Sinusoidal flow generating device

A flow generation, sinusoidal technology, applied in the direction of machine/engine, liquid variable capacity machinery, multi-cylinder pump, etc., can solve the problems of large energy loss, unsatisfactory input signal, large pump mechanical structure, etc., and achieve low manufacturing and processing costs. , Easy to use and maintain, simple and compact structure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

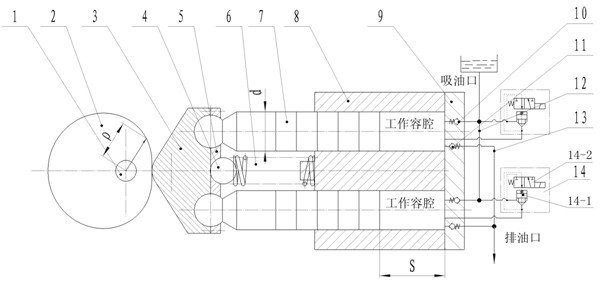

[0017] The present invention will be described in further detail below in conjunction with the accompanying drawings and specific embodiments.

[0018] Such as figure 1 as shown,

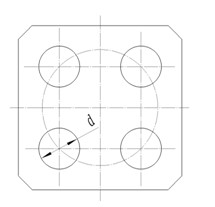

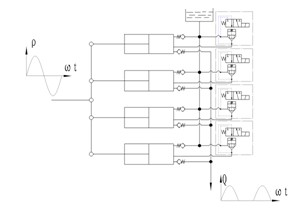

[0019] The cam 2 rotates continuously around the rotating shaft 1, the center of the rotating shaft 1 coincides with the center of the base circle of the cam, and the rotational angular velocity is ω. The profile of the cam 2 is a cosine curve shape, which satisfies the following geometric relationship:

[0020] Let the radius of the base circle of the cam be r, the lift of the cam be s, the lift is equal to the movement stroke s of the plunger, t is time, and the cosine contour curve equation of the cam expressed in polar coordinates with the center of the base circle as the origin is:

[0021] (1)

[0022] Since the slider is in direct contact with the cam, this equation is also the displacement equation of the plunger.

[0023] Derivation of formula (1) can get the plunger motion v...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com