Patents

Literature

338 results about "Maximum error" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

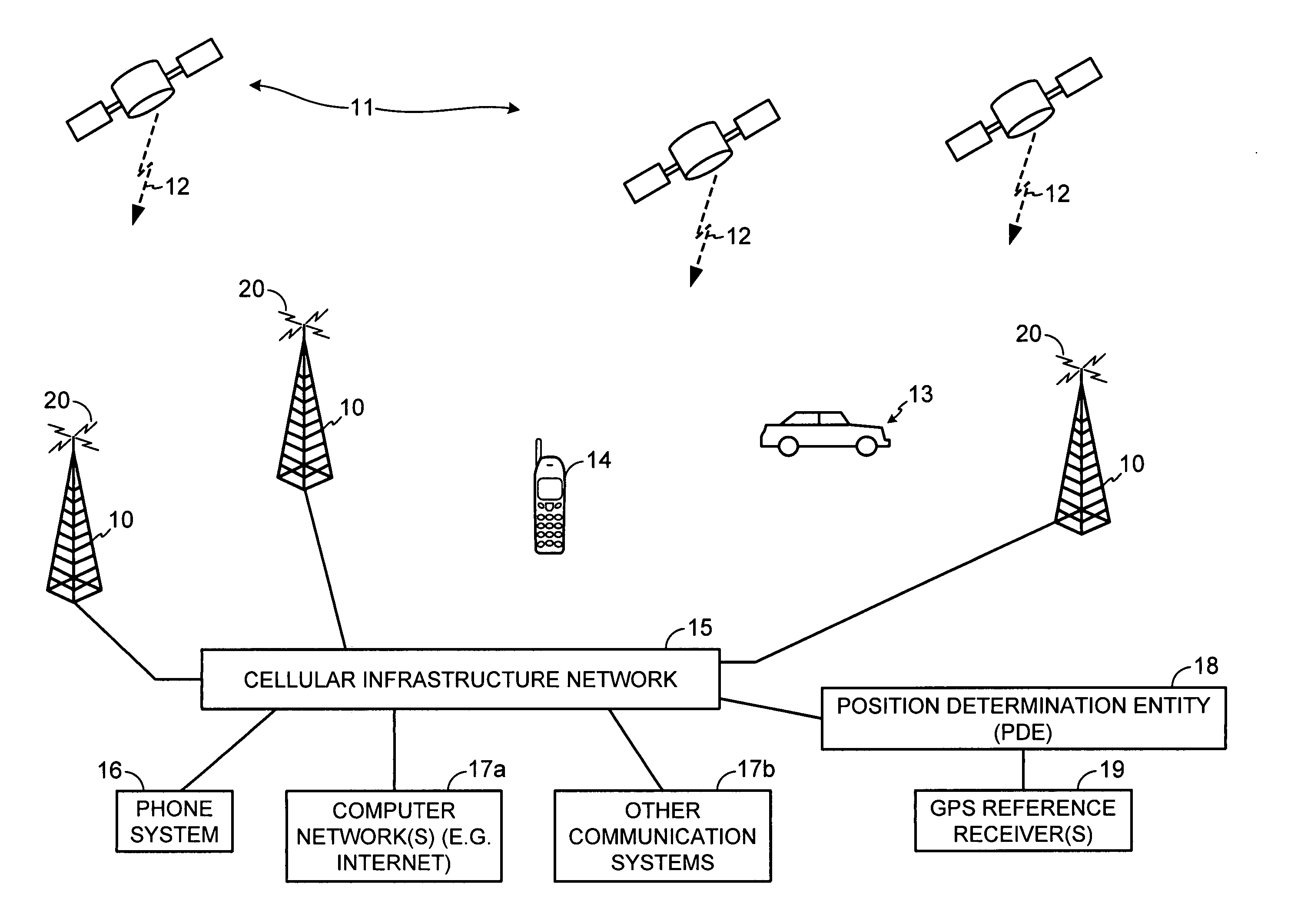

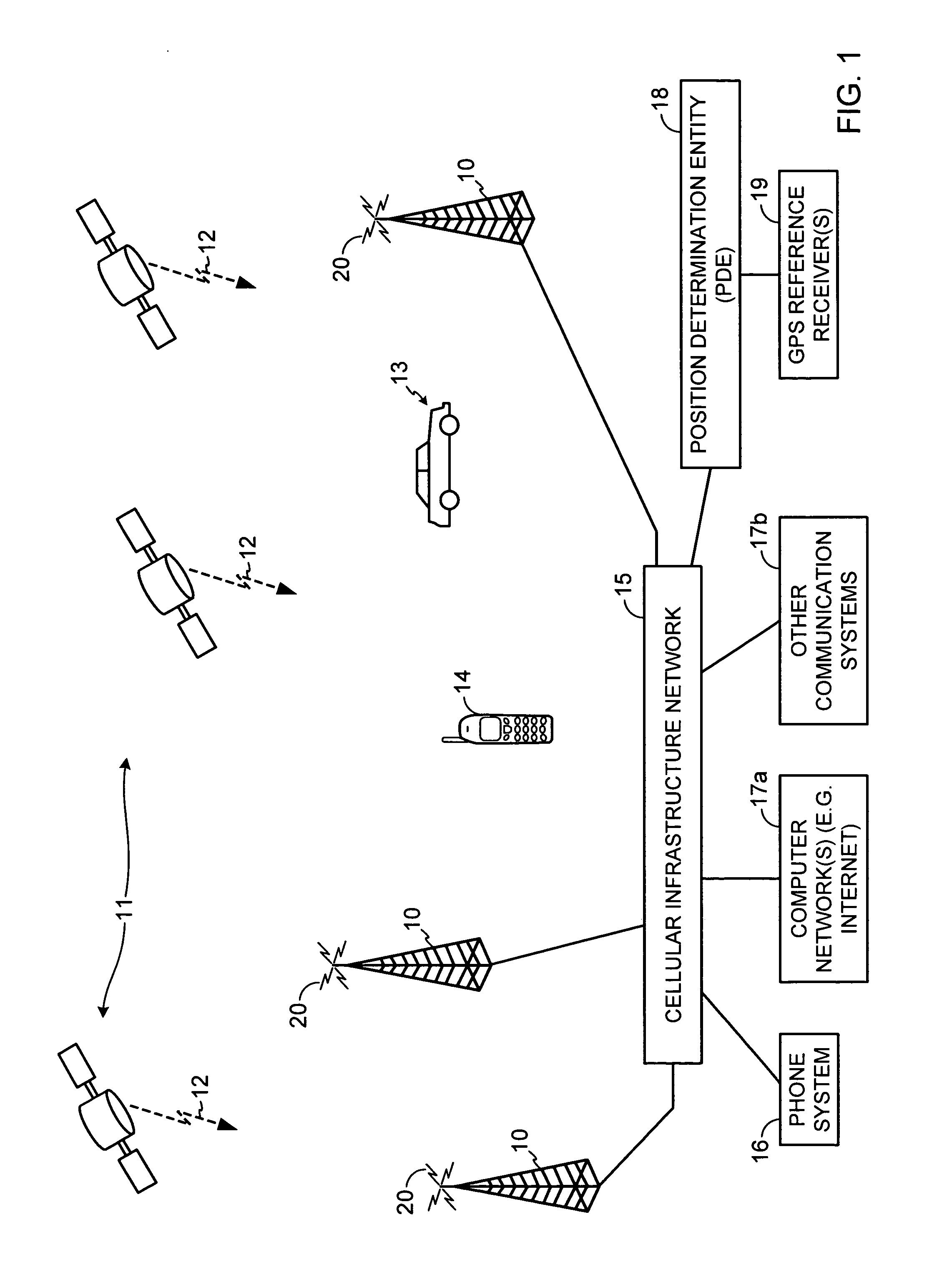

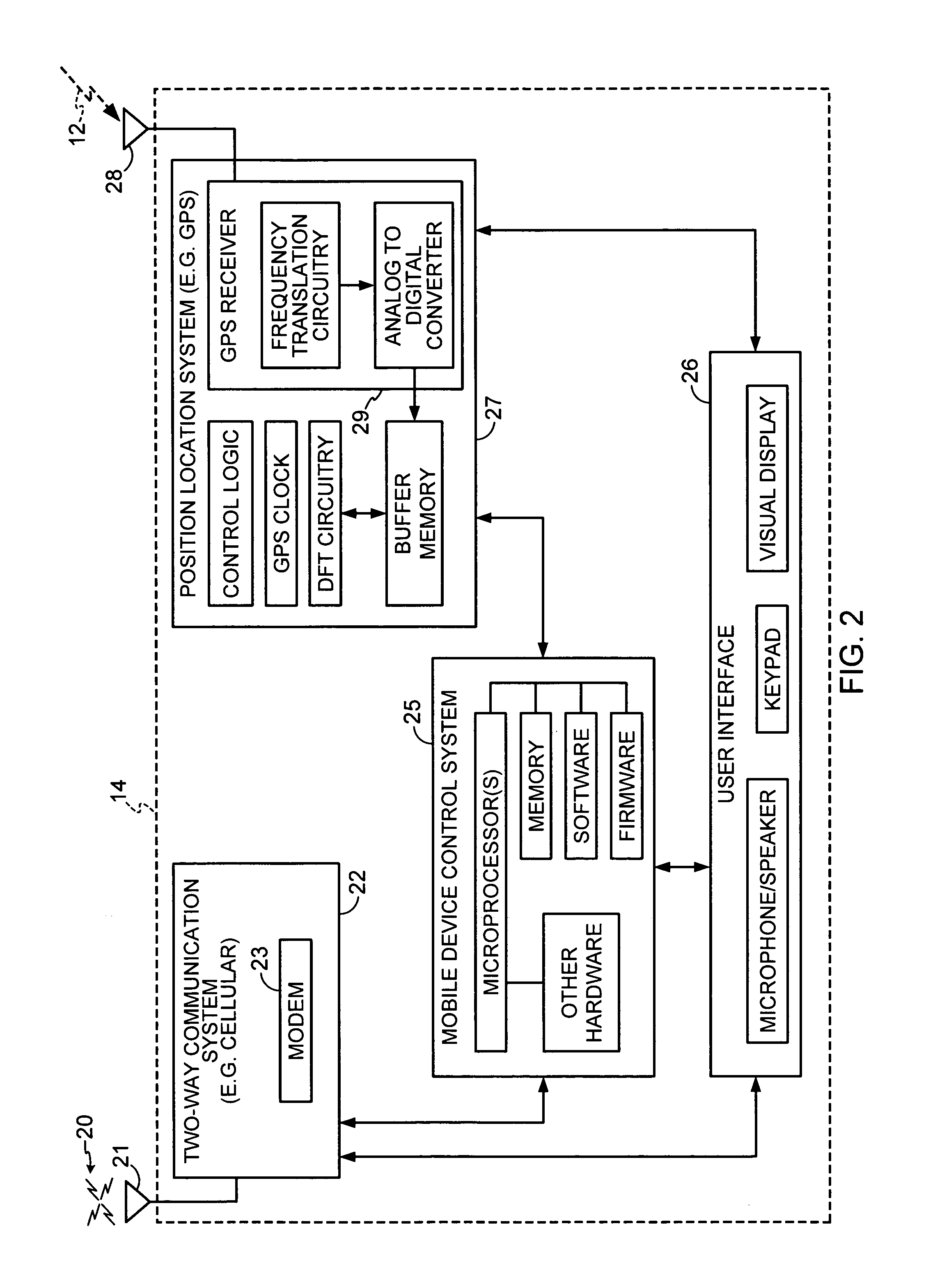

GPS position tracking method with variable updating rate for power conservation

ActiveUS20060211430A1Low possible update rateReduce power consumptionPosition fixationSubstation equipmentMaximum errorUser input

A system and method in which the position update rate is adaptively modified, based on previous position measurements. By adjusting the update rate based on velocity predictions from two or more position fixes, a lower update rate may be used without exceeding the maximum error. Lowering the update rate reduces power consumption in the UE, providing longer battery operation. The updating method may comprise periodically repeating the velocity prediction and periodically adjusting the update rate responsive thereto. The update rate may be adjusted using additional information such as an acceleration prediction, a minimum update rate, or a preferred error. In some embodiments a model for user movement may be used to provide more accurate predictions, for example, stationary, walking, jogging, city driving, and freeway driving. The updating method may comprise receiving user input regarding the maximum position error.

Owner:QUALCOMM INC

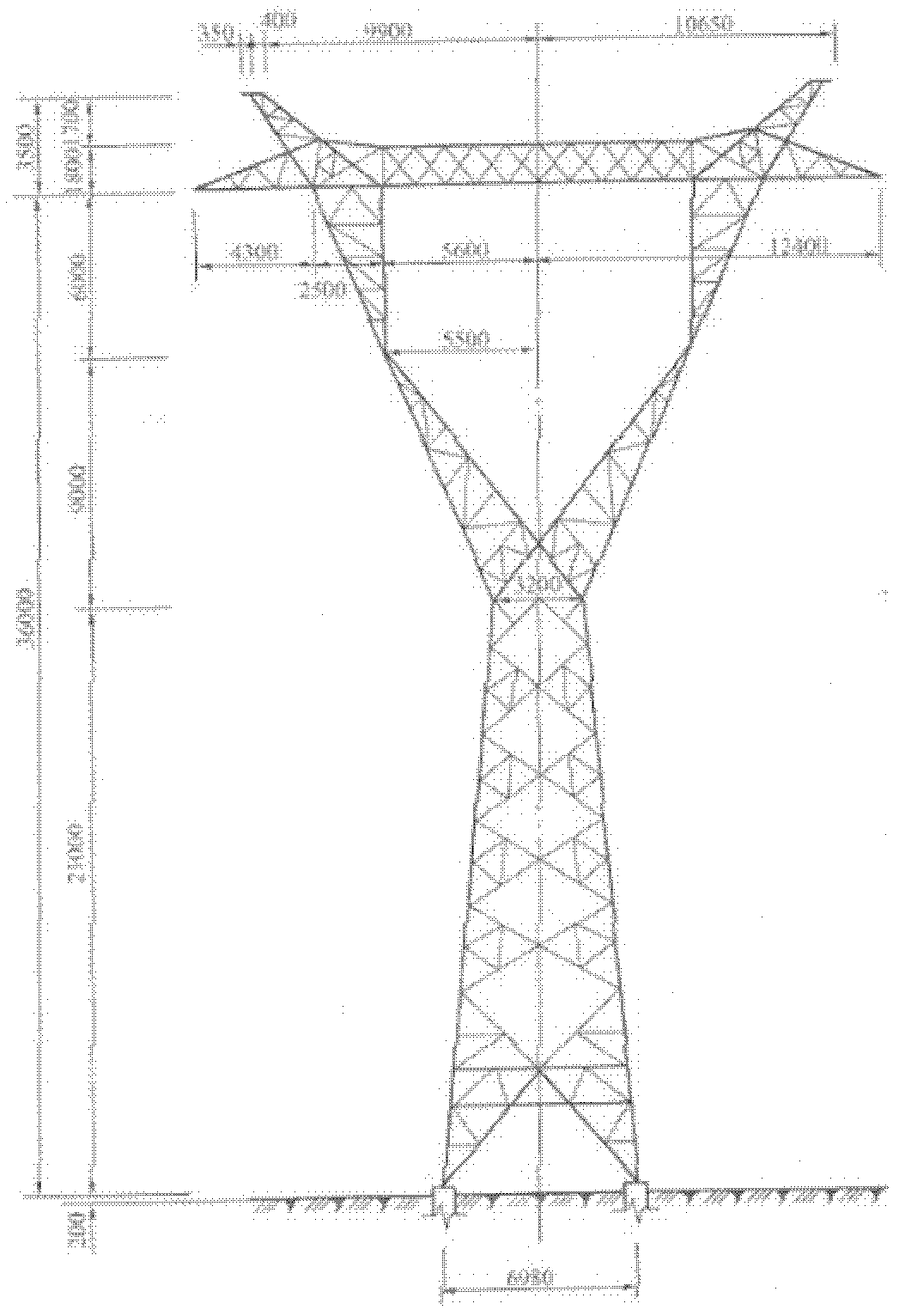

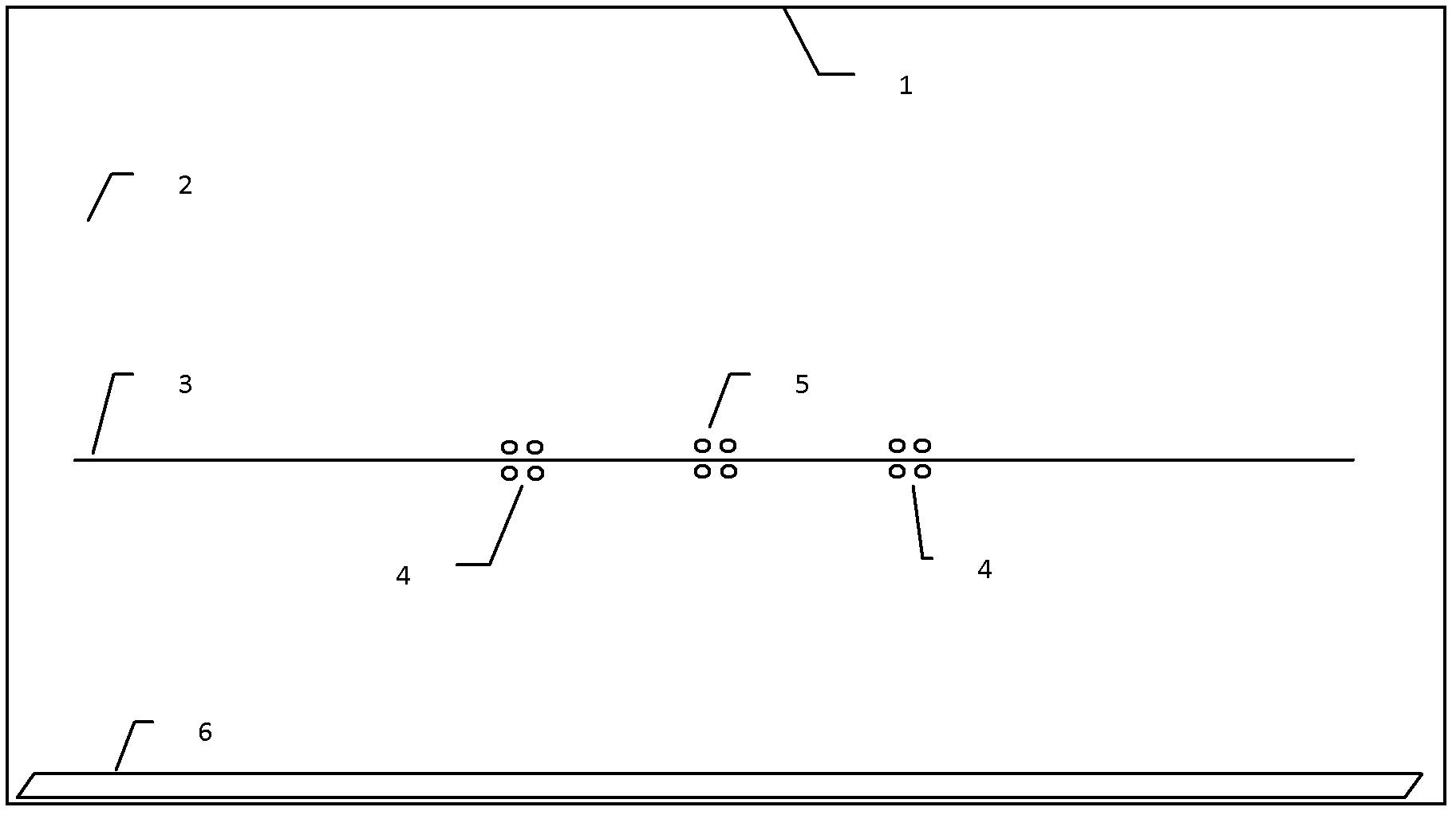

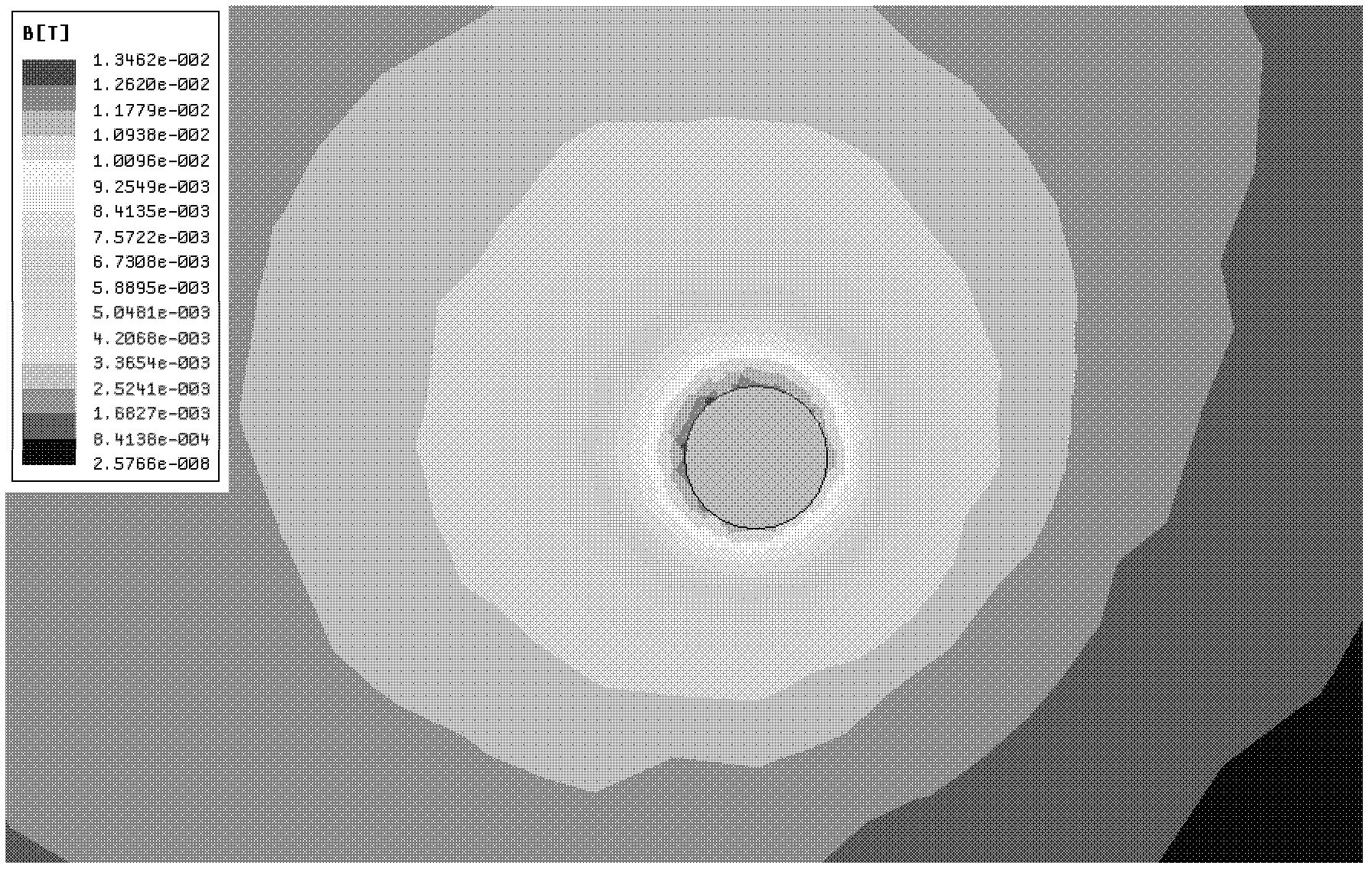

Method for detecting safe power-line-cruising distance of UAV (unmanned aerial vehicle)

ActiveCN102591355AReduce the risk factorImprove stability and reliabilityPosition/course control in three dimensionsApparatus for overhead lines/cablesElectromagnetic shieldingEngineering

The invention discloses a method for detecting the safe power-line-cruising distance of a UAV (unmanned aerial vehicle), which comprises the following steps of: (1) carrying out analysis according to the characteristics of electromagnetic fields of to-be-detected high-tension transmission lines in different voltage levels, and establishing corresponding electromagnetic-field simulation calculation models; (2) determining the maximum errors of electronic devices (which are susceptible to electromagnetic interference) carried by the power-line-cruising UAV and measuring devices used in the process of route planning making before routing inspection; (3) according to the requirements of the determined electronic devices on electromagnetic fields in the process of normal operating, by using the electromagnetic-field simulation calculation models of the high-tension transmission lines in different voltage levels and electromagnetic-field simulation calculation software, calculating the similarities and differences of an electromagnetic environment when the UAV has different distances away from a transmission conductor in the process of carrying out line-cruising operation on each high-tension transmission line, thereby determining the range of the safe distance between the UAV and the transmission conductor; and (4) carrying out line-cruising by the UAV according to the determined safe distance of each to-be-detected transmission line, thereby avoiding the situations that the devices run disorderly, the flight communication is interfered, a flight mission is failed, and the like caused by the electromagnetic field of the transmission conductor, and then ensuring the safety, stability and reliability of a flight.

Owner:STATE GRID INTELLIGENCE TECH CO LTD

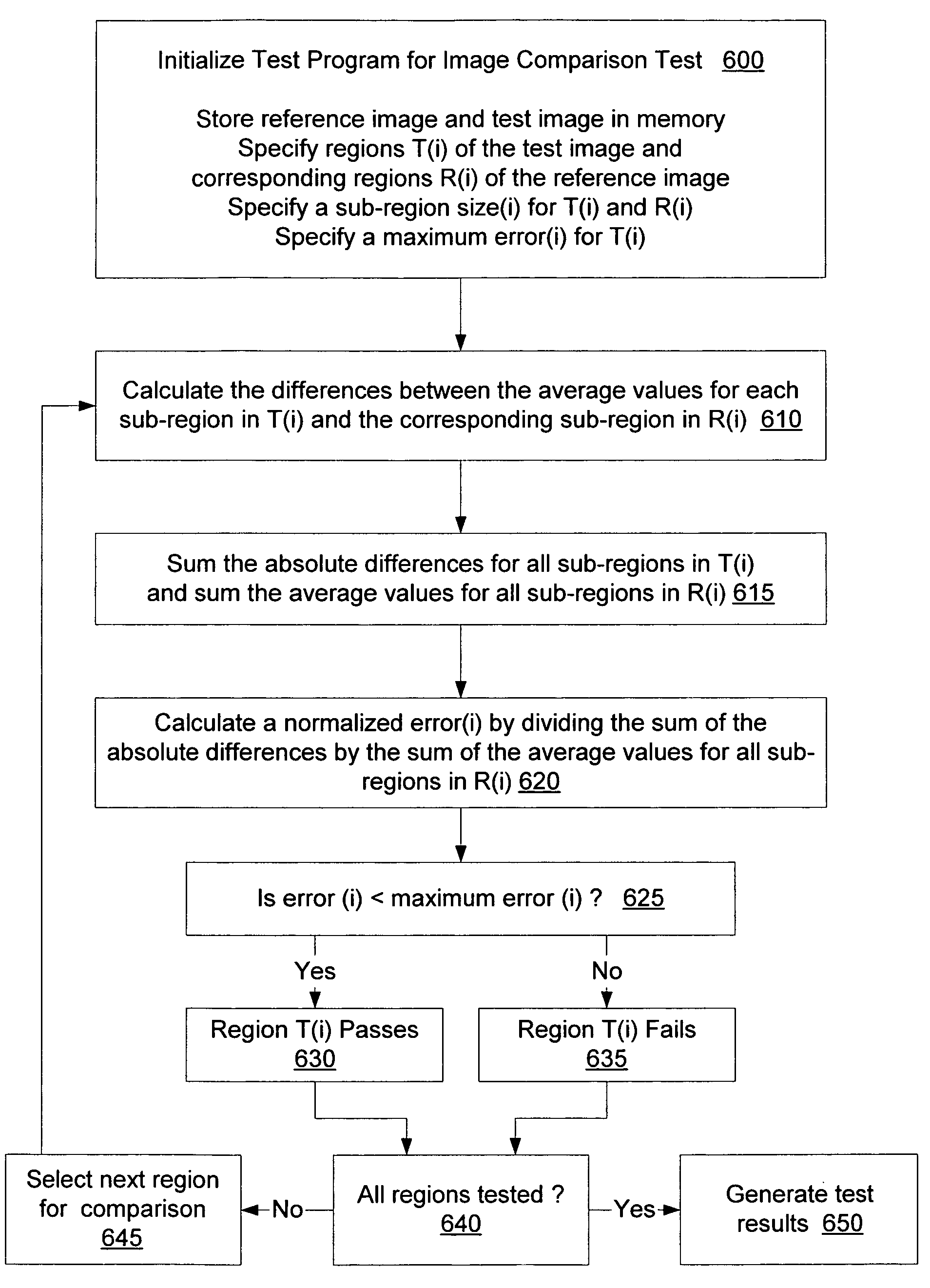

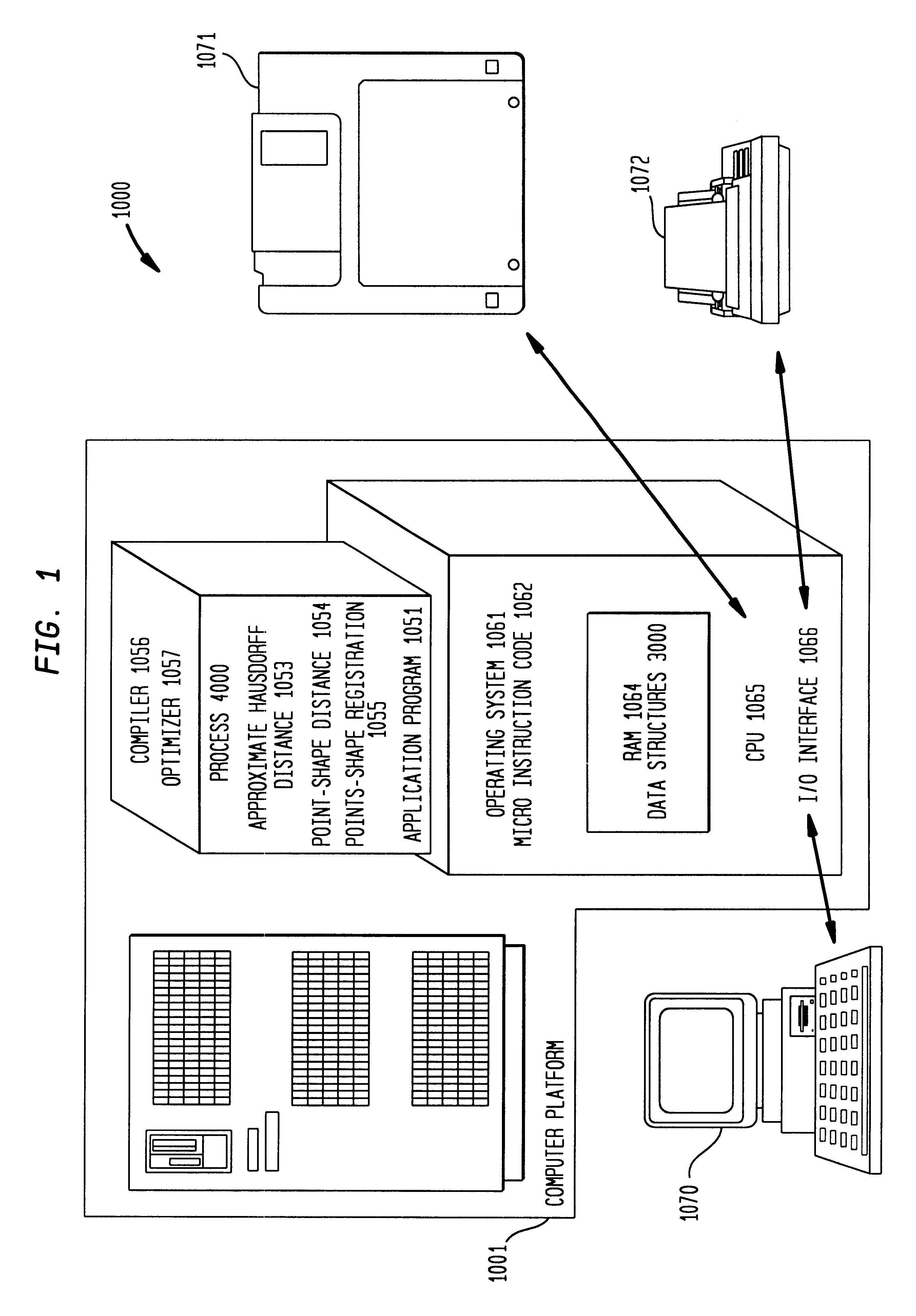

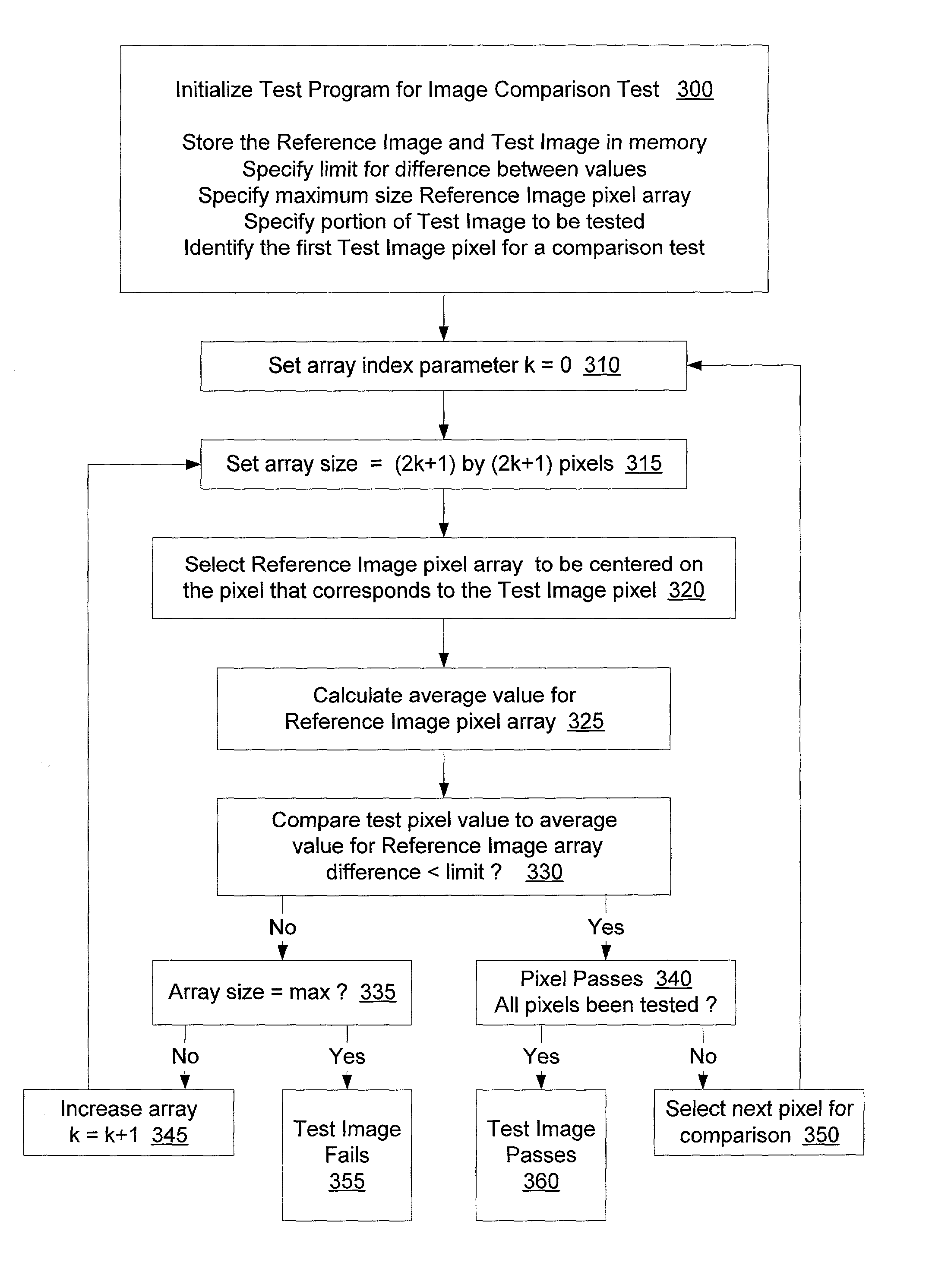

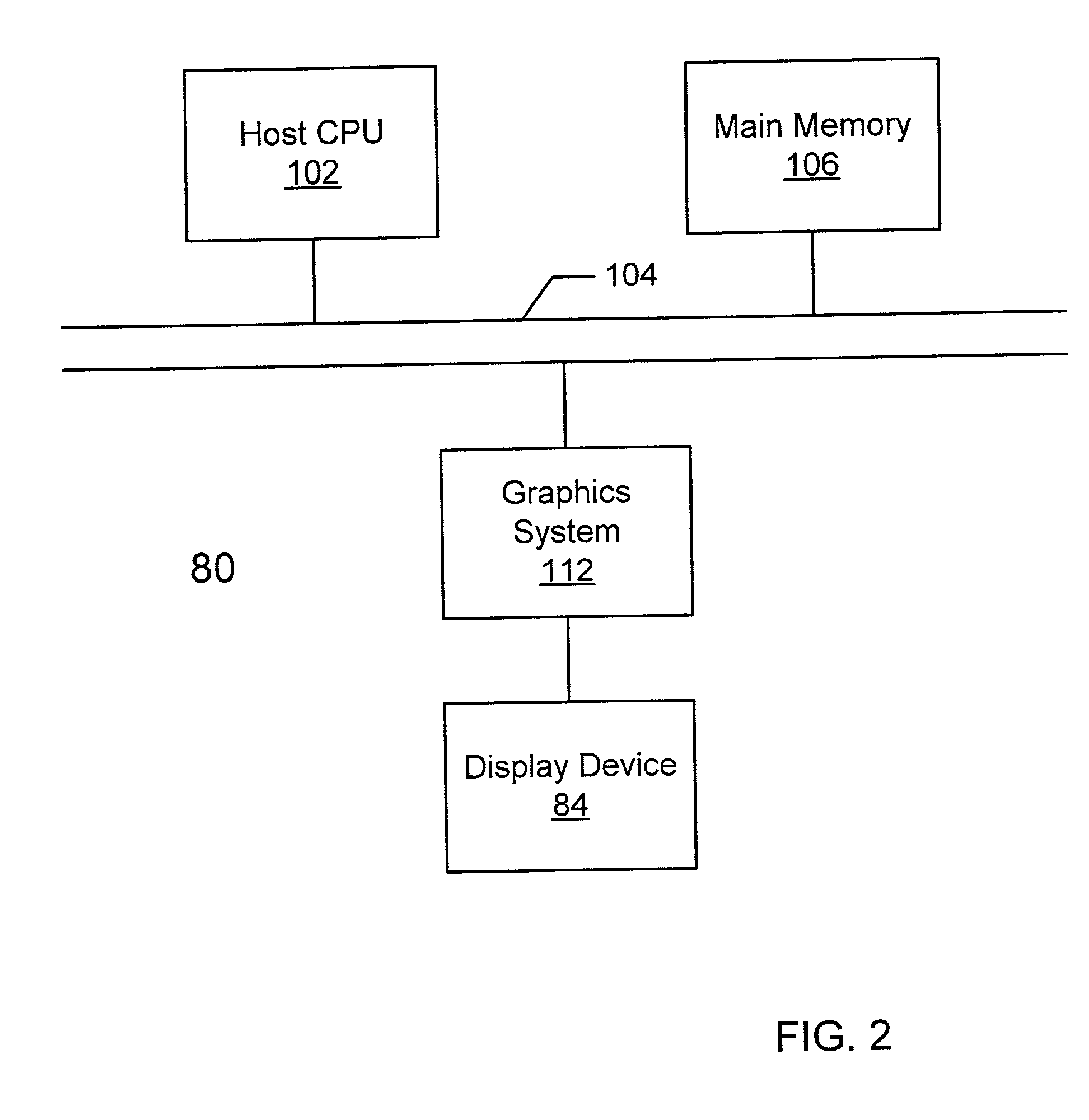

Method and apparatus for global image quantification verification

ActiveUS7092572B2Reduce in quantityEffectively blurredImage analysisCharacter and pattern recognitionGraphicsMaximum error

A method and apparatus are disclosed for testing the accuracy of digital test images generated by a computer graphics program executed on a computer graphics system. A test program is utilized to compare the test image with a reference image. The user defines regions of interest and a maximum error for each region. This allows the user to focus on a particular object or group of objects. Global image quantification verification generates one measurement of error or image difference for each region of the test image. Each region is divided into sub-regions and an average color value is calculated for each sub-region and the corresponding sub-region in the reference image. The differences between the averages for corresponding sub-regions in the test and reference images are calculated. A test image region may be unacceptably different from a reference image if a normalized sum of the absolute differences exceeds the maximum error.

Owner:ORACLE INT CORP

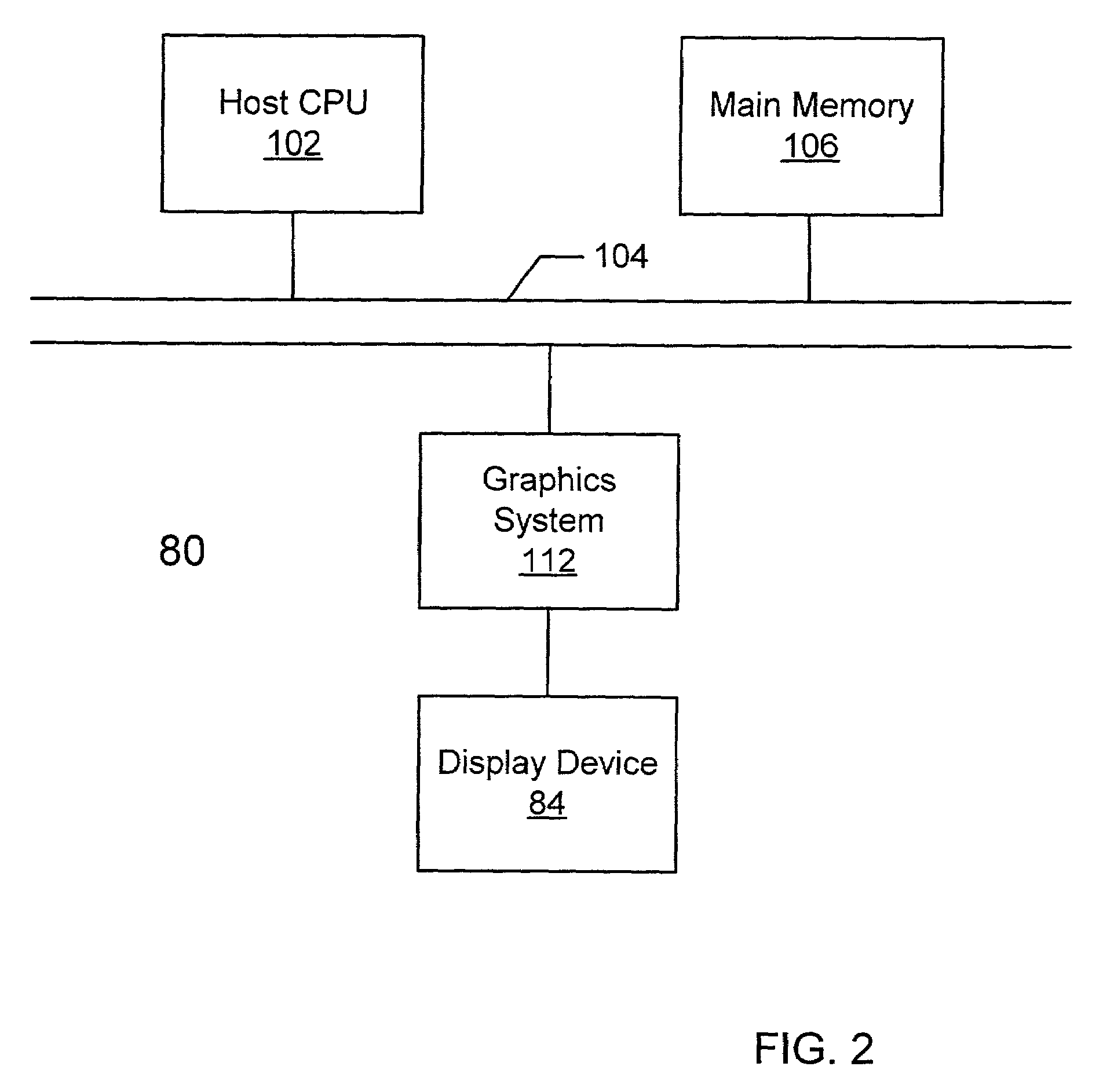

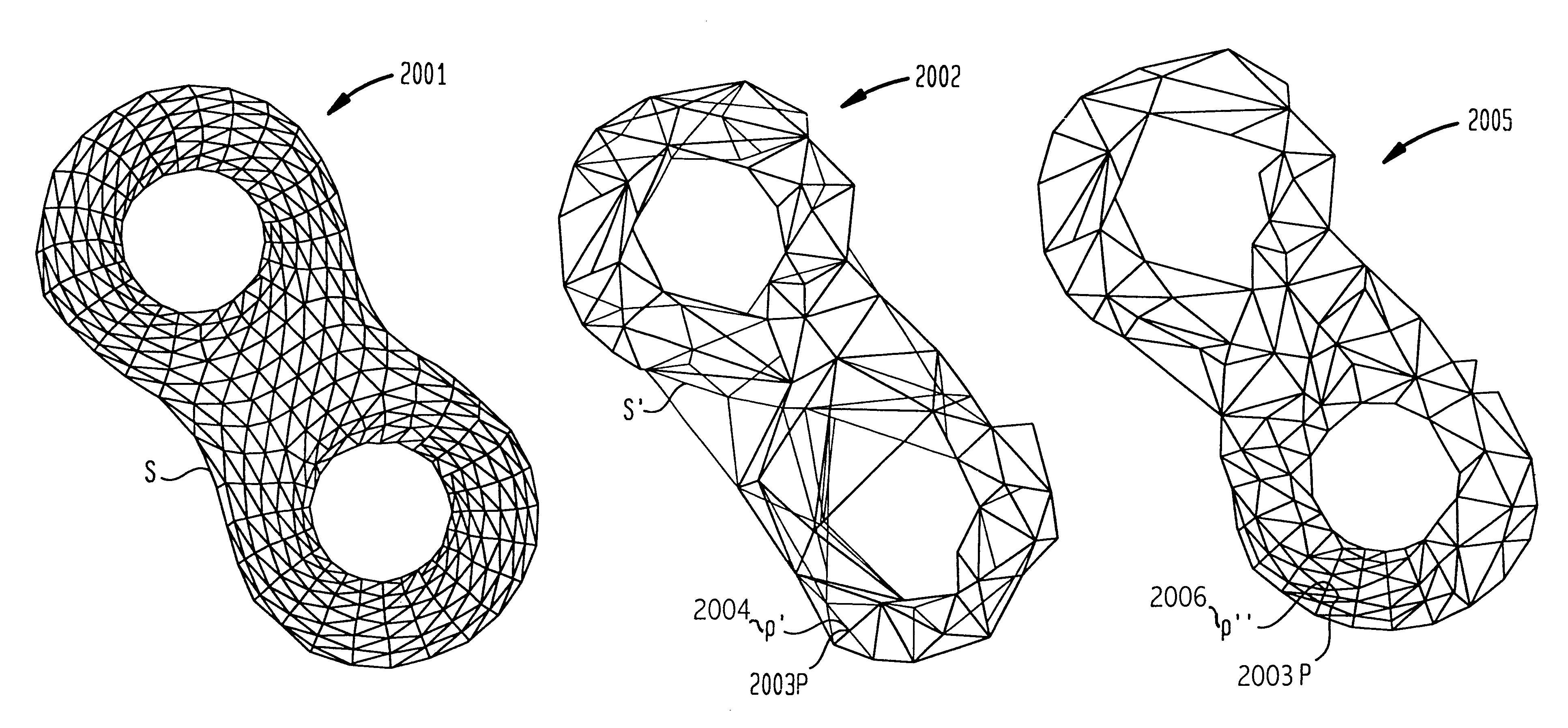

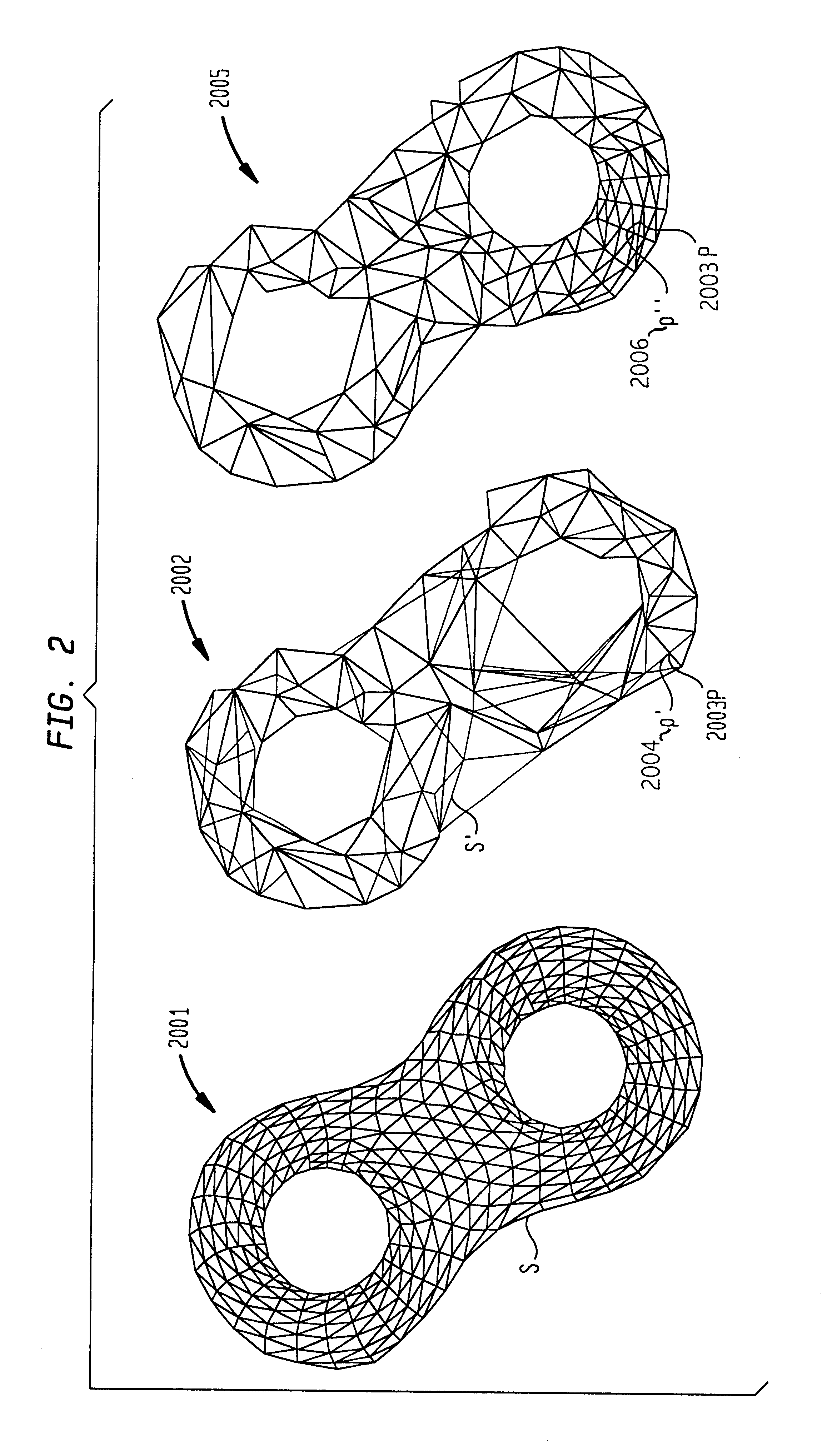

System and method for finding the distance from a moving query point to the closest point on one or more convex or non-convex shapes

The present invention is a computer system and method for determining the closest point on a shape (2 dimensional or 3 dimensional surface) to any general query point. The system has one or more central processing units (CPUs), one or more memories, and one or more geometric model portions stored in one or more of the memories. The geometric model portions have a plurality of line segments (polygons), each of the line segments (polygons) being between a first and a second endpoint (having a polygon boundary). The line segments and end points (polygons and polygon boundaries) are connected to form a shape (in 3 dimensions, a surface) with one or more parameters. Parameters can include geometric position, time, temperature, pressure, flow, color, texture, or any other descriptive value. A multiresolution process that creates one or more models of the shape (surface). The models having a hierarchy of resolutions. Each model has one or more model line segments (model polygons) that approximate one or more of the line segments (polygons). Each model line segment (model polygons) is associated with an error. A distance process, for every model line segment (polygon), determines a distance between a closest point on one or more of the model line segments and a query point. The distance represents one or a combination of two or more of the parameters. The process further determines a confidence level in terms of an upper bound and a lower bound of an envelope enclosing the segment (polygon). The closest point is within the envelope-the upper bound representing an upper limit of the parameter in the envelope determined by an upper error of the respective model containing the model line segment and the lower bound representing a lower limit of the parameter in the envelope determined by a lower error of the respective model. A priority process orders the model line segments (polygons) according to their respective lower bounds and if a maximum error for every one of the model line segments is less than a threshold. The priority process also selects the smallest distance as the minimum distance between the query point and the shape.

Owner:UNILOC 2017 LLC

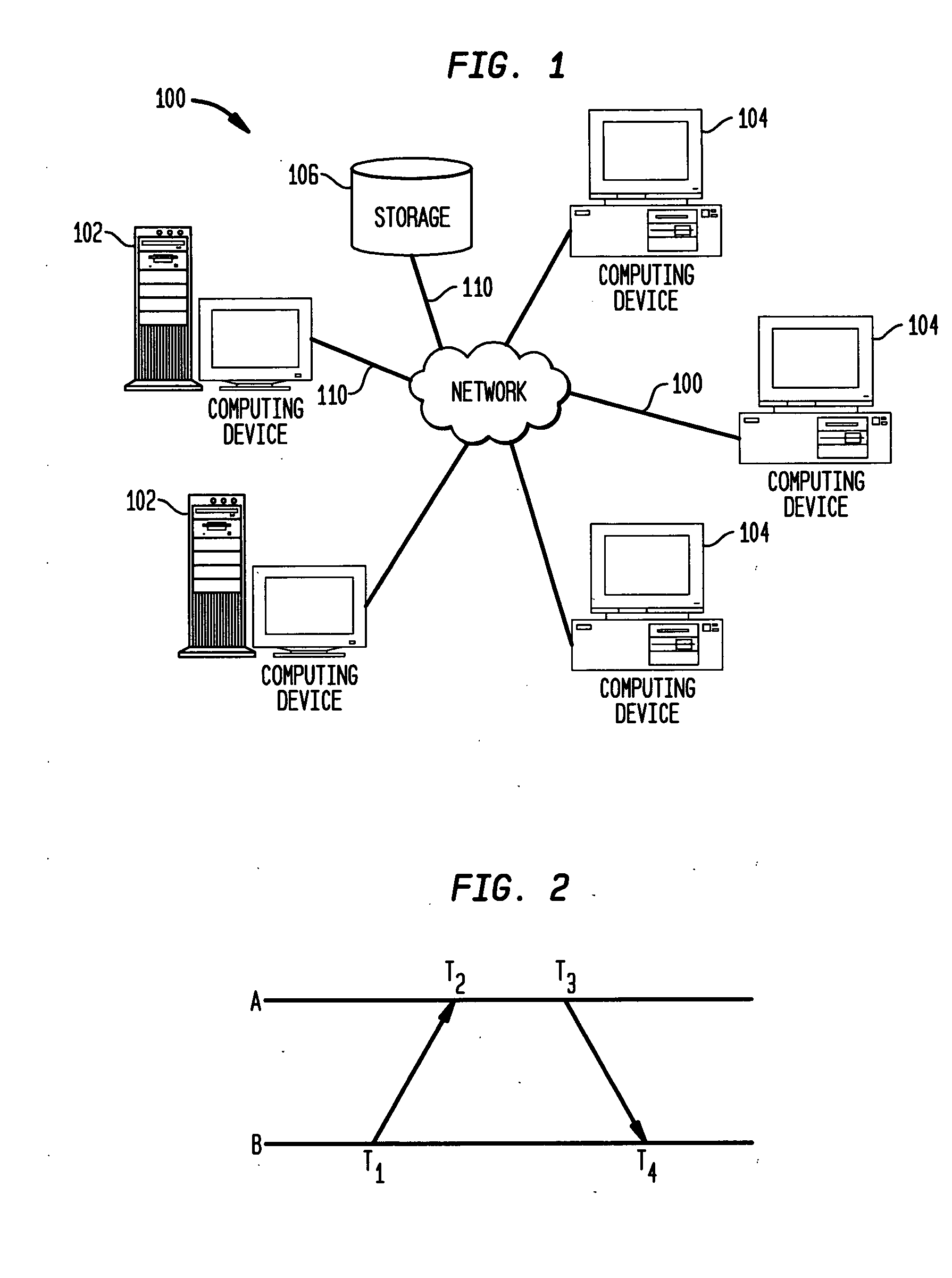

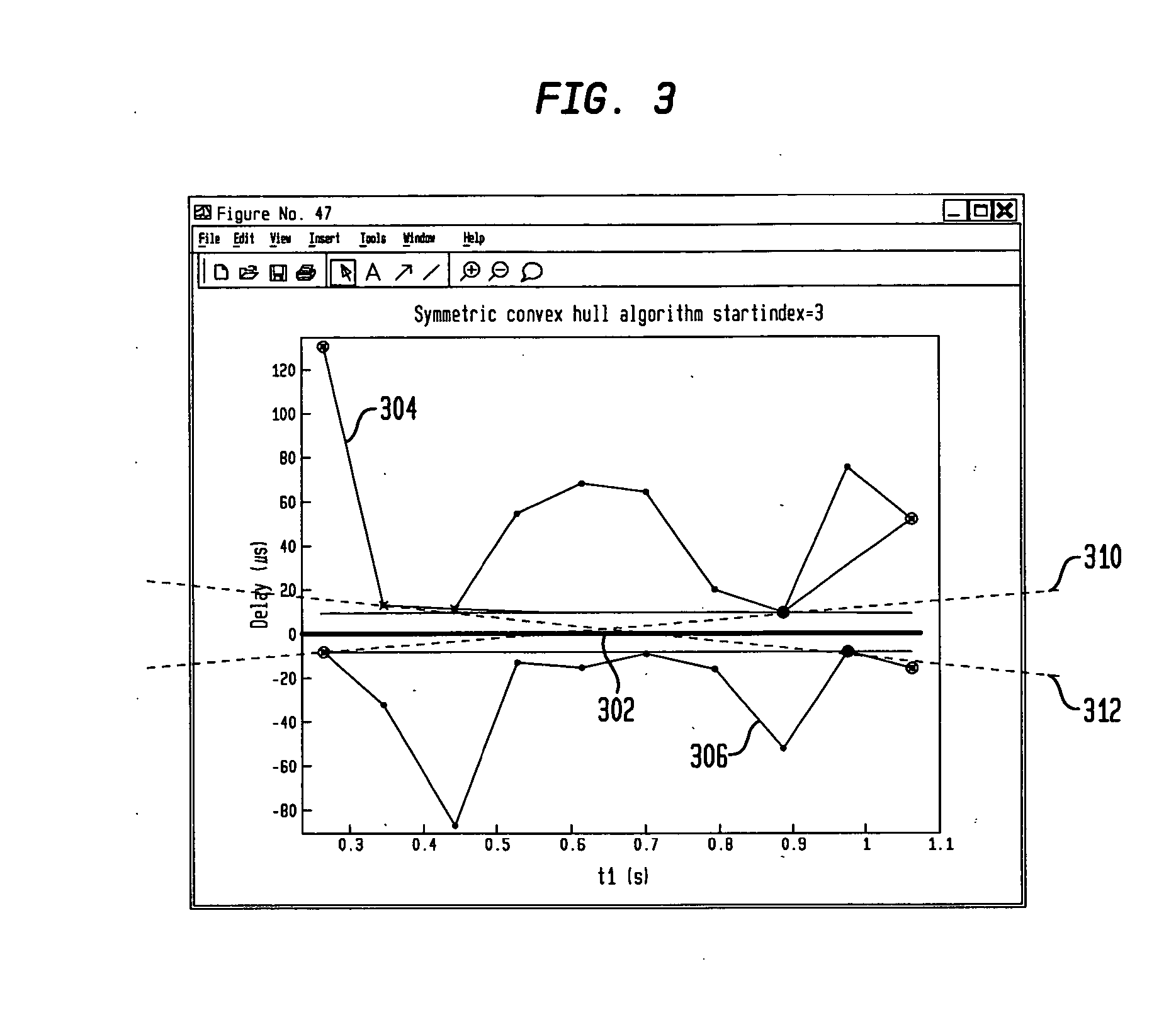

Clock filter dispersion

Disclosed are a method and system to estimate the maximum error in the clock offset and skew estimation between two clocks in a computer system. The method comprises the steps of obtaining a first set of data values representing a forward delay between the first and second clocks, and obtaining a second set of data values representing a negative backward delay between the first and second clocks. The method comprises the further step of forming a lower convex hull for said first set of data values, and forming an upper convex hull for said second set of data values. First and second parallel lines are formed between the upper and lower convex hulls, and these parallel lines are used to estimate the worst case error for the offset, skew rate and dispersion of said first and second clocks.

Owner:IBM CORP

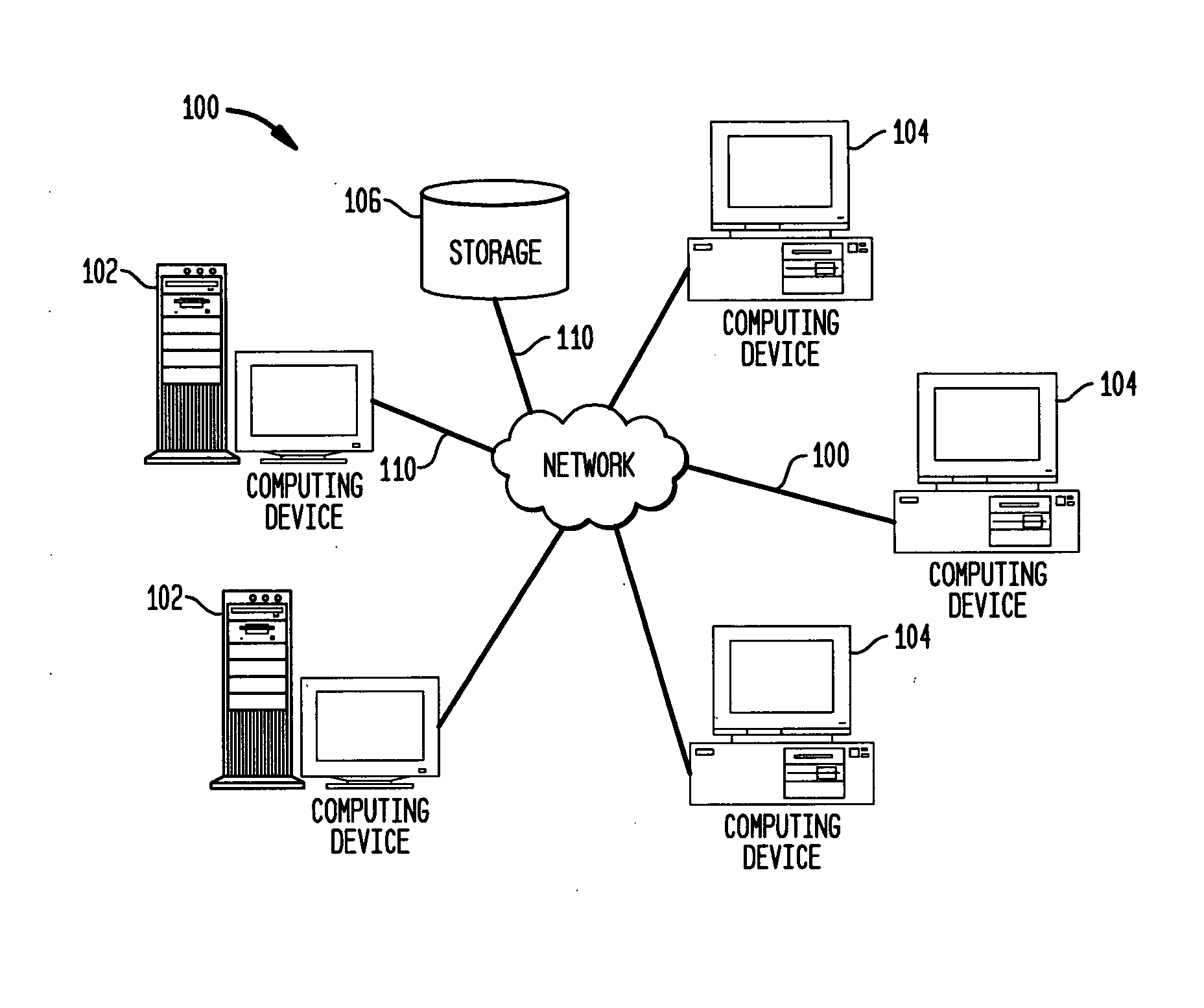

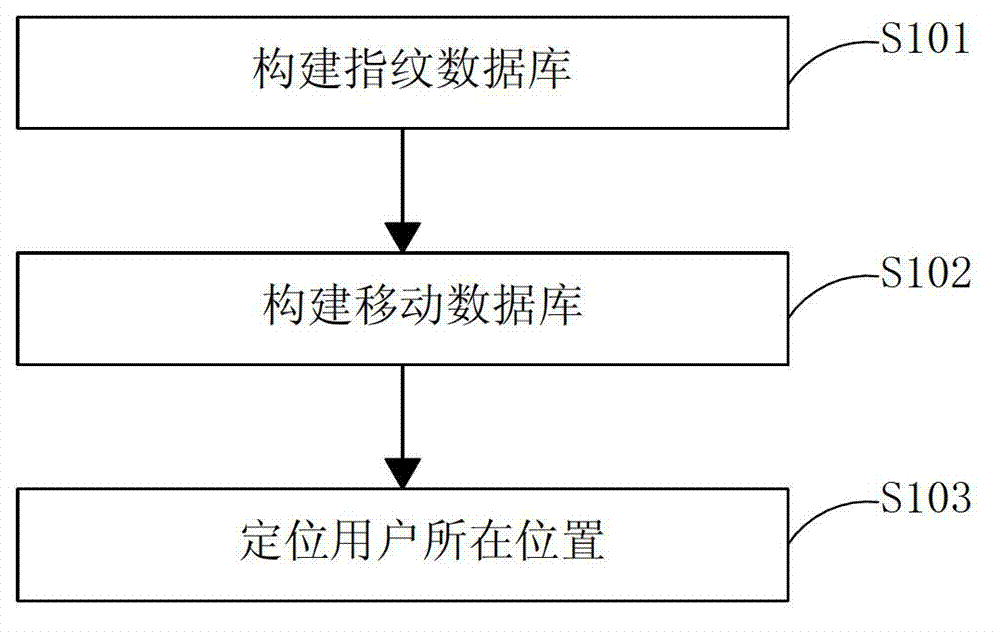

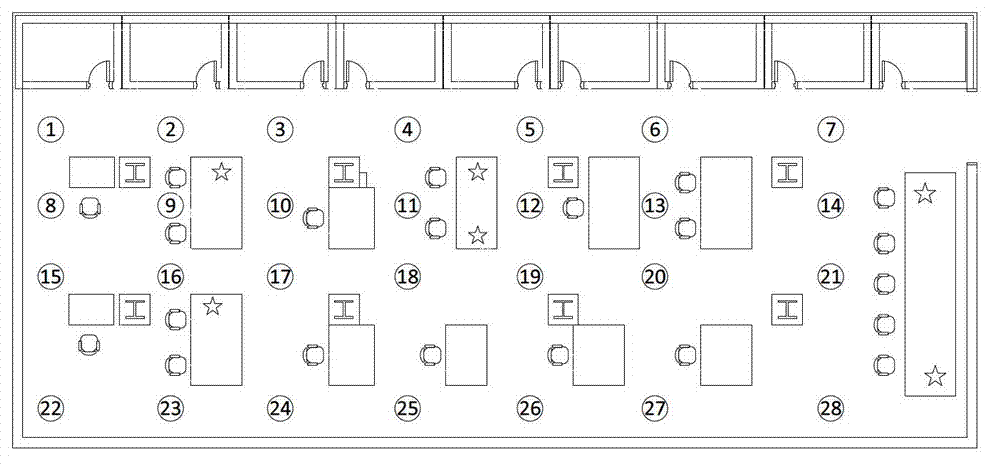

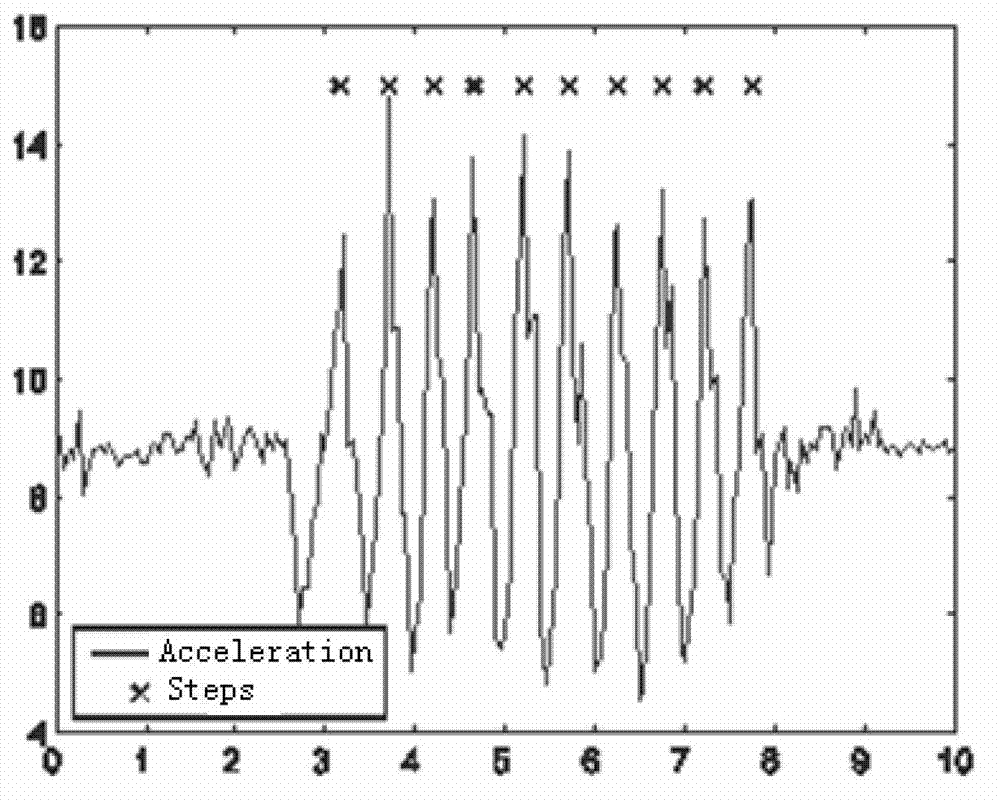

Mobile auxiliary indoor positioning method and system based on smart phone platform

ActiveCN102905368AHigh positioning accuracySmall maximum errorSpecial data processing applicationsWireless communicationMaximum errorEmbedded system

The invention discloses a mobile auxiliary indoor positioning method and a mobile auxiliary indoor positioning system based on a smart phone platform. For the mobile auxiliary indoor positioning method and the mobile auxiliary indoor positioning system, the position of a user in a room is located by establishing a fingerprint database and a mobile database. The positioning method comprises the following steps of: after receiving a positioning request sent by a user, collecting RSSI (received signal strength indicator) fingerprints of the position of the user according to the positioning request, matching the RSSI fingerprints with RSSI fingerprints in the fingerprint database, and returning a set containing candidate positions with fixed quantity according to the matching result; according to data in the mobile data, the information of moving information and moving distance of the user, calculating the candidate positions in the set containing the candidate positions with the fixed quantity as the probability of the position of the user, so as to obtain the position of the user. Compared with the traditional indoor positioning method, the mobile auxiliary indoor positioning and the mobile auxiliary indoor positioning system have the advantages of high positioning precision and small maximum error, and can continuously and accurately positioning in a positioning process in real time.

Owner:北京泰豪信息科技有限公司

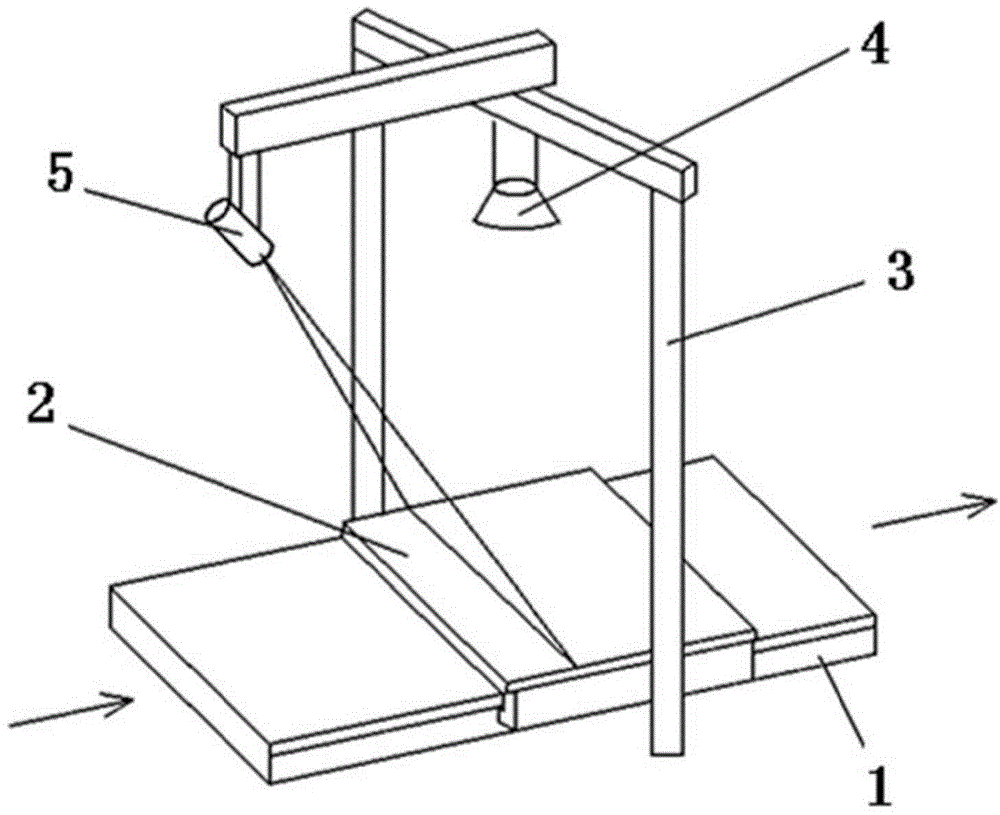

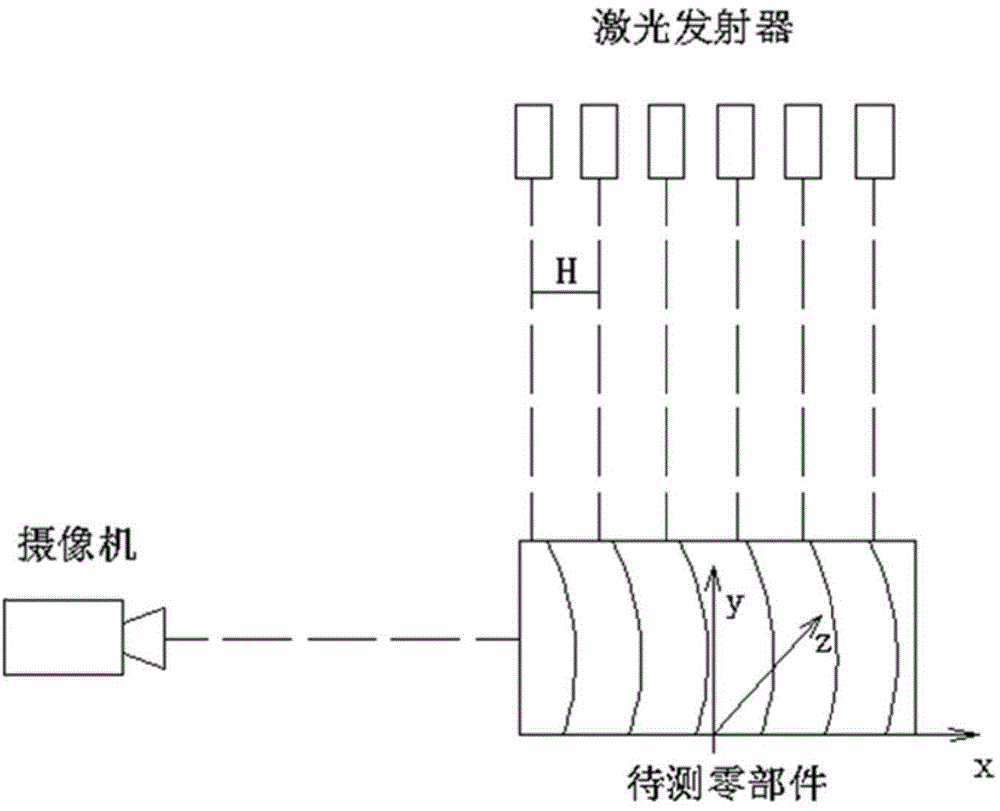

Component quality checking device based on line laser three-dimensional measurement and detection method of device

InactiveCN104913737AImprove detection efficiencyExpedited screeningUsing optical meansGraphicsMaximum error

The invention provides a component quality checking device based on line laser three-dimensional measurement and detection method of the device. The quality checking device includes a mobile platform mounted on a guide rail and capable of sliding along the guide rail at a uniform speed. To-be-checked components are fixed on the mobile platform. A camera and a plurality of laser emitters are mounted above the guide rail through a mount. The camera collects images which are casted to the surfaces of the to-be-checked components by the laser emitters and deformed due to surface modulation. The camera transmits the collected image data to a computer for analysis and treatment. According to the detection method, by casting linear stripes emitted by the laser emitters to the surface of the to-be-checked components for linear scanning and by utilizing the camera for collecting image information on the to-be-checked components continuously, measured three-dimensional point cloud data and initially designed three-dimensional image are compared and analyzed in the same coordinate system for judging whether the maximum error is within the maximum permissible error range or not and screening out qualified components. The device provided by the invention is high in detection precision and realizes automatic and flow line production.

Owner:CHANGAN UNIV

Method for compensating precision milling deformation of thin-wall blade

InactiveCN102880756AThe direct effect is obviousImprove machining accuracySpecial data processing applicationsMaximum errorEngineering

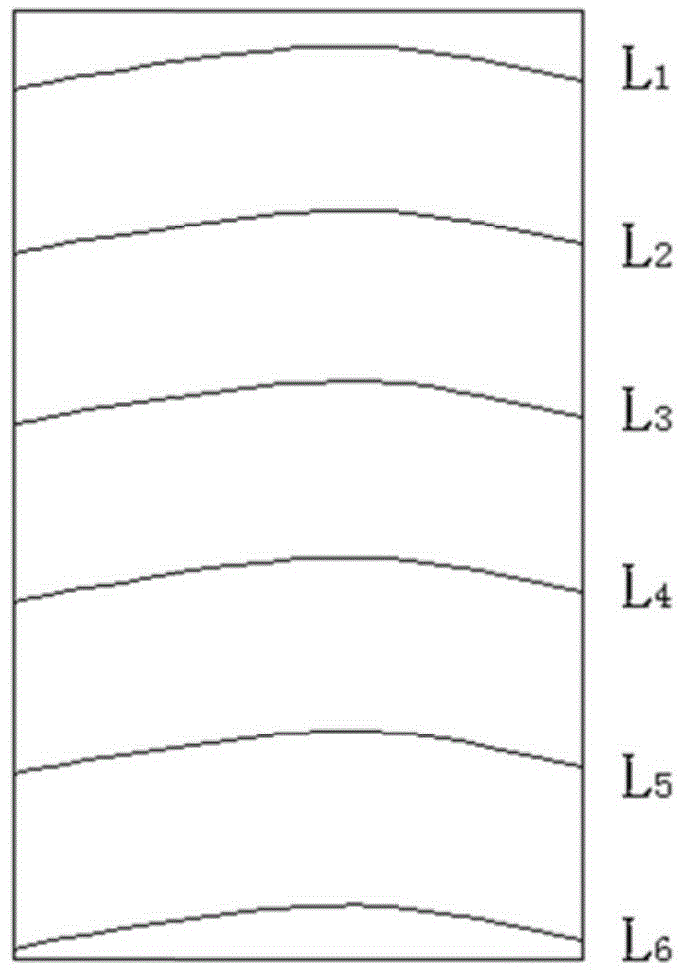

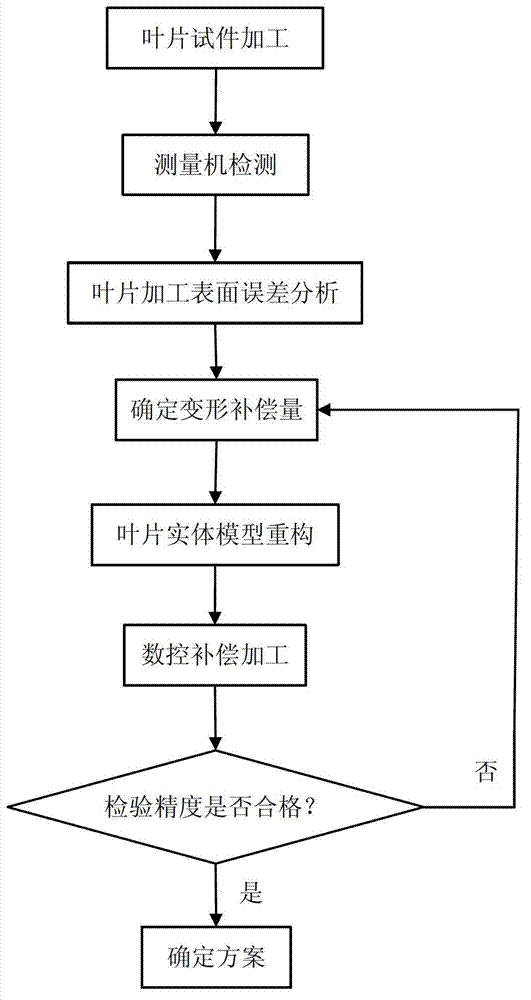

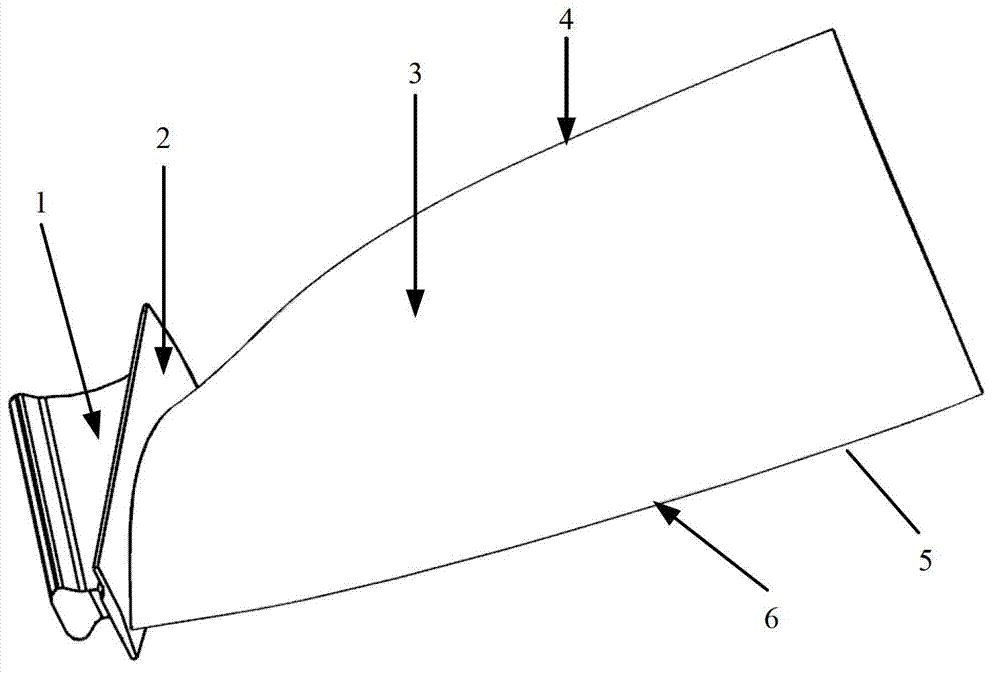

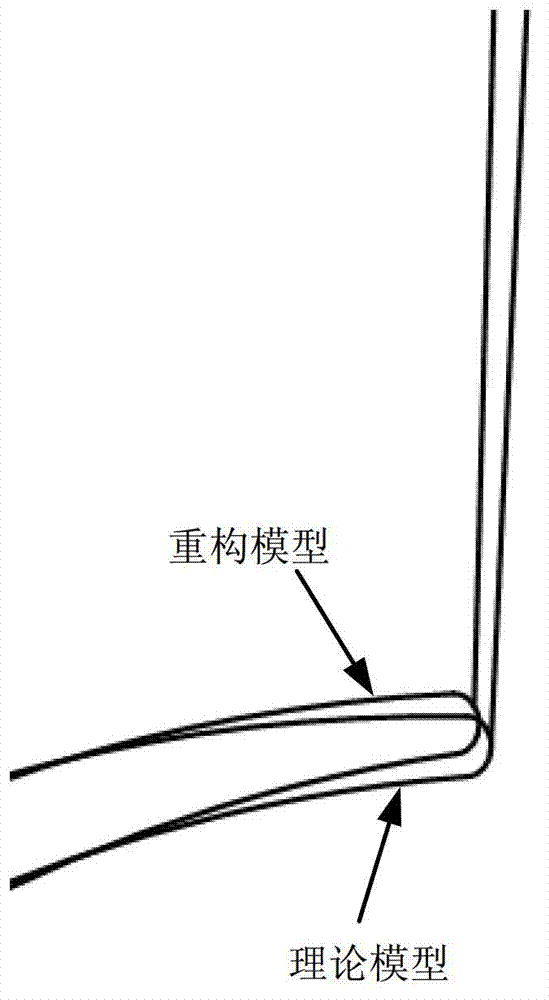

The invention provides a method for compensating precision milling deformation of a thin-wall blade. The method includes extracting blade sections perpendicular to a parameter v-direction; measuring error mean values of the various sections after the blade is machined according to an initial three-dimensional model and using the error mean values as primary compensation quantities for the sections; reconstructing a three-dimensional blade model after the various sections are primarily compensated; machining the blade according to the reconstructed three-dimensional blade model; measuring maximum error values of the various sections; computing precise deformation compensation quantities for the various sections; secondarily reconstructing a three-dimensional blade model after the various sections are compensated according to the precise deformation compensation quantities; machining the blade according to the secondarily reconstructed three-dimensional blade model; and measuring errors of the various sections to judge whether design requirements are met or not. The method is favorable for improving the machining precision of the blade and the profile tolerance of the surface of the blade and reducing compensation frequency, machining frequency and workload of follow-up working procedures.

Owner:NORTHWESTERN POLYTECHNICAL UNIV

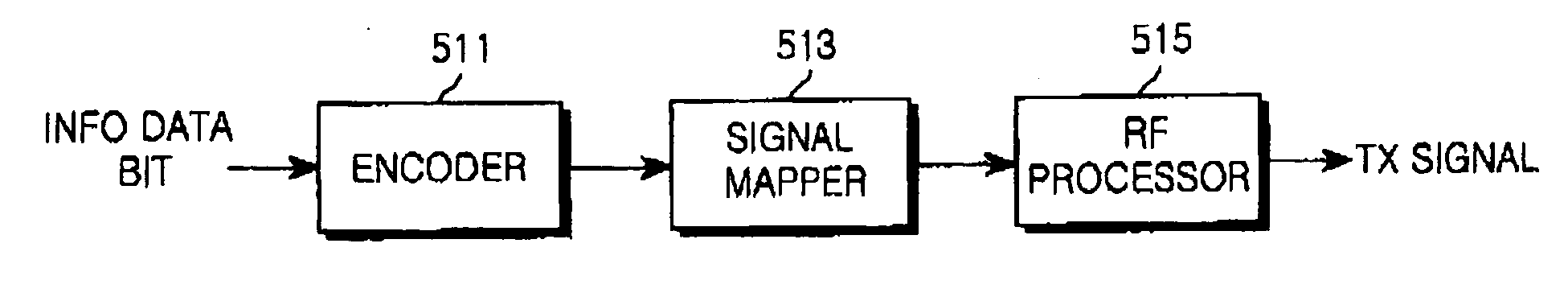

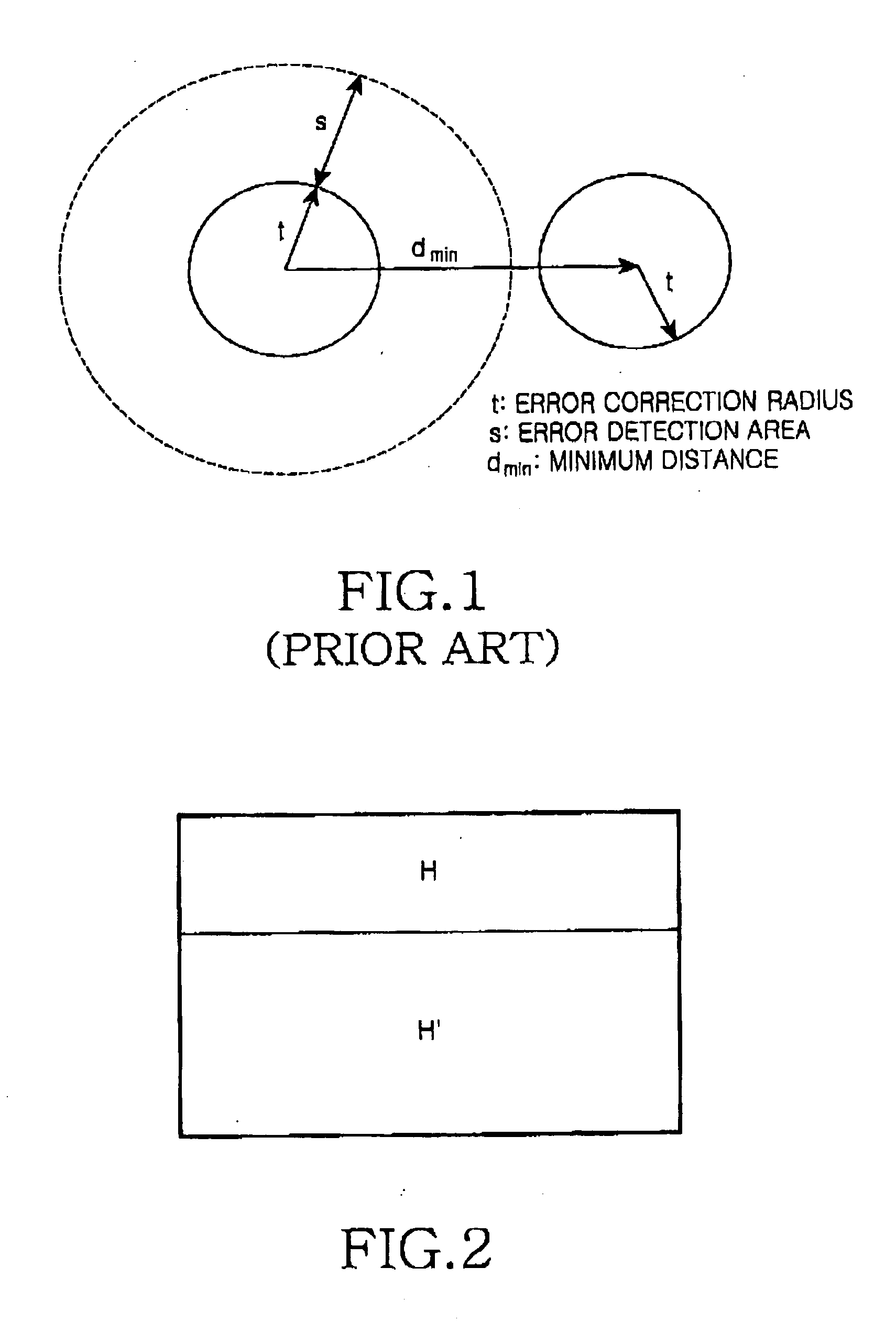

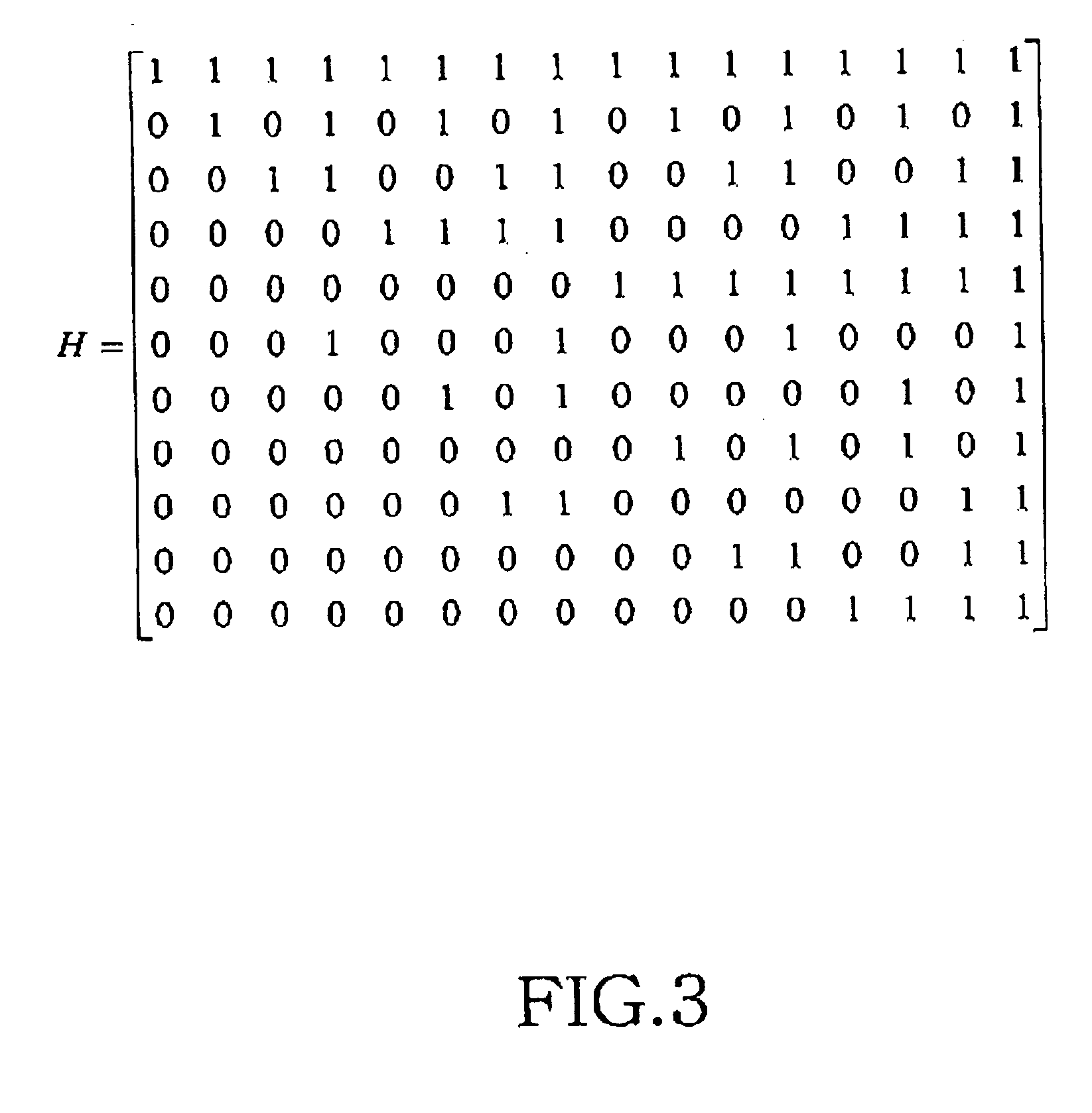

Apparatus and method for encoding and decoding a low density parity check code with maximum error correction and error detection capability

ActiveUS20050235195A1Good error correction capability capabilityGood error capability detection capabilityError detection/correctionError correction/detection using multiple parity bitsMaximum errorBlock code

An apparatus and method for decoding a Low Density Parity Check (LDPC) code having a maximum error correction capability and an error detection capability. In the apparatus, a decoder receives a signal, and decodes the received signal according to a second parity check matrix having parity check expressions obtained by selecting a predetermined number of dependent parity check expressions among dependent parity check expressions generated by combining, with a predetermined scheme, parity check expressions representing rows of a first parity check matrix obtained by encoding information data into a block code having an optimum minimum distance considering a predetermined coding rate, and adding the selected dependent parity check expressions to the parity check expressions of the first parity check matrix. An error detector determines if there is an error in a signal output from the decoder.

Owner:SAMSUNG ELECTRONICS CO LTD

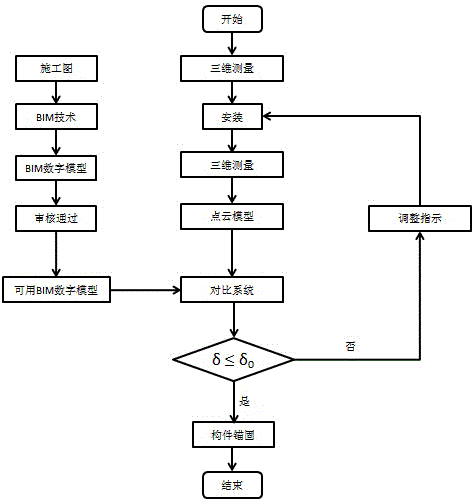

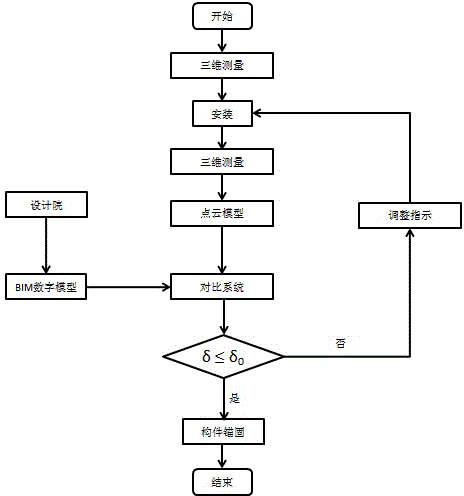

Digital installation method for high-rise steel structure based on BIM and three-dimensional measurement

InactiveCN104899378AImprove construction efficiencyAvoid reworkData processing applicationsBuilding material handlingMaximum errorPoint cloud

The invention provides a digital installation method for a high-rise steel structure based on BIM and three-dimensional measurement. The method includes following steps: step 1, establishing a BIM three-dimensional digital model of the high-rise steel structure; step 2, installing a three-dimensional measuring system at the spot and measuring a point cloud model of a member; step 3, processing the point cloud model by a contrast system and calculating the maximum error in the contrast system; step 4, giving an instruction of an adjusting method for on-site installation if the maximum error Delta>Delta0; and step 5, anchoring the member if the on-site member position error satisfies the requirement so that accurate installation of the member of the high-rise steel structure is realized. According to the method, aiming to the characteristics of high structure and complicated space of high-rise steel, BIM and three-dimensional measurement technologies are employed, and on-site accurate installation of the steel structure is realized.

Owner:SHANGHAI UNIV

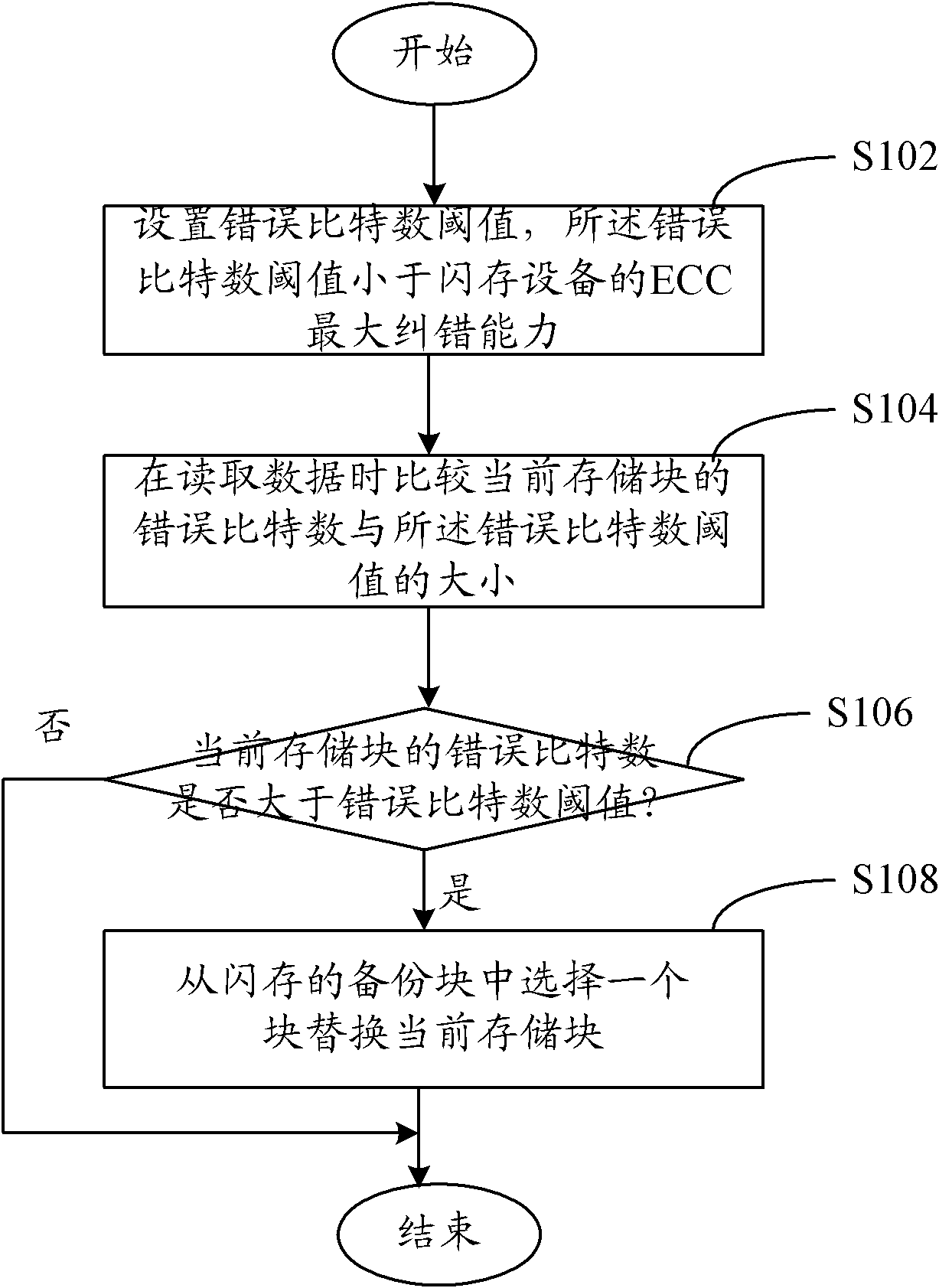

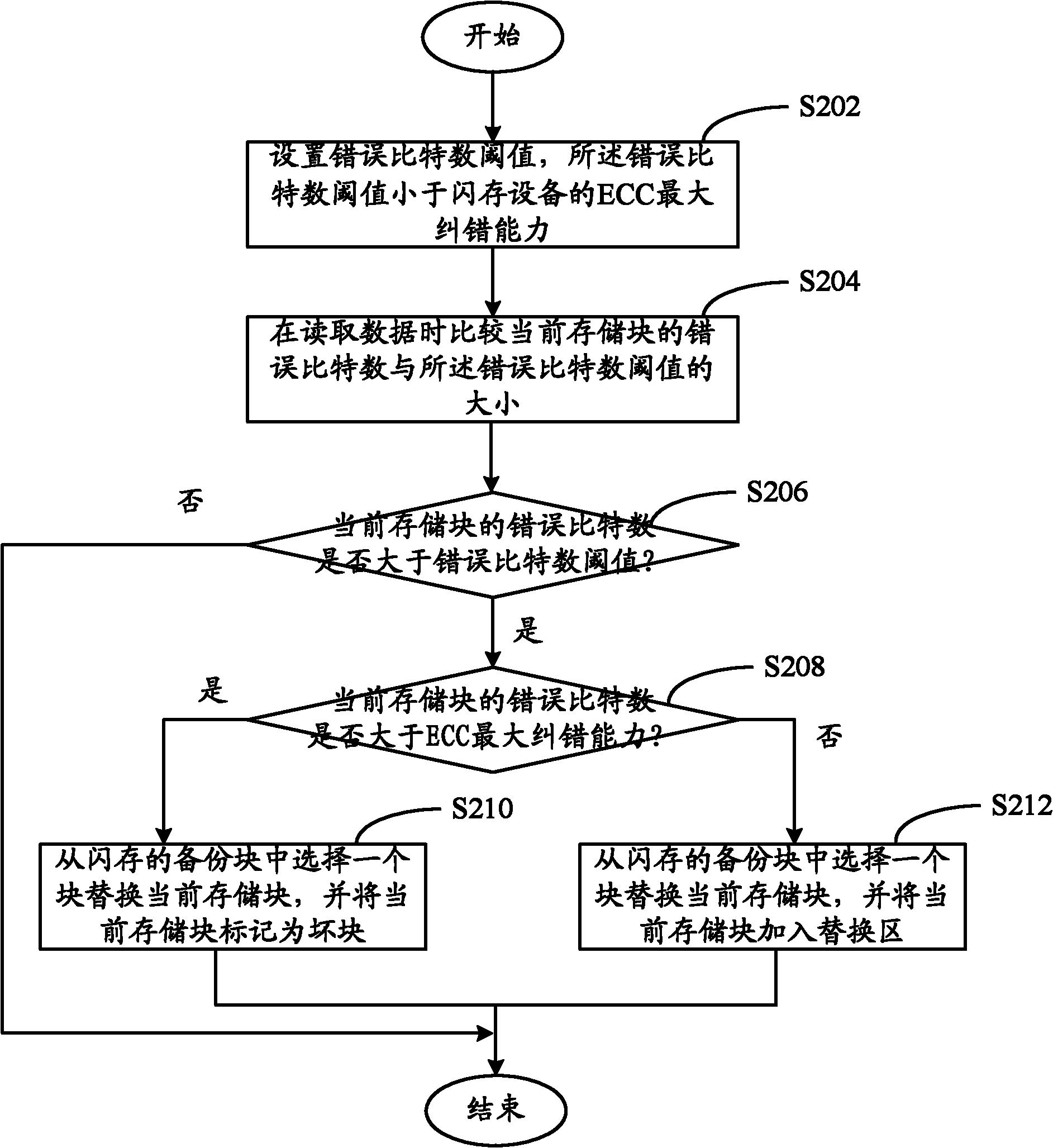

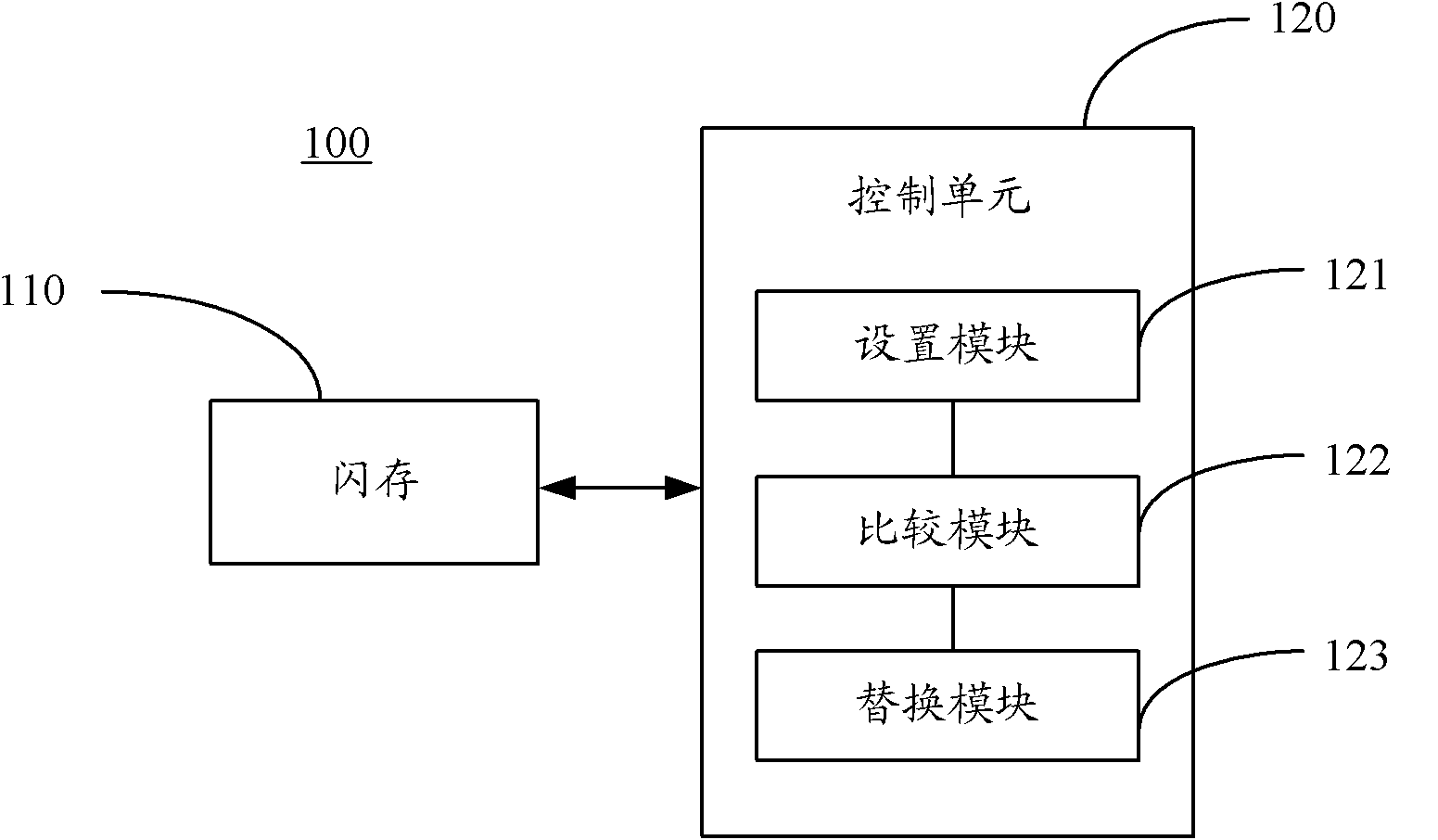

Flash memory equipment, and method and system for managing storage blocks in same

ActiveCN102073563AReduce error rateExtended service lifeRedundant data error correctionRedundant hardware error correctionMaximum errorError correcting

The invention relates to a method for managing storage blocks in flash memory equipment, which comprises the following steps of: setting an error bit number threshold value, wherein the error bit number threshold value is smaller than the maximum error correcting capability of an error correcting code (ECC) of the flash memory equipment; comparing the error bit number of the current storage block with the error bit number threshold value when reading data; and if the error bit number of the current storage block is more than the error bit number threshold value, selecting a block to replace the current storage block from backup blocks of a flash memory. By the method, the error rate of the flash memory equipment can be reduced, so that the service life of the flash memory equipment is prolonged. In addition, the invention provides the flash memory equipment and a system for managing the storage blocks in the flash memory equipment.

Owner:SHENZHEN NETCOM ELECTRONICS CO LTD

Method and apparatus for global image quantification verification

ActiveUS20030185446A1Image analysisCharacter and pattern recognitionImage QuantificationMaximum error

A method and apparatus are disclosed for testing the accuracy of digital test images generated by a computer graphics program executed on a computer graphics system. A test program is utilized to compare the test image with a reference image. The user defines regions of interest and a maximum error for each region. This allows the user to focus on a particular object or group of objects. Global image quantification verification generates one measurement of error or image difference for each region of the test image. Each region is divided into sub-regions and an average color value is calculated for each sub-region and the corresponding sub-region in the reference image. The differences between the averages for corresponding sub-regions in the test and reference images are calculated. A test image region may be unacceptably different from a reference image if a normalized sum of the absolute differences exceeds the maximum error.

Owner:ORACLE INT CORP

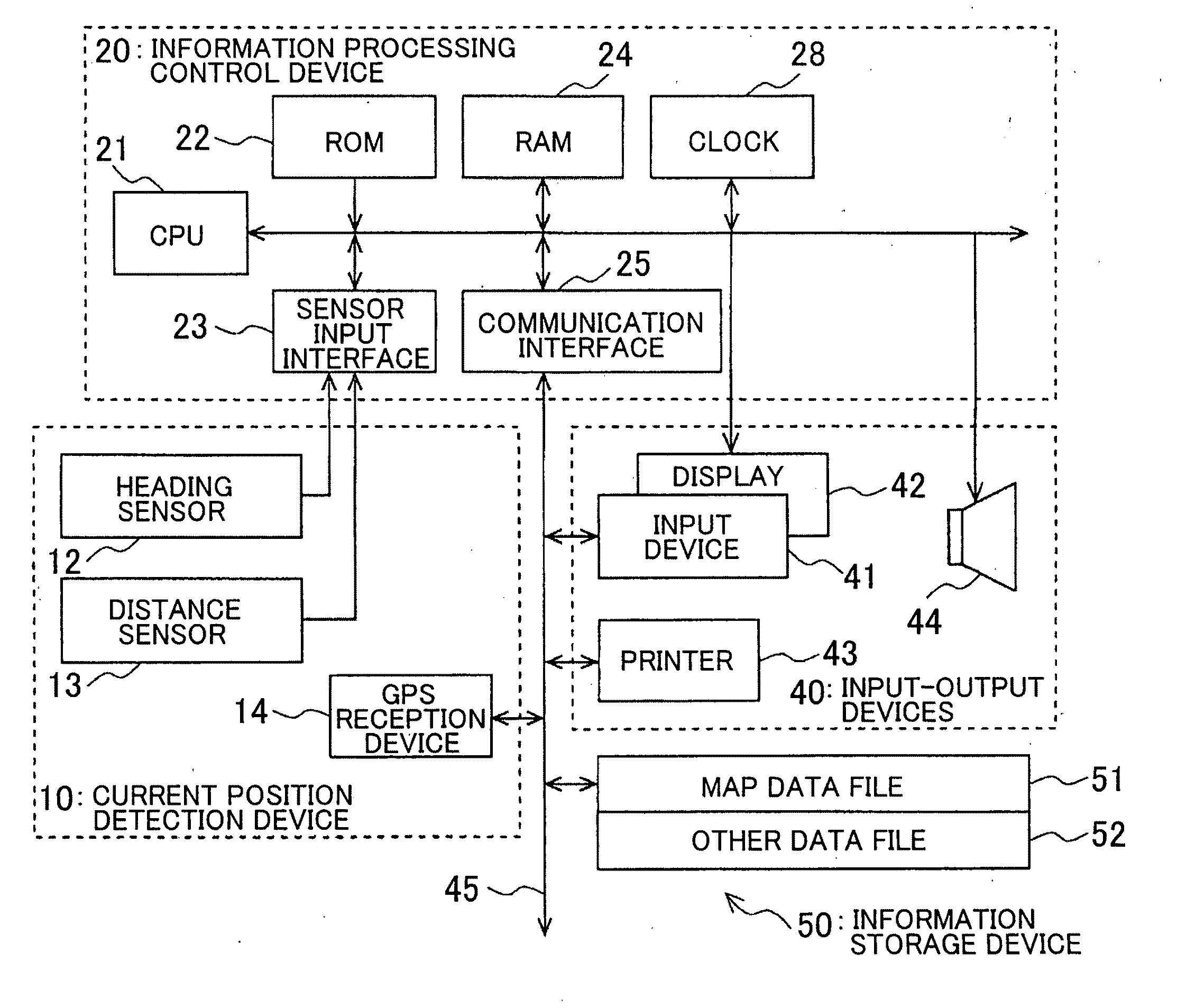

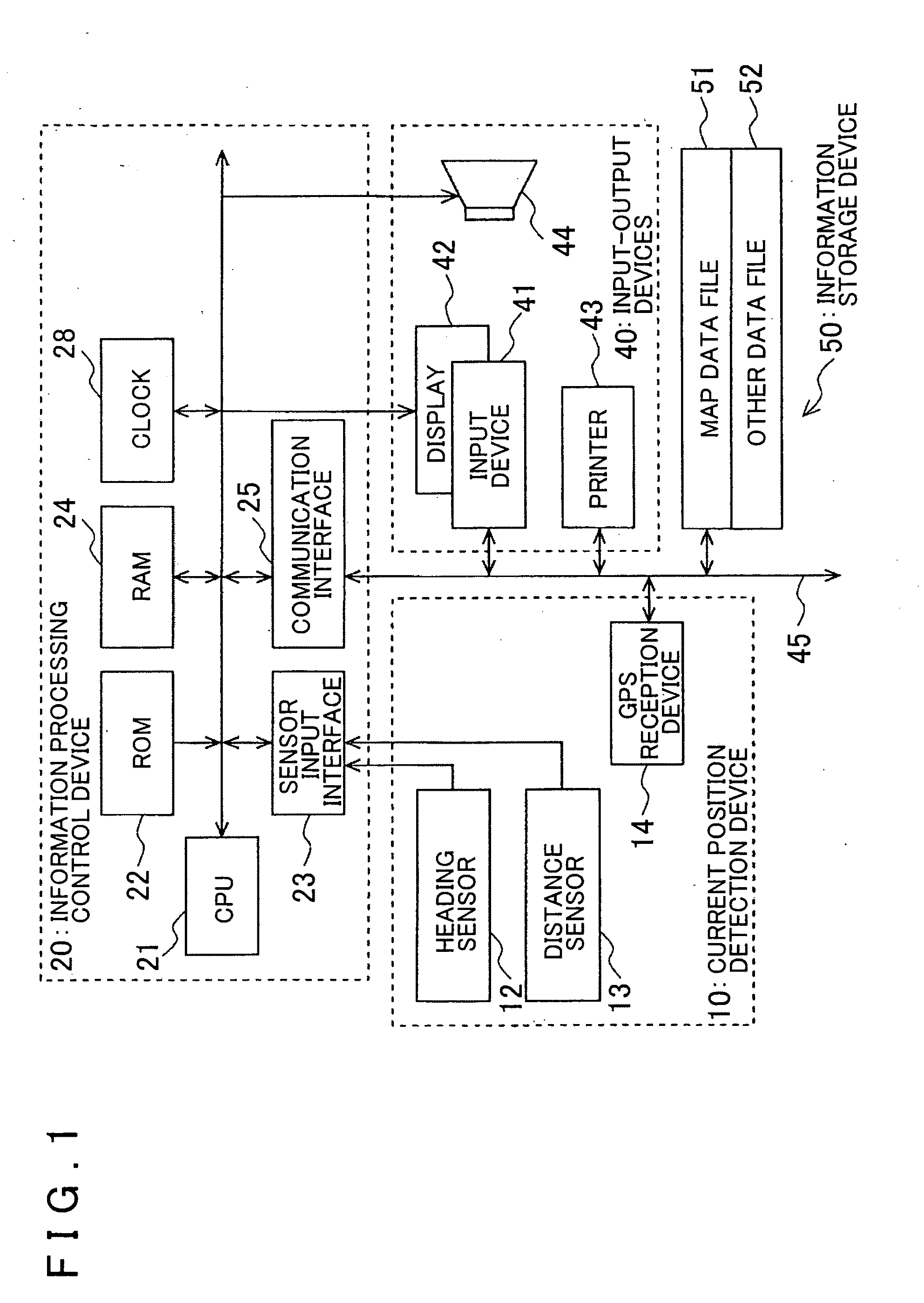

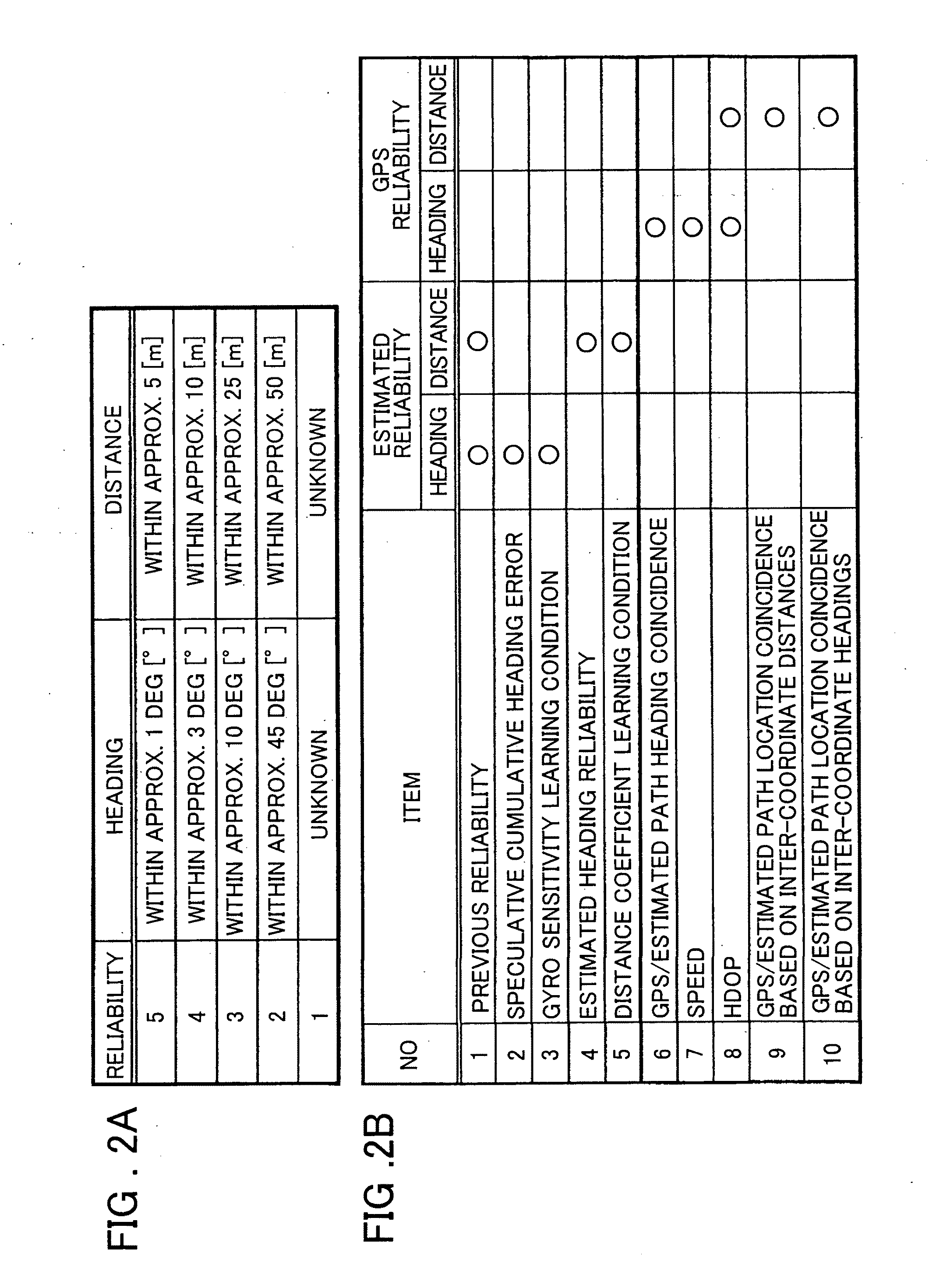

Navigation device, method, and program

ActiveUS20100217517A1Reduce false matchesTravel path can be correctedInstruments for road network navigationRoad vehicles traffic controlMaximum errorPoint correlation

Devices, methods, and programs correct an estimated path found by dead reckoning navigation. A point correlation value s is calculated based on a distance to a reliability circle whose radius is a speculative maximum error e that indicates a distance of an error range with respect to a GPS position. A correlation value Sp of an estimated path and a correlation value Sq of a candidate path are calculated from cumulative values of the point correlation values s. A correction that moves the estimated path is not performed if the correlation value Sq of the candidate path becomes worse than the correlation value Sp of the estimated path, and the correction of the estimated path is performed if the correlation value Sq of the candidate path does not become worse than the correlation value Sp of the estimated path. Thus, false matching can be further reduced, and the travel path can be suitably corrected.

Owner:AISIN AW CO LTD

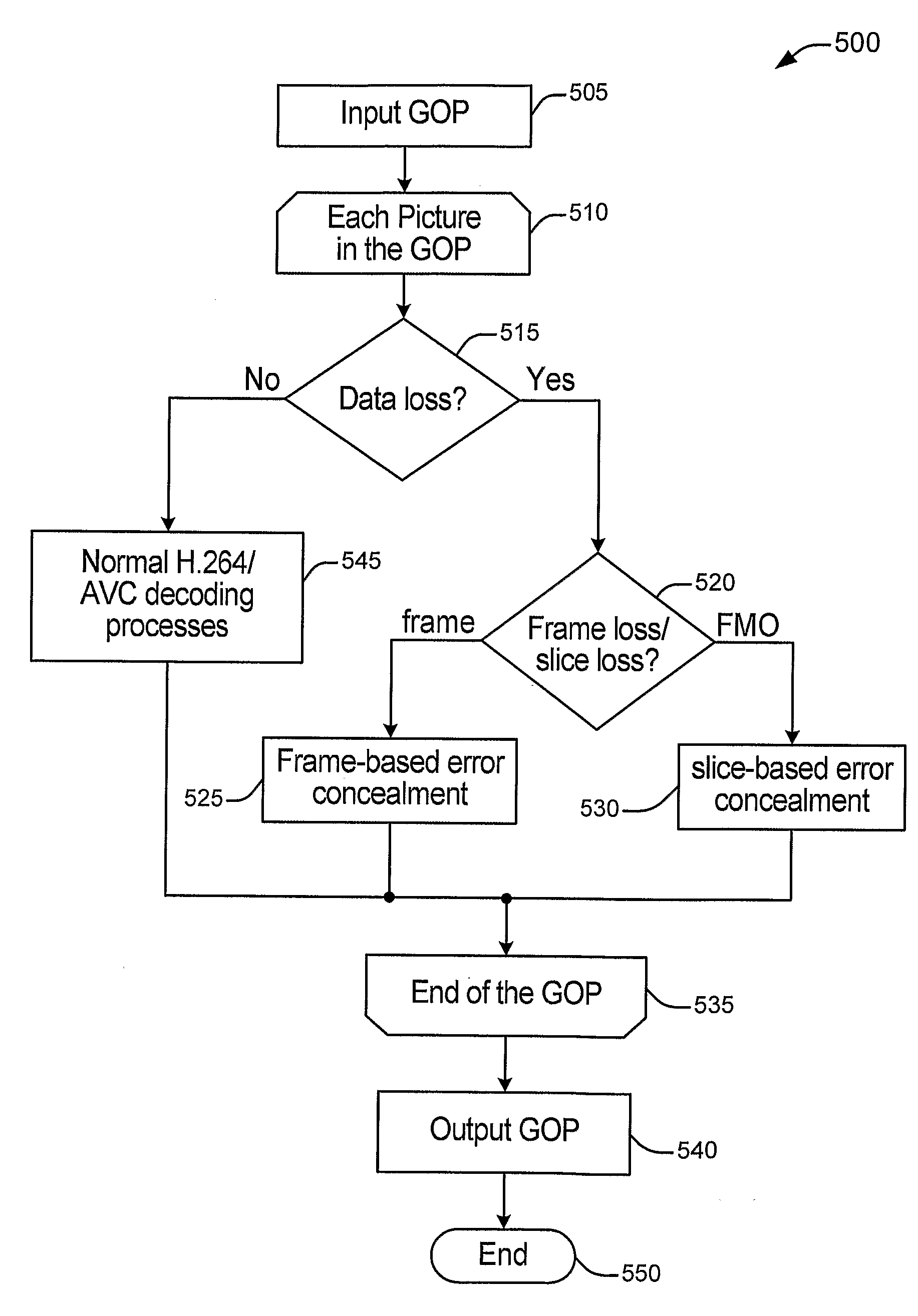

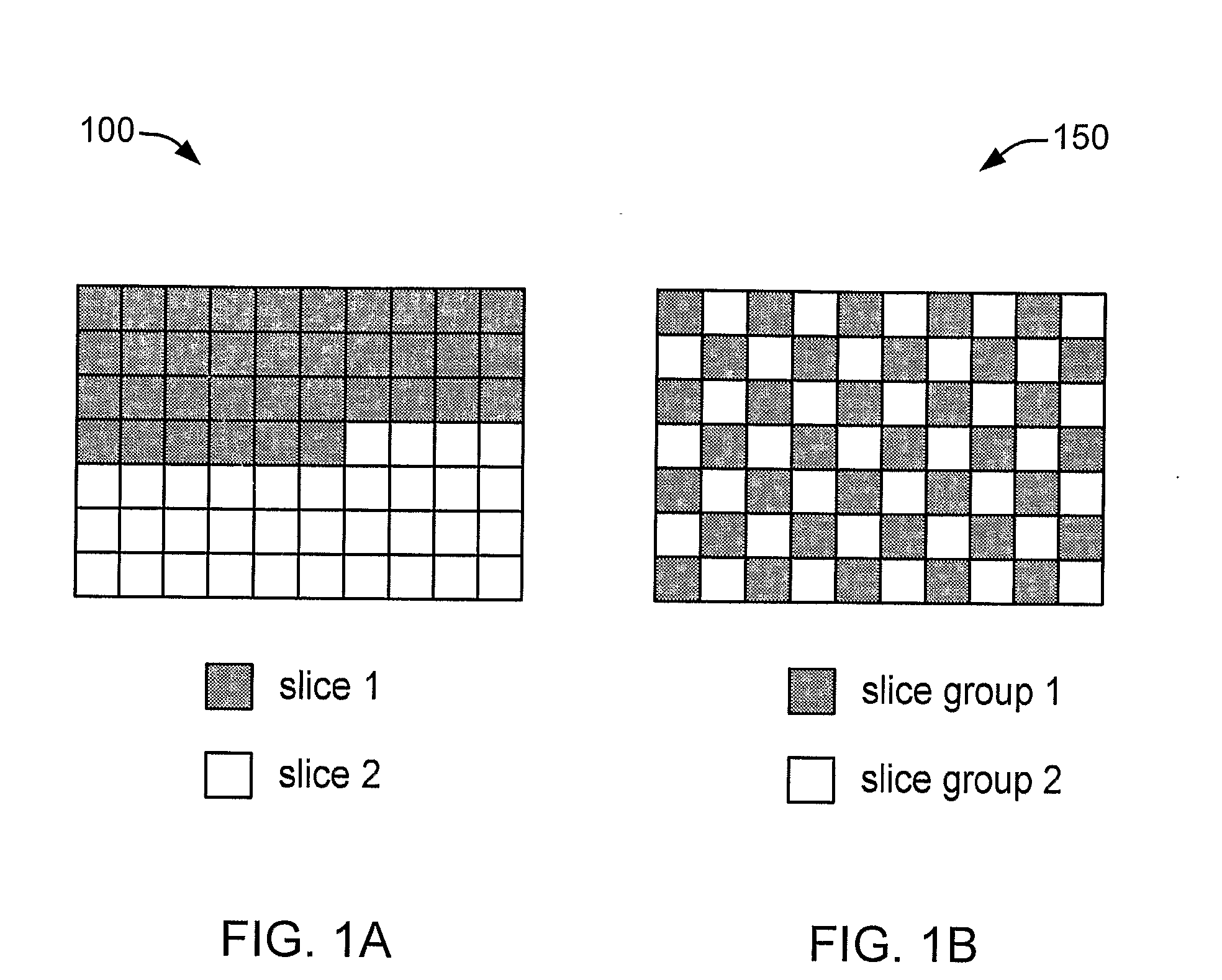

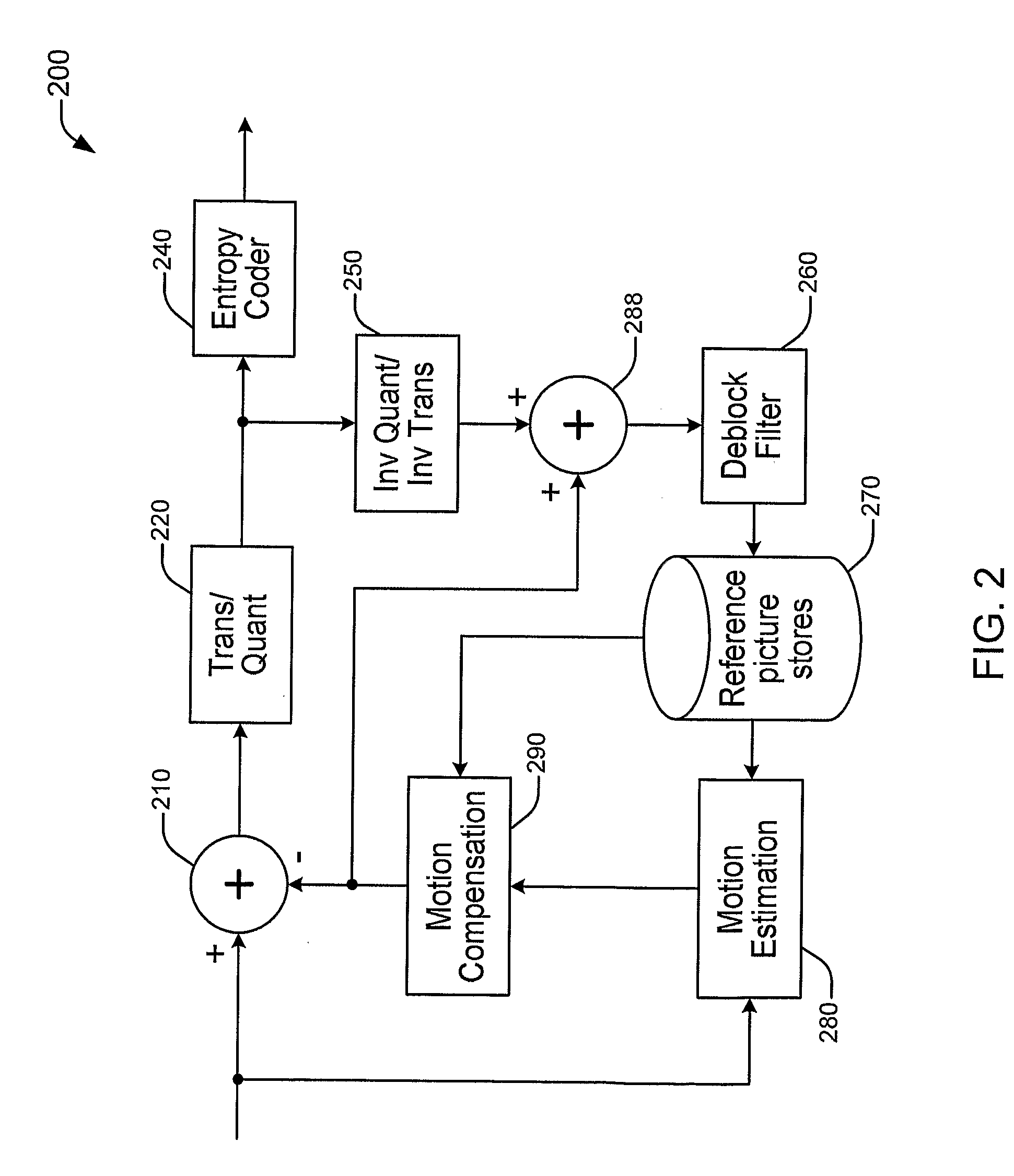

Method and Apparatus for Optimization of Frame Selection for Flexible Macroblock Ordering (FMO) Video Encoding

InactiveUS20090086827A1Color television with pulse code modulationColor television with bandwidth reductionMaximum errorGroup of pictures

There are provided a method and apparatus for optimizing frame selection for flexible macroblock ordering video encoding. A video encoder includes an encoder for encoding a group of pictures by selecting between a frame mode and at least one flexible macroblock ordering mode. The pictures in the group are allowed to be concurrently encoded in different ones of the frame mode and the least one flexible macroblock ordering mode. The mode selection for each of the pictures in the group is based on an achieved maximum error resilience capability for the group of pictures.

Owner:THOMSON LICENSING SA

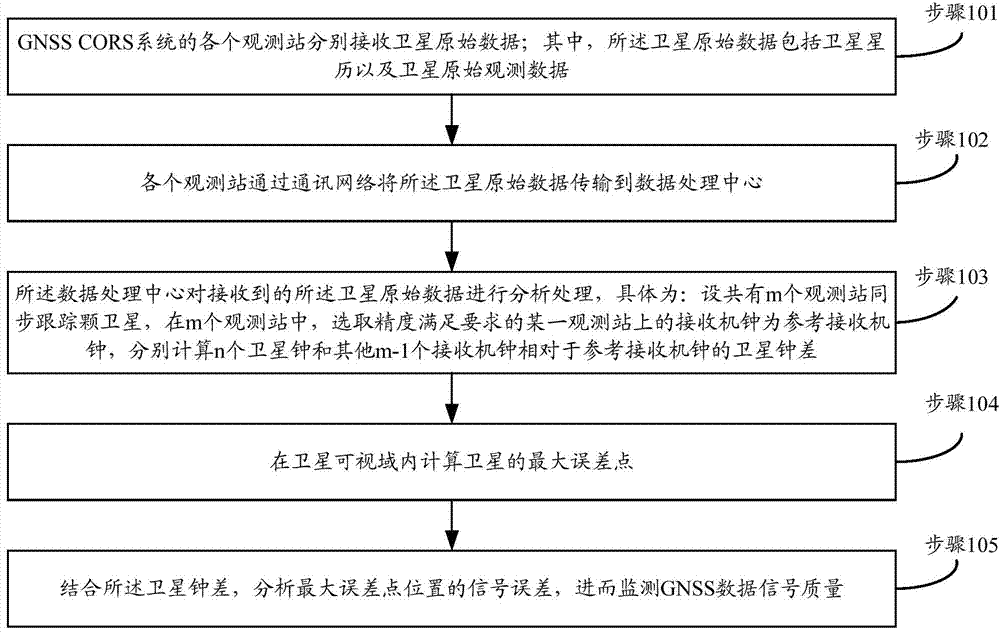

GNSS data signal quality monitor method

The invention provides a GNSS data signal quality monitor method. The GNSS data signal quality monitor method includes the steps that every observation station receives original satellite data and transmits the original satellite data to a data processing center via a communication network; the data processing center calculates the satellite clock error of n satellite clocks and other (m-1) receiver clocks relative to a reference receiver clock; the maximum error point of a satellite is calculated within the visible range of the satellite; the signal error of the maximum error point position is analyzed according to the satellite clock error, and then the GNSS data signal quality is monitored. According to the GNSS data signal quality monitor method, when the GNSS data signal quality is monitored, the satellite clock error accuracy, space signal forecast accuracy and space data signal quality monitor accuracy are monitored in real time, and as the accuracy is compared with a threshold value and is monitored and issued in real time, the GNSS data signal quality can be monitored in real time.

Owner:CHINESE ACAD OF SURVEYING & MAPPING

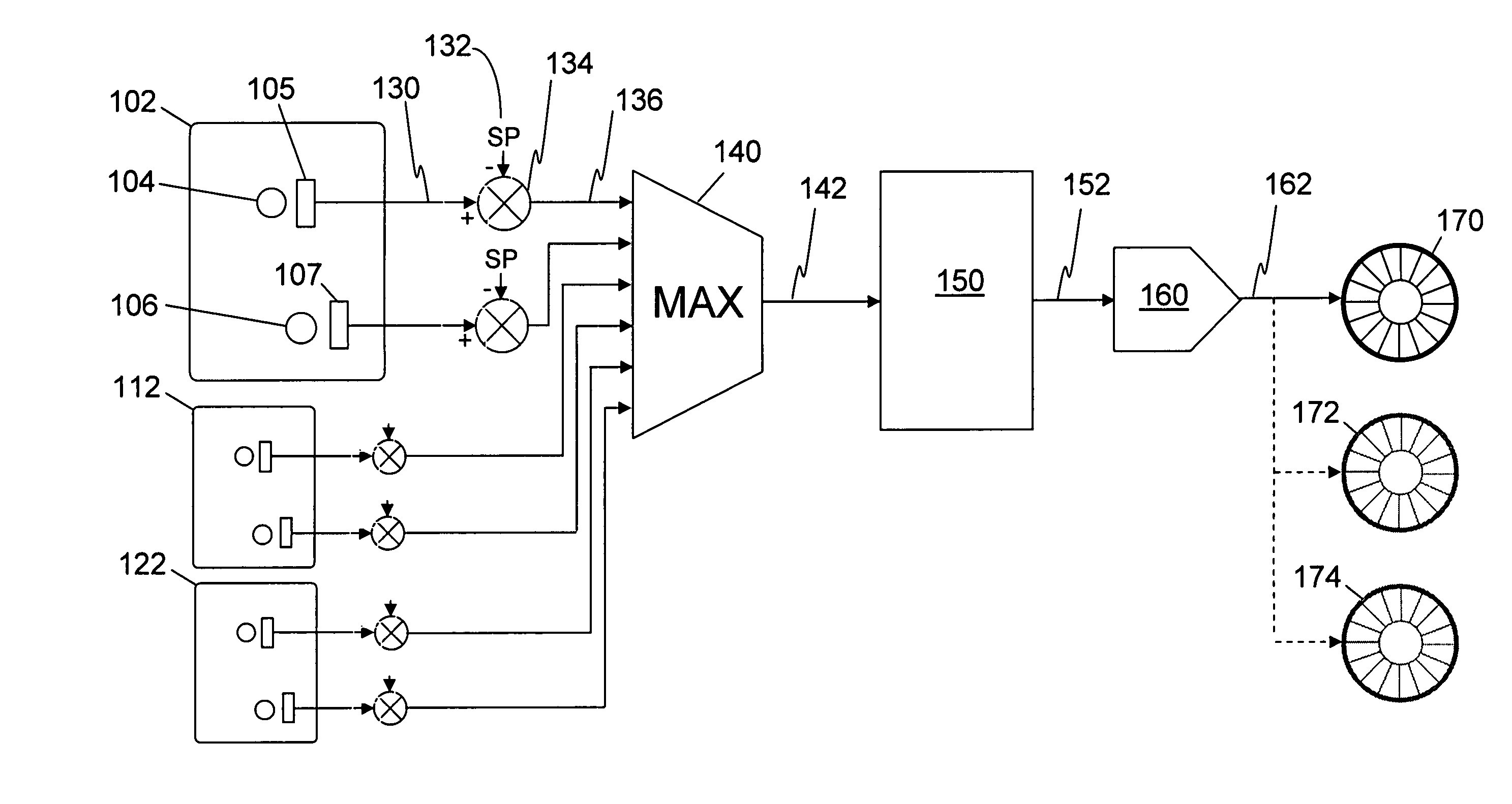

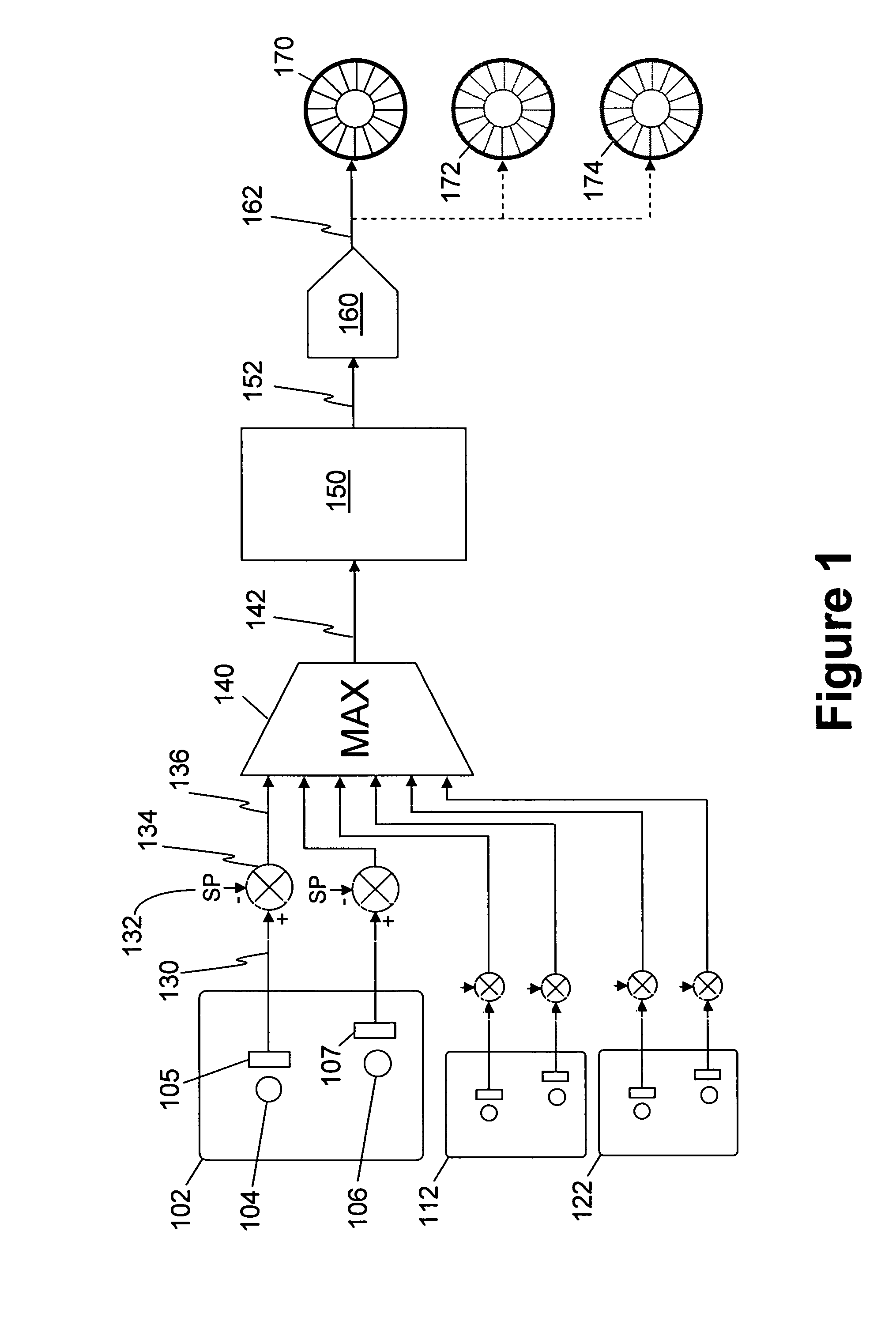

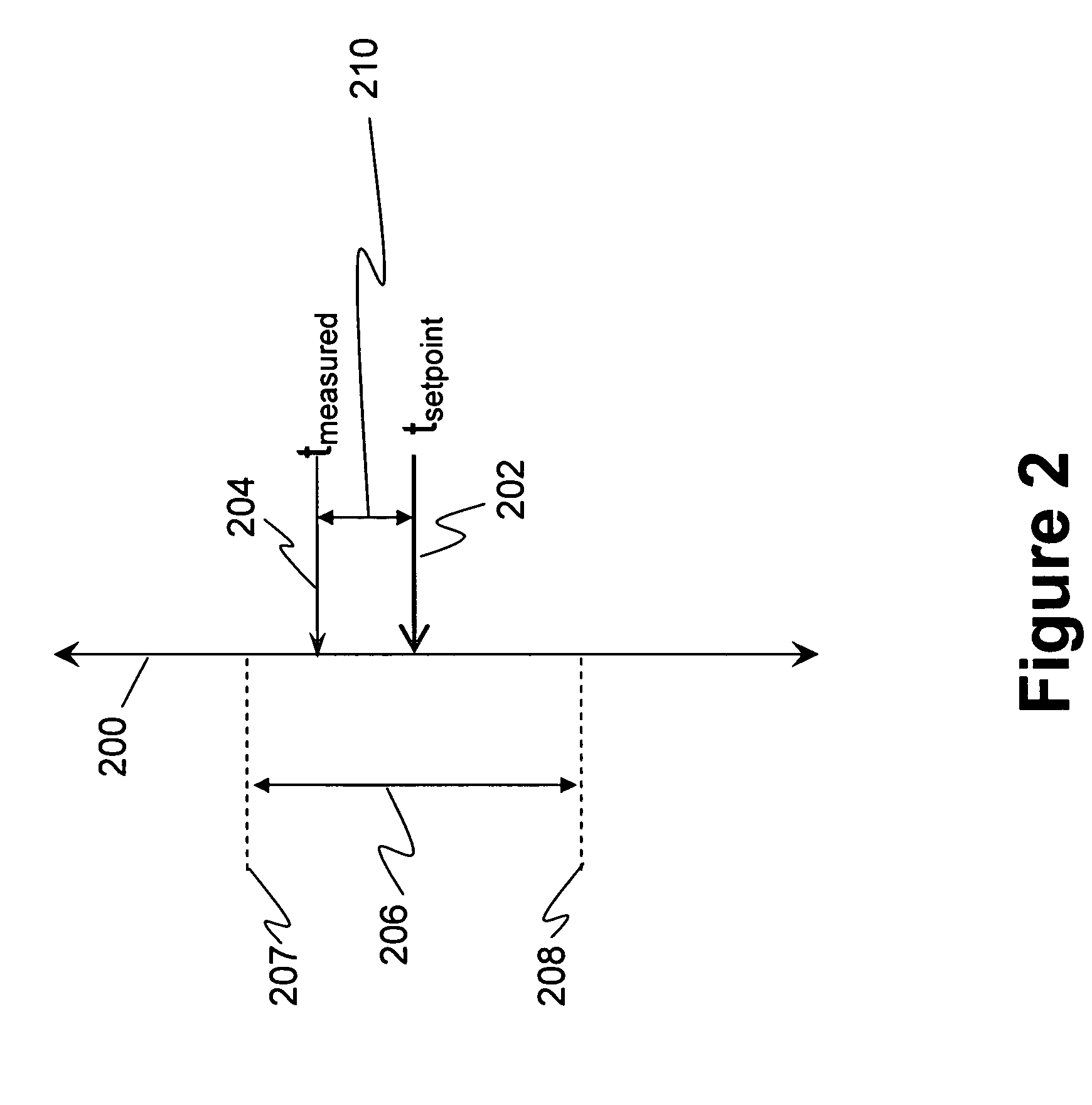

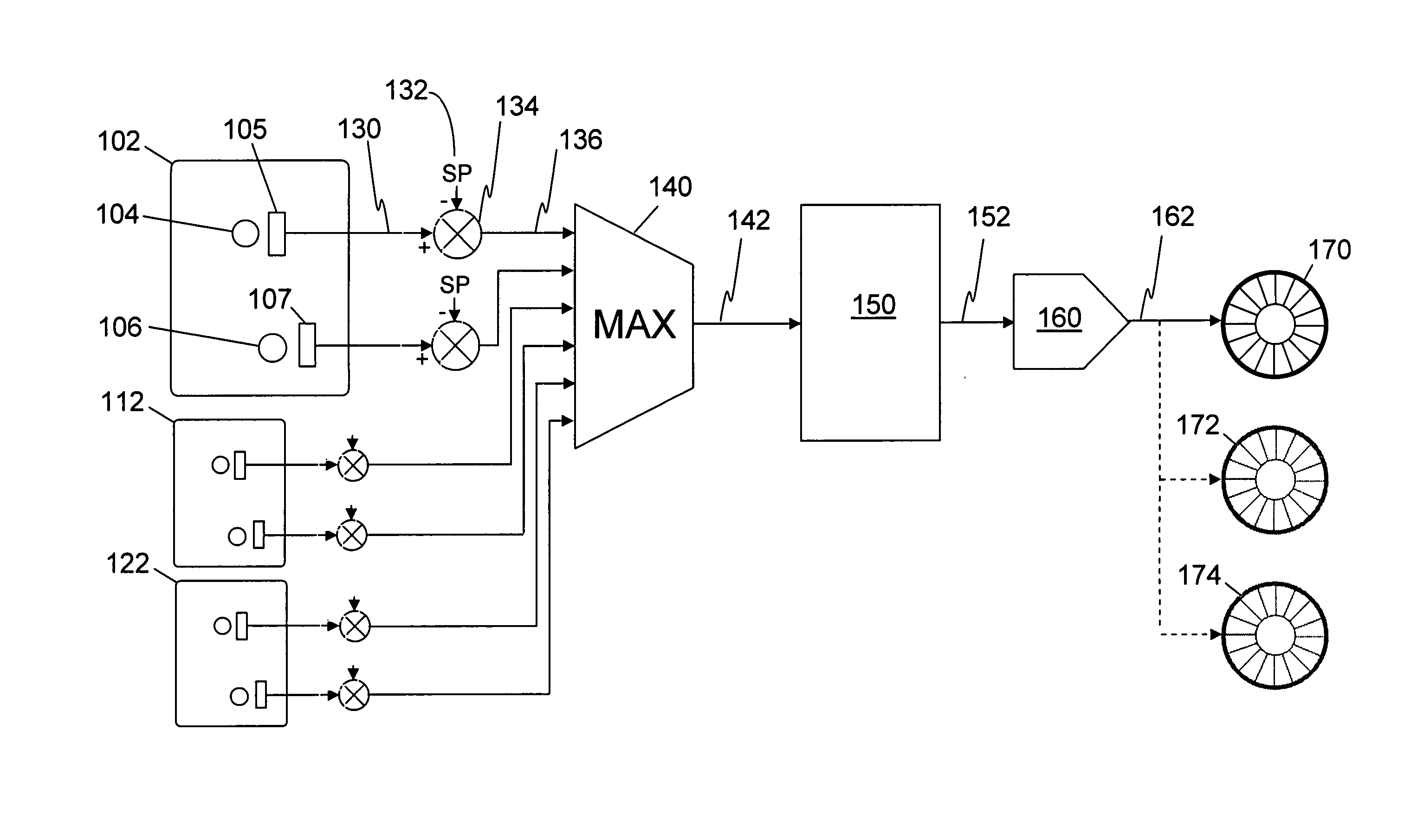

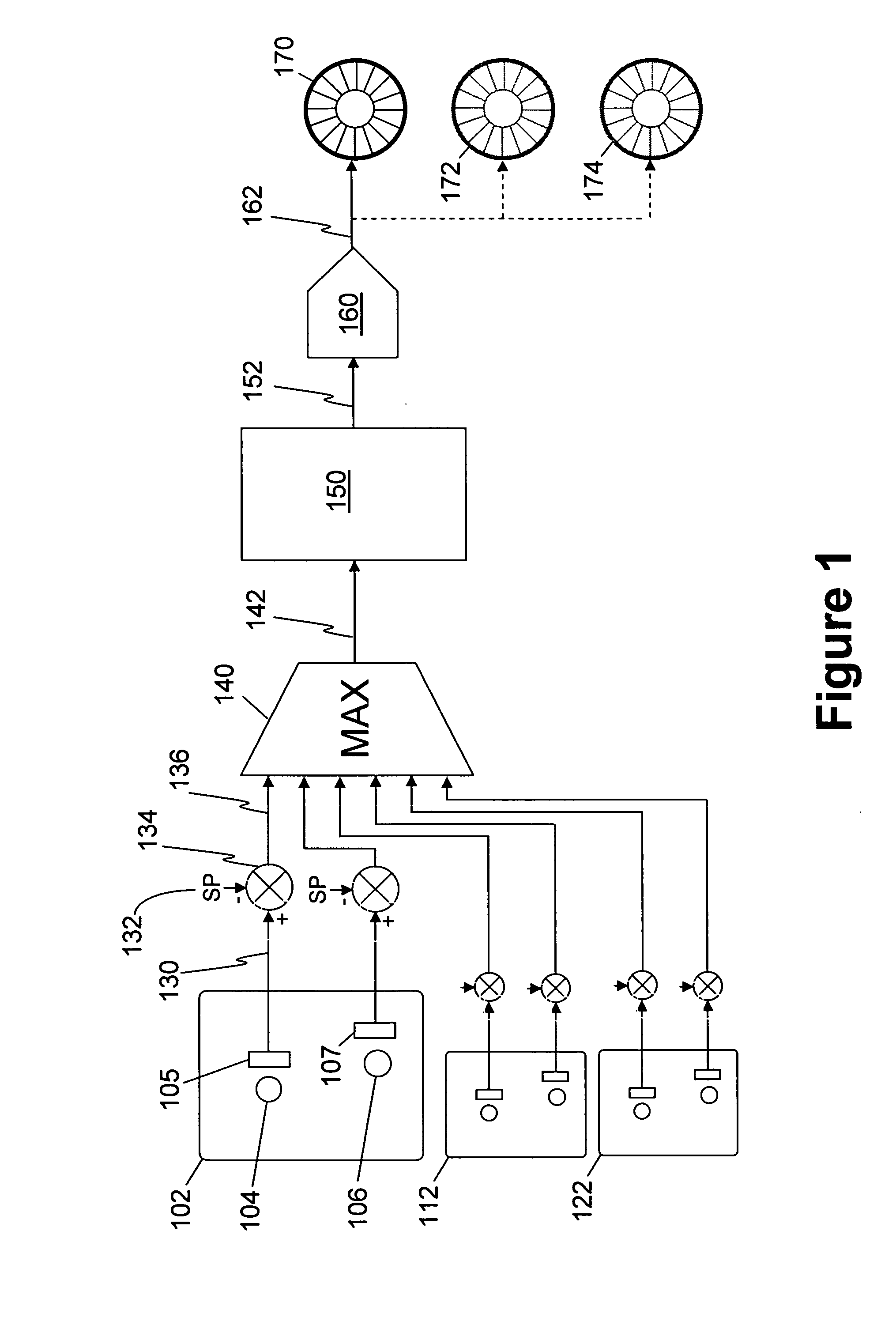

Acoustic noise reduction using fan speed control

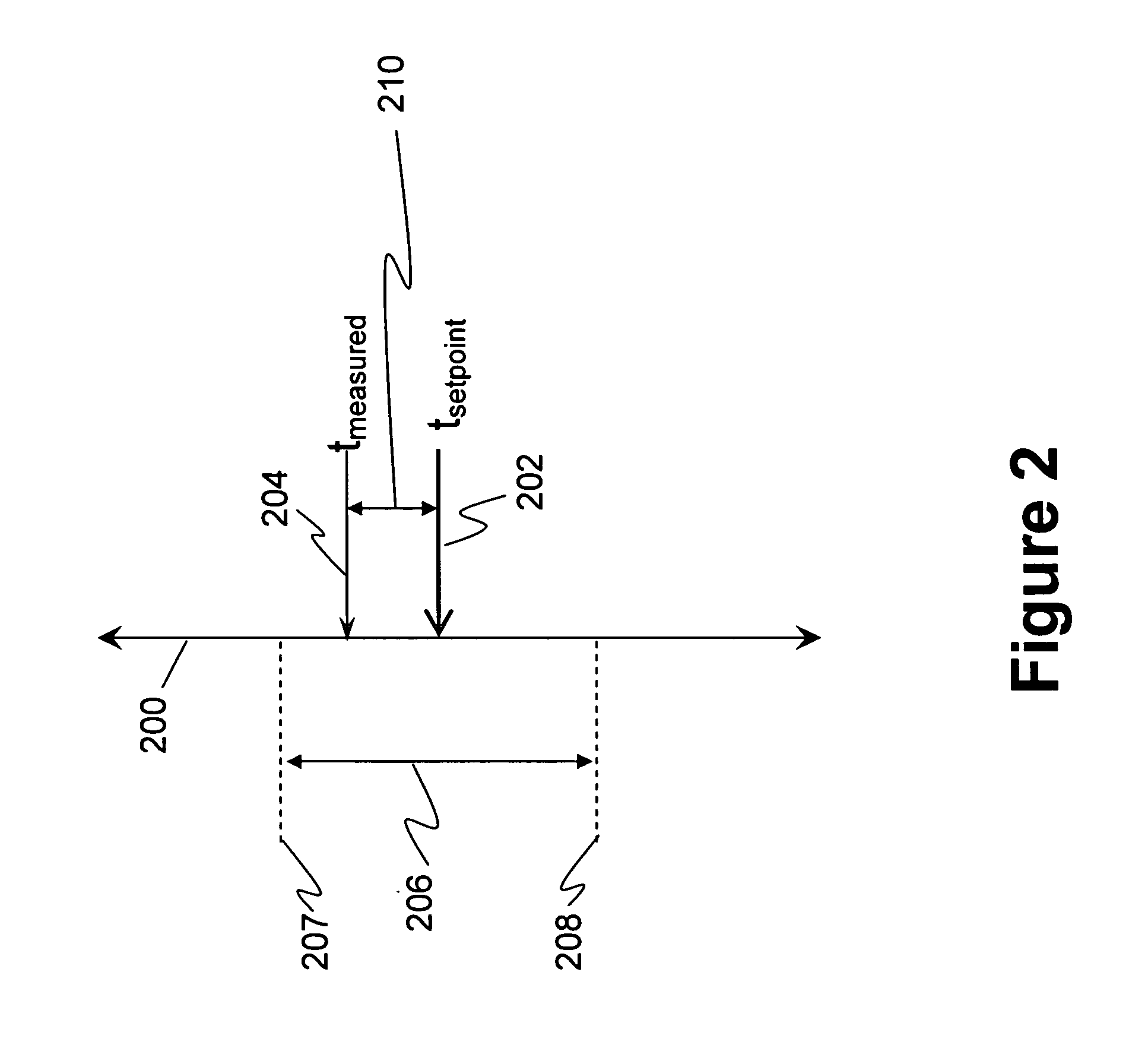

ActiveUS7331532B2Lower levelShorten speedMotor/generator/converter stoppersDC motor speed/torque controlMaximum errorAcoustic noise reduction

A method and apparatus is disclosed for acoustic noise reduction using fan speed control. The acoustic noise reduction using fan speed control includes a plurality of temperature detectors disposed at a plurality of locations within an electronics equipment enclosure, each detector having an associated setpoint temperature. An error value is determined for each temperature detector, the error consisting of the difference between the detected temperature and the associated setpoint temperature. The maximum error among all error values is then identified and the operating speed of a cooling fan in is set in response to this maximum error. Advantages include providing a fan speed directly related to electronics temperature which inherently accounts for higher ambient temperatures, enclosure altitude, electronics power consumption, and air filter clogging. The acoustic noise reduction using fan speed control is particularly useful for overcoming the need to overcompensate fan speed, thereby resulting in higher than necessary noise levels in order to accommodate worse-case conditions known in the art.

Owner:CIENA

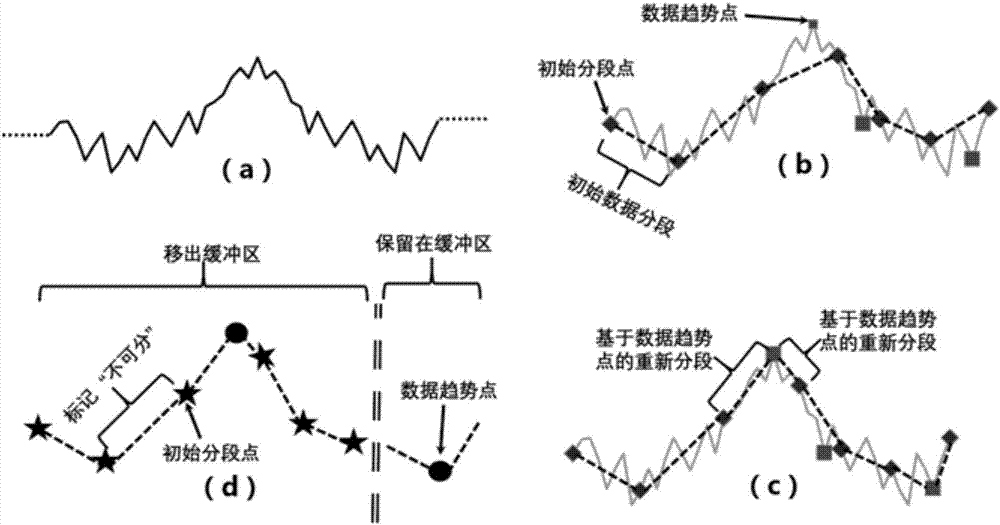

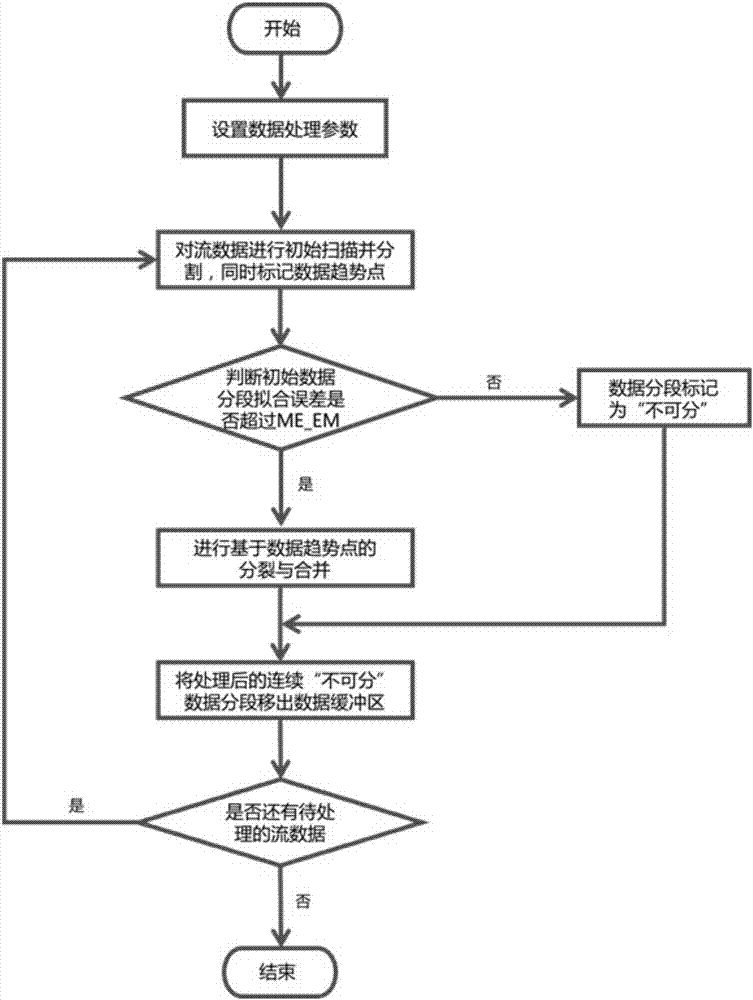

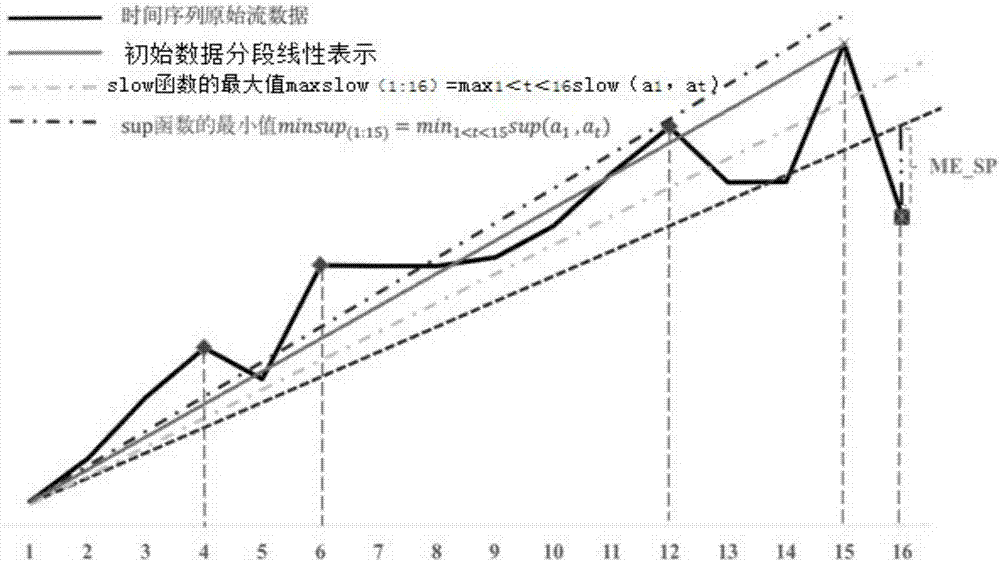

Streaming time series data dimensionality reduction and simplified representation method based on piecewise linear representation

InactiveCN106960059AGuaranteed Dimensionality Reduction ResultsImprove fitting accuracySpecial data processing applicationsMaximum errorStreaming data

The invention relates to a streaming time series data dimensionality reduction and simplified representation method based on piecewise linear representation. The method comprises the following steps that: S1: presetting data segments and compression parameters; S2: carrying out data scanning on streaming time series data in a slide window way, and entering a streaming data buffer zone; S3: judging whether the fitting error of an initial segmented data segment exceeds an ME_ES (Maximum Error for Entire Segment) or not, carrying out reservation if the fitting error of the initial segmented data segment exceeds the ME_ES, and marking the initial data segment as "inseparable", and if the fitting error of the initial segmented data segment does not exceed the ME_ES, carrying out secondary optimal segmentation; and S4: moving the data segment which is marked as "inseparable" in the streaming data buffer zone out of the streaming data buffer zone, judging whether the streaming time series data to be processed is in the presence or not, if the streaming time series data to be processed is in the presence, returning to the S2, and otherwise, ending. By use of the method, data dimensionality reduction execution efficiency is guaranteed to a high limit, the fitting accuracy of data simplified representation is optimized to a certain range, and accuracy and the execution efficiency of data representation can be improved.

Owner:SHANDONG UNIV

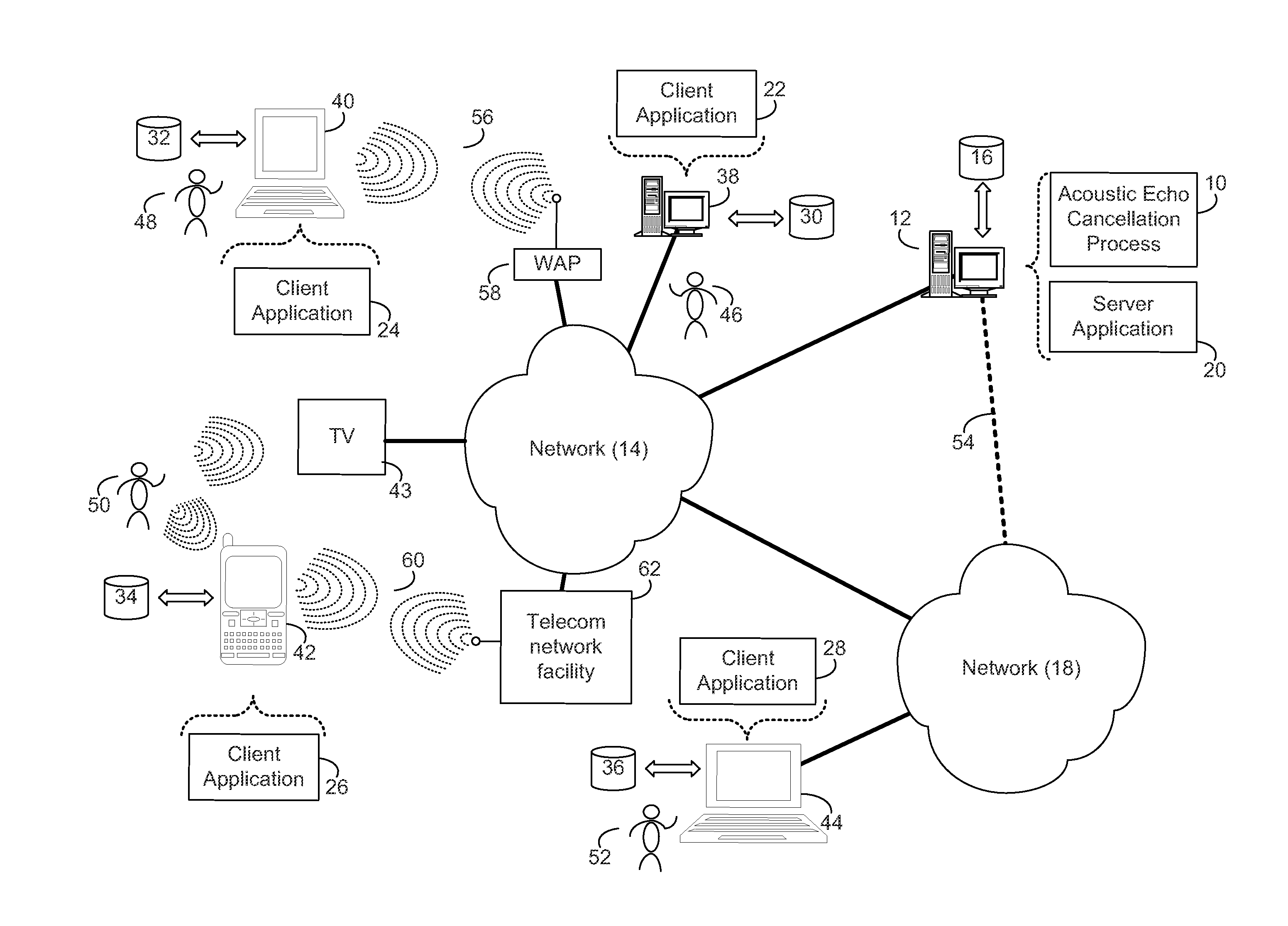

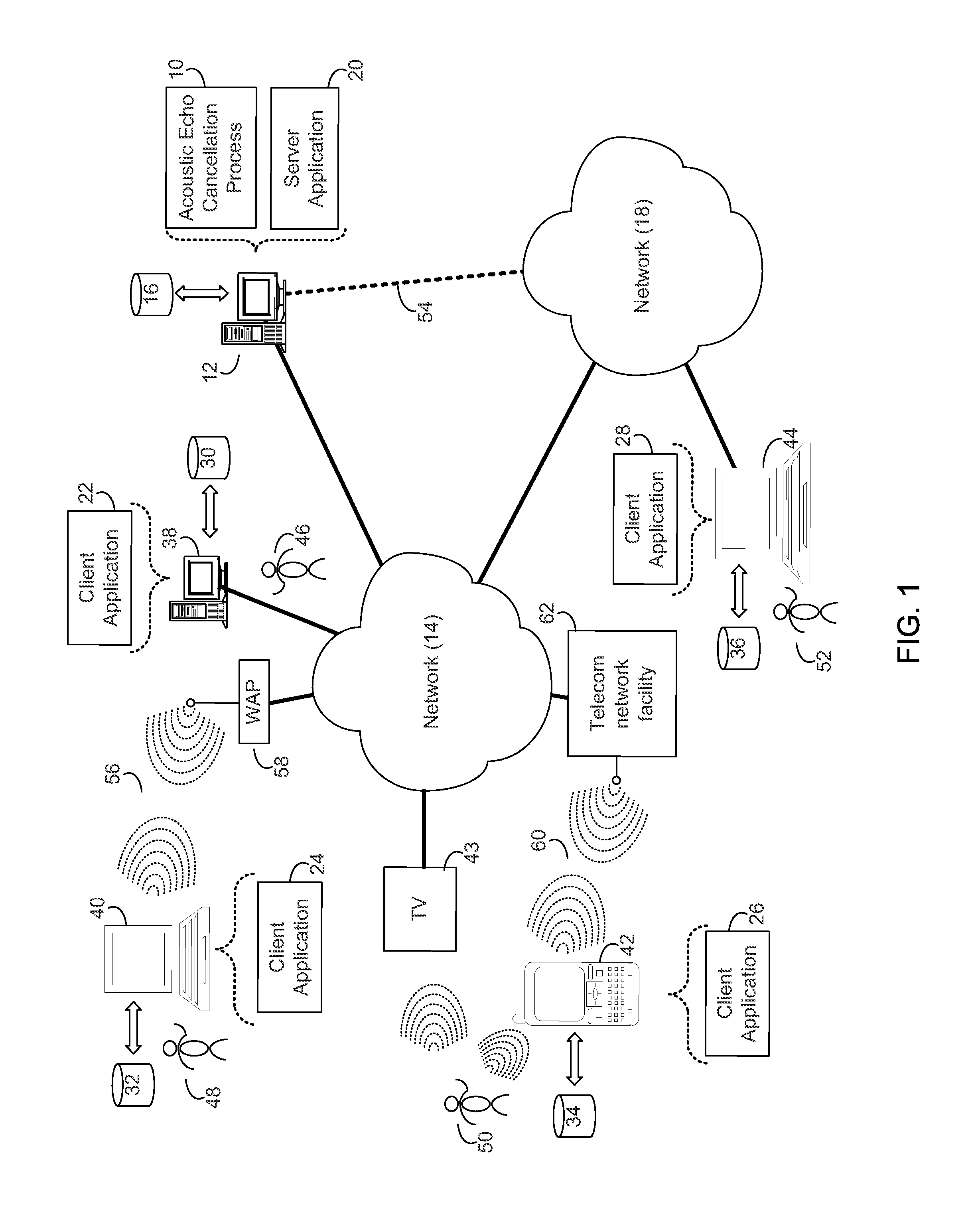

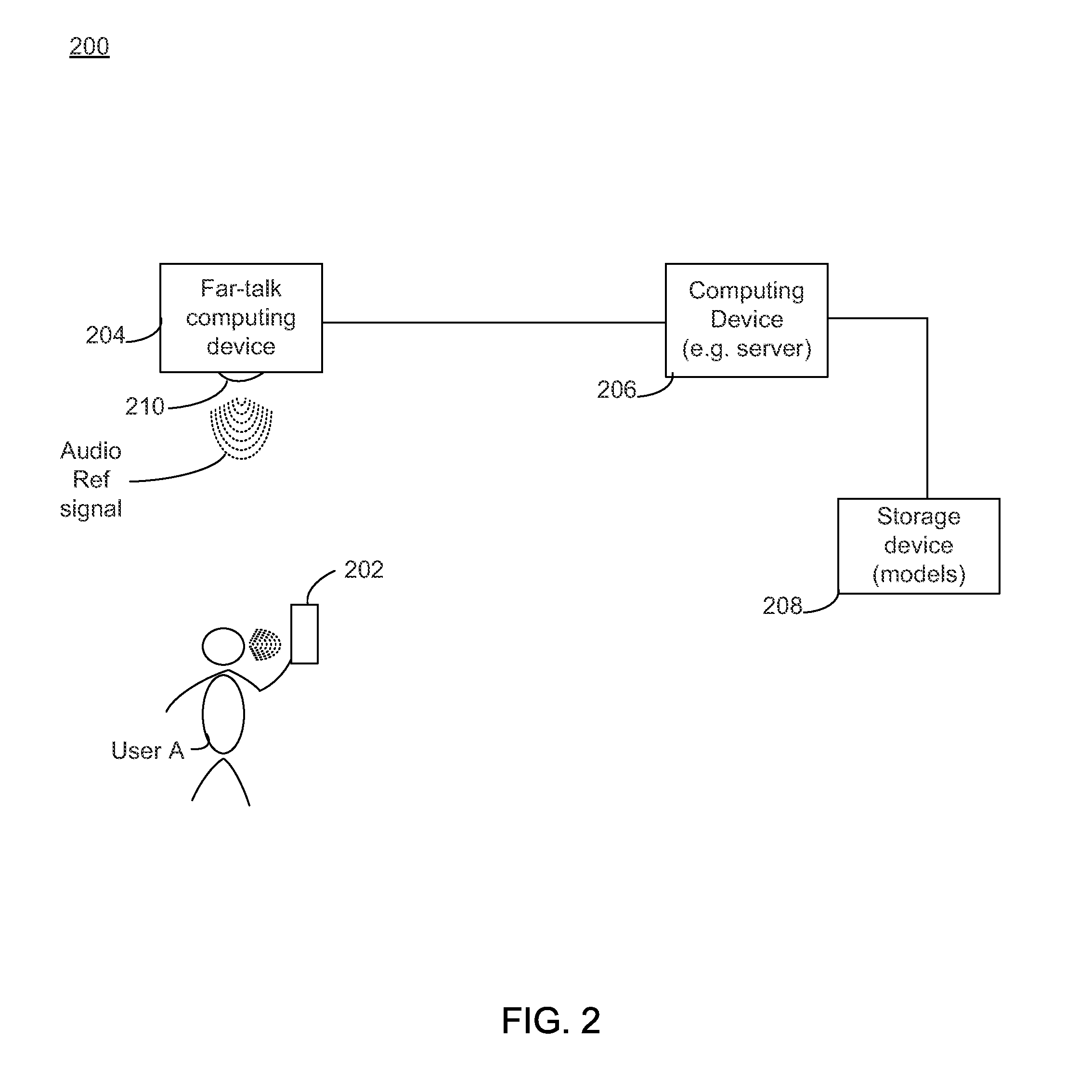

System and method for acoustic echo cancellation

ActiveUS20160044159A1Two-way loud-speaking telephone systemsEcho suppressors/cancellersMaximum errorAudio filter

A system and method for acoustic echo cancellation is provided. Embodiments may include receiving, at one or more microphones, an audio reference signal from an audio speaker. Embodiments may also include filtering the audio reference signal using one or more adaptive audio filters. Embodiments may further include analyzing a level of signal energy of the audio reference signal with regard to time, frequency and audio channel to identify at least one maximum error contribution point. Embodiments may also include updating the one or more adaptive audio filters based upon, at least in part, the analyzed audio reference signal.

Owner:CERENCE OPERATING CO

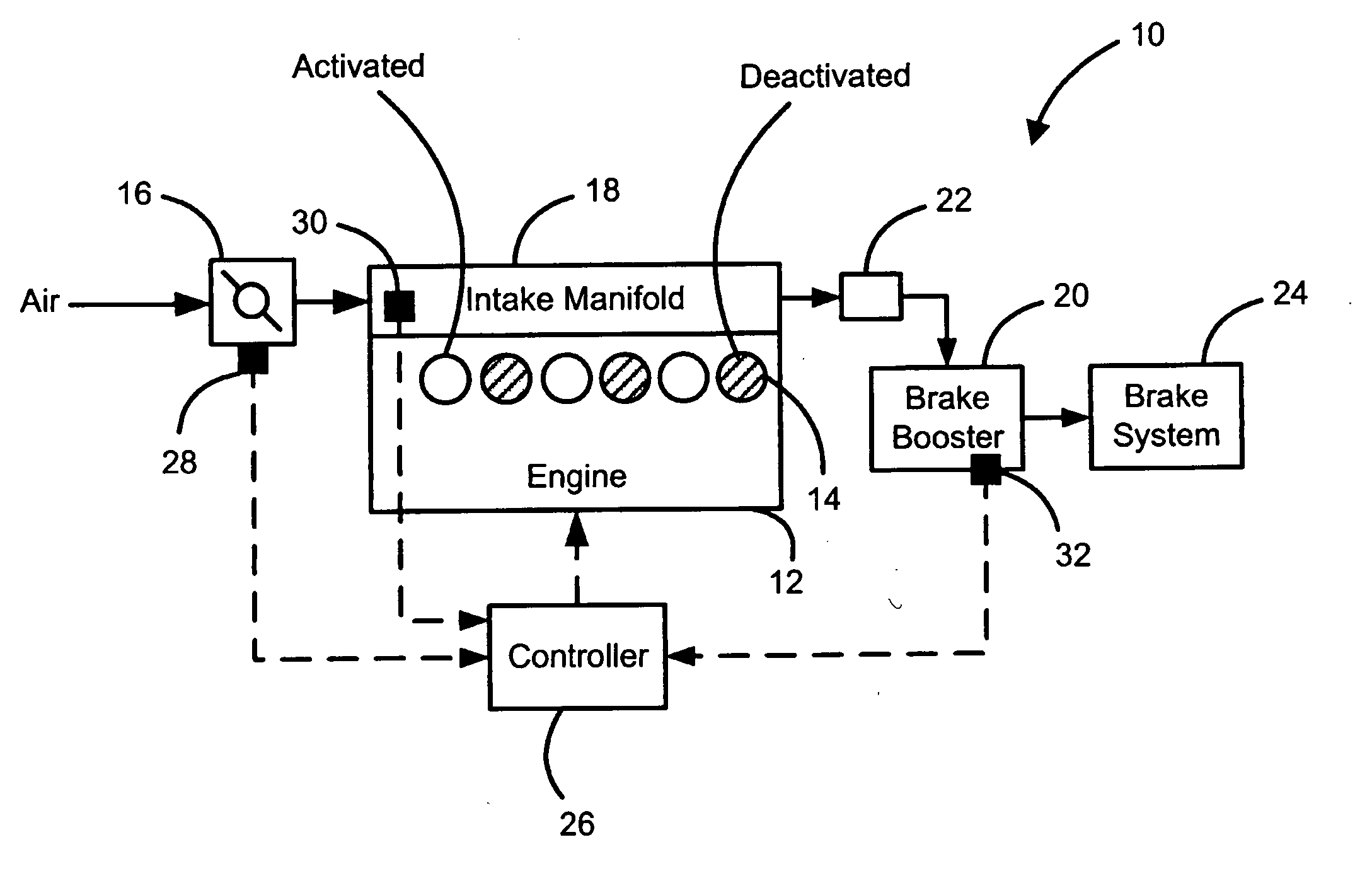

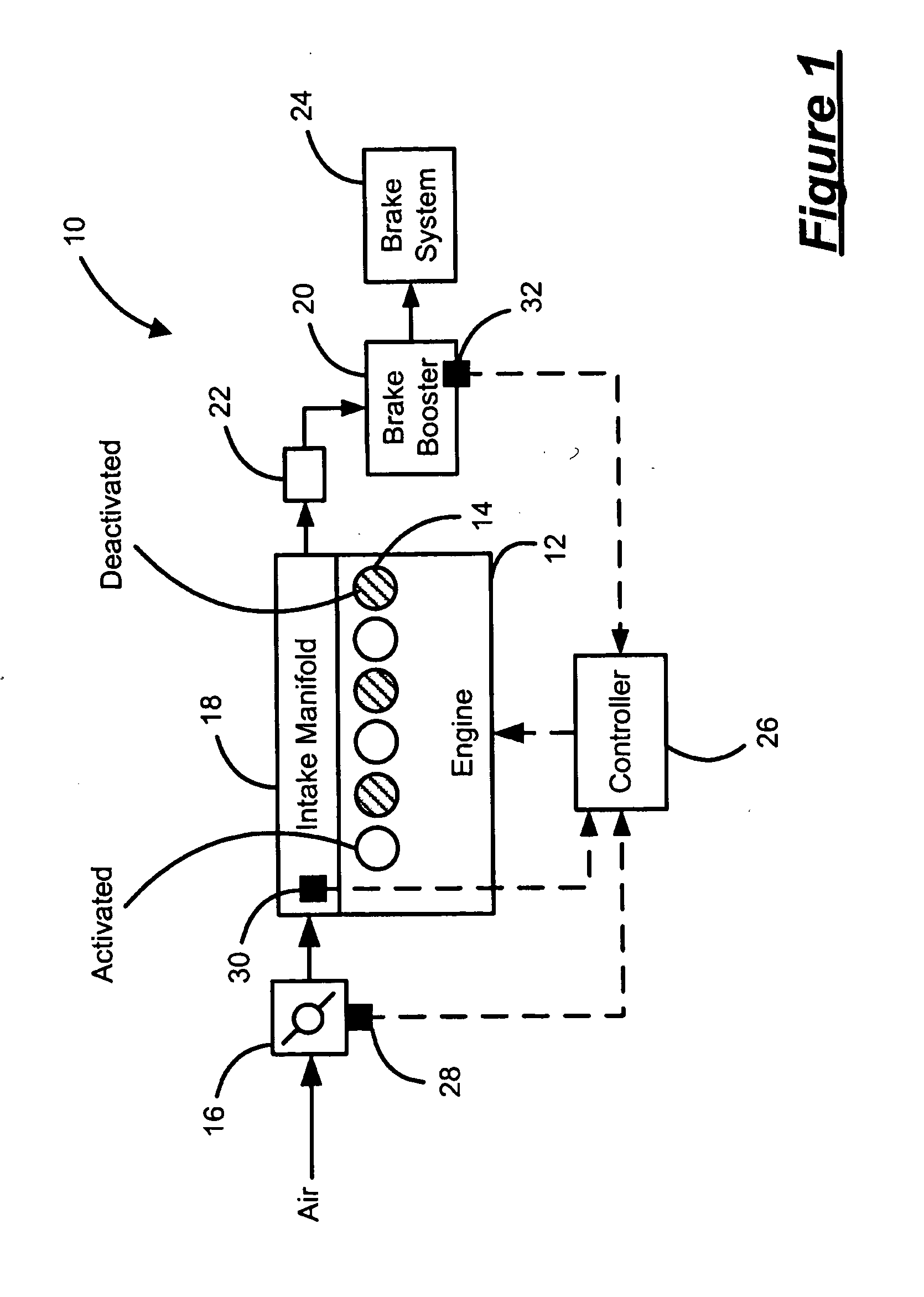

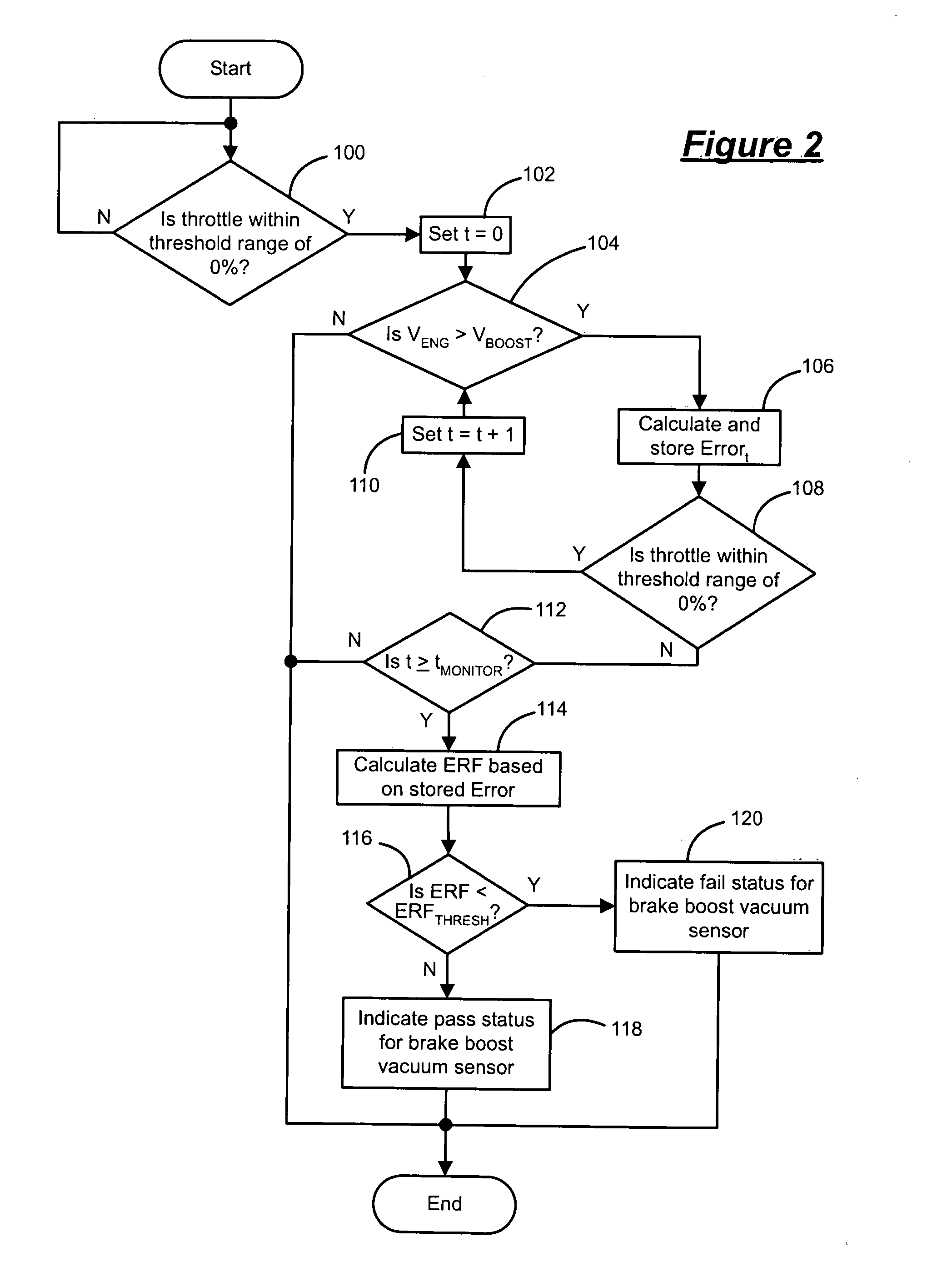

Brake booster vacuum sensor diagnostic

A diagnostic system for a brake booster sensor includes a monitor that monitors a maximum error and a minimum error based on a brake booster sensor signal over a monitoring period. A first comparator determines one of a pass status and a fail status of the brake booster sensor based on the maximum error and the minimum error.

Owner:GM GLOBAL TECH OPERATIONS LLC

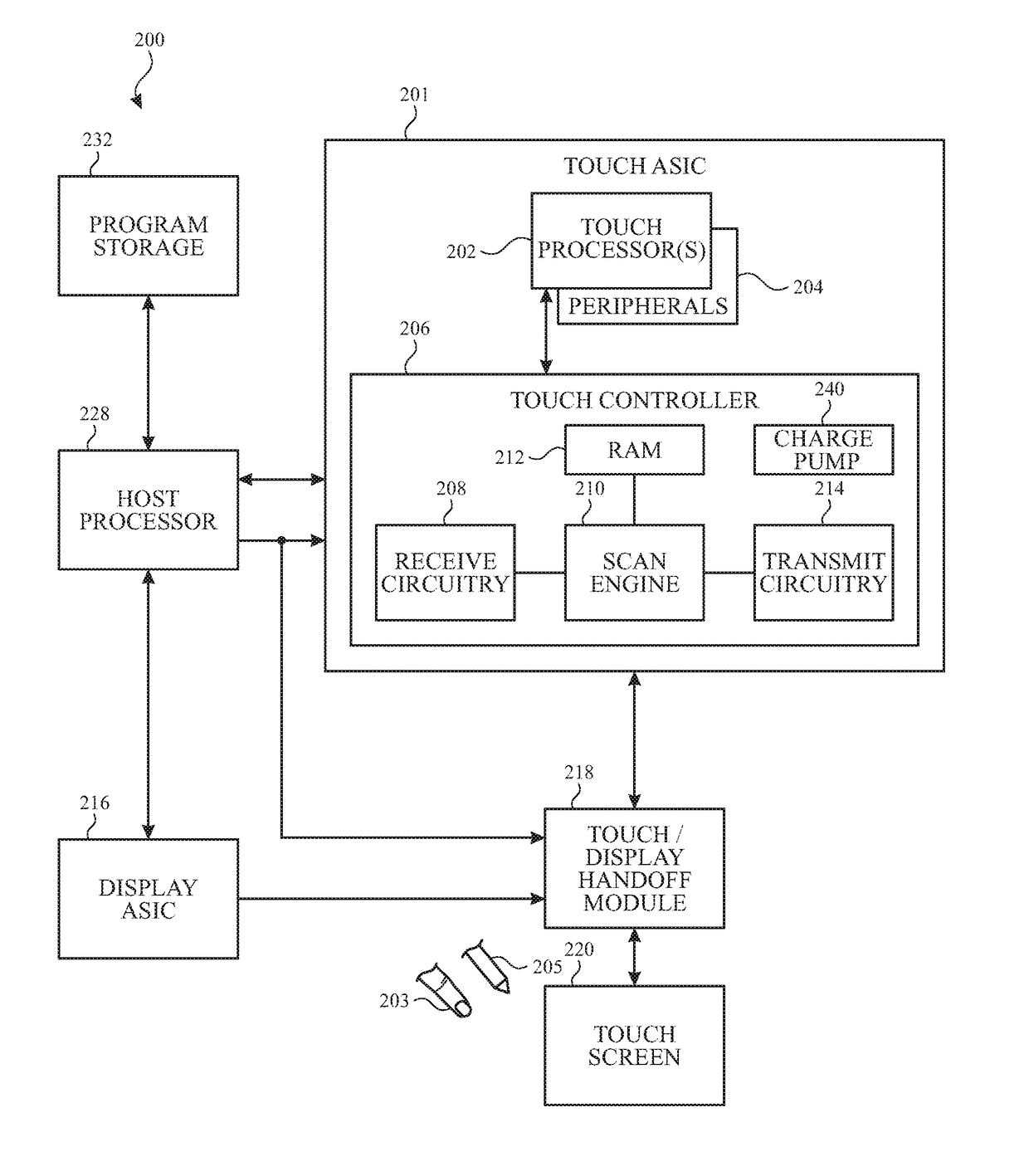

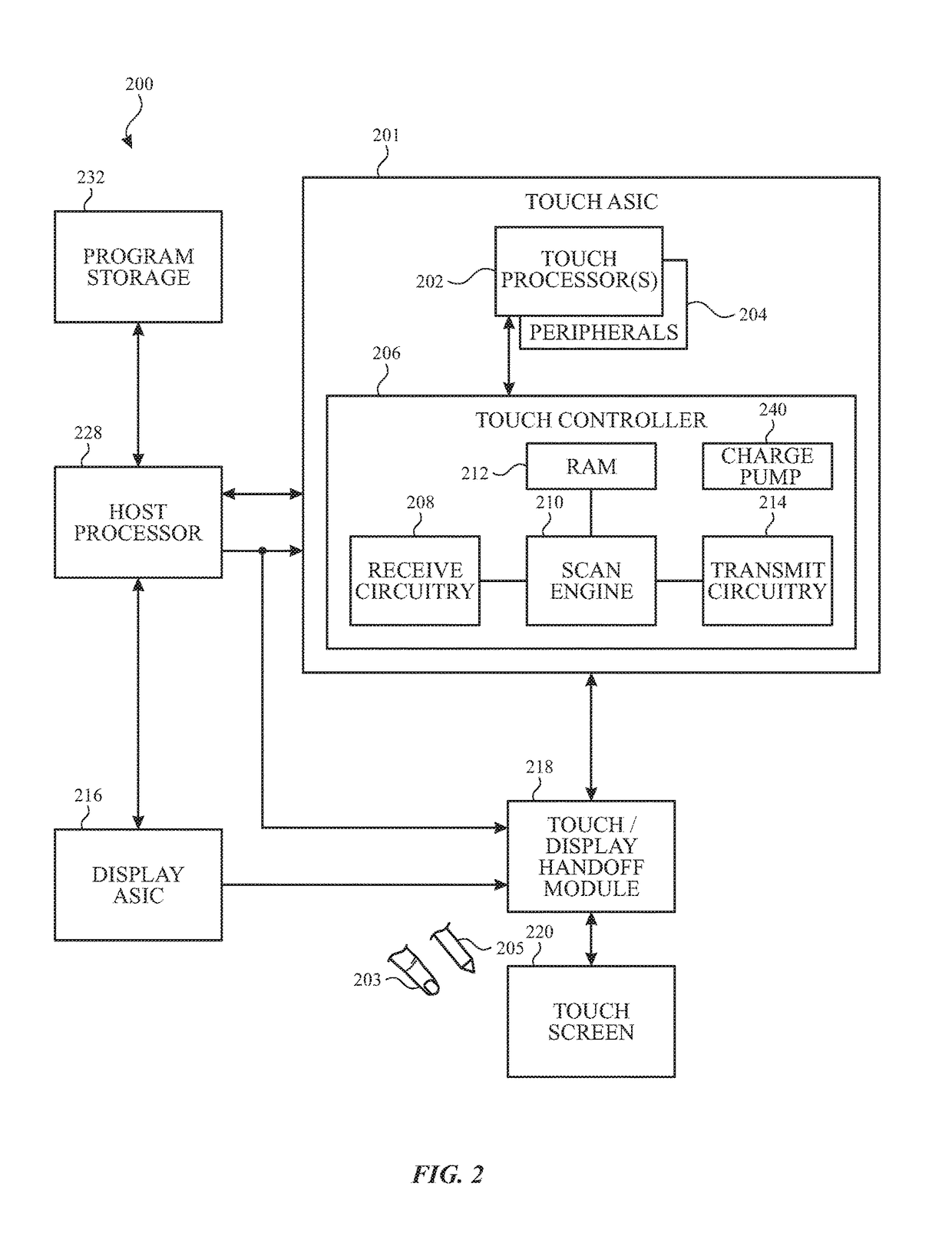

Touch induced flicker mitigation for variable refresh rate display

ActiveUS20180059868A1Mitigation of touch induced flickerReduce the required powerCathode-ray tube indicatorsNon-linear opticsMaximum errorTouch Senses

Touch induced flicker for variable refresh rate (VRR) displays can be reduced by adjusting one or more voltages. Synchronization of touch sensing operations after an immediate exit can introduce flicker issues into the VRR display. In some examples, the touched induced flicker can be reduced or eliminated by tuning the voltage on a common electrode (Vcom) to a tuning point that reduces a maximum error below a threshold, irrespective of refresh rate. In some examples, touch induced flicker can be reduced or eliminated by monitoring average Vcom, and when the change in average Vcom exceeds a threshold, Vcom can be adjusted to counteract the change in average Vcom due to the variable refresh rate and / or immediate exit. In some examples, touch induced flicker can be reduced or eliminated by applying a direct current (DC) pedestal to pixel gate lines during touch sensing scans.

Owner:APPLE INC

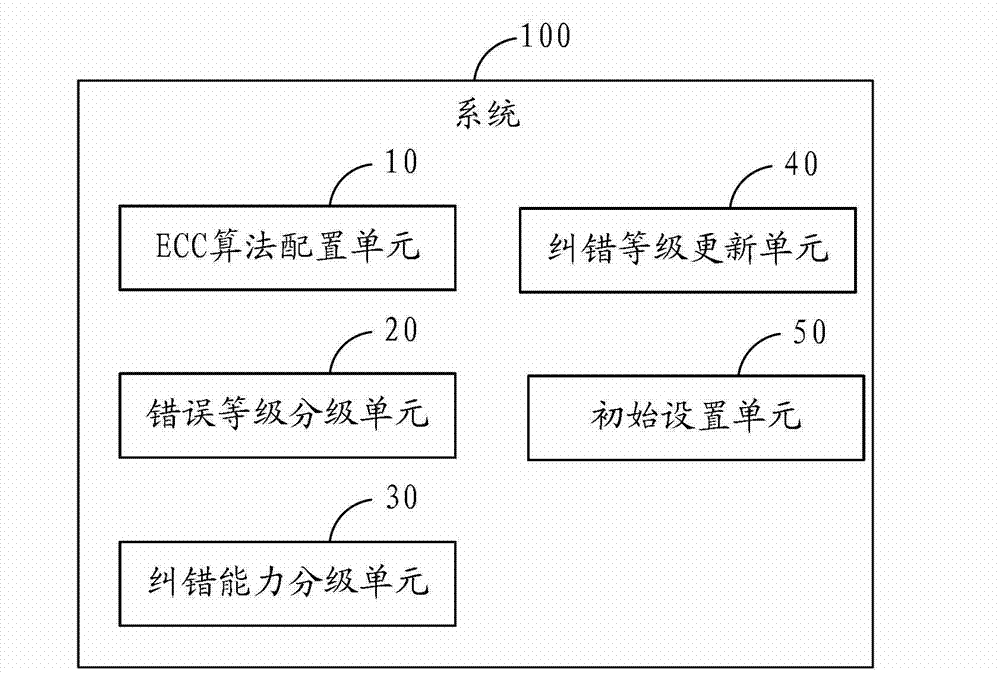

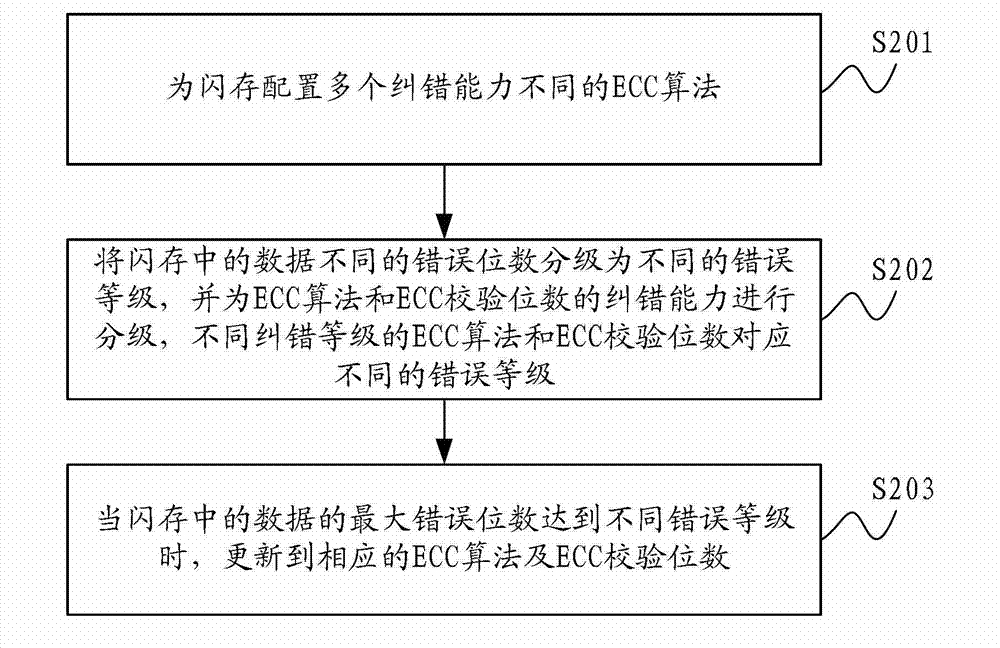

Method, system, and flash memory of ECC dynamic adjustment

InactiveCN102969028AExtended service lifeReduce computing power consumptionStatic storageMaximum errorComputer science

The invention is suitable for the technical field of flash memory storage, and provides a method, a system, and a flash memory of an ECC dynamic adjustment. The method comprises configuring a plurality of ECC algorithms with different error correction capability for the flash memory; grading error bits with different data in the flash memory into different error grades, and grading the error correction capability of the ECC algorithms and the ECC check bits, with the ECC algorithms and the ECC check bits of different error correction grades being corresponding to different error grades; and updating to corresponding ECC algorithms and the ECC check bits when maximum error bit of the data in the flash memory reaches different error grades. Therefore, the method dynamically adjusts ECC bits at different stages in the life cycle for an NAND Flash, thereby realizing balance of an access rate and a service life of NAND Flash.

Owner:RAMAXEL TECH SHENZHEN

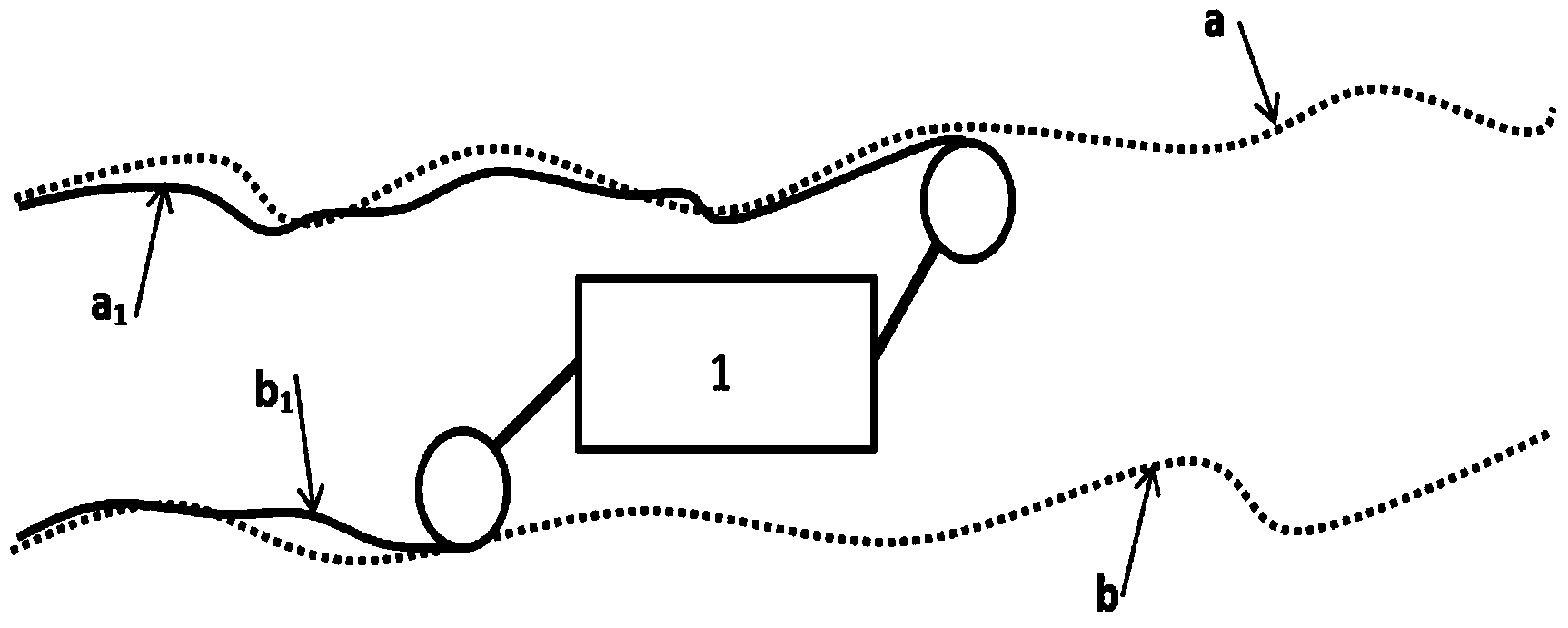

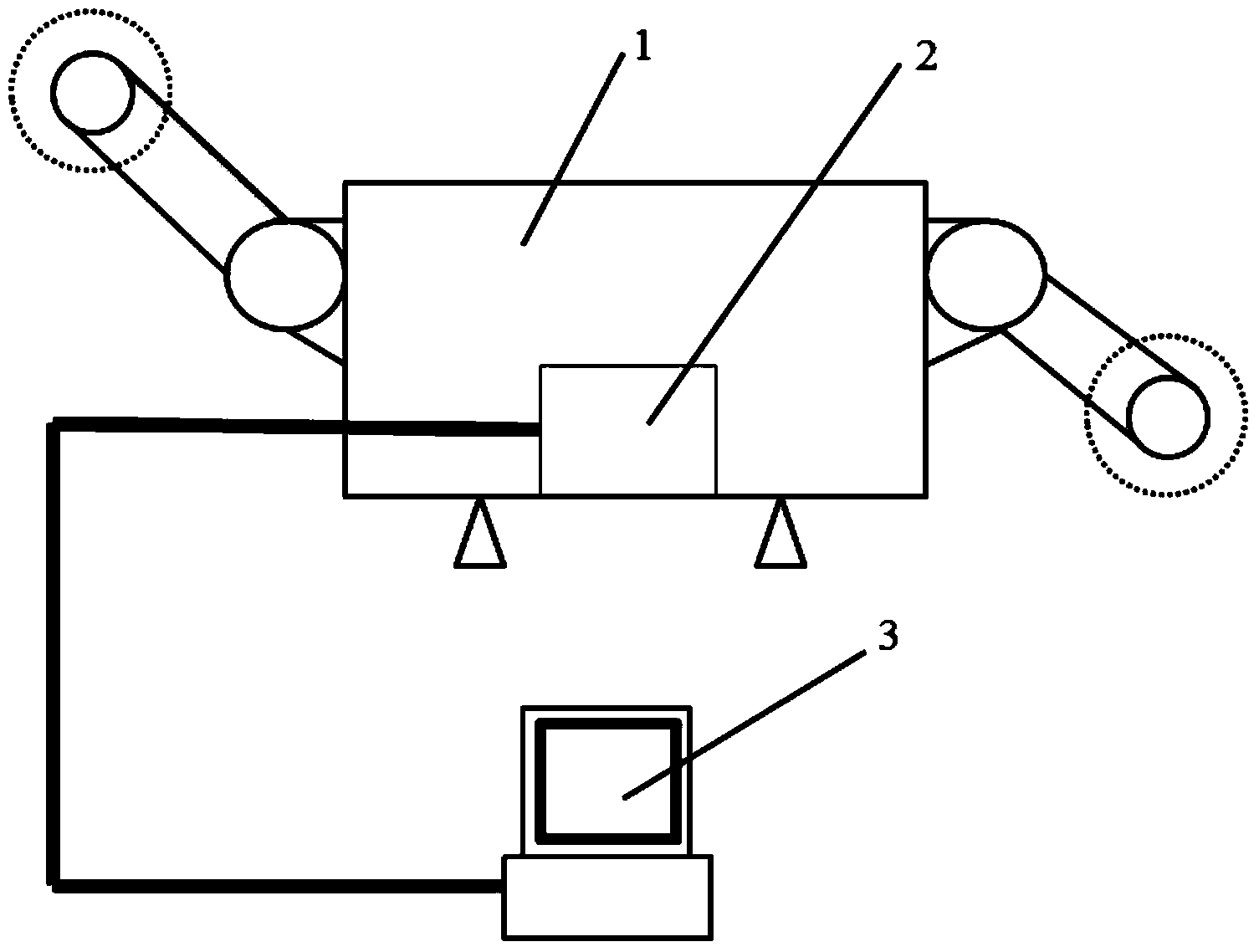

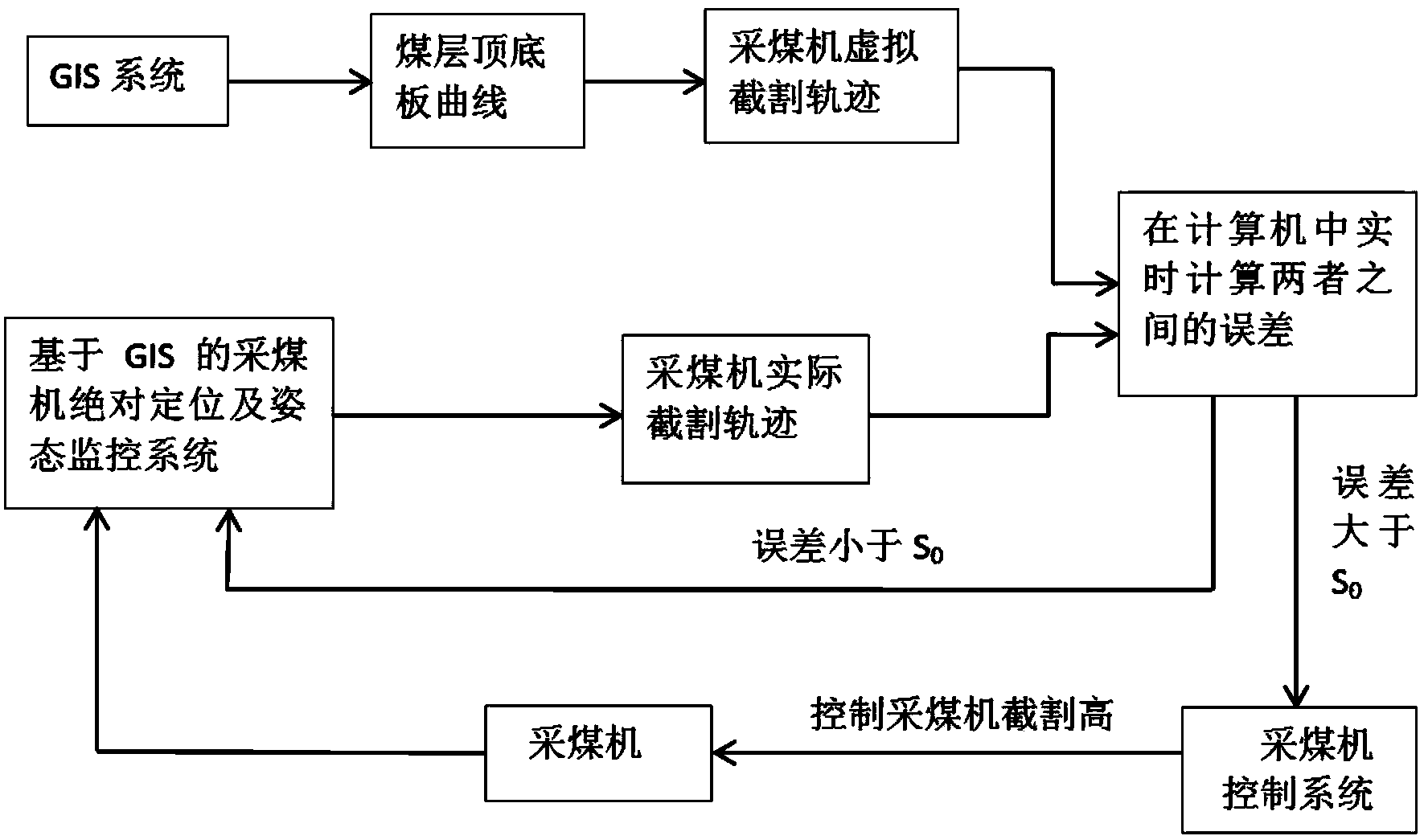

Self-adaptive cutting method for coal mining machine based on virtual trajectory control

InactiveCN103835719ARealize active controlProtection securitySlitting machinesCutting machinesMaximum errorMachine control

The invention discloses a self-adaptive cutting method for a coal mining machine based on virtual trajectory control, belonging to a cutting trajectory control method of the coal mining machine. The method comprises the following steps: the virtual cutting trajectory is set as a cutting trajectory of the coal mining machine, a roller can cut along the set virtual trajectory after the coal mining machine is started, and the error S between the practical cutting trajectory and the virtual trajectory of the coal mining machine is calculated in real time when the coal mining machine runs, when the error S is more than the maximum error S0 required to be controlled in the practical mining process, a coal mining machine control system is adopted to automatically control the cutting trajectory of the coal mining machine, that is, the height of the cutting roller of the coal mining machine can be adjusted, so that self-adaptive cutting of the coal mining machine based on virtual trajectory control is realized and the problem that the cutting trajectory of an existing coal mining machine is adjusted passively is solved. According to the method, the geological information of a mining area and the cutting trajectory of the coal mining machine can be fused, the cutting trajectory of the coal mining machine can be actively adjusted, the equipment loss and the fault rate are reduced, the cutting effect of the coal mining machine is good and the recovery rate and the coal quality are improved.

Owner:CHINA UNIV OF MINING & TECH

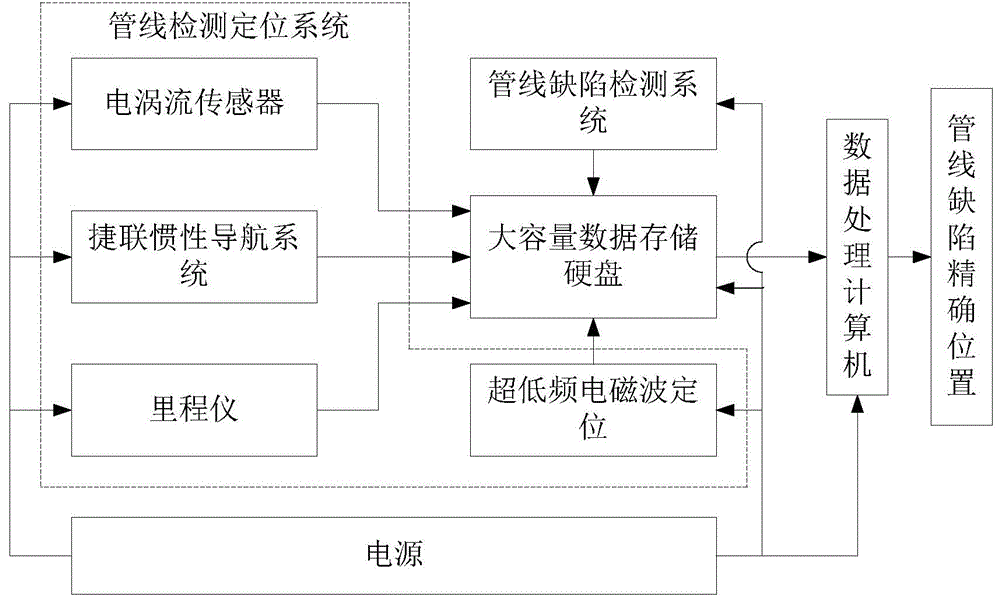

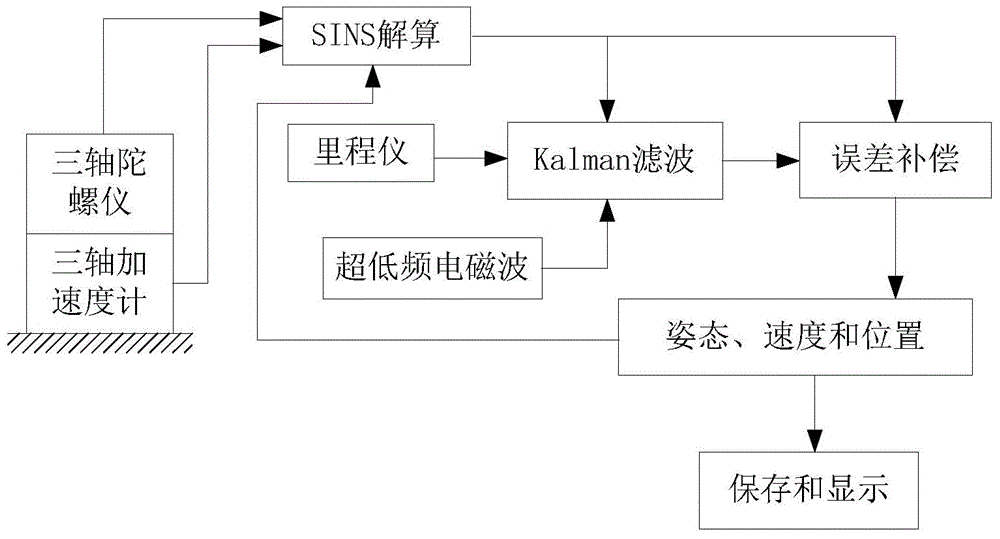

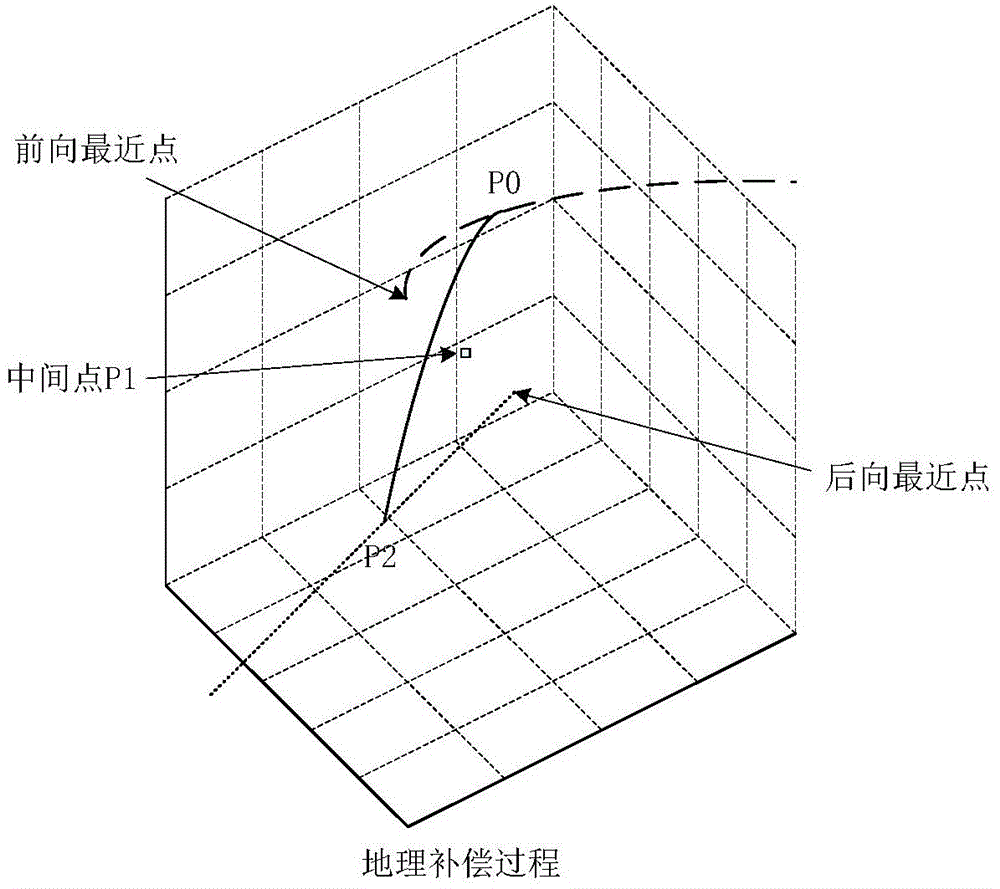

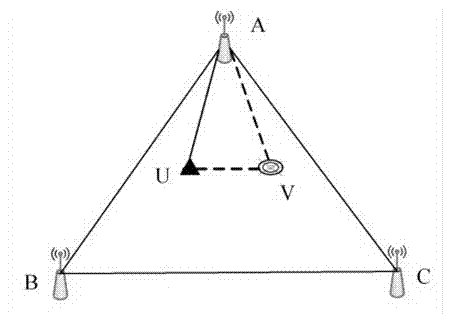

Geographic coordinate compensation method for seabed oil-gas pipeline detection positioning system

ActiveCN104535063APrecise positioningAccurate locationNavigational calculation instrumentsNavigation by speed/acceleration measurementsOcean bottomFilter algorithm

The invention belongs to the seabed oil-gas pipeline detection positioning field, and concretely relates to a geographic coordinate compensation method for a seabed oil-gas pipeline detection positioning system. The method comprises employing a metal weld quantity detected by a current vortex sensor to determine a system-located steel pipe segment, so as to realize coarse positioning; employing a mileage gauge / ultralow-frequency electromagnetic wave correction method to calculate a strapdown inertial navigation system positioned by the pipeline and perform error compensation, taking mileage increment and an ultralow-frequency electromagnetic wave positioning signal as observed value, taking state error as a state variable, and employing Kalman filtering to estimate the state error; and combining a quadratic Bayes curve method and a forward and backward filtering algorithm to reduce the maximum error. The provided method is applicable to precise positioning of any pipeline detection positioning system based on a strapdown inertial navigation system, is capable of substantially reducing the accumulation effect of strapdown inertial navigation system error along with time when single filtering is performed, and is capable of reducing positioning error to one fourth of the original positioning error.

Owner:HARBIN ENG UNIV

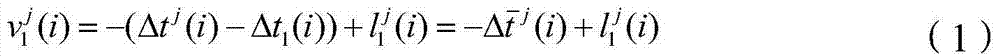

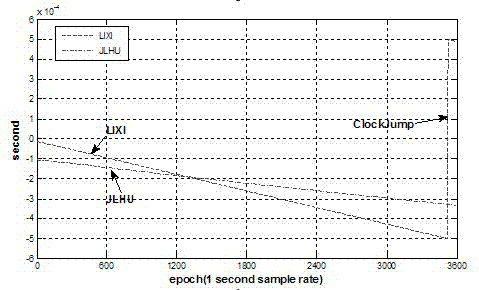

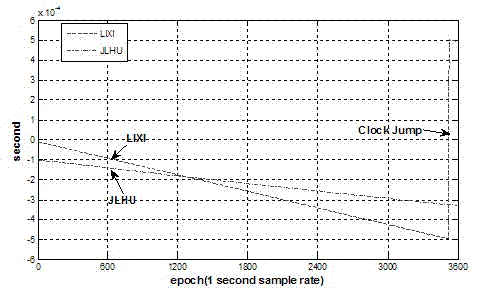

Multi-constellation single base station receiver clock difference estimation method

InactiveCN103197326ARealize high-precision positioningEffective estimateSatellite radio beaconingMaximum errorEstimation methods

The invention discloses a multi-constellation single base station receiver clock difference estimation method. When multi-constellation data are in fusion process, positions of satellites when signals are emitted cannot be accurately confirmed due to different receiver clock differences among different constellations and the effect of delaying of signal propagation, error terms which are related to the satellite speed and caused by receiver clock differences still can cause changing of errors and affect an actual positioning effect, wherein the maximum error can reach 1m. In the calculation of the positions of the satellites, the receiver clock differences are estimated, the time delaying of the signal propagation is corrected, the receiver clock differences are resolved through a Kalman filtering method, and accordingly the method is practical and can obtain accurate geometrical distance between receivers with corrected receiver clock differences and the satellites. The method can reduce the effect of the receiver clock differences which are related to the satellite speed to a submillimeter level, is suitable for a receiver with clock jumping being one millisecond, and achieves high-accuracy positioning of the multi-constellation fusion.

Owner:SOUTHEAST UNIV

Acoustic noise reduction using fan speed control

ActiveUS20050275365A1Big errorReduce aerodynamic noiseMotor/generator/converter stoppersDC motor speed/torque controlMaximum errorAcoustic noise reduction

A method and apparatus is disclosed for acoustic noise reduction using fan speed control. The acoustic noise reduction using fan speed control includes a plurality of temperature detectors disposed at a plurality of locations within an electronics equipment enclosure, each detector having an associated setpoint temperature. An error value is determined for each temperature detector, the error consisting of the difference between the detected temperature and the associated setpoint temperature. The maximum error among all error values is then identified and the operating speed of a cooling fan in is set in response to this maximum error. Advantages include providing a fan speed directly related to electronics temperature which inherently accounts for higher ambient temperatures, enclosure altitude, electronics power consumption, and air filter clogging. The acoustic noise reduction using fan speed control is particularly useful for overcoming the need to overcompensate fan speed, thereby resulting in higher than necessary noise levels in order to accommodate worse-case conditions known in the art.

Owner:CIENA

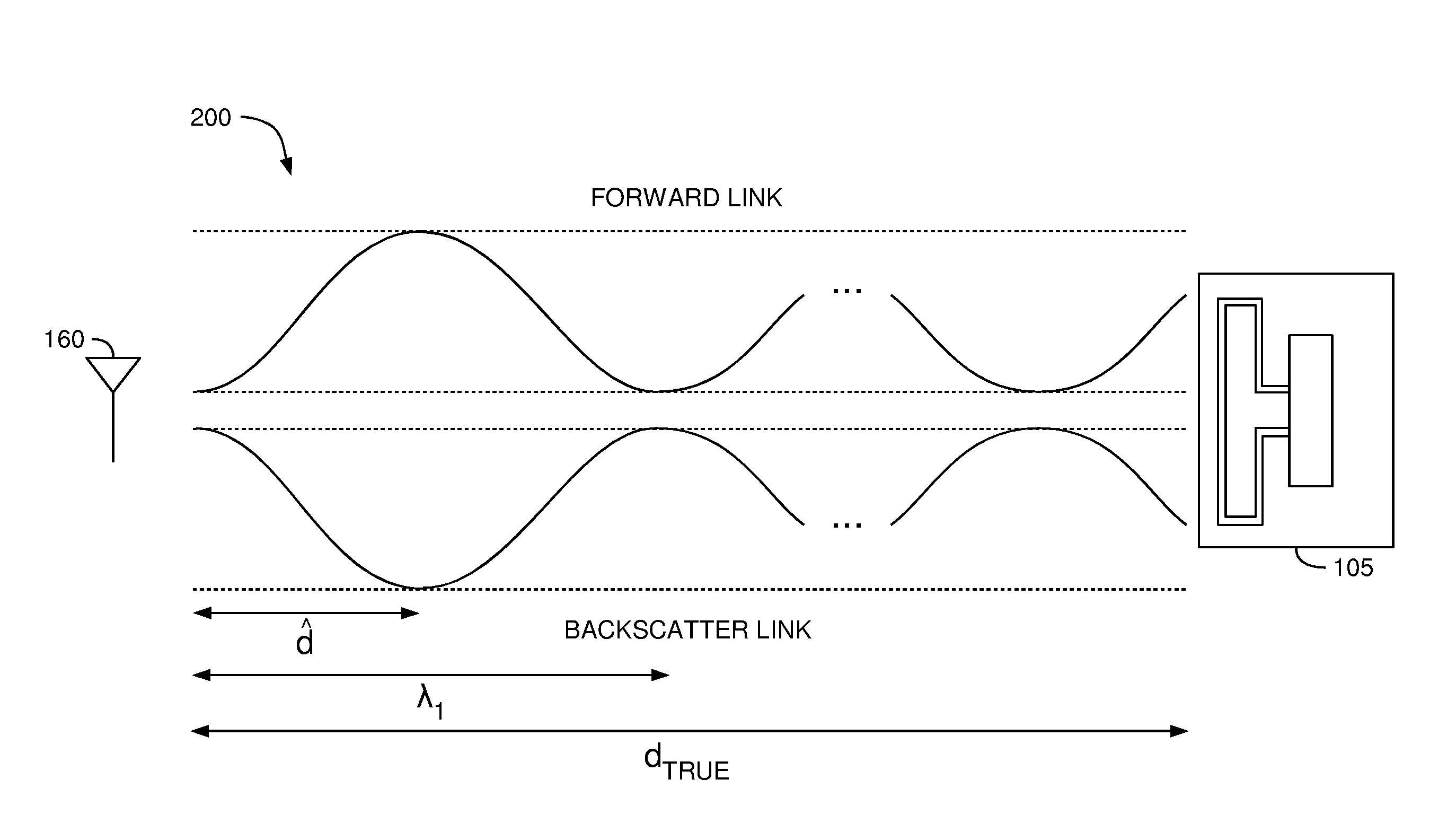

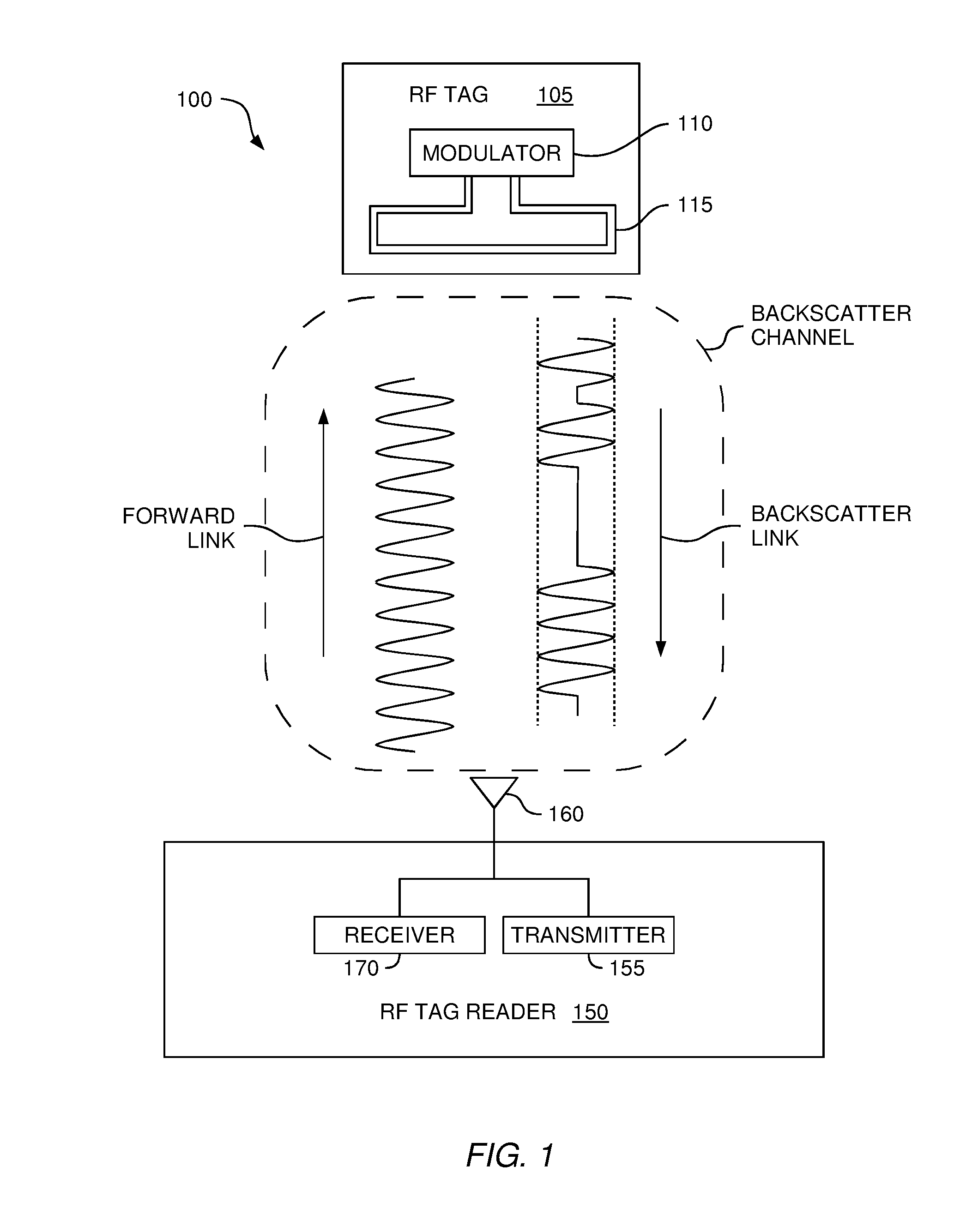

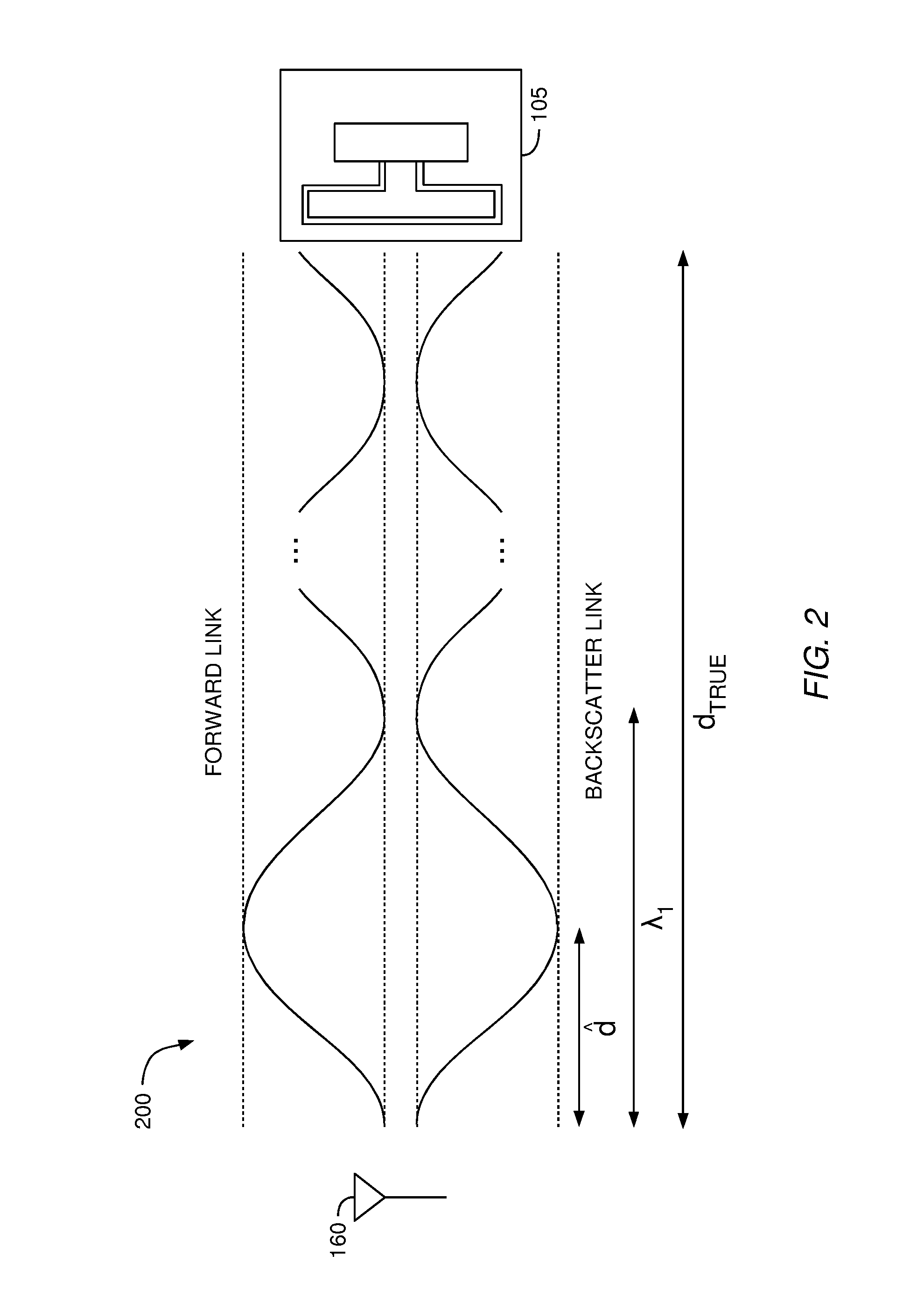

Phase-based ranging for backscatter RFID tags

ActiveUS20140184447A1Reduce error impactReduce impactDirection finders using radio wavesRadio wave reradiation/reflectionMaximum errorAmbiguity

A RF tag reader may use spatial averaging to compensate for the limitations of performing multi-frequency continuous-wave ranging (MFCW) in a bandwidth-limited environment. Although MFCW provides an estimate of the separation distance between a RF tag and the tag reader with errors that vary widely, the error values form a pattern based on the separation distance. That is, as the separation distance increases or decreases, the error values oscillate between maximum and minimum values centered on the correct separation distance. Accordingly, in one embodiment, the receiver uses spatial averaging to average out this oscillating error (e.g., the maximum errors are counter-balanced by the minimum errors). The more accurate, spatially-averaged MFCW estimate may then be used to resolve the cycle ambiguity in continuous-wave ranging to identify the separation distance between the RF tag and the tag reader.

Owner:DISNEY ENTERPRISES INC

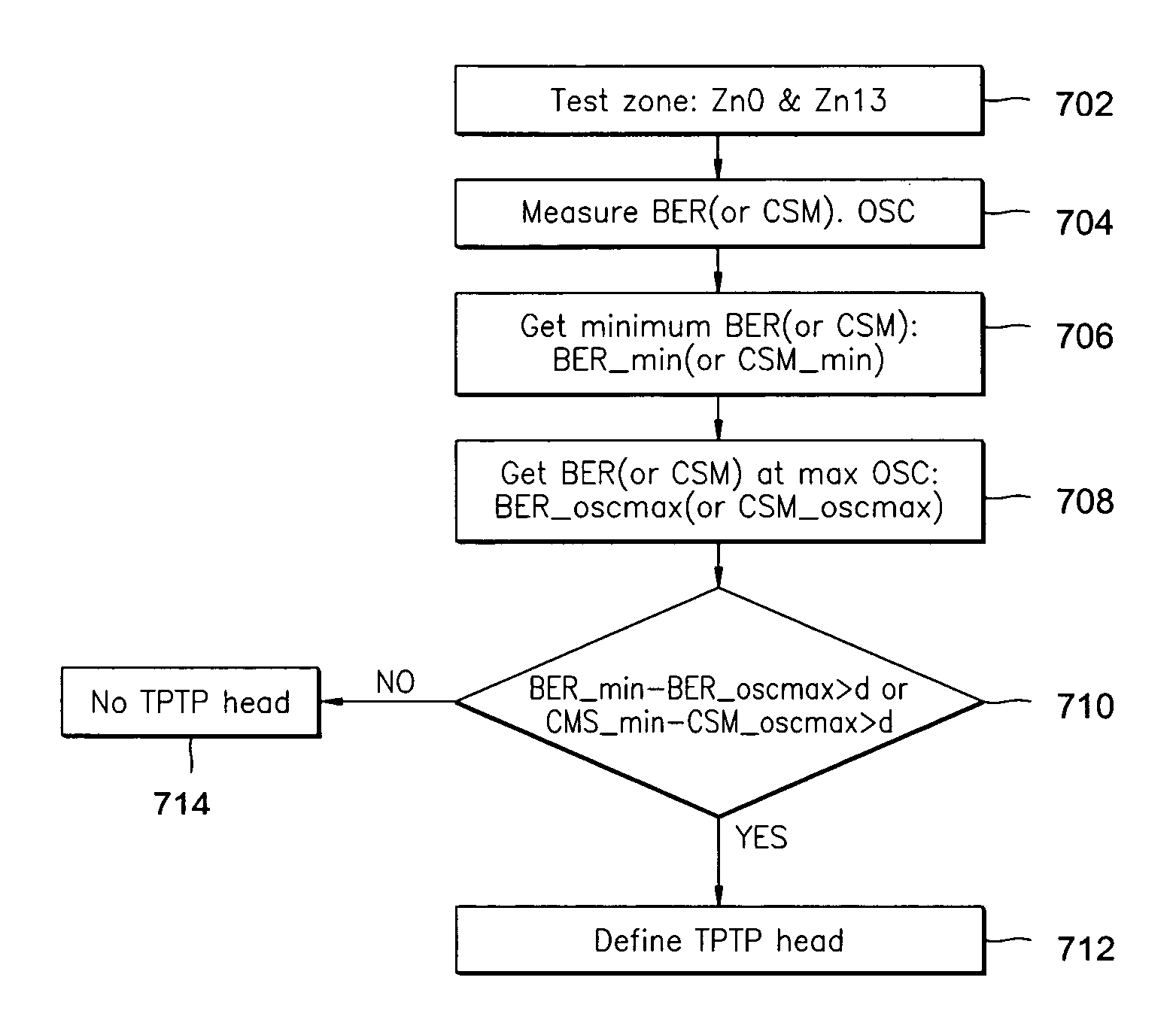

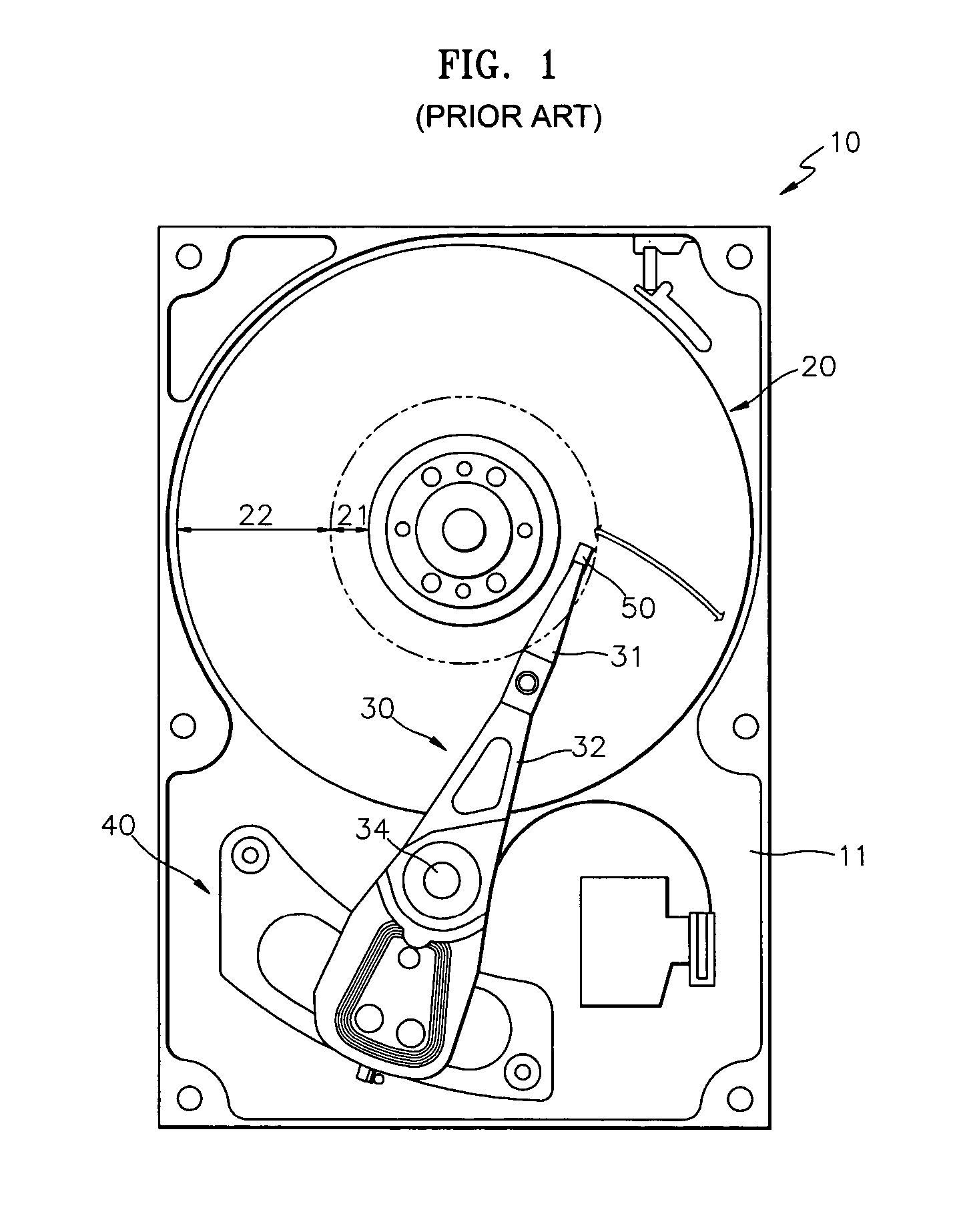

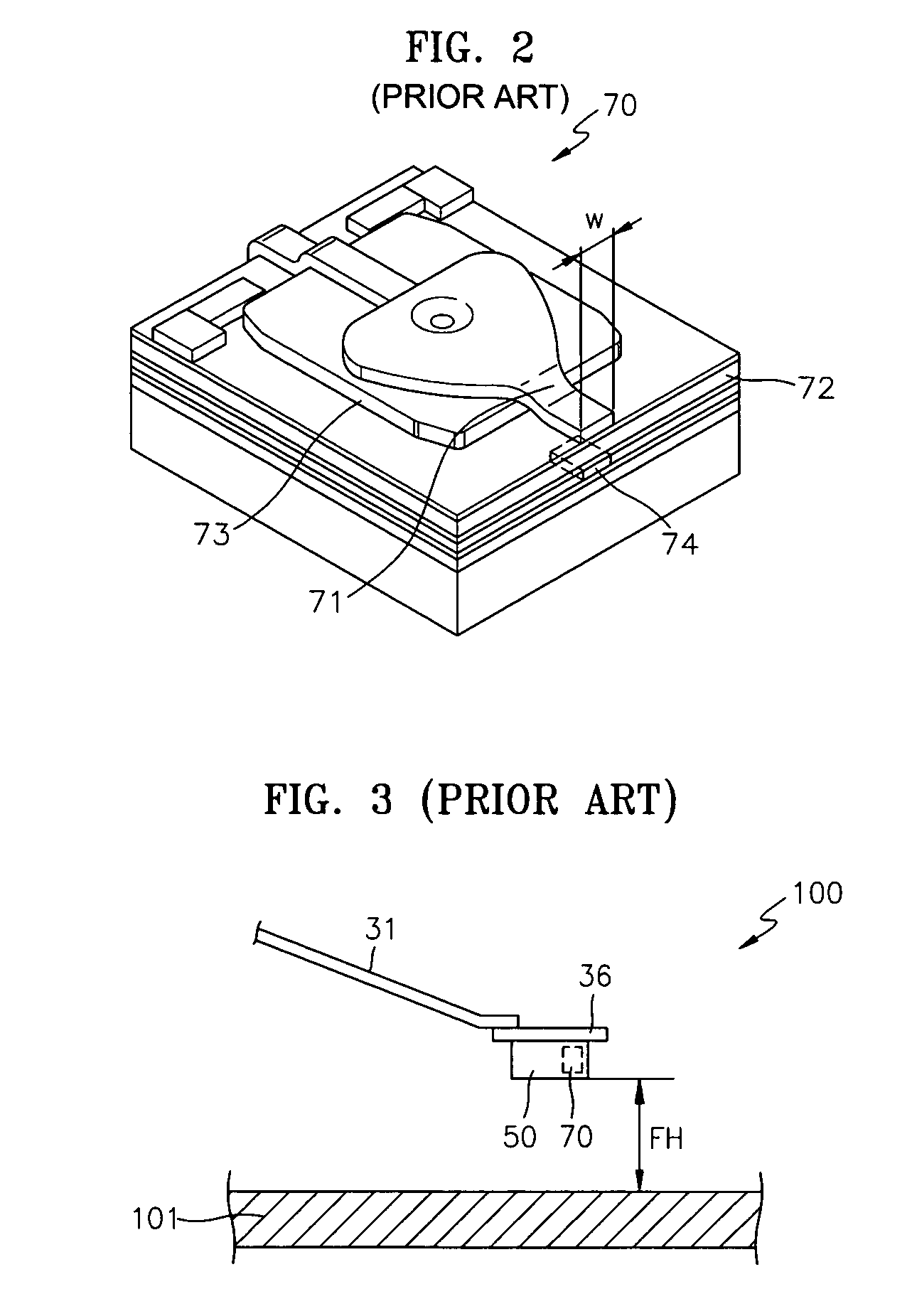

Methods of measuring TPTP of magnetic head and controlling recording current

InactiveUS6999256B2Driving/moving recording headsRecord information storageMaximum errorHard disc drive

A method of measuring the degree of thermal pole tip protrusion (TPTP) of a magnetic head and controlling a recording current in consideration of the degree of TPTP, in relation to a hard disk drive includes measuring the rate of errors contained in data by performing writing and reading operations while changing the level of an overshoot current (OSC), detecting a minimum error rate and a maximum error rate while changing a range of the OSC, and determining the degree of TPTP by measuring the difference between the minimum error rate and the error rate at the maximum OSC.

Owner:SAMSUNG ELECTRONICS CO LTD

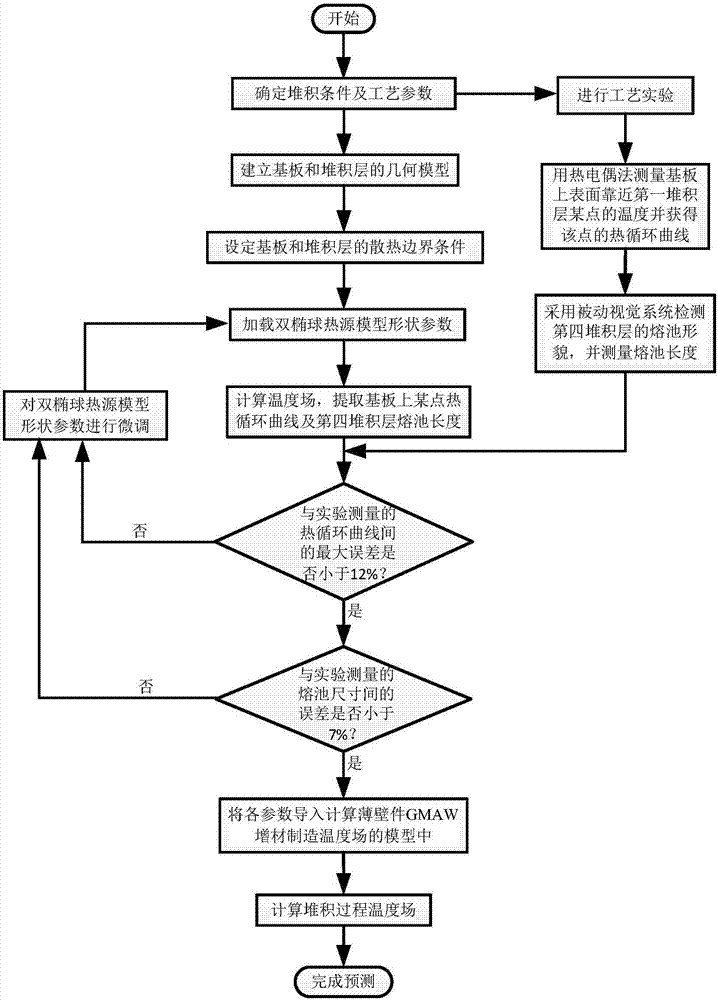

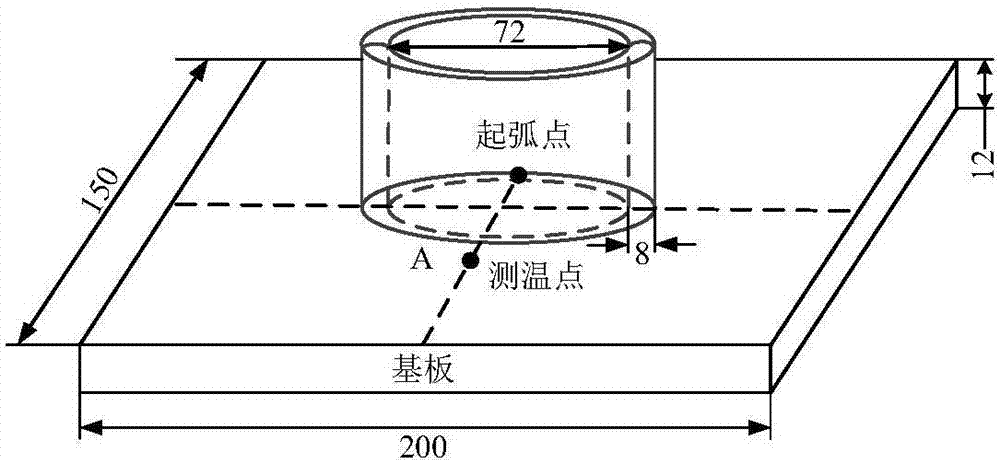

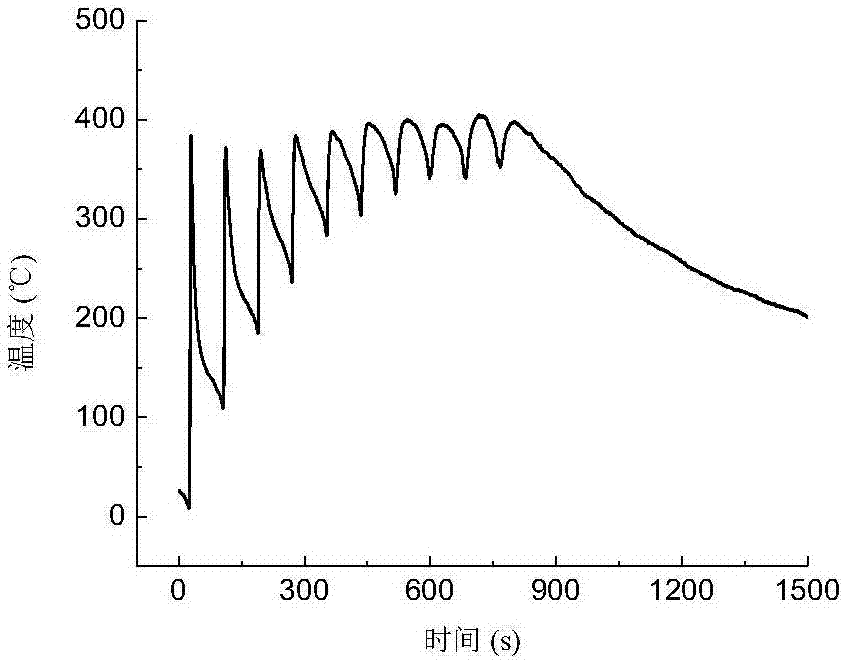

Thin-walled component arc wire filling additive manufacturing temperature field predicting method

ActiveCN106909714APredicted temperature fieldReliable methodGeometric CADDesign optimisation/simulationMelting tankPredictive methods

The invention relates to a thin-walled component arc wire filling additive manufacturing temperature field predicting method. The method includes the steps that a stacking condition of a thin-walled component is determined; a thermal cycle curve is measured; the shape of any stacking layer molten pool above a second stacking layer is observed; a model is built and grids are divided; a heat dissipation boundary condition and a heat source parameter are loaded; a model temperature field is calculated, a thermal cycle parameter is extracted, the length of the stacking layer molten pools is measured, and compared with test data, the maximum error of thermal cycles and size errors of the molten pools are all smaller than preset values through a fine-tuning heat source model shape parameter; the fine-tuning model shape parameter is loaded in a numerical model of the thin-walled component, and arc wire filling additive manufacturing temperature field predicting is completed. The numerical calculation method is adopted, by comparing the thermal cycle parameters on a substrate with the sizes of the molten pools of the stacking layers, thin-walled component arc wire filling additive manufacturing temperature field predicting is accurately completed, and a theoretical basis is provided for solving residual stress and deformation problems caused in the thin-walled component arc wire filling additive manufacturing process.

Owner:SOUTHWEST JIAOTONG UNIV

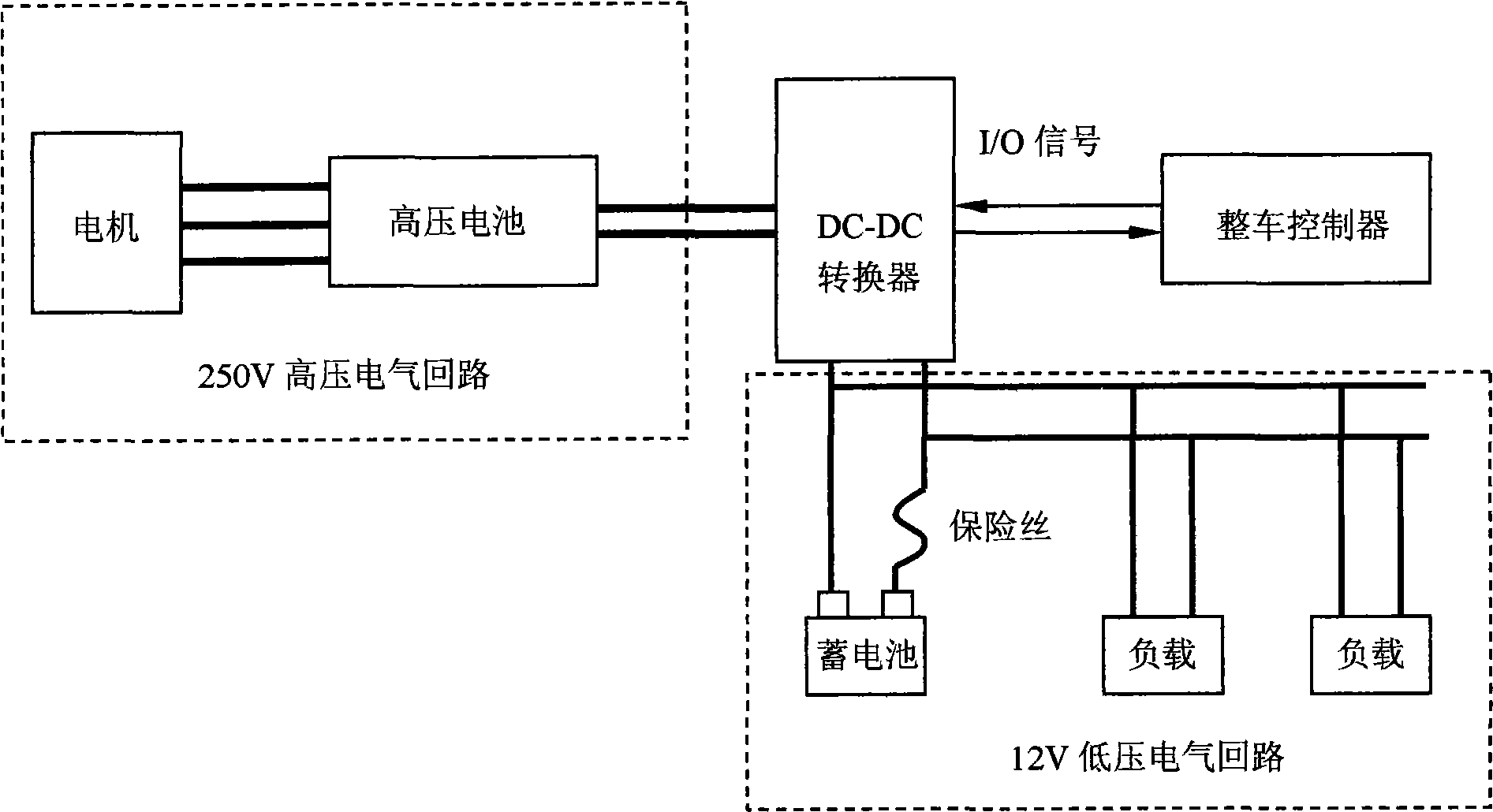

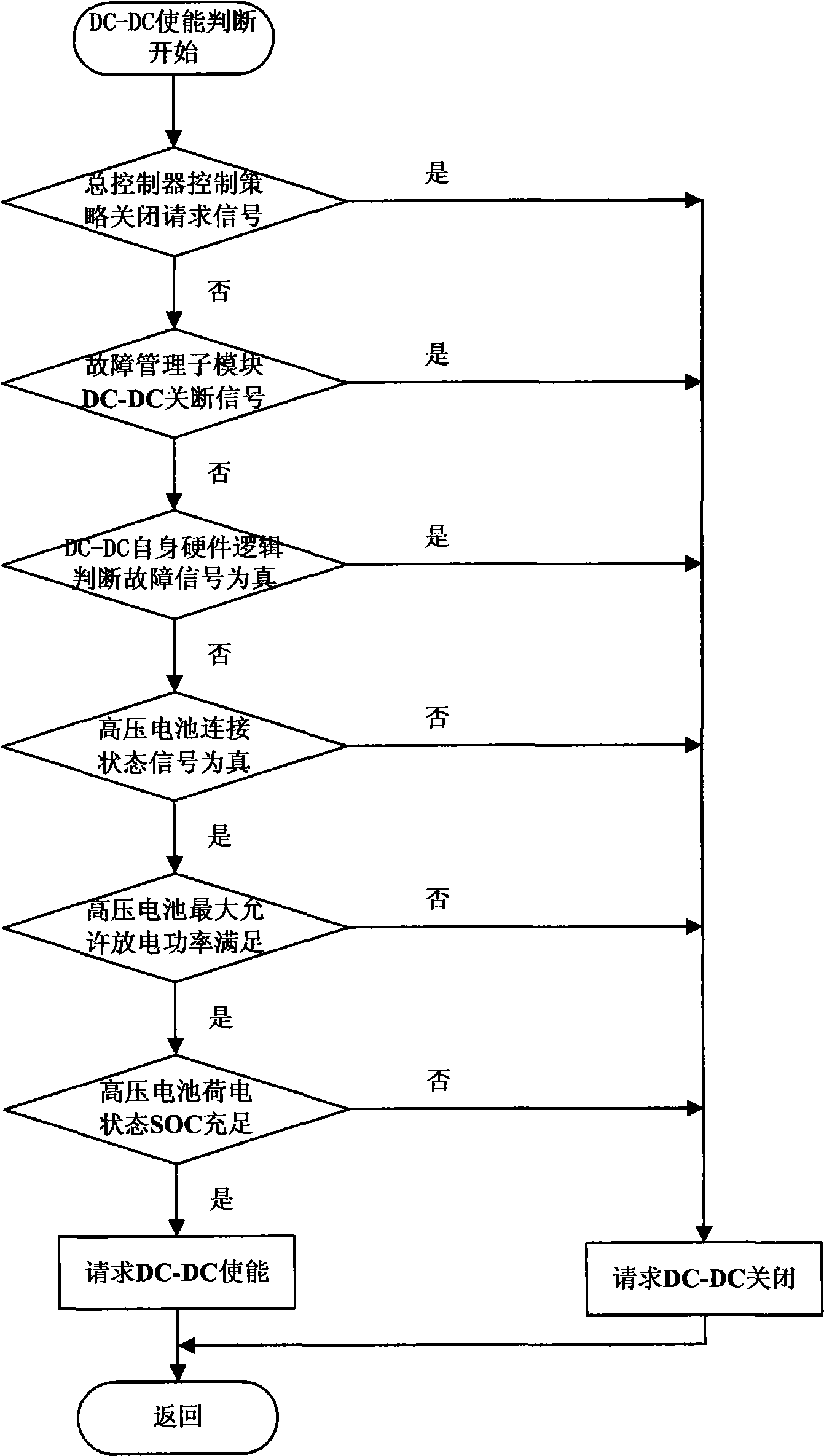

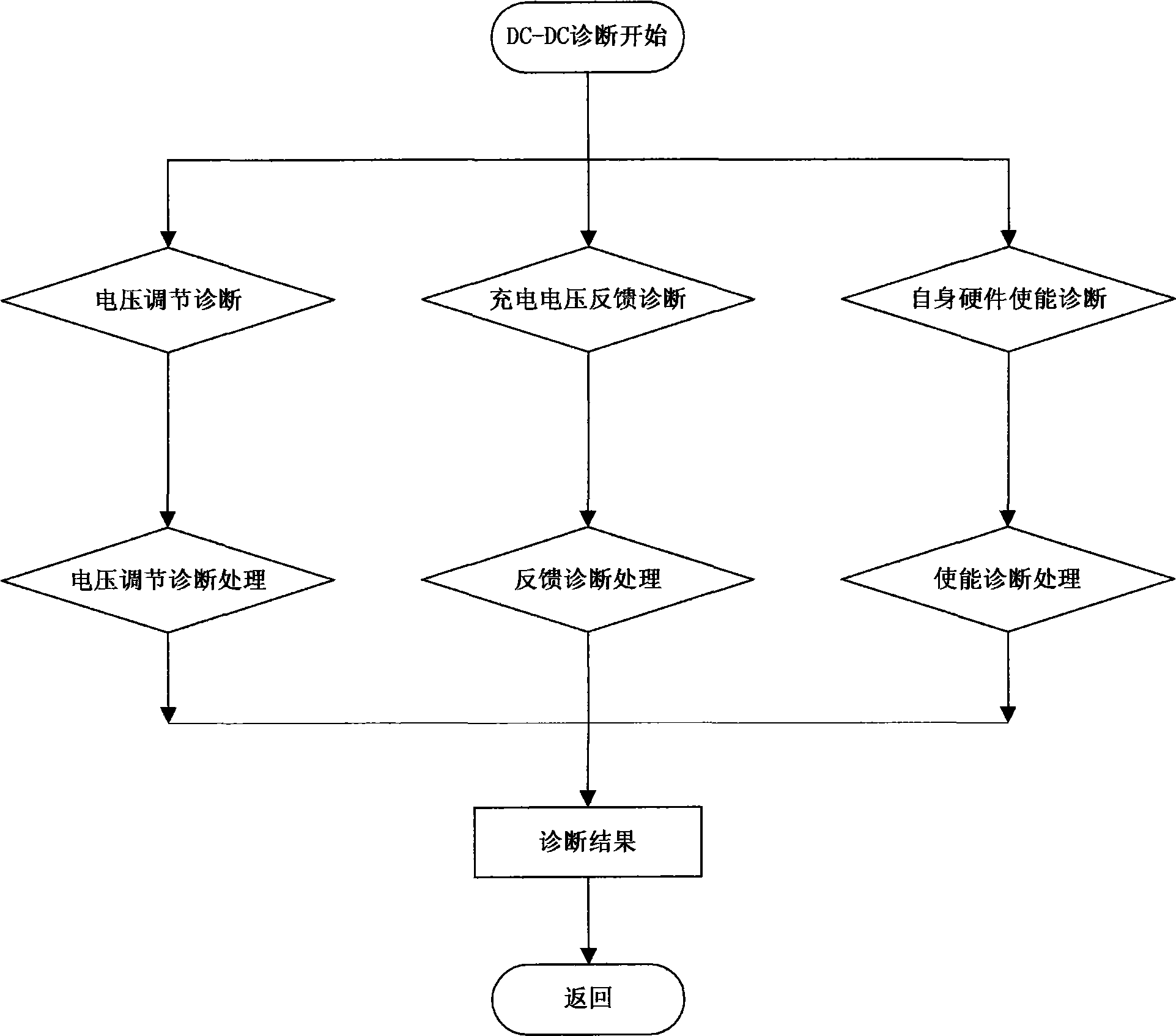

DC-DC converter fault diagnosis method for pure electric automobile

InactiveCN101545940AAchieve protectionBatteries circuit arrangementsElectrical testingMaximum errorDc dc converter

The invention discloses a DC-DC converter fault diagnosis method for pure electric automobile. The DC-DC converter is diagnosed if there has some fault according to corresponding parameter state as output voltage value, voltage of low voltage battery and loaded current value of whole automobile; output voltage target control value of DC-DC converter is set according to environment temperature, and maximum error of the actual output voltage and target voltage control value is set; when actual voltage value of filtered low voltage 12V battery is higher than sum of set maximum error and target control value, and DC-DC converter is in working state, it is considered that fault occurs in DC-DC converter output voltage control logic. The fault diagnosis method of the invention can quickly and effectively detect possible fault, thereby provides better protection for DC-DC converter.

Owner:CHERY AUTOMOBILE CO LTD

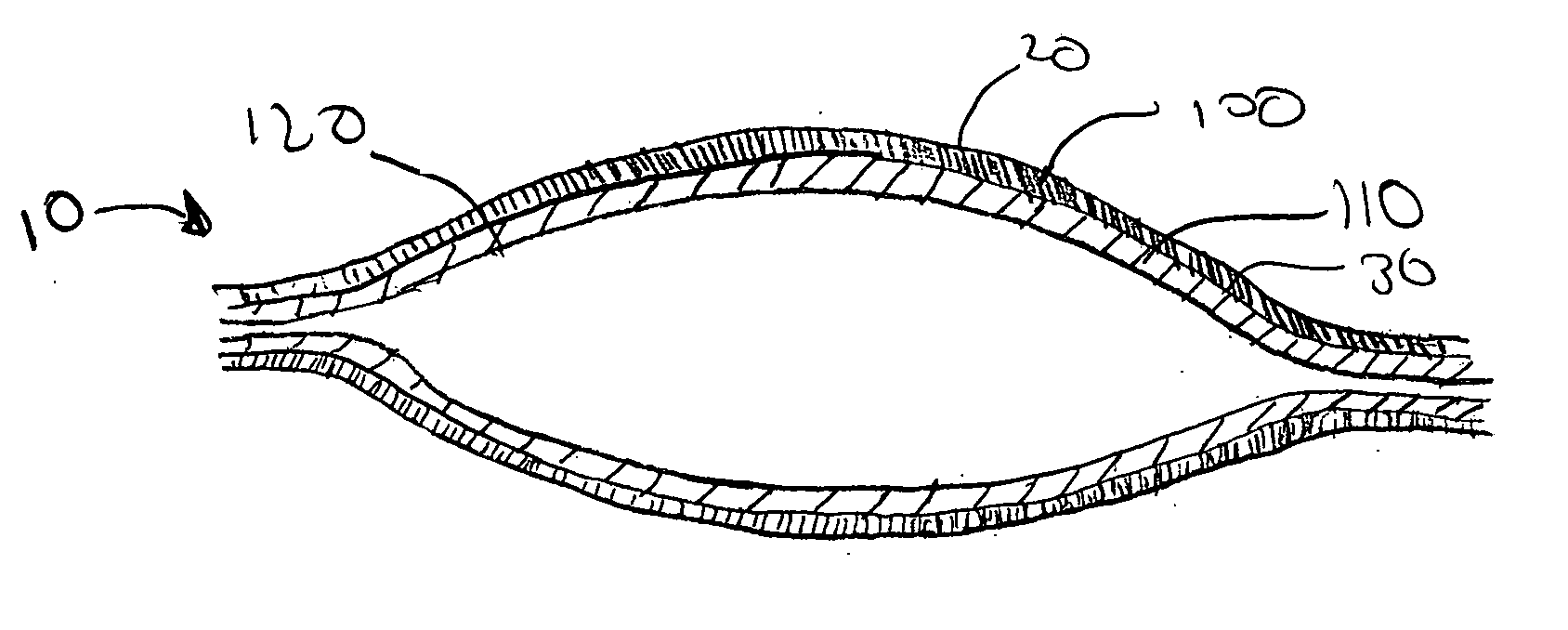

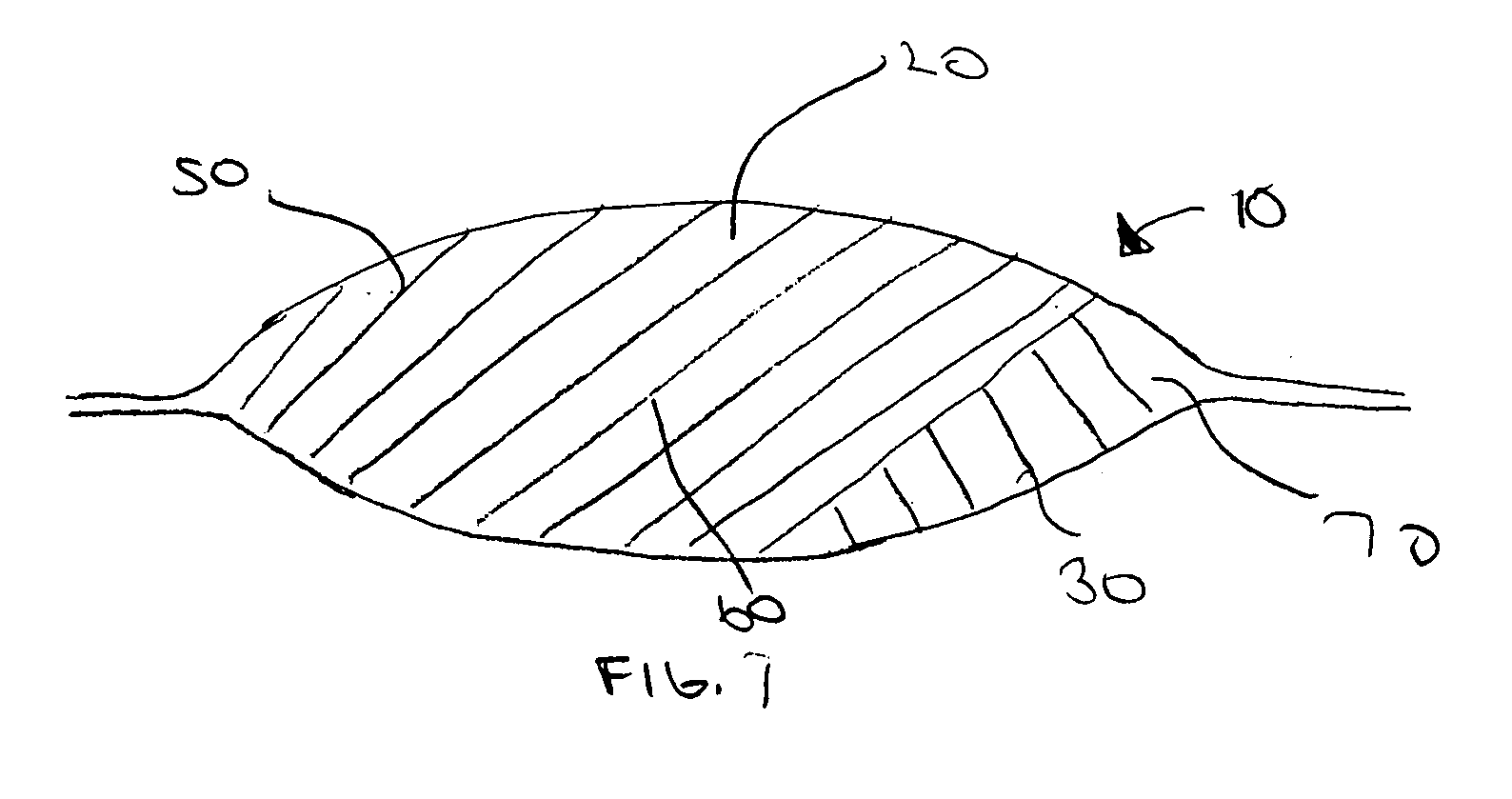

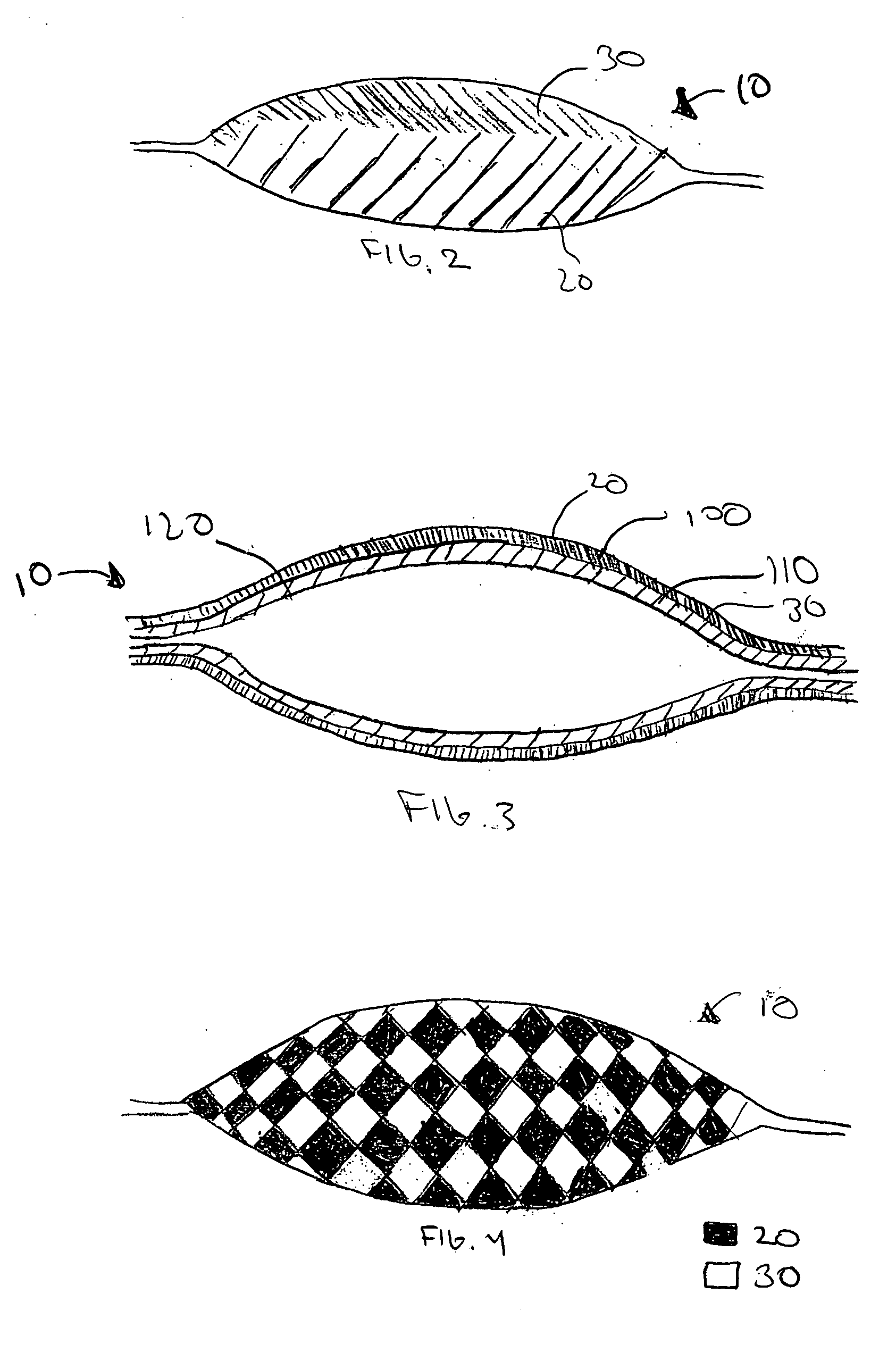

Multi-step method of manufacturing a medical device

A multi-step method of manufacturing a medical device containing therapeutic agents that results in a lower maximum error in the amount of therapeutic agents actually disposed thereon and that allows for differential drug release kinetics along the length of the medical device.

Owner:BOSTON SCI SCIMED INC

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com