Patents

Literature

59results about How to "High speed drive" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

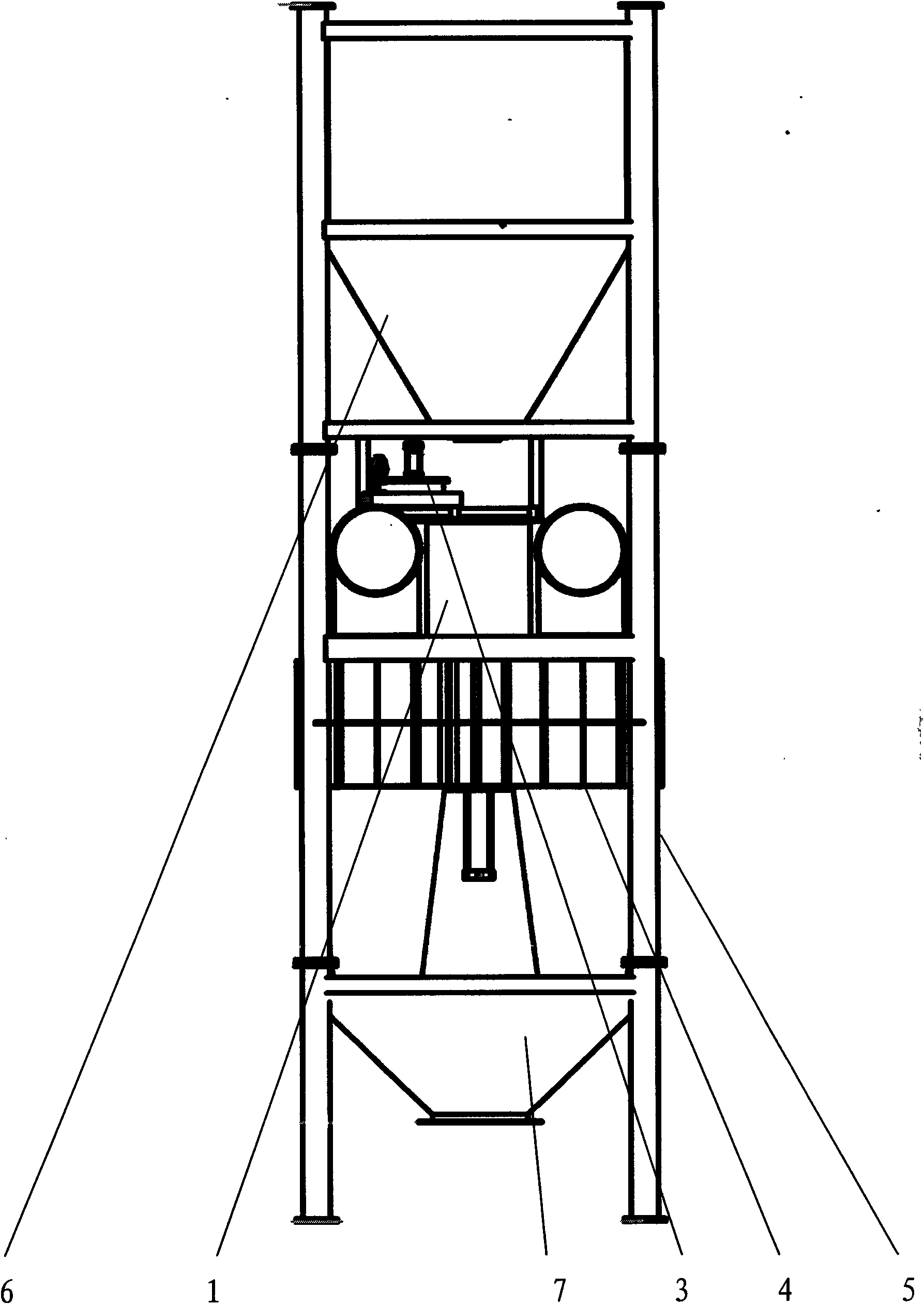

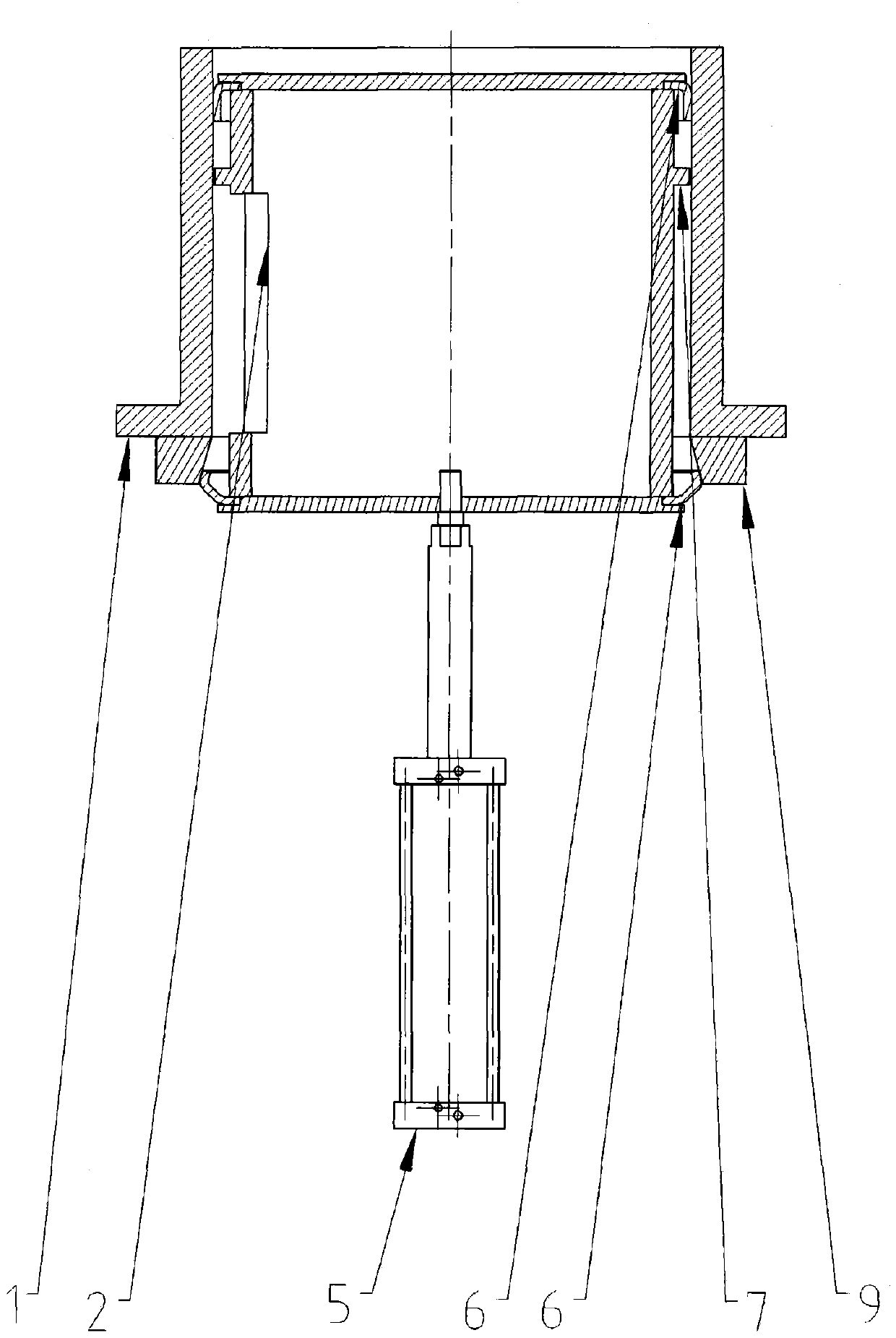

Numerically controlled continuous steam explosion machine

InactiveCN102600763AAchieving suddennessGuarantee the same effect of steam explosionPressurized chemical processFixed ratioEngineering

The invention relates to a production device for steam explosion pretreatment of biomass, in particular to a pretreatment device for the industry of biomass utilization, and provides a numerically controlled continuous steam explosion machine, which can complete supersonic steam explosion in milliseconds (0.00875s) based on the principle of a sliding cover. Since the cross-sectional area of the steam explosion machine for gas discharging, i.e. the cross-sectional area of the sliding cover, is equal to the cross-sectional area of a high-pressure cylinder, the cross-sectional area of the steam explosion machine for gas discharging and the steam explosion treatment volume form a fixed ratio, the problem that the gas discharging time is prolonged along with increase in the treatment volume in the traditional hot blowing process can be solved, and the power and density of steam explosion can be increased by three orders of magnitude. Moreover, the 'rawness and maturity' of materials which are subjected to batch treatment can be kept identical, and a foundation is laid for the consistency of industrial biochemical treatment. Meanwhile, the machine has the function of feeding and discharging materials automatically and the continuous steam explosion production can be realized.

Owner:于政道

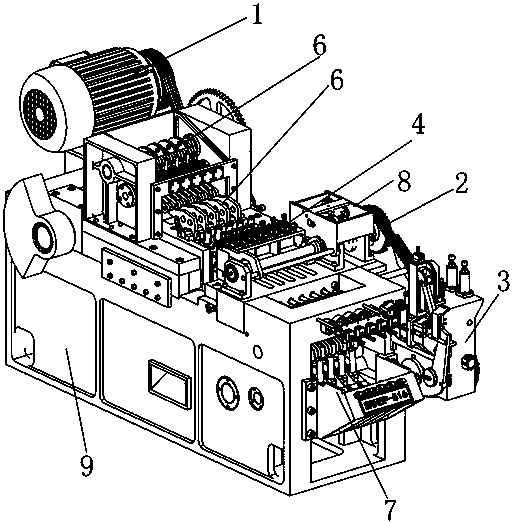

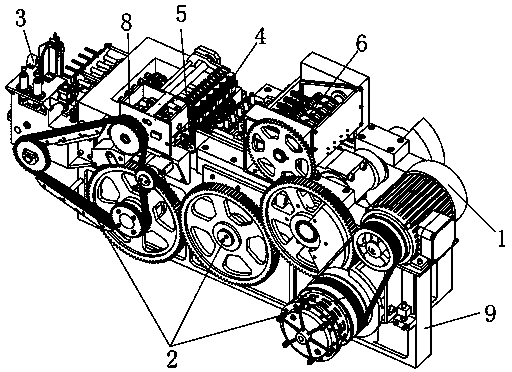

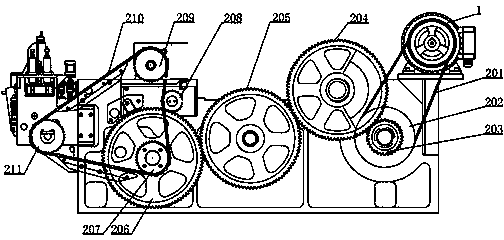

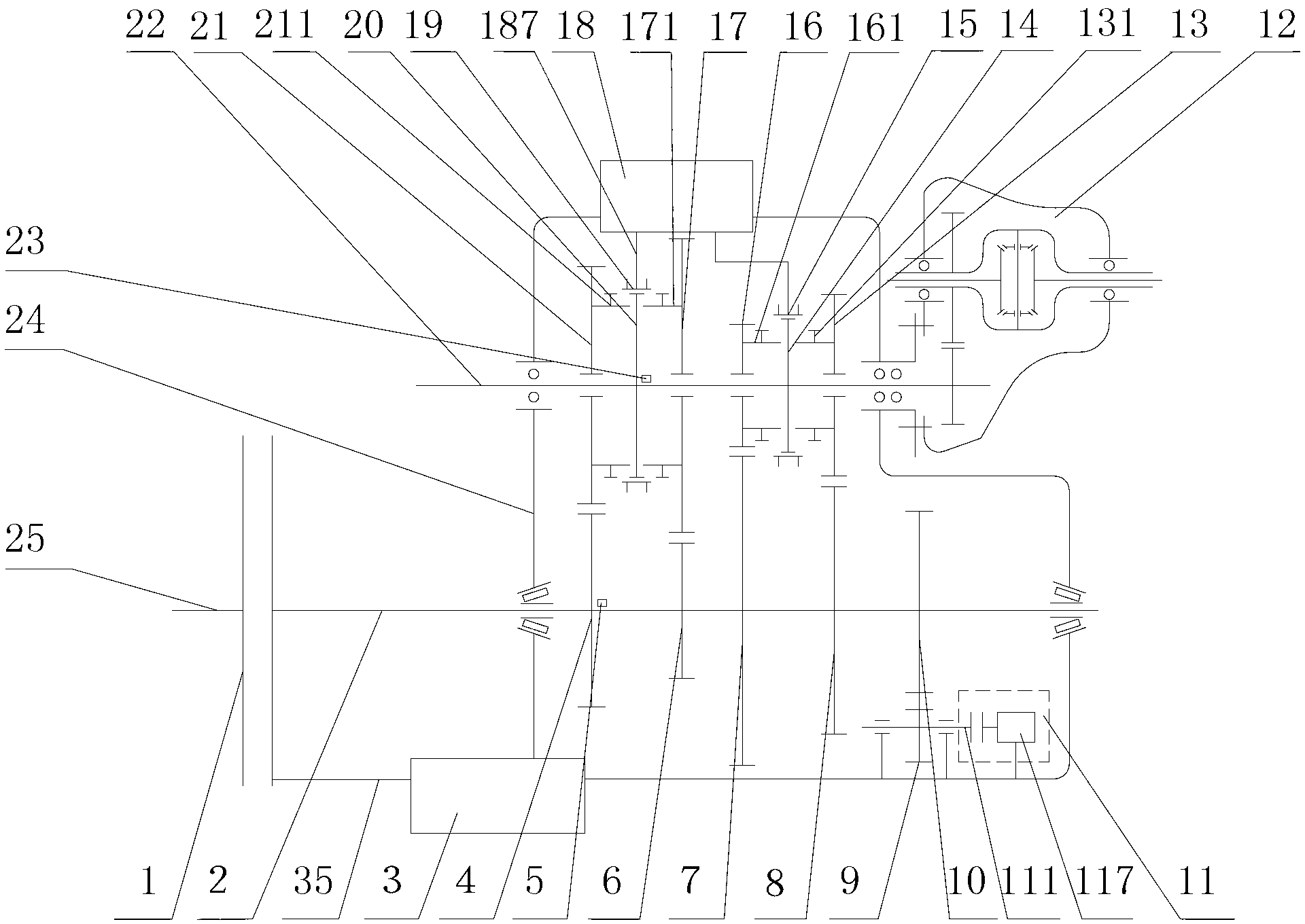

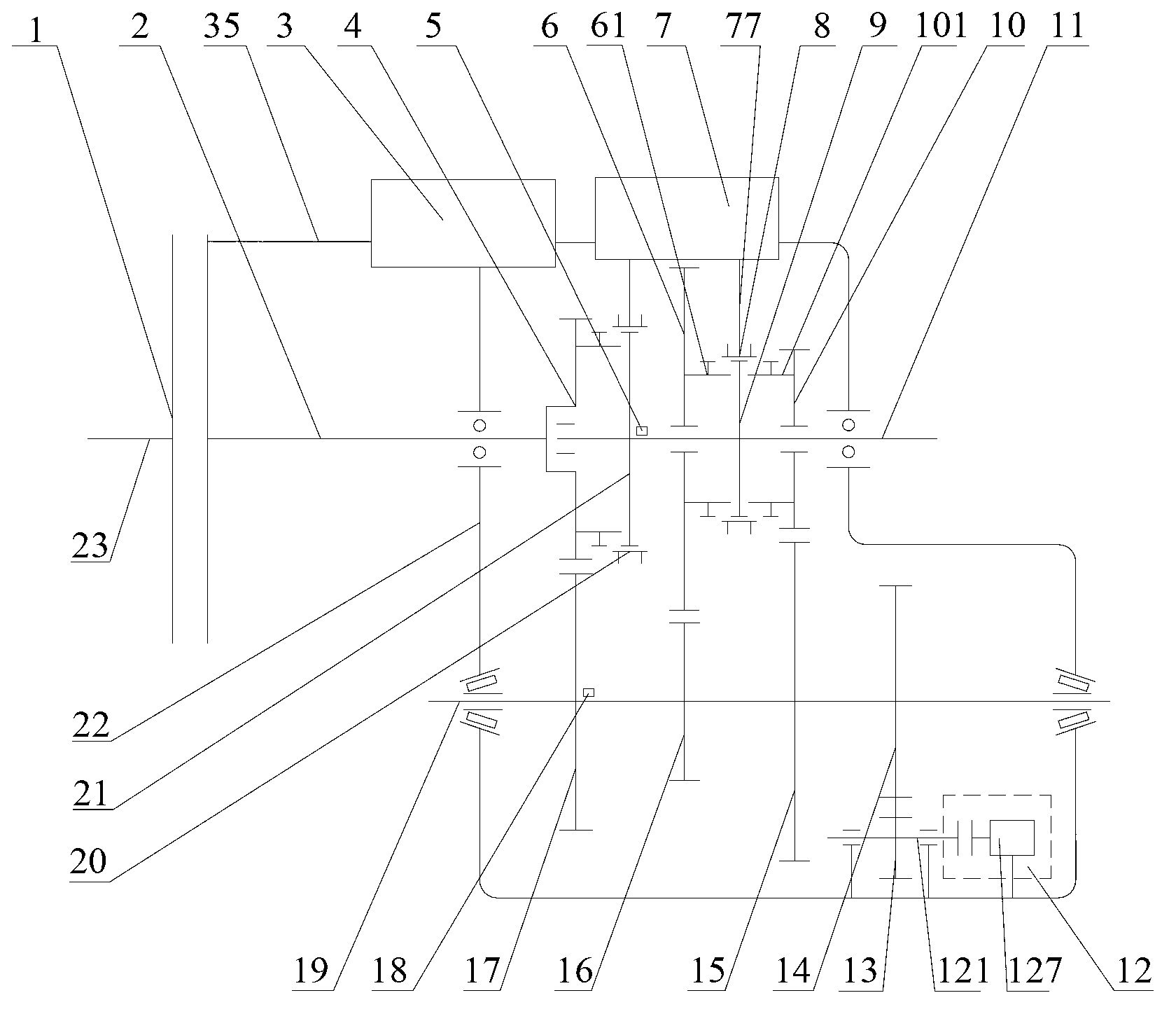

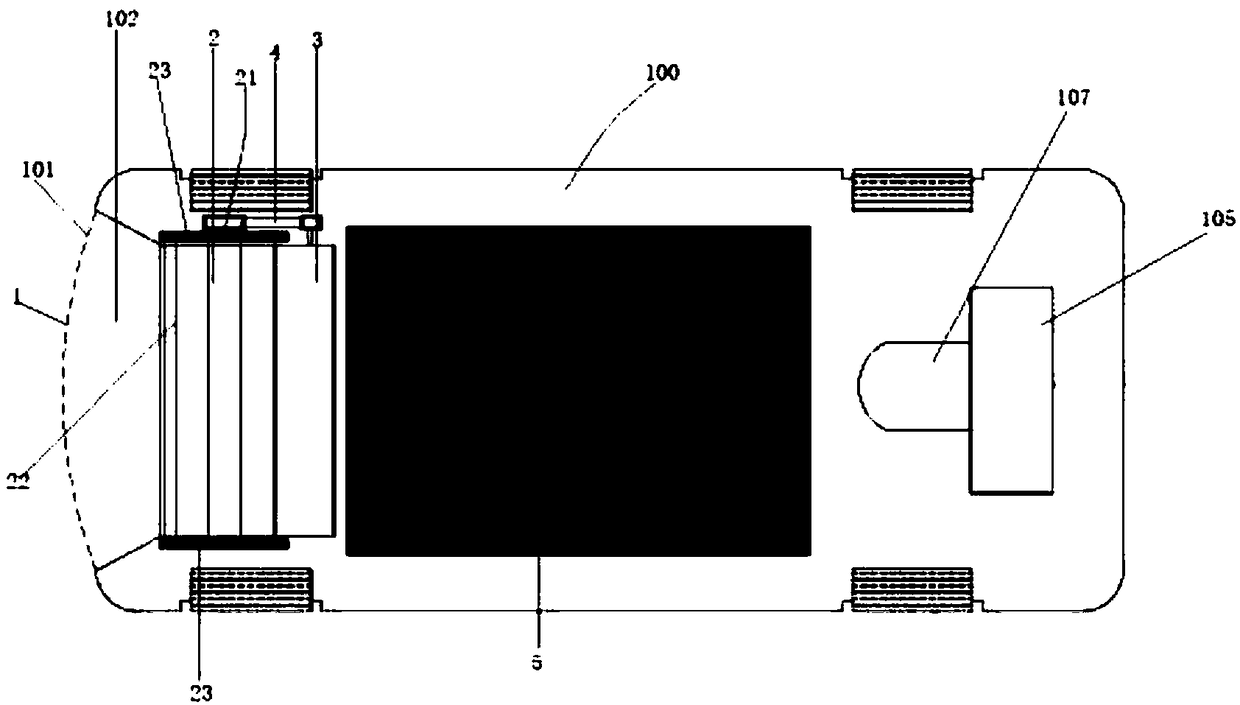

Cold heading machine

ActiveCN104174802AMeet sporting requirementsNot easy to move at high speedUpsetting pressesSwagging pressesMotor driveBack support

The invention discloses a cold heading machine. The cold heading machine comprises a machine body, wherein a main motor, a drive system, a linear feeding device, a rotary clamp, a cutter system, an adjustable male die ejecting mechanism and a closed back support are arranged on the machine body; the main motor is arranged at a first end of the machine body, and the drive system is arranged at an output end of the main motor; the linear feeding device is arranged at a second end of the machine body, and the closed back support is arranged on one side of the feeding device; the rotary clamp and the male die ejecting mechanism are arranged in the middle of the machine body; and the cutter system is arranged below the rotary clamp. After the main motor of the machine is started, the main motor drives the linear feeding device, the rotary clamp, cutters, the male die ejecting mechanism and the like through the drive system to finish processing steps of feeding, cutting, upsetting, finished product ejecting and the like. The cold heading machine has the advantages that the drive efficiency can be improved, the high-speed driving is realized, the working efficiency and precision of the cold heading machine are improved, and the like.

Owner:HUANGSHAN SHENGRUI HEAVY IND MACHINERY

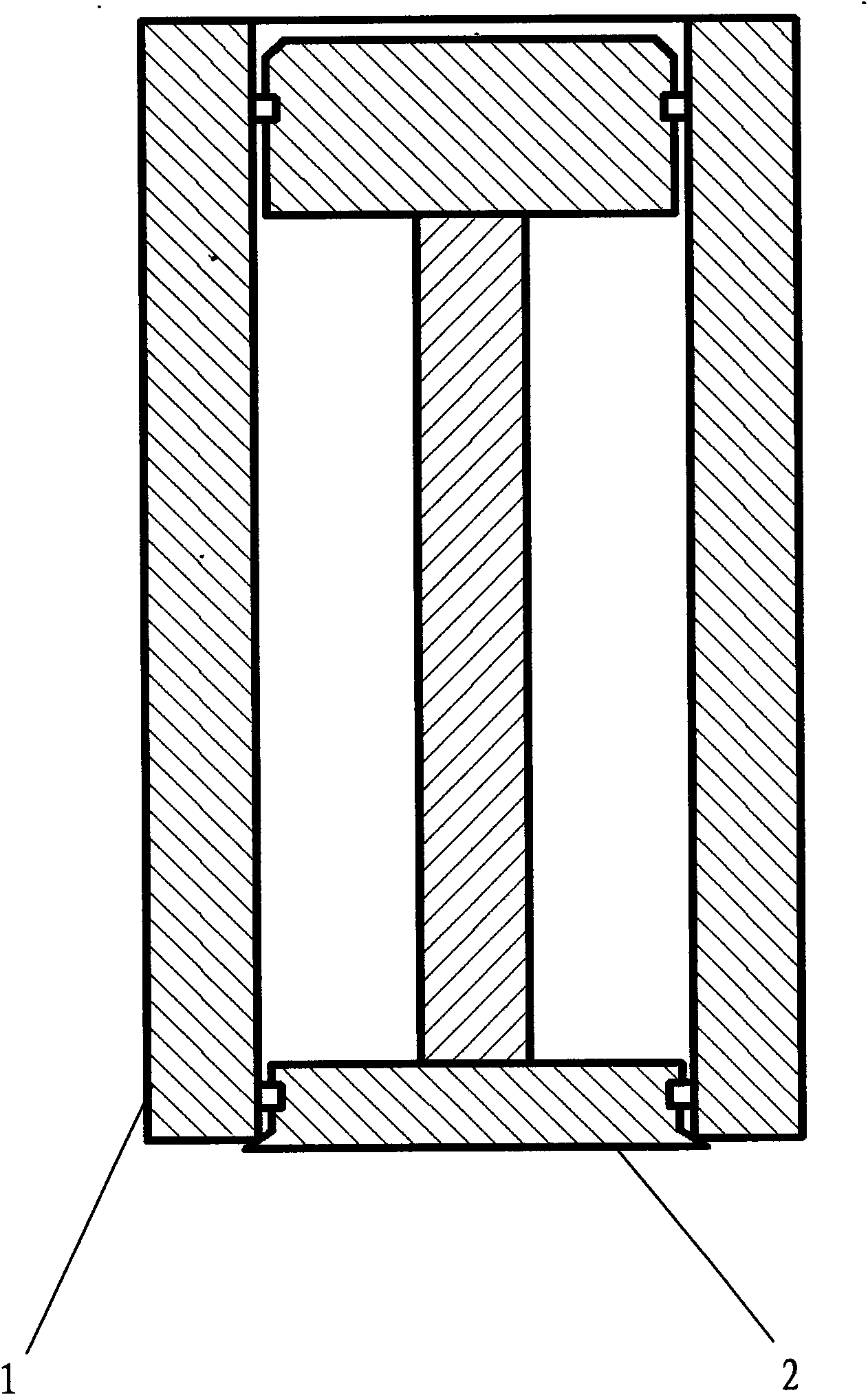

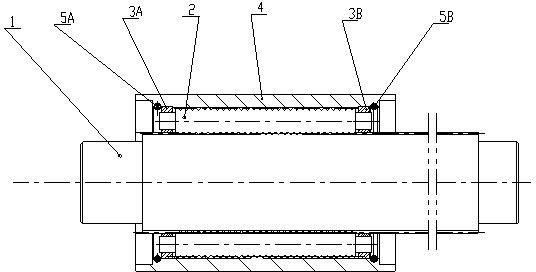

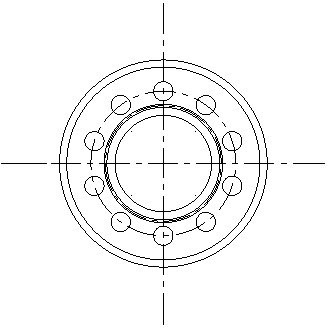

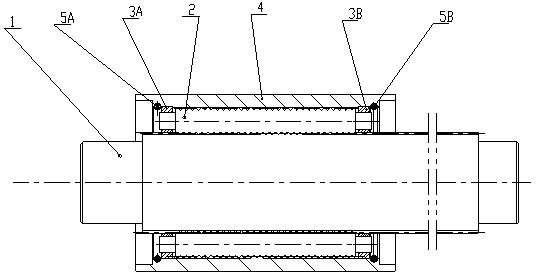

Planetary roller screw

The invention provides a planetary roller screw which is simple and compact in structure, large in bearing ability, difficult to wear, wide in screw pitch range, capable of realizing high-speed operation and high in reliability. The structure of the planetary roller screw comprises a screw, one or more rollers, two roller planetary retainers, a nut and two limiting spacer rings. The planetary roller screw is small in axial gap, high in transmission efficiency and capable of realizing high-speed transmission from a small screw pitch to an extra large helical pitch, not only can realize conversion of rotary motion and linear motion, but also can realize high-speed rotation of the screw and the rotary motion of the nut in a corresponding speed ratio.

Owner:扬州众孚传动科技有限公司

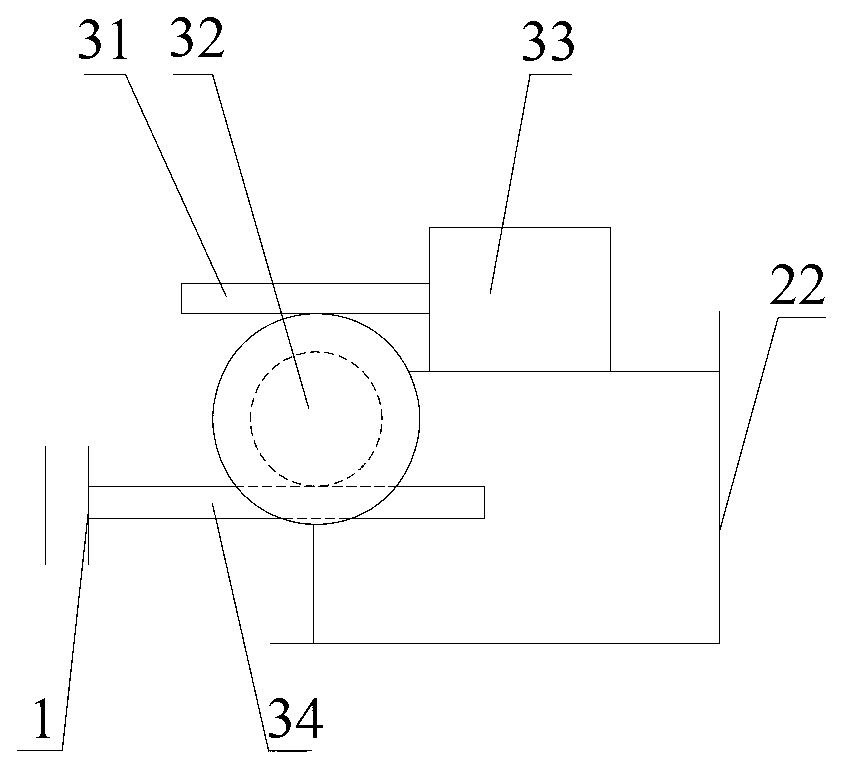

Synchronizer-free gear shifting system for input shaft speed regulation for electric automobile

ActiveCN102840281AReduced load and power requirementsEasy to driveToothed gearingsGearing controlClutchDrive motor

The invention relates to a driving motor front-engine rear-drive automatic mechanical gearbox gear shifting system, in particular to a synchronizer-free gear shifting automatic mechanical gearbox on the basis of few-gear middle shaft active speed regulation, and belongs to the technical field of automobile control. The system comprises an input shaft, an output shaft, driving and driven gears for each gear, a spline hub, an engagement sleeve, a sensor, a speed regulating motor, a speed regulating motor transmission mechanism, a clutch operation mechanism, a gear shifting executing mechanism and a controller. The system realizes the synchronism of the engagement sleeve and a target-gear gear during the gear shifting through the regulation on the input shaft rotating speed under the condition of the motive power interruption of the speed regulating motor, a synchronizer with high requirements on materials is omitted, the cost is favorably reduced, and meanwhile, the problem that the starting and acceleration performance and the relative high-speed running of a small-size pure electric automobile cannot be simultaneously considered can be favorably solved.

Owner:TSINGHUA UNIV

Synchronizer-free shifting system for regulating speed of intermediate shaft of electric automobile

ActiveCN102840309AReduce loadReduced Power RequirementsGearboxesMechanical actuated clutchesElectric machineDrive motor

The invention relates to a front-engine rear-drive automatic mechanical transmission case shifting system for a driving motor, in particular to a synchronizer-free shifting automatic mechanical transmission case for regulating the speed of an intermediate shaft based on a small quantity of gears, belonging to the technical field of automobile control. The system comprises an input shaft, an intermediate shaft, an output shaft, driving and driven gears for each gear, a splined hub, a jointing sleeve, a sensor, a speed regulating motor, a speed regulating motor transmission mechanism, a clutch operating mechanism, a shifting executing mechanism and a controller. According to the system, the rotating speed of the intermediate shaft is regulated through the speed regulating motor, so that synchronization of the jointing sleeve and a target gear during shifting is realized, a synchronizer with high material requirements is eliminated, reduction in the cost is facilitated, and the effect of compatibility among startup, accelerating performance and relatively high-speed running of a small-sized pure electric automobile is realized simultaneously.

Owner:TSINGHUA UNIV +1

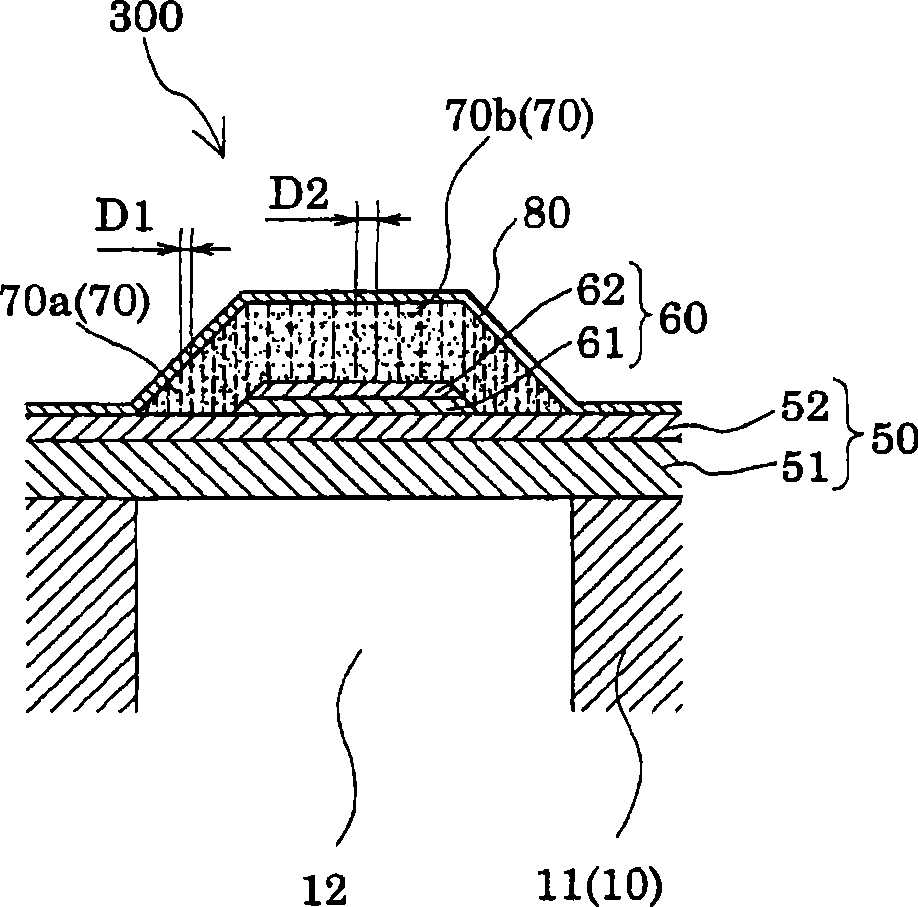

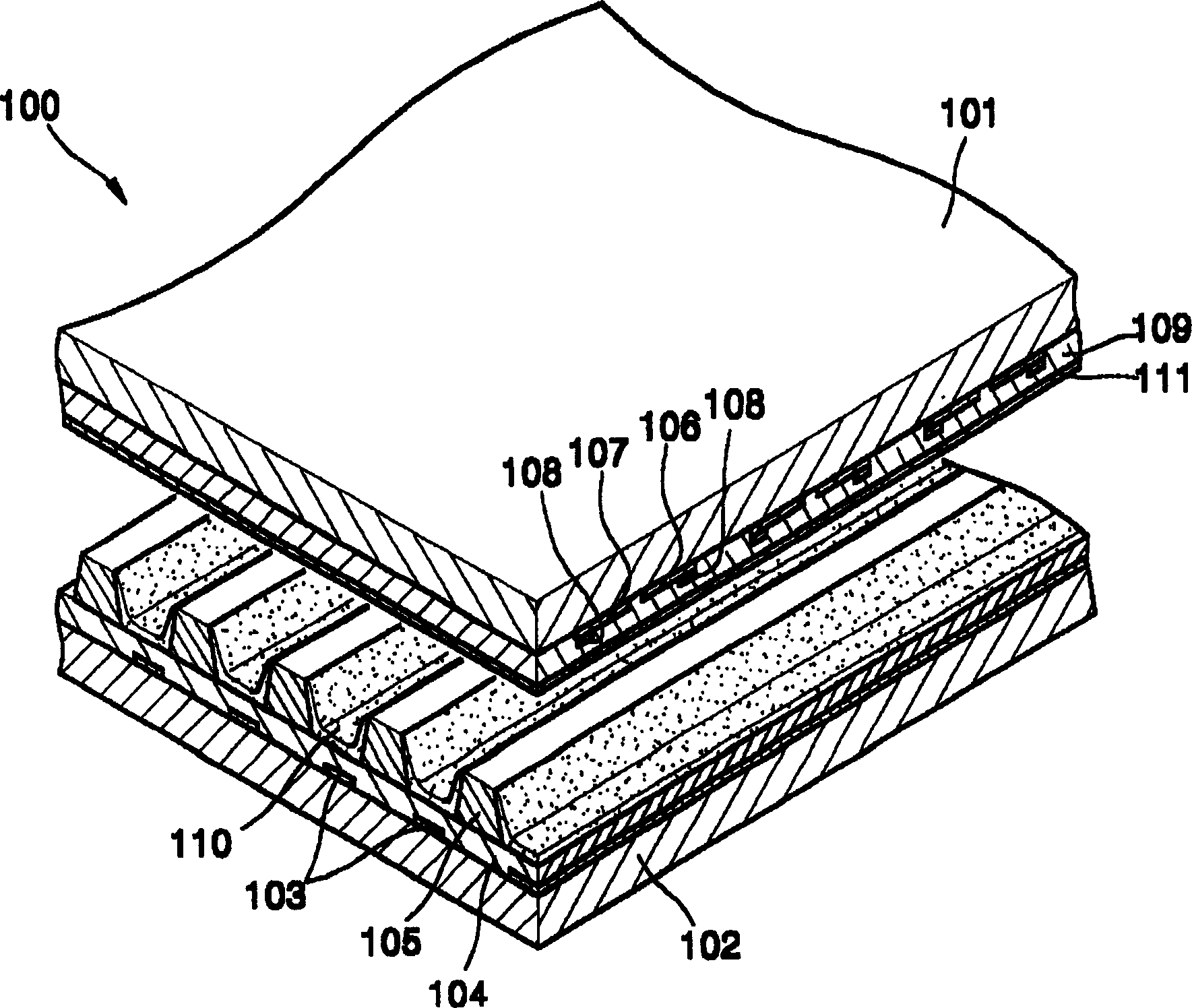

Liquid ejecting head, liquid ejecting apparatus, and actuator

The invention provides a liquid ejecting head, a liquid ejecting apparatus and an actuator capable of improving shift characteristics of piezoelectric element to implement high-speed driving and preventing damage of the piezoelectric layer to improve durability. A end face of a piezoelectric layer is composed of inclined planes in a incline mode of end of a lower electrode side is outsider than a upper electrode side. The lower electrode for composing piezoelectric elements has a width smaller than the width of the pressure generating chambers. The piezoelectric layer has a larger width than the lower electrode to cover end faces of the lower electrode. The vibration plate has a top layer formed of a titanium oxide (TiOx) insulator film. The lower electrode has a top layer formed of a lanthanum nickel oxide (LaNi[y]Ox) orientation control layer. The orientation control layer and at least part of the piezoelectric layer disposed on the orientation control layer are formed of perovskite crystals having a (113) preferred orientation.

Owner:SEIKO EPSON CORP

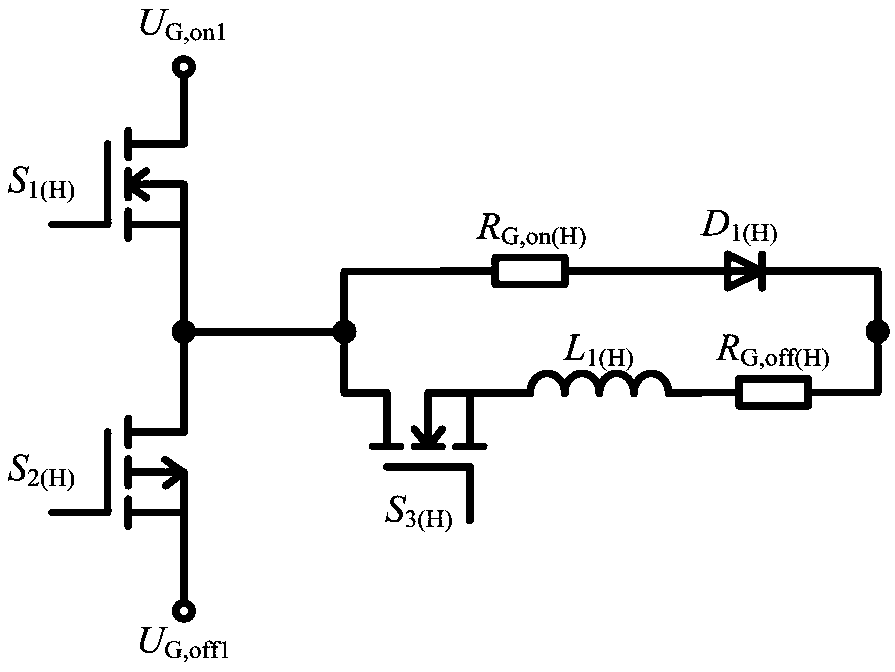

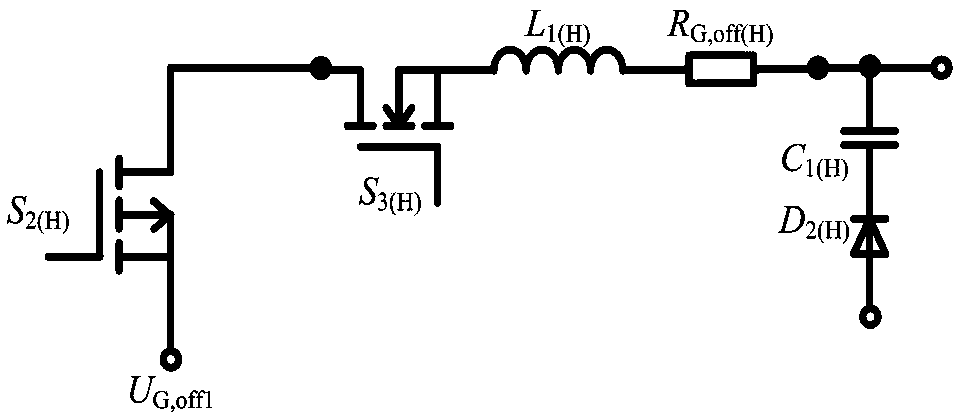

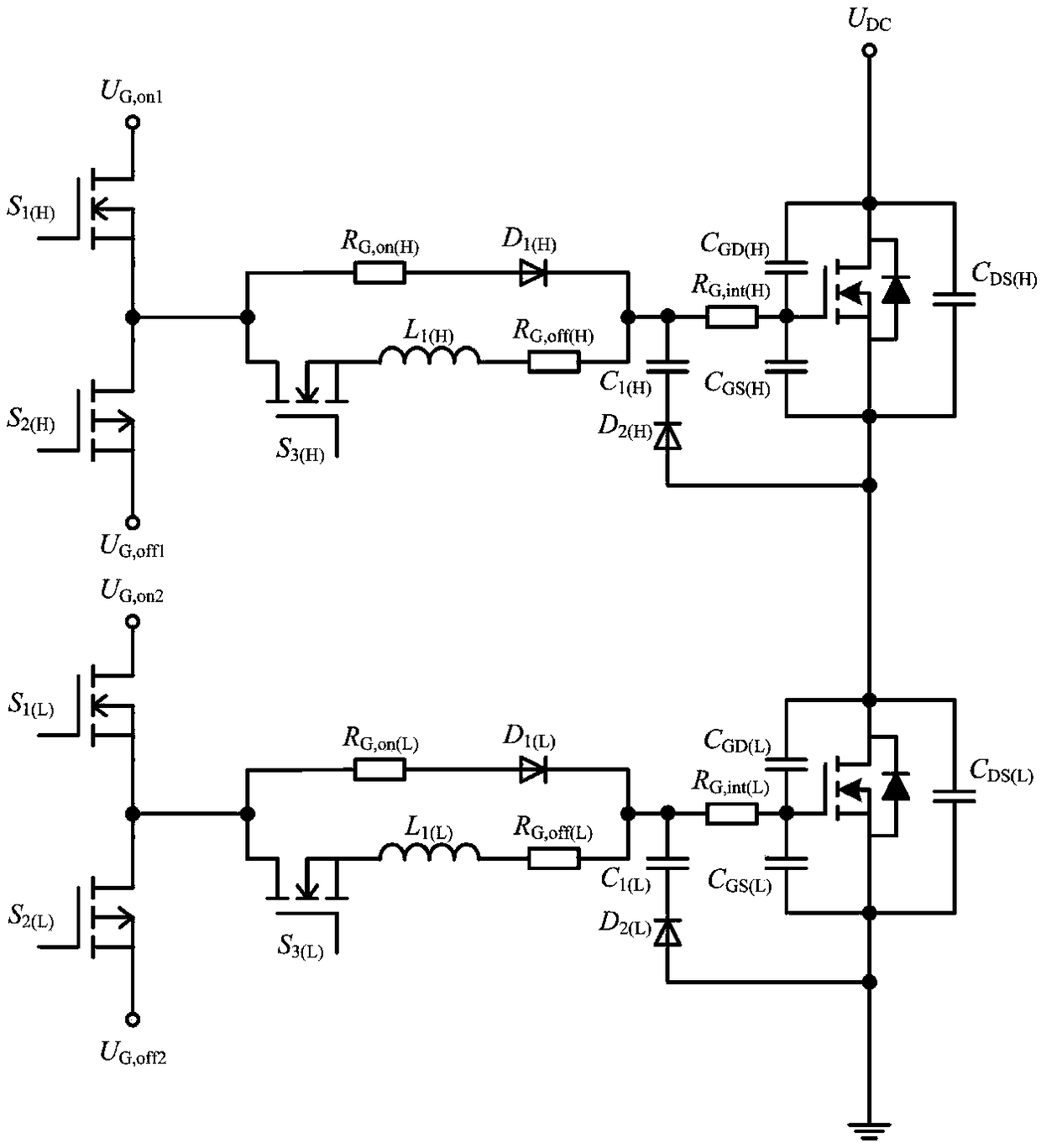

Resonant SiC MOSFET bridge arm crosstalk suppression drive circuit and control method thereof

InactiveCN109450233ADoes not affect lifeSuppression of crosstalk phenomenonEfficient power electronics conversionPower conversion systemsMOSFETEngineering

The invention provides a resonant SiC MOSFET bridge arm crosstalk suppression drive circuit and a control method thereof. The circuit comprises a first voltage totem pole structure circuit connected between a first forward power supply and a first reverse power supply of an upper bridge arm; a first drive resistor circuit; a first low impedance circuit connected between a gate and a source of an upper tube; a second voltage totem pole structure circuit connected between a second forward power supply and a second reverse power supply of a lower bridge arm; a second drive resistor circuit; and asecond low impedance circuit connected between the gate and the source of a lower tube. An input end of the first drive resistor circuit is connected with an output end of the first voltage totem pole structure circuit, and an output end is connected with the gate of the upper tube. The input end of the second drive resistor circuit is connected with the output end of the second voltage totem pole structure circuit, and the output end is connected with the gate of the lower tube. The upper tube is connected with the lower tube. According to the circuit, performance advantage of a SiC MOSFET high speed switch can be exerted fully, a bridge arm crosstalk suppression function is realized, and moreover, the high speed switch also can be realized.

Owner:NANJING UNIV OF AERONAUTICS & ASTRONAUTICS

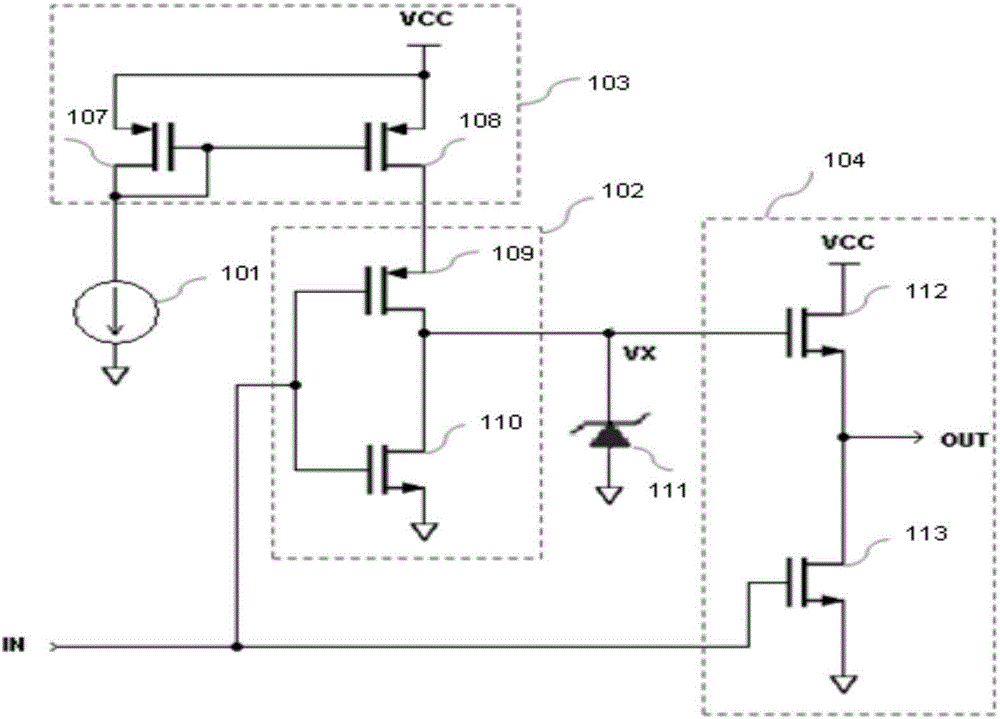

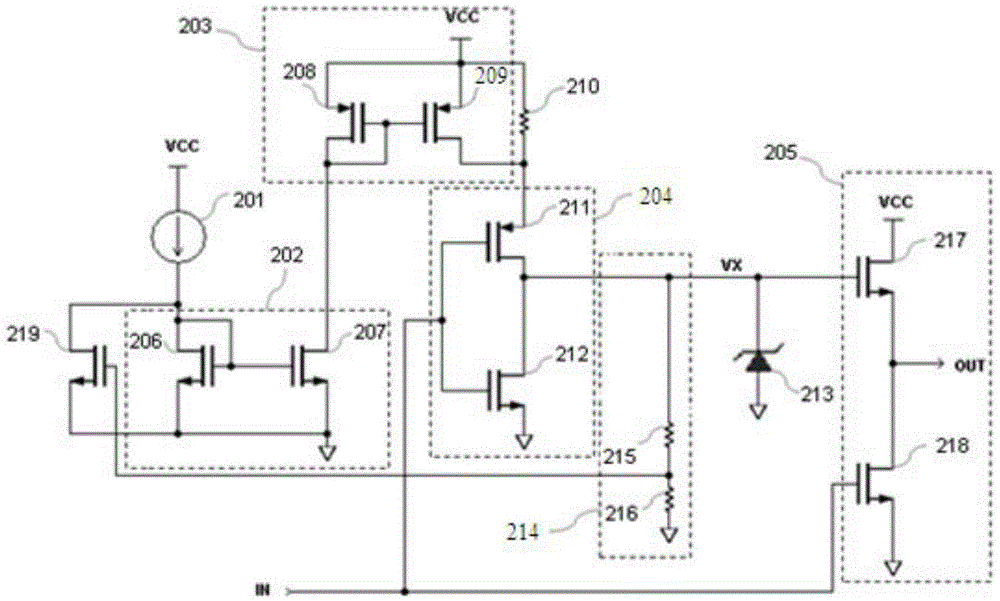

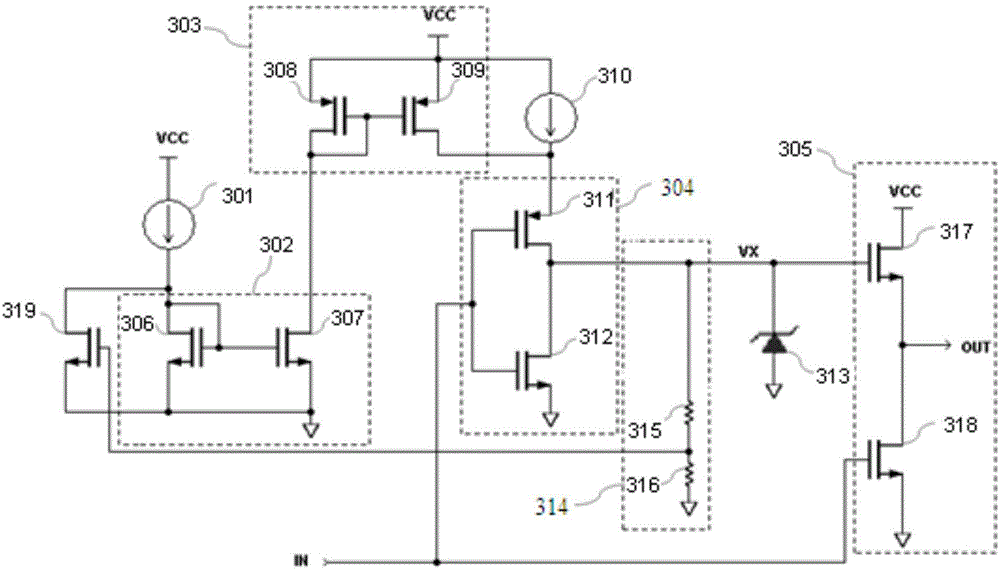

Clamp drive circuit

ActiveCN104158386AReduce power consumptionHigh speed drivePower conversion systemsElectrical resistance and conductanceEngineering

The invention relates to a clamp drive circuit which comprises a bias current source, an acceleration current mirror with a fourth MOS (metal oxide semiconductor) tube, a phase inverter with a fifth MOS tube, a totem-pole output driver with an upper drive tube, a conversion current mirror, a current mirror switch tube used for switching on and off the conversion current mirror, a stable voltage maintaining resistor or a constant current source connected between the source and the drain of the fourth MOS tube, and a clamp sampling circuit connected between the grid of the drive tube and the ground. According to the clamp drive circuit, the conversion current mirror is switched off and the acceleration current mirror is driven through the current mirror switch tube by the clamp sampling circuit so as to completely switch off high drive acceleration current; by adding the stable voltage maintaining resistor or the constant current source, the circuit consumption is reduced while high-speed drive is realized; meanwhile, due to the existence of the stable voltage maintaining resistor or the constant current source, the clamp voltage is stable in the establishment process, and the dependency degree of the whole circuit to a process is low.

Owner:SHANGHAI ORIENT CHIP TECH CO LTD

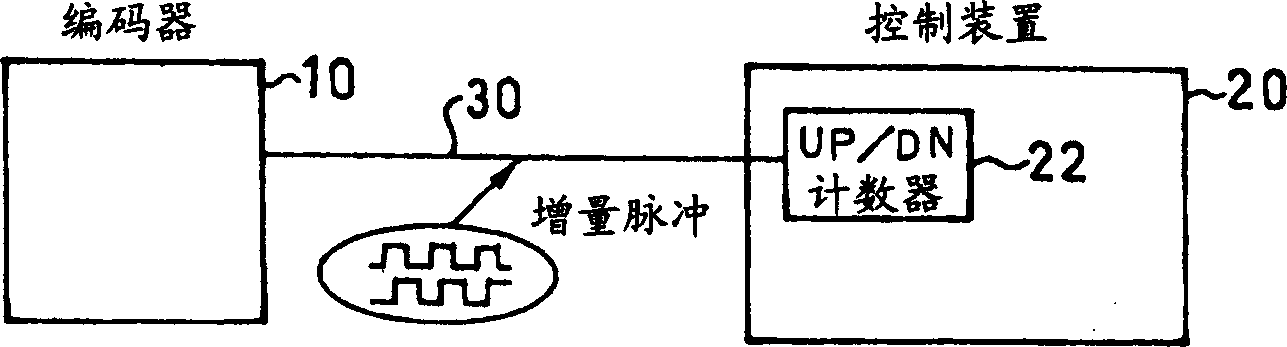

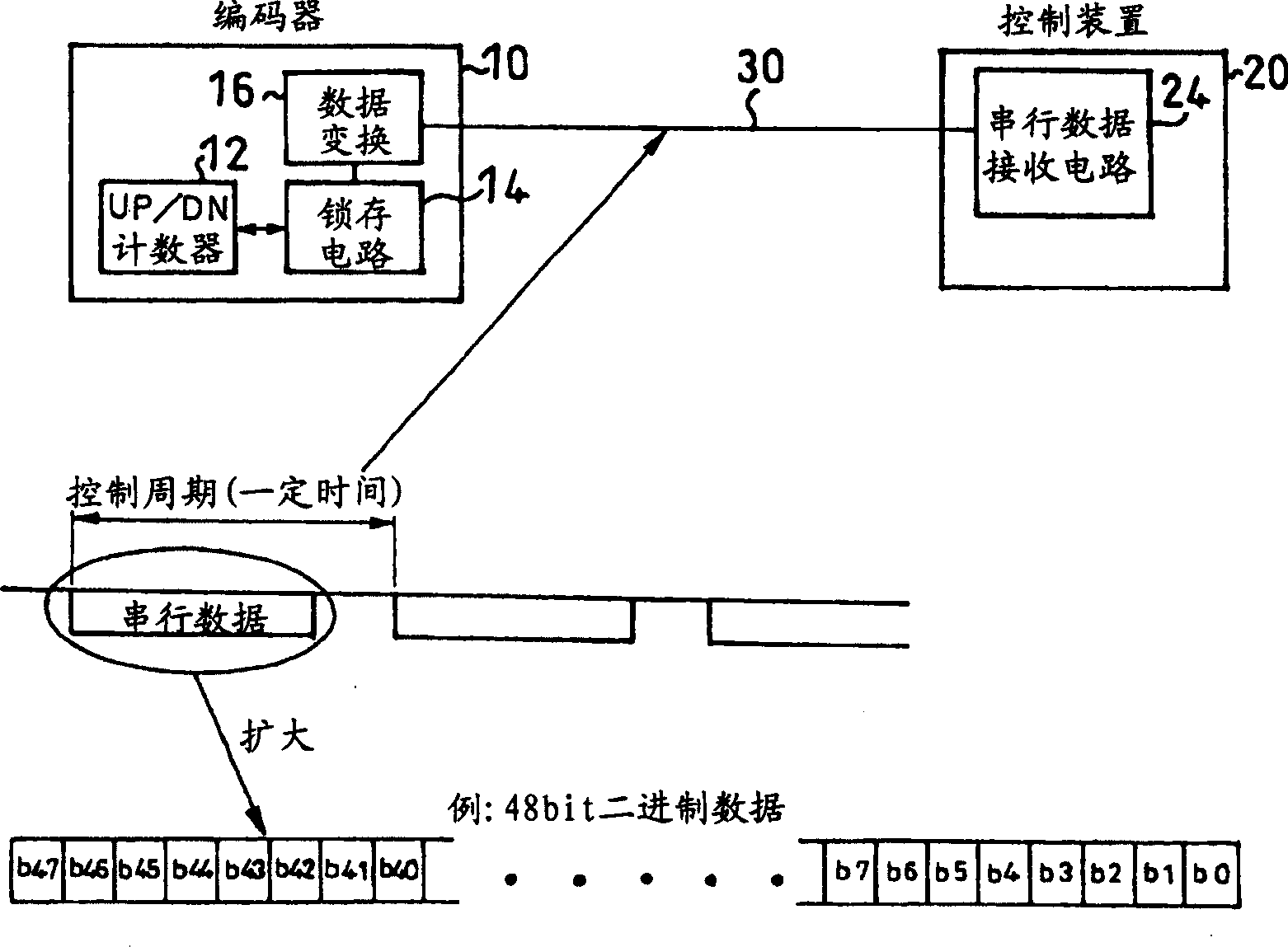

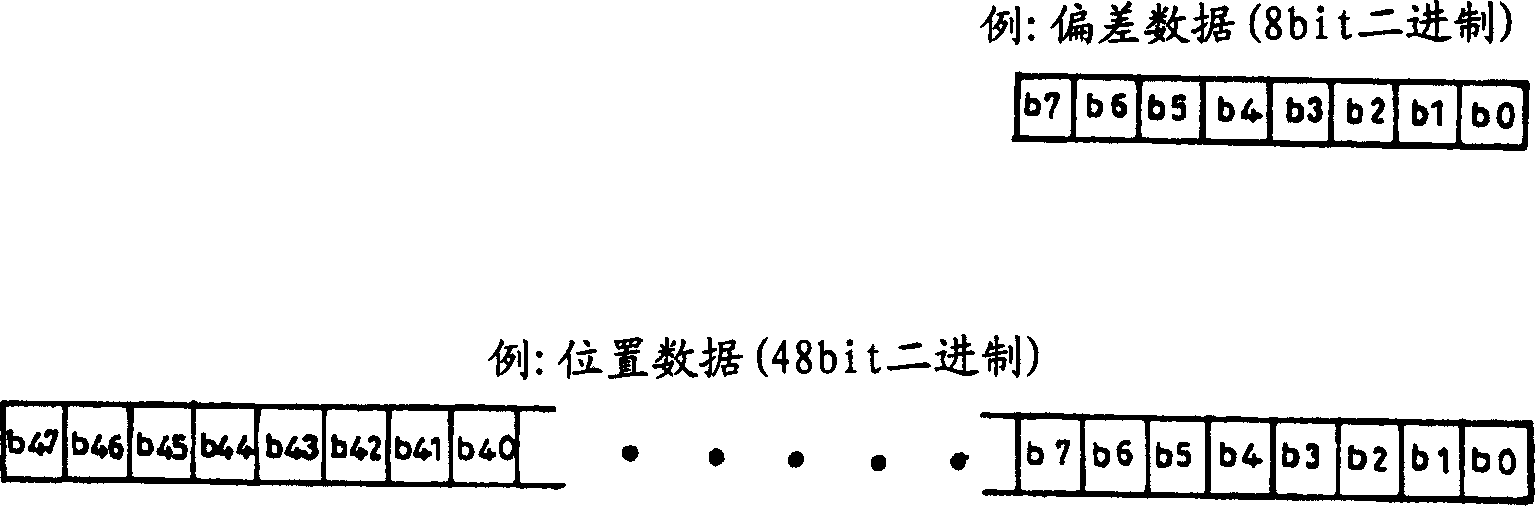

Data transceiving method and device of coder

InactiveCN1540291AHigh speed driveHigh resolutionConverting sensor output electrically/magneticallyControl systemReliability engineering

When data detected by an encoder is transmitted / received in predetermined cycles in a measuring device using a sampling control system for controlling a position or a speed at predetermined time intervals, positional data is divided so as to be output with deviation data output each time. The divided positional data are reconstituted so as to transmit the positional data within a control cycle.

Owner:MITUTOYO CORP

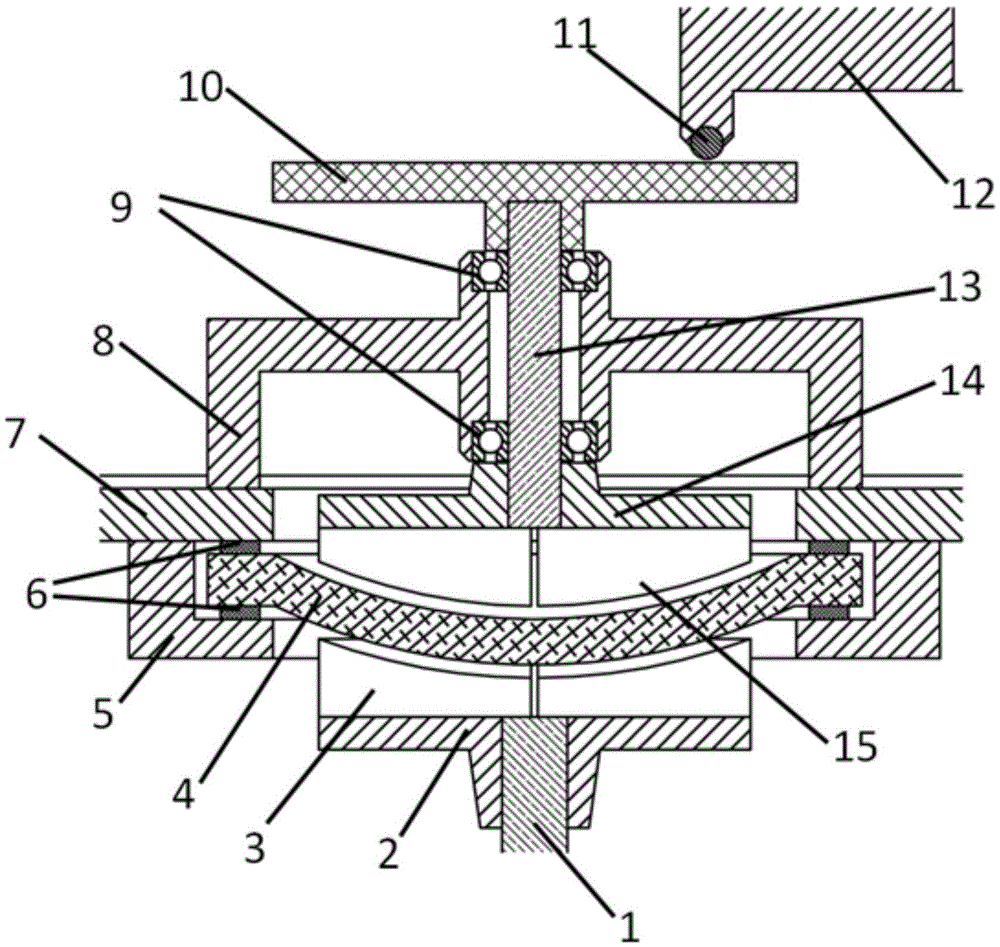

High-vacuum high-speed rotating magnetic transmission device of friction testing machine

ActiveCN105628602AHigh vacuum sealing requirementsReduced eddy current lossUsing mechanical meansInvestigating abrasion/wear resistanceDrive shaftEngineering

The invention relates to a high-vacuum high-speed rotating magnetic transmission device of a friction testing machine. The high-vacuum high-speed rotating magnetic transmission device comprises an outer driving shaft, an inner driven shaft, an inner permanent magnet, an inner permanent magnet fixing seat, an outer permanent magnet, an outer permanent magnet fixing seat, a rotating disc, a bearing support, a quartz separation component and a loading rod. The inner permanent magnet fixing seat is fixed to the lower portion of the inner driven shaft, and the inner permanent magnet is fixed to the lower portion of the inner permanent magnet fixing seat. The outer permanent magnet is opposite to the inner permanent magnet and fixed to the upper portion of the outer permanent magnet fixing seat, the outer permanent magnet fixing seat an the outer driving shaft are fixedly connected, and the inner permanent magnet and the outer permanent magnet are separated through the profiled quartz separation component. The quartz separation component and the bearing support cooperate to seal the inner driven shaft, the inner permanent magnet fixing seat and the inner permanent magnet in a sealed vacuum space. The outer driving shaft and the inner driven shaft are coaxially arranged. The rotating disc and the upper portion of the inner driven shaft are fixedly connected in a sealed mode. The loading rod is arranged above the rotating disc, and a friction test piece on the loading rod makes contact with the rotating disc.

Owner:SHANGHAI JIAO TONG UNIV

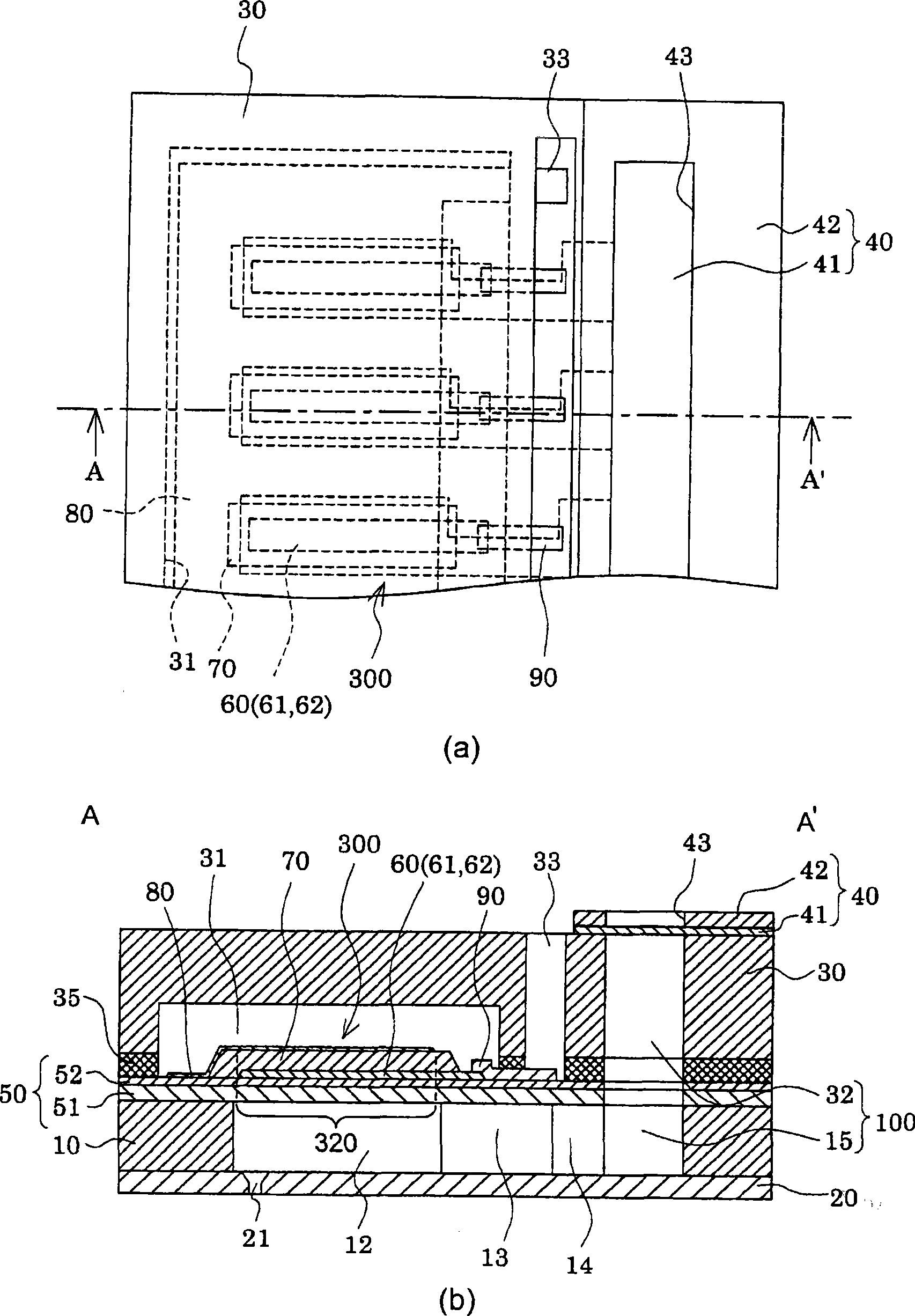

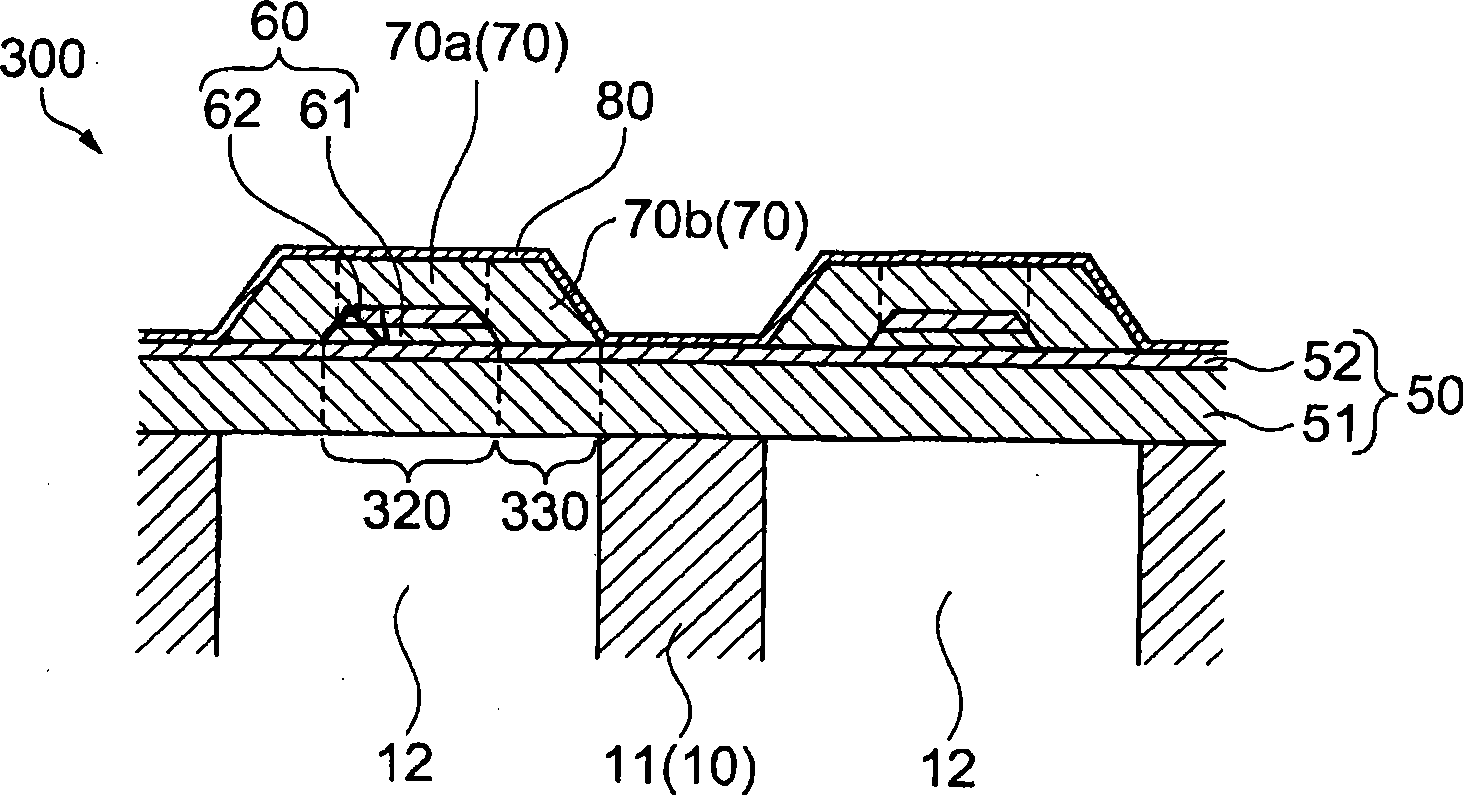

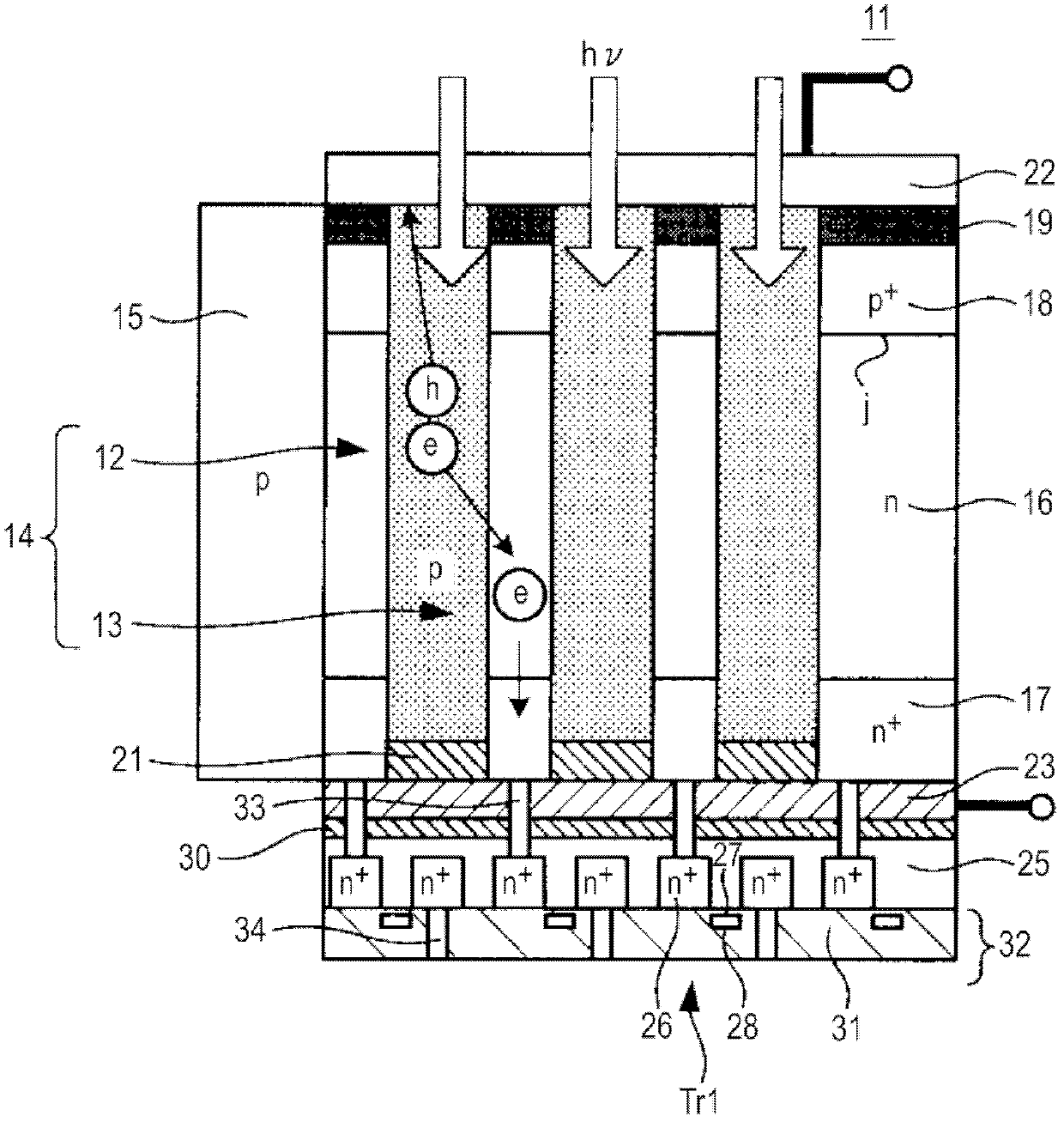

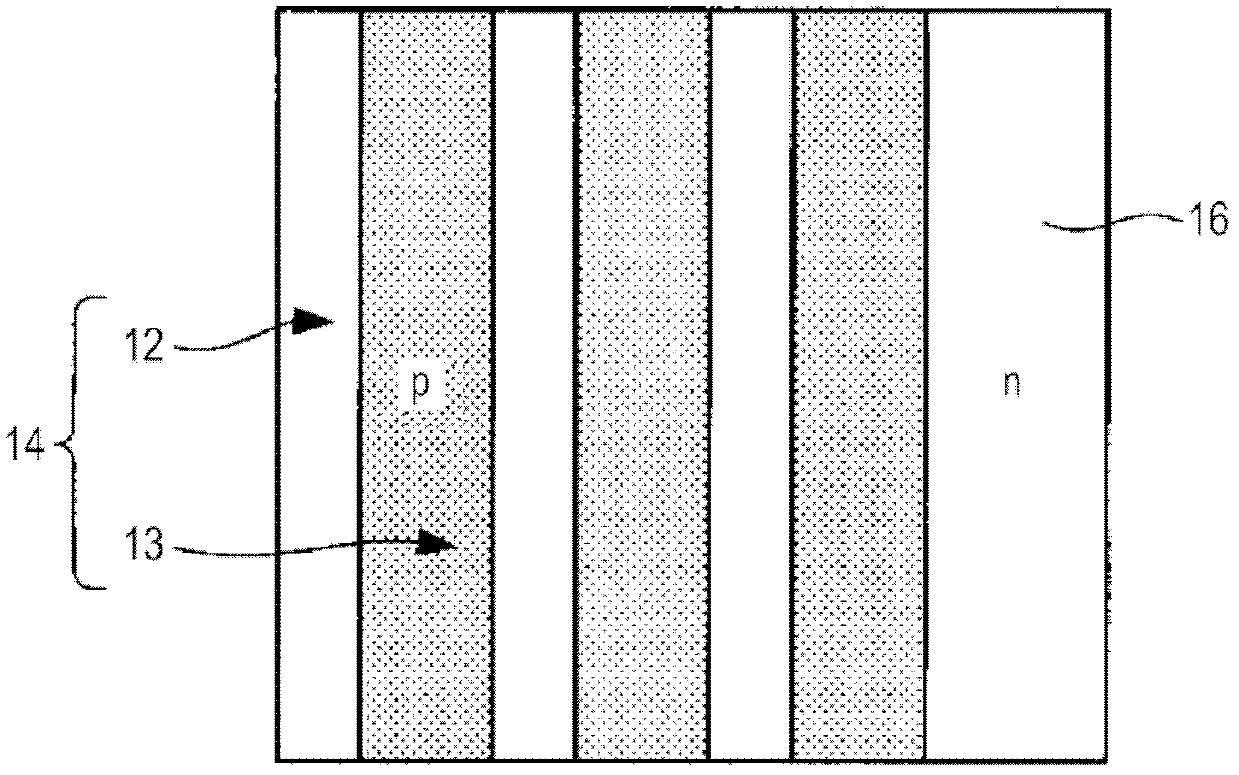

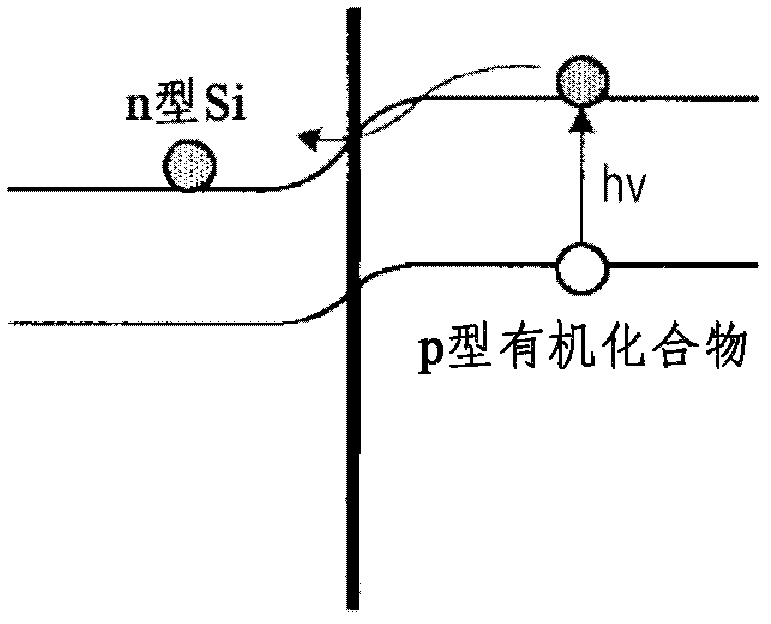

Solid-state imaging device, manufacturing method thereof, and electronic apparatus

InactiveCN102386202AHigh sensitivityHigh speed and stable driveTelevision system detailsFinal product manufactureEngineeringPhotoelectric conversion

The invention provides a solid-state imaging device, a manufacturing method thereof, and an electronic apparatus comprising the solid-state imaging device. The solid-state imaging device includes: pixels each including a hybrid photoelectric conversion portion and pixel transistors, wherein the hybrid photoelectric conversion portion includes a semiconductor layer having a p-n junction, a plurality of columnar or cylindrical hollow-shaped organic material layers disposed in the semiconductor layer, and a pair of electrodes disposed above and below the semiconductor layer and the organic material layers, wherein charges generated in the organic material layers through photoelectric conversion move inside the semiconductor layer so as to be guided to a charge accumulation region, and wherein the solid-state imaging device is configured as a back-illuminated type in which light is incident from a surface opposite to the surface on which the pixel transistors are formed. The solid-state imaging device in the invention improves sensitivity and can realize high-speed and stable drive.

Owner:SONY CORP

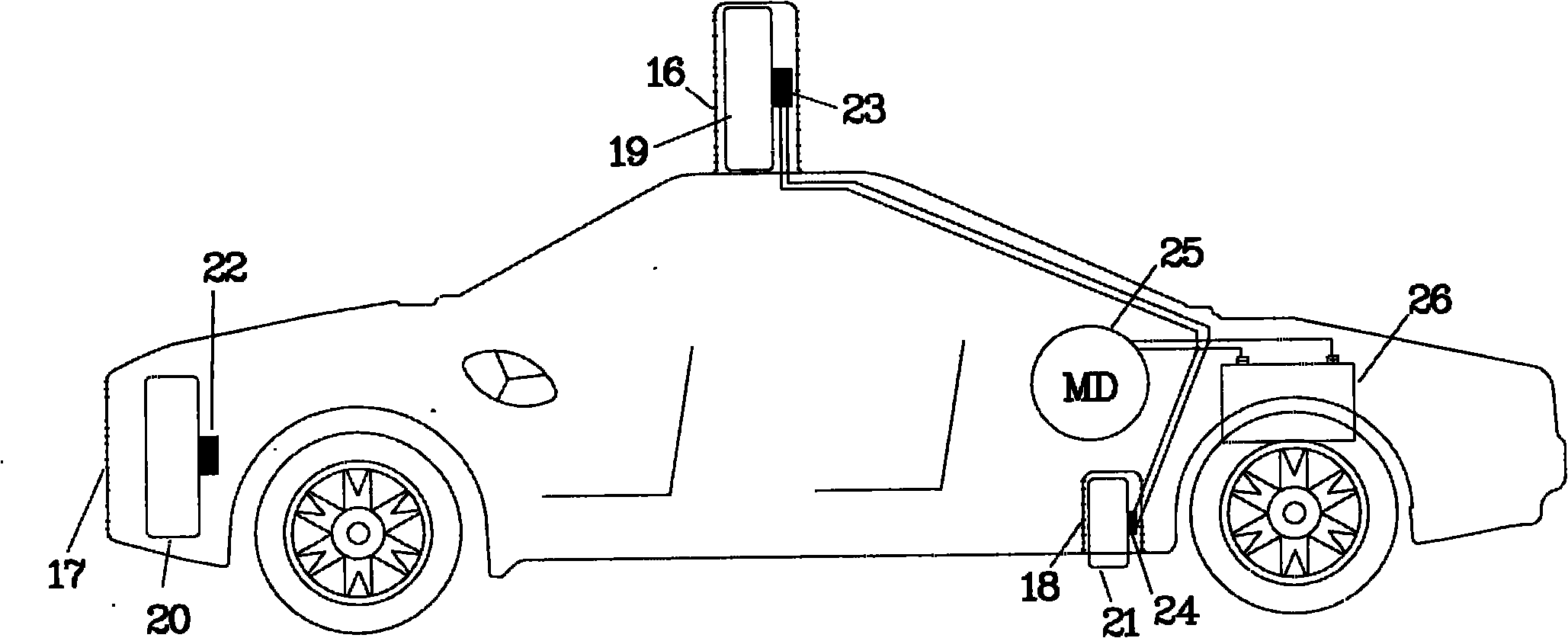

Vehicle-mounted wind-driven generator system

InactiveCN101850717AHigh speed driveIncrease mileageAuxillary drivesVehicular energy storageWind drivenElectrical battery

The invention discloses a vehicle-mounted wind-driven generator system, which converts resistance wind energy generated by an automobile in running process into electric energy by a particularly designed vehicle-mounted wind-driven generator system. The generated electric energy is used for charging vehicle-mounted batteries in one aspect and supplying power to an automobile motor in another aspect in the running process of the automobile; thus, the running speed and the driving mileage of an electric automobile and a hybrid electric vehicle are improved.

Owner:曾君旺

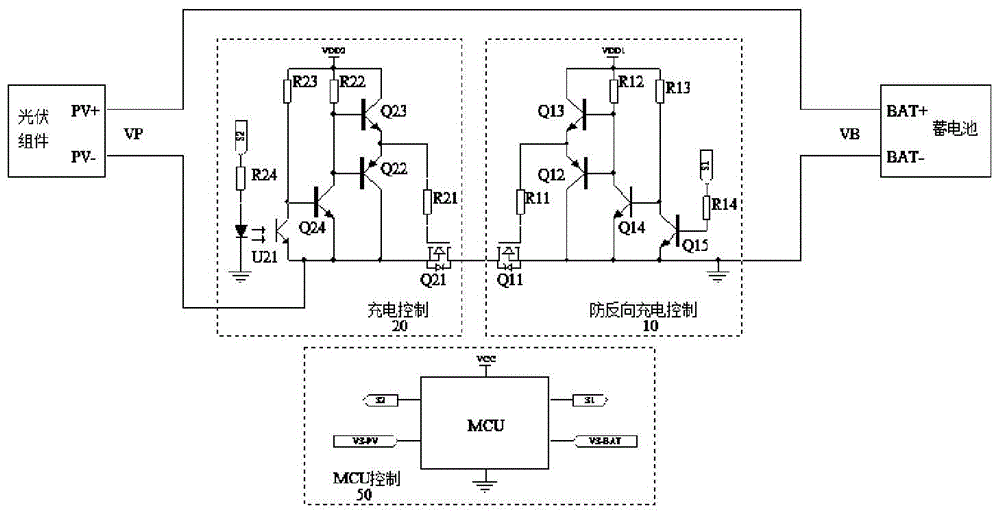

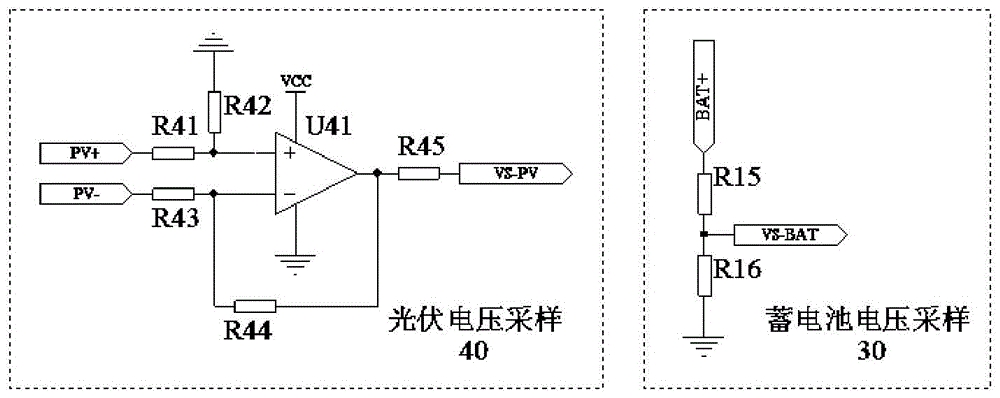

Photovoltaic charging control system and control method

ActiveCN104821620ASolve the sampling problemSolve control problemsBatteries circuit arrangementsElectric powerControl systemCharge control

The invention provides a photovoltaic charging control system. The system comprises a control module and a voltage sampling module, one end of the control module is connected with a photovoltaic assembly, and the other end of the control module is connected with a storage battery; the control module comprises a charging control module, an anti-reverse charging control module and an MCU control module; and the voltage sampling module comprises a photovoltaic voltage sampling module and a storage battery voltage sampling module. The control system can samples a photovoltaic voltage in real time, and has the advantages of simple structure, low cost, high-speed switching, high stability and high reliability. The invention further provides a control method based on the photovoltaic charging control system, and solves the sampling problem of an existing common anode charging circuit in a switch tube turn-off period and the control problem when a circuit does not share the ground.

Owner:湖南终南山科技发展有限公司

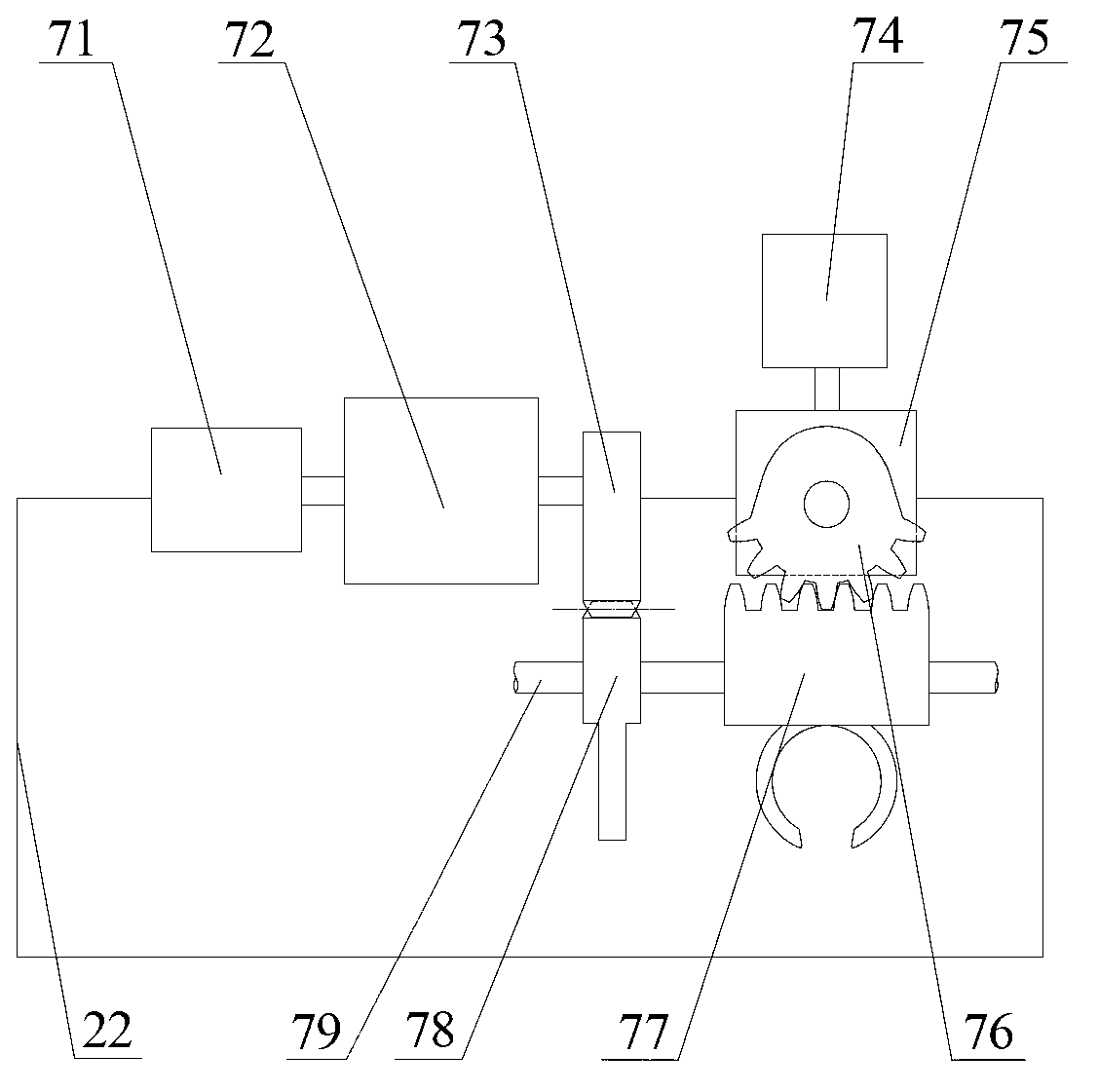

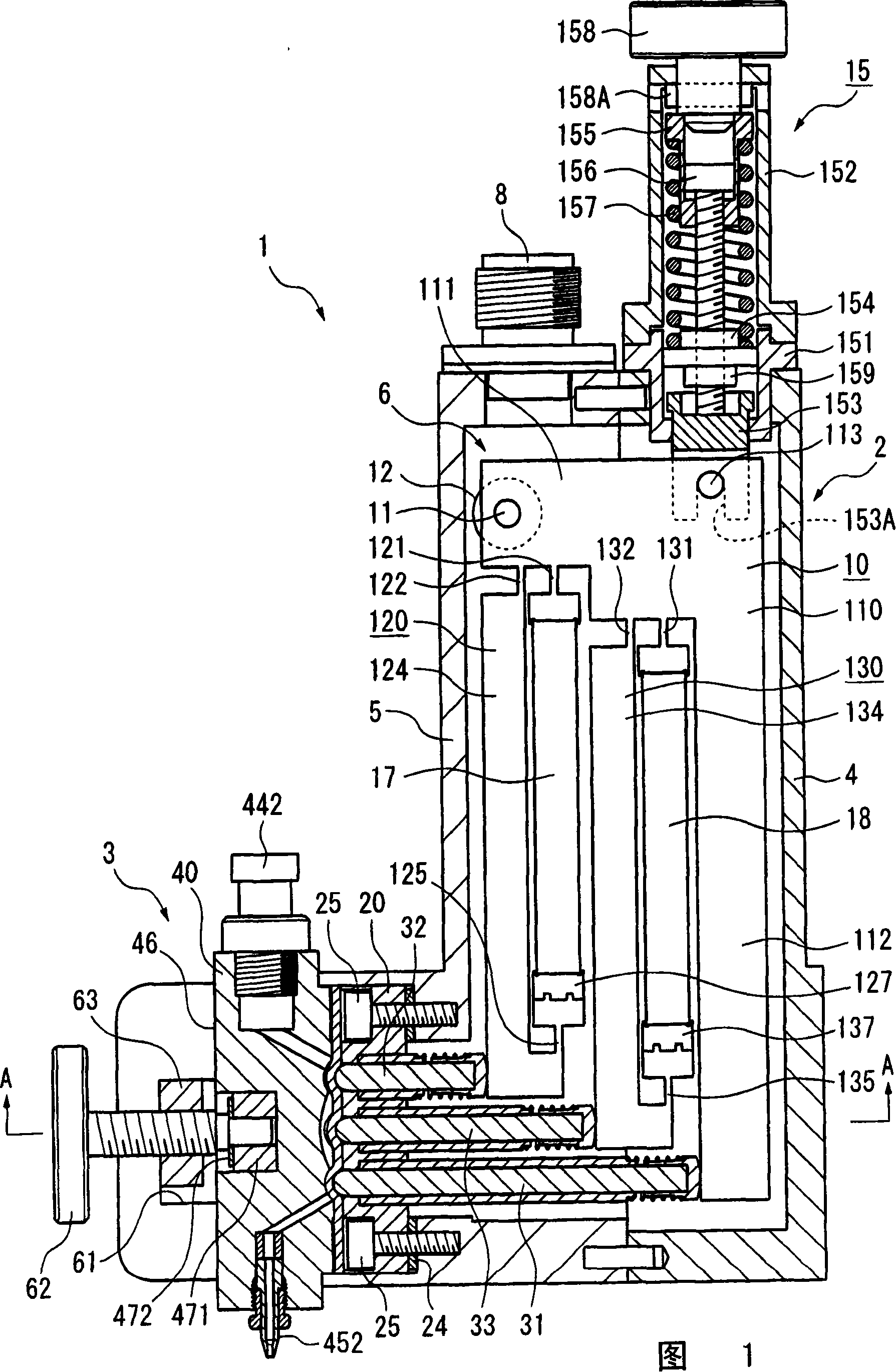

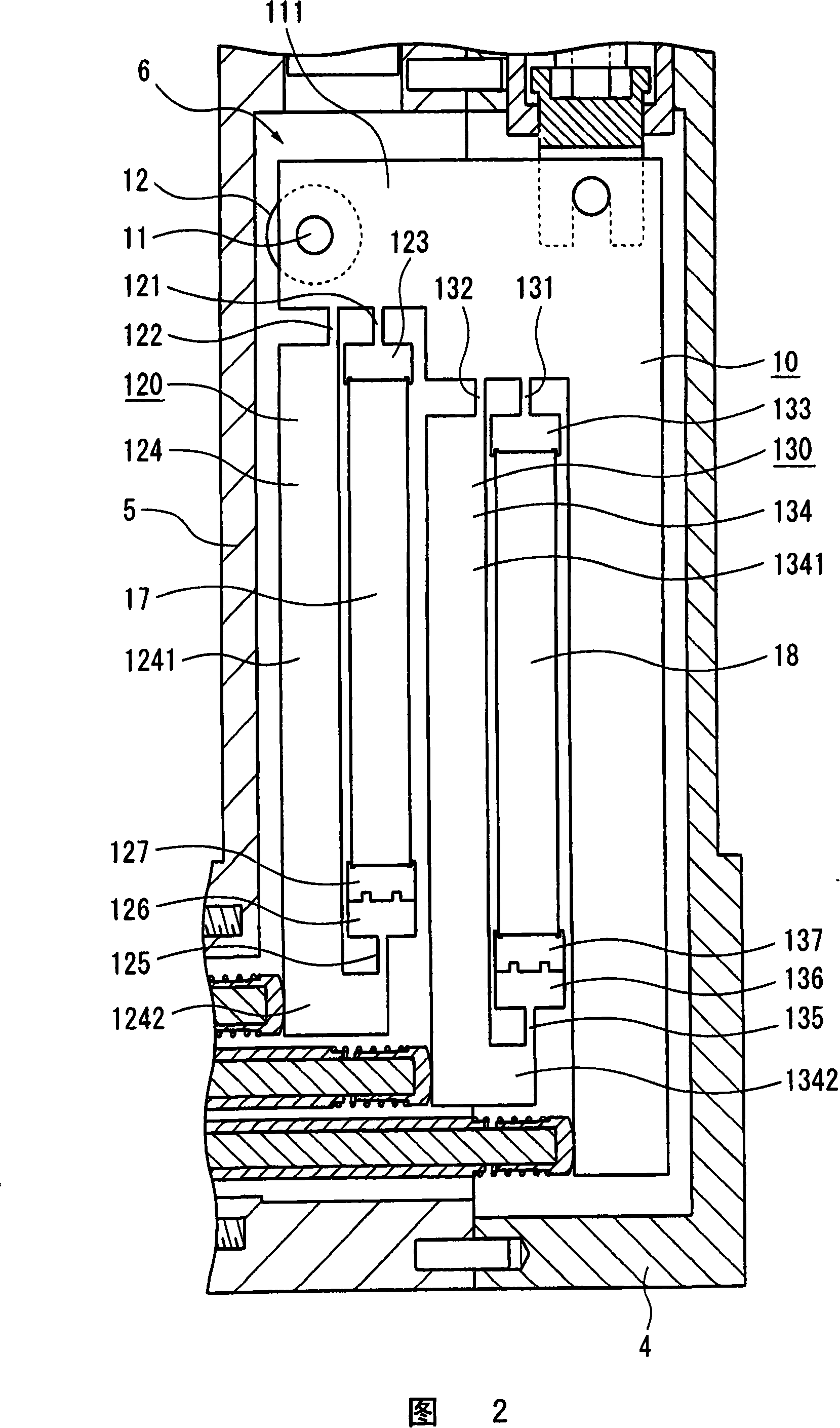

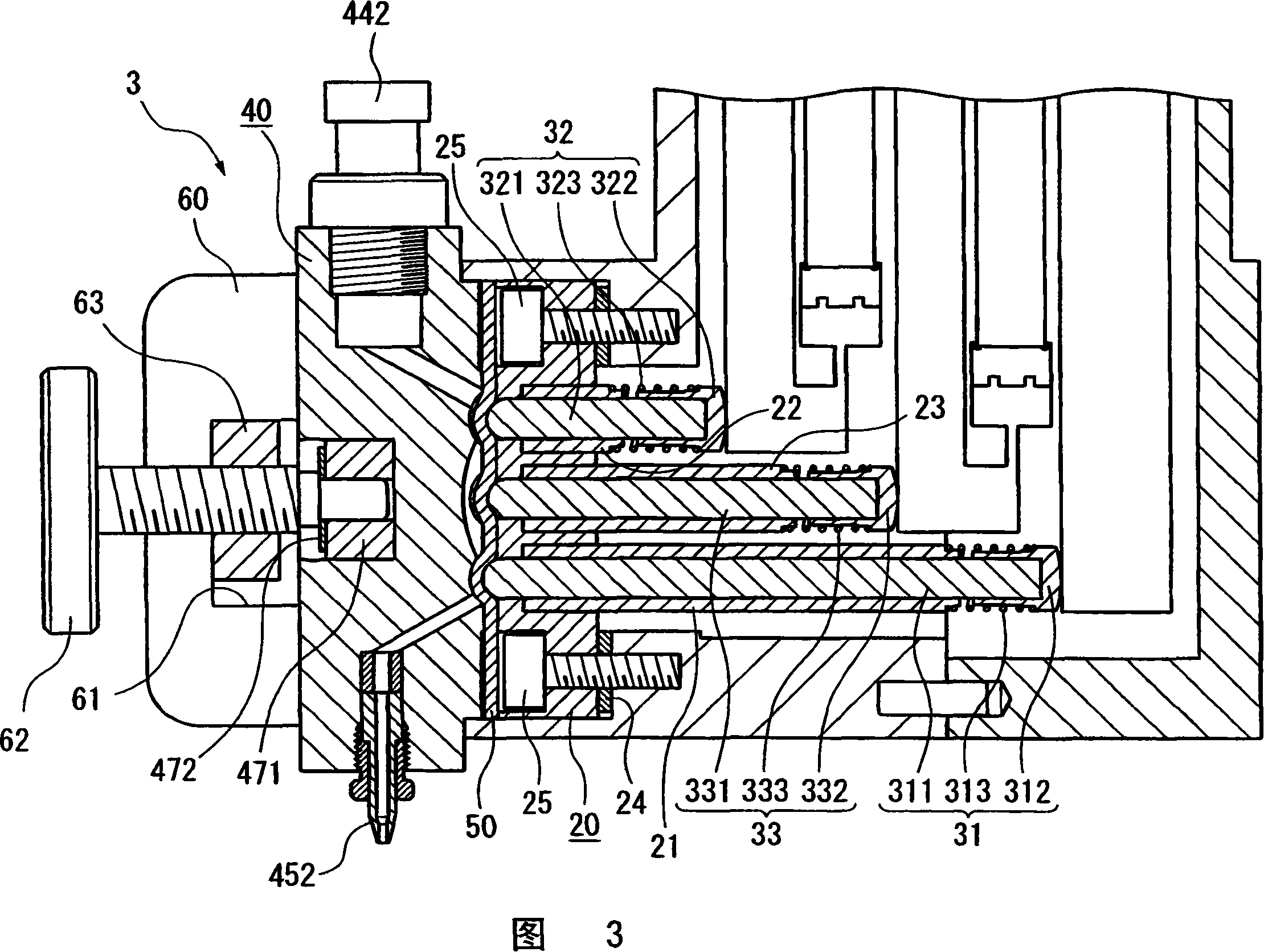

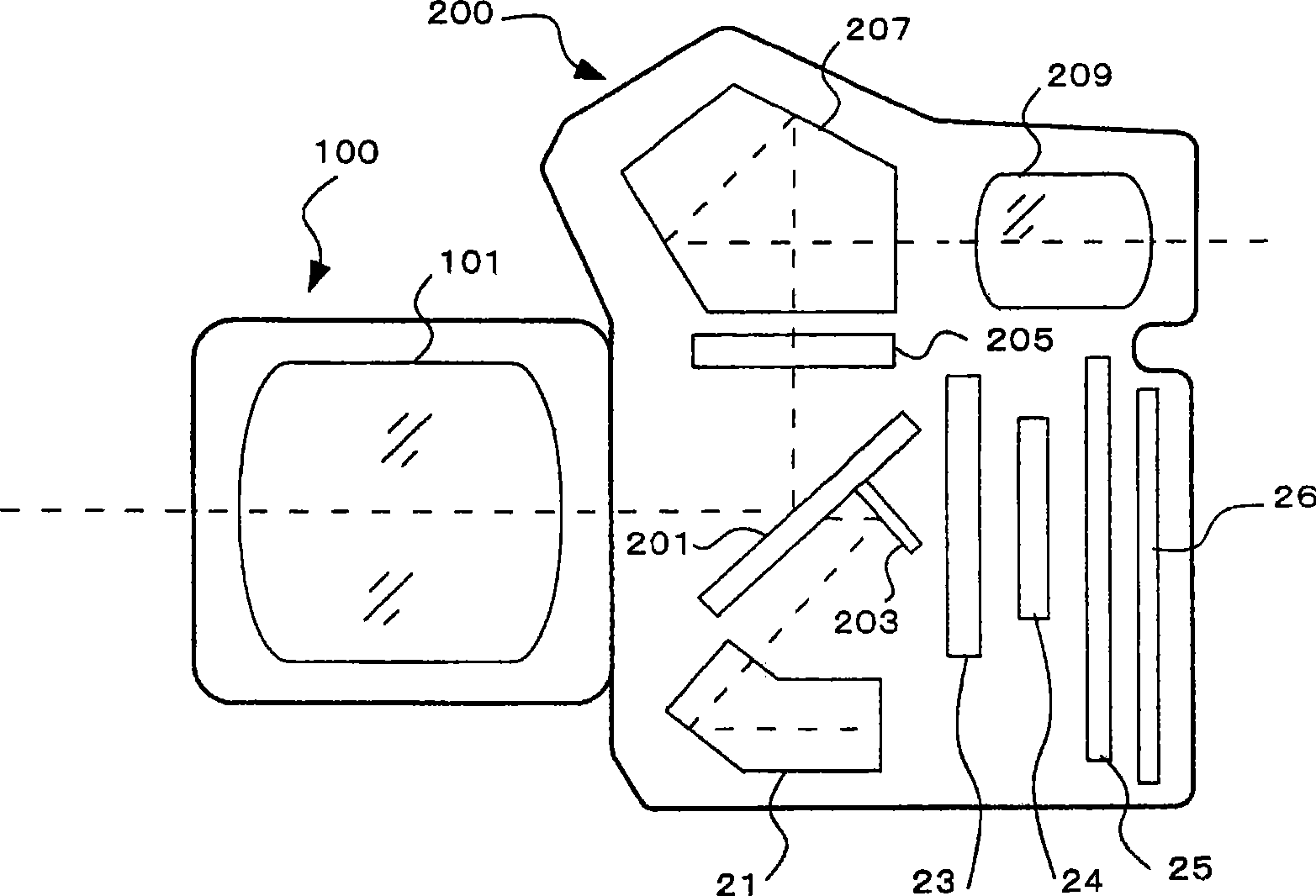

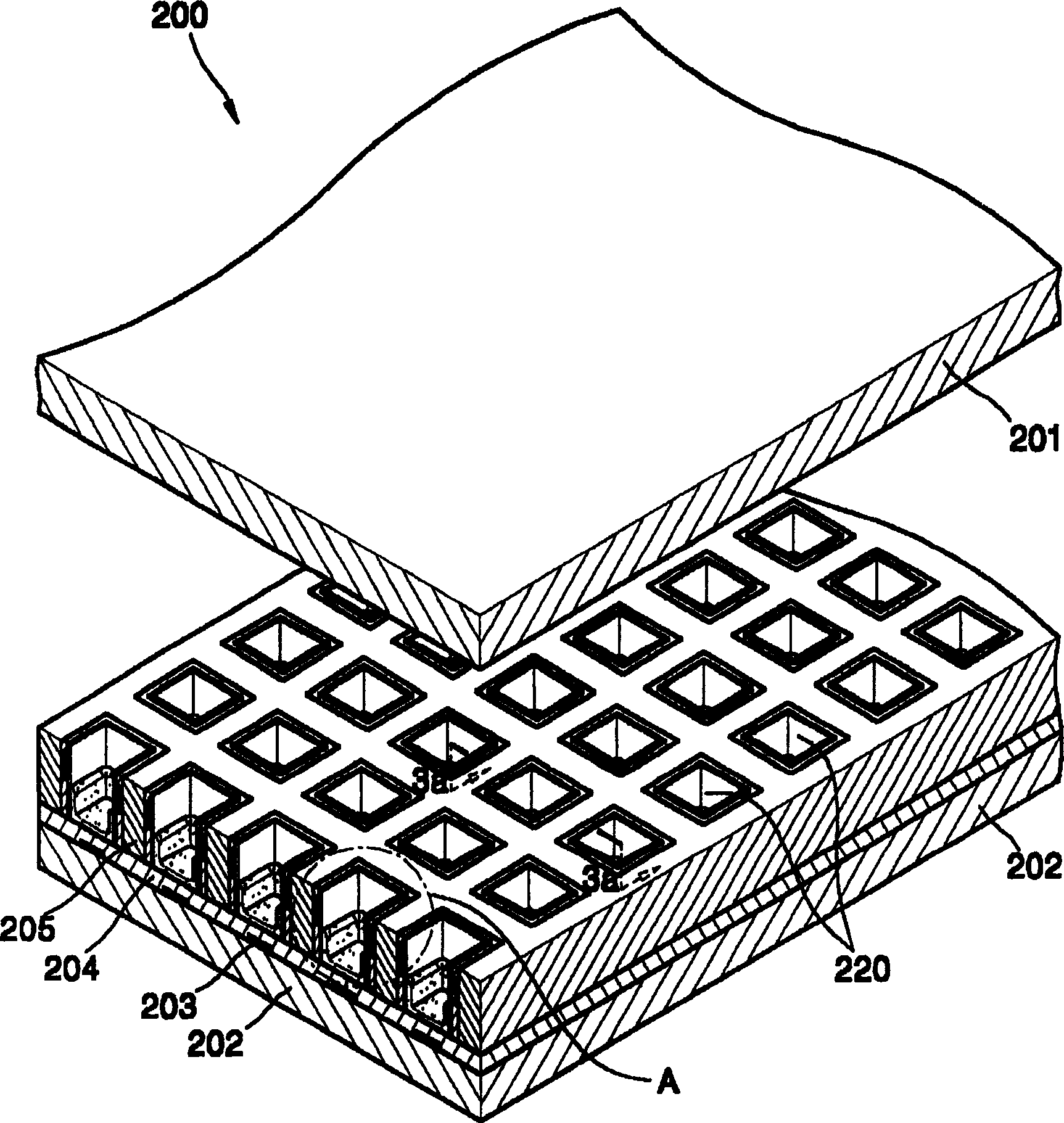

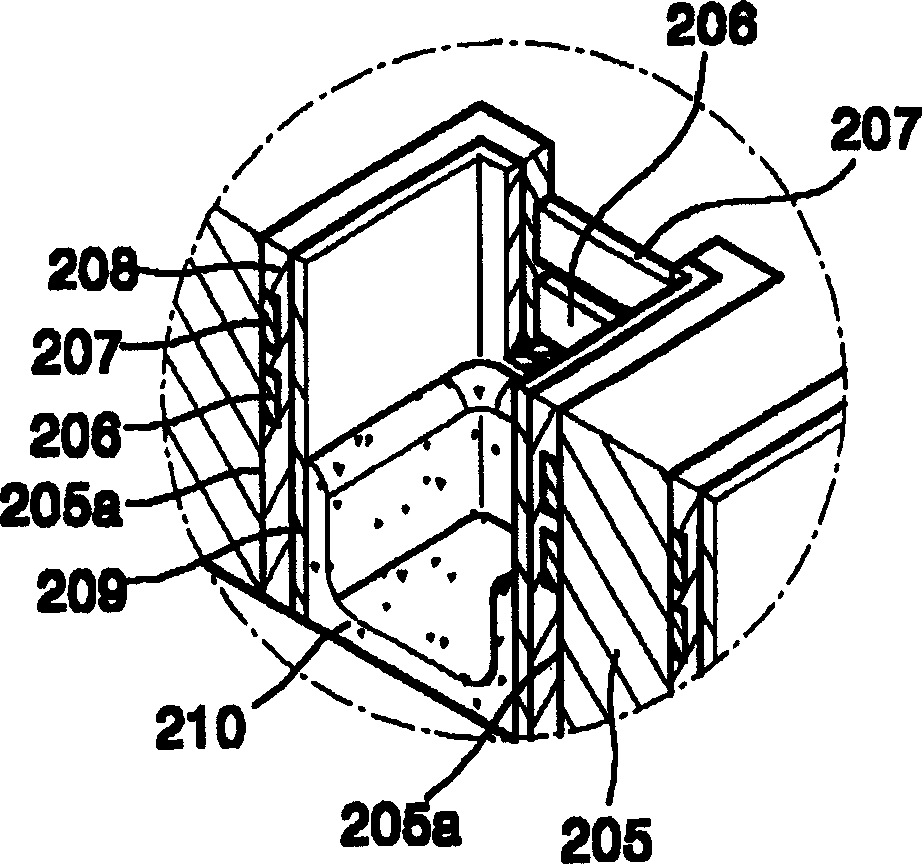

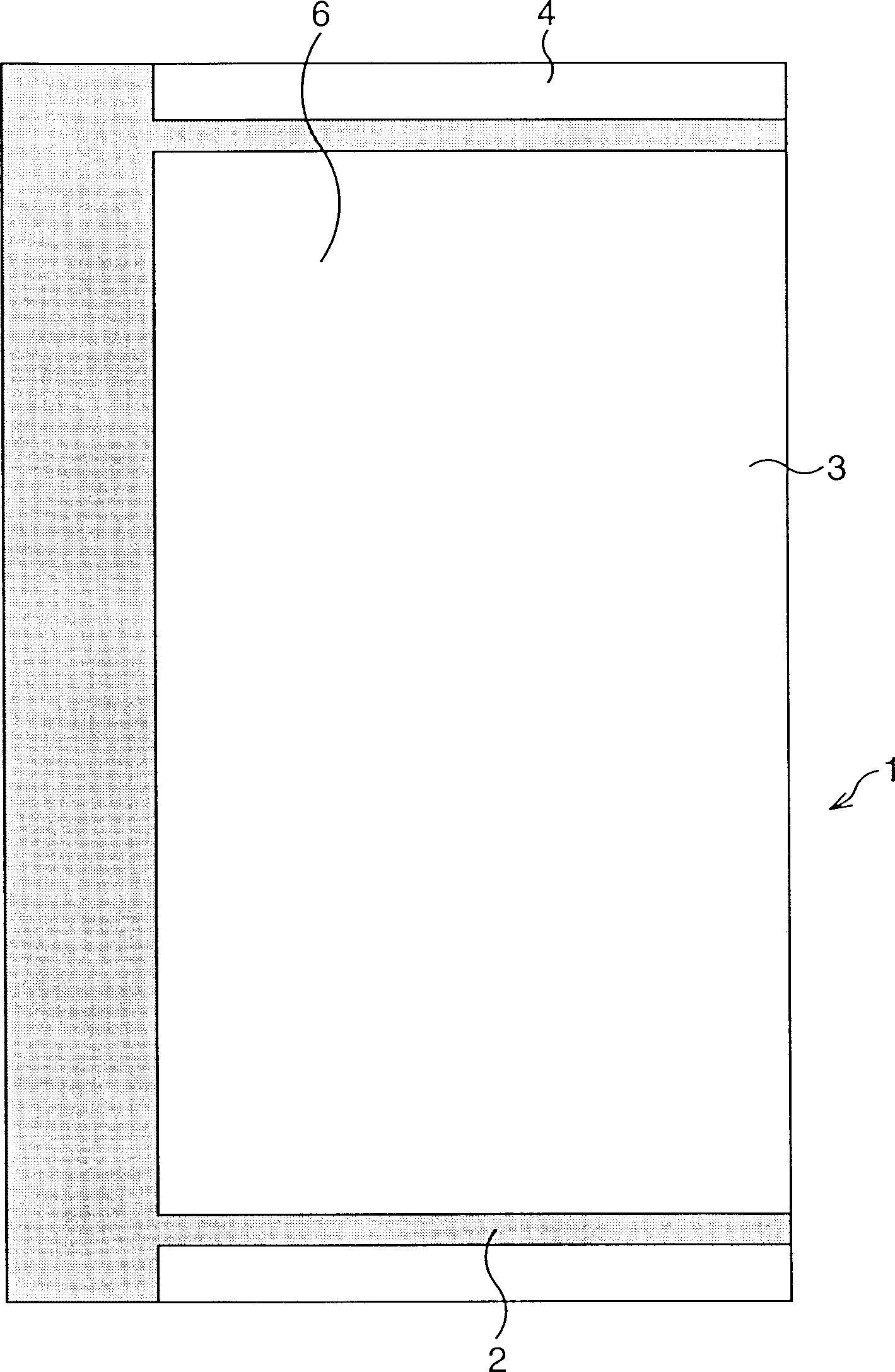

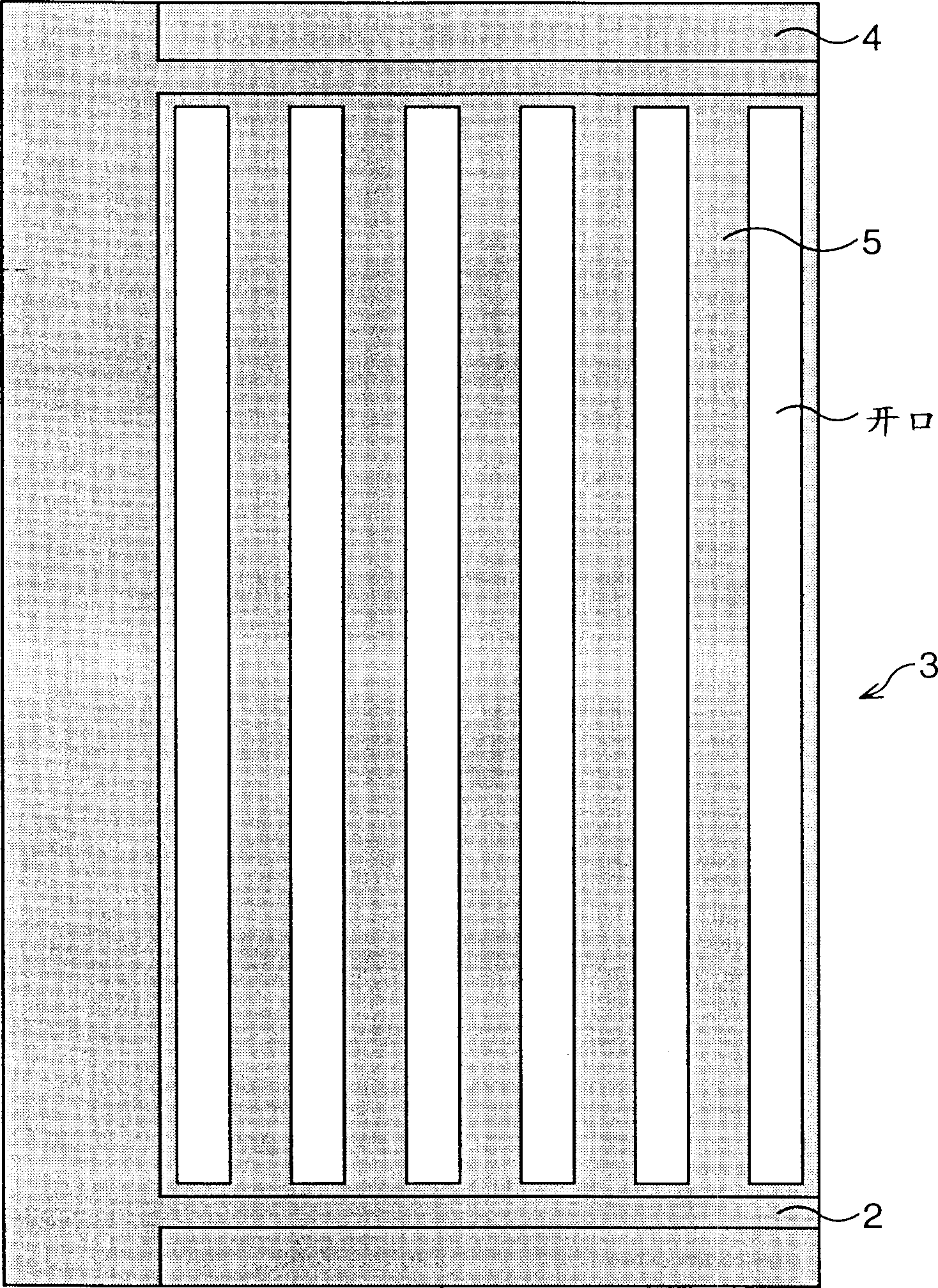

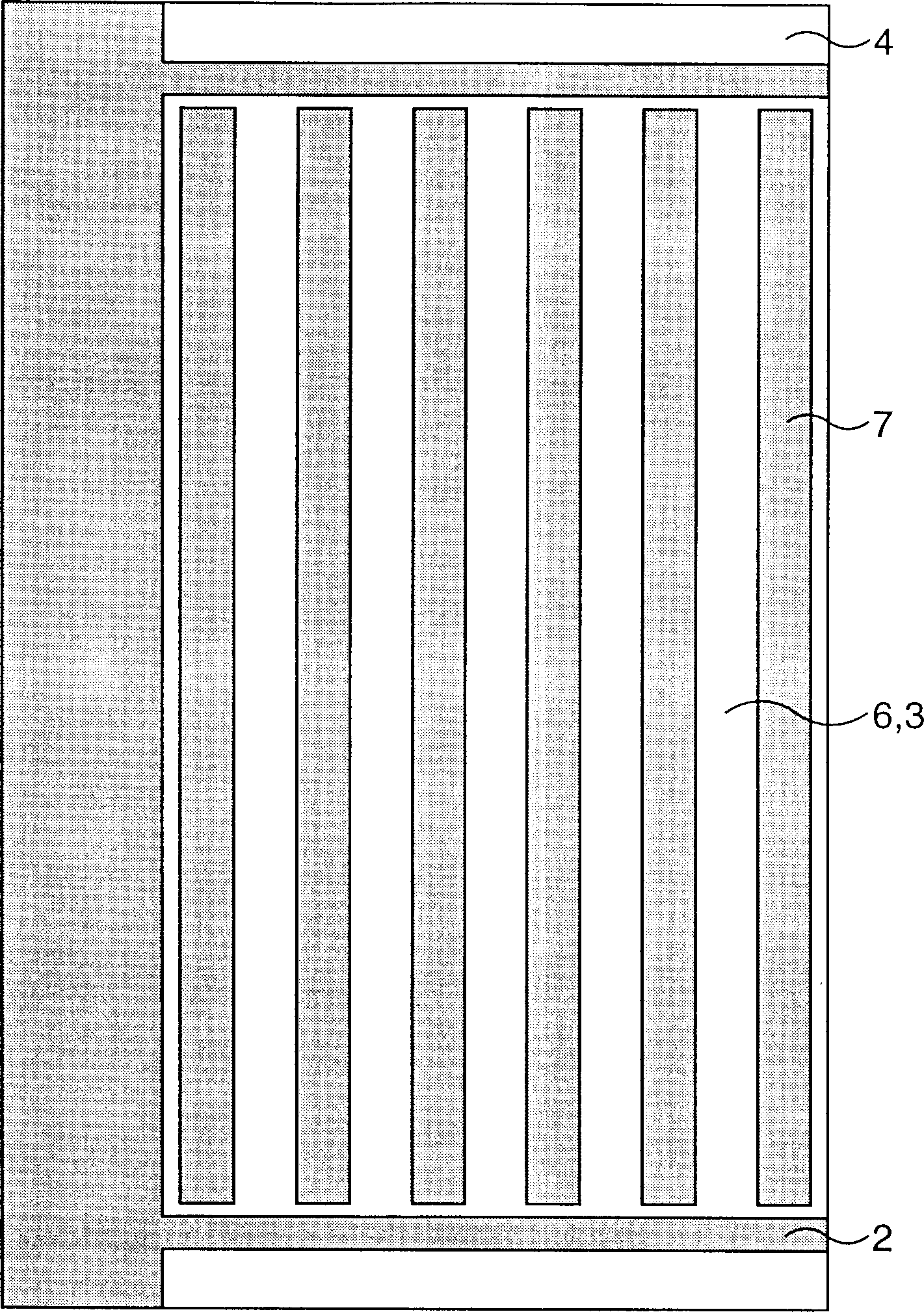

Piezoelectric drive device and liquid discharging device

InactiveCN101113726AHigh speed driveReduce intervalPiezoelectric/electrostriction/magnetostriction machinesFlexible member pumpsElectricityActuator

The piezoelectric driving device (2) of the present invention comprises a casing (4, 5) and a driving device main body (6). The driving device main body is provided with a displacement amplifying plate (10), a force applying mechanism (15), and piezoelectric elements (17, 18). The displacement amplifying plate is equipped with a main body (110) that is energized and rotated by the force applying mechanism (15), and amplifies the displacement when the piezoelectric elements (17, 18) are elongated. A displacement amplifying part (120) for displacement in an orthogonal direction. In a state where no voltage is applied to the piezoelectric element, the first driven body (31) is moved by the main body portion biased by the biasing mechanism. When a voltage is applied to the piezoelectric element (17), the second driven body (32) is moved by the displacement amplifier (120). When a voltage is further applied to the piezoelectric element (17) from the state where the driven body (32) is in contact with the object, and the displacement of the displacement amplification part is enlarged, the main body part (110) and the driven body (31) overcome The elastic force described above moves in a direction opposite to the direction in which the force is applied.

Owner:NOIBERUKU

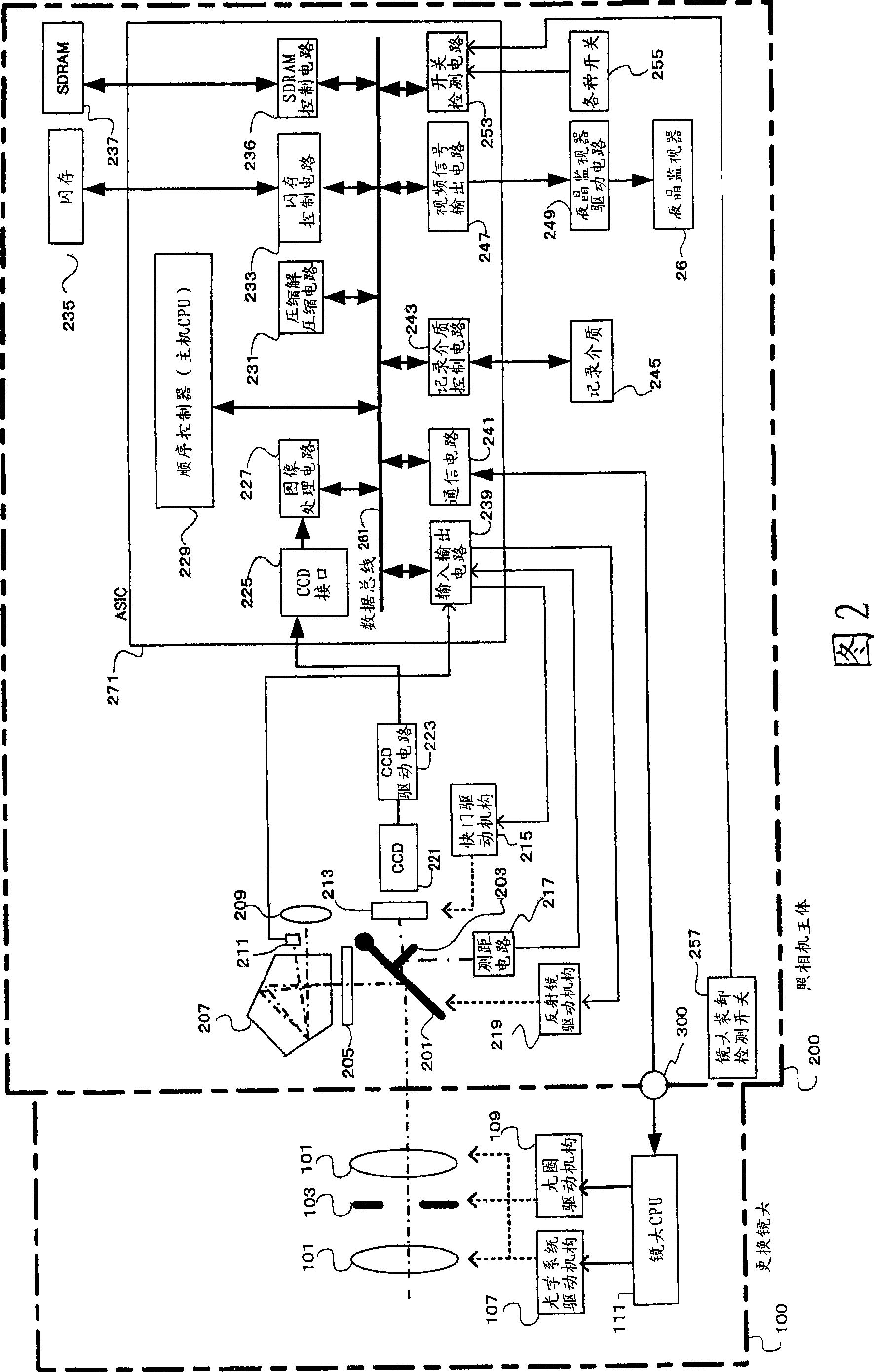

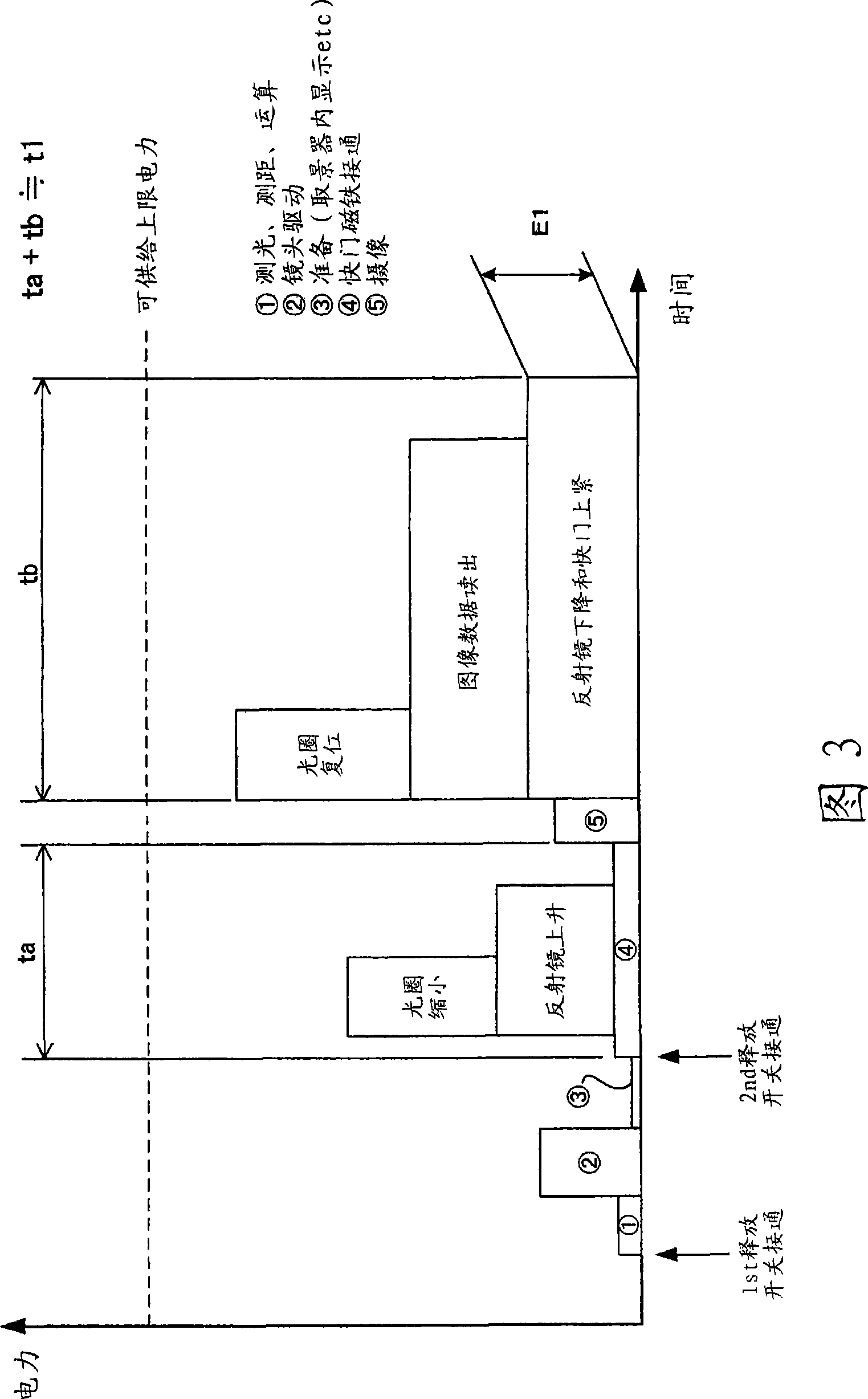

Camera

ActiveCN101435974AHigh speed driveLow latencyTelevision system detailsColor television detailsTime delaysEmbedded system

The invention provides a camera which can be driven in a high speed and shorten time delay in the case of carrying out shutter action in a second shooting preparation state such as the live view display. When the camera is in a live view display state, the magnet adsorption (S5) in the shutter first curtain is relieved, thus allowing the shutter first curtain to move and carrying out live view display (S7) according to the output from CCD221; in such moment, shutter rear curtain keeps in a connection (absorption) state, and the shutter is in an open state. The AF switch is put through (S11), and the shutter rear curtain also keeps in an open state when the phase separation AF based on TTL measuring distance, thus reducing the tight load on the shutter and shortening time delay.

Owner:奥之心数字科技株式会社

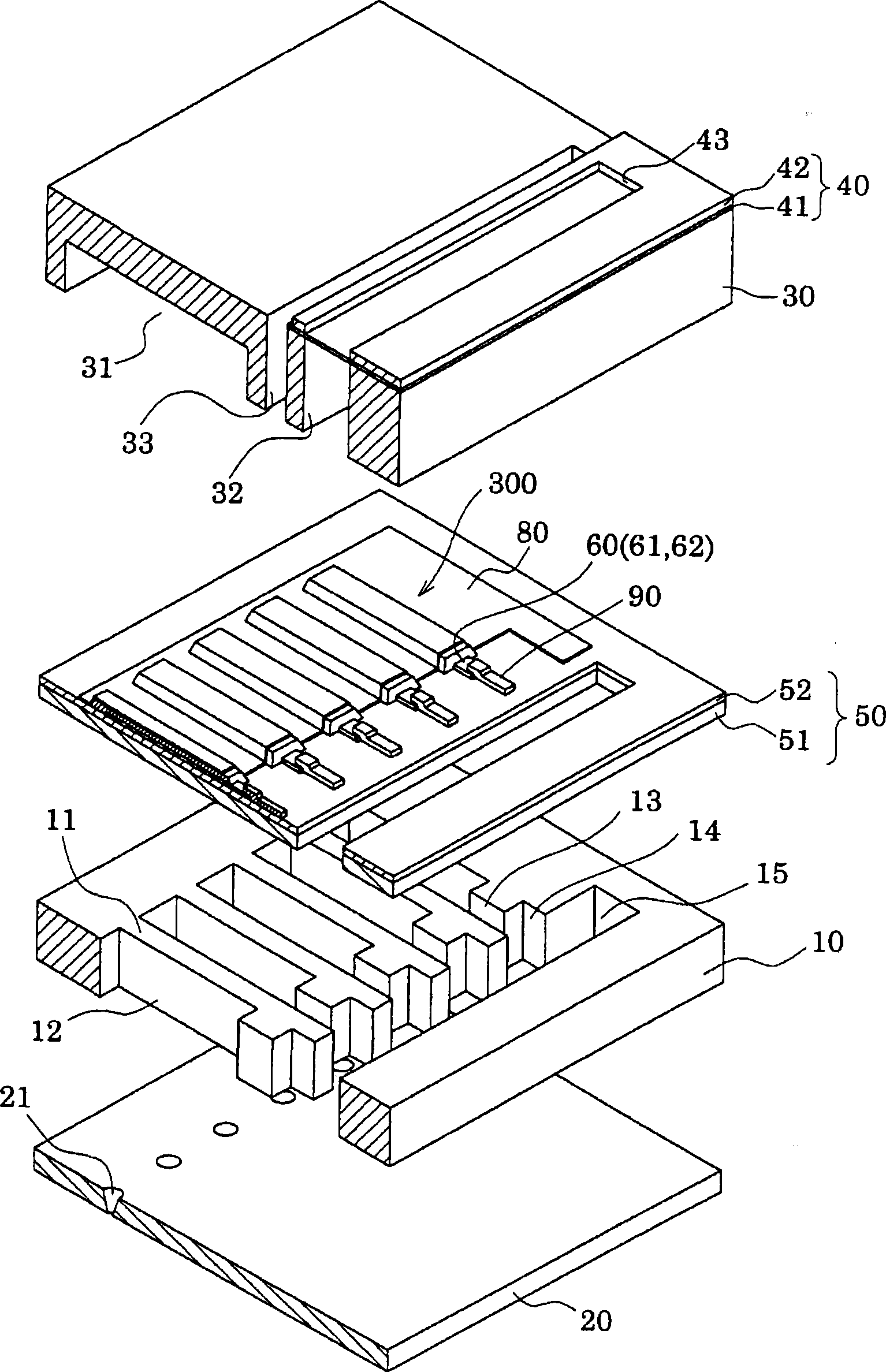

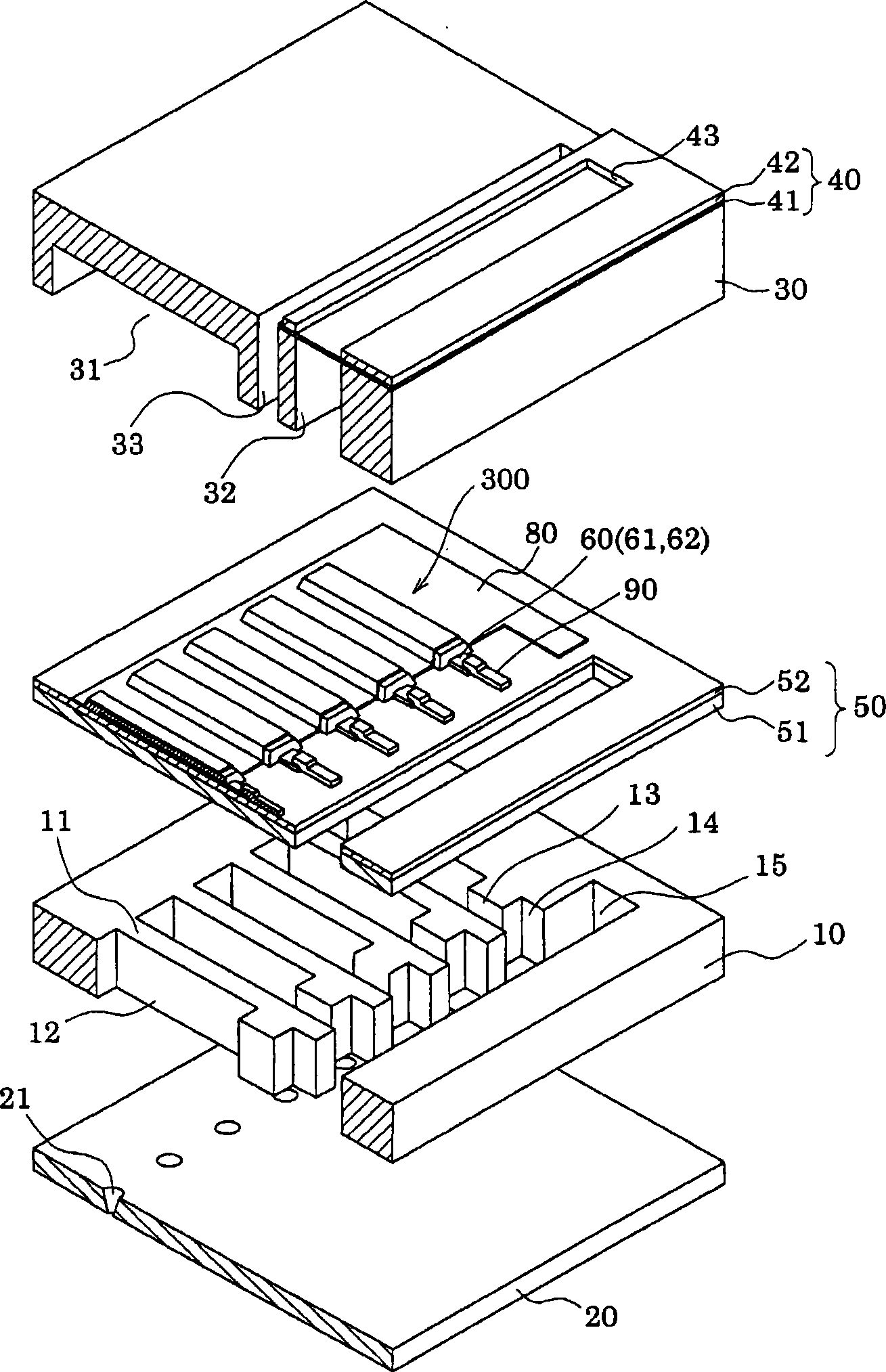

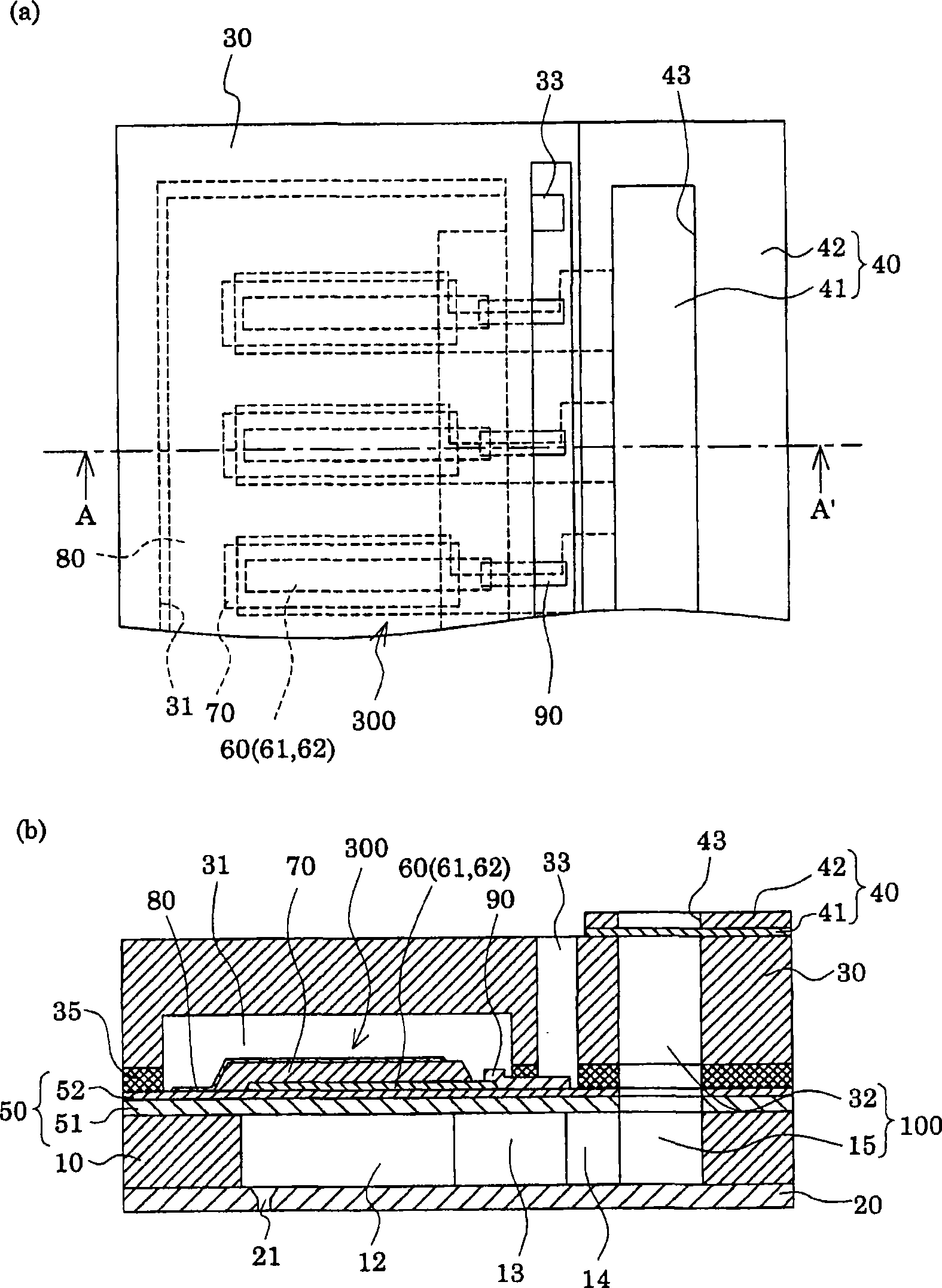

Liquid ejecting head, liquid ejecting apparatus, and actuator

InactiveCN101544114AHigh crystallinityIncreased durabilityPiezoelectric/electrostrictive device manufacture/assemblyPiezoelectric/electrostrictive device material selectionLiquid jetLanthanum

The invention provides a liquid ejecting head, a liquid ejecting apparatus and an actuator capable of improving shift characteristics of piezoelectric element to implement high-speed driving and preventing damage of the piezoelectric layer to improve durability. A end face of a piezoelectric layer (70) is composed of inclined planes in a incline mode of end of a lower electrode side is outsider than a upper electrode side. The lower electrode (60) for composing piezoelectric elements has a width smaller than the width of the pressure generating chambers (12). The piezoelectric layer (70) has a larger width than the lower electrode (60) to cover end faces of the lower electrode (60). The vibration plate (50) has a top layer formed of a titanium oxide (TiOx) insulator film (52). The lower electrode has a top layer formed of a lanthanum nickel oxide (LaNiyOx) orientation control layer (62). The piezoelectric layer (70) is formed of columnar crystals, and one part of the piezoelectric layer (70a) disposed on the insulator film (52) has a smaller average grain size than the other part of the piezoelectric layer (70b) disposed on the orientation control layer (62).

Owner:SEIKO EPSON CORP

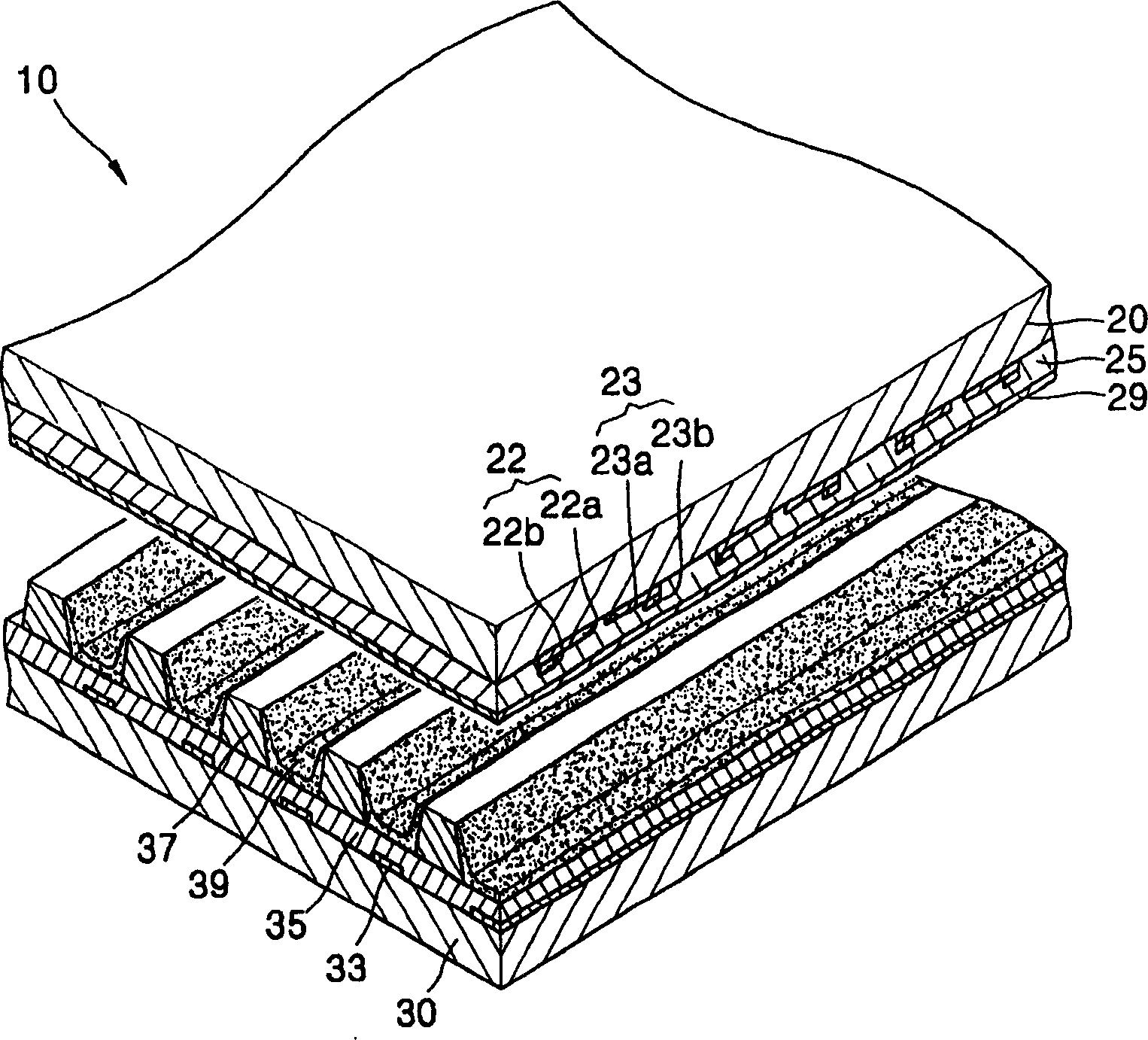

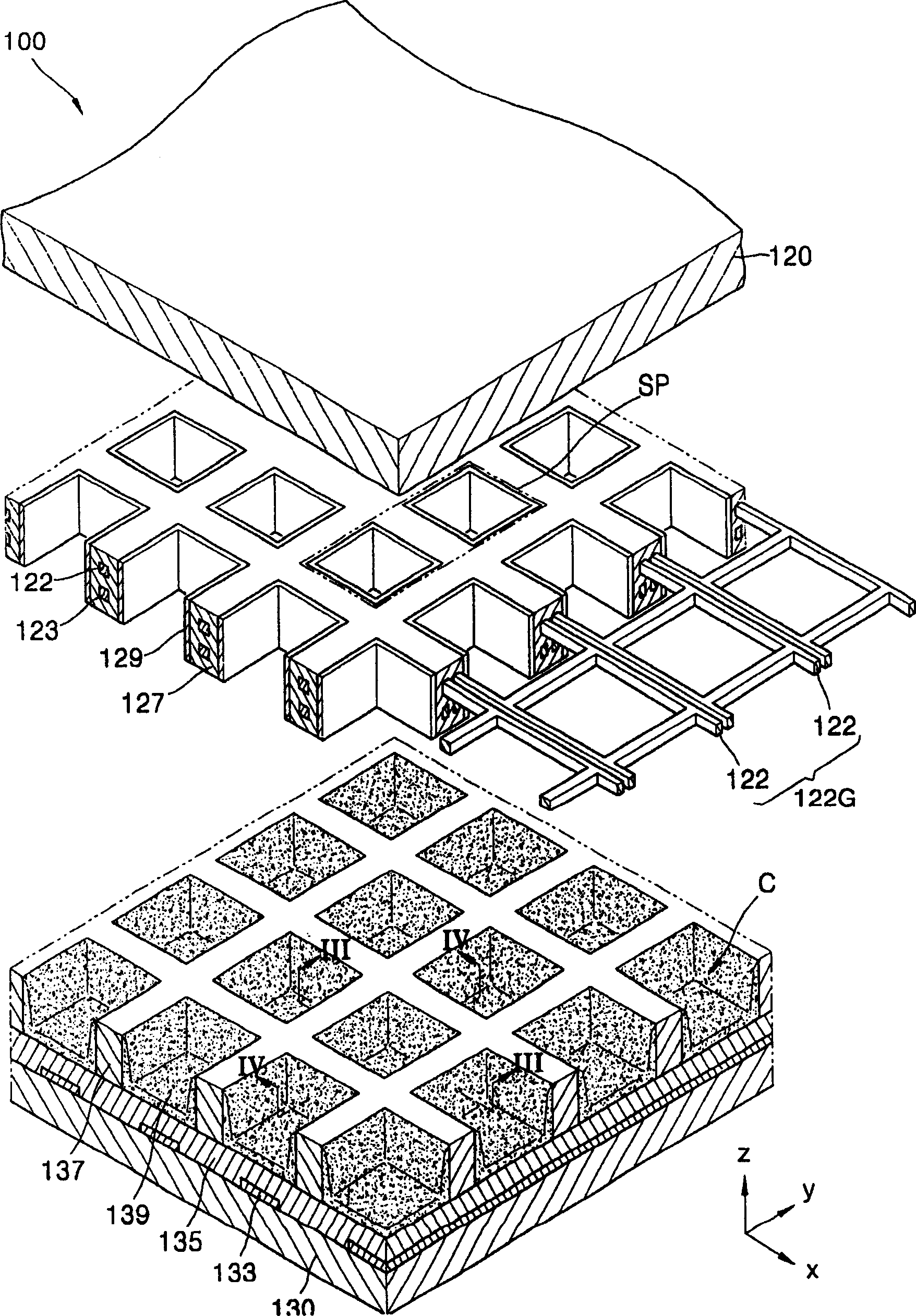

Plasma display panel

InactiveCN1612280AReduce the driving voltageFast discharge response speedAddress electrodesSustain/scan electrodesOptoelectronicsPlasma display

A plasma display panel includes a pair of substrates (201;202) spaced apart from each other and facing each other, a visible light generator (210) arranged between the pair of substrates (201;202), and an electrode layer (206) adapted to apply the same potential to a plane arranged between the pair of substrates (201;202) at a predetermined angle with respect to a direction perpendicular to the pair of substrates (201;202).

Owner:SAMSUNG SDI CO LTD

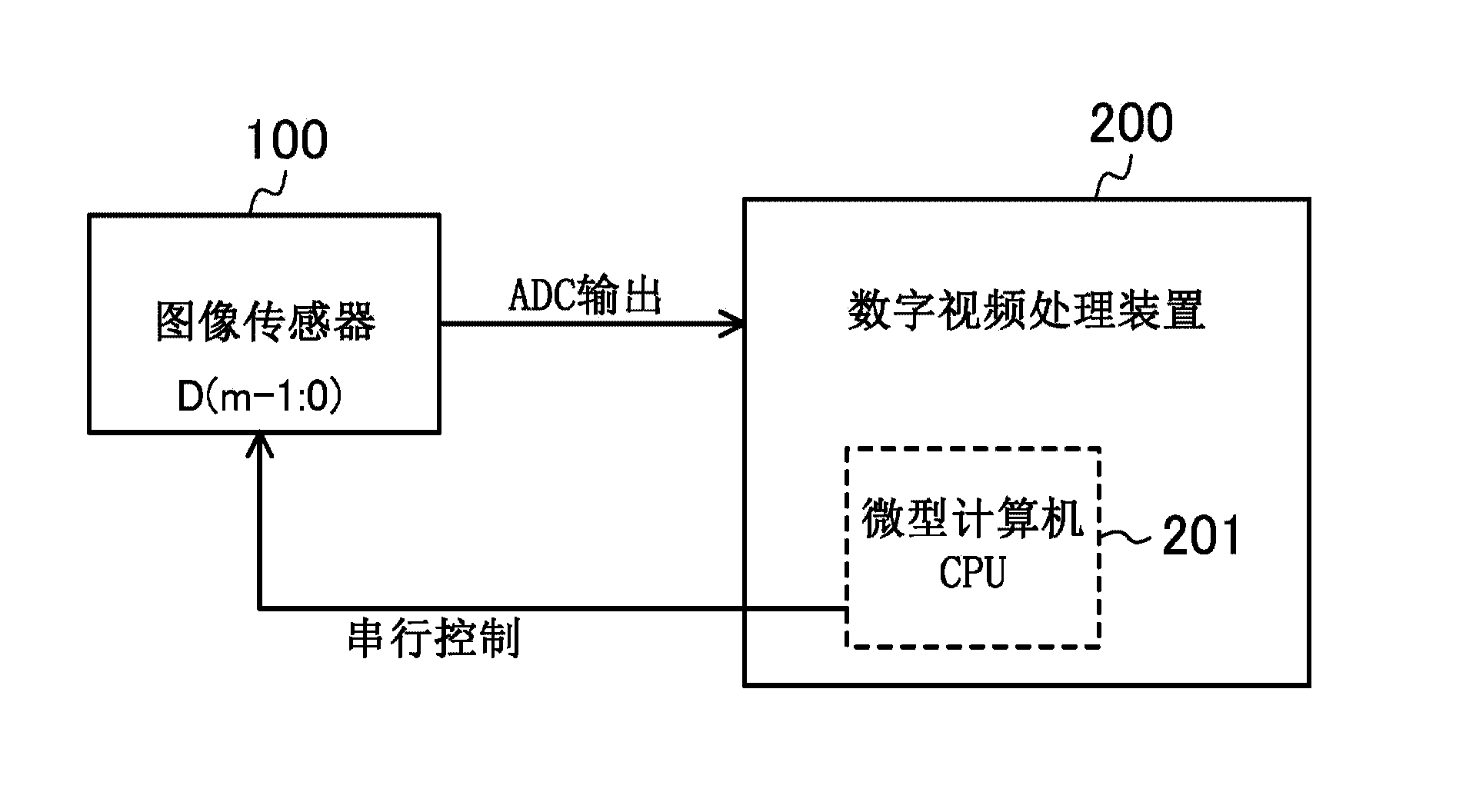

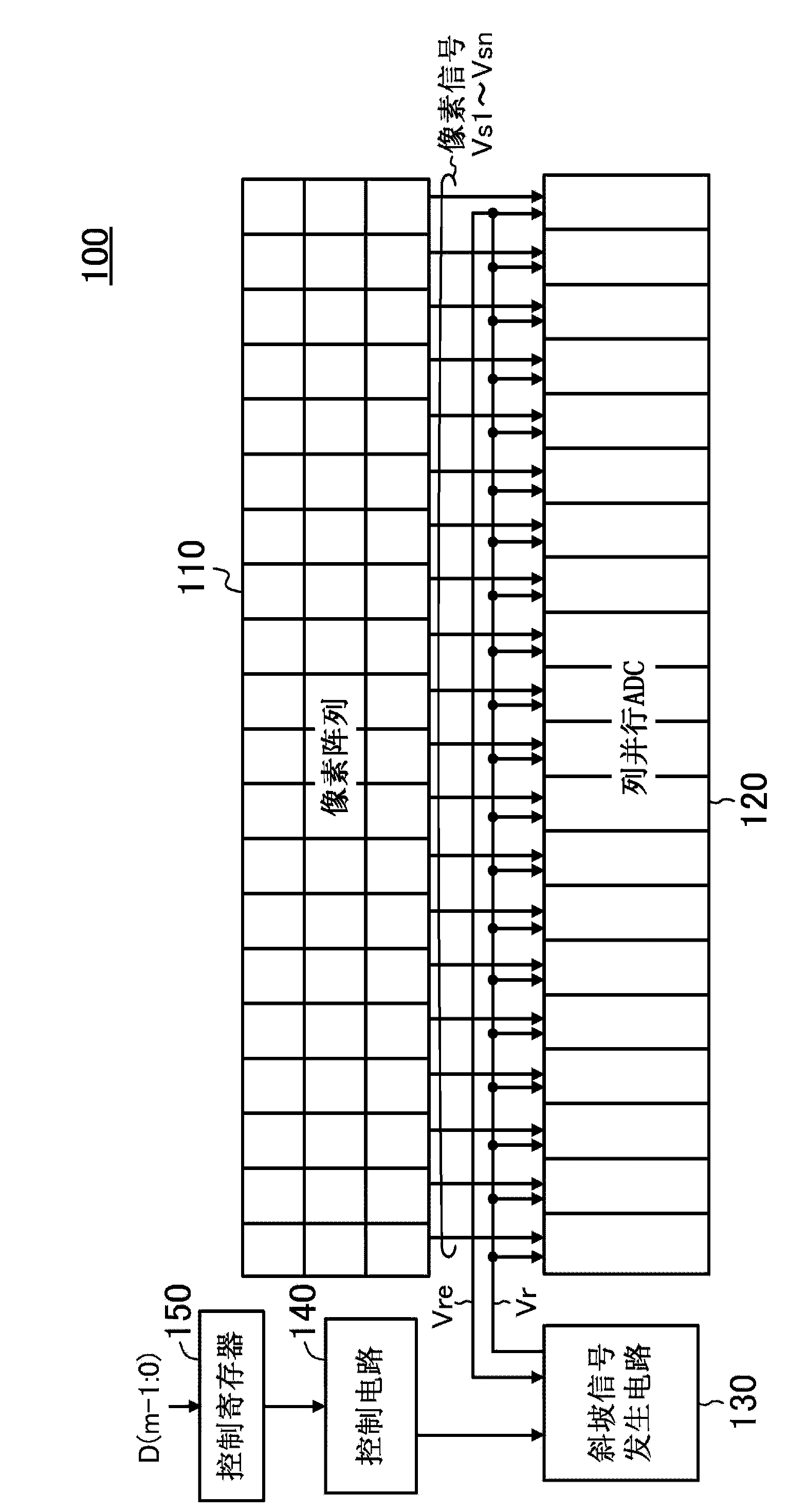

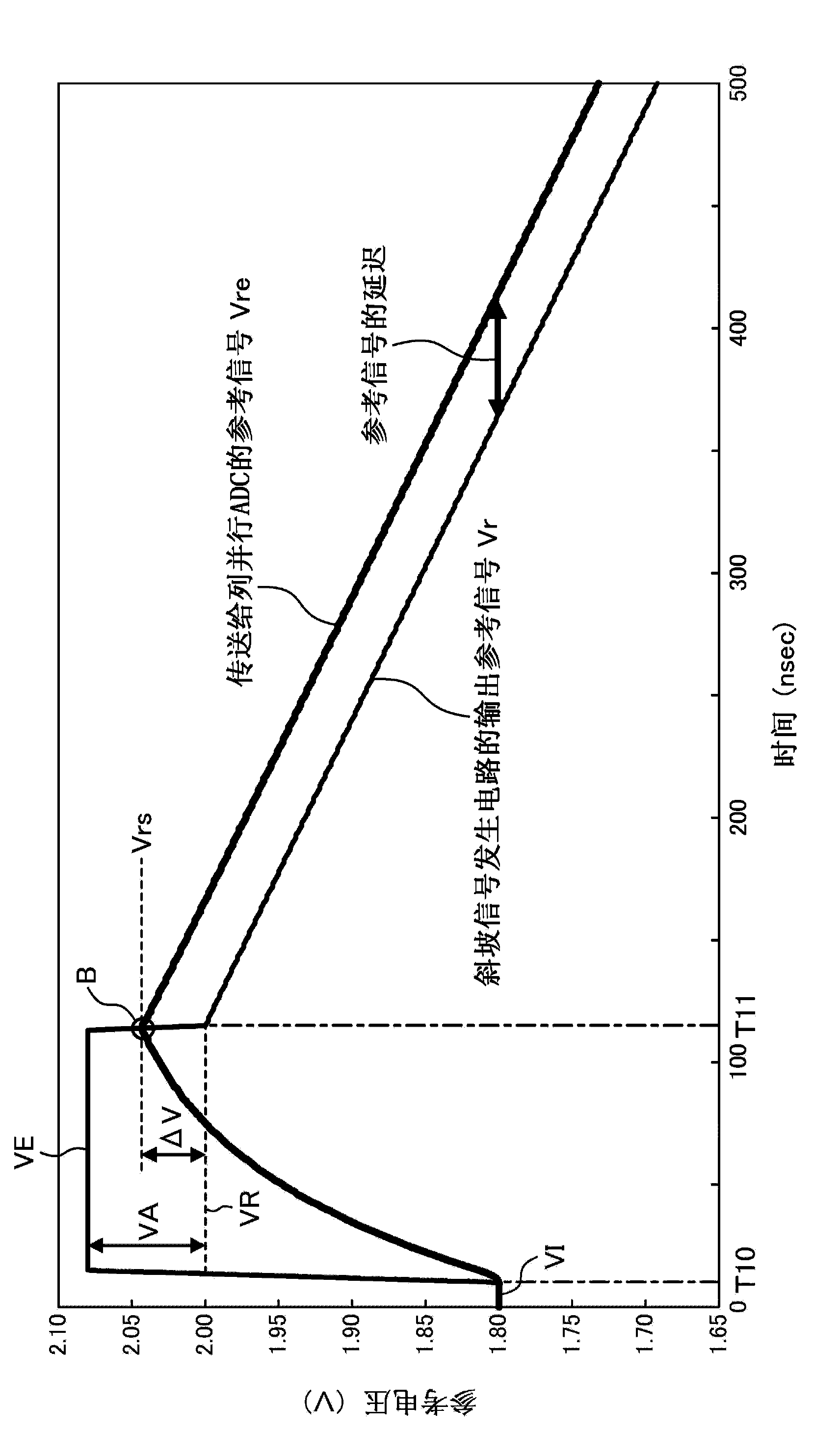

Ramp generator circuit, and image sensor and image capture device comprising same

InactiveCN103477628AAccurate AD conversionShorten the timeAnalogue/digital conversionTelevision system detailsVoltage generatorEngineering

A ramp generator circuit (130) comprises a reference voltage generator unit (134), which, prior to a comparison operation of an analog-digital conversion circuit (120), converts a voltage of a reference signal (Vr) to a comparison apparatus setting voltage (VR) which corrects a voltage disparity between the reference signal (Vr) and an analog input signal (Vs1-Vsn), and outputs a ramp signal as a base point of the comparison apparatus setting voltage (VR) together with the commencement of the comparison operation. The ramp generator circuit (130) further comprises a function which adds a prescribed enhanced voltage (VA) to the comparison apparatus setting voltage (VR) prior to the comparison operation.

Owner:PANASONIC CORP

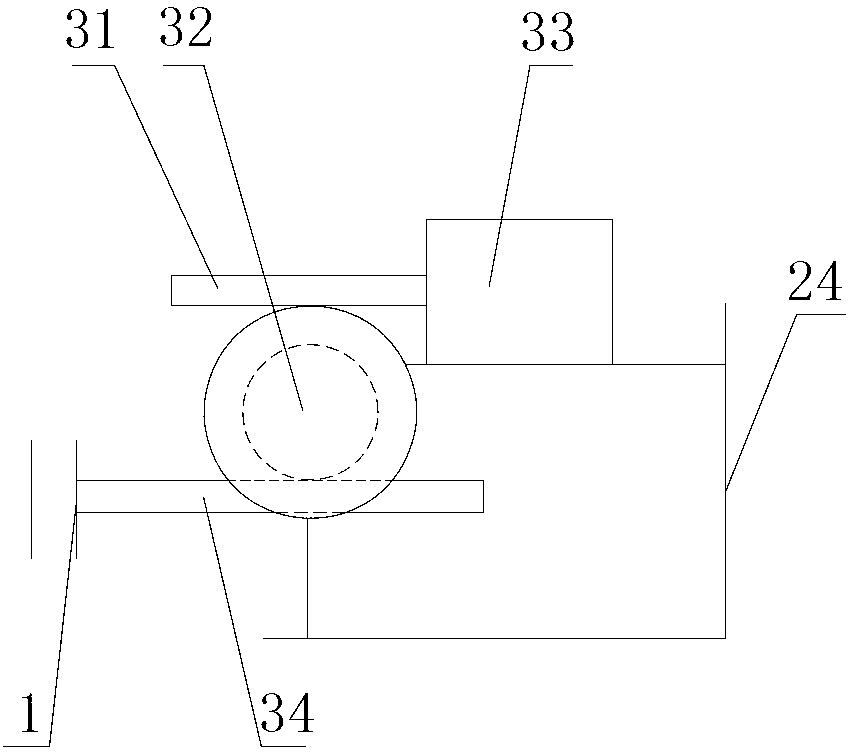

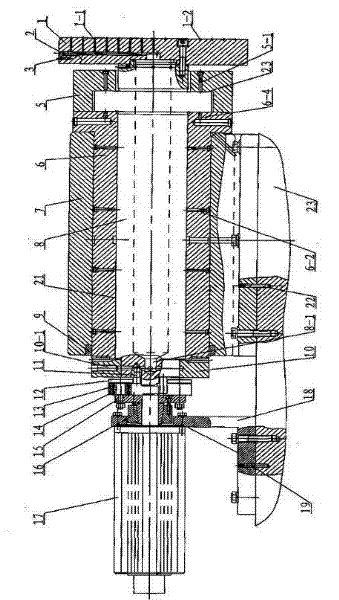

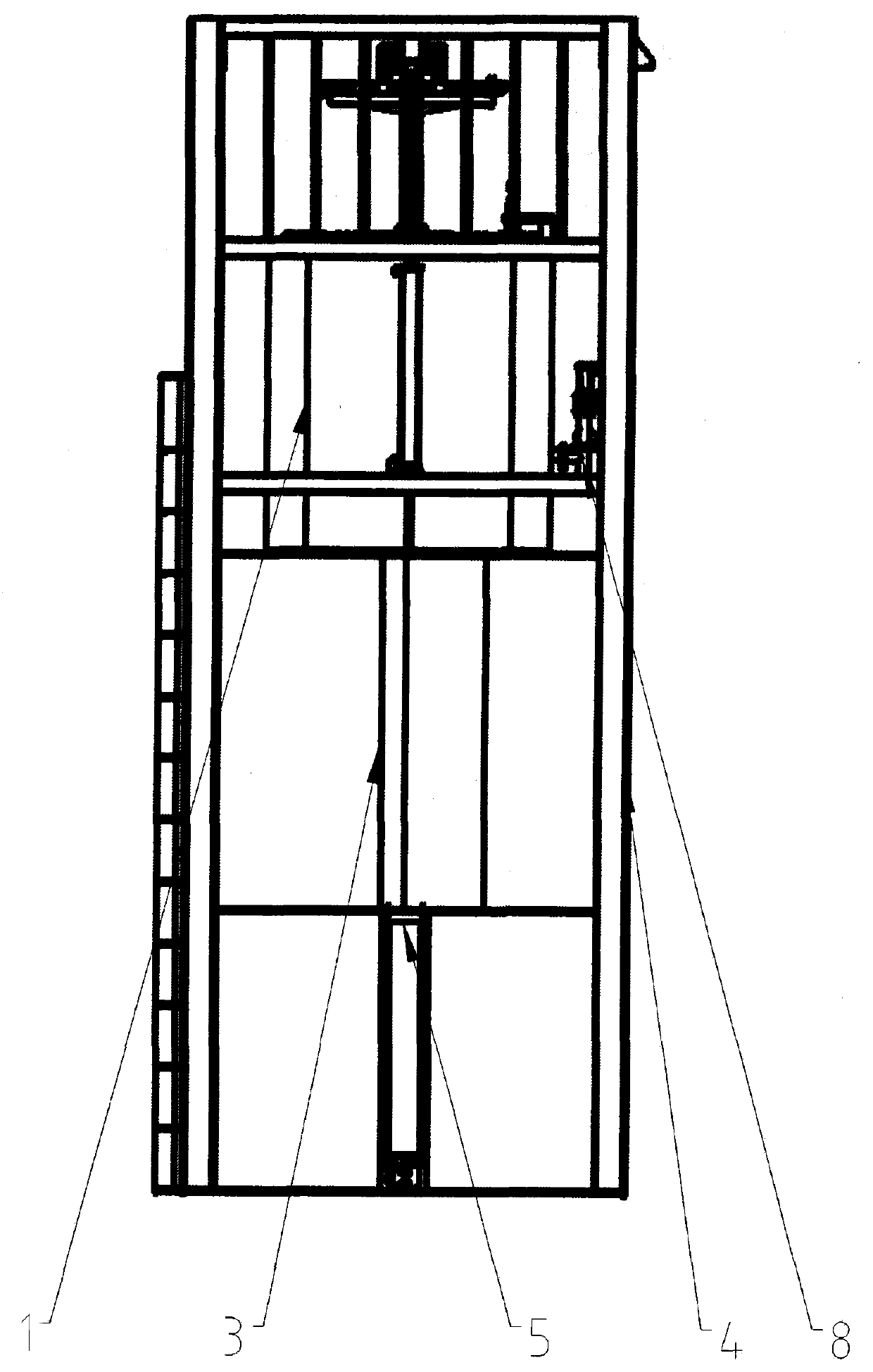

Separating type flexibly driven spindle system for high-precision processing machine tool

InactiveCN102476193AReduce the impact of rotation accuracyImprove dynamic characteristicsDriving apparatusElectric machineEngineering

The invention relates to a separating type flexibly driven spindle system for a high-precision processing machine tool, in order to solve the problems that a motor and a spindle of a spindle system in ultra-precision processing equipment are in rigid connection, a power transmission effect is inferior and the rotation precision of the spindle is influenced by the rigid connection. After an alternated current servo motor of the separating type flexibly driven spindle system is electrified, the alternated current servo motor starts to run so as to drive a flexible driving component to rotate, and a rotating torsion is generated by a driving lever under the driving of a flat belt which is rotated so as to drive the spindle to rotate and cut. High-pressure air enters from an axial air inlet, is throttled by a radial throttling hole, and then a radial air static pressure film is formed at a radial air film clearance by the high-pressure air; the radial air static pressure film is used for supporting the spindle and a radial load of the spindle; an axial air static pressure film is formed at an axial air film clearance by the high-pressure air after the high-pressure air is throttled by a first axial throttling hole; and the axial air static pressure film is used for supporting the spindle and an axial load of the spindle. The separating type flexibly driven spindle system provided by the invention is used for ultra-precision turning lathes and ultra-precision milling machines in various forms.

Owner:DALIAN CHUANGDA TECH TRADE MARKET

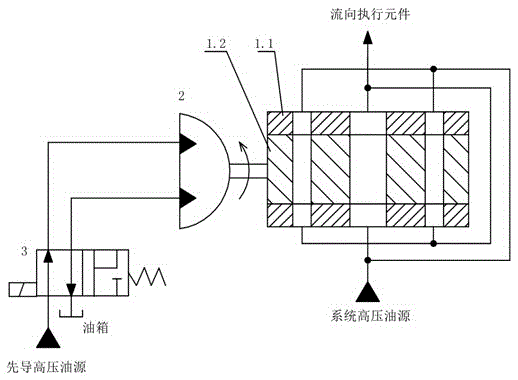

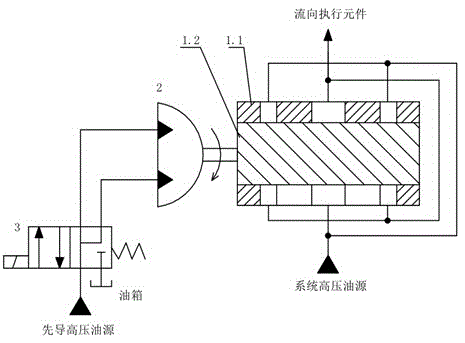

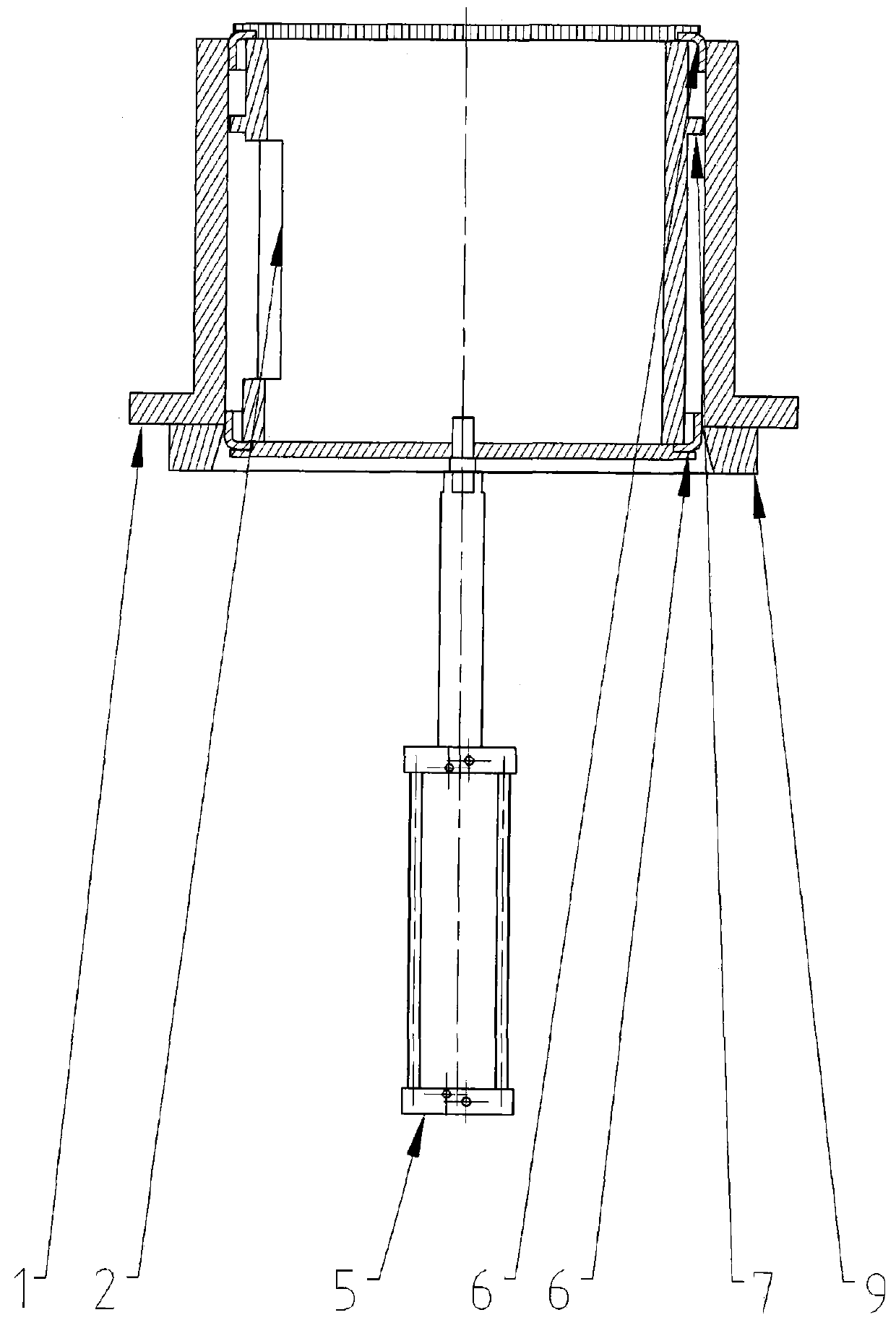

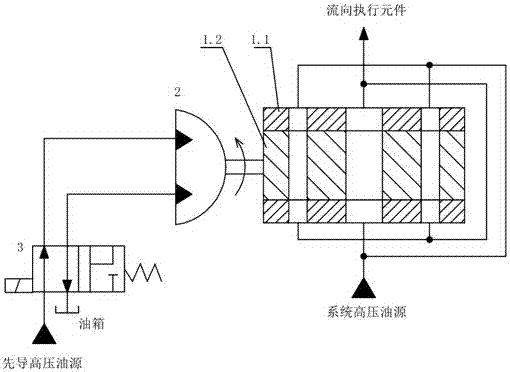

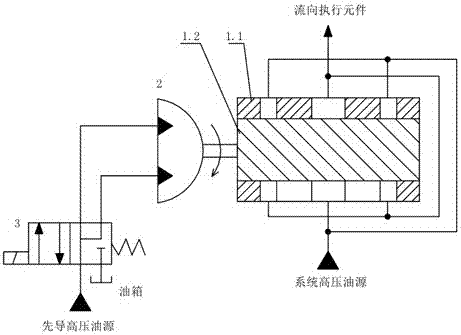

Low-power-consumption and large-flow high-speed switching valve

ActiveCN105114386ASmall overcurrent pressure lossReduce power consumptionServomotor componentsRotary valveEngineering

The invention discloses a low-power-consumption and large-flow high-speed switching valve. The switching valve is of a rotary valve structure. Rotation of a valve element of the switching valve is controlled by a differential swinging cylinder. The rotating direction of the differential swinging cylinder is controlled through a two-position four-way high-speed switching valve body. Three through flow passages are formed in the valve element in the radial direction and sequentially distributed in the axial direction, and the distances between the center lines of the adjacent flow passages in the axial direction are equal. The passage area of the middle flow passage is twice the passage areas of the two end flow passages, and the passage areas of the two end flow passages are equal. The flowing direction of oil in the middle flow passage is opposite to the flowing direction of oil in the two end flow passages. Inlets and outlets of the three flow passages are communicated respectively. When the high-speed switching valve body is in the totally-opening state, the flow passages are in a through pipe type, the passage pressure losses of a valve opening are small, and low-power-consumption and large-flow flowing of oil can be achieved.

Owner:OCEAN RES CENT OF ZHOUSHAN ZHEJIANG UNIV

Semiconductor device and producing method thereof

InactiveCN1423318AHigh speed driveAvoid short circuitTransistorSolid-state devicesBit lineEngineering

Owner:FUJITSU LTD

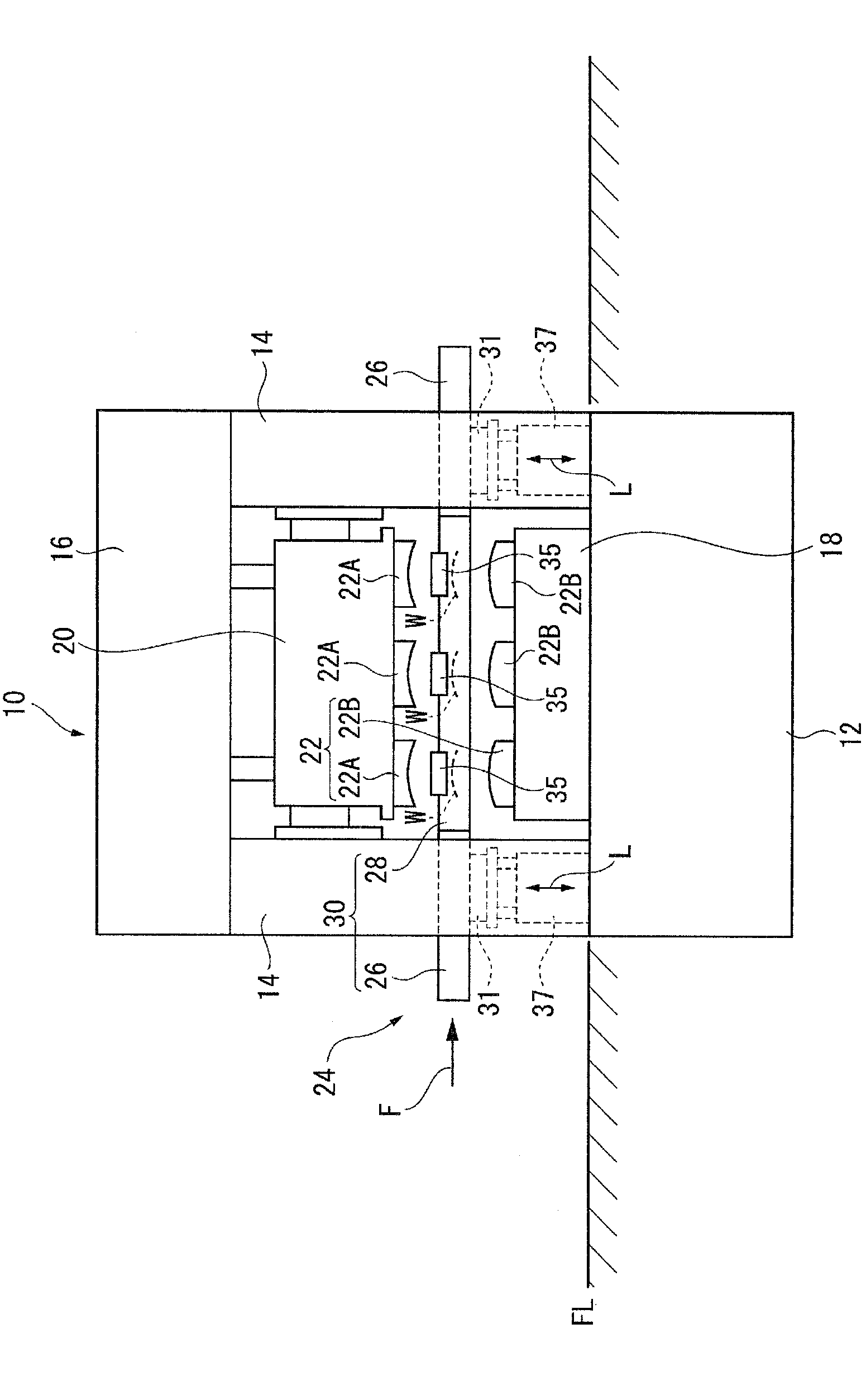

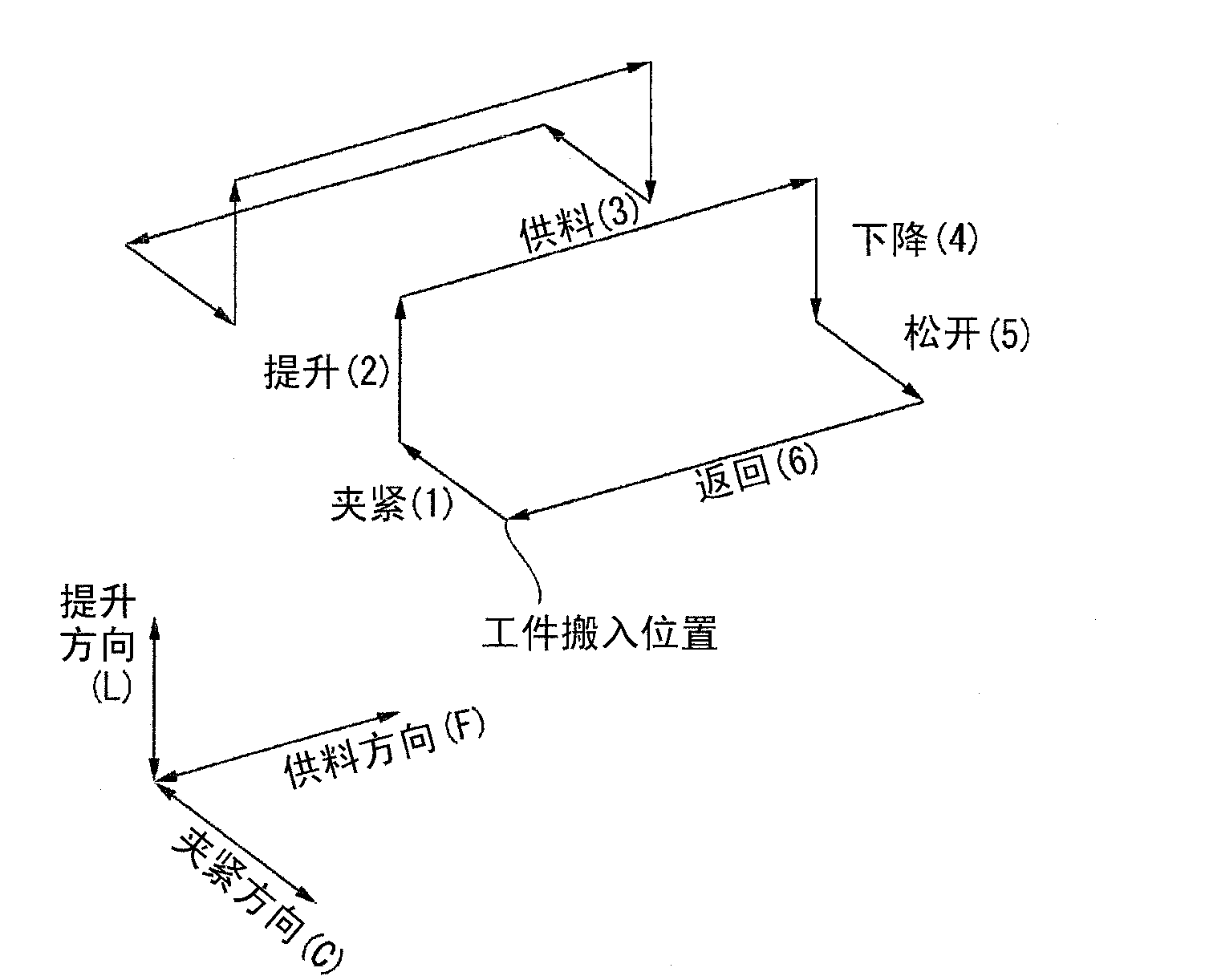

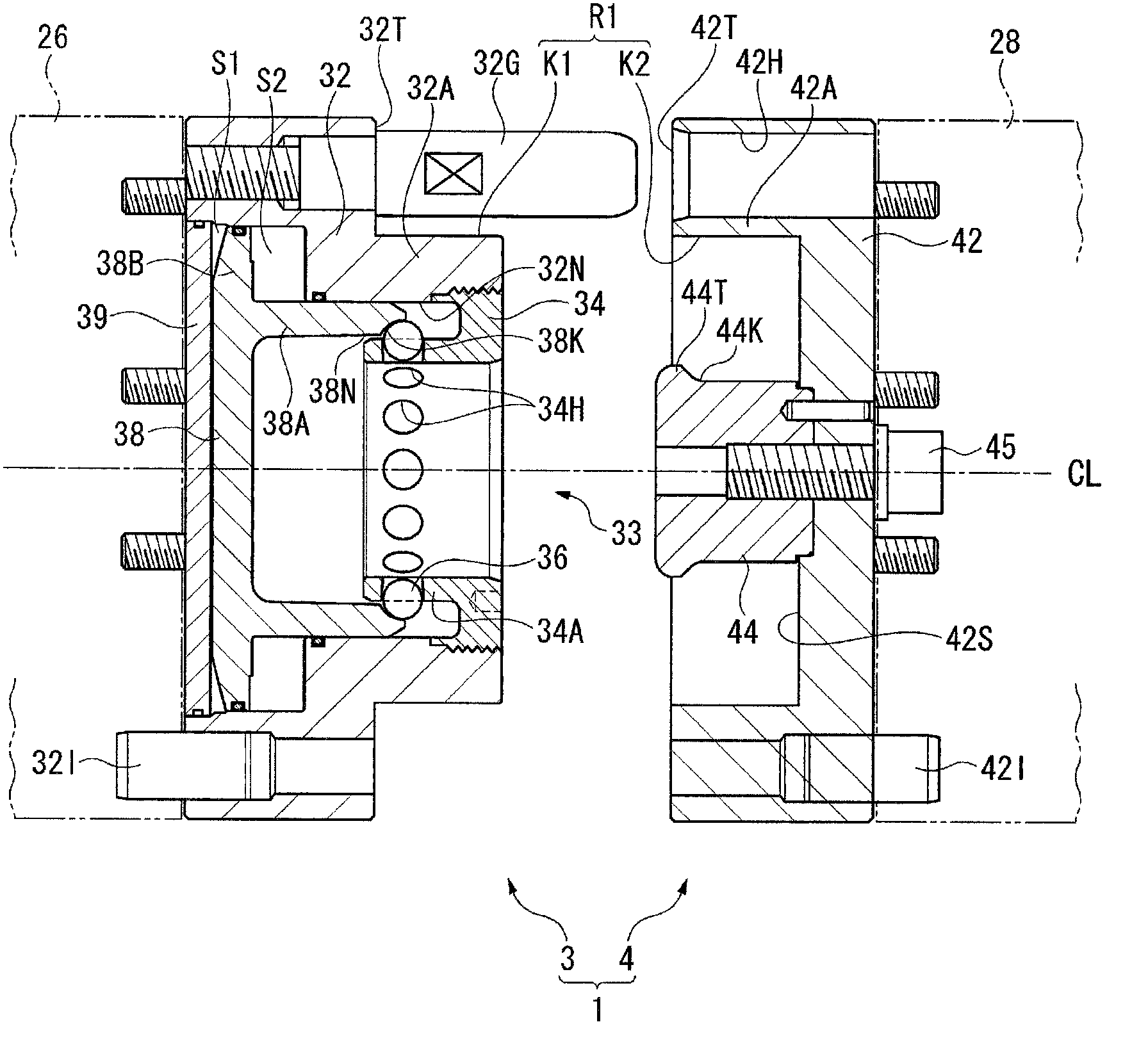

Transfer bar

ActiveCN102725081AImprove rigidityResistance to bending momentMetal-working feeding devicesPositioning devicesEngineeringMechanical engineering

Owner:KOMATSU LTD +2

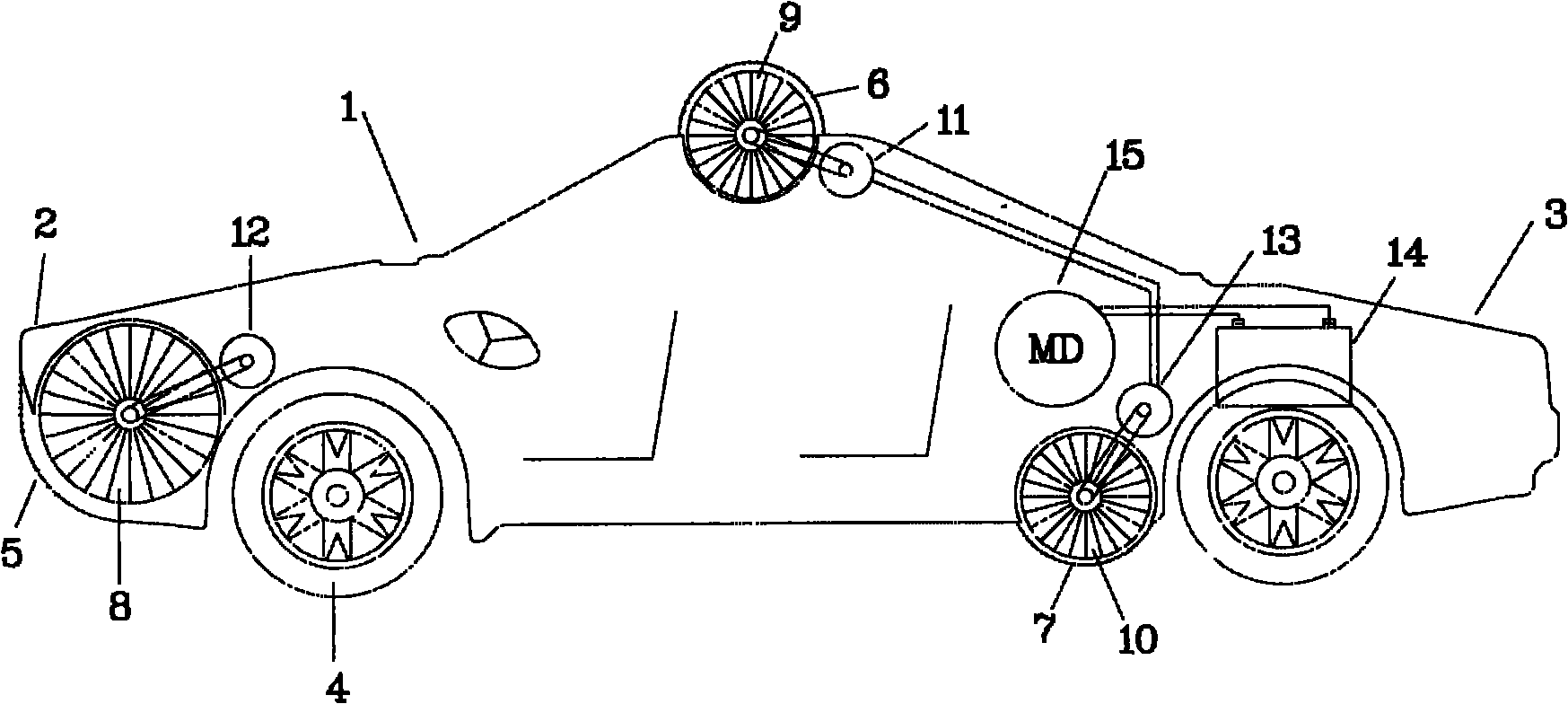

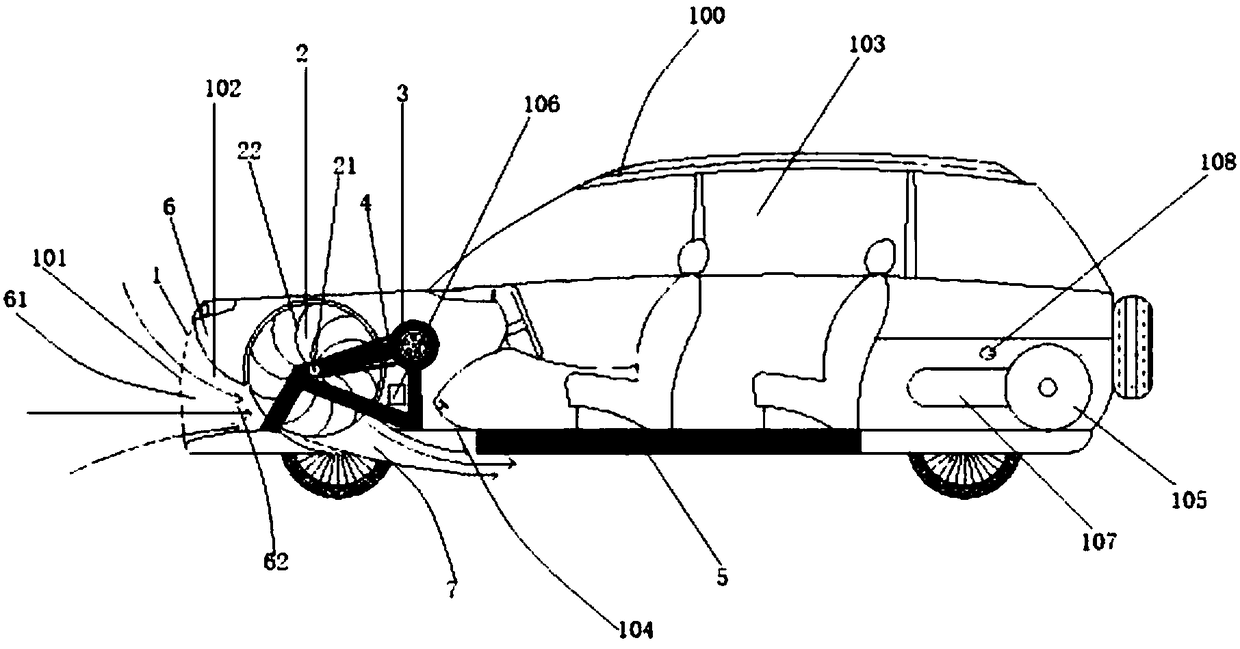

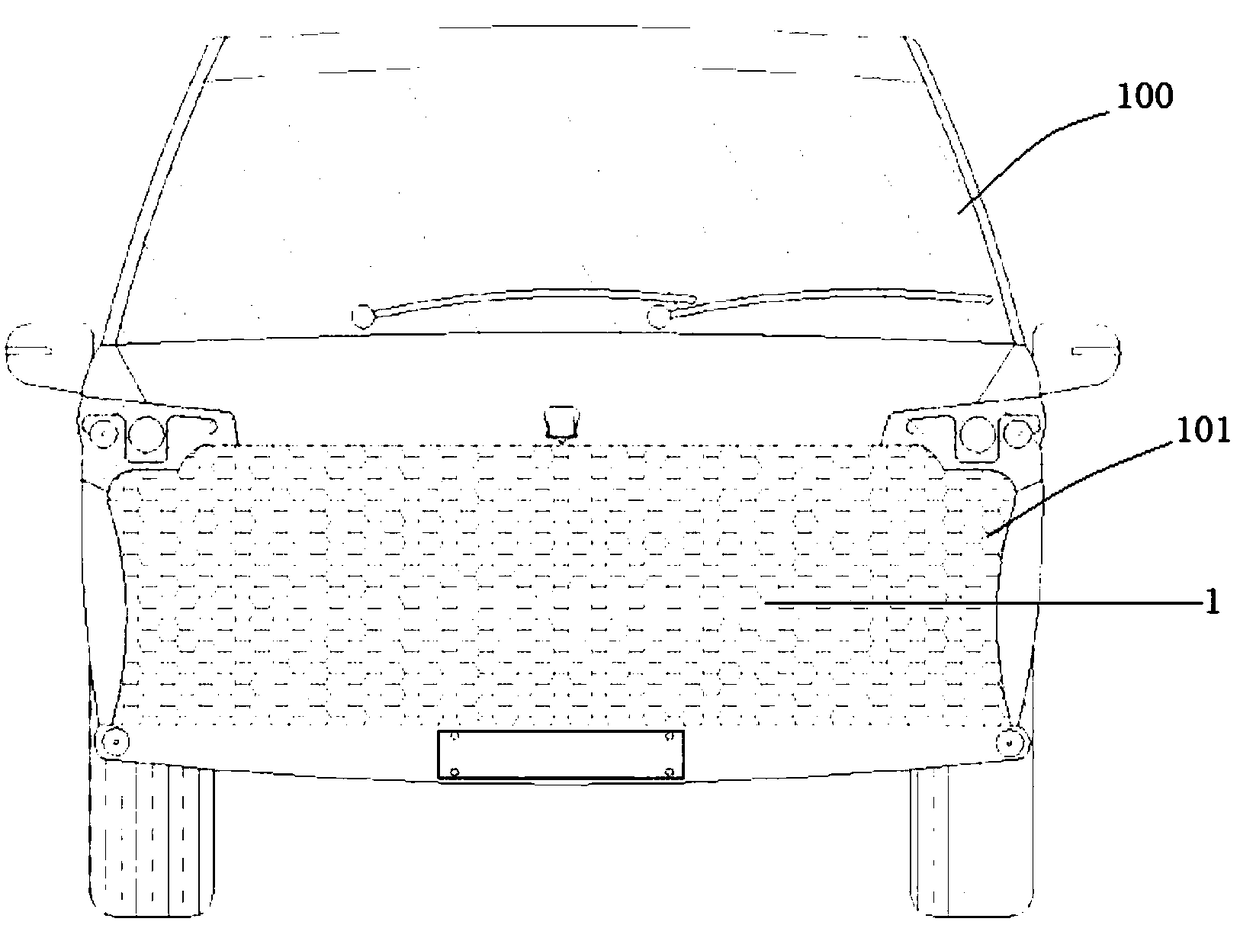

Wind power traveling electric automobile

InactiveCN108482132AReduce wind resistanceAchieve energy saving effectCharging stationsElectric vehicle charging technologyPower batteryElectric machine

The invention relates to a wind power traveling electric automobile. The automobile comprises a large air inlet formed in an air-inlet grille of the electric automobile, a wind wheel erected in a front cabin of the electric automobile, corresponding to the large air inlet and comprising a shaft rod and multiple fan blades arranged on the outer wall of the shaft rod in a surrounding mode, an electric generator erected in an engine compartment close to one side of a cab, and a storage battery arranged on an electric automobile chassis, wherein the power input end of the electric generator is sleeved with a transmission belt, and one end of the shaft rod is sleeved with the other end of the transmission belt; and the input end of the storage battery is electrically connected with the output end of the electric generator, and the output end of the storage battery is electrically connected with a power motor in the electric automobile. The electric automobile uses air from the large air inlet for driving the wind wheel to generate power, electric energy is stored in the storage battery to be used by the power battery, the large air inlet is ingeniously used for reducing the wind drag inthe vehicle traveling process, an energy saving effect is achieved, and the electric automobile basically can infinitely cruise when traveling on an expressway at the speed of over 60 miles per hour.

Owner:陈自平

Petroleum mixing and conveying pump

InactiveCN106968960AReduce flow viscosityHigh speed driveSpecific fluid pumpsPump componentsImpellerEngineering

The invention relates to a petroleum mixing and conveying pump. The pump casing body is divided into an inflow cavity and a driving cavity; the constricted end of the inflow cavity is provided with a feeding port; A pressure impeller with a conical table structure is rotatably connected to the tail, and the pressure impeller includes a support block. A number of driving blades coplanar with the axis of the support block are arranged in an array on the support block. A plurality of discharge nozzles are arranged in an annular array on the inner wall of the inflow cavity corresponding to the distribution plate. A centrifugal impeller is rotatably connected in the driving cavity. The centrifugal impeller includes a rotating block. The annular array is provided with a number of centrifugal blades on the rotating block. The centrifugal impeller The support block and the rotating block of the pressure impeller are coaxially rotated and fixed, and a number of inflow nozzles are arranged in an annular array on the inner wall of the driving cavity. The inner wall is provided with a liquid inlet, and a liquid discharge port is provided at the end of the axis of the drive cavity.

Owner:YANCHENG JINRUI PETROLEUM MACHINERY CO LTD

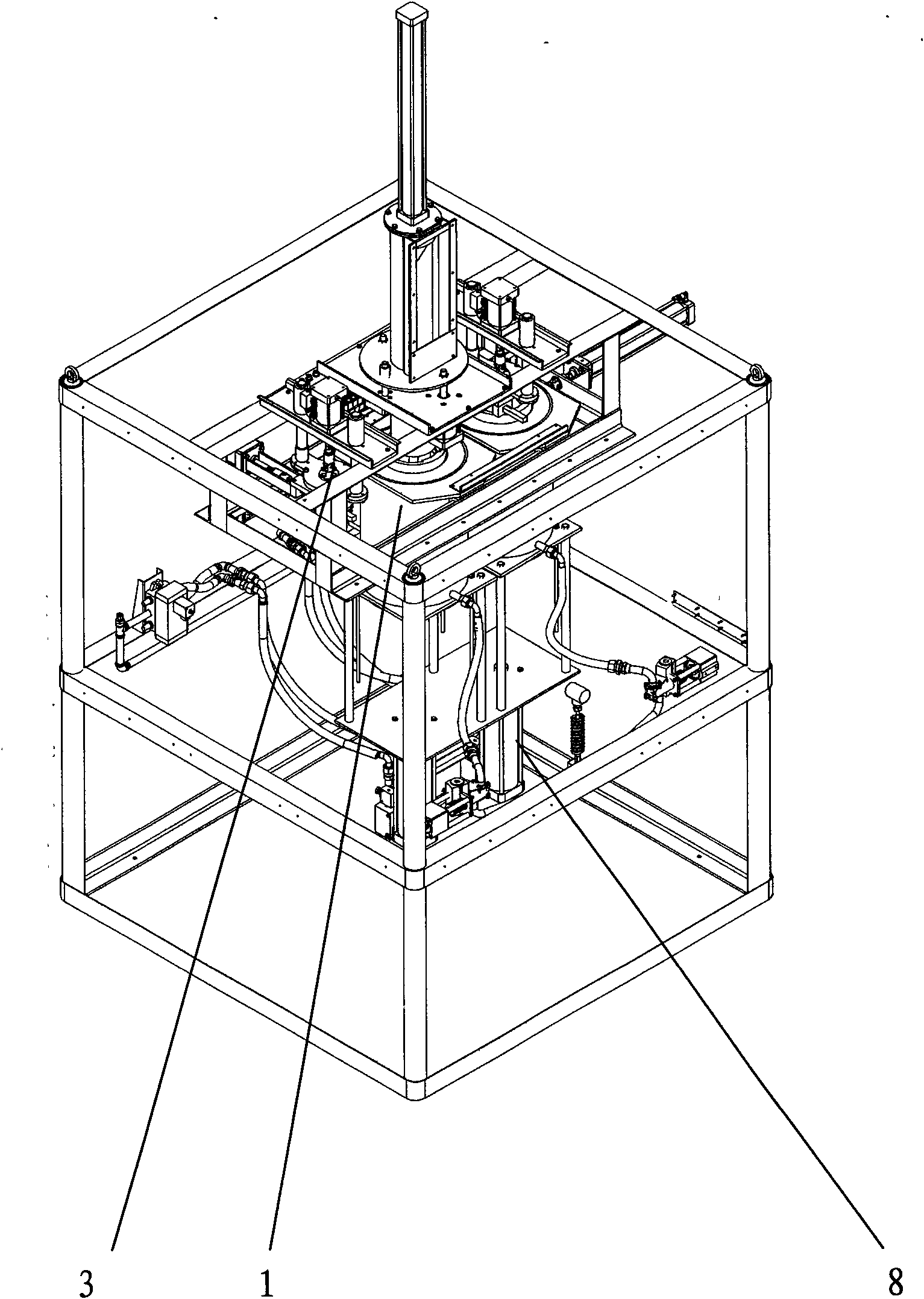

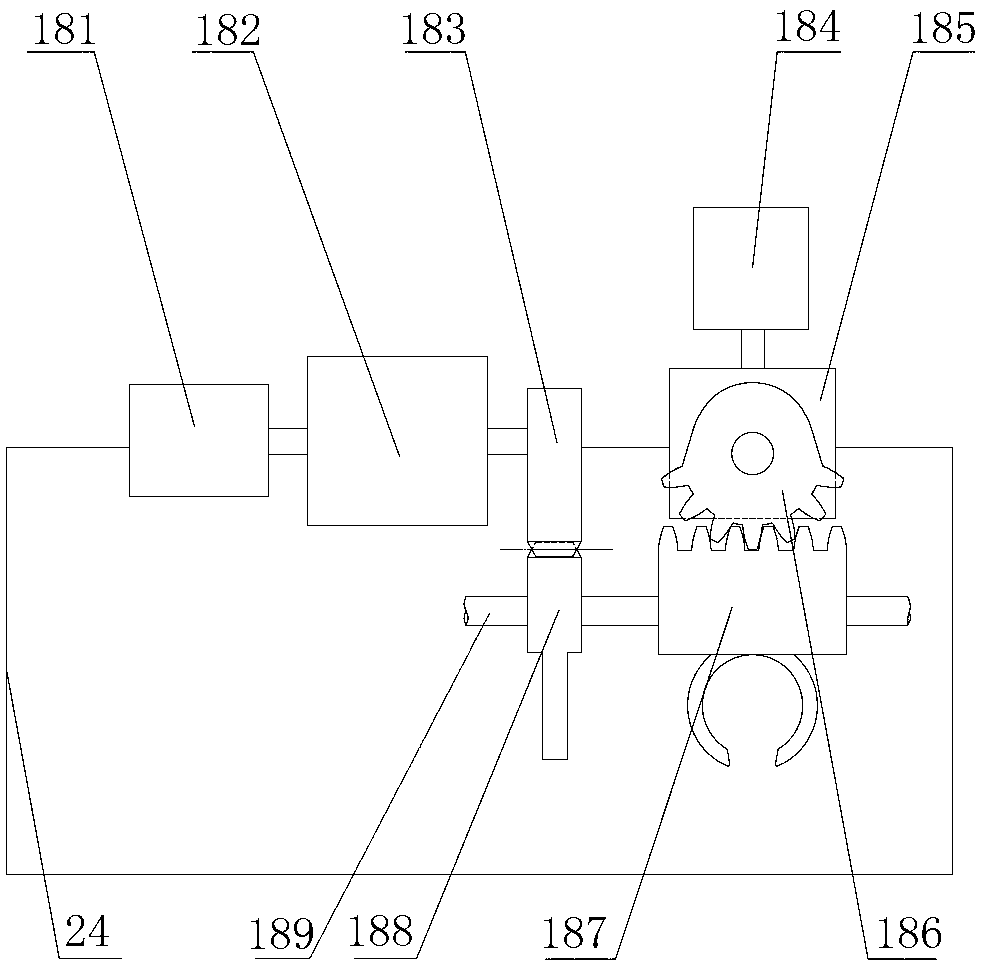

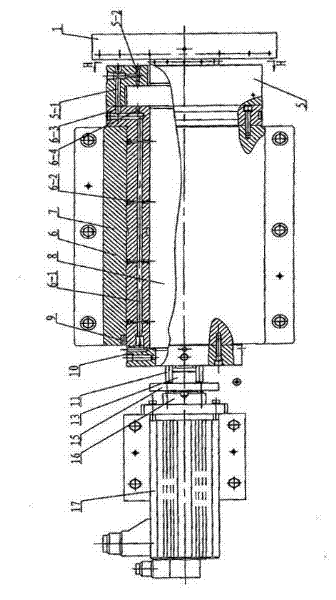

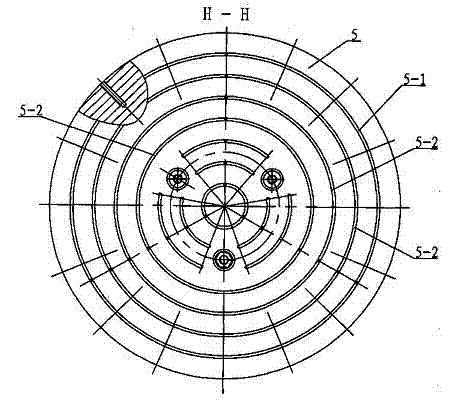

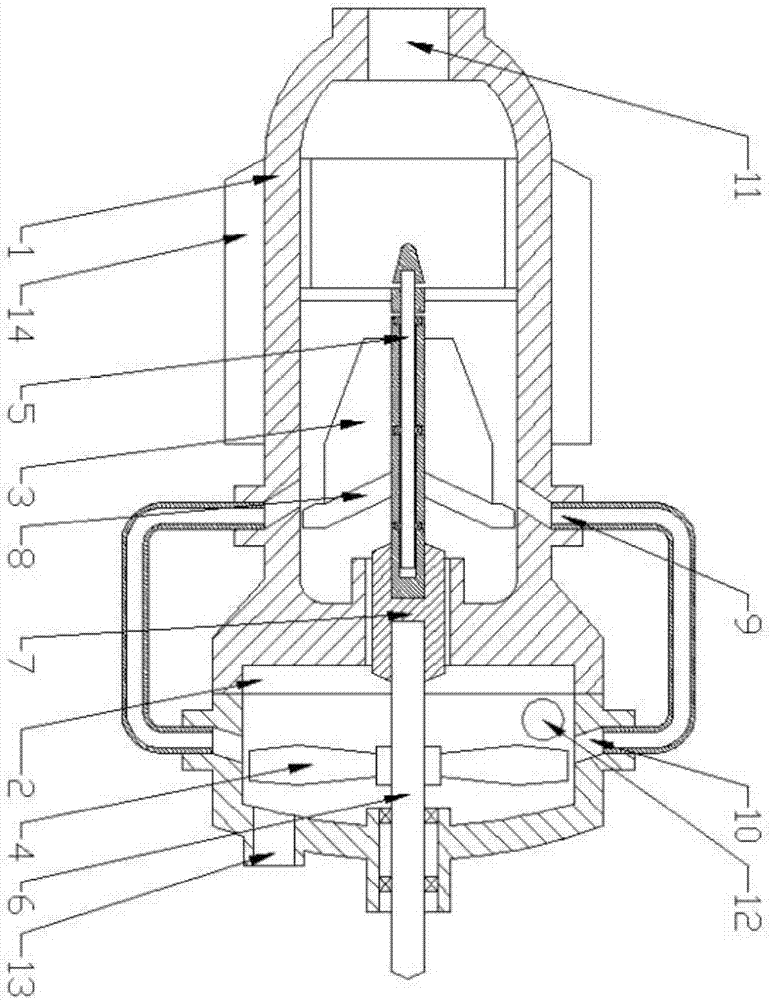

Instantaneous ejection steam explosion machine

ActiveCN105642188BAchieving suddennessGuarantee the same effect of steam explosionPressurized chemical processProcess scaleTime extension

The invention relates to production equipment for steam explosion treatment of micropore structure substances, and the equipment is key treatment equipment of biomass utilization, biochemical engineering, fermentation brewing, solid waste treatment and other industries. The invention provides an instantaneous ejection type steam explosion machine utilizing the steam ejection principle to complete the steam explosion process. Opening of an explosion channel of the steam explosion machine utilizes the steam ejection pressure generated by section difference, thus overcoming the problem of prolonged deflation time along with treatment volume increase in traditional hot blow process. With the increase of the cylinder volume, the section difference also increases accordingly, so that the cylinder ejection velocity can maintain consistent, thus laying the foundation for process scale-up.

Owner:中集竹链科技有限公司

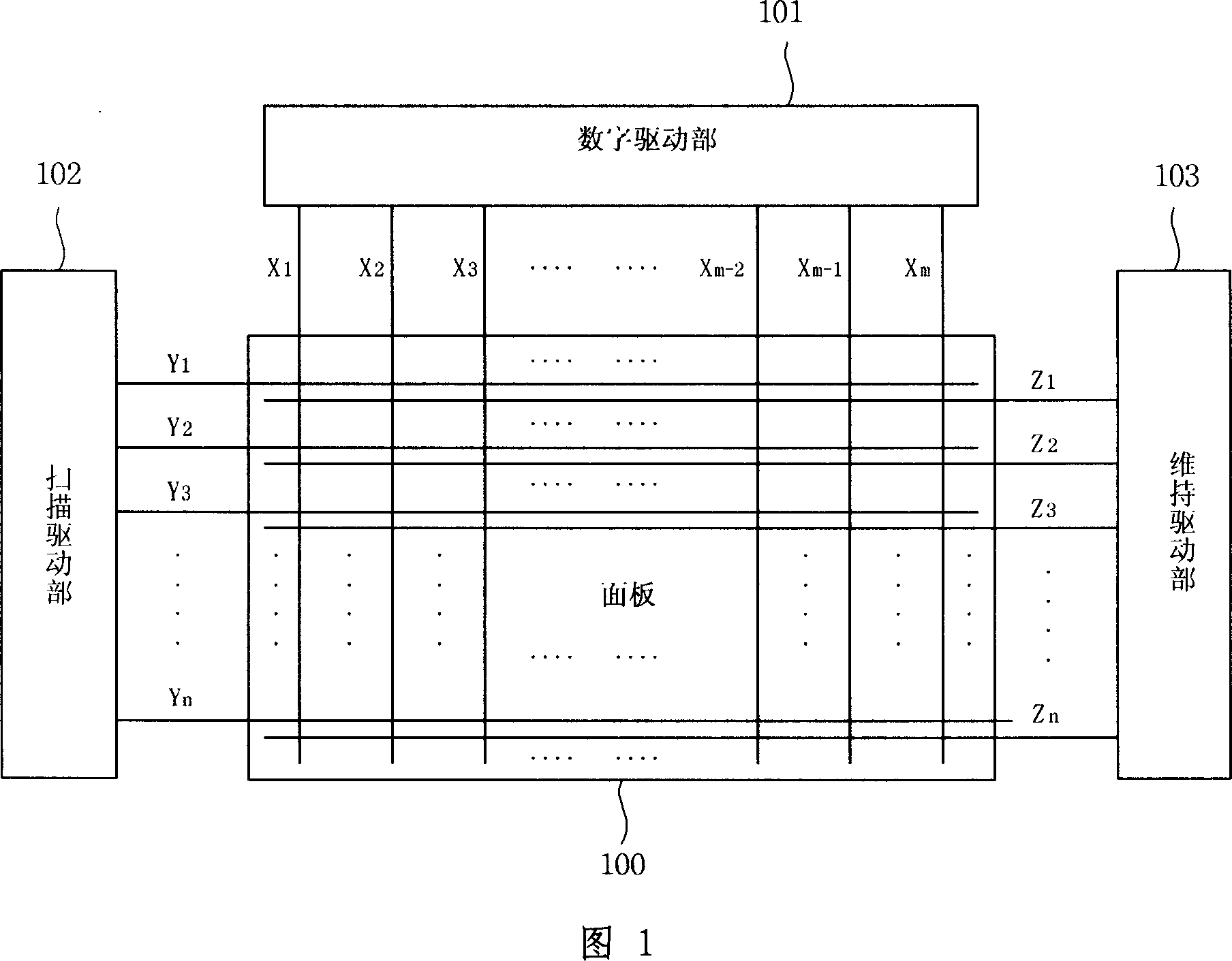

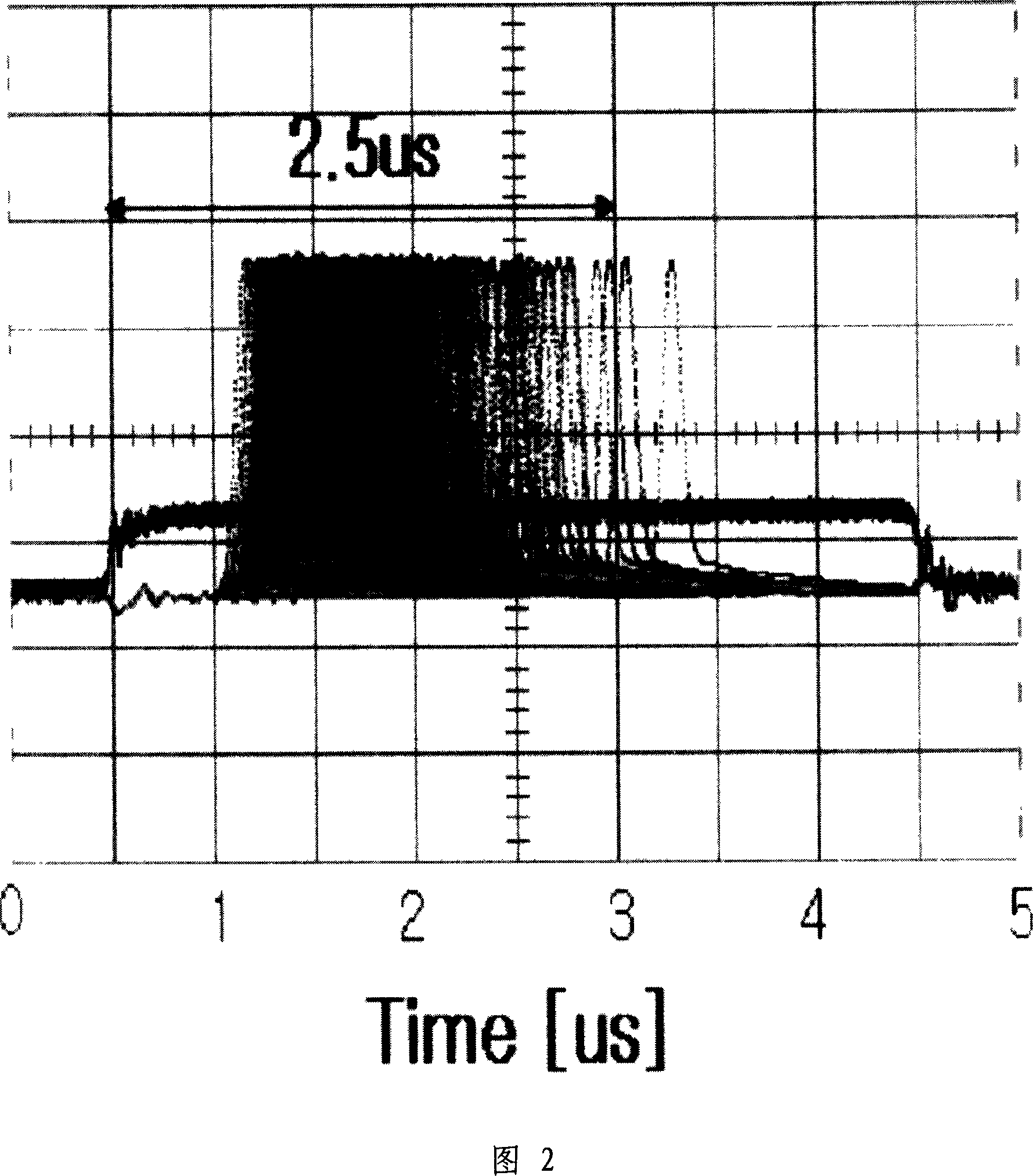

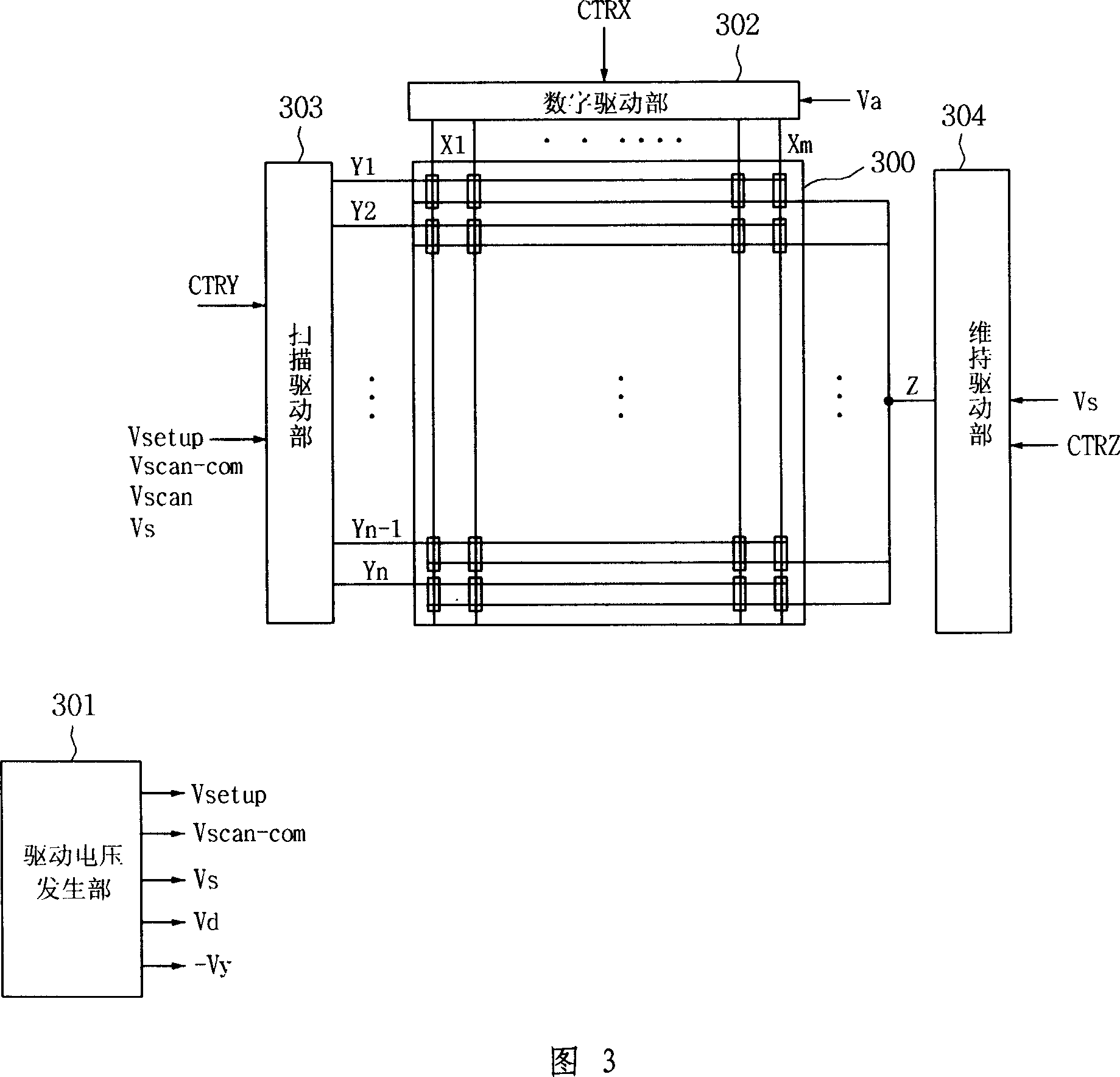

Plasma display device and its driving method

InactiveCN1975839AEnsure wall chargePrevent misdischargeStatic indicating devicesCold-cathode tubesPulse controlDisplay device

The present invention relates to a plasma display device, and more specifically, relates to a plasma display device and a driving method thereof for adjusting a positive waveform voltage negatively applied to a sustain electrode, improving discharge accuracy, and improving jitter characteristics . As described above, the plasma display device in the present invention includes: a plasma display panel including sustain electrodes; a sustain drive unit that drives the sustain electrodes; and controls the sustain drive unit so that subfields (frame) During the falling edge period of sub-field) and the positioning period or during any one of the positioning periods, the positive polarity waveform voltage applied to the above-mentioned sustain electrode is changed from the first voltage level to the second voltage level with a certain gradient. The drive pulse control unit.

Owner:LG ELECTRONICS(NANJING) PLASMA CO LTD

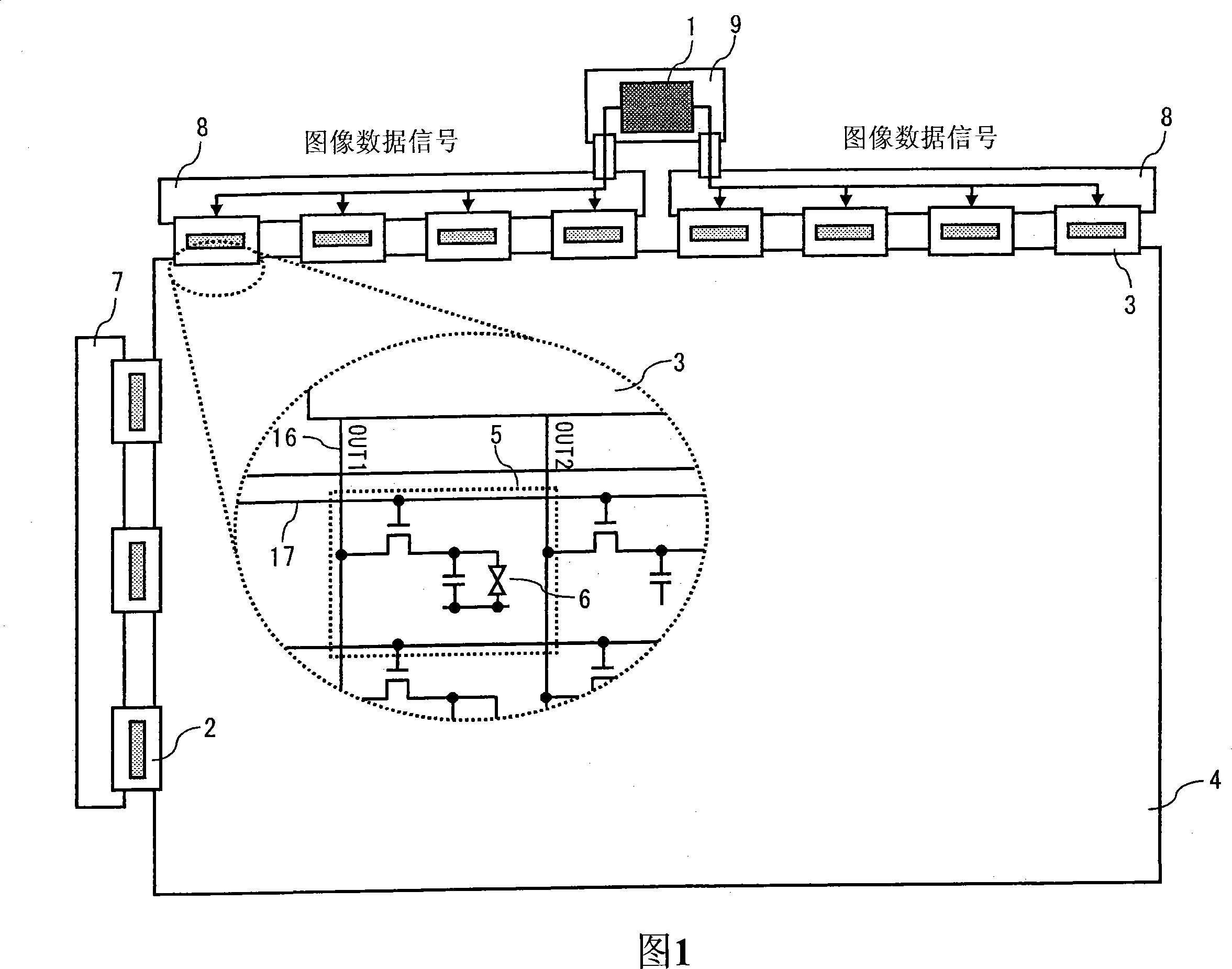

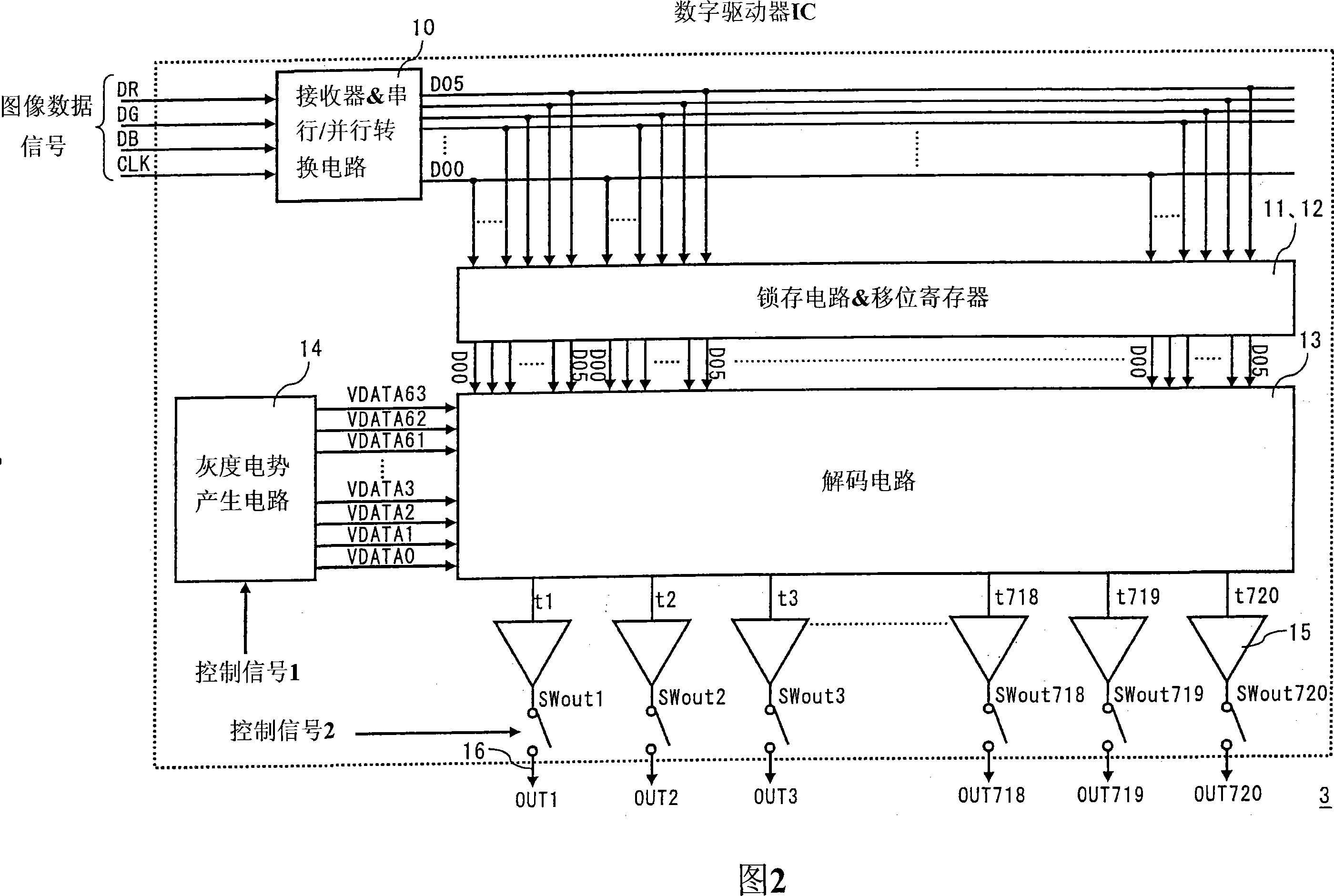

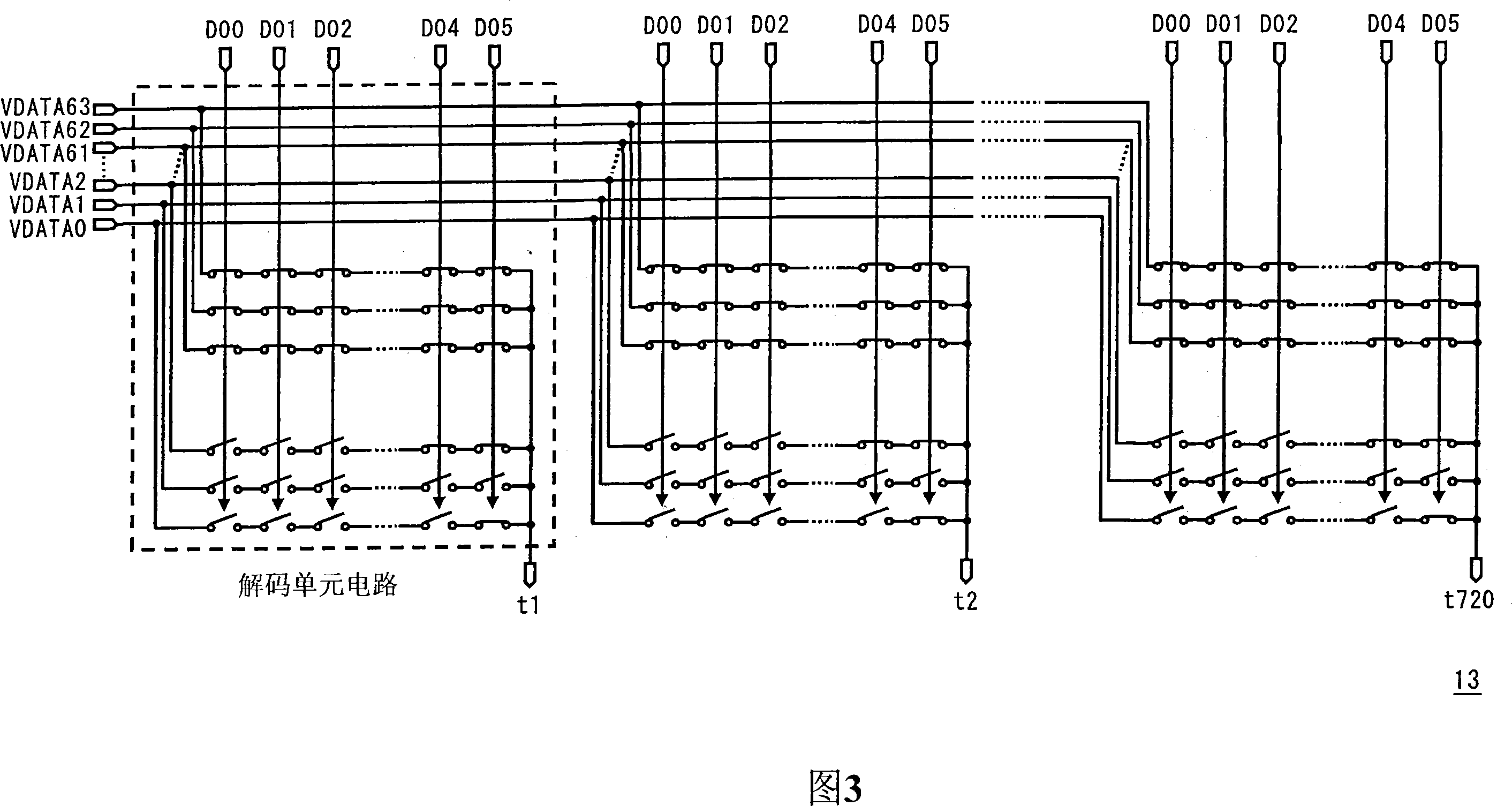

Gradation potential generation circuit, data driver of display device and the display device

InactiveCN101226723AReduce areaEasy to driveStatic indicating devicesElectrical resistance and conductanceControl signal

The invention relates to a gray scale potential generating circuit, a data driver and a display device of a display device. The gray-scale potential generating circuit includes: a first gradient resistance circuit, the first and second reference voltages are provided at both ends thereof to generate j gray-scale potentials (j is an integer of 2 or greater) and the generated The j grayscale potentials of are output to j first nodes, wherein the j grayscale potentials are generated by dividing the first and second reference voltages; the second gradient resistance circuit is generated from the j grayscale potentials generated by the first gradient resistance circuit k gray-scale potentials (where j>k) are generated in the potentials, and k switches, according to the first control signal, the k gray-scale potentials generated by the second gradient resistance circuit are provided to k of the j first nodes the first node.

Owner:RENESAS ELECTRONICS CORP

Plasma display panel

InactiveCN1691254AImprove luminous efficiencyPrevent image agingSustain/scan electrodesGas discharge vessels/containersFluorescencePhosphor

Owner:SAMSUNG SDI CO LTD

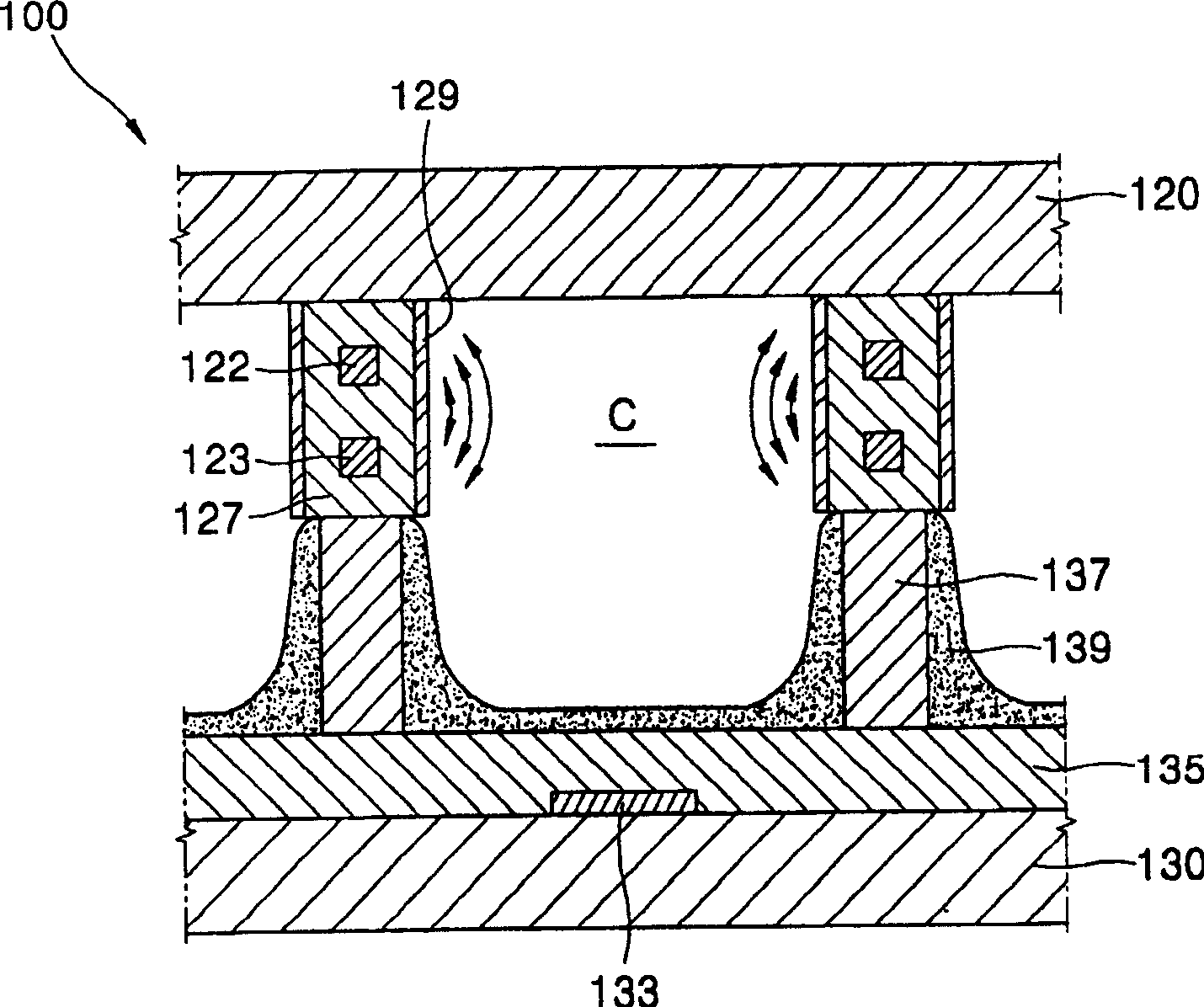

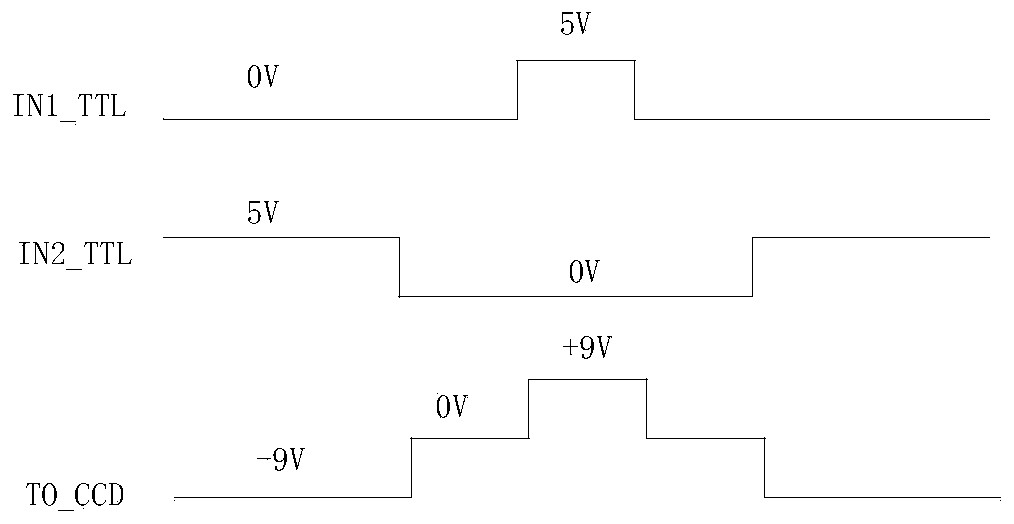

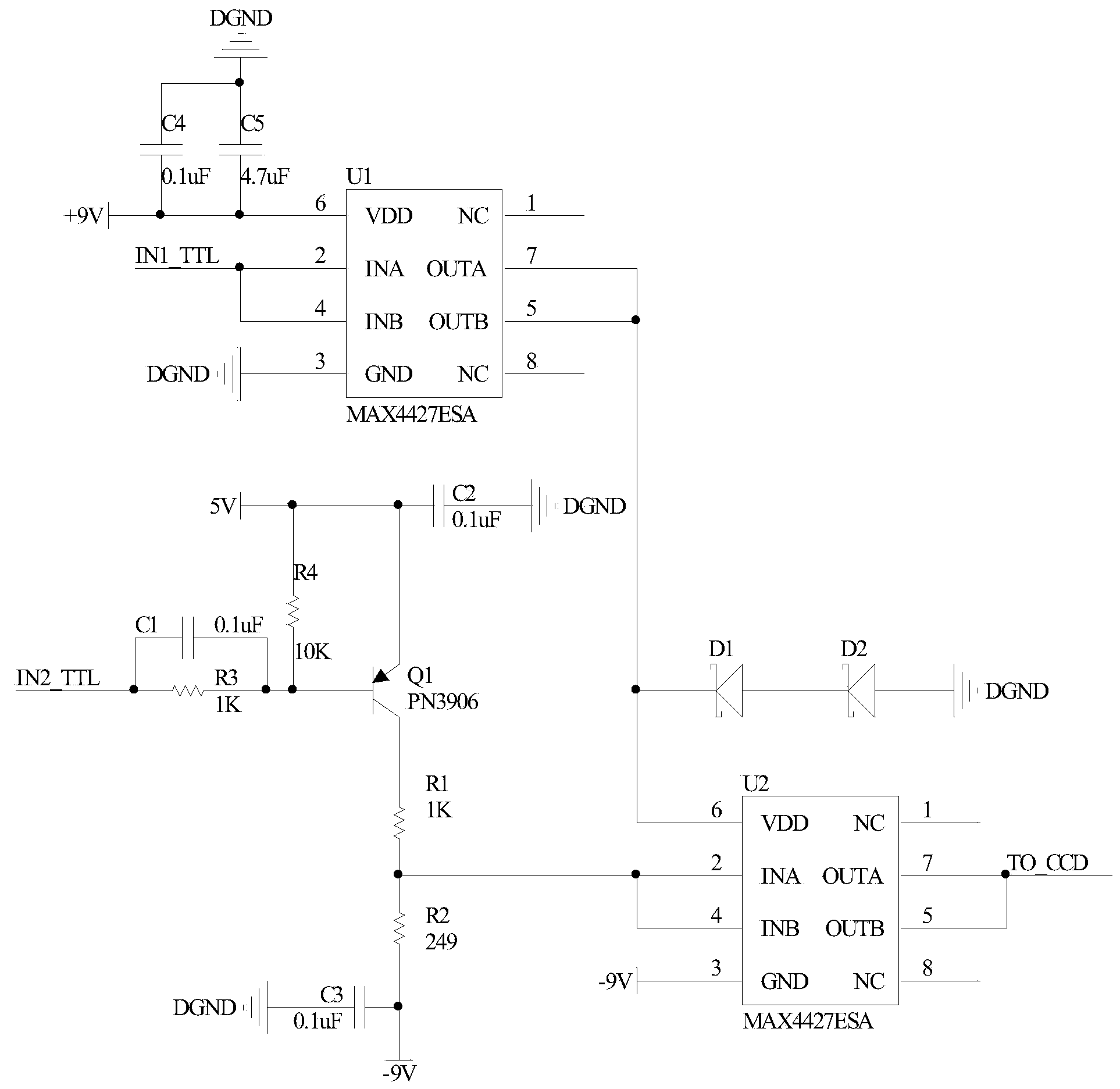

Special three-level drive circuit for CCD

InactiveCN103546142AAmplitude stableMeet high-speed driveLogic circuits coupling/interface using field-effect transistorsImage sensorEngineering

The invention provides a special three-level drive circuit for a CCD. The special three-level drive circuit for the CCD solves the problem that an existing three-level signal drive design scheme of a CCD image sensor is complex. The drive circuit comprises a first driver, a second driver and a triode. Both the first driver and the second driver comprise VDD ends, GND ends, signal input ends and signal output ends. The drive circuit is provided with two input ends and one output end. The two input ends of the drive circuit are the first input end and the second input end respectively. The first input end is connected with the signal input end of the first driver, and the second input end is connected with the base electrode of the triode. The signal output end of the second driver serves as the output end of the drive circuit. The special three-level drive circuit for the CCD can generate CCD sensor three-level signals of which the amplitude is stable.

Owner:XI'AN INST OF OPTICS & FINE MECHANICS - CHINESE ACAD OF SCI

Low power consumption, large flow, high-speed on-off valve

ActiveCN105114386BSmall overcurrent pressure lossReduce power consumptionServomotor componentsRotary valveEngineering

The invention discloses a low-power-consumption and large-flow high-speed switching valve. The switching valve is of a rotary valve structure. Rotation of a valve element of the switching valve is controlled by a differential swinging cylinder. The rotating direction of the differential swinging cylinder is controlled through a two-position four-way high-speed switching valve body. Three through flow passages are formed in the valve element in the radial direction and sequentially distributed in the axial direction, and the distances between the center lines of the adjacent flow passages in the axial direction are equal. The passage area of the middle flow passage is twice the passage areas of the two end flow passages, and the passage areas of the two end flow passages are equal. The flowing direction of oil in the middle flow passage is opposite to the flowing direction of oil in the two end flow passages. Inlets and outlets of the three flow passages are communicated respectively. When the high-speed switching valve body is in the totally-opening state, the flow passages are in a through pipe type, the passage pressure losses of a valve opening are small, and low-power-consumption and large-flow flowing of oil can be achieved.

Owner:OCEAN RES CENT OF ZHOUSHAN ZHEJIANG UNIV

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com