Component quality checking device based on line laser three-dimensional measurement and detection method of device

A quality inspection method and three-dimensional measurement technology, applied to measuring devices, optical devices, instruments, etc., can solve the problems of weak anti-interference, low inspection accuracy, and low efficiency, and achieve good anti-interference and stability, quality The effect of high inspection accuracy and improved detection efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0035] The present invention will be further described in detail below in conjunction with the accompanying drawings.

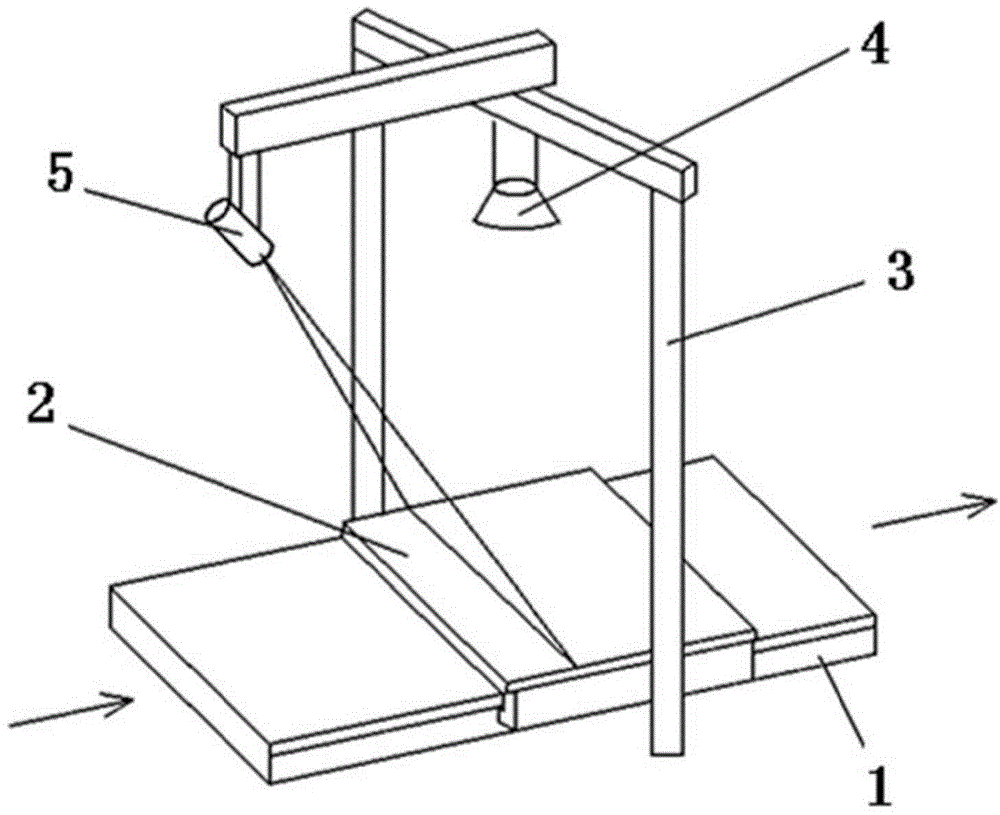

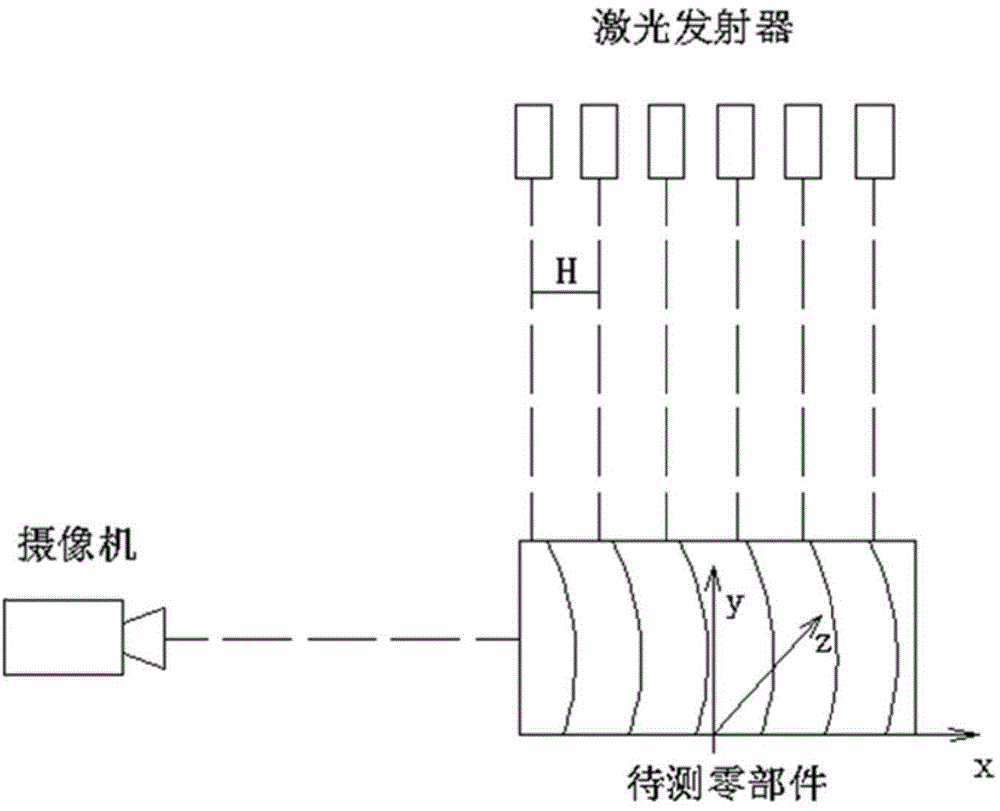

[0036] see figure 1 , the present invention is based on the line laser three-dimensional measurement of the parts quality inspection device, including a laser transmitter 5, a camera 4, a guide rail 1, a mobile platform 2, a bracket 3, a calibration board 6 and a computer;

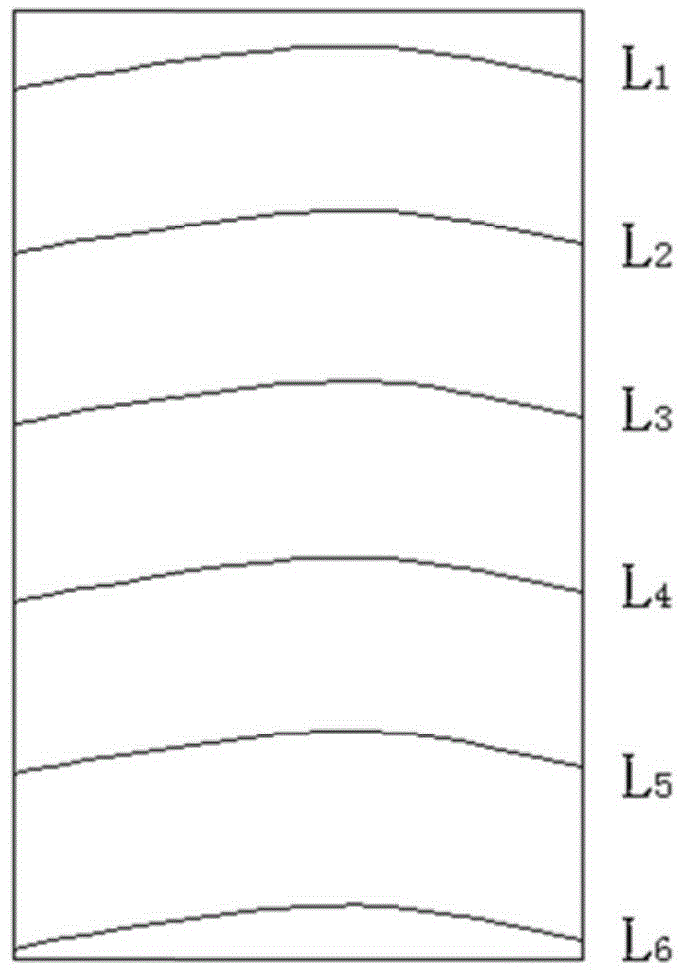

[0037] The laser transmitter 5 adopts six laser transmitters 5 arranged in a straight line, and the distance between two adjacent ones is H, and is used to project six linear stripes with equal spacing H on the component to be tested; the camera 4 is a high-speed CCD camera, which is connected with six The laser emitters 5 are arranged in a collinear arrangement, and are used to collect the images projected by the laser emitters 5 on the surface of the auto parts to be tested and deformed after being modulated by the surface; the computer image signal input end is connected with the image...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com