Patents

Literature

151results about How to "Reduce manufacturing and tooling costs" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

High strength and high toughness foamed SiC/Al material and its preparing method

The present invention relates to heterogeneous foamed ceramic / metal material, and is especially one kind of high strength and high toughness foamed SiC / Al material and its preparation process. The foamed SiC / Al material has basic units of closed polygonal ring to form connected 3D network structure, and each of the closed polygonal ring units is heterogeneous foamed ribs comprising SiC in 50-95 vol% and metal Al in 5-50 vol% and with the relative density not lower than 99 %. The foamed SiC / Al material is prepared through organic foam soaking, hot pressing to densify, pressure injection filling, thermal decomposition and reaction sintering. The preparation process is simple and low in cost.

Owner:INST OF METAL RESEARCH - CHINESE ACAD OF SCI

High heat conductivity and high strength dense heterogeneous foamed SiC/Cu material and its preparing method

The present invention relates to heterogeneous foamed ceramic / metal material, and is especially a kind of high strength, high density and high heat conductivity heterogeneous foamed SiC / Cu material and its preparation process. The foamed SiC / Cu material has basic units of closed polygonal ring to form connected 3D network structure, and each of the closed polygonal ring units is heterogeneous foamed ribs comprising SiC in 50-95 vol% and metal Cu in 5-50 vol% and with the relative density not lower than 99 %. The foamed SiC / Cu material is prepared through organic foam soaking, hot pressing to densify, pressure injection filling, thermal decomposition and reaction sintering. The preparation process is simple and low in cost.

Owner:INST OF METAL RESEARCH - CHINESE ACAD OF SCI

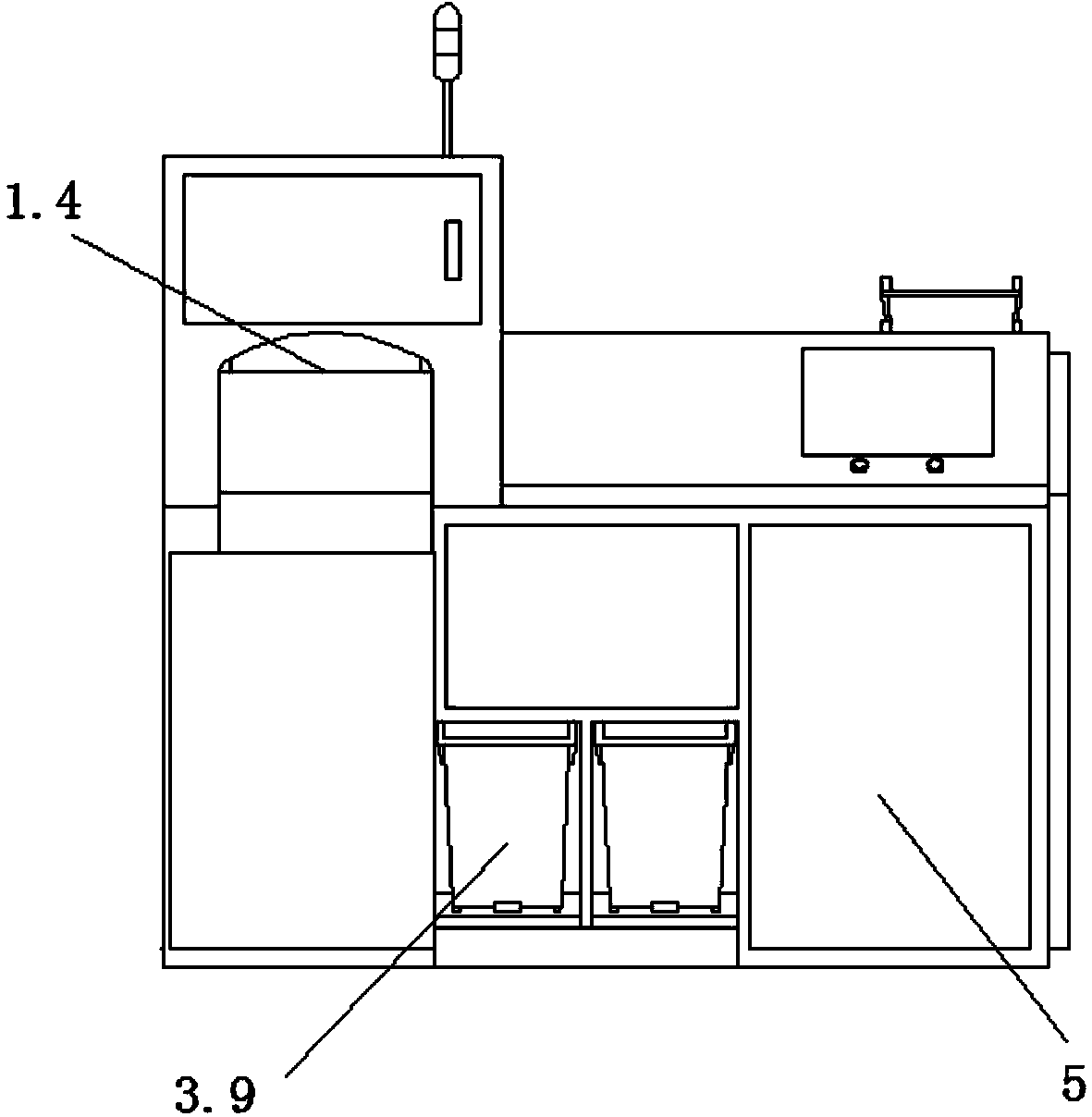

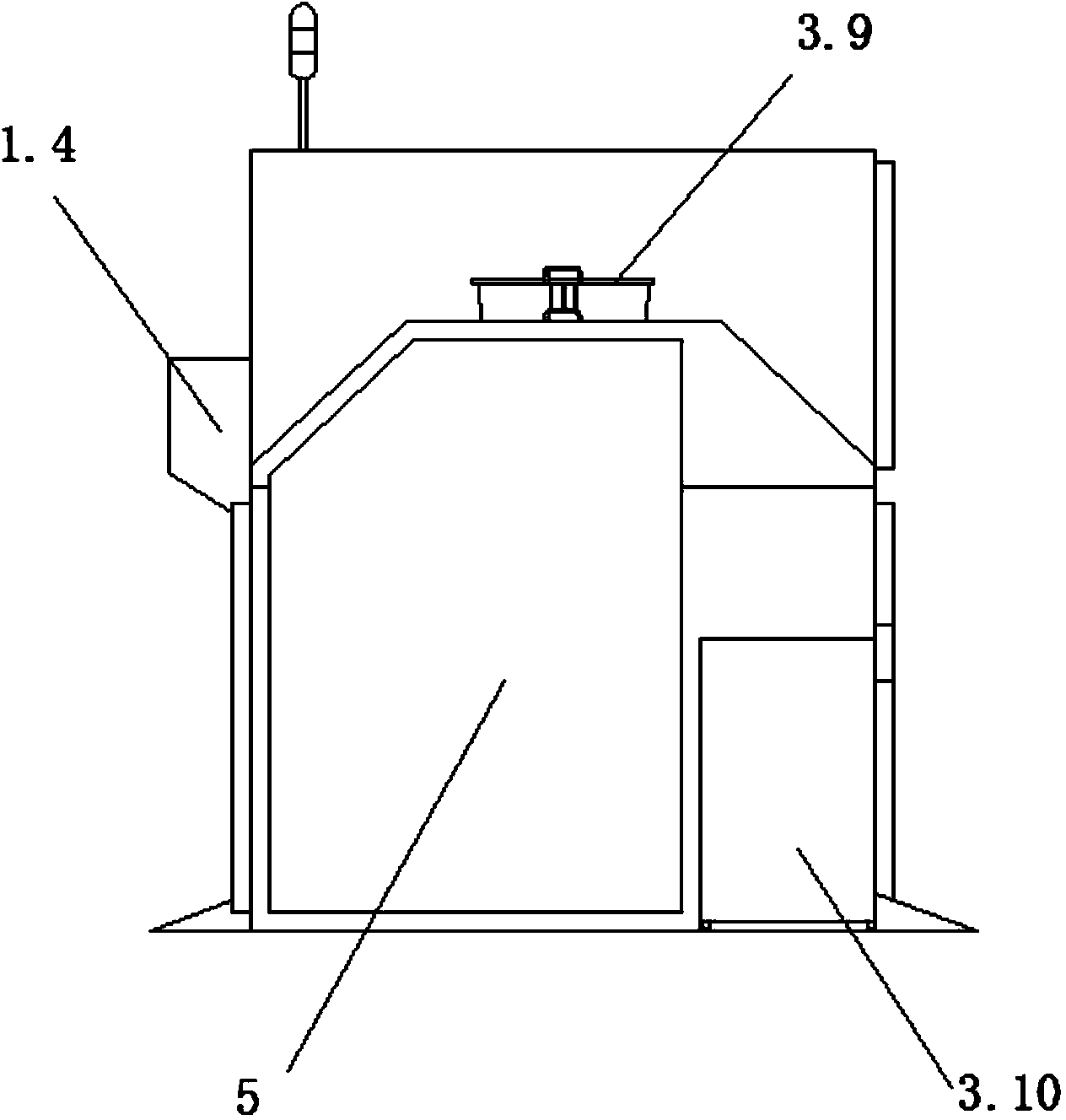

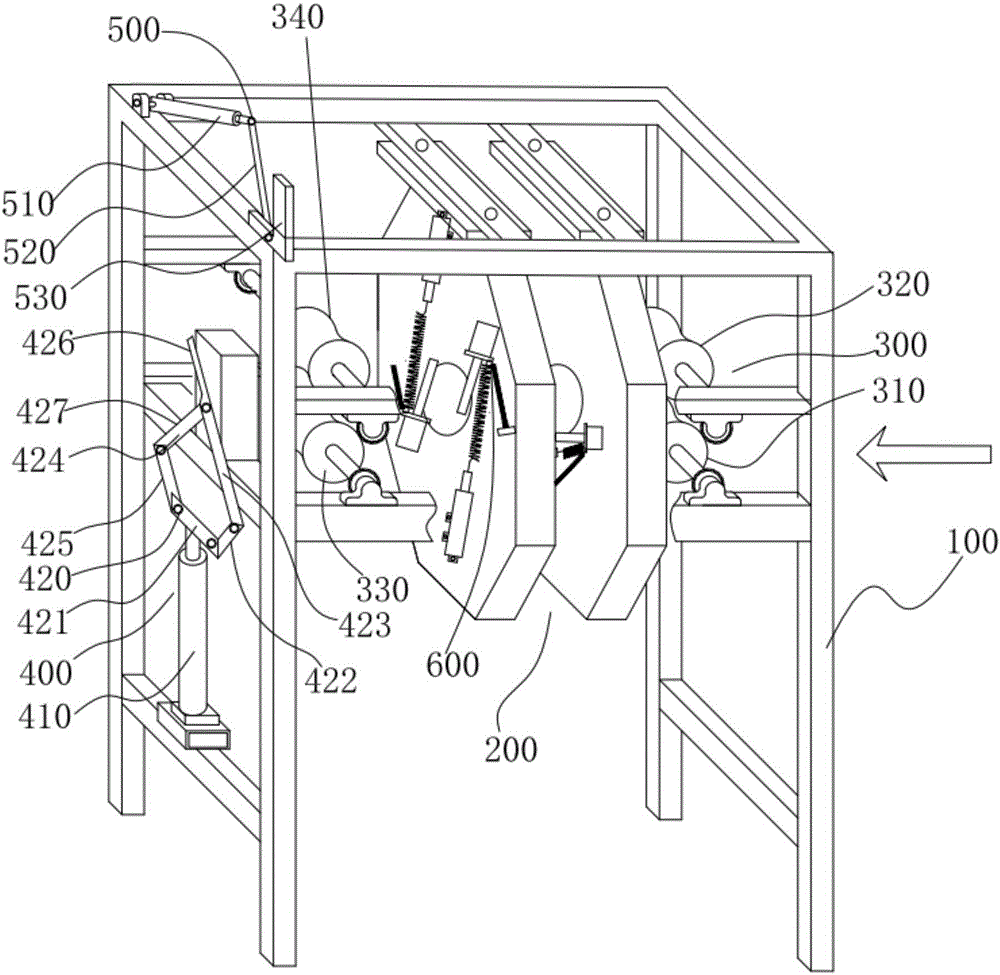

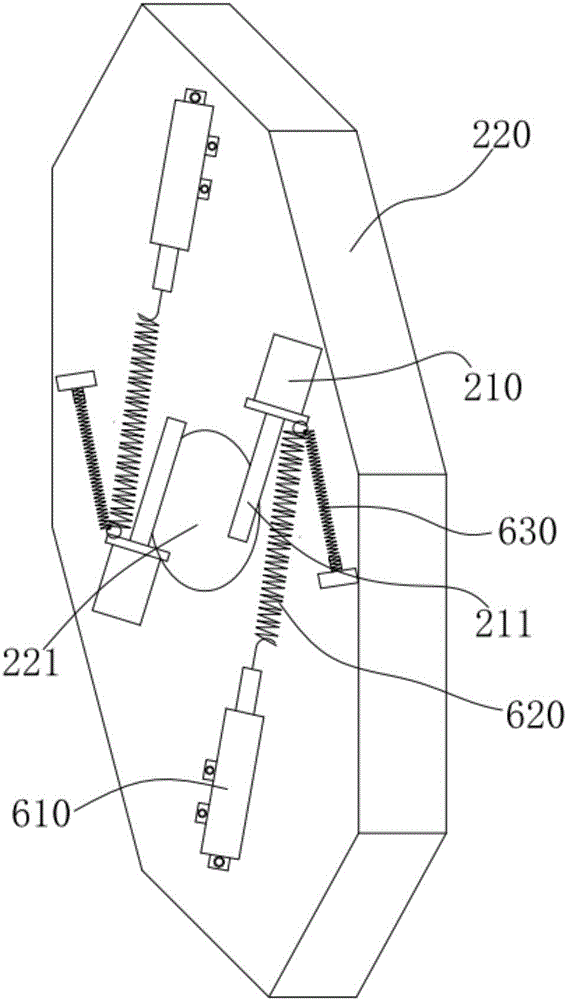

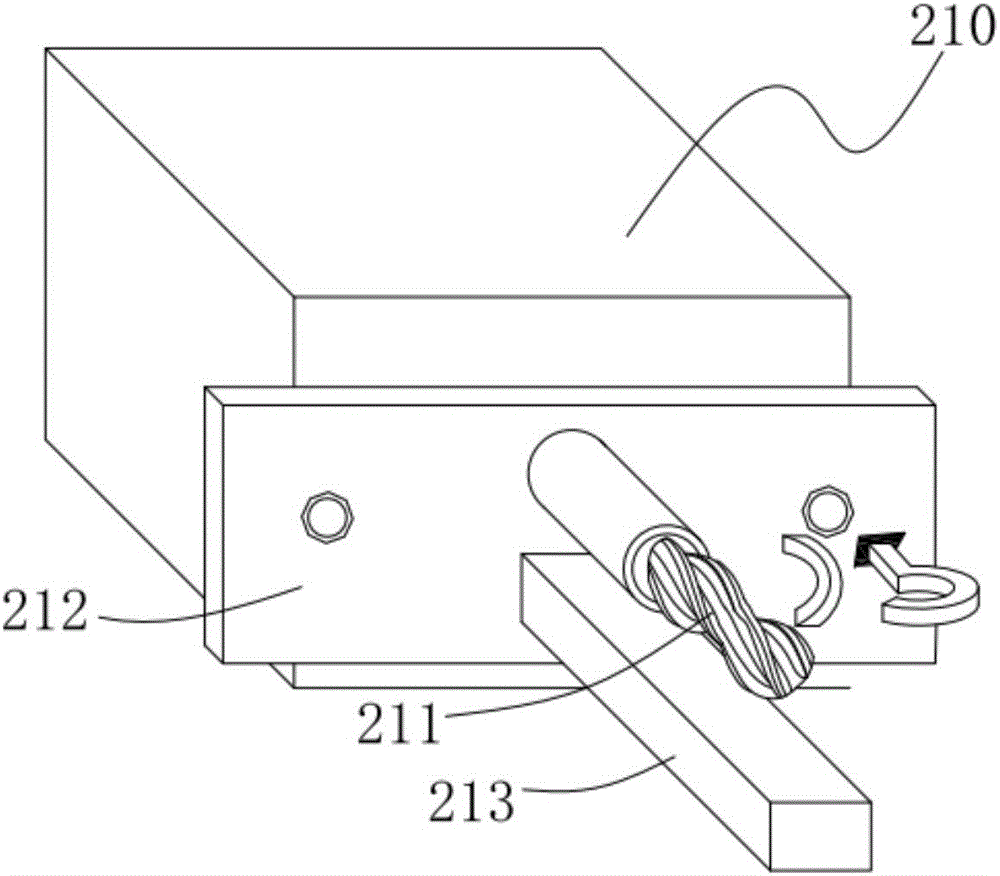

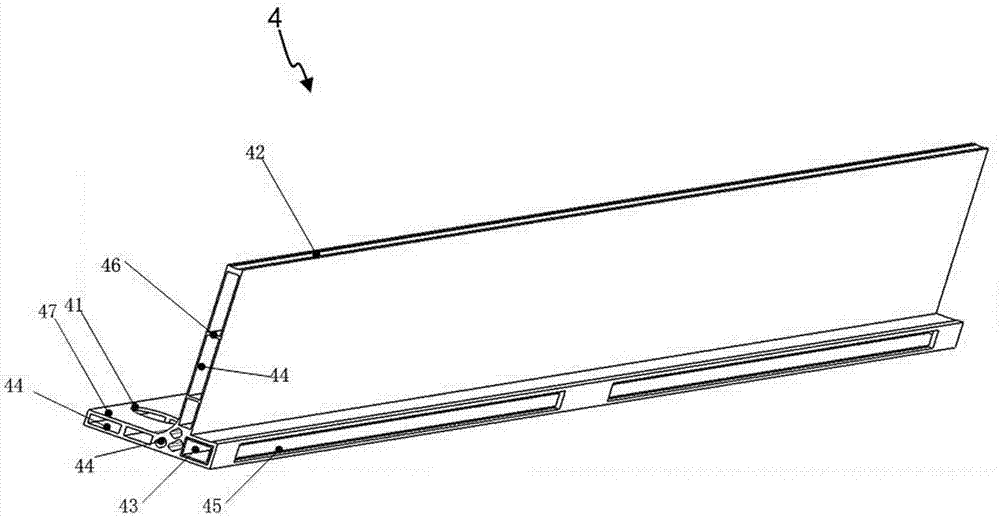

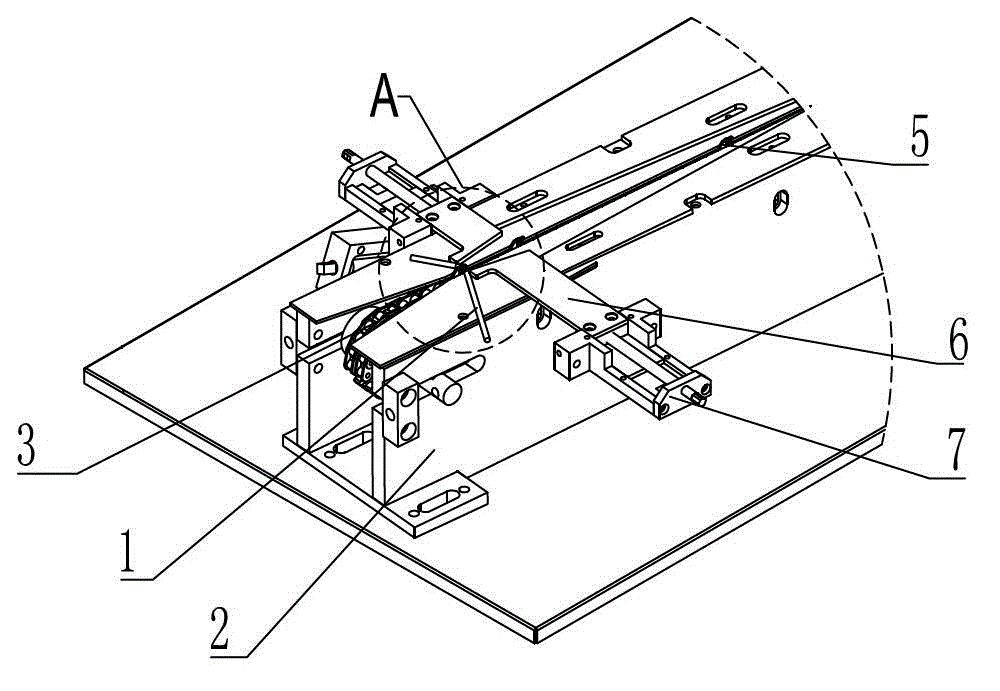

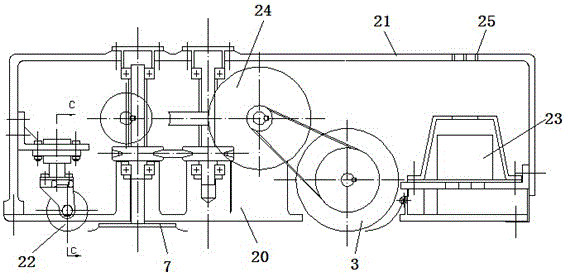

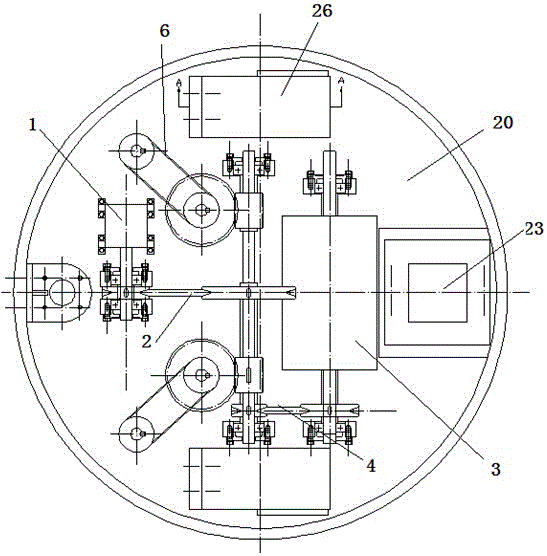

Pipe arrangement machine with function of distinguishing colors of bobbins

ActiveCN104030089AThe structure of the whole machine is simpleReduce manufacturing and tooling costsFilament handlingEngineeringBobbin

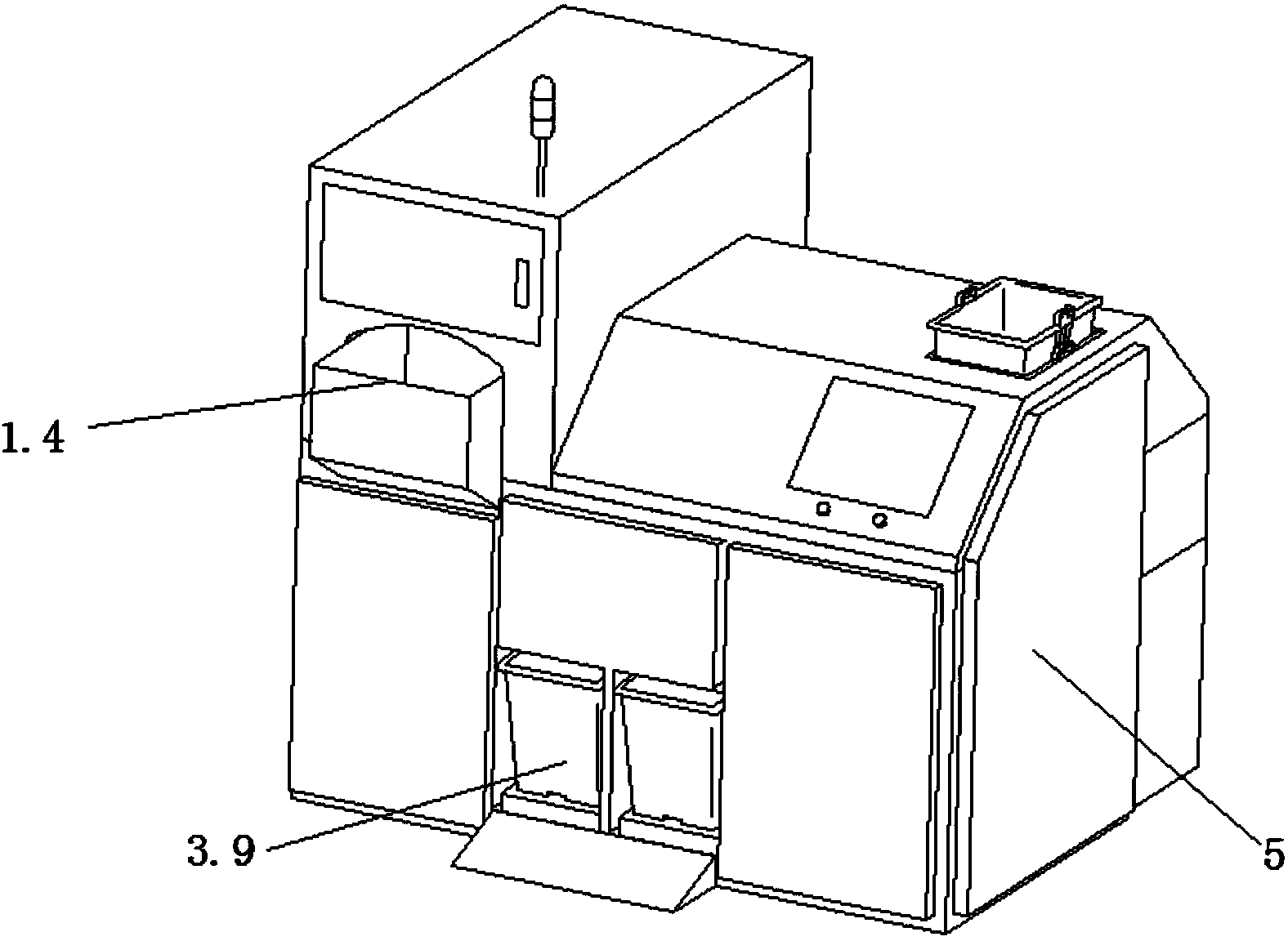

The invention provides a pipe arrangement machine with a function of distinguishing colors of bobbins. The pipe arrangement machine is characterized by comprising a pipe storage mechanism (1), a separate detection pipe turning mechanism (2), a rack (4) and a shell (5), wherein the pipe storage mechanism (1) comprises a lifter (1.1), a lifting block group (1.2) and a pipe receiving box (1.4); the separate detection pipe turning mechanism (2) comprises a sample pipe frame (2.1), a vision sensor (2.4), a pipe passing channel (2.5), a pipe conveying machine (2.6), a waste pipe channel (2.7), a pipe falling channel mechanism (2.8) and a separate detection pushing frame (2.9). The pipe arrangement machine further comprises an automatic basket replacement mechanism (3). According to the pipe arrangement machine with the function of distinguishing the colors of the bobbins, separate detection color comparison is directly perfomed; due to the arrangement of automatic basket replacement mechanism, manual operation is not needed; the pipe arrangement machine is simple in structure and low in processing and manufacturing cost.

Owner:BEIJING DAHENG IMAGE VISION

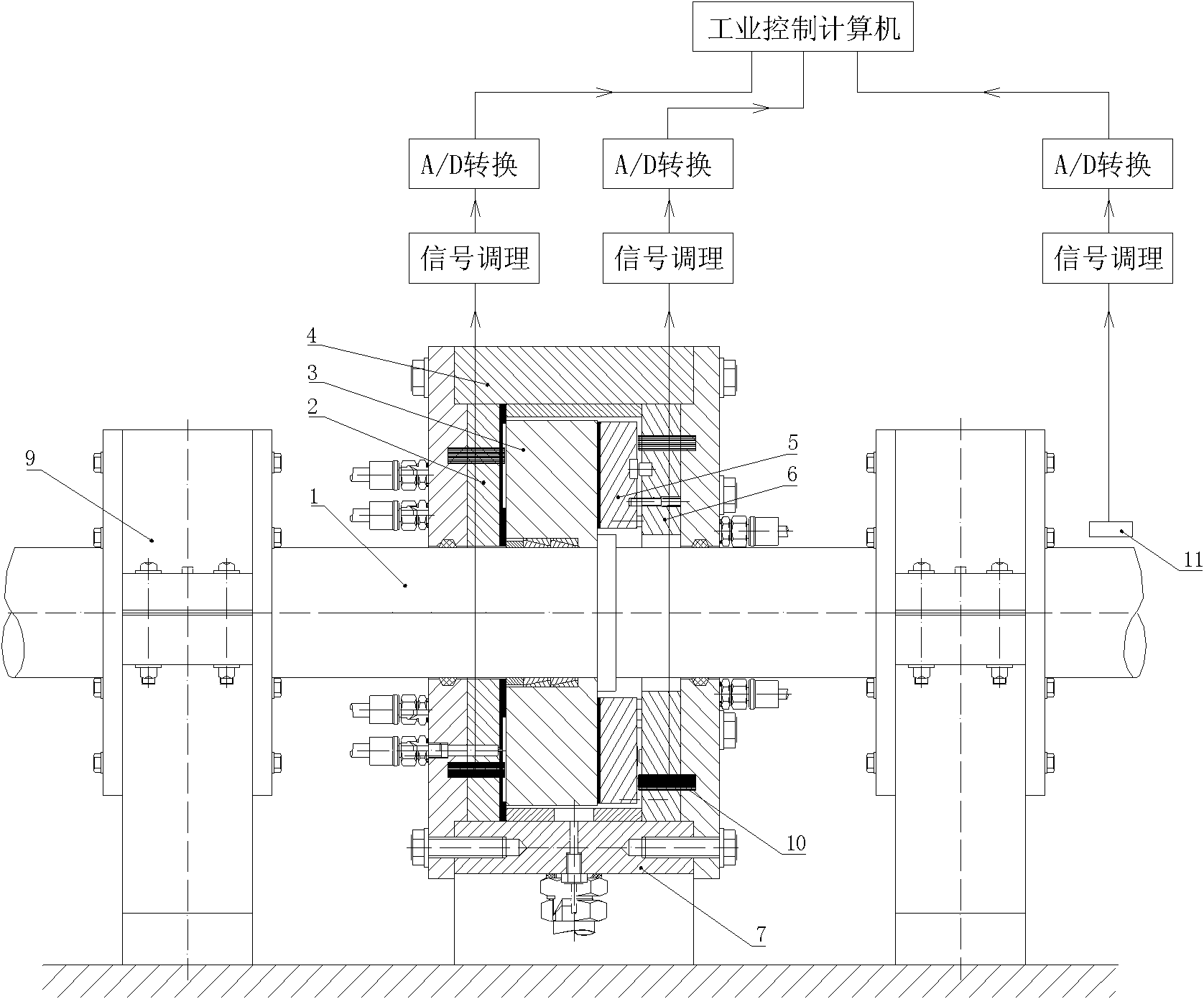

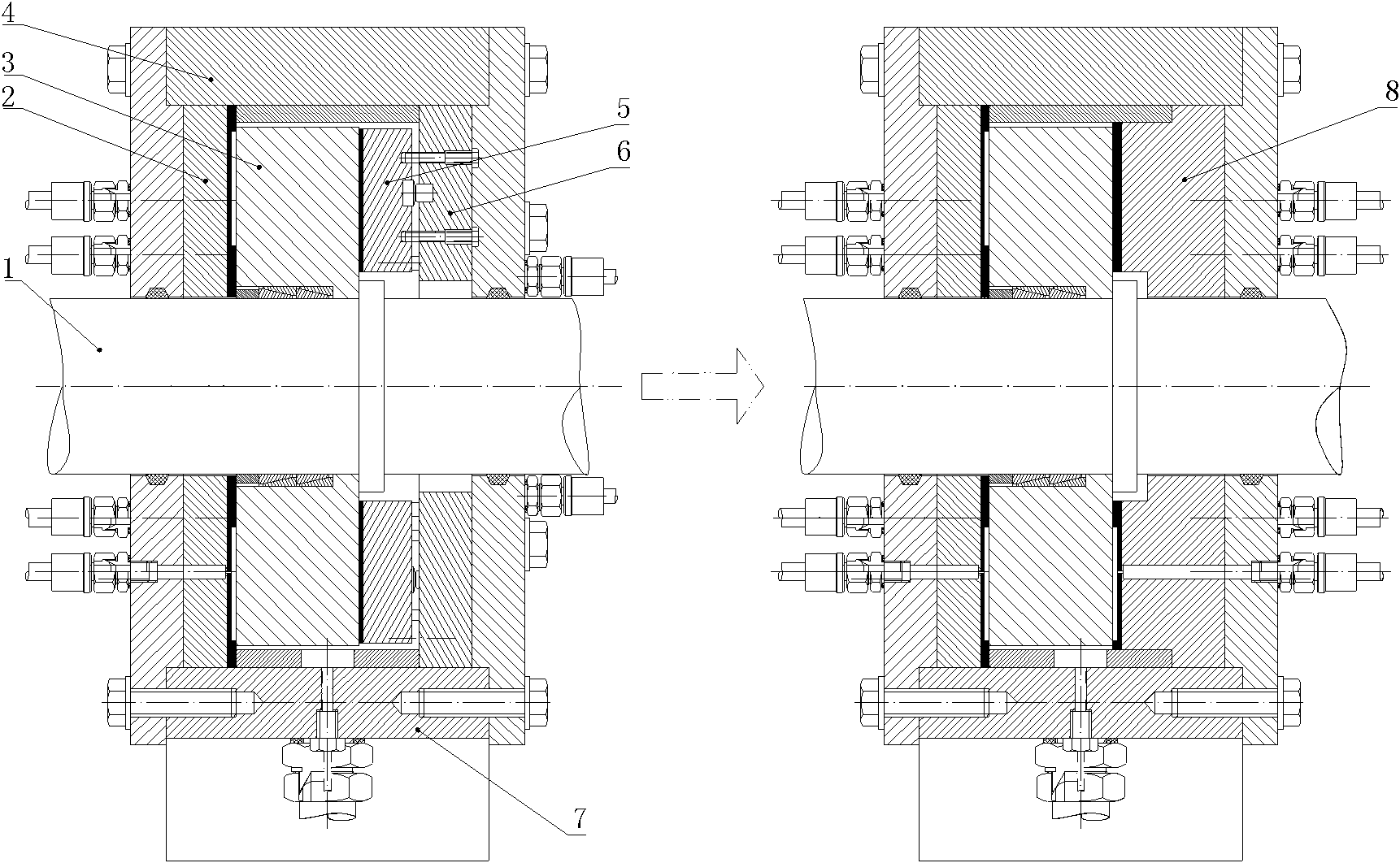

Decoupling measurement method for dynamic rigidity of hydrodynamic thrust bearing

InactiveCN102032988ARealization of dynamic stiffness testSimple structureMachine bearings testingThrust bearingDynamic pressure

The invention discloses a decoupling measurement method for testing the dynamic rigidity of a hydrodynamic thrust bearing. For realizing the decoupling measurement of the hydrodynamic thrust bearing of which the axial static load is implemented by hydraulic loading, the method comprises the following steps that: firstly, before performing dynamic rigidity test, a static rigidity test with simple operation and accurate measurement is performed by using an auxiliary device, and the influence of the oil film of a static pressure oil cavity and the influence of the oil film of a dynamic pressure oil cavity on the overall rigidity of the thrust bearing are obtained from static rigidity; and secondly, the dynamic rigidity test of the bearing system is performed, and the dynamic rigidity of the thrust bearing is calculated by using the rate of the influence of the dynamic pressure oil film on the overall rigidity of the thrust bearing, which is obtained in the static rigidity test.

Owner:XI AN JIAOTONG UNIV

A sugarcane peeling machine

InactiveCN106072690ATo achieve the purpose of peelingSimple structureVegetable peelingElectric machineryEngineering

The invention provides a sugarcane peeling machine comprising a rack and a peeling mechanism arranged on the rack. The peeling mechanism comprises motors and installing plates; the peripheral side of an output rotating shaft of each motor is provided with cutter teeth; the middle portion of each installing plate is provided with a through hole used for entry and exit of sugarcanes; the multiple motors are hinged to two side surfaces of the installing plates; the output rotating shafts of the motors are arranged to surround the peripheral edges of the through holes; each motor makes the corresponding output rotating shaft get close to the axis of the corresponding through hole via an elastic part. The cutter teeth on the output rotating shafts of the multiple motors work on the peripheral side of a sugarcane entering the through holes, so that the sugarcane is peeled. The peeling mechanism employed by the sugarcane peeling machine is fixed and sugarcanes are peeled through the rotation of the output rotating shafts of the motors in different directions; the sugarcane peeling machine is simple and effective in structure, high in peeling efficiency and convenient to use.

Owner:上海傻海食品机械有限公司

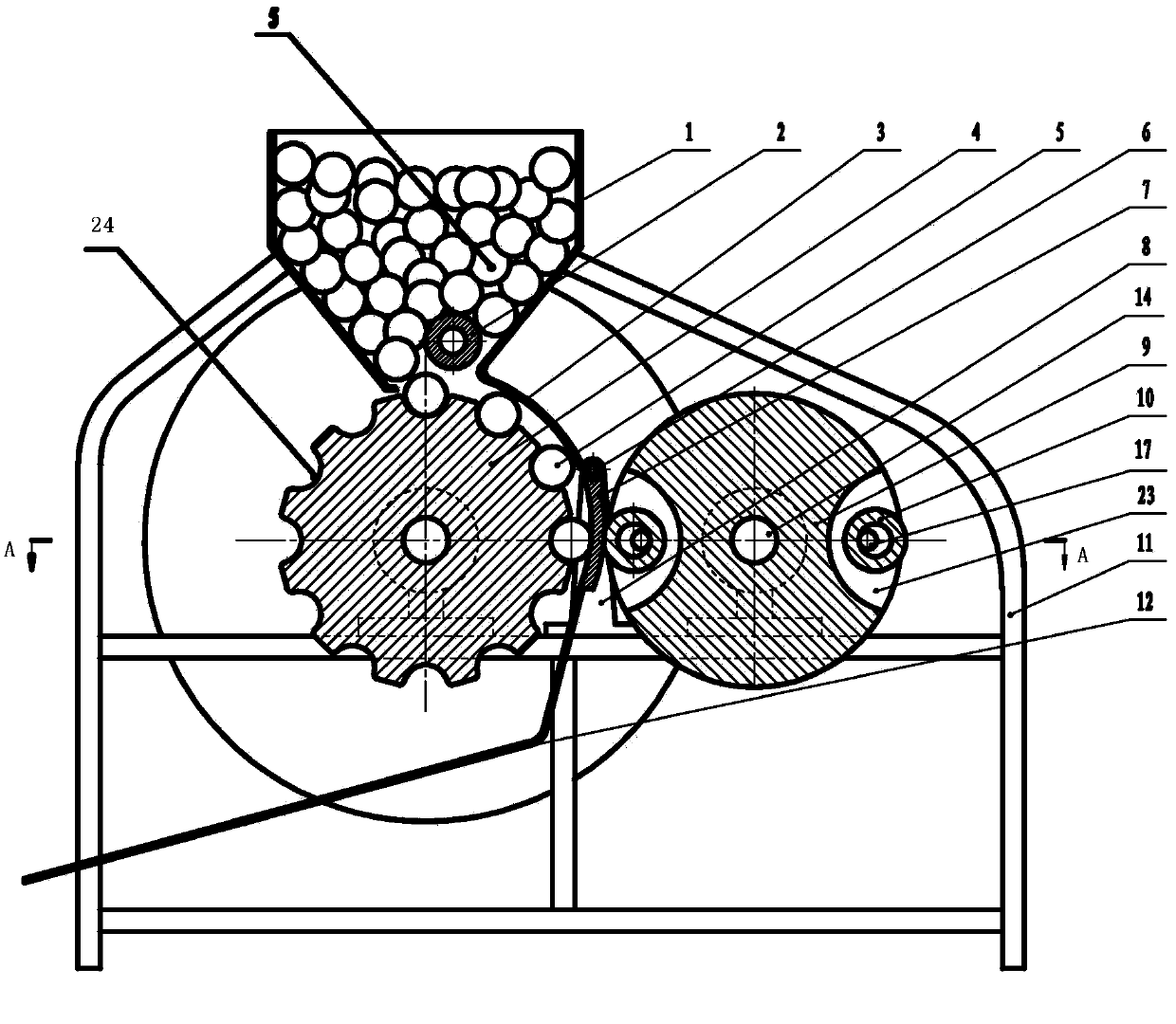

Manual pecan shell breaking device

InactiveCN104026709AEven by forceReduce breakage rateHuskingHullingEngineeringMechanical engineering

The invention discloses a manual pecan shell breaking device comprising a frame. The frame is provided with a feeding hopper, a transmission mechanism and a shell breaking mechanism. The transmission mechanism comprises a first central shaft and a second central shaft which are mounted on the frame, the first central shaft is provided with a small gear, the second central shaft is provided with a large gear, and the small gear and the large gear are mounted in an engaged manner; a hitting drum is fixedly connected to the first central shaft, and a material carrying drum is fixedly connected to the second central shaft; the circumference of the hitting drum is provided with evenly-distributed radial arc hitting wheel grooves along the axis, the hitting drum is provided with hitting wheel shafts sleeved with hitting wheels, and the hitting wheels are located in the arc hitting wheel grooves. Evenly-distributed spherical pits are formed in the circumference of the material carrying roller axially. The device has the advantages that structure is simple, usage is facilitated, requirements of pecan sorting are lowered, processing efficiency is improved greatly, and processing cost is reduced.

Owner:金华景腾科技有限公司

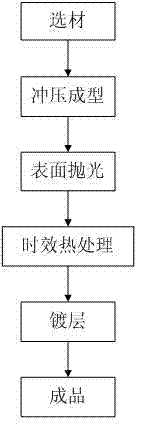

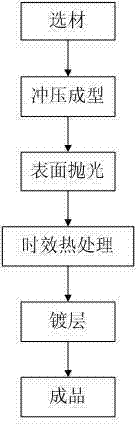

Processing technology for needle plate

The invention discloses a processing technology for a needle plate, which comprises the following steps: (1) selecting materials: selecting a thin bronze band plate as a substrate; (2) punching and forming: punching and forming the substrate; (3) polishing the surface, thereby obtaining a semi-finished product; (4) aging heat treatment: treating at 350-450 DEG C for 2.5-4 hours until the hardness reaches HV380-420; and (5) plating: plating a chrome plated layer or nickel-based alloy plated layer on the surface, wherein the hardness of the surface of the plated layer is HV800-1000. The processing technology for the needle plate disclosed by the invention is simple and feasible, is high in success rate and is low in processing cost. The finished product is high in hardness and long in service life.

Owner:常熟市宏达印染机械有限公司

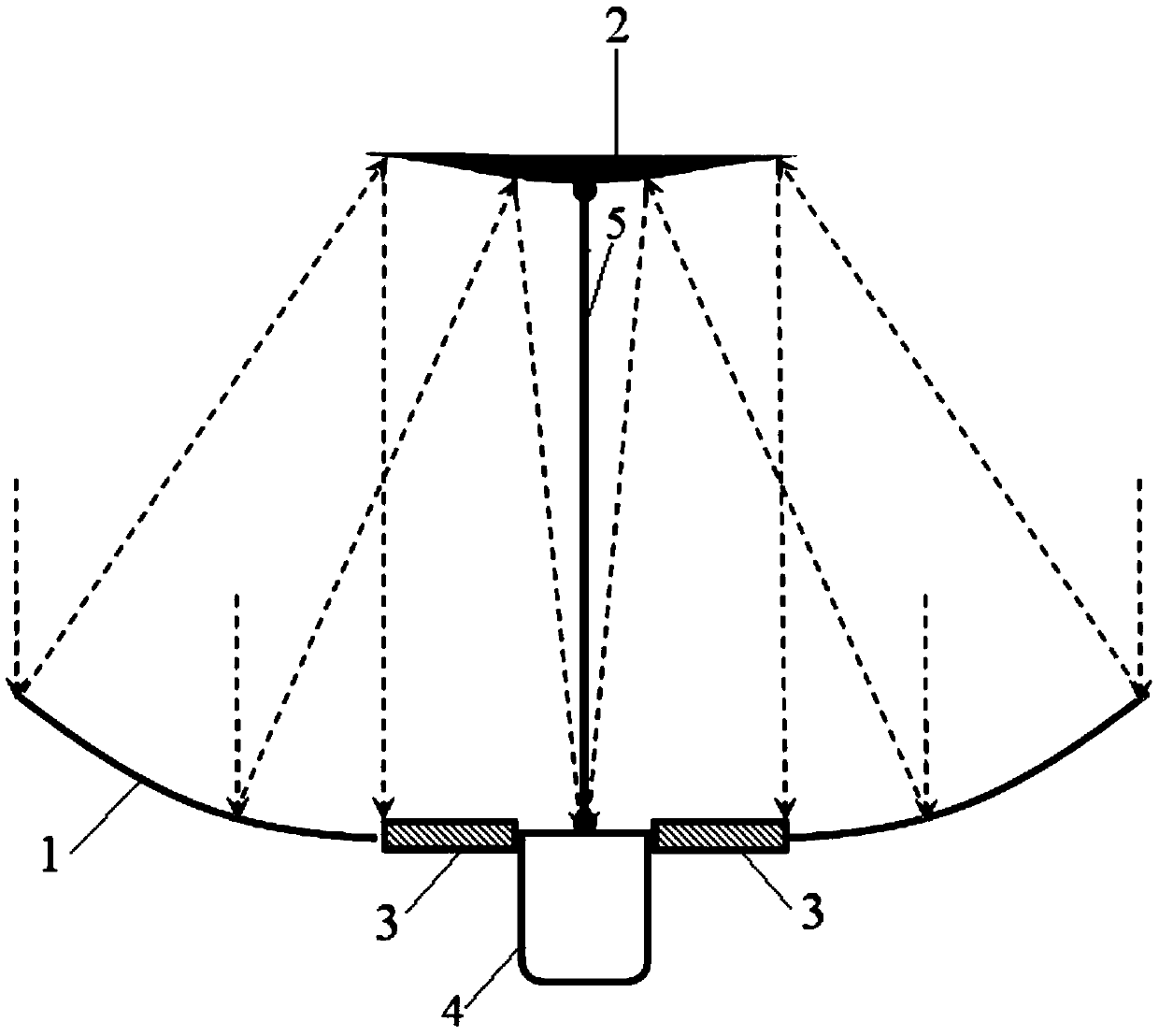

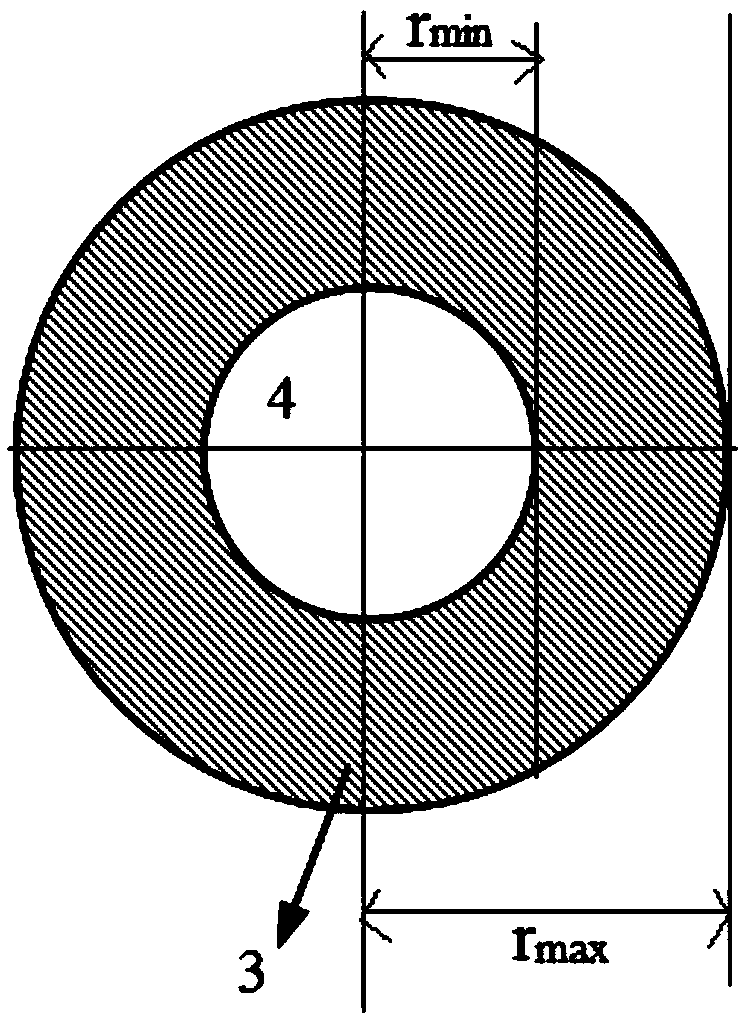

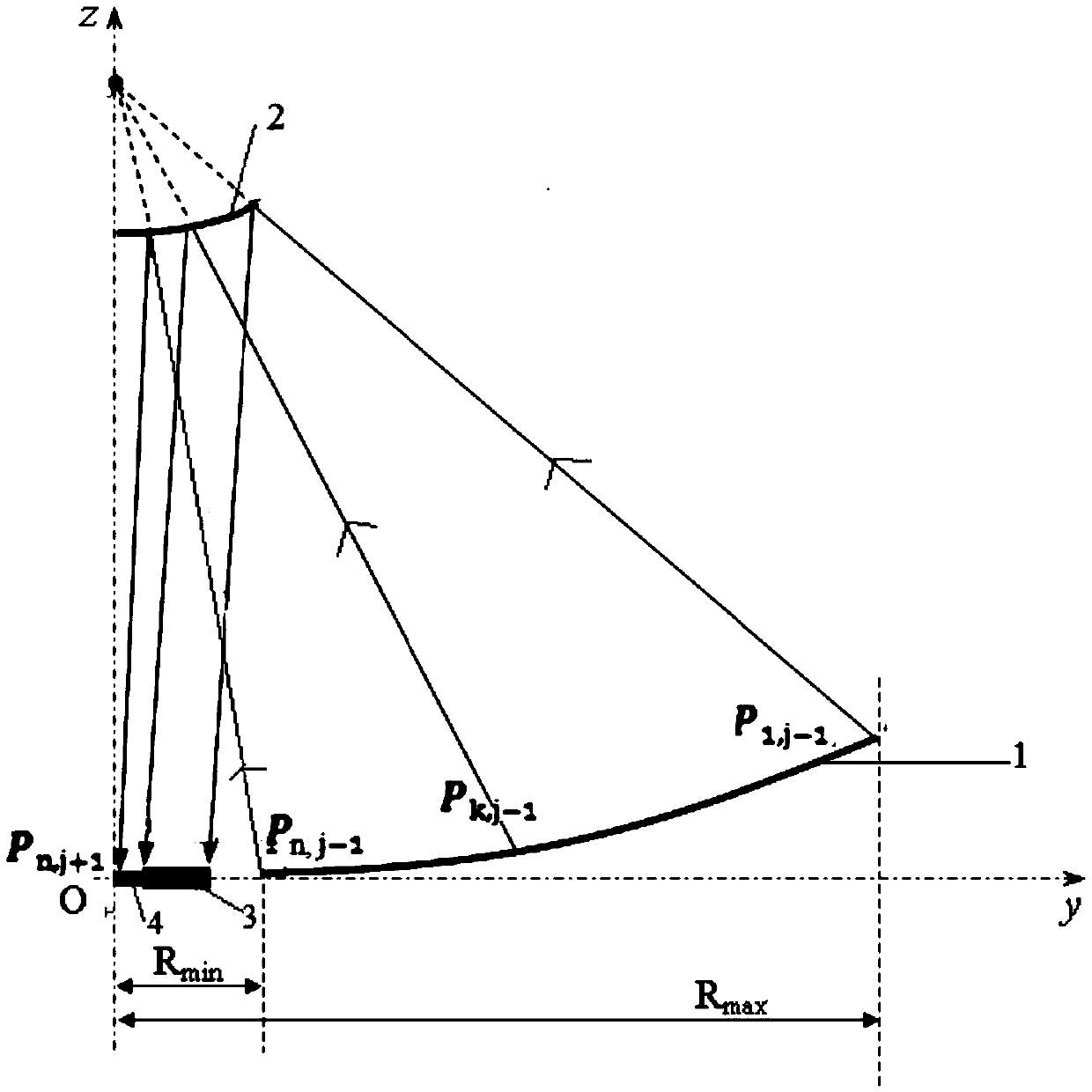

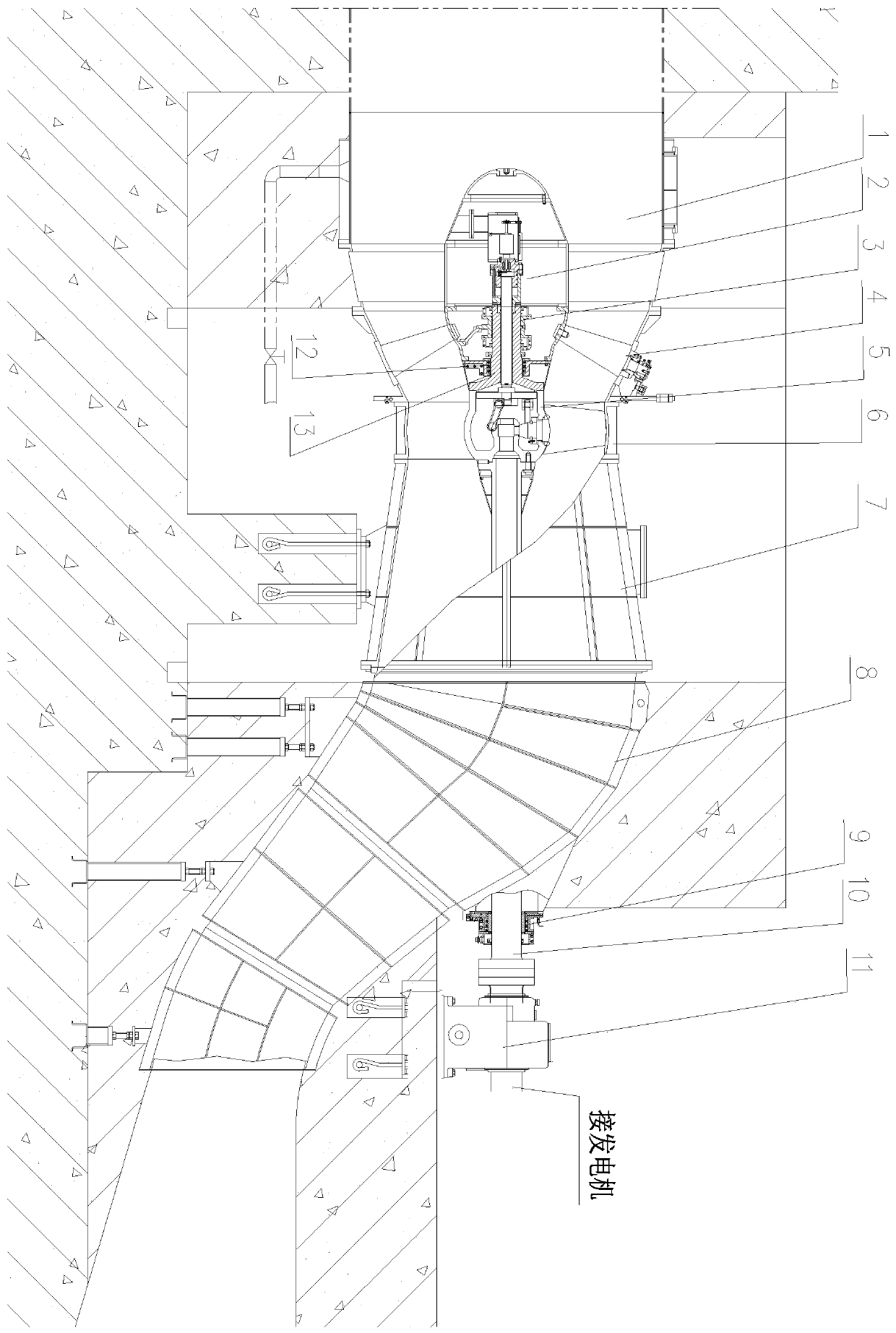

Free-surface secondary reflection concentrator system for efficient solar energy thermal/electric conversion

ActiveCN105509339AIncrease profitImprove conversion efficiencySolar heating energySolar heat devicesElectricityCells panel

The invention relates to a concentrator system for efficient solar energy thermal / electric conversion, in particular to a free-surface secondary reflection concentrator system for efficient solar energy thermal / electric conversion. The invention aims at solving the technical problem that at present, the area of an entrance of a heat absorption cavity of the traditional solar dish type concentration system is limited, so that the traditional solar dish type concentration system is not capable of receiving the energy of all light spots and can intercept the energy of the light spots; therefore, resource waste is caused. The free-surface secondary reflection concentrator system for efficient solar energy thermal / electric conversion comprises a primary mirror, a secondary mirror and a receiver, wherein the primary mirror, the secondary mirror and the receiver respectively have an axisymmetric structure and are arranged coaxially; the receiver consists of a heat absorber, a concentrating photovoltaic cell panel and a flange; the concentrating photovoltaic cell panel is arranged at the outer side of the flange; a free-form surface of the secondary mirror is determined as follows: 1, dissociaton of a starting point and a target point; 2, solution of discrete points of the free-form surface of the secondary mirror; 3, drawing of the surface of the secondary mirror. The free-surface secondary reflection concentrator system for efficient solar energy thermal / electric conversion is applied to the field of solar energy.

Owner:HARBIN INST OF TECH

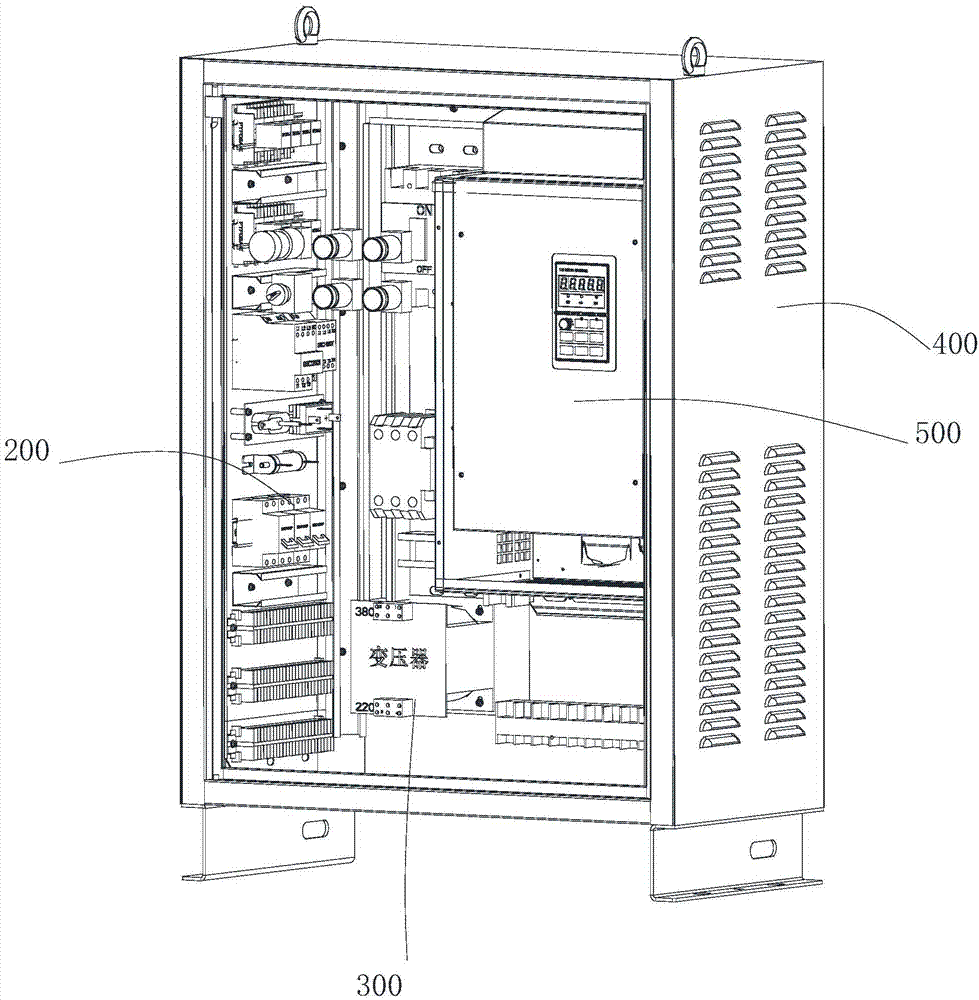

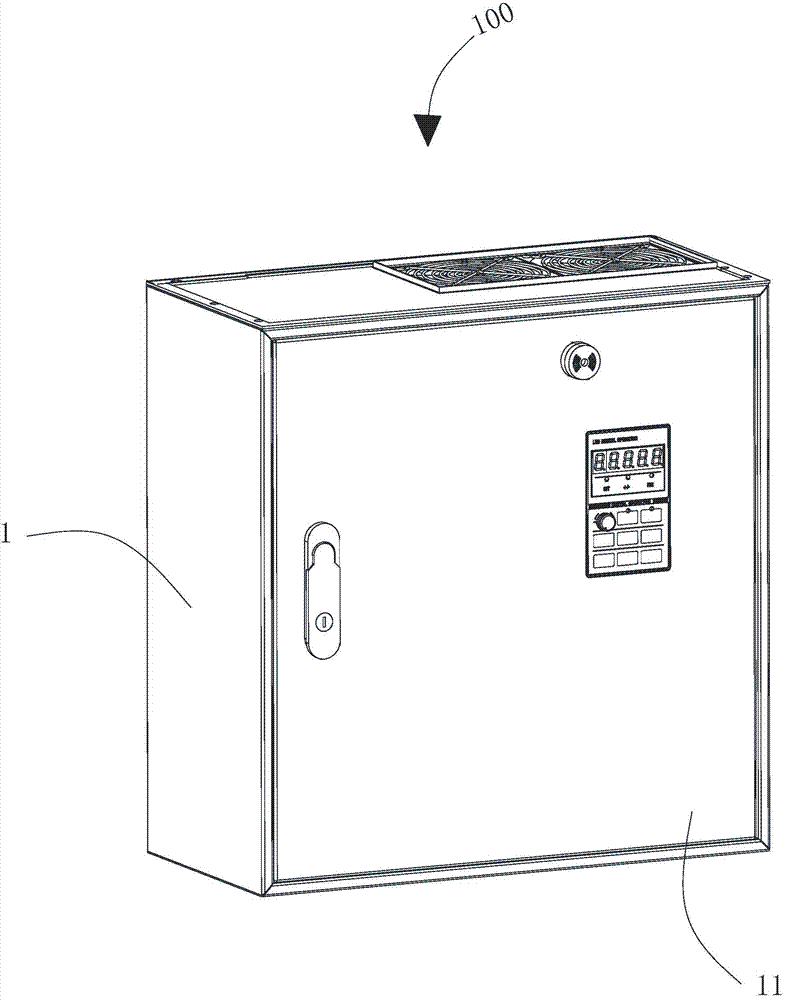

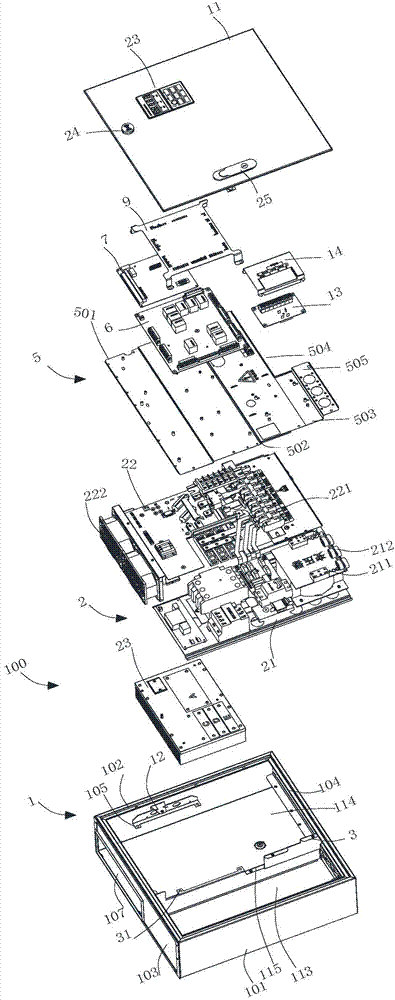

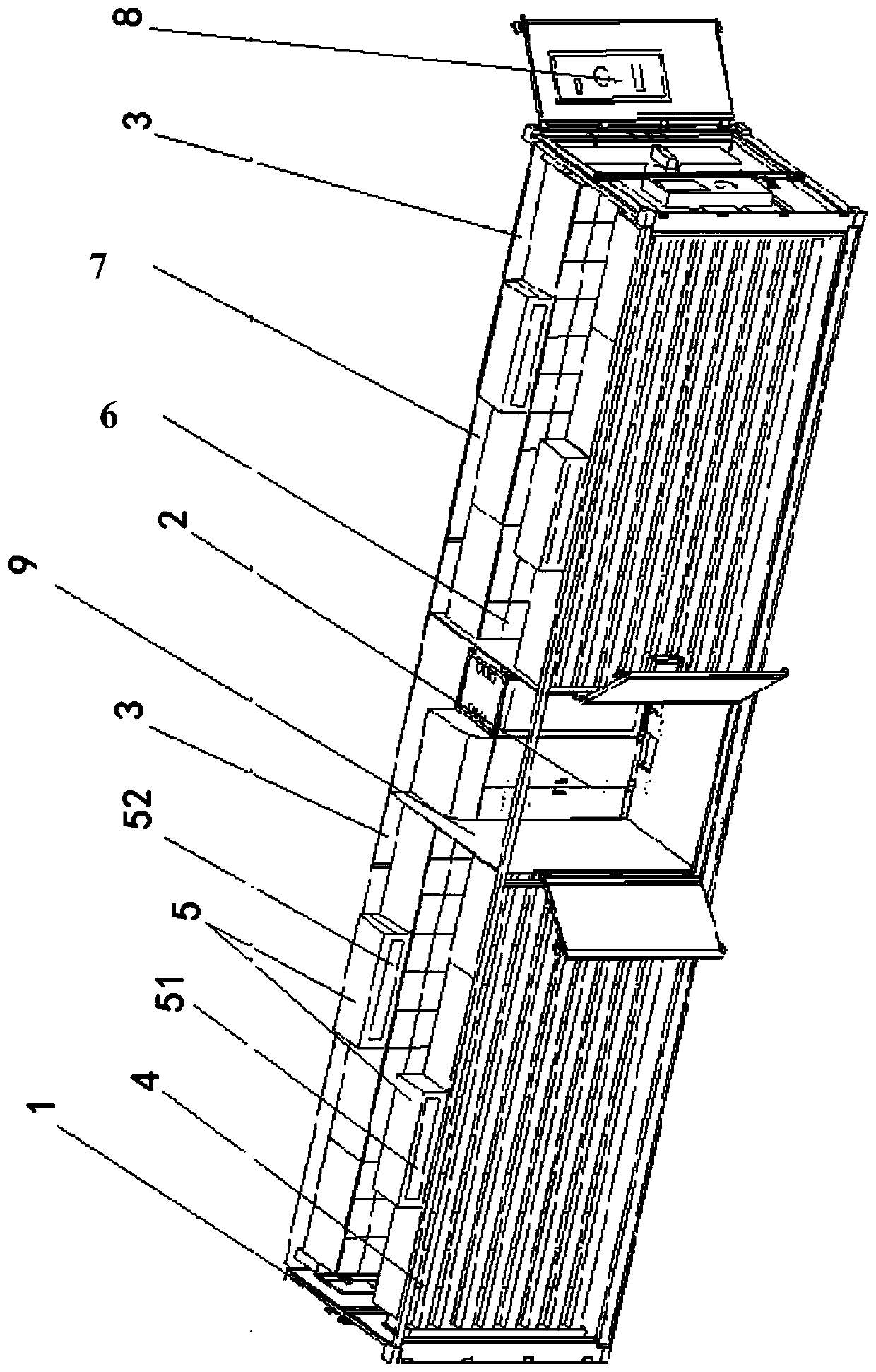

Elevator control cabinet

ActiveCN103693518ACompact structureReduce volumeCasings/cabinets/drawers detailsElevatorsFrequency changerElectricity

The invention provides an elevator control cabinet. The elevator control cabinet comprises a cabinet body (1) with a storage space and an electrical element which is stored in the storage space, wherein the electrical element comprises a variable-frequency device (2), an elevator control loop circuit board (6) and a frequency converter control loop circuit board (7), which are mutually electrically connected with one another, a first separation plate (5) is also arranged in the storage space of the cabinet body (1), the storage space is divided by the first separation plate (5) into a first storage space (111) and a second storage space; the elevator control loop circuit board (6) and the frequency converter control loop circuit board (7) are stored in the first storage space (111) and are respectively and fixedly connected onto the first separation plate (5); the variable-frequency device (2) is stored in the second storage space. The elevator control cabinet has the characteristics of small size and light weight.

Owner:SHENZHEN SINE ELECTRIC

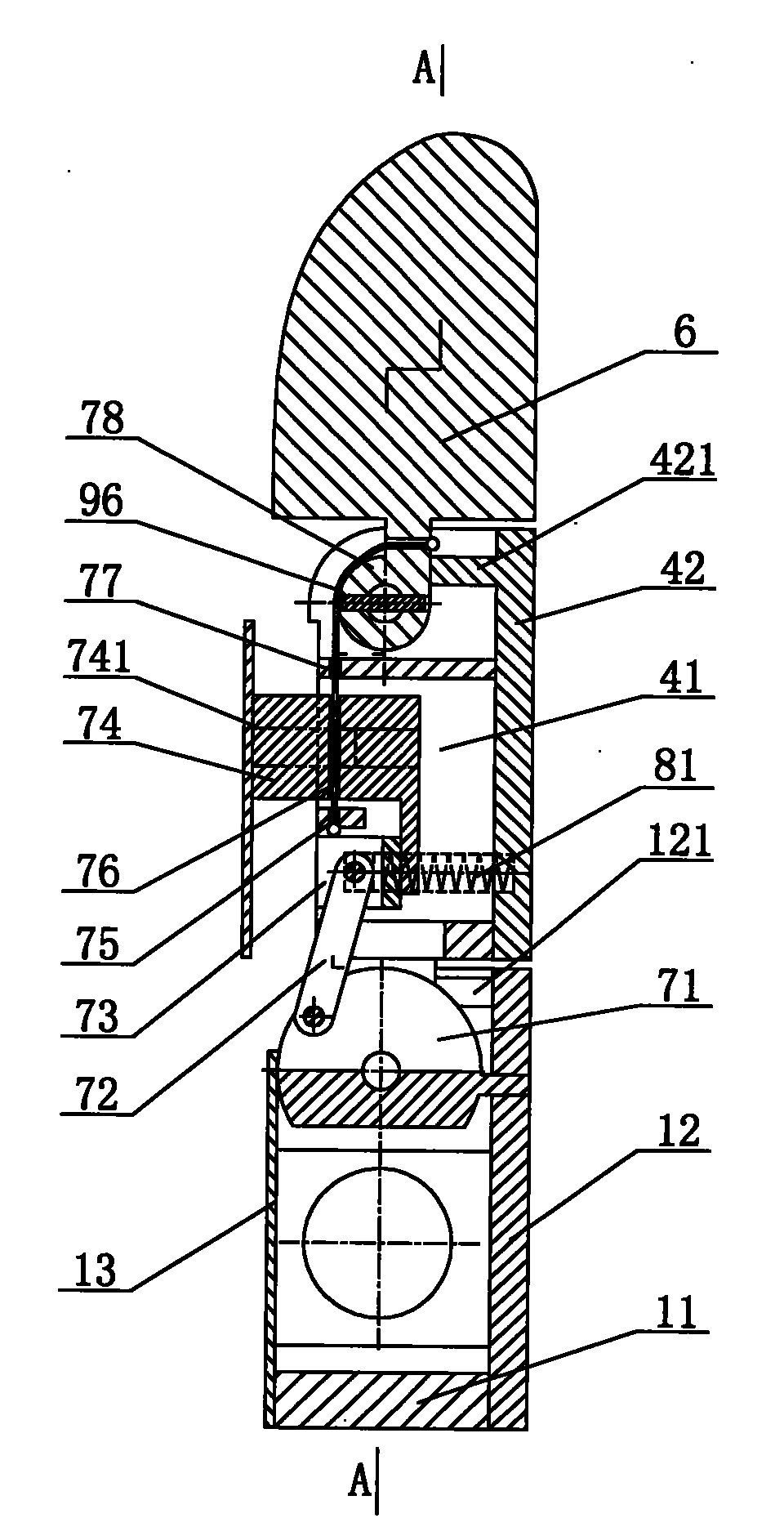

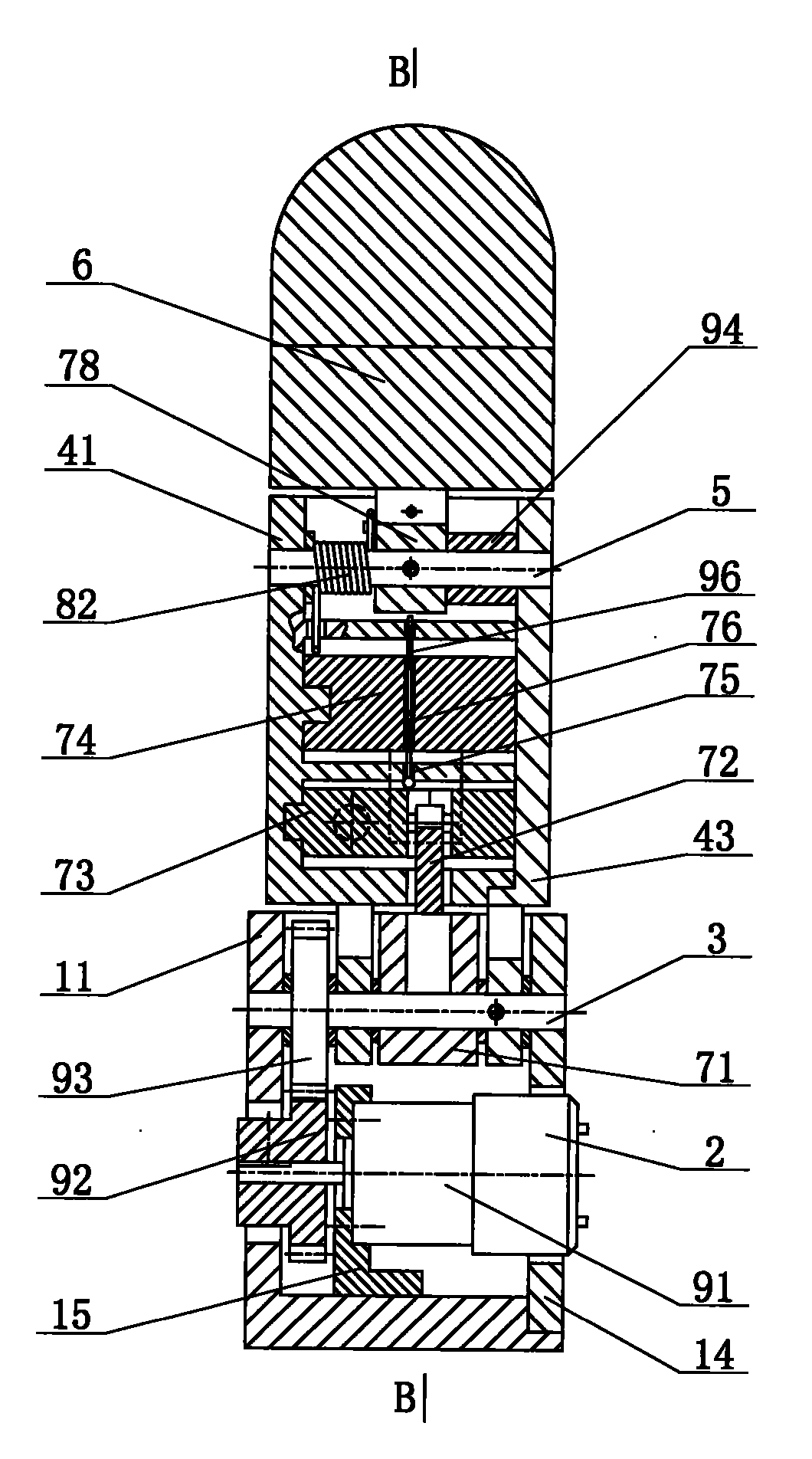

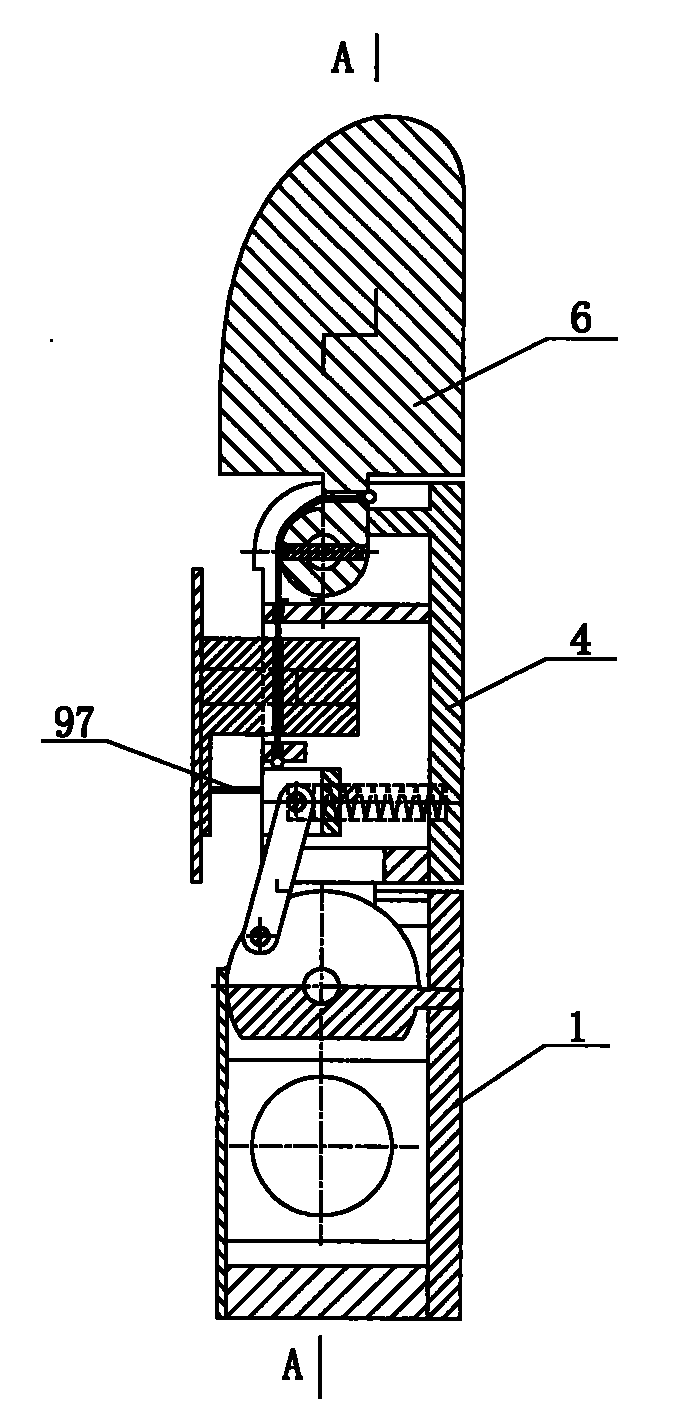

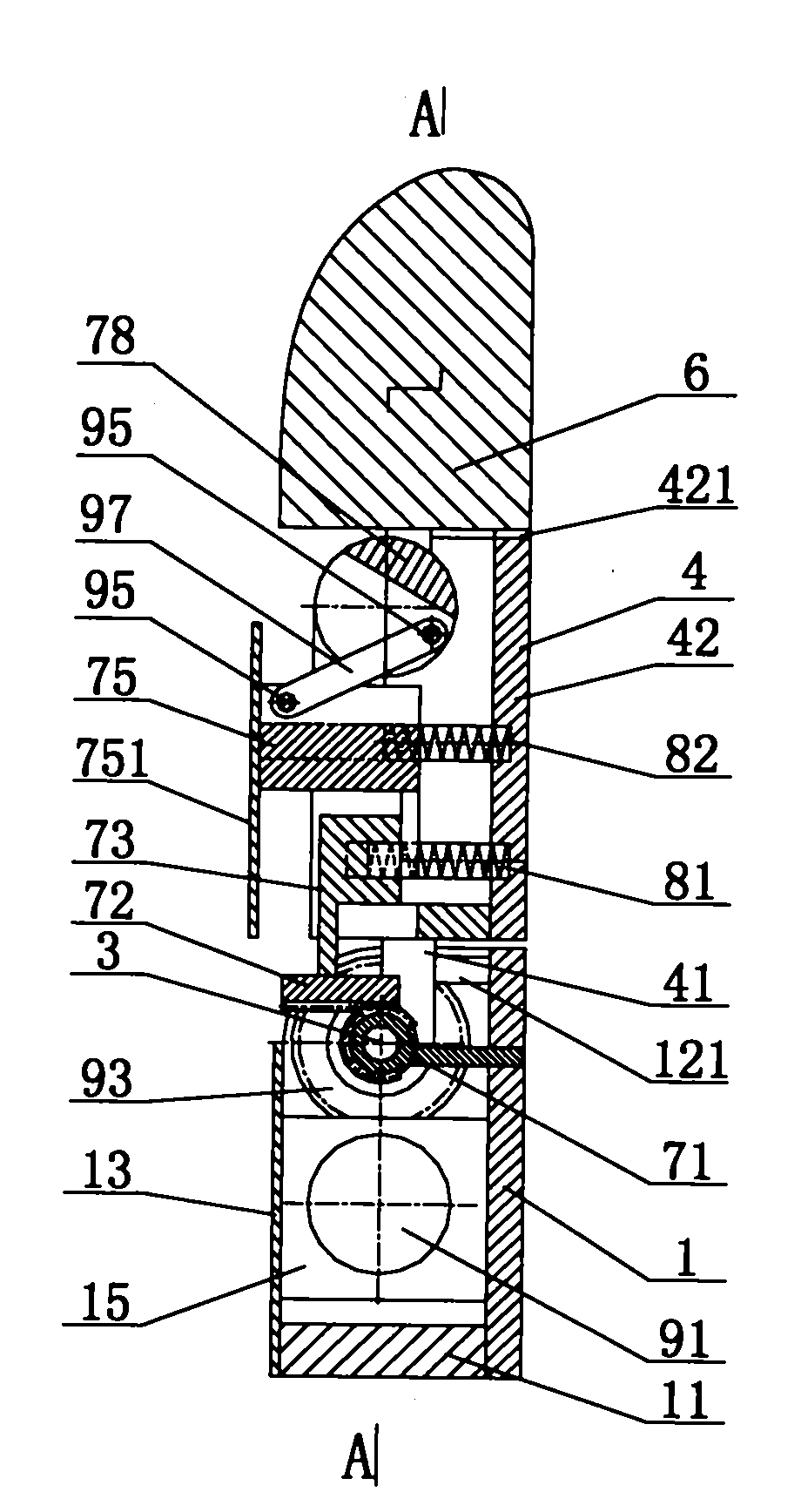

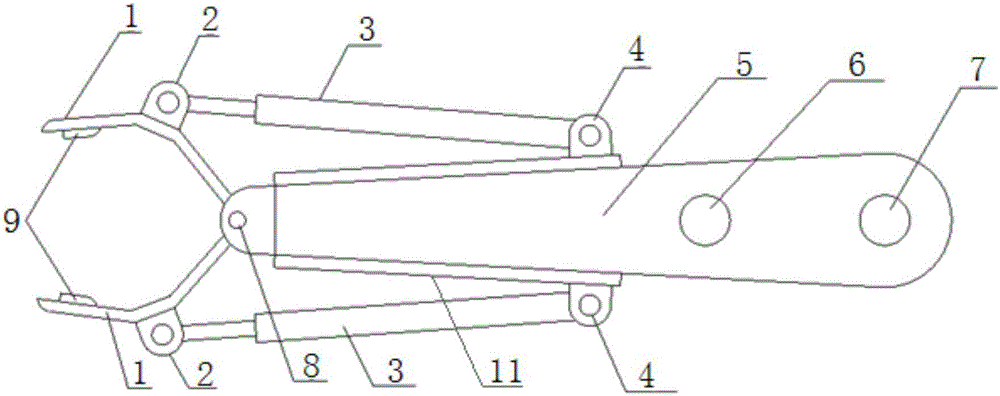

Crank block type flexible piece parallel coupled under-actuated finger device

The invention discloses a crank block type flexible piece parallel coupled under-actuated finger device, which belongs to the technical field of anthropomorphic robot fingers. The device comprises a pedestal, a proximal joint shaft, a first finger section, a far joint shaft, a second finger section, a dial plate, a connecting rod, a flexible piece and a spring piece. The device achieves the transmission effect of tightly combining coupled rotation and under-actuated rotation, can couple anthropomorphic grab, and has under-actuated adaptive function. The whole finger has a compact structure, and the manufacturing and machining costs are low; and the coupled transmission and the under-actuated transmission are organically fused, natural decoupling is realized in an active contact mode of a slide block, the decoupling does not consume motor power, and the utilization rate of energy is high. With a similar appearance as a human finger, the device can be used as a finger of a robot hand or a part of a finger, and can achieve good effects of high joint freedom degree and high adaptability of the anthropomorphic robot hand by combining a plurality of fingers to form the robot hand.

Owner:WUXI RES INST OF APPLIED TECH TSINGHUA UNIV +1

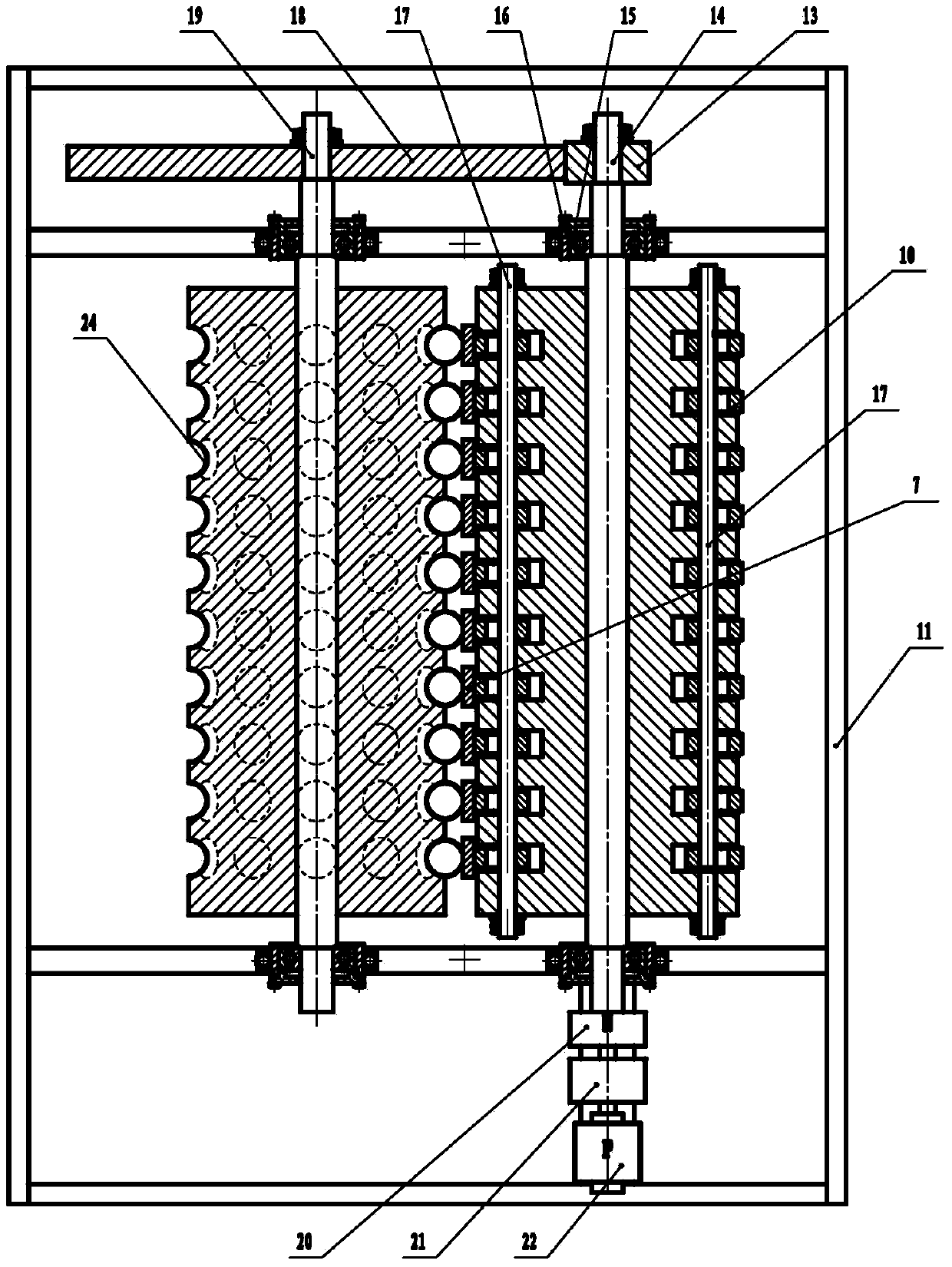

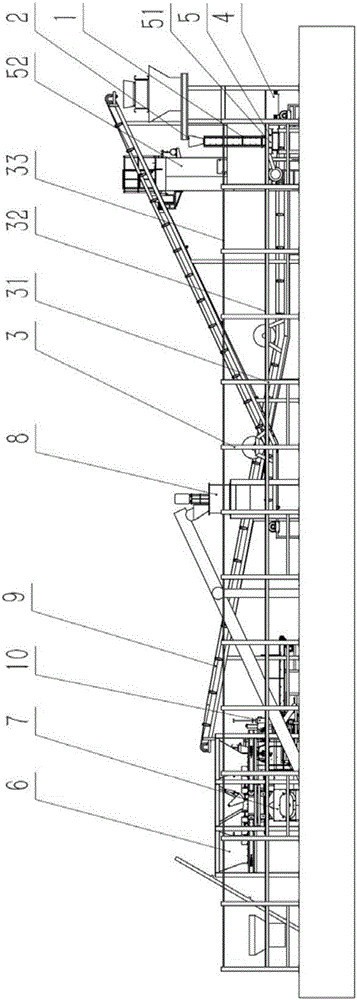

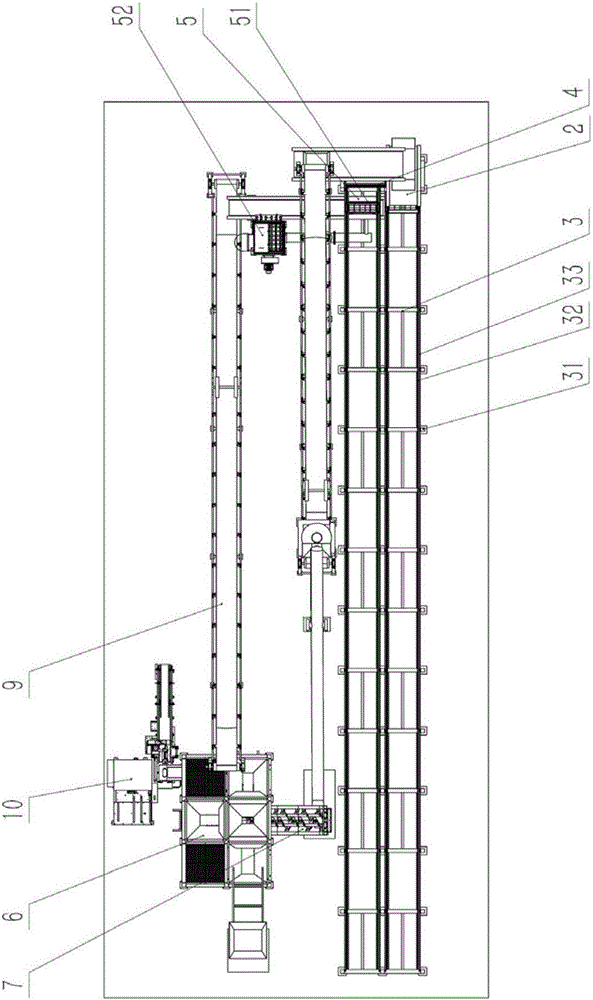

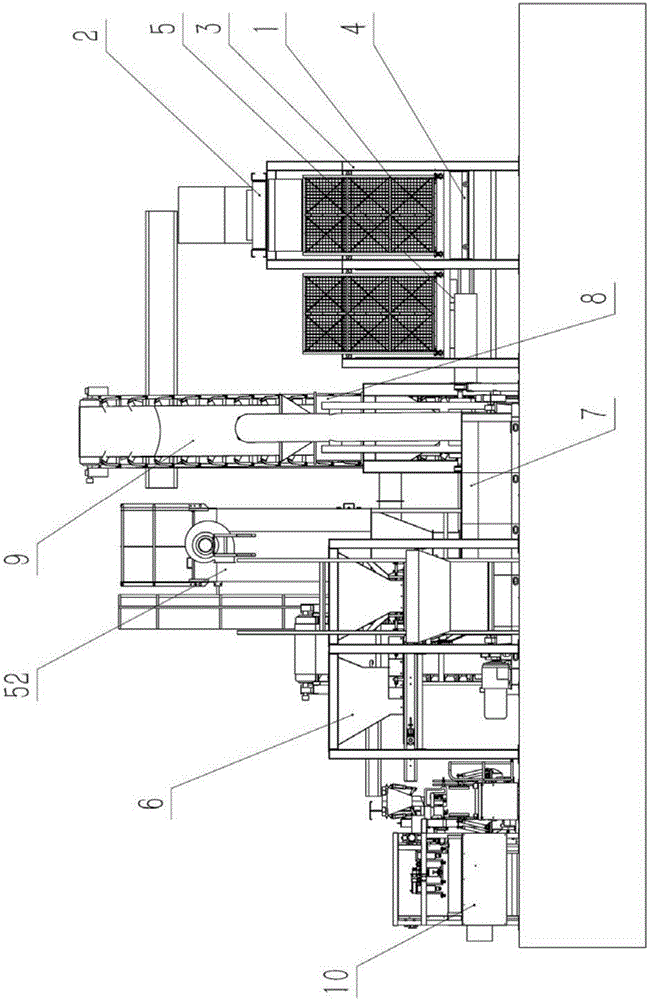

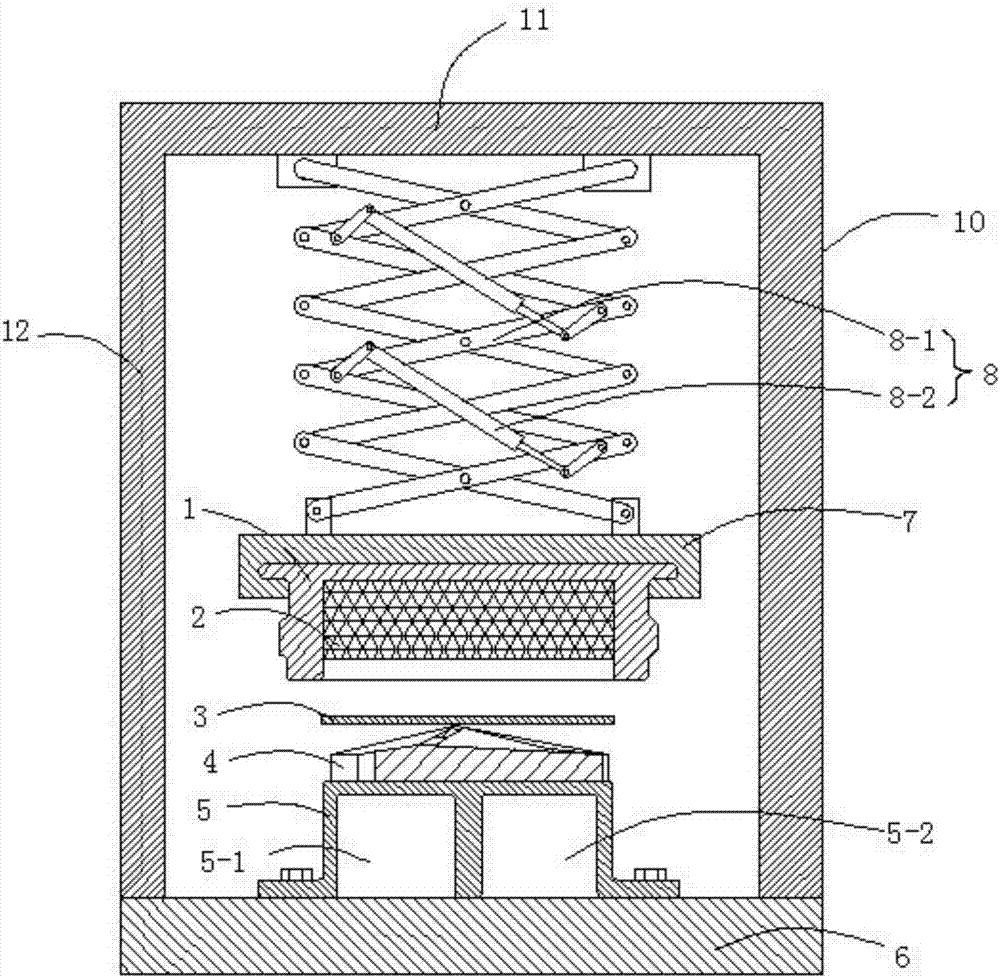

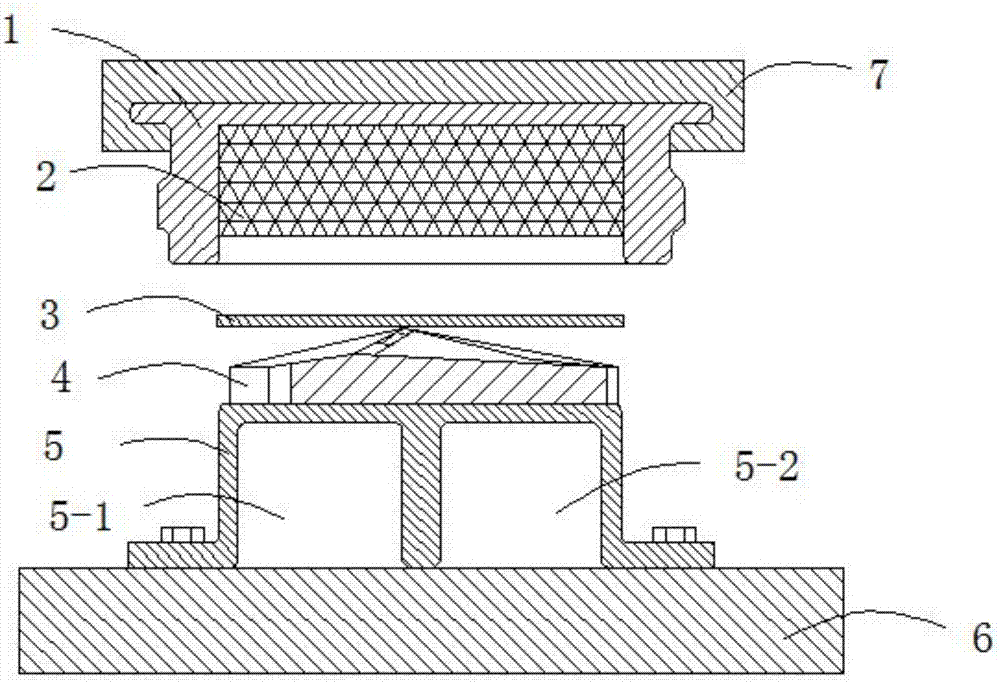

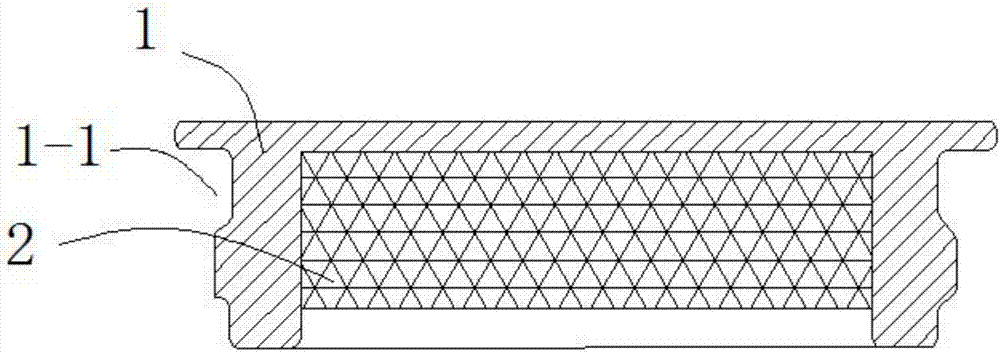

Vertical tray fermentation system and fermentation method

ActiveCN106673742AIncrease heightReduce manufacturing costBio-organic fraction processingOrganic fertiliser preparationEngineeringFermentation system

The invention discloses a vertical tray fermentation system. The vertical tray fermentation system comprises a vertical fermentation tray, a tray loading machine, a tray sliding device and a tray rail replacing device; the vertical fermentation tray is born and slid on the tray sliding device and a tray rail replacing device, the tray loading machine is arranged above the vertical fermentation tray and the end part of the tray sliding device; the tray rail replacing device is arranged and mounted at the end part of the tray sliding device; a fermentation method of the vertical tray fermentation system comprises the following steps: S1, preparing the system, S2, mixing materials, S3, stirring the materials, S4, crushing the materials, S5, loading the materials into the tray, S6, sliding the tray and fermenting the materials, S7, discharging the materials from the tray, S8, replacing rails for the tray and making the tray circularly charge the materials. The technical problems to be solved by the vertical tray fermentation system are to lower manufacturing and processing difficulties and manufacturing and using costs of the vertical tray fermentation system, avoid operation processes of stacking, unstacking, tray dumping, material pouring and the like, and facilitate long-distance transportation.

Owner:GUANGXI LIYUANBAO SCI & TECH

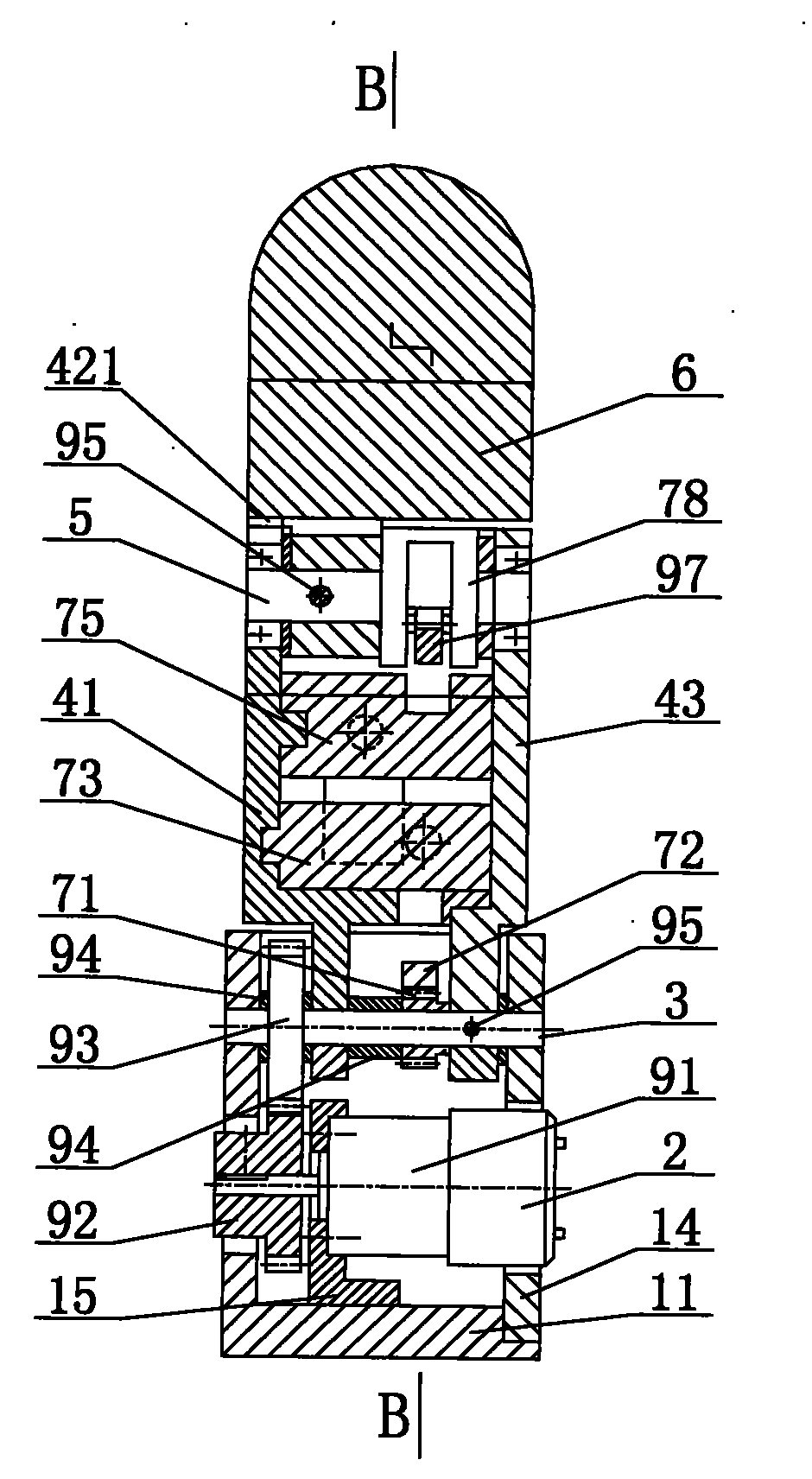

Rack crank slide block type parallel coupling under-driving robot finger device

InactiveCN101829993ANo power consumptionHigh joint freedomJointsGripping headsShortest distanceProcessing cost

The invention relates to a rack crank slide block type parallel coupling under-driving finger device which belongs to the technical field of impersonating robot hands and comprises a base, a near joint axis, a first finger section, a far joint axis, a second finger section, a link, a dial, a motor, a rack and a spring part. The device realizes a transmission effect with the combination of coupling rotation and under-driving rotation, realizes impersonating catching by coupling, and also has an under-driving self-adaptive function. The whole finger has compact structure and low manufacturing and processing costs. Natural decoupling is realized in a movable contact mode of a slide block, without power consumption of the motor and with high utilization rate. A crack slide block mechanism of the second finger section can move by a short distance by a driving slide block to realize the large-angle rotation of the second finger section. The shape of the device is similar to that of a human finger. The device can be used as a finger or a part of the finger of the robot hand; a plurality of fingers can also be combined into the robot hand to achieve good effects of high joint freedom and high self-adaptability of the impersonating robot hand.

Owner:WUXI RES INST OF APPLIED TECH TSINGHUA UNIV +1

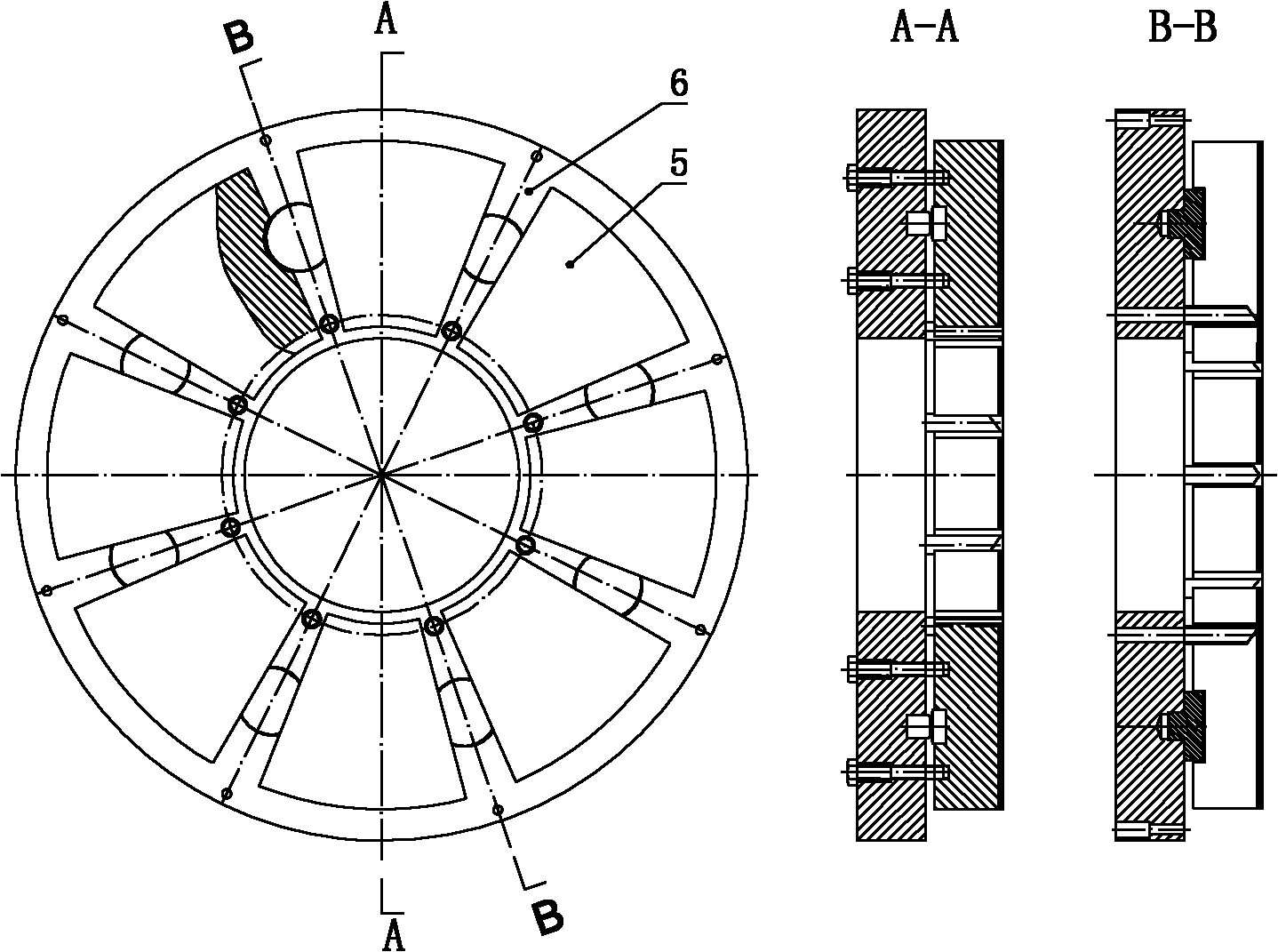

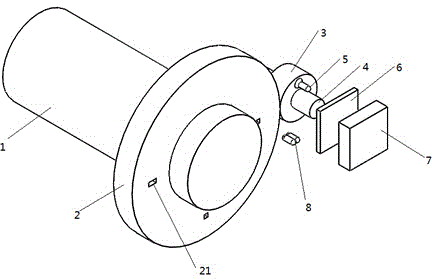

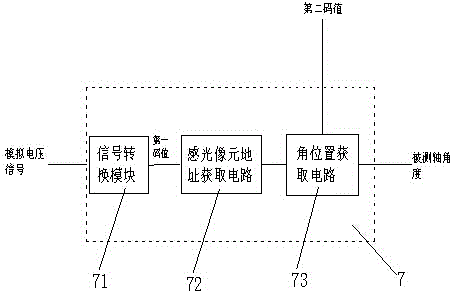

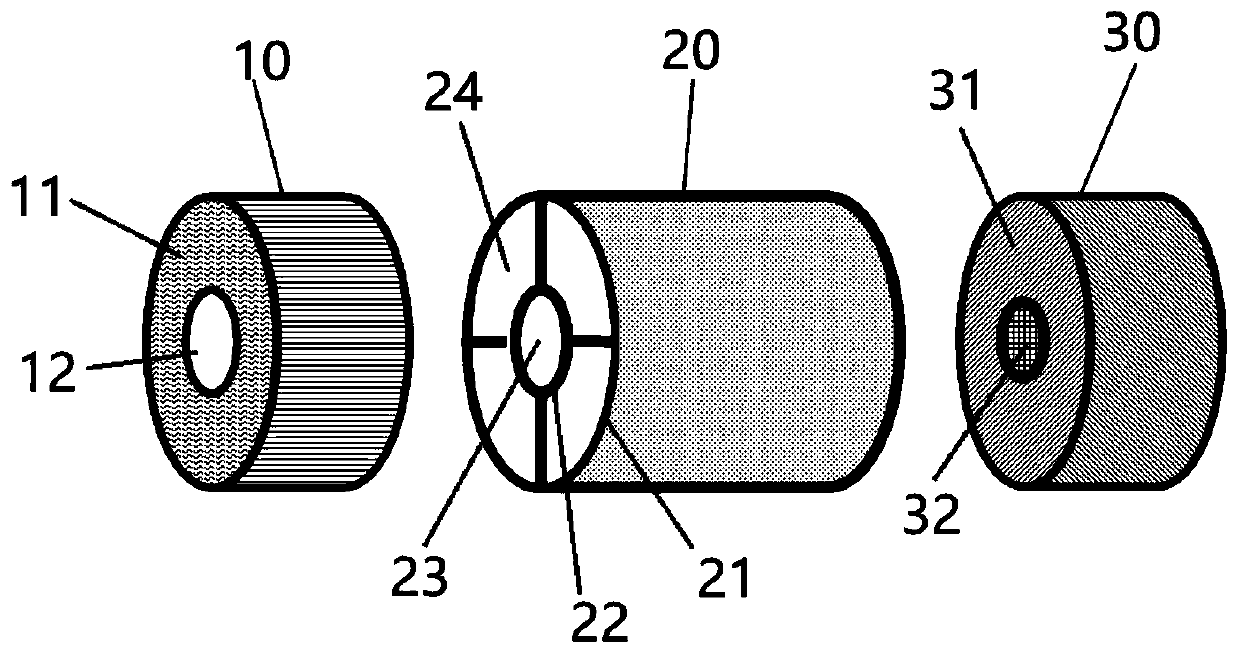

Photosensitive resistance encoder based on mechanical subdivision and measuring method thereof

ActiveCN104596554ALow costHigh-resolutionUsing optical meansConverting sensor output opticallyDrive wheelDrive shaft

The invention discloses a photosensitive resistance encoder based on mechanical subdivision, belonging to the field of an encoder; the photosensitive resistance encoder comprises a spindle; a driving wheel is fixed on the spindle; a driven wheel is equipped and connected with the driving wheel in a matching manner; the driven wheel is fixedly installed on a driven shaft and fixedly provided with a first laser source; a photosensitive resistance area array is located in front of the first laser source; an area array signal processing is connected with the photosensitive resistance area array; a second laser source is located in front of the driven wheel; and a driving wheel code value processing system is located behind the driving wheel. The invention further discloses a measuring method for the encoder. The encoding resolution ratio of the photosensitive resistance area array is subdivided in a mechanical transmission manner; the problem of high cost caused by too large size of the photosensitive resistance area array is solved, and meanwhile, the technical difficulty of the resolution ratio of the present encoder limited by a coded disc is also solved; and the resolution ratio of the encoder is improved greatly.

Owner:嘉兴笼列电子商务有限公司

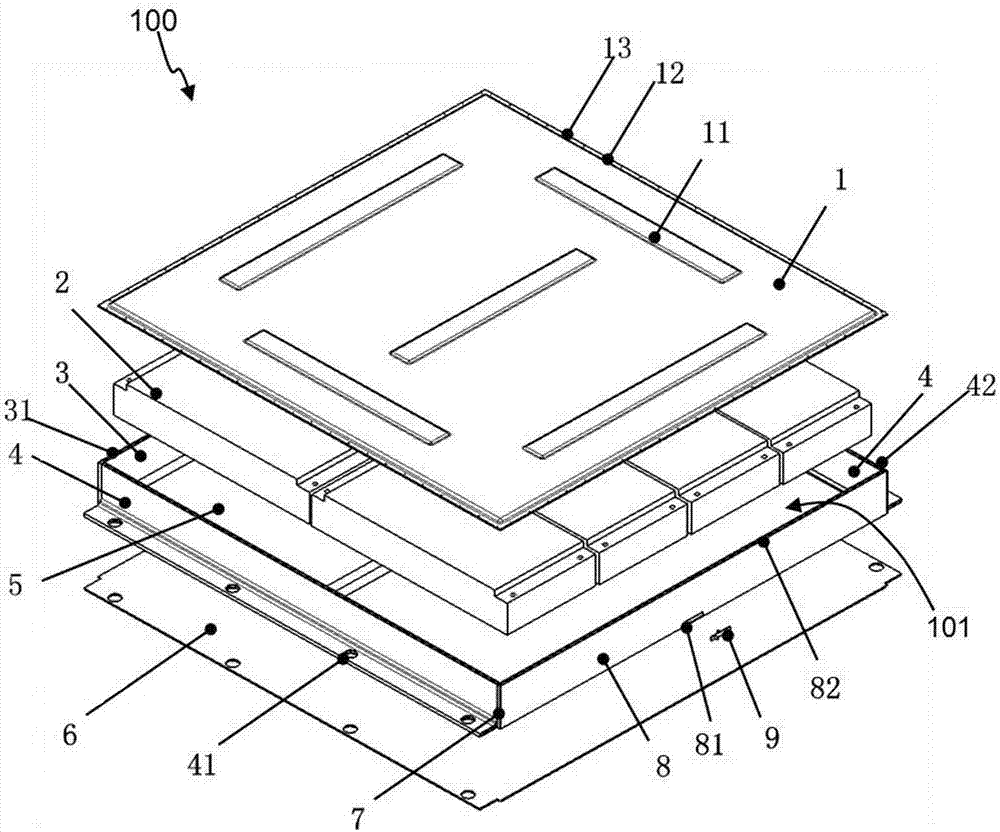

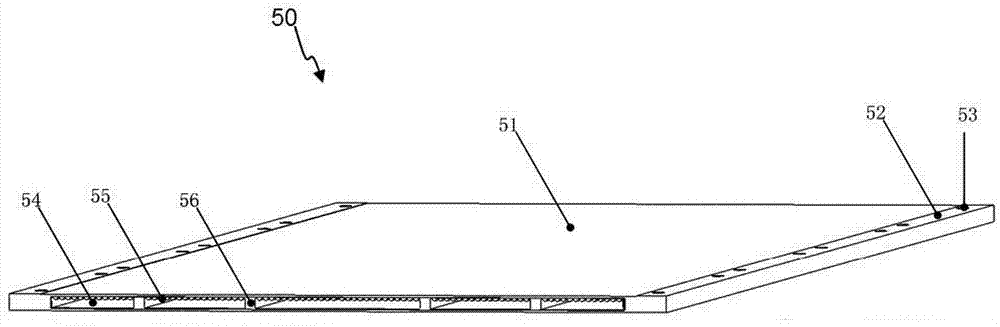

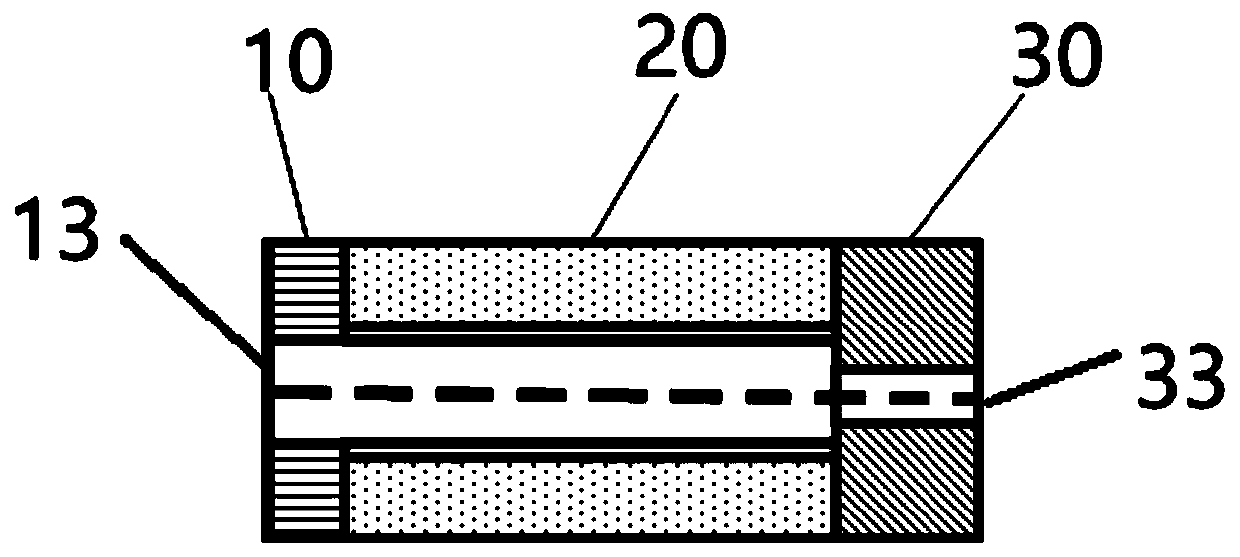

Battery pack housing with heat exchange function and battery pack

PendingCN107331920AHigh material utilizationReduce manufacturing and tooling costsBattery isolationSecondary cellsElectrical batteryEngineering

The invention provides a battery pack housing with heat exchange function and a battery pack, and belongs to the technical field of batteries. The battery pack housing comprises a heat exchange substrate and multiple side plates which are fixed on the heat exchange substrate, wherein the heat exchange substrate and multiple side plates are basically enclosed in order to form a cavity for accommodating and fixing one or more battery modules; the heat exchange substrate is formed by assembling one or several heat exchange substrate units, and each heat exchange substrate unit has an integral structure and multiple first channels are arranged therein; each side plate has an integral structure and at least one second channel is arranged therein; side plates and one or several heat exchange substrate units of the heat exchange substrate are welded, so that the first channels and multiple second channels are used together for forming heat exchange circulating channels, wherein liquid inlets and liquid outlets of the heat exchange circulating channels are arranged on at least one side plate which is provided with the second channels. The battery pack housing has the advantages of good utilization rate of materials, low cost, good extendability, and good reliability.

Owner:NIO CO LTD

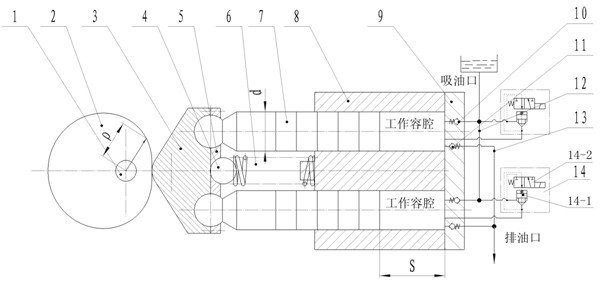

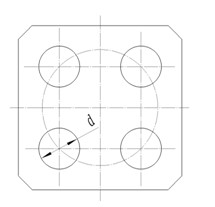

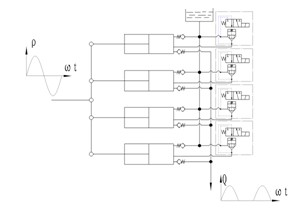

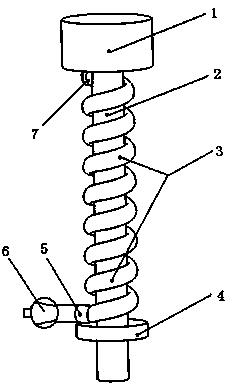

Sinusoidal flow generating device

InactiveCN102425533ACompact structureReduce sizePositive-displacement liquid enginesMulti-cylinder pumpsReciprocating motionEngineering

The invention discloses a sinusoidal flow generating device, which comprises a sliding block. The sliding block is connected with a cam, the other side of the sliding block is connected with the top ends of a plurality of plungers, the rod parts of the plungers are arranged in plunger holes in a cylinder, an elastic device is arranged between the sliding block and the cylinder, and the plungers can reciprocate in the plunger holes in the cylinder. The contour shape of the cam meets the following curve equation: Rho=r+s / 2(1-cos(Omega t), wherein r is the radius of the base circle of the cam, s is the lift of the cam, and Omega is the rotating angular speed. An electromagnetic one-way valve is arranged in a working cavity formed between each plunger and each plunger hole of the cylinder, the oil inlet of the electromagnetic one-way valve is connected with the working cavity, and the oil outlet of the electromagnetic one-way valve is connected with an oil feeding channel of the flow generating device to control the number of the plungers engaged in flow output simultaneously and to realize the adjustment and the control of the amplitude of sinusoidal flow. The defect that only approximate sinusoidal flow signals can be obtained when a crank-connecting rod mechanism or an eccentric wheel mechanism is adopted to drive the plungers to move is overcome, and standard sinusoidal flow signals can be provided for testing the performance of mechanical parts needing sinusoidal flow as an input signal.

Owner:CHONGQING TECH & BUSINESS UNIV

High-reliability energy storage system and energy storage container

PendingCN110797489AImprove reliabilityPrecise coolingSecondary cellsFire rescueElectrical batteryBattery system

The invention provides a high-reliability energy storage system and an energy storage container. The energy storage system comprises a box body, wherein an equipment cavity and at least two battery cavities are formed in the box body, and at least one battery cavity is located on a first side of the equipment cavity. The invention provides an energy storage system with high reliability and an energy storage container. Electrical equipment and a battery cluster are respectively arranged in the equipment cavity and a battery cavity, the safety risk is effectively reduced, so the risk of fire isavoided, the size of a battery cabin is reduced relative to the whole box body, a front-back ventilation mode is adopted, an indoor unit can perform accurate heat dissipation of the battery cluster, the battery clusters are symmetrically arranged at two ends of an equipment cabin, short circuit of battery wiring caused by condensation is effectively avoided, so an electrical wiring distance is symmetrically shortened, line loss of a power line and a sampling line of a battery system is reduced, acquisition precision and communication stability are improved, and manufacturing and processing cost is reduced due to the standard consistent wiring harness design.

Owner:GREE ELECTRIC APPLIANCES INC

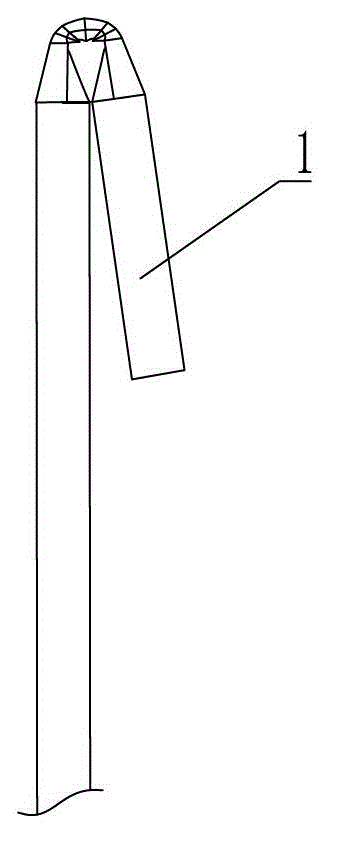

Molding mechanism for bending of suction tube

The invention relates to a molding mechanism for bending of a suction tube, wherein the molding mechanism for the bending of the suction tube is used on a suction tube packing machine. The molding mechanism for the bending of the suction tube comprises a chain, a hook mold, a check block and an unhooking block, wherein the chain rotates driven by a chain driving component which is installed on a machine frame, the hook mold comprises a main hook and a pressing hook, the main hook and the pressing hook are connected on the chain in a chaining mode, the hook mold is provided with a concave part which is used for containing a suction tube, a groove is arranged in the inner side of the concave part, a hole in the pressing hook is connected with the chain in the axial direction and is capable of rotating, the pressing hook slides on a track, the track is fixed on the machine frame, the check block is fixed on the machine frame through an adjustable block component, the adjustable block component is used for fixing the check block and adjusting position of the check block, and the unhooking block is fixed on the machine frame at the tail end of the track. The molding mechanism for the bending of the suction tube has the advantages that the structure is simple, a heating process and a contracting process are not needed when the bending position of the suction tube is machined, and cost for manufacturing and machining of the suction tube is reduced.

Owner:SHENZHEN JINDIAN MACHINERY AUTOMATION CO LTD

Rapid prototyping device for special-shaped sheet metal parts

PendingCN107377777AReduce labor intensitySolve the labor-intensiveShaping toolsEngineeringRapid prototyping

The invention discloses a rapid prototyping device for special-shaped sheet metal parts, and relates to rapid prototyping equipment for sheet metal parts. The rapid prototyping device comprises an upper die base, a concave die which is clamped inside the upper die base, a lower die base, a forming support terrace die which is fixed on the lower die base and matched with the concave die, the concave die is a concave die with a semi-closed cavity, a rubber plate is arranged inside the concave die with the semi-closed cavity, the thickness of the rubber plate is less than the depth of the semi-closed cavity, a forming workpiece feta membrane for supporting a workpiece to be machined is fixedly arranged on the forming support terrace die, and a pressure elevating mechanism is connected to the upper die base. According to the rapid prototyping device for special-shaped sheet metal parts, the surfaces of the obtained parts are smooth and flat, and the defects of indentation, scratches and convex-concave shapes appearing on the surfaces of the parts when the traditional methods are used for forming the parts are resolved.

Owner:郑州郑飞机电技术有限责任公司

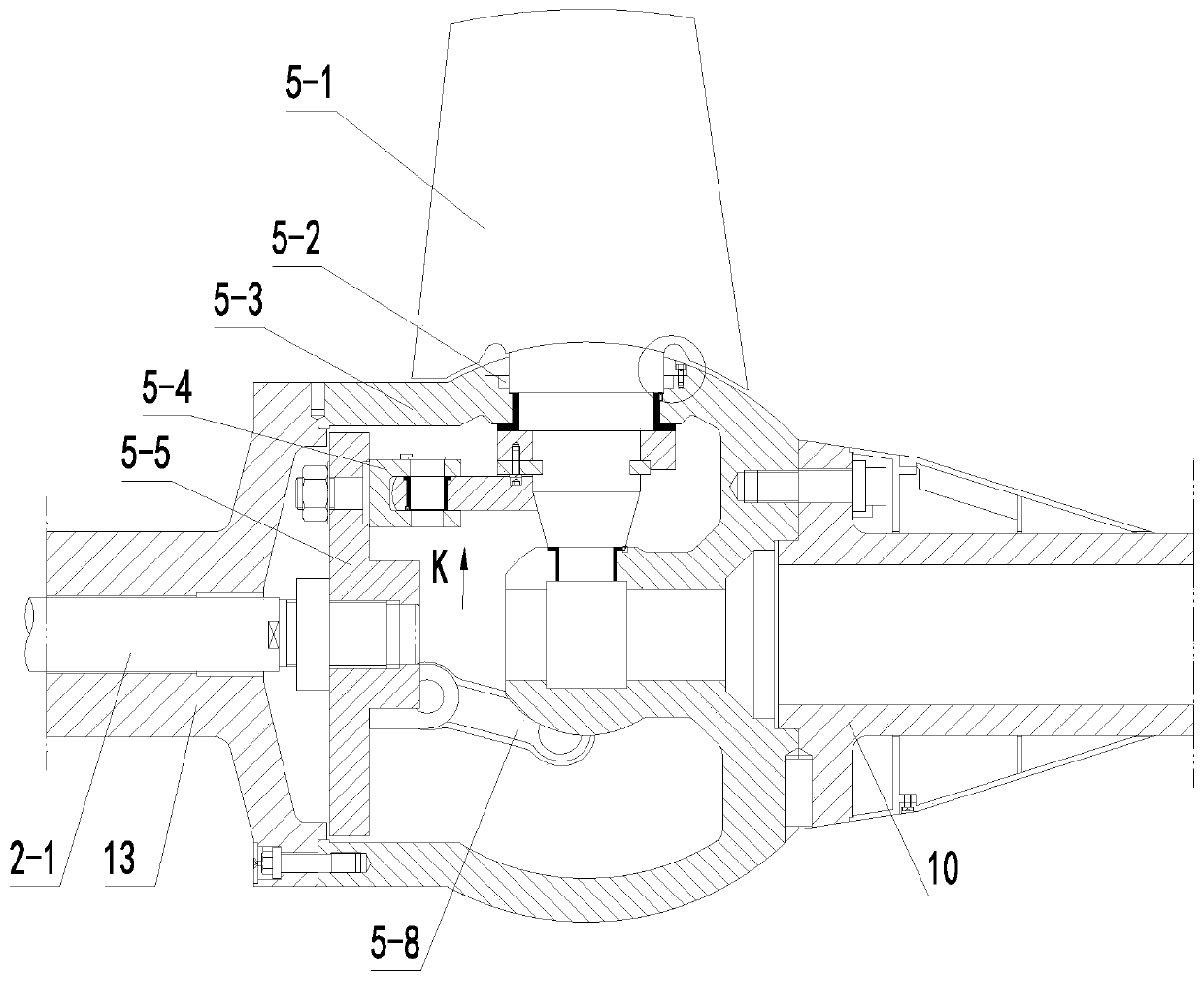

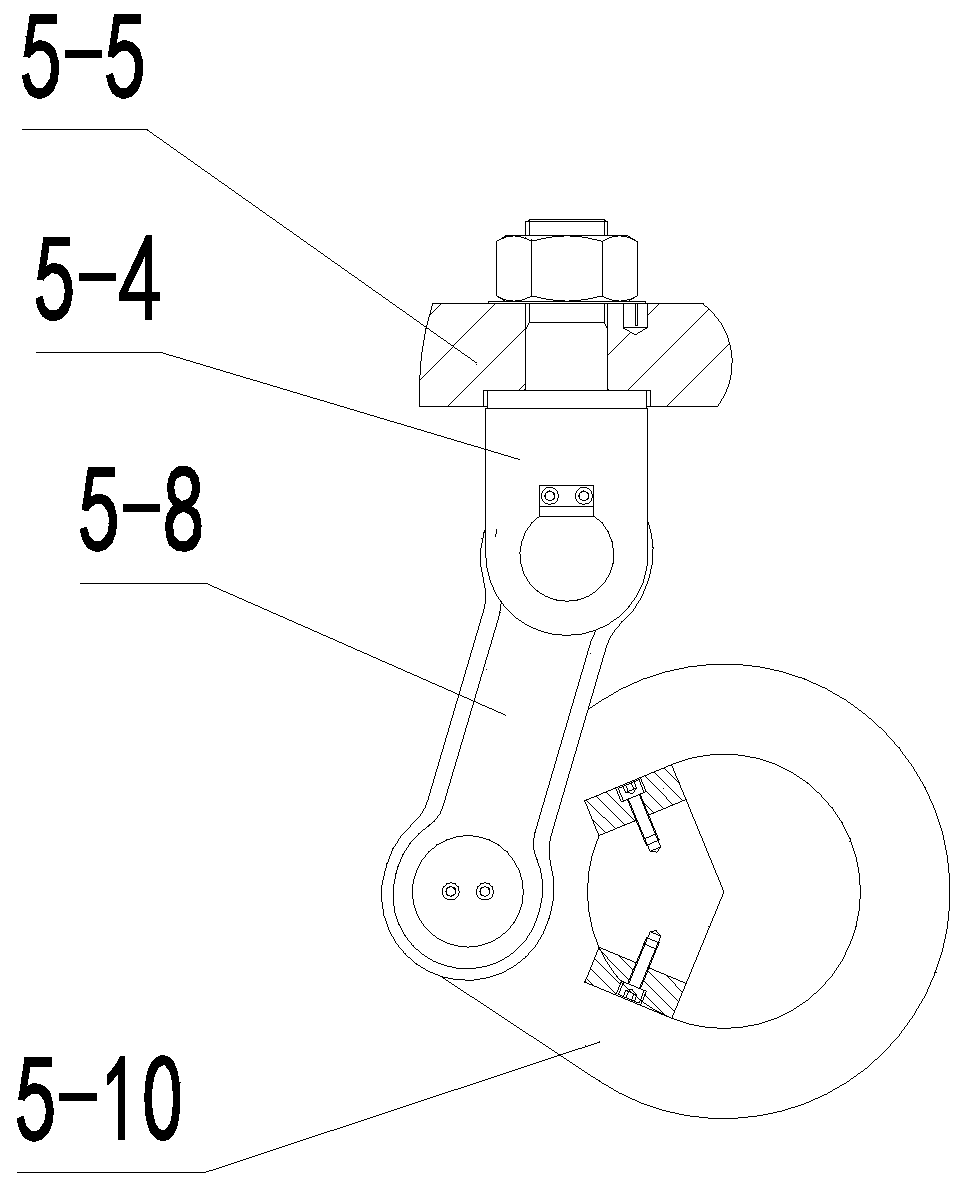

Shaft-extending cross-flow propeller type water turbine

InactiveCN110671253ASimple structureEasy to processHydro energy generationReaction enginesWater turbinePropeller

The invention relates to a shaft-extending cross-flow propeller type water turbine. The shaft-extending cross-flow propeller type water turbine comprises a water inlet part, a water guide mechanism, aleading bearing mechanism, a front spindle, a front spindle seal, a runner mechanism, a runner chamber, a tail water conical pipe, an S-shaped tail water elbow pipe, a rear spindle, a rear spindle sealing mechanism and a thrust combination bearing, wherein the inner diameter of the runner chamber is of a spherical shape, the runner blade of the runner mechanism is a rotatable runner blade, the outer edge of the runner blade of the runner mechanism is spherical, the fixed propeller runner of the water turbine is designed into the rotating propeller runner structure for the first time in China,the shaft-extending cross-flow water turbine blade can be kept in a co-linkage manner along with the change of the water head and the load, the operating range of the water turbine is expanded, the efficiency of the water turbine is improved, and the stability of the unit is improved.

Owner:湖南云箭集团有限公司

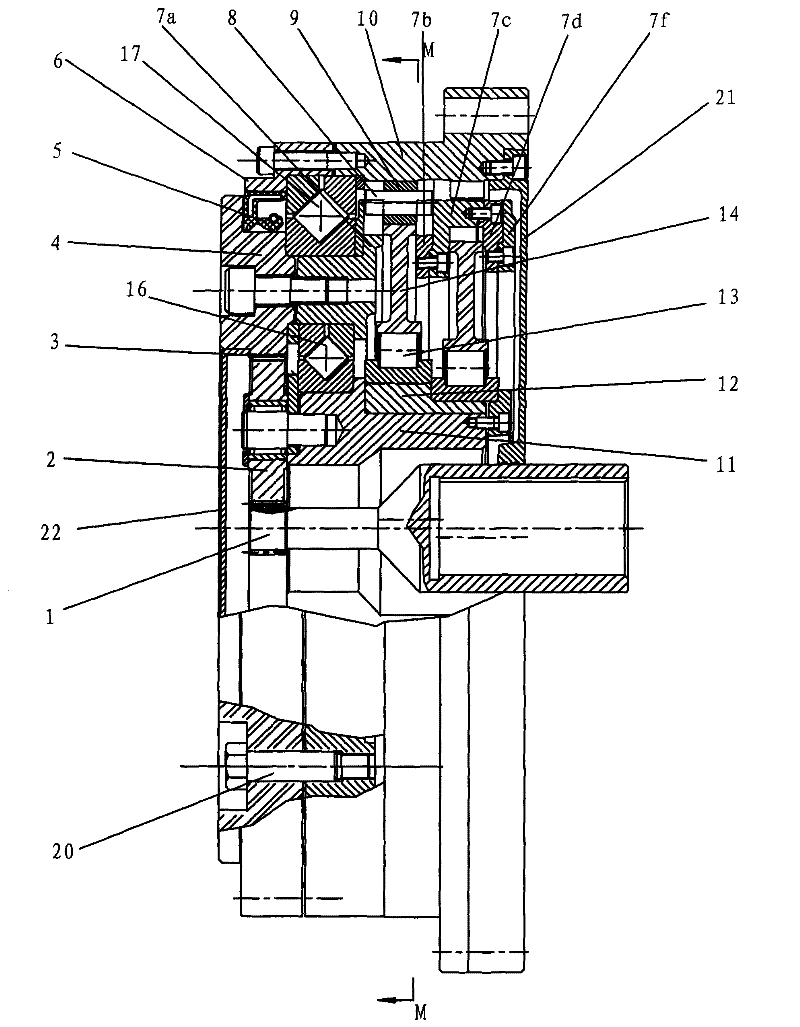

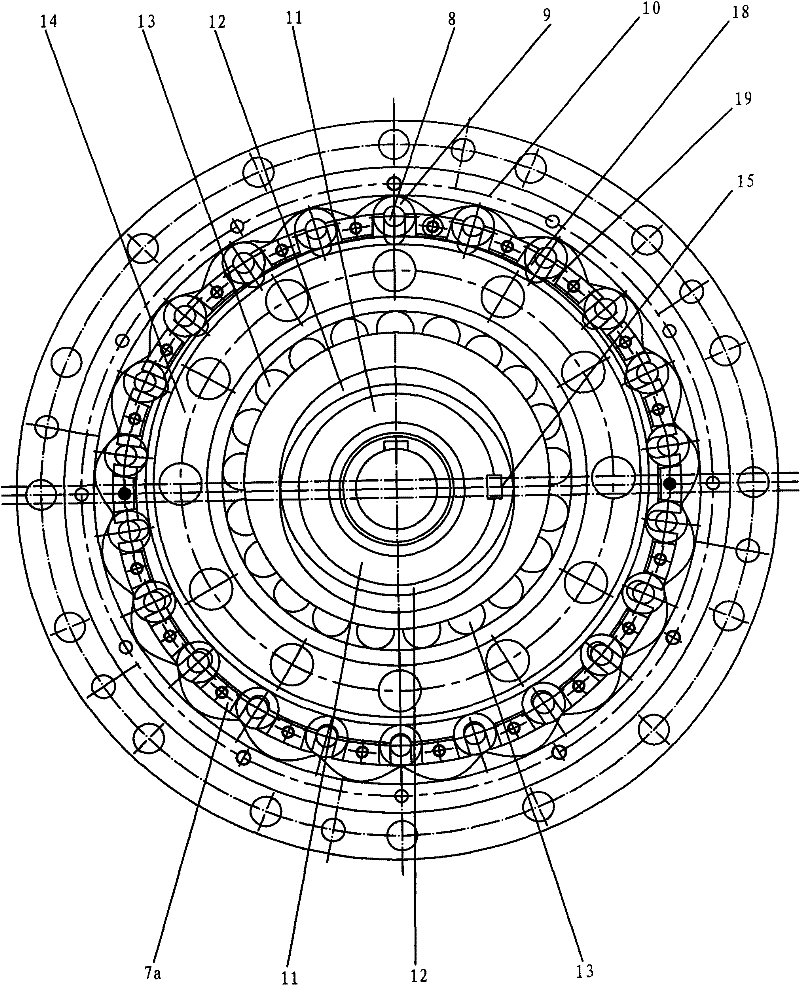

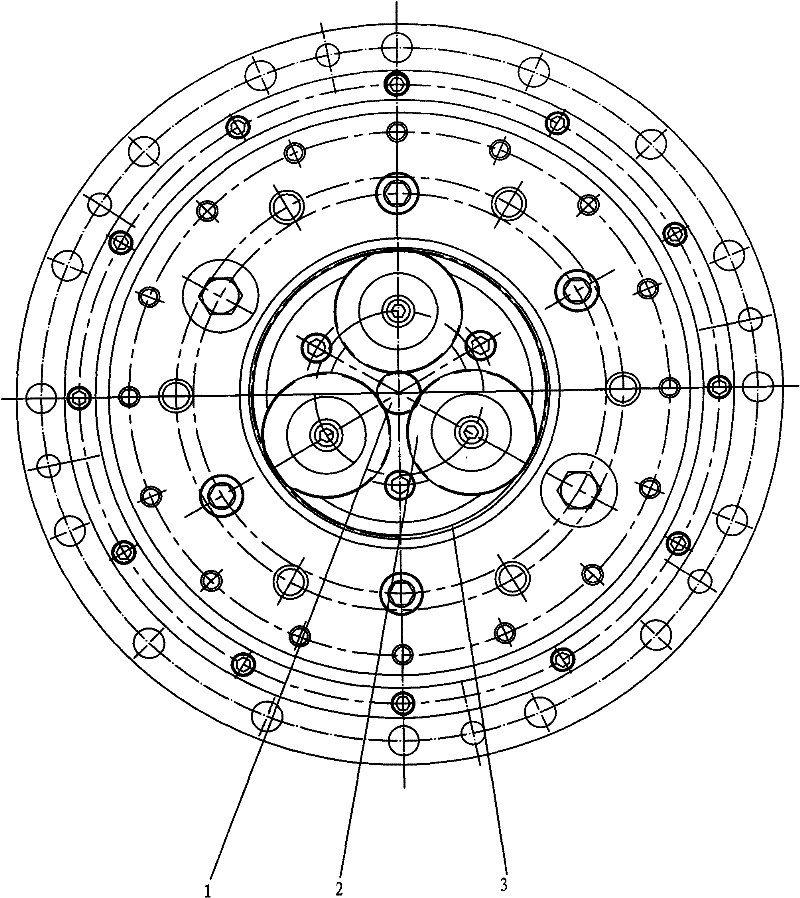

Composite rolling active-tooth transmission device and method for performing transmission by using the same

InactiveCN102691752AImprove power densityIncrease stiffnessToothed gearingsGearing detailsShock waveGear wheel

The invention relates to a composite rolling active-tooth transmission device and a method for performing transmission by using the same. The transmission device comprises an active-tooth transmission wheel train, a planetary gear train and outer transmission disks. Planetary gears of the planetary gear train are rotationally arranged on end faces of a shock shaft of the active-tooth transmission wheel train. A first crossed roller bearing is arranged between an active-tooth semi-disc of the active-tooth transmission wheel train and a fixed gear of the active-tooth transmission wheel train, and a second crossed roller bearing is arranged between the active-tooth semi-disc and the shock shaft. The outer transmission disks are connected with an active-tooth semi-disc, and internal teeth engaged with the planetary gears are arranged on the outer transmission disks. A central gear of the planetary gear train is supported and positioned by a prime mover, or a bearing is arranged in the shock shaft and the central gear is arranged on a central shaft passing through the bearing. According to the invention, not only the density of transmitted power is increased, the size is reduced, and the whole rolling active-tooth transmission structure is more compact, but also stiffness and precision of the transmission system are improved, and manufacturing and processing cost is greatly reduced.

Owner:陈仕贤

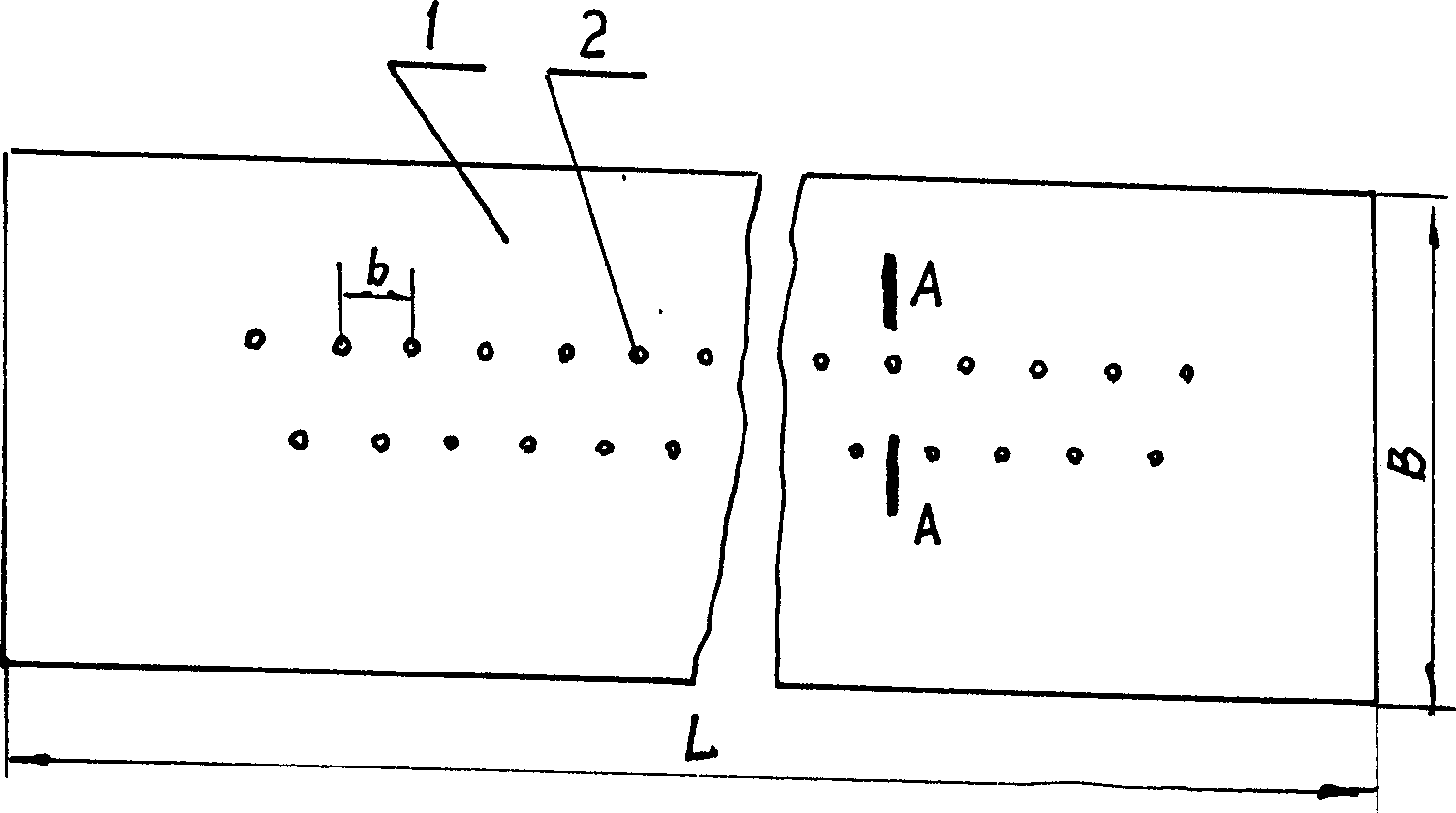

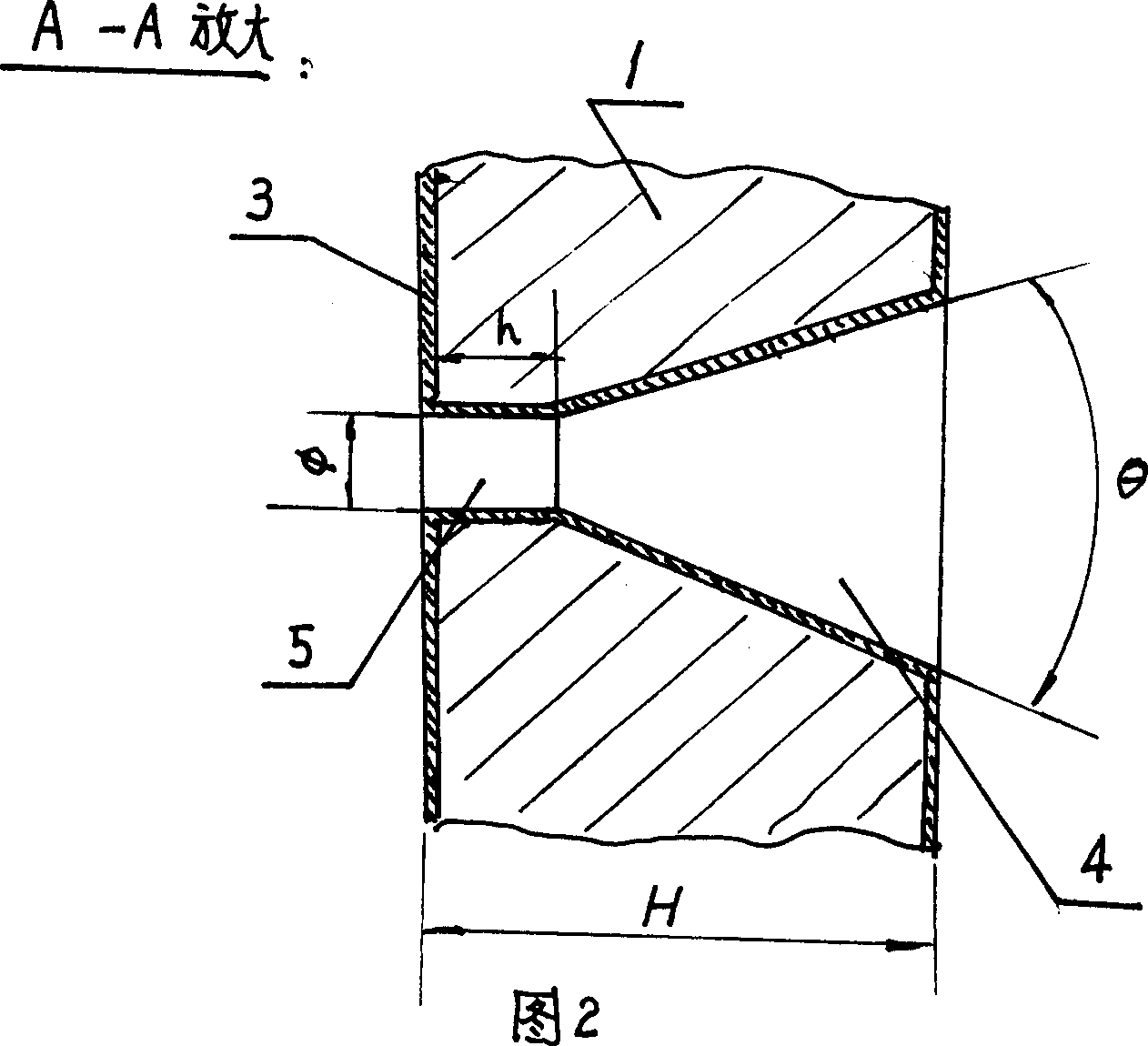

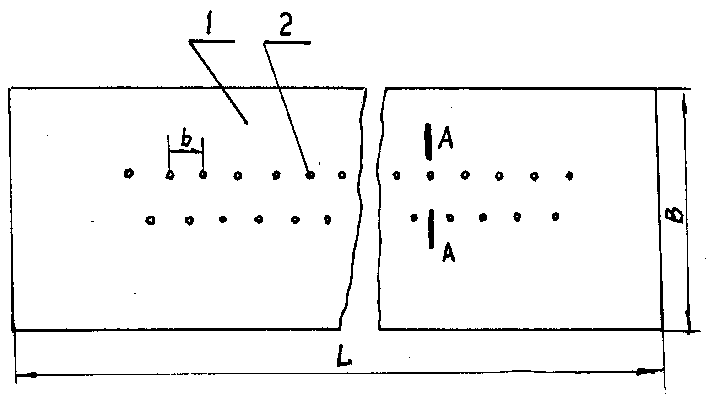

Hydraulic needle plate and its manufacture process

InactiveCN1468996AIncreased deformation resistanceGreatly slow down its water spray small deformation resistanceNeedling machinesManufacturing cost reductionHardness

The present invention is hydraulic needle plate and its manufacture process. The hydraulic needle plate is manufactured with bronze and through machining and ageing treatment, or with pure titanium and through machining and surface nitridation treatment. The hydraulic needle plate has high surface hardness, long service life, good machining performance and low manufacture cost.

Owner:金学民

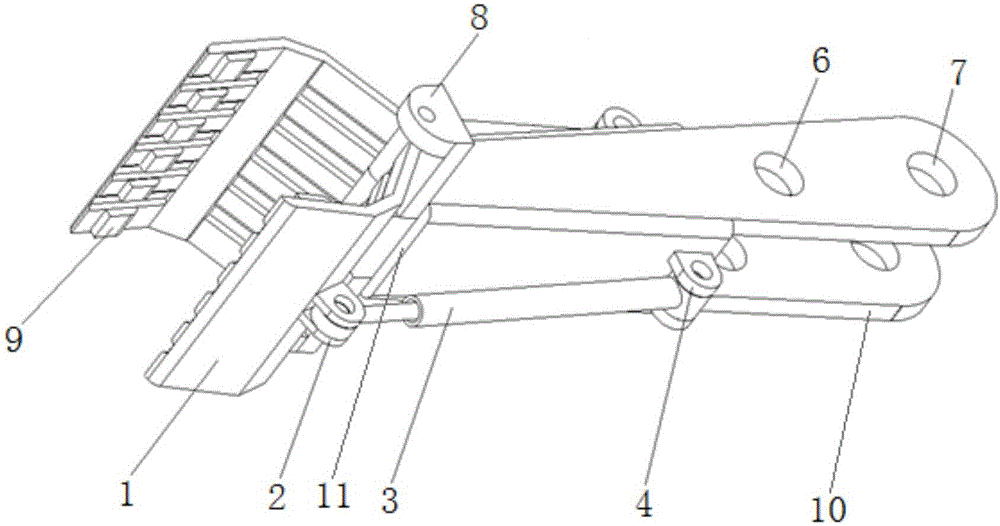

Gripper device for disaster relief car

InactiveCN106041880AAccurate and stable gripReduce manufacturing costGripping headsHydraulic cylinderGrip force

The invention relates to a gripper device for a disaster relief car. The gripper device is arranged on a big arm of the disaster relief car, and comprises a pair of oppositely arranged gripper clamp plates, a pair of hydraulic cylinders respectively in transmission connection with the gripper clamp plates on the corresponding sides and small arms hinged to the gripper clamp plates and the hydraulic cylinders, wherein the small arms are hinged to the big arm of the disaster relief car. According to the gripper device, the gripper clamp plates on the corresponding sides are controlled to open or close by stretching of pistons in the hydraulic cylinders so as to grip objects. Compared with the prior art, the gripper device can be directly mounted on big arms of such engineering vehicles as disaster relief cars and excavators to directly finish gripping or executing operation, and has the advantages that smooth falling hillstone can be reliably clamped during gripping and objects can be accurately and stably gripped; the rescue efficiency is greatly improved; the production cost of the special engineering vehicles is lowered; the gripping force is big; the flexibility is excellent; and the effectiveness of such engineering vehicles as the disaster relief cars can be played as much as possible.

Owner:SHANGHAI UNIV OF ENG SCI

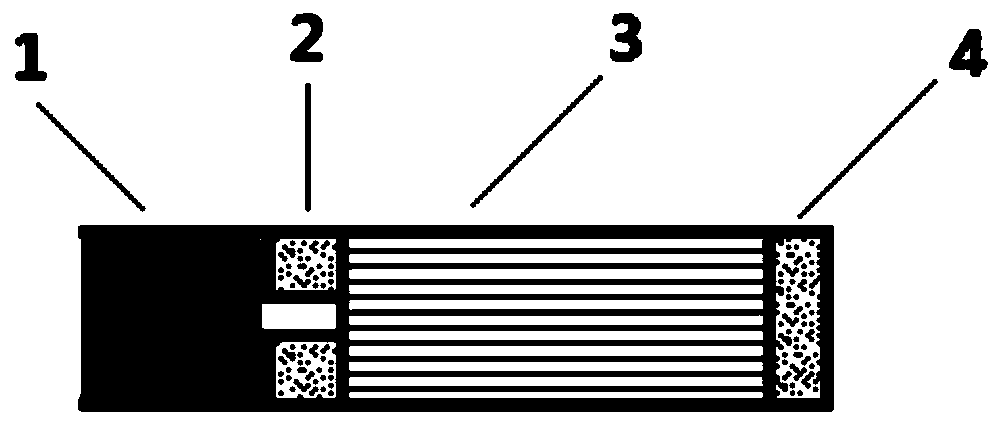

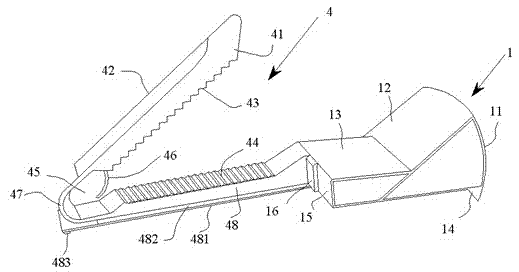

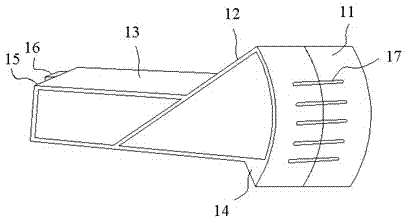

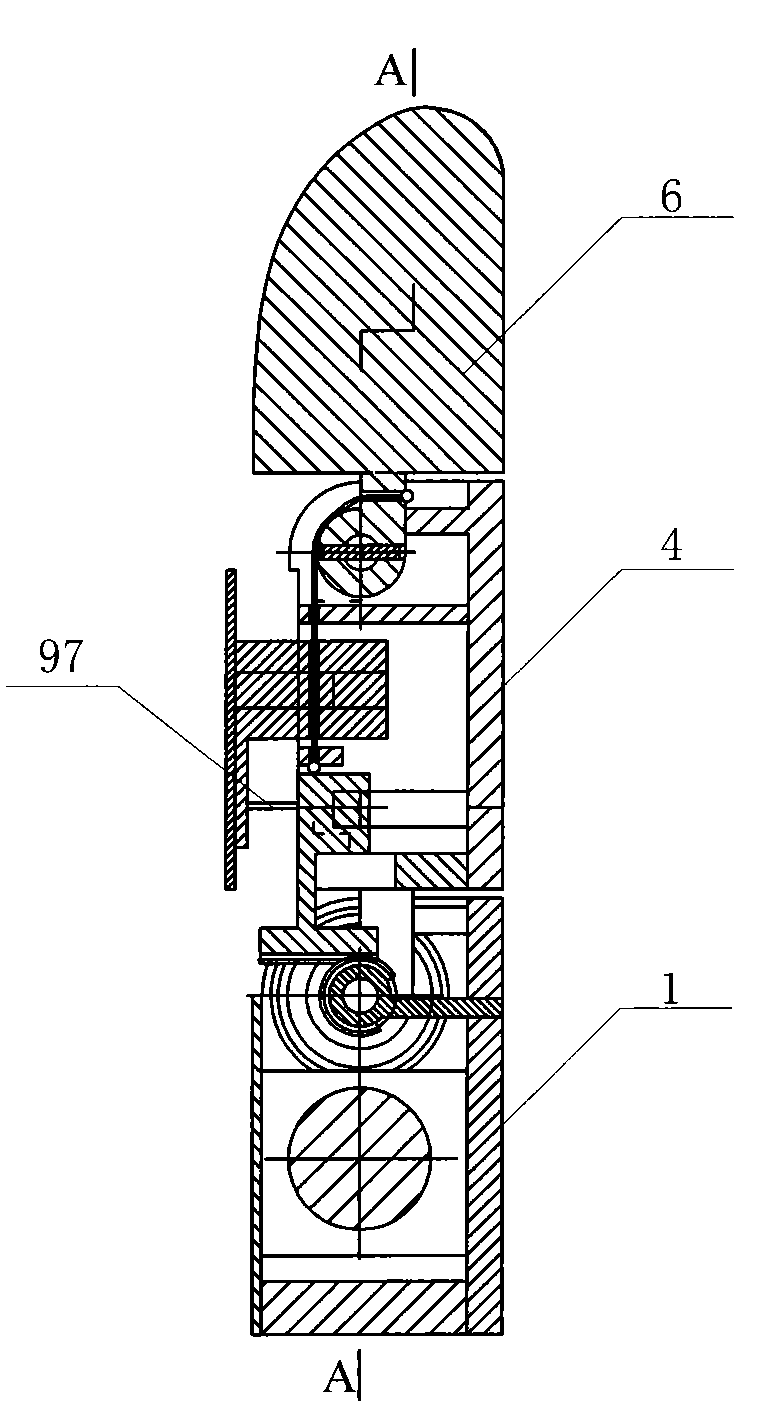

Aerosol cooling device

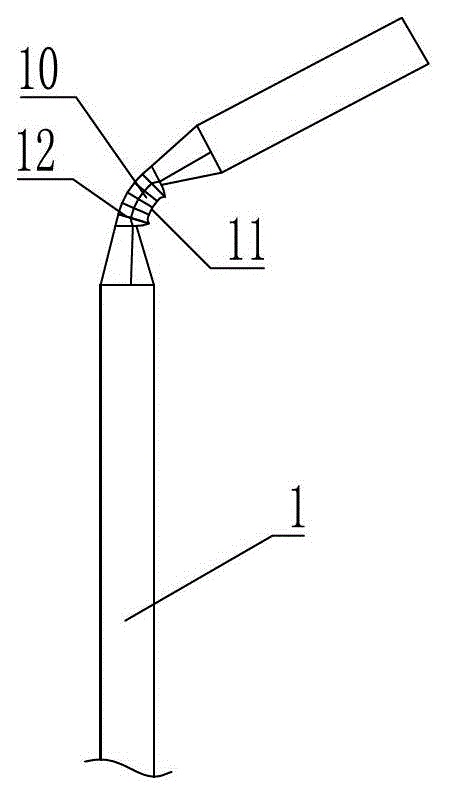

PendingCN109820244AReduce surface temperatureReduce the temperatureCigar manufactureTobacco smoke filtersMedicineHeat not burn

The invention relates to an aerosol cooling device, and further relates to an aerosol product comprising the aerosol cooling device and a heat-not-burn cigarette comprising the aerosol product. The aerosol cooling device can be used for reducing the temperature of aerosol generated by the heat-not-burn cigarette so that the mouth cannot be scalded when a customer smokes the heat-not-burn cigarette.

Owner:CHINA TOBACCO FUJIAN IND

Cleaning robot

ActiveCN105030165AImprove machinabilityReduce manufacturing and tooling costsMachine detailsFloor sweeping machinesDrive wheelMotor drive

The invention relates to a cleaning robot. The cleaning robot comprises a sweeping mechanism, a waste collecting device, driving wheels, a driven wheel, a base and an upper cover. The two driving wheels are arranged below the two sides of the rear of the base respectively, the driven wheel is a universal wheel and is installed below the front of the base, and the sweeping mechanism is composed of front small brushes, a rear big brush and a motor driving device. The two front small brushes are vertically arranged on the lower surface of the front of the base respectively, the rear big brush is transversely installed on the lower surface of the middle of the base, the two front small brushes and the rear big brush are connected with the motor driving device, the rotating directions of the two front small brushes are reverse, and the waste collecting device is installed inside the part, at rear of the rear big brush, of the base. Compared with the prior art, the cleaning robot is provided with different transmission mechanisms and the waste collecting device of different structures, and accordingly, different waste treatment modes are achieved. Compared with a product in the prior art, the ground can be effectively cleaned, and the cleaning robot is easy to maintain, convenient to disassemble and assemble and not prone to damaging people or objects in a room.

Owner:SHANGHAI UNIVERSITY OF ELECTRIC POWER

Gas spring device

InactiveCN103398125AEasy to use operation methodUnique structural designGas based dampersRubber materialGas spring

The invention discloses a gas spring device. The gas spring device is mainly composed of a load bearing device, a spring rod, a spiral gas spring, a gasket, a valve core, an air compressor and a seal valve. The spiral gas spring is a spiral high-pressure rubber pipe made of rubber material, and the spiral gas spring circles around the spring rod; the seal valve is arranged at the top end of the spiral gas spring, and the valve core is arranged at the tail end of the spiral gas spring; the air compressor is connected with the valve core, and through the valve core, high-pressure air is ejected into the spiral gas spring by the air compressor. According to the gas spring device, due to the fact that the high-pressure air is ejected into the spiral gas spring, the function of an original gas spring is achieved, and the good effect is achieved. The gas spring device is simple and special in structural design, simple in using and operating method, low in manufacturing and processing cost, and easy to maintain, and has relatively wide market prospect and promotion value.

Owner:林建斌

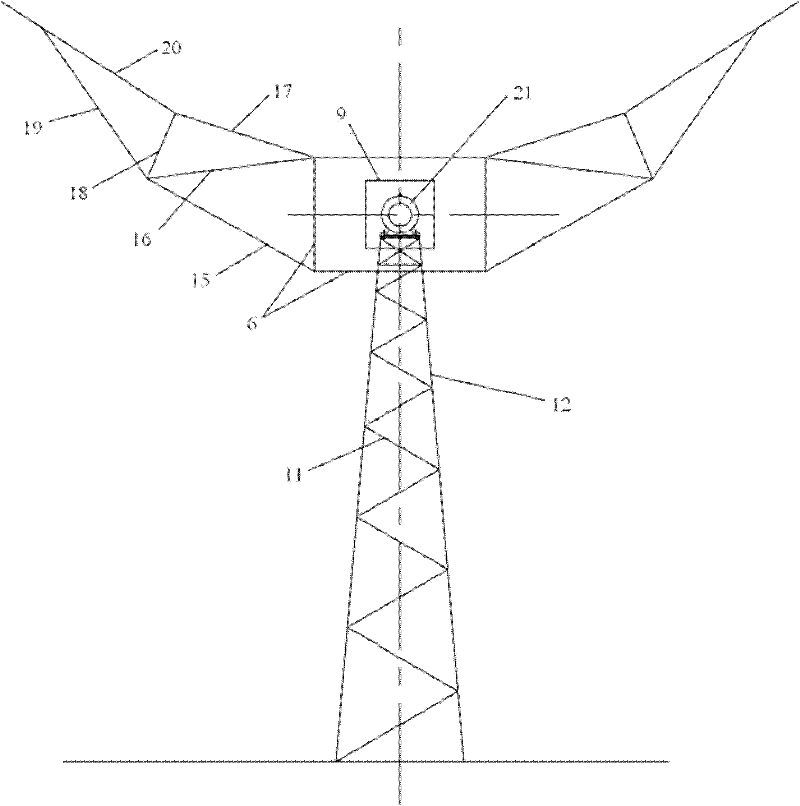

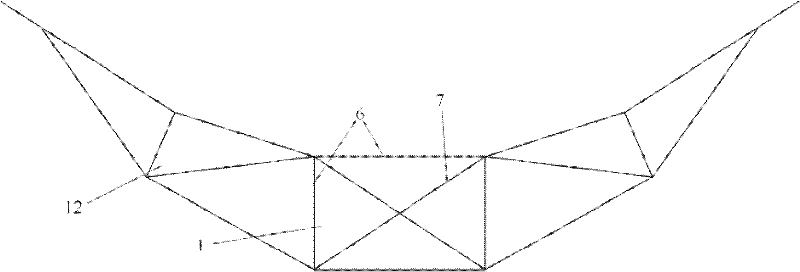

Spatial truss-type trough-type solar thermal power collector element support

ActiveCN102297537ASimple structureUse less materialSolar heat devicesSolar thermal energy generationWork periodCollector device

The invention belongs to the technical field of grooved light-gathering solar thermal power generation and particularly relates to a space truss type grooved solar thermal power generation heat collector element bracket. The bracket comprises a space truss, rotating shaft assemblies, bearing assemblies and phi-shaped support leg members, wherein the bearing assemblies are arranged at the tops of the two phi-shaped support leg members; the rotating shaft assemblies are arranged at two ends of the space truss and also arranged on the bearing assemblies, so that the space truss is erected between the two phi-shaped support leg members and can rotate along the rotating shaft assemblies; and n groups of dual-wing racks are fixed on the space truss along the length direction of the space truss.The space truss type grooved solar thermal power generation heat collector element bracket disclosed by the invention has a simple structure, thus the manufacturing cost is greatly reduced; the most of mechanical members can adopt prefabricated members, thus the production process is simplified; and the strength is high, thus optical performance of the heat collector during work period can be ensured.

Owner:GUODIAN LONGYUAN POWER TECH ENG +1

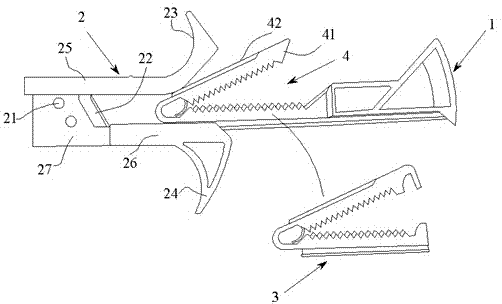

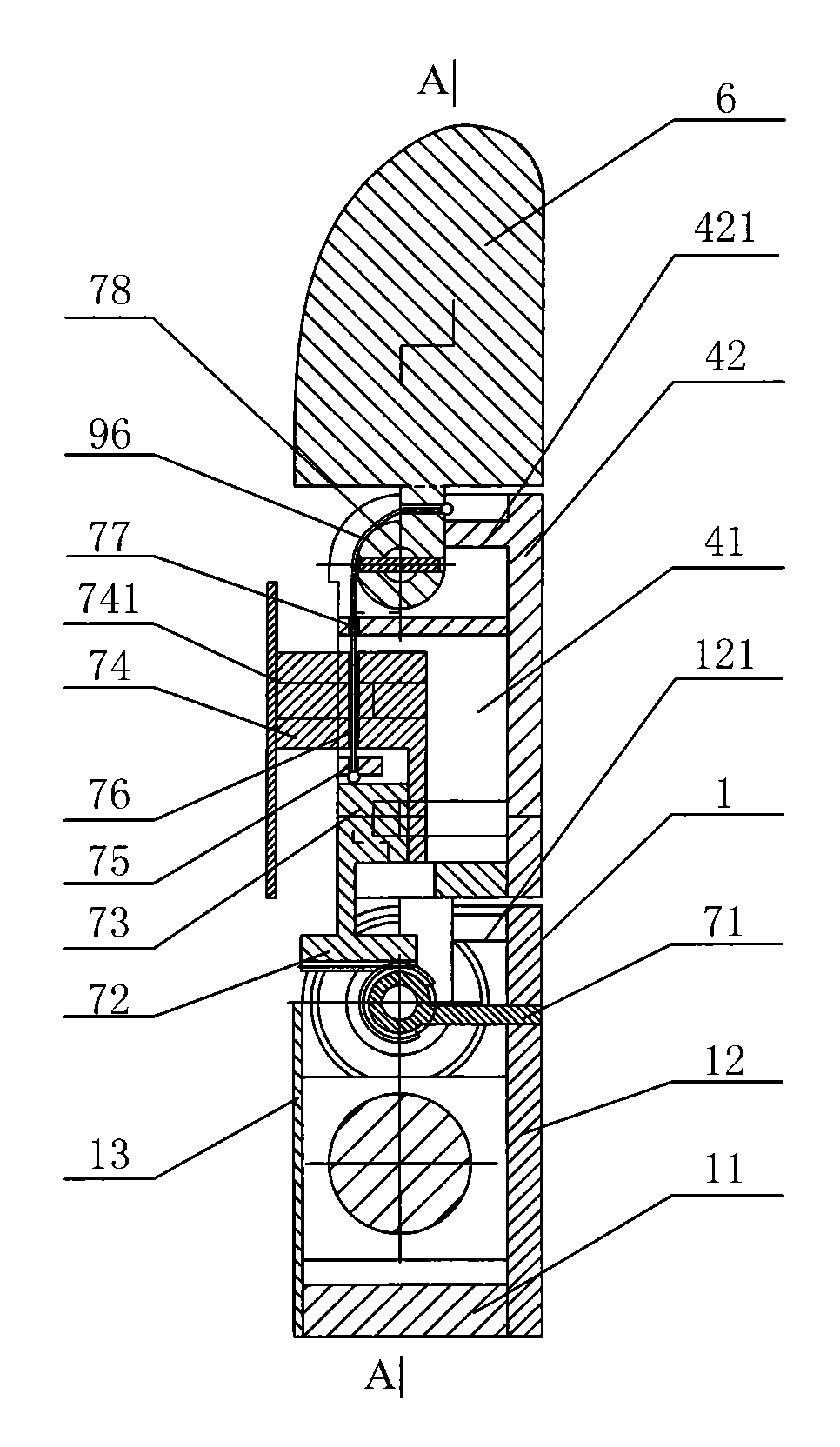

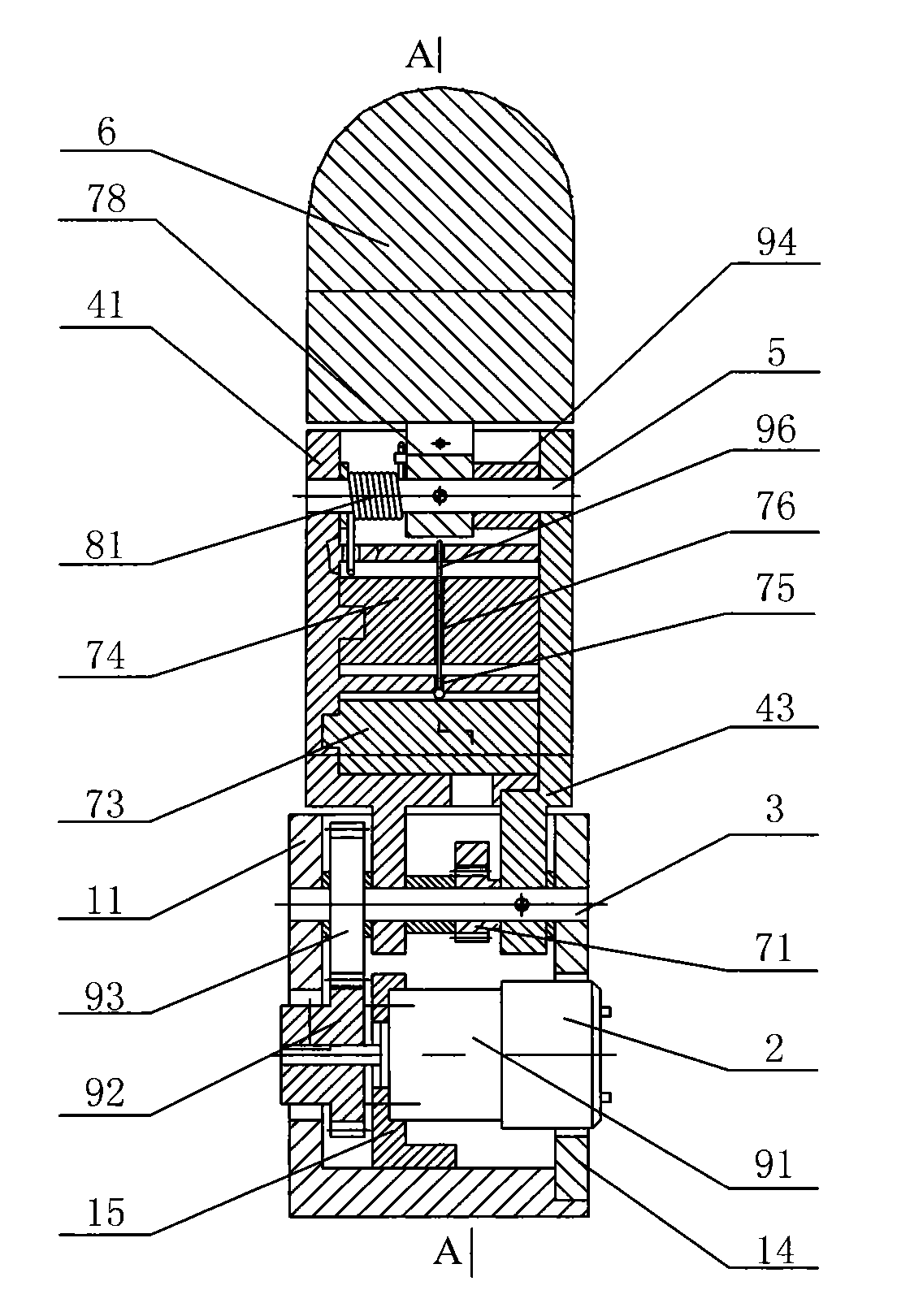

Infant umbilical cord cutting clamp

InactiveCN104207816AAvoid infectionEasy to operateObstetrical instrumentsWound clampsEngineeringFull Term Infant

The invention discloses an infant umbilical cord cutting clamp, which consists of four parts, including a push button part (1), a clamping seat part (2), a separation clamp (3) and a push button clamp (4), wherein the push button clamp (4) and the push button part (1) are of an integral structure; the clamping seat part (2) is provided with a cutter (22); the clamping seat part (2) is provided with a left sliding rail and a right sliding rail; the cutter (22) is vertically arranged between the two sliding rails, and the blade of the cutter (22) faces to the direction of the push button part (1); the separation clamp (3) and the push button clamp (4) respectively slide to the direction of the blade in the left sliding rail and the right sliding rail of the clamping seat part (2) so as to cut off an infant umbilical cord clamped between the separation clamp (3) and the push button clamp (4). The infant umbilical cord cutting clamp is suitable for cutting off the umbilical cord of a newly-born infant and has the advantages that the umbilical cord is jointly clamped by the separation clamp and the push button clamp to slide to the blade, so that the blade can directly cut off the umbilical cord, and the umbilical cord still can be clamped after the umbilical cord falls to avoid infection.

Owner:贵州高澄医疗器械有限公司

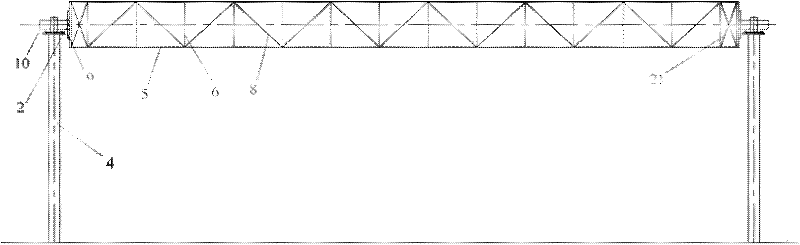

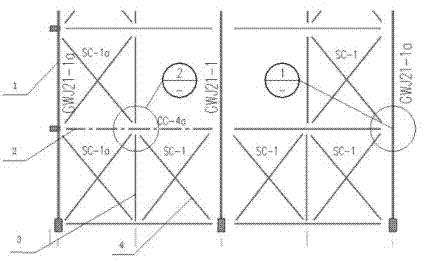

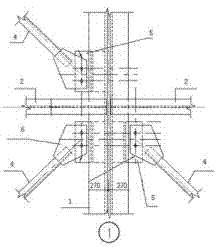

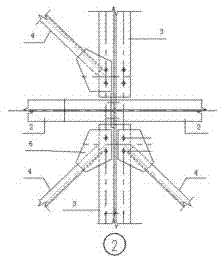

Built-up connection structure and built-up connection method for roof support and I-steel purlins

The invention relates to the technical field of arrangement of steel structure roof support, and discloses a built-up connection structure and a built-up connection method for roof support and I-steel purlins. The built-up connection structure is provided with a plurality of steel roof truss structures and a plurality of roof support structures which are connected into a net-shaped connection structure. Each steel roof truss structure comprises a steel roof truss upper chord and a purlin which are perpendicularly connected in a cross mode. Four corners of the panel point where each purlin is connected with each steel roof truss upper chord are connected with a roof support rod in an inclined mode through a structural steel piece and a connecting plate. Each roof support structure comprises a connecting beam and a purlin which are perpendicularly connected in an overlapped mode. Four corners of the panel point where each purlin is connected with each connecting beam are connected with the roof support structure in an inclined mode through a connecting plate. According to the built-up connection structure and the built-up connection method for the roof support and the I-steel purlins, the purlins can concurrently serve as pressure levers so as to prevent the roof upper chords from being unstable along the side direction. Meanwhile, the purlins and the connecting beams can further and concurrently serve as tie bars of the roof support. The area of the roof support is divided into sizes with good economical efficiency and applicability. The built-up connection structure is convenient to arrange, simple in structure, easy to machine and low in manufacture and machining cost.

Owner:芜湖金康建设工程有限公司

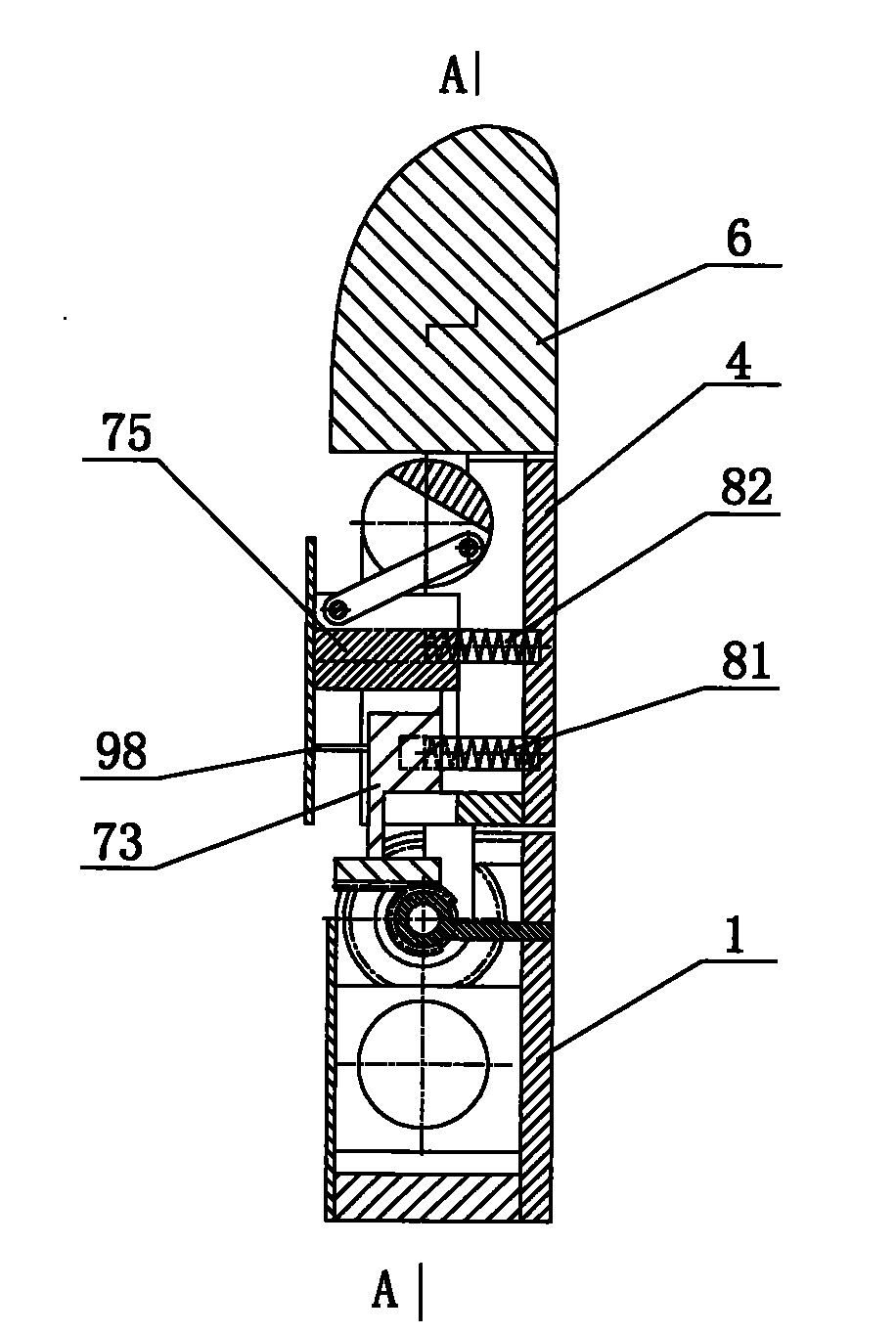

Flexible part and rack type parallel finger device integrating coupling and under-actuation

A flexible part and rack type parallel finger device integrating coupling and under-actuation belongs to the technical field of humanoid robot hands. The device comprises a base, a near joint bearing, a first finger segment, a far joint bearing, a second finger segment, gears, a rack, a flexible part and spring parts. The device realizes the transmission effect of close integration of coupling transmission and under-actuated transmission, can couple humanoid grabbing and has the function of under-actuated adaptation. The whole finger has concise structure and low manufacturing cost. Coupling transmission and under-actuated transmission are organically integrated. Natural decoupling is realized by flexible contact of the slider, which does not consume motor power and is high in energy utilization rate. The device has appearance similar to that of the human finger, can be used as one finger or a part of the fingers of the robot hand and can combine a plurality of fingers to form the robot hand to achieve the excellent effects of high degree of freedom of joints and high adaptability of the humanoid robot hand.

Owner:WUXI RES INST OF APPLIED TECH TSINGHUA UNIV +1

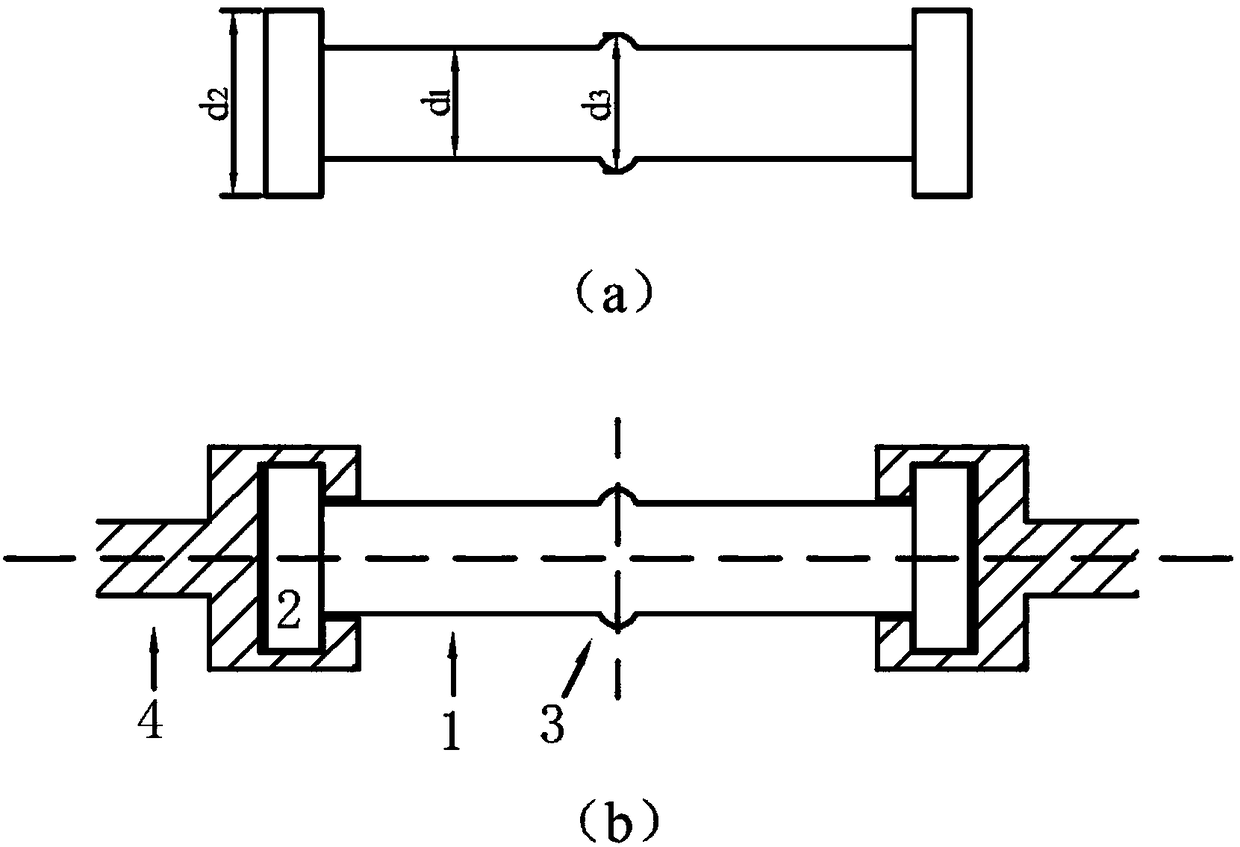

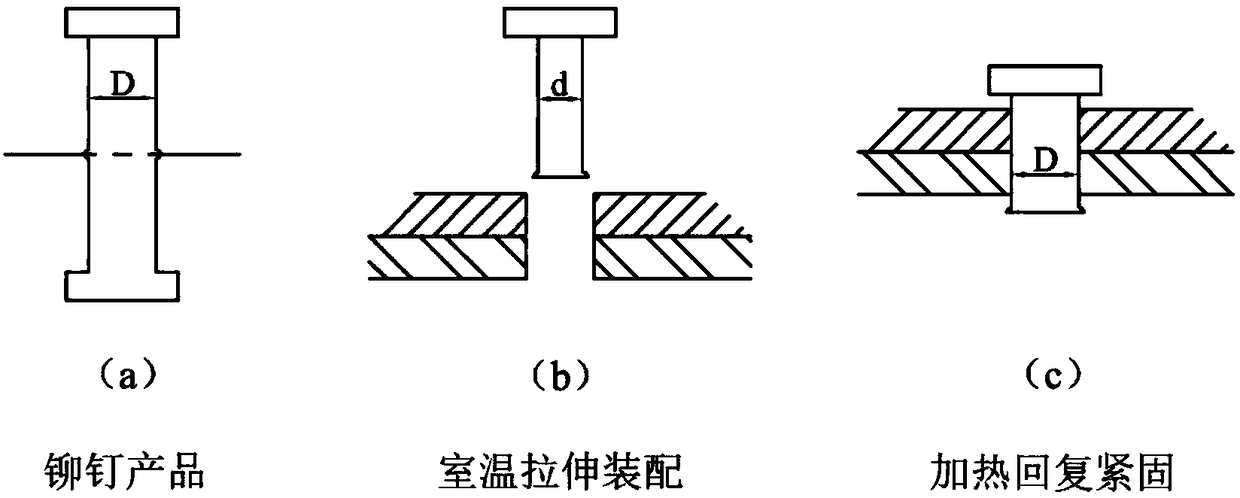

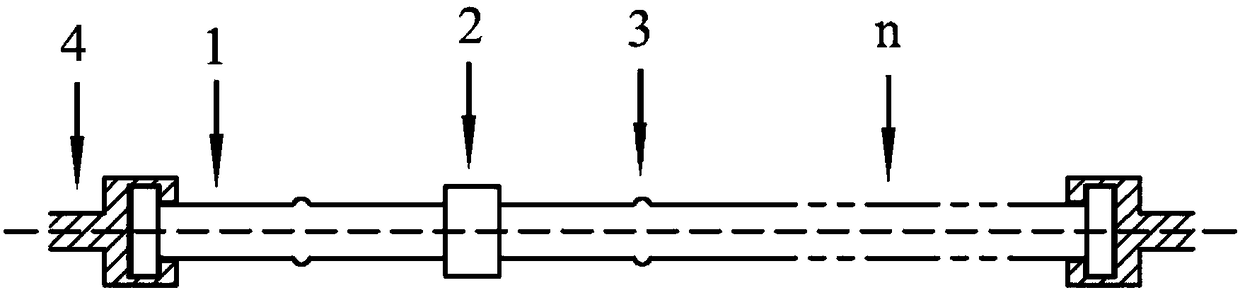

Ti base shape memory alloy rivet fastening piece and manufacturing method thereof

The invention provides a Ti base shape memory alloy rivet fastening piece and a manufacturing method thereof. The product is prepared by adopting a Ti base shape memory alloy; the shape is designed asa symmetric structure; two ends are rivet round heads or countersunk heads; and convex points are designed in the structure symmetric center. 2-4% of deformation is generated through symmetric stretching in production and process; then, a rivet finished product is obtained through cutting along the middle part of each convex point; and the connecting part is heated to recover an initial shape toachieve an excellent fastening effect. A special stretching device is designed for series connection or parallel connection of the same uniform pre-deformed rivet products obtained through consistentstretching and cutting. The manufacturing method is convenient, efficient and reliable, and is broad in application prospect.

Owner:烟台浩忆生物科技有限公司

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com