Transfer bar

一种传动杆、移动杆的技术,应用在传动杆领域,能够解决传动杆高速驱动化障碍、无法对抗弯曲力矩、负载刚性低等问题,达到实现轻量化、润滑简单、平衡性良好的效果

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

no. 1 approach 〕

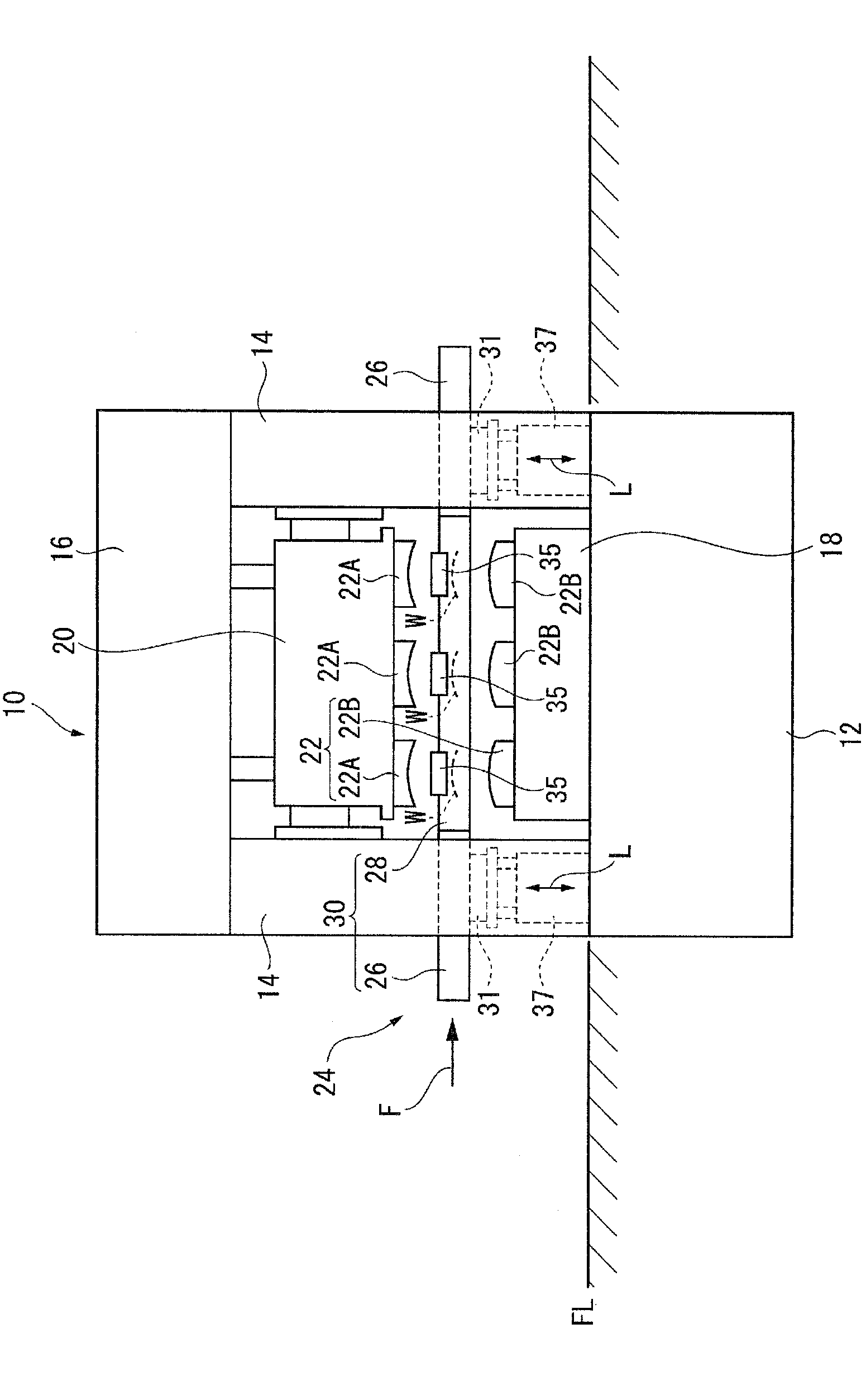

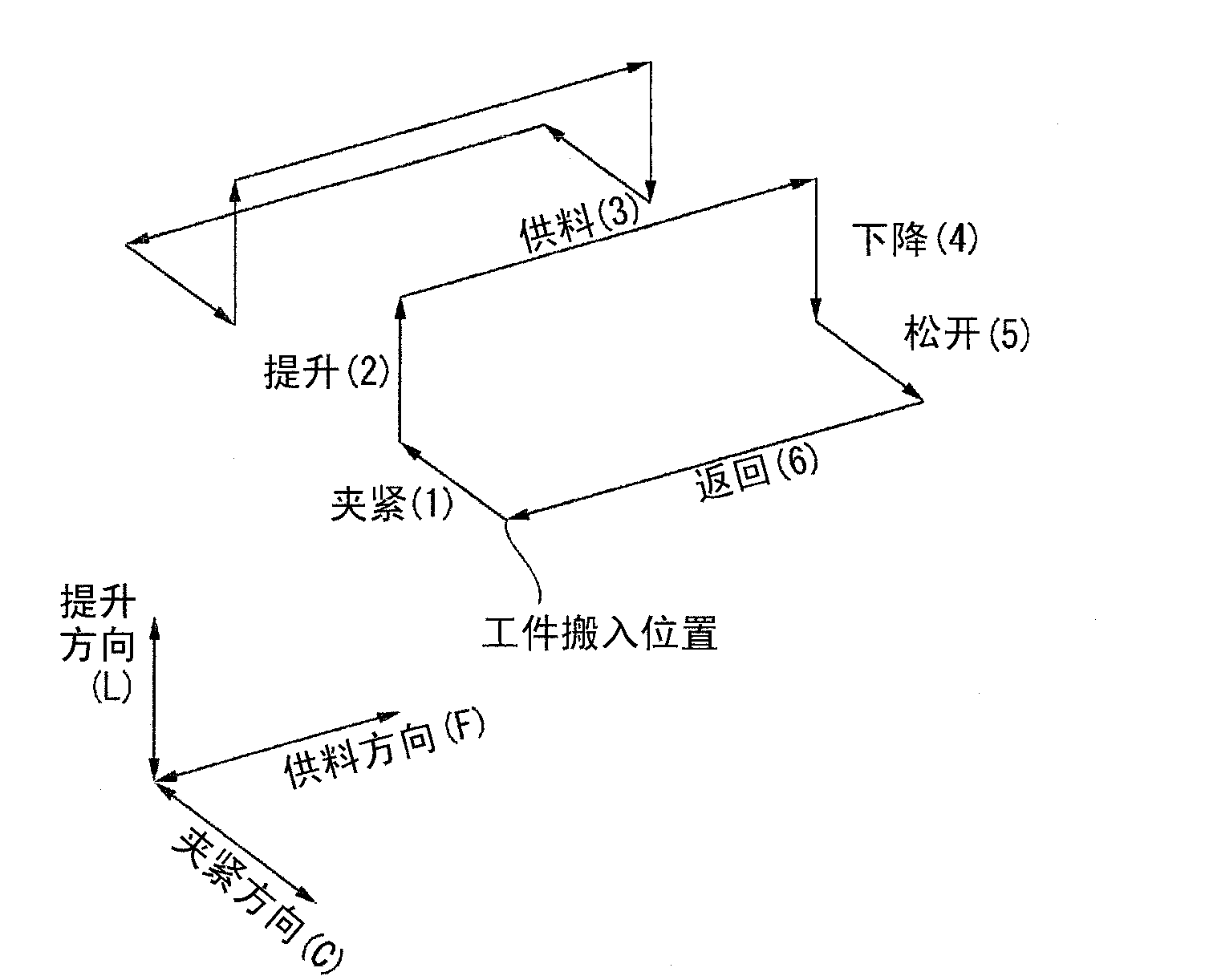

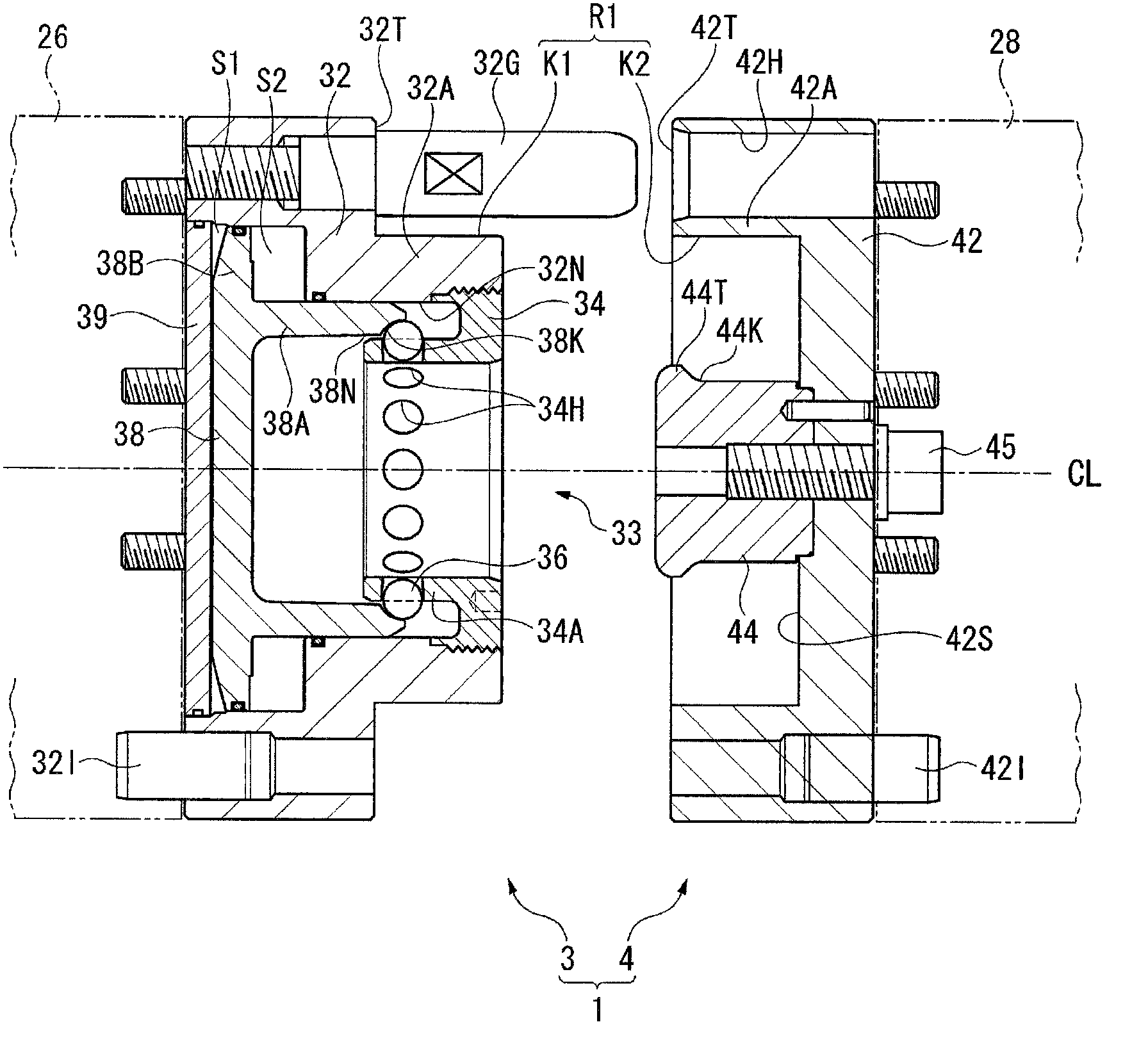

[0037] Hereinafter, the first embodiment of the present invention will be described in detail using the drawings. figure 1 A continuous automatic press machine 10 as a press machine is shown in a front view, and a machine tool 12 having a rectangular shape in plan view is buried under the floor FL. Columnar columns 14 are erected at four corners of the machine tool 12 in plan view. A beam 16 is supported on these four columns. A slider 20 is suspended from the beam 16 , and the slider 20 can be driven up and down by an appropriate drive mechanism inside the beam 16 . The press body of the continuous automatic press machine 10 is thus formed.

[0038] A movable workbench 18 is provided on the machine tool 12 . The movable table 18 can be smoothly carried out from the press main body to the outside or carried in from the outside along an appropriate guide mechanism such as rails. A lower mold 22B among the molds 22 for processing the workpiece W is mounted on the upper surfa...

no. 2 approach 〕

[0065] Image 6 The second embodiment of the present invention is shown. In the first embodiment, the male fitting portion K1 and the female fitting portion K2 of the first connection portion R1 are formed by planes parallel to the central axis CL, but in this embodiment, each is formed by a truncated conical cone. face formed. That is, the male fitting part K1 is formed as a frustum-shaped outer peripheral tapered surface that decreases in diameter toward the tip in the fitting direction (same as the connecting direction), and the female fitting part K2 is formed as a tapered surface on the outer peripheral side that decreases in diameter toward the fitting direction. The tapered surface on the inner peripheral side of the truncated conical shape that expands at the front end.

[0066] According to such a second embodiment, there is an effect that the respective fitting portions K1 , K2 can be reliably brought into ground contact with each other over the entire circumferenc...

no. 3 approach 〕

[0068] Figure 7 The third embodiment of the present invention is shown. In the first embodiment, the ball 36 is used as the moving member of the present invention, but in this embodiment, the cylindrical roller 51 having a predetermined length is used. Therefore, on the holding member 34, instead of the inner cylindrical portion 34A described in the first embodiment, a square inner square tube portion 34C is provided, and each piece portion forming the inner square tube portion 34C is provided with a The through-holes 34H opened in a square shape each accommodate a roller 51 in each through-hole 34H.

[0069] On the other hand, in the plunger 38 , the front end side of the intermediate cylindrical portion 38A becomes the intermediate square cylindrical portion 38C. Furthermore, in the remaining side outer profile member 32, the inner peripheral shape of the outer cylindrical portion 32A is defined by the circular opening portion contacted by the outer peripheral surface of ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com