Patents

Literature

155 results about "Rail inspection" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Rail inspection is the practice of examining rail tracks for flaws that could lead to catastrophic failures. According to the United States Federal Railroad Administration Office of Safety Analysis, track defects are the second leading cause of accidents on railways in the United States. The leading cause of railway accidents is attributed to human error. The contribution of poor management decisions to rail accidents caused by infrequent or inadequate rail inspection is significant but not reported by the FRA, only the NTSB. Every year, North American railroads spend millions of dollars to inspect the rails for internal and external flaws. Nondestructive testing (NDT) methods are used as a preventative measures against track failures and possible derailment.

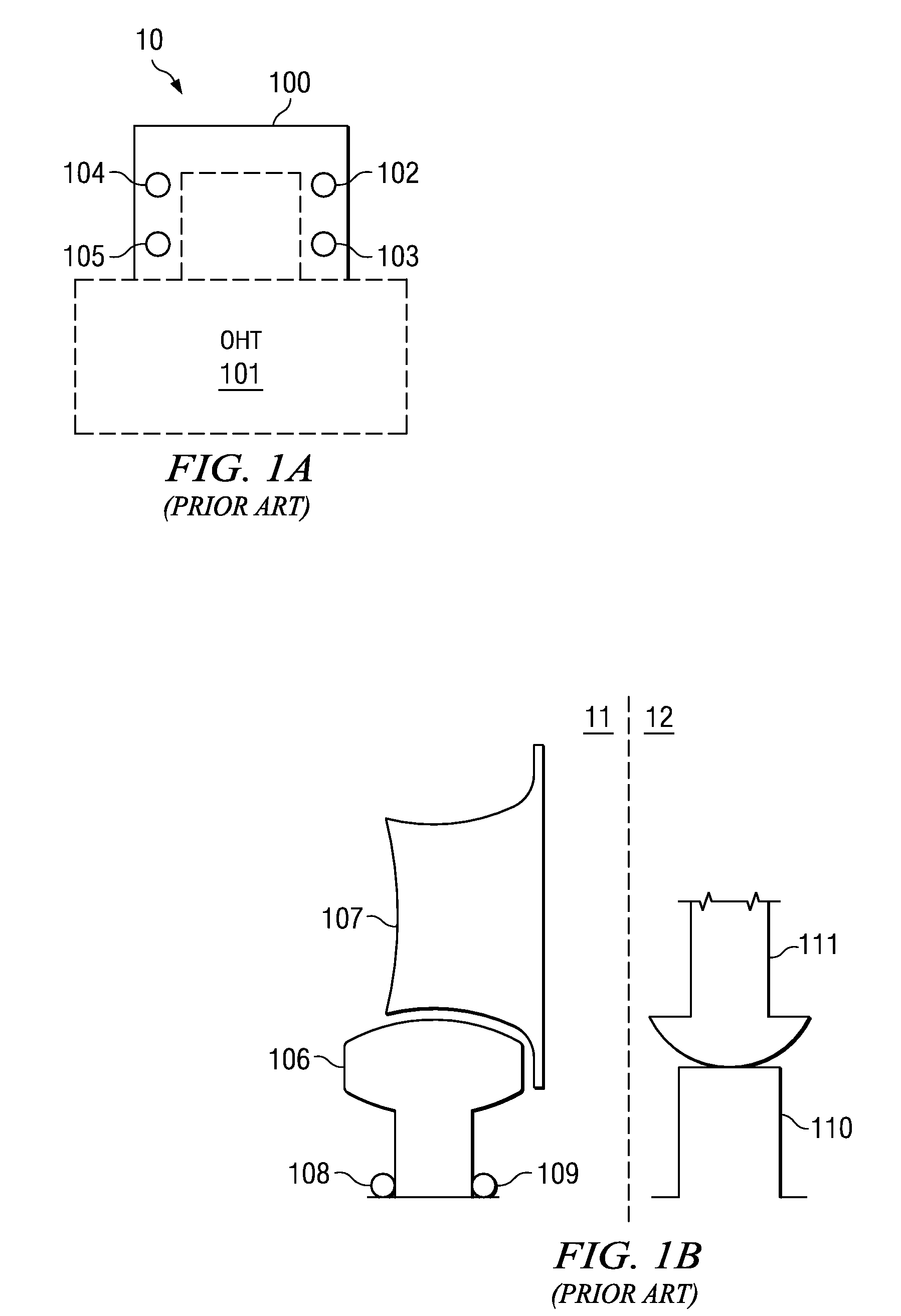

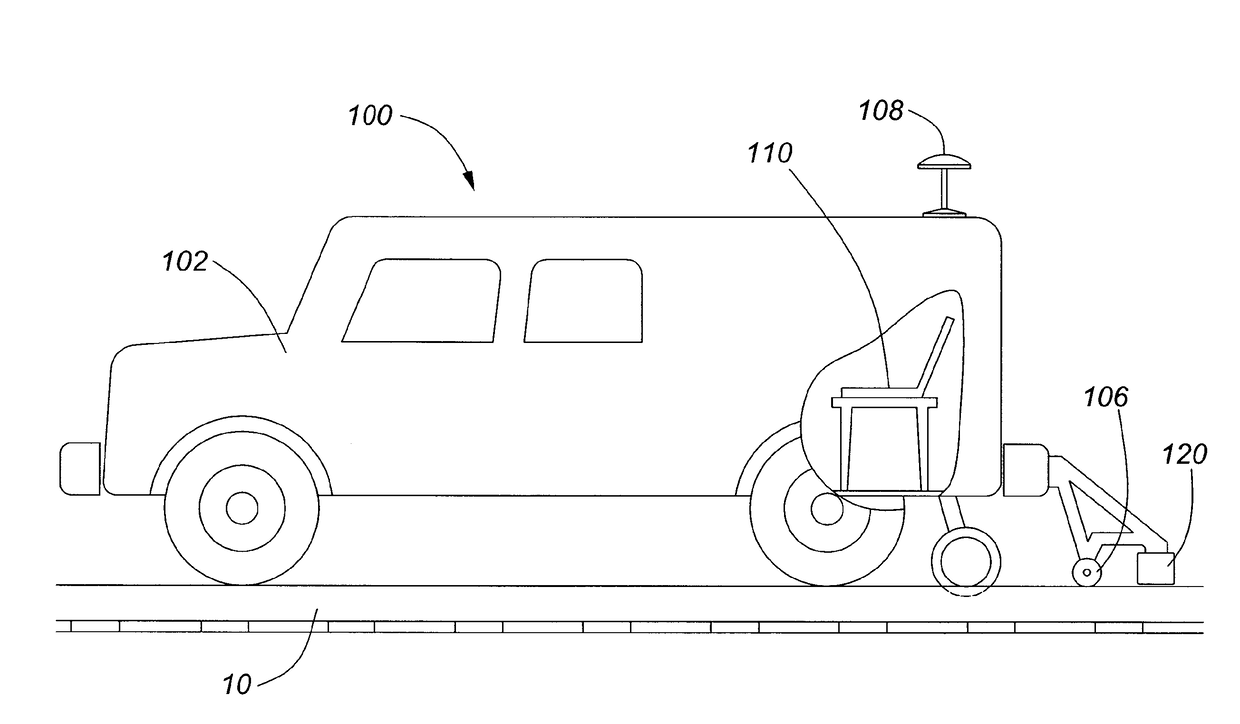

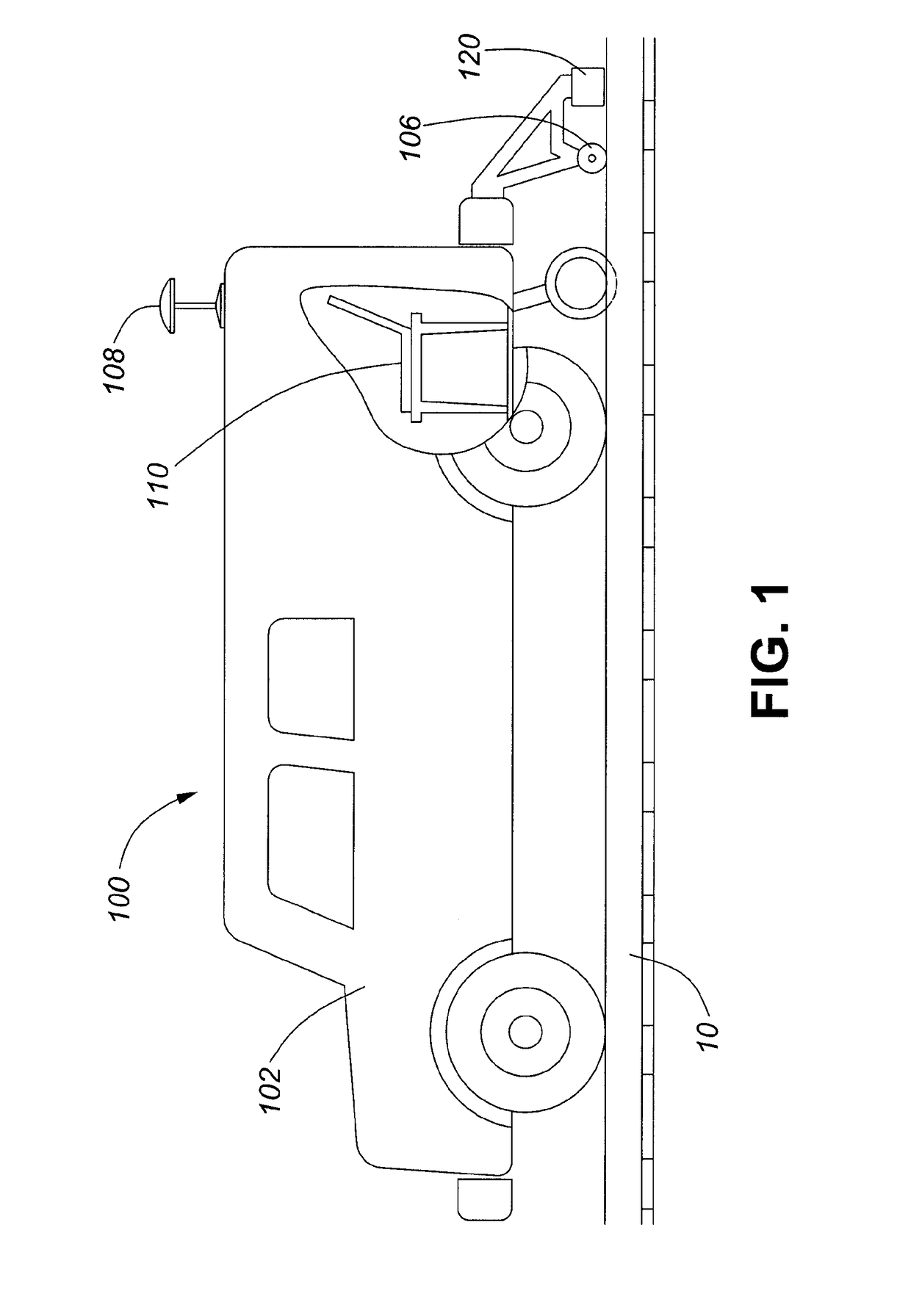

Rail inspection system

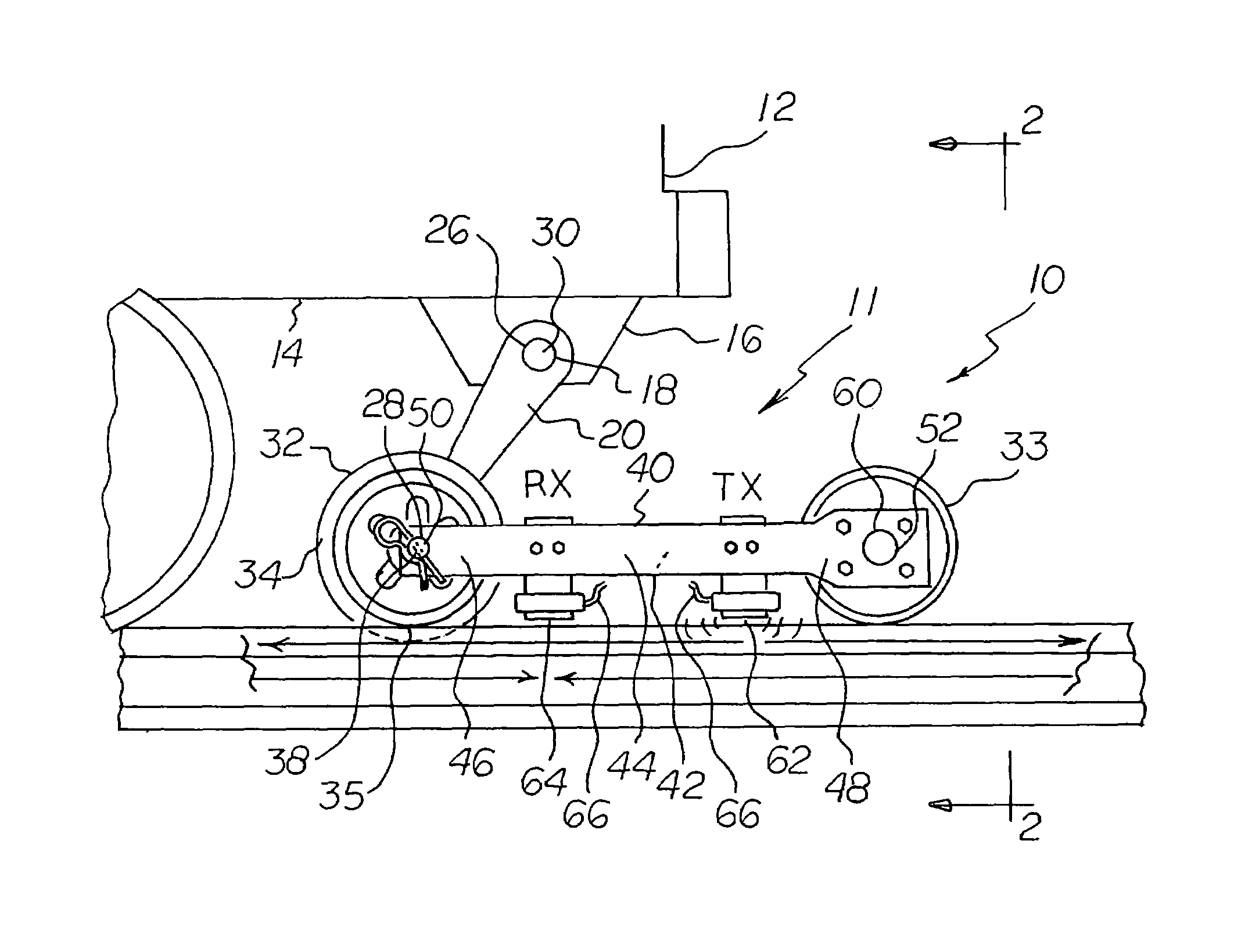

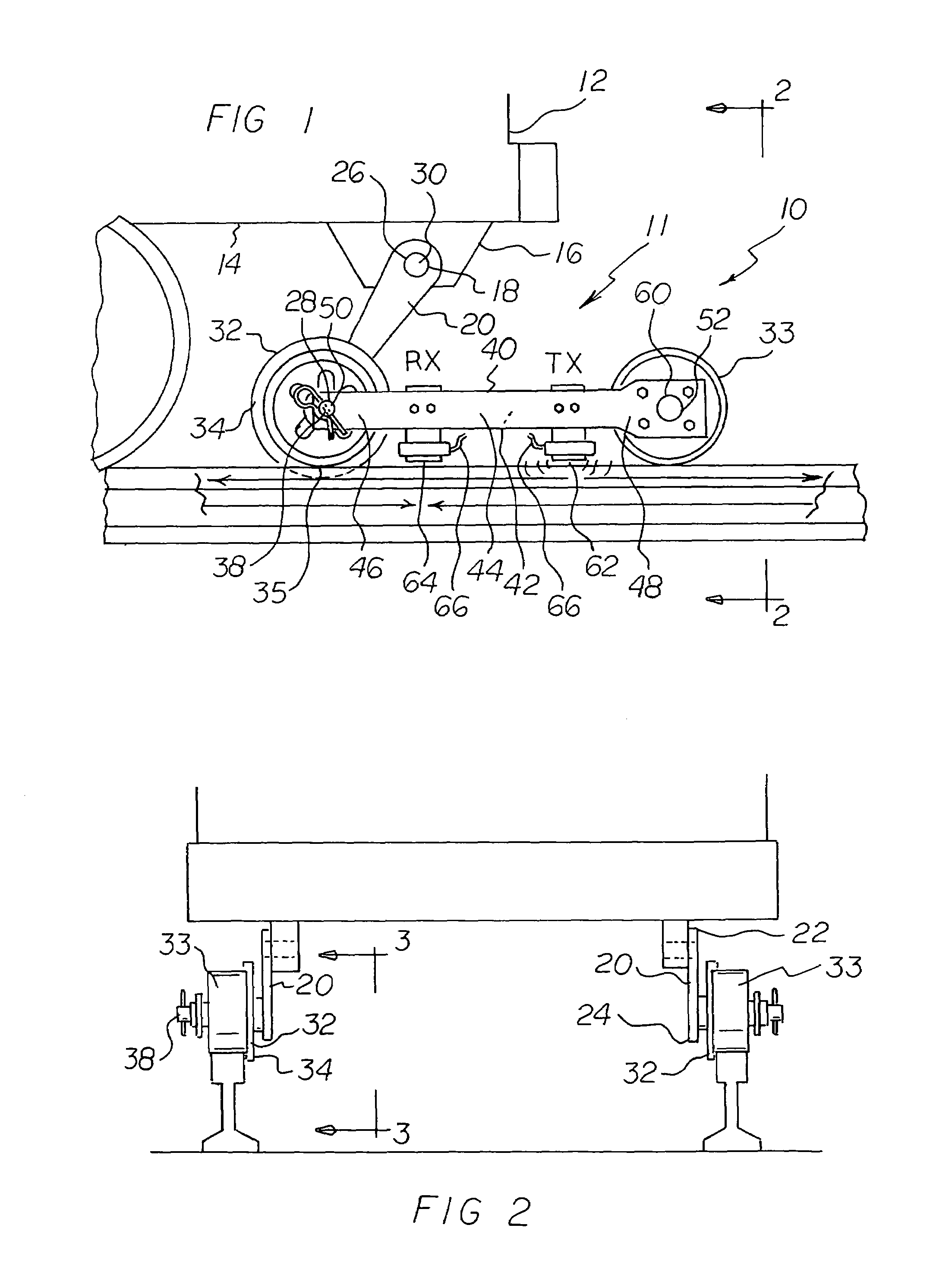

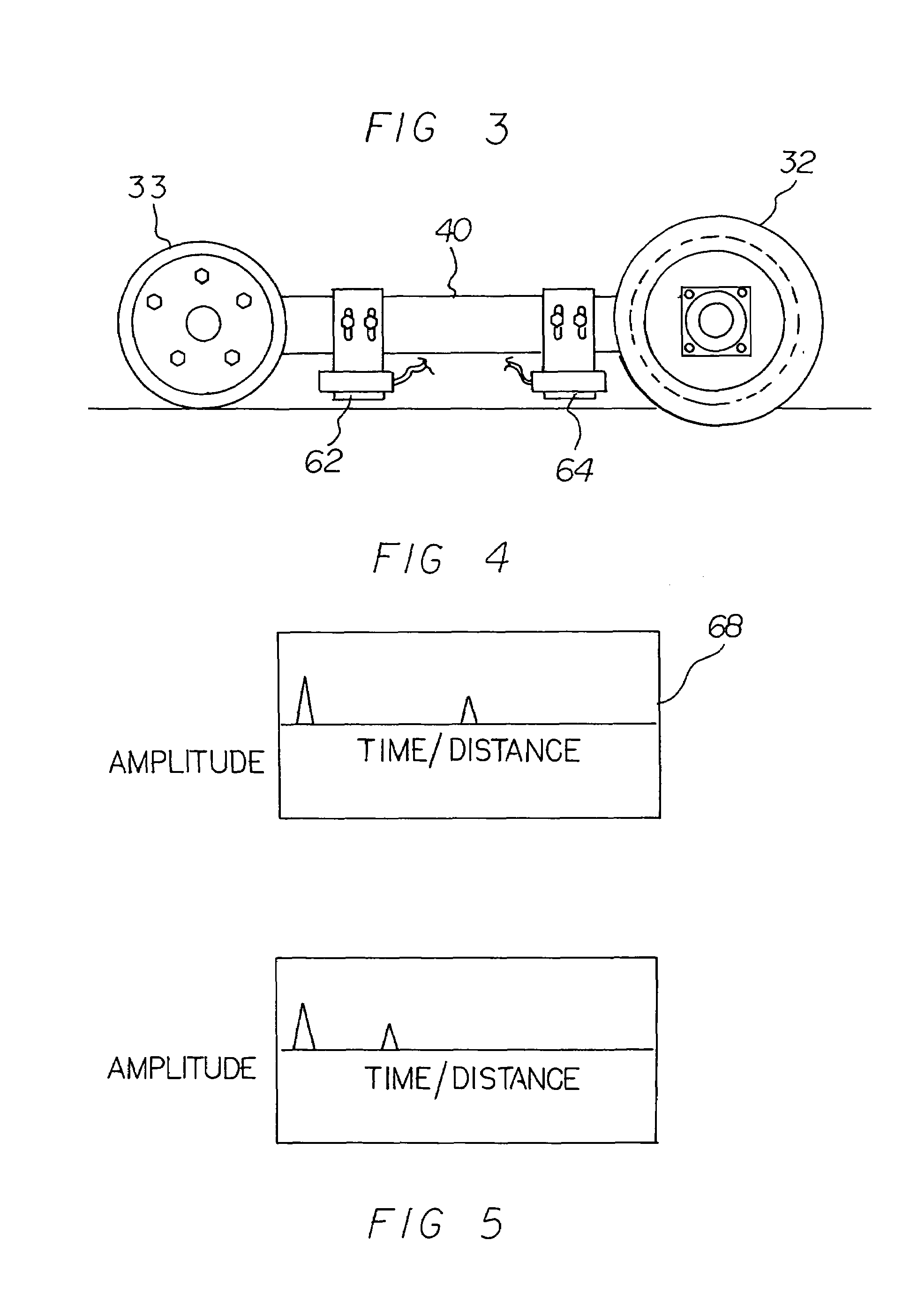

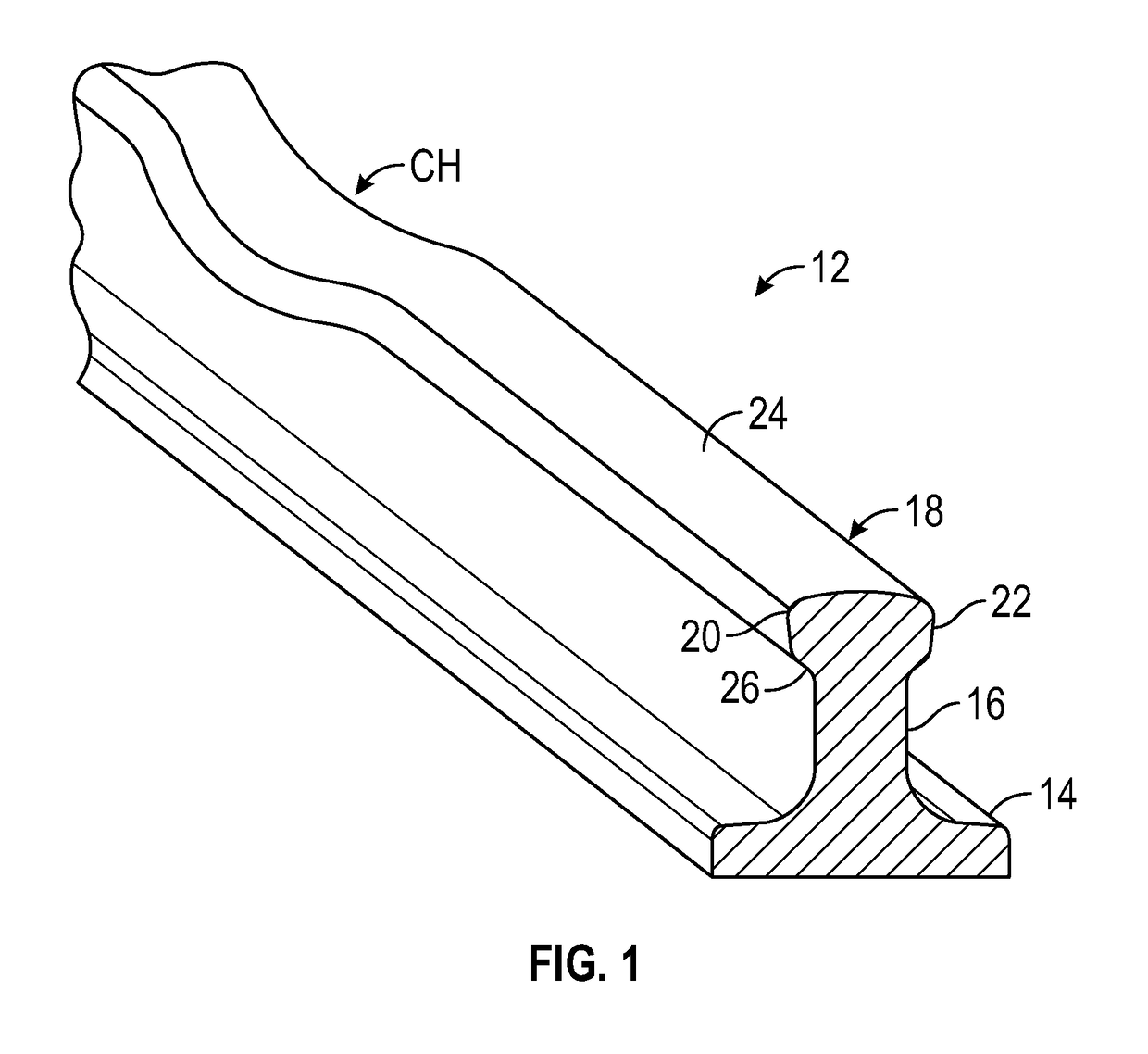

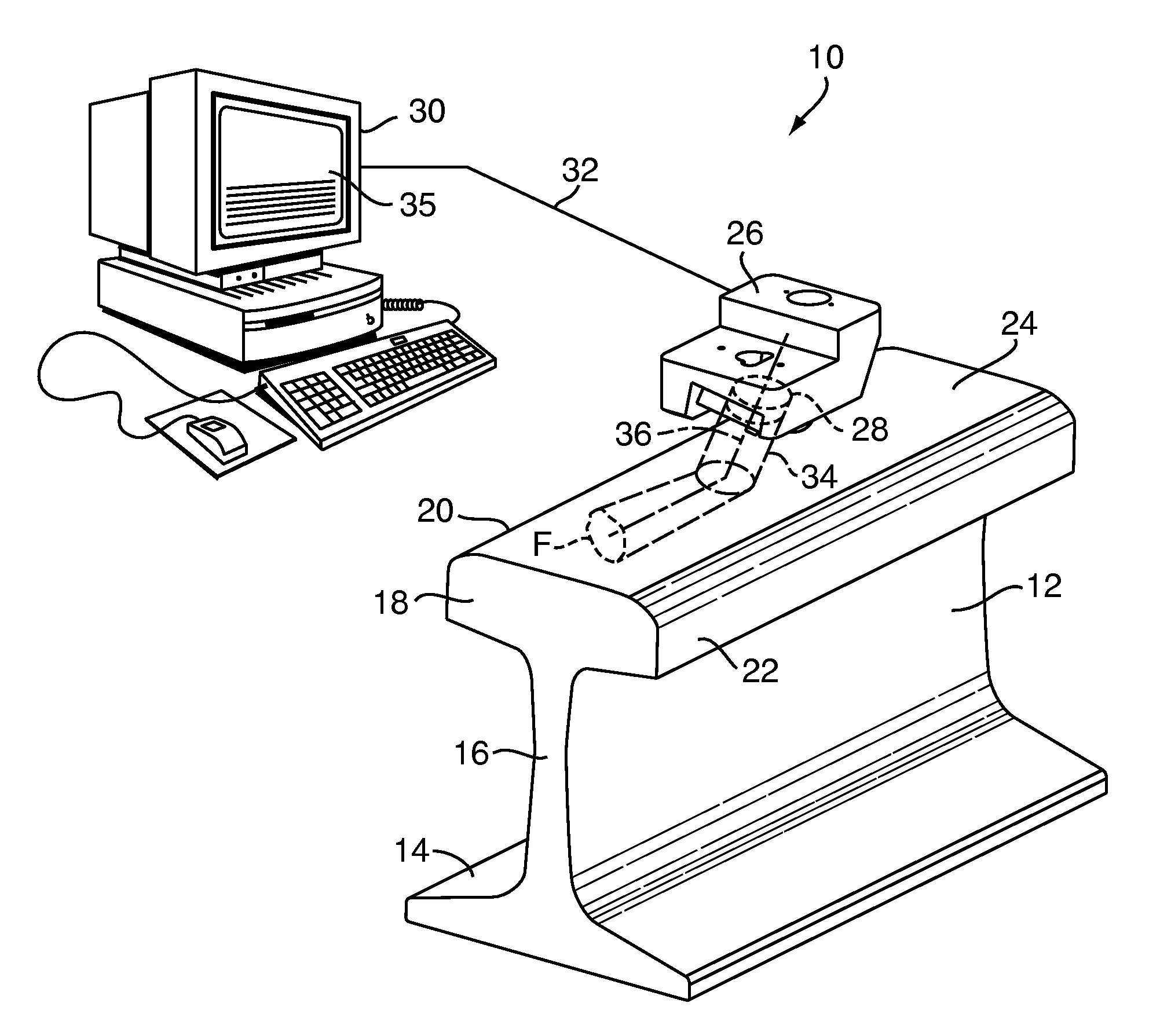

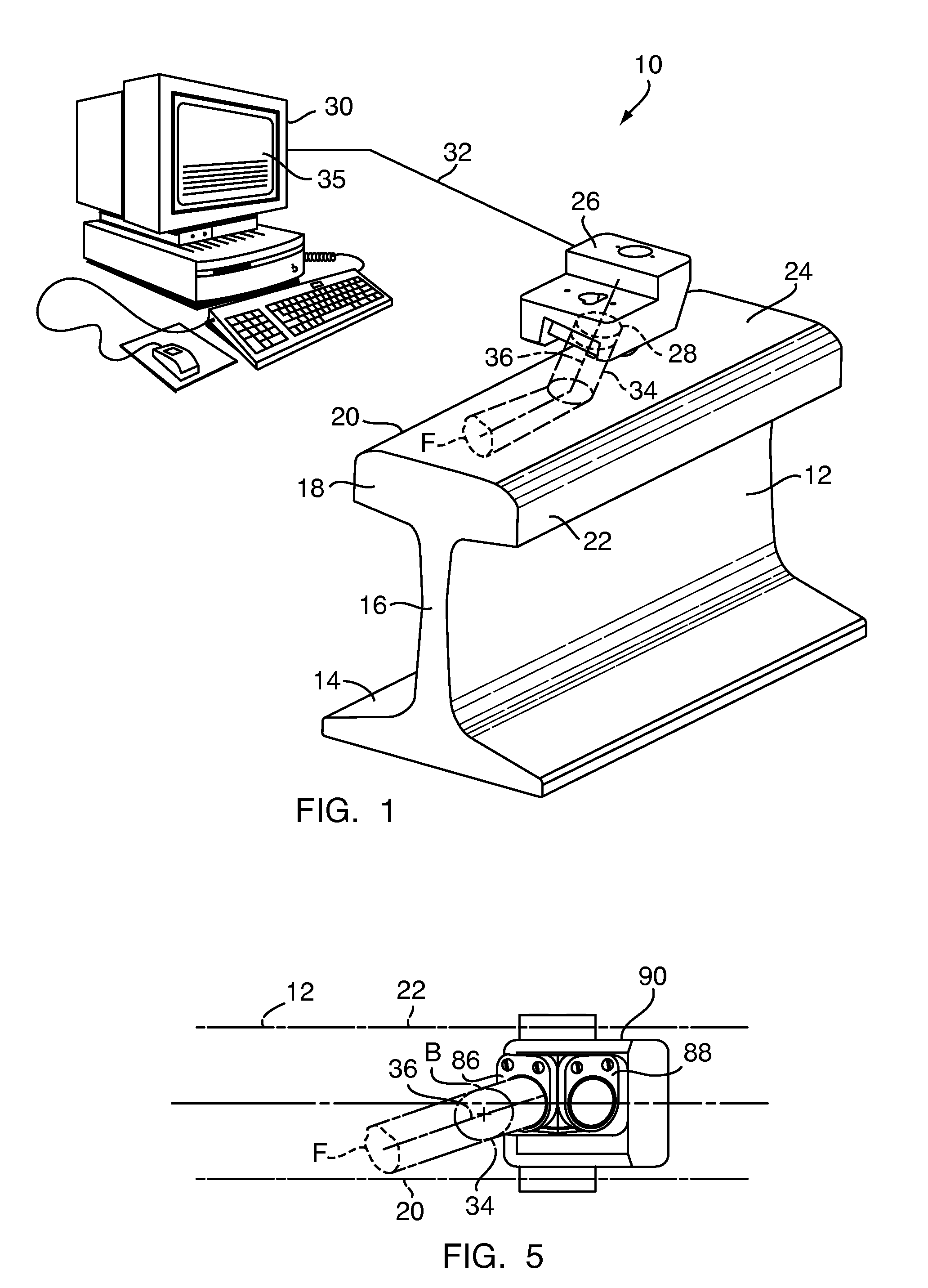

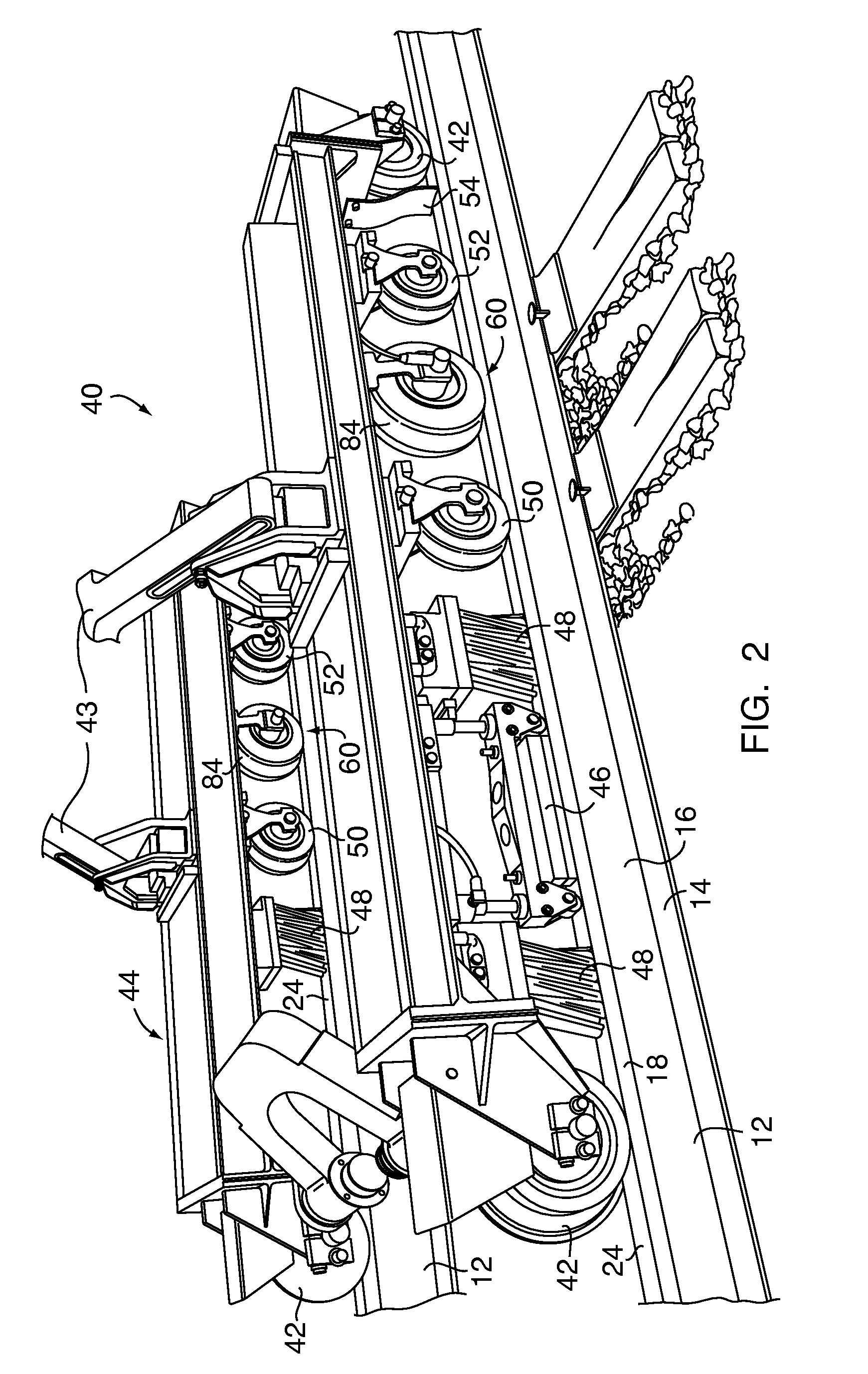

InactiveUS7389694B1Easily and efficiently manufactured and marketedDurable and reliable constructionAnalysing fluids using sonic/ultrasonic/infrasonic wavesAnalysing solids using sonic/ultrasonic/infrasonic wavesRail inspectionEngineering

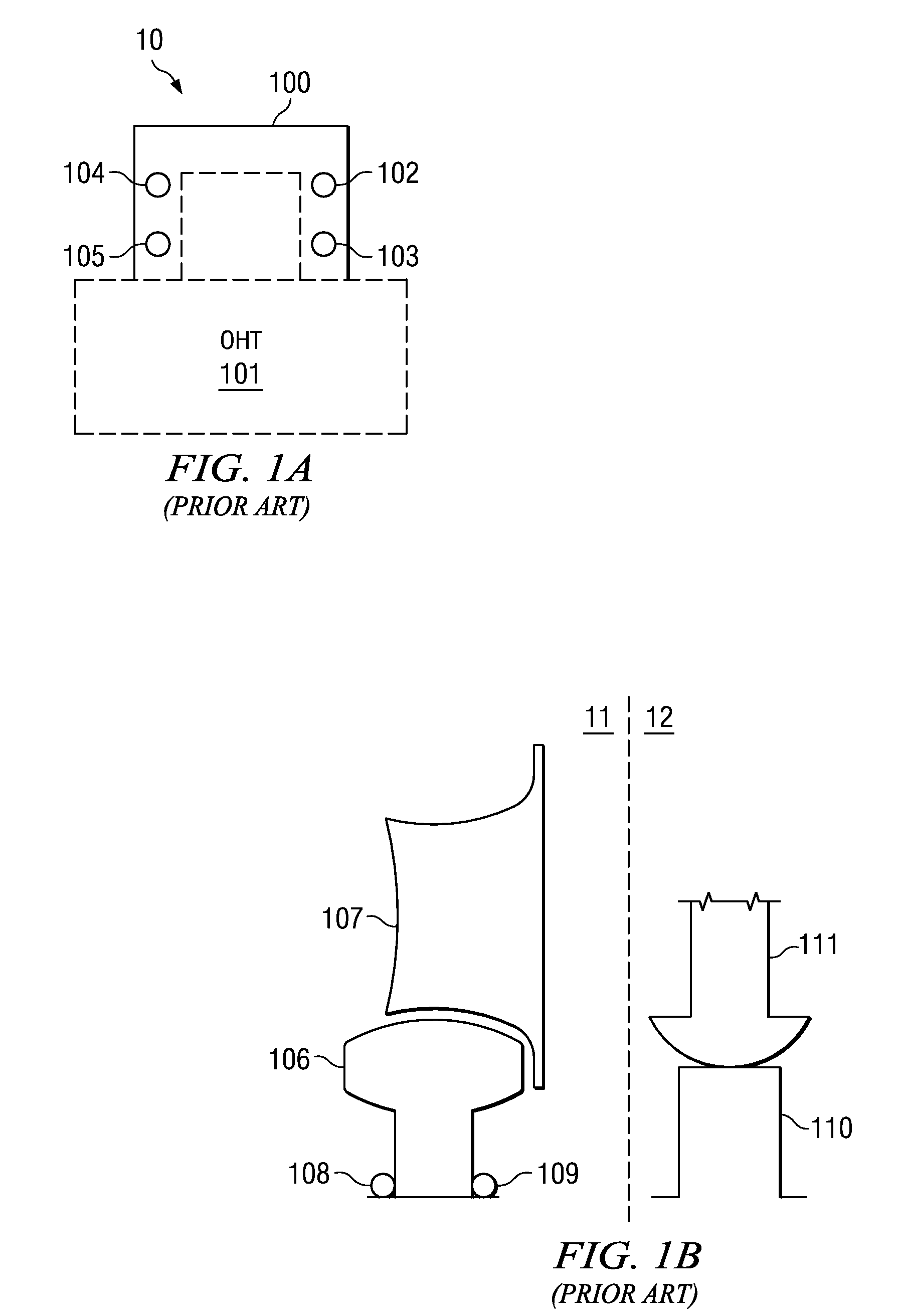

An apparatus rides along a rail of a railroad track. A transmitter transmits ultrasonic guided waves bidirectionally along the rail while the apparatus and transmitter are moving along the railroad track. A sensor detects flaws in response to the transmitted ultrasonic guided waves while the apparatus, transmitter and sensor are moving along the railroad track. An electronic coupler operatively couples the sensor to monitoring equipment.

Owner:WAVESINSOLIDS

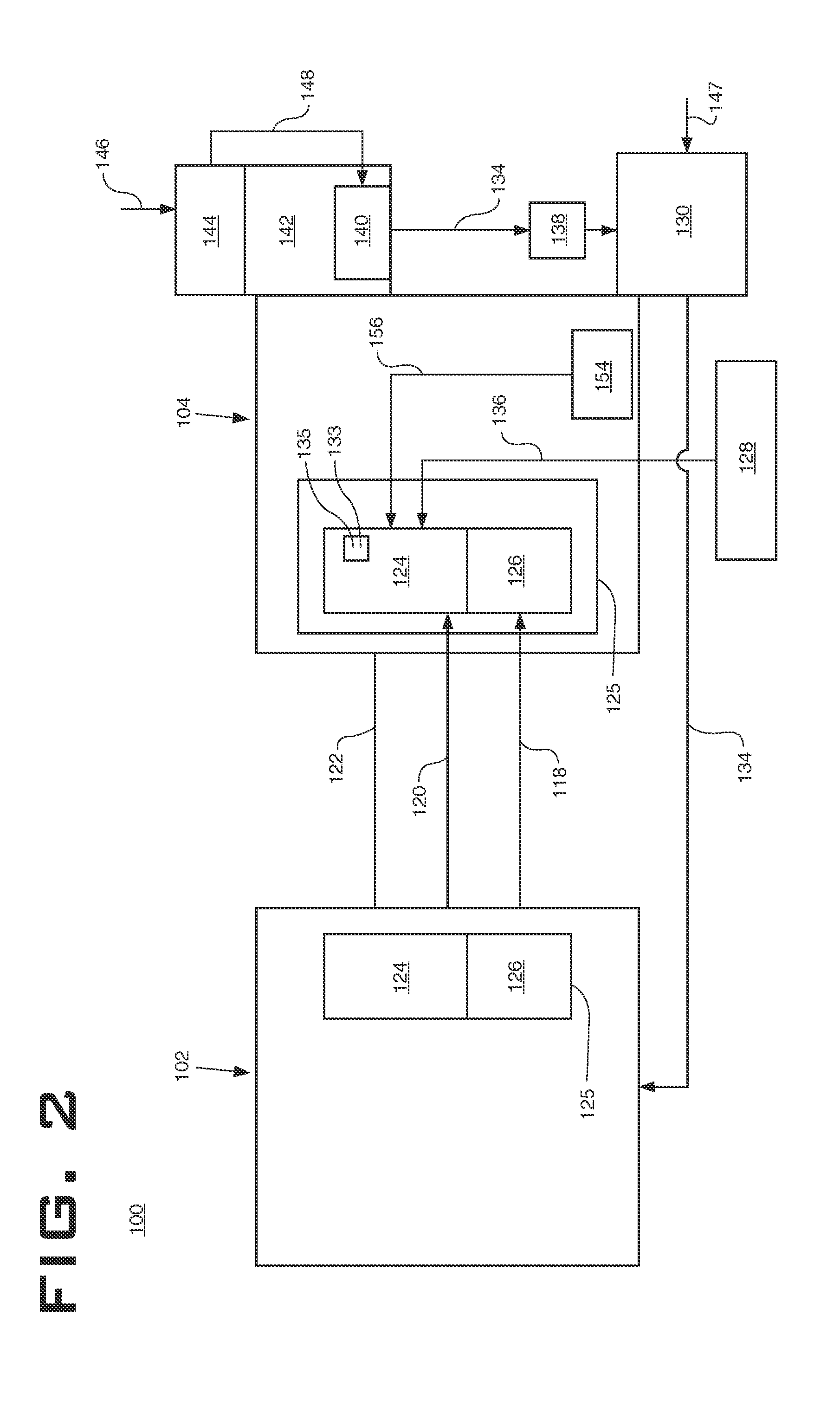

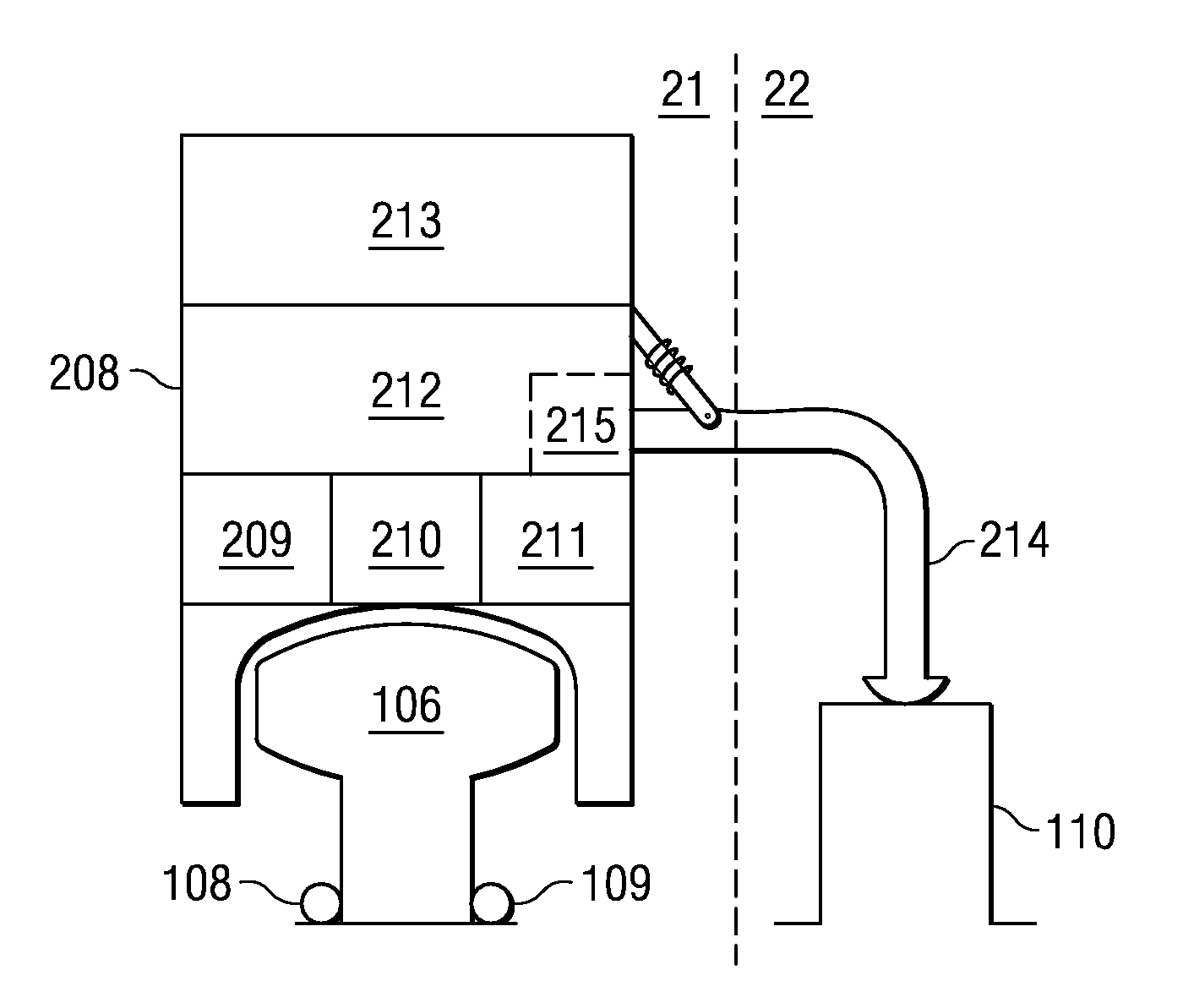

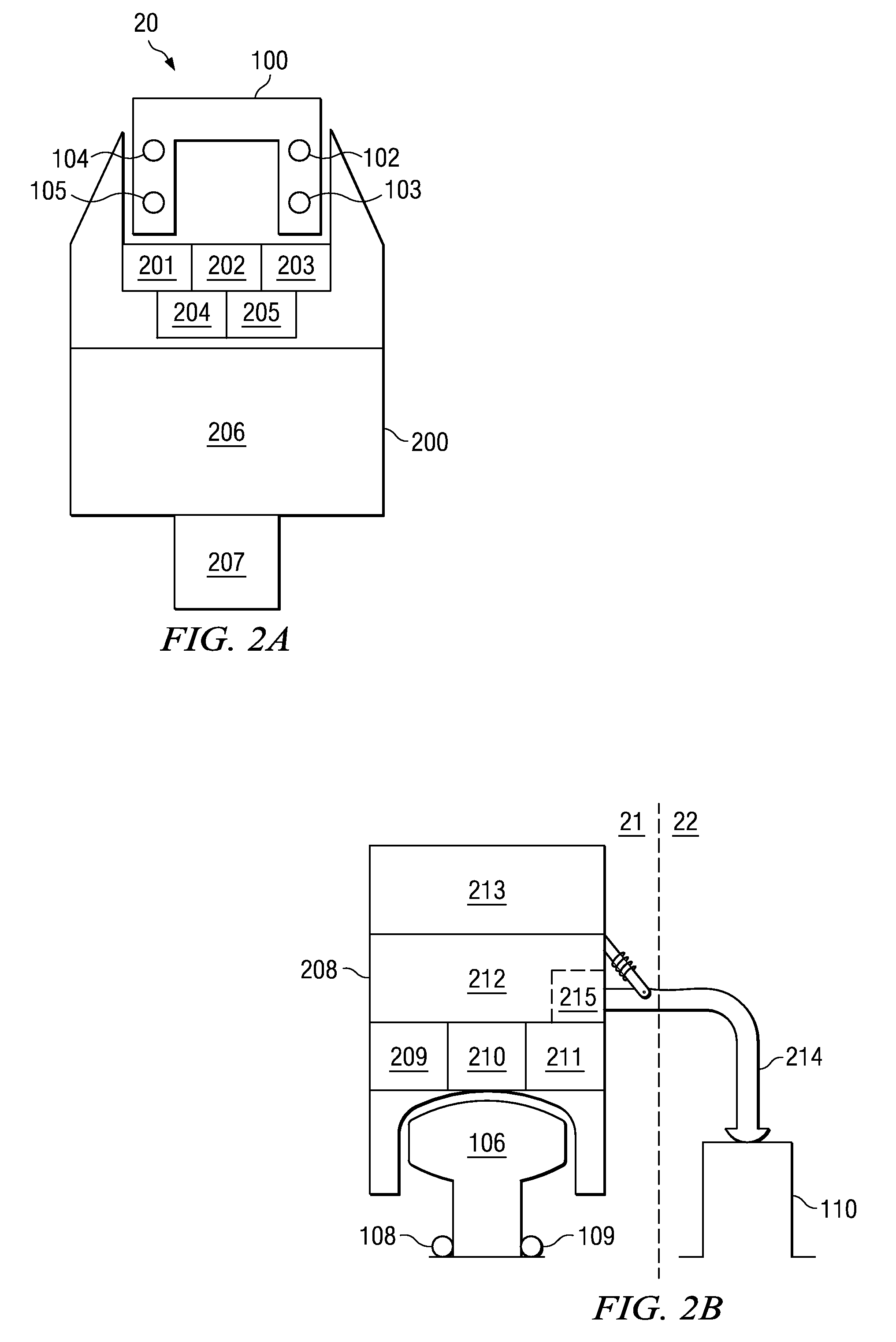

Enhanced Rail Inspection

Owner:TAIWAN SEMICON MFG CO LTD

Railway inspection system

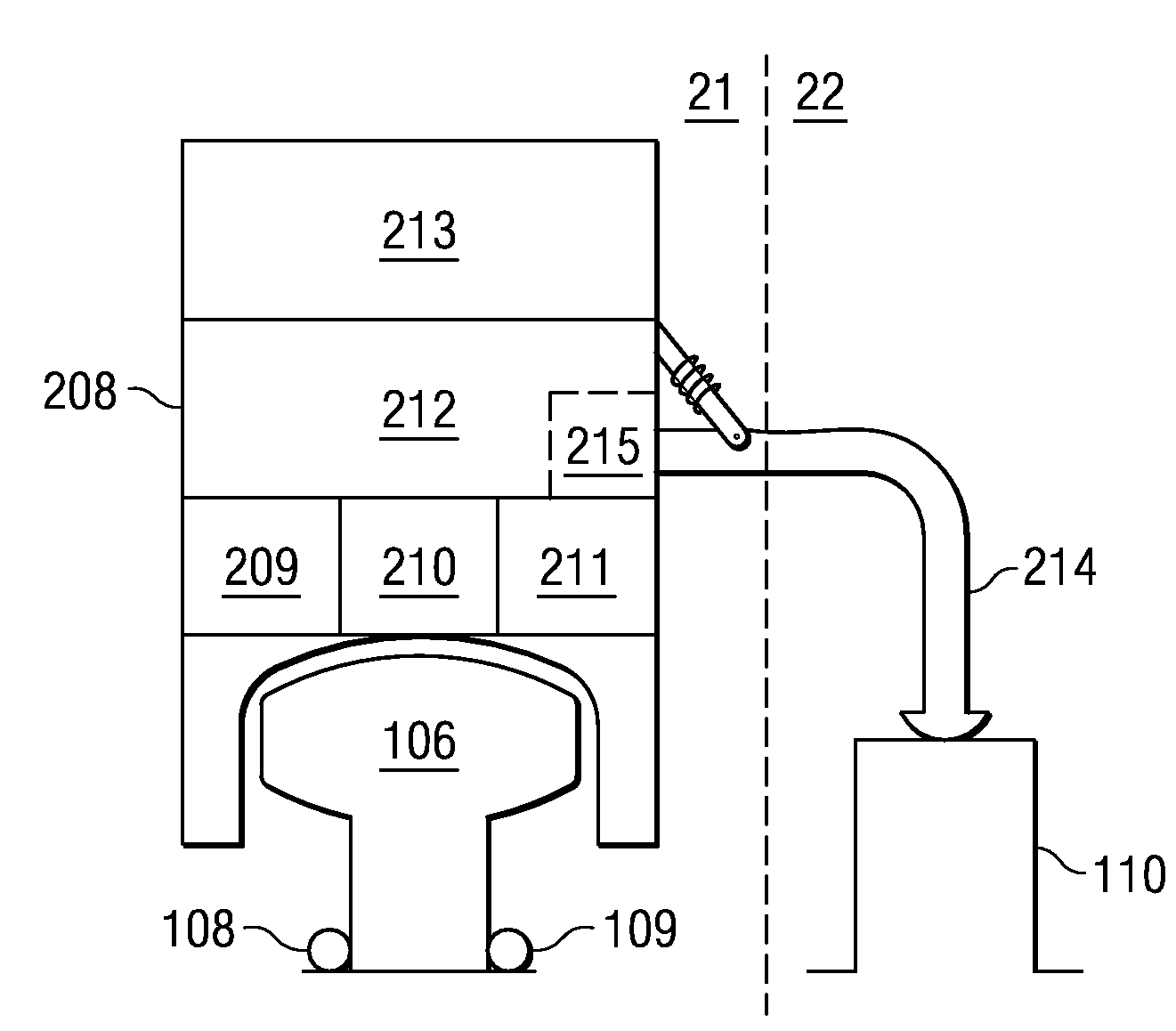

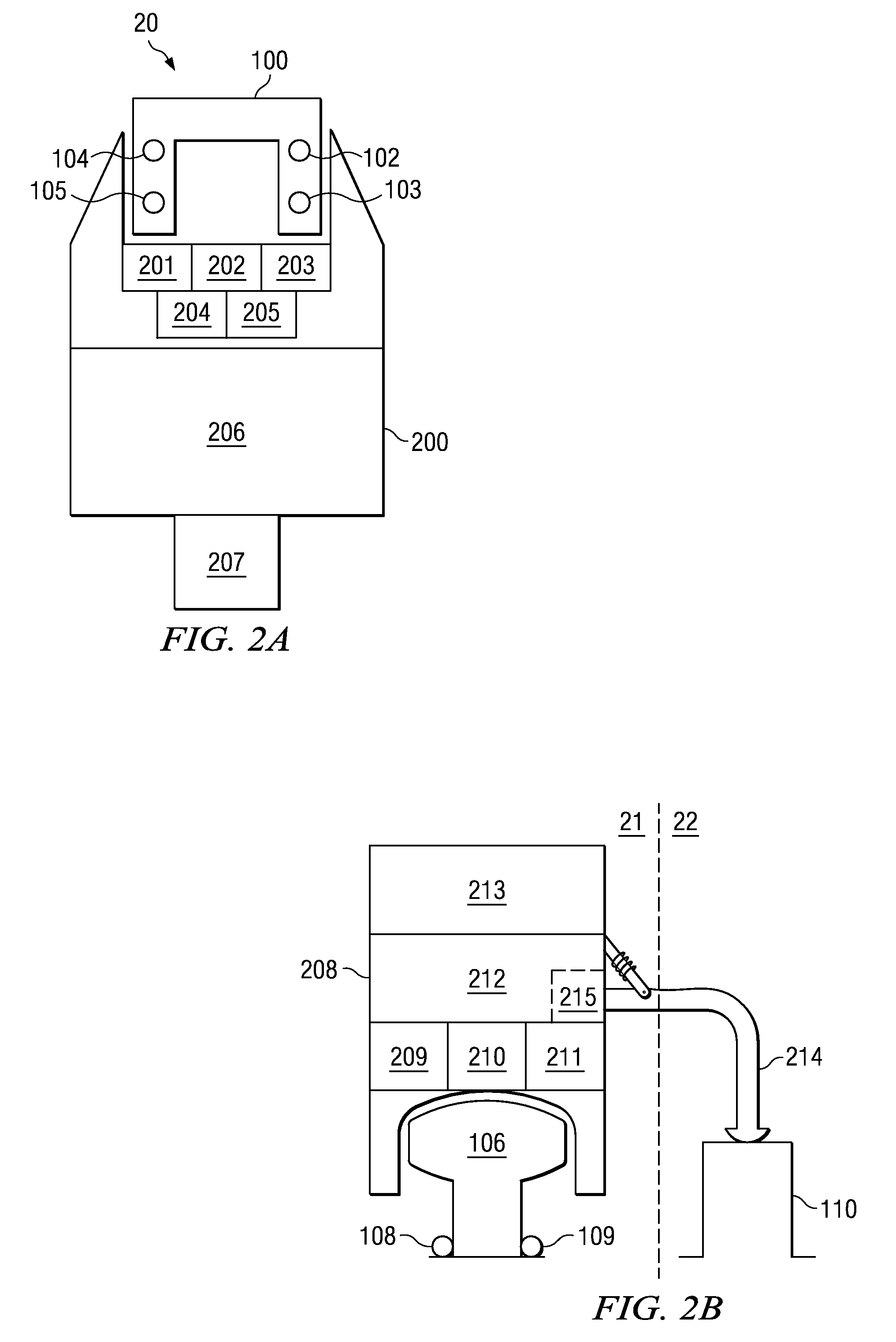

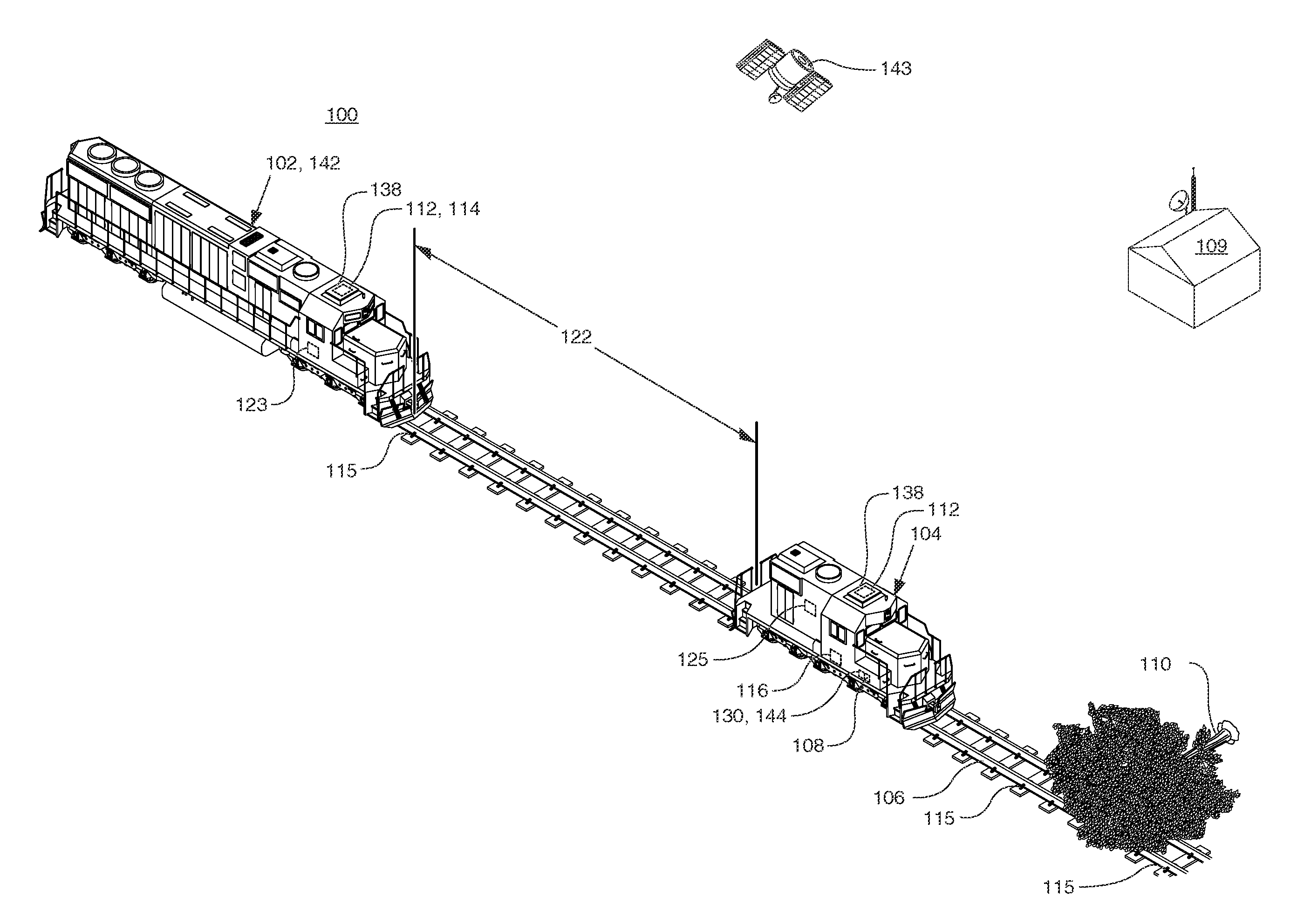

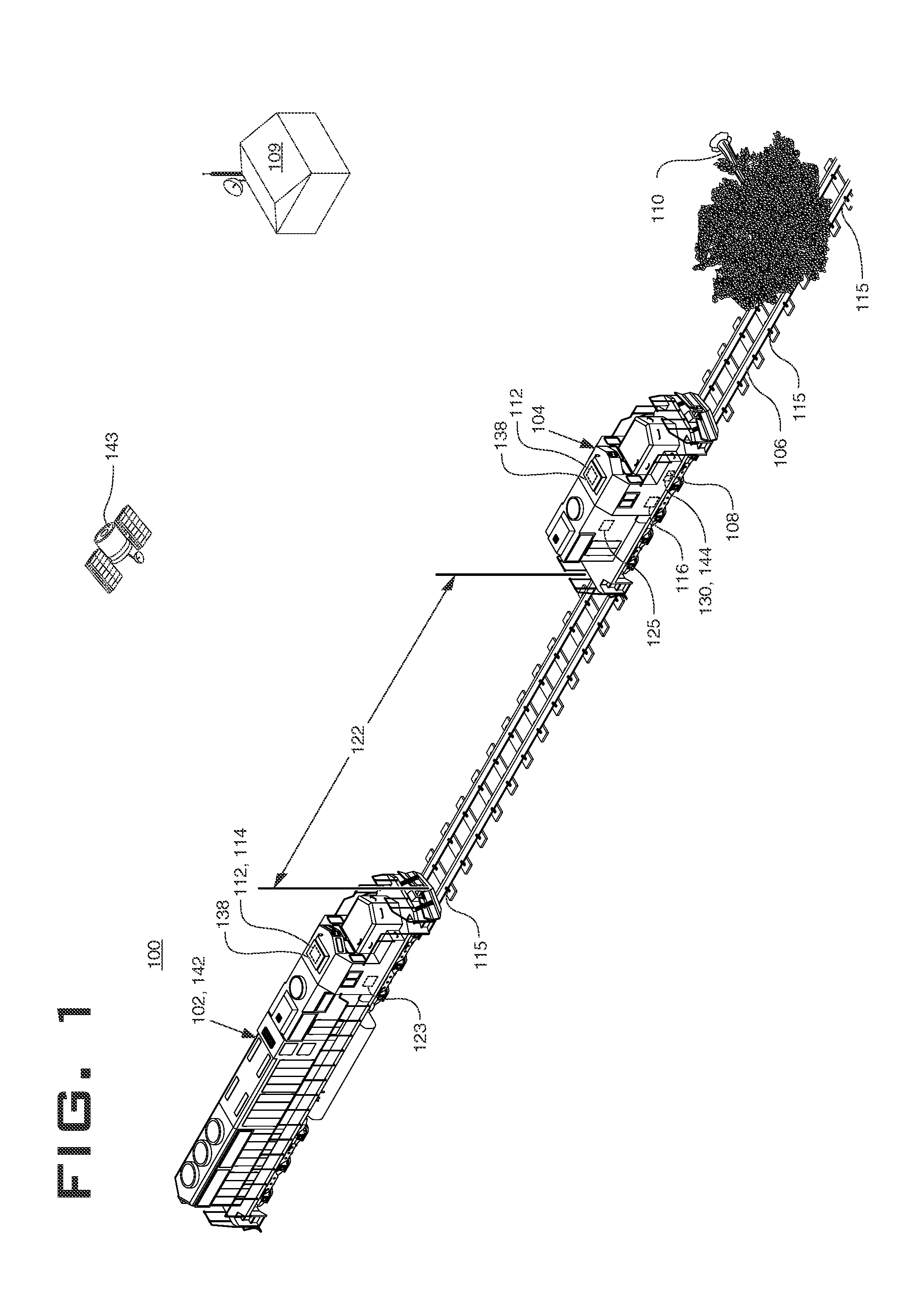

In one aspect of the present disclosure, a railway inspection system is shown. The system includes: an unmanned self-propelled vehicle, a sensor, a position system and a control system. The unmanned self-propelled vehicle is adapted to travel on a railway track ahead of the train and has a sensor configured to detect an adverse railway condition. The positioning system is configured to determine the position of the self-propelled vehicle. The control system in communication with the sensor and the train; wherein the control system communicates the adverse railway condition to the train.

Owner:ELECTRO-MOTIVE DIESEL

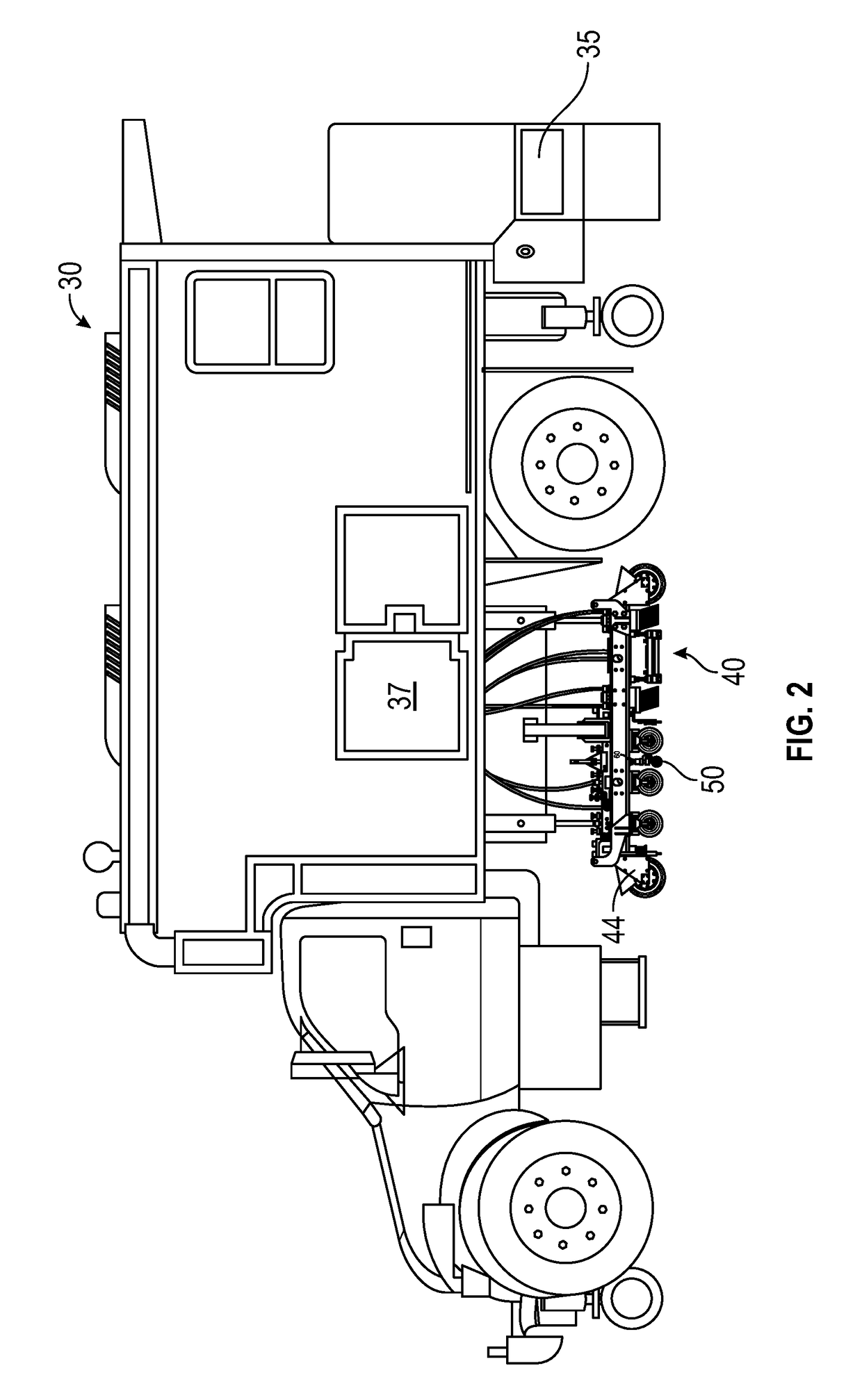

Enhanced rail inspection

Rail inspection is discussed that employs a monitor vehicle running on one or more tracks of a rail system that performs physical rail inspection in combination with monitoring and analysis of other system parameters that accompany the physical rail.

Owner:TAIWAN SEMICON MFG CO LTD

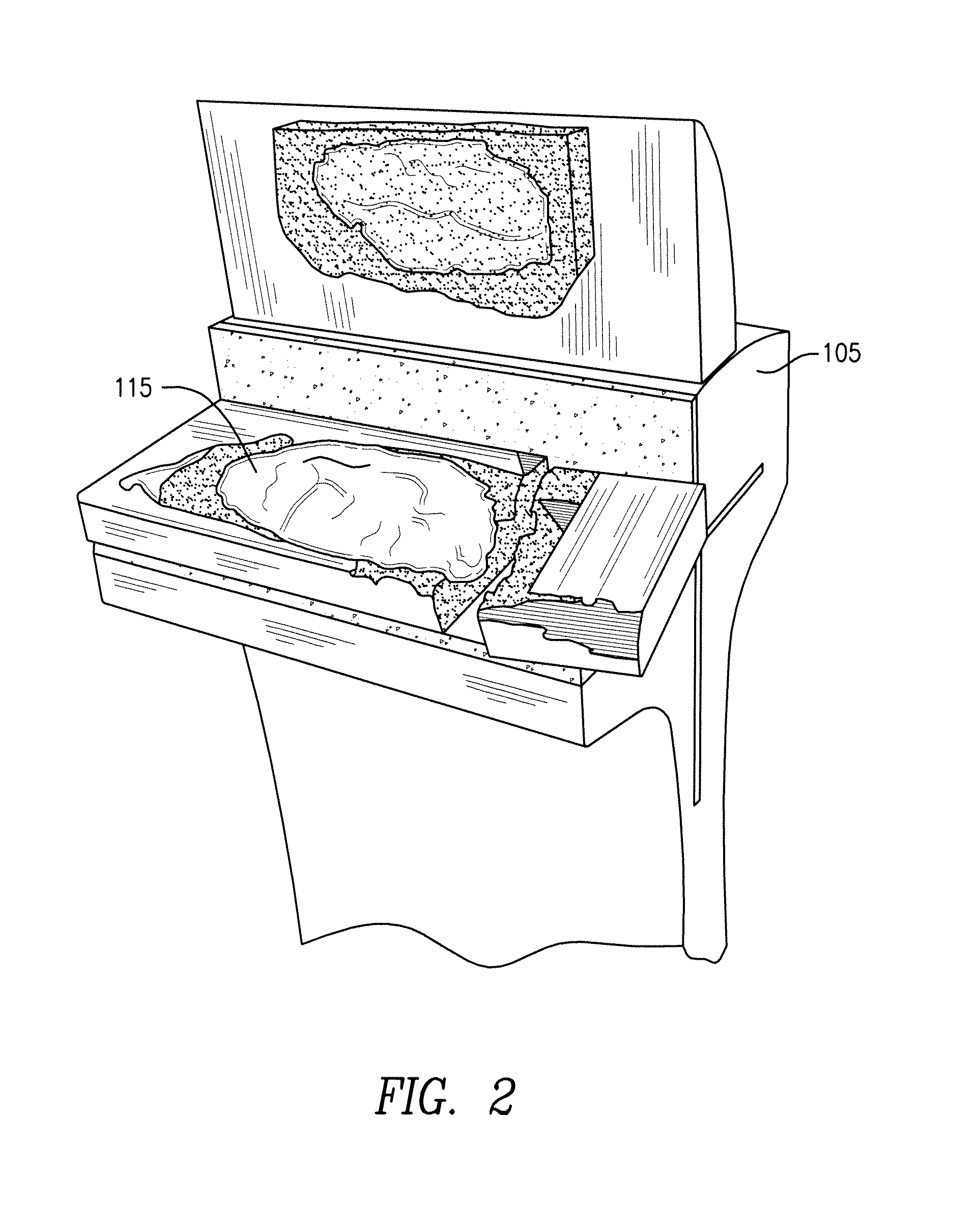

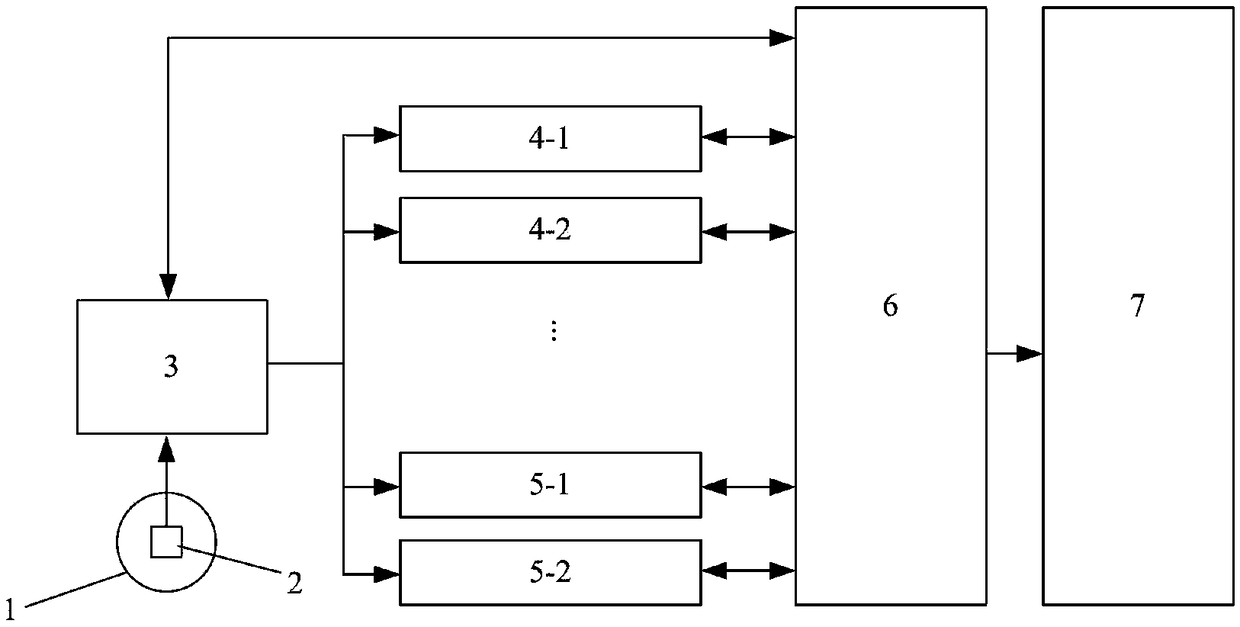

Rail inspection system and method

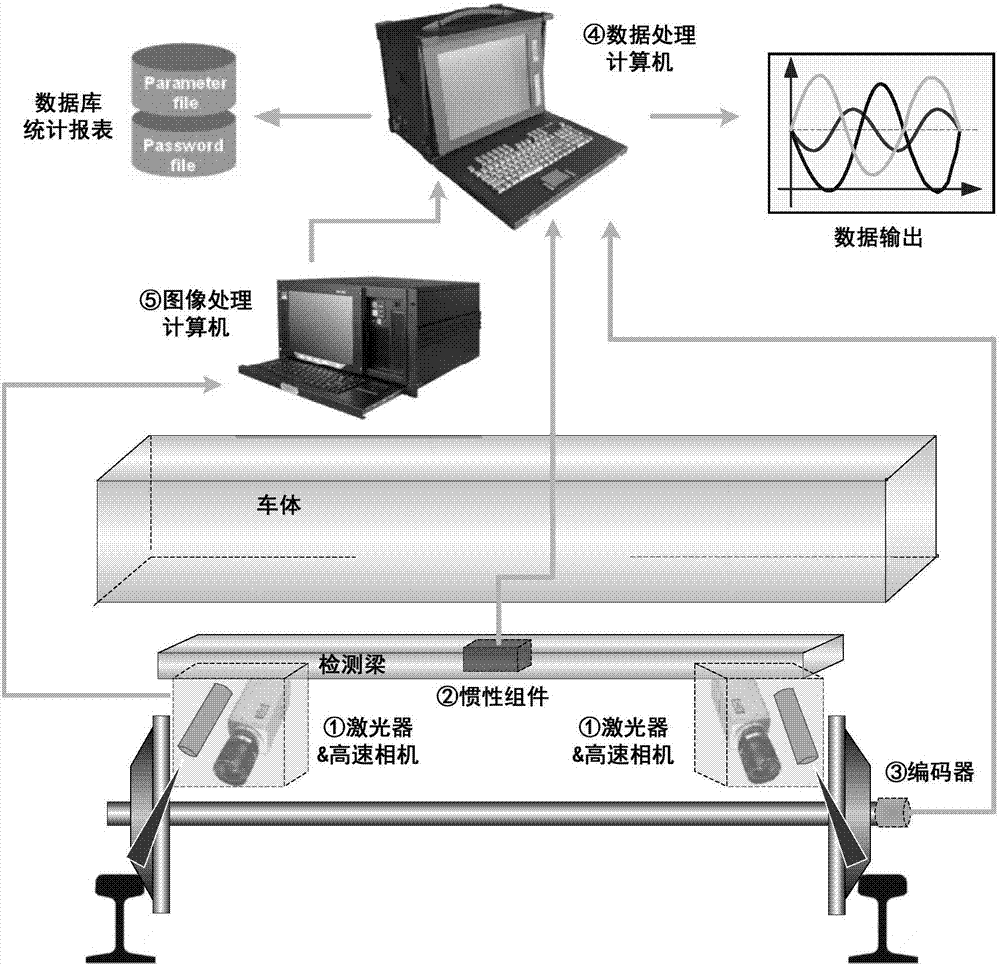

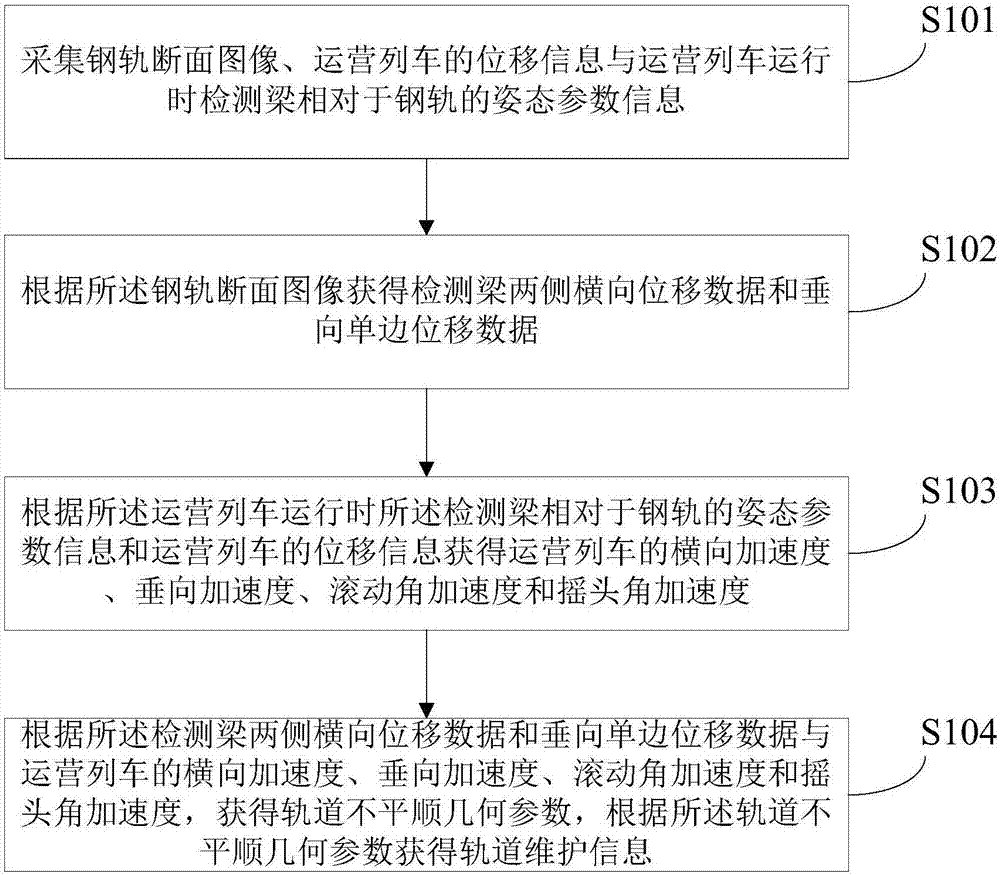

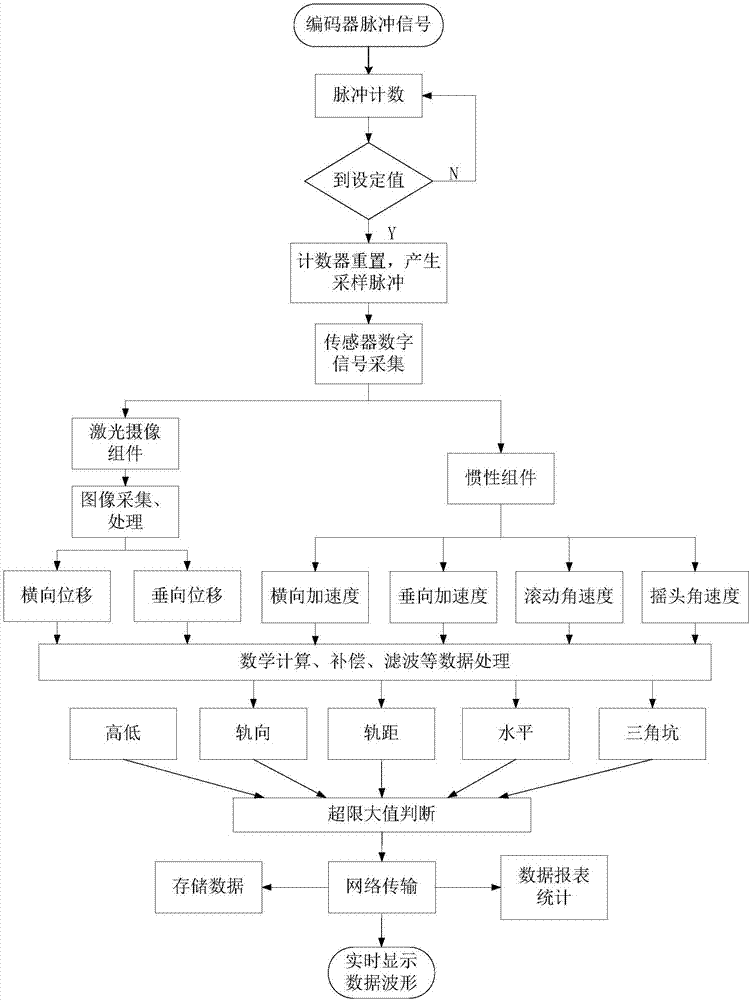

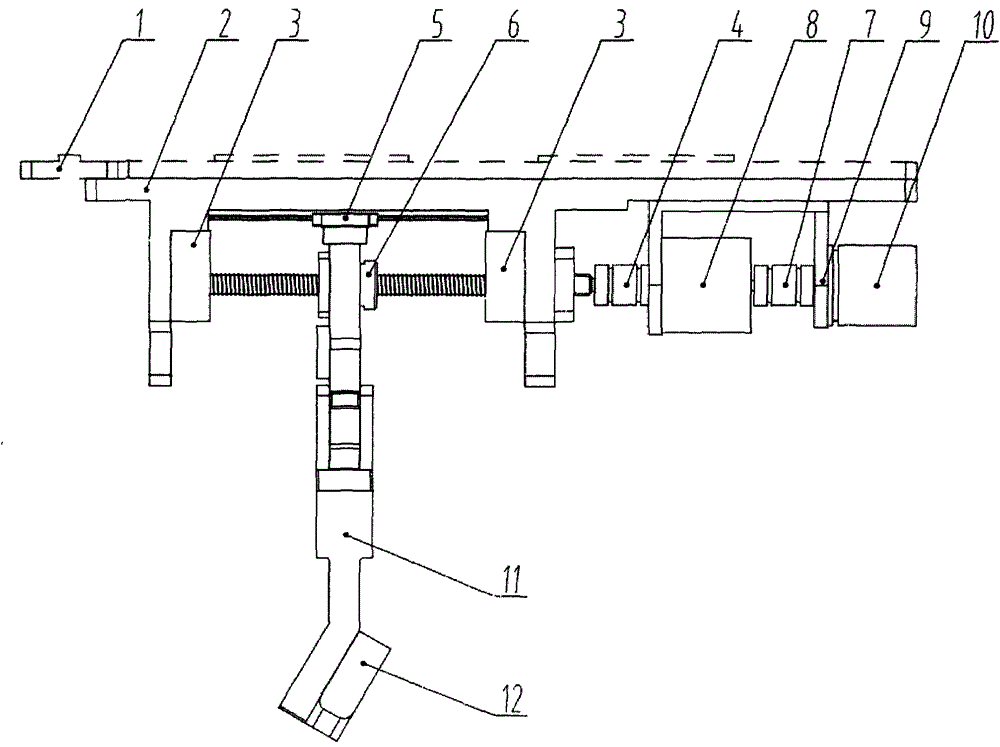

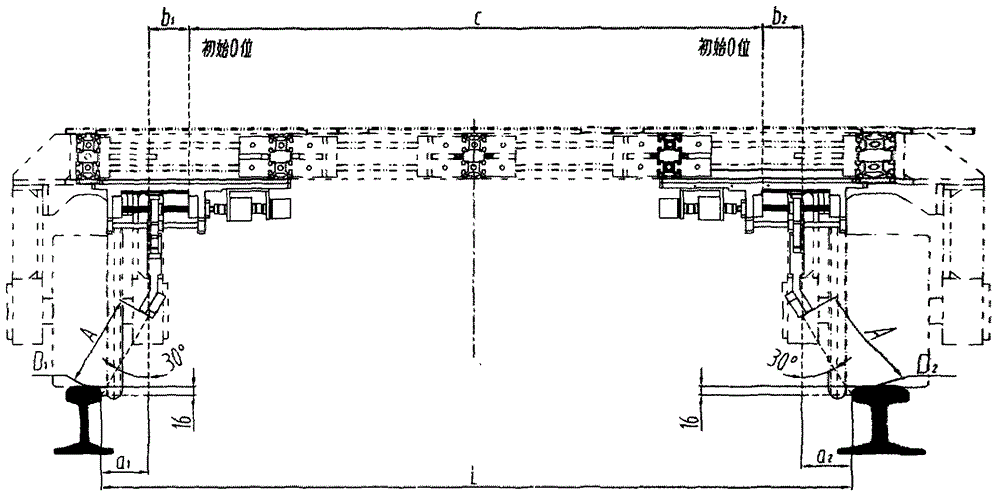

ActiveCN107284473ALower requirementExpand the scope of installationRailway signalling and safetyRail inspectionVisual inspection

The invention provides a rail inspection system and method; the system applied to an operating train comprises image acquisition modules, an inertial module, an encoding module and a processing module; the image acquisition modules are arranged on two sides of an inspection beam of the operating train and are used for acquiring section images of a steel rail; the inertial module is arranged at the center of the inspection beam and is used for measuring attitude parameter information of the inspection beam relative to the steel rail when the operating train runs; an encoder is disposed on an axle of the operating trail and is used for acquiring displacement information of the operating train; the processing module is in communication connection with the image acquisition module, the inertial module and the encoder and is used for calculating according to the section images of the steel rail, the attitude parameter information and the displacement information to obtain unevenness geometric parameters of the rail, and for acquiring rail maintenance information according to the unevenness geometric parameters of the rail.

Owner:BEIJING IMAP TECH +4

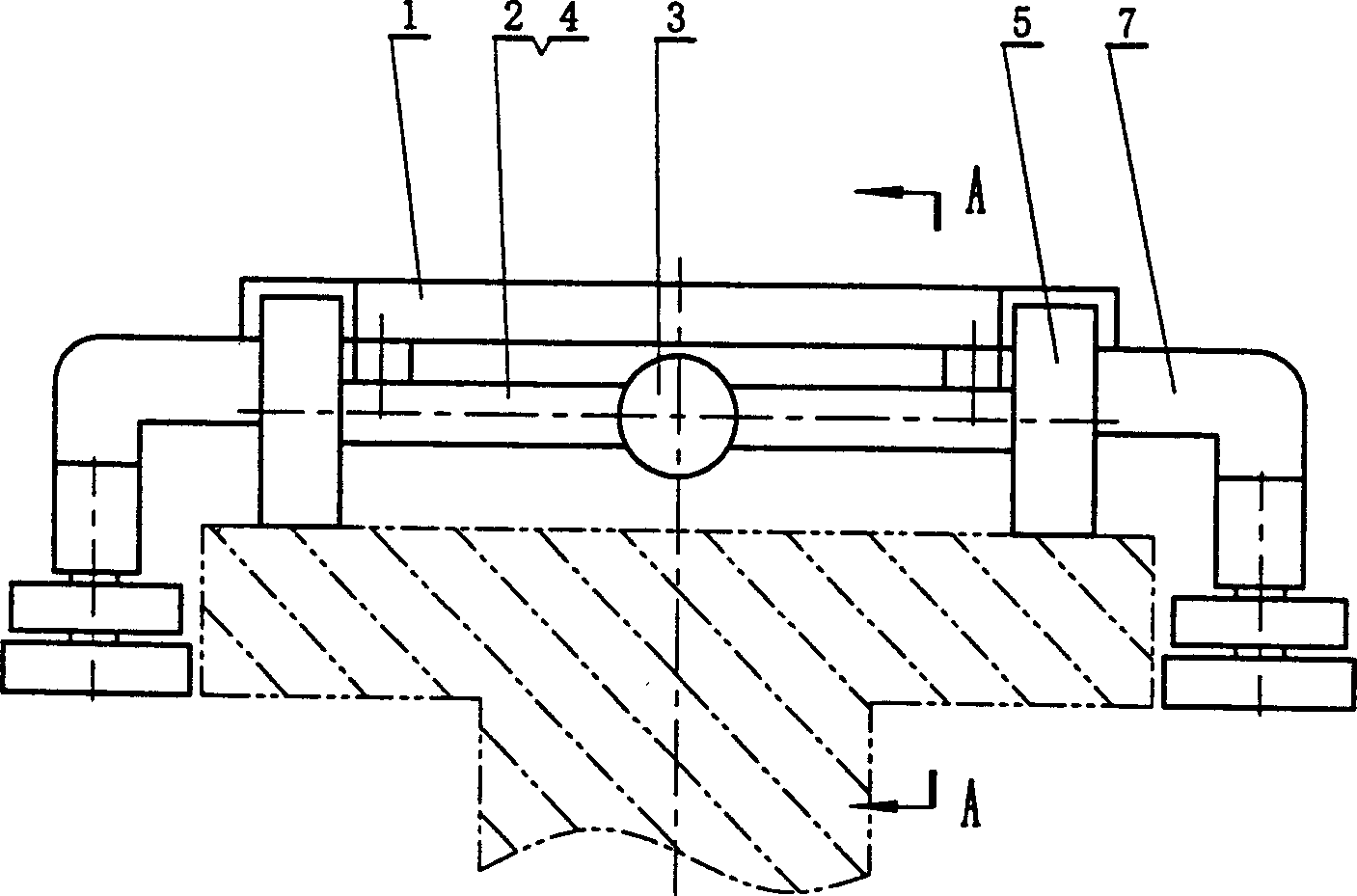

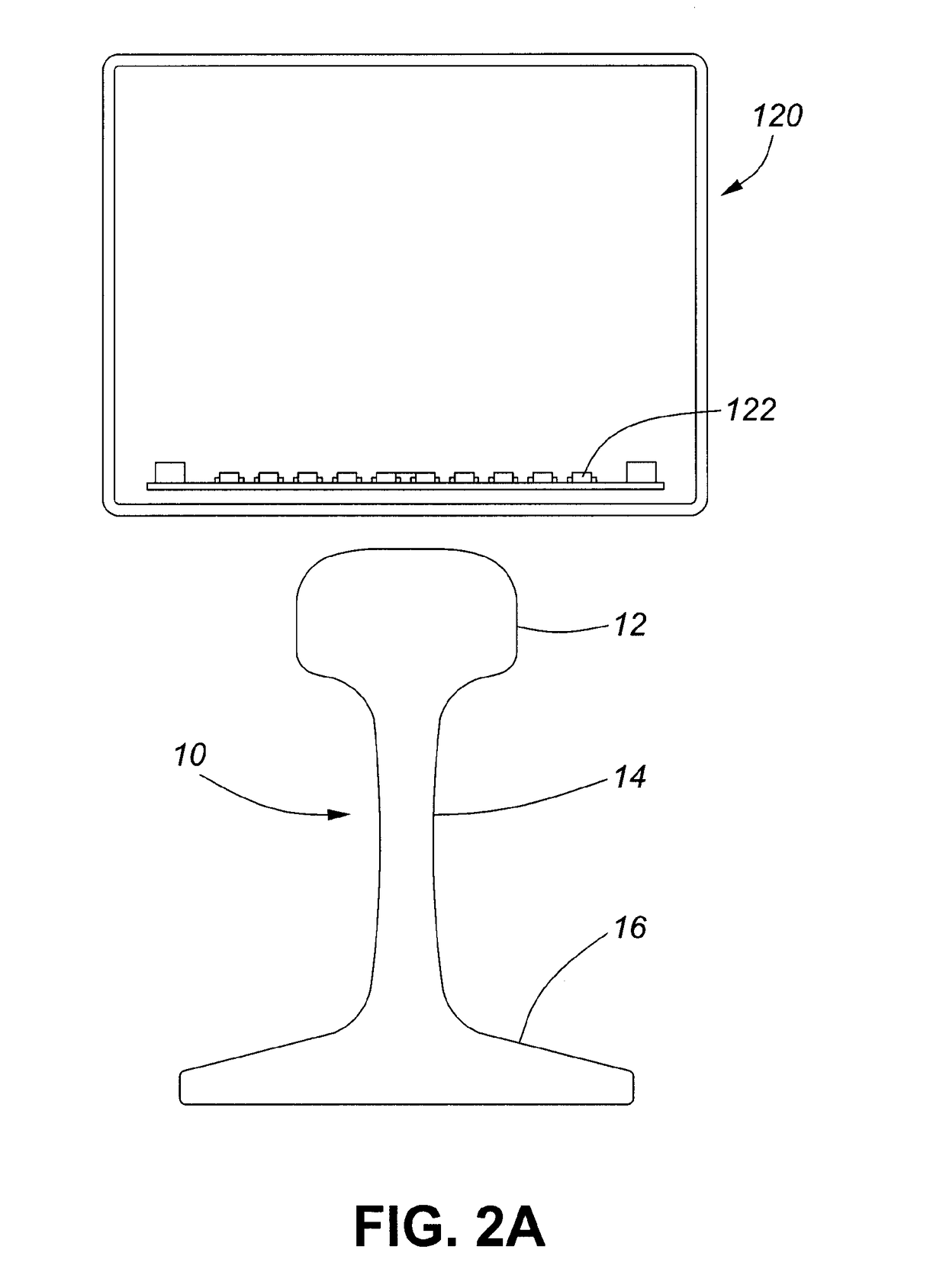

Rail inspection apparatus and method

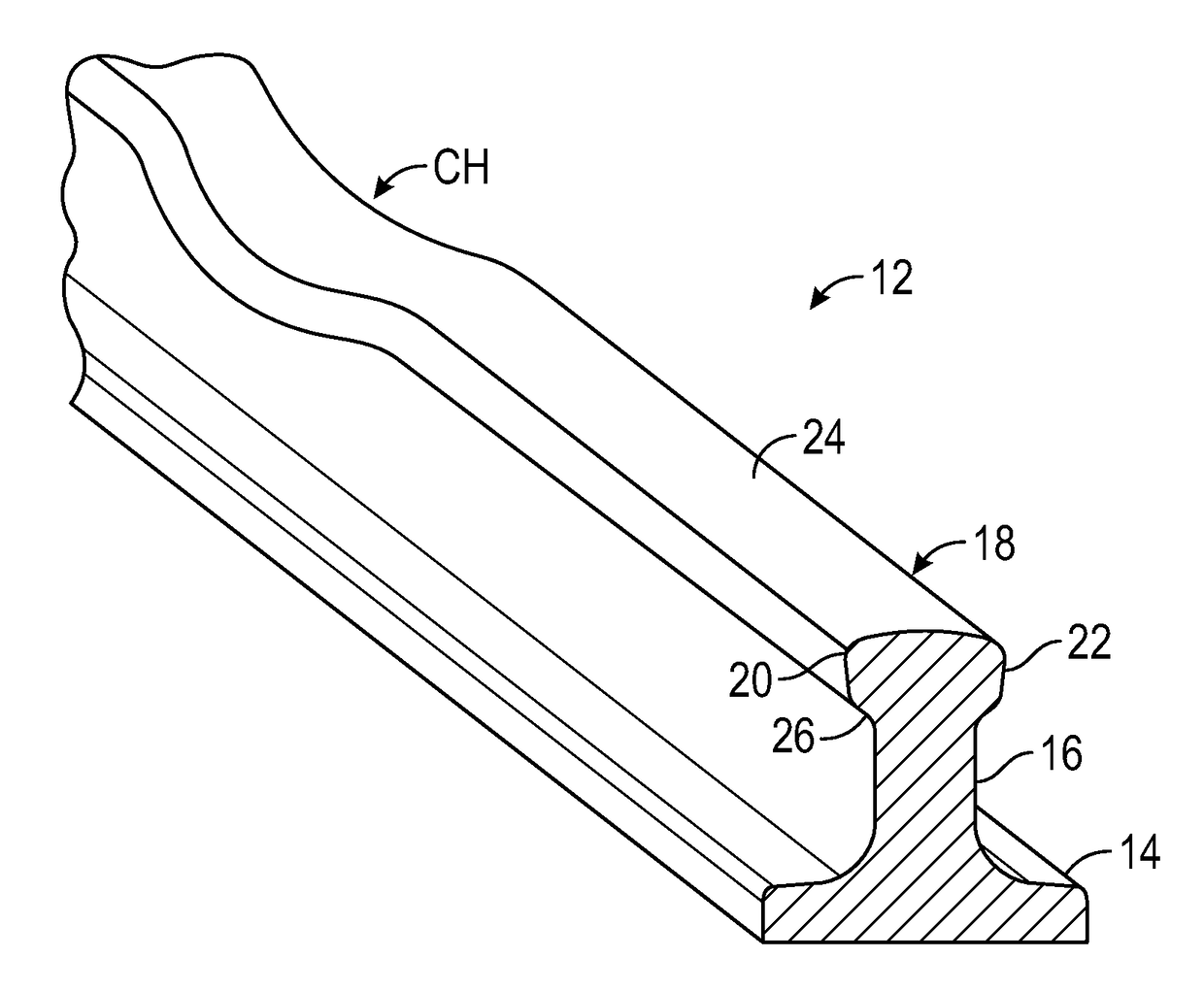

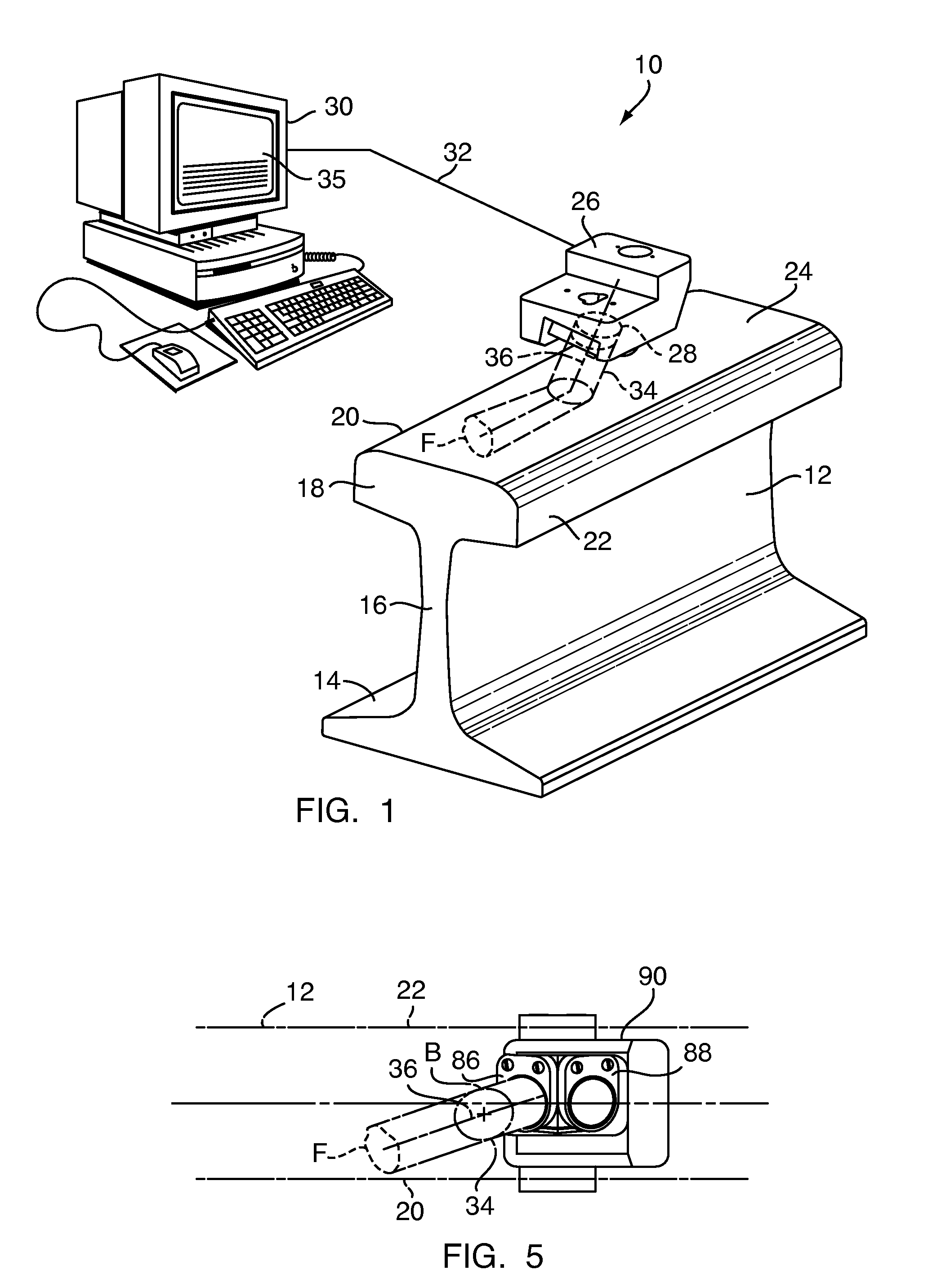

ActiveUS20170205379A1Material analysis using sonic/ultrasonic/infrasonic wavesRail inspectionEngineering

An apparatus and method for rail inspection include a inspection carriage that moves atop a rail and carries a rail height sensor directed toward the rail. The rail height sensor generates a signal correlated with a vertical position (height) of the rail relative to the carriage as the carriage moves along the rail. A signal processor converts the rail height signal to a log of rail heights along the rail. Further processing of the log, e.g., in the signal processor, identifies crushed head defects in the rail.

Owner:SPERRY RAIL HLDG

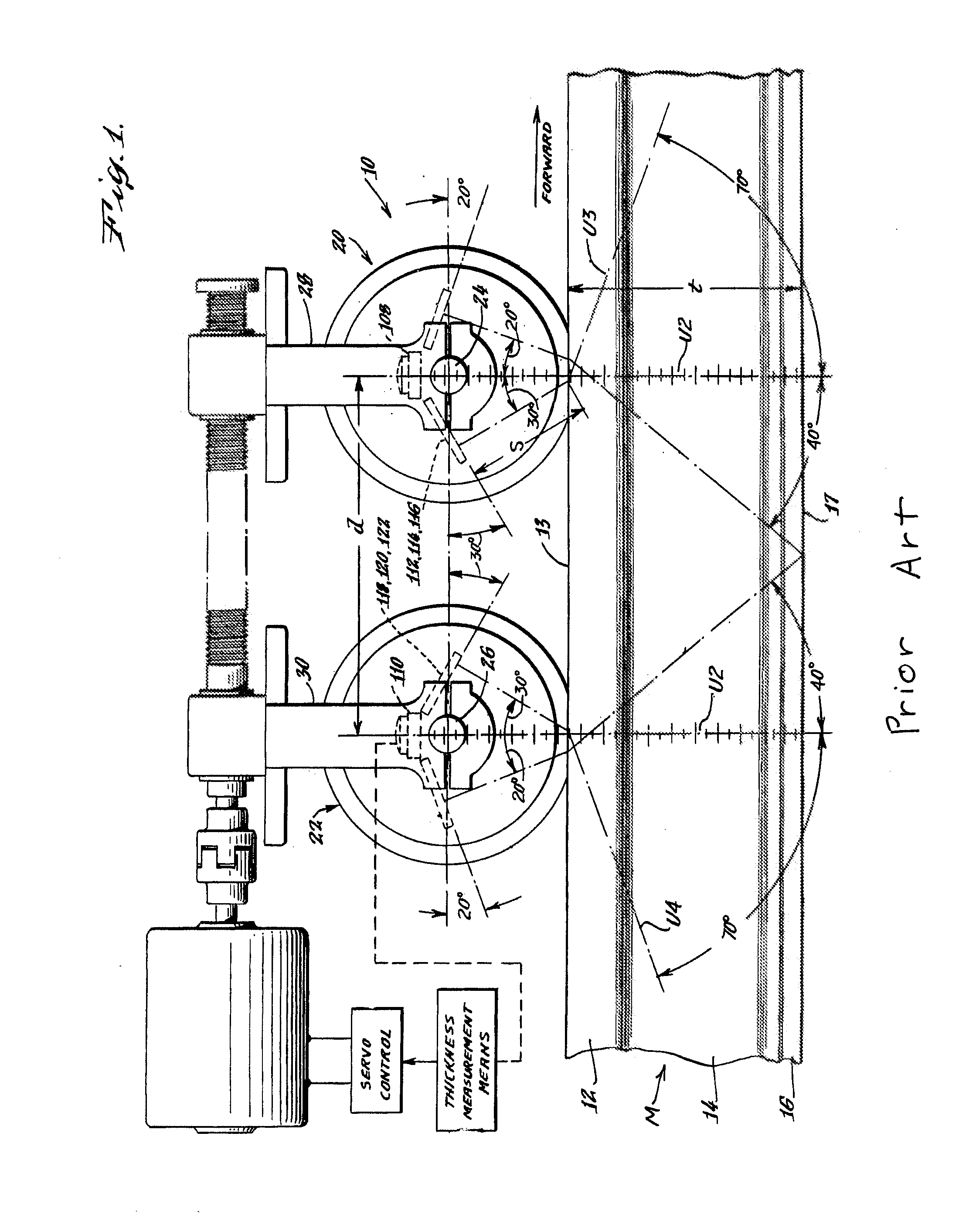

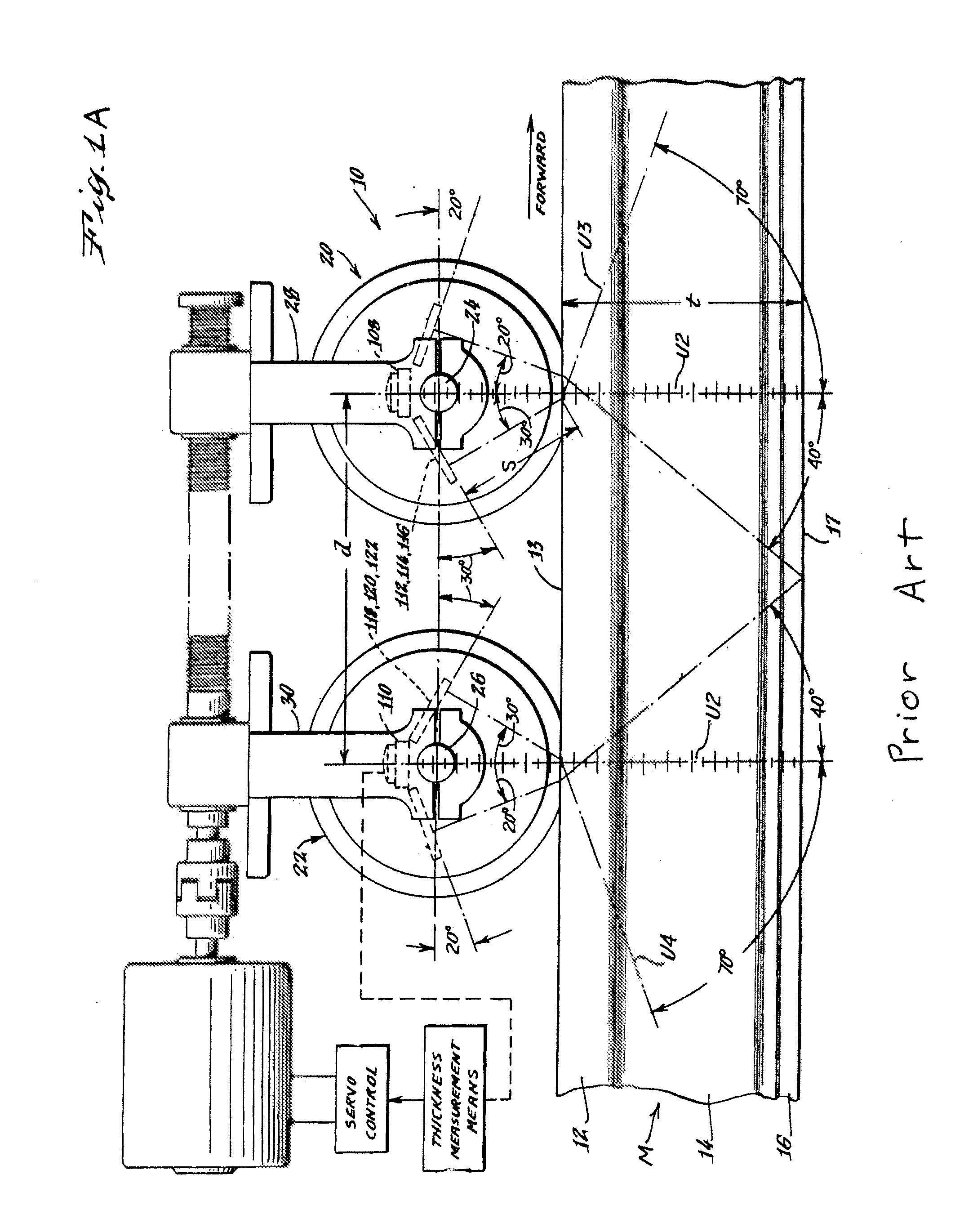

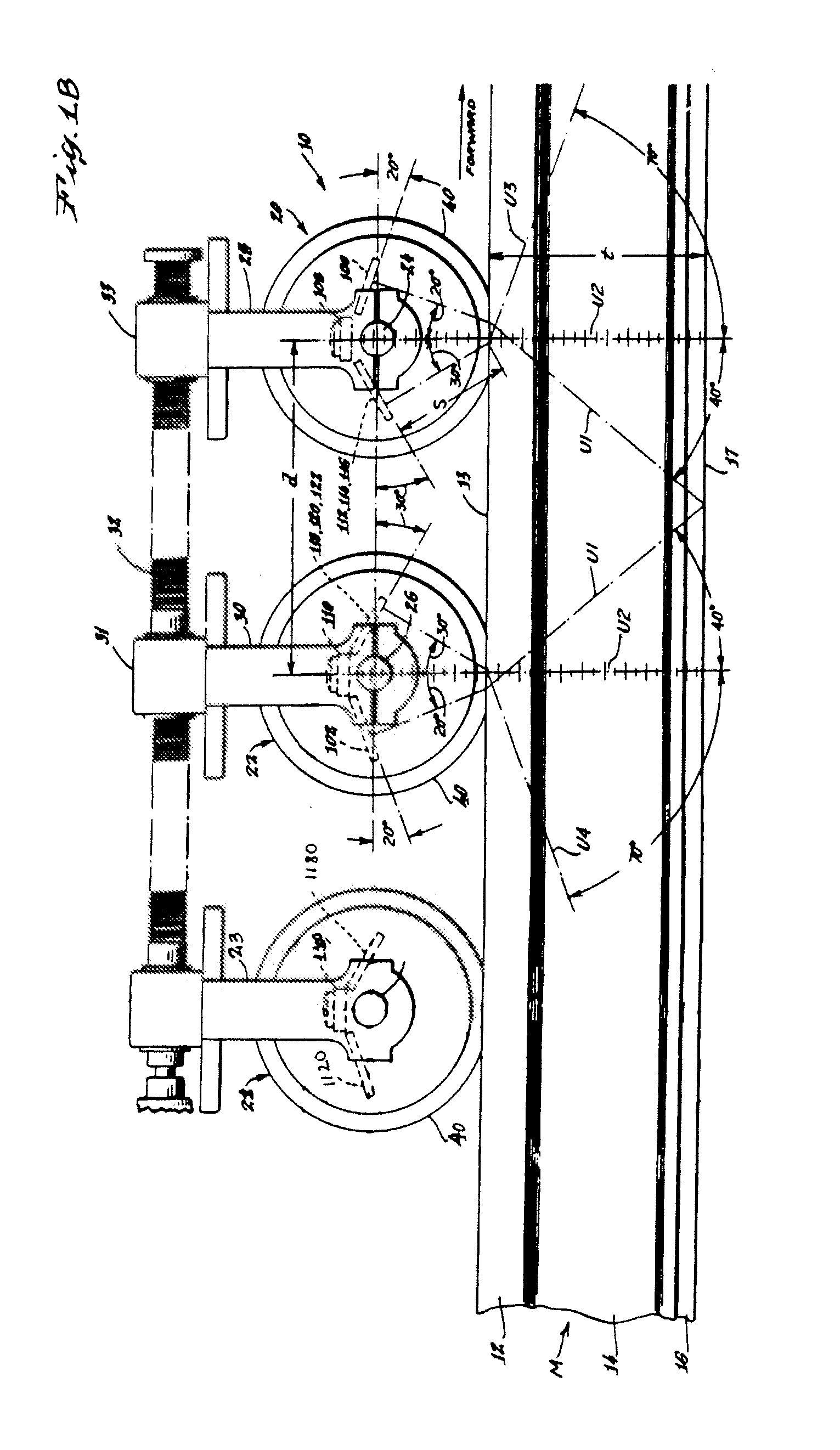

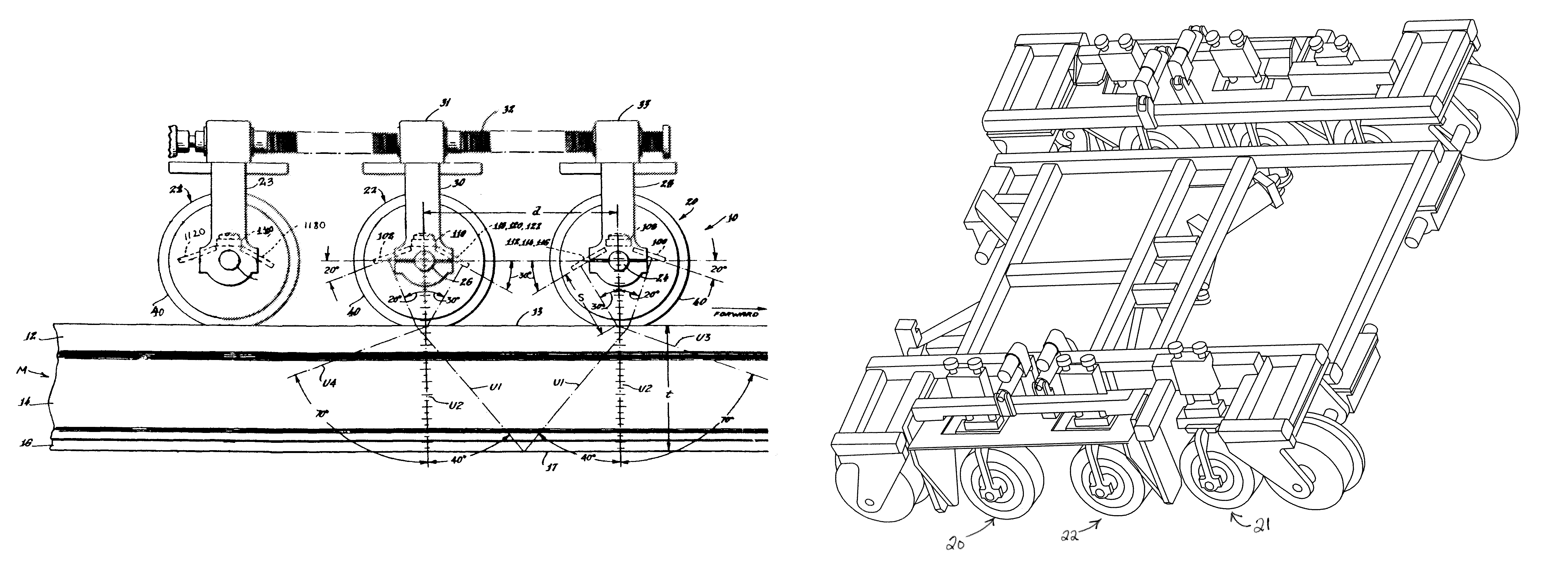

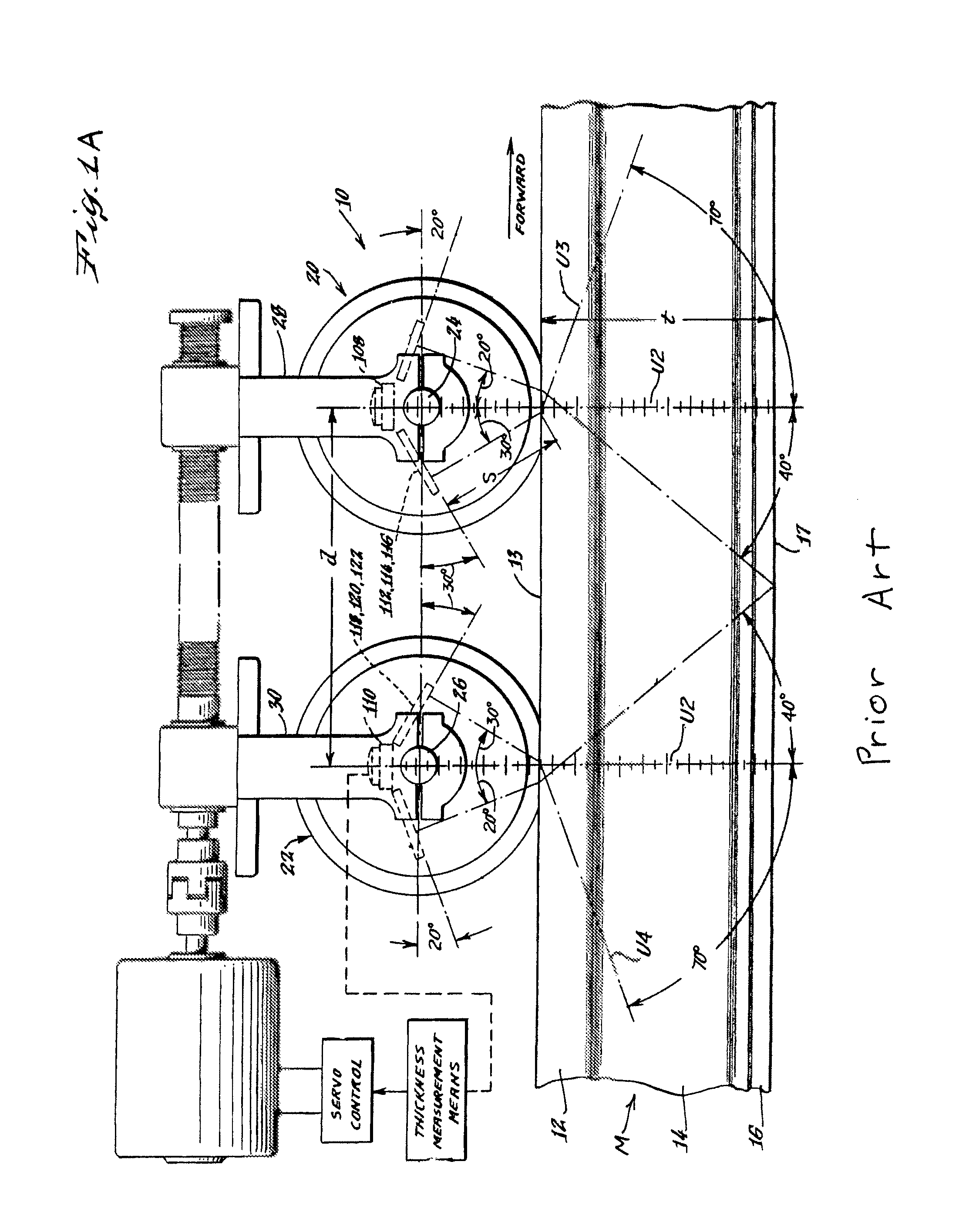

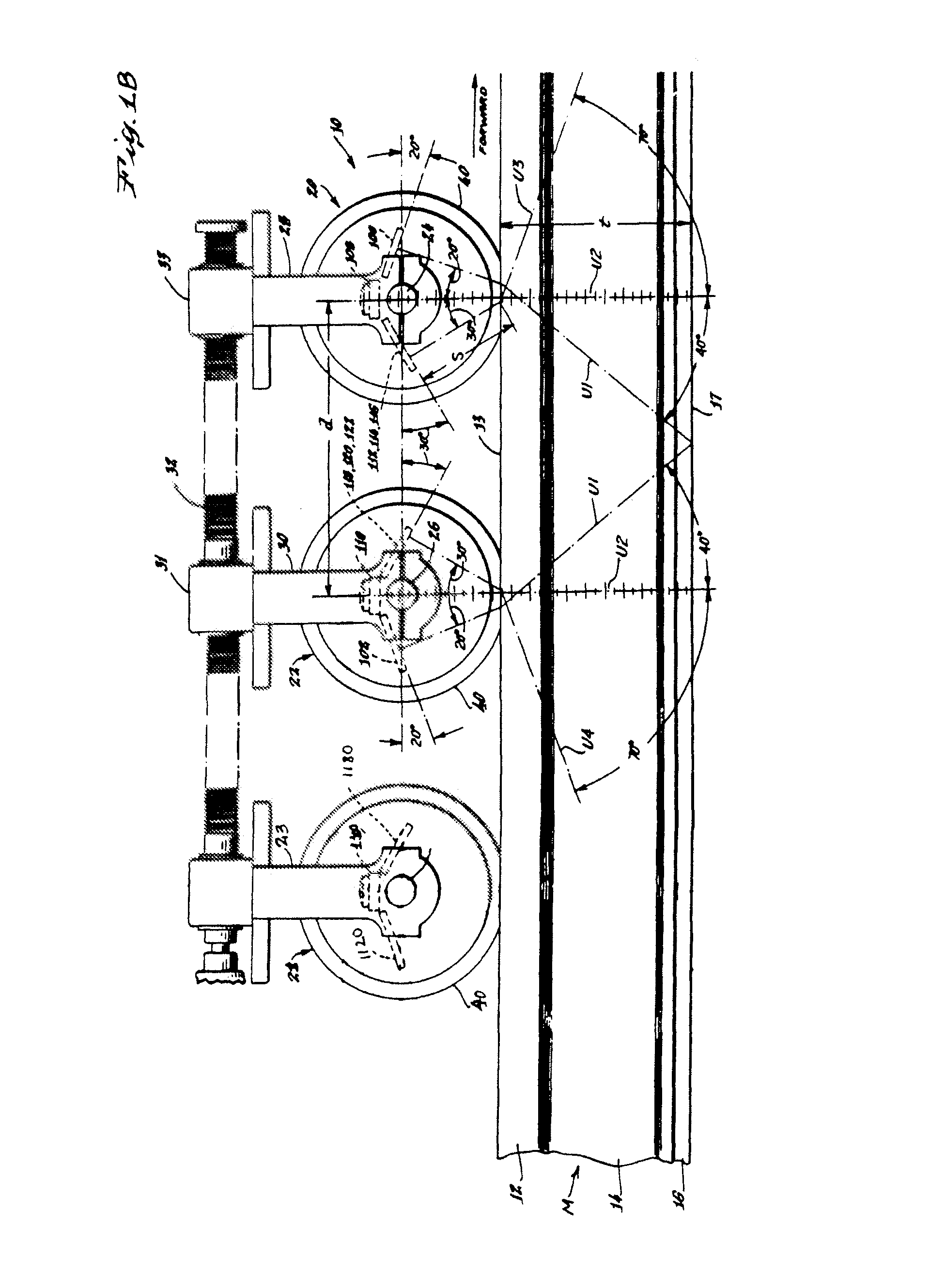

Method of and an apparatus for in situ ultrasonic rail inspection of a railroad rail

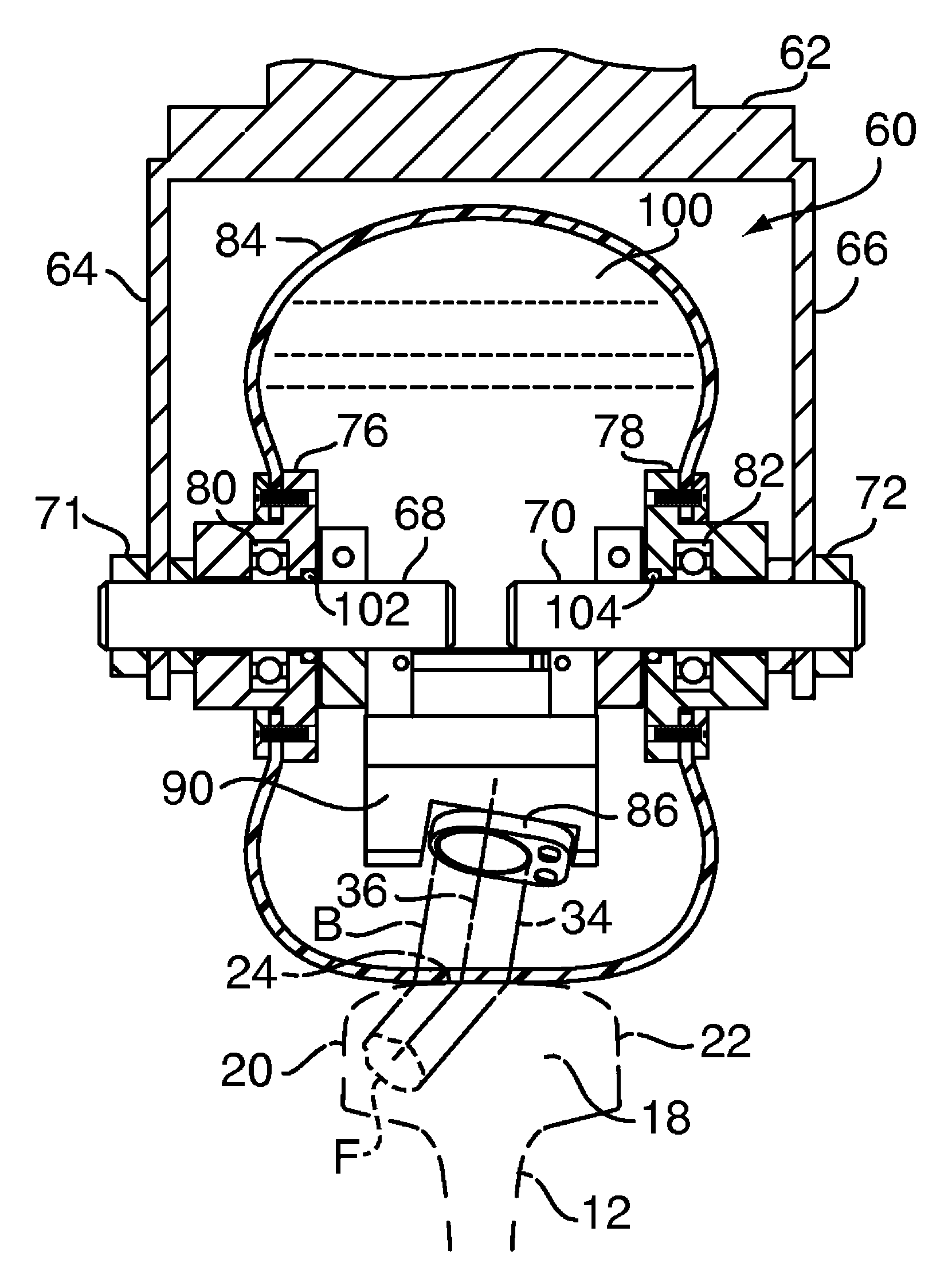

ActiveUS7849748B2Analysing solids using sonic/ultrasonic/infrasonic wavesSpecific gravity measurementRail inspectionUltrasonic beam

An ultrasonic railroad rail inspection system, apparatus and method for in situ rail inspection including a wheel assembly containing a fluid-filled tire and an ultrasonic transducer mounted within the wheel assembly. The transducer is supported in the tire such that the ultrasonic beam generated by the transducer has a beam axis that intersects a head of a railroad rail at a position offset from the longitudinal median plane of the rail to the side of the head penetrated by the ultrasonic beam. The ultrasonic beam is reflected by flaws in the rail in the form of echoes. The echoes return to the transducer identifying the location of flaws.

Owner:SPERRY RAIL HLDG

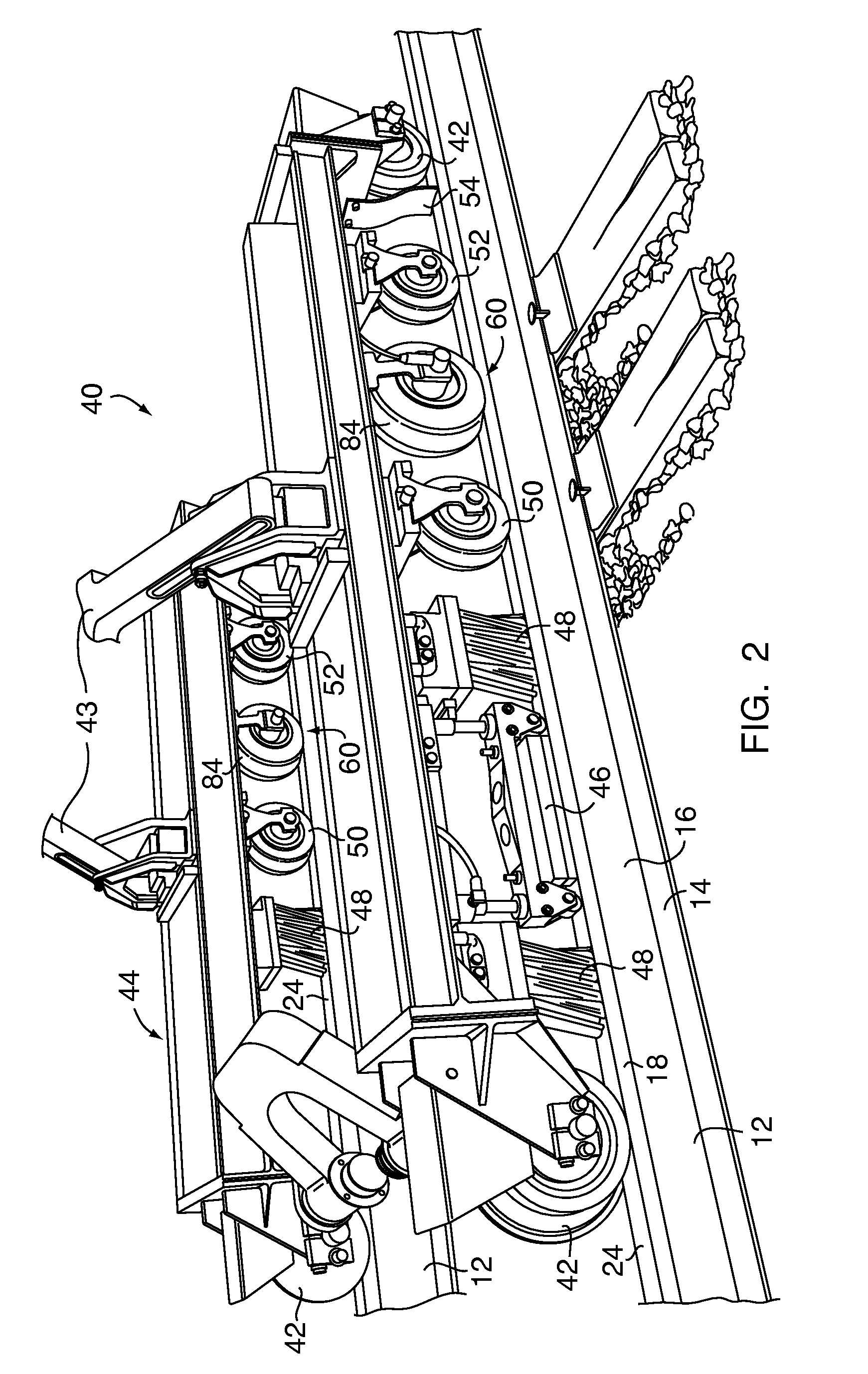

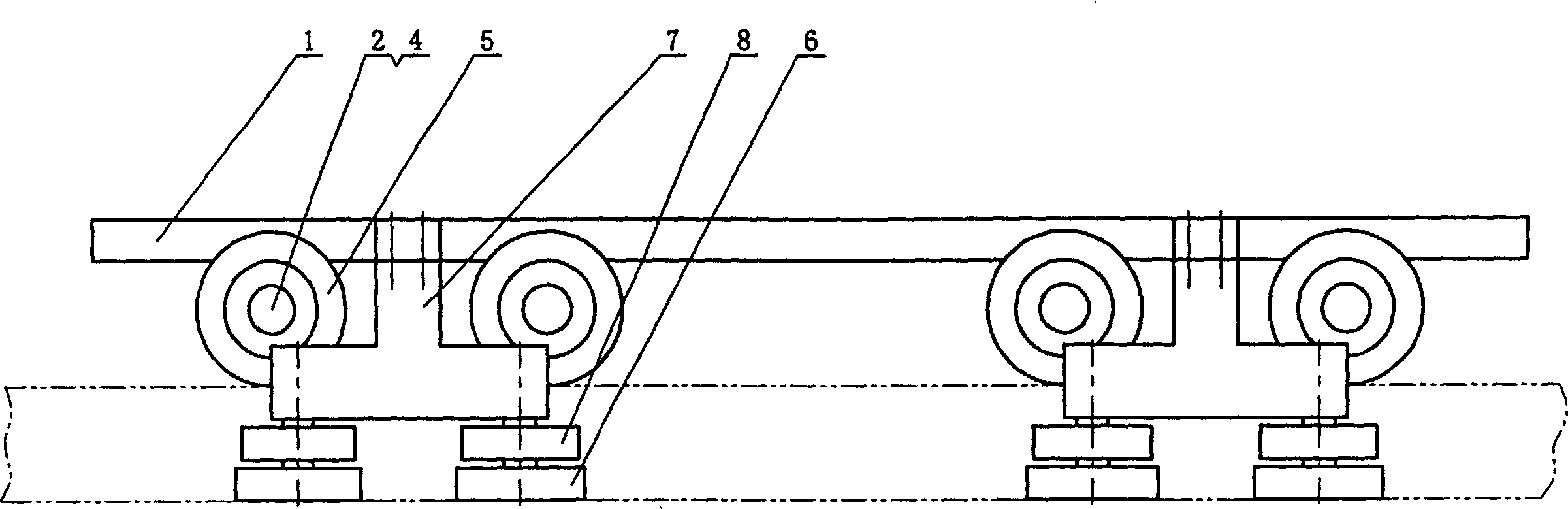

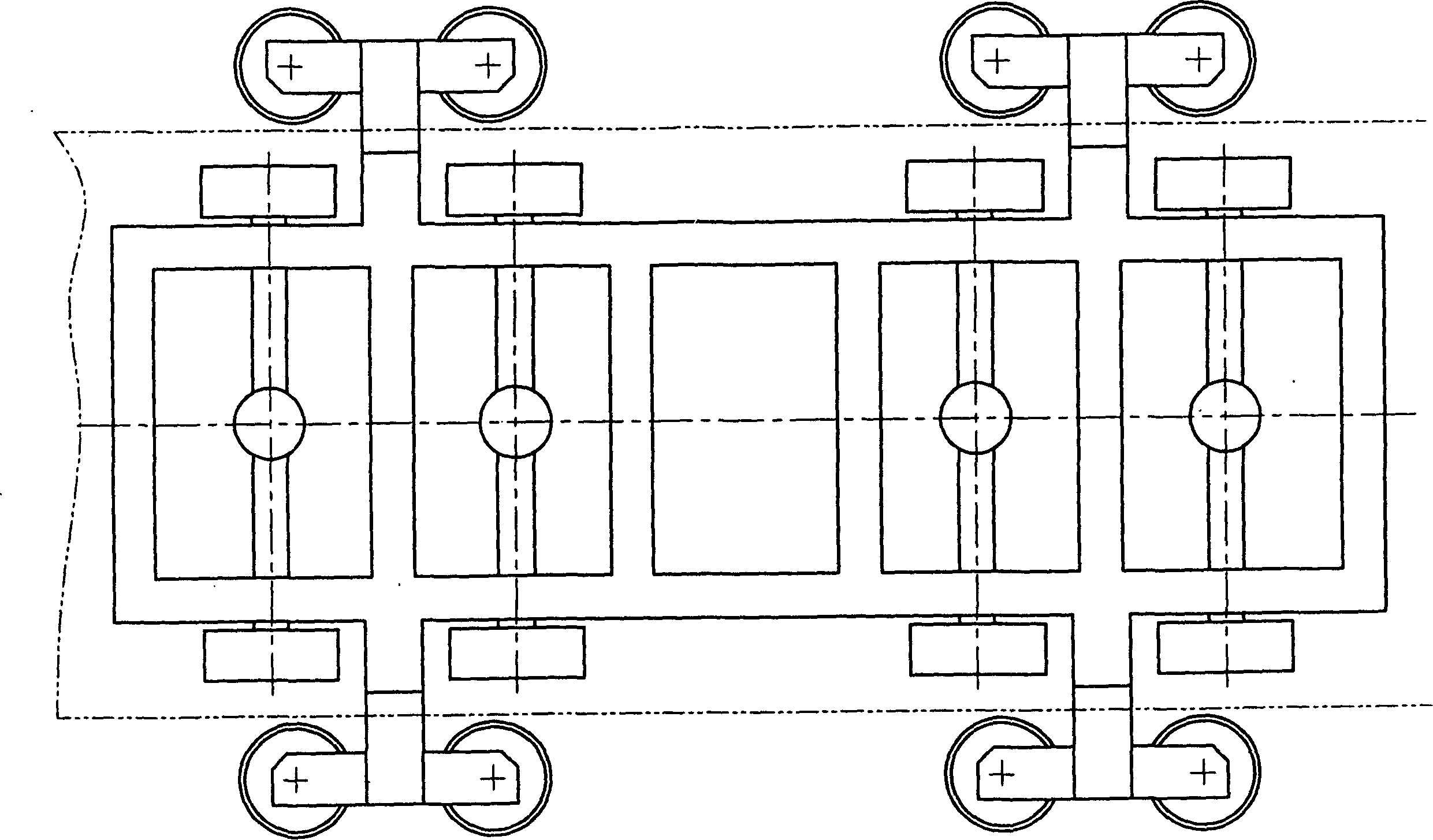

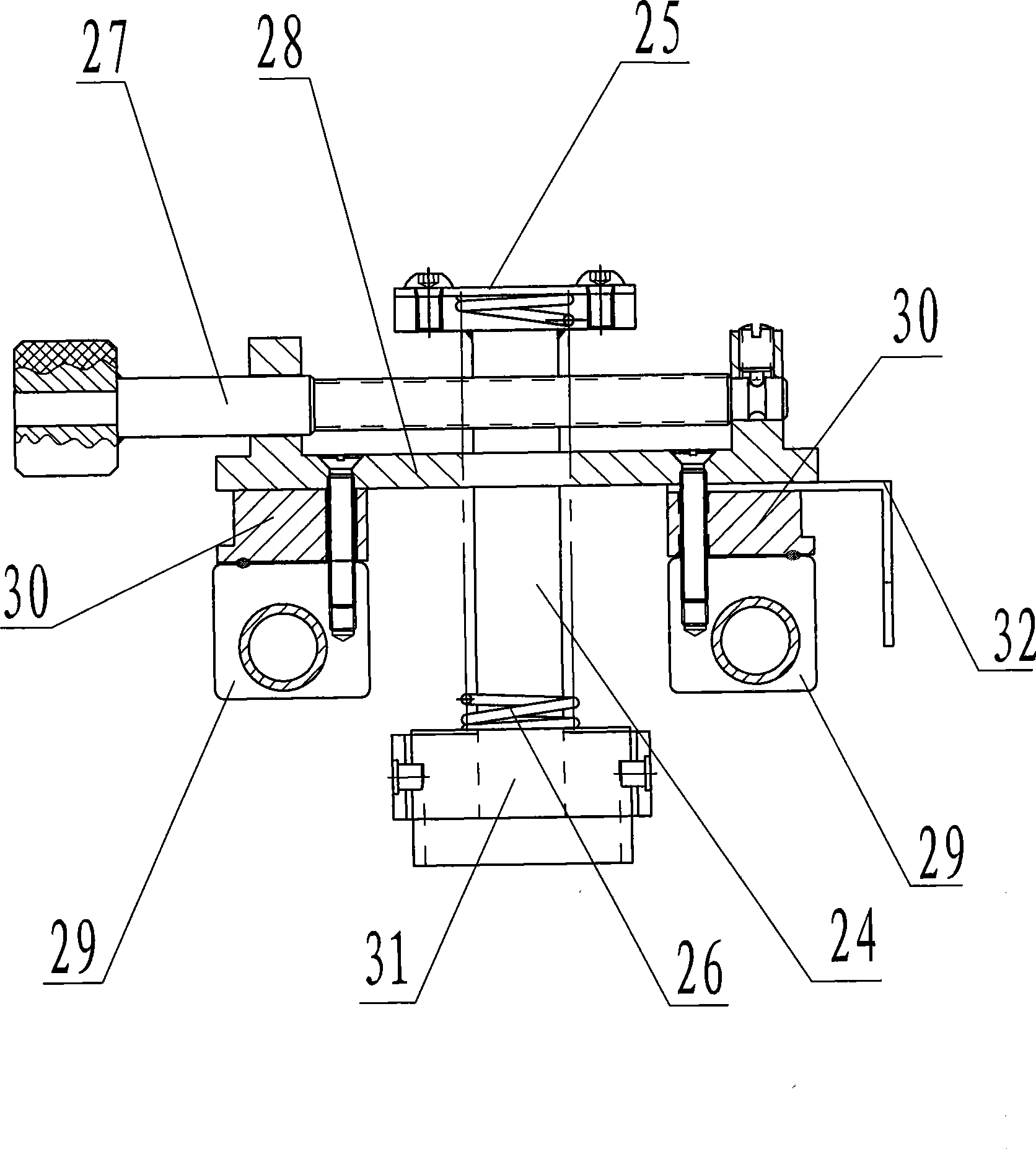

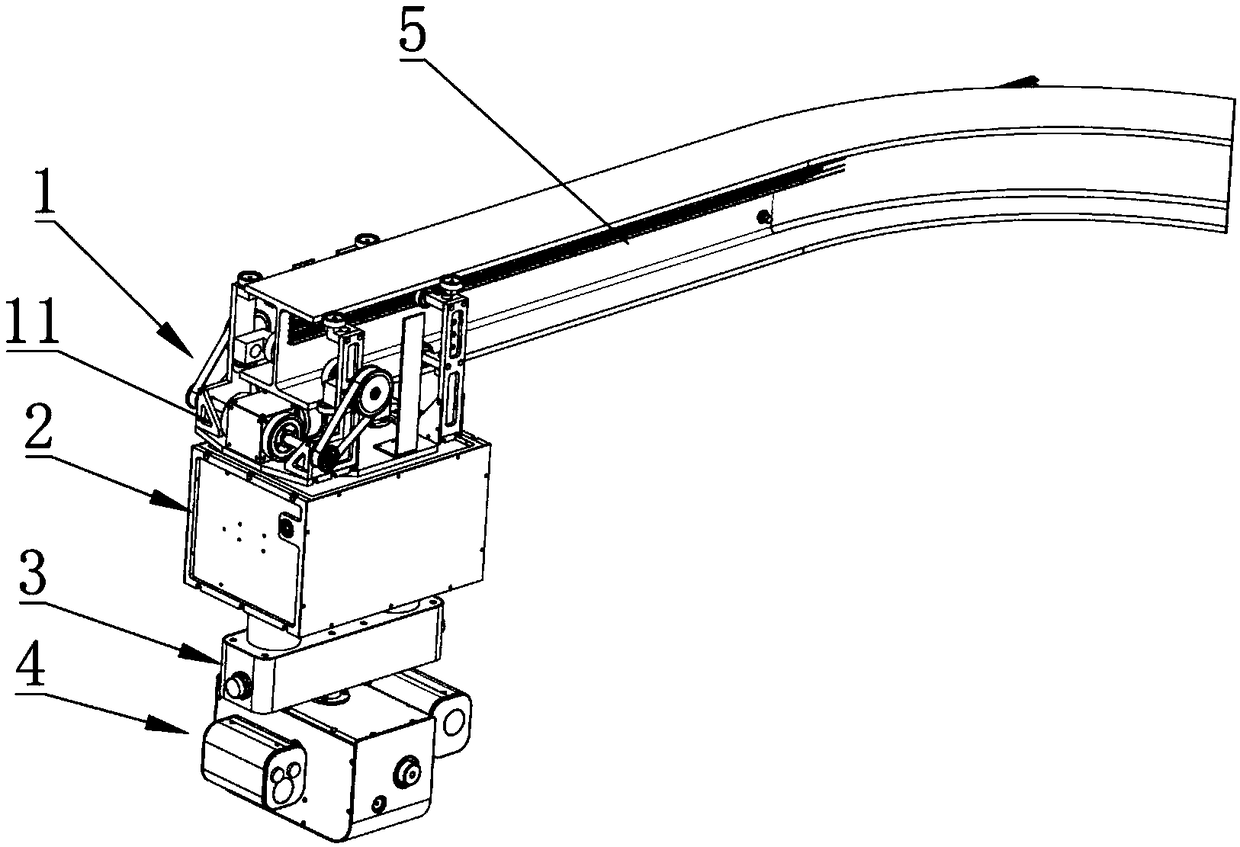

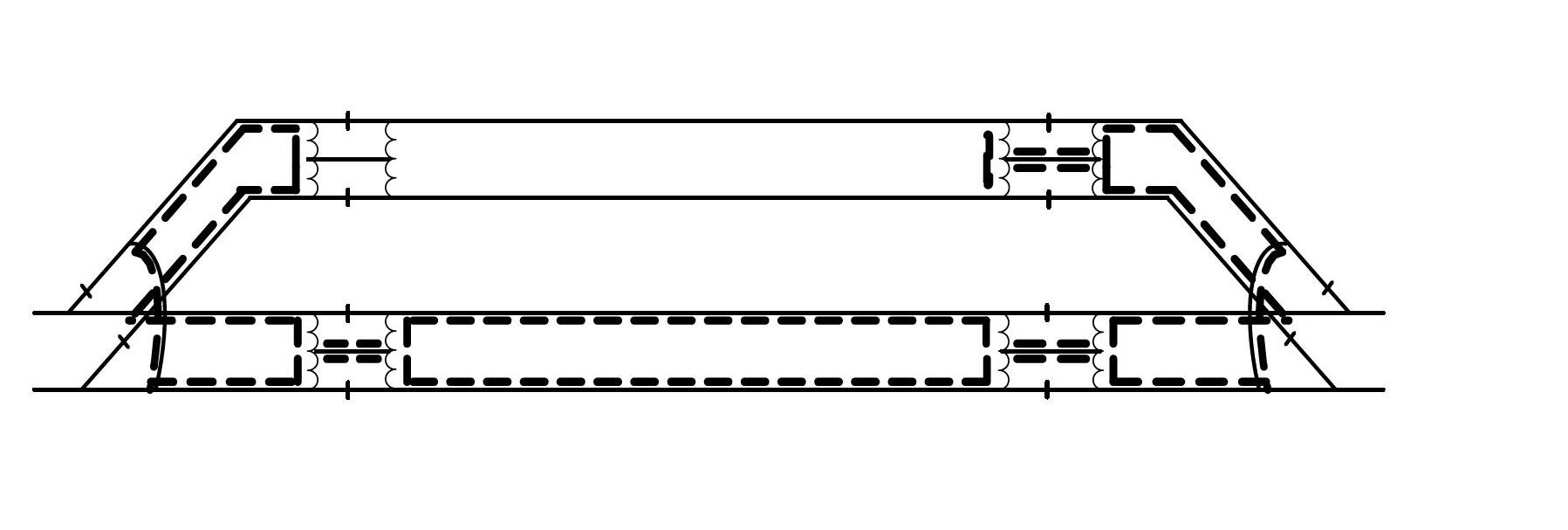

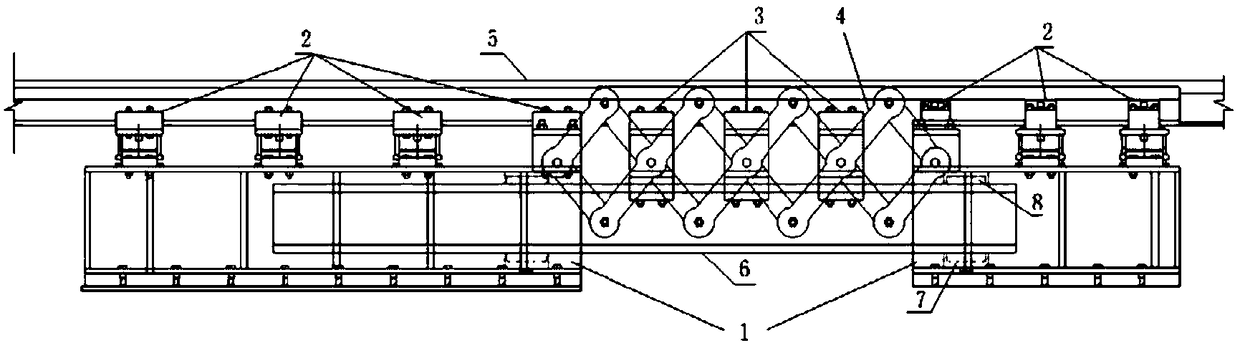

Magnetic suspension rail inspection vehicle chassis with guide wheel system

InactiveCN1544278APrevent slippingIncrease frictionRailway inspection trolleysRail inspectionEngineering

The invention is a chassis of magnetic suspension test vehicle with guide wheel system, including: underframe, vehicle driving bridge, gear differential, semishaft, rubber tyre wheel, rubber tyre guide wheels, and guide wheel frame. There are several vehicle bridges parallelly fixed on the underframe, and the middle and inside of the underframe are set with the gear differential and the semishaft, respectively, and the rubber tyre wheel are set at tow ends of the underframe, the rubber tyer guide wheels are set on the wheel shafts at two ends of the guide wheel frame and can freely rotate, many groups of guide wheel frames are allocated vertically and symmetrically along the underframe and fixed at the bottom of the two opposite sides of the underframe, the axis of the rubber tyre guide wheel is vertical to that of the rubber tyre wheel, the distance between the flanges of the corresponding guide wheels on two side of the underframe is greater than the width of the guide surface of the guide rail, and thus the flanges provide side location support and guide for the test vehicle safely running on the magnetic suspension railway beams along the railway. It has reasonable structure, smooth running and good guiding performance, and low running noise.

Owner:TONGJI UNIV +1

Method of and an apparatus for in situ ultrasonic rail inspection of a railroad rail

ActiveUS20090282923A1Analysing solids using sonic/ultrasonic/infrasonic wavesSpecific gravity measurementRail inspectionUltrasonic beam

An ultrasonic railroad rail inspection system, apparatus and method for in situ rail inspection including a wheel assembly containing a fluid-filled tire and an ultrasonic transducer mounted within the wheel assembly. The transducer is supported in the tire such that the ultrasonic beam generated by the transducer has a beam axis that intersects a head of a railroad rail at a position offset from the longitudinal median plane of the rail to the side of the head penetrated by the ultrasonic beam. The ultrasonic beam is reflected by flaws in the rail in the form of echoes. The echoes return to the transducer identifying the location of flaws.

Owner:SPERRY RAIL HLDG

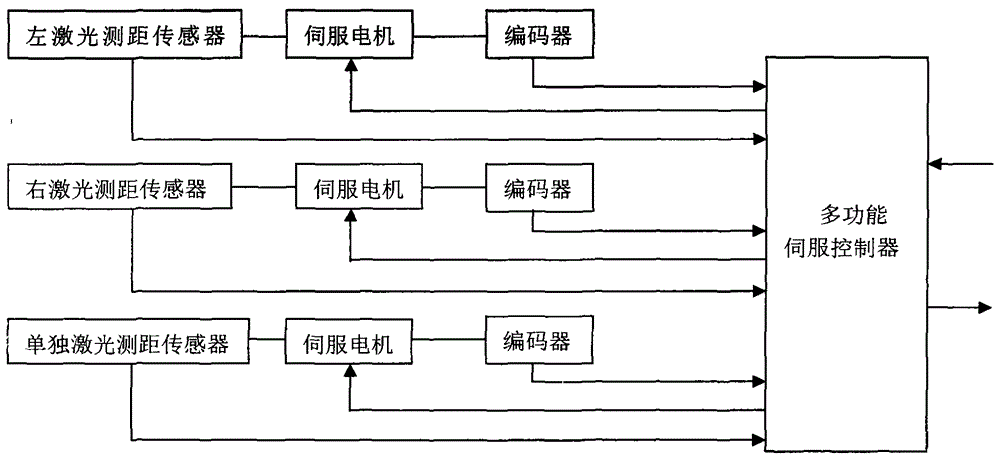

Dynamic noncontact rail gauge measuring system and method thereof

The invention discloses a dynamic noncontact rail gauge measuring system and a method thereof. The dynamic noncontact rail gauge measuring system based on a laser ranging sensor of the triangulation principle is composed of three identical gauge measuring components and a multifunctional servo controller component capable of controlling the three identical gauge measuring components simultaneously. The dynamic noncontact rail gauge measuring system and the method thereof are used for a rail parameter dynamic detection trolley to realize noncontact gauge measurement, the highest detection speed can be 60kg / h and measuring precision can be + / -0.2m so that the dynamic noncontact rail gauge measuring system and the method thereof have a function of correcting heading direction of a high-speed rail inspection trolley, and are simple in structure, high in stability of the measuring result and favorable for popularization and application on various rail inspection trolleys.

Owner:北京星网宇达科技股份有限公司

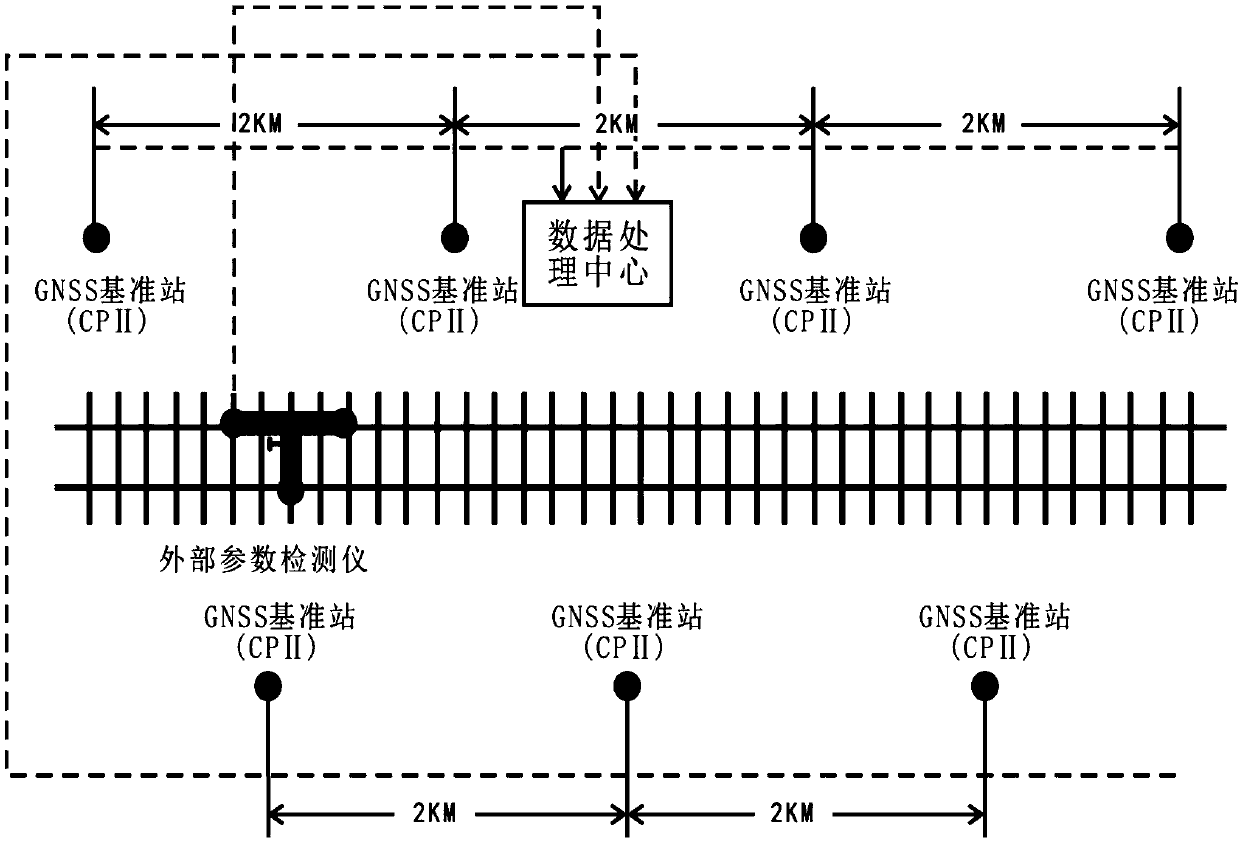

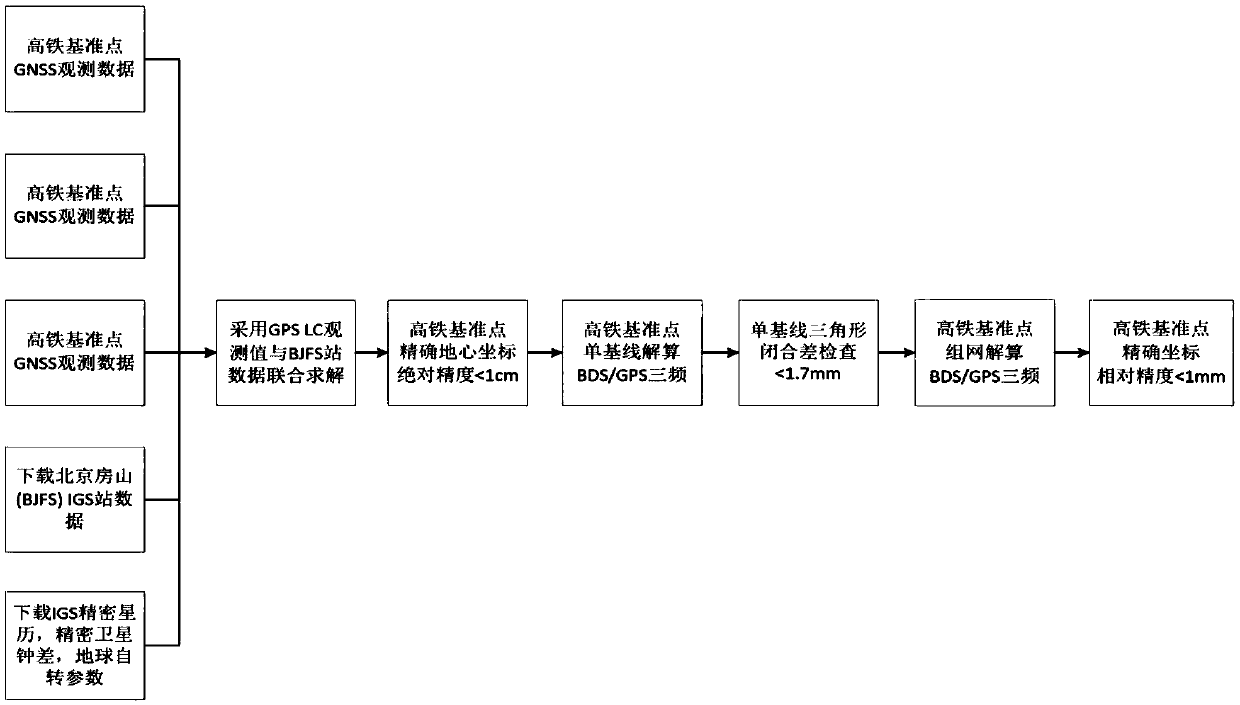

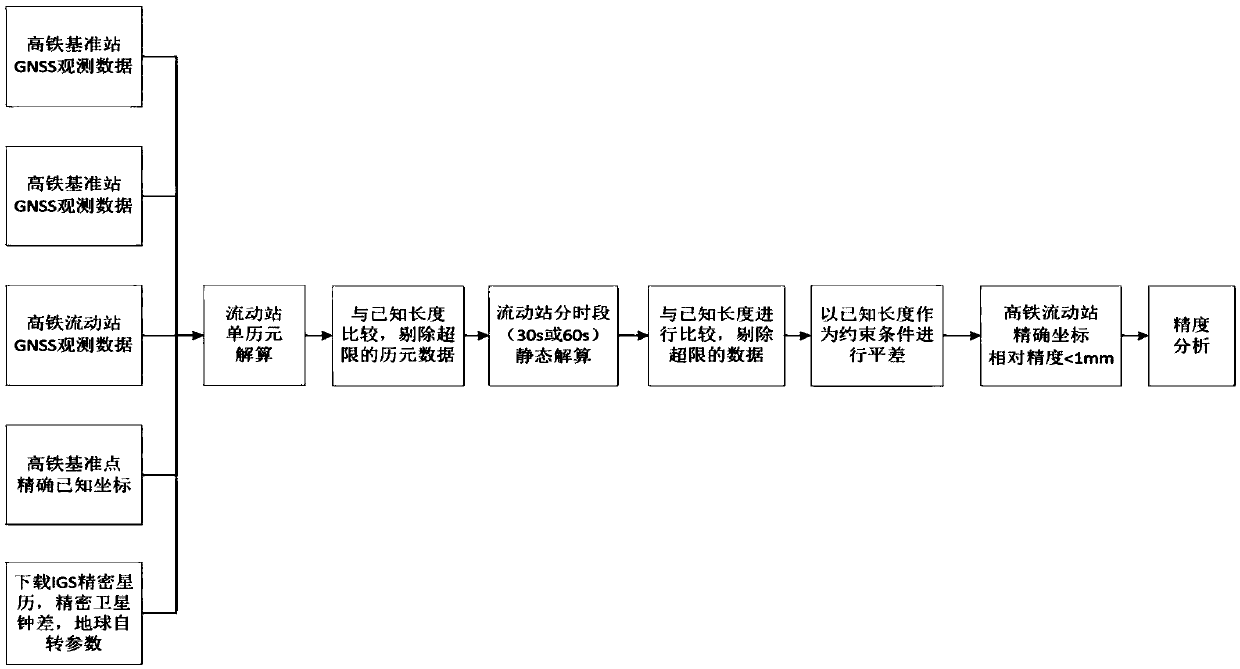

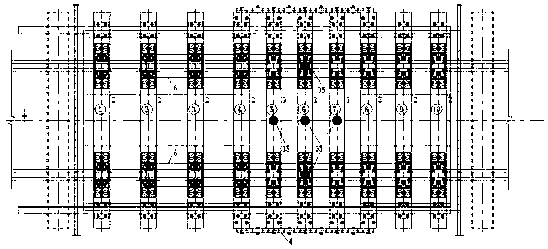

High-speed rail smoothness detection system and method based on satellite positioning and inertial navigation.

ActiveCN109552356AImprove detection efficiencyHigh precisionRailway inspection trolleysRailway auxillary equipmentRail inspectionEngineering

The invention relates to the field of high-speed rail smoothness detection and in particular to a high-speed rail smoothness detection system and method based on satellite positioning and inertial navigation. The system and method can obtain high-precision external geometric parameters of a rail by arranging the GT-CORS base station network by establishing a GNSS reference station on the CPII. Through a gauge detection device, a sleeper identification device, an odometer on a rail detection vehicle and in combination with the acquisition of the accurate coordinate results of three GNSS antennas, the rail parameters can be calculated to guide the precise rail adjustment. Large-scale satellite positioning monitoring point networking method millimeter-level joint solution and three-antenna GNSS rail inspection equipment short baseline fast and millimeter-level solution method achieves precision of plane 1 to 2mm and an elevation measurement error of + / - 2.5mm. The method avoids the dependence on CPIII, increases rail detection speed from the original 100m / h to 1000m / h d, greatly improves the detection efficiency of the external parameters of the rail, significantly reduces economic cost, and has broad technical development and application prospects.

Owner:山东北斗华宸导航技术股份有限公司 +1

Method and system for non-destructive rail inspection

InactiveUS20170176389A1Magnetic gradient measurementsRailway signalling and safetyMagnetic field gradientRail inspection

The present invention relates to a method for identifying and locating a defect in a metal rail, and includes the steps of positioning a first magnetic sensor at a distance above a rail, the first magnetic sensor being configured to measure a magnetic field of the rail; advancing the sensor along a length of the rail; sampling magnetic field measurements; determining multiple magnetic field gradients over different pluralities of samples; identifying a defect in the rail based on a change in one or more of the magnetic field gradients; and determining a position of the defect at a particular distance from the magnetic sensor based on a degree of variation in the magnetic field gradients.

Owner:PURETECH VENTURES

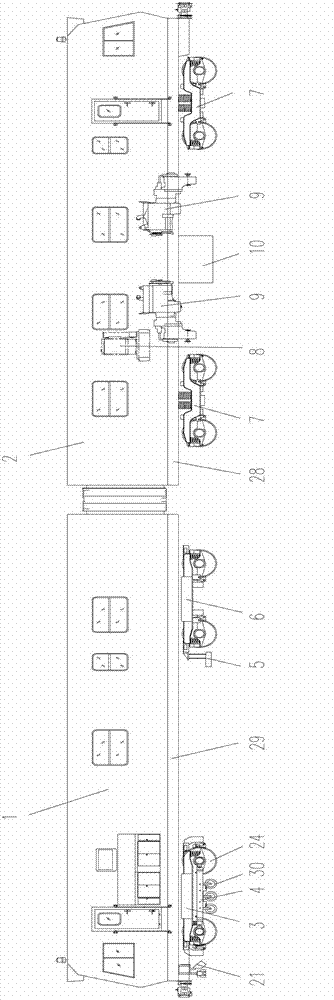

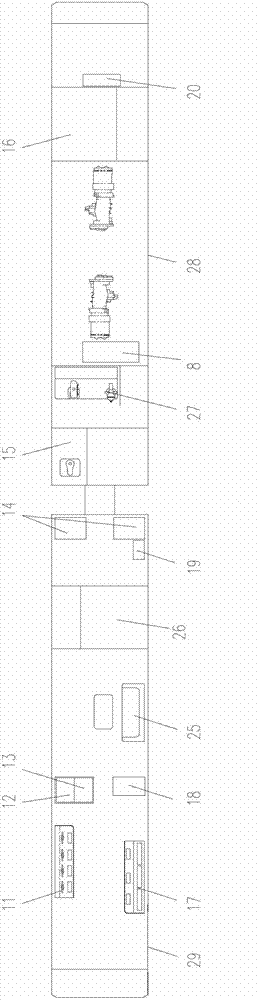

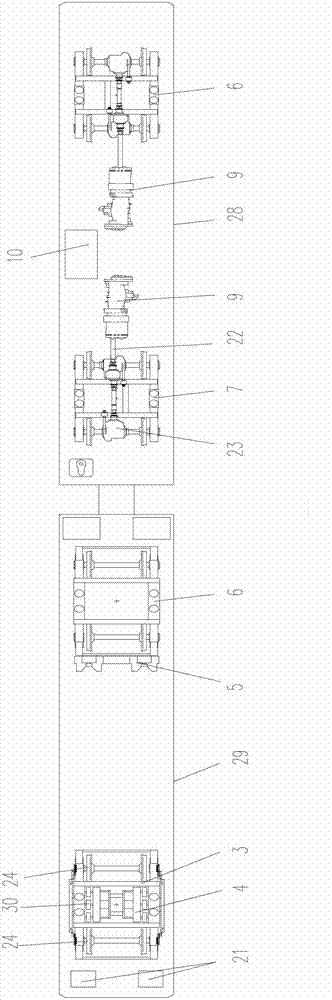

Multifunctional inspection detecting vehicle used for railway steel rail

ActiveCN102826096AImprove accuracyImprove securityRailway inspection trolleysRailway auxillary equipmentBogieRail inspection

The invention provides a multifunctional inspection detecting vehicle used for a railway steel rail. The multifunctional inspection detecting vehicle comprises an inspection vehicle and a tractor; the rear end of the tractor is connected with one end of the inspection vehicle to drive the inspection vehicle to walk; a front steering frame of the inspection vehicle is provided with a steel rail detecting device; a rear steering frame is provided with a steel rail profile inspection device; the lower end of a vehicle body I is provided with a rail state patrolling device; the upper end of the vehicle body I is provided with a steel rail detecting device control cabinet, a steel rail detecting device operation table, a steel rail profile inspection device control cabinet, a rail state patrolling device control cabinet and an operation table; the tractor is provided with two sets of power devices; the two sets of power devices respectively drive the front and rear two steering frames; and the tractor is further provided with an alternating current generator I and an alternating current generator II. The multifunction inspection detecting vehicle provided by the invention is simple in structure, comprehensive in function, is rational and practicable, and can meet various inspection requirements of railway rails; the overall vehicle has good running stability, and the requirements of 80 km / h and above steel rail inspection speed can be met.

Owner:BAOJI CSR TIMES ENG MACHINERY

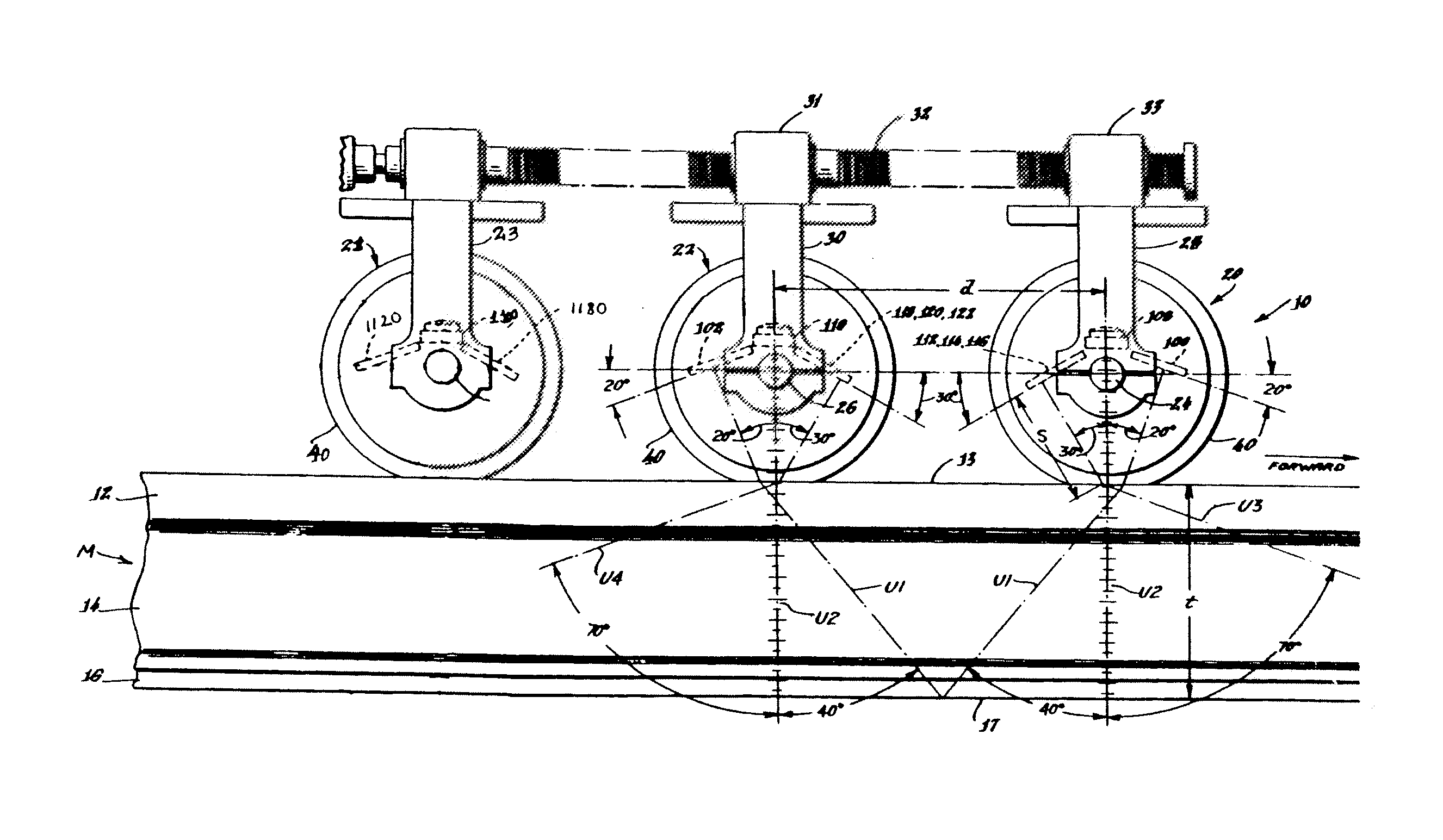

Method and apparatus for detecting internal rail defects

InactiveUS20090266166A1Analysing solids using sonic/ultrasonic/infrasonic wavesRail inspectionUltrasonic beam

An ultrasonic rail inspection system designed to detect defects in a rail which result from longitudinal cracks that propagate in the horizontal and transverse plane of the rail. Detection of this type of defect is possible by directing an ultrasonic beam into the rail at a predetermined angle from the perpendicular to the surface of the rail. The predetermined angle must be sufficient to detect these normally undetectable defects and can be in the range of 8° to 14° from the perpendicular.

Owner:PAGANO DOMINICK A

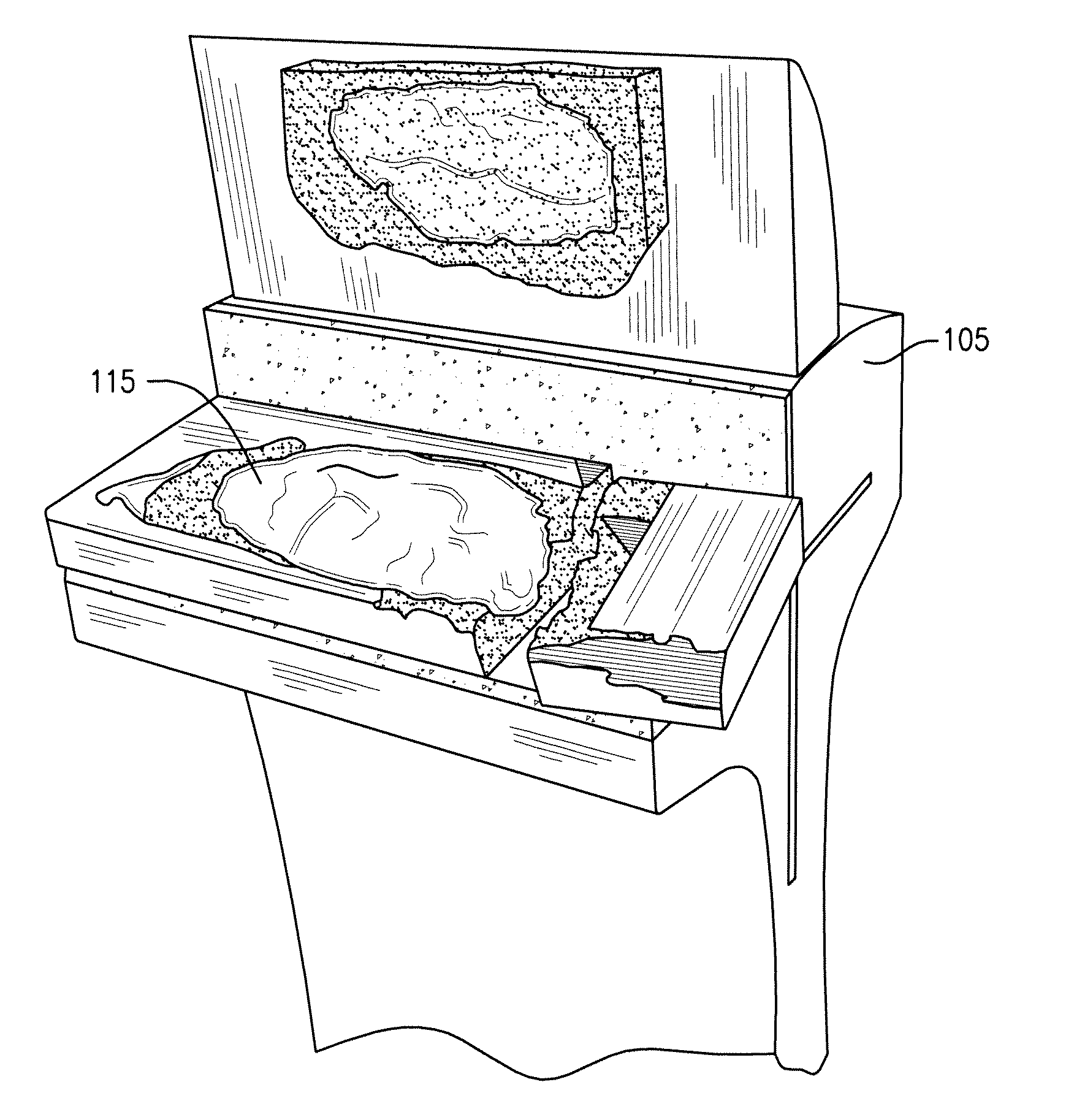

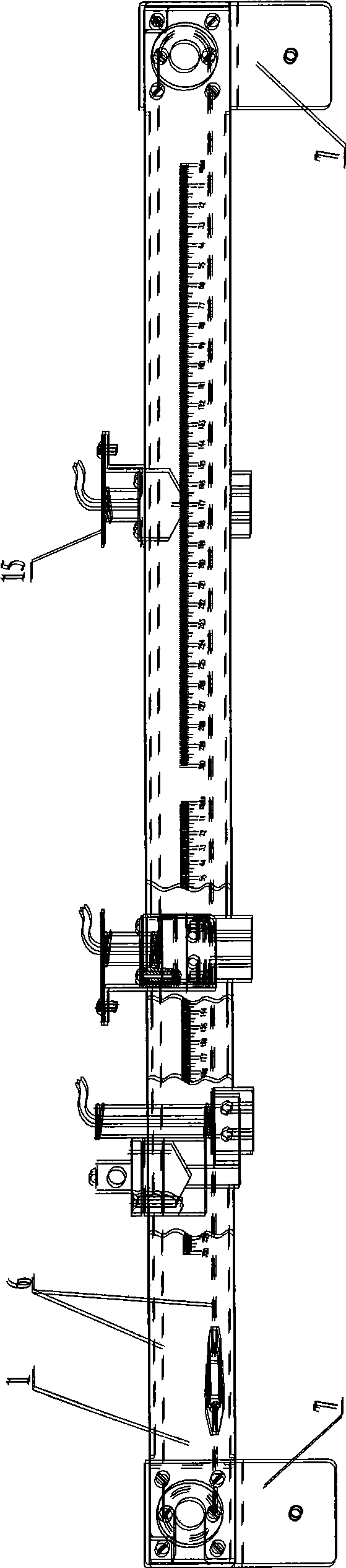

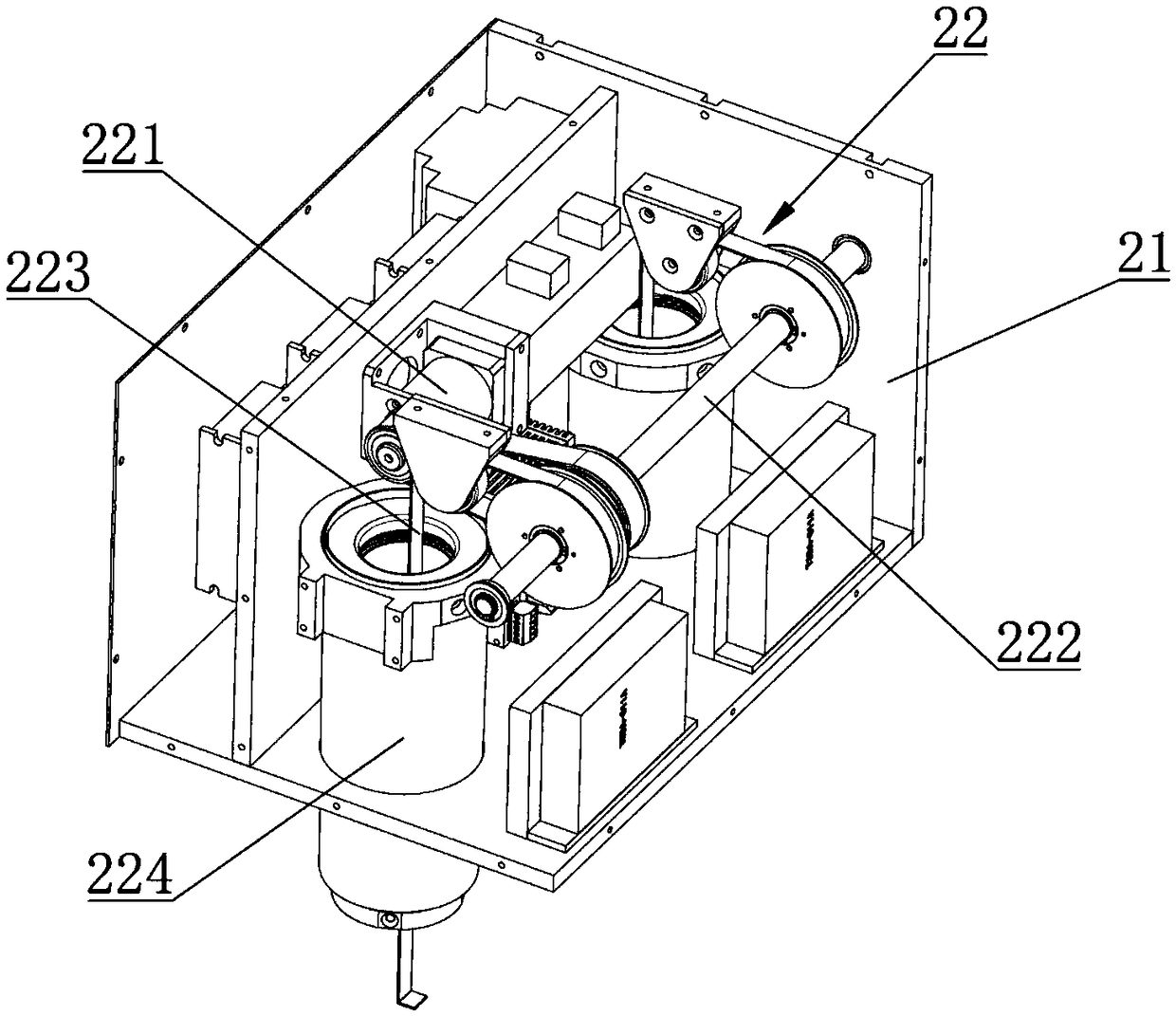

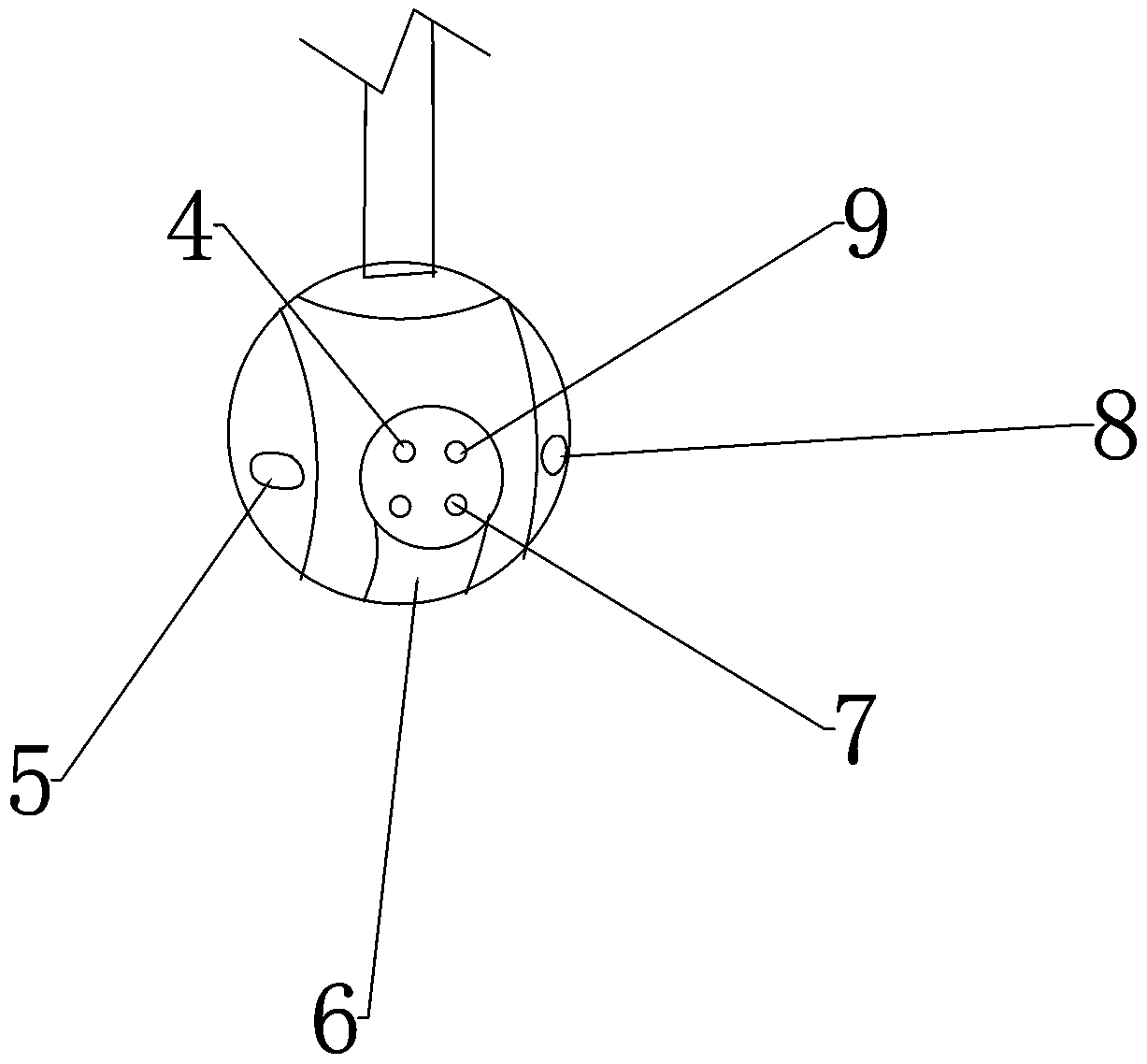

Scanning device for rail seam inspection

InactiveCN101520437ARealization of flaw detectionImprove the accuracy of flaw detectionAnalysing solids using sonic/ultrasonic/infrasonic wavesRail inspectionVisual inspection

The invention discloses a scanning device for rail seam inspection. Two ends of a rectangular support frame (1) are provided with 'n' shaped fixing pins (7); two ends of a slide rail (2) are fixed on two ends of the rectangular support frame (1); a first probe case fixed mount (3), a second probe case fixed mount (4) and a third probe case fixed mount (5) are arranged on the slide rail (2) and can slide freely along the slide rail (2); two ends of the rectangular support frame (1) are provided with a rotating shaft (11) of an inhaul cable respectively; and the inhaul cable (6) is winded on two rotating shafts (11) of the inhaul cable along the direction of the slide rail. The scanning device has a simple structure and convenient operation, and adopts mechanical scanning to replace the prior manual inspection of seam inspection, thereby greatly improving the accuracy of rail inspection, and realizing inspections on a plurality of seams.

Owner:四川兴天源材料检测技术有限公司

Method and apparatus for detecting internal rail defects

ActiveUS20130111997A1Analysing solids using sonic/ultrasonic/infrasonic wavesRail inspectionUltrasonic beam

An ultrasonic rail inspection system designed to detect defects in a rail which result from longitudinal cracks that propagate in the horizontal and transverse plane of the rail. Detection of this type of defect is possible by directing an ultrasonic beam into the rail at a predetermined angle from the perpendicular to the surface of the rail. The predetermined angle must be sufficient to detect these normally undetectable defects and can be in the range of 8° to 14° from the perpendicular.

Owner:NORDCO WISCONSIN

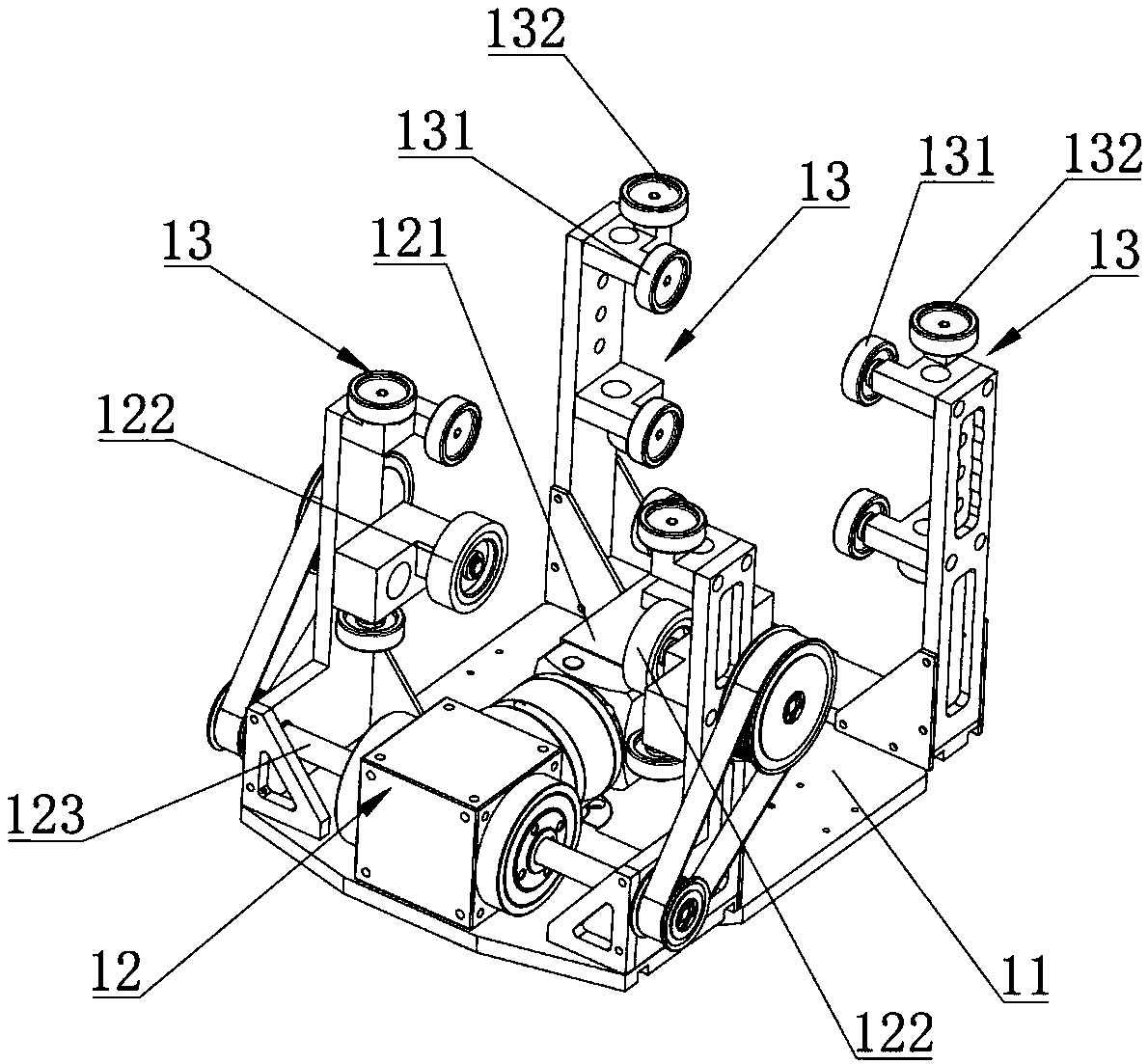

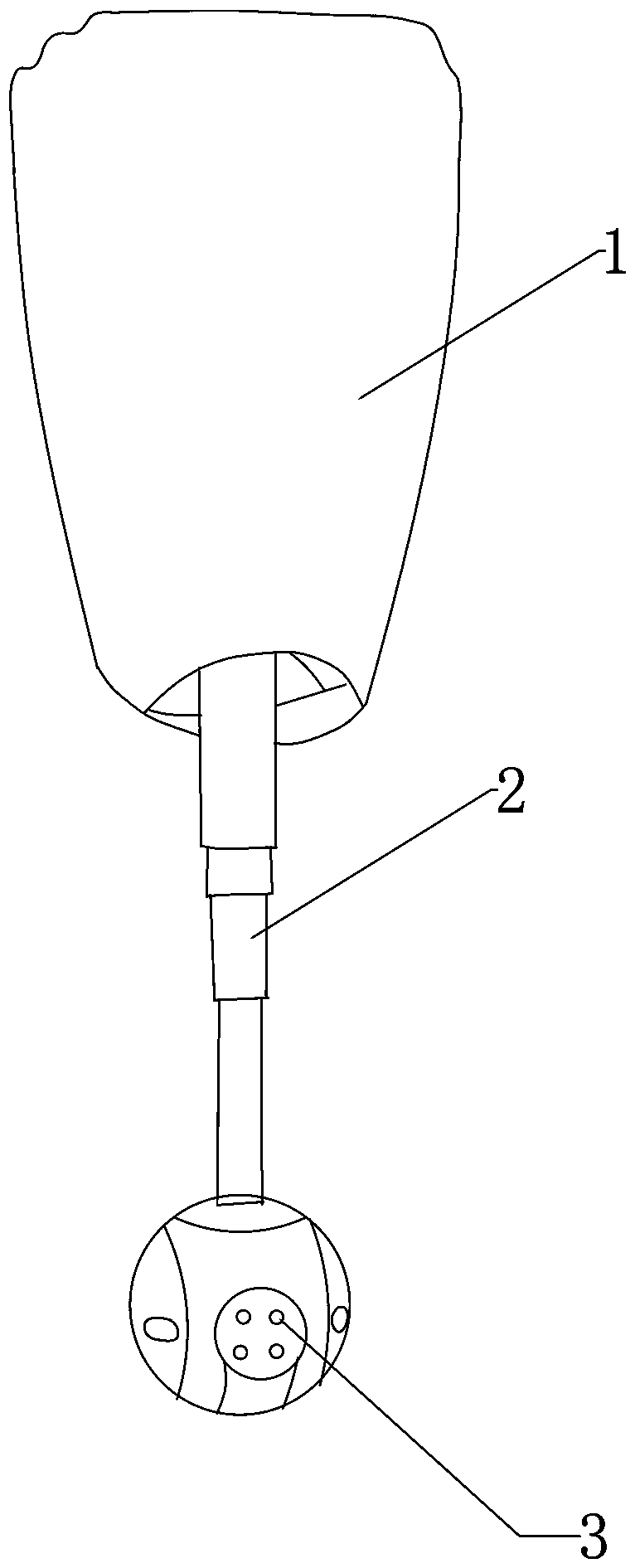

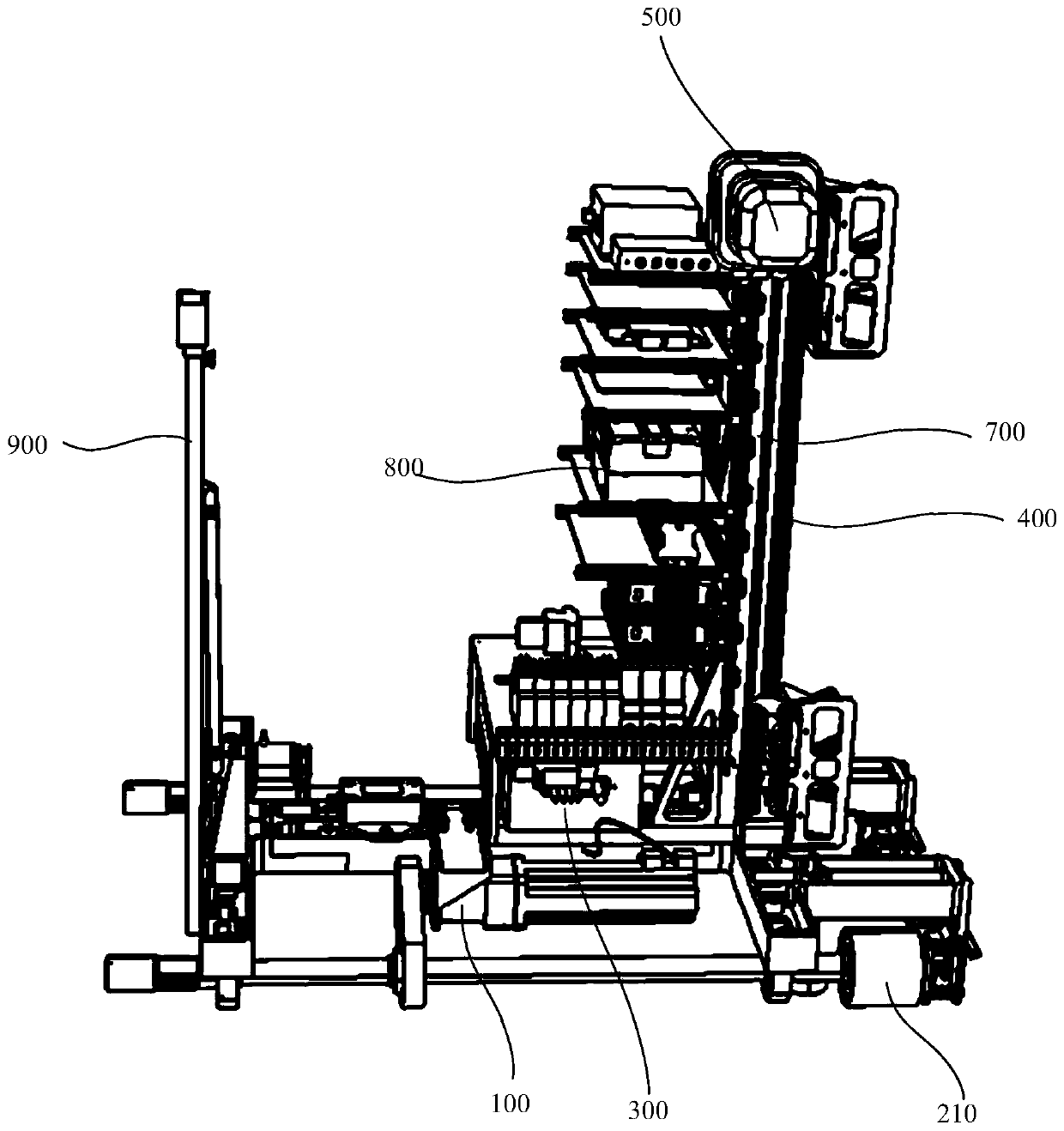

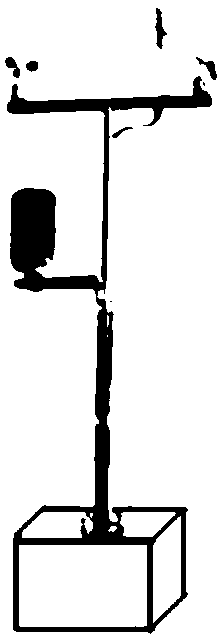

Rail inspection robot

PendingCN109079748AEasy to moveAchieve freedomMeasurement devicesManipulatorRail inspectionSimulation

The invention relates to the technical field of overhaul of substation equipment and particularly relates to a rail inspection robot. The rail inspection robot comprises a rail movement device, a lifting device, a Z-axis rotation device and a detection device which are sequentially connected; the rail movement device comprises a supporting frame, a driving supporting assembly for moving on the inner surface of a groove of an I-shaped rail and a driven guide assembly for being attached to the I-shaped rail; the supporting frame is connected with the lifting device; the lifting device comprisesa lifting frame; the lifting frame is provided with a lifting assembly for enabling the Z-axis rotation device to be lifted and descended; the Z-axis rotation device comprises a rotation shaft; and the rotation shaft is connected with the detection device. The invention provides the inspection robot convenient to move on the rail; and by the lifting device and the Z-axis rotation device, a degreeof freedom of the detection device in a Z-axis direction and a Z-axis rotation direction in the rail moving process is implemented, so that the detection device can acquire working data of the substation equipment at more different angles, and detection efficiency and the detection accuracy degree are improved.

Owner:广东省机器人创新中心有限公司

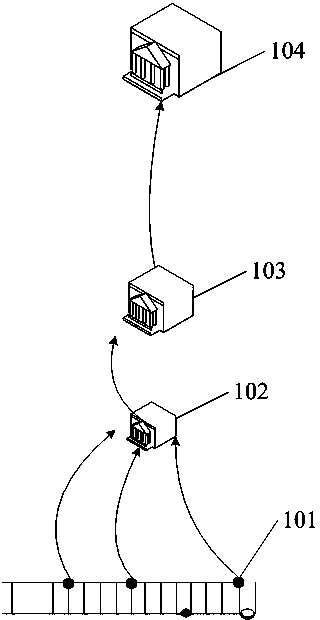

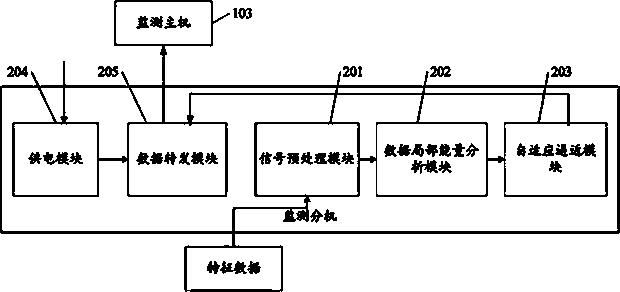

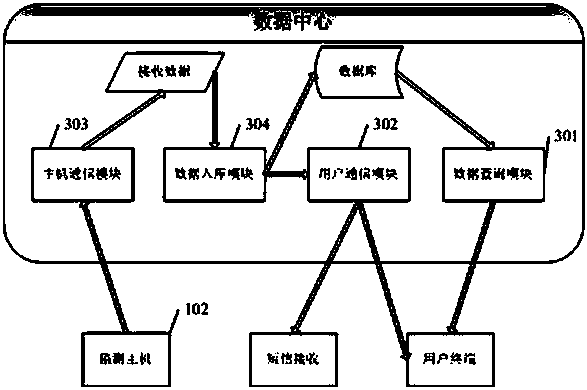

Turnout steel rail damage monitoring method and device

ActiveCN104176092AEfficient identificationAvoid detection blind spotsRailway traffic control systemsRailway auxillary equipmentRail inspectionData center

The invention relates to the technical field of railway equipment and provides a turnout steel rail damage monitoring method and device. The device comprises a sensor, a monitoring extension, a monitoring host and a data center, wherein the sensor is mounted on a turnout steel rail and transmits collected characteristic data to the monitoring extension; after processing the characteristic data, the monitoring extension transmits processing results to the monitoring host; the monitoring host processes the processing results and performs appointed distribution; the data center manages the entire device and controls a client terminal according to reprocessed data The turnout steel rail damage monitoring device solves the technical problem that, when rail circuits and large rail inspection vehicles are utilized to detecting damage of steel rails, rapidly-developed tiny cracks cannot be identified effectively and accordingly lead to non-detection zones. Further, the turnout steel rail damage monitoring device can effectively identify the tiny cracks on the turnout steel rail to overcome the non-detection zones.

Owner:SICHUAN SOUTHWEST JIAOTONG UNIV RAILWAY DEV

Method and apparatus for detecting internal rail defects

ActiveUS9010186B2Analysing solids using sonic/ultrasonic/infrasonic wavesRail inspectionSystems design

An ultrasonic rail inspection system designed to detect defects in a rail which result from longitudinal cracks that propagate in the horizontal and transverse plane of the rail. Detection of this type of defect is possible by directing an ultrasonic beam into the rail at a predetermined angle from the perpendicular to the surface of the rail. The predetermined angle must be sufficient to detect these normally undetectable defects and can be in the range of 8° to 14° from the perpendicular.

Owner:NORDCO WISCONSIN

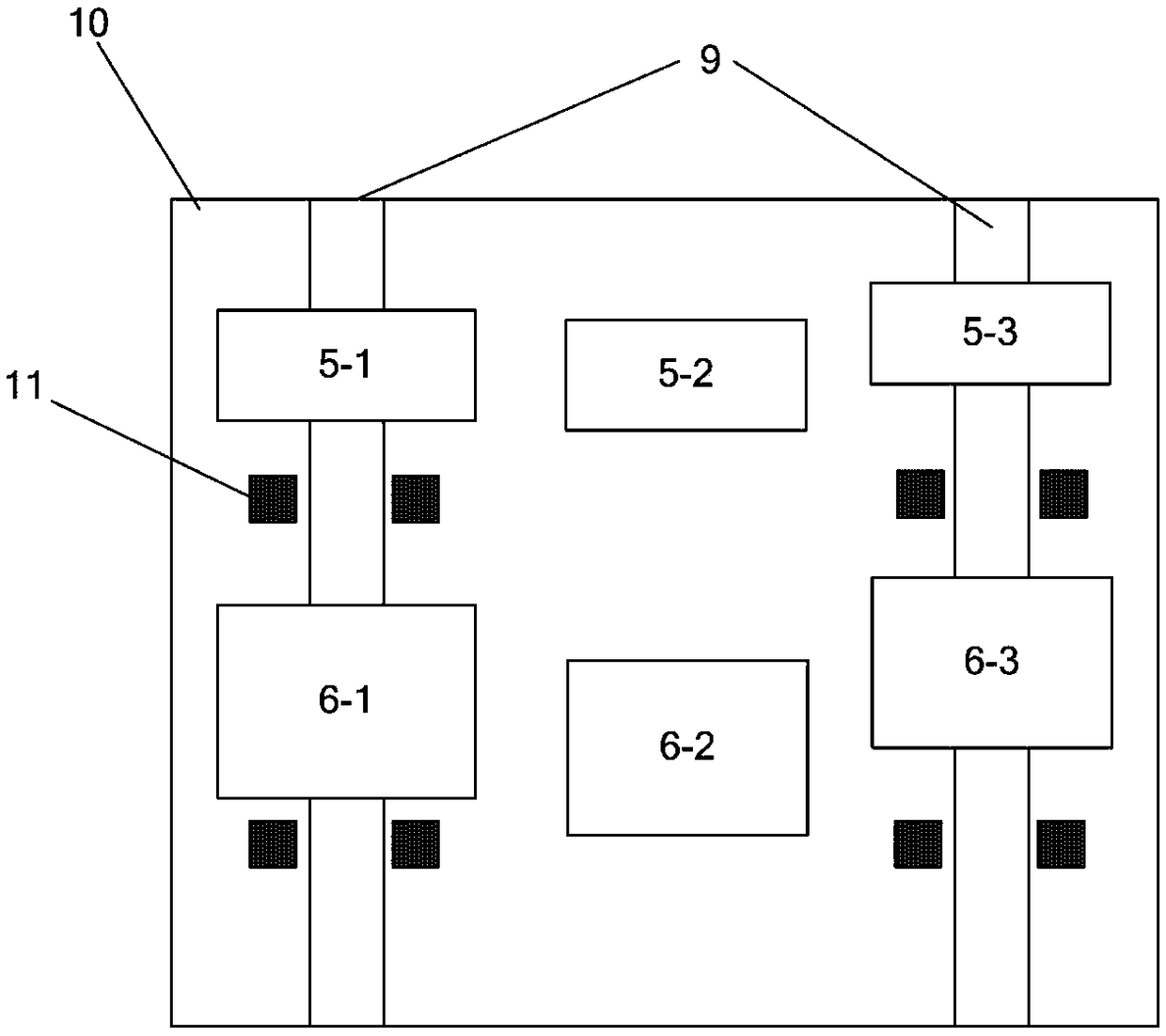

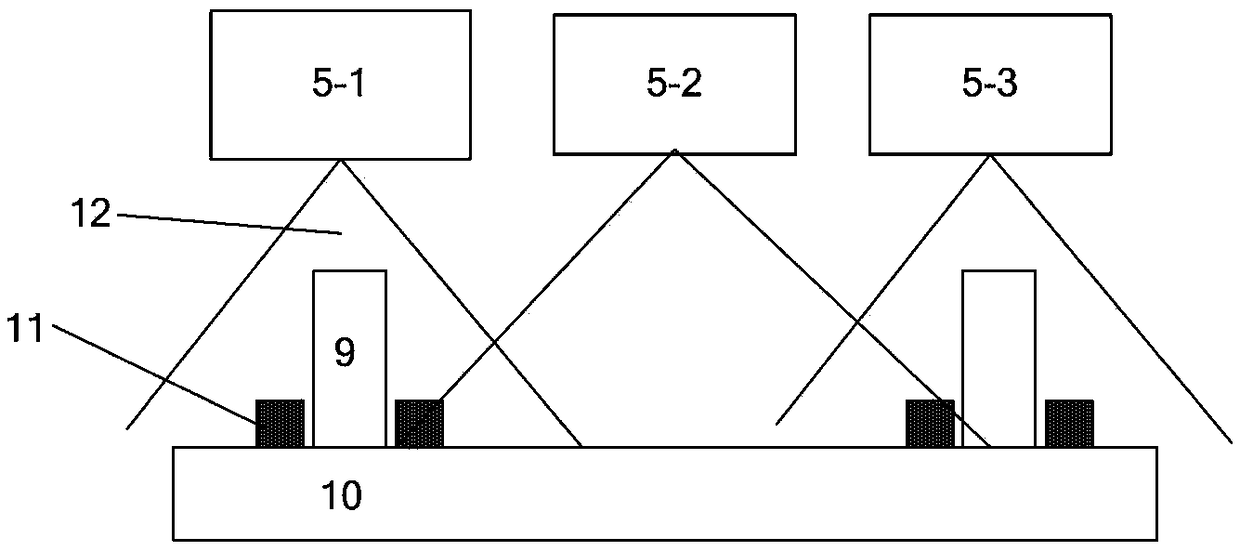

Rail visual inspection two-dimensional and three-dimensional fusion imaging system

PendingCN109142382ARealize Fusion ImagingSmall sizeOptically investigating flaws/contaminationControl signalData acquisition

The invention discloses a rail visual inspection two-dimensional and three-dimensional fusion imaging system, which aims at the problems of low efficiency and high cost in the existing rail manual inspection and is used for acquiring rail surface two-dimensional image and three-dimensional morphology data and providing effective data for rail automatic inspection. The system consists of a two-dimensional and three-dimensional imaging module, an imaging control module, a data acquisition module and a two-dimensional and three-dimensional data fusion module, wherein the two-dimensional and three-dimensional imaging module consists of a plurality of two-dimensional imaging devices and three-dimensional imaging devices; imaging / measuring areas of the adjacent two-dimensional / three-dimensionalimaging devices are partially superposed and can perform full-coverage two-dimensional / three-dimensional imaging on a steel rail system, a fastener system and a ballast bed system; the imaging controlmodule is used for generating an imaging control system; the data acquisition module is used for acquiring two-dimensional / three-dimensional imaging data; and the two-dimensional and three-dimensional data fusion module is used for performing pixel alignment and fusion on the two-dimensional and three-dimensional imaging data. The imaging system can provide effective data for rail automatic inspection, improve the rail inspection efficiency and effectively guarantee the rail operation safety.

Owner:成都精工华耀科技有限公司

Intelligent rail inspection machine and method thereof

InactiveCN110866993AImprove work efficiencyTelevision system detailsChecking time patrolsRail inspectionTrackway

The invention discloses an intelligent rail inspection machine and a method thereof. The intelligent track inspection machine comprises an in-station terminal, an inspection machine body and a slidingcontact line guide rail. The inspection machine comprises an inspection machine body, an inspection machine telescopic rod and an inspection machine camera; a visible light video monitor, an infraredcamera, a high-definition camera and an intercom system are arranged on the inspection machine camera, and an ultrasonic sensor and a transient earth electric wave are arranged at the two sides of the inspection machine camera respectively. According to the invention, the inspection rail is arranged in the air indoors, and the inspection machine can move transversely and vertically, so the indoorenvironment can be monitored in all directions, an alarm can be given when data exceeds the limit, a remote control command can be issued, the real-time monitoring and remote control of the running state and working parameters of equipment can be completed, and the working efficiency is improved.

Owner:河南嘉瑞电力工程有限公司

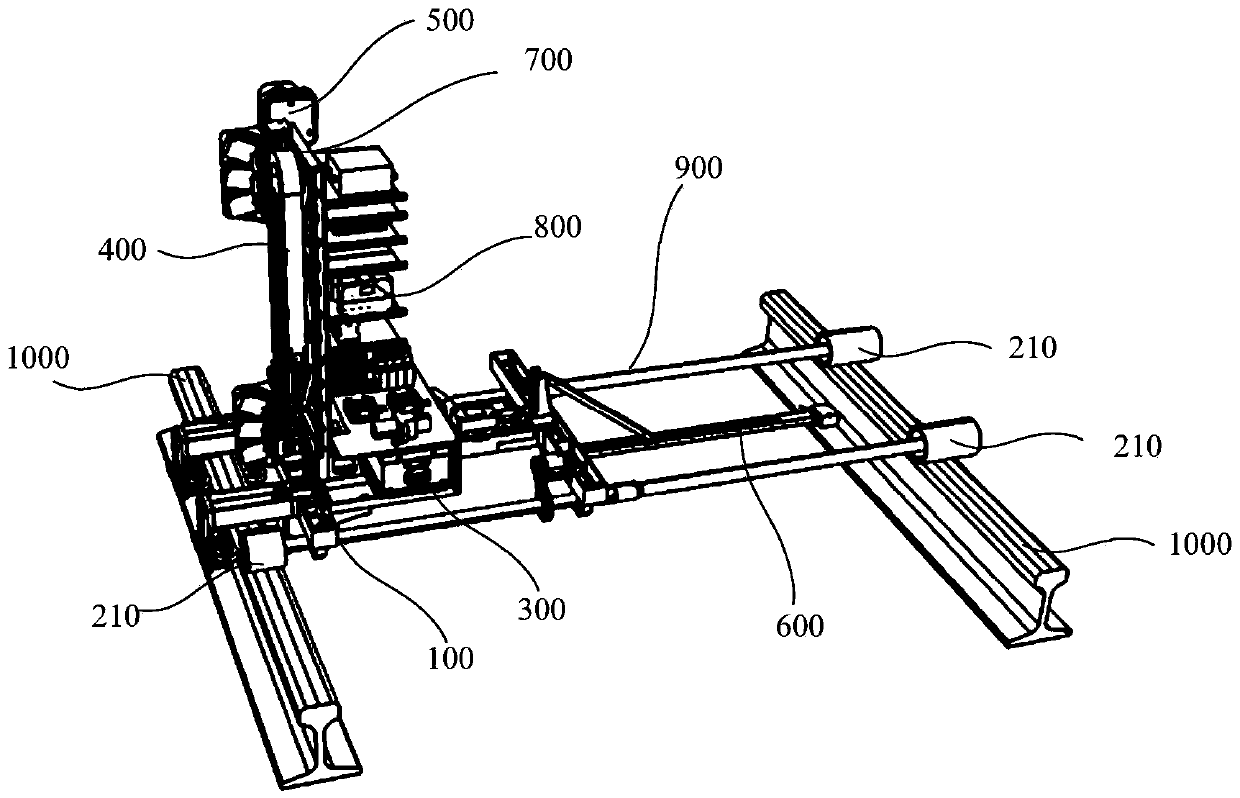

Rail inspection robot

PendingCN110193837AHigh measurement accuracyImprove labor safetyMeasurement devicesManipulatorRail inspectionObservational error

The invention provides a rail inspection robot. The rail inspection robot comprises a chassis, a walking mechanism, a power supply and a measurement mechanism; the walking mechanism comprises wheels and a transmission part, the two ends of the transmission part are connected with the wheels and the power supply respectively, and the power supply drives the wheels to walk on a rail through the transmission part; the measurement mechanism comprises a distance sensor, and the distance sensor can move up and down in the direction vertical to the chassis. The robot is adopted for replacing a workerto measure the height of a platform and the distance between the platform and the rail, the measurement precision can be improved, measurement errors caused by manual operation are avoided, the laborintensity is also lowered, and the labor safety is improved.

Owner:JD DIGITS HAIYI INFORMATION TECHNOLOGY CO LTD

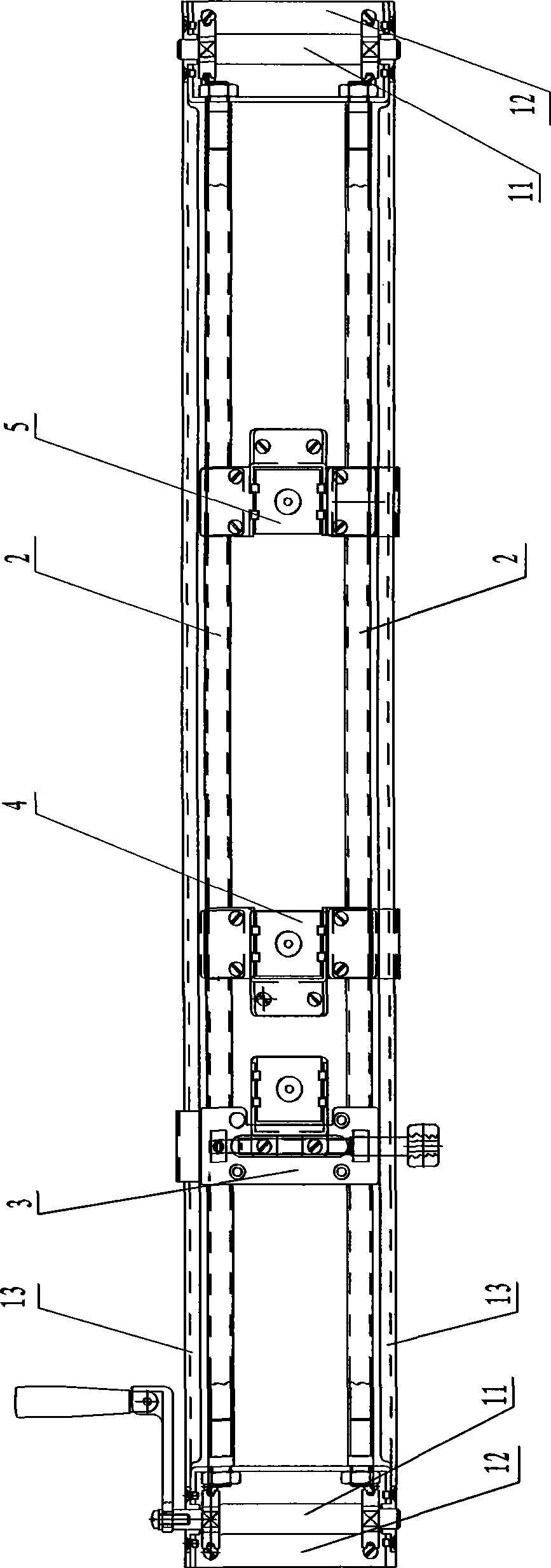

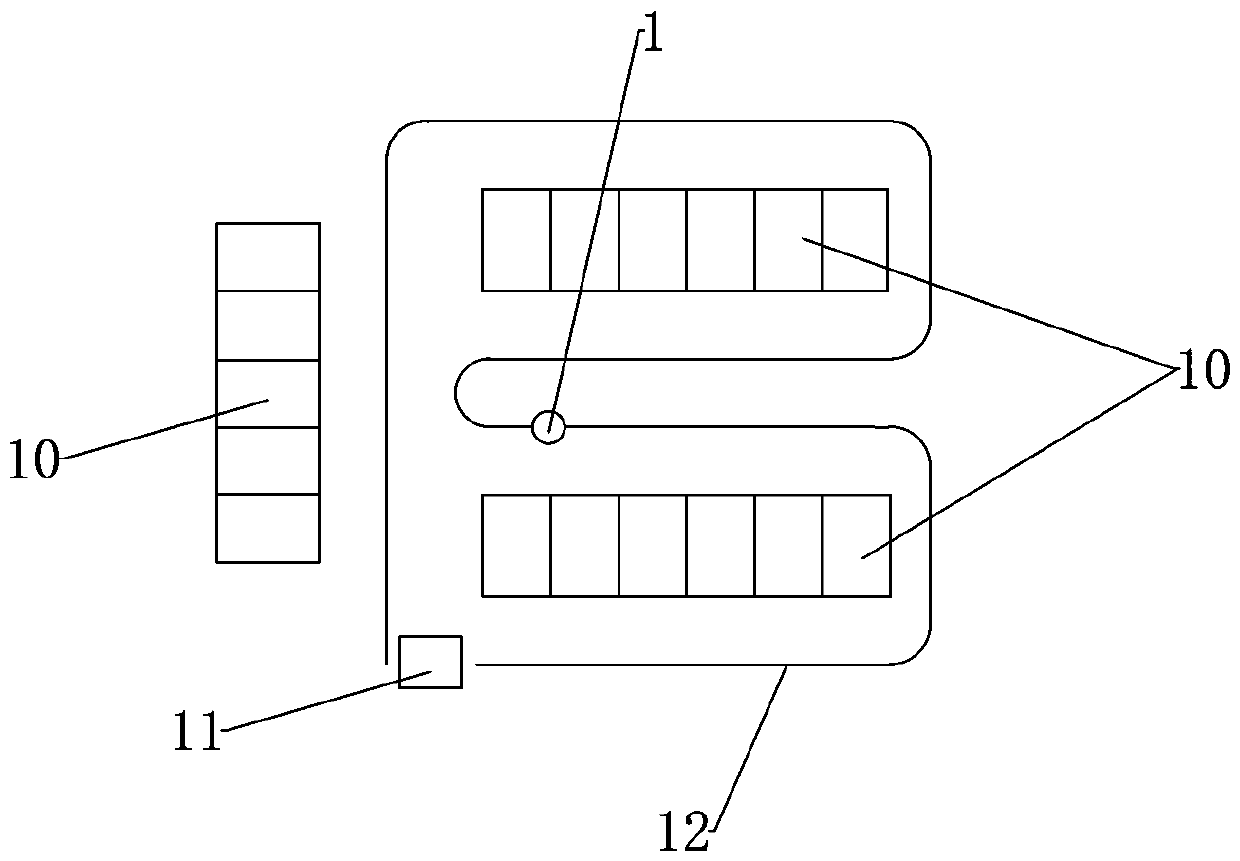

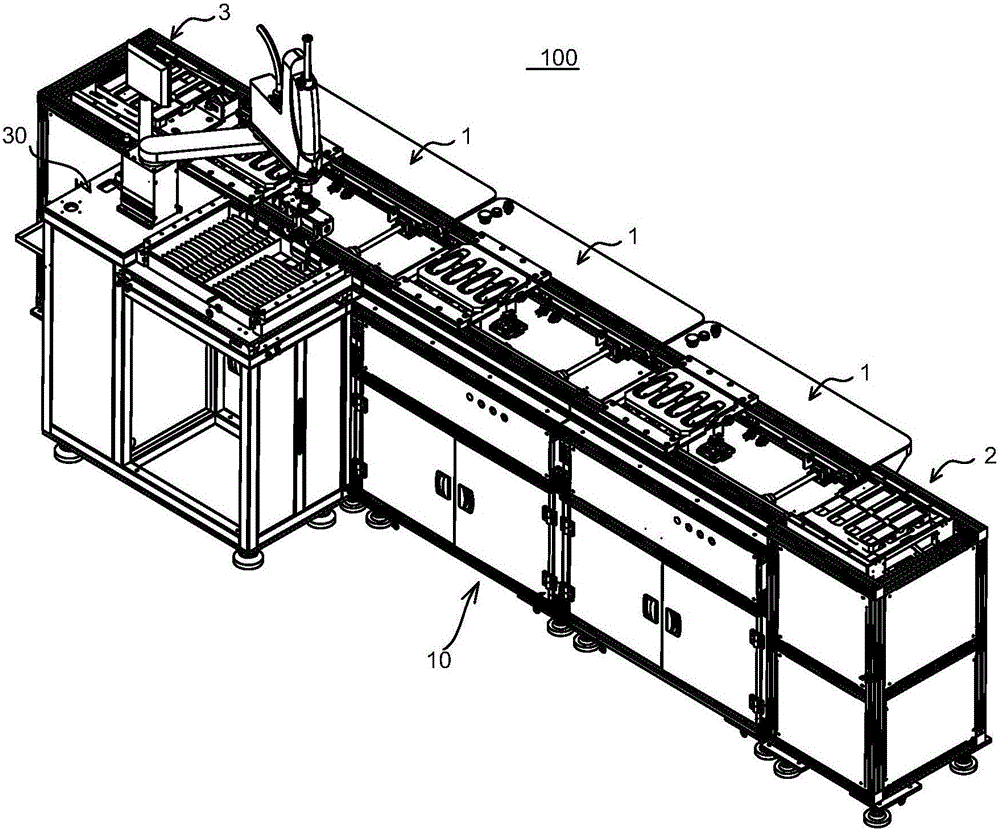

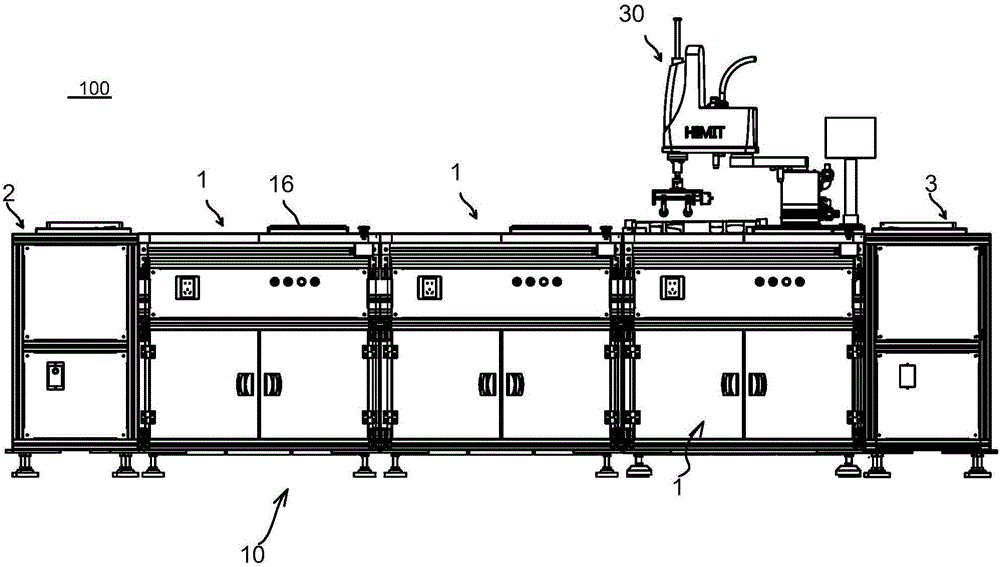

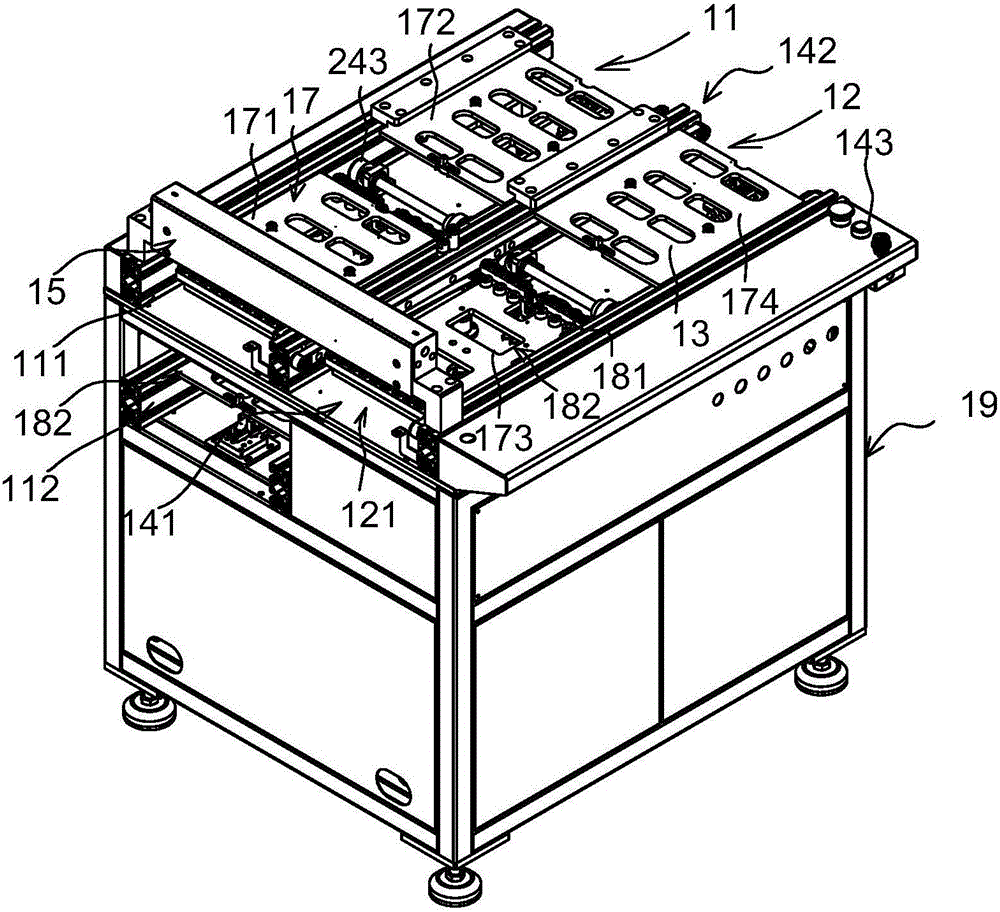

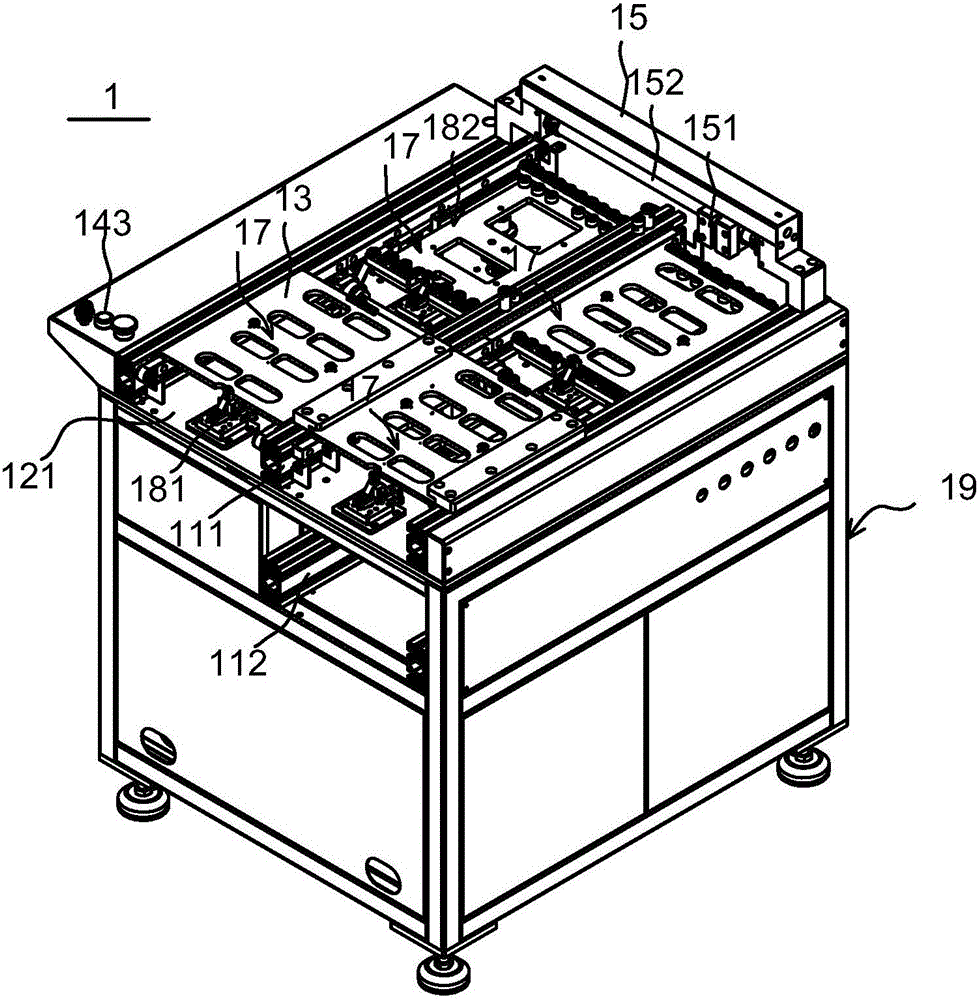

Mobile phone automation production line and running method thereof

ActiveCN105773144AOperation does not affectIncrease productivityAssembly machinesProduction lineRail inspection

The invention discloses a mobile phone automation production line and a running method of the line. The mobile phone automation production line comprises an inspection conveyor assembling line, and the inspection conveyor assembling line comprises a plurality of double-rail inspection conveyors which are connected in sequence; each double-rail inspection conveyor comprises a fixing frame, a first rail device which is mounted on the fixing frame and used for conveying mobile phone products or parts under the normal mode, a second rail device used for conveying the mobile phone products or parts under the abnormal mode and a moving plate used for containing the mobile phone products or parts; each first rail device comprises a first upper circulation rail assembly and a first lower circulation rail assembly, wherein each first upper circulation rail assembly is used for conveying the corresponding moving plate containing the mobile phone products or parts to the discharging side from the feeding side, and each first lower circulation rail assembly is used for enabling the corresponding moving plate to circularly return to the feeding side from the discharging side; and each second rail device comprises a second upper circulation rail assembly. The mobile phone automation production line can achieve multiple running modes, and when a certain device fails, operation of the whole mobile phone automation production line is not affected.

Owner:蒋雨亭

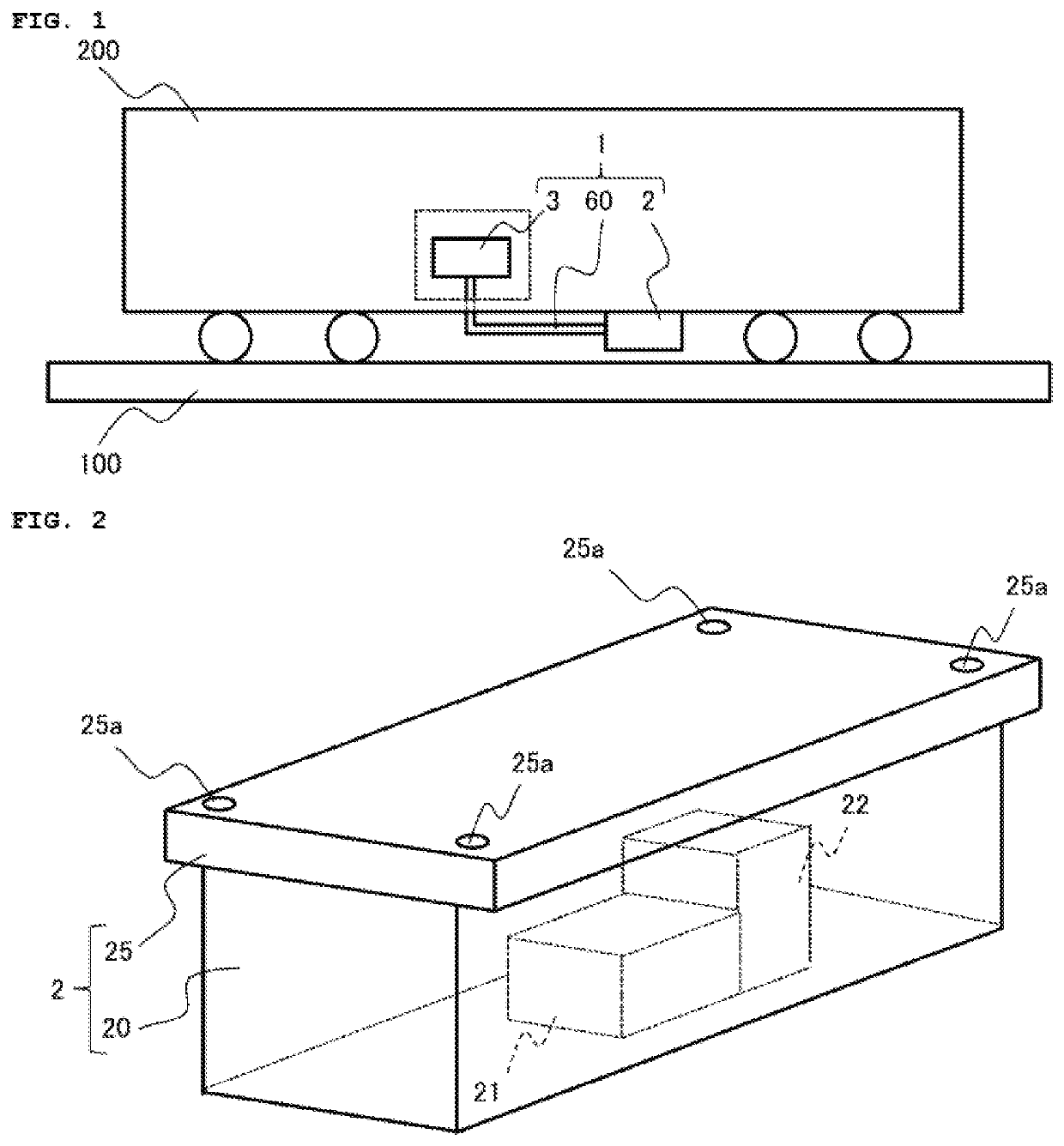

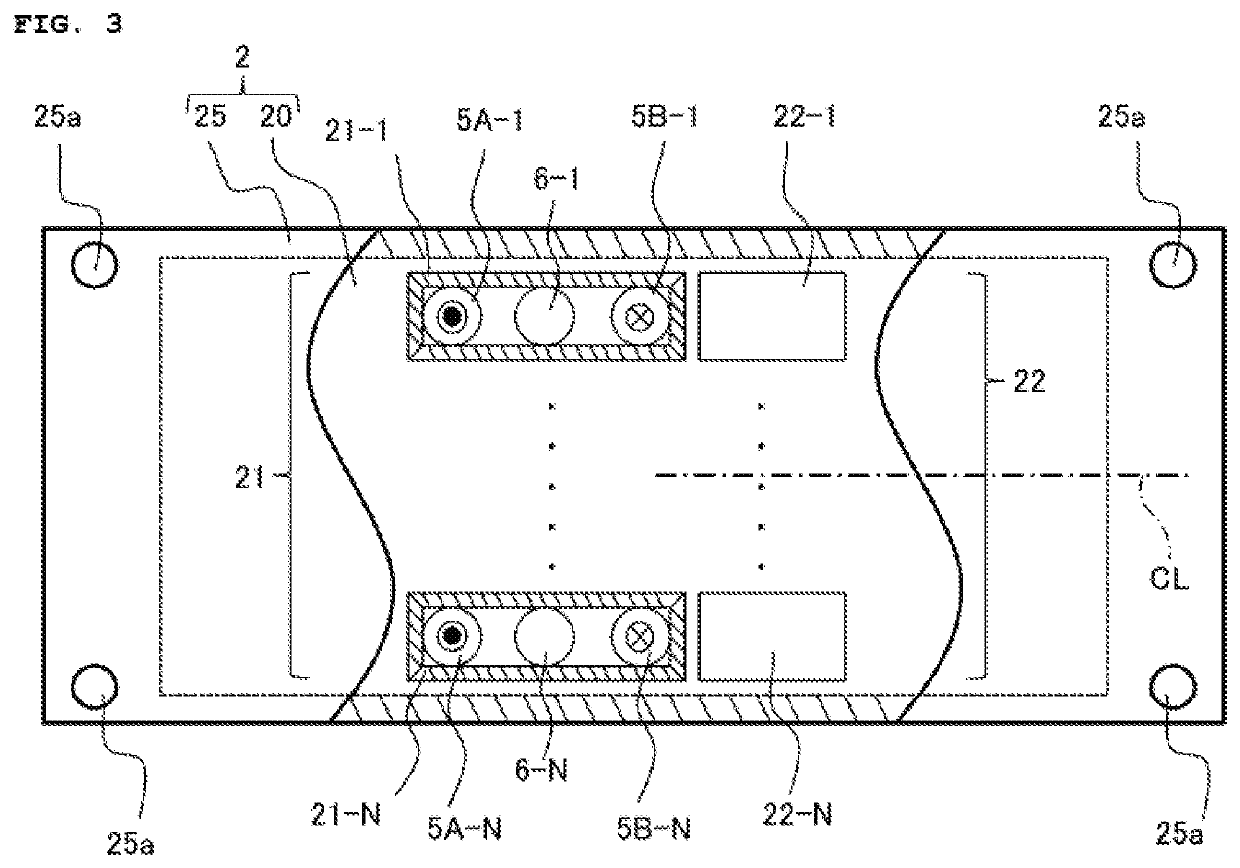

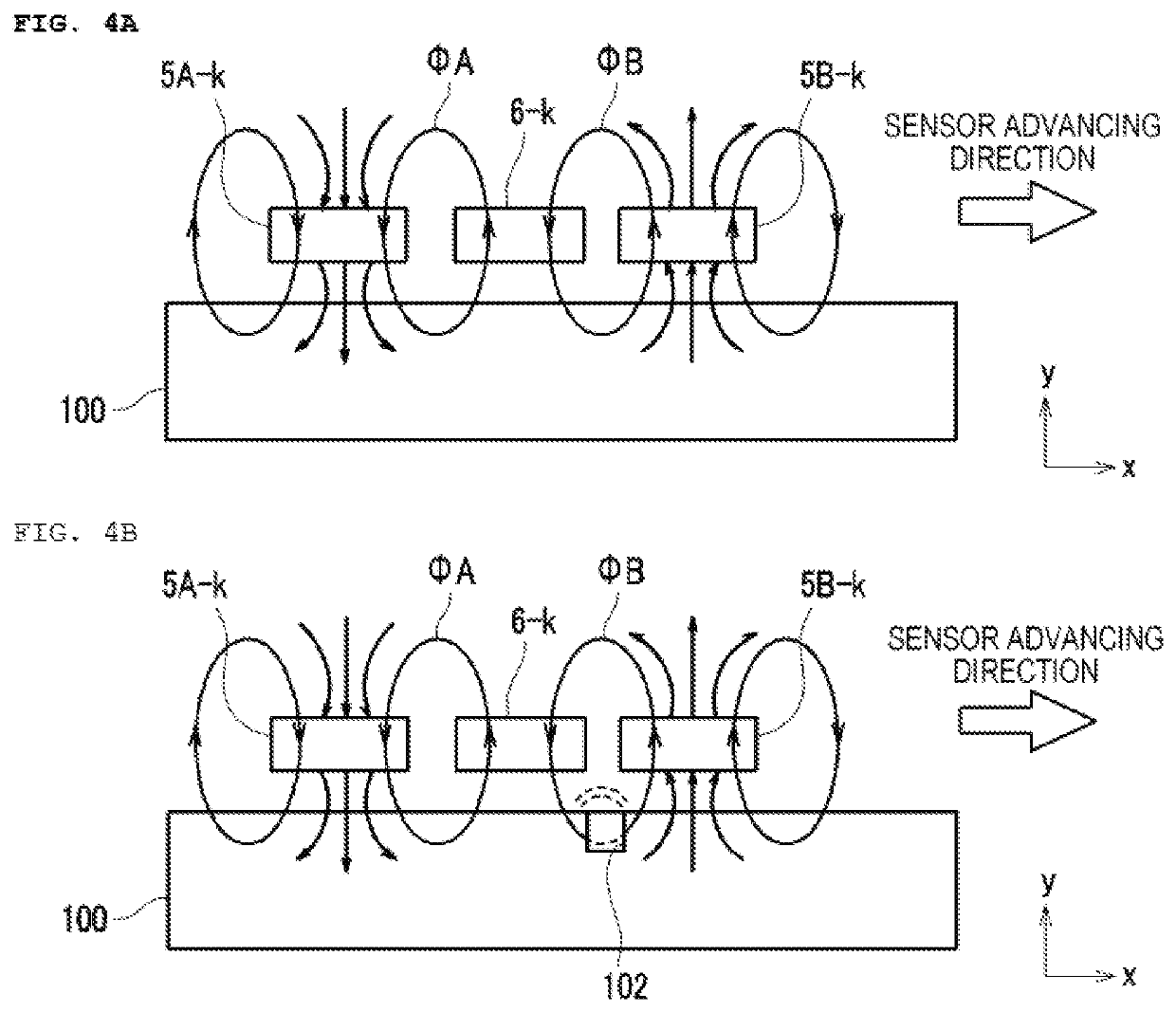

Rail inspection system

ActiveUS10989694B2Accurate detectionRailway signalling and safetyRailway auxillary equipmentRail inspectionStructural engineering

Provided is a rail inspection system capable of accurately detecting a defect of a railroad rail. The system includes: a sensor part group that has a plurality of sensor parts having receiver coils, and first oscillator coils and second oscillator coils corresponding to the receiver coils being arranged in a line parallel in a width direction of a railroad rail to be inspected; an oscillation part that supplies an oscillation signal to each of the first oscillator coils and the second oscillator coils; and a detection part group that has a plurality of detection parts to detect, with respect to an output signal from each of the receiver coils when the sensor part group moves in a laying direction of the railroad rail, a first inspection signal corresponding to a first phase of the output signal and a second inspection signal corresponding to a second phase of the output signal.

Owner:HITACHI HIGH TECH SOLUTIONS CORP

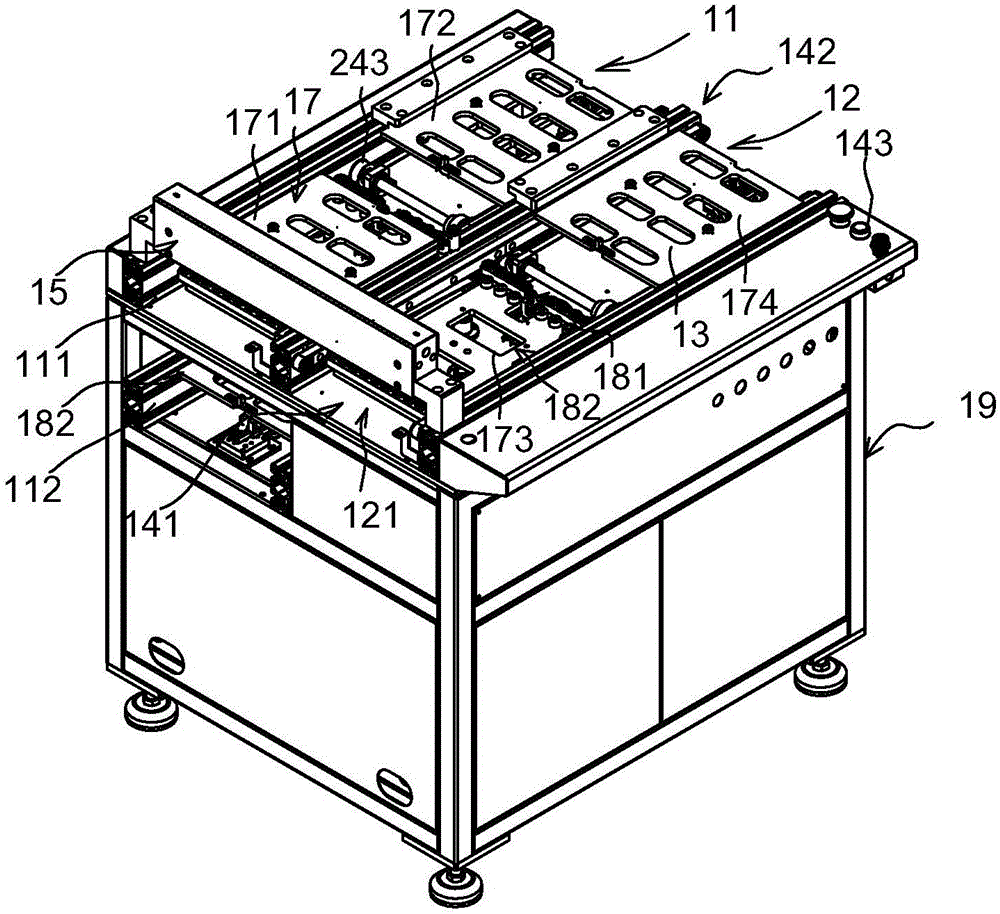

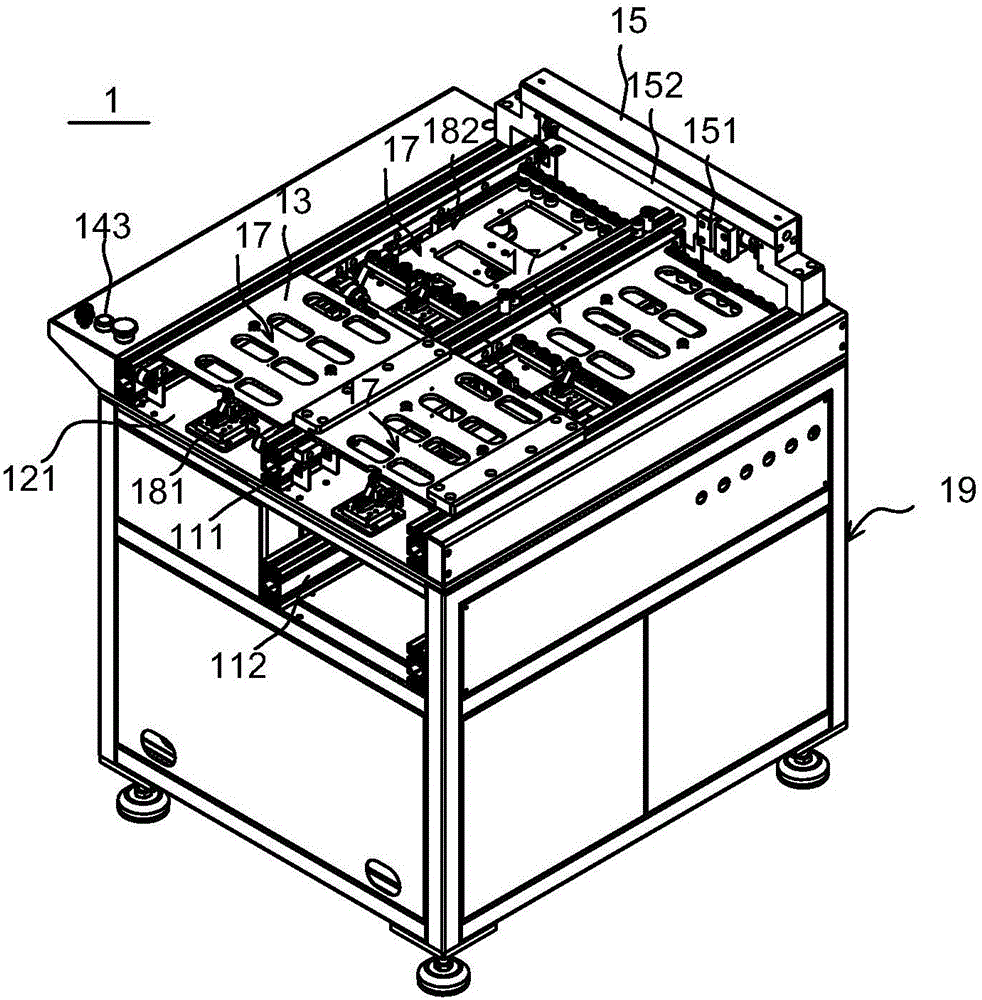

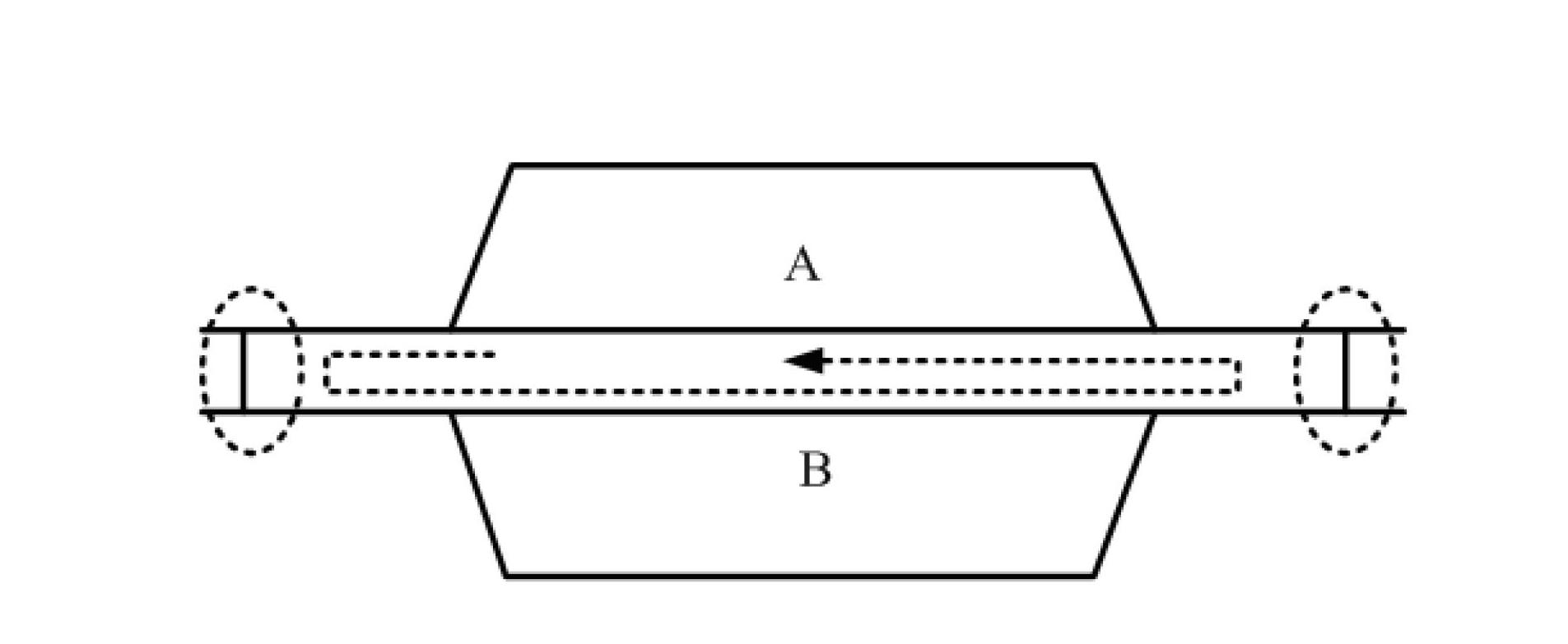

Double-rail inspection conveyor and operation method thereof and automatic production line adopting double-rail inspection conveyor

ActiveCN105775640ADoes not affect operationIncrease productivityMechanical conveyorsRail inspectionProduction line

The invention discloses a double-rail inspection conveyor. The double-rail inspection conveyor comprises a fixed frame, a first rail device, a second rail device and movable plates. The first rail device is mounted on the fixed frame and used for conveying products or product parts in a normal mode. The second rail device is used for conveying the products or the product parts in an abnormal mode. The movable plates are used for containing the products or the product parts. A feeding side and a discharging side are arranged on the two sides of the fixed frame correspondingly. The first rail device comprises a first upper circulation rail assembly used for conveying the movable plates containing the products or the product parts to the discharging side from the feeding side and a first lower circulation rail assembly used for enabling the movable plates to circulate back to the feeding side from the discharging side. The second rail device comprises a second upper circulation rail assembly. The invention further discloses an operation method of the double-rail inspection conveyor. The invention further discloses an automatic production line adopting the double-rail inspection conveyor. Multiple operation modes can be achieved, and when a certain device of the automatic production line breaks down, operation of the whole production line is not influenced.

Owner:海铭德(岳阳)科技有限公司

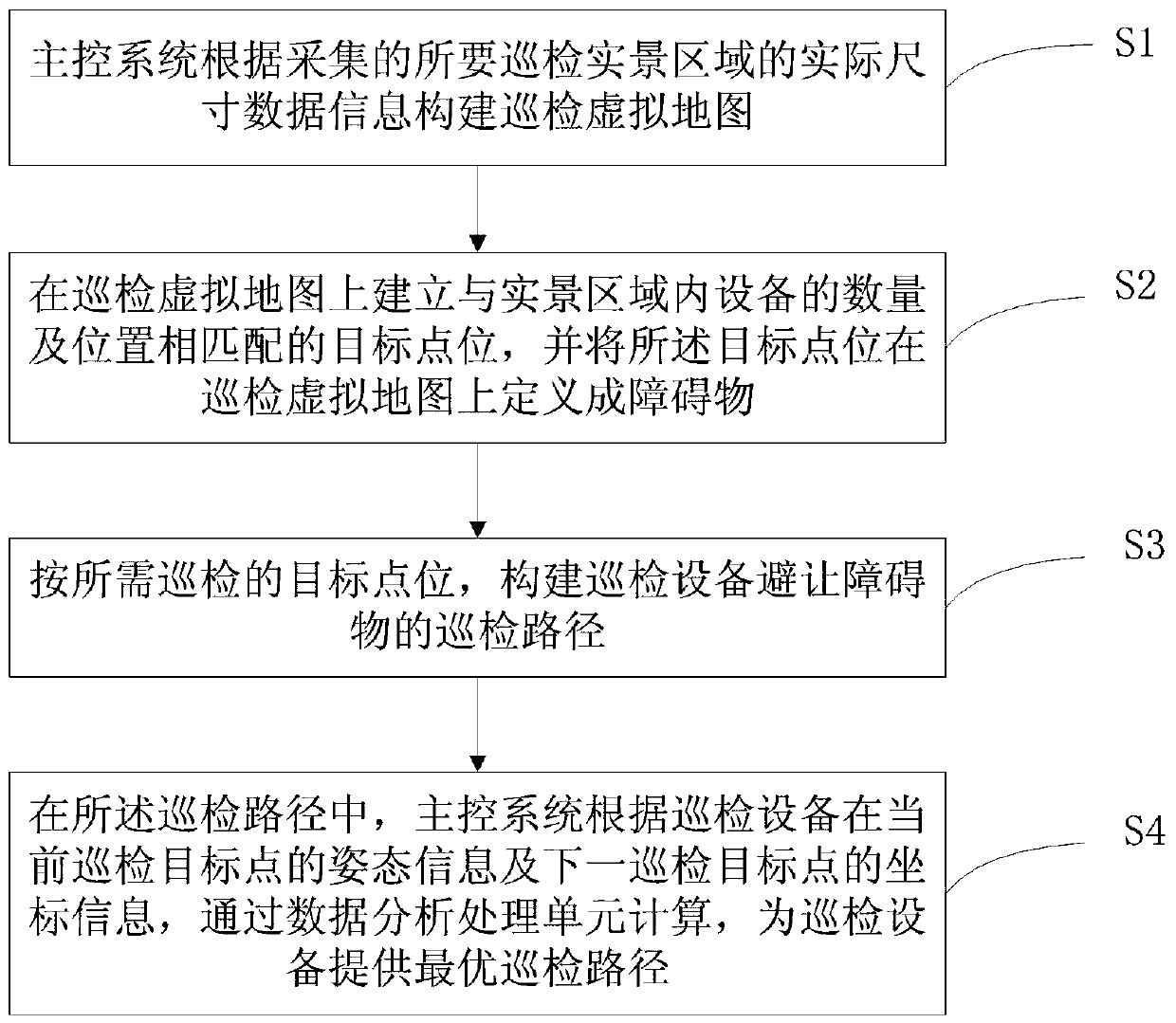

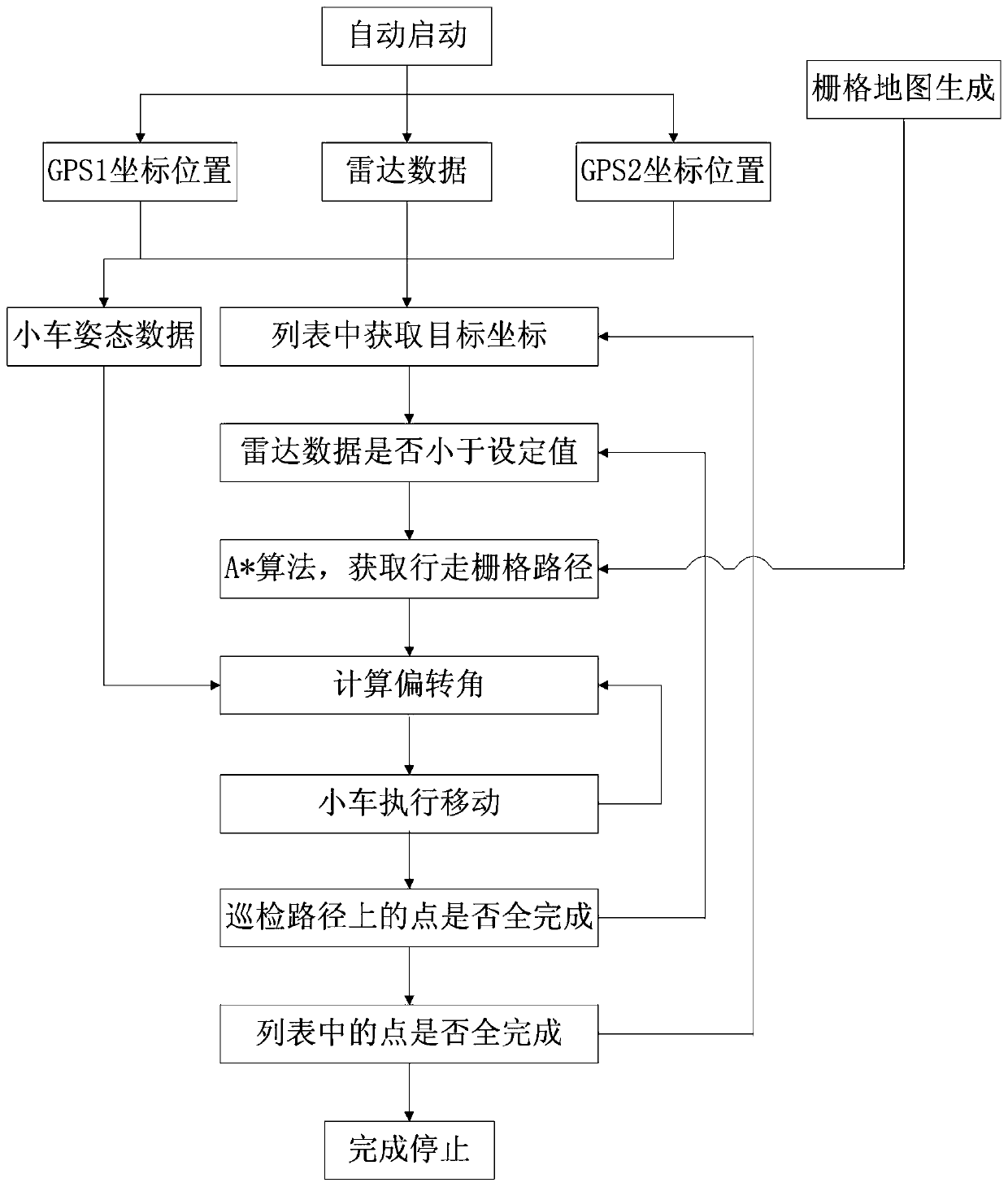

Equipment inspection method in area and inspection equipment

InactiveCN110111442ASolve derailmentFix angle errorTransmission systemsRegistering/indicating working of machinesRail inspectionControl system

The invention relates to an equipment inspection method in an area. The method comprises following steps: S1, establishing an inspection virtual map; S2, defining obstacles on the inspection virtual map; S3, presetting inspection paths, and establishing an inspection path through which the inspection equipment can avoid obstacles according to target sites to be inspected; and S4, providing an optimal inspection path among the inspection paths for the inspection equipment by a master control system through calculation by a data analysis processing unit according to gesture information of the inspection equipment at a current inspection target site and coordinate information of a next inspection target site. The method has following beneficial effects that indoor and outdoor conventional item inspection of a power substation is realized, defects of derailing, angle error and fixed routing of rail inspection are overcome thoroughly, dual-differential GPS positioning utilizes an intelligent trailing manner, that is, a base station plus a mobile station, the base station sends a resolved error to the mobile station in an RF manner, the mobile station resolves the GPS position and then the error sent by the base station is subtracted from the GPS position, then the accurate position is obtained, and the error is within 10MM.

Owner:湖北南邦创电科技有限公司

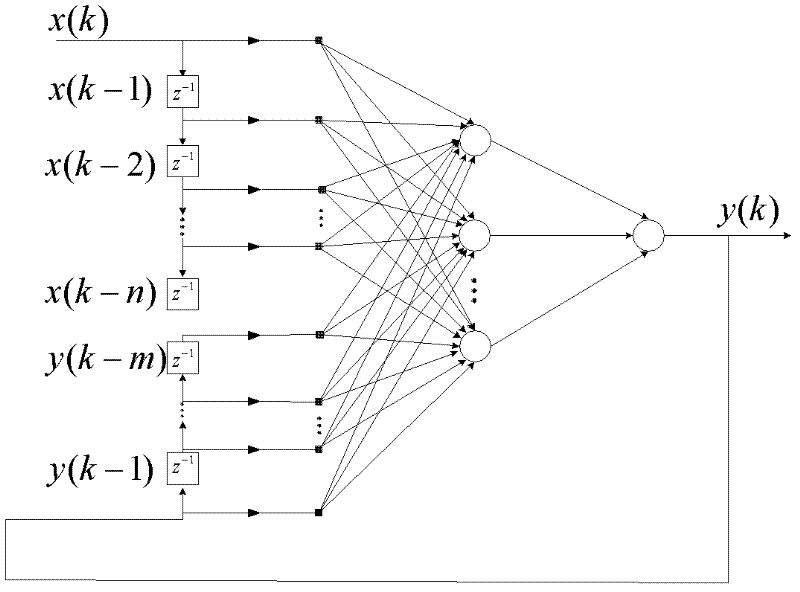

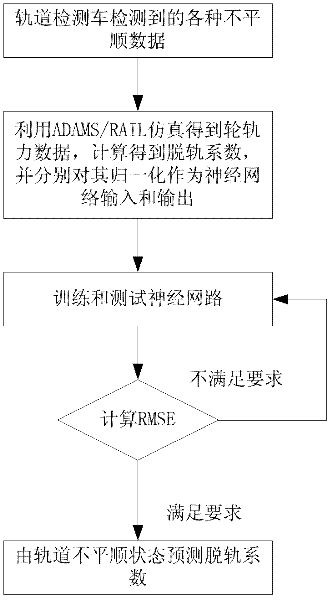

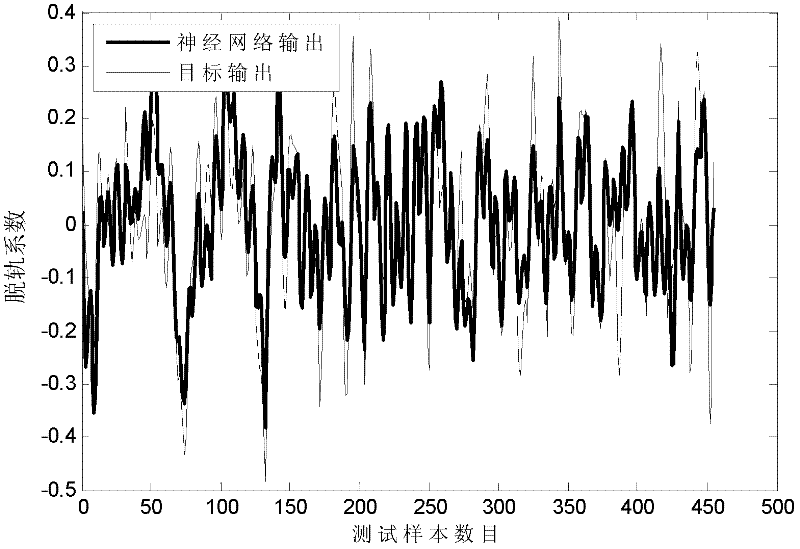

Method for predicting derailment coefficients

InactiveCN102567786AImprove accuracyAccurate prediction of derailment coefficientNeural learning methodsRail inspectionPredictive methods

The invention discloses a method for predicting derailment coefficients in the technical field of railway safety. The method comprises the following steps of: firstly, acquiring left-rail height irregularity data, left-rail rail direction irregularity data, right-rail height irregularity data and right-rail rail direction irregularity data of rails by using a rail inspection vehicle; secondly, by using professional automatic dynamic analysis of mechanical system (ADAMS) / Rail software, simulating the acquired data to obtain data of wheel-rail forces including a vertical wheel-rail force and a horizontal wheel-rail force so as to obtain the derailment coefficients, and normalizing the derailment coefficients; thirdly, by using a selected training sample, training a non-linear auto-regressive with exogenous input (NARX) neural network prediction model; fourthly, testing the trained NARX neural network prediction model, and outputting derailment coefficient data which are tested; and finally, analyzing the derailment coefficient data in a test sample and the derailment coefficient data which are obtained through a tested neural network, and evaluating the performance of the NARX neural network prediction model. By adoption of the method, the derailment coefficients can be accurately predicted, the accuracy in evaluation of railway running safety is improved, and great practical significance is provided for rail traffic safety control.

Owner:BEIJING JIAOTONG UNIV

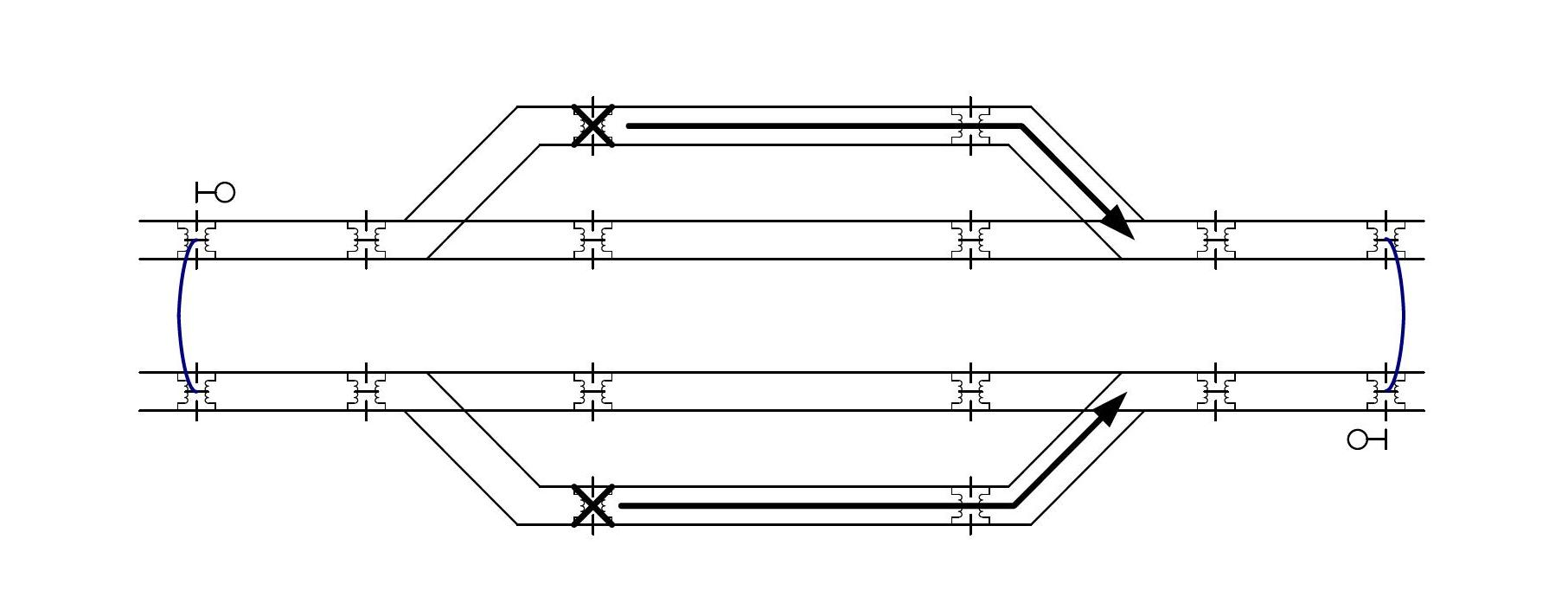

Device for realizing safe base reflow of voice frequency system track circuit in railroad station

ActiveCN102658783AGuaranteed broken rail inspectionFeatures guaranteed to be checkedPower railsRail inspectionTransformer

The invention discloses a device for realizing the safe base reflow of a voice frequency system track circuit in a railroad station, which is used for realizing the safe base reflow of all the voice frequency track circuits in the high-speed and common-speed railroad station. The device comprises a safe type reflow electric reactor and a choke transformer; the safe type reflow electric reactor is connected with transverse connecting center wires of adjoining choke transformers at two ends of a mechanical insulating section in series; the adjoining choke transformers arranged the two ends of the mechanical insulating section are used for switching on traction current to pass through the mechanical insulating section; and the safe type reflow electric reactor is used for guaranteeing the broken rail inspection of the track circuit in the case of the realization of the safe base reflow.

Owner:CRSC RESEARCH & DESIGN INSTITUTE GROUP CO LTD

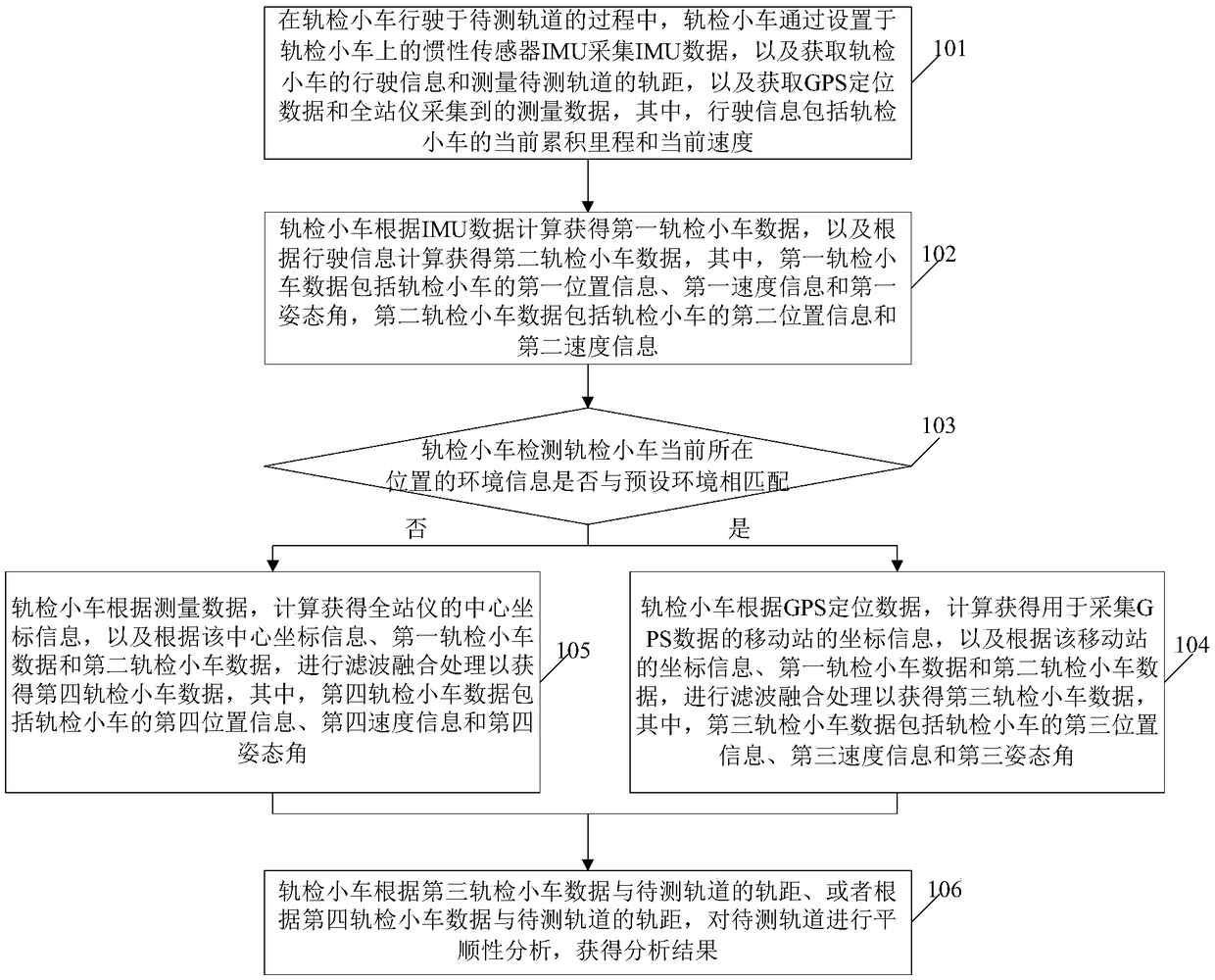

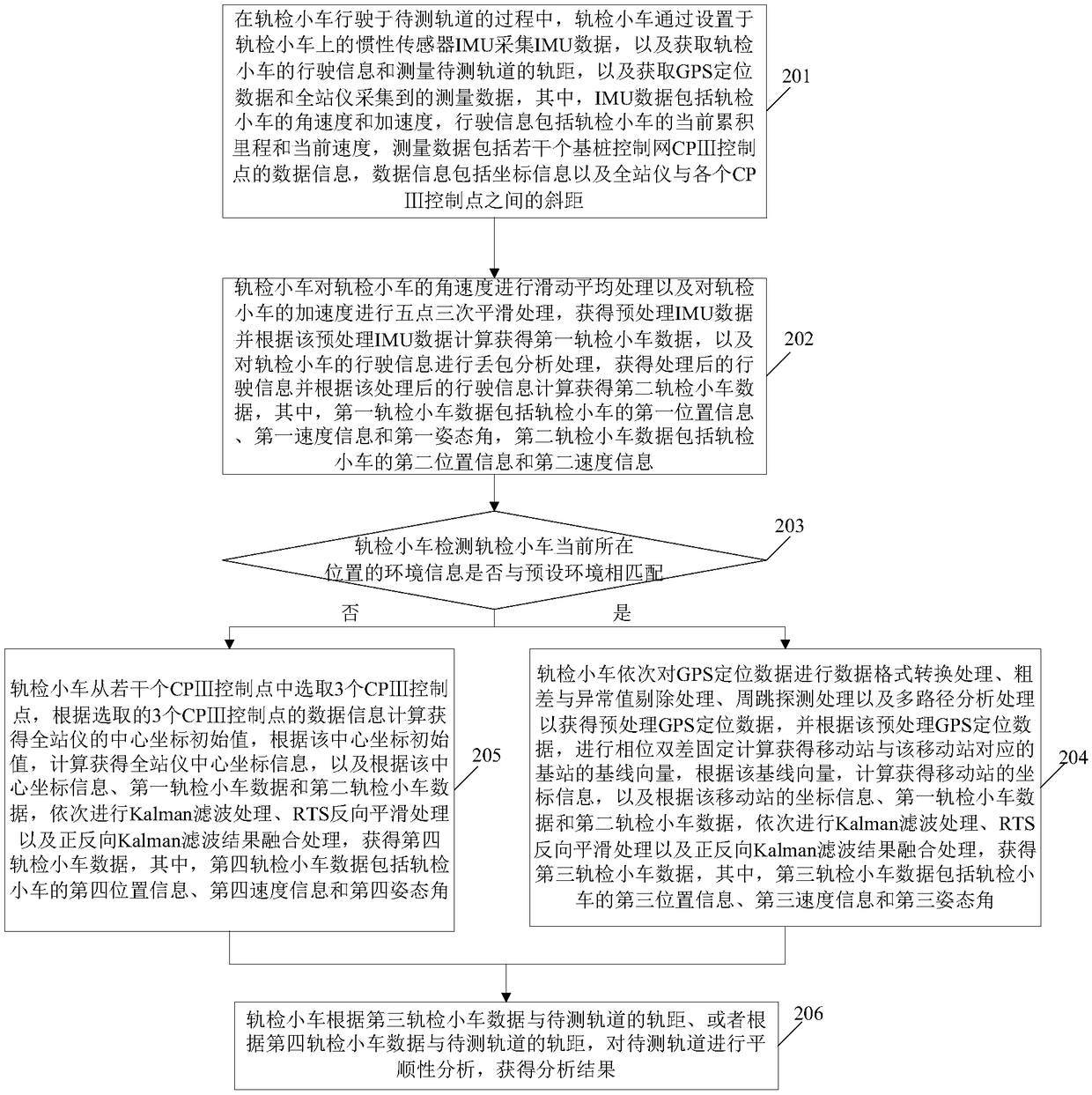

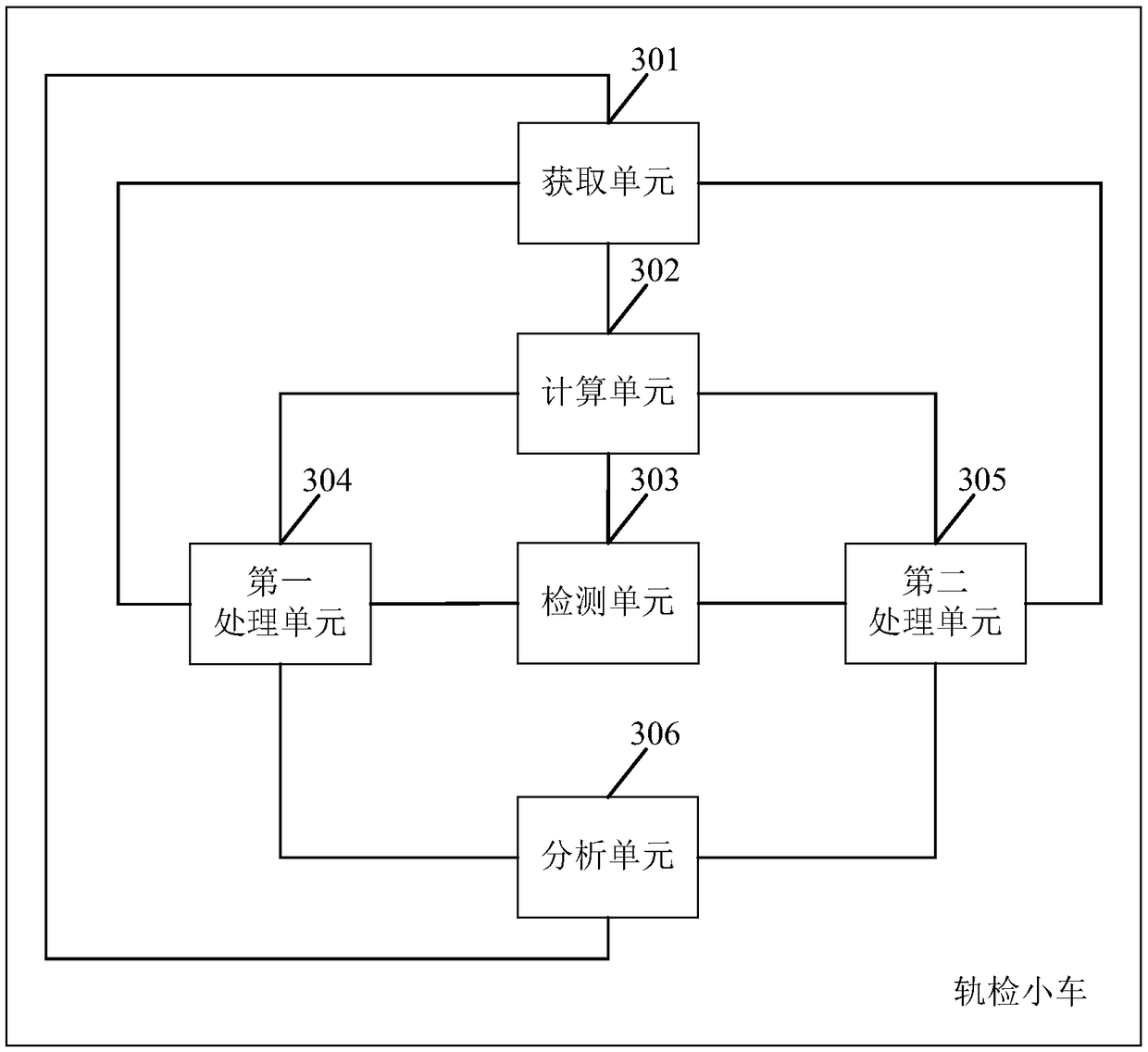

Track detection method and track inspection trolley

ActiveCN109080648AHigh measurement accuracyImprove work efficiencyRailway inspection trolleysRailway auxillary equipmentRail inspectionEngineering

The embodiment of the invention discloses a track detection method and a track inspection trolley. The method comprises the following steps: obtaining IMU data, traveling information on the track inspection trolley, track gauge of a tested track, GPS positioning data and measurement data of a total station; Calculating a first rail inspection trolley data and a second rail inspection trolley data;Detecting the environmental information of the current position of the track inspection trolley; When the surrounding environment indicated by the environmental information matches with the preset environment, calculating the coordinate information of the mobile station and obtaining the data of the third track inspection trolley by combining the data of the first track inspection trolley and thedata of the second track inspection trolley; When there is a mismatch, the center coordinate information of the total station instrument is calculated and the data of the first track inspection trolley and the second track inspection trolley are combined to obtain the data of the fourth track inspection trolley. According to the third track inspection trolley data or the fourth track inspection trolley data, combined with the gauge for ride comfort analysis to obtain the analysis results. By implementing the embodiment of the invention, different working modes can be selected for different application scenes, and the measurement accuracy and the work efficiency can be improved.

Owner:GUANGZHOU GEOELECTRON

Intelligent monitoring system for beam end expansion device of long-span railway steel bridge

PendingCN109238374ARealize intelligent monitoringEnables continuous monitoringProgramme controlMeasurement devicesVideo monitoringState prediction

The invention relates to an intelligent monitoring system for a beam end expansion device of a long-span railway steel bridge. The intelligent monitoring system comprises an environmental impact variable monitoring sub-module, a main guide bridge beam end displacement monitoring sub-module, an expansion device main body monitoring sub-module, a beam end running condition monitoring sub-module anda rail inspection vehicle beam end detection sub-module. Through adoption of the intelligent monitoring system, intelligent monitoring of the beam end expansion device is realized, and monitoring content covers environmental impact variables; main lead bridge end displacement monitoring is realized; longitudinal and lateral displacement monitoring of the expansion device, vertical deflection and strain monitoring, and video monitoring are realized; beam end driving state monitoring is realized; and access to rail inspection vehicle detection data is realized. The intelligent monitoring systemrealizes automatic real-time monitoring and evaluation of the working state of the beam end expansion device, has the functions of intelligent monitoring, data analysis and evaluation, and state prediction and diagnosis, covers the monitoring of various static and dynamic parameters of environments and structures as well as driving state, and provides technical reference for the engineering department.

Owner:RAILWAY ENG RES INST CHINA ACADEMY OF RAILWAY SCI +2

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com