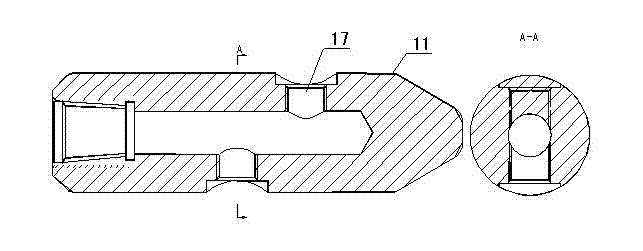

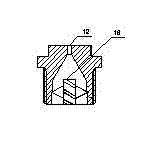

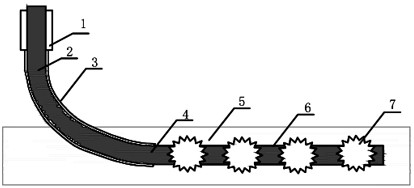

The invention relates to coalmine gas extraction and permeability enhancement equipment and technology, and discloses a coal seam reaming system using three-dimensional (3D) swirling water jet. The system is connected to a high-pressure rotary joint through a high-pressure hose provided with a stop valve by virtue of a high-pressure hydraulic pump station and is characterized by being connected to a high-pressure water jet drill stem through a drilling machine, wherein the front end of the high-pressure water jet drill stem is connected with a high-pressure water jet head with nozzle bases; and high-pressure swirling water jet nozzles are arranged on the nozzle bases. The invention further discloses a coal seam reaming and fracturing method for permeability enhancement using the 3D swirling water jet. In the coal seam reaming method using the 3D swirling water jet, coal is sheared so as to lower the hydraulic pressure loss, improve the cutting efficiency and increase the cracks and bore diameter of the coal; high-pressure water is injected so as to fracture the coal between a hydraulic reamed hole and control bored holes; and a coal seam is fully depressurized within a large range so as to shorten the pre-extraction time of the coal seam.

Owner:CCTEG SHENYANG RES INST +1

Coal seam pre-splitting method based on gas extraction

The invention relates to a coal seam pre-splitting method based on gas extraction, which adopts a 'CO2 gas extraction device' as a tool to blast and pre-split a pre-mined coal seam, so as to increase the crack of the coal seam, drive out gas absorbed on the coal seam and extract the gas. The method particularly comprises the following steps: drilling a hole on the working surface of a pre-mined coal seam, filling CO2 gas extraction device into the drilled hole, sealing the drilled hole, detonating the CO2 gas extraction device, releasing high-pressure CO2 gas for deep-hole impact and pre-splitting of the coal seam, taking out the CO2 gas extraction device, and connecting the drilled hole with a gas extraction system to extract gas. The pre-splitting method of the invention can greatly enhance the permeability of the coal seam, promote the gas dissociation in the coal seam, and improve the underground gas extraction efficiency of the coal mine.

Owner:山西锦浩诚科技有限公司

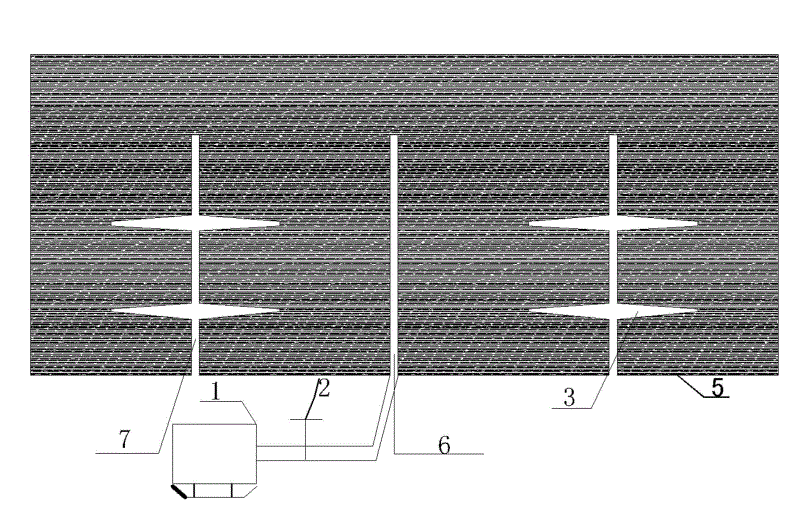

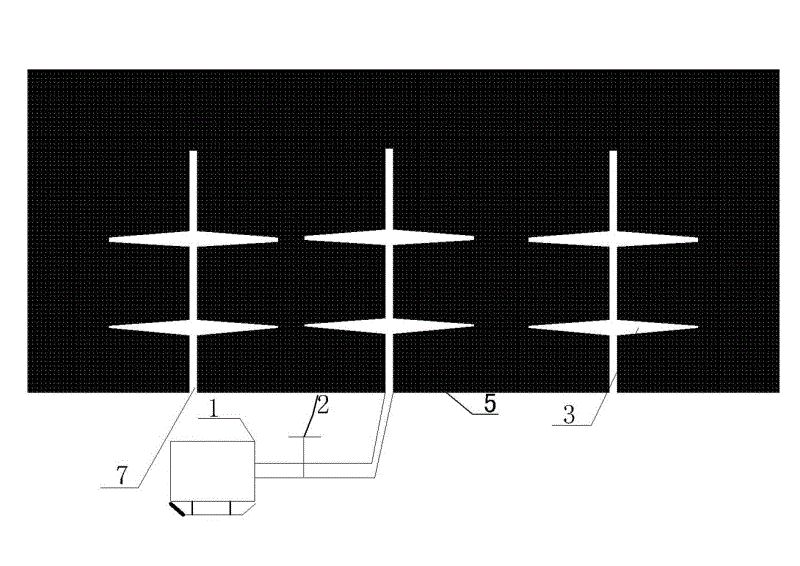

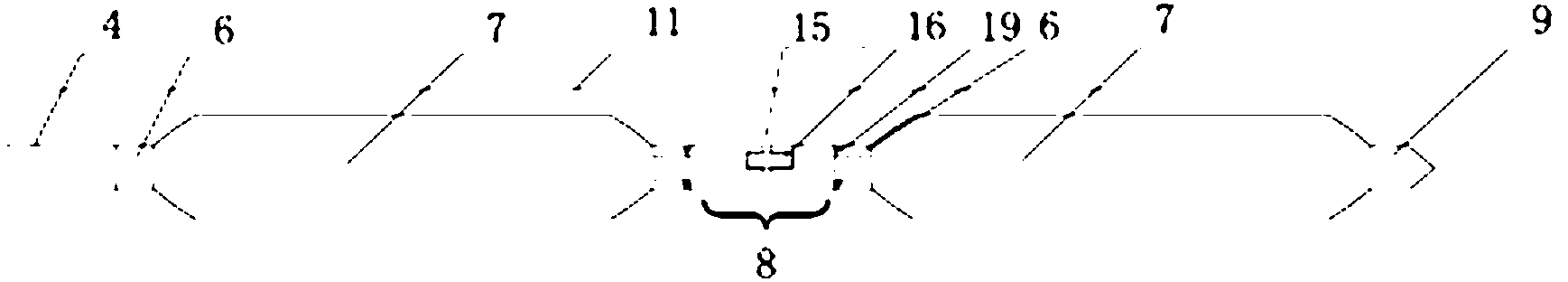

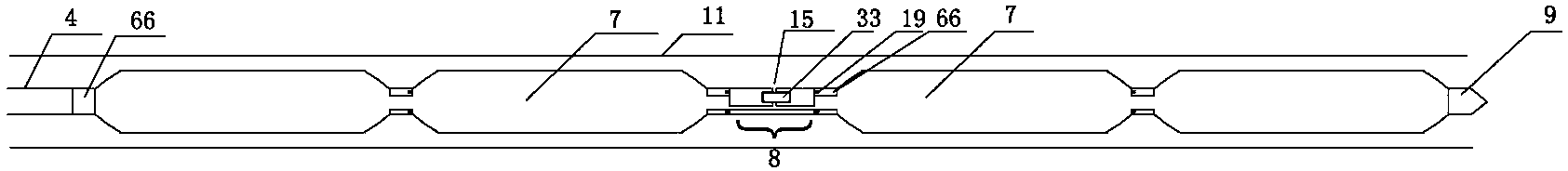

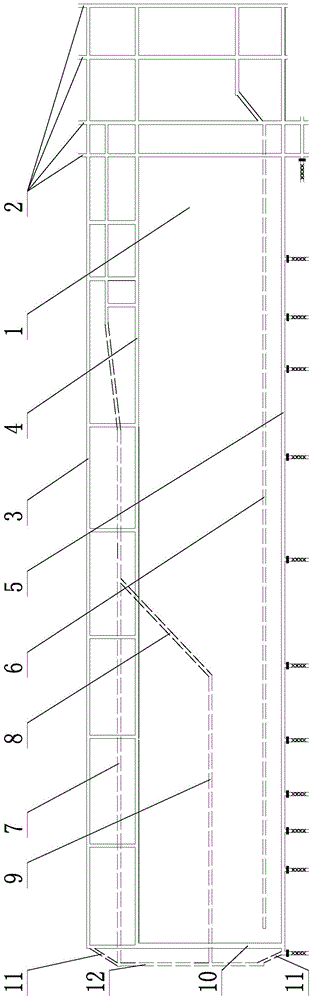

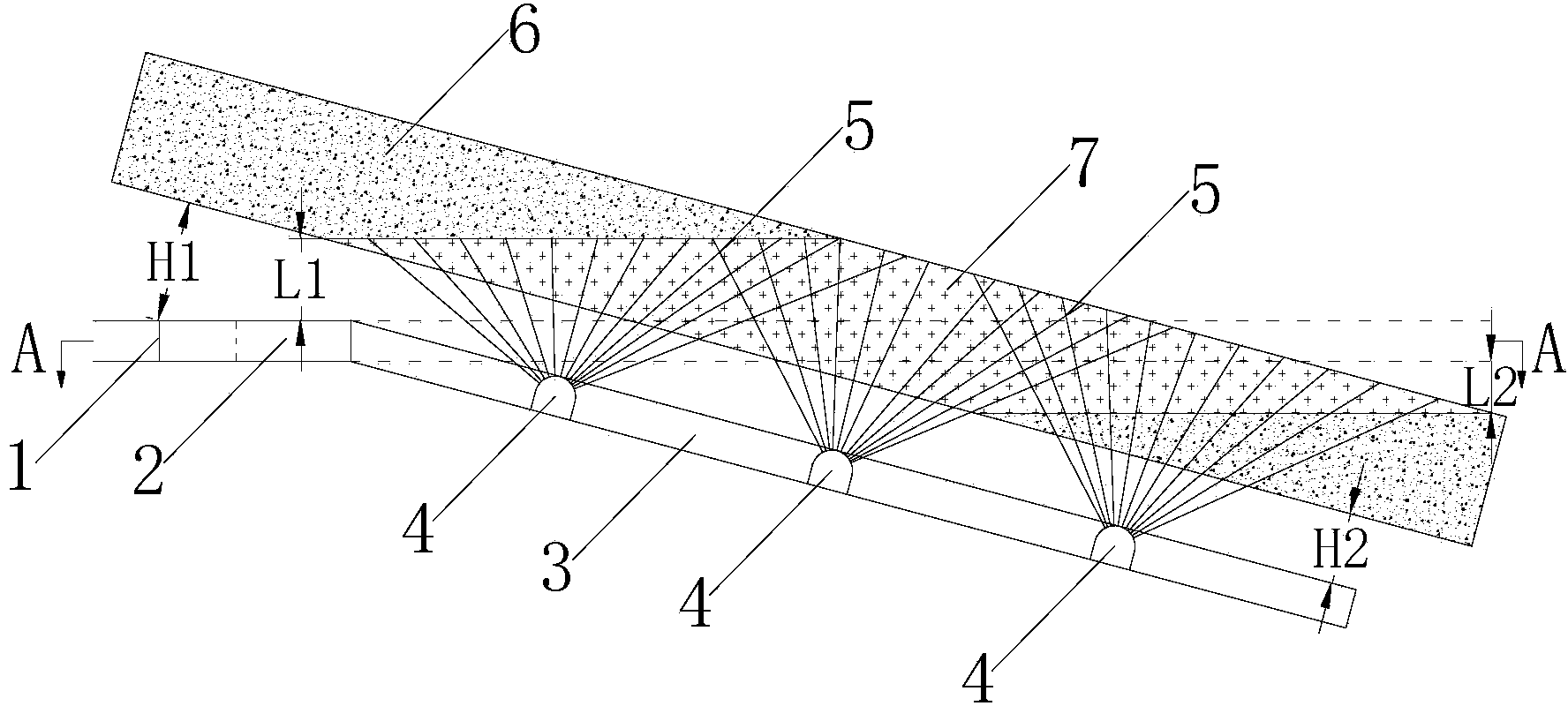

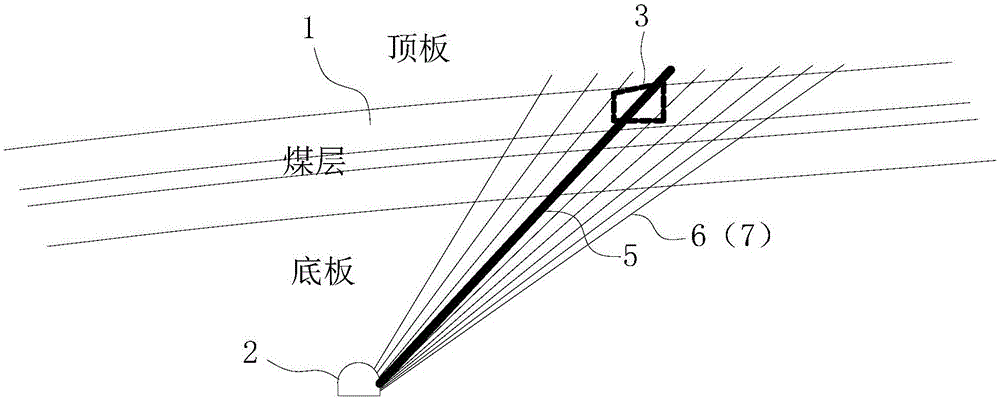

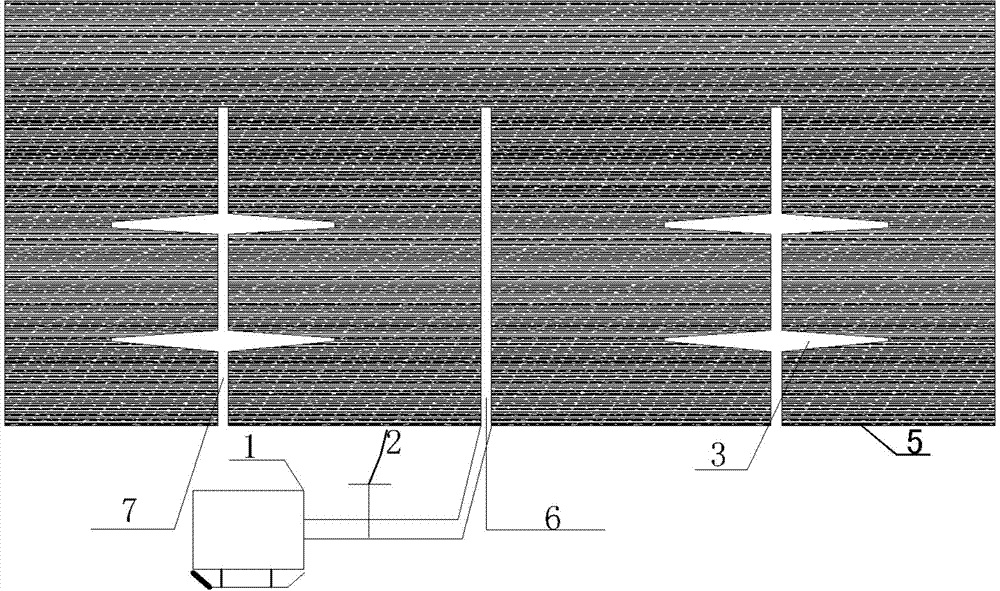

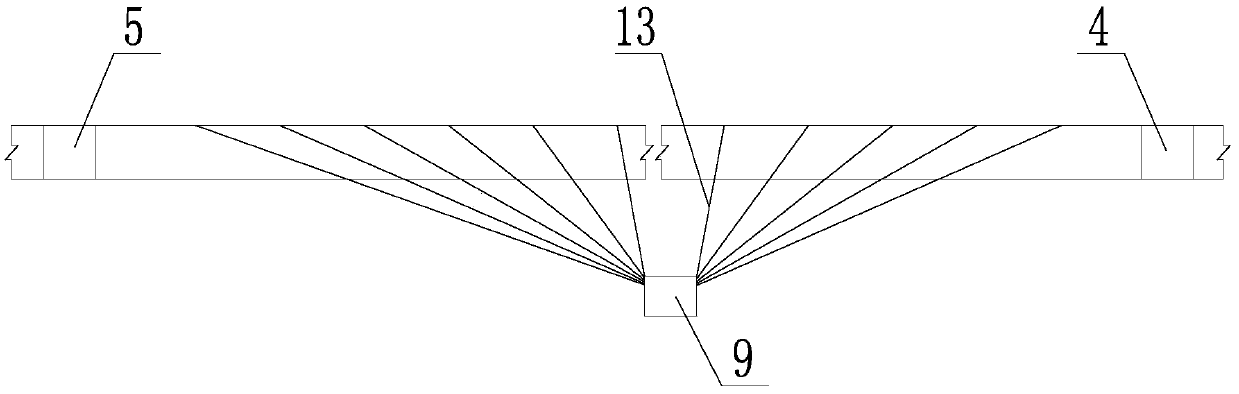

Directional hydraulic pressing penetration, permeability increase and outburst elimination method of guide groove

ActiveCN102619552ALarge range of pressure reliefImprove breathabilityFluid removalDirectional drillingMining engineeringHigh pressure water

The invention relates to a directional hydraulic pressing penetration, permeability increase and outburst elimination method of a guide groove, which comprises the steps of (1) constructing a guide groove drill or the guide groove drill and control drills in a coal seam; (2) forming a guide groove in the guide groove drill in advance; (3) utilizing the guide groove drill or the control drills to perform hydraulic fractures, utilizing the guide groove and the control drills to perform directional control on the hydraulic fractures, enabling the coal body between the guide groove drill or the guide groove drill and the control drills to be pressed into penetration, forming multiple fractures among drills, and enabling a large amount of nickings to be brought out through the high-pressure water; and (4) after the fractures finish, enabling all the drills to be sealed and accessed into a drainage system, and beginning extraction. By means of the method, the number of pressing penetration of drills can be increased by 50%, the pressure relief scope of the coal seam is increased by over one time, the permeability of the coal seam is remarkably improved, gas extraction is increased by more than four times, measure drills can be reduced by about 60%, fore-pumping time is effectively reduced, area outburst elimination is achieved, and gas hazards can be reduced to the largest extent.

Owner:CCTEG SHENYANG RES INST

Coal mine underground high-power electric knock assisted hydraulic fracturing permeability enhancement method

ActiveCN105275443AIncrease the number of cracksIncrease the lengthFluid removalGas removalShock waveHigh energy

The invention relates to a coal mine underground high-power electric knock assisted hydraulic fracturing permeability enhancement method suitable for increasing extraction radius and total extraction amount of gas extraction drilling. The method comprises the following steps that: a borehole extends from one side of a laneway to a coal seam is constructed; a high-voltage pulse discharger which is installed at the front end of a fracturing steel pipe is sent to the bottom of the borehole; a hole packer, which is separated from the orifice of the borehole by 2 to 3m, is installed on the borehole; the outer end of the fracturing steel pipe is connected with a high-pressure pump station through a high-pressure rubber hose; and the high-voltage pulse discharger is connected with a high-voltage electric pulse generator through a cable; after water with a certain pressure is injected into the borehole, the high-voltage electric pulse generator is started so as to apply high-power electric knock assisted hydraulic fracturing to the coal seam; after the high-power electric knock assisted hydraulic fracturing, the high-voltage pulse discharger and the fracturing steel pipe are quitted; and a gas extraction pipeline is connected into the borehole. According to the method of the invention, high energy released by high-voltage electric pulses is utilized to form shock waves in the water, and therefore, a large number of cracks can be formed in the coal seam, and primary cracks are extended. With the method adopted, the permeability coefficient of a coal body can be increased by 100 to 300 times, and single-hole gas extraction efficiency can be effectively improved.

Owner:CHINA UNIV OF MINING & TECH

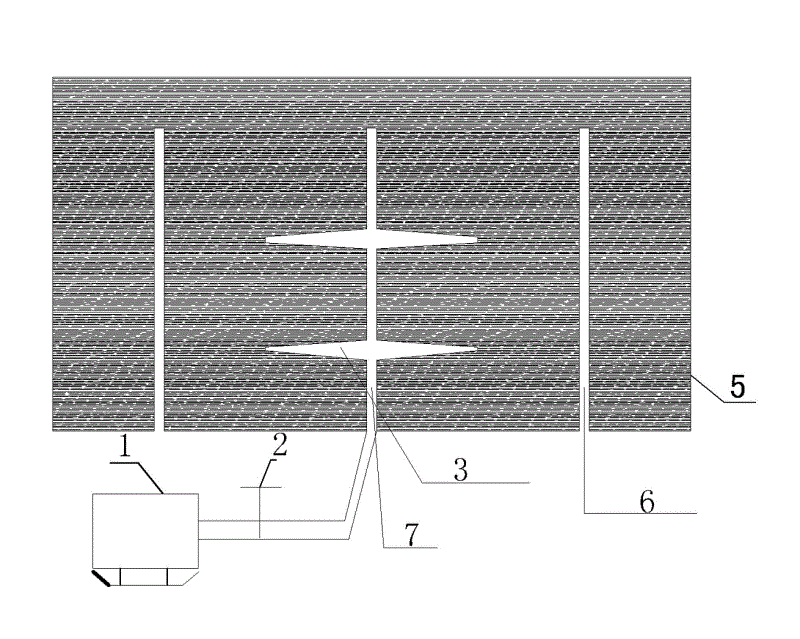

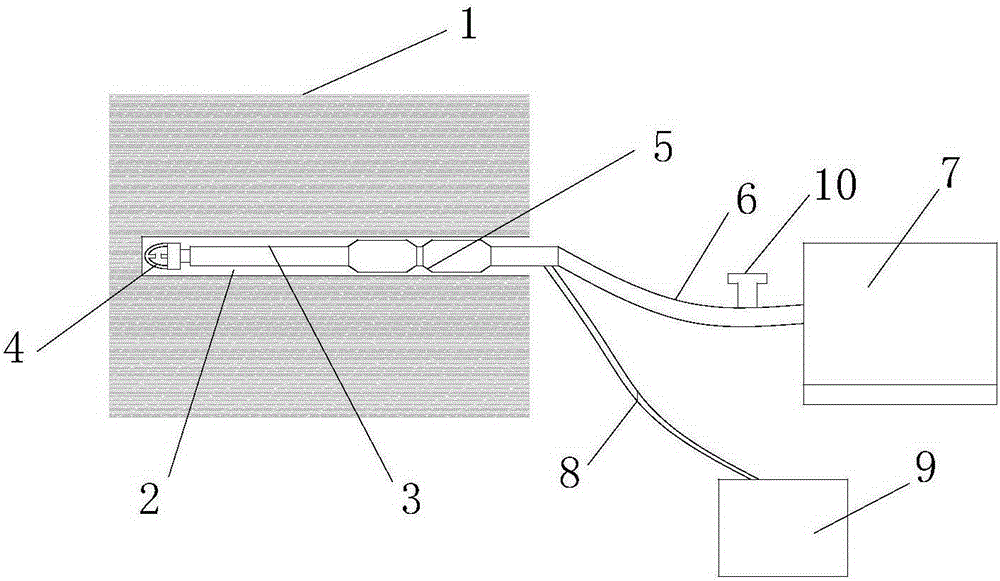

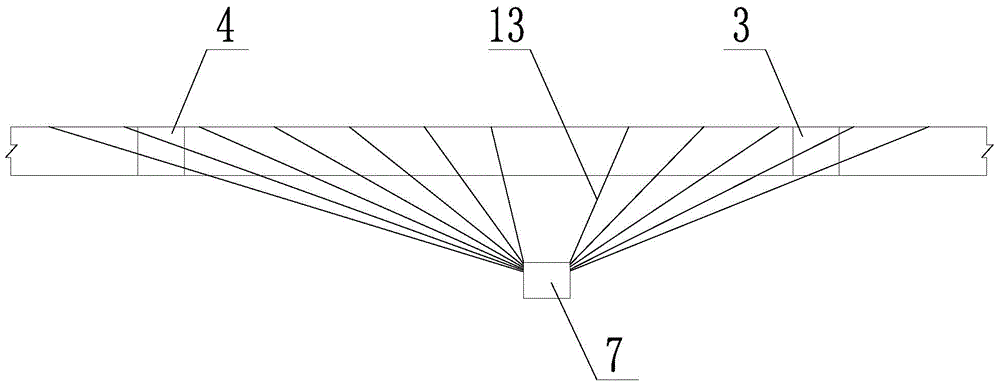

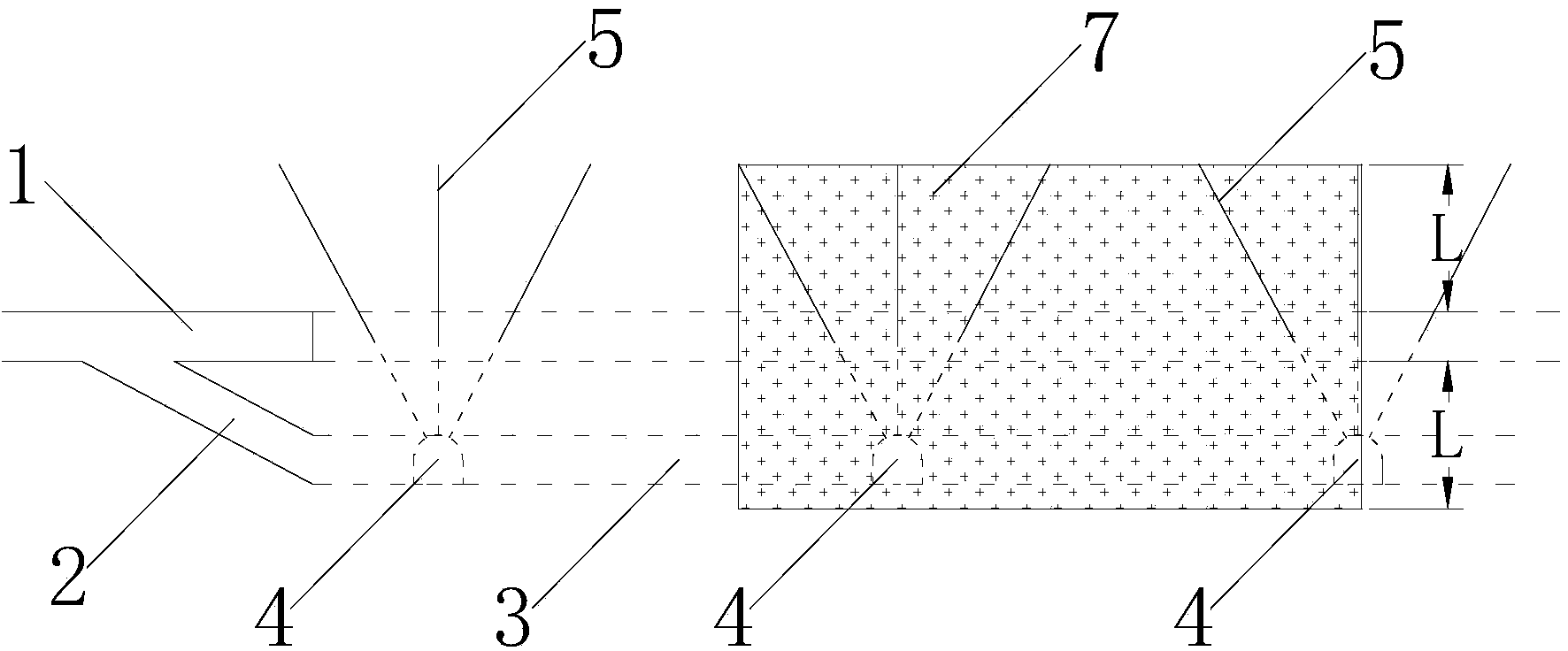

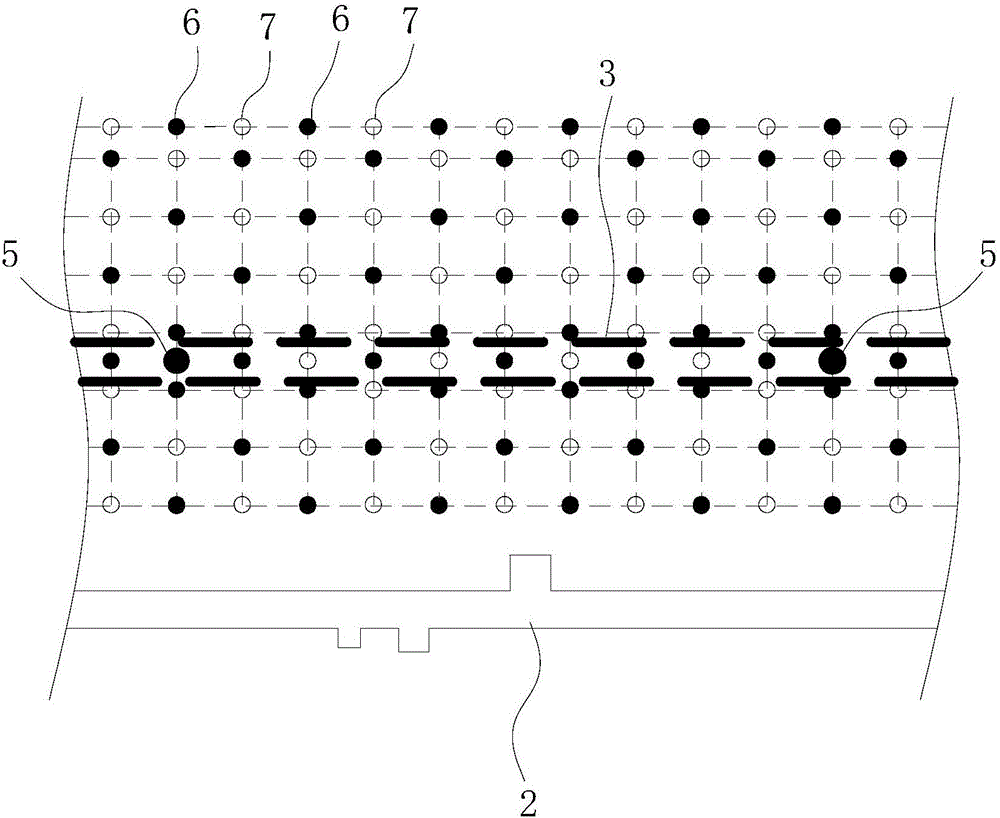

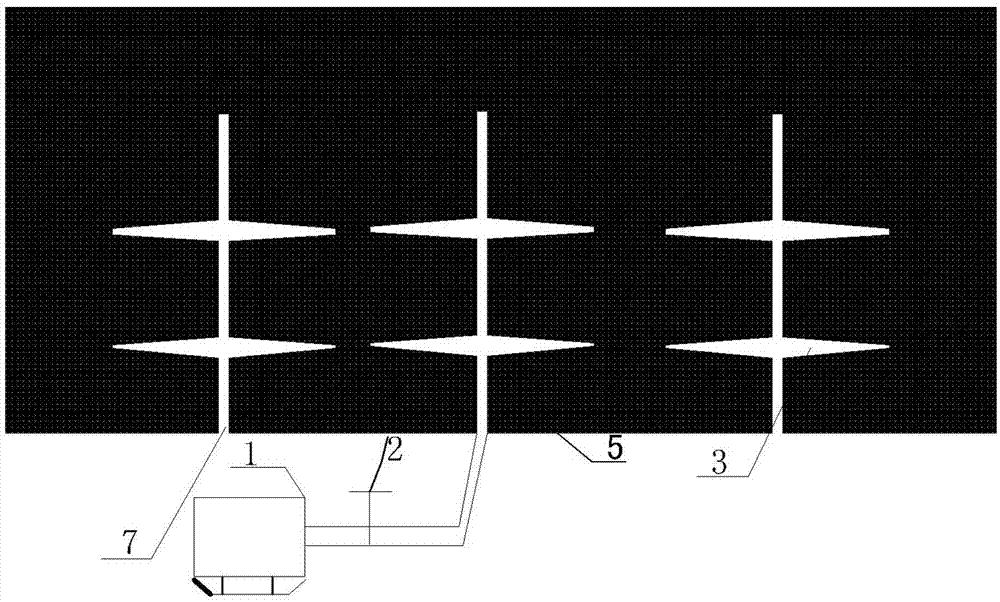

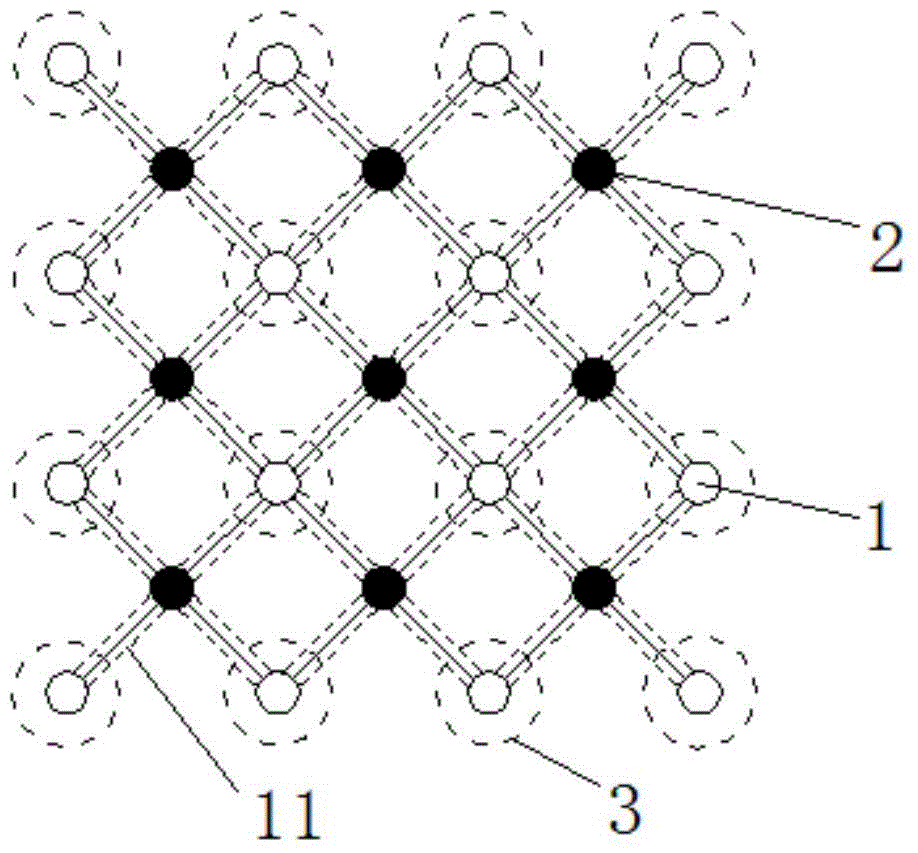

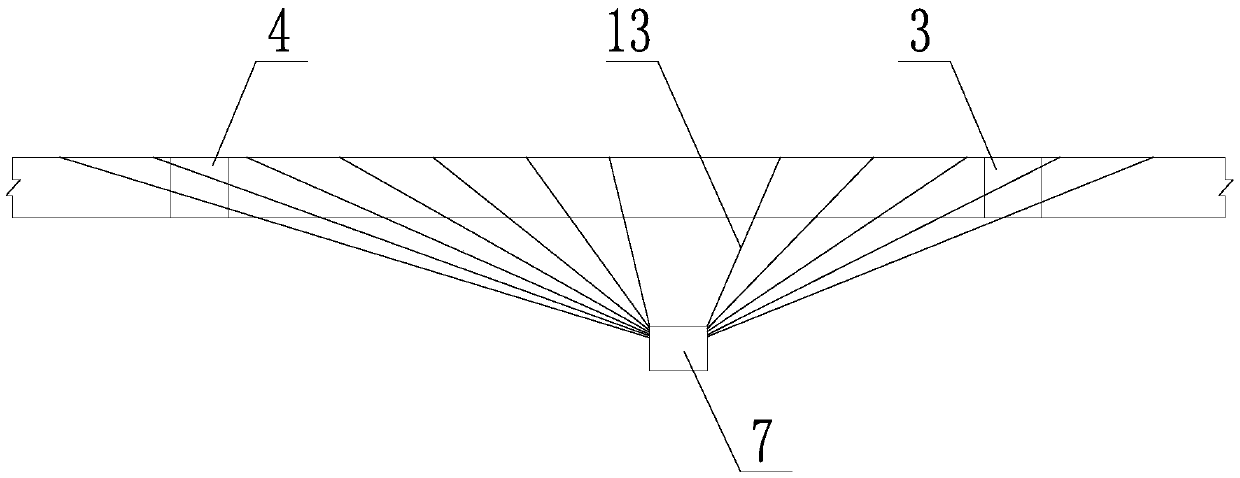

Slotting and fracturing cooperation networking permeability increasing method for low-permeability coal seam

ActiveCN104389631AImprove breathabilityIncreased air permeability coefficientFluid removalGas removalHigh pressure waterHigh pressure

The invention provides a slotting and fracturing cooperation networking permeability increasing method for a low-permeability coal seam, which is applicable to regional gas control for high-gas-content low-permeability coal seams. The permeability increasing method comprises the following steps that: firstly, hole positions of slotting drill holes and fracturing drill holes are arranged alternately at a floor suction roadway in a networking arrangement mode; each slotting drill hole is subjected to high-pressure water jet flow slotting to form an annular slotted hole; and then, each fracturing drill hole is subjected to segmented fracturing, and a fracture net is formed in the coal seam. The slotting drill holes and the fracturing drill holes are in cooperative arrangement; the slotted holes formed by slotting are used for controlling the expanding direction of fracturing cracks; the number of cracks in the coal seam can be effectively increased through segmented fracturing multiple times; and good conditions are created for the drill hole gas extraction and the gas flowing in the coal seam. After the fracturing cracks are communicated with the slotted holes, a crack network is formed in the coal seam; the permeability coefficient of a coal body around the drill holes can be improved by 150 to 400 times; the single-drill-hole gas extraction effective influence range can be expanded by 2 to 4 times; the drill hole gas extraction quantity can be increased by 3 to 6 times; and the gas pre-extraction time in the high-gas outburst coal seam can be effectively shortened.

Owner:CHINA UNIV OF MINING & TECH

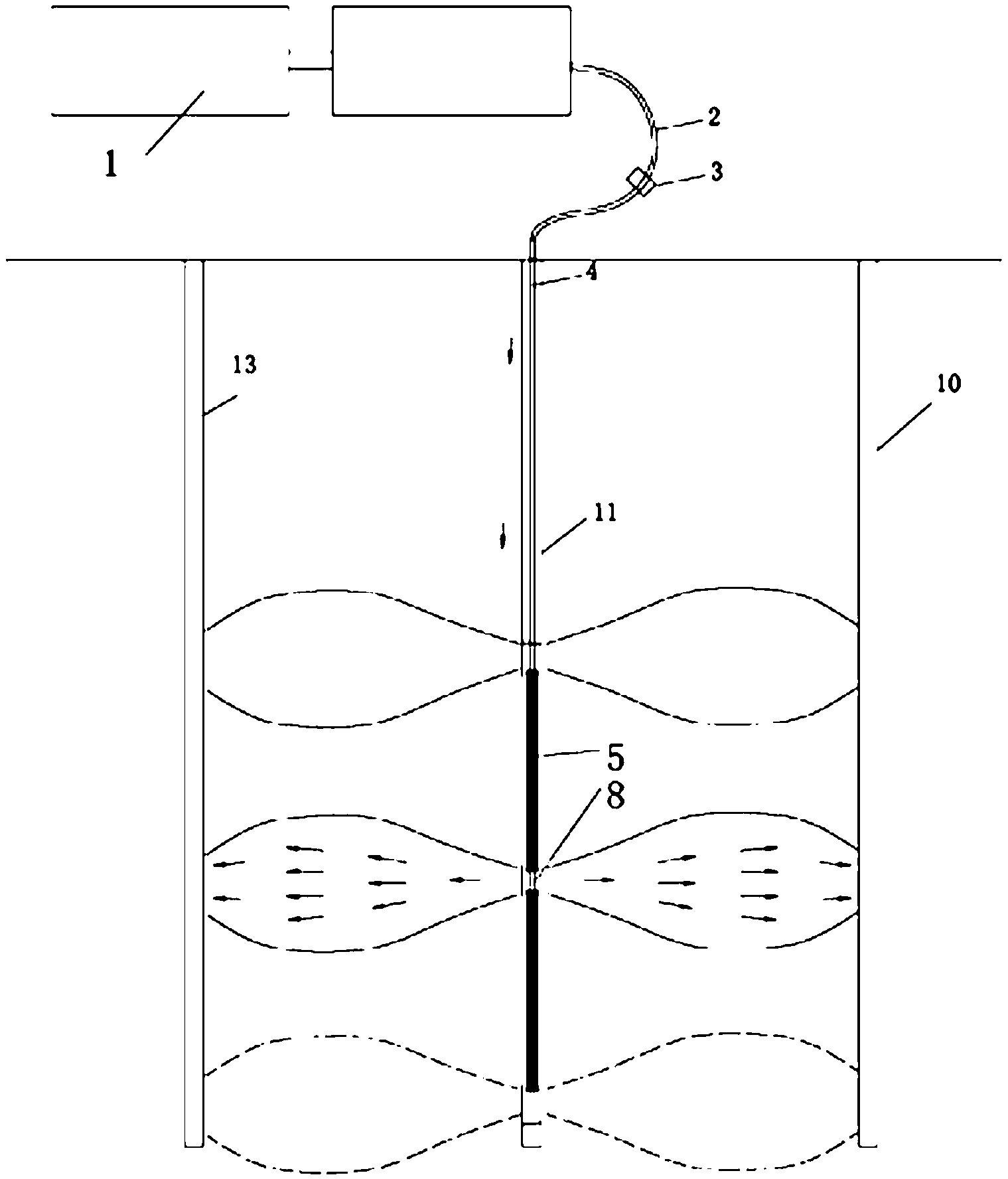

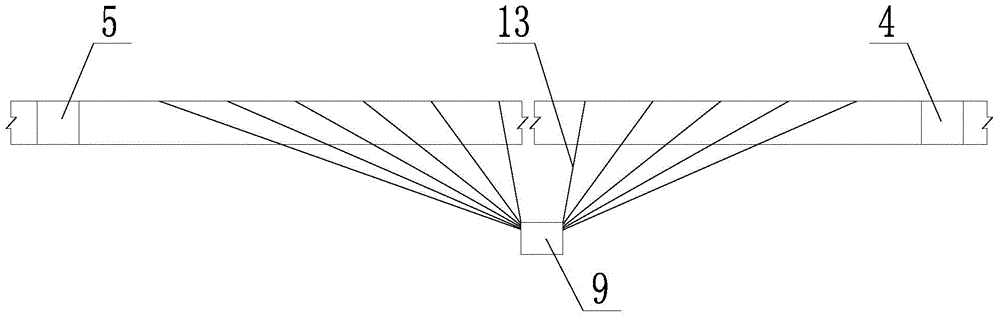

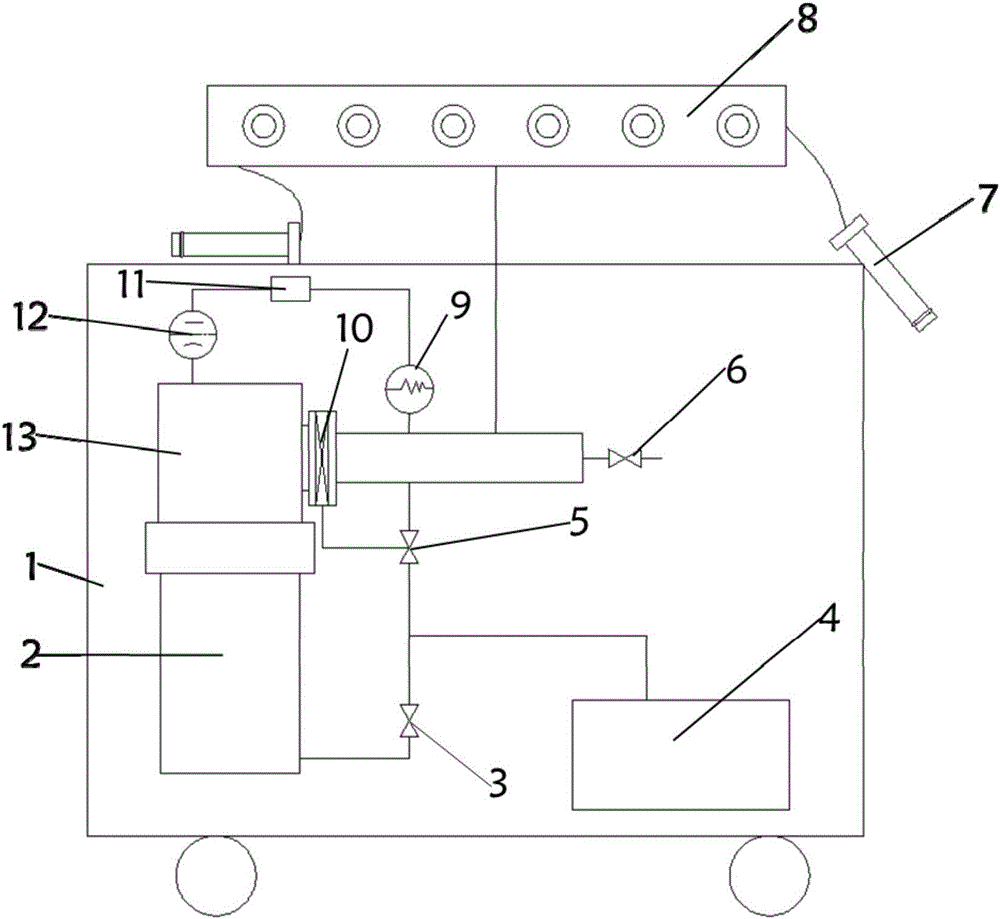

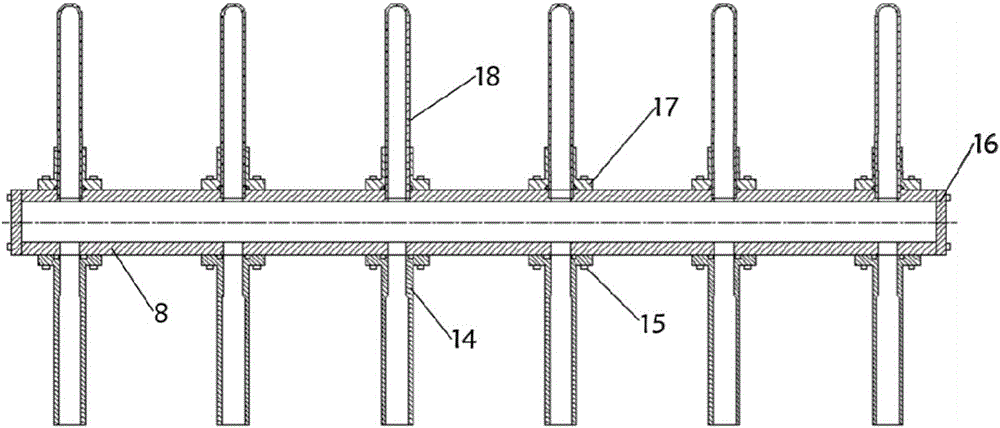

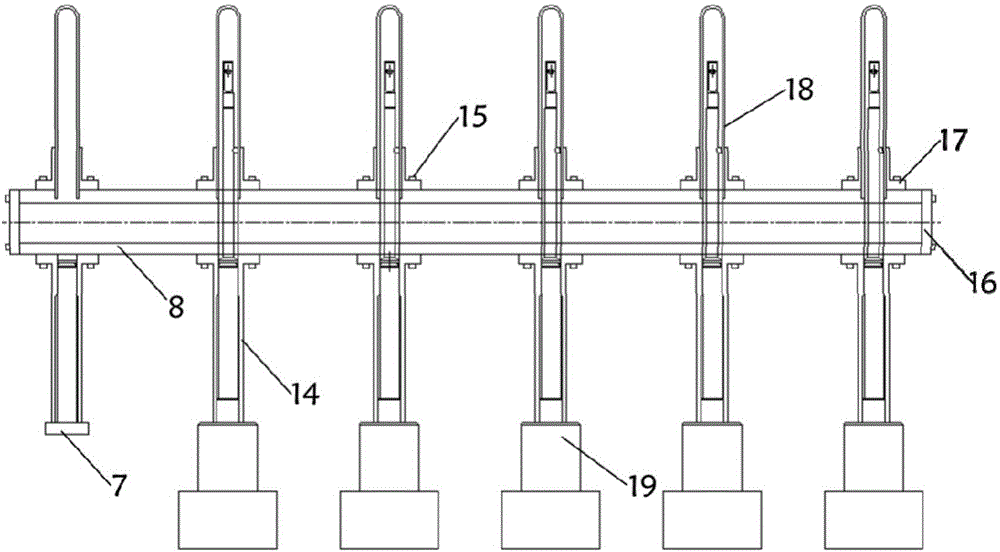

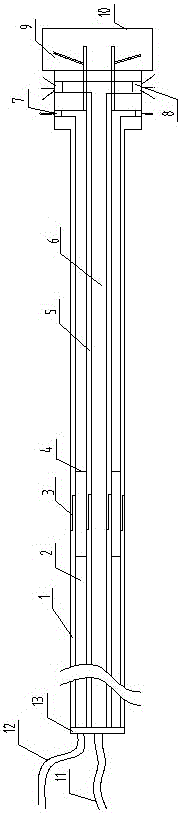

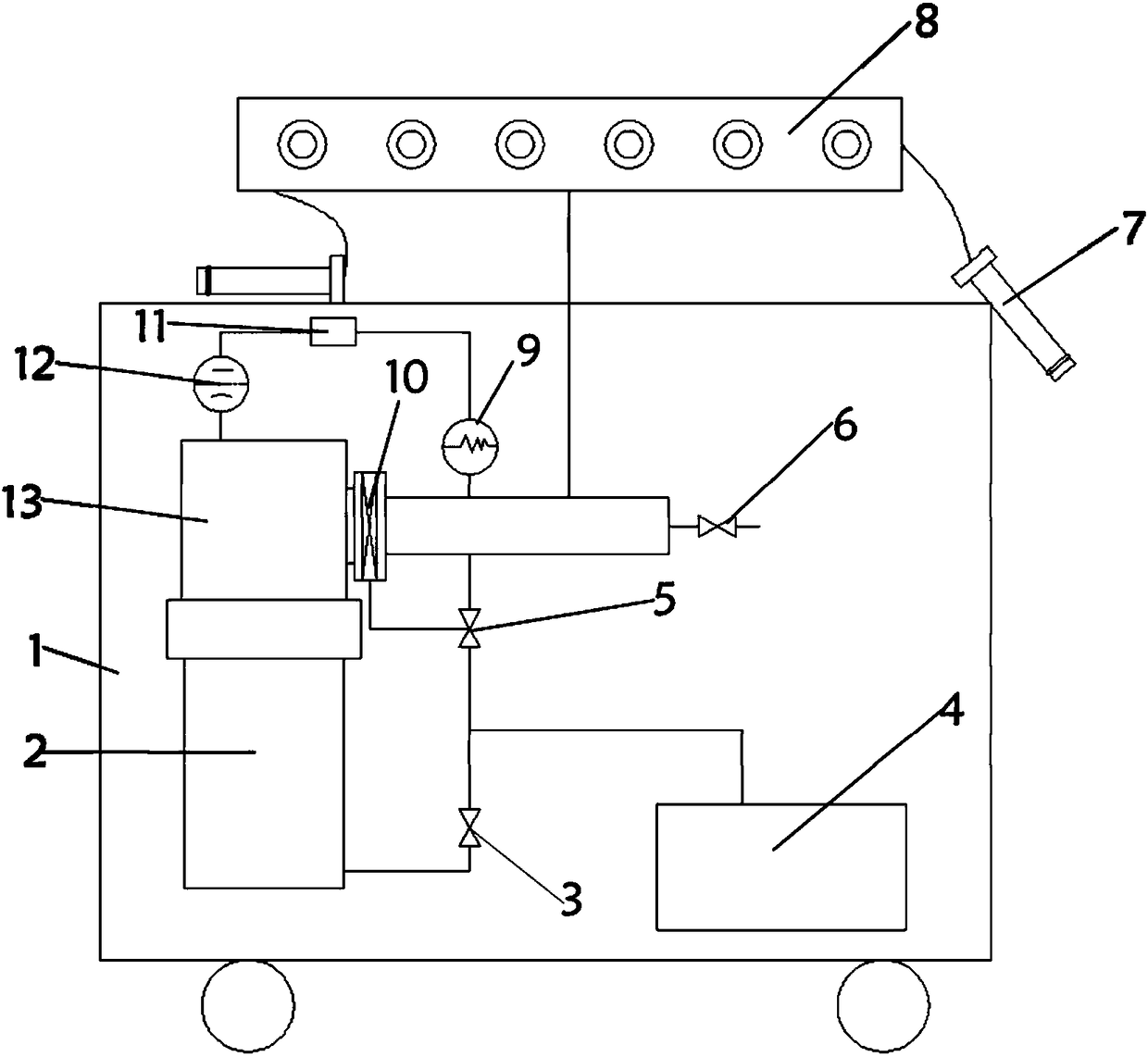

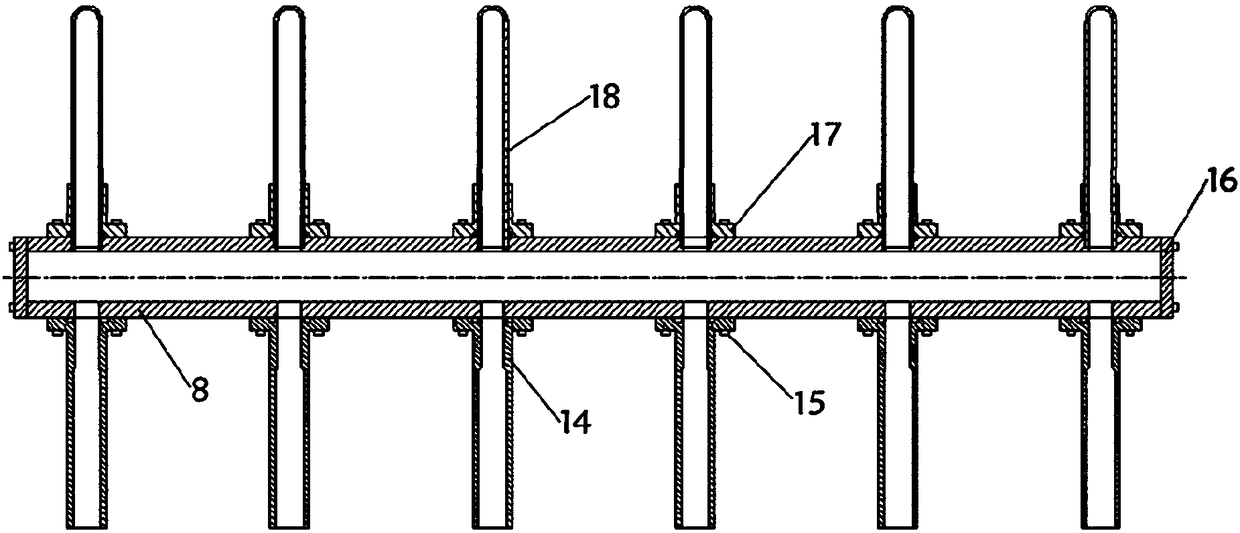

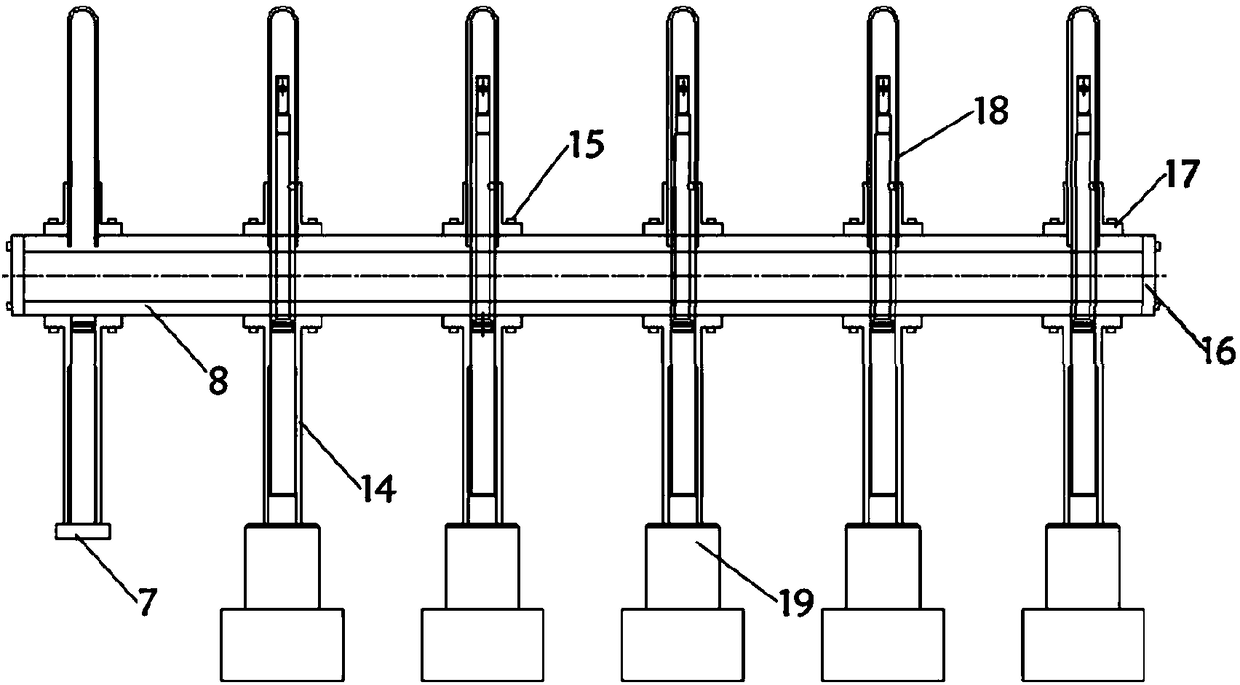

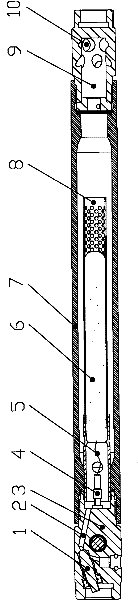

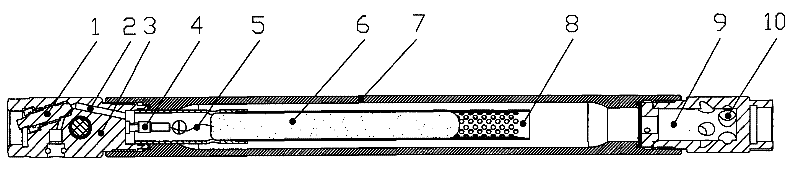

Segmental hydraulic fracturing coal seam pressure releasing device and method

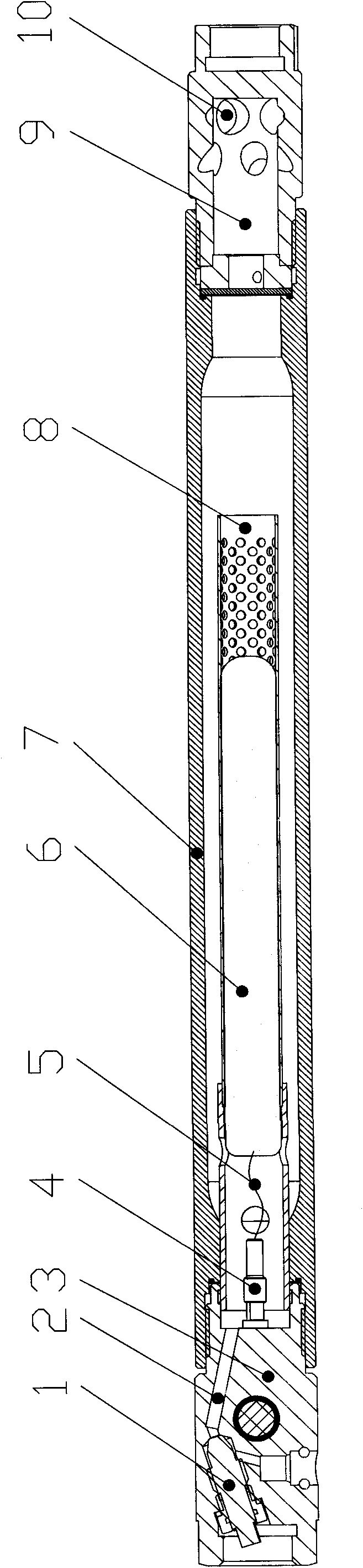

InactiveCN102704905AFull pressure reliefLarge range of pressure reliefFluid removalGas removalCoal dustHydraulic pump

The invention relates to a segmental hydraulic fracturing coal seam pressure releasing device. A high pressure hydraulic pump station is connected to a segmental hydraulic fracturing hole packer through a high pressure hose and a steel push rod; and after the hole packer is fed into a fracturing hole by the push rod, water flows from the high pressure hydraulic pump station to the segmental hydraulic fracturing hole packer through the high pressure hose, flows through a pressure reducing mechanism and is injected into coal for hydraulic fracturing. Water flow also makes hole packing capsules on two sides of a water outlet swell to achieve a sealing effect, and a fracturing range is controlled between the two capsules. Due to the action of the pressure reducing mechanism, the pressure of the hole packing capsules is always greater than that of the water outlet to realize self sealing. During field implementation, a seam hole can be divided into a plurality of segments and is subjected to fracturing segment by segment; meanwhile, a control hole parallel to the fracturing hole is constructed to increase a free face and can drain, bring out coal dust and achieve a hydraulic loosening effect, and the coal between the hydraulic fracturing hole and the control hole is penetrated through pressure finally, so that the coal seam releases pressure fully, the pre-extraction time of the coal seam is shortened and the extraction rate is improved.

Owner:CCTEG SHENYANG RES INST

Gas control method for large-mining-height working face of high gas coal seam

The invention provides a gas control method for a large-mining-height working face of a high gas coal seam, and belongs to the technical field of safety of mines. The gas control method comprises the steps of arranging a first bed extraction tunnel during excavating at the working face; upwards arranging a crossing hole through the first bed extraction tunnel to pre-extract gas; arranging and cutting holes in the bed extraction tunnel to pre-extract gas; arranging an inclined connection roadway to form a ventilation circuit; arranging a second bed extraction tunnel and a connection roadway; pre-extracting gas through the crossing hole which is upwards arranged through the first bed extraction tunnel; arranging a high extraction tunnel to reach a gob caving slit band; arranging the crossing hole in the high extraction tunnel; pumping gas at the high extraction tunnel. According to the gas control method for the large-mining-height working face of the high gas coal seam, gas pumping drilling holes are arranged in each tunnel, a gas treatment scheme under the combination of the bed extraction tunnel, the high extraction tunnel and the current coal seam extraction is created, and therefore, the gas emission rate in the excavating and recovery periods at the working face can be effectively reduced, the continuing speed of recovery at the working face is raised, the gas accumulated at the working face and upper corners and ultralimit of gas can be effectively avoided, and as a result, the safety in production at the working face can be ensured.

Owner:LIAONING TECHNICAL UNIVERSITY

Liquid carbon dioxide bomb, propping agent blasting anti-reflection method and device

InactiveCN106703773AImprove permeabilityImprove breathabilityFluid removalCoal mine methaneEngineering

The invention relates to a liquid carbon dioxide bomb and a propping agent blasting anti-reflection method and a device. The device comprises a liquid storage tube provided with a priming device and liquid carbon dioxide. A releasing tube with propping agent inside is arranged in the front part of the liquid storage tube. A plurality of spray-holes are disposed on the tube wall of the releasing tube. The propping agent is wrapped in a thin strip-shape with plastic film and put into the releasing tube. High-pressure gases produced by vaporized liquid CO2 after liquid CO2 bomb detonates in coal seam form a large number of fractures in drill holes. The high-pressure gas destroys the plastic film wrapping the propping agent during an explosion process. The propping agent with the high-pressure gases enters into coal seam fractures and fractures formed by propping, prolongs existing time of the fractures. The fractures have big presplit radius in coal seam, which can effectively reduce drilling hole amounts in a current extraction and exploitation system in underground coal mines, improve extraction efficiency, reduce pre-extraction time of gas and extraction cost of gas in coal mine, improve a production efficiency of coal, and enhance security of coal production.

Owner:CHINA UNIV OF MINING & TECH

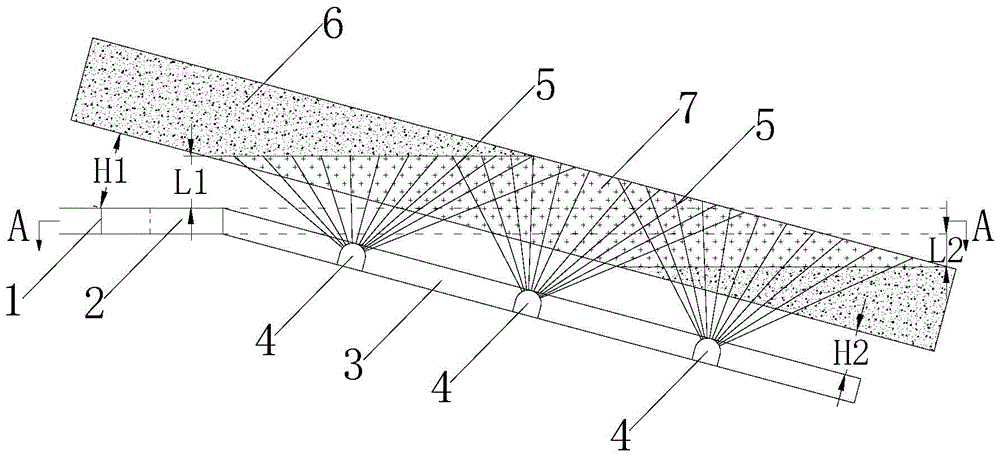

Gentle dip super-high seam rock cross-cut coal uncovering method

ActiveCN103510958AUniform coverageReduce the difficulty of homeworkUnderground miningSurface miningGeomorphologyCross cut

The invention discloses a gentle dip super-high seam rock cross-cut coal uncovering method, and is particularly suitable for protruded risk coal seam with small dip angle and large thickness of underground coal mine. When the rock cross cut is tunneled to be the vertical distance of 12 m relative to the coal seam, an inclined rock cross cut is dug on the right side of the rock cross cut; when the inclined rock cross cut is tunneled to be the vertical distance of 7 m relative to the coal seam, a coal bottom road is dug head-on on the inclined rock cross cut; the coal bottom road is parallel to the rock cross cut and tipsily dug along the coal seam. A plurality of drill sites are uniformly arranged in the coal bottom road which is completed; holes are drilled from the drill sites to the coal seam construction hydraulic cutting slot to pre-extract the coal seam gas; when the gas is extracted to reach the standard, the rock cross cut is recovered to tunnel in the original direction; the coal seam is penetrated to enter 2 m of roof, so that the coal uncovering work is completed. By construction of the coal bottom road, the gentle dip long drill holes which restrain the coal uncovering speed are transformed to the coal bottom layer-crossing drill holes, so that the bottleneck problem that the gentle dip super high seam is slow to uncover is solved, safe and quick coal uncovering is realized, and the method can be widely applied.

Owner:CHINA UNIV OF MINING & TECH

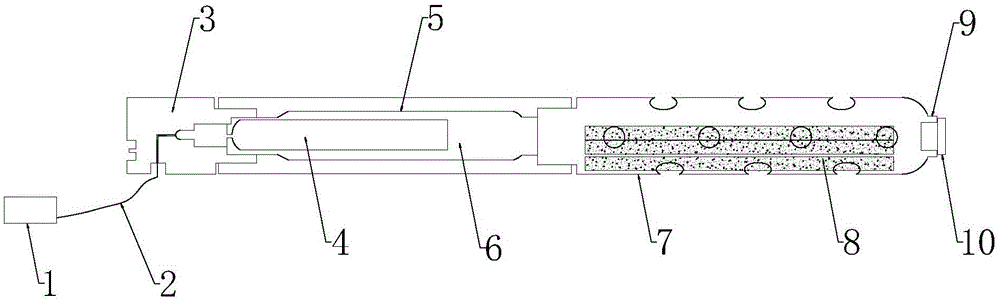

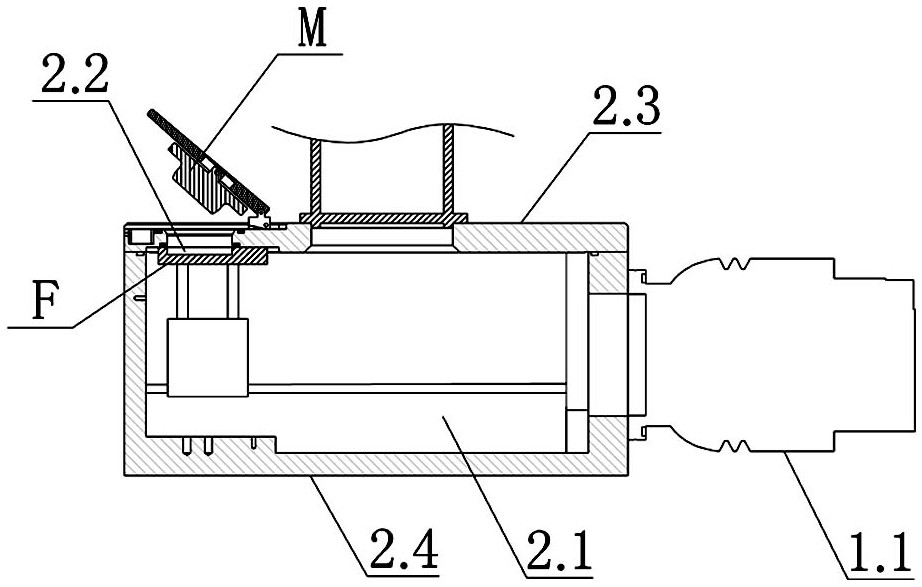

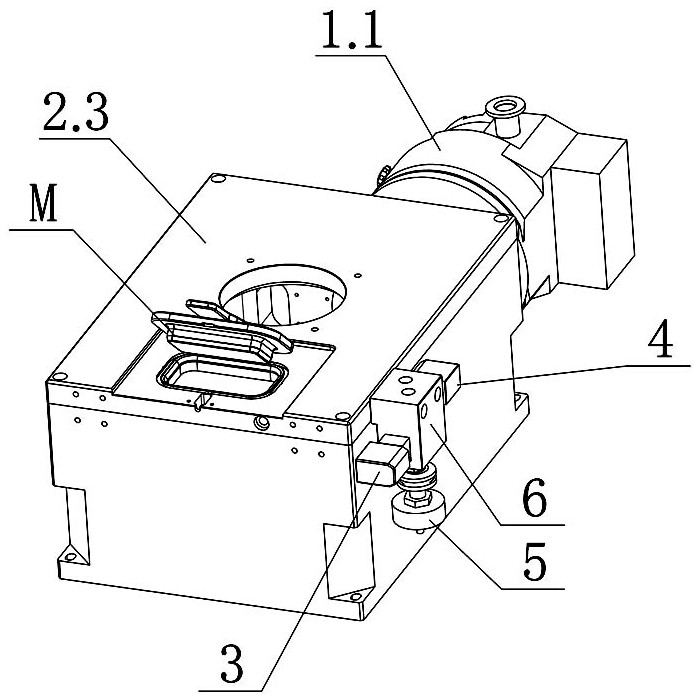

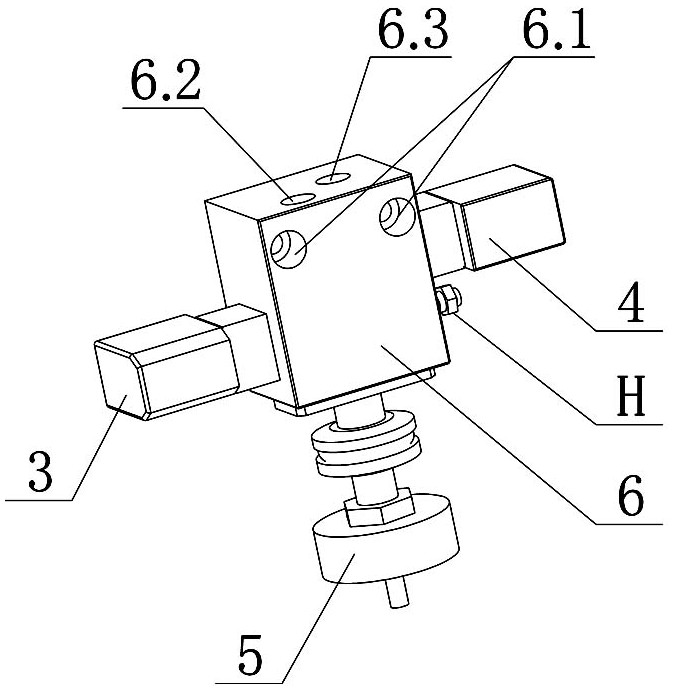

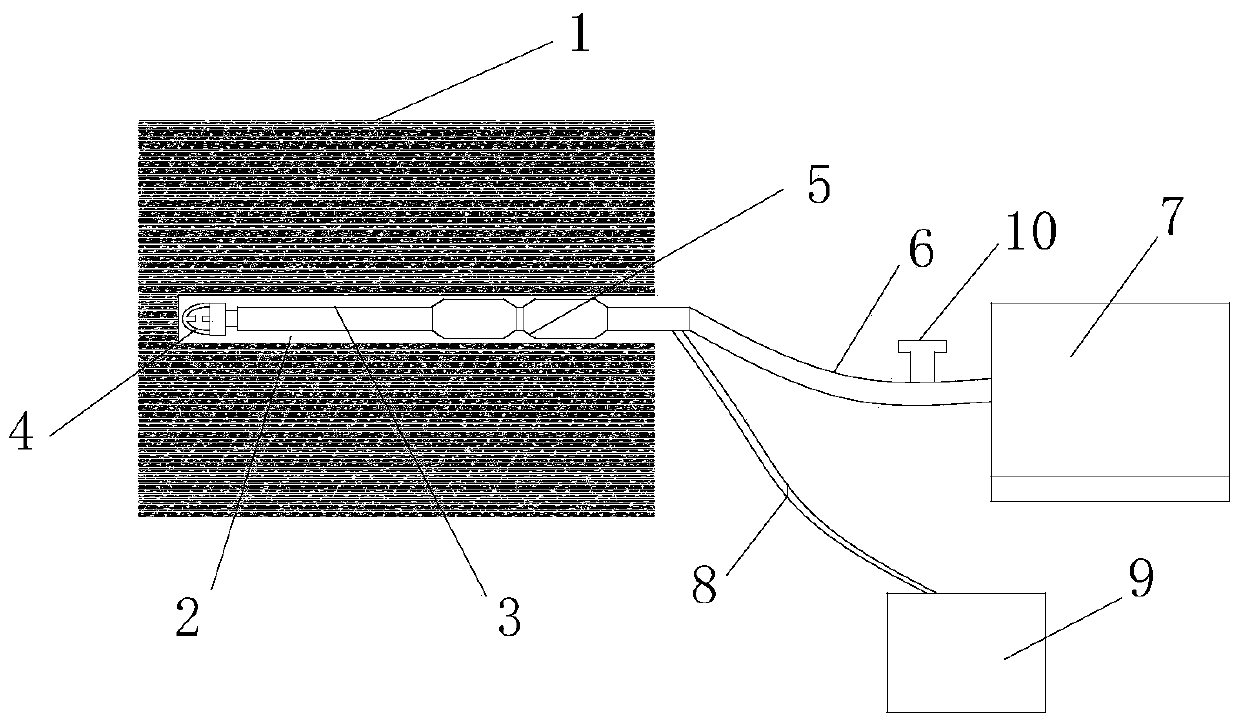

Vacuum storing and testing device for transmission electron microscope sample rods

ActiveCN106783494AReduce pollutionExtended service lifeElectric discharge tubesVacuum gaugesVacuum pressureEngineering

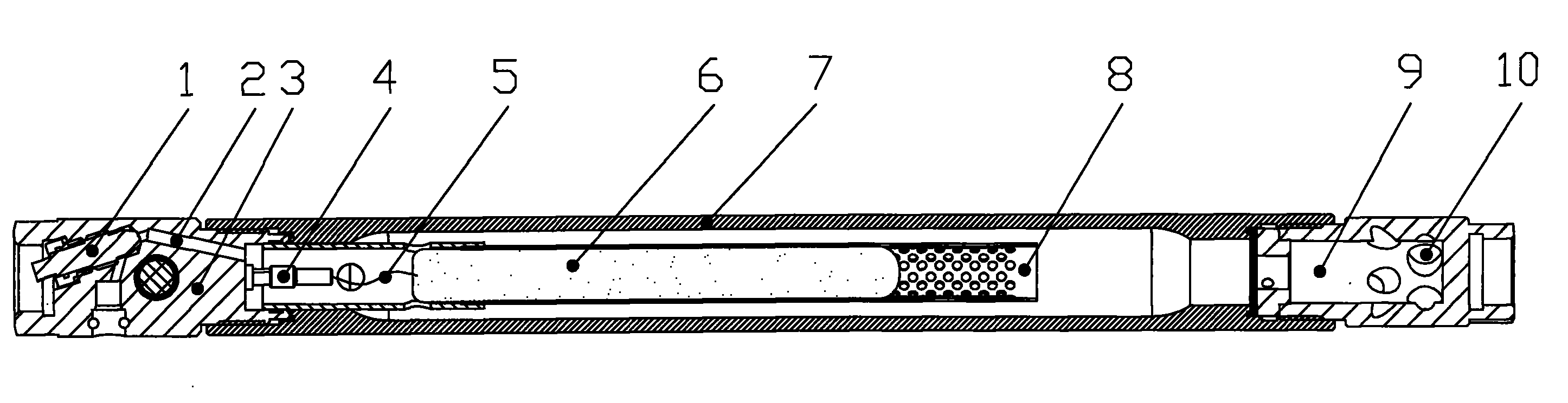

A vacuum storing and testing device for transmission electron microscope sample rods belongs to the field of transmission electron microscope vacuum fittings. In storage of the sample rods, energizing testing and heating testing can be performed on the sample rods. The device comprises the components of a movable frame, a vacuum pump system, a vacuum measuring-and-displaying system, a vacuum cap, a valve system, a sample rod storing assembly and a plug. The device realizes simultaneous storage of multiple sample rods and is provided with an adding window which is reserved. The device can pump the air pressure in a chamber from atmosphere pressure to 4*10<-4> Pa within five minutes, and a limit vacuum pressure can reach 5*10<-5> Pa. The vacuum storing and testing device has advantages of effectively preventing electron microscope pollution caused by pollution or erosion by the sample rods in placement at outside, greatly reducing pre-pumping time of the sample rods in the electron microscope, realizing higher speed in reaching a stable vacuum degree of the electron microscope and prolonging service life of the sample rods. The vacuum storing and testing device further realizes benefits of convenient operation, high vacuum degree, easy adding of sample rod storing stations, and high suitability for different types of transmission electron microscope sample rods.

Owner:BEIJING UNIV OF TECH

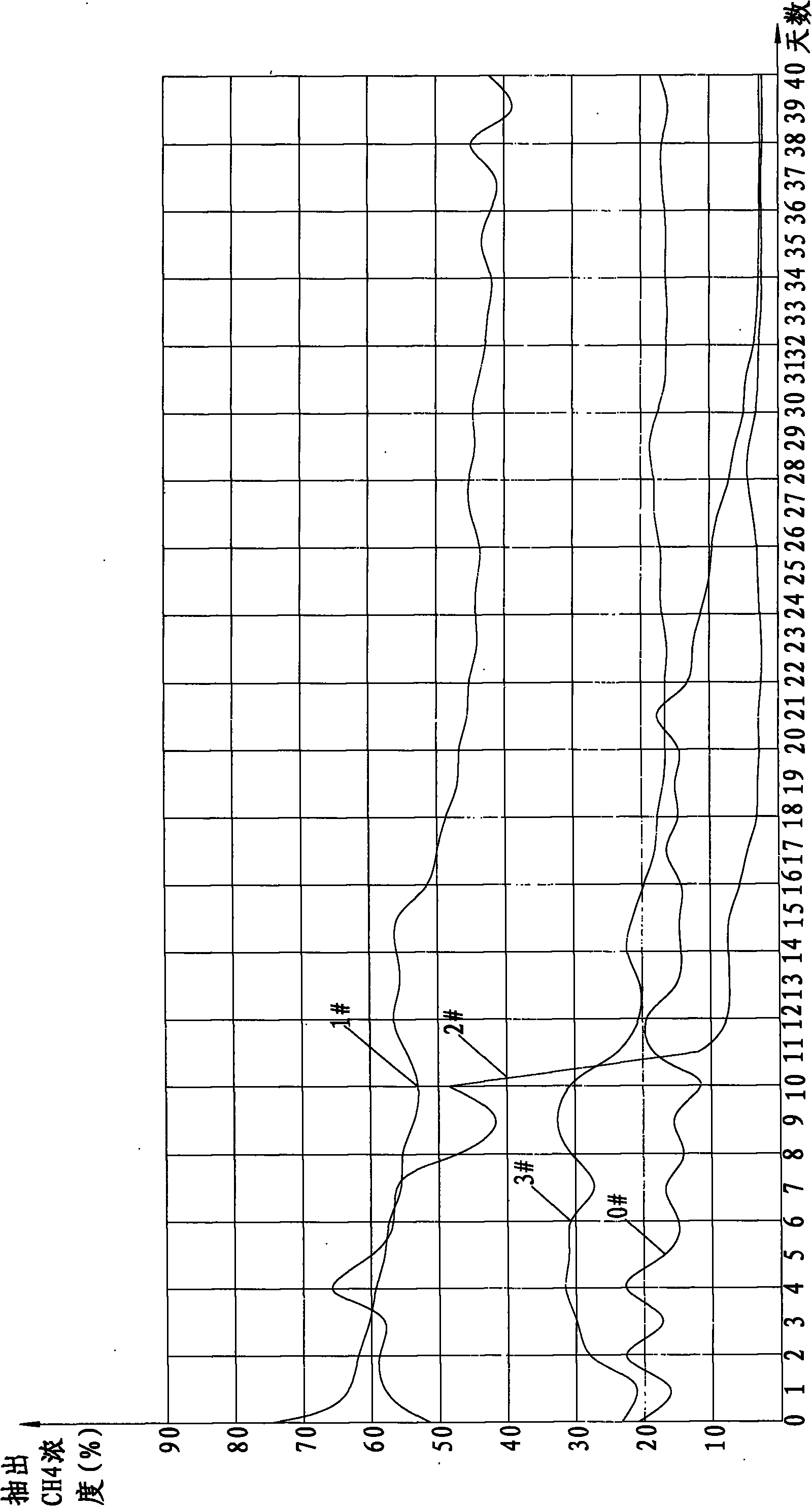

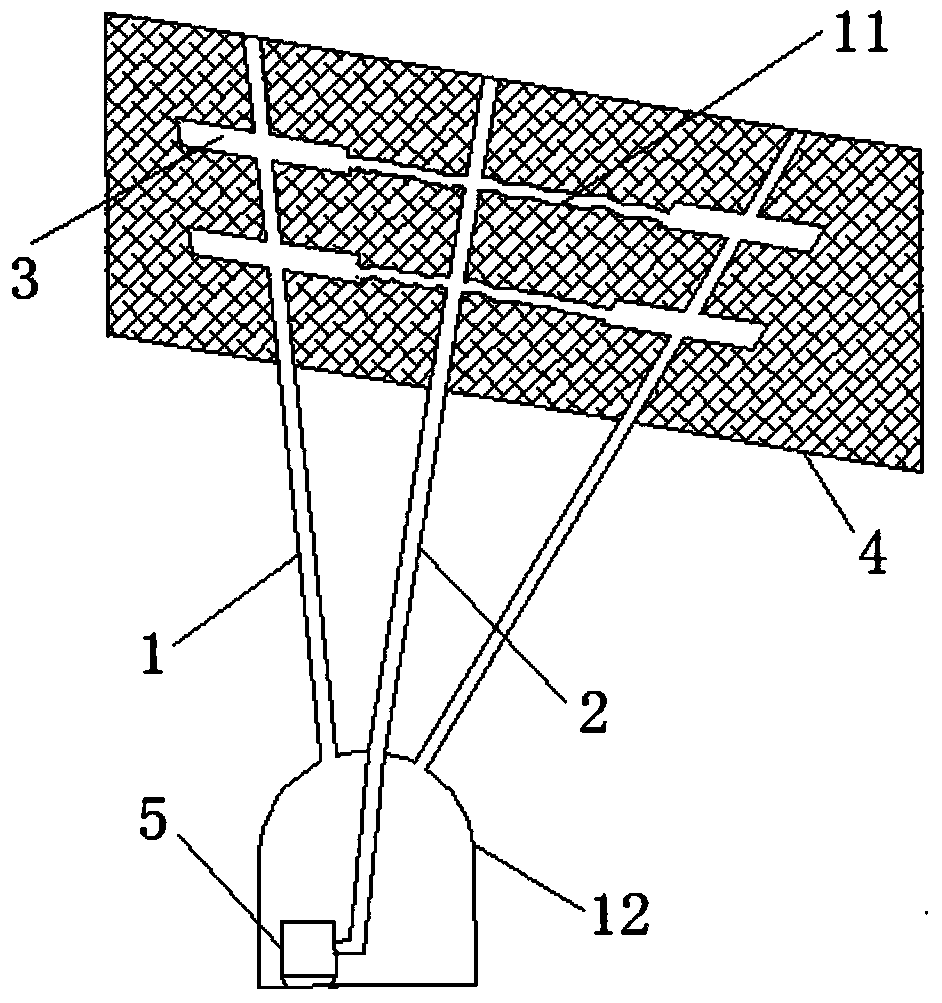

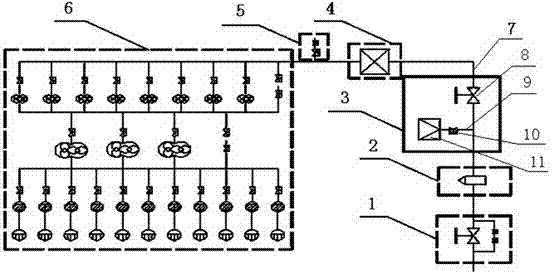

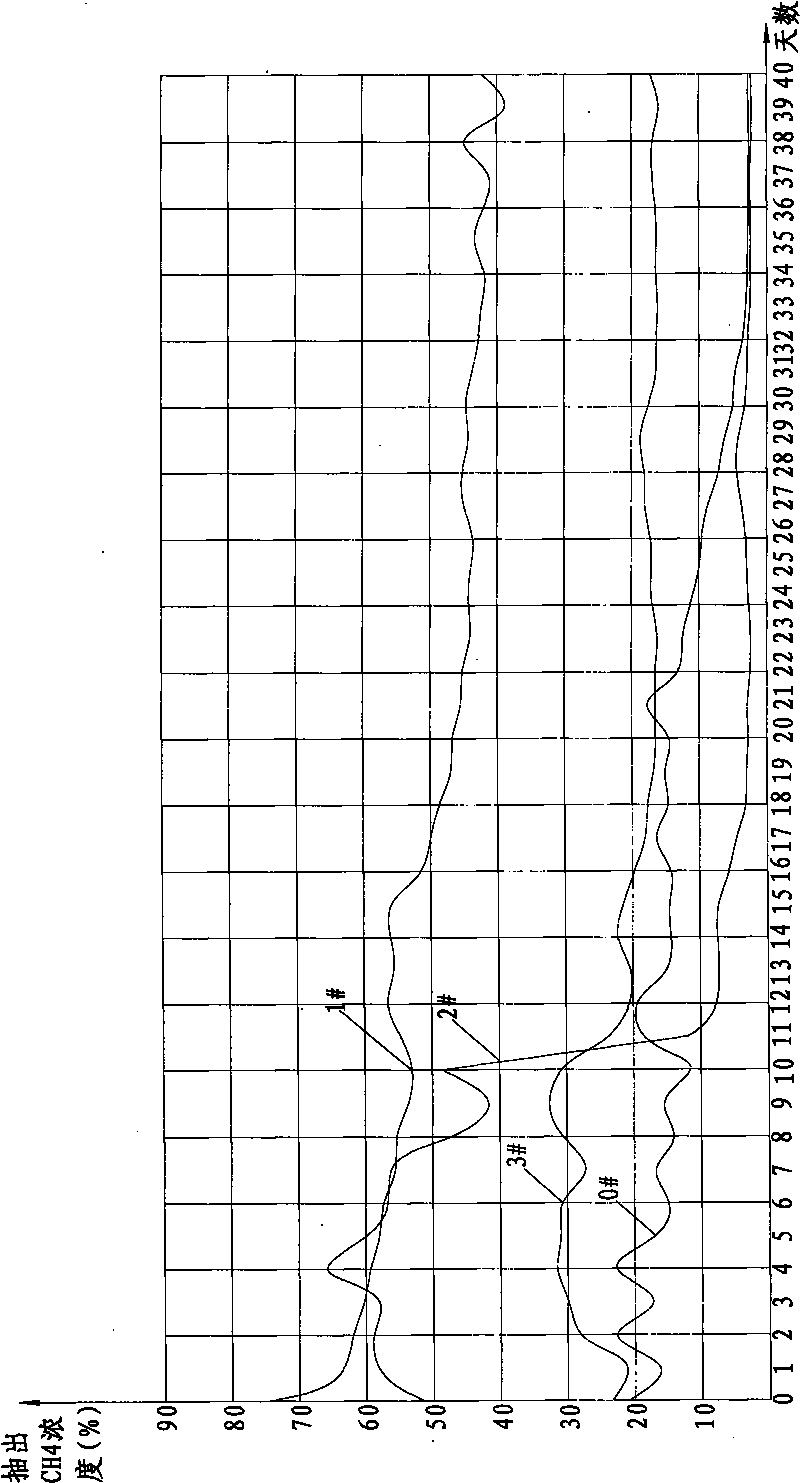

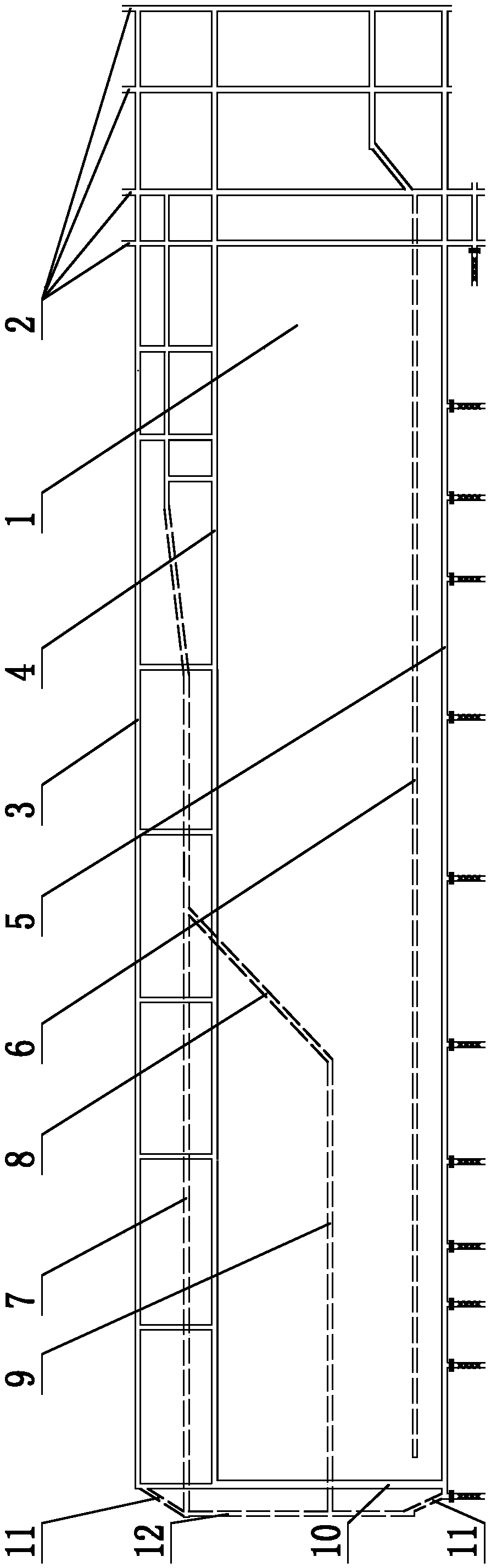

Positive pressure and negative pressure combined gas drainage process by pressurizing coal body of thick coal seam

ActiveCN103147788AImprove the effectShorten prepumping timeFluid removalGas removalCoalEnvironmental geology

The invention provides a positive pressure and negative pressure combined gas drainage process by pressurizing a coal body of a thick coal seam. The process comprises the following steps of: 1) arranging and drilling holes: selecting drilling distances, array pitches, angles, hole diameters and hole lengths according to the occurrence situation and the drainage radius of a coal seam to be subjected to drainage; 2) carrying out drilling construction and sealing holes: determining angles and directions of a drilling machine to carry out the drilling construction to keep the stability of the drilling machine in a construction period; and sealing the holes after the drilling is finished; 3) injecting water into the coal body and pressurizing: pressurizing the water and injecting into the coal body to fill cracks in the coal body; and 4) carrying out gas drainage: carrying out the gas drainage after carrying out the drilling construction, sealing the holes and stabilizing, and injecting the water into the coal body and pressurizing. With the adoption of the process disclosed by the invention, the gas drainage effect is greatly improved, and the pre-drainage time of gas is greatly shortened, so that the exploiting time of coal is correspondingly increased; and meanwhile, the drainage efficiency is high, the gas concentration in an air flow in a production period is low, an over-limit alarming phenomenon is avoided, and the production efficiency is improved.

Owner:山东新特能源装备科技有限公司

Low-air-permeable coal bed static blasting anti-reflection gas extraction method

ActiveCN109458214AGuaranteed stabilitySlow generationMining devicesDisloding machinesHydration reactionEngineering

The invention discloses a low-air-permeable coal bed static blasting anti-reflection gas extraction method. Multiple roof bedding drill holes are constructed along the coal bed top plate, the drill holes are filled with silent breakers which are subjected to a hydration reaction to generate radial compressive stress and tensile stress to hole walls, when the tensile stress exceeds tensile strengthof coal bed roof rock, the coal bed roof starts to generate cracks, that is to say, a gas migration and output passage is built in the coal bed roof rock, the roof bedding drill holes are subjected to repairing, hole sealing and networking extraction, and coal bed gas is extracted indirectly. Meanwhile, a group of coal bed bedding drill holes are constructed in a coal bed, and migration of the coal bed gas to the roof bedding drill holes is accelerated. After it is determined that extraction reaches the standard, progressive cover type tunneling is conducted, and finally rapid tunneling of alow-air-permeable coal bed coal rod is achieved. Accordingly, by conducting static blasting fracture on the roof bedding drill holes, the gas migration and output passage is built in the coal bed roofrock, and the extraction amount and extraction rate of the low-air-permeable coal bed gas are increased.

Owner:HENAN POLYTECHNIC UNIV

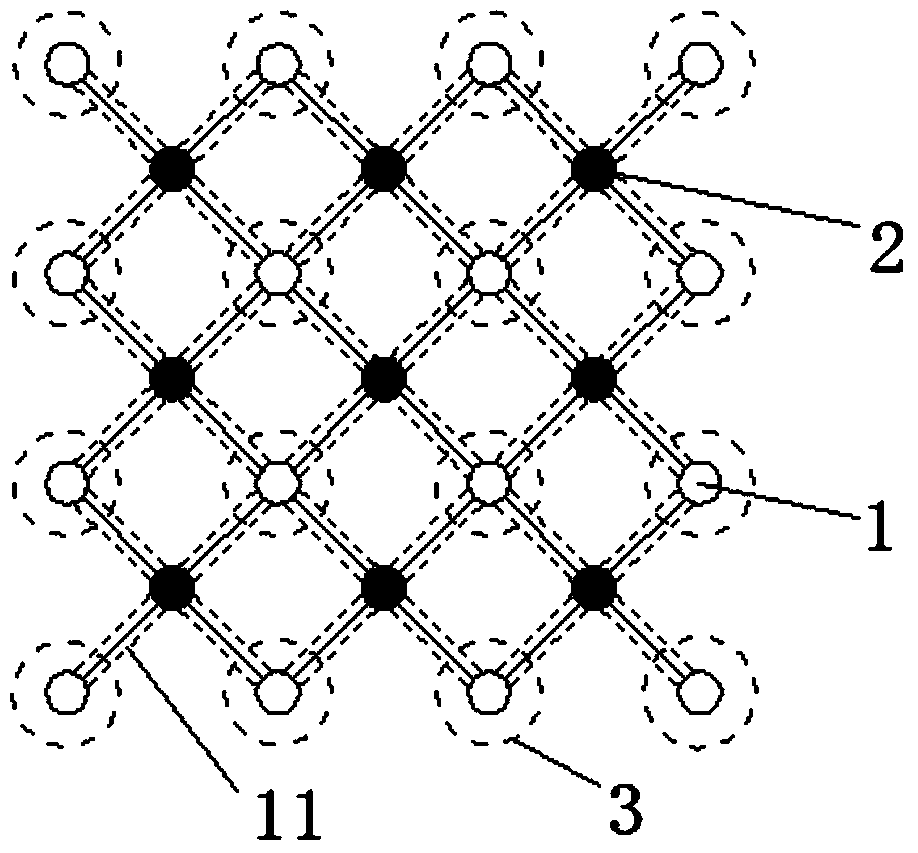

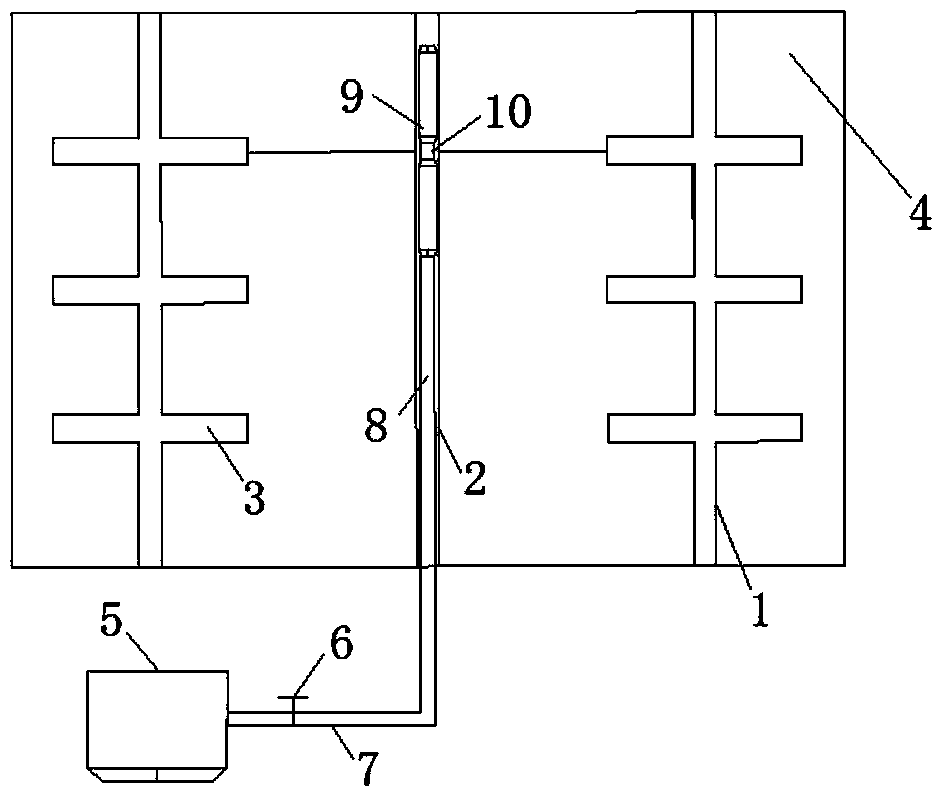

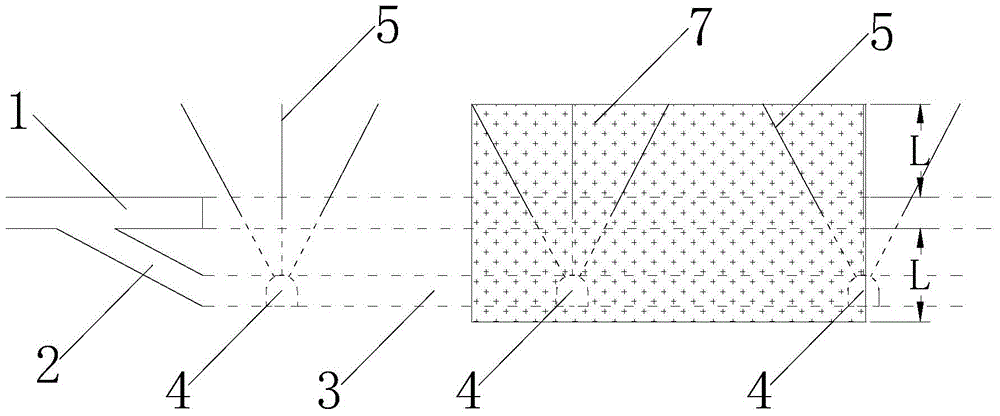

Coal seam hydraulic pressure jetting breathability-improving system and construction method thereof

InactiveCN106368730AImprove breathabilitySpeed up circulationFluid removalGas removalEngineeringHigh pressure water

The invention belongs to the technical field of coal mine safety production construction and particularly relates to a coal seam hydraulic pressure jetting breathability-improving system and a construction method thereof. The system comprises a base plate roadway located below a coal seam, and a plurality of drill holes are formed radially in the coal seam direction in the base plate roadway, a plurality of flushing holes and fracturing holes are formed between the drill holes at intervals, each fracturing hole penetrates out of a tunneling strip, and the fracturing holes are formed at interval in a - shape in the tunneling strip extending direction. The fracturing holes are sealed, high-pressure water injection devices are arranged in the fracturing holes, and flushing drill bits are arranged in the flushing holes. Hydraulic punching measures are adopted for a coal seam having undergone hydraulic fracturing, the hydraulic fracturing and hydraulic punching are optimized, the breathability of the coal seam is improved, gas circulation is accelerated, a pre-extraction effect is multiplied, a pre-extraction range is wider, gas is extracted more thoroughly, and an effect is better.

Owner:HUAINAN MINING IND GRP

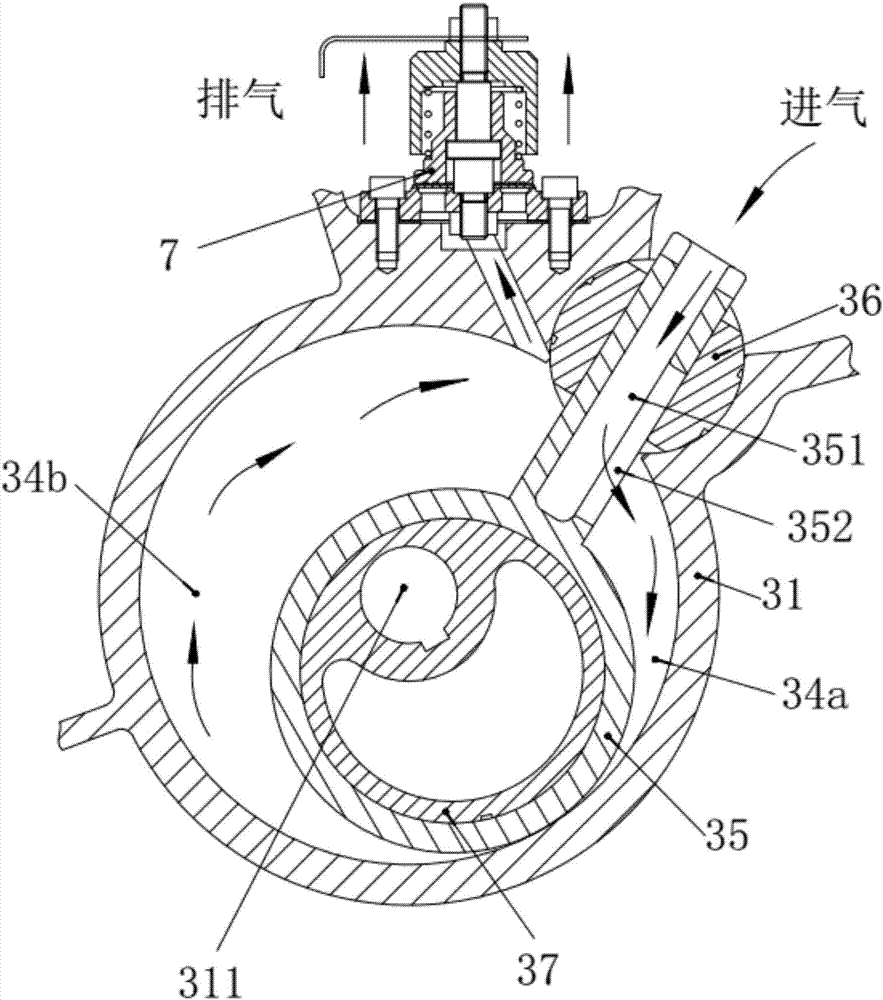

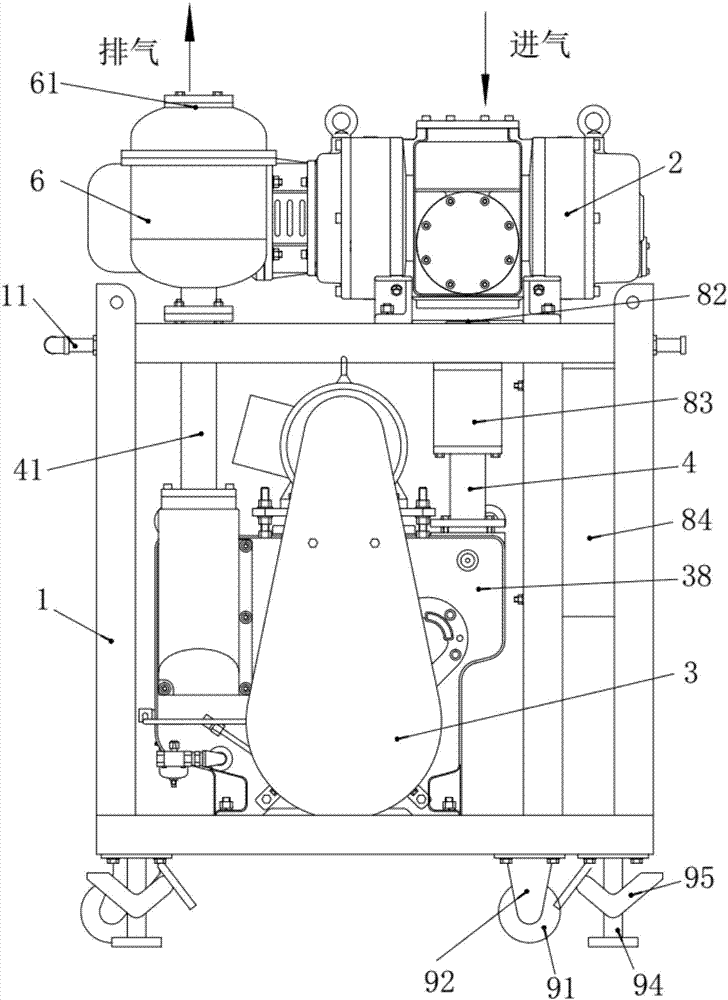

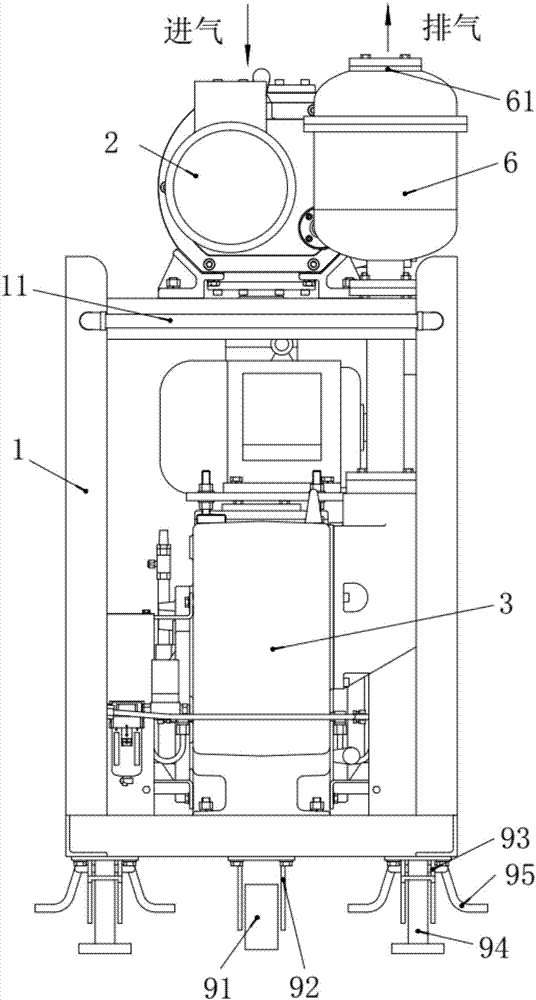

Moving type roots and slide valve vacuum unit

PendingCN107542662AExtended service lifeEasy transferRotary piston pumpsRotary piston liquid enginesVacuum pumpingSpool valve

The invention belongs to the technical field of vacuum devices and particularly relates to a moving type roots slide valve vacuum unit comprising a machine frame and a pump group installed on the machine frame. A slide device is arranged on the lower side of the machine frame. The pump group comprises a roots vacuum pump and a slide vacuum pump. The roots vacuum pump is located above the slide valve vacuum pump and is connected with a slide valve vacuum pump inlet of the slide valve vacuum pump through a connection pipeline. The slide valve vacuum pump is provided with an oil tank. An oil misteliminating device is connected with the upper side of the oil tank. The oil mist eliminating device is provided with a final air outlet. The machine frame is further provided with an electronic control cabinet controlling the unit to work. The slide device is arranged below the machine frame, so that the whole unit can be slid and transferred all around; according to the position where vacuumizing is actually needed, the machine frame and the whole unit can be directly moved to the needed position, moving is convenient, the pump group does not need to be disassembled, the service life of thepump group is prolonged, time and effort are saved, and the application range is wide.

Owner:浙江力鑫真空设备有限公司

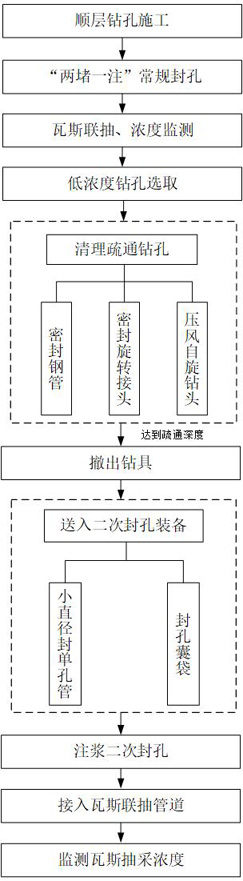

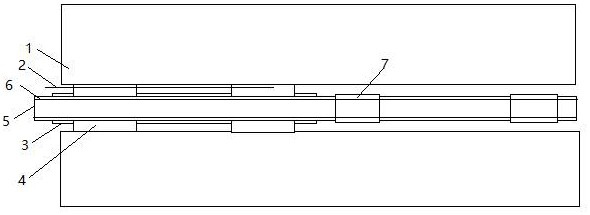

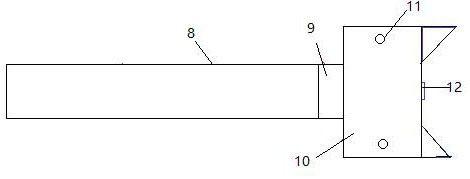

Secondary hole sealing method for underground coal mine gas drainage drill hole

ActiveCN113756742AIncrease extraction concentrationImprove extraction efficiencyMining devicesGas removalSlagCoal

The invention discloses a secondary hole sealing method for an underground coal mine gas drainage drill hole. The secondary hole sealing method comprises the following steps that (1) a bag type grouting hole sealing device and a two-blocking one-injecting hole sealing process are adopted for implementing first-time hole sealing and continuous drainage; (2) during gas drainage, a low-concentration gas drainage drill hole is selected, and a connected gas drainage pipeline is disconnected; (3) a sealing steel pipe is connected with a compressed air self-rotating drill bit and then inserted into a first-time hole sealing pipe, a high-pressure air supply pipeline is connected, and coal slag in the hole sealing pipe and the drill hole is cleaned through the compressed air self-rotating drill bit and high-pressure air blowing; (4) the sealing steel pipe is withdrawn, and a second-time hole sealing device is plugged into the first-time hole sealing pipe to a designed position; (5) grouting is conducted on the second-time hole sealing device for implementing secondary hole sealing; and (6) a hole sealing pipe of the second-time hole sealing device is connected into the gas drainage pipeline for gas drainage. According to the secondary hole sealing method for the underground coal mine gas drainage drill hole, the application engineering cost is low, the process is relatively simple, the drainage efficiency is fully improved, the drainage time is shortened, and gas disasters are eliminated to the maximum extent.

Owner:山西兰花科创玉溪煤矿有限责任公司 +1

Vacuumizing system suitable for mass spectrometer

The invention discloses a vacuumizing system suitable for a mass spectrometer. The vacuumizing system comprises a first air exhaust unit and a second air exhaust unit. The first air exhaust unit comprises a molecular pump and a mechanical pump which are connected with each other, and an air exhaust opening of the molecular pump is connected with a vacuum chamber of the mass spectrometer; and the second air exhaust unit comprises a vacuum air path, an air inlet valve and a pre-extraction valve, one end of the vacuum air path is connected with a transition chamber of the mass spectrometer, the other end of the vacuum air path is divided into two paths, the first path is connected with the outside atmosphere through the air inlet valve, and the second path is connected with the vacuum chamber through the pre-extraction valve. According to the invention, the connection between the vacuum chamber and the transition chamber is realized by utilizing the pre-extraction valve, and the molecular pump can indirectly vacuumize the transition chamber through the vacuum chamber during vacuumizing so that the rapid pre-pumping of the transition chamber is realized, sample injection waiting time of a sample is greatly shortened, and the detection efficiency is improved.

Owner:AUTOBIO LABTEC INSTR CO LTD

Directional hydraulic pressing penetration, permeability increase and outburst elimination method of guide groove

ActiveCN102619552BLarge range of pressure reliefImprove breathabilityFluid removalDirectional drillingMining engineeringHigh pressure water

Owner:CCTEG SHENYANG RES INST

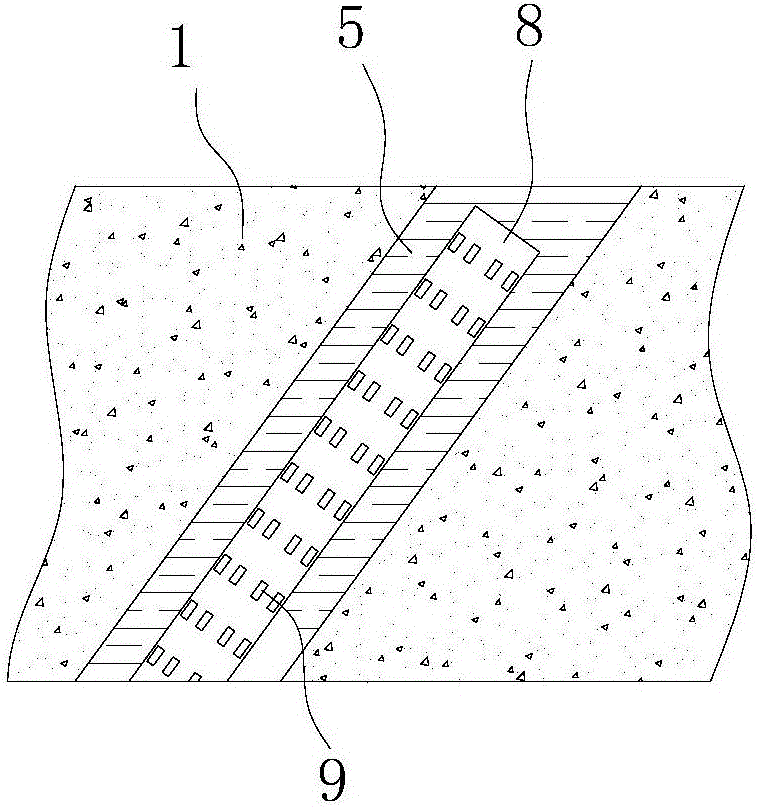

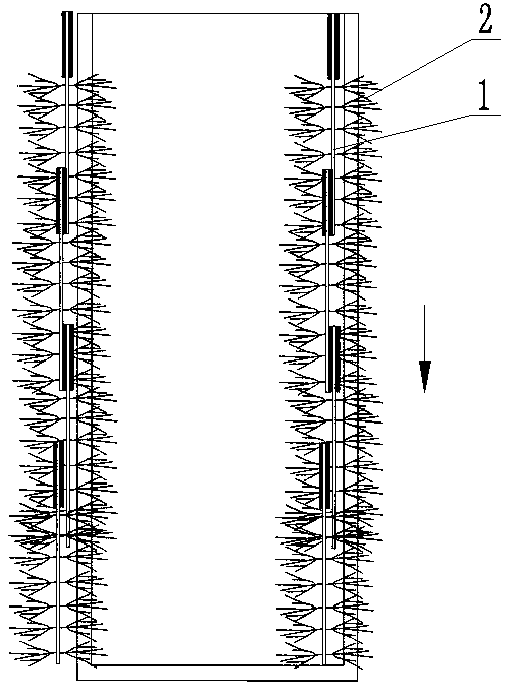

Shotcrete anti-collapse drilling method in soft coal seam

ActiveCN104747075BLittle impact on air permeabilityImprove pumping efficiencyFlushingSealing/packingSpray nozzleStoping

An anti-collapsing drilling method for grout spraying of a soft coal seam includes the following steps that first, an anti-collapsing drilling device for grout spraying of the soft coal seam is machined and tested; second, technological parameters of the anti-collapsing drilling device for grout spraying are designed; third, hole reinforcing grout is prepared, and the solidification property of the grout is tested; fourth, the anti-collapsing drilling device for grout spraying of the soft coal seam is installed; fifth, anti-collapsing drilling for grout spraying is performed; sixth, drilling stops till the designed depth is achieved, clean water is used for cleaning a grout spraying pipeline and a spray nozzle, and a drill stem and a drill bit are withdrawn. Due to the adoption of the method, the efficiency for drilling bedding holes in the soft coal seam is substantially improved, the hole forming rate for drilling holes in 100 meters is substantially increased, and time for drilling the bedding holes in the soft coal seam is shortened; the gas drainage efficiency of the bedding holes in the soft coal seam is substantially improved, and time for gas pre-drainage of the soft coal seam is greatly shortened; the probability that gas exceeds the limit is greatly reduced in the tunneling and stoping period, and valuable time and a safety guarantee are provided for safe and efficient stoping and tunneling of a coal mine.

Owner:河南理工大学科技园有限责任公司

A gas drainage method for anti-permeability by static blasting in low-permeability coal seams

ActiveCN109458214BGuaranteed stabilitySlow generationMining devicesDisloding machinesHydration reactionMining engineering

The invention discloses a low-air-permeable coal bed static blasting anti-reflection gas extraction method. Multiple roof bedding drill holes are constructed along the coal bed top plate, the drill holes are filled with silent breakers which are subjected to a hydration reaction to generate radial compressive stress and tensile stress to hole walls, when the tensile stress exceeds tensile strengthof coal bed roof rock, the coal bed roof starts to generate cracks, that is to say, a gas migration and output passage is built in the coal bed roof rock, the roof bedding drill holes are subjected to repairing, hole sealing and networking extraction, and coal bed gas is extracted indirectly. Meanwhile, a group of coal bed bedding drill holes are constructed in a coal bed, and migration of the coal bed gas to the roof bedding drill holes is accelerated. After it is determined that extraction reaches the standard, progressive cover type tunneling is conducted, and finally rapid tunneling of alow-air-permeable coal bed coal rod is achieved. Accordingly, by conducting static blasting fracture on the roof bedding drill holes, the gas migration and output passage is built in the coal bed roofrock, and the extraction amount and extraction rate of the low-air-permeable coal bed gas are increased.

Owner:HENAN POLYTECHNIC UNIV

A progressive shield type gas pressure relief and extraction method

ActiveCN106894837BImprove extraction efficiencyReduce the number of drilled holesFluid removalGas removalPunchingEngineering

The invention provides a progressive shielding type gas depressurizing extraction method which is particularly suitable for depressurizing outburst elimination extraction of coal roadway strip gas in a soft high-outburst coal seam through seam-penetration drilling holes. The seam-penetration drilling holes are constructed in the portions, on the two sides of an upper coal roadway, of the coal seam from a base plate roadway. Since the high-gas-outburst coal seam has high outburst tendency, the depressurizing permeation increasing measure of direct drilling hole construction can cause severe disturbance to an original coal body to induce a hole jetting phenomenon, the coupling mode of common drilling holes and punching and cutting drilling holes under the condition of base plate seam penetration is built, and the drilling holes are divided into the partition holes, the shielding holes and the depressurizing holes. Through reasonable arrangement of the common seam-penetration drilling holes and the drilling, punching and cutting drilling coupled depressurizing drilling holes, the gas extraction effect of the area coal body is improved, the phenomena of an outburst elimination blanking zone and hole jetting are voided, the drilling construction speed in remarkably increased, and the gas extraction effect is remarkably improved, and the technology has good adaptability to all coal seams of different occurrence states.

Owner:CHINA UNIV OF MINING & TECH

Combined pressure positive and negative pressure drainage technology for coal body in thick coal seam

ActiveCN103147788BImprove the extraction effectShorten prepumping timeFluid removalGas removalPositive pressureGas concentration

Owner:山东新特能源装备科技有限公司

A vacuum storage and testing device for transmission electron microscope sample rod

ActiveCN106783494BReduce pollutionExtended service lifeElectric discharge tubesVacuum gaugesVacuum pressureElectron microscope

Owner:BEIJING UNIV OF TECH

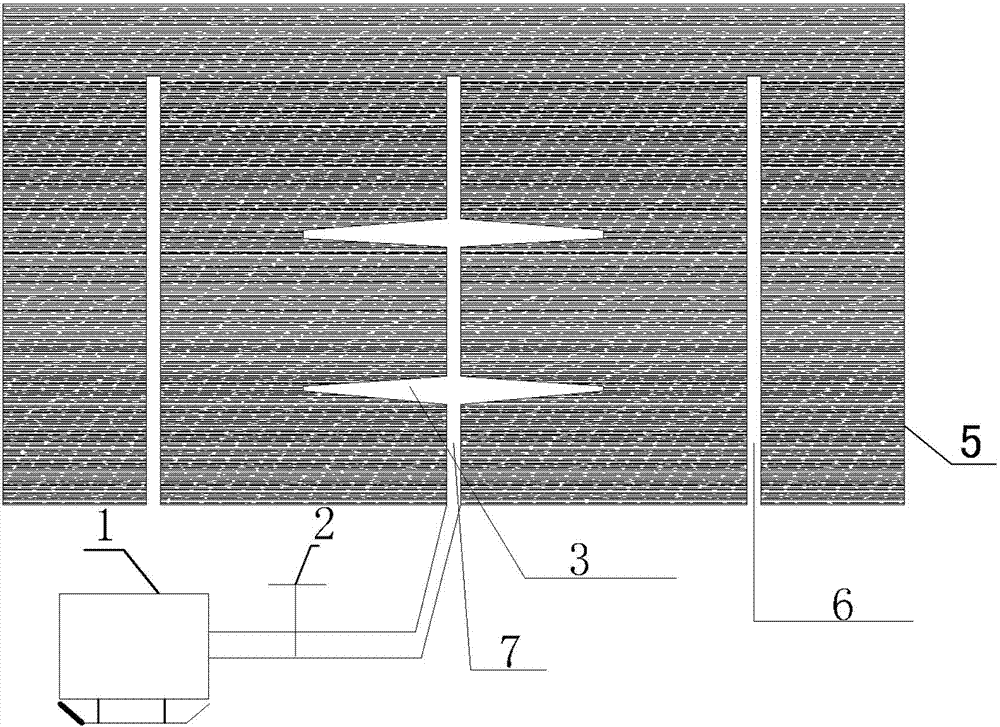

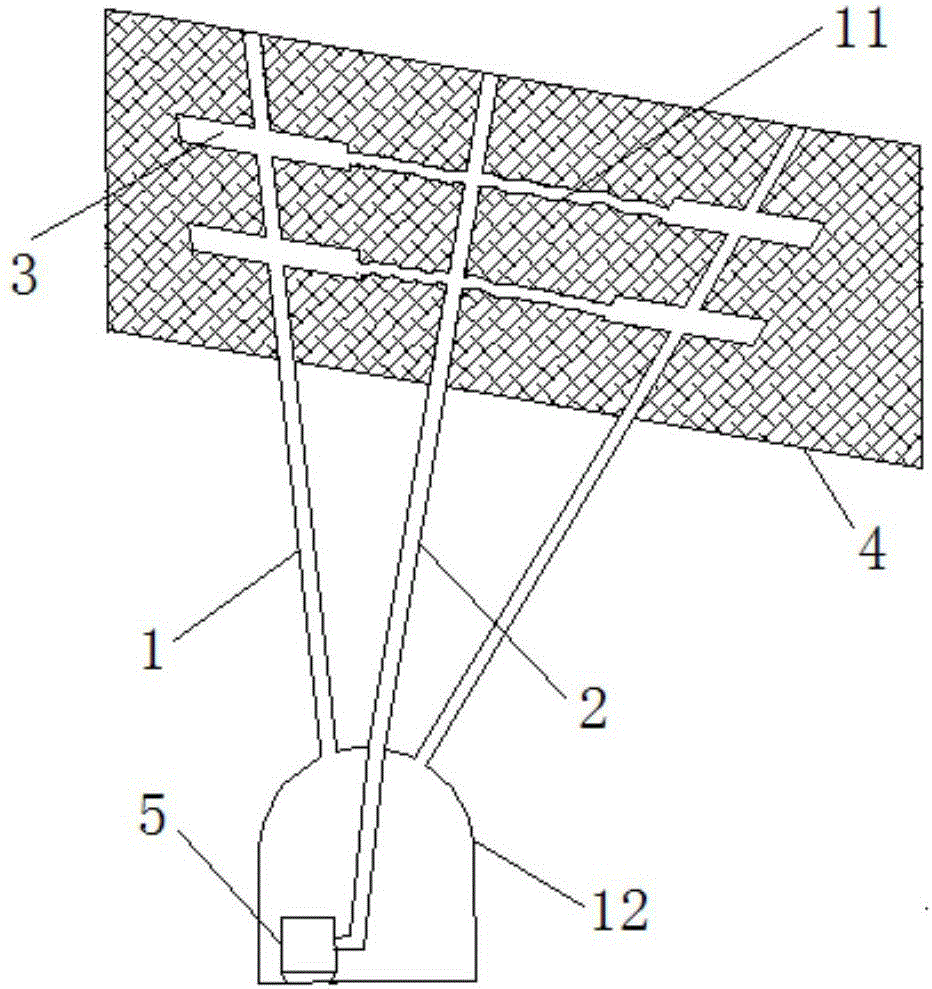

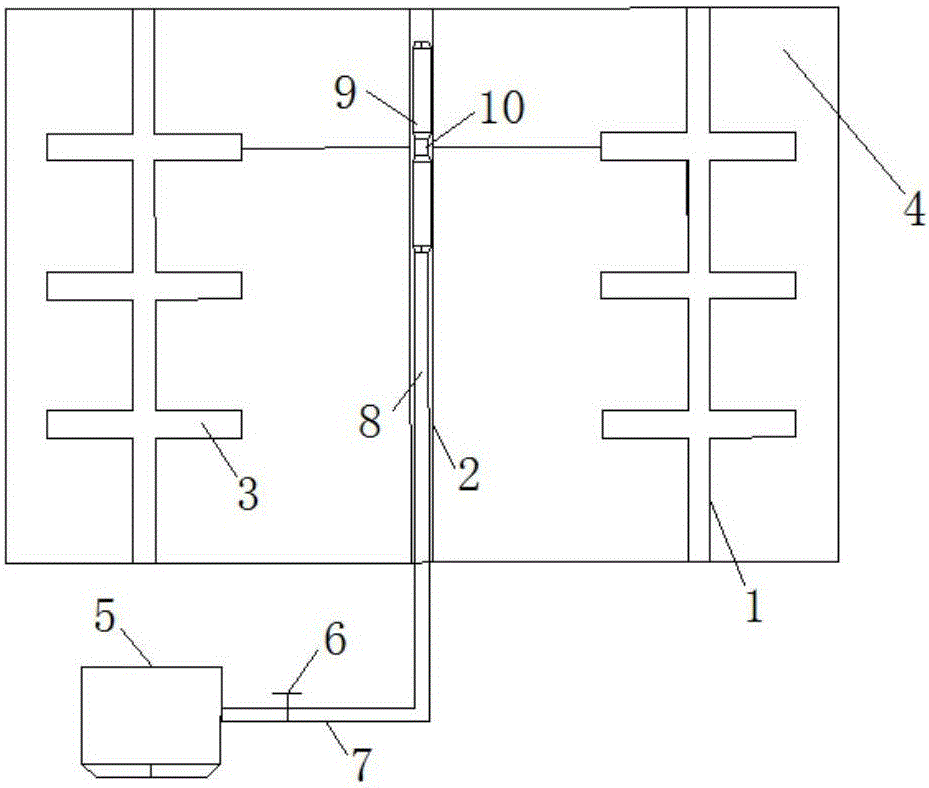

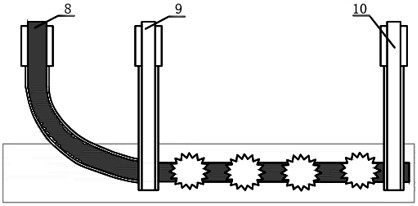

A method of operating a vacuum system with a pre-extraction device

The invention relates to a vacuum-pumping system with a pre-drainage device and an operation method, and belongs to the technical field of smelting in a metallurgical industry. The technical scheme is as follows: a pre-drainage device (3 ) is arranged between a coarse filter module (2) and a fine filter module (4), and comprises a valve A (8), a branch pipeline (9), a valve B (10) and a tank body (11); the valve A (8) is arranged on a main pipeline (7) between the coarse filter module (2) and the fine filter module (4); the branch pipeline (9) is arranged on the main pipeline (7) between the valve A (8) and the coarse filter module (2); the branch pipeline (9) is connected with the tank body (11); the valve B (10) is arranged between the branch pipeline (9) and the tank body (11). The vacuum-pumping system has the beneficial effects that the pre-drainage time of 67pa of atmosphere in a vacuum furnace is reduced; the temperature of molten steel is ensured; the temperature and the dust content of a mixed gas are reduced; the service life of the filler of the fine filter module is prolonged; the fault rate of a degassing module is reduced; the maintenance cost of the degassing module is also reduced.

Owner:唐山志威科技有限公司

A high-power electric detonation-assisted hydraulic fracturing anti-permeability method in underground coal mines

ActiveCN105275443BIncrease the number of cracksIncrease the lengthFluid removalGas removalShock waveDetonation

The invention relates to a coal mine underground high-power electric knock assisted hydraulic fracturing permeability enhancement method suitable for increasing extraction radius and total extraction amount of gas extraction drilling. The method comprises the following steps that: a borehole extends from one side of a laneway to a coal seam is constructed; a high-voltage pulse discharger which is installed at the front end of a fracturing steel pipe is sent to the bottom of the borehole; a hole packer, which is separated from the orifice of the borehole by 2 to 3m, is installed on the borehole; the outer end of the fracturing steel pipe is connected with a high-pressure pump station through a high-pressure rubber hose; and the high-voltage pulse discharger is connected with a high-voltage electric pulse generator through a cable; after water with a certain pressure is injected into the borehole, the high-voltage electric pulse generator is started so as to apply high-power electric knock assisted hydraulic fracturing to the coal seam; after the high-power electric knock assisted hydraulic fracturing, the high-voltage pulse discharger and the fracturing steel pipe are quitted; and a gas extraction pipeline is connected into the borehole. According to the method of the invention, high energy released by high-voltage electric pulses is utilized to form shock waves in the water, and therefore, a large number of cracks can be formed in the coal seam, and primary cracks are extended. With the method adopted, the permeability coefficient of a coal body can be increased by 100 to 300 times, and single-hole gas extraction efficiency can be effectively improved.

Owner:CHINA UNIV OF MINING & TECH

A collaborative network-based permeability-enhancing method for slotting and fracturing in low-permeability coal seams

ActiveCN104389631BImprove breathabilityIncreased air permeability coefficientFluid removalGas removalHigh pressure waterHigh pressure

The invention provides a slotting and fracturing cooperation networking permeability increasing method for a low-permeability coal seam, which is applicable to regional gas control for high-gas-content low-permeability coal seams. The permeability increasing method comprises the following steps that: firstly, hole positions of slotting drill holes and fracturing drill holes are arranged alternately at a floor suction roadway in a networking arrangement mode; each slotting drill hole is subjected to high-pressure water jet flow slotting to form an annular slotted hole; and then, each fracturing drill hole is subjected to segmented fracturing, and a fracture net is formed in the coal seam. The slotting drill holes and the fracturing drill holes are in cooperative arrangement; the slotted holes formed by slotting are used for controlling the expanding direction of fracturing cracks; the number of cracks in the coal seam can be effectively increased through segmented fracturing multiple times; and good conditions are created for the drill hole gas extraction and the gas flowing in the coal seam. After the fracturing cracks are communicated with the slotted holes, a crack network is formed in the coal seam; the permeability coefficient of a coal body around the drill holes can be improved by 150 to 400 times; the single-drill-hole gas extraction effective influence range can be expanded by 2 to 4 times; the drill hole gas extraction quantity can be increased by 3 to 6 times; and the gas pre-extraction time in the high-gas outburst coal seam can be effectively shortened.

Owner:CHINA UNIV OF MINING & TECH

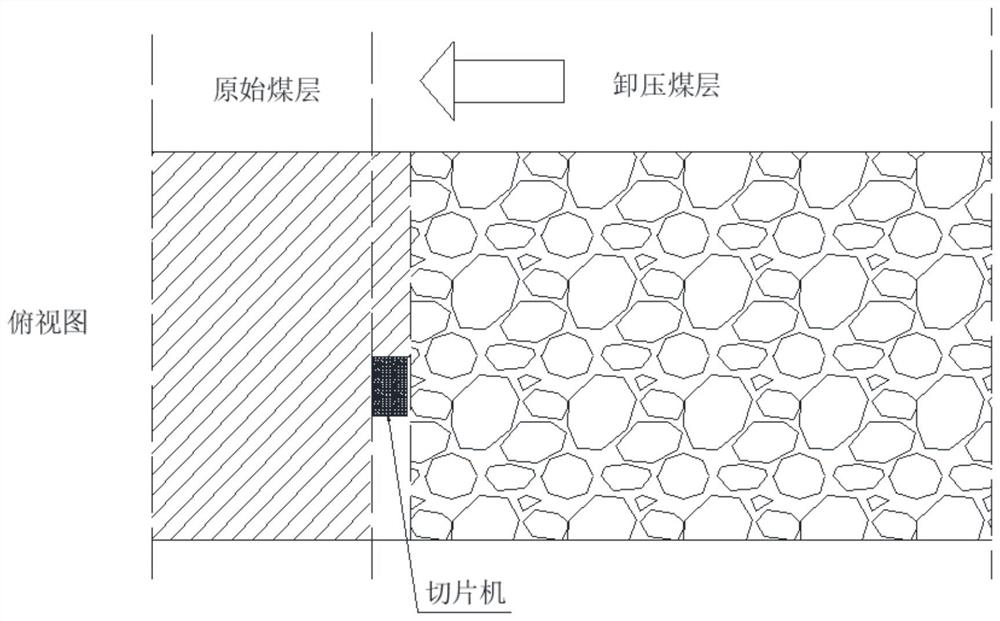

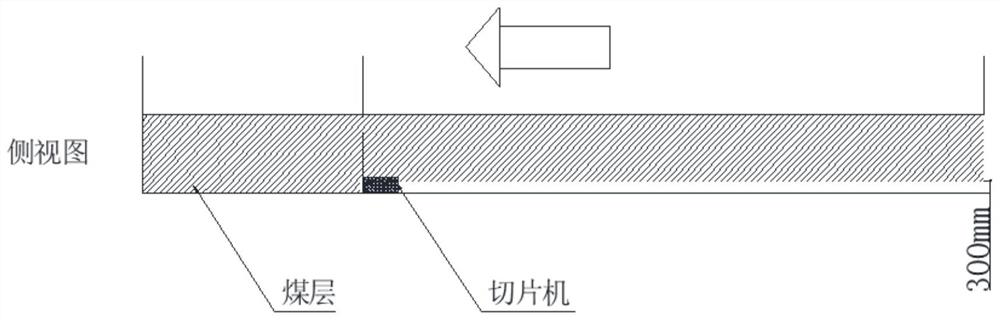

Coal seam region slicing, pressure relief and permeability increasing method based on 'mining protective layer' principle

ActiveCN111622760AInhibit productionIncreased air permeability coefficientUnderground miningFluid removalMining engineeringMechanical engineering

The invention belongs to the technical field of coal mine safety, and relates to a coal seam region slicing, pressure relief and permeability increasing method based on a 'mining protective layer' principle. A slicer machine head reciprocates along a vertical gateway to cut a coal body; cut-off coal debris is conveyed out through a scraper conveyer; and a cutting boundary of a slicer moves along with a heading end at a certain speed in the direction towards an open-off cut of a stope face, sufficient pressure relief is realized on a coal body of a rear region due to a free space 200-300 mm wide cut by the slicer, an original gas pressure of a coal seam is reduced to close to zero (gauge pressure), and a gas permeability coefficient is increased by two or more orders of magnitude. By meansof the coal seam region slicing, pressure relief and permeability increasing method, sufficient pressure relief is realized on a protruding coal seam, the technical and economic problem that there isno protective layers for the protruding coal seam for mining is solved, and for those protruding mines where only construction of coal seam drilling and coal seam gas pre-drainage serves as a regionalanti-protruding measure, the brand-new solution of a regional anti-protruding technology is provided.

Owner:CHINA COAL TECH & ENG GRP CHONGQING RES INST CO LTD

Coal seam pre-splitting method based on gas extraction

ActiveCN101813002BRealize extraction and utilizationImprove extraction efficiencyGas removalProduct gasHigh pressure

The invention relates to a coal seam pre-splitting method based on gas extraction, which adopts a 'CO2 gas extraction device' as a tool to blast and pre-split a pre-mined coal seam, so as to increase the crack of the coal seam, drive out gas absorbed on the coal seam and extract the gas. The method particularly comprises the following steps: drilling a hole on the working surface of a pre-mined coal seam, filling CO2 gas extraction device into the drilled hole, sealing the drilled hole, detonating the CO2 gas extraction device, releasing high-pressure CO2 gas for deep-hole impact and pre-splitting of the coal seam, taking out the CO2 gas extraction device, and connecting the drilled hole with a gas extraction system to extract gas. The pre-splitting method of the invention can greatly enhance the permeability of the coal seam, promote the gas dissociation in the coal seam, and improve the underground gas extraction efficiency of the coal mine.

Owner:山西锦浩诚科技有限公司

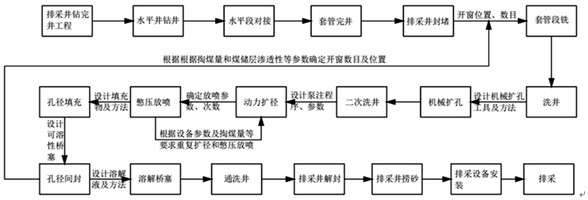

A Drainage Method for Coalbed Gas Horizontal Wells with Power Expansion, Pressure Relief and Permeability Enhancement

ActiveCN112593912BFast desorptionIncrease production capacityFluid removalDirectional drillingGlass fiberMining engineering

A kind of coal seam -level yarn power -dynamic diameter dynamic diameter discharge and increased pumping method, which belongs to the field of mines gas treatment and coalbed methane, can solve the large amount of coal digging projects, high costs, under wells under the well, high cost, high cost, high cost, and high costs.There is a problem with hidden safety hazards in gas pumping. In the mine preparatory area and pioneering preparation area, the ground horizontal shaft is arranged along the recovery work surface to carry out gas pre -pumping, the horizontal well is empty, and the three -open shaft structure.The sleeve or glass reinforcement sleeve, the horizontal section performs high -pressure air power expansion diameter, determine the diameter and quantity of the diameter according to the diameter of the diameter.Unsolle, improve the capacity of ground coal seams, and ensure the sustainable and high yield of coalbed methane.Gradually replaced the bottom of the bottom of the well, shorten the pre -drawing time under the well, eliminate the prominent safety hazards of the underground gas, and reduce the risk of gas overrun and the cost of mining of coal mines.

Owner:SHANXI JINCHENG ANTHRACITE COAL MINING GRP CO LTD

A gas control method for working face with large mining height in high gas coal seam

Owner:LIAONING TECHNICAL UNIVERSITY

A kind of gently inclined super thick coal seam Shimen coal excavation method

ActiveCN103510958BUniform coverageReduce the difficulty of homeworkUnderground miningSurface miningCross cutDrill floor

Owner:CHINA UNIV OF MINING & TECH

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com