Digital image based detection method of surface flaw of steel rail

A technology for rails and defects, applied in the fields of transportation, industrial monitoring, digital image processing and pattern recognition, can solve the problems of slow detection, weak robustness, difficult performance and robustness to satisfy users, etc., to eliminate noise. , The effect of fast detection speed and high detection accuracy

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0031] Embodiment 1: Application in Track Inspection Vehicle

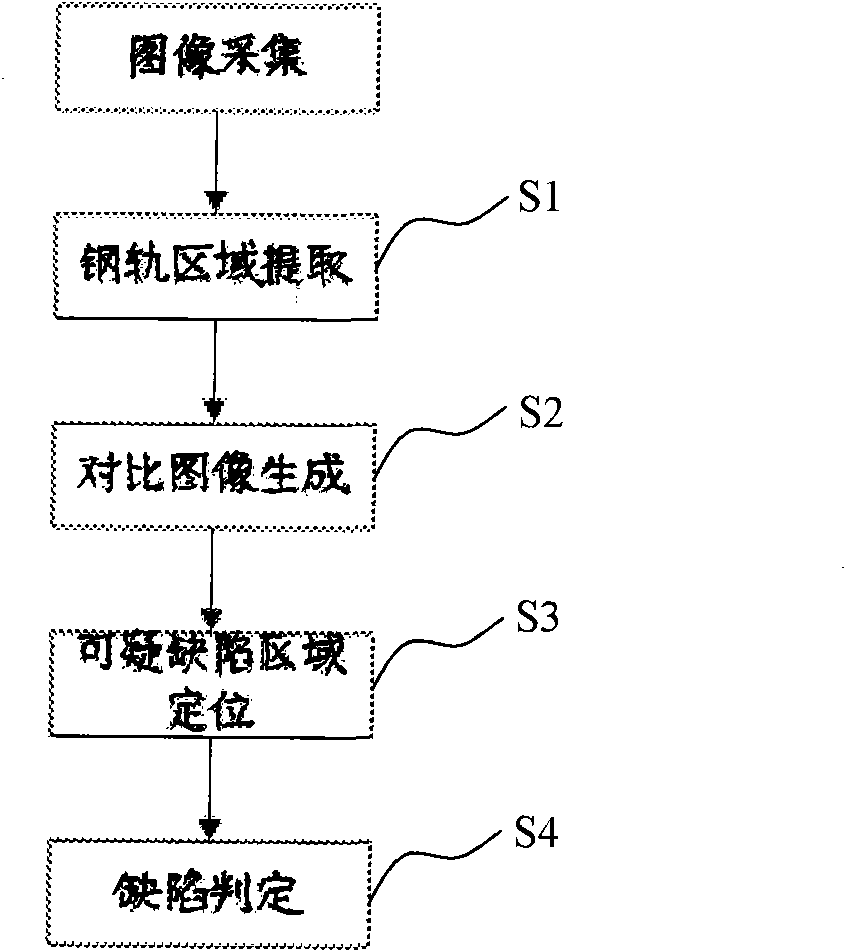

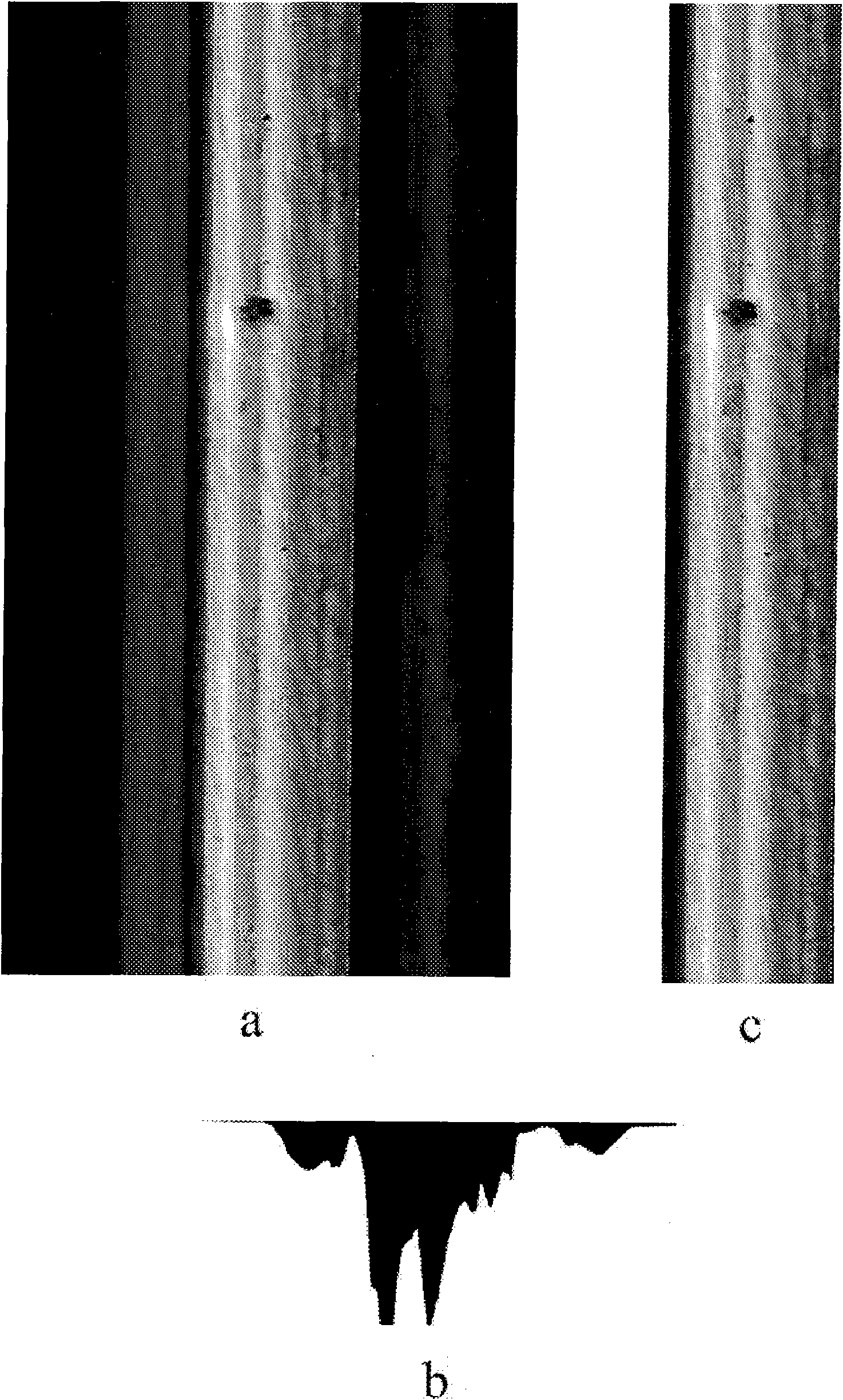

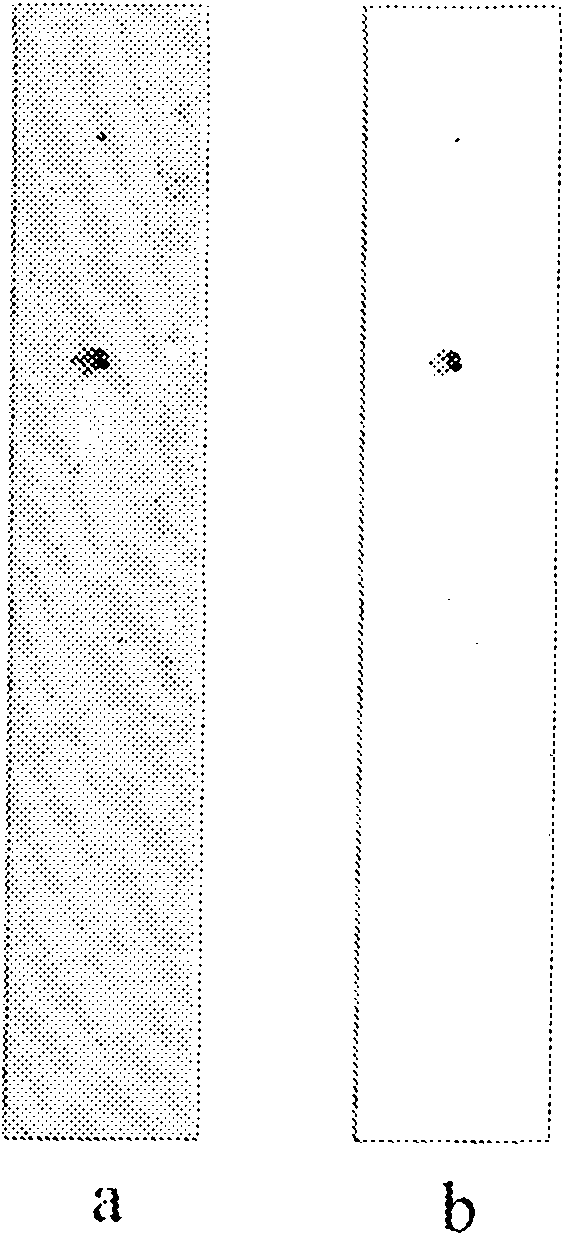

[0032] The track inspection vehicle is an important equipment specially used to detect the safety technical parameters of the high-speed railway track and roadbed, and to ensure the safety of high-speed trains. Among them, the rail surface defect is a very important detection target of the rail inspection vehicle. The present invention is especially suitable for rail inspection vehicles. The high-speed camera on the inspection vehicle collects the images of the rail surface in real time, and as the input of the method provided by the present invention, the method will automatically analyze the input and collected images, identify and locate rail defects, and the steps include: Rail area extraction, contrast map generation, suspicious defect area location, defect judgment, the flow chart is shown infigure 1 .

[0033] Step S1: Rail region extraction

[0034] The gray value of the area where the rail is located in ...

Embodiment 2

[0073] Embodiment 2: Application in Portable Rail Surface Defect Detection Equipment

[0074] Portable rail surface defect detection equipment is a handheld device that is equipped with a camera and an embedded computing platform. The present invention can also run on an embedded platform. The device first scans the rail and collects images of the rail, and then intelligently analyzes and collects the image through the method provided by the present invention to identify defects on the surface of the rail. The implementation steps are similar to the description in Embodiment 1 .

Embodiment 3

[0075] Embodiment 3: Application in Quality Monitoring of Strip Steel Production Line

[0076] Strip steel is a narrow and long steel plate produced to meet the needs of different industrial sectors. Defects on the surface of the strip are an important factor affecting the quality of its products. Therefore, the present invention can also be applied to the quality monitoring of the steel strip production line. At the end of the strip line, the strip passes through the image acquisition system. Then, the method provided by the present invention automatically analyzes and collects images, and intelligently identifies defects on the surface of the steel strip, and its implementation steps are similar to the description in Embodiment 1.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com