Patents

Literature

346results about How to "Accurate filling" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

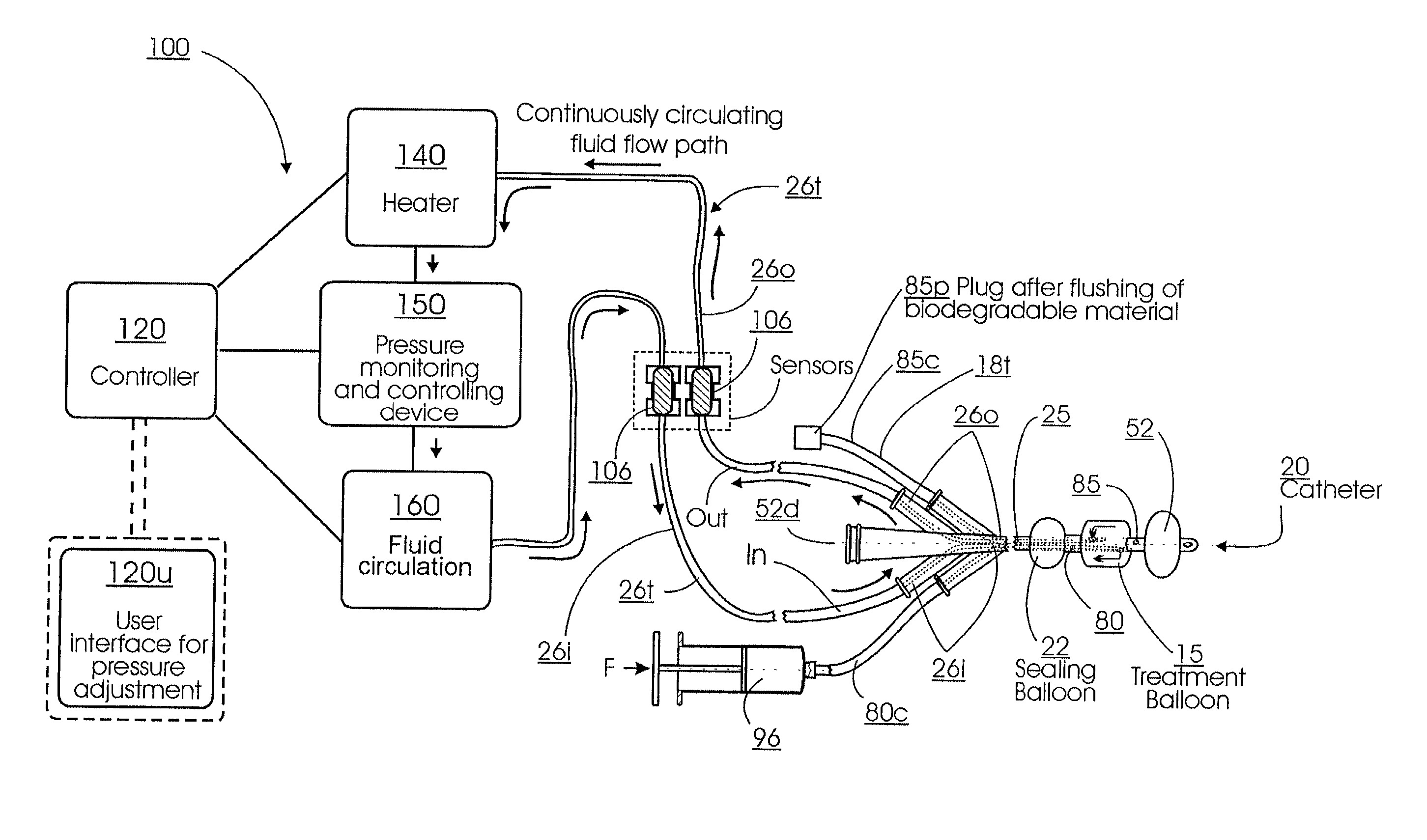

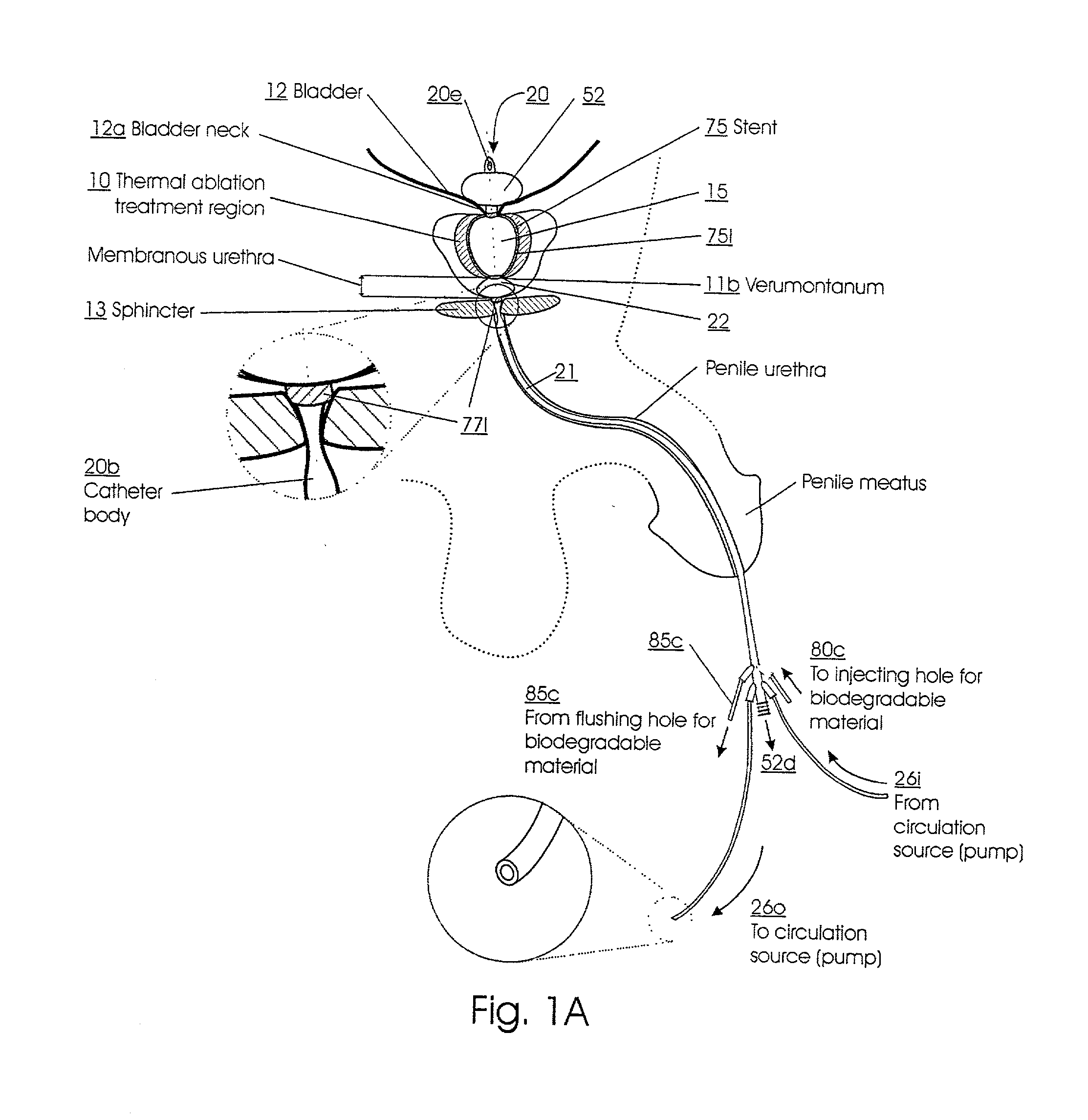

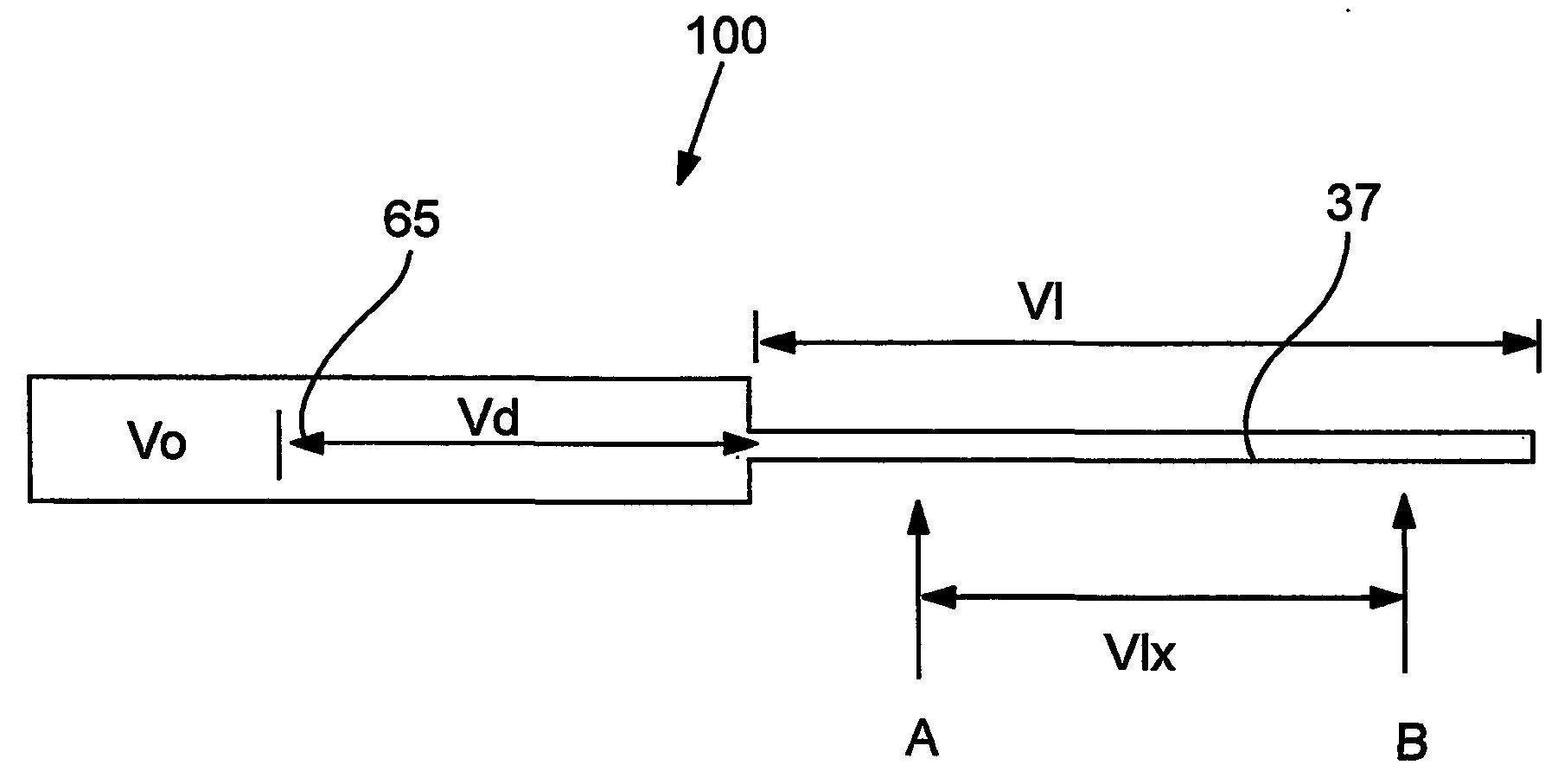

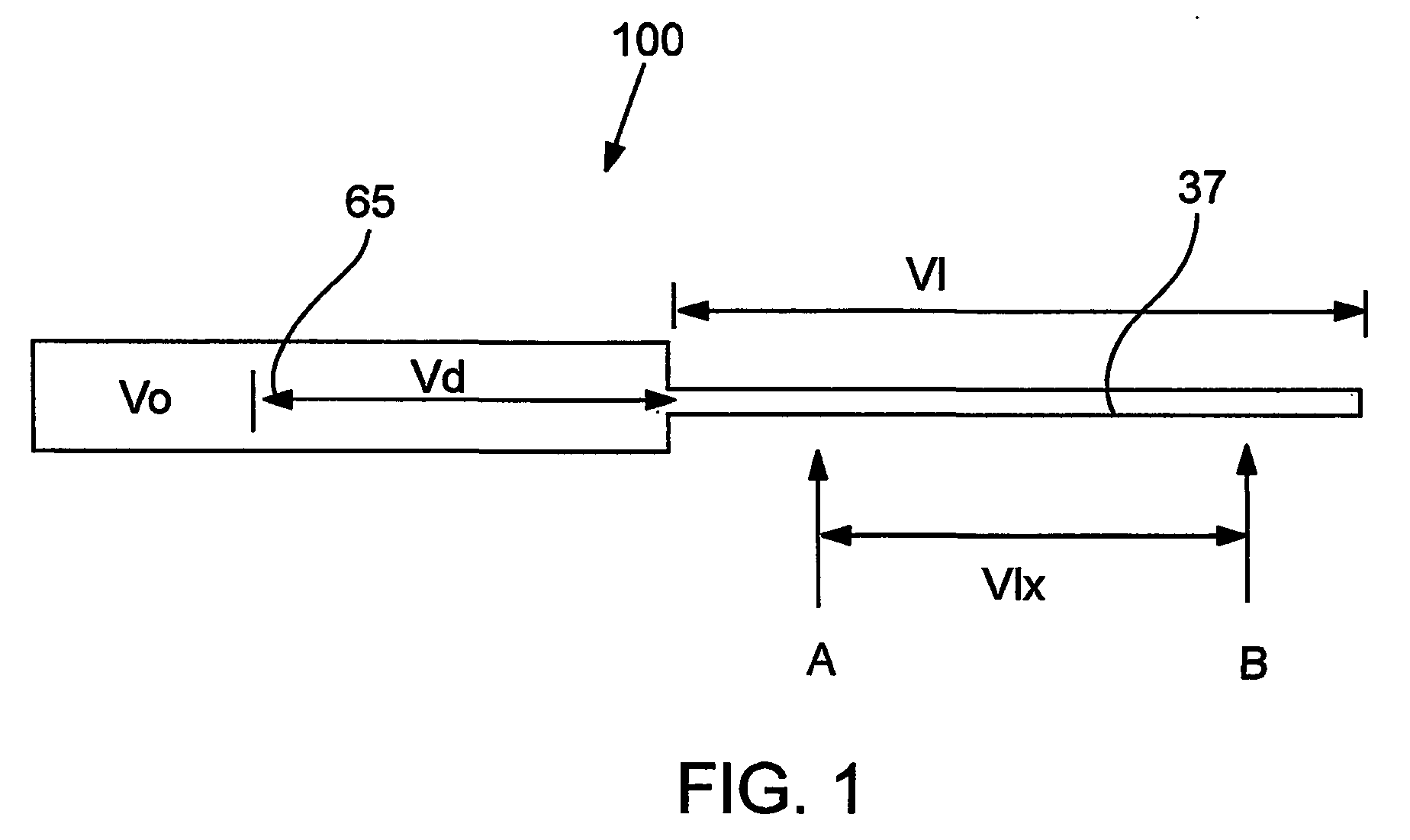

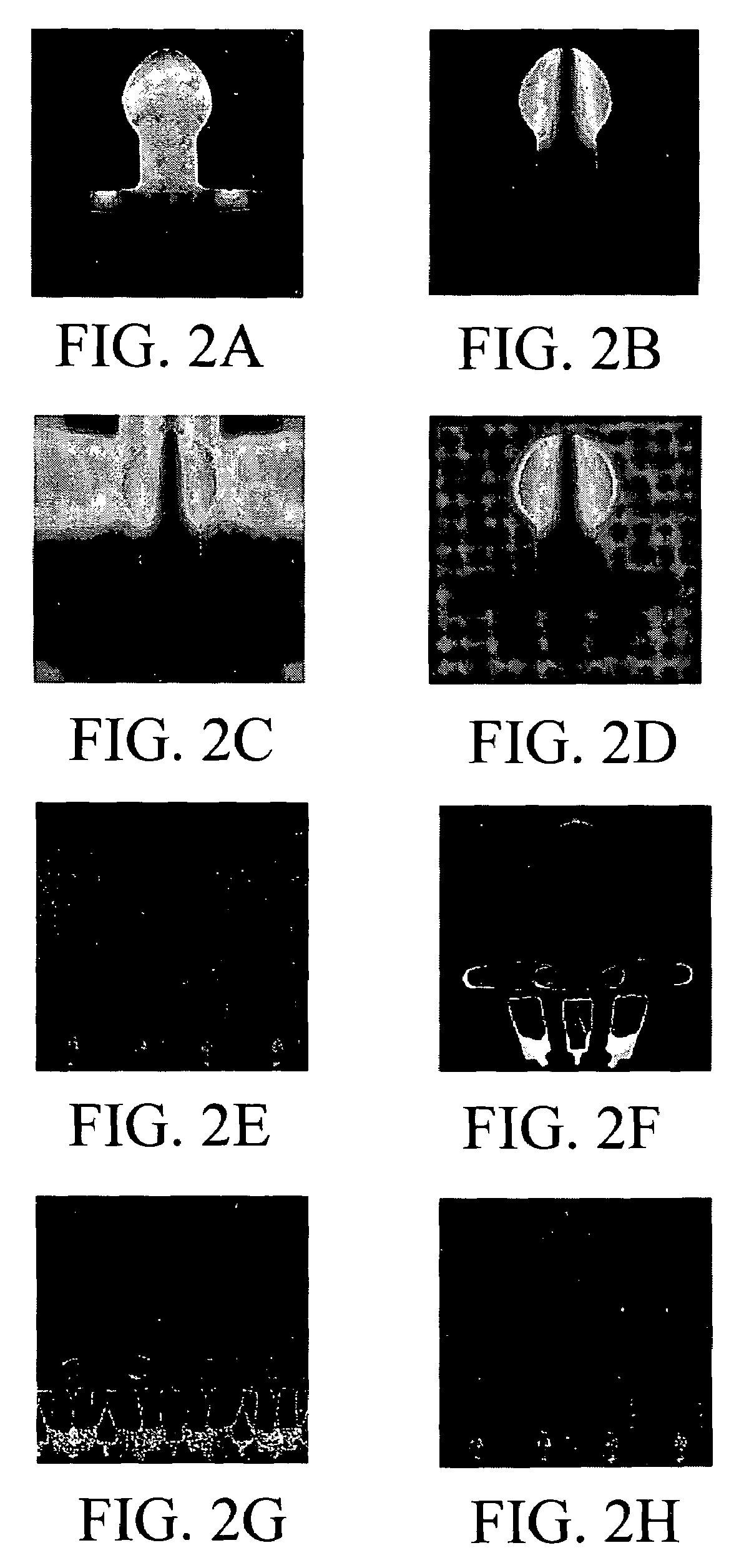

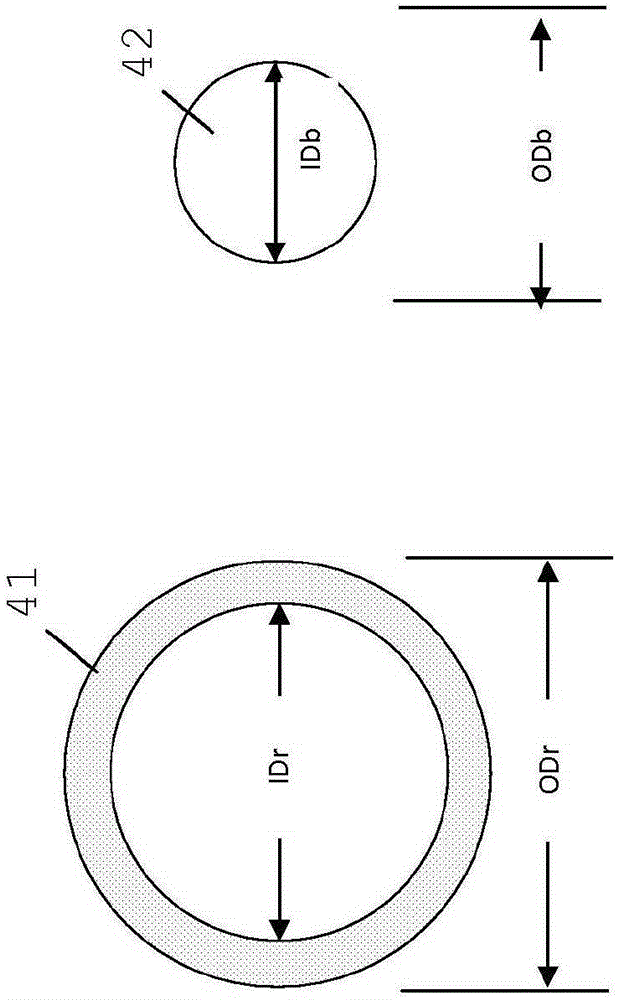

Methods for treating the prostate and inhibiting obstruction of the prostatic urethra using biodegradable stents

InactiveUS20020082610A1Avoid obstructionReduce widthStentsEar treatmentUrethraBiodegradable scaffold

Methods of treating the prostate include administering a thermal ablation therapy and inhibiting the obstruction or closure of the prostatic urethral opening by forming a biodegradable stent in situ in the subject such that the stent attaches to the walls of the prostatic urethra. A related method of treating BPH includes thermally treating or ablating localized tissue in the prostate with a treatment catheter and inserting flowable stent material via the treatment catheter into the prostate (either before, during, or after the thermal treatment), forming the flowable stent material so that it defines a stent that remains in position after removal of the treatment catheter to inhibit the closure of the urinary passage. Associated stents and catheters are included.

Owner:JPMORGAN CHASE BANK AS ADMINISTATIVE AGENT

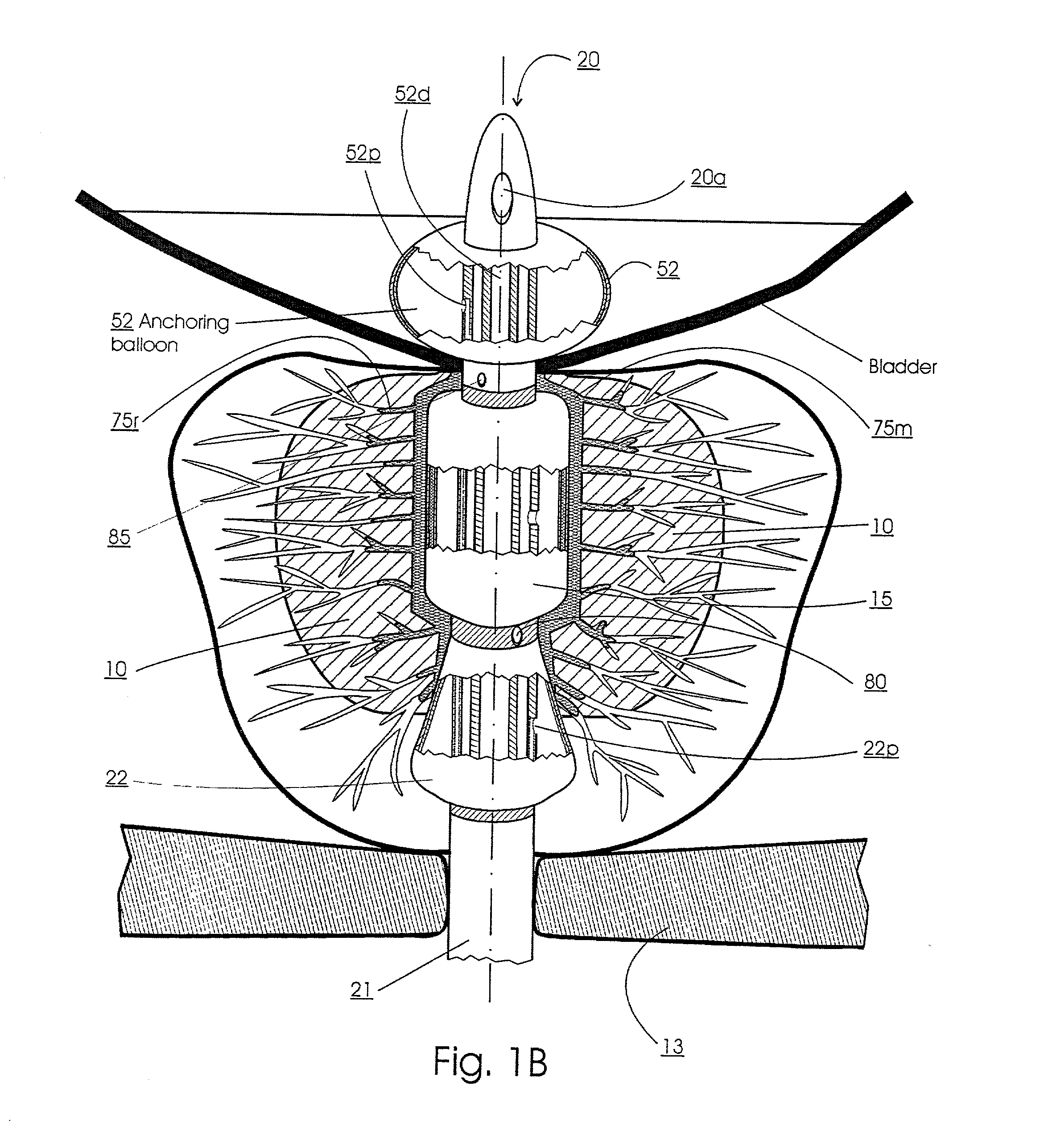

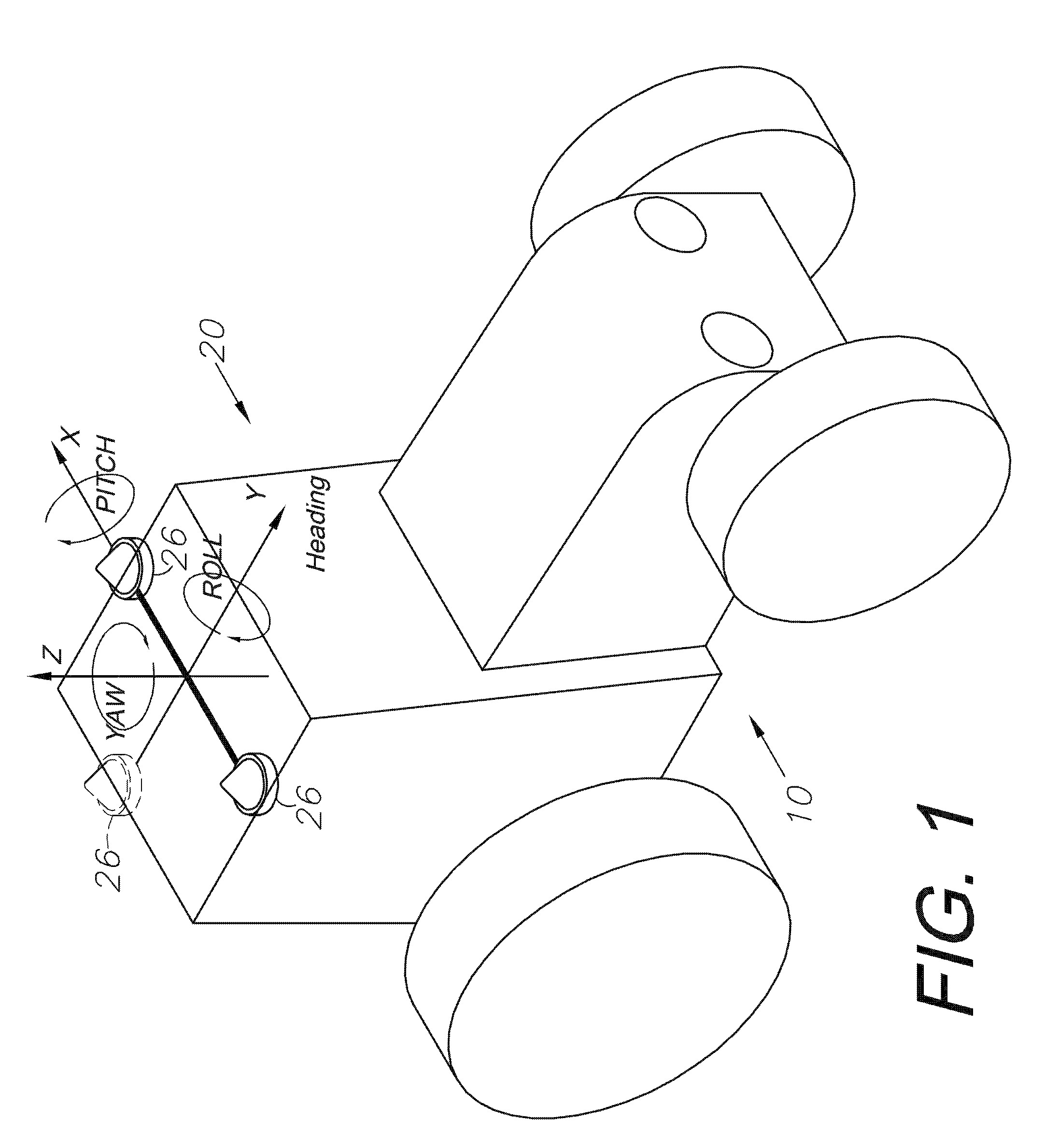

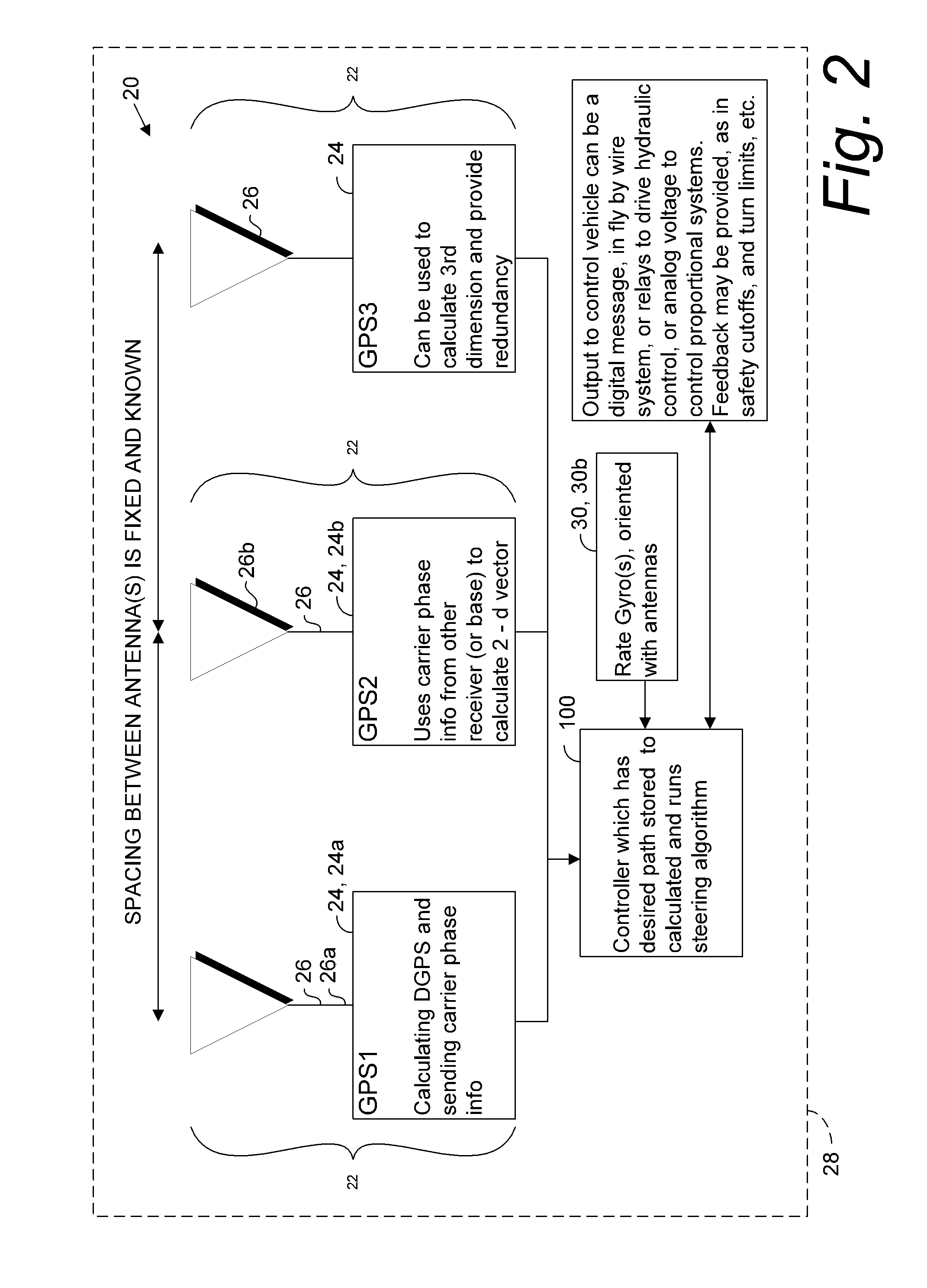

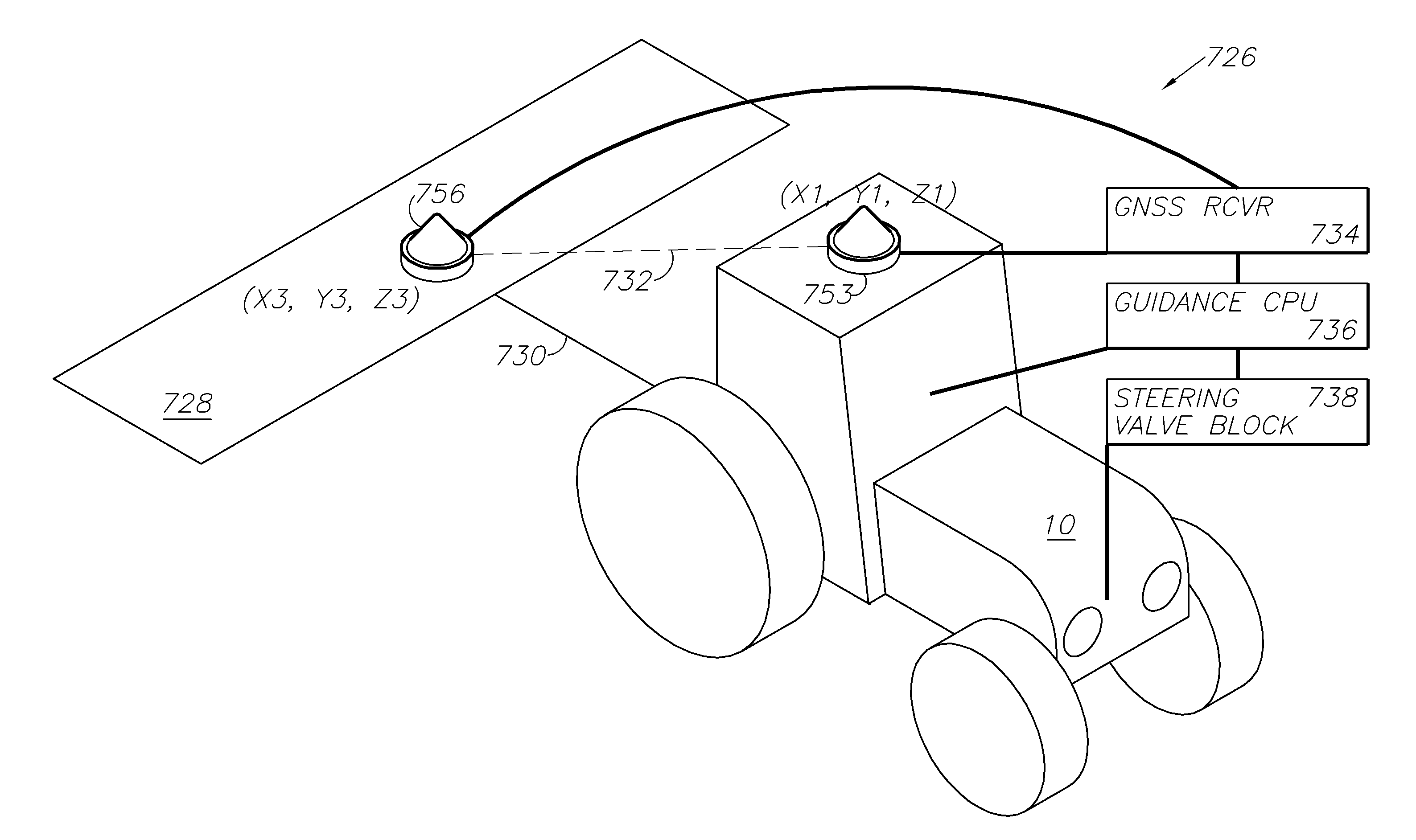

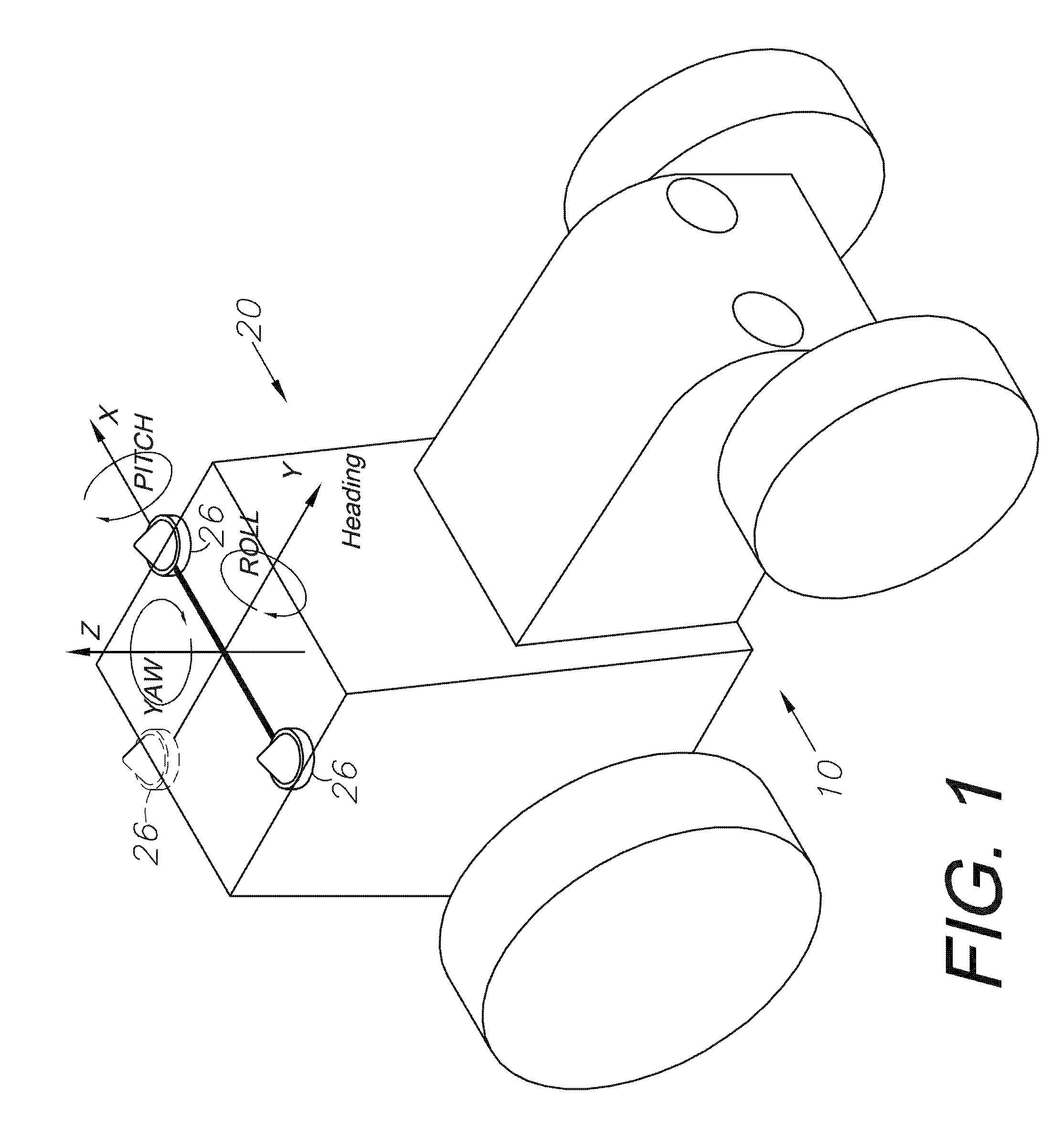

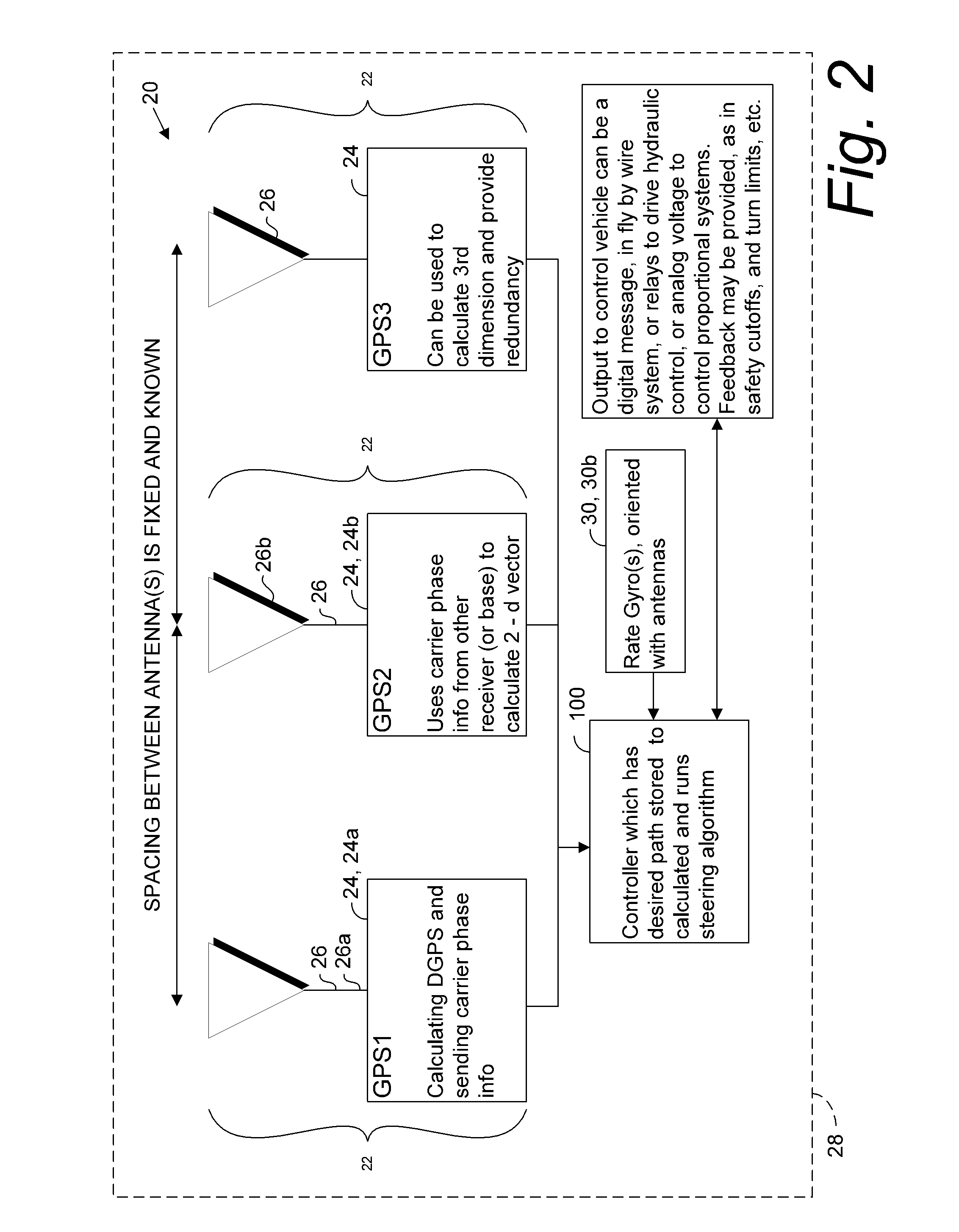

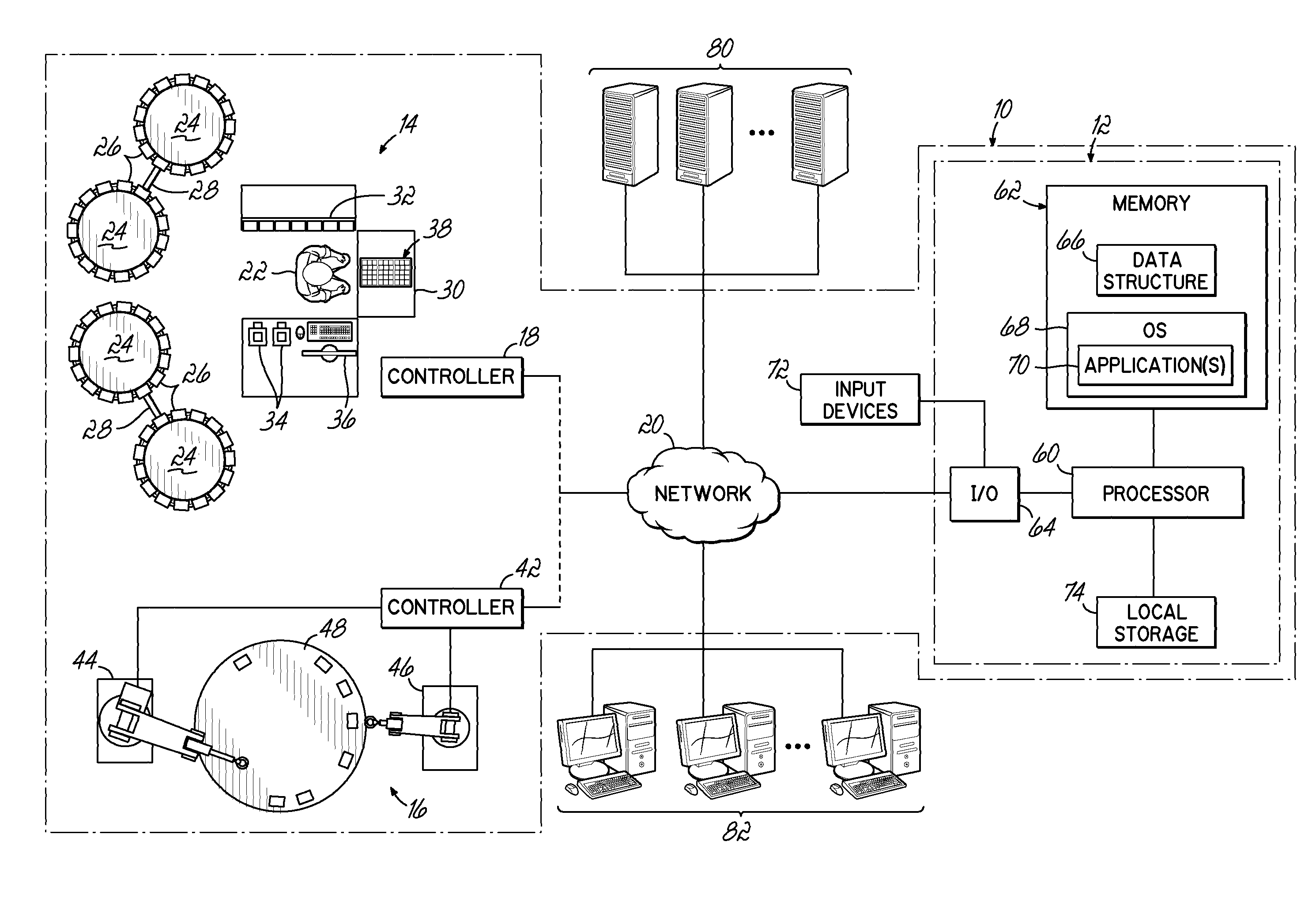

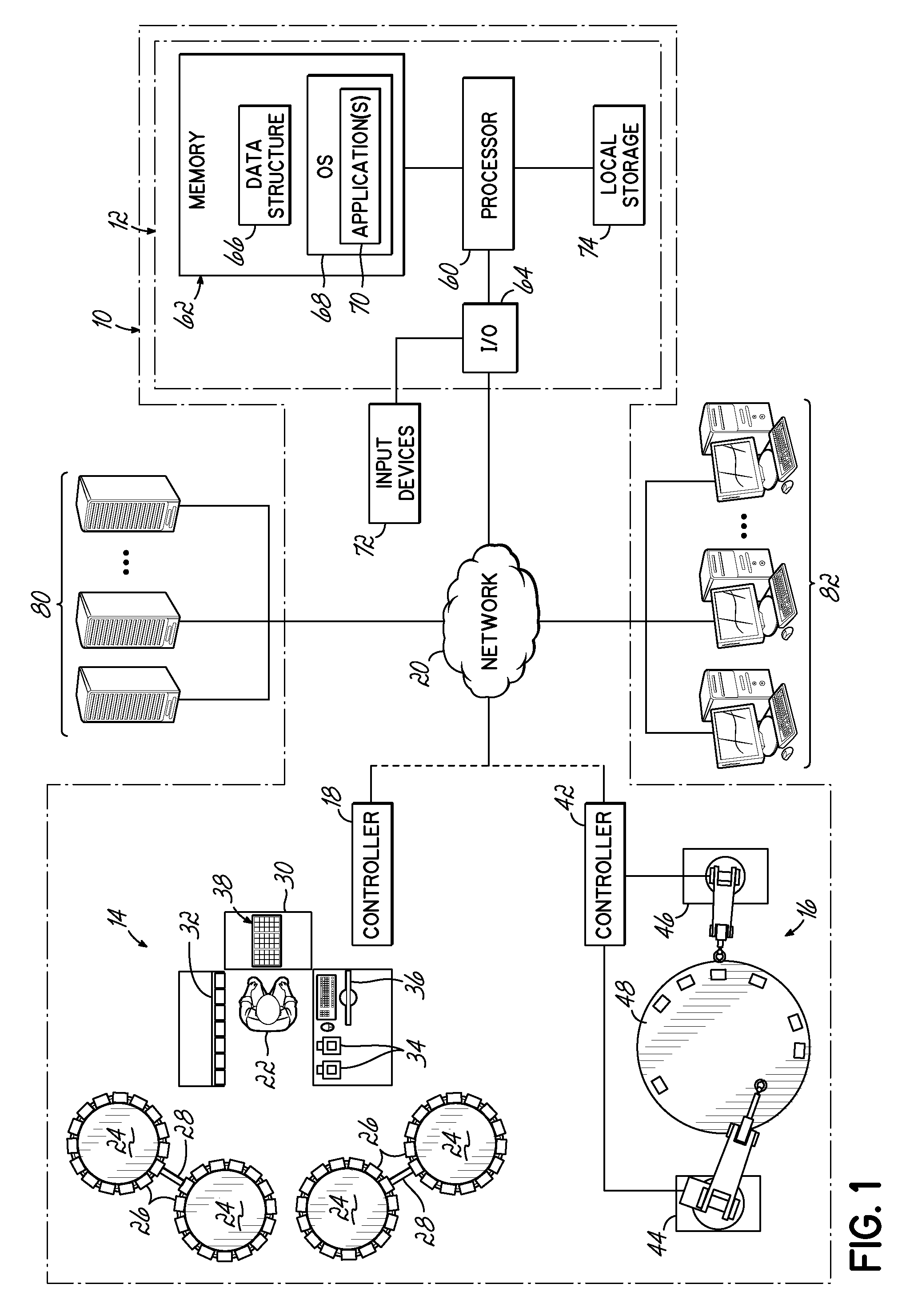

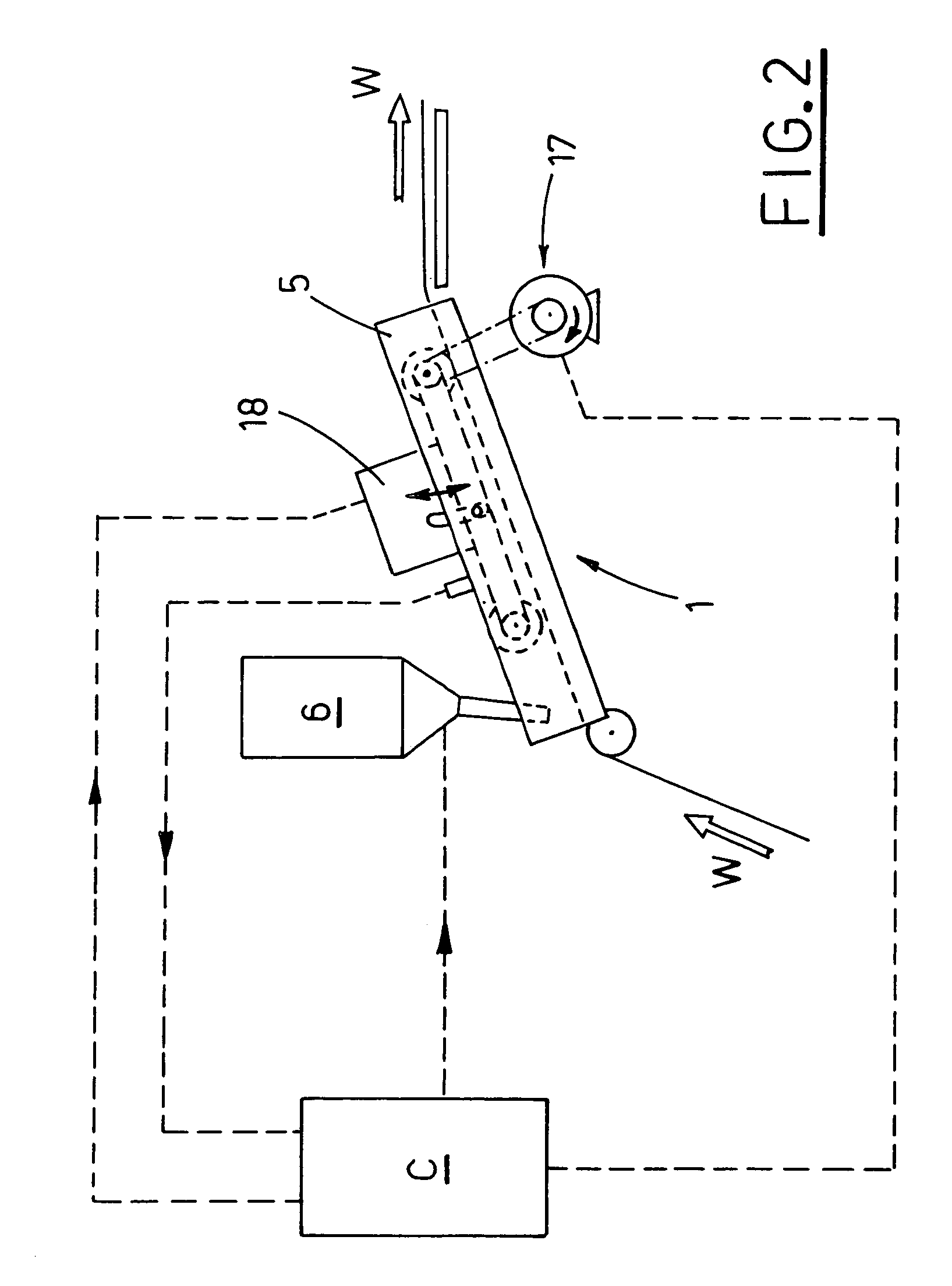

GNSS guidance and machine control

ActiveUS20120174445A1Accurate fillingEasy to correctNavigation instrumentsGuiding agricultural machinesGyroscopeMachine control

A global navigation satellite sensor system (GNSS) and gyroscope control system for vehicle steering control comprising a GNSS receiver and antennas at a fixed spacing to determine a vehicle position, velocity and at least one of a heading angle, a pitch angle and a roll angle based on carrier phase position differences. The roll angle facilitates correction of the lateral motion induced position errors resultant from motion of the antennae as the vehicle moves based on an offset to ground and the roll angle. Alternative aspects include multiple-antenna GNSS guidance methods for high-dynamic roll compensation, real-time kinematic (RTK) using single-frequency (L1) receivers, fixed and moving baselines between antennas, multi-position GNSS tail guidance (“breadcrumb following”) for crosstrack error correction, guiding multiple vehicles and pieces of equipment relative to each other, and snow grooming equipment and method applications.

Owner:AGJUNCTION

GNSS guidance and machine control

ActiveUS20100312428A1Accurate fillingEasy to correctGuiding agricultural machinesSatellite radio beaconingSteering controlFixed interval

A global navigation satellite sensor system (GNSS) and gyroscope control system for vehicle steering control comprising a GNSS receiver and antennas at a fixed spacing to determine a vehicle position, velocity and at least one of a heading angle, a pitch angle and a roll angle based on carrier phase position differences. The roll angle facilitates correction of the lateral motion induced position errors resultant from motion of the antennae as the vehicle moves based on an offset to ground and the roll angle. The system also includes a control system configured to receive the vehicle position, heading, and at least one of roll and pitch, and configured to generate a steering command to a vehicle steering system. The system includes gyroscopes for determining system attitude change with respect to multiple axes for integrating with GNSS-derived positioning information to determine vehicle position, velocity, rate-of-turn, attitude and other operating characteristics. A vehicle control method includes the steps of computing a position and a heading for the vehicle using GNSS positioning and a rate gyro for determining vehicle attitude, which is used for generating a steering command. Alternative aspects include multiple-antenna GNSS guidance methods for high-dynamic roll compensation, real-time kinematic (RTK) using single-frequency (L1) receivers, fixed and moving baselines between antennas, multi-position GNSS tail guidance (“breadcrumb following”) for crosstrack error correction, guiding multiple vehicles and pieces of equipment relative to each other and earth-moving equipment and method applications.

Owner:AGJUNCTION

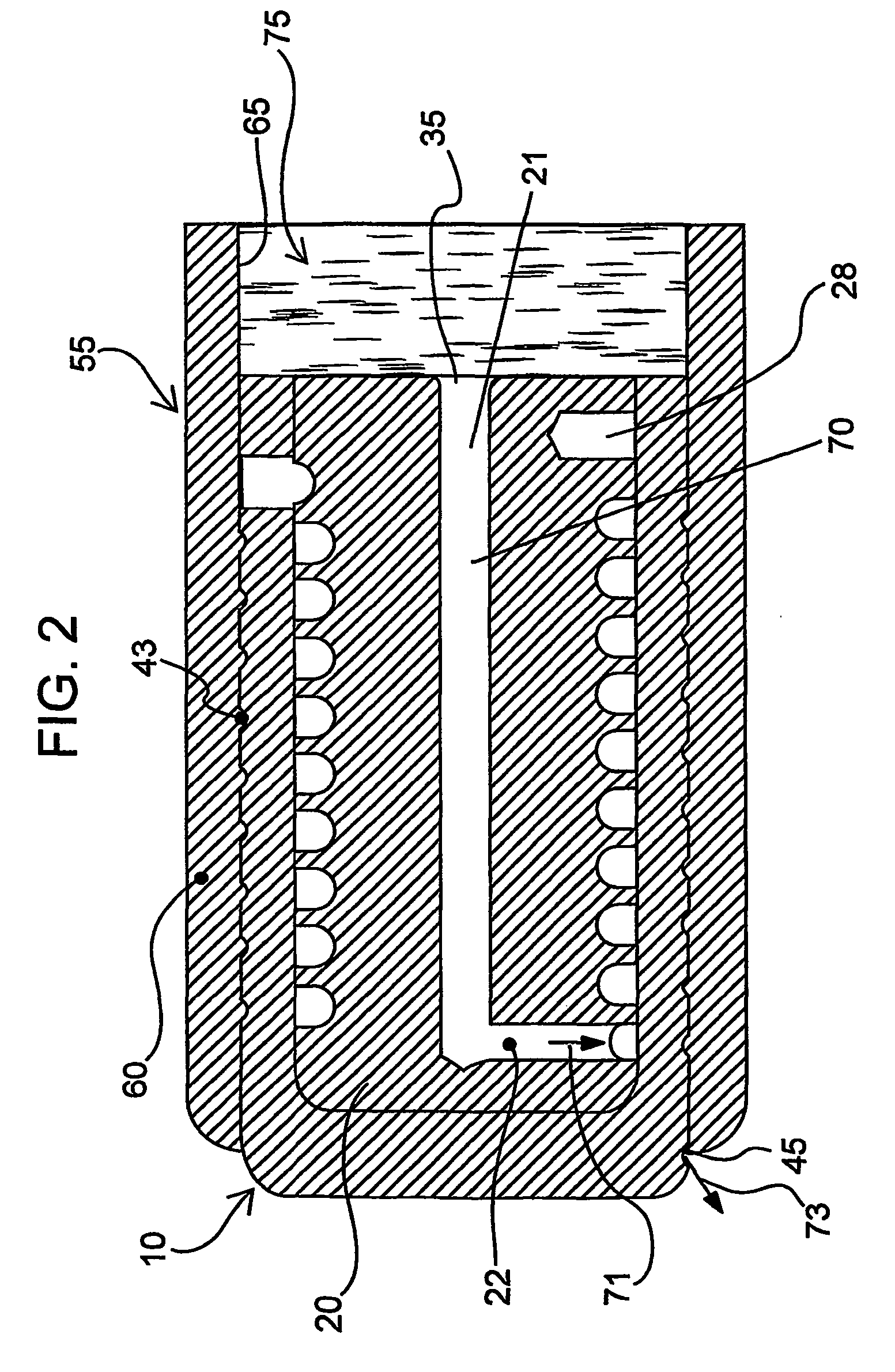

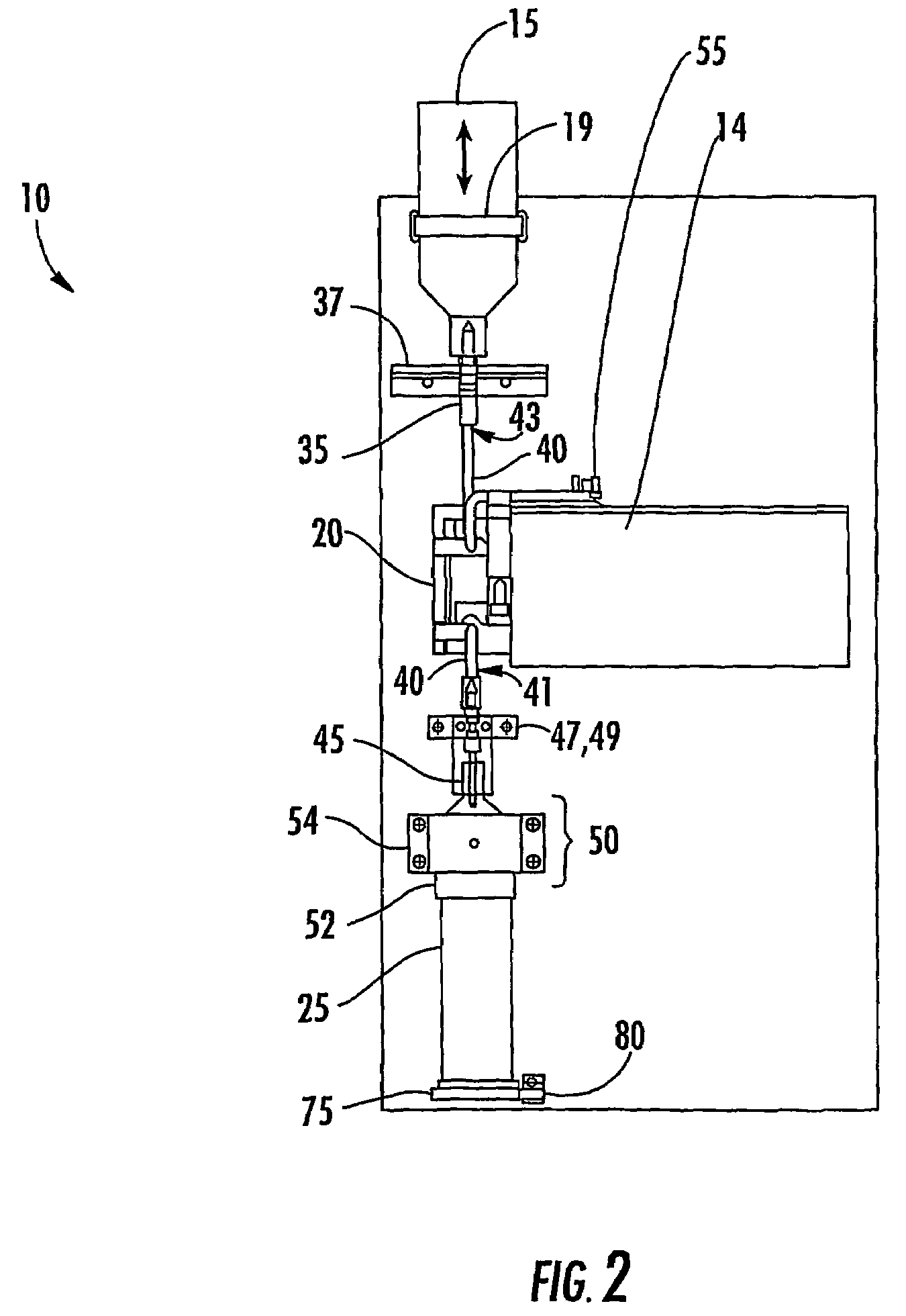

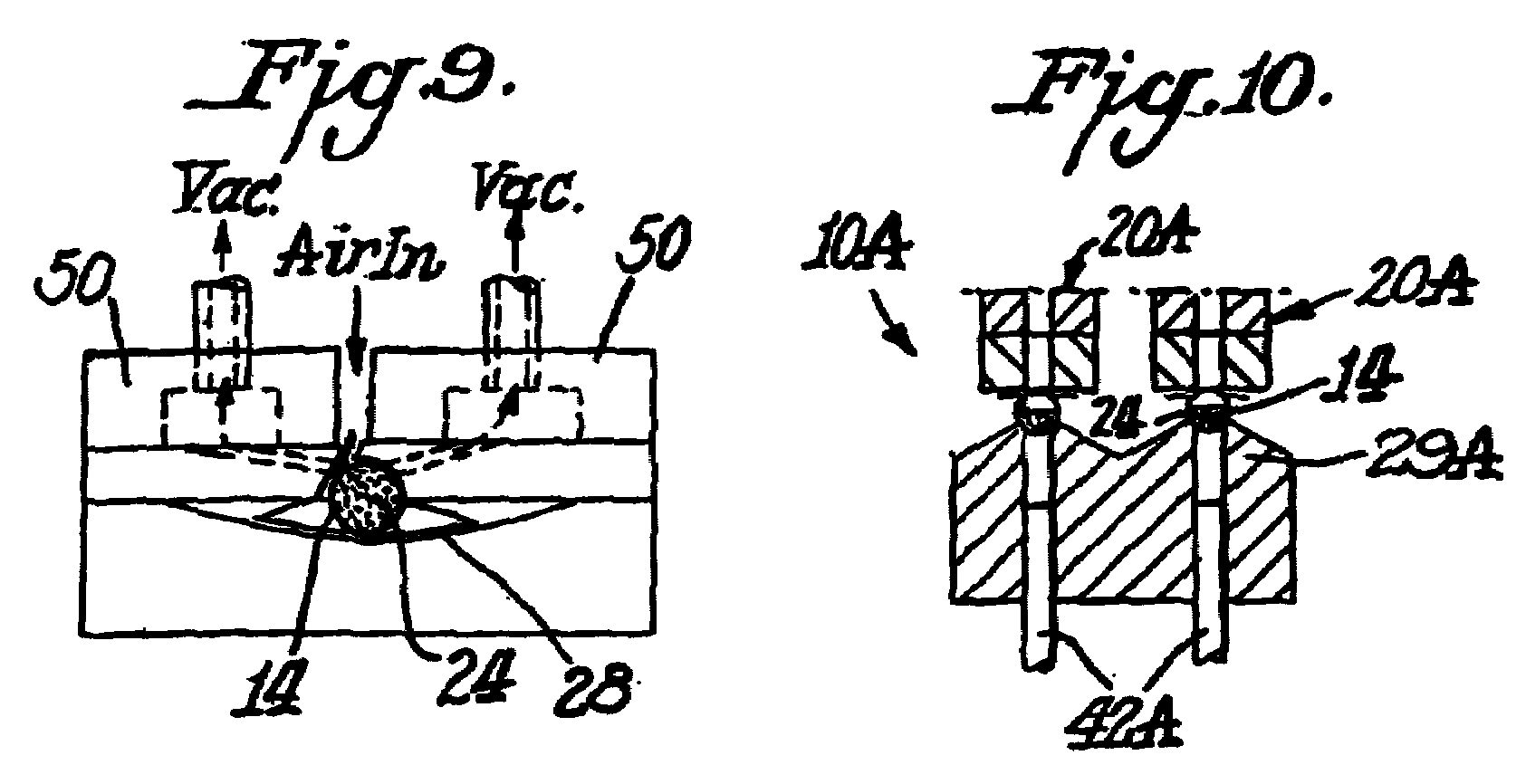

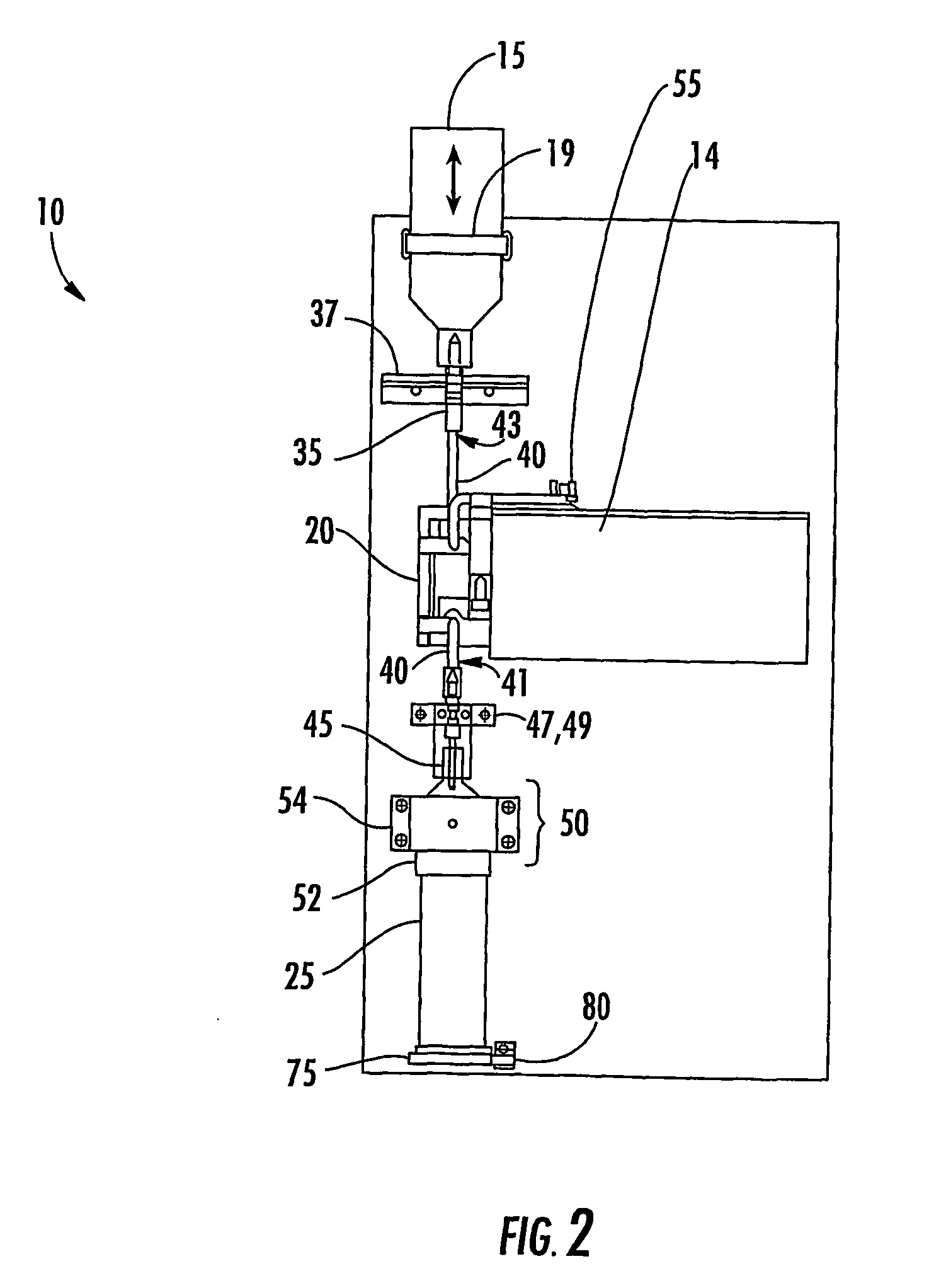

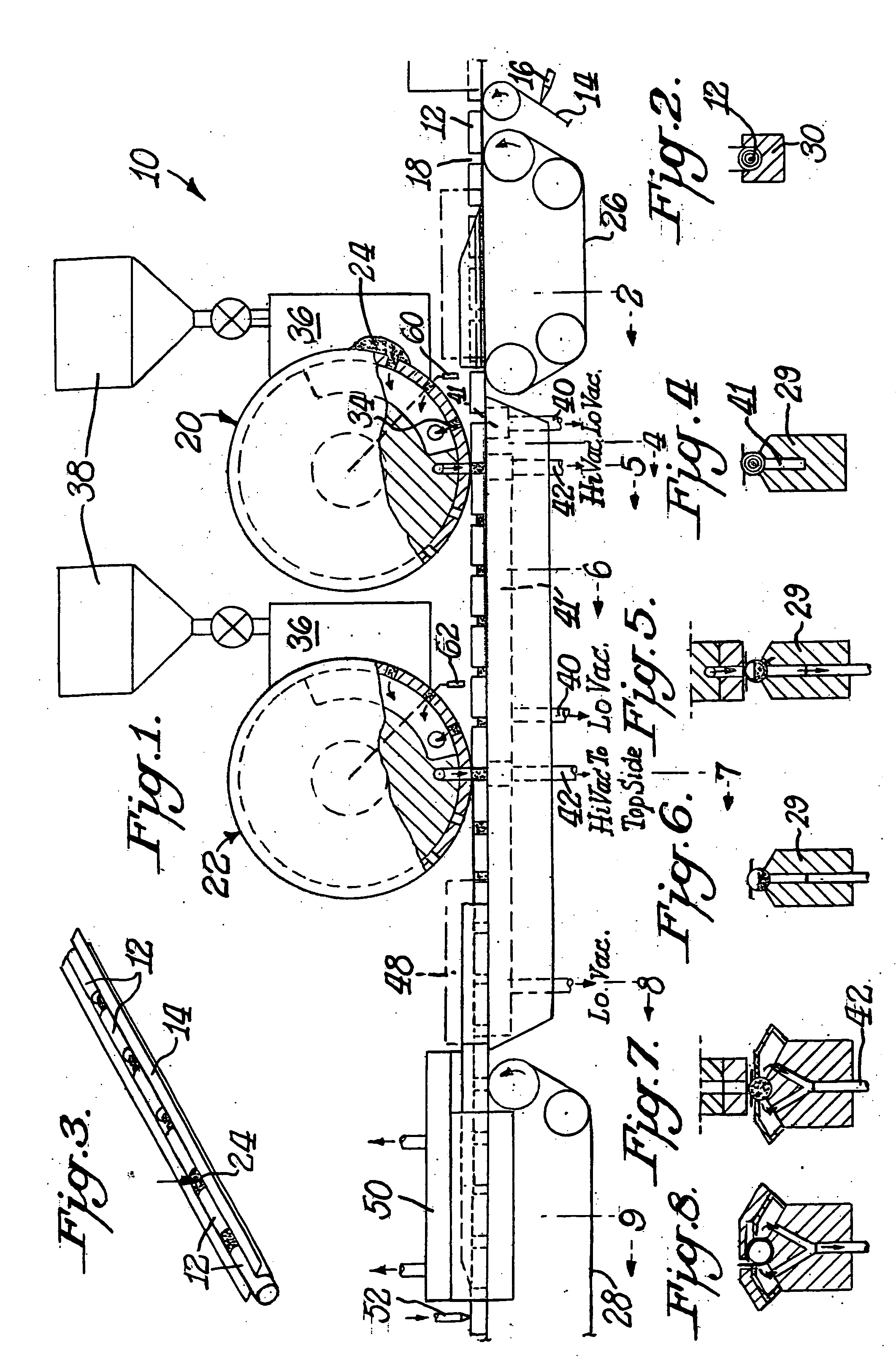

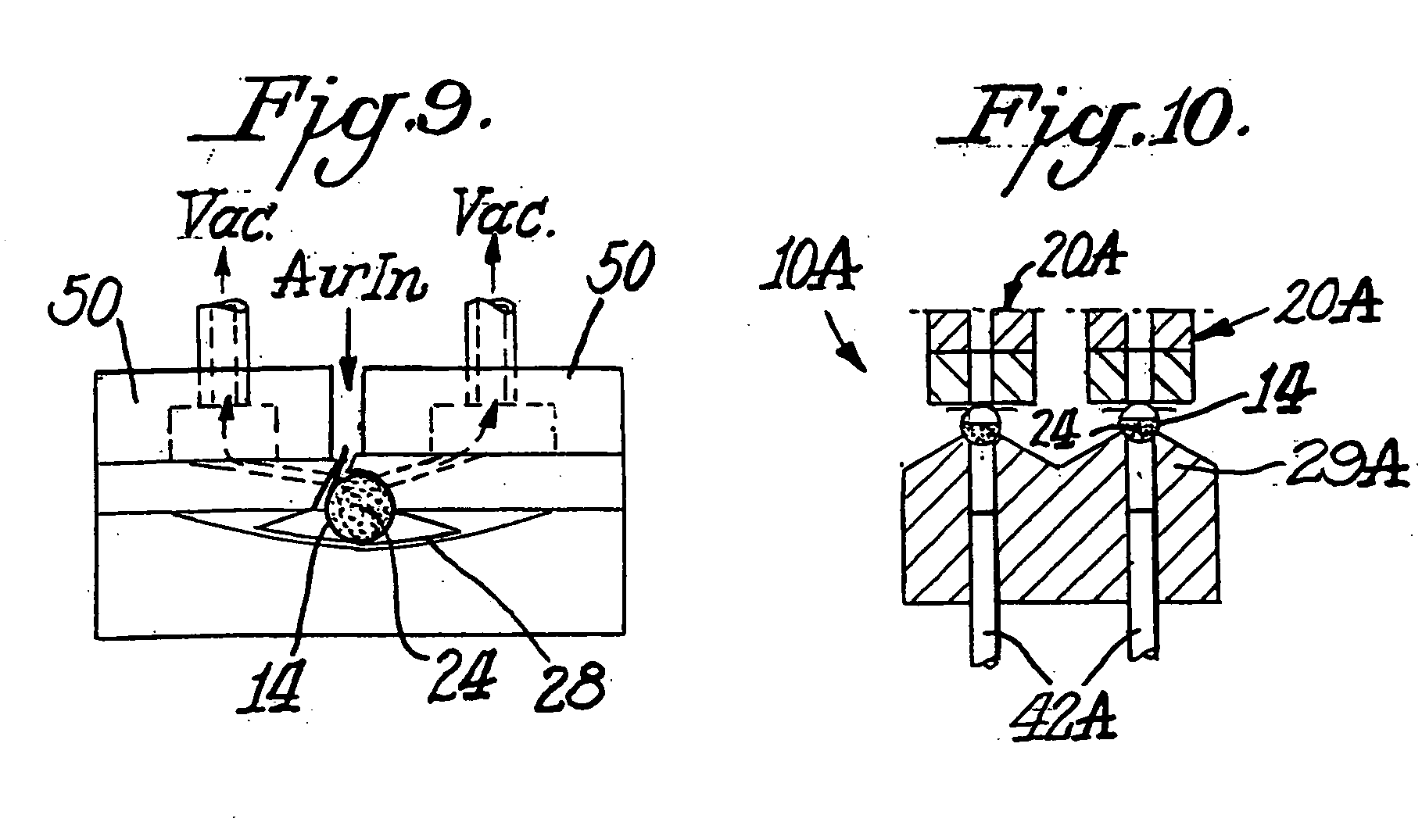

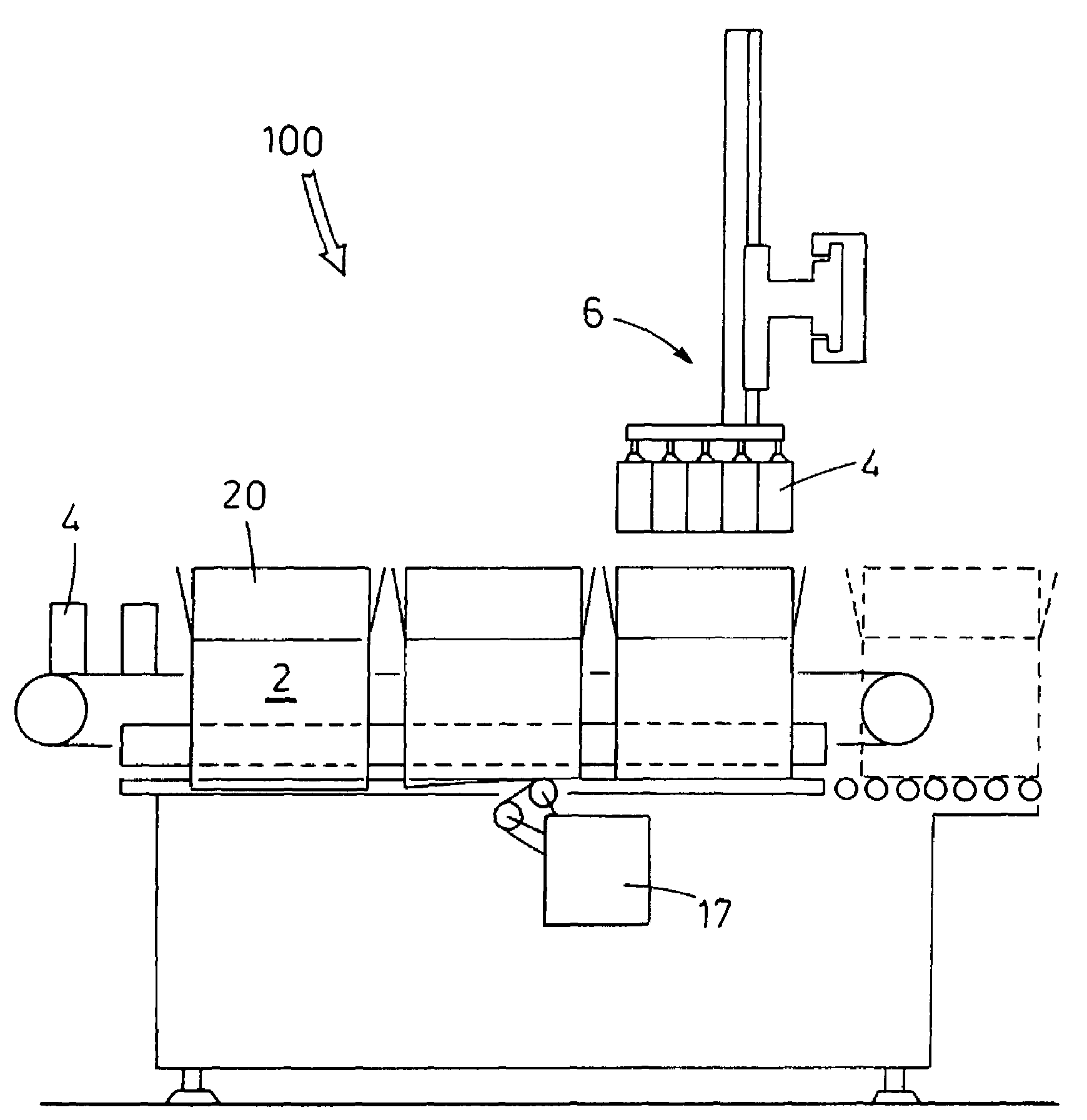

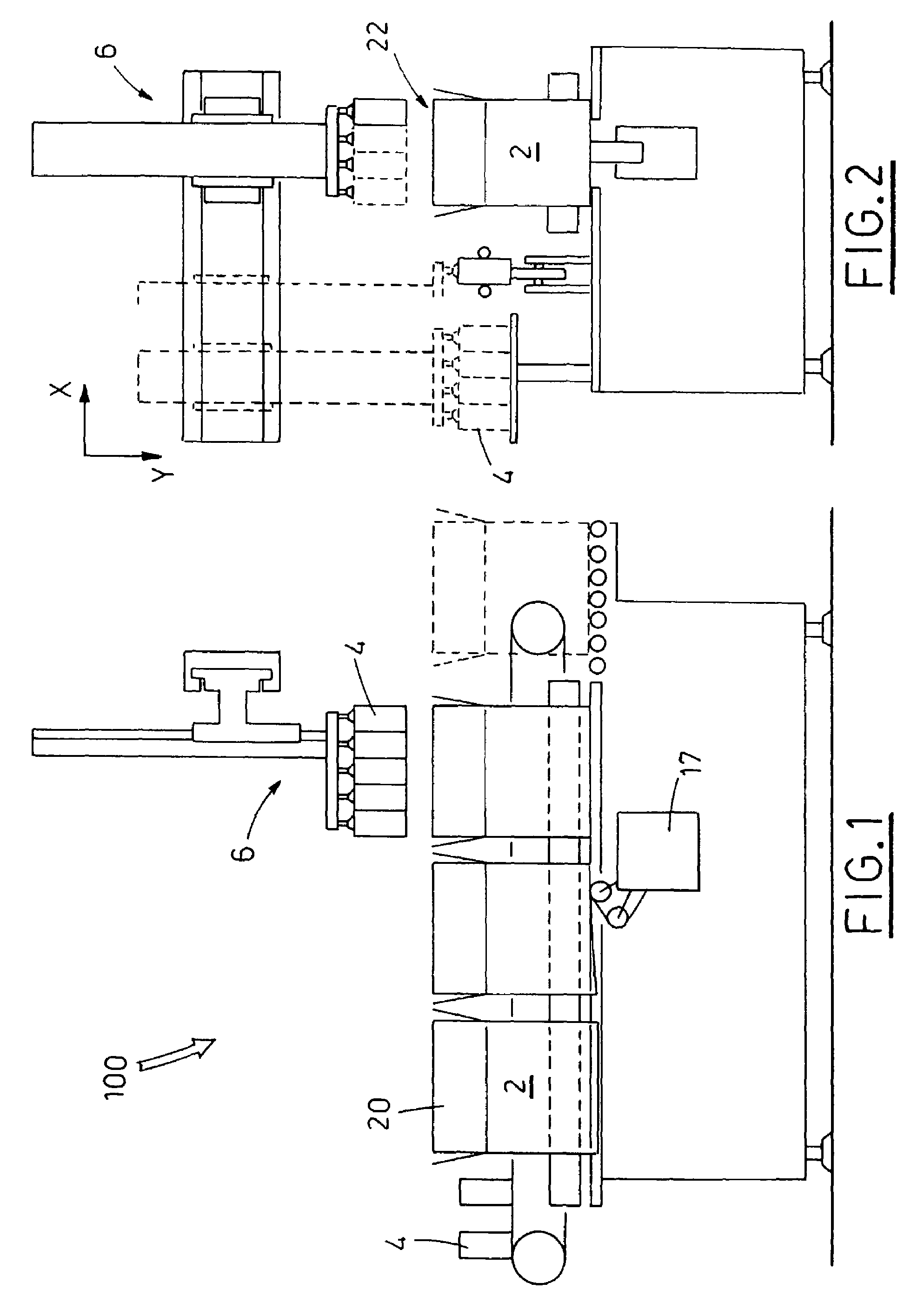

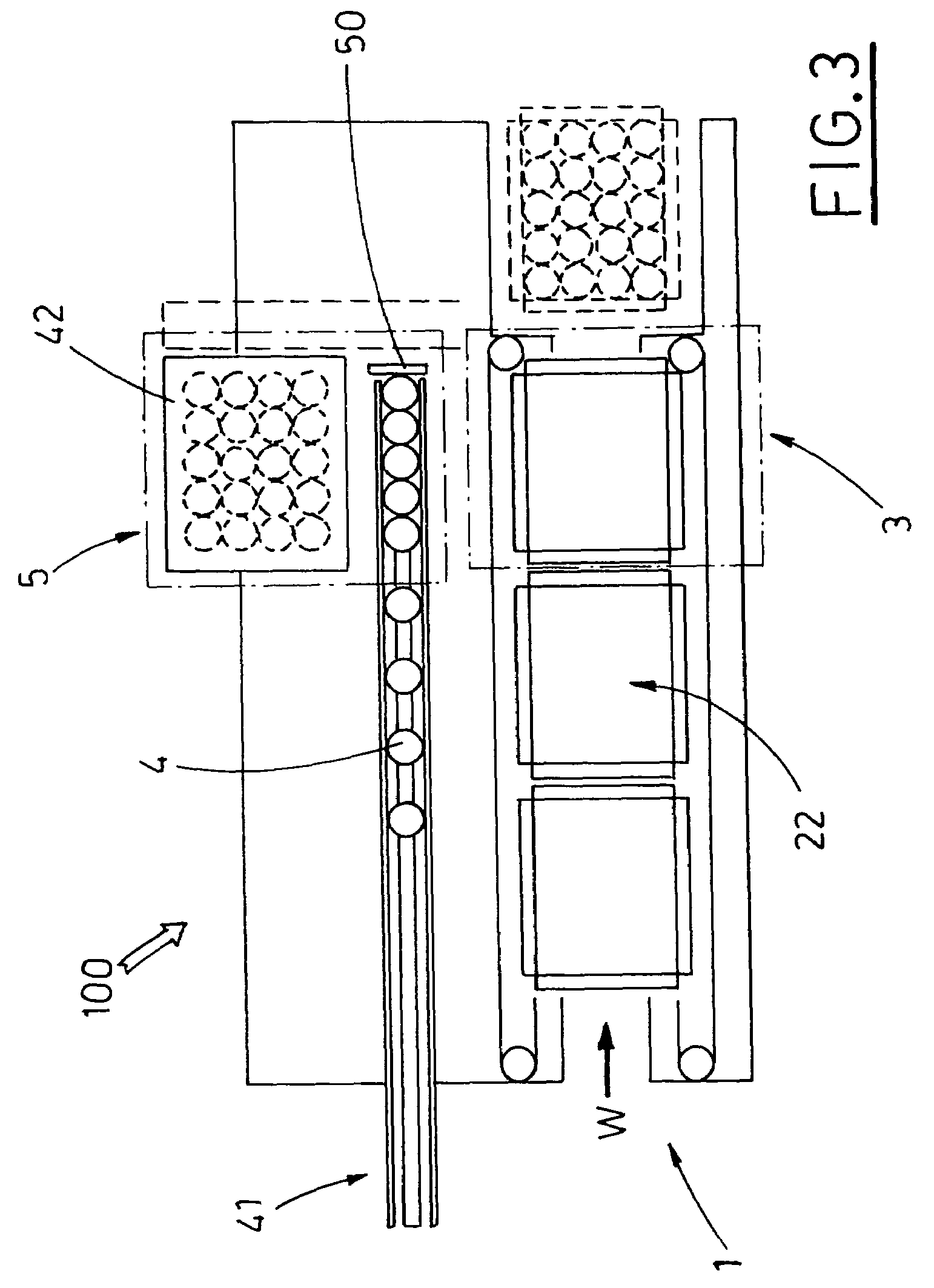

Apparatus and method for filling cavities with metered amounts of granular particles

InactiveUS6837281B2Accurate fillingFast transferLiquid fillingSolid materialEngineeringVacuum chamber

A method and apparatus for delivering predetermined amounts of material, the apparatus including a vertical drop chute, a filling chamber, a rotating wheel with pockets, a central stationary drum with at least one vacuum chamber and an air jet, and a vacuum rail for transporting an article underneath the rotating wheel and transferring the particles from pockets in the wheel to cavities in the article. The particles can be carbon or charcoal granules and the article can be a cigarette filter rod.

Owner:PHILIP MORRIS USA INC

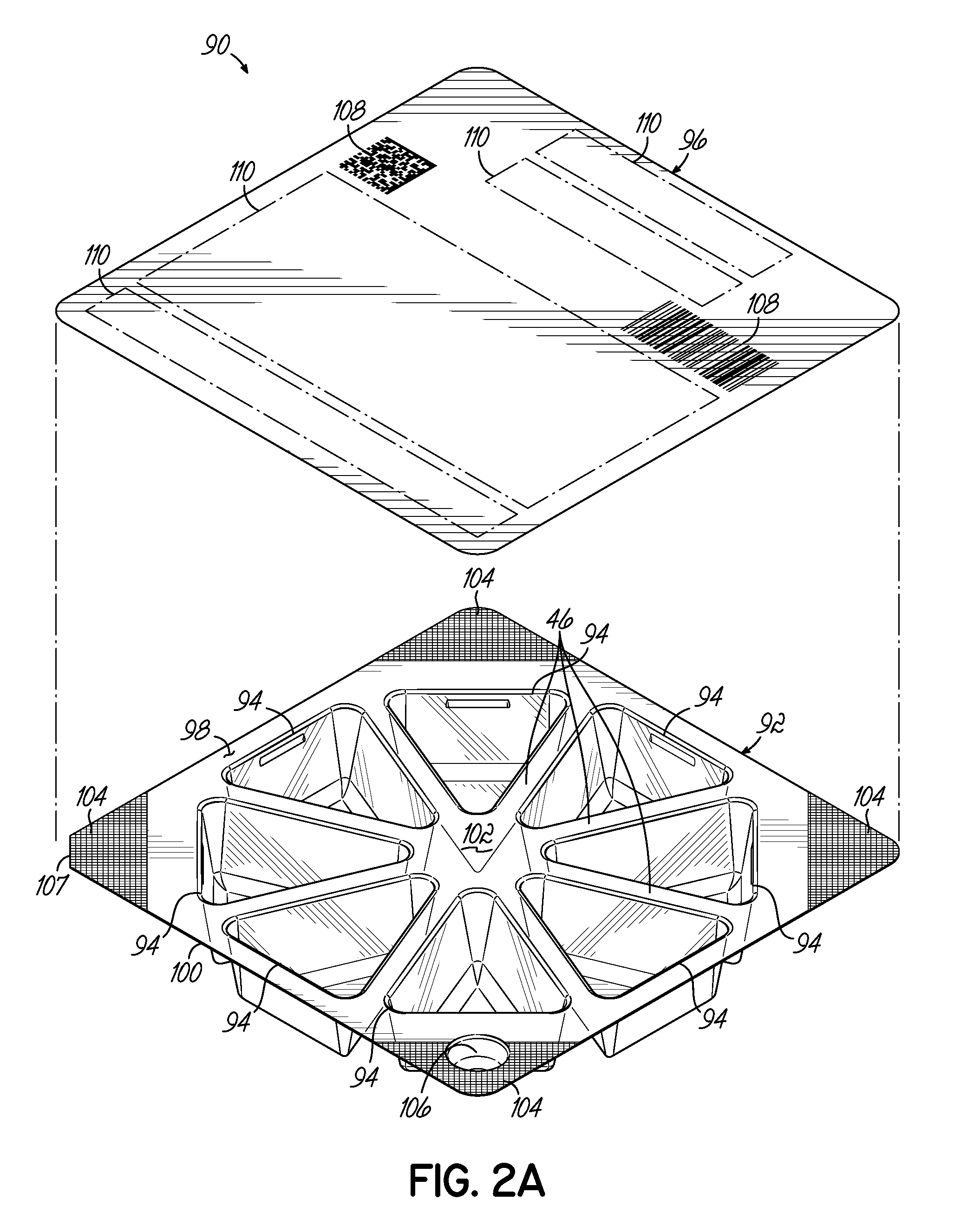

Methods and apparatus for filling of packagings with medications

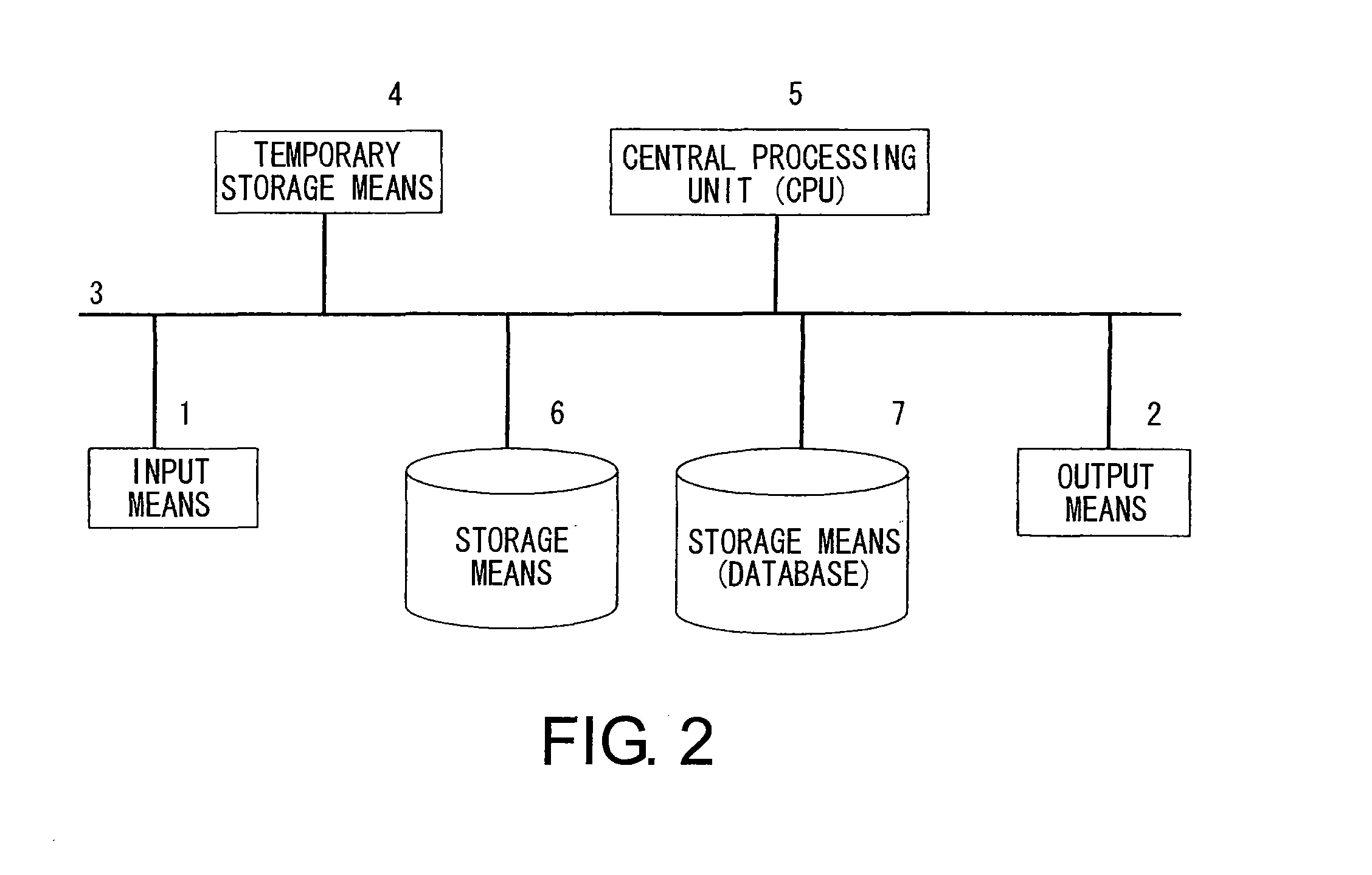

ActiveUS20130018503A1Simplify the management processPatient compliance is goodDrug and medicationsDigital data processing detailsDrug dispensingEngineering

Methods for filling packagings with at least one medication include producing filling instructions, operating a packaging station to fill packagings, and verifying that each of the packagings is filled correctly. The production of filling instructions includes an allocation of medications to separated compartments in the packagings. Each packaging receives a single medication pass for a specified time on a specified day, or a medicine pass for administration on an as needed basis. The packaging station may include a manual packaging station at which an operator follows prompts to move canisters of medications, pills from the canisters, and trays of packagings to fill the packagings. The manual packaging station includes a shutter assembly with shutters configured to selectively provide access to only one compartment in each packaging at a time, thereby reducing the likelihood of filling errors. Apparatus for filling packagings may include the same manual packaging station.

Owner:OMNICARE LLC

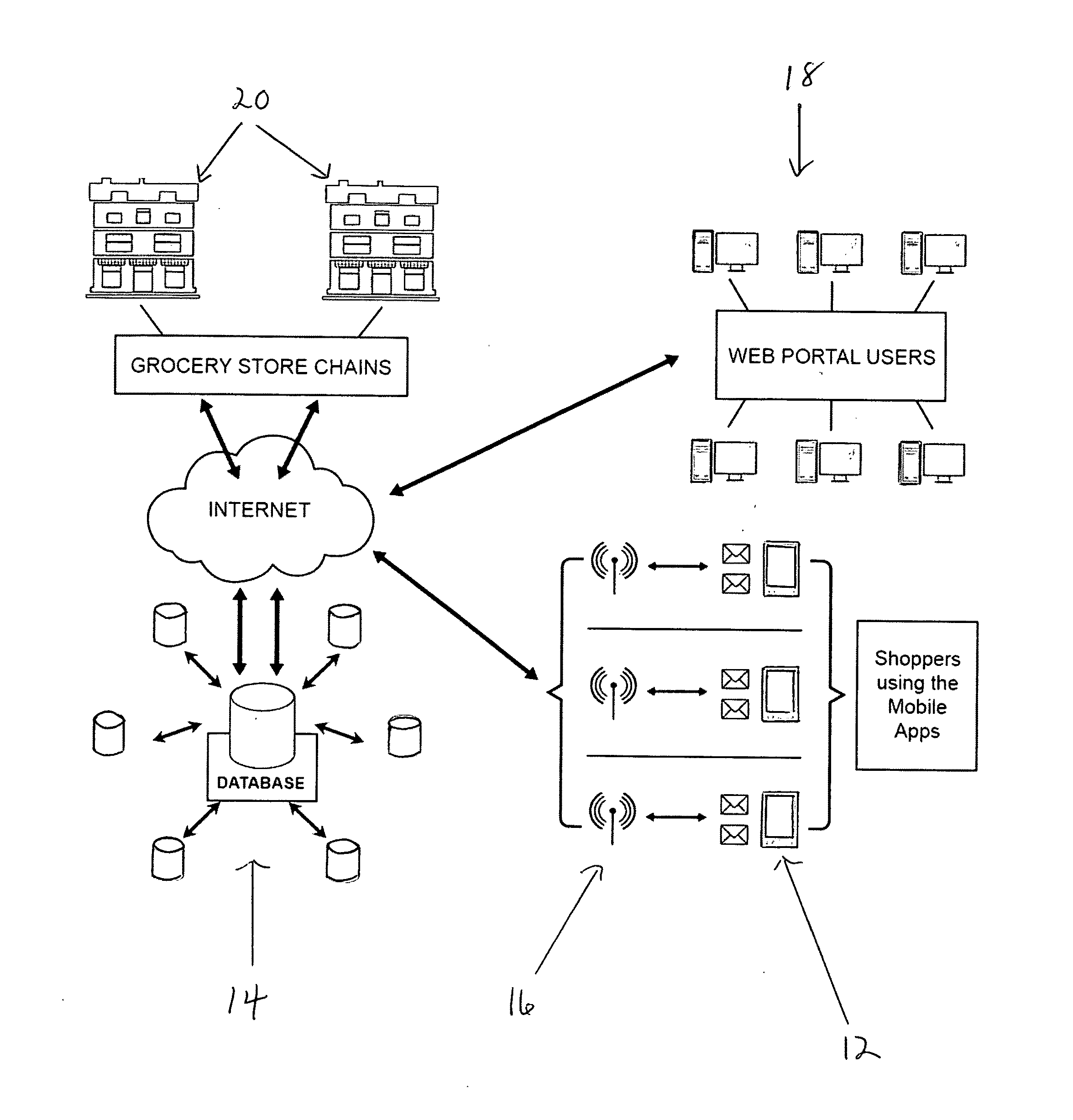

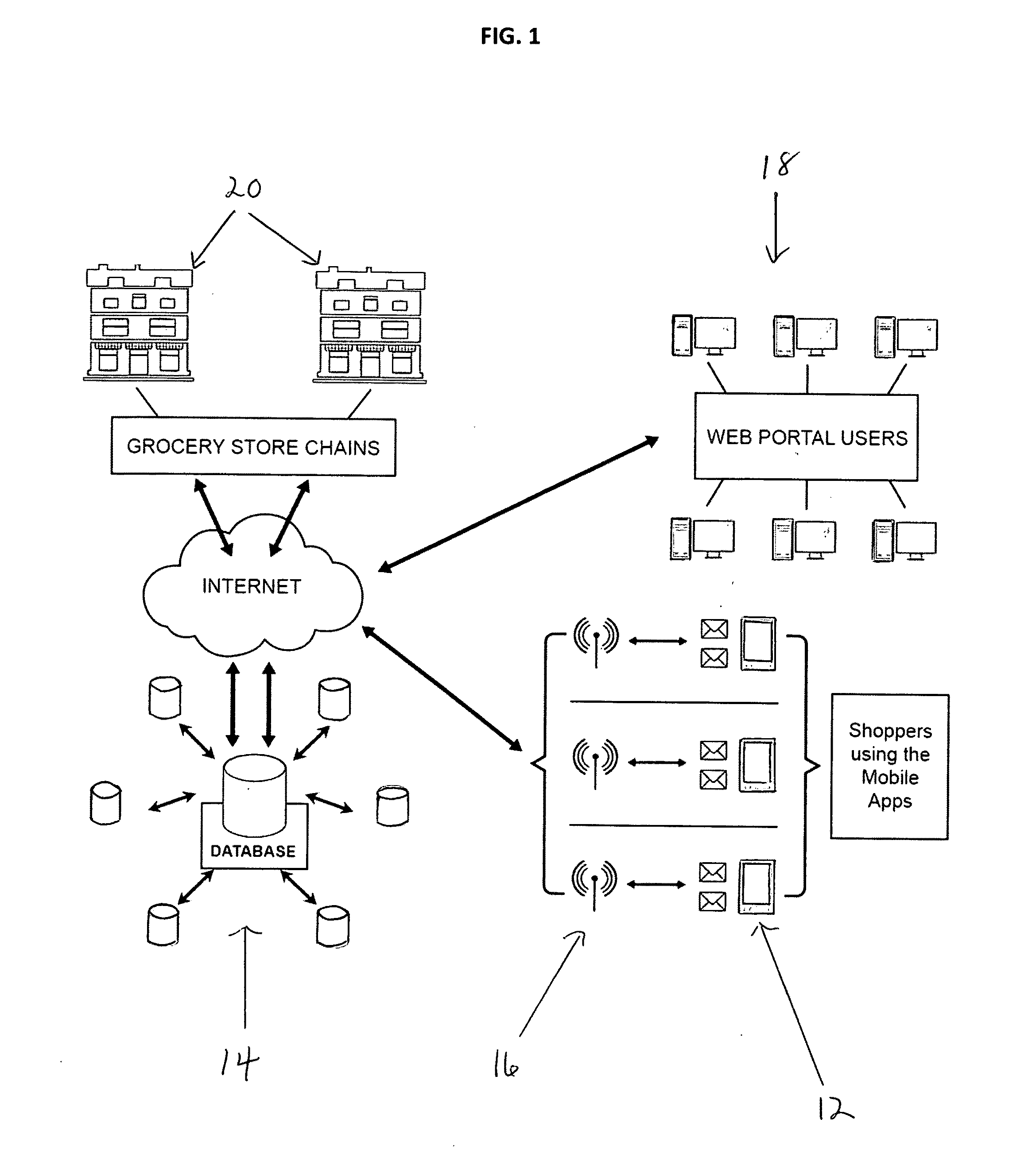

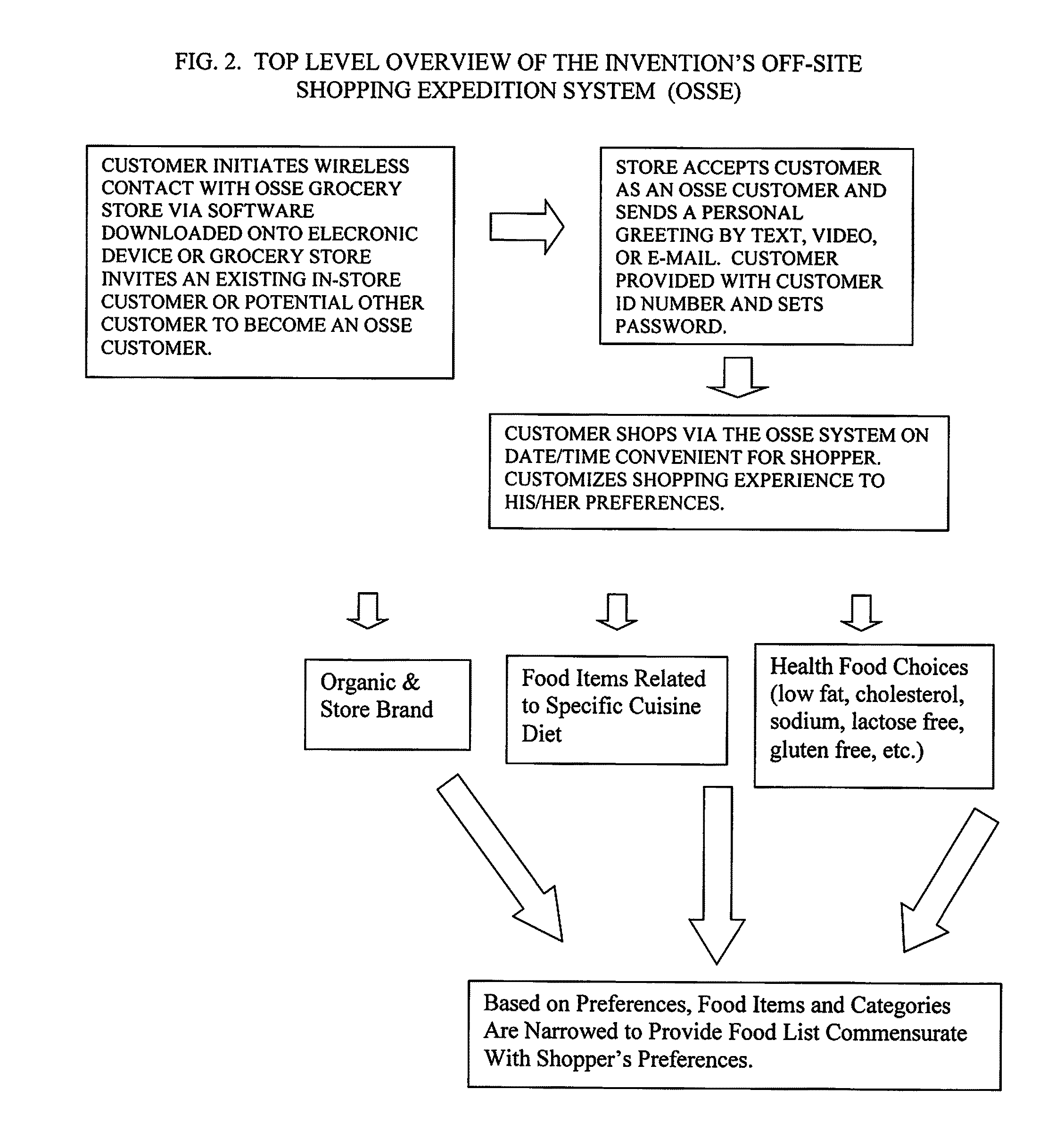

System and Method for Maximizing Food Selection Options According to Shopper Preferences, Health Requirements, and Price Preferences and Ensuring Selected Food Freshness to Provide a Complete, Efficient, and Enjoyable Off-Site Grocery Shopping Experience that Benefits Both the Off-Site Shopper and the Grocery Retailer

InactiveUS20160086255A1Accurate fillingCost efficientDigital data information retrievalBuying/selling/leasing transactionsOrder fulfillmentAdditive ingredient

An integrated shopping and order fulfillment method and system is described whereby the customer is able to tailor her grocery shopping list according to her selected preferences from the product inventory offered by a retailer grocer and viewable on the user's mobile phone device. Once the order is placed, the system initiates its order fulfillment methodology whereby a unique barcode is generated for tracking all packages associated with the order. The items are sorted according to their assigned perishability ranking to generate a packing order list for use by the retailer grocer. The packing order list provides an optimized packing order schedule to ensure the freshness of all perishable items upon the order's pickup and delivery. Selected preferences may include red alert options to warn the consumer of an undesired level of a designated ingredient and black out options to eliminate the posting of a particular food type during shopping.

Owner:SAINFORT MAJNHEIV +1

Devices and methods for controlled delivery from a drug delivery device

InactiveUS20050070883A1Accurate fillingDampen effect of thermal expansionMedical devicesPressure infusionDrug reservoirFrit

The invention features a plug for use with a drug delivery device, wherein the plug defines an expansion control channel, which accommodates thermal expansion of a formulation in a reservoir of a drug delivery device, and an exit channel. In one embodiment, the plug comprises an inner plug member and an outer plug member, which members define an expansion control channel to facilitate release of entrapped air and to accommodate thermal expansion of formulation from the sealed drug reservoir. The plug further defines an exit channel, and may optionally further comprise a frit positioned within the flow pathway just prior to the delivery outlet, or both.

Owner:BROWN JAMES E +6

Method for applying an in-painting technique to correct images in parallel imaging

InactiveUS7230429B1Increase reduce factor of K-spaceImprove efficiencyMagnetic measurementsElectric/magnetic detectionMedical imagingCoil sensitivity

The subject invention pertains to a method and apparatus for producing sensitivity maps with respect to medical imaging. The subject invention relates to a method for applying an inpainting model to correct images in parallel imaging. Some images, such as coil sensitivity maps and intensity correction maps, have no signal at some places and may have noise. Advantageously, the subject invention allows an accurate method to fill in holes in sensitivity maps, where holes can arise when, for example, the pixel intensity magnitudes for two images being used to create the sensitivity map are zero. A specific embodiment of the subject invention can accomplish de-noise, interpolation, and extrapolation simultaneously for these types of maps such that the local texture can be carefully protected.

Owner:INVIVO CORP

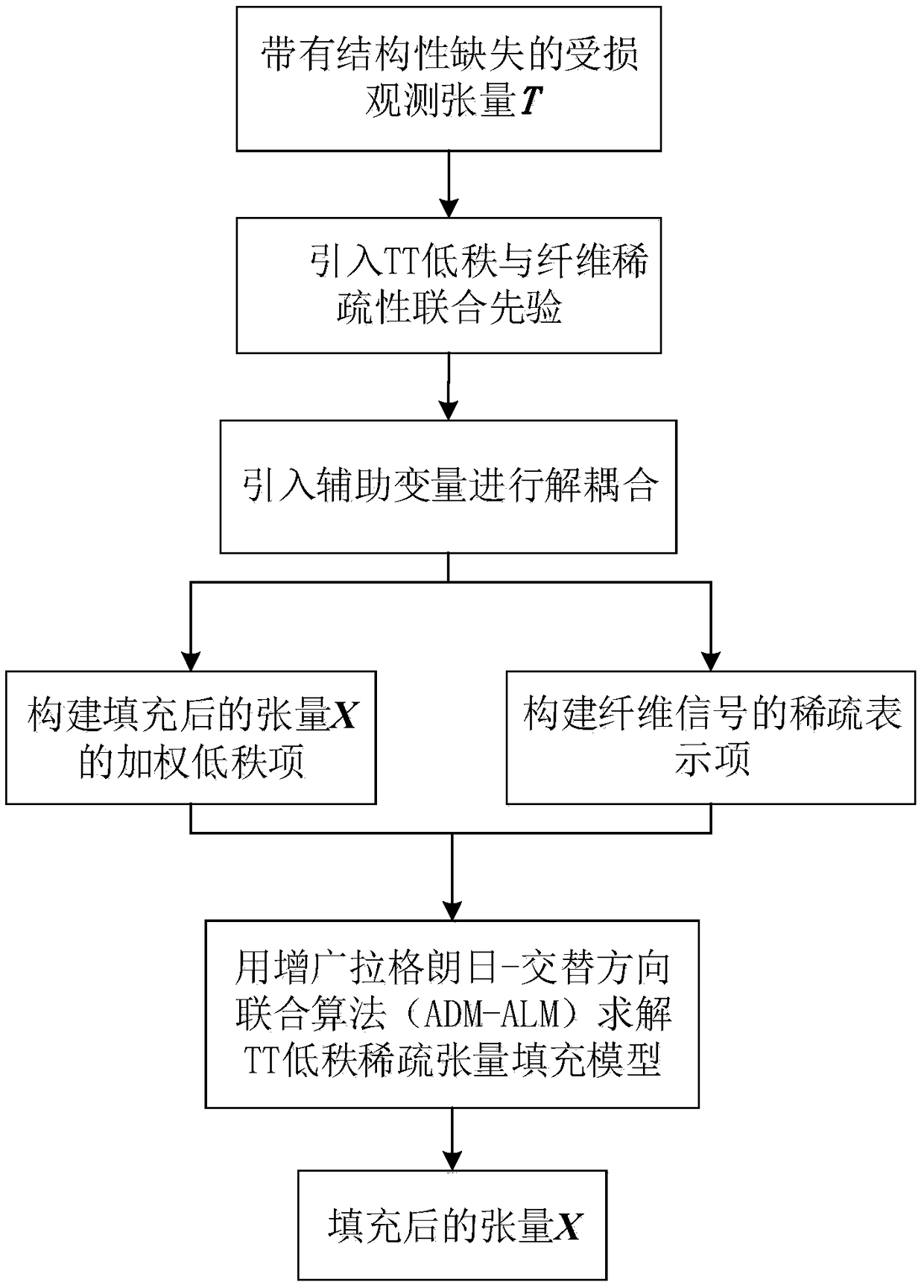

Tensor structural missing filling method based on joint low rank and sparse representation

PendingCN109241491ARealize the solutionAccurate fillingComplex mathematical operationsData dredgingFiber

The invention relates to the field of computer vision. In order to propose a tensor structural missing filling method and realize the accurate filling of the structural missing tensor, the tensor structural missing filling method based on the combination of low rank and sparse representation and the TT low rank tensor filling theory are introduced into the TT low rank prior to constrain the potential tensor. At the same time, considering that the fiber signal along each dimension of the tensor can be sparsely represented by a dictionary, and the missing fiber of the previous dimension can be recovered by sparse constraint on the fiber signal in the next dimension, sparse constraint is introduced for each dimension of the fiber signal; based on the sparse apriori of the combined TT low rankand each dimension, the tensor filling problem with structural defects is formulated as a constrained optimization problem, so that the tensor filling problem with structural defects can be realized.The invention is mainly applied to video image inpainting, recommendation system, data mining and multi-classification learning occasions.

Owner:TIANJIN UNIV

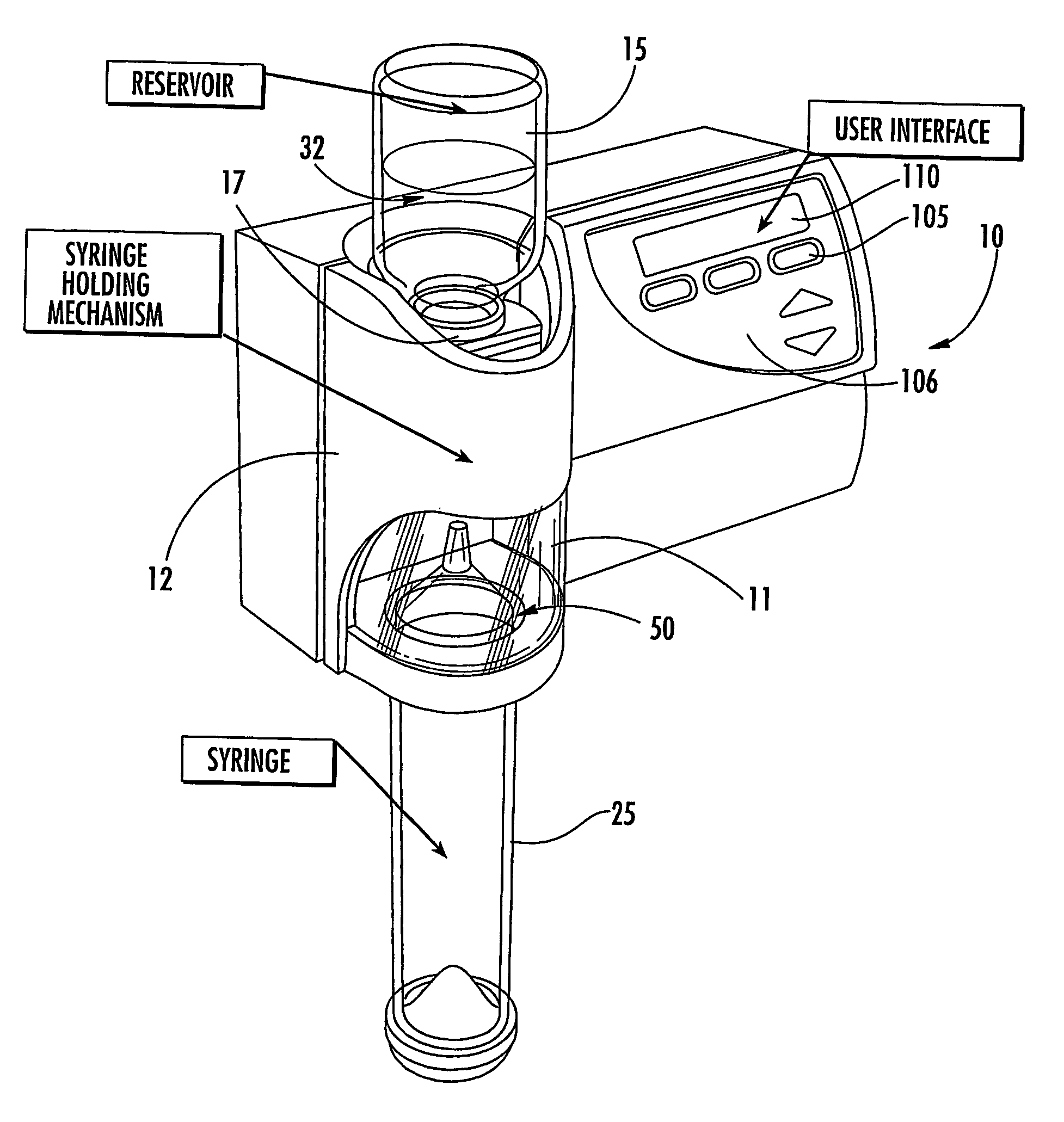

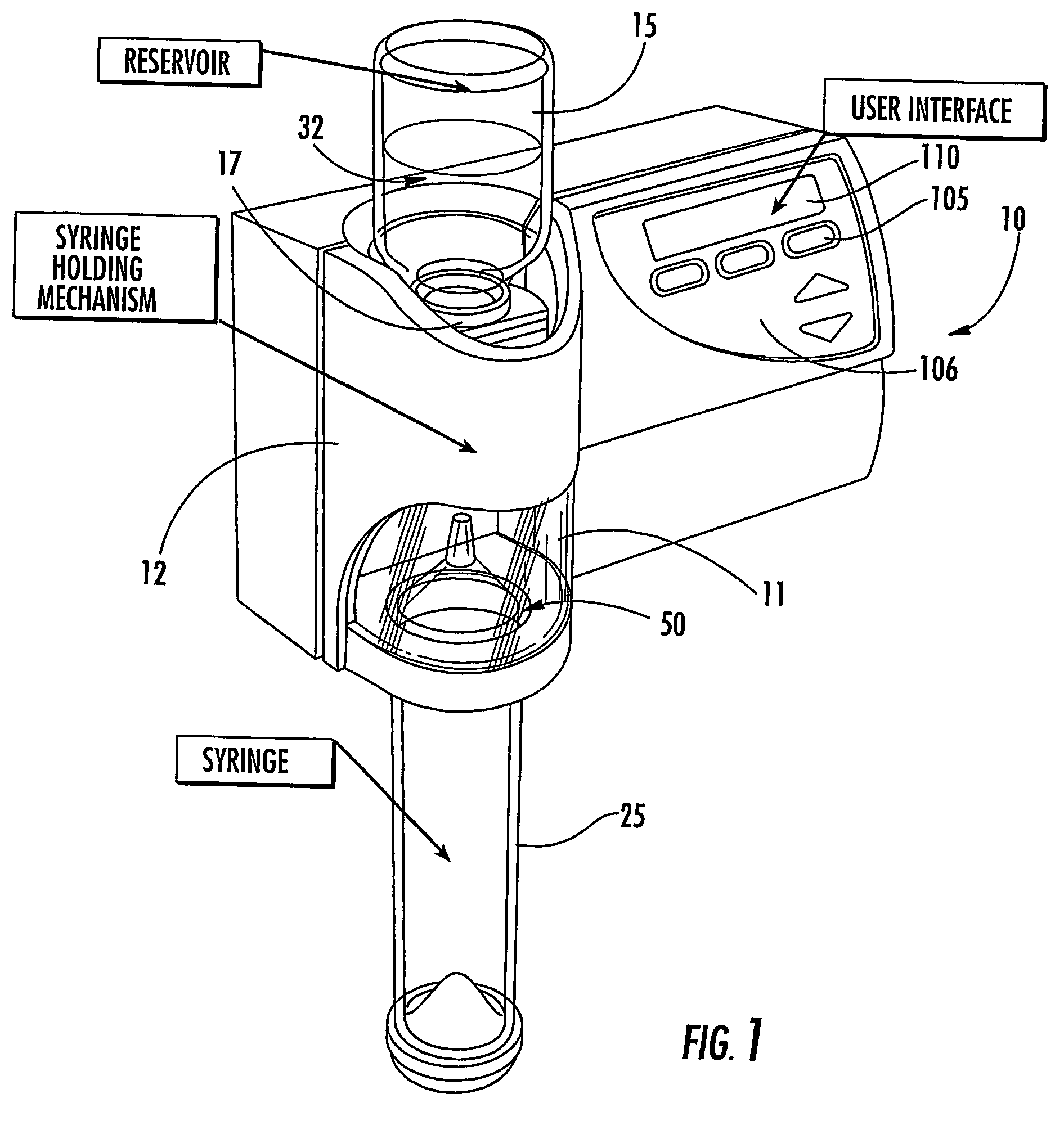

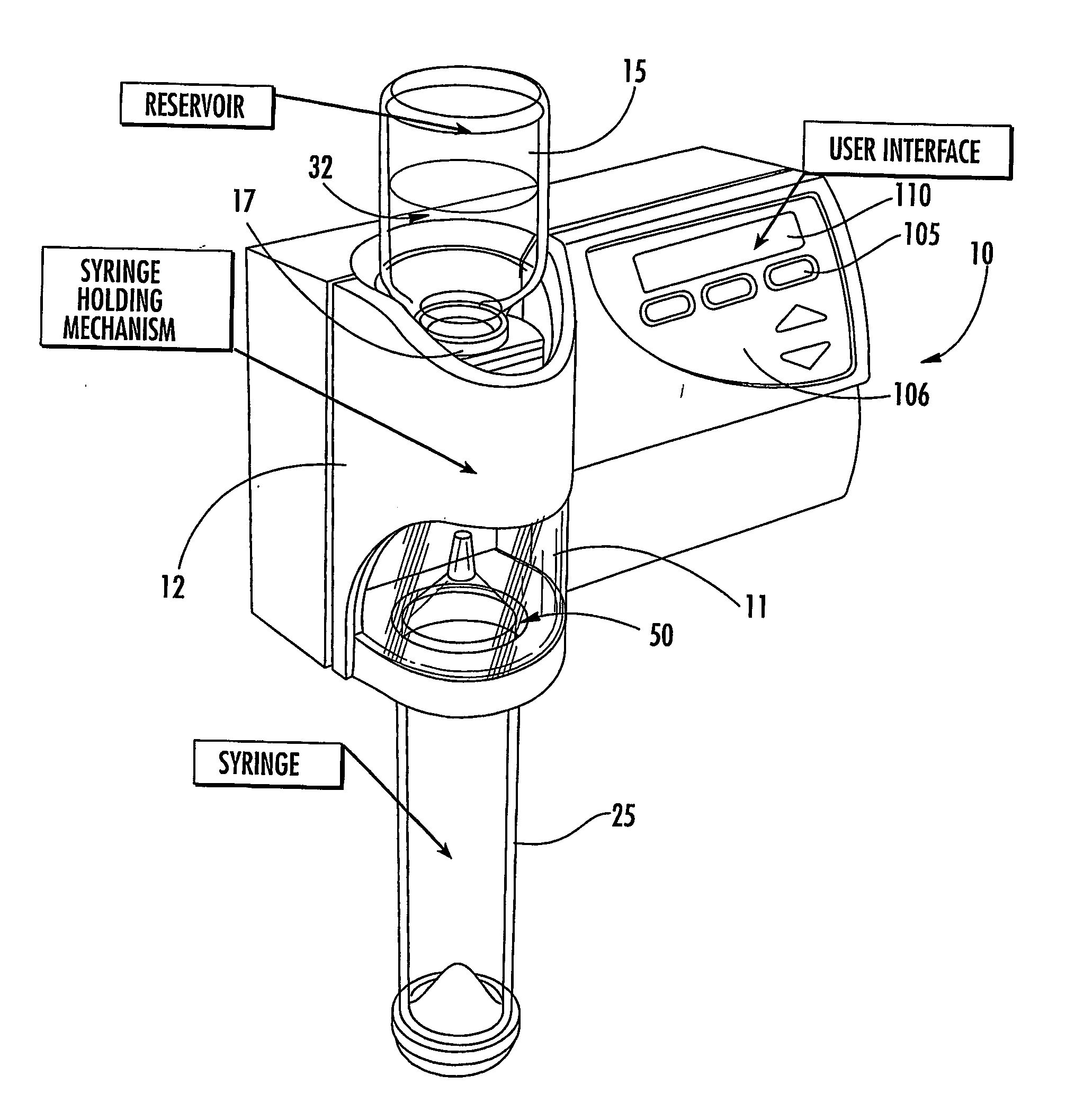

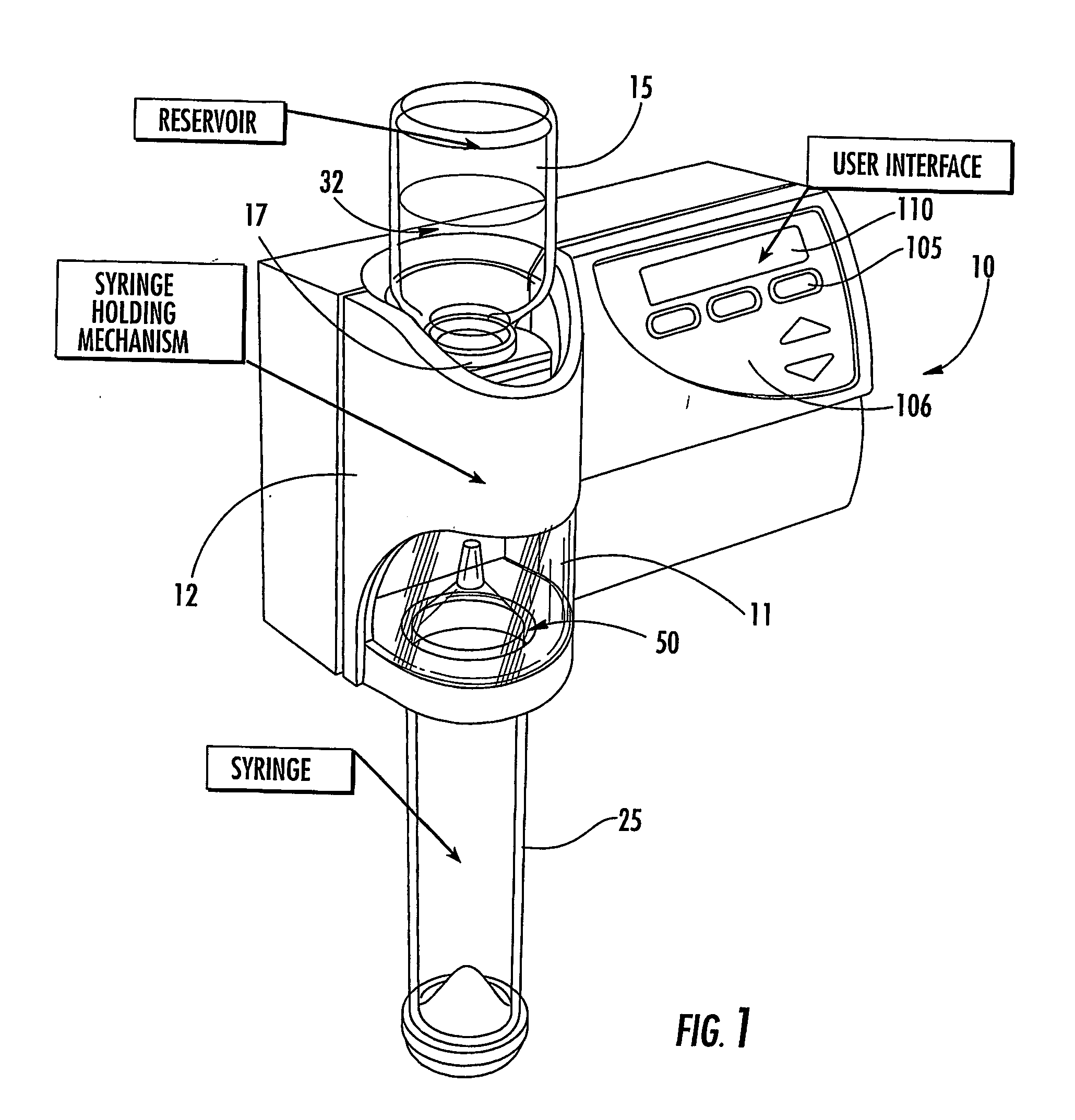

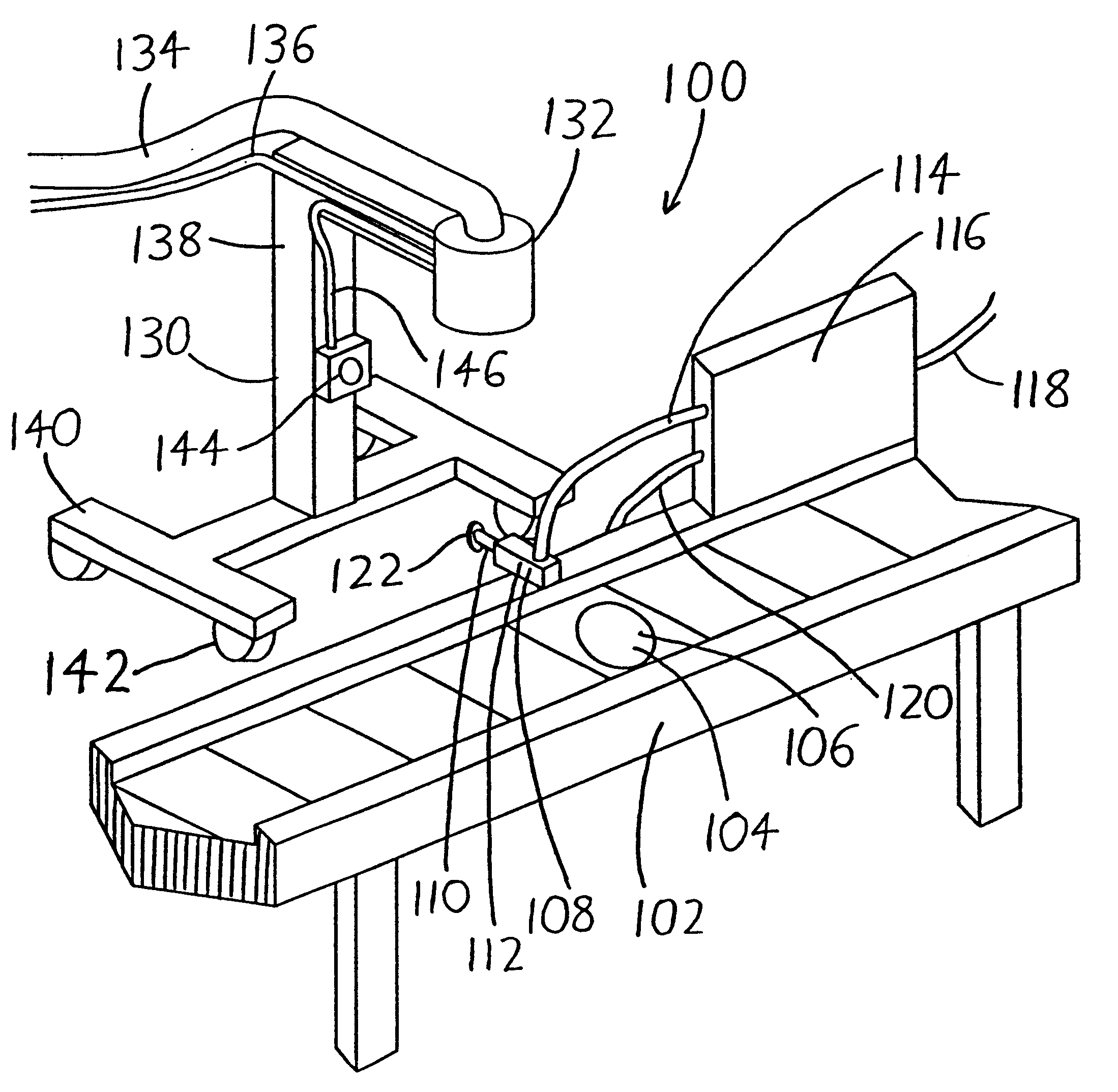

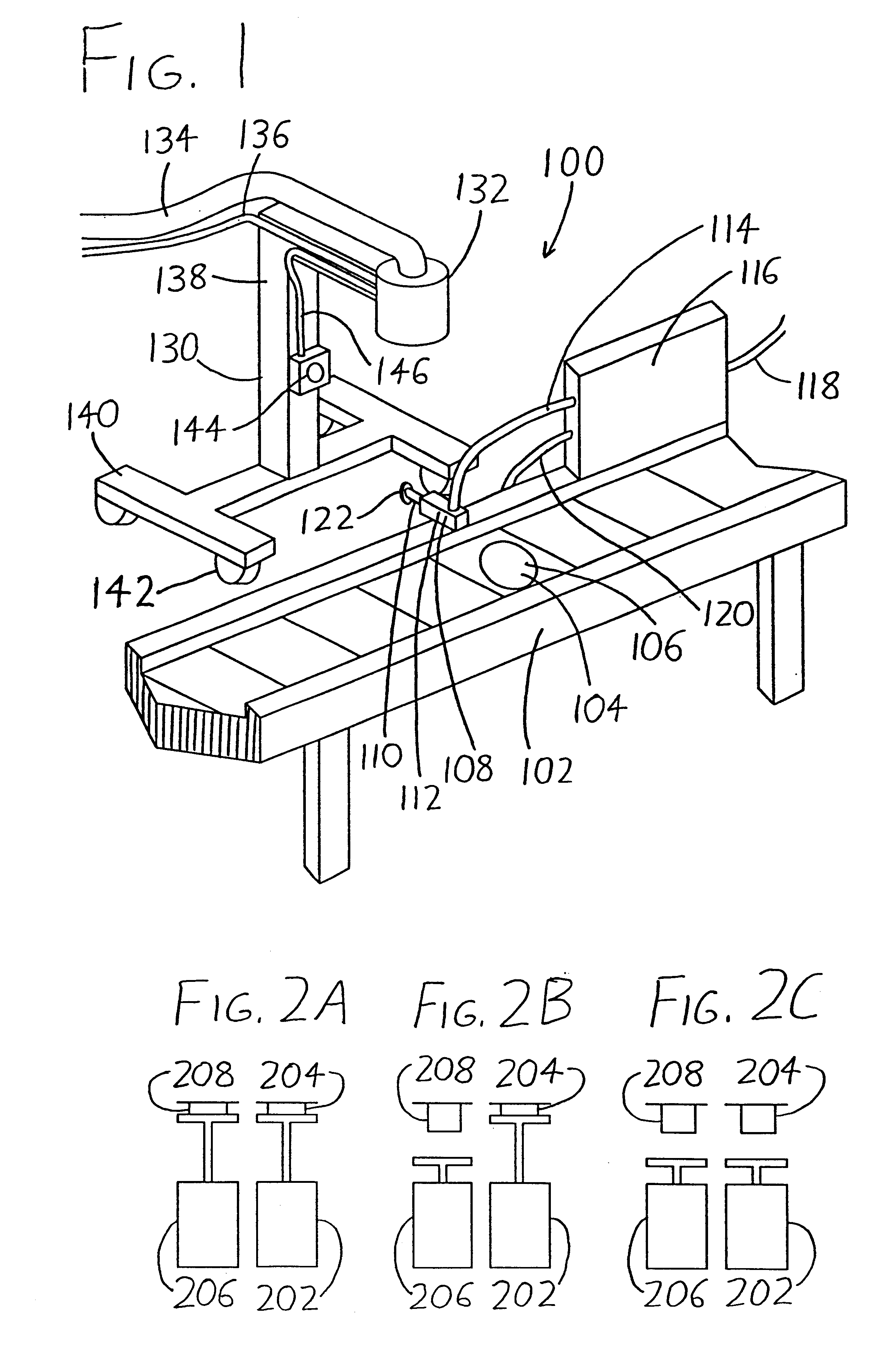

Peristaltic syringe filling station

ActiveUS7703483B2Easy to operateThe right amountIntravenous devicesSolid materialBiomedical engineeringUser interface

Owner:ACIST MEDICAL SYST

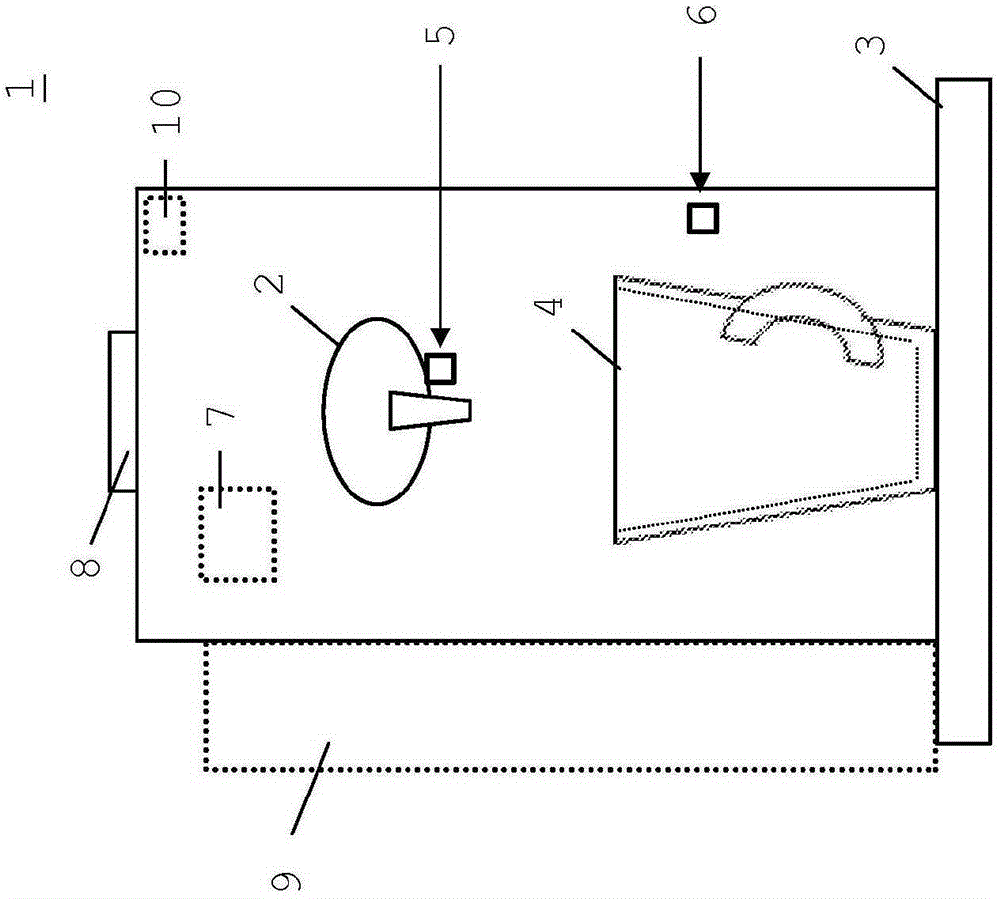

Beverage preparation machine capable of determining a beverage volume of receptacles and corresponding method

InactiveCN105228943AHigh volume calculation accuracyAccurate calculationBeverage vesselsLiquid dispensingComputer visionUser interface

A beverage preparation machine (1) comprises a first camera (5) for capturing a first image of a receptacle (4), and a second camera (6) for capturing a second image of the receptacle (4). The machine (1) further comprises a control unit (7) configured to determine a receptacle volume based on the first image and the second image, and to determine a beverage volume to be dispensed based on the receptacle volume and a selected filling level or percentage. Regardless of the shape, volume, and / or material of the receptacle (4), the filling level or percentage for dispensing the beverage can be freely selected via a user interface (8).

Owner:NESTEC SA

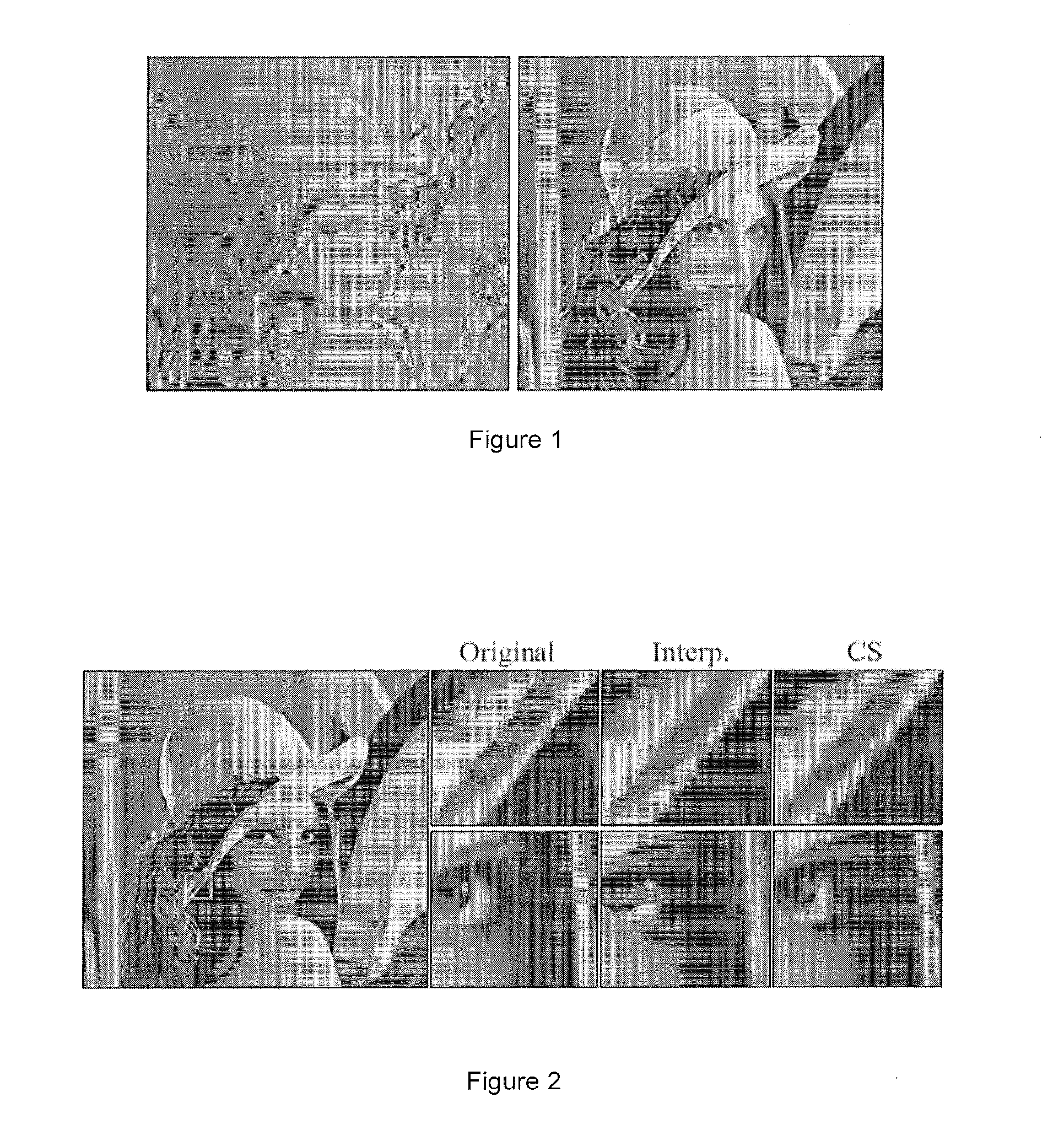

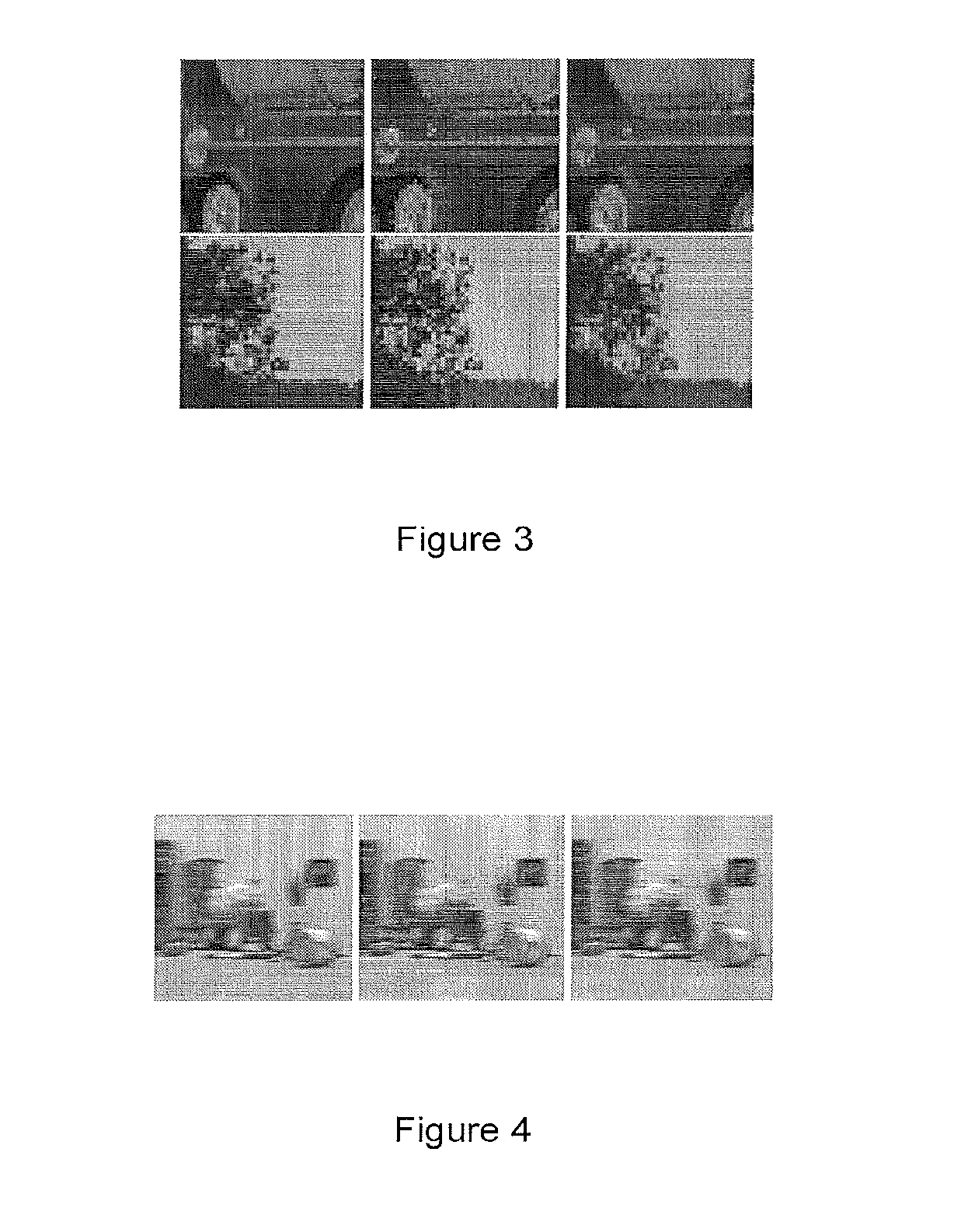

System and methods of compressed sensing as applied to computer graphics and computer imaging

ActiveUS20120294543A1Accurate reconstructionAccurate signalCharacter and pattern recognitionImage data processing detailsGraphicsCompressed sensing

Compressed sensing can be mapped to a more general set of problems in computer graphics and computer imaging. Representation of a rendered scene in the formulation y=Âx produces higher-quality rendering with less samples than previous approaches. A filter formulation Φ makes point samples compatible with wavelet and therefore allows reconstruction of 2-D images from a set of measured pixels (point samples).

Owner:STC UNM

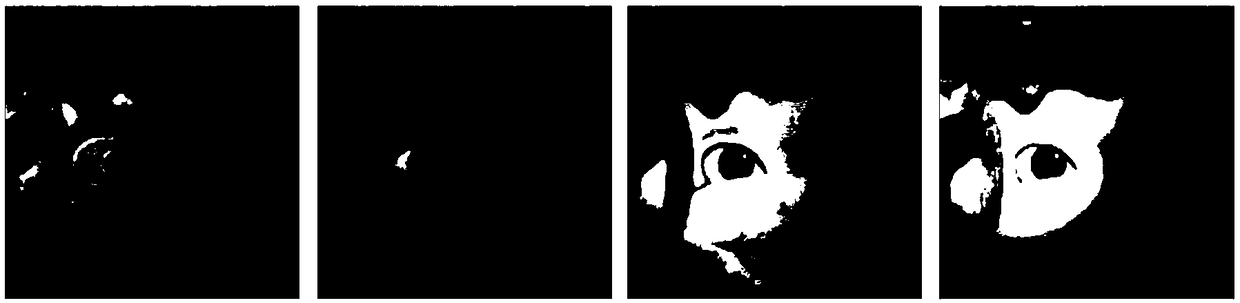

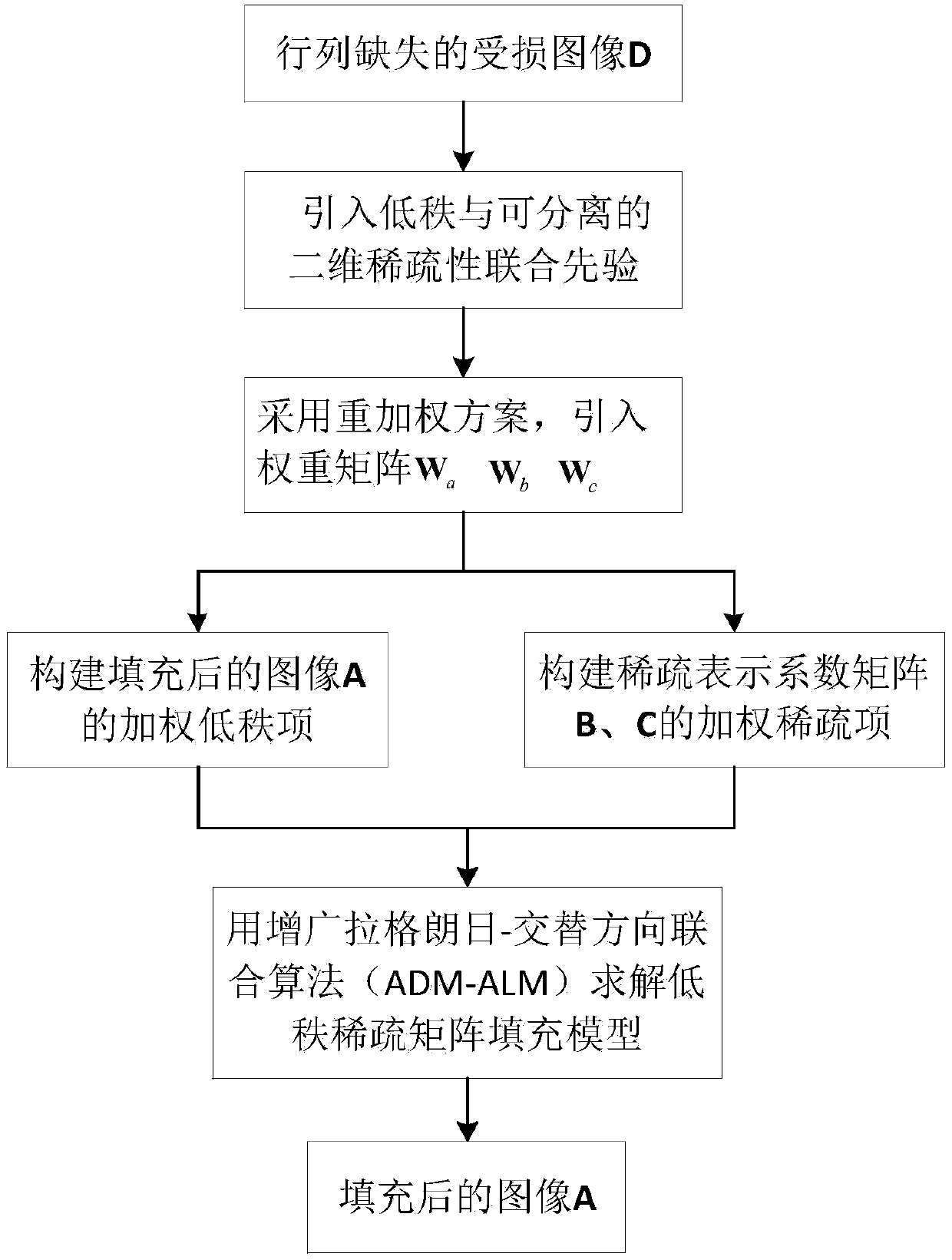

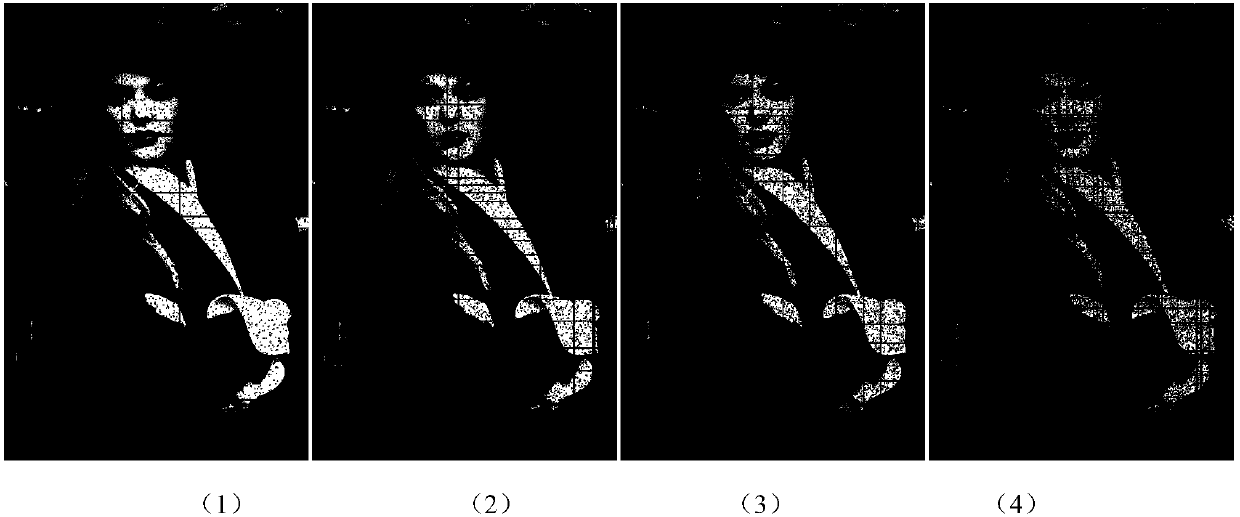

Row and column loss image filling method based on low-rank matrix reconstruction and sparse representation

InactiveCN107133930ARealize the solutionAccurate fillingImage enhancementCharacter and pattern recognitionVision processingAlgorithm

The invention belongs to the field of computer vision, and aims at achieving the accurate filling of a pixel row and column loss image. The technical scheme employed in the invention is that a row and column loss image filling method based on low-rank matrix reconstruction and sparse representation comprises the steps: introducing low-rank priori to carry out the constraining of a potential image based on the low-rank matrix reconstruction theory; introducing a separable two-dimensional sparse priori based on the sparse representation theory with the consideration to a condition that the sparse representation of each column of a row loss image can be achieved through a column dictionary and the sparse representation of each row of a column loss image can be achieved through a row dictionary; specifically describing a filling problem of an image with the row and column loss into a solving problem of a constraint optimization equation based on the above combined low-rank and separable two-dimensional sparse priori, thereby achieving the filling of the row and column loss image. The method is mainly used for a computer vision processing occasion.

Owner:TIANJIN UNIV

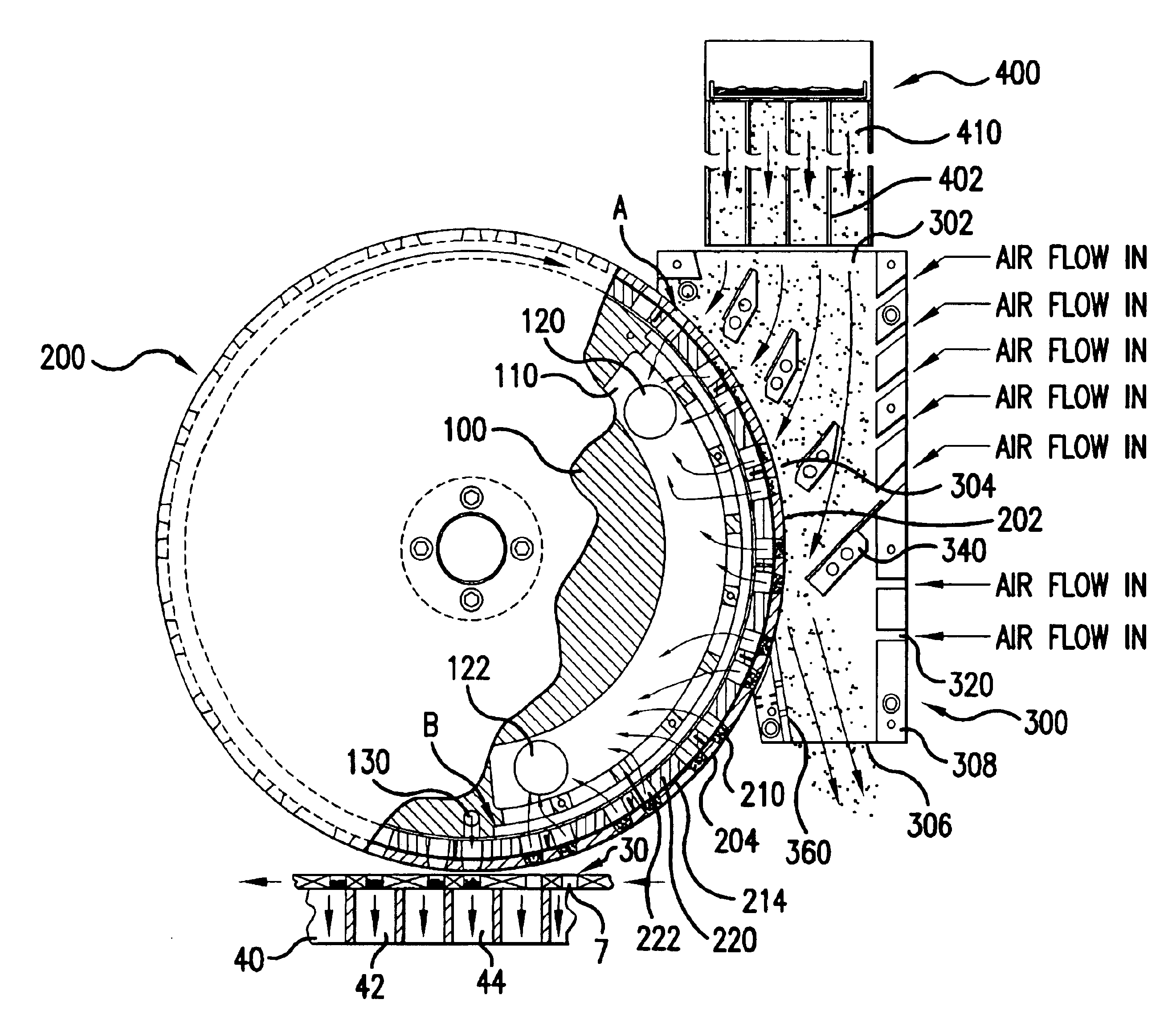

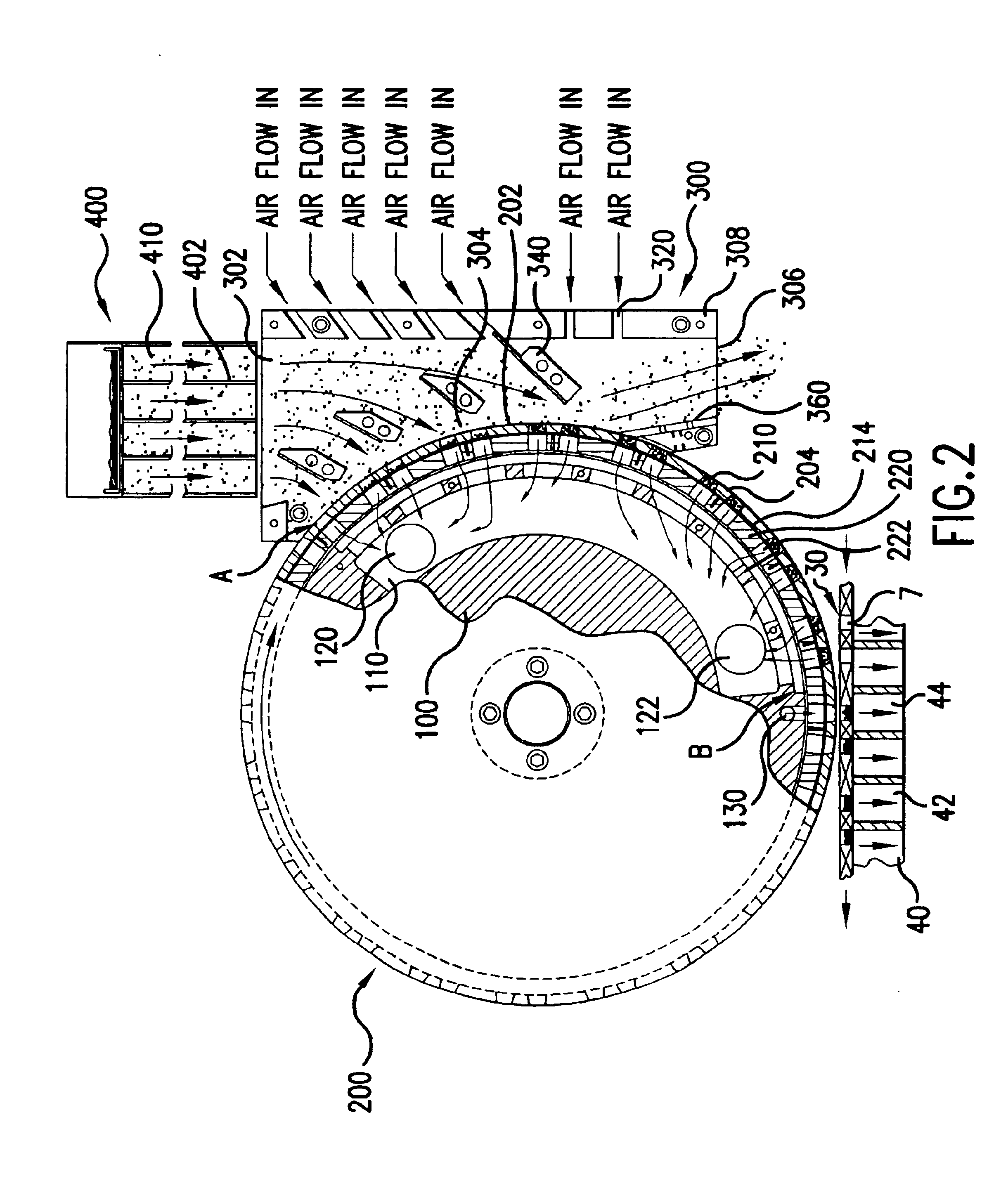

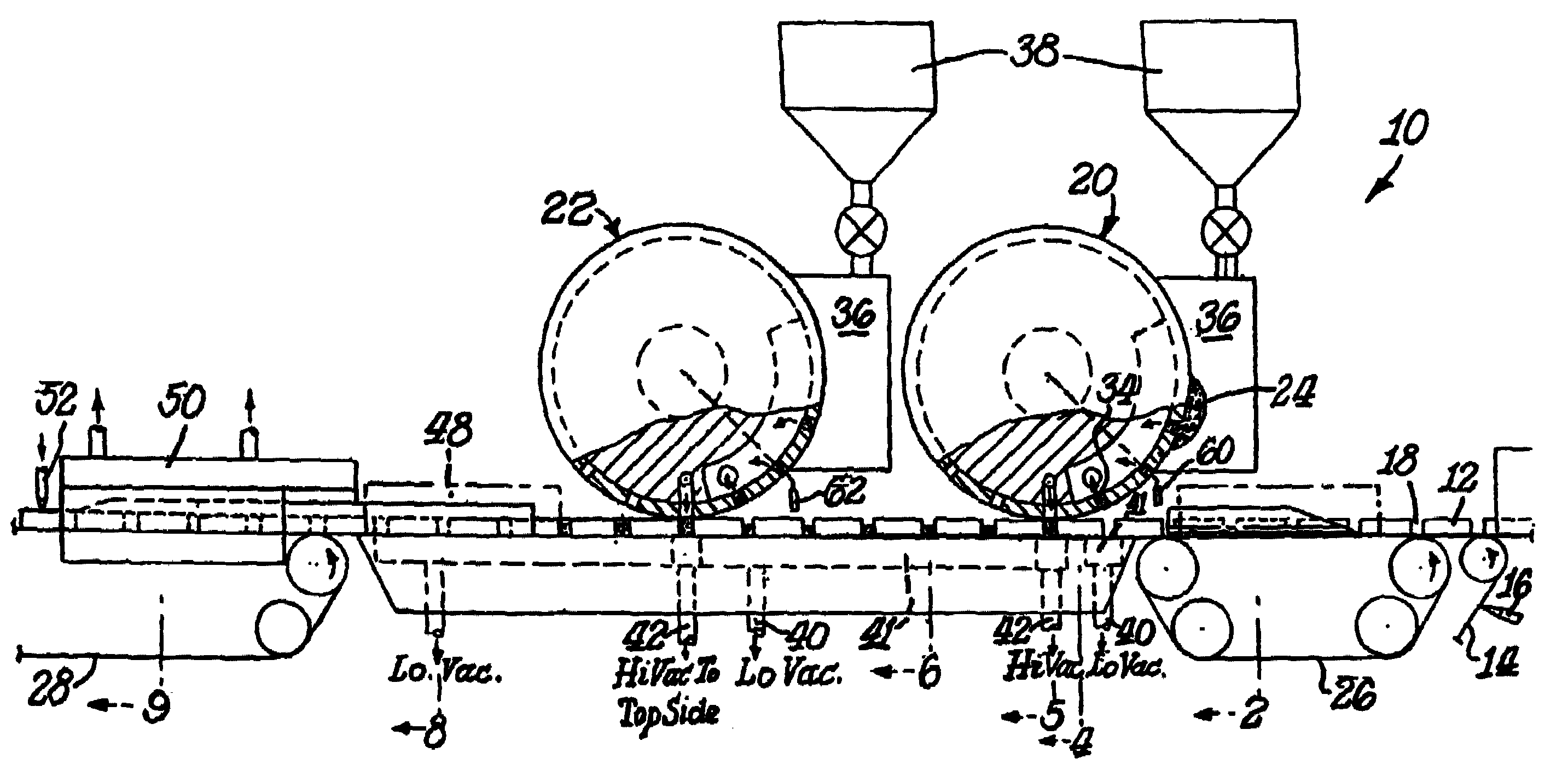

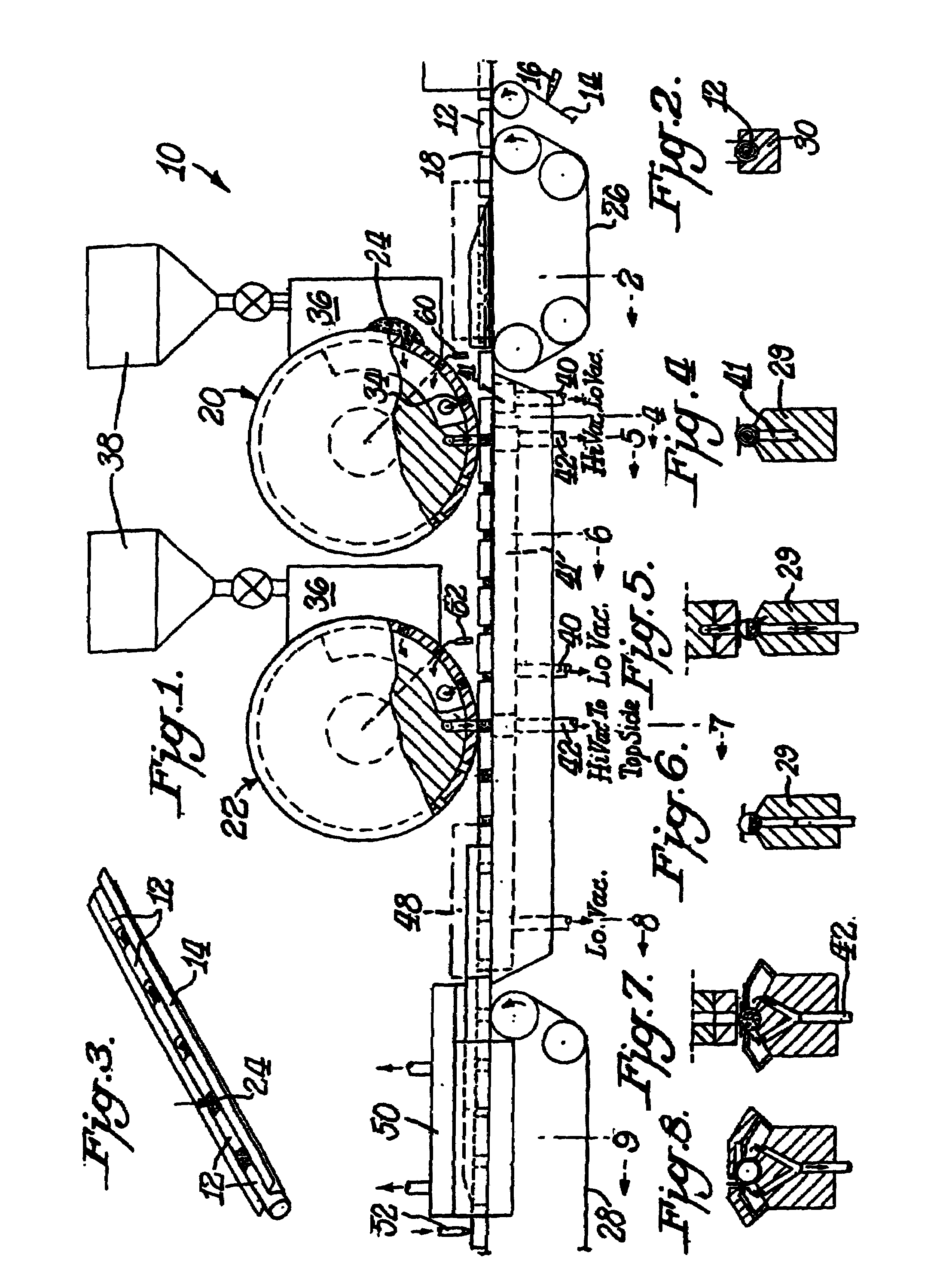

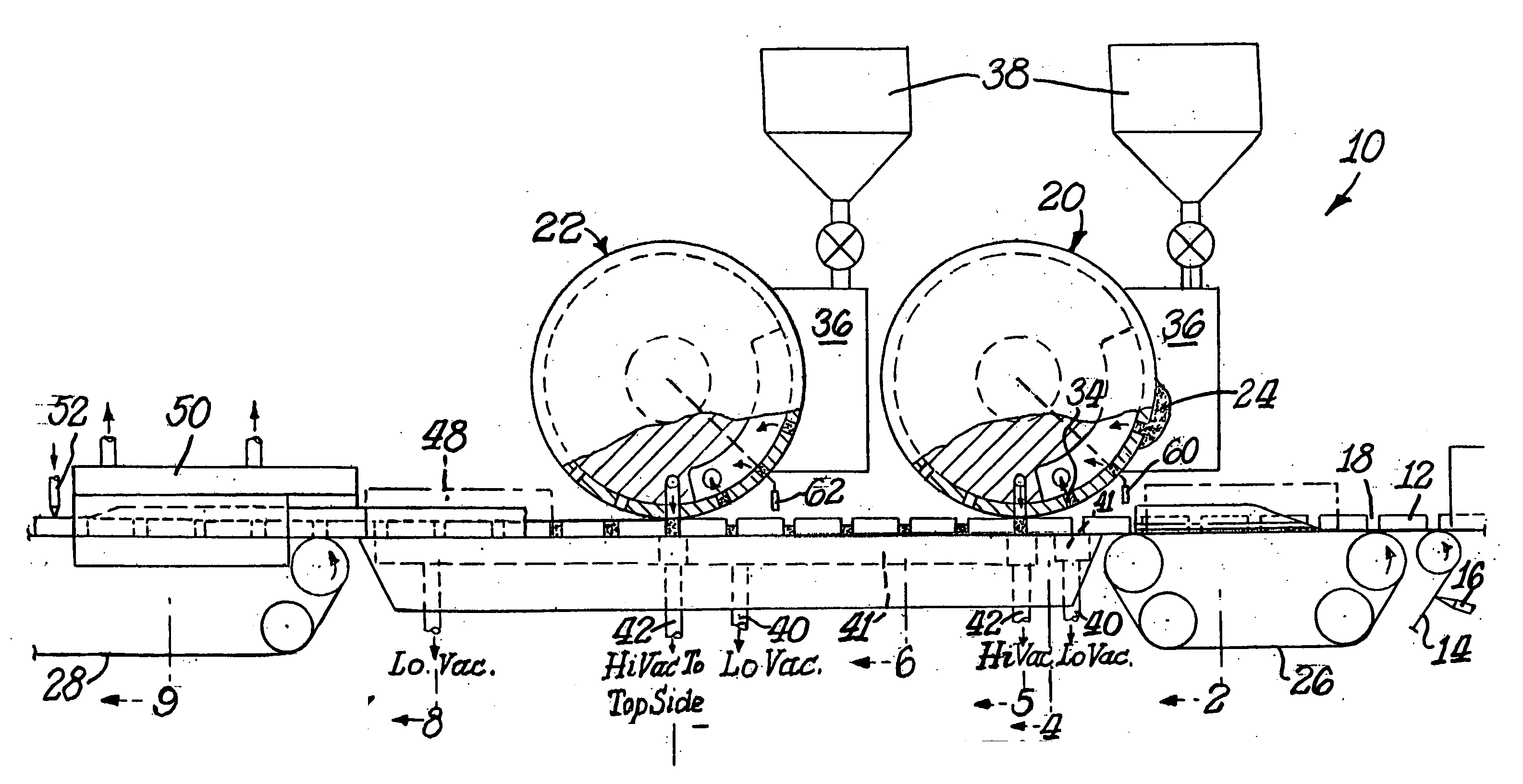

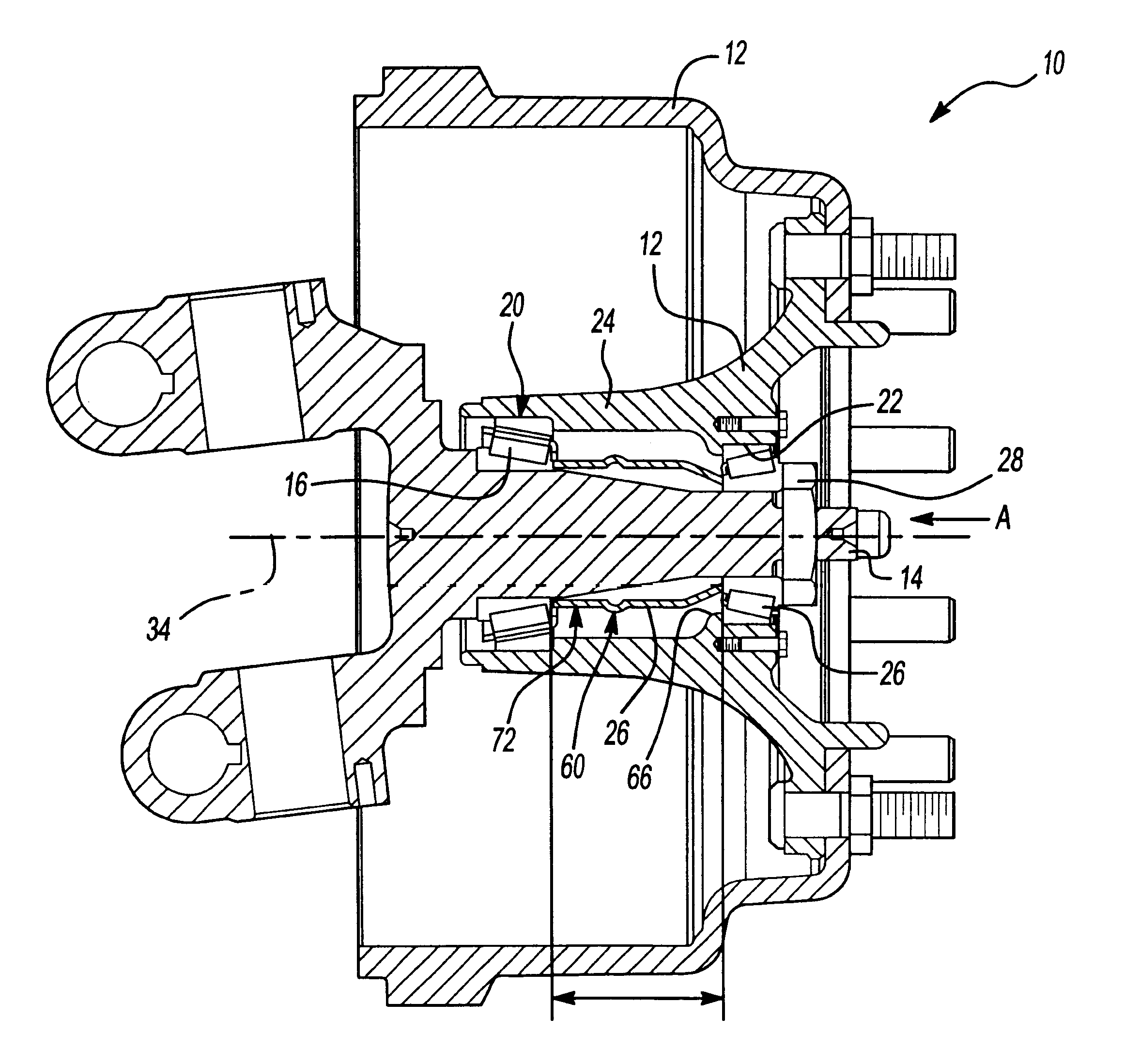

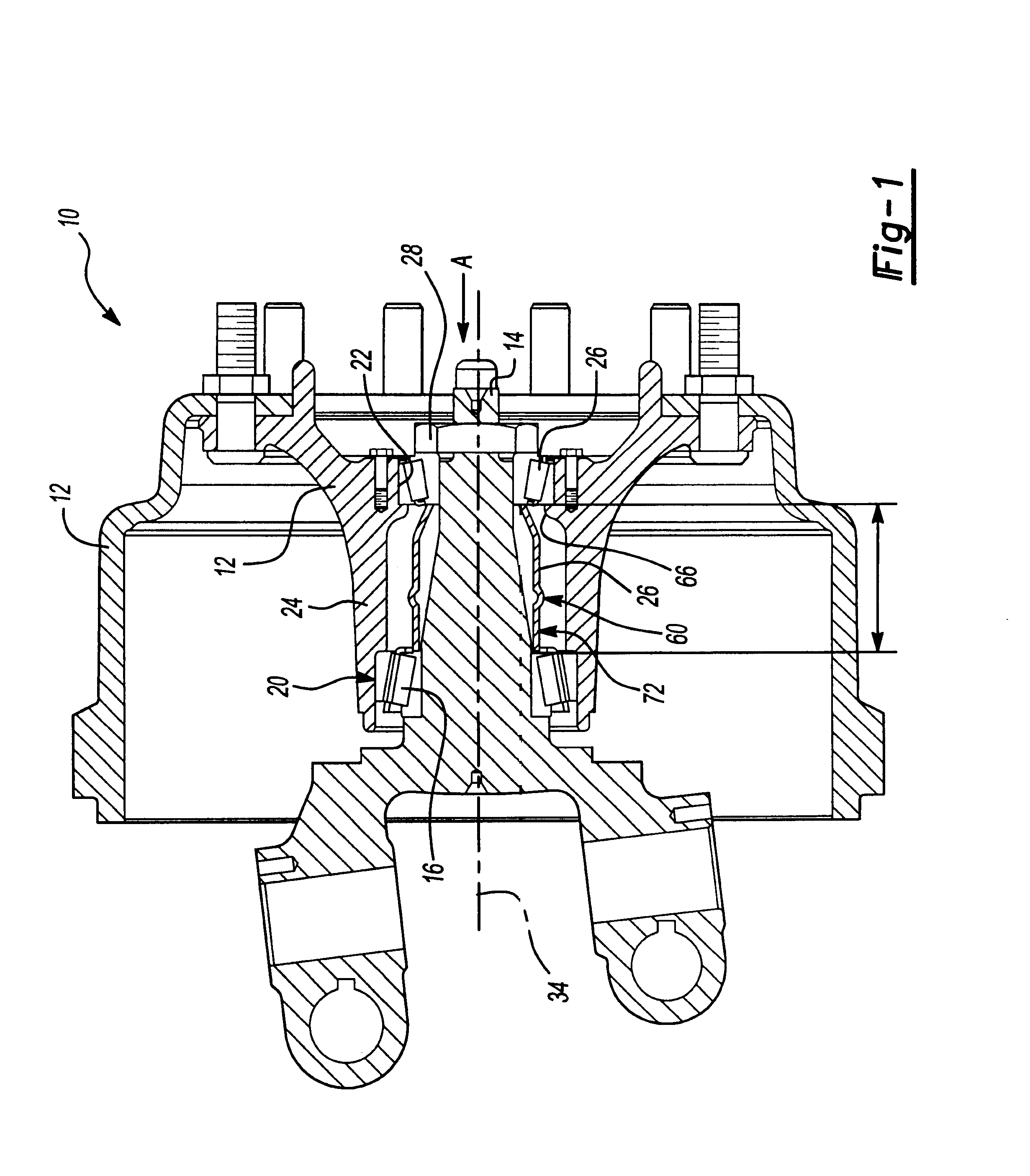

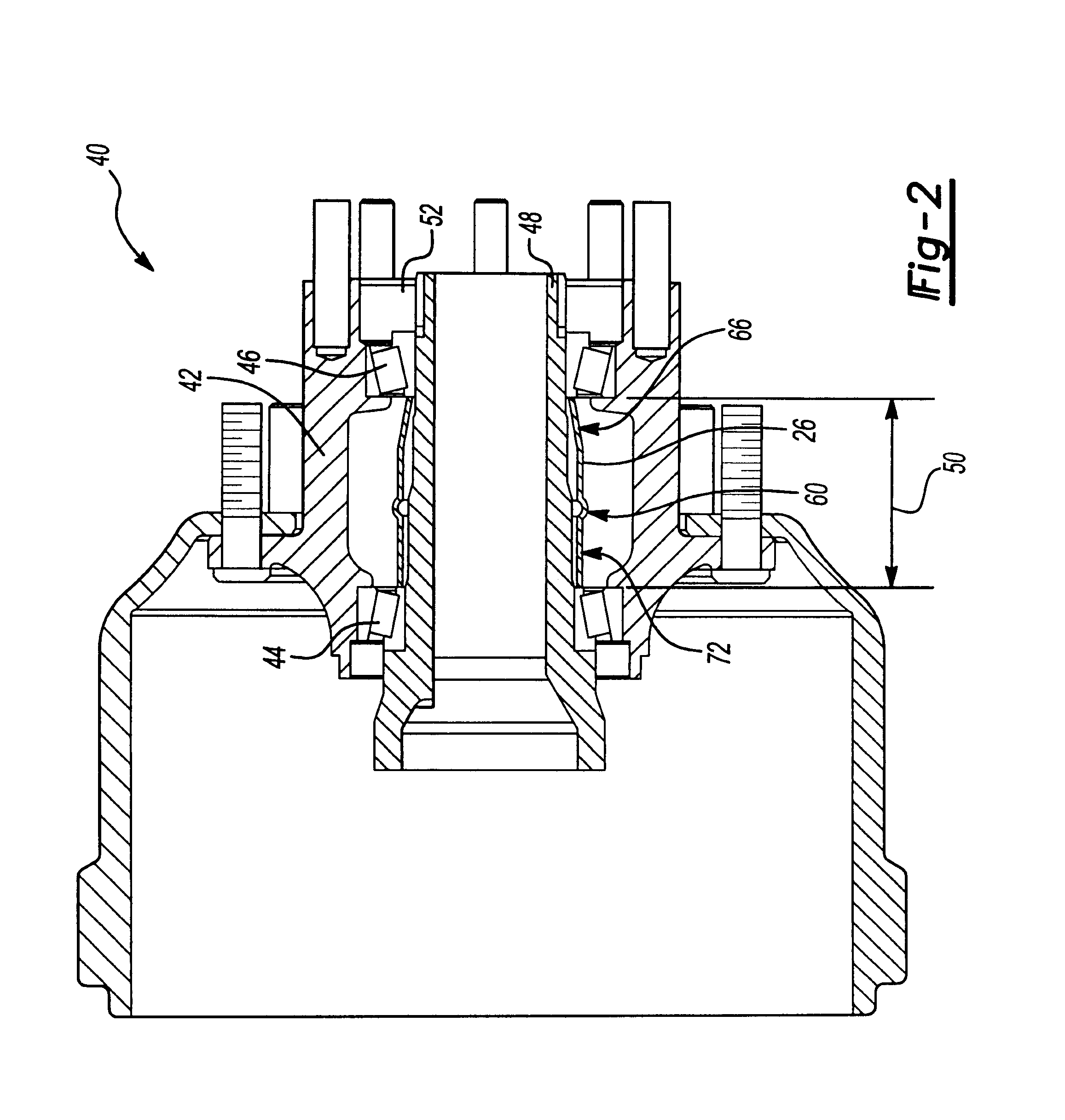

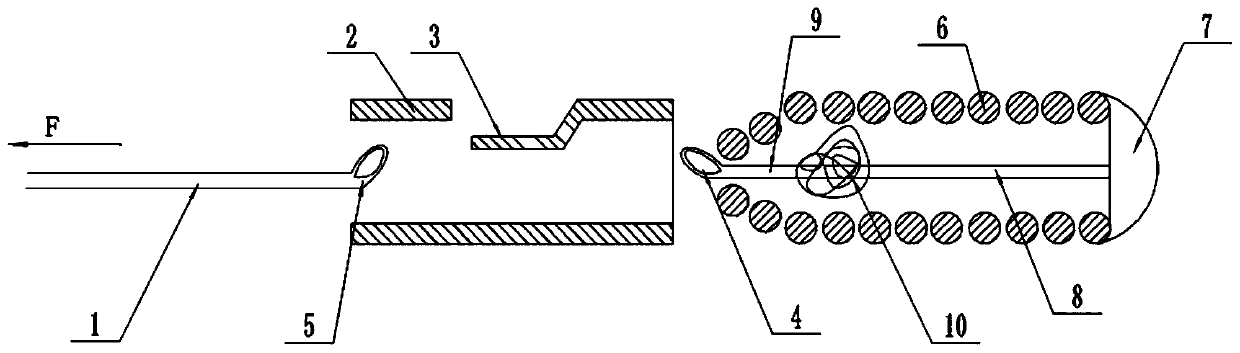

Dual station applicator wheels for filling cavities with metered amounts of particulate material

InactiveUS7093625B2Accurate fillingFast transferLiquid fillingConfectioneryEngineeringMechanical engineering

Apparatus and method for filling spaced apart cavities with particulate material include a transport for moving the cavities along a path of travel. The cavities are partially filled with particulate material at an upstream location while applying vacuum underneath each cavity during such partial filling. The partially filled cavities are then completely filled with a downstream deposit of particulate material while applying vacuum to the upper sides of each cavity during such filling. The combination of vacuum applied underneath the cavity during partial fill and vacuum applied to the top sides of the cavity during complete fill produces approximately 100% cavity fill with minimal extraneous scatter of particulate material.

Owner:PHILIP MORRIS USA INC

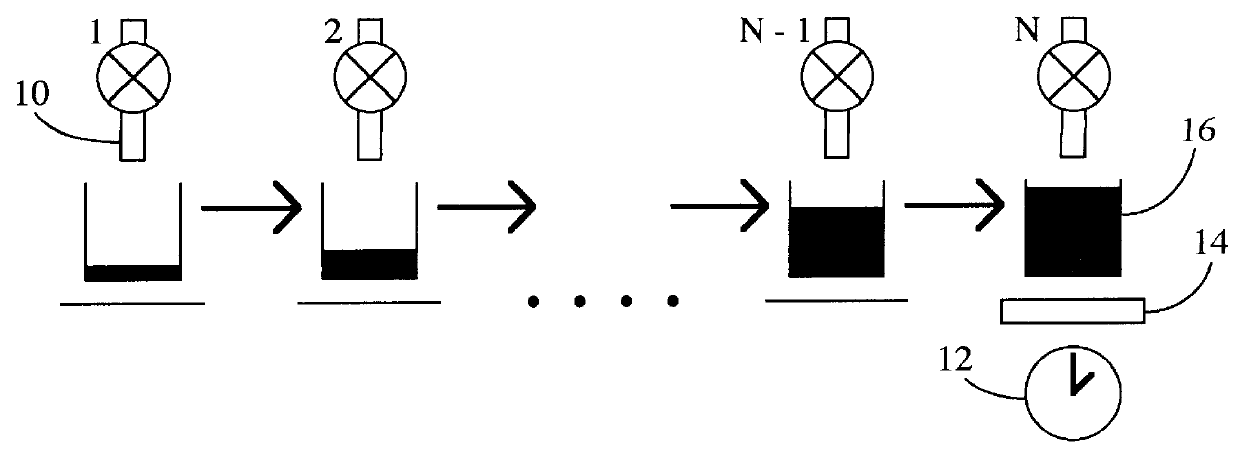

Fluid filling system with fill time optimization

A fluid filling system is disclosed wherein containers to be filled with fluid materials are supplied first to one or more time-metered filling stations, and then to a weight-metered filling station. At first, the time-metered filling station(s) is / are inactive, and only the weight-metered filling station is used to fill a first container to a desired final weight. A timer is used to monitor the filling time necessary to reach the desired final weight. When later containers are then supplied to the time-metered filling station(s), they are filled at each time-metered station for a filling time which is dependent on the previously measured filling time for the weight-metered filling station. These containers are then "topped off" by the weight-metered filling station to precisely fill them to the desired final weight, and the time required for such topping off is measured for use in subsequent modification of the filling times at the time-metered filling stations. For each container, the filling time at each time-metered filling station is dependent on the filling time at the weight-metered filling station in such a manner that the two will converge towards each other with successive containers until they are substantially or exactly equal. Preferably, the dependence between the time-metered filling time and weight-metered filling time are such that ttimed(t)=tN(t-1)+Qx[tN(t-1)-ttimed(t-1)]wherein tN(t-1) is the filling time at the weight-metering filling station for a prior container; ttimed(t) is the filling time at the time-metering filling station for the prior container; ttimed(t-1) is the filling time at the time-metering filling station for the prior container; Q is a predetermined real number.

Owner:IDEAL PAK MASSMAN LLC

Methods For Analyzing Interactions Between Proteins And Sugar Chains

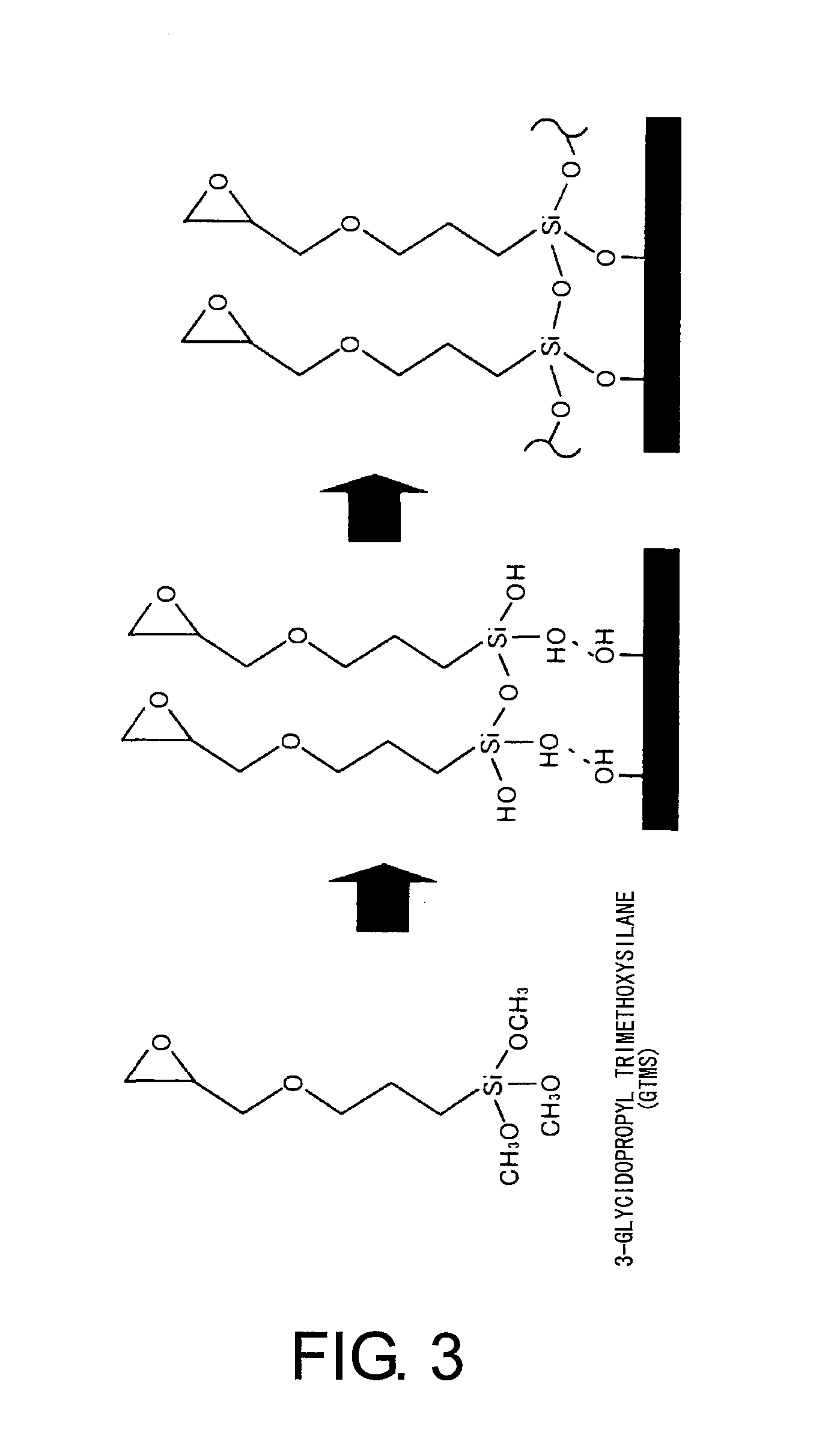

ActiveUS20070202535A1High densityRaise the ratioBioreactor/fermenter combinationsBiological substance pretreatmentsSugarOrganic chemistry

As a result of investigating the optimum conditions of methods for immobilizing proteins that interact with sugar chains onto a substrate, it was revealed that coating the surface of a slide glass with GTMS enables immobilization at a higher S / N ratio than conventionally possible. Moreover, by using a substrate to which a rubber with a number of holes was affixed to form a number of reaction vessels, and further by spotting lectins onto the substrate and washing with PBST, the weak interactions between sugar chains and lectins were successfully detected with improved sensitivity. In addition, by introducing an evanescent excitation-type scanner, it became possible to detect the interactions between lectins and sugar chains without washing away the probe solution.

Owner:NAT INST OF ADVANCED IND SCI & TECH

Peristaltic Syringe Filling Station

ActiveUS20080053560A1Easy to operateThe right amountIntravenous devicesSolid materialSyringeBiomedical engineering

The present invention is directed to a syringe filling station that can fill a syringe with a specified volume of fluid. In one embodiment, the syringe filling station comprises a reservoir attachment, a fluid delivery system, a syringe retaining guide, and a pump to move fluid from a reservoir to a syringe. The fluid delivery system may comprise a sterile consumable cartridge that is insertable into the filling station and defines a fluid pathway from a reservoir to a syringe. The syringe filling station may also include a user interface. An operator can input commands into the user interface to specify the amount of fluid to dispense into the syringe. The user interface may be connected to a processor that controls the rate of pumping and thereby can fill a syringe with a desired amount of fluid. The filling station may also include sensors that detect air in the tubing, depletion of the reservoir, among other things.

Owner:ACIST MEDICAL SYST

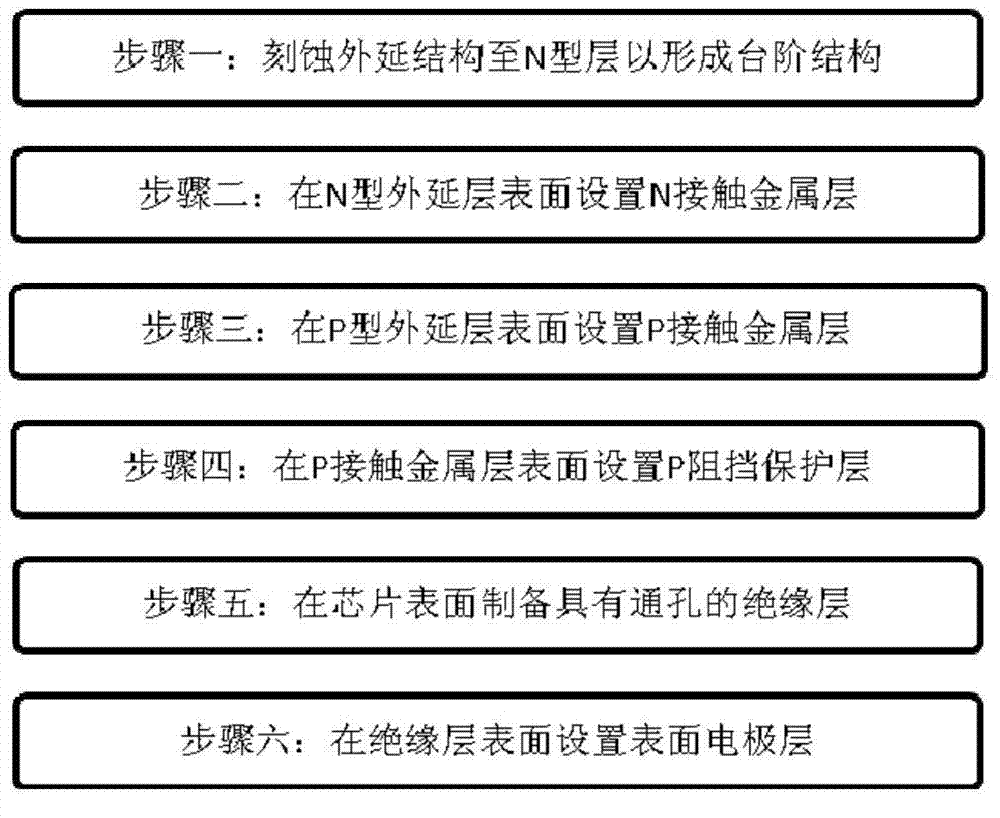

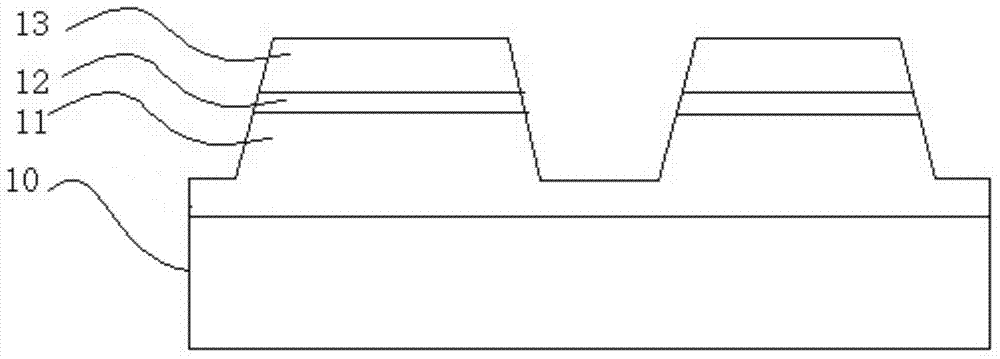

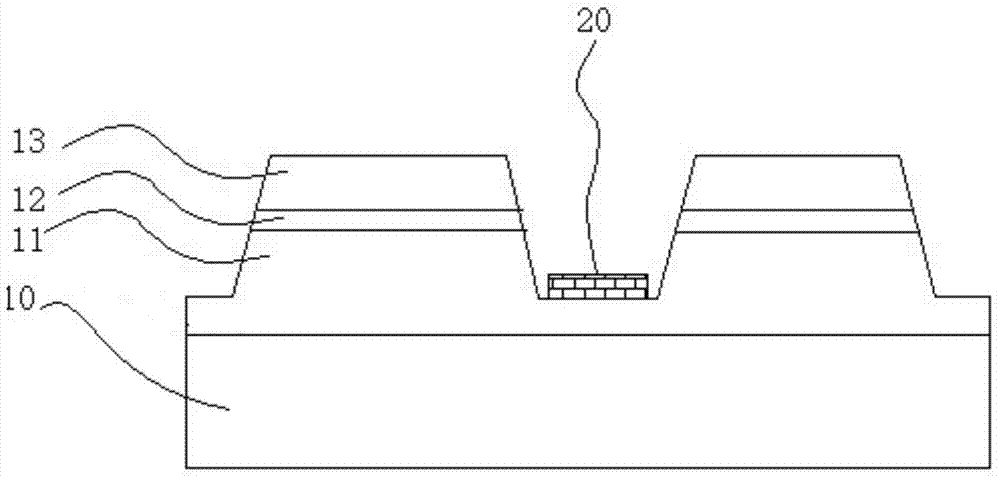

Flip LED (light-emitting diode) chip with high luminous efficiency and good heat radiating performance and preparation method thereof

ActiveCN104505446AGood electrical and thermal conductivityIncrease reflective areaSemiconductor devicesLight-emitting diodeMetal

The invention provides a flip LED (light-emitting diode) chip with high luminous efficiency and good heat radiating performance and a preparation method thereof. The LED chip comprises an epitaxial substrate, wherein an N type epitaxial layer, a light-emitting layer and a P type epitaxial layer are sequentially laminated on the upper surface of the epitaxial substrate; a concave hole is formed in the P type epitaxial layer, downwards penetrates through the light-emitting layer and extends to the N type epitaxial layer; a P contact metal layer, a P baffle protecting layer and a P surface electrode layer are sequentially laminated on the upper surface of the P type epitaxial layer; the lower surface of the P baffle protecting layer and the upper surface of the P contact metal layer are overlapped; an N contact metal layer and an N surface electrode layer are sequentially laminated on the upper surface of the N type epitaxial layer corresponding to the bottom of the concave hole; a clearance is reserved between the N contact metal layer and the edge of the concave hole; an insulating layer is arranged on the wall surface of the clearance. The flip LED chip provided by the invention has high heat-conducting property and conductivity, and improvement of the luminous efficiency of the LED chip is facilitated by the structure.

Owner:APT ELECTRONICS

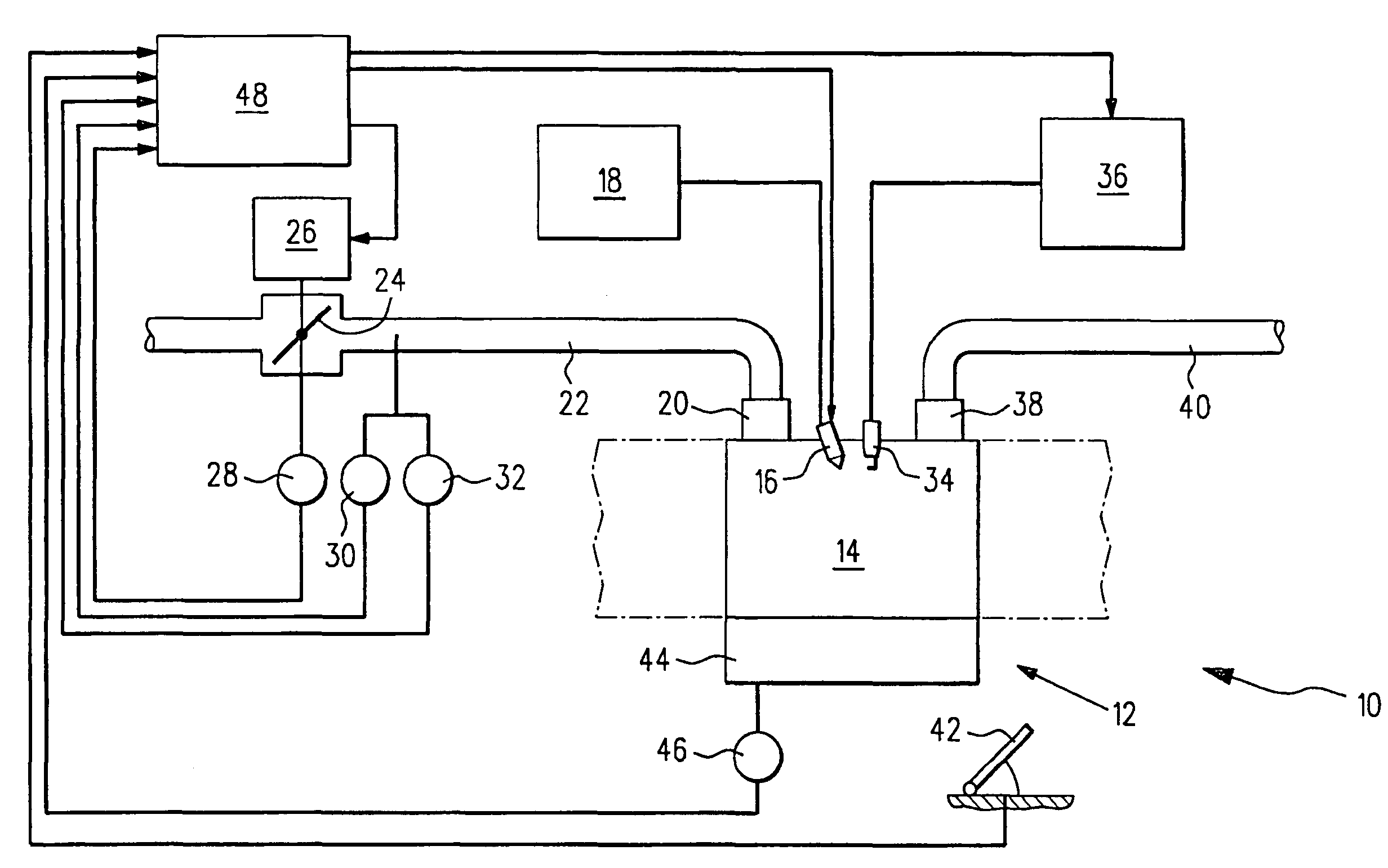

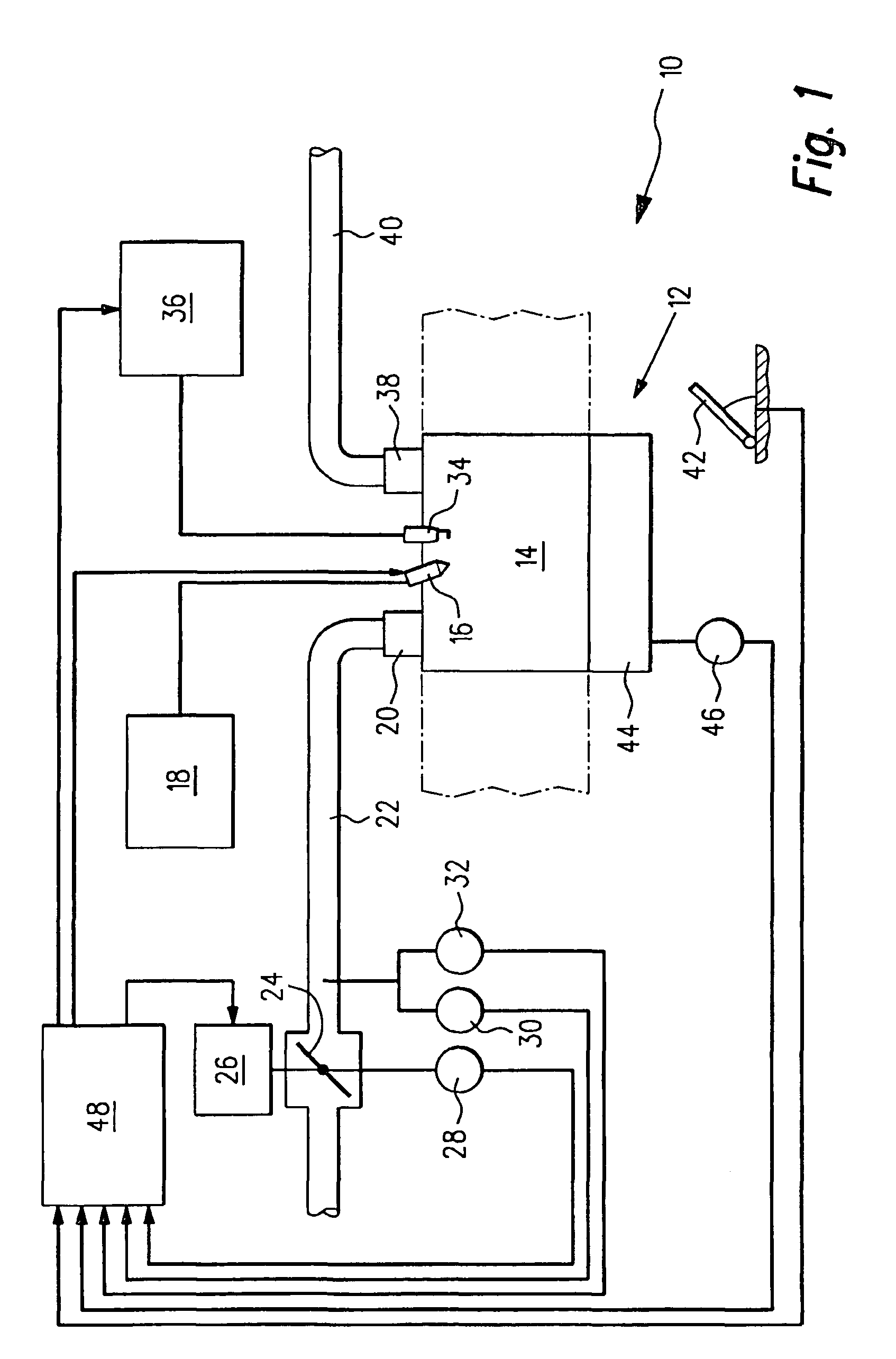

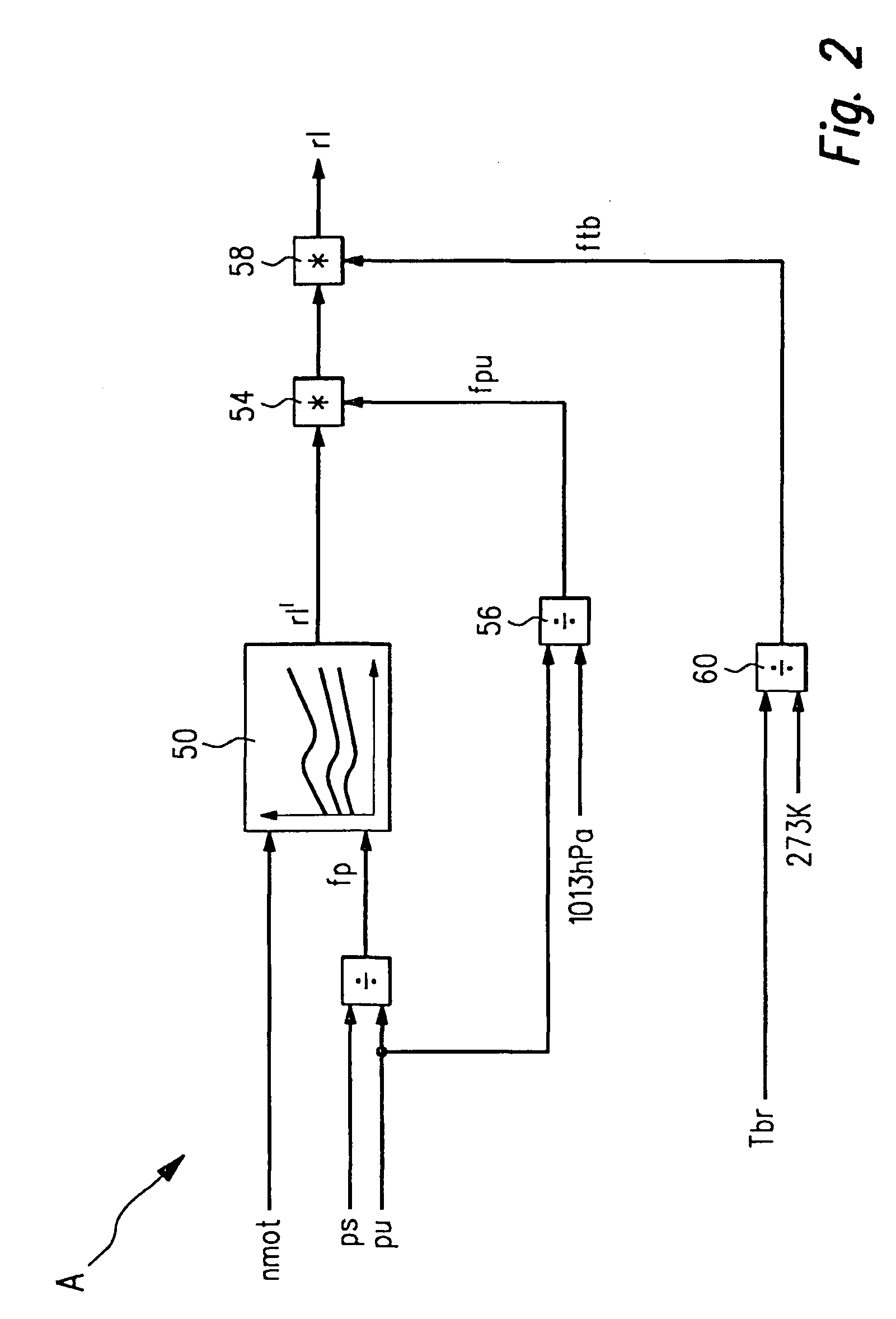

Method for operating an internal combustion engine

ActiveUS7415345B2Improve accuracyIncrease consumptionElectrical controlDigital data processing detailsExternal combustion engineAmbient pressure

In operation of an internal combustion engine, an air filling (rl) in a combustion chamber is ascertained, taking into account a pressure (ps) in an intake conduit. It is proposed that the air filling (rl) be ascertained on the basis of a model (A), which as its input variables receives an rpm (nmot) of a crankshaft and a ratio of the pressure (ps) in the intake conduit (22) to an ambient pressure (pu).

Owner:ROBERT BOSCH GMBH

Dual station applicator wheels for filling cavities with metered amounts of particulate material

InactiveUS20050112228A1Accurate fillingFast transferLiquid fillingConfectioneryEngineeringMechanical engineering

Apparatus and method for filling spaced apart cavities with particulate material include a transport for moving the cavities along a path of travel. The cavities are partially filled with particulate material at an upstream location while applying vacuum underneath each cavity during such partial filling. The partially filled cavities are then completely filled with a downstream deposit of particulate material while applying vacuum to the upper sides of each cavity during such filling. The combination of vacuum applied underneath the cavity during partial fill and vacuum applied to the top sides of the cavity during complete fill produces approximately 100% cavity fill with minimal extraneous scatter of particulate material.

Owner:PHILIP MORRIS USA INC

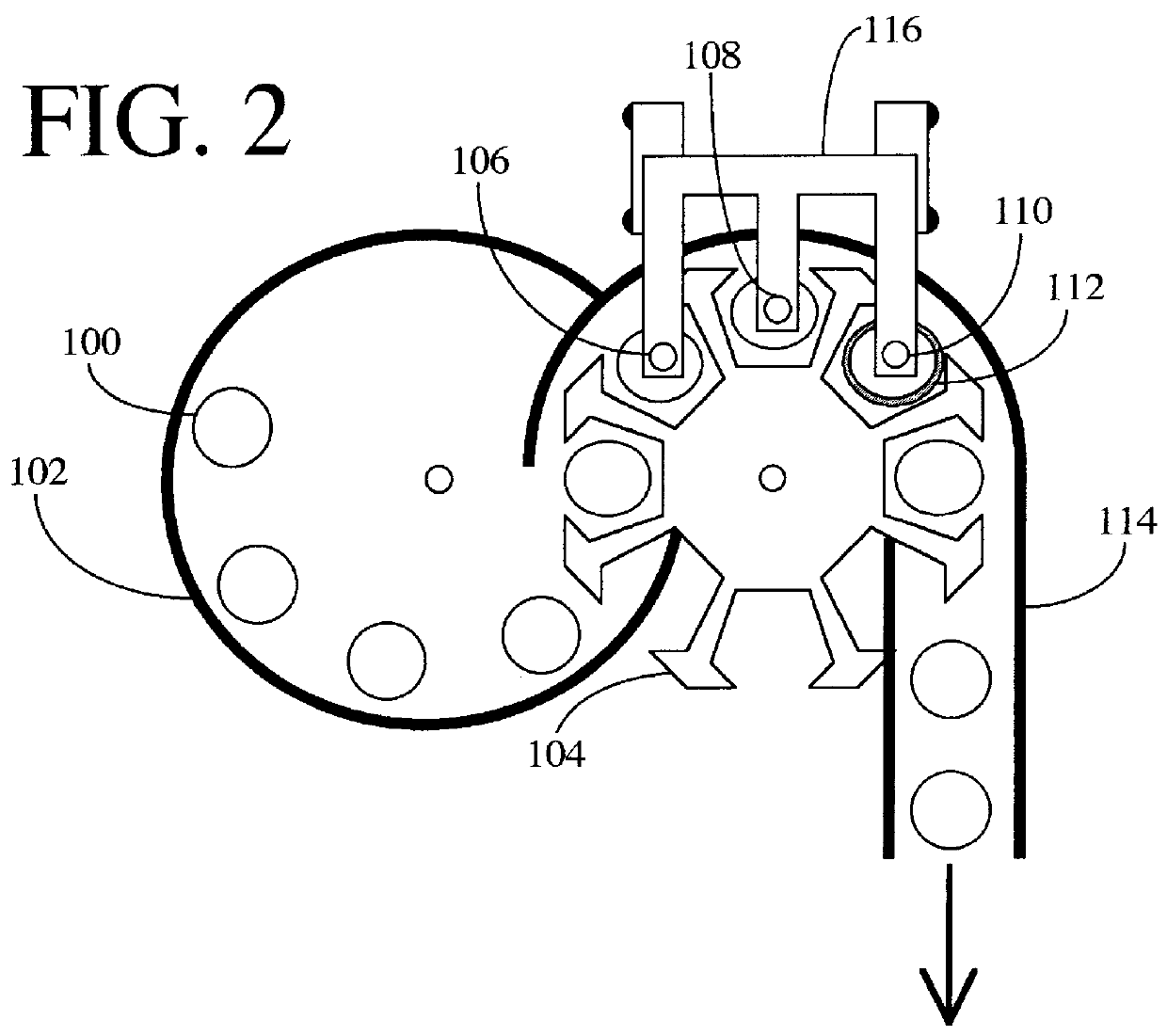

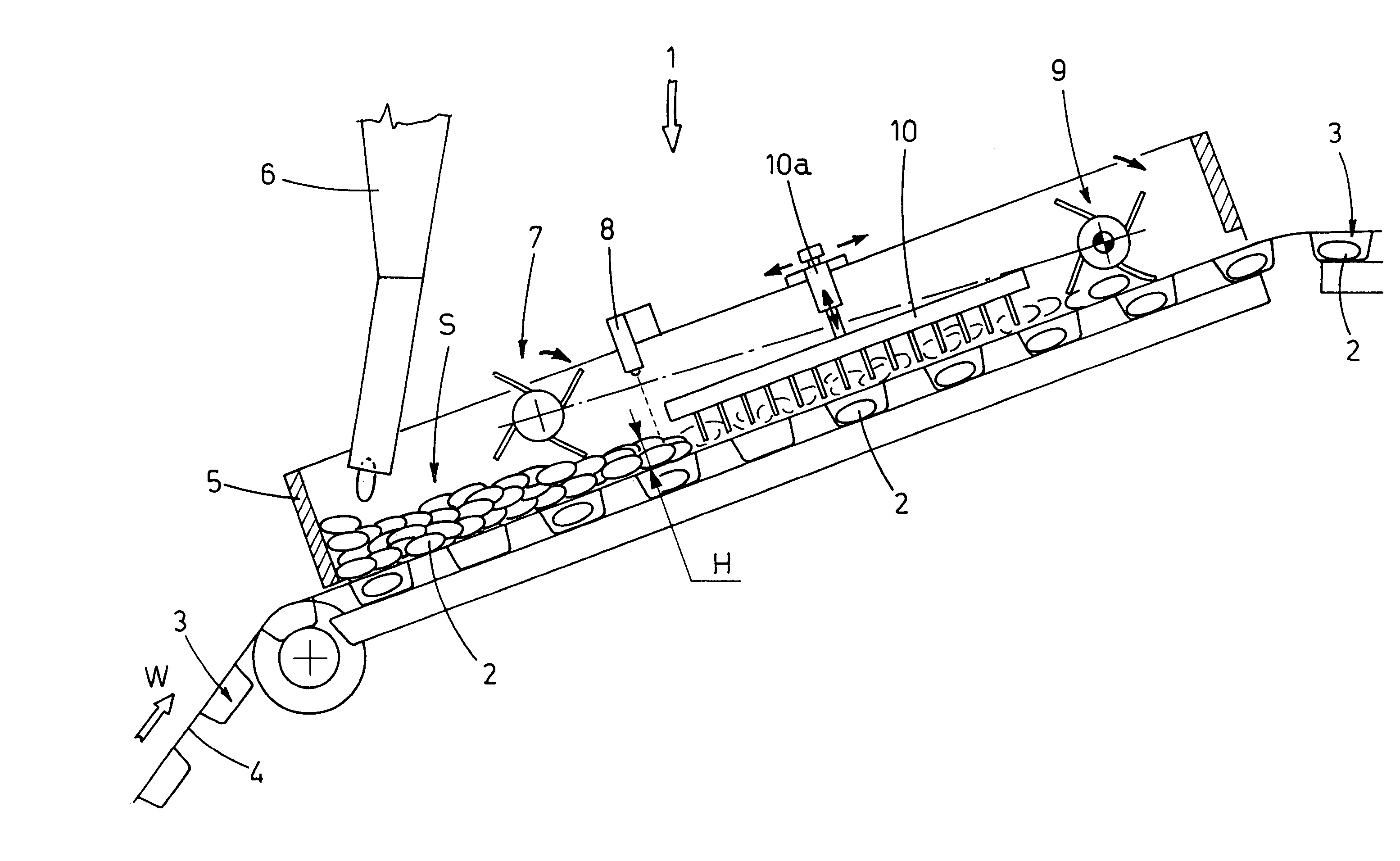

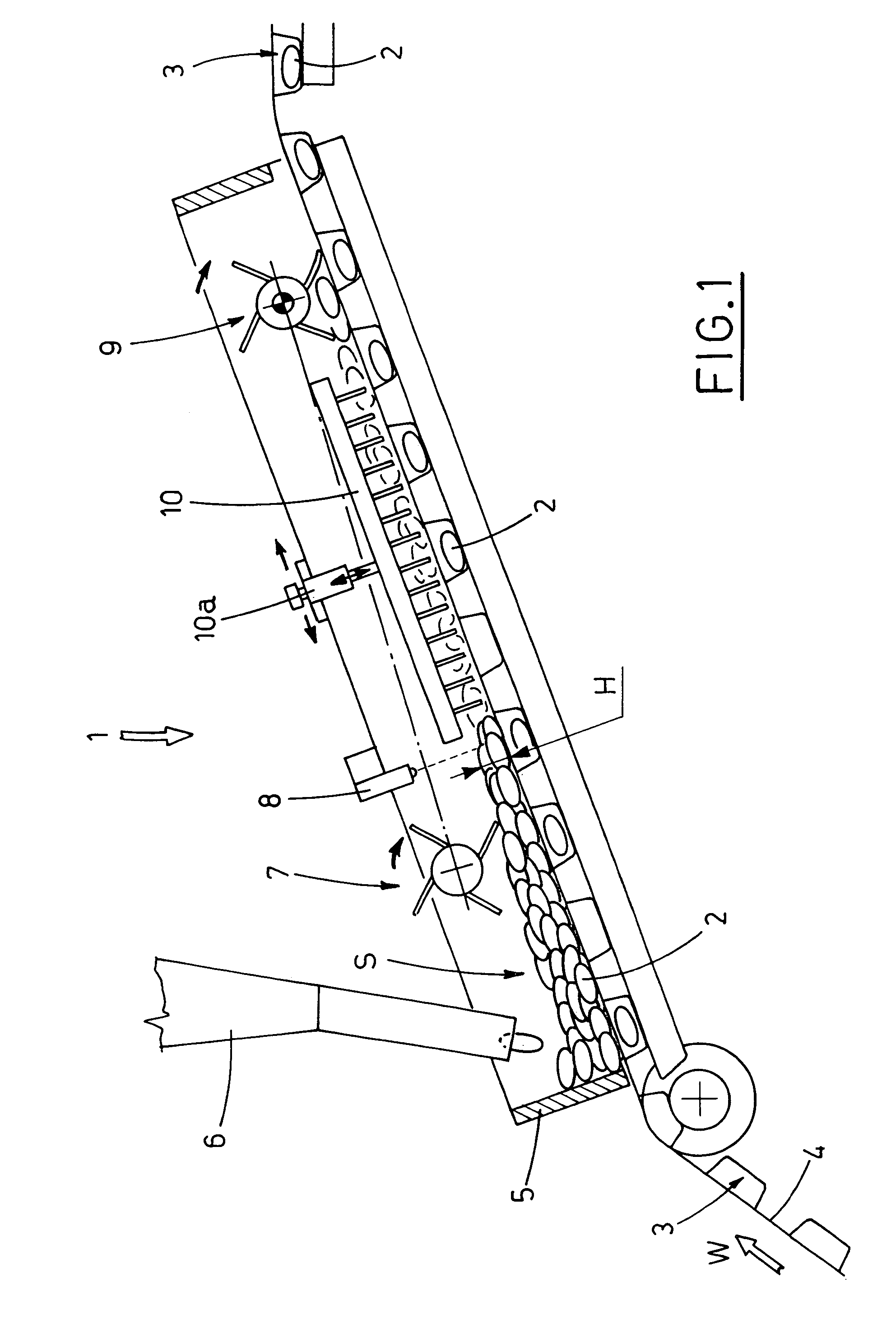

Apparatus for feeding articles to a blister band

ActiveUS7128100B2Avoid damageAccurate fillingLiquid fillingControl devices for conveyorsEngineeringBlisters

In an apparatus for feeding articles to a blister band, a box-like container, situated close to said band, is fed by a delivering device with a quantity of articles such as to allow accumulation of the articles on the surface of the band. A brush strikes and pushes the articles in a direction opposite to a forwarding direction of the band. A sensor, downstream of the brush, detects the thickness of the layer of articles on the band and interacts with the brush to maintain substantially constant the thickness of the layer of articles.

Owner:MARCHESINI GROUP SPA

Method and device for adjusting bearing assembly for a wheel hub

A wheel hub assembly including first and second bearing assemblies positioned on opposite sides of a spacer. The spacer includes at least one opening to allow lubricant to flow through the spacer. The spacer includes a first section deformable such that an overall length of the spacer is reduced a predetermined amount in response to the application of a predetermined load to set a distance between the first and second bearing assemblies. The assembly further includes a spindle having external threads and a nut having internal threads engaged with the spindle to secure the bearing assemblies and spacer within the wheel hub assembly.

Owner:MERITOR LIGHT VEHICLE TECH LLC

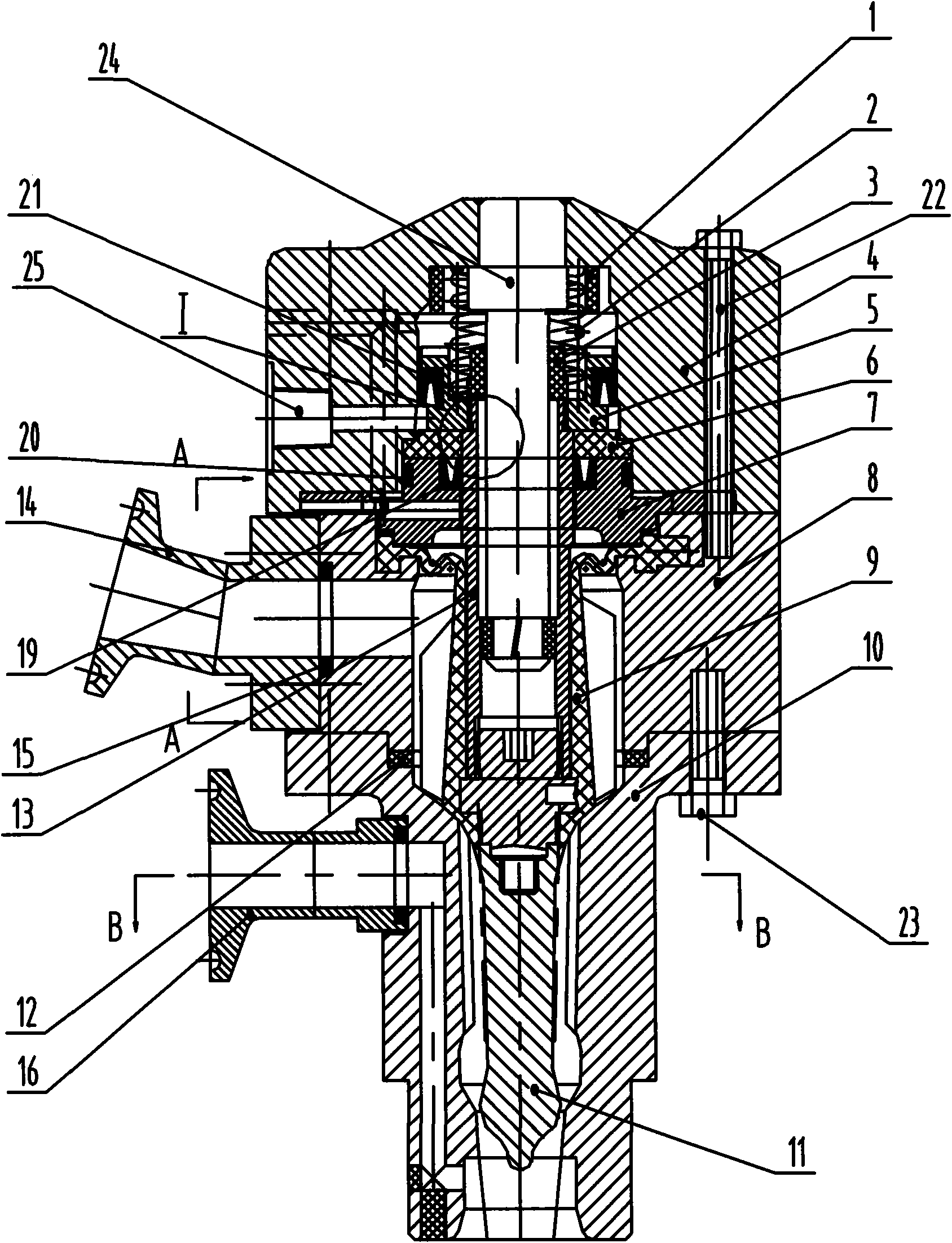

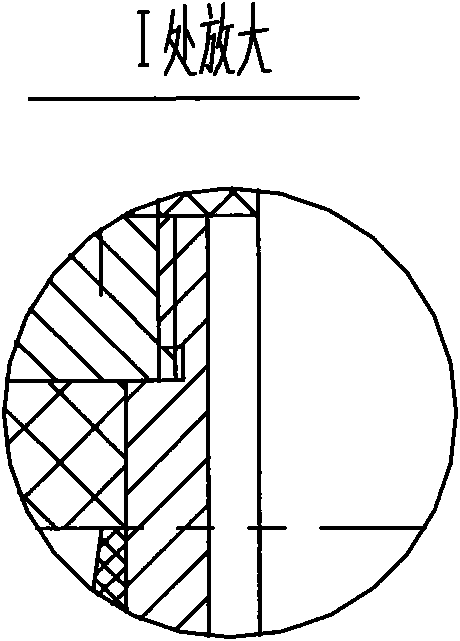

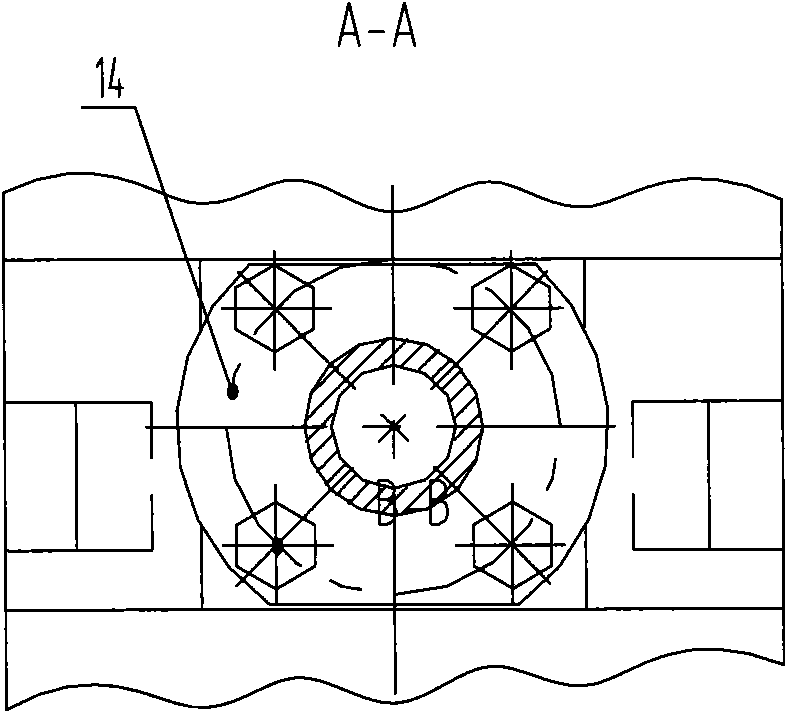

Sterile filling valve

InactiveCN101659387ANot pollutedEasy to replaceBottle-handling machinesLiquid bottlingProduction lineEngineering

The invention discloses a sterile filling valve applied to a sterile cold filling production line of beverage products. The filling valve comprises a material flowing cavity channel, and a valve opening and closing device is combined with a valve body into a whole, and the valve opening and closing device and the valve body are completely separated into two parts by an air and liquid separation film. The design guarantees the sanitation requirement of the sterile filling, and reduces the interference on the material flowing by the complicated design, so the material is favorable to flow, and the cavity channel is convenient to clean in all directions. The filling valve is integrally arranged on a mounting hole of a rotary table of a filling machine, and pairwise pressed by press plates, sothe valve can be conveniently mounted and detached. A pipeline of the filling valve is provided with an electromagnetic flow meter and a metal film valve for accurately controlling the filling accuracy. The valve adopts the filling method of not contacting bottle openings, so the pollution can not be caused even if the polluted bottles exist. Various functions of accurate filling of various levels, filling under the condition of bottle existence, no filling under the condition of no bottle, filling stop under the condition of bottle fulfillment, and the like can be realized by a filling control unit.

Owner:南京轻机包装机械有限公司

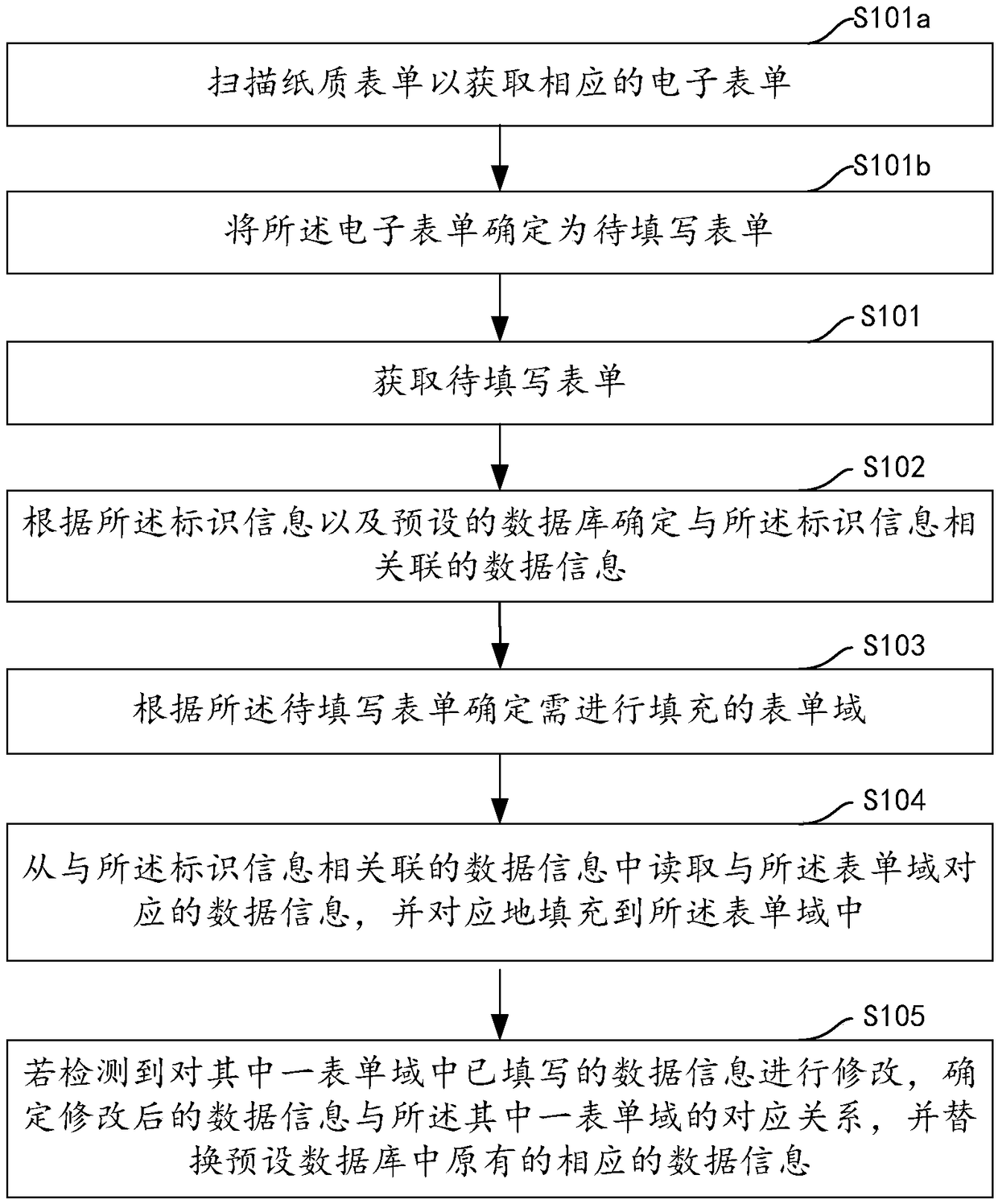

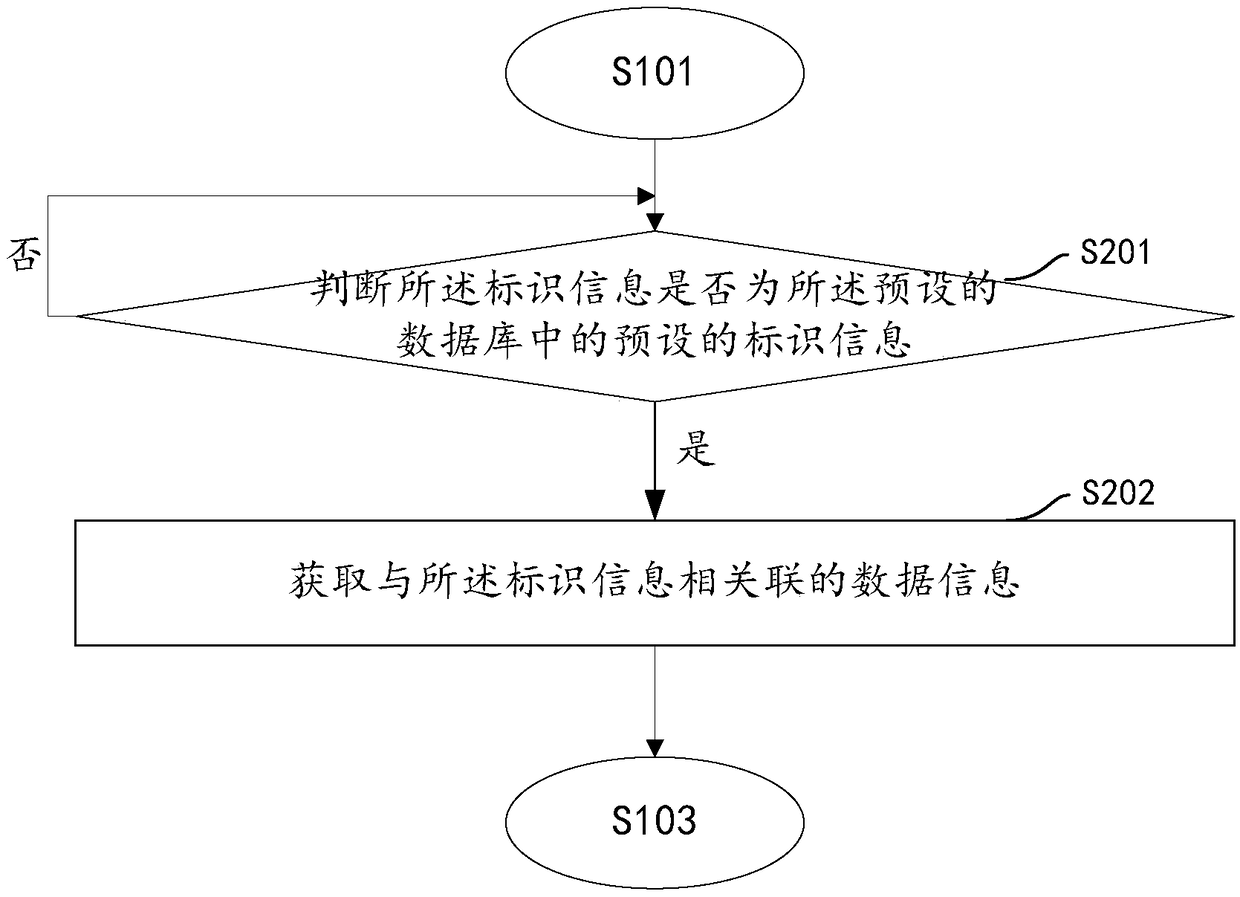

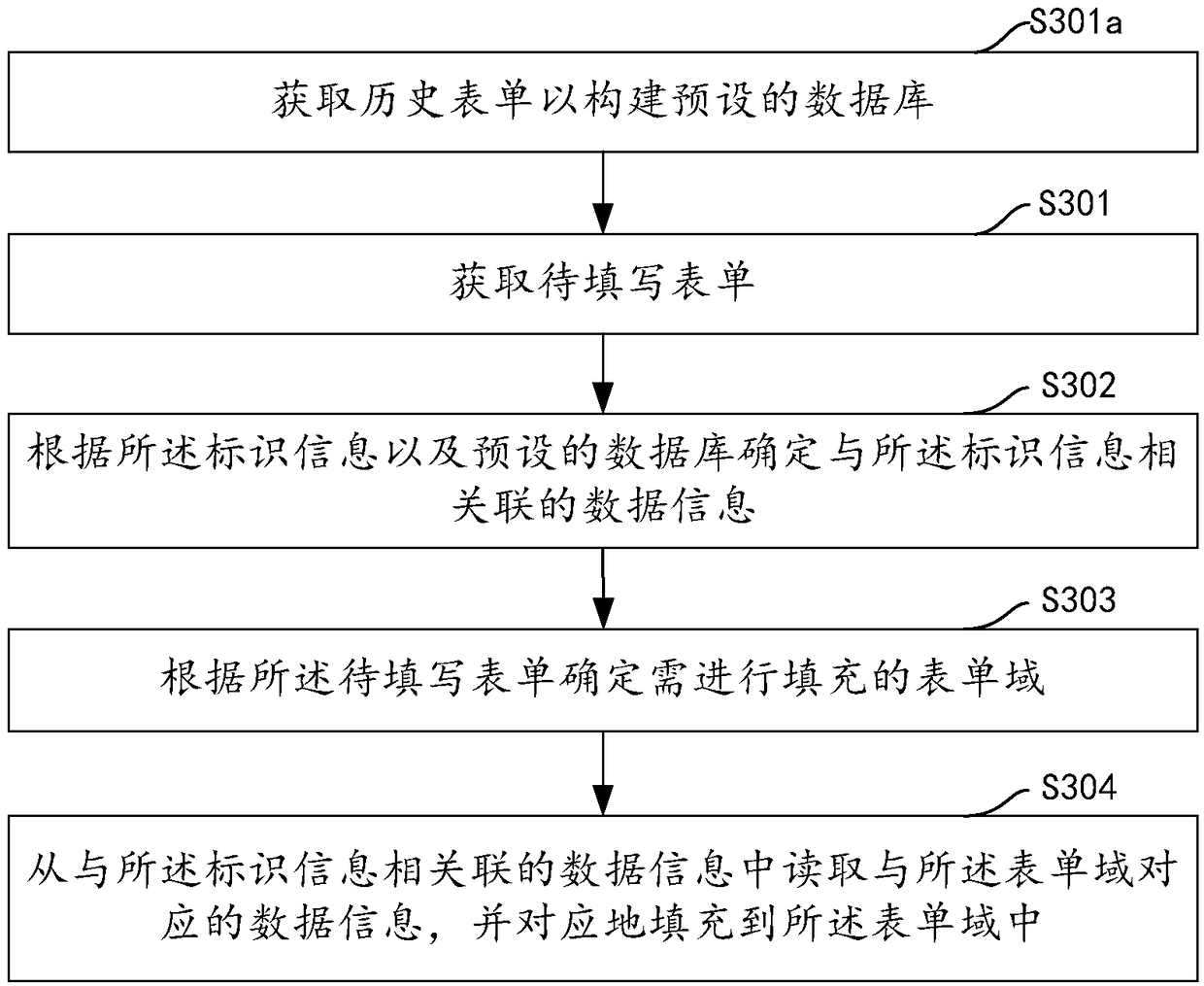

Format form auto-filling method, device, compute device and storage medium

PendingCN109308350AAvoid duplicationAvoid filling mistakesNatural language data processingSpecial data processing applicationsData informationDatabase

The embodiment of the invention discloses a method, a device, a computer device and a storage medium for automatically filling a format form, wherein, the method comprises the steps of obtaining a form to be filled, and the form to be filled comprises identification information; Determining data information associated with the identification information according to the identification informationand a preset database; Determining a form field to be filled according to the form to be filled, wherein different form fields are used for correspondingly filling different types of data information;Data information corresponding to the form field is read from data information associated with the identification information and filled into the form field correspondingly. The invention can quicklyand accurately fill in the form, and also can improve the work efficiency and the use experience degree of the user.

Owner:PINGAN PUHUI ENTERPRISE MANAGEMENT CO LTD

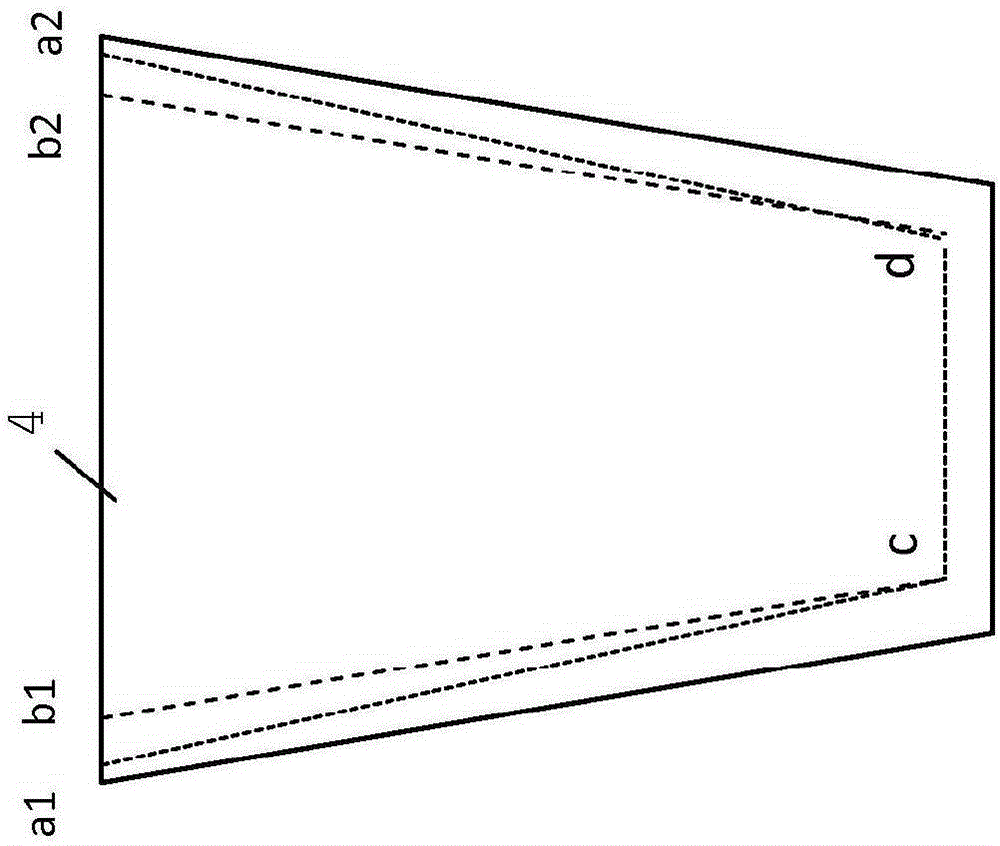

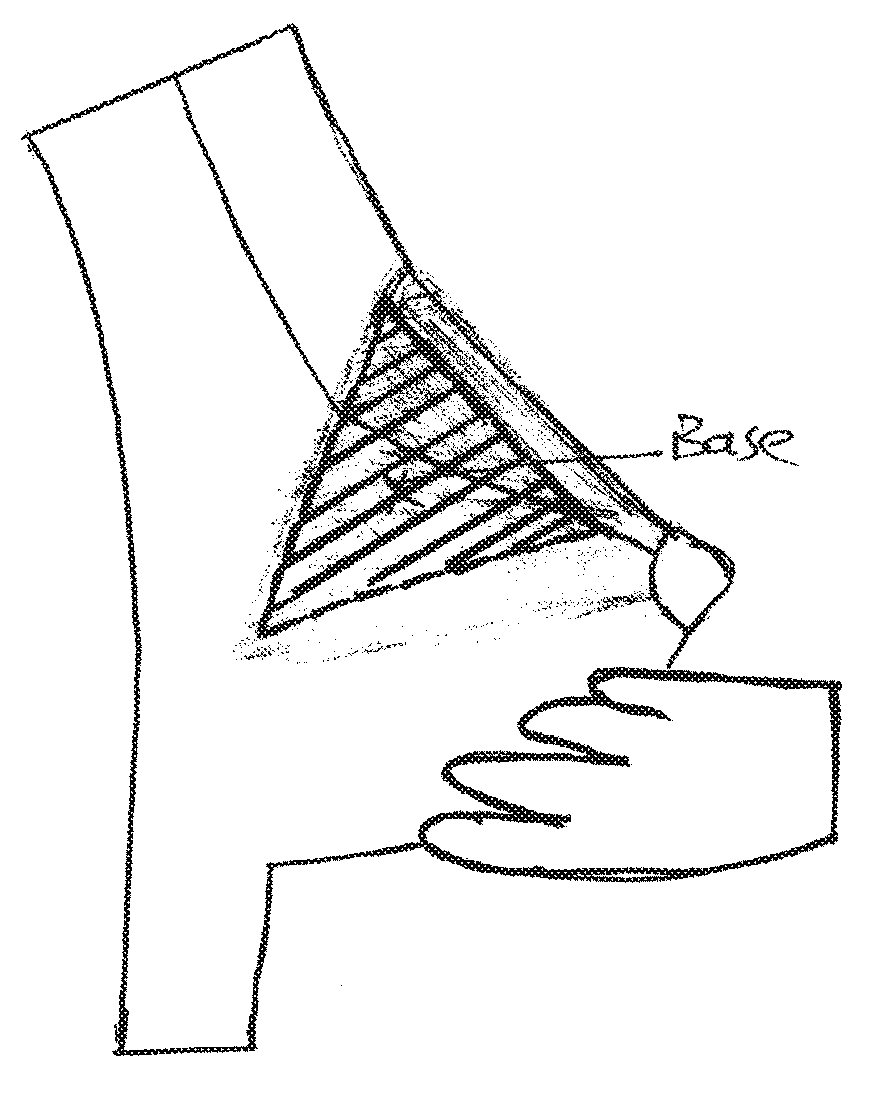

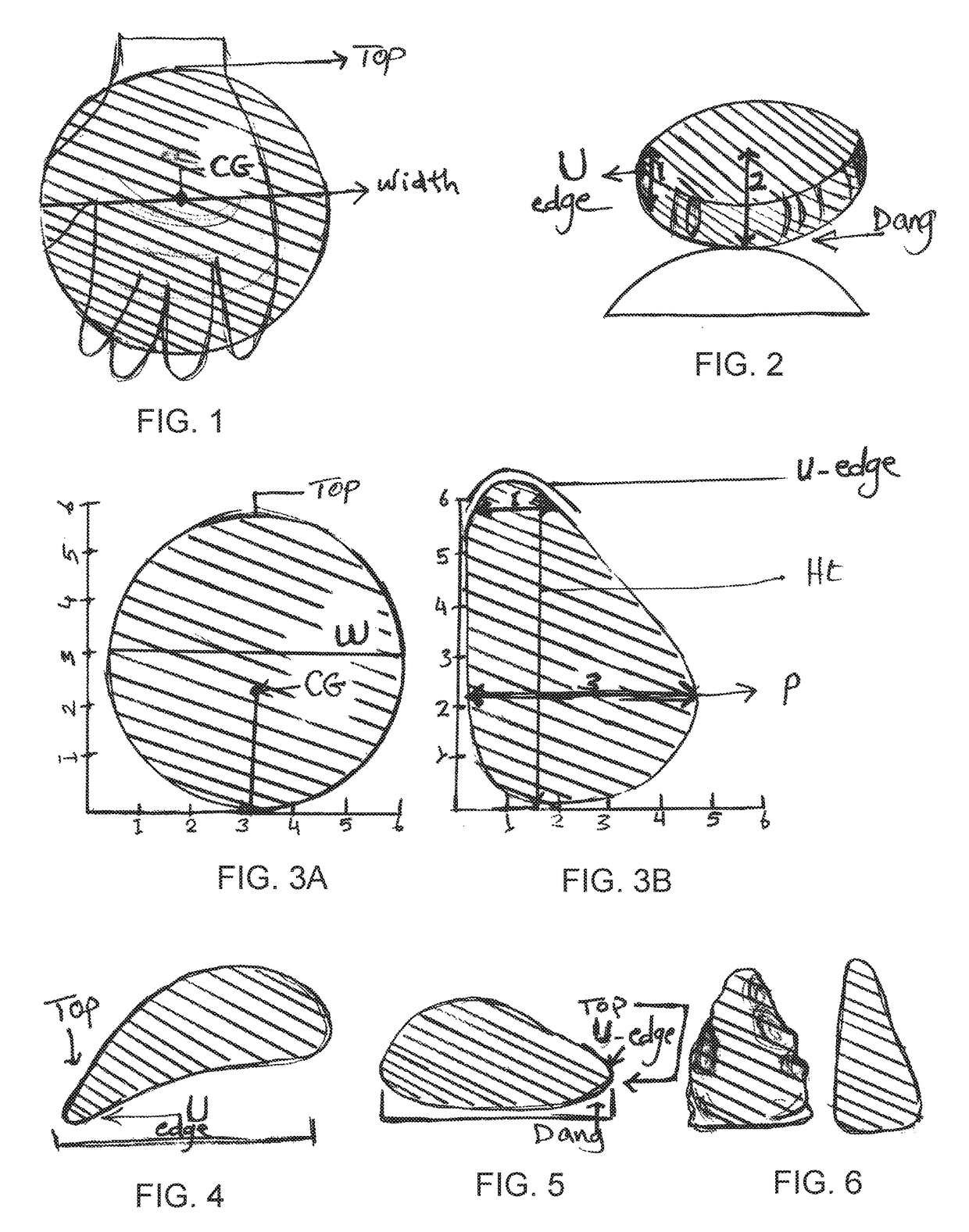

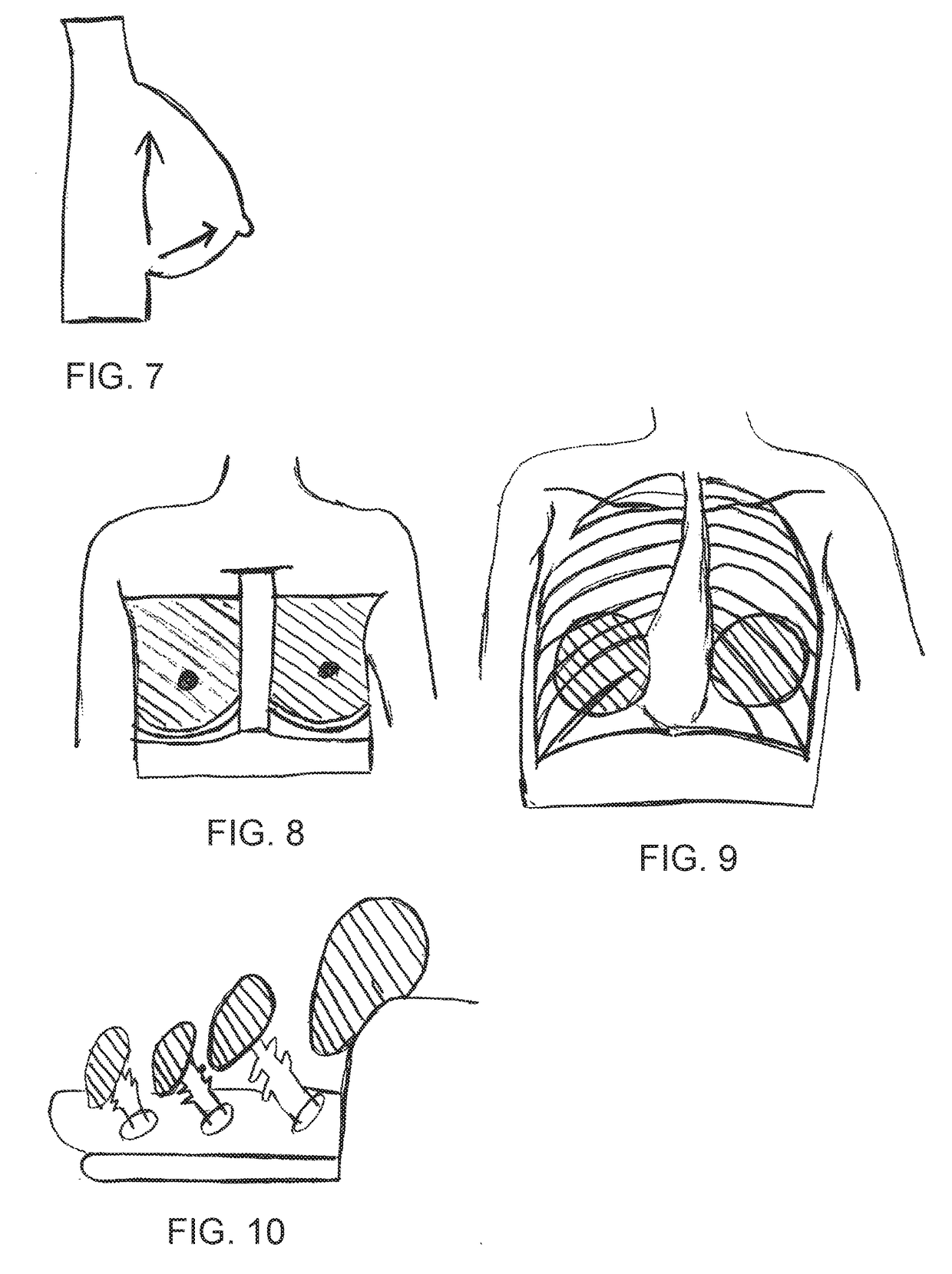

Pyramid-shaped breast implant for breast augmentation and/or breast lift with a method of use and production of the same

ActiveUS9707073B2Preventing step-off deformityIncrease the lengthMammary implantsCosmetic implantsBreast implantAcute angle

A breast implant device product that mimic the natural pectoral fat pad of the breast and is characterized by an incomplete pyramid with isosceles triangular base and wedge-shaped edges and sloping faces that meet at acute angles with variable degree located medially, laterally and on the top and a footprint characterized by a semicircular lower portion and an oval paraboloid upper portion and a center of gravity located closer to the base than to the profile, the said footprint is advantageously converging and moving towards the underlying surface as the chest wall with a method of manufacturing and a method of use of the said implant including a breast pyramid sizing system.

Owner:APEX MEDICAL DEVICE DESIGN LLC

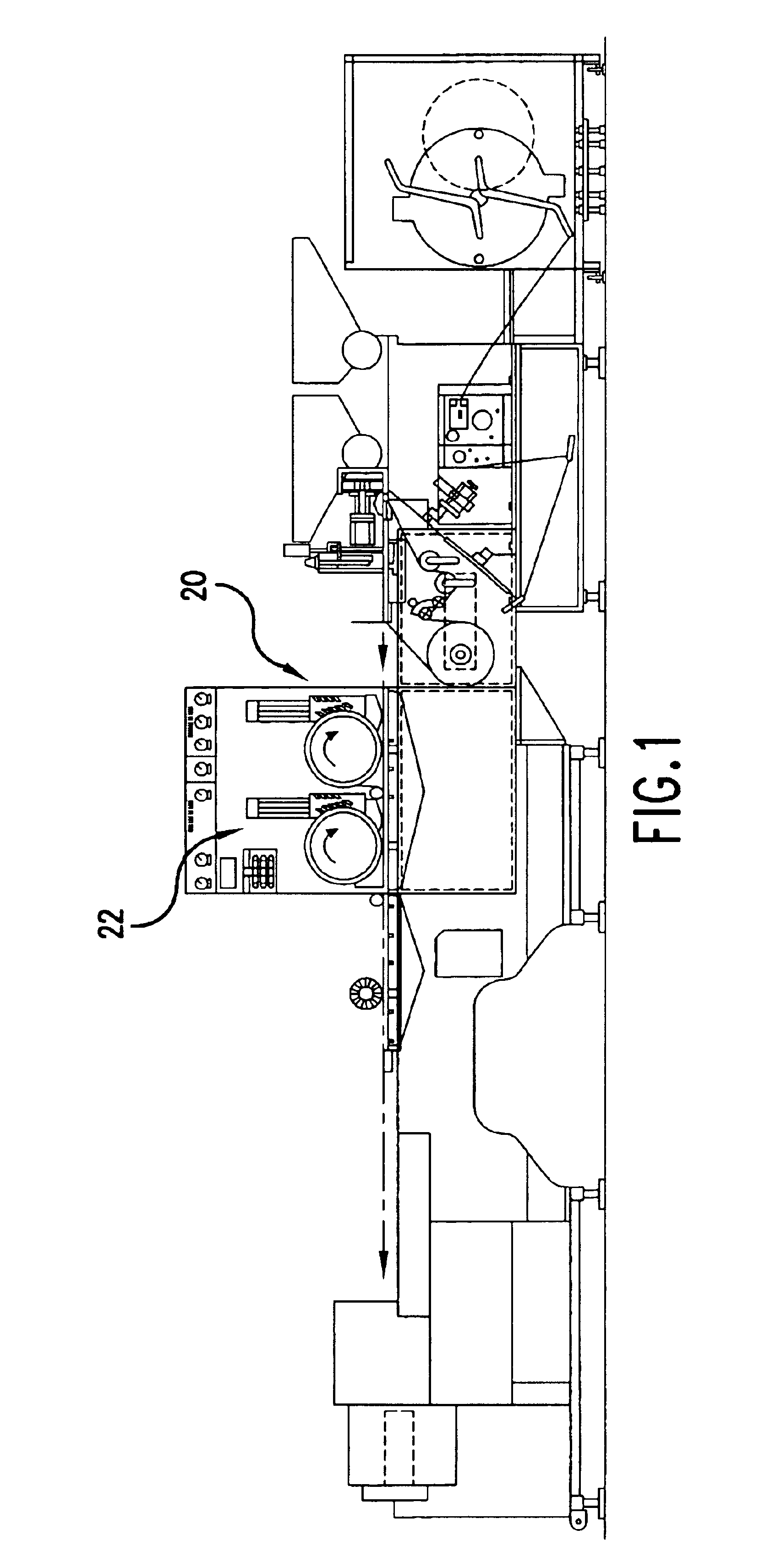

Semi-automatic boxing machine

InactiveUS7219485B2Increase flexibilityImprove versatilitySolid materialLiquid materialCartoning machineSemi automatic

Owner:MARCHESINI GROUP SPA

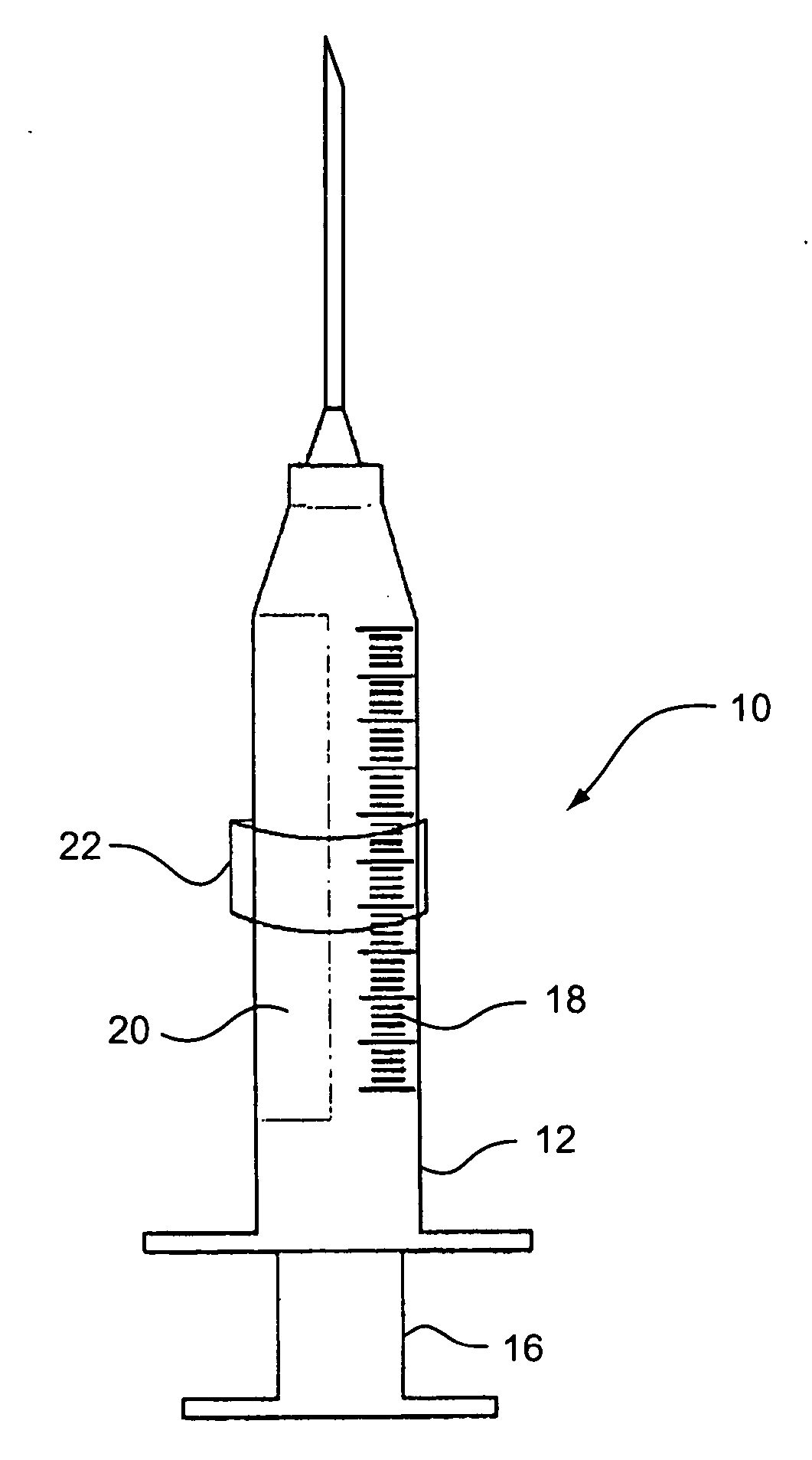

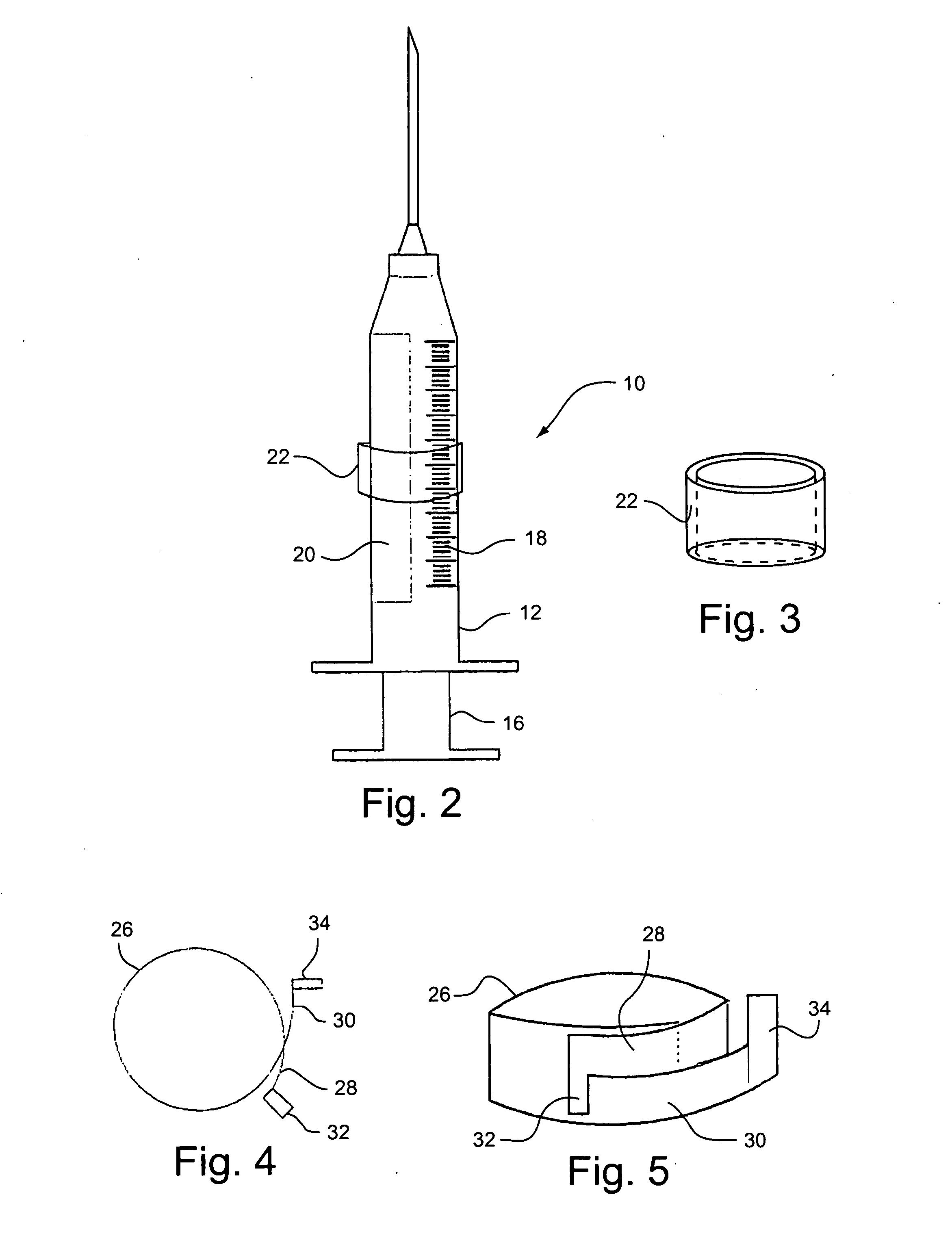

Syringe marking template

InactiveUS20070088285A1Easily readEnhance abilityMedical devicesIntravenous devicesSyringeEngineering

A syringe includes an elongated syringe barrel formed of a transparent material; a cannula adjacent one end of the barrel for transmission of fluid into our out of the barrel; a plunger disposed in the barrel and extending through an opposite end of the barrel from the one end; index markings along one side of the barrel for use in identifying various dosage amounts; and a collar moveable along the barrel facilitating indication of a custom marking of a desired dosage amount on the barrel.

Owner:INVIRO MEDICAL DEVICES LTD

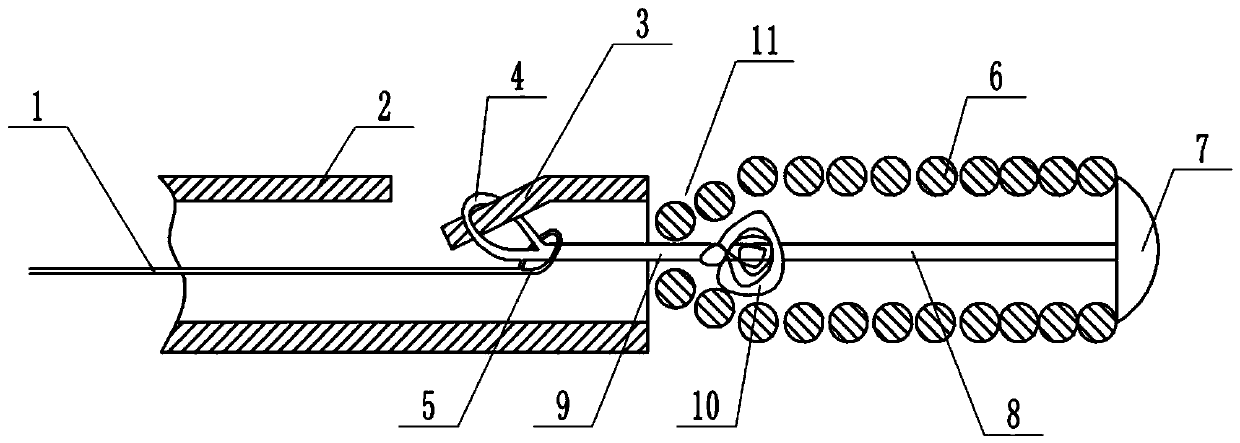

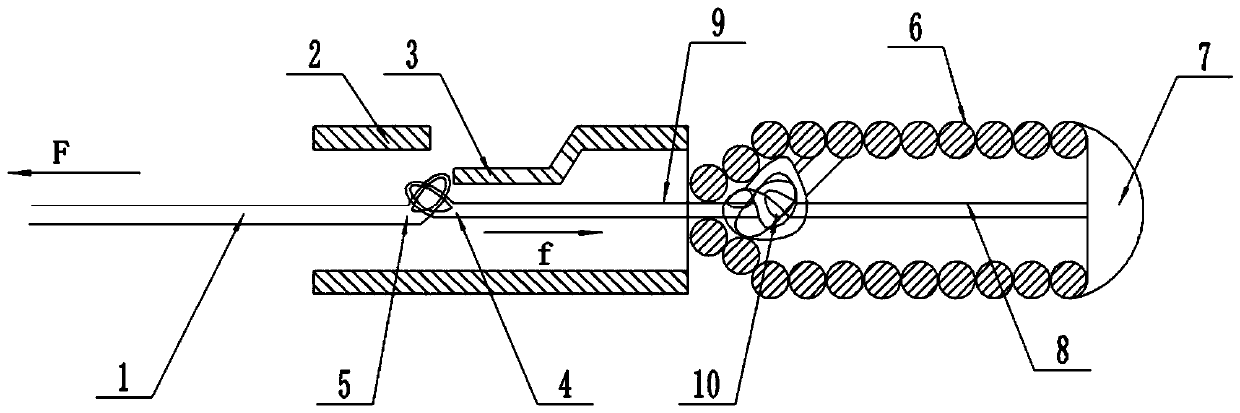

Mechanically-releasing spring ring system

ActiveCN110974332ASimple preparation processReduce manufacturing and tooling costsOcculdersTreatment effectApparatus instruments

The invention relates to the field of medical instruments, in particular to a mechanically-releasing spring ring system. The system comprises a push rod, a spring ring and a connecting assembly, wherein the connecting assembly is sleeved with the spring ring; the end, away from the push rod, of the spring ring is fixedly connected to the connecting assembly; the other end of the spring ring abutsagainst the far end of the push rod; and the connecting assembly is connected to the push rod. According to a scheme in the invention, a spring ring with a smaller specification is convenient to install, so the treatment effect of aneurysm is improved.

Owner:珠海神平医疗有限公司

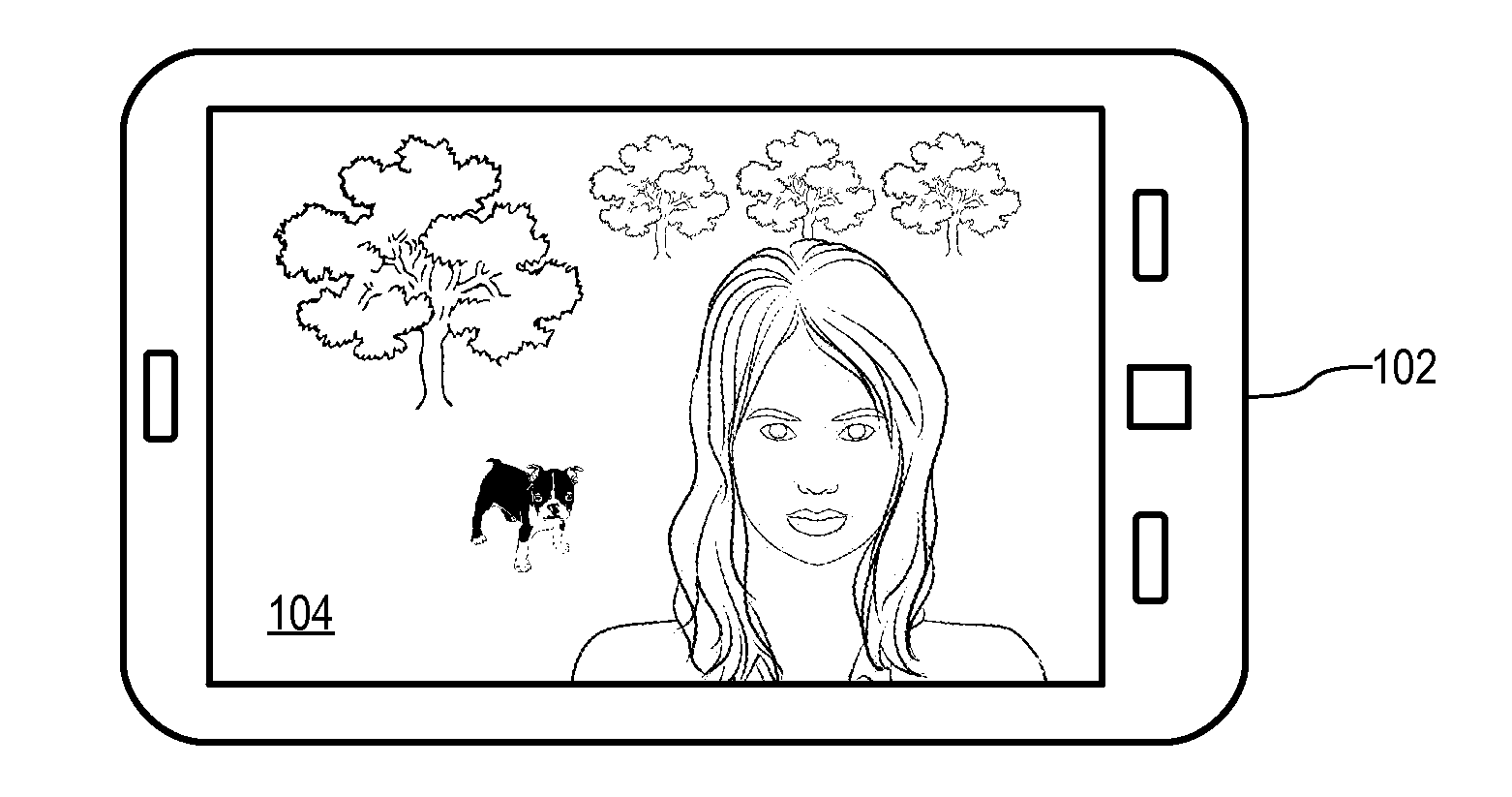

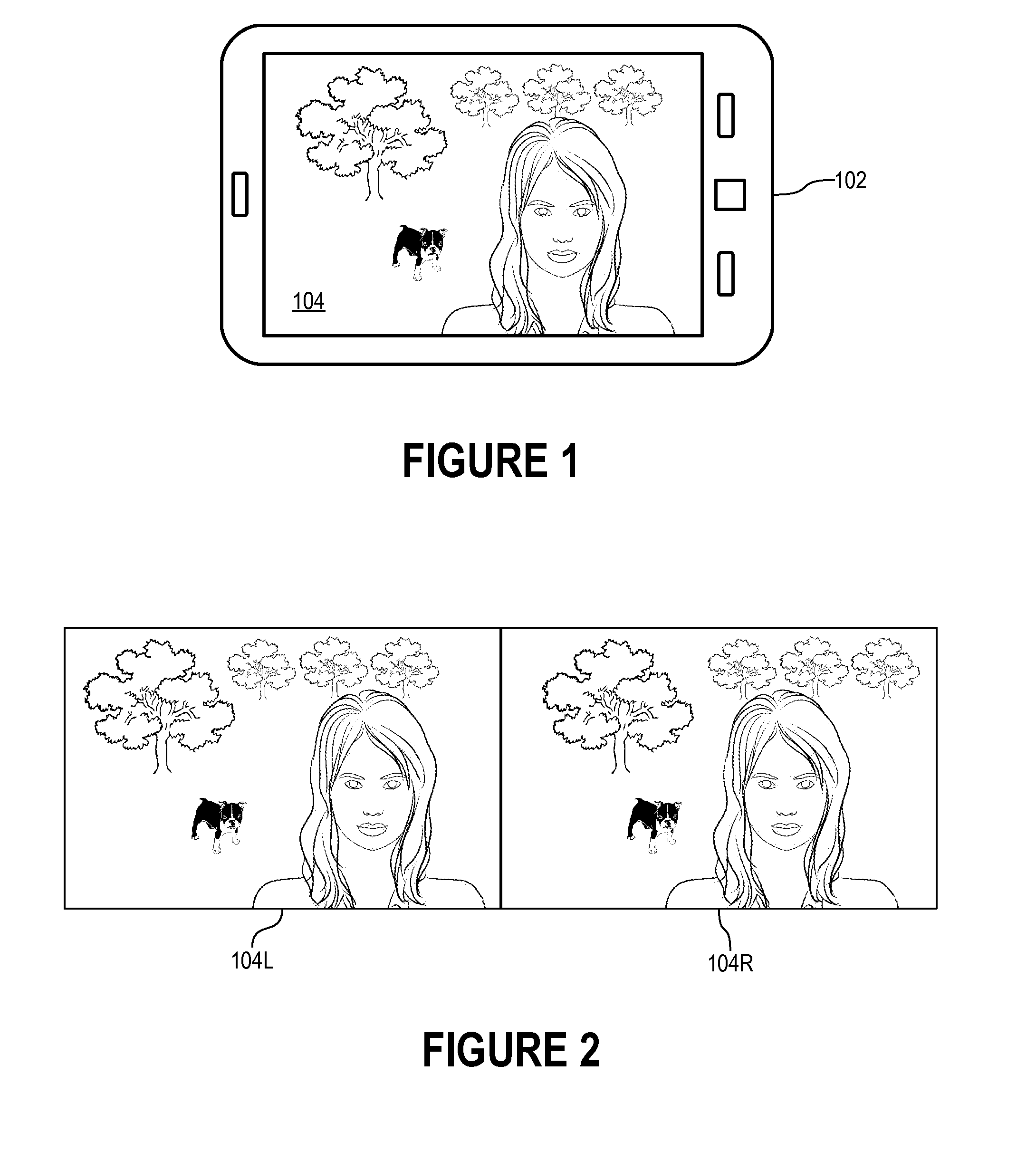

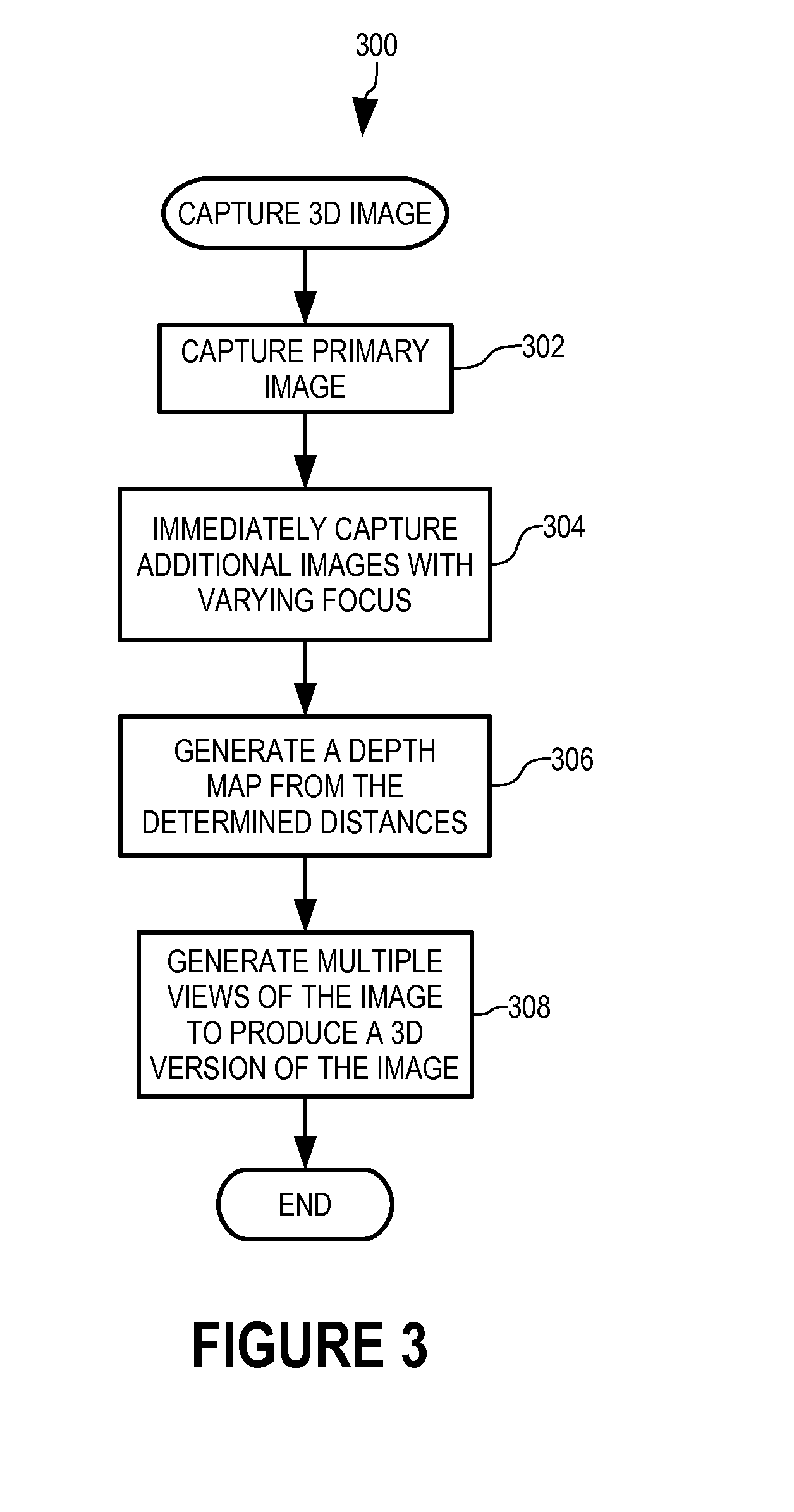

Capture of three-dimensional images using a single-view camera

InactiveUS20150271467A1Accurate fillingQuality improvementImage enhancementTelevision system detailsView cameraAutofocus

A single-lens camera captures a two-dimensional image and, nearly contemporaneously, manipulates focus of the camera to provide information regarding the distance from the camera of objects shown in the image. With this distance information, the camera synthesizes multiple views of the image to produce a three-dimensional view of the image. The camera can select a number of points of interest and engage an autofocus function to determine a focal length for which the point of interest is in particularly good focus or can capture a number of additional images at various focal lengths and identify portions of the additional images that are in relatively sharp focus. The distance estimates can be improved by identifying elements in the original image that are co-located with electronic beacons whose relative locations are known to the camera.

Owner:WEINSTOCK NEAL

Mobile fluid product filling system with fast setup

InactiveUS6595250B1Fast shut-down and start-up timeReduce maintenanceSolid materialLiquid materialMechanical engineering

A fluid filling system has a filling unit which is repositionable with respect to a filling station. The filling unit includes a filling head and a dispensing switch. The filling station has a filling position at which a container may be placed for filling with fluid. A container fill sensor is provided at the filling position so that it may detect the degree to which a container is filled. A movable switching member is also provided on the filling station, and it communicates with the container fill sensor and moves to different positions in accordance with the degree to which a container at the filling position is filled. The filling unit is repositionable with respect to the filling station so that the filling unit may be situated adjacent the filling station with its filling head situated over the filling position, or may be moved to allow the filling unit to rest at other locations. When the filling unit is resting adjacent the filling station with its filling head situated over the filling position (i.e., when it is in the ready-to-fill position), the switching member and dispensing switch are adjacently situated between the filling unit and filling station so that the switching member may actuate the dispensing switch. Thus, when the container fill sensor detects that container filling is to occur (or is to cease), the switching member is actuated, which in turn actuates the dispensing switch to change the filling head between its filling state and its nonflow state in accordance with the filling detected by the container fill sensor.

Owner:IDEAL MFG & SALES

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com