Patents

Literature

79results about How to "Simple lubrication" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

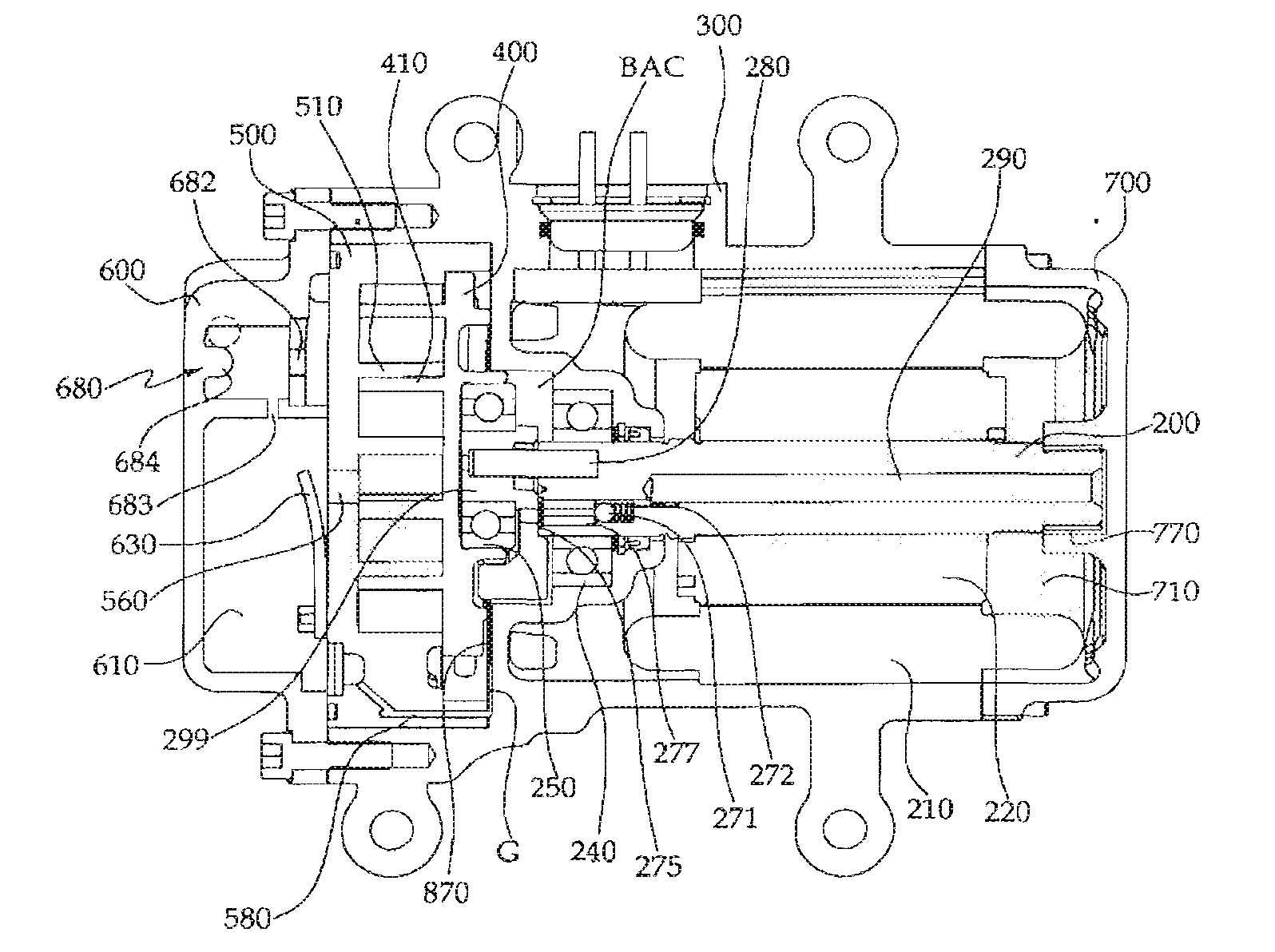

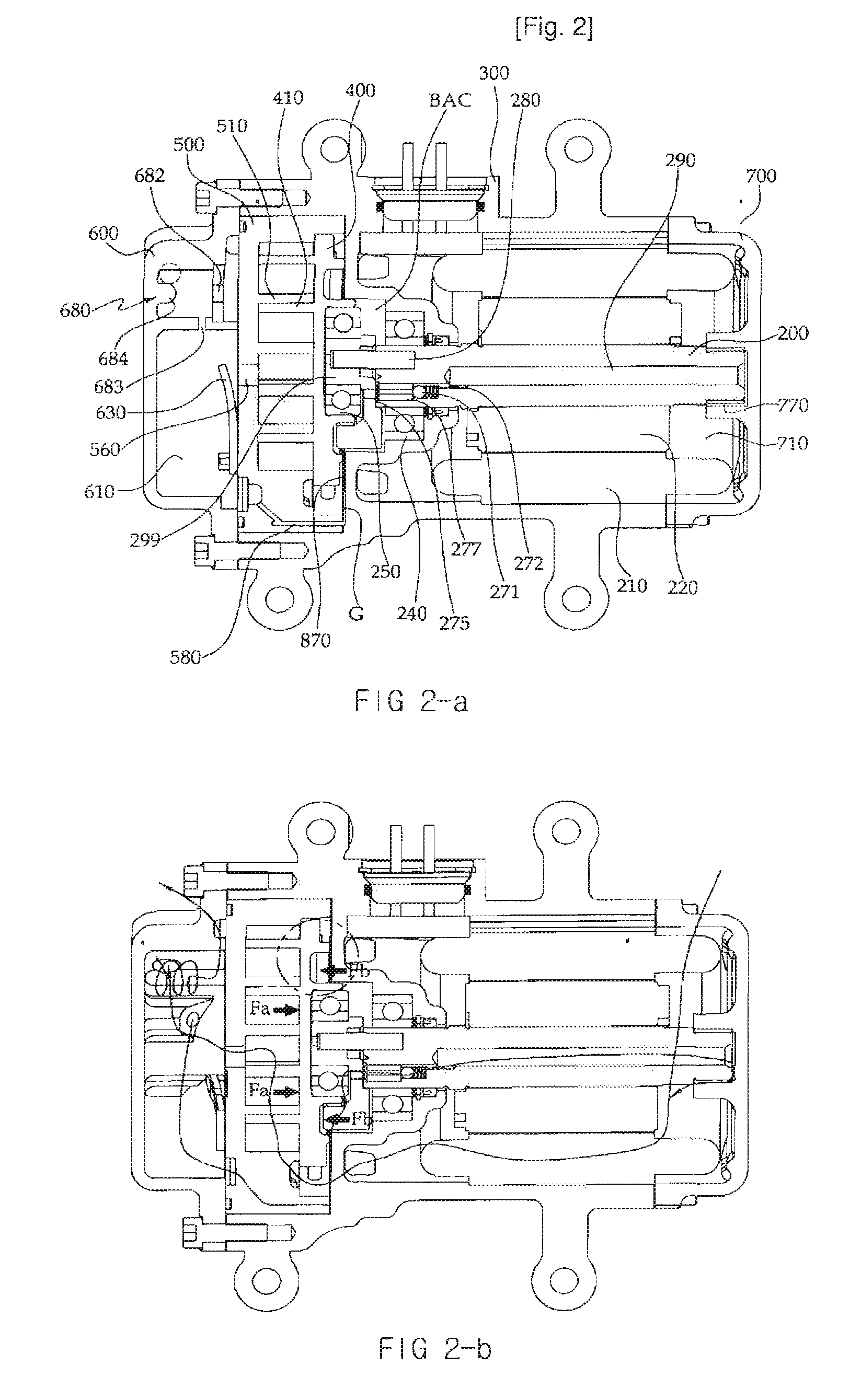

Scroll compressor improved in function of oil circulation and back pressure control

ActiveUS20090191081A1Function increaseSimple lubricationRotary/oscillating piston combinations for elastic fluidsEngine of arcuate-engagement typeDrive shaftEngineering

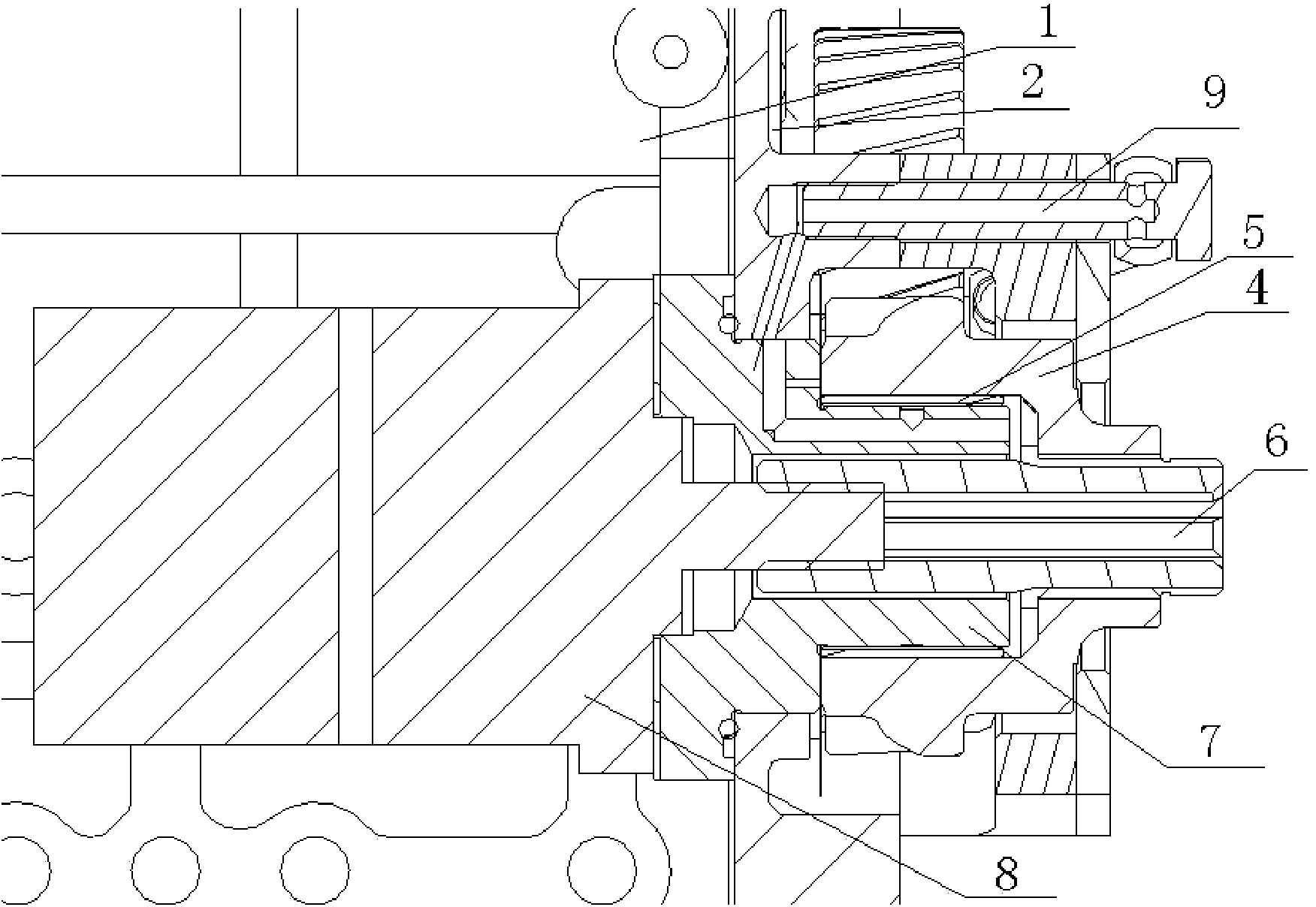

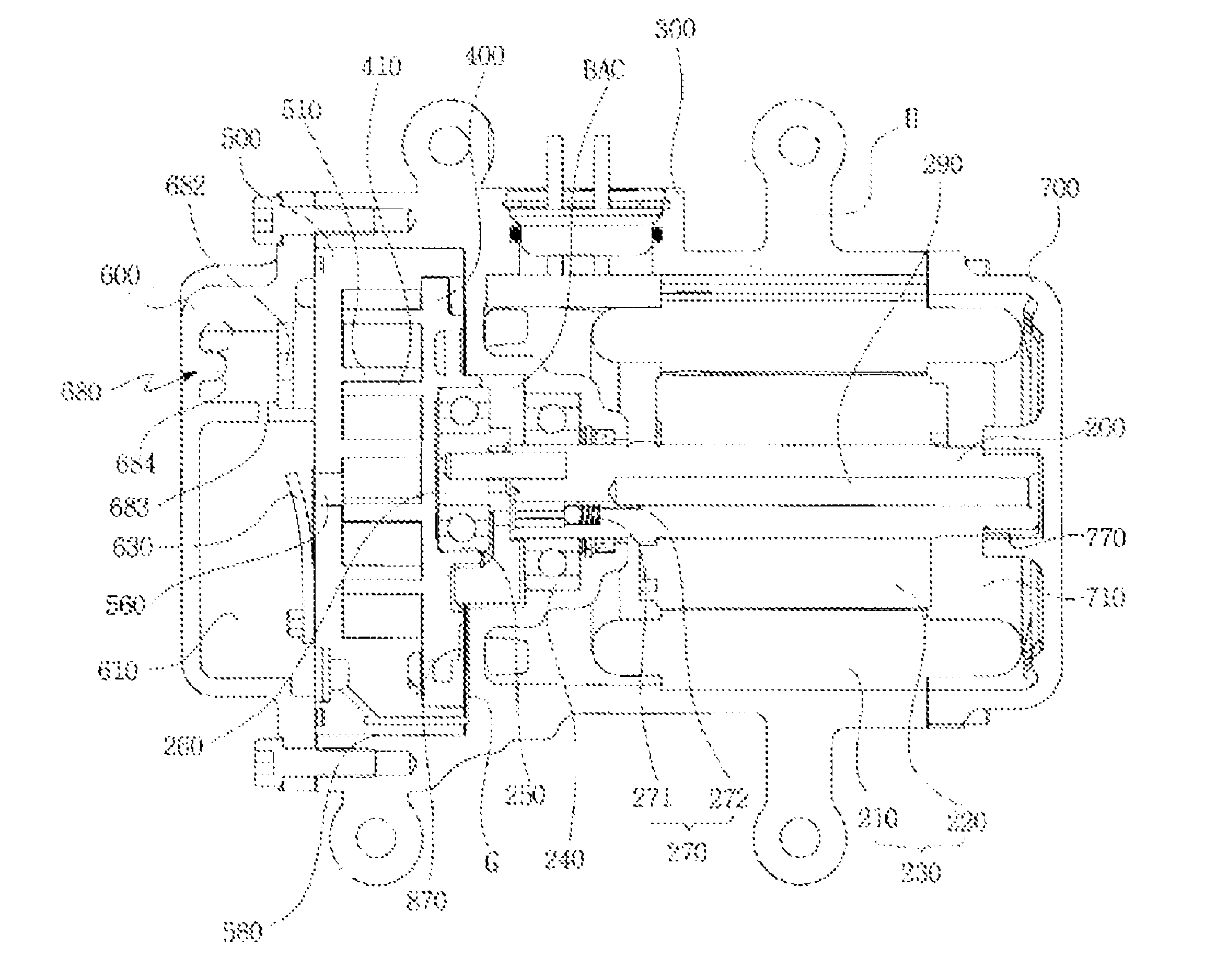

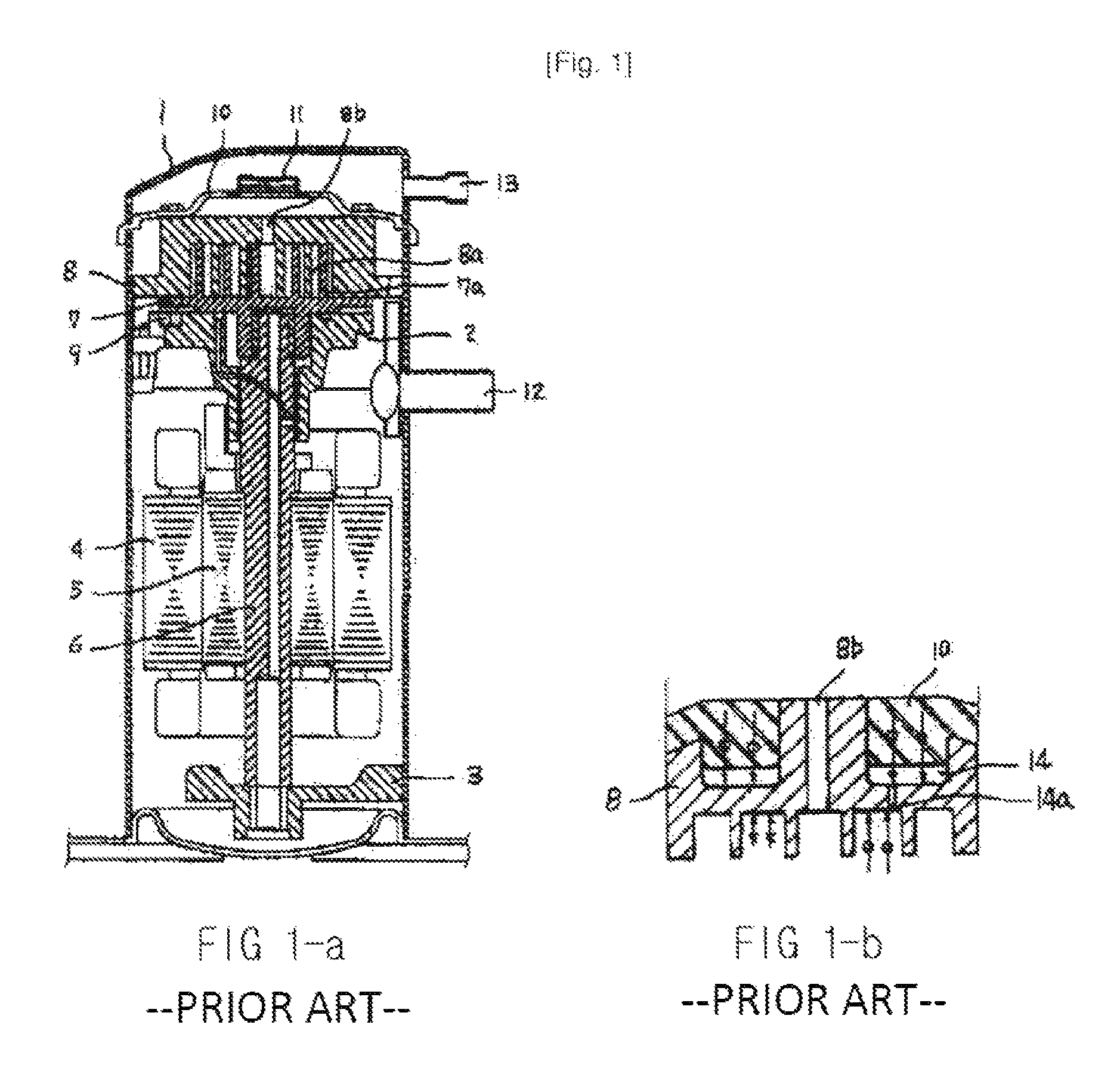

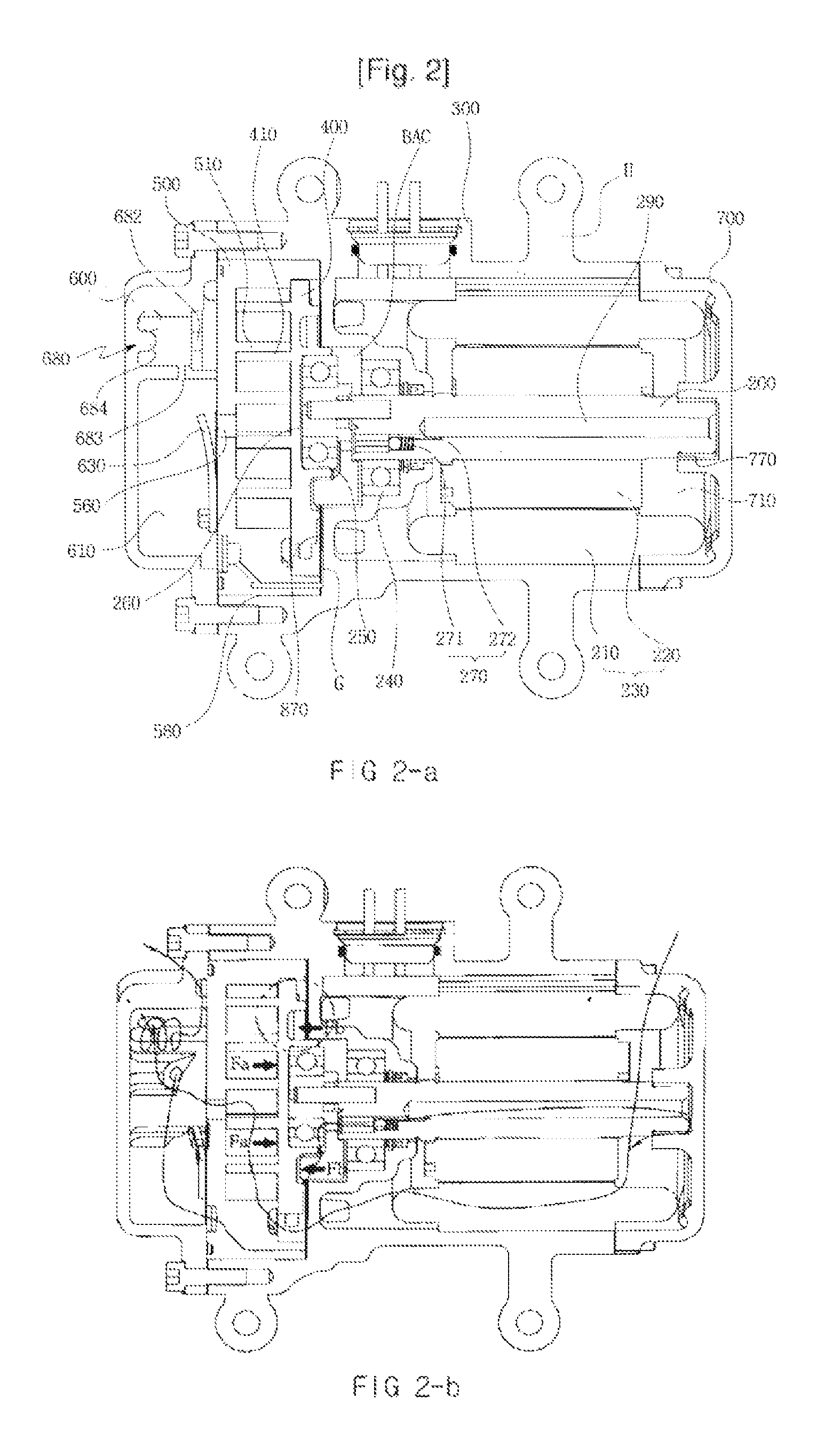

Provided is a scroll compressor having an improved function of oil circulation and back pressure control. The scroll compressor includes: a housing; a drive part for generating a rotational force; a drive shaft driven by the drive part; and a scroll compression part including a stationary scroll fixed regardless of rotation of the drive shaft and having a scroll wrap for compressing sucked fluid and a discharge port for supplying coolant into a discharge chamber, and an orbiting scroll orbited depending on rotation of the drive shaft and having a scroll wrap, characterized in that the coolant compressed by the scroll compression part is conveyed to the discharge chamber, the coolant of the discharge chamber is separated into oil and gas in an oil separator, the gas being discharged through a discharge hole and the oil being supplied into a back pressure chamber through a return path formed in the stationary scroll, and the oil is returned into a suction chamber through a back pressure adjustment valve.

Owner:DOOWON TECHN COLLEGE +1

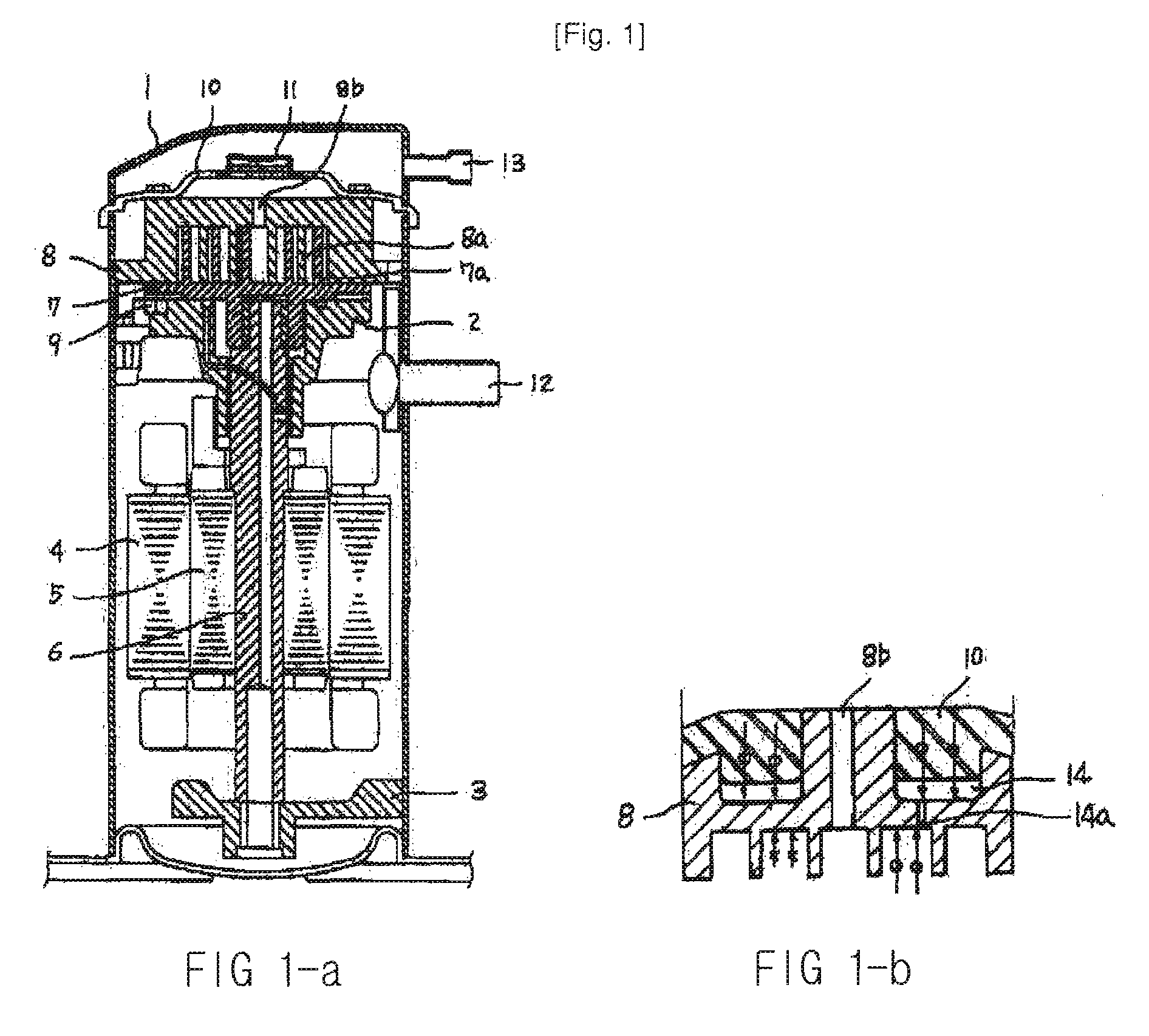

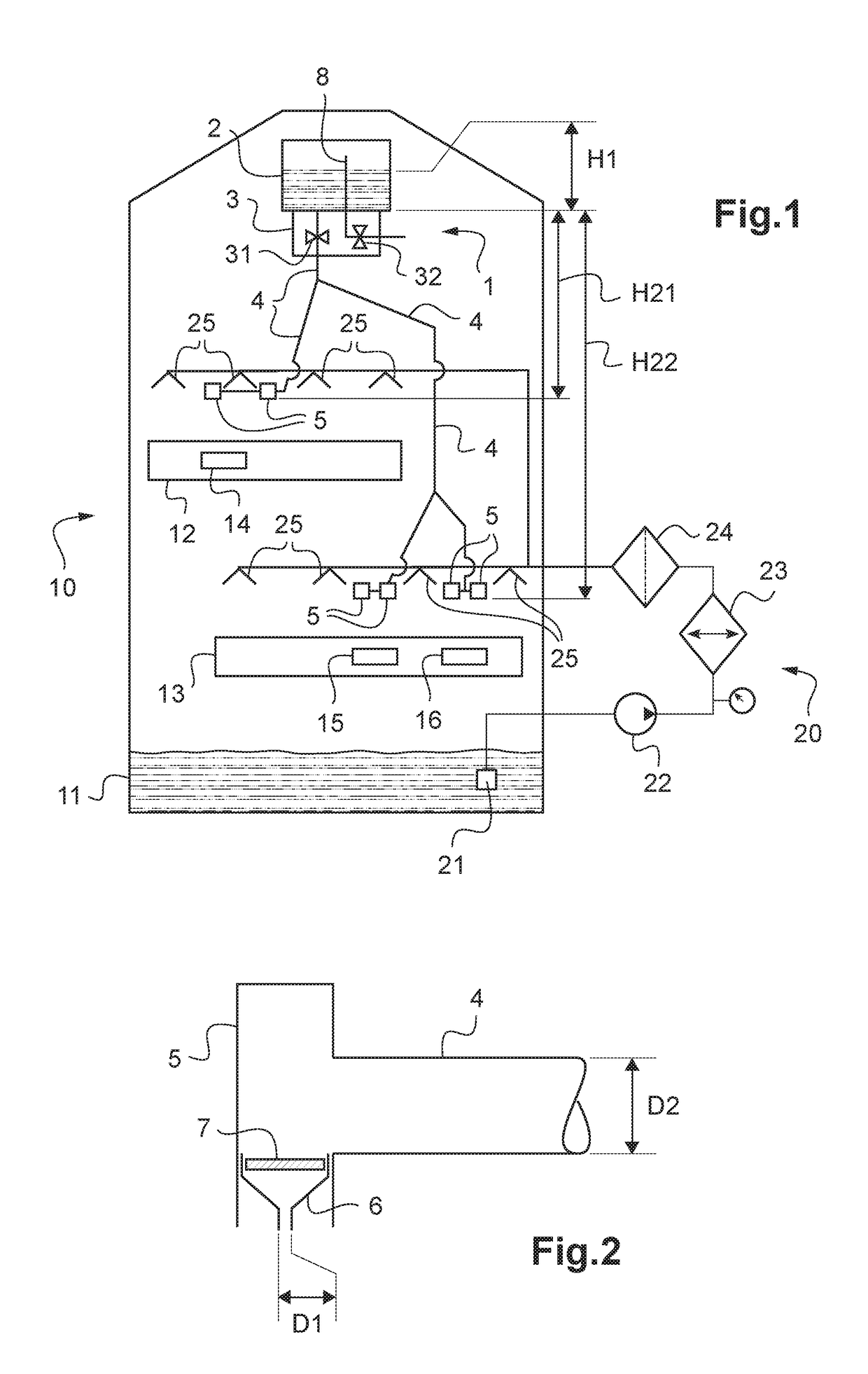

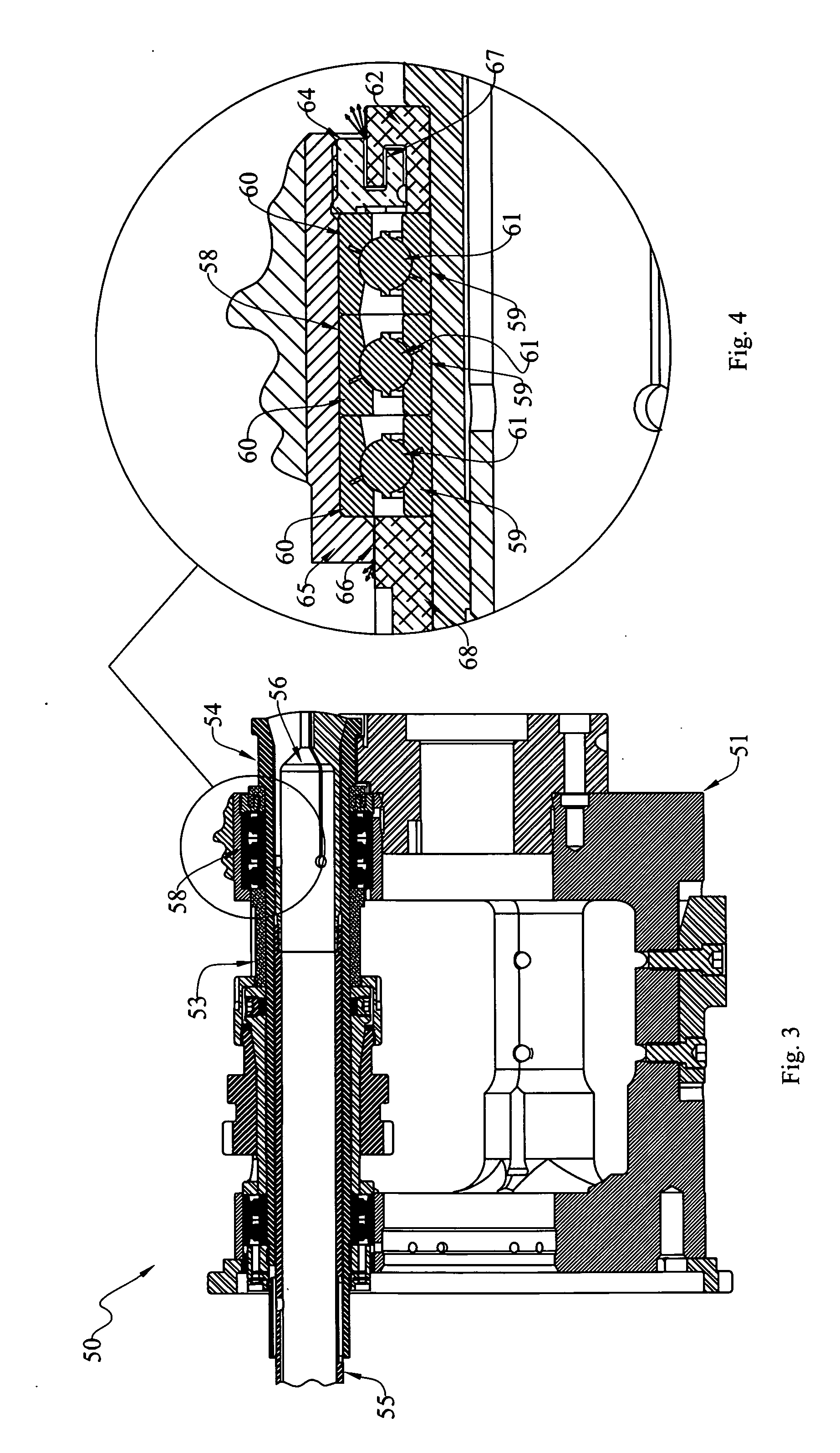

Emergency lubrication device of simplified architecture for a power transmission main gearbox of an aircraft

ActiveUS20170175875A1Improve reliabilityCost reductionAircraft componentsValve arrangementsAirplaneLubrication

An emergency lubrication device of simplified architecture for a mechanical system. The emergency lubrication device has a tank, trigger means, at least one pipe, and at least one distribution means. The tank contains a lubrication liquid and it is arranged inside the mechanical system and above the pipes and the distribution means. Each distribution means includes at least one constriction means for limiting the flow rate of the lubrication liquid. The lubrication liquid is heated by the mechanical system, and the viscosity of the lubrication liquid decreases so that the flow rate of the lubrication liquid through each distribution means is substantially equal to or greater than a minimum flow rate so long as the tank contains the lubrication liquid.

Owner:EUROCOPTER

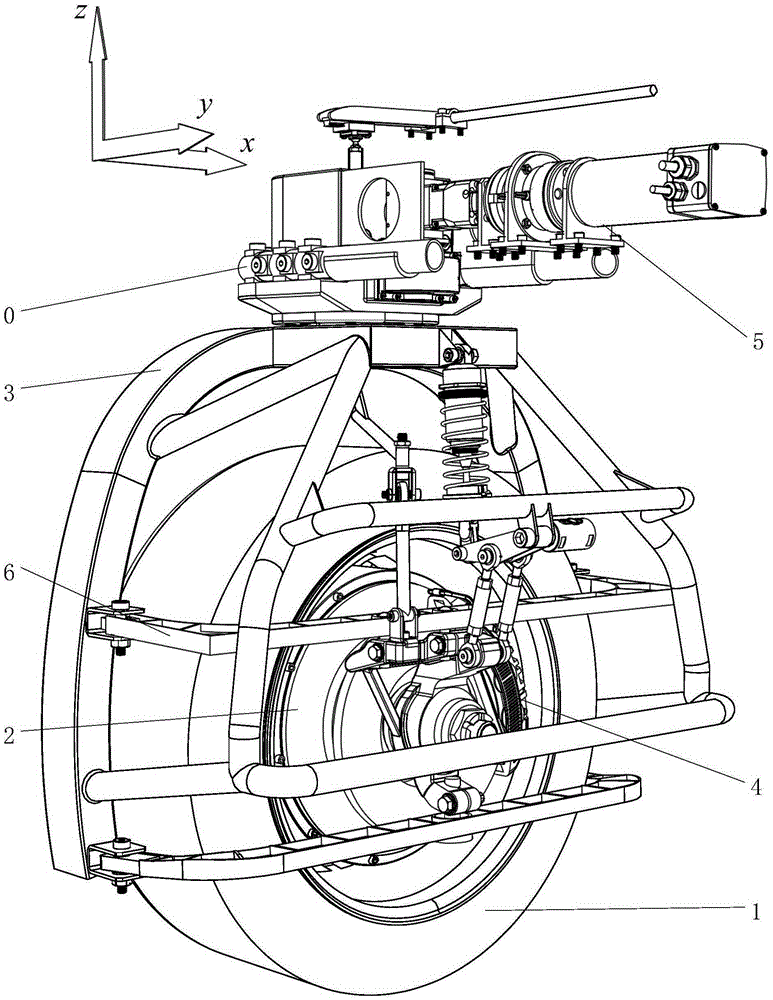

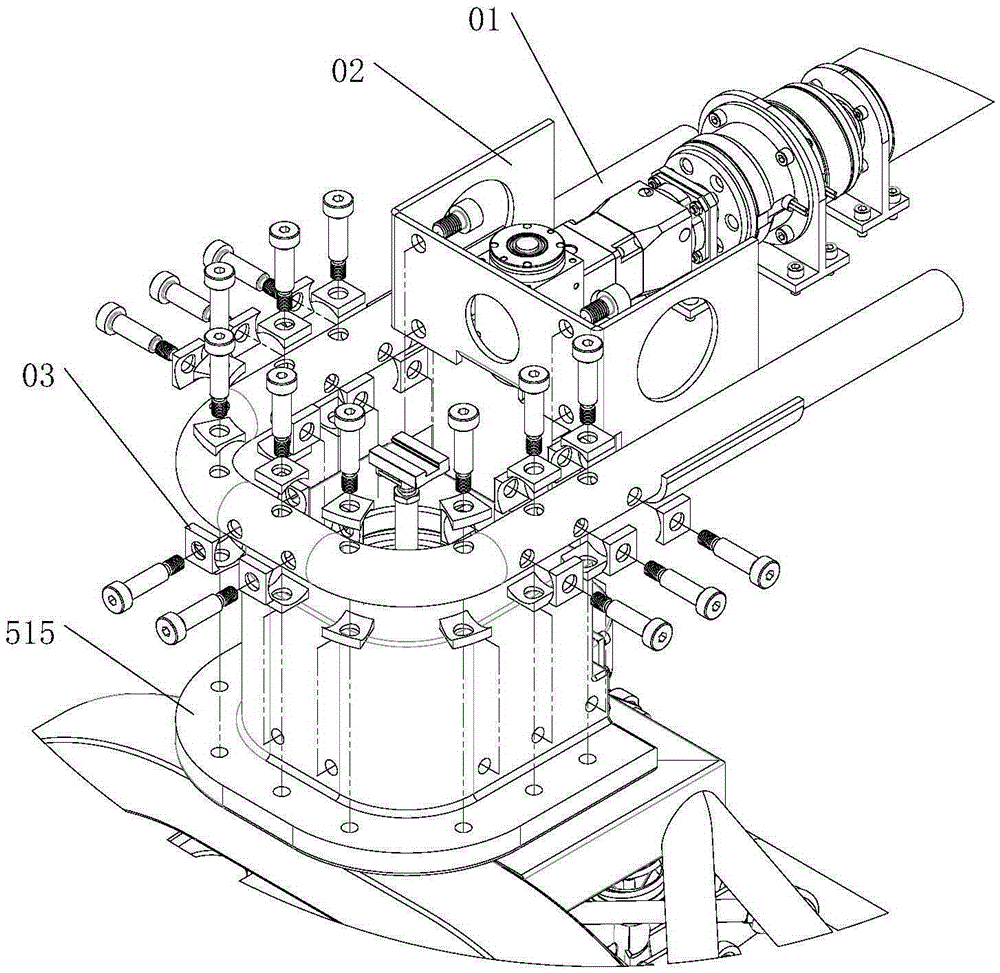

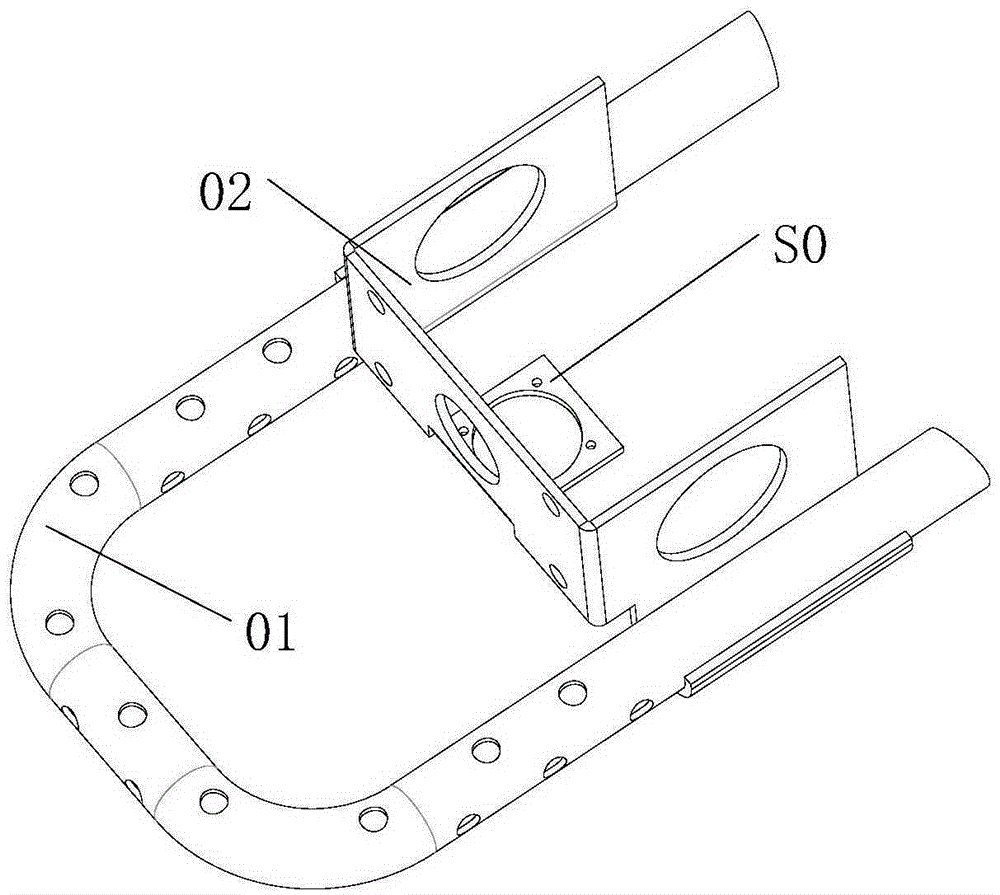

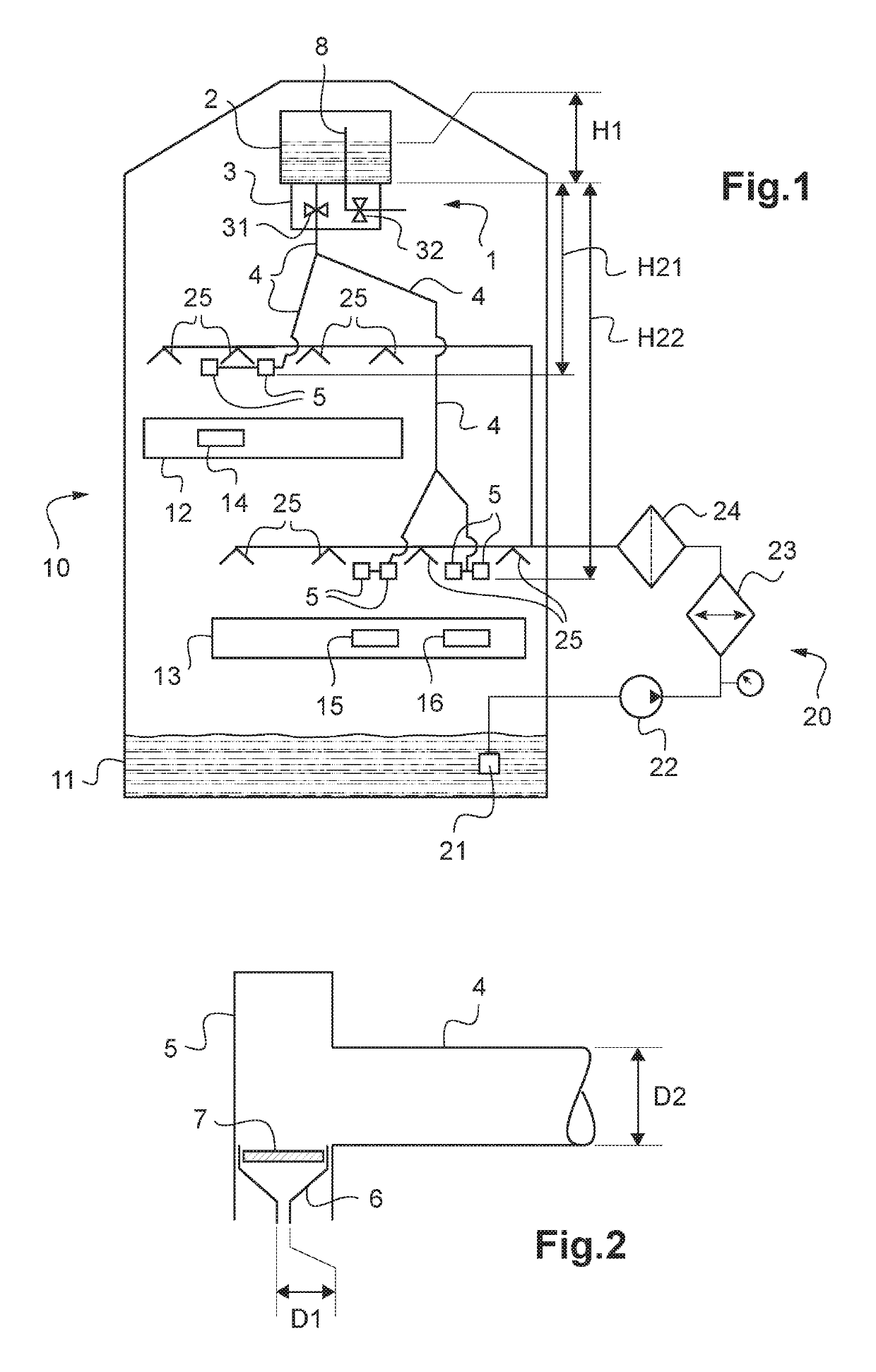

Suspension system and steering system for distributed driving and independent steering electric automobile

ActiveCN105415996AImprove groundingReduce wearElectrical steeringPivoted suspension armsDouble wishbone suspensionGround state

The invention discloses a suspension system and steering system for a distributed driving and independent steering electric automobile. The suspension system and steering system is fixed to an automobile body through an installation support and comprises wheels, a hub motor, a wheel support, a brake, a steering system body and a double-cross-arm suspension system. The steering system body is installed on the installation support of the automobile body, the wheel support is connected with the output end of the steering system, the double-cross-arm suspension system is installed on the wheel support, and the movement of the double-cross-arm suspension system does not interfere with the movement of the steering system body. By means of the suspension system and steering system, the double-cross-arm suspension system with a lateral stabilizer is integrated while each wheel can have large steering angular capability, so that the grounding state of tires is improved, the attachment limit is increased, friction of the tires is reduced, and the side lurch rigidity of the automobile is increased; thus, the control stability is improved, and the whole system is easy to calibrate.

Owner:JILIN UNIV

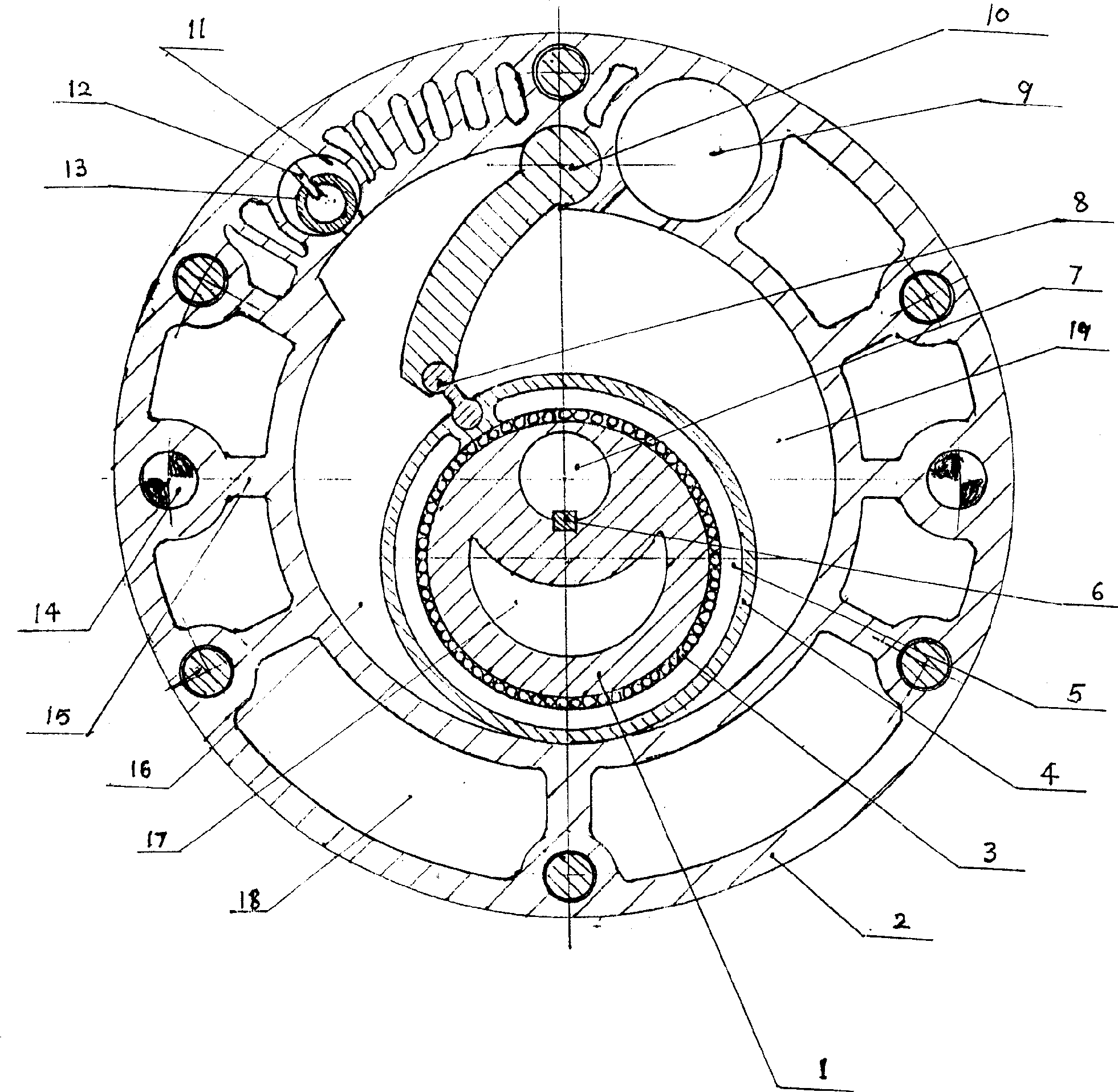

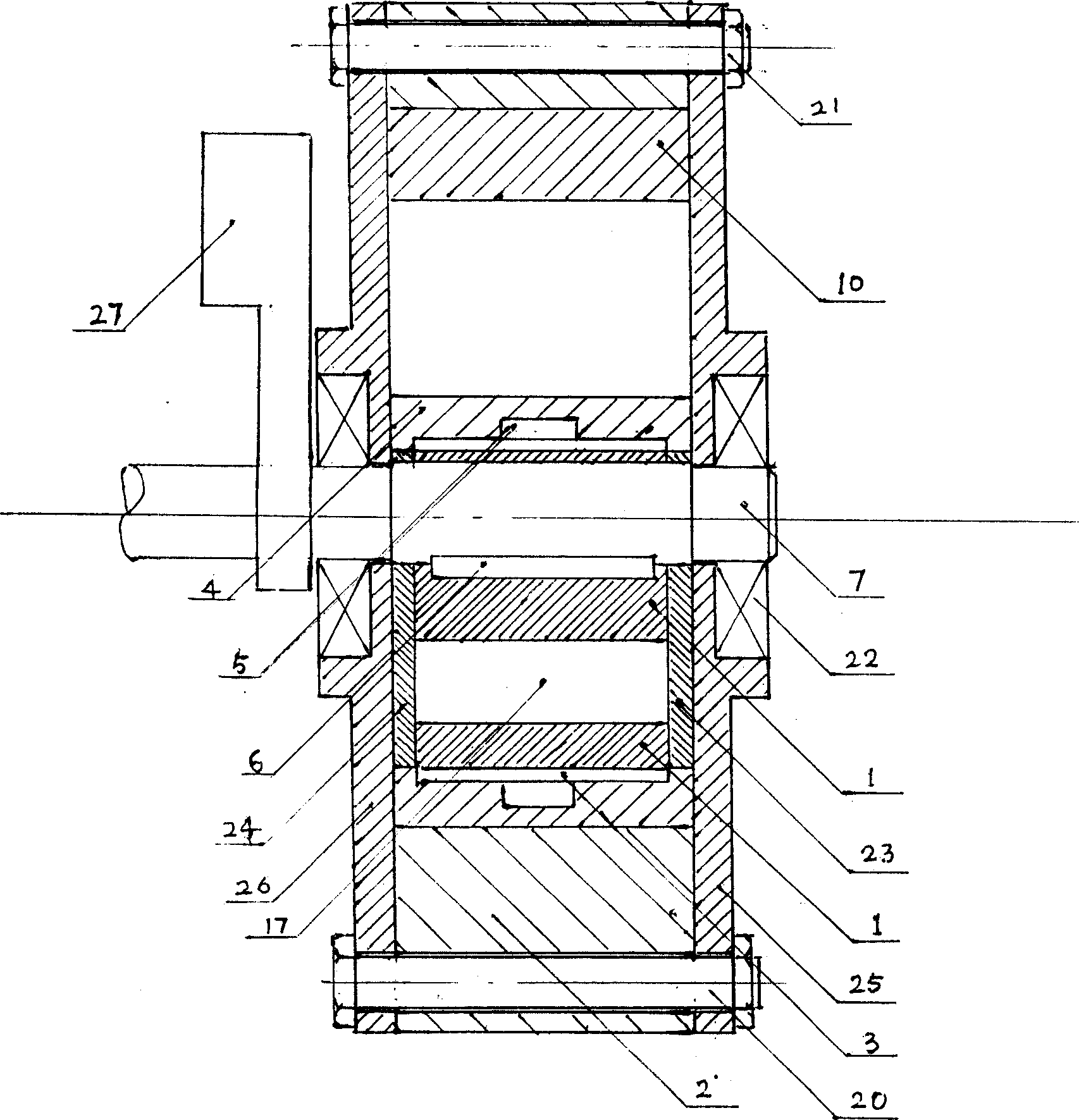

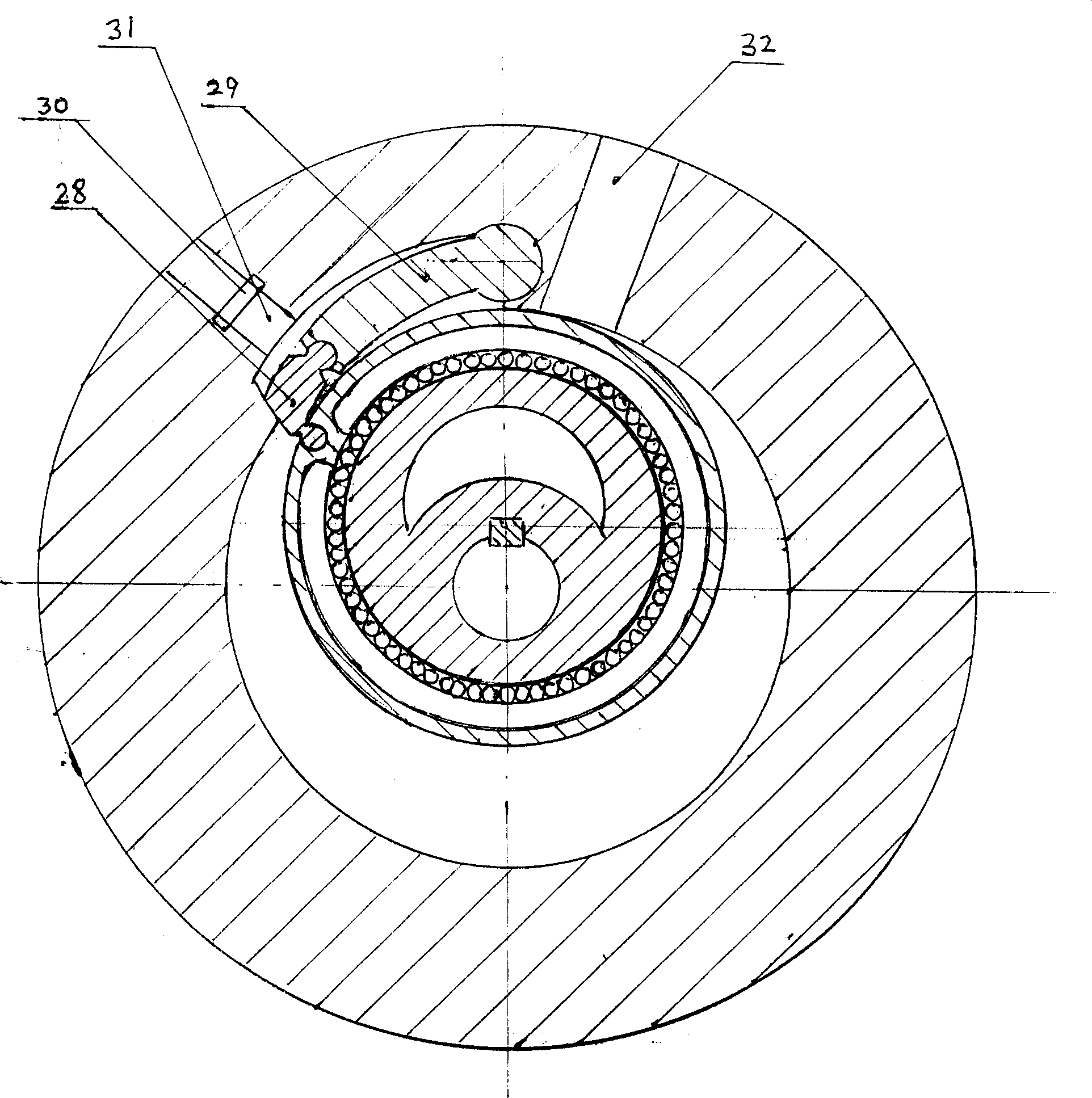

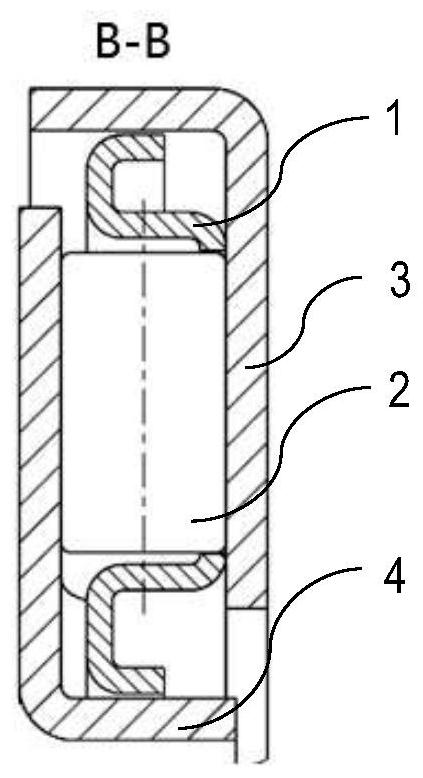

Rotor pump

InactiveCN1707110AReduce lossSimple lubricationRotary piston pumpsRotary piston liquid enginesEngineeringCylinder block

The present invention provides one kind of rotor pump. The rotor pump includes one stator inside cylinder; one front stator end cap and one back stator end cap concentric with the cylinder; one eccentric rotor assembly comprising rotator, movable ring, rolling bearing and movable sealing end caps; and one separator between the high pressure cavity and the low pressure cavity with integrated rotating shaft and arc block, and one or several movable joints.

Owner:云晓璎

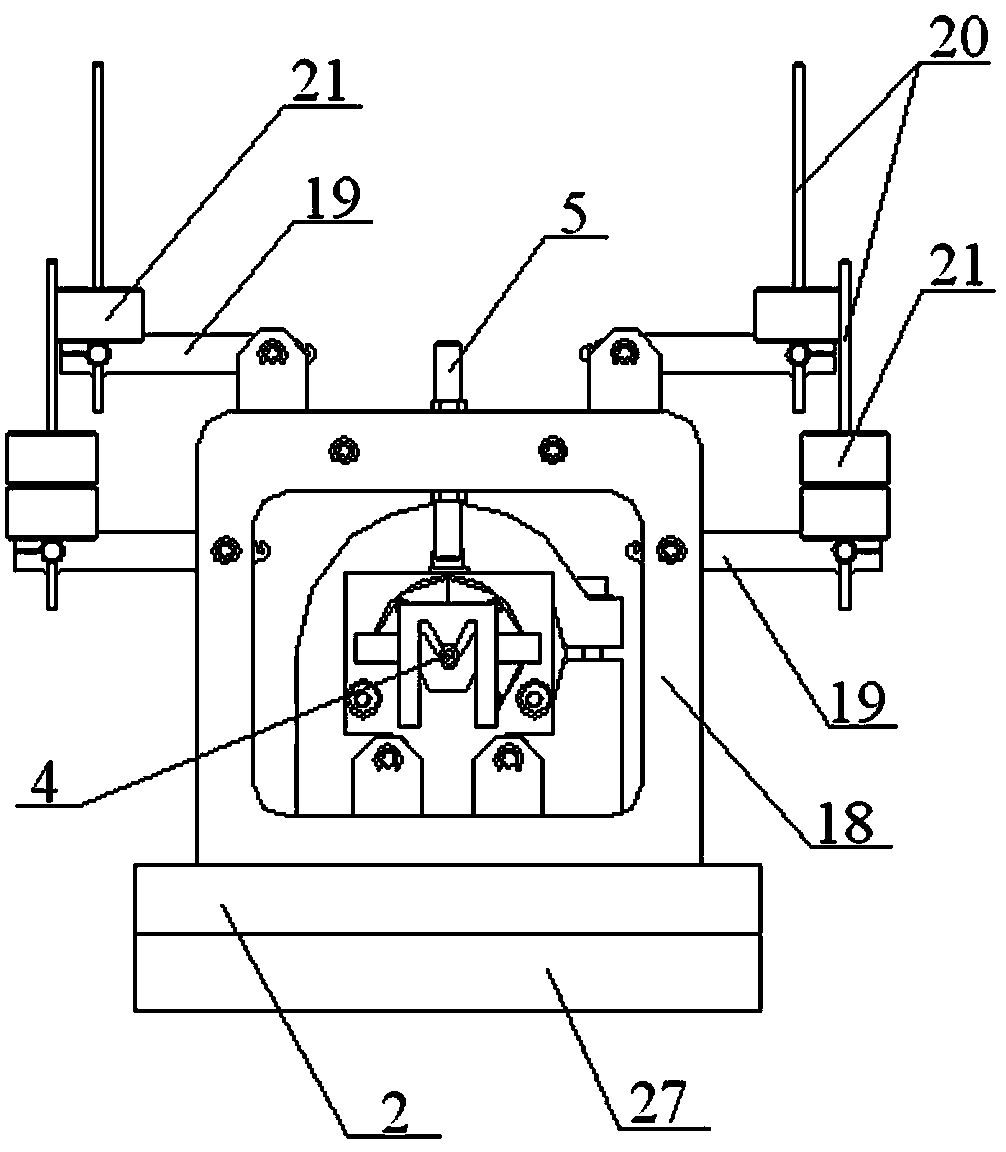

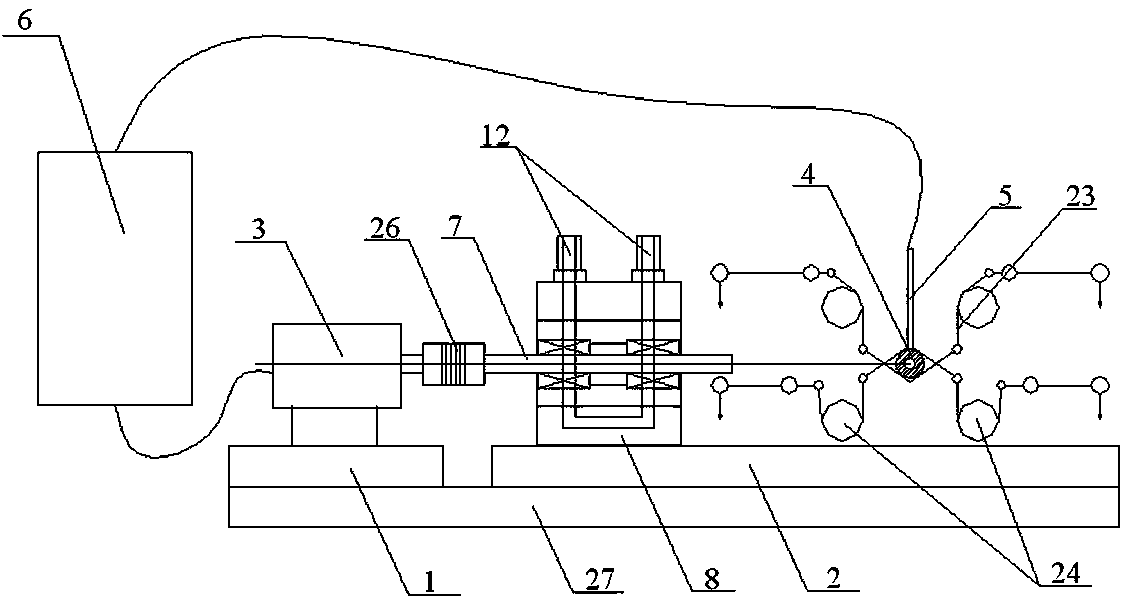

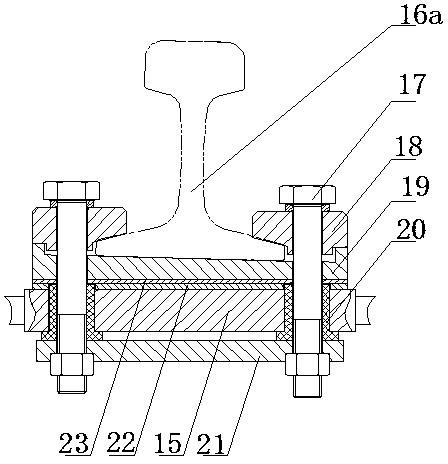

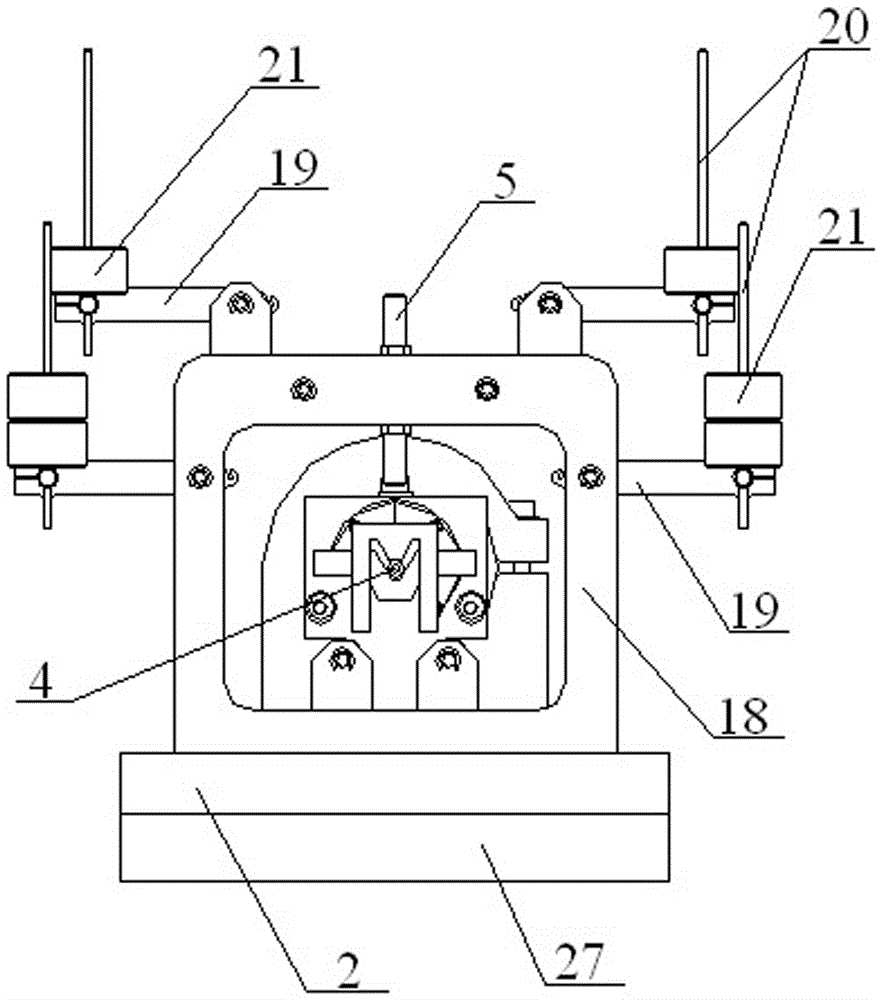

Clamping device

InactiveCN102366897AHigh positioning accuracyReduce frictionPositioning apparatusMetal-working holdersEngineeringIndustrial engineering

The invention discloses a clamping device. The middle zone of a workbench is a workpiece positioning zone; the workbench is provided with chutes positioned on the left and the right of the workpiece positioning zone; the workbench is also symmetrically provided with one pair of clamping mechanisms positioned on the left and the right of the workpiece positioning zone; each clamping mechanism comprises a driving device and a fixture fixedly connected with the driving device; the fixture is in sliding fit in the chute on the workbench; a controller used for giving an action order is fixed on the workbench; and the output end of the controller is electrically connected with the driving device of the clamping mechanism. The clamping device is favorable for improving the positioning precision of a workpiece to be processed.

Owner:CHANGZHOU SHENGFA BULB FACTORY

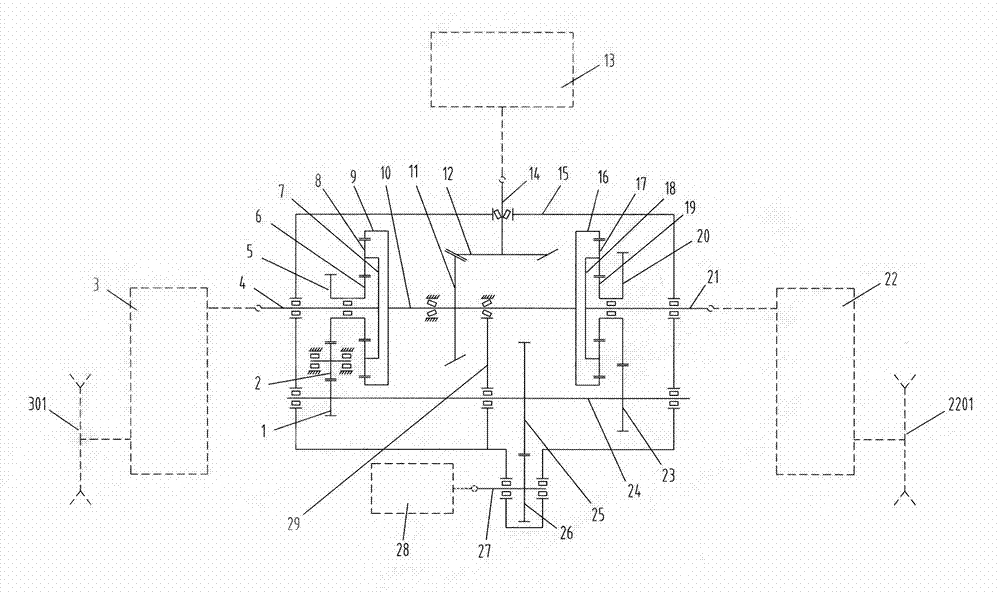

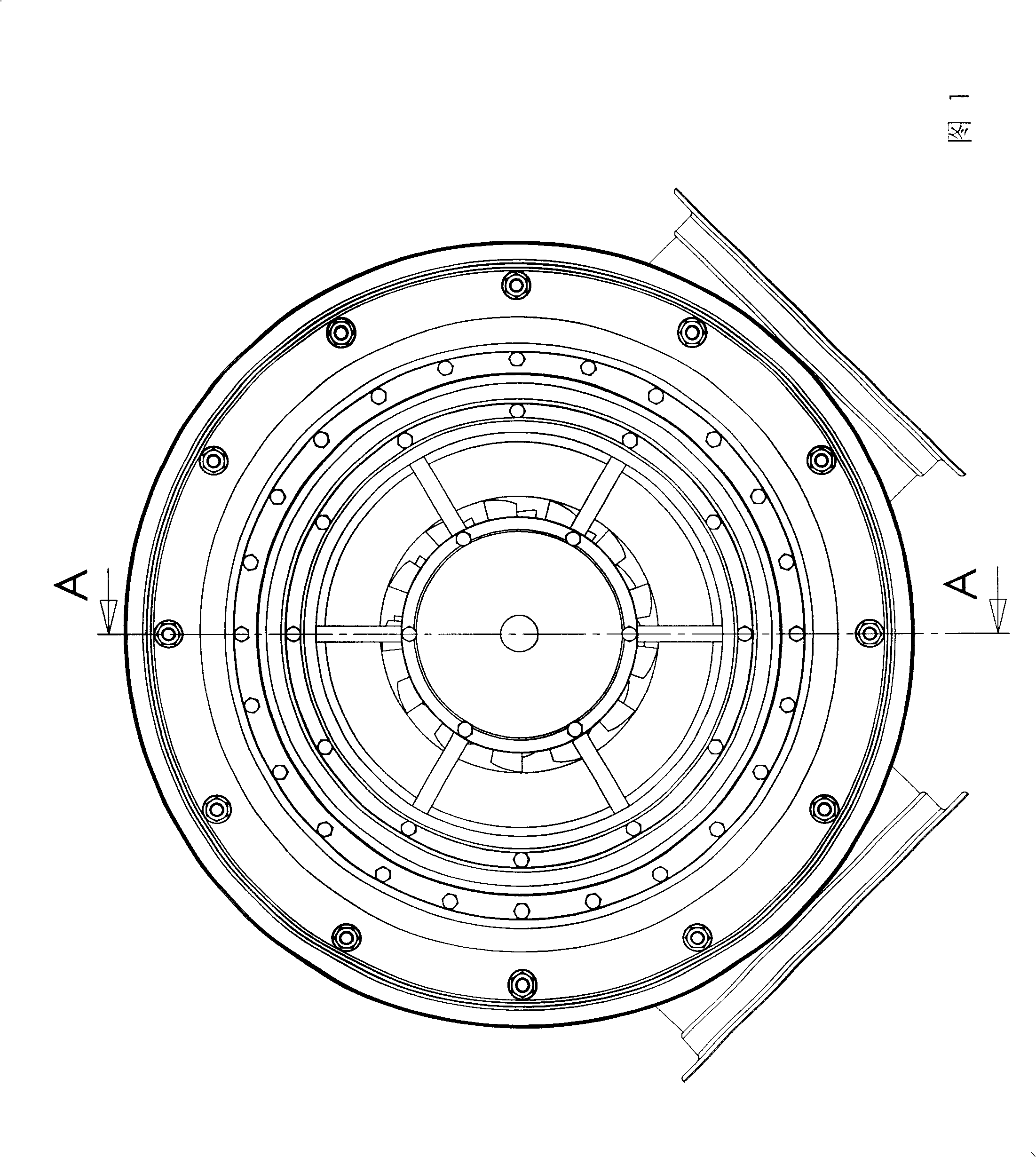

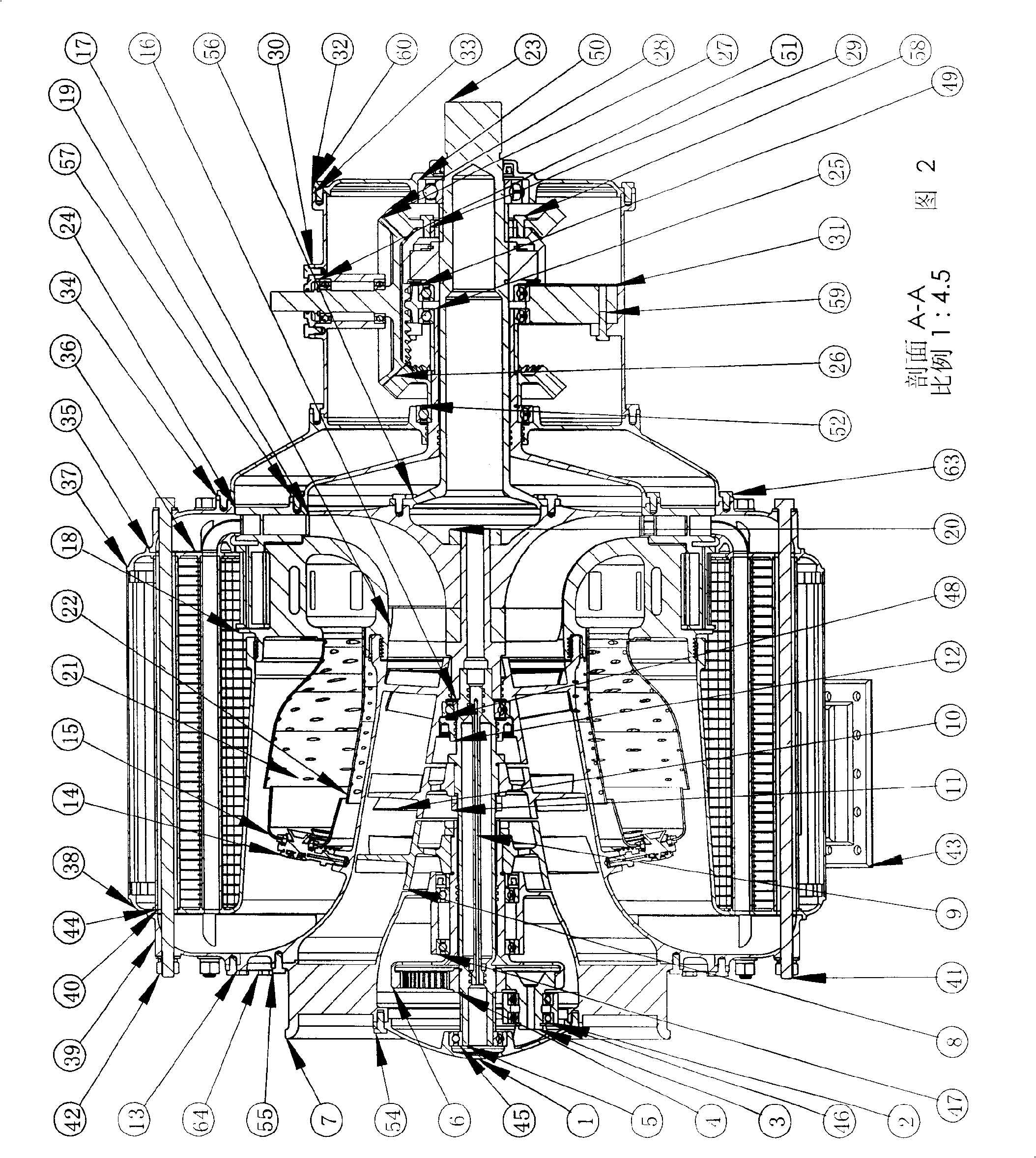

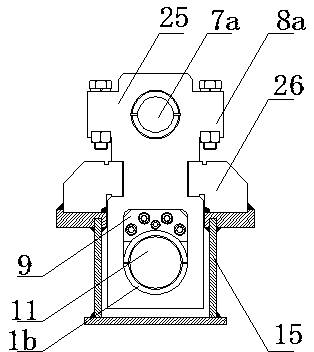

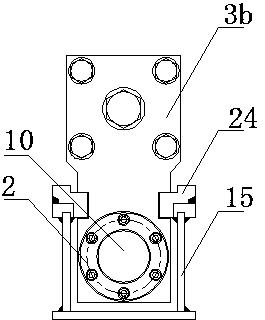

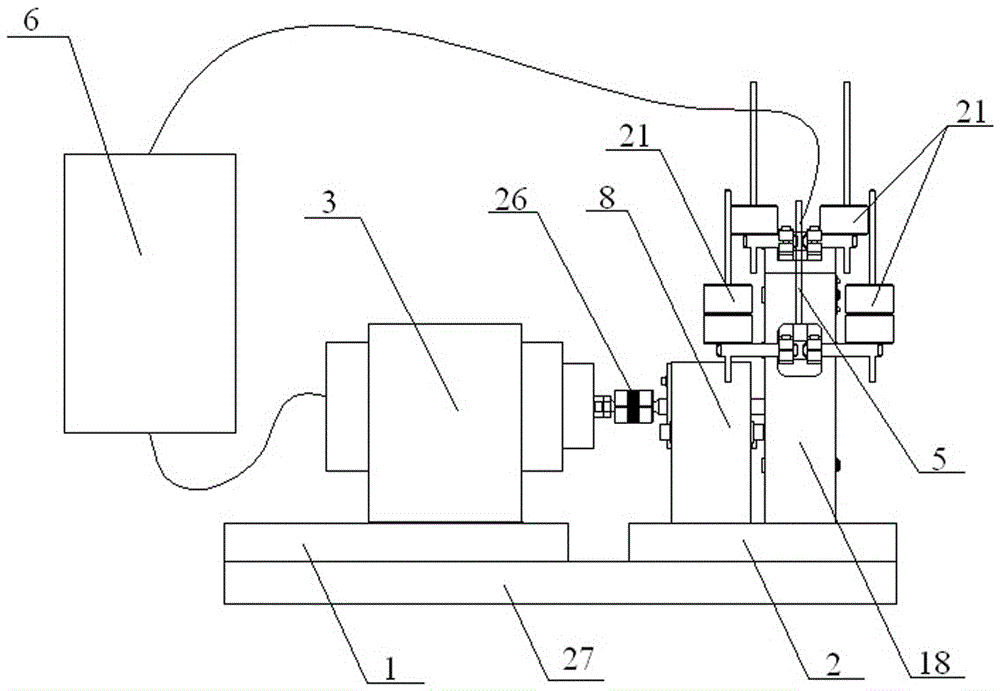

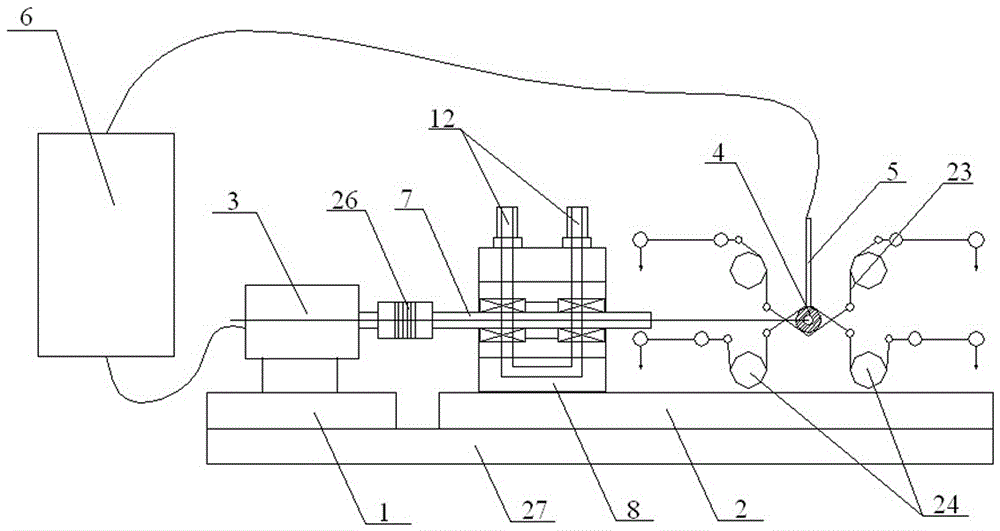

Comprehensive performance testing machine for ultra-high speed oil bearing

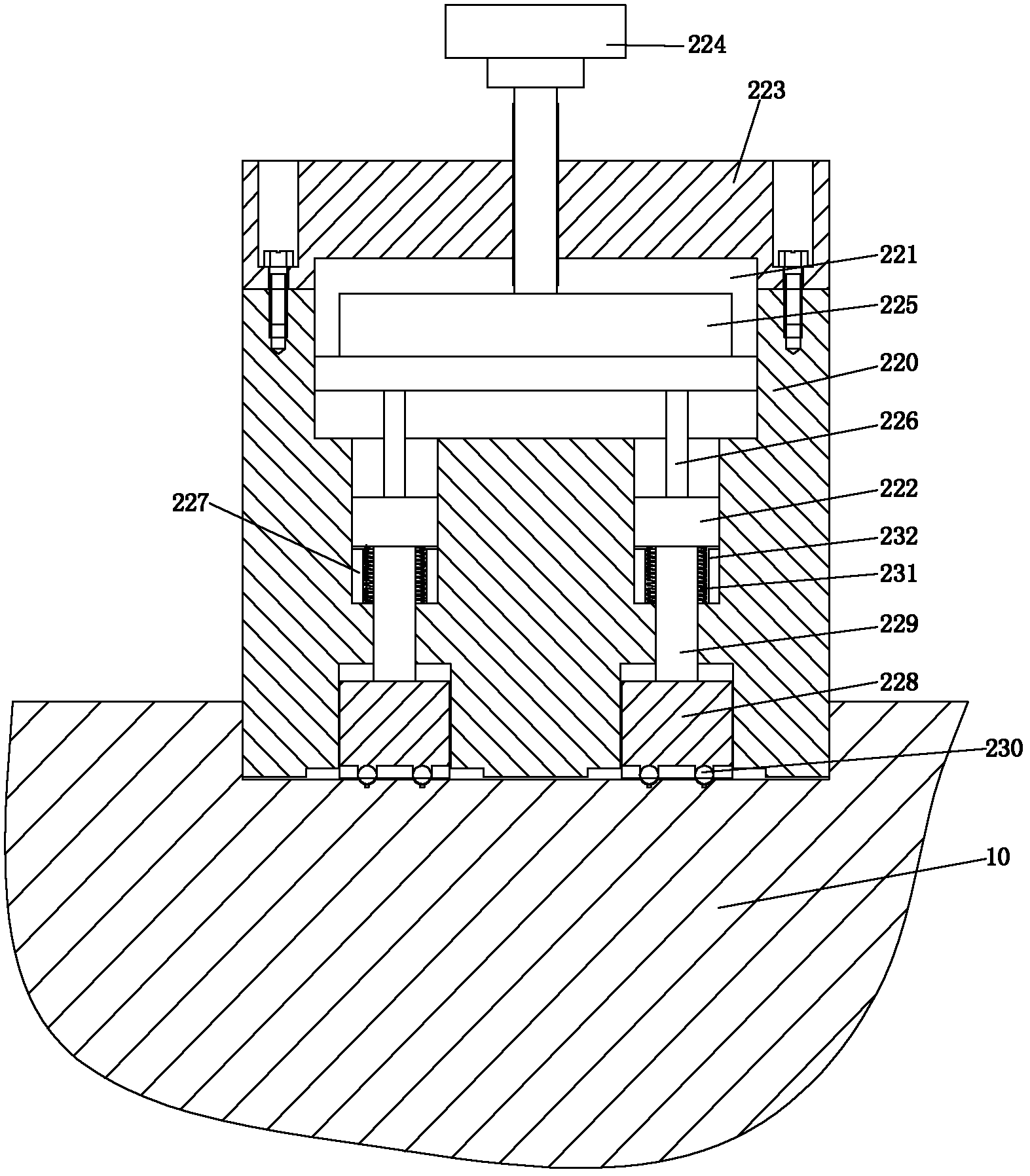

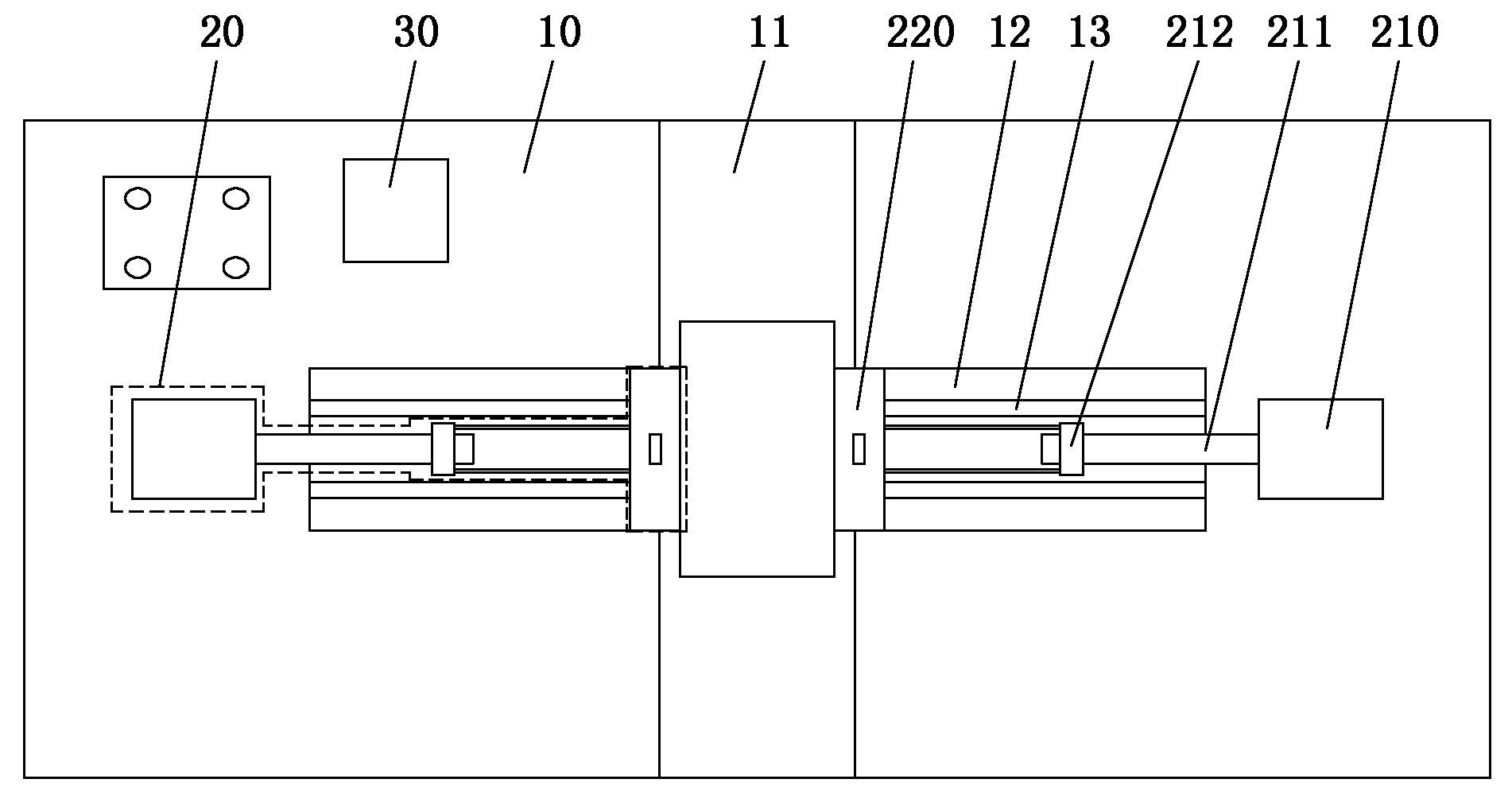

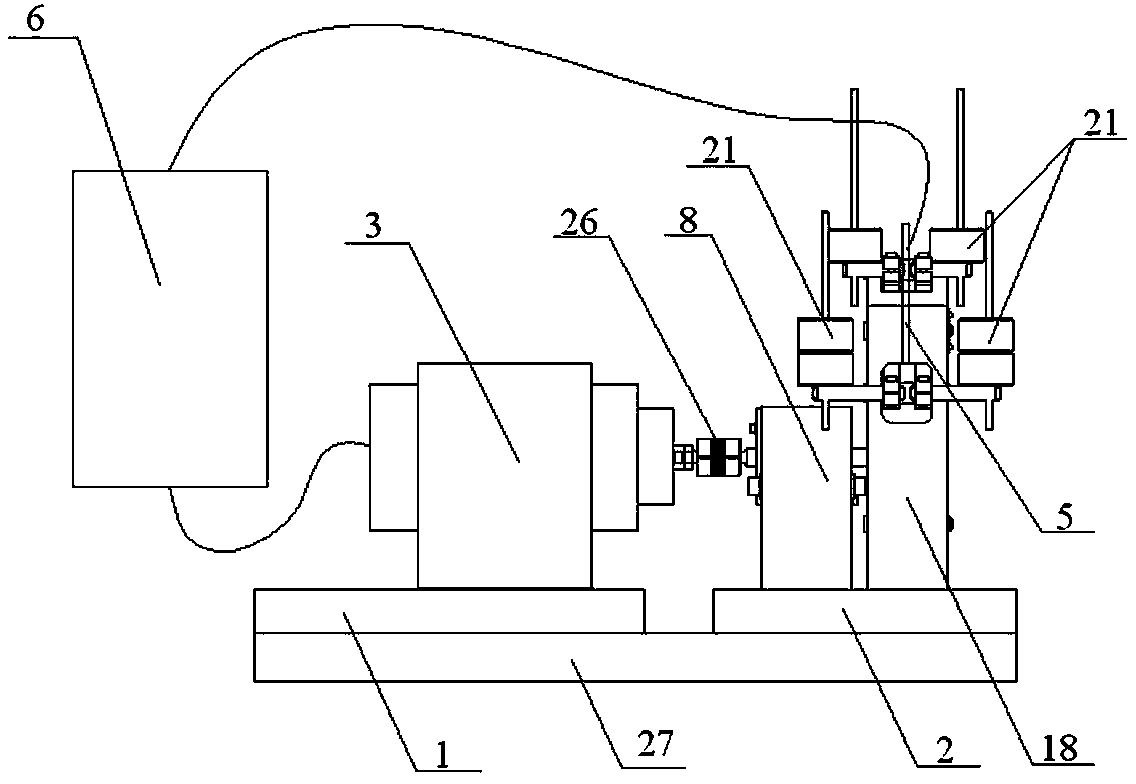

A comprehensive performance testing machine for an ultra-high speed oil bearing comprises a clamping device for clamping the oil bearing to be tested, a loading device used for applying loading force on the oil bearing to be tested through the clamping device, a dynamic pressure test shaft matched with an inner hole of the oil bearing to be tested, a rotation supporting device used for supporting the dynamic pressure test shaft and a driving device, wherein a temperature measuring hole used for a temperature sensor to be inserted is formed in the top of the clamping device, and both the temperature sensor and the driving device are both connected with an external electric control cabinet; the clamping device is composed of an upper clamping block and a lower clamping block, the oil bearing to be tested is clamped between the upper clamping block and the lower clamping block, the lower clamping block is arranged in a suspended mode through lifting ropes, connected with the loading device, at the two ends of the lower clamping block, and the loading device applies downward loading force on the upper clamping block. The comprehensive performance testing machine for the ultra-high speed oil bearing is overall high in repeatability and accuracy, long in service life, capable of having the self-cooling function, easy to operate and lubricate, simple in structure, low in manufacturing cost, stable in performance, high in intelligence degree and good in practical effect.

Owner:洛阳精一新材料科技有限公司

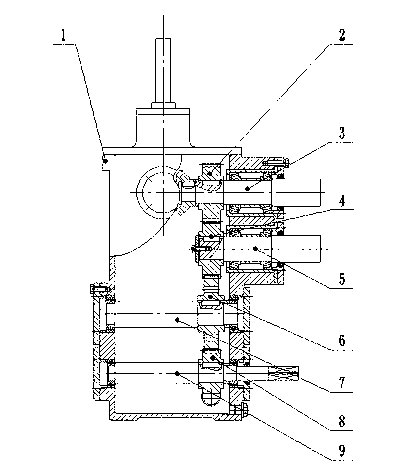

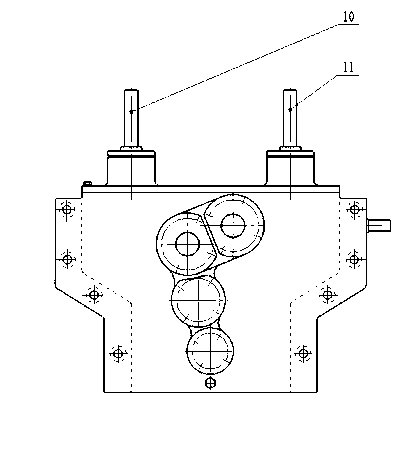

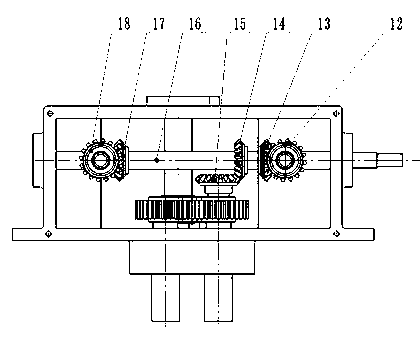

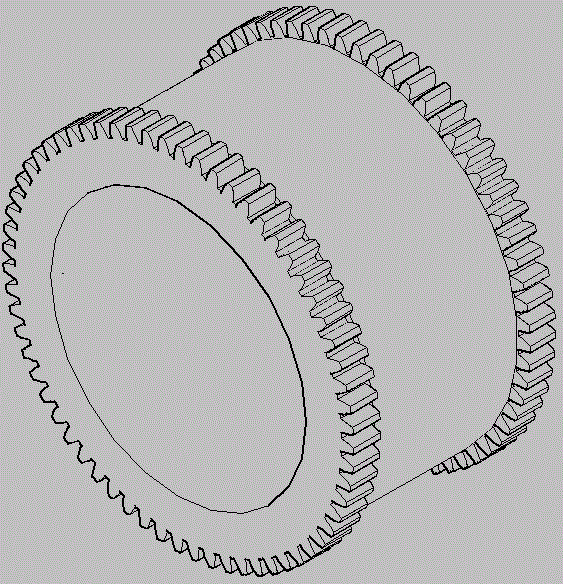

Compound transmission mechanism

InactiveCN103244635ASimple lubricationSimple structureToothed gearingsFluid gearingsTransmission systemAerospace engineering

The invention discloses a compound transmission mechanism. The compound transmission mechanism comprises two planet rows. Tooth rings of the two planet rows are fixed at two ends of an intermediate shaft respectively in a back-to-back mode, two planet carriers are fixed on a left side shaft and a right side shaft respectively, and a first gear and a second gear are processed on a left sun wheel and a right sun wheel respectively in a conjoined mode and are respectively meshed with a third gear and a fourth gear which are fixed on a zero shaft. The zero shaft is provided with a fifth gear, and the fifth gear is meshed with a sixth gear positioned on a second input shaft. A crawler type bulldozer adopting the compound transmission mechanism can achieve on-site center steering, power loss is small, the high-speed working condition requirements can be met, and the compound transmission mechanism is suitable for a crawler type bulldozer transmission system.

Owner:中国人民解放军63983部队

Contrarotating rotary spraying engine

InactiveCN101349197AShort axial distanceShort thermal stressContinuous combustion chamberGas turbine plantsHigh energyMechanical energy

The invention provides a contra-rotating rotary-jetting engine which can remarkably raise heat efficiency and reduce pollutant emission, manufacturing cost as well as maintenance cost. The engine works by utilizing a principle that a rotary jet turbine of the engine ejects fuel gas at high speed from a tangential spout to allow the self of the rotary jet turbine to rotate reversely so as to convert fuel gas internal energy into mechanical energy; meanwhile, the engine also utilizes a tangential impact turbine to recycle the kinetic energy of the fuel gas ejected from the rotary jet turbine, utilizes a heat regenerator to realize regenerative cycle, adopts a contra-rotating axial flow and contra-rotating centrifugal pressure gas technique to obtain high total pressure ratio, adopts a rotary flame tube technique to obtain high fuel gas temperature in front of the turbine, adopts the novel structural design to greatly reduce the number of components and the consumption of precious materials, and adopts a power confluence mechanism of a cone gear and an overrunning clutch to realize the power confluent output of the mechanical energy of the rotary jet turbine and the tangential impact turbine. Therefore, the engine has high energy conversion efficiency, low manufacturing cost and pollutant emission.

Owner:蔡盛龙

Cold-heading finished silk treatment process

InactiveCN103540944ALow decarbonization rateSimple lubricationFurnace typesMetallic material coating processesOXALIC ACID DIHYDRATEAcid washing

Owner:浙江瑞利紧固件有限公司

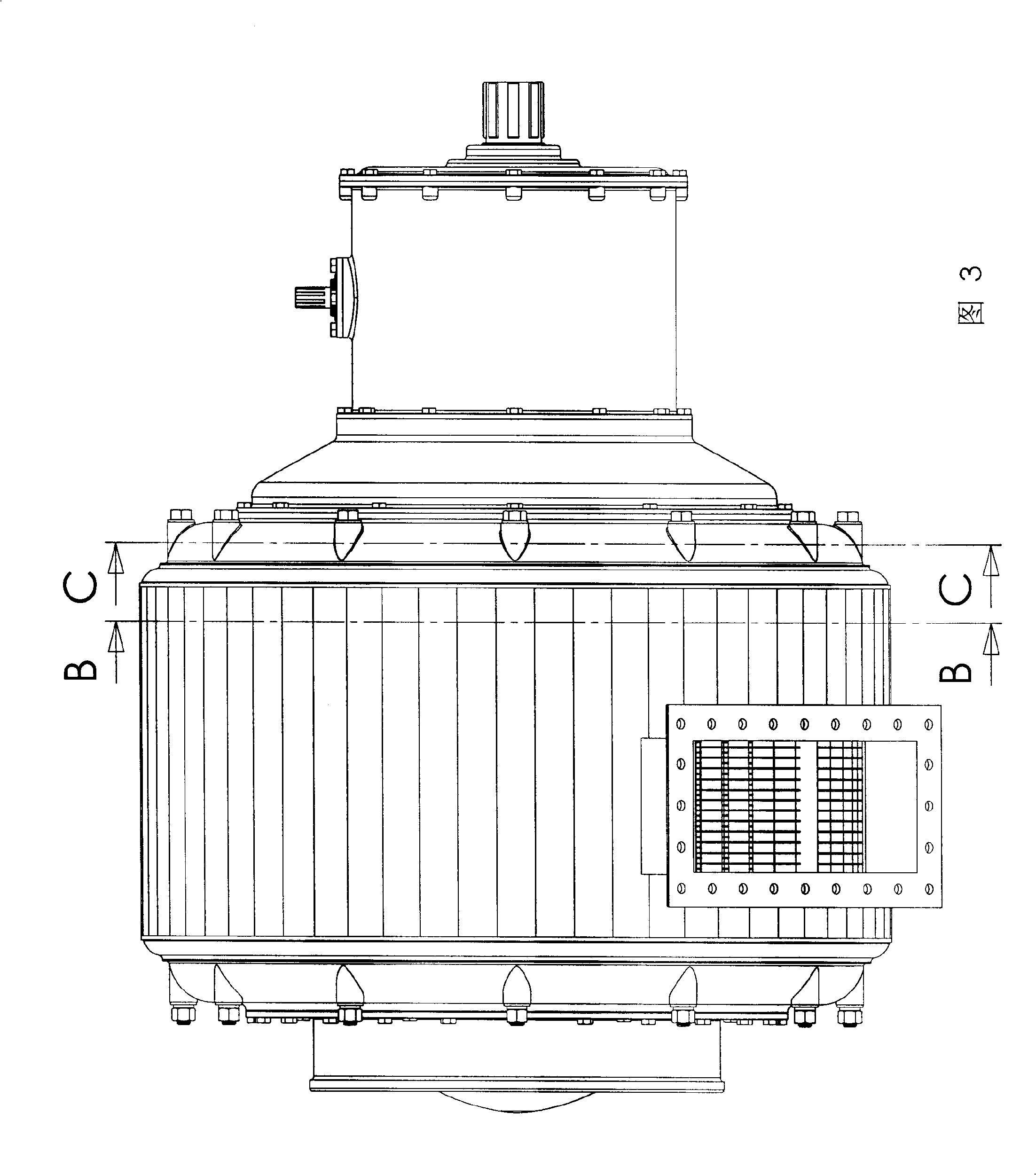

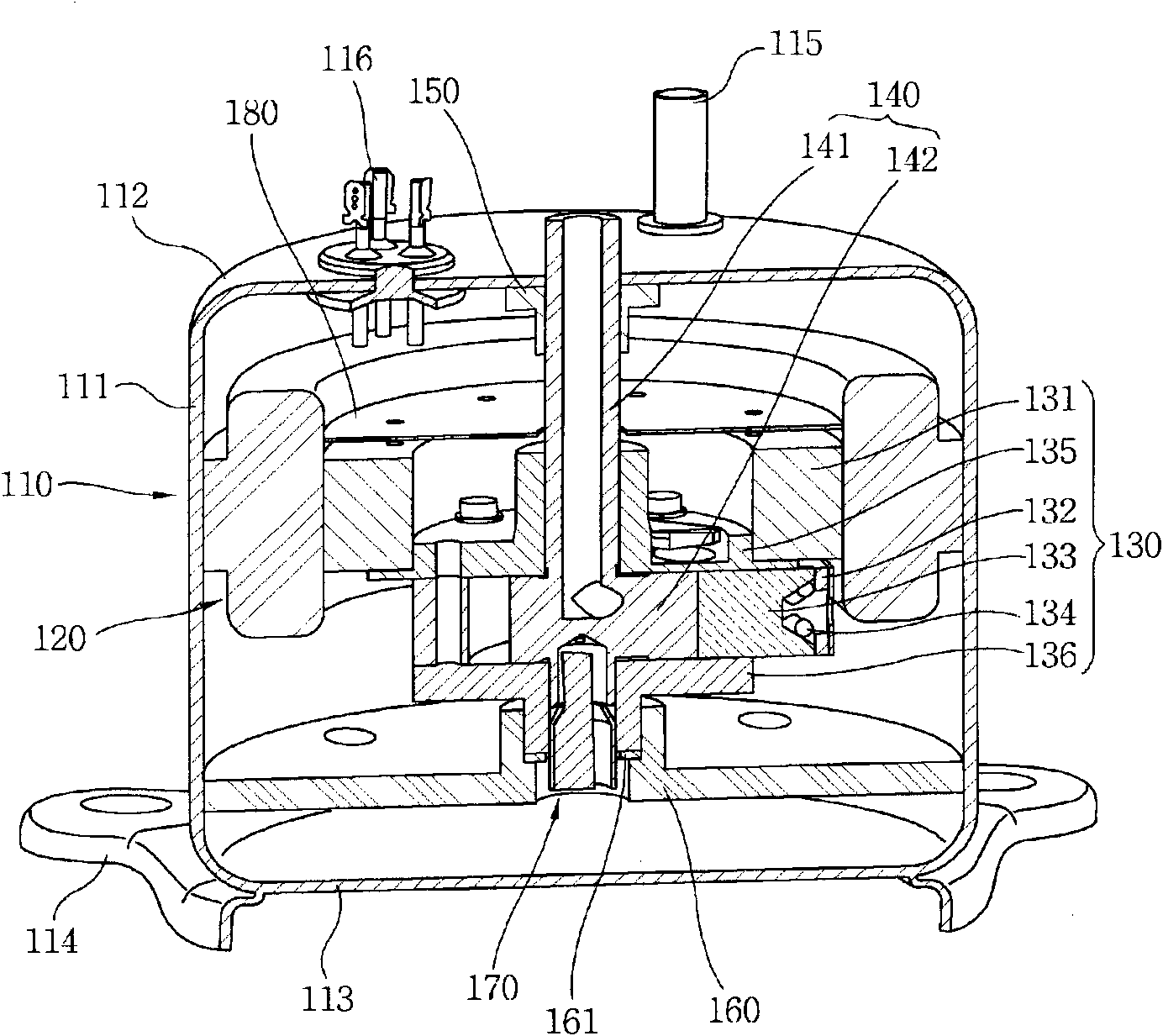

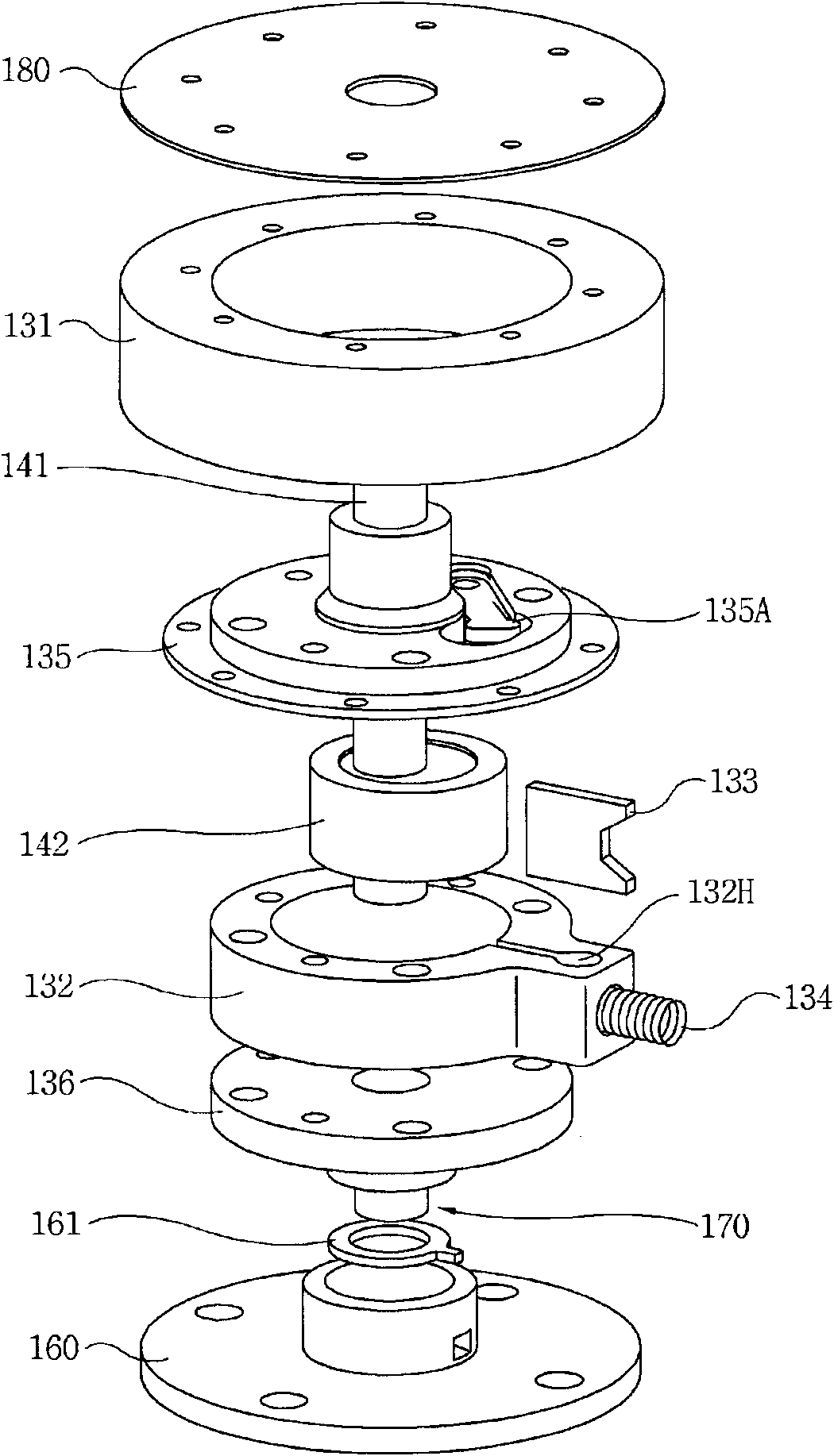

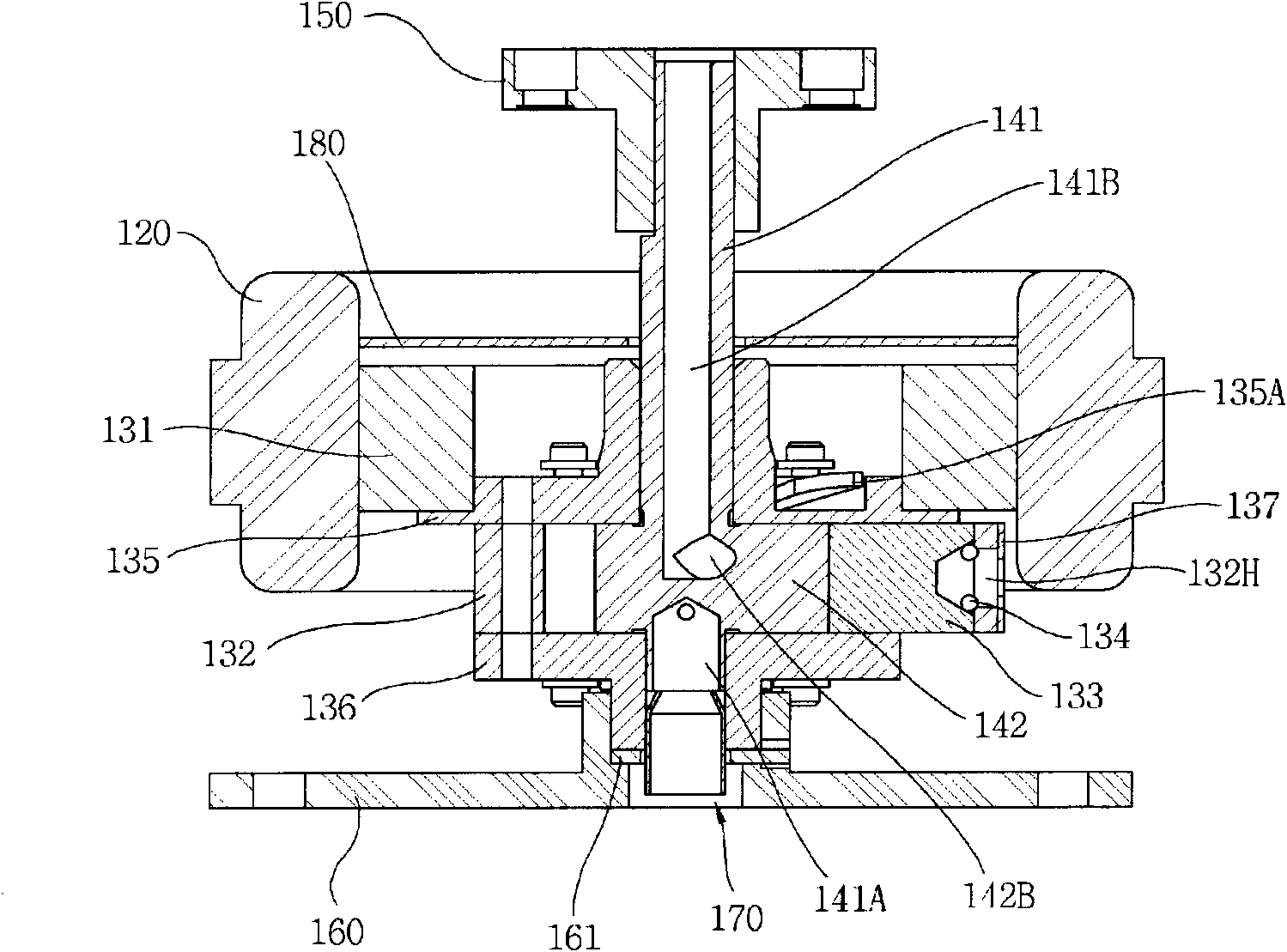

Compressor

InactiveCN102472275AImprove structural stabilityEasy to assembleRotary/oscillating piston combinations for elastic fluidsRotary piston pumpsEngineeringRefrigerant

The present invention relates to a compressor in which a rotary member (130) suspended on a stationary member (140) is rotated to compress the refrigerant. The rotary member (130) is suspended on a first portion of the stationary member and rotatably supported on a second portion of the stationary member, which is spaced a distance the first portion of the stationary member to thereby achieve structural stability, improve operational reliability and reduce vibrations. The components can be easily centered and assembled with excellent assembly characteristics. In addition, the mounting structure of an elastically-supported vane (133) is improved to ensure lubrication performance and operational reliability. Moreover, a mounting structure for a vane (234), which incorporates a roller(233), is improved to reduce vibration and prevent refrigerant leakage, which leads to high compression efficiency.

Owner:LG ELECTRONICS INC

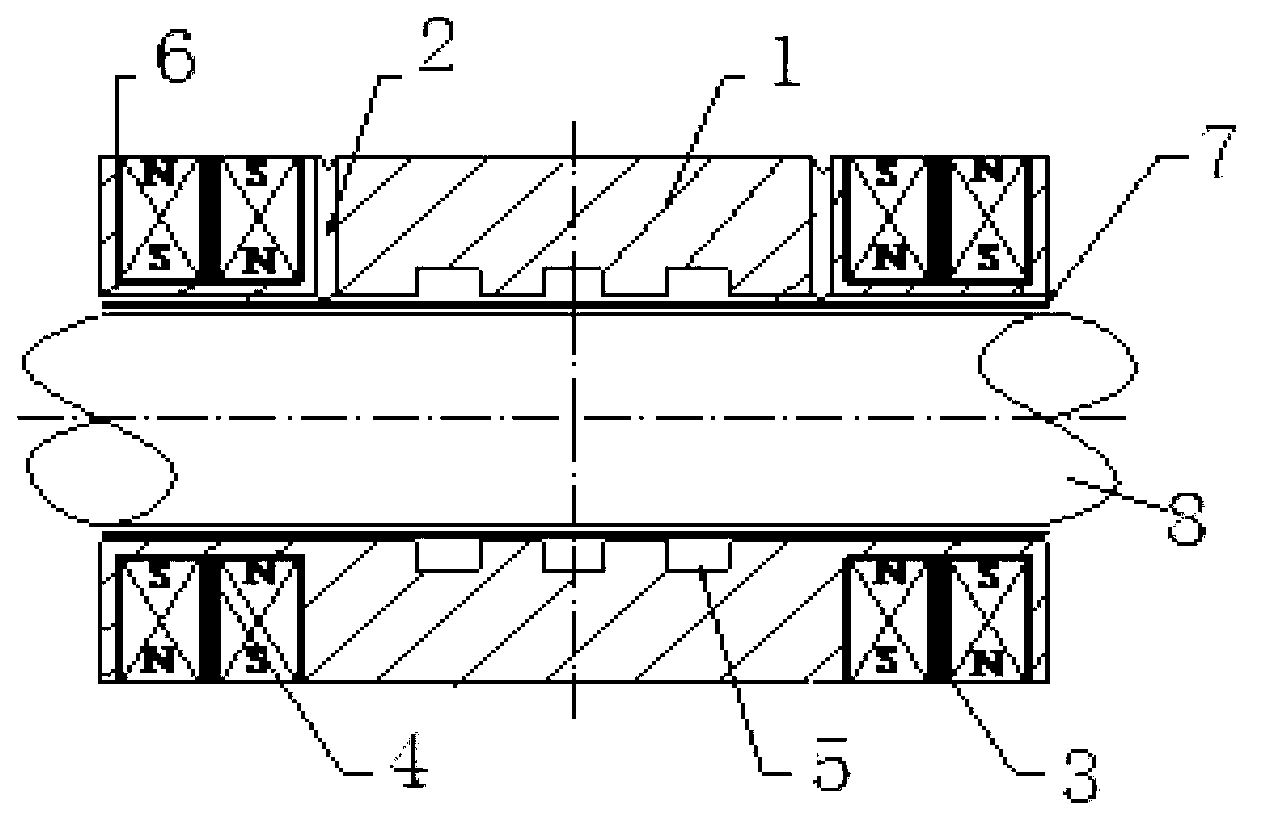

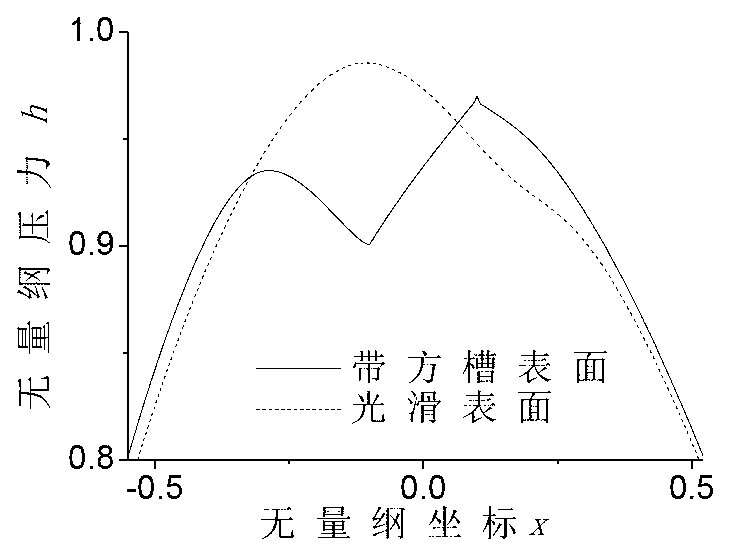

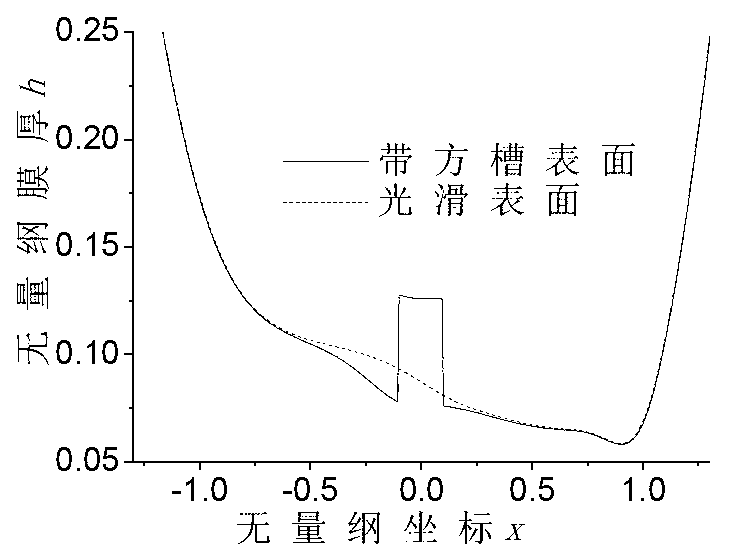

Slide bearing with grooves and lubricating method

InactiveCN103062220AReduce friction and wearThickness of magnetic fluid lubricant filmBearingsEngine lubricationLubricationSurface-active agents

The invention discloses a slide bearing with grooves and a lubricating method, wherein the slide bearing with grooves comprises an inner hole and an excircle; an inner groove is arranged in the middle of the inner hole and two ends of the excircle are provided with outer grooves; the outer grooves are provided with permanent magnets; a magnetofluid hole is formed between each outer groove and the middle of the slide bearing; the permanent magnets are annular permanent magnets; each outer groove is internally provided with a plurality of annular permanent magnets which are separated by permanent magnet baffle rings; and elastic baffle rings are arranged between the annular permanent magnets and axial end surfaces of the outer grooves. The tensioning degree among the magnets is regulated by regulating the number or widths of the elastic baffle rings among the magnets, the operation comprises the following step that water-based magnetic fluid lubricating agents are injected between the slide bearing and a matched surface of a rotary shaft through the magnetofluid hole, wherein the water-based magnetic fluid lubricating agents mainly comprise a water-based liquid carrier, water-based magnetic fluid nano Fe3O4 particles and polyaniline surface active agents. Lubrication without leakage can be realized, so that the slide bearing is environment-friendly, and can operate reliably, thus the service life of the slide bearing is prolonged.

Owner:QINGDAO TECHNOLOGICAL UNIVERSITY

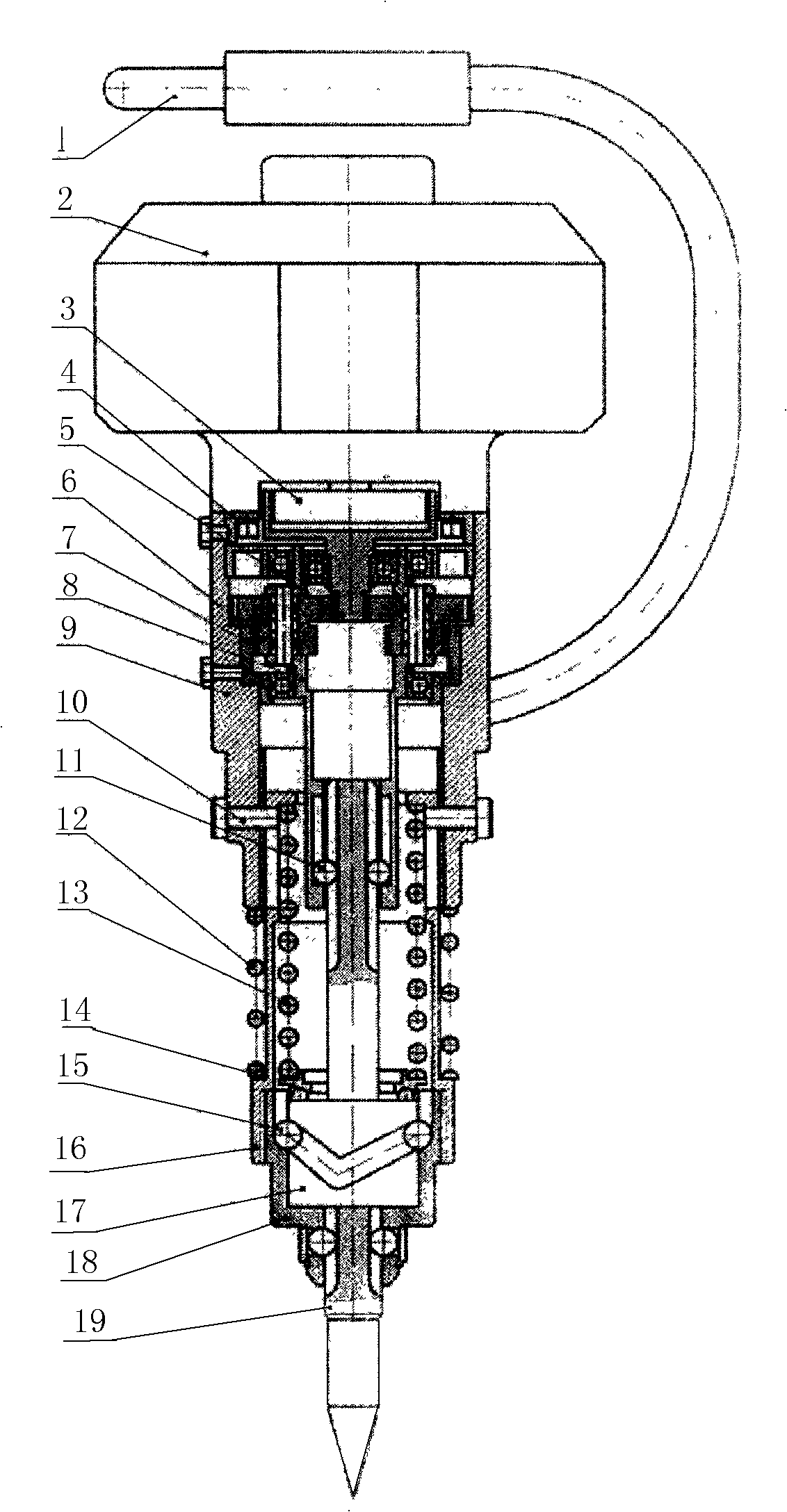

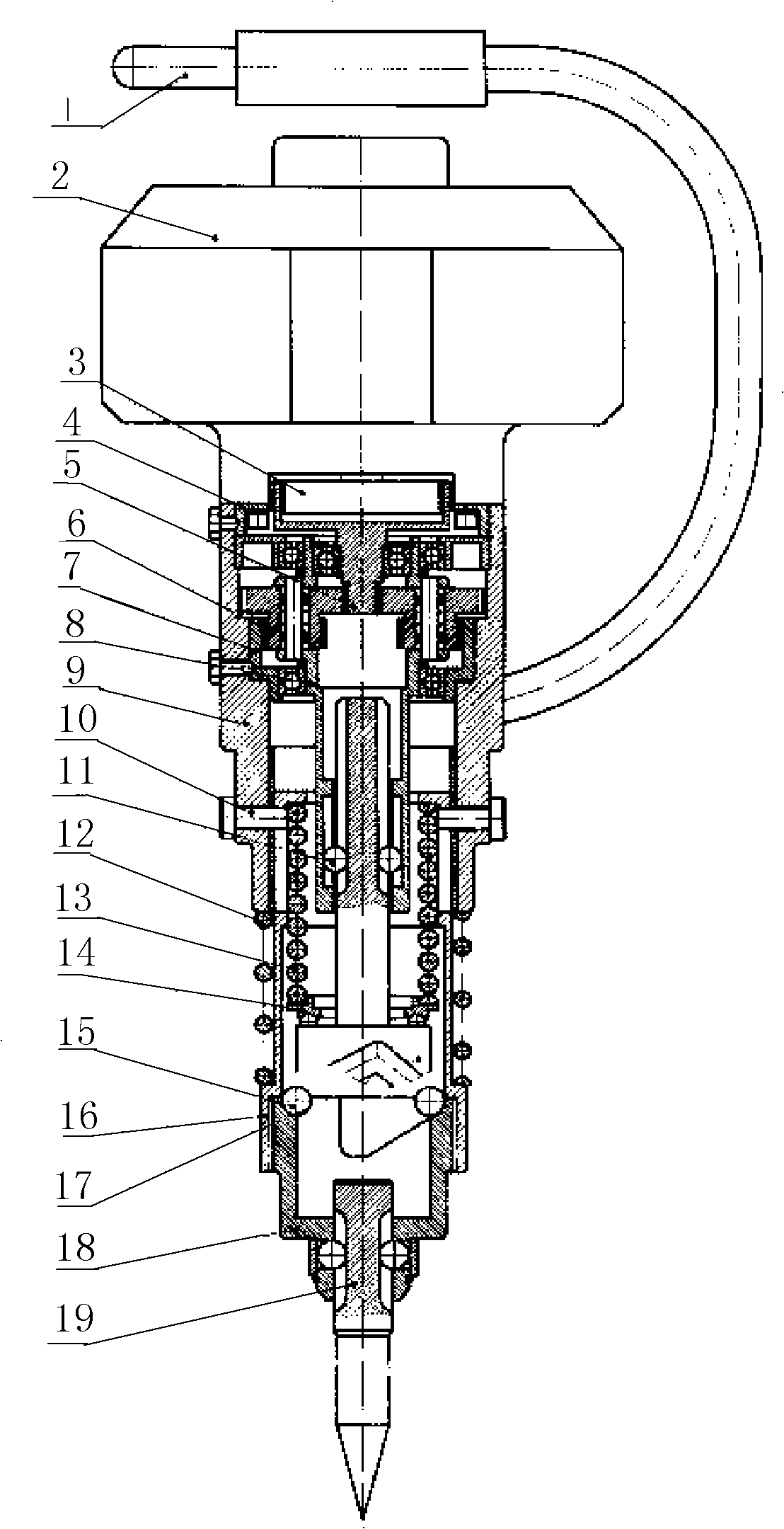

Impacting pickaxe

InactiveCN101264598ASimple structureReduce feverBallastwayPortable percussive toolsReciprocating motionThrust bearing

The invention discloses an impact pickaxe with a power unit, belonging to the technical field of power tools, which is characterized in that the lower part of the impact pickaxe is sleeved with a pickaxe cylinder through a pin and a slotted hole, a vibration damping spring is arranged between the pickaxe and the pickaxe cylinder, a pickaxe hammer is arranged in the pickaxe cylinder, the hammer handle of the pickaxe hammer is connected with the output shaft of a reducing device through a keyway and a steel ball arranged in the keyway, an impact spring is connected between the pickaxe hammer and the pickaxe cylinder through a thrust bearing, the hammer head of the pickaxe hammer is shelled with an impact sleeve which is fixed in the pickaxe cylinder, a ball race which can enable the pickaxe to do reciprocating movement is arranged between the impact sleeve and the hammer head of the pickaxe hammer, a steel ball is arranged in the ball race, and the top of the pickaxe bar passes the impact sleeve and is arranged on the bottom of the pickaxe hammer. The impact pickaxe with the power unit has the advantages of reducing the recoil vibration of the impact pickaxe, improving the operation comfort, extending the service life of machine members, lowering manufacturing and maintenance costs, and reducing energy consumption; the impact pickaxe is mainly used in the crushing of concrete, rock, asphalt, and the tamping of rail ballast.

Owner:欧阳文生

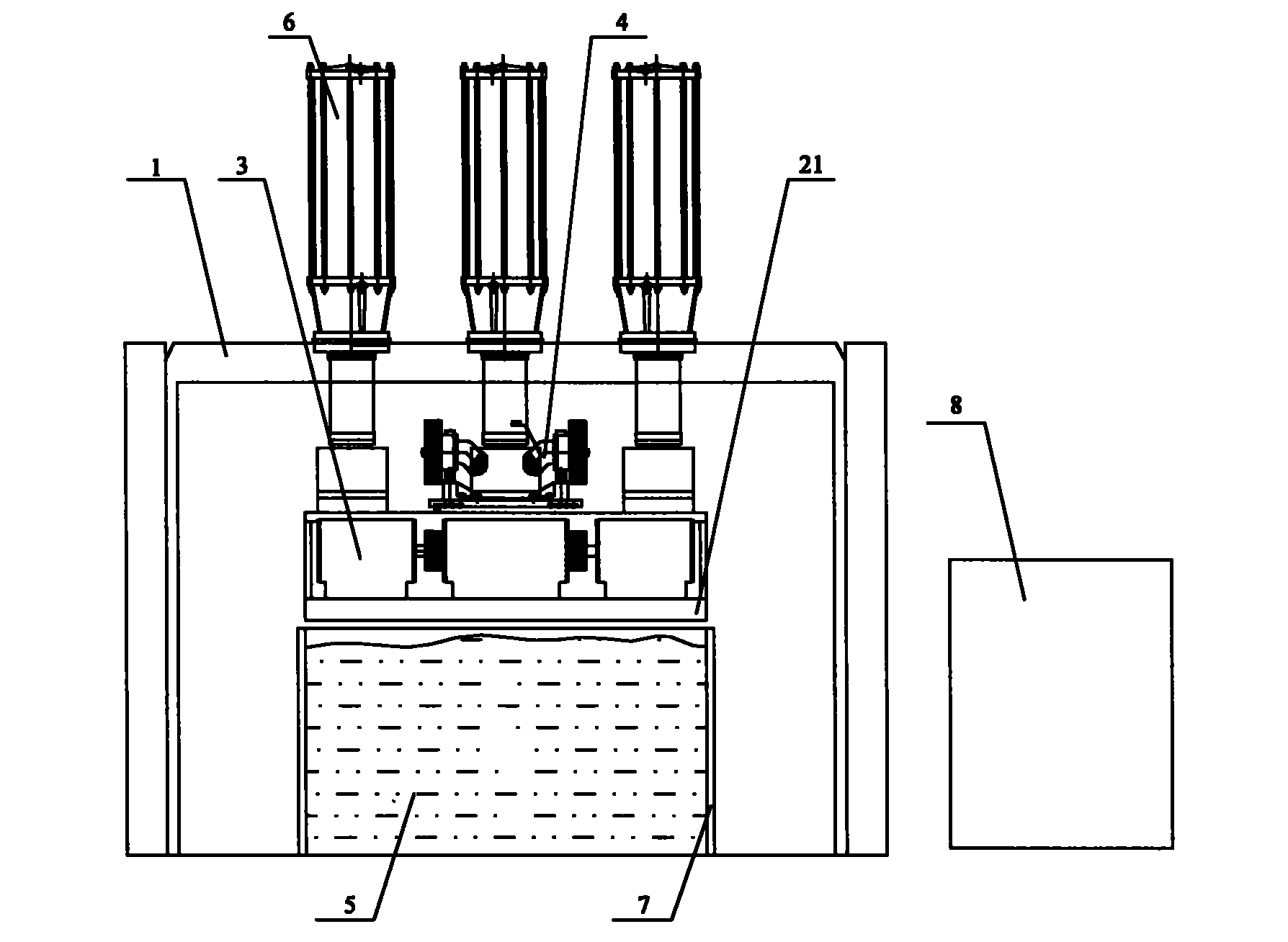

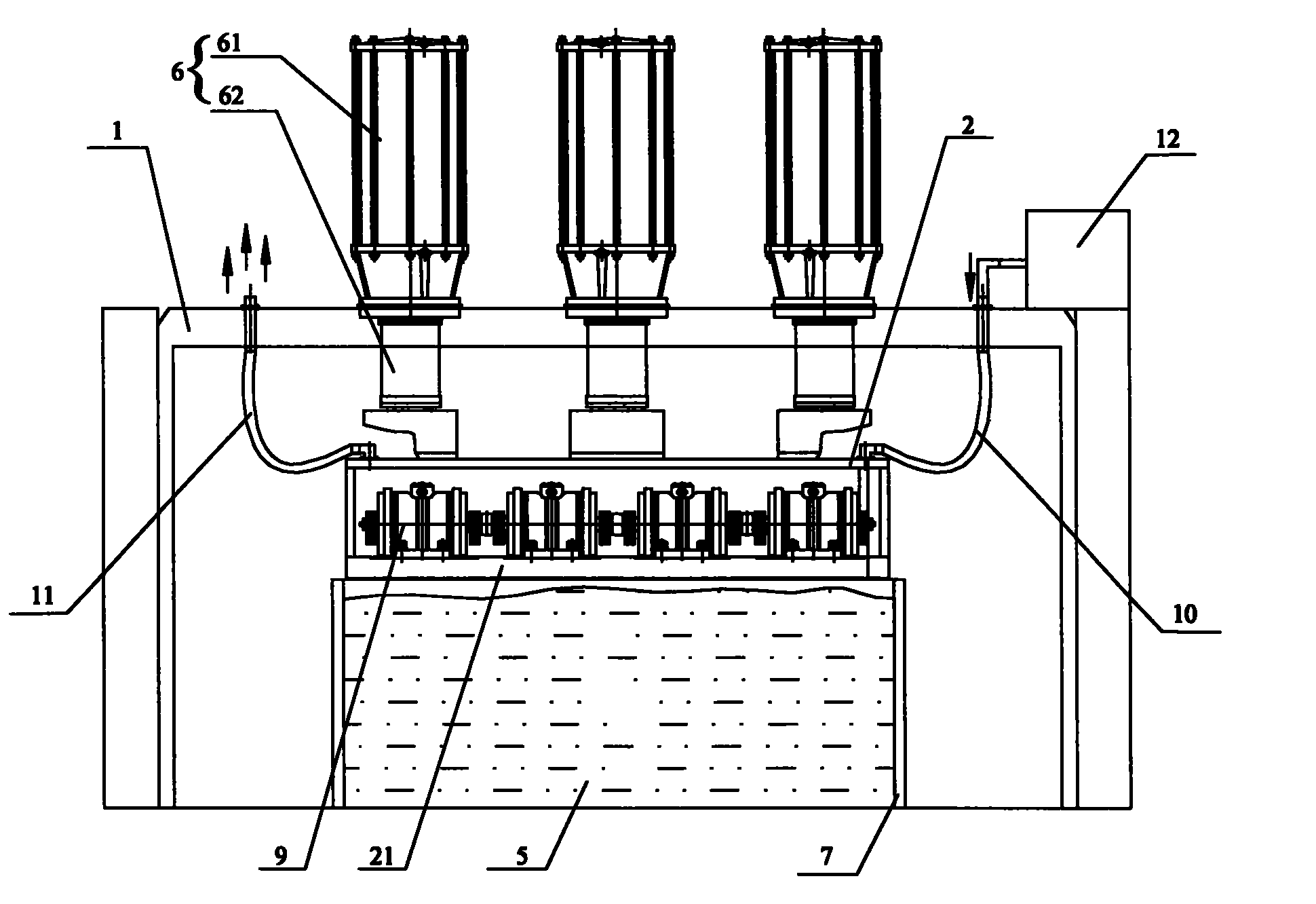

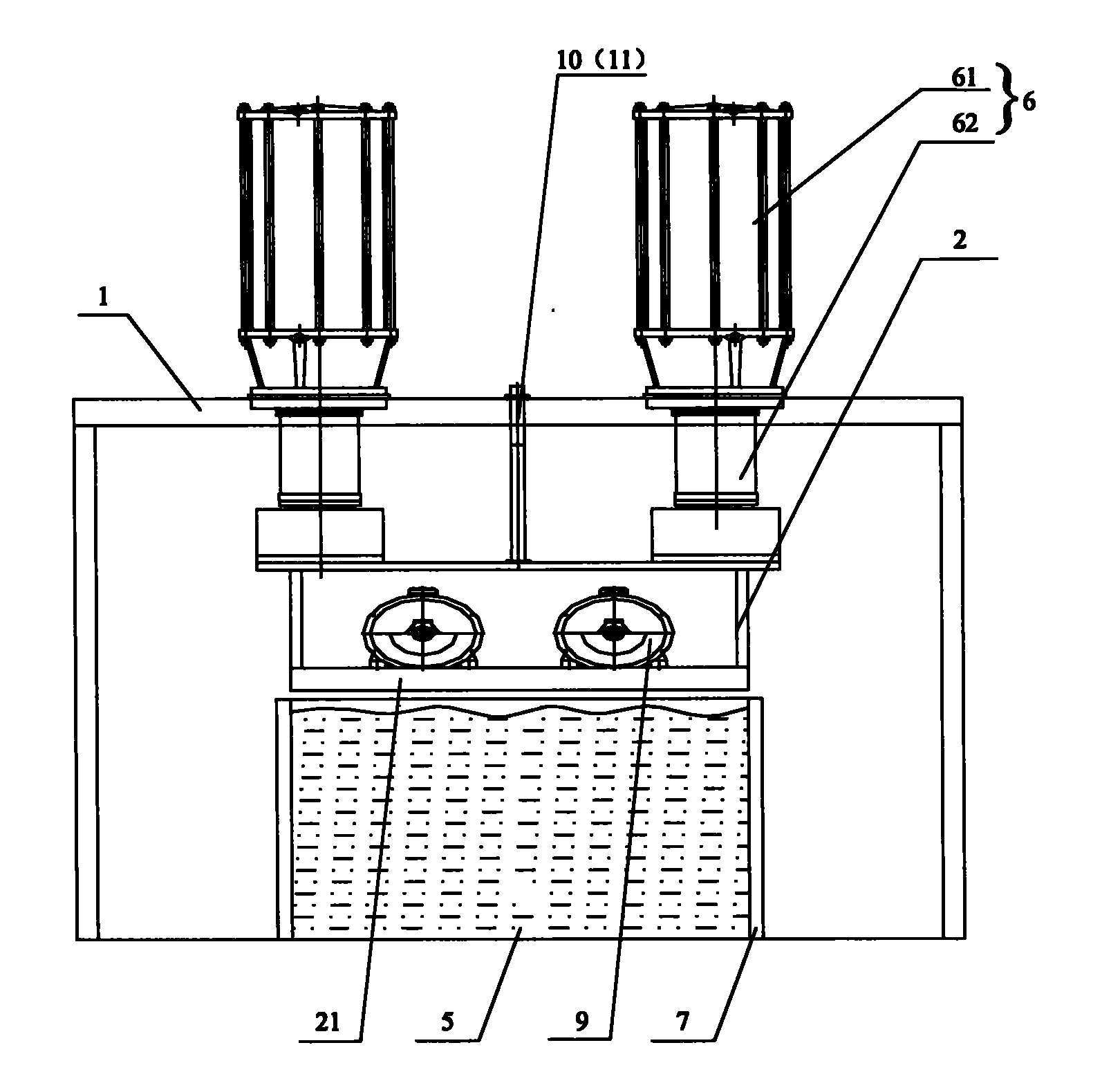

Pressing equipment

The invention provides pressing equipment, comprising a vacuum chamber and a pressurizing mechanism, wherein the pressurizing mechanism comprises a plurality of cylinders and a plurality of pressurizing telescopic rods; the plurality of cylinders are externally arranged above the outer part of the vacuum chamber; the plurality of pressurizing telescopic rods are arranged in the vacuum chamber; the cylinders are correspondingly connected with the pressurizing telescopic rods; in the vacuum chamber, pressing head bodies are connected below the pressurizing telescopic rods; and each pressing head body comprises a sealed cavity for pressing a pressing head of a blank, and is internally provided with at least one vibration motor for providing vibration force for the pressing head. In the pressing equipment, the mechanical defects that an original box body type vibrator is large in power loss, difficult in lubrication, complex in structure, difficult in repairing and maintenance and high in cost and the like are overcome. The pressing equipment is characterized in that the frequency is high, the vibration force is large, the lubrication is easy, the repairing and the maintenance are easy and the cost is low and the like. On the basis of the vibration motor, the pressing equipment has the advantages that the frequency is high and the vibration is large and the like, so that the quality of an artificial stone plate is improved.

Owner:KEDA INDUSTRIAL GROUP CO LTD

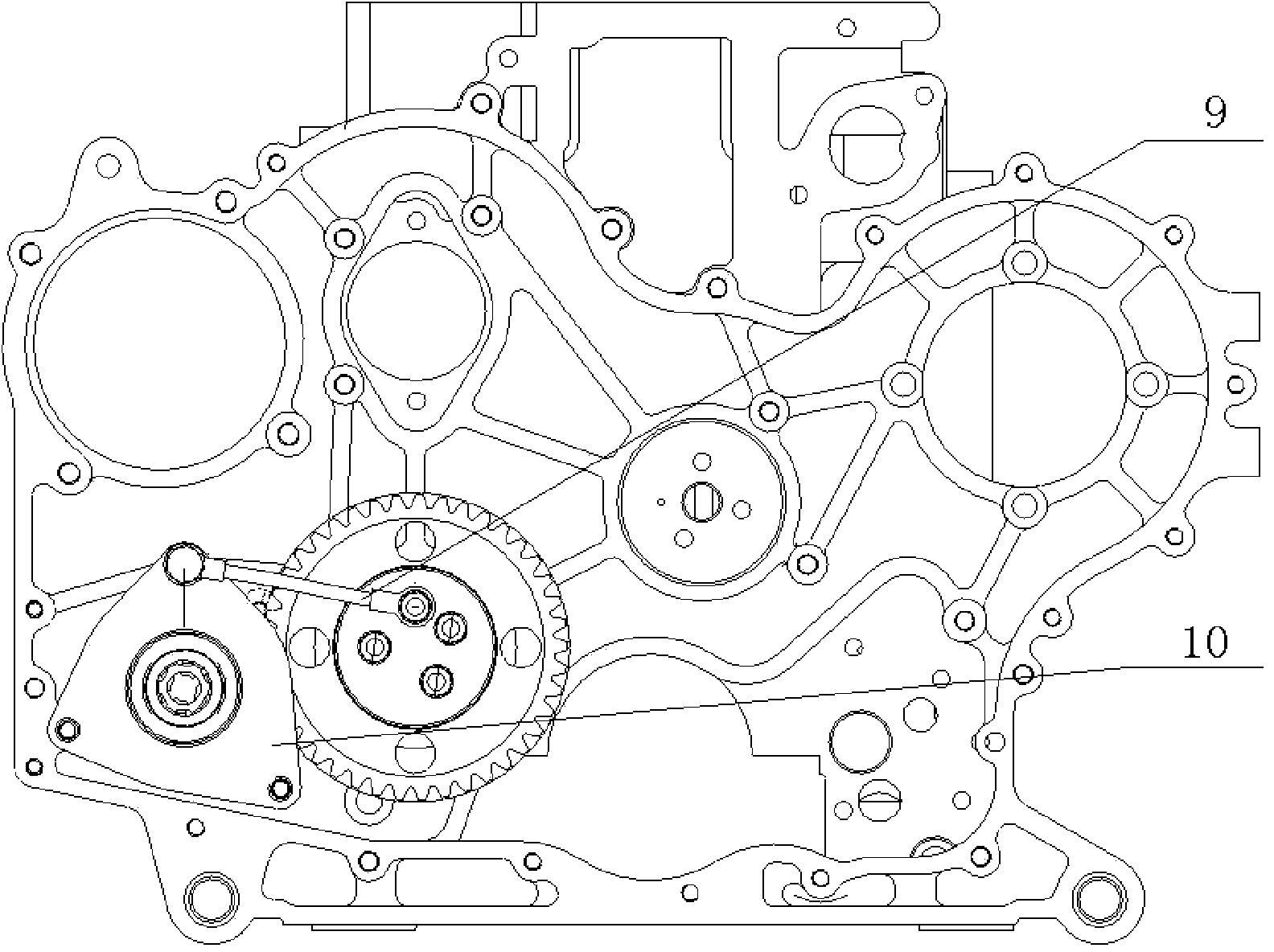

Auxiliary power output structure of diesel engine

The invention discloses an auxiliary power output structure of a diesel engine. The auxiliary power output structure is used for mounting a hydraulic pump and providing power for the hydraulic pump. A gear chamber of the diesel engine and the side face of a gear chamber cover are provided with mounting connectors. The auxiliary power output structure comprises a mounting connecting block and a hydraulic pump gear. The mounting connecting block is provided with a chamber for mounting a gear. The mounting connecting block is provided with a mounting end opening and a hydraulic pump mounting end. The mounting end opening and the mounting connecting opening are matched. The chamber is communicated with the gear chamber. The hydraulic pump gear is arranged in the chamber through a bearing pack. The bearing pack comprises an inner bearing and an outer bearing. The hydraulic pump gear protrudes out of the mounting end opening and can be meshed with the gear in the gear chamber. Lubricating oil in the gear chamber can directly lubricate the hydraulic pump gear and the bearing pack. The structure is convenient to mount and maintain, lubricating is easy, and the structure is simple.

Owner:GUANGXI YUCHAI MASCH CO LTD

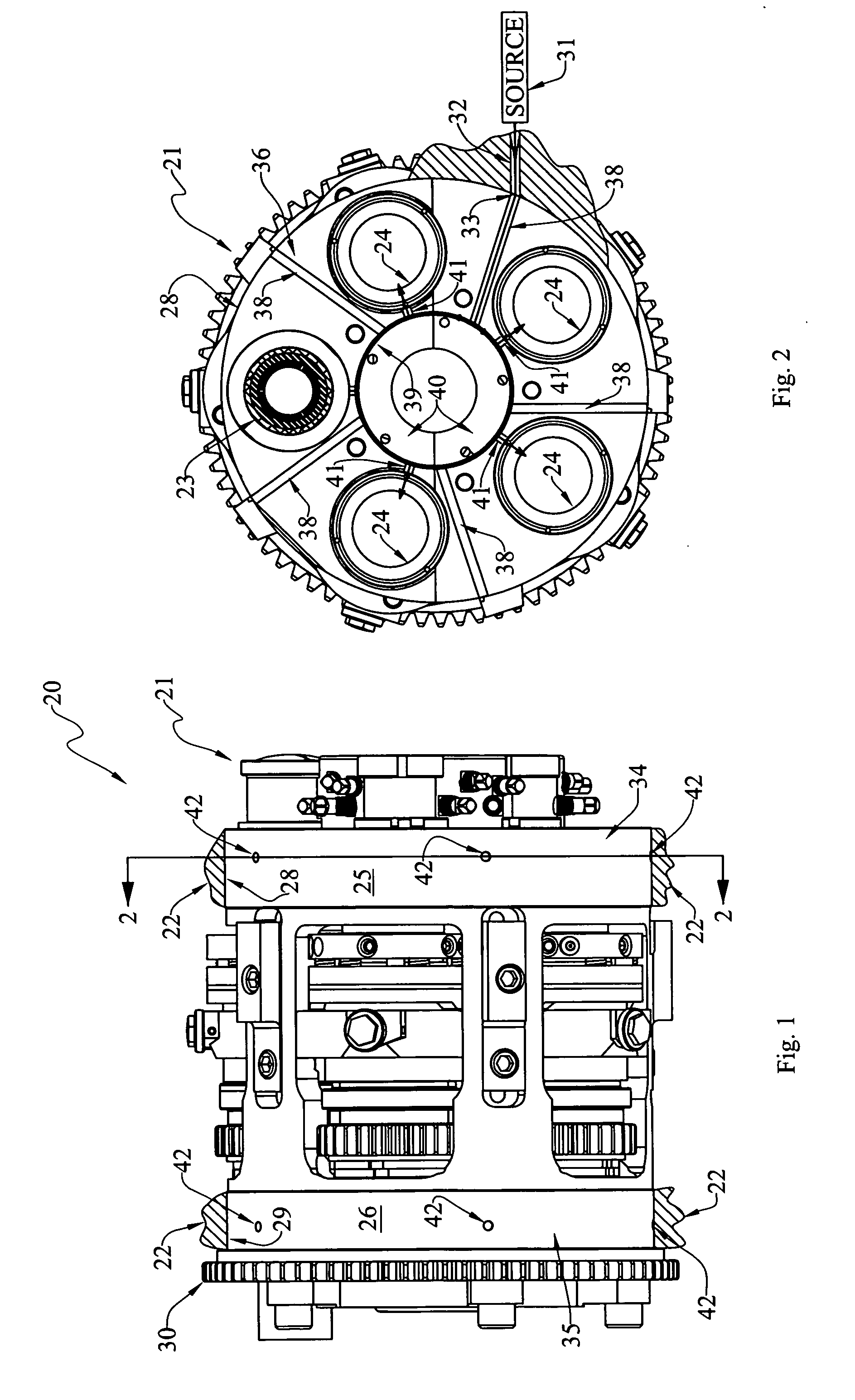

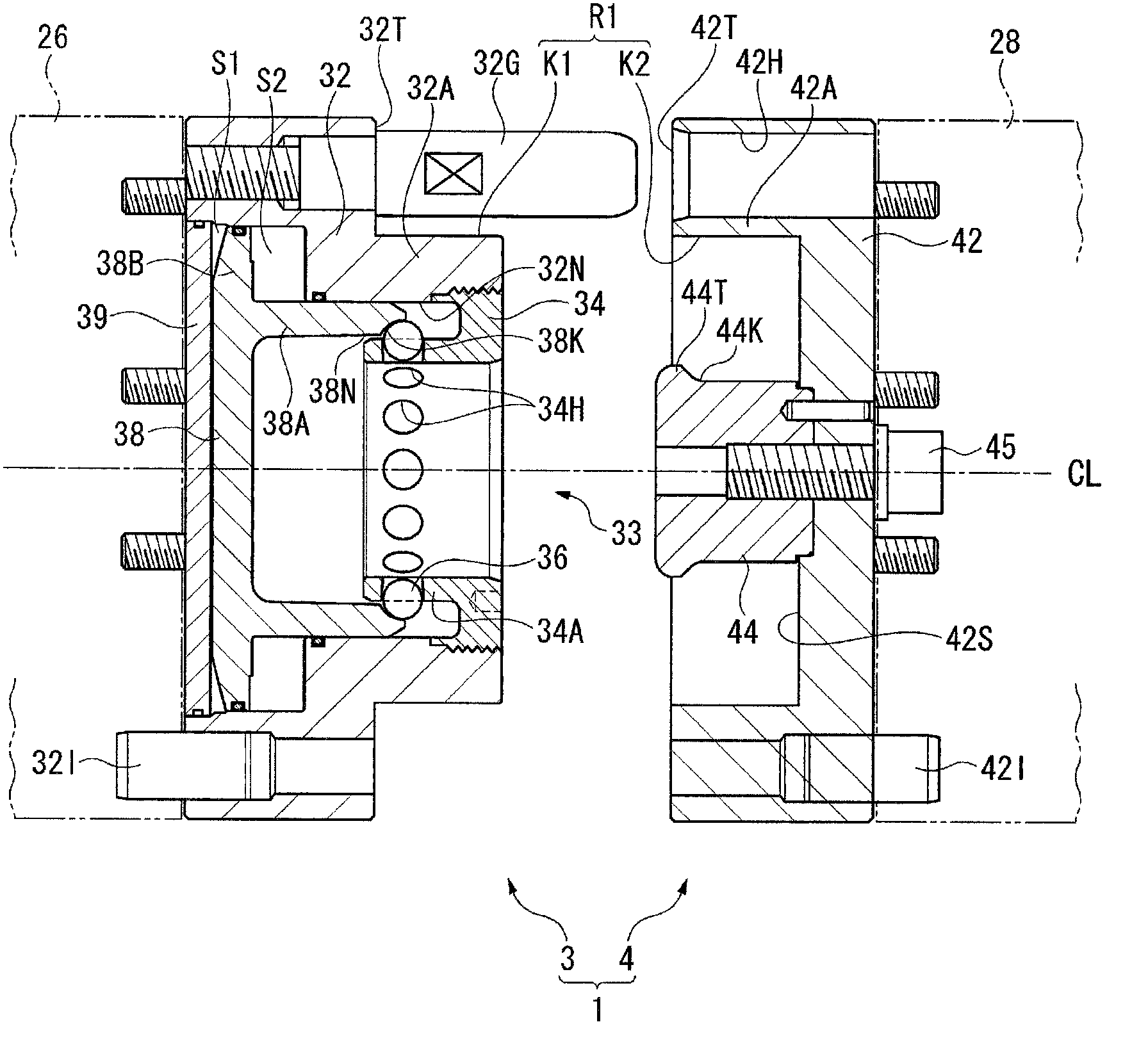

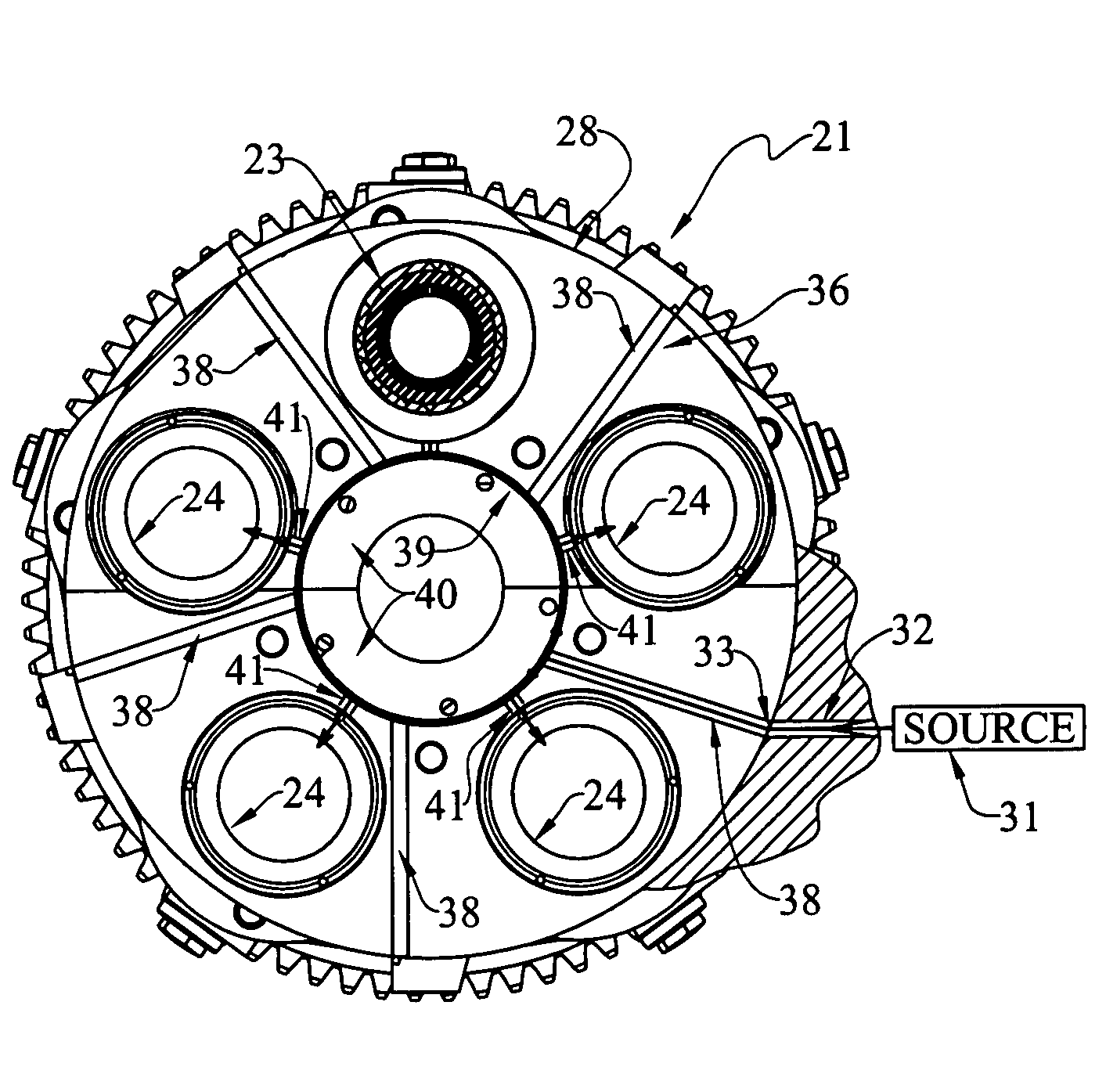

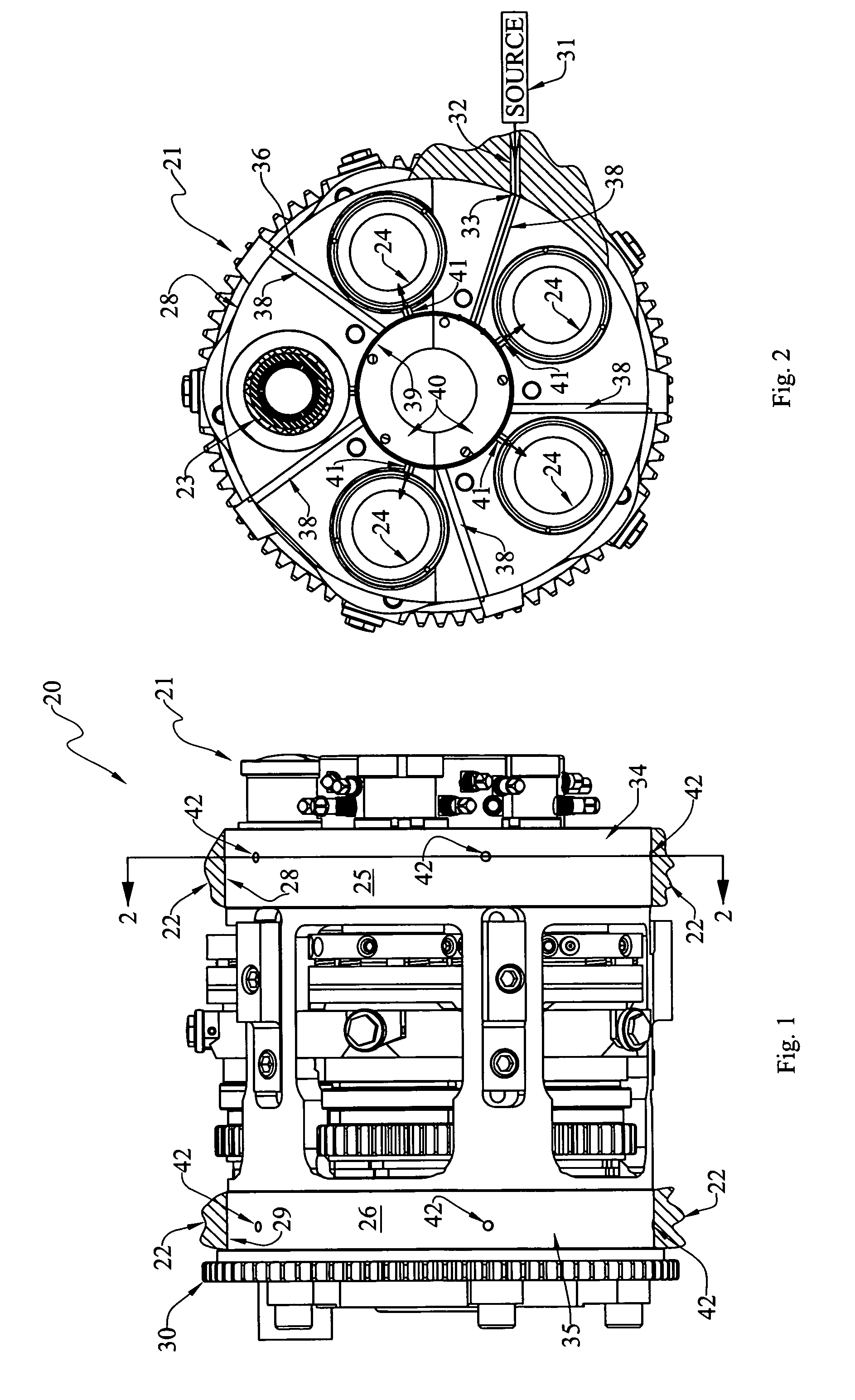

Lubrication system for a multi-spindle automatic screw machine

ActiveUS20070144317A1Reduce decreaseReduces potential leakage pathLathesMachine tool componentsEngineeringBearing surface

An automatic screw machine (20) has a body (22), and a head (21) that is rotatably mounted on the body and that is adapted to be selectively rotated relative to the body between any of a plurality of index positions. The body and head have closely-spaced and facing bearing surfaces (25, 28 and 26, 29), have spindles (23) journalled on the head for rotation relative thereto, and have a source of pressurized lubricant. The improvement broadly includes: at least one body passageway (32) communicating the source with the body bearing surface, the intersection of each body passageway with the body bearing surface defining a body port (33); a head passageway (36) communicating the head bearing surface with the spindle, the intersection of said head passageway with said head bearing surface defining at least one head port (42); and the body and head passageways being so configured and arranged such that lubricant may flow from the source to the spindle only when the head is in the vicinity of the index position such that the body and head ports overlap one another.

Owner:BRINKMAN PROD INC

Emergency lubrication device of simplified architecture for a power transmission main gearbox of an aircraft

ActiveUS10415692B2Simple lubricationImprove reliabilityAircraft componentsValve arrangementsEngineeringLubrication

An emergency lubrication device of simplified architecture for a mechanical system. The emergency lubrication device has a tank, trigger means, at least one pipe, and at least one distribution means. The tank contains a lubrication liquid and it is arranged inside the mechanical system and above the pipes and the distribution means. Each distribution means includes at least one constriction means for limiting the flow rate of the lubrication liquid. The lubrication liquid is heated by the mechanical system, and the viscosity of the lubrication liquid decreases so that the flow rate of the lubrication liquid through each distribution means is substantially equal to or greater than a minimum flow rate so long as the tank contains the lubrication liquid.

Owner:EUROCOPTER

Composite lubricating grease for heavy load bearing and preparation method thereof

PendingCN107502405AUniform sizeImproves strength and hardnessCarbon preparation/purificationAdditivesLithiumEvaporation

The invention relates to the field of lubricating grease, in particular to composite lubricating grease for a heavy load bearing and a preparation method thereof. The composite lubricating grease is prepared from the following ingredients in percentage by weight: 99.2 to 99.8 percent of lithium-based lubricating grease and 0.2 to 0.8 percent of micro carbon spheres and nanometer particles. The micro carbon spheres and nanometer particles are uniformly distributed in the lithium-based lubricating grease by using ethanol as carriers. Compared with the existing ordinary lithium-based lubricating grease, the composite lubricating grease prepared after the ethanol evaporation has the advantage that the improvement is realized in aspects of friction heating, friction mark area and the like.

Owner:HENAN UNIV OF SCI & TECH

Gearbox of corn combine harvester for spikes and stalks

The invention relates to a gearbox of a corn combine harvester for spikes and stalks. The gearbox mainly comprises a box body, a power input shaft, a conveying chain I transmission shaft, a conveying chain II transmission shaft, an upper spike picking roll shaft, a lower spike picking roll shaft, a middle transmission shaft, a cutting hobbing cutter shaft and bevel gears and straight gears which are both arranged on the shafts. The power input shaft drives the conveying chain I transmission shaft and the conveying chain II transmission shaft trough meshing of the bevel gears, and drives the upper spike picking roll shaft through meshing of the bevel gears. The upper spike picking roll shaft drives the lower spike picking roll shaft through meshing of the straight gears, the lower spike picking roll shaft drives the middle transmission shaft through meshing of the straight gears, and the middle transmission shaft drives the cutting hobbing cutter shaft through meshing of the straight gears. All gear transmissions happen in the box body so that the gearbox is convenient to lubricate, simple in structure and high in reliability.

Owner:SHANDONG UNIV OF TECH

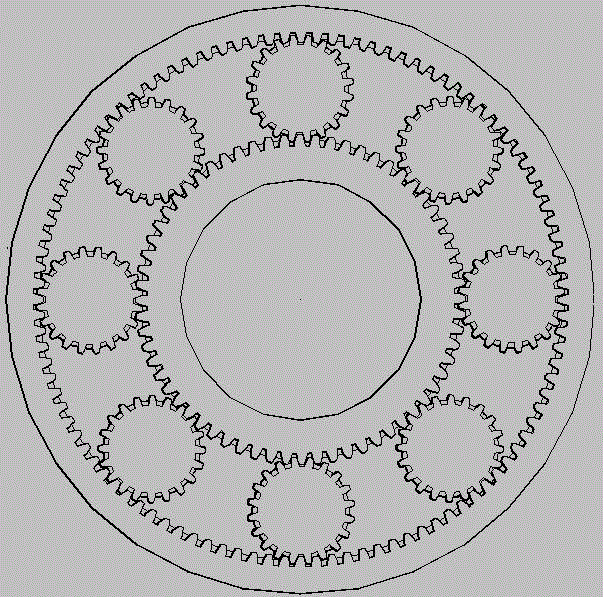

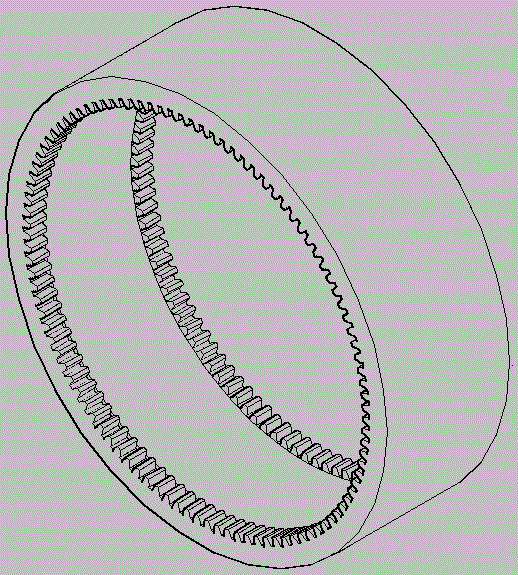

Planetary roller bearing

ActiveCN105805239AIncrease speedImprove efficiencyRolling contact bearingsToothed gearingsRolling-element bearingGear wheel

The invention discloses a planetary roller bearing, relates to the field of mechanical bearings, in particular to a high-speed precise heavy-duty bearing. Two sets of planetary gears are utilized for replacing an ordinary rolling bearing retainer, and the problems that according to the ordinary bearing retainer, due to the fact that the retainer is rubbed and abraded during high-speed running, a rolling body bounces and deviates from the rolling direction, heating of a bearing is intensified, the load is low, and even the bearing is in failure are solved. The planetary roller bearing is the precise heavy-duty bearing high in rotating speed and efficiency, long in service life and high in stability, the lubricating requirement is lower than that of a conventional bearing, and the maintaining cost is low.

Owner:王福成

Horizontal pushing and clamping type two-cylinder double-side braking retarder actuator

The invention relates to a horizontal pushing and clamping type two-cylinder double-side braking retarder actuator comprising a bearer beam, inner supports, outer supports, brake rails and cylinders. The inner supports and the outer supports are arranged on two sides of two base rails, respectively. One brake rail is disposed on the inner supports. The other brake rail is arranged on the outer supports. The cylinders arranged over the bearer beam are connected with the inner supports. A brake unit is provided for any base rail. The actuator can be used with an electro-hydraulic control system to allow single-rail vehicle control and double-rail vehicle control, six-stage control can be achieved, many-stage vehicle control is available, and vehicle control precision is improved. The use of rectangular guide rails ensures large contact area of a kinematic pair and small pressure; lubricating is easy; wear loss is low; the service life is long; a processing technique is simple.

Owner:西安优势铁路新技术有限责任公司

Scroll compressor improved in function of oil circulation and back pressure control

ActiveUS8075291B2Function increaseSimple lubricationRotary/oscillating piston combinations for elastic fluidsEngine of arcuate-engagement typeDrive shaftCoolant

Provided is a scroll compressor having an improved function of oil circulation and back pressure control. The scroll compressor includes: a housing; a drive part for generating a rotational force; a drive shaft driven by the drive part; and a scroll compression part including a stationary scroll fixed regardless of rotation of the drive shaft and having a scroll wrap for compressing sucked fluid and a discharge port for supplying coolant into a discharge chamber, and an orbiting scroll orbited depending on rotation of the drive shaft and having a scroll wrap, characterized in that the coolant compressed by the scroll compression part is conveyed to the discharge chamber, the coolant of the discharge chamber is separated into oil and gas in an oil separator, the gas being discharged through a discharge hole and the oil being supplied into a back pressure chamber through a return path formed in the stationary scroll, and the oil is returned into a suction chamber through a back pressure adjustment valve.

Owner:DOOWON TECHN COLLEGE +1

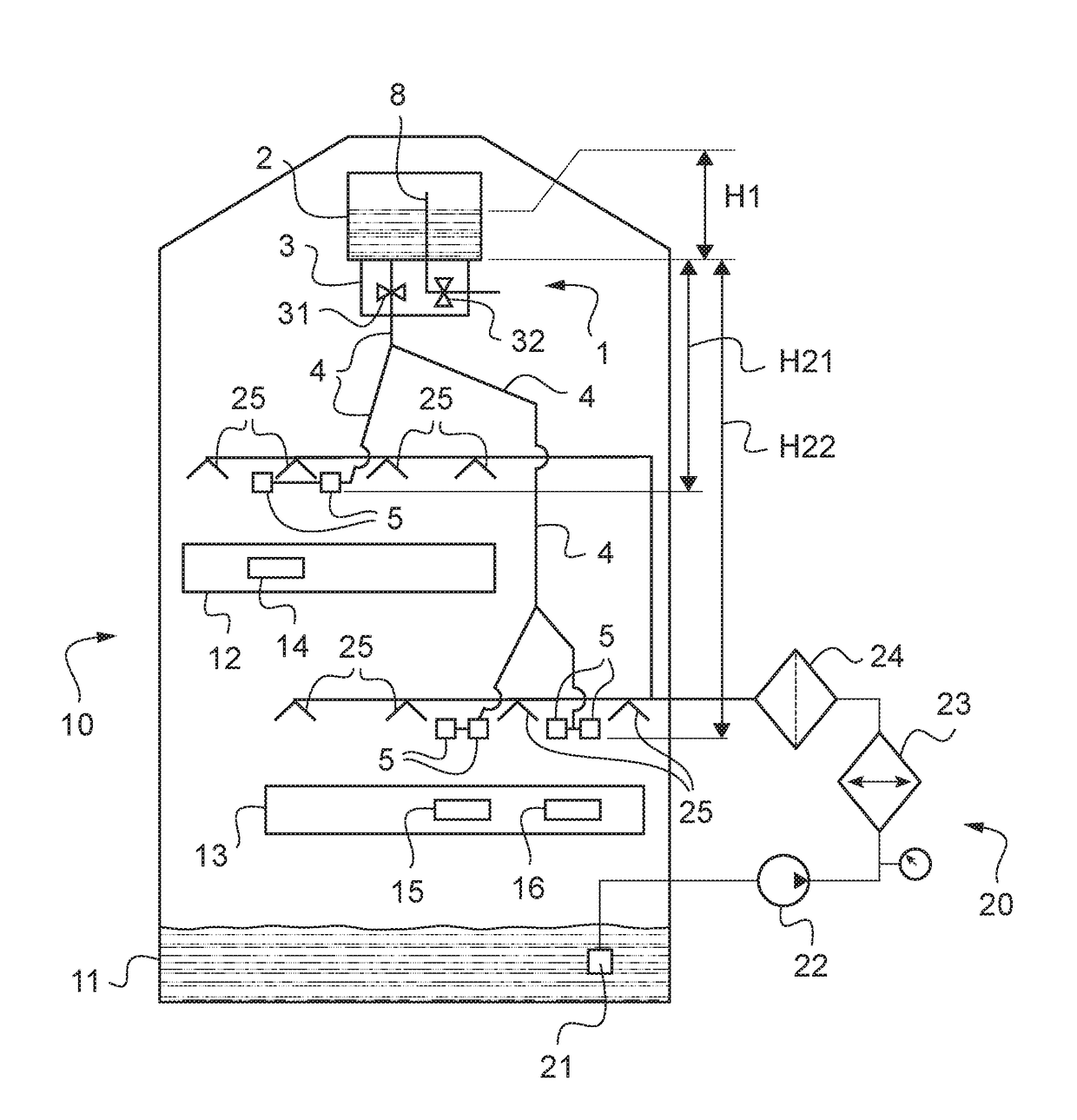

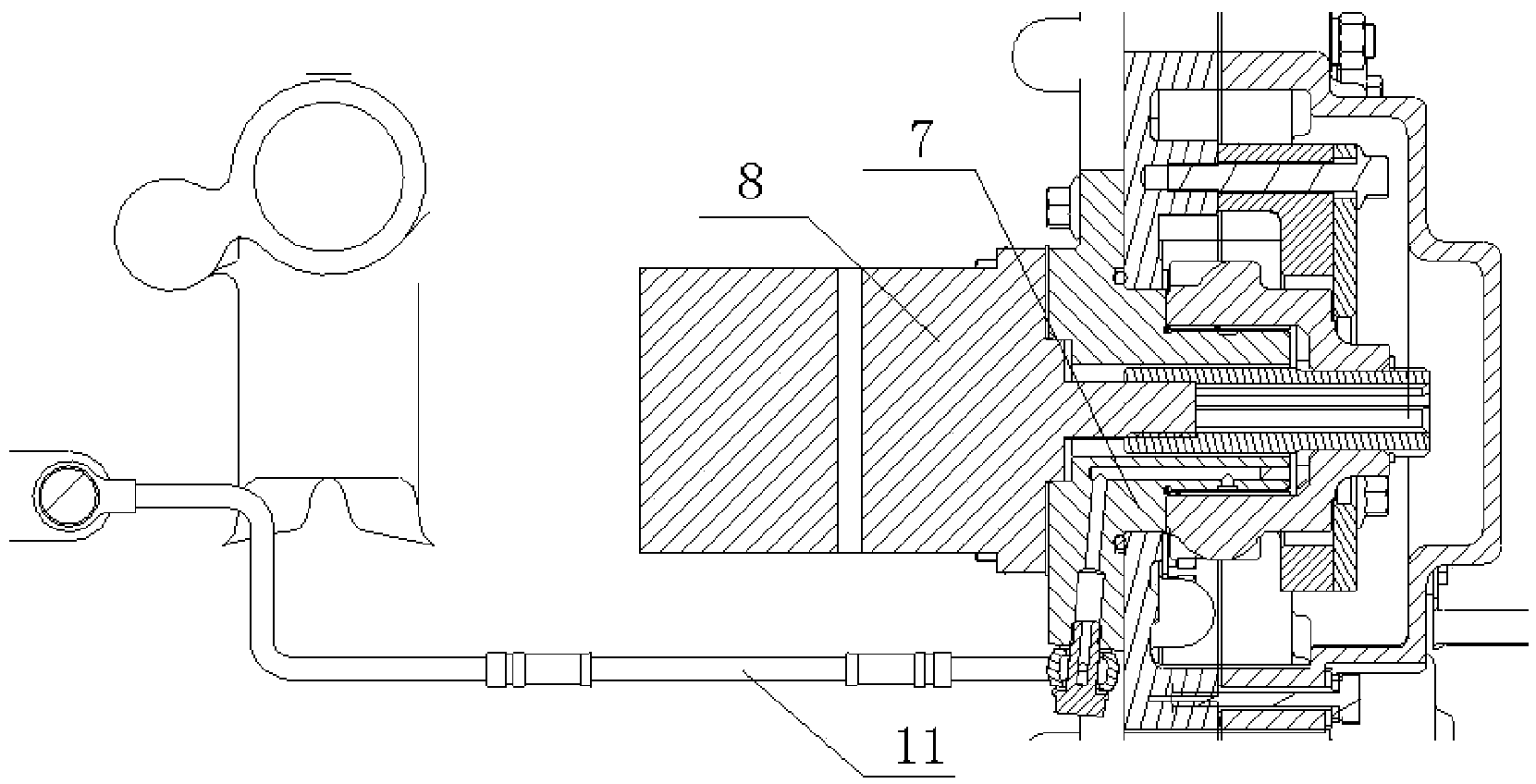

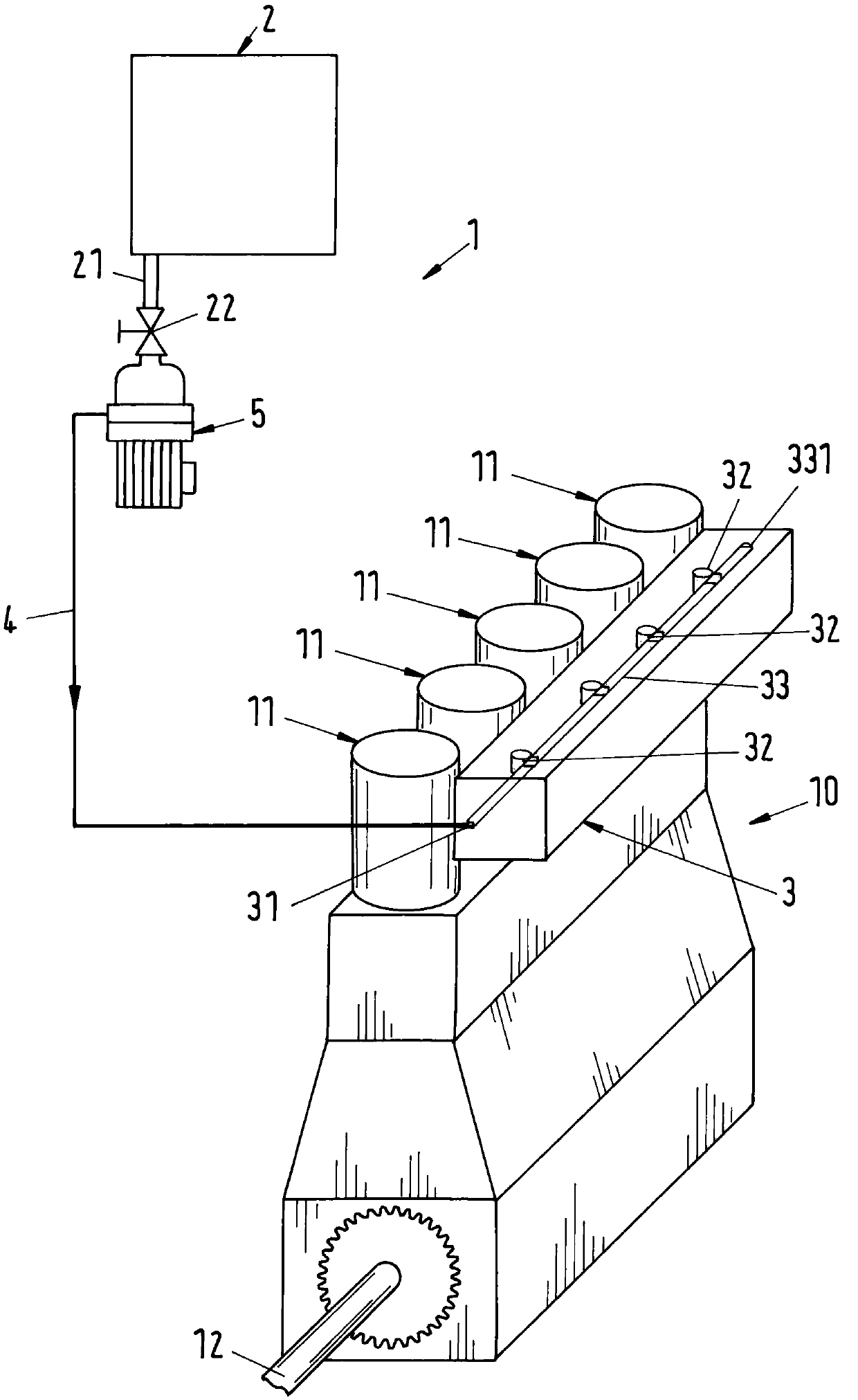

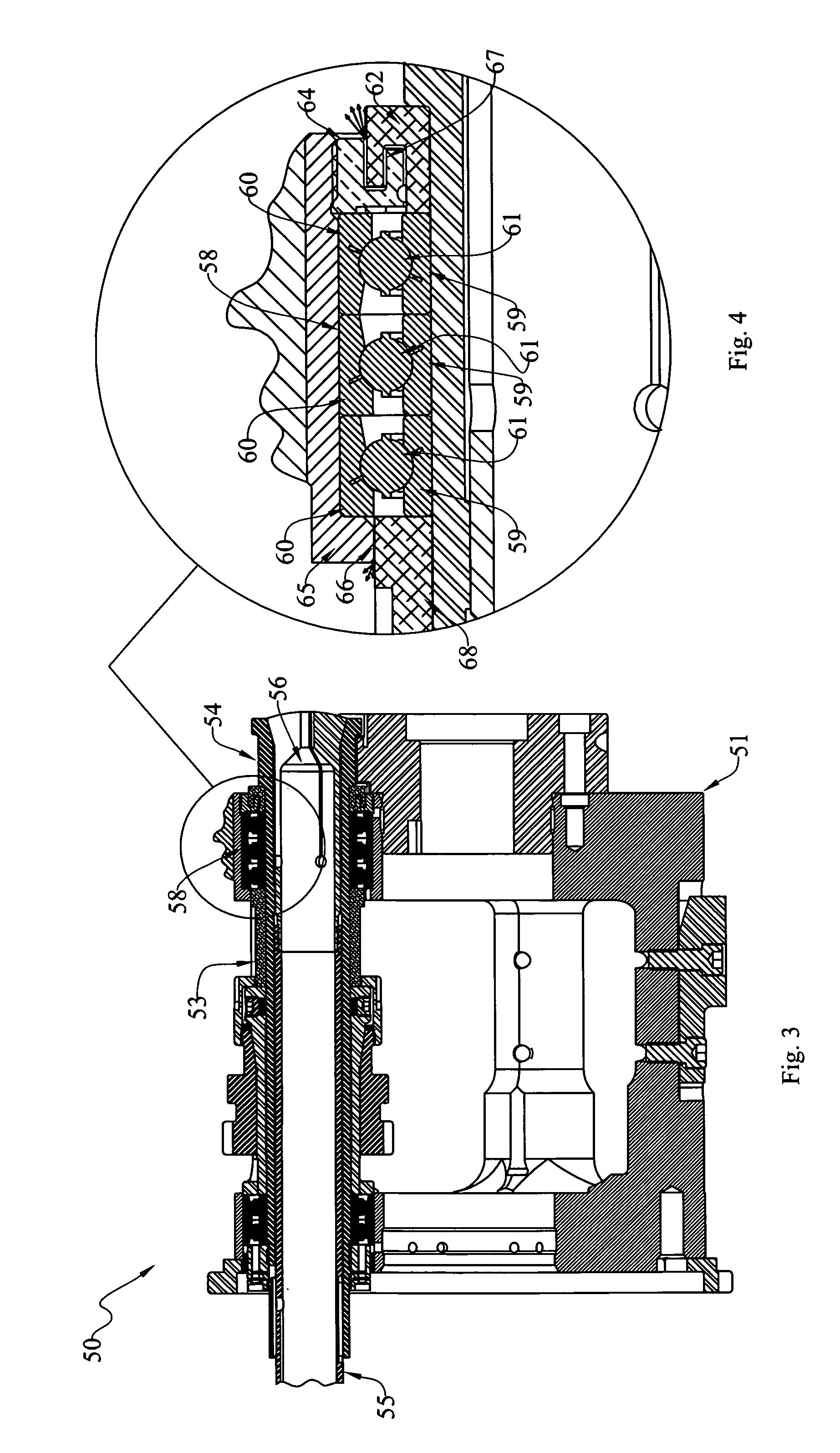

Lubrication arrangement for large diesel engine

PendingCN109763872AAccurate operationAccurate fillingMachines/enginesPressure lubrication with lubrication pumpLine tubingDiesel engine

The invention proposes a lubrication arrangement for a large diesel engine, in particular to the lubrication arrangement for the lubrication of cylinders (11) of a large diesel engine (10), comprisinga reservoir (2) for a lubricant, a lubrication device (3) for being mounted to the large diesel engine (10), and a supply line (4) connecting the reservoir (2) with an inlet (31) of the lubrication device (3) for delivering the lubricant from the reservoir (2) to the lubrication device (3), wherein the lubrication device (3) comprises a plurality of injection pumps (32) for delivering the lubricant into the cylinders (11), and wherein a feed pump (5) is provided, which is arranged to pressurize the lubricant in the supply line (4), so that the lubricant is supplied with an overpressure to theinlet (31) of the lubrication device (3). In addition, a combination of a lubrication arrangement and a large diesel engine is proposed.

Owner:WINTERTHUR GAS & DIESEL

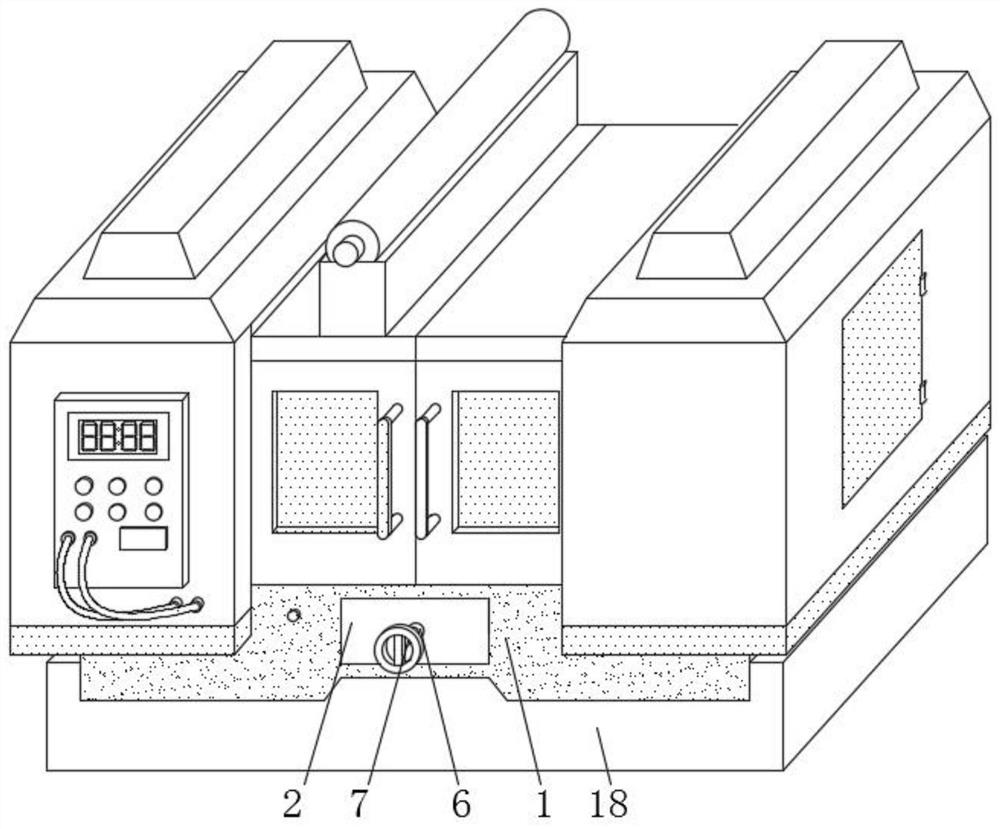

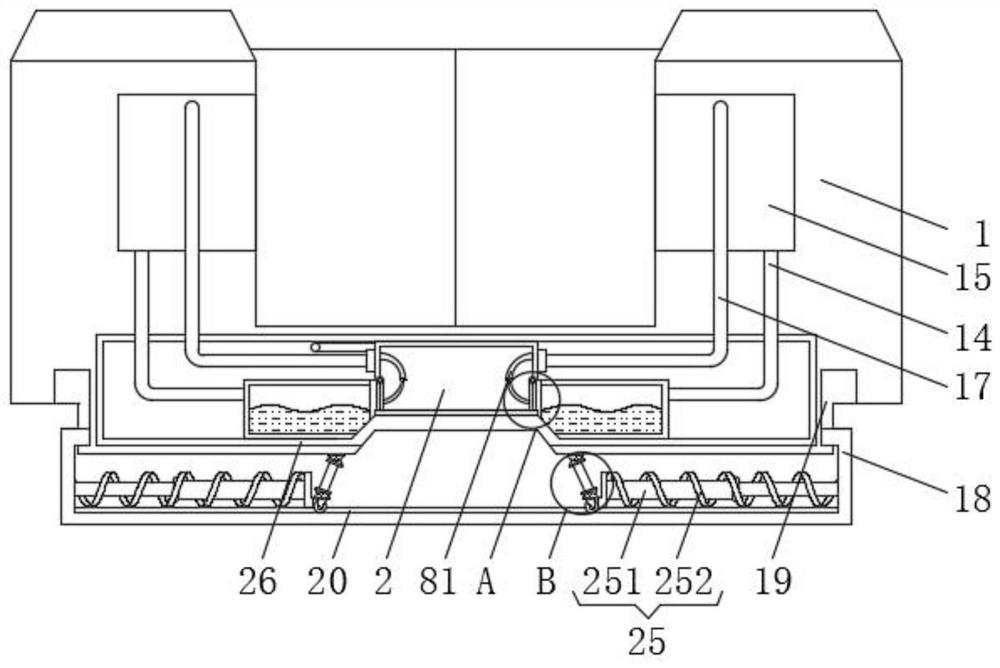

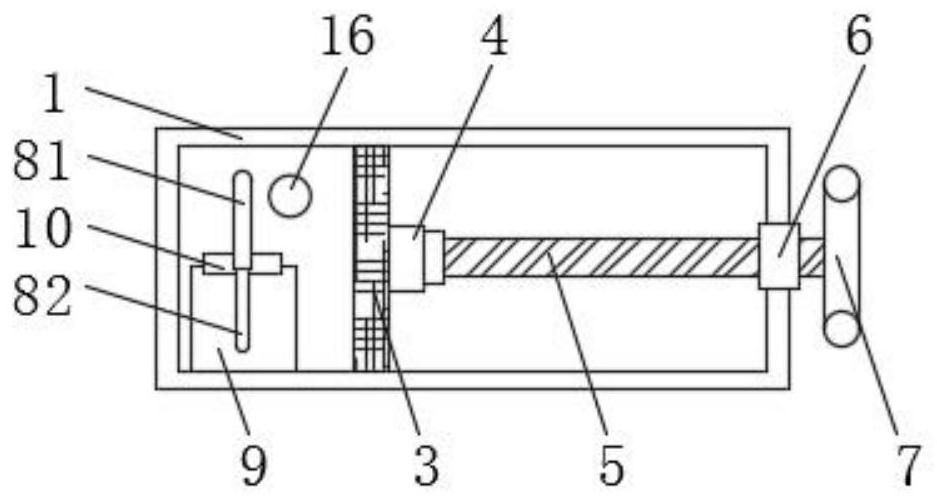

Noise reduction device for vertical machining center

InactiveCN111872738ATimely lubricationSimple lubricationMaintainance and safety accessoriesGear driveGear wheel

The invention discloses a noise reduction device for a vertical machining center, and belongs to the technical field of vertical machining centers. The noise reduction device comprises a vertical machining center body, an oil tank is fixedly connected to the lower surface of the inner wall of the vertical machining center body, a piston plate is arranged in the oil tank, and a rotating mechanism is clamped to the front surface of the piston plate; and one end of the front surface of the rotating mechanism is fixedly connected with one end of the back surface of a threaded rod. According to thenoise reduction device for the vertical machining center, through the arrangement of a first connecting pipe, an oil storage tank and the oil tank, a worker can lubricate a transmission mechanism boxin the vertical machining center body in time, the surface of a gear is not prone to being too dry after oil lubrication, due to the fact that a tooth surface of the gear is isolated through oil, direct contact between metal is avoided, dry friction is changed into liquid friction, the loss of the gear is reduced, the service life of the gear is guaranteed, and noise between gear transmission iseffectively reduced.

Owner:襄阳吉盛邦机械有限公司

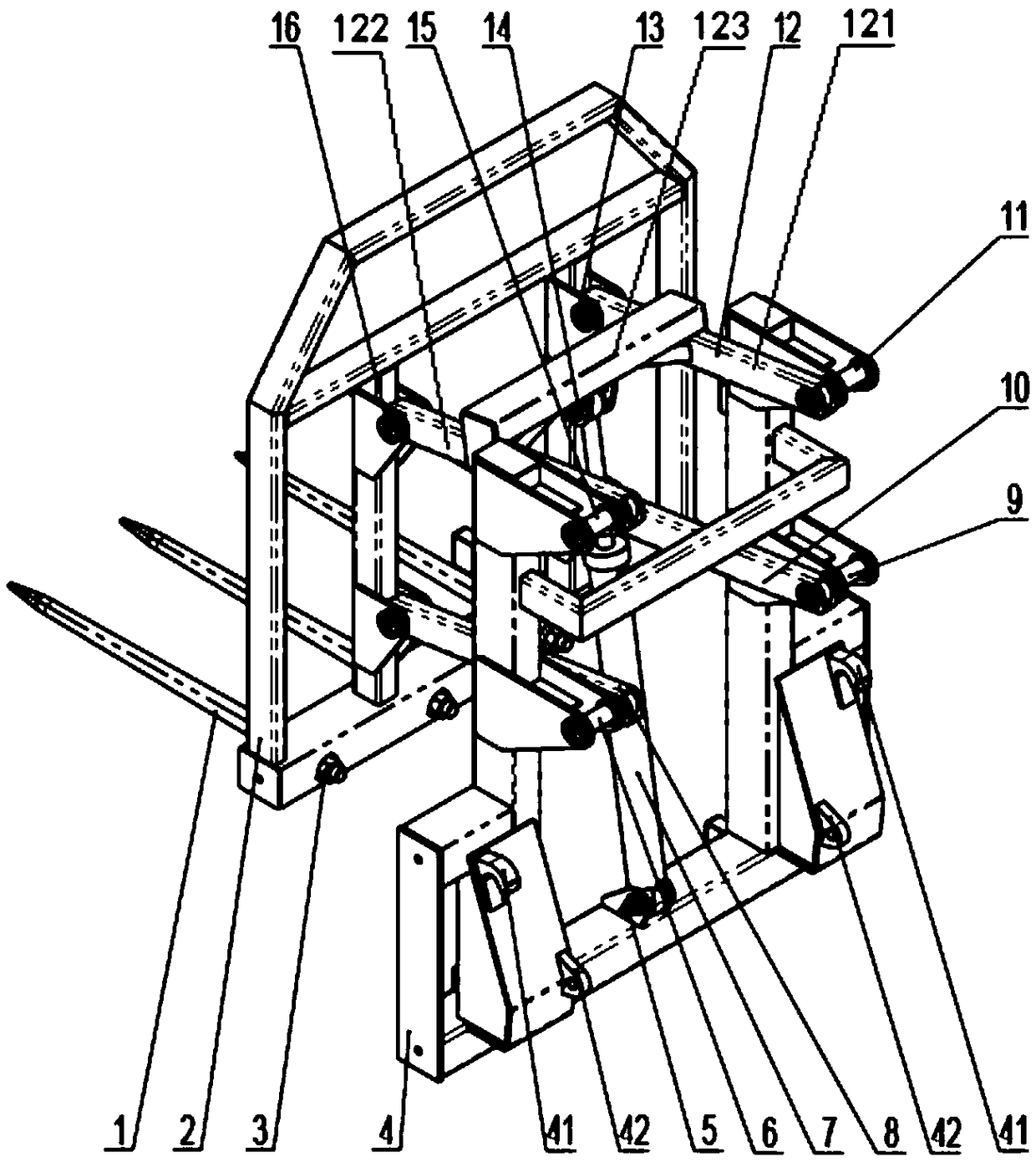

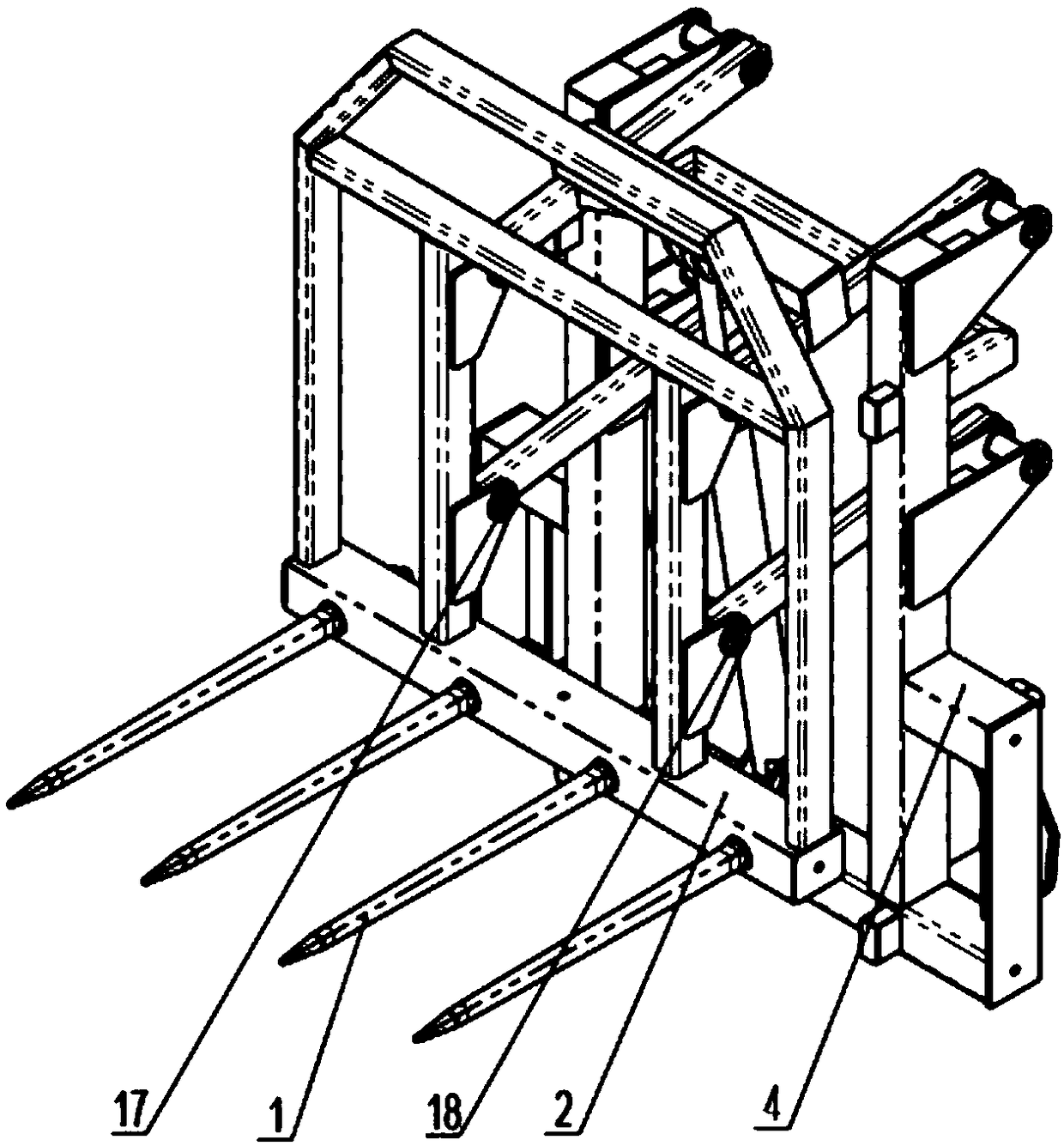

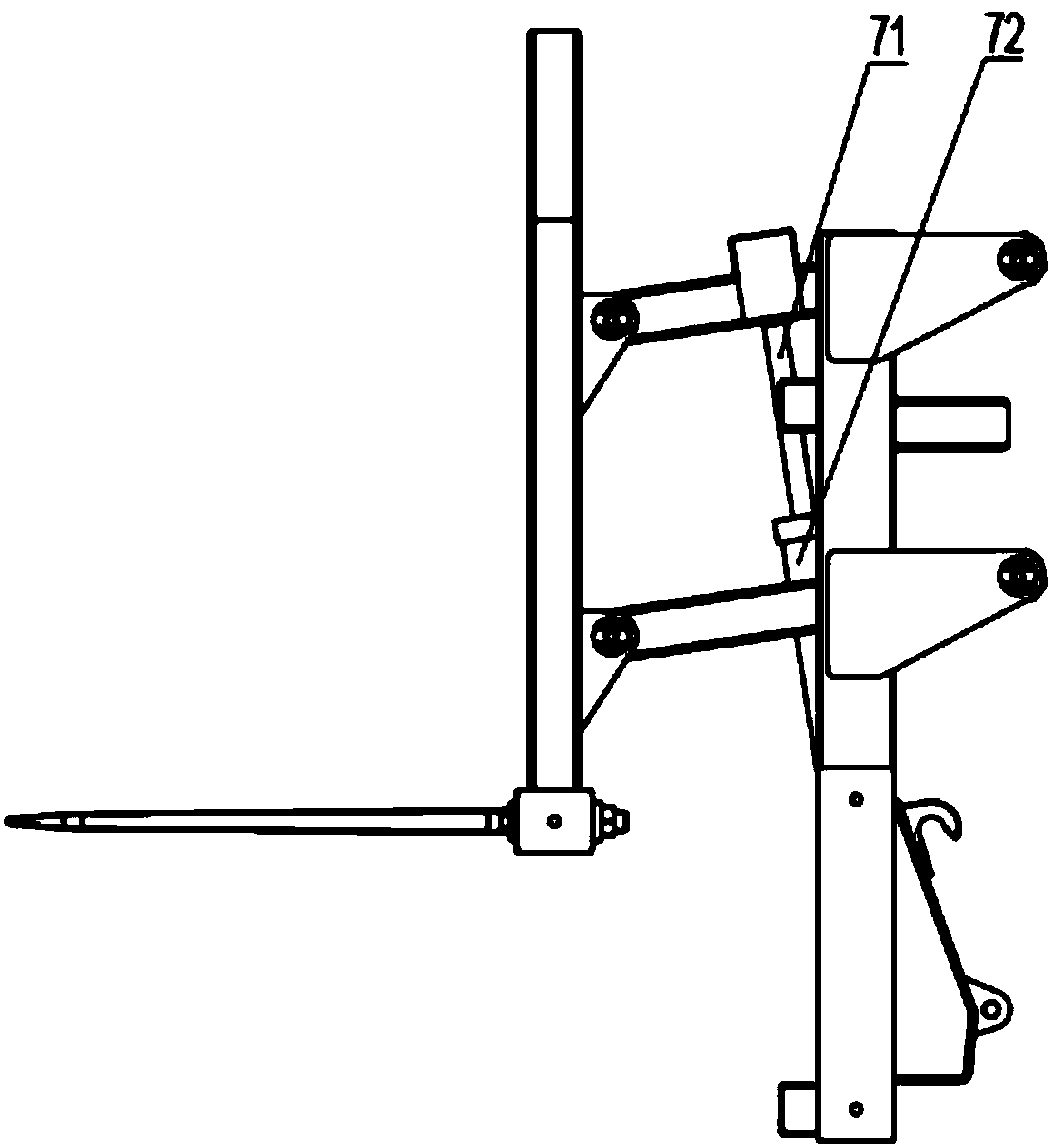

Liftable bale fork fast to replace

PendingCN109362358ACompatible with increasingly higher loading heightsCompact structureHarvestersFixed frameEngineering

The invention discloses a liftable bale fork fast to replace. The bale fork comprises fork teeth, a lifting frame, a fixing frame, an upper pull rod, a lower pull rod I, a lower pull rod II and an oilcylinder; the fork teeth are installed in insertion holes of the lifting frame, and the tail ends of the fork teeth are locked by locknuts; the front end of the upper pull rod is connected with the lifting frame through a pin shaft I and a pin shaft II, and the rear end of the upper pull rod is connected with the fixing frame through a pin shaft III and a pin shaft IV; the front end of the lowerpull rod I is connected with the lifting frame through a pin shaft V, and the rear end of the lower pull rod I is connected with the fixing frame through a pin shaft VI; the front end of the lower pull rod II is connected with the lifting frame through a pin shaft VII, and the rear end of the lower pull rod II is connected with the fixing frame through a pin shaft VIII; a cylinder body of the oilcylinder is connected with the fixing frame through a pin shaft IX, and the end of a piston rod of the oil cylinder is connected with the upper pull rod through a pin shaft X.

Owner:SHANDONG ACADEMY OF AGRI MACHINERY SCI +1

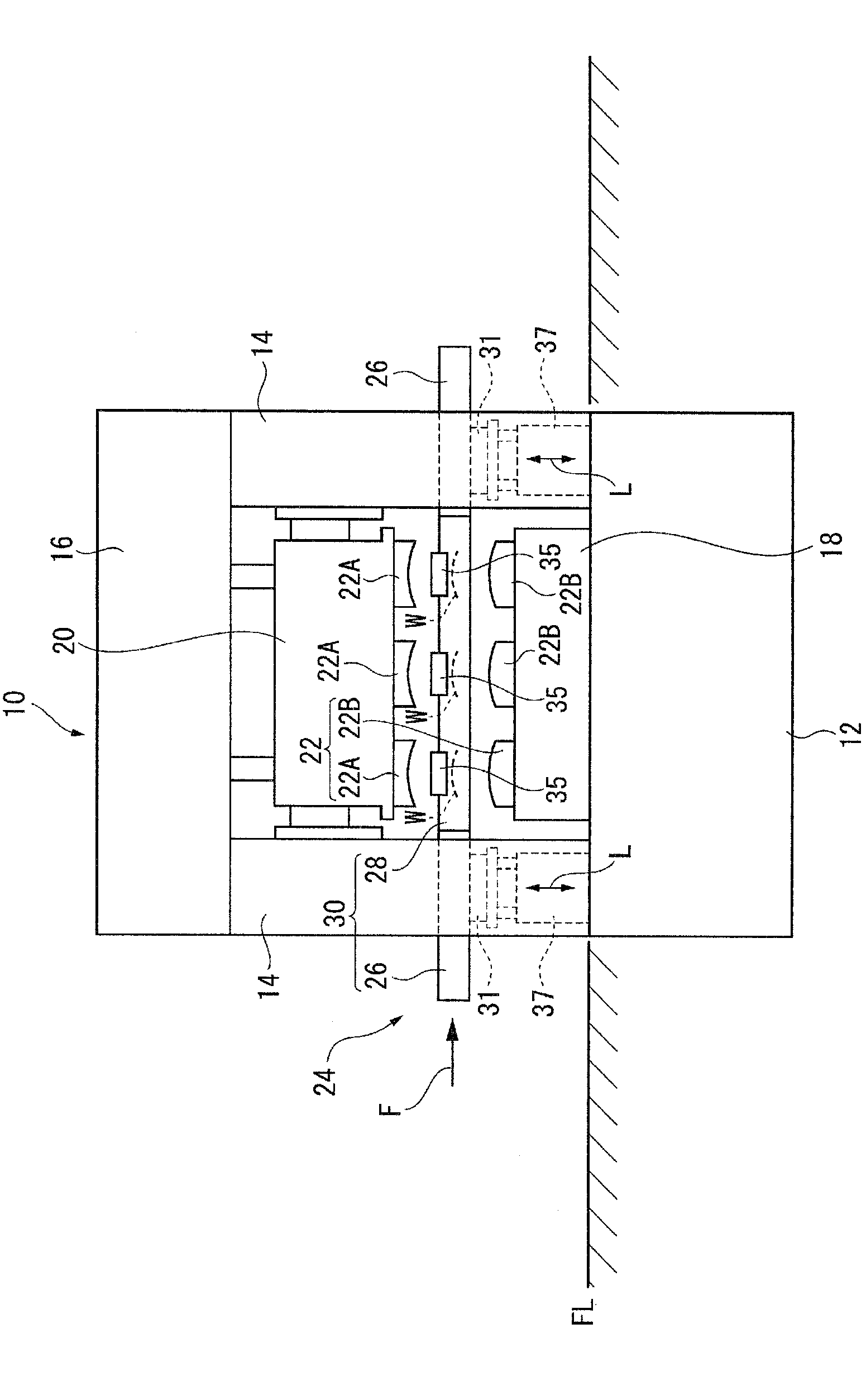

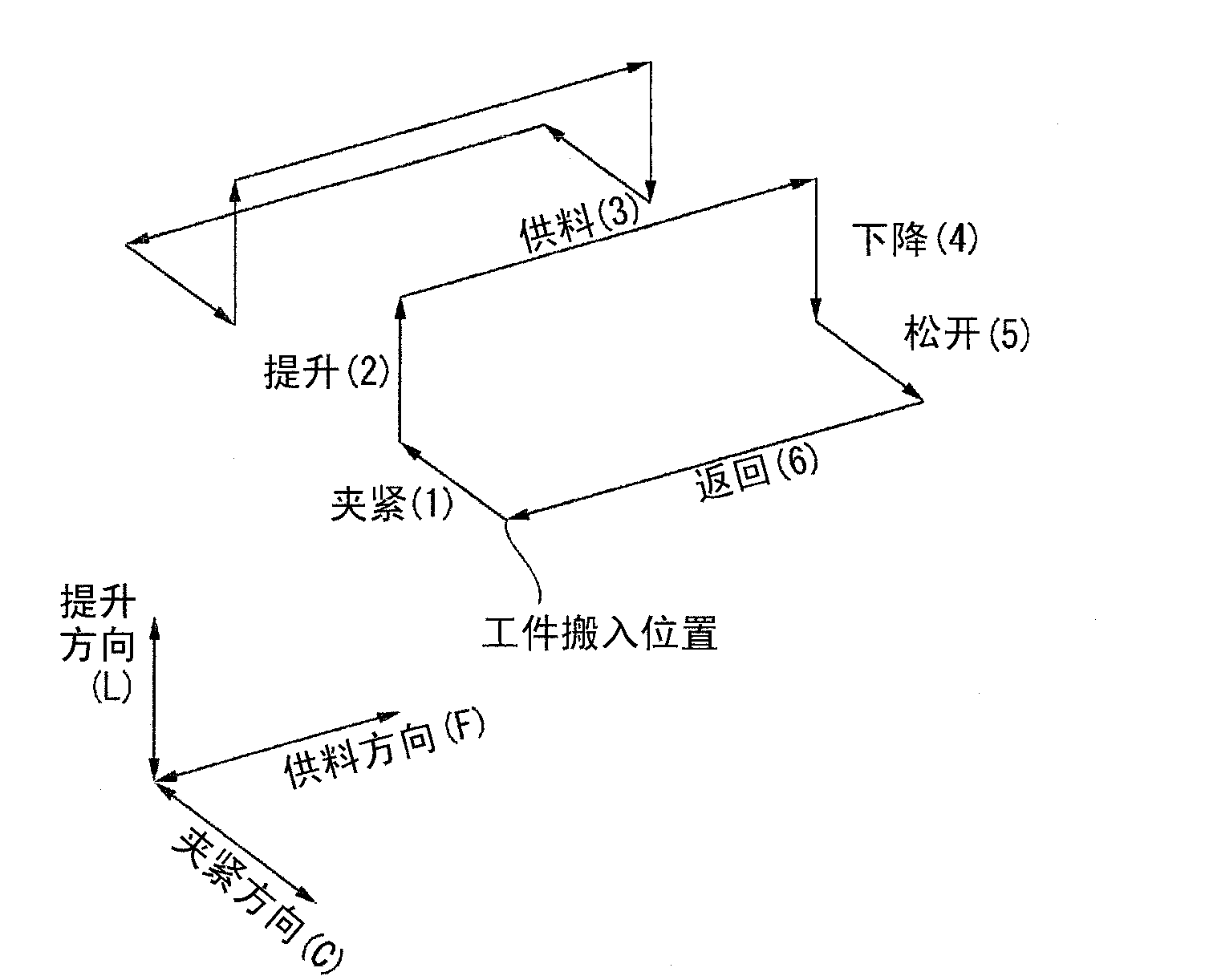

Transfer bar

ActiveCN102725081AImprove rigidityResistance to bending momentMetal-working feeding devicesPositioning devicesEngineeringMechanical engineering

Owner:KOMATSU LTD +2

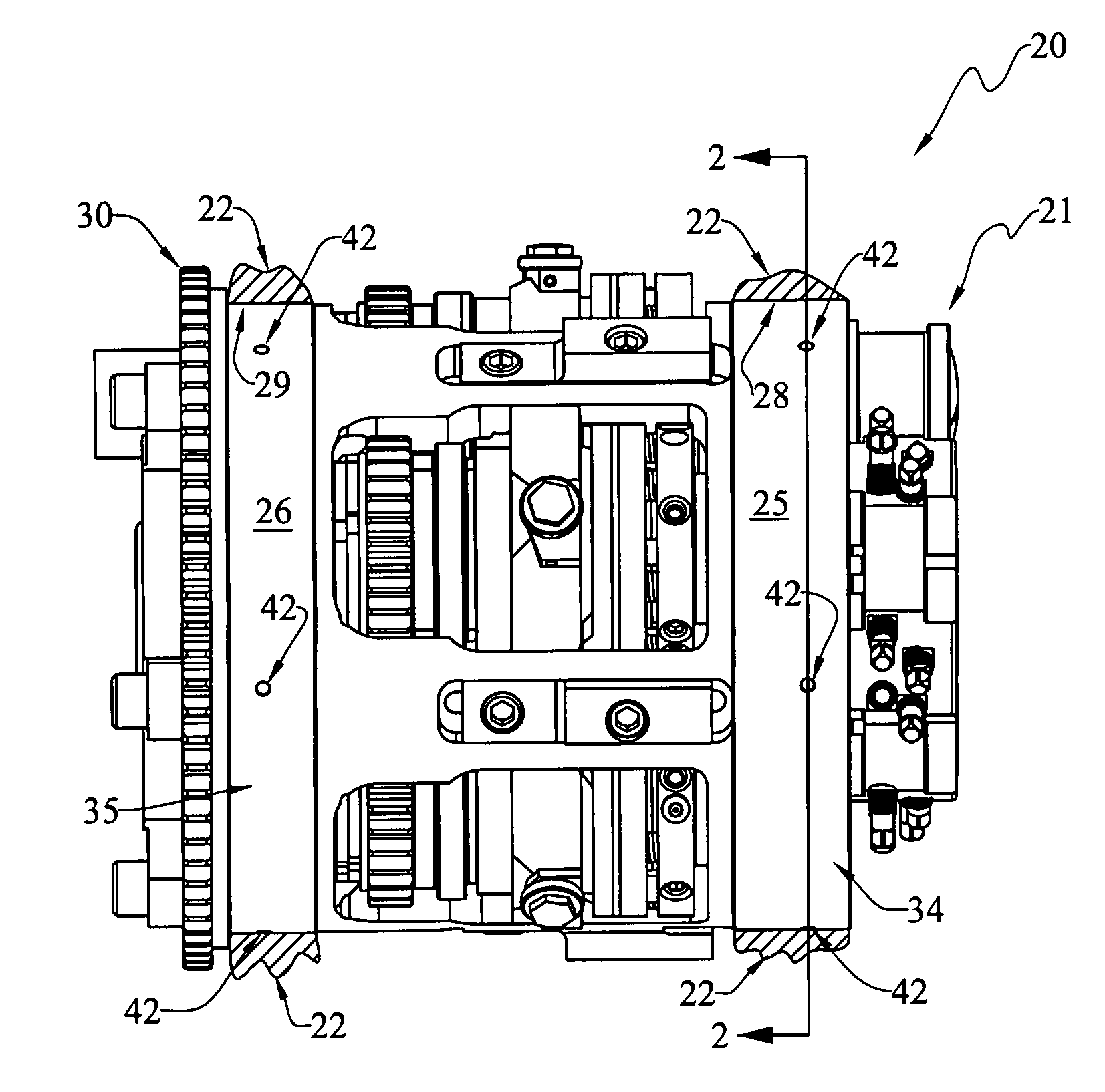

Lubrication system for a multi-spindle automatic screw machine

ActiveUS7946204B2Reduce decreaseReduce leakageLathesAutomatic conveying/guiding stockEngineeringBearing surface

An automatic screw machine (20) has a body (22), and a head (21) that is rotatably mounted on the body and that is adapted to be selectively rotated relative to the body between any of a plurality of index positions. The body and head have closely-spaced and facing bearing surfaces (25, 28 and 26, 29), have spindles (23) journalled on the head for rotation relative thereto, and have a source of pressurized lubricant. The improvement broadly includes: at least one body passageway (32) communicating the source with the body bearing surface, the intersection of each body passageway with the body bearing surface defining a body port (33); a head passageway (36) communicating the head bearing surface with the spindle, the intersection of said head passageway with said head bearing surface defining at least one head port (42); and the body and head passageways being so configured and arranged such that lubricant may flow from the source to the spindle only when the head is in the vicinity of the index position such that the body and head ports overlap one another.

Owner:BRINKMAN PROD INC

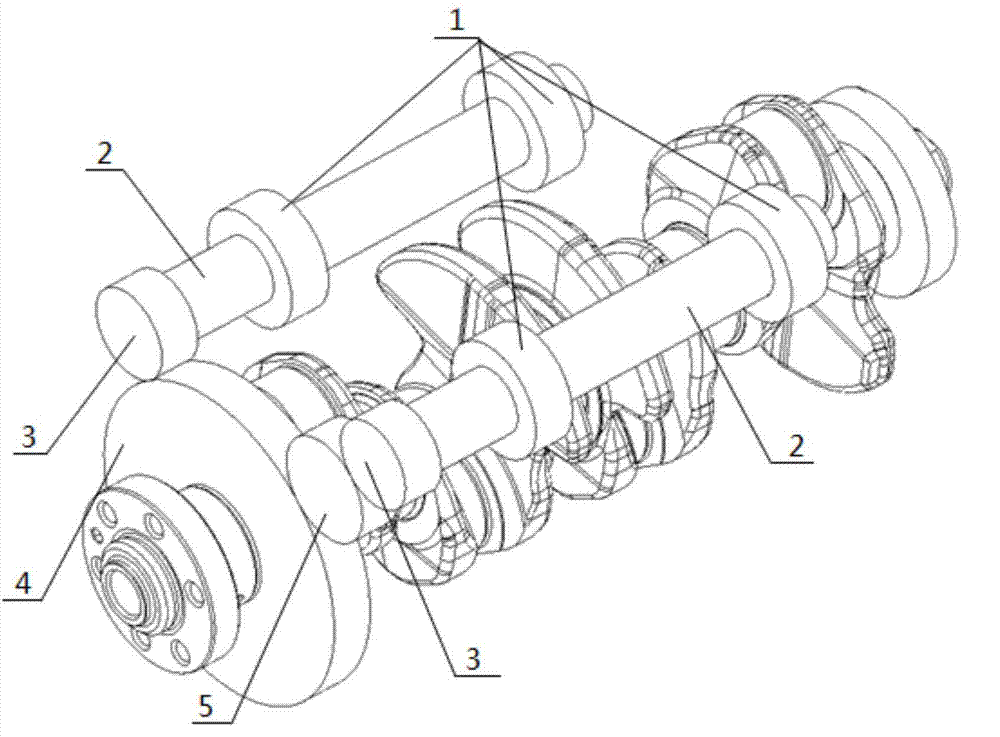

Driving structure of four cylinder engine balance shaft

InactiveCN104776157ASave layout spaceRealize separate driveInertia force compensationMachines/enginesEngineeringLubrication

The invention discloses a driving structure of a four cylinder engine balance shaft. The driving structure of the four cylinder engine balance shaft comprises two pairs of supporting bearings, two balance shafts, two transmission gears, one drive gear and one idle pulley, wherein the drive gear is installed at a first crank arm or formed directly by processing the first crank arm; two balance shafts are respectively installed at the left side and the right side of a four cylinder engine body; the front ends of the two balance shafts are respectively equipped with the transmission gears; one side, equipped with one transmission gear, of one balance shaft is provided with the idle pulley; the idle pulley is engaged with the transmission gears; the drive gear directly drives the transmission gears or drives the transmission gears through the idle pulley; the four cylinder engine body is provided with balance shaft mounting holes; the supporting bearings are installed in the mounting holes in an interference manner; the balance shafts are mounted from one end of the four cylinder engine body and thrust; each balance shaft is supported by two supporting bearings. The driving structure of the four cylinder engine balance shaft provided by the invention has the following advantages that a balance driving mechanism is arranged at the inside of the engine body, compared with the manner of being arranged at the outside, the structure, lubrication and sealing design of a front cover cap can be simplified.

Owner:CHINA NORTH ENGINE INST TIANJIN

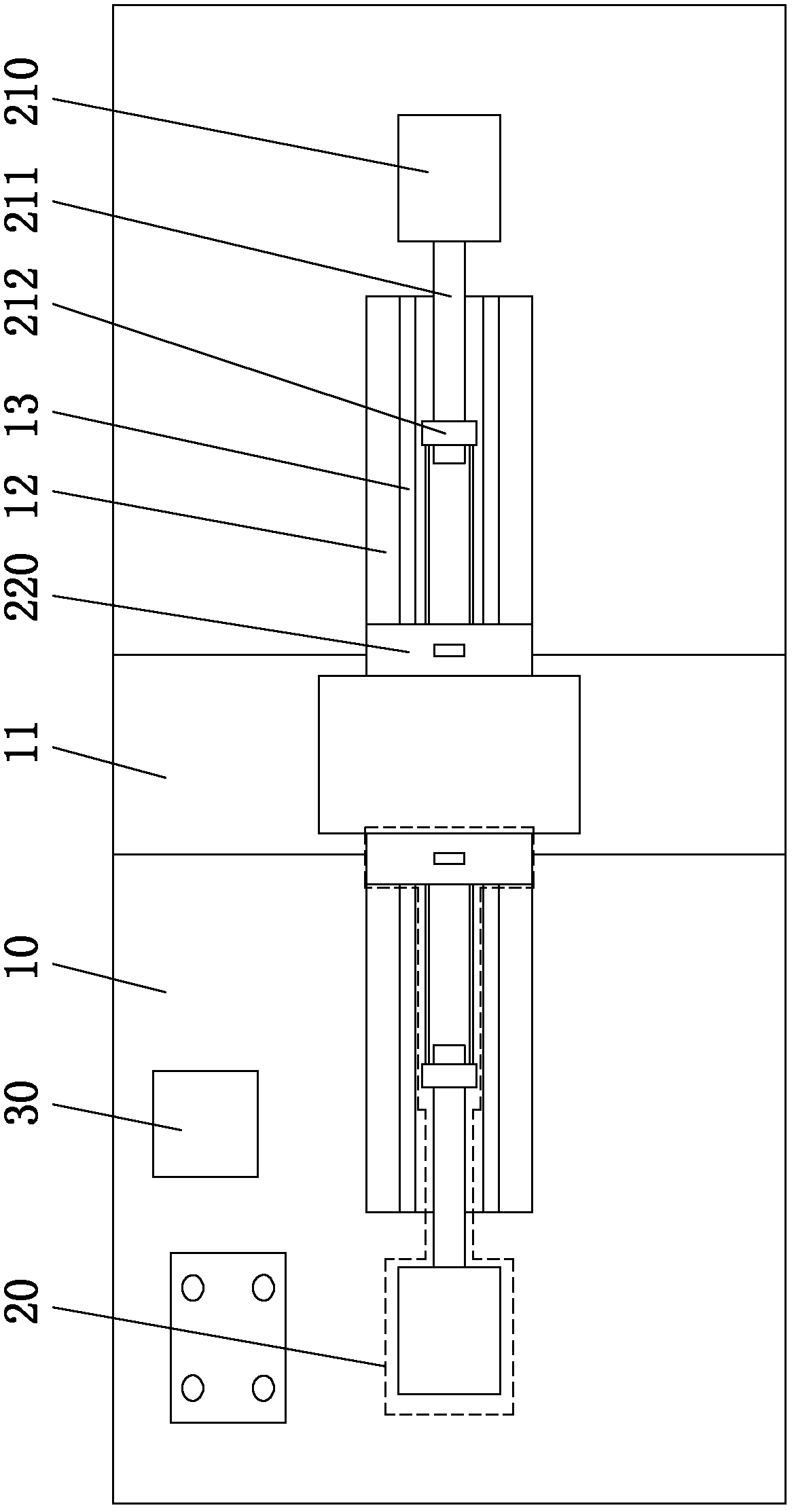

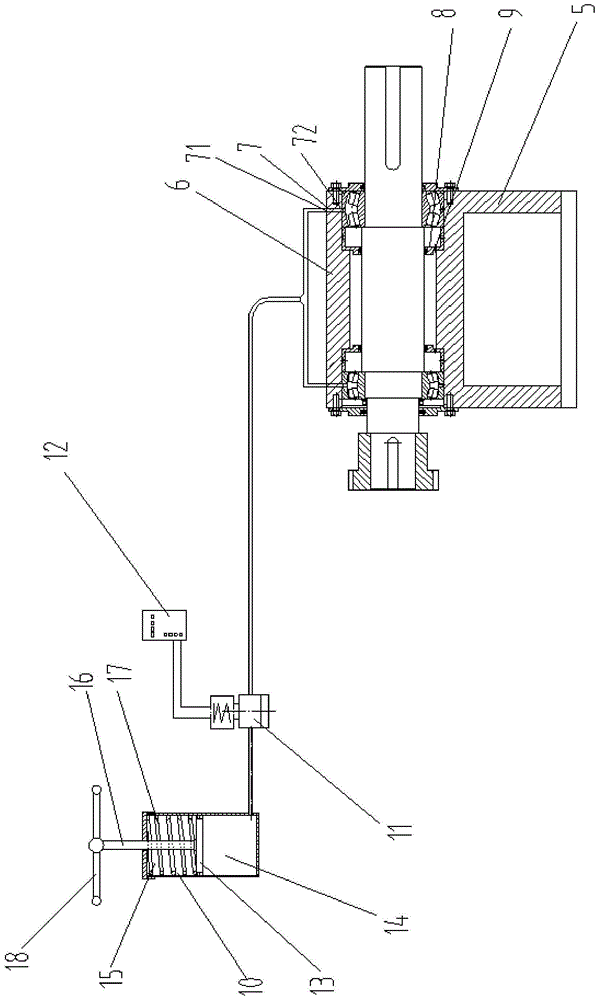

Ultra-high-speed oil-impregnated bearing comprehensive performance testing machine

A comprehensive performance testing machine for an ultra-high speed oil bearing comprises a clamping device for clamping the oil bearing to be tested, a loading device used for applying loading force on the oil bearing to be tested through the clamping device, a dynamic pressure test shaft matched with an inner hole of the oil bearing to be tested, a rotation supporting device used for supporting the dynamic pressure test shaft and a driving device, wherein a temperature measuring hole used for a temperature sensor to be inserted is formed in the top of the clamping device, and both the temperature sensor and the driving device are both connected with an external electric control cabinet; the clamping device is composed of an upper clamping block and a lower clamping block, the oil bearing to be tested is clamped between the upper clamping block and the lower clamping block, the lower clamping block is arranged in a suspended mode through lifting ropes, connected with the loading device, at the two ends of the lower clamping block, and the loading device applies downward loading force on the upper clamping block. The comprehensive performance testing machine for the ultra-high speed oil bearing is overall high in repeatability and accuracy, long in service life, capable of having the self-cooling function, easy to operate and lubricate, simple in structure, low in manufacturing cost, stable in performance, high in intelligence degree and good in practical effect.

Owner:洛阳精一新材料科技有限公司

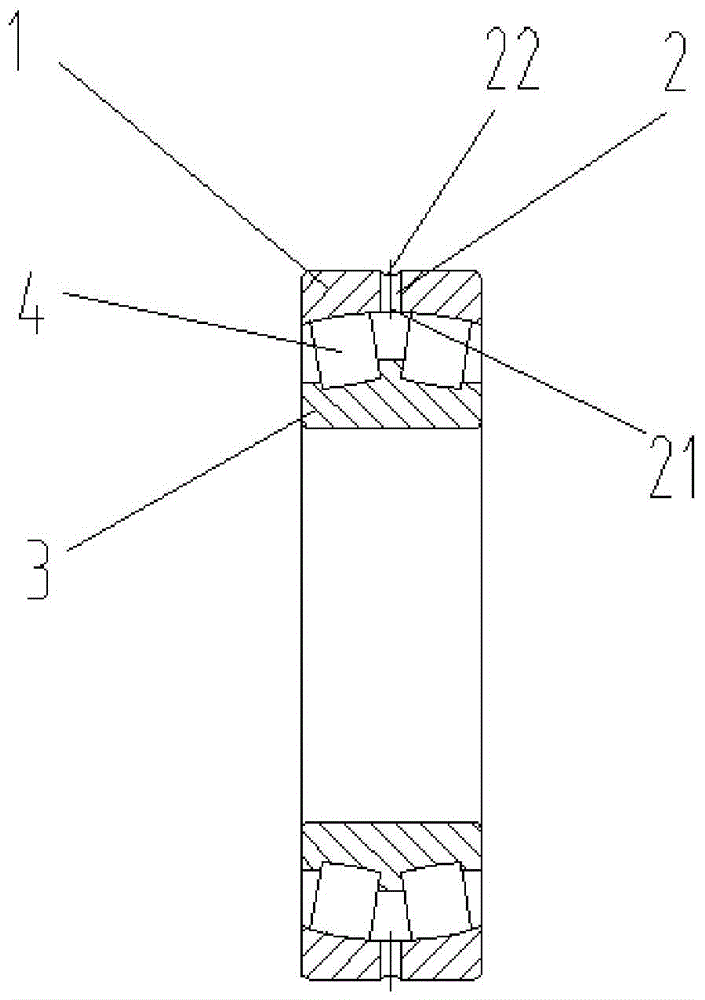

Bearing, bearing installation structure and bearing lubricating system

The invention discloses a bearing, a bearing installation structure and a bearing lubricating system. The bearing comprises a bearing outer ring (1), and the bearing outer ring (1) is provided with an oil channel (2) which communicates the outer circumferential surface and the inner circumferential surface of the bearing outer ring (1). The bearing can be easily and completely lubricated by oil.

Owner:CHNA ENERGY INVESTMENT CORP LTD +2

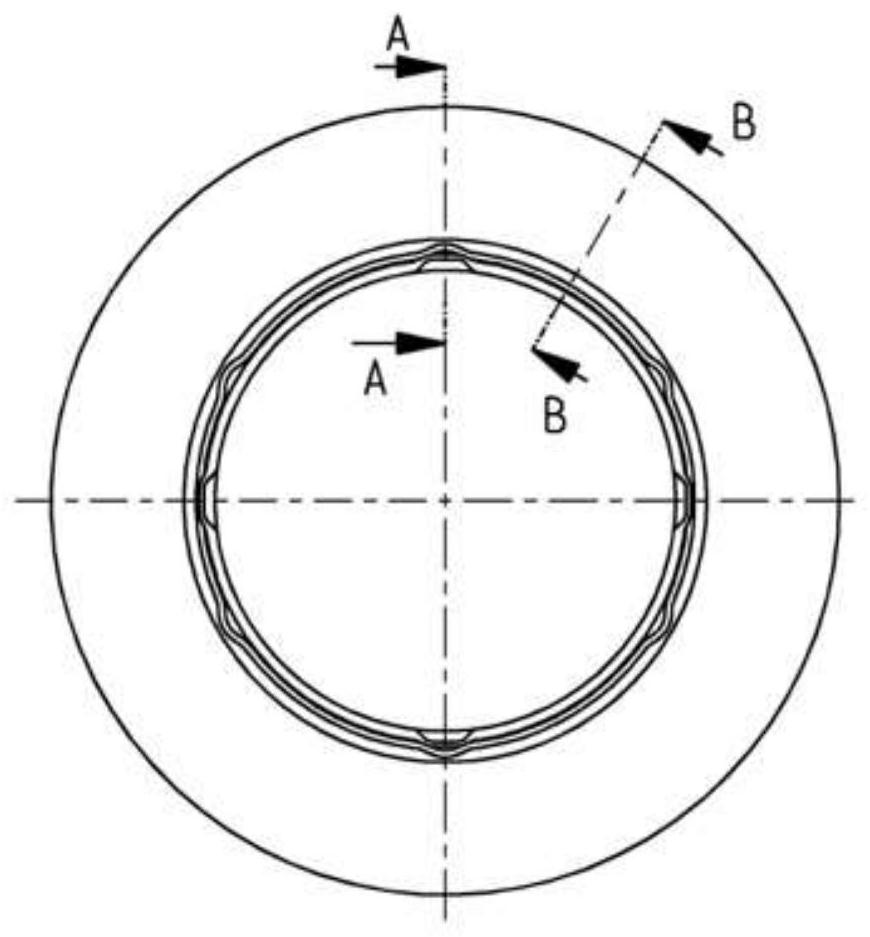

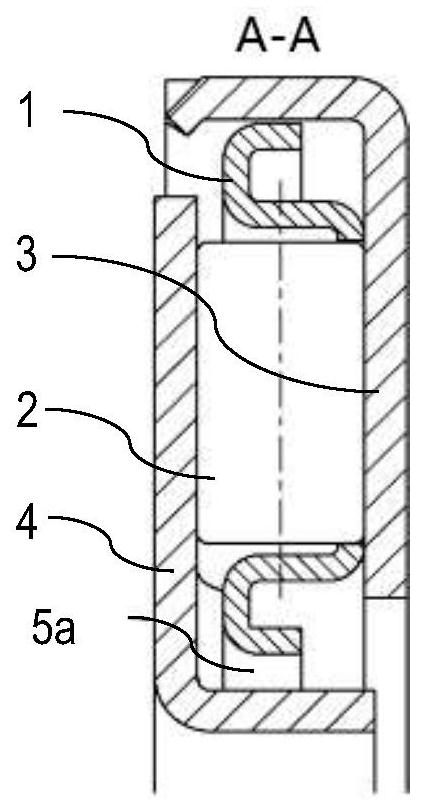

Holder, rolling body and holder assembly and thrust bearing

PendingCN113137428AIncrease circulation spacePromote circulationShaftsBearing componentsClassical mechanicsThrust bearing

The invention relates to a holder, a rolling body and holder assembly and a thrust bearing. The holder (1) is integrally constructed to be annular and is provided with pockets distributed in the circumferential direction, wherein the pockets penetrate through the two axial ends of the holder (1) in the axial direction, grooves (5a and 5b) for flowing of a lubricant are formed in the outer circumference and / or the inner circumference of the holder (1), and the grooves (5a and 5b) penetrate through the two axial ends of the holder (1) in the axial direction. The rolling body and holder assembly comprises the holder (1) and a plurality of rolling bodies (2), wherein the rolling bodies (2) are arranged in the pockets of the holder (1). The thrust bearing comprises the rolling body and holder assembly or at least one thrust gasket (3 and 4), and the thrust gaskets (3 and 4) are arranged on the axial end sides of the rolling body and holder assembly.

Owner:SCHAEFFLER TECH AG & CO KG

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com