Patents

Literature

159results about How to "Reduce impact loss" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

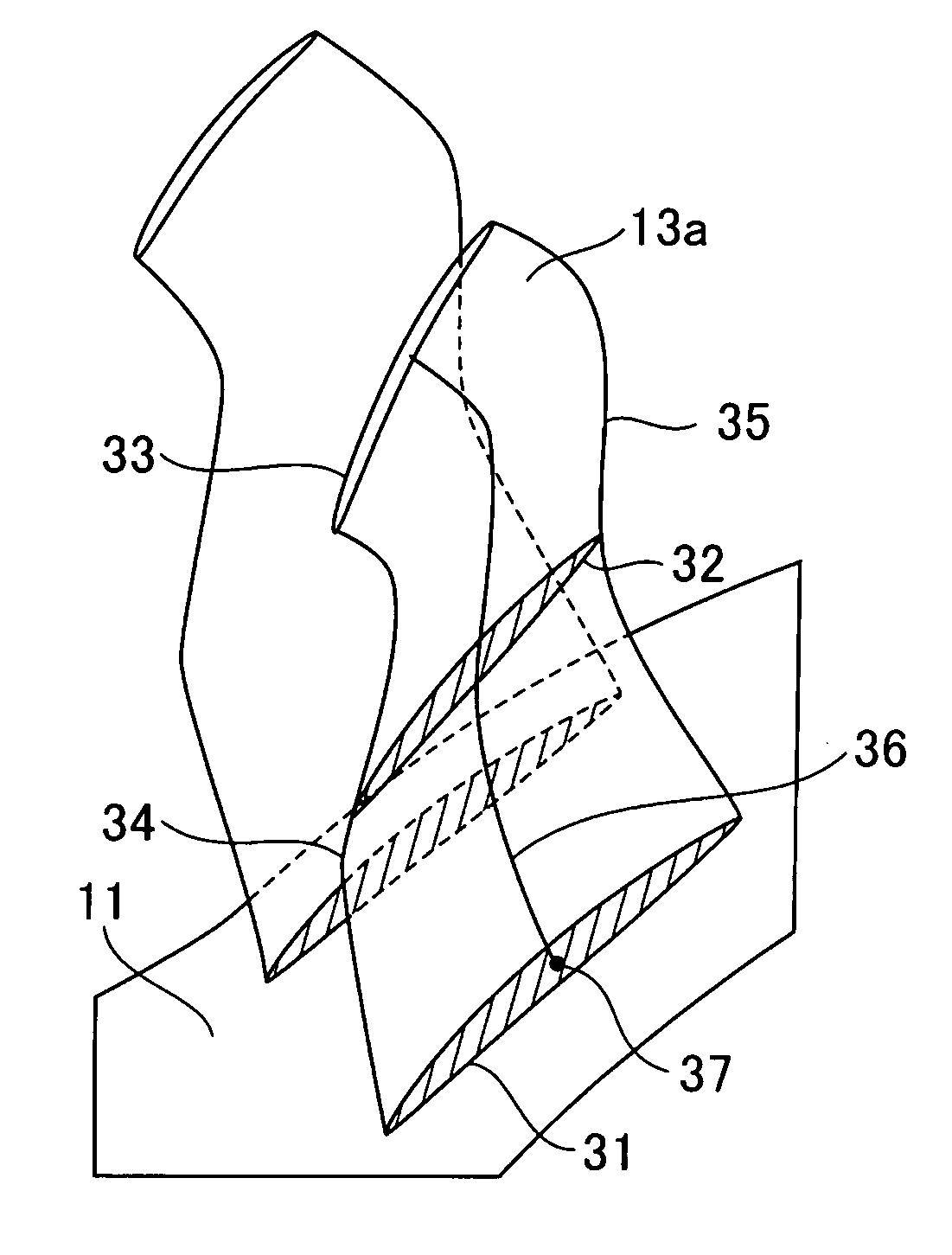

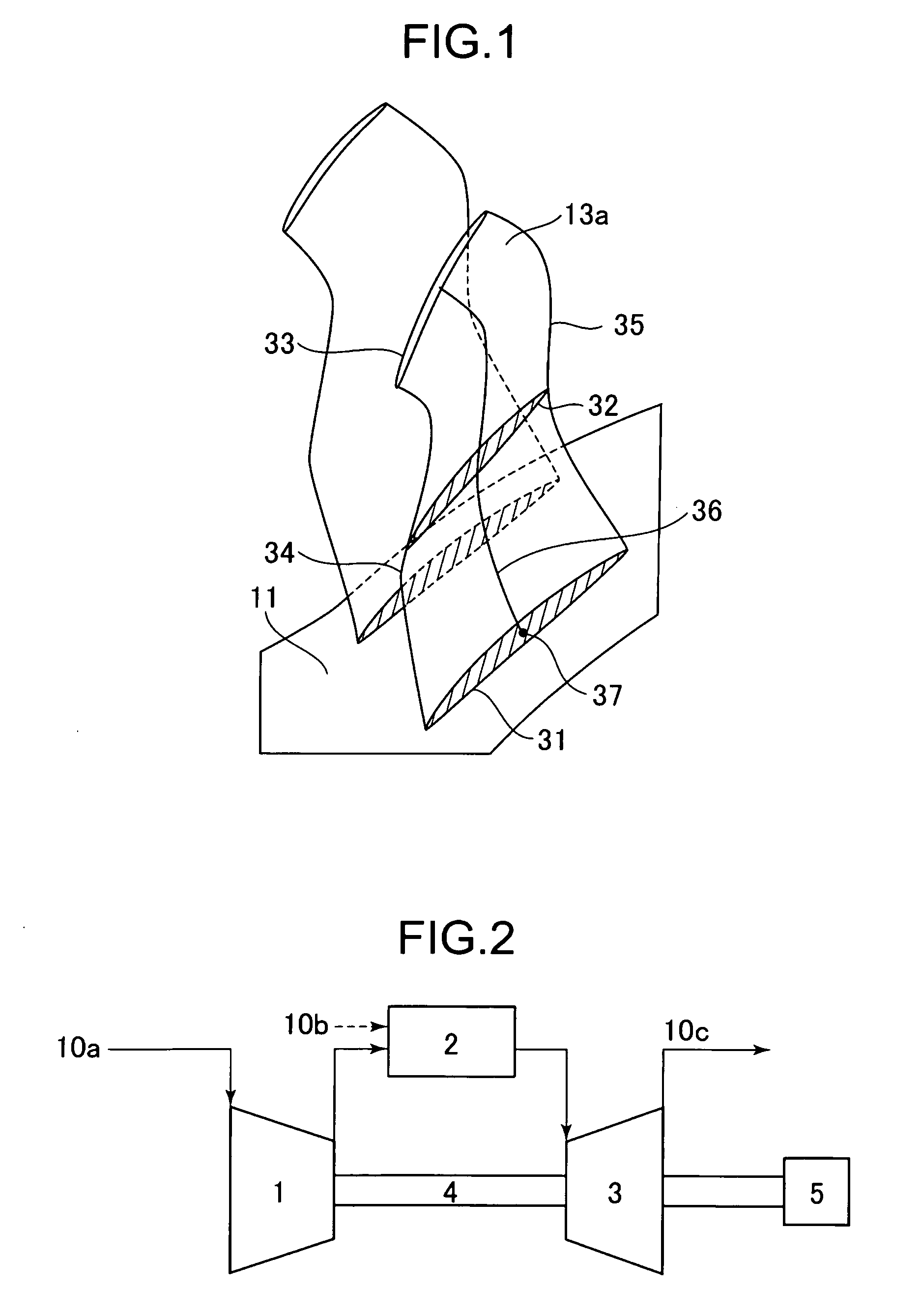

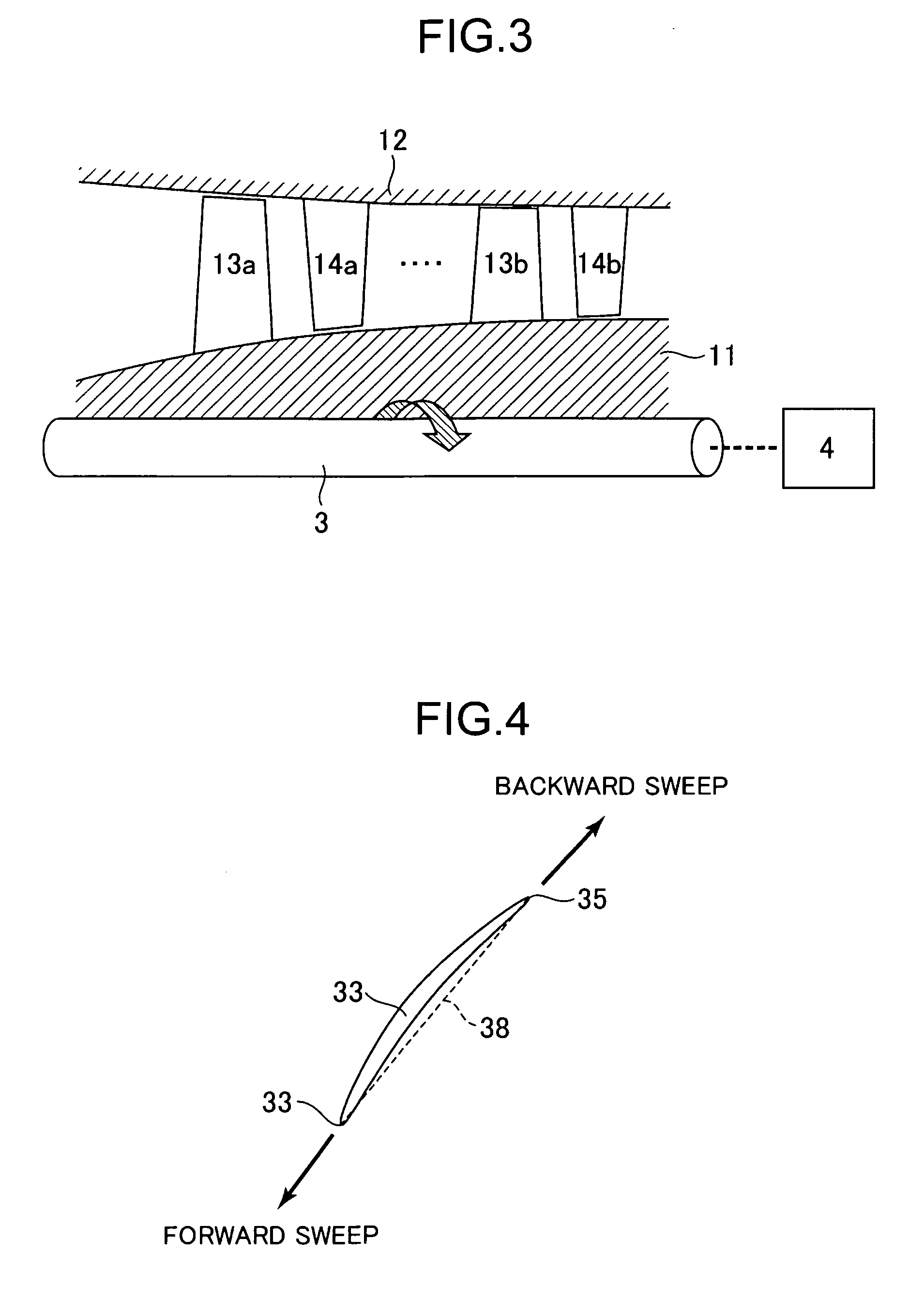

Transonic blade

ActiveUS20100215503A1Reduce various lossesImprove local stressPropellersReaction enginesLeading edgeWorking fluid

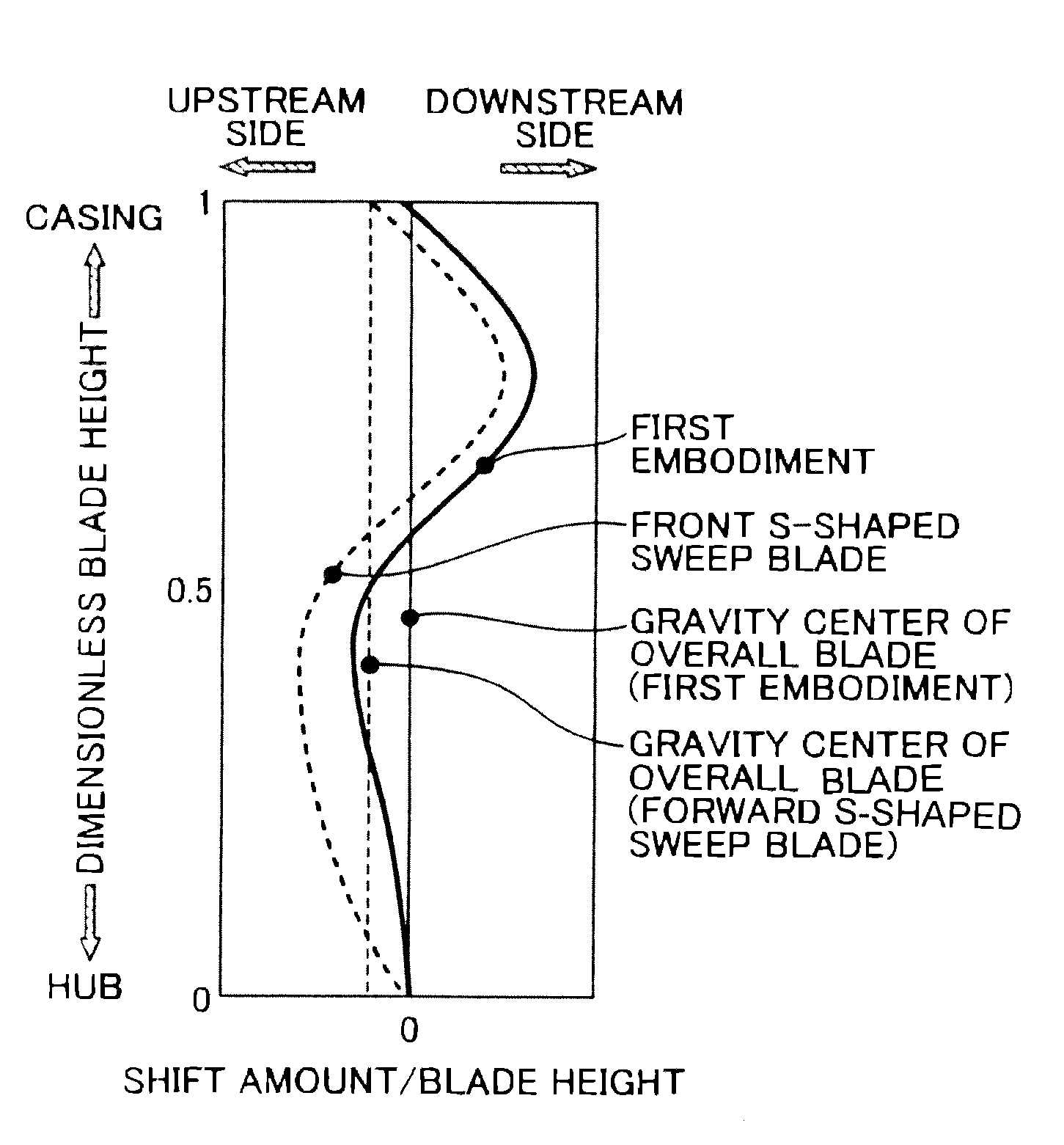

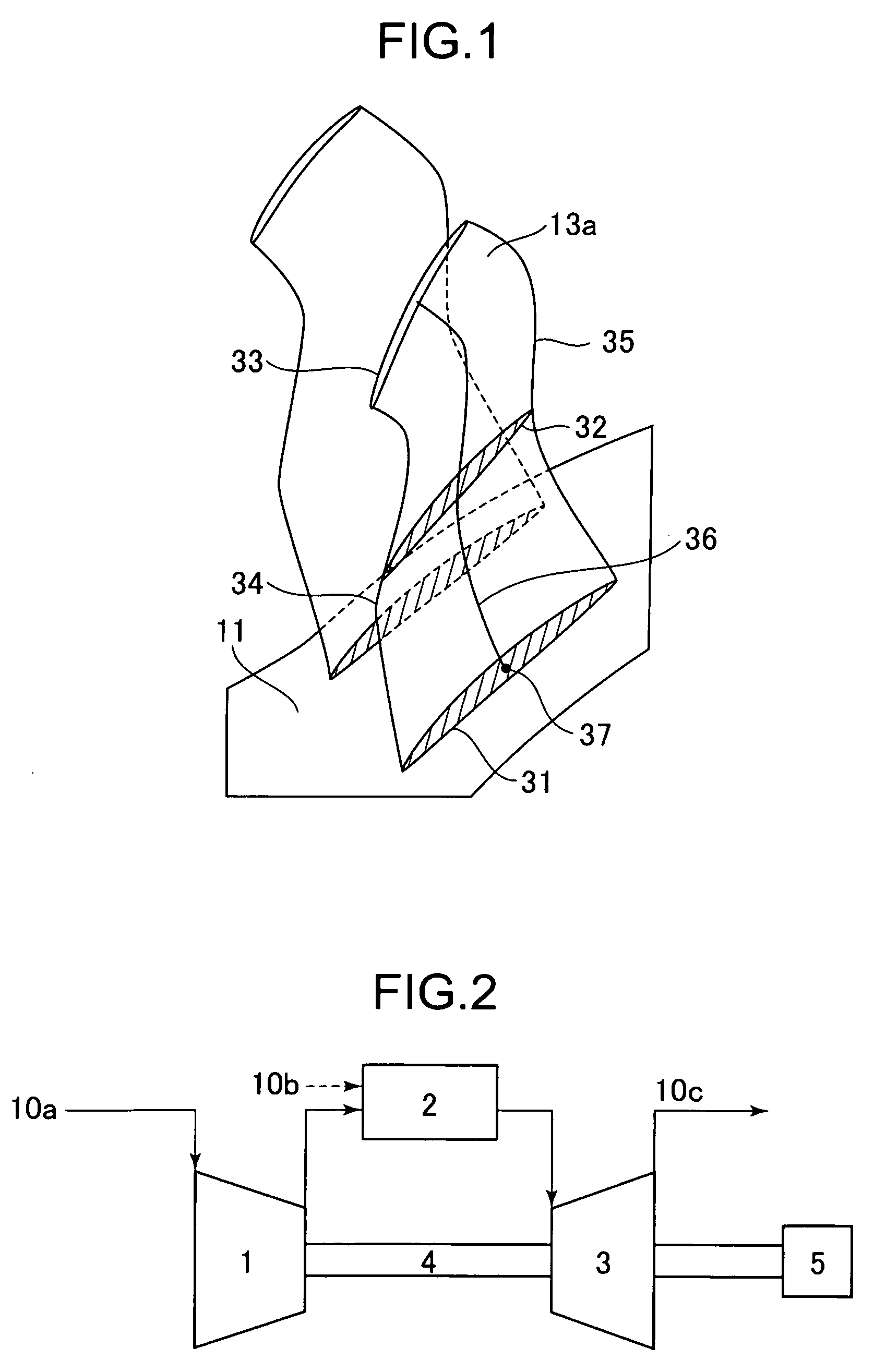

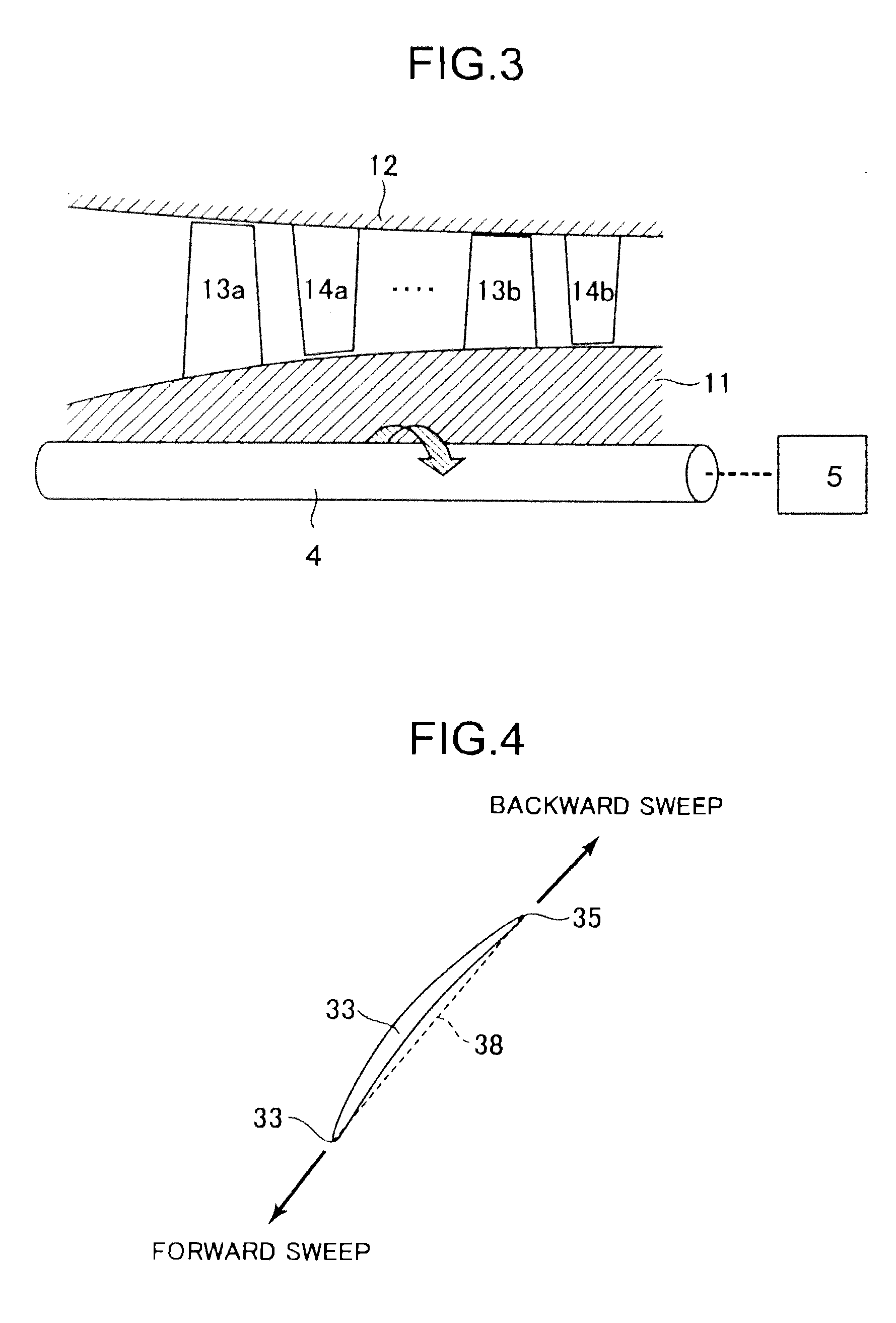

A transonic blade is provided that operates in a flow field where flow has a transonic speed or higher in an axial-flow rotating machine and that concurrently achieves a reduction in shock loss and in the local stress of the blade.The transonic blade includes a hub cross-sectional surface joined to a rotating shaft or an outer circumferential side casing of a rotating machine; a tip cross-sectional surface located furthest from the hub cross-sectional surface in a spanwise direction which is a vertical direction of the rotating shaft; a leading edge located on an upstream side; and a trailing edge located on a downstream side. At least a part of a passing working fluid flow has a transonic speed or higher. A portion of a stacking line which is a line connecting together respective gravity centers of cross-sectional surfaces located from the hub cross-sectional surface to the tip cross-sectional surface is located on a downstream side of a stacking center in a flow direction of a working fluid main flow.

Owner:MITSUBISHI POWER LTD

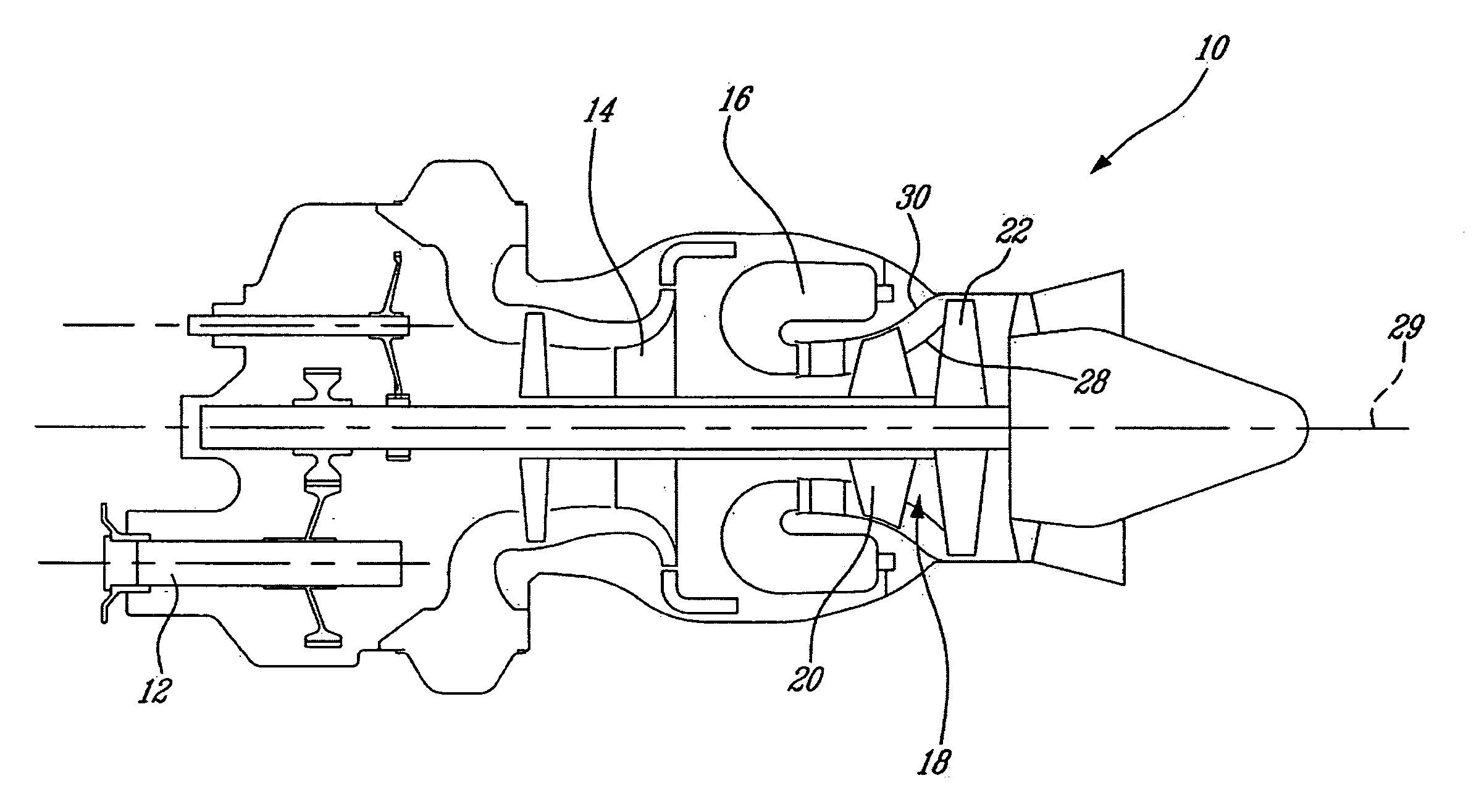

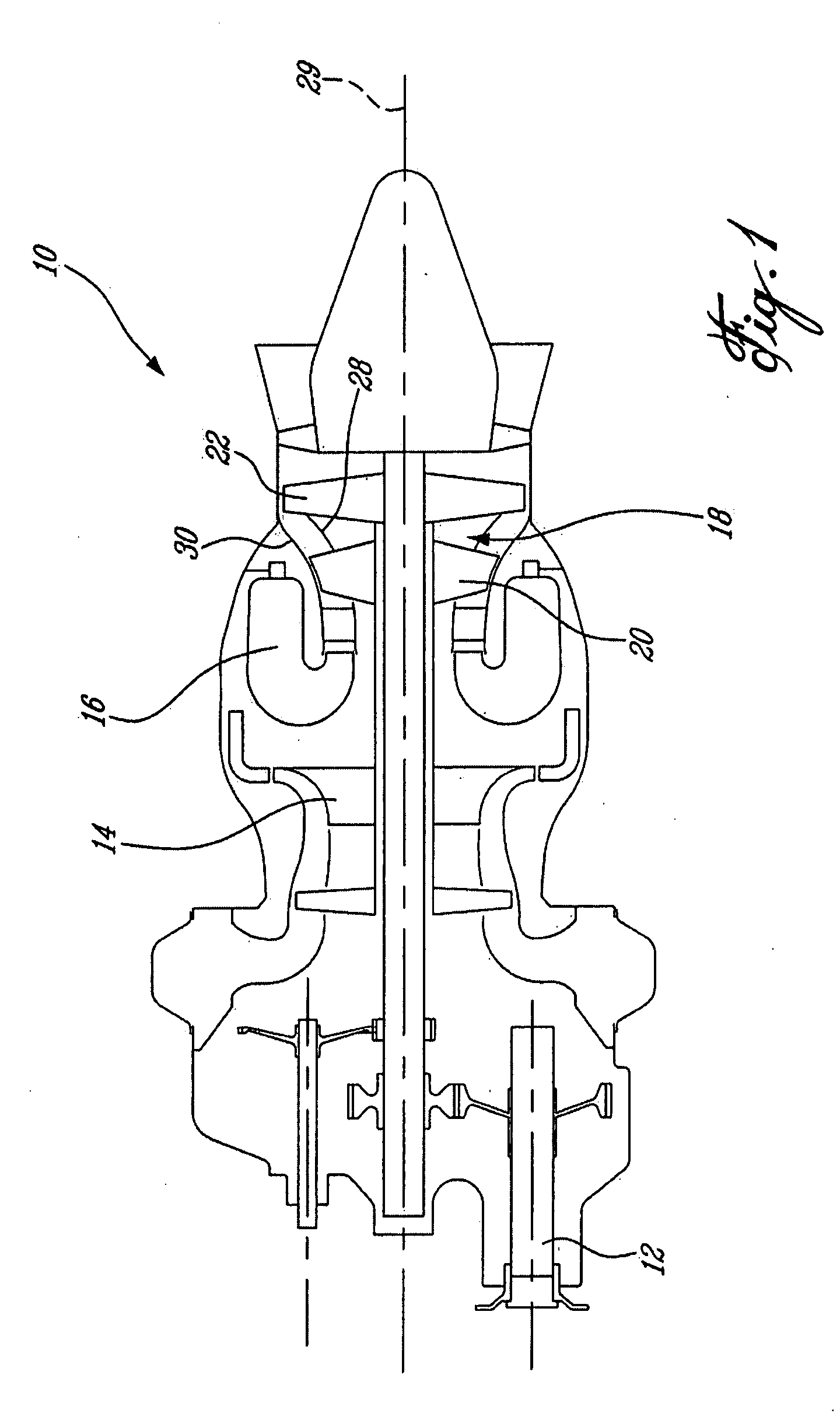

HP turbine vane airfoil profile

ActiveUS7568891B2Minimize secondary lossesReduce impact lossPropellersEngine manufactureSingle stageTurbine blade

A single stage high pressure turbine vane includes an airfoil having a profile substantially in accordance with at least an intermediate portion of the Cartesian coordinate values of X, Y and Z set forth in Table 2. The X and Y values are distances, which when smoothly connected by an appropriate continuing curve, define airfoil profile sections at each distance Z. The profile sections at each distance Z are joined smoothly to one another to form a complete airfoil shape.

Owner:PRATT & WHITNEY CANADA CORP

Compressor turbine vane airfoil profile

ActiveUS20090116967A1Minimize secondary lossReduce impact lossPropellersEngine manufactureSingle stageTurbine blade

A single stage high pressure turbine vane includes an airfoil having a profile substantially in accordance with at least an intermediate portion of the Cartesian coordinate values of X, Y and Z set forth in Table 2. The X and Y values are distances, which when smoothly connected by an appropriate continuing curve, define airfoil profile sections at each distance Z. The profile sections at each distance Z are joined smoothly to one another to form a complete airfoil shape.

Owner:PRATT & WHITNEY CANADA CORP

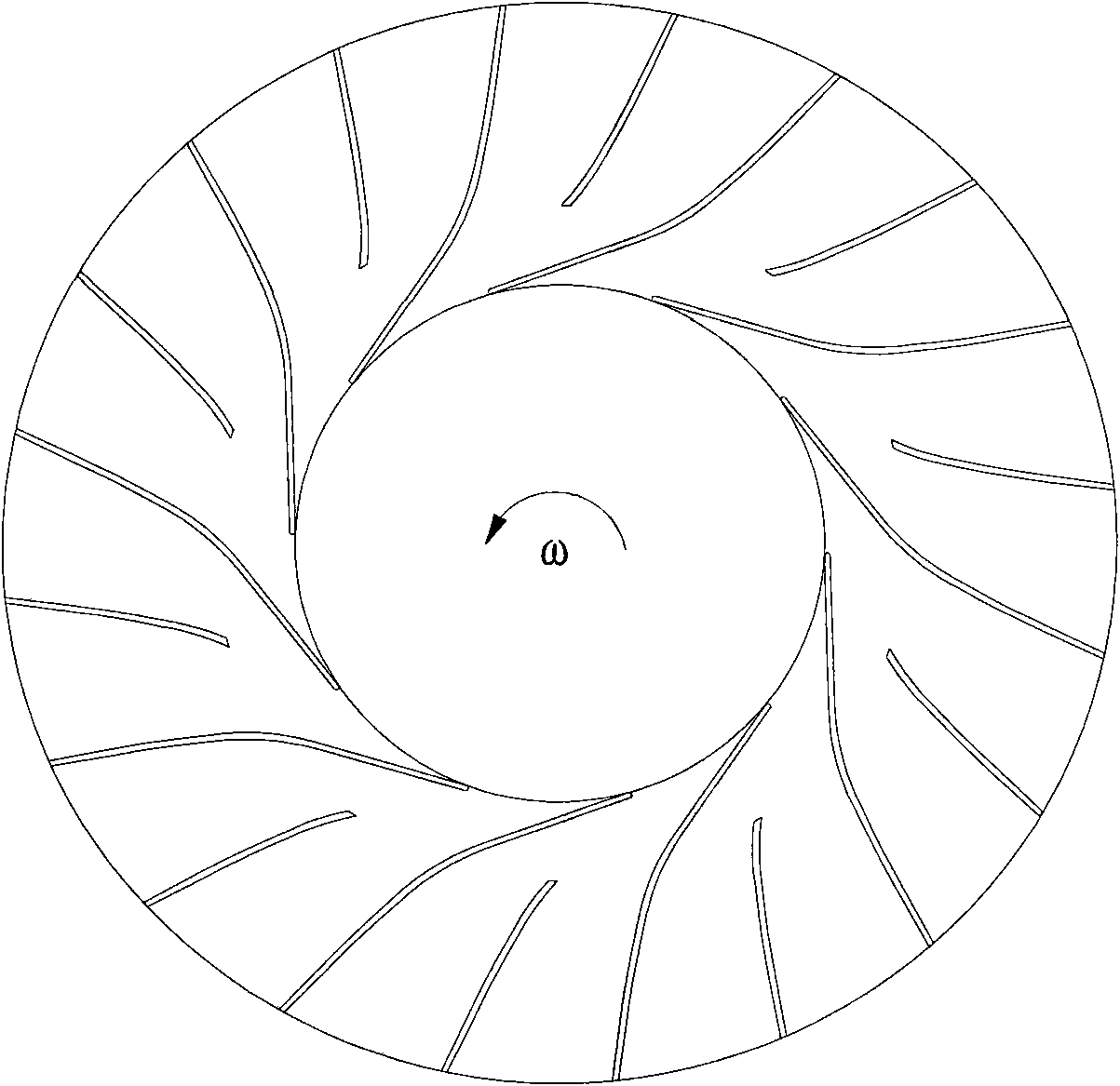

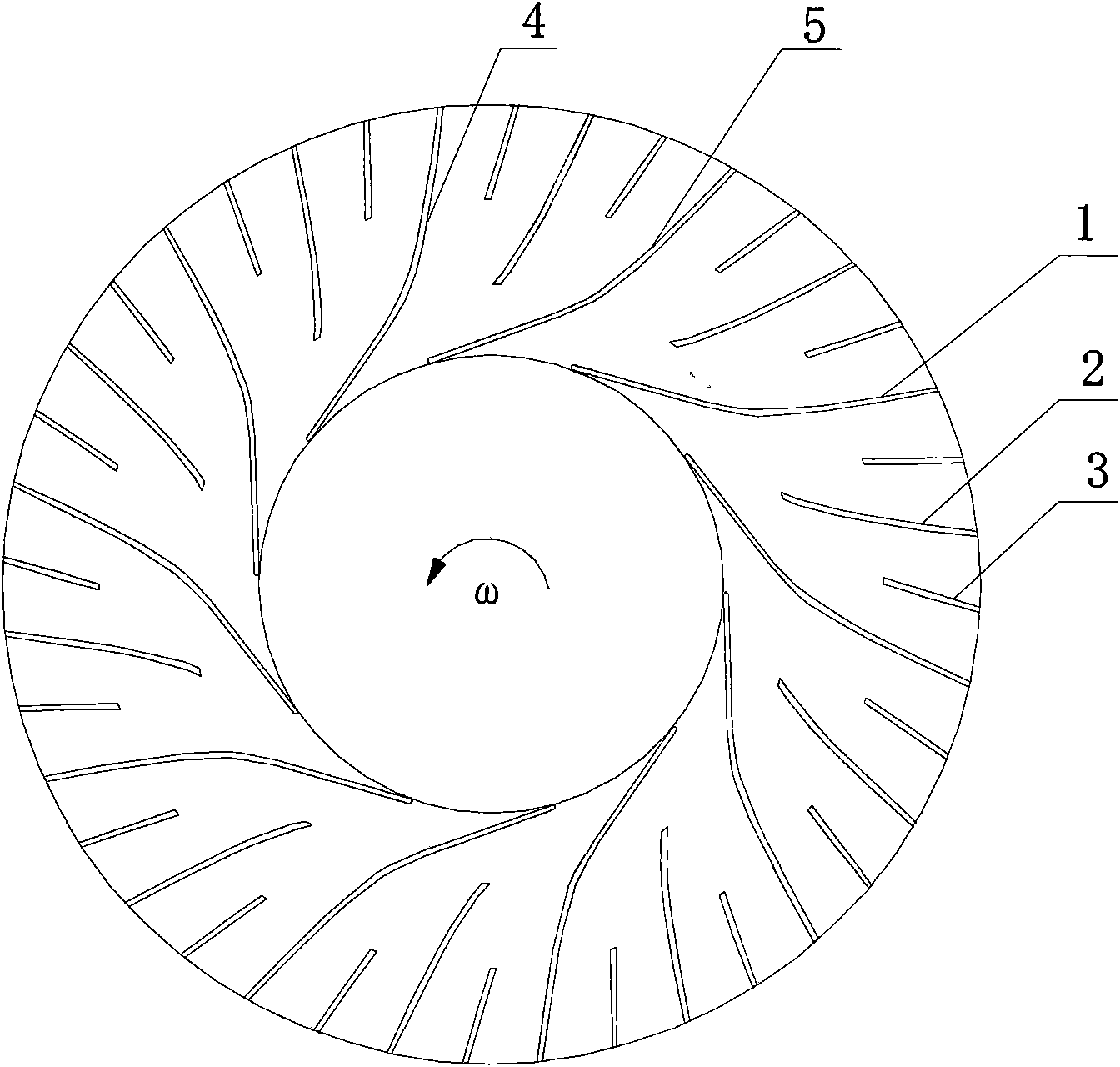

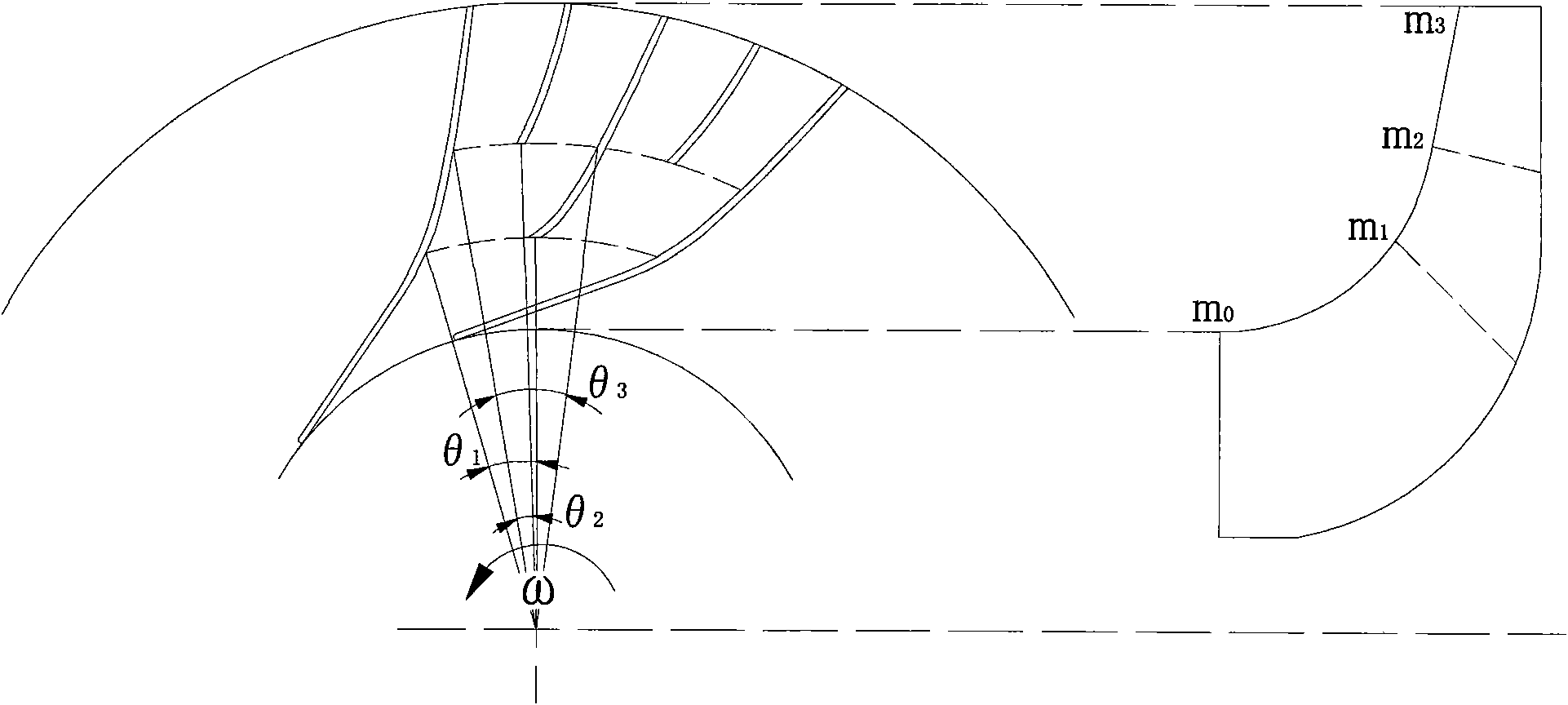

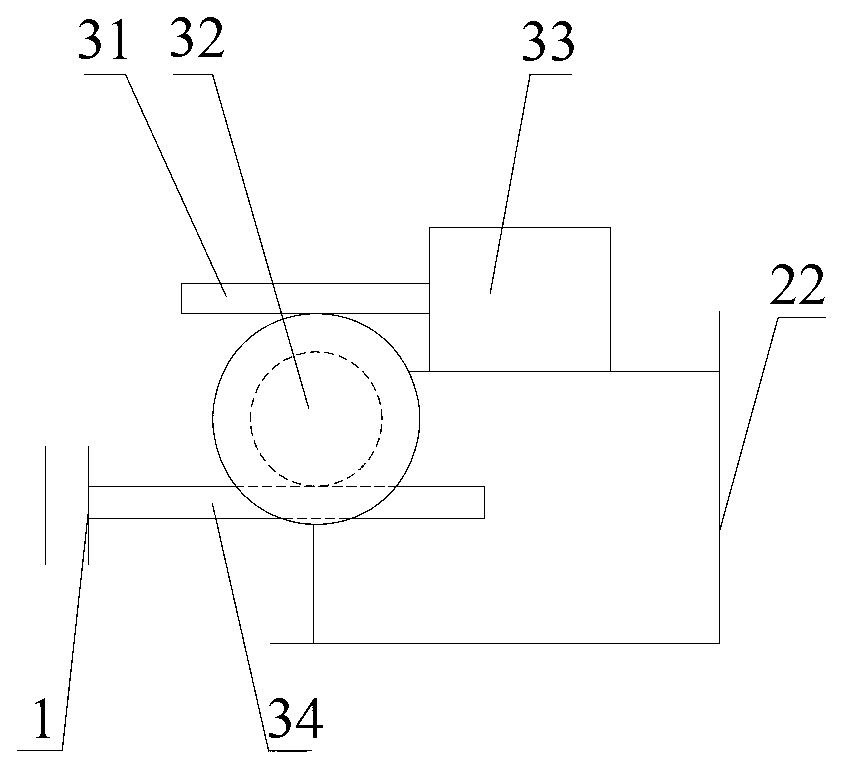

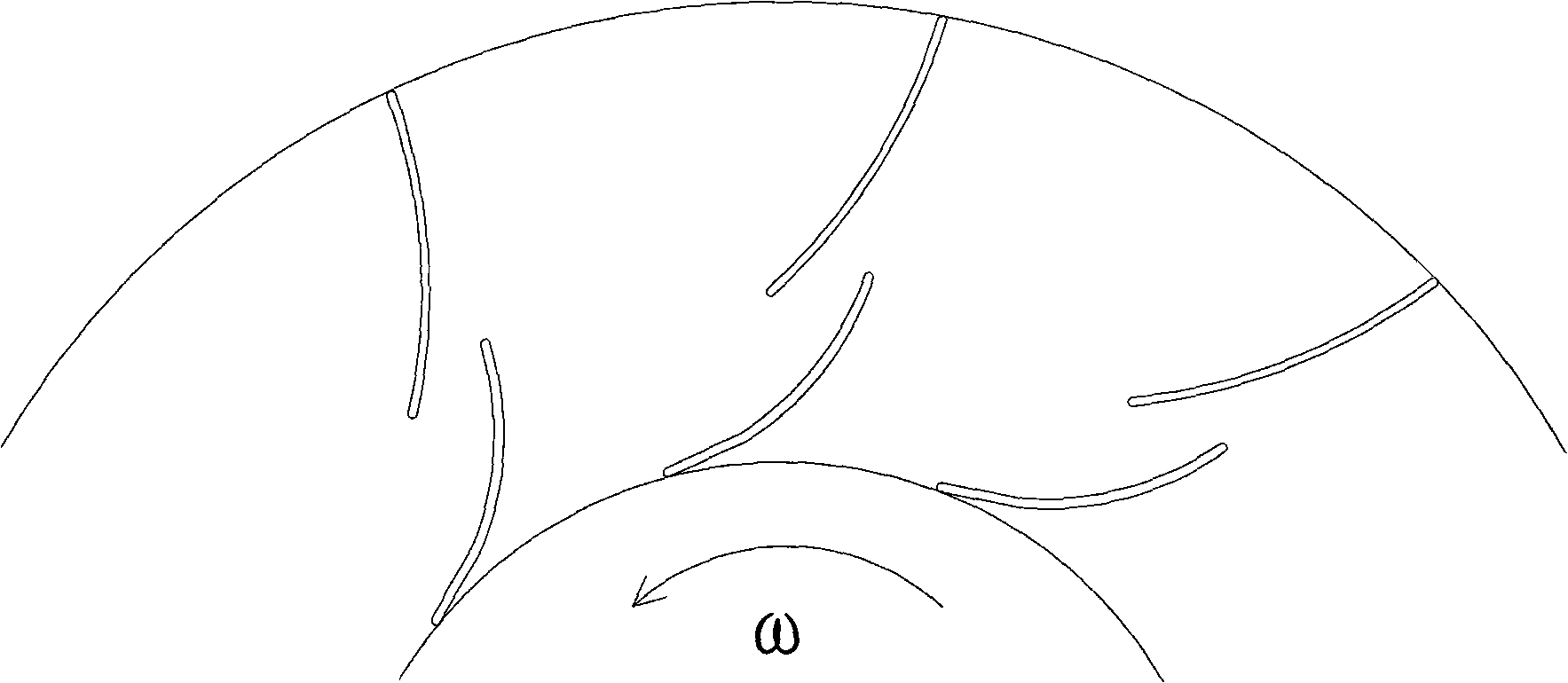

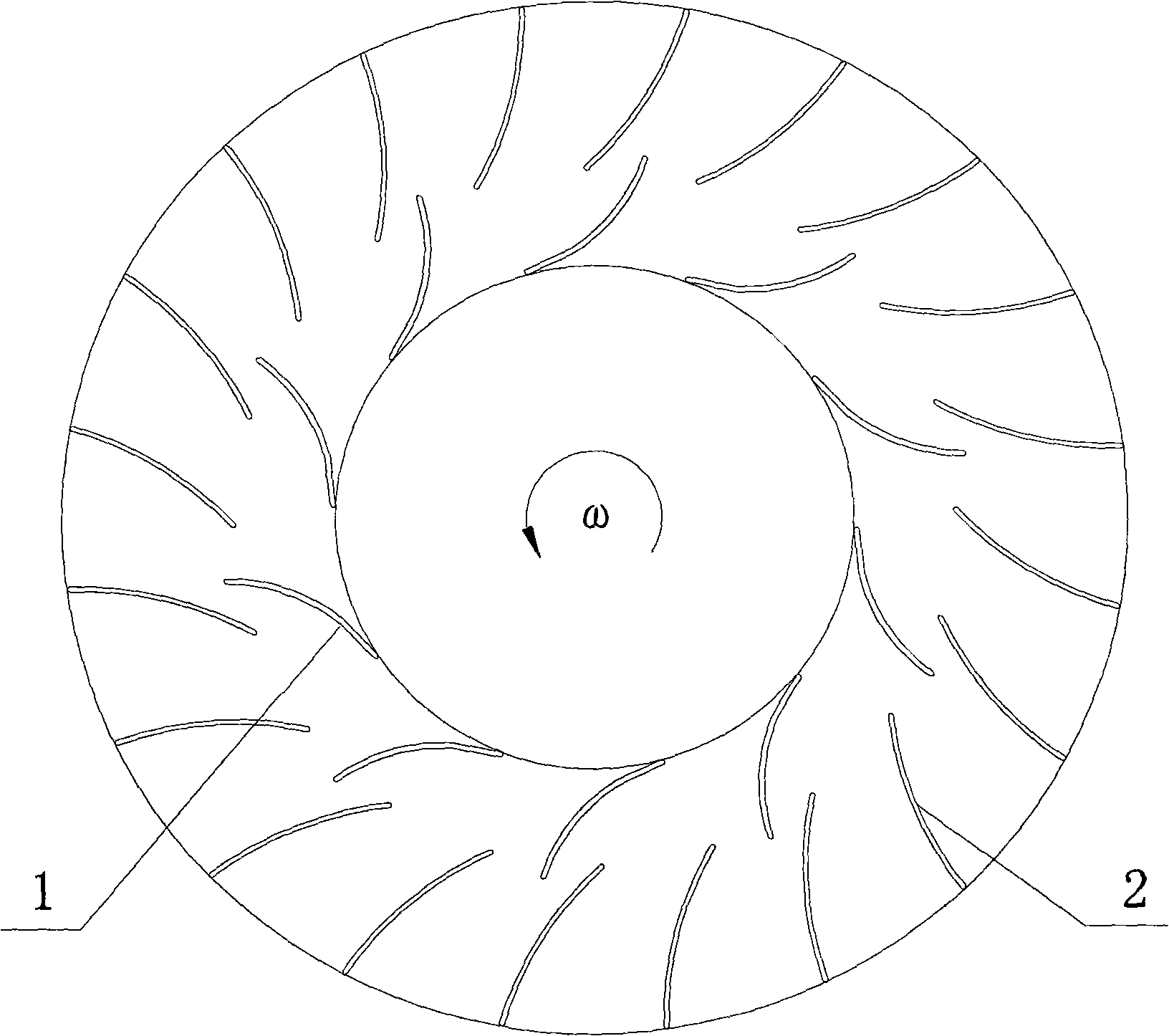

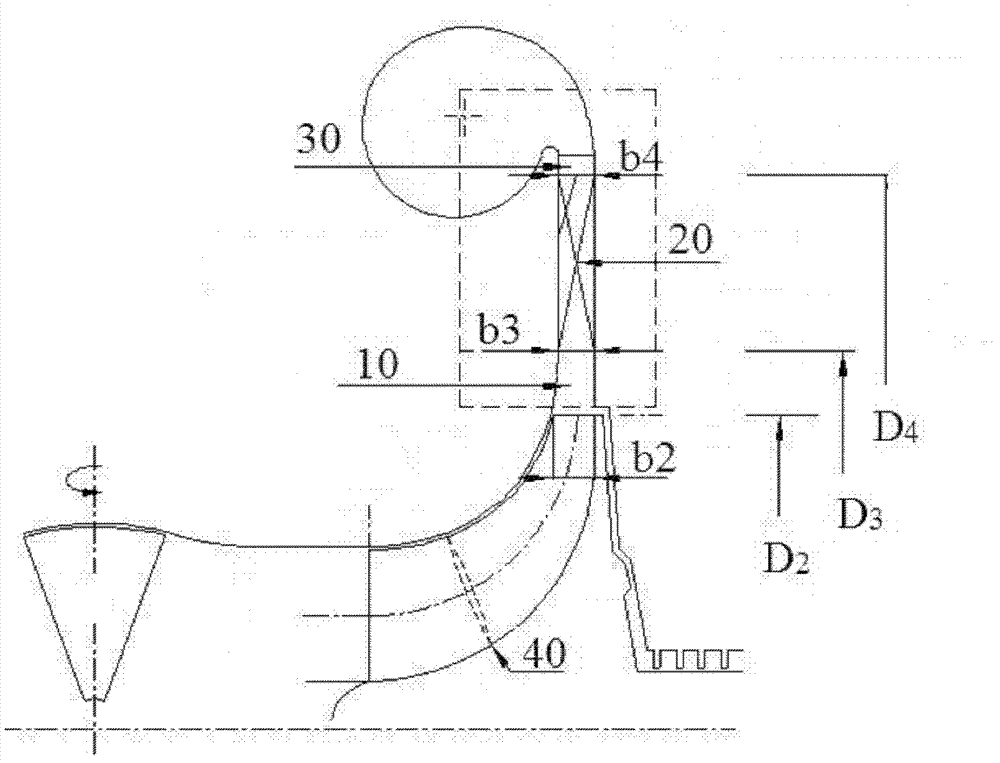

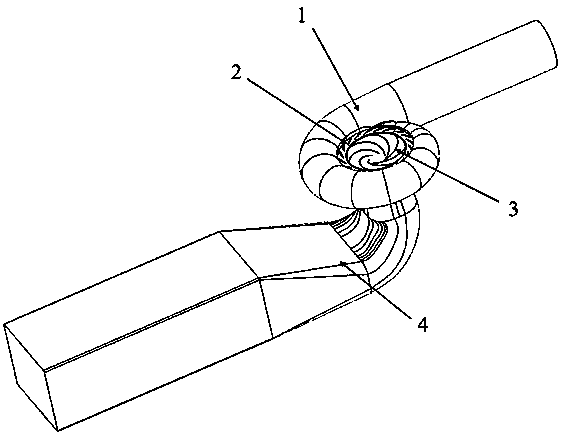

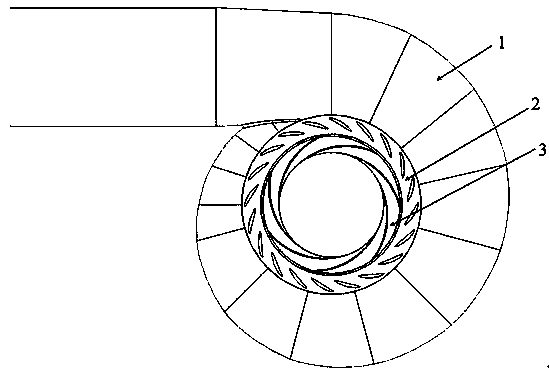

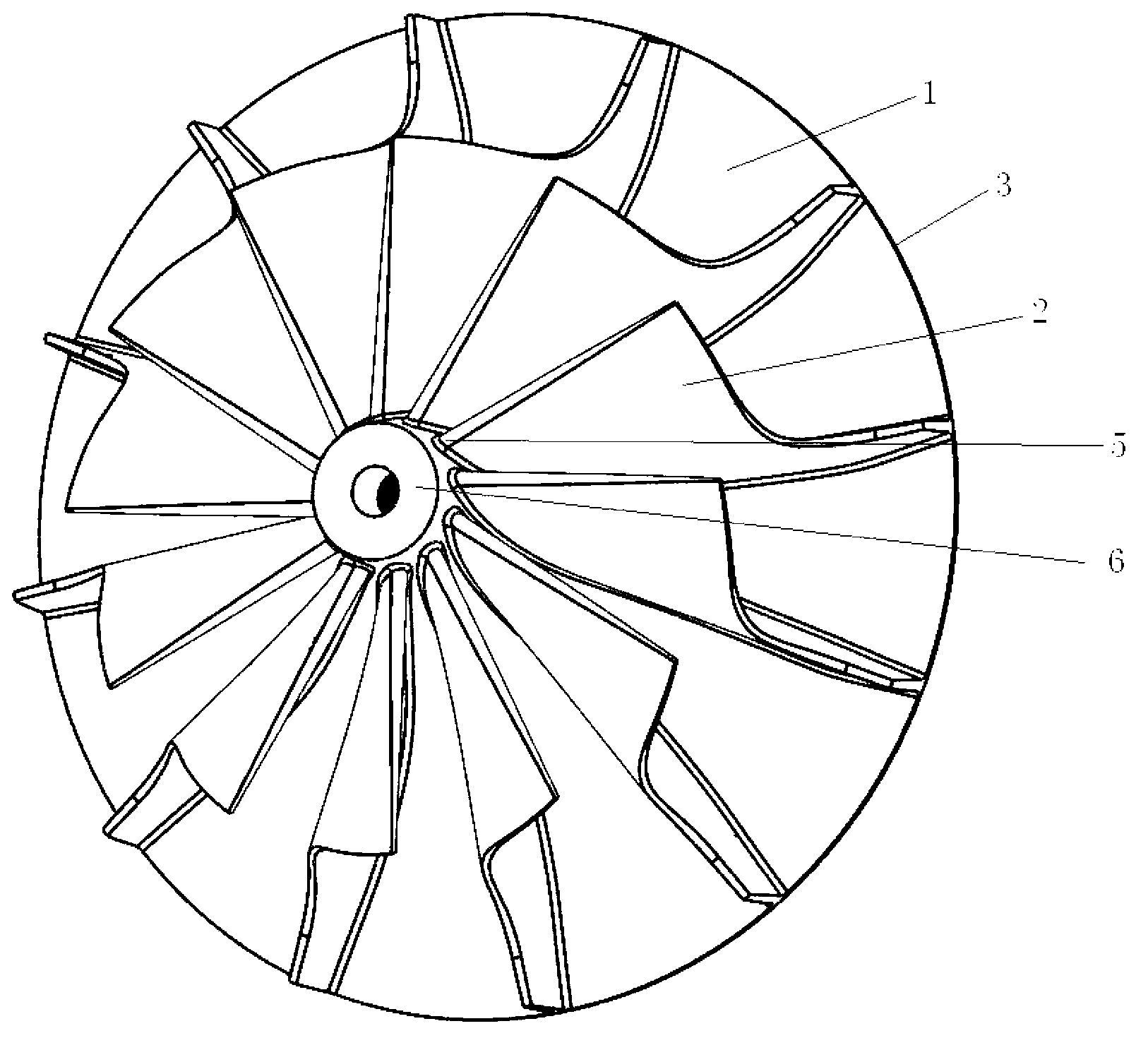

Secondary splitter blade type centrifugal impeller

InactiveCN101598138AImprove mobilityImprove flow efficiencyPump componentsPumpsImpellerAerodynamic load

The invention discloses a secondary splitter blade type centrifugal impeller, comprising a long blade extending from impeller inlet to impeller outlet. The suction surface of the long blade and the pressure surface of an adjacent long blade form a complete air flow passage; wherein a middle blade is arranged between the two long blades to form a primary splitter blade; the two sides of the middle blade are respectively provided with a short blade to form a secondary splitter blade; the inlet of the middle blade deflects toward the suction surface in the air flow passage; the inlet at the wheel disc side of the short blade deflects towards the suction surface in the air flow passage, and the inlet at the wheel cap of the short blade deflects towards one side of the pressure surface in the air flow passage; the number ratio of the long, middle and short blades is 1:1:2; and the long, middle and short blades are evenly distributed at the periphery of the outlet of the impeller. The centrifugal impeller of the invention gradually increases splitter blades, and can effectively allocate blade passage gas flow and blade aerodynamic load, improve flow uniformity at the impeller outlet and improve pressurizing capacity and steady operation range of the centrifugal impeller.

Owner:XI AN JIAOTONG UNIV

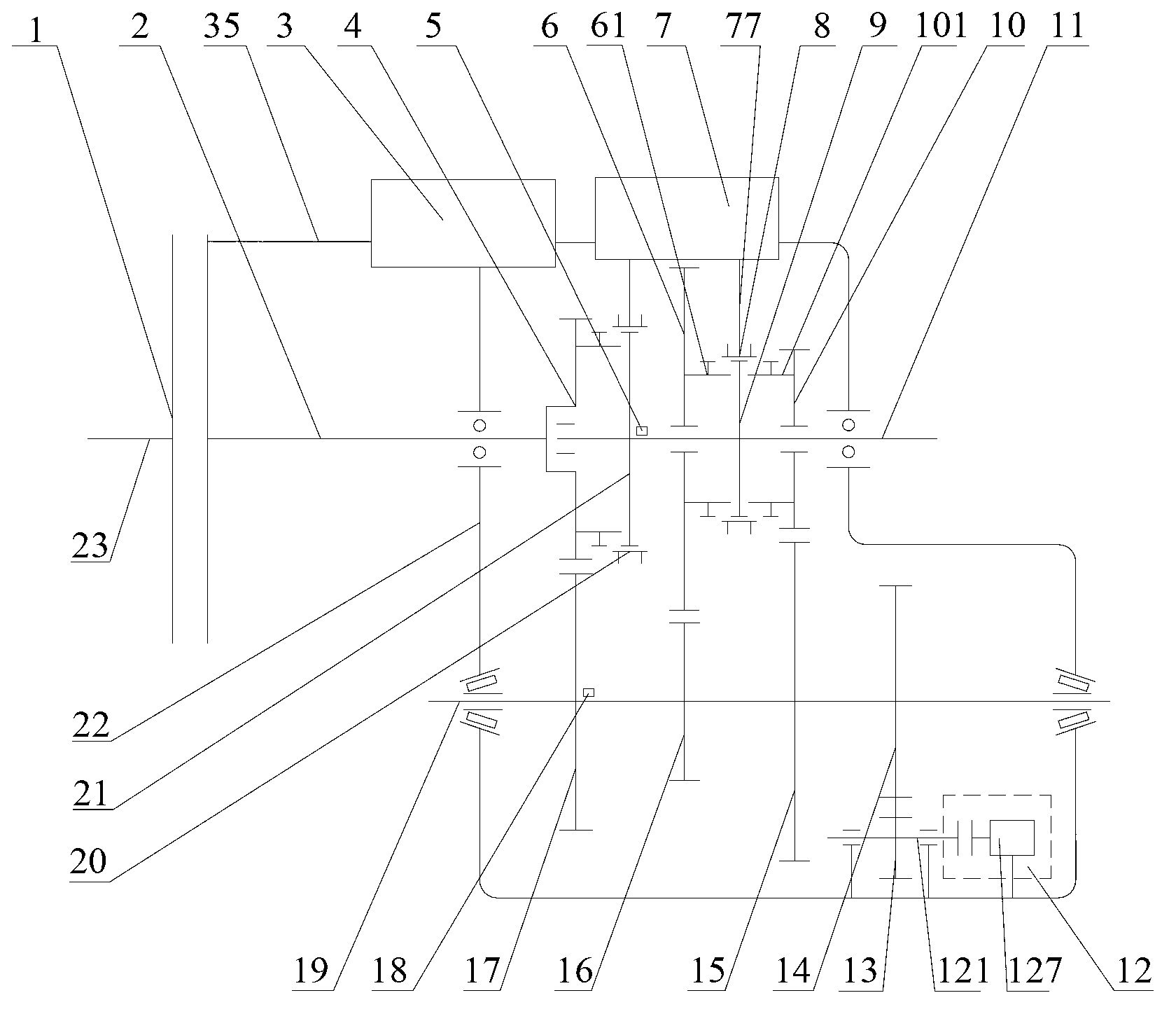

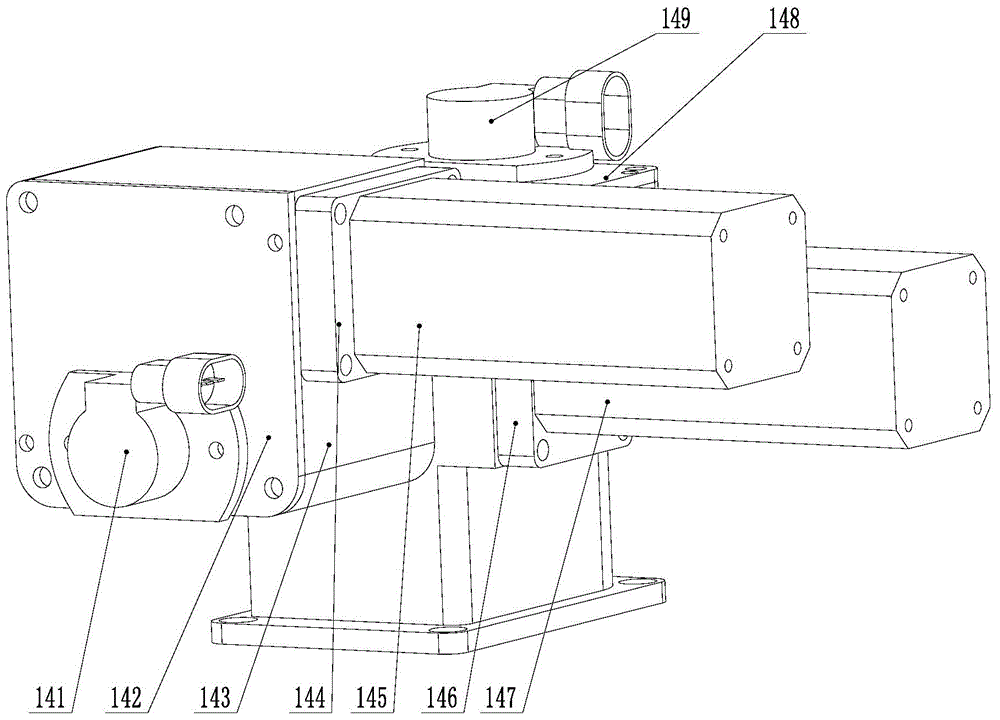

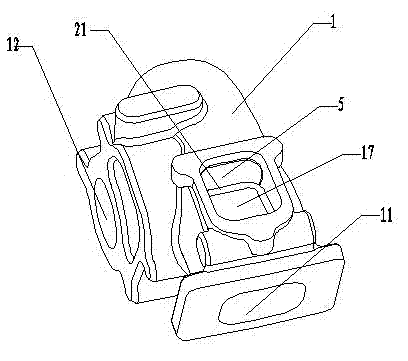

Synchronizer-free shifting system for regulating speed of intermediate shaft of electric automobile

ActiveCN102840309AReduce loadReduced Power RequirementsGearboxesMechanical actuated clutchesElectric machineDrive motor

The invention relates to a front-engine rear-drive automatic mechanical transmission case shifting system for a driving motor, in particular to a synchronizer-free shifting automatic mechanical transmission case for regulating the speed of an intermediate shaft based on a small quantity of gears, belonging to the technical field of automobile control. The system comprises an input shaft, an intermediate shaft, an output shaft, driving and driven gears for each gear, a splined hub, a jointing sleeve, a sensor, a speed regulating motor, a speed regulating motor transmission mechanism, a clutch operating mechanism, a shifting executing mechanism and a controller. According to the system, the rotating speed of the intermediate shaft is regulated through the speed regulating motor, so that synchronization of the jointing sleeve and a target gear during shifting is realized, a synchronizer with high material requirements is eliminated, reduction in the cost is facilitated, and the effect of compatibility among startup, accelerating performance and relatively high-speed running of a small-sized pure electric automobile is realized simultaneously.

Owner:TSINGHUA UNIV +1

Motor and AMT (automated mechanical transmission) integration-based electric vehicle driving system and driving method

InactiveCN103552448ASmall sizeFlexible and convenient layoutSpeed controllerElectric propulsion mountingBrushless motorsElectric machine

The invention discloses a motor and AMT (automated mechanical transmission) integration-based electric vehicle driving system and a motor and AMT integration-based electric vehicle driving method. The driving system comprises a driving motor, a motor controller, a transmission drive assembly, a gear selection and shifting execution mechanism and a controller for the gear selection and shifting execution mechanism, wherein the transmission drive assembly comprises driving and driven gears of four gears, two splined hubs, two jointing sleeves and an output sensor; the driving motor is a direct current brushless motor; an output shaft of the driving motor is provided with an internal spline; a shell of the driving motor is integrally and directly connected with a transmission case through fine thread screws after being positioned through fixing pins; the output shaft, with the internal spline, of the motor is positioned in the motor; an input shaft of a transmission is directly inserted into the motor to be connected with the output shaft, with the internal spline, of the motor. According to the system, a clutch is eliminated, so that power interruption time during gear shifting is reduced, and the cost is also lowered; the jointing sleeves and the gears of a target gear can be synchronized during gear shifting by actively regulating the speed of the driving motor, and a synchronizer with high requirements on materials is eliminated from the transmission, so that the cost is further lowered.

Owner:张利鹏 +1

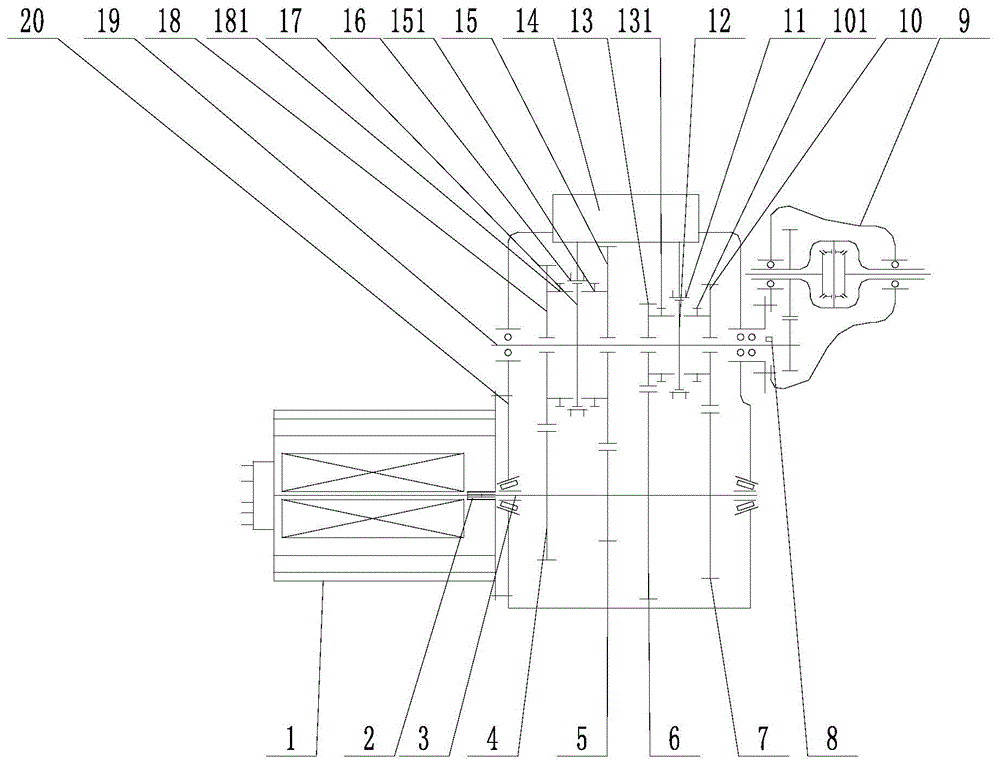

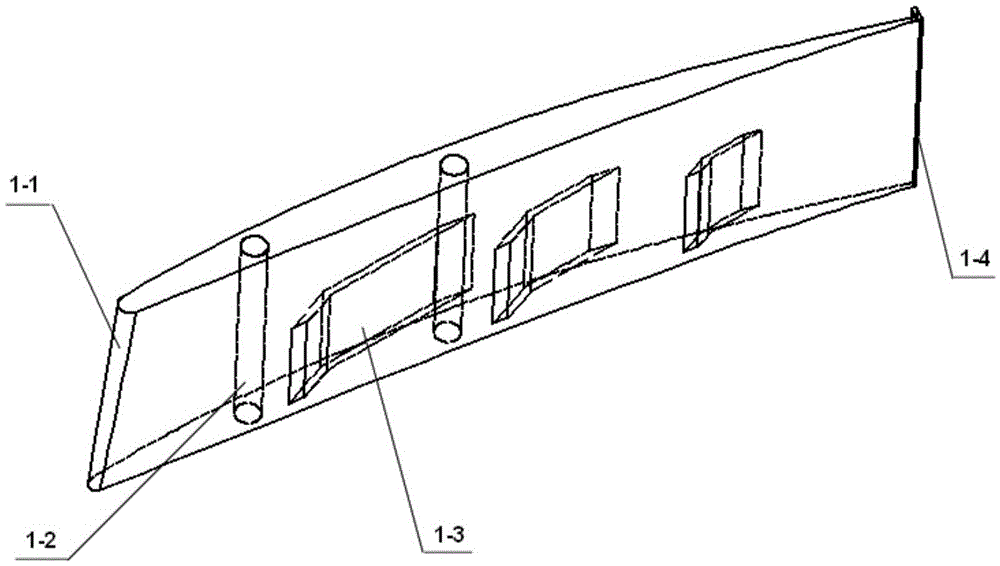

Pressure expander of centrifugal compressor

ActiveCN105650032AImprove the diffusion capacityImprove operational efficiencyEngine manufacturePump componentsSuction stressWork performance

The invention discloses a pressure expander of a centrifugal compressor. The structure of the pressure expander is improved, and high application value is achieved for further improving working performance of the pressure expander. A short blade is arranged in runners of every two adjacent long blades; the front edges of the long blades are curved surfaces and are arranged obliquely, and the included angles between front edge lines and the central axis of a wheel disc are 6 degrees to 8 degrees; the radius of curvature of the front edges of the long blades is gradually increased from the wheel disc to a wheel cover; each long blade is provided with three broken-line-shaped channels penetrating through a corresponding pressure surface and a corresponding suction surface; tail edge wing tips are arranged on the portions, located on the pressure surfaces, of the rear edges of the long blades. Occurrence of separation of airflow on the surfaces of the blades is restrained through the short blades in the runners of the adjacent long blades; the pressure differences between the pressure surfaces and the suction surfaces are reduced through the broken-line-shaped channels, the adverse pressure gradient is reduced, and separate airflow on boundary layers of the suction surfaces at the tails of part of the blades is effectively blown away; increase of wing tip vortexes generated by the pressure differences between the suction surfaces and the pressure surfaces on the rear edges of traditional wing-type blades can be restrained through parabola-shaped winglets on the tail edges.

Owner:嘉兴芸诗娇电子商务有限公司

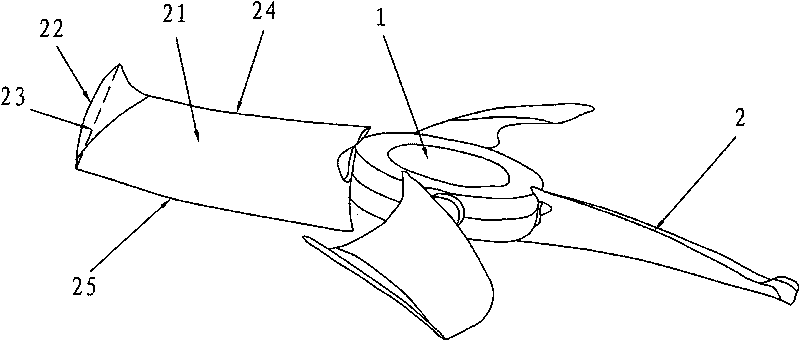

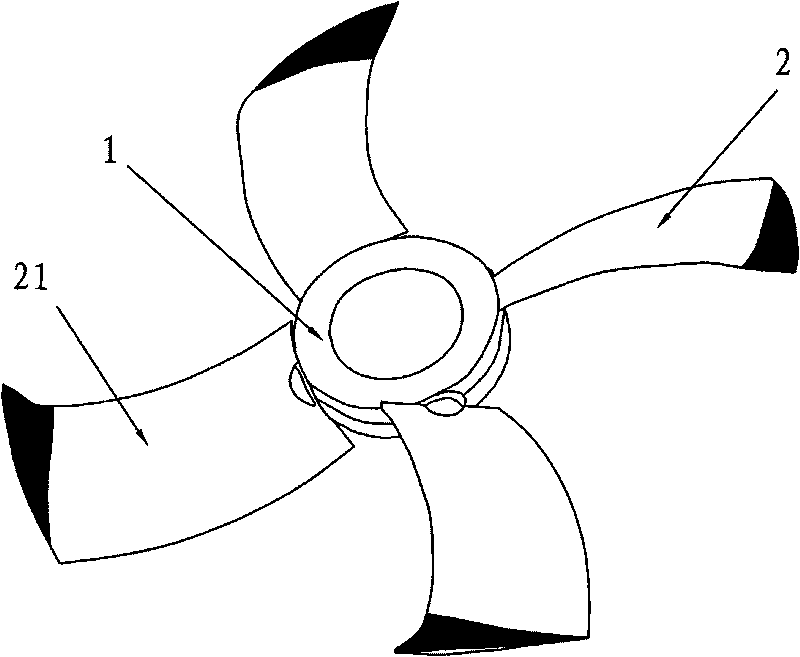

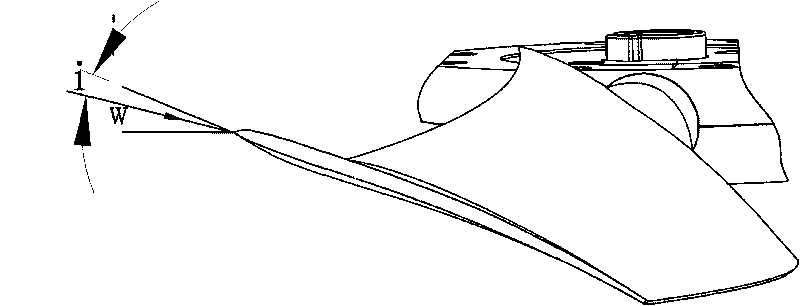

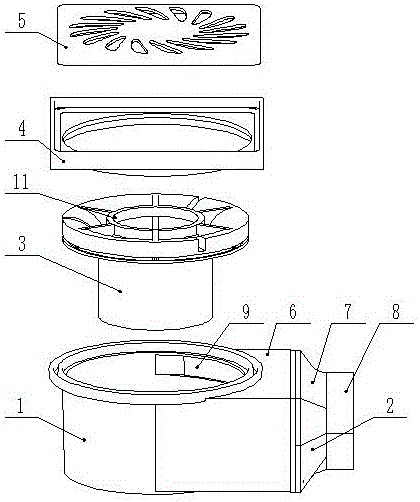

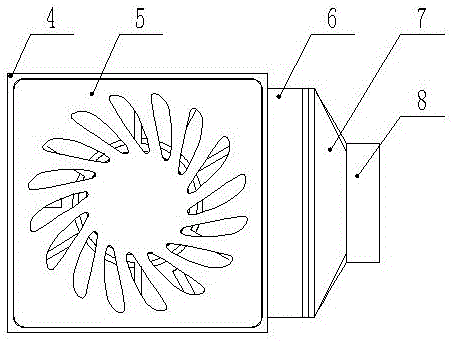

Axial flow wind wheel with improved blades

The invention discloses an axial flow wind wheel with improved blades, which comprises a wheel hub and a blade, and the blade and the wheel hub are formed as a whole. The invention is characterized in that the external circumferential part of the blade is bent from a windward side to a leeward side, and the bent width is gradually decreased from a front edge to a tailing edge; by adopting the structure, the leakage vortex at the external circumferential front edge and the air stream disturbance at the apex of the blade can be controlled. When the axial flow wind wheel rotates, the leeward side at the front edge of the blade has lower pressure, so as to cause large pressure difference between the windward side and the leeward side at the front edge of the blade, and turns up the apex of the blade towards the windward side, thus the pressure difference at the two sides of the apex of a blade can be reduced, and the leakage vortex at the external circumference of the blade can be inhibited. The angle that the air stream enters the front edge of the blade is greatly changed from the wheel hub to the external circumference, which can effectively reduce air-inlet impact loss, achieve the purpose of promoting the efficiency of the wind wheel; and meanwhile, when an impeller rotates, as the angle of attach of the air current i is smaller, the cutting air stream without impact at the front edge of the blade can generate lower pressure disturbance, thus playing an obvious role in reducing noise.

Owner:GUANGDONG SUNWILL PRECISING PLASITC CO LTD

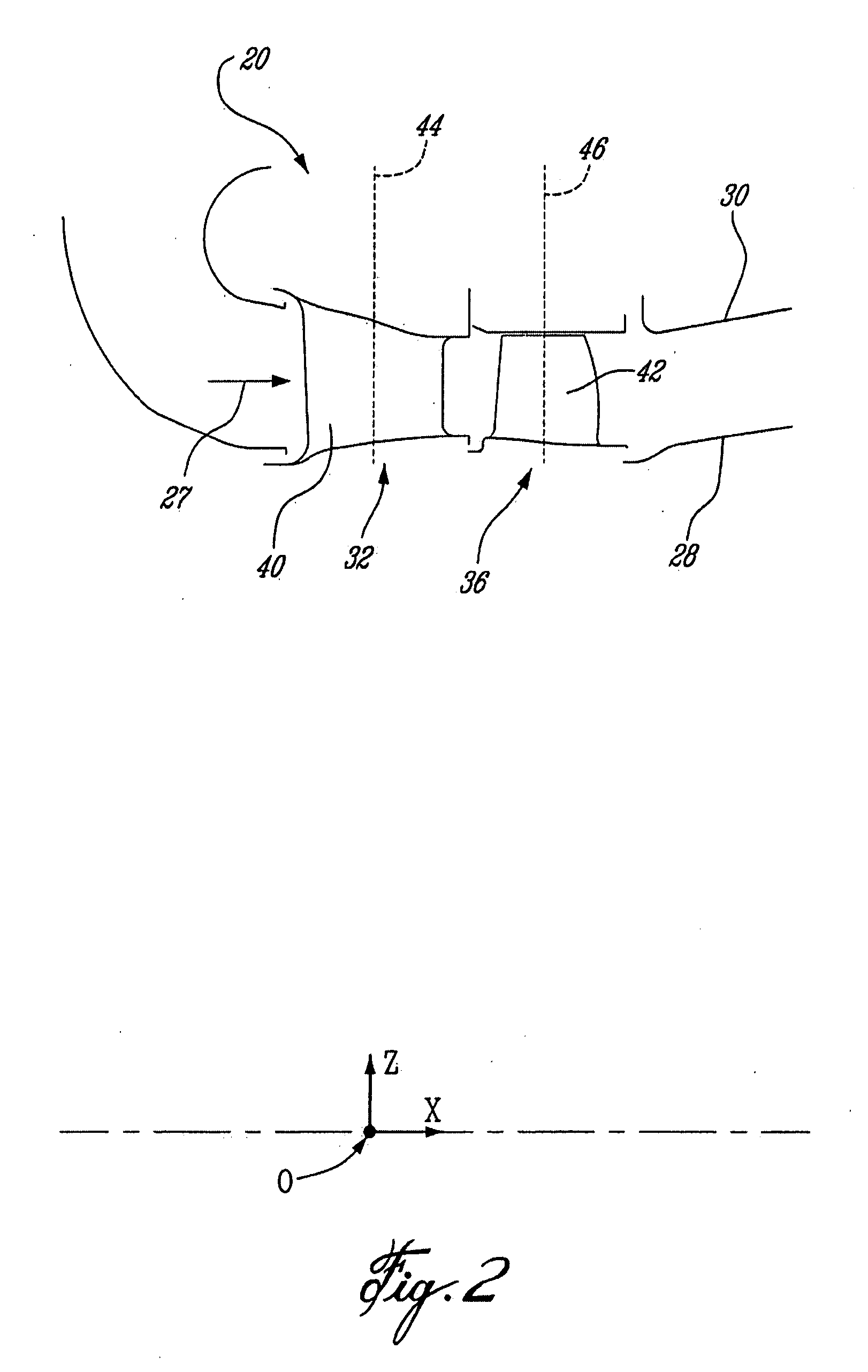

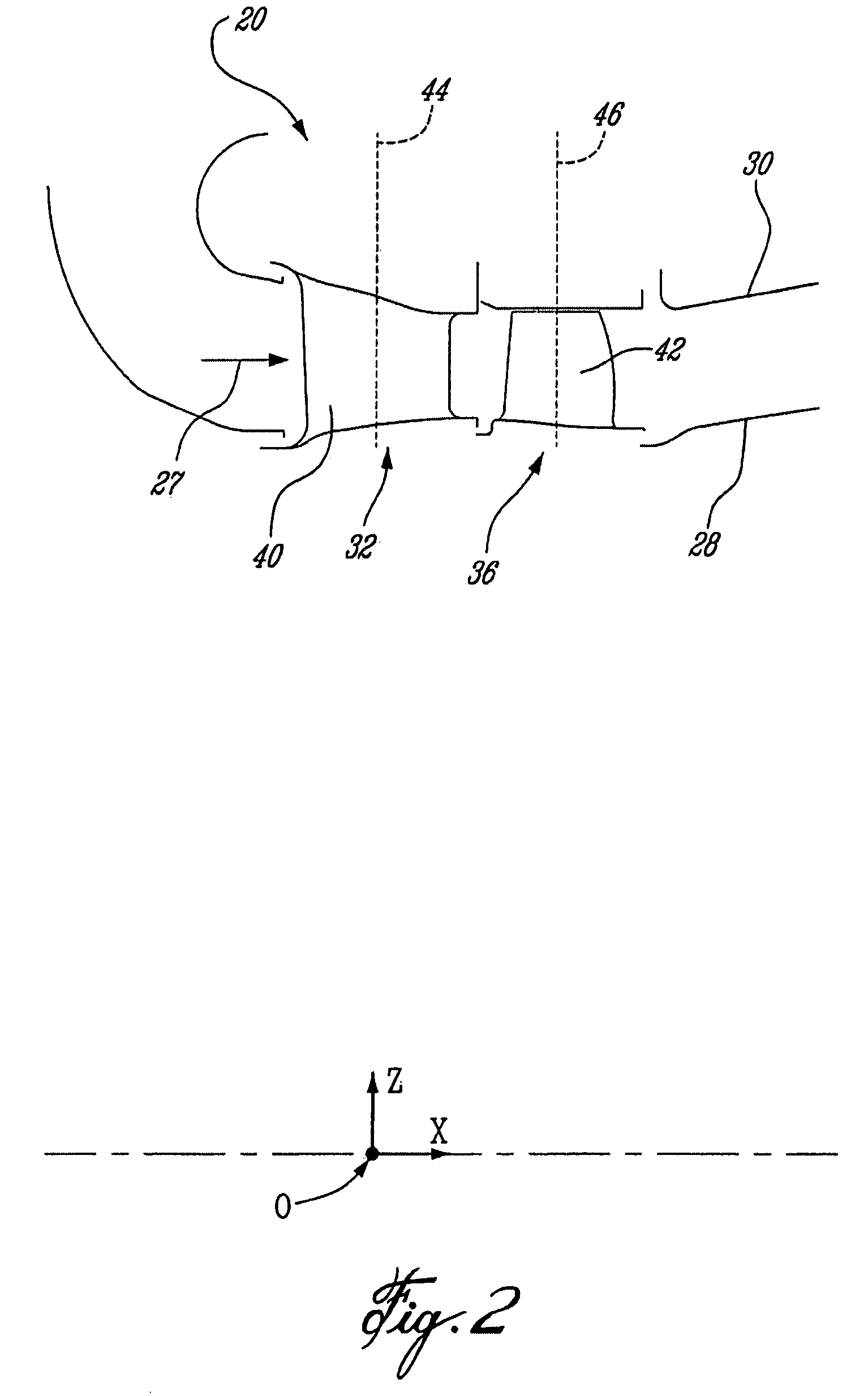

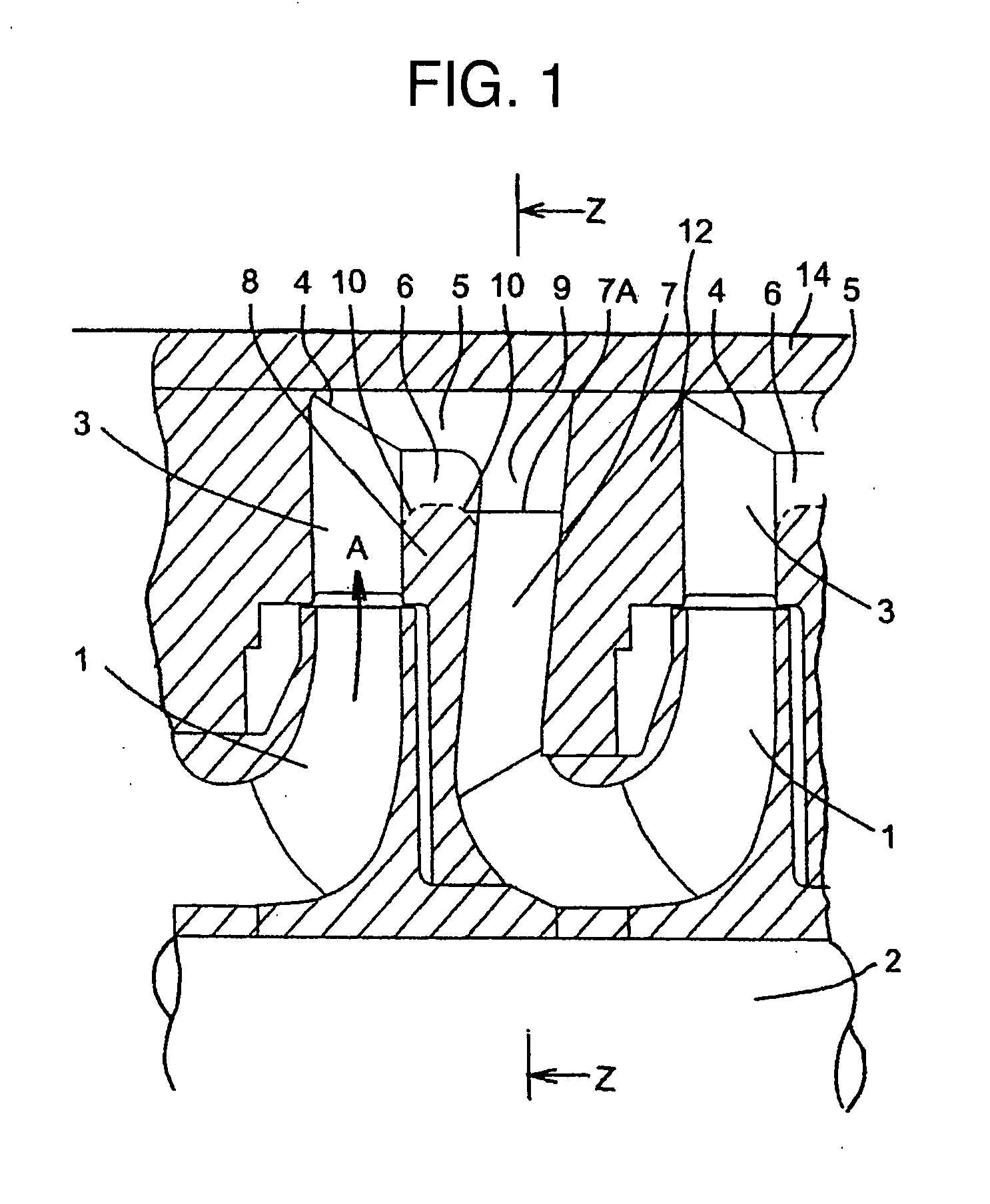

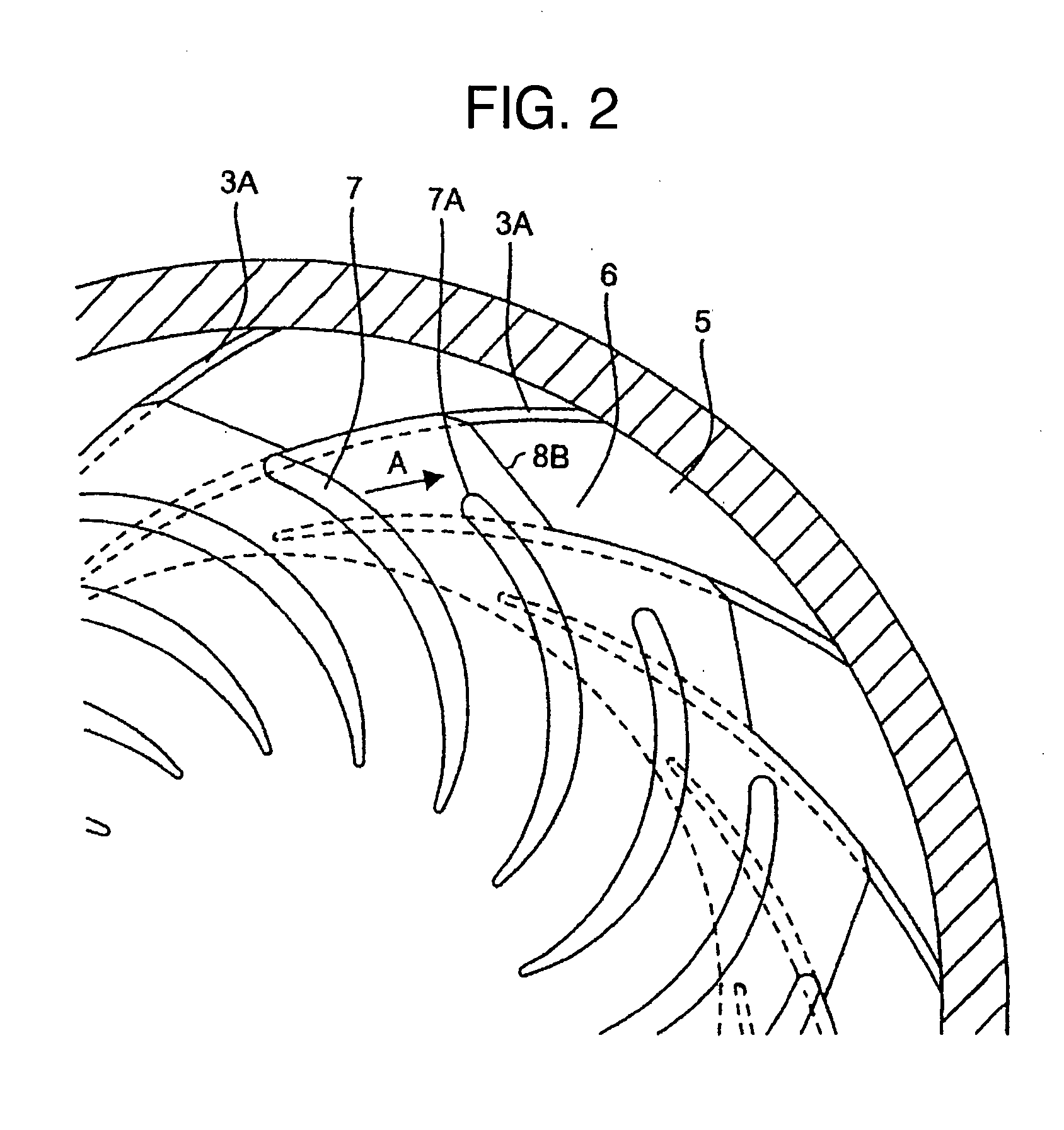

Transonic blade

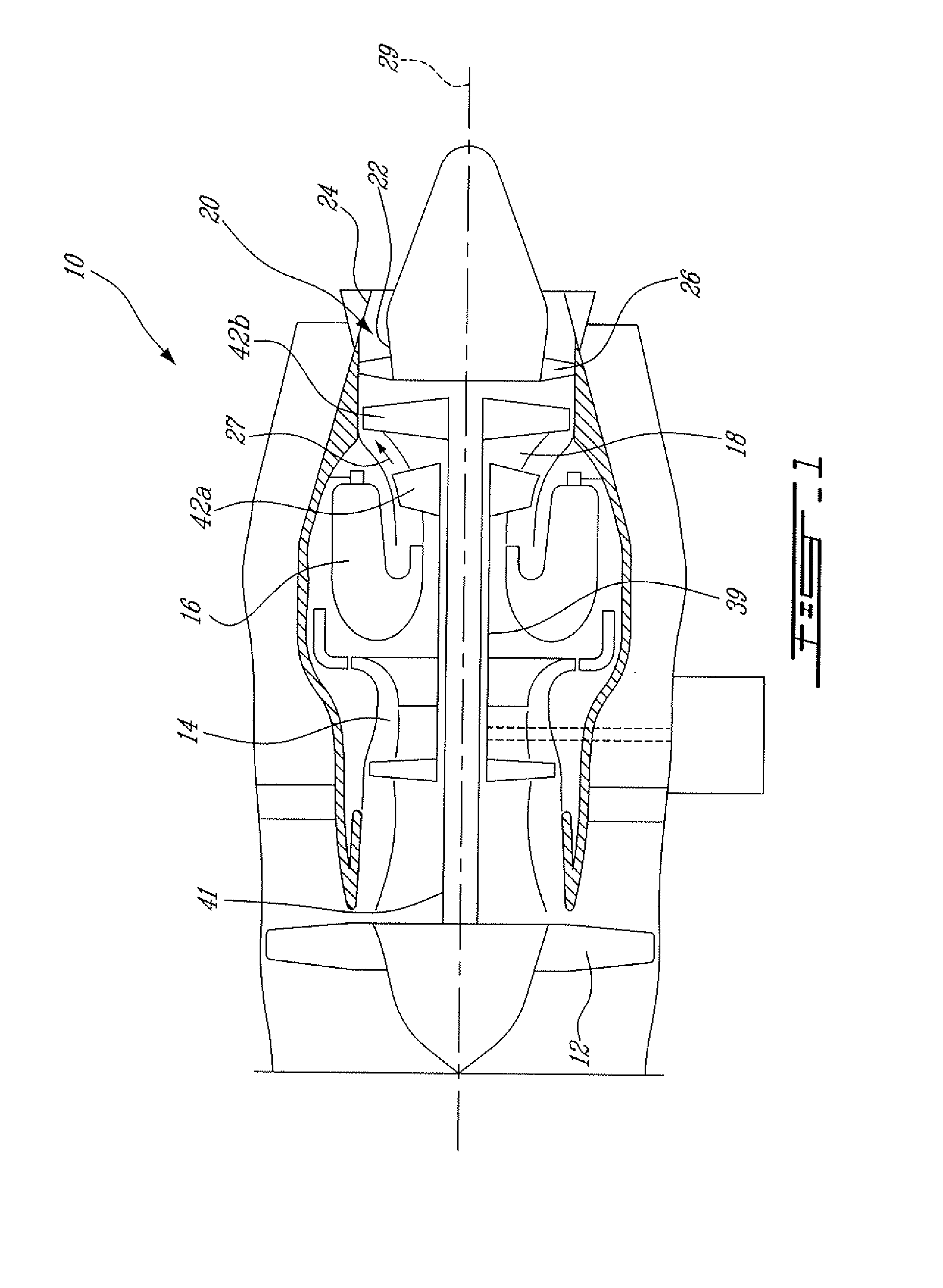

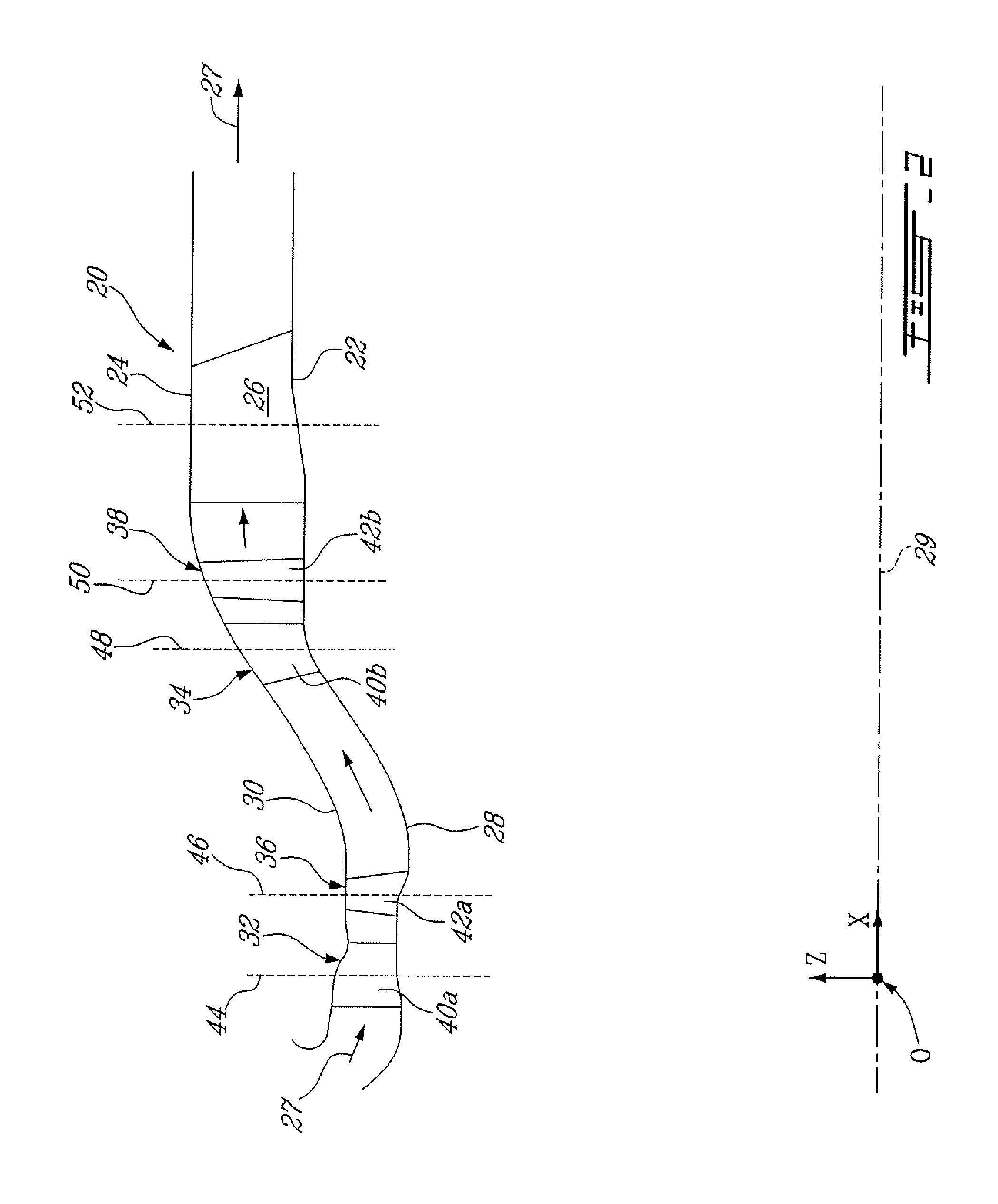

ActiveUS8425185B2Reduce various lossesImprove local stressPropellersReaction enginesLeading edgeWorking fluid

A transonic blade is provided that operates in a flow field where flow has a transonic speed or higher in an axial-flow rotating machine and that concurrently achieves a reduction in shock loss and in the local stress of the blade. The transonic blade includes a hub cross-sectional surface joined to a rotating shaft or an outer circumferential side casing of a rotating machine; a tip cross-sectional surface located furthest from the hub cross-sectional surface in a spanwise direction which is a vertical direction of the rotating shaft; a leading edge located on an upstream side; and a trailing edge located on a downstream side. At least a part of a passing working fluid flow has a transonic speed or higher. A portion of a stacking line which is a line connecting together respective gravity centers of cross-sectional surfaces located from the hub cross-sectional surface to the tip cross-sectional surface is located on a downstream side of a stacking center in a flow direction of a working fluid main flow.

Owner:MITSUBISHI POWER LTD

Hp turbine vane airfoil profile

ActiveUS20080118361A1Minimize secondary lossesReduce impact lossPropellersEngine manufactureSingle stageTurbine blade

A single stage high pressure turbine vane includes an airfoil having a profile substantially in accordance with at least an intermediate portion of the Cartesian coordinate values of X, Y and Z set forth in Table 2. The X and Y values are distances, which when smoothly connected by an appropriate continuing curve, define airfoil profile sections at each distance Z. The profile sections at each distance Z are joined smoothly to one another to form a complete airfoil shape.

Owner:PRATT & WHITNEY CANADA CORP

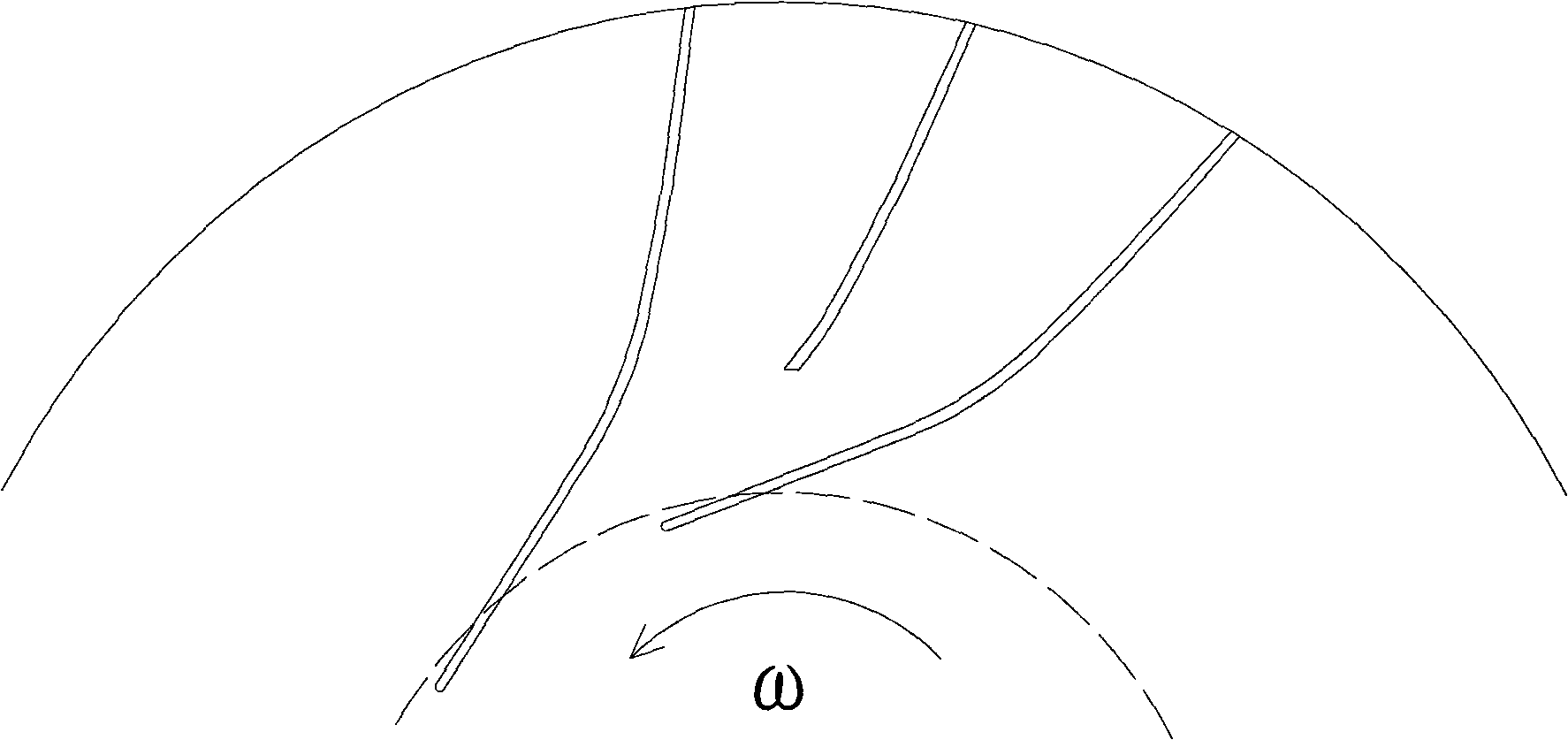

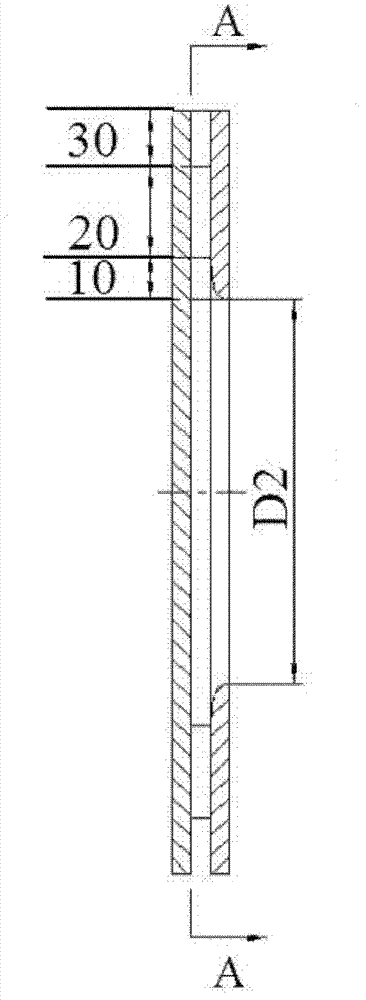

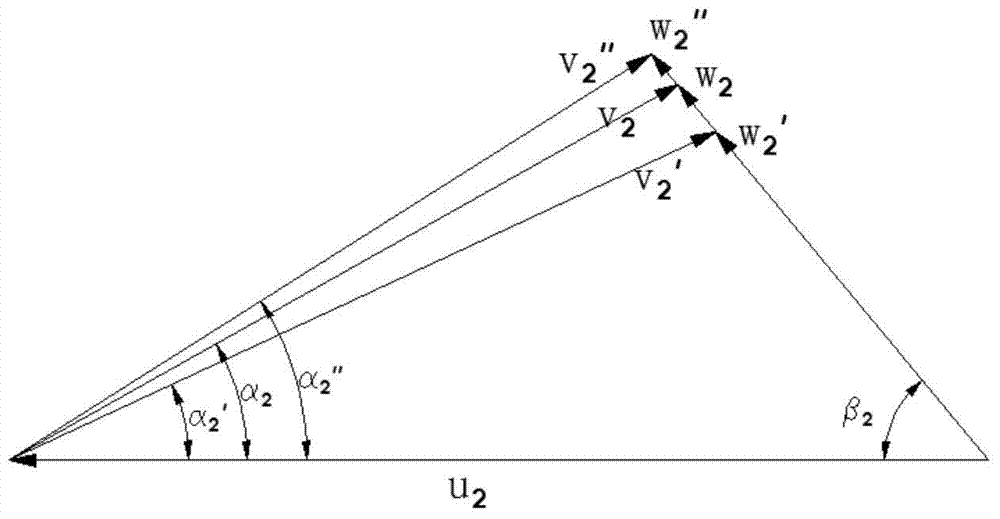

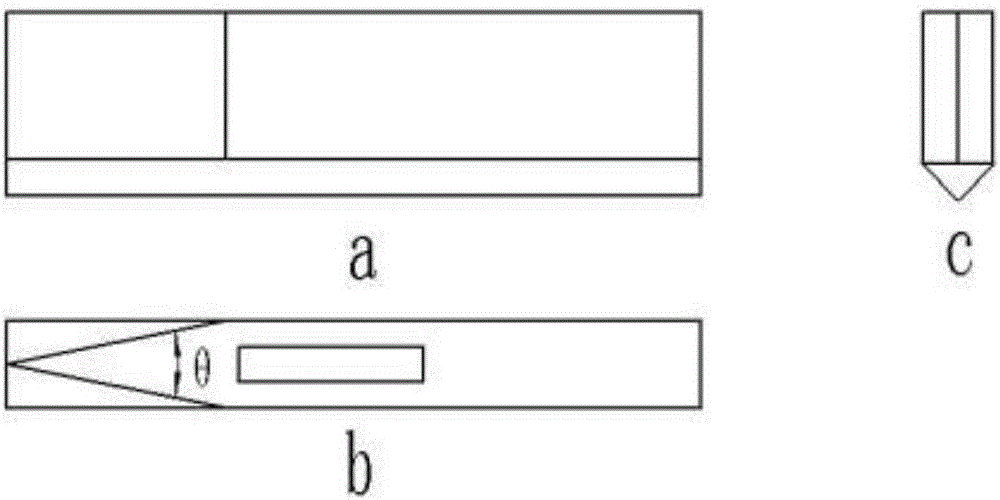

1/2 type tandem-blade type transonic speed centrifugal impeller

InactiveCN101576091AExpand the effective flow areaIncrease clogged flowPump componentsPumpsImpellerTransonic

The invention discloses a 1 / 2 type tandem-blade type transonic speed centrifugal impeller, which comprises an inducer consisting of a front row of blades and a guide wheel consisting of a back row of blades, wherein the front and the back rows of the blades have three-dimensional distorted shapes and are divided, staggered and overlapped with one another. The centrifugal impeller is characterized in that the number ratio of the front row of the blades to the back row of the blades is 1:2. In the centrifugal impeller, the front row of the blades are arranged with low consistency and the back row of the blades are arranged with high consistency so that the effective through-flow area is enlarged and the blockage flow is increased; and the evenness of the flow at the outlet of the impeller is improved so that the wake losses and the shock losses between the impeller and a diffuser are reduced, the efficiency of the whole stage is improved, and the surge margin is enlarged.

Owner:XI AN JIAOTONG UNIV

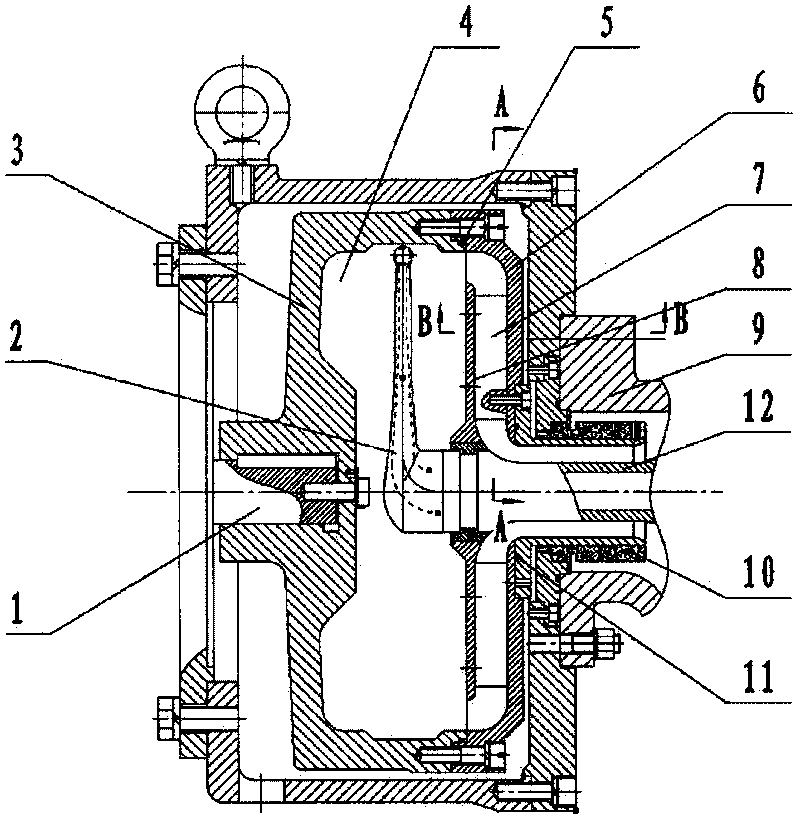

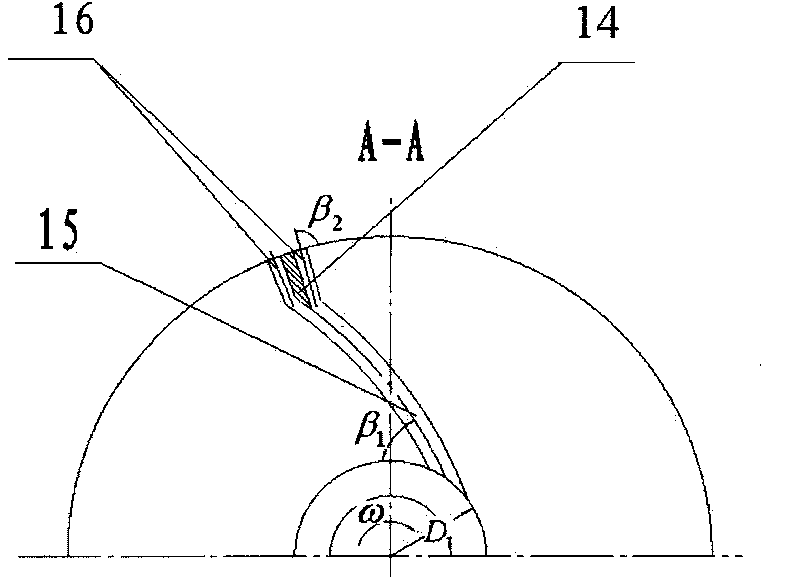

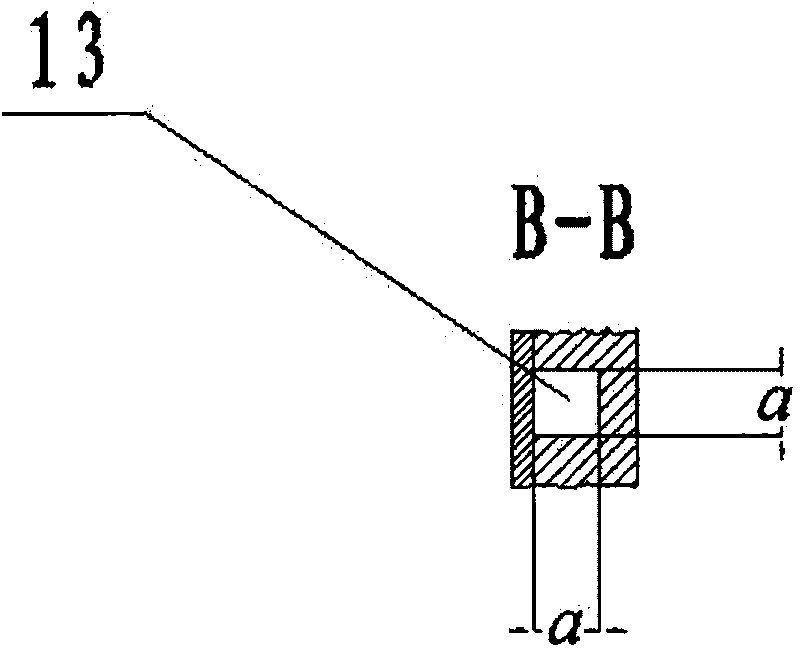

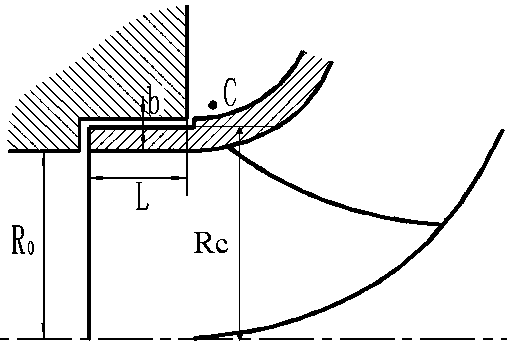

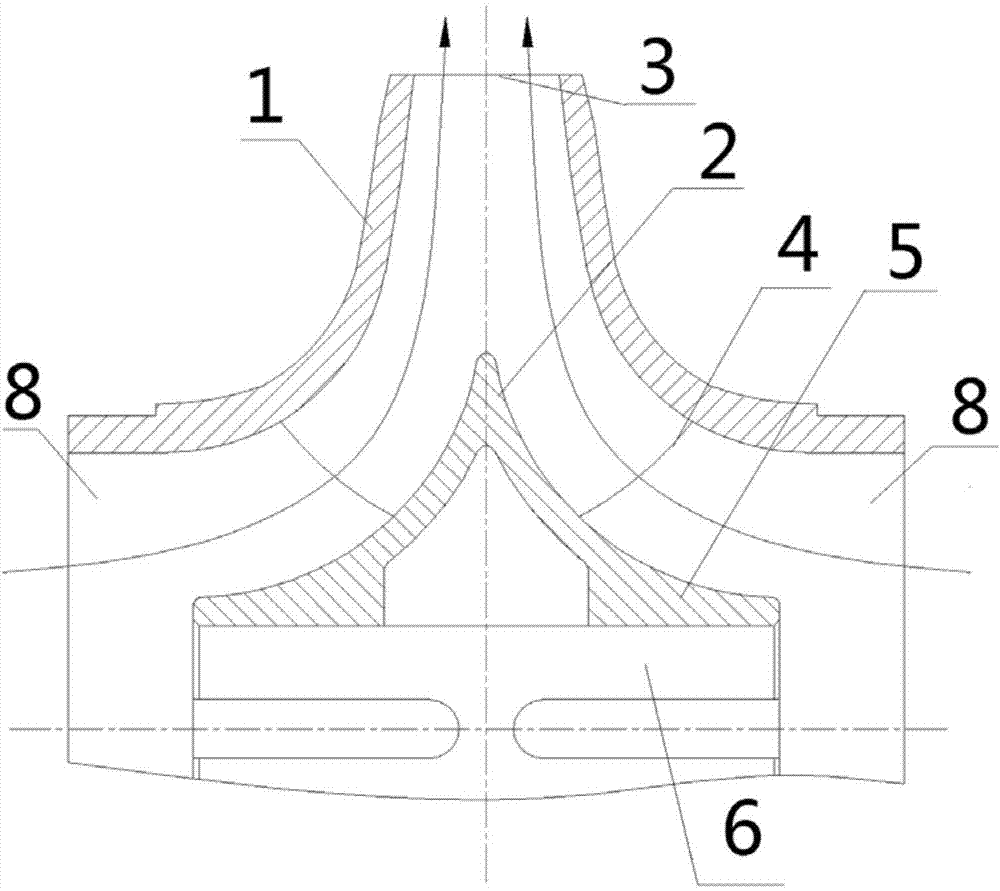

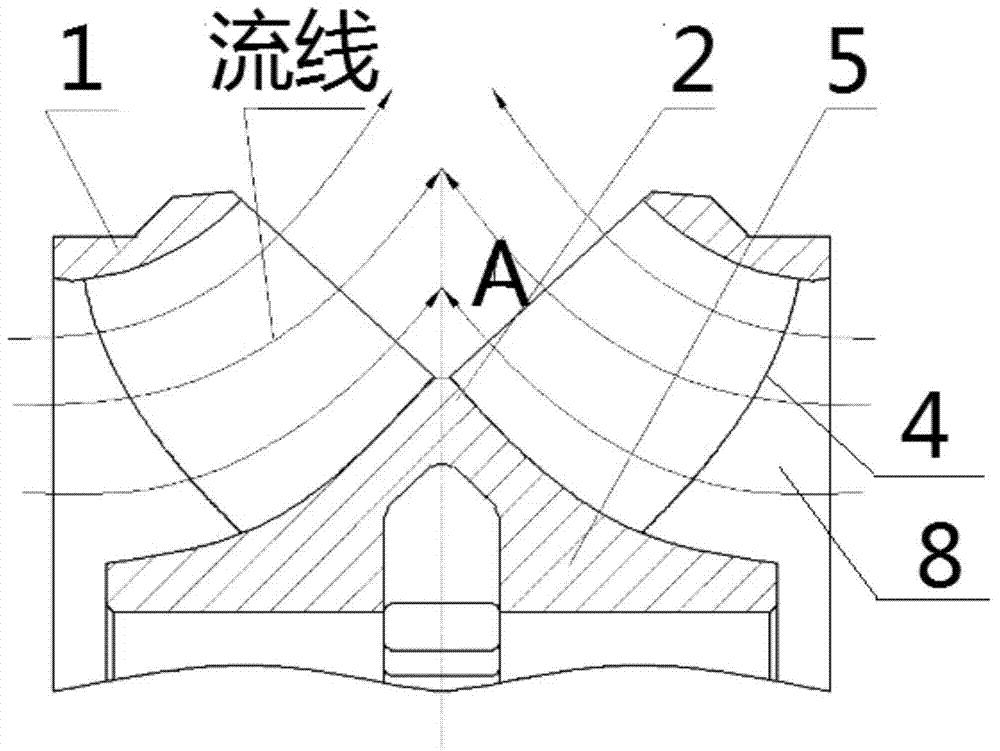

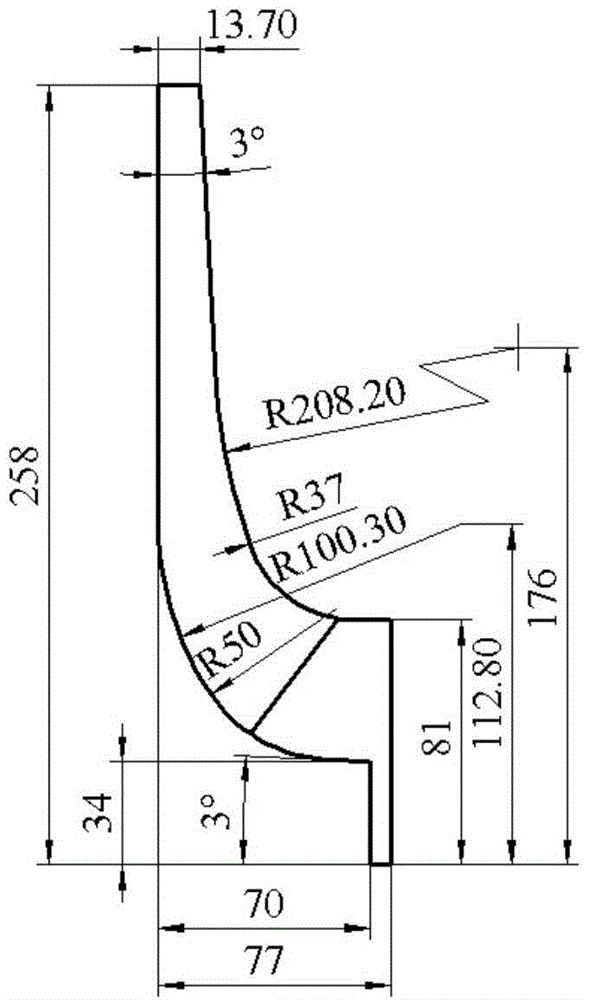

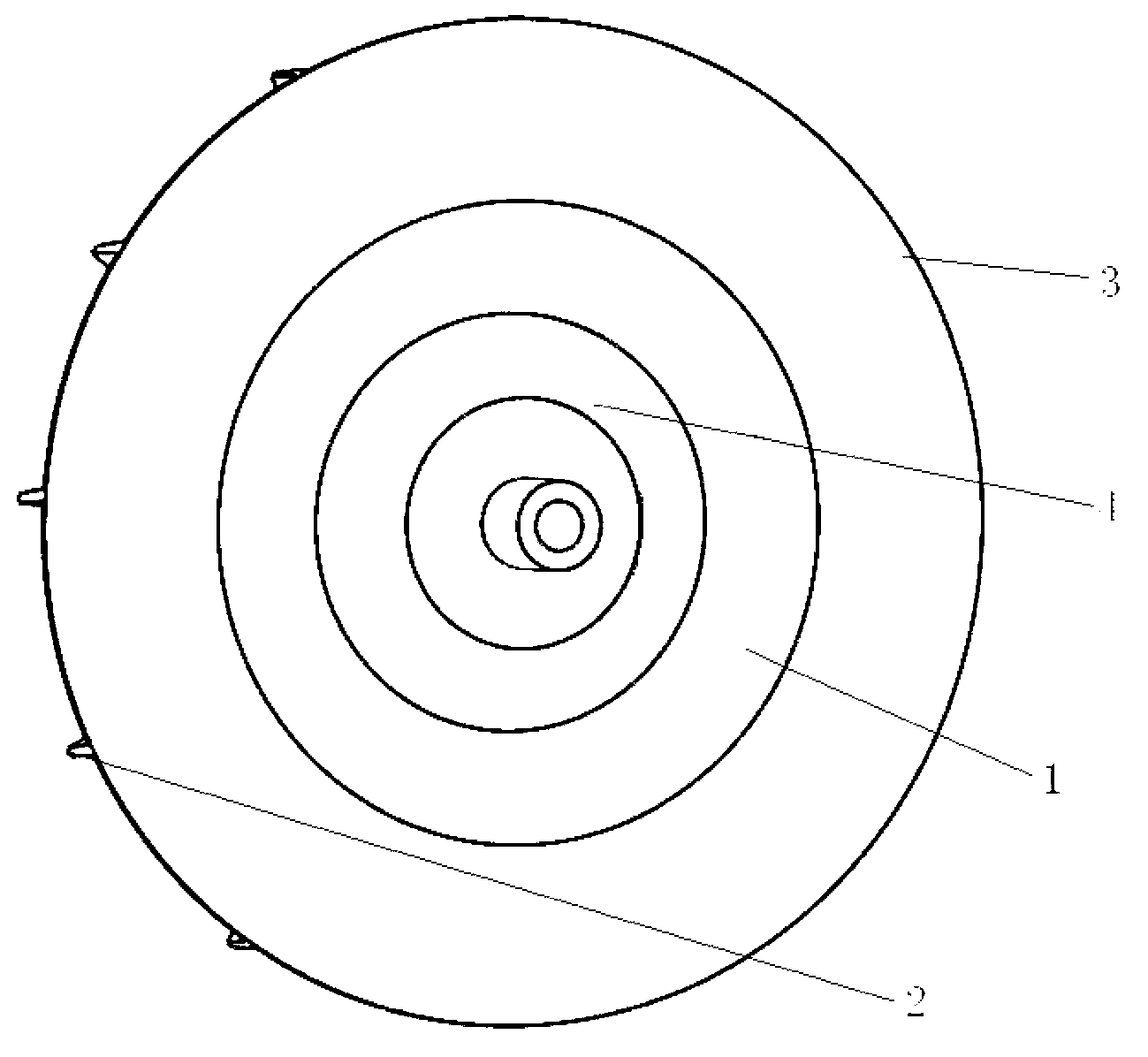

Impeller structure of rotary shell type pump

InactiveCN101725561AGuaranteed dimensional accuracyGuaranteed uniformityPump componentsPumpsImpellerSurface roughness

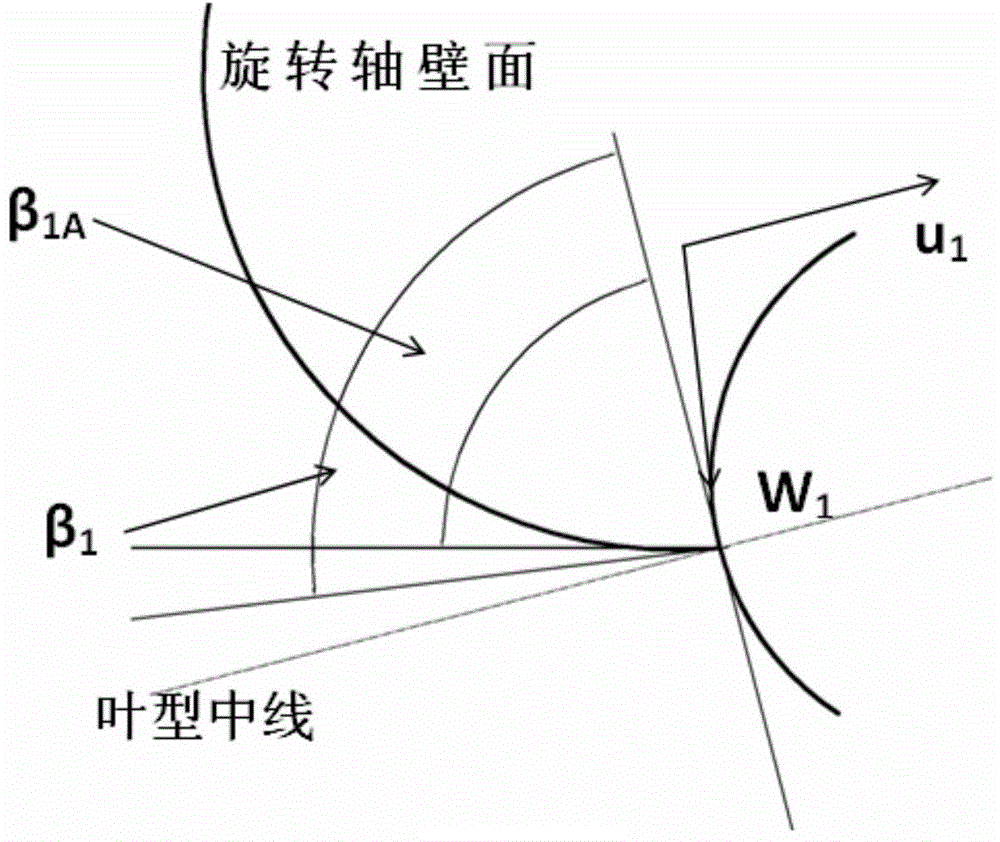

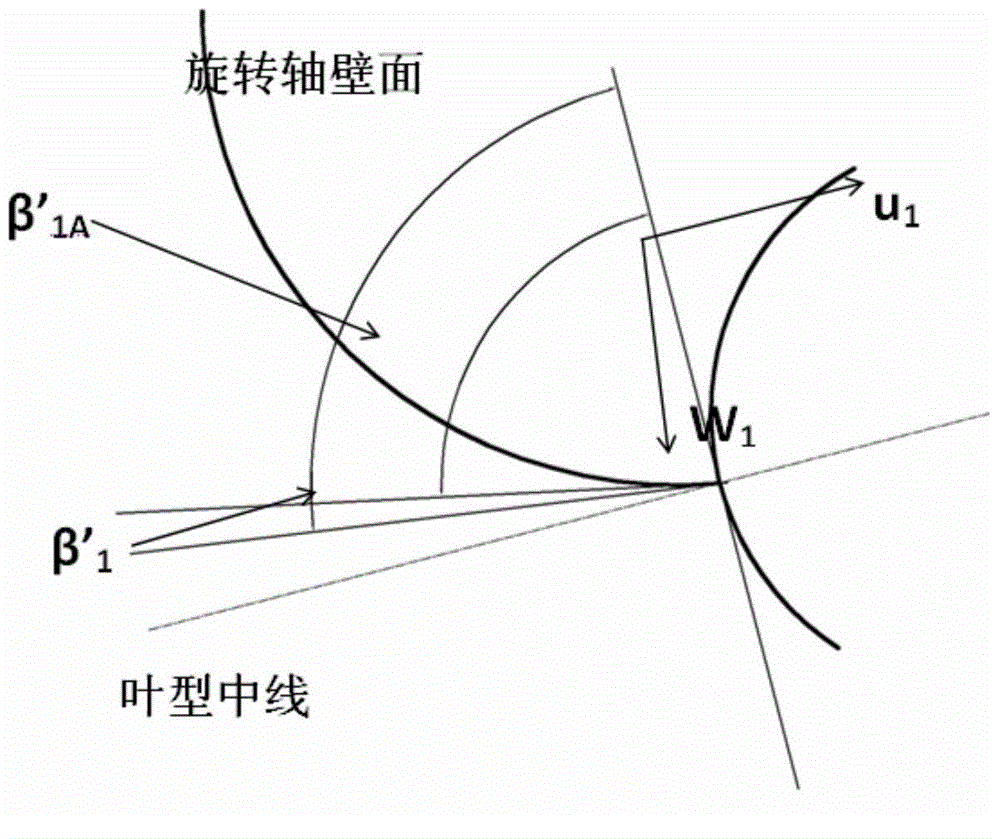

The invention discloses an impeller structure of a rotary shell type pump, which comprises impeller blades positioned between a front cover plate and a back cover plate. The adjoining impeller blades are formed into impeller flow passageways. The impeller structure is characterized in that each impeller flow passageway consists of an impeller inlet flow passageway and an impeller outlet flow passageway; each impeller inlet flow passageway is an arc flow passageway, wherein the length of the arc flow passageway is 60-70% of that of the impeller flow passageway, and an inclined angle beta1 arranged between the midline of each impeller inlet flow passageway and an inlet distribution circle is from 20 to 40 degrees; and each impeller outlet flow passageway is provided with two outlet radial branch flow passageways. The impeller flow passageways of the impeller structure effectively restrains the generation of axial whirlpool and flow separation; a smaller inlet angle can lead the impact loss of the inlet to be reduced; the branch of the outlet flow passageway leads the liquid which flows into a shell to be more even; and the milling machine of the flow passageways can obtain small surface roughness to achieve the aim for improving the waterpower efficiency of the impeller.

Owner:JIANGSU UNIV

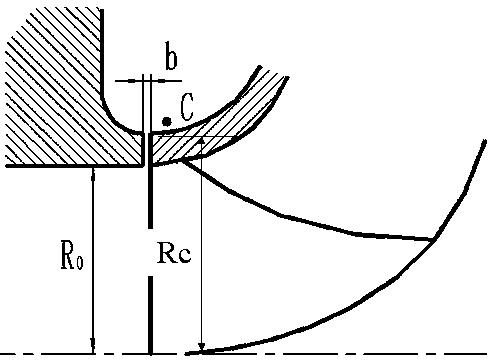

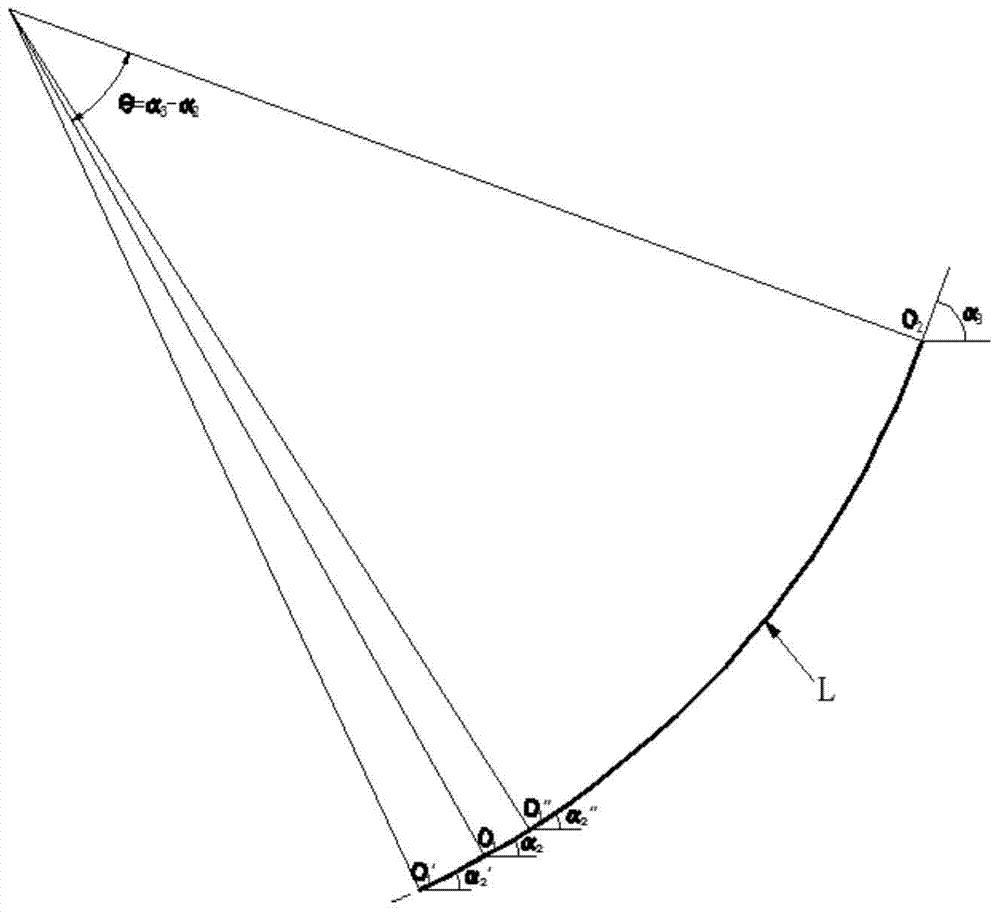

Centrifugal impeller geometry optimization designing method capable of improving pump efficiency

InactiveCN103452900AImprove performanceReduce impact lossPump componentsPumpsFriction lossEngineering

The invention discloses a centrifugal impeller geometry optimization designing method which is capable of improving pump efficiency. The method includes establishing a optimizing model of the centrifugal impeller geometry with efficiency iterations, calculating volumetric efficiency eta v and mechanical efficiency eta m of a pump at a design point, and performing efficiency iterations during the process of impeller geometry optimization. The beta 2, namely the sum of two losses of the impeller to allow h to be minimum, and a corresponding R2 are the final solution of the design. The centrifugal impeller geometry optimization designing method is capable of improving efficiency of the centrifugal pump, performances of the pump are improved in a wider range, and minimum sum of impeller outlet impact loss and friction loss of the impeller disc can be acquired by calculating the efficiency iterations of the centrifugal impeller geometry; computer software program can be written to implement accurate calculation of the centrifugal impeller geometry, design is facilitated, speed is high, design and produce accuracy of the centrifugal impeller can be improved effectively, and the method is adaptable to industrial design and production.

Owner:CHENGDU YONGYI PUMPS

Low-denseness blade diffuser and production method thereof

ActiveCN103244461AIncrease the degree of diffusionReduce power consumptionPump componentsPumpsImpellerEngineering

The invention provides a low-denseness blade diffuser and a production method thereof. The low-denseness blade diffuser is arranged between an outlet of vane wheels and an inlet of volutes of a compressor, and comprises a non-blade inlet section, a low-denseness blade section and a non-blade outlet section. The inlet of the non-blade entrance section is communicated with the outlet of the vane wheels, blades are arranged inside the low-denseness blade section, and the inlet of the low-denseness blade section is communicated with the outlet of the non-blade inlet section, the inlet of the non-blade outlet section is communicated with the outlet of the low-denseness blade section and the outlet of the same is communicated with the inlet of the volutes. The low-denseness blade diffuser has the advantages that diffusion degree of the diffuser is improved, wasted works of the compressor is reduced and efficiency is improved by adopting the low-denseness blade; and the non-blade sections are addedly arranged on the front and back of the blade section to overcome defects of regular poor adaptability of variable working conditions of the blade diffuser, impact losses under variable working conditions are reduced, and working ranges of the compressor are widened.

Owner:GREE ELECTRIC APPLIANCES INC

Compressor turbine vane airfoil profile

ActiveUS7862303B2Minimize secondary lossesReduce impact lossPropellersEngine manufactureSingle stageTurbine blade

Owner:PRATT & WHITNEY CANADA CORP

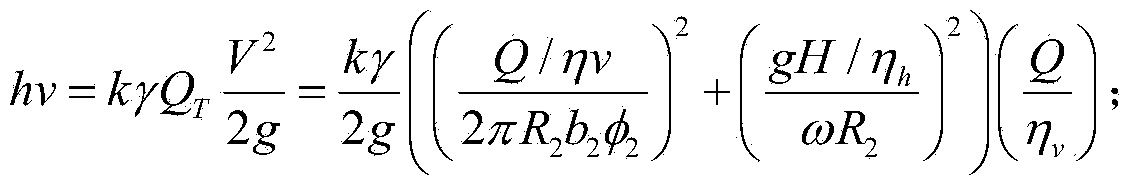

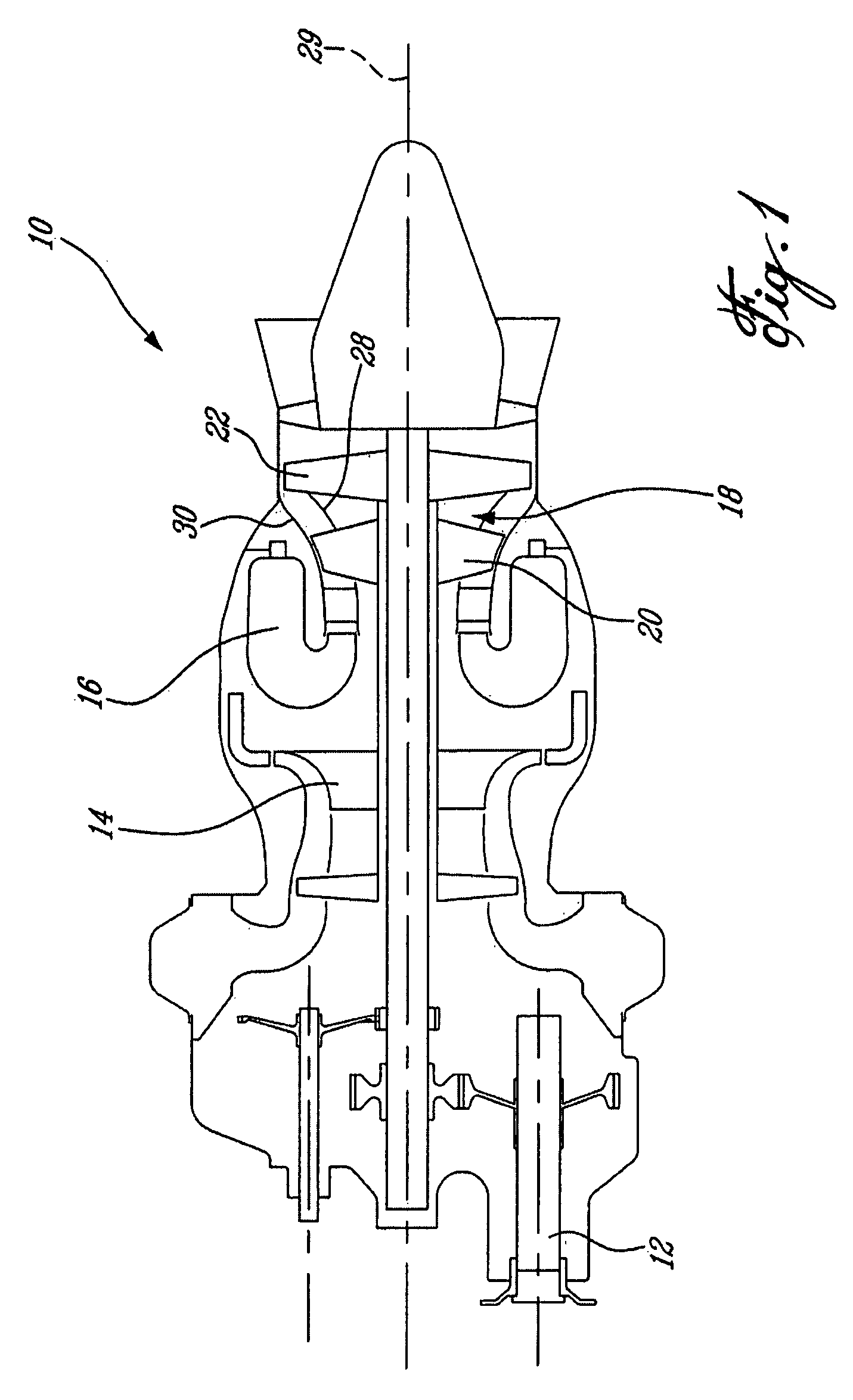

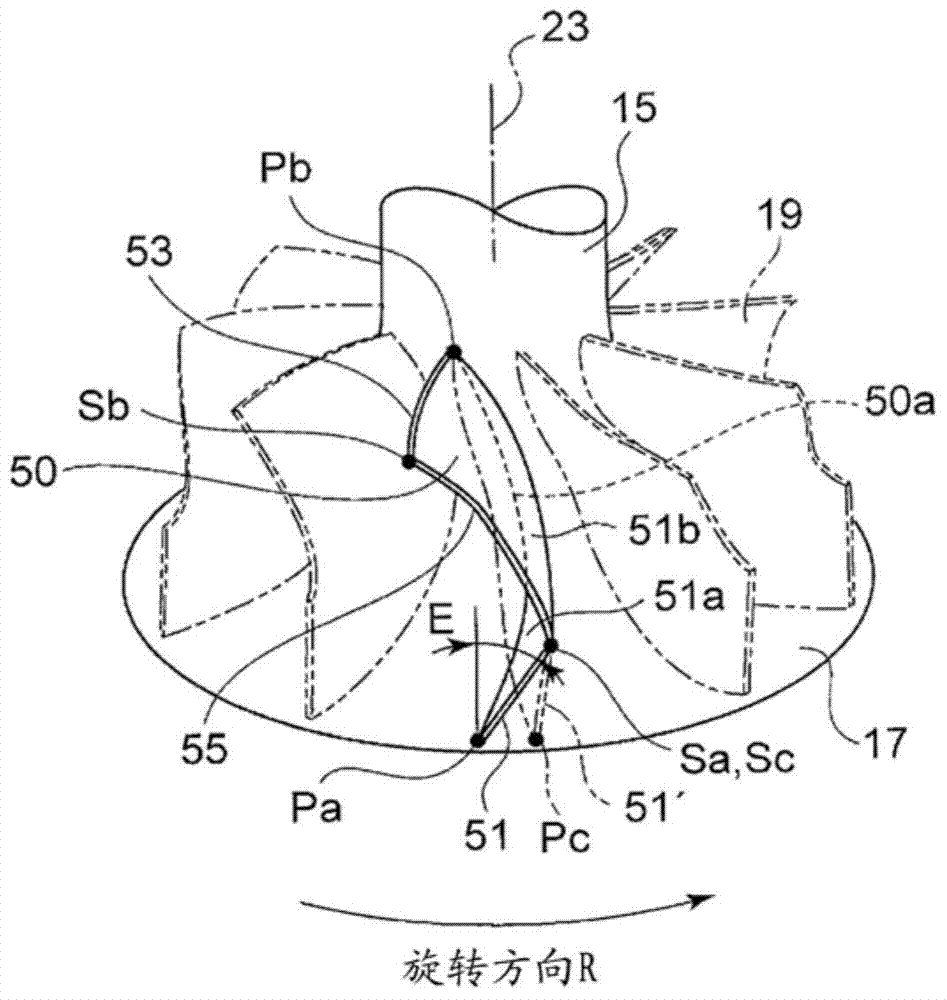

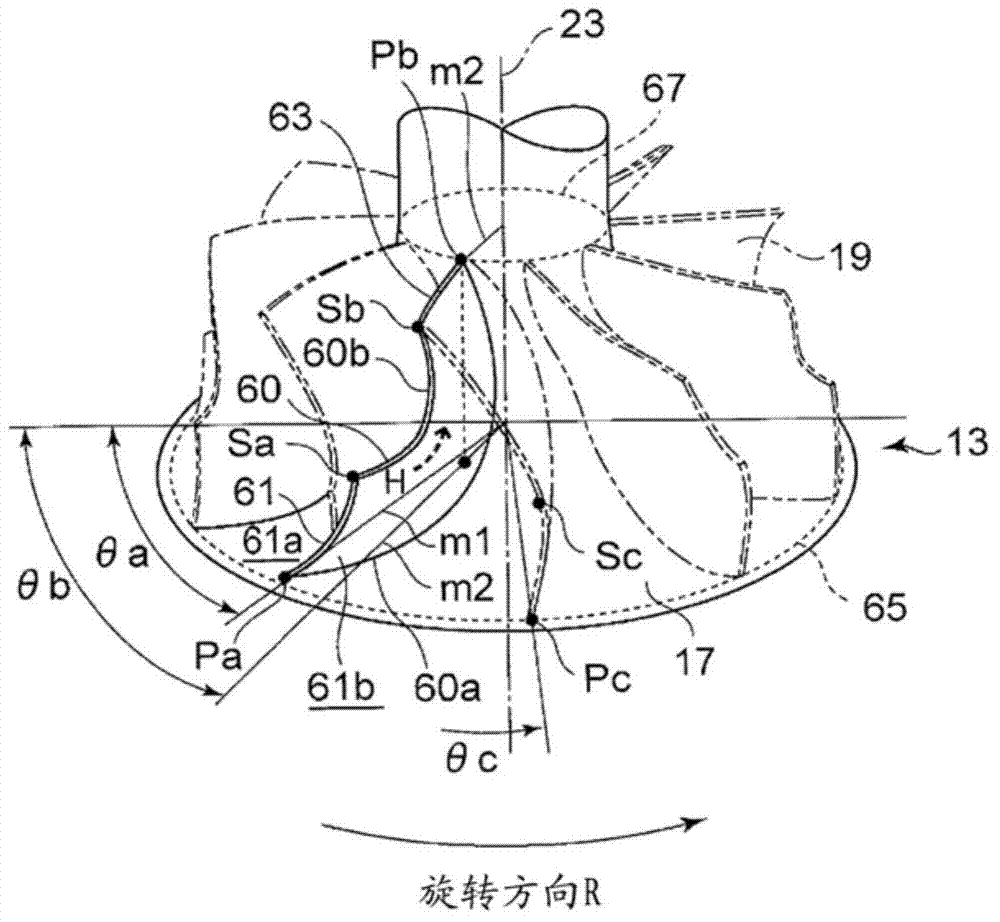

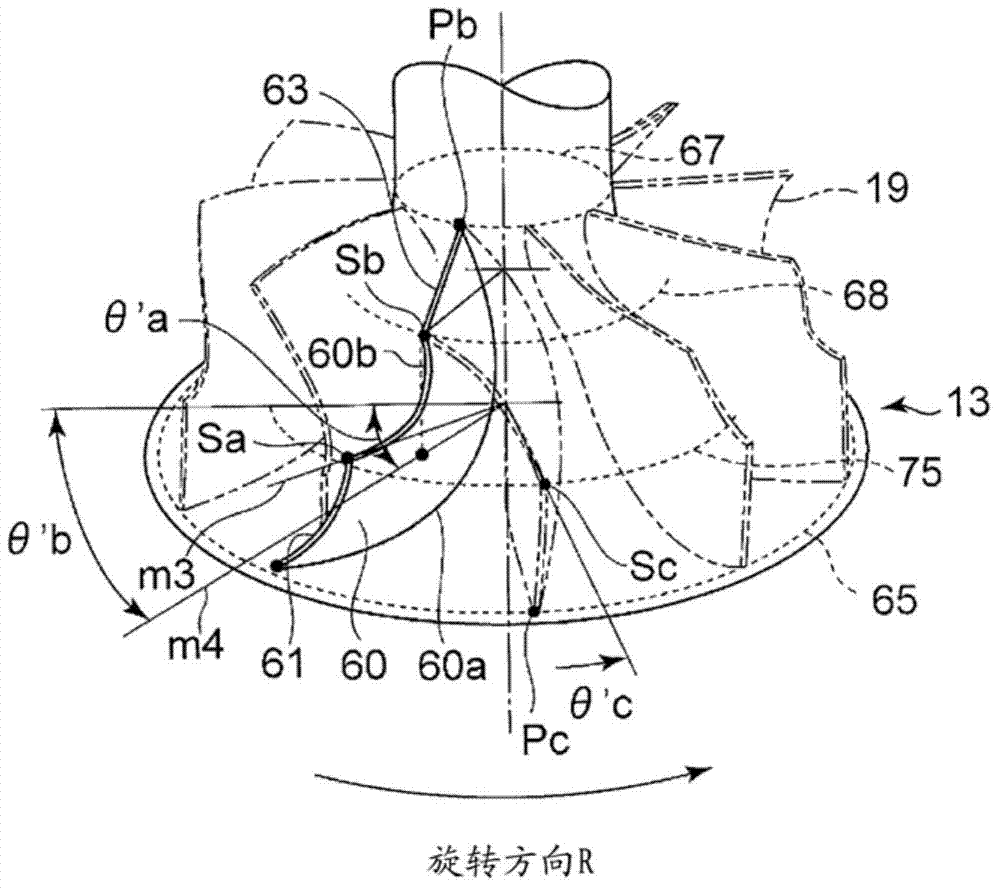

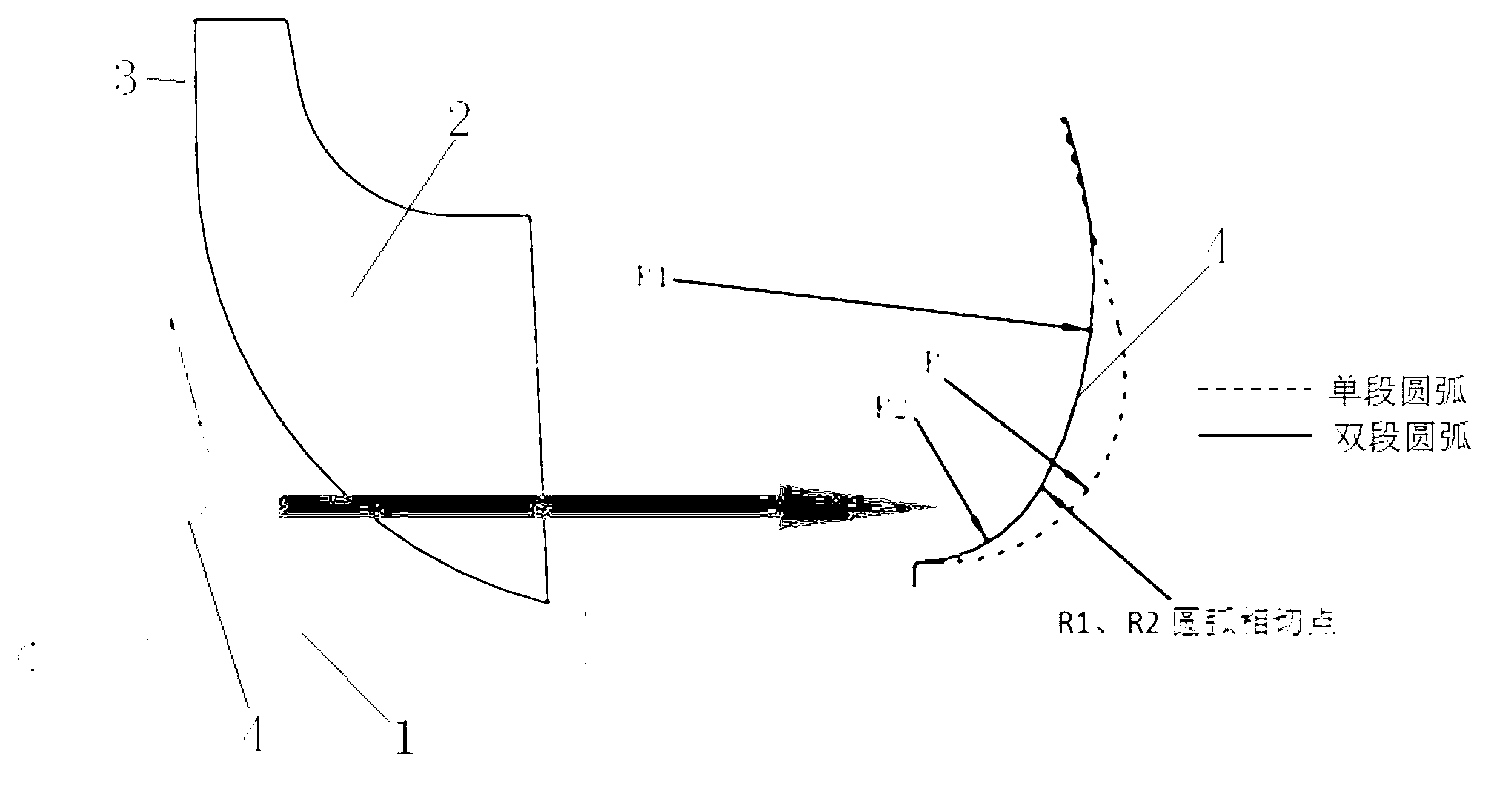

Radial turbine rotor blade

ActiveCN104854325AReduce impact lossImprove turbine efficiencyBlade accessoriesCombustion enginesRotational axisLeading edge

[Problem] To provide a radial turbine rotor blade whereby, even if a variable nozzle mechanism in a variable-geometry turbocharger is closed down, resulting in a flow field with a low turbine velocity ratio (U / C0), inflowing-gas impact losses at the leading edge of the rotor blade are reduced, improving turbine efficiency. [Solution] This radial turbine rotor blade is characterized in that: with respect to the direction of rotation (R) of the rotor blade (50), the hub-side corner (Pa) of the leading edge (51) of the rotor blade (50) is behind the shroud-side corner (Sc) of said leading edge (51); and in a radial view of the rotor blade (50), a line that connects the aforementioned shroud-side corner (Sc) to the hub-side corner (Pa) forms a 30-70° angle with a line that extends in the direction of the axis of rotation from the shroud-side corner (Sc) of the leading edge (51) to the surface of the hub (17).

Owner:MITSUBISHI HEAVY IND LTD

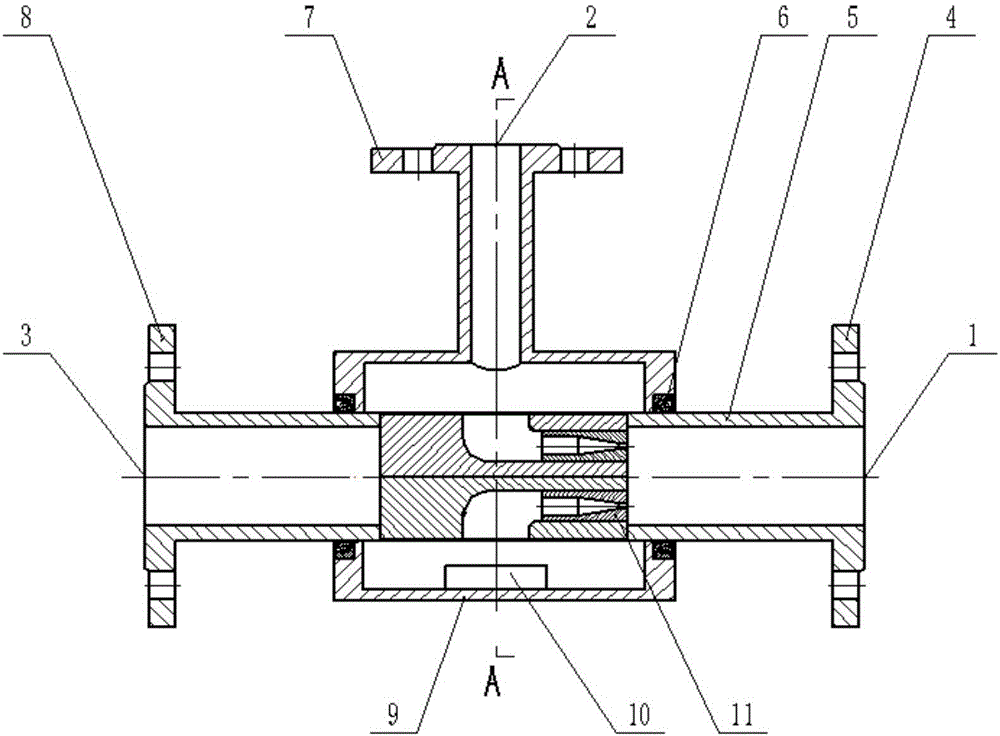

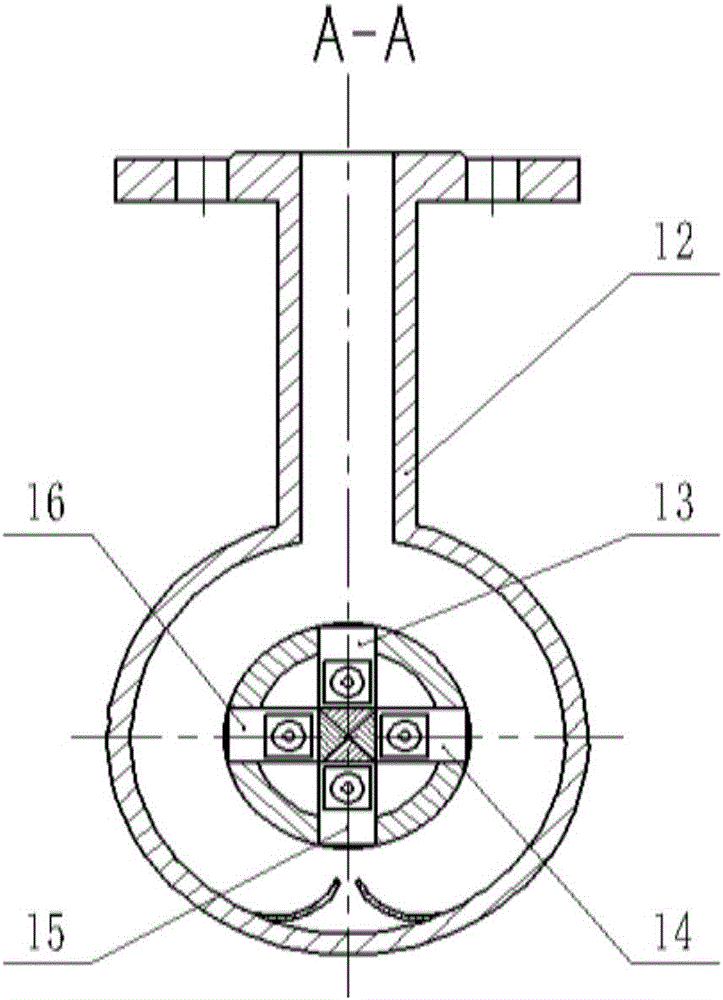

Hydrodynamic tool for cleaning pipes and channels

InactiveUS6089243AReduce impact lossReduce turbulent flowHollow article cleaningCleaning using liquidsWater dischargeEngineering

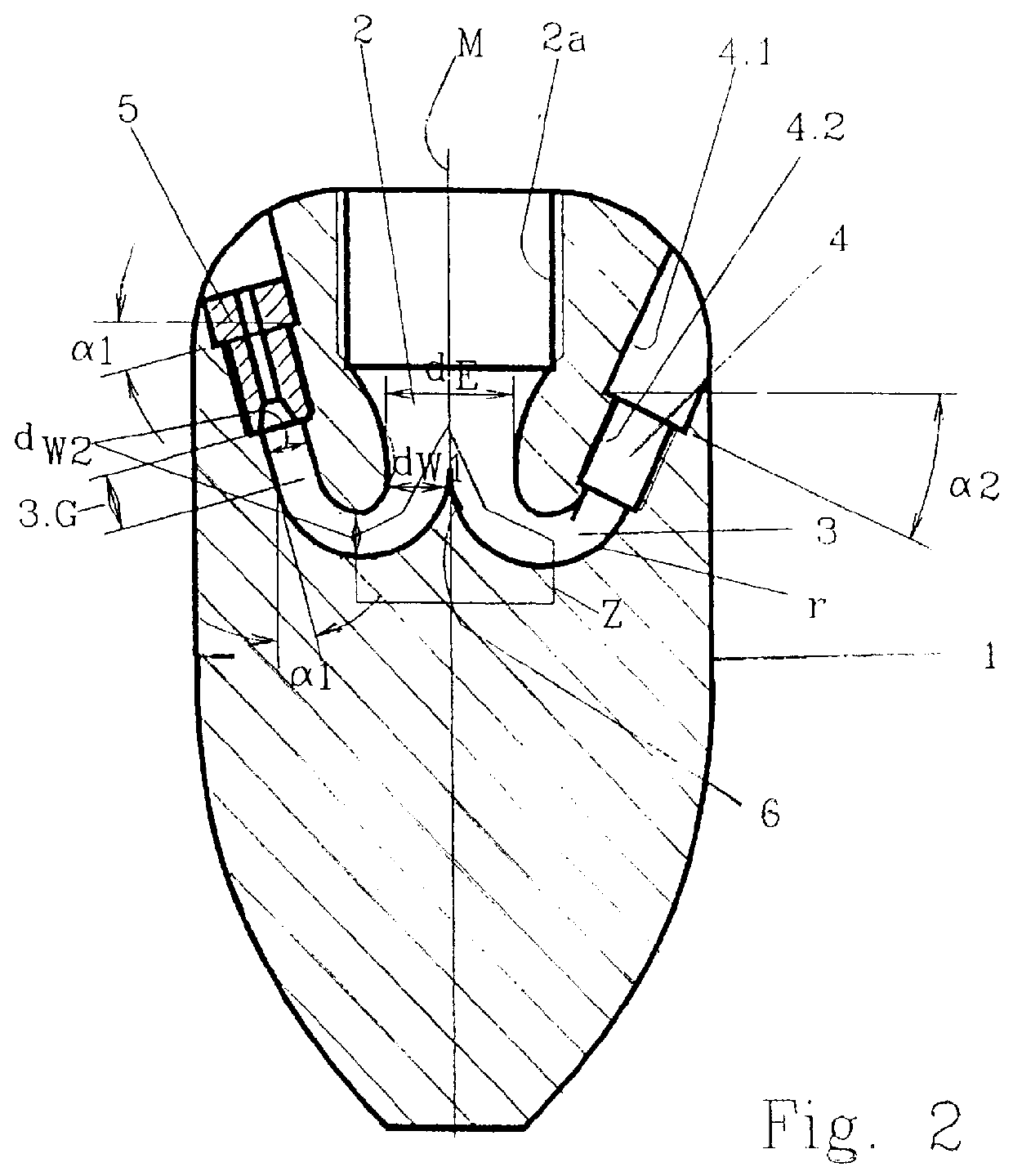

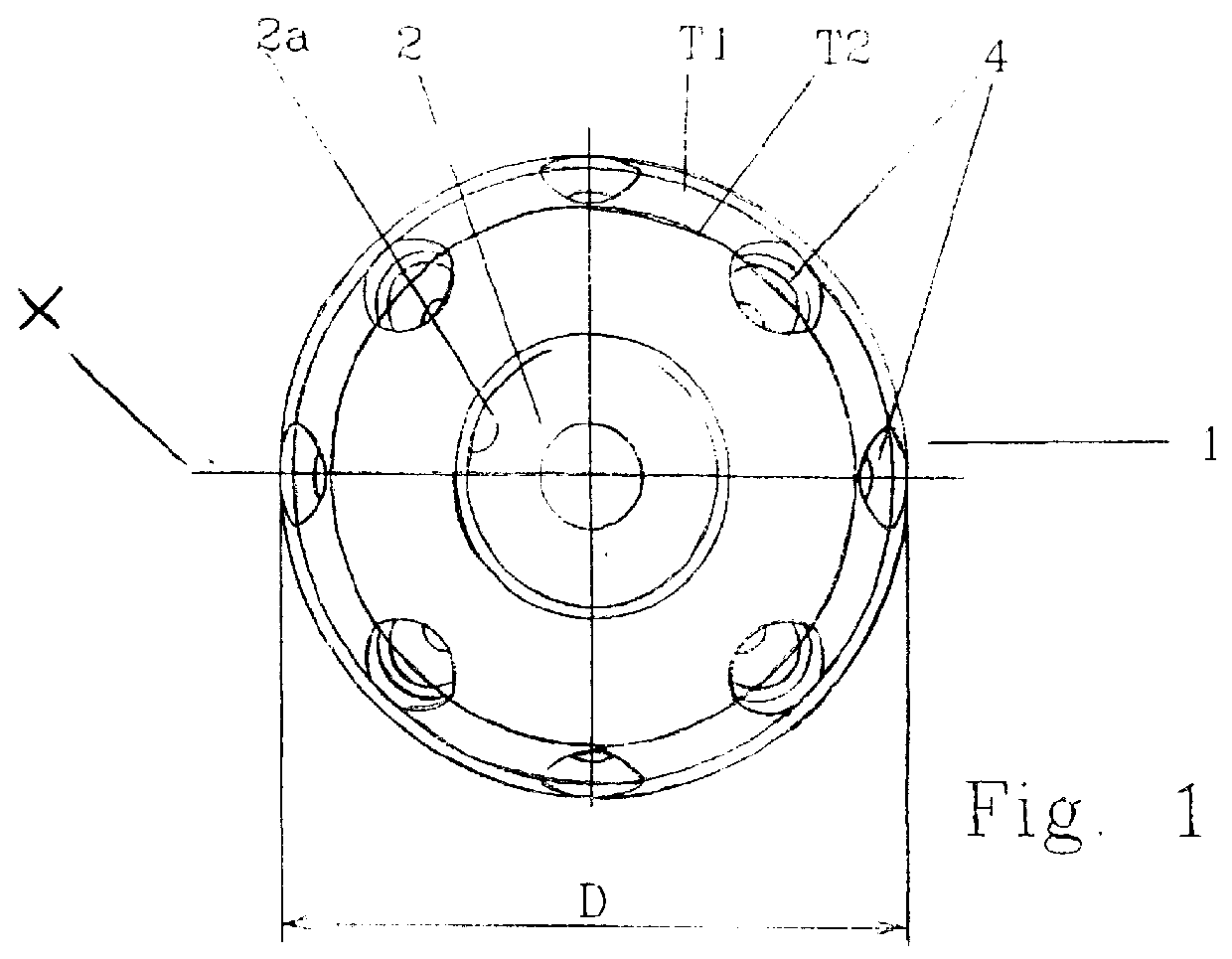

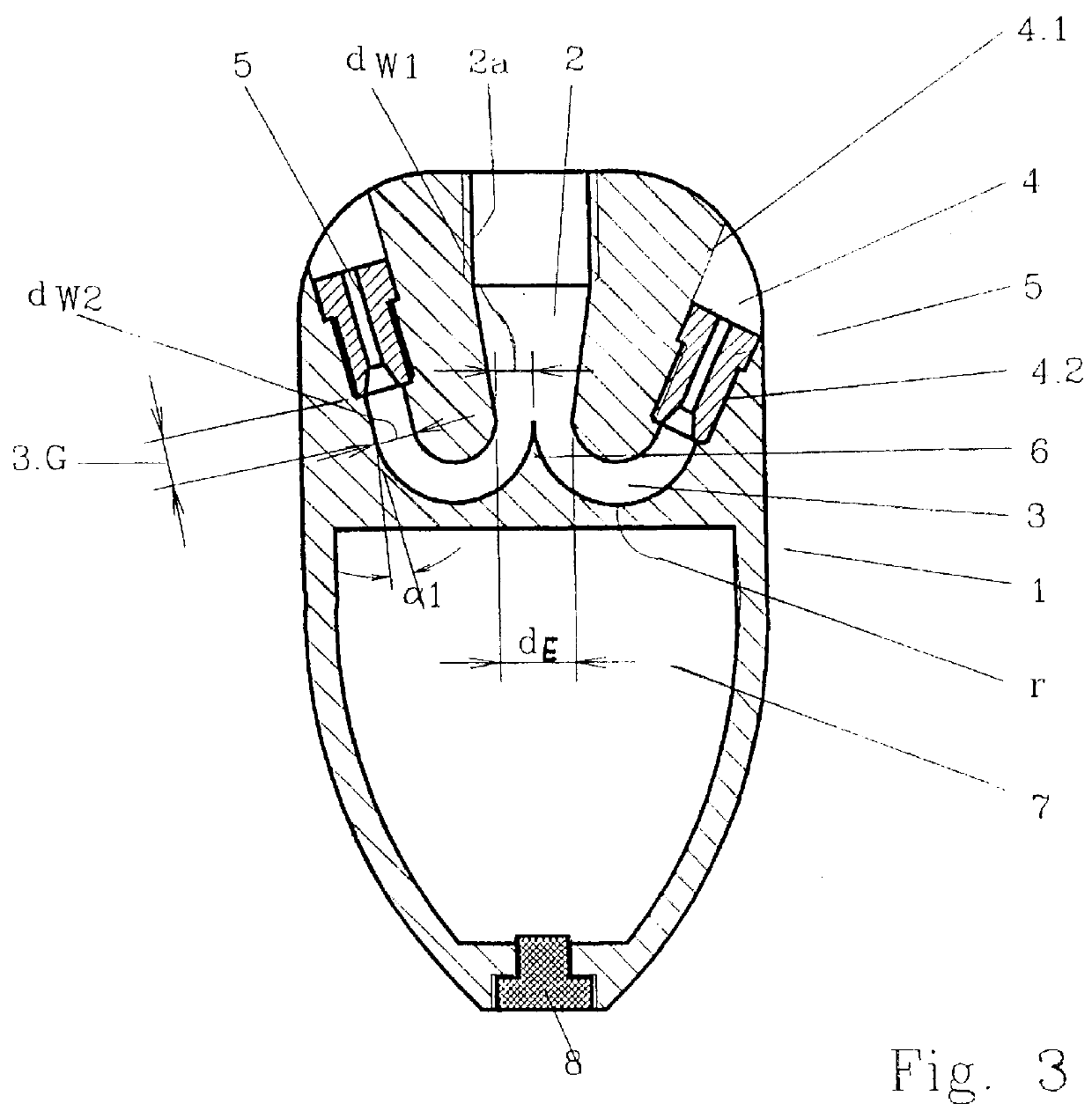

A hydrodynamic tool for the cleaning of pipes and channels exhibits a pressurized water-entry inlet opening (2) connected to pressurized water-discharge outlet openings (4) through water guide channels (3). The water guide channels (3) are continuously connected to the pressurized water-entry inlet opening (2) with a hose connection (2a). The water guide channels (3) exhibit a largest possible deflection radius (r) and partially converge into one another. At least two water guide channels (3) rest with the innermost point of the diameter (dW1) at the center point (M) and with their outermost point of the diameter (dW1) at the outer diameter (dE) of the pressurized water-entry inlet opening (2). The water guide channels (3), corresponding to the arrangement of the pressurized water-discharge outlet openings (4), are either merging into the end of the deflection radius (r) or into the straight line region (3.G) and in an angle ( alpha ) to the respective pressurized water-discharge outlet openings (4).

Owner:KURT HORGER

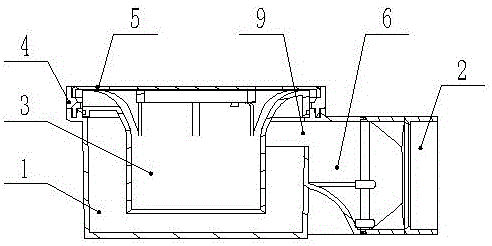

Centrifugal blower volute of range hood

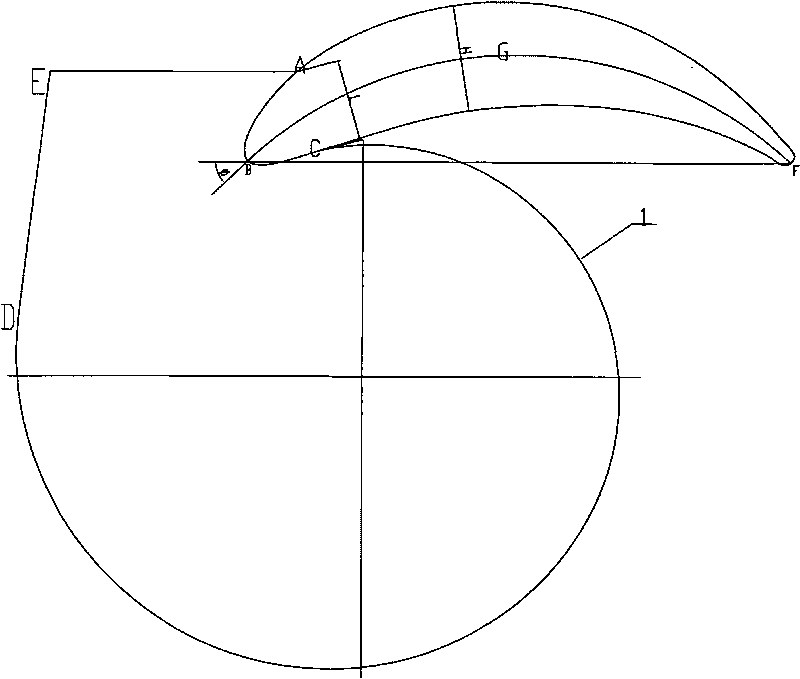

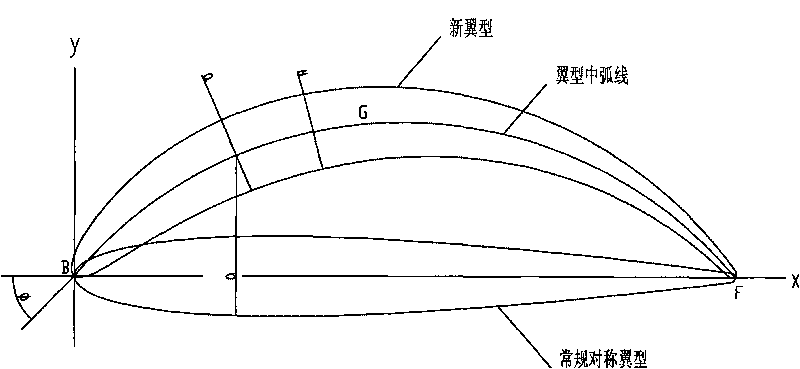

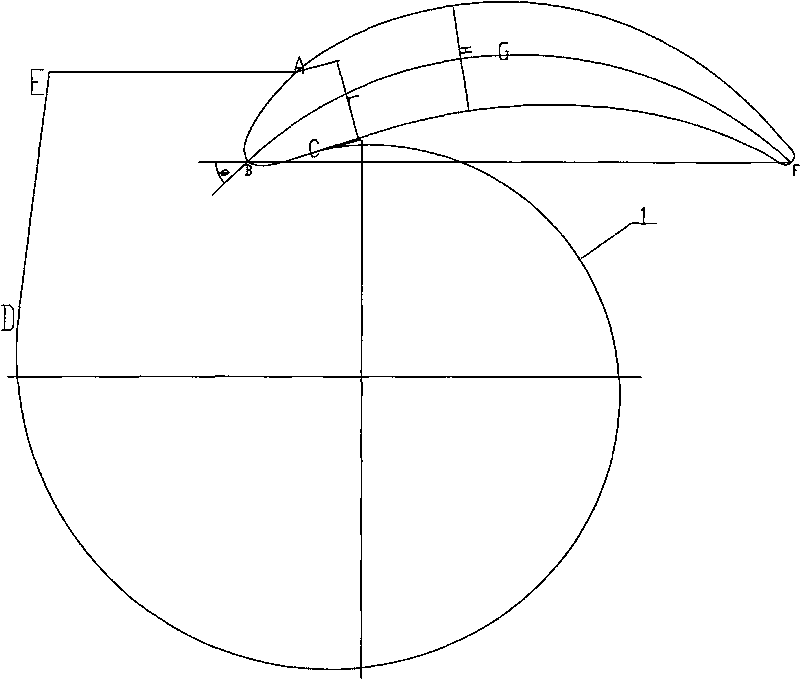

The invention relates to a centrifugal blower volute of a range hood. A molded line of the volute (1) consists of a first curve AB, a second curve BC, a log spiral CD and a straight line DE which are in smooth transition connection with each other, and the first curve AB and the second curve BC which form a volute tongue are front edge parts of a wing profile molded line, wherein the first curve AB is the front edge part of a wing profile upper airfoil molded line BAF, the second curve BC is the front edge part of a wing profile lower airfoil molded line BCF, and the upper airfoil molded line BAF and the lower airfoil molded line BCF form the wing profile molded line. The centrifugal blower volute uses the wing profile front edge parts with good streamline forms as the molded lines of the centrifugal blower volute tongue. The volute adopting the wing profile volute tongue can greatly reduce the probability of generating flow separations and back flows at the volute tongue and reduce impact losses, and is favorable for improving the wind quantity, the wind pressure and the efficiency of a centrifugal blower and reducing aerodynamic noises.

Owner:MIDEA GRP CO LTD

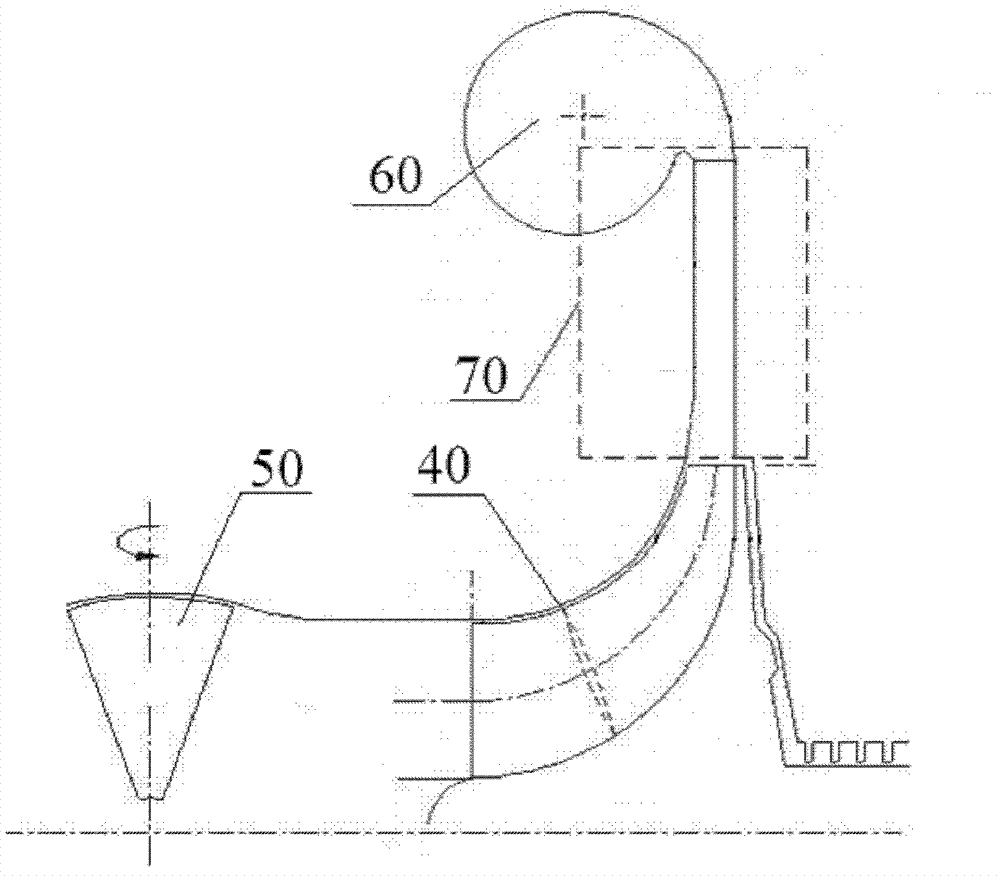

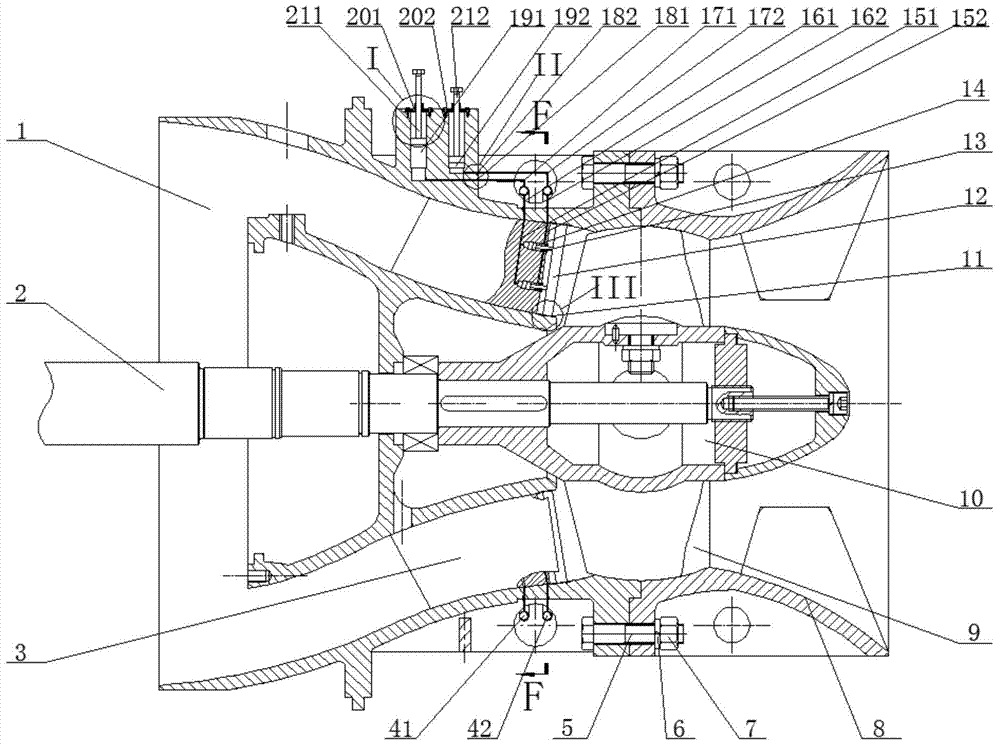

Volute type centrifugal pump with movable guide vane

The invention discloses a volute type centrifugal pump with a movable guide vane. According to the volute type centrifugal pump with the movable guide vane, a rectifying grid is arranged at an outletof a suction elbow pipe, so that the energy loss of fluid at an inlet of a flow channel is reduced, the cavitation performance is improved, and vibration and noise are reduced. The movable guide vanestructure of the volute type centrifugal pump with the movable guide vane is arranged between an impeller outlet and a volute inlet, the angle of the guide vane can be adjusted according to differentworking conditions, and the flow at the impeller outlet can be rectified under different working conditions, so that the influence of unbalanced force is reduced, and the operation stability of a large unit is improved. Moreover, the structure is beneficial to reducing the impact loss caused by the fact that the water flow impacts the guide vane when the liquid flow at the impeller outlet enters the guide vane, so that the efficiency of the large centrifugal pump is improved.

Owner:JIANGSU UNIV

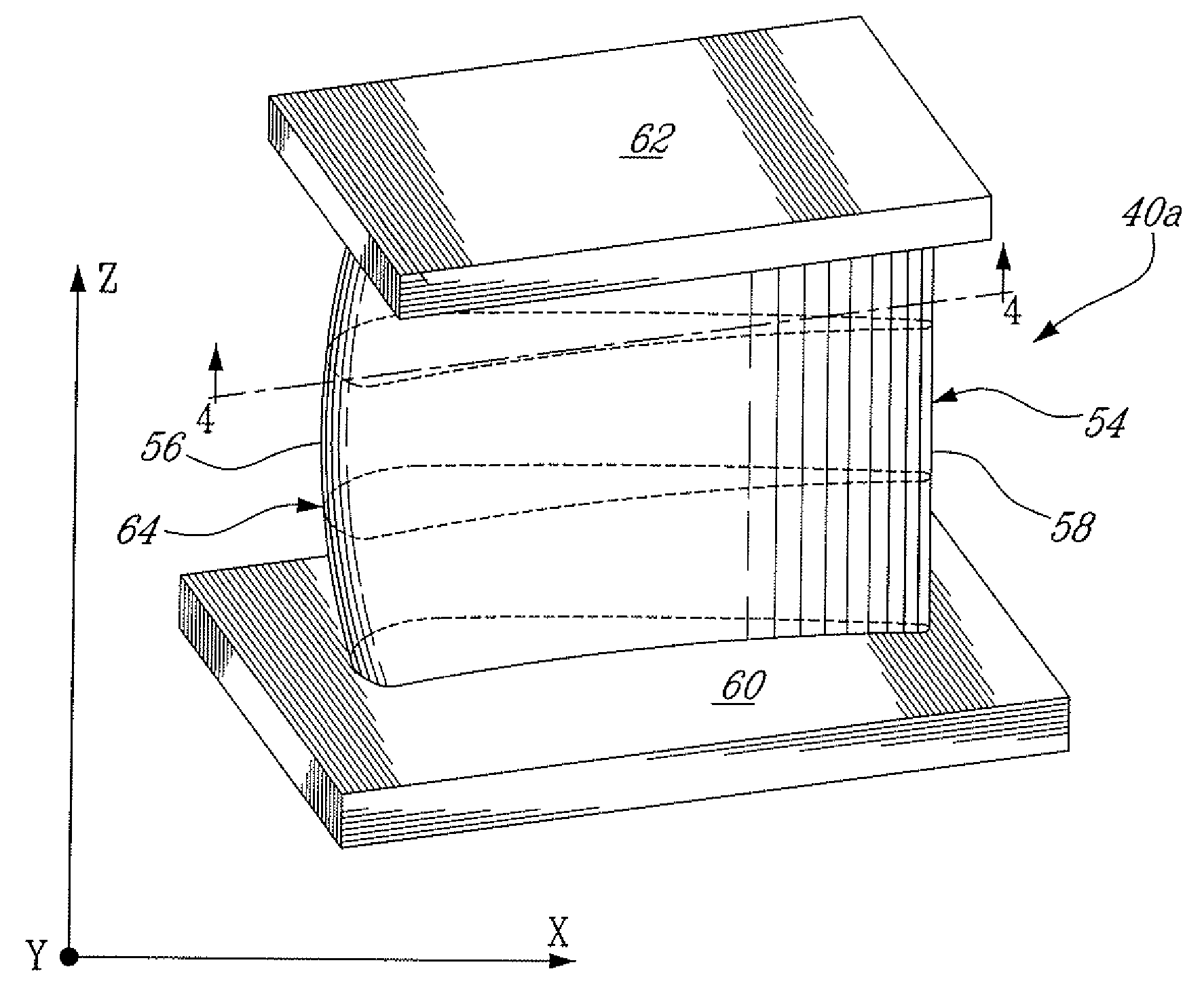

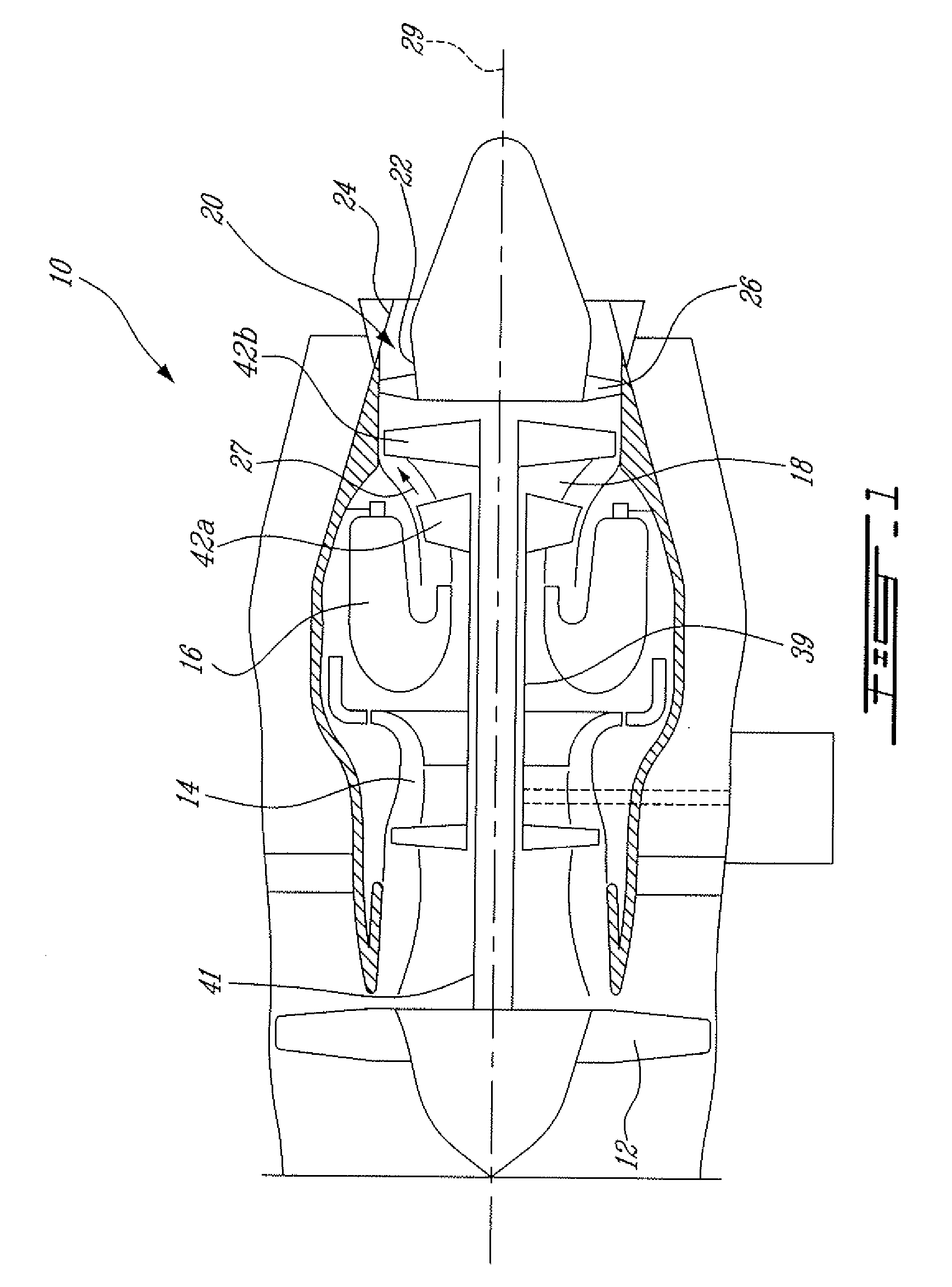

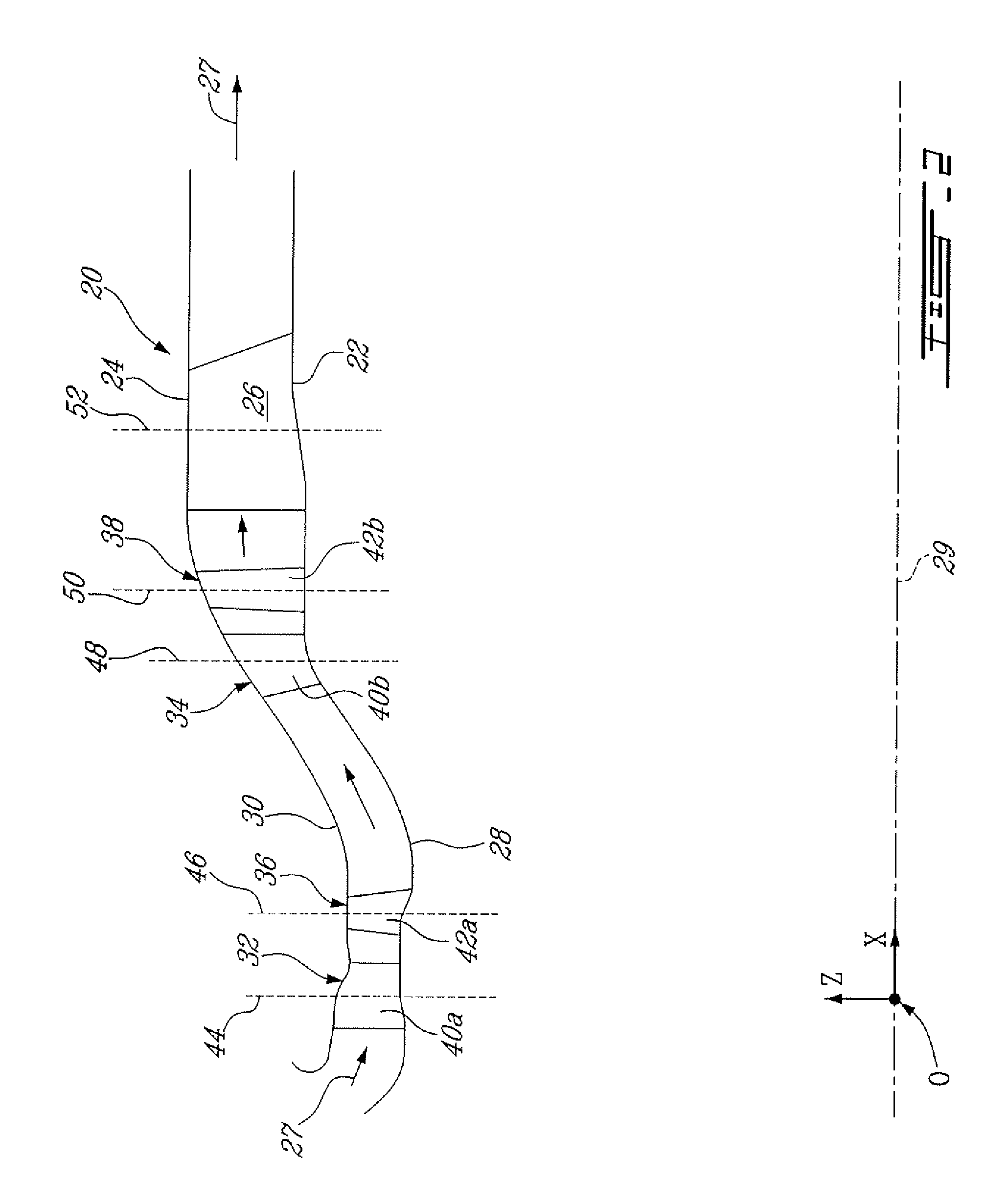

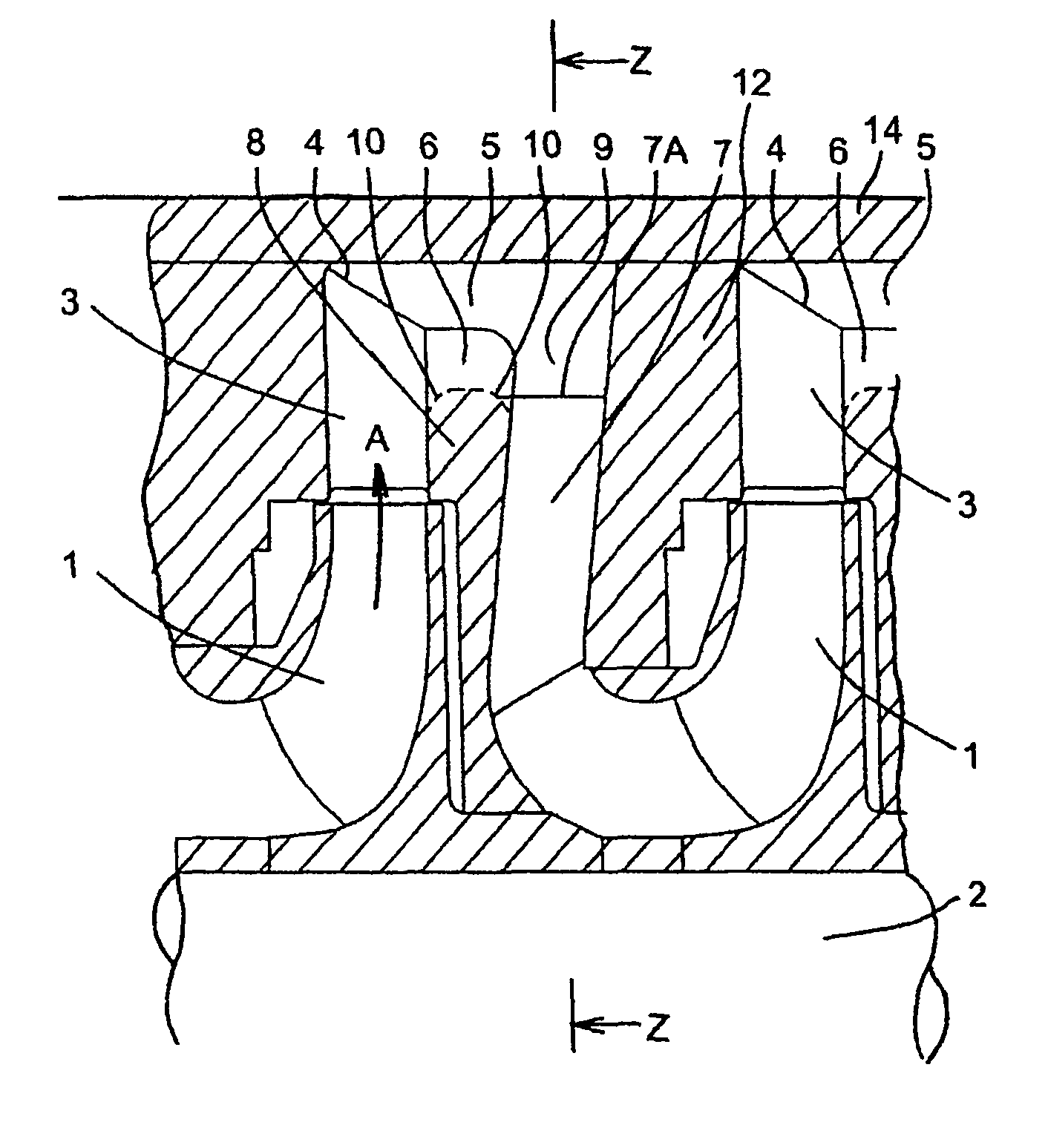

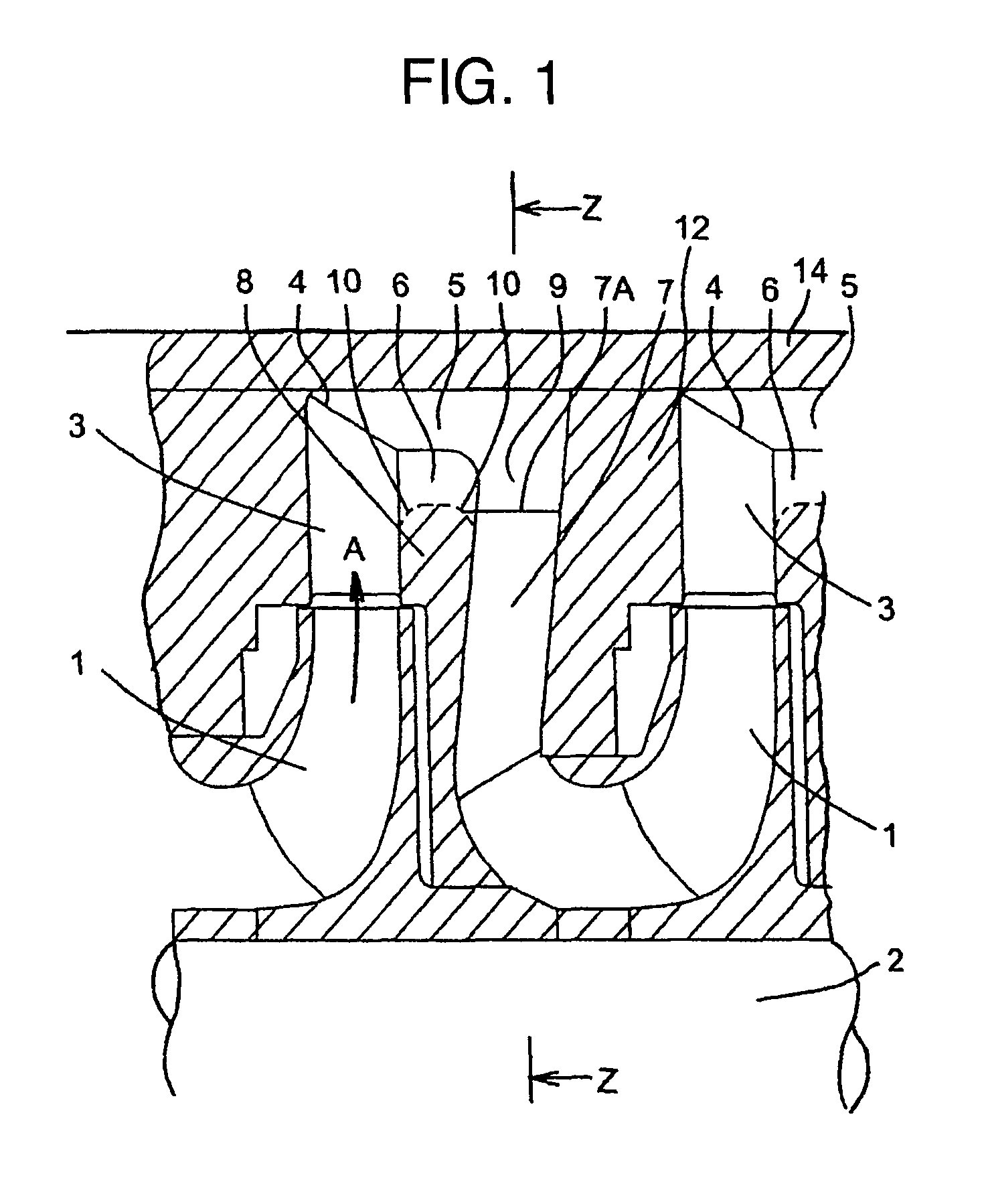

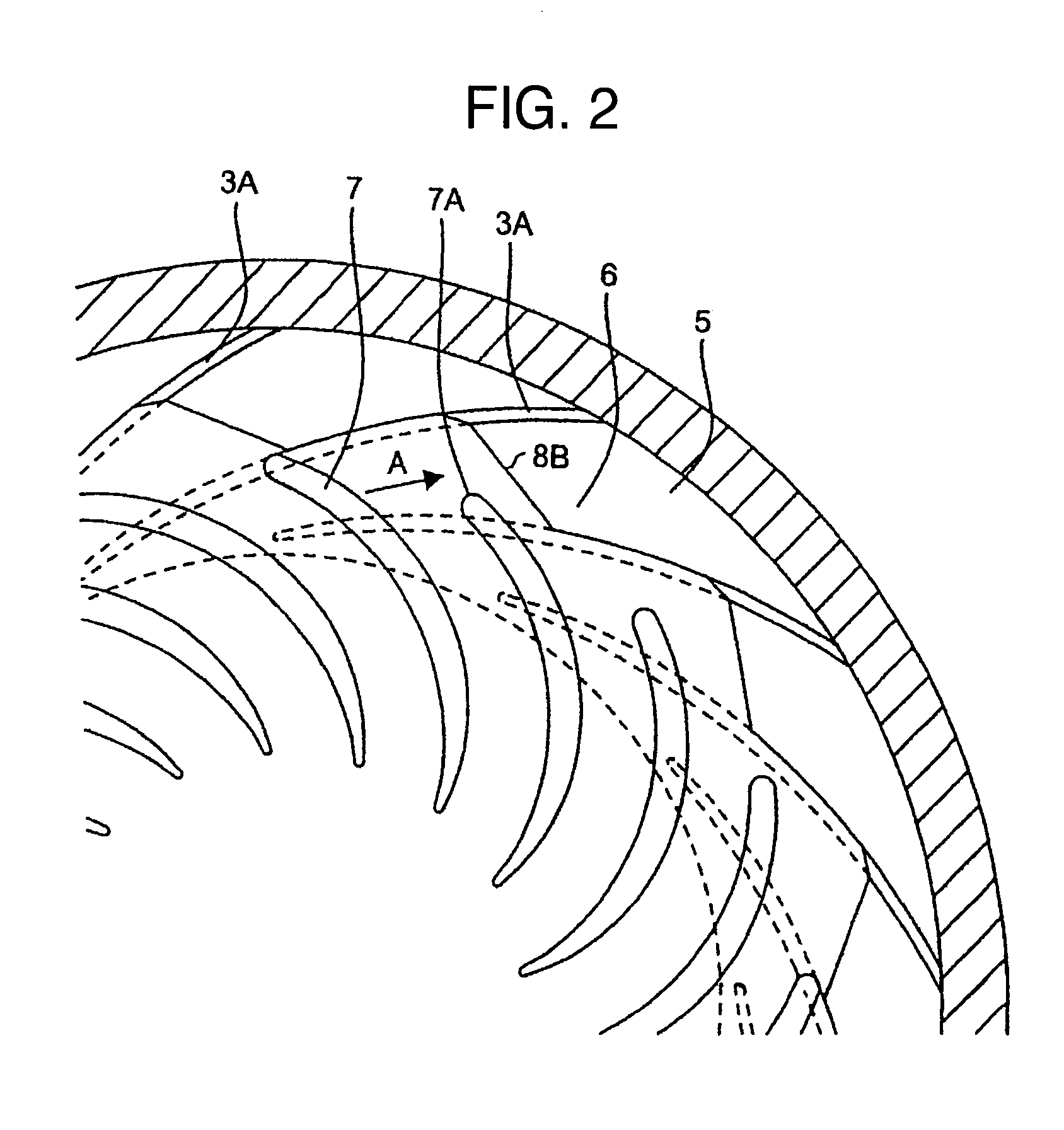

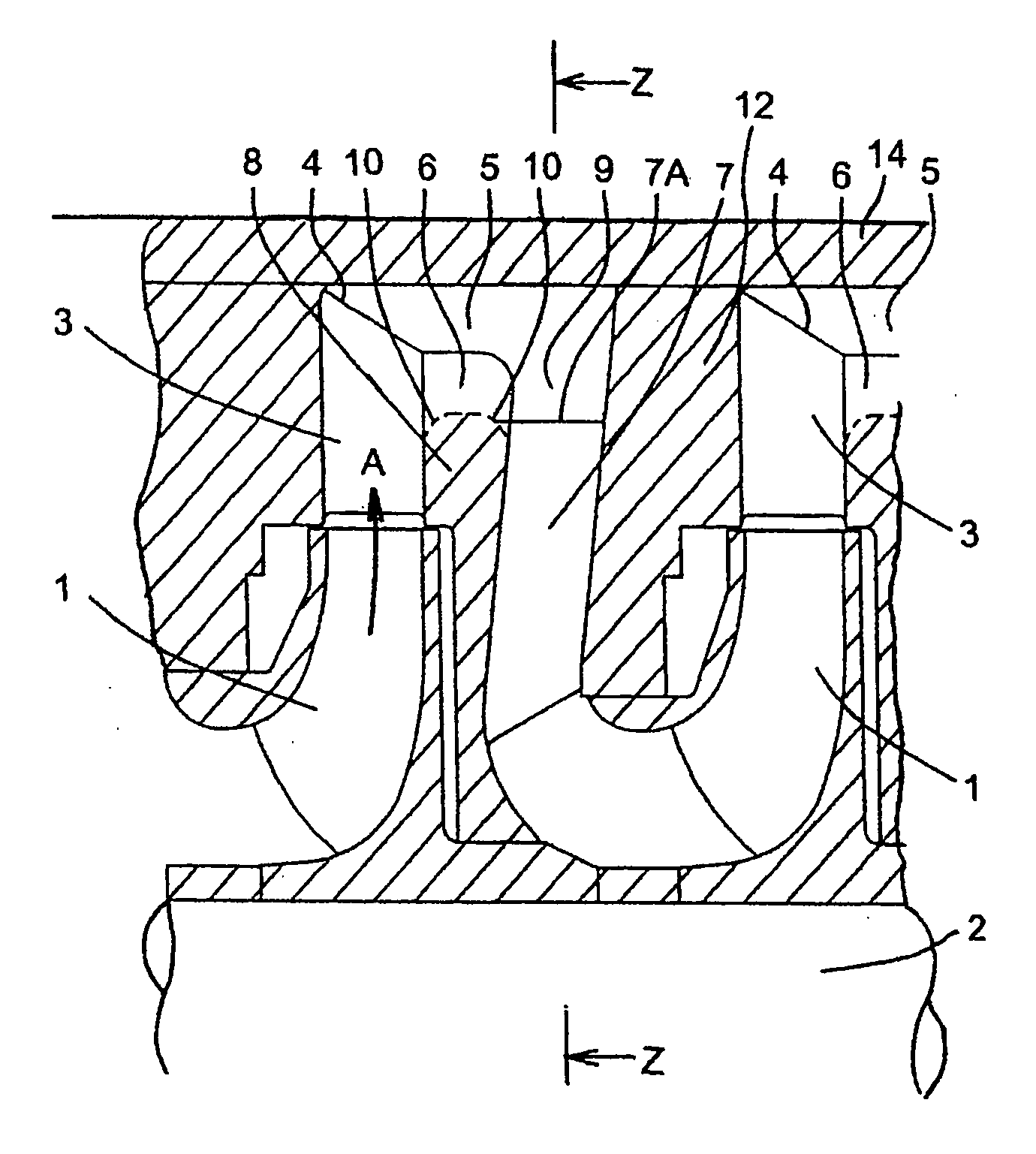

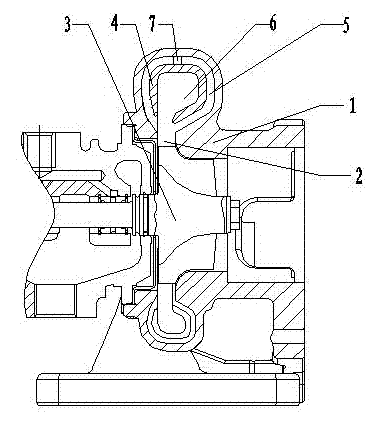

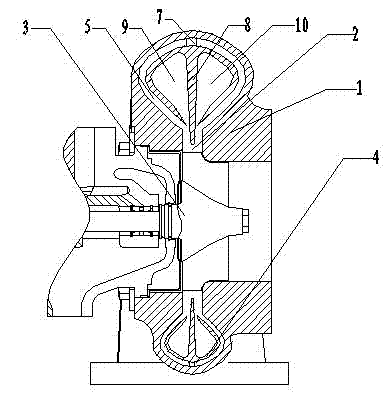

Centrifugal turbomachinery

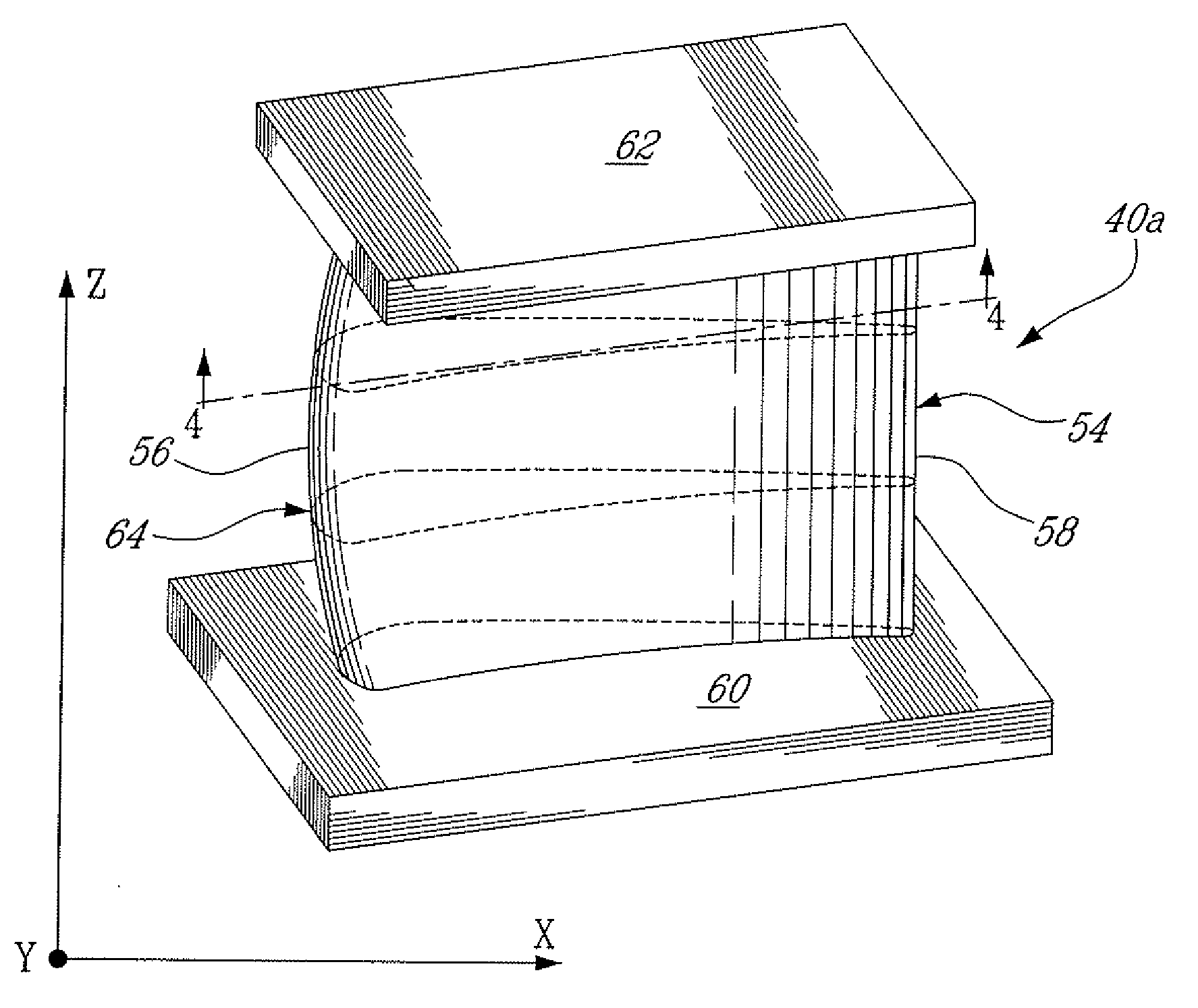

ActiveUS8075260B2Lower a fluid loss in a centrifugal turbomachineryImprove performancePump componentsWorking fluid for enginesImpellerMaximum diameter

A centrifugal turbomachinery in accordance with the present invention can lower a fluid loss in a return flow path. In the centrifugal turbomachinery, a plurality of centrifugal impellers is attached to a rotating shaft, and the centrifugal turbomachinery is provided with a diffuser having a plurality of blades introducing a fluid boosted by a front stage impeller to a rear stage impeller, and a return flow path means. The return flow path means has a side plate arranged in a back surface side of the front stage impeller, a plate opposing the side plate and arranged in a front surface side of the rear stage impeller, and a plurality of blades arranged between the side plate and the plate so as to be spaced in a peripheral direction. A maximum diameter portion of the side plate is changed in the peripheral direction.

Owner:HITACHI IND PROD LTD

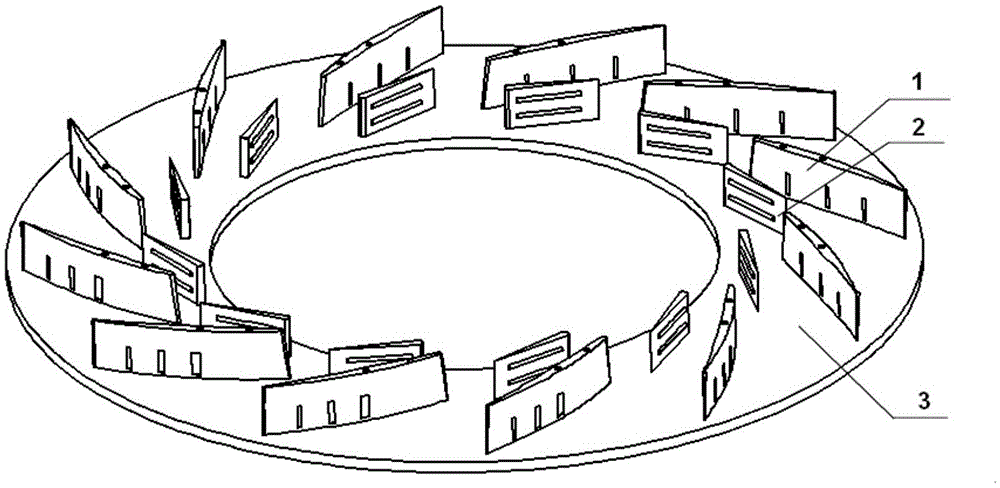

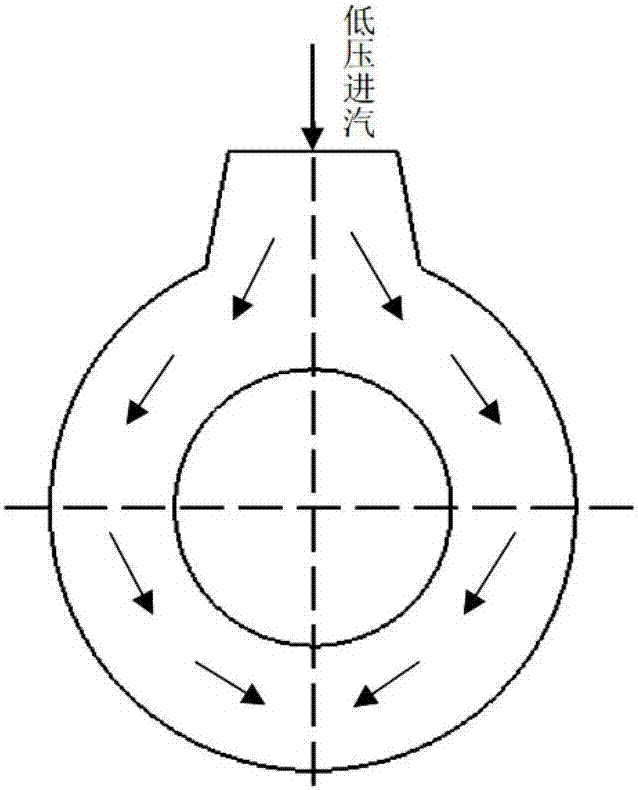

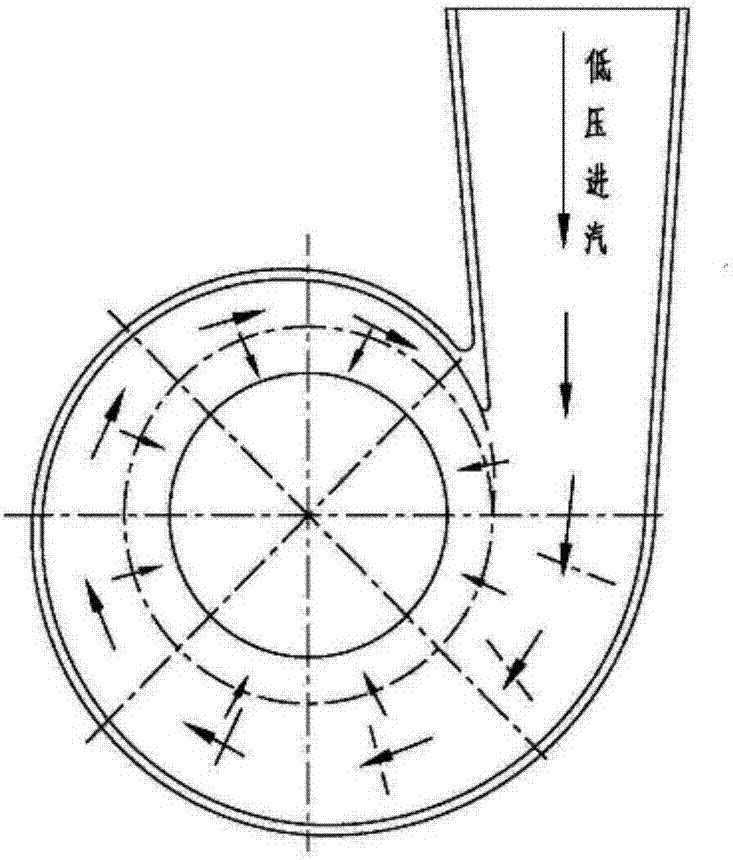

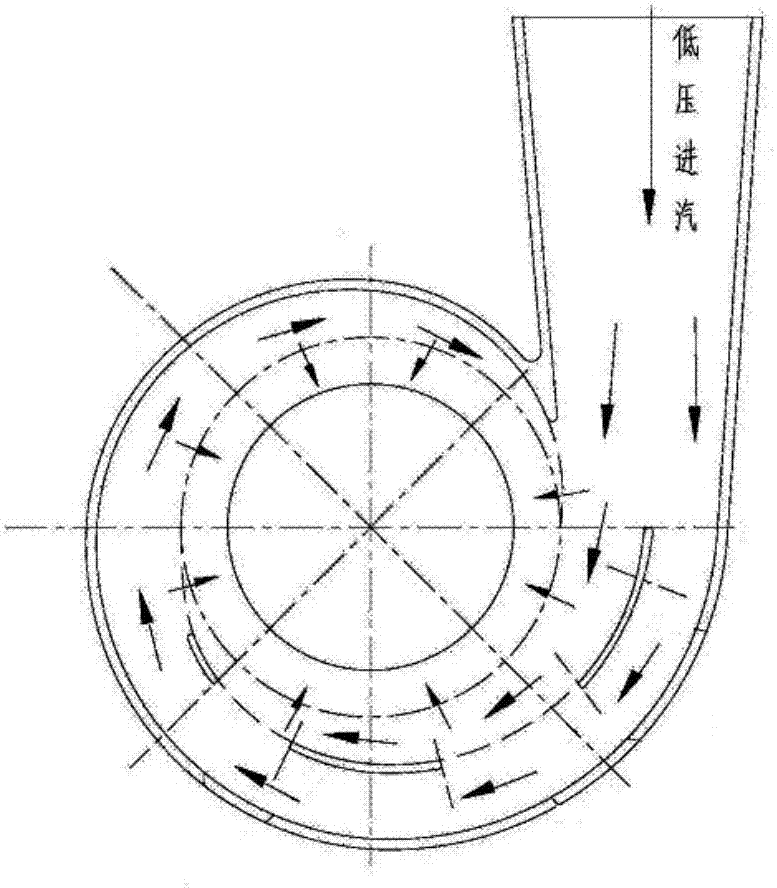

Uniform steam admission/supplement device for steam turbine

ActiveCN107965354AImprove efficiencyRealize a reasonable distributionStatorsMachines/enginesUnit operationEngineering

The invention discloses a uniform steam admission / supplement device for a steam turbine. The uniform steam admission / supplement device comprises an annular steam admission flow passage housing and ansteam admission pipeline housing communicating with the steam admission flow passage housing; a steam admission flow passage of a steam flow passage housing is arranged in an axially symmetrical mode,and a cross-sectional area of the steam admission flow passage decreases monotonously in the flow direction of steam admission; the steam admission flow passage housing communicates with the largestcross-sectional area of the steam admission flow passage, and a plurality of steam flow guide vanes are axially and symmetrically arranged on the inner wall of the steam admission flow passage of thesteam flow passage housing. From the point of view of reducing the steam loss and reducing the impact of a steam flow on a rotor, the uniform steam admission / supplement device for the steam turbine adopts a variable cross-section cavity design to adapt to the flow variation of steam during the flowing process, the flow velocity distribution of the steam in each section of the steam admission flowpassage tends to be uniform, the steam admission pressure and temperature loss are reduced, and the efficiency of the steam turbine is improved; the steam admission volume tends to be evenly distributed in the circumferential direction by rationally arranging the steam flow guide vanes, the steam flow force generated by the steam admission to the rotor is reduced, and the safety and stability of the unit operation are improved.

Owner:XI AN JIAOTONG UNIV

Double-suction impeller

InactiveCN104279180AExpand the specific speed rangeDesign parameters have not changedPump componentsPumpsImpellerAxial force

The invention discloses a double-suction impeller, comprising a front cover board, a rear cover board, blades, a hub and a shaft, wherein the outlet edge of a water outlet is V-shaped; a partition plate which protrudes upwards is arranged on the peak of the V-shape and on the rear cover board; two edges of the partition plate are respectively in an inward concave arc shape; the partition plate is in smooth transition along the runner change shape. According to the double-suction impeller, the specific speed of the impeller is increased, the hydraulic loss is reduced to the maximal extent, and the double-suction impeller is symmetric in structure, free of axial force and stable in operation.

Owner:兰州国器装备制造集团有限公司

Method for improving cavitation-erosion performance of centrifugal pump

The invention relates to a method for improving the cavitation-erosion performance of a centrifugal pump. According to the method for improving the cavitation-erosion performance of the centrifugal pump, through the reducing of a blade head impact angle, the impact of a blade and incoming flow is reduced, the impact condition of impeller head liquid flow and the blade is improved, and the adaptation to the incoming flow can be better achieved. The width of an impeller channel is increased, the curves of a front cover plate and a back cover plate are adjusted, the impact loss due to the fact that the liquid flow is absorbed into the impeller from an outlet position is reduced, the effective working area of the centrifugal pump is improved, and the energy waste is reduced. Through the above improvement, the speed of fluid in the pump is more even, the phenomenon of over low local pressure is improved, and therefore the cavitation-erosion performance of the centrifugal pump is improved.

Owner:CHINA JILIANG UNIV

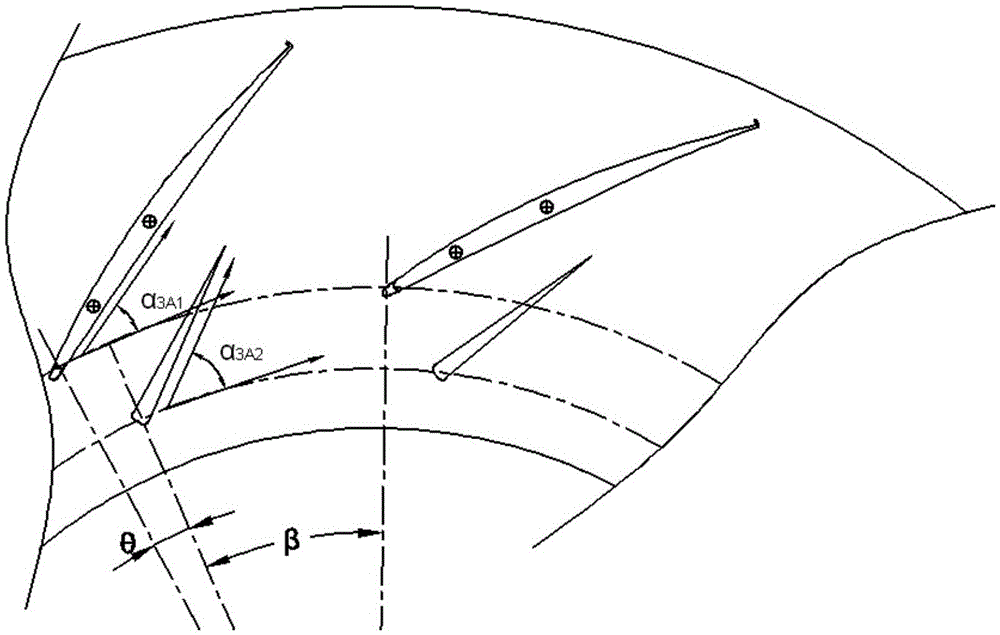

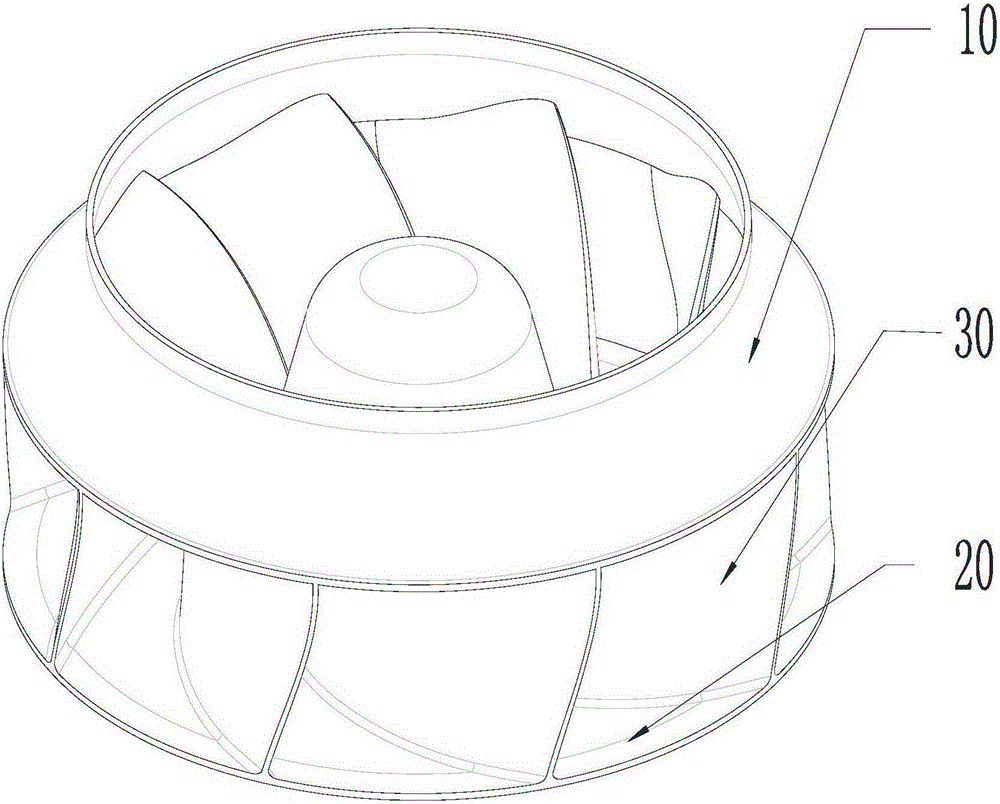

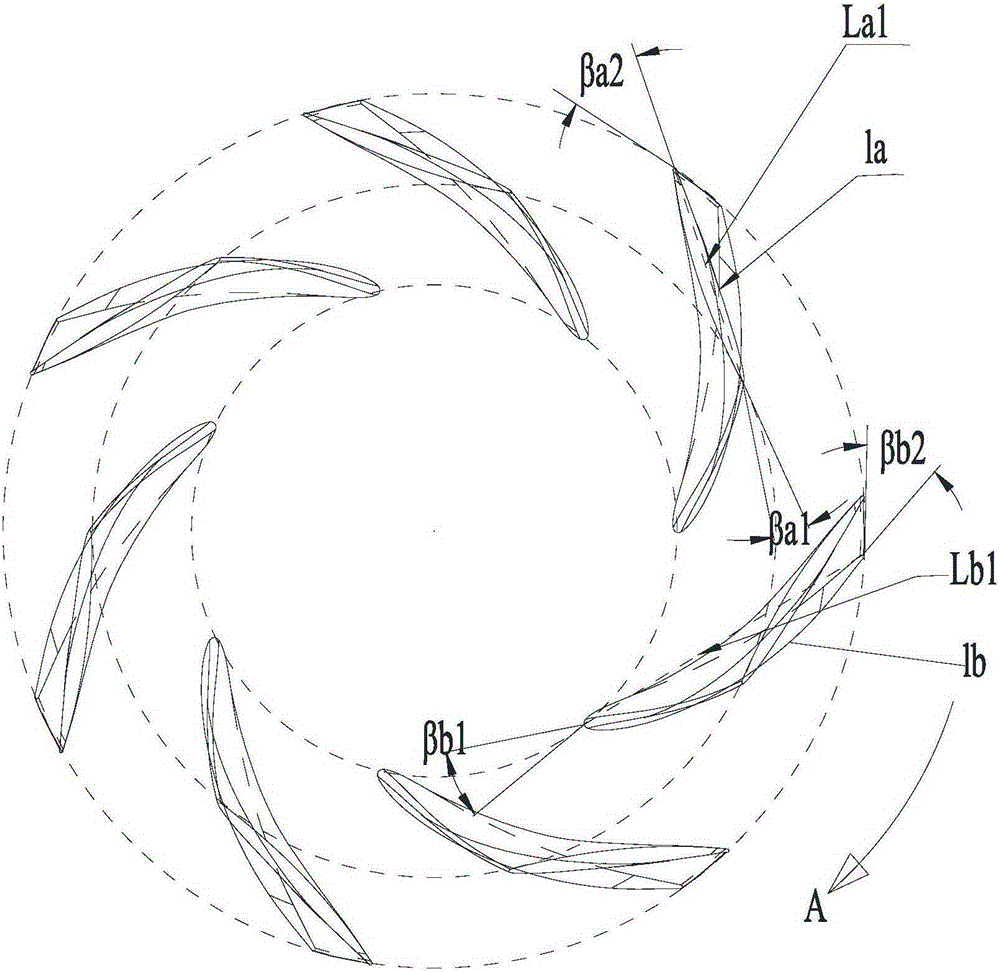

Centrifugal fan blade and centrifugal fan

ActiveCN105275875AImprove aerodynamic efficiencyReduce impact lossPump componentsPumpsAgricultural engineeringCentrifugal force

The invention provides a centrifugal fan blade and a centrifugal fan. The centrifugal fan blade comprises a front cover plate (10), a rear cover plate (20) and a plurality of blades (30) arranged between the front cover plate (10) and the rear cover plate (20). Blade profile inlet angles at the joints of the blades (30) and the front cover plate (10) are betaa1, and blade profile inlet angles at the joints of the blades (30) and the rear cover plate (20) are betab1, wherein betaa1 is smaller than betab1. According to the centrifugal fan blade and the centrifugal fan, the blade profile inlet angles at the joints of the blades (30) and the front cover plate (10) are smaller than the blade profile inlet angles at the joints of the blades (30) and the rear cover plate (20), and therefore the impact of airflow at an inlet can be reduced, noise is lowered, and the pneumatic efficiency of the fan blade is improved.

Owner:GREE ELECTRIC APPLIANCES INC

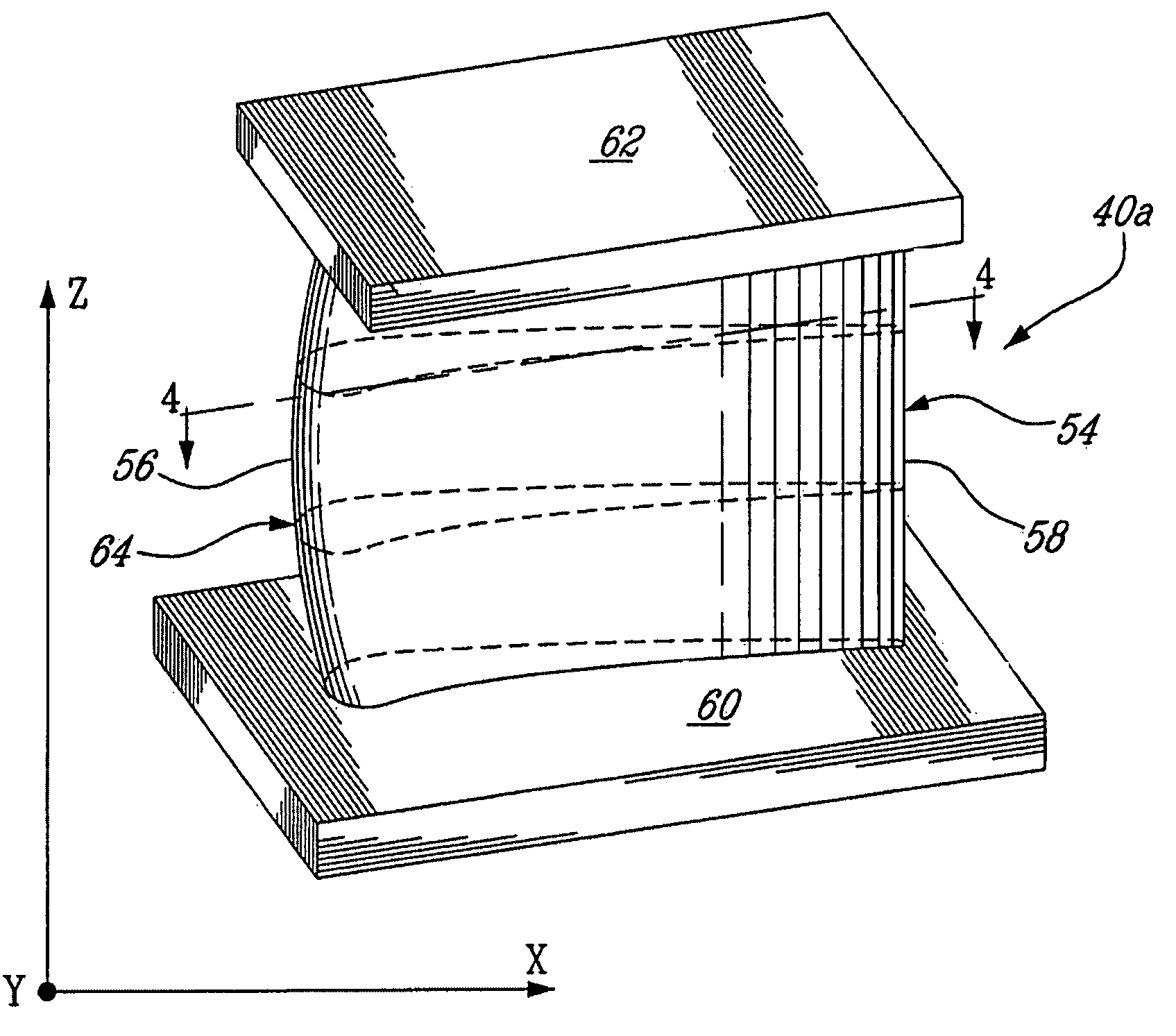

Centrifugal turbomachinery

ActiveUS20070217909A1Reduce impact lossWithout lowering fluid performancePump componentsWorking fluid for enginesImpellerMaximum diameter

A centrifugal turbomachinery in accordance with the present invention can lower a fluid loss in a return flow path. In the centrifugal turbomachinery, a plurality of centrifugal impellers is attached to a rotating shaft, and the centrifugal turbomachinery is provided with a diffuser having a plurality of blades introducing a fluid boosted by a front stage impeller to a rear stage impeller, and a return flow path means. The return flow path means has a side plate arranged in a back surface side of the front stage impeller, a plate opposing the side plate and arranged in a front surface side of the rear stage impeller, and a plurality of blades arranged between the side plate and the plate so as to be spaced in a peripheral direction. A maximum diameter portion of the side plate is changed in the peripheral direction.

Owner:HITACHI IND PROD LTD

Two-channel variable-section volute device with flow-guiding blades

ActiveCN102562185AReduce impact lossImprove efficiencyInternal combustion piston enginesEngine componentsLow speedPulse energy

The invention discloses a two-channel variable-section volute device with flow-guiding blades, which comprises a volute. A volute air inlet, a volute air outlet, a volute air inlet flow channel and a volute diffusing channel are arranged in the volute, a pneumatic partition plate is arranged in the volute air inlet flow channel and divides the volute air inlet flow channel into a volute air inlet inner flow channel and a volute air inlet outer flow channel, the volute air inlet outer flow channel is located on the outer side of the circumference of the volute air inlet inner flow channel, and the position of the volute air inlet outer flow channel and the position of the volute air inlet inner flow channel which are close to the volute diffusing channel are respectively provided with a no-blade nozzle. A plurality of wing-shaped pneumatic flow-guiding blades are annularly evenly arranged at the position inside the volute air inlet outer flow channel close to the no-blade nozzle. For a pulse pressurizing system, the inner flow channel works at an engine low-speed area, and the pulse energy can be utilized better. When at a high speed, the outer flow channel does not need to be divided into two flow channels, enough energy can be obtained through one flow channel, a product structure is further simplified, and the product weight is reduced.

Owner:康跃科技(山东)有限公司

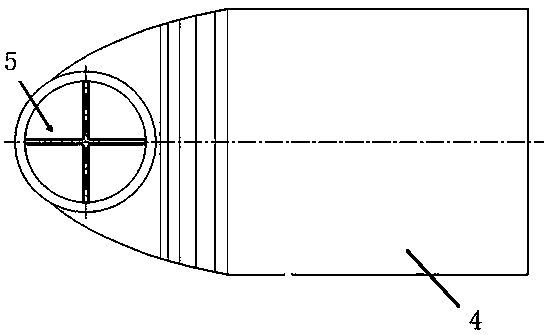

Centripetal impeller for gas turbine engine

ActiveCN103306739AReduce centrifugal loadAvoid restrictionsPump componentsBlade accessoriesImpellerEngineering

The invention discloses a centripetal impeller for a gas turbine engine, which comprises an impeller disk (1) and blades (2). The blades (2) are arranged on the surface of the impeller disk (1), and extend to a rim (3) outside the impeller disk (1); the impeller disk (1) at the backs of the blades (2) is provided with a pocket (4); at least two circular arc surfaces are formed in the pocket (4). The pocket is processed at the position at the back of the impeller to reduce a centrifugal load borne by an impeller center so as to reduce stress. Due to the structural characteristics of the centripetal impeller, the pocket cannot be excessively deep dug and the fillet radius also cannot be excessively large; the adoption of a multi-section circular arc structure of the pocket can effectively solve the problem of limitation of the fillet radius; aiming at the pocket, the multi-section circular arc structure is adopted, a large circular arc radius is adopted in a region with a large stress and a small circular arc radius is adopted in a region with a small stress. According to the novel structure, the stress can be greatly reduced in a small space range and service life is prolonged.

Owner:CHINA AVIATION POWER MACHINE INST

High-flow cross-draining water-sealing floor drain

PendingCN106759810ASimple structureIncrease drainage flowSewerage structuresClimate change adaptationEngineeringStreamflow

The invention relates to a high-flow cross-draining water-sealing floor drain, belongs to the technical field of floor drains and provides a cross-draining floor drain small in size, high in flow capacity and compatible with washing machine drainage; according to the technical scheme, a floor drain body is a container with a top opening, a water-sealing cover is in the shape of a ring having the inner cylindrical face extended down to form a barrel, the water-sealing cover is arranged inside the floor drain body, the bottom of the barrel hangs in the air, the ring of the upper portion of the water-sealing cover adapts to the upper portion of the floor drain body in shape and is locked to the upper portion of the floor drain body, a water seal is formed between the water-sealing cover and the floor drain body, a frame is mounted above the water-sealing cover and the floor drain body, and a grate is mounted in the frame; the outer side of the floor drain body is connected with a water outgoing pipe, the water outgoing pipe includes a square tube segment, a transition segment and a circular tube segment, the square tube segment is connected to the outer wall of the floor drain body, and the upper portion of the sidewall of the floor drain body inside the square tube segment is provided with a horizontal water outlet; the high-flow cross-draining water-sealing floor drain is suitable for cross-draining pipelines.

Owner:TAIYUAN KINDER SANITARY WARE & EQUIP CO LTD

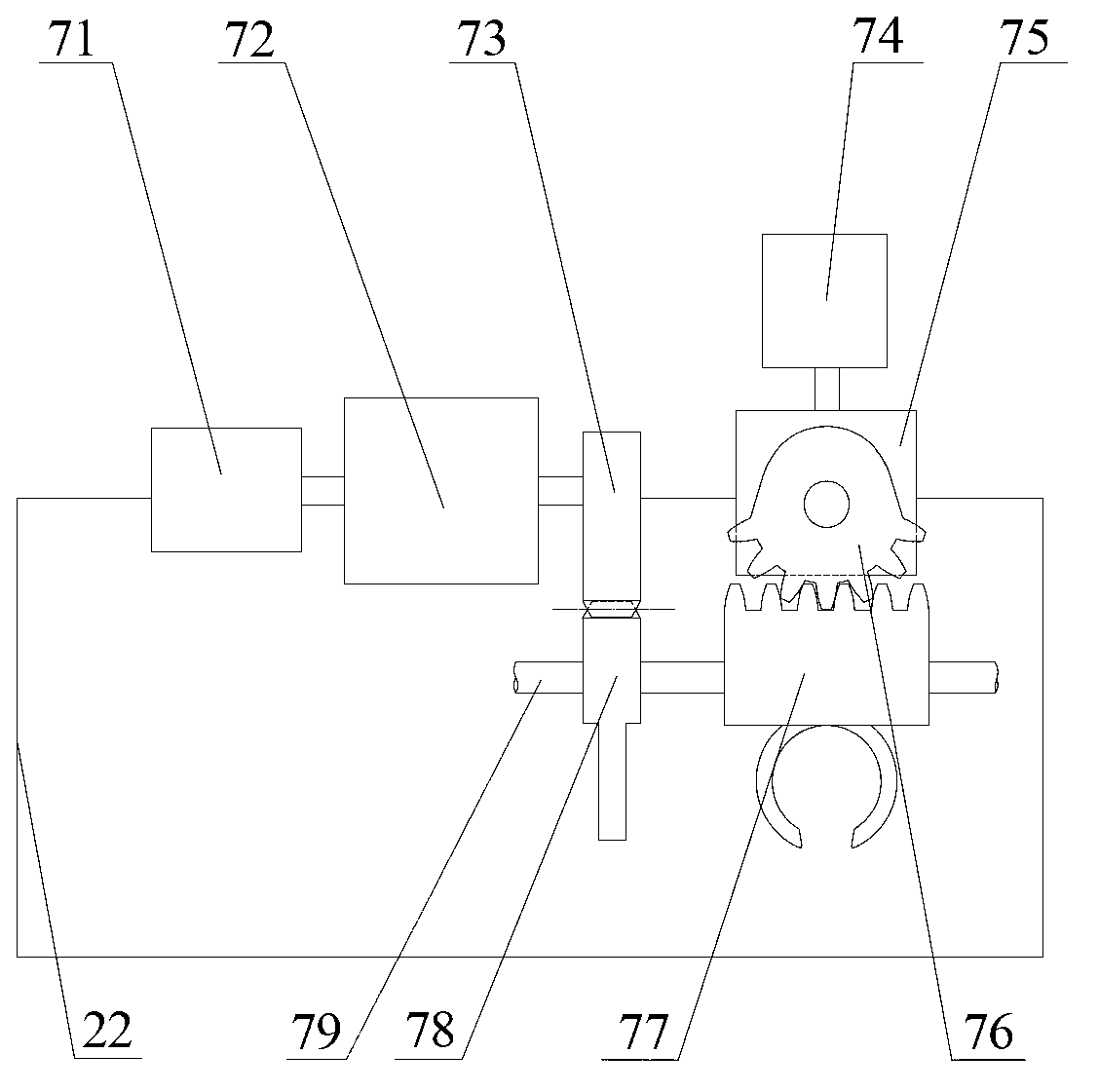

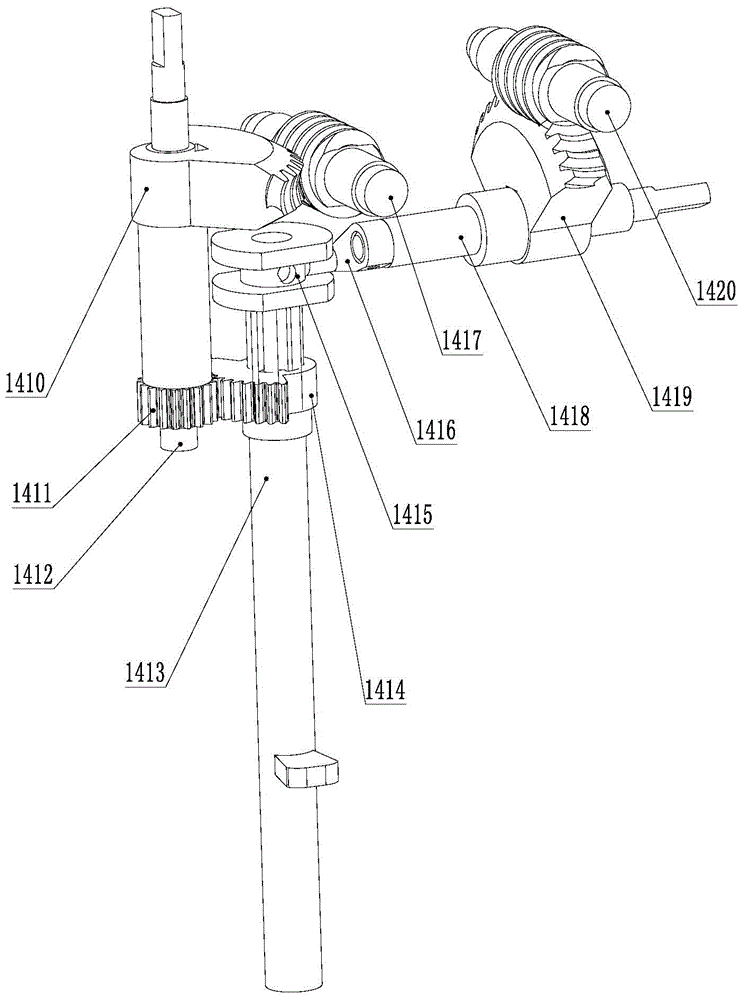

Fixed guide vane body inlet angle adjustable axial flow pump

InactiveCN104776061AImprove operational efficiencyImprove job stabilityPump componentsPumpsAxial-flow pumpImpeller

The invention relates to the technical field of water pumps, in particular to a fixed guide vane body inlet angle adjustable axial flow pump which comprises an impeller chamber (9), a water inlet horn mouth (8), an impeller body (10), a guide vane body (1) and a pump shaft (2). The guide vane body (1) comprises a plurality of guide vanes (3) and a dispersing pipe. The axial flow pump further comprises an adjusting system which comprises a control unit, a middle unit and an executing unit. According to different working conditions, a proper guide vane inlet angle is adjusted, so that the guide vane inlet angle is matched with an impeller flow-out angle, the circular rector of the fixed guide vane body is changed, accordingly, stress is improved, then, hydraulic loss such as impact and streaming around is lowered, energy loss is lowered, the operation stability of the pump is improved, and finally the purpose of axial flow pump performance improving is achieved.

Owner:CHINA AGRI UNIV

High-efficiency gas and liquid mixer for gas and liquid two-phase flow experiment

ActiveCN106215734AEasy to moveIncrease contact areaFlow mixersTransportation and packagingGas phaseSpray nozzle

The invention relates to a gas and liquid mixer, in particular to a high-efficiency gas and liquid mixer for a gas and liquid two-phase flow experiment table. The high-efficiency gas and liquid mixer is characterized in that gas conveying separating plates are arranged in a main flow pipe, and are used for conveying gas phase, and an angle of attack at the front part of each gas conveying separating plate is favorable for the flowing of fluid, so as to reduce the resistance loss; a shrinkage type spray pipe is arranged at the tail part of each gas conveying separating plate, and the inlet cross section is designed, so that the air flow which flows out of each spray nozzle has the same outlet state; under the spraying action of spray pipes, the contact area of gas and liquid is increased, the mixing is uniform, and the stress produced by mixing is uniformly distributed when each gas conveying separating plate is arranged in an axis symmetric way; guide vanes which are symmetrically arranged in a sleeve cylinder are used for guiding flow, so that the impact loss of flowing is reduced; after calculating, the inlet length of each gas conveying separating plate, and the value range of the length of each guide vane are obtained, so that the impact loss of flowing is reduced, and the stable flowing state is furthest maintained.

Owner:JIANGSU UNIV ZHENJIANG RES INST OF FLUID ENG EQUIP TECH

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com