Patents

Literature

427results about How to "Improve flow efficiency" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Test method for set top box and test system thereof

InactiveCN102665093AImprove flow efficiencyReduce testing costsTelevision systemsClassified informationSoftware engineering

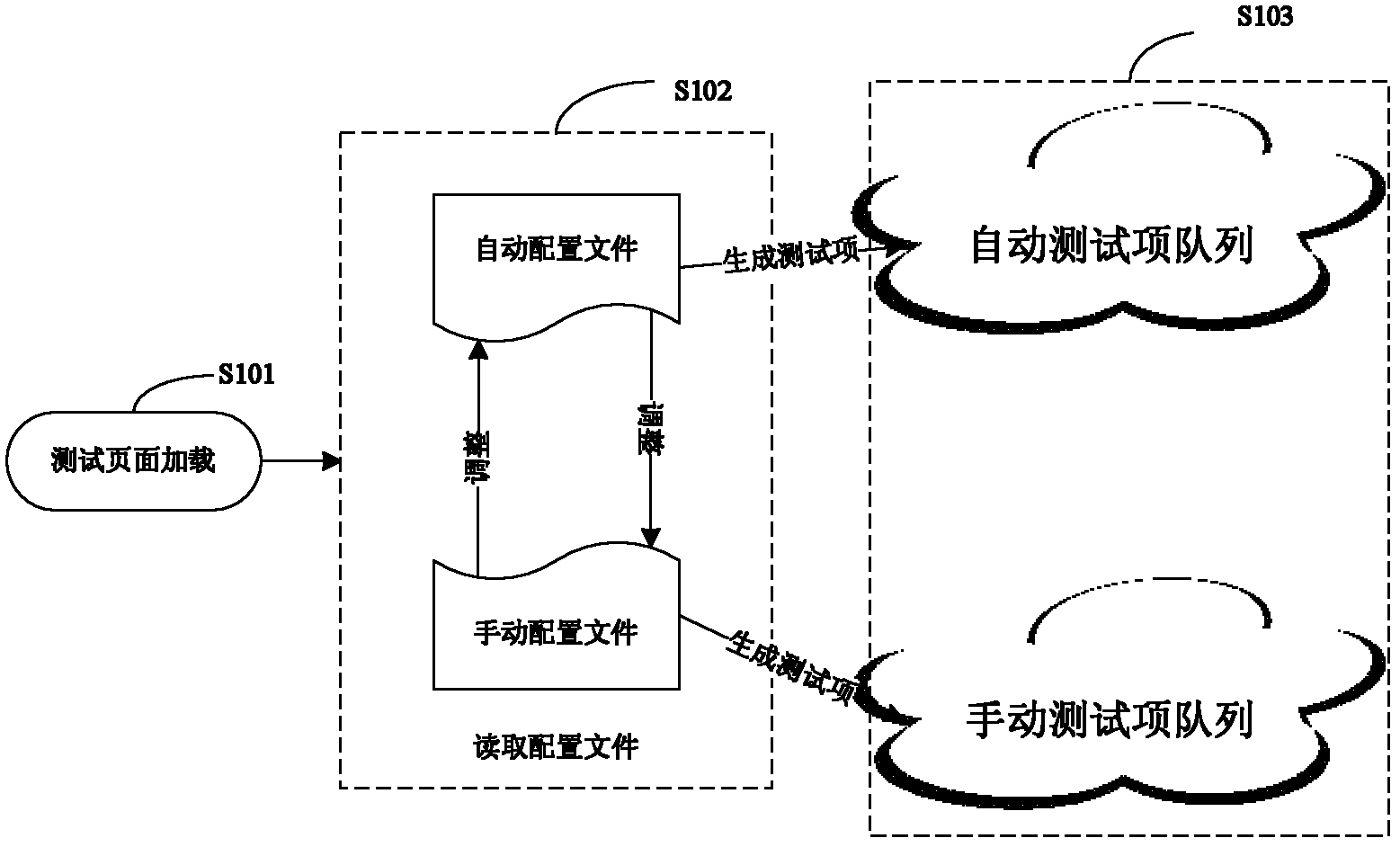

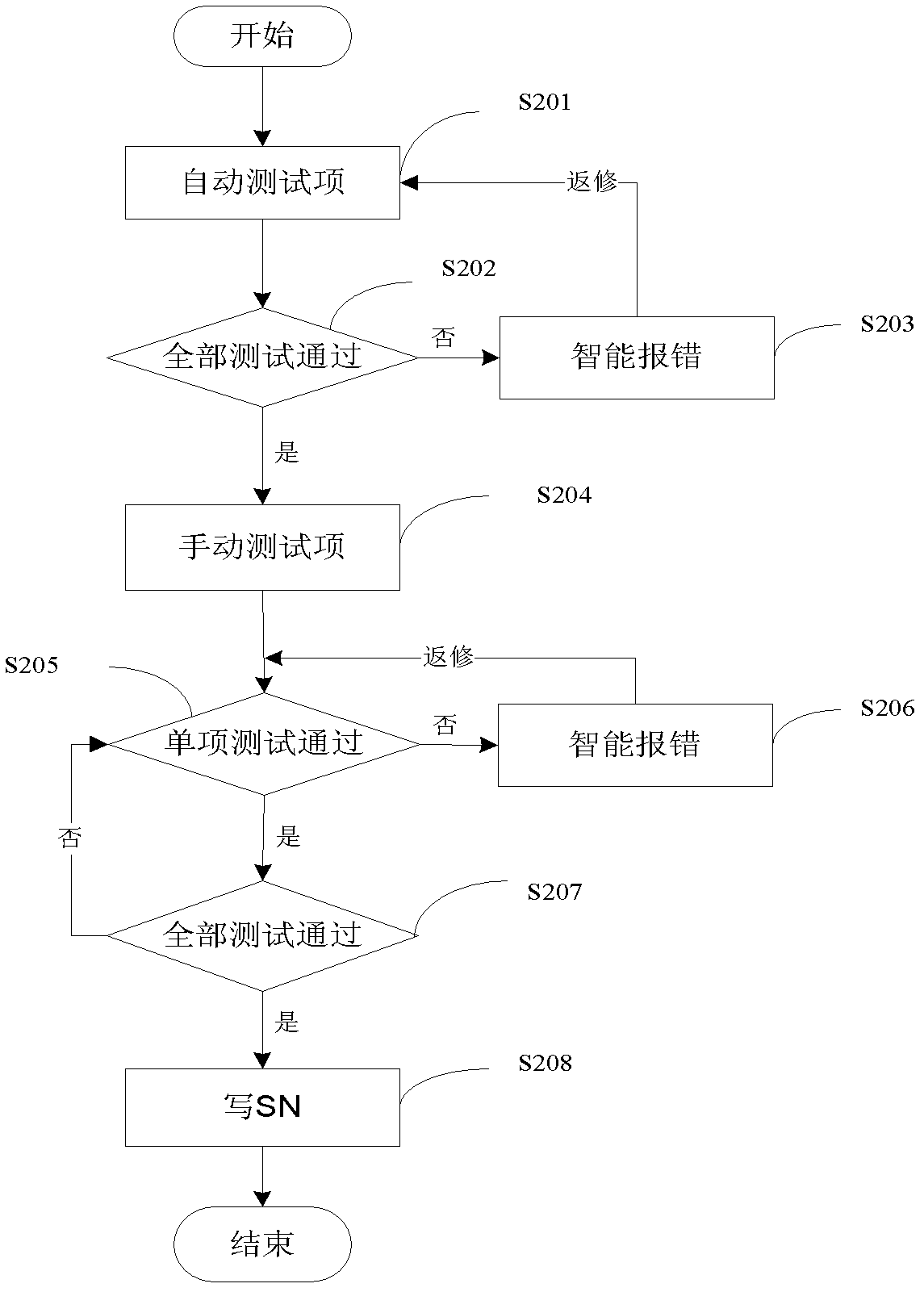

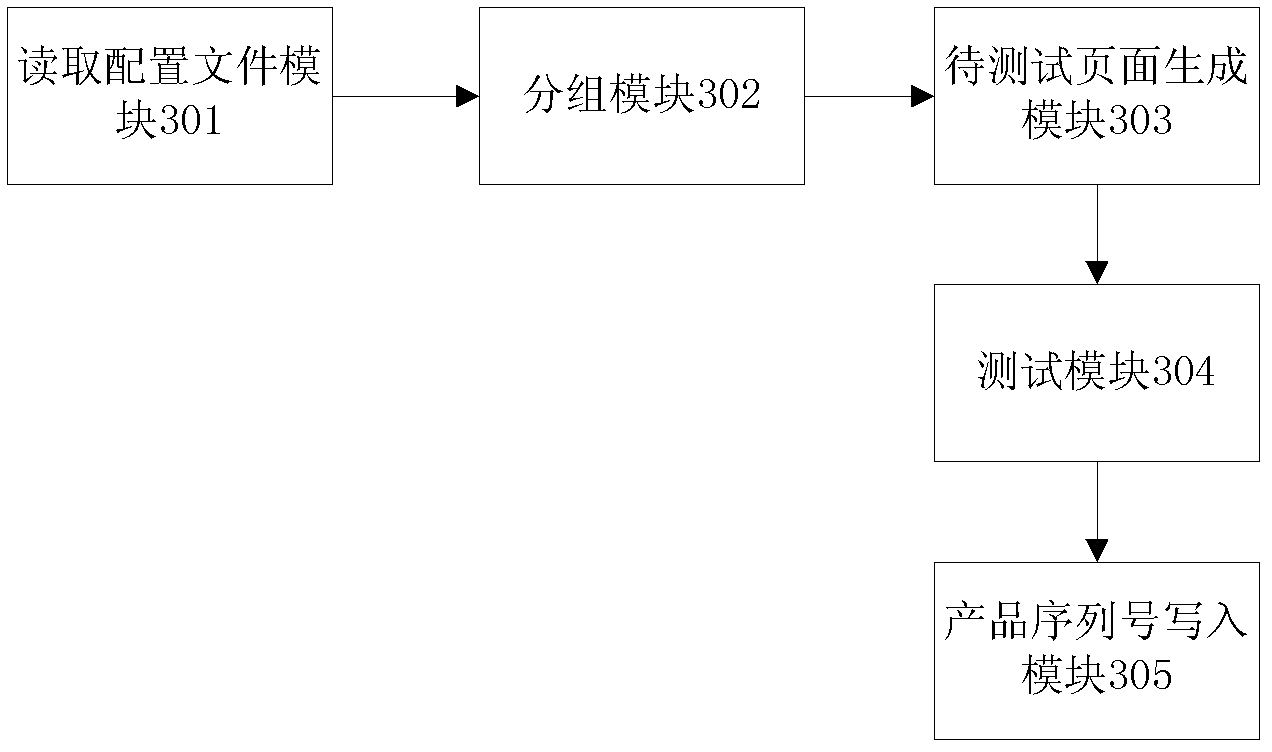

The invention discloses a test method for a set top box and a test system thereof. The test method comprises the following steps: reading configuration files of the set top box, the configuration files comprise ID of items to be tested and previously set classified information of the test items; according to the preset, dividing the configuration files into an automatic configuration file group and a hand-operated configuration file group; according to the automatic configuration file group, generating an automatic to-be-tested page containing an automatic test item queue, and according to the hand-operated configuration file group, generating a hand-operated to-be-tested page containing a hand-operated test item queue; testing according to the sequence of the automatic test item queue and the hand-operated test item queue in the to-be-tested pages; writing a serial number (SN) of a product into the set top box when all the items to be tested in the two test pages pass the test. The test method enables reduction of the test cost and improvement of the testing line efficiency.

Owner:SHENZHEN JIUZHOU ELECTRIC

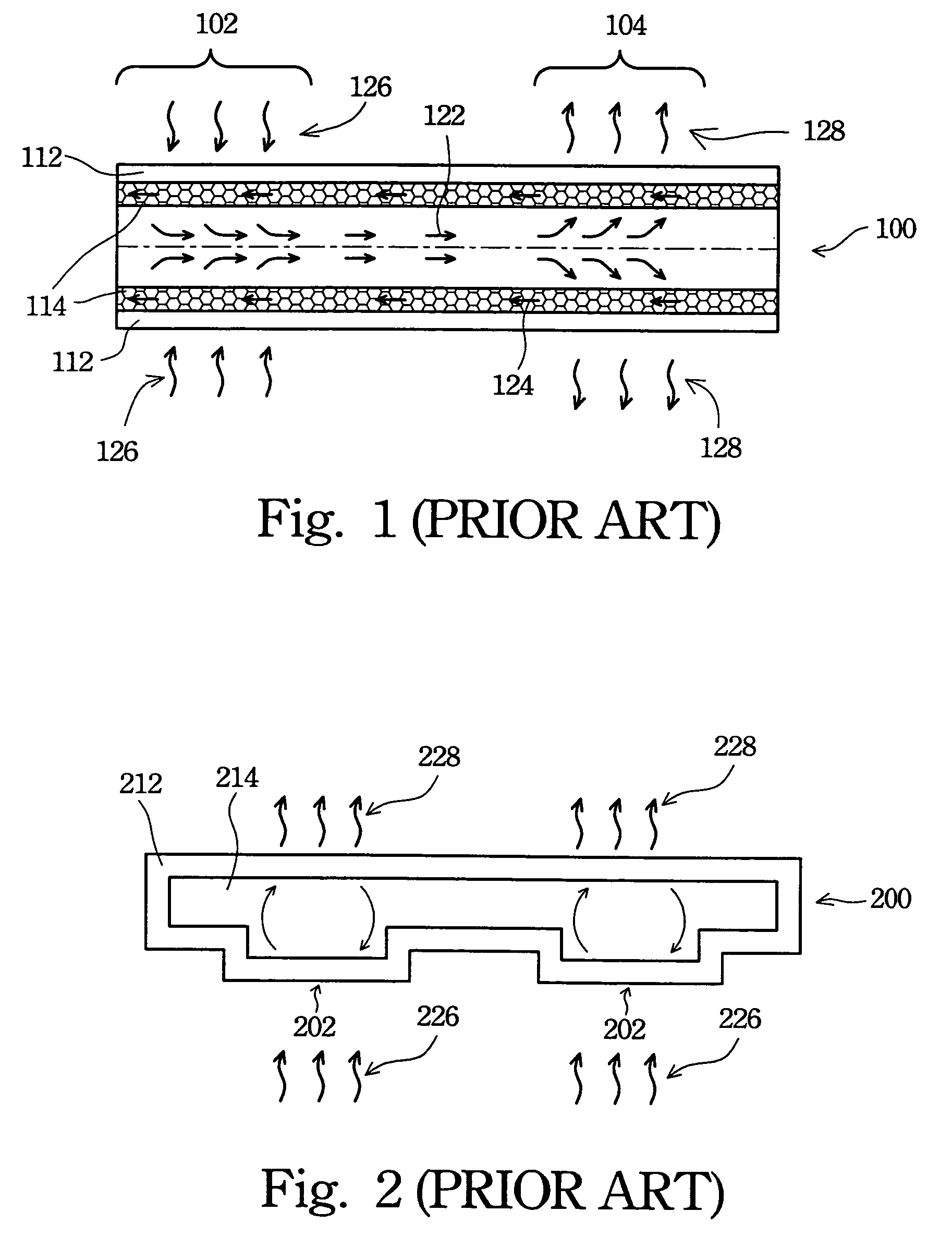

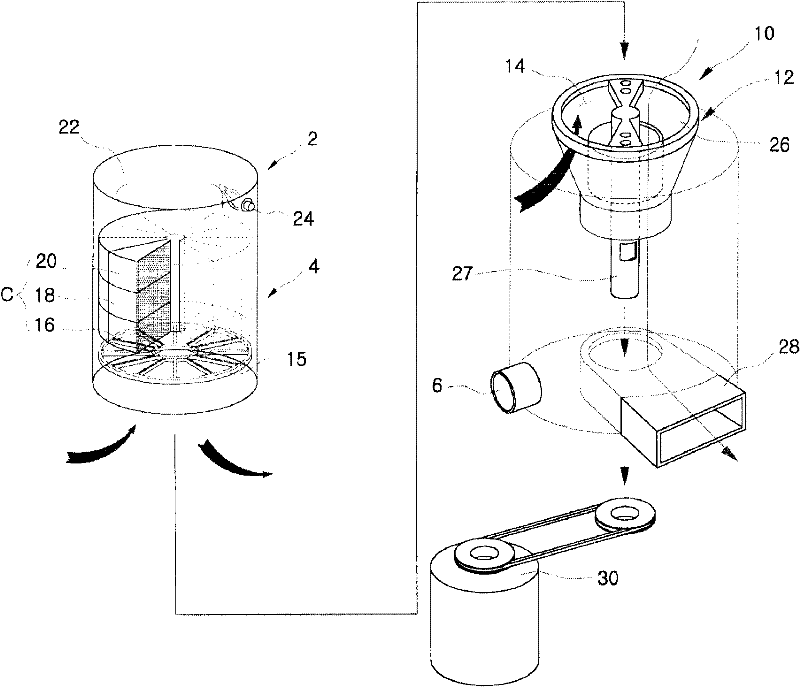

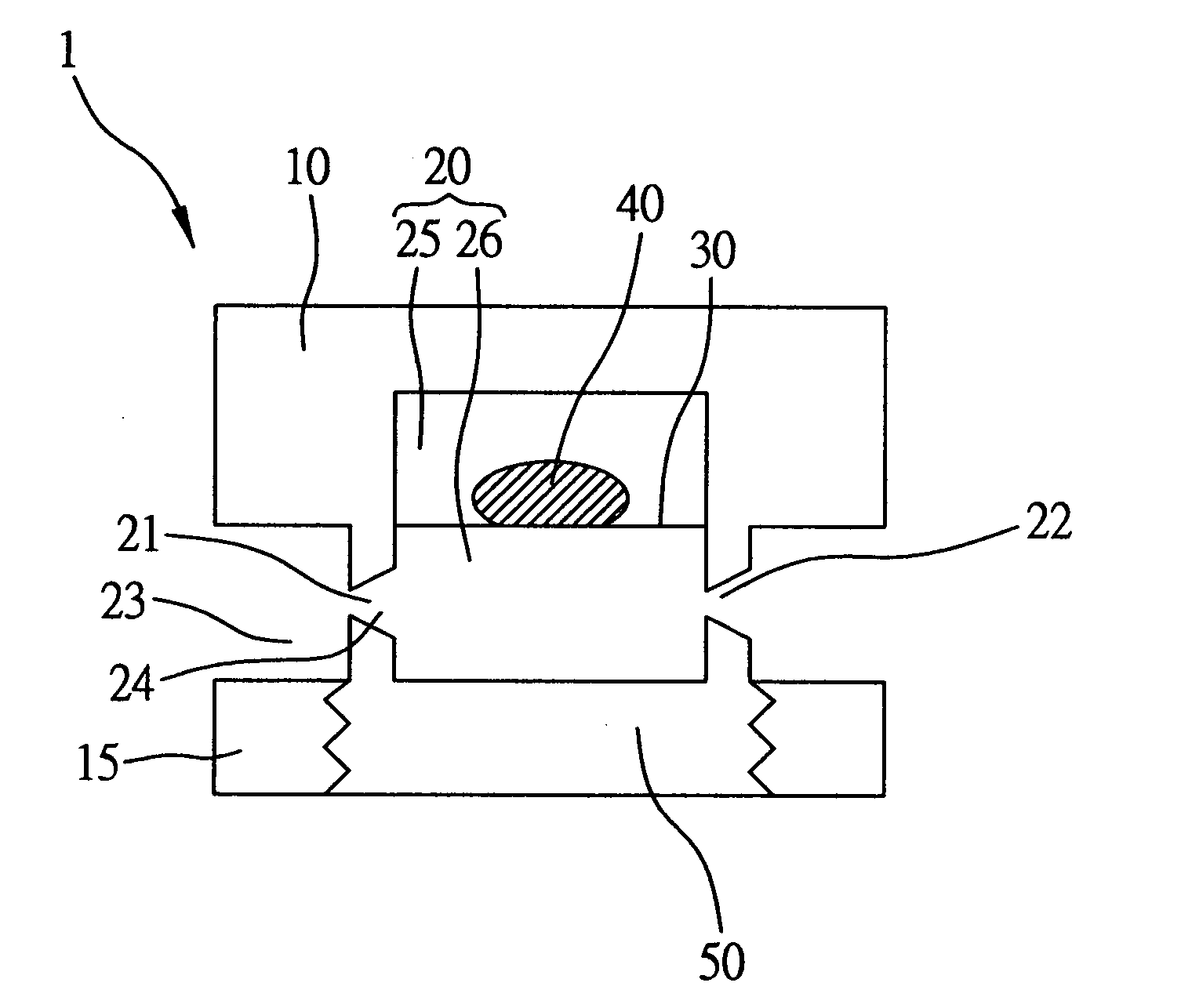

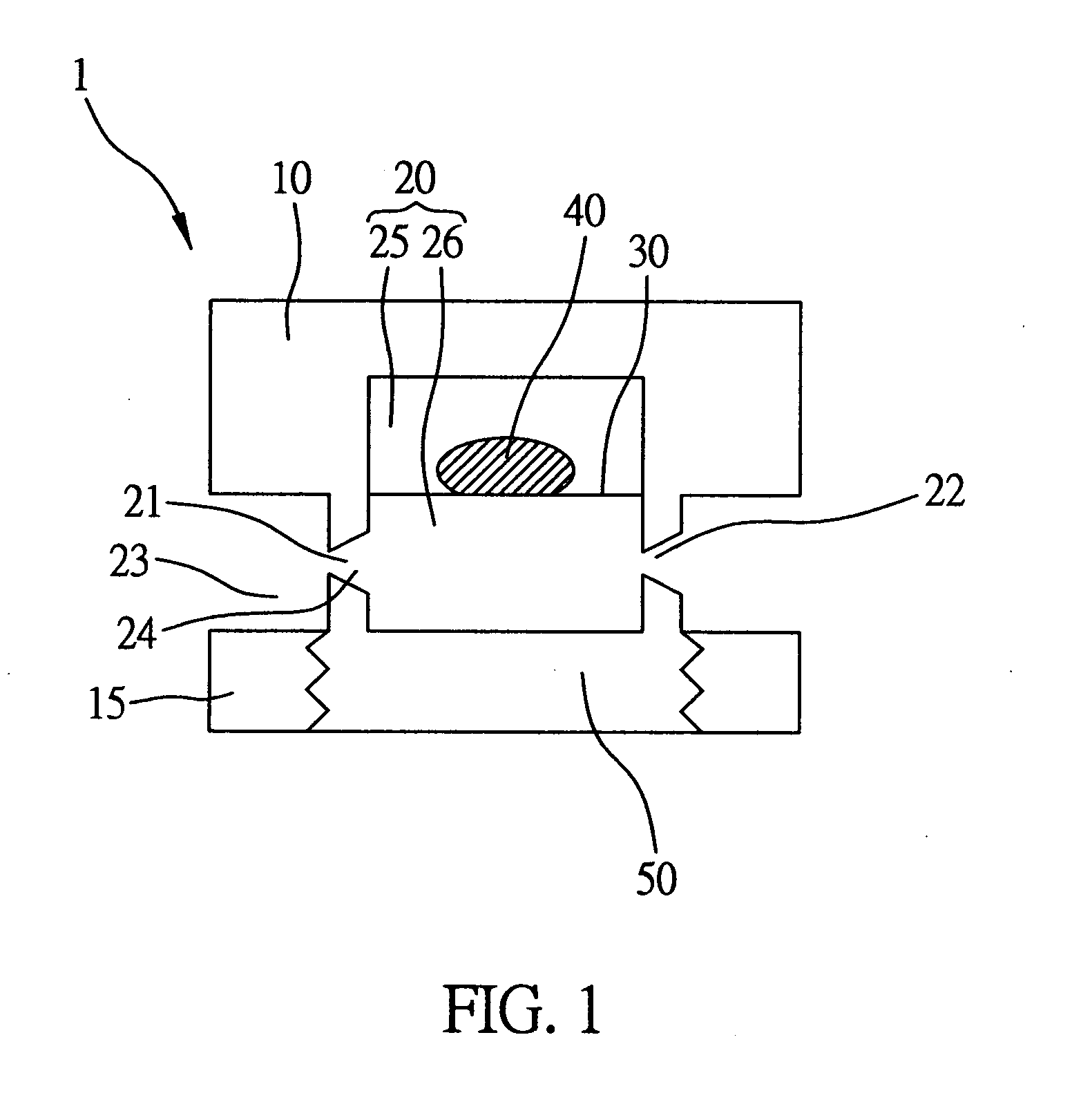

Circulative cooling apparatus

InactiveUS7007746B2Keep dryImprove flow efficiencySemiconductor/solid-state device detailsSolid-state devicesWorking fluidEngineering

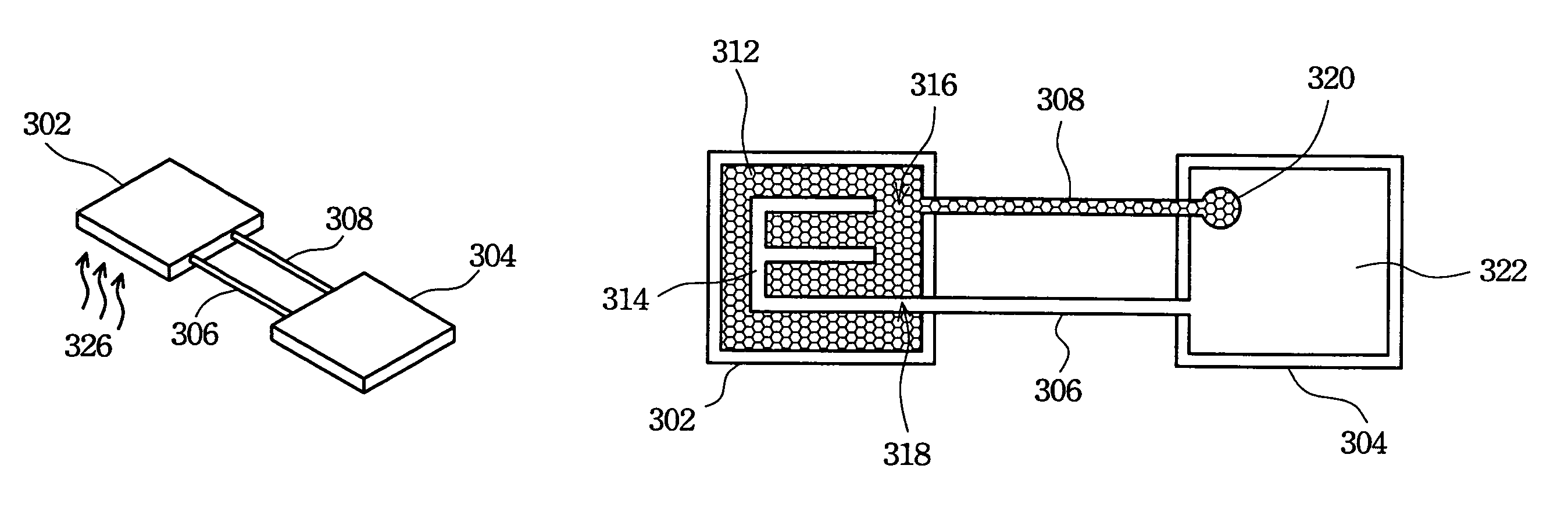

The circulative cooling apparatus has a first chamber, a second chamber, a first pipe, and a second pipe. There are porous structures on internal walls of the first chamber and the second pipe. There is work fluid in the second chamber and the porous structures. The work fluid is evaporated by heat in the first chamber, and owing to the pressure drop the vapor of the work fluid moves to the second chamber through the first pipe. Then the vapor of the work fluid condenses into the work fluid in the second chamber. Afterward the work fluid is transported back to the first chamber through the second pipe using the porous structures thereof, thus forming a circulative cooling apparatus.

Owner:DELTA ELECTRONICS INC

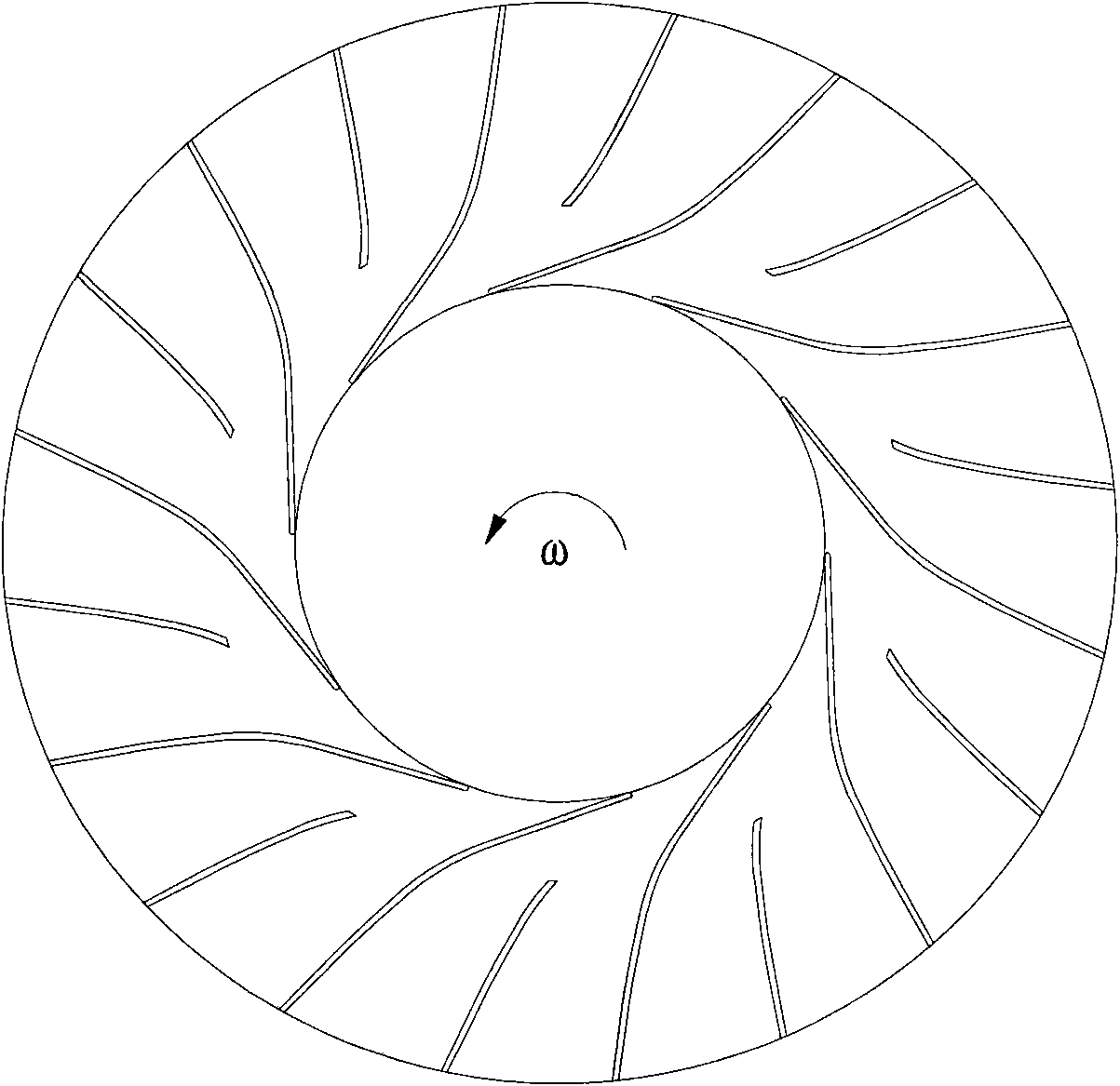

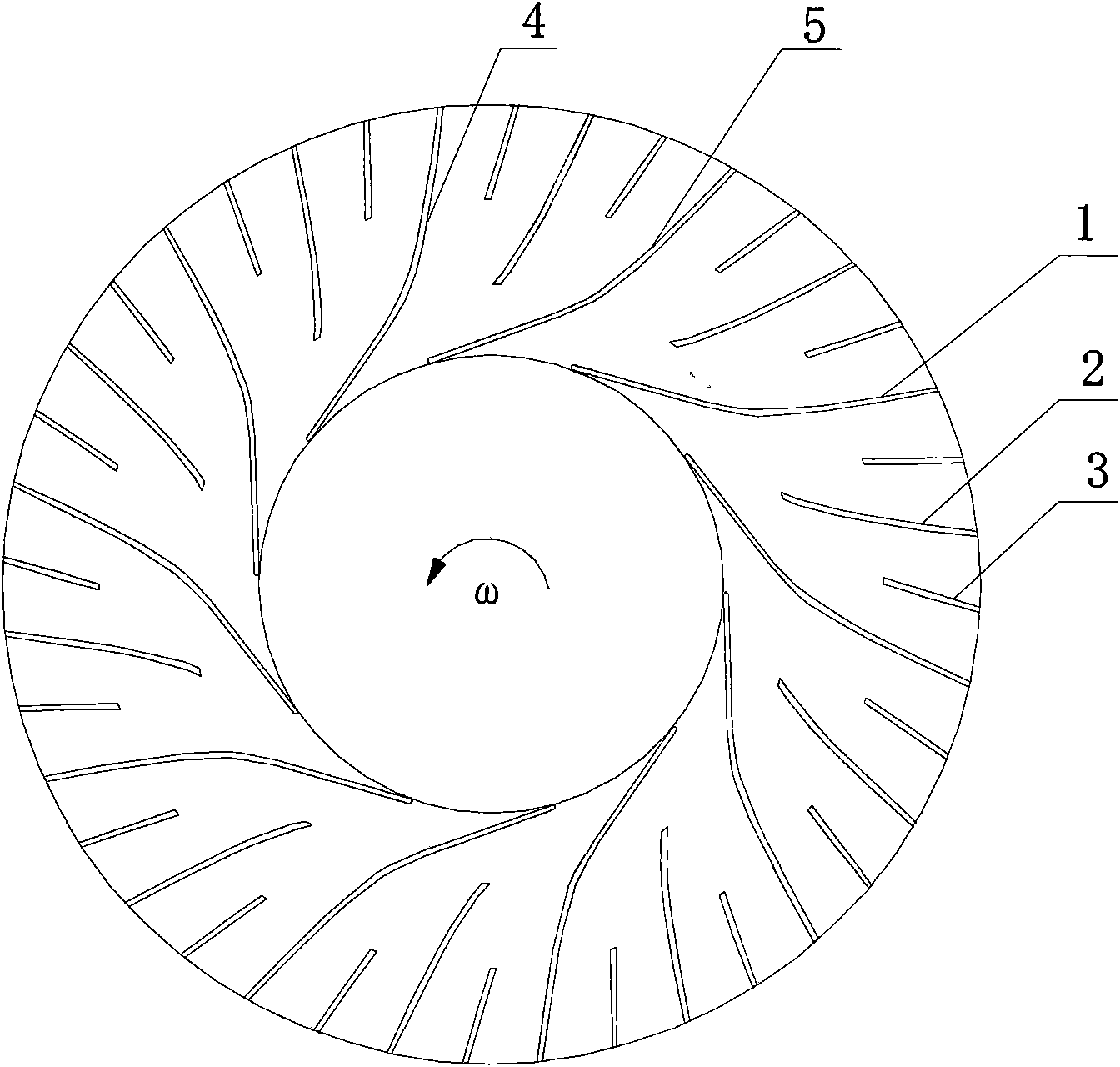

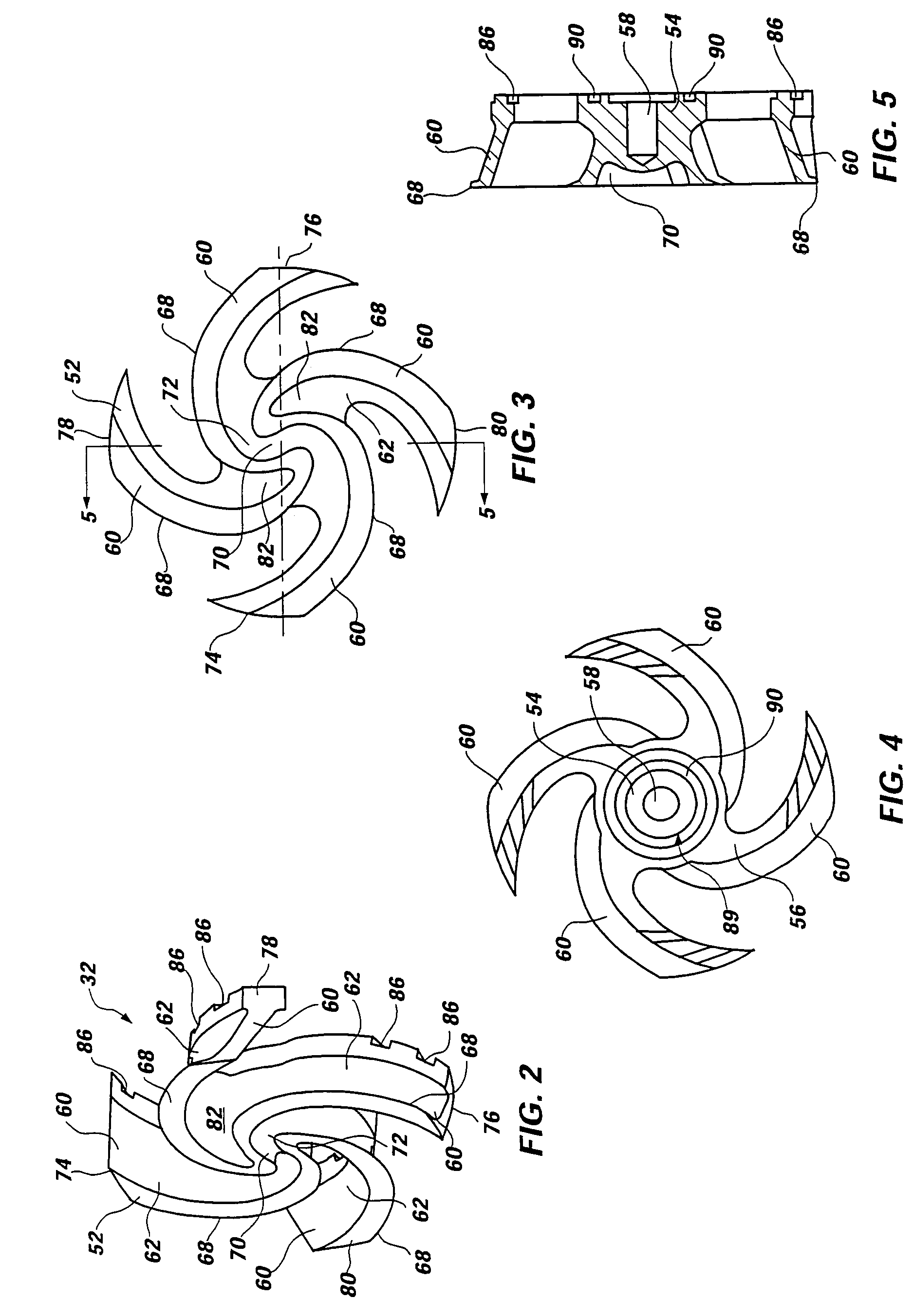

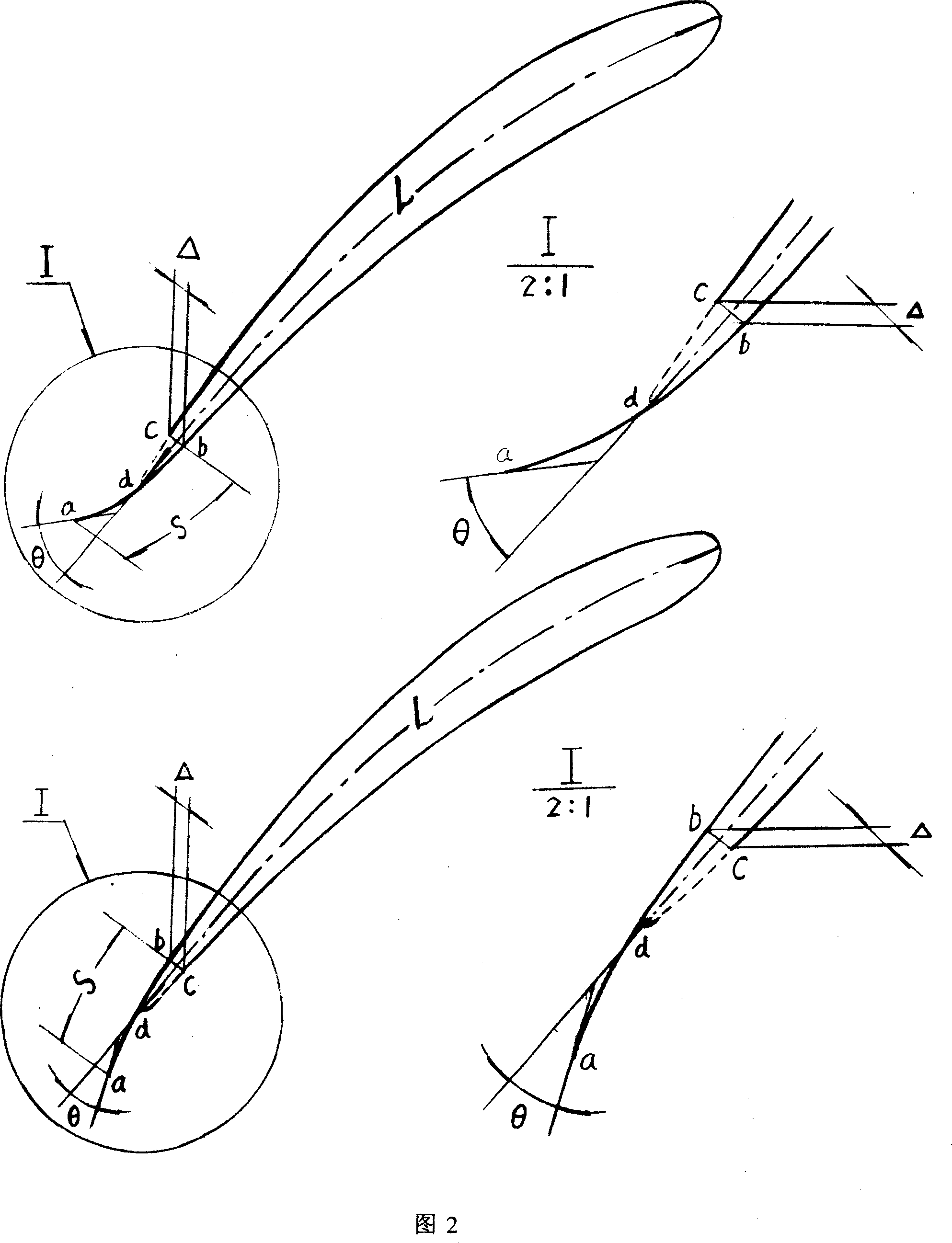

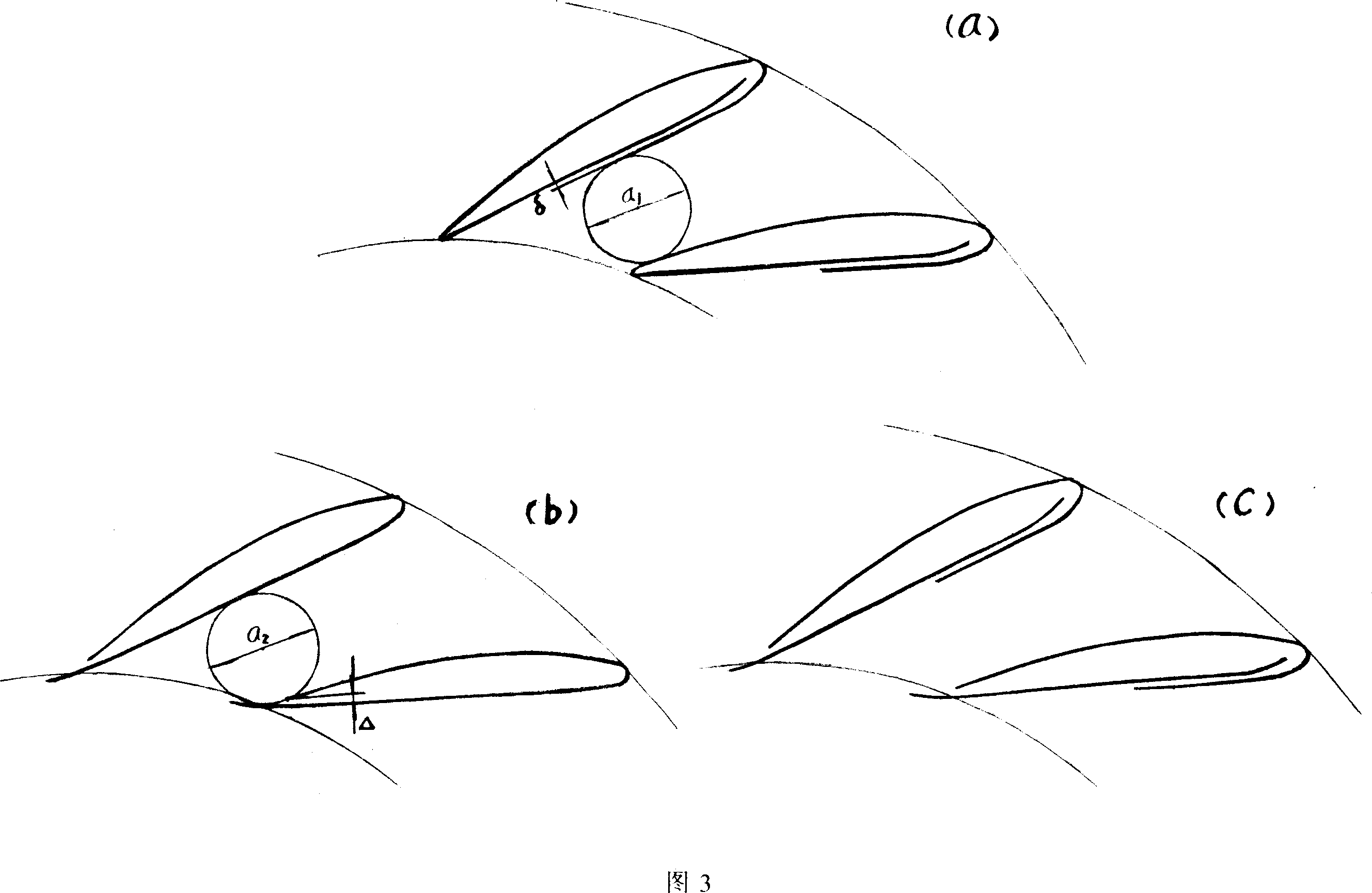

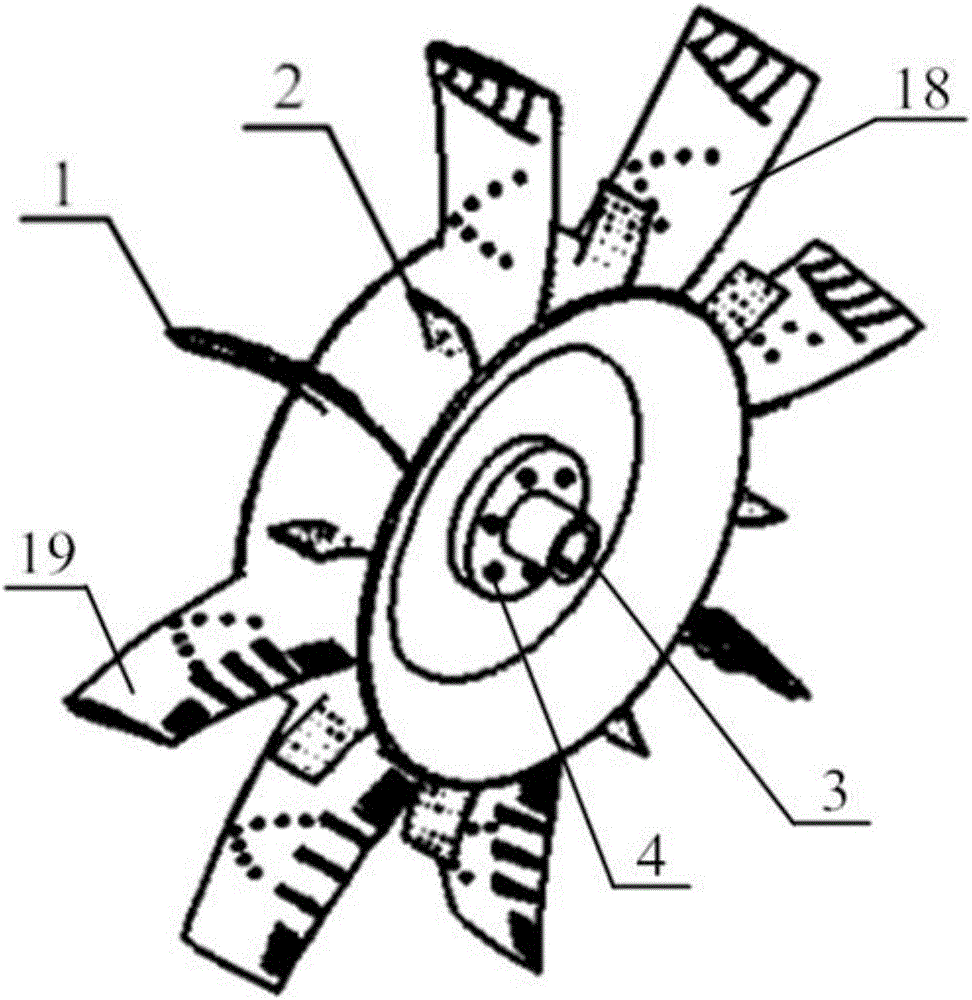

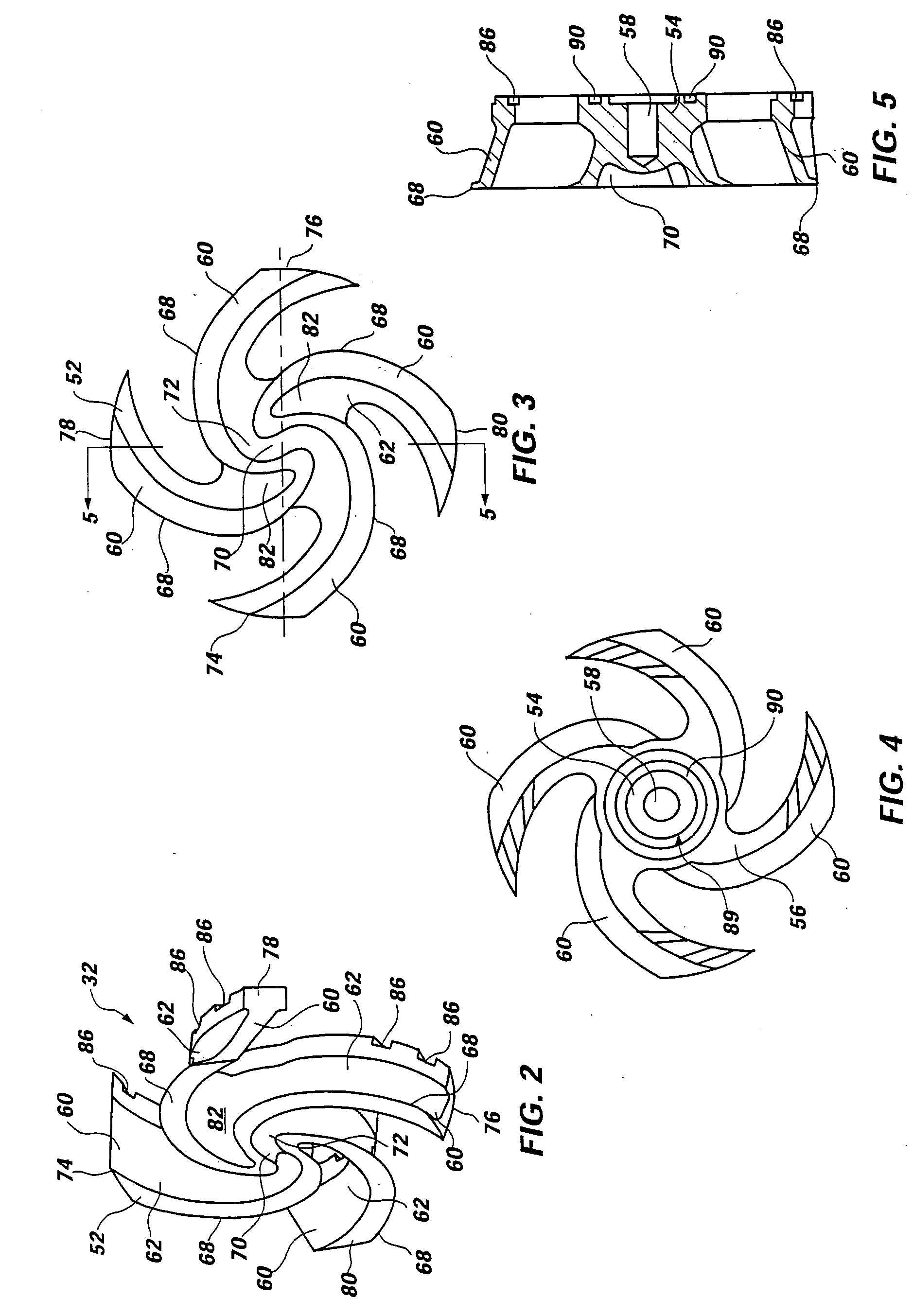

Secondary splitter blade type centrifugal impeller

InactiveCN101598138AImprove mobilityImprove flow efficiencyPump componentsPumpsImpellerAerodynamic load

The invention discloses a secondary splitter blade type centrifugal impeller, comprising a long blade extending from impeller inlet to impeller outlet. The suction surface of the long blade and the pressure surface of an adjacent long blade form a complete air flow passage; wherein a middle blade is arranged between the two long blades to form a primary splitter blade; the two sides of the middle blade are respectively provided with a short blade to form a secondary splitter blade; the inlet of the middle blade deflects toward the suction surface in the air flow passage; the inlet at the wheel disc side of the short blade deflects towards the suction surface in the air flow passage, and the inlet at the wheel cap of the short blade deflects towards one side of the pressure surface in the air flow passage; the number ratio of the long, middle and short blades is 1:1:2; and the long, middle and short blades are evenly distributed at the periphery of the outlet of the impeller. The centrifugal impeller of the invention gradually increases splitter blades, and can effectively allocate blade passage gas flow and blade aerodynamic load, improve flow uniformity at the impeller outlet and improve pressurizing capacity and steady operation range of the centrifugal impeller.

Owner:XI AN JIAOTONG UNIV

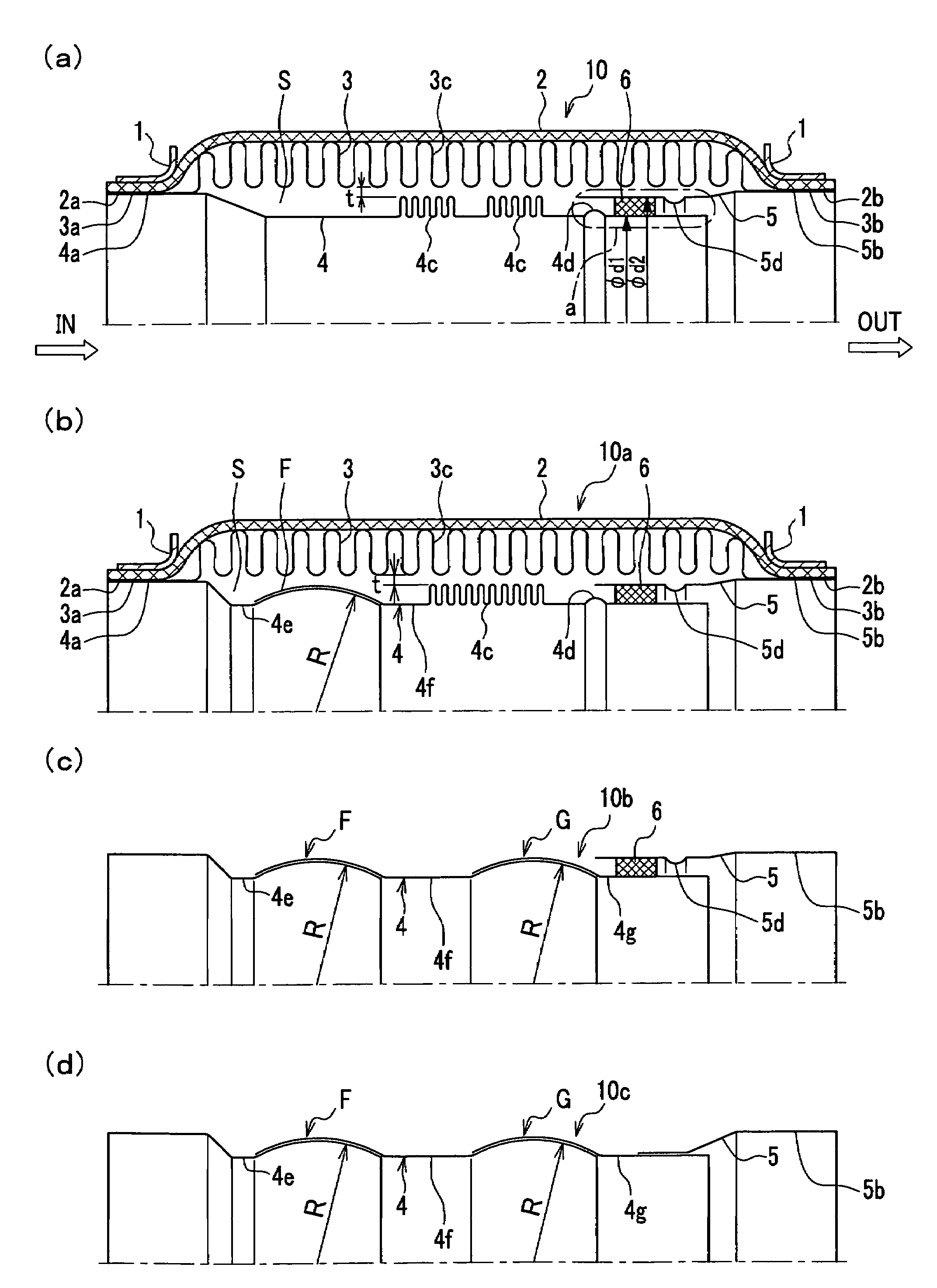

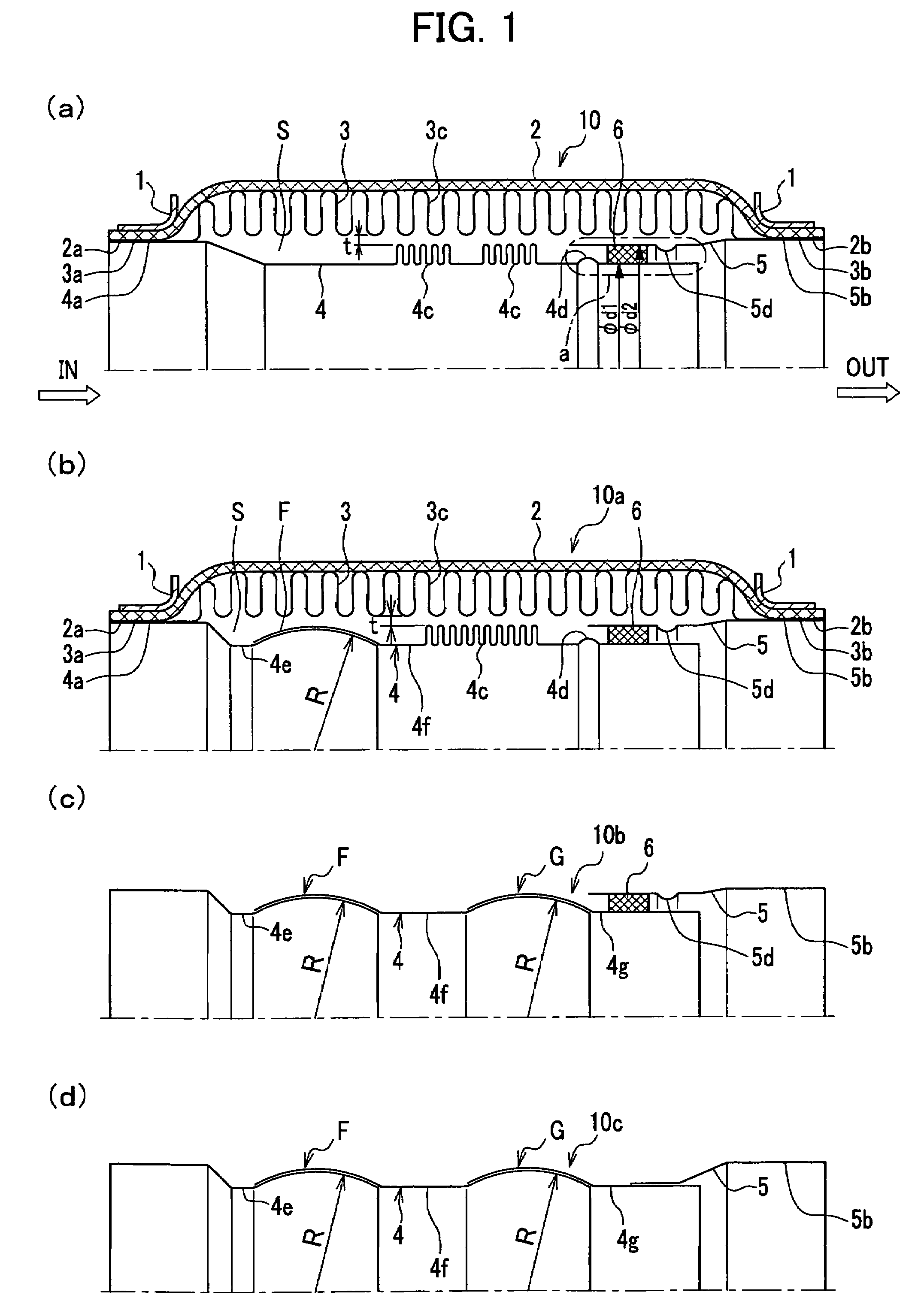

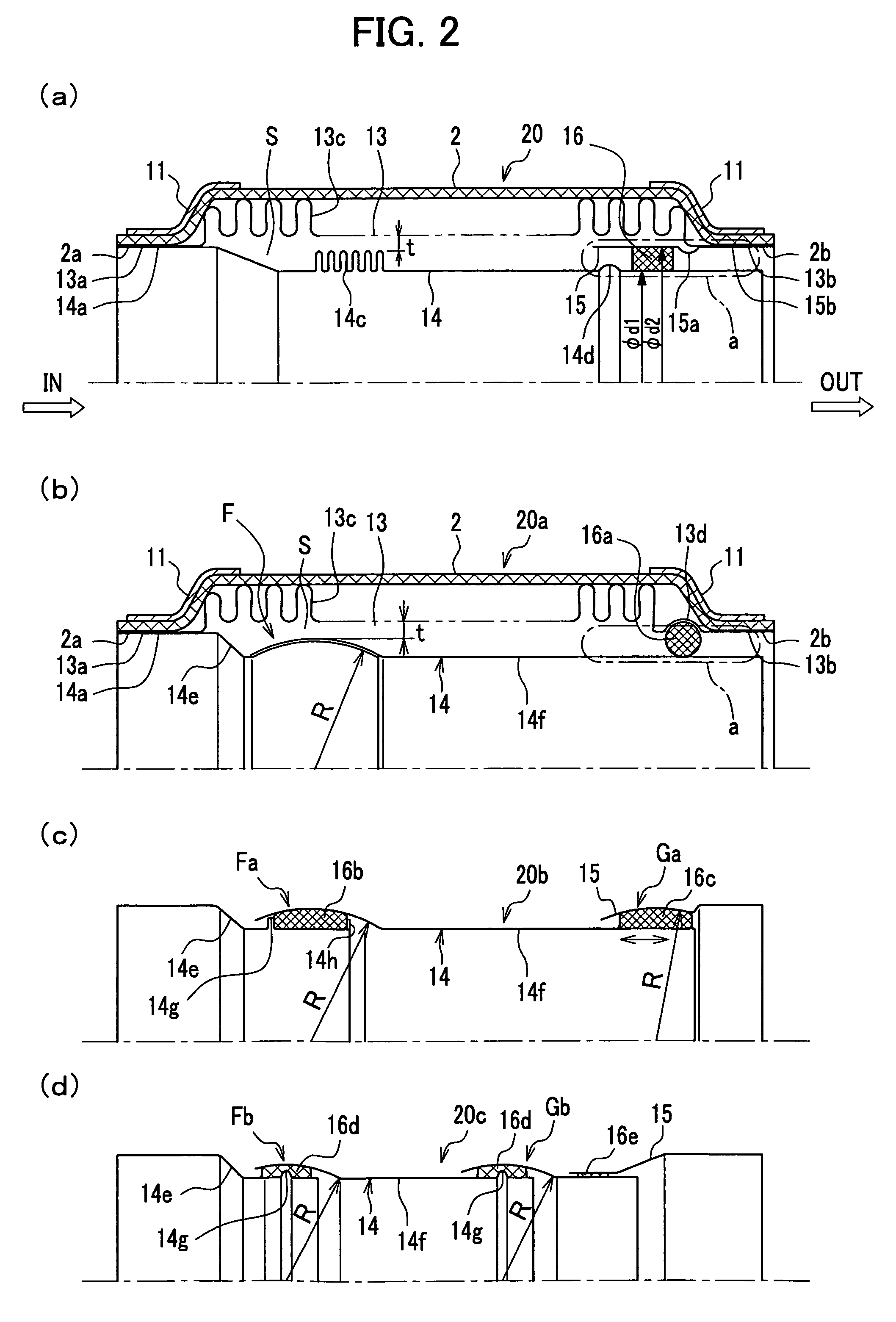

Flexible tube

InactiveUS7451785B2Improve abilitiesIncreased durabilityExhaust apparatusSilencing apparatusBiological activationCatalytic converter

A flexible tube 10 of the present invention is disposed downstream of a exhaust path from an engine E, and formed of an outer bellows 3 as an outer tube and an inner bellows 4 as an inner tube; pleats 4c,4c of the inner bellows 4 are smaller in depth and pitch than the pleats 3c of the outer bellows 3, and the buffering space S is provided with a gap t between the pleats bottoms of the outer bellows 3 and the pleats tops of the inner bellows 4, and further, a partition 17 that splits the exhaust path is disposed in the inner bellows 4. For this reason, sound insulation effect is improved, and the lowering of the temperature of the exhaust gas is suppressed, leading to quick temperature rise of the exhaust gas to be fed into the catalytic converter, thereby promoting the activation of the catalysts and improving the capability to purify exhaust gas, and the exhaust efficiency can be improved thereby increasing output performance of the engine.

Owner:HIROTEC CORP

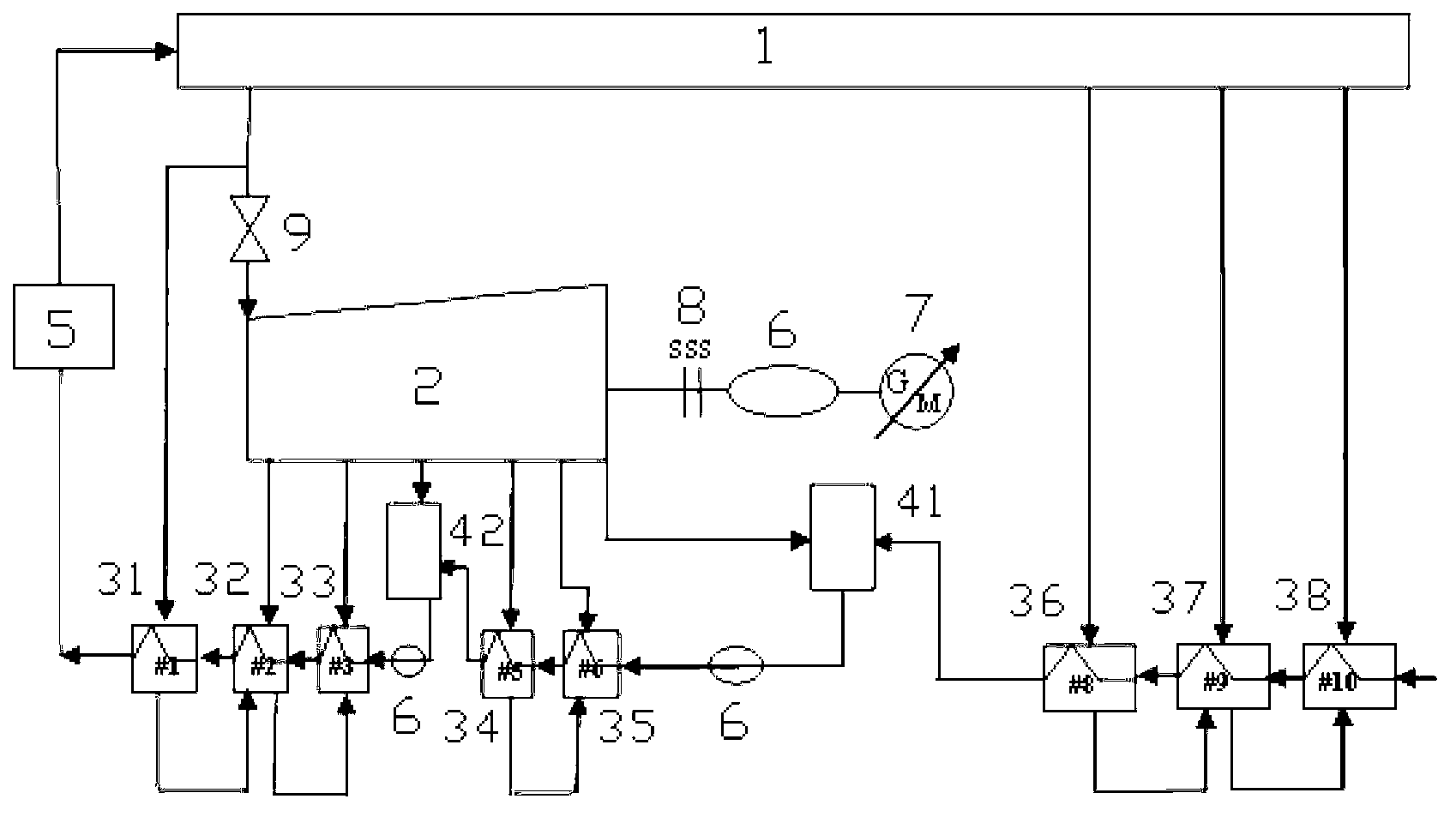

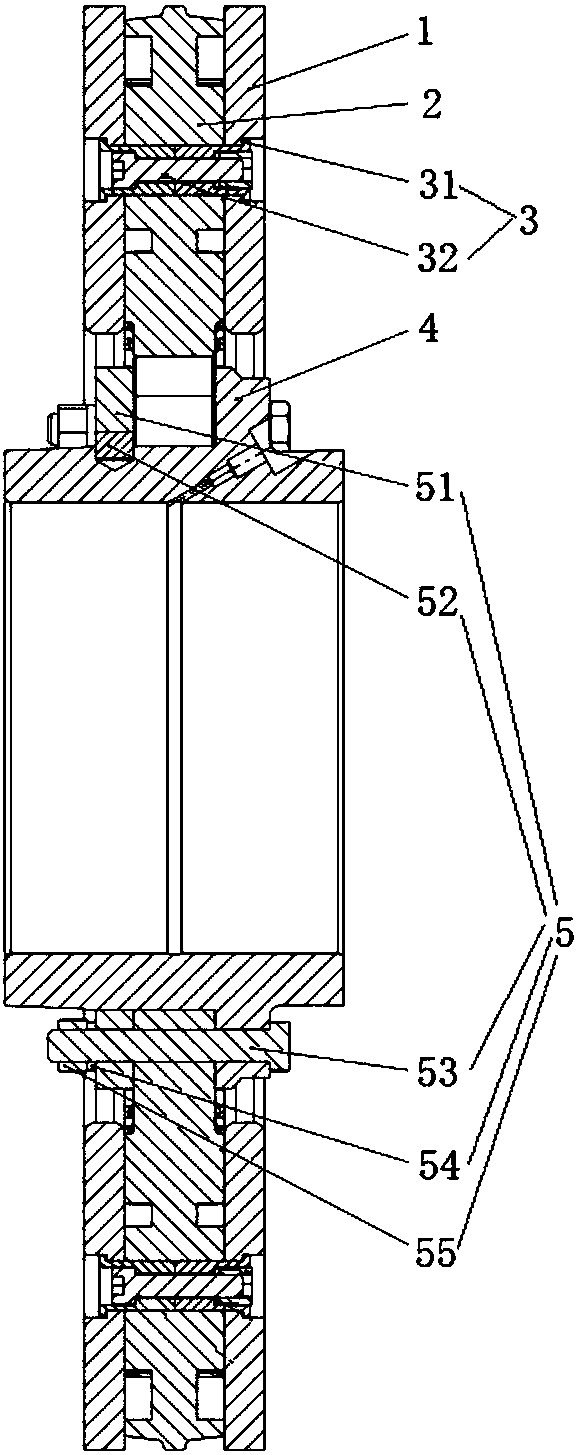

Double-turbine steam thermodynamic system with regenerative steam extraction function

InactiveCN103195521AImprove flow efficiencyReduce axial sizeSteam useCombined combustion mitigationEngineeringDeaerator

The invention provides a double-turbine steam thermodynamic system with a regenerative steam extraction function. The double-turbine steam thermodynamic system comprises a large steam turbine, a small steam turbine and a regenerative cycle unit. The regenerative cycle unit comprises one or a plurality of high-pressure heaters, one or a plurality of medium-pressure heaters, one or a plurality of low-pressure heaters and two deaerators, and a water circulating pipeline is communicated with a boiler via the low-pressure heaters, the low-pressure deaerator, the medium-pressure heaters, the high-pressure deaerator and the high-pressure heaters sequentially. The double-turbine steam thermodynamic system with the regenerative steam extraction function has the advantages that medium-pressure cylinders of the large steam turbine do not need to be provided with steam extraction openings for regenerative steam extraction owing to the double-deaerator structure, medium-pressure cylinder structures of the large steam turbine are greatly simplified, the axial dimension of an integral unit is reduced, and the through-flow capacity of the large steam turbine is improved; and sufficient flow and sufficient power for the small steam turbine can be guaranteed, a complicated logic balance system for the power of the small steam turbine is omitted, and accordingly the integral system is simple and reliable.

Owner:SHANGHAI TURBINE

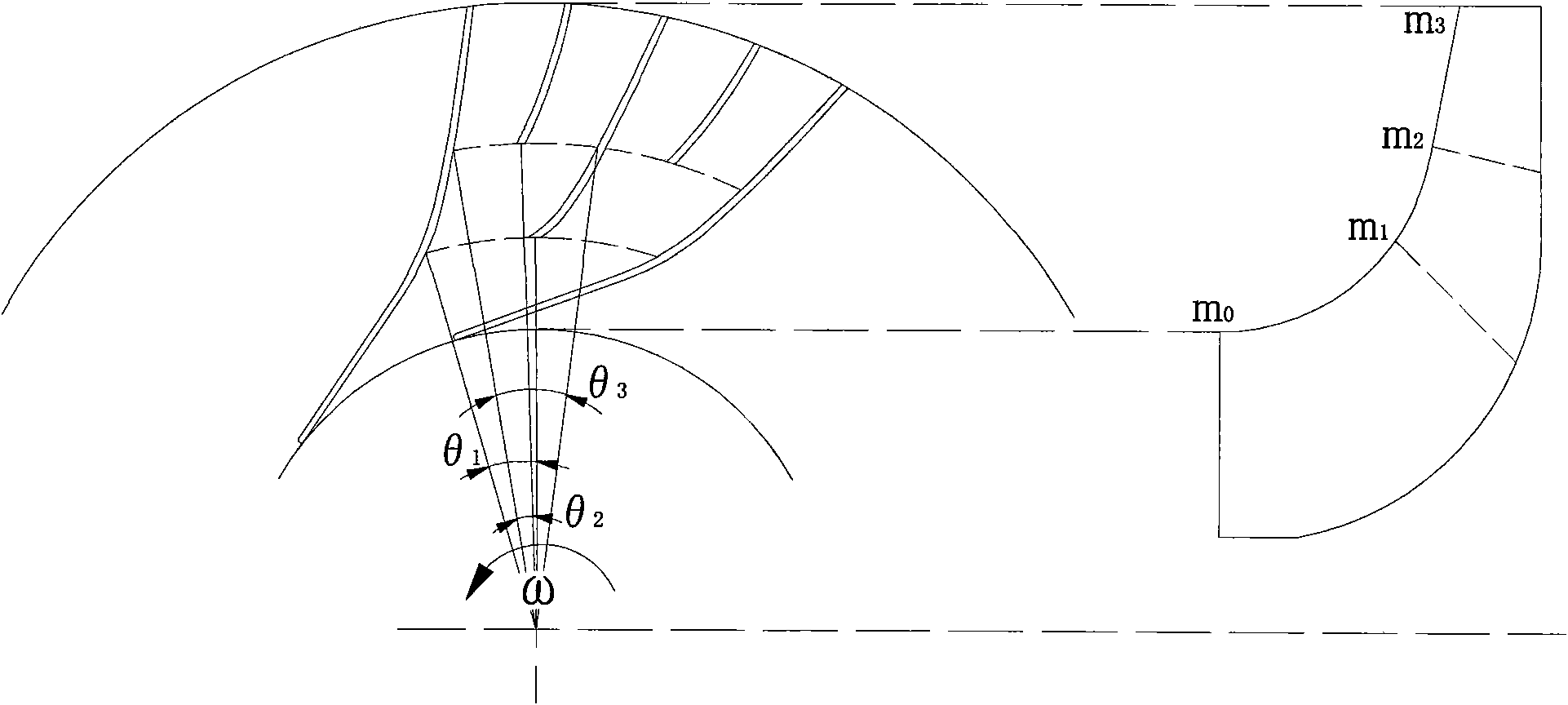

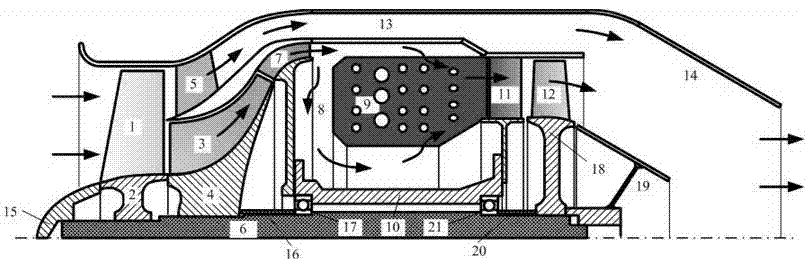

Single rotor minitype turbofan engine adopting axial flow oblique flow serial composite compressing system

ActiveCN103161608AIncrease the overall boost ratioImproved thermodynamic cyclePump installationsJet propulsion plantsImpellerCombustion chamber

The invention provides a single rotor minitype turbofan engine adopting an axial flow oblique flow serial composite compressing system. The structure of the single rotor minitype turbofan engine adopting the axial flow oblique flow serial composite compressing system is that airflow of an outer duct of a turbofan engine and the airflow which enters into a combustor of an inner duct are both supplied by the axial flow oblique flow serial composite compressing system, the axial flow oblique flow serial composite compressing system adopts a combination of both an axial flow fan rotor and an oblique flow compressor rotor, and provides pressure boosting airflow for both the inner duct and the outer duct. The serial axial flow fan rotor is relative to the portion of the inner duct, and directly forms an oblique flow compressor impeller to a serial blade lattice form; a row of stator impellers is arranged on the axial flow fan rotor corresponding to the portion of the outer duct, the air flow is adjusted to the rear direction of the meridian plane through rectification deceleration, and flows into a turbofan engine outer duct bypass along the outer surface of an intermediary cartridge receiver. The single rotor minitype turbofan engine adopting the axial flow oblique flow serial composite compressing system has the advantages of being capable of realizing to provide the pressure boosting airflow for the inner duct and the outer duct by the needs of the turbofan engine, lowering an oil consumption rate of the engine, improving windward side thrust of each unit of the engine, and effectively improving voyage and enhancing load when the single rotor minitype turbofan engine adopting the axial flow oblique flow serial composite compressing system is applied in carriers of unmanned planes, loitering munitions, and the like.

Owner:南京凌日星能源科技有限公司

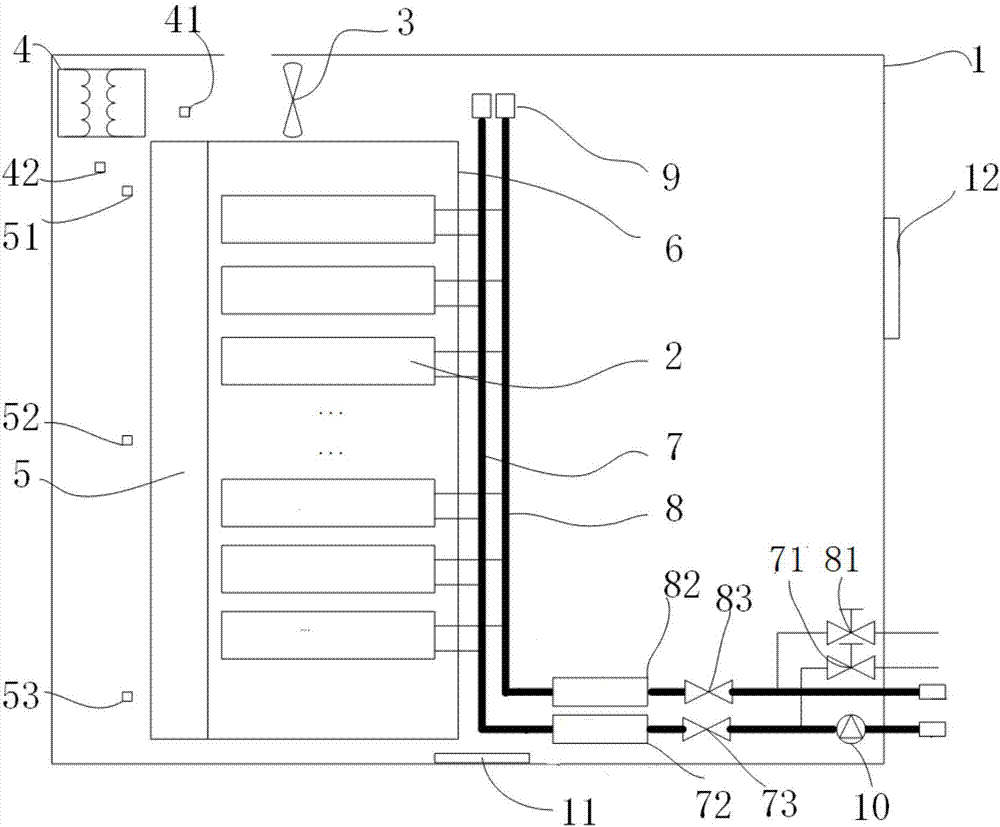

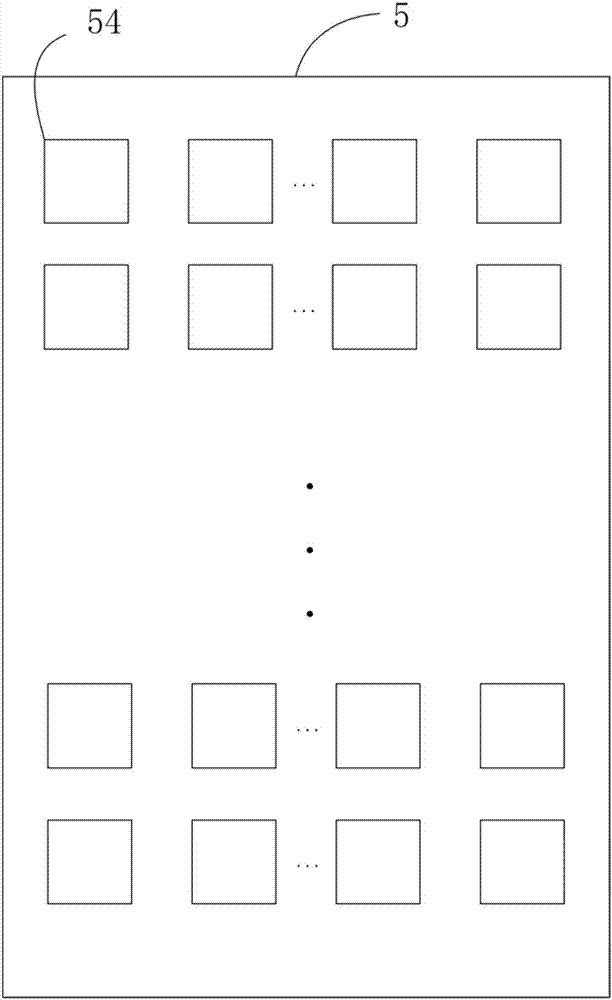

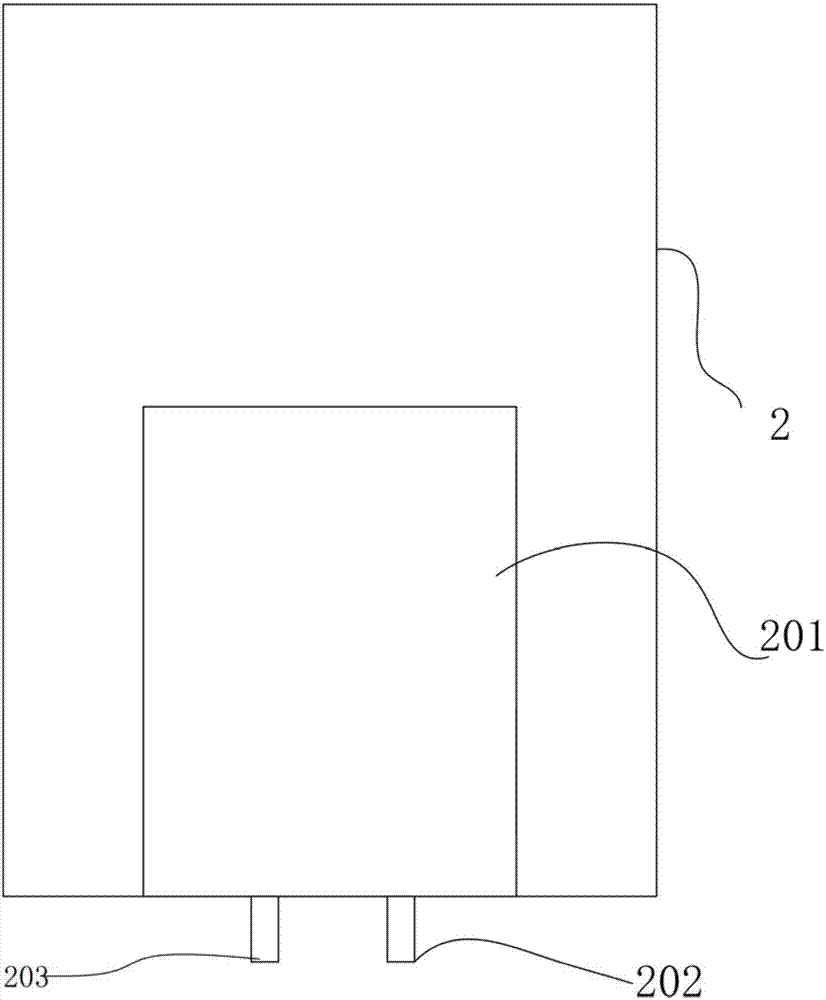

Liquid cooling-air-cooling heat radiation combined intelligent server cabinet and control method thereof

PendingCN107960049AImprove flow efficiencyImprove heat transfer efficiencyCooling/ventilation/heating modificationsData centerEngineering

The invention relates to a liquid cooling-air-cooling heat radiation combined intelligent server cabinet comprising an outer cabinet and an inner cabinet arranged in the outer cabinet; a plurality ofservers are arranged in the inner cabinet; a liquid cooling heat radiation unit is arranged in each sever, and respectively provided a liquid inlet and a liquid outlet; a main liquid supply pipe and amain liquid return pipe are arranged between the inner cabinet and the outer cabinet; all liquid inlets are respectively connected with the main liquid supply pipe; all liquid outlets are respectively connected with the main liquid return pipe; the main liquid supply pipe is provided with a water pump; one ends of the main liquid supply pipe and the main liquid return pipe extend outside the outer cabinet and are connected with an external pipe; an air cooling channel and the liquid cooling pipe are arranged in the cabinet, thus solving the problems that existing most data centers have no standard cabinet when employing liquid cooling; in addition, the air cooling channel is reserved, thus leaving enough design space for many liquid cooling solutions.

Owner:SOUTH CHINA UNIV OF TECH +1

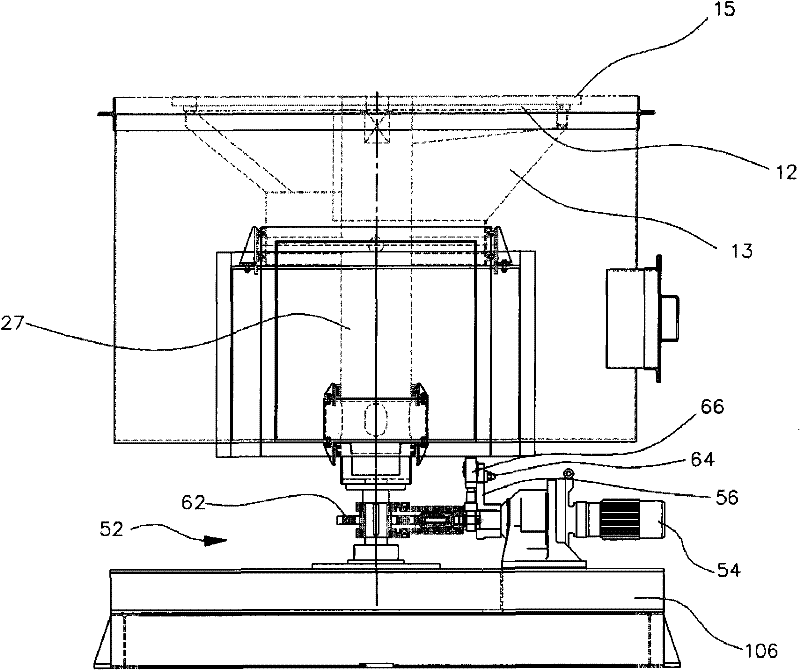

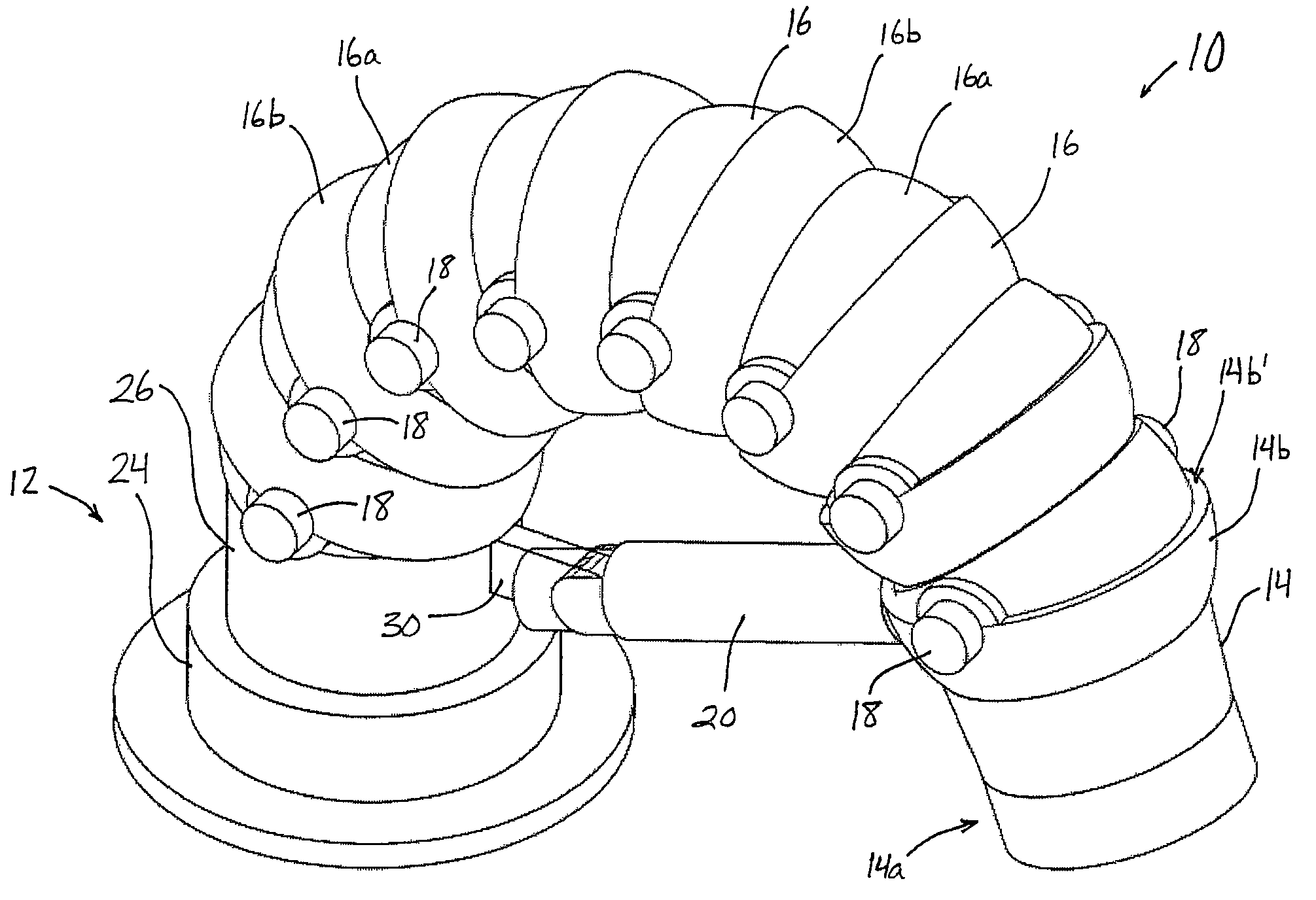

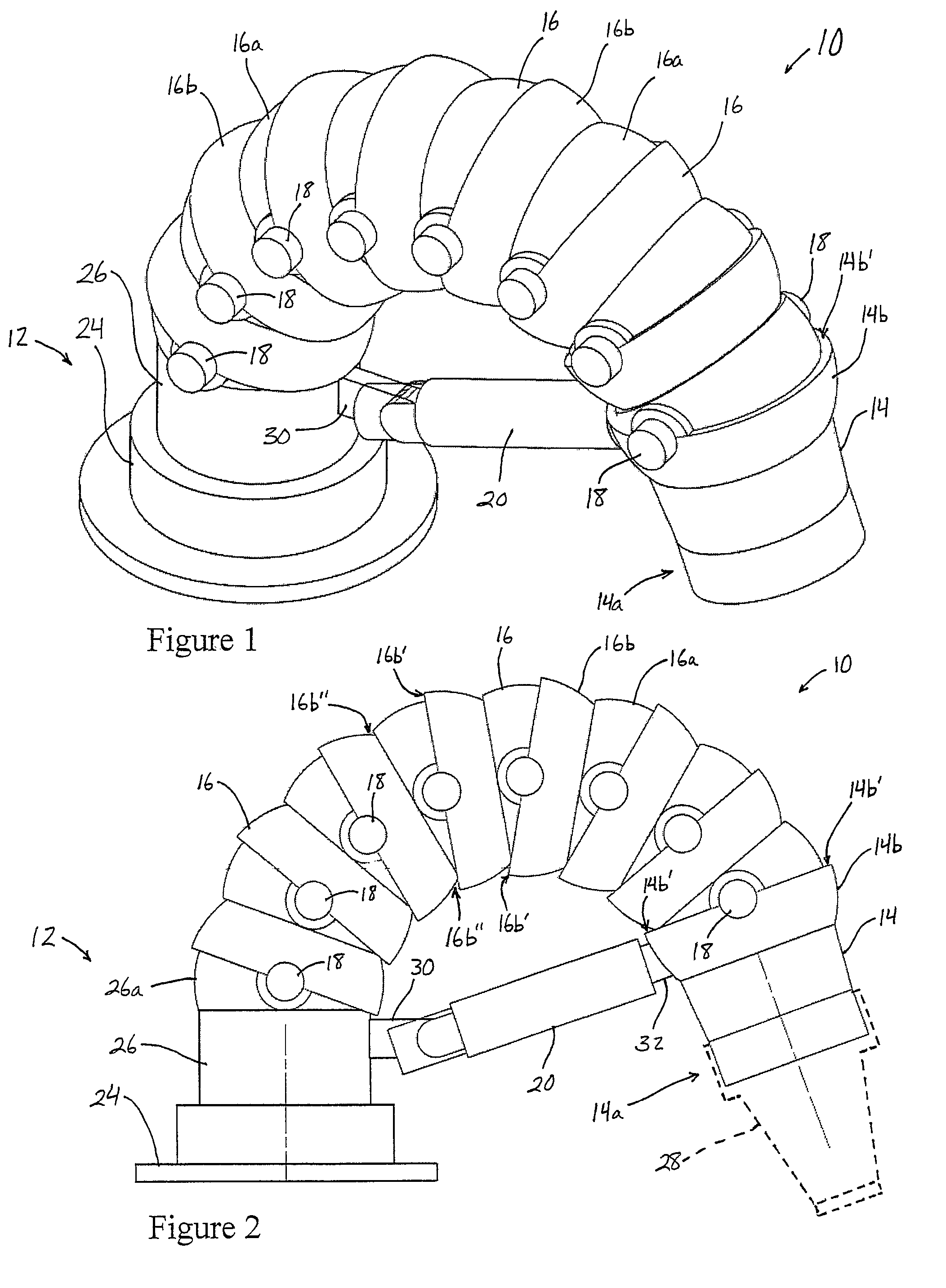

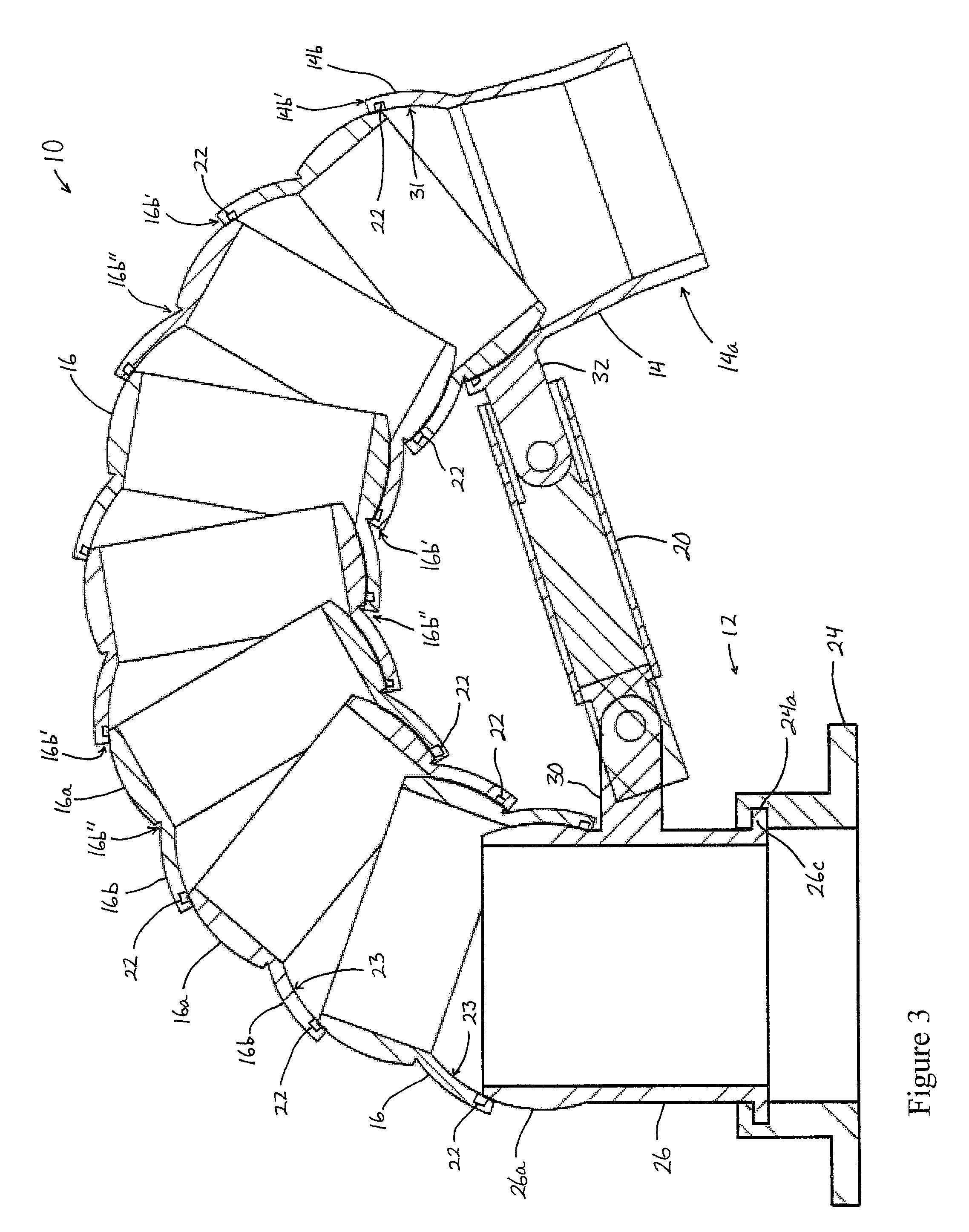

Separate rotary valve assembly for changing air direction of regenerative combustion device and regenerative combustion system including the same

InactiveCN102261663AAvoid damageReduce frictional resistanceIndirect carbon-dioxide mitigationIncinerator apparatusCircular discCombustion system

The invention provides a separable rotary valve assembly for shifting wind of a heat accumulating burning device, which configure an upper portion rotating distributing board of a rotor of the separable rotary valve assembly detachably installed on the heat accumulating burning device and disposed in a wind shifting device to a be hollow circular disc, particularly, clean gas injecting holes are disposed along the circumferential direction of the upper portion rotating distributing board to supply clean gas along the whole circumferential direction of the upper portion rotating distributing board, and a clean gas supply channel is disposed along the upper surface of a rotating gas distributing chamber at the lower part of the upper portion rotating distributing board, a fine gap within a set range disposed between the upper portion rotating distributing board and a lower portion fixed distributing board of the distributing chamber fixedly disposed on the upper portion rotating distributing board is kept to prevent friction loss, and a gas curtain is formed via the fine gap ejecting the clean gas, thereby providing a cooling function of absorbing high heat, also, a gap fine adjusting device is additionally added at the lower portion of the rotor to adjust the above fine gap.

Owner:ACE TECH

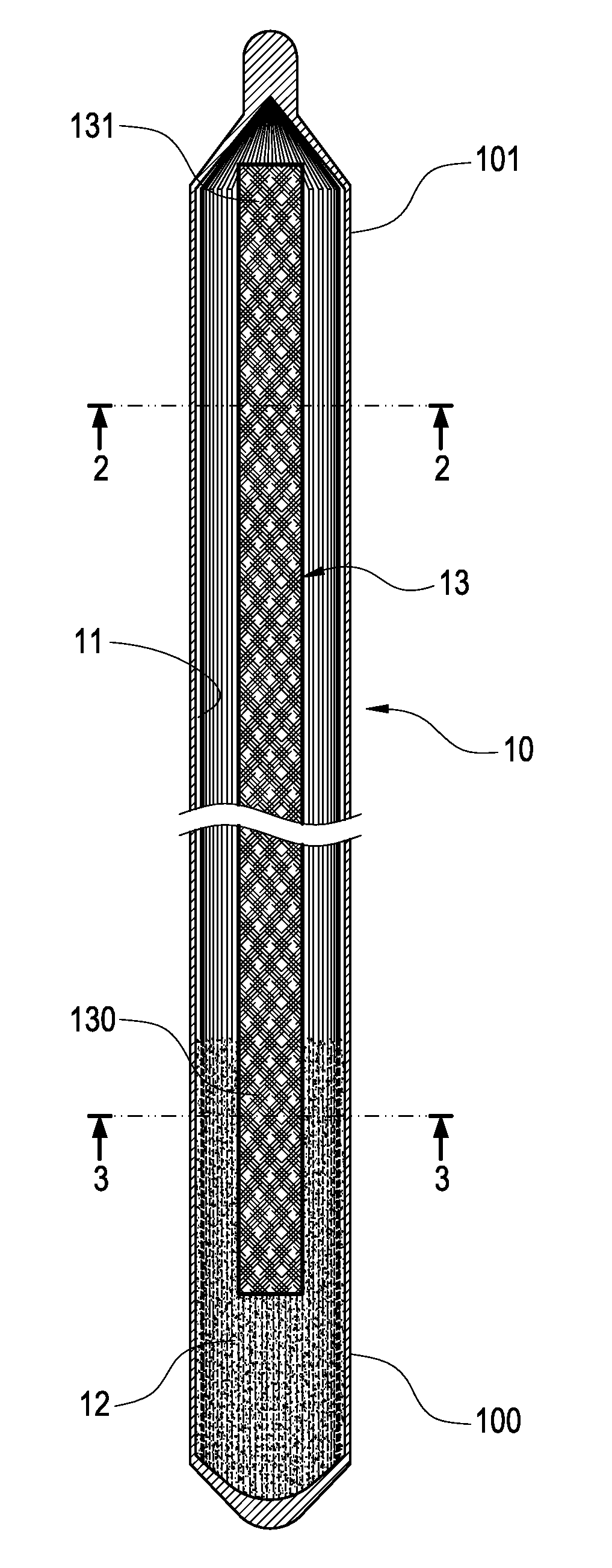

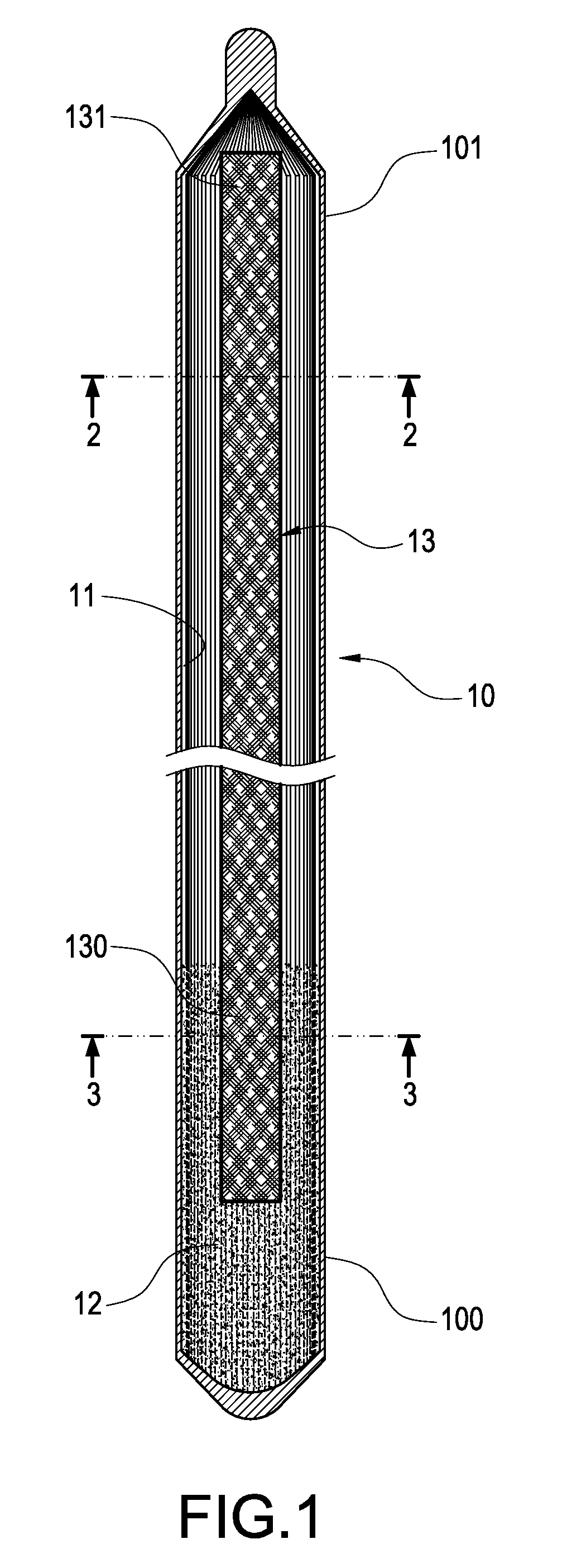

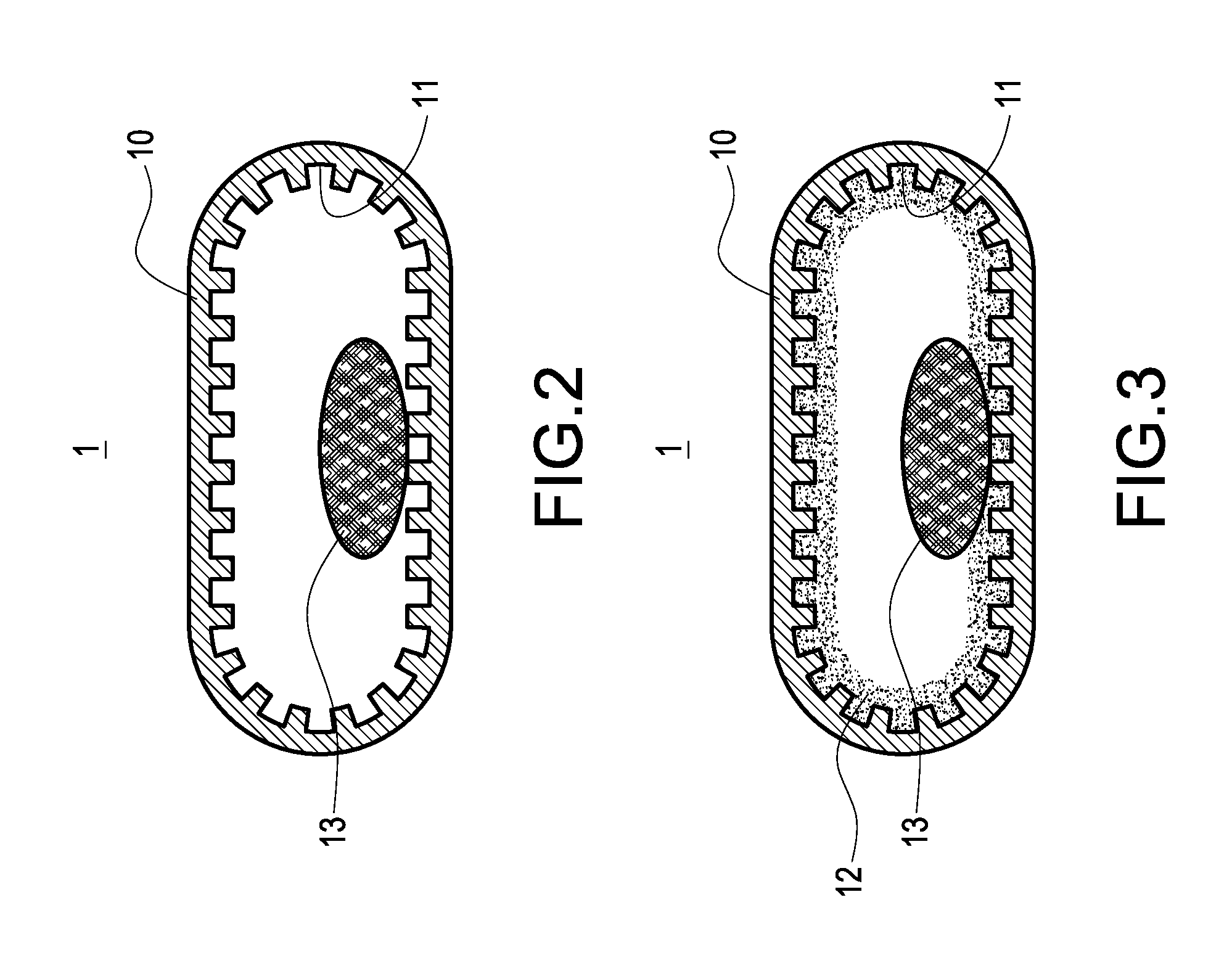

Heat pipe with composite wick structure

InactiveUS20120048517A1Improve efficiencyImprove flow efficiencyIndirect heat exchangersFiberEngineering

The heat pipe of the invention includes a tube in which an evaporating portion and a condensing portion are defined; a grooved wick longitudinally and entirely disposed on an inner wall of the tube and communicating the evaporating portion with the condensing portion; a porous wick only disposed on the inner wall of the evaporating portion and covering the grooved wick in the evaporating portion; and a fiber wick in a shape of a strip, whose one end connects the porous wick and whose the other end longitudinally extends to the condensing portion.

Owner:KUNSHAN JUZHONG ELECTRONICS

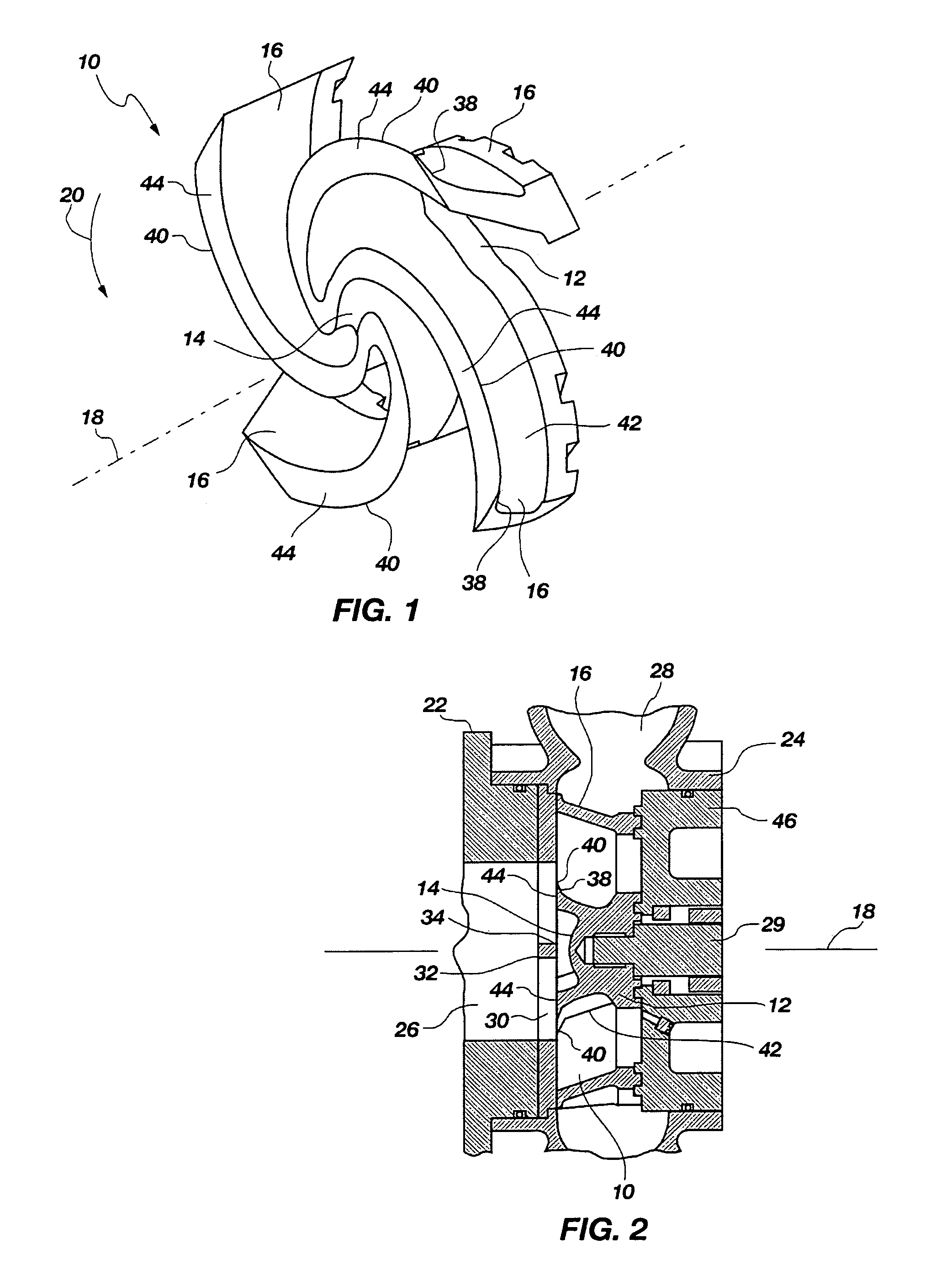

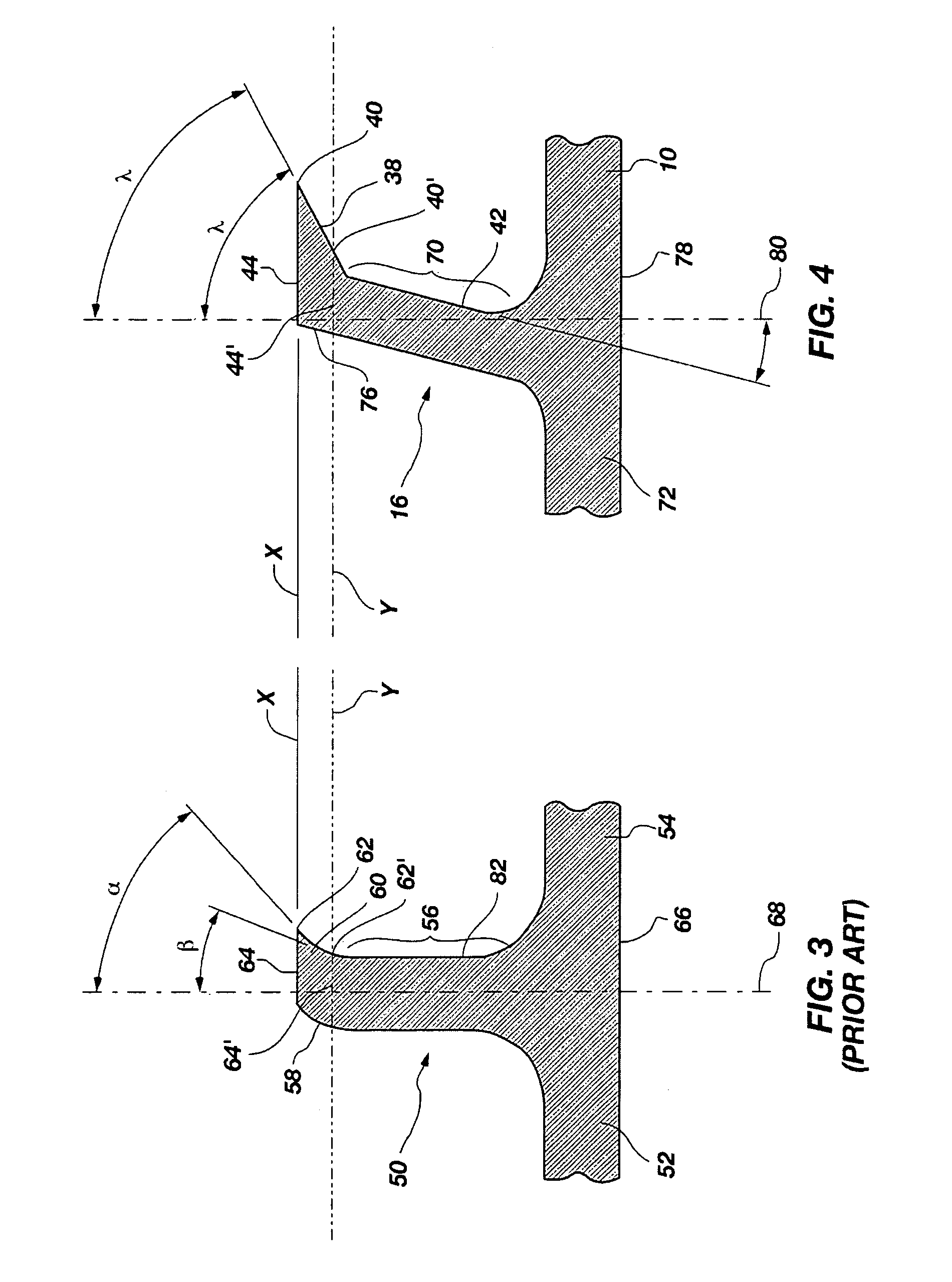

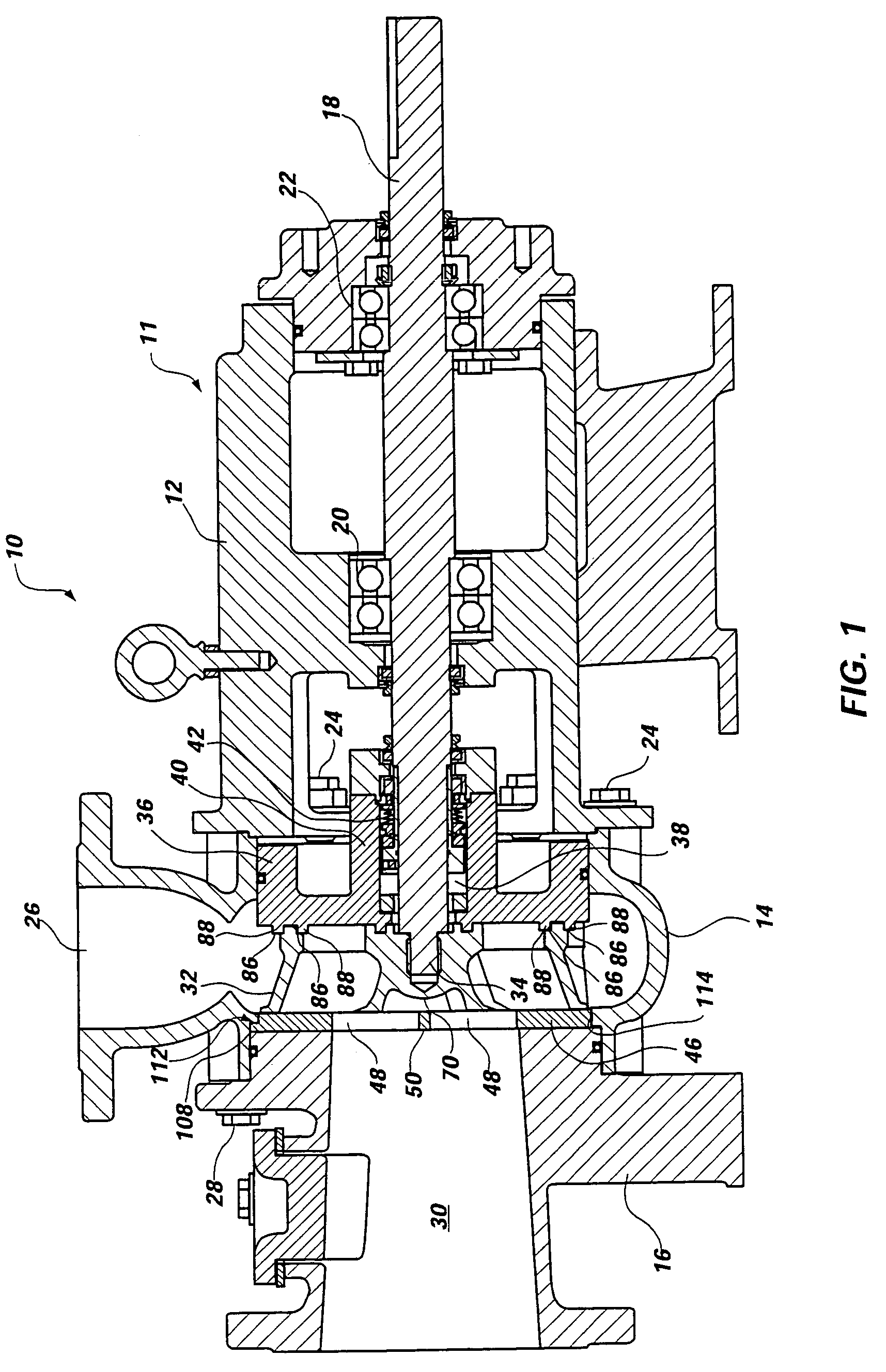

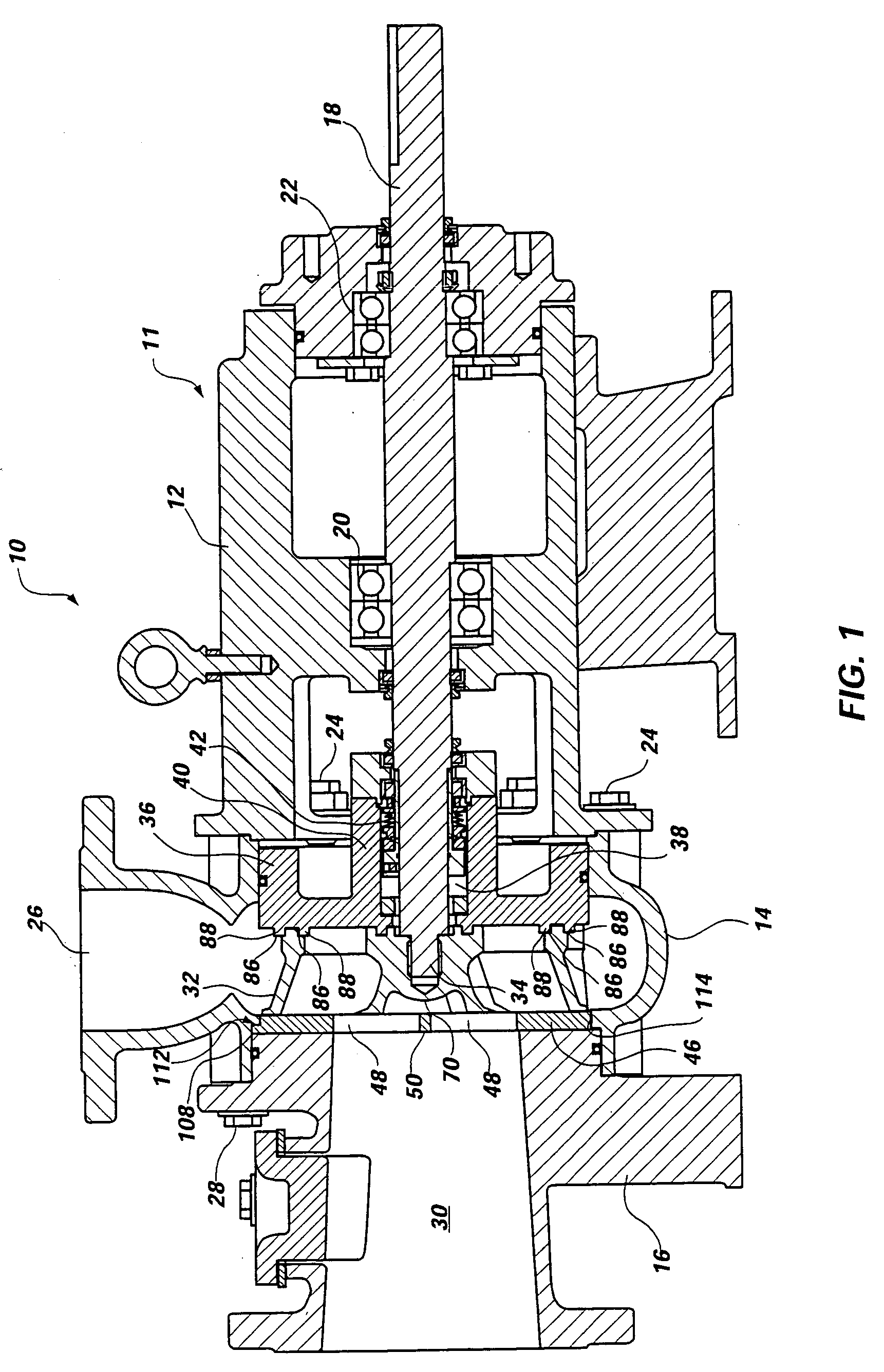

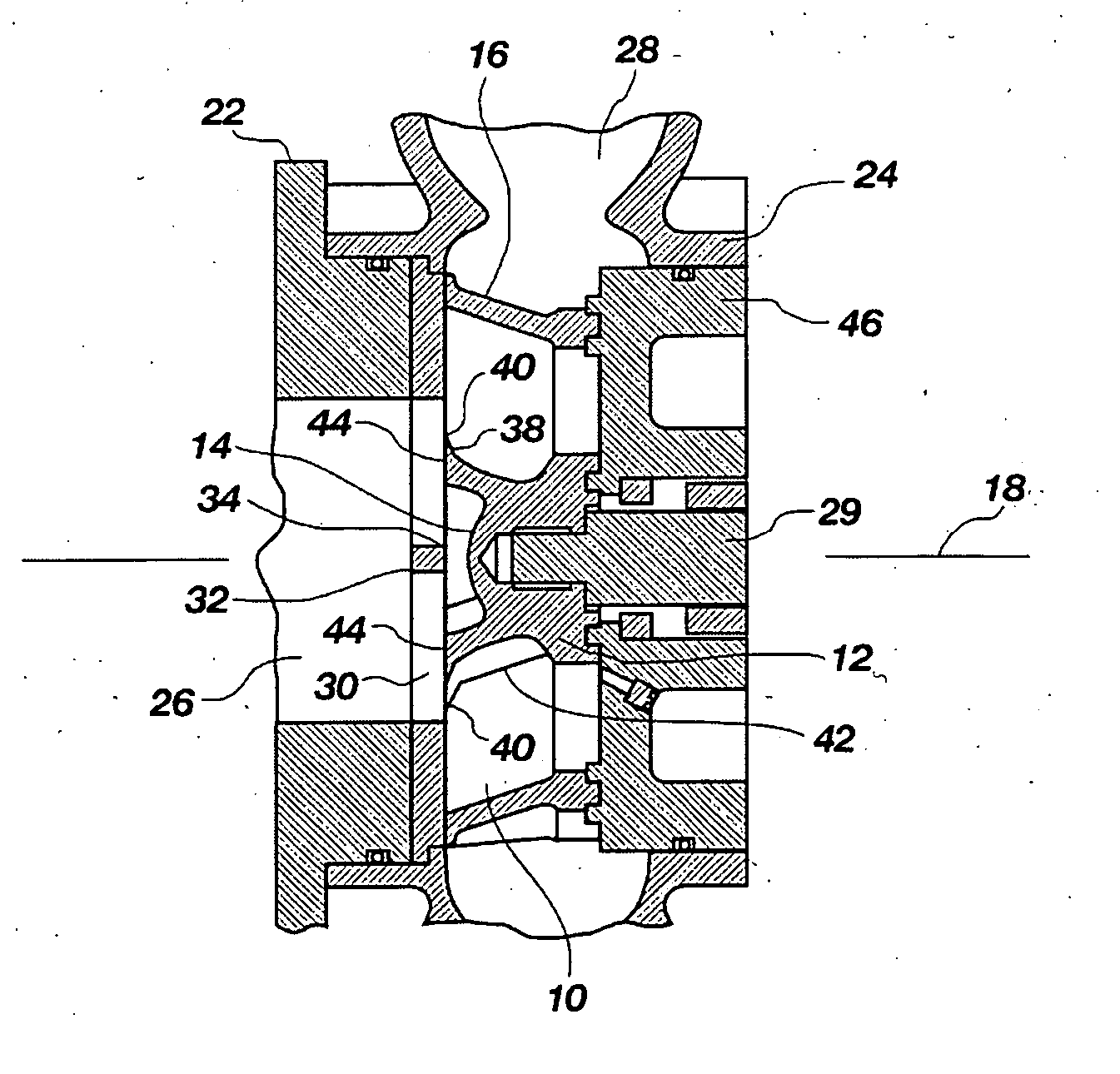

Impeller vane configuration for a centrifugal pump

InactiveUS7114925B2Improves hydraulicsAggressive profileSpecific fluid pumpsPropellersLeading edgeContinuous use

Owner:ENVIROTECH PUMPSYSTEMS INC

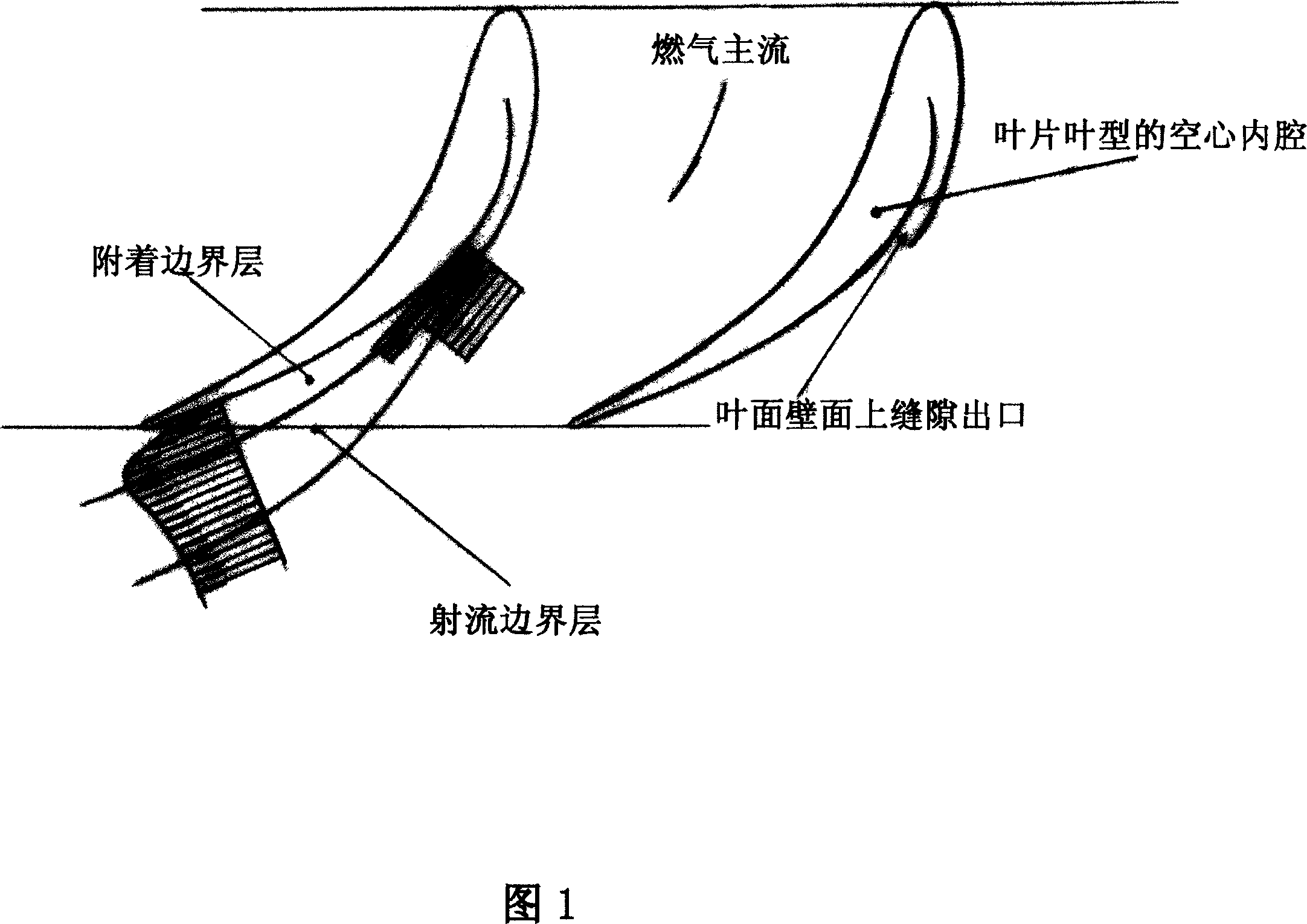

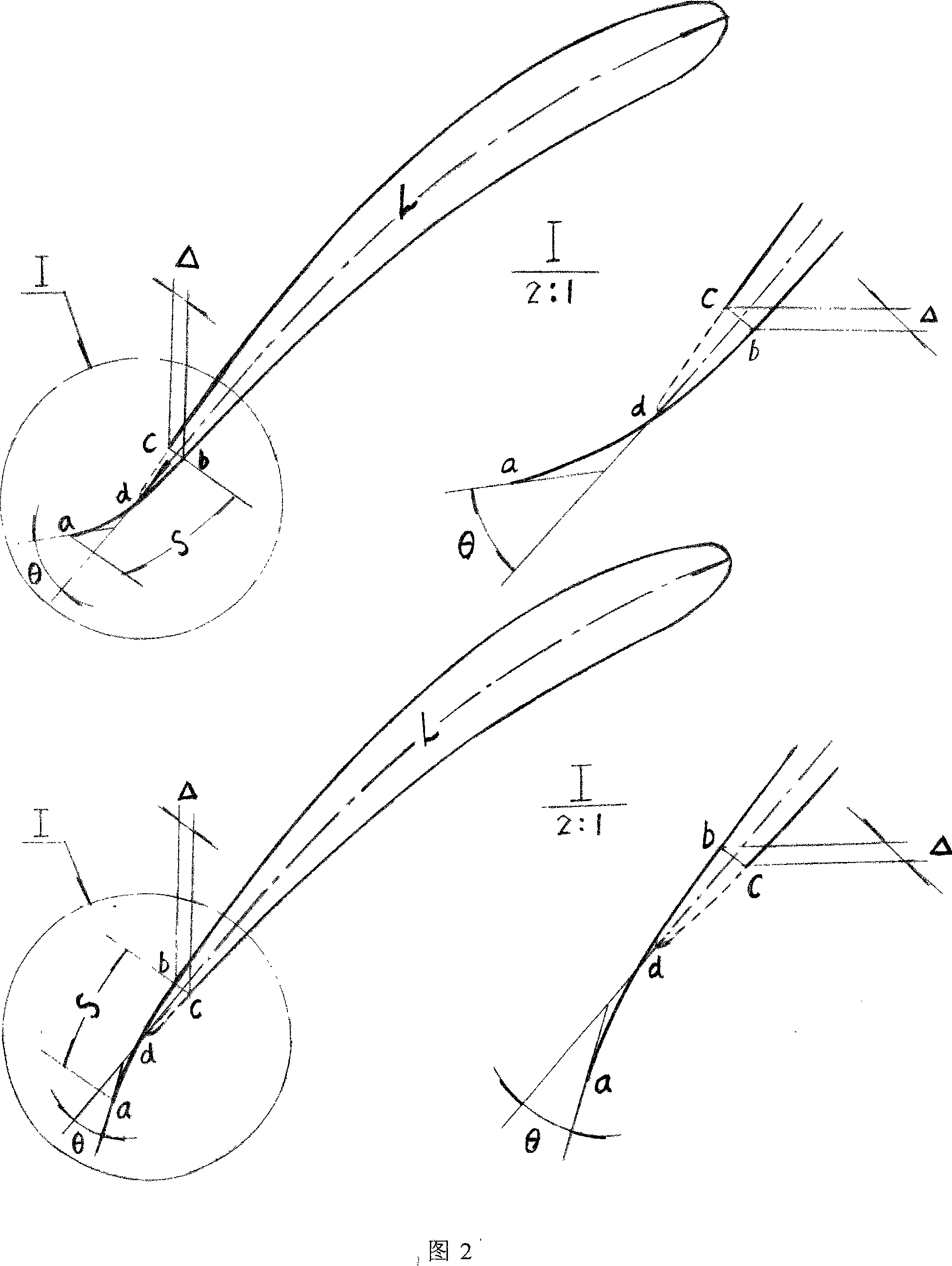

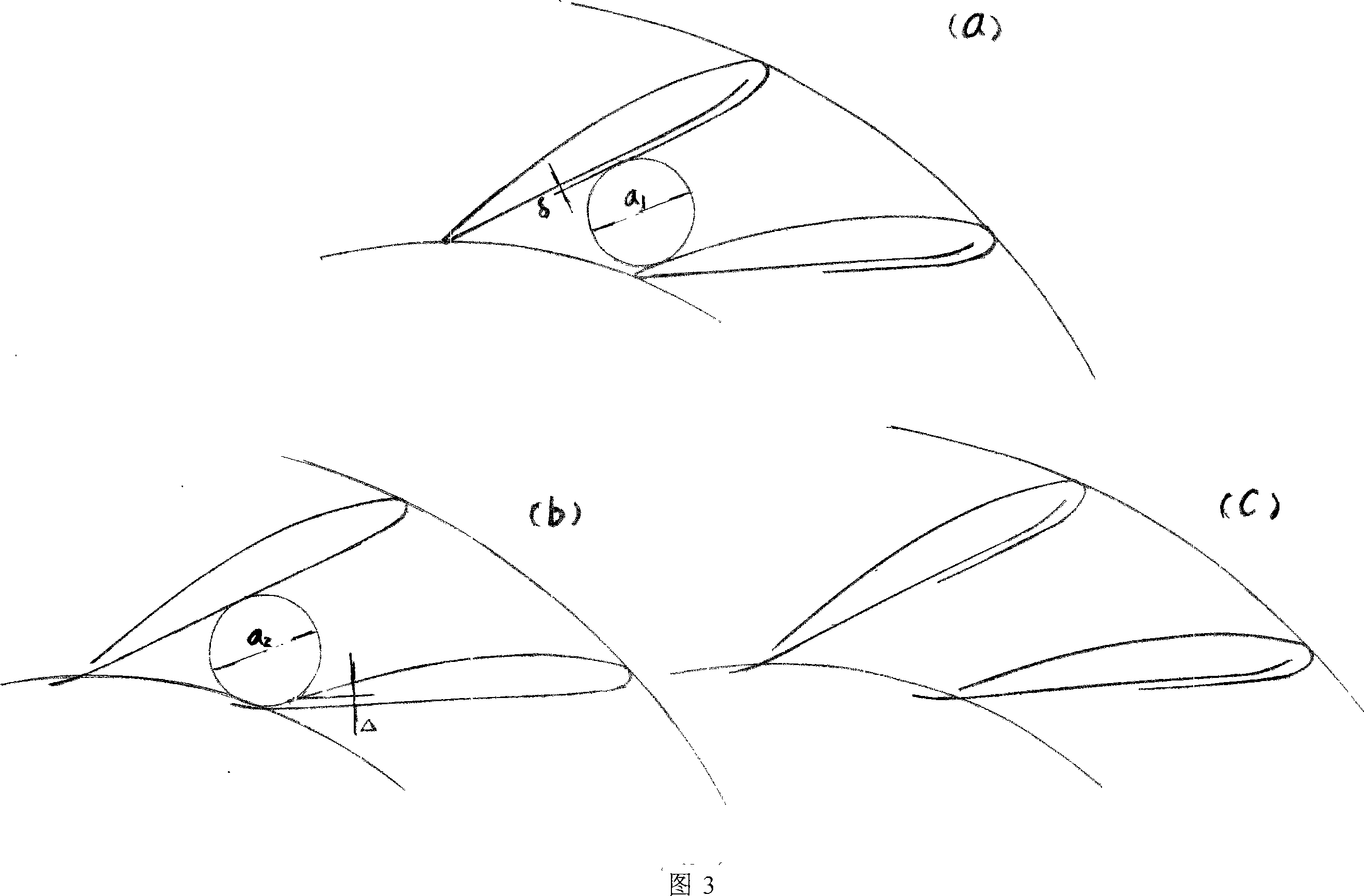

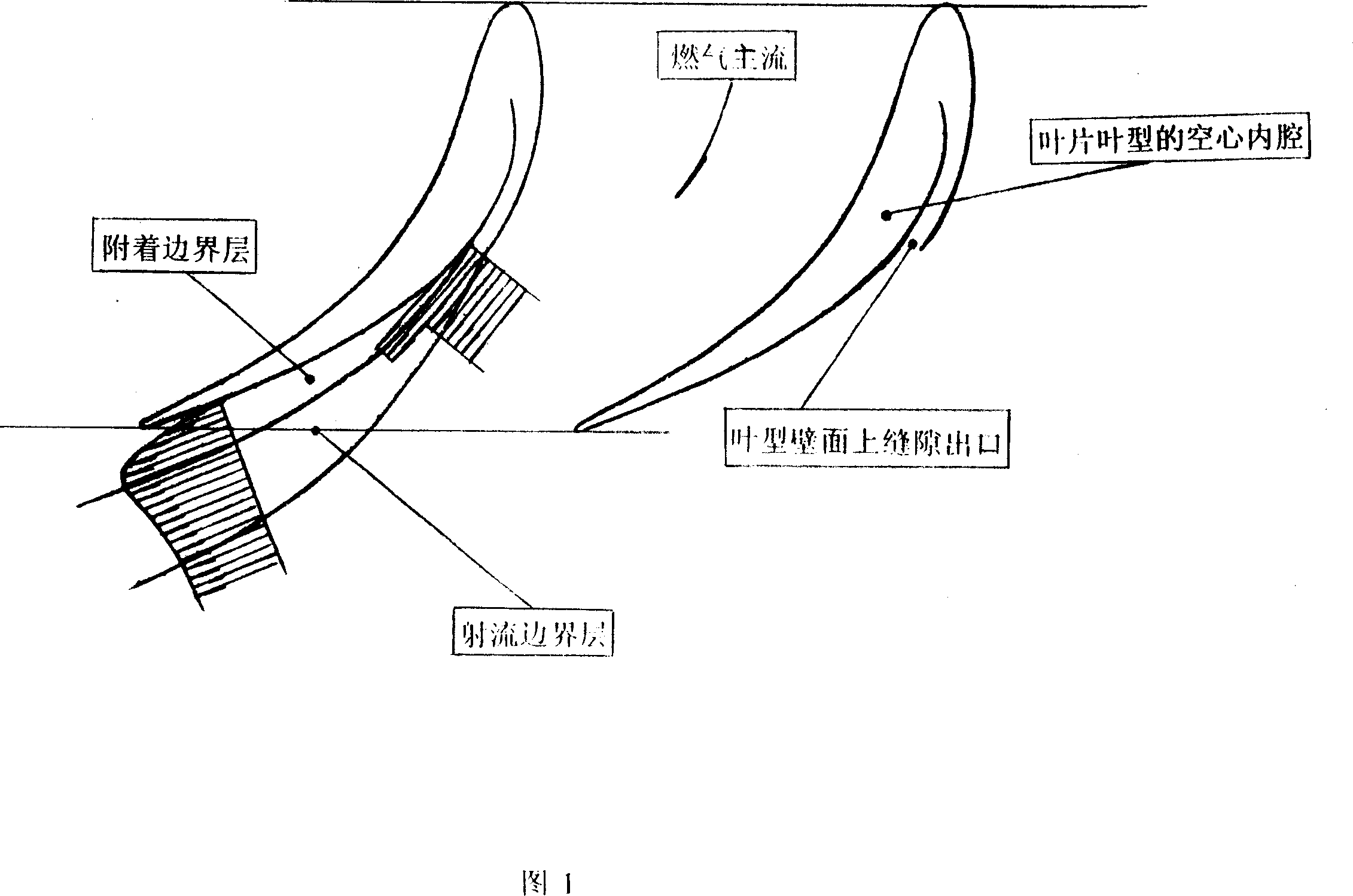

Outlet flowing intersecting surface changing adjustable turbo nozzle ring

InactiveCN101113678ALow efficiencyLarge leak lossInternal combustion piston enginesEngine componentsExternal energyTurbocharger

The invention relates to a turbine nozzle ring used in turbochargers. Compressed air from an outlet of an air compressor of the turbocharger and / or an external source goes through a hollow internal cavity of the nozzle vanes or a hollow sandwich near the internal wall of an intake pipe of a vane-less spiral case and blows directly to the nozzle vane ring or main burning gas flow at a flow passage and / or an outlet of the vane-less spiral case through a ventilation groove gap cut between a vane-shaped back side (or front side) and / or a rear margin part or through circular arc-shaped ventilation gap of the outlet of the hollow sandwich near the zero-degree section of the tip of the vane-less spiral case, making the mixed air of blowing flow from the gaps and the main flow change the flow direction at the outlet of the nozzle ring and causing the change of the flow angle (namely flow section) at the outlet. The invention has the advantages of wide range of control simple structure, low cost, safety and reliability, high efficiency, straightforward control and being applicable for turbochargers and being capable of making use of external air, additional pressure and external energy to supply auxiliary power.

Owner:孙敏超 +1

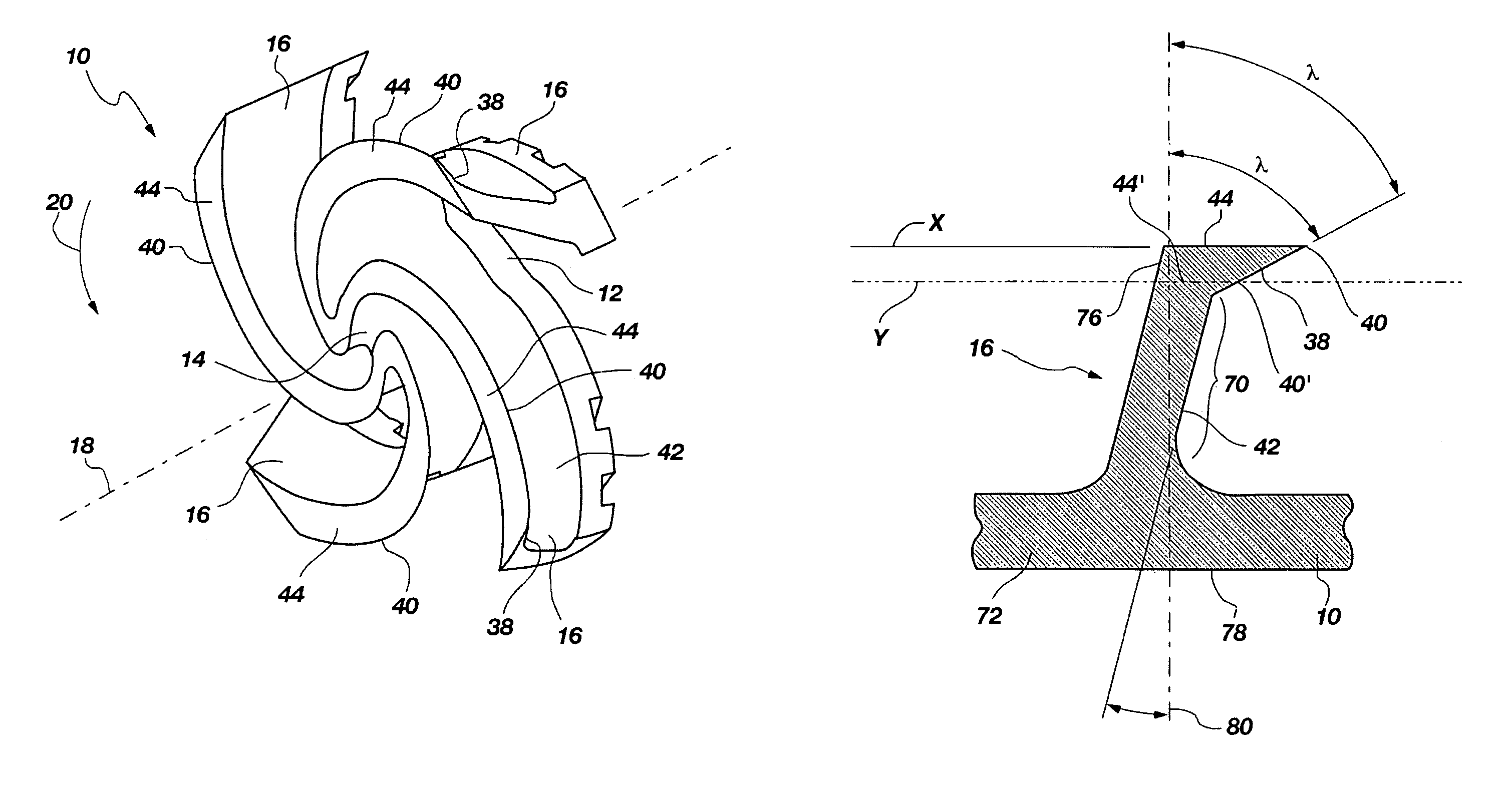

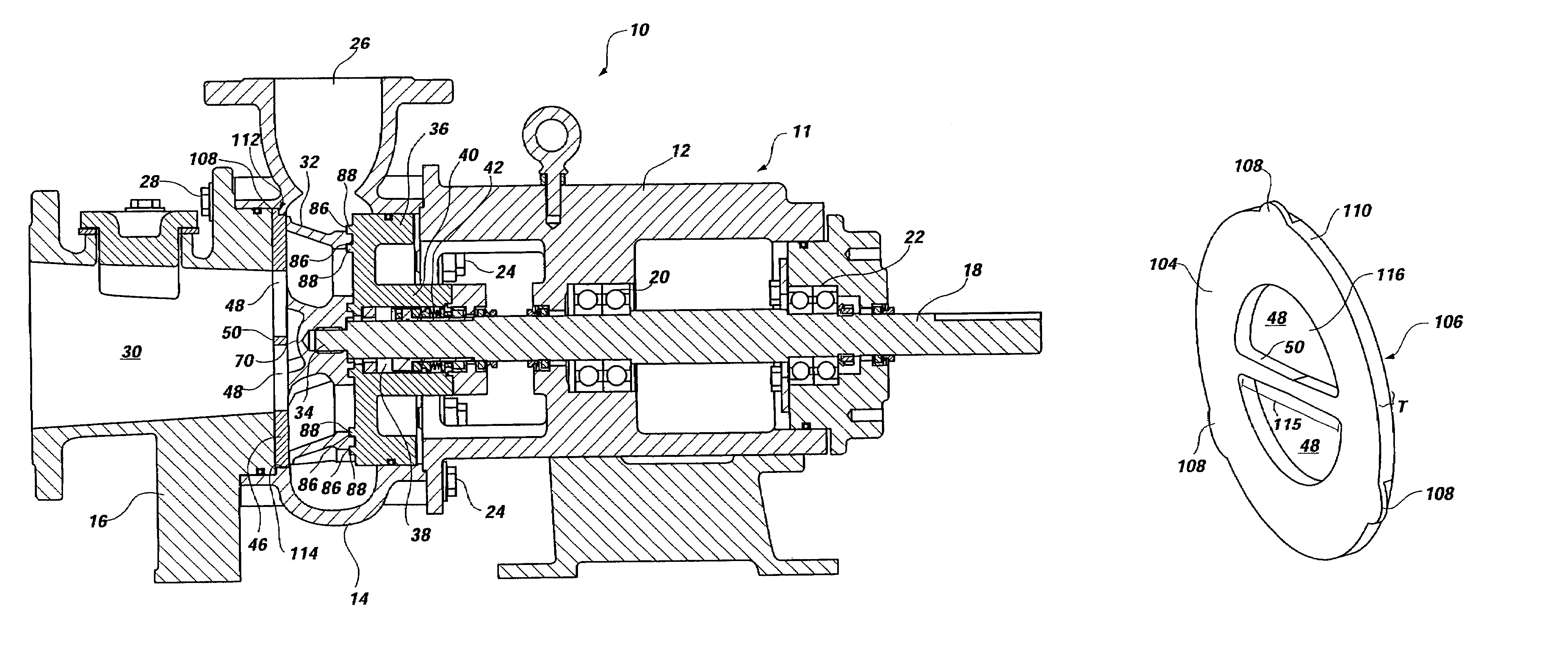

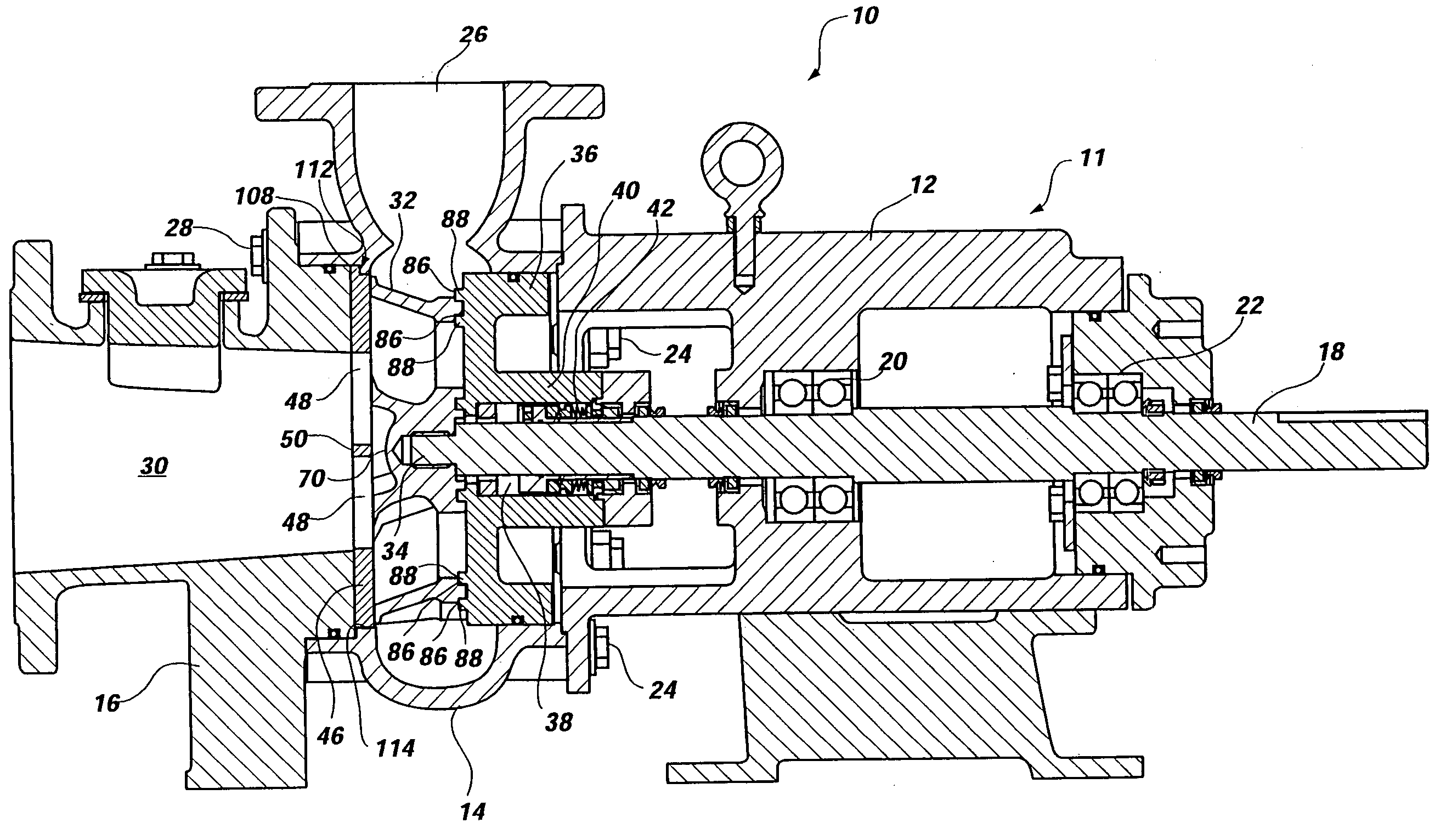

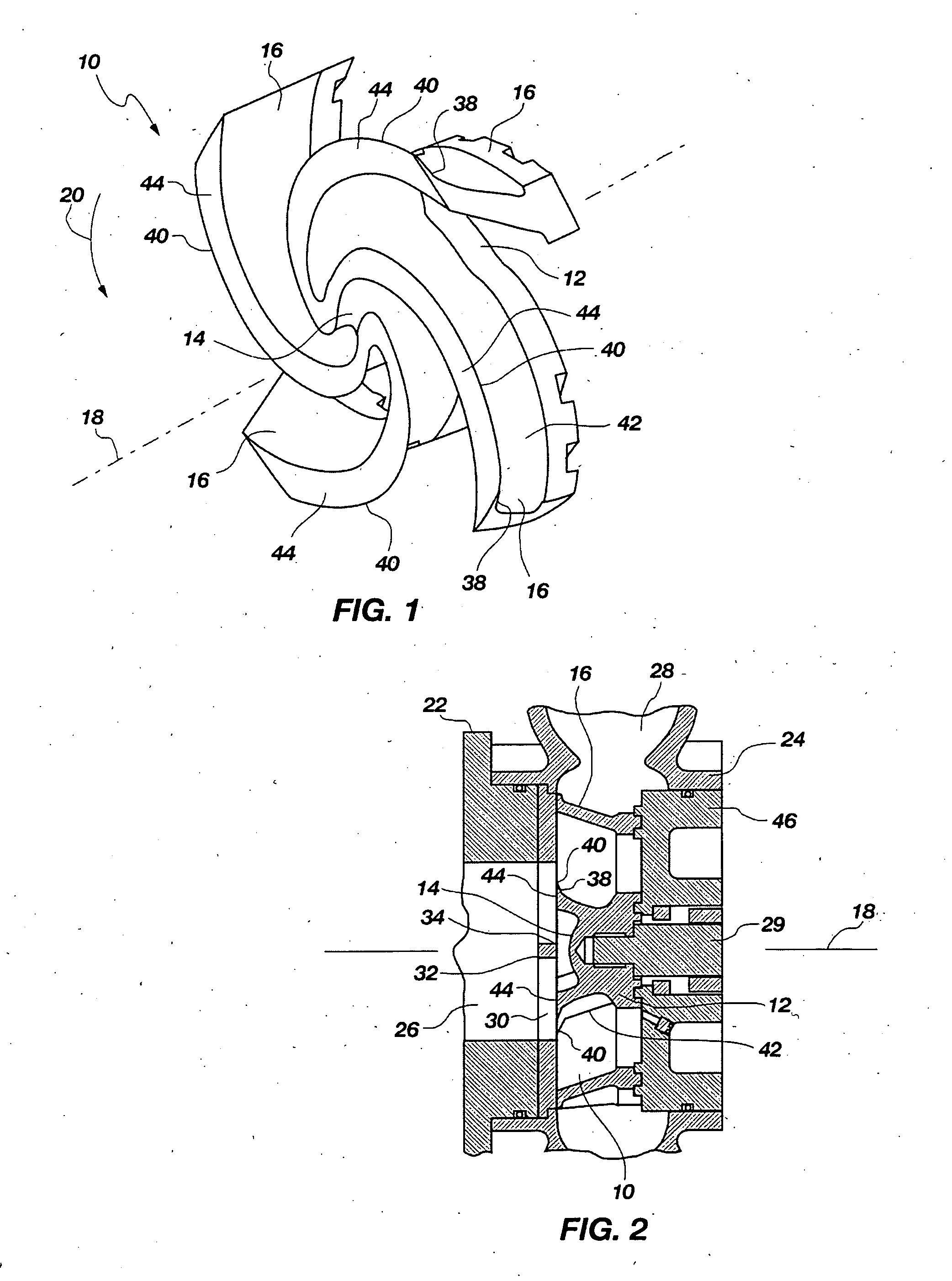

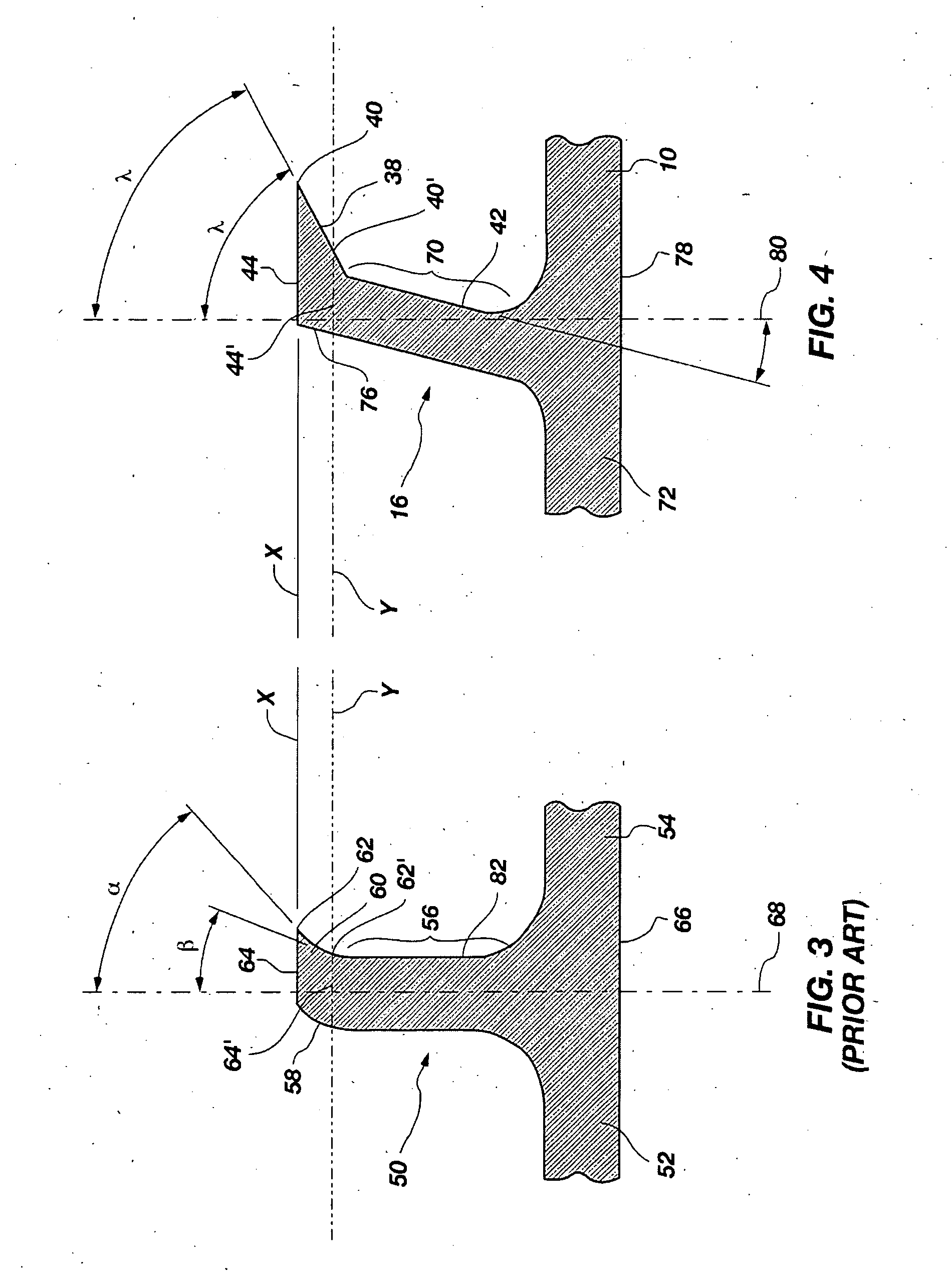

Pump impeller and chopper plate for a centrifugal pump

InactiveUS7080797B2Improve flow efficiencyImprove efficiencySpecific fluid pumpsGas current separationChopper pumpsEngineering

A centrifugal pump of the chopper type is disclosed which is structured with a chopper plate and impeller that are configured with an open eye or “hubless” arrangement such that processing of solids through the pump does not result in clogging of solids at or near the center of the impeller, thereby producing a dead zone. Because the configuration of the chopper pump of the present invention avoids the development of a central dead zone or clogging of solids, and provides for flow of solids and fluid through the eye of the impeller, pump efficiencies are markedly improved.

Owner:ENVIROTECH PUMPSYSTEMS INC

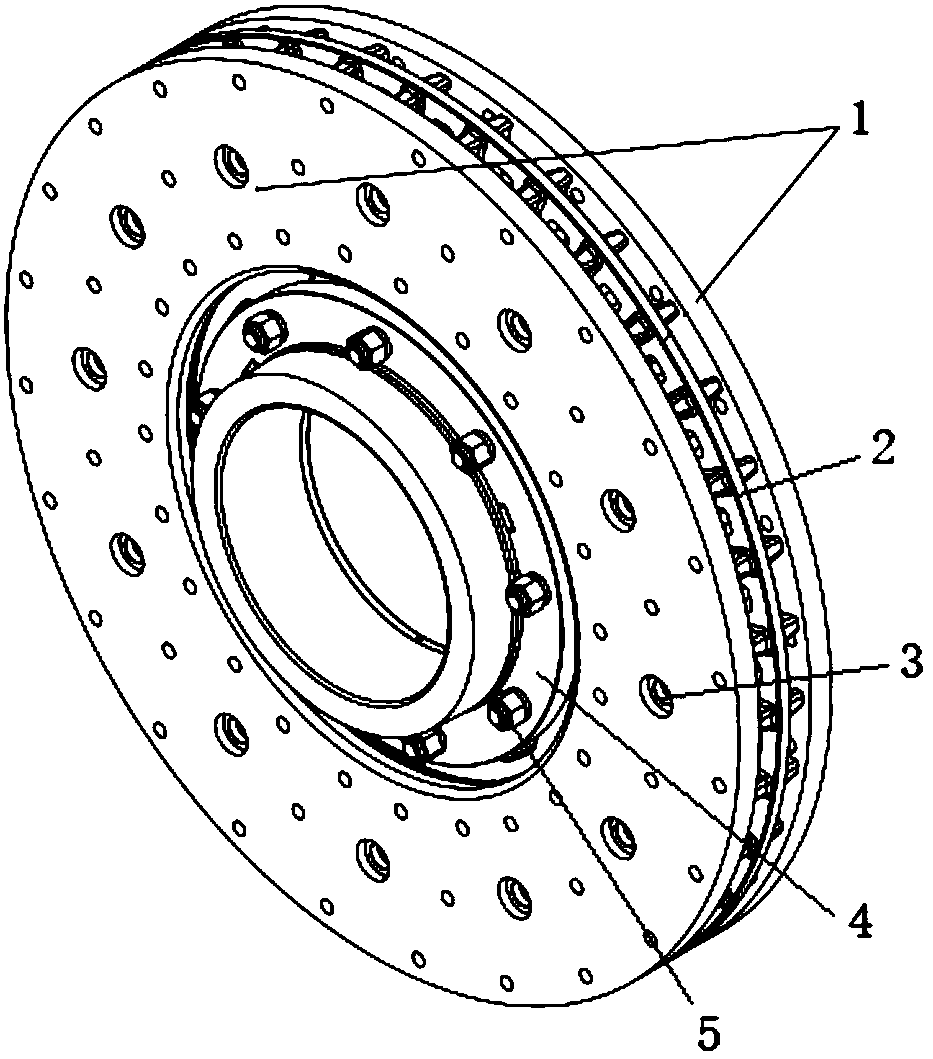

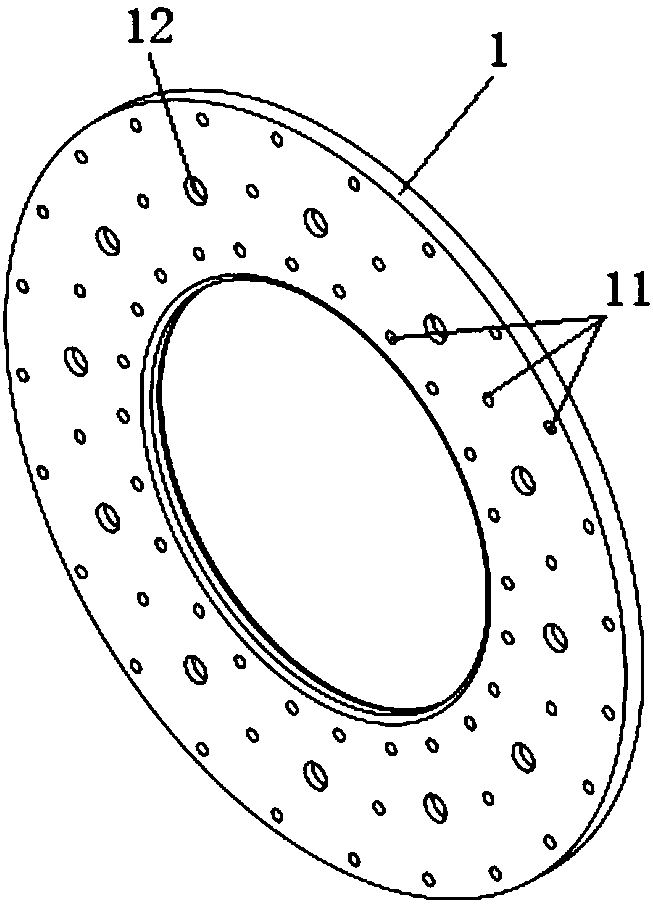

Shaft-mounted brake disc module for high-speed train

PendingCN108317194ASolve processing technology problemsSolve the cooling problemBraking discsTemperature resistanceEnergy consumption

The invention discloses a shaft-mounted brake disc module for a high-speed train. The module comprises brake discs, a support disc and a disc hub; two sets of brake discs are provided, are coaxially laminated on the disc surfaces on the two sides of the support disc, and are clamped and locked with the support disc through first connecting structures; the brake discs are composite material brake discs with smooth disc surfaces on two sides; heat dissipating structures are arranged on the disc surfaces on the two sides of the support disc, and are laminated with the brake discs to form heat dissipating channels; and a connecting flange is arranged on an inner ring of the support disc, and is fixedly sleeved with the disc hub through a second connecting structure. Compared with a traditionaloverall brake disc, the module has the characteristics of simple structure, reliable connection, high-temperature resistance, convenience to maintain, light weight and good braking effect, reduces the energy consumption in operation and braking of the high-speed train, realizes application of a composite friction material to a high-speed train braking system, and greatly saves the high-speed train company operation and maintenance costs.

Owner:HUNAN SHIXIN NEW MATERIALS CO LTD

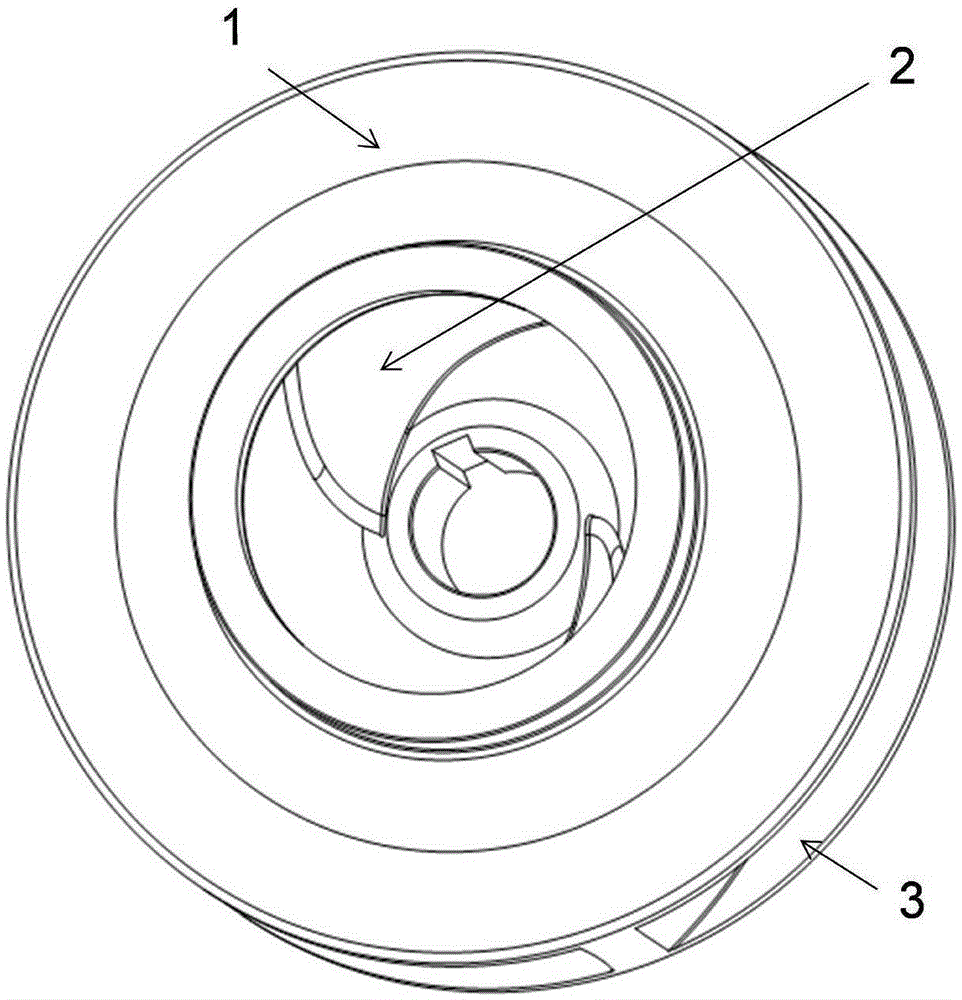

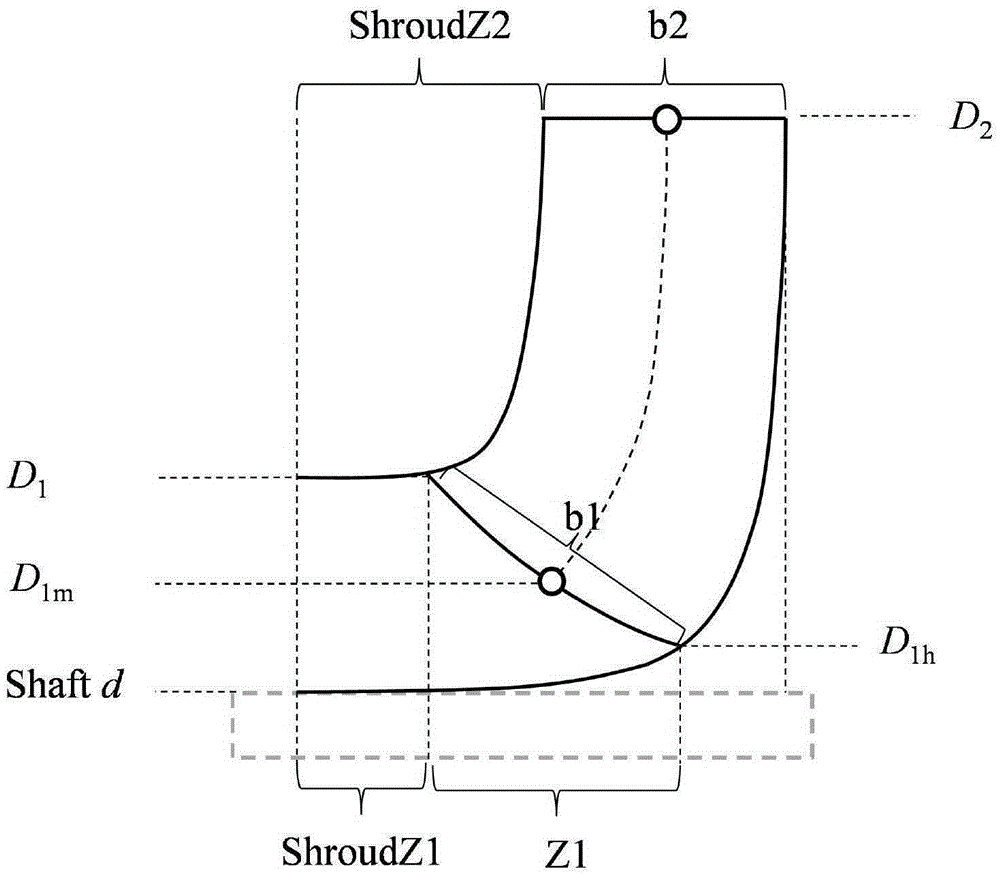

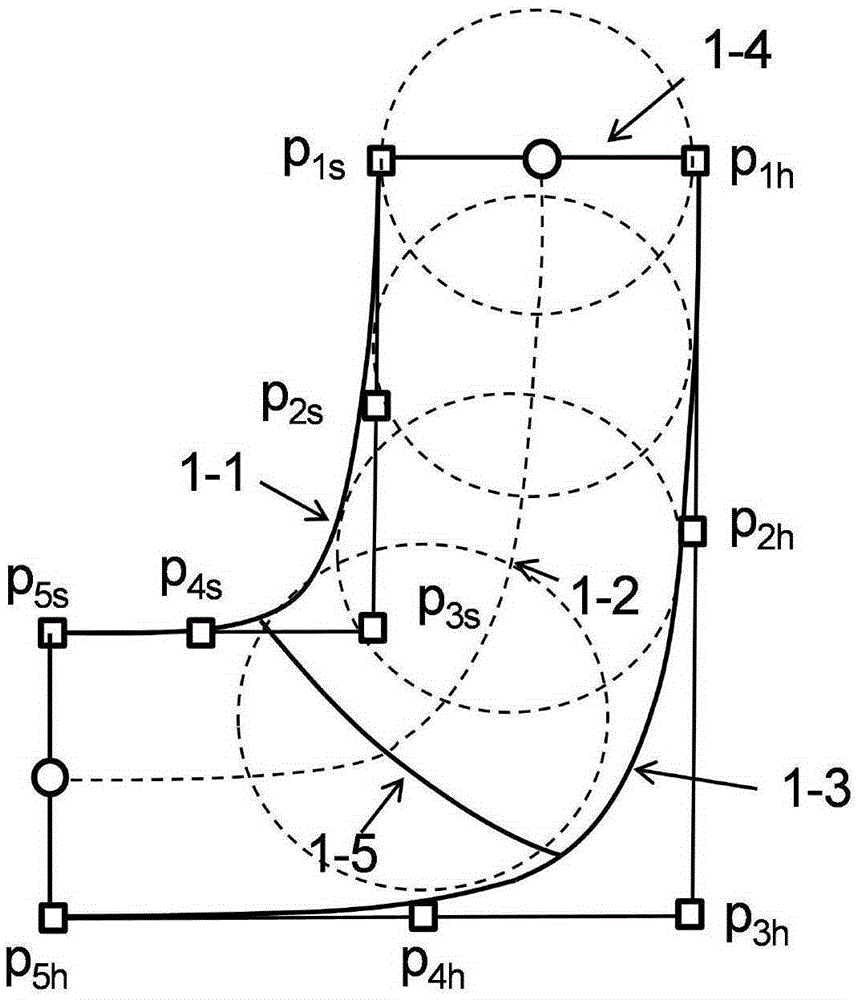

Hydraulic design method for double-blade non-block centrifugal impeller

InactiveCN105240310AImprove hydraulic efficiencyImprove flow stabilityPump componentsPumpsImpellerGenetic algorithm

The invention discloses a hydraulic design method for a double-blade non-block centrifugal impeller. The double-blade non-block centrifugal impeller structurally comprises a front cover plate, blades and a rear cover plate. The hydraulic design method comprises the steps that (1) the main hydraulic geometrical parameters of the double-blade non-block centrifugal impeller are worked out based on a velocity coefficient method; (2) the shapes of the axial surfaces of the blades are controlled based on a quadratic Bezier curve control algorithm; (3) the molded line installation angles of the blades are controlled based on a quartic Bezier curve control algorithm; (4) optimization design is conducted on the double-blade non-block centrifugal impeller based on a non-dominated sorting genetic algorithm (NSGA) II; and (5) the double-blade non-block centrifugal impeller according with the given flow, the given lift, the given pump efficiency and the given rotating speed value is manufactured by using the data obtained in the step (1) to step (4) as the dimension parameters of the double-blade non-block centrifugal impeller. By the adoption of the double-blade non-block centrifugal impeller designed through the method, the flow capacity and the anti-twining capacity of the impeller can be improved, the internal flowing condition of the impeller is improved, and the operating stability and the hydraulic efficiency of the impeller are improved.

Owner:ZHEJIANG COLLEGE OF ZHEJIANG UNIV OF TECHOLOGY

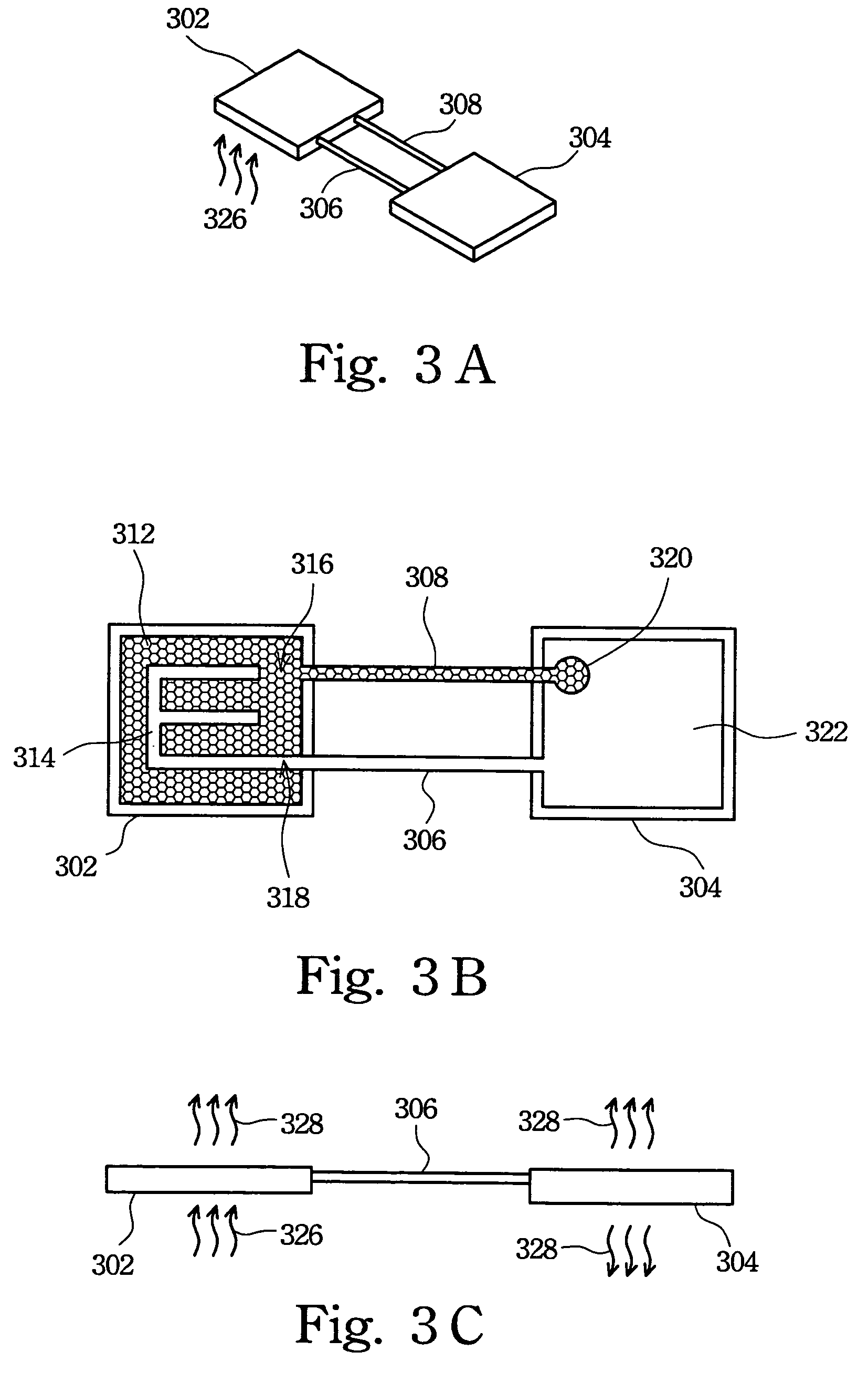

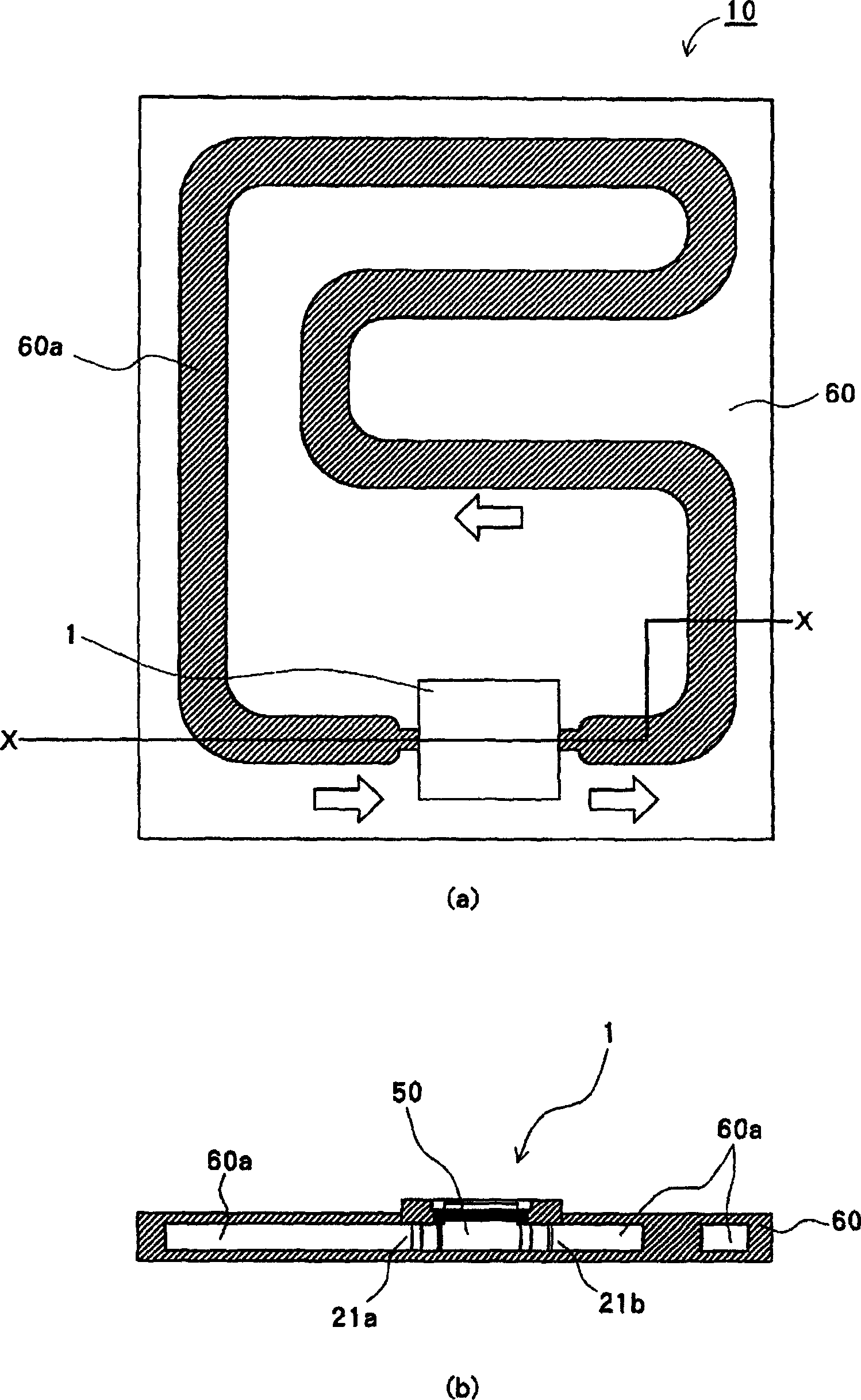

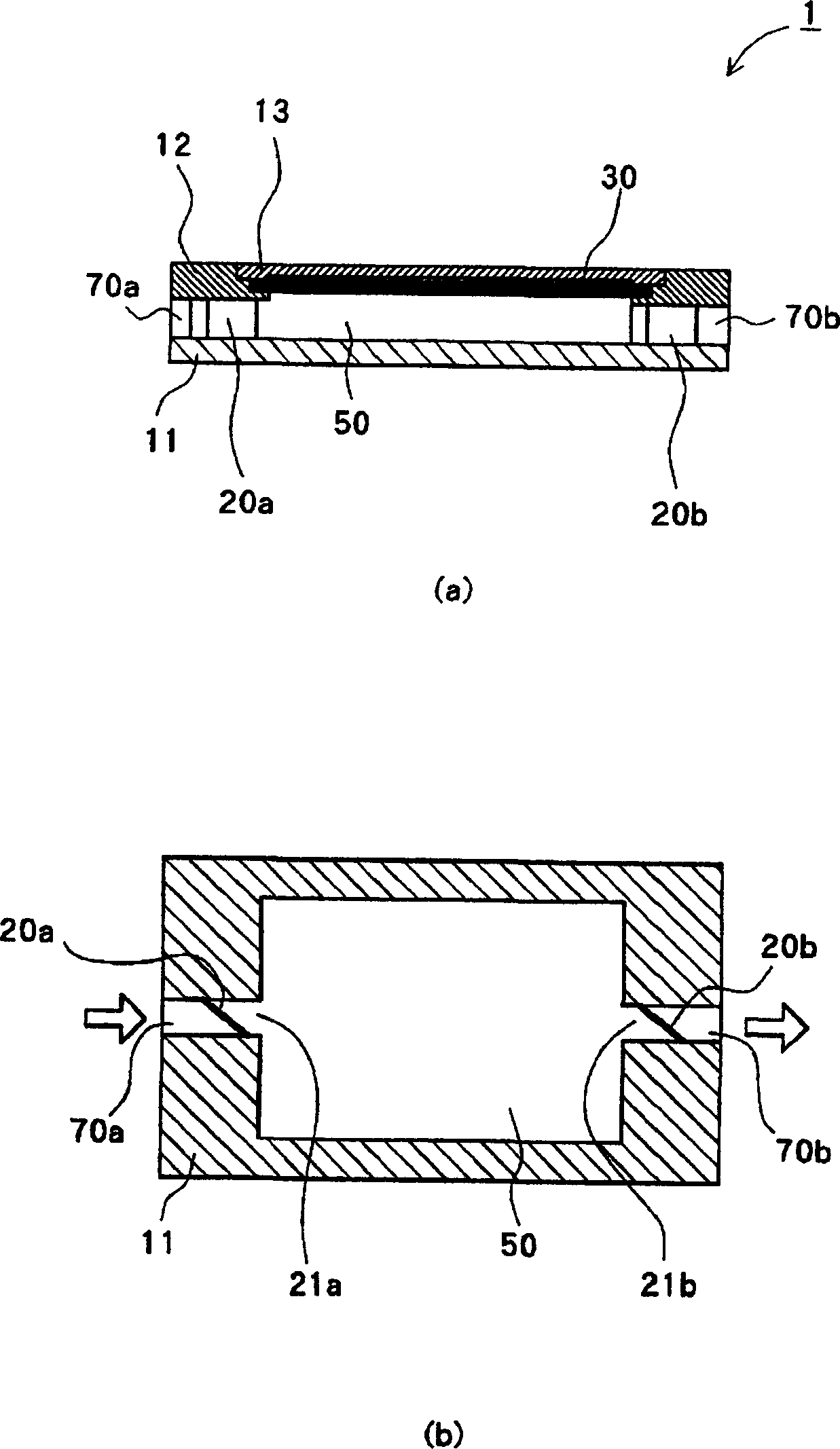

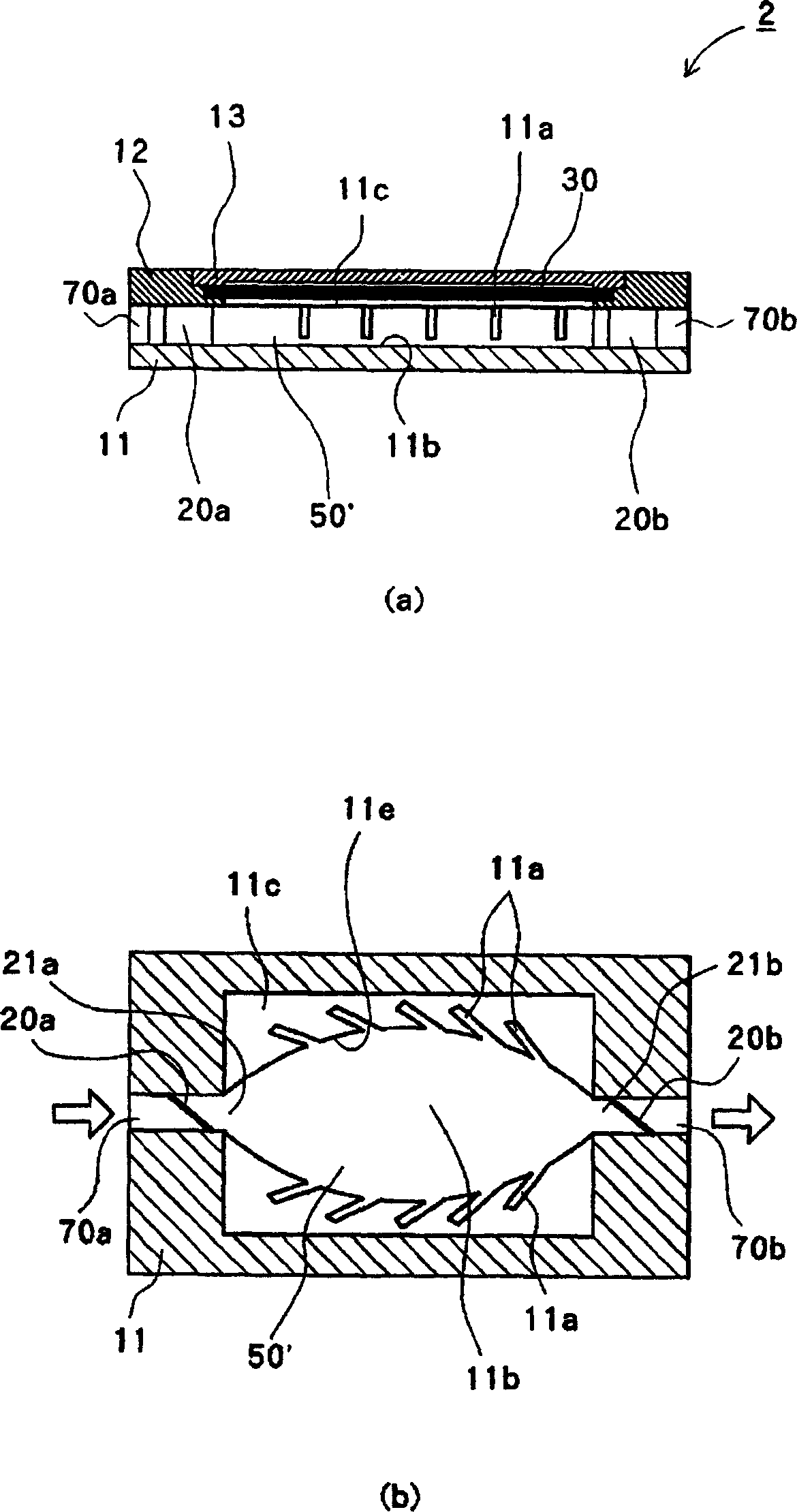

Micro pump using ferrofluid or magneto-rheological fluid

InactiveUS20050069424A1Improve flow efficiencyImprove pump efficiencyPositive displacement pump componentsFlexible member pumpsWorking fluidMagnetorheological fluid

A micro pump using a ferro-fluid / magneto-rheological fluid to drive a working fluid is proposed. The micro pump has a body with an accommodating space and an opening that communicates with the accommodating space. A ferro-fluid / magneto-rheological fluid and a magnetic field generating unit are disposed on the body. As the ferro-fluid / magneto-rheological fluid is attracted to the magnetic field after being magnetized, the ferro-fluid / magneto-rheological fluid is deformed or shifted to drive the working fluid, so as to control the working fluid to flow in and out of the accommodating space. Accordingly, the pump is improved for its efficiency and precision to control the flow while the back flow of the working fluid is prevented.

Owner:IND TECH RES INST

Changeable outlet flow section turbine jet nozzle ring

InactiveCN101050722ASmall footprintReduce manufacturing costInternal combustion piston enginesAirflowExternal combustion engine

The present invention belongs to the field of internal combustion engine turbocharging technology, in particular, it relates to a turbine nozzle ring used in turbocharger. Said invention provides the working principle of said turbine nozzle ring, and also provides the concrete structure of said turbine nozzle ring and its manufacture method.

Owner:孙敏超

Diaphragm pump and cooling system with the diaphragm pump

InactiveCN1833105AReduce thicknessReduce volumeFlexible member pumpsPositive-displacement liquid enginesDiaphragm pumpCheck valve

Owner:NEC CORP

Air treatment device with heated volatile dispenser

InactiveUS20070194144A1Low costEasy to assembleSpray nozzlesTobacco devicesCompound (substance)Air treatment

Disclosed is a device suitable for dispensing air treatment chemicals by heating a substrate impregnated with the chemicals. The device has a heater in the form of a table where a face of the table radiates heat directly to the impregnated substrate. The substrate releases the air treatment chemical back towards the heater. A transverse air pathway permits venting of the volatile chemical. Also disclosed are methods for assembling such devices.

Owner:DAVIS BRIAN T +3

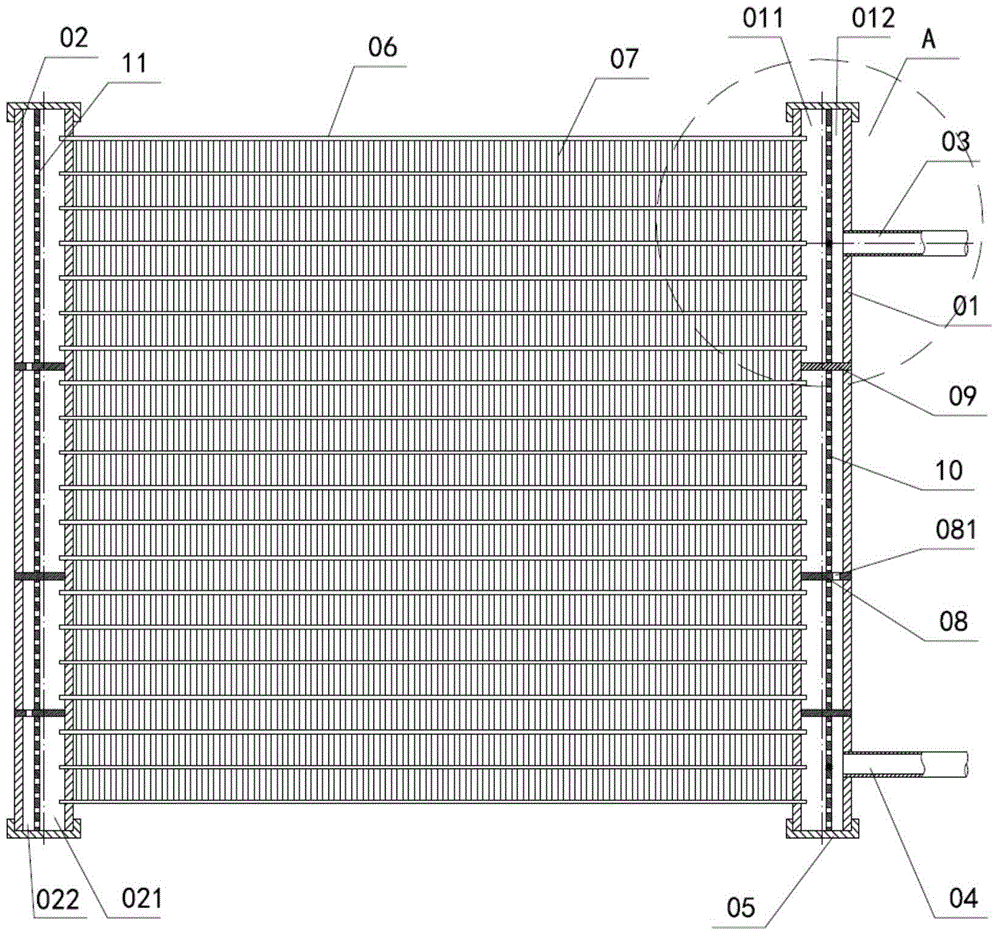

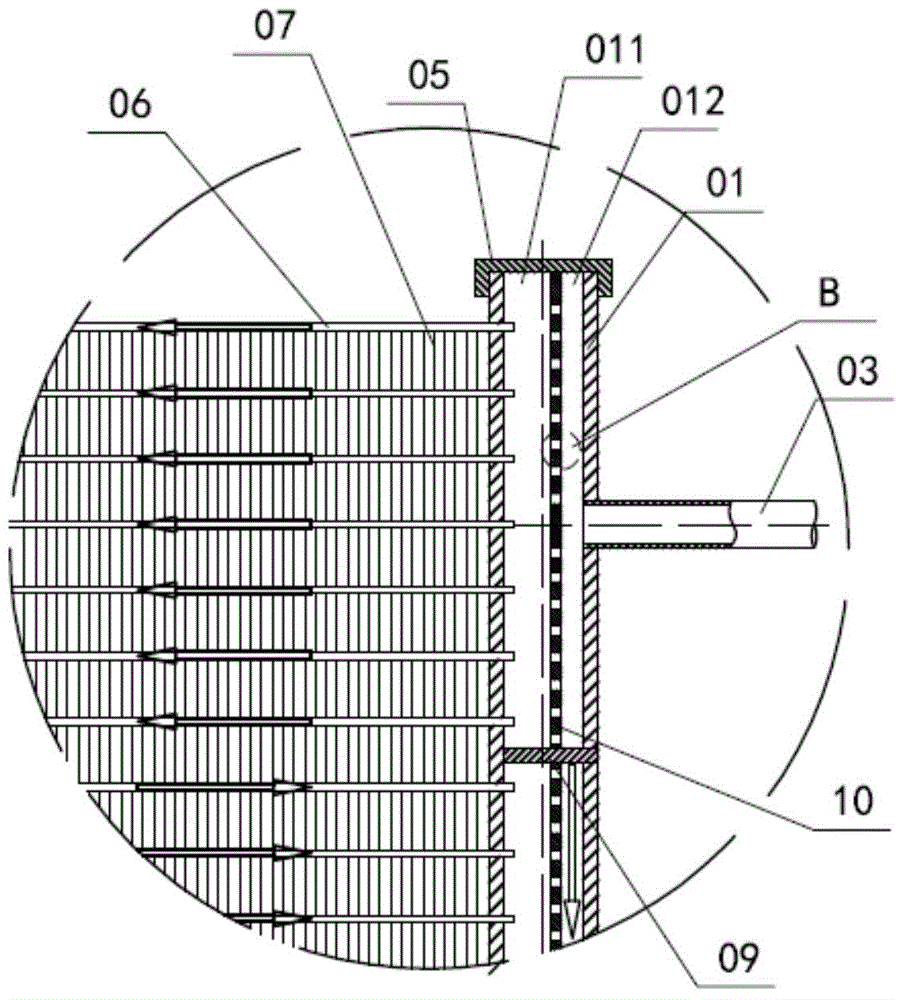

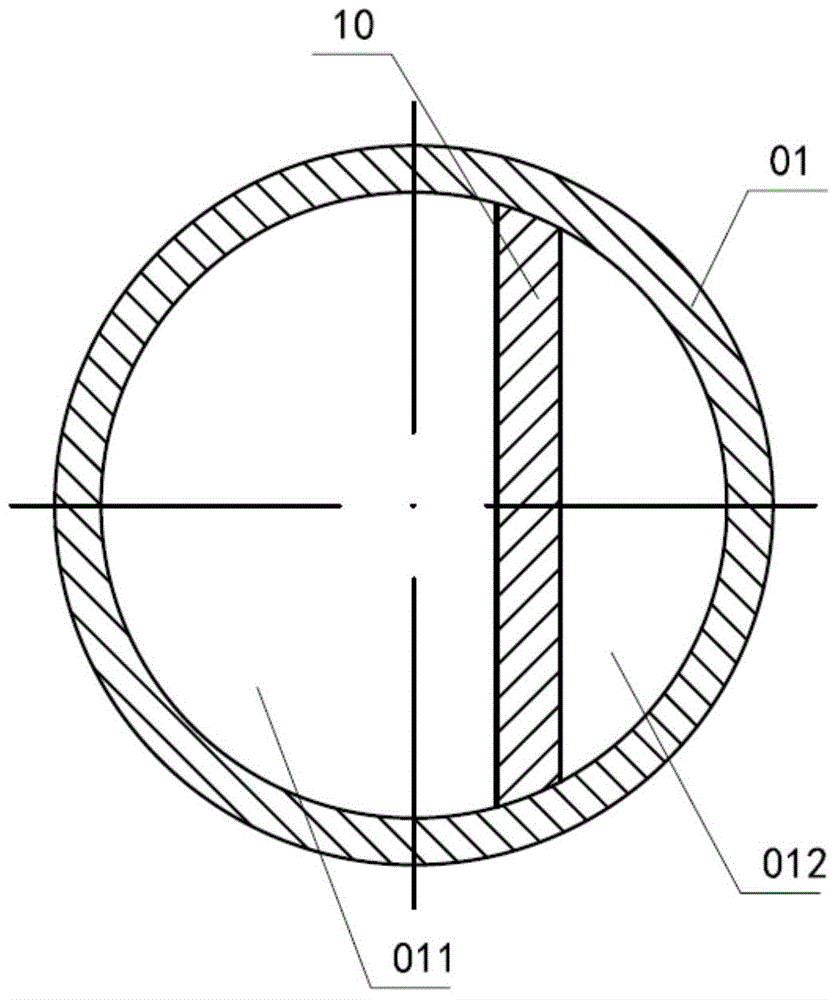

Microchannel heat exchanger capable of uniformly distributing refrigerant flow

InactiveCN105020940AEvenly distributedUniform resistanceEvaporators/condensersStationary conduit assembliesEngineeringRefrigerant

The invention relates to a microchannel heat exchanger capable of uniformly distributing a refrigerant flow. The microchannel heat exchanger comprises a first air collecting pipe, a second air collecting pipe, a first pipe port and a second pipe port, wherein air collecting pipe end covers are respectively arranged at the two ends of the first air collecting pipe and the second air collecting pipe; a first flow equalizing plate and a second flow equalizing plate parallel to axles of the first air collecting pipe and the second air collecting pipe are respectively arranged in the first air collecting pipe and the second air collecting pipe for dividing the air collecting pipes into first and second inner cavity parts and first and second outer cavity parts; multiple flow equalizing plate through holes are respectively formed in the flow equalizing plates; holeless baffle plates and hole baffle plates are alternately arranged in the first air collecting pipe from the direction of the first pipe port; and baffle plate through holes of the hole baffle plates are positioned on the first and second outer cavity parts. A working medium flows into the cavities through the first flow equalizing plate, uniformly enters microchannel flat pipes by the multiple flow equalizing plate through holes on the first flow equalizing plate, and enters the microchannel flat pipes through the multiple flow equalizing plate through holes on the second flow equalizing plate, so that the purpose of uniform distribution of working medium flows is realized.

Owner:GD MIDEA HEATING & VENTILATING EQUIP CO LTD +1

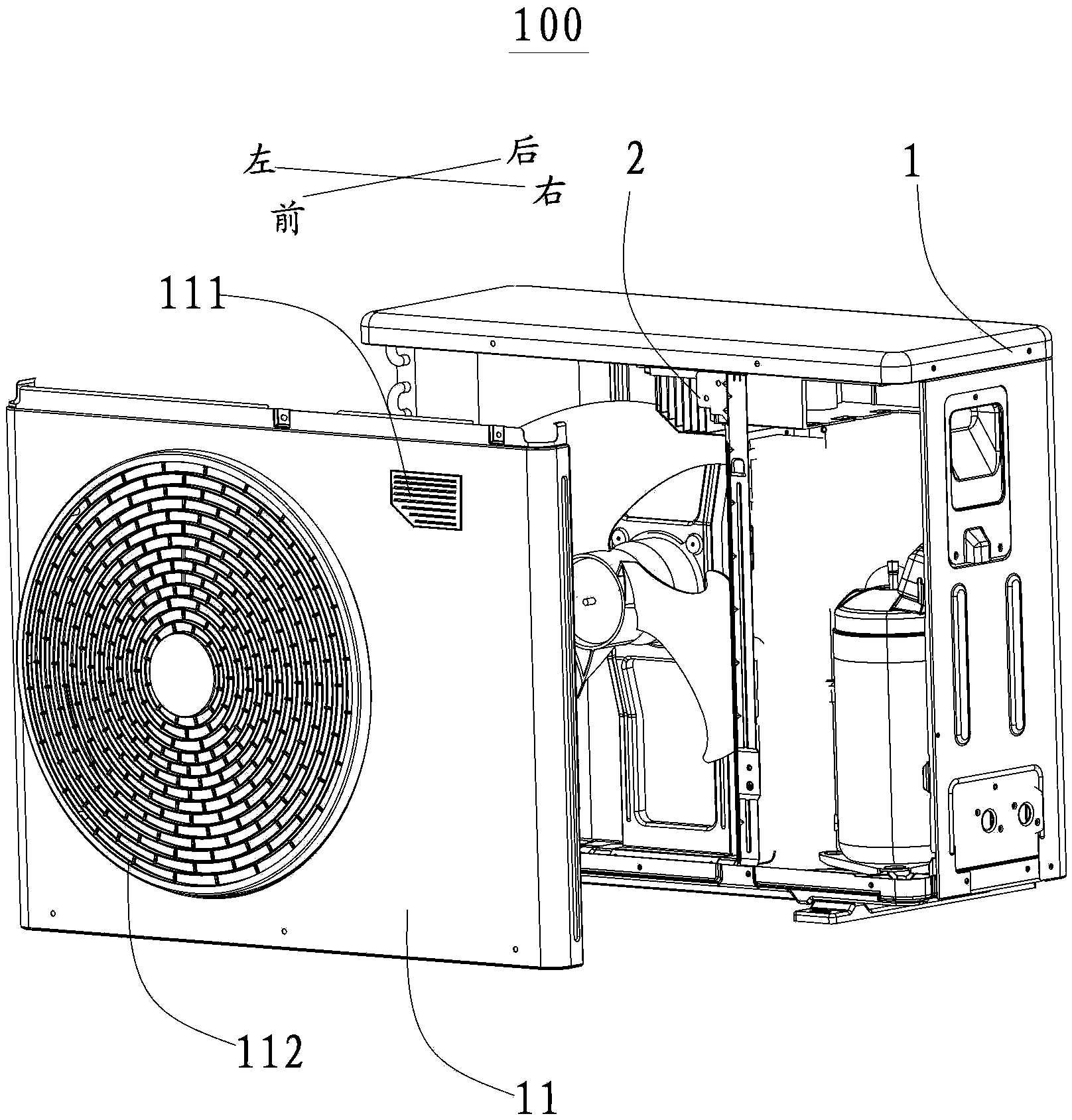

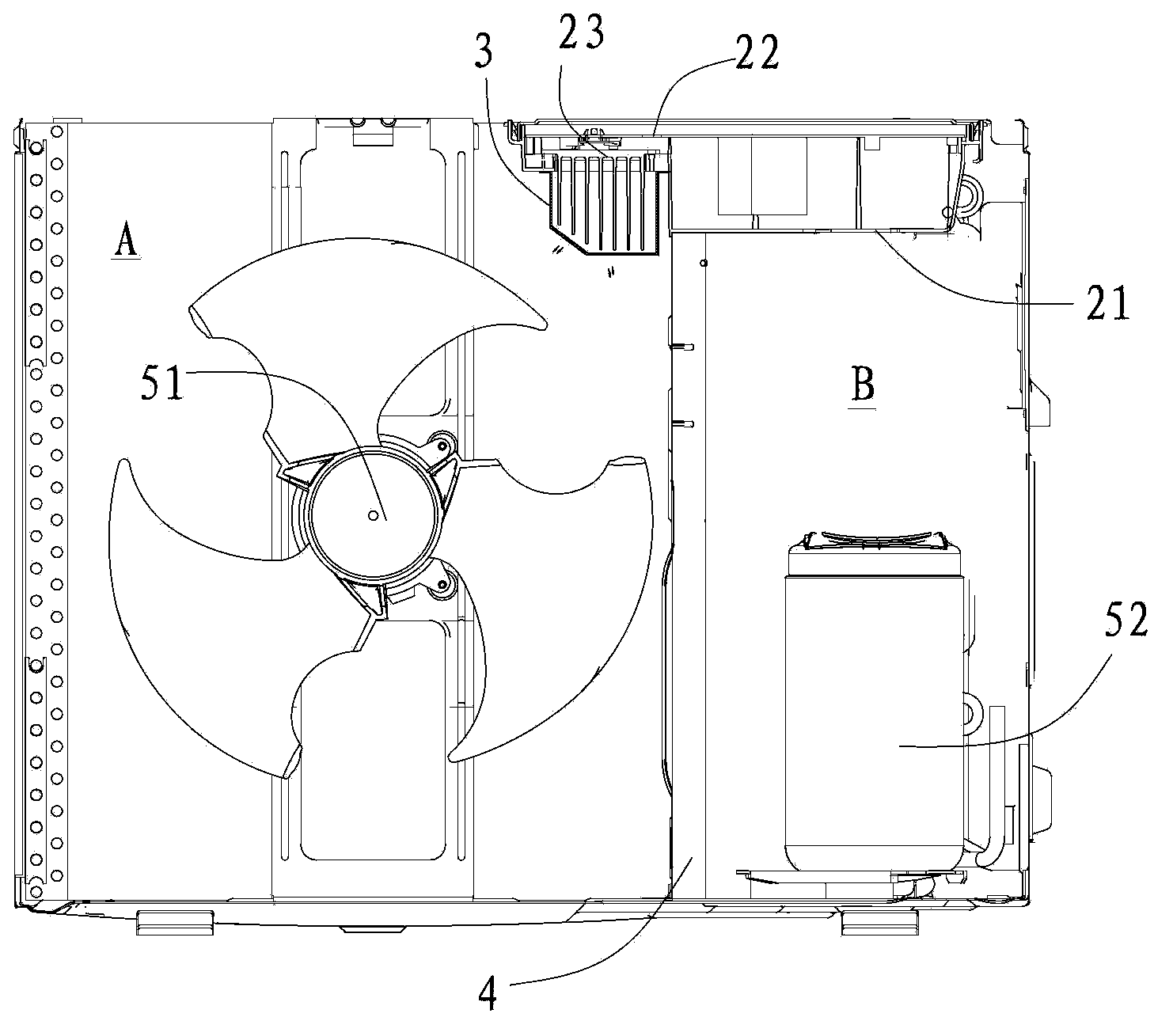

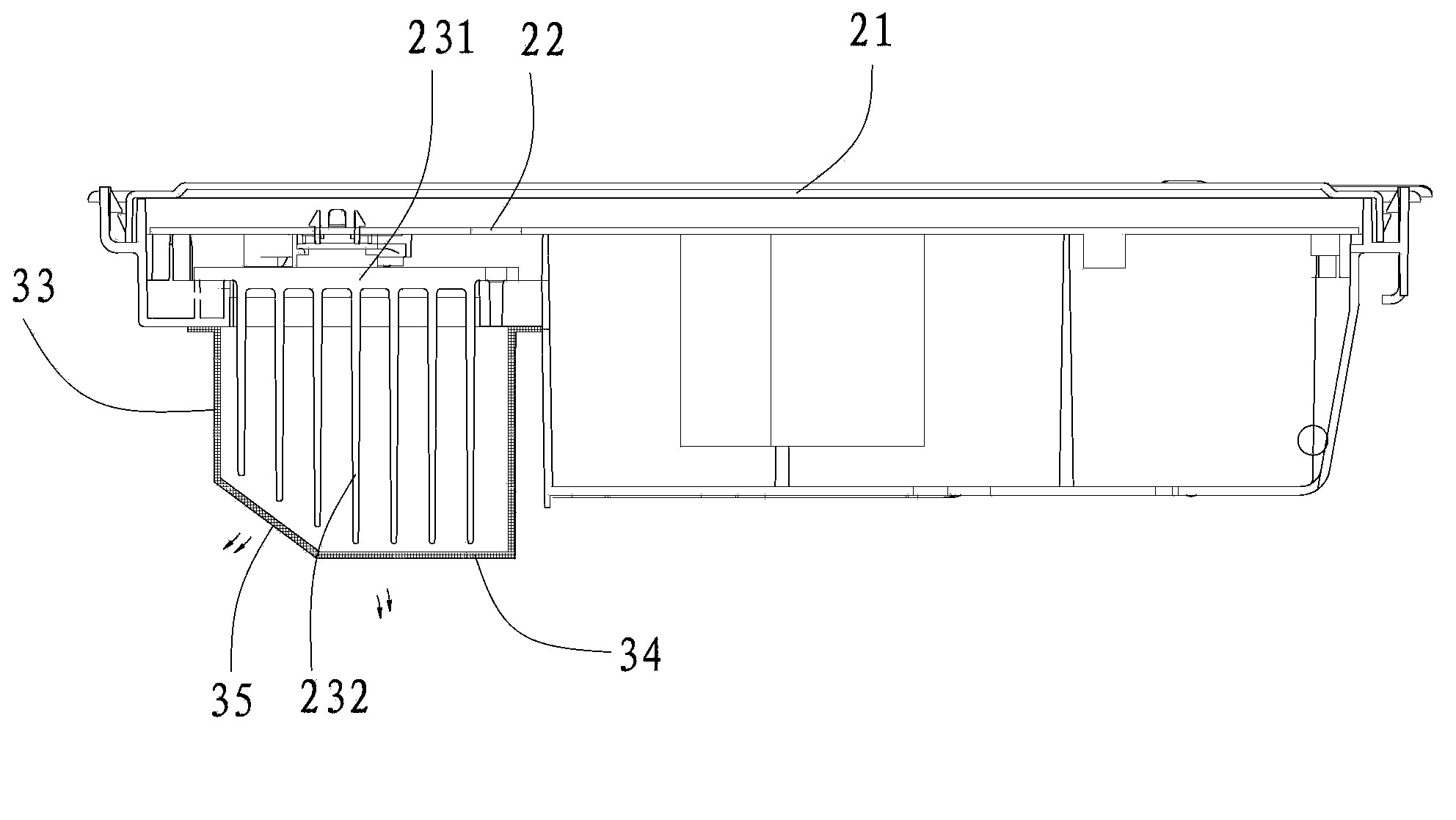

Outdoor unit of air conditioner

ActiveCN104251523AImprove cooling effectShorten the flow pathLighting and heating apparatusAir conditioning systemsEngineeringElectric control

The invention discloses an outdoor unit of an air conditioner. The outdoor unit comprises an outdoor unit shell, an electric control box and an isolating part, wherein the outdoor unit shell comprises a front panel; the front panel is provided with a front panel air inlet; the electric control box is arranged in the outdoor unit shell, and comprises an electric control box shell, a PCB (Printed Circuit Board) and a radiator; the PCB is arranged in the electric control box shell; the radiator is connected with the PCB; a part of the radiator extends out of the electric control box shell; the isolating part coats the outside of a part, which extends out of the electric control box shell, of the radiator; an isolating part air inlet and an isolating part air outlet are formed in the isolating part; the air inlet of the isolating part is in hermetic fit with the front panel, and the isolating part air inlet is opposite to the front panel air inlet; the isolating part air outlet is communicated with the inside of the outdoor unit shell. The outdoor unit of the air conditioner disclosed by the invention has an improved heat dissipation structure, so that the heat dissipation effect of the PCB in the electric control box is enhanced.

Owner:HANDAN MIDEA REFRIGERATION EQUIP

Turbine nozzle ring with adjustable and variable outlet flowing angle

InactiveCN102094705ASmall footprintReduce manufacturing costInternal combustion piston enginesStatorsJet flowTurbocharger

The invention relates to a turbine nozzle ring in a turbocharger. Pressurized air flowing out from an outlet manifold bypass of an air compressor of the turbocharger per se and / or compressed air of an external air source (or exhaust fuel gas flowing out from an outlet manifold bypass of an exhaust pipe of an internal-combustion engine) passes through the hollow cavity of a nozzle blade or a hollow interlayer nearby the inner wall of a bladeless volute inlet pipe, and jets and blows a nozzle blade ring or the interior of a bladeless volute runner and / or a main fuel gas flow in a downstream way from a blade profile back (or ventral face) and / or a through-flow slit cut at the tail edge part (a jet deflection arc guide plate is connected to the back of the tail edge slit) or an annular arc through-flow gap at a hollow interlayer outlet nearby the zero-degree section of a bladeless volute tongue tip and the jet deflection arc guide plate connected thereafter, so that the air flow formed by mixing the gap jet flow and the main flow generates flow direction deflection at the outlet of the nozzle ring to cause the change of an outlet airflow angle (namely outlet flowing section area). The turbine nozzle ring has the advantages of high control strength, simple structure, low cost, safety, reliability, high efficiency, convenience for control and applicability for the gasoline engine turbocharger, and the additional air has the functions of additional pressurization and auxiliary energy application.

Owner:孙敏超 +1

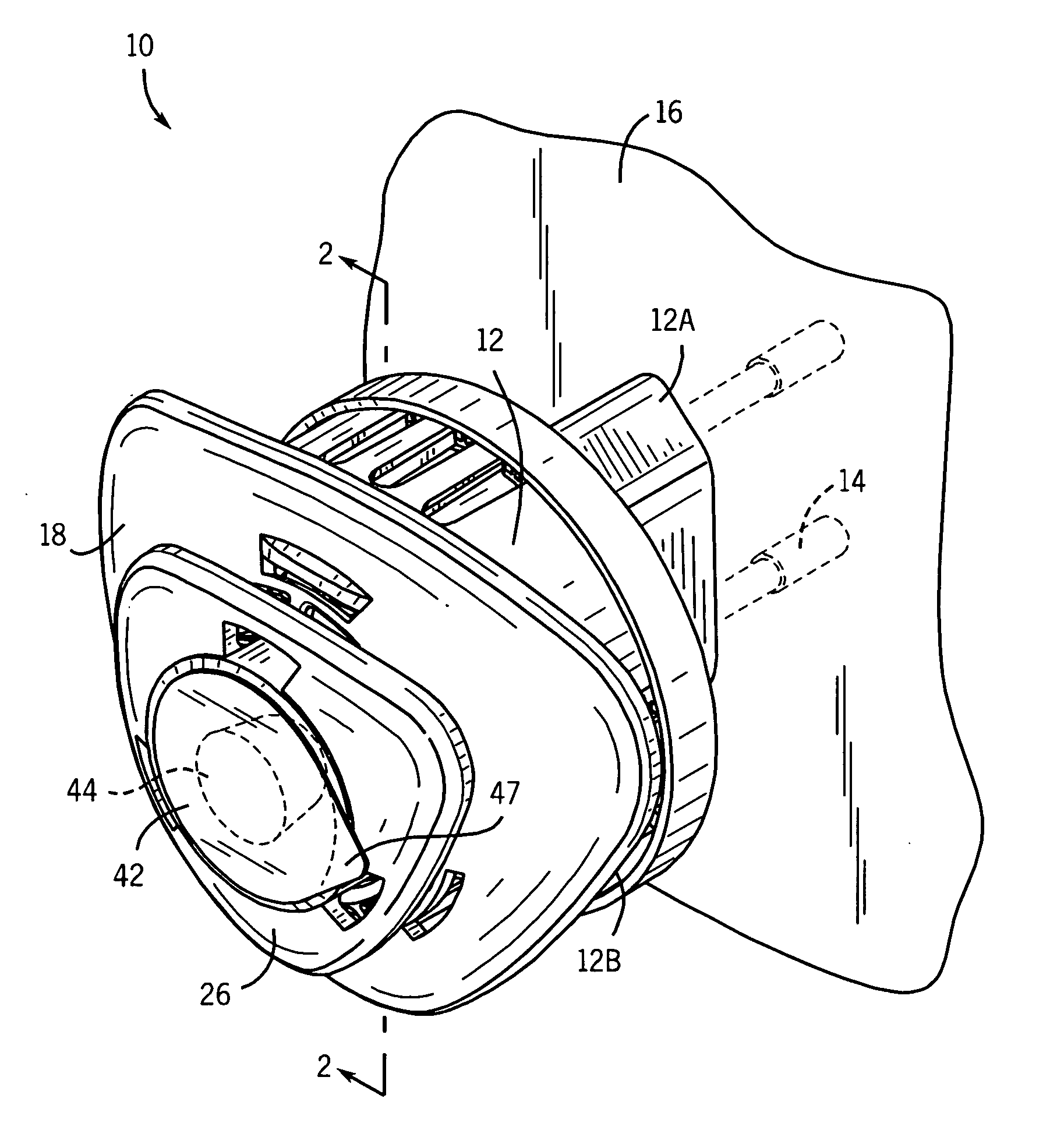

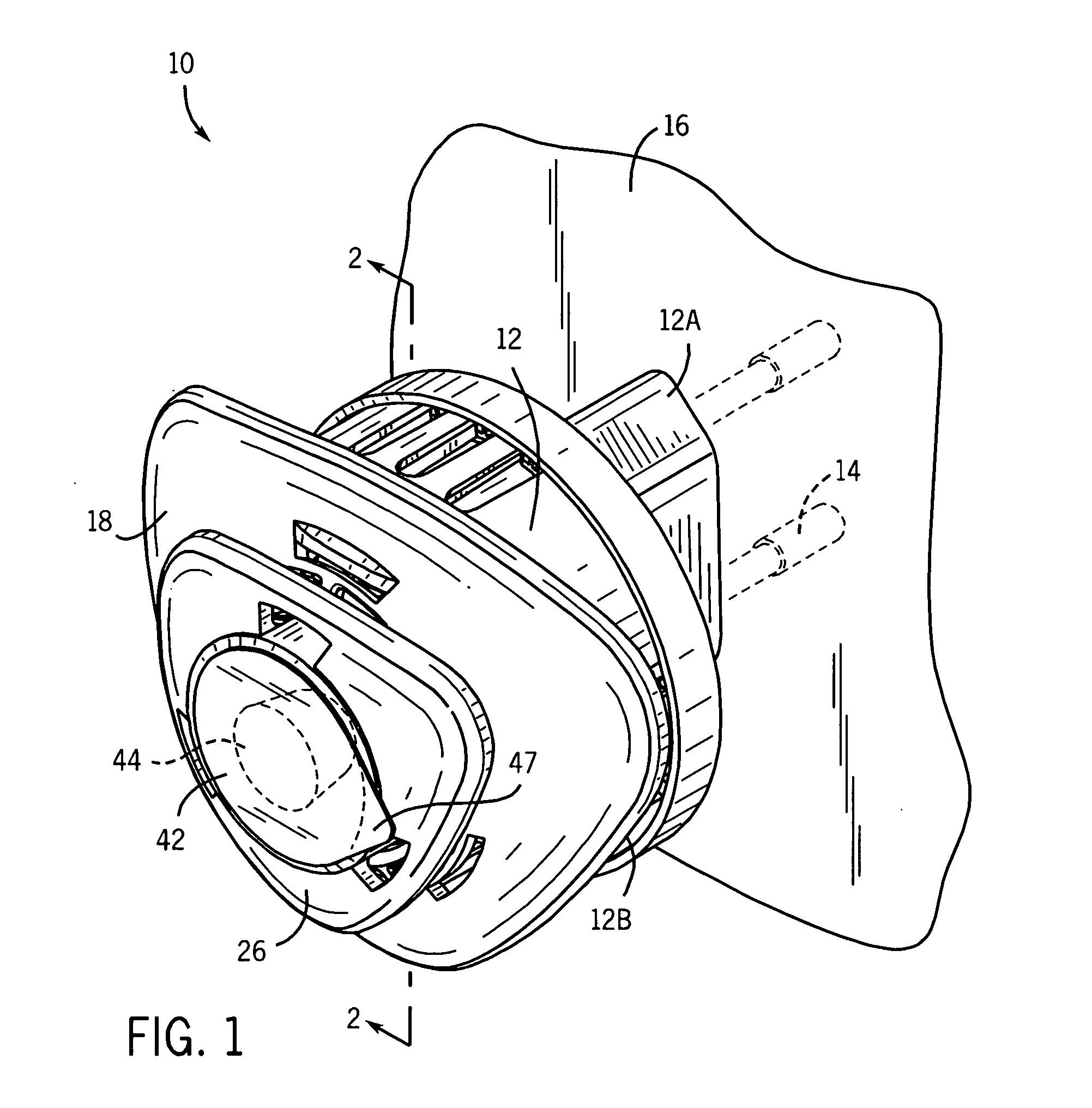

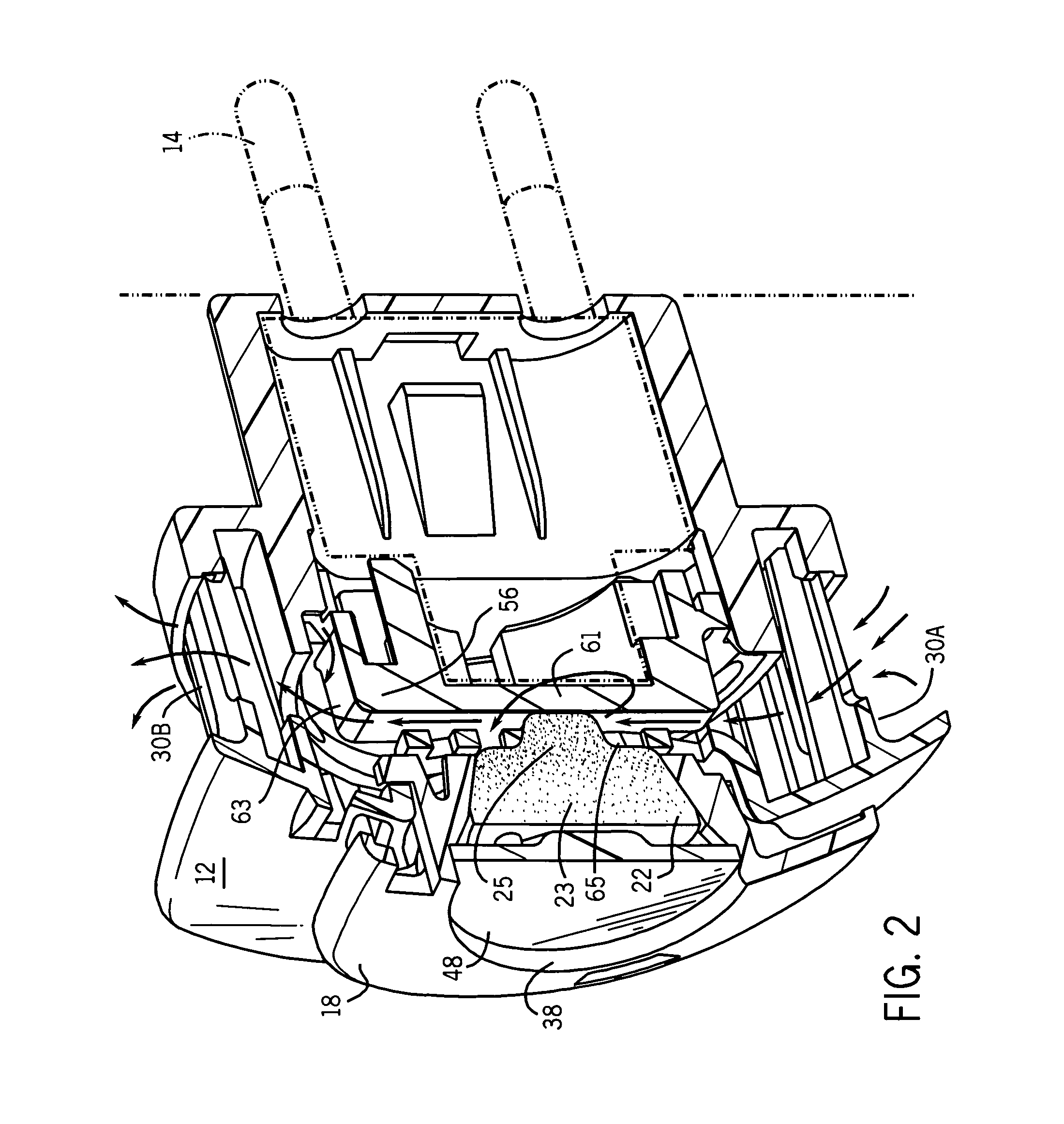

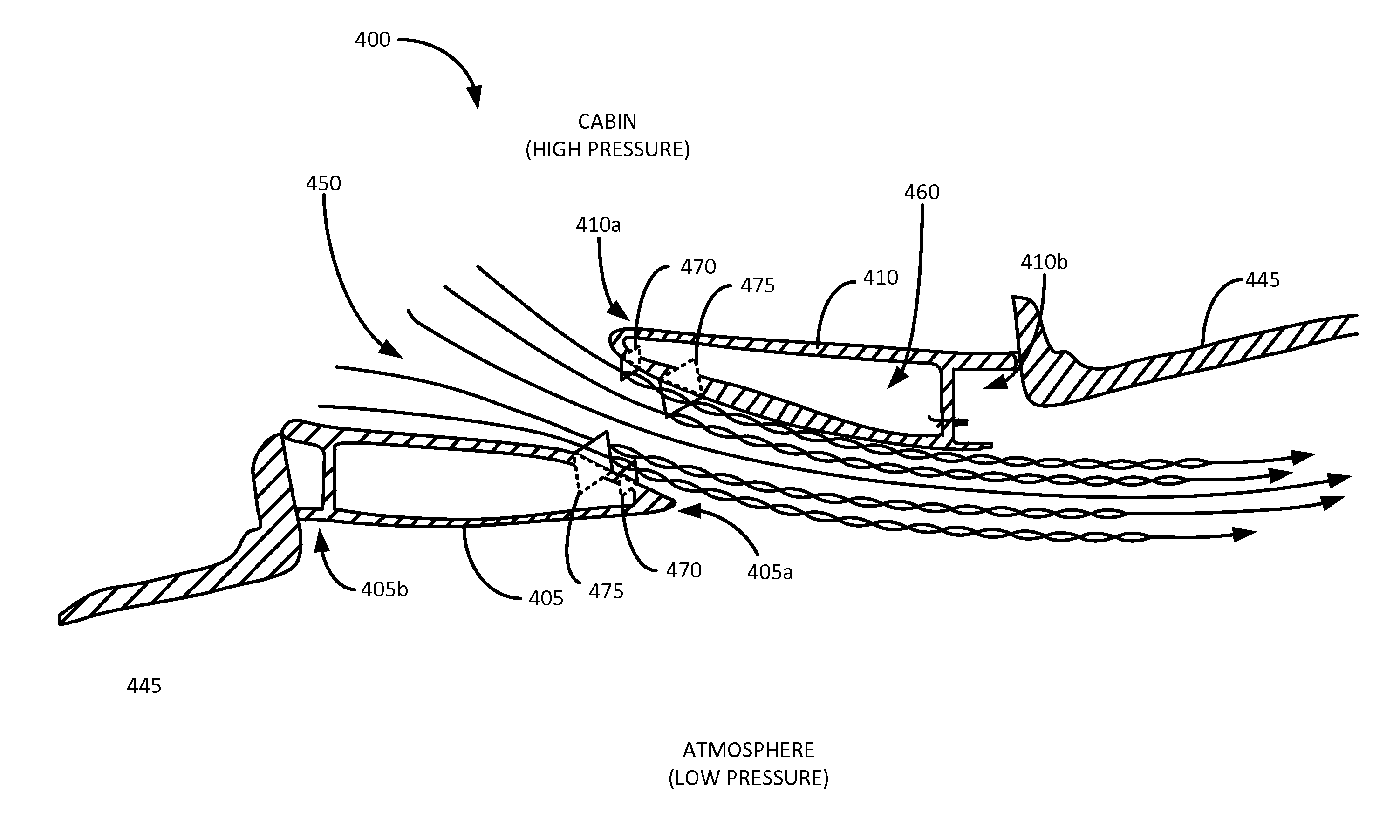

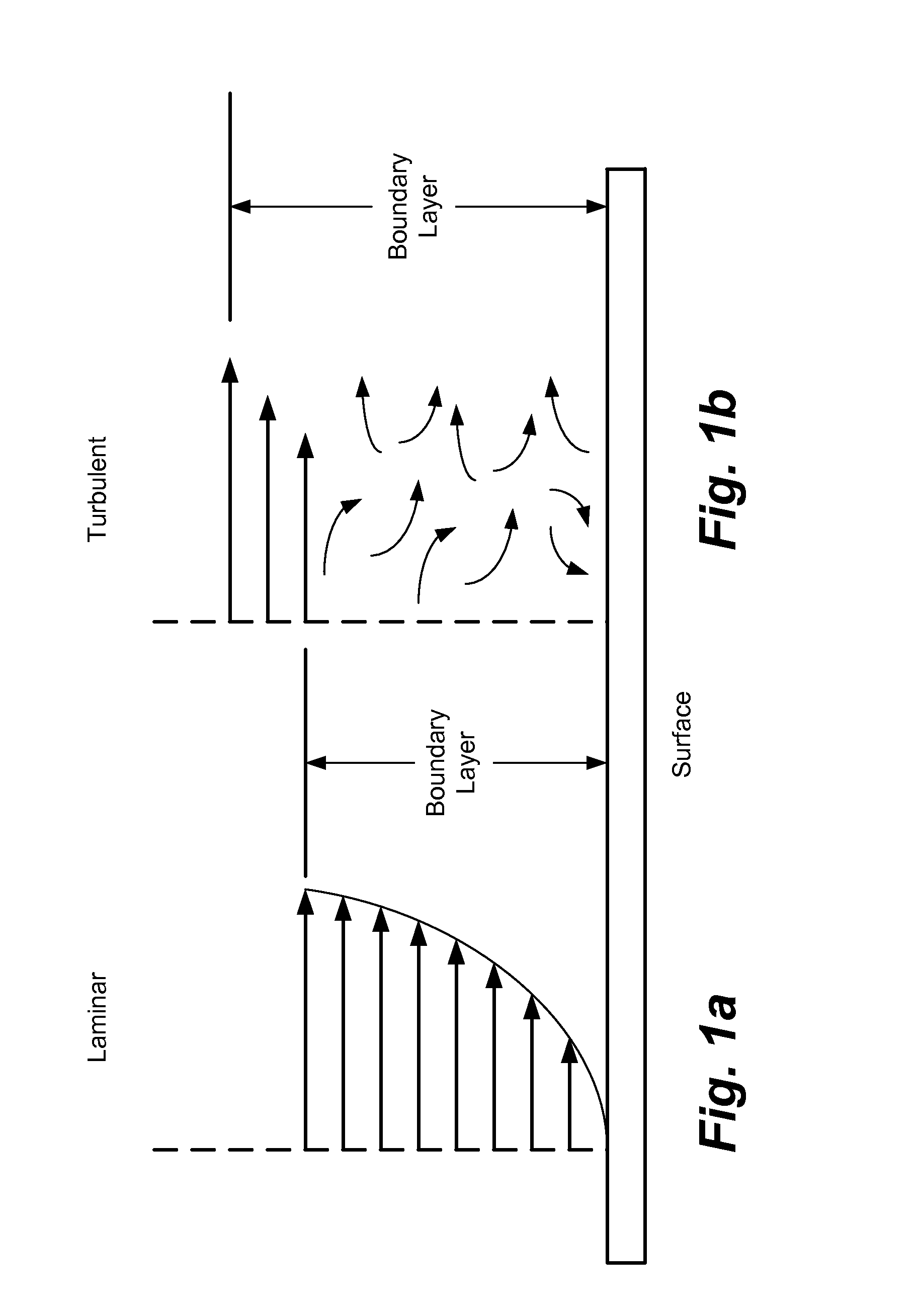

Cabin Pressure Outflow Valve Noise Suppression Devices and Methods

ActiveUS20160229540A1Reduce cabin noiseImprove flow efficiencyAir-treating devicesAir-treatment apparatus arrangementsInternal pressureBroadband noise

A system and method for regulating pressure inside a vehicle (“cabin pressure”) with reduced noise is disclosed. The system can include a forward gate and an aft gate that can be moved from a closed position to an open position to release cabin pressure in a controlled manner. The forward gate and the aft gate can comprise one or more flow disruptors. A first portion of the flow disruptors can be fixed and a second portion can be moveable between a retracted position and a deployed in position. In the retracted position the one or more flow disruptors can reduce broadband noise through the system by smoothing air flow therethrough. In the second position, the one or more flow disruptors can create boundary layer turbulence. The boundary layer turbulence can prevent, or delay, flow separation reducing tonal noises therethrough. In this manner, flow efficiency can be increased and noise reduced.

Owner:THE BOEING CO

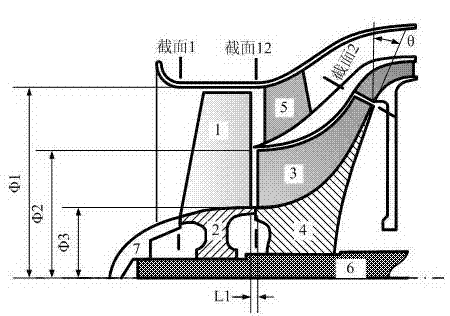

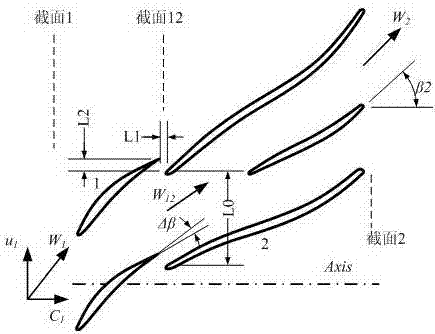

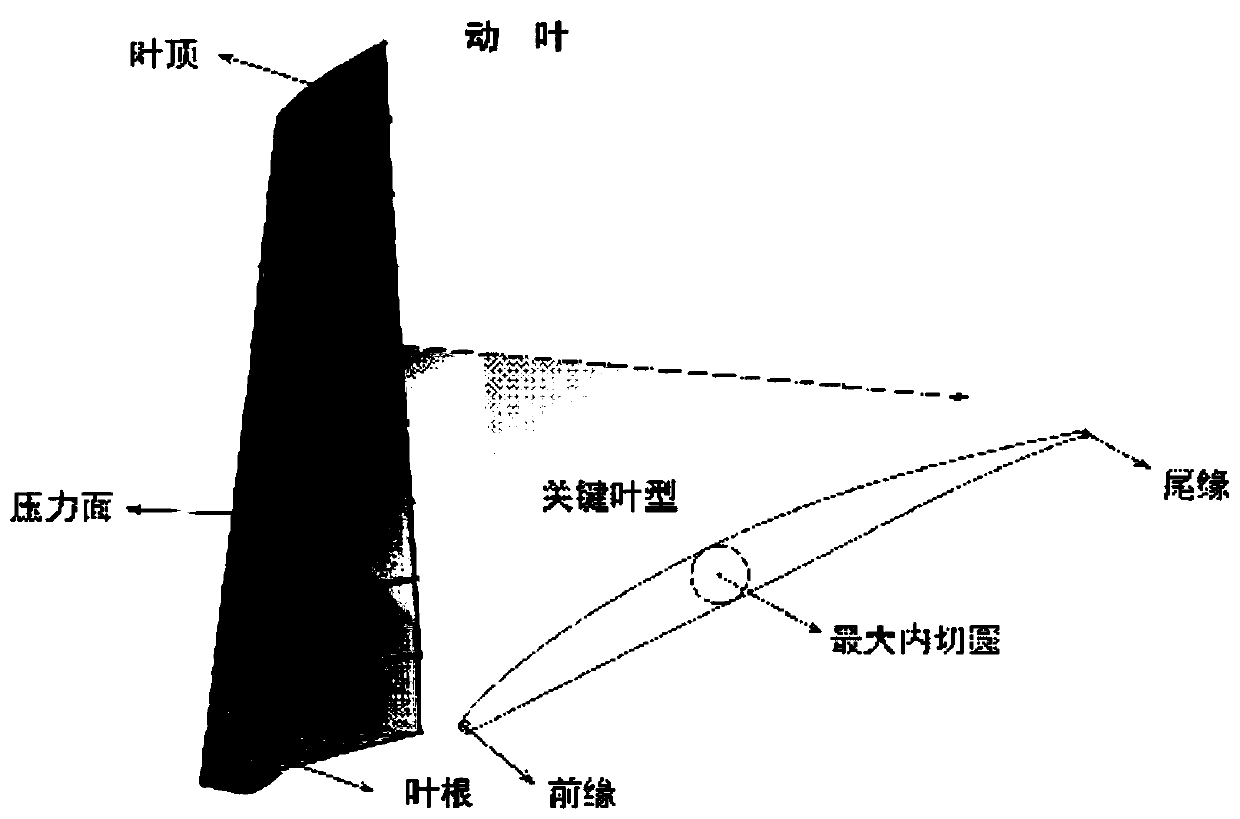

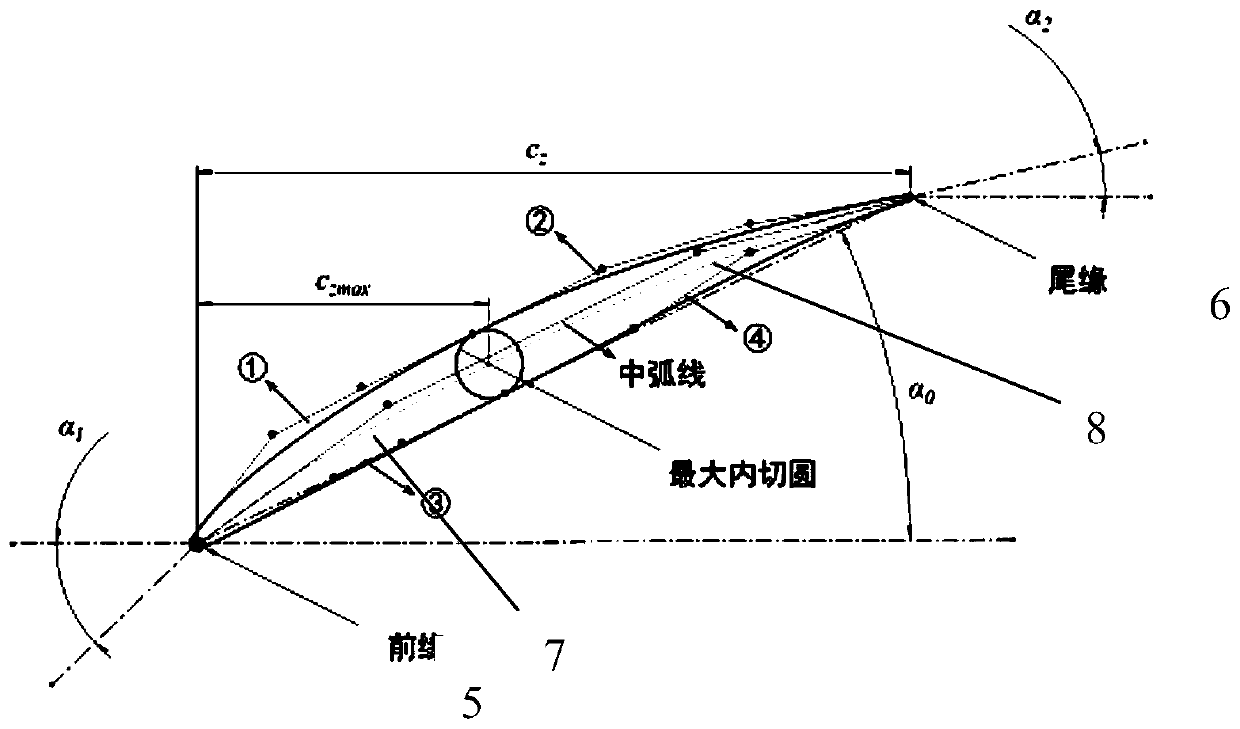

Two-dimensional blade profile optimization method for compressor considering low Reynolds number working performance

ActiveCN109779972AImprove aerodynamic performanceIncrease stall marginPump componentsPumpsGenetic algorithmEngineering

The invention relates to a two-dimensional blade profile optimization method for a compressor considering a low Reynolds number working performance; the optimization method is characterized by comprising the following steps of: step 1: analyzing the meridional flow performance of a prototype multistage axial flow compressor at different rotating speeds; step 2: determining a key two-dimensional blade profile section to be optimized; step 3: performing parametric fitting to the key two-dimensional blade profile in step 2; step 4: analyzing the aerodynamic performance of the two-dimensional blade profile, and analyzing the aerodynamic performance of the parameterized two-dimensional blade profile to obtain the variable attack angle performance of the blade profile under a low Reynolds numberworking condition and the variable attack angle performance under a high Reynolds number working condition; and step 5: optimizing the modeling parameters of the two-dimensional blade profile, adjusting the two-dimensional modeling parameters according to the variable attack angle performance parameters of the two-dimensional blade profile obtained in step 4 at different Reynolds numbers, using agenetic algorithm to circularly iterate steps 3 and 4 until a two-dimensional blade profile design reducing loss and increasing stall margin is obtained, and then obtaining a new two-dimensional blade profile. According to the invention, the performance optimization of the two-dimensional blade profile of the axial flow compressor at different Reynolds numbers and different attack angles is realized; the designed working performance of the compressor is improved while the aerodynamic performance of the compressor at the low rotation speed working condition is improved; and the flow efficiencyis improved while the normal starting and stable working of the compressor are ensured.

Owner:HANGZHOU TURBINE POWER GRP

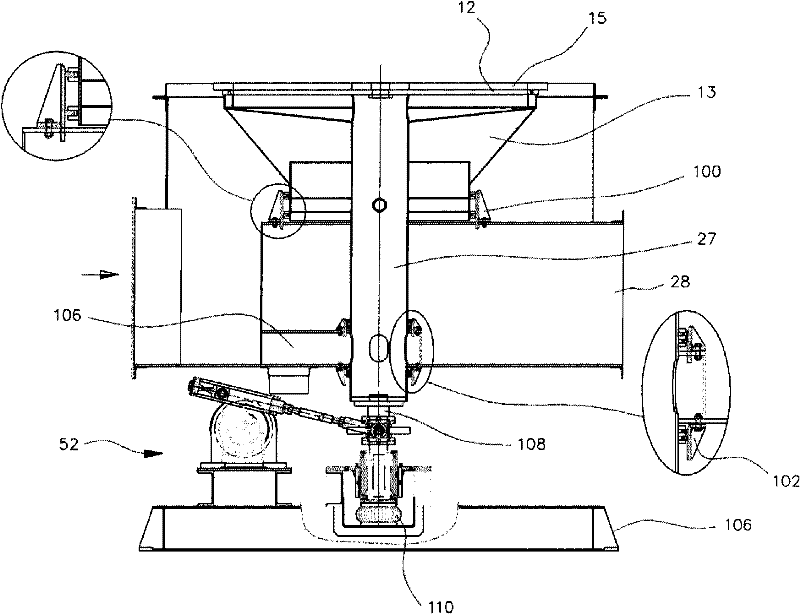

Fire-fighting monitor

ActiveUS7802630B2Simple and inexpensive designSmall spacingSpraying apparatusAdjustable jointsEngineeringMechanical engineering

Owner:ELKHART BRASS MFG

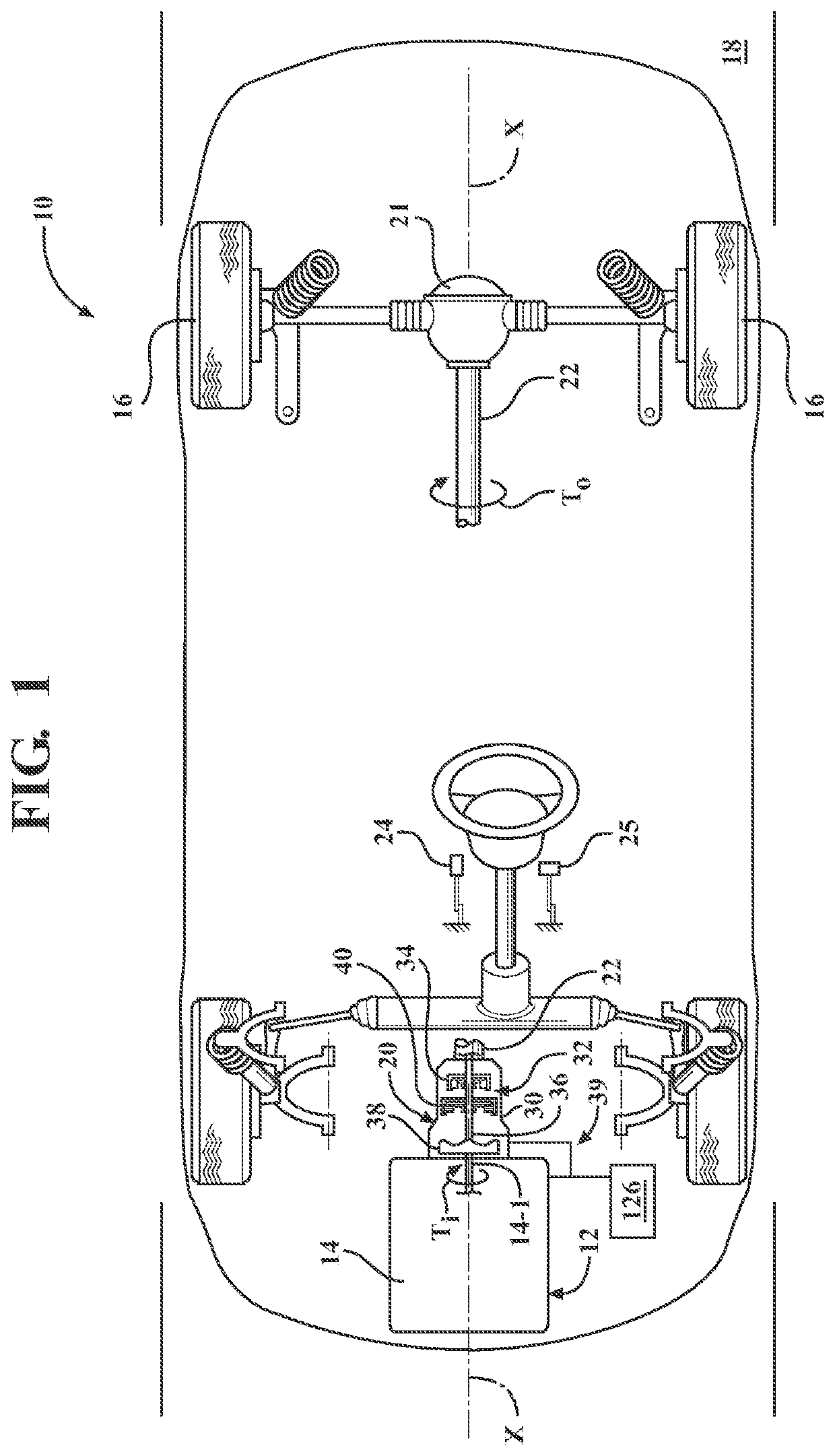

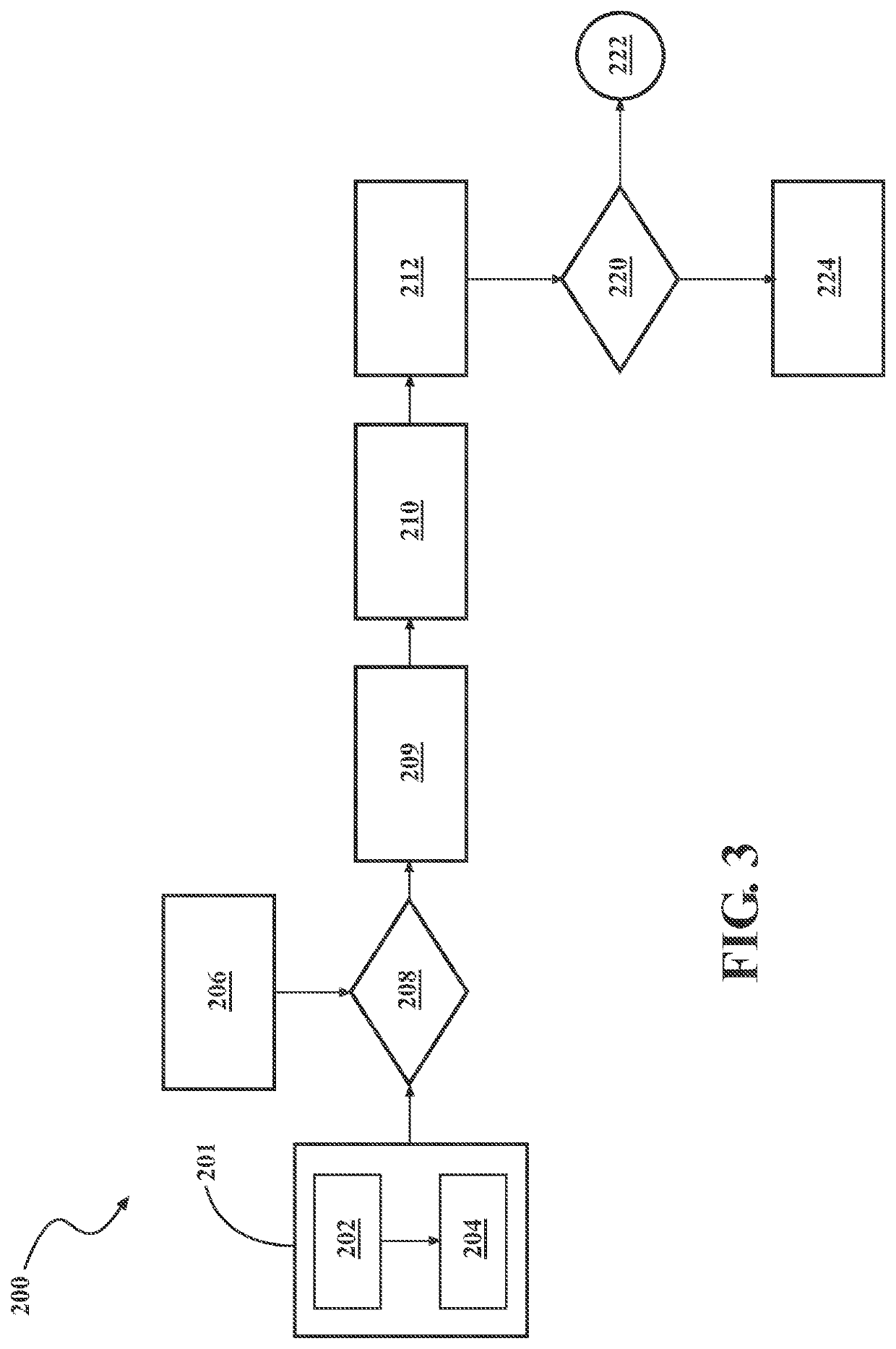

Torque converter clutch control system health estimation

ActiveUS20200040988A1Reduced controllabilityReduce speedClutchesRegistering/indicating working of vehiclesClutch controlPrincipal component analysis

A method of, and a system for, controlling and predicting the health of a torque converter clutch control system is provided. The method includes determining, via a controller, rotational input and output speeds of the torque converter and a torque converter clutch slip. The method also includes determining, via the controller, whether a set of predetermined conditions are met for predicting the health of the torque converter clutch control system. The method includes gathering a plurality of initial features of the vehicle propulsion system, determining statistical information about the plurality of initial features, and selecting at least one feature of the vehicle propulsion system based on the statistical information. Furthermore, the method includes classifying the health of the torque converter clutch control system based on the selected feature or features. In some forms, principal component analysis is used to select the feature or features used for classification.

Owner:GM GLOBAL TECH OPERATIONS LLC

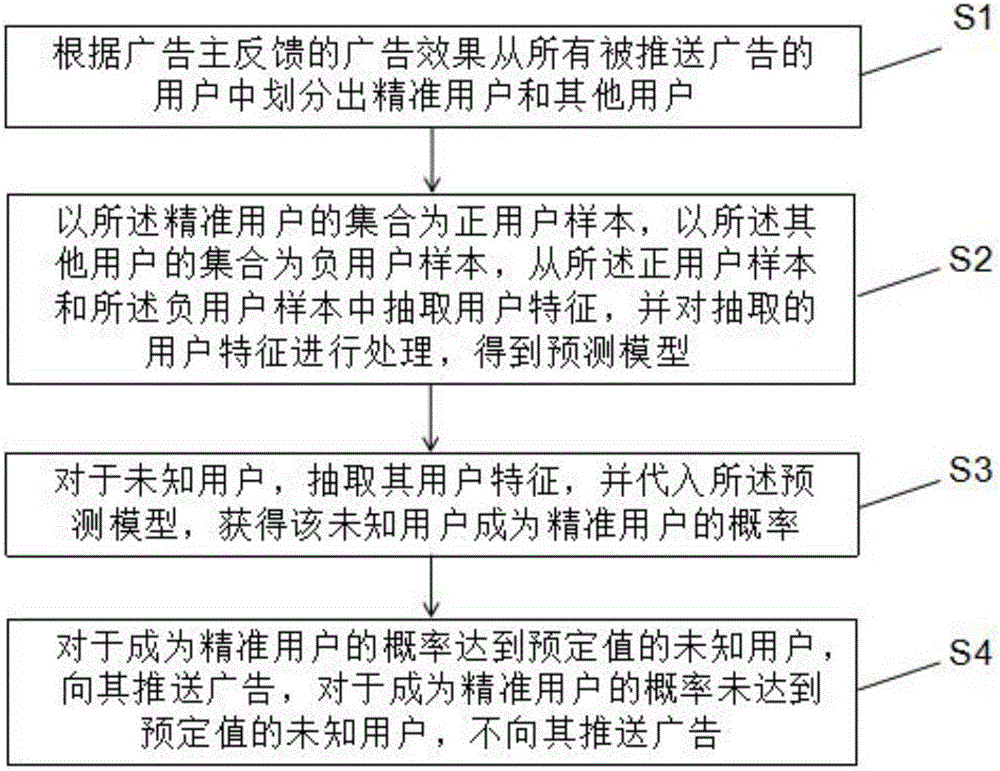

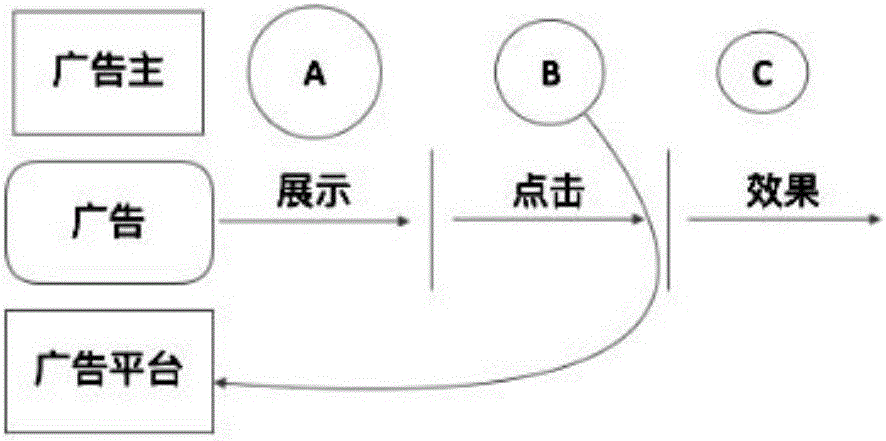

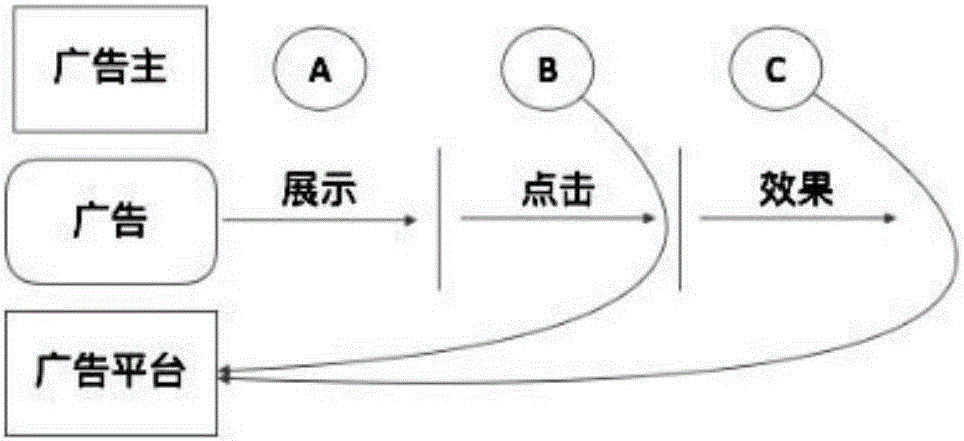

Advertisement promotion method combined with advertiser effect feedbacks

InactiveCN106022836AWith a clear purposeExcavate accuratelyMarketingComputer scienceCost performance

The invention discloses an advertisement promotion method combined with advertiser effect feedbacks. The method comprises: according to advertisement effect fed back by an advertiser, all users to whom an advertisement is pushed are divided into accurate users and other users; a set of the accurate users is taken as a positive user sample and a set of the other users is a negative user sample, user features are extracted from the positive user sample and the negative user sample, the extracted user features are processed, and a prediction model is obtained; for an unknown user, user features of the unknown user are extracted and applied to the prediction model, and the probability of the unknown user becoming an accurate user is obtained; the advertisement is pushed to the unknown user whose probability of becoming an accurate user reaches a preset value, and is not pushed to the unknown user whose probability of becoming an accurate user does not reach the preset value. The method can improve the cost-performance ratio of advertisement delivery and the promotion efficiency of the whole advertisement platform.

Owner:SHENZHEN ZHUIYI TECH CO LTD

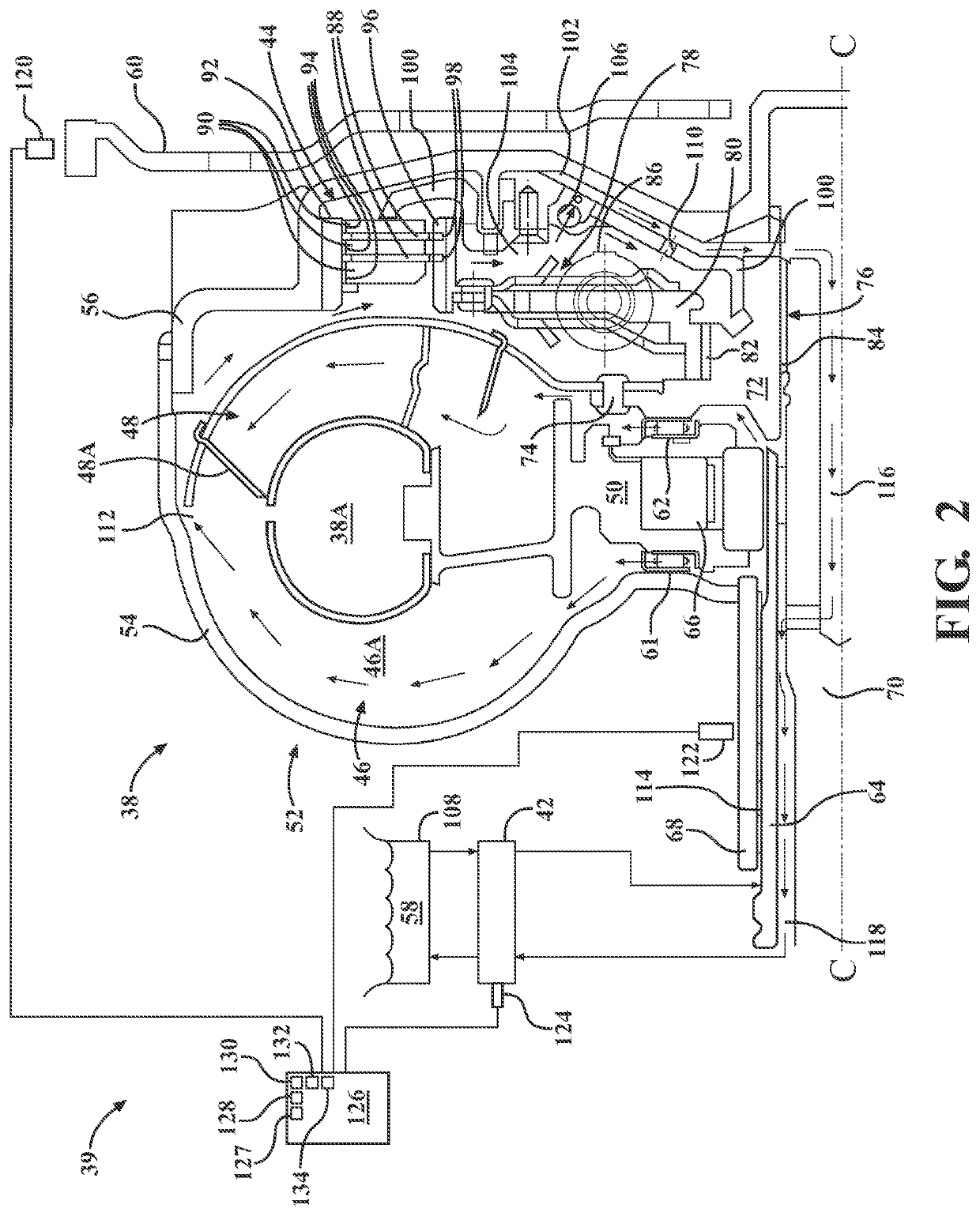

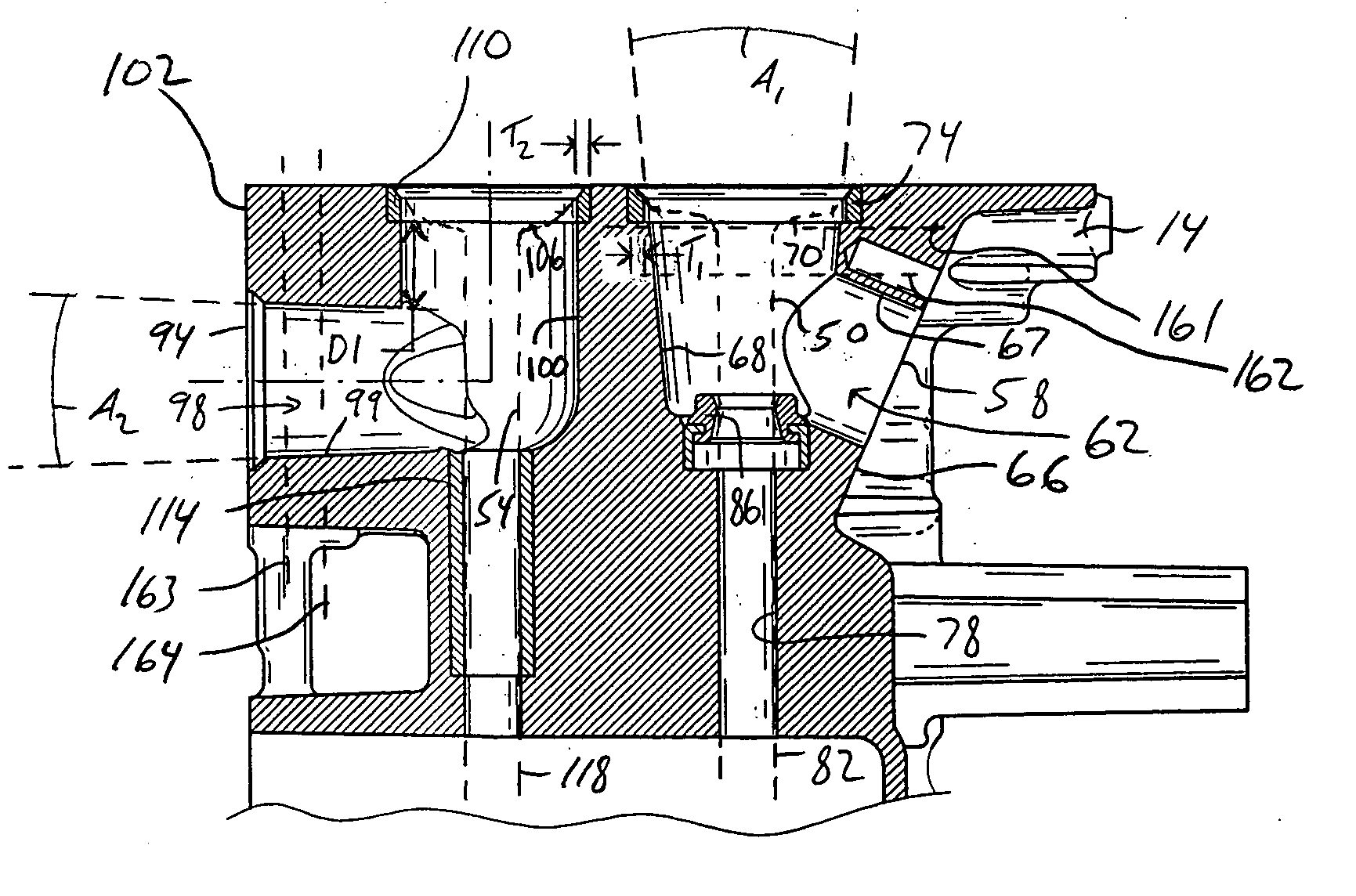

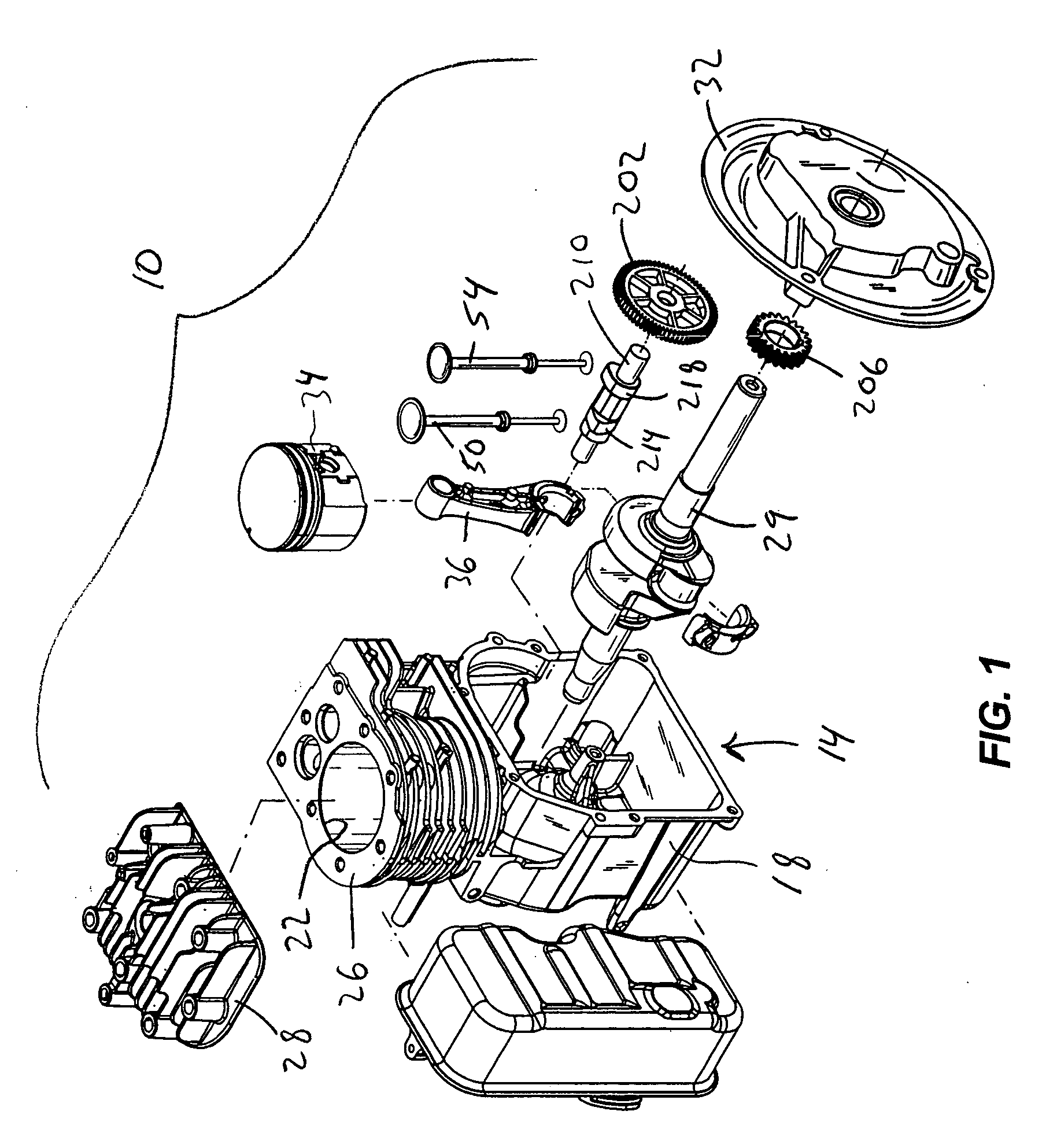

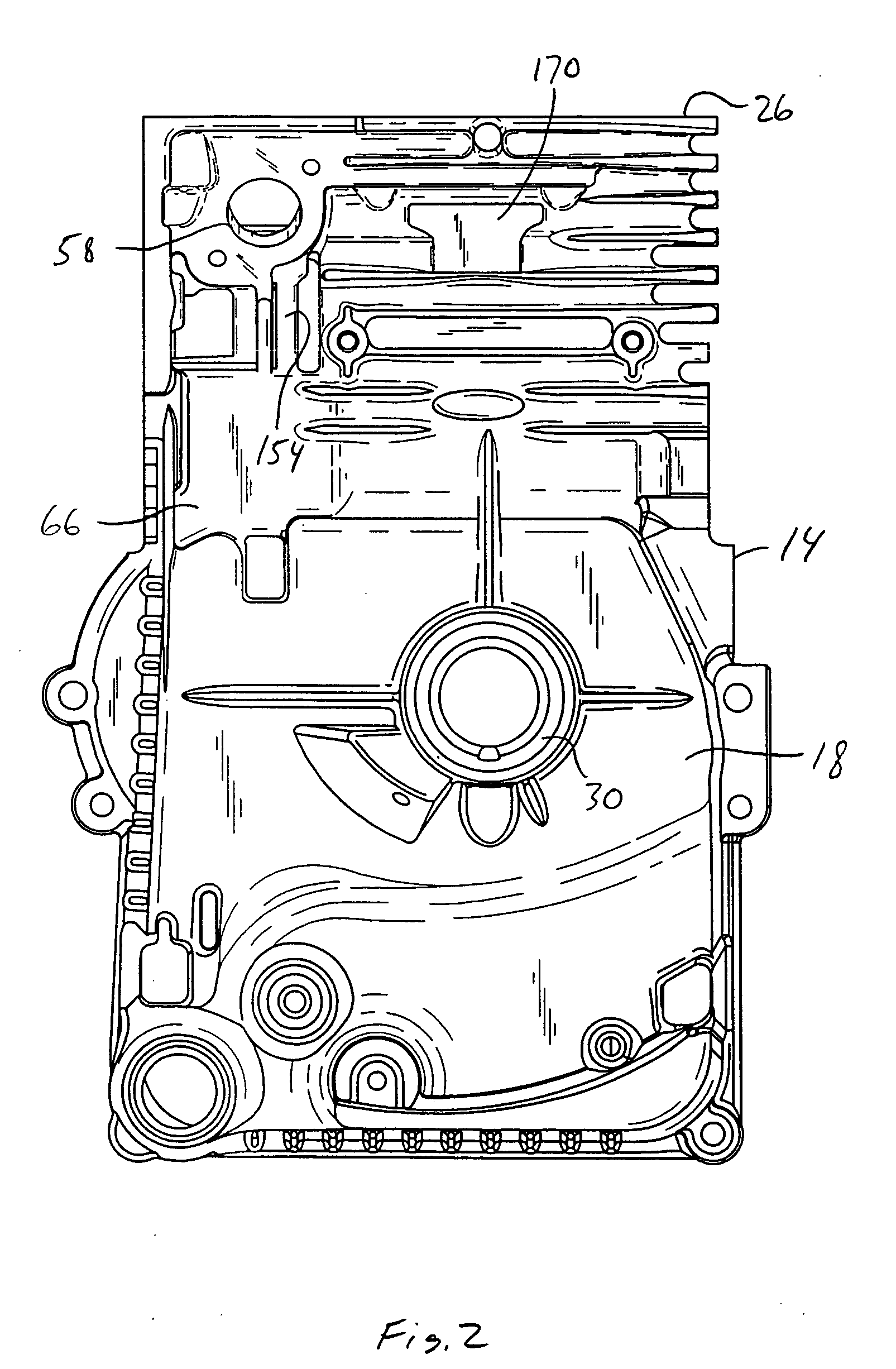

Air flow arrangement for a reduced-emission single cylinder engine

InactiveUS20060037577A1Improves air-fuel mixingAccurate CalibrationCylinder headsCylindersSingle-cylinder engineAirflow

The present invention provides a reduced emission, single cylinder engine incorporating an air flow arrangement for improving flow efficiency of the intake air drawn into the engine and the exhaust discharged from the engine.

Owner:BRIGGS & STRATTON

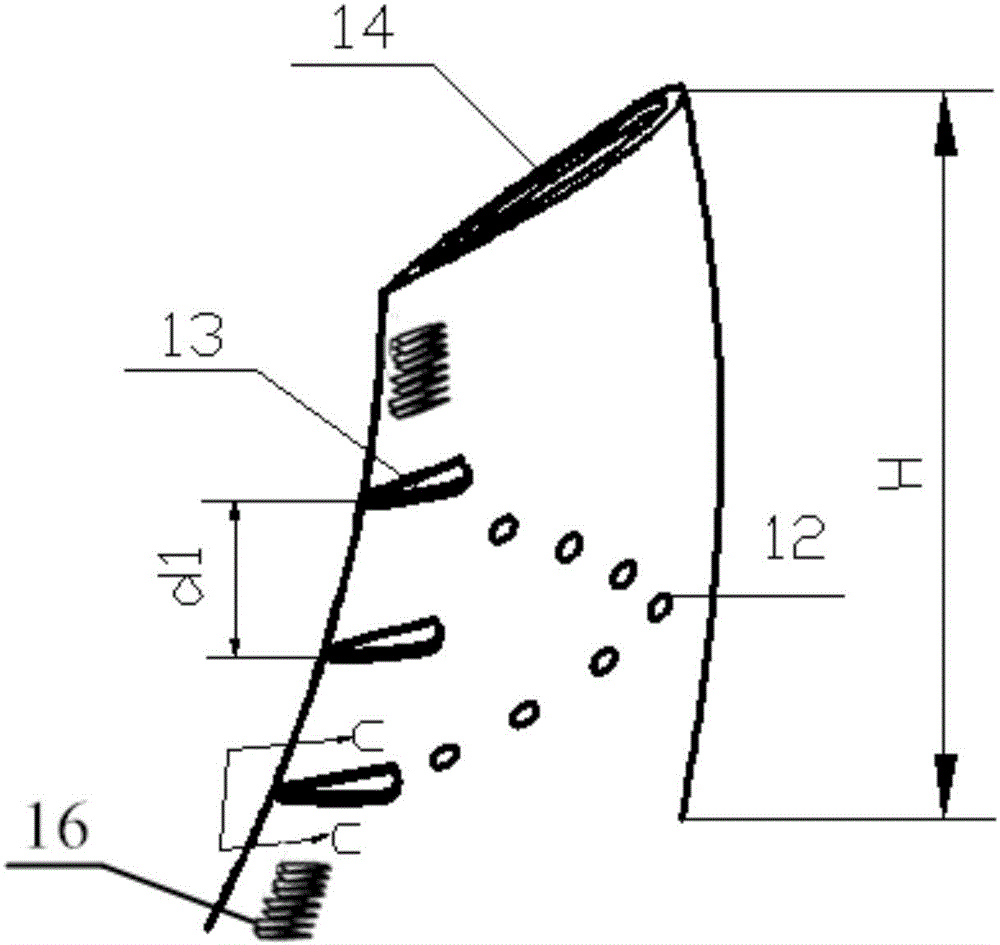

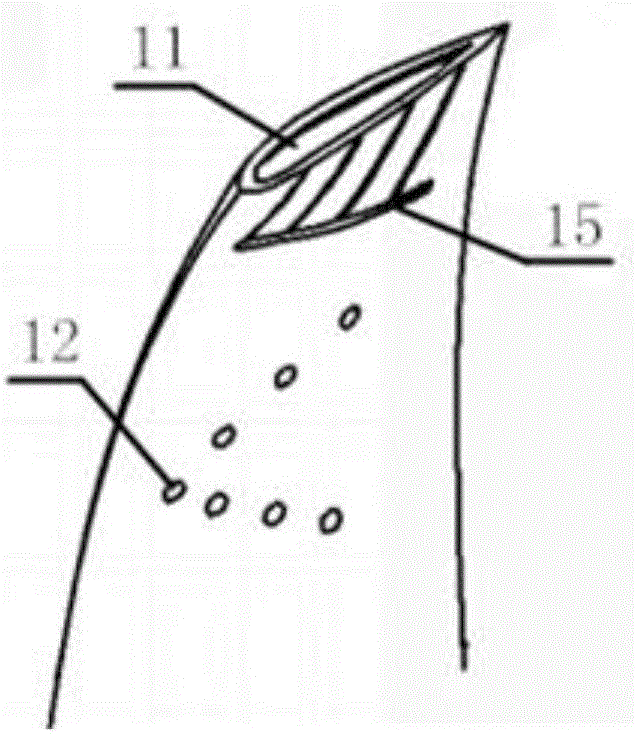

Axial flow fan ternary impeller with vein-shaped structure and nonuniform empennage

The invention discloses an axial flow fan ternary impeller with a vein-shaped structure and a nonuniform empennage. The axial flow fan ternary impeller comprises a hub, and a connecting piece for a shaft sleeve fixed on the hub. The axial flow fan ternary impeller further comprises twisted blades and splitter blades fixedly connected to the hub; the twisted blades include suction surfaces and pressure surfaces; wing-shaped grooves are formed in the tops of the twisted blades; vein-shaped grooves are formed in the upper half parts of the pressure surfaces of the twisted blades; the wing-shaped grooves are communicated with the vein-shaped grooves through exhaust ports; winglet projections and dense winglets are arranged at the tail parts of the suction furnaces of the twisted blades; the dense winglets are arranged on two sides of the winglet projections; parabola small holes are formed in the twisted blades; the splitter blades are arranged between two adjacent twisted blades; and the heights of the splitter blades are smaller than the heights of the twisted blades by one half.

Owner:杭州宏德智能装备科技有限公司

Pump impeller and chopper plate for a centrifugal pump

InactiveUS20050045757A1Improve flow efficiencyImprove efficiencySpecific fluid pumpsPump componentsChopper pumpsCentrifugal pump

A centrifugal pump of the chopper type is disclosed which is structured with a chopper plate and impeller that are configured with an open eye or “hubless” arrangement such that processing of solids through the pump does not result in clogging of solids at or near the center of the impeller, thereby producing a dead zone. Because the configuration of the chopper pump of the present invention avoids the development of a central dead zone or clogging of solids, and provides for flow of solids and fluid through the eye of the impeller, pump efficiencies are markedly improved.

Owner:ENVIROTECH PUMPSYSTEMS INC

Impeller vane configuration for a centrifugal pump

InactiveUS20050207891A1Improves hydraulicsAggressive profileSpecific fluid pumpsPropellersLeading edgeContinuous use

A pump impeller for use in industrial pumps of the centrifugal type is disclosed in which the vanes of the pump impeller are particularly configured to maintain pumping efficiency as the vane wears over continuous use or operation of the pump. The impeller vane is configured to continuously present an aggressive cutting surface at the leading edge of the vane even though the vane may become degraded and worn through continuous use.

Owner:ENVIROTECH PUMPSYSTEMS INC

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com