Separate rotary valve assembly for changing air direction of regenerative combustion device and regenerative combustion system including the same

A technology of combustion device and wind direction conversion, applied in combustion method, combustion type, lighting and heating equipment, etc., can solve problems such as mixing and reduction of gas flow efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

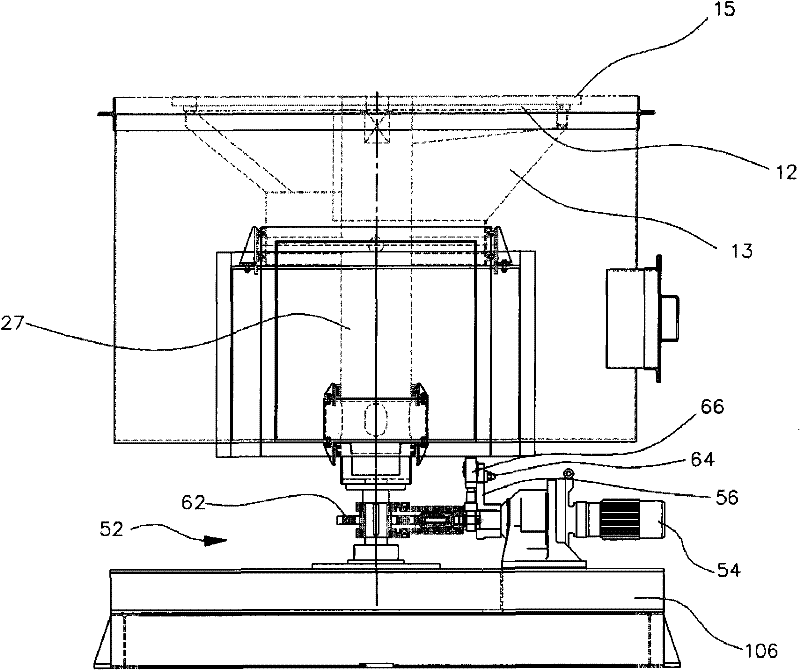

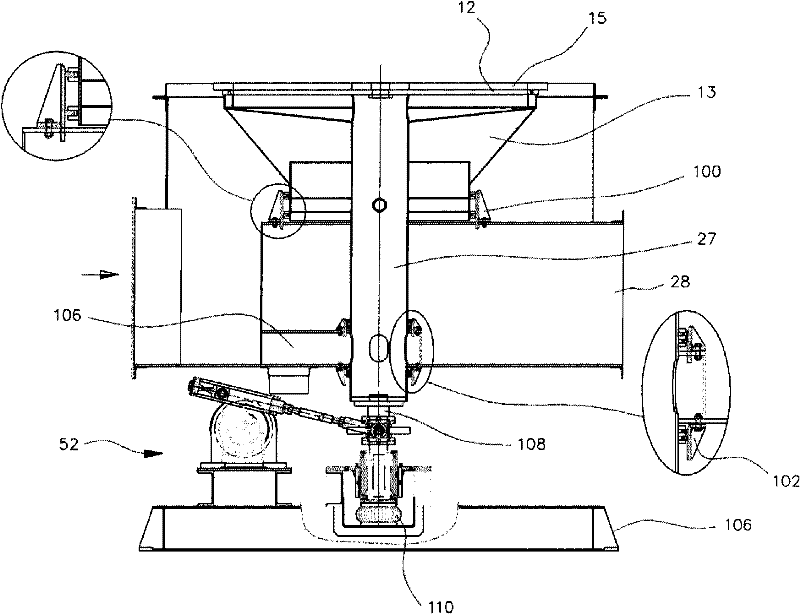

[0050] Hereinafter, preferred embodiments of the present invention will be described in detail with reference to the accompanying drawings.

[0051] First, refer to the Figure 4 to Figure 16 Basic structural diagram and detailed structural diagram of the present invention of the preferred embodiment shown, and as Figure 17 to Figure 31 The operational state diagrams and other embodiments shown illustrate the preferred embodiments of the present invention.

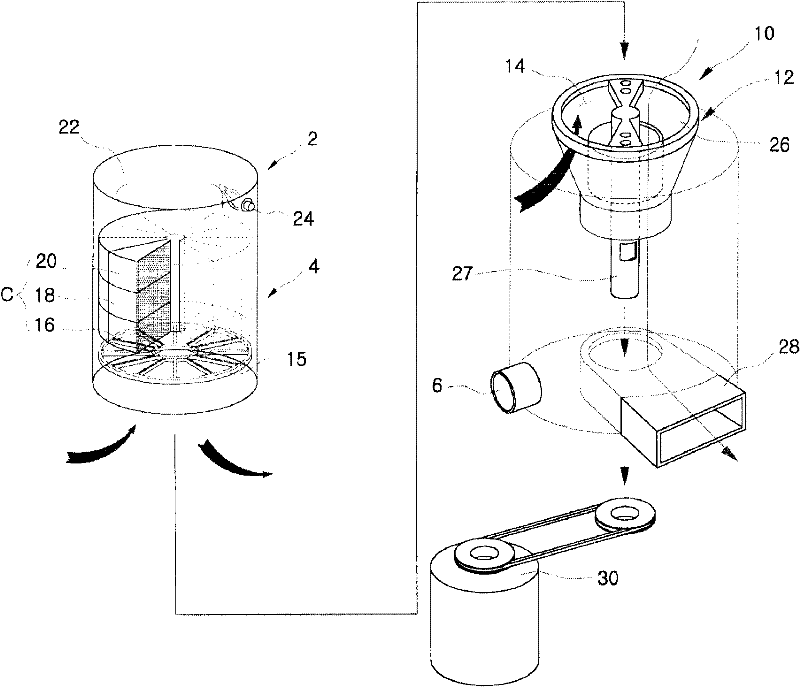

[0052] see Figure 4 to Figure 8 , the regenerative combustion system using the wind direction conversion device for the regenerative combustion device according to the present invention has the following structure as a whole, between the regenerative combustion device 100 and the gas pipeline part 400, there is a A circular dome-shaped distribution chamber 200 and a rotor 300 of the wind direction converter. Among them, the above-mentioned regenerative combustion device 100 includes: an incineration chamber 110 for in...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com