Coal mine underground high-power electric knock assisted hydraulic fracturing permeability enhancement method

A hydraulic fracturing, high-power technology, applied in mining equipment, earthwork drilling, wellbore/well components, etc., can solve the problems of small drilling radius, small fracture extension range, low coal seam permeability, etc. Achieve the effects of shortening the pre-pumping time, increasing the number of fractures, and increasing the total amount of pumping

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0015] Below in conjunction with accompanying drawing, the example of the present invention will be further described:

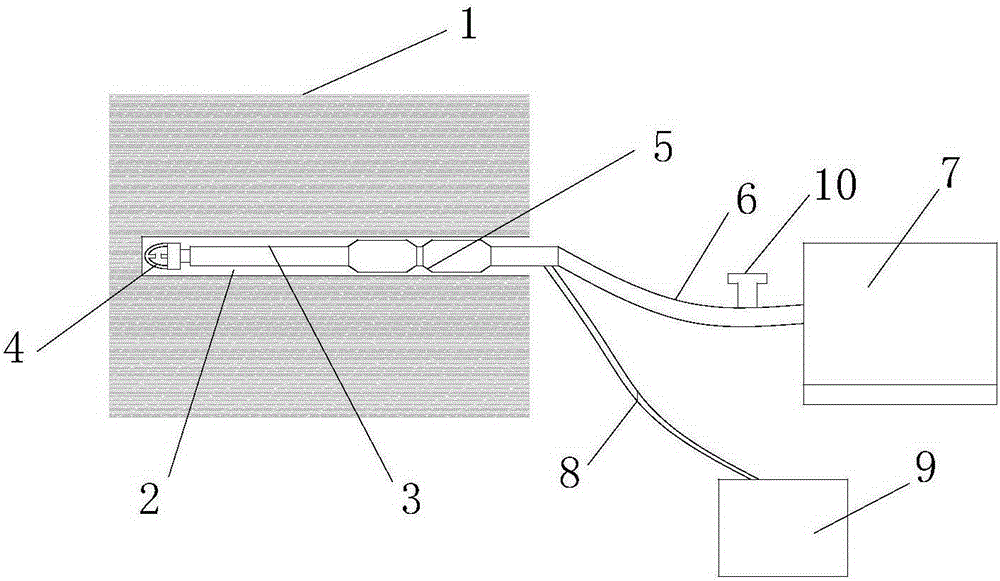

[0016] Such as figure 1 As shown, the underground high-power electric detonation auxiliary hydraulic fracturing anti-permeability method of coal mine of the present invention, the specific steps are as follows:

[0017] (1) Drilling 2 is constructed from the side of the roadway to the coal seam 1. After the drilling 2 is completed, the fracturing steel pipe 3 with the high-voltage pulse arrester 4 installed at the front end is sent to the bottom of the borehole 2, and the pipe connected to the high-voltage pulse arrester 4 is drawn out. Cable 8, connect the cable 8 to the high-voltage electric pulse generator 9, install the hole sealer 5 at the place 2-3m away from the bore hole 2, seal the hole between the fracturing steel pipe 3 and the bore hole 2, and place the The exposed end of the fracturing steel pipe 3 is connected to the high-pressure pump station...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com