Appearance inspection machine for printed circuit board

A printed circuit board, appearance inspection technology, applied in the direction of measuring devices, material analysis through optical means, instruments, etc., can solve the problems of difficult quality control of printed circuit boards, slow detection speed, inadaptability, etc., to improve simplicity And reliability, fast detection speed, and the effect of improving the operation rate

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0027] In order to facilitate the understanding of those skilled in the art, the present invention will be described in detail below in conjunction with the embodiments and accompanying drawings:

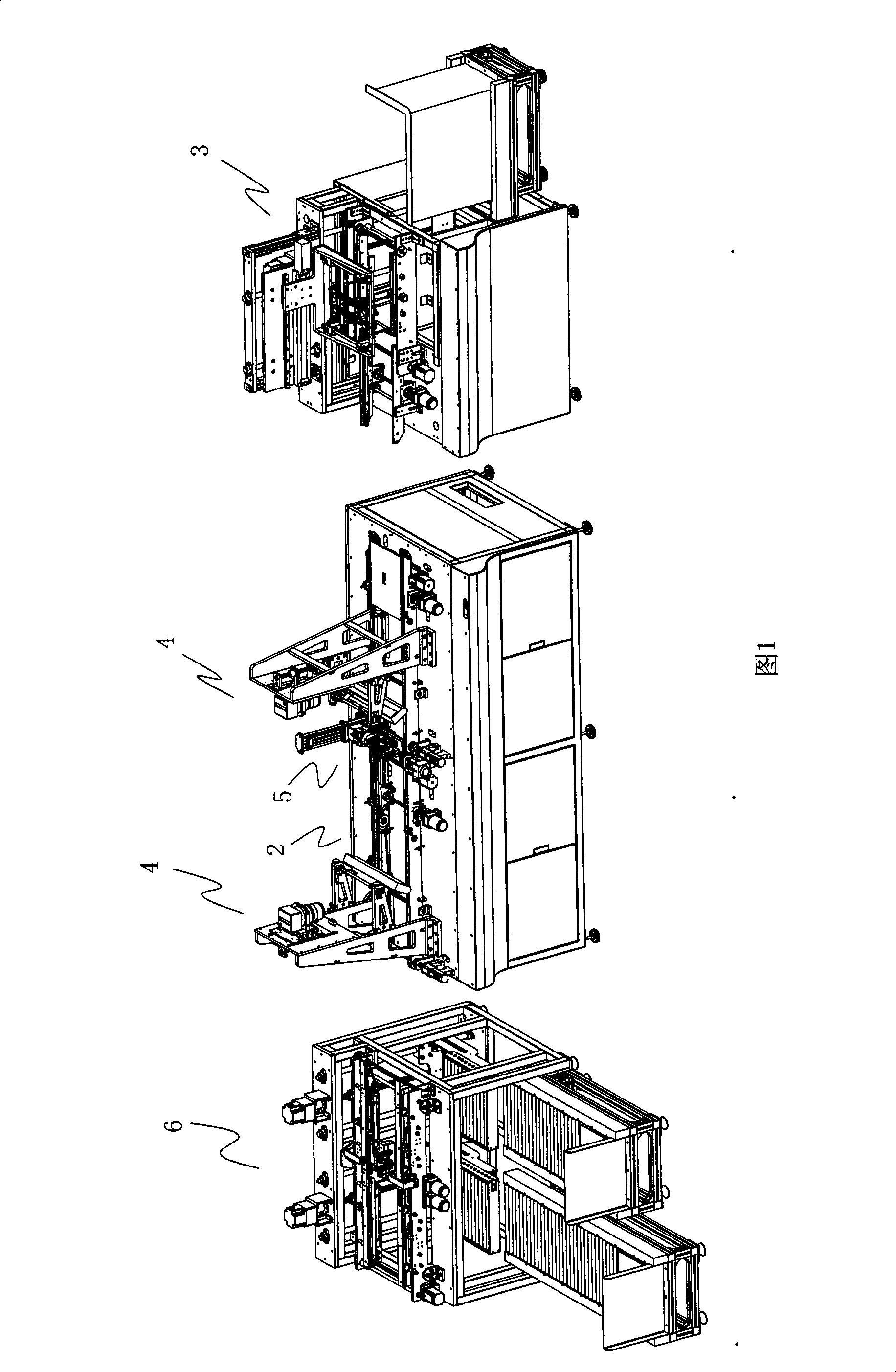

[0028] As shown in Figure 1, the machine disclosed in this embodiment is a printed circuit board appearance inspection machine specially used to check whether the printed circuit is qualified during the production process of the printed circuit board.

[0029] The machine mainly includes a conveying mechanism 2, a loading mechanism 3, a scanning mechanism 4, a turning mechanism 5, a sorting mechanism 6 and a control host for controlling the coordinated operation of each mechanism. Each mechanism is fixed on the frame 1.

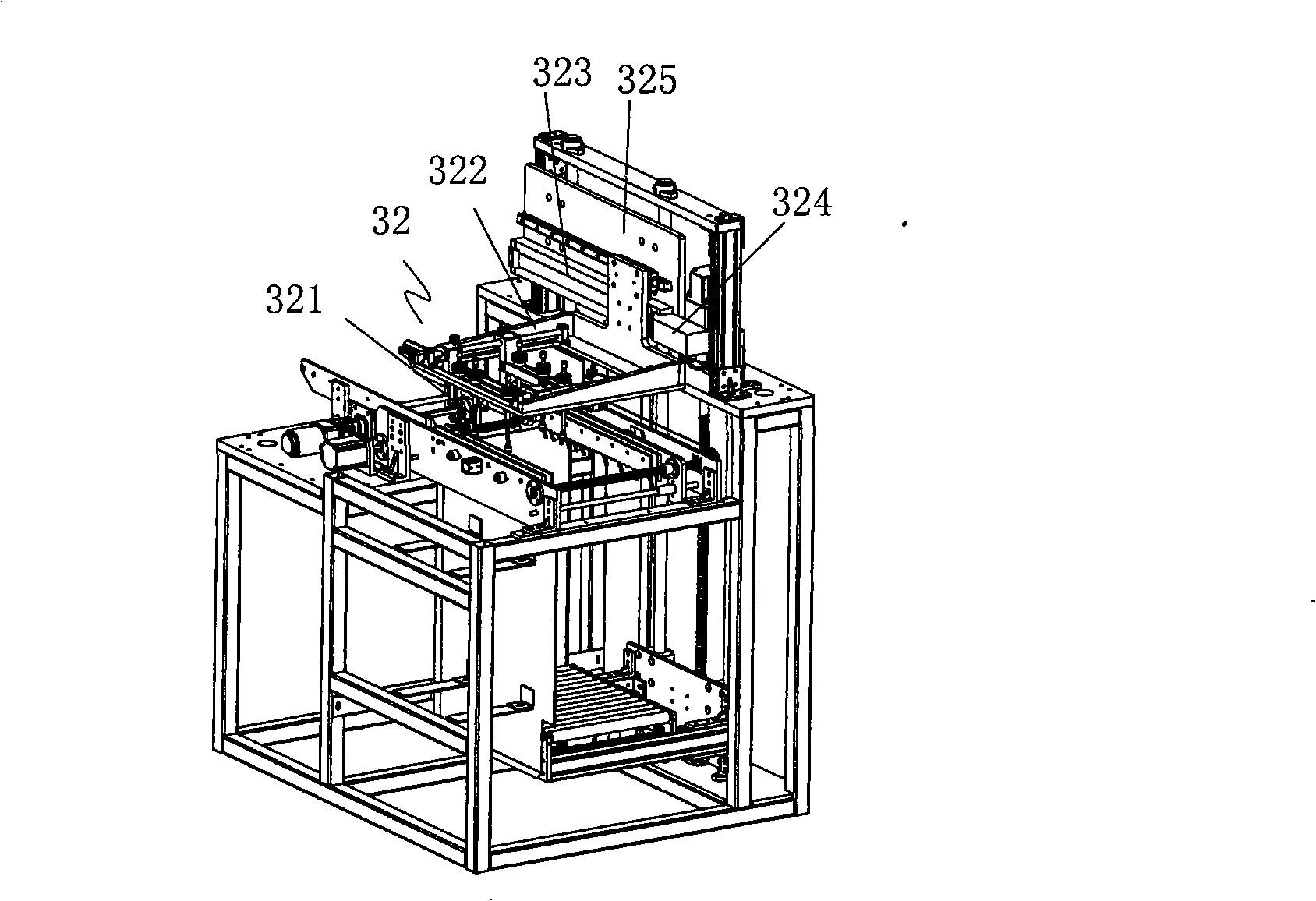

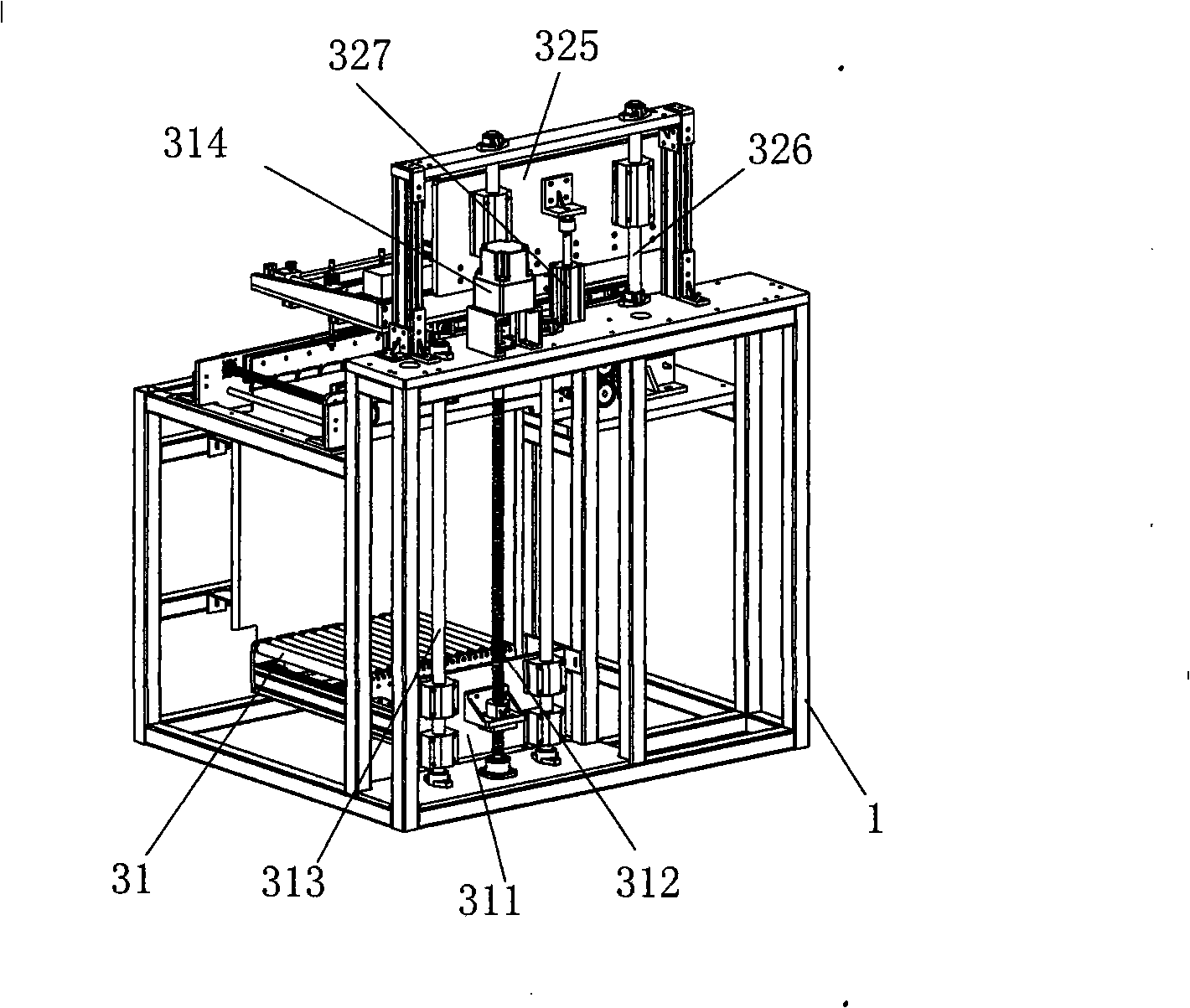

[0030] Wherein, the upper plate mechanism 3 is located at the front end of the frame 1, and is used to send the printed circuit board to be inspected to the conveying mechanism. This mechanism comprises the lifting platform 31 that lifts the printed circuit board ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com